Process and apparatus for assembling infusion unit titrimeter assembly

An assembly process and a technology for assembling devices, which are applied in the direction of instruments introduced into the body, can solve the problems of inability to use the infusion set dripping funnel assembly and the inability to solve the assembly of the infusion set dripping funnel assembly, so as to save manpower, arrange the assembly sequence reasonably, and work efficiently. high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

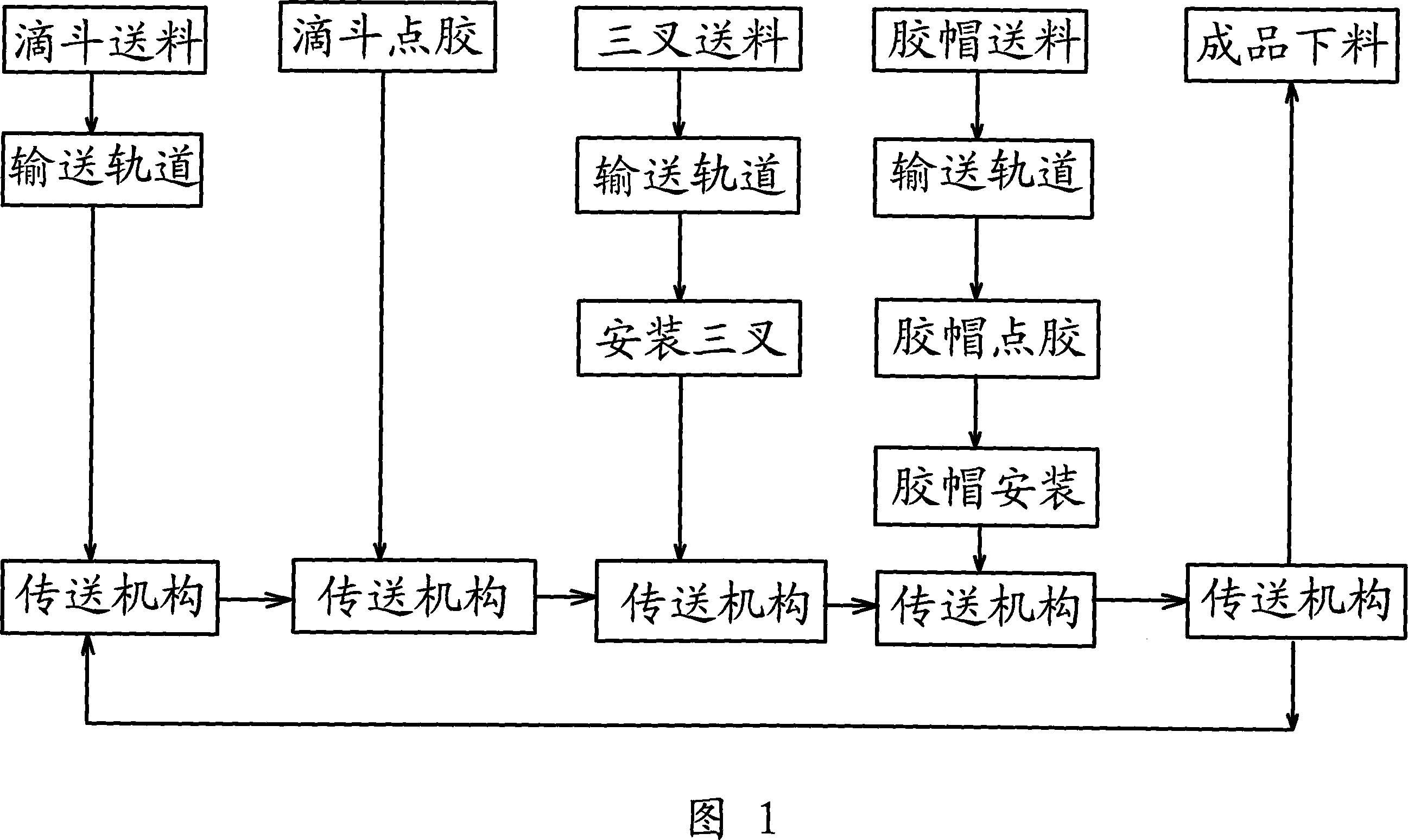

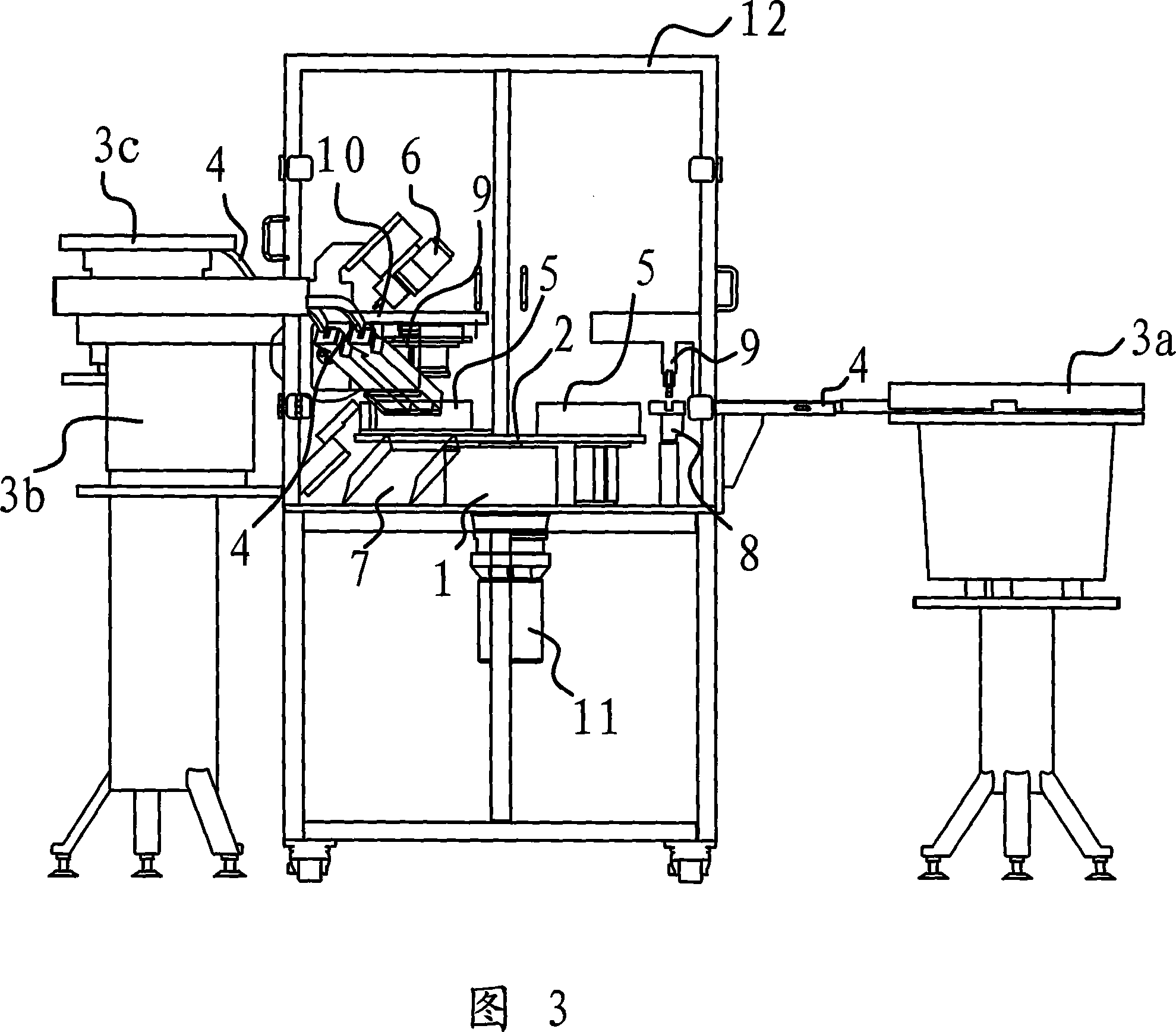

[0033] As shown in Figure 1, the assembly process of the dropping hopper assembly of the infusion set includes the following steps: a. Place the dropping hopper, the trident and the rubber cap in their respective feeders, and each feeder arranges the raw materials placed therein. After that, they are arranged in an orderly manner on the respective conveying tracks 4; b. the dripping funnels on the conveying track 4 are sequentially sent to the conveying mechanism for circular transport, and the dripping funnels are fixed by the clamps 5 to be transported to the next station. During this process, glue is applied on the inner surface of the dripping funnel; c. When the dripping funnel after the glue is applied is sent to the conveying track 4 equipped with tridents, the tridents are sent into the transmission mechanism and inserted into the conveyor belt of the station. On the dripping hopper, the dripping hopper equipped with a three-prong continues to be transmitted on the tran...

Embodiment 2

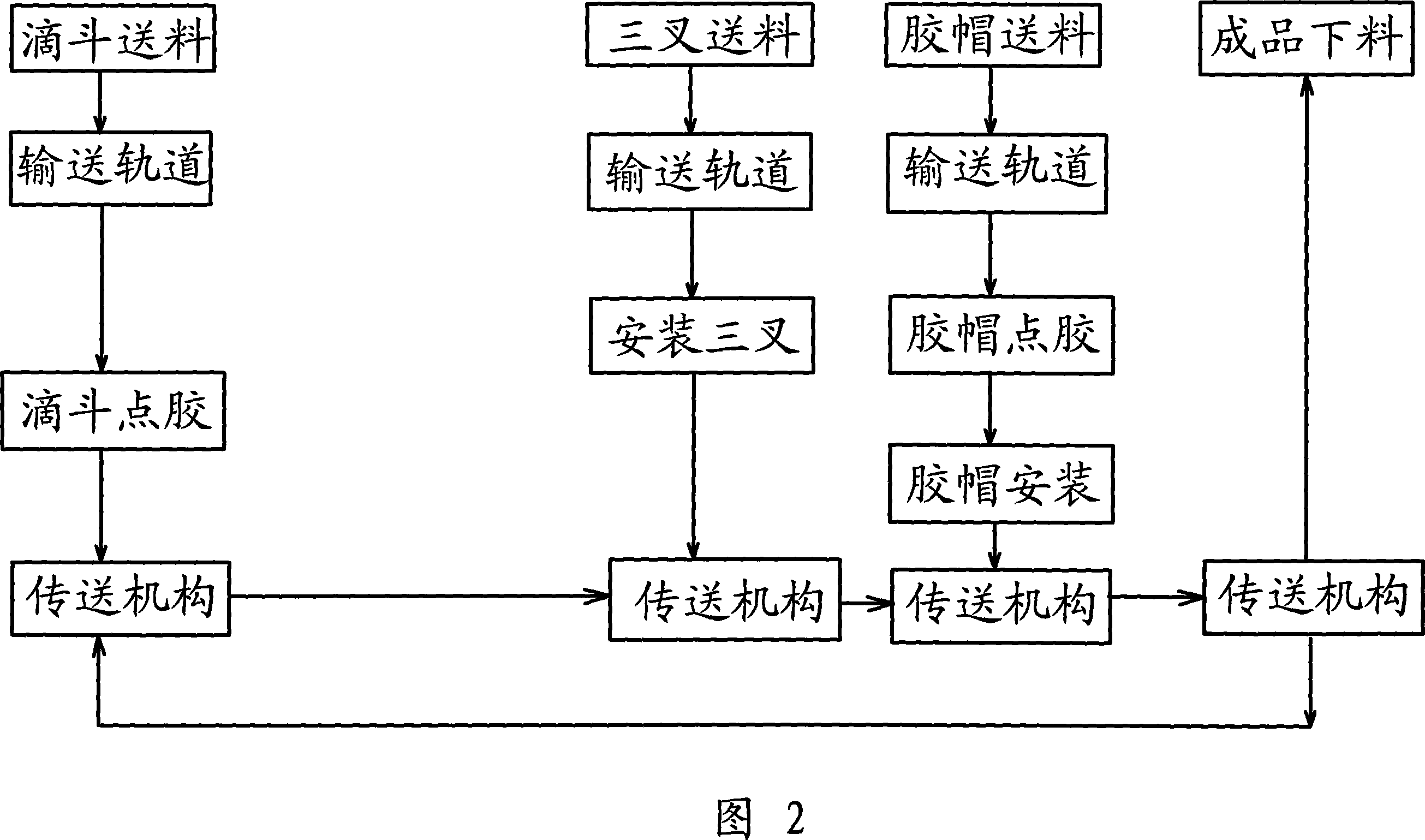

[0043] As shown in Figure 2, in the present embodiment, in step b of the assembly process, when the dropping funnel is transferred from the delivery track 4 to the delivery mechanism, the dispensing mechanism 6 arranged between the delivery track 4 and the delivery mechanism Apply glue evenly on the inner surface of the dropping funnel. Correspondingly, in the assembly device, the dispensing mechanism 6 is arranged between the conveying track 4 and the turntable 2 . The rest are the same as in Example 1, and will not be described in detail herein.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com