Network connector assembly device

A technology for network connectors and assembly equipment, which is applied to the assembly/disassembly of contacts and the manufacture of contacts, etc. It can solve the problems of high labor intensity, low production efficiency, and high probability of safety hazards for operators, and reduce the number of labor and labor. Quantity, improve production efficiency, speed up the effect of assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention is further described in conjunction with the following examples.

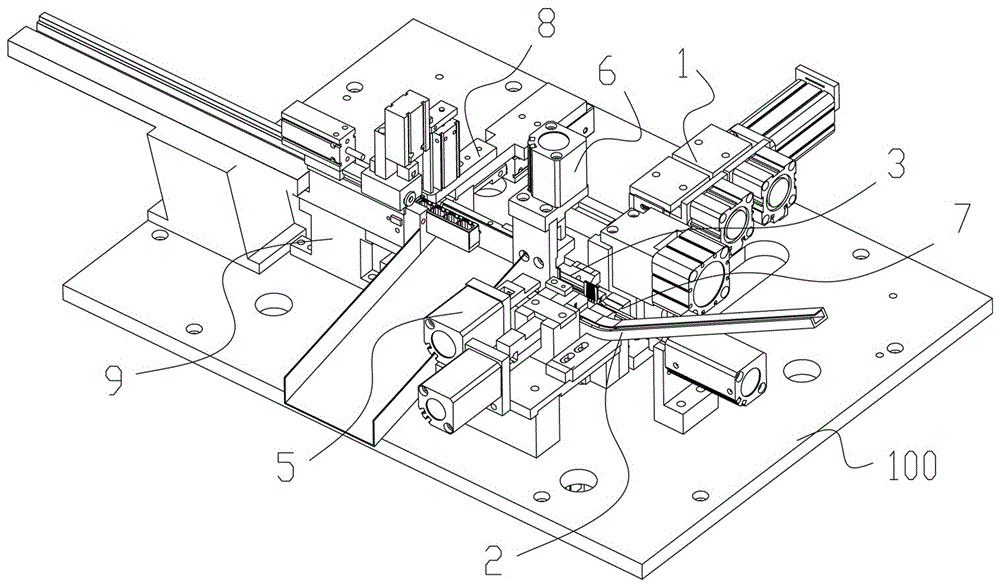

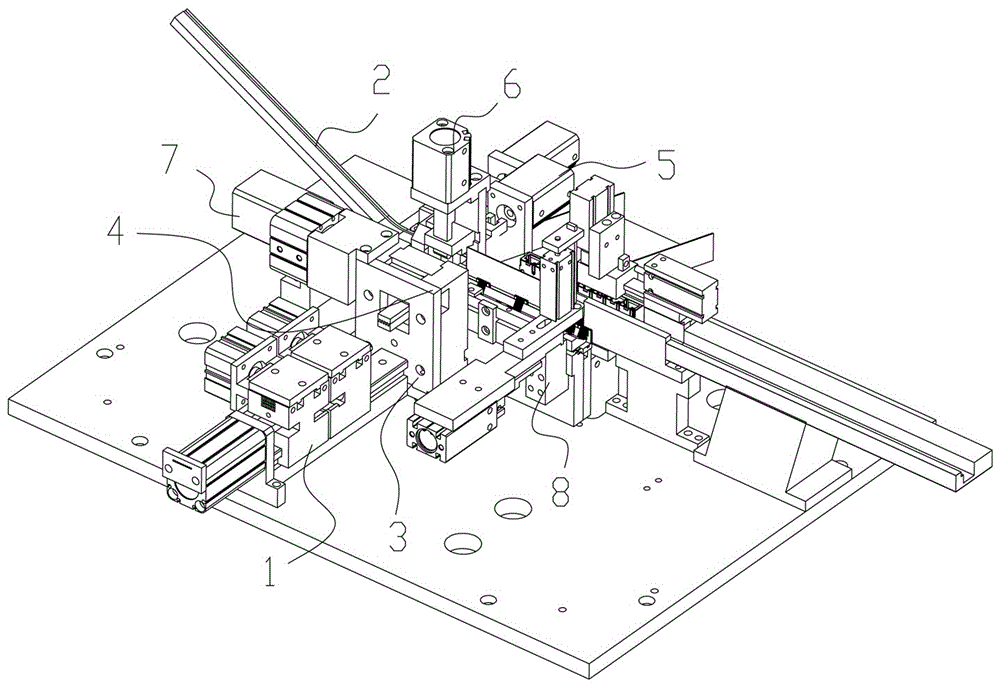

[0042] Such as Figure 1 to Figure 5 As shown, a network connector assembly device described in this embodiment includes a frame 100 and a shell feeding mechanism 2, a gold wire feeding mechanism 1, a gold wire inserting mechanism 3, and a gold wire cutting mechanism arranged on the frame 100. Material mechanism 4, first bending mechanism 5, second bending mechanism 6, shell moving mechanism 7, connector moving mechanism 8, connector detection mechanism and connector blanking mechanism 9;

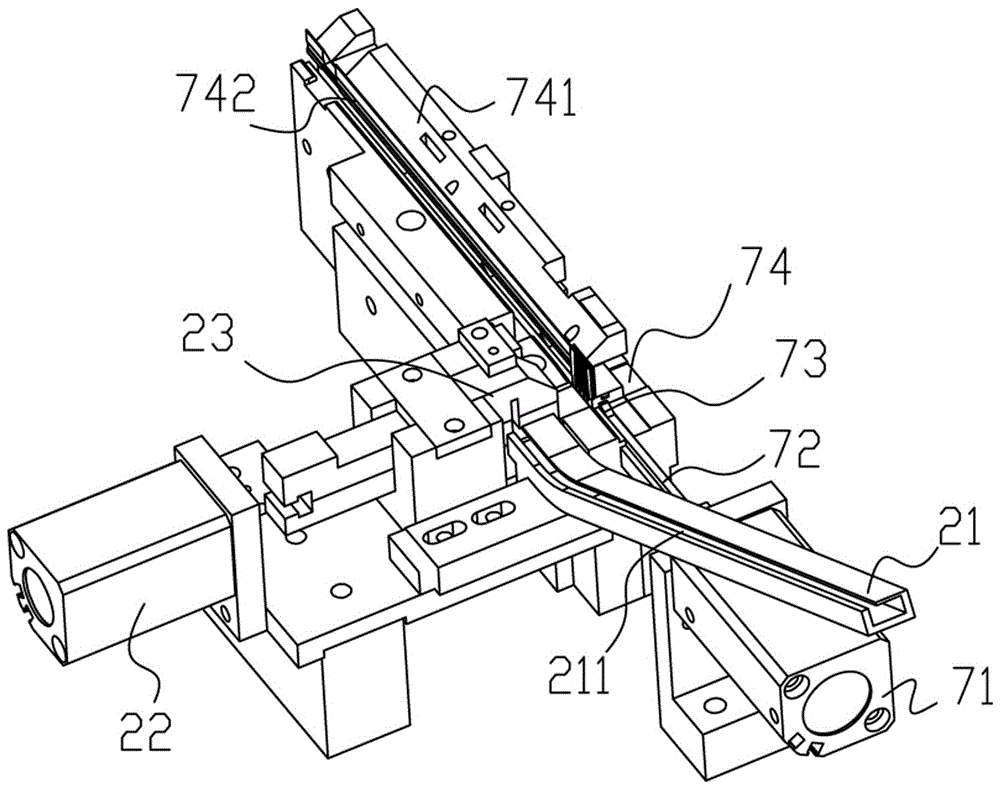

[0043] The housing moving mechanism 7 includes a first cylinder 71, a first push rod 72, a first push block 73 arranged on the first push rod 72, and a fixing plate 74 connected with the first push rod 72; The push rod 72 is connected with the first cylinder 71;

[0044] The shell feeding mechanism 2 includes a guide rail 21, a second cylinder 22, and a second push block 23 for pushing the shel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com