Patents

Literature

1385results about "Cable installations in underground tubes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

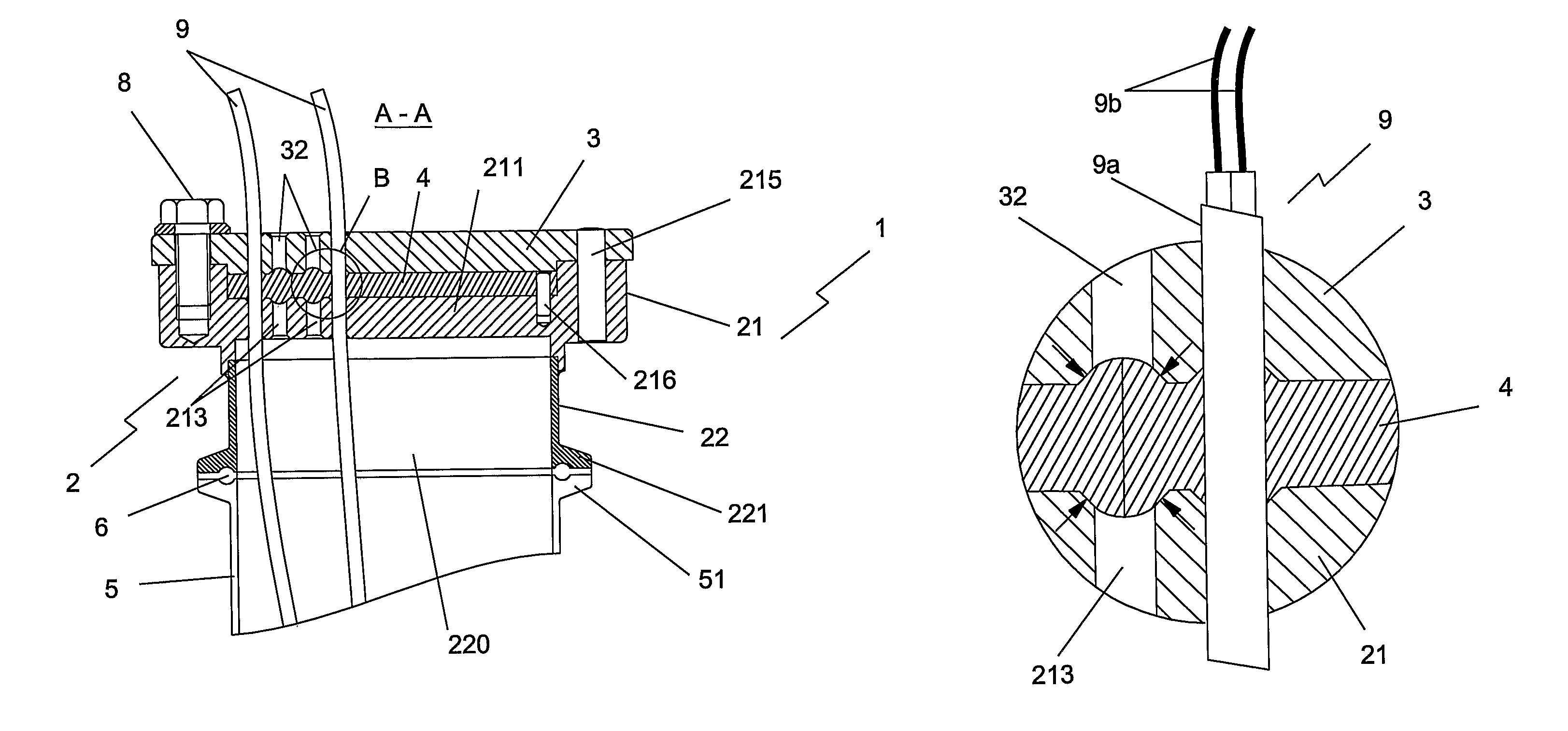

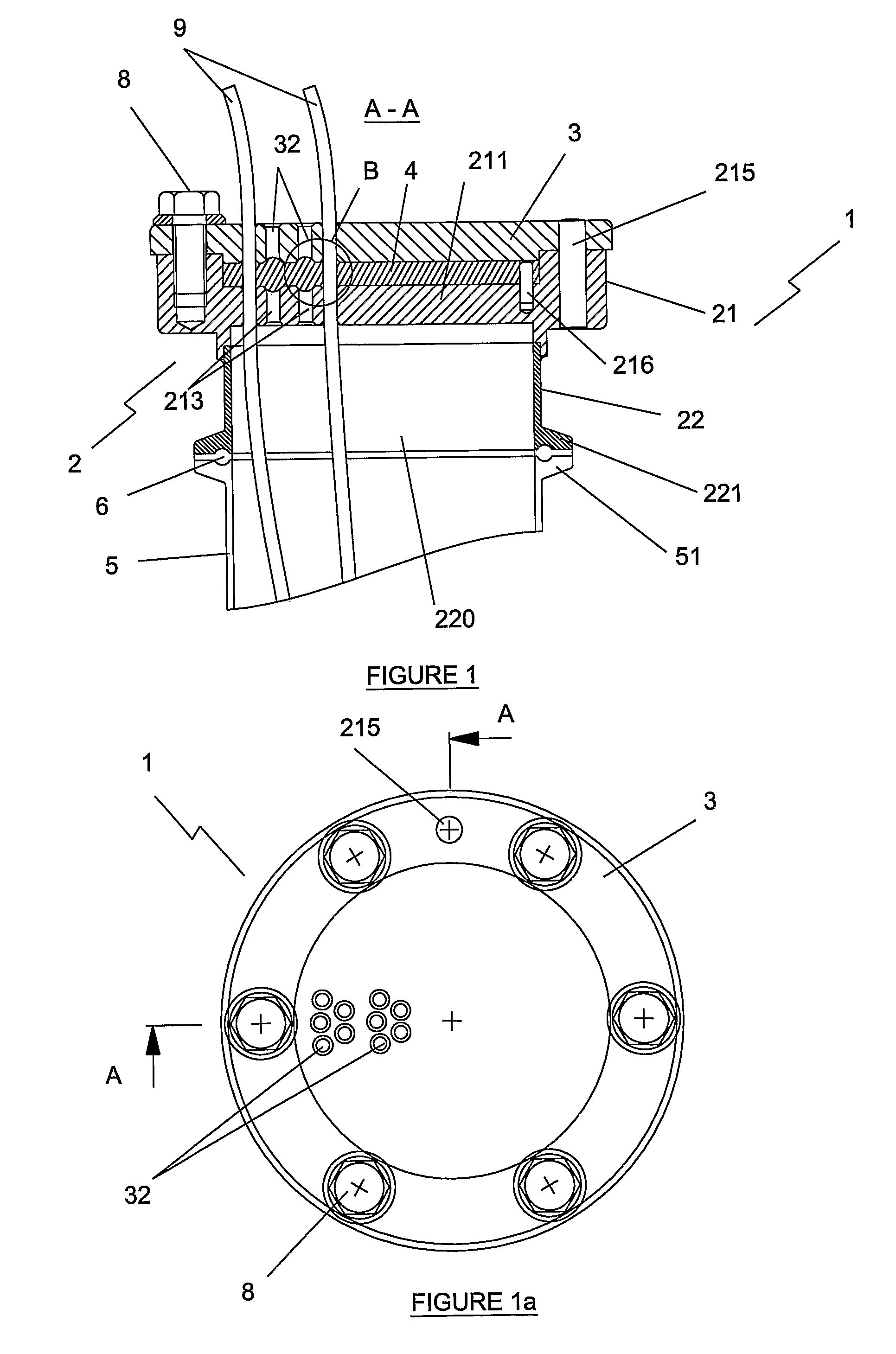

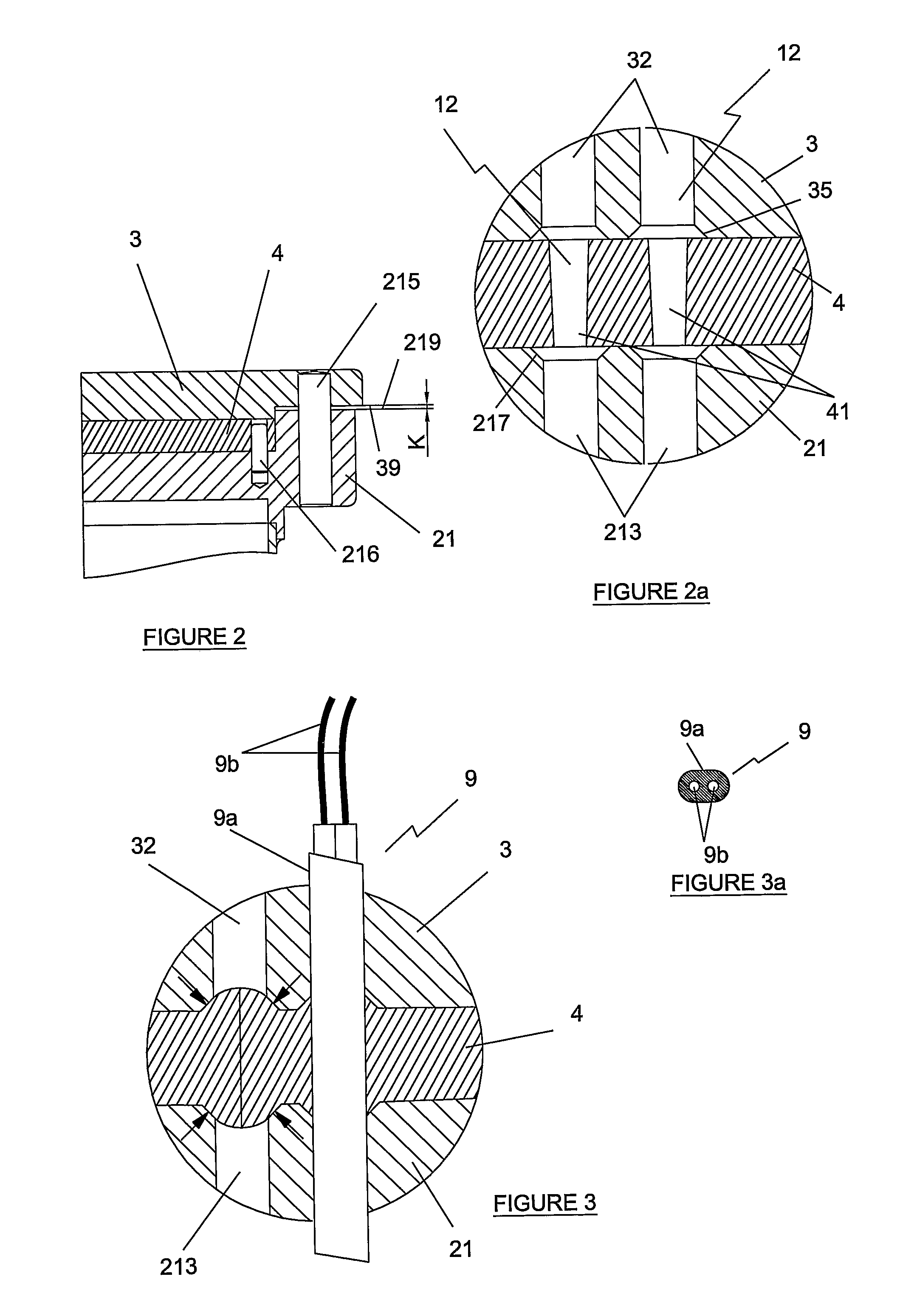

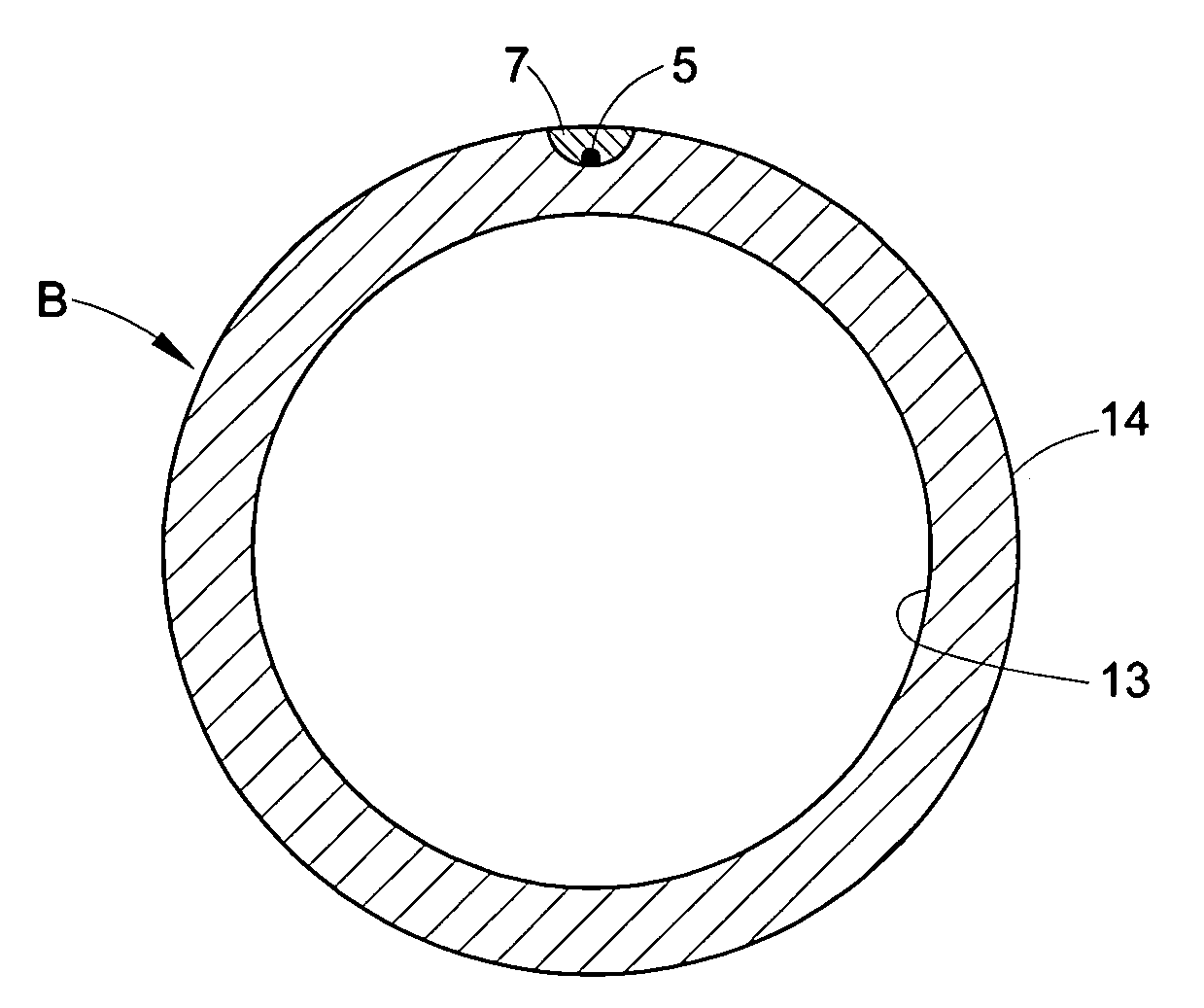

Bulkhead connector

The present invention relates to a bulkhead connector assembly providing a sealing arrangement for sealingly feeding a conduit between two environments. The assembly provides a first and second coupling components having a first and second surface respectively. A gap is formed between the first and second surfaces. The first coupling component has an aperture which extends between the first surface and a first environment and the second coupling component has an aperture which extends between the second surface and a second environment. Each aperture is adapted for receiving a conduit therethrough. A resiliently deformable gasket is provided to be placed into the gap and the gasket also is provided with a bore for a conduit to pass through the gasket. Means for compressing the gasket in the gap are provided to deform the gasket on compression so as to collapse the gasket bore against itself or against any conduit occupying the bore, so as to form a leak-proof seal between the apertures of the coupling components and the gasket.

Owner:GL TOOL & MFG

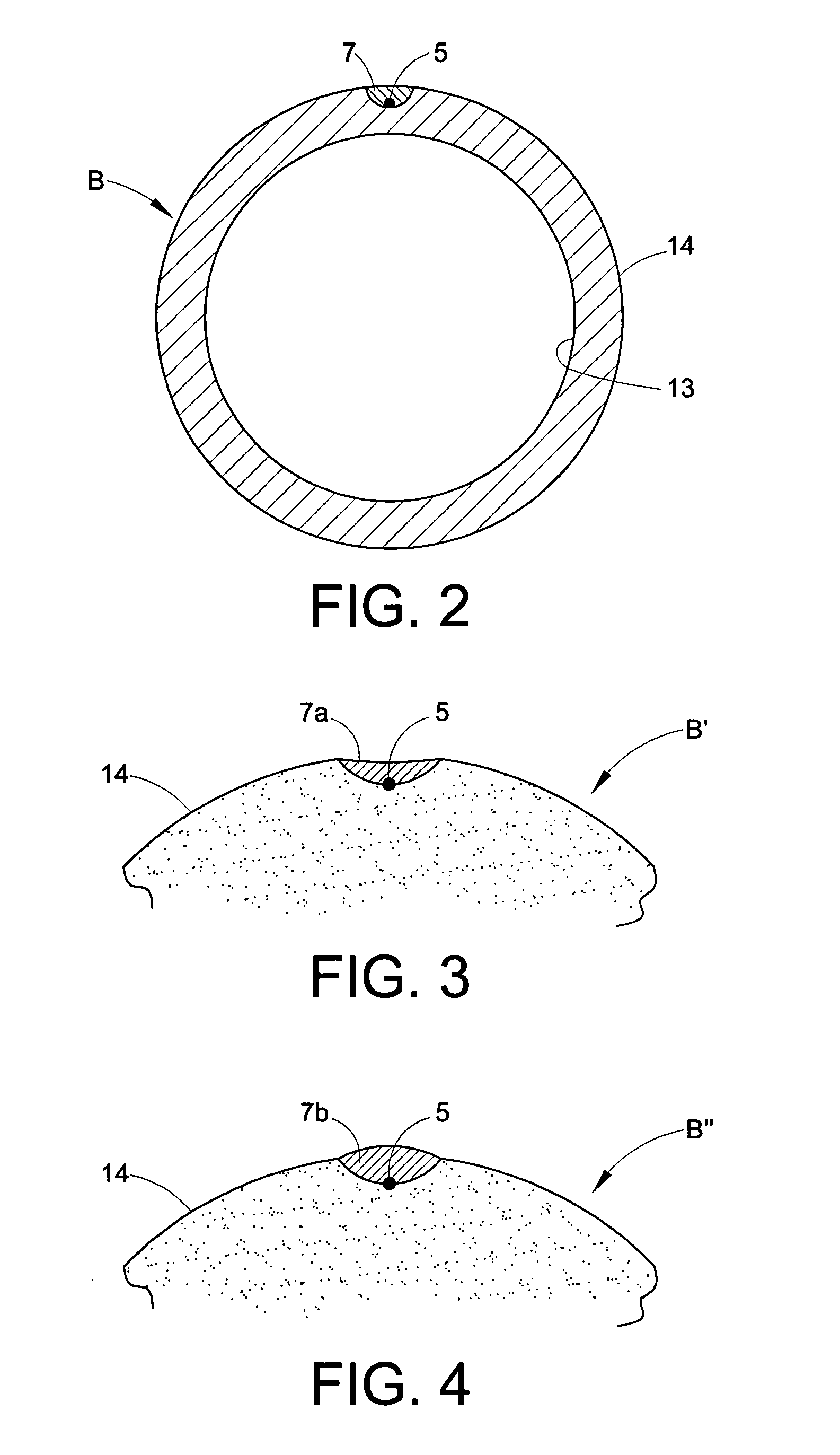

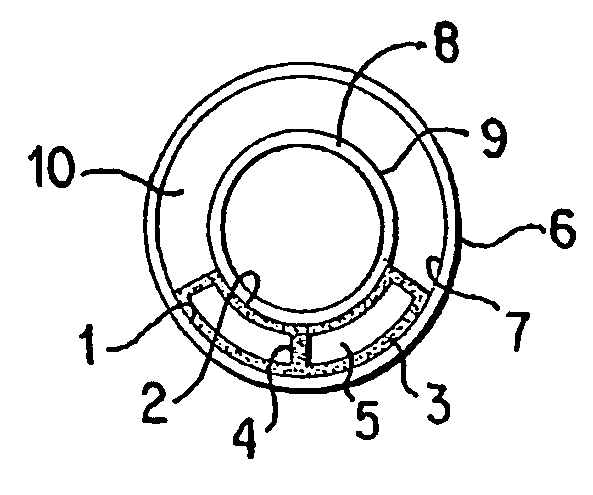

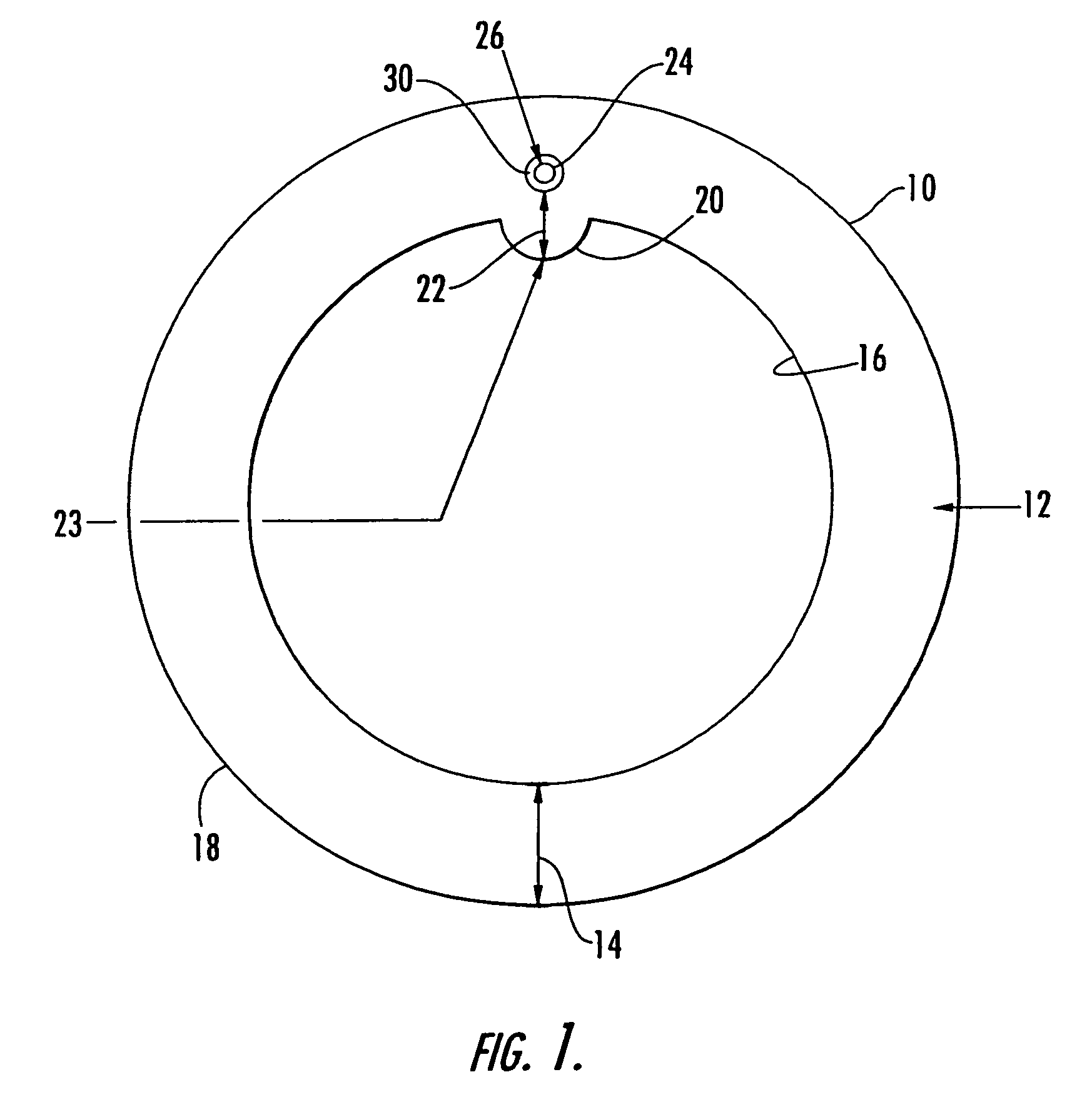

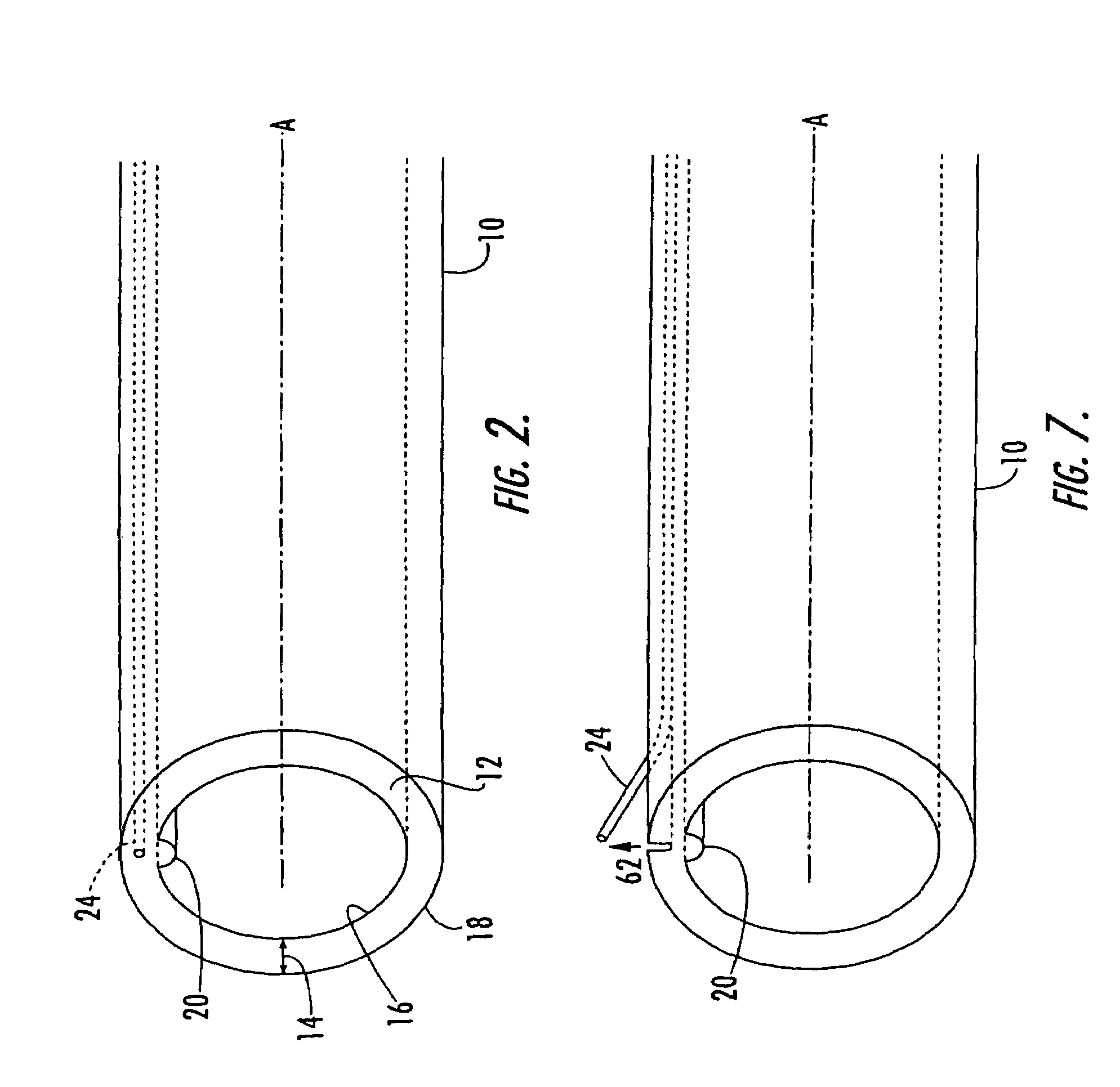

Duct with wire locator

InactiveUS6933438B1Convenient ArrangementEasily exposedPipe laying and repairSubstation/switching arrangement detailsPlastic materialsEngineering

A cylindrical duct of plastic material is coextruded with a longitudinal wire located between the duct inner and outer surfaces, and with a stripe of a different color plastic material than the duct overlying the wire. The stripe is of a softer plastic material than the duct plastic material to facilitate cutting of same to expose the wire, but is compatible with the duct plastic material so as to crosslink therewith.

Owner:BOREFLEX

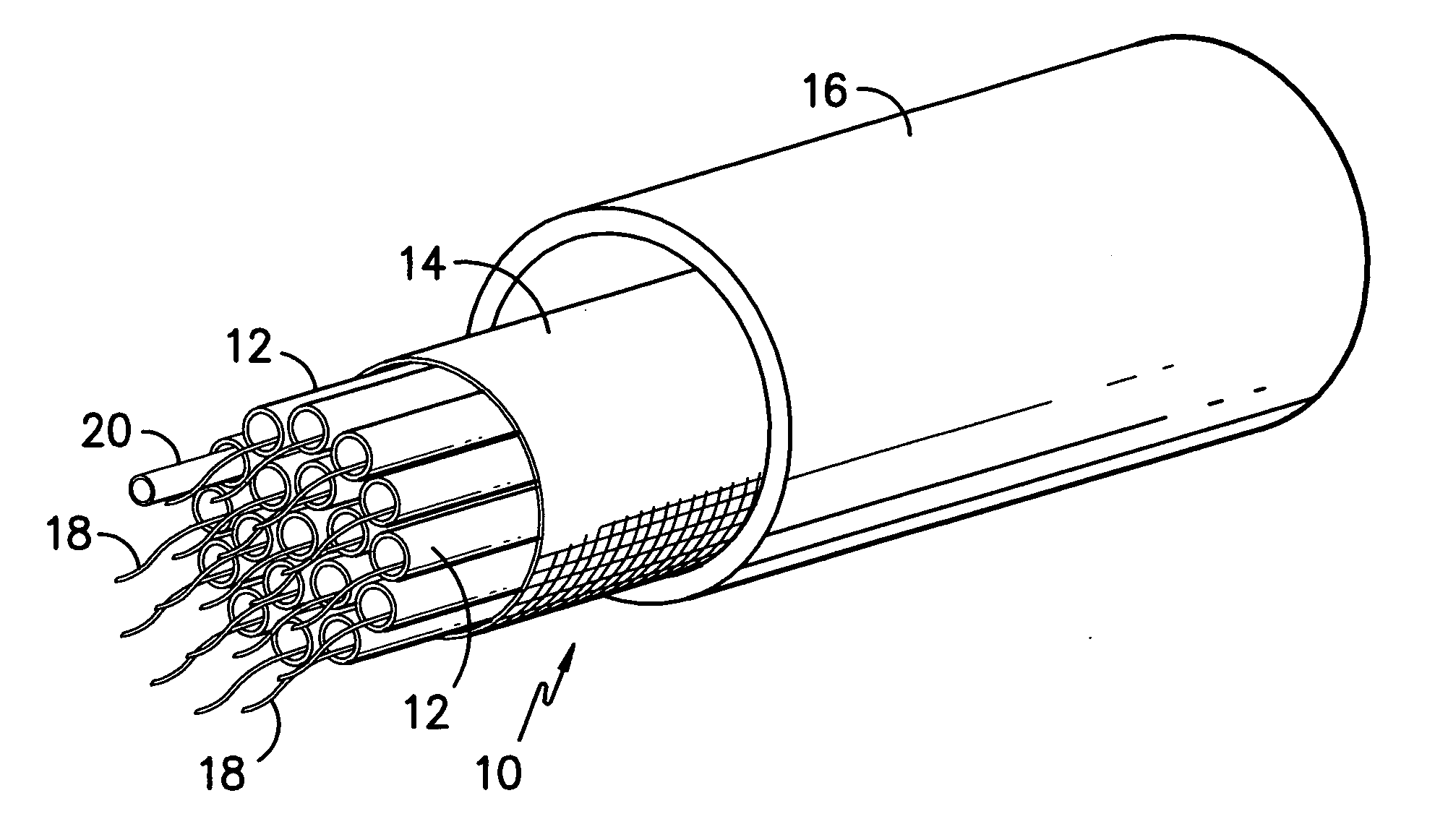

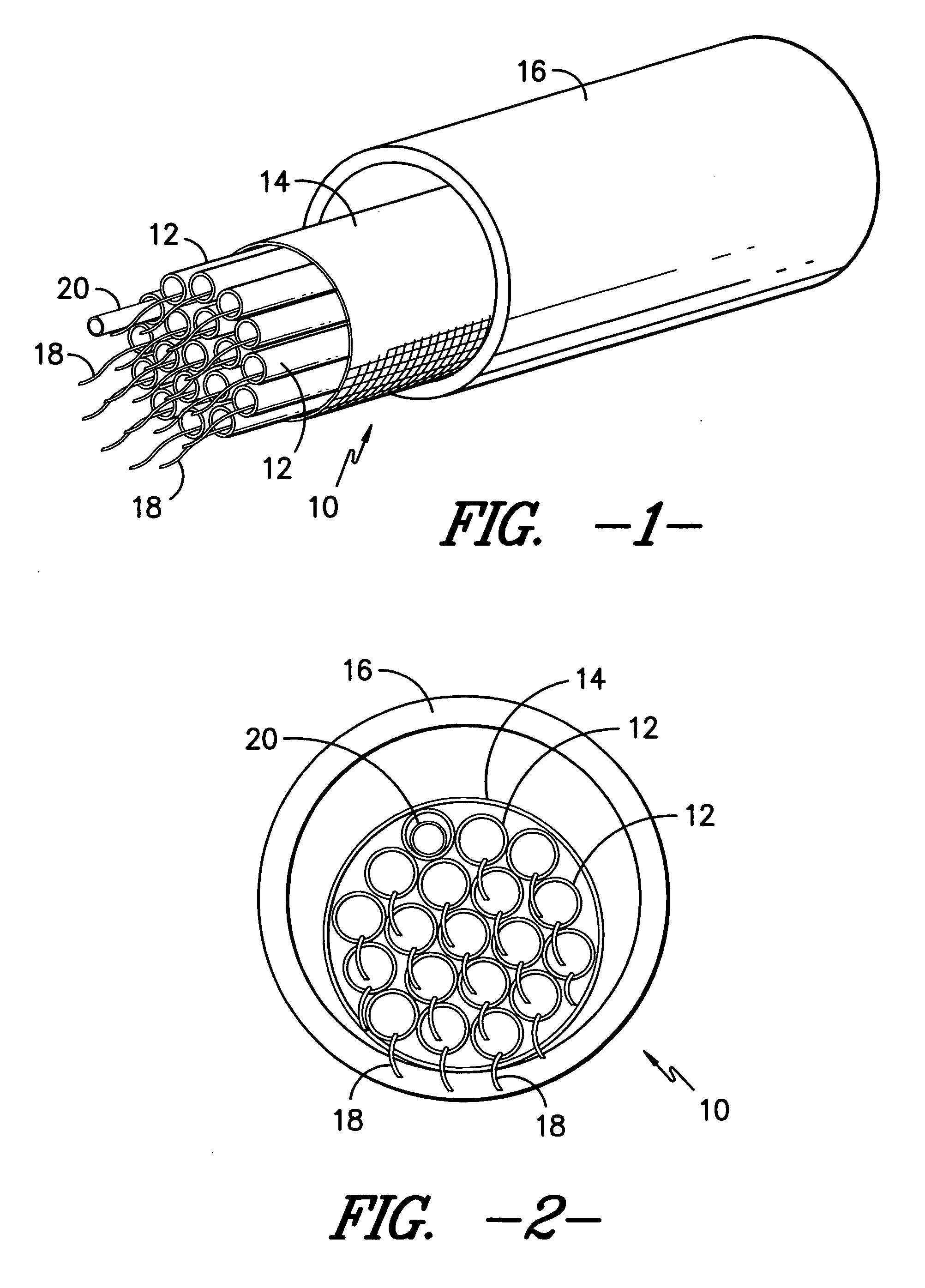

Innerduct guide tube assembly for fiber optic cable

A flexible innerduct guide tube assembly configured to contain a cable within a conduit is provided. The innerduct assembly includes a plurality of guide tubes, each tube configured to contain at least one cable, wherein the tubes are disposed and bundled within a protective textile sleeve. Each guide tube may contain means for pulling a cable into the tube, and such pulling means may include pull cord or tape, or any other means suitable for installing a cable into the guide tube. Other principal features of the invention relate to the material of which the innerduct guide tube assembly is formed, as well as methods for manufacturing and using the innerduct assembly.

Owner:MILLIKEN & CO

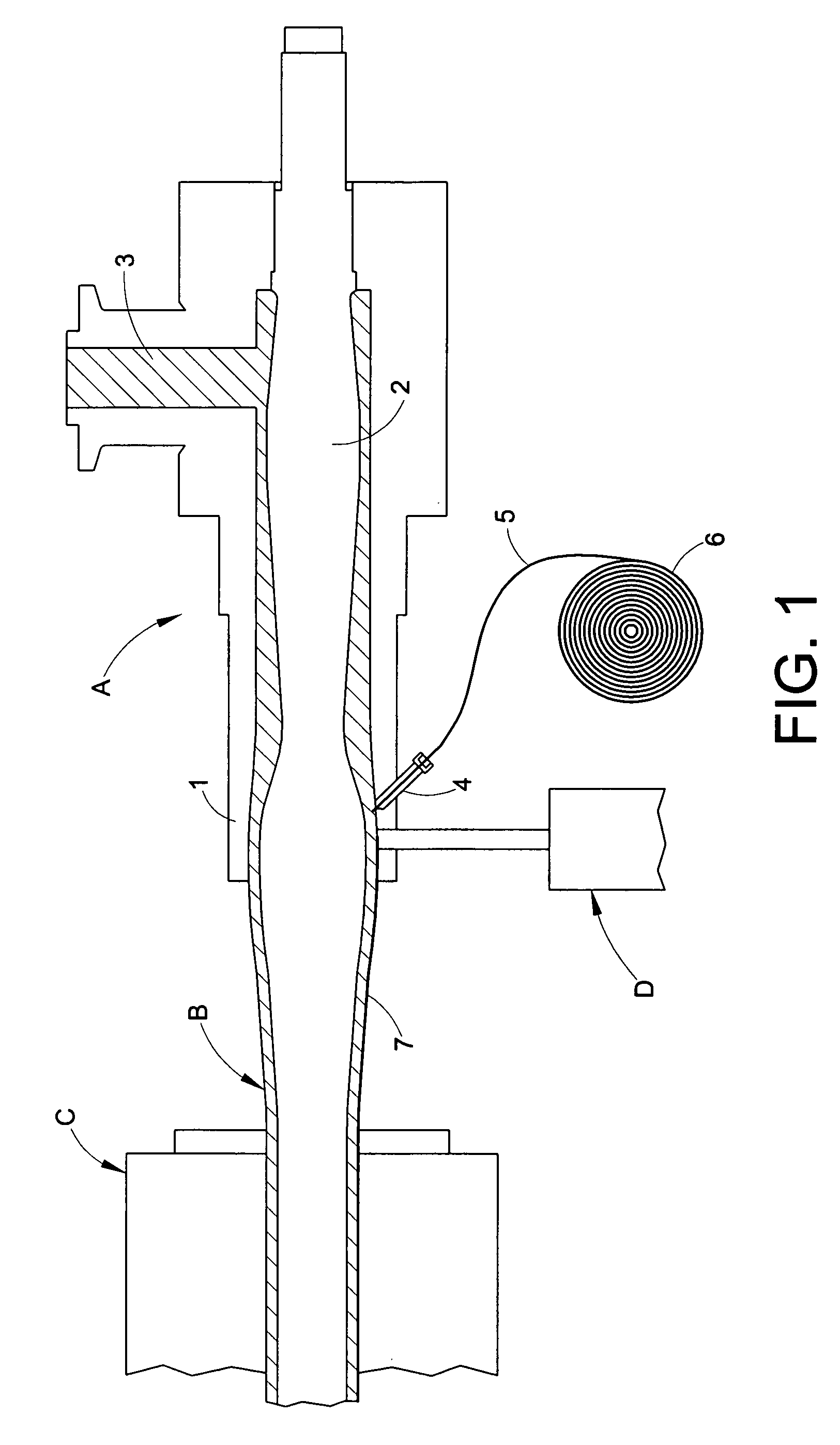

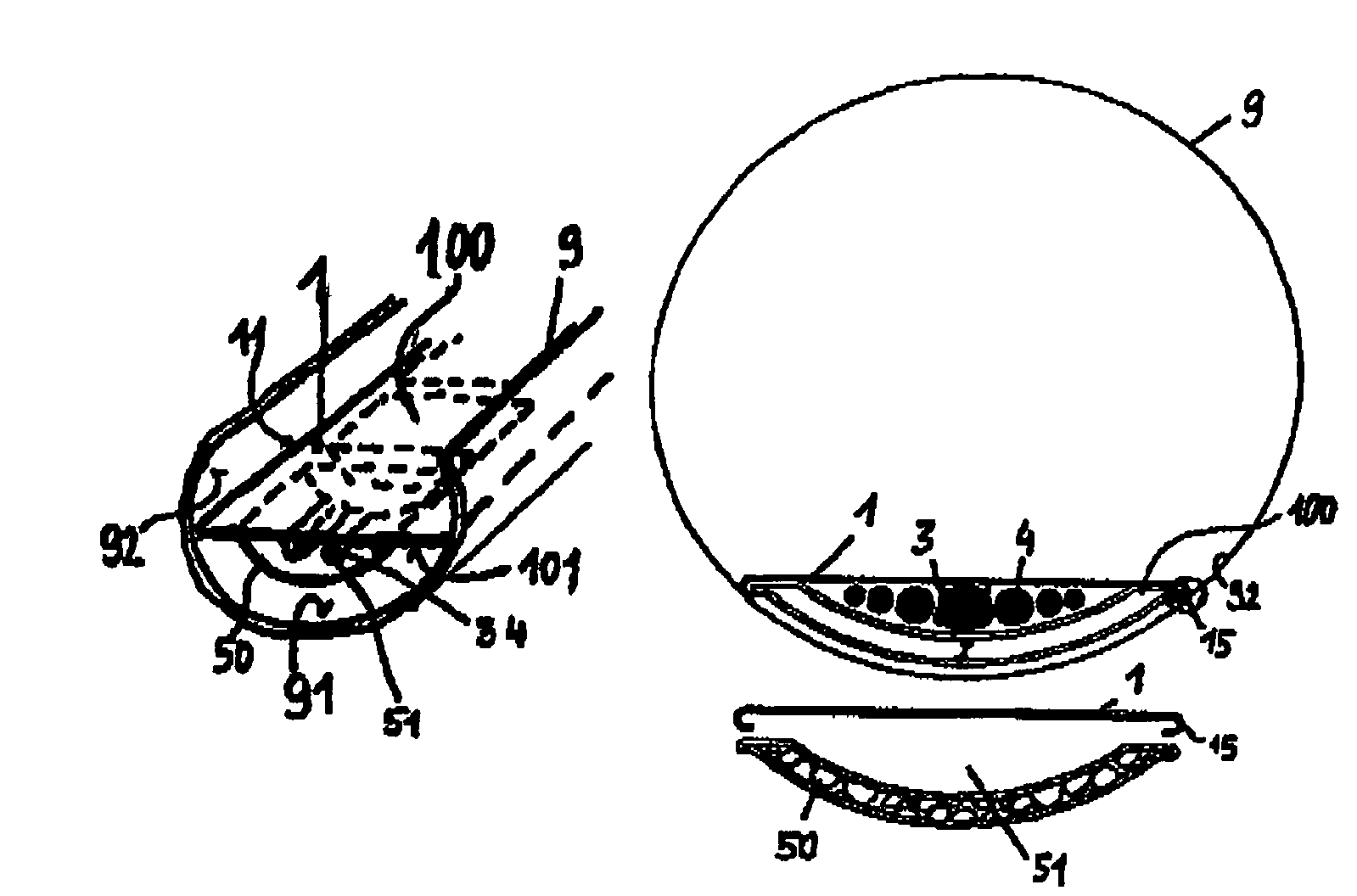

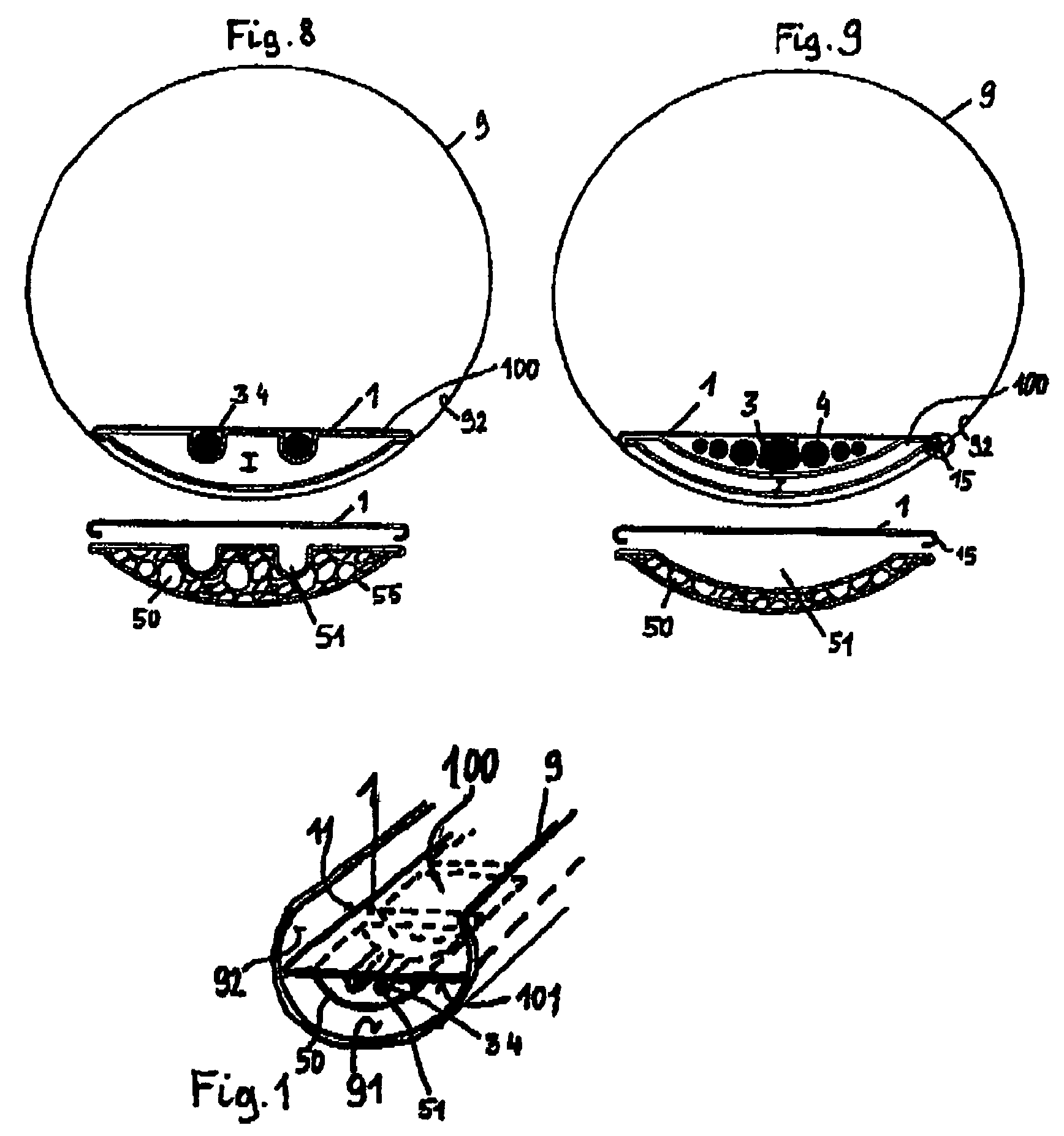

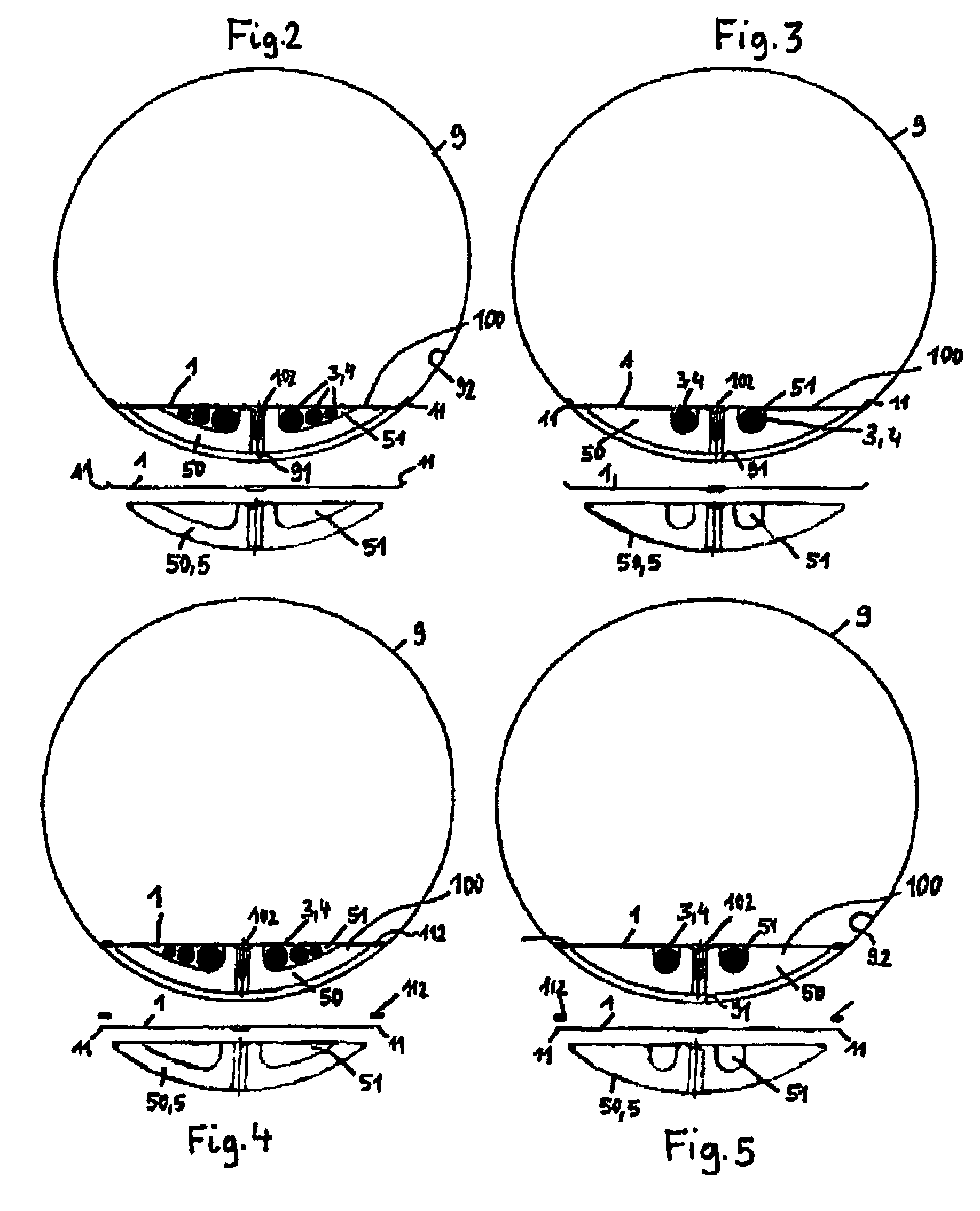

Cable laying configuration

InactiveUS7514628B2Low manipulationThe material is lowPipe supportsPipe laying and repairFiberFluid transport

A laid cable configuration contains cables, preferably electric cables, data and information transport cables and / or control cables, in particular fiber optic cables, and fluid transport tubes and is to be disposed in galleries, tunnels, shafts, pipes, channels or the like, in particular water and / or waste-water guiding systems. The configuration contains at least one cable which is to be laid, which can be unwound from a drum from the region of an opening providing access to an installation shaft or access shaft toward the respective pipe or channel, or drawn or fixed in a stationary manner in the pipe, channel or the like. The configuration includes a flexible and / or articulated carrier band having lateral edges that are laid against an inner wall surface of the pipe or the channel. A weighting body is suspended from the carrier band.

Owner:CABLERUNNER AUSTRIA GMBH & CO KG +1

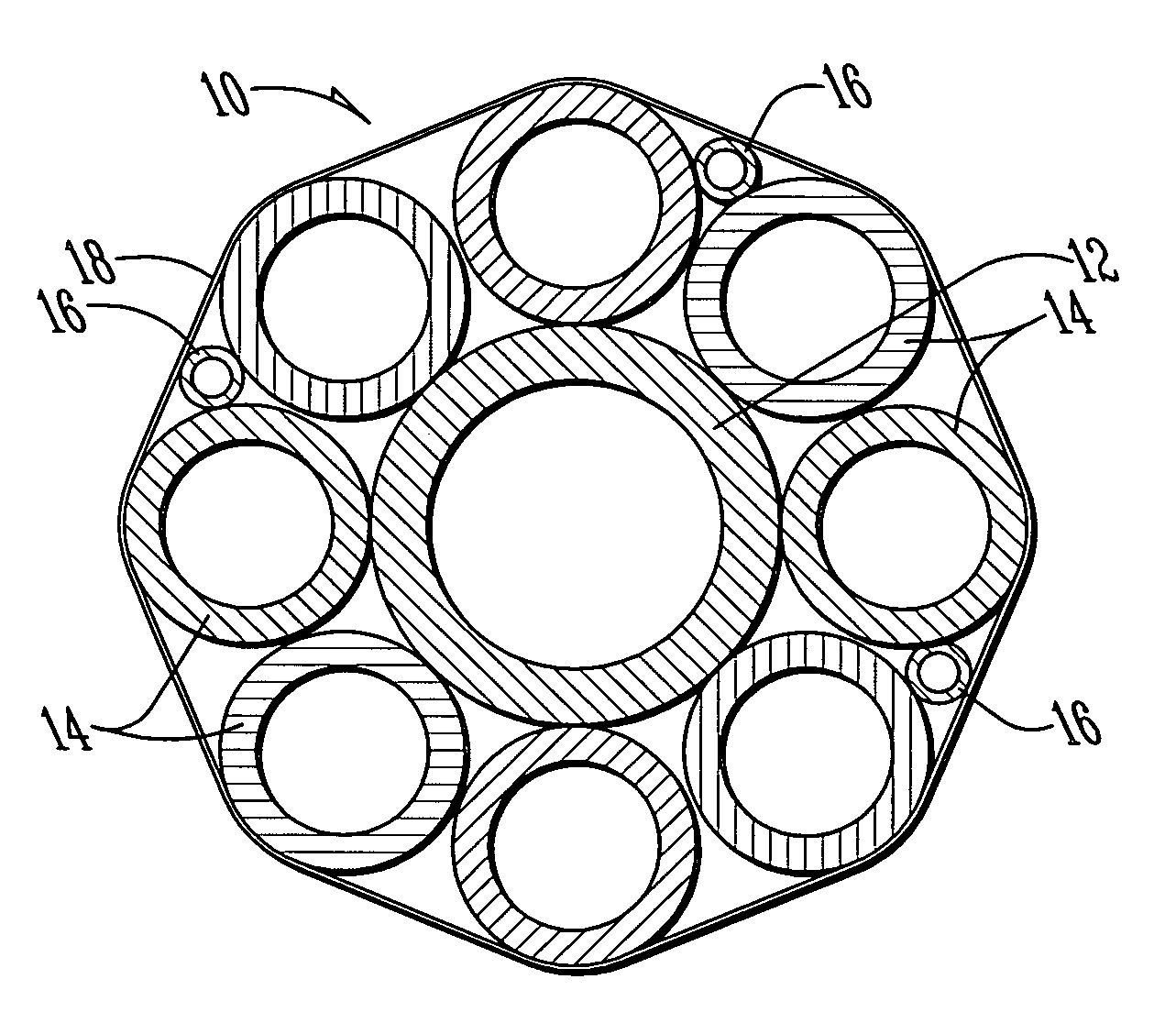

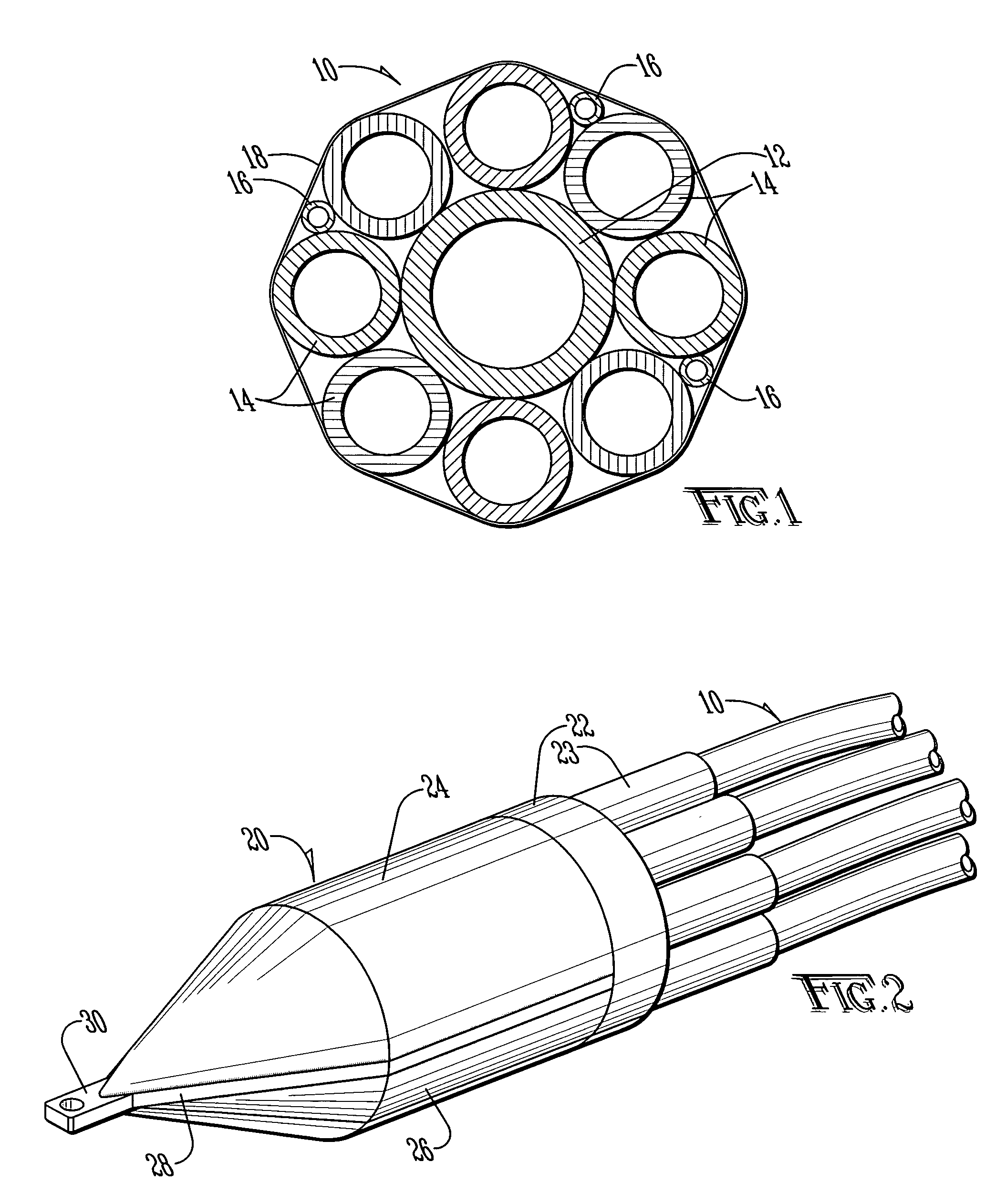

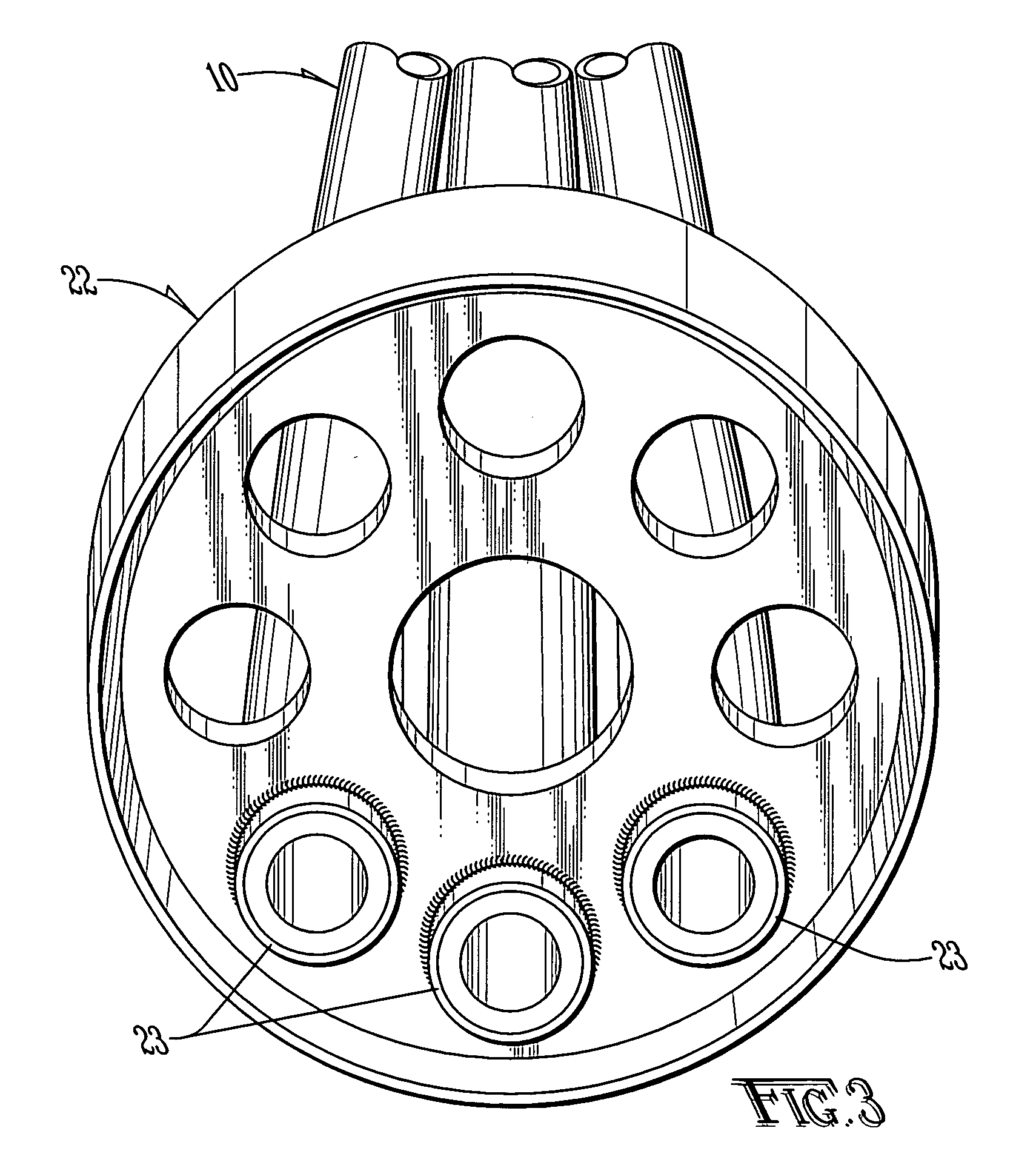

Pipe bundle for underground installation

InactiveUS6979776B1Optimizing electrical/magnetic characteristic of designLittle strengthPipe laying and repairWaterborne vesselsEngineeringMechanical engineering

A pipe conduit bundle for installation into a wellbore using horizontal drilling techniques is disclosed. The pipe conduit does not require an outer casing for construction. The pipe bundle configuration is formed by pipes of varying sizes in a particular configuration, with bindings interspaced along the length of the pipes such that the pipe bundle deflects as a single unit during installation. A pulling head is attached to the bundle, which is hollow to allow liquid entering one pipe to be distributed to other pipes. Liquids such as water may be used to fill the pipes to reduce buoyancy, and thereby reduce drag, during installation of the bundle.

Owner:ENTERGY LOUSNA

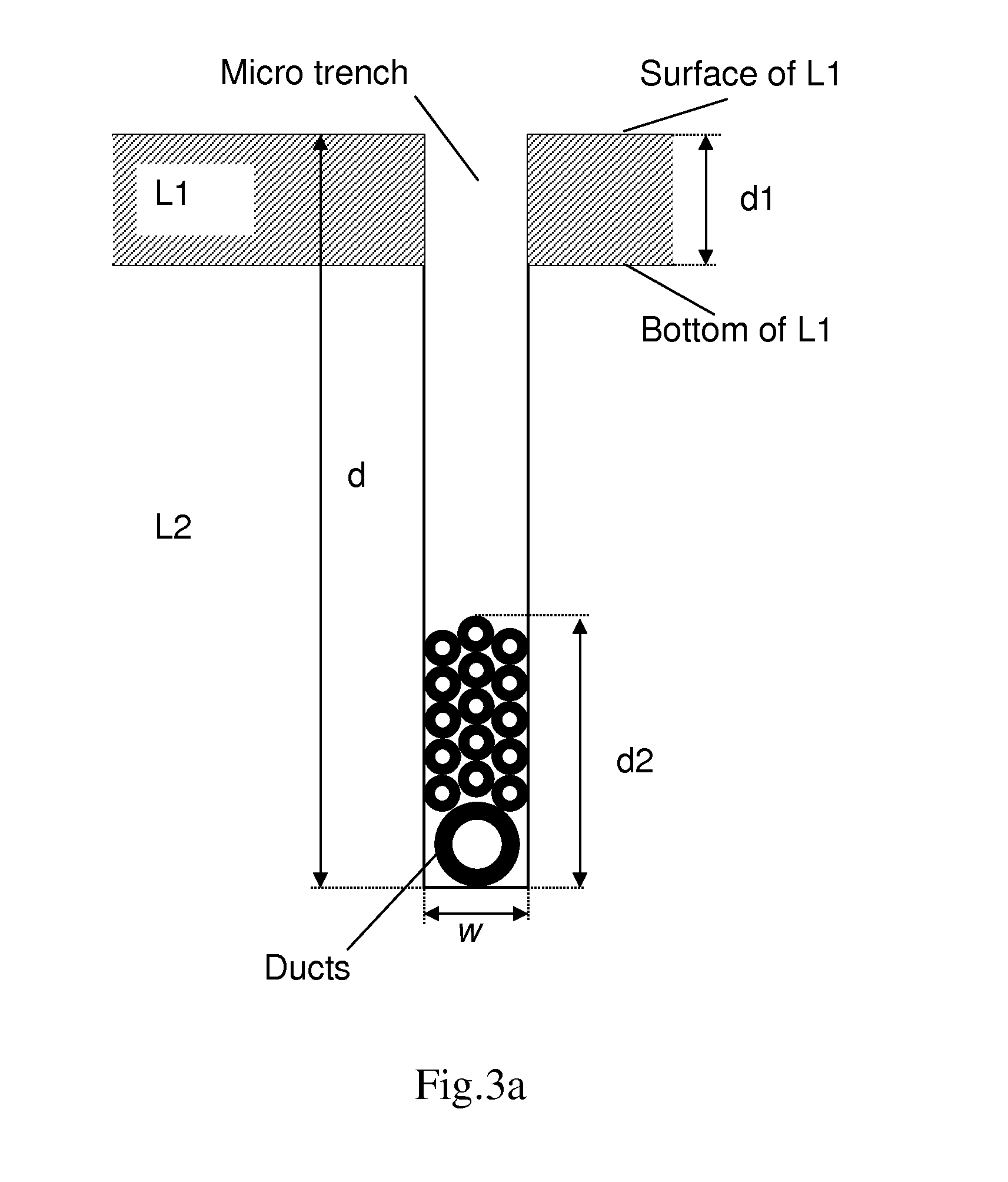

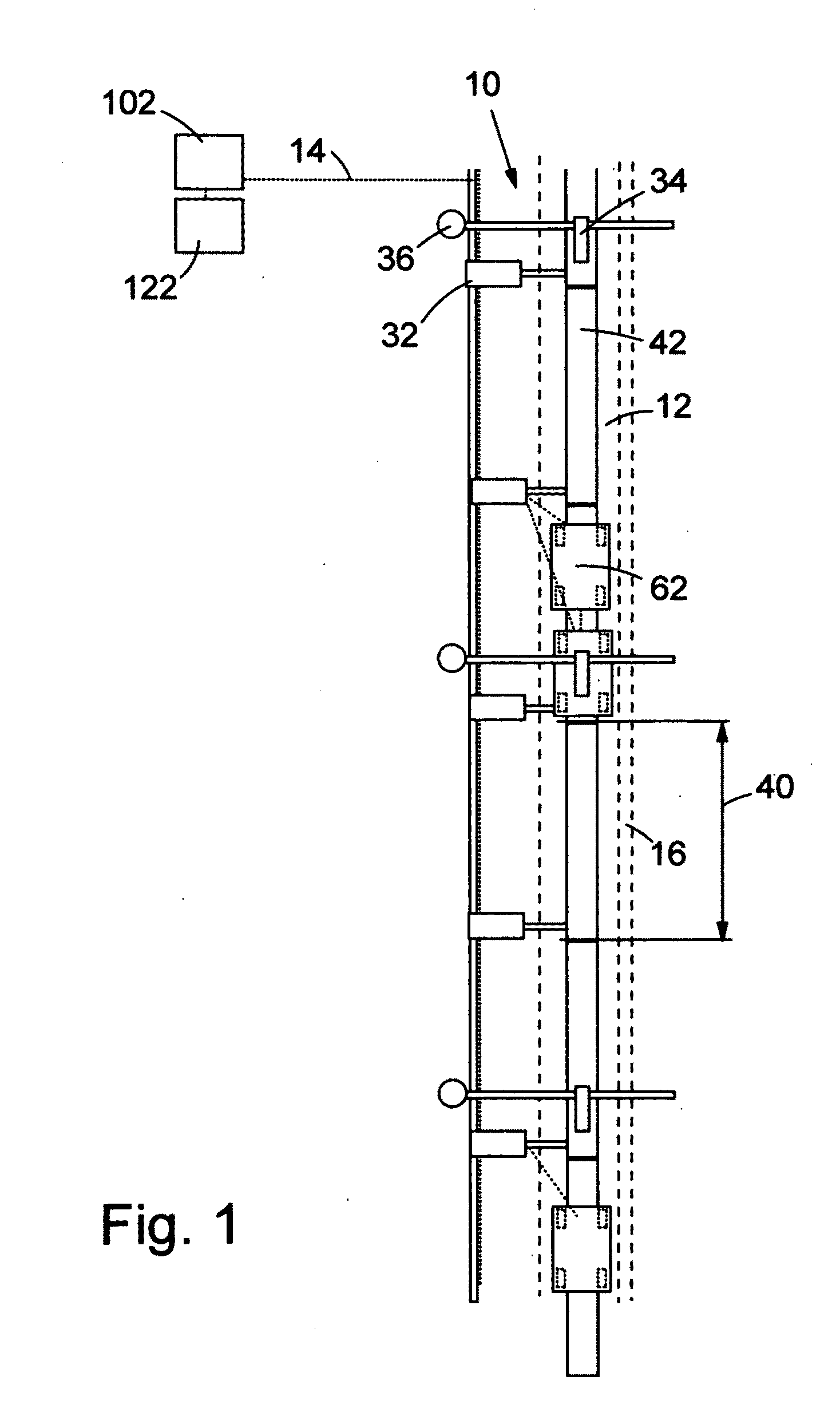

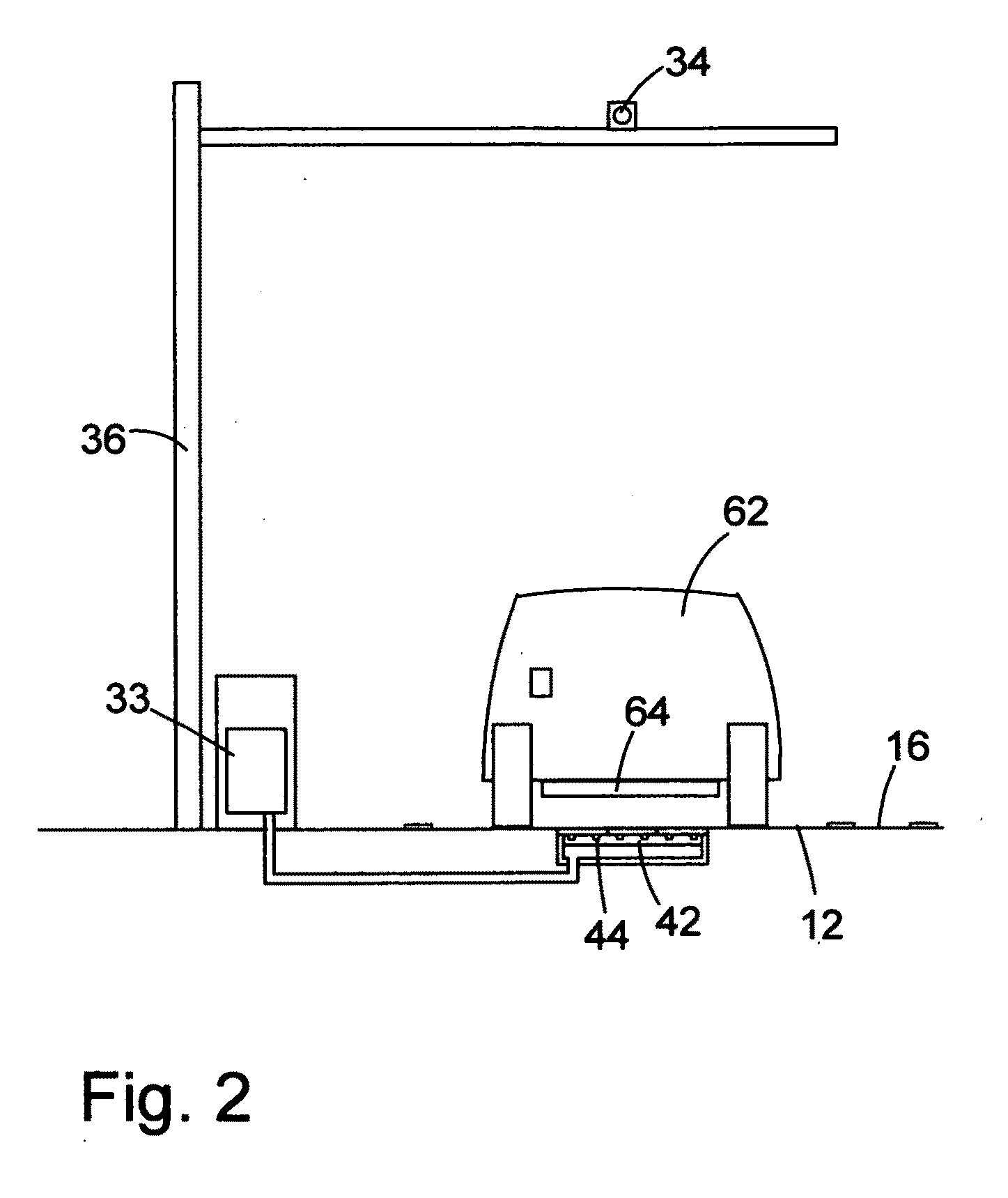

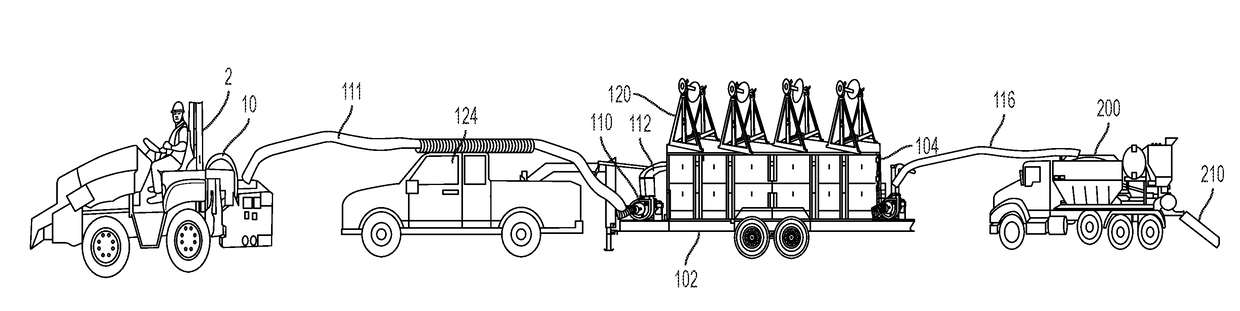

Method for placing at least one duct/communication cable below a road surface in an area

ActiveUS20130294839A1Low costNetwork securitySoil-shifting machines/dredgersFoundation engineeringEngineeringRoad surface

Owner:GUSTAVSSON CONNY MR +2

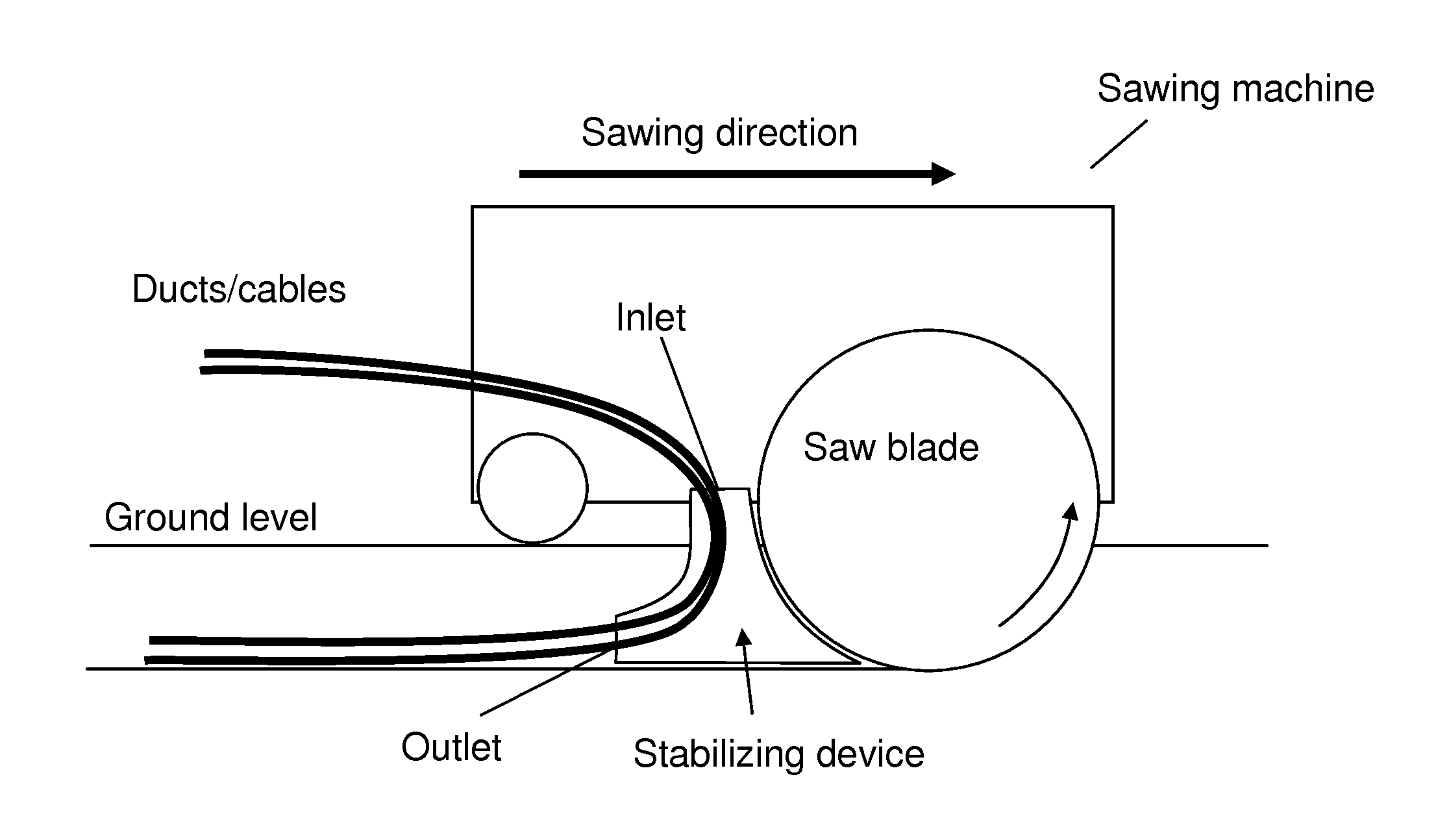

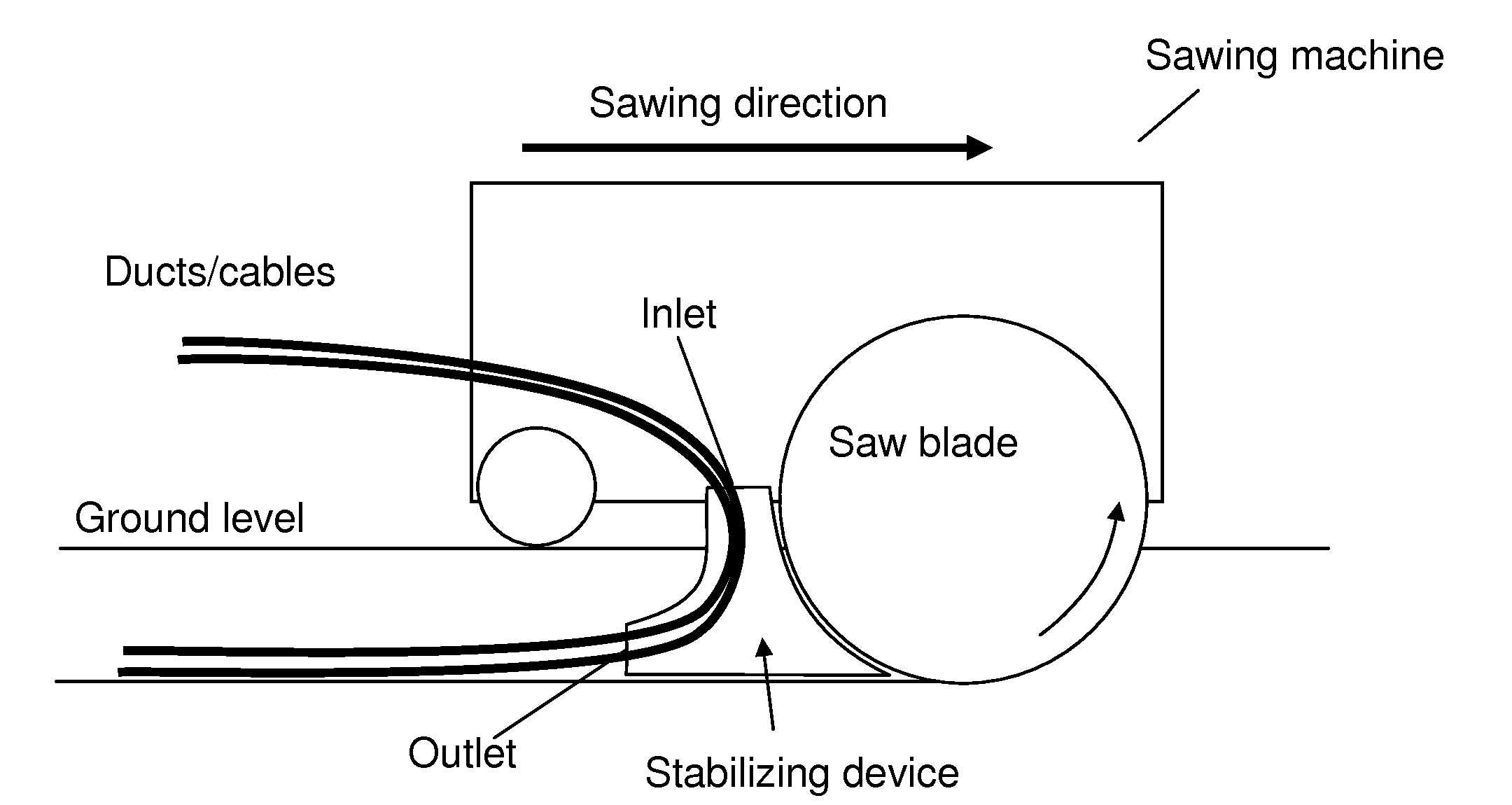

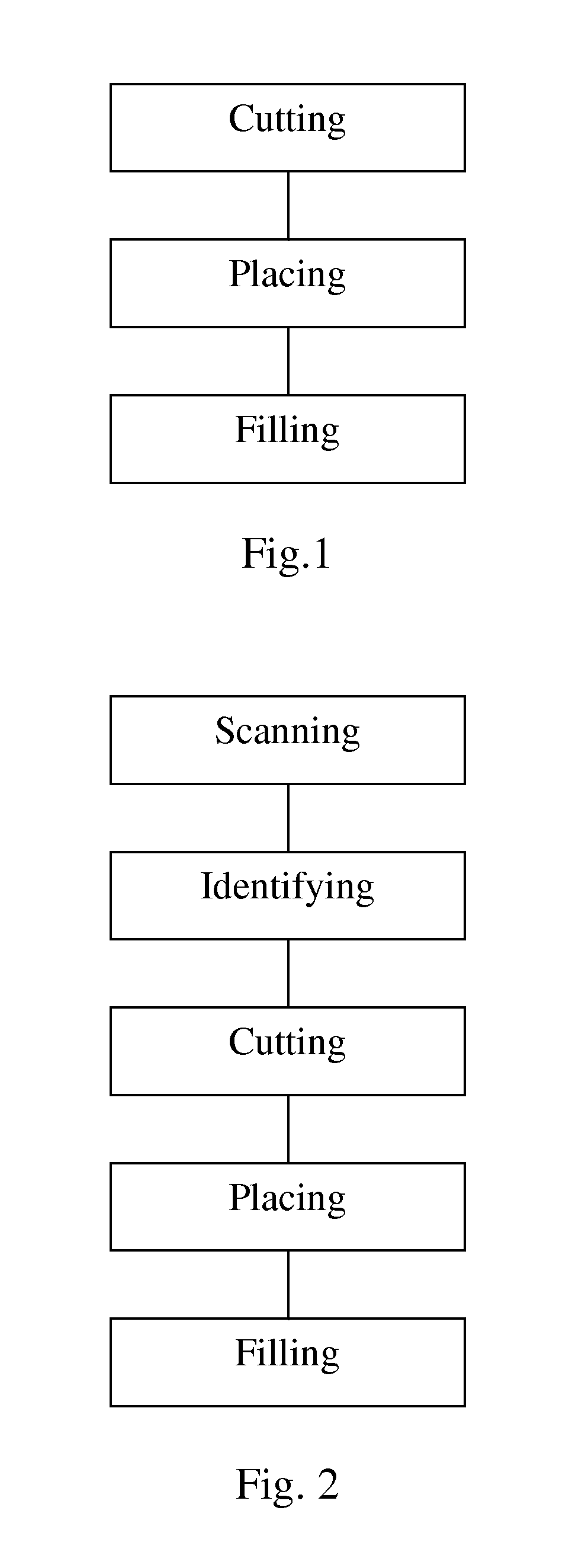

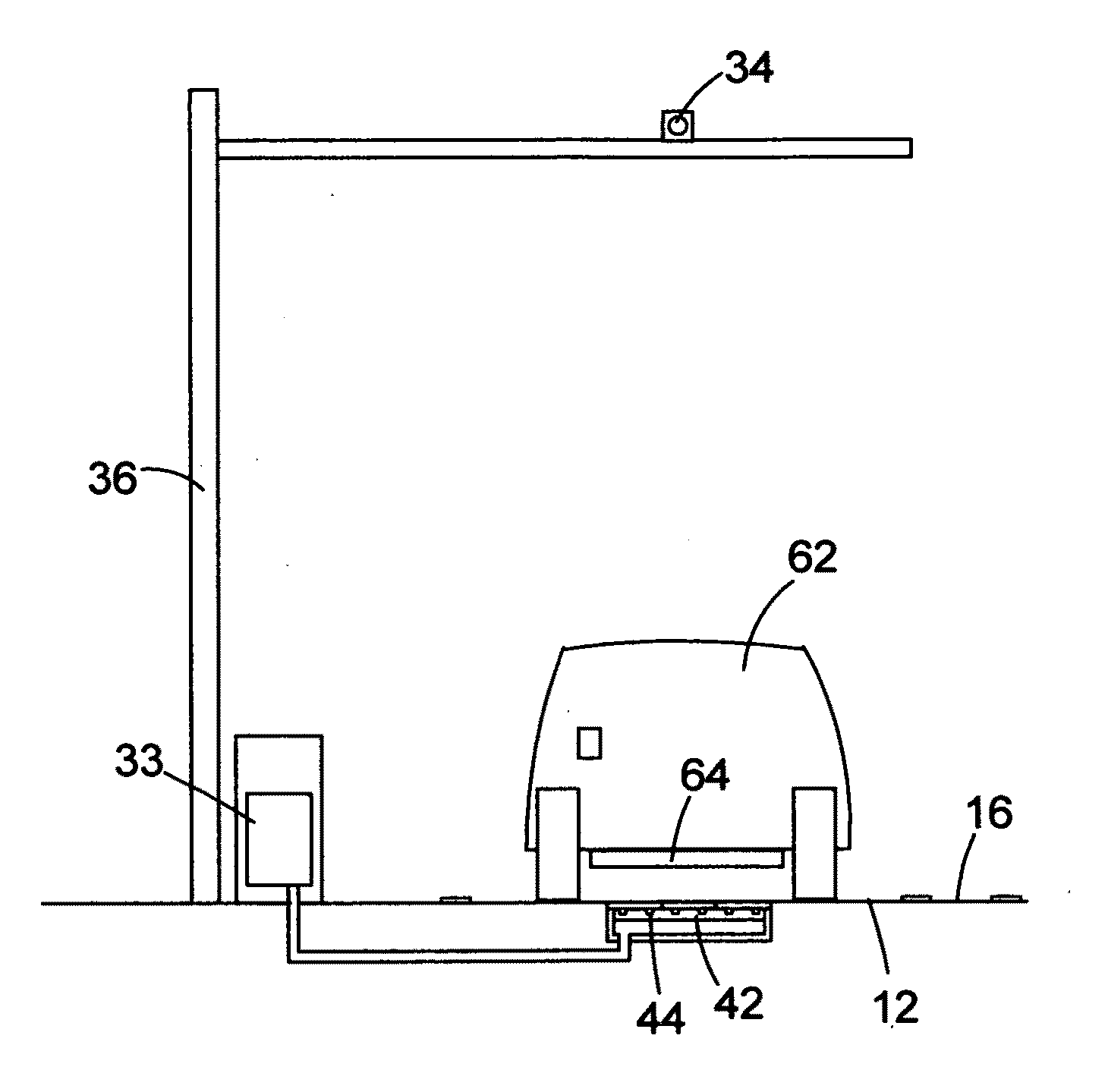

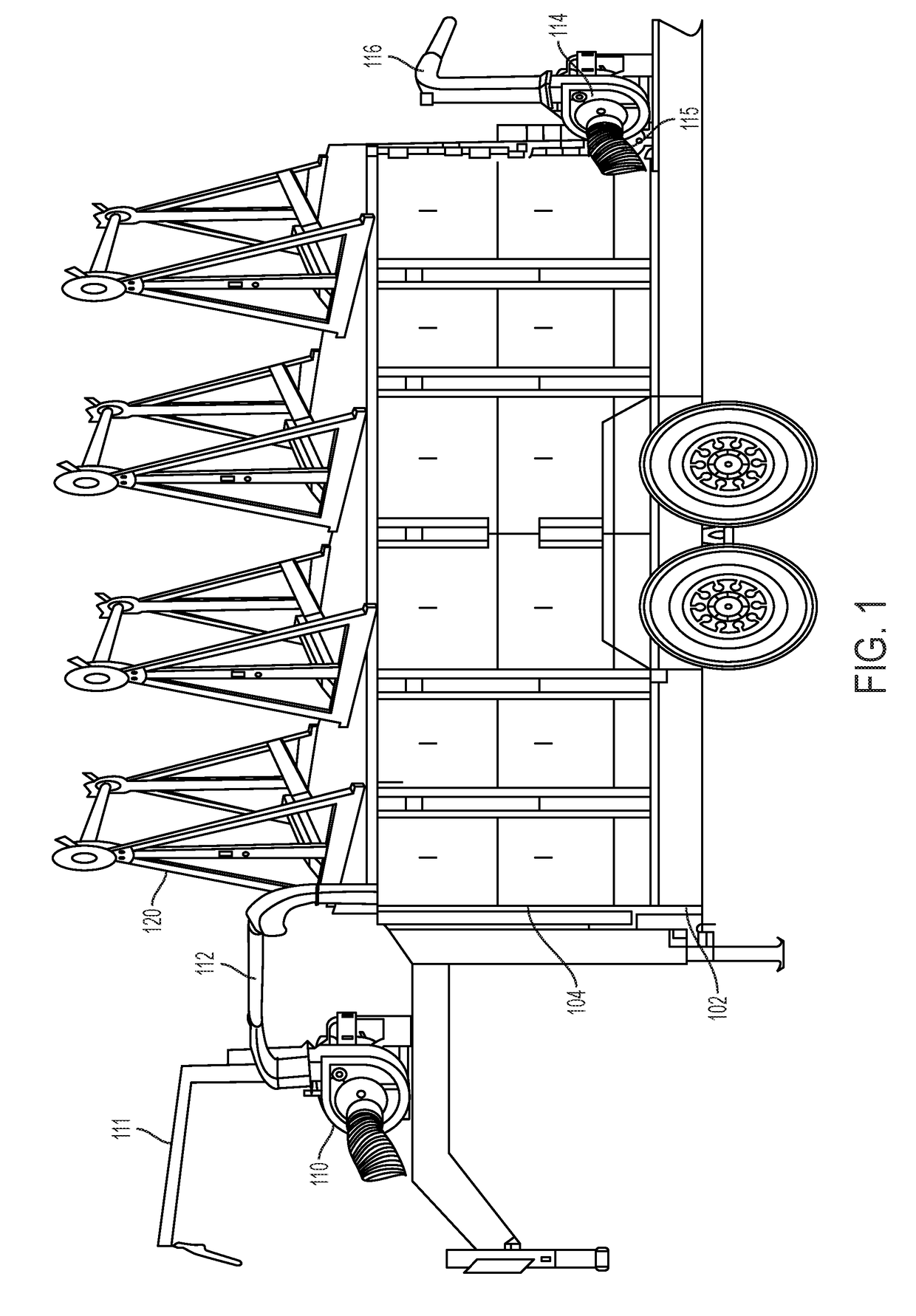

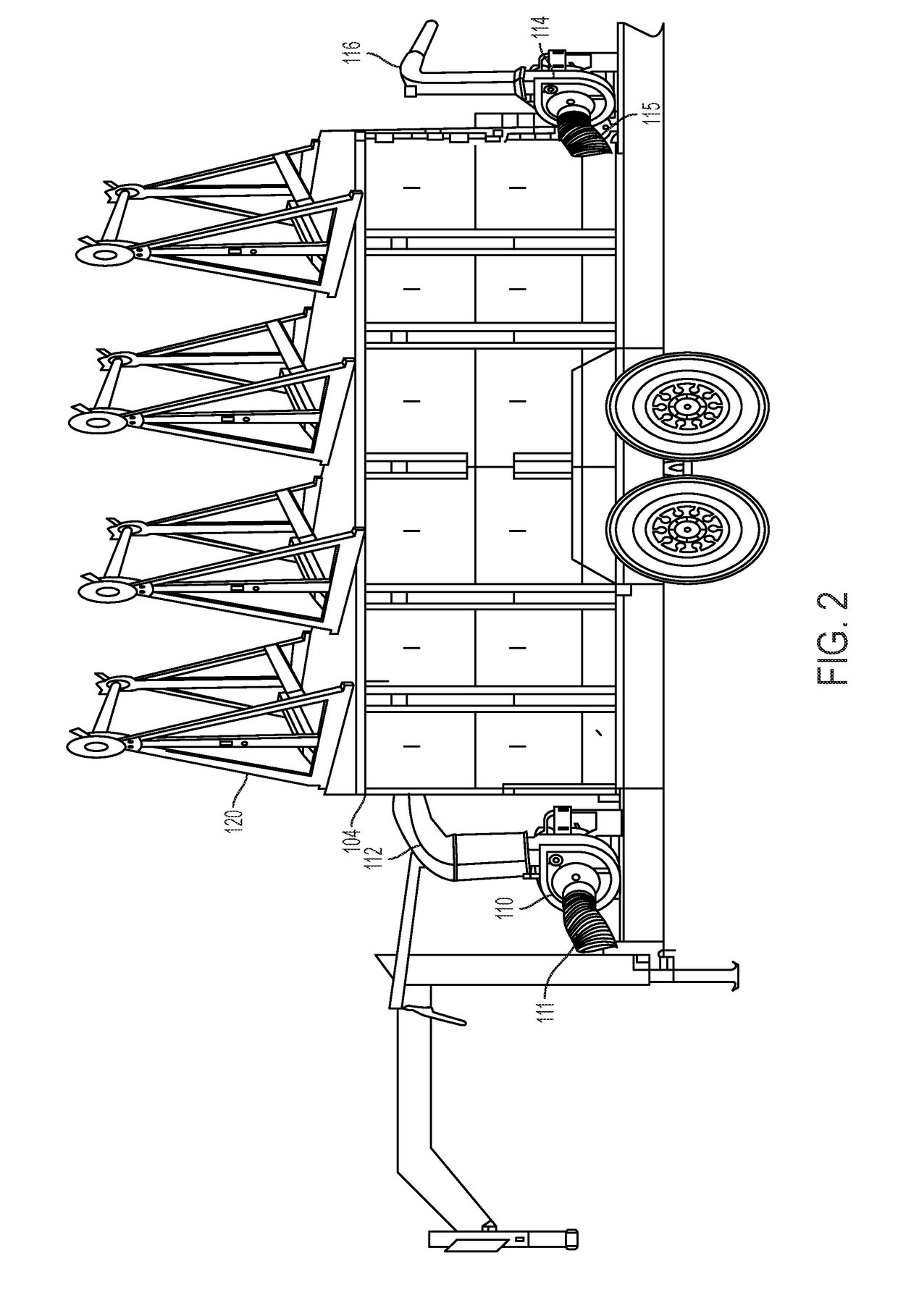

Machine for sawing trenches and placing ducts/cables

ActiveUS20130216313A1Shorten the timeSave moneySoil-shifting machines/dredgersFoundation engineeringEngineeringStructural engineering

The present invention relates to a machine arranged for sawing micro trenches and placing ducts / communication cables in micro trenches, said machine comprising a saw blade arranged for sawing a micro trench in an area; said machine further comprises a stabilizing device arranged for stabilizing the walls of said micro trench when placing ducts / communication cables into said micro trench, said stabilizing device being positioned immediately behind said saw blade in said micro trench, and said stabilizing device comprising guiding means for guiding at least one duct / communication cable when placed into said micro trench.

Owner:GUSTAVSSON CONNY MR +2

Modular Ducting Section Adapted for Laing End-To-End and Side by Side Forming a Networked Utilities Ducting System and Rain and Run-Off Water Management System

ActiveUS20130121761A1Cost-effectiveLow-cost installationCable installations in surface ductsGround-workCycloneRoad surface

The invention integrates the functionality of: kerbs, gutters, pathways, into a surface accessible networked utility ducting system and a a rain and run-off water management system.It is comprised of a base section formed a combination of one or more open topped utility access channels, an open topped water catchment channel, a slopped flange and one or more open sided access and or open topped feeder line distribution channels.The invention includes features for the isolation of electric power channels from contact with other utilities such as gas, water, or communications.The invention includes features for, integration with existing stormwater systems such as overflow points.The invention provides utilities access pathway all the way to an end users premises with minimal need for digging or disturbance of footpaths or paved surfaces this is a major improvement upon the prior art which tranforms the economics of surface accessible utility ducting systems.The invention includes covers, which are interchangeable, may take various forms, such as a pavement and kerb, a driveway ramp or a wheel chair access ramp. This allows the invention to be economically adapted to changes in kerb requirements as changes to the pathways and kerbs occur along their length and as requirements change over time, this solves the problems associated with the prior art which can not be readily adapted to all the variations found in kerbs and gutters along the length of the kerb and pavement or as they occur over time.The invention enables rain and run-off water to be isolated from contamination and managed to preserve its value and usefulness.The invention lowers the cost of, and, increases the speed, of new service deployment thereby overcoming the major economic barriers to market entry of new distributed utility services.The invention is to be manufactured in most cases as precast modules. The channels, lids, access boxes are linked by flexible interstitial joints which enable the system so formed to change direction to conform with the contours of the landscape in which it is located. In most cases the material of construction will be a dense, reinforced material such as concrete. When so constructed the invention will resist the effects of earthquakes, cyclones, flooding, tornados, and tsunamis.

Owner:DIXON GUY ANDREW COTTERILL

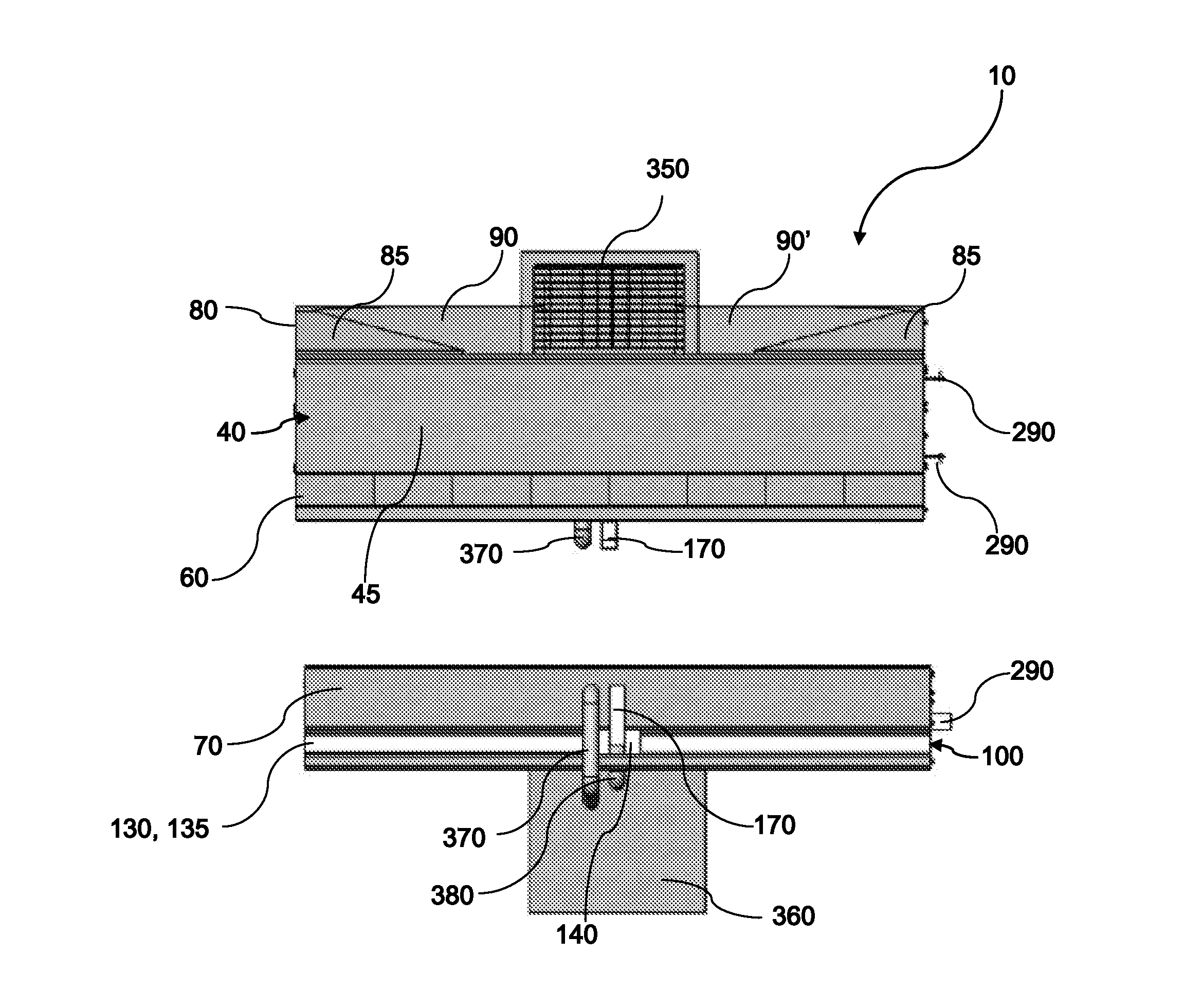

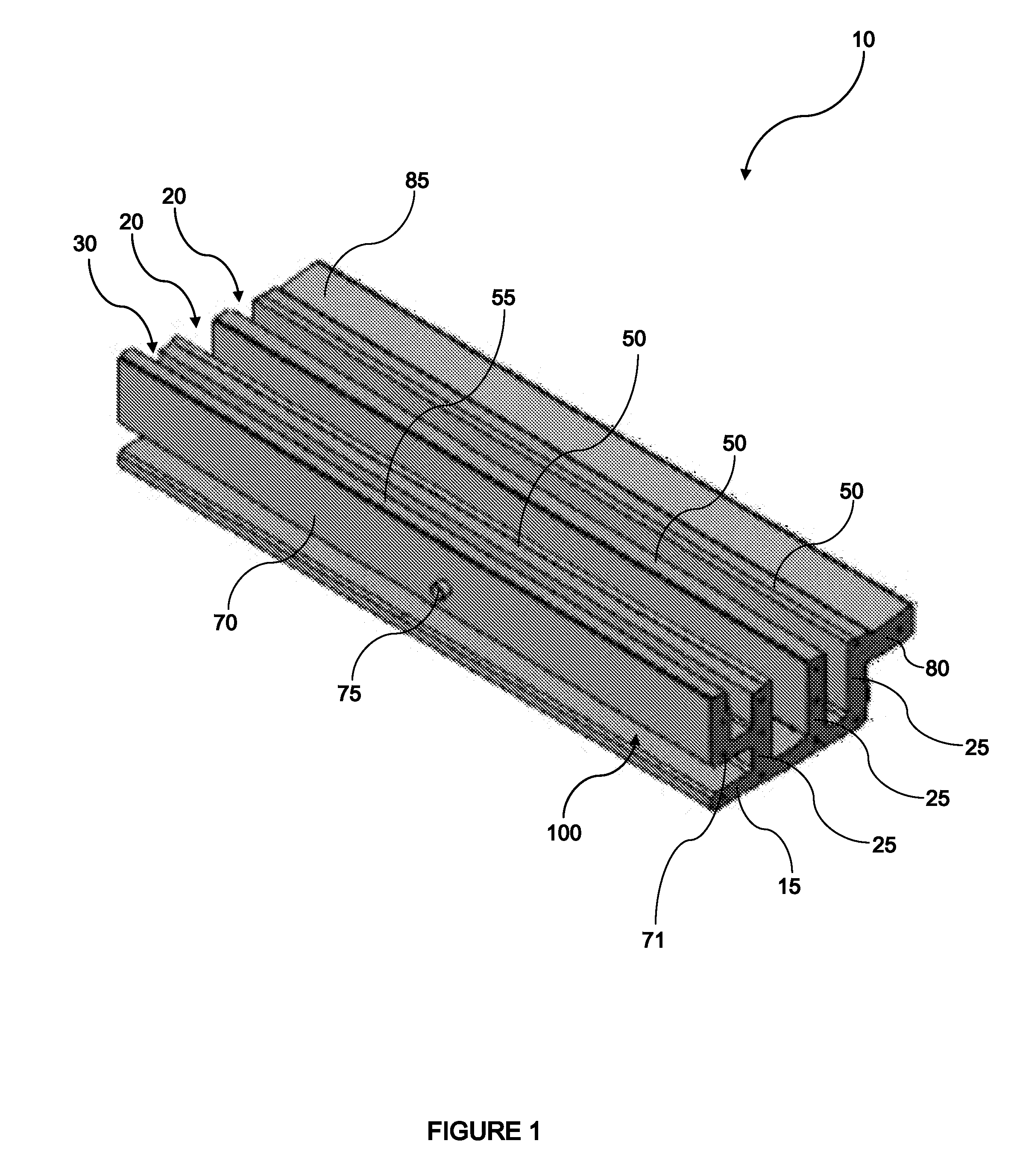

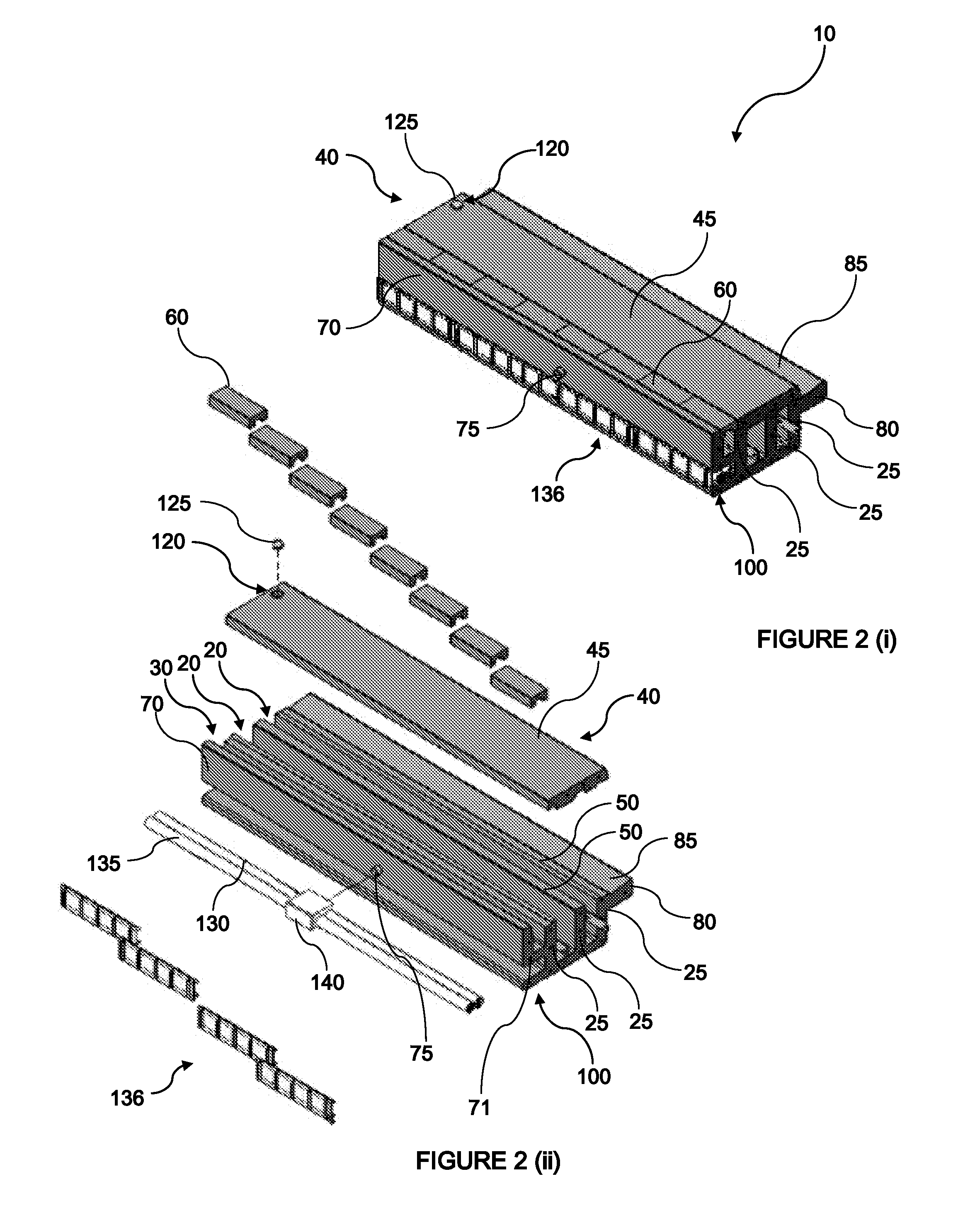

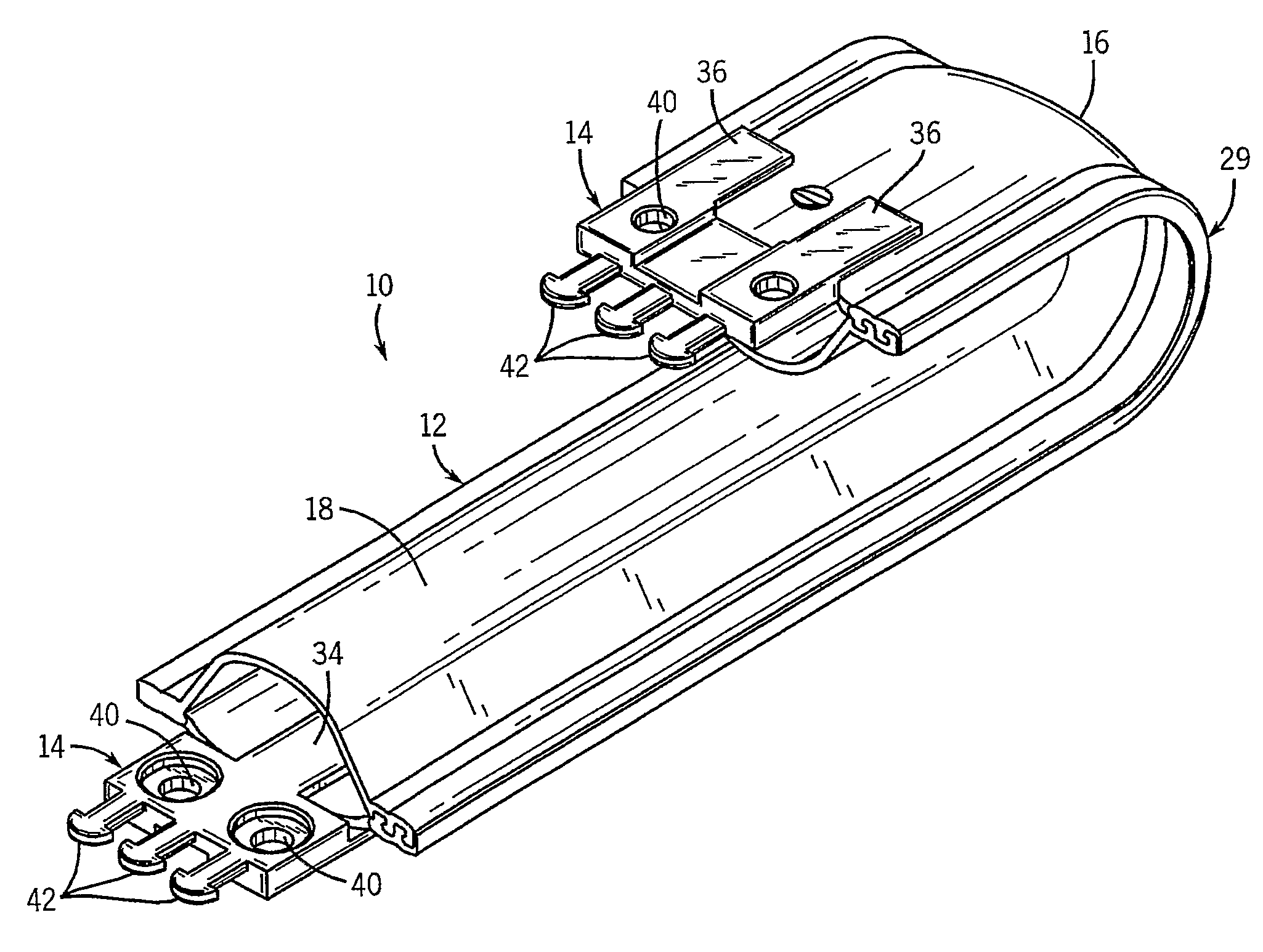

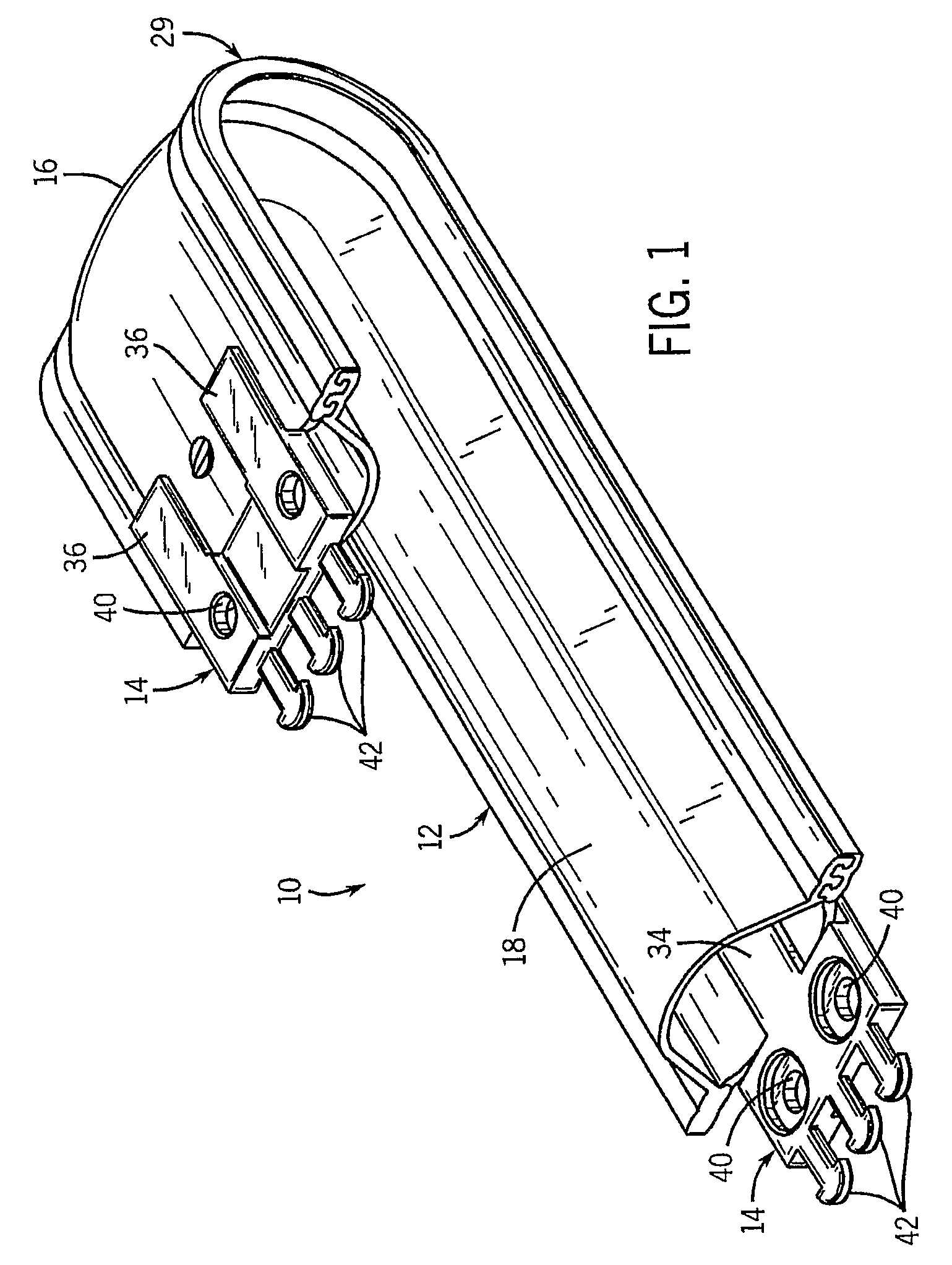

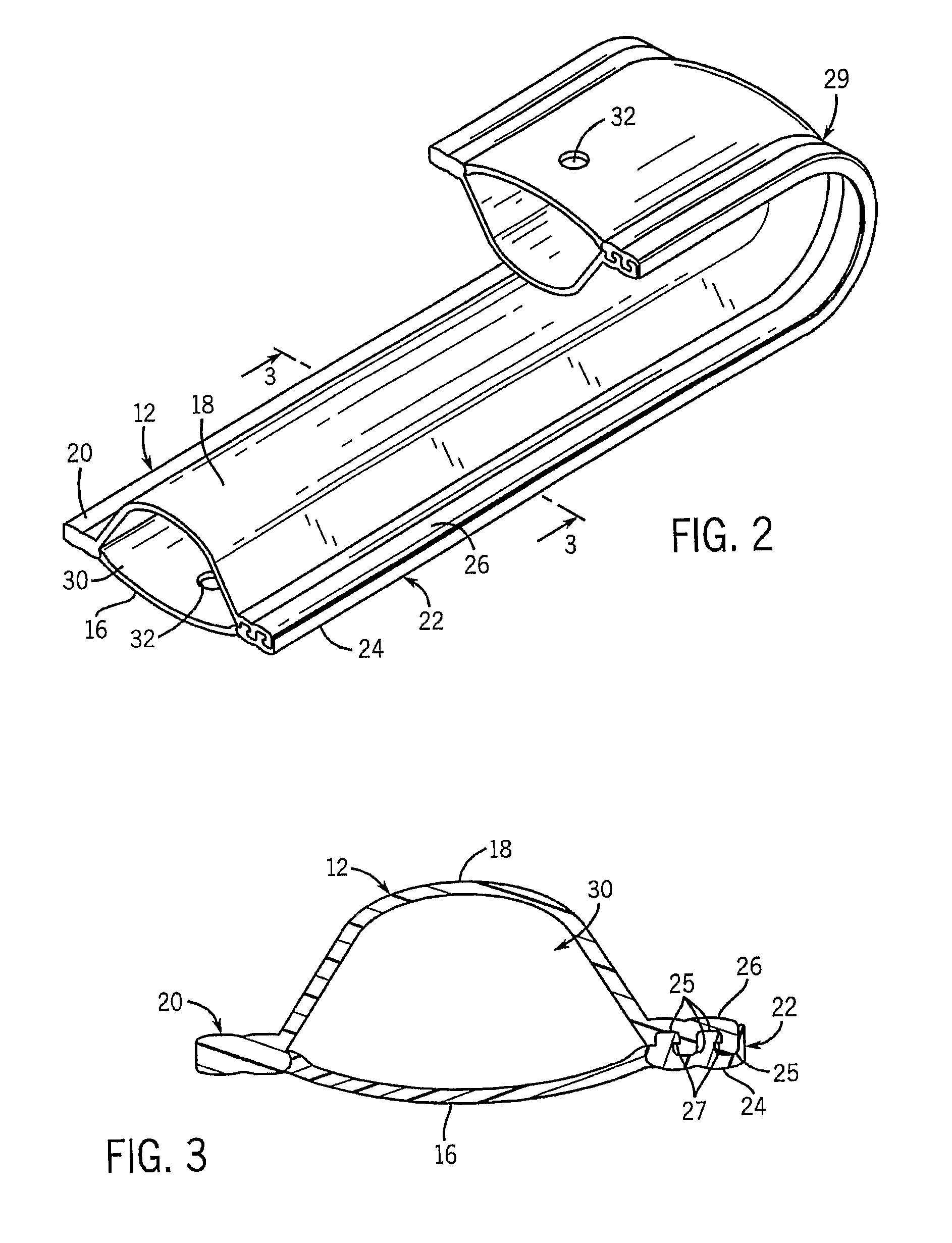

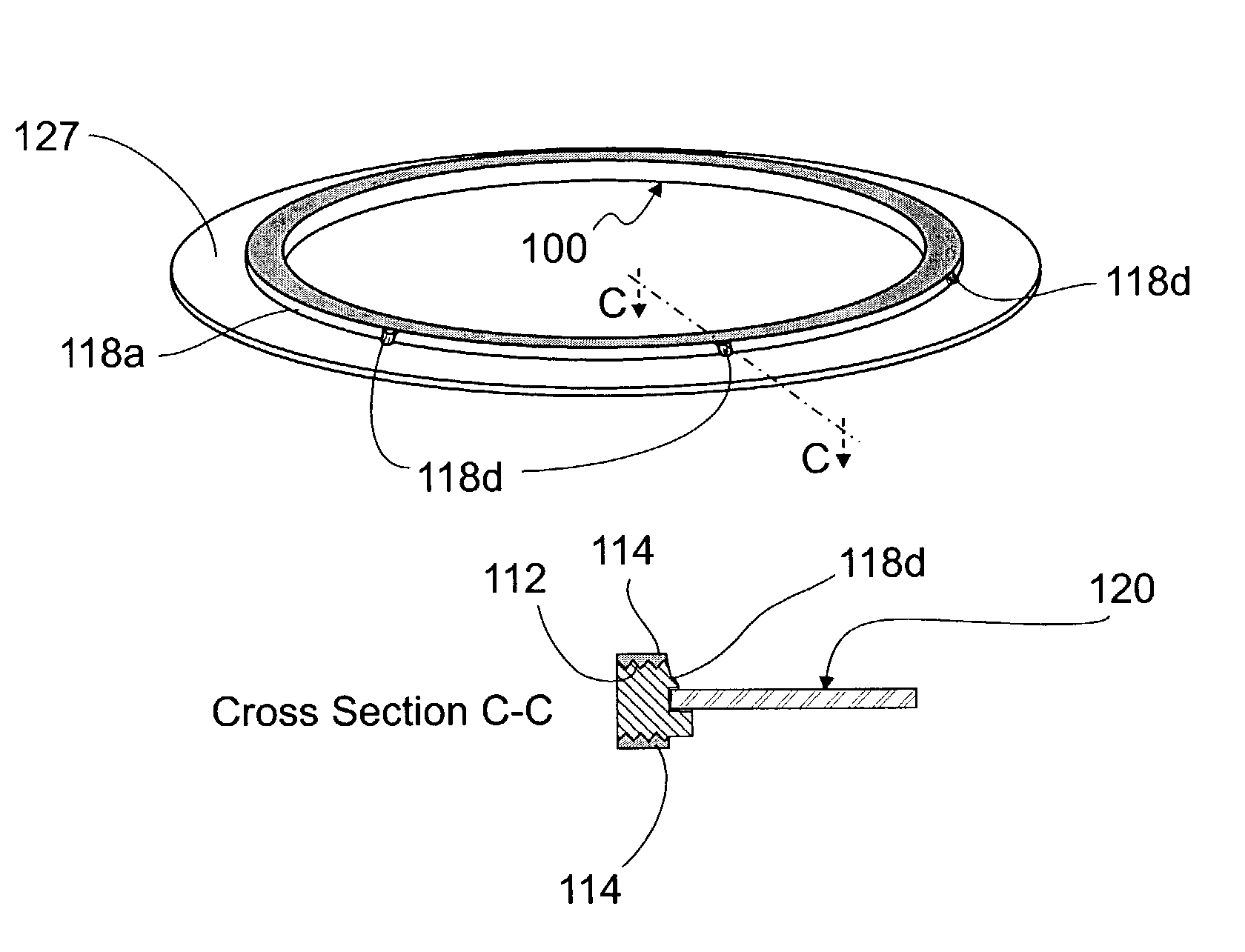

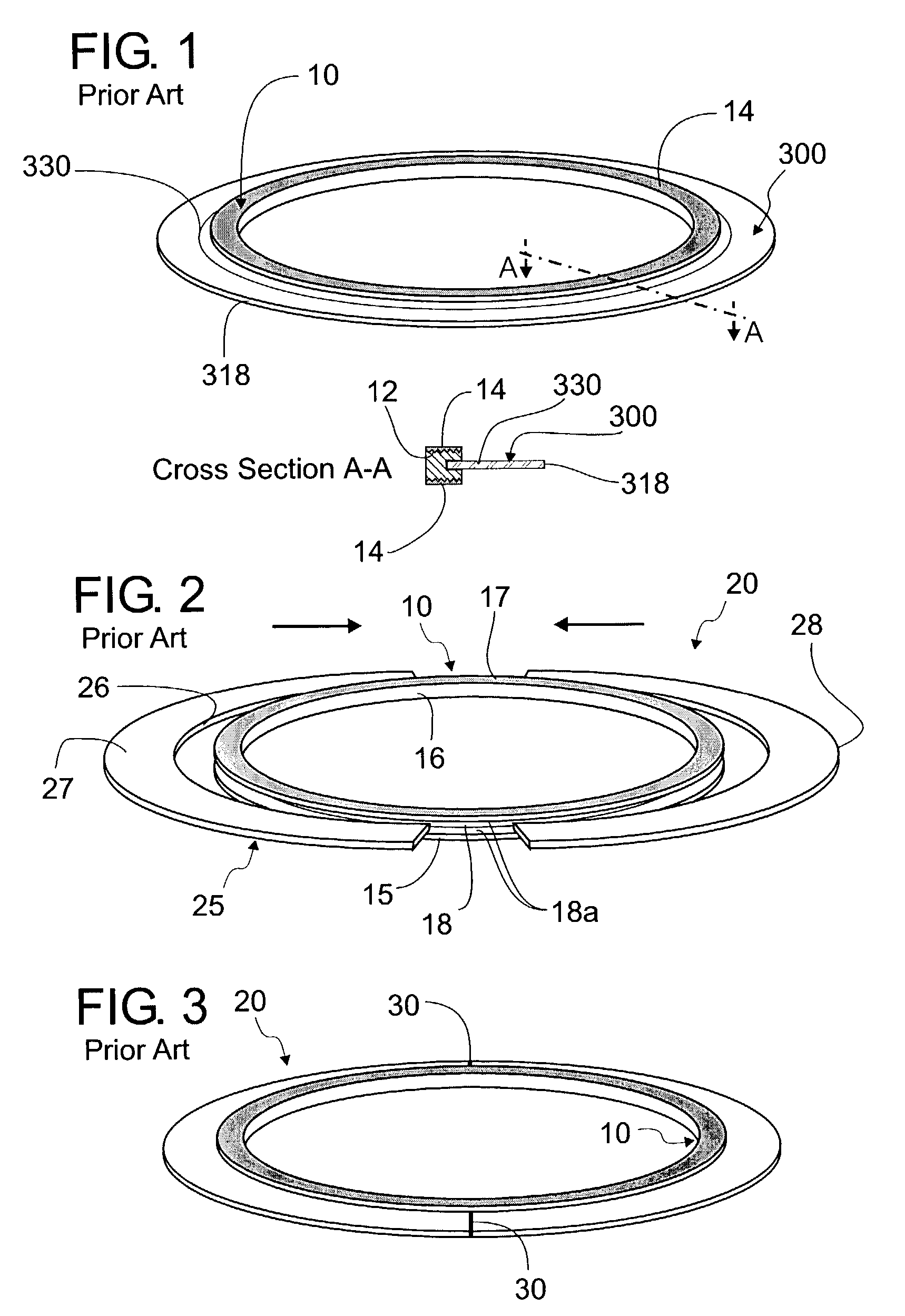

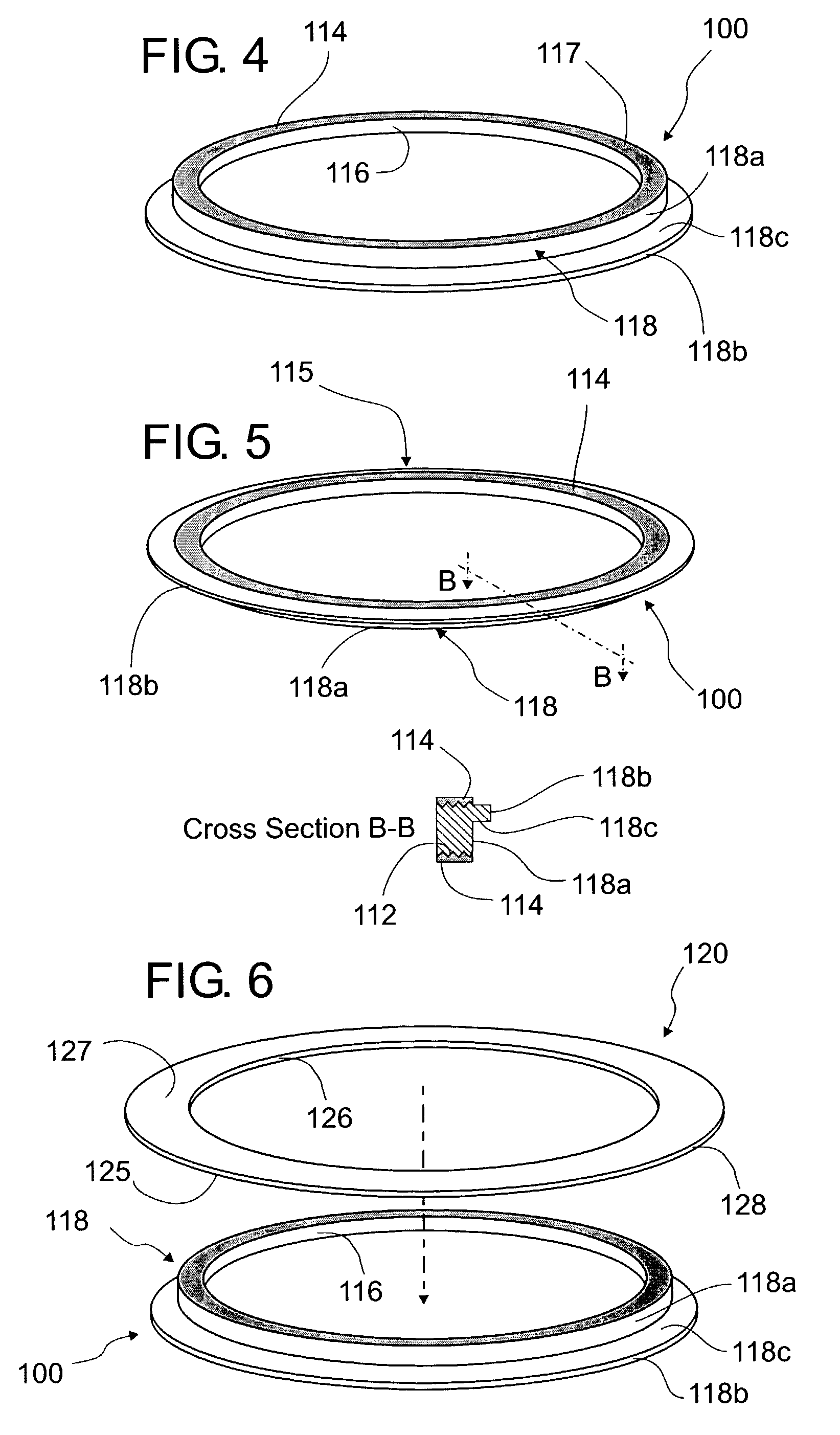

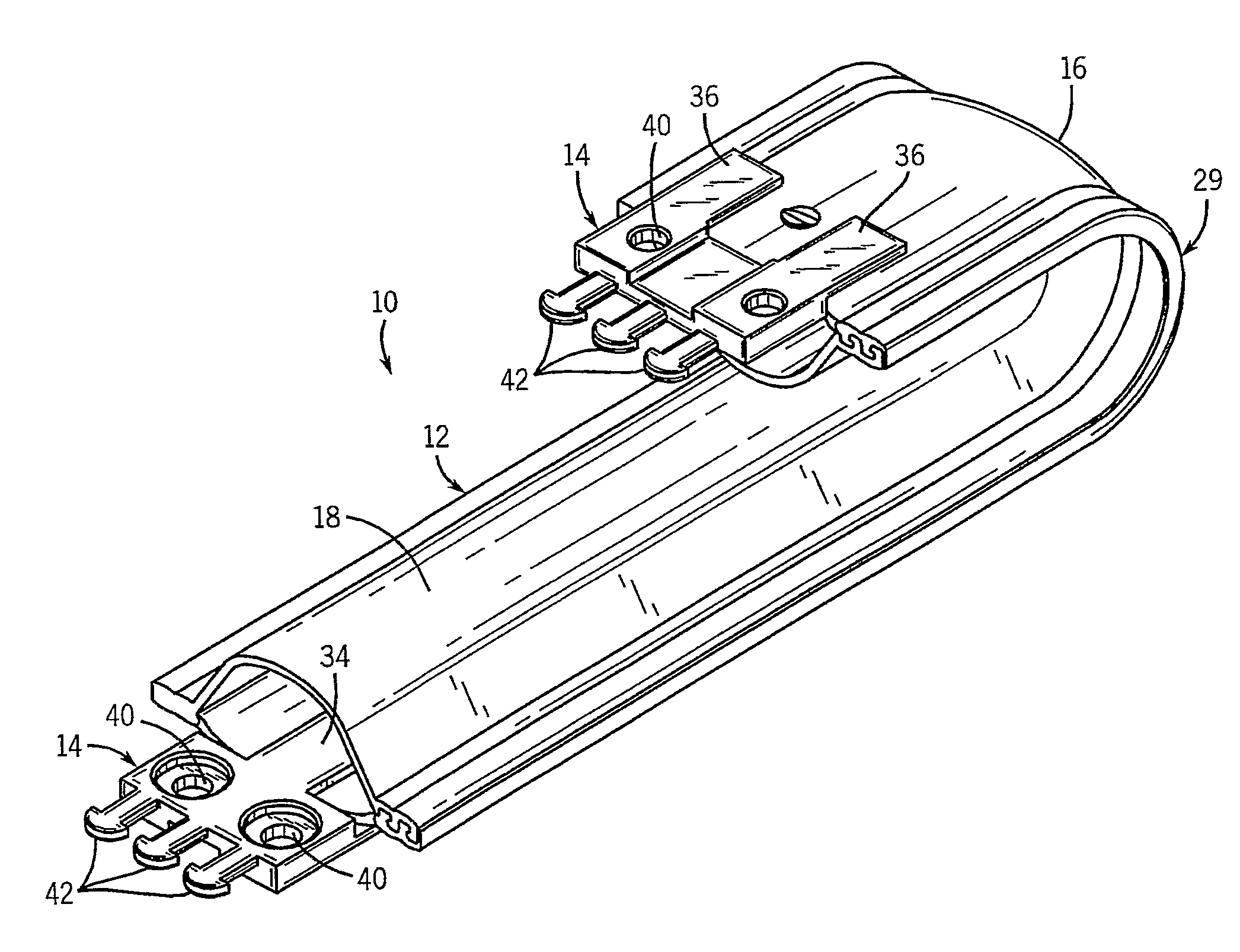

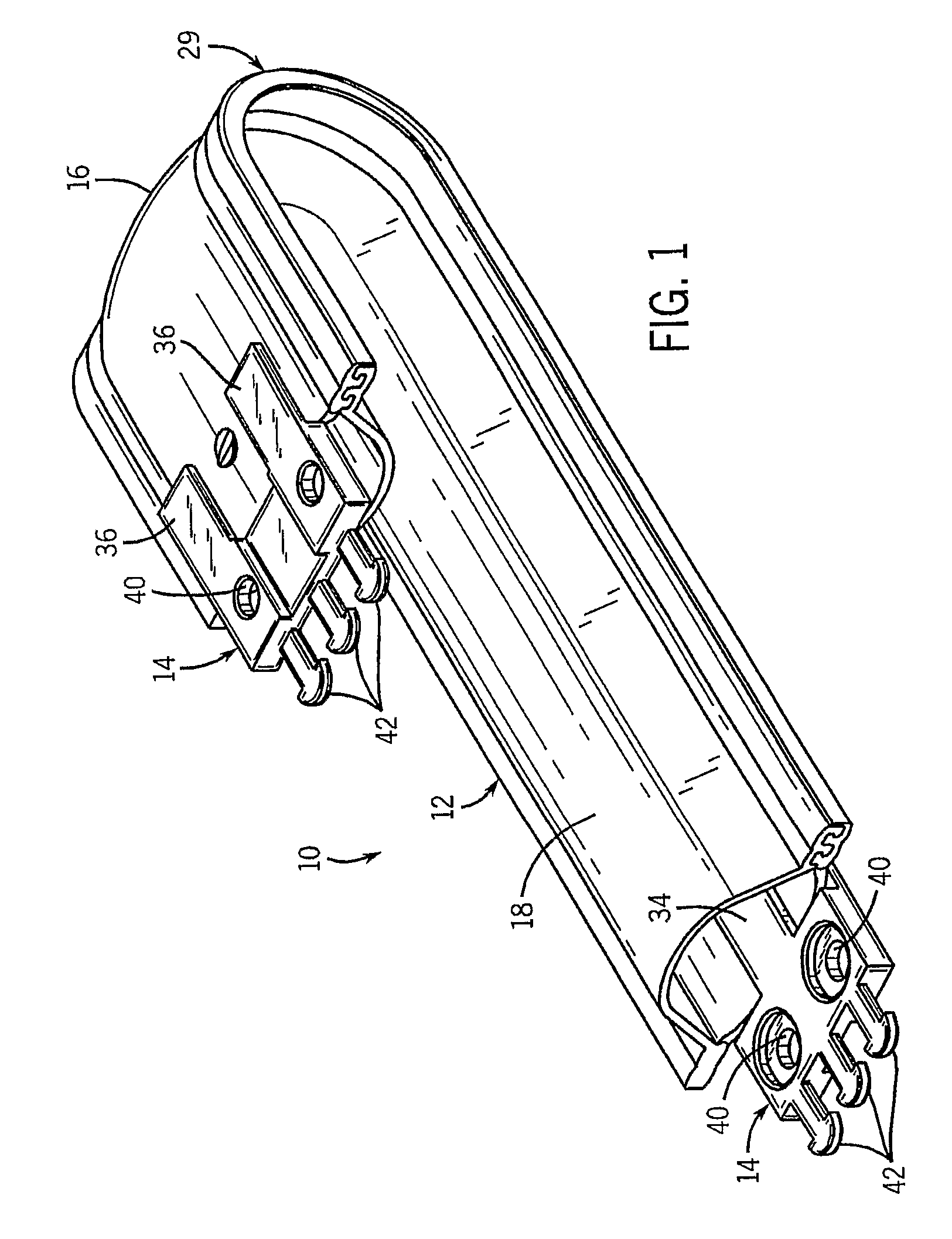

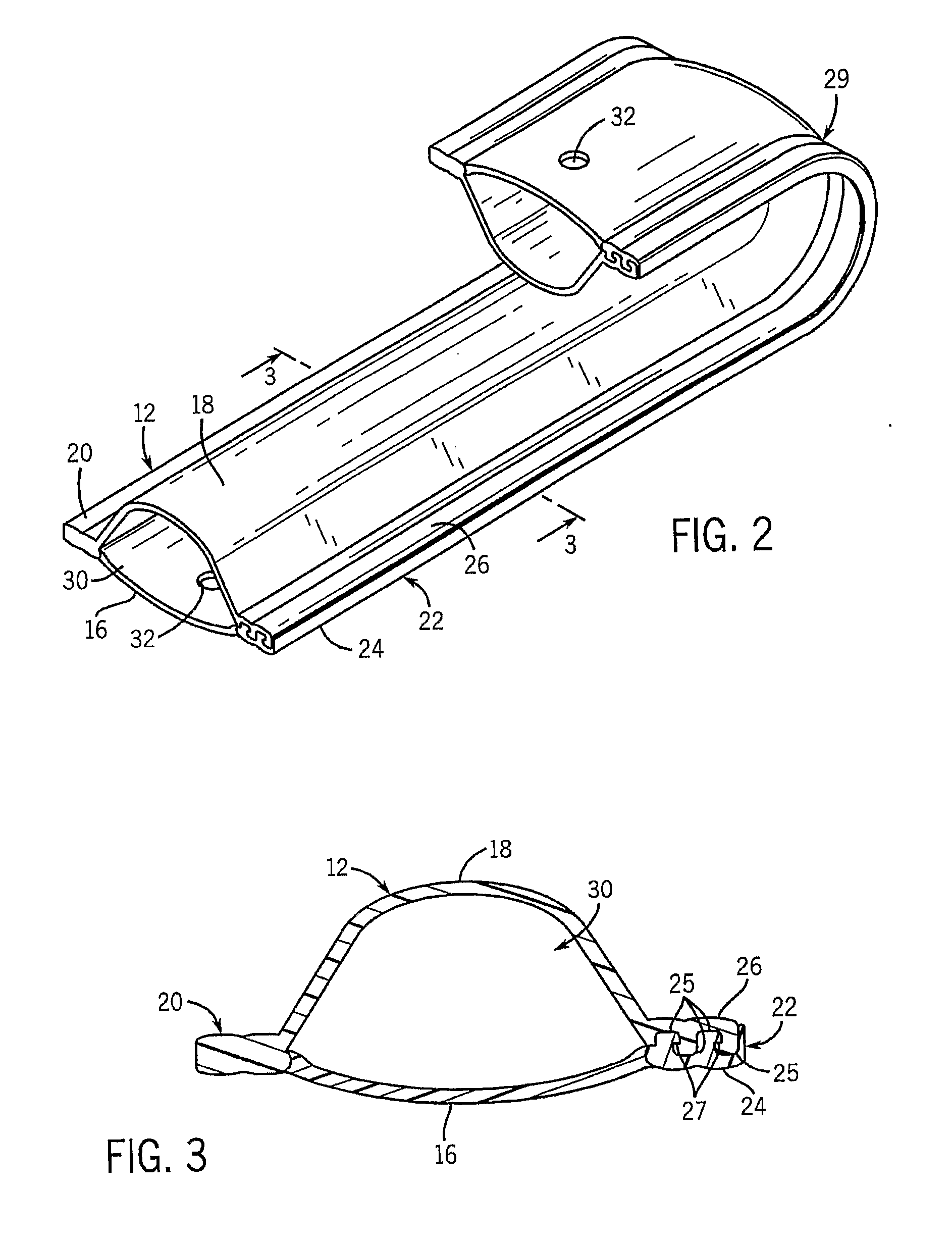

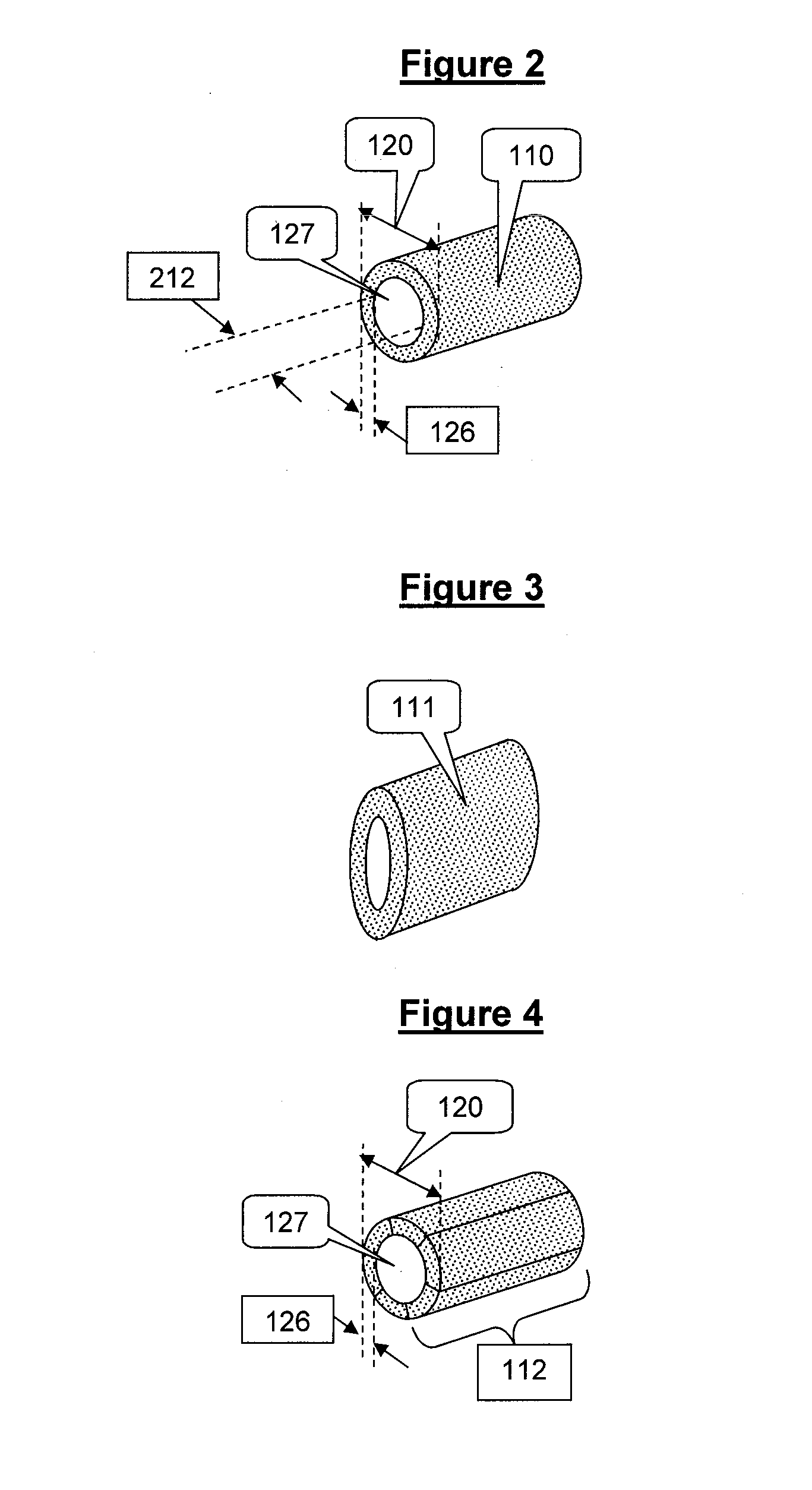

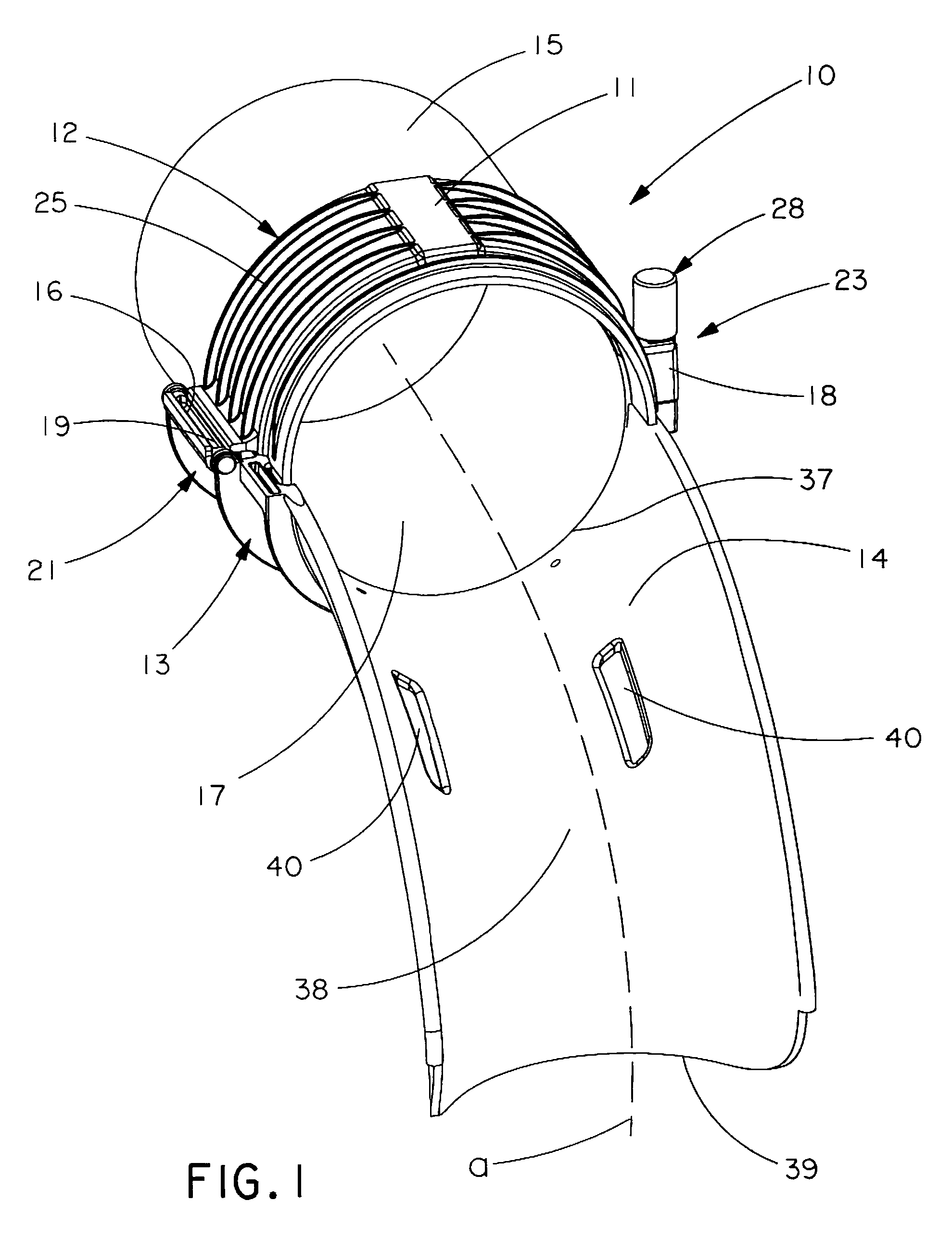

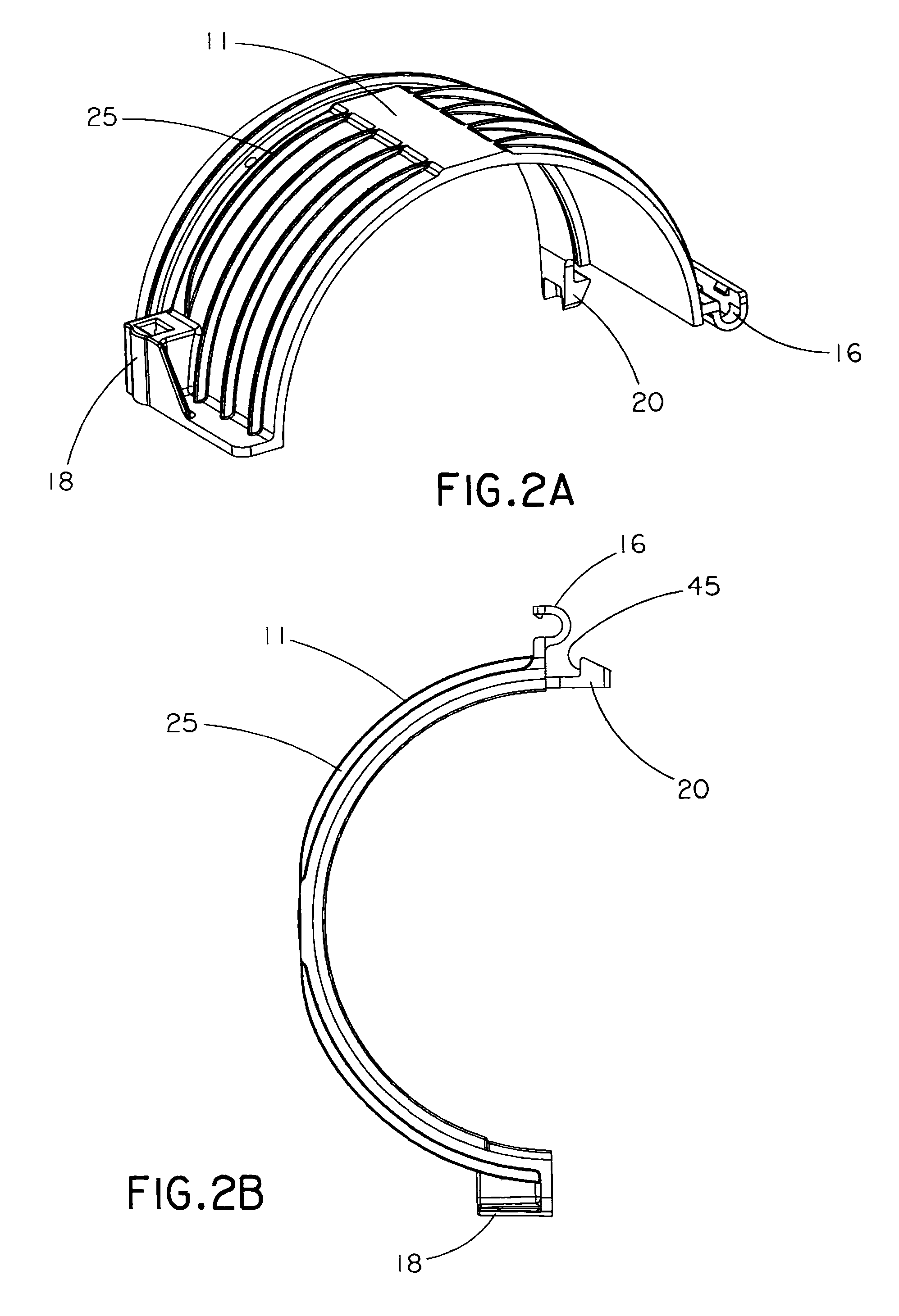

Monolithic enclosed cable carrier

InactiveUS7784259B2Small sizeSoft materialPipe supportsCable arrangements between relatively-moving partsEngineeringCable carrier

A cable carrier (10) has top (18) and bottom (16) longitudinally continuous sides, with one side (18) more flexible and the opposite side (16) less flexible. The sides are made of continuous sheets of material to define a closed tubular shape in which energy carriers can be housed and supported. The sheets may be integral, or have integral parts, and can be extruded. The carrier may be longitudinally openable with a zipper structure (125) to permit loading of energy carriers.

Owner:DYNATECT MFG

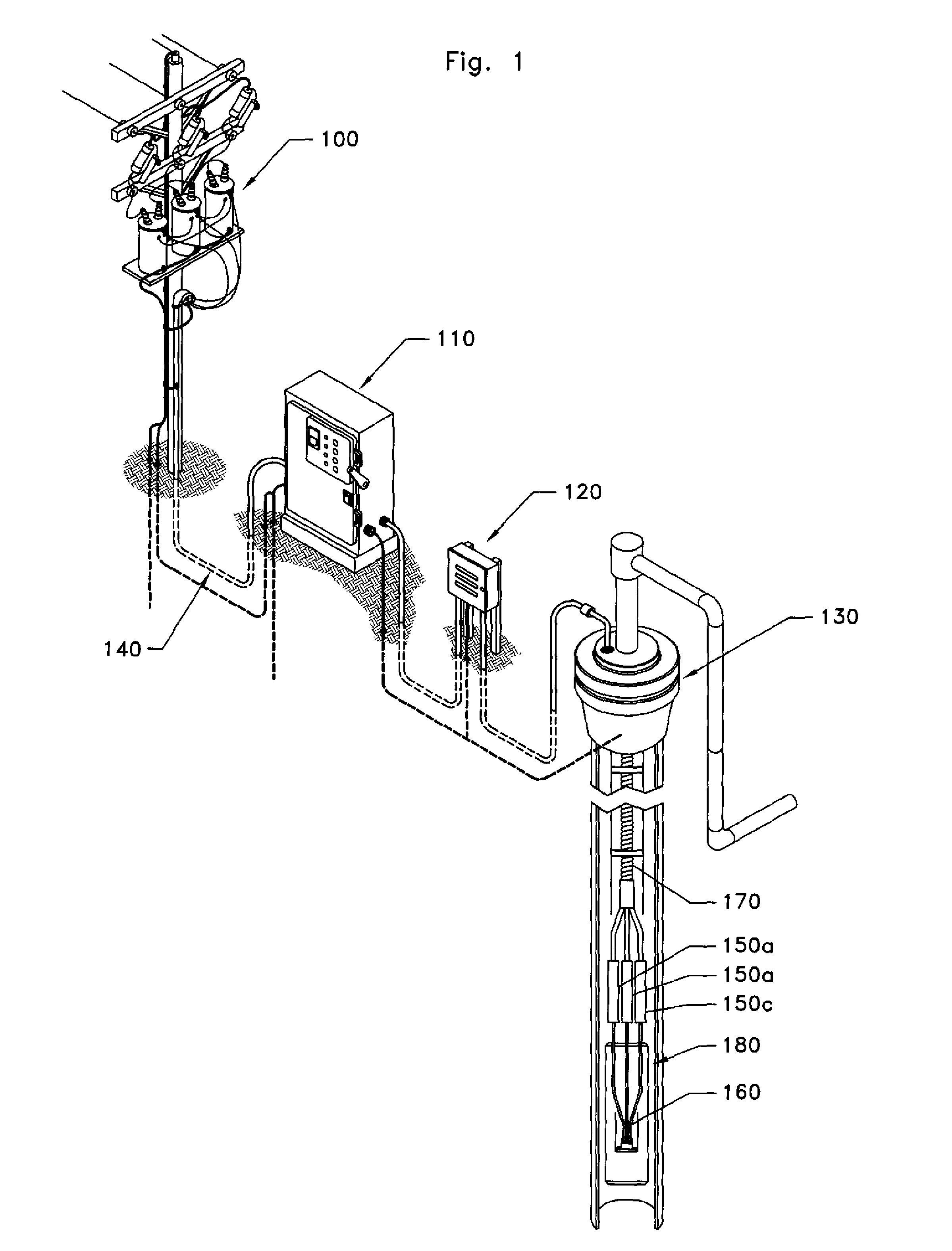

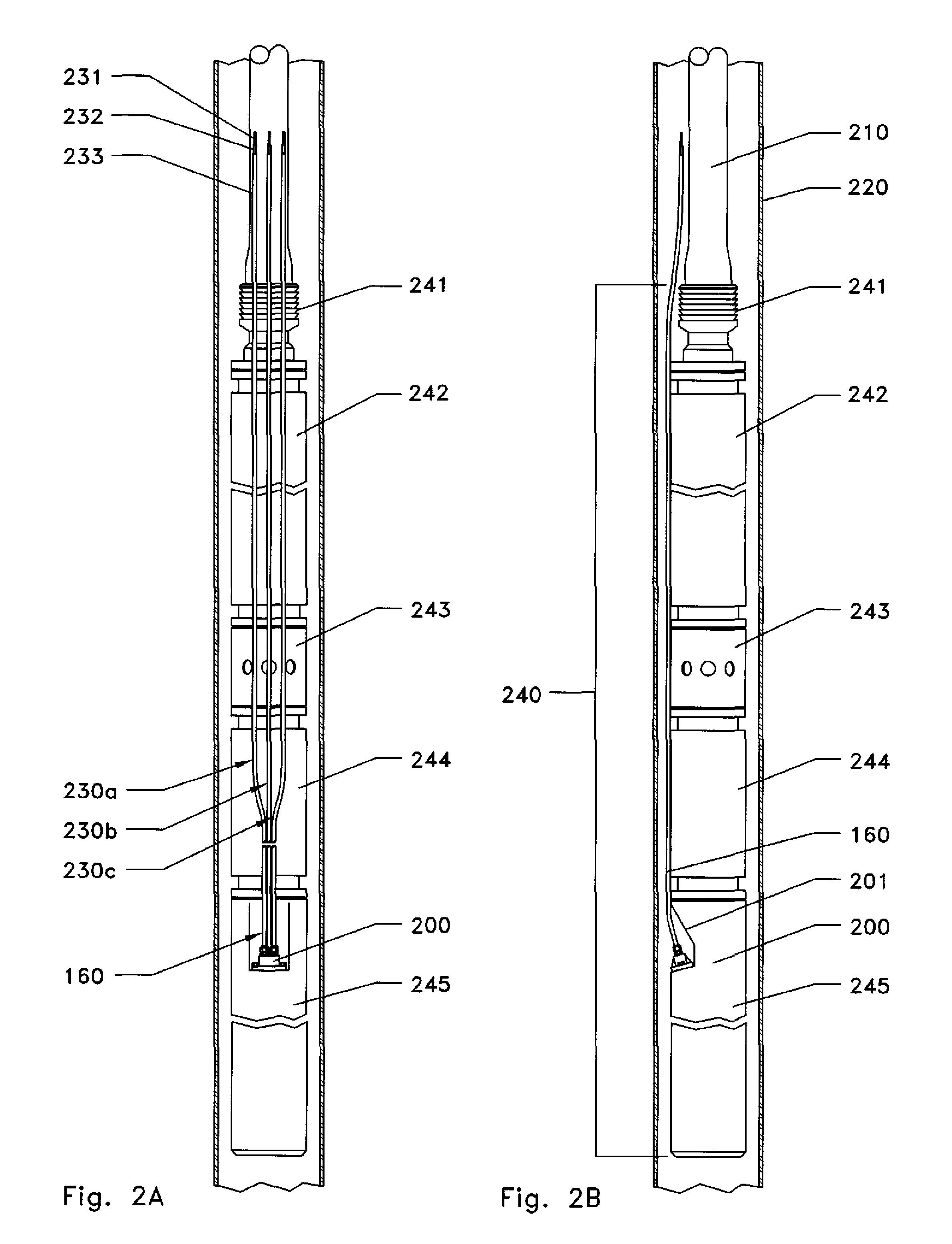

Electrical connector for insulated conductive wires encapsulated in protective tubing

A connector for electrically and mechanically connecting insulated conductor wires encapsulated in protective tubing. Embodiments of the connector provide a protective outer sheathing that circumscribes the conductive and insulating structures within the connector. The connector is formed with a plurality of tubular fitting assemblies for securely attaching the connector to down hole electrical power cables. The connector is also formed with an internal insulating boot having an internal passage adapted to surround the conductive elements of the connector to provide a reliable down hole electrical connector.

Owner:QUICK CONNECTORS

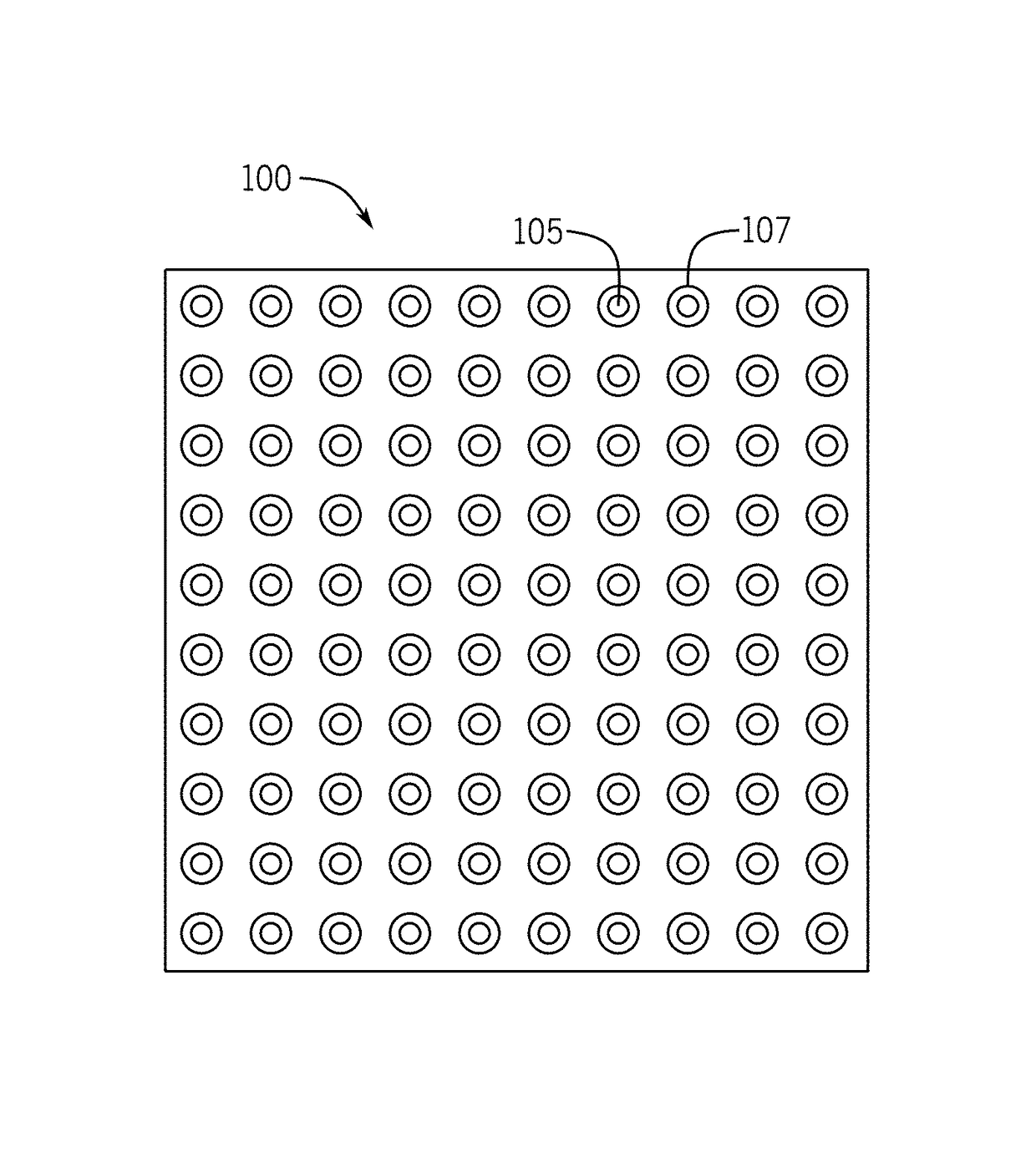

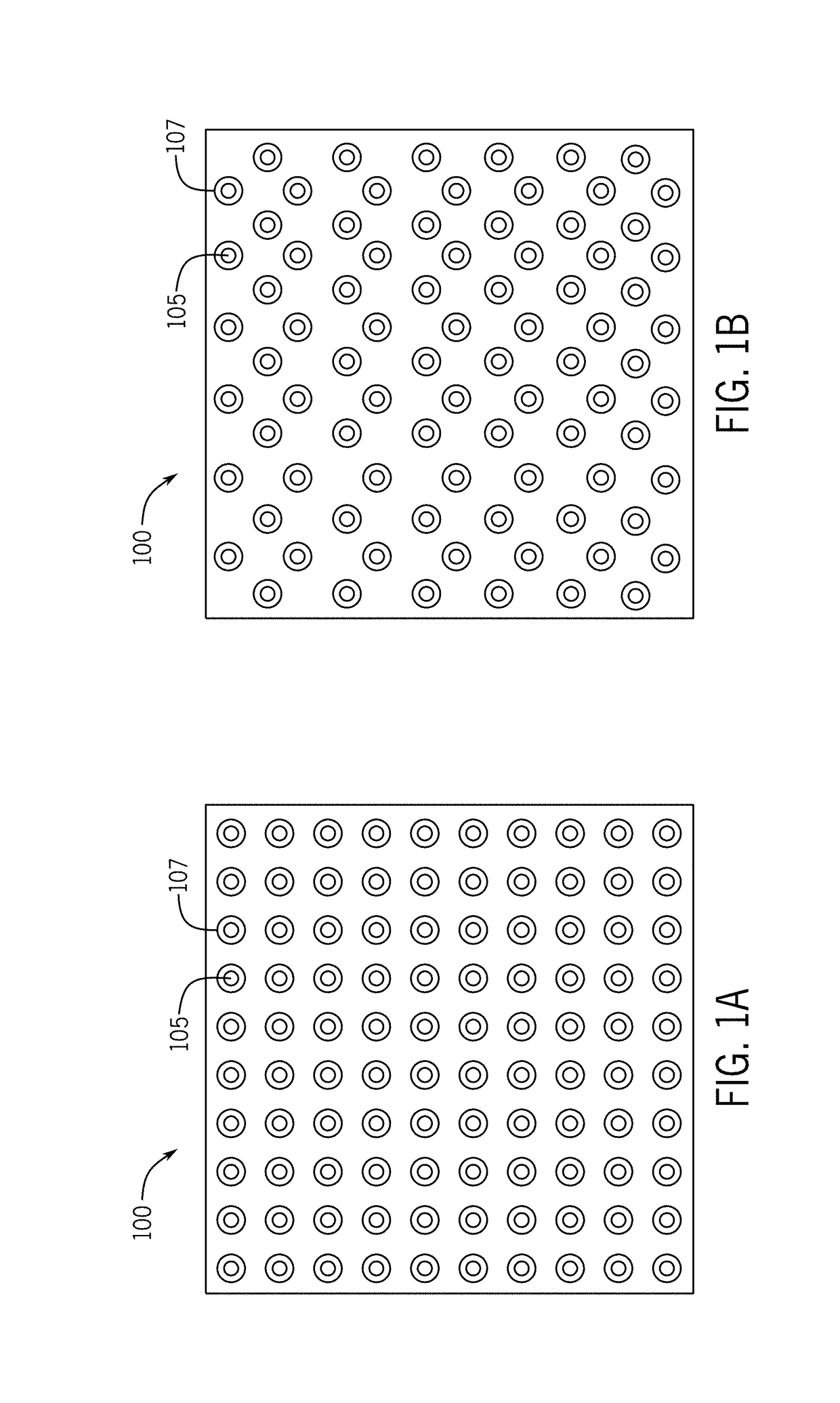

Tactile warning panel apparatus and system with smart technology

ActiveUS20170252256A1Enhancing urban mobilityImprove securitySingle unit pavingsCable installations in cable chambersElectricityTouch Perception

The present invention relates to tactile warning panels, and in particular to tactile warning panels that are designed and built with multifunction / multipurpose capabilities that serve the visually impaired and enable the deployment of smart city technology by integrating tactile warning systems and subsurface enclosures that can withstand pressures of five (5) tons up to and exceeding sixty (60) tons and incorporate small cells, beacons, sensors, Fog Computing, electric energy generation, rechargeable power supplies, wireless M2M communication and a plethora of other smart city technologies.

Owner:BRANDBUMPS

Gasket seal for flanges of piping and equipment, a method for manufacturing gasket seals, and a sealing ring for a gasket seal

A gasket seal for piping and equipment flanges comprises a sealing ring and a centralization ring, preferably concentric rings made of a metallic alloy. The sealing ring has an outer contour surface having a substantially L-shaped cross-section comprising an innermost portion and an outermost portion extending axially and a radial portion interconnecting the inner and the outer portions. The centralization ring has an inner contour surface defining a central opening, substantially coincident with the innermost portion of the outer contour surface of the sealing ring, so that the latter can be fitted into the opening as far as the radial portion of its outer contour surface. A deformation is made on the innermost portion of the outer contour surface of the sealing ring, forming a projection, whereby the centralization ring can be retained between the projection and radial portion without the centralization ring needing to be separated and then welded.

Owner:MANEGRO ADMINISTRACAO E PARTICIPACOES

Monolithic Enclosed Cable Carrier

InactiveUS20080217487A1Small sizeSoft materialPipe supportsCable arrangements between relatively-moving partsCable carrierEnergy carrier

A cable carrier (10) has top (18) and bottom (16) longitudinally continuous sides, with one side (18) more flexible and the opposite side (16) less flexible. The sides are made of continuous sheets of material to define a closed tubular shape in which energy carriers can be housed and supported. The sheets may be integral, or have integral parts, and can be extruded. The carrier may be longitudinally openable with a zipper structure (125) to permit loading of energy carriers.

Owner:DYNATECT MFG

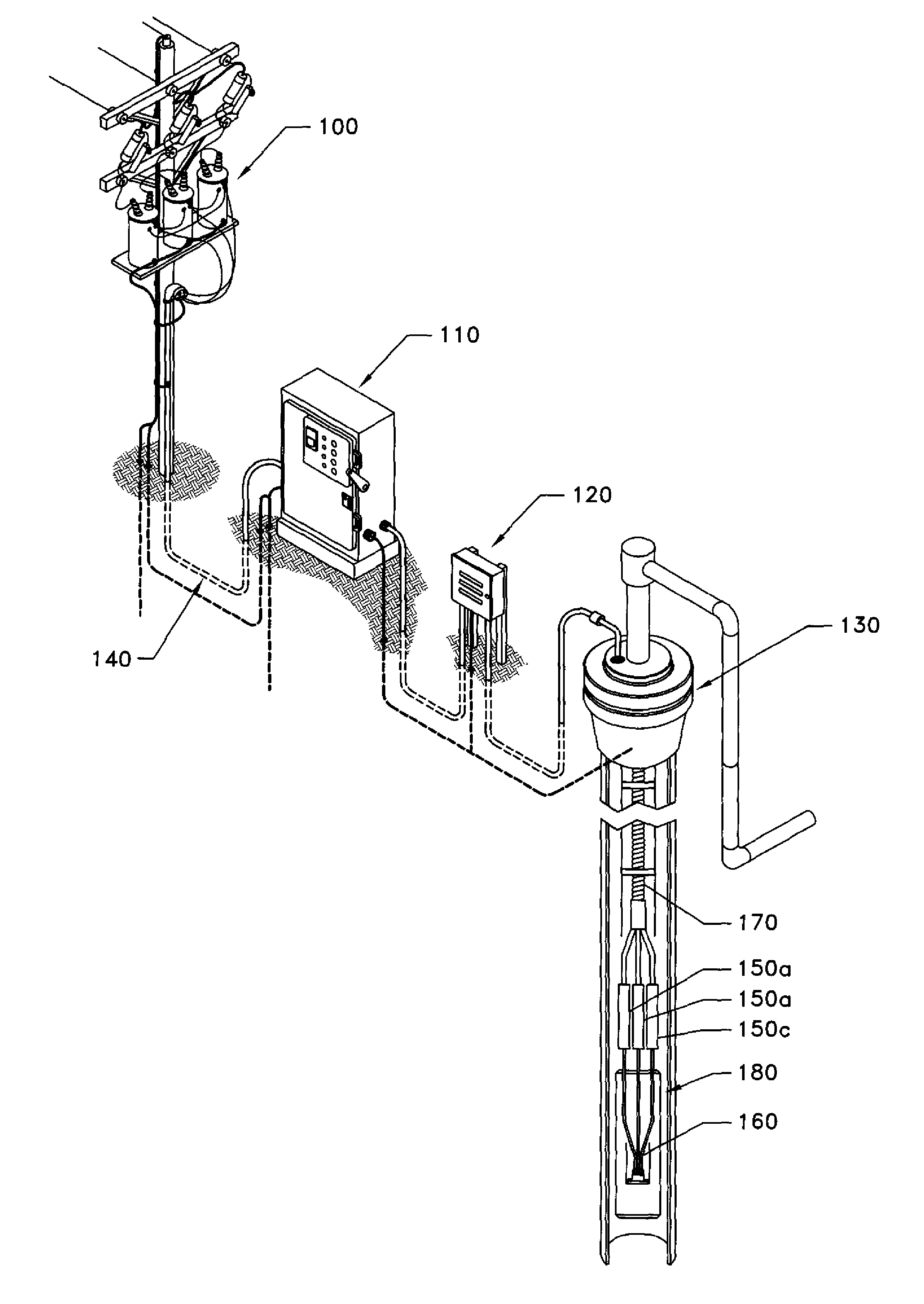

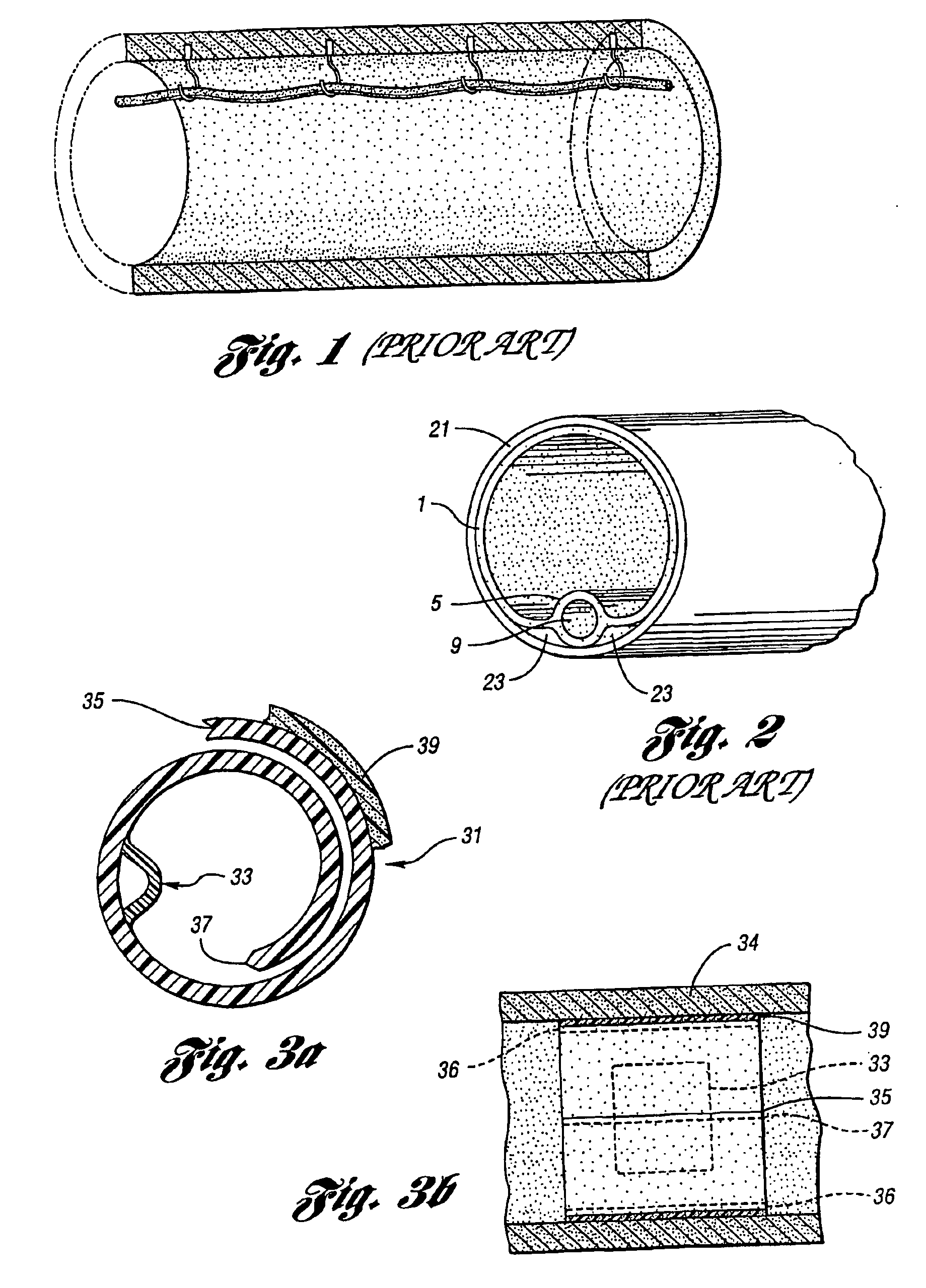

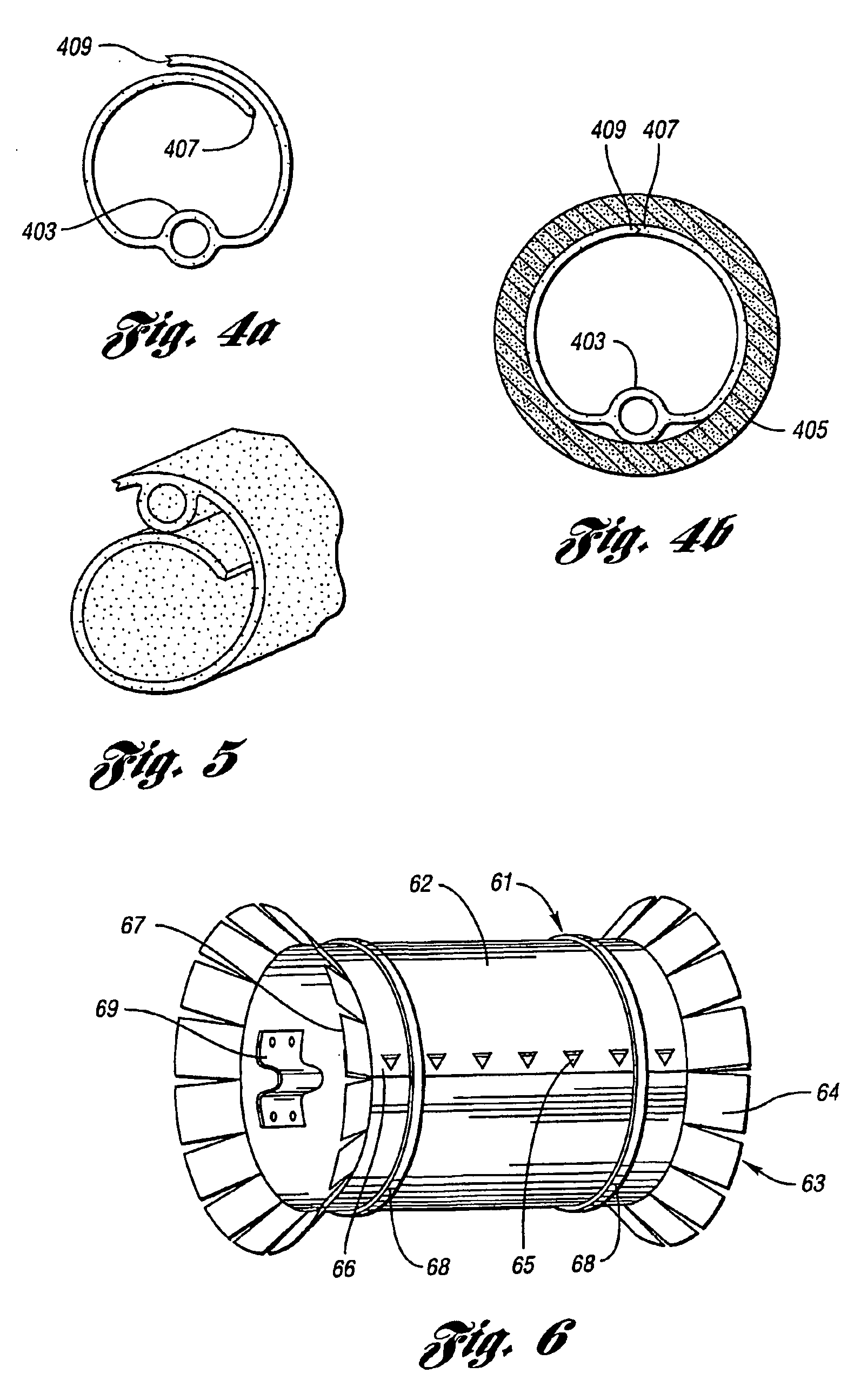

Method and apparatus for routing cable in existing pipelines

Supports for routing cables in existing pipelines are flexible cable supports containing minimally one hollow passage to receive a cable, and are installed between an existing pipeline inner wall and a structural liner. The cable supports have an elongate cross-section transverse to their length and are of sufficient flexibility to conform to the interior wall of the pipeline.

Owner:ULC TECH LLC

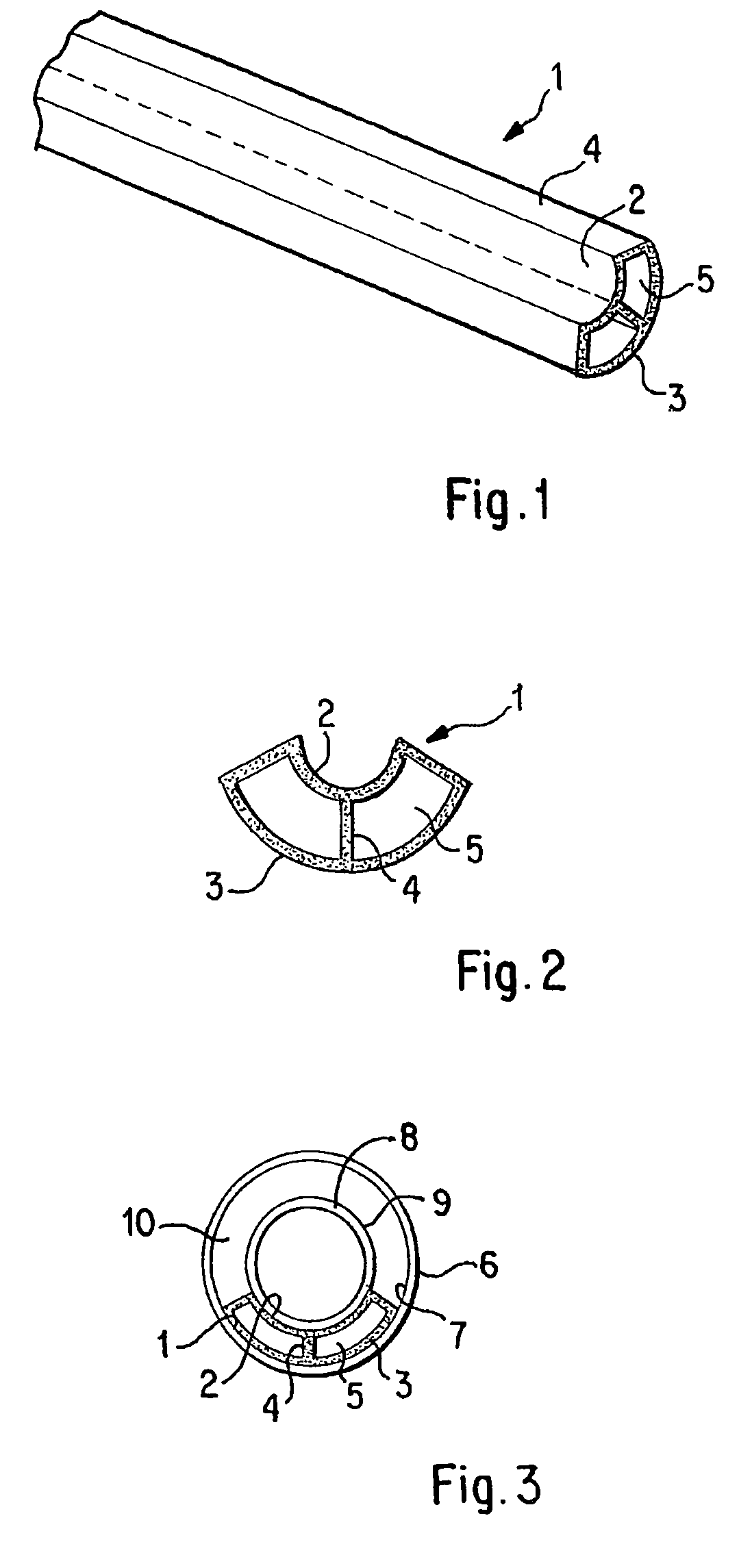

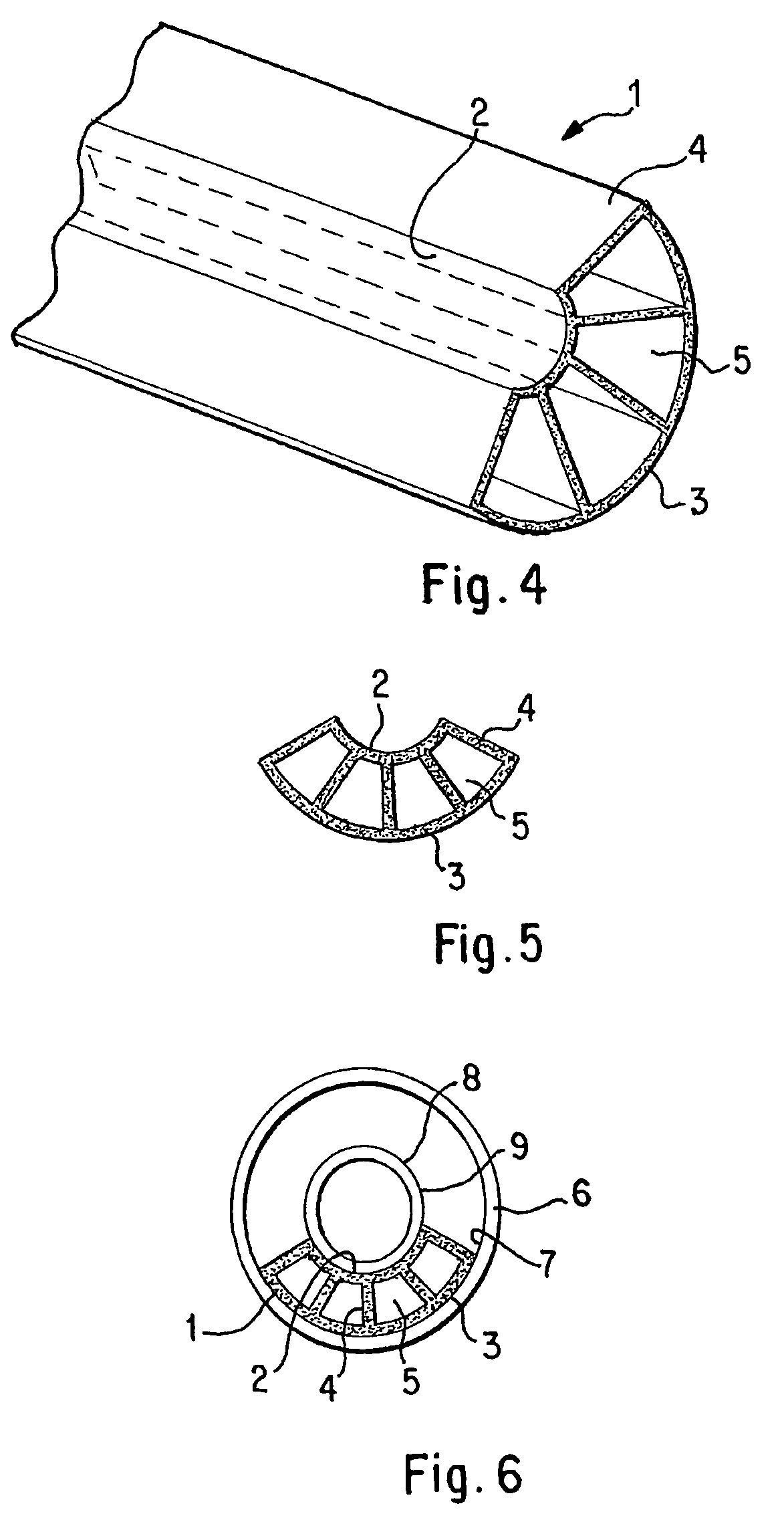

Pipe insert and pipe assembly formed therewith

InactiveUS7156126B2Easy to manufactureEasy to installPipe supportsInsulated cablesEngineeringSynthetic resin

A synthetic resin pipe insert for insertion in an existing pipe or for use in the manufacture of new pipe to form a multi-channel pipe. The insert has a curved cross sectional configuration which defines a segment of a circle with a convexly curved radially outer wall and a concavely curved radially inner wall and a plurality of radial walls extending between the curved, radially inner and outer walls to form at least two linear channels. A curved inner pipe member may optionally be fitted against the concavely curved radially inner wall. The pipe insert of the invention facilitates multiple utility connections, such as cable TV and sewer, in a single pipe assembly.

Owner:PIPELINE INSERT TECH

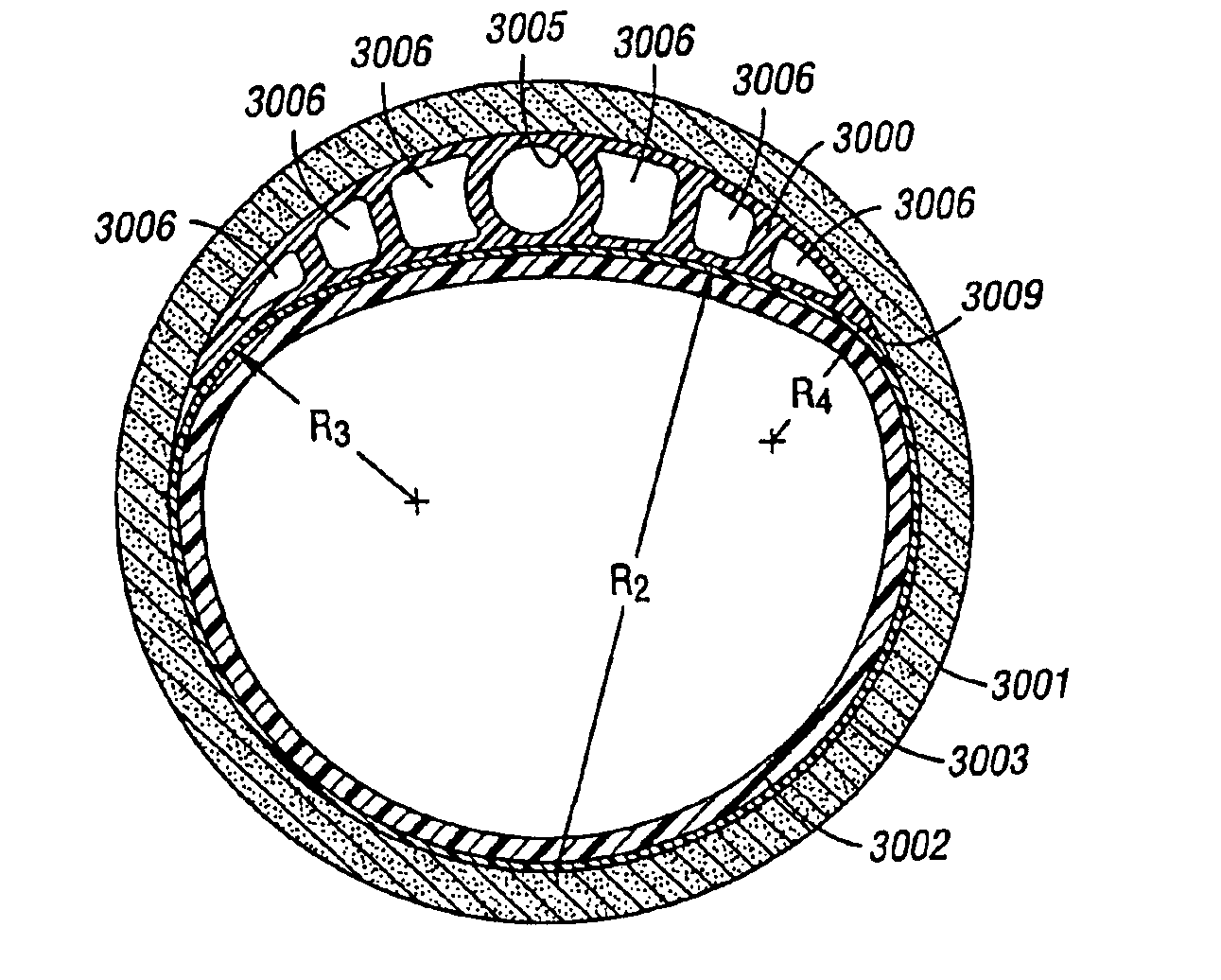

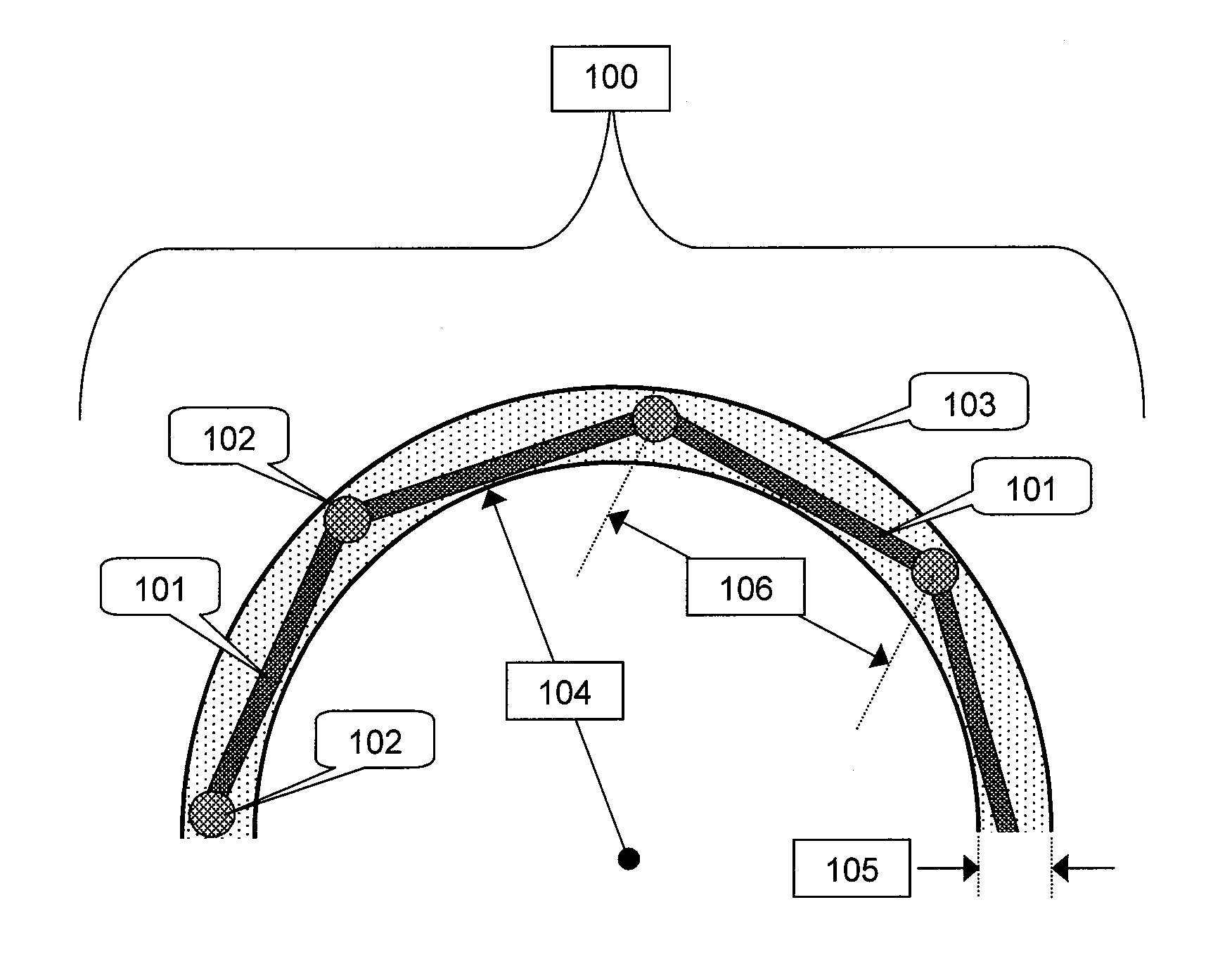

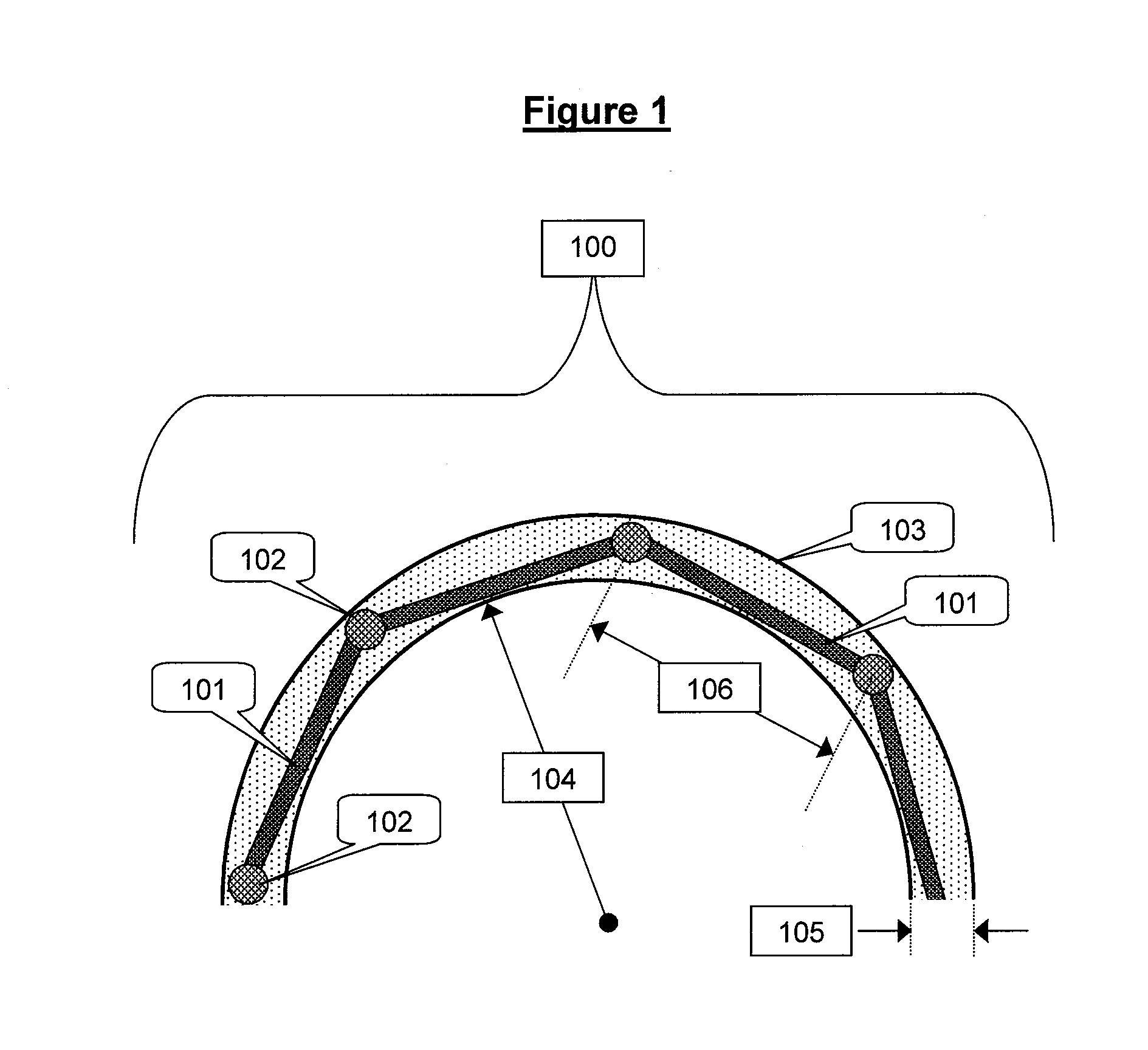

Underground modular high-voltage direct current electric power transmission system

InactiveUS20120181082A1Small diameterCable installations in underground tubesCable junctionsElectric power transmissionTransmission line

High capacity (10 GW, for example) passively cooled non-superconducting underground high voltage direct current electric power transmission lines (100) of very low loss (1% per 1,000 km, for example) and competitive cost. The transmission lines (100) include segment modules (101) linked together with compliant splice modules (102) between the segments (101), typically installed in a protective conduit (103). The segment modules (101) include relatively rigid pipe-shaped conductors (117) insulated by pipe-like solid insulating layers (131) to form segment modules (101) that resemble pipe. The segment modules (101) are linked together through radially and axially compliant splice modules (102) to form the transmission line (100). There are preferably wheels (300) deployed to ease insertion and removal of the assembled segment modules (101) and splice modules (102) into the conduit (103), to center each segment module (101) within the conduit (103), and / or to provide motive force and / or braking to allow the assembled segment modules (101) and splice modules (102) to be installed on a slope.

Owner:INNOLITH ASSESTS AG

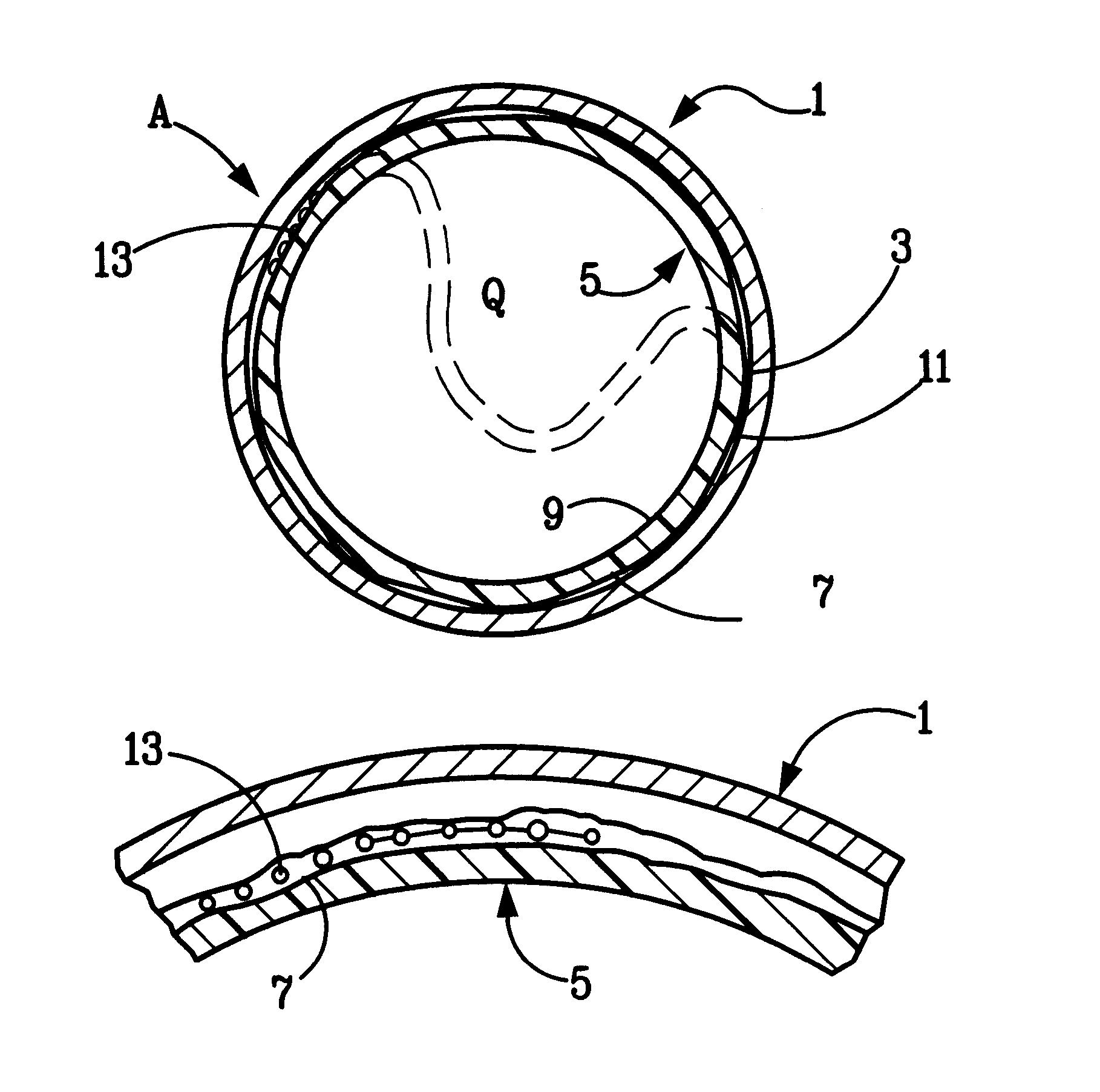

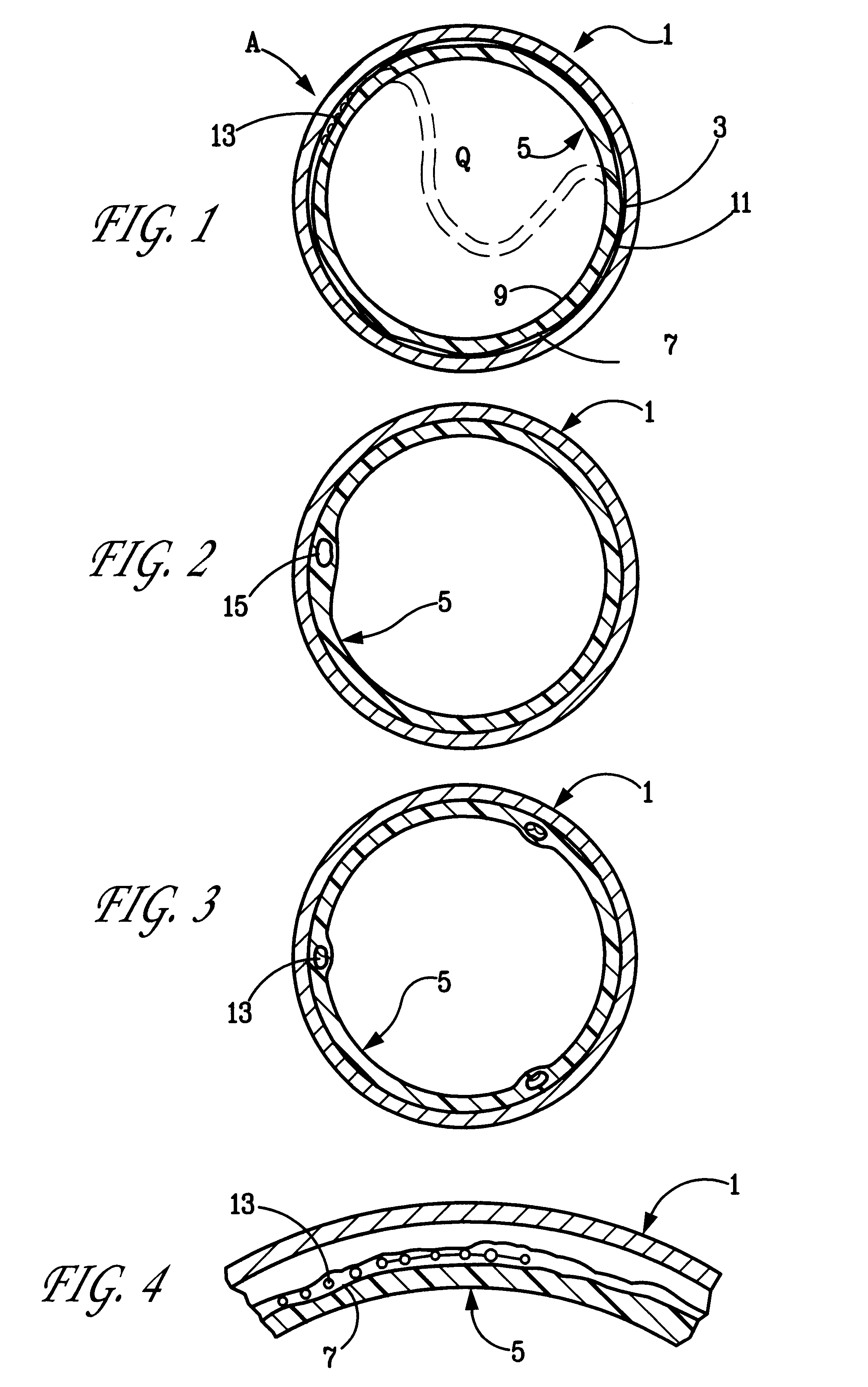

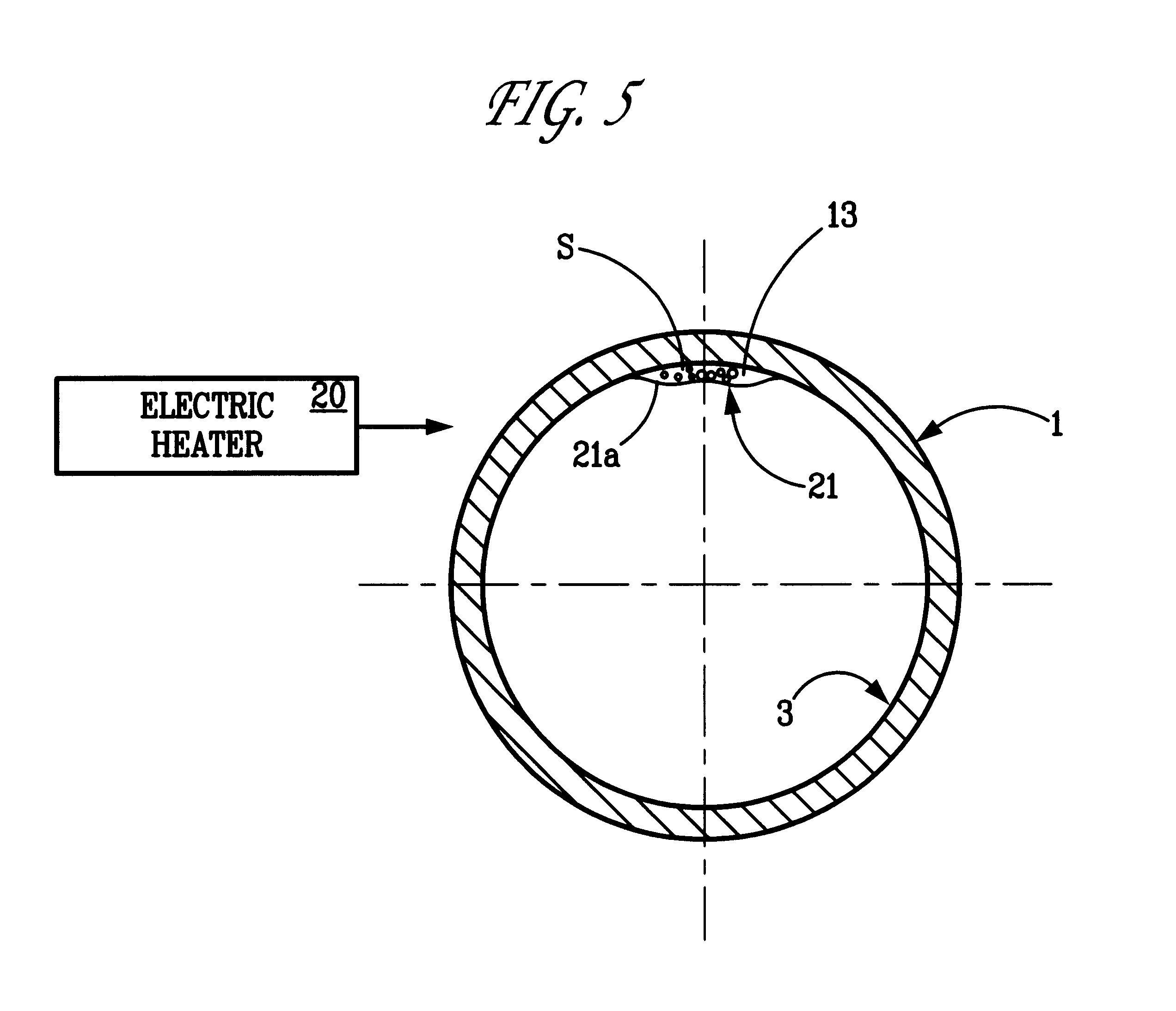

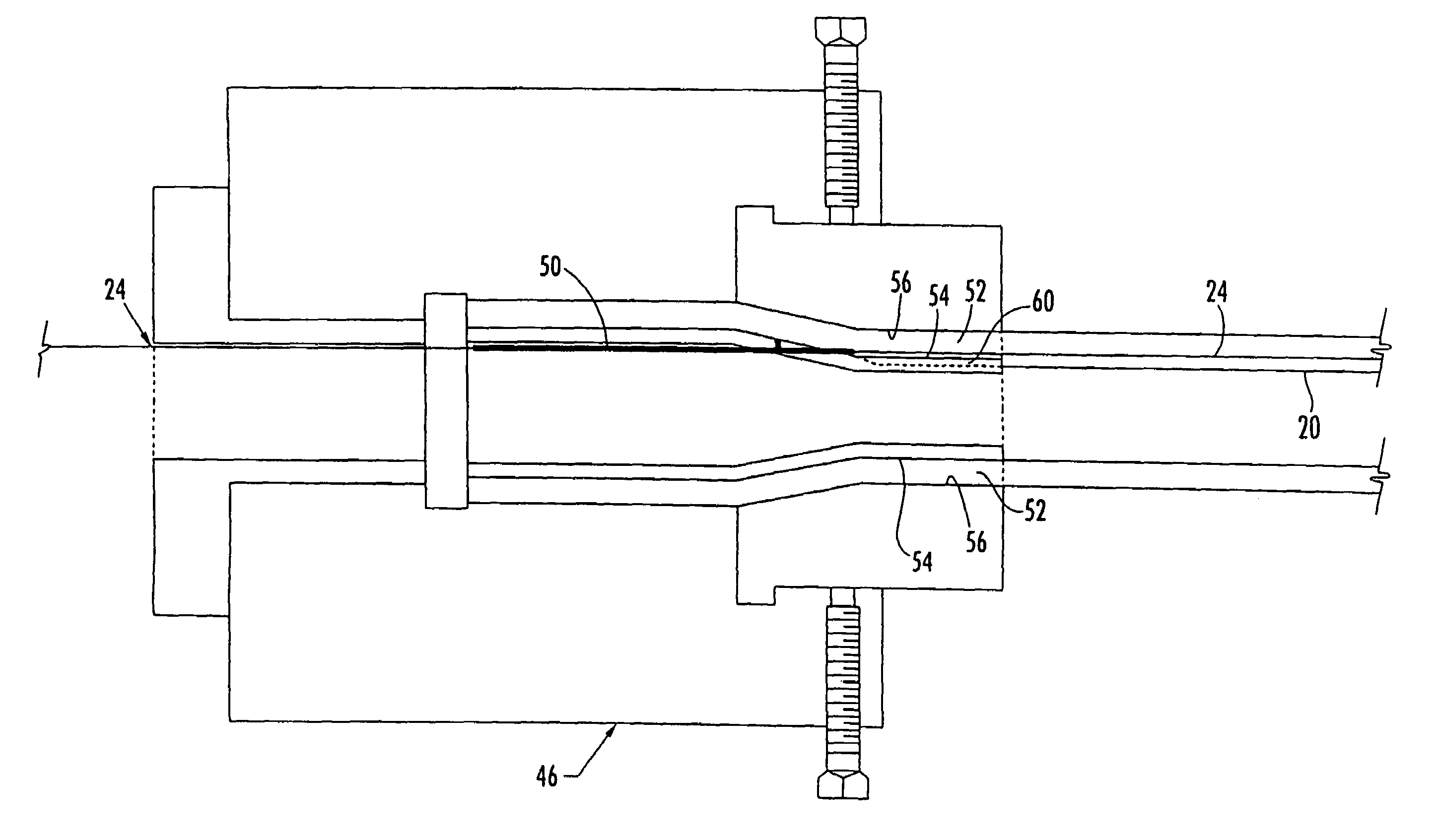

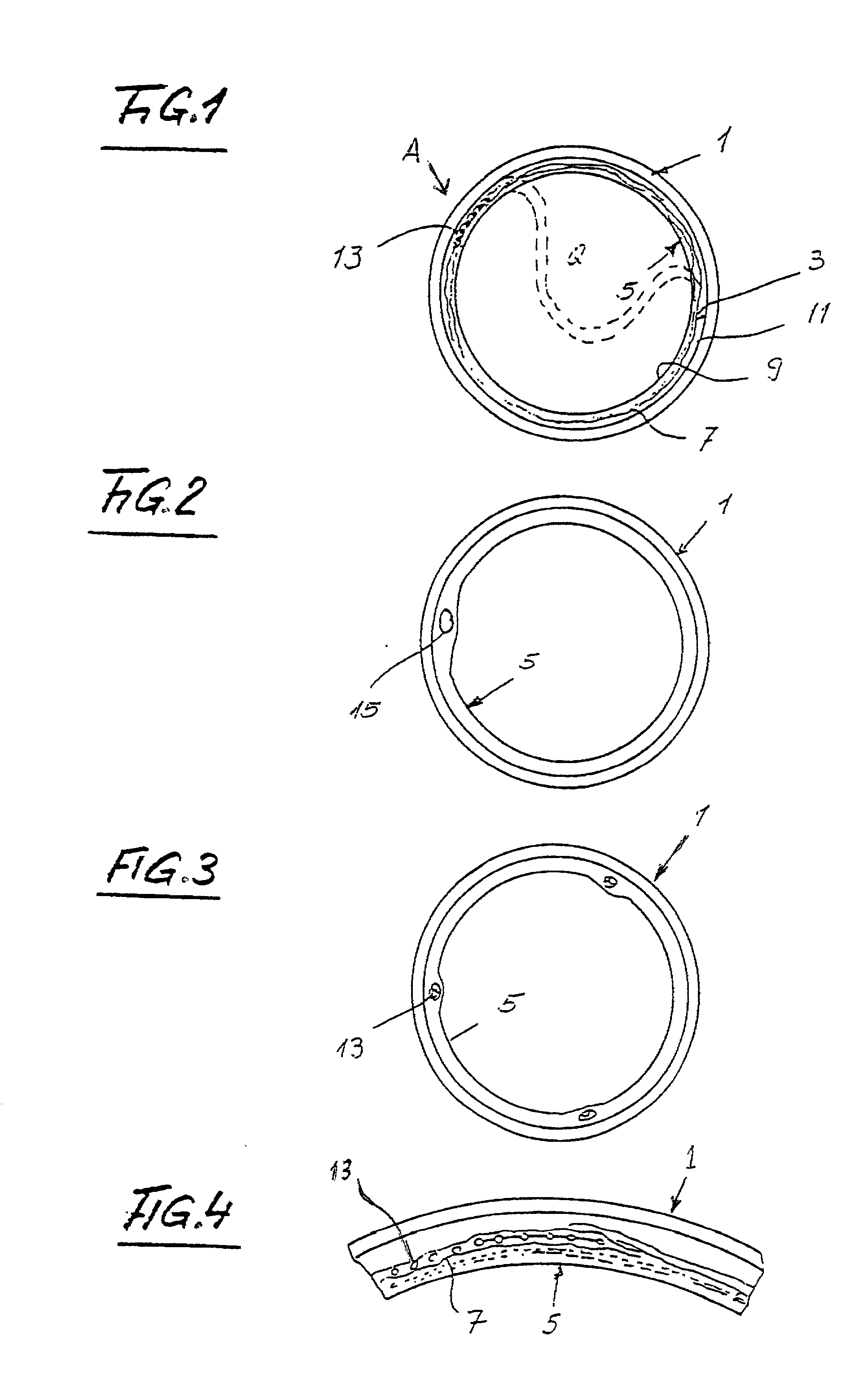

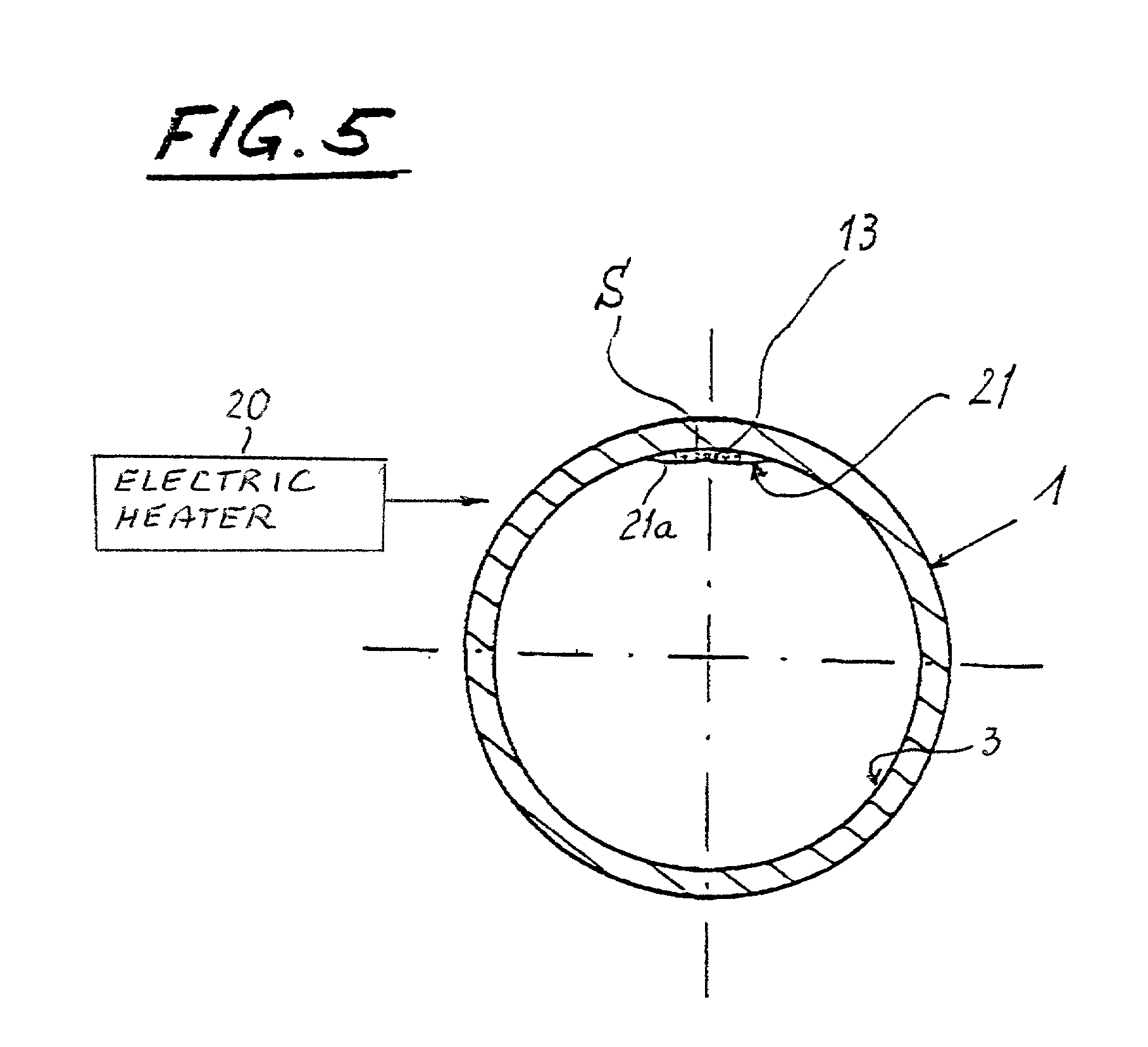

Method of laying data cables and the like in underground pipes and pipe-cable combinations

InactiveUS6572306B2Ensure protectionLabelling non-rigid containersUnderground chambersSewageEngineering

One or more electric and / or data transmitting cables are confined in an elongated strip-shaped body containing a hardenable resin or the like, and the body is placed against a portion of the internal surface of an underground sewage, water or other pipe. An expandible tubular liner is thereupon introduced into the pipe and is expanded to press the body against the pipe. The body is caused to set, by conveying a hot fluid through the liner and / or by electrically heating the cable or cables, and to adhere to the internal surface of the pipe. The liner can remain in the pipe and can be bonded to the strip-shaped body and / or to the remaining portion of the internal surface of the pipe. Alternatively, the liner is caused to collapse and is withdrawn from the pipe once the strip-shaped body is bonded to the internal surface of the pipe.

Owner:PRUSAK MARTIN

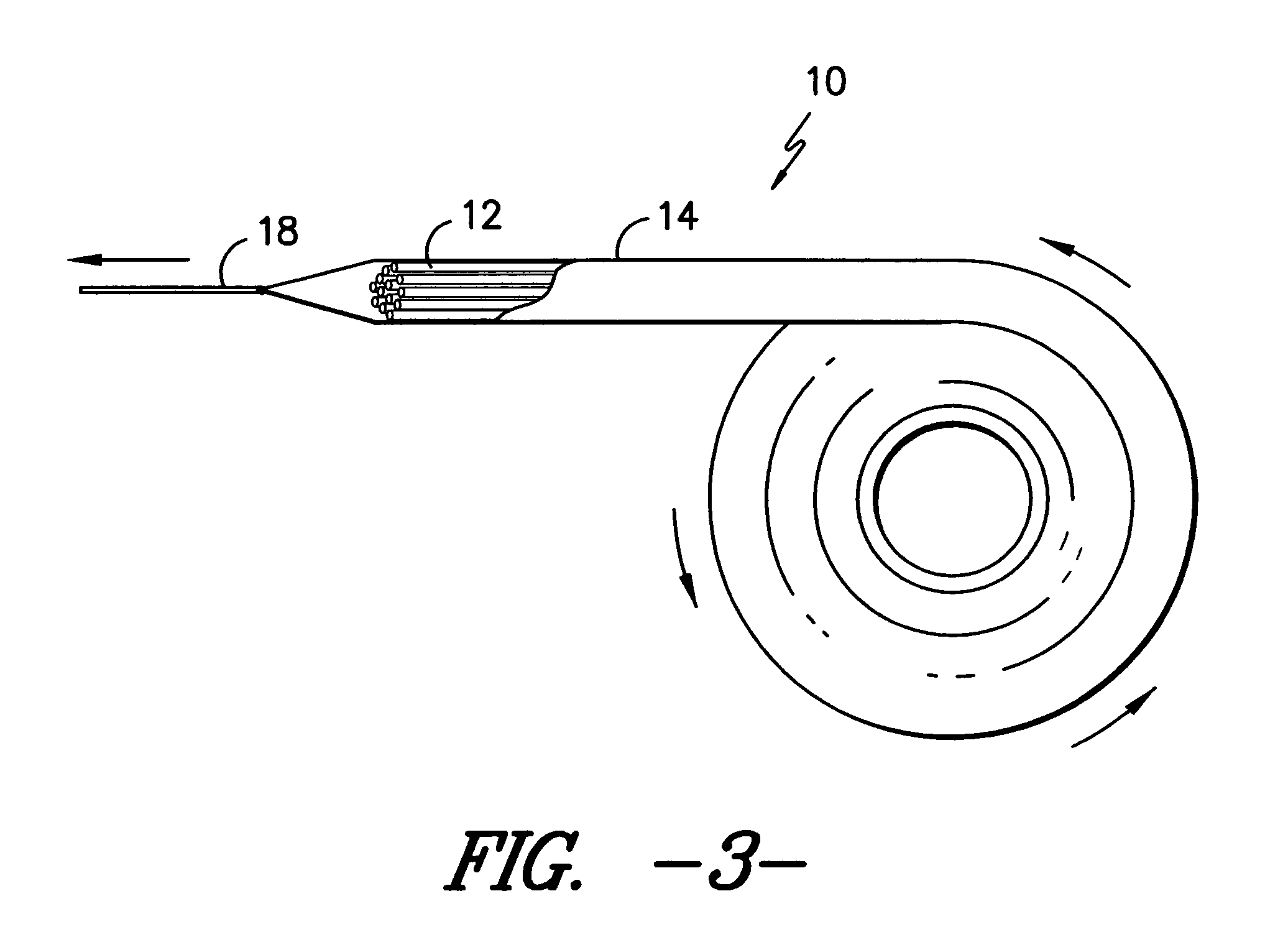

Toneable conduit and method of preparing same

InactiveUS7279643B2Easy to detectAvoid moisture leakagePipe laying and repairPipe elementsCatheterEngineering

The invention is a toneable conduit that can transmit a signal and be readily detected by toning equipment. The conduit can be coupled with other conduit to provide extended lengths of conduit. The toneable conduit includes an elongate polymeric tube having a wall with an interior surface, an exterior surface, and a predetermined wall thickness. A channel preferably extends longitudinally within the wall of the elongate polymeric tube; a stabilizing rib extends longitudinally along the interior surface of the wall of the elongate polymeric tube and is located radially inward from the channel. A continuous wire is coincident with the channel in the elongate polymeric tube and preferably coated with a composition that prevents it from adhering to the polymer melt that forms the elongate polymeric tube. The present invention includes methods of making the toneable conduit and methods of coupling a first toneable conduit with a second toneable conduit.

Owner:DURA LINE CORP A CORP OF KY

Electric highway system

InactiveUS20110094840A1Easy to detectPromote repairAnalogue computers for vehiclesRail devicesHighway systemElectrical conductor

The electric highway includes at least one electrified lane that may be separated from other non-electrified lanes by a non-elevated strip of dividers, a roadside subsystem that includes a system operation monitoring center that monitors system operation; a plurality of roadside conductor assemblies, each of which includes at least one roadside conductor laid within a coaxial pipe made of a non-magnet field shielding material, and its / their housing in the traffic lane; a roadside part of an on-board part of a lateral location sensor; a plurality of roadside controller each of which includes a power supply assembly, at least one communication device housed in a roadside box, and a plurality of roadside posts with a camera affixed to it. The electric highway system is monitored continuously at the system operation monitoring center.

Owner:SAKITA MASAMI

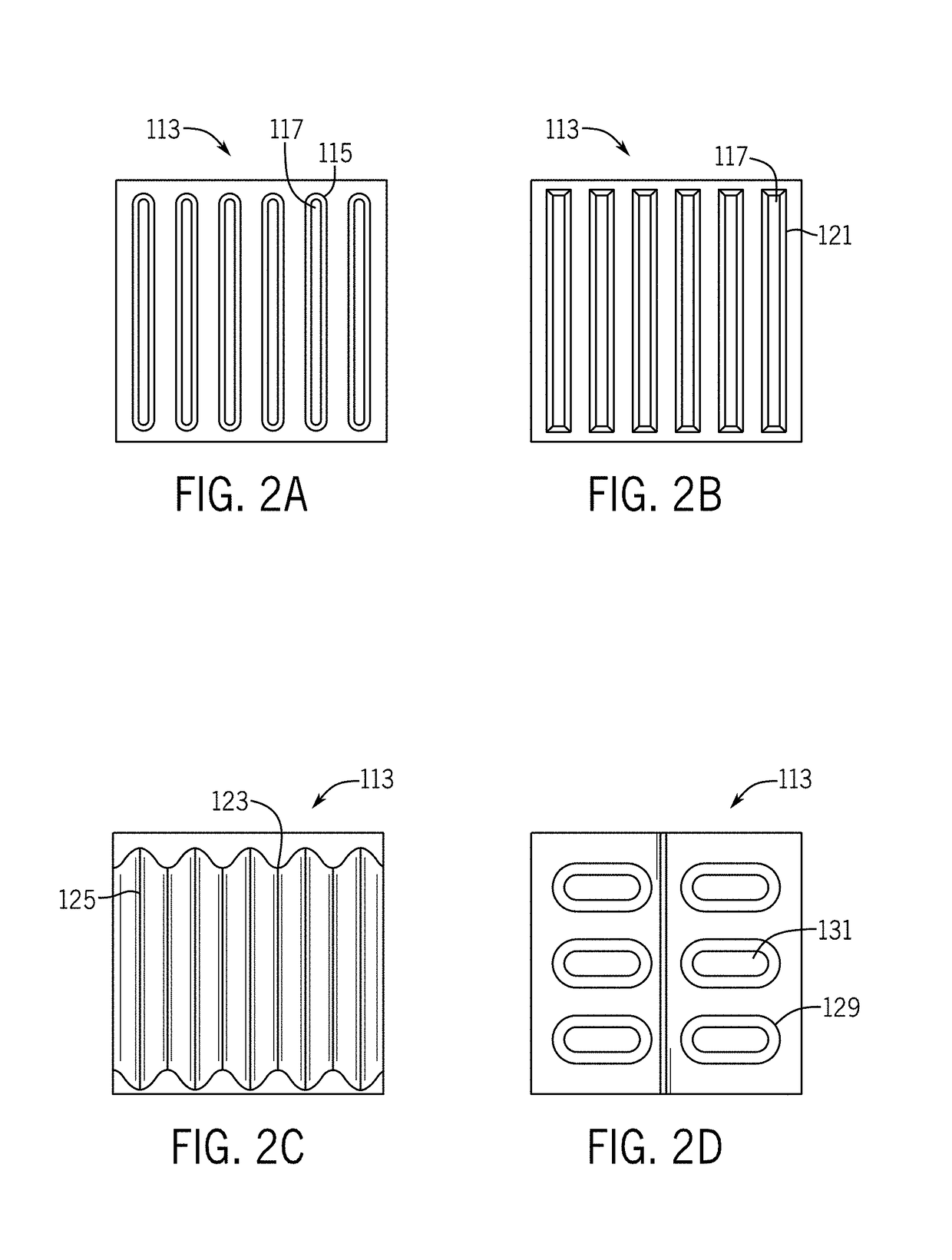

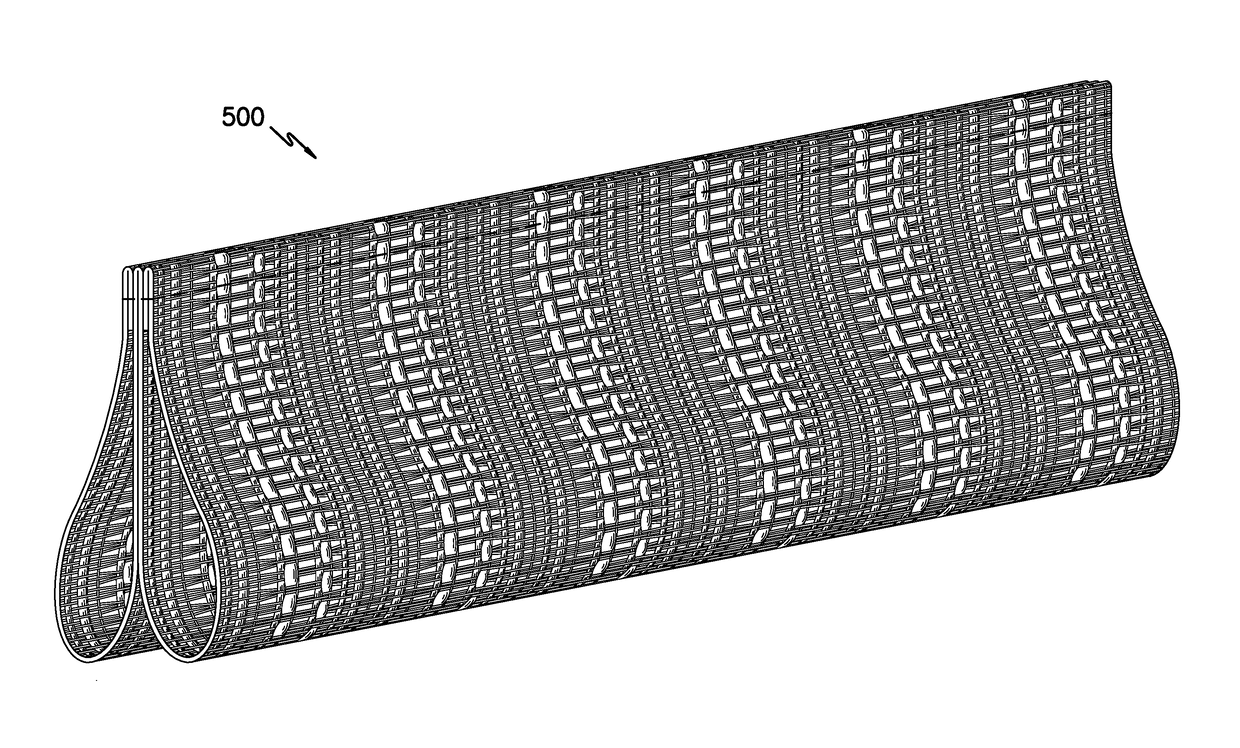

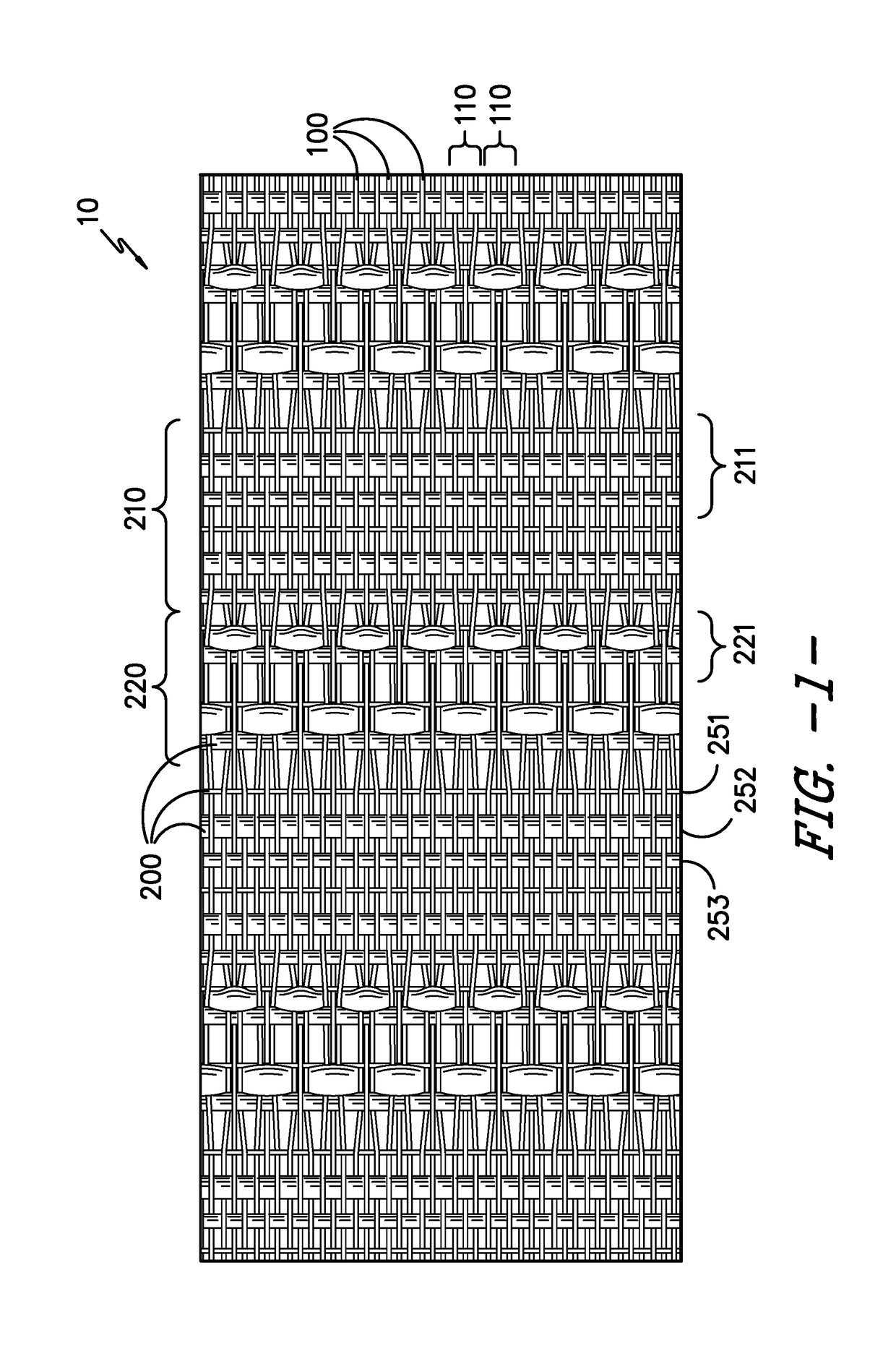

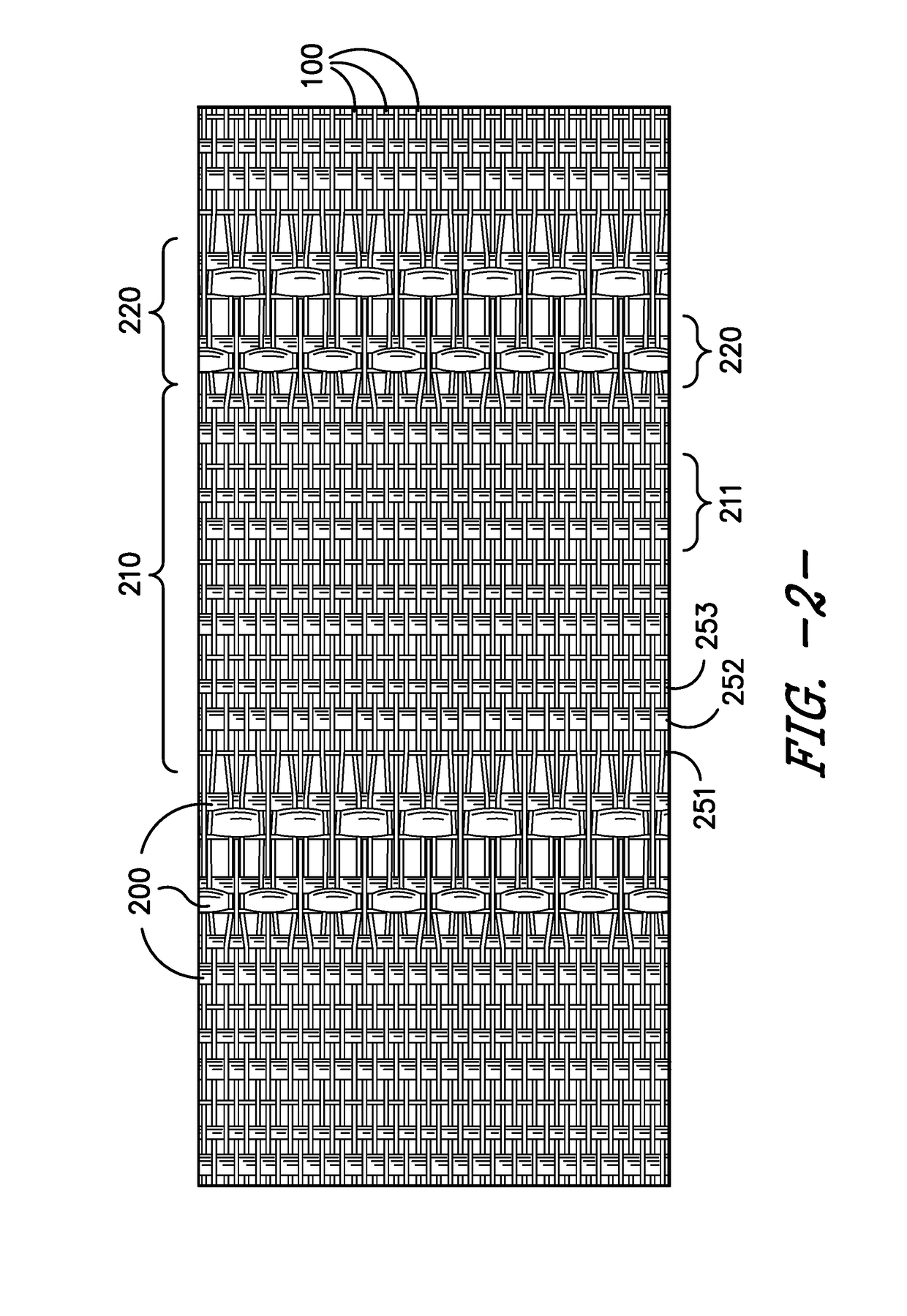

Partial float weave fabric

ActiveUS20170145603A1Optical fibre/cable installationCable installations in underground tubesEngineeringWeft yarn

A woven fabric containing an alternating pattern containing first weave zones and partial float weave zones. The woven fabric contains a plurality warp yarns arranged into groupings of warp yarns. In each first weave zone, the picks of weft yarns contain a repeating first weft pattern. In each partial float zone, the picks of weft yarns within the partial float weave zone contain a repeating second weft pattern of at least one monofilament yarn and at least one multiple-inserted multifilament yarn. Within the partial float zone, only a portion of the warp yarns within at least a portion of the warp groupings float over 3 weft yarns including floating over at least one multiple-inserted multifilament weft yarn in at least a portion of weft pattern repeats. An innerduct structure containing the woven fabric is also described.

Owner:MILLIKEN & CO

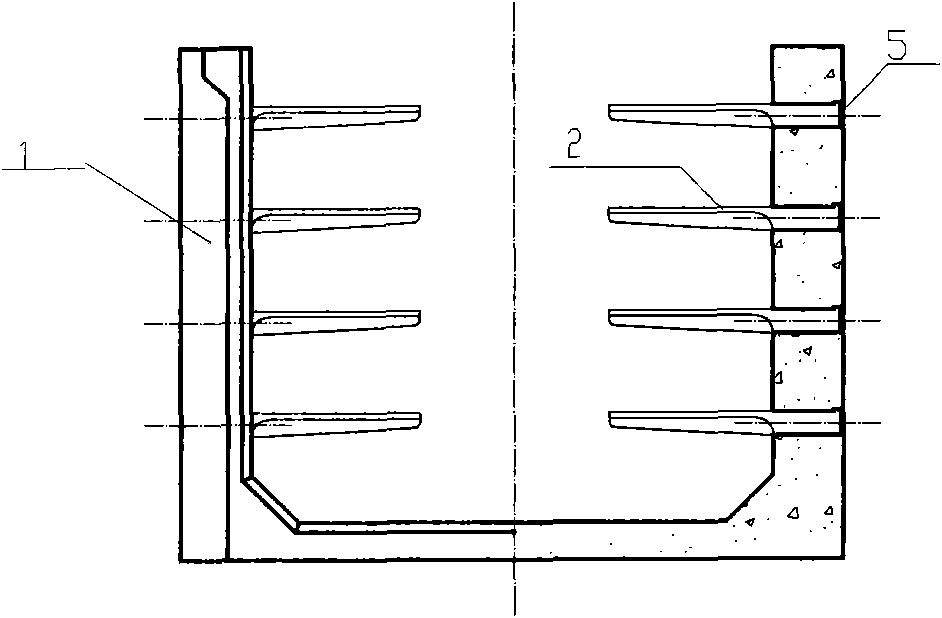

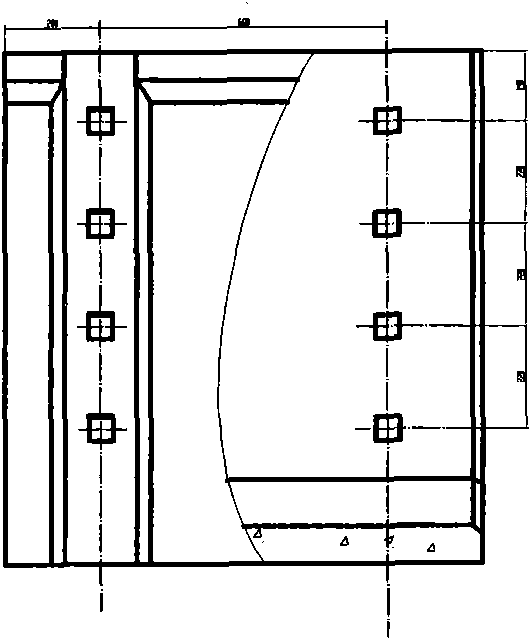

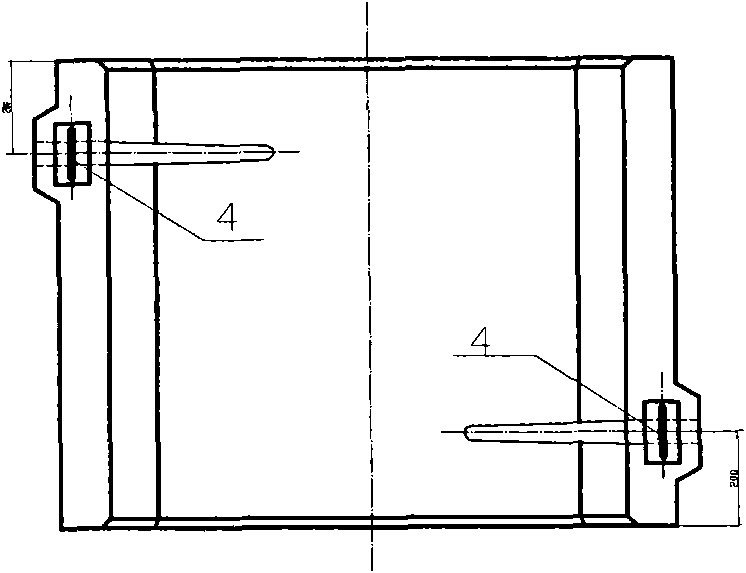

Combined cable trench

ActiveCN101820156AConvenient for manual workFast assemblyCable installations on groundCable installations in underground tubesWorking environmentCement mortar

The invention discloses a combined cable trench, which comprises a trench body and a bracket. Each side of the trench body is provided with a row of reserved cable bracket holes along the length direction of the trench; the bracket is directly embedded in the reserved hole by an embedding method; and then the reserved bracket hole is blocked with cement mortar on the tail part of the bracket. Compared with the prior art, the combined cable trench ensures more convenient manual operation, and the cable trench body can be industrially produced by using a pre-fabricating form and then assembled on site so as to get rid of the on-site construction without influence on the working environment; the cable trench is assembled with the bracket in one step and then lifted for connection; and the cable trench has the advantages of quick assembling speed, high efficiency, low construction cost, high overall strength and high durability.

Owner:黄贺明

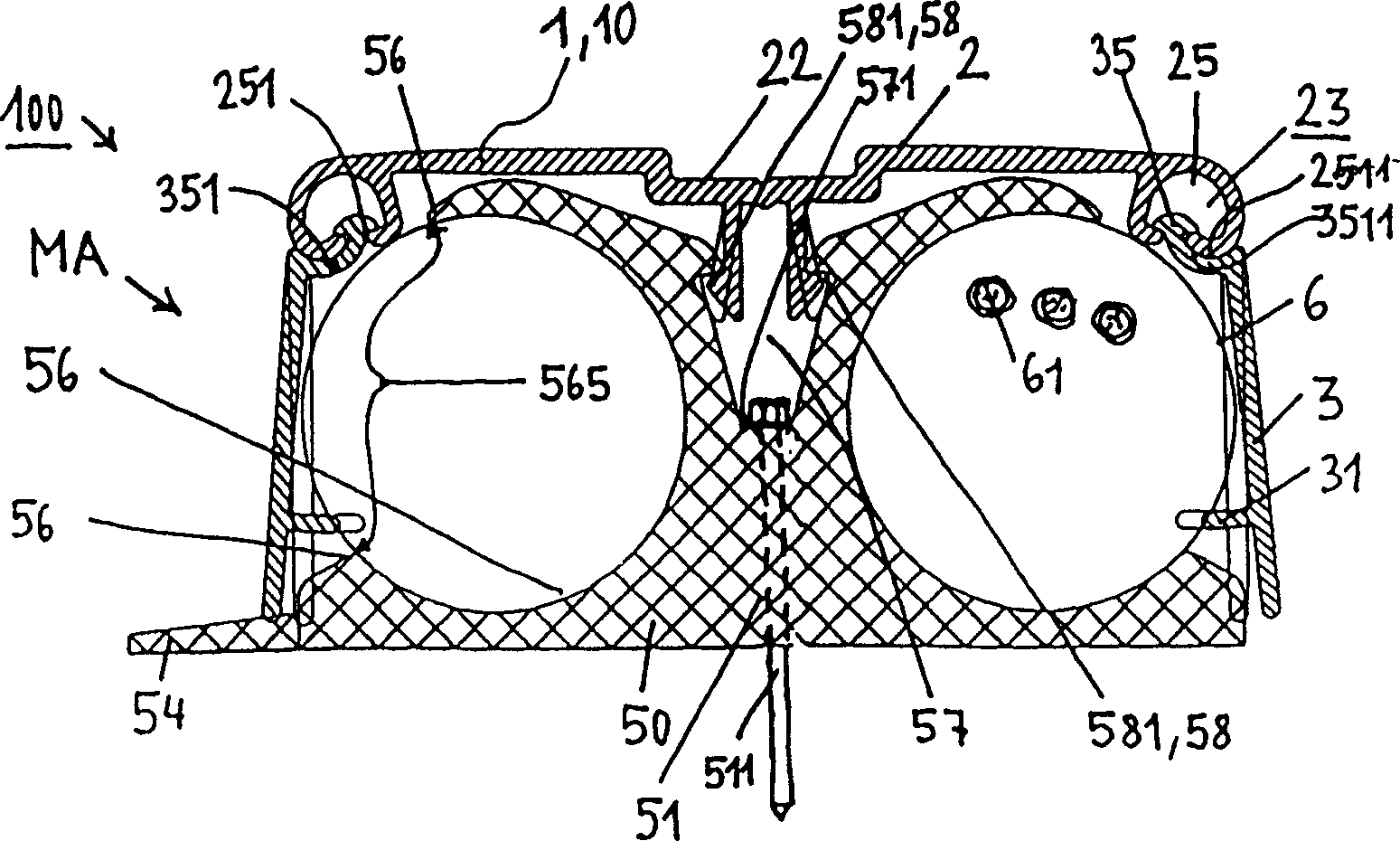

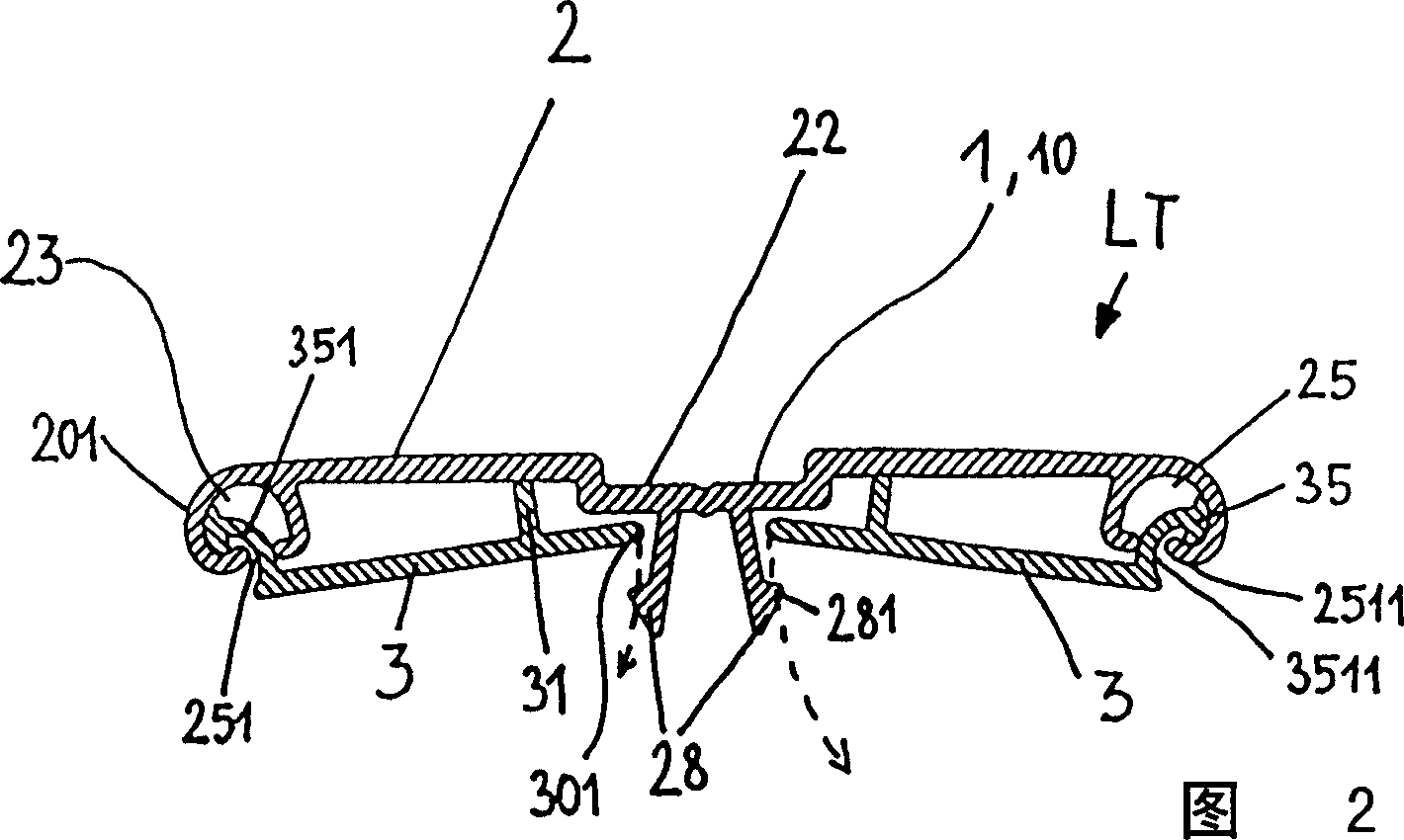

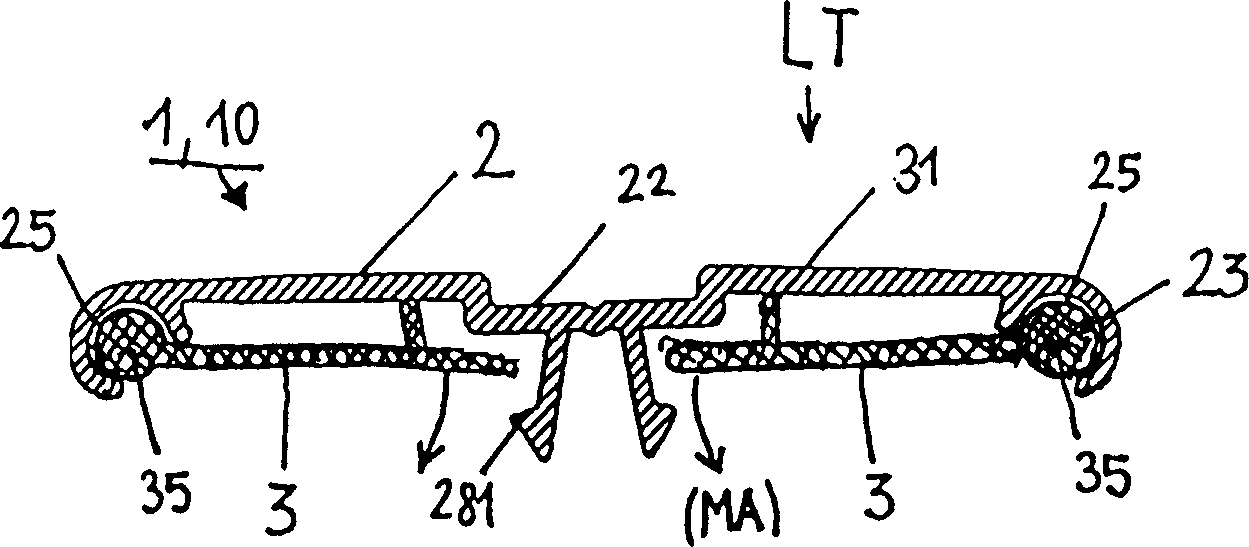

Installation and cover device for cables and method for installation thereof

InactiveCN1589515ACable installations on groundCable installations in surface ductsFront coverLine tubing

The invention relates to an installation device for cables (6) to be laid along a wall, comprising cable holders (5) and a cover (10). According to the invention, the cover (10) is embodied as a cable cover profile strip (1) which may be wound on a winding body for the installation thereof and comprising a front cover strip (2) and side cover strips (3) extending from the both side edges (201) thereof, whereby the both side cover strips (3) are connected to the front cover strip (2) by means of a folding or jointed connection. The both side cover strips (3) run in the same direction as the front cover strip (2) in the folded state (LT) with the free side edges (301) thereof folded in on each other and each of the both side cover strips (3) may be brought into an installation position (MA),perpendicular to the front cover strip (2) by folding out away from the same.

Owner:CABLERUNNER AUSTRIA GMBH & CO KG

Buried device identifier fill and method of identifying a burried device using the device identifier fill

InactiveUS20180156357A1Cable installations on groundPipe laying and repairEngineeringDevice Identifiers

Owner:CCIIP LLC

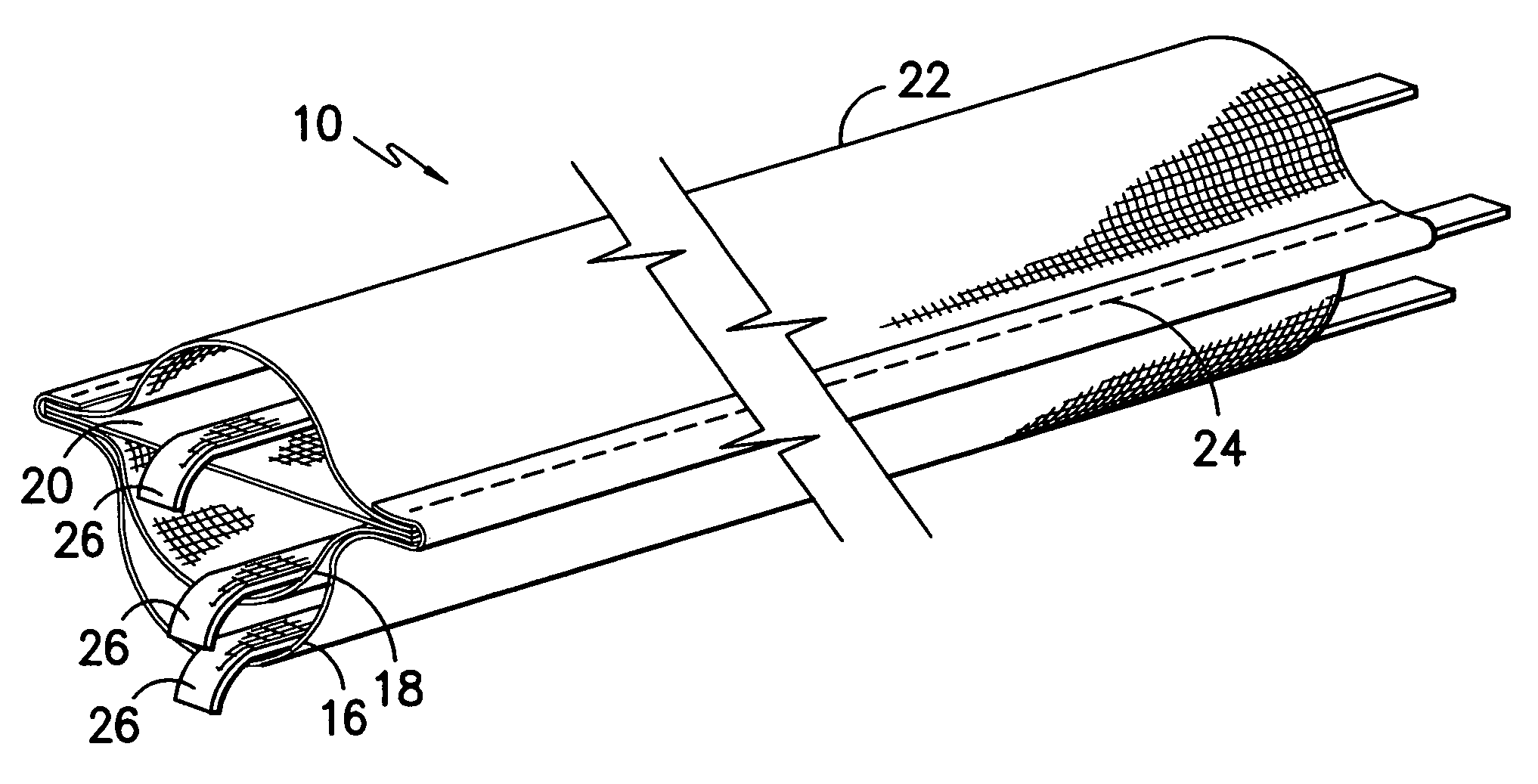

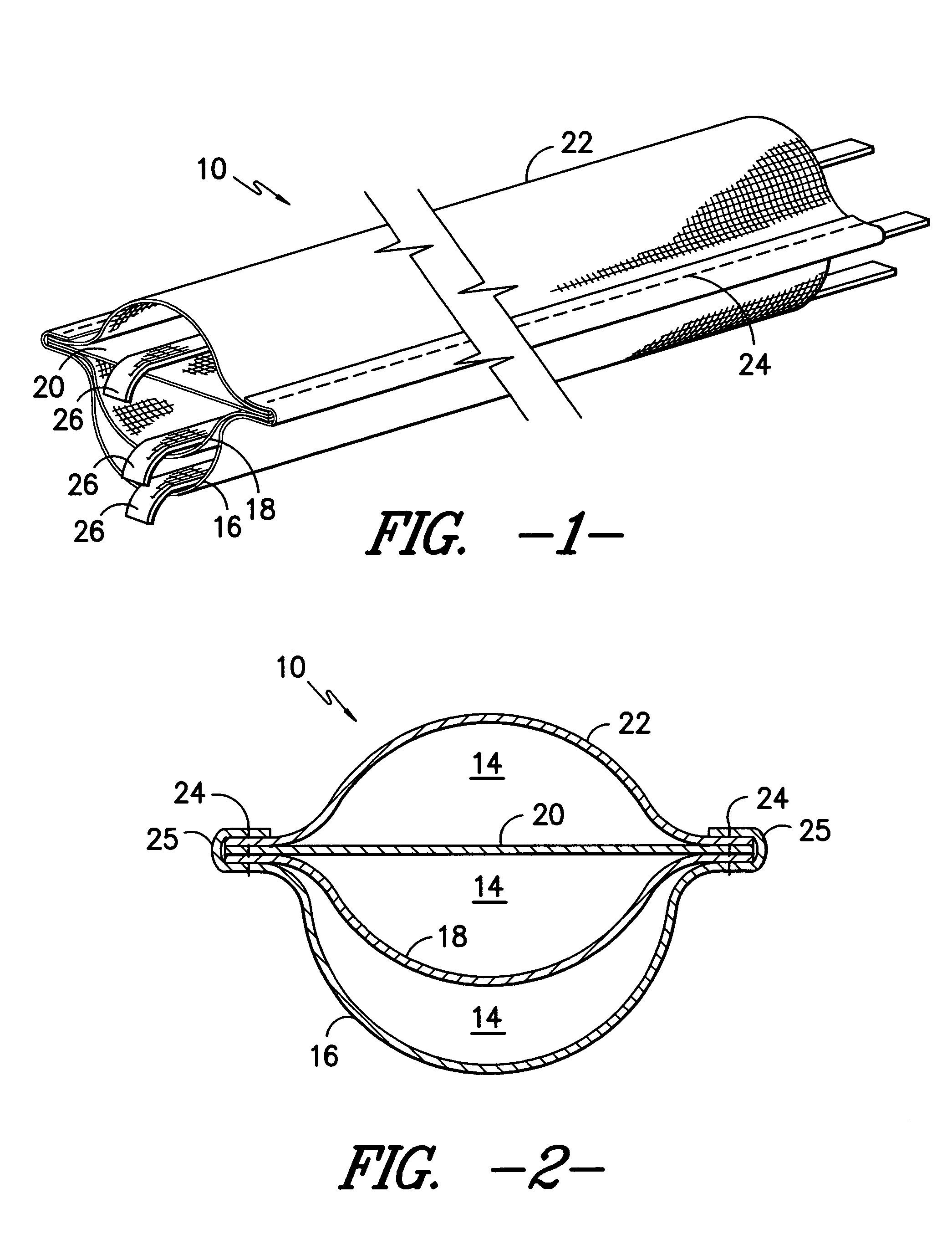

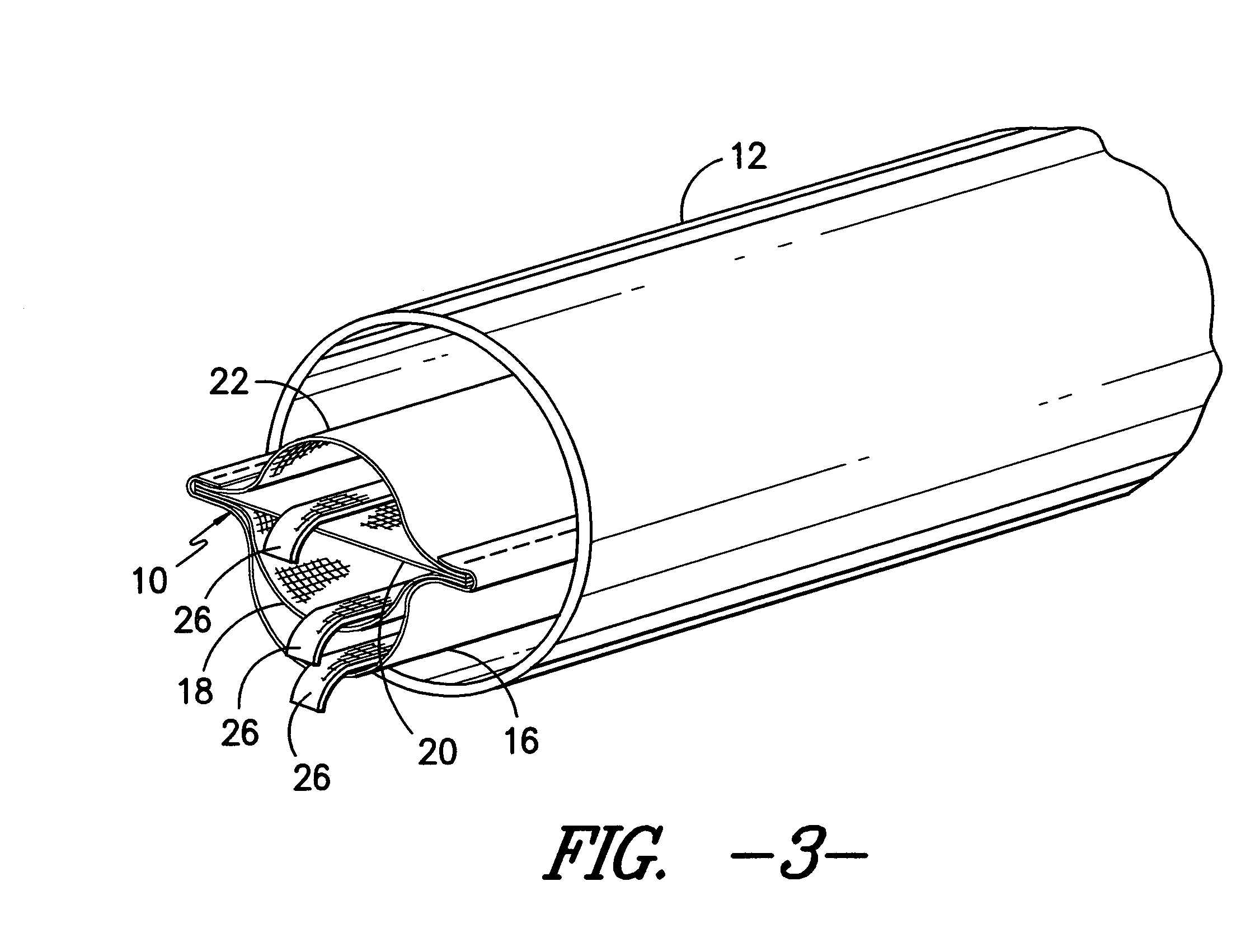

Conduit insert for optical fiber cable

A flexible innerduct structure is configured to contain a cable within a conduit. The innerduct structure includes a pair of adjacent strip-shaped layers of flexible material that are joined along their longitudinal edges to define a channel through which the cable can extend longitudinally through the innerduct structure between the layers. The adjacent layers have differing widths between their longitudinal edges, whereby the wider layer bulges away from the narrower layer to impart an open configuration to the channel. Other features of the innerduct structure relate to the material of which it is formed. Such features includes the structure of the material, such as a woven structure, and further include properties such as melting point, tensile strength, elongation, coefficient of friction, crimp resistance and compression recovery.

Owner:MILLIKEN & CO

Device for fixing a tubular element in an inaccessible cavity

InactiveUS6604549B2Quick installationInstallation economyPipe supportsRod connectionsMechanical engineeringSectional plane

Owner:ALCATEL LUCENT SAS

Conduit attachment apparatus

A conduit attachment apparatus is secured to an open end of a conduit for holding cables or wires. In one embodiment the conduit attachment apparatus comprises a spillway and a securement collar. The spillway is adapted to provide bend radius control to cables or wires extending out of the conduit. The securement collar is adapted to secure and remove the spillway from the conduit. In another embodiment, the securement collar can be installed without the use of tools and can rotate up to approximately 180° about the spillway.

Owner:PANDUIT

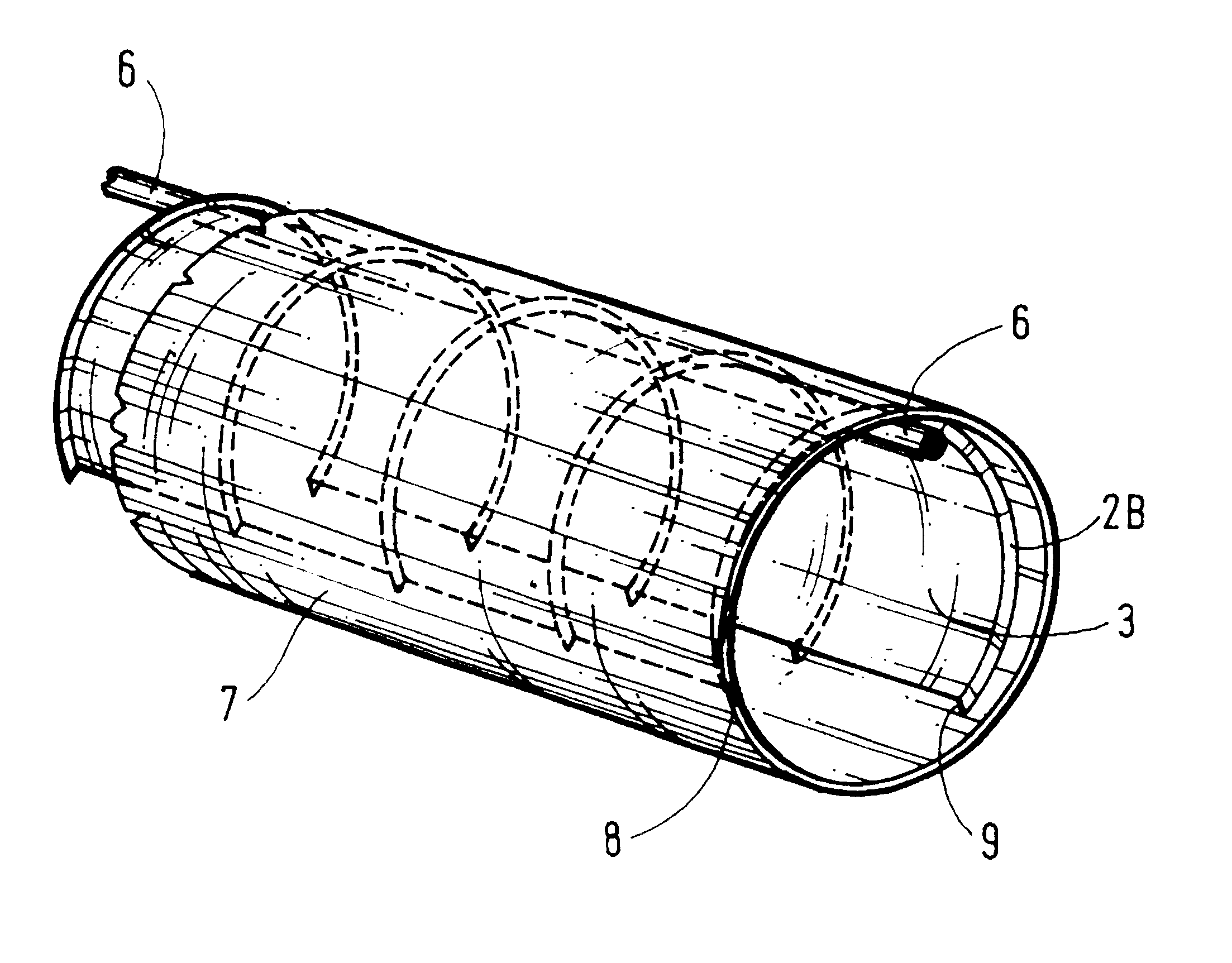

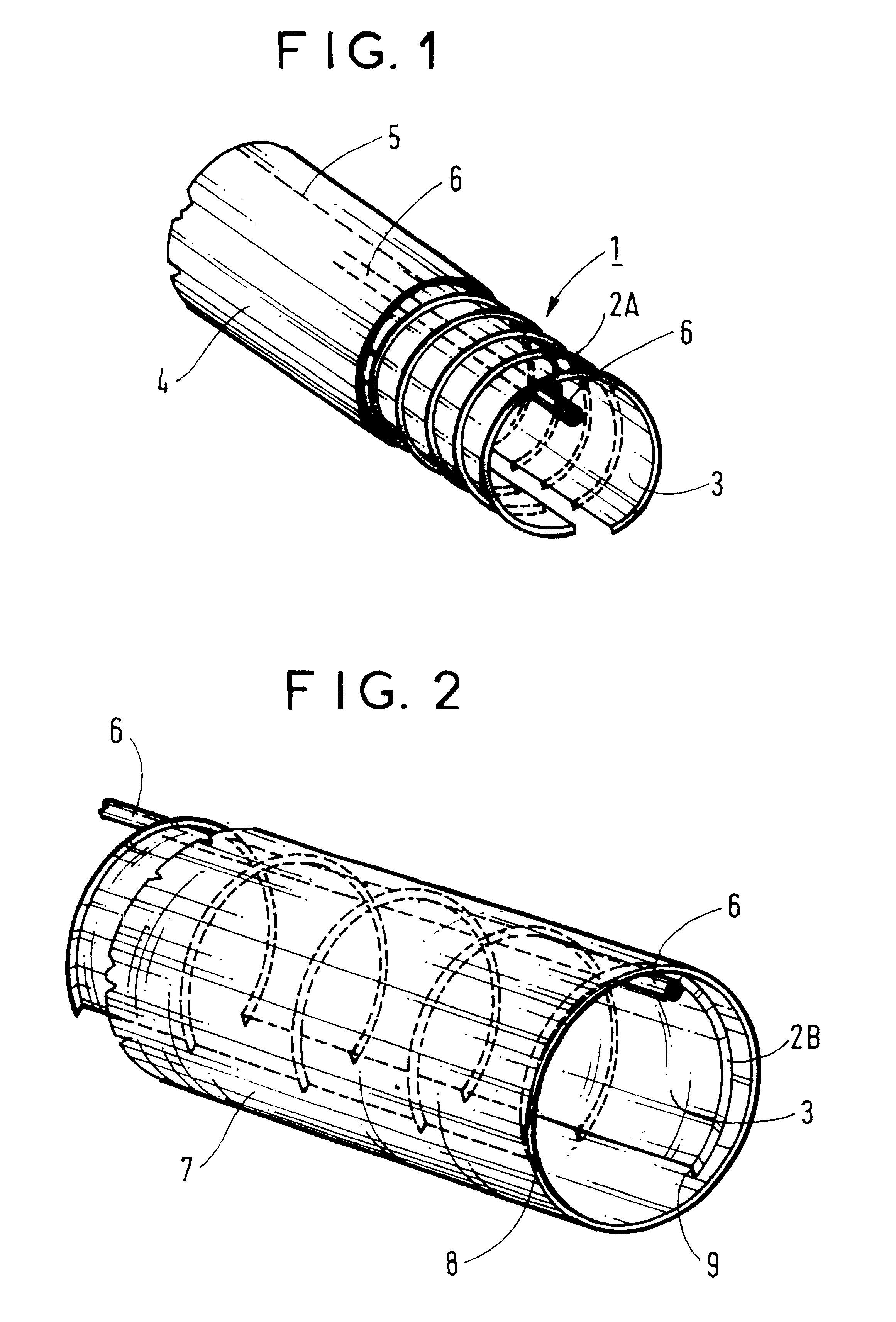

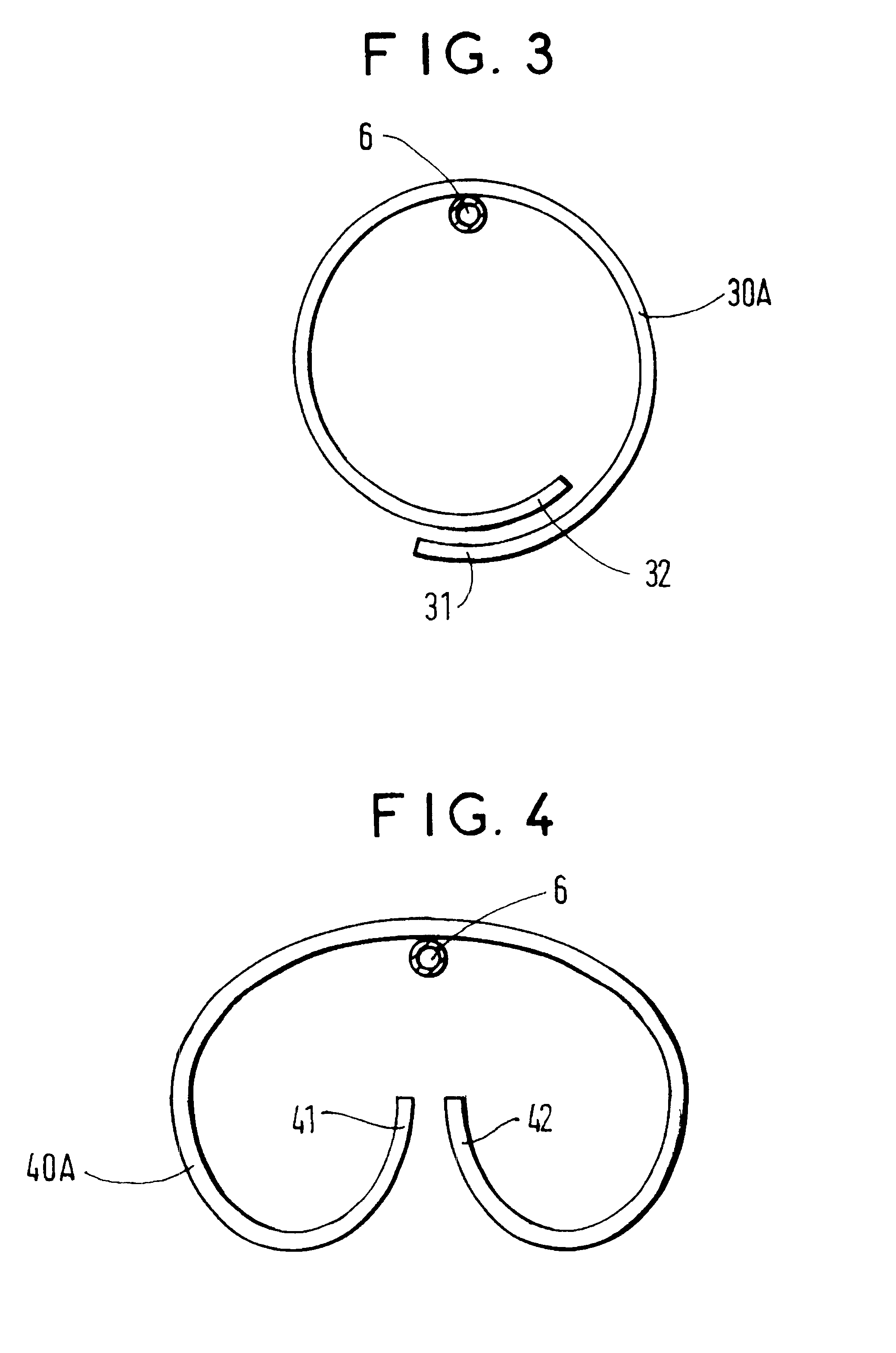

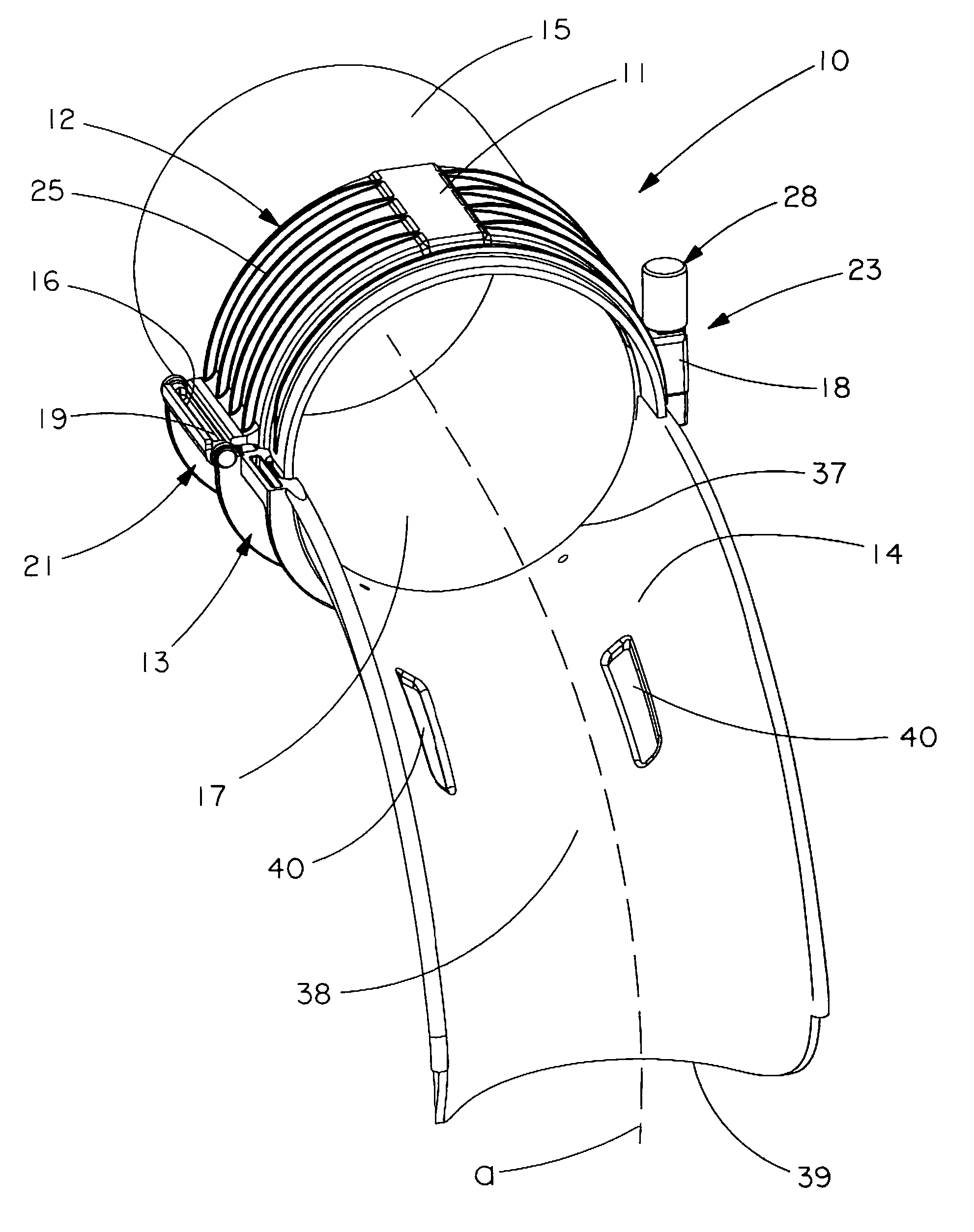

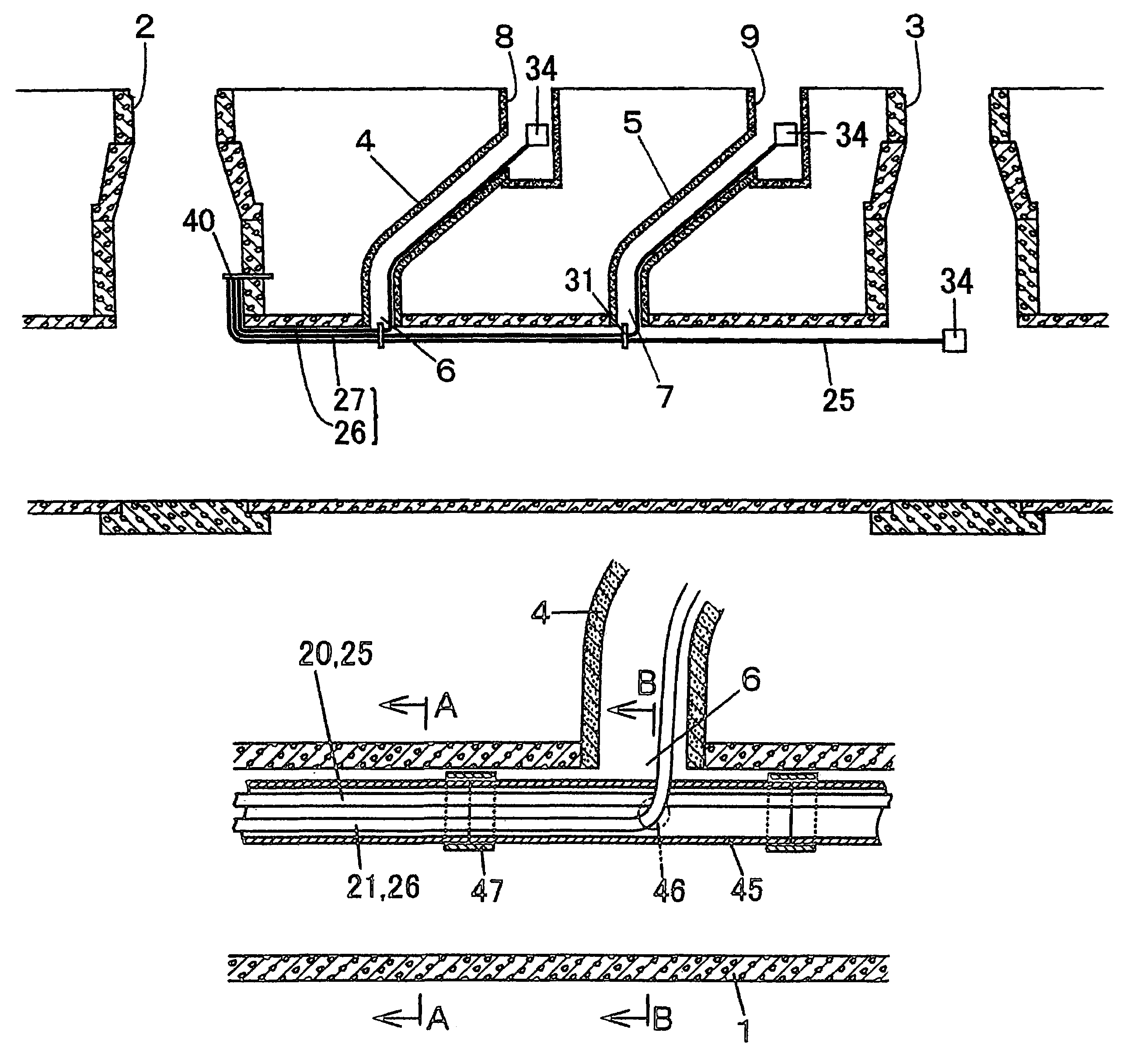

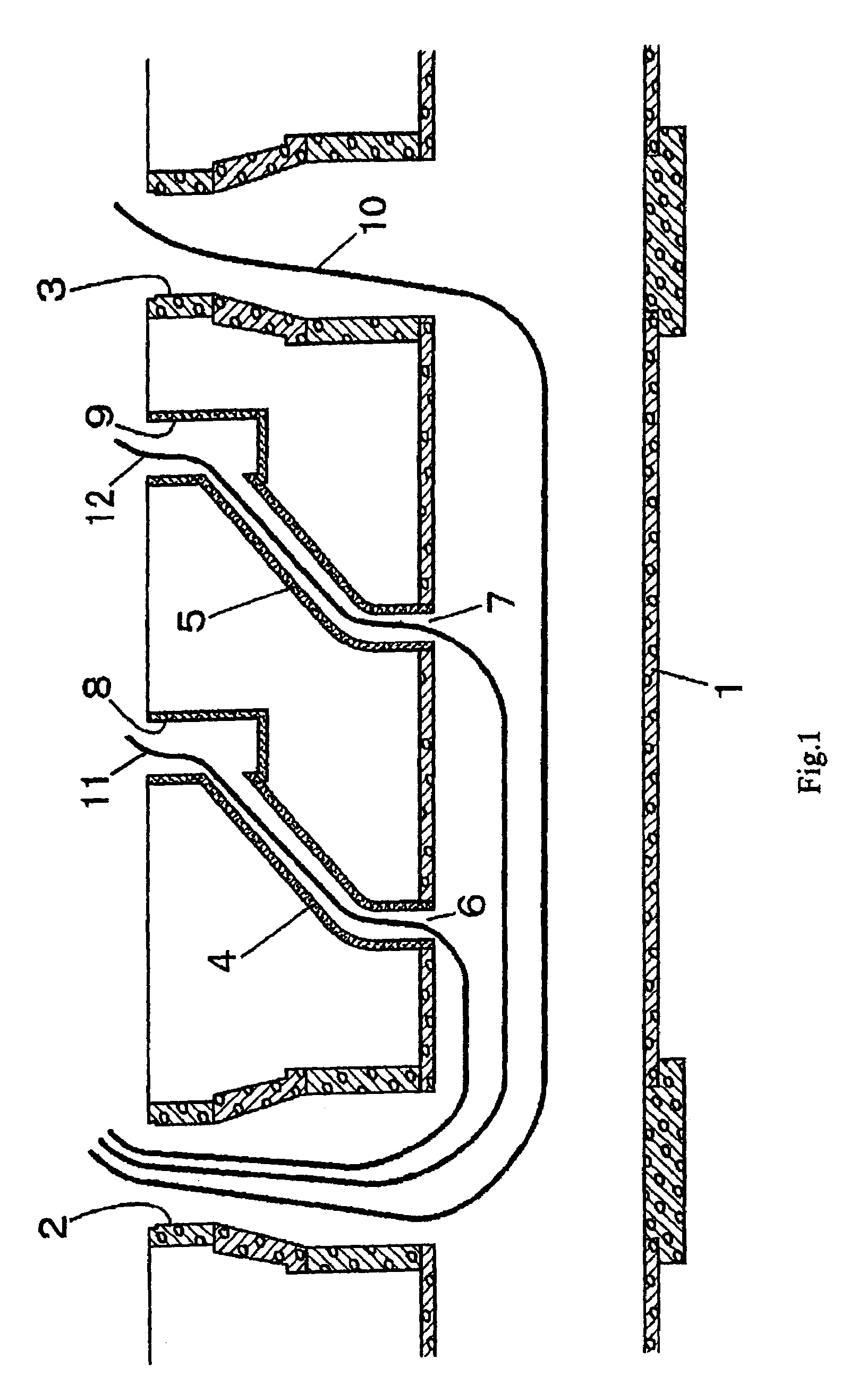

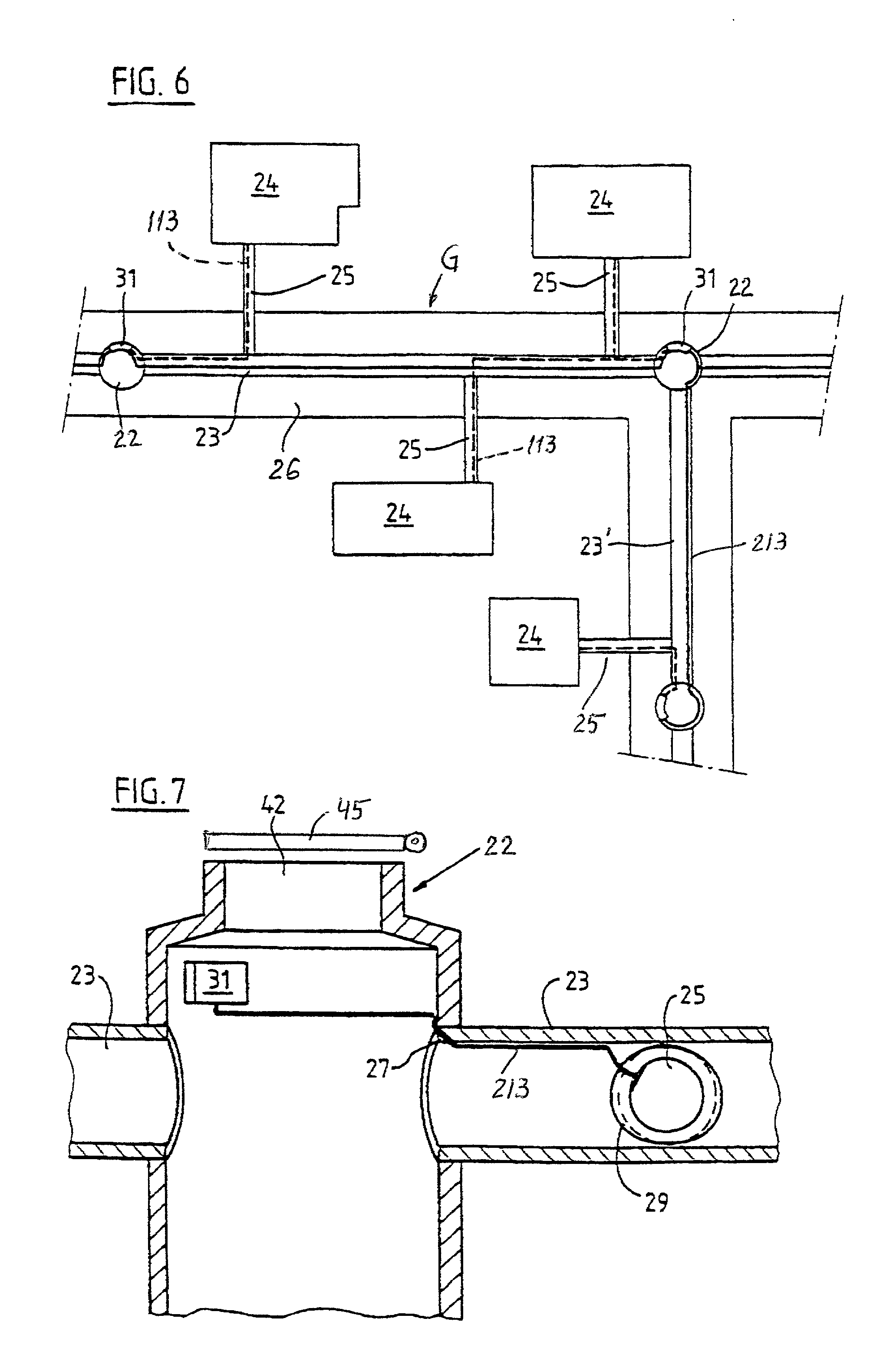

Method and structure for laying communication cable in underground line, and members used for laying

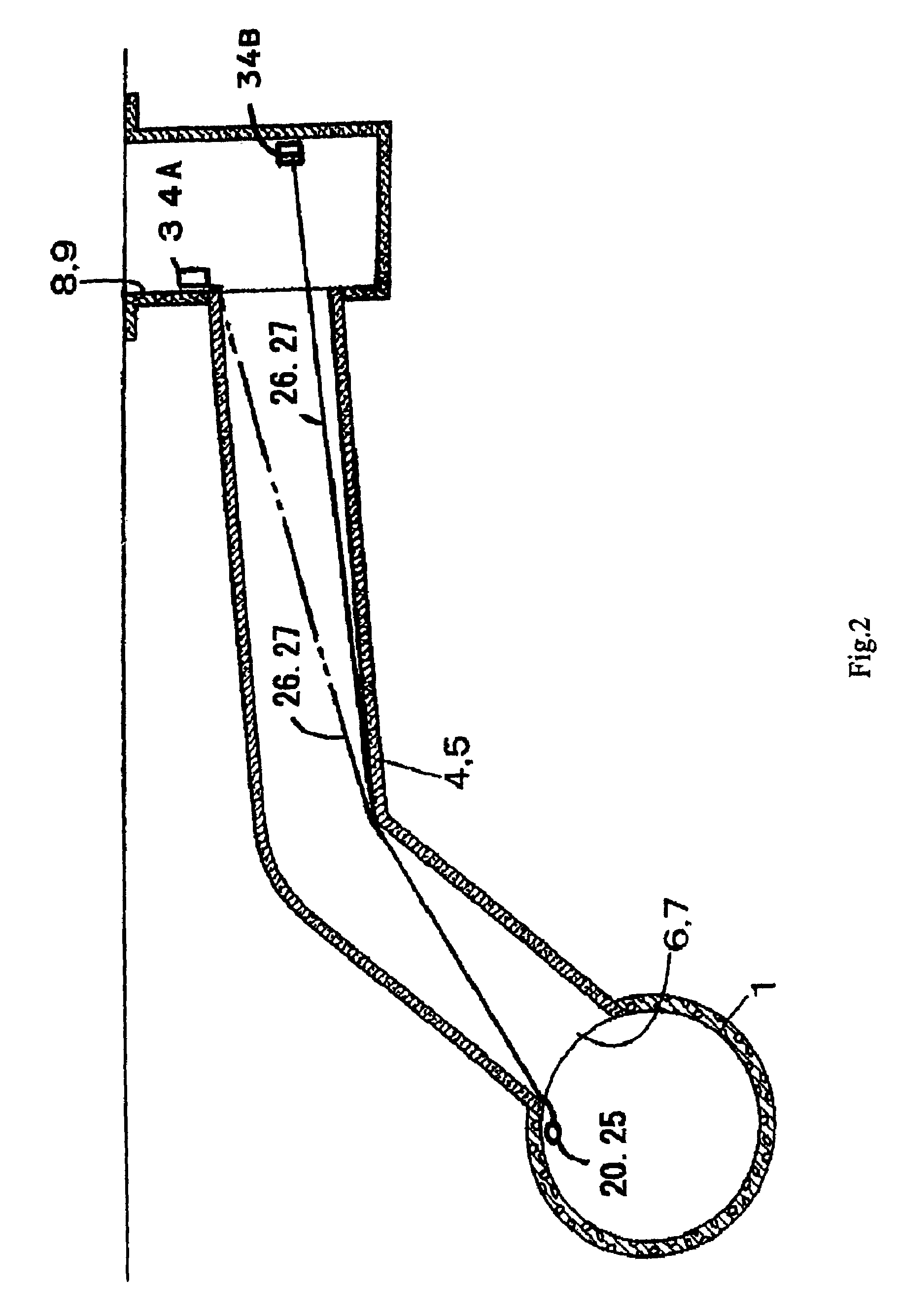

A laying method for laying communication cables (16) is provided which allows to lay optical fiber cables (20) in an underground pipeline such as a sewage pipe neither placing direct tension nor allowing slack on them, and for a main pipe in which a plurality of optical fiber cables (20) are to be laid, the method also allows to lay optical fiber cables (20) in the upper space of inside the pipeline and to obviate the need of an expensive robot for the laying operation. In the proposed laying method, a high-strength low-elongation tension member is disposed to be slidable in the lengthwise direction along each optical fiber cable (20, 21, 22), and the tension members (25, 26, 27) are drawn into the underground pipeline (1) to tension the trunk tension member (25) thereby stretching the trunk tension member (25) substantially straight in the underground pipeline (1), and thus the optical fiber cables (20, 21, 22) are laid in the upper space of inside the underground pipeline (1). Also the branch tension member (26, 27) is tensioned in the branch pipe (4, 5) to lay the optical fiber cables (21, 22) in the branch pipe without allowing slack.

Owner:ASHIMORI INDS +1

Method of laying data cables and the like in underground pipes and pipe-cable combinations

InactiveUS20010043839A1Protect chemical damageProtect mechanical damageUnderground chambersLabelling articlesEngineeringSewage

One or more electric and / or data transmitting cables are confined in an elongated strip-shaped body containing a hardenable resin or the like, and the body is placed against a portion of the internal surface of an underground sewage, water or other pipe. An expandible tubular liner is thereupon introduced into the pipe and is expanded to press the body against the pipe. The body is caused to set, by conveying a hot fluid through the liner and / or by electrically heating the cable or cables, and to adhere to the internal surface of the pipe. The liner can remain in the pipe and can be bonded to the strip-shaped body and / or to the remaining portion of the internal surface of the pipe. Alternatively, the liner is caused to collapse and is withdrawn from the pipe once the strip-shaped body is bonded to the internal surface of the pipe.

Owner:PRUSAK MARTIN

Polyethylene cable duct

ActiveCN102617914AHigh tensile strengthNo brittle crackingCable installations in underground tubesPolymer scienceCrack resistance

The invention discloses a polyethylene cable duct. The polyethylene cable duct is characterized by being prepared from a modified polyethylene material; and the modified polyethylene material consists of the following components by weight: 100 parts of base material, 1 to 5 parts of ethylene propylene diene monomer resin, 0.1 to 1 part of polytetrafluoroethylene, 0.1 to 1 part of calcium stearate, 0.1 to 1 part of polyethylene wax and 0.01 to 0.1 part of pigment, wherein the base material consists of 85 to 95 weight percent of high-density polyethylene and 5 to 15 weight percent of ultra-high molecular weight polyethylene. The polyethylene cable duct has the following excellent performance: (1) high tensile strength; (2) high impact strength: the polyethylene cable duct has excellent low-temperature impact resistance and extremely low brittleness temperature and can be safely used at the temperature of between 20 DEG C below zero and 60 DEG C; (3) high abrasion resistance; (4) high toughness, flexibility and shock resistance; (5) high stress cracking resistance and low notch sensitivity; (6) corrosion resistance and long service life; and (7) simplicity in cable threading.

Owner:GUANGDONG SANLING PLASTIC PIPE MATERIAL

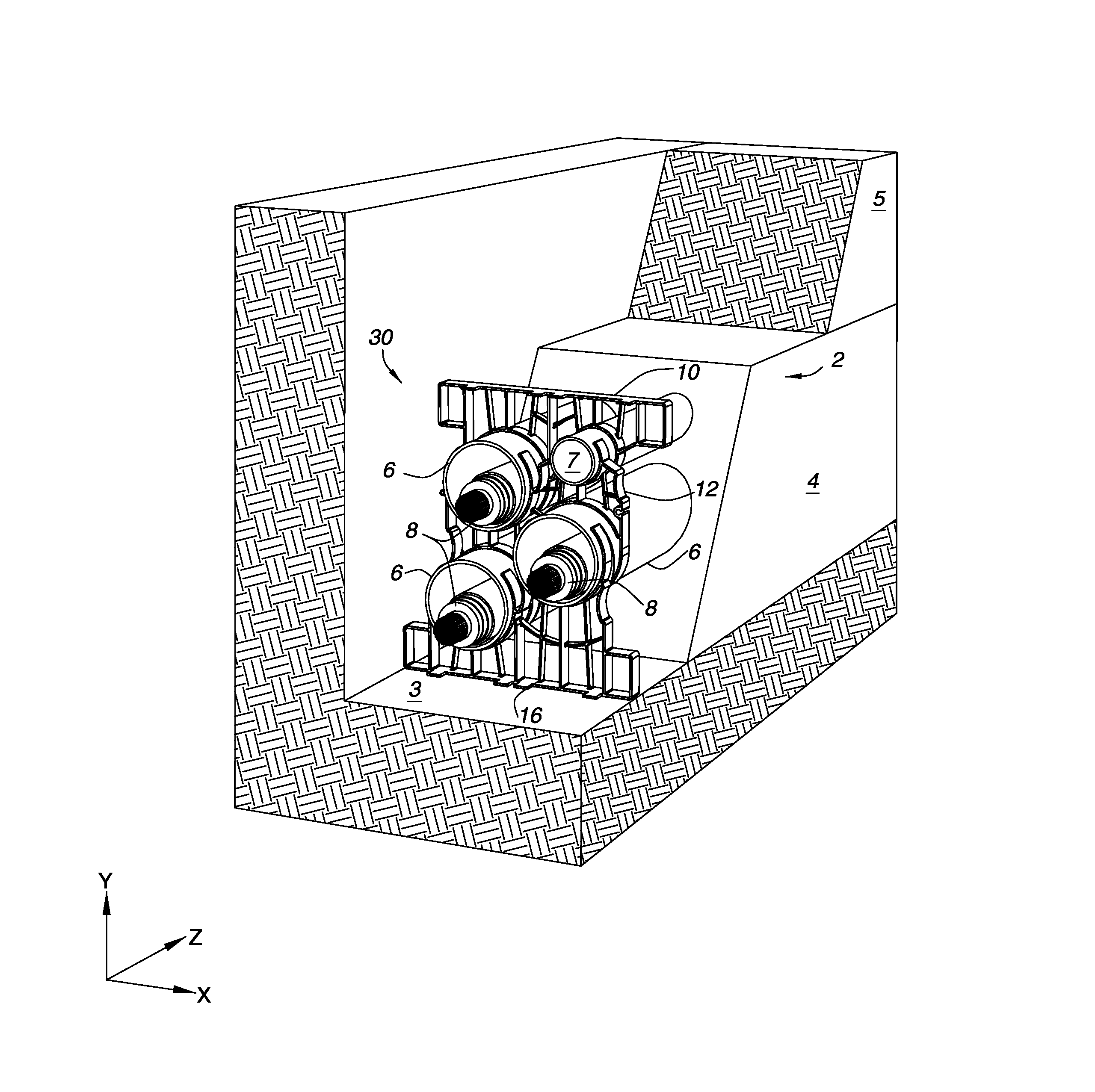

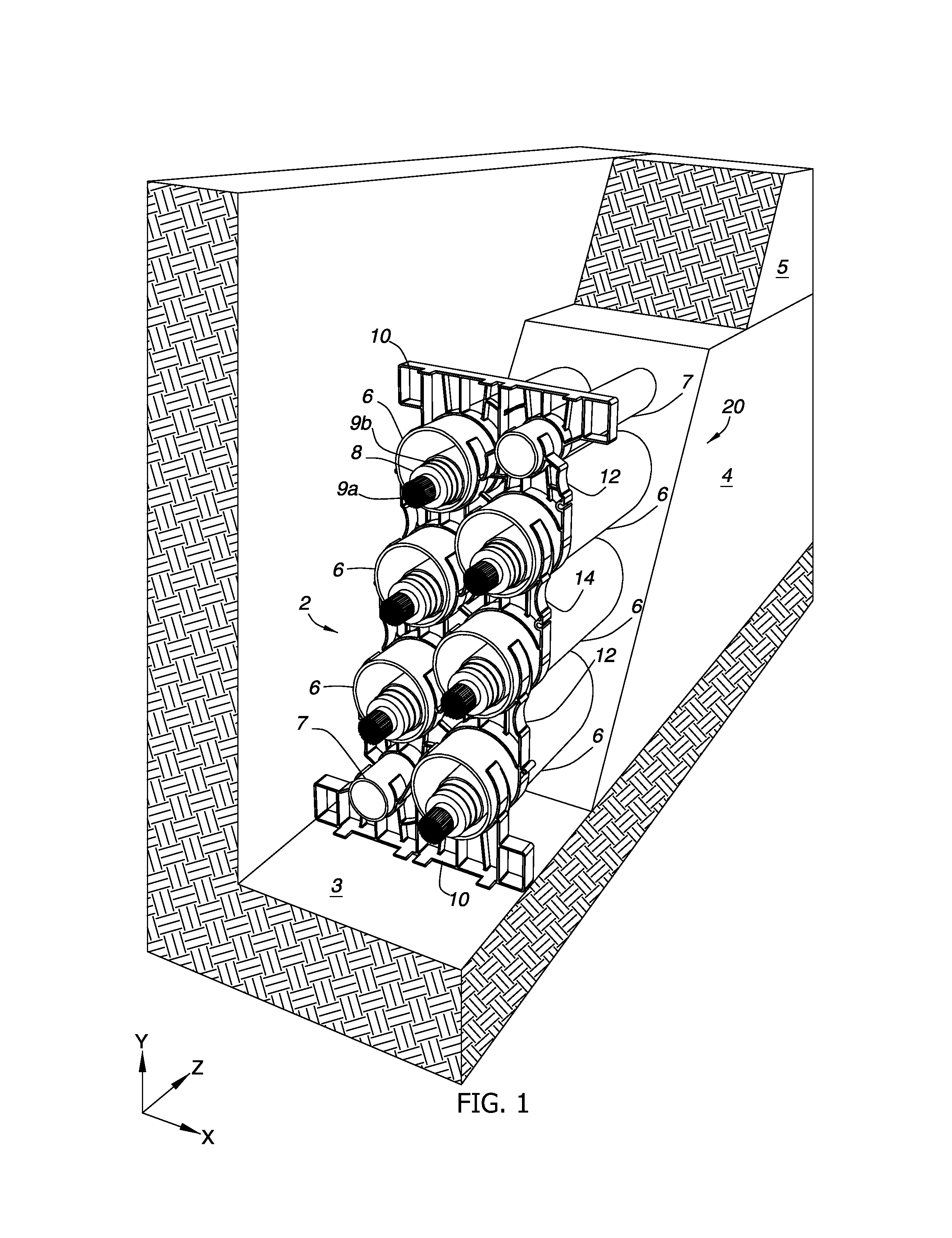

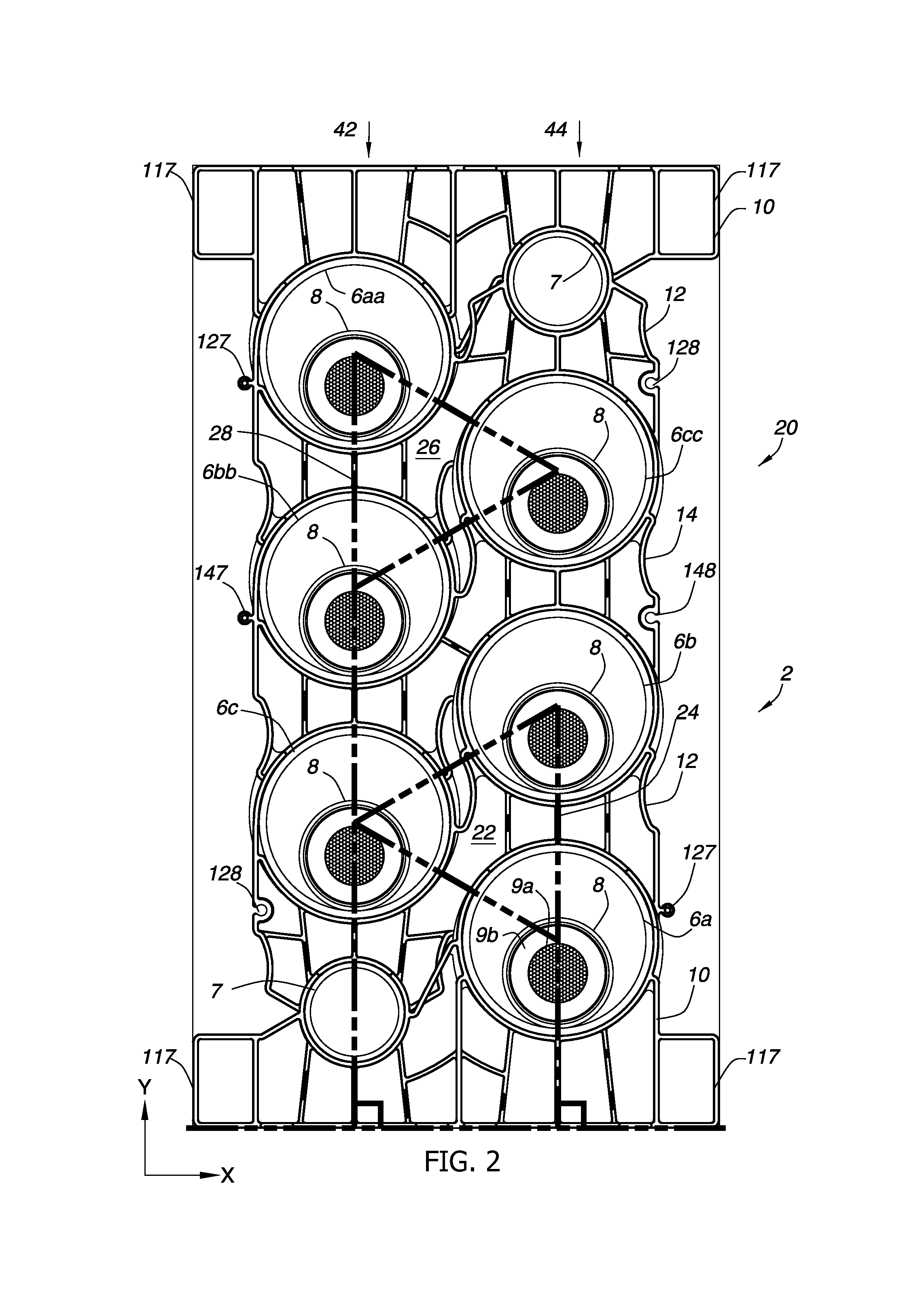

Low EMF compact duct spacer

ActiveUS8783631B2Pipe supportsCable installations in underground tubesPhase cancellationAbove ground

Conduit spacers useful in preparing duct banks with reduced electromagnetic fields (EMF) are disclosed. The conduit spacers are designed to maximize phase cancellation of EMF from a closely-spaced series of electric power cables placed in conduits supported underground by the conduit spacers. The spacers are also designed to minimize the EMF above ground by reducing the distance needed to bury the cables for a given EMF above ground. In one embodiment, the spacers place conduits adjacent one another for maximum cancellation of a single three-phase cable installation. In another embodiment, the spacers place conduits adjacent one another for maximum cancellation for a dual three-phase cable installation, including cross-phase cancellation, e.g., A-B-C and C-B-A.

Owner:UNDERGROUND DEVICES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com