Automation mounting equipment for connector outer shell and rubber core

A technology for assembling equipment and connectors, which is applied to the assembly/disassembly, connection of contacts, circuit/collector components, etc., which can solve problems such as low production efficiency, large consumption of human resources, and high labor intensity of operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

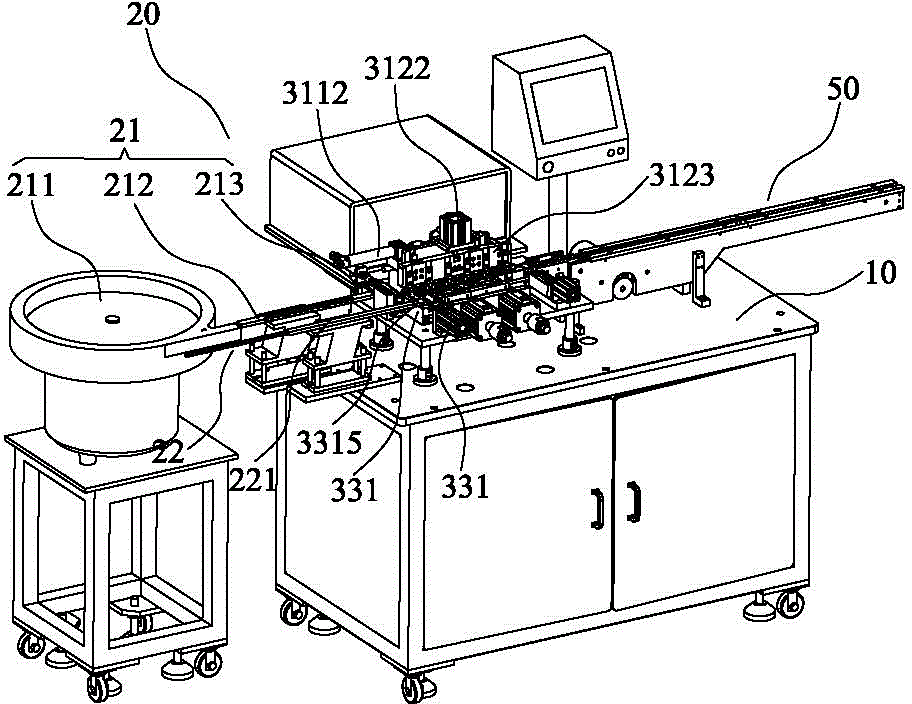

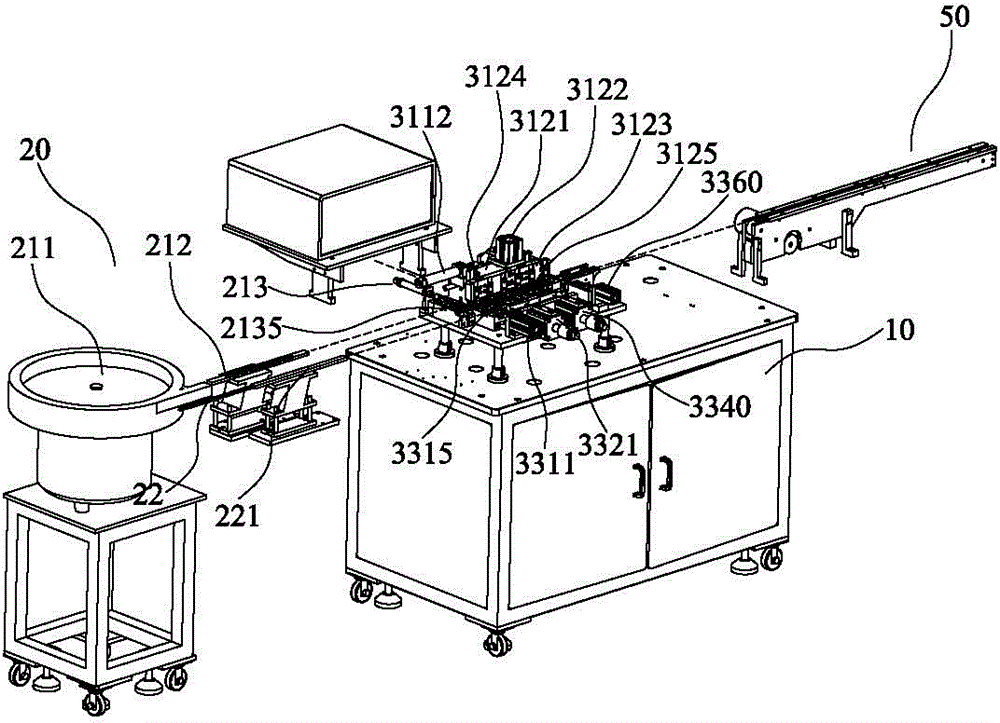

[0072] The present invention as Figure 1 to Figure 14 As shown, a connector shell and rubber core automatic assembly equipment, including a frame 10 and a feeding device 20, a plug assembly device 30, an electrical testing device 40 and a discharging device sequentially arranged on the frame 10 50, of which:

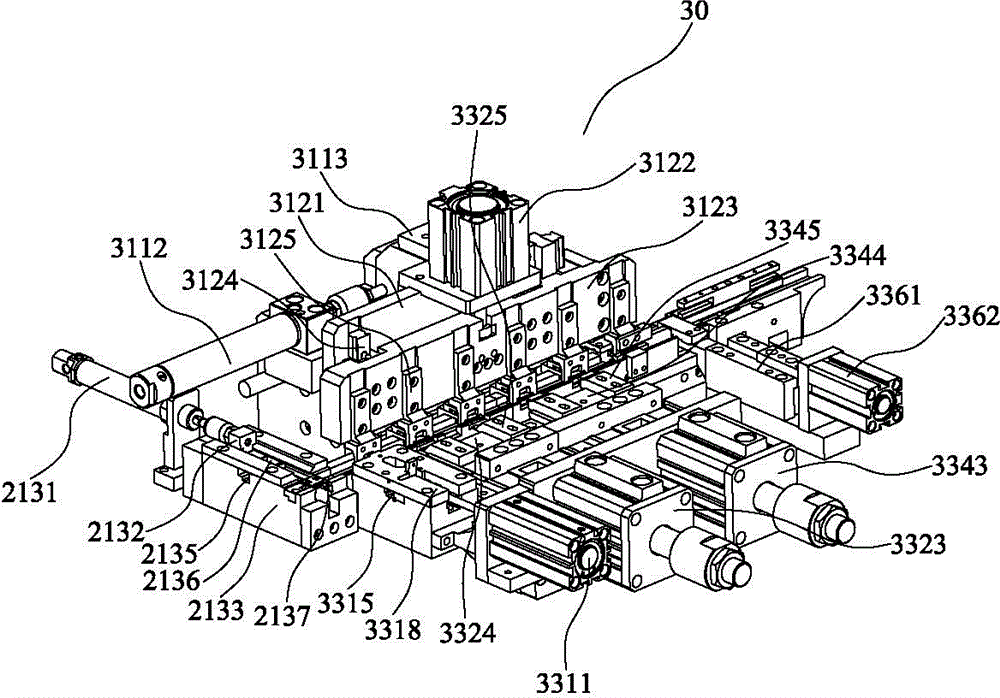

[0073] The feeding device 20 includes a shell conveying mechanism 21 and a rubber core conveying mechanism 22. The shell conveying mechanism 21 includes a vibrating plate 211, a shell conveying belt 212 and a shell pushing assembly 213. One end of the shell conveying belt 212 is connected to the discharge of the vibrating plate 211 The housing pushing assembly 213 includes a housing pushing cylinder 2131, a housing resisting member 2132 and a housing sliding seat 2133. The housing sliding seat 2133 is provided with a housing slideway 2134 for the housing to move. The side wall is provided with a casing inlet 2135 for the casing to enter, and the casing inlet 2135 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com