Automatic laminating machine

A laminating machine and automatic technology, applied in container manufacturing machinery, paper/cardboard containers, box making operations, etc., can solve the problems of slow manual assembly speed, high production cost and labor cost, and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

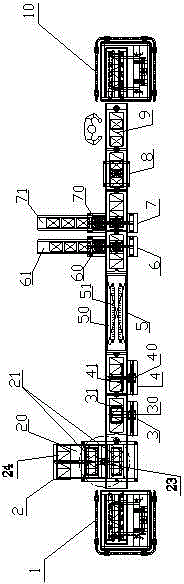

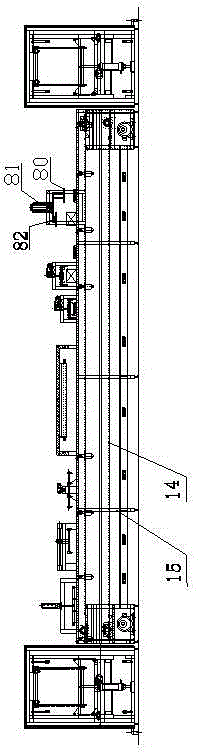

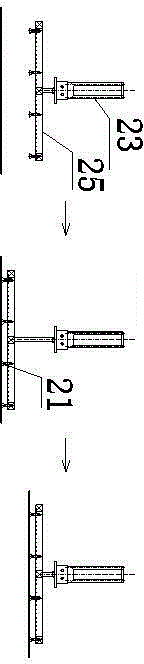

[0018] In this example, refer to Figure 1 to Figure 4 As shown, an automatic laminating machine includes a frame 15 and a conveyor belt 14 arranged on the frame. 4. Glue pre-drying device 5, small inner box sticking device 6, large inner box sticking device 7, pneumatic pressing device 8 and finished product receiving place 9, the automatic laminating machine is also equipped with a device for controlling the reclaiming device 2, The PLC control system (not shown) of the horizontal gluing device 3, the longitudinal gluing device 4, the glue pre-drying device 5, the small inner box sticking device 6, the large inner box sticking device 7 and the pneumatic pressing device 8; The retrieving device 2 includes a leather shell hopper 24, an automatic material distribution cylinder (not shown), a loading platform 20 and an extension swing cylinder 23, the automatic material distribution cylinder is connected to the leather shell hopper 24, and the loading platform 20 is arranged on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com