Patents

Literature

1487results about How to "Fast assembly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

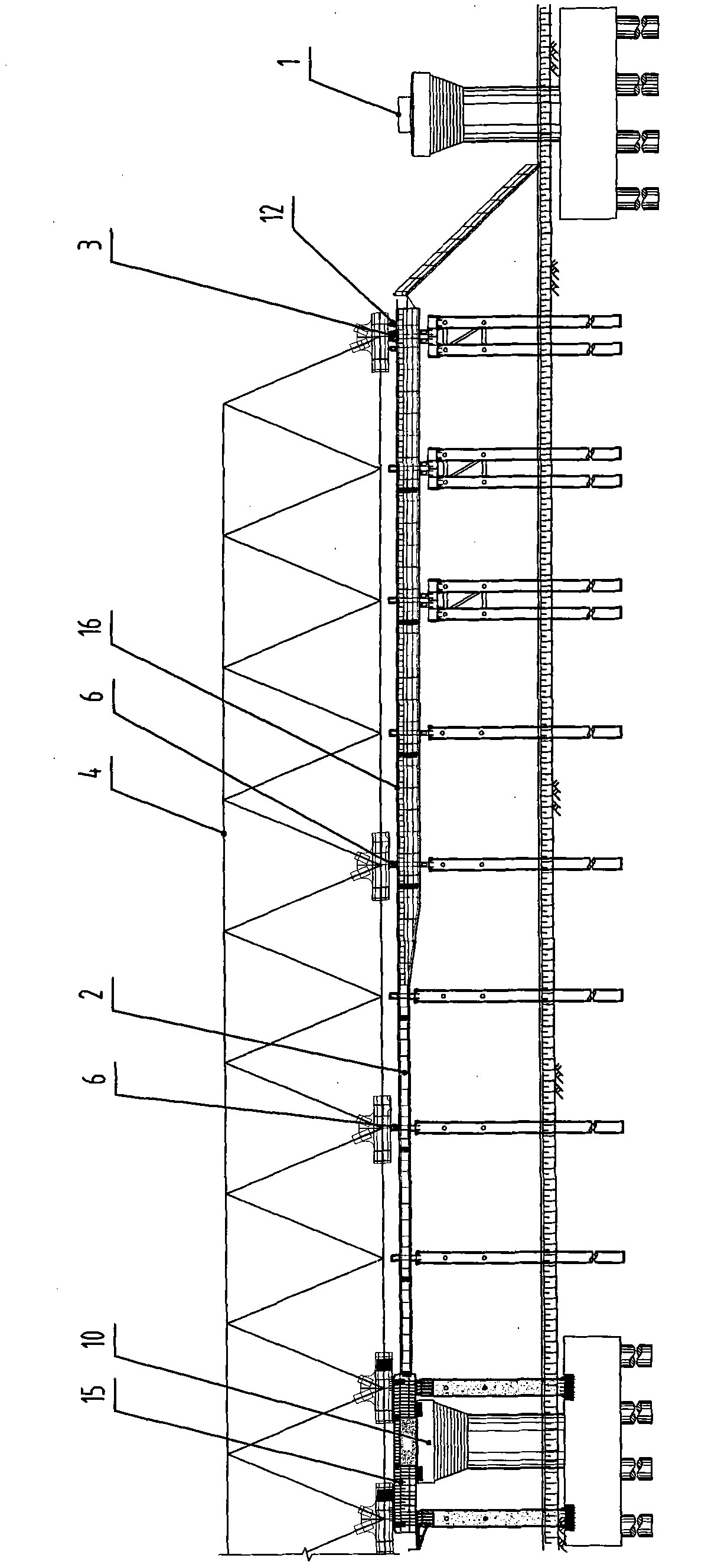

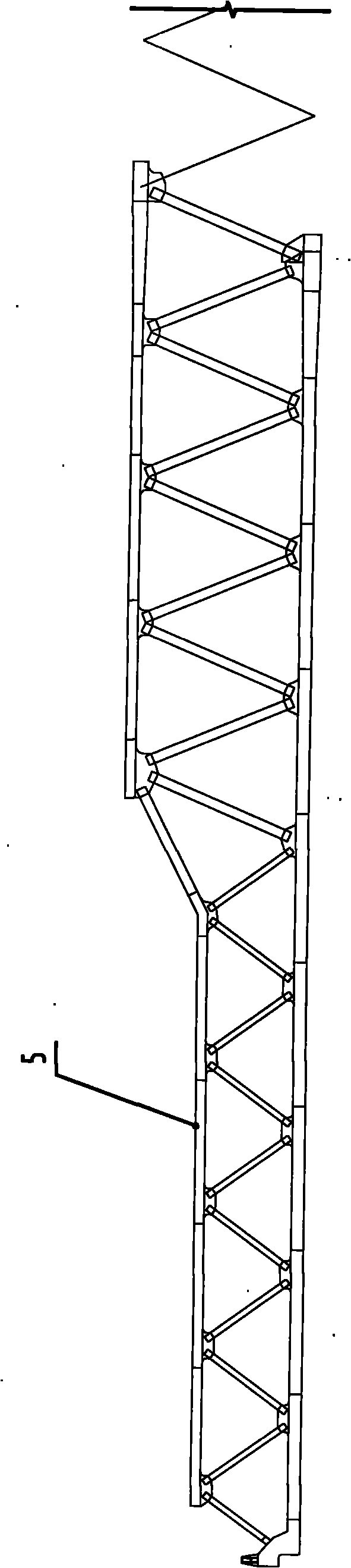

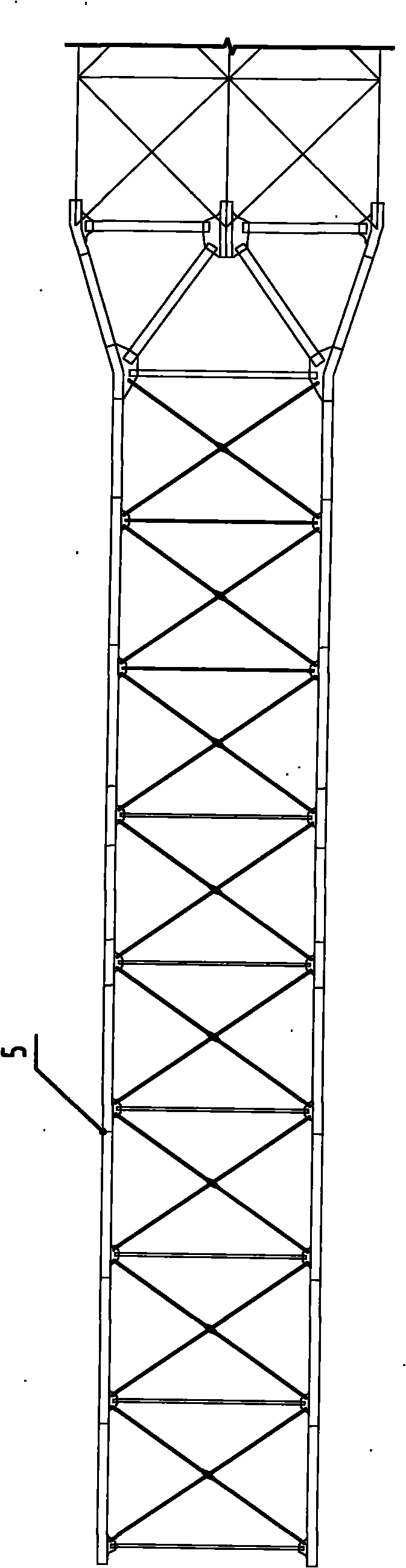

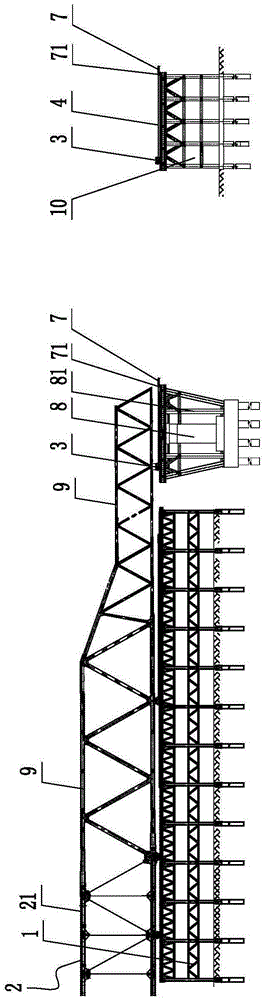

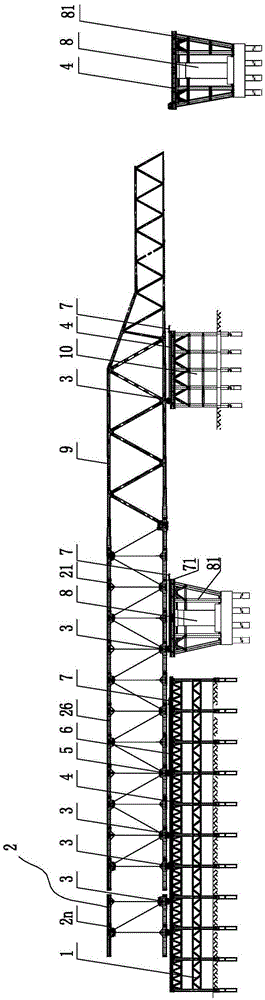

Multipoint synchronous push construction method for porous large-span continuous steel truss girder

ActiveCN101831874AEasy constructionReduce labor intensityBridge erection/assemblyControl systemEngineering

The invention discloses a multipoint synchronous push construction method for a porous large-span continuous steel truss girder, which comprises the following steps of: (1) assembling a steel truss girder assembling platform and a push slideway in a shoreside bridge pier position; (2) assembling a section of steel truss girder and a guide girder on the steel truss girder assembling platform; (3) installing a vertical jack for carrying out support conversion on the steel truss girder and then installing a continuous push jack, a steel strand and an electrohydraulic integrated control system; (4) operating the electrohydraulic integrated control system for carrying out push operation on the steel truss girder; and (5) after the push operation of the section of steel truss girder is finished, continuously assembling the steel truss girder on the steel truss girder assembling platform, carrying out next push operation, repeating the step for circulating operation and finishing the push construction of the porous large-span steel truss girder. The invention has the advantages of short construction period, safe construction, quality guarantee, low cost, and the like, realizes the push operation of the large-span steel truss girder, saves the construction cost, and reduces the pollution to a river channel.

Owner:1ST ENG OF CHINA ZHONGTIE MAJORBRIDGE GROUP +1

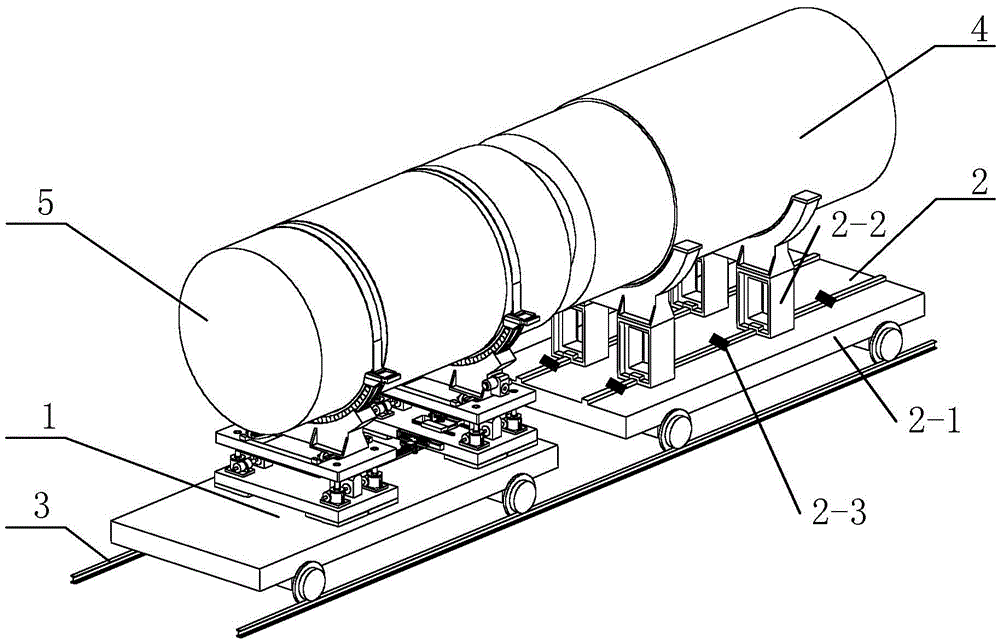

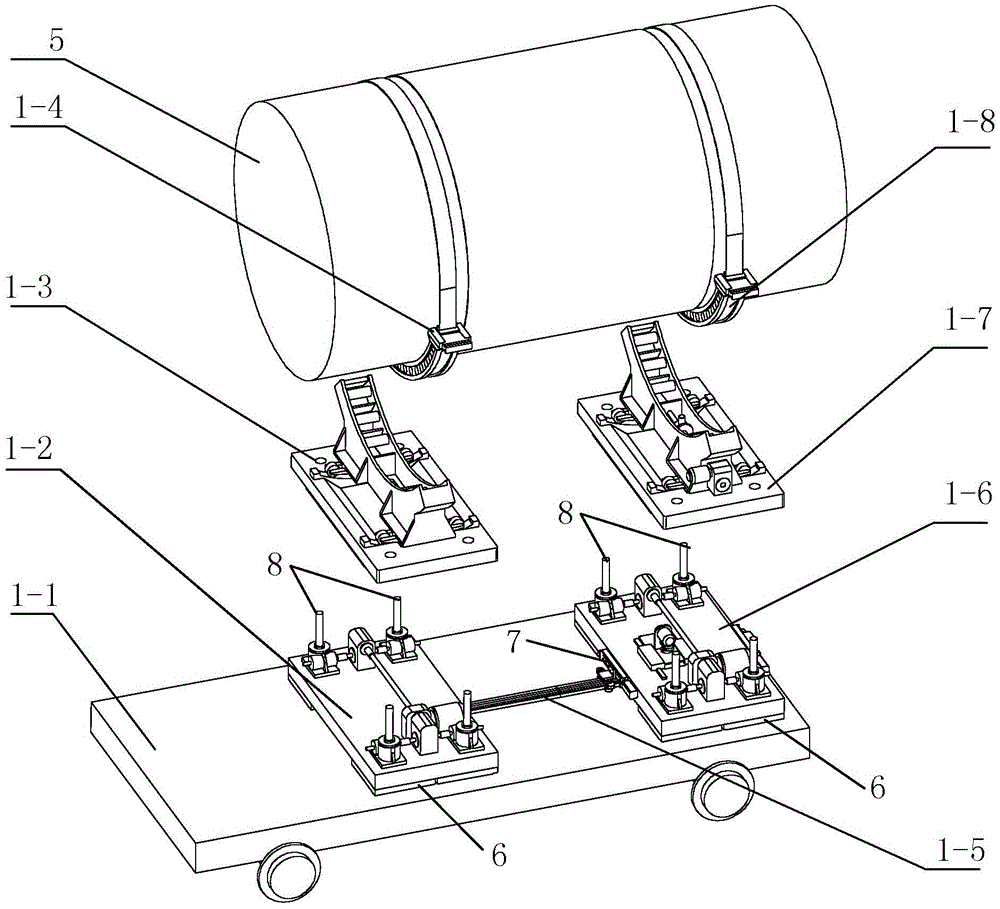

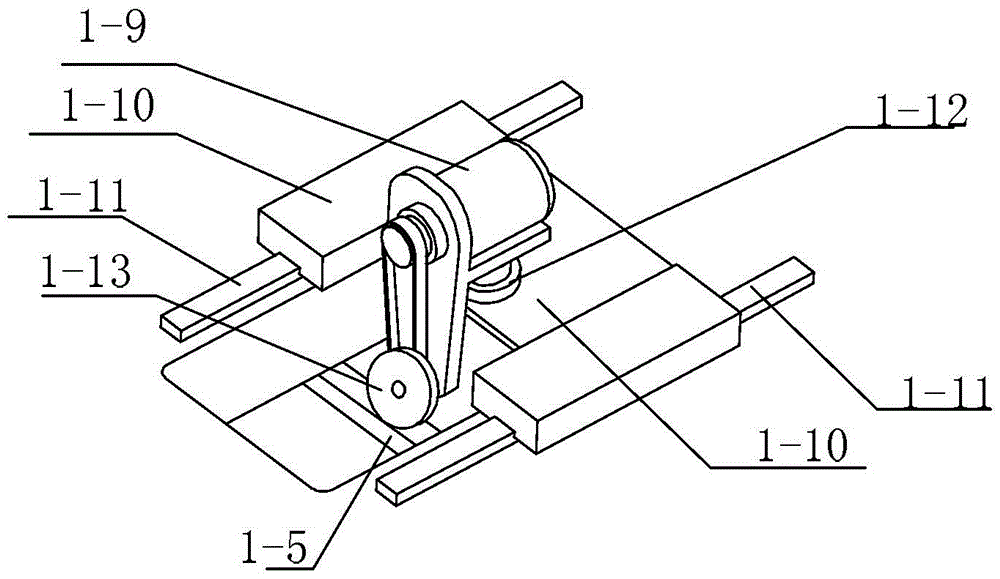

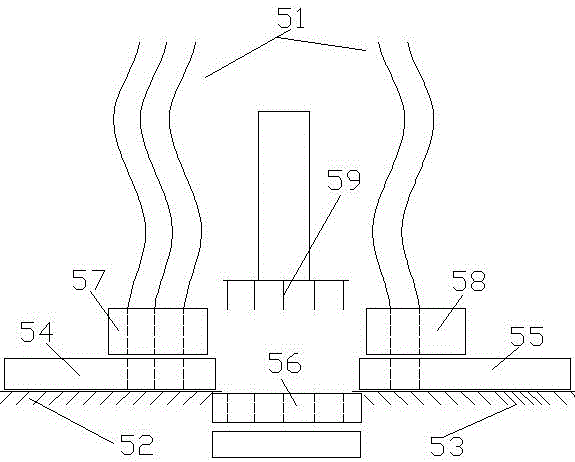

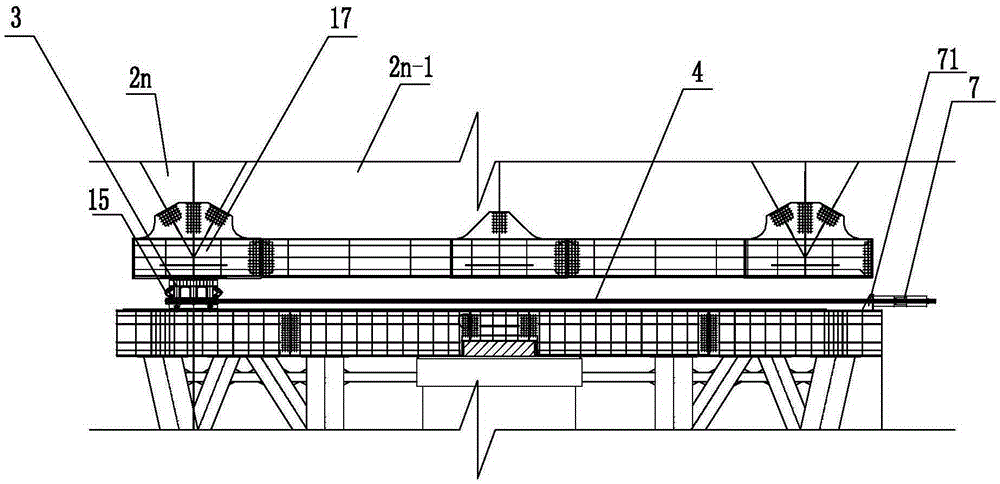

Air-floating type flexible assembly butt-joint system

ActiveCN105619049AImprove assembly efficiencyImprove assembly qualityMetal working apparatusButt jointEngineering

The invention relates to an air-floating type flexible assembly butt-joint system, which relates to the technical field of flexible assembly, and aims at solving problems of low assembling precision, inferior efficiency and inferior flexibility of traditional large-scale cabin section type products. The air-floating type flexible assembly butt-joint system comprises a driving assembly butt-joint vehicle, a driven assembly butt-joint vehicle and a rail, wherein the driving assembly butt-joint vehicle and the driven assembly butt-joint vehicle slide along the same rail; the driven assembly butt-joint vehicle is used for lifting a driven butt-joint cabin section; the driving assembly butt-joint vehicle is used for lifting a driving butt-joint cabin section and controlling the driving butt-joint cabin section to move for butt joint along the extending direction of the rail, move along the direction vertical to the extending direction of the rail, vertically move along the longitudinal direction, rotate in a yawing form, rotate in a pitching form and rotate in a rolling form, so that the butt joint between the driving butt-joint cabin section and the driven butt-joint cabin section lifted on the driven assembly butt-joint vehicle is realized; the driving assembly butt-joint vehicle is used for lifting the driving butt-joint cabin section in an air-floating form. The air-floating type flexible assembly butt joint system is mainly used for fine butt-jointing of large-scale cabin section type products.

Owner:HARBIN INST OF TECH

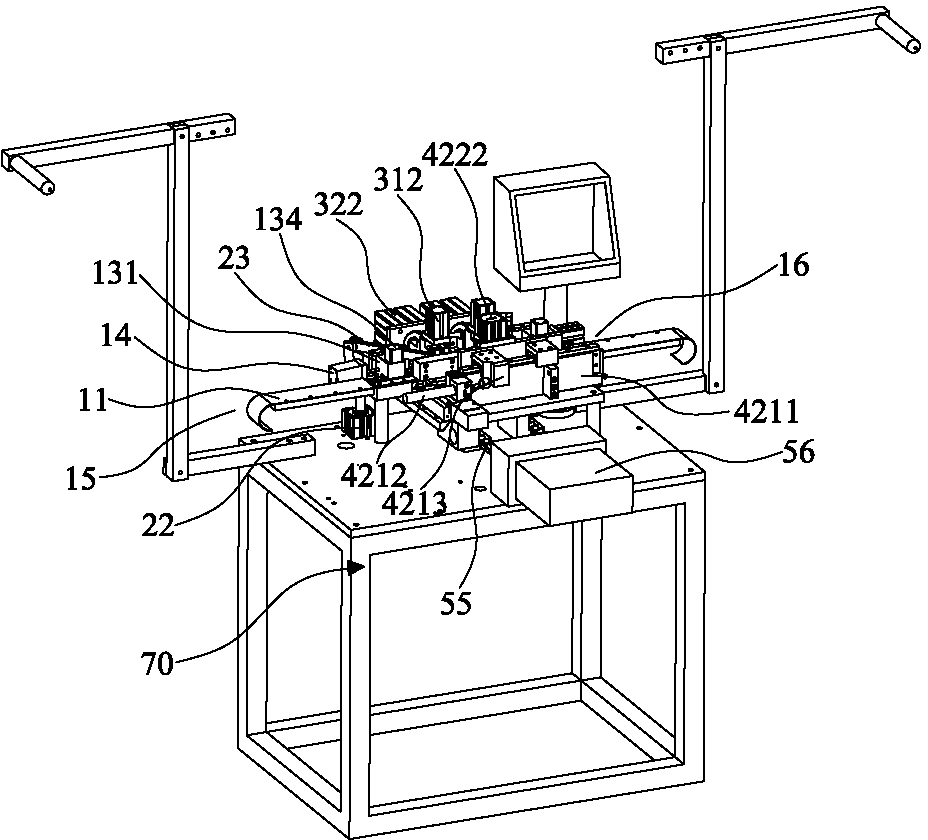

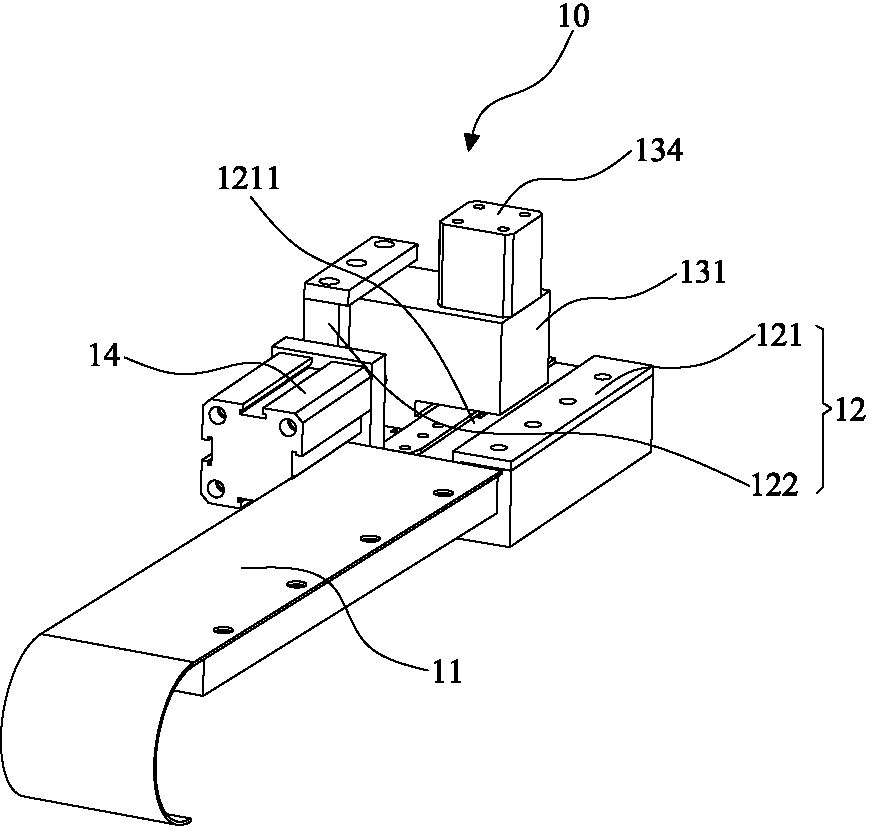

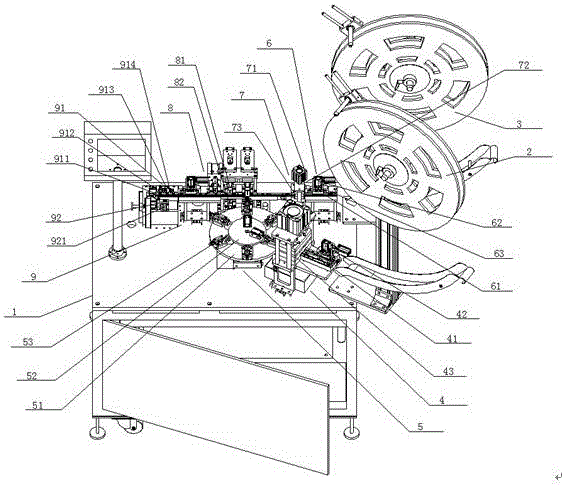

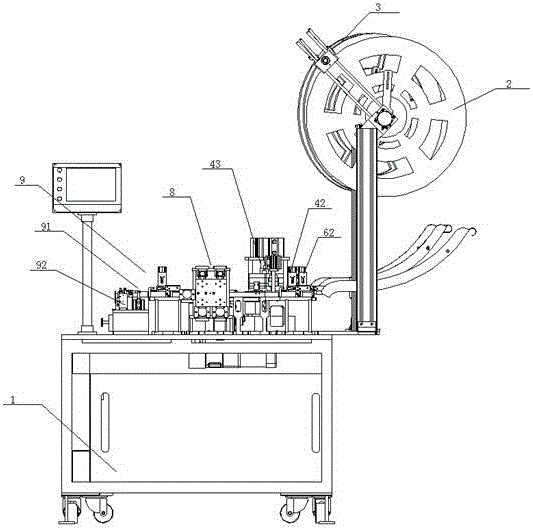

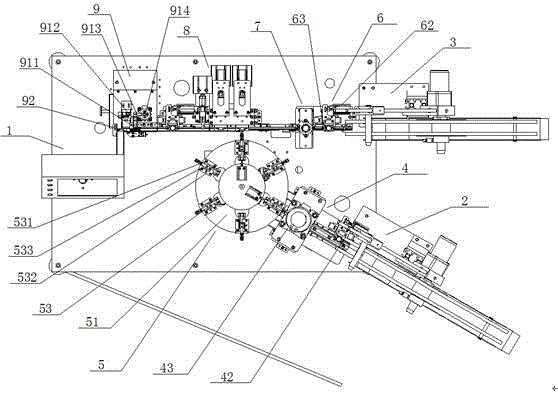

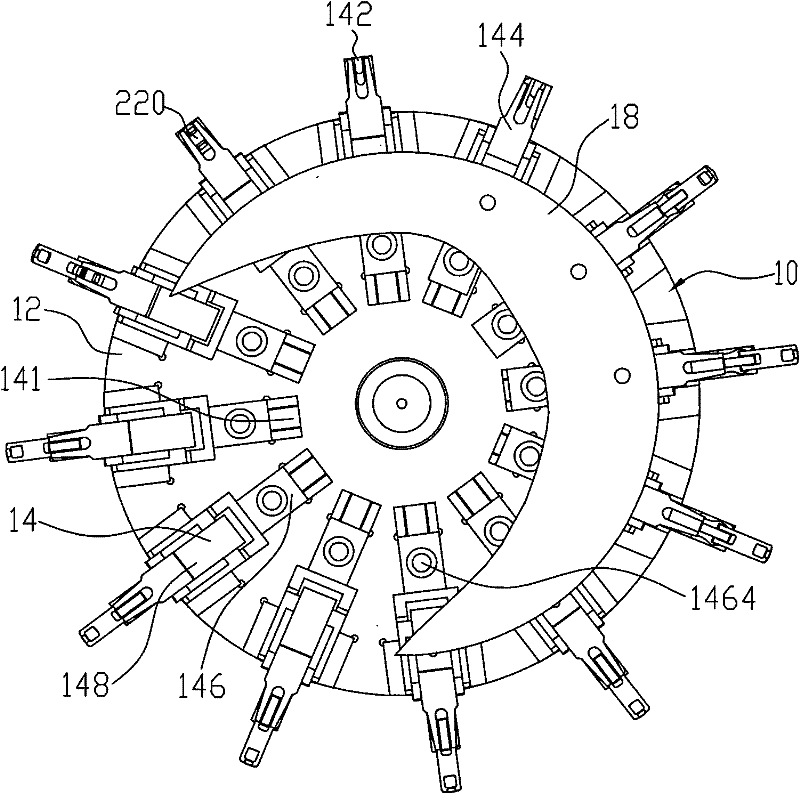

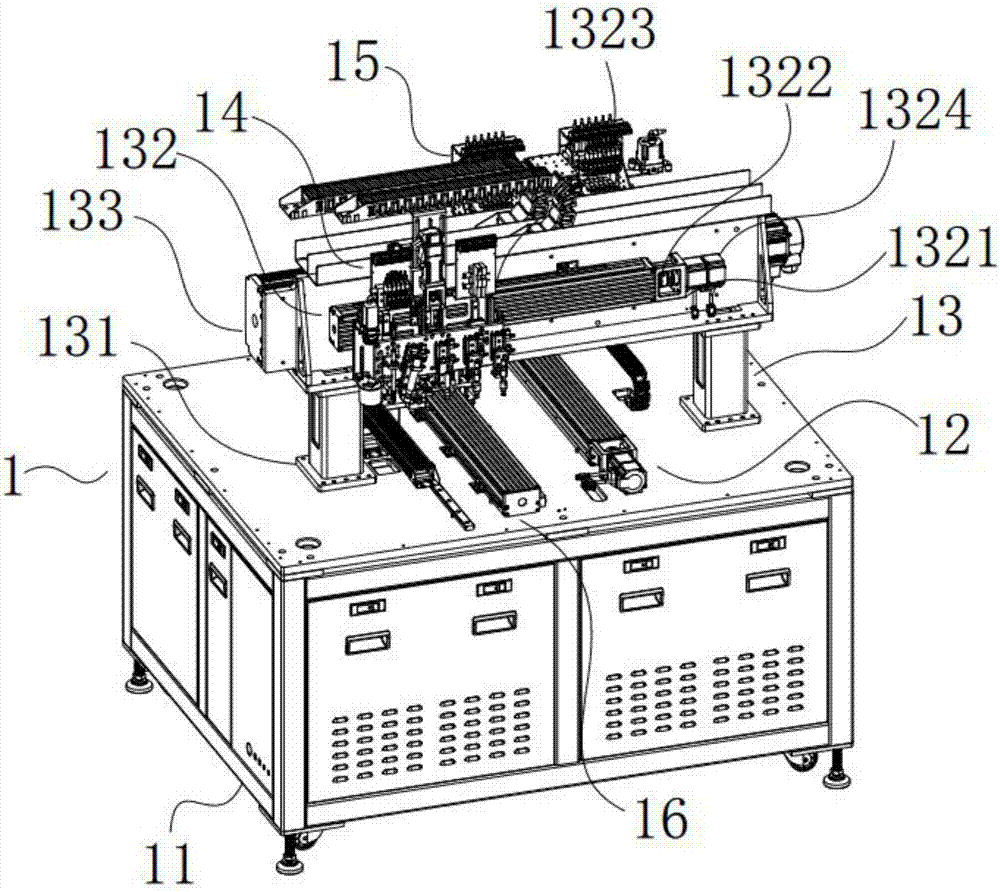

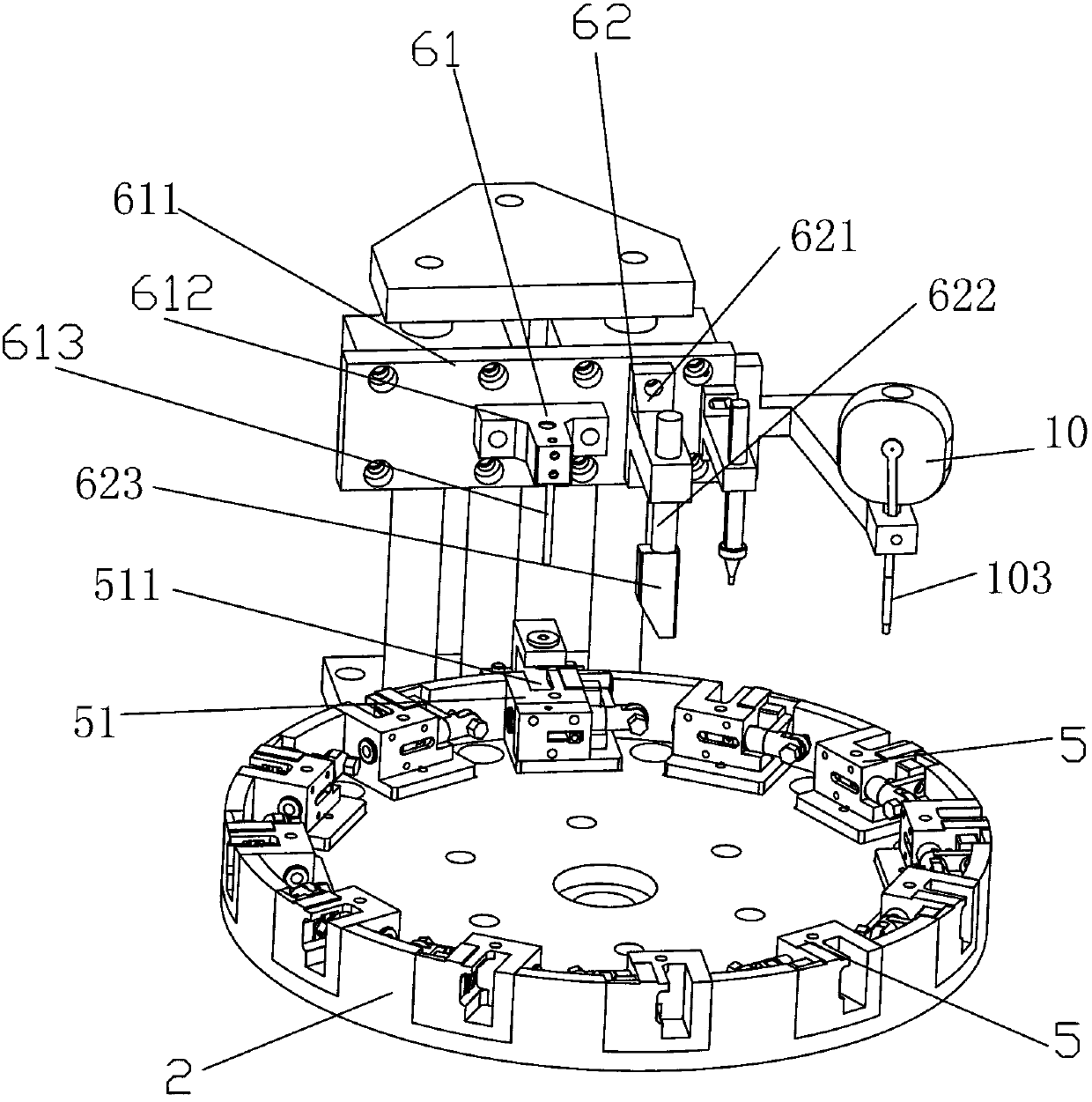

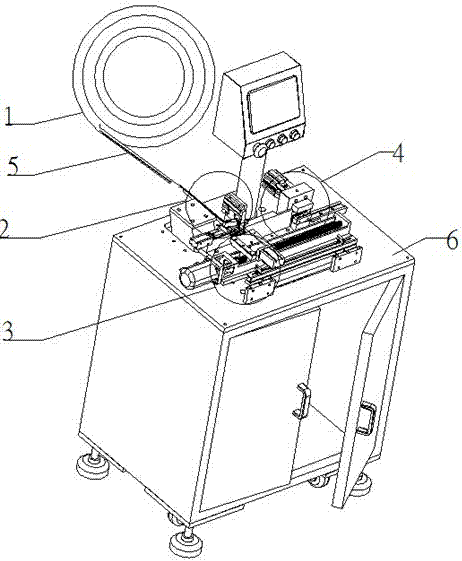

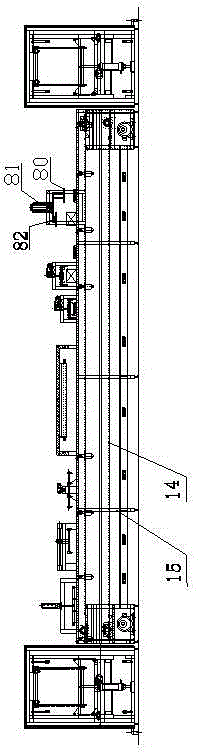

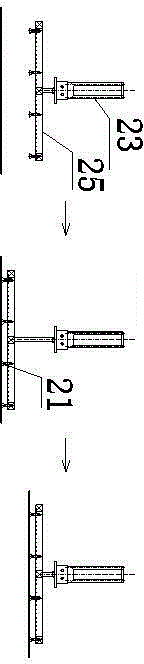

Connector terminal automation assembling equipment

InactiveCN103107474AFast and precise automatic assemblyFast assemblyContact member manufacturingContact member assembly/disassemblyStructural engineeringMechanical engineering

The invention discloses connector terminal automation assembling equipment. The assembling equipment comprises a rack, a terminal material belts feeding device, a terminal material belt cutting device, a terminal insertion device, a terminal seat feeding device, a terminal material belt excessive material cutting device and a terminal bending device, wherein the terminal material belts feeding device, the terminal material belt cutting device, the terminal insertion device, the terminal seat feeding device, the terminal material belt excessive material cutting device and the terminal bending device are arranged on the rack. Thus, through mutual matching of the terminal material belts feeding device, the terminal material belt cutting device, the terminal insertion device, the terminal seat feeding device, the terminal material belt excessive material cutting device and the terminal bending device, terminal material belt automatic feeding and quick and accurate automatic assembling of terminals and terminal seats are realized. Consequently, manual assembling is substituted, assembling speed of the terminals and the terminal seats is quickened, production efficiency of connectors is improved, meanwhile, the number of needed workers and labor amount are reduced, and production cost is reduced.

Owner:DONGGUAN KECHENDA ELECTRONICS TECH

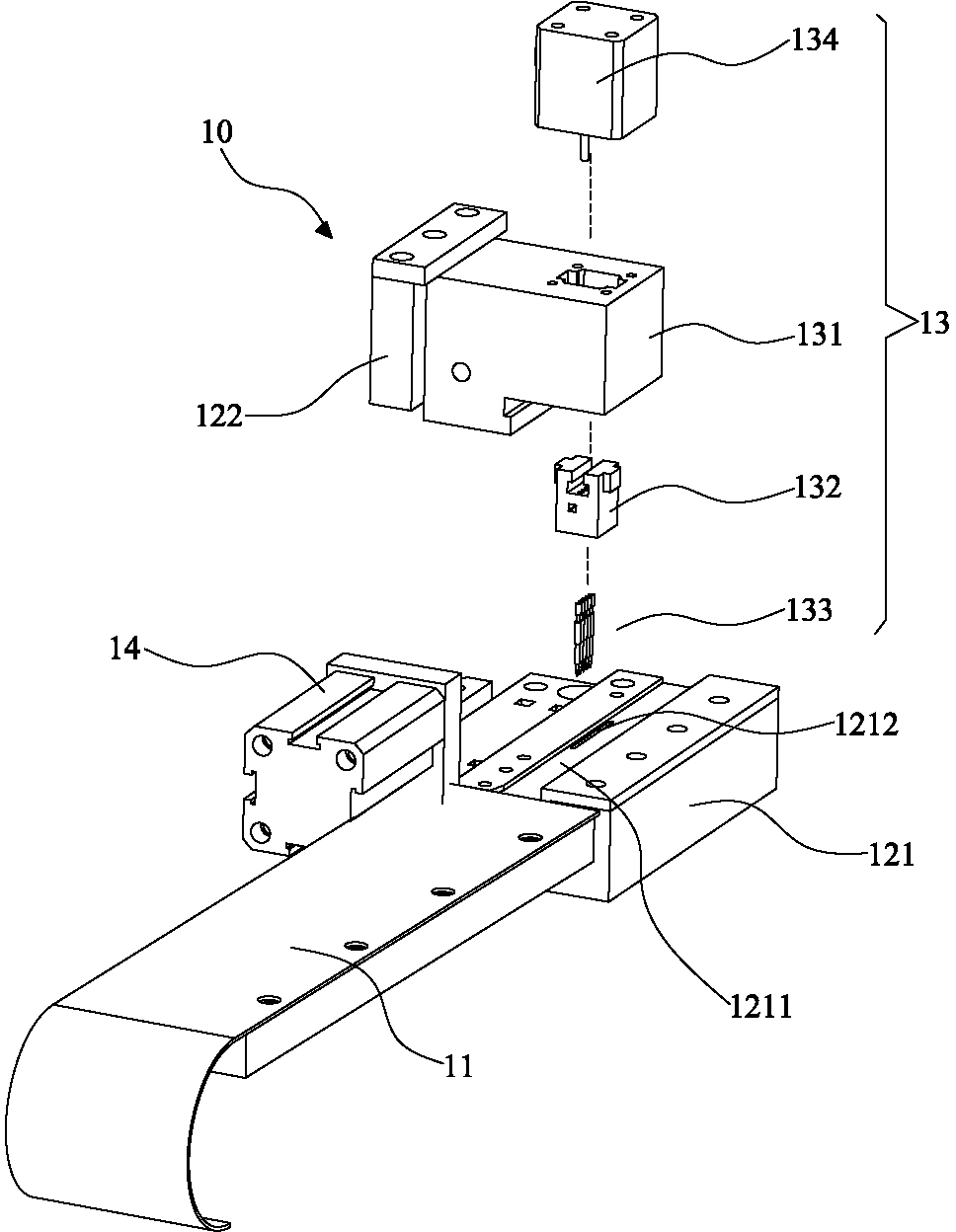

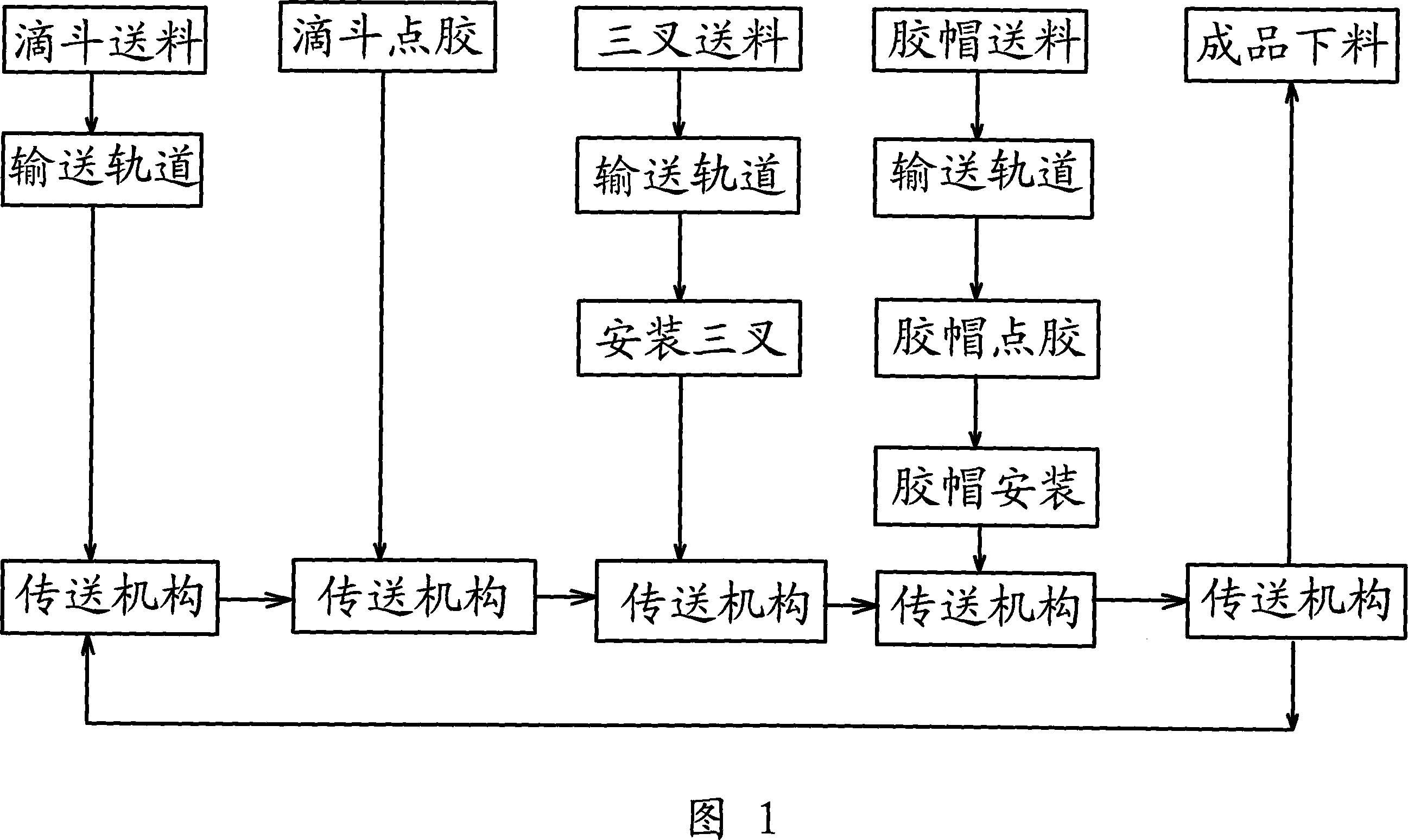

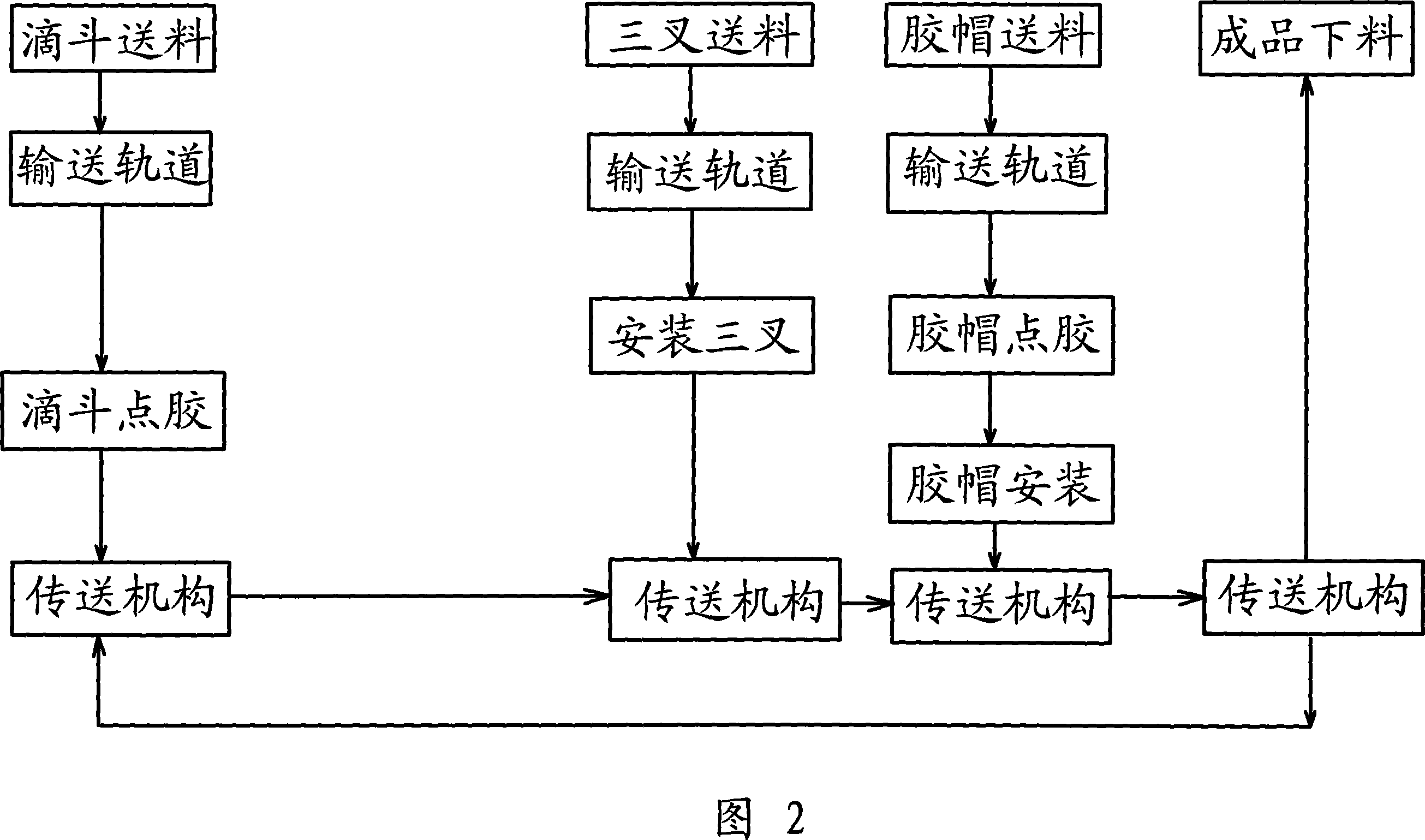

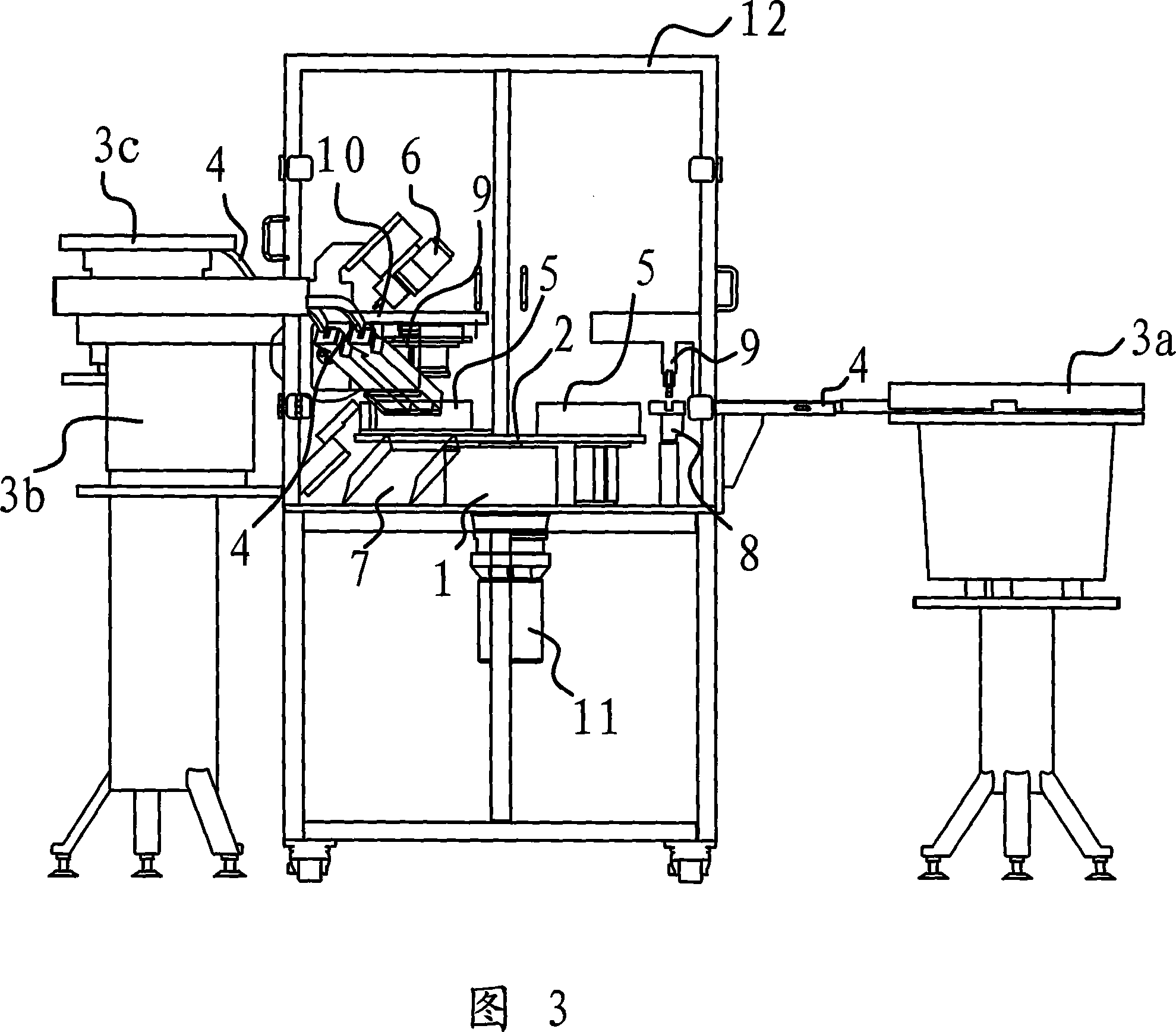

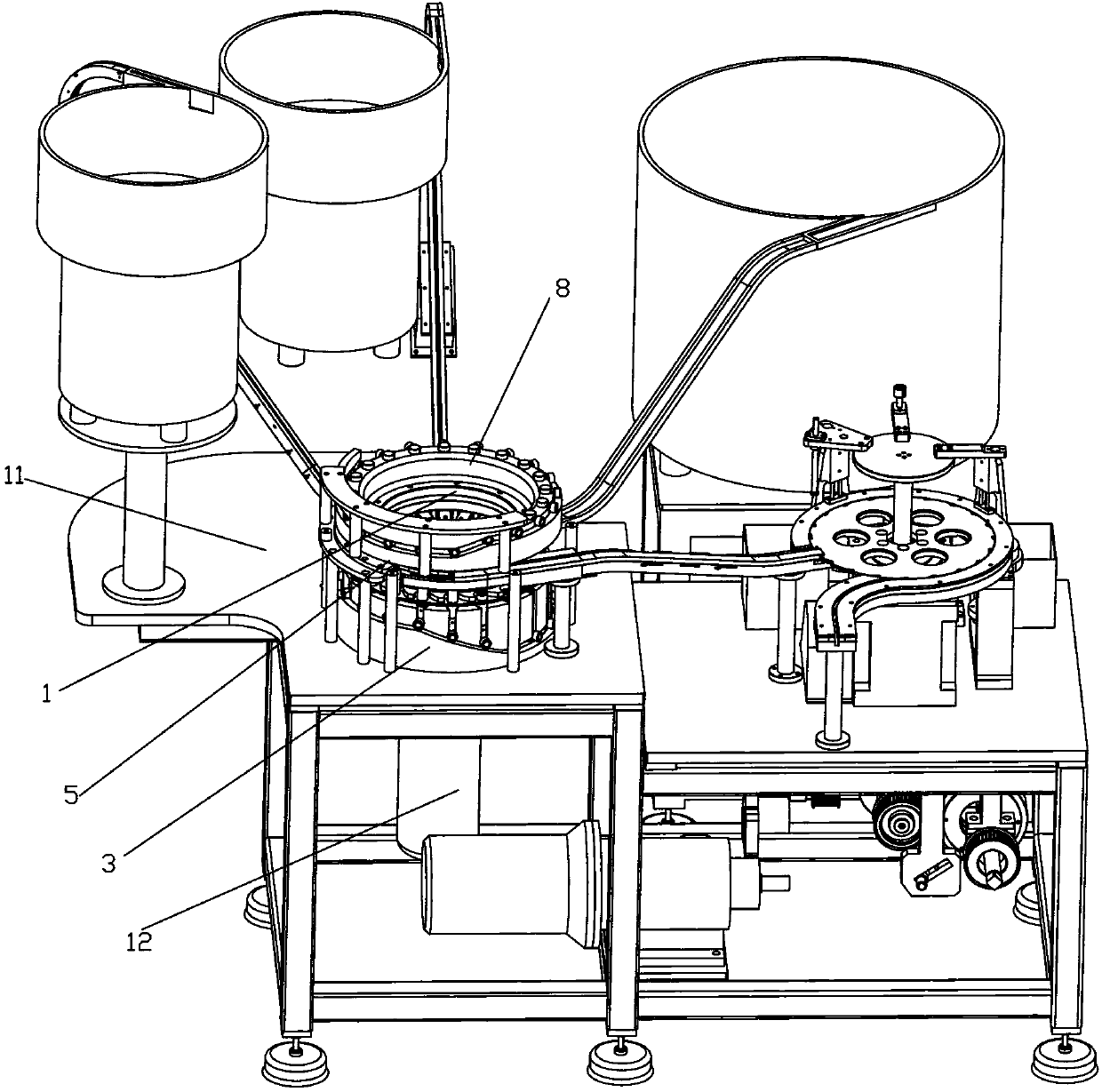

Process and apparatus for assembling infusion unit titrimeter assembly

A technology for automatically assembling the dripping hopper module of perfusion device includes such steps as putting the dripping hoppers, three-way tubes and rubber caps in feeders, arranging them on respective conveying tracks, conveying the dripping hopper in transfer mechanism, fixing, transferring to next workstation, coating adhesive, inserting a three-way tube in it, continuous transferring, installing rubber cap, and releasing the module. Its apparatus is composed of rotary axle, rotary table fixed to said rotary axle, feeders, adhesive applying mechanism and discharger.

Owner:MAIDER MEDICAL IND EQUIP

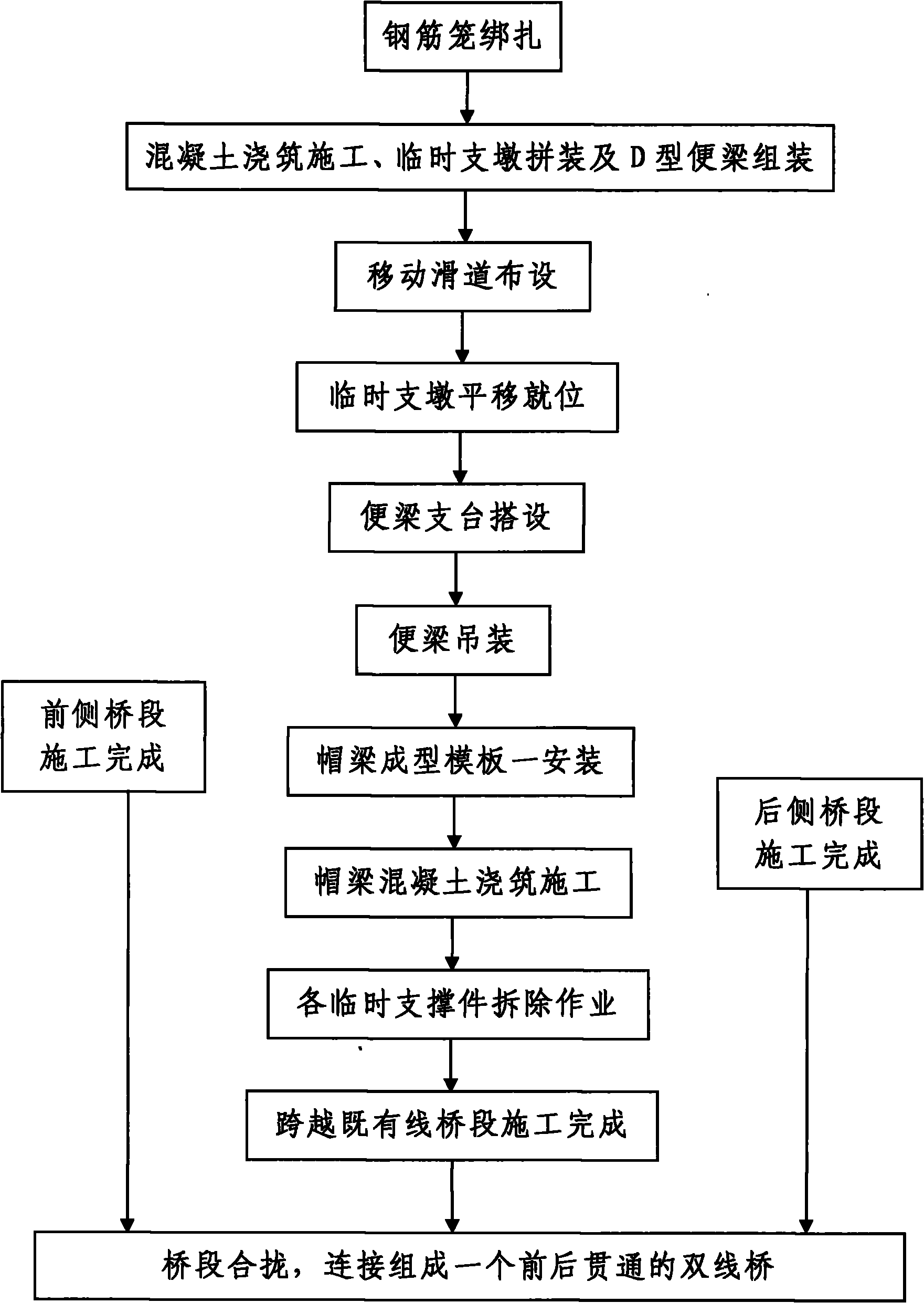

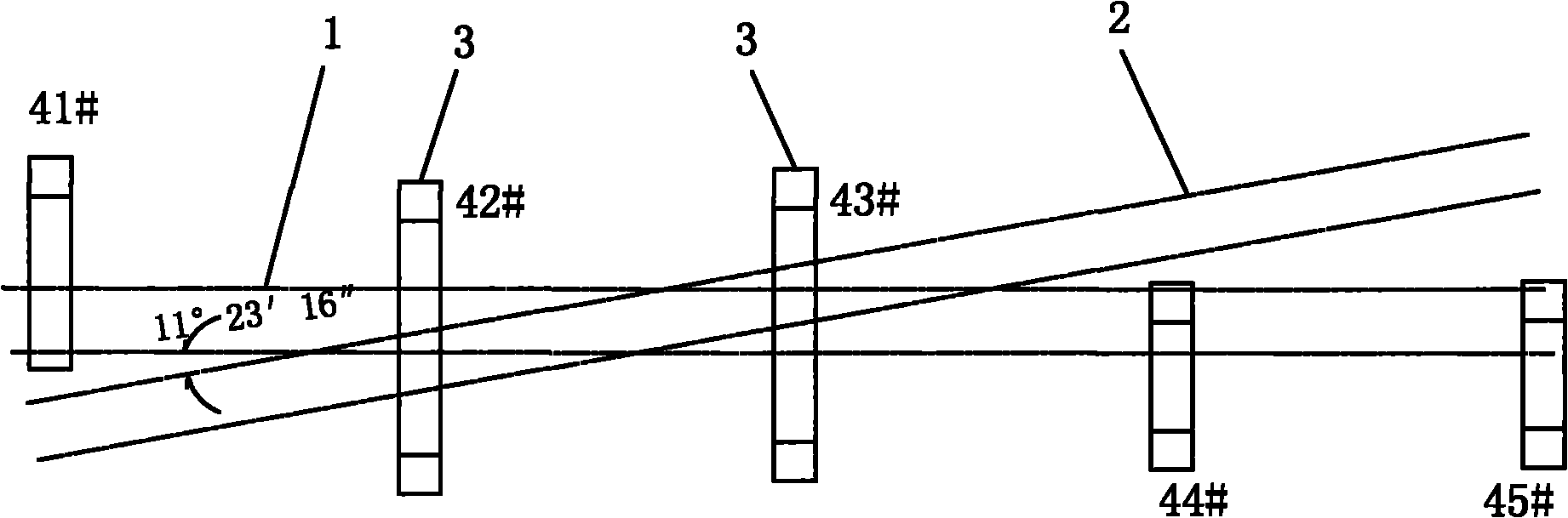

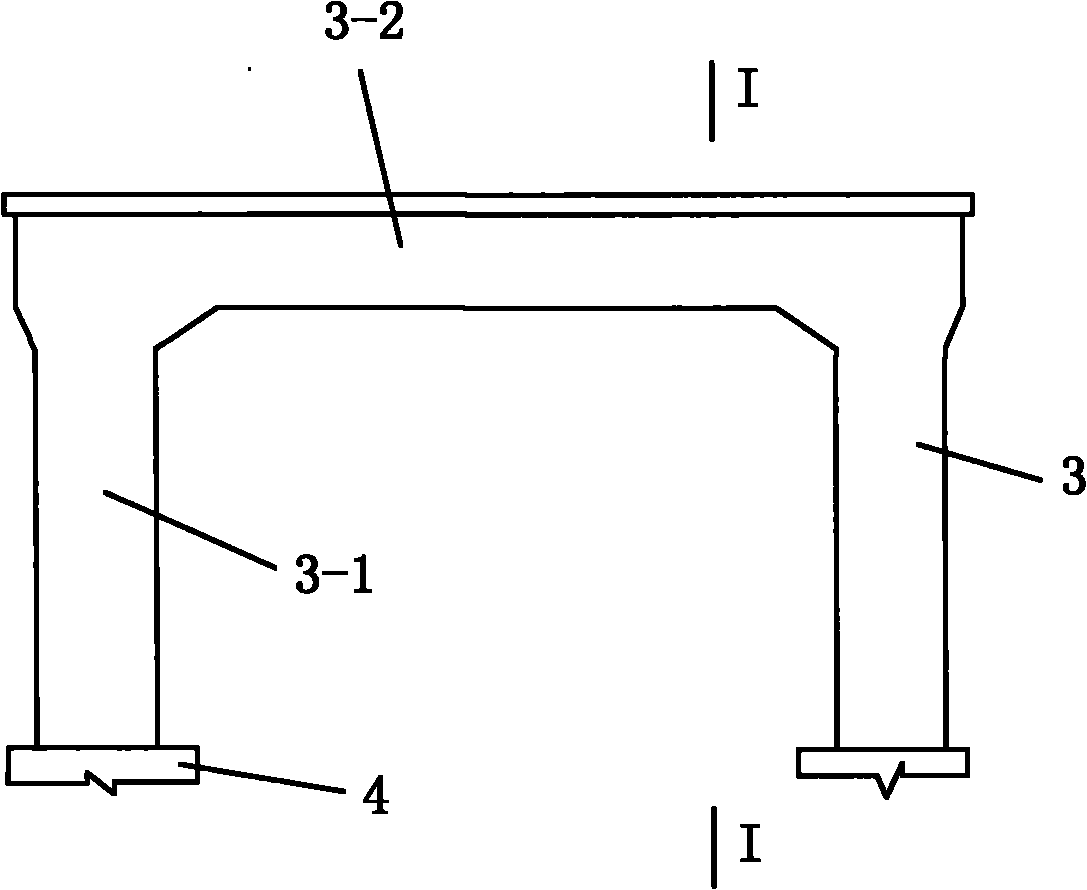

Double track bridge construction process crossing existing railway operational lines

ActiveCN101838968AReduce distractionsImprove construction progressBridge erection/assemblyButtressSafety risk

The invention discloses a double track bridge construction process crossing existing railway operational lines, and the constructed double track bridge comprises a front side bridge section, a crossed existing line bridge section with mutually connected front and rear ends and a rear side bridge section. The process comprises the following steps: 1) synchronously constructing the front side bridge section, the crossed existing line bridge section and the rear side bridge section, wherein the crossed existing line bridge section is constructed as follows: binding reinforcement cages, concreting, assembling temporary buttresses and D-shaped temporary beams, arranging movable slide rails, carrying out translation insertion on the temporary buttresses, setting up temporary beam supporters, hoisting the temporary beams, installing cap beam forming templates, concreting cap beams and removing all temporary strut members; and 2) folding the bridge sections. The invention has the advantages of reasonable design, convenient construction, low investment cost, good use effect, high construction efficiency, short construction period and low safety risk, and can effectively solve the actual problems such as large construction difficulty, long construction period, high investment cost, high safety risk and the like in the construction process of the crossed existing line gate piers.

Owner:CHINA RAILWAY 20 BUREAU GRP +3

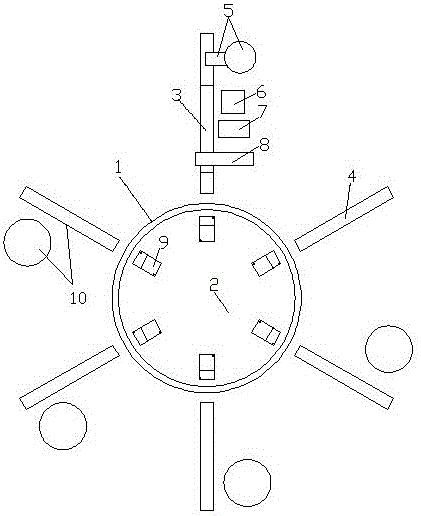

Automatic water meter gear assembling machine and assembling method thereof

ActiveCN106271601AFast assemblyImprove efficiencyAssembly machinesMetal working apparatusEngineeringAssembly machine

The invention provides an automatic water meter gear assembling machine and an assembling method thereof. The automatic water meter gear assembling machine comprises a base, wherein an annular rotating disc is arranged on the base; an input rail, an output rail and a plurality of groups of gear conveying units are arranged on the peripheral side of the annular rotating disc; a gear shaft conveying and inserting device, a gear shaft detection device, a removal device and an oiling device are arranged in the input rail direction. Compared with the prior art, the automatic water meter gear assembling machine disclosed by the invention has the advantages of high assembling speed, high efficiency and the like.

Owner:泰安轻松表计有限公司

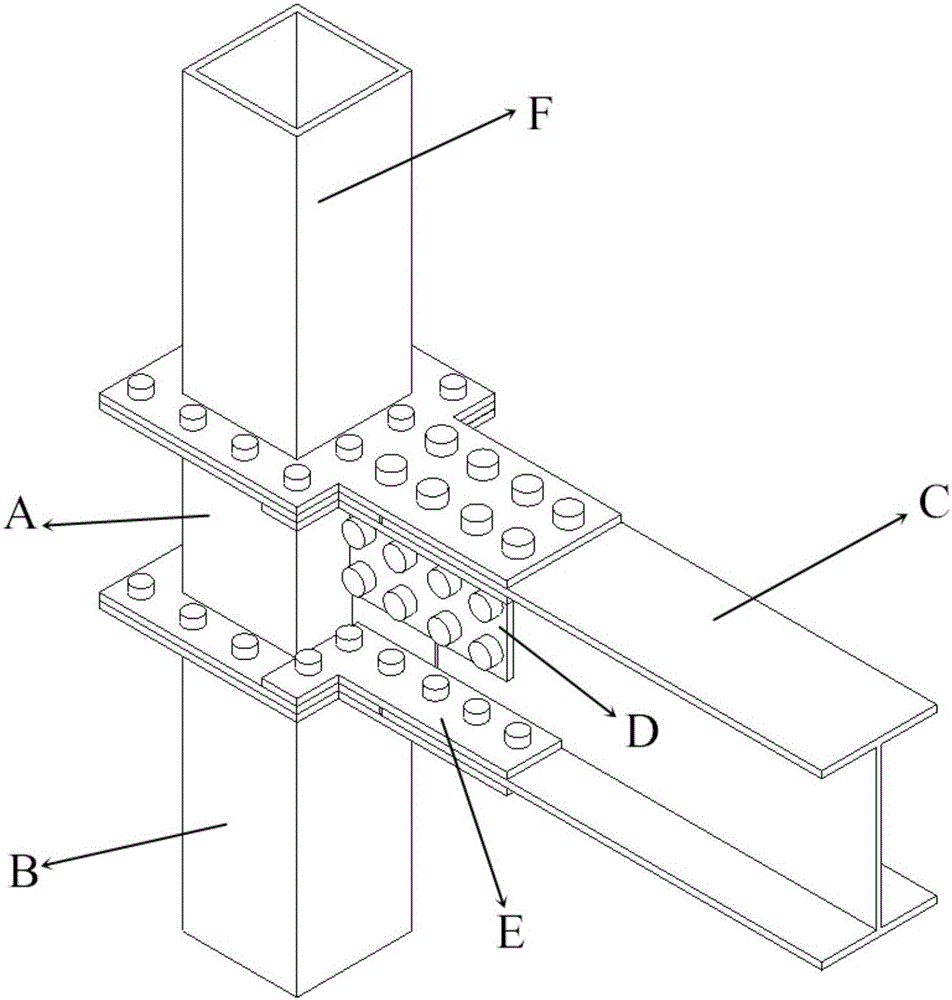

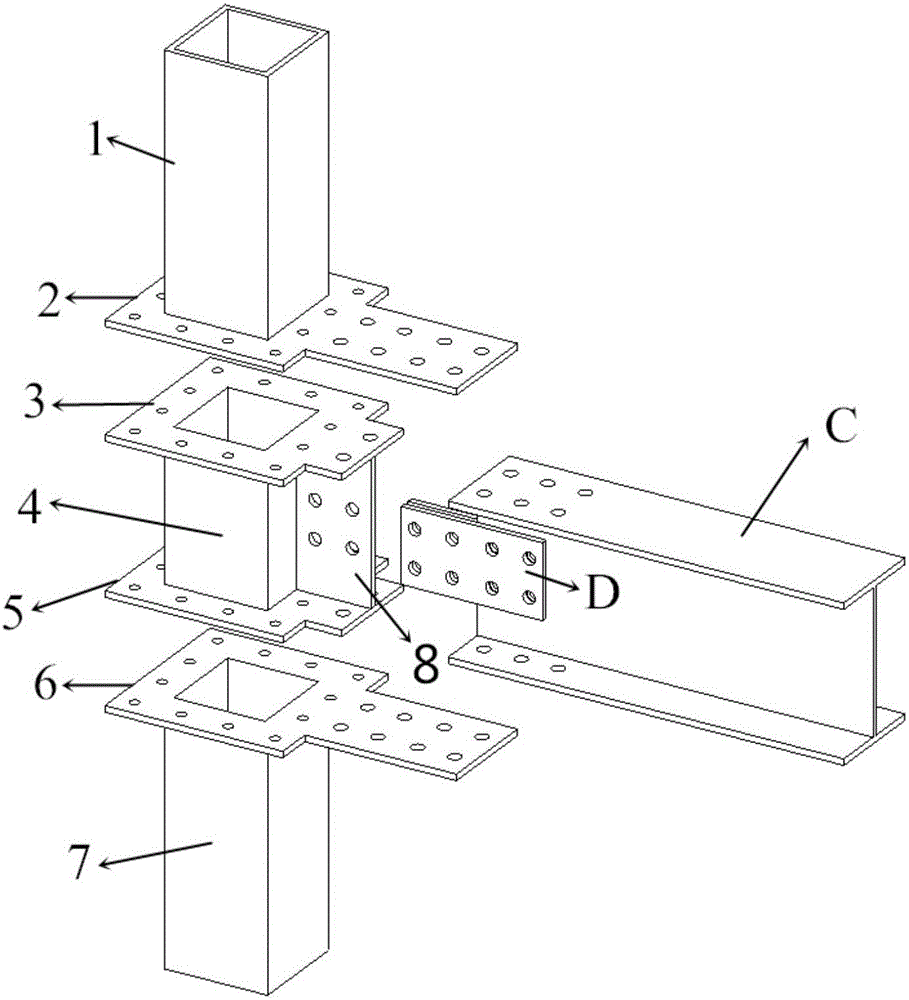

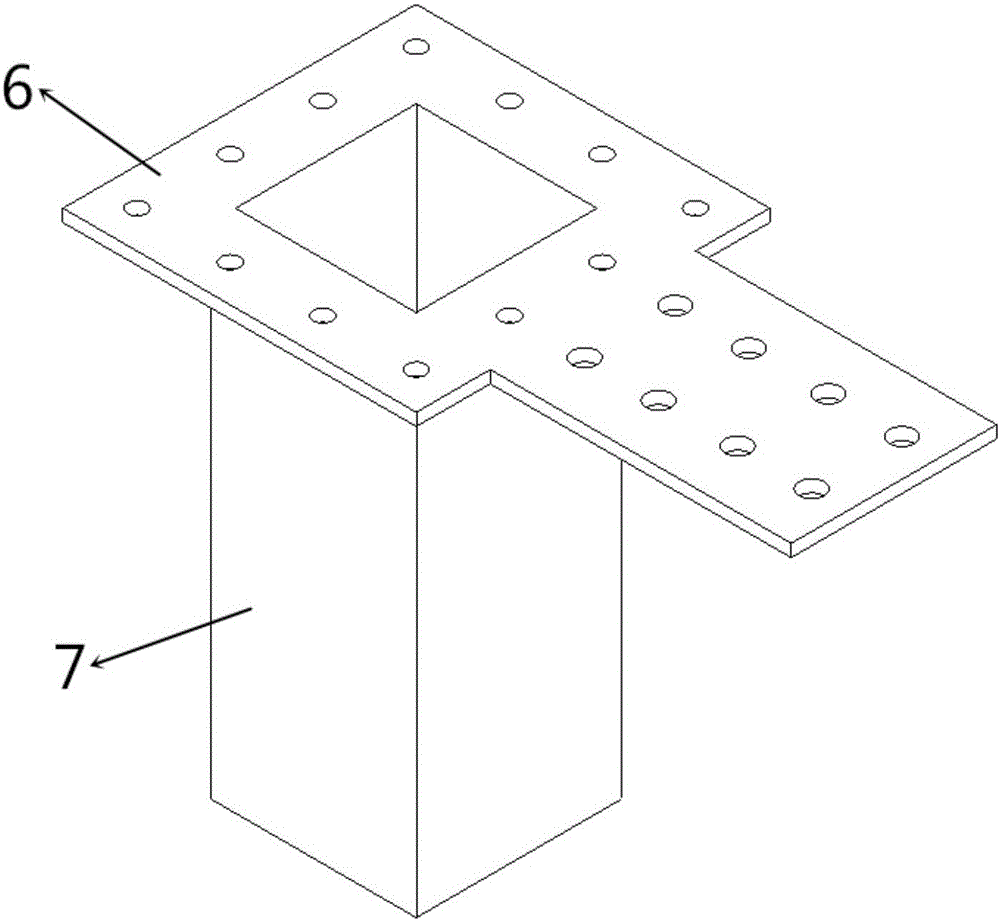

Fabricated beam-column bolt joint connection device with cover plate and double flanges

ActiveCN105888060AMeet the mechanical propertiesEasy to assembleProtective buildings/sheltersShock proofingEngineeringUltimate tensile strength

The invention discloses a fabricated beam-column bolt joint connection device with a cover plate and double flanges, and belongs to the technical field of structural engineering. The fabricated beam-column bolt joint connection device comprises an upper column flange plate (2), an upper column square-steel tubular column (1), column base flange plates (3) and (5), a column base square-steel tubular column (4), a shear plate (8), a lower column flange plate (6), a lower column square-steel tubular column (7), an H-shaped steel beam C, an attaching plate D and a clamping plate E. The upper square-steel tubular column and the lower square-steel tubular column are welded to the flange plates integrally in a factory. A column base in the middle is formed by integral welding of the upper flange plate, the lower flange plate, the middle square-steel tubular column and the shear plate in the factory. The welded portions can be completed in the factory, bolts are adopted for on-site assembly and are fastened conveniently and quickly, construction speed and quality are increased greatly, and the fabricated beam-column bolt joint connection device is suitable for the development of fabricated steel structures. According to the fabricated beam-column bolt joint connection device, joints are semi-rigid, with high ductility and bearing capability; clamping plates are made from steel material with low strength, so that earthquake energy can be dissipated fully and post-earthquake restoration is facilitated.

Owner:BEIJING UNIV OF TECH

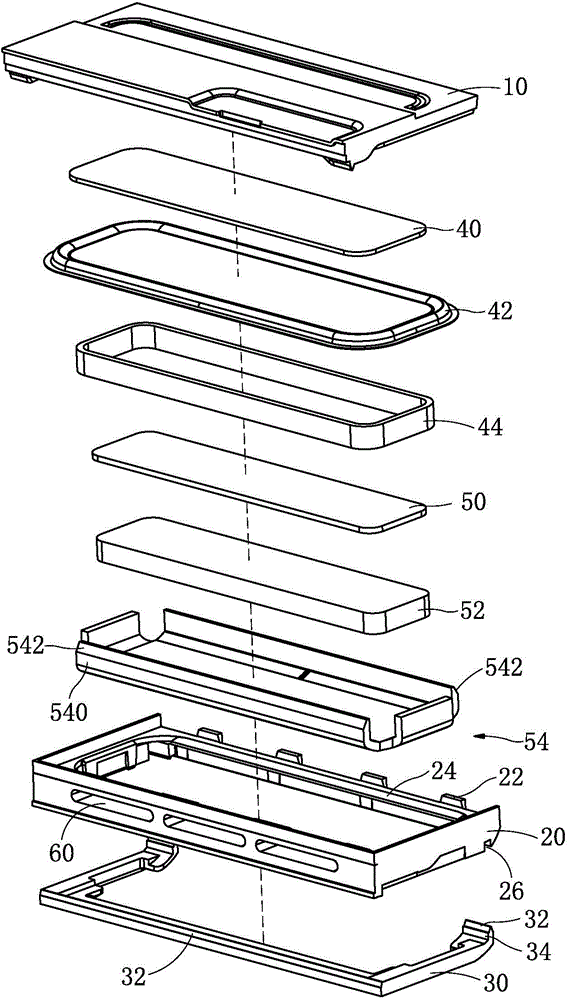

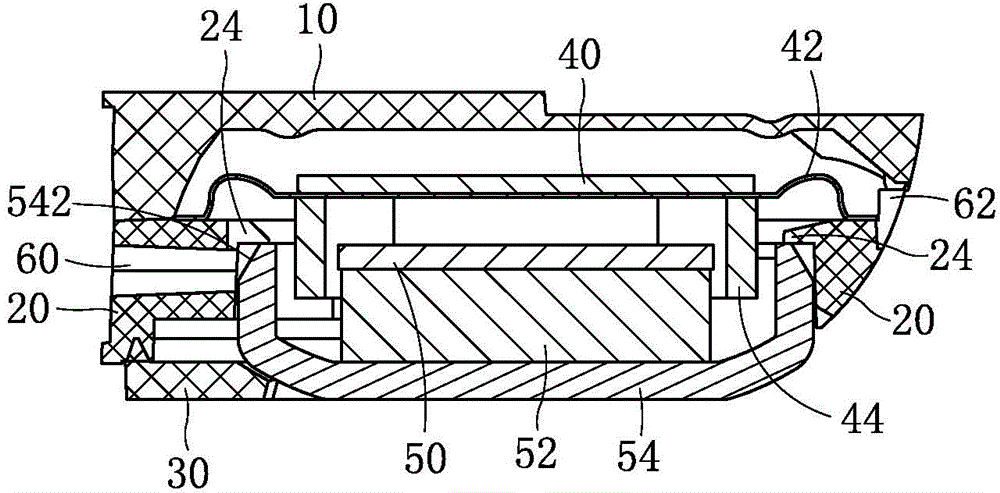

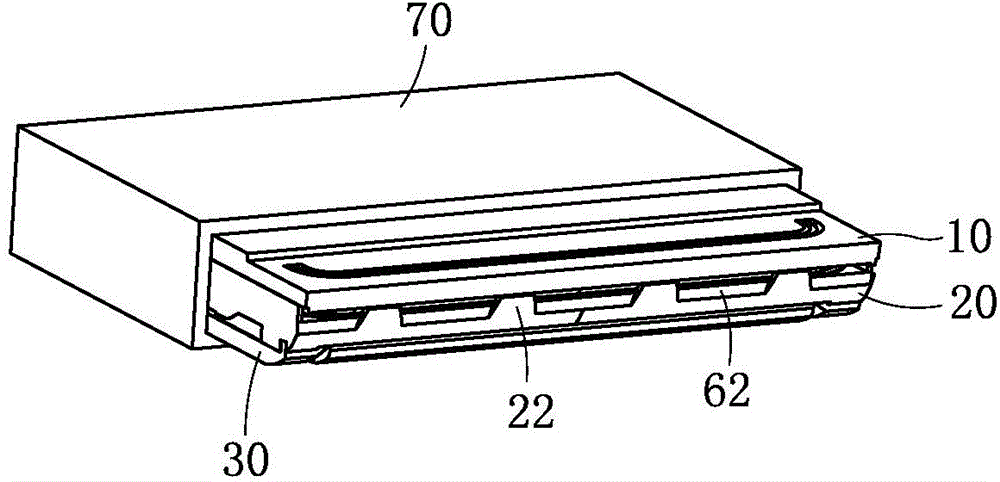

Loudspeaker module

ActiveCN104540080AImprove low frequency performanceGuaranteed low frequency performanceLoudspeaker transducer fixingSubstation equipmentDistortionLoudspeaker

The invention discloses a loudspeaker module, and relates to the technical field of electroacoustic products. The loudspeaker module is arranged in an electronic terminal, and comprises a shell, a vibrating system and a magnetic circuit system are contained in the shell, the magnetic circuit system comprises a basin stand fixed to the shell, a magnet and a washer are fixed in the basin stand in sequence, and rear sound output holes are formed in the positions, corresponding to the side walls of the basin stand, of the shell, and communicated with an inner cavity of the module and an inner cavity of the electronic terminal. Chamfered planes are arranged at the upper ends of the side walls, corresponding to the rear sound output holes, of the basin stand, and arranged on the sides, close to the rear sound output holes, of the side walls of the basin stand. According to the loudspeaker module, the technical problem that a loudspeaker module in the prior art is large in size and low in frequency, and distortion occurs easily is solved, the loudspeaker module guarantees acoustic performance, meanwhile, the size is reduced to the minimum, the need for the light, thin and small electronic terminal is met, stability is high, and the service life is long.

Owner:GOERTEK INC

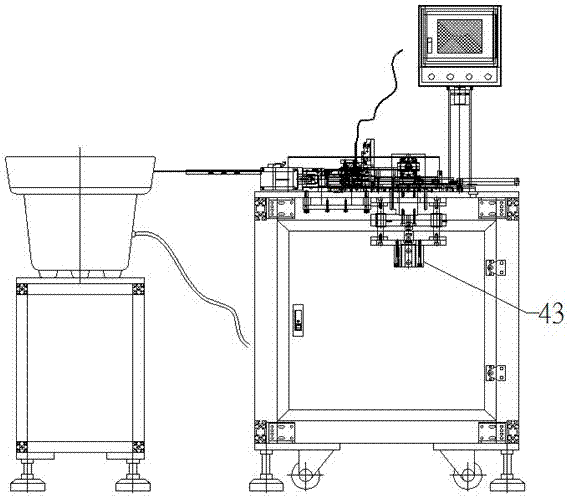

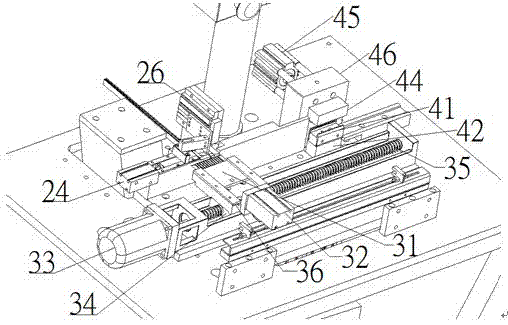

Universal USB connector assembly machine

InactiveCN106654799AReduce manufacturing costFast assemblyContact member cases/bases manufactureContact member assembly/disassemblyEconomic benefitsWork in process

The invention discloses a universal USB connector assembly machine, which comprises a rack, an iron shell discharge plate, a semi-finished product discharge plate, an iron shell feeding and cutting mechanism, a product carrier mechanism, a material strip feeding mechanism, a material strip bending mechanism, a riveting assembly mechanism and a finished product work station, wherein the iron shell discharge plate, the semi-finished product discharge plate, the iron shell feeding and cutting mechanism, the product carrier mechanism, the material strip feeding mechanism, the material strip bending mechanism, the riveting assembly mechanism and the finished product work station are intensively arranged on the rack; the iron shell discharge plate cuts an iron shell through the iron shell feeding and cutting mechanism and then conveys the iron shell to the product carrier mechanism; and the semi-finished product discharge plate conveys a semi-finished product to the material strip bending mechanism through the material strip feeding mechanism, and the semi-finished product is nested with the iron shell through the riveting assembly mechanism and then is conveyed to the finished product work station. The semi-finished product is automatically nested and locked with the iron shell to complete finished product assembly of a USB connector, full-automatic work is adopted in the whole process, the assembly speed is high, connection is accurate and firm, the production efficiency is greatly improved, the universal USB connector assembly machine can be suitable for finished product assembly of different types of USB connectors and is good in universality and good in economic benefit, and the enterprise production cost is reduced.

Owner:苏州市宏越自动化机械设备有限公司

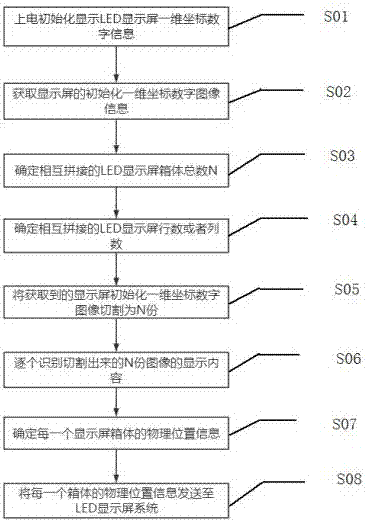

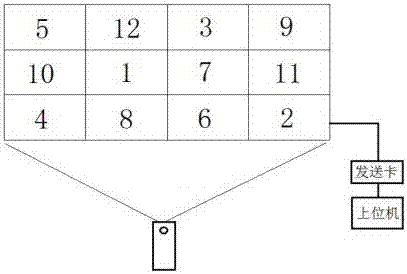

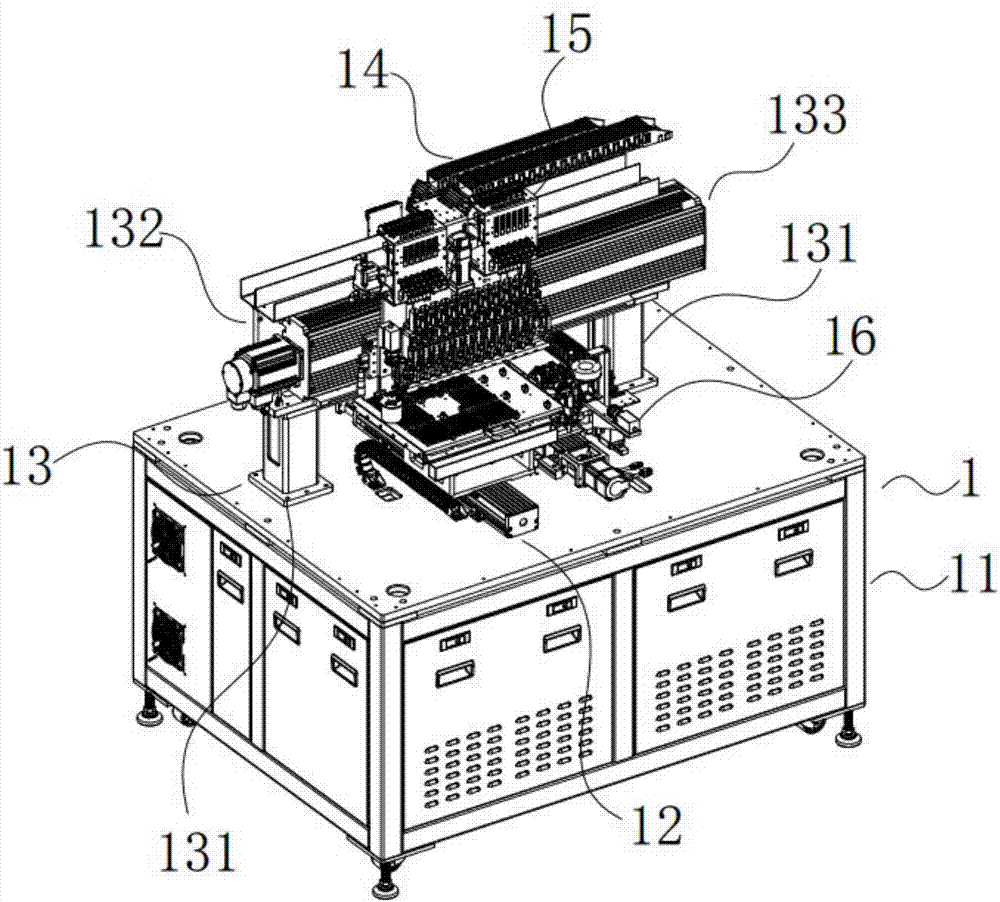

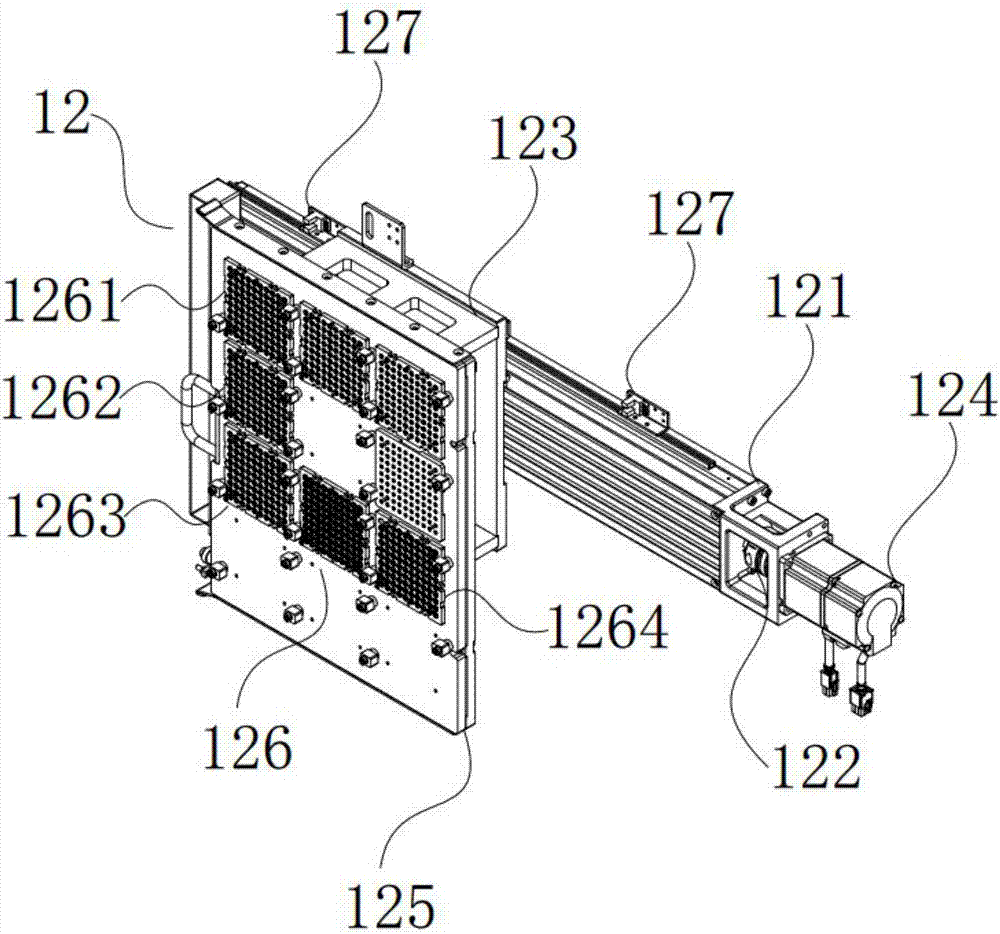

Automatic continuous screen method of LED display

ActiveCN107239252ALow costFast assemblyStatic indicating devicesInput/output processes for data processingLED displayImaging processing

The invention discloses an automatic continuous screen method of an LED display. The method comprises the steps that digital information of one-dimensional coordinates of an LED display screen is displayed at the initialization of a power-on operation; digital image information of the initialized one-dimensional coordinates is obtained; the total number N of LED display screen cases is determined; the number of rows or columns of the LED display screen is determined; the digital image of the initialized one-dimensional coordinates of the display screen is cut into N parts according to the row and column arrangement situation of the cases through a specific image processing technology; the content information of the cut-out N parts of images is identified; physical location information of the corresponding display screen cases is determined through the display content of each part of cut image; the physical location information of each display screen case is sent to an LED display screen control system. The automatic continuous screen method of the LED display solves the problem of high cost caused by extra increase in number of hardware such as transmitters, receivers and the like as required by existing LED display automatic continuous screens.

Owner:SHENZHEN ABSEN OPTOELECTRONIC CO LTD +1

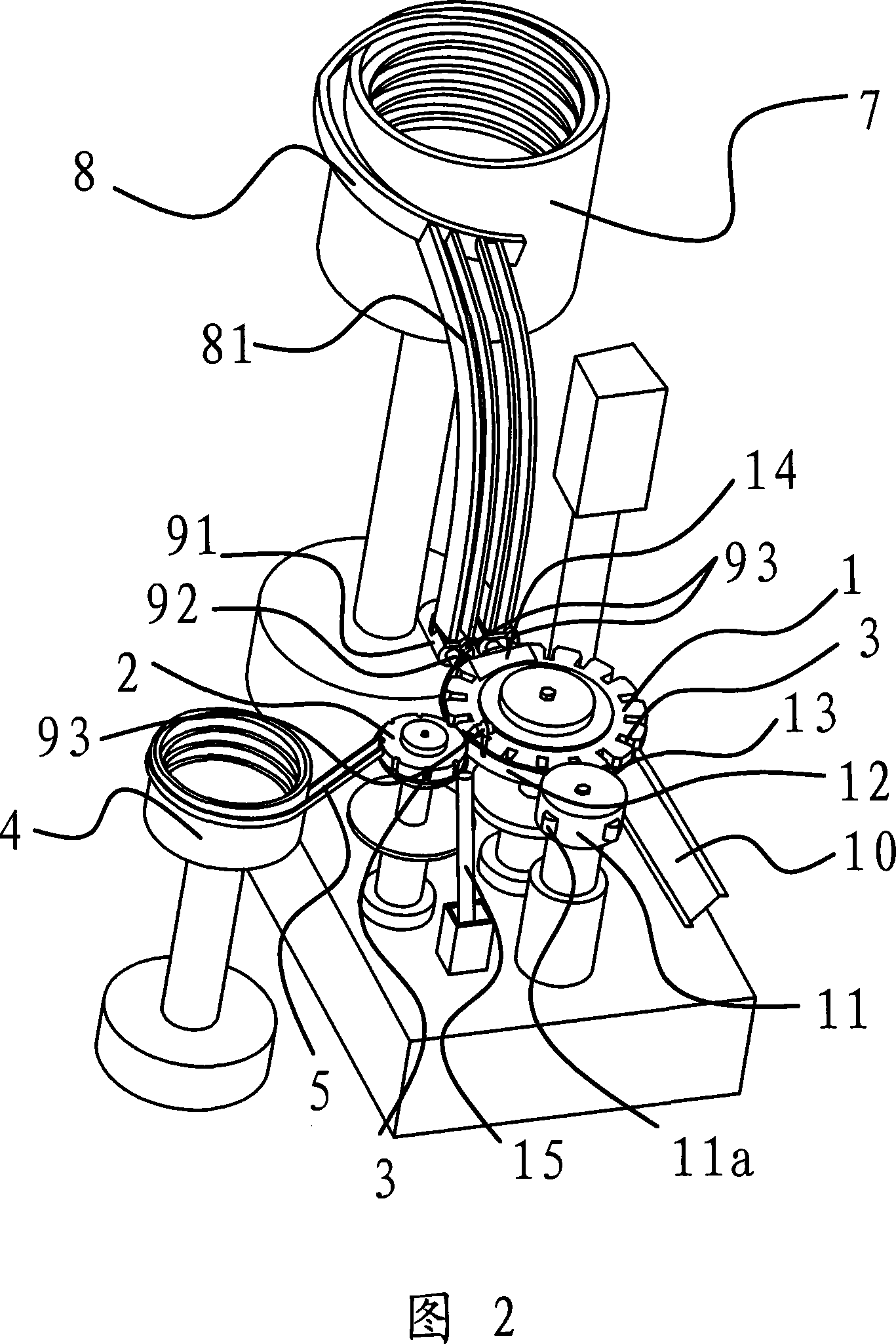

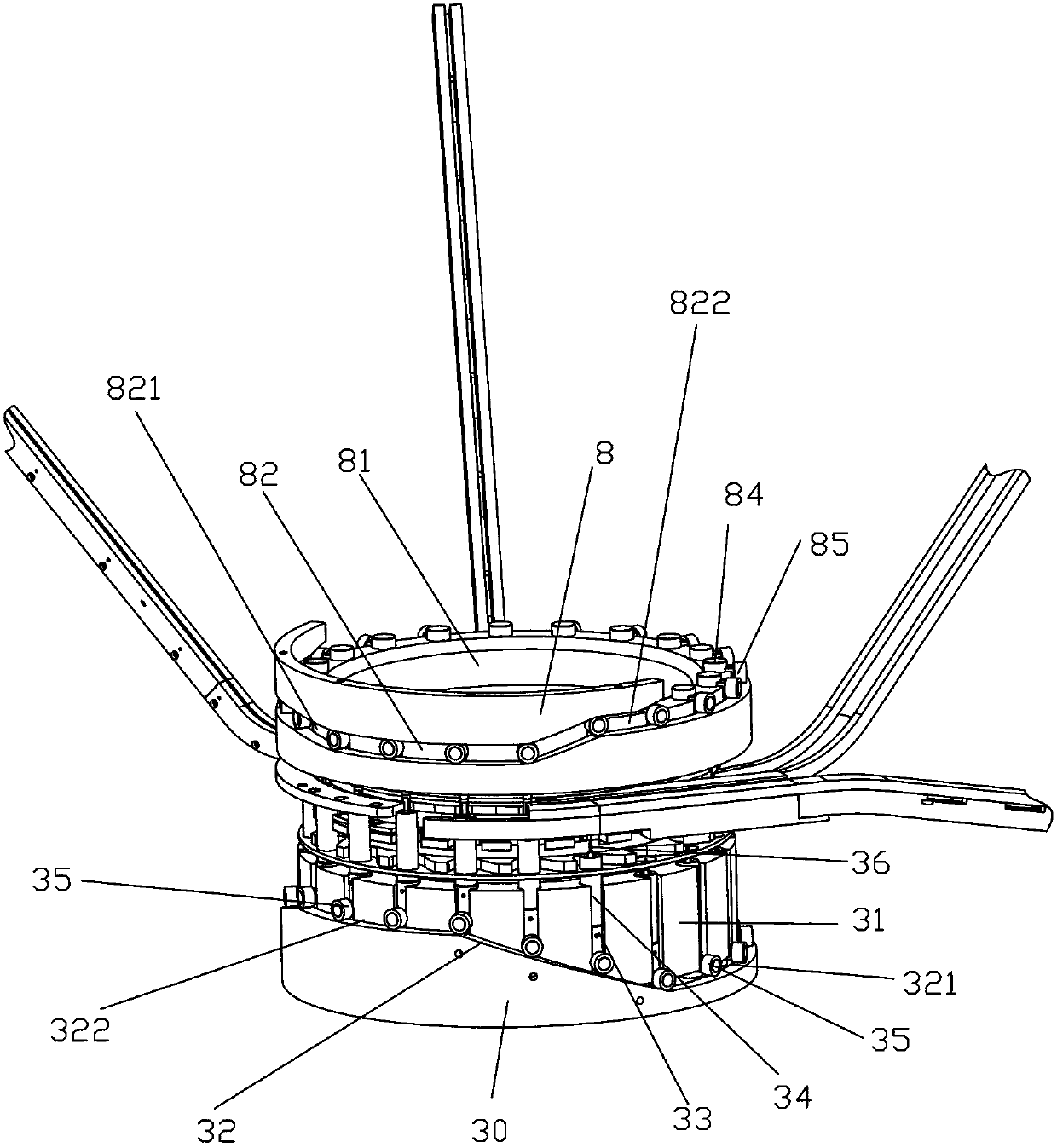

Valve assembling machine

The invention discloses a valve assembling machine. The machine comprises a main disc assembling machine frame, wherein the main disc assembling machine frame is provided with a drive device and a transmission device; the main disc assembling machine frame is also provided with a lower ejector rod turnplate assembly, a cap feed assembly, a valve rod feed assembly, a valve nozzle feed assembly and an upper pilot ejector rod turnplate assembly which are sequentially connected to the transmission shaft of the transmission device from the bottom to the top; and the main disc assembling machine frame is provided with a discharge rail. The cap, the valve nozzle and the valve rod for assembling the valve can work mechanically and automatically, the assembling speed is high with high efficiency, and the cost is reduced.

Owner:ZHONGSHAN MEIJIESHI PACKAGING PROD

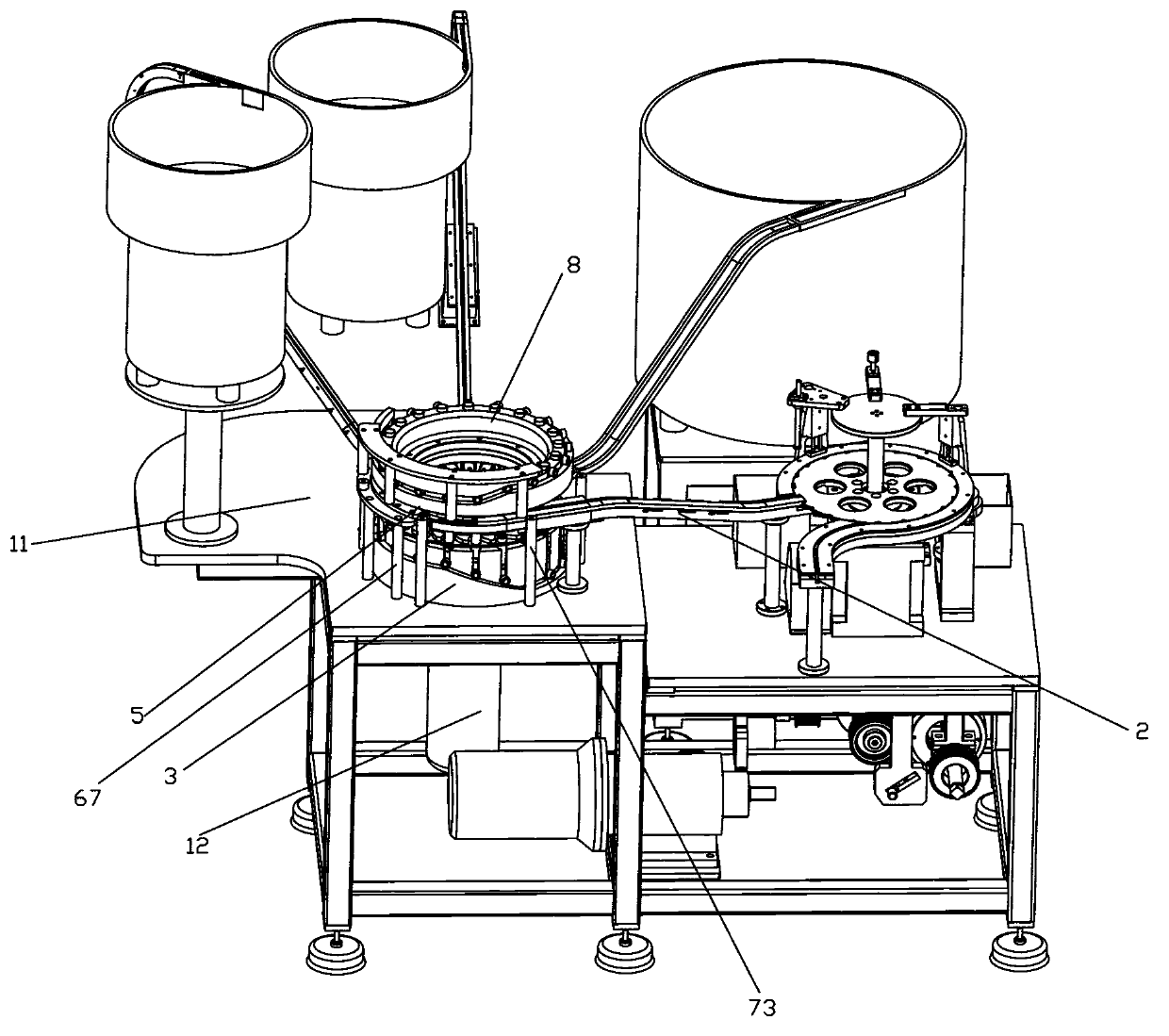

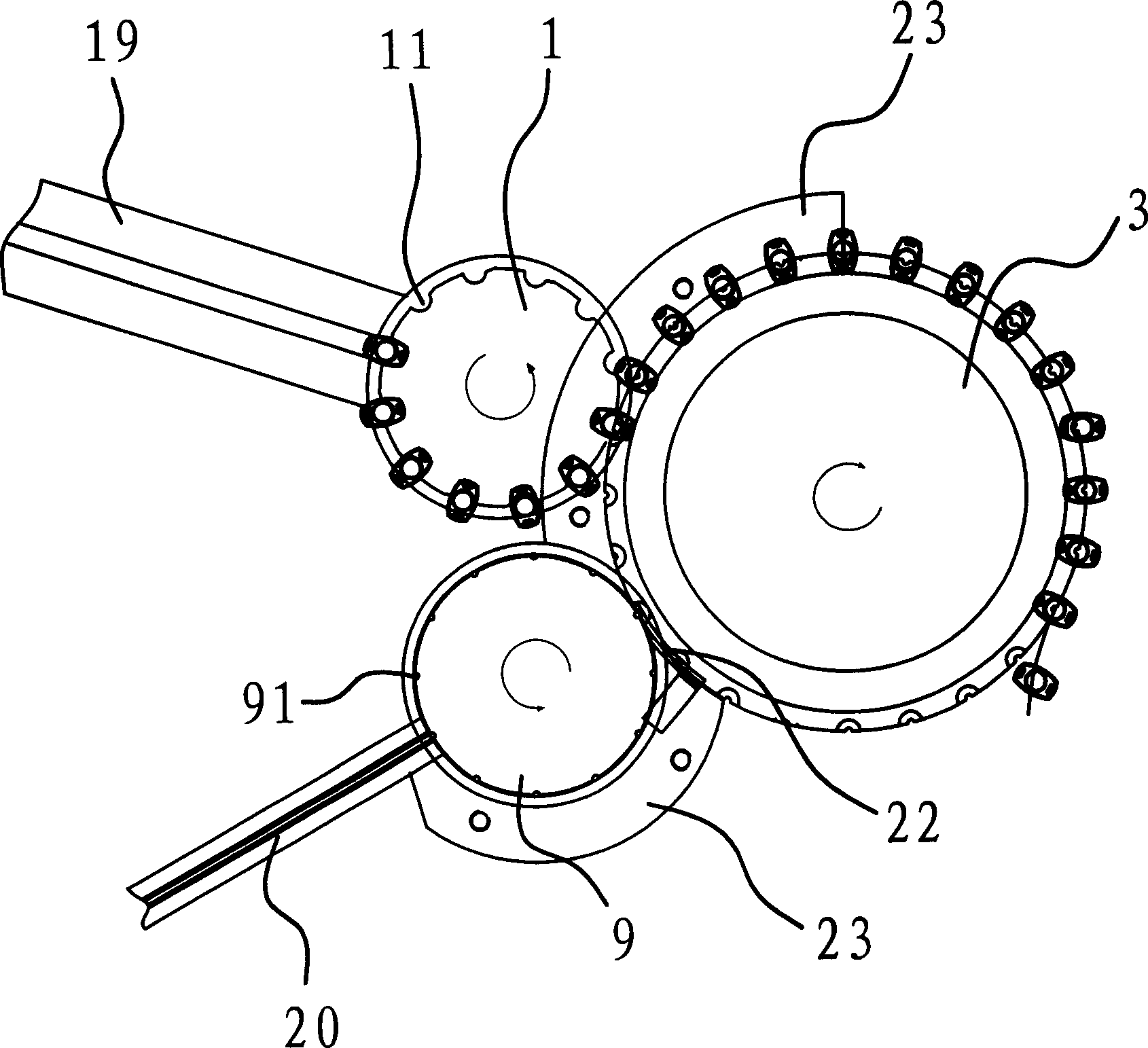

Automatic assembling machine for transfusion regulator

InactiveCN101234469AAssembly automationImprove reliabilityInfusion devicesAssembly machinesKludgeAssembly machine

The invention provides an automatic assembly machine of an infusion regulator, belonging to a mechanical technique field, which solves the problems of low assembling efficiency and low product quality of the existing kludge assembly, and comprises a shell rotary table and a roller rotary table; the edges of each rotary table are respectively provided with notches, and a roller feeder is connected with the shell rotary table by a wheel transportation guide rail; a shell feeder which is arranged on the lateral part of the shell rotary table is connected with the shell rotary table by a shell transportation guide rail, and a shell feed mechanism which is arranged between the discharge hole of the shell transportation guide rail and the shell rotary table comprises a shell feed cylinder which is connected with a shell pusher; a top pressure drum, the edge of which is tangent with the edge of the shell rotary table, is arranged on the lateral side of the shell rotary table, and a jacking block is arranged on the edge of the top pressure drum. The automatic assembly machine of the infusion regulator has the advantages of novel structure, automatic assembly, high assembling efficiency and excellent coordination between the shell and the roller.

Owner:王兴章

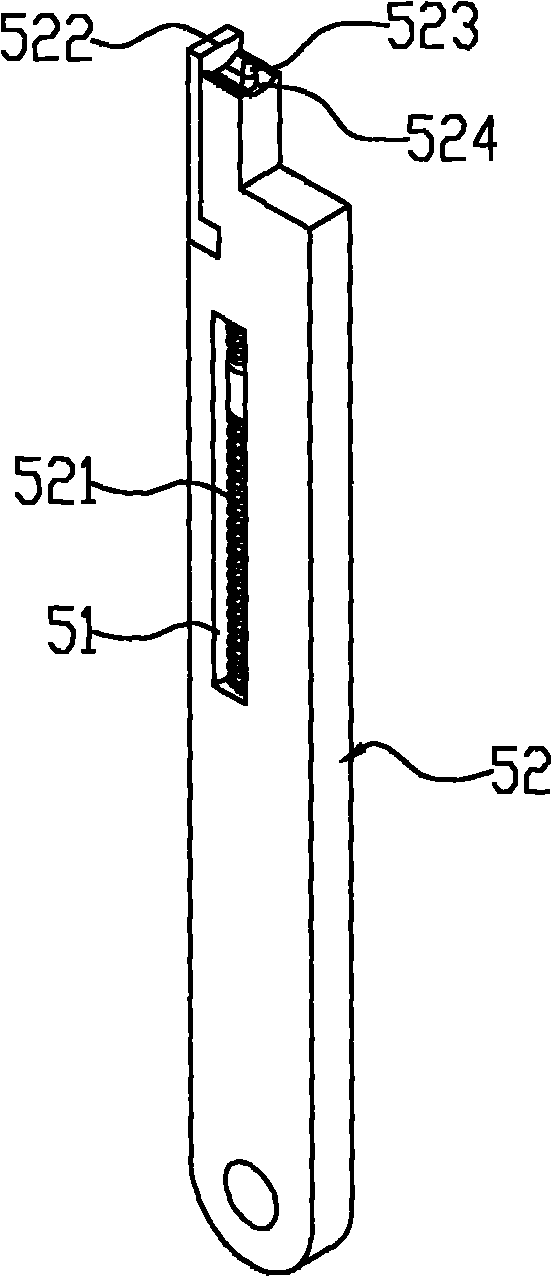

Puller shrapnel assembling machine

The invention relates to a puller shrapnel assembling machine, used for slicing elastic cord into shrapnel and assembling the shrapnel onto the puller body. The puller shrapnel assembling machine comprises a puller conveying mechanism, an elastic core conveying mechanism, a control circuit, a puller locating mechanism and a punching riveting mechanism; wherein the puller locating mechanism comprises a locating plate, the locating plate is provided with a locating cave, the side of the locating plate at the locating cave is provided with a punching base plate, the punching riveting mechanism comprises a transmission mechanism and a punching riveting knife, one end of the punching riveting knife is connected with the transmission mechanism, the other end of the punching riveting knife is provided with a punching knife edge and a riveting knife edge; when in operation, the puller conveying mechanism conveys the puller body into the locating cave of the locating plate, the elastic core conveying mechanism conveys the elastic cord onto the punching base plate of the locating plate, the punching knife edge on the punching riveting knife punches the elastic cord on the punching base plate into a shrapnel, and the riveting knife edge rivets one end of the shrapnel on the puller body. The puller shrapnel assembling machine has the advantage of simple structure.

Owner:FUJIAN SBS ZIPPER SCI & TECH CO LTD

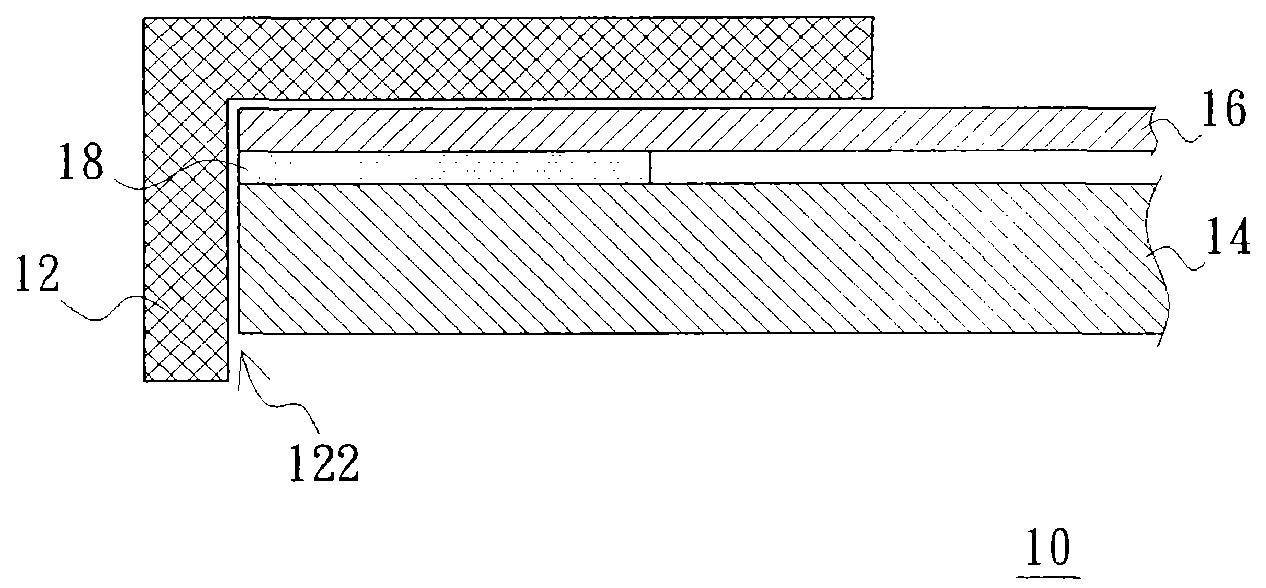

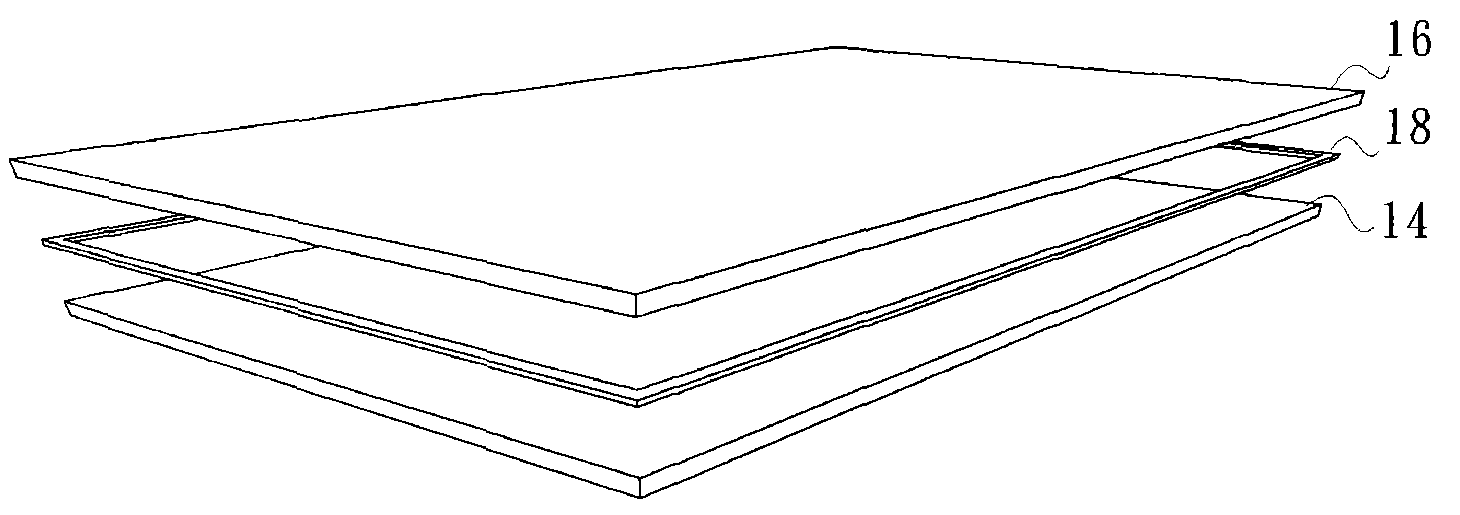

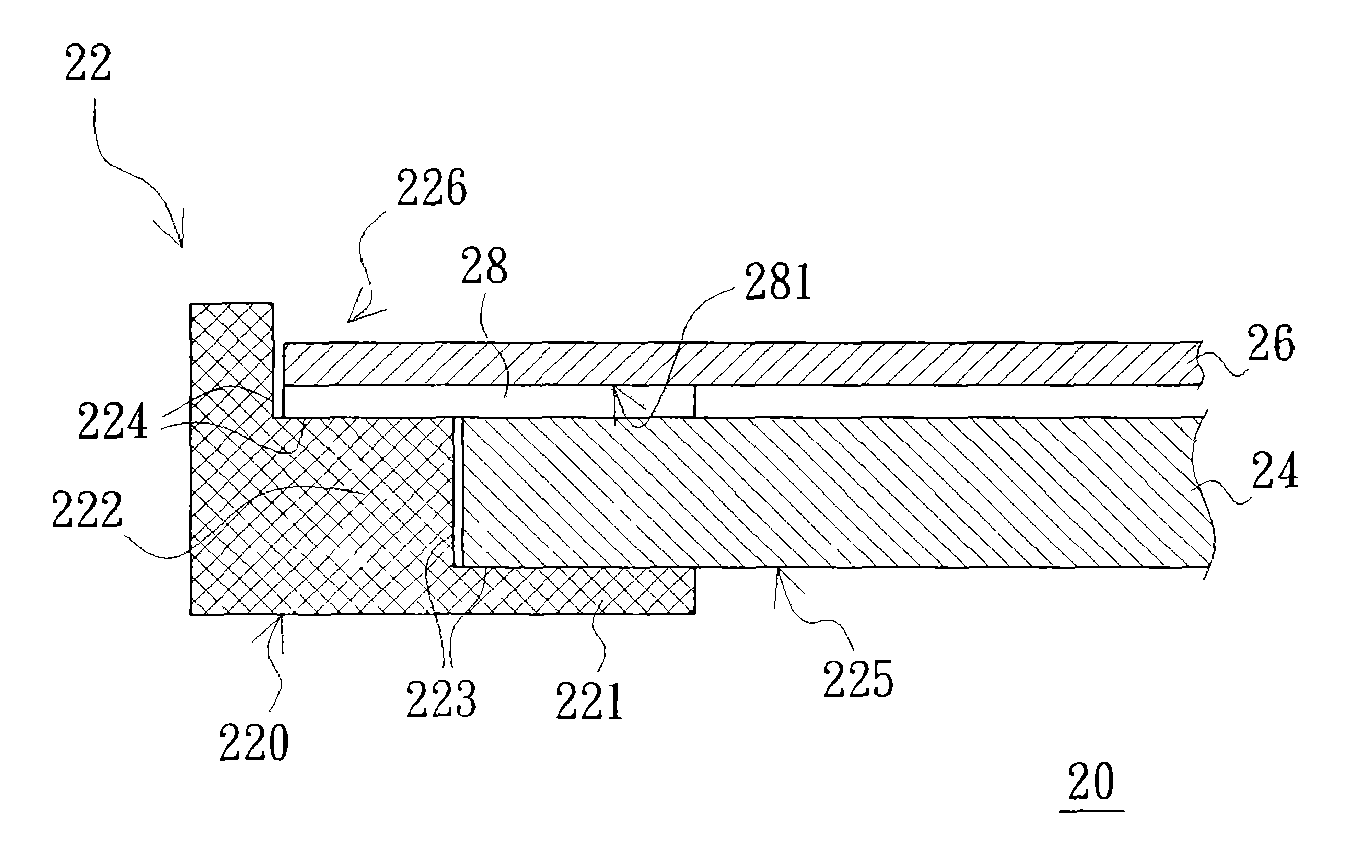

Touch display device

InactiveCN102033635AEasy to assembleSimplify the assembly processStatic indicating devicesNon-linear opticsDisplay deviceEngineering

The invention relates to a touch display device which comprises a frame, a display panel and a touch panel, wherein the inner side wall of the frame is provided with a first stepped part and a second stepped part; the height of the second stepped part relative to the bottom of the frame is larger than the height of the first stepped part relative to the bottom of the frame, a first containing cavity is formed by the enclosure of the first stepped part, and the display panel is positioned in the first containing cavity; and a second containing cavity is formed by the enclosure of the second stepped part, and the touch panel is positioned in the second containing cavity. The touch display device has the advantage of being easy to assemble.

Owner:AU OPTRONICS CORP

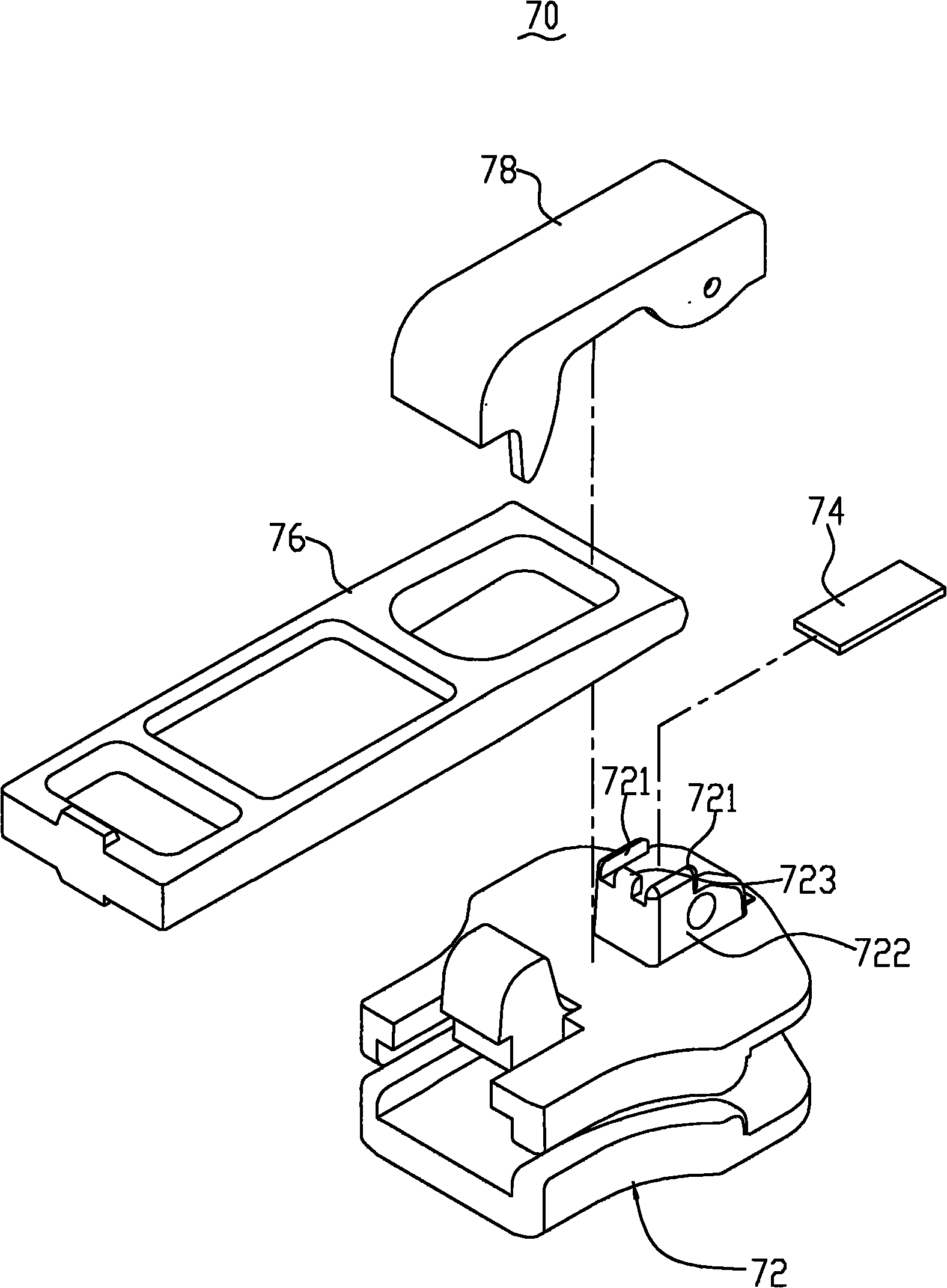

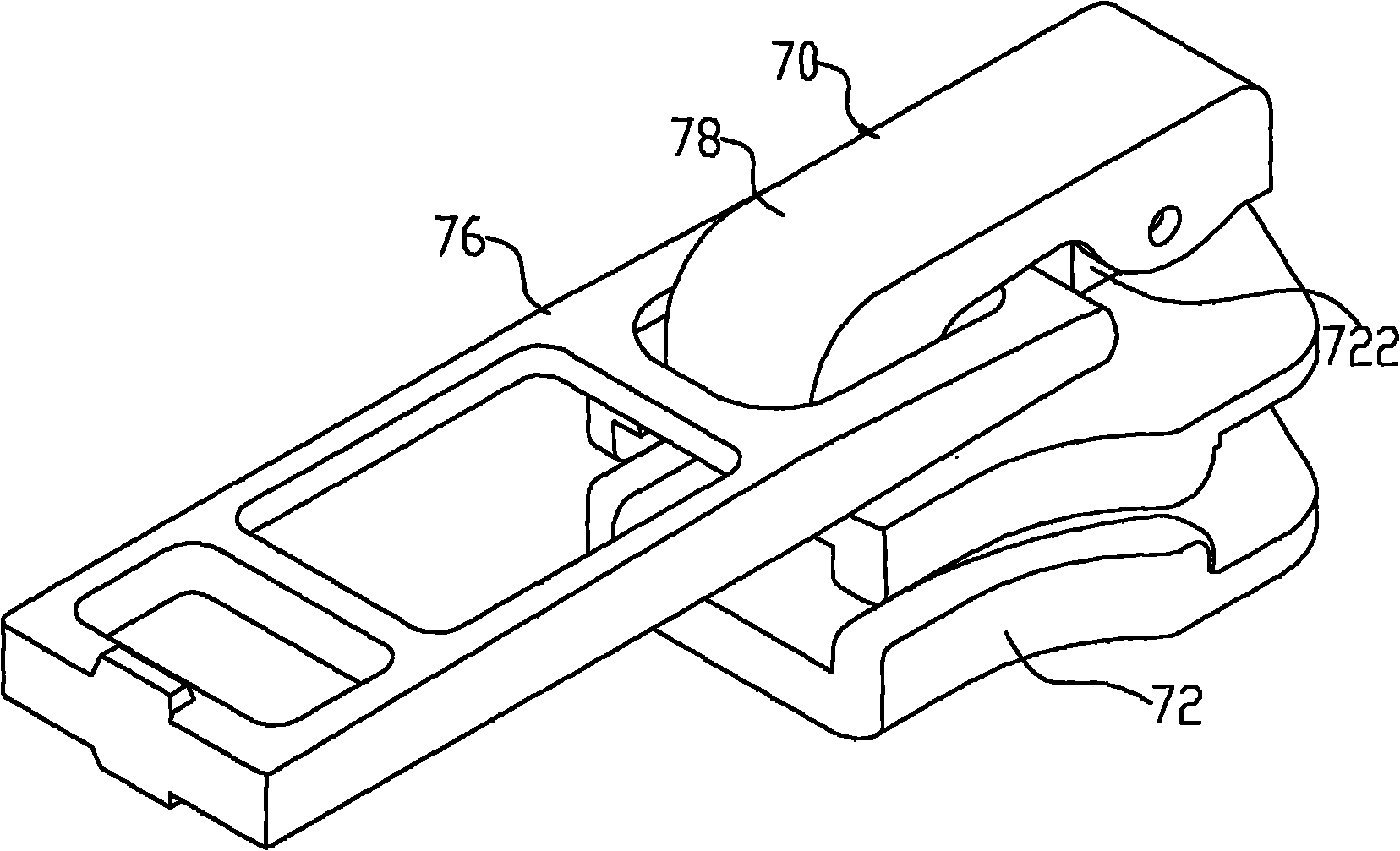

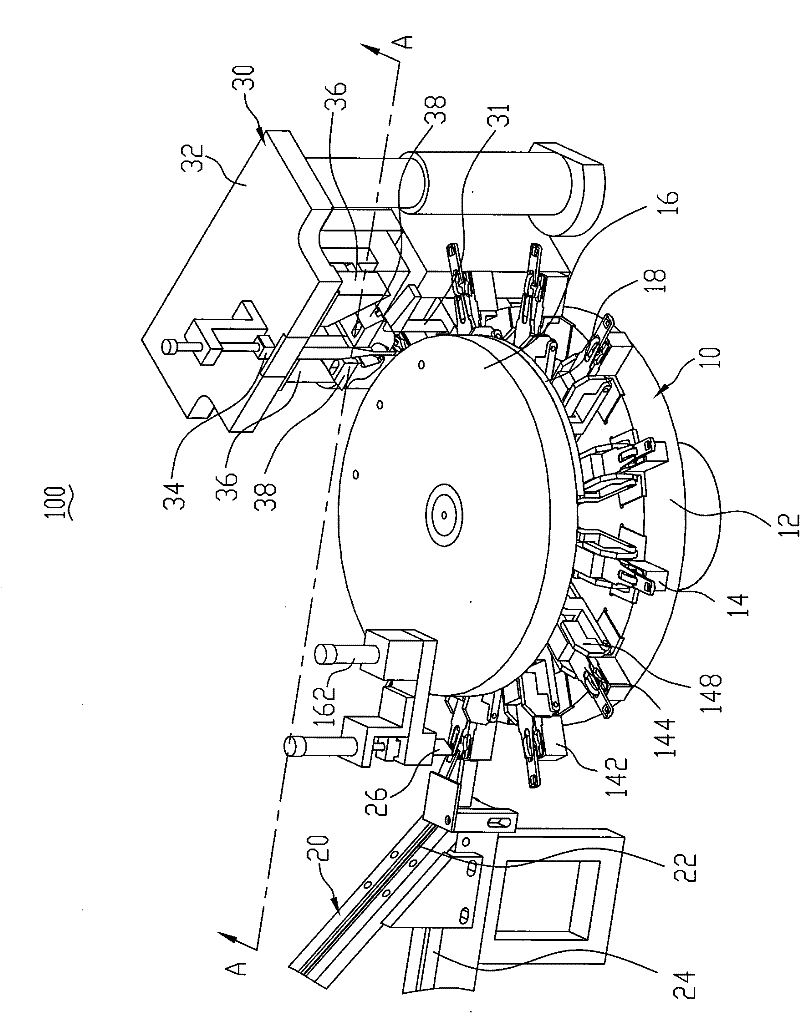

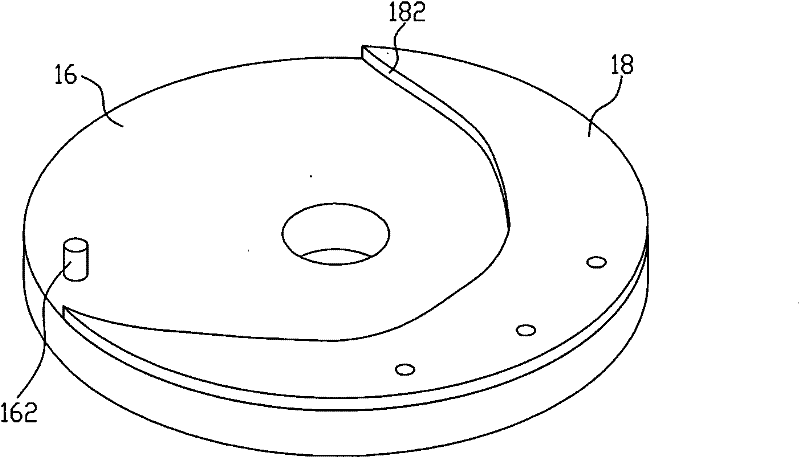

Transmitting mechanism of zipper head assembling machine and zipper head assembling machine using same

The invention provides a transmitting mechanism of a zipper head assembling machine and the zipper head assembling machine using the transmitting mechanism. The transmitting mechanism of the zipper head assembling machine comprises a rotating disc, a fixed disc and at least an assembling fixture arranged on the rotating disc, wherein the fixed disc is arranged above the rotating disc; each assembling fixture comprises a bearing platform, a clamping sheet and a sliding part; one end of the clamping sheet is connected to the sliding part, and the other end of the clamping sheet is arranged correspondingly to the bearing platform; the sliding part can be connected to the rotating disc in a sliding manner in the radial direction along the rotating disc; a guide rail is arranged on the fixed disc correspondingly to the sliding part; and when the rotating disc rotates, the guide rail can drive the sliding part to move in the radial direction. The zipper head assembling machine has the advantages that zipper pulls in different shapes can be assembled, the structure is simple and the assembling speed is quick.

Owner:FUJIAN SBS ZIPPER SCI & TECH CO LTD

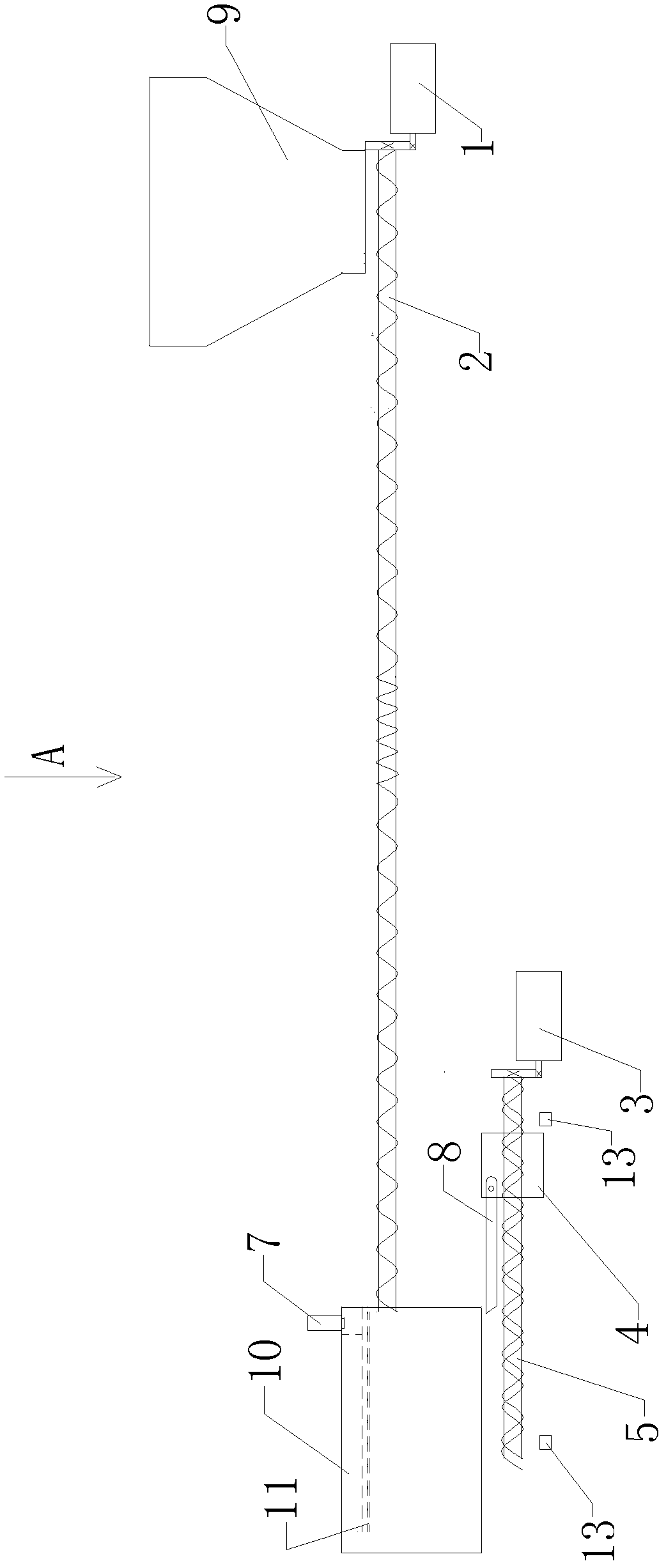

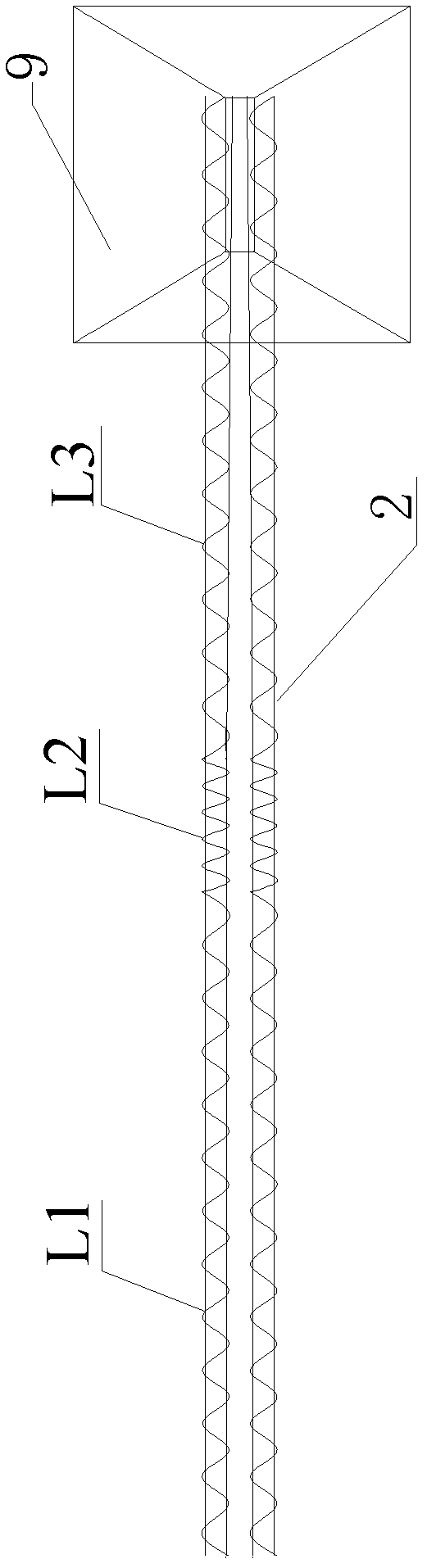

Automatic bullet sorting and assembling device

InactiveCN102564220AThe overall structure is simple and reliableFast assemblyAmmunition loadingButt jointEngineering

The invention discloses an automatic bullet sorting and assembling device, which comprises a bin with a vibration source, conveying screw rods, a magazine clip butt joint device and a clamping device. A discharge outlet of the bin with the vibration source is connected with a feed inlet of the magazine clip butt joint device by a bullet conveying channel formed by the two conveying screw rods, the two conveying screw rods are provided with threads and are driven by conveying motors, the feed inlet of the magazine clip butt joint device is provided with a counter, the magazine clip butt joint device is provided with a clamp strip matching with a groove at the end of a bullet, the clamping device consists of a clamping screw, a clamping motor, a nut pair, a rotatable ejector rod and a stop block, the clamping motor is used for driving the clamping screw, the nut pair matches with the clamping screw, the rotatable ejector rod is connected with the nut pair, and the stop block limits the nut pair. The automatic bullet sorting and assembling device has the advantages of simple and reliable structure, fast assembly speed, high assembly efficiency and the like, and is suitable for various places including field shooting training, shooting venues, actual combats and the like, and labor intensity of soldiers and shooting personnel is greatly reduced.

Owner:ZHEJIANG UNIV

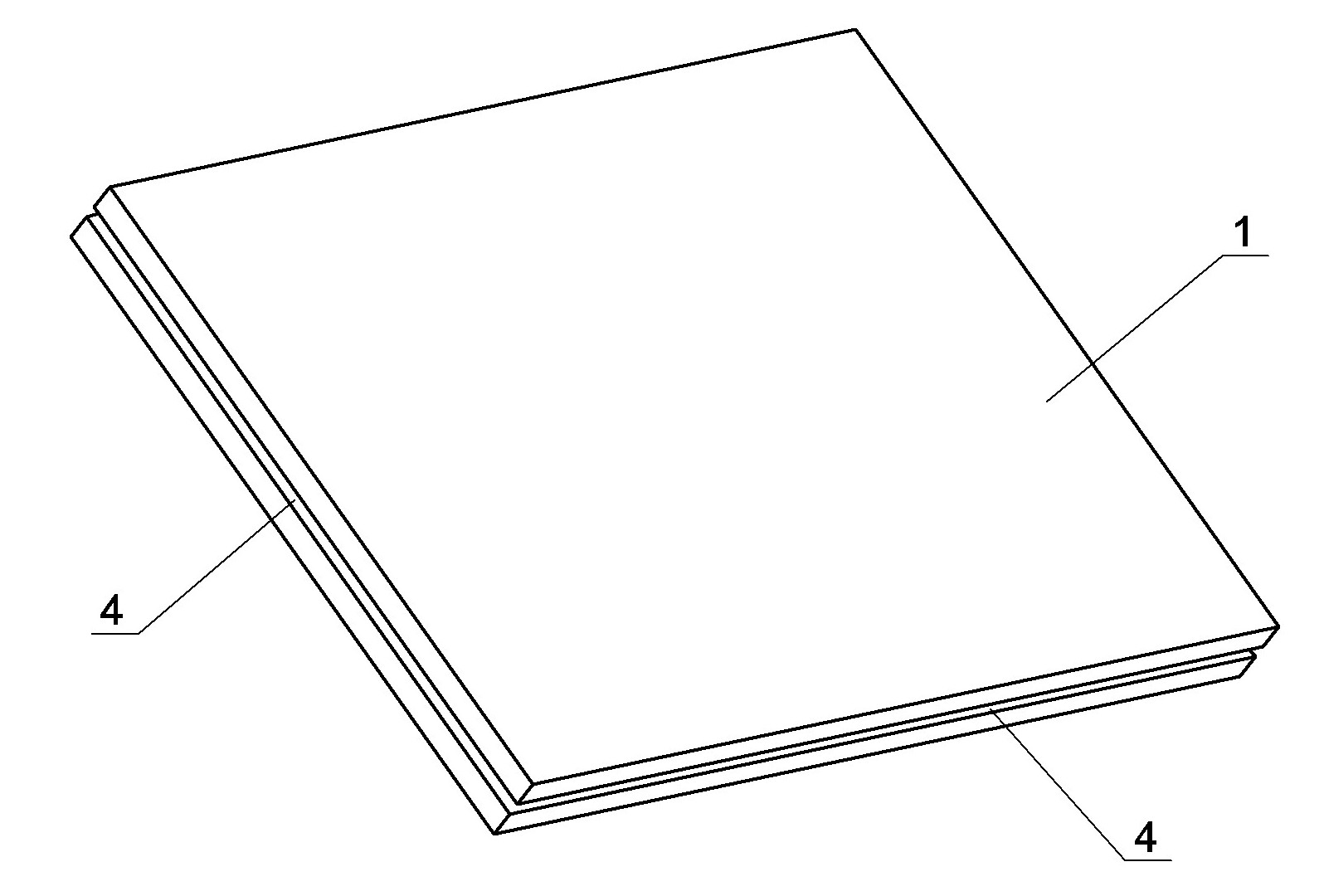

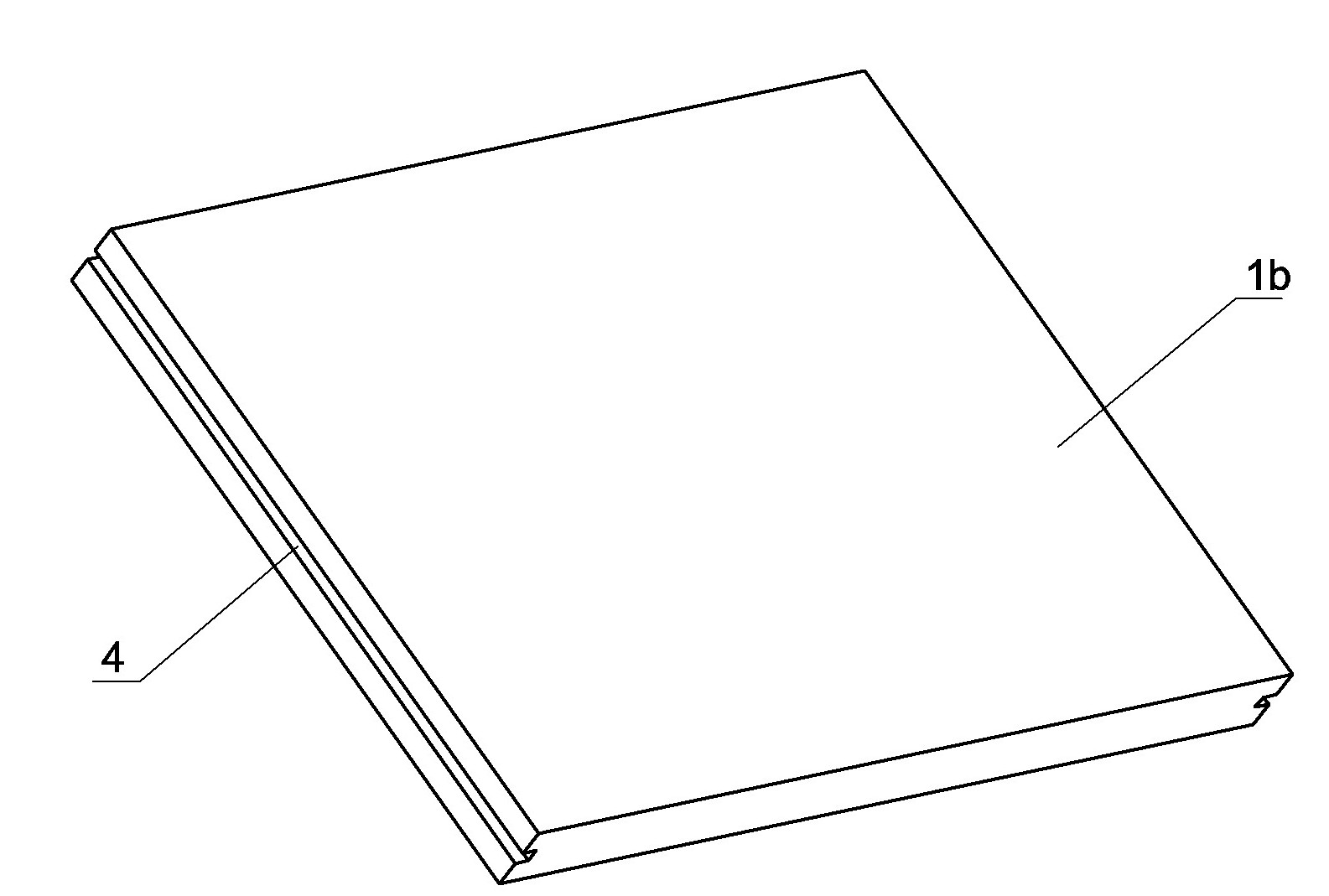

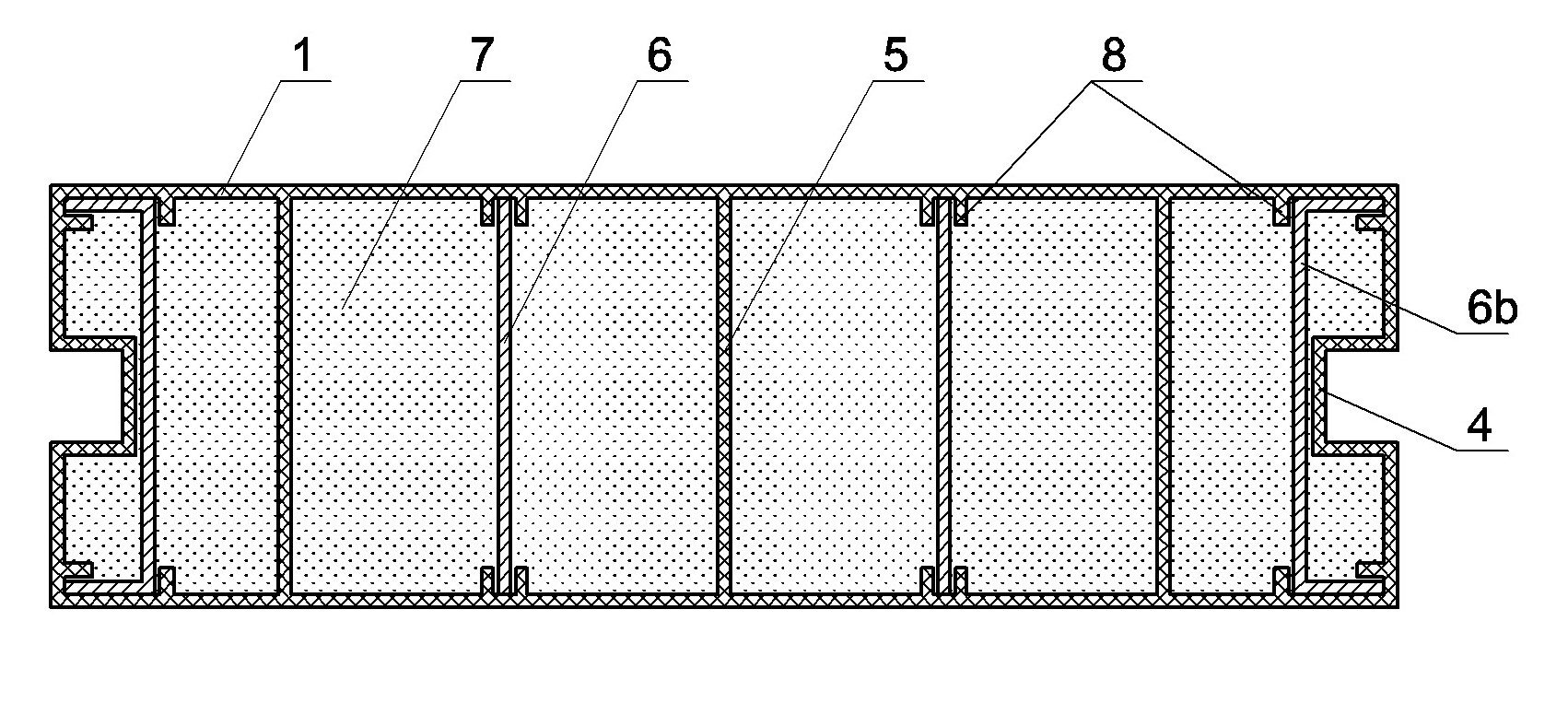

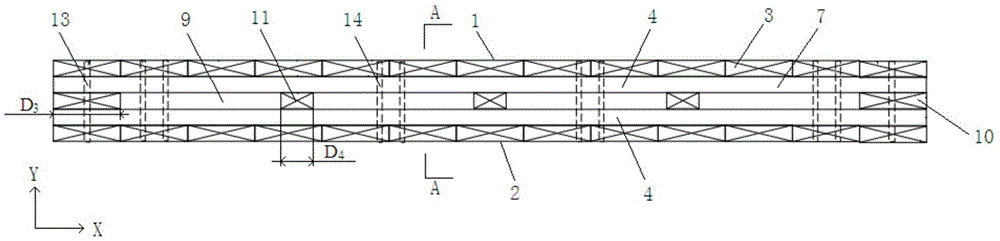

Hollow filled plastic-steel building template and composite structure

InactiveCN101956454AHigh strengthEasy to demouldForms/shuttering/falseworksForming/stuttering elementsPrismEngineering

The invention relates to a hollow filled plastic-steel building template and a composite structure. The inner lateral surfaces of the building template are provided with longitudinal slots enclosed by double flanges respectively; hard supporting plates are inserted and fixed between every two opposite longitudinal slots; the centers of the two opposite lateral surfaces or three or four lateral surfaces of the building template are provided with grooves parallel to corresponding relatively-longer side edges respectively; and a lightweight filling material is filled into the cavity of the template. The composite structure consists of the template, corner connecting pieces and middle prisms, wherein the side edges of the corner connecting pieces are provided with longitudinal ribs which are matched with corresponding grooves on each side edge of the template; the middle prisms are matched with the grooves on each side edge of the building template; and simultaneously, each prism has a width which is twice that of the groove. The hollow filled plastic-steel building template integrates the advantages and characteristics of a steel formwork, a timber formwork and a hollow plastic formwork, has the advantages of strong strength, long service life, smoothness, easy de-molding, no bend, no deformation, lightweight and flexible mounting and dismounting, can improve the working efficiency and is applied to popularization and implementation.

Owner:徐秀良

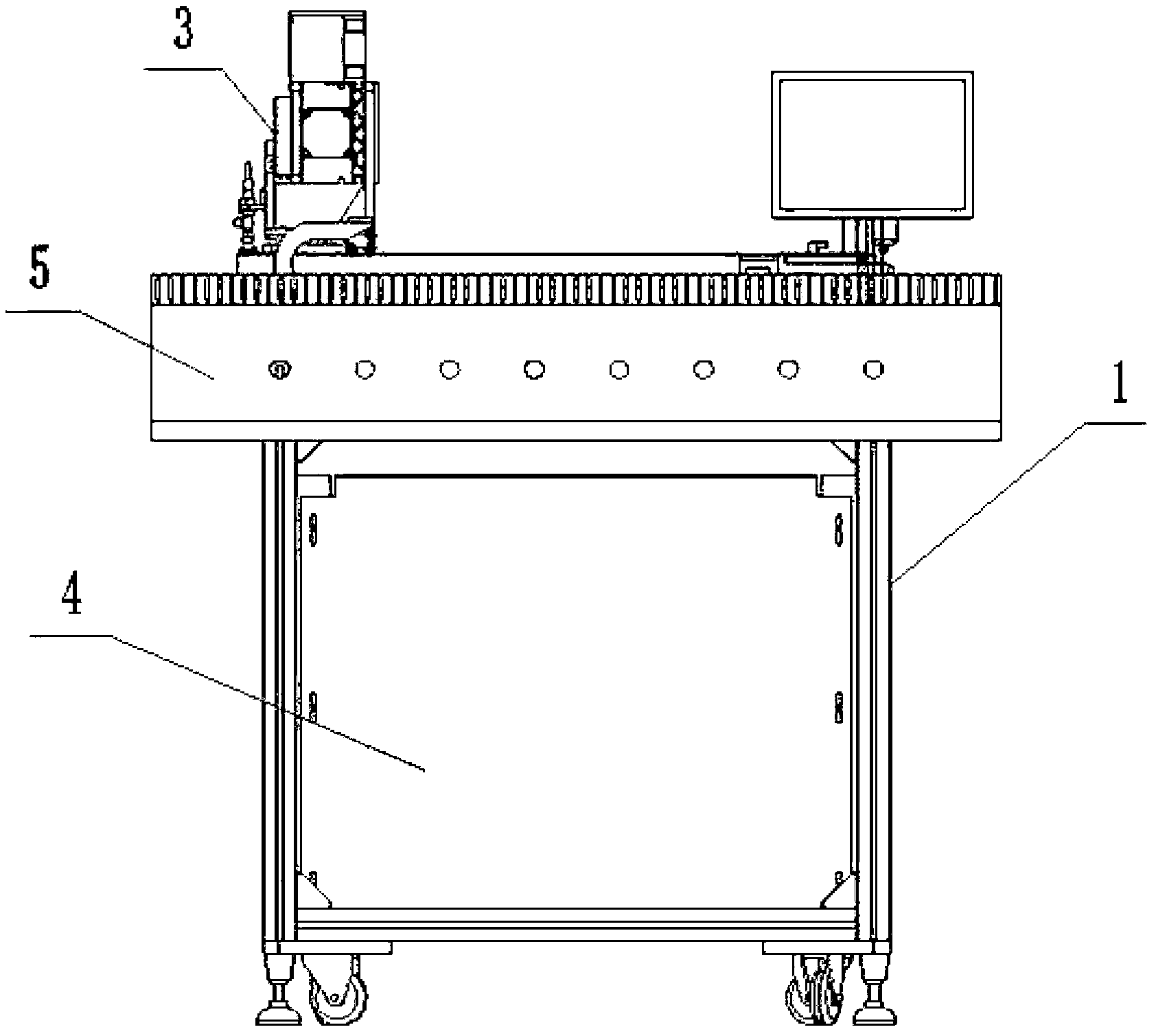

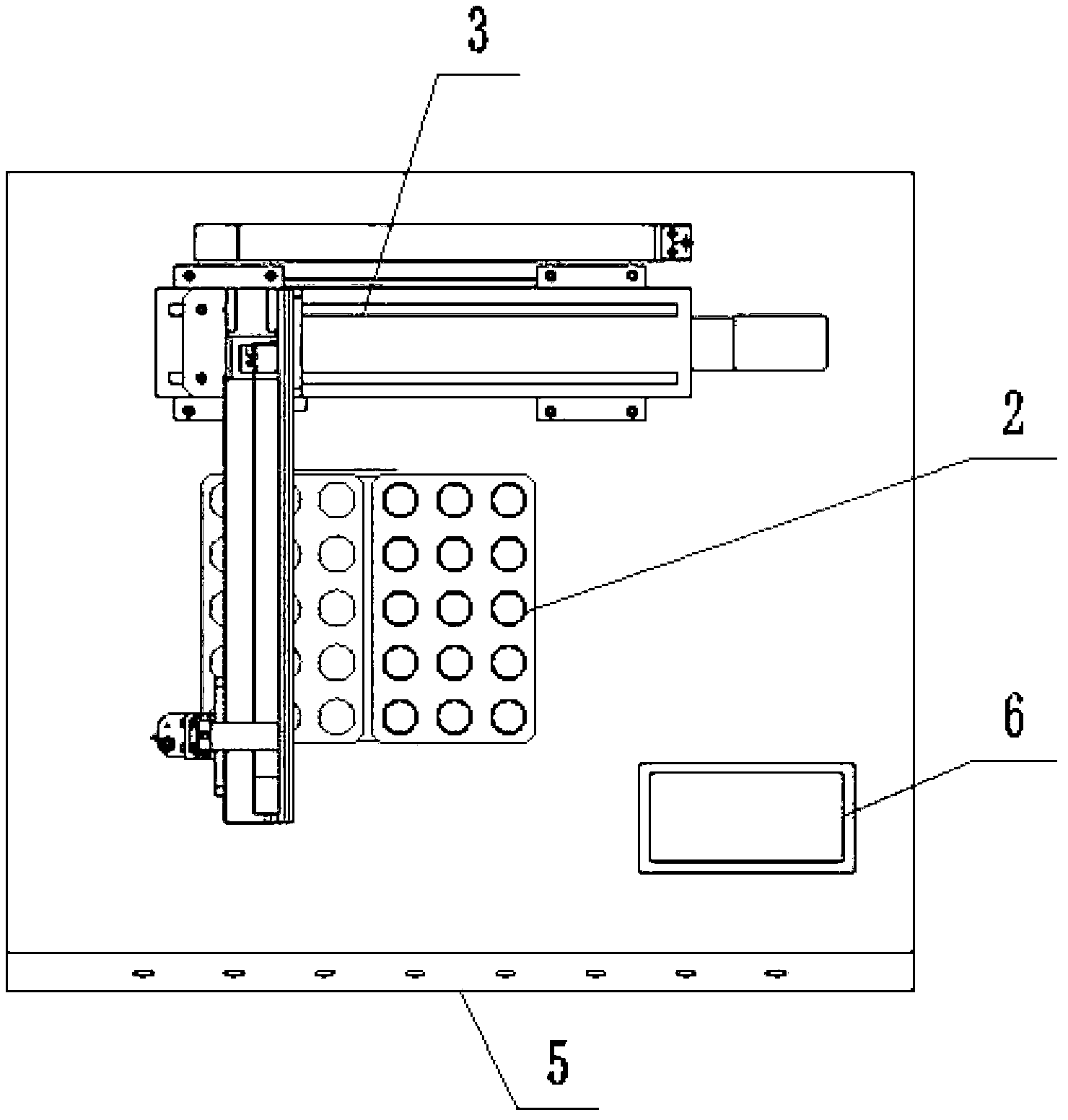

Mobile phone lens assembly equipment

ActiveCN106944827AImprove yield rateSimple structureAssembly machinesMountingsEngineeringMobile phone

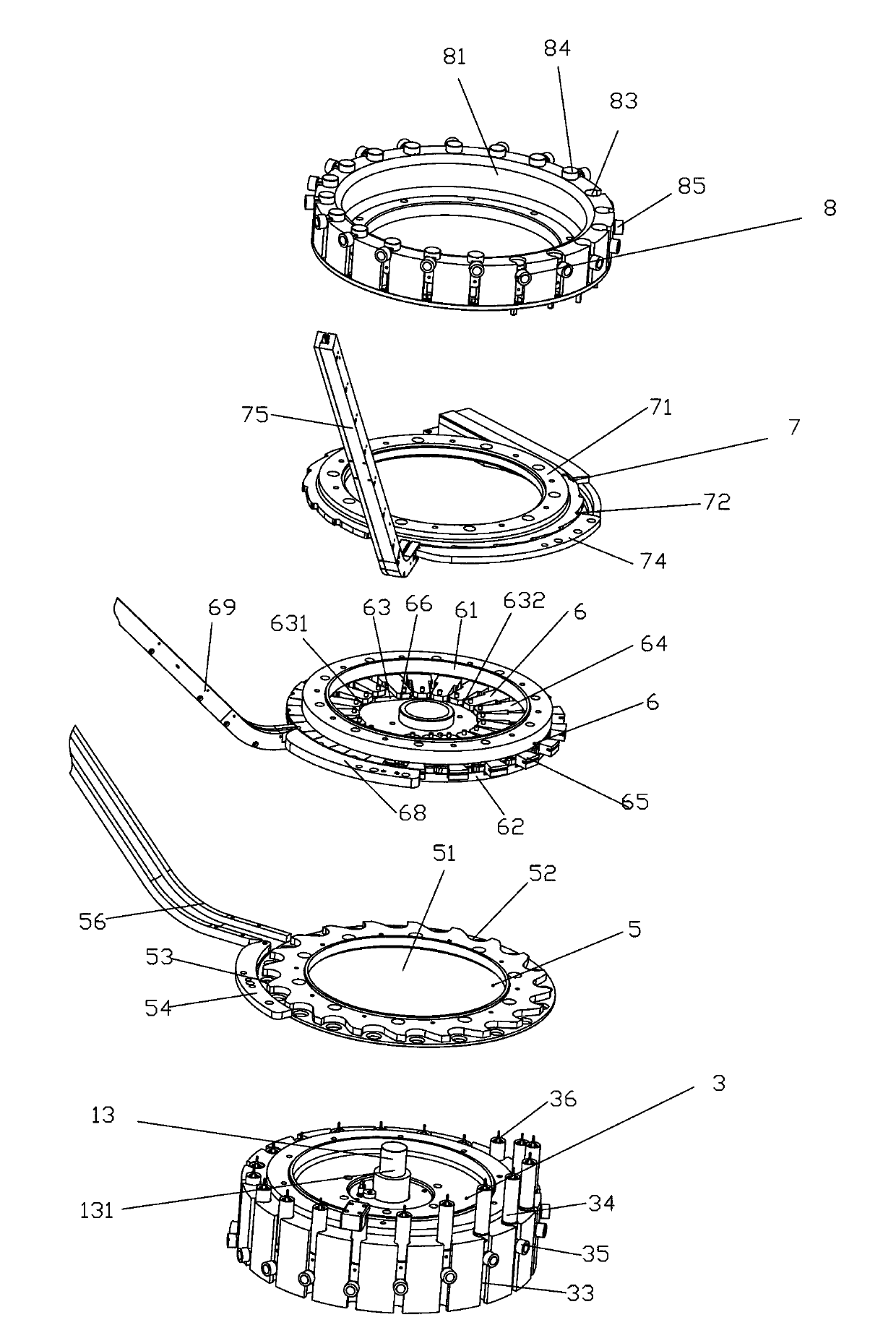

The invention relates to mobile phone lens assembly equipment. The mobile phone lens assembly equipment comprises a frame, a supply module, a moving device, a taking and curing device, a sucking device and a fixed rotating device. The supply module is arranged on the frame. The moving device is arranged on the frame, and is positioned on one side of the supply module. The taking and curing device and the sucking device are arranged on the moving device, and are corresponding to the supply module; and the sucking device is positioned on one side of the taking and curing device. The fixed rotating device is arranged on the frame, is positioned on one side of the moving device, and is respectively corresponding to the taking and curing device and the sucking device. The mobile phone lens assembly equipment is simple in structure, automatically assembles a lens, a pressure ring and a light shielding piece onto a lens cone to form a mobile phone lens, is fast in assembly speed, is high in mobile phone lens yield, reduces enterprise producers, and improves the enterprise production efficiency.

Owner:HUIZHOU DESAY AUTOMATION TECH

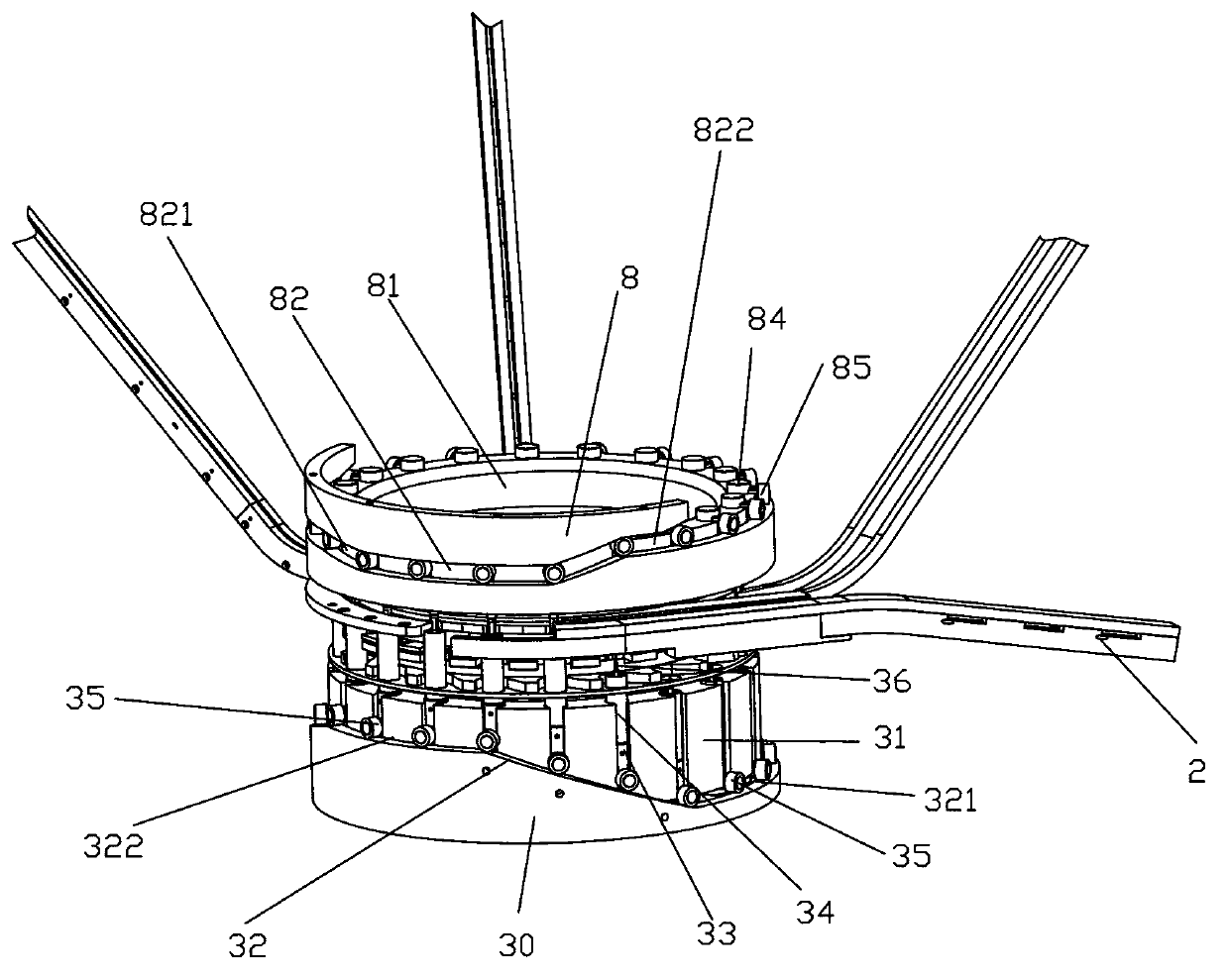

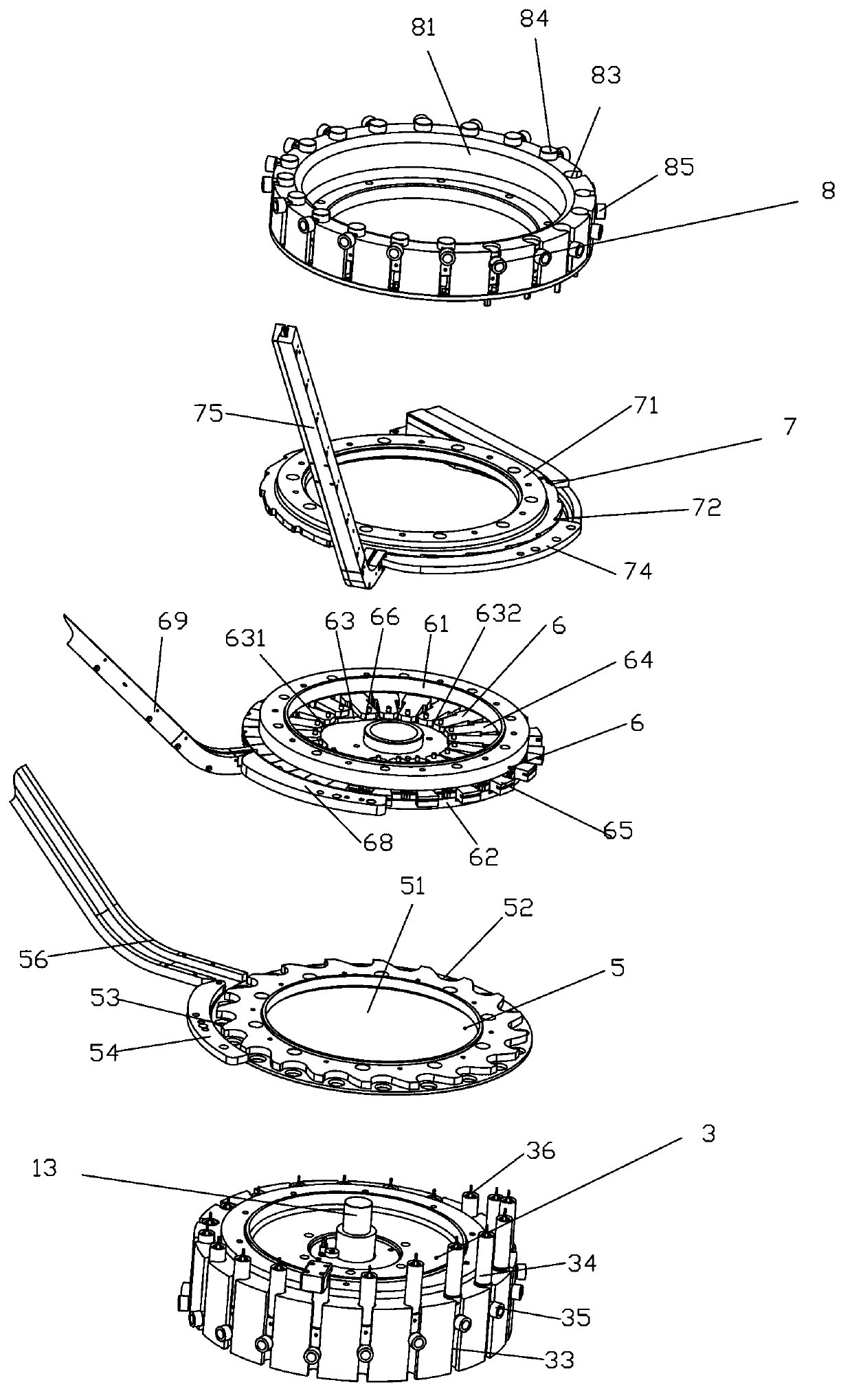

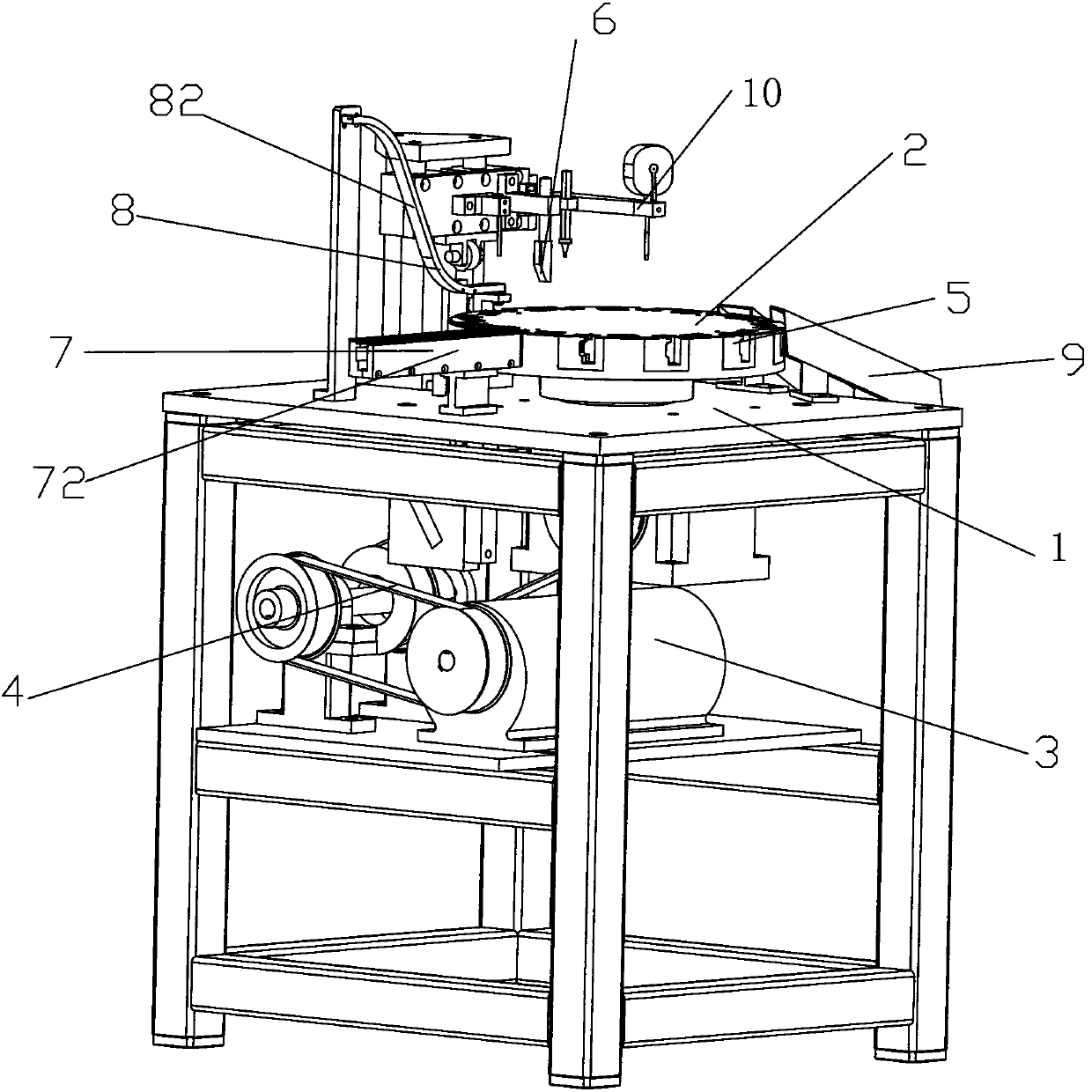

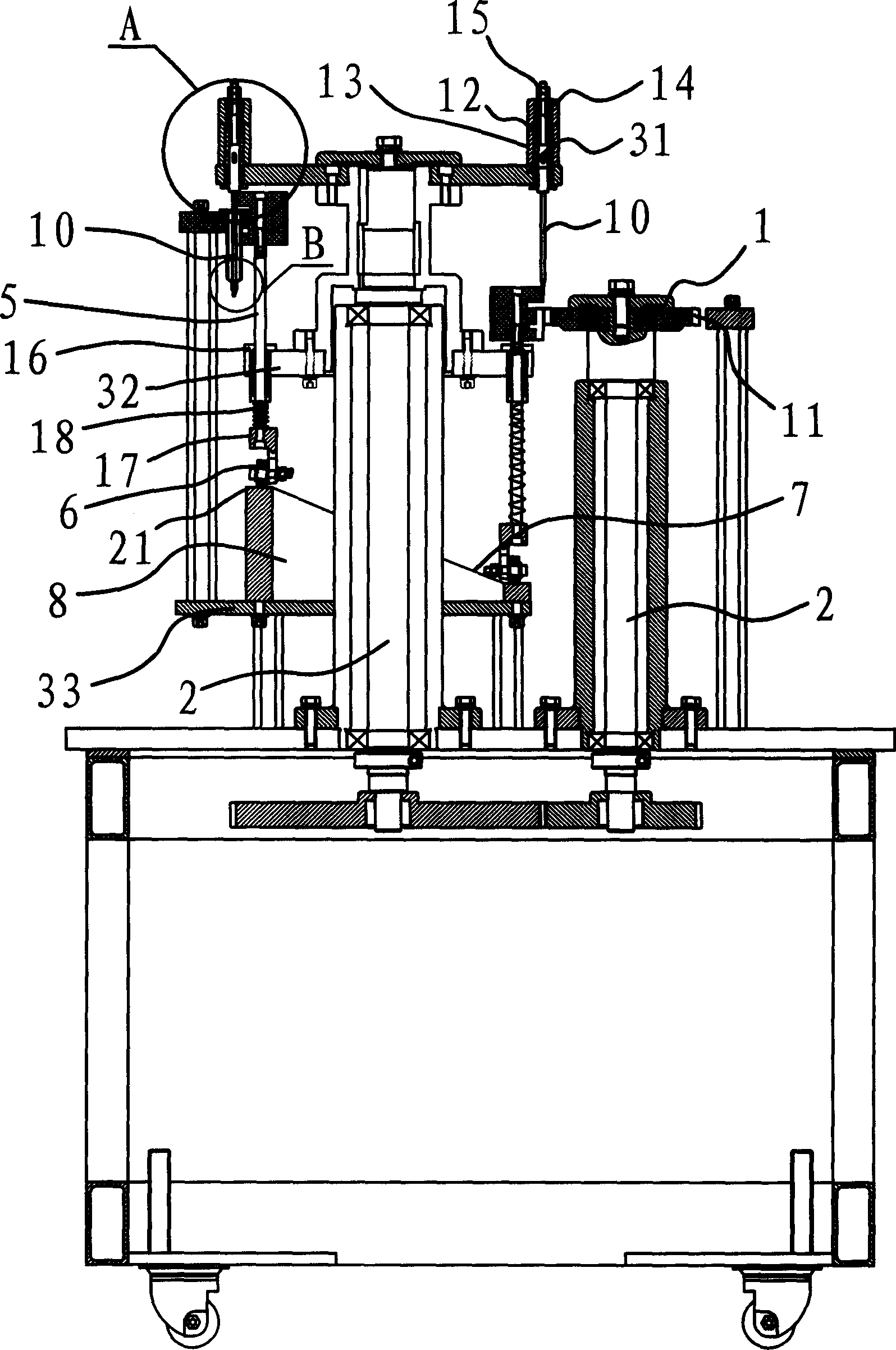

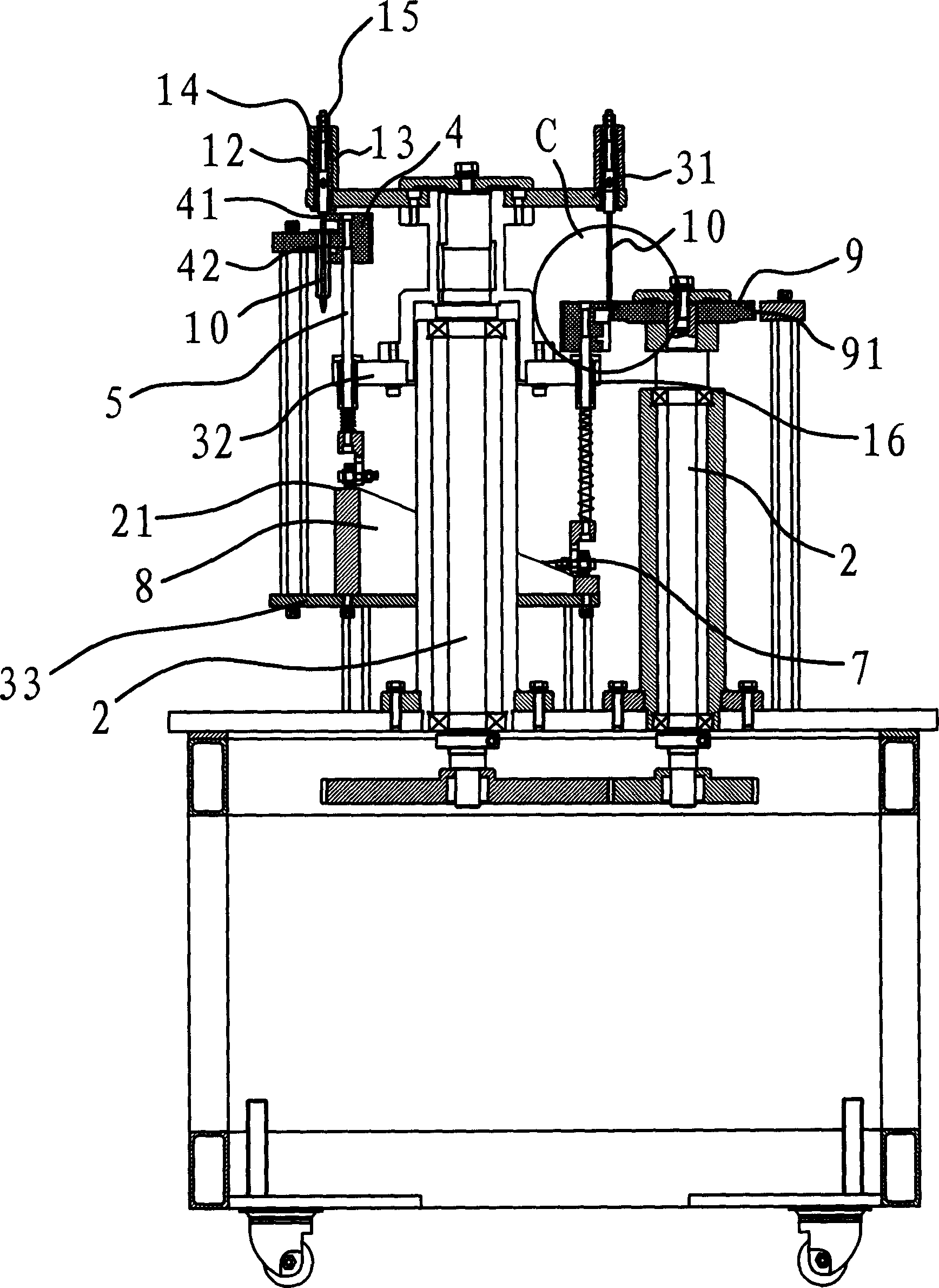

Equipment for assembling atomizing nozzle and pressing nozzle of aerosol valve

The invention discloses equipment for assembling an atomizing nozzle and a pressing nozzle of an aerosol valve. The equipment is characterized by comprising a frame, wherein a rotating disc capable of rotating on the frame as well as a driving device and a transmission gear for driving the rotating disc to rotate are arranged on the frame; a plurality of pressing nozzle fixing devices are arranged on the rotating disc; an atomizing nozzle pushing and assembling mechanism for pushing the atomizing nozzle so as to assemble the atomizing nozzle and the pressing nozzle into a whole is arranged beside the rotating disc; and a pressing nozzle feeding device for feeding the pressing nozzle into the pressing nozzle fixing devices, an atomizing nozzle feeding device for feeding the atomizing nozzle into the atomizing nozzle pushing and assembling mechanism, and a discharge device are also arranged on the frame. By adopting the equipment, the mechanical automation of operations of assembling the atomizing nozzle and the pressing nozzle is completely realized, the assembling speed is high, the efficiency is high, and the cost is reduced.

Owner:ZHONGSHAN MEIJIESHI PACKAGING PROD

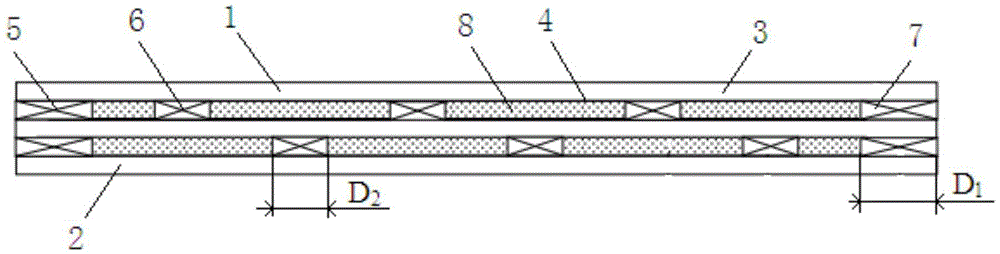

Hollow cross-ply laminated building block bearing plate

ActiveCN105544757AImprove mechanical performanceQuality improvementHeat proofingSound proofingInsulation layerPulp and paper industry

The invention relates to a hollow cross-ply laminated building block bearing plate which comprises an inner layer plate body and an outer layer plate body. At least two heat preservation or sound insulation layers are arranged in a first cavity formed between the inner layer plate body and the outer layer plate body. Each heat preservation or sound insulation layer comprises first wood boards arranged at the two ends of the first cavity, and second wood boards arranged in a cavity between the two first wood boards at intervals, cavities formed between every two second wood boards and between the first wood boards and the second wood boards are filled with non-bearing heat preservation boards or non-bearing sound insulation materials, a second cavity is formed between every two heat preservation or sound insulation layers, and third wood boards are arranged at the two ends of each second cavity respectively. The hollow design is adopted, and the heat preservation or sound insulation layers are embedded in plate bodies, so that good heat preservation performance or sound insulation performance is achieved, and heat preservation protection or sound insulation treatment does not need to be carried out outside the plate bodies any more; the boards in the plate bodies are distributed in a cross-ply mode, so that the plate bodies have good stress performance and are light and good in economic effect, the manufacturing cost is reduced, and environment pollution is effectively avoided.

Owner:张延年

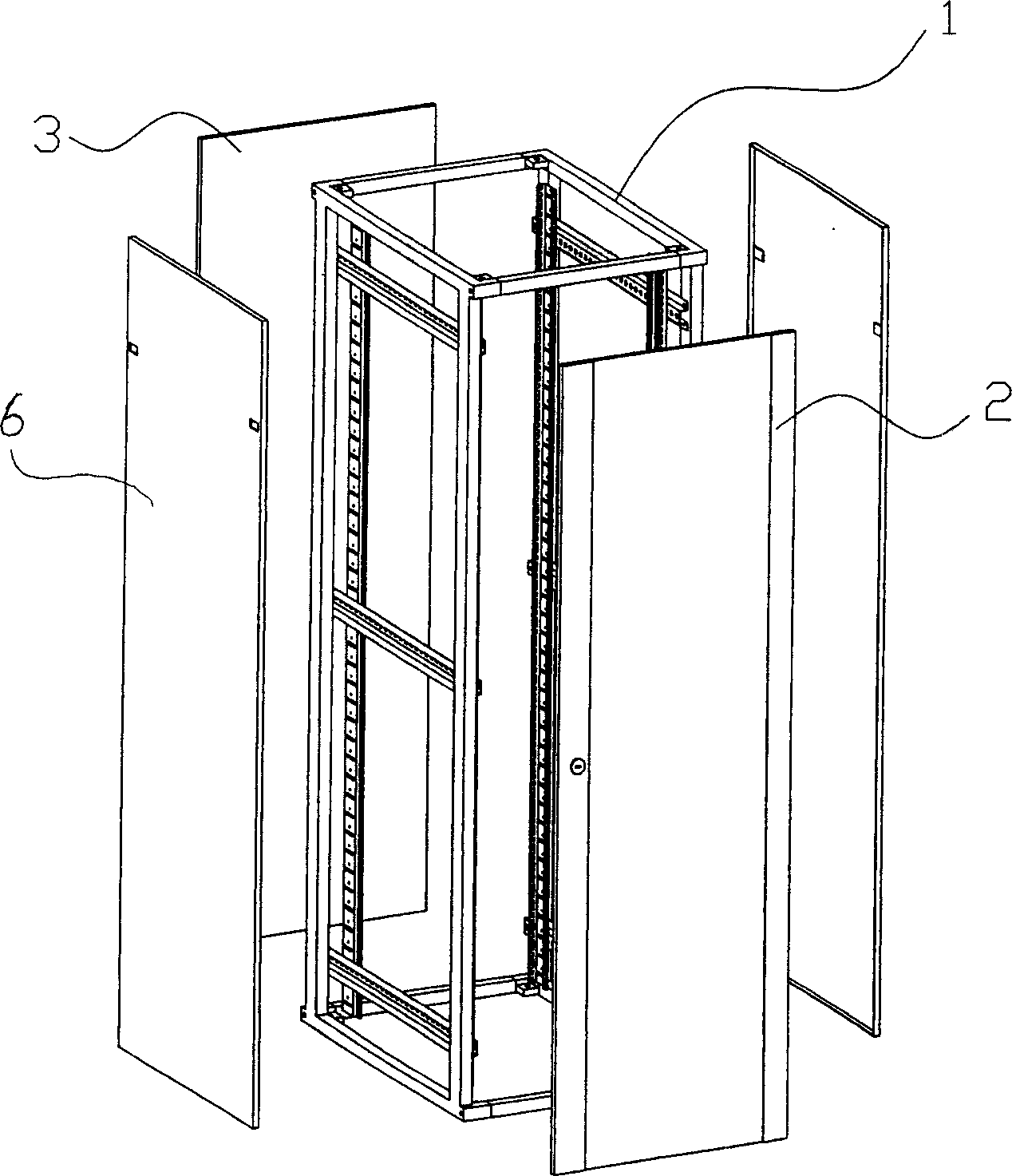

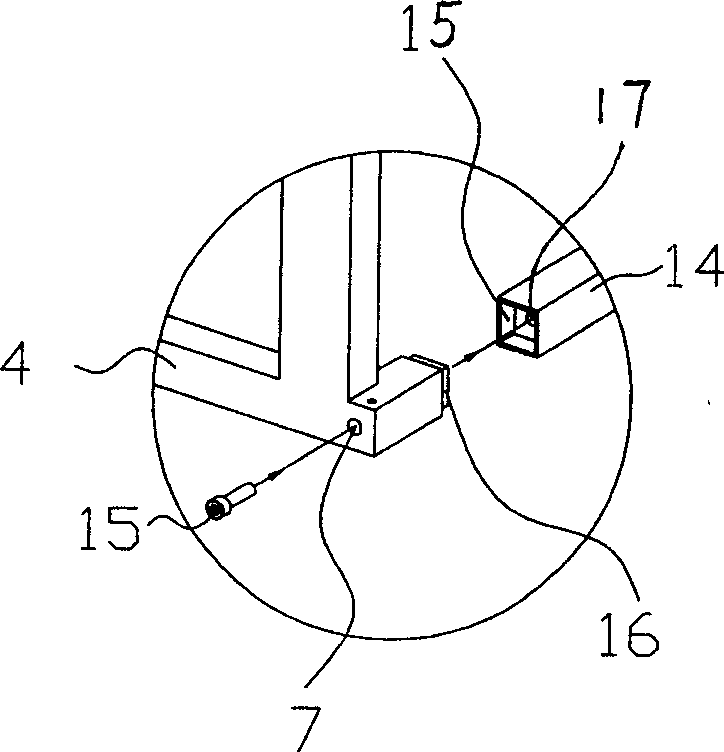

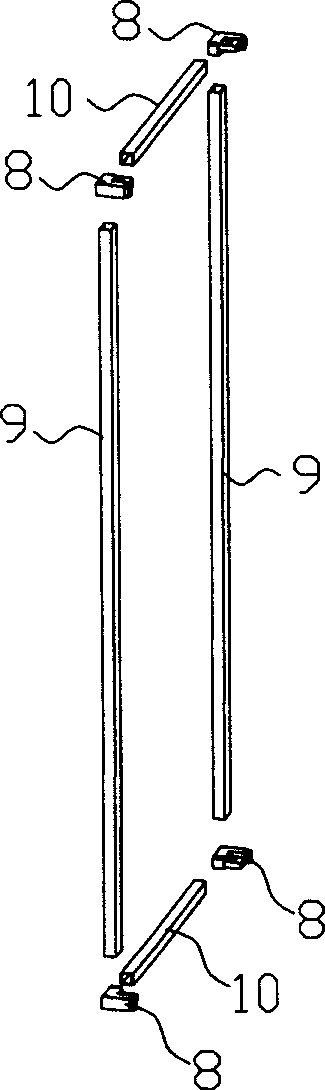

Fast assembled machine cabinet

InactiveCN1668169ARapid assembly prototypingReduce in quantityCasings/cabinets/drawers detailsInstrument housingEngineeringBackplane

A quickly assembled cabinet includes a frame, a door, back plates and screws characterizing that the frame is composed of two surrounding frames, four connection bars connected by eight screws, the surrounding frame component is composed of surrounding frames and door plate, bars and assembly strips preset on it, four corners of the corresponding side of the frames are set with inserted plugs matched to the sag holes of the connecting bats, four corners of the frame sides are corresponding to the inserted plug positions, which are set with stepped through holes for guiding in screws and fastening, both ends of the connecting bars are set with sag holes matched with the inserted plugs, bottom of the holes are set with screw holes corresponding to the stepped through holes.

Owner:SHENZHEN TOTEN COMM TECH

Vertical automatic mounting device for connector push rods

The invention relates to a vertical automatic mounting device for connector push rods. The vertical automatic mounting device sequentially comprises a vibrating disk, a misplacement mechanism, a material translation mechanism, an assembling mechanism and a rack, wherein the misplacement mechanism is butted with the vibrating disk through a feeding pipeline, the material translation mechanism is used for carrying a plurality of connector push rods and then conveying the connector push rods to mounting positions, the assembling mechanism is used for finishing the assembly of the connector push rods and connector main bodies, and the rack is used for fixedly arranging all mechanisms and components. The vertical automatic mounting device for the connector push rods has the advantages that the automated assembling operation of a whole assembling process for the connector push rods can be achieved, and the structure of the vertical automatic mounting device is little in space occupation, convenient in mounting and low in manufacturing cost compared with the traditional structure; and meanwhile, on the basis that the machining quality is ensured, the assembly of the connector push rods can be realized in a single cycle, the machining speed is high, and the production efficiency can be doubled.

Owner:AMPHENOL AORORA TECH (HUIZHOU) CO LTD

Automatic laminating machine

ActiveCN104002502ASave human effortReduce labor costsBox making operationsPaper-makingProduction lineProgrammable logic controller

The invention discloses an automatic laminating machine. The automatic laminating machine comprises a rack and a conveying belt which is arranged on the rack, a take out device, a transverse gluing device, a longitudinal gluing device, a glue pre-drying device, a small inner box laminating device, a large inner box laminating device, a pneumatic compression device and a finished product collecting place are sequentially arranged on the conveying belt, and a programmable logic controller (PLC) control system is arranged in the automatic laminating machine and used for controlling the take out device, the transverse gluing device, the longitudinal gluing device, the glue pre-drying device, the small inner box laminating device, the large inner box laminating device and the pneumatic compression device. By means of the automatic laminating machine, streamline operation of a assembling process of packing boxes can be achieved, 24 persons are required in previous production lines, merely 12 persons are required in the streamline operation, thereby, manpower can be saved, meanwhile, manpower costs and production costs are correspondingly lowered, 20 seconds are required when a product is produced previously, only 5 seconds are required when the product is produced in the streamline operation, and the producing efficiency is increased.

Owner:DONGGUAN BRDASON ULTRASONIC EQUIP CO LTD

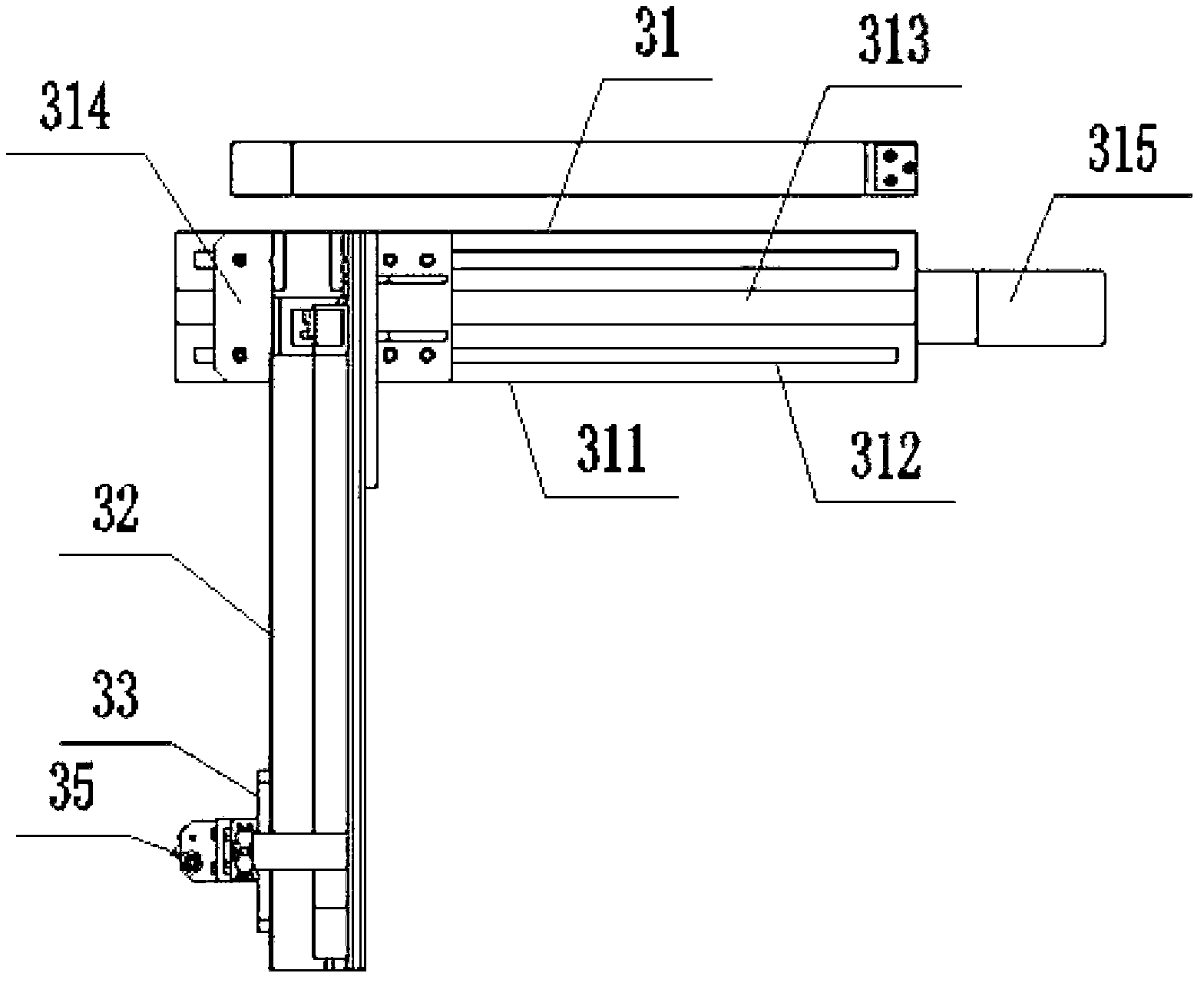

Three-freedom-degree table tennis carrying mechanical arm

InactiveCN103213121AFast assemblyGood debugging effectProgramme-controlled manipulatorGripping headsOrthogonal coordinatesControl system

Owner:JIANGSU HUIBO ROBOTICS TECH CO LTD

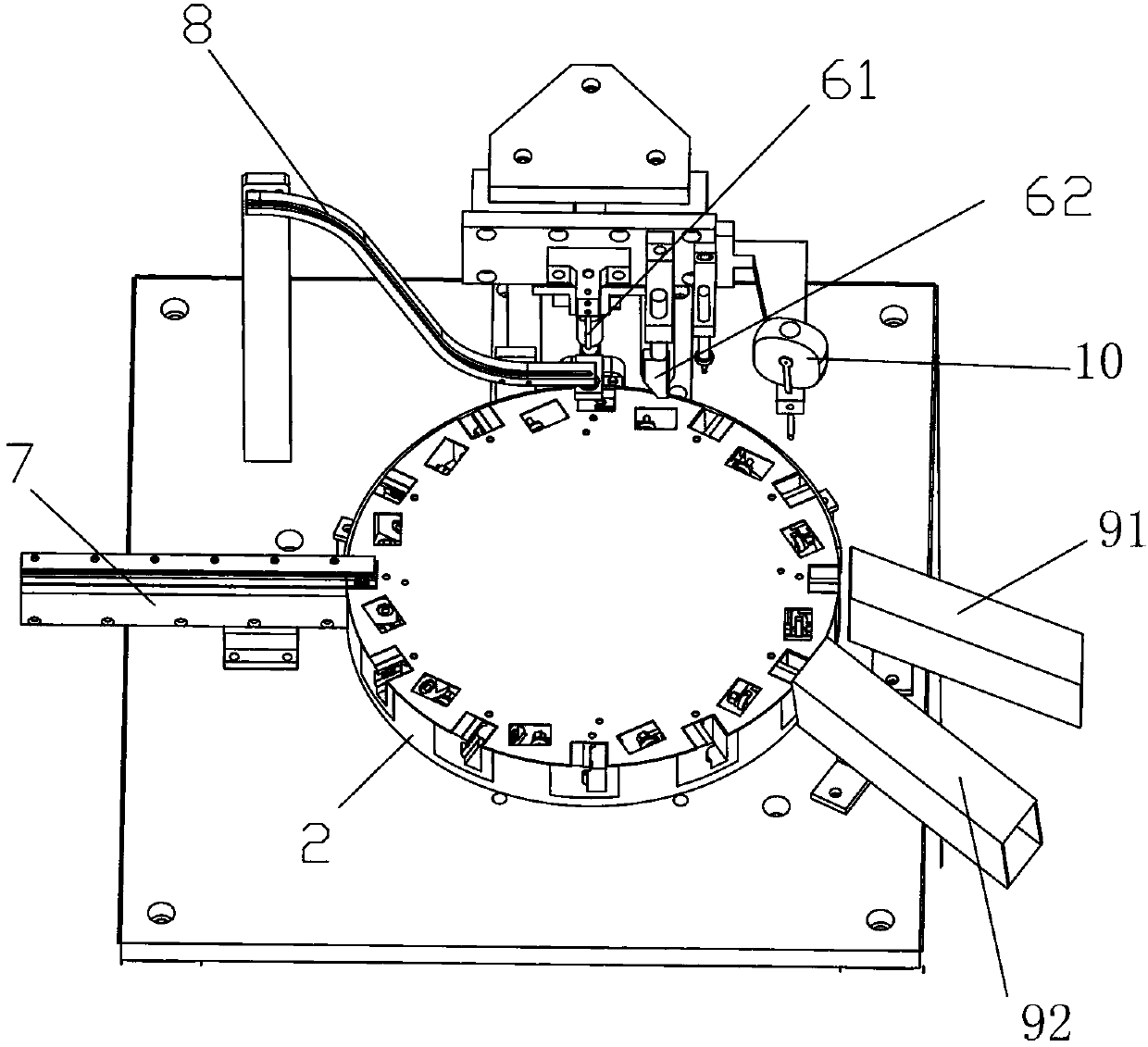

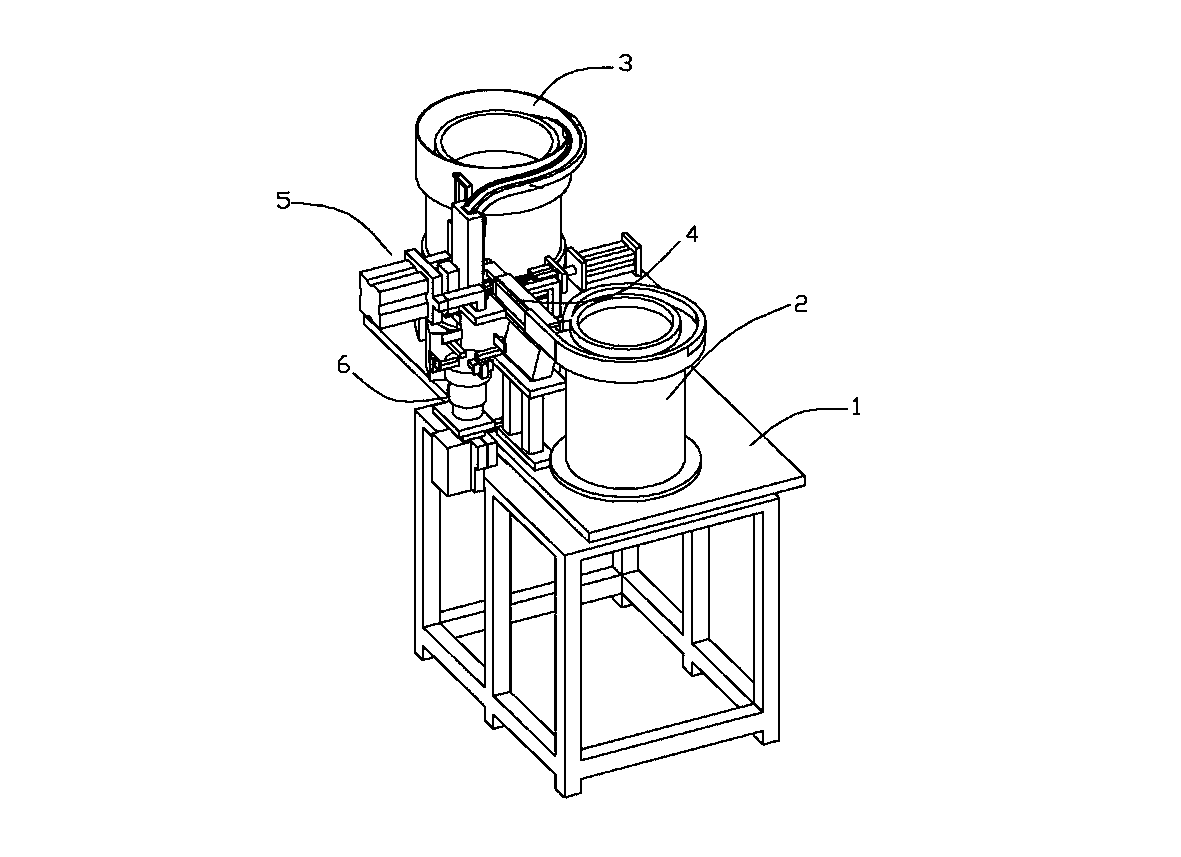

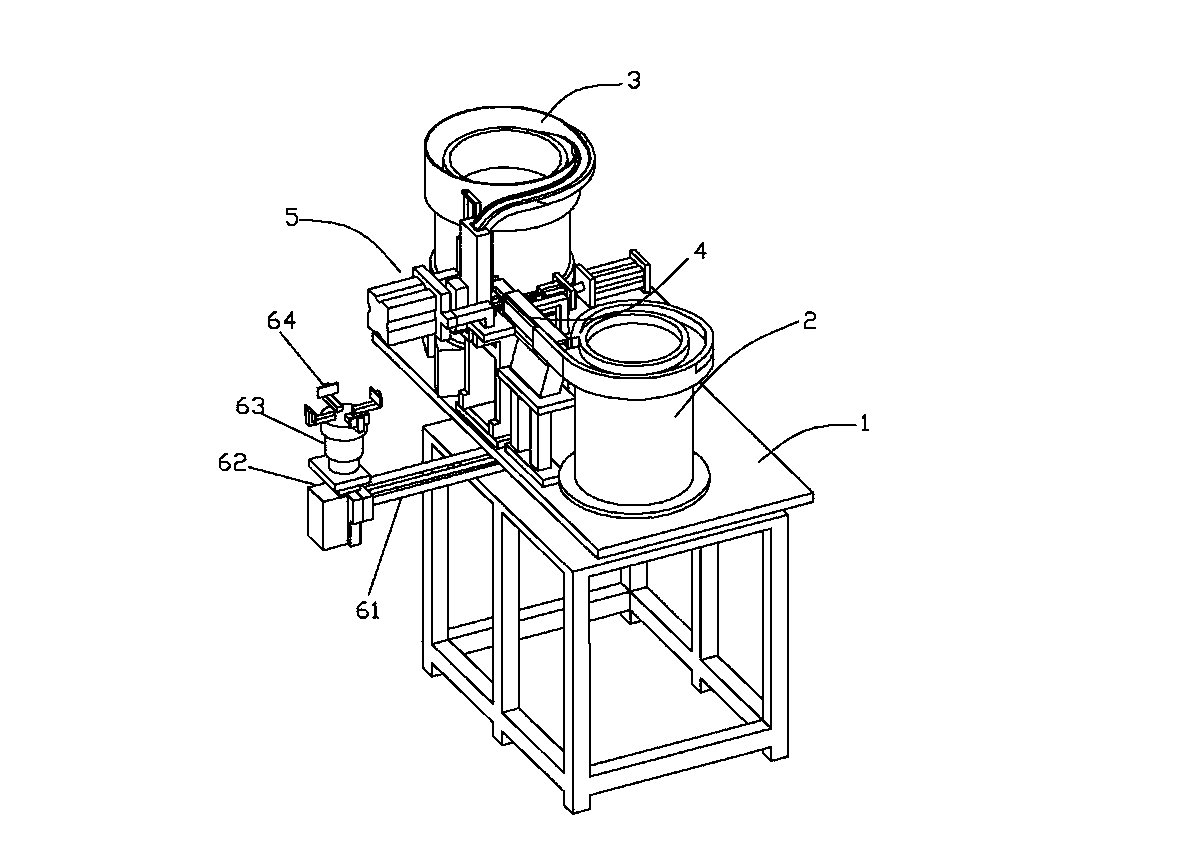

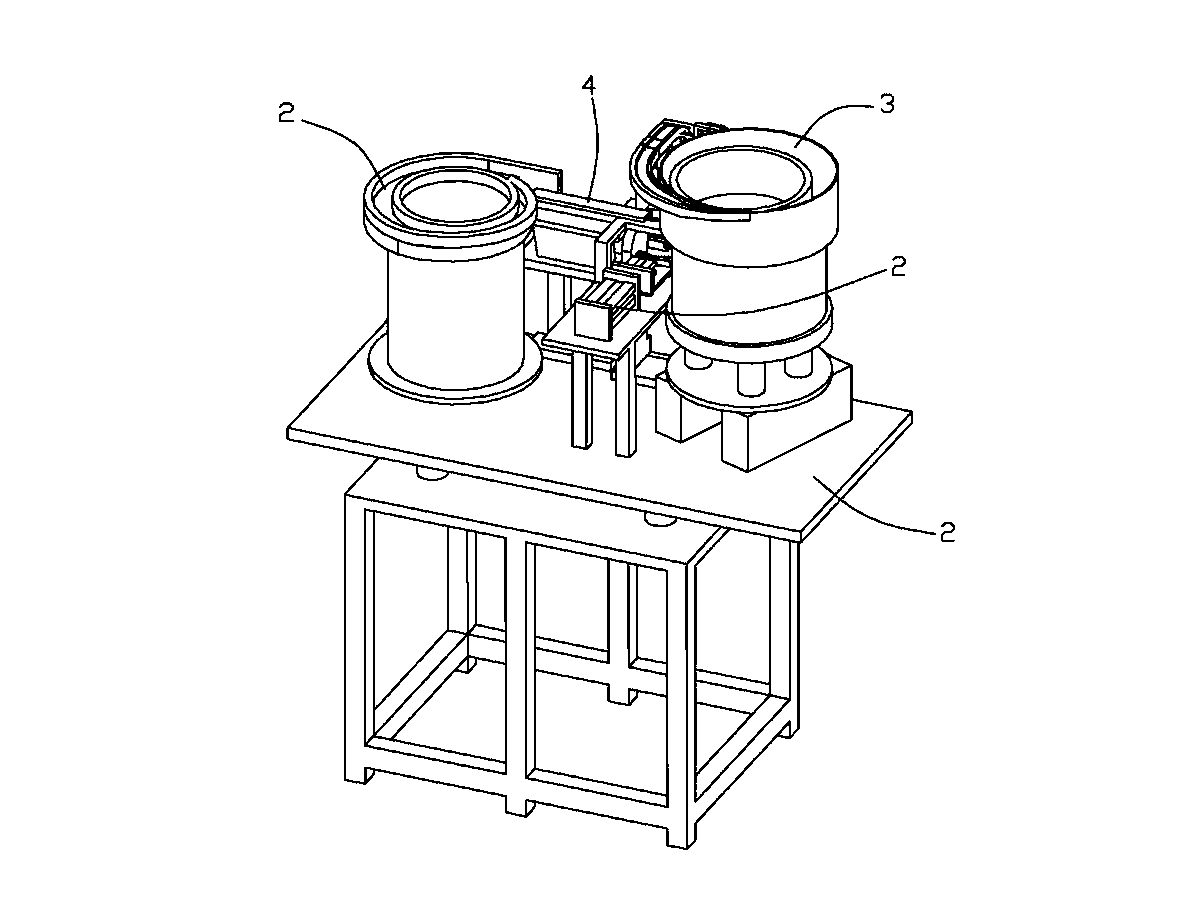

Automatic installation device of switch socket junction box connecting sheet

InactiveCN103269006AFast assemblyCost-effectiveContact member assembly/disassemblyEngineeringJunction box

The invention relates to an automatic installation device of a switch socket junction box connecting sheet. The automatic installation device of the switch socket junction box connecting sheet comprises a rack 1, wherein a vibration disc, a tool mechanism 5 and a junction box pushing mechanism 6 are arranged on the rack 1, the vibration disc comprises a connecting sheet vibration disc 2 and a fastening buckle vibration disc 3, the connecting sheet vibration disc 2 and the fastening buckle vibration disc 3 are communicated with the tool mechanism 5, and the junction box pushing mechanism 6 is arranged below the tool mechanism 5. An ejector block pushed by an air cylinder is matched with a locking block to achieve fixing of the connecting sheet, the installation process of the whole connecting sheet does not need manual operation, labor cost is greatly saved, installation speed is improved, and cost performance of products is improved.

Owner:罗邦君

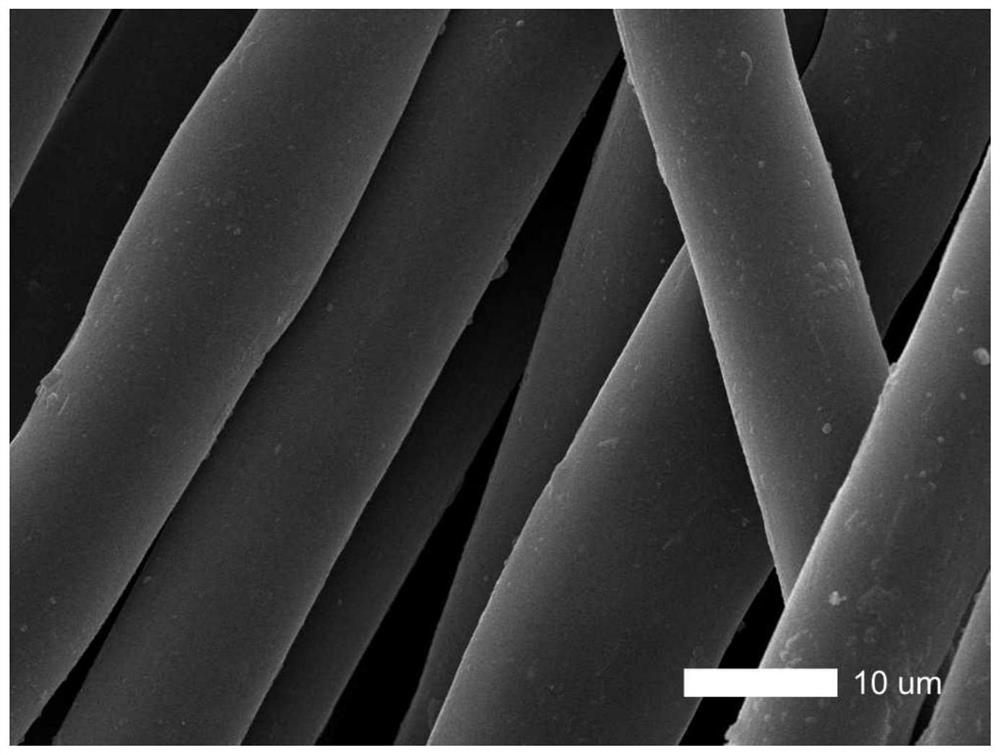

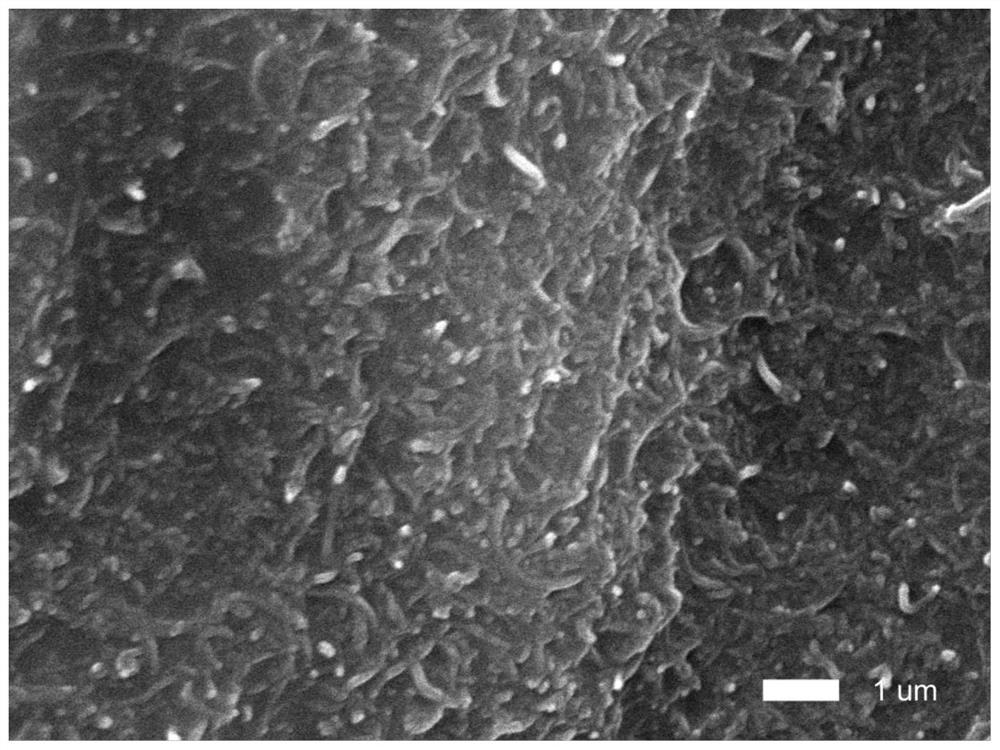

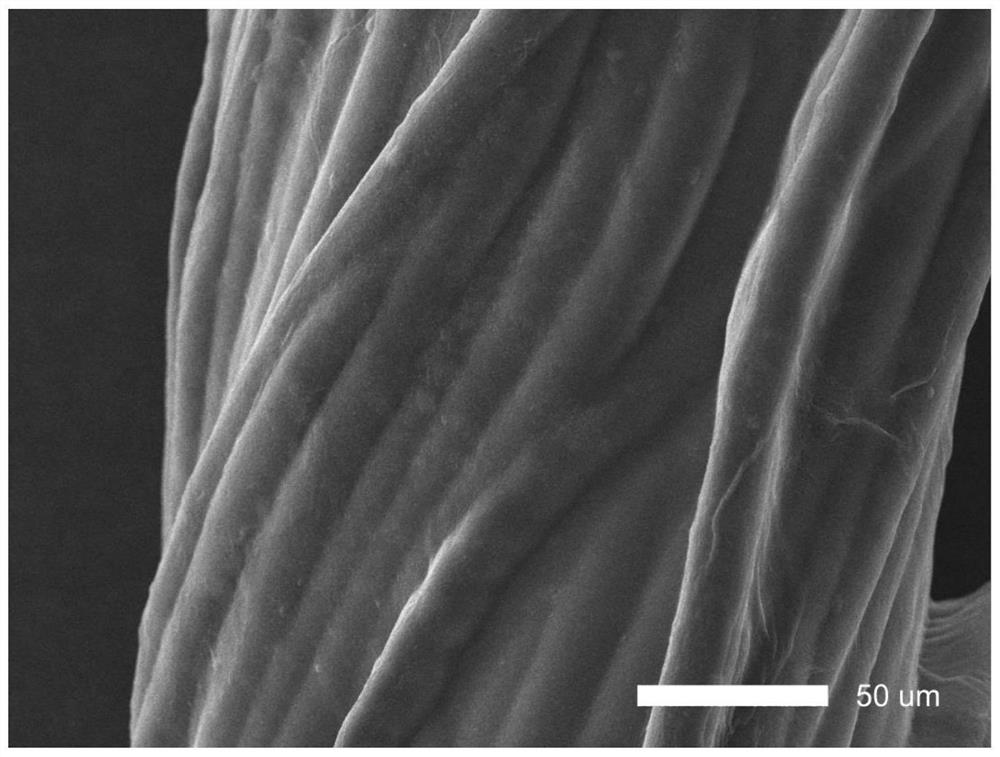

Layer-by-layer self-assembly composite conductive fiber bundle and preparation method thereof

ActiveCN111636195AImprove conductivityHigh specific surface areaPhysical treatmentFiber bundleConductive coating

The invention provides a layer-by-layer self-assembly composite conductive fiber bundle and a preparation method thereof. The method comprises the following steps that firstly, a fiber bundle is subjected to oxygen plasma pretreatment to finish physical modification of fibers, so that the surface of the fiber bundle has a certain active group; and then, through a layer-by-layer self-assembly method, electropositive substances and electronegative substances are alternately deposited on the surface of the fiber bundle through the combination of electrostatic forces of positive charges and negative charges to form a composite conductive coating, in this way, the layer-by-layer self-assembly composite conductive fiber bundle formed by compositing a fiber bundle body and the composite conductive coating deposited on the fiber bundle body is prepared. The preparation method is simple and controllable, and the conductivity of the composite conductive fiber bundle can be regulated and controlled by controlling the self-assembly time, the number of self-assembly layers and the type and concentration of electropositive / electronegative substances; and the conductive coating of the prepared composite conductive fiber bundle is uniform and compact in structure and excellent in conductivity, and can be widely applied to the fields of wearable electronic devices, energy storage, sensing and the like.

Owner:WUHAN TEXTILE UNIV

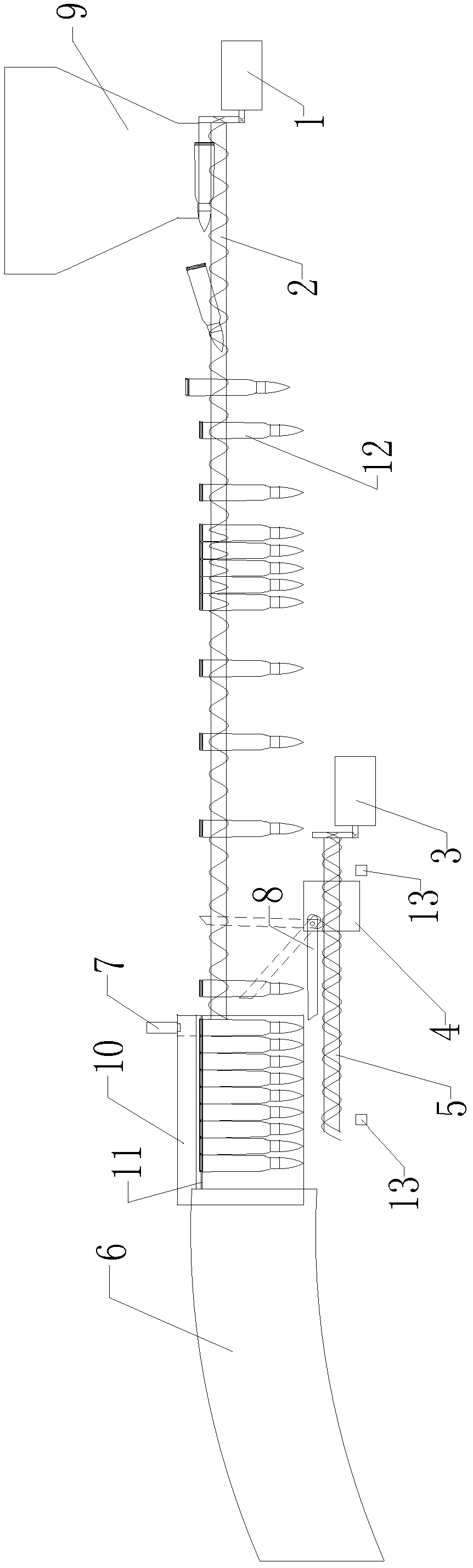

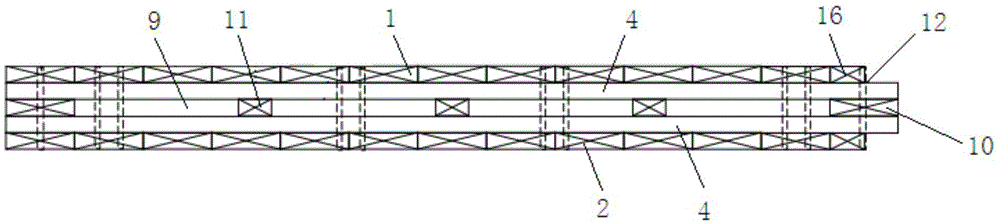

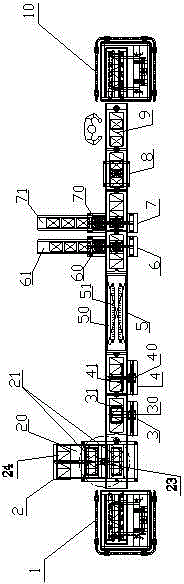

Large-span continuous steel truss multi-point synchronous automatic cyclic alternating sliding shoe push system and construction method thereof

ActiveCN105274942AAutomatically corrects lateral misalignmentSave manual disassembly timeBridge erection/assemblyHydraulic cylinderControl system

The invention discloses a large-span continuous steel truss multi-point synchronous automatic cyclic alternating sliding shoe push system. The system comprises a steel truss assembling platform, push steel launching noses, temporary piers, slideways and a control system. The slideways comprise primary slideways and secondary slideways, and the primary slideways are provided with push sliding shoes capable of vertical height adjustment for installing reaction frames of continuous push jacks of push steel trusses on the front ends of the primary slideways; the two sides of each push sliding shoe are each provided with a push sliding shoe transverse jack, the continuous push jacks, the push sliding shoe transverse jacks and push sliding shoe vertical jacks form a push slip hydraulic jack system, each set of jacks are provided with a pressure sensor and a displacement sensor for detecting pressure of each jack, displacement of each hydraulic cylinder and concrete positions of the push sliding shoes; and control data of the hydro-electric control system on each slideway is fed back to a master control computer in a concentrated mode, and the computer emits control instructions to the hydro-electric control systems so as to realize push construction synchronization. The construction method is fast, safe and reliable.

Owner:LIUZHOU OVM ENG

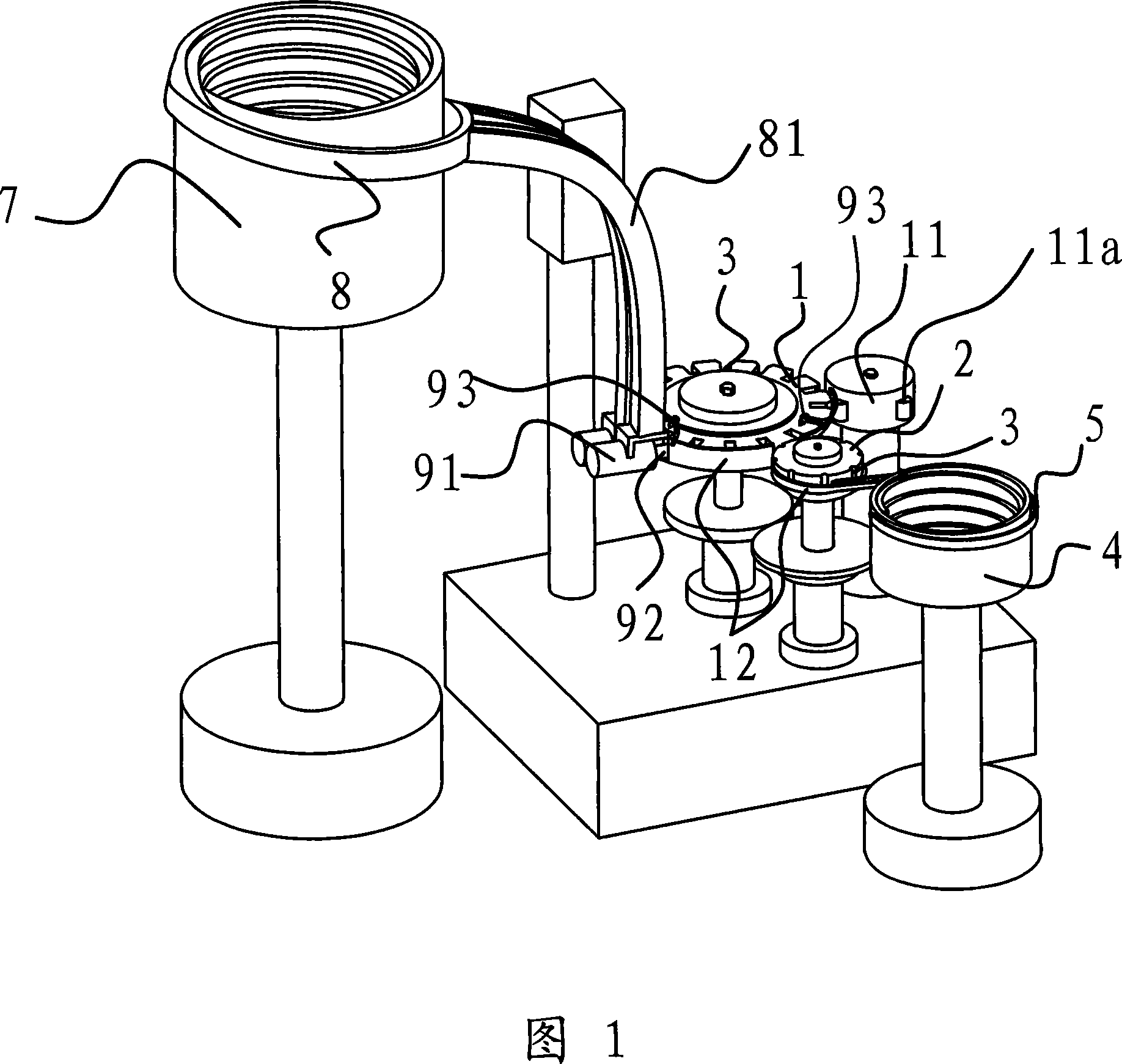

Valve assembling mechanism

The invention discloses a valve assembling mechanism. The mechanism is characterized by comprising a main disc assembling machine frame, wherein the main disc assembling machine frame is provided with a drive device and a transmission device; and the main disc assembling machine frame is also provided with a lower ejector rod turnplate assembly, a cap feed assembly, a valve rod feed assembly, a valve nozzle feed assembly and an upper pilot ejector rod turnplate assembly which are sequentially connected to the transmission shaft of the transmission device from the bottom to the top. The cap, the valve nozzle and the valve rod for assembling the valve can work mechanically and automatically, the assembling speed is high with high efficiency, and the cost is reduced.

Owner:ZHONGSHAN MEIJIESHI PACKAGING PROD

Assembling unit of safety self-destruction syringe assembling machine

InactiveCN1806860AReasonable designSimple structureInfusion syringesIntravenous devicesEngineeringEdge matching

The invention discloses a safety destruct-style injector assembling machine assemble device relating to medical appliance preparing device, which consists of loading rotary table and injection tube rotary table. The invention is characterized by the following: the loading rotary table is contact with injection tube rotary table and needle seat rotary table; the outboard of every slide block installs at least one group of upper coves and lower coves in one-to-one correspondence; the cove of injection tube distributing homogeneously on injection tube rotary table edge matches along with lower cove; the cove of needle seat distributing homogeneously on needle seat edge is corresponding to upper cove; the thimble corresponding to upper cove and lower cove is installed on the upper rotary table of loading rotary table; the bottom of tangential area between loading rotary table and needle seat rotary table; there is an uptilted slant face along with rotating direction of loading rotary table and needle seat rotary table.

Owner:王兴章

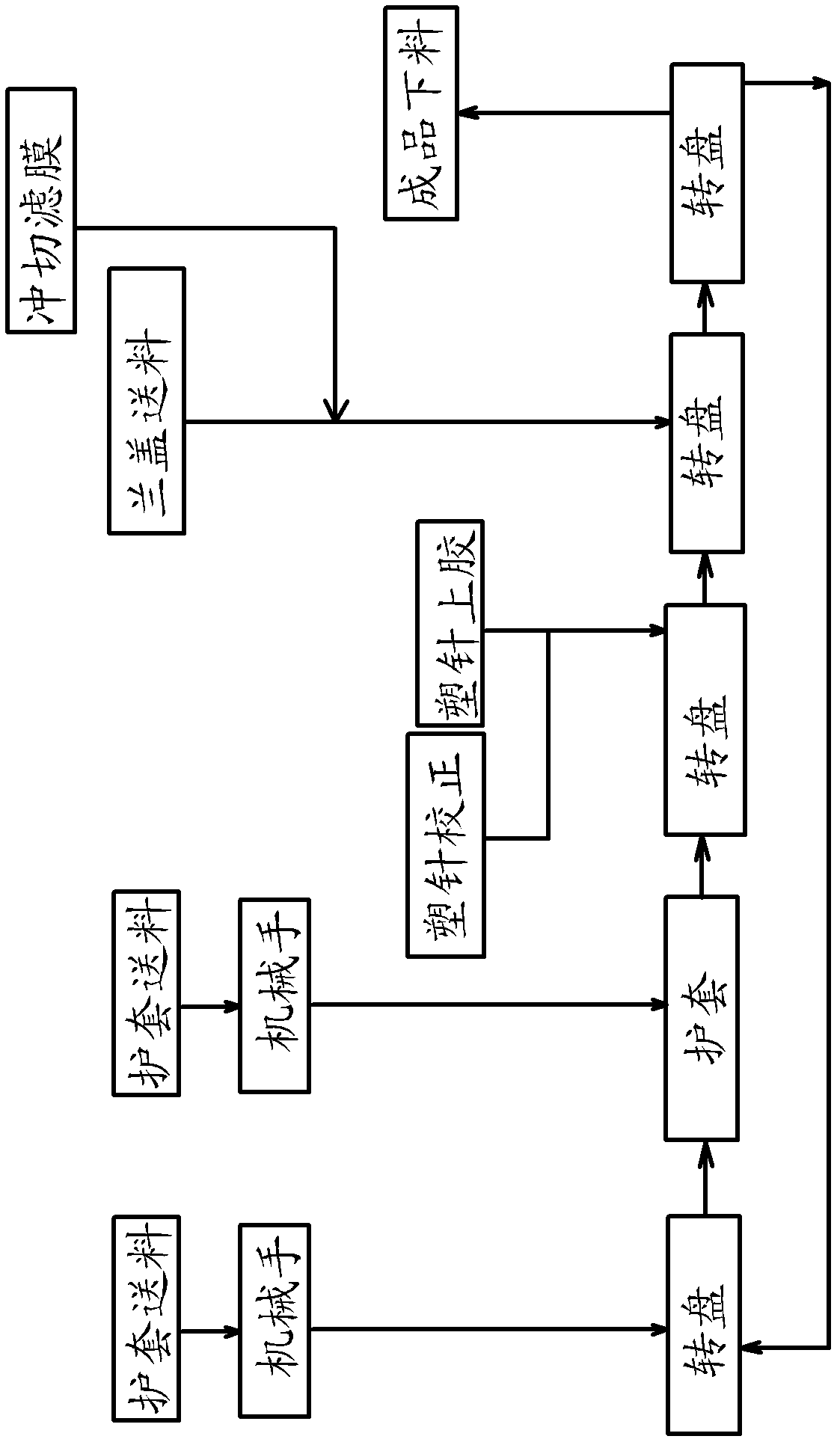

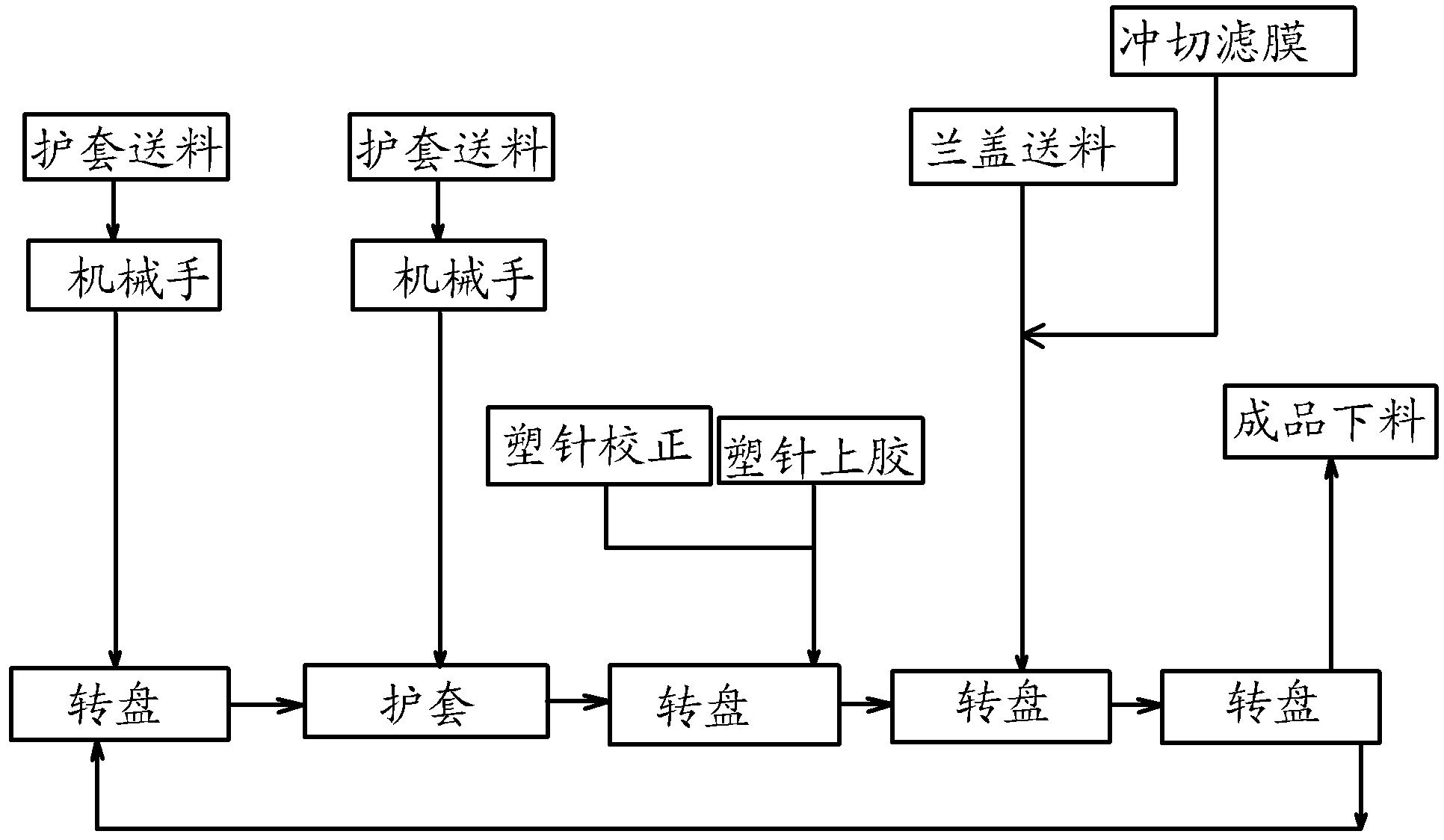

Assembling process of medical plastic needle assembly

The invention provides an assembling process of a medical plastic needle assembly, belonging to an assembling process and solving the problem that the traditional assembling process has complicated flows, low assembling efficiency, high pollution and medical use unavailability. According to the assembling process of the medical plastic needle assembly, a plastic needle comprises a tubular needle body, wherein one end of the need body is used for puncturing a puncturing part of a medicine bottle and the puncturing part is provided with a liquid inlet; the side part of the plastic needle is provided with an air exhaust pipe which is communicated with the liquid inlet, and the opposite end of the puncturing part of the needle body is provided with a liquid outlet. The assembling process comprises the following steps of: conveying a protecting bush, connecting the protecting bush with the plastic needle, coating glue to the liquid inlet, connecting an air filtering membrane, connecting a flange cover and blanking. The assembling process of the medical plastic needle assembly has the advantages of simple process flow, operation smoothness, safety and sanitation, low artificial pollution, high assembling speed, high working efficiency and the like.

Owner:浙江东美智能设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com