Puller shrapnel assembling machine

An assembly machine and shrapnel technology, applied in the direction of sliding fastener components, applications, fasteners, etc., can solve the problems of complex manufacturing process, slow manufacturing speed, many processes and devices, etc., and achieve the effect of simple structure and fast assembly speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

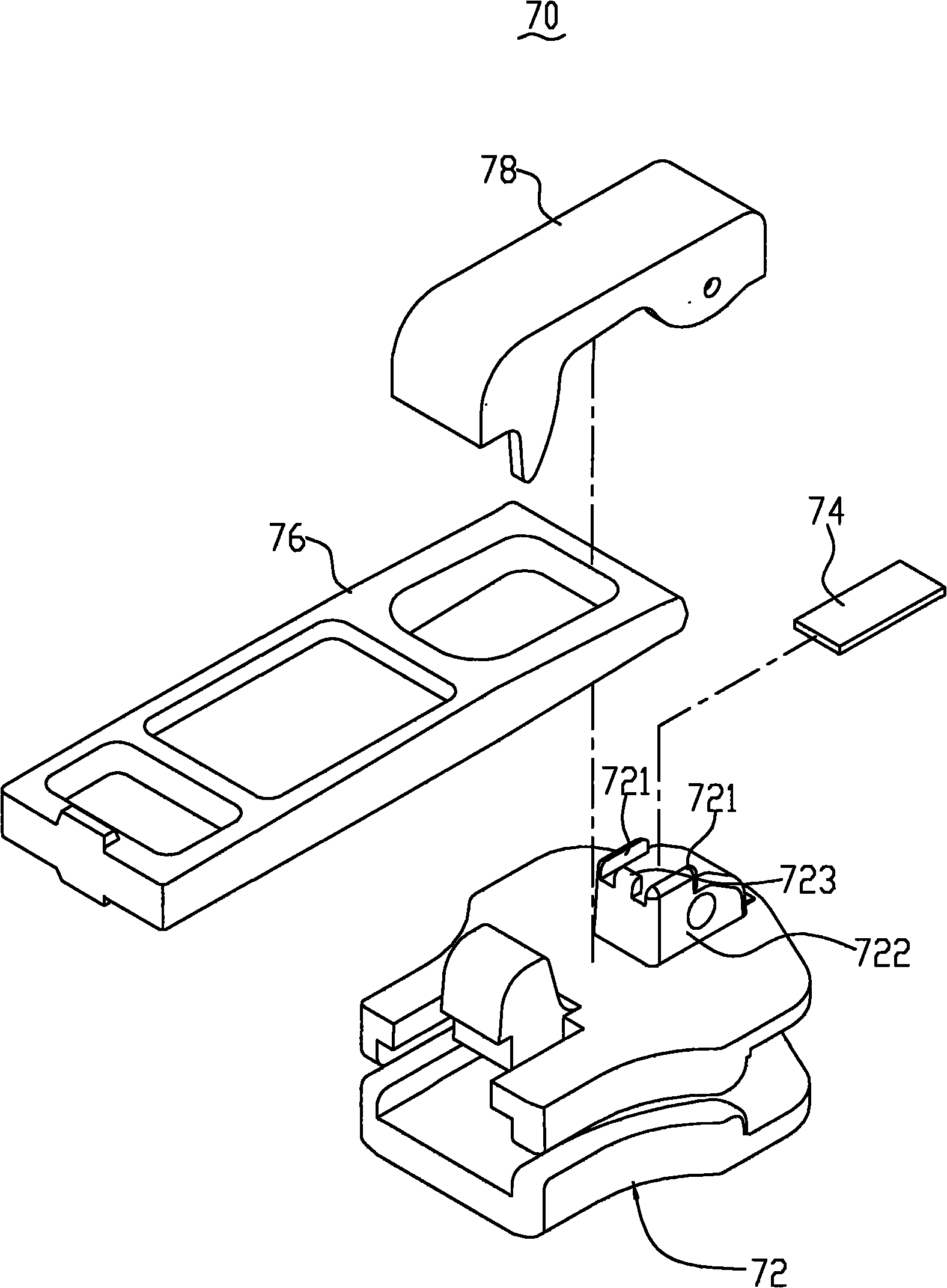

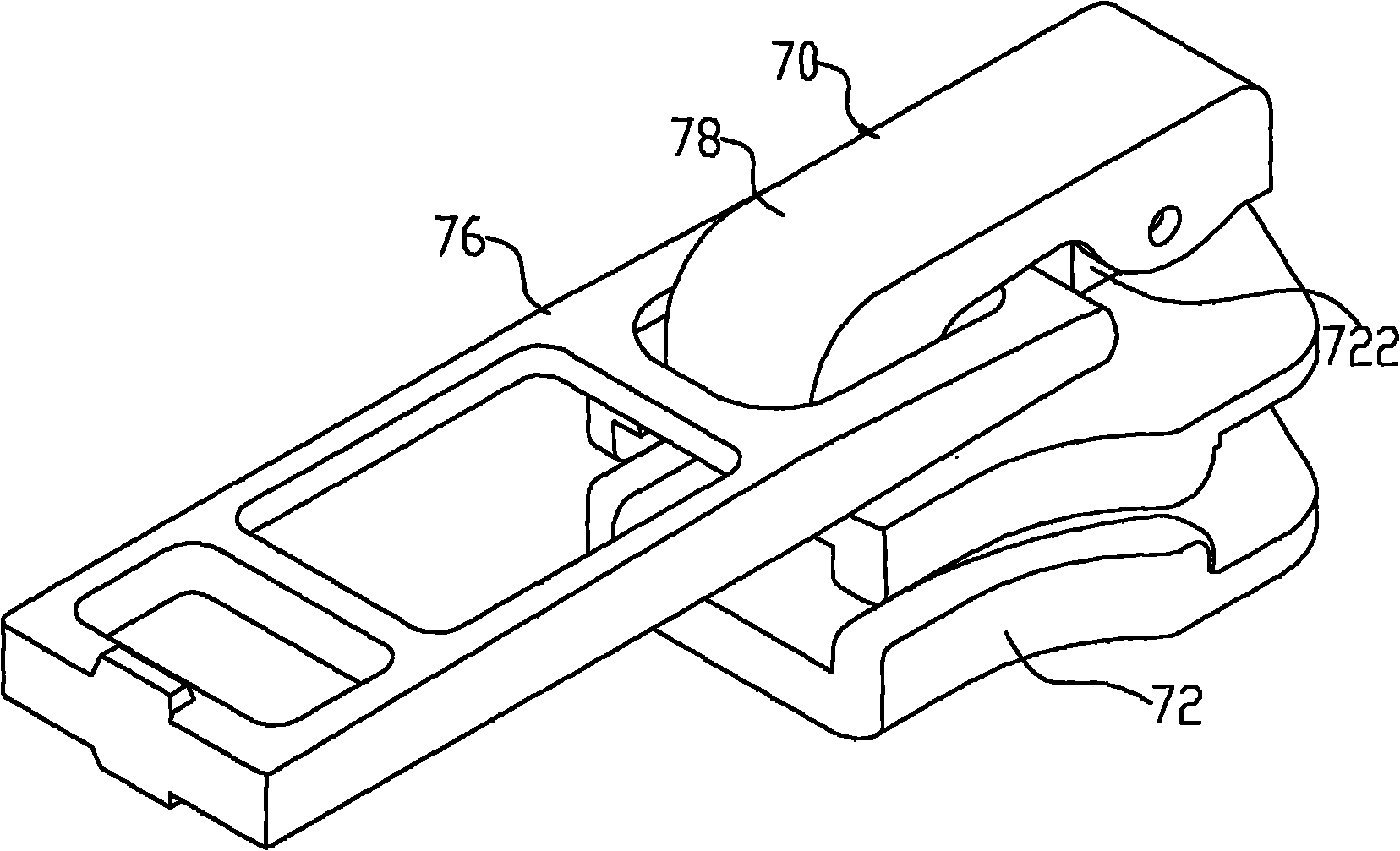

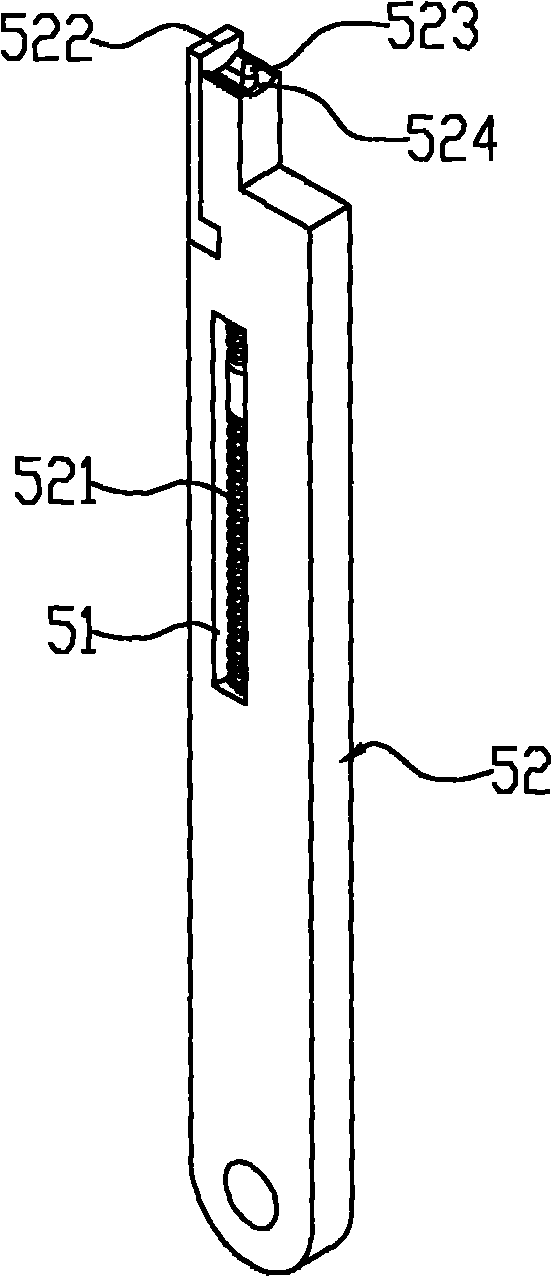

[0050] figure 1 Shown is a three-dimensional exploded view of a new type of slider. The slider 70 includes a slider body 72 , an elastic piece 74 , a pull piece 76 and a cap 78 . The top surface of the slider body 72 is provided with a connecting block 722, and the top surface of the connecting block 722 is provided with two opposite positioning blocks 721 and a resisting block 723, the resisting block 723 is located on one side of the two positioning blocks 721 and It forms a semi-closed structure with the two positioning blocks 721 . The elastic sheet 74 is a strip-shaped sheet structure, and the elastic sheet 74 is made of a metal elastic wire 740 with good elasticity (such as image 3 shown) cut out. The assembly sequence of the slider 70 is as follows: first, one end of the elastic piece 74 is clamped and fixed by the two positioning blocks 721; then, the pull piece 76 is placed on the cap 78, and then the cap 78 is pivoted On the connection block 722, the other end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com