Jet grouting device with rotating roller bearing within casing pipe and rotating pipe

a technology of rotating roller bearing and grouting device, which is applied in the direction of bulkheads/piles, construction, foundation engineering, etc., can solve the problems of not being suitable for the purpose, hammering the milling or drilling operation,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038]The present invention is directed to a “Jet Grouting Device”. More specifically, the unique feature of the design is that the jet grouting operation is accomplished with minimal equipment and size providing multiple uses in compact, remote or confined areas eliminating the need for less portable and larger heavy equipment.

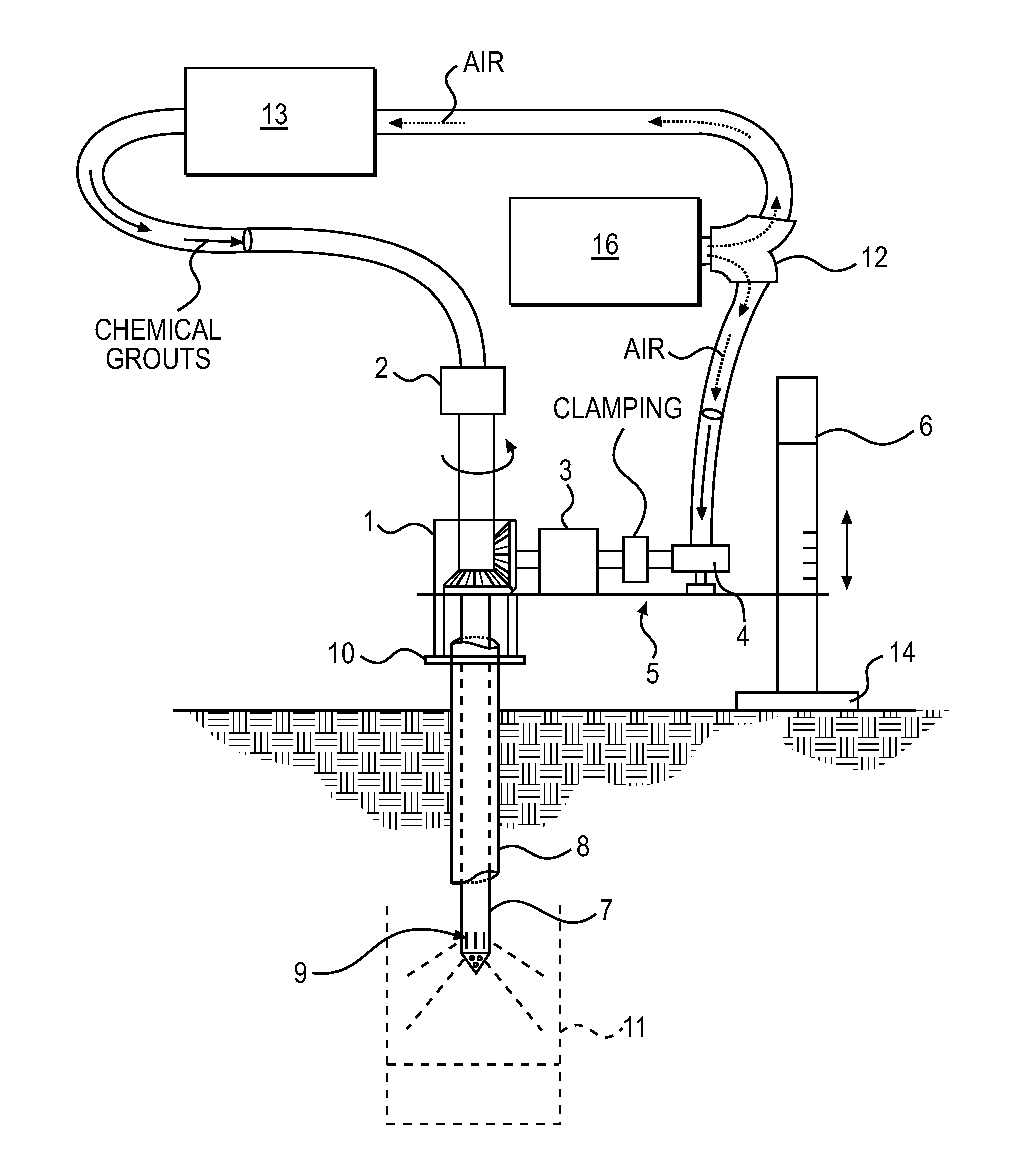

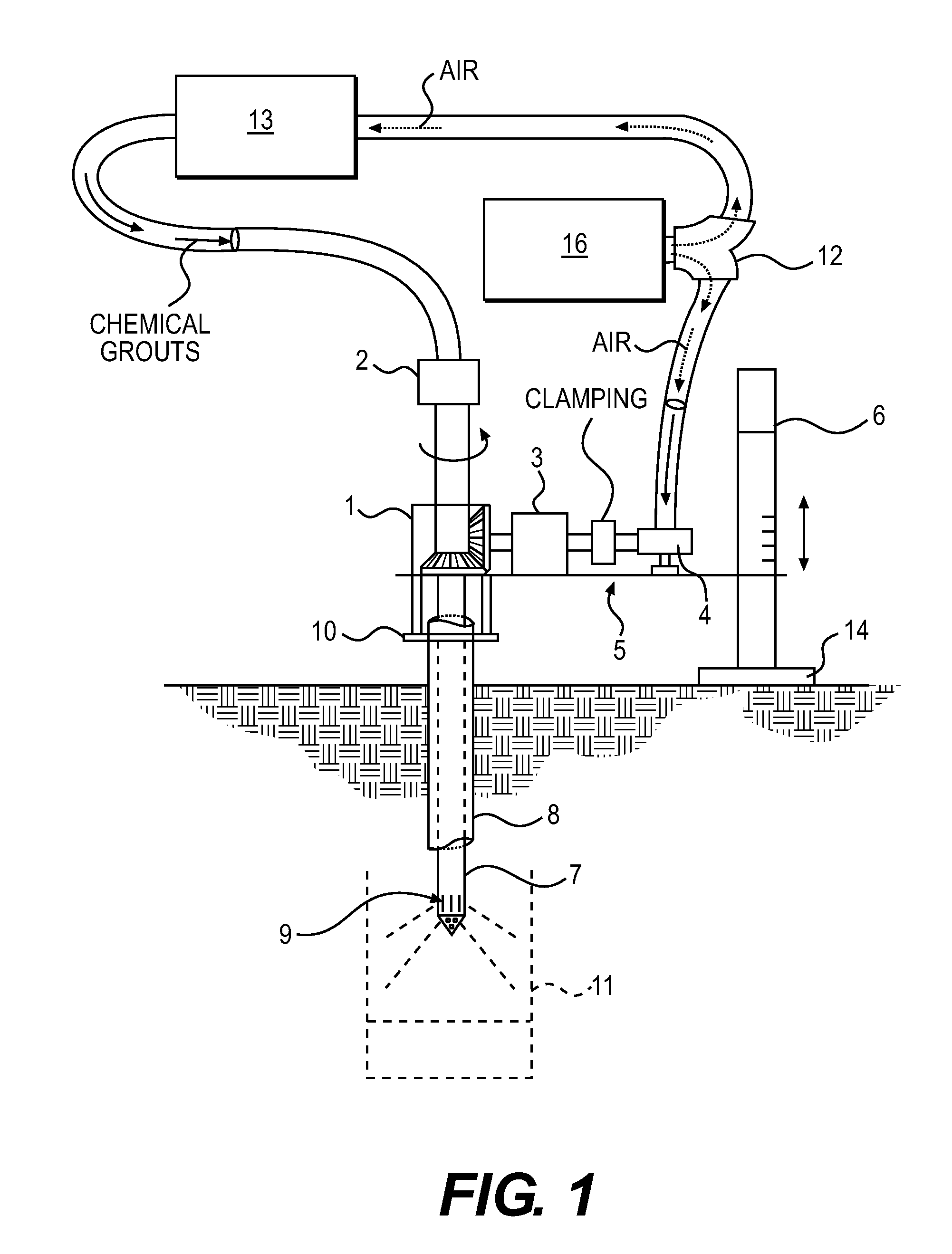

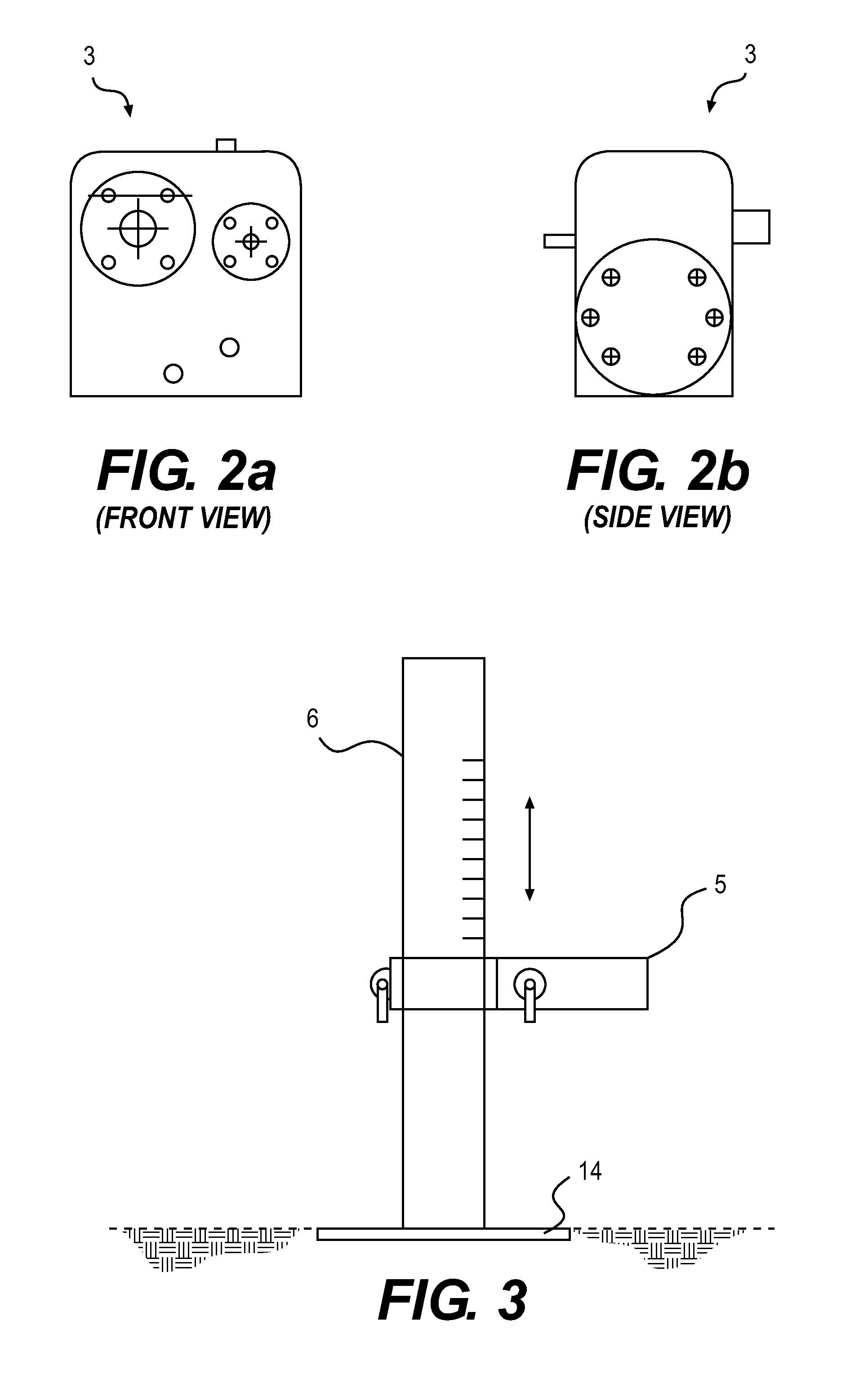

[0039]FIGS. 1 and 4 illustrate the operating position of the jet grouting device according to the present invention. The jet grouting device has a stand (6) which is generally supported by a floor base (14) on the ground and a shelf (5) which is adjustable vertically up or down. Optionally, a pneumatic, electric motor or hand crank can be used for lifting and lowering shelf (5). An air motor (4) is attached to the shelf by bolts or other means in several places. The output shaft of the air motor (4) is clamped to a gear speed reducer (3) also mounted to shelf (5) shown in FIG. 4. As shown in FIG. 1, a 90° degree or right angle gear coupling (1) are attached t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com