Connector terminal automation assembling equipment

A technology of connector terminals and assembly equipment, which is applied in the assembly/disassembly of contacts, manufacturing of contacts, etc., can solve the problems of large consumption of human resources, low production efficiency, and high defective rate of electrical connectors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

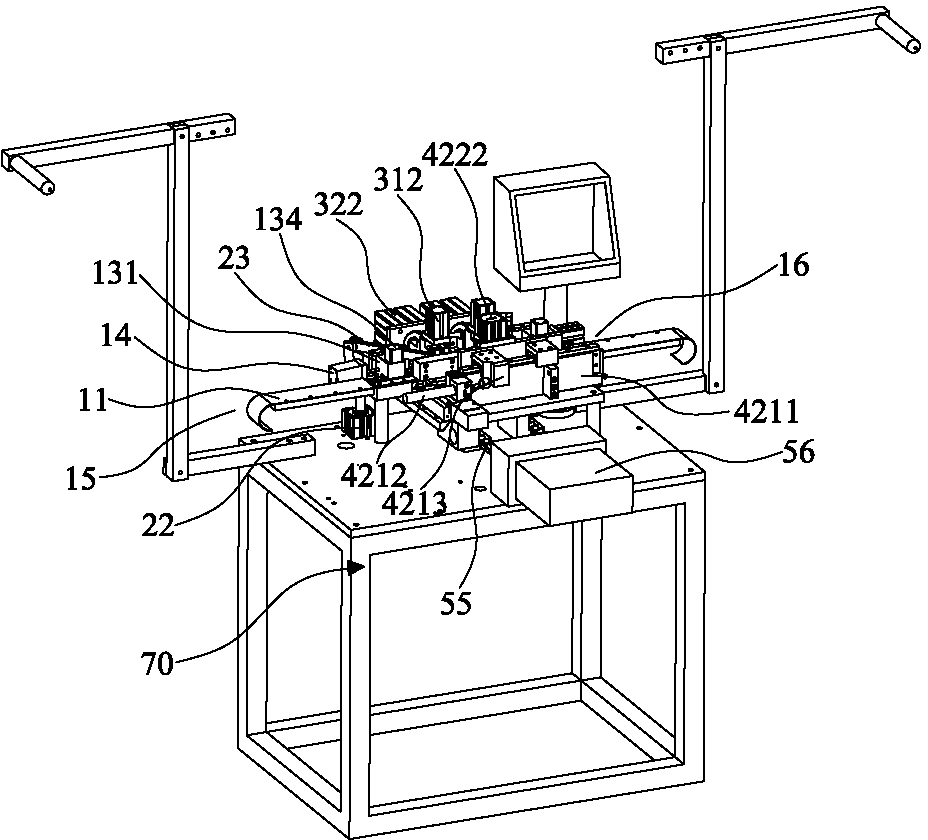

[0072] The present invention as Figure 1 to Figure 15 As shown, an automatic assembly equipment for connector terminals includes a frame 70 and a terminal strip feeding device 10 , a terminal strip cutting device 20 , a terminal inserting device 30 , and a terminal base feeding device 40 arranged on the frame 70 . The terminal strip remaining material removal device 50 and the terminal bending device 60, wherein:

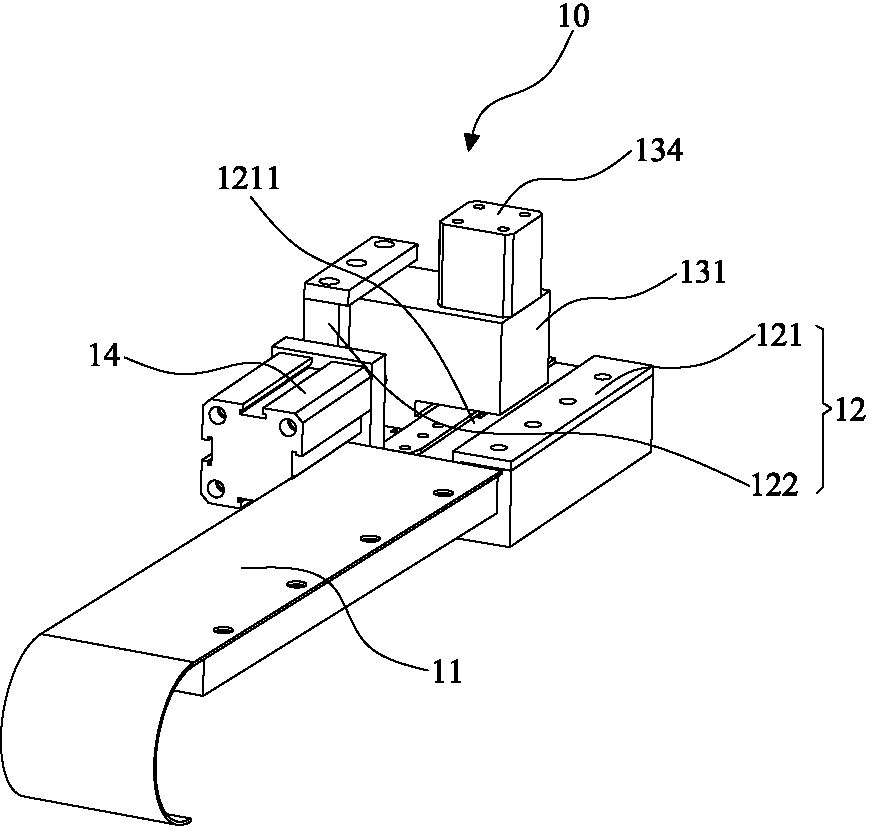

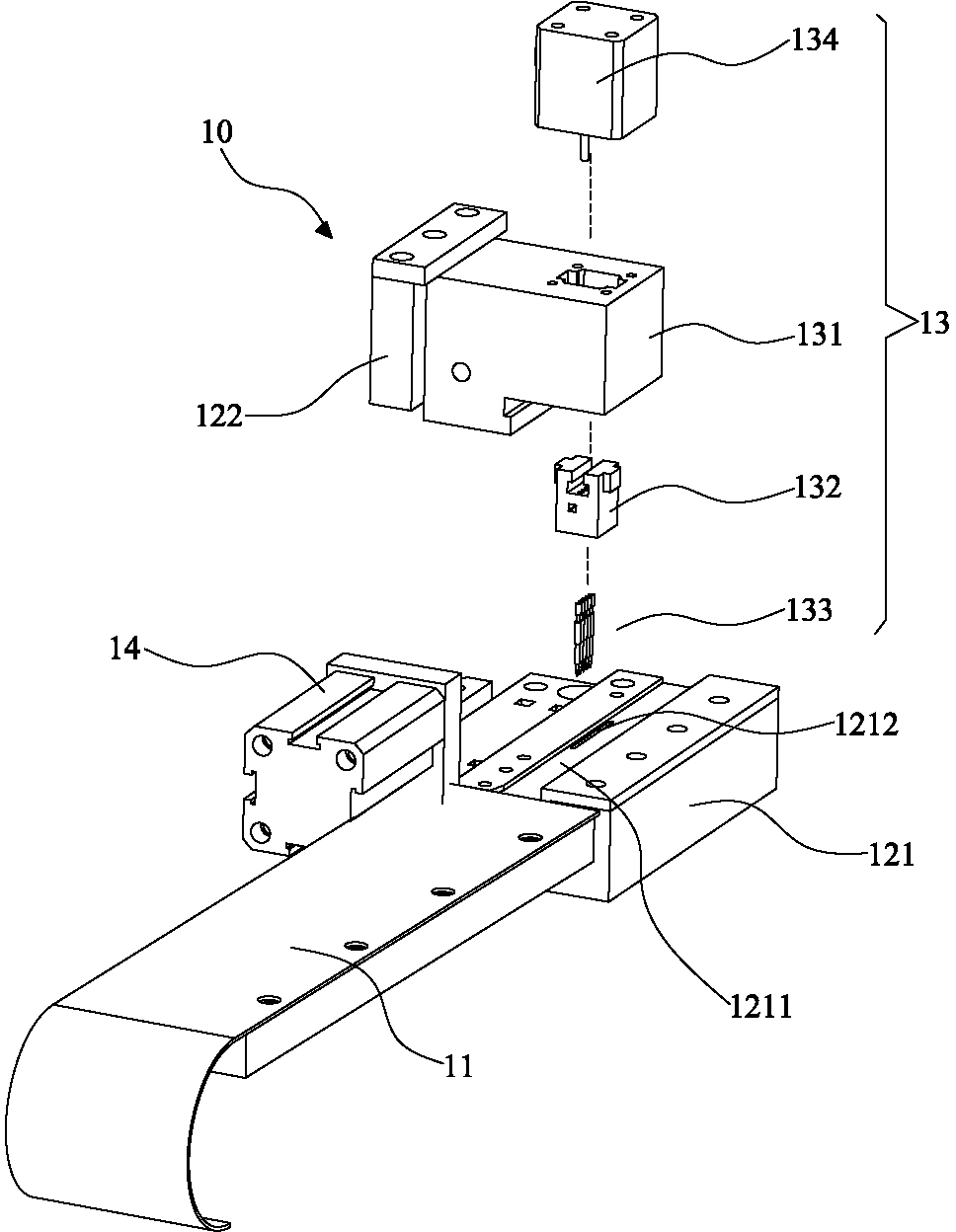

[0073] The terminal strip feeding device 10, such as Figure 1 to Figure 3 As shown, it includes a material guide plate 11, a guide rail mechanism 12, a terminal strip clamping mechanism 13, and a horizontal push cylinder 14. The guide rail mechanism 12 includes a bottom plate 121 and a vertical limit plate 122. The bottom plate 121 is provided with The guide rail 1211 and the slot 1212, the vertical limiting plate 122 is vertically fixed on one side of the guide rail 1211, the terminal strip clamping mechanism 13 includes a sliding seat 131, a push piece 132, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com