Patents

Literature

2020 results about "Pneumatic motor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A pneumatic motor (air motor) or compressed air engine is a type of motor which does mechanical work by expanding compressed air. Pneumatic motors generally convert the compressed air energy to mechanical work through either linear or rotary motion. Linear motion can come from either a diaphragm or piston actuator, while rotary motion is supplied by either a vane type air motor, piston air motor, air turbine or gear type motor.

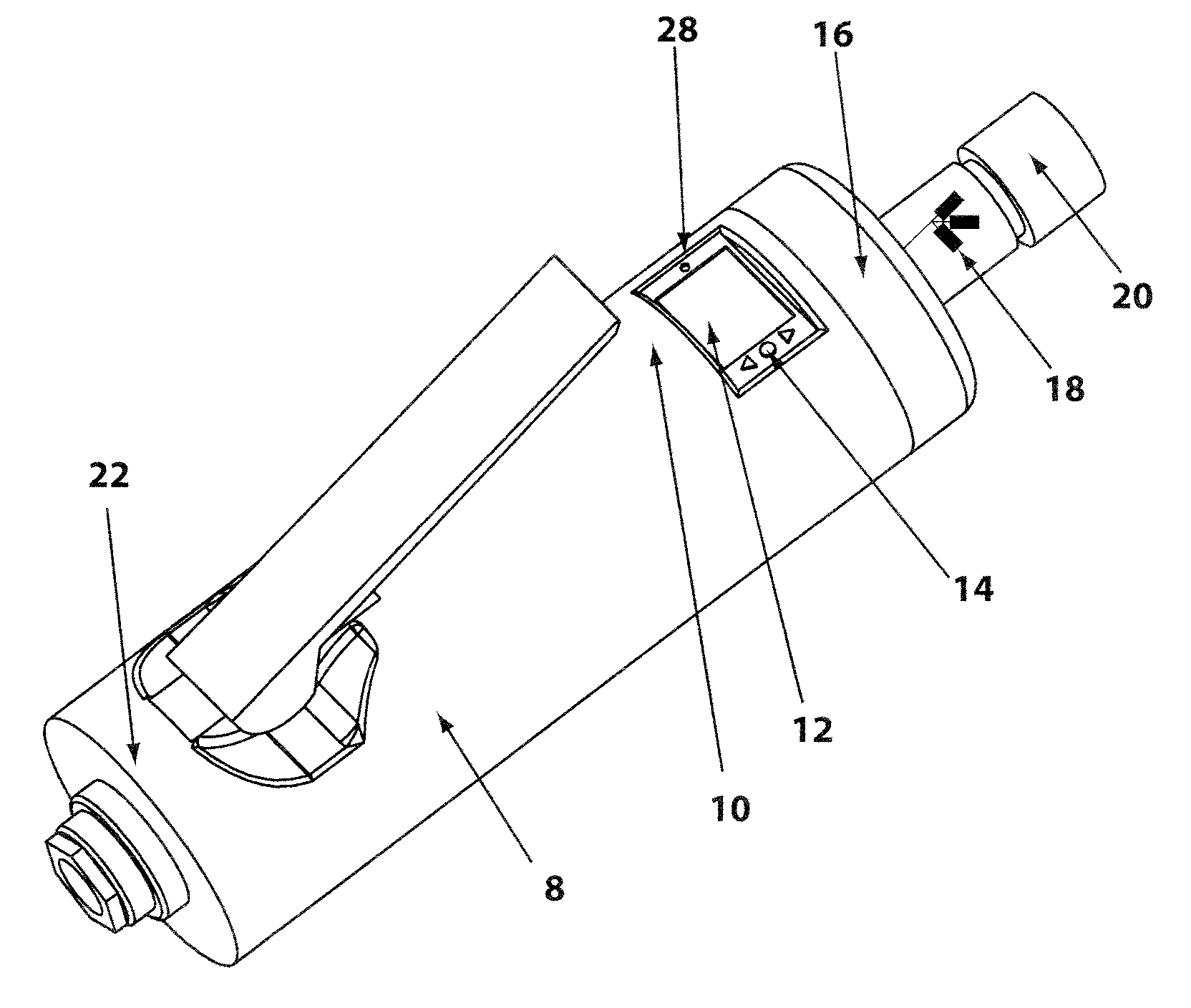

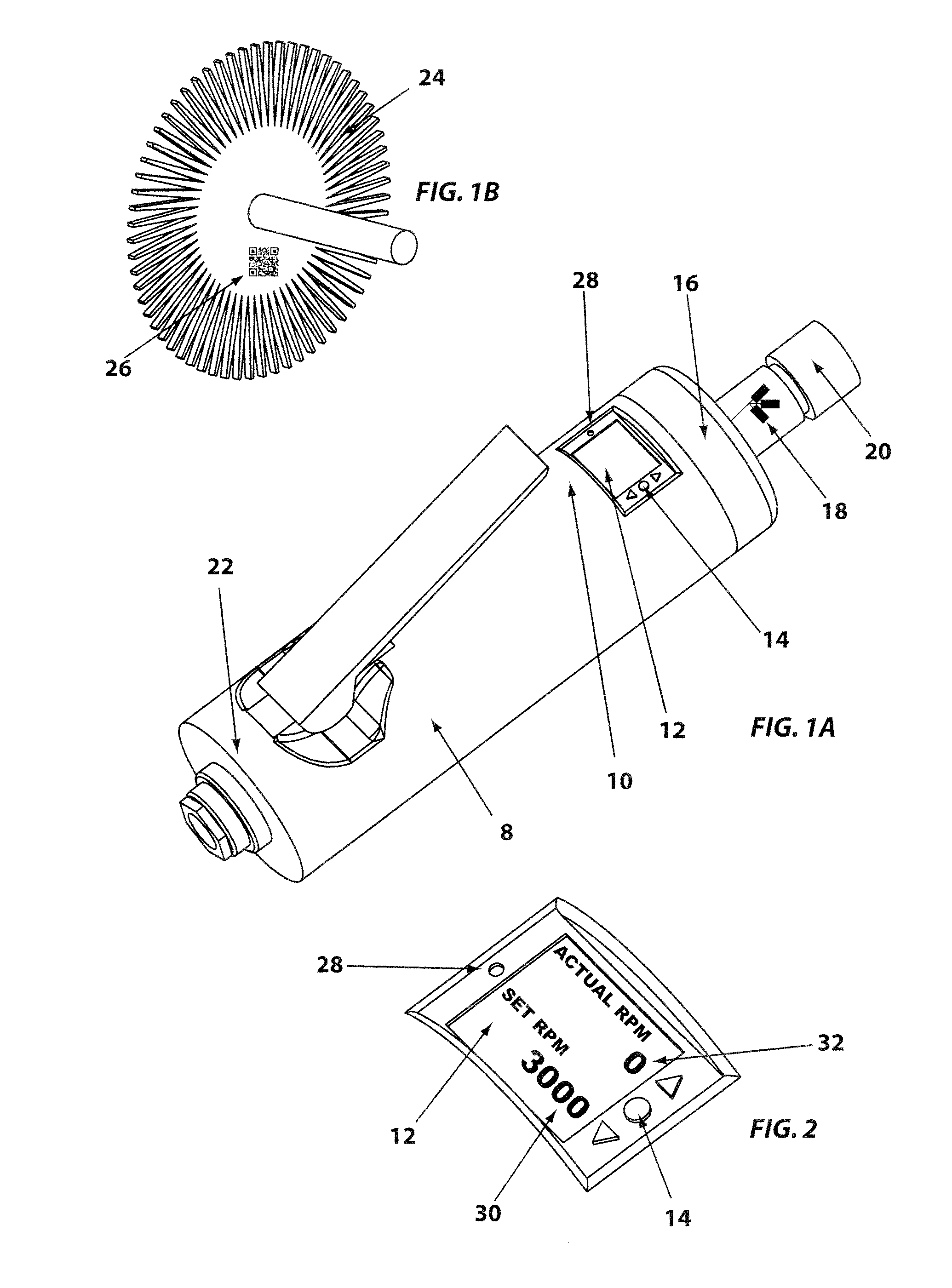

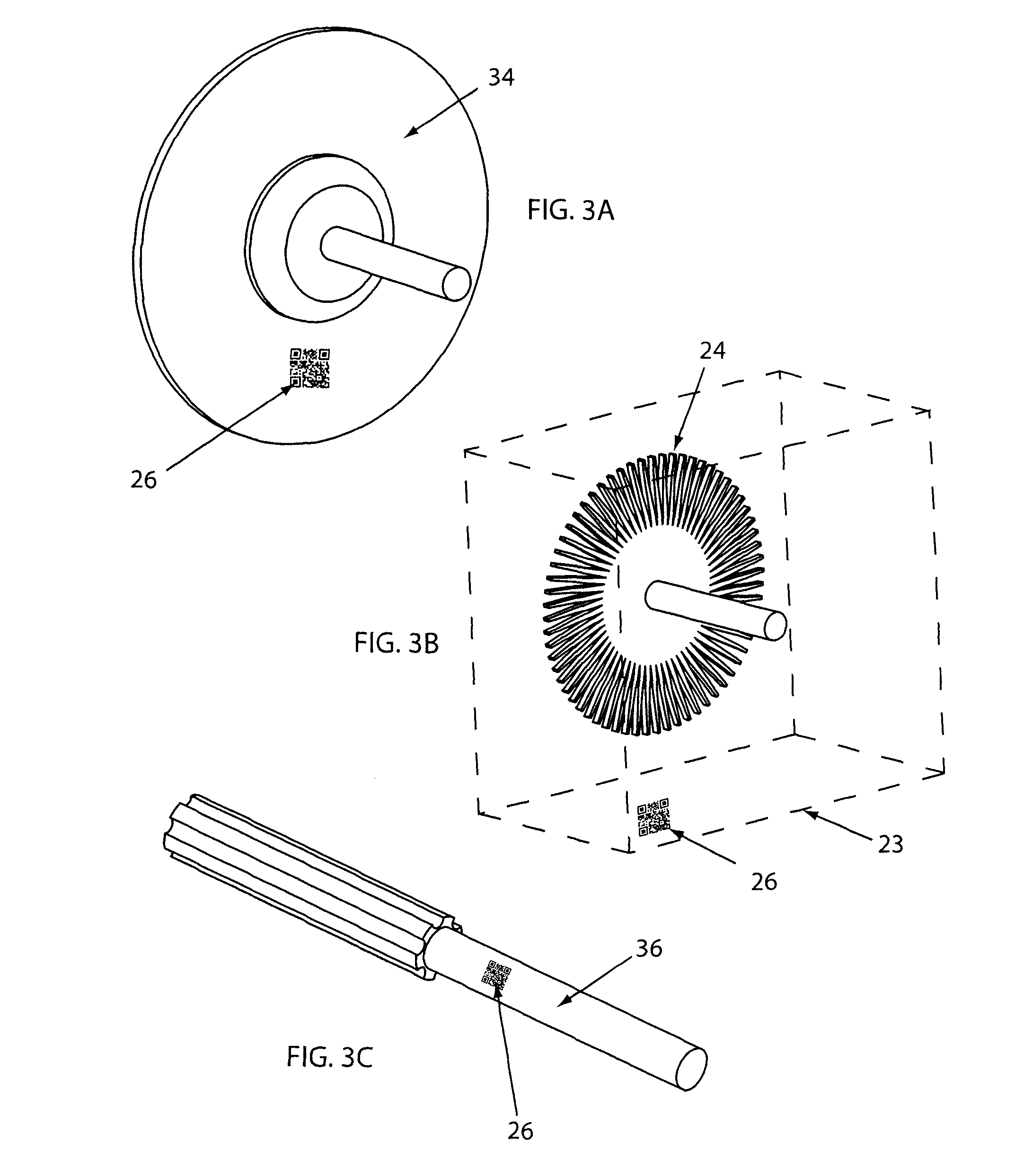

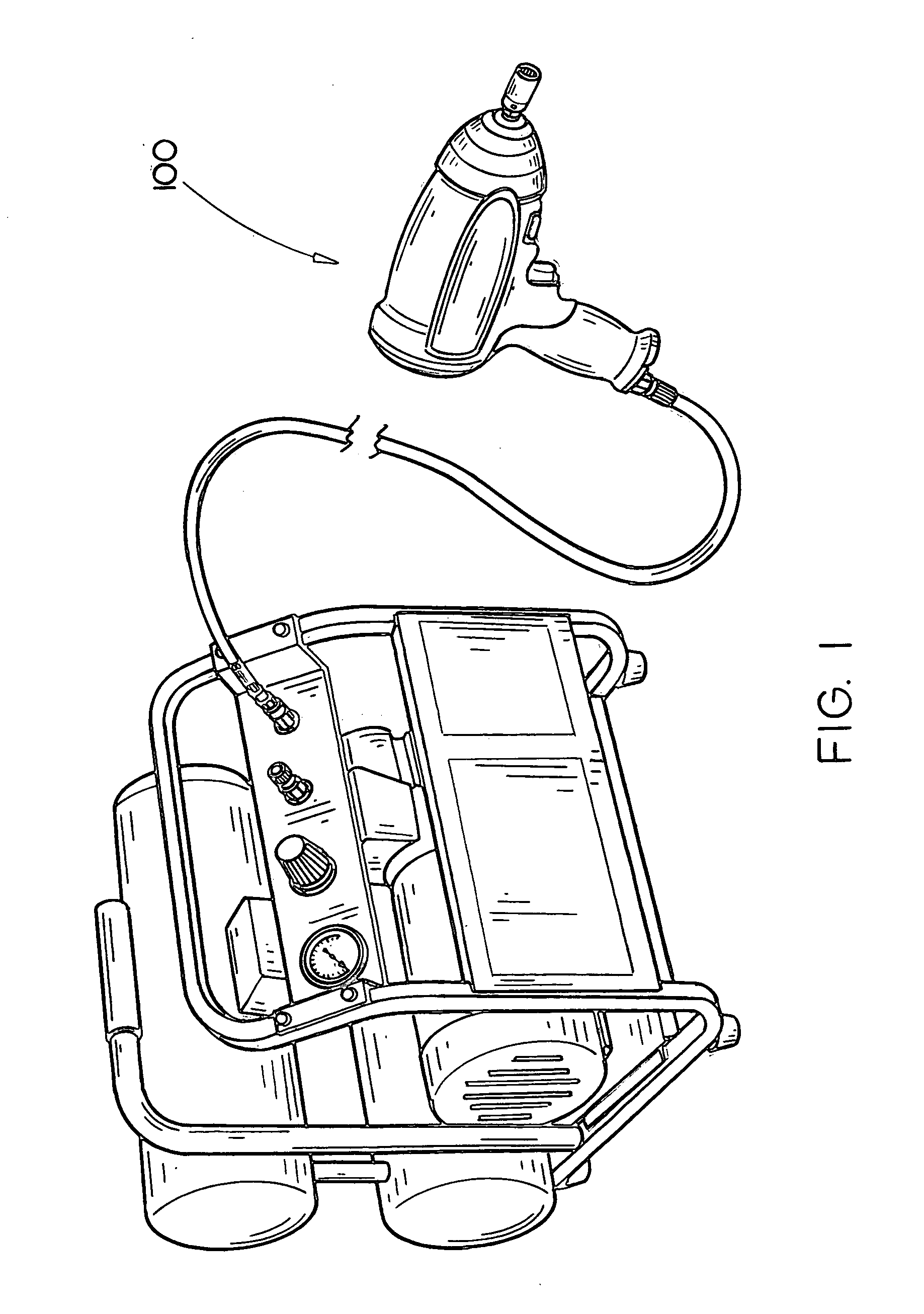

Controlled electro-pneumatic power tools and interactive consumable

Owner:FORGUES SYLVAIN +1

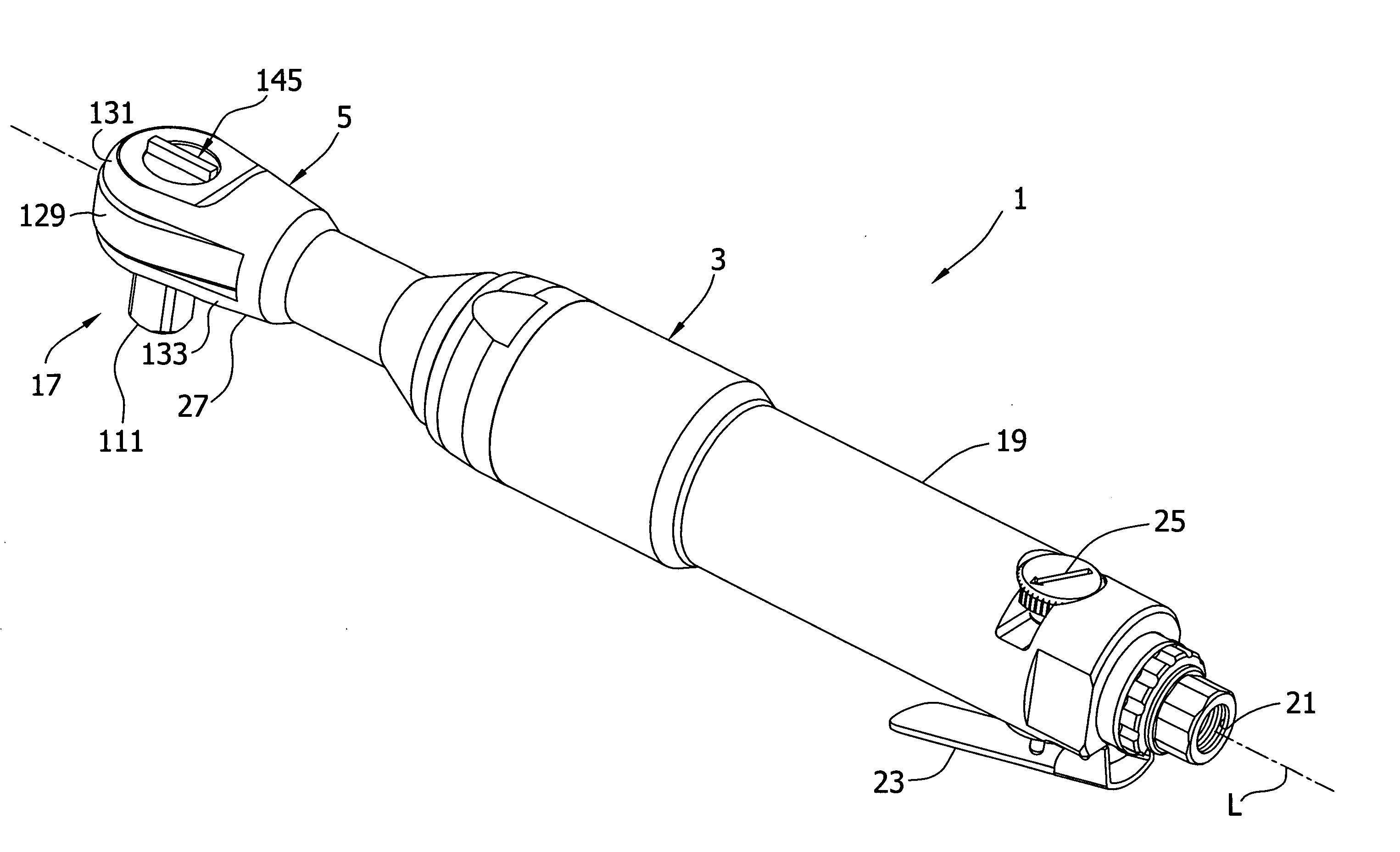

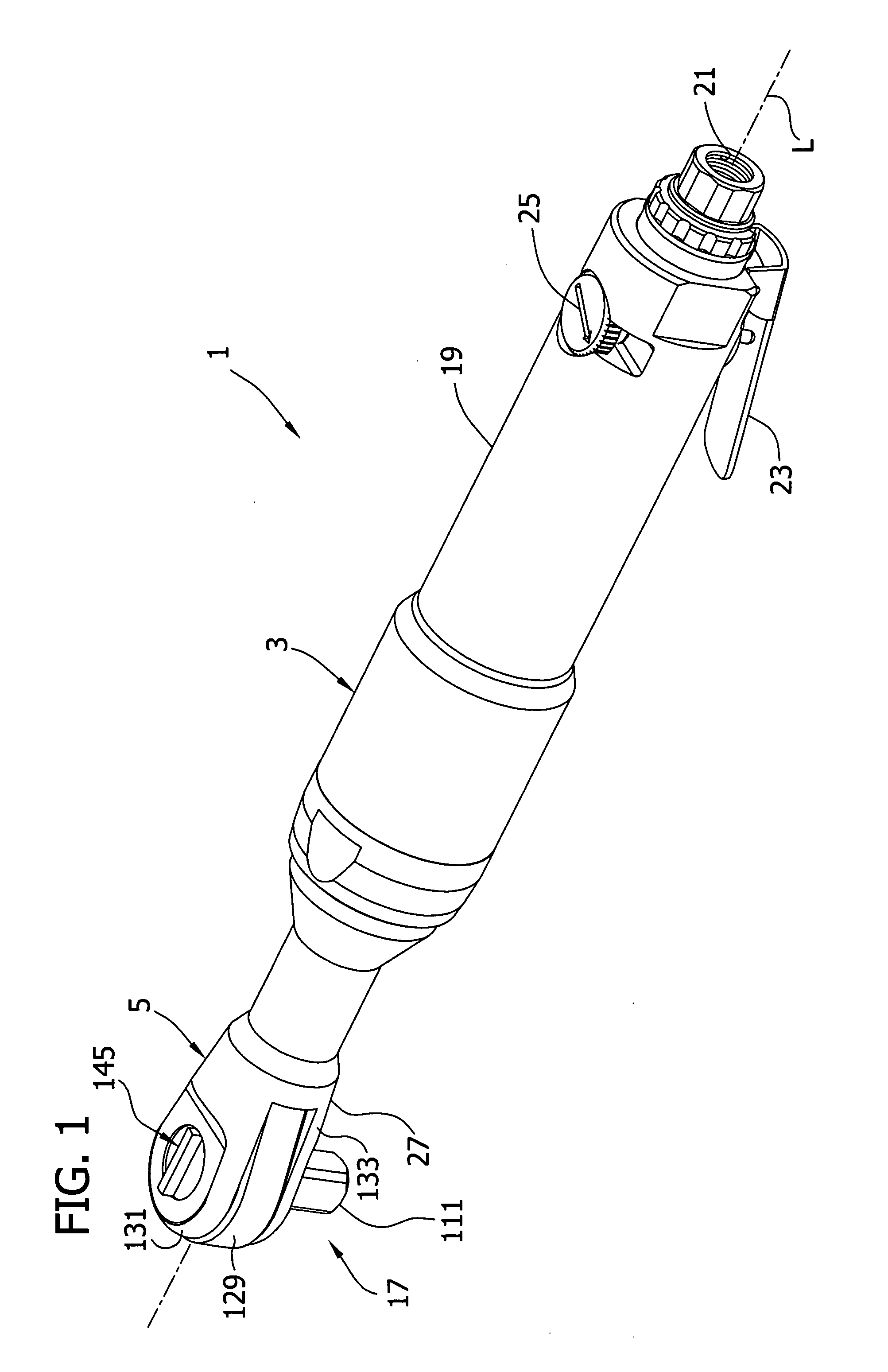

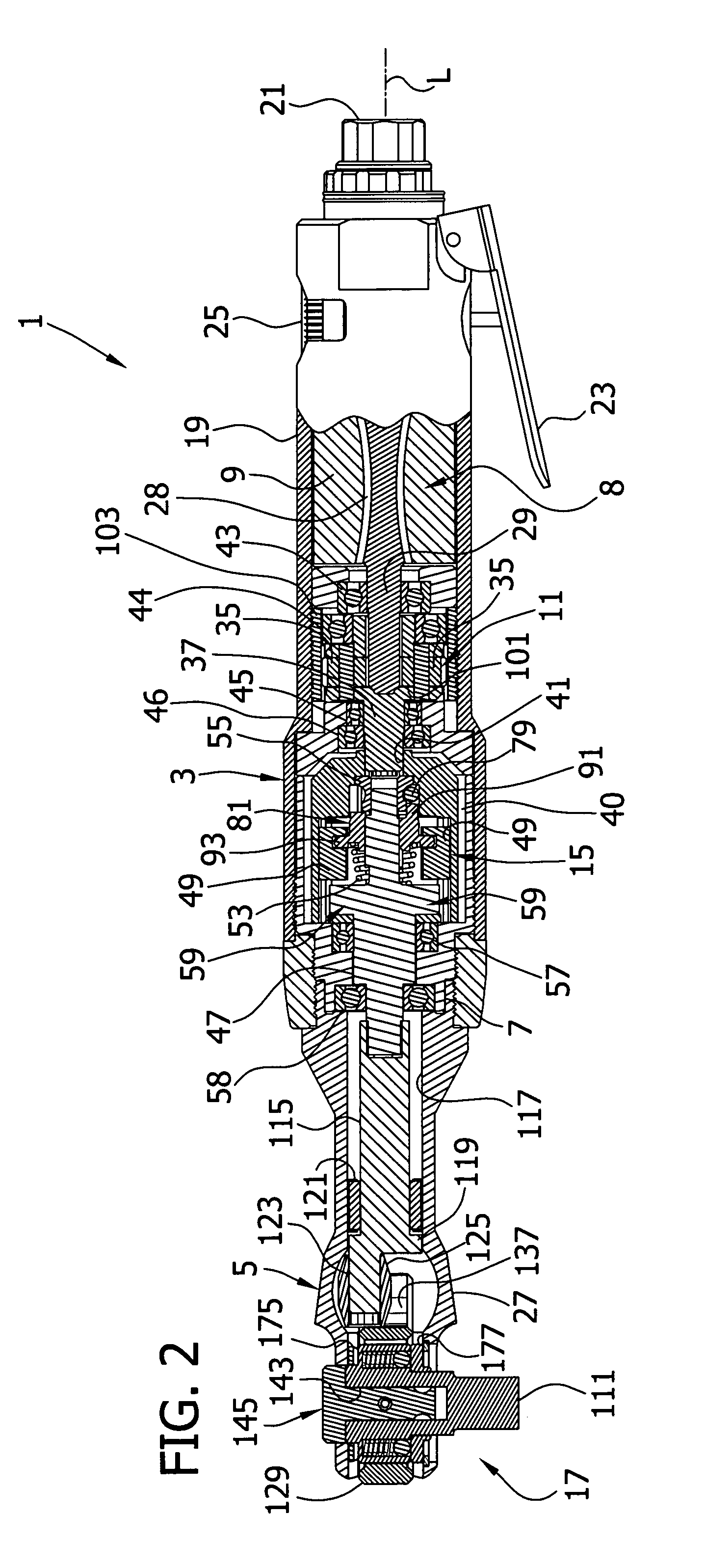

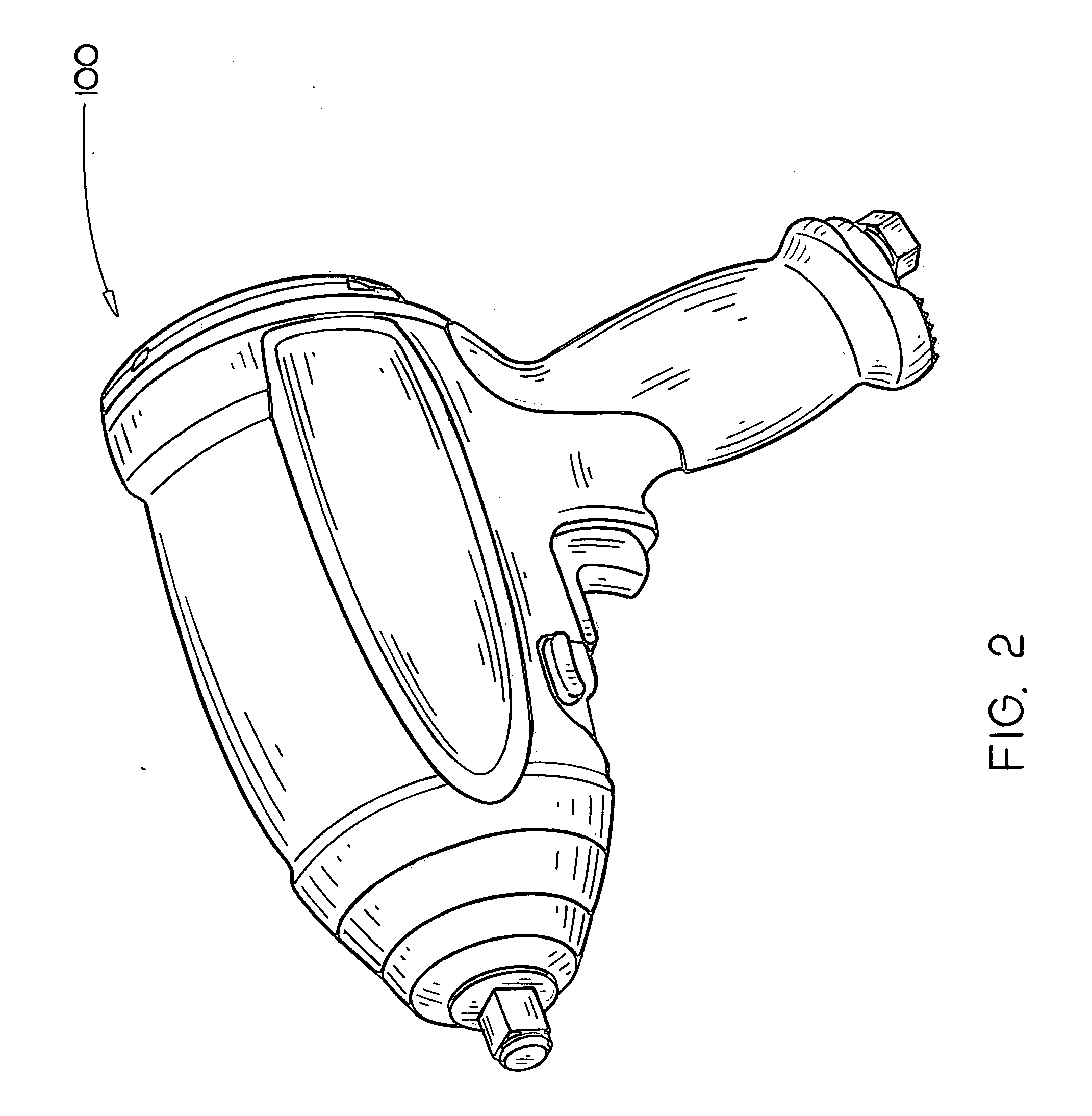

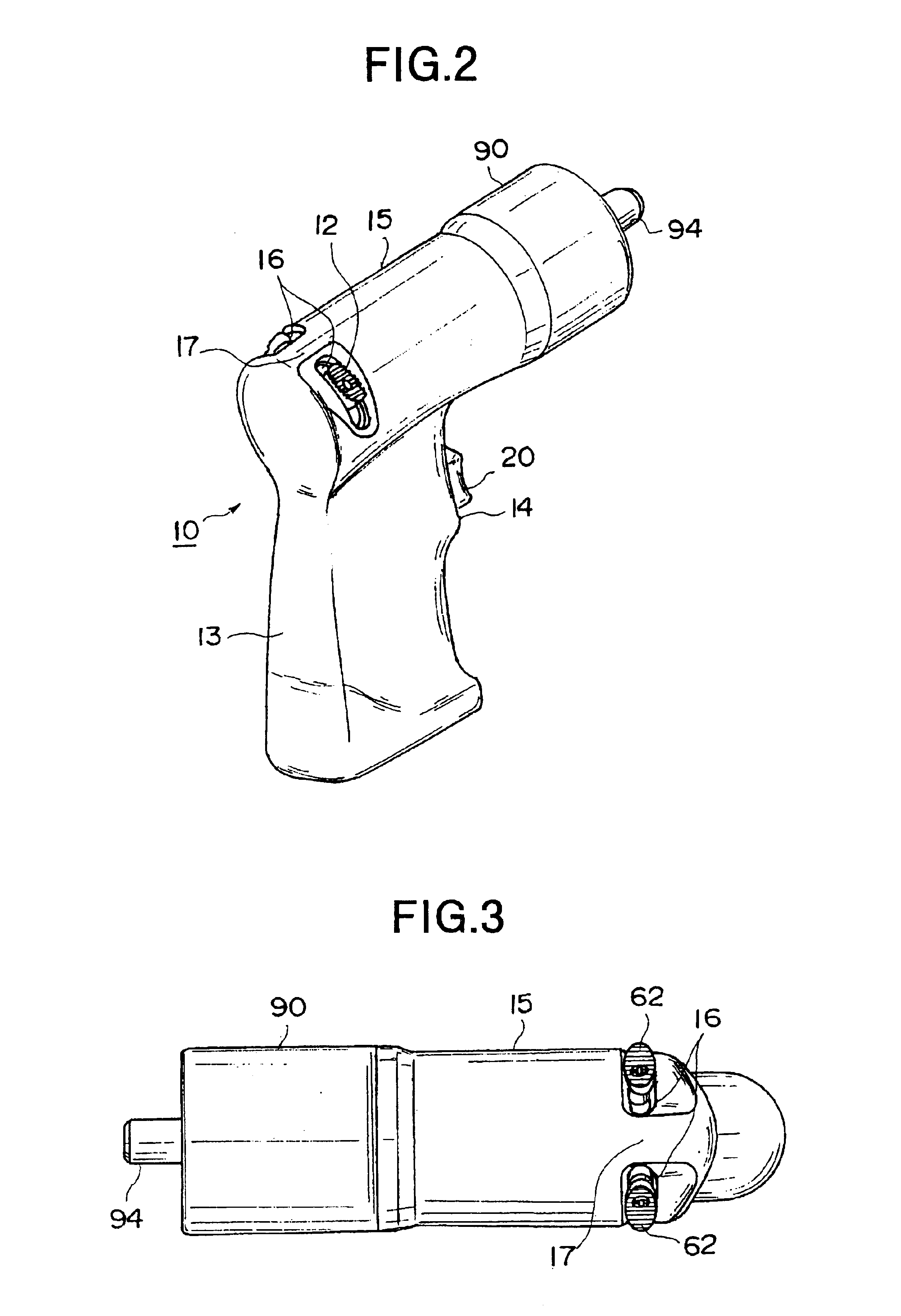

Air powered wrench device with pivotable head and method of using

InactiveUS6928902B1Easy and efficient to manufactureLower sales priceSpannersWrenchesBall bearingUniversal joint

An air powered wrench device with a pivotable head and associated method of using. The device comprises a handle pivotally attached to an arm. The handle comprises a housing, an air intake nozzle, an air driven motor, a drive shaft, a ball bearing collar, a universal joint, an on / off button, a trigger switch, a directional throw switch, a lock pin, a spring, and a pivot post. The arm is pivotally attached to the handle via the pivot post. The arm includes: an outer casing, an extension rod, a ball bearing sleeve, a first pawl gear, a second pawl gear, and a bit connector. The method of using the device comprises the steps of adjoining, affixing, aligning, allowing, enshrouding, getting, moving, obtaining, putting, rotating, shifting, squeezing, and tightening.

Owner:EYSSALLENNE LUIS P

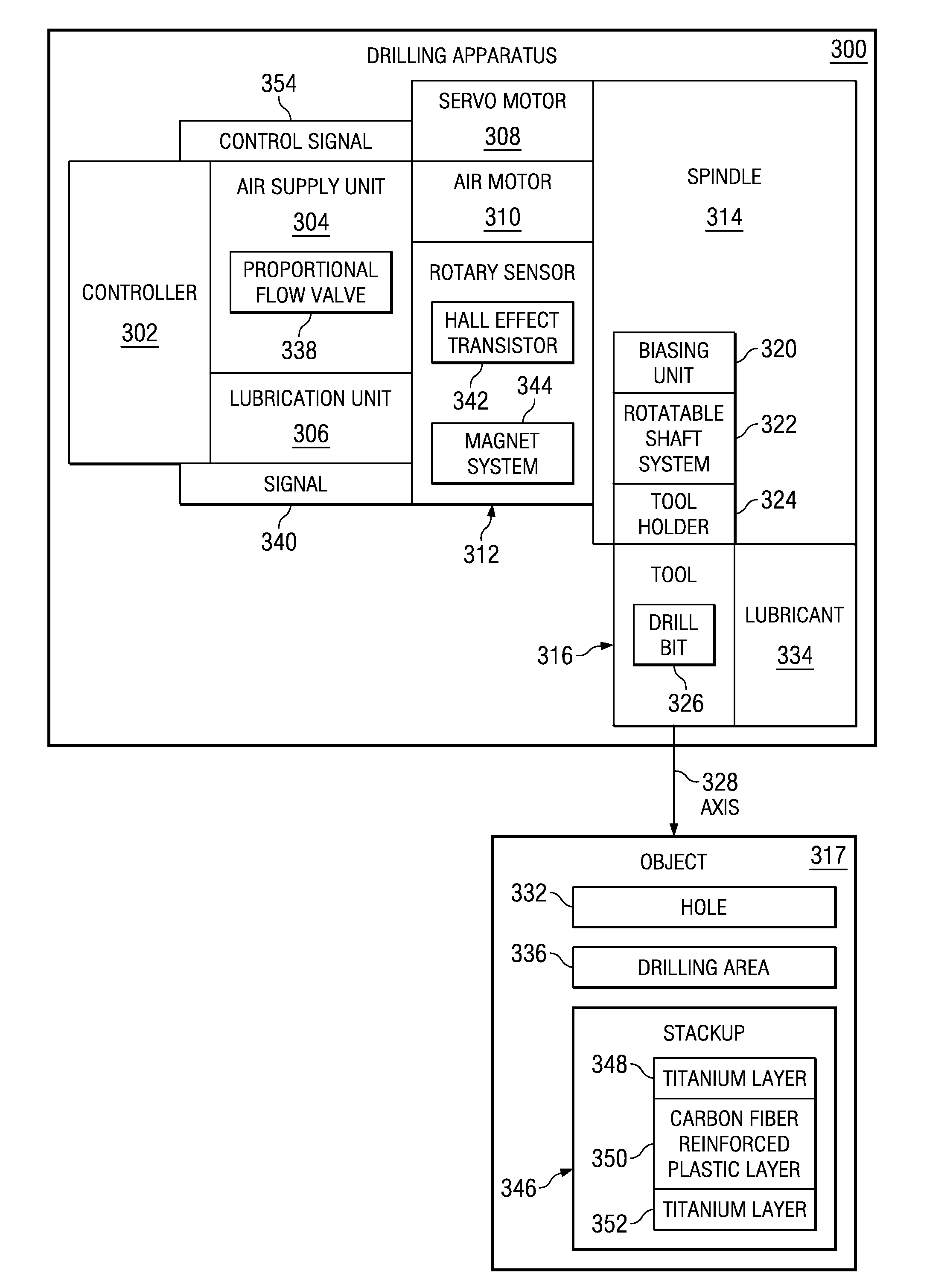

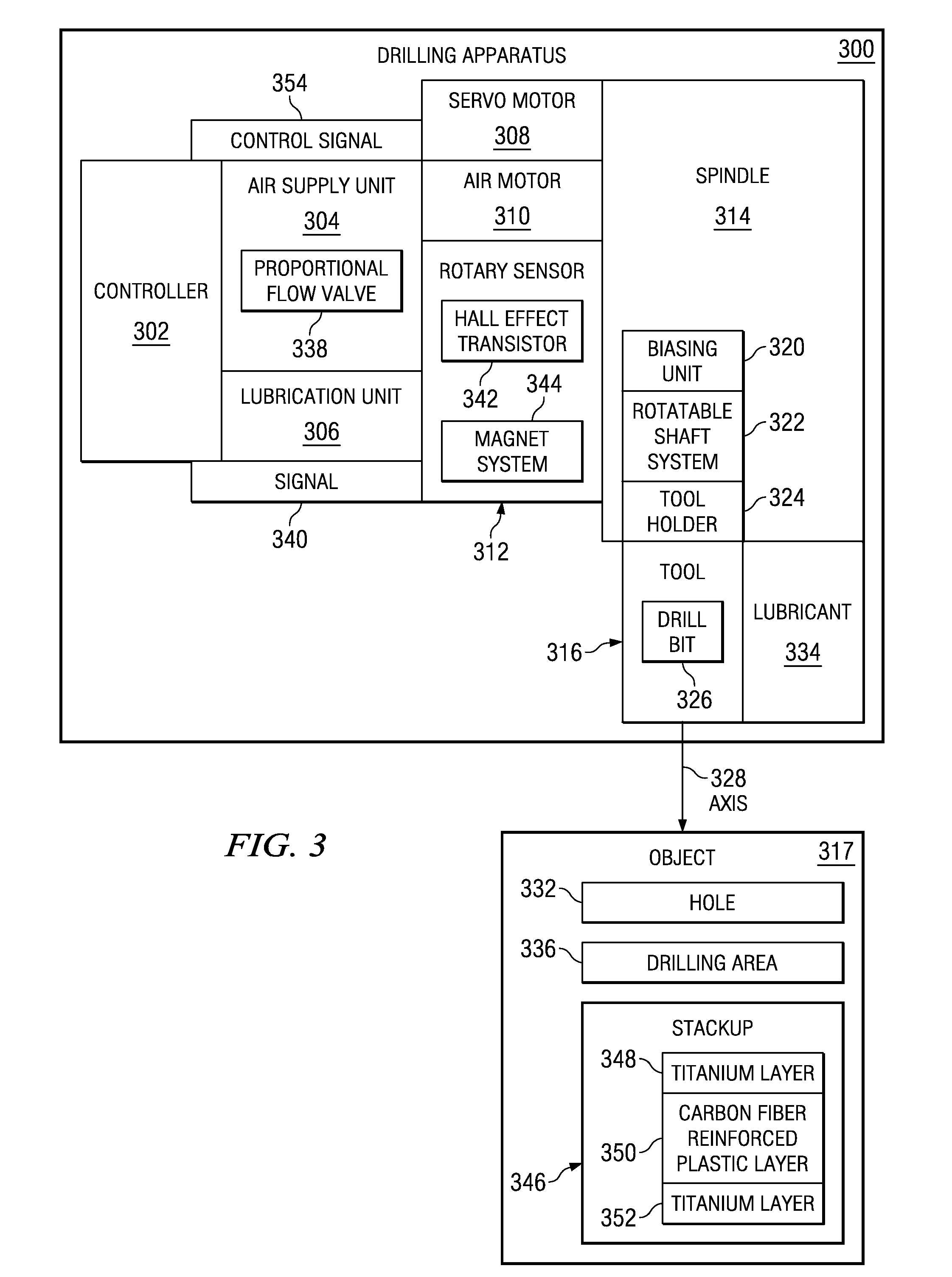

Adaptive positive feed drilling system

An apparatus for a drilling operation. In one advantageous embodiment, the drilling operation includes a motor, a rotary sensor, and a controller connected to the rotary sensor. The rotary sensor may be capable of generating a signal in response to rotary movement of the drill motor. The controller may be capable of monitoring a speed of the air motor from the signal generated by the rotary sensor and may be capable of identifying a change from a current layer in a stackup to a new layer in the stackup using the signal.

Owner:THE BOEING CO

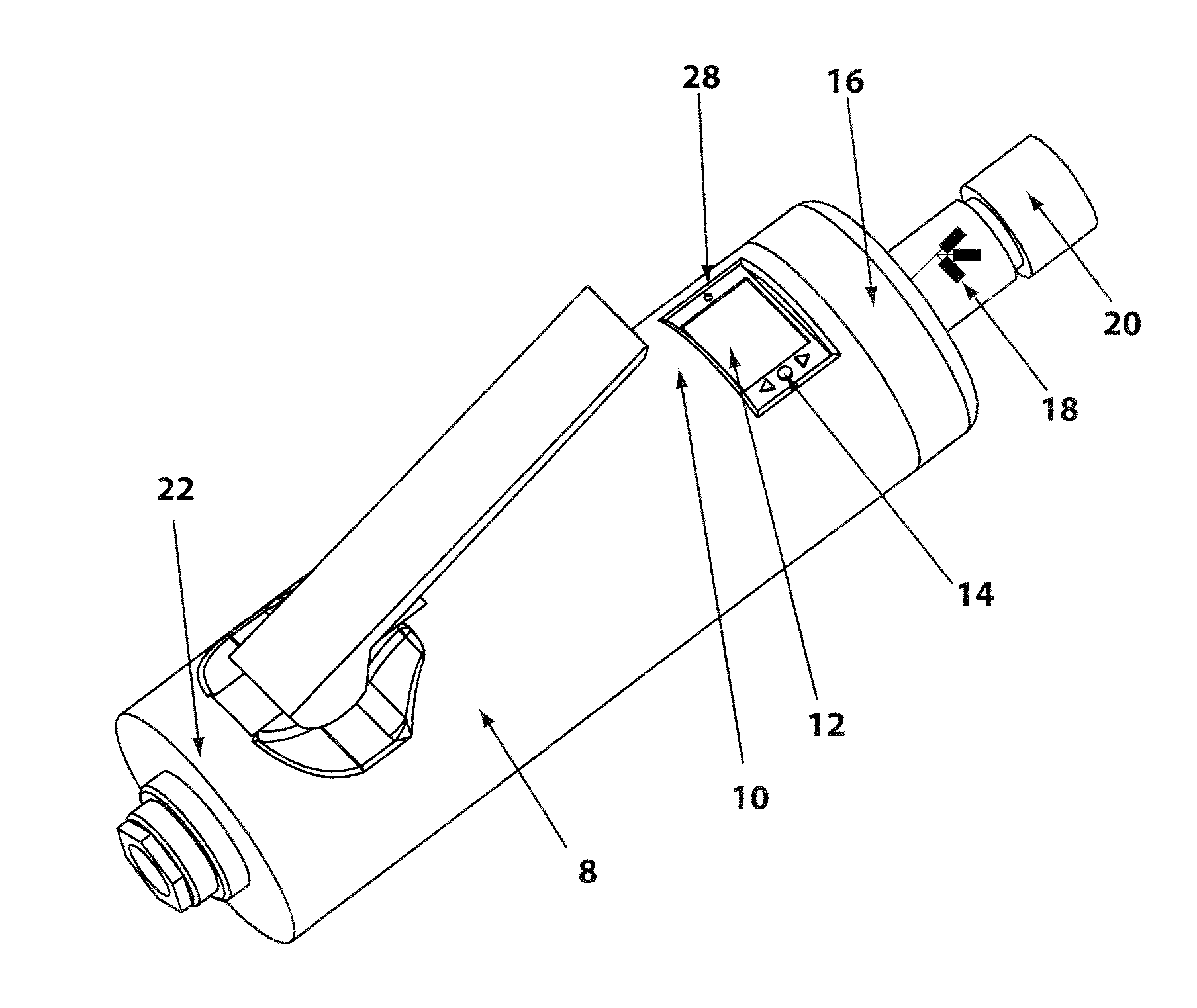

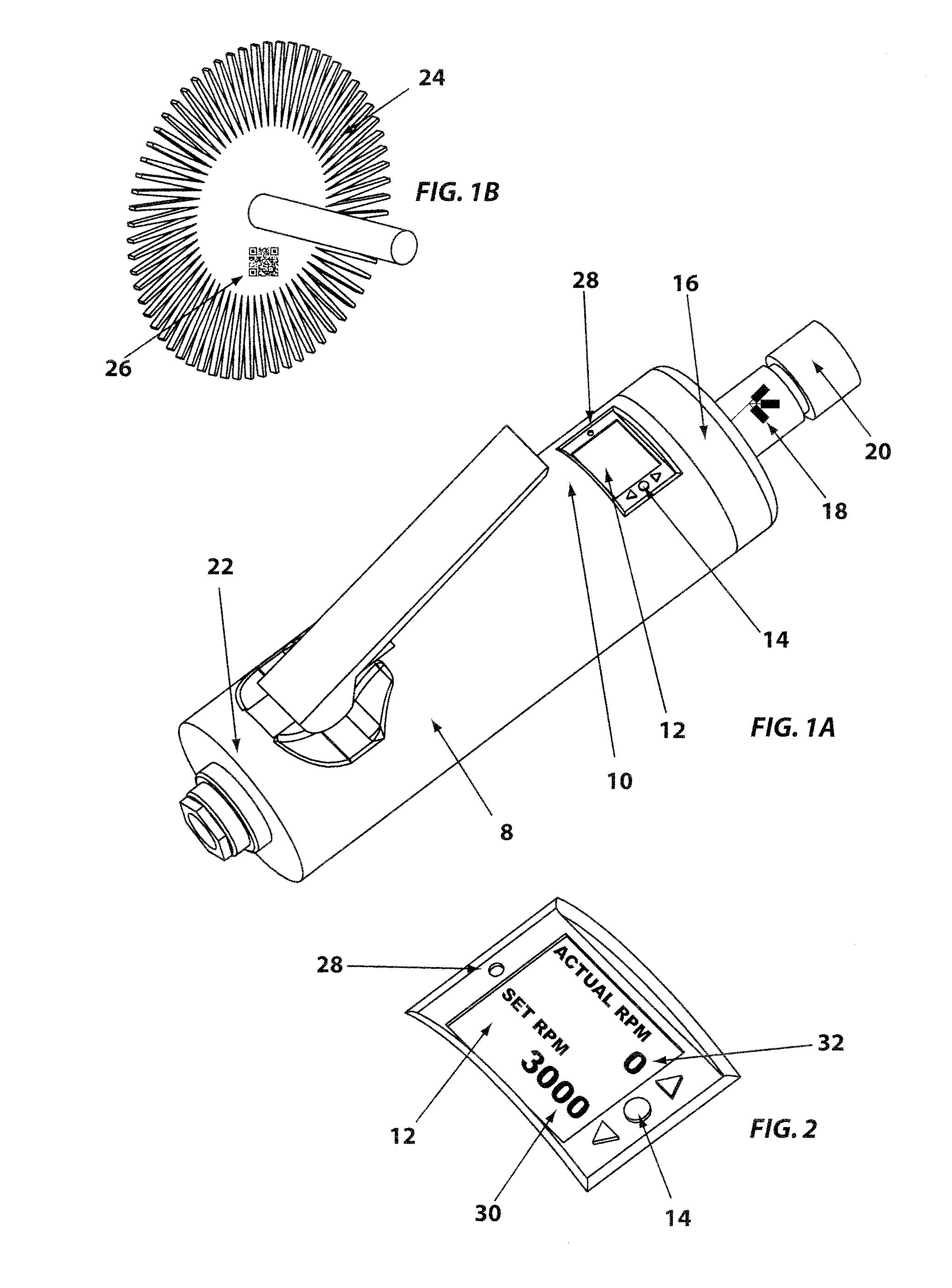

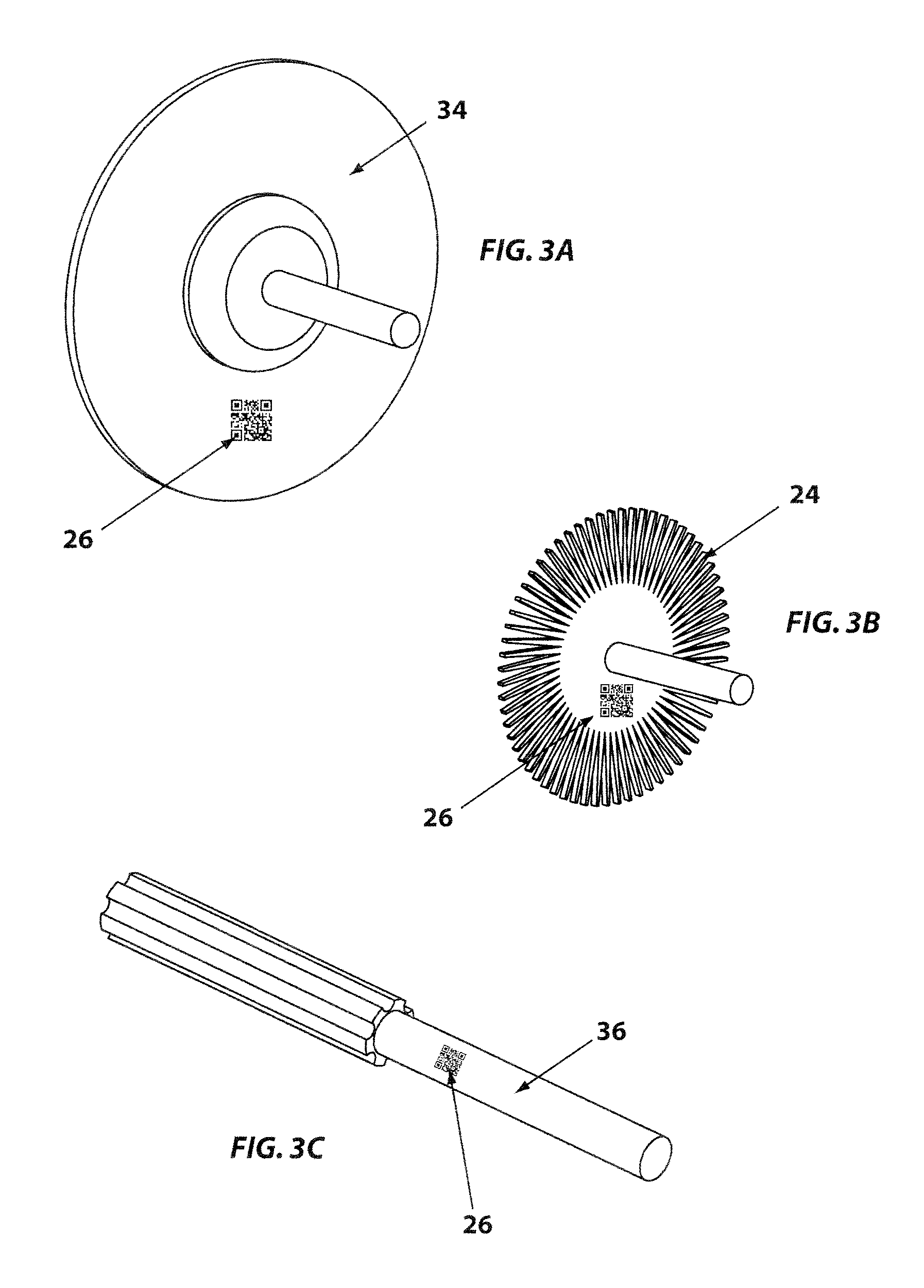

Controlled electro-pneumatic power tools and interactive consumable

ActiveUS20120007748A1Electric signal transmission systemsTelemetry/telecontrol selection arrangementsMicrocontrollerElectrical battery

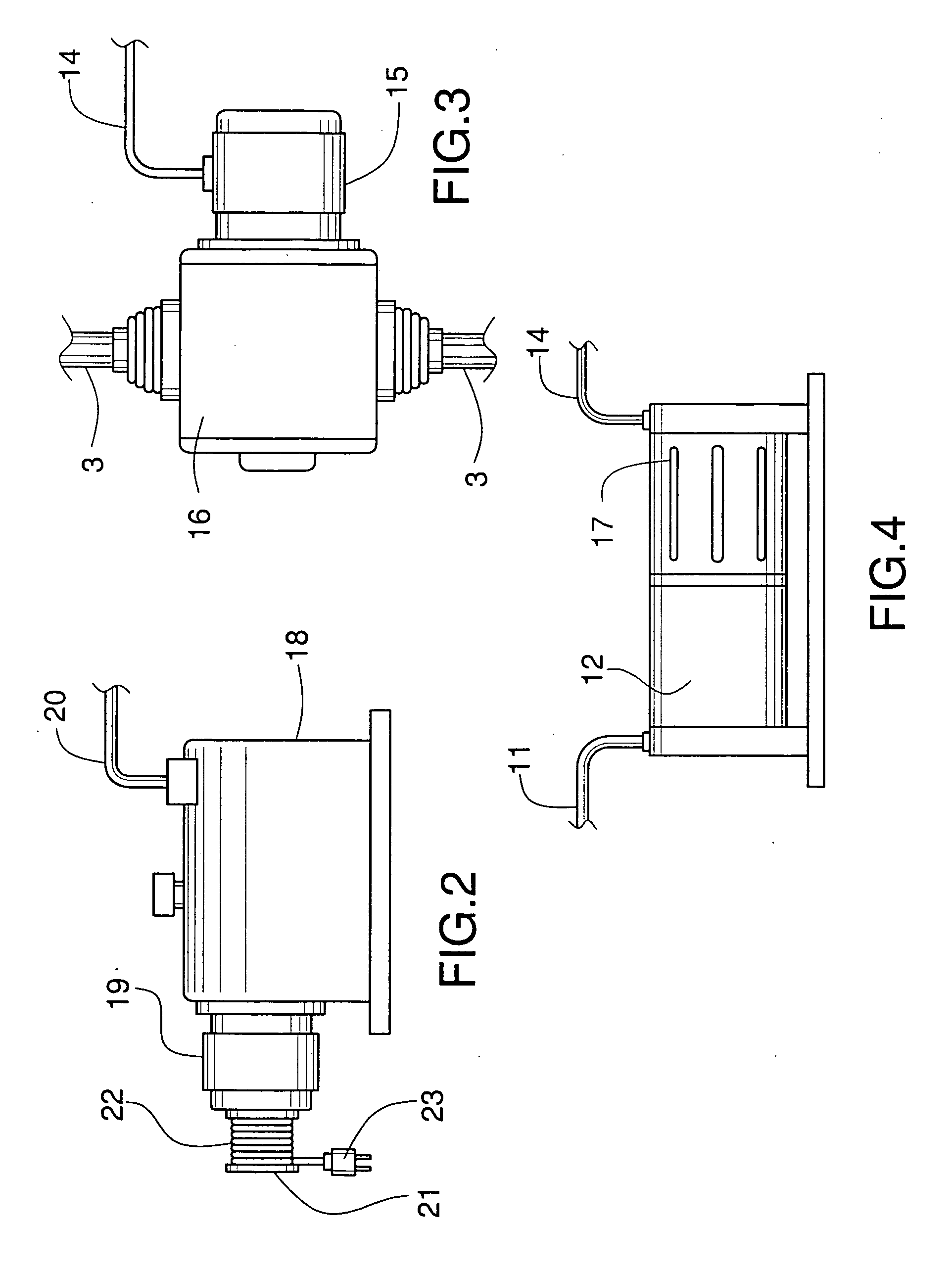

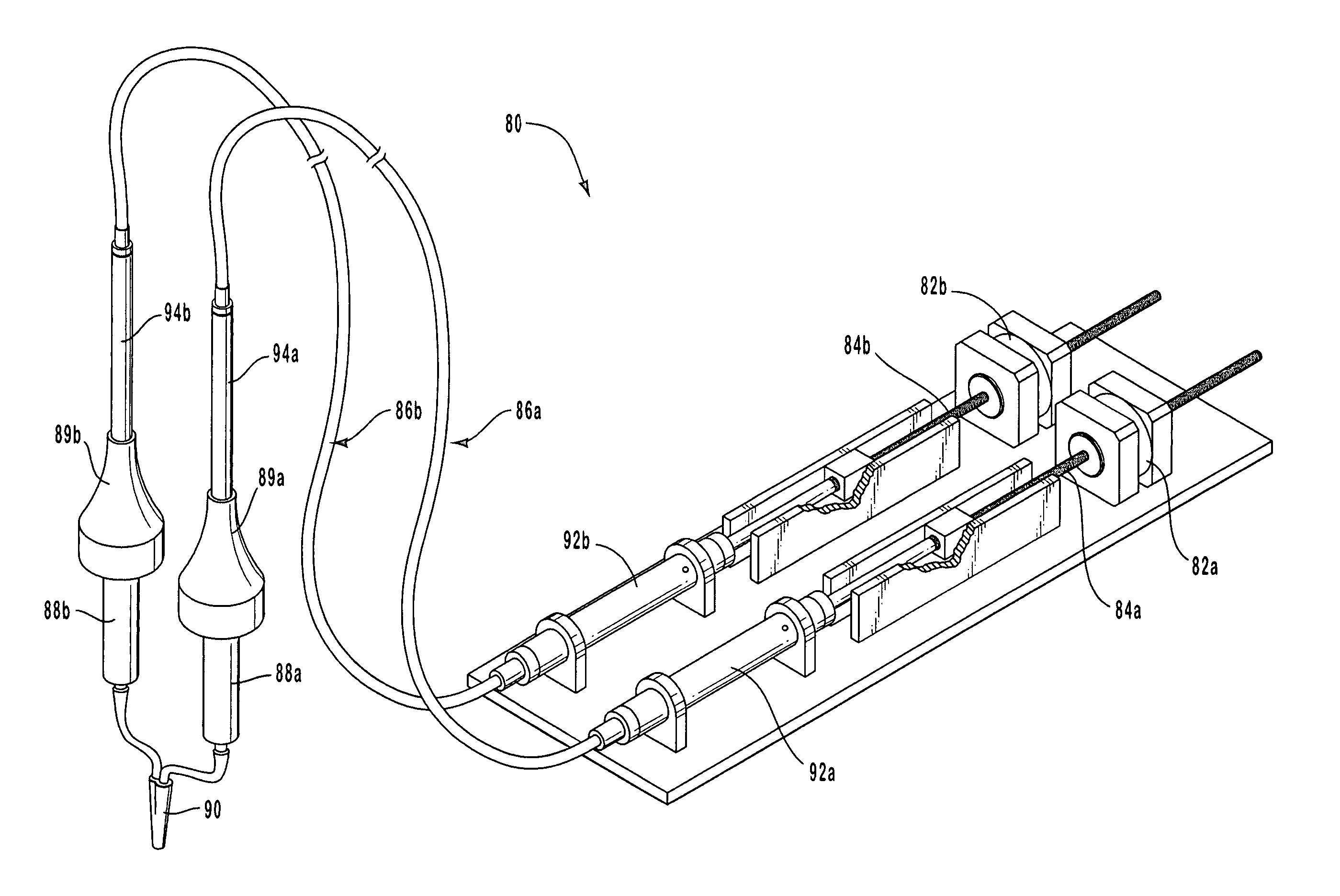

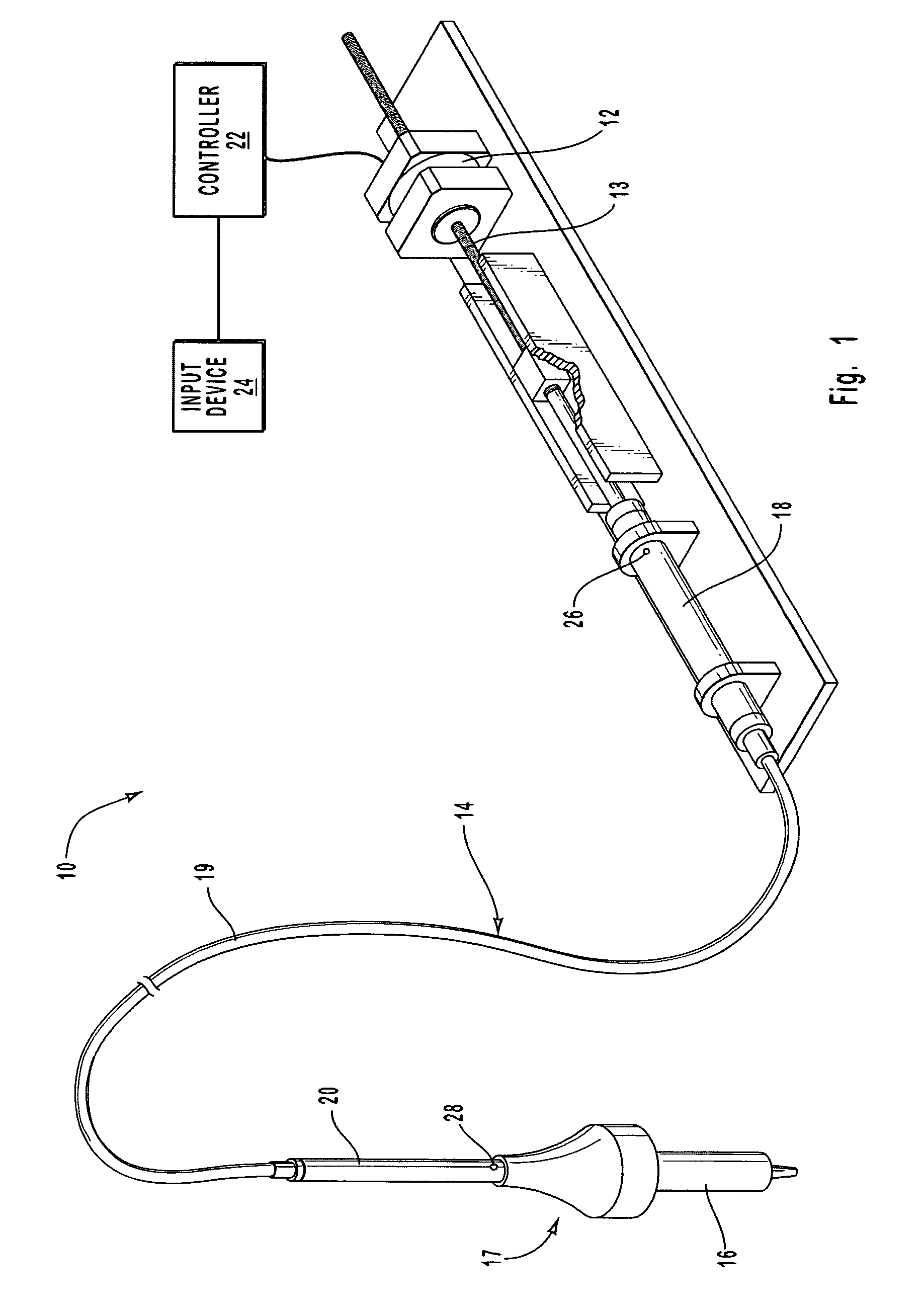

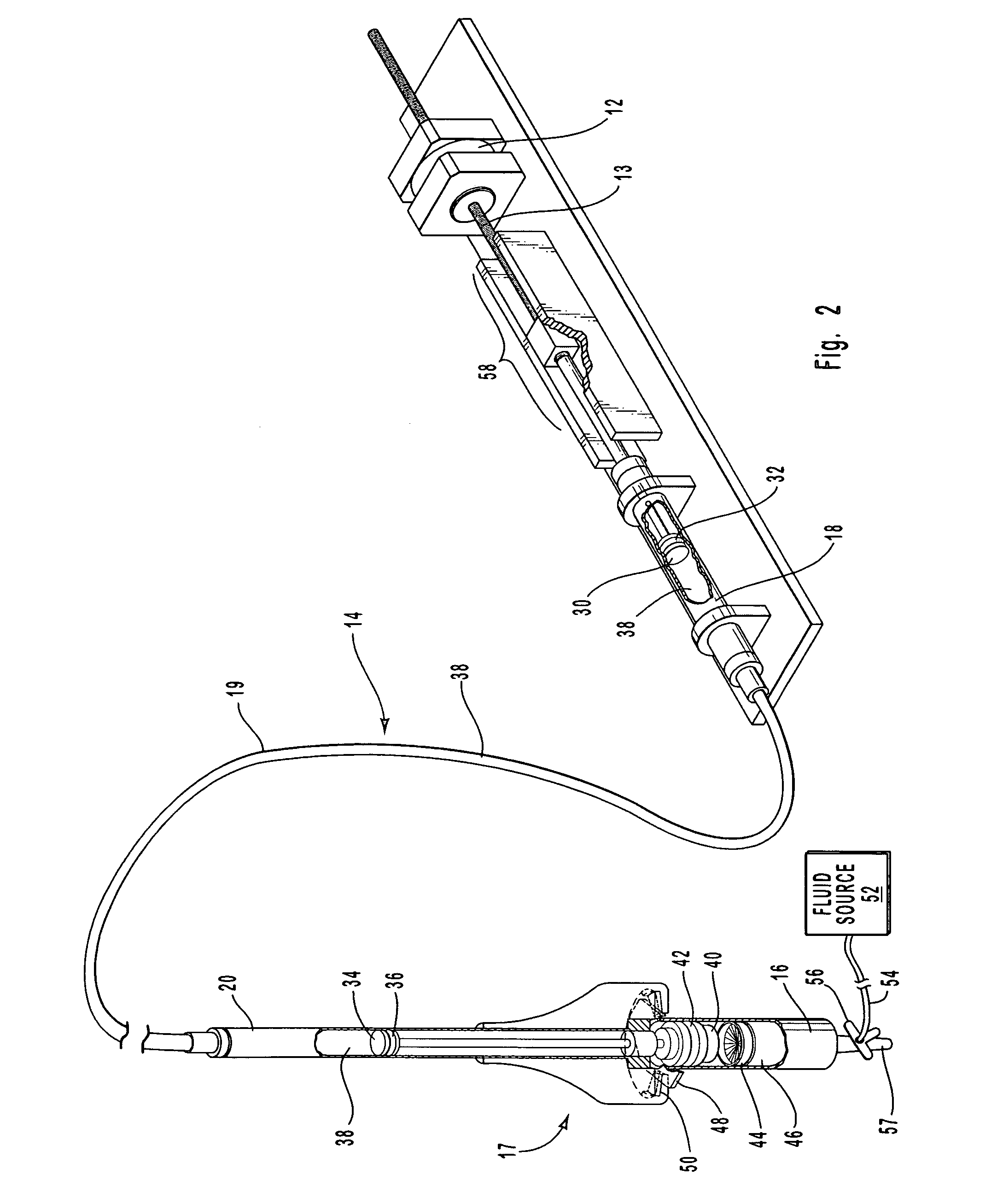

A controlled electro-pneumatic power tool includes an electro-mechanical adjustable valve, a pneumatic motor and a rotational speed sensor connected to a microcontroller for the selection, monitoring and adjustement of the rotational speed in real time. The electro-pneumatic power tool may include input buttons, data ports to save data and a communication port to read / write data from an interactive consumable. The electo-pneumatic power tool may also include a battery and a generator as well as a variable speed transmission with flexible shaft and lightweight handpiece. Using the communication port, important data for the consumable, such as optimum rotation speed, optimum applied pressure and average usage time, can be transmitted to the controlled electro-pneumatic power tool. The controlled electro-pneumatic power tool can read and utilise the transmitted data to select, adjust and maintain the optimum process parameters for the consumable without any input from the operator person. Furthermore, the communicated data can be used to warn the operator person that the tool used is inadequate for the selected consumable, to caution the operator person if he is using the consumable inadequately and to advise him when the consumable should be replaced for safe operation. This will increase the safety of the operator person, improve the quality of the work performed with pneumatic power tools and limit potential damages to the parts being treated.

Owner:FORGUES SYLVAIN +1

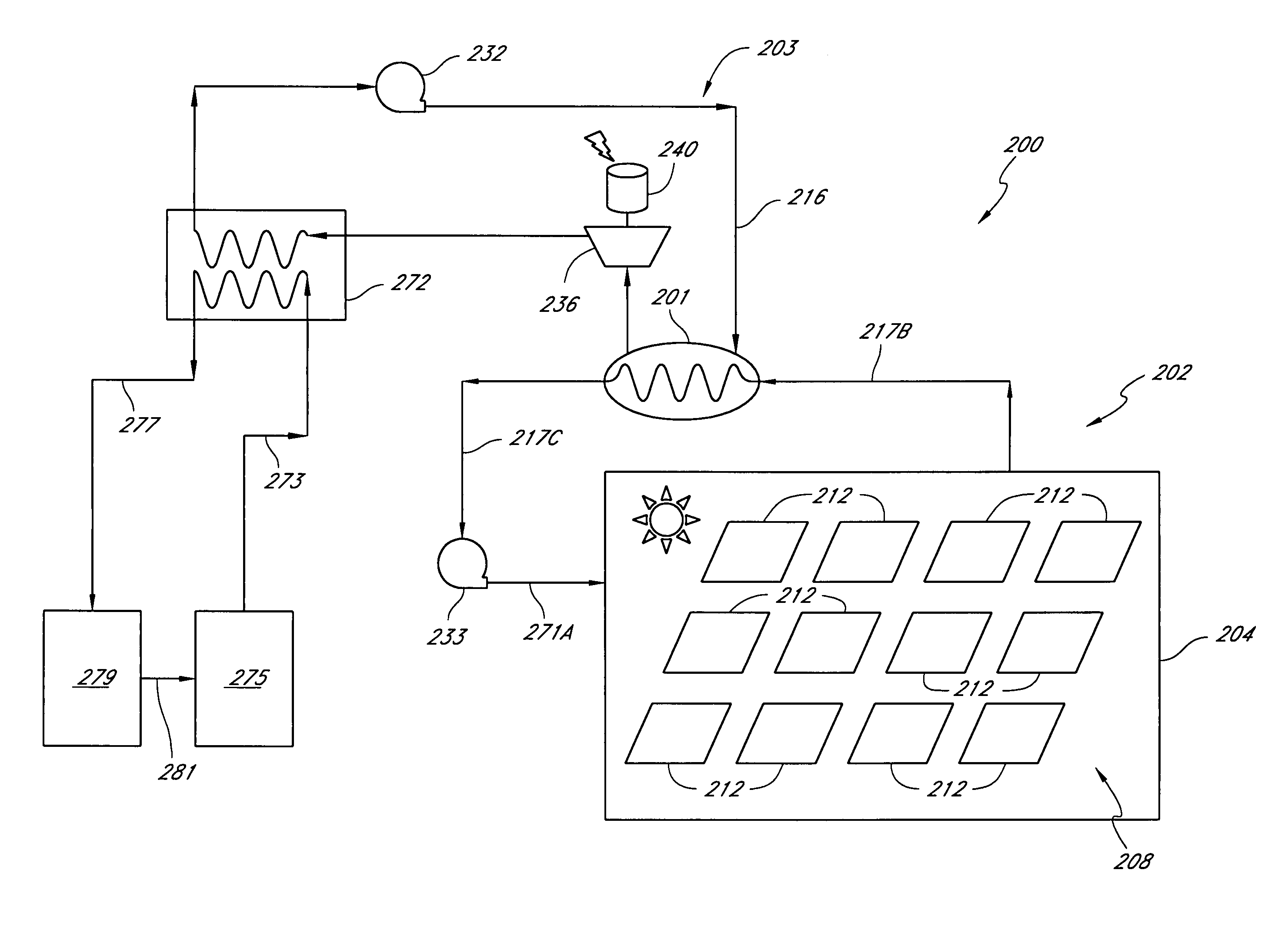

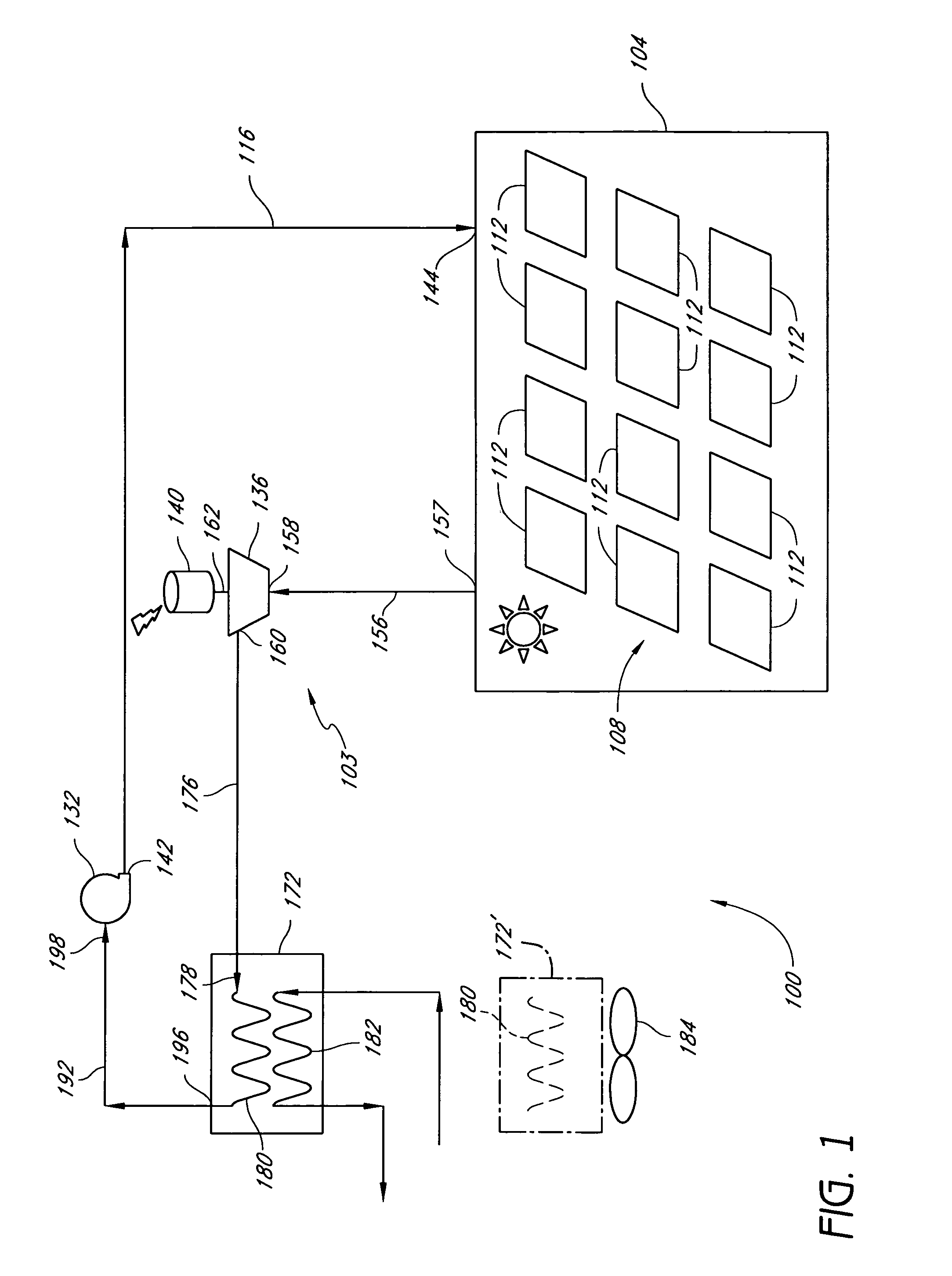

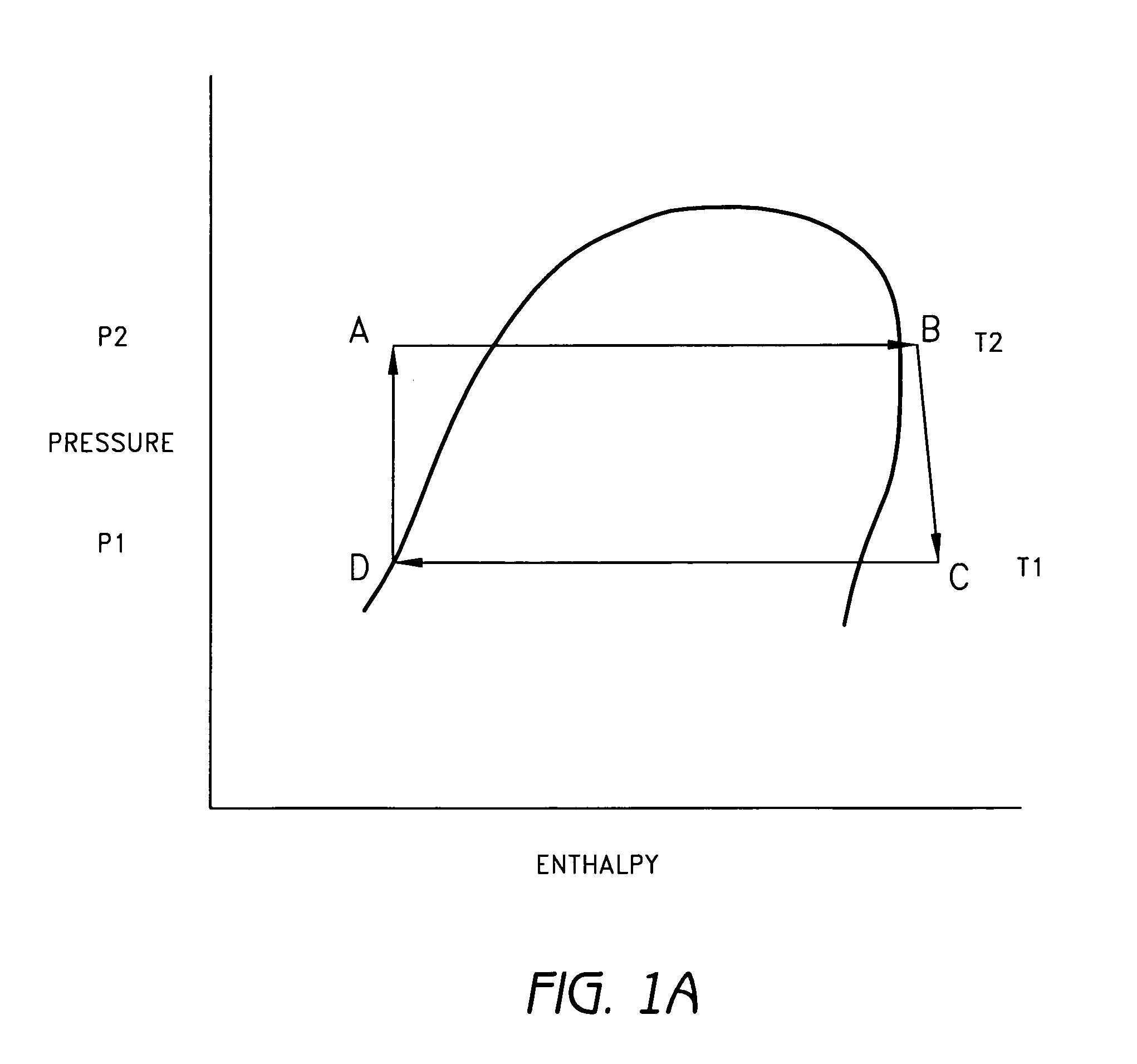

Solar power generation system

InactiveUS7340899B1Low costLess efficiencySolar heating energyAuxillary drivesSolar generatorPlate heat exchanger

An economical solar generator system is provided wherein the solar energy collector is constructed from a plurality of heat exchangers of the kind used as evaporators in automobile air conditioners. The solar generator system includes a plurality of said heat exchangers connected to receive incoming liquefied refrigerant under pressure. The number of such heat exchangers is sufficient to collect solar energy sufficient to induce a phase change from a liquid to a gas state. The solar generator system also includes an air motor and an electric generator. The air motor is coupled to the outflow heated gas from the plurality of heat exchangers. The air motor is rotated by the heated gas. The electrical generator is coupled to the air motor so that rotation of said air motor causes rotation of said generator.

Owner:SOLAR ENERGY PRODN CORP

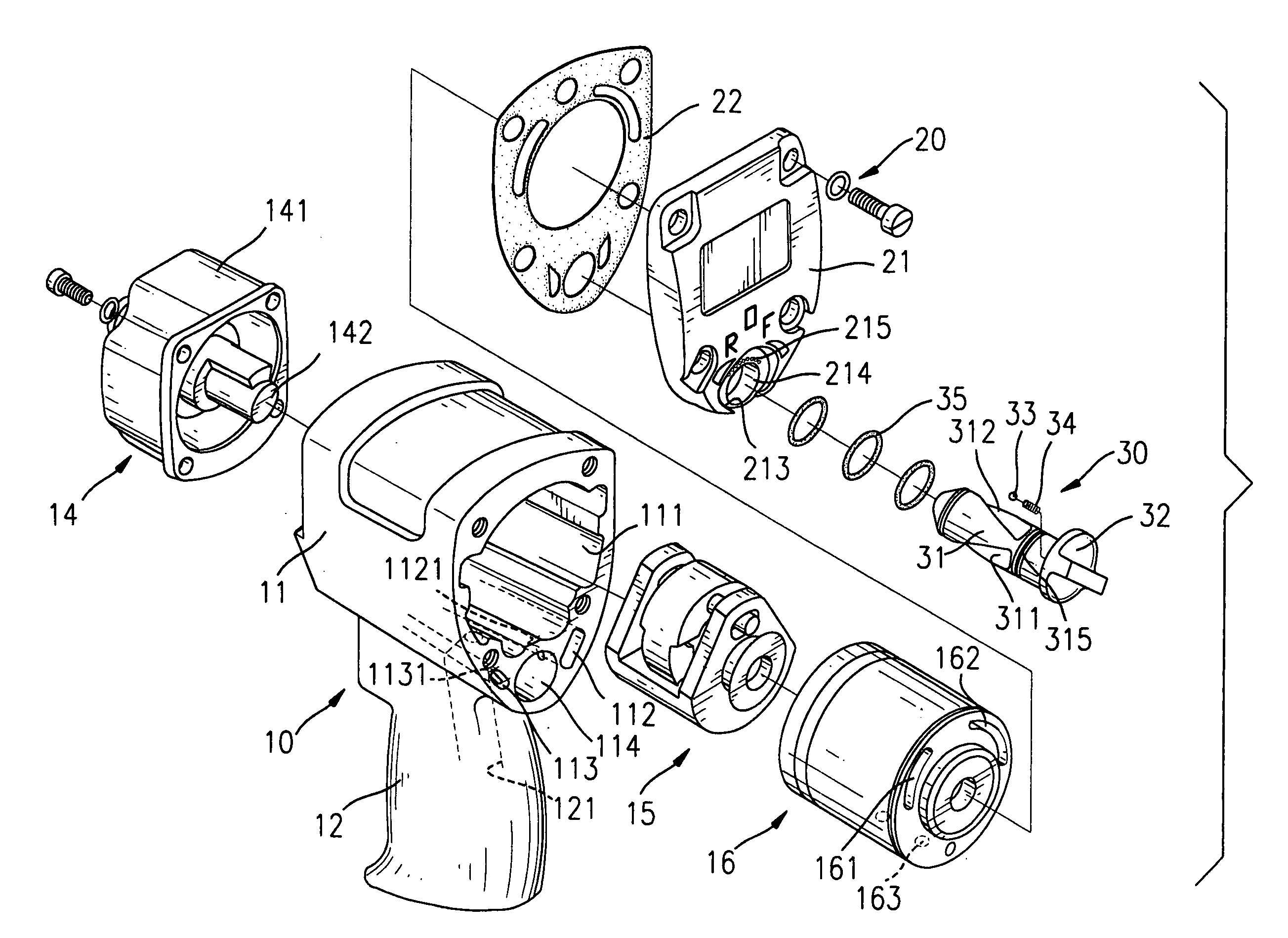

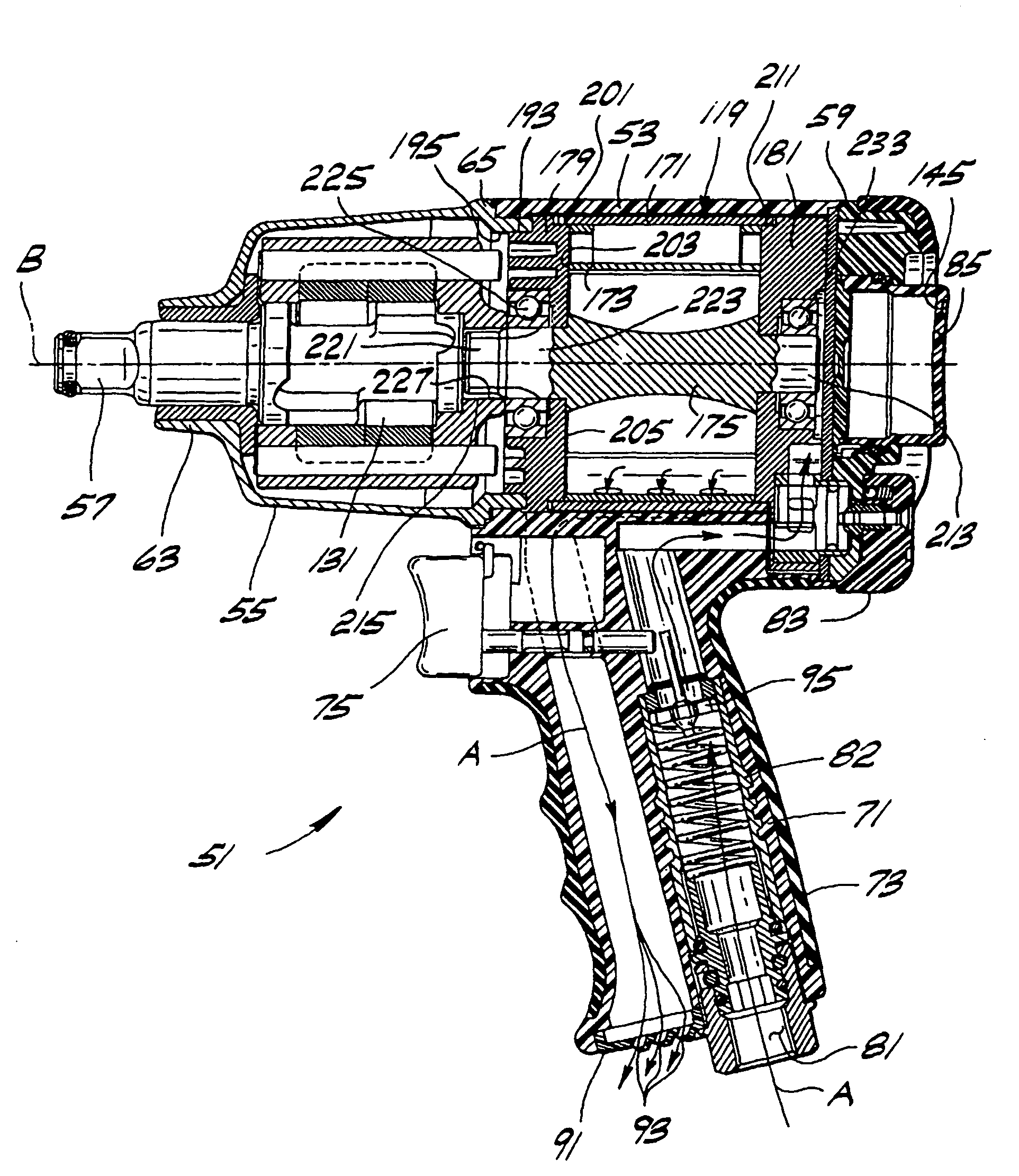

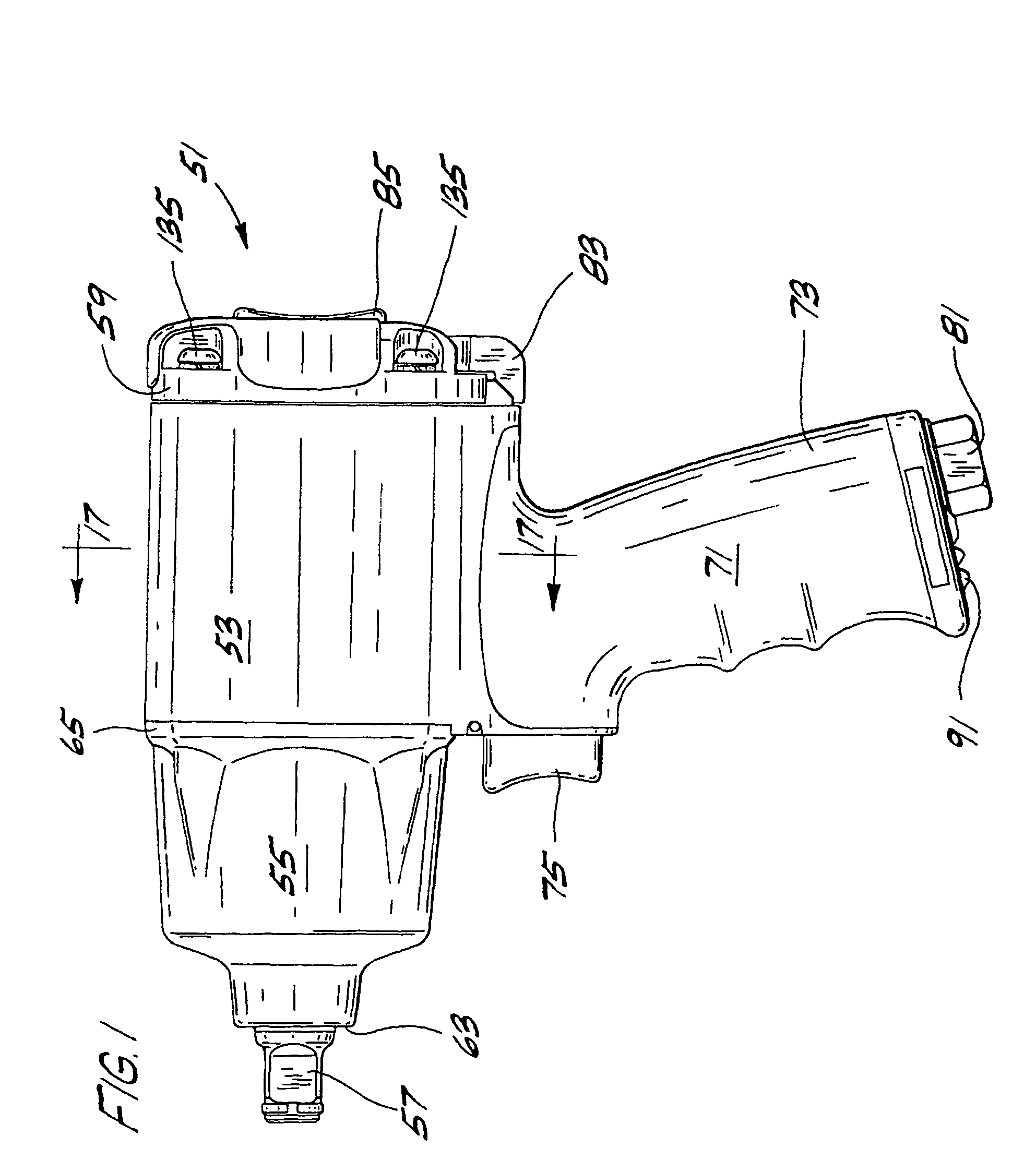

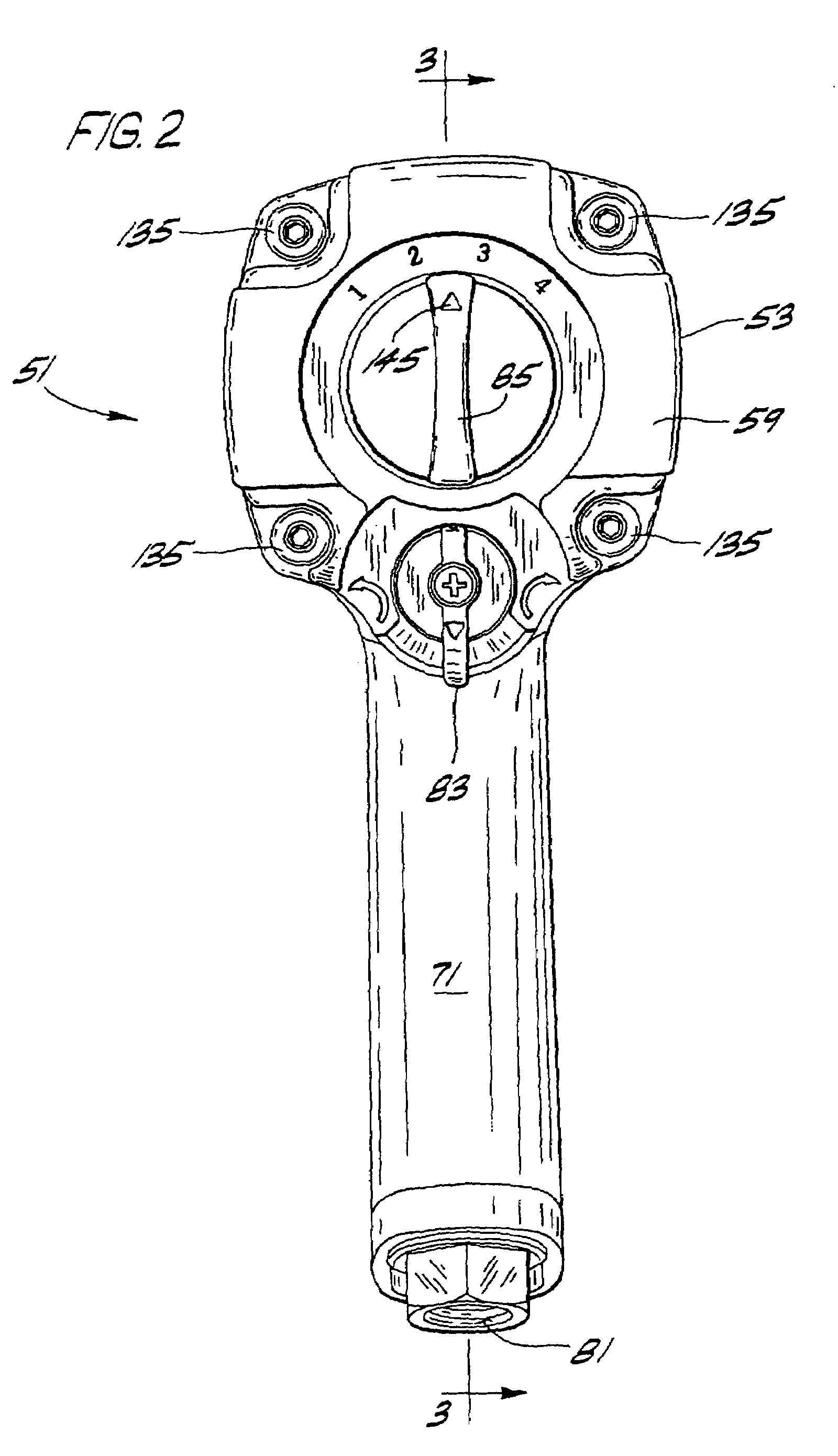

Bidirectional pneumatic impact wrench

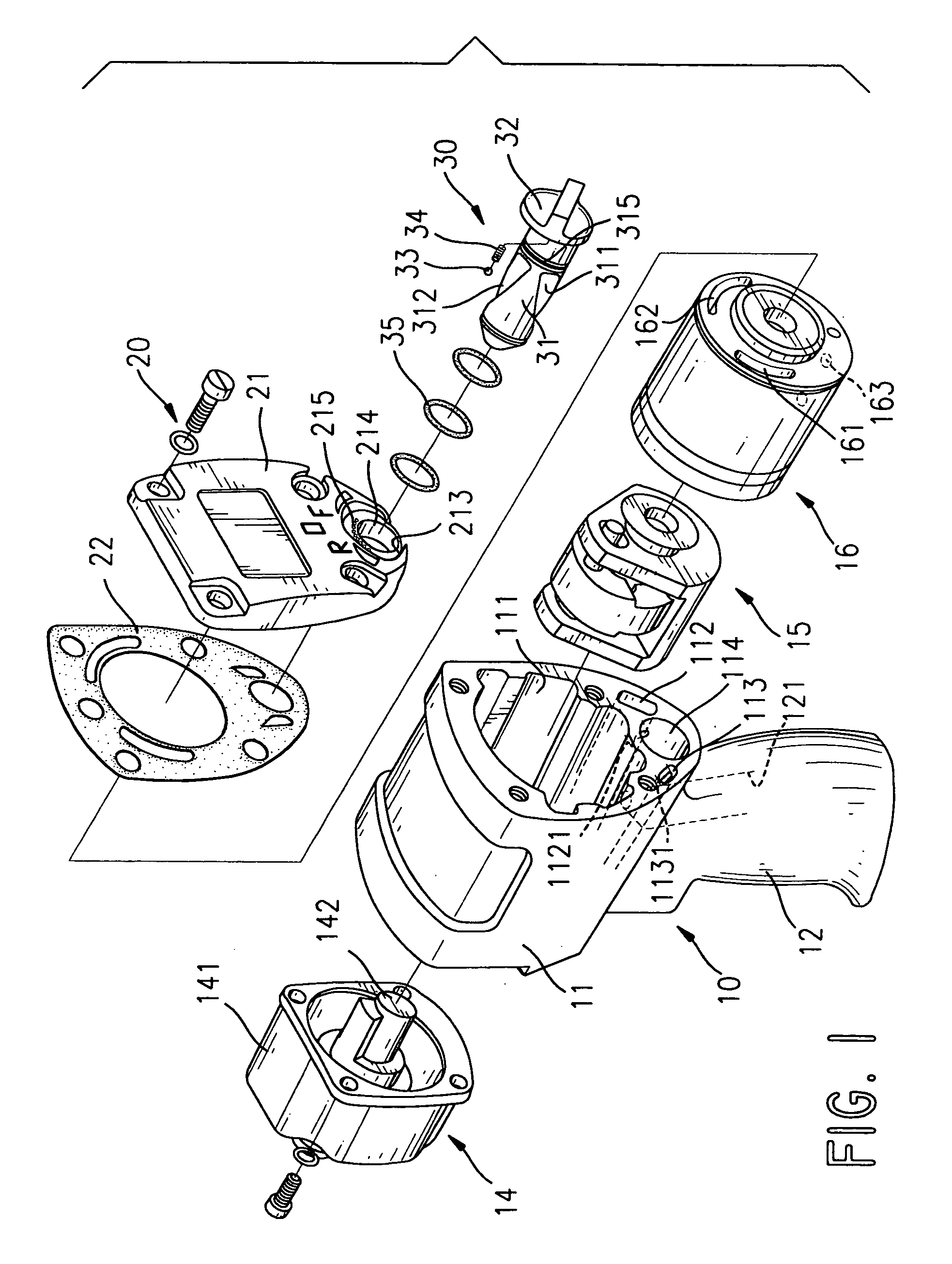

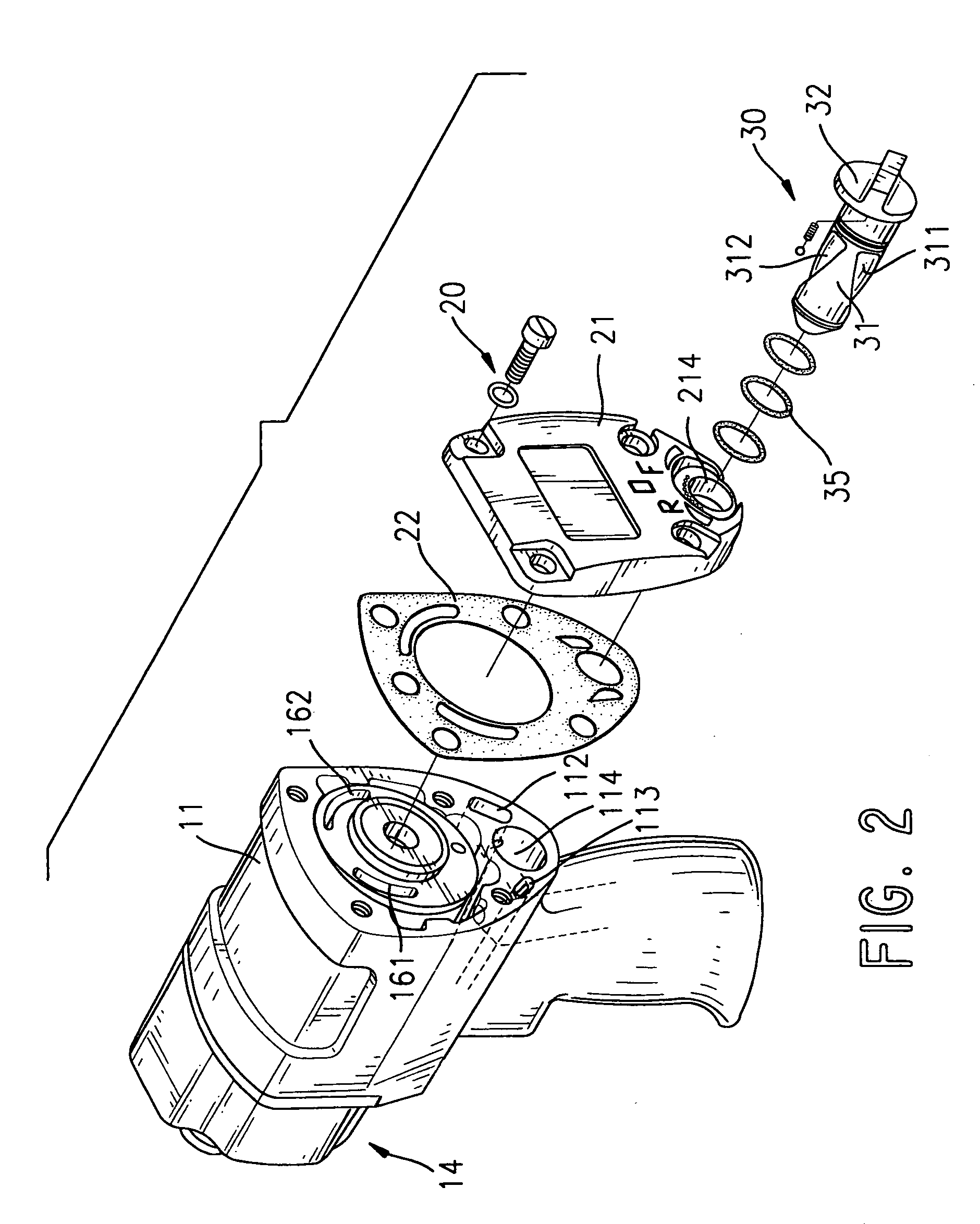

InactiveUS6883619B1Simple structureEfficiently directsOperator-supported drilling machinesPower driven toolsControl valvesImpact wrench

A bidirectional pneumatic impact wrench has a pneumatic motor and an air control valve. The pneumatic motor has a forward air inlet and a reverse air inlet. The air control valve directs compressed air selectively into either the forward air inlet or the reverse air inlet to change the direction of rotation of the pneumatic motor and includes a rotatable shaft. The shaft has an exterior surface and a spiral forward air groove and reverse air groove that are symmetrically defined in the exterior surface to direct the compressed air efficiently. The air control valve is simple to fabricate and directs the compressed air efficiently into the pneumatic motor to improve power and efficiency of the pneumatic motor.

Owner:HUANG YUNG CHAO

Compressed air powered vehicle

InactiveUS20060225941A1Electric propulsion mountingGas pressure propulsion mountingElectricityElectric drive

A compressed air powered vehicle is disclosed. The vehicle includes a vehicle chassis having wheels. An electric drive motor drivingly engages at least one of the wheels. An electric generator is electrically connected to the electric drive motor, and an air motor drivingly engaging the electric generator. A compressed air source is pneumatically connected to the air motor, and an air compressor is provided on the chassis and pneumatically connected to the compressed air source to replenish compressed air in the compressed air tanks as needed.

Owner:COLE WILLIAM JAY

Hydraulically and volumetrically dispensing fluid

InactiveUS6957747B2Allocation is accurateAccurate dispensing volumeOpening closed containersBottle/container closureEngineeringCatheter

Owner:NORDSON CORP

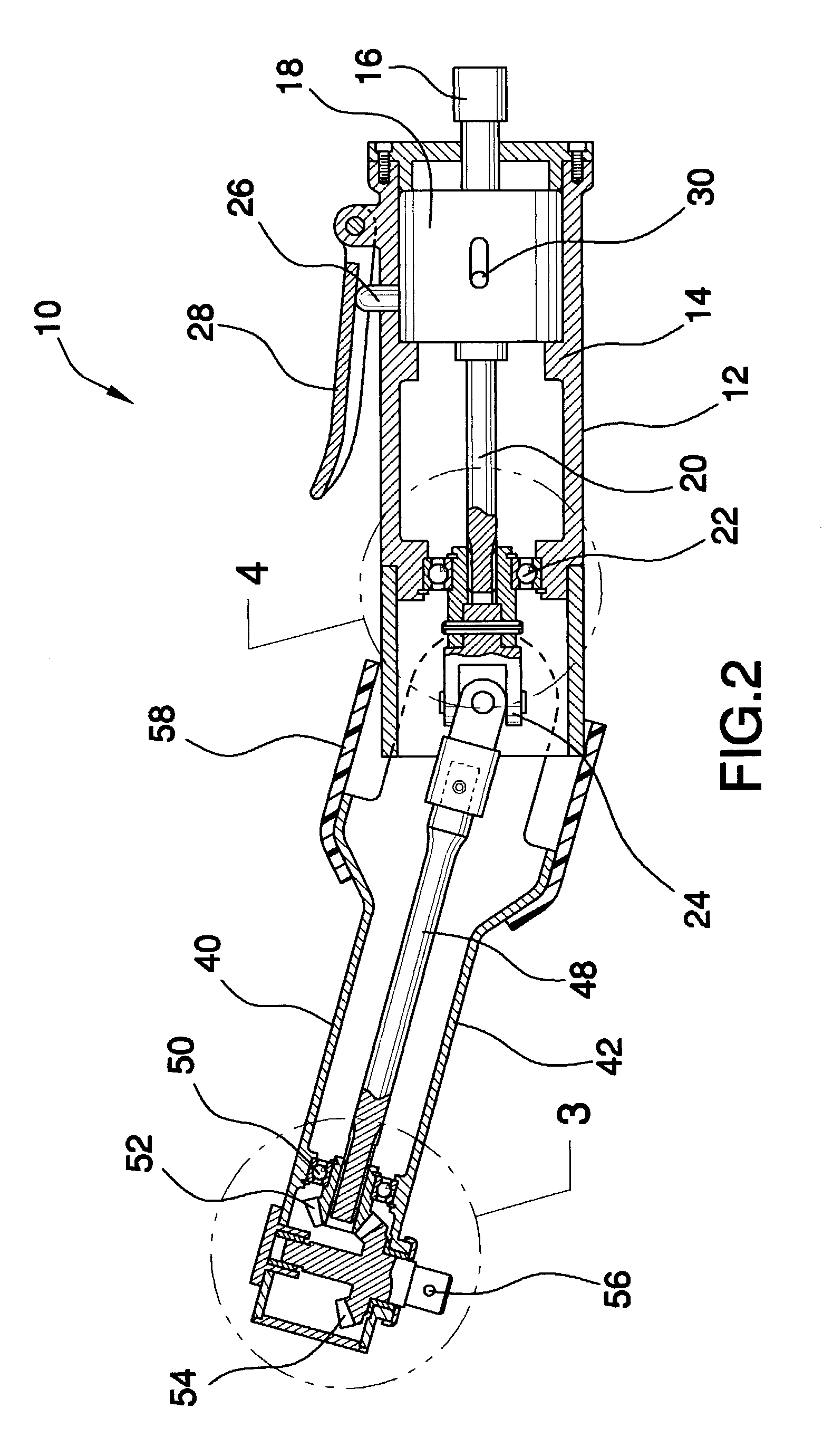

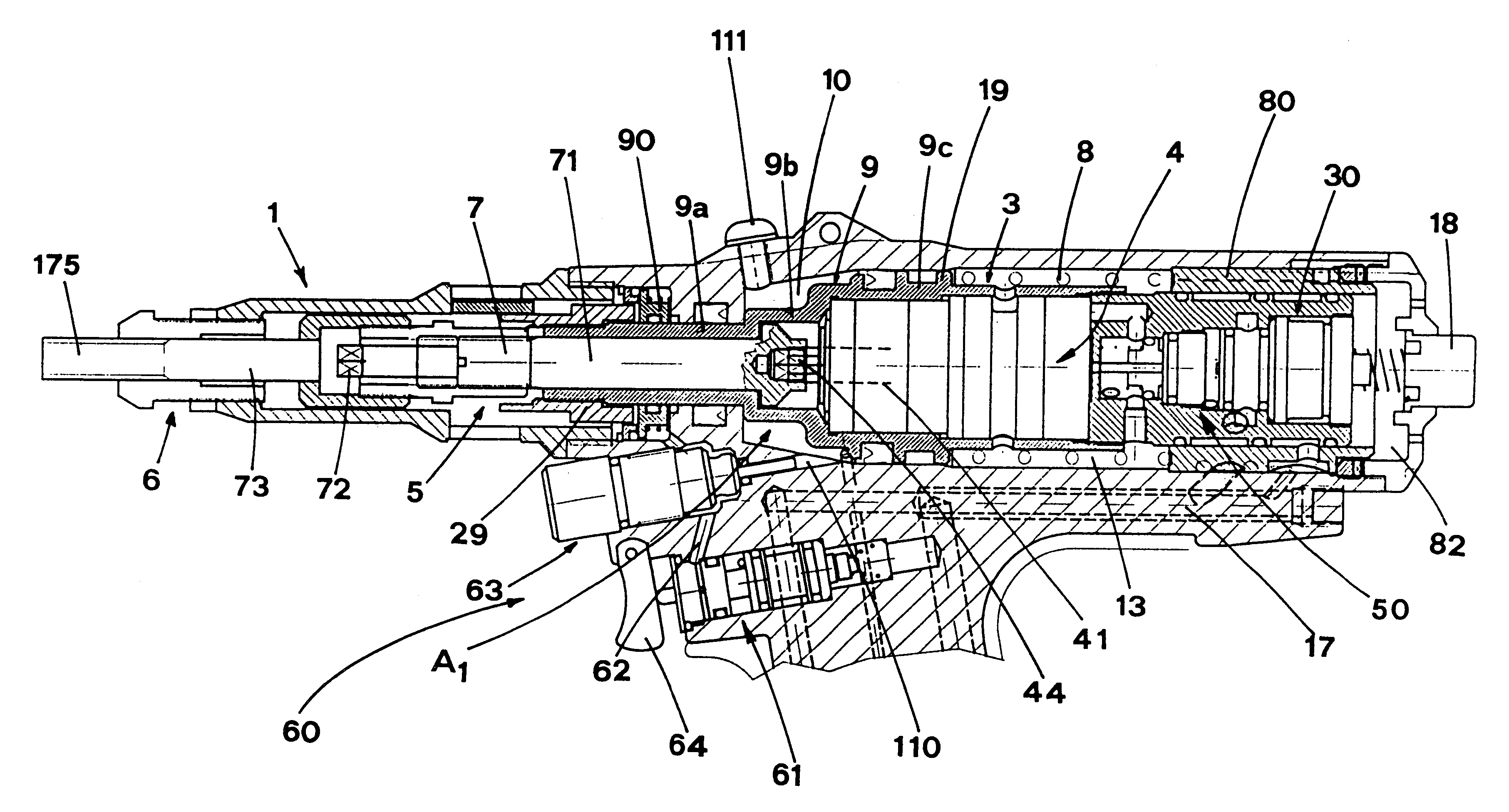

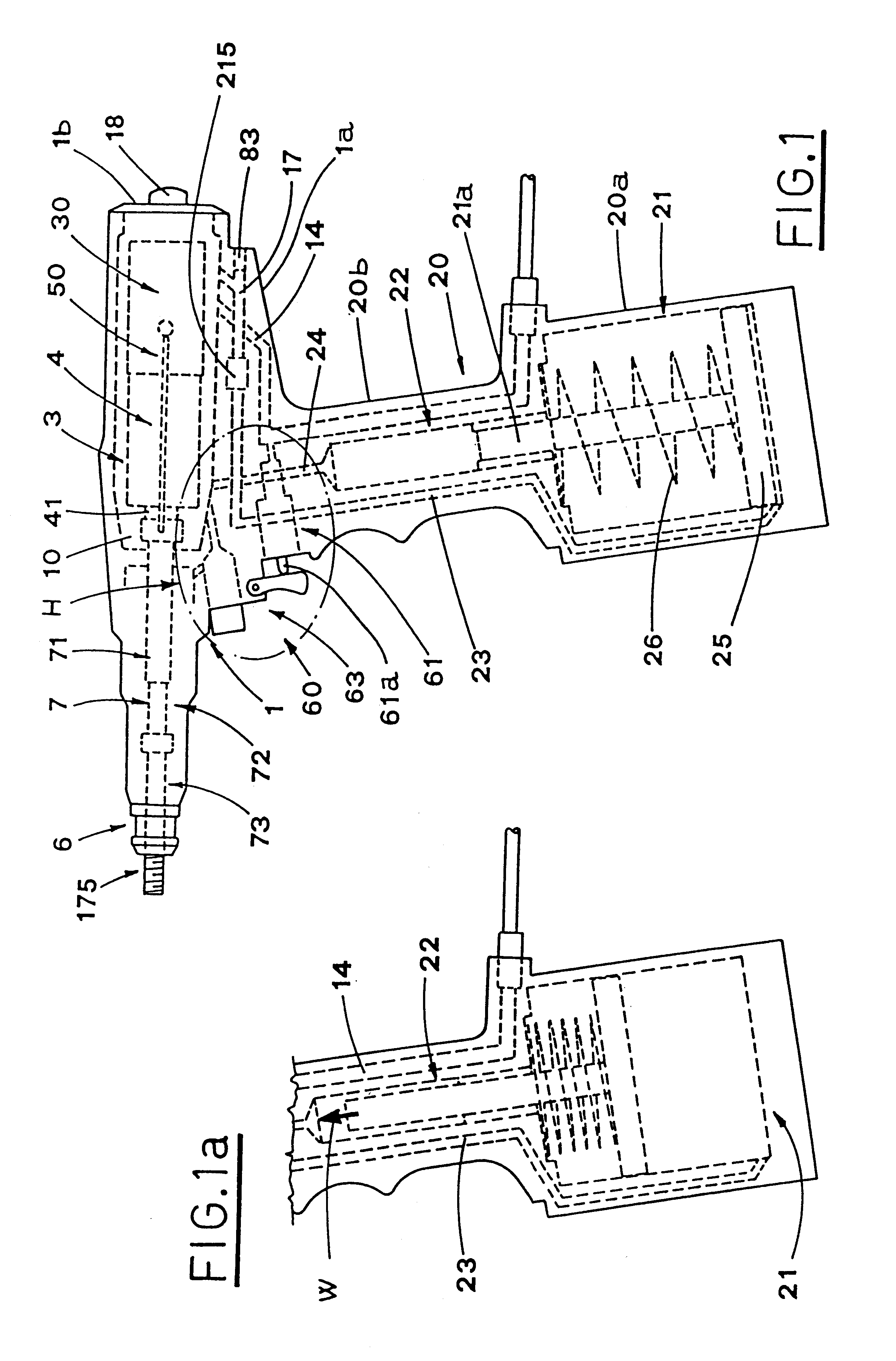

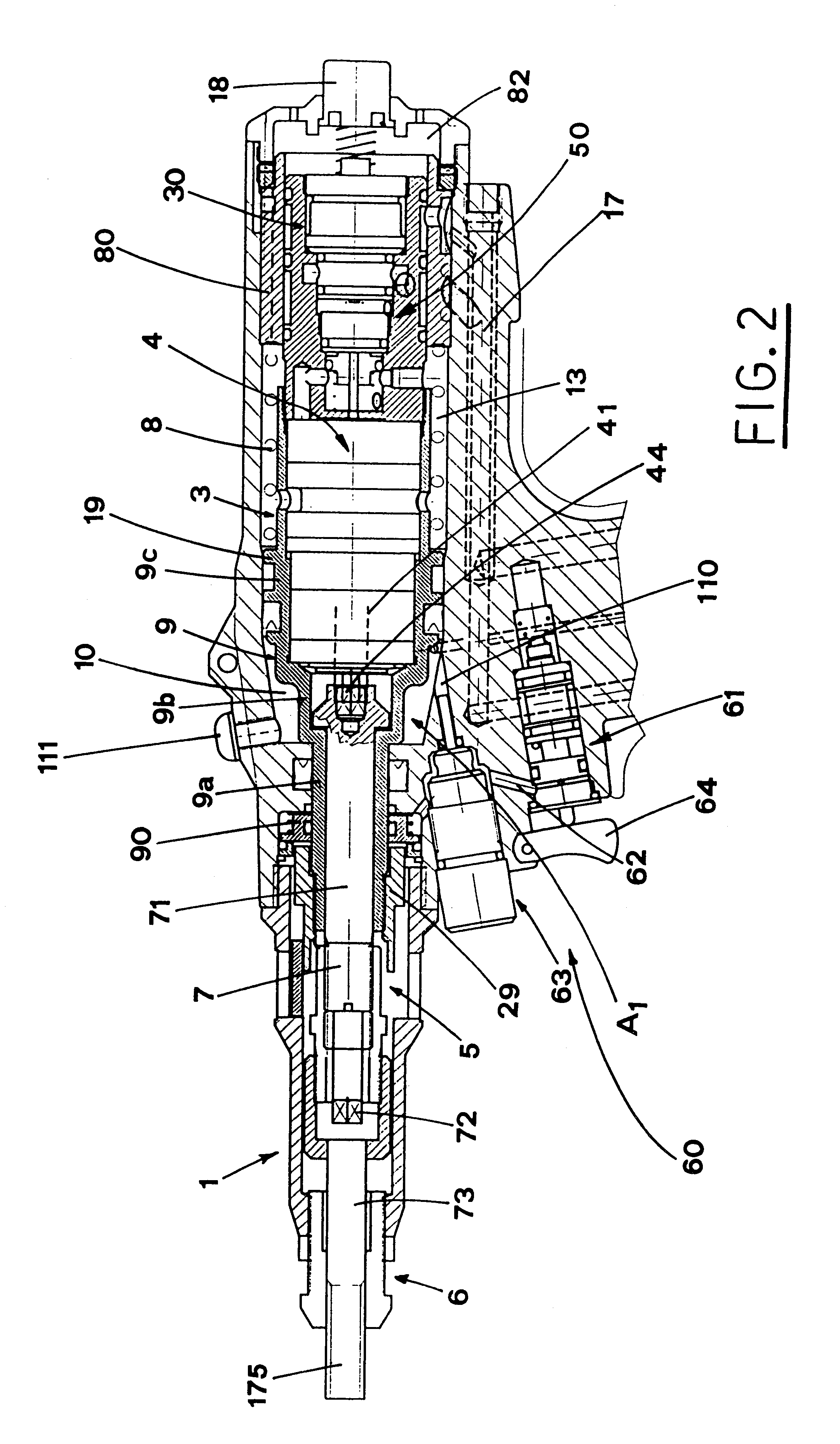

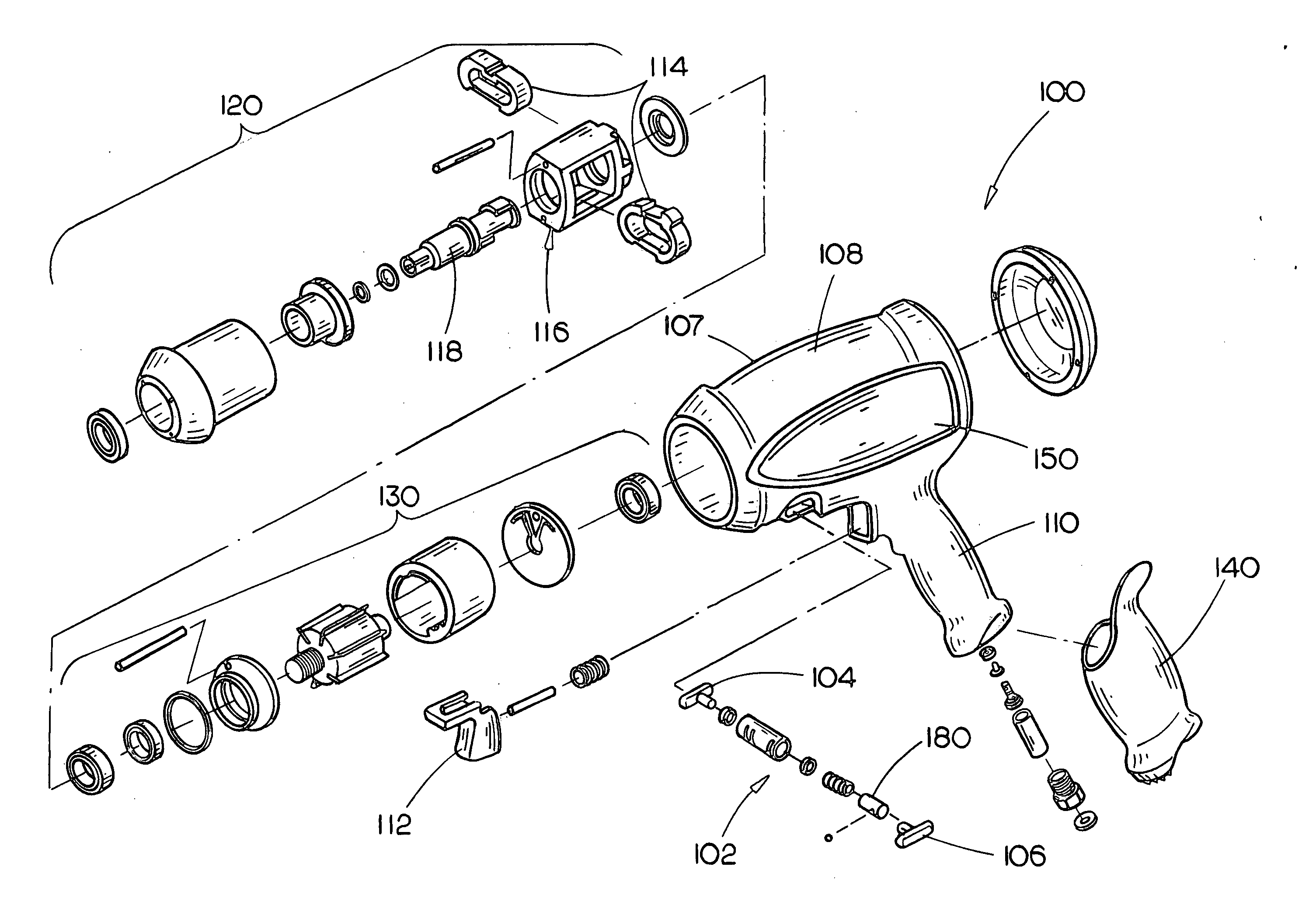

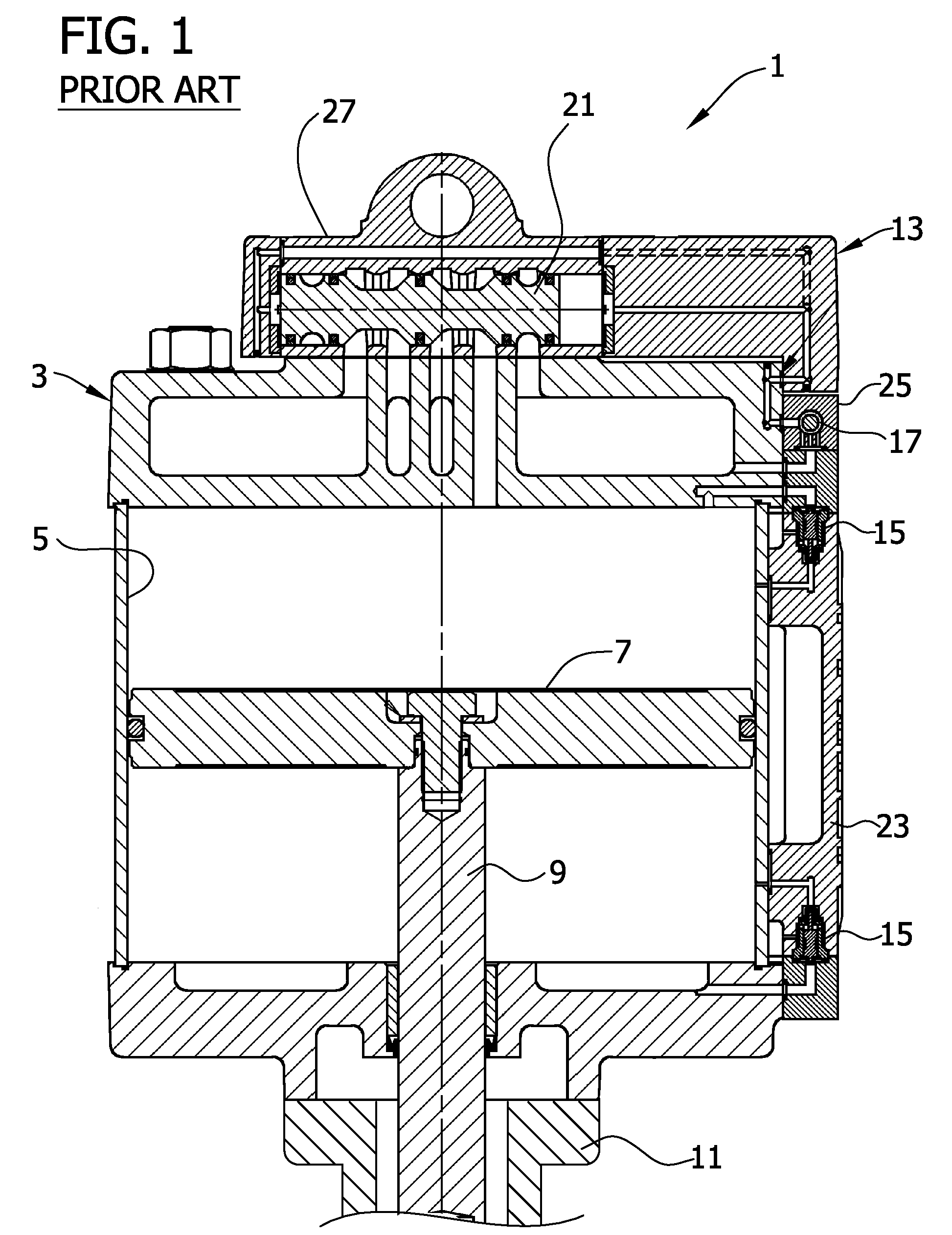

Pneumatic-hydraulic rivet gun

InactiveUS6272899B1Simple and quick controlEasy to handlePortable power-driven toolsMetal working apparatusHydraulic cylinderInlet valve

A rivet gun includes a pneumatic motor (4), that drives a segment stem 7. A pneumatic cylinder (21) actuates a hydraulic cylinder (22) which sends oil under pressure to an expansion chamber (10) provided for moving back the segment stem (7) and buckling the rivet (2) fixing it to a laminate structure (100). The rivet gun also includes a change-over switching device (30) linked to controls (50,60) for reversing rotation of the motor (4). The controls (60) include an inlet valve (61) operated by a trigger (64) for connecting a compressed air infeed duct 14 with a feed-discharge duct (23) leading to the pneumatic cylinder (21). A discharge valve (63) is disposed in series with the inlet valve (61) and has an adjustment ring (176) for adjusting of the maximum traction force. Another discharge valve (90) is disposed in series with the discharge valve (63) previously mentioned and is provided for adjustment of the stroke of the segment stem (7).

Owner:OBER UTENSILI PNEUMATICI

Pneumatic rotary tool

InactiveUS6880645B2Low costEasy to useConstructionsReciprocating drilling machinesPlastic materialsPneumatic tool

Owner:S P AIR

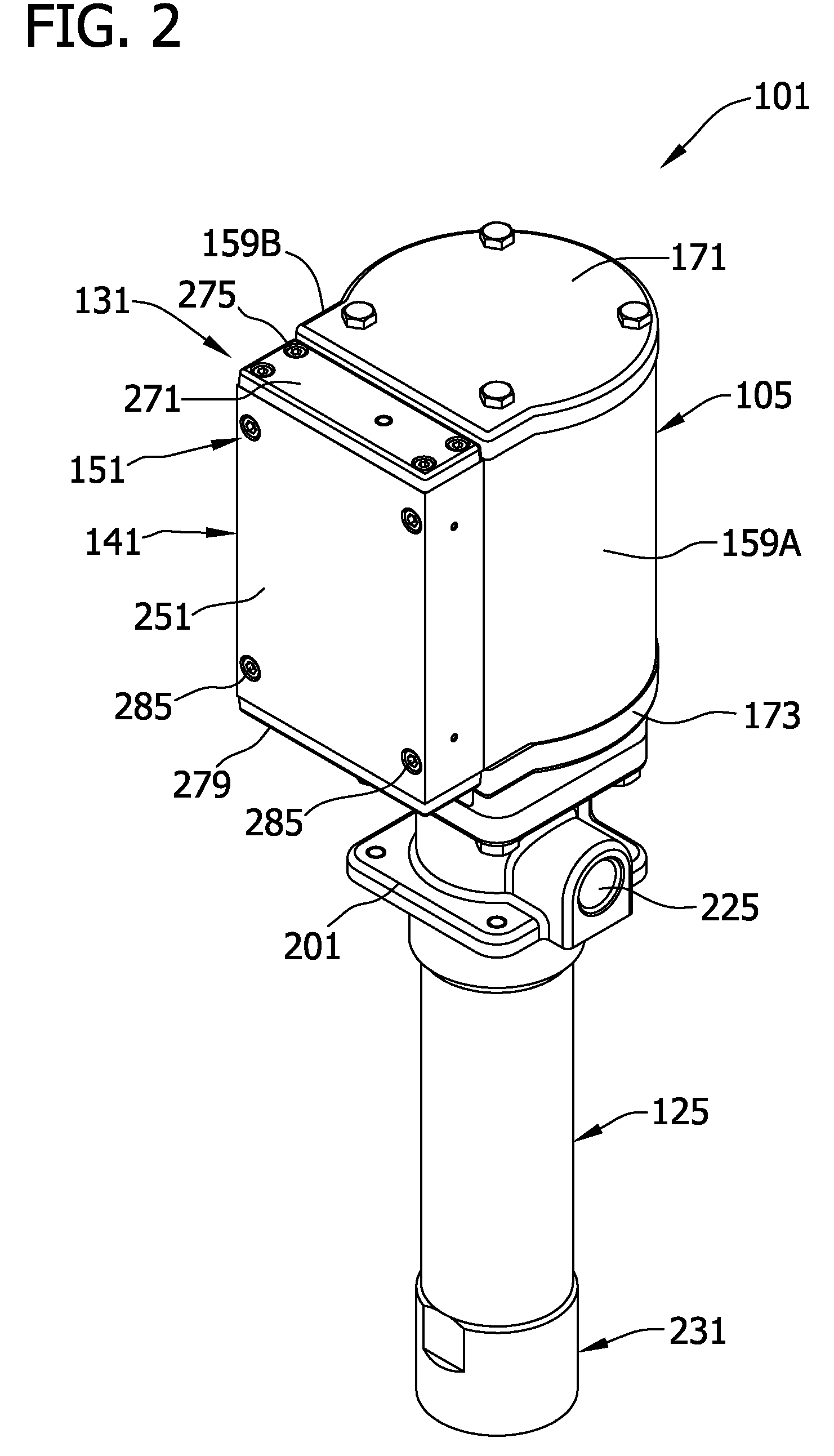

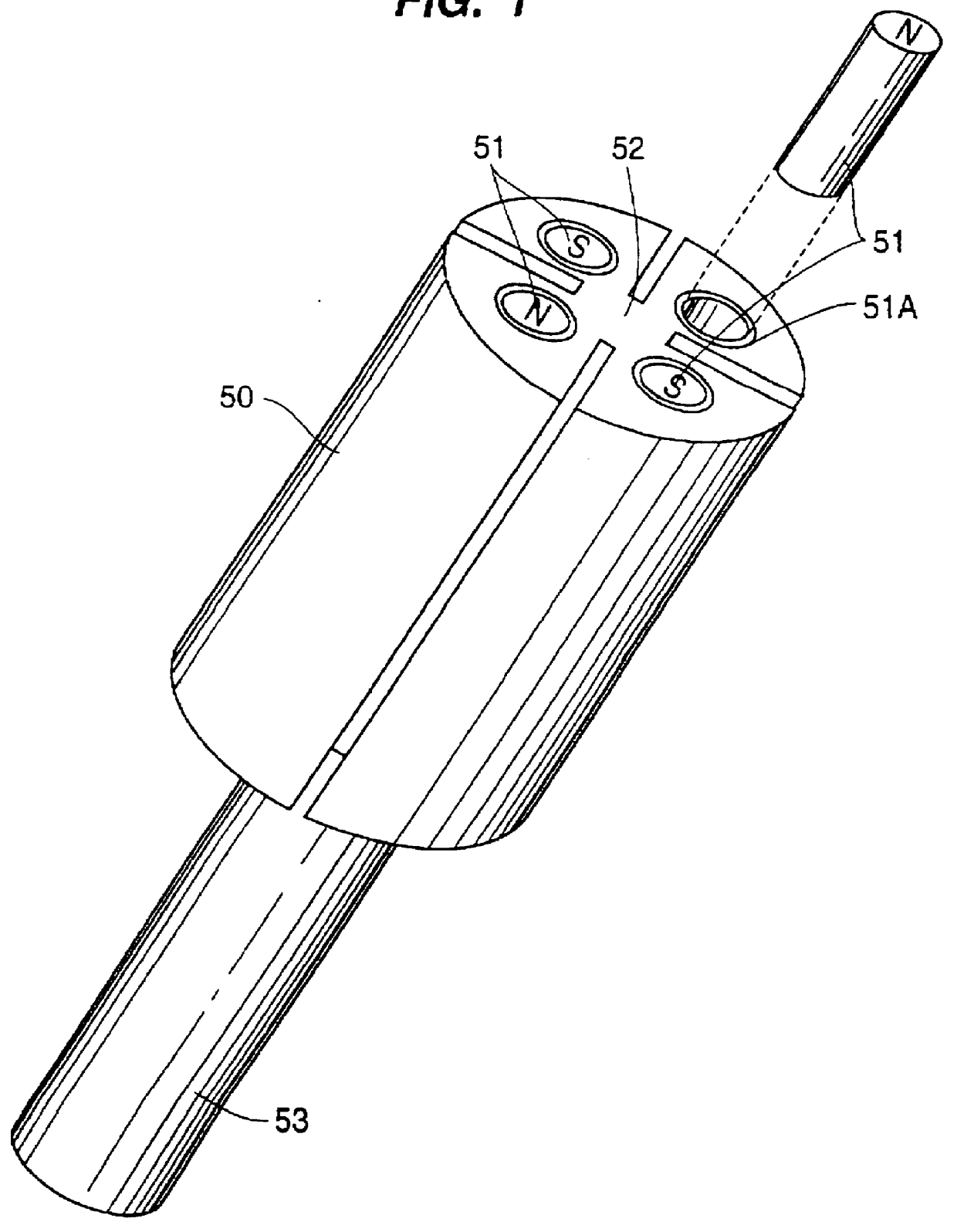

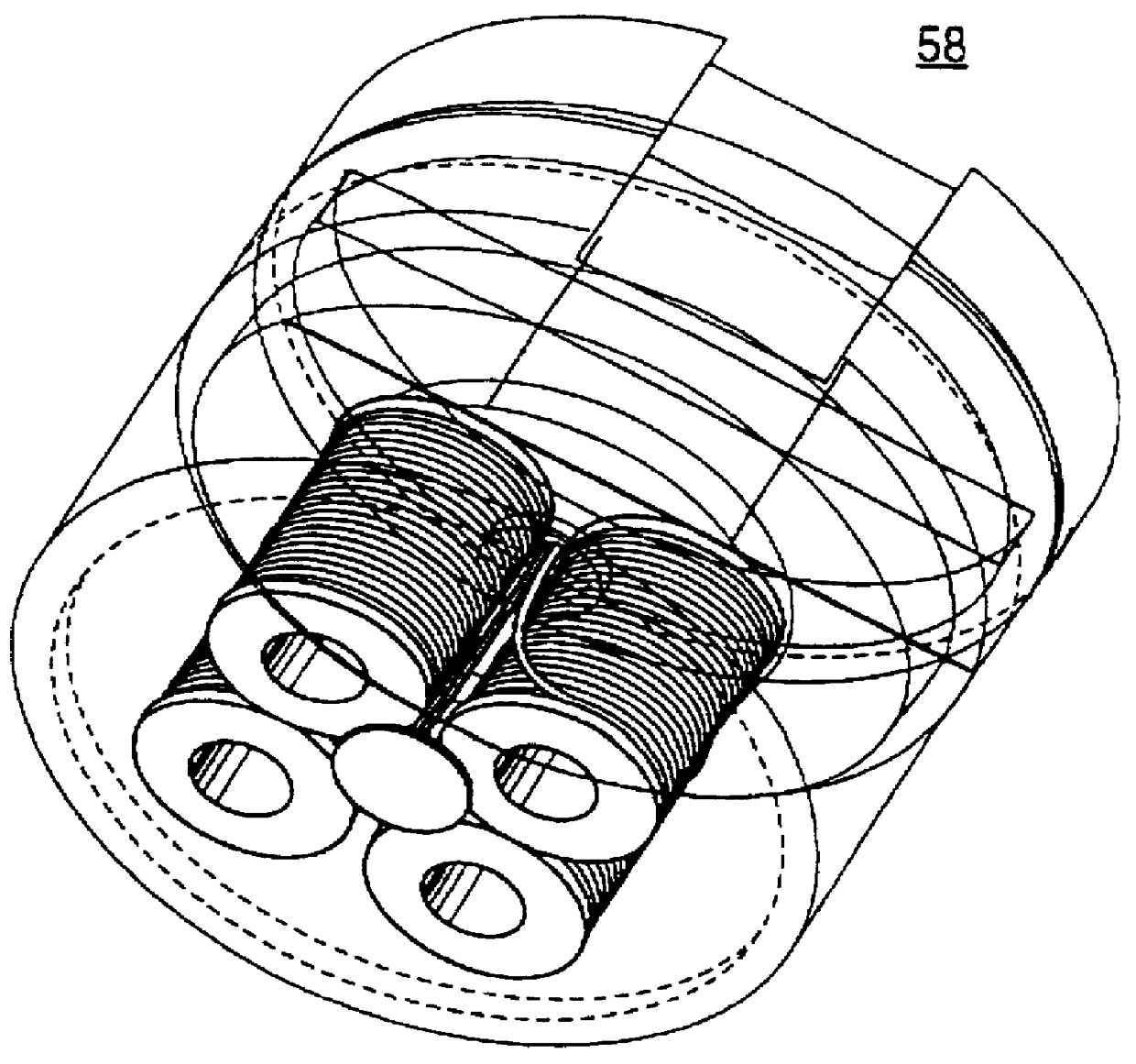

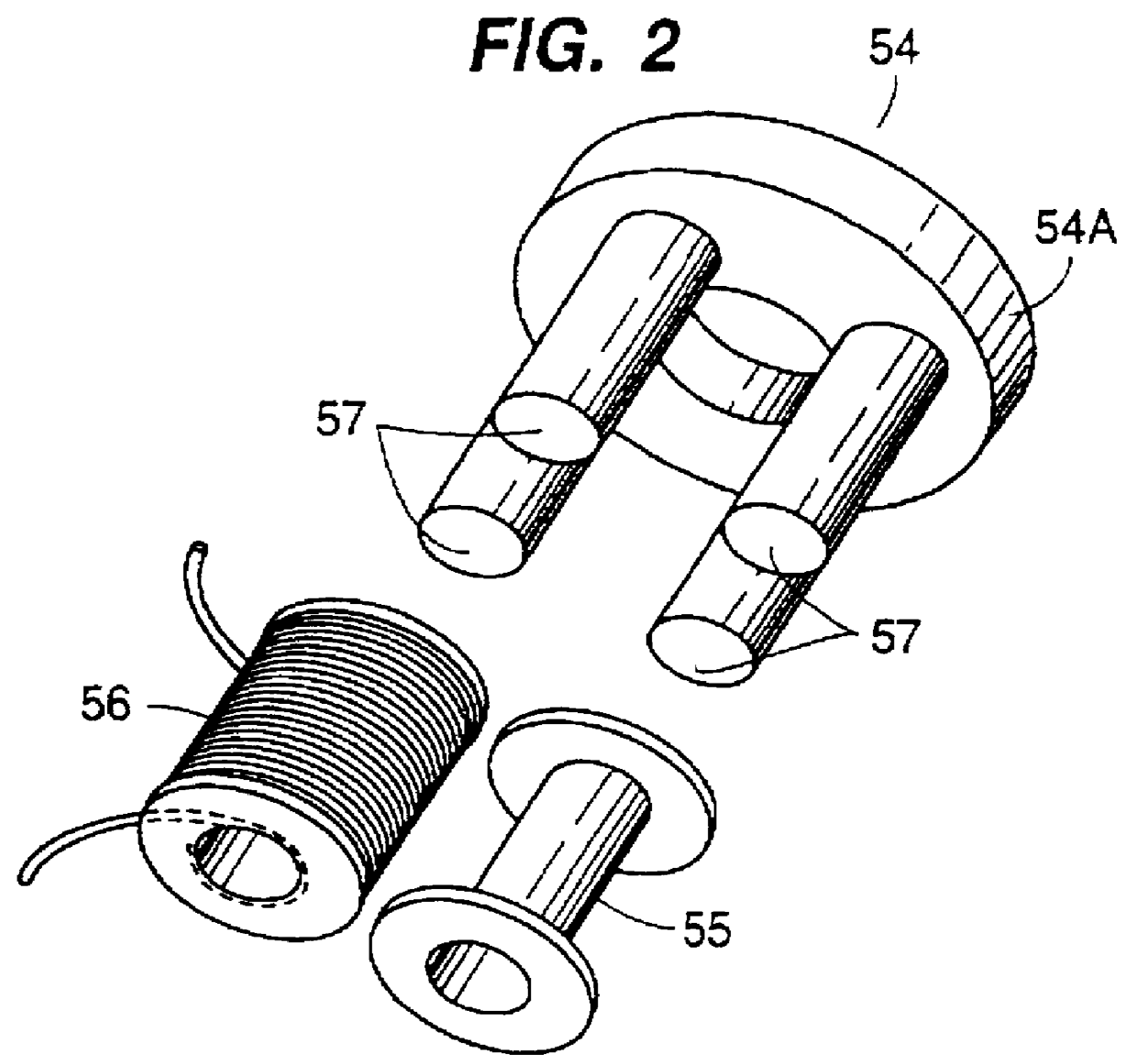

Magnetically sequenced pneumatic motor

A pneumatic motor having a piston and a magnetically actuated valve. The magnetically actuated valve may be adjacent the piston and, in some embodiments, include a spool valve.

Owner:CARLISLE FLUID TECH INC

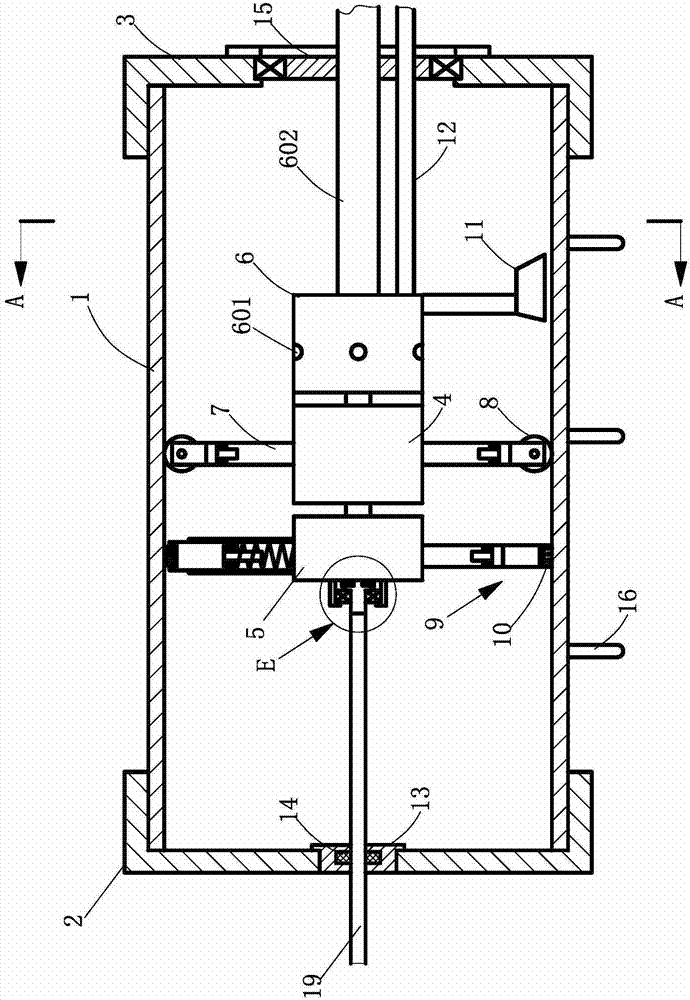

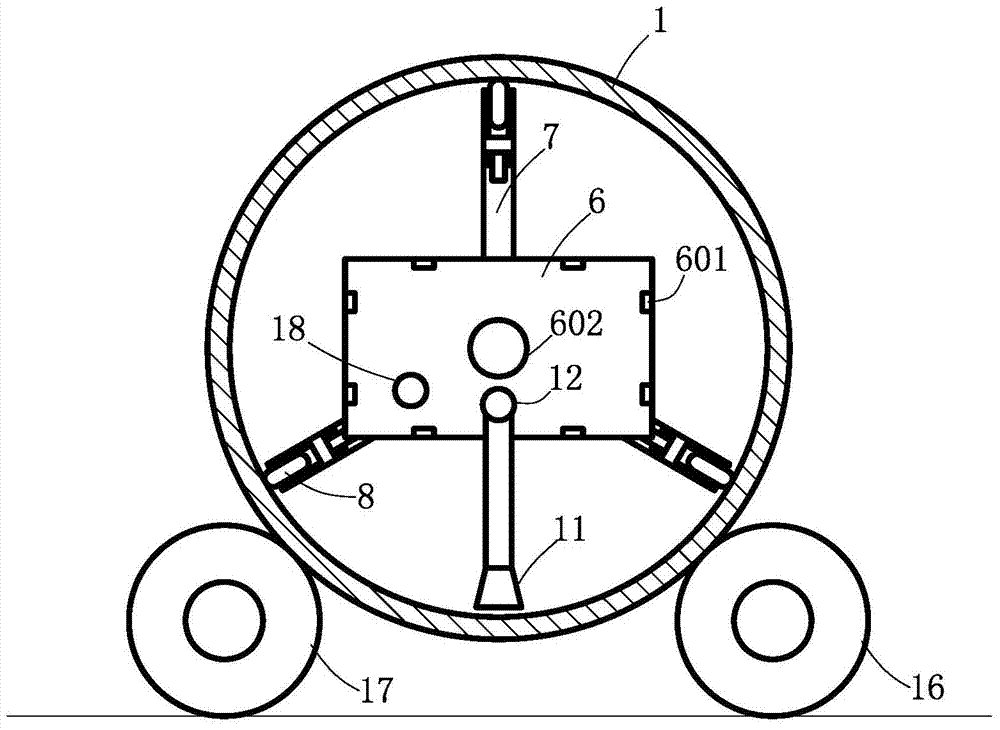

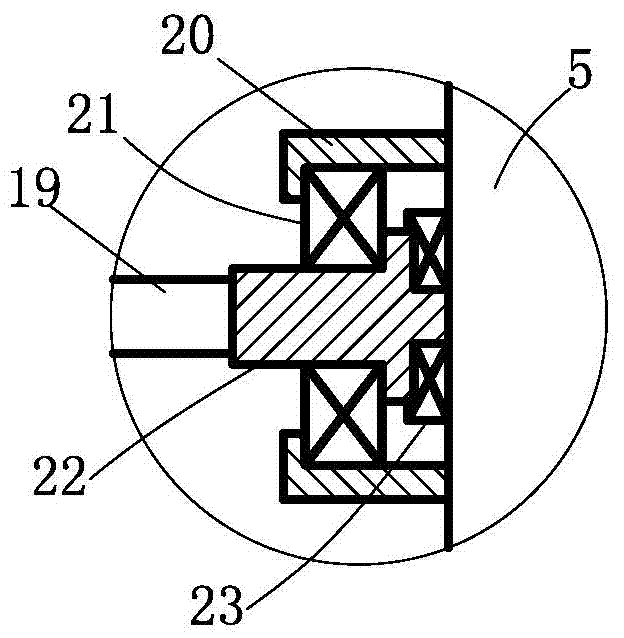

Pipeline inner wall rust removal device

ActiveCN104723223AAvoid pollutionReduce direct damageGrinding machinesAbrasive machine appurtenancesPneumatic motorPollution

The invention discloses a pipeline inner wall rust removal device, belonging to the technical field of polishing units. The device comprises a first end cover and a second end cover which are hermetically installed at two ends of the pipeline, a rust removal trolley is arranged in the pipeline, the dust removal trolley comprises a pneumatic motor with dual output shafts, a shell of the pneumatic motor is provided with a plurality of support shafts, the end part of each support shaft is provided with a roller wheel, a grinding disc is fixedly installed on the output shaft of the pneumatic motor, close to the first end cover, and is provided with a plurality of support rods in the radial direction, the end part of each support rod is provided with an abrasive disc, the output shaft of the pneumatic motor, close to the second end cover, is connected with a shot-blasting machine in a transmission manner; the end part of the grinding disc is connected with a traction rope, the traction rope extends out of the first end cover, one end of the shot-blasting machine, close to the second end cover, is connected with a shot feeding pipe, the pneumatic motor is connected with a gas inlet pipe, the shot feeding pipe and the gas inlet pipe extend out of the second end cover. The pipeline inner wall rust removal device can be used for solving the technical problems that the pipeline inner wall is serious in rust removal pollution and the rust removal effect is poor, and can be widely applied to pipeline cleaning.

Owner:SHANGHAI HONGPU STEEL STRUCTURE ENG

Hand tool with impact drive and speed reducing mechanism

ActiveUS7080578B2Reduce speedEasy to driveOperator-supported drilling machinesSpannersGear wheelHand tool

Owner:VESSEL FUKUCHIYAMA

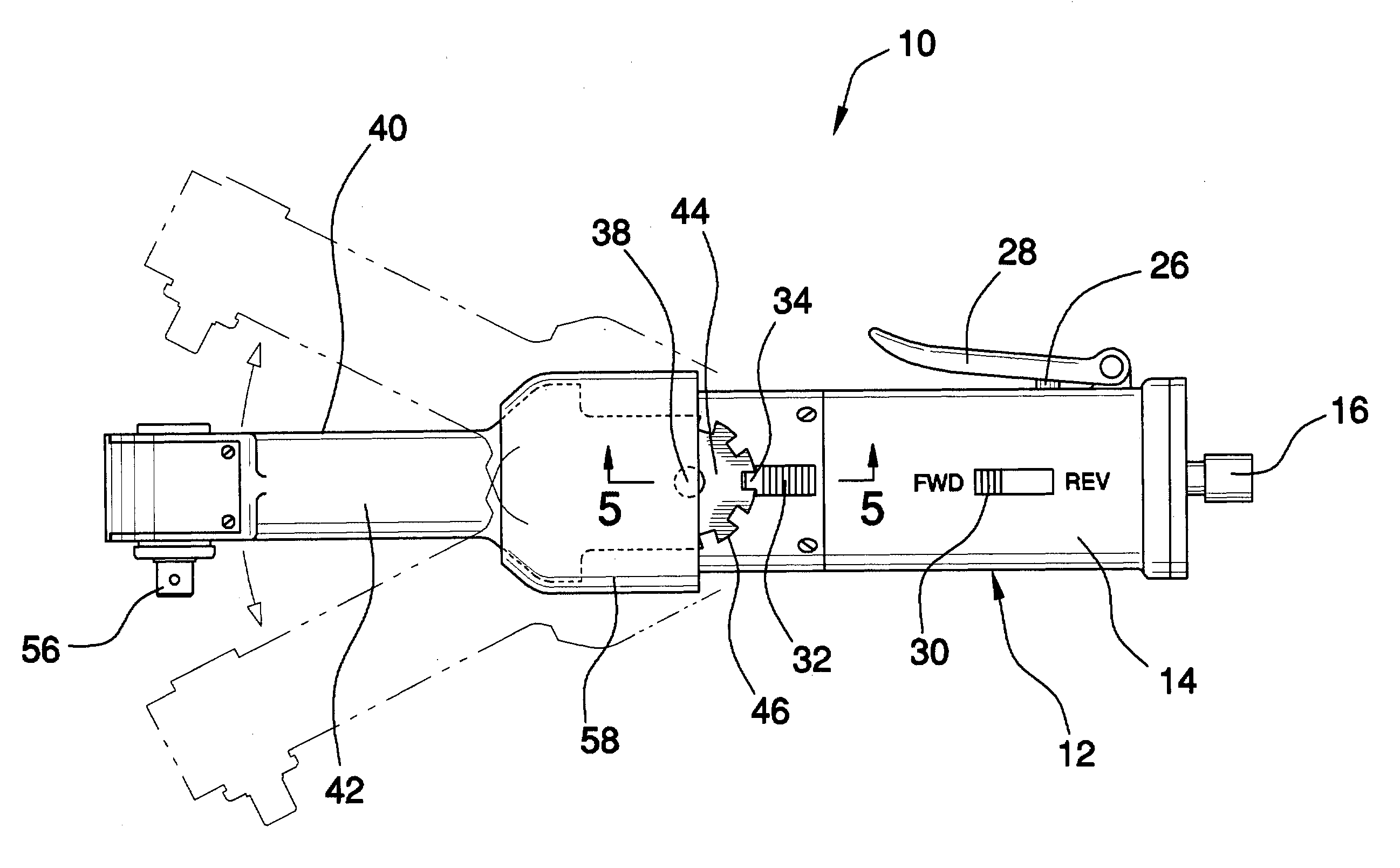

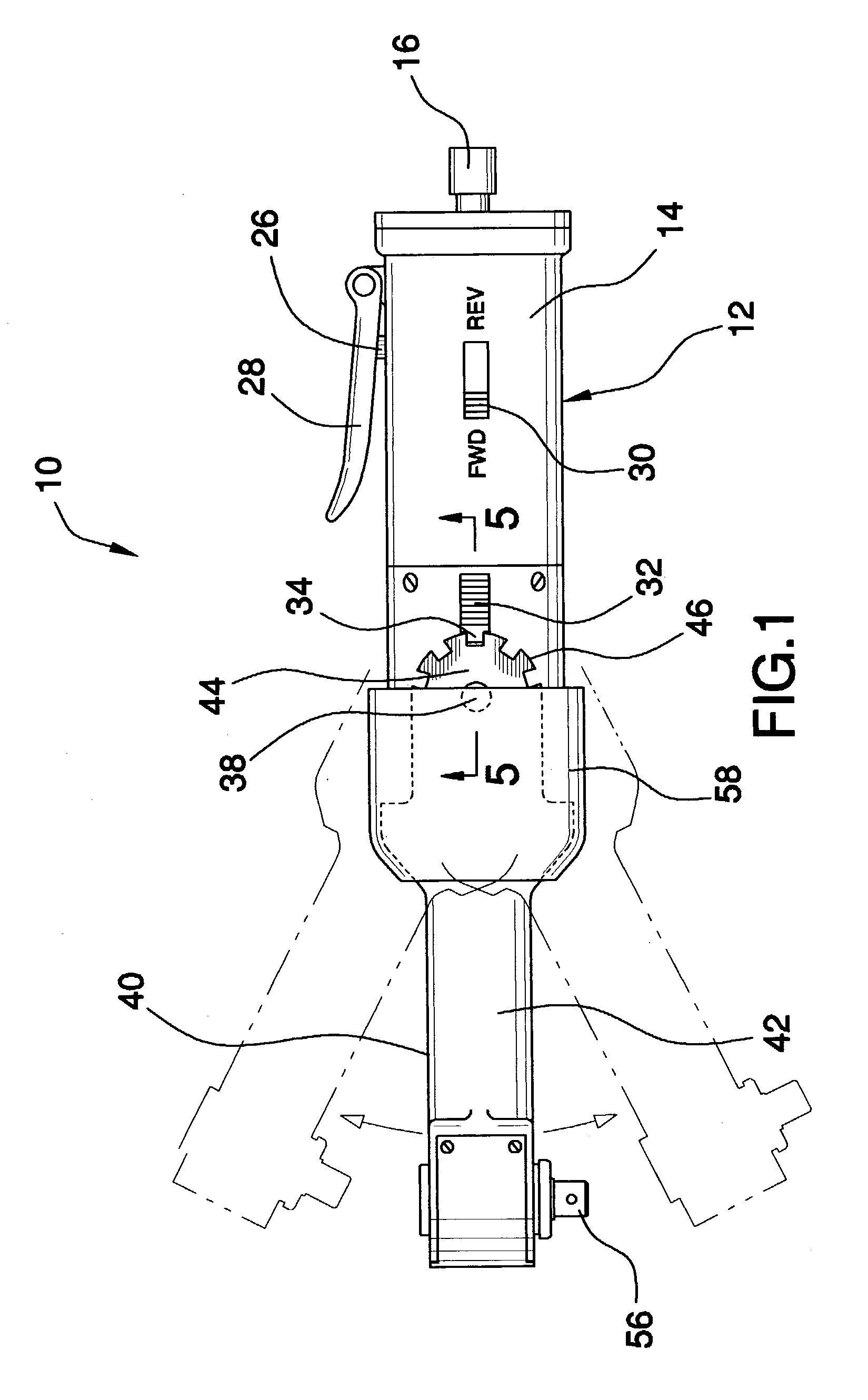

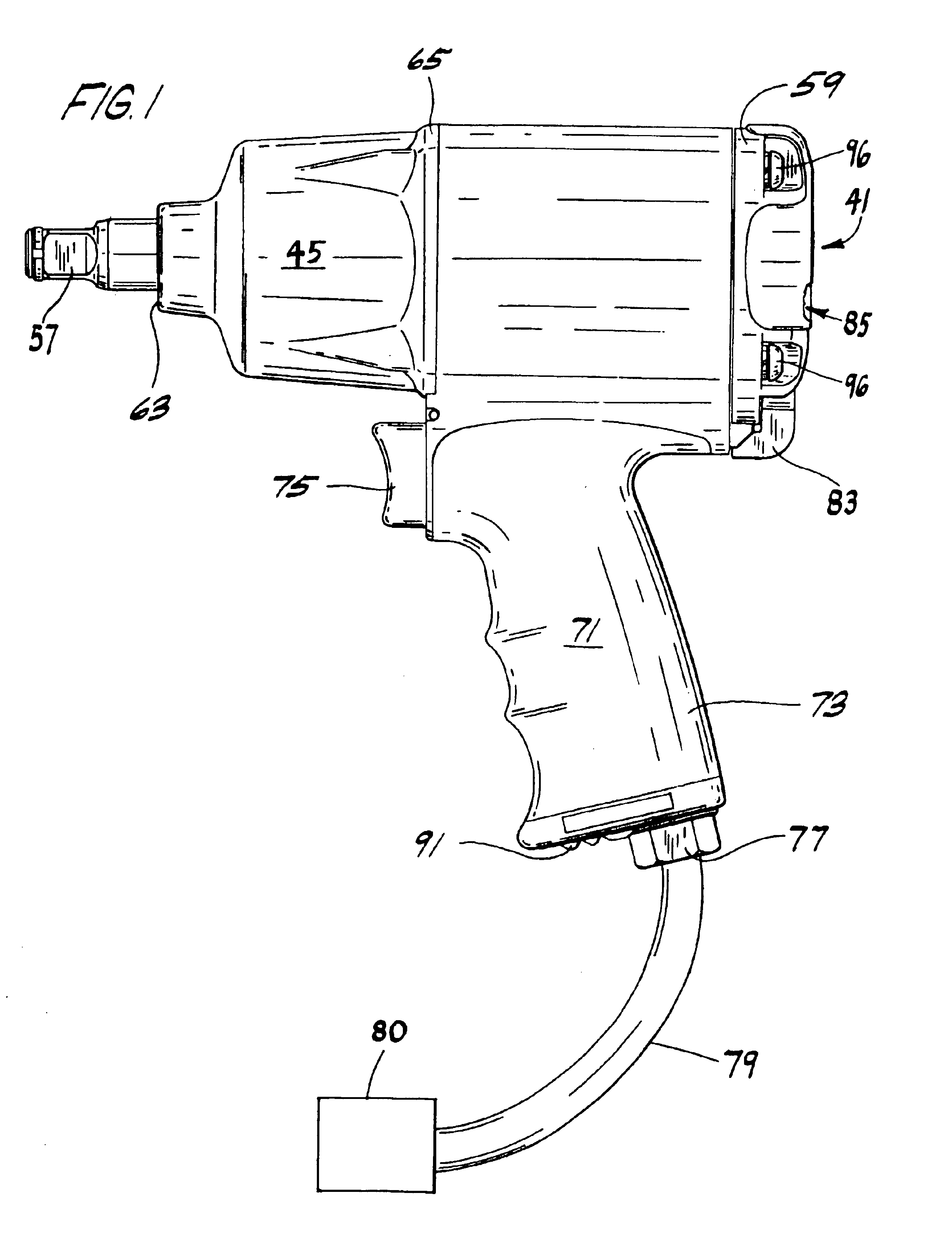

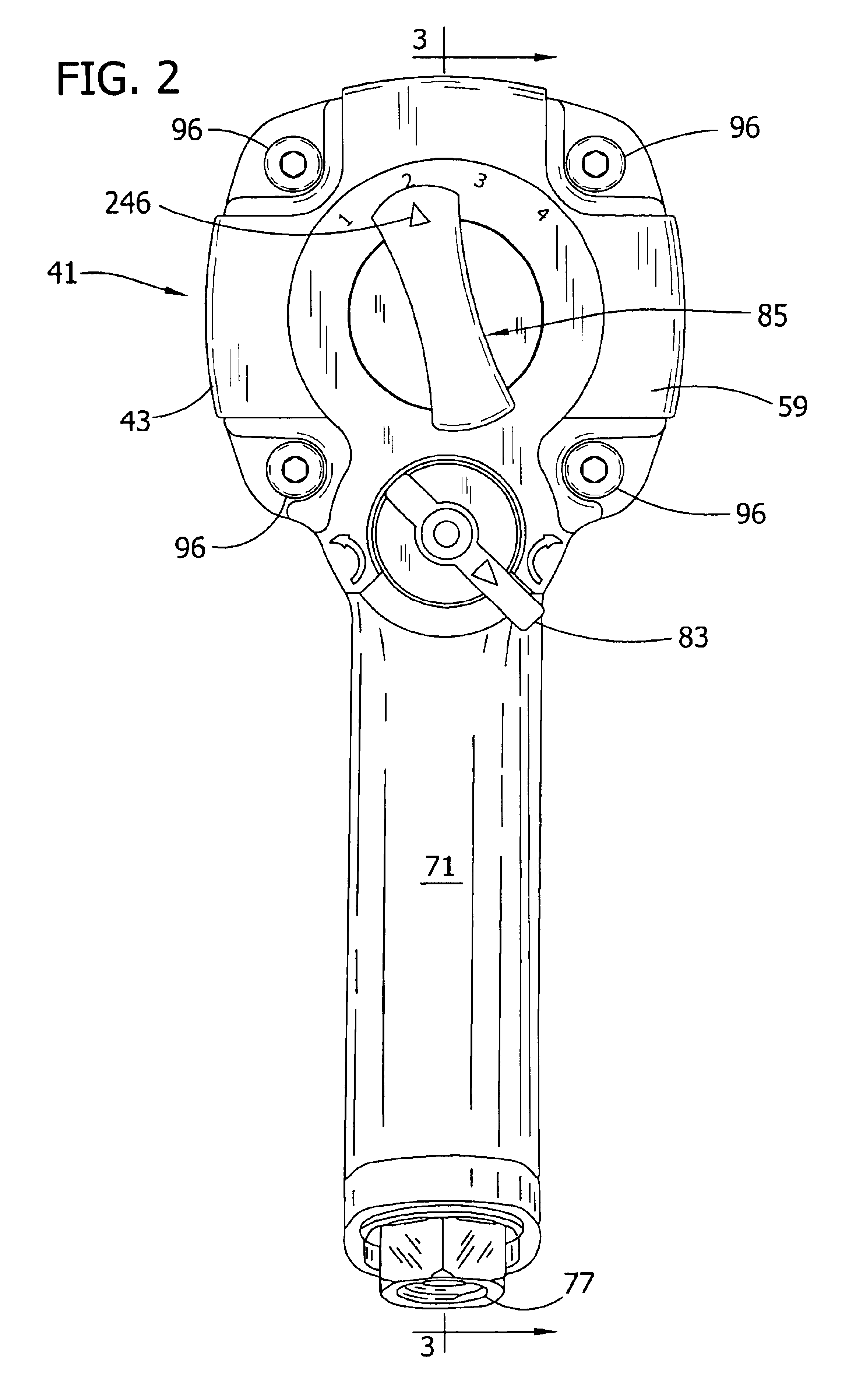

Pneumatically powered rotary tool having linear forward and reverse switch

A pneumatically powered rotary tool includes a linear forward and reverse switch assembly for alternatively setting the air motor of the tool to rotate the drive assembly of the tool in either of the clockwise direction or the counterclockwise direction. The switch assembly slides linearly along an axis generally perpendicular to the drive assembly between a first position for setting the air motor to rotate the drive assembly in the clockwise direction and a second position for setting the air motor to rotate the drive assembly in the counterclockwise direction. The switch assembly is positioned adjacent to the trigger so that the switch assembly can be slid between the first position and the second position by the index finger and thumb of the hand of the user gripping the handle portion without releasing the handle portion.

Owner:BLACK & DECKER INC

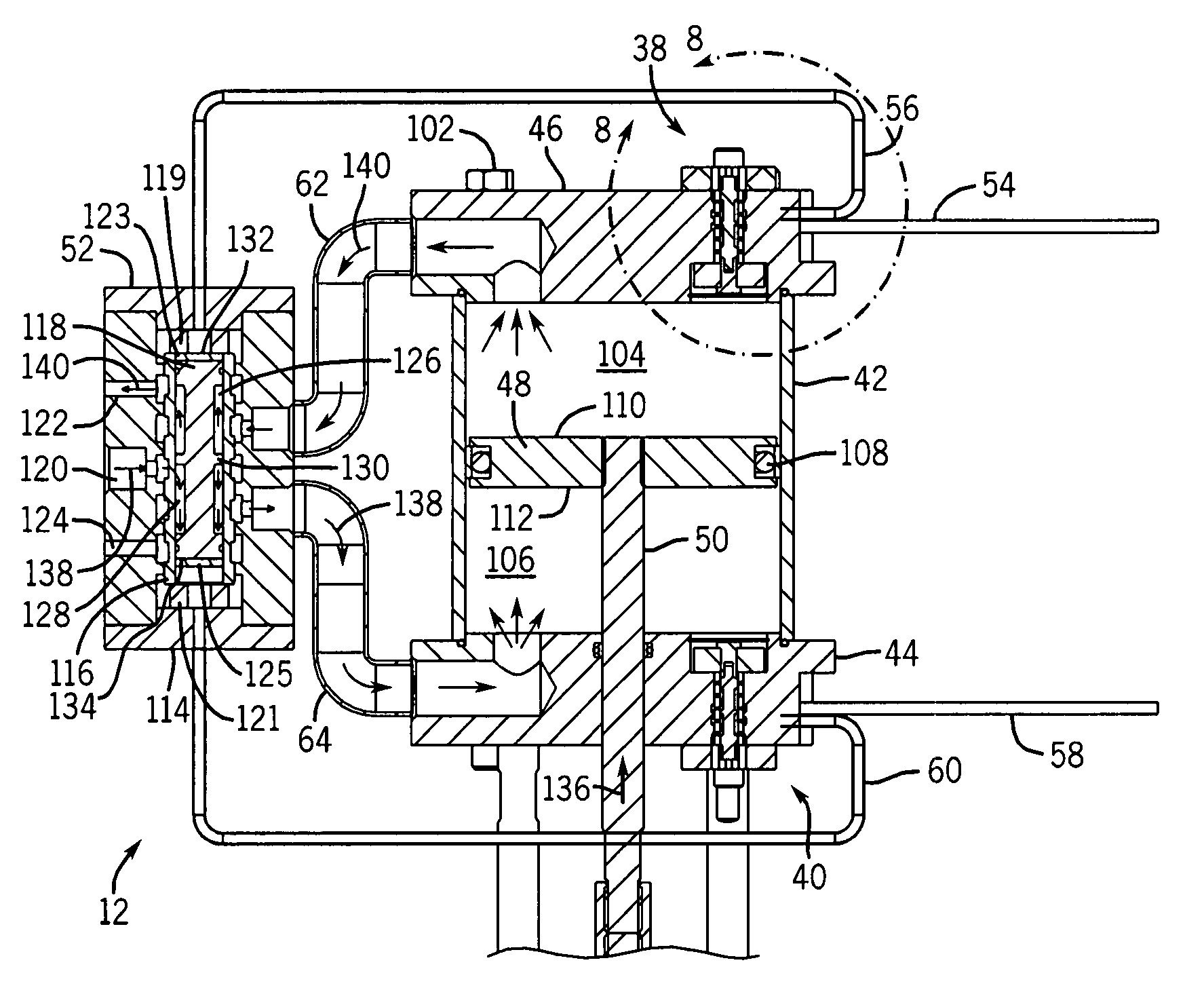

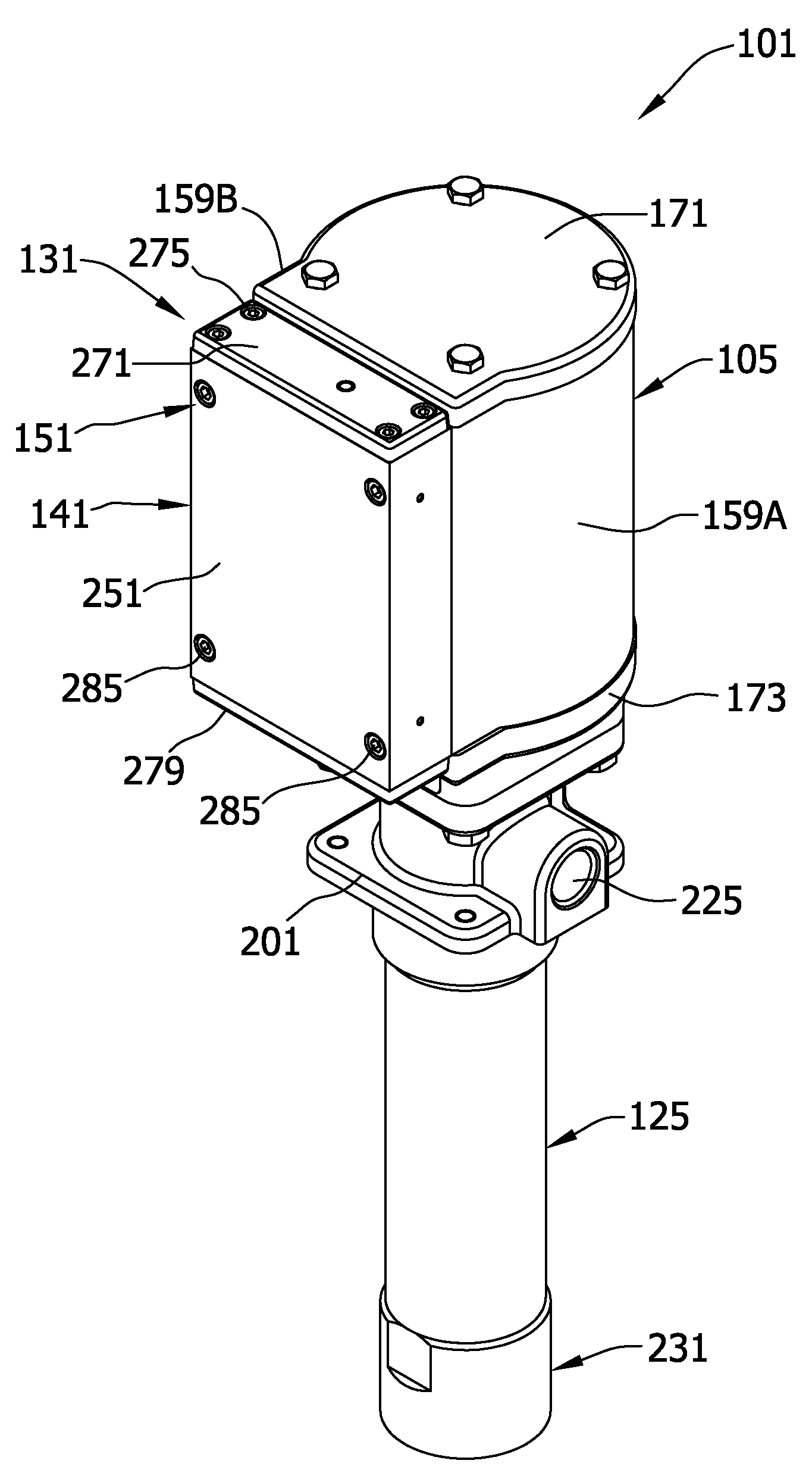

Air-Operated Pump

An air-operated pump for pumping material such as oil or grease. The pump is powered by an air motor which operates to reciprocate a piston and plunger to effect a pumping action. The air motor is modular in that the air valve system is contained in a single housing fastened to the pump head. The housing is removable as a unit from the pump head to facilitate servicing of the air valve system.

Owner:LINCOLN INDUSTRIES CORP

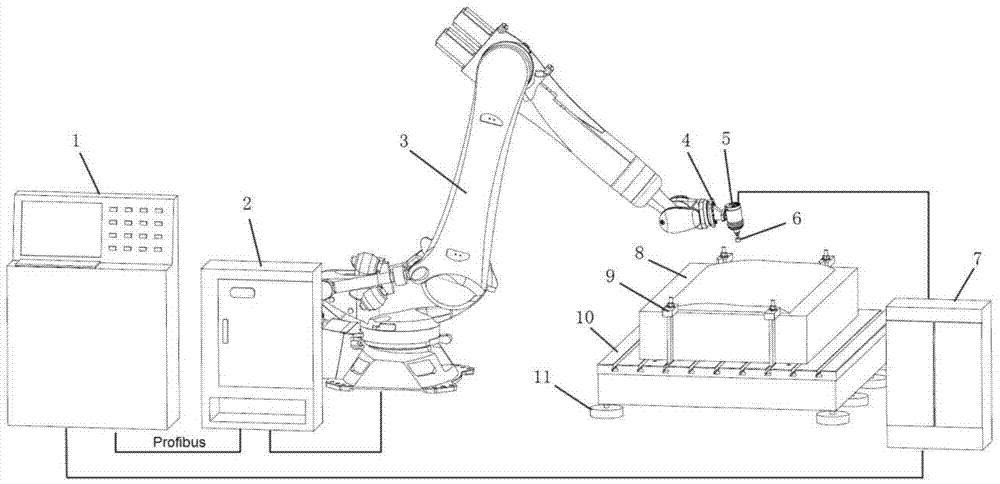

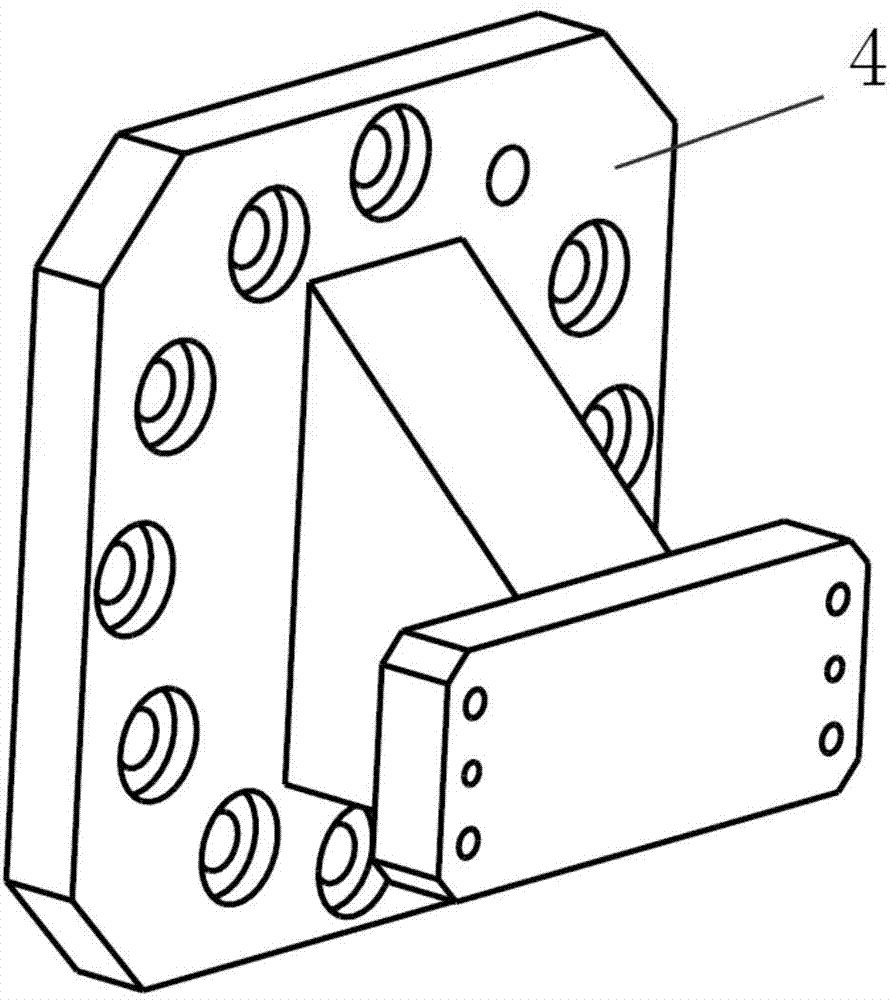

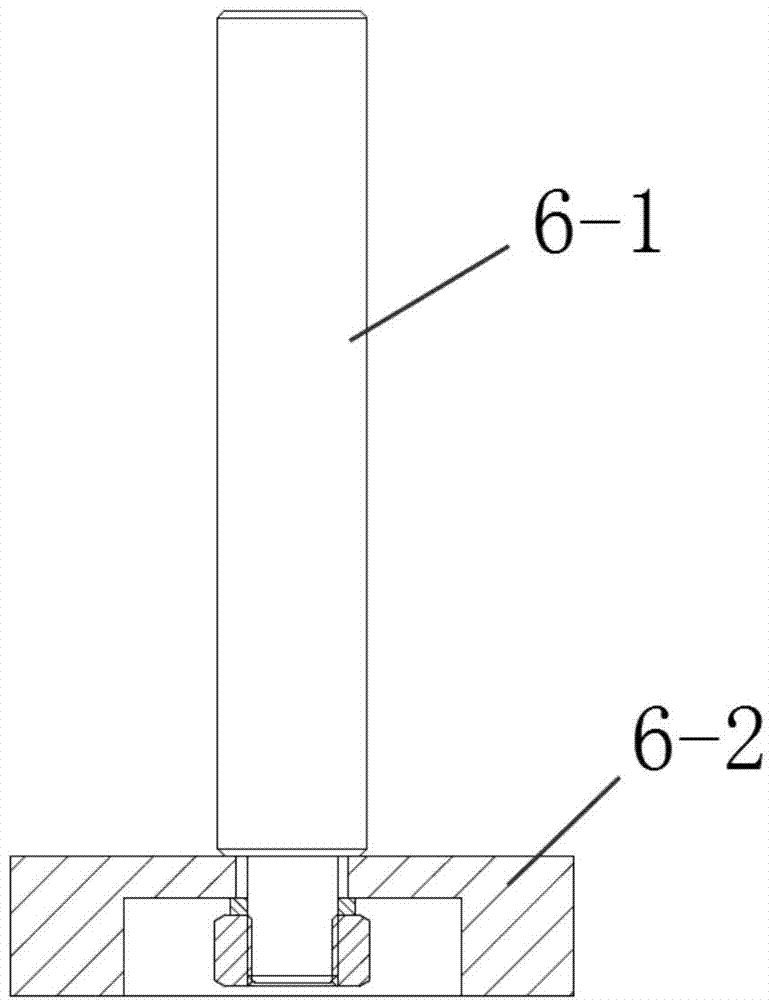

Free-form surface robot polishing system

ActiveCN103878666AWith soft force control functionKeep the pressure constantGrinding drivesGrinding machinesFree formMachined surface

The invention discloses a free-form surface robot polishing system. The system comprises a workbench, an industrial robot, a robot control cabinet, a polishing tool, a pneumatic main shaft, a connecting part, a pneumatic control cabinet and a system control cabinet. The system is high in automation degree, high in flexibility and particularly suitable for polishing a free-form surface. Specifically, the pneumatic main shaft fixed at the tail end of the industrial robot is used for clamping the polishing tool, the machined surface is tightly pressed by the polishing tool all the time by means of the pneumatic compliant force control function of the pneumatic main shaft, constant pressure is kept, the pose of the industrial robot is adjusted according to a planned route, the polishing pressure is in the normal direction of the machined surface, the polishing tool rotates at high speed through a pneumatic motor of the pneumatic main shaft, and then the industrial robot drives the polishing tool to polish a part according to the planned route.

Owner:中科君胜(深圳)智能数据科技发展有限公司

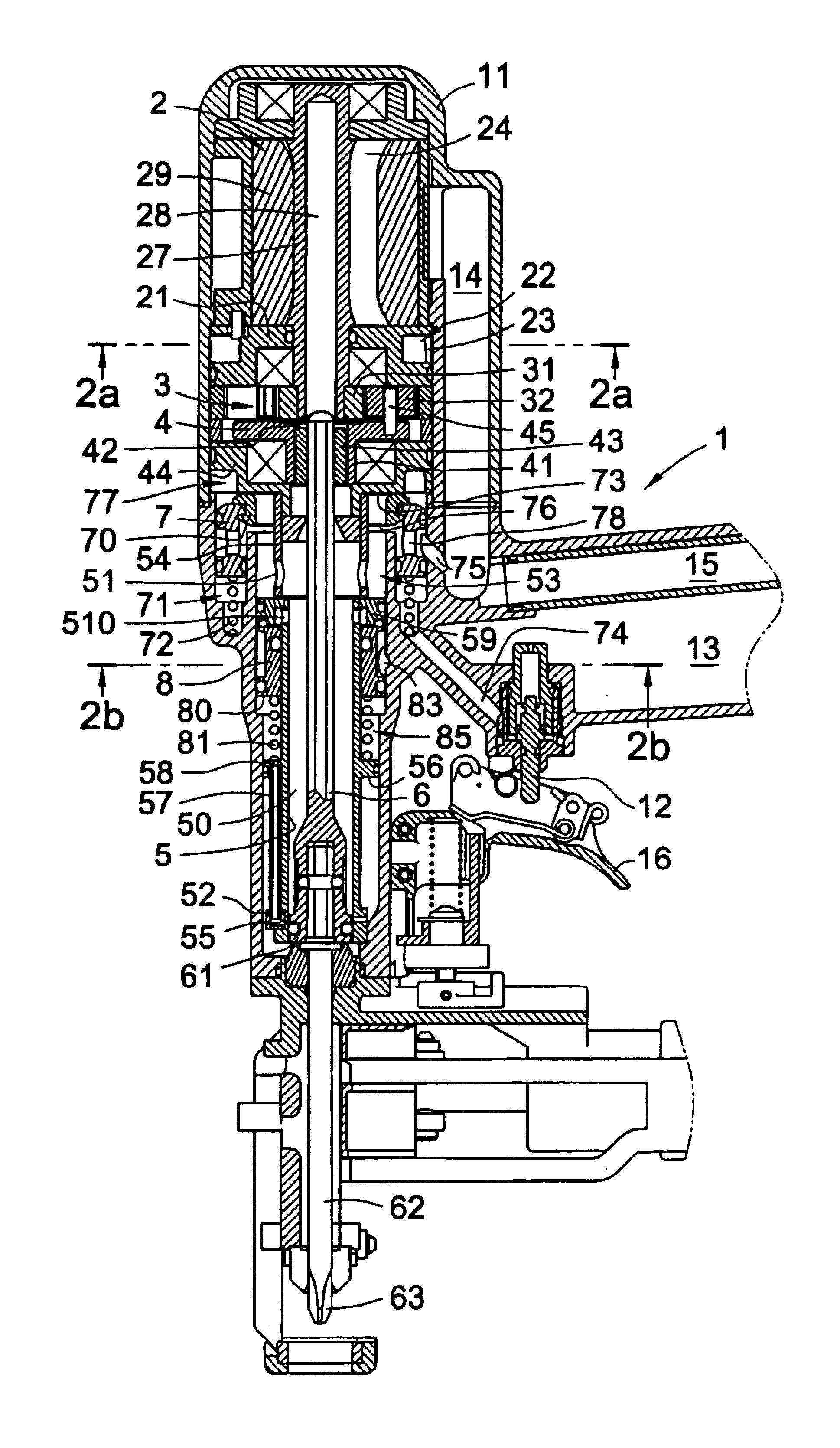

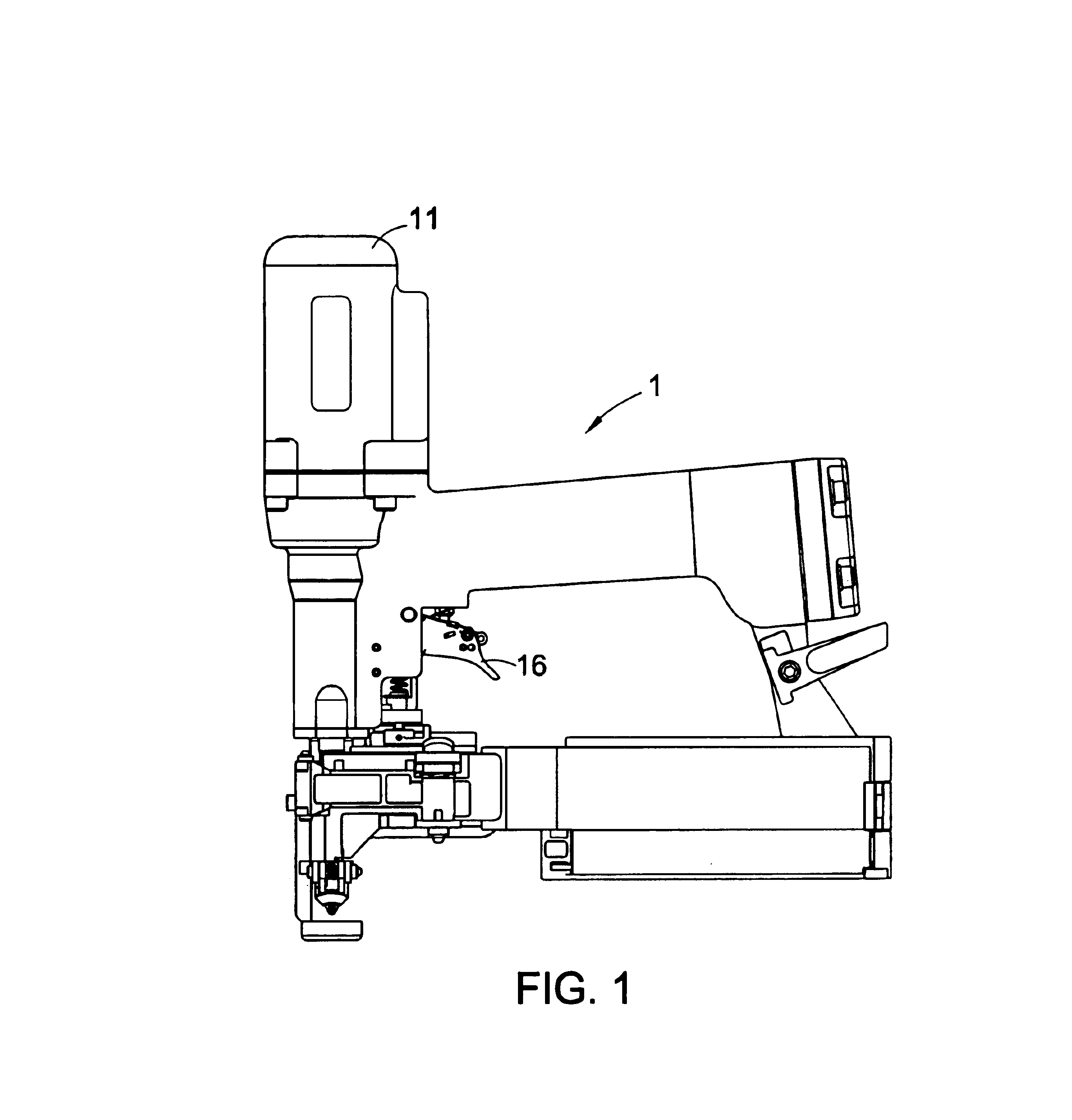

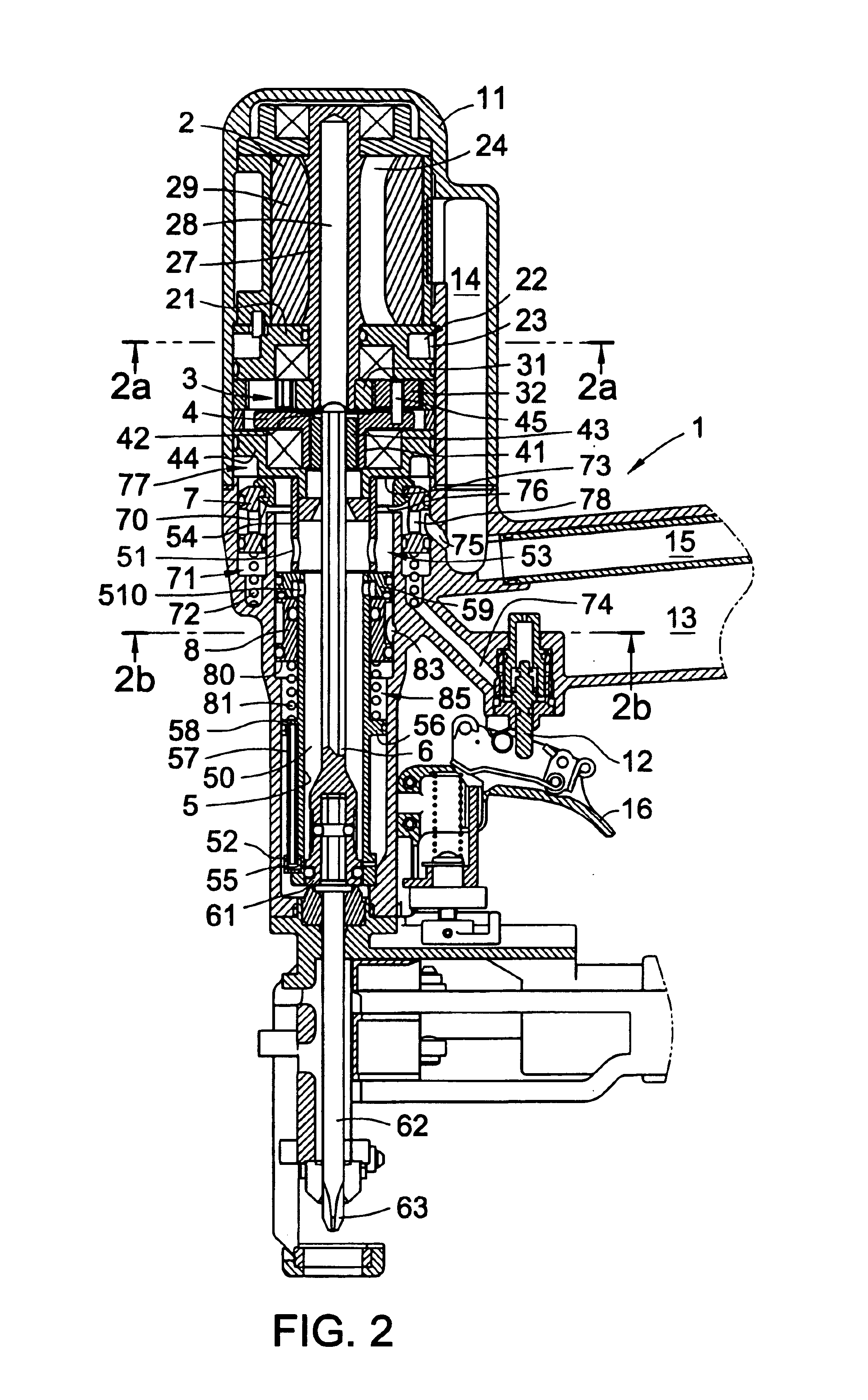

Pneumatic motor driving valve of screw nail gun

A pneumatic motor driving valve of a screw nail gun has a driving valve for control the pneumatic motor to be operated steadily. A downward pressing spring is installed around an outer wall of the cylinder of the gun body and an annular control valve is installed around the outer wall of the cylinder so that the annular control valve presses the downward pressing spring for actuating of the opening of the air inlet valve of the air inlet channel of the pneumatic motor. An annular control valve around an outer wall of the cylinder can accumulate the pressure in the gun body to a predetermined value so as to open the driving valve. Thereby, the pneumatic motor can provide a larger stable twisting force to beat and rotate a screw nail.

Owner:DE POAN PNEUMATIC

Air tool

InactiveUSRE36917E1Solve excessive vibrationSmall sizeMachines/enginesWrenchesPower capabilityBattery charge

An improved air tool includes an integrated air motor and electrical generator wherein the stator is positioned on a side of the rotor body opposite the working end of the tool to reduce vibrations transmitted to the stator. The stator is also positioned between the compressed air inlet and the rotor body such that compressed air flows across the stator to prevent overheating of the stator. The air tool includes an indicating circuit connected to the battery charging circuit for indicating a battery charge condition, a battery discharge condition, and a low lubrication condition of the air vanes. A light ring assembly is attached to the working end of the tool housing to provide light at the working end of the tool. Materials chosen for the magnets and the poles of the stator increase the power capability of the electrical generator. An illuminating apparatus for a conventional air tool includes a light ring with integral generator.

Owner:VOLT AIRE CORP

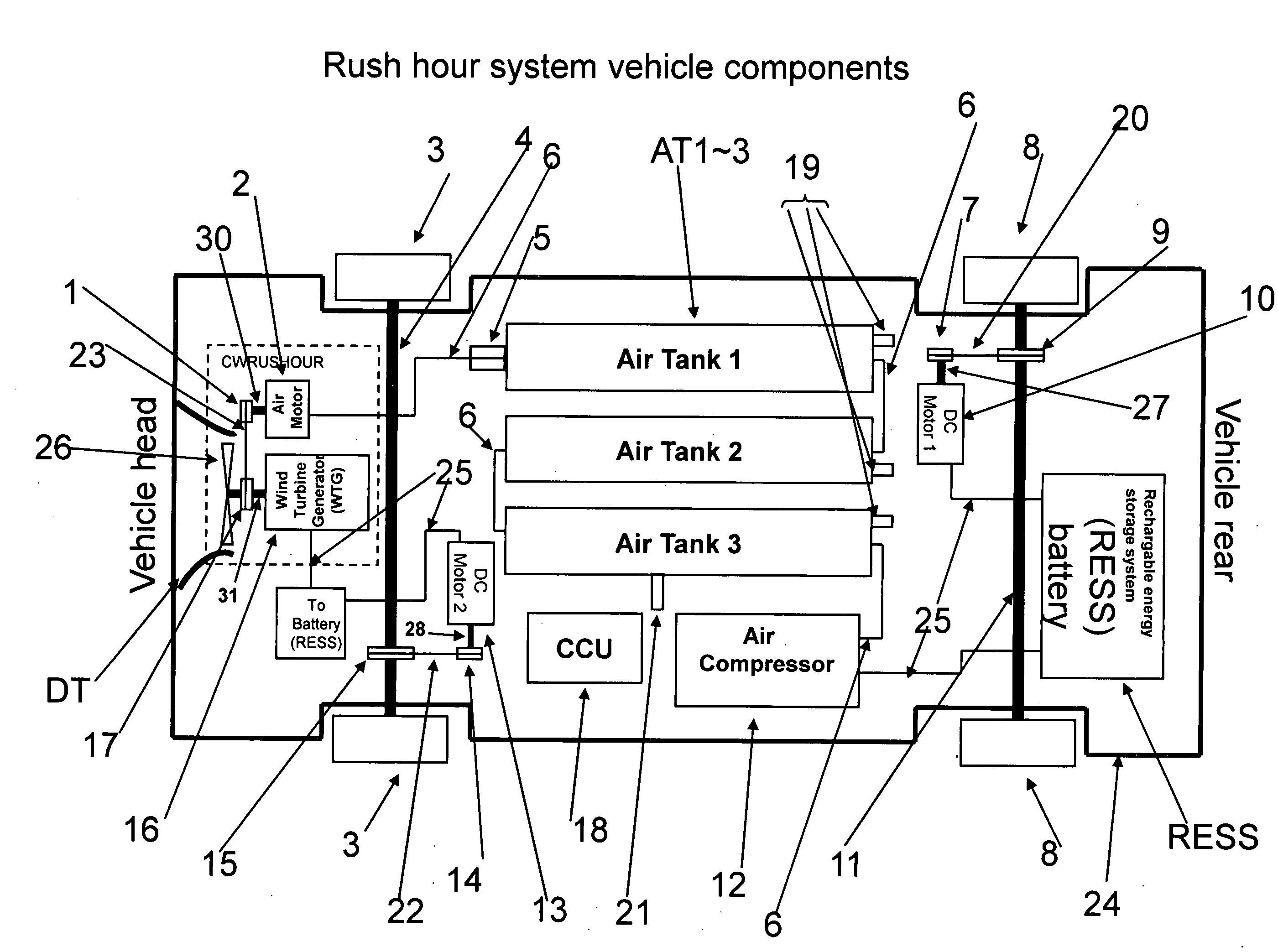

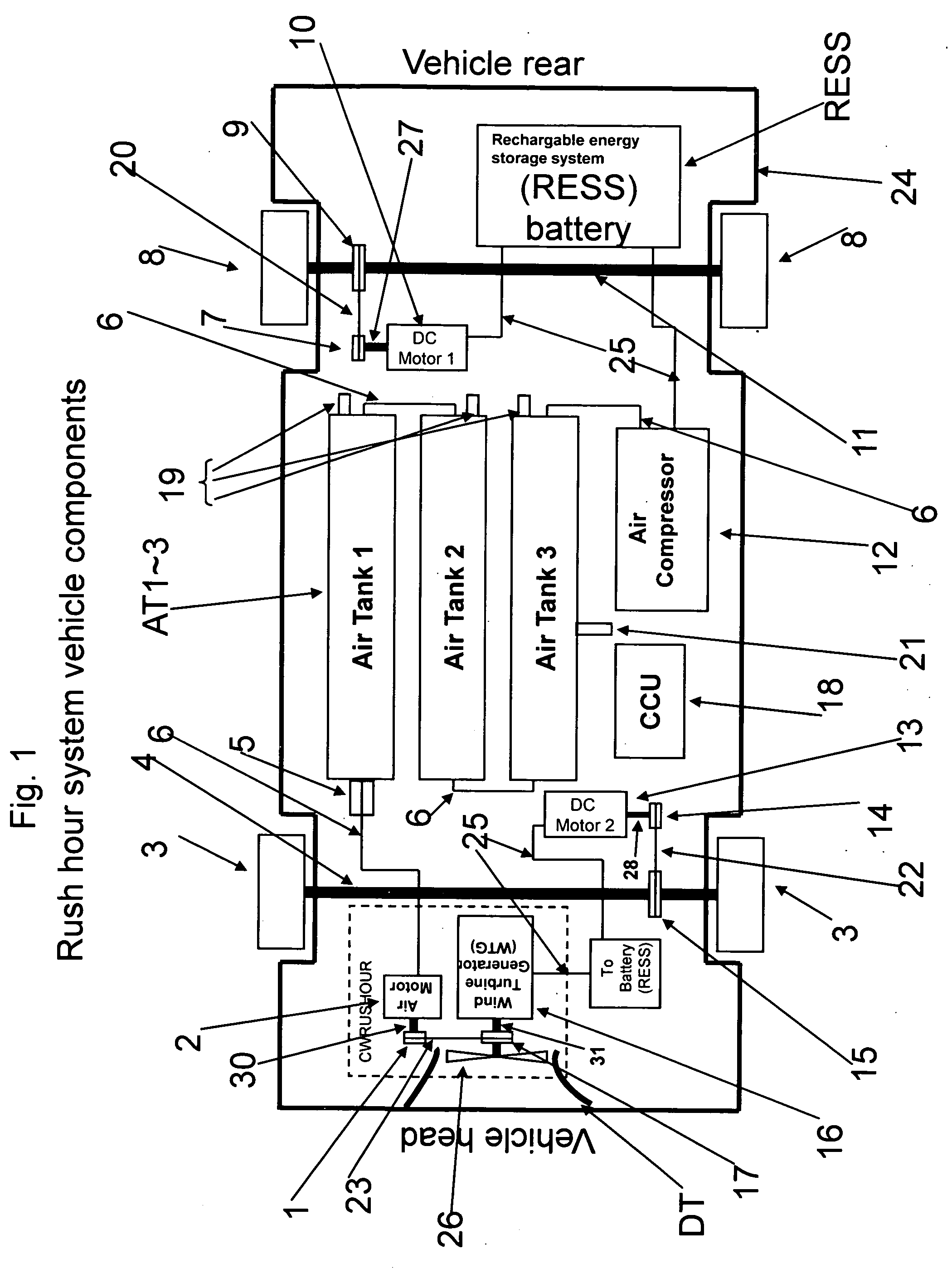

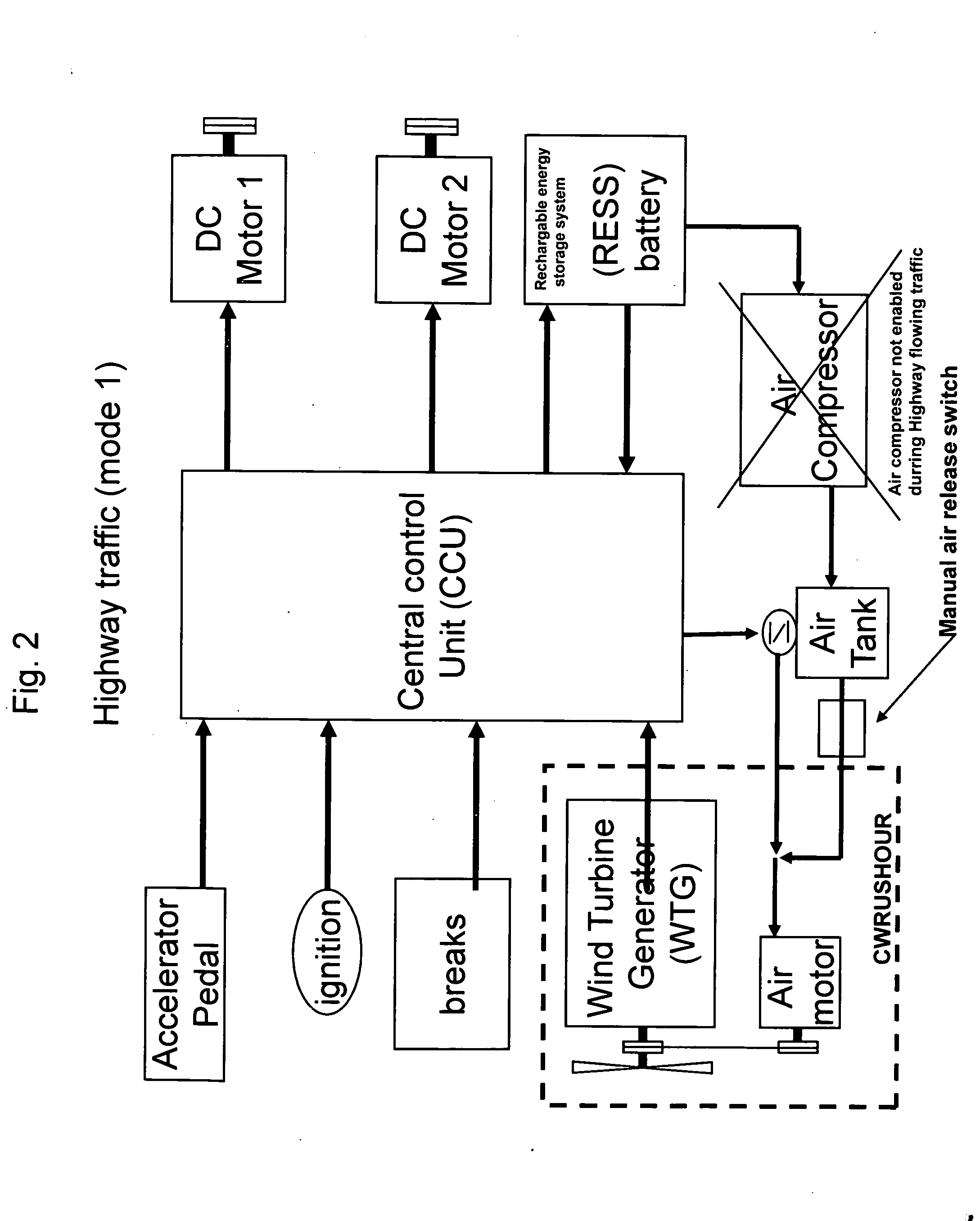

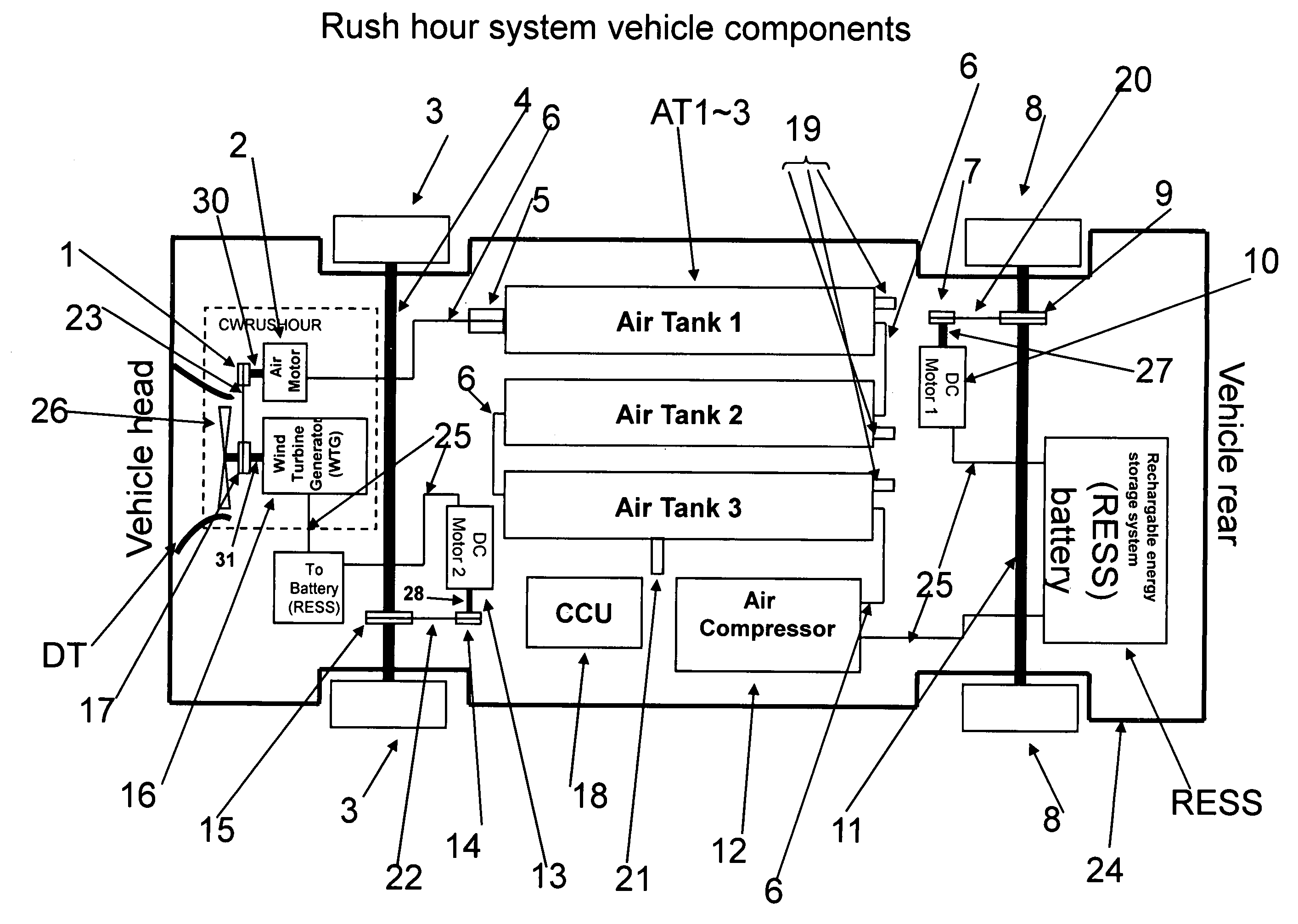

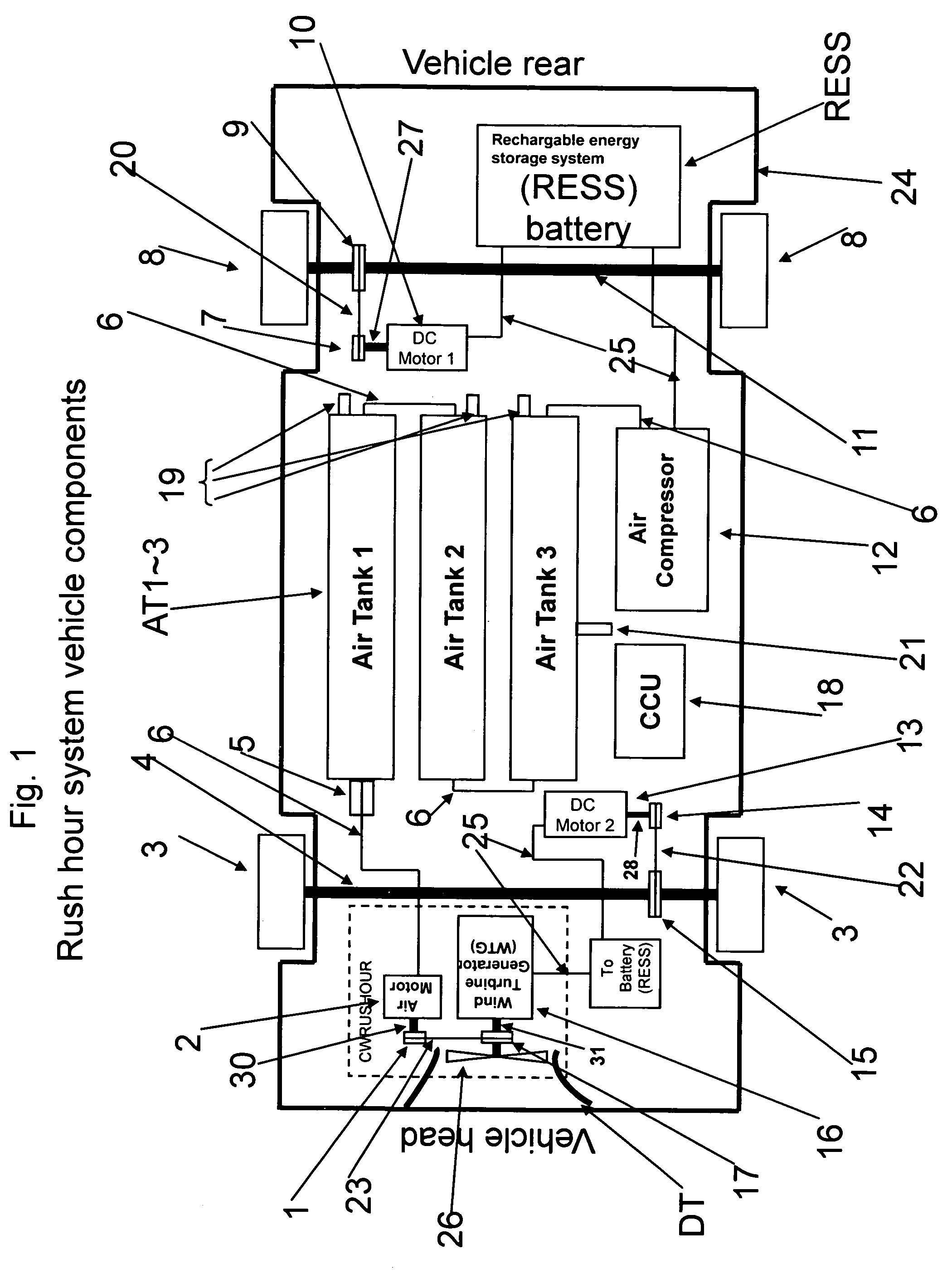

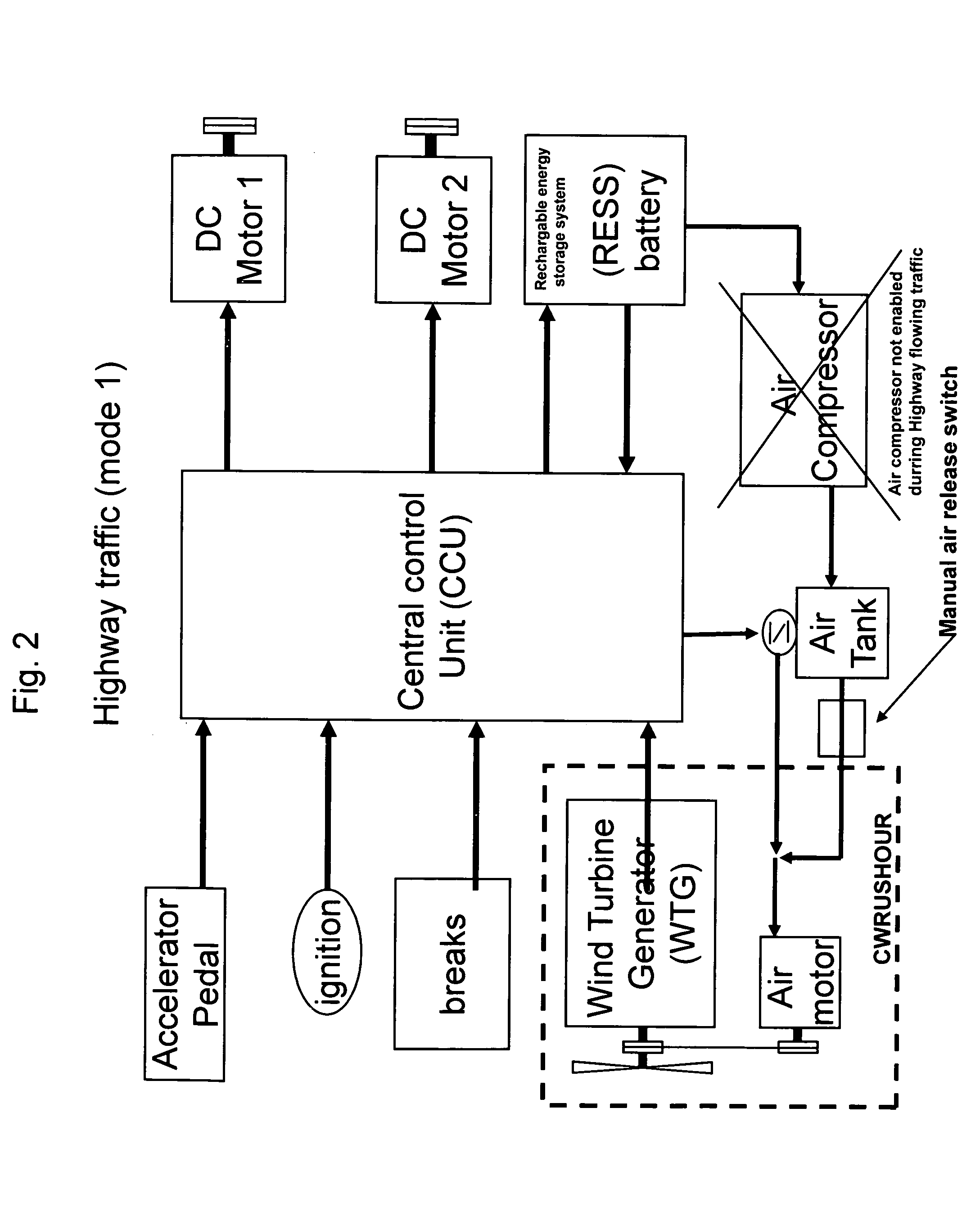

Air electric vehicle

InactiveUS20090301796A1Eliminate CO2 emissionsReduce battery sizeAuxillary drivesRailway vehiclesGas compressorHigh pressure

An all electric vehicle that produces zero CO2 emissions and capable of traveling an unlimited amount of mileage is presented. This vehicle is considered air and electric because it uses a wind turbine generator, compressed air and a high voltage battery to generate electricity to power the DC motors that drive this vehicle. Therefore this vehicle is called the Wind Turbine Generator Air Electric Vehicle (WTGAEV). There exists an integrated system that enables this vehicle to maintain a consistent energy supply to automatically recharge the high voltage battery. This integrated system consists of a wind turbine generator (WTG), air motor, air compressor, air tank, and battery. The power train receives its energy from the motion of the vehicle. When the vehicle is in forward motion the air flow from the nose of the vehicle is collected and directed toward the blades of the WTG which generates electric.

Owner:WEDDERBURN JR COSBURN HENRY +1

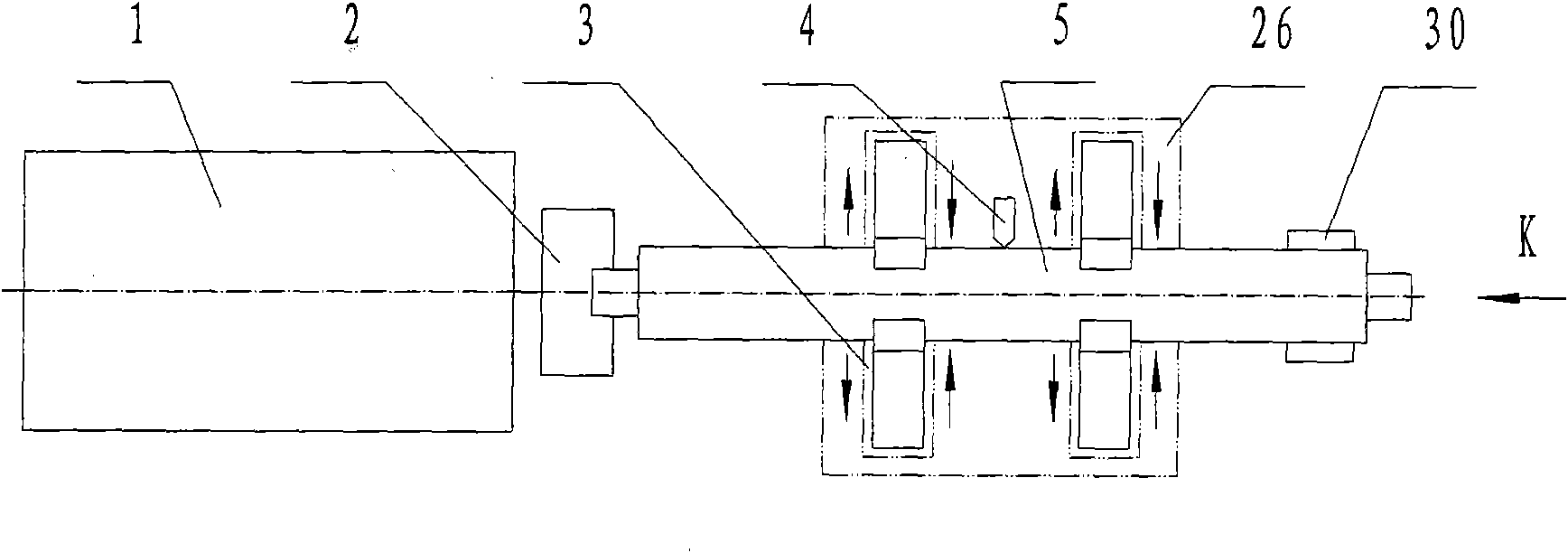

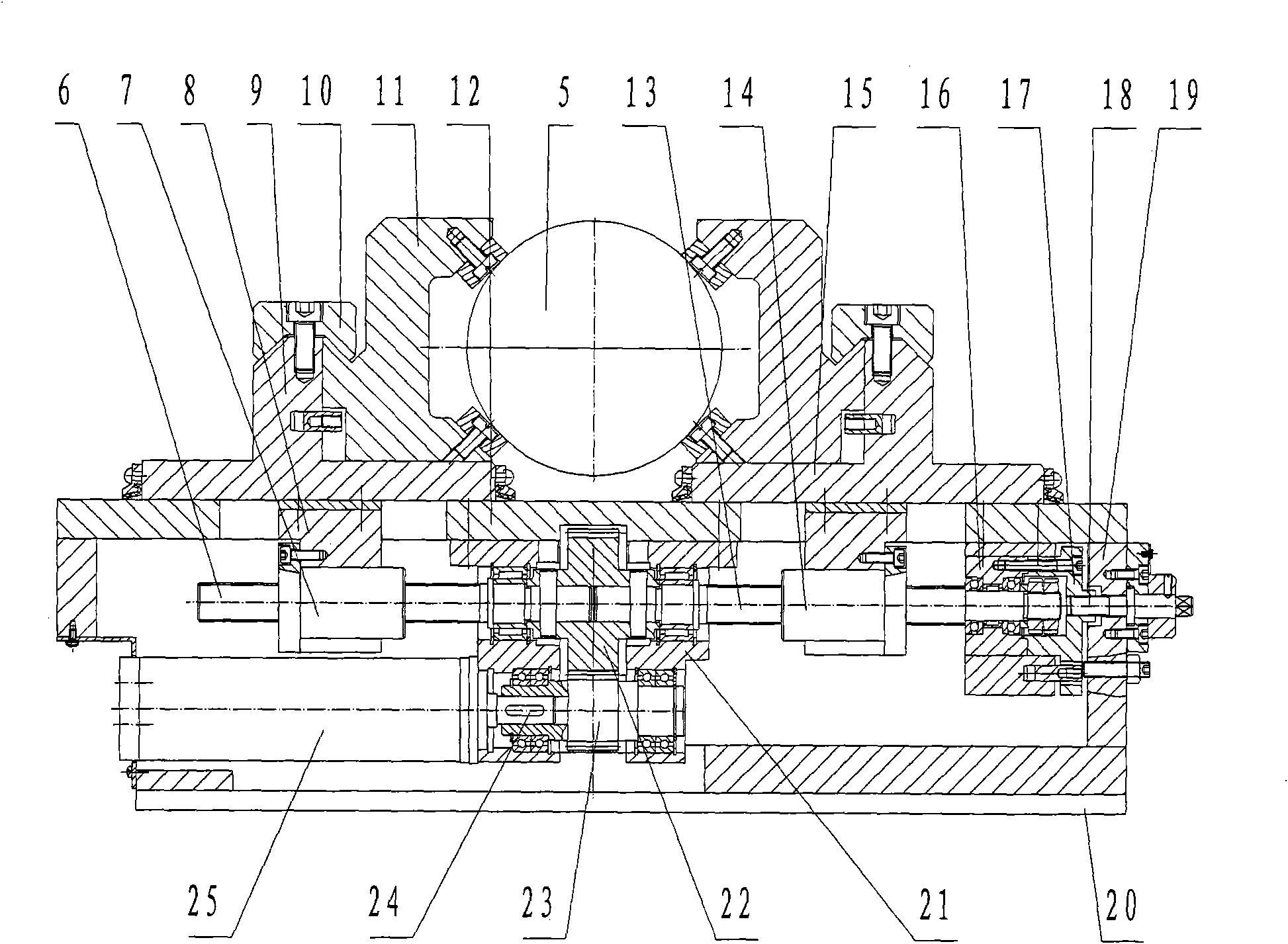

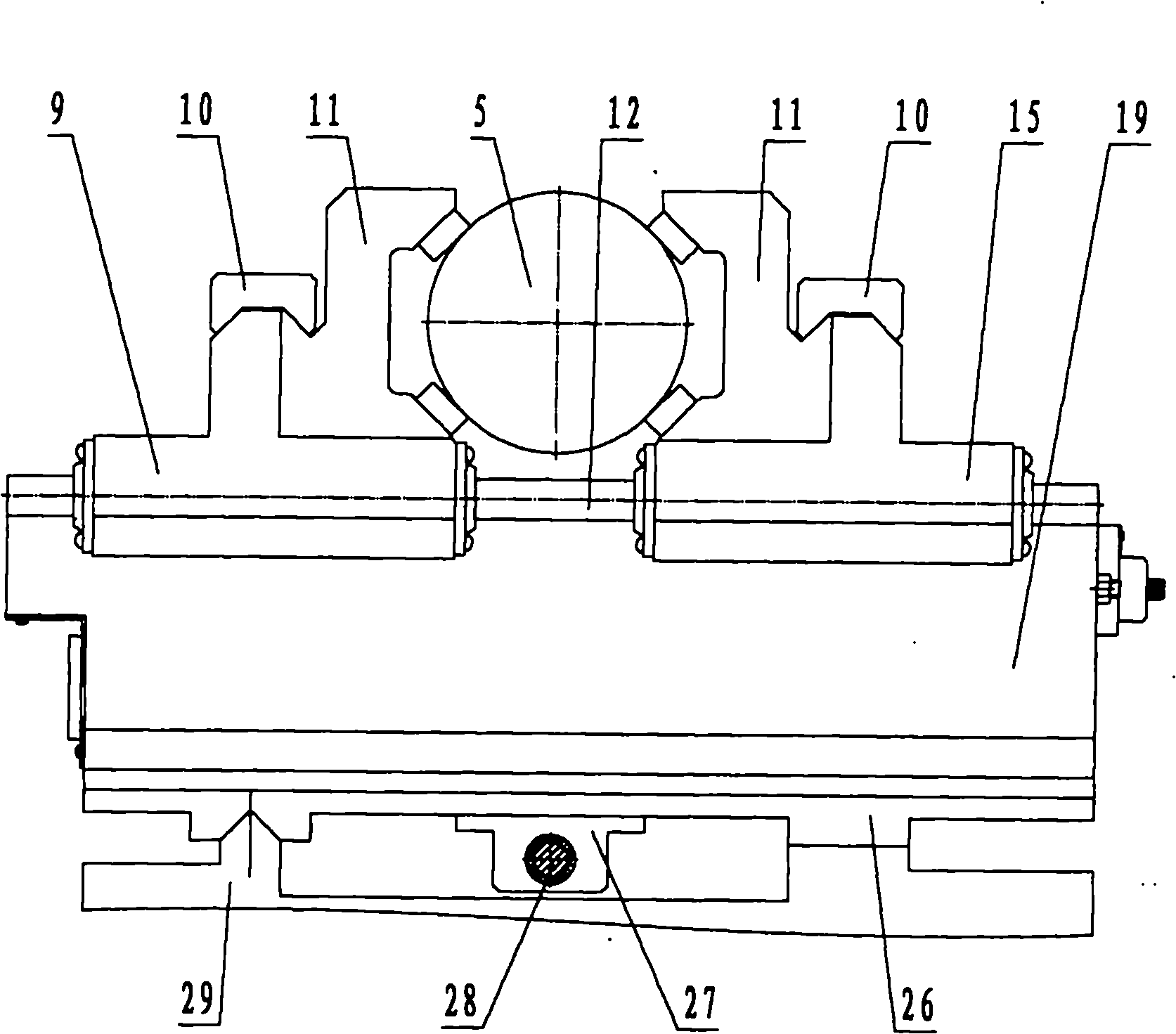

Workpiece positioning and clamping device for thread cutting machine

ActiveCN102039535APositioning is simple and fastGuaranteed processing resultsPositioning apparatusMetal-working holdersGear wheelEngineering

The invention discloses a workpiece positioning and clamping device for a thread cutting machine, comprising a supporting seat with an inner cavity, a running mechanism arranged on the upper plane of the supporting seat and a drive mechanism arranged inside the cavity of the supporting seat. The running mechanism consists of two V-shaped claws, a left dragging plate and a right dragging plate, wherein the openings of the two V-shaped claws opposite and the left dragging plate and the right dragging plate form a pair of jaws capable of opening and closing; the drive mechanism is arranged in the cavity of the supporting seat and comprises a pneumatic motor fixed at one side of the cavity of the supporting seat, a set of gears and pinions installed in the center of the cavity of the supporting seat in a meshed way, a left handed ballscrew pair and a right handed ballscrew pair, wherein the pinions are sleeved with the motor by a shaft, the two ballscrew pairs are inserted into inner bores of the gears by shafts, and ball nuts are respectively and fixedly connected with the left dragging plate and the right dragging plate. The device has functions of excircle automatic positioning andself-adaptively clamping and protecting and can stably follow up the cutting motion of a cutter so that a certain cutting depth is kept between the cutter and the excircle of each section of a workpiece.

Owner:陕西汉江机床有限公司

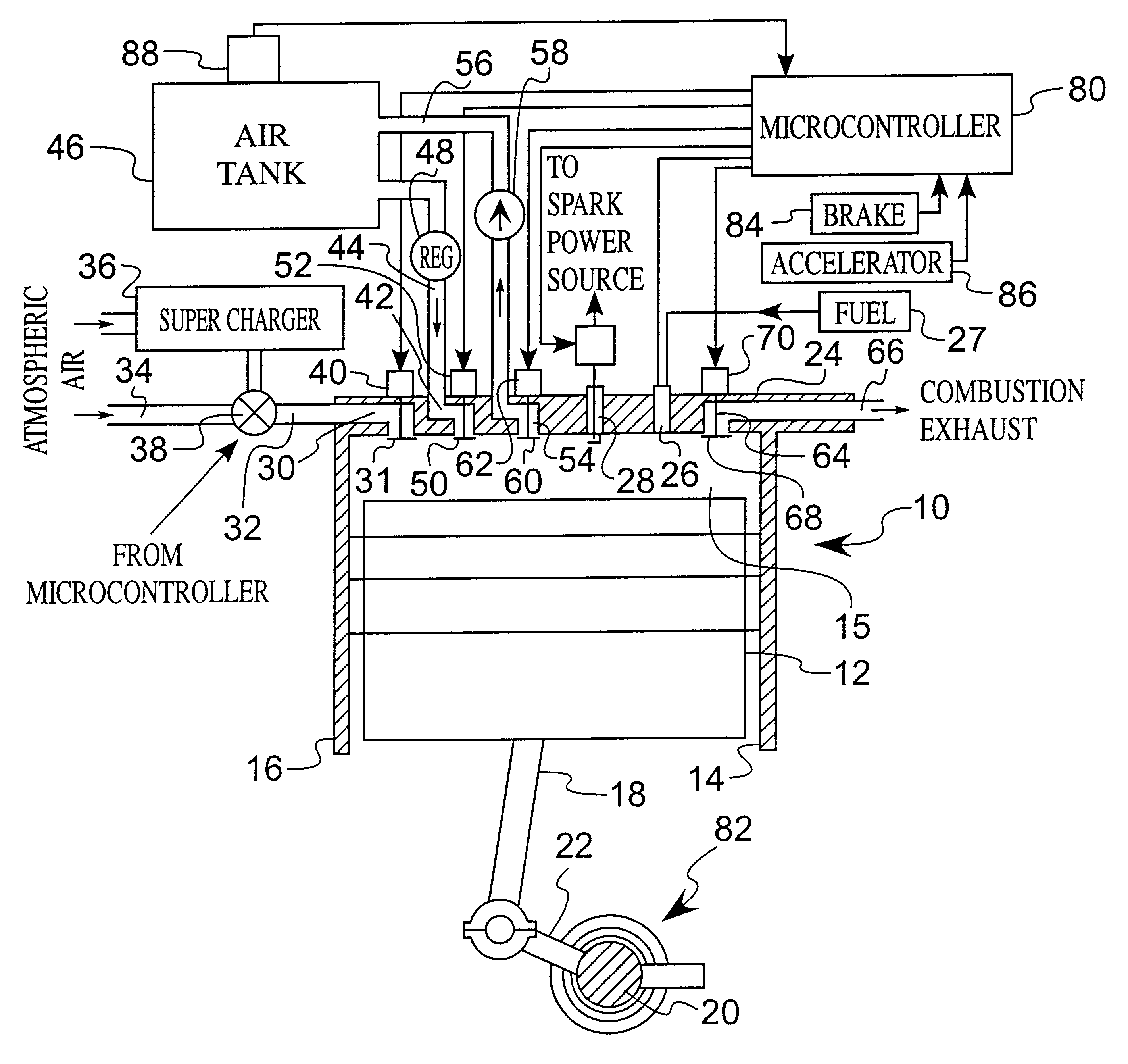

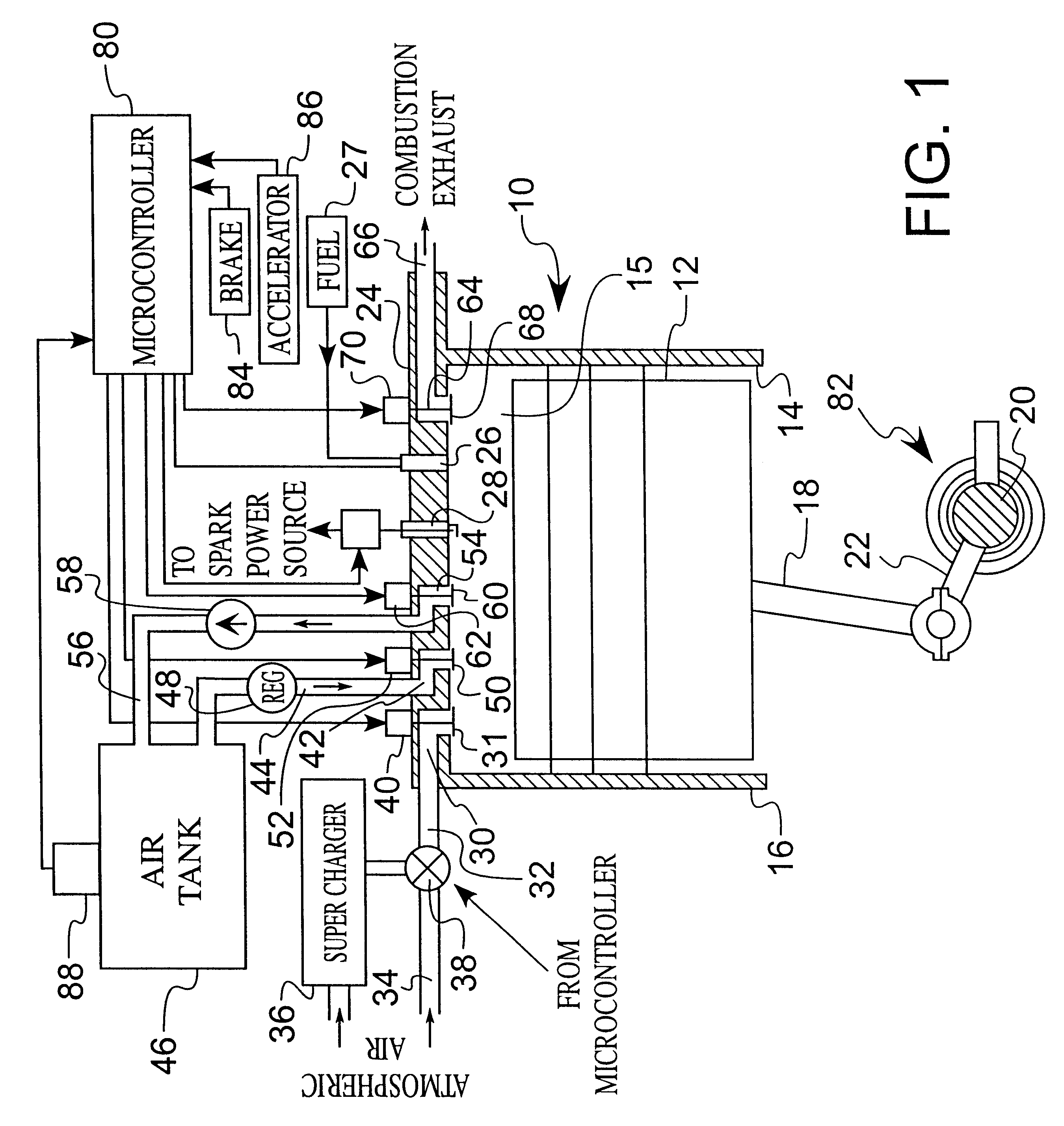

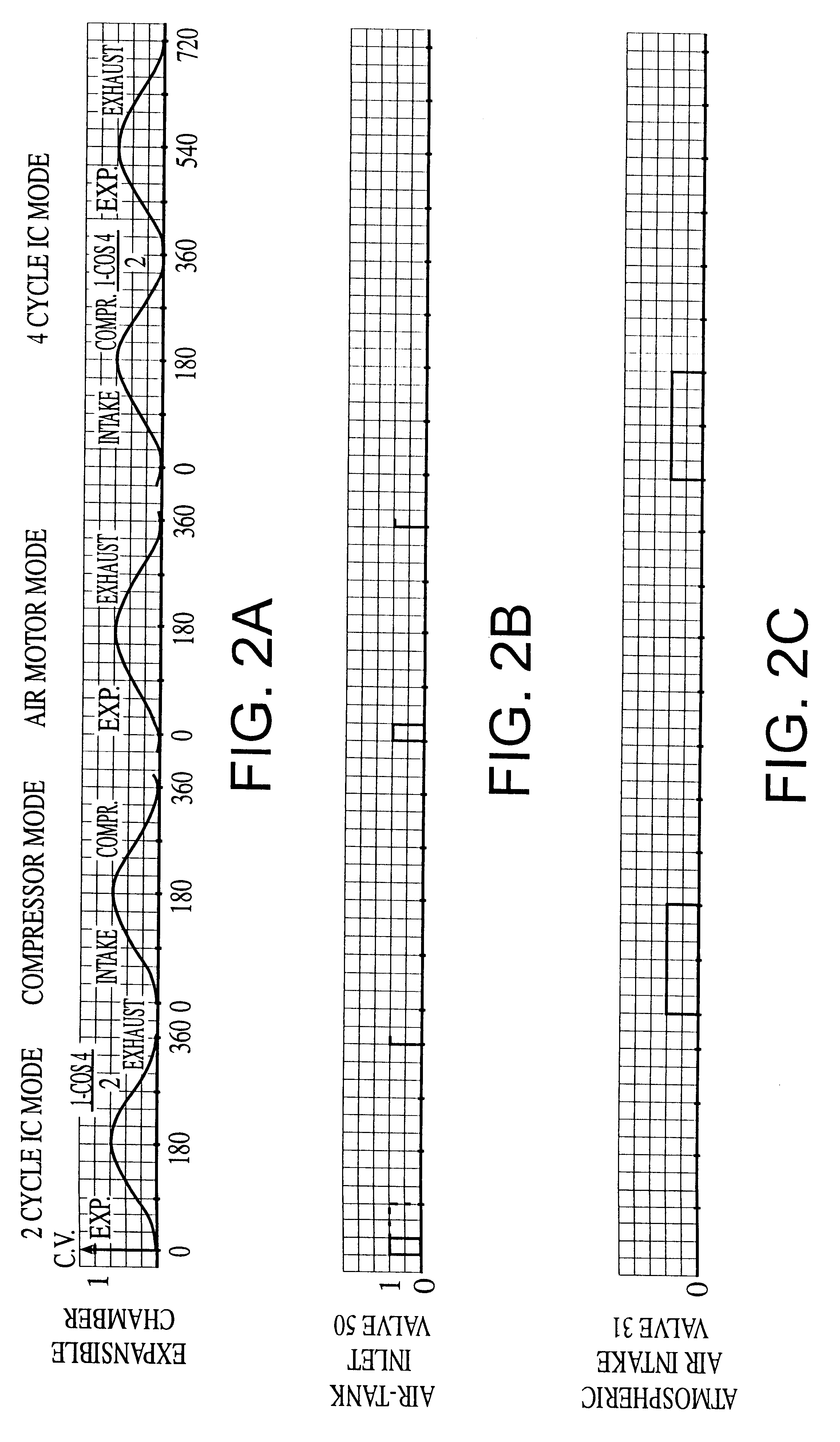

Hybrid expansible chamber engine with internal combustion and pneumatic modes

InactiveUS6568186B2Efficiently meetReciprocating combination enginesCombination enginesMicrocontrollerCombustion

A hybrid engine, having a plurality of coupled expansible chamber devices, preferably a piston in a cylinder, each capable of operating in any one of an internal combustion mode, an air pump / compressor mode and an air motor mode. The modes are controlled by a microcontroller which controls the valves, ignition source and fuel source. The mode for each expansible chamber device is computed and independently selected by the microcontroller and the combination of modes at any instant is switched to optimize engine operation for the operating conditions at that instant.

Owner:NANO PRECISION

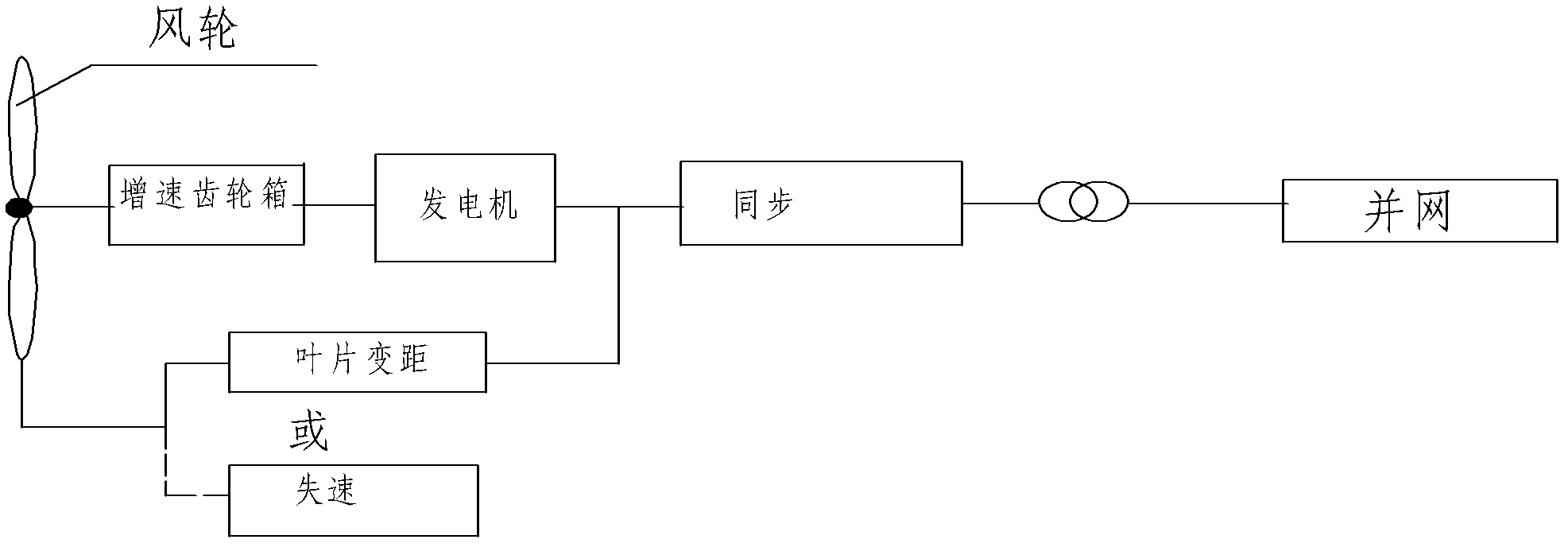

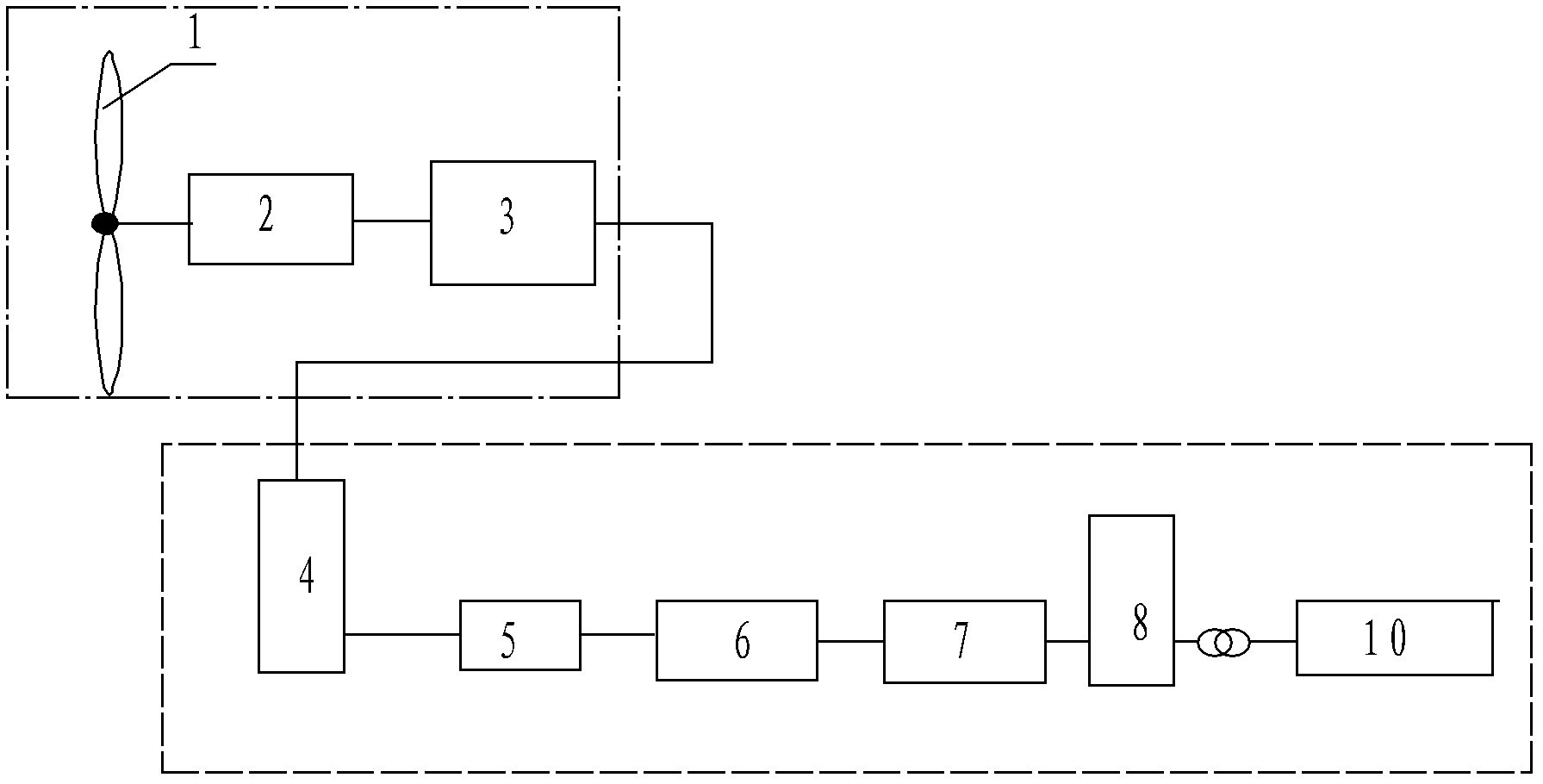

Air compression energy storage wind power generation method and generating set thereof

InactiveCN102305193AImprove efficiencySmall radius of rotationFrom solar energyFinal product manufactureMechanical energyAir compressor

The invention discloses an air compression energy storage wind power generation method and a generating set thereof for overcoming the rotation rate limitation and the problems of a rigid drive system in the prior art. The air compression energy storage wind power generation method comprises the following steps: 1, wind wheels convert the kinetic energy of wind into mechanical energy; 2, the wind wheels drive an air compressor to work so as to generate compressed air; 3, an air storage tank stores the compressed air; 4, the compressed air drives an air motor or a steam turbine; 5, the air motor or the steam turbine drives the generator to generate electricity; and 6, the surplus electric energy is stored. The invention also provides an air compression energy storage wind power generating set and a surplus electric energy storage device. The air compression energy storage wind power generating set comprises wind wheels, a speed increasing gear case, an air compressor, an air storage tank, an electric control valve, an air motor or a gas turbine and a generator. In the surplus electric energy storage device, the wind wheels and the speed increasing gear case of the air compression energy storage wind power generating set are replaced by electromotors, and other parts are the same as those of the air compression energy storage wind power generating set.

Owner:初立森

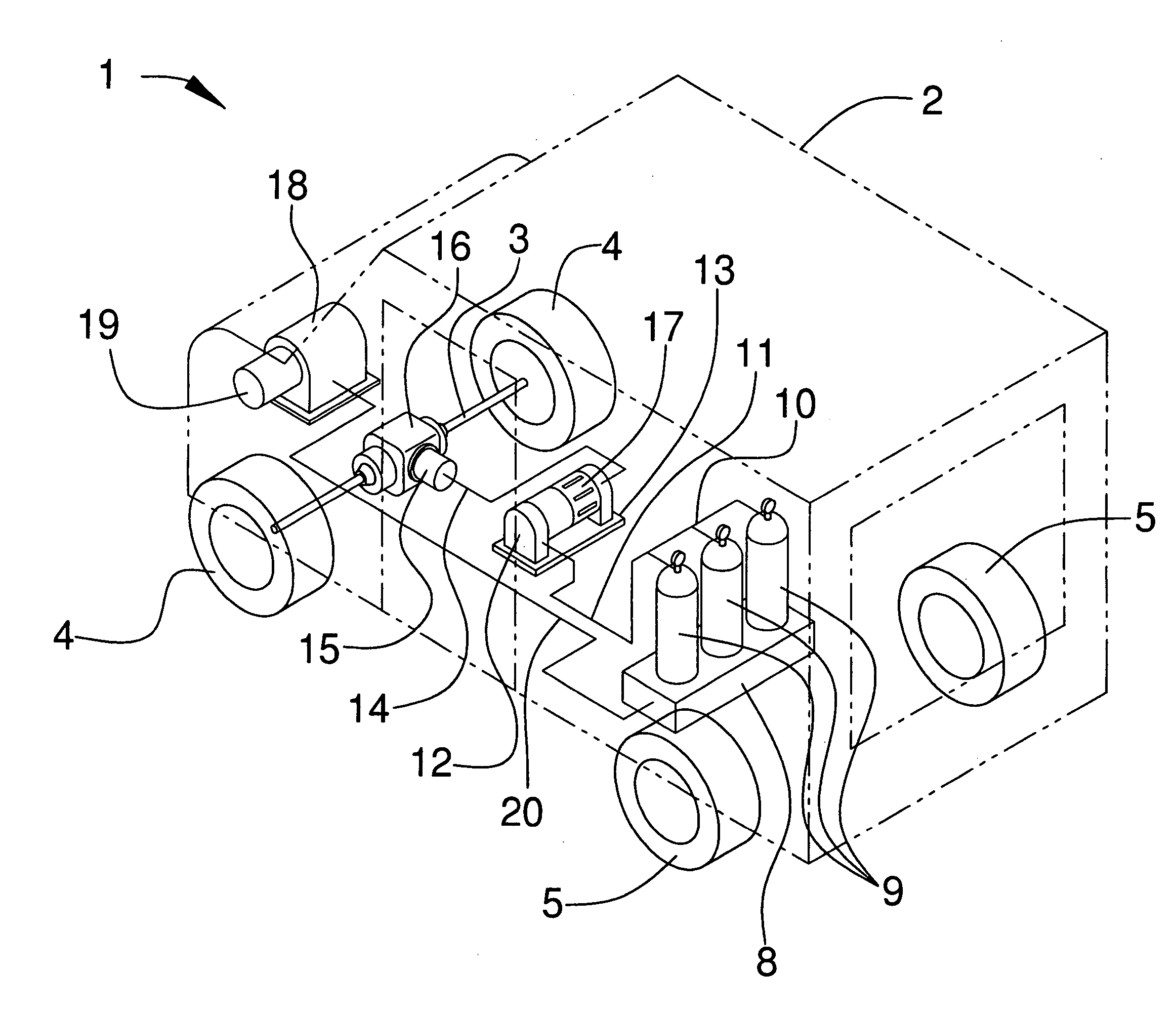

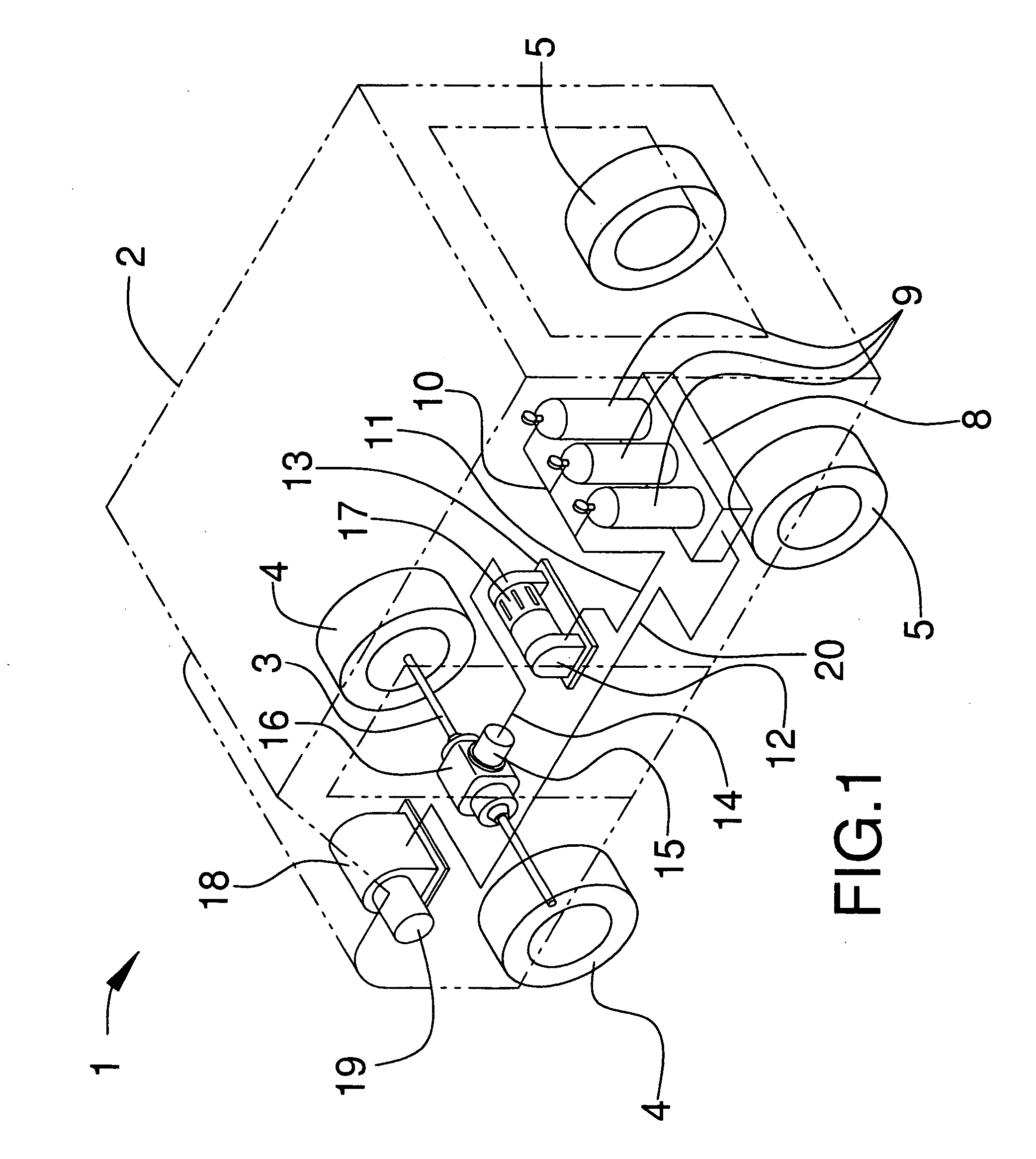

Air electric vehicle

InactiveUS7828091B2Eliminate CO2 emissionsSmall sizeAuxillary drivesRailway vehiclesGas compressorHigh pressure

An all electric vehicle that produces zero CO2 emissions and capable of traveling an unlimited amount of mileage is presented. This vehicle is considered air and electric because it uses a wind turbine generator, compressed air and a high voltage battery to generate electricity to power the DC motors that drive this vehicle. Therefore this vehicle is called the Wind Turbine Generator Air Electric Vehicle (WTGAEV). There exists an integrated system that enables this vehicle to maintain a consistent energy supply to automatically recharge the high voltage battery. This integrated system consists of a wind turbine generator (WTG), air motor, air compressor, air tank, and battery. The power train receives its energy from the motion of the vehicle. When the vehicle is in forward motion the air flow from the nose of the vehicle is collected and directed toward the blades of the WTG which generates electric.

Owner:WEDDERBURN JR COSBURN HENRY +1

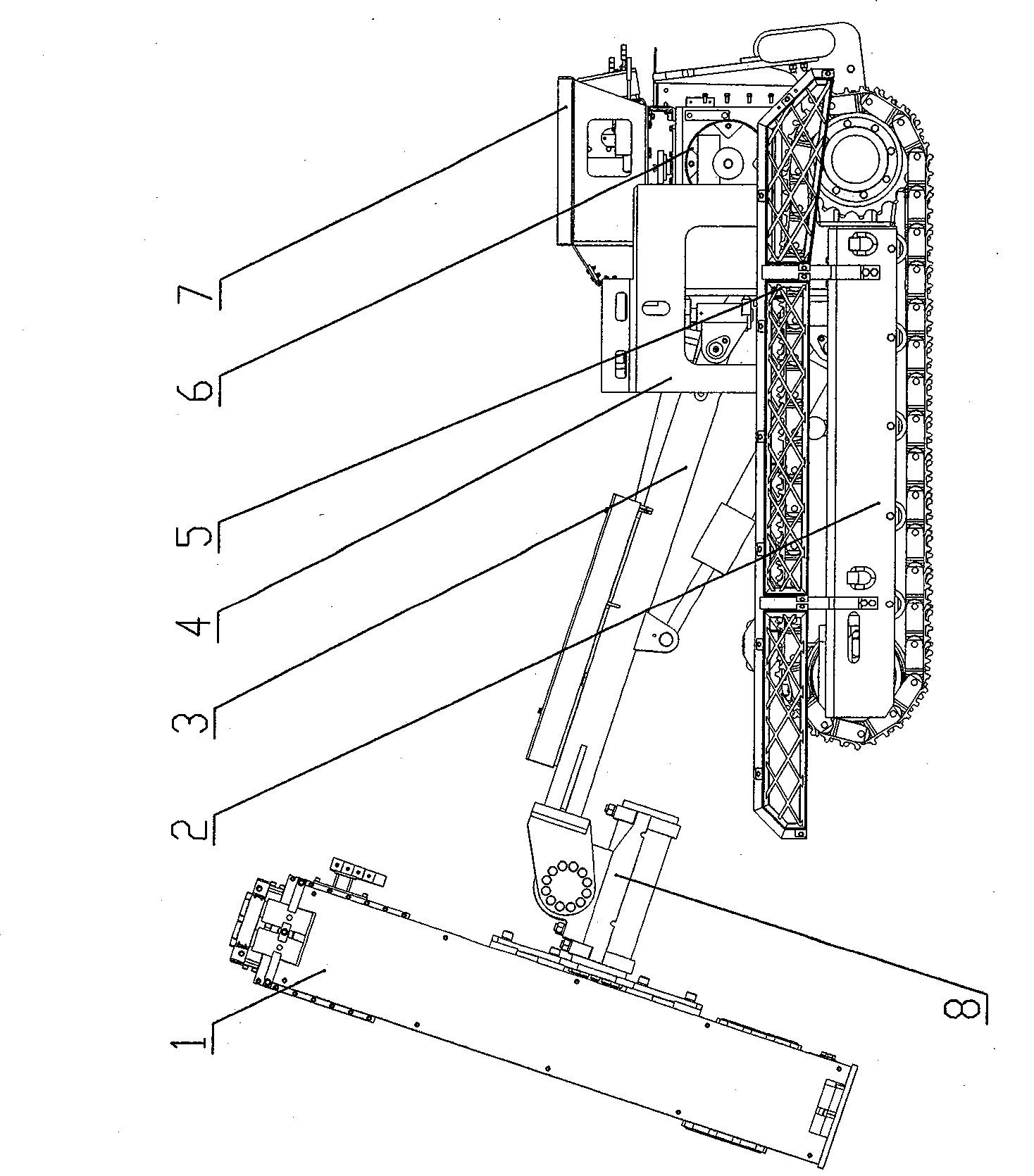

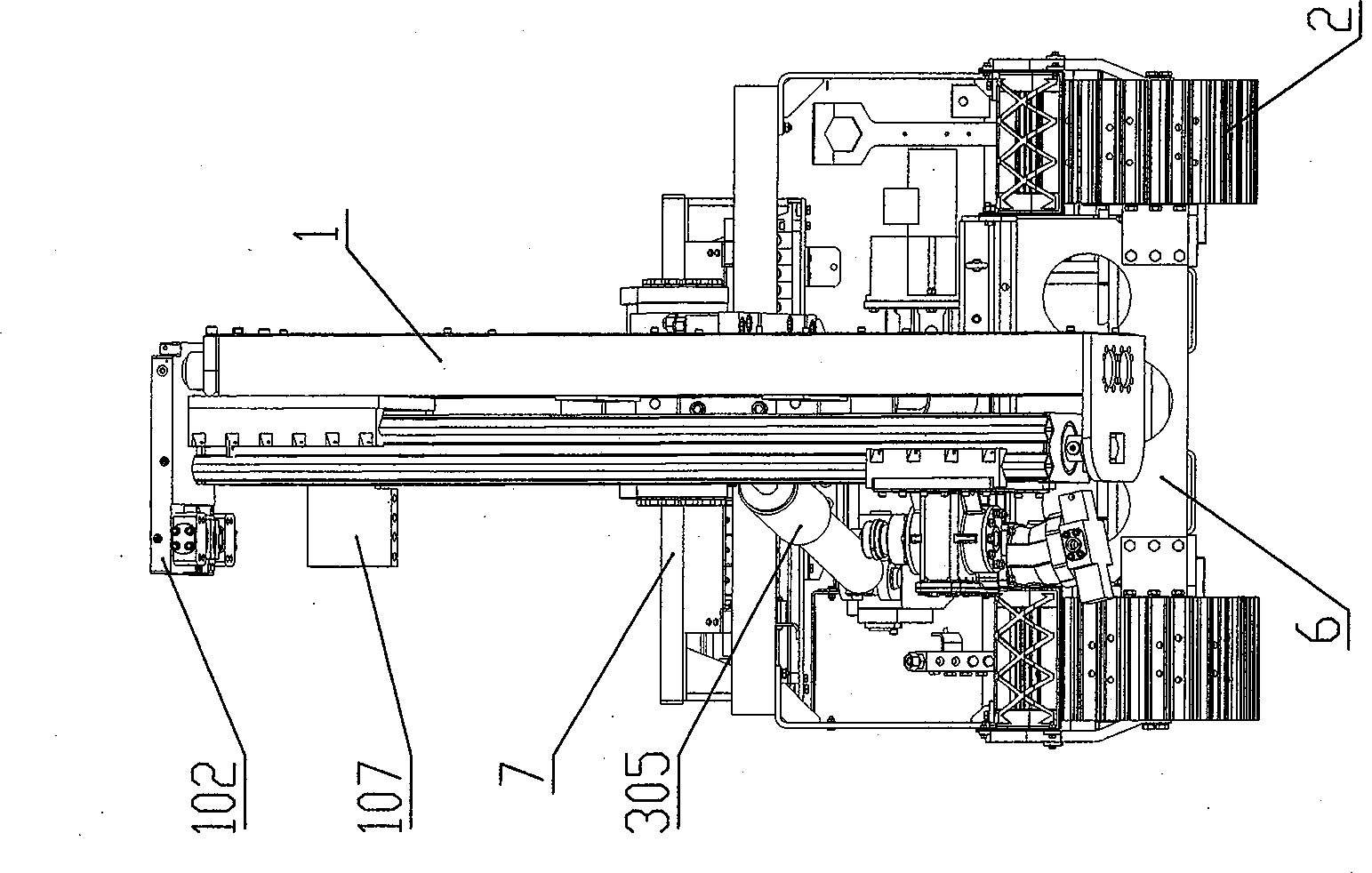

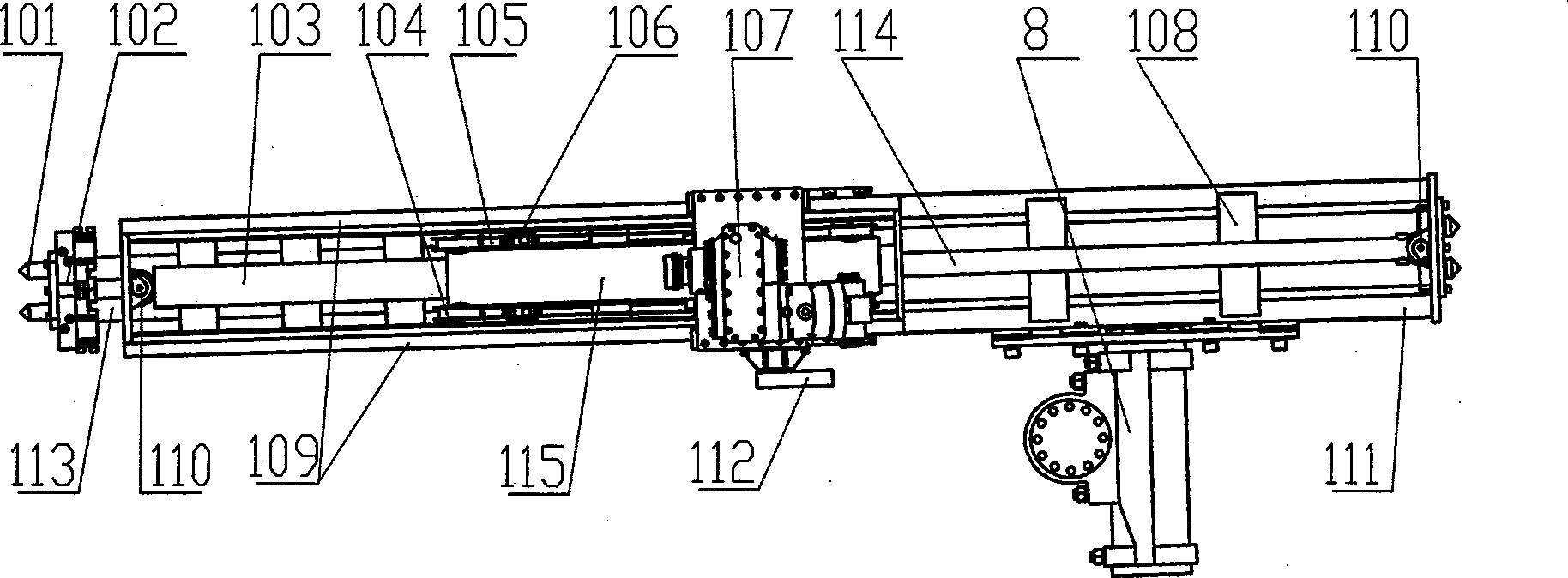

Pneumatic crawler hydraulic jumbo

InactiveCN101509350AAvoid it happening againTimely processingConstructionsDrilling drivesClosed loop designElectric devices

The invention discloses a pneumatic crawler-type hydraulic drill carriage which comprises a carriage body, a travelling gear, a working device for drilling connected with the carriage body, a hydraulic system for driving the devices, and an operating device; a pneumatic motor is used as power of the hydraulic system and operation of the drill carriage; an operating device, which adopts closed loop design, is used for driving the pneumatic motor, the pneumatic system, the hydraulic system and the various acting components to act; the travelling device is crawler-typed; a swinging device, which consists of a swinging arm and a cylinder, is arranged at the front of the carriage body; the front end of the swinging device is connected with the working device for drilling by a universal rotating device; the working device consists of a feeding device which comprises a supporting device, a secondary cylinder, and a chain pushing mechanism; and the pneumatic crawler-type hydraulic drill carriage uses a method combining water and gas to clean the boreholes. The pneumatic crawler-type hydraulic drill applies especially to mass drilling work sites of which change continuously; the whole carriage is free of electric devices and the pneumatic crawler-type hydraulic drill applies particularly to high gassy mine and can carry out universal hole drilling.

Owner:JIKAI EQUIP MFG CO LTD

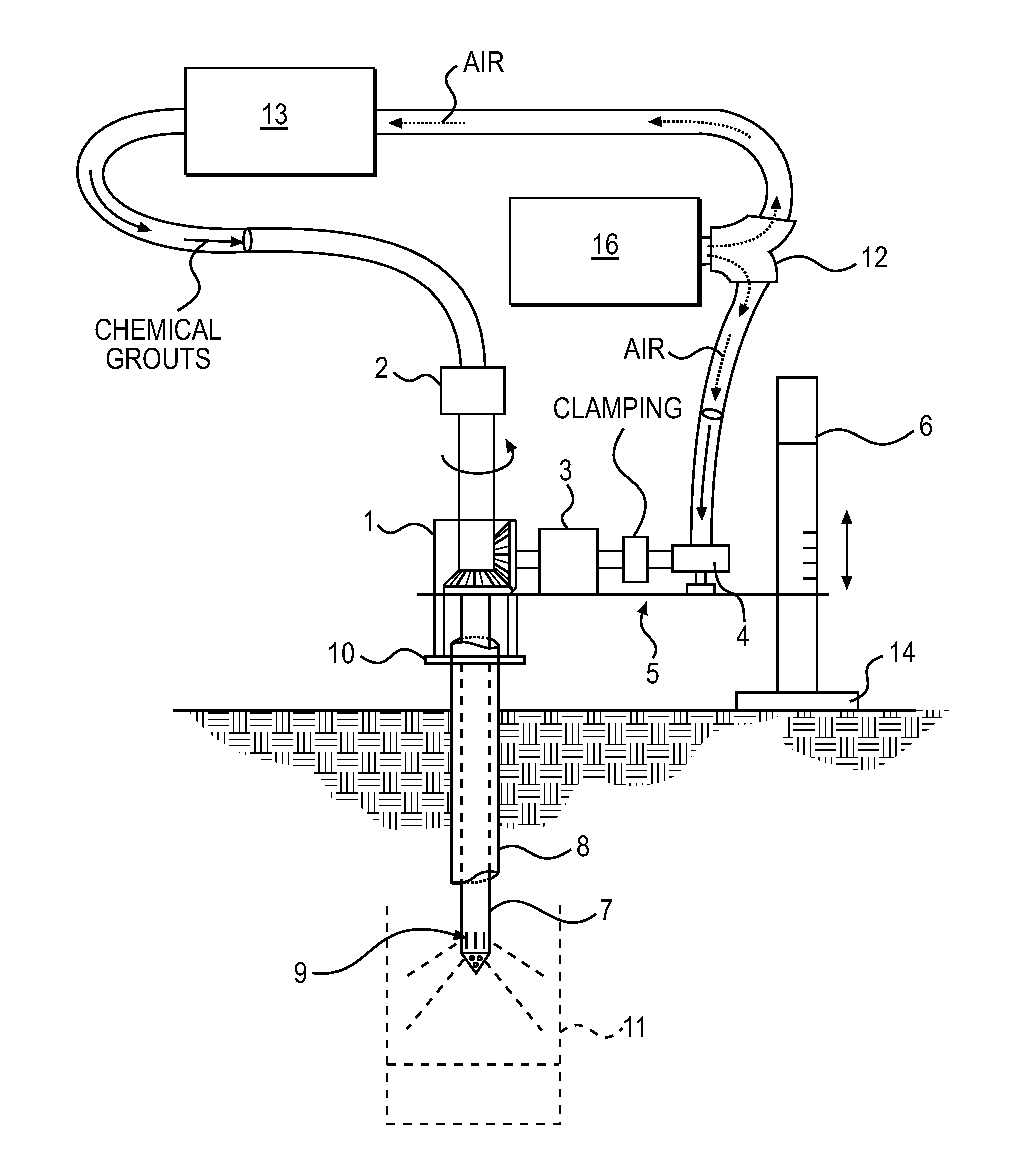

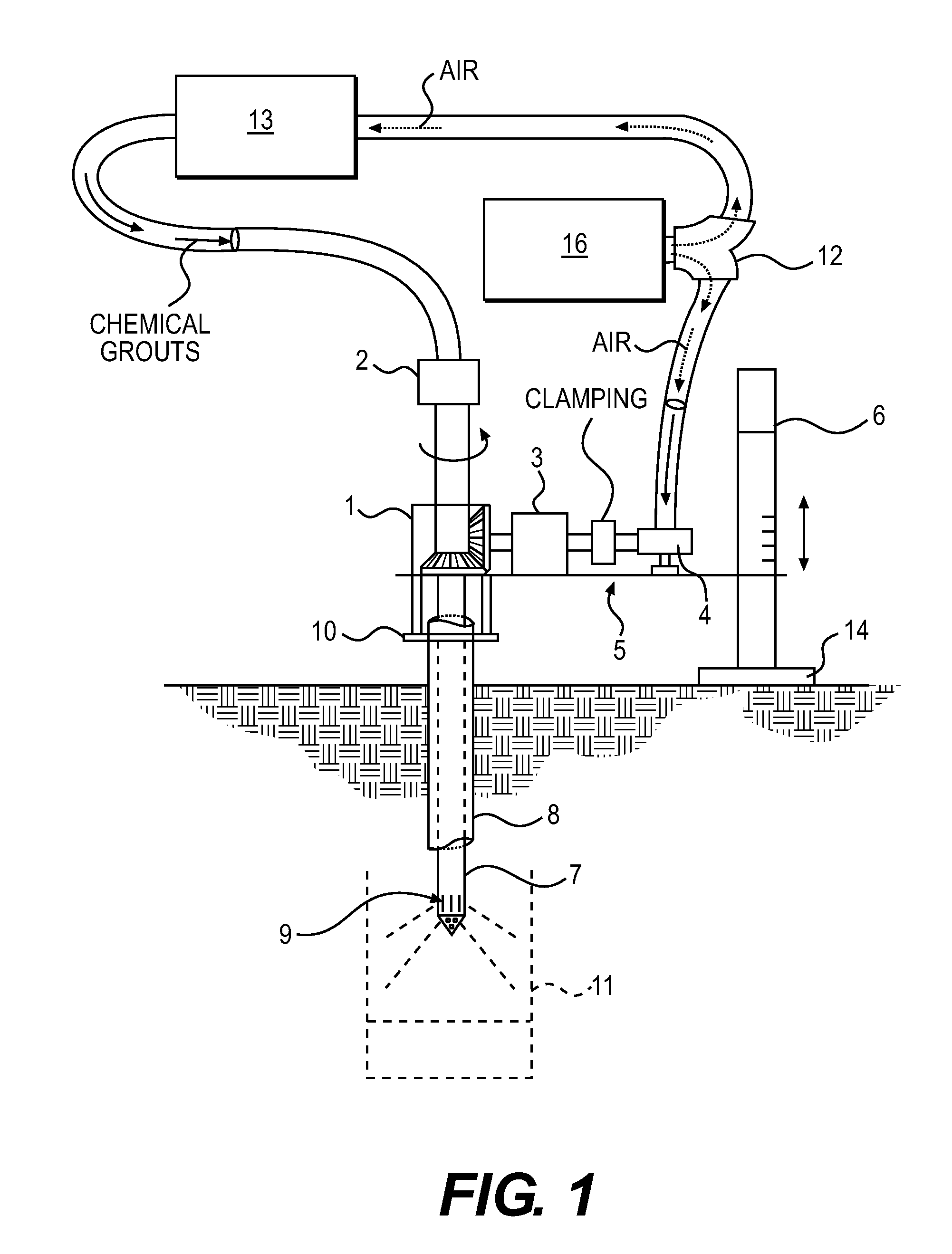

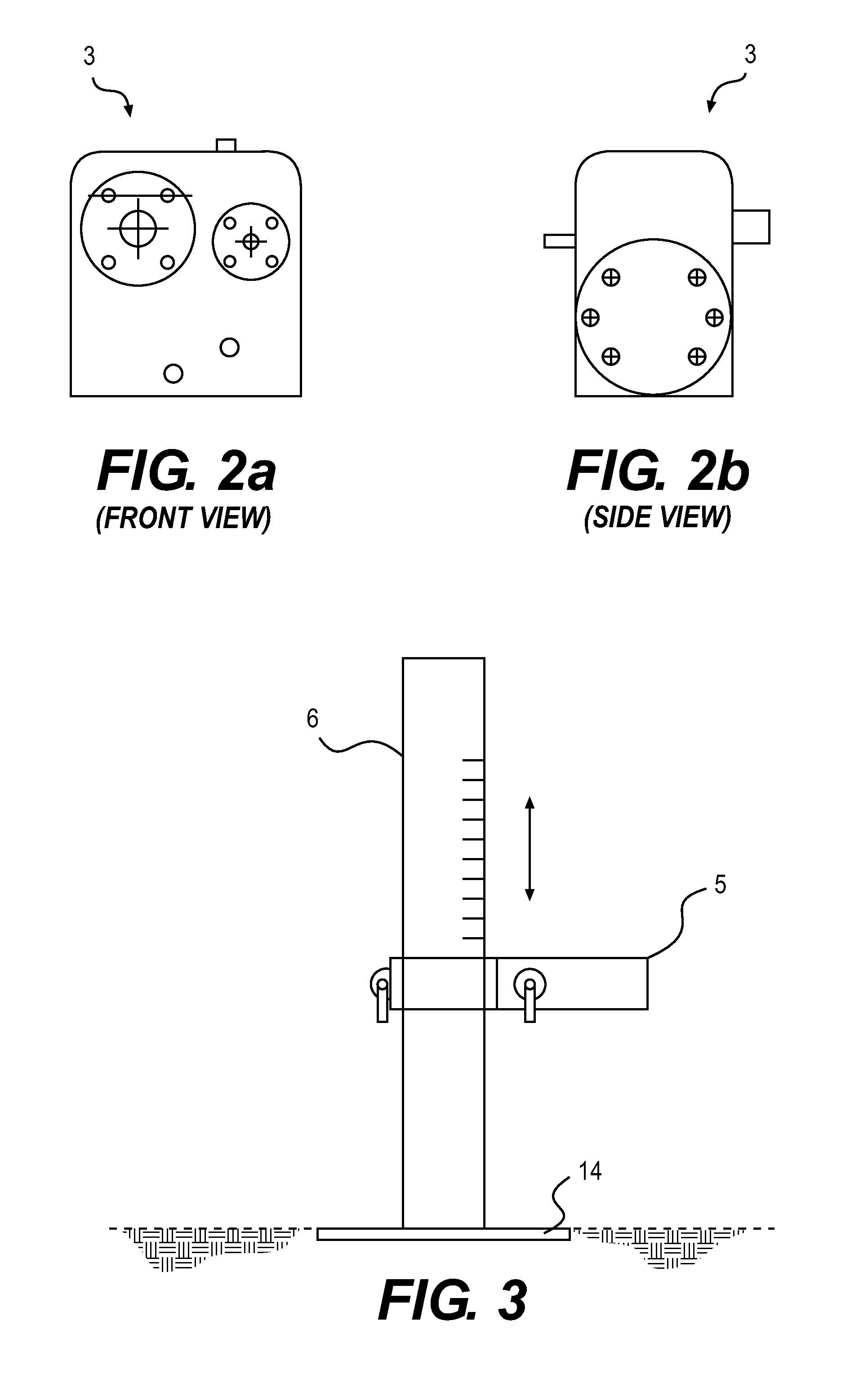

Jet grouting device with rotating roller bearing within casing pipe and rotating pipe

A high pressure jet grouting device generally employed with a portable stand comprised of a vertically adjustable shelf forming a platform for attaching an air motor, reduction gearing box and a releasable right angle gear box. High pressure air is pumped to the air motor and a grouting pump, the air pressure is used to turn the right angle gear and a rotatable pipe inside a casing pipe. The grouting material under pressure from the air compressor is pumped through a hose to a swivel connection on the end portion of a rotating pipe to inject the grout into the ground from a spray nozzle located at the opposite end of the rotating pipe inserted in the ground. A rotating roller bearing is provided between casing pipe and the rotating pipe. The device is small and does not require a heavy drill rig as the drilling operation is separately performed from the grouting process.

Owner:SSESCO INC

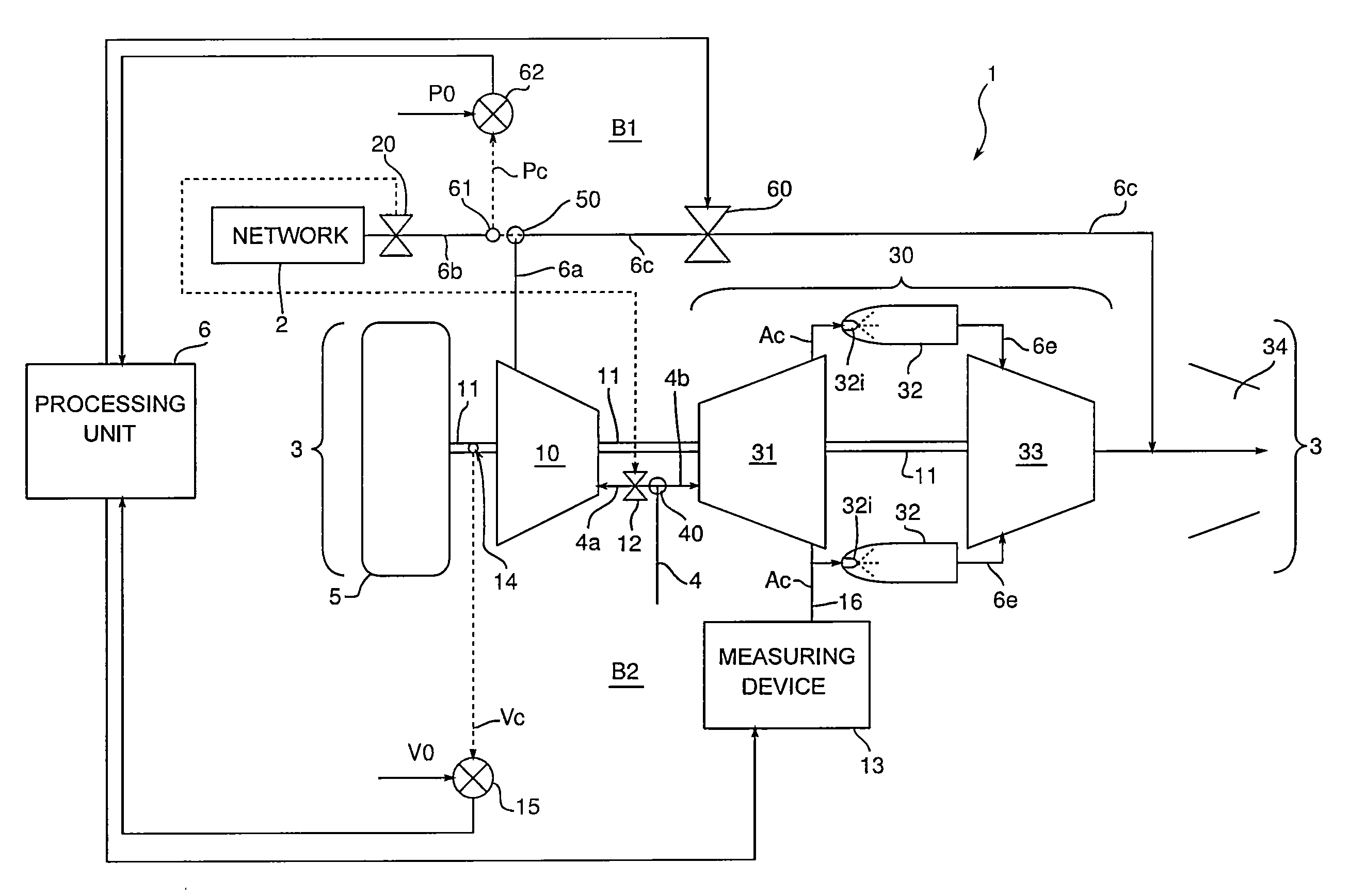

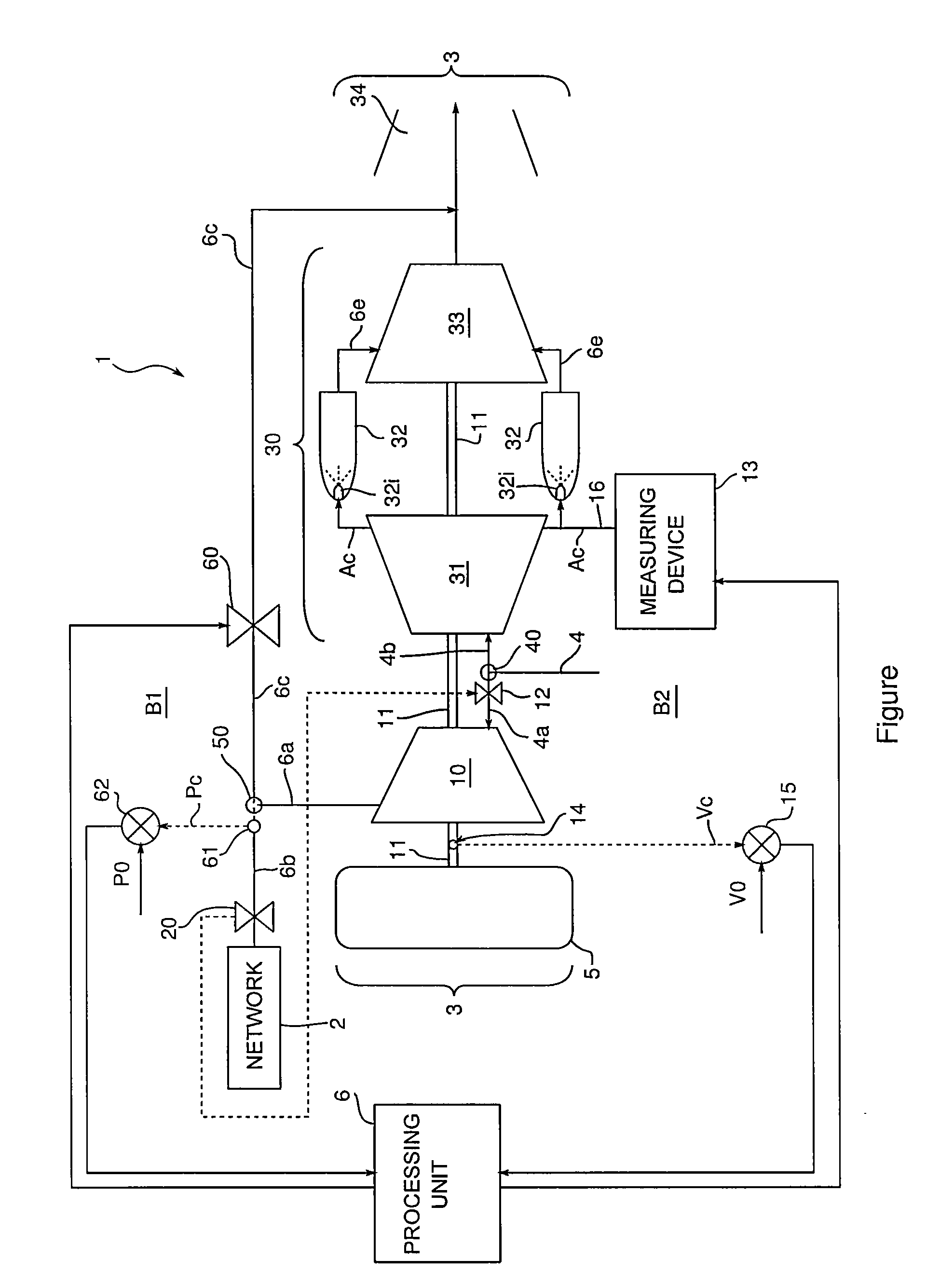

Controlling method and system for compressed air supply to a pneumatic network, in particular in an aircraft

A system for supplying compressed air to a pneumatic network includes a load compressor, an air supply and a power shaft driving the load compressor. The system also includes in an air outlet of such load compressor, a connecting channel connected, on the one side, with a channel connected with the pneumatic network and, on the other side, with an air discharge conduct towards an exhaust nozzle. Air flow rate bleed valves are controlled by a processing unit via servo-loops as a function of the pressure sensors and the speed sensor.

Owner:SAFRAN POWER UNITS

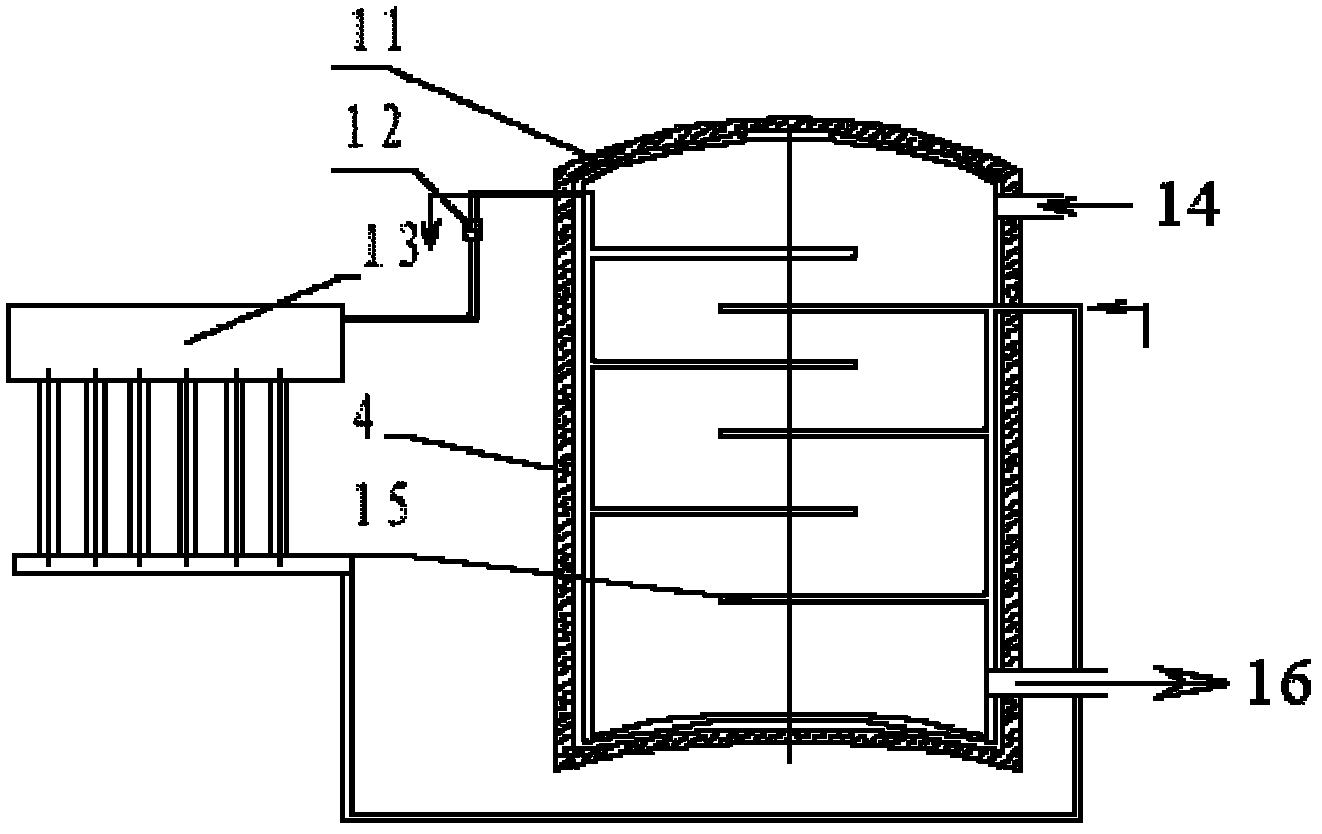

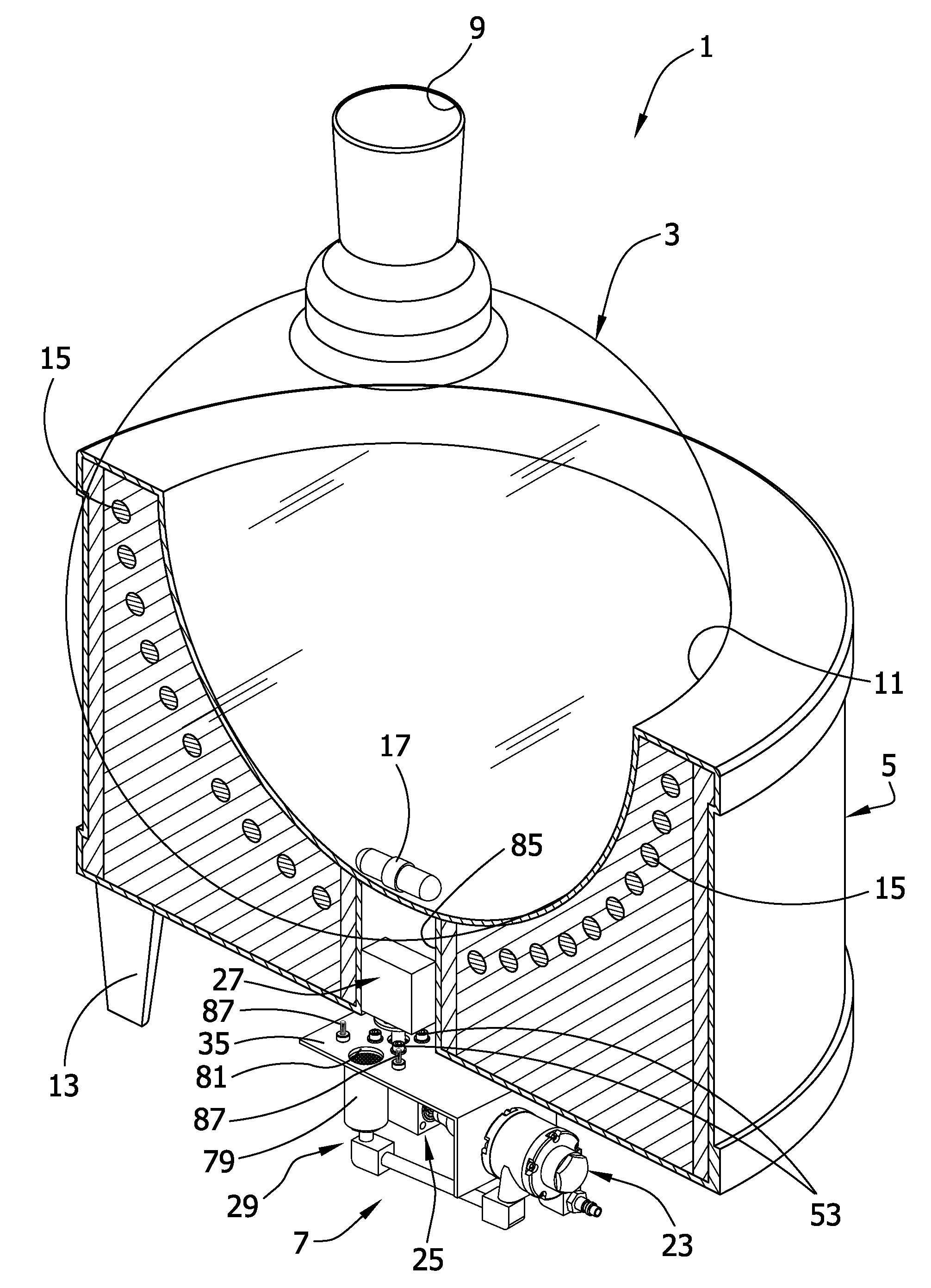

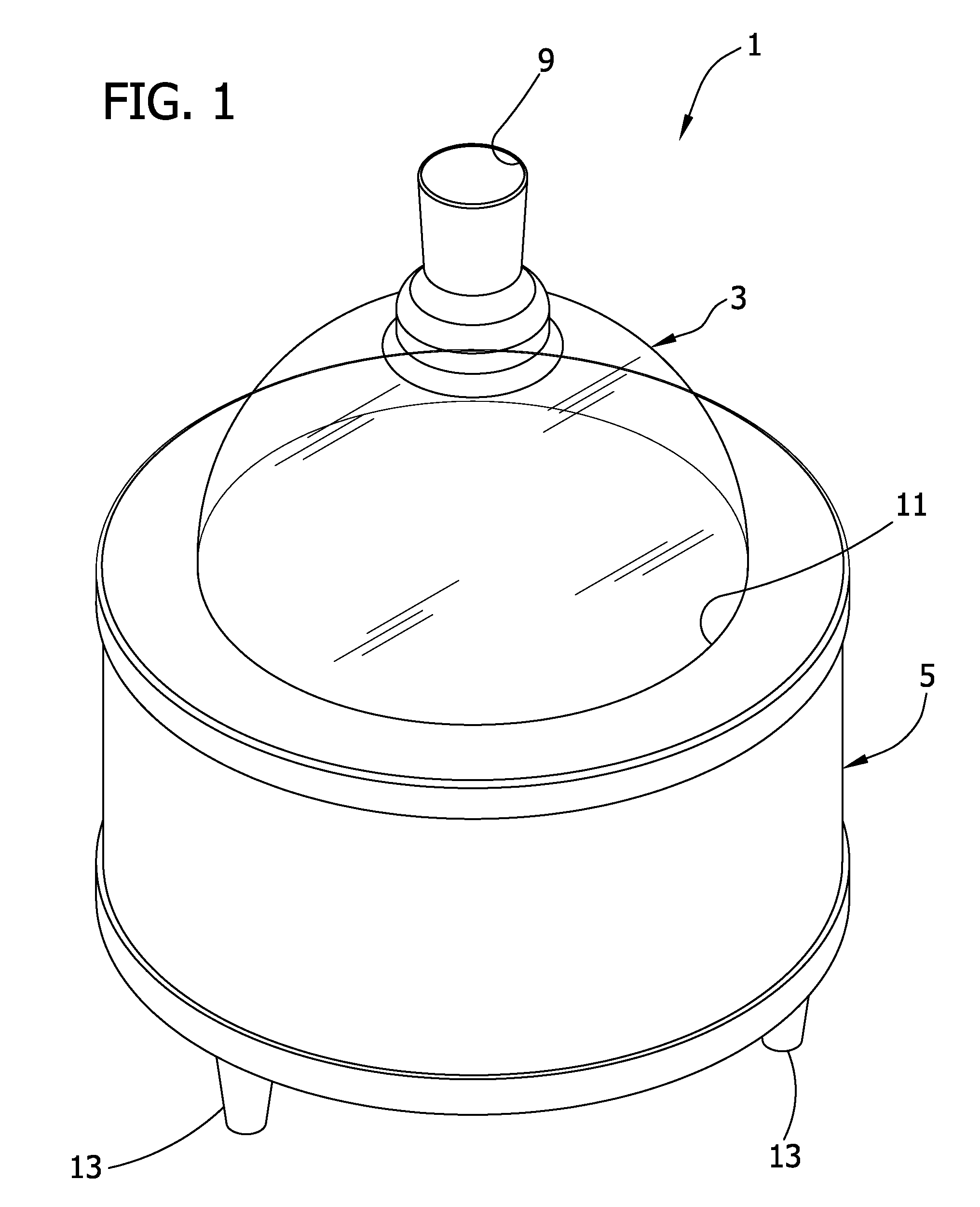

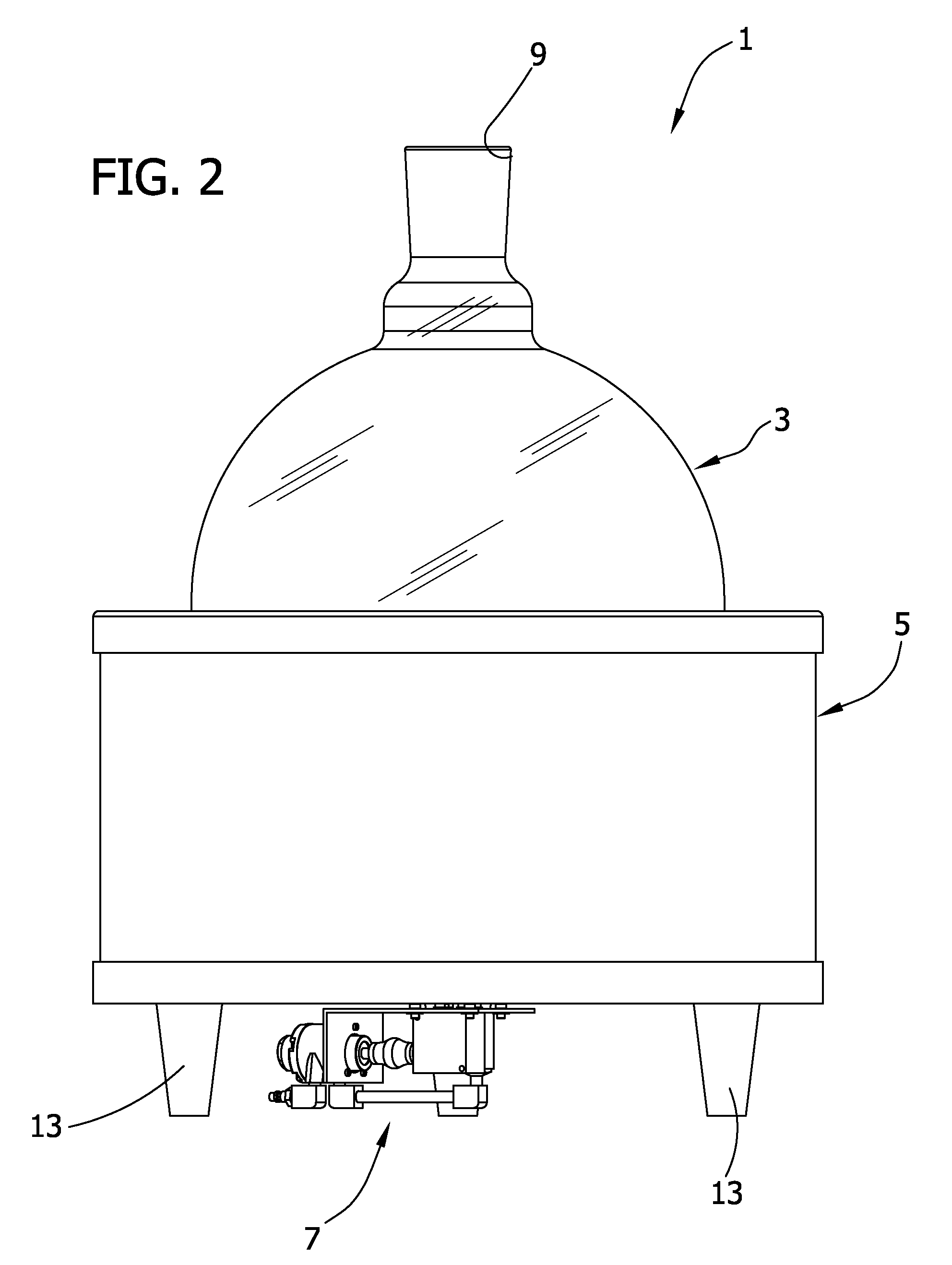

Magnetic Stirrer

InactiveUS20080013400A1Transportation and packagingMixer accessoriesMagnetic tension forceEngineering

A magnetic stirring system includes a stir-mantle and a magnetic stirring apparatus used for stirring / mixing materials in a flask. A rare-earth magnet is mounted on the magnetic stirring apparatus and is driven in rotation by a pneumatic motor. The rare-earth magnet is coupled to a magnetic stir bar in the flask for conjoint rotation so that the stir-bar stirs / mixes the materials in the flask. An exhaust is included to channel air from the motor to the rare-earth magnet and to direct the air to flow over the magnet to control the temperature of the magnet.

Owner:SIGMA ALDRICH CO LLC

Pneumatic rotary tool

InactiveUS7404450B2Reduce back pressureLow costConstructionsReciprocating drilling machinesPneumatic toolLate stage

A pneumatic rotary tool has a housing formed primarily from plastic so that the weight and price of the tool are substantially reduced. The air motor is formed for economic assembly while permitting greater structural stability should the housing deflect under an impact. The tool includes a torque selector which controls the amount of pressurized air allowed to enter the air motor, thereby controlling the torque output of the motor. The user may adjust the torque selector to a number of set positions which correspond to discrete torque values. The tool additionally incorporates early and late stage exhaust ports, so that backpressure within the air motor does not slow motor rotation or decrease tool power.

Owner:S P AIR

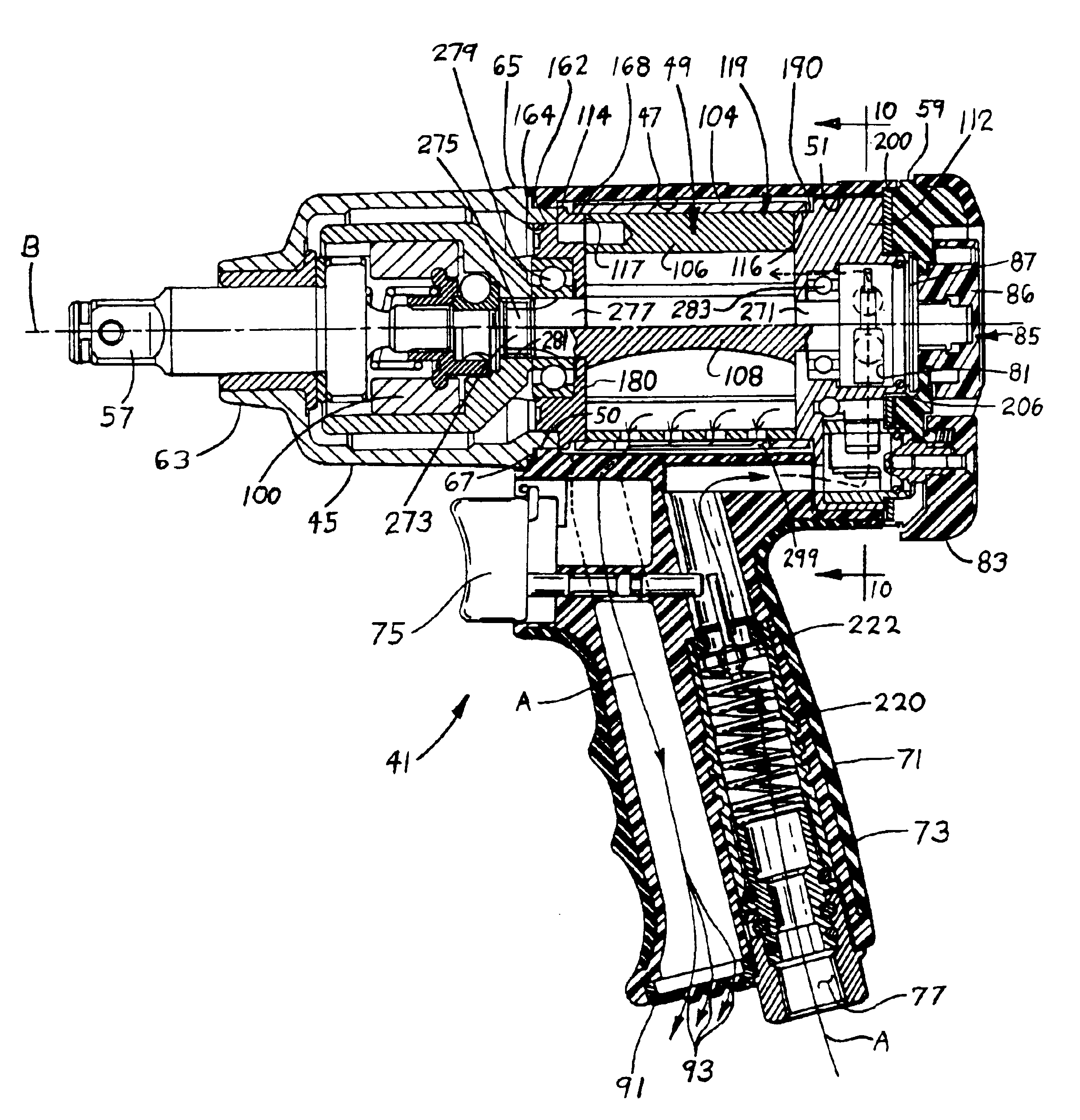

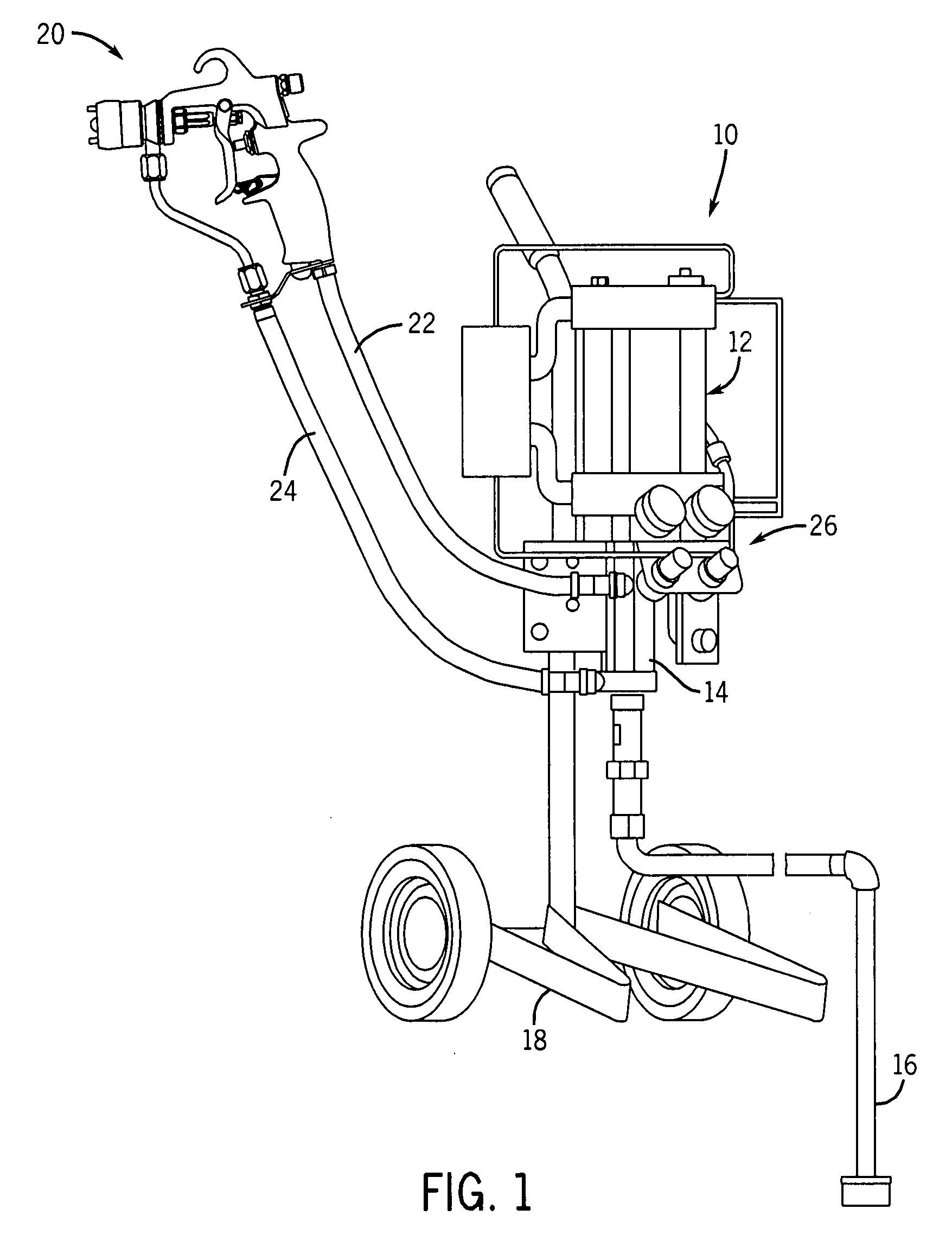

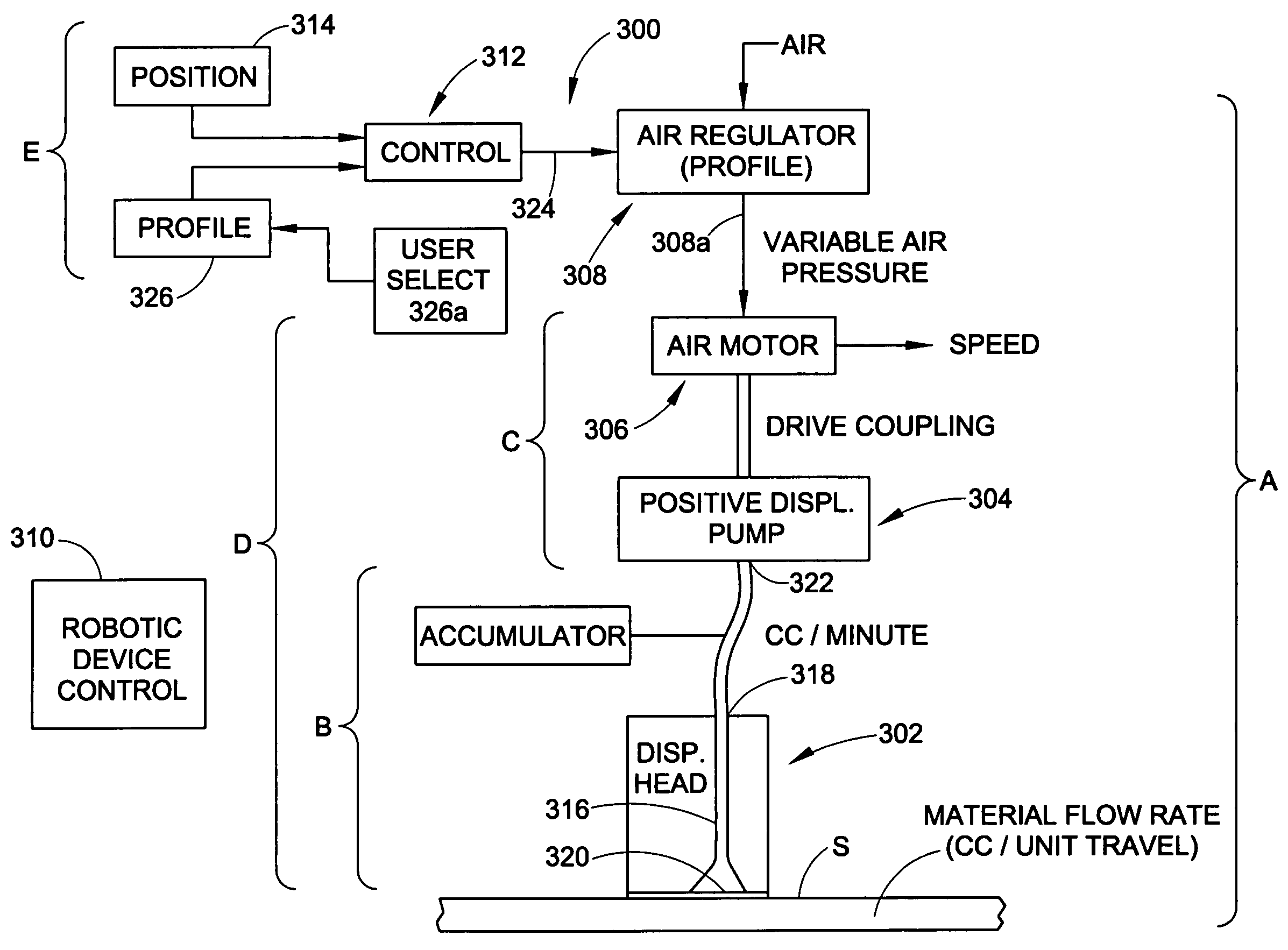

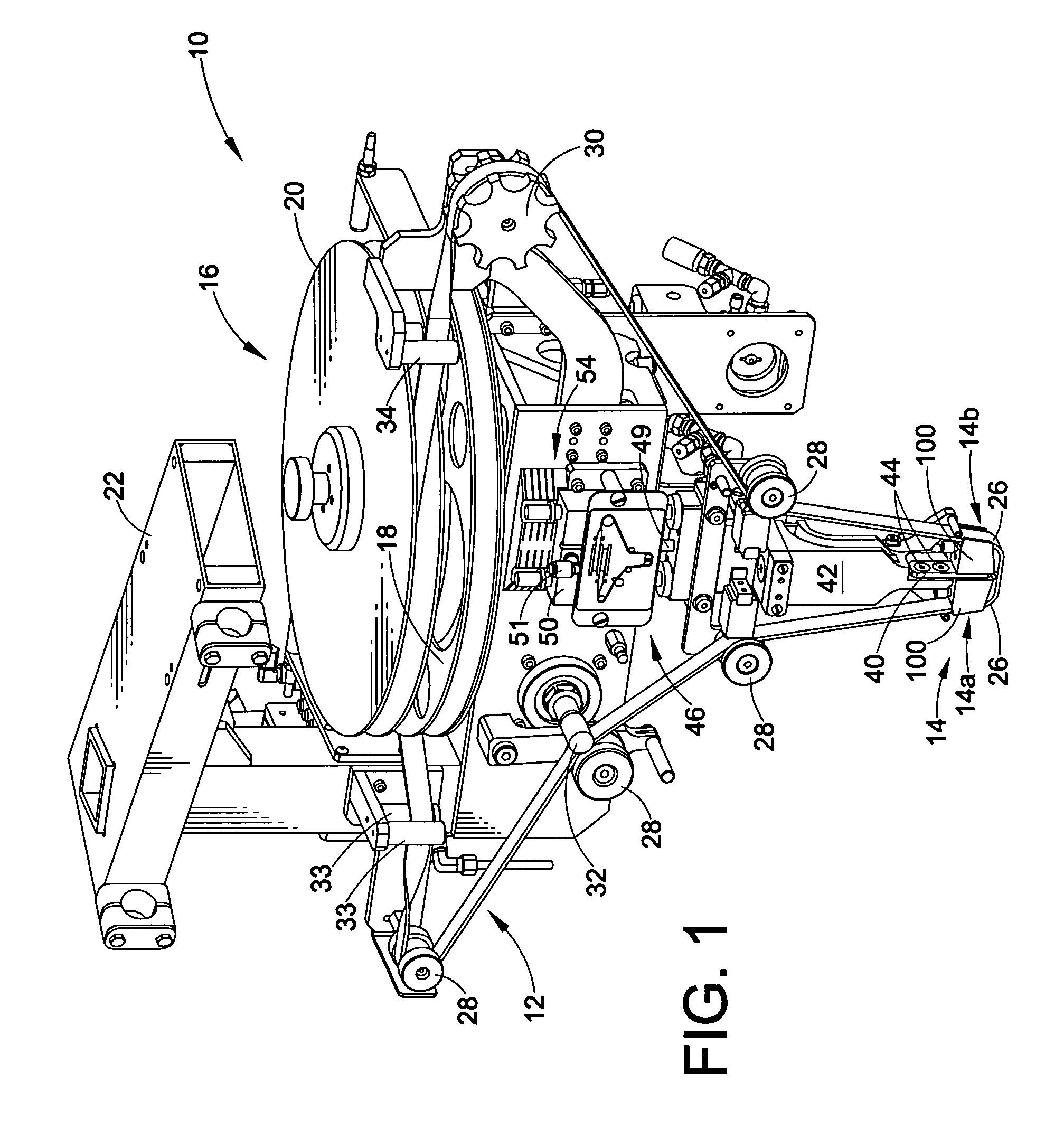

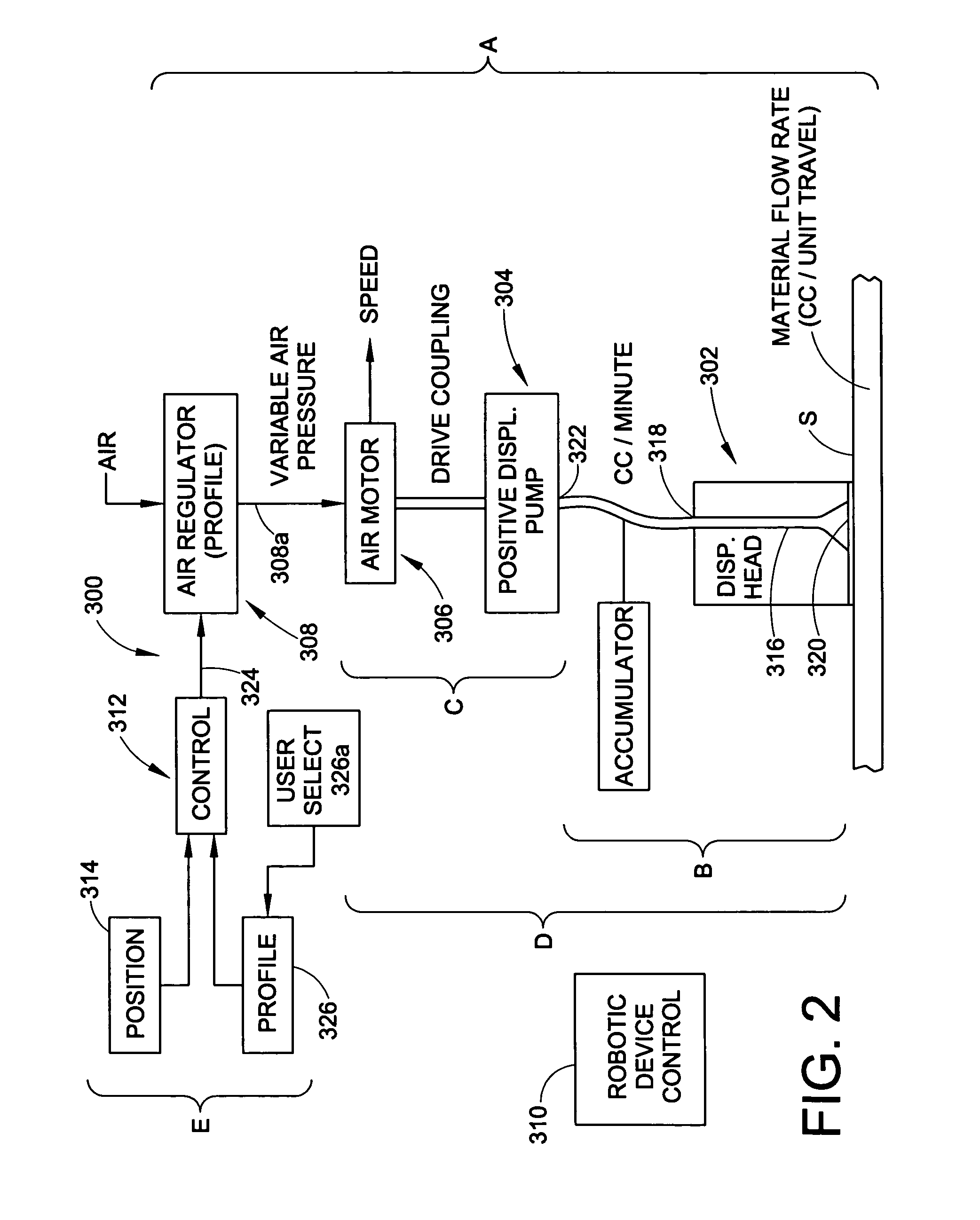

Fluid dispenser with positive displacement pump

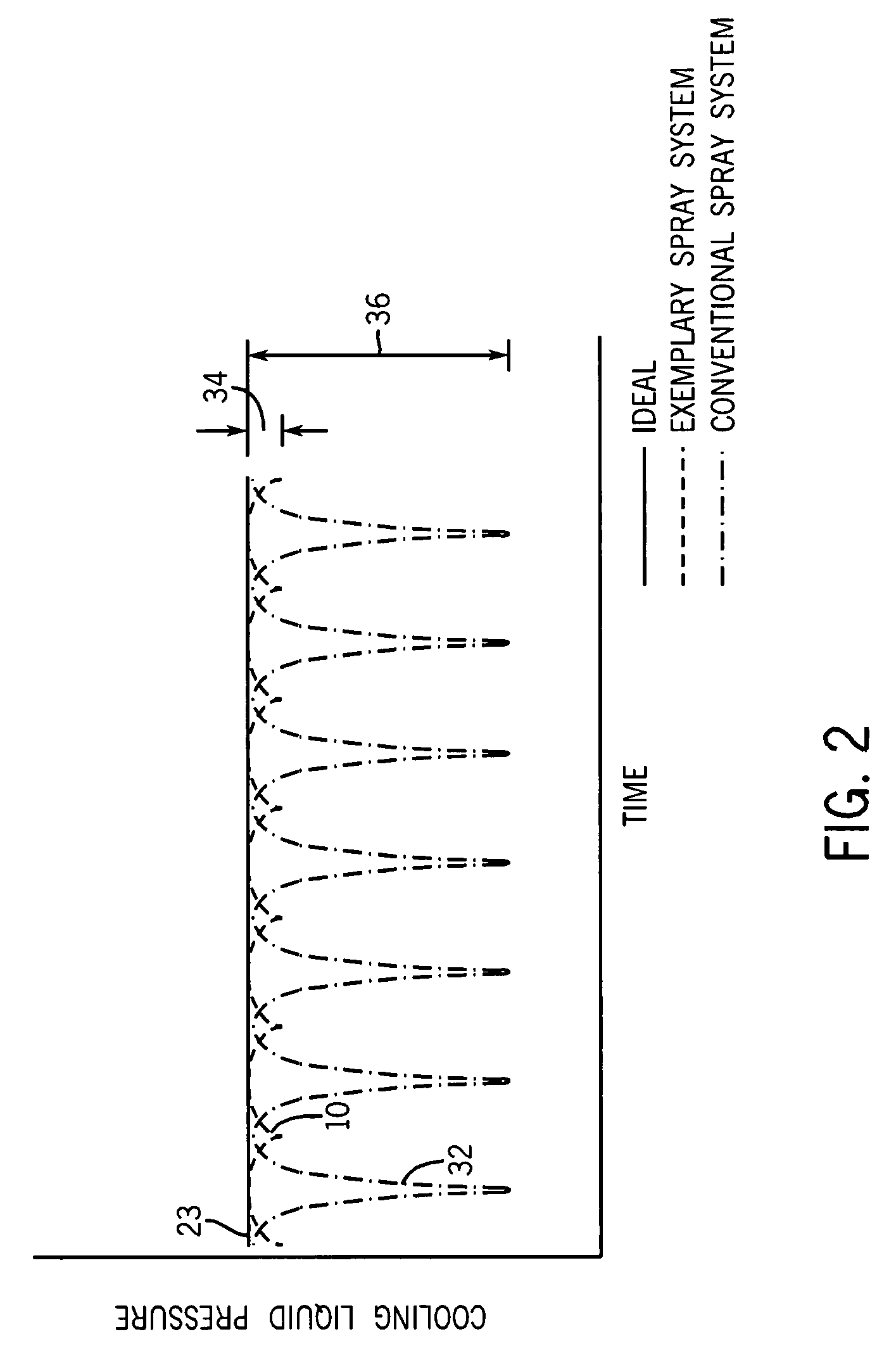

ActiveUS7575633B2Facilitate material flowLow pressureLiquid surface applicatorsLiquid spraying apparatusMotor speedMotor drive

Fluid dispensing apparatus uses positive displacement of the fluid for accurate metering of the quantity of liquid applied to a surface. Positive displacement includes a metering volume that is filled and emptied so that each cycle corresponds to an accurate volume of material dispensed independent of viscosity. In one embodiment, a positive displacement pump is used with a variable speed air motor. The air motor drives the pump. A variable output air regulator supplies air pressure to run the air motor based on a position signal. A profile may be used to relate position with motor speed and to control quantity to be dispensed.

Owner:SWAGELOK CO +1

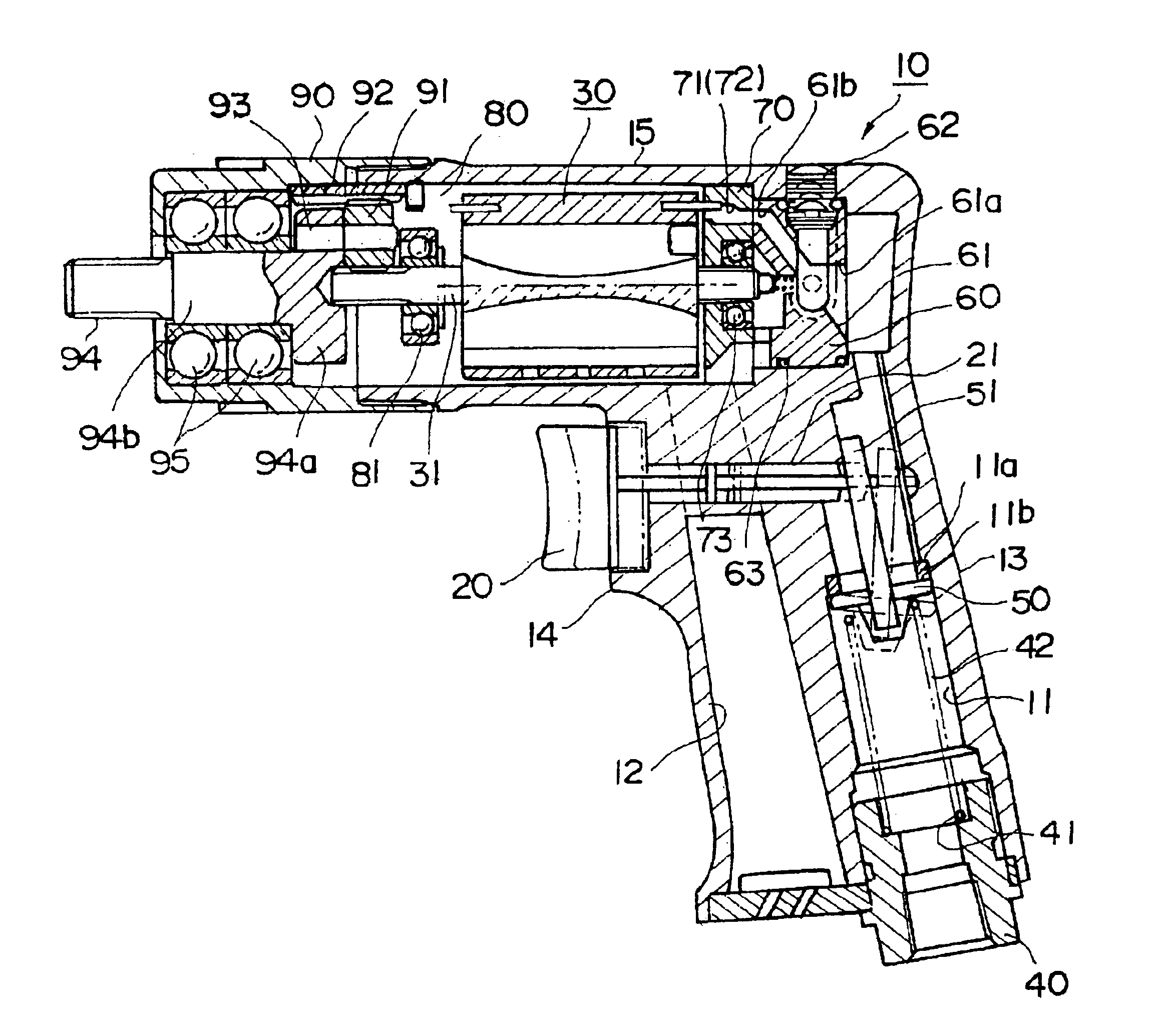

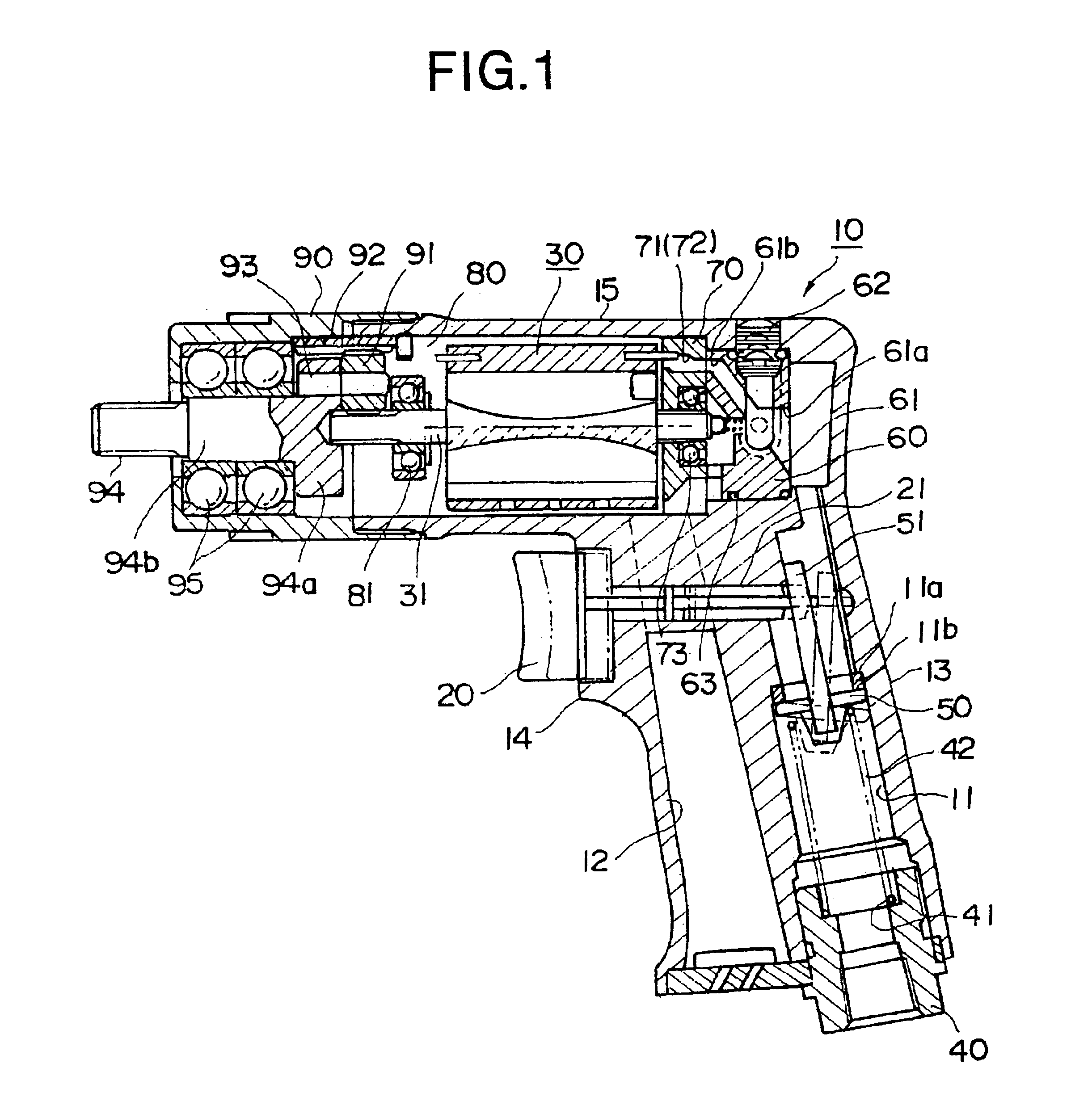

Air drill

An air drill includes a body having a grip portion having an air supply passage and an air exhaust passage formed therein, a trigger portion formed above the grip portion and supporting a trigger, and a cylinder portion formed above the trigger portion and accommodating an air motor. A reverse valve is disposed within the cylinder portion in order to switch the direction of rotation of the air motor between forward and reverse directions. Two reverse levers are disposed in an upper portion of the reverse valve and slidably accommodated in two slit-shaped openings, respectively, which are formed in a grip-portion-side end of the cylinder portion.

Owner:SHINANO SEISAKUSHO

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com