High voltage static power shuttle nano-spinning device

A high-voltage electrostatic and nano-spinning technology, applied in textiles and papermaking, filament/thread forming, fiber processing, etc., can solve the problems of discontinuous spinning and reduce the mechanical strength of nanofibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

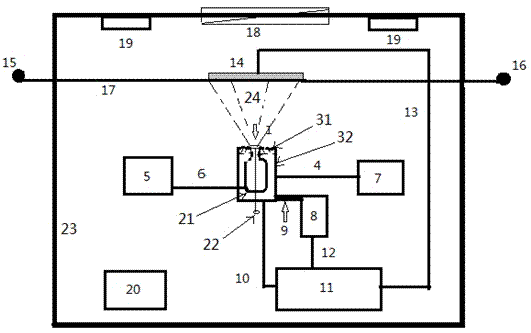

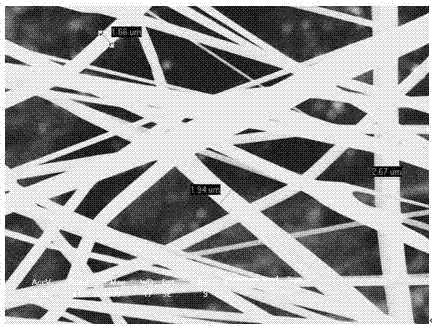

[0021] Add 3 g of polyethylene terephthalate (PET, molecular weight: 25000) pellets to 24 ml of trifluoroacetic acid (F 3 CHCOOH) and 6ml dichloromethane (CH 2 Cl 2 ) in a mixed solution with a volume ratio of 4:1, and dissolved with magnetic stirring at room temperature for 2 hours to obtain an electrospinning solution; add 10 ml of the obtained electrospinning solution to the storage tank (5) . Adjust the electronically controlled thermostat in the box, and the temperature and humidity will reach 25°C and 30RH% respectively, and stabilize for 2 minutes. Turn on the high-voltage electrostatic generator (11), the positive pressure power pump (7), and the cavitation machine (8), and slowly adjust the voltage to 80 kV; the height of the receiving plate is 33.5 cm. At this time, a jet appeared on the surface of the spinneret (1), and splitting occurred, and PET nanofiber non-woven fabric was formed on the receiving substrate, and the spinning was completed within 5 minutes, an...

Embodiment 2

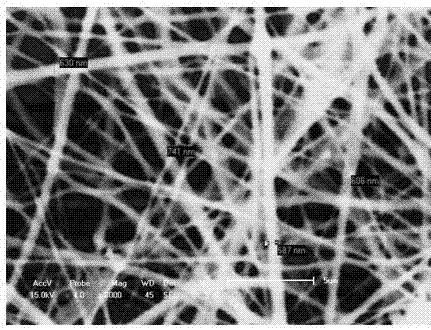

[0023]Add 6 g of polyethylene terephthalate (PET, molecular weight: 25000) pellets to 24 ml of trifluoroacetic acid (F 3 CHCOOH) and 6ml dichloromethane (CH 2 Cl 2 ) in a mixed solution with a volume ratio of 4:1, and dissolved with magnetic stirring at room temperature for 2 hours to obtain an electrospinning solution; 10 ml of the obtained electrospinning solution was added to the storage tank (5). Adjust the electronically controlled thermostat in the box, and the temperature and humidity will reach 25°C and 30RH% respectively, and stabilize for 2 minutes. Turn on the high-voltage electrostatic generator (11), positive pressure power pump (7), and cavitation machine (8), and slowly adjust the voltage to 80kV; the height of the receiving plate is 33.5cm. At this time, a jet flow appears on the surface of the spinneret (1), and splitting occurs, and PET nanofiber non-woven fabric is formed on the receiving substrate, and the spinning is completed within 5 minutes, and the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gap width | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com