An automatic assembly machine for horn connectors

A technology of horn connectors and automatic assembly machines, applied in the assembly/disassembly of contacts, etc., can solve the problems of high probability of safety hazards, low production efficiency, and high labor intensity of operators, so as to reduce production costs and improve production efficiency , The effect of reducing the number of labor and the amount of labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

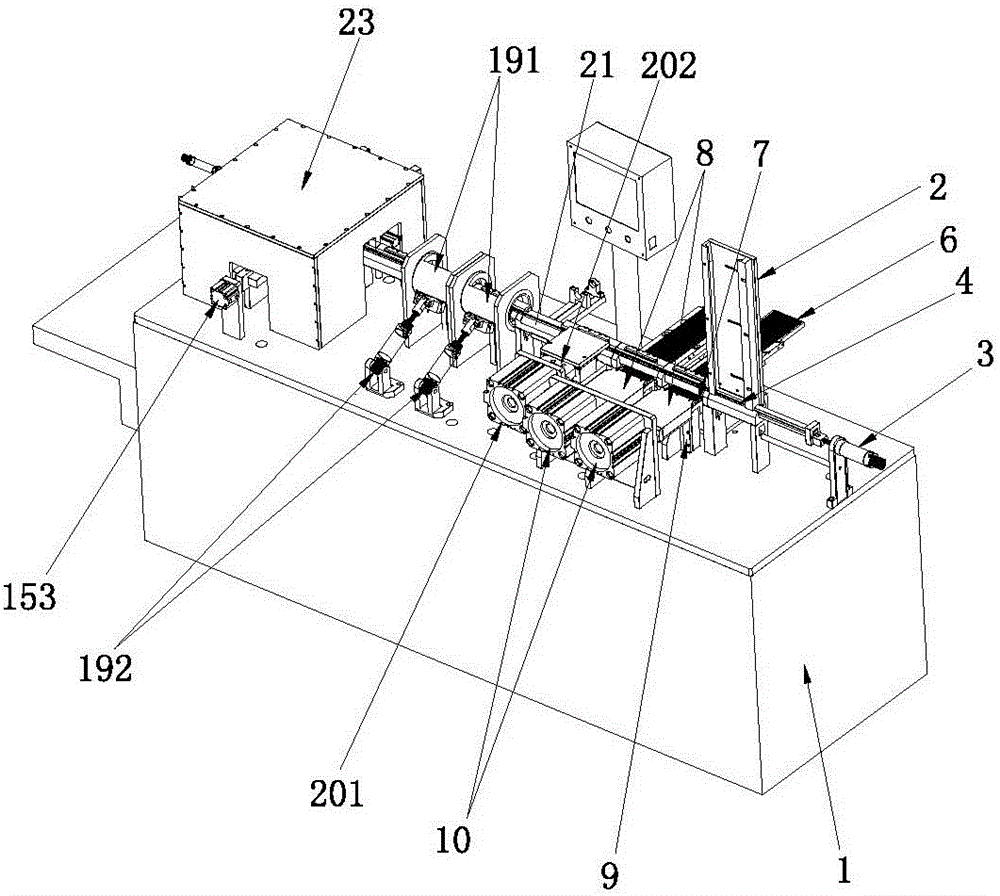

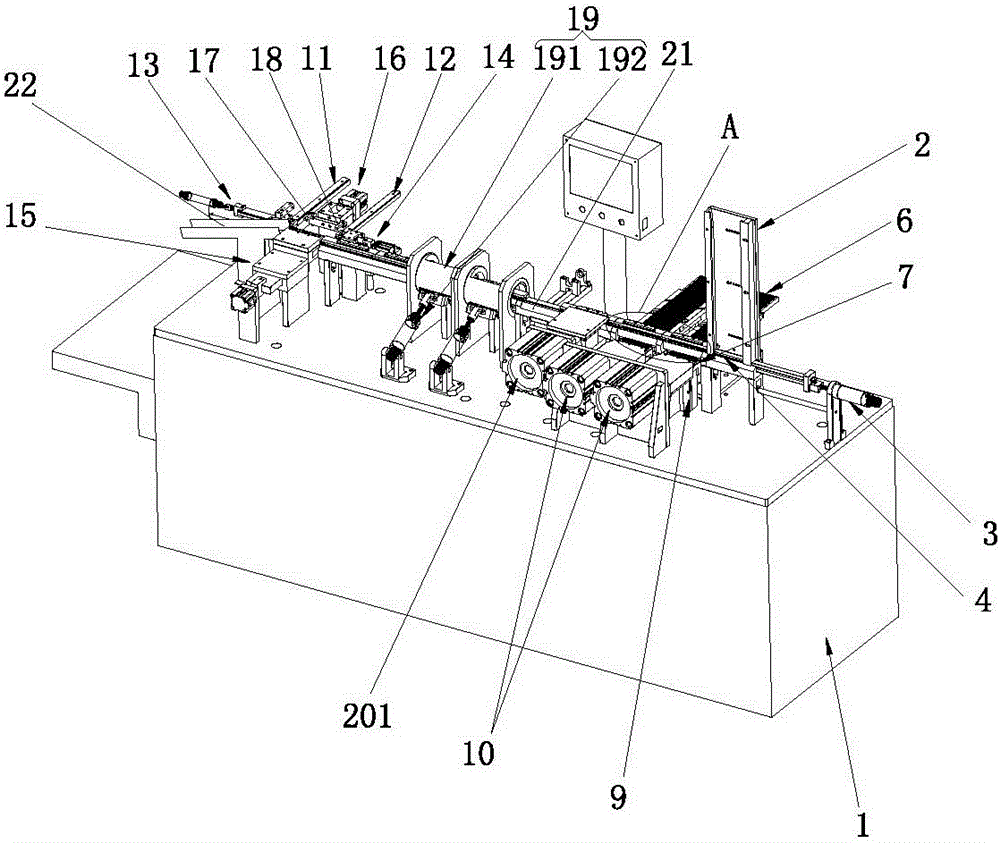

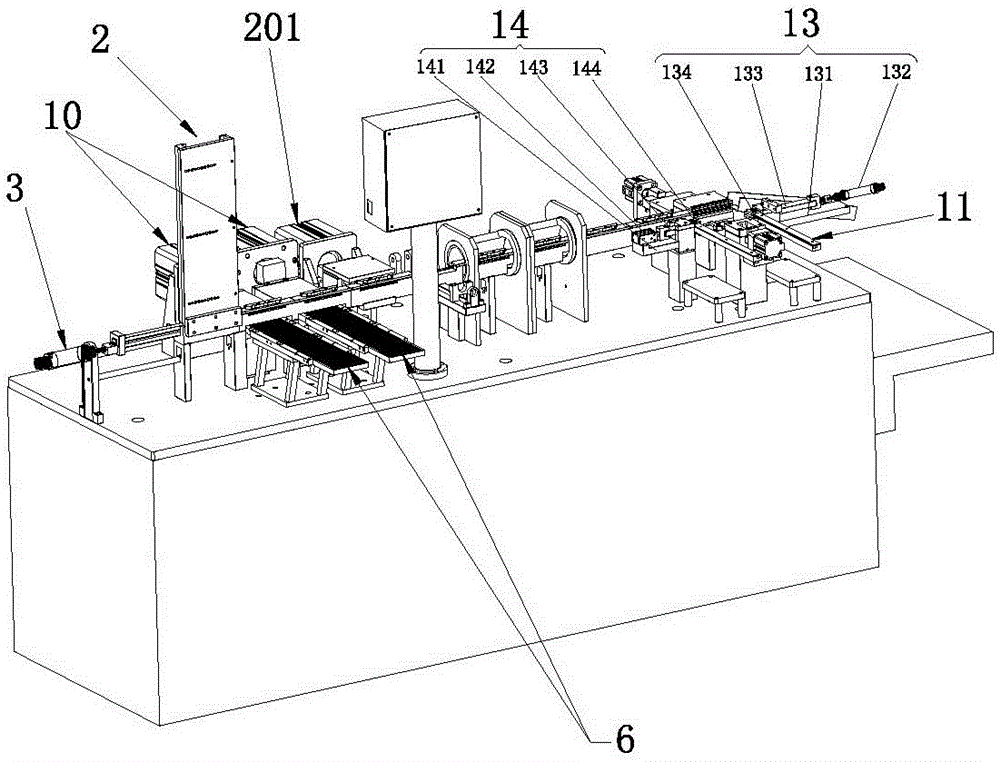

[0046] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention. see Figure 1 to Figure 9 , the present invention will be described in detail below in conjunction with the accompanying drawings, wherein the orientations described in this embodiment are all in the form of Figure 4 direction as a reference.

[0047] The horn connector described in the present invention includes a plastic rubber core and ear buckles arranged at both ends of the plastic rubber core. The two ends of the plastic rubber core are provided with hinged round holes, and the ear buckle is provided with a hinged buckle. The hinged buckle is shaped like a hinged circle. The hole matches the oval shape, and the earbud is hinged with the hinged round hole through the hinged buckle. In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com