Patents

Literature

341 results about "Impact wrench" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An impact wrench (also known as an impactor, impact gun, air wrench, air gun, rattle gun, torque gun, windy gun) is a socket wrench power tool designed to deliver high torque output with minimal exertion by the user, by storing energy in a rotating mass, then delivering it suddenly to the output shaft.

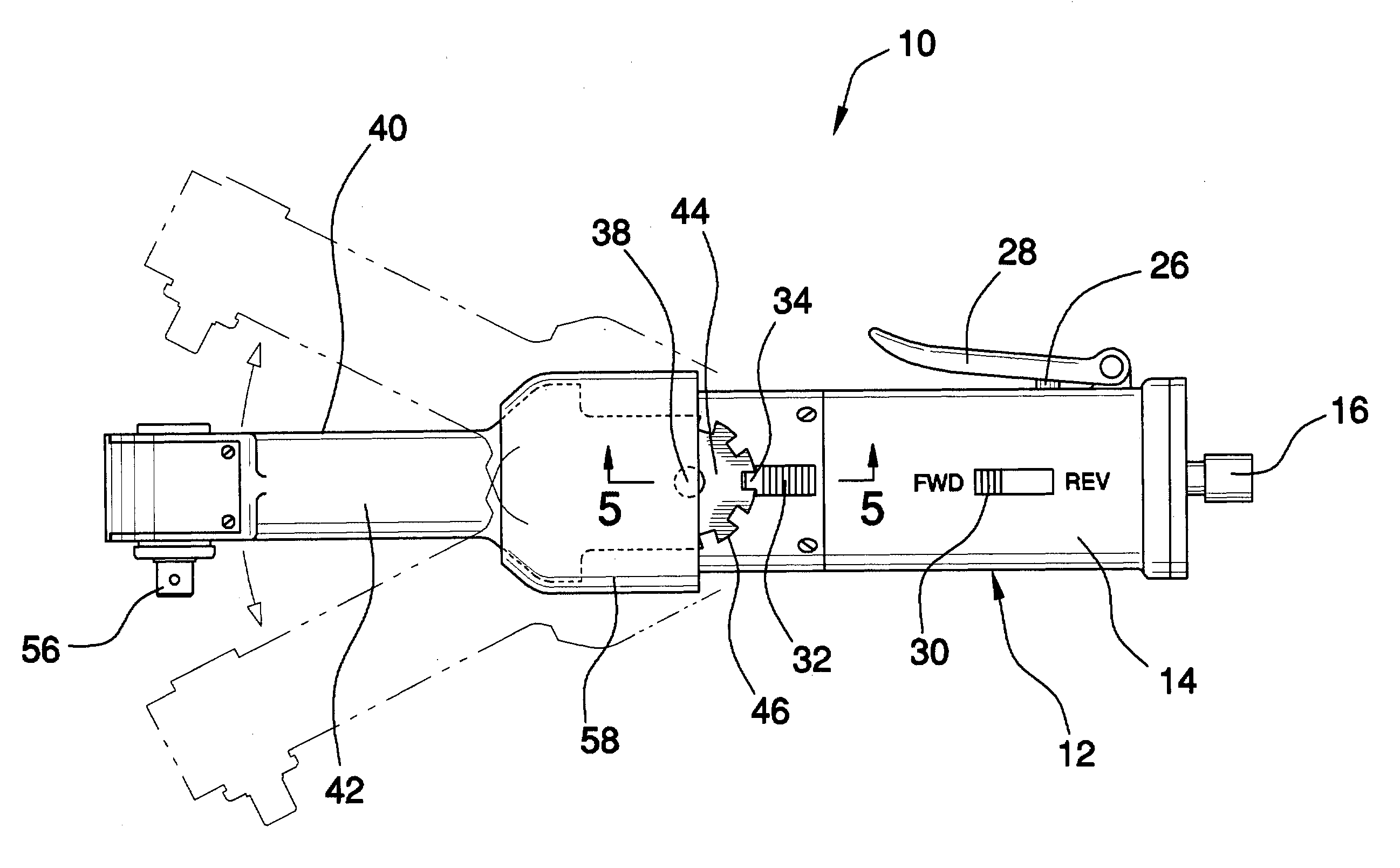

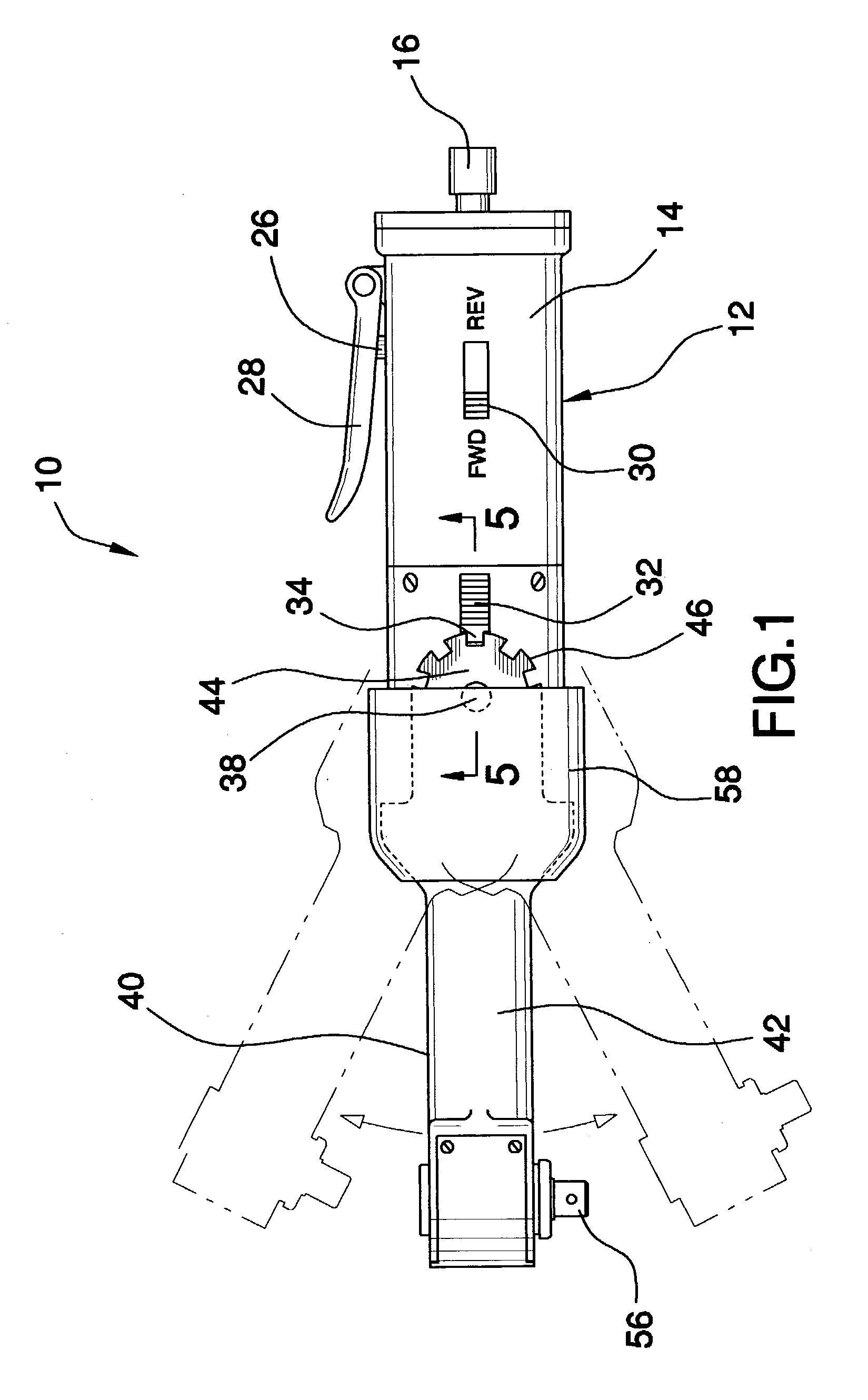

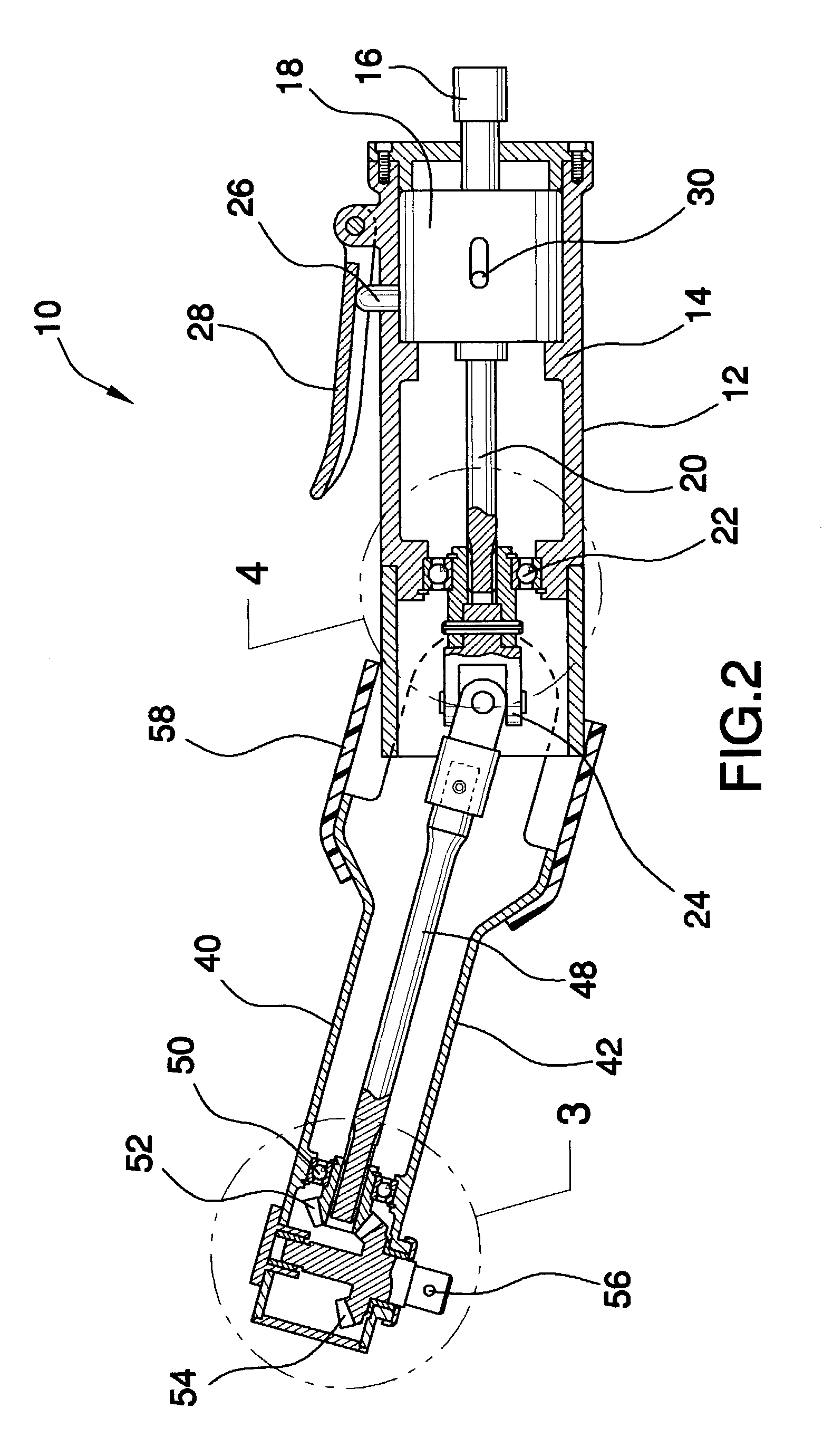

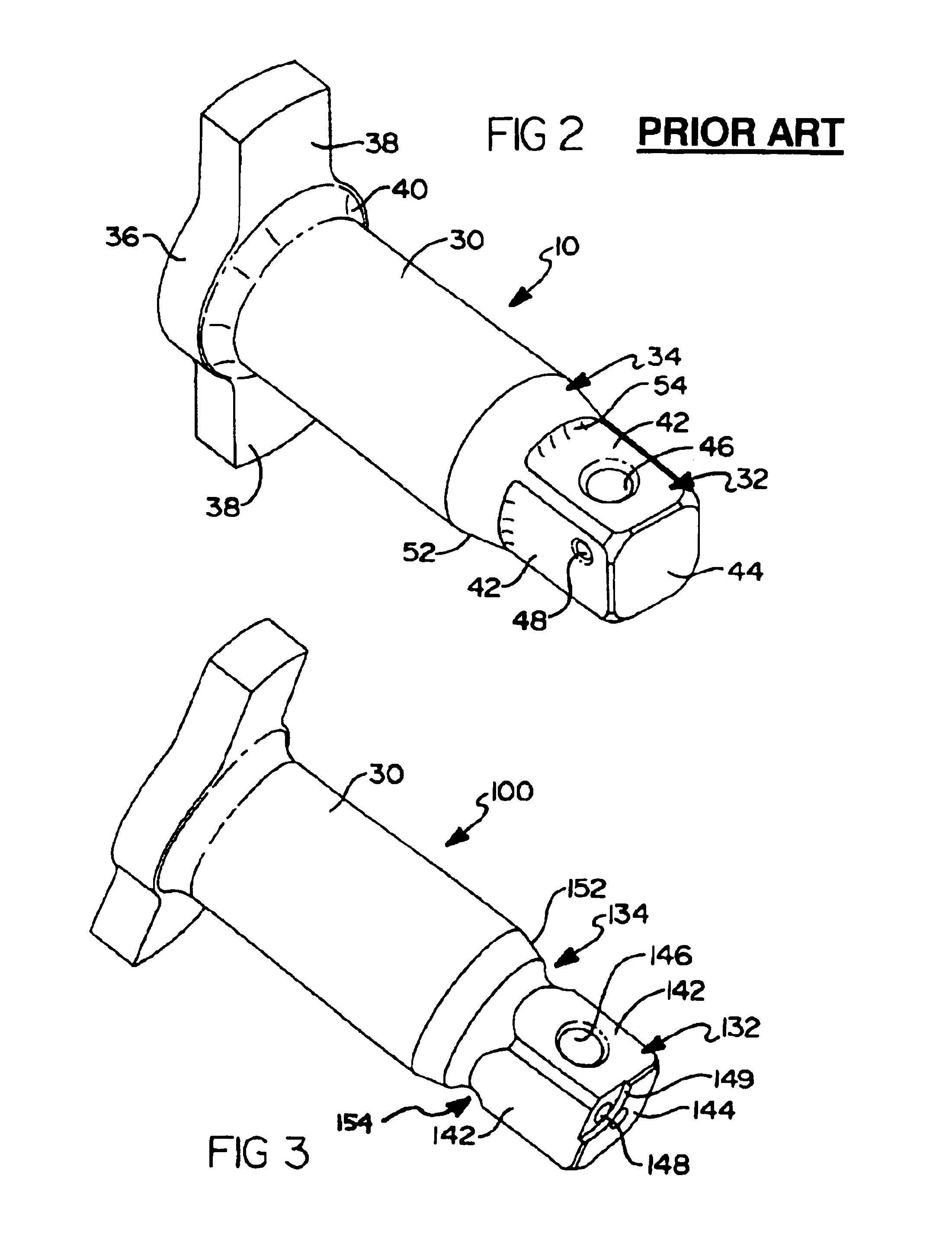

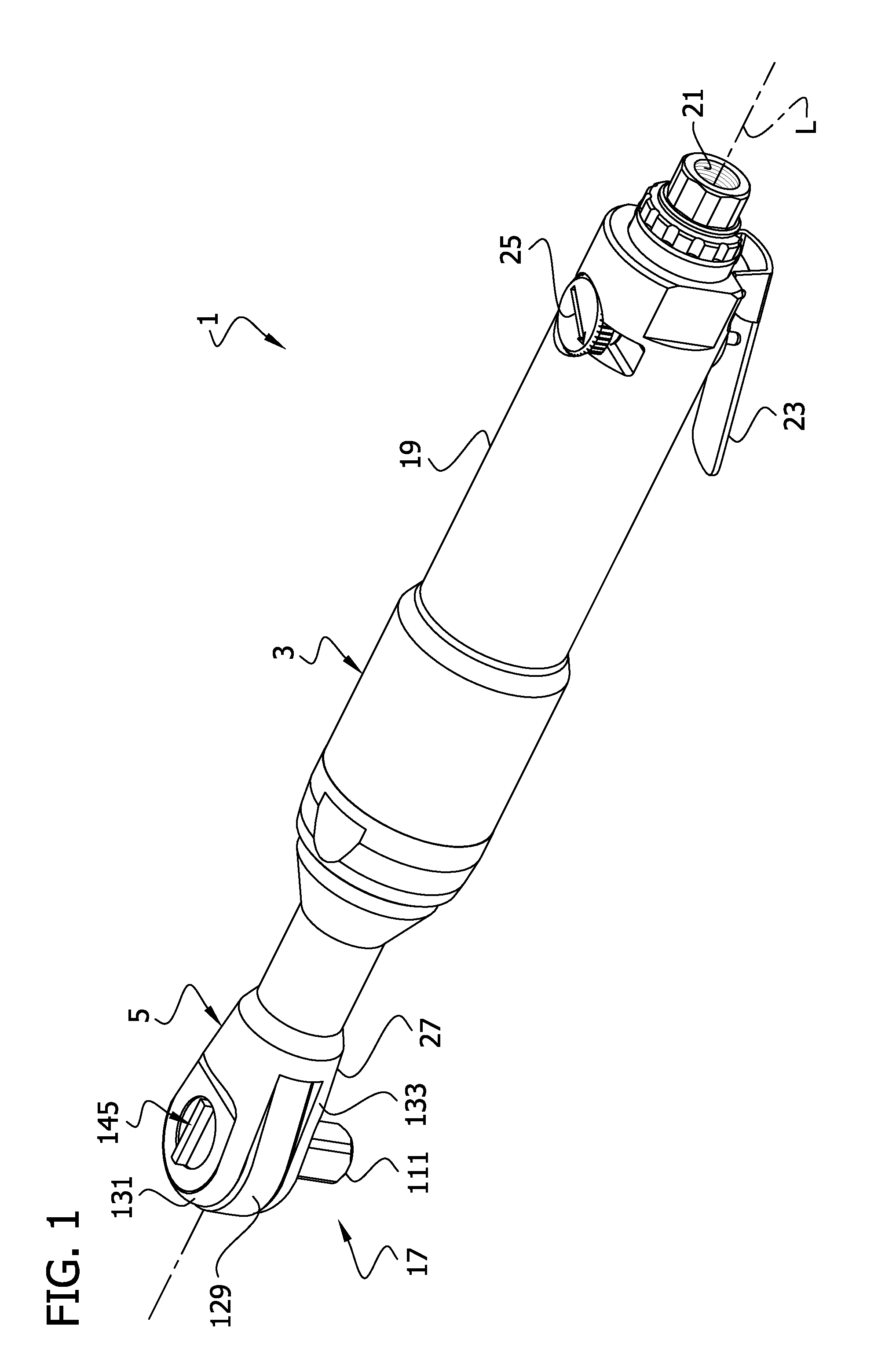

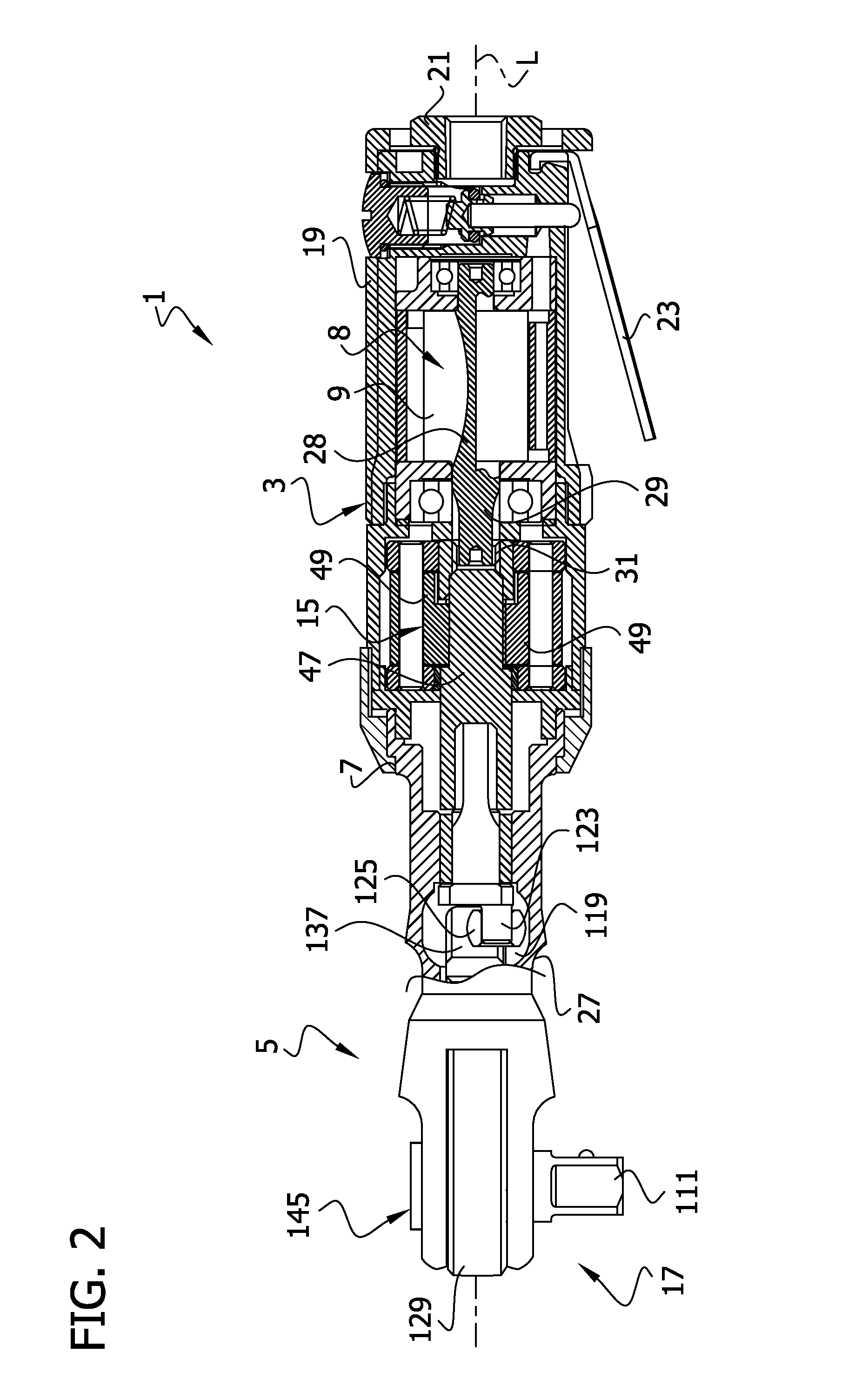

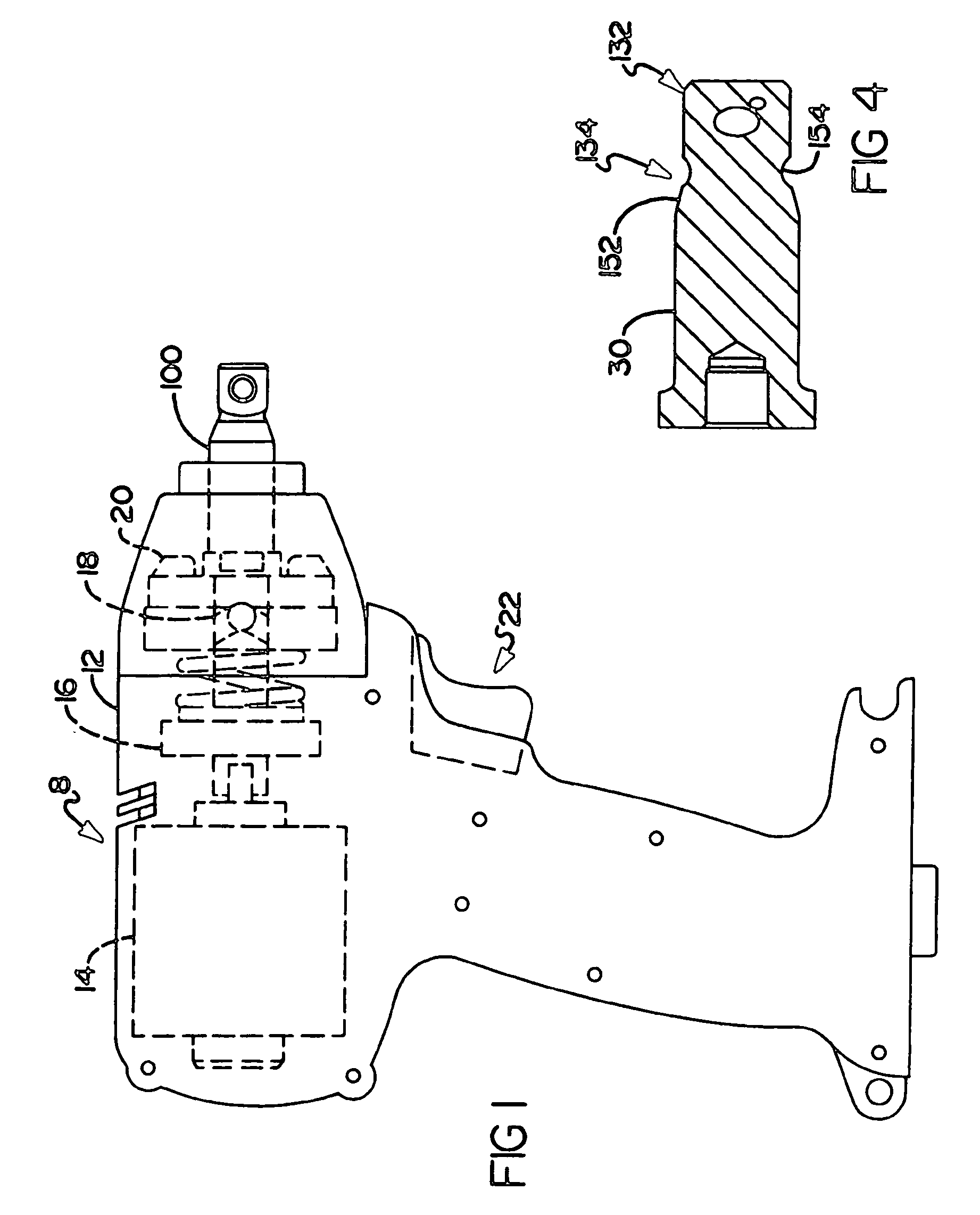

Air powered wrench device with pivotable head and method of using

InactiveUS6928902B1Easy and efficient to manufactureLower sales priceSpannersWrenchesBall bearingUniversal joint

An air powered wrench device with a pivotable head and associated method of using. The device comprises a handle pivotally attached to an arm. The handle comprises a housing, an air intake nozzle, an air driven motor, a drive shaft, a ball bearing collar, a universal joint, an on / off button, a trigger switch, a directional throw switch, a lock pin, a spring, and a pivot post. The arm is pivotally attached to the handle via the pivot post. The arm includes: an outer casing, an extension rod, a ball bearing sleeve, a first pawl gear, a second pawl gear, and a bit connector. The method of using the device comprises the steps of adjoining, affixing, aligning, allowing, enshrouding, getting, moving, obtaining, putting, rotating, shifting, squeezing, and tightening.

Owner:EYSSALLENNE LUIS P

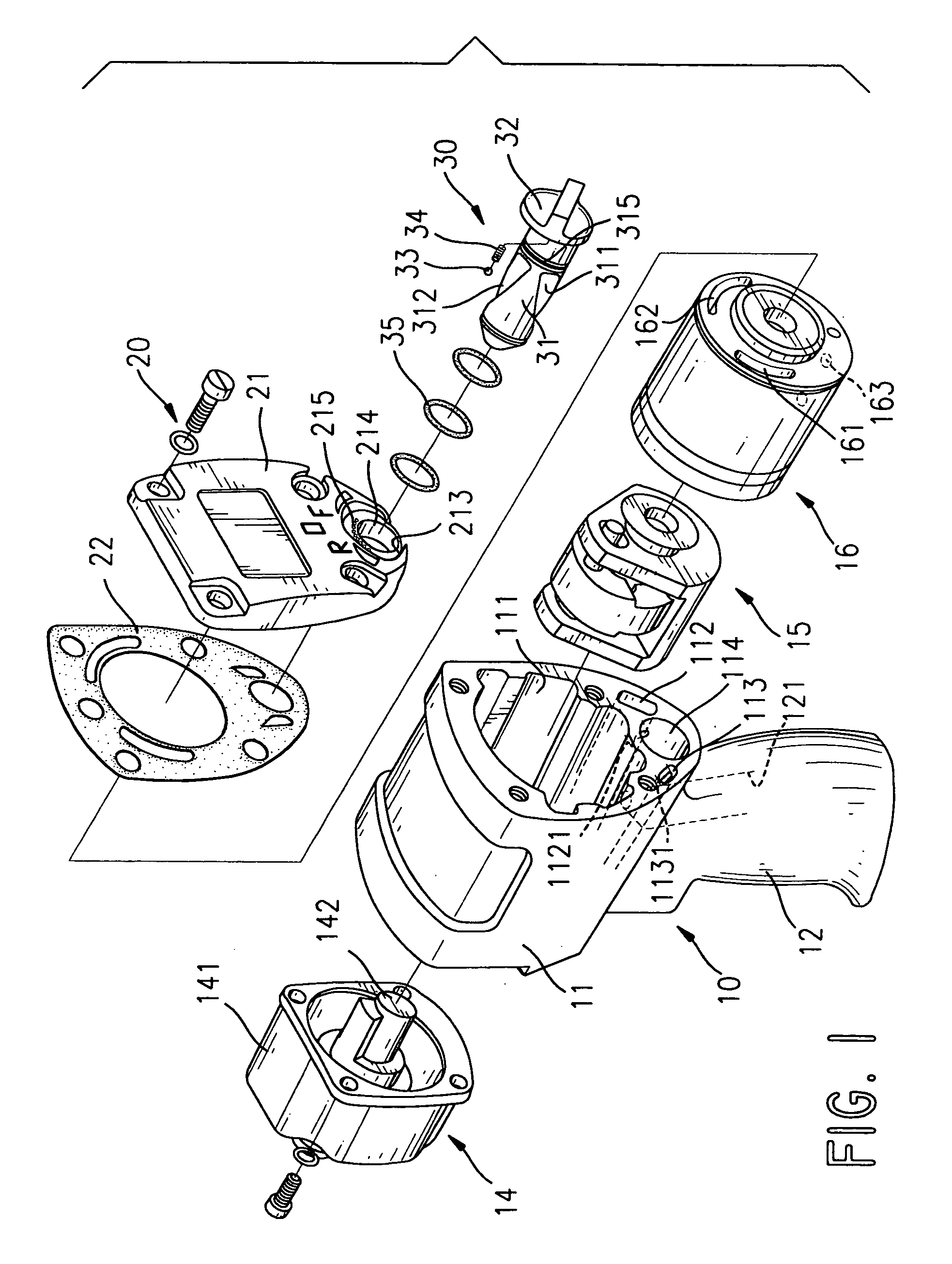

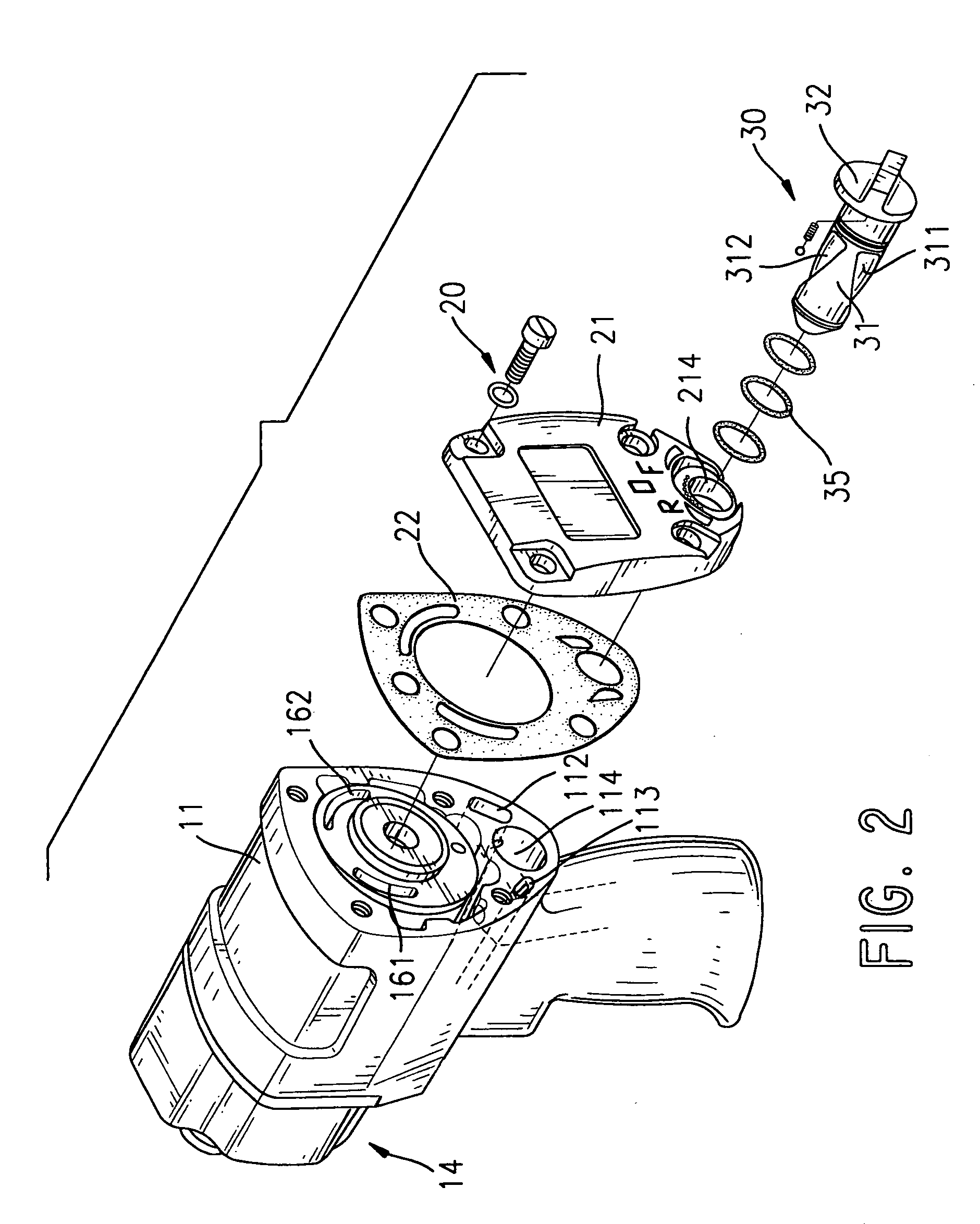

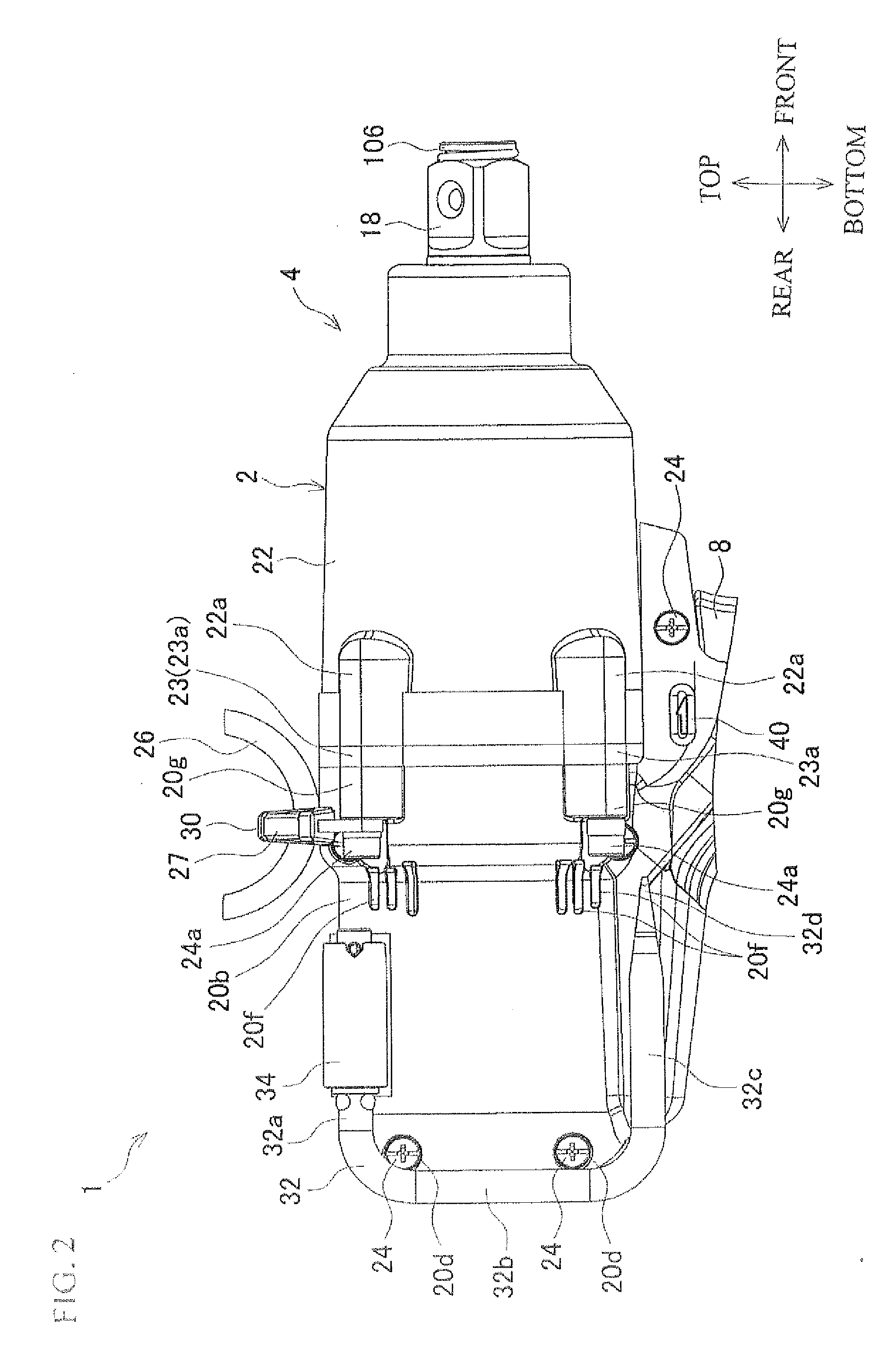

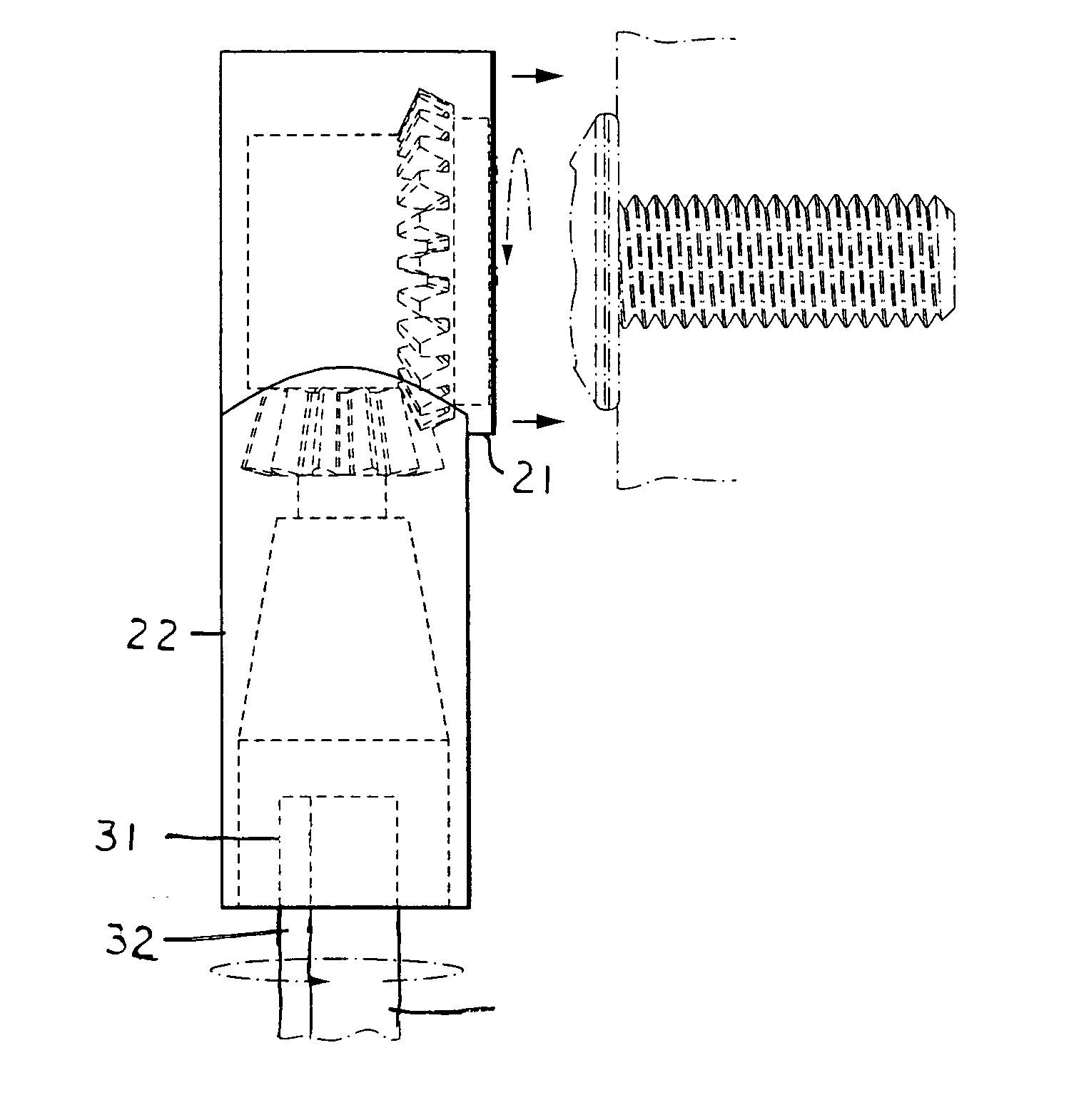

Bidirectional pneumatic impact wrench

InactiveUS6883619B1Simple structureEfficiently directsOperator-supported drilling machinesPower driven toolsControl valvesImpact wrench

A bidirectional pneumatic impact wrench has a pneumatic motor and an air control valve. The pneumatic motor has a forward air inlet and a reverse air inlet. The air control valve directs compressed air selectively into either the forward air inlet or the reverse air inlet to change the direction of rotation of the pneumatic motor and includes a rotatable shaft. The shaft has an exterior surface and a spiral forward air groove and reverse air groove that are symmetrically defined in the exterior surface to direct the compressed air efficiently. The air control valve is simple to fabricate and directs the compressed air efficiently into the pneumatic motor to improve power and efficiency of the pneumatic motor.

Owner:HUANG YUNG CHAO

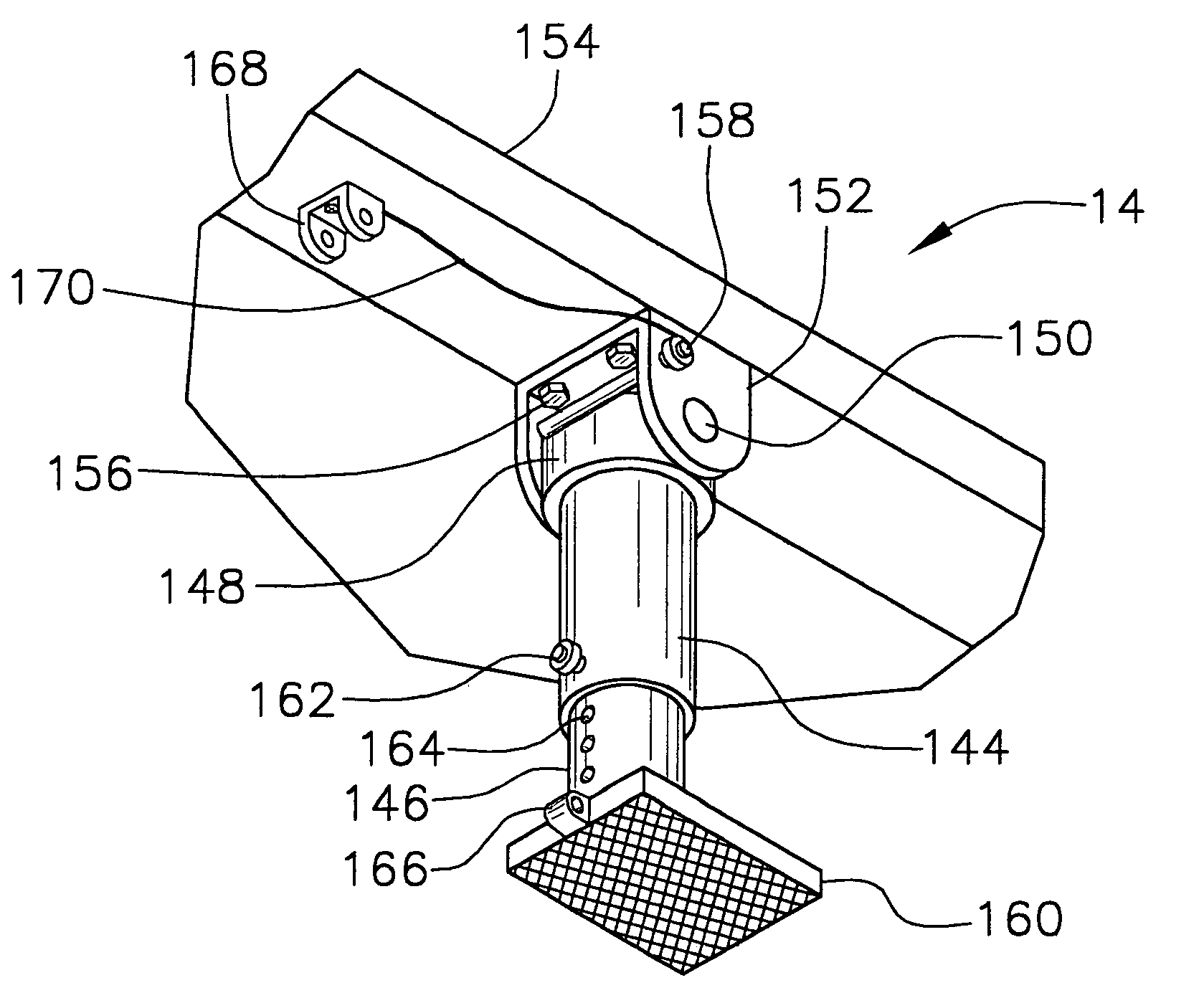

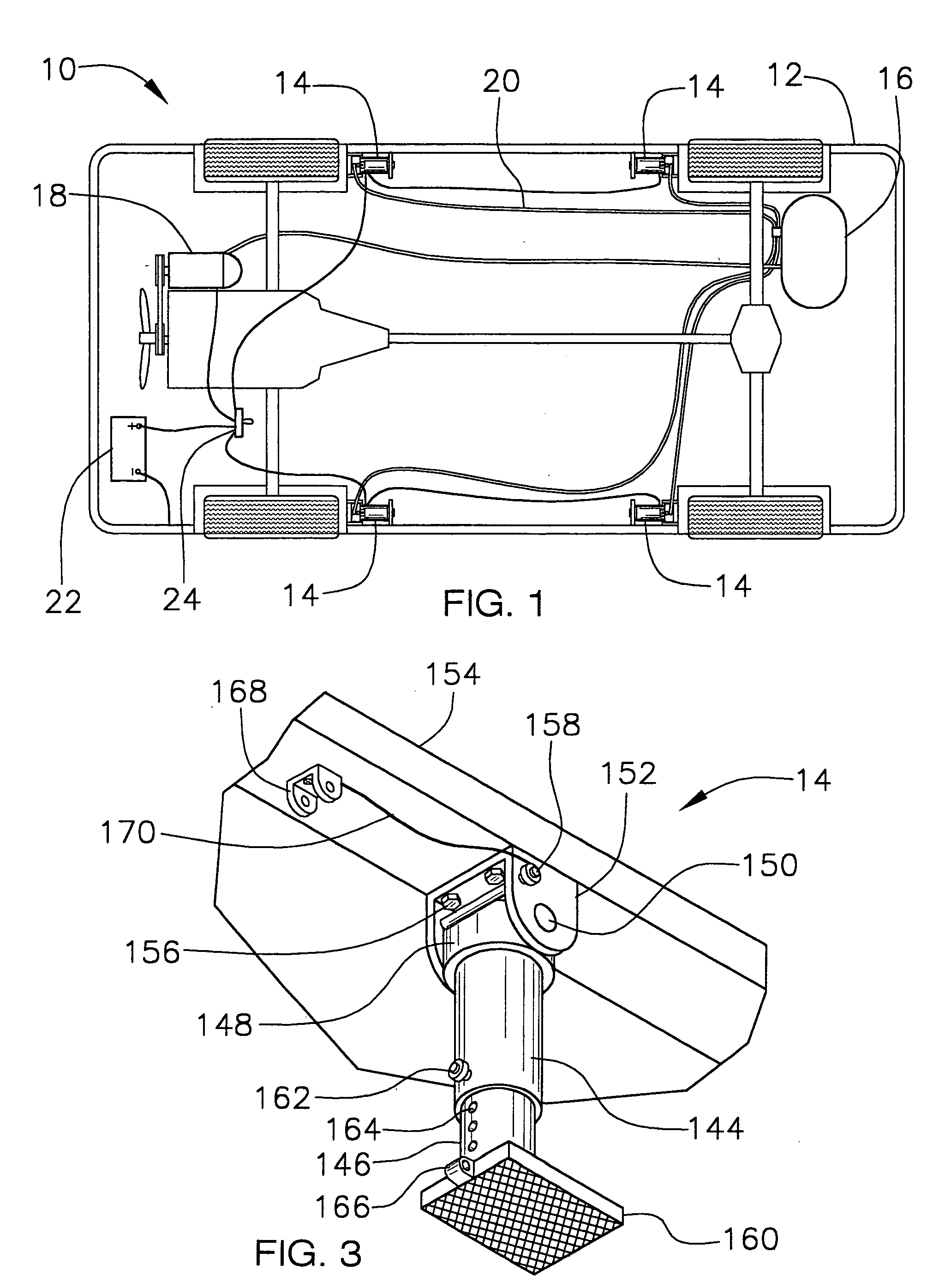

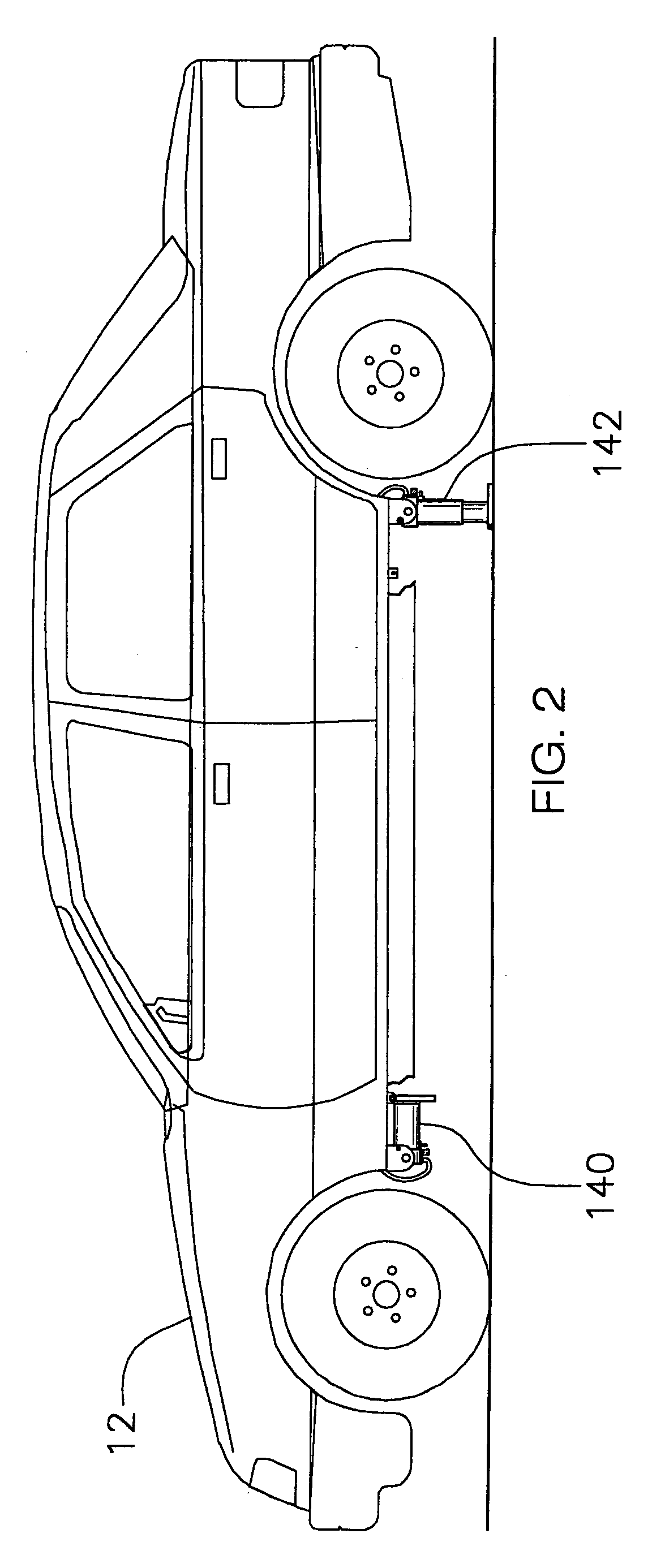

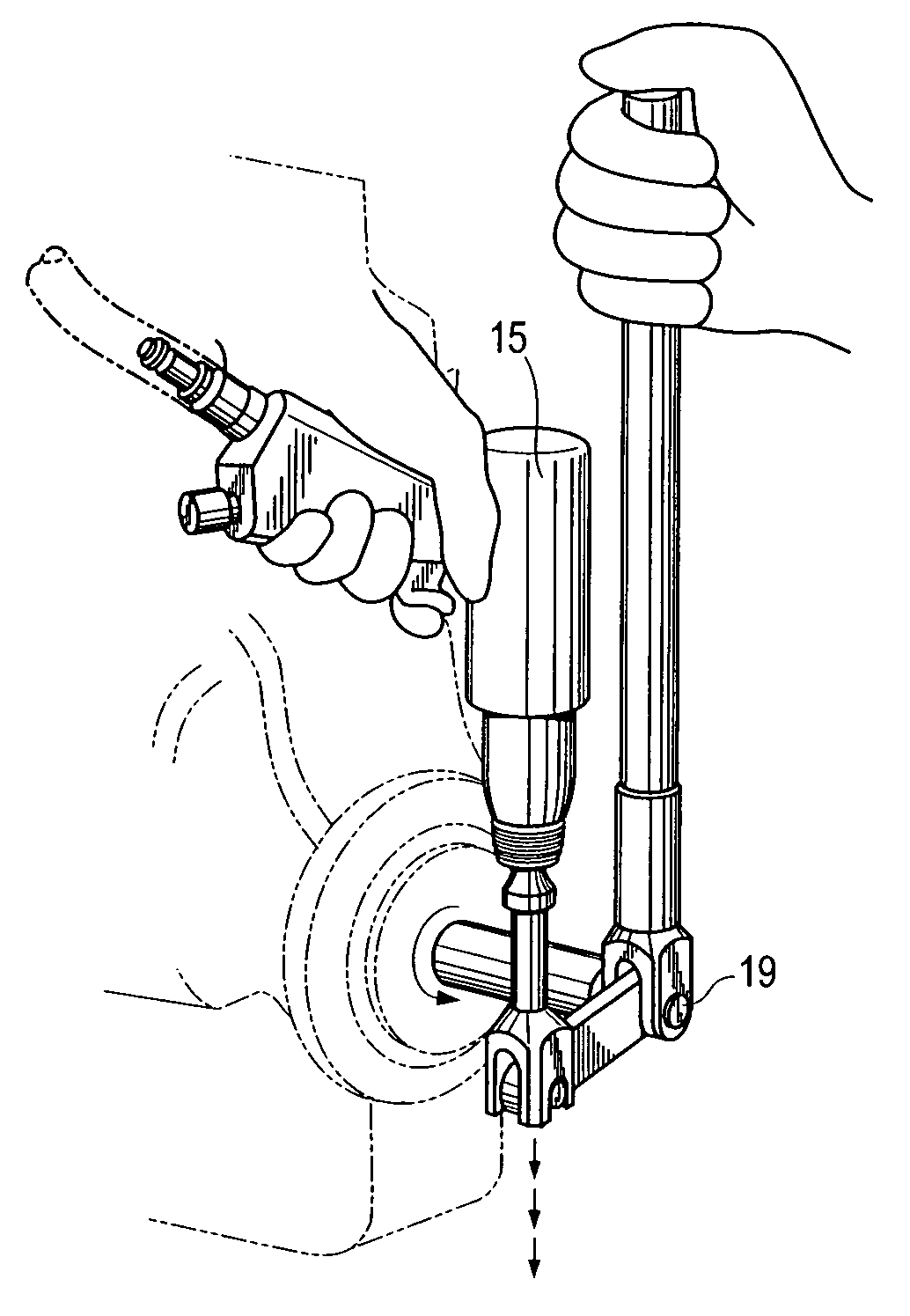

Motor vehicle pneumatic jacklift system

InactiveUS6895648B1Easy to modifyEasy and efficient to manufactureVehicle fittings for liftingVehicle cleaning apparatusSolenoid valveGas compressor

A permanently mounted pneumatic jack (jacklift) system for motor vehicles, as well as an impact wrench for removing and installing lug nuts. The system provides a quick and safe means of lifting one or more tires off the ground for replacement of a spare or rotating the tires on a motor vehicle. The present invention comprises two or more (typically four) pneumatic jacks, a system ON / OFF switch, an air compressor, a 120-psi air tank, air lines (hoses), individual jack extend / retract switches, jack position-locking pins, safety-locking pins, and impact wrench. Each jack can be locked in a horizontal stowaway or vertical operational position. The jack is cylindrical shaped with a telescopic body that can be extended or retracted as needed to raise and lower the vehicle. A solid cylindrical lift rod slides inside a cylindrical outer housing with a high-pressure seal means used to maintain pressure on the support rod. A ground support foot (plate) is mounted on the lower end of the solid cylindrical lift rod to provide sufficient traction with the ground to support the lifting process. A quick release air coupler is included on the pneumatic chamber to support the use of an air hose and impact wrench. An extend / retract toggle switch is included on each jack to control a solenoid valve to allow the air to flow into the jack. A quick release safety-locking pin is used to mechanically pin the solid cylindrical lift rod to the outer housing once the desired height is achieved to assure that the vehicle does not fall down in the event of a high-pressure air loss, thereby providing safety to the person(s) working around the vehicle. An air compressor located in the engine compartment of the vehicle is mechanically belt-driven off the engine. A high-pressure air line carries the air to a high-pressure (at least 120-psi) air tank located in the trunk or other suitable storage area on the vehicle. Separate air lines extend from the air tank to the individual jacks.

Owner:WILLETT MICHAEL J

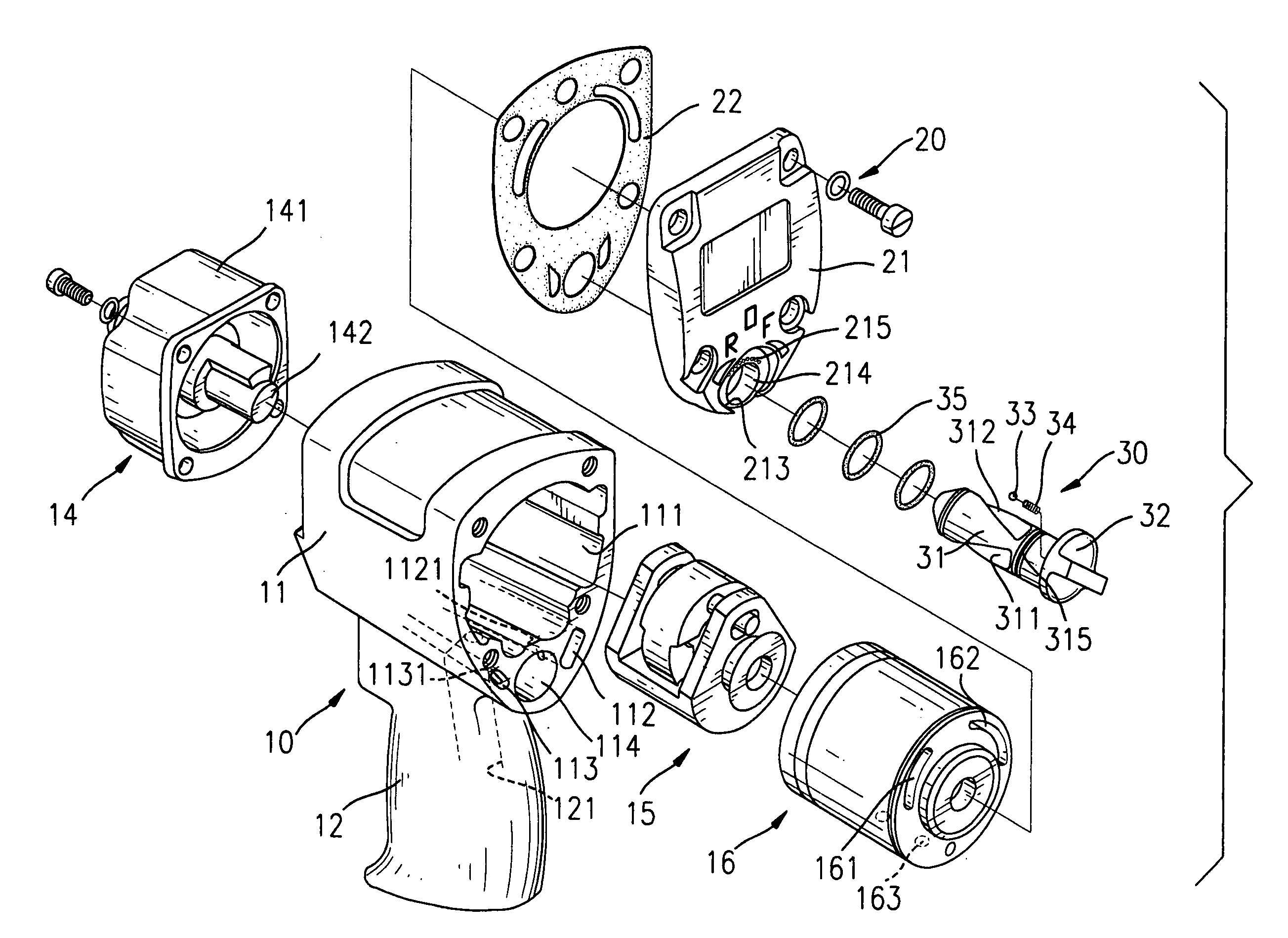

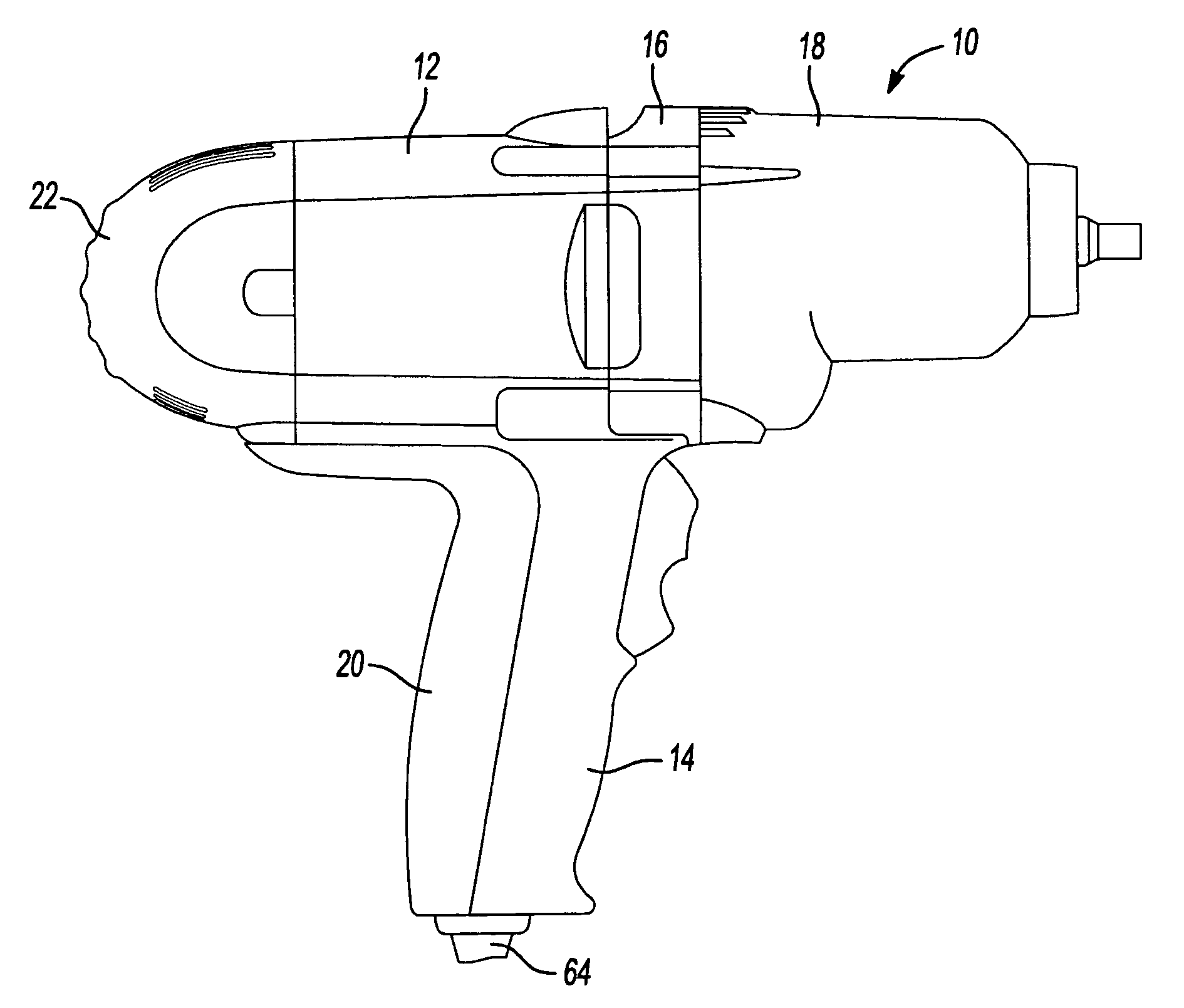

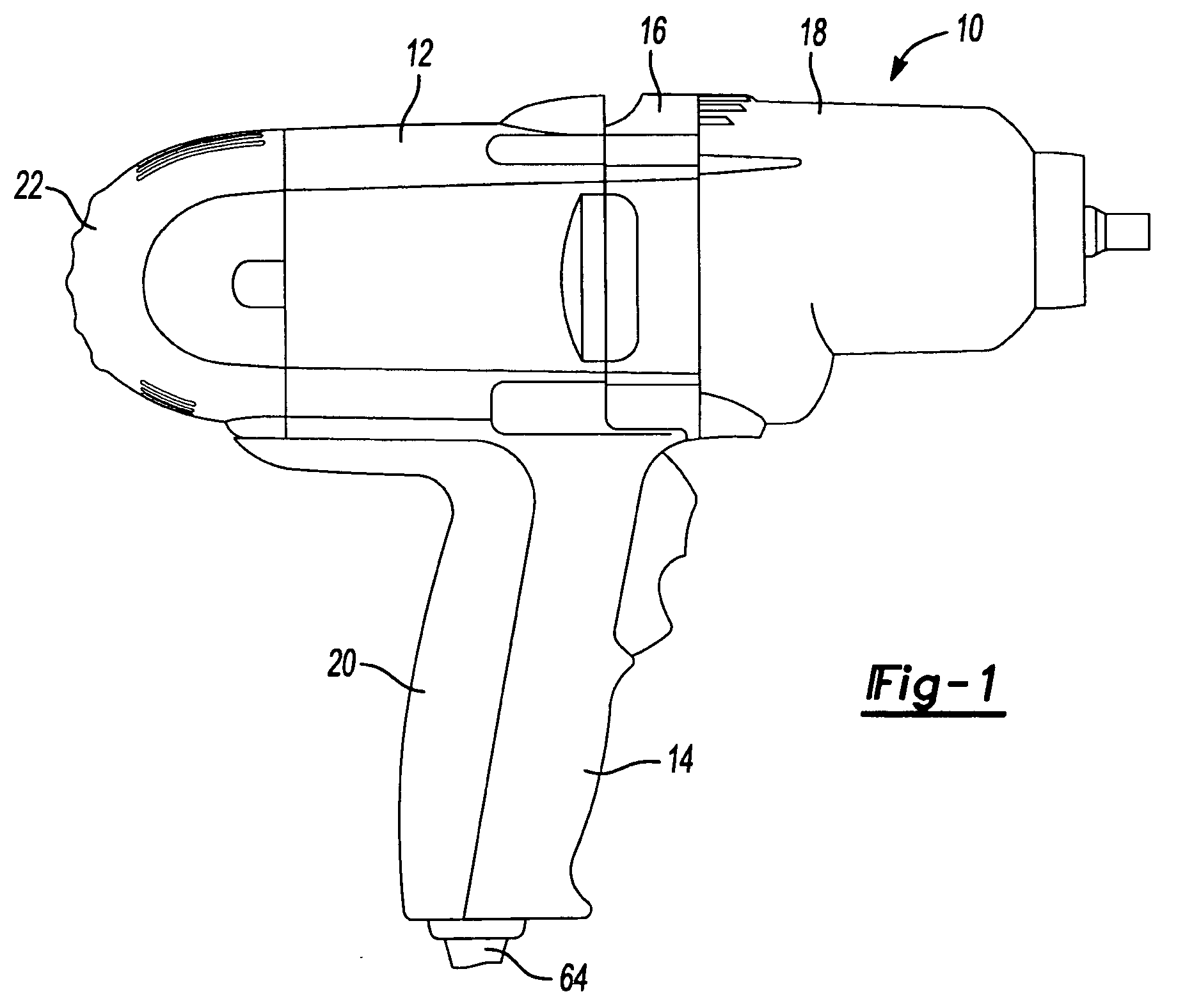

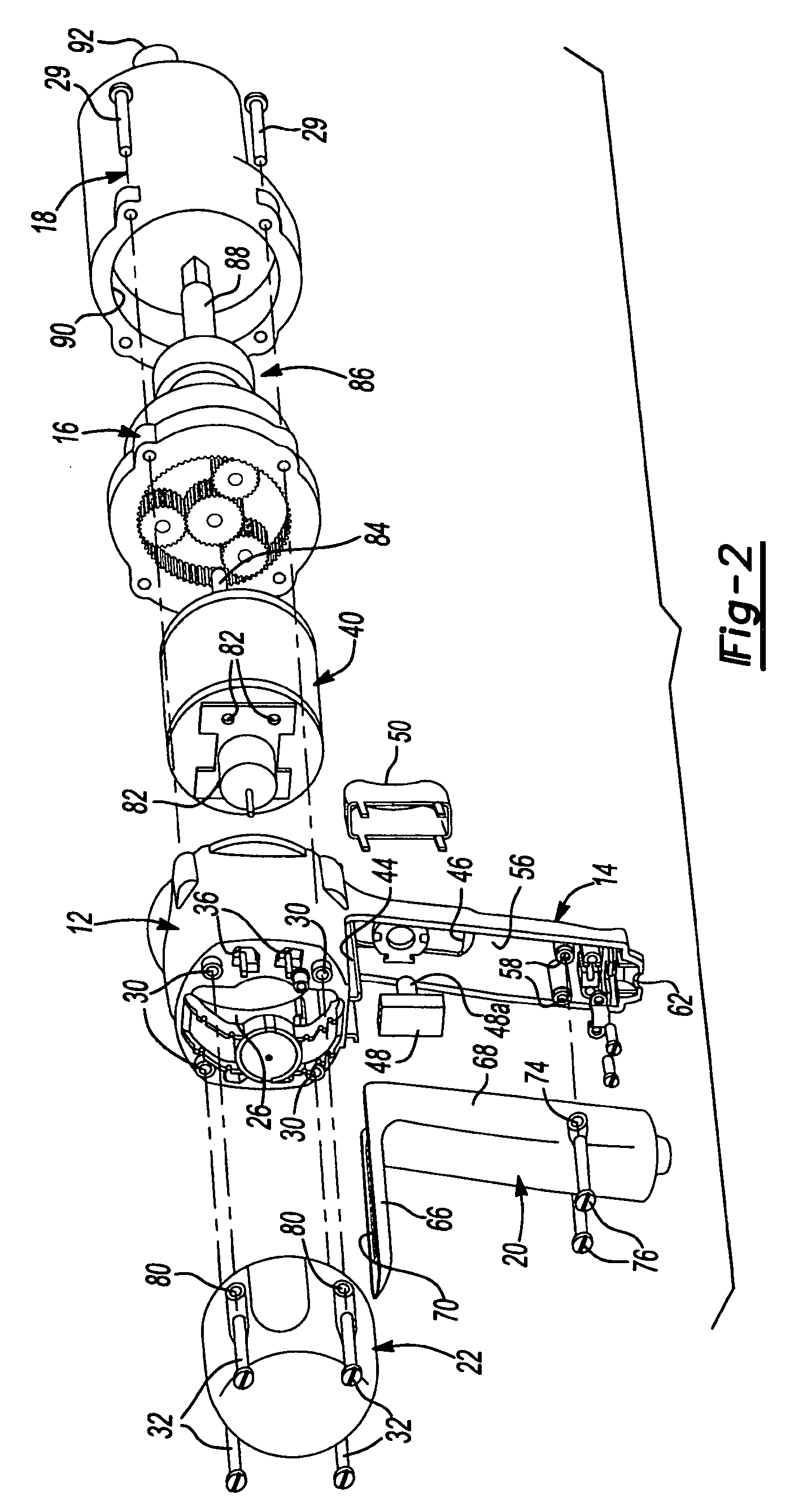

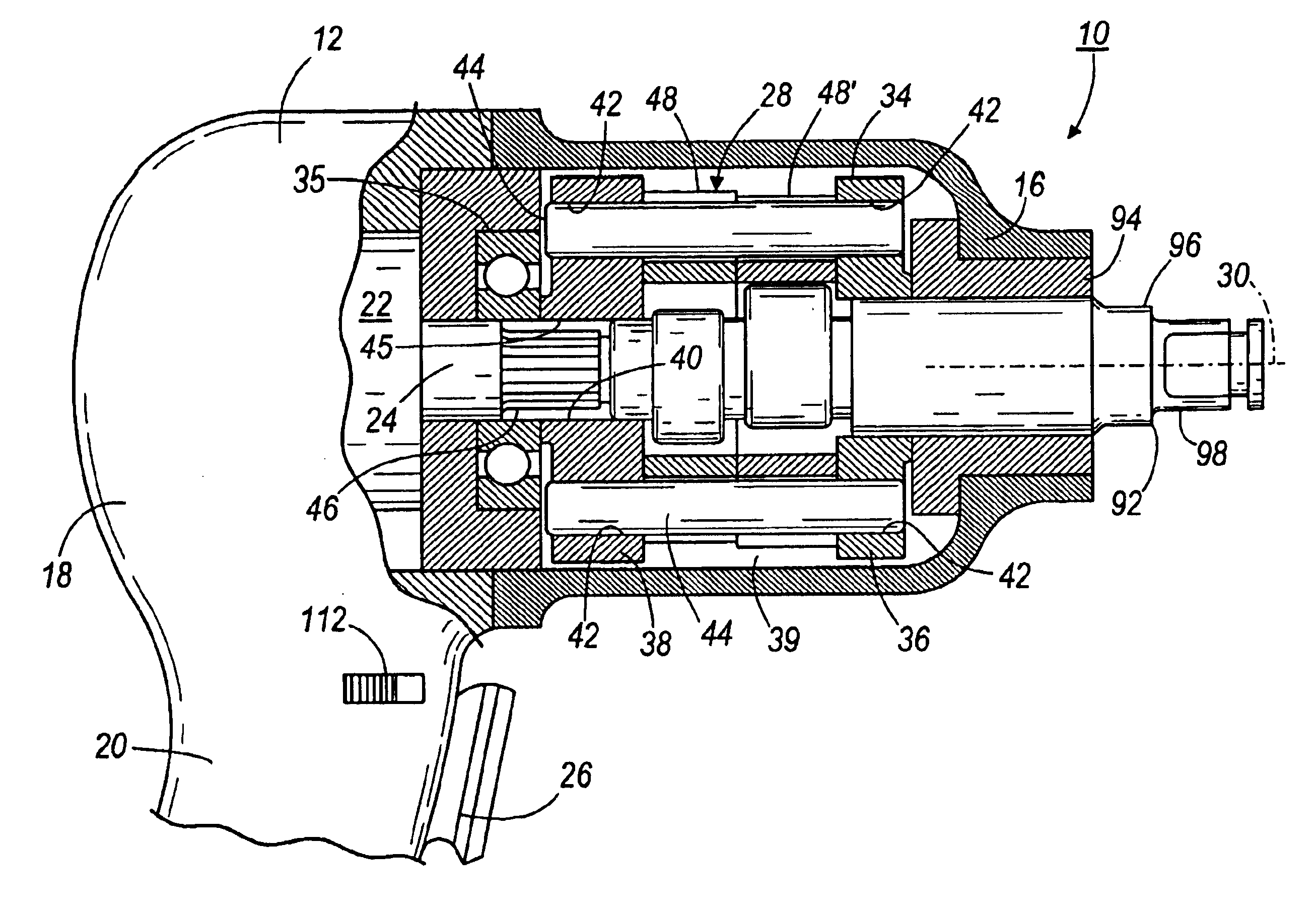

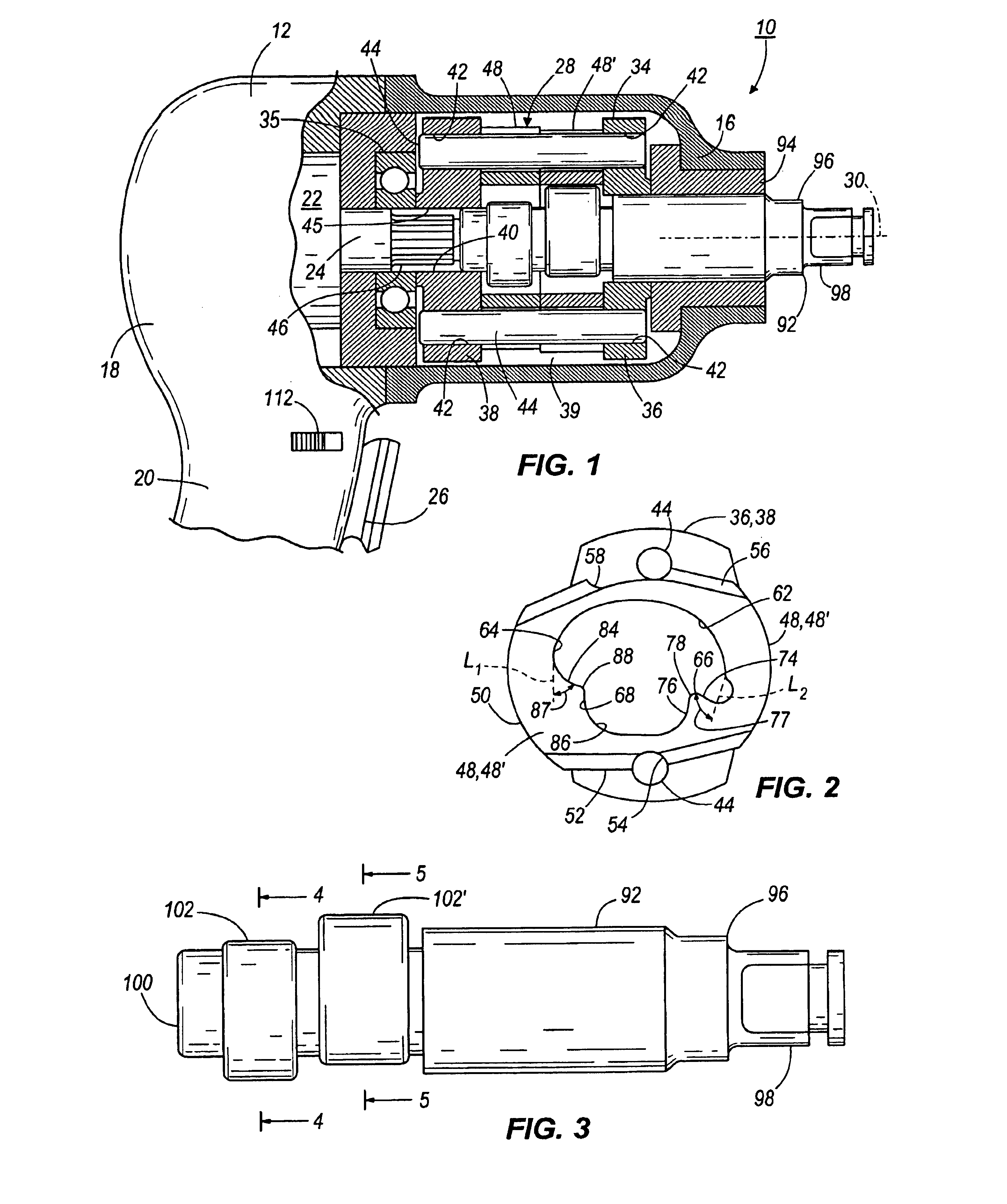

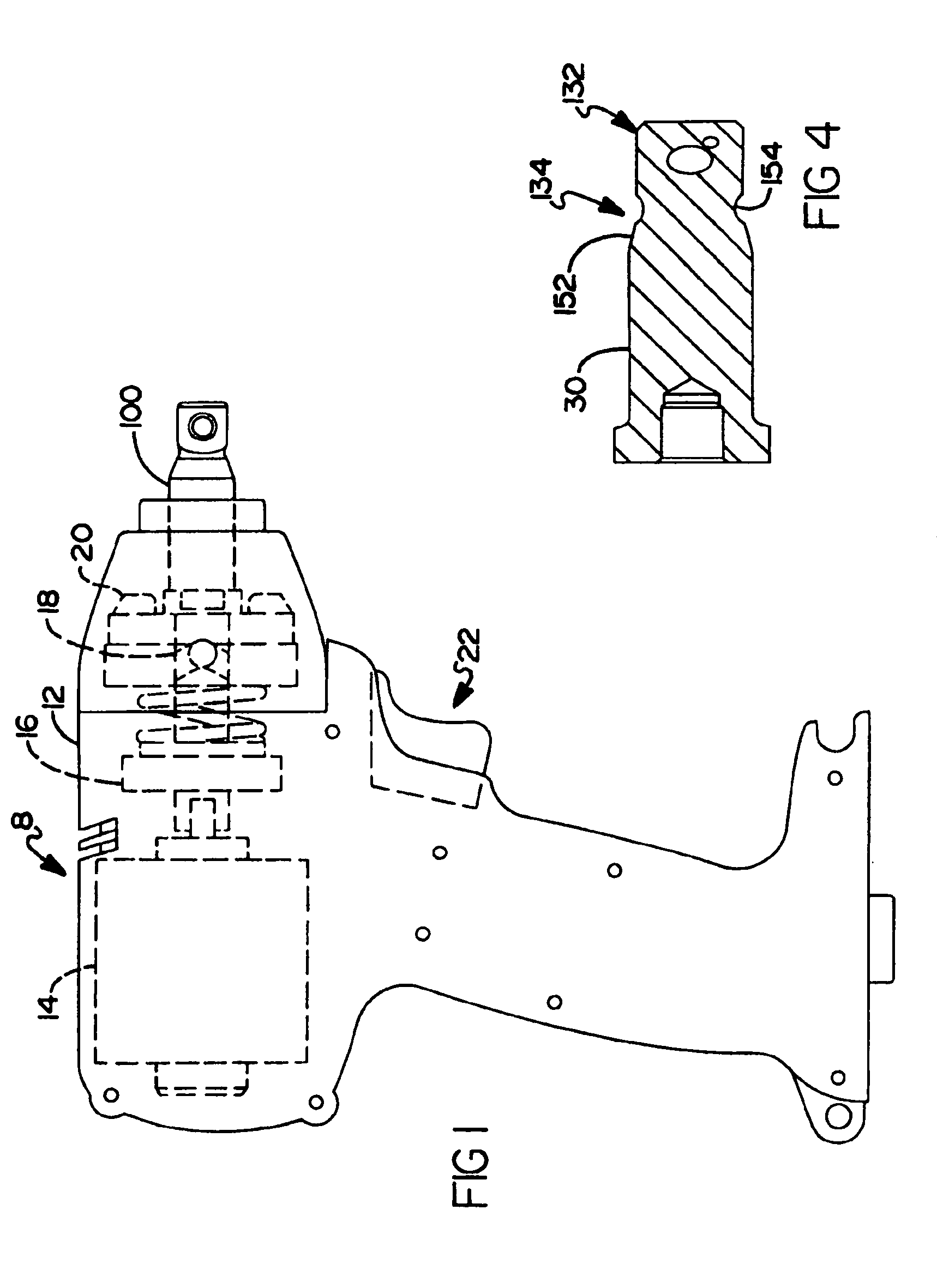

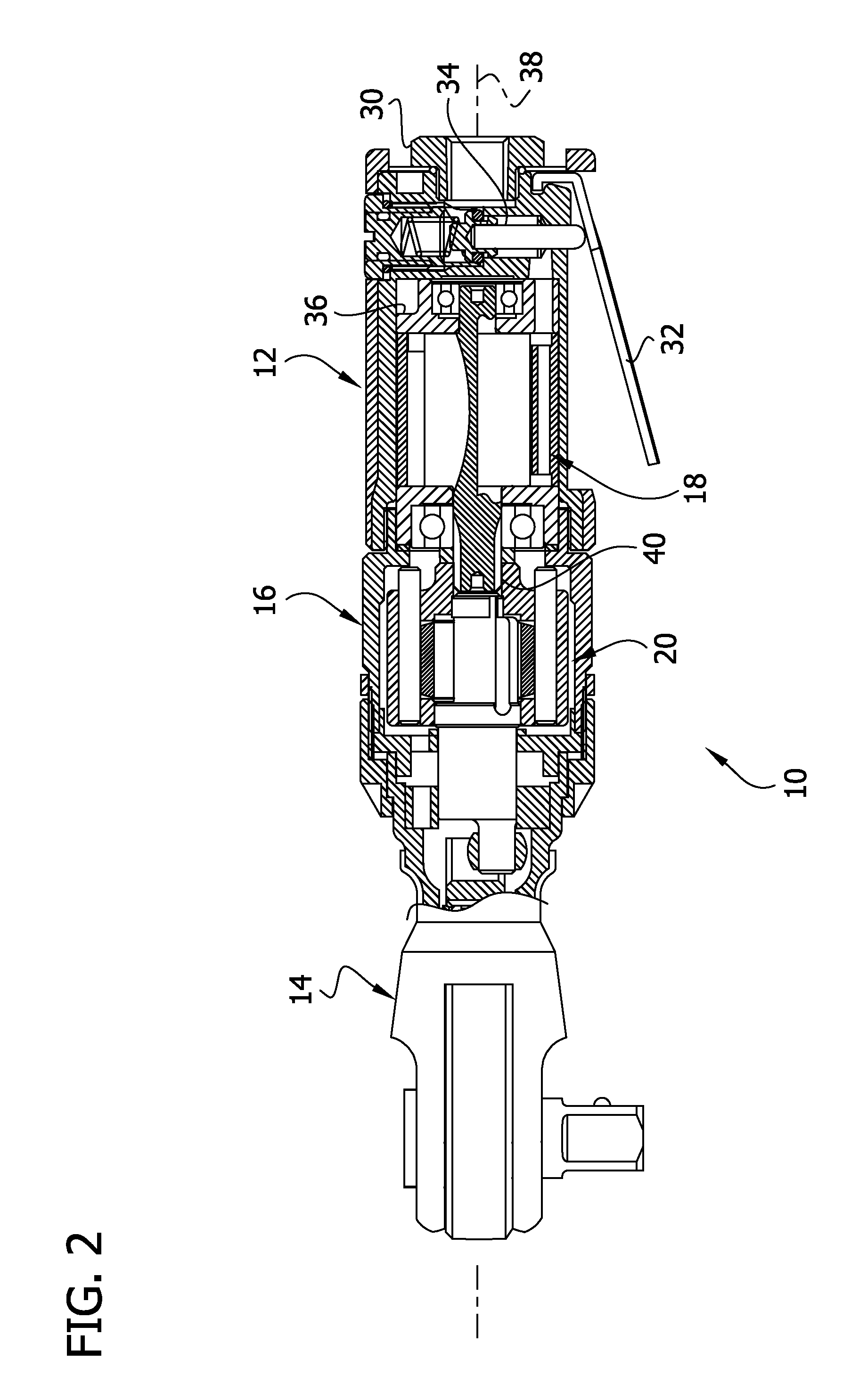

Motor housing and assembly process for impact wrench

ActiveUS20050257945A1Simplifies wire-up of power toolEasy to assembleDrilling rodsConstructionsEngineeringPower tool

A handle for a power tool is provided including a field case and front handle portion formed as a single piece. The front handle portion has an opening in a rear side thereof for receiving the wiring for the power tool. The wiring is connected to a motor that is mounted in the field case. A rear handle portion is attached to the front handle portion for covering the opening in the rear of the front handle portion. An end cap is connected to a rear of the field case for covering the remaining exposed wires connected to the motor. With the front handle design, the wire-up of the power tool can be completed from one side of the tool without having to turn the tool over during the wire-up process.

Owner:BLACK & DECKER INC

Rotary tool

A rotary tool, such as an impact wrench, operable in a forward mode and a reverse mode. The rotary tool includes a housing having a forward end and supporting a motor. The motor has a motor shaft extending axially through the housing and defining an axis. The rotary tool also include a frame supported in the housing and being rotatable relative to the housing about the axis, an output shaft supported in the forward end of the housing and rotatable about the axis, and a hammer pivotably coupled to the frame and defining a central aperture. The hammer has a first jaw and a second jaw extending into the central aperture. The first jaw and the second jaw are non-symmetrical.

Owner:INGERSOLL RAND IND U S INC

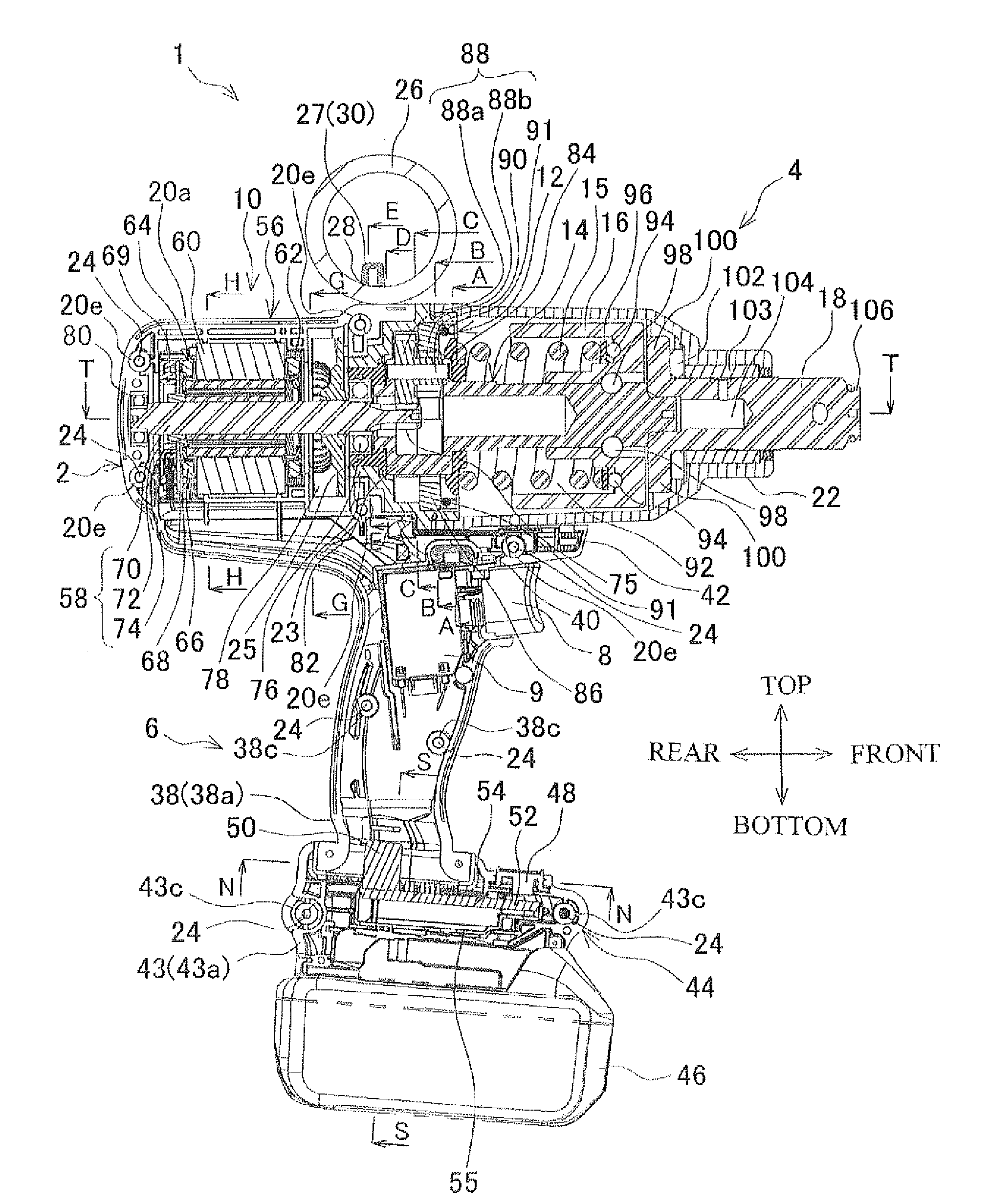

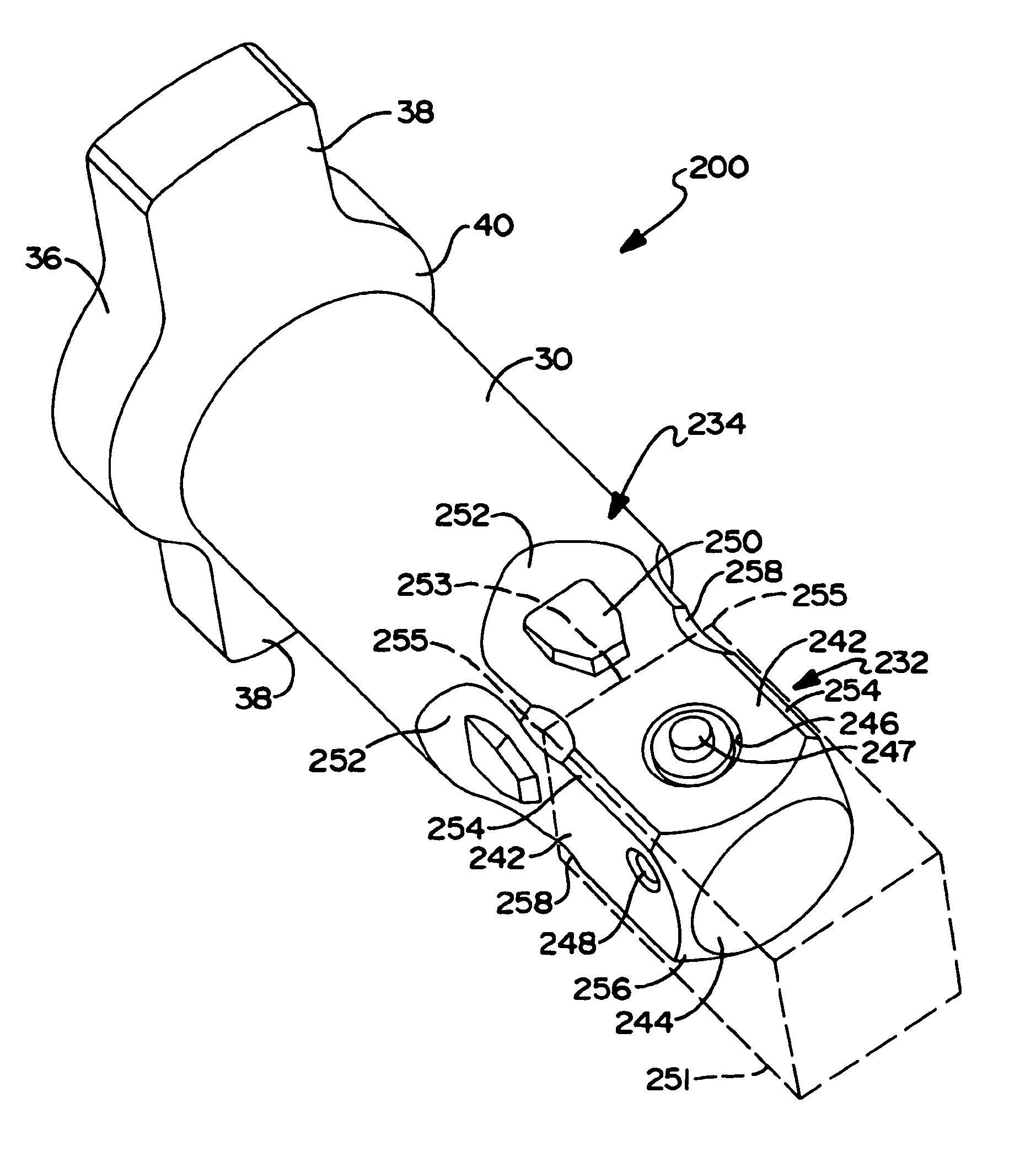

Power tool and rotary impact tool

ActiveUS20150343617A1Avoid spreadingSufficient performanceOperator-supported drilling machinesPortable power-driven toolsEngineeringPower tool

To provide a power tool and a rotary impact tool capable of suppressing transmission of vibration to a circuit board and so on from a drive portion connecting to a motor as a vibration generation source. An impact wrench includes a motor housing which houses a motor or a grip housing, a battery holding housing connecting to the motor housing or the grip housing through an elastic body and a control circuit board housed in the battery holding housing for controlling the motor.

Owner:MAKITA CORP

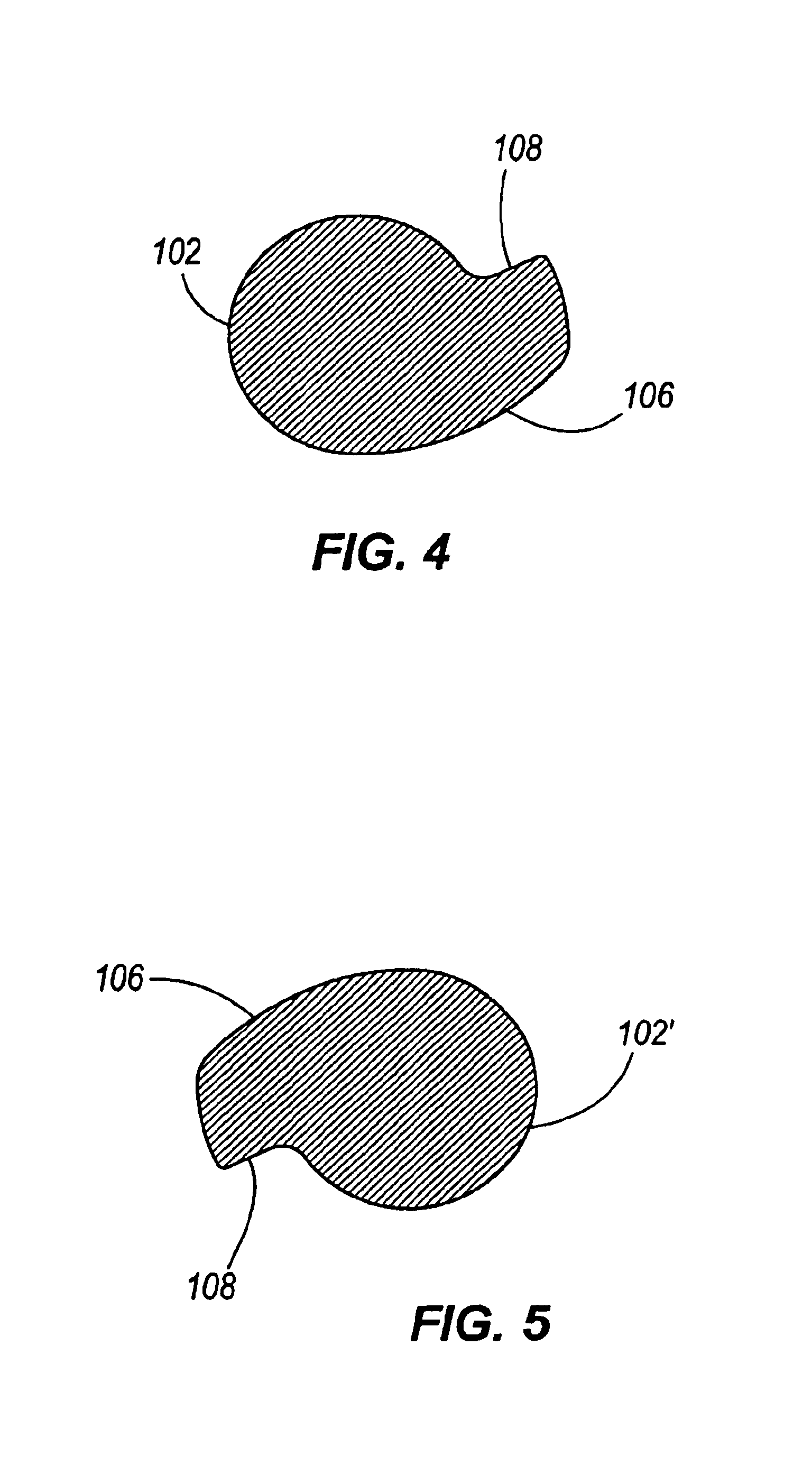

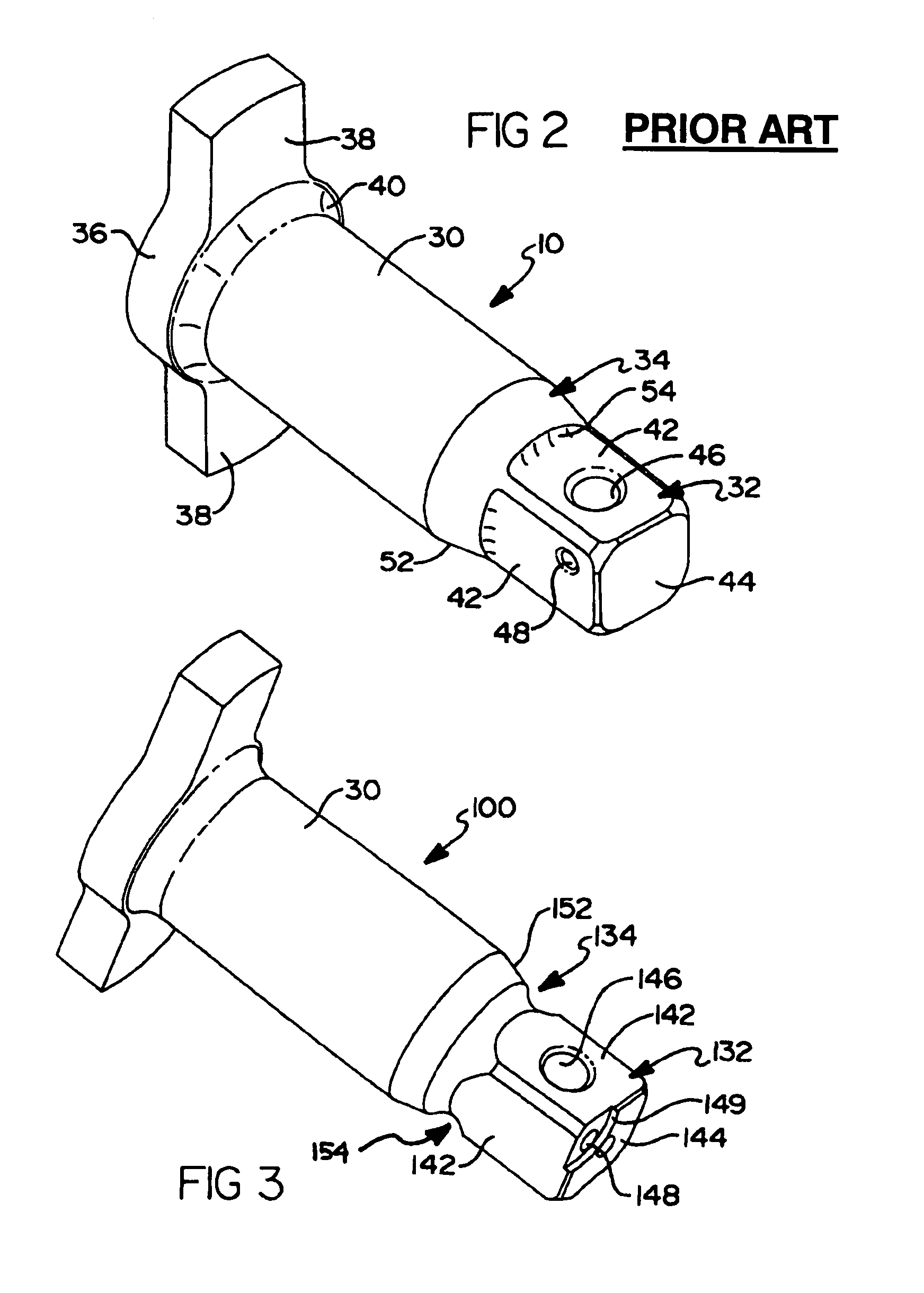

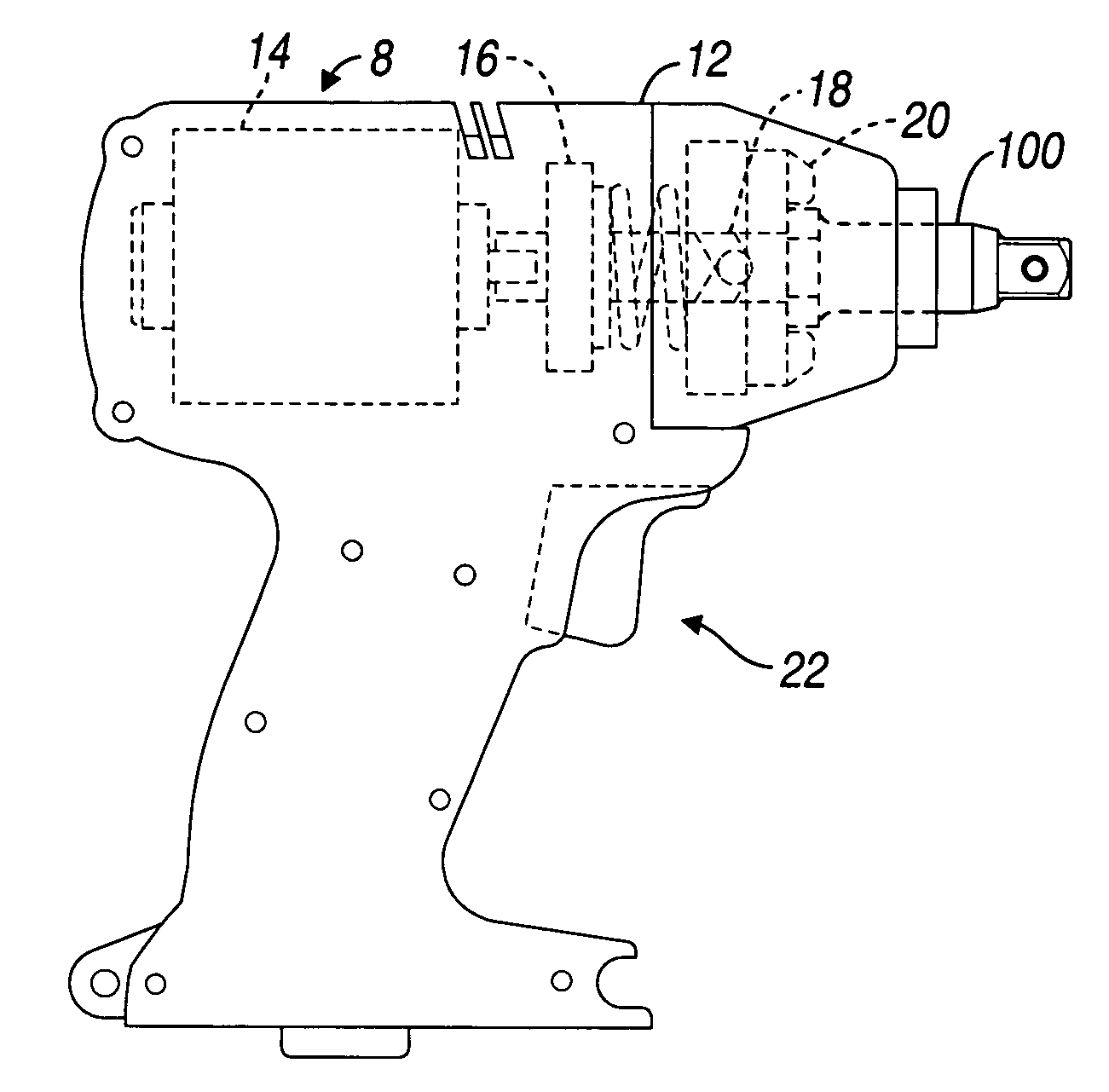

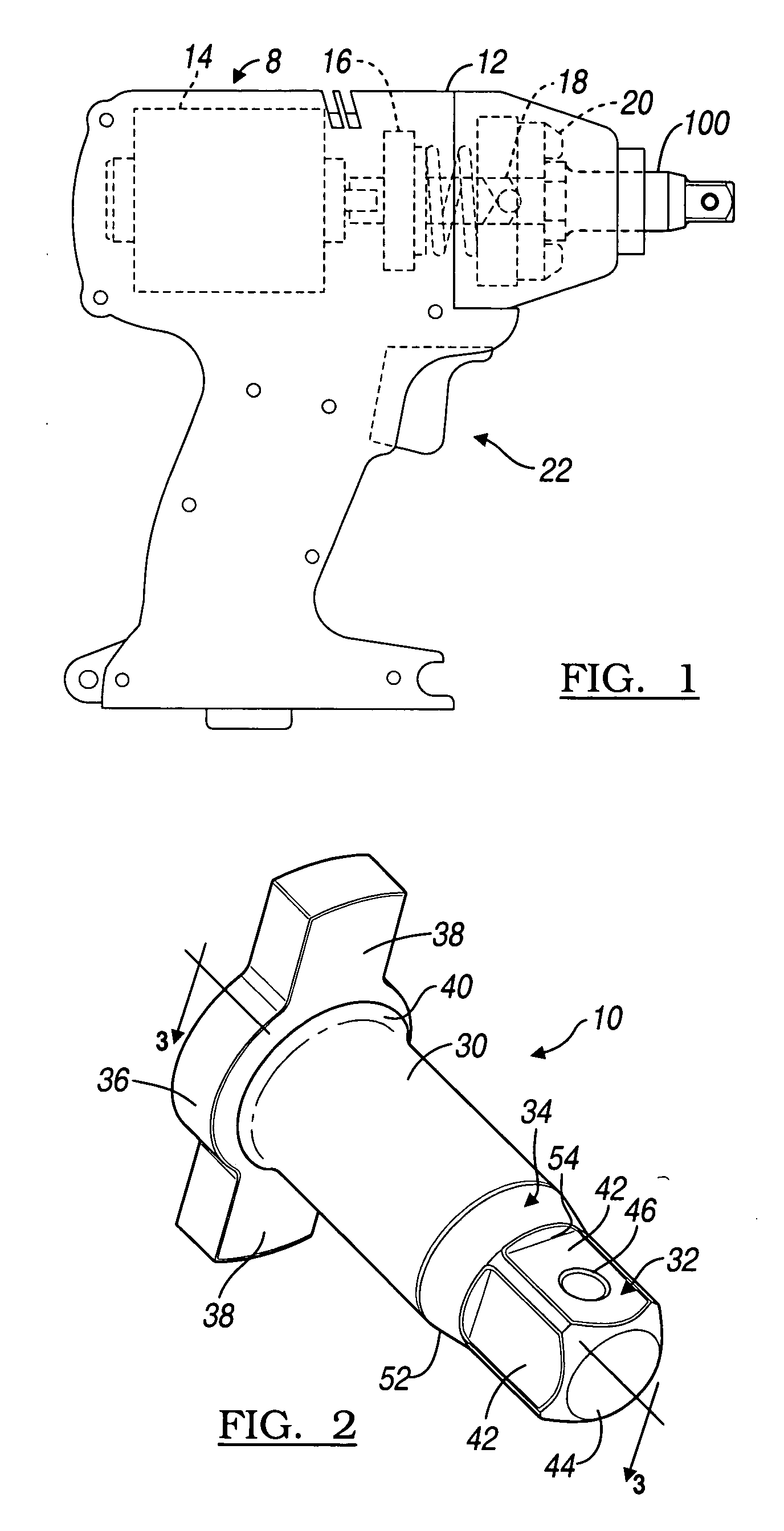

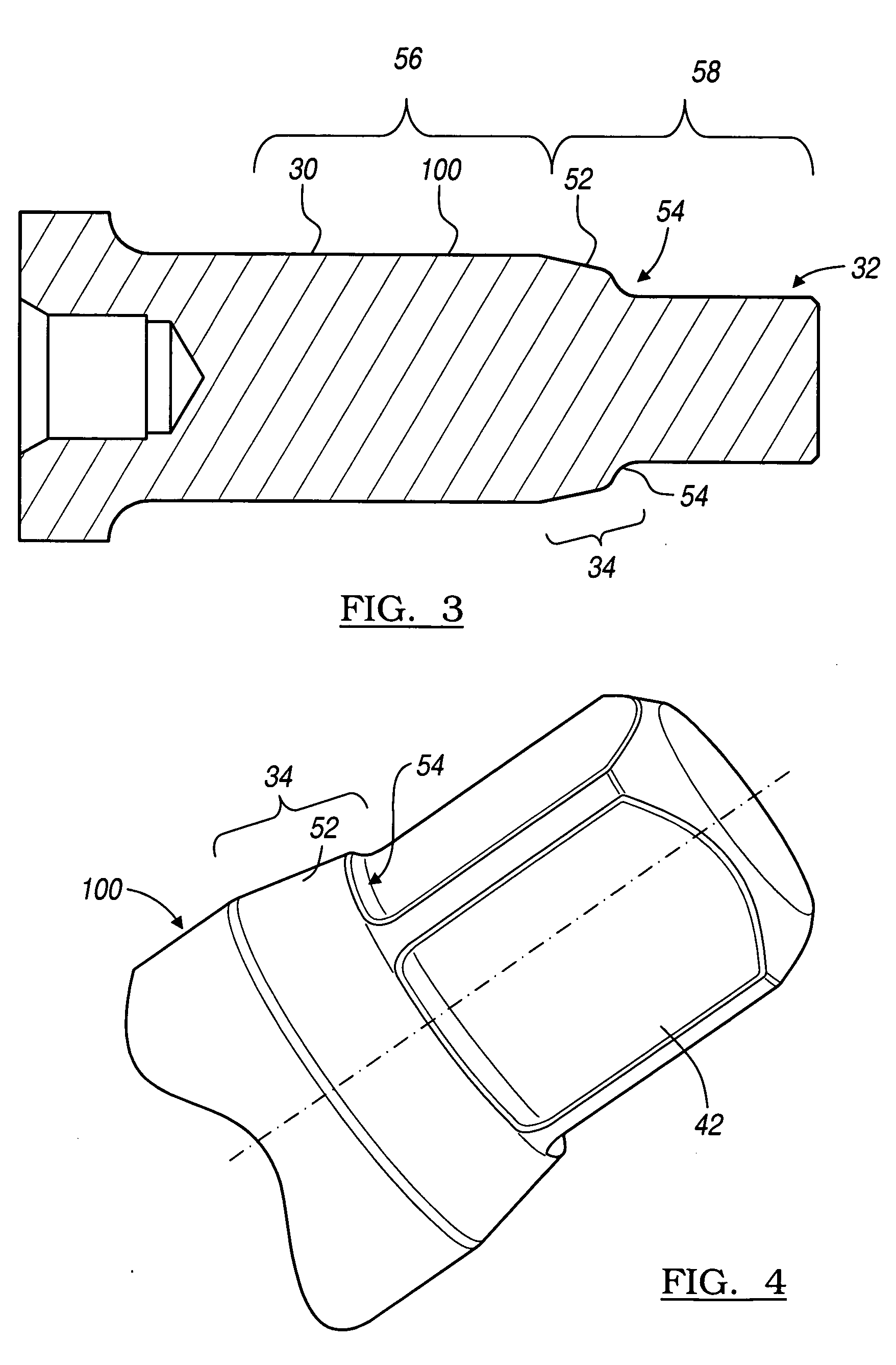

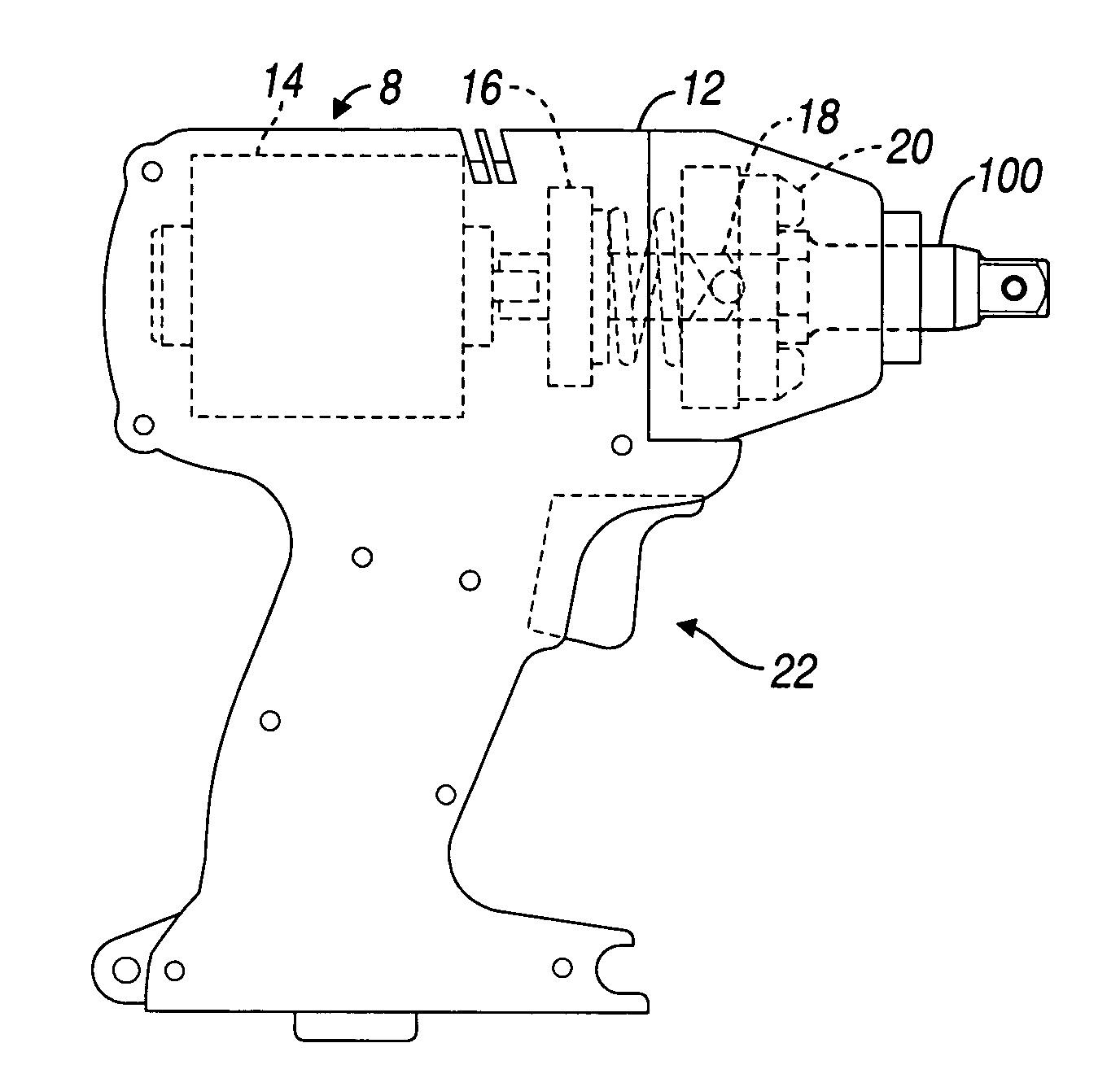

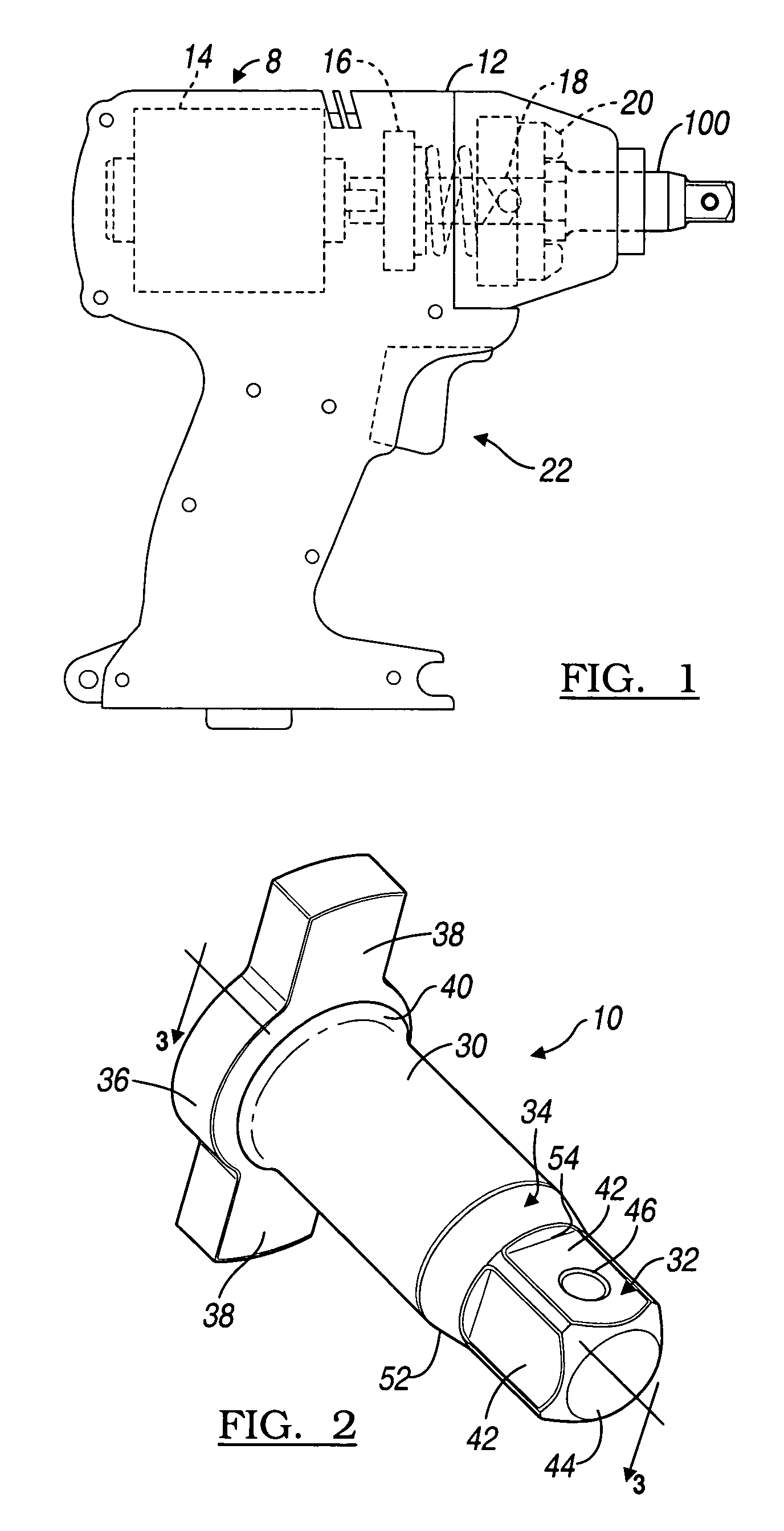

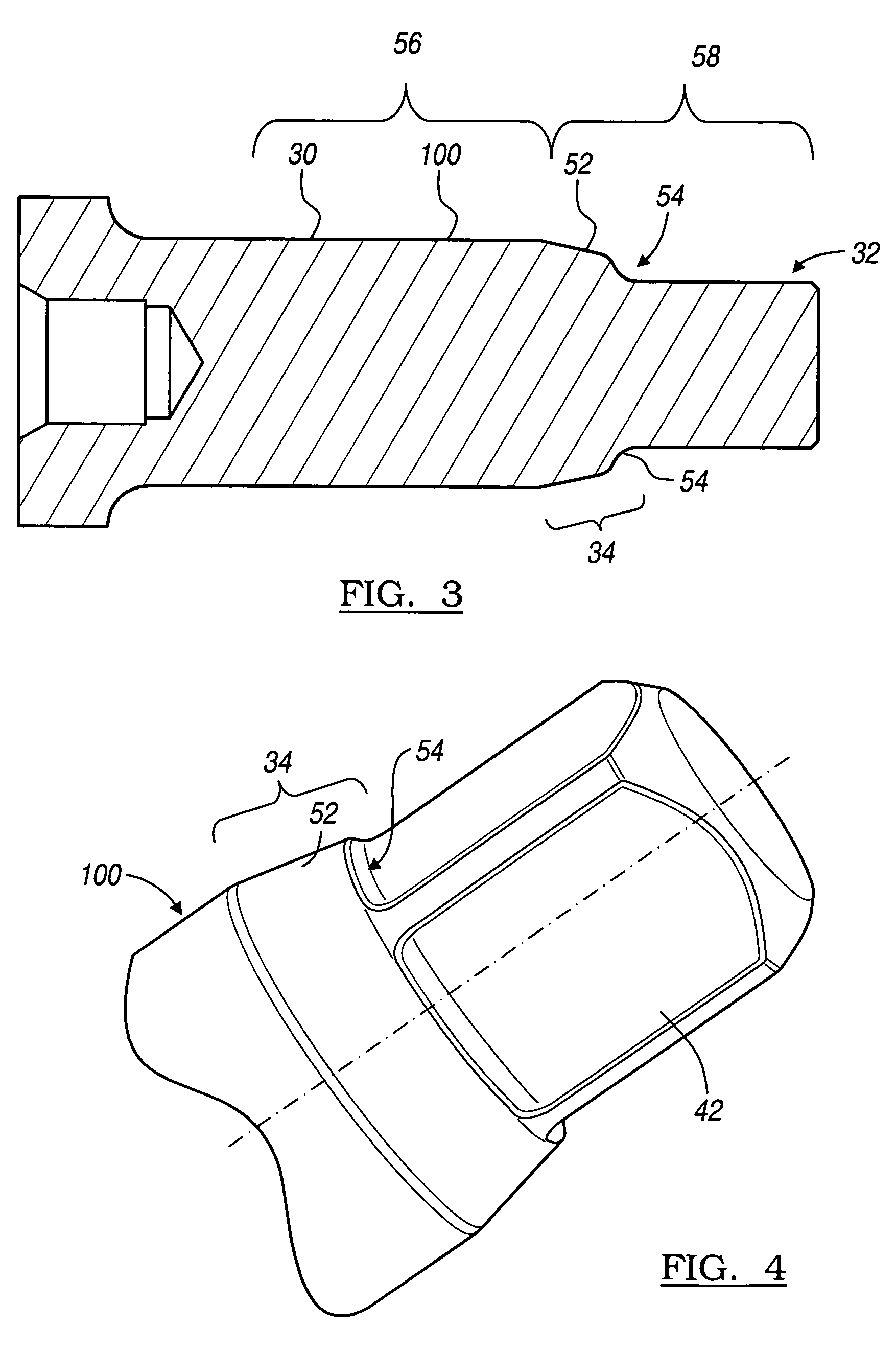

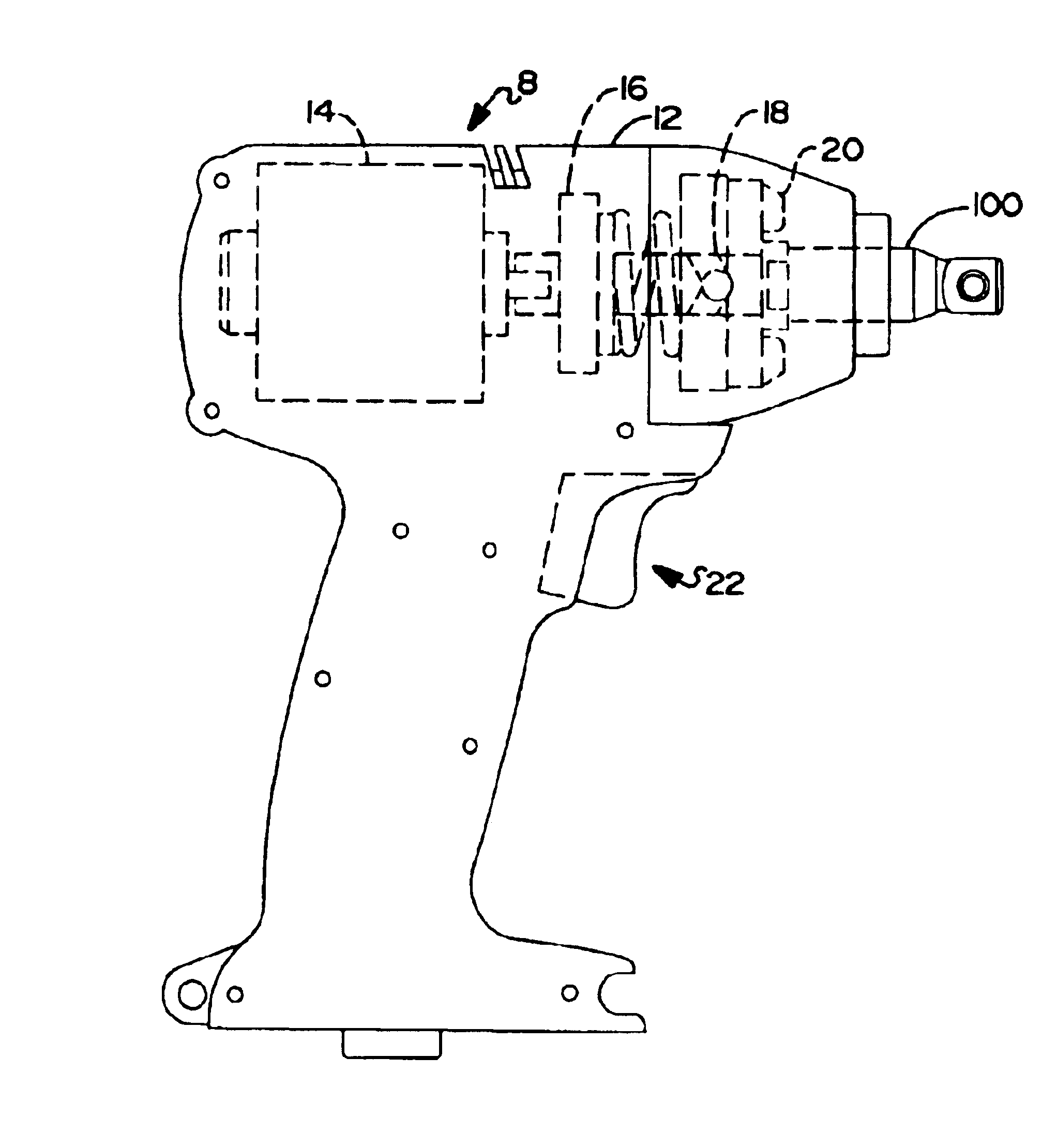

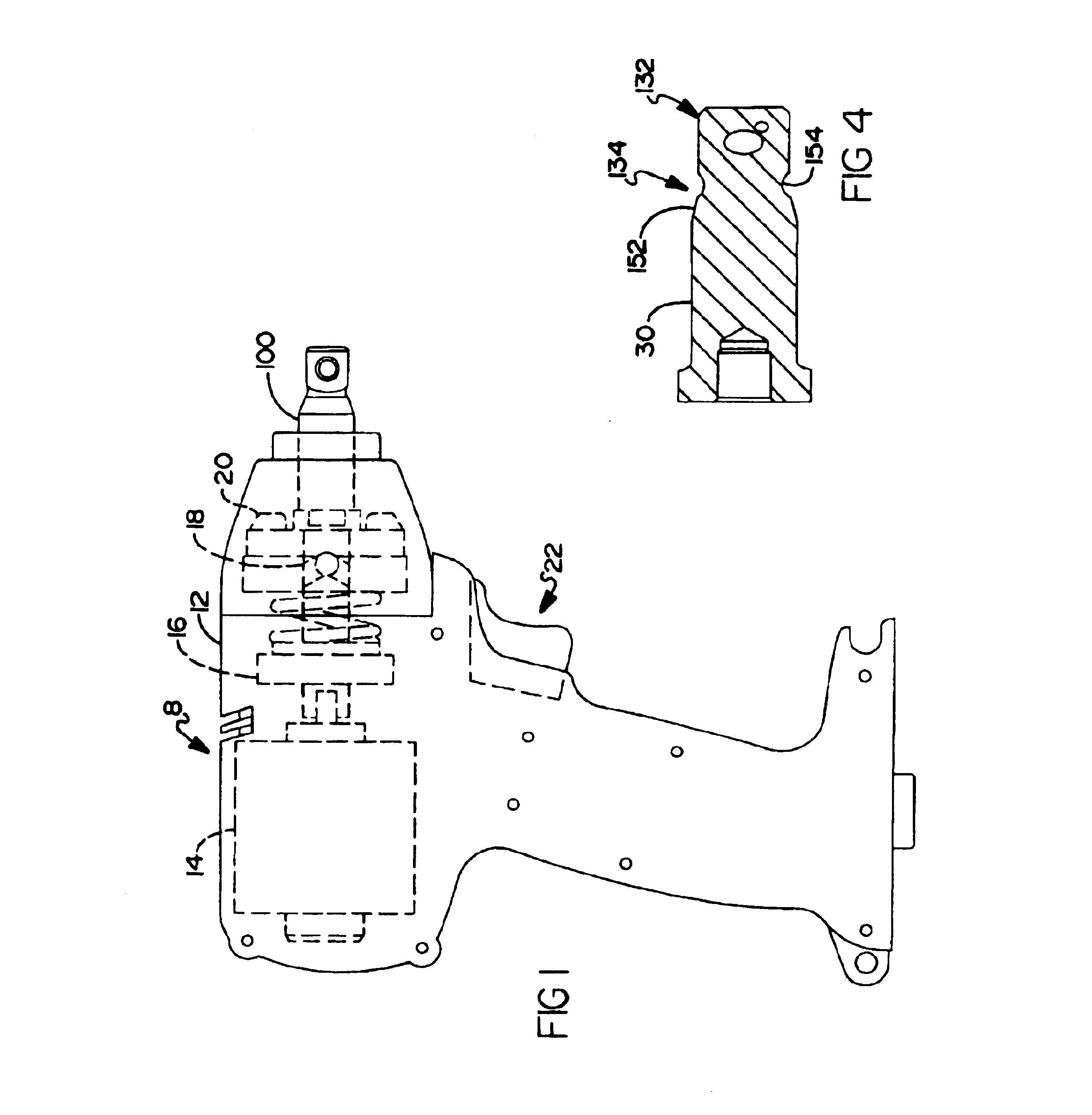

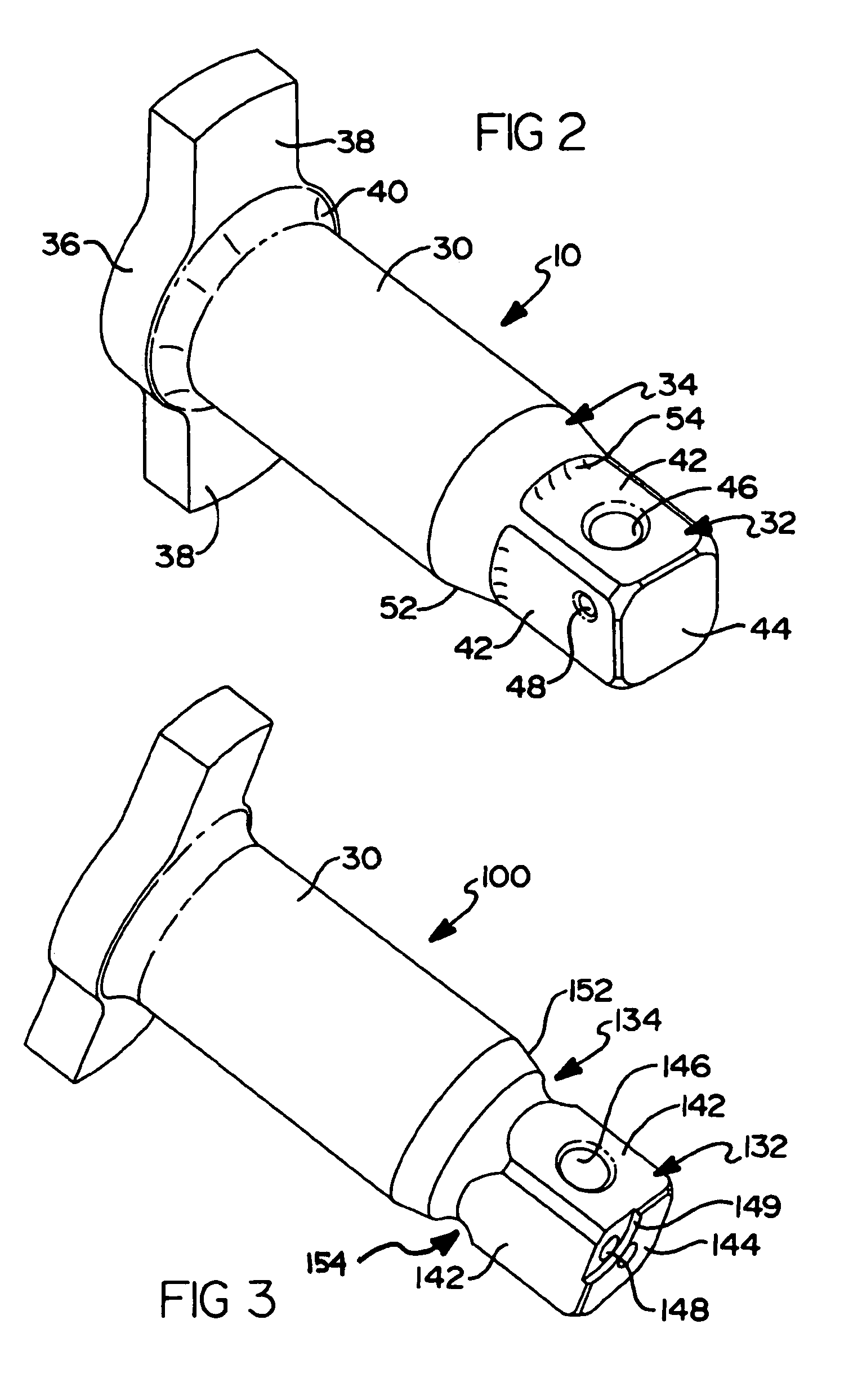

Impact wrench having an improved anvil to square driver transition

An anvil adapted to be received within an impact wrench comprises a round body and a square head. The square head is formed at an end of the round body. A tapered ramp extends from the round body to the square head. A radius is formed in the tapered ramp. The radius is defined by a removal of material in the tapered ramp.

Owner:BLACK & DECKER INC

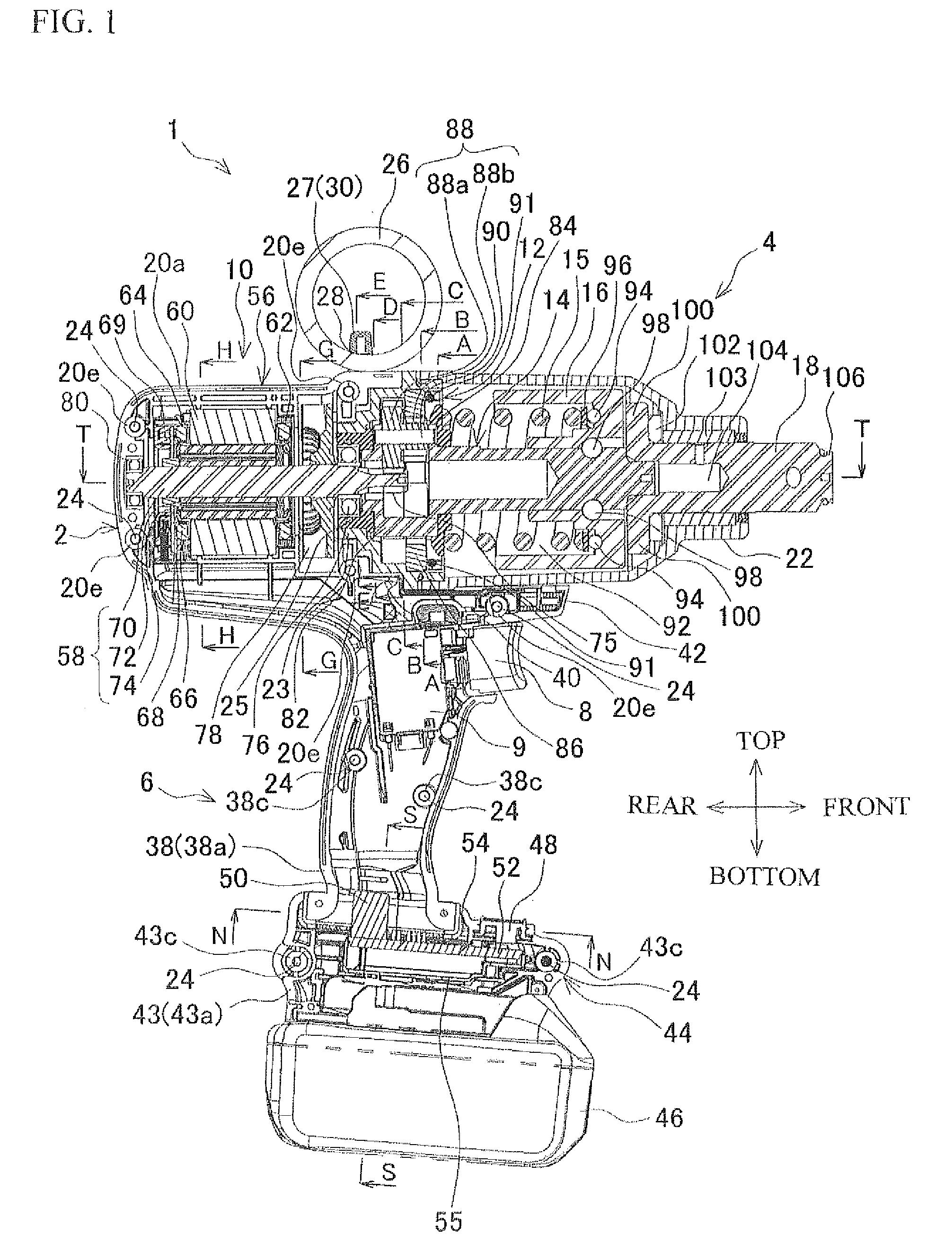

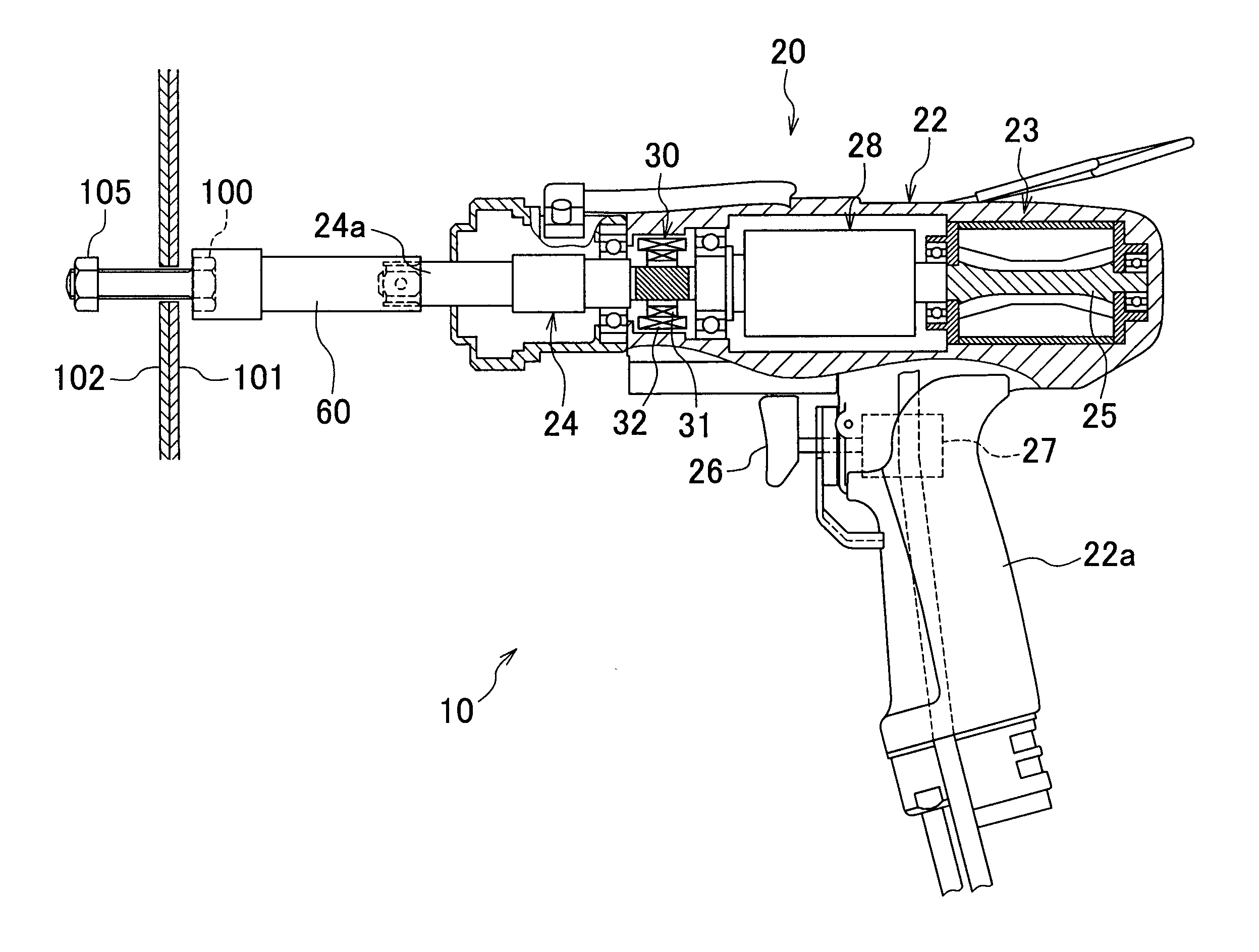

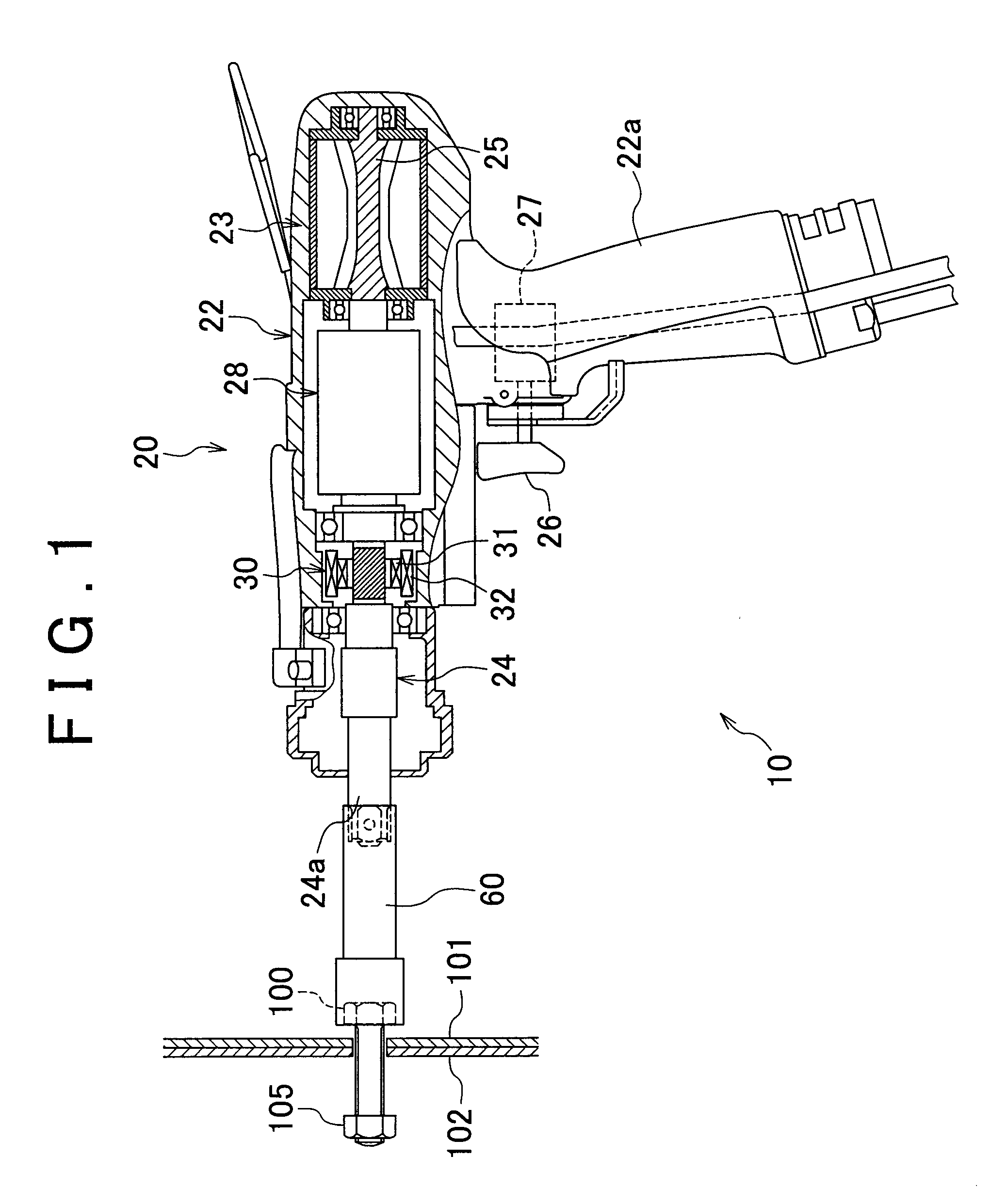

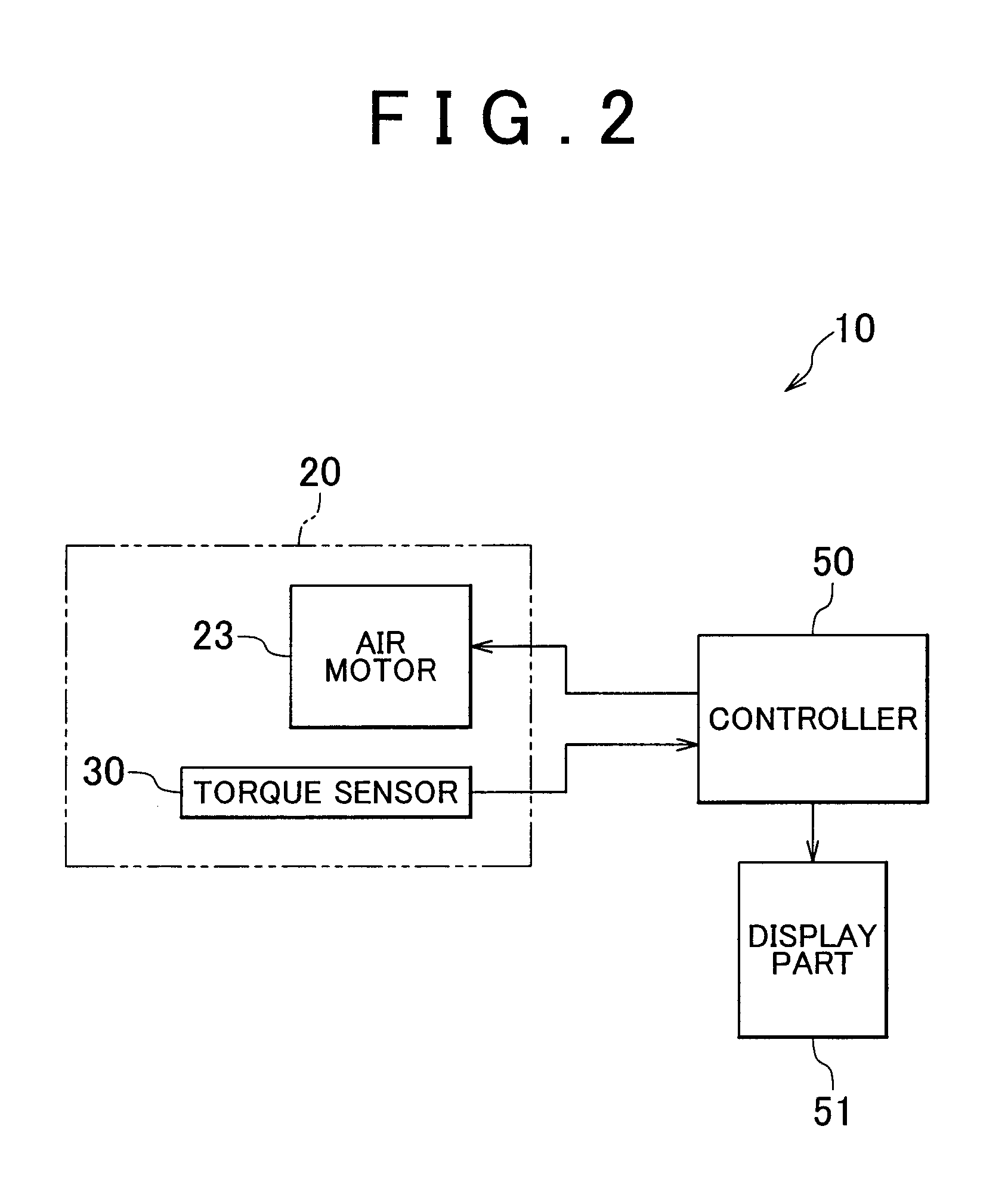

Impact tightening tool

An impact wrench which includes an air motor and a main shaft that is rotated by pulsed impact torque that is converted from rotary torque from the air motor to tighten a bolt, is provided with a torque sensor that detects a tightening torque on the bolt, and a controller that performs control functions to tighten the bolt, and the controller changes the rotational speed of the air motor to tighten up the bolt when the tightening torque that is detected by the torque sensor becomes equal to or higher than a prescribed value.

Owner:TOYOTA JIDOSHA KK

Impact wrench having an improved anvil to square driver transition

Owner:BLACK & DECKER INC

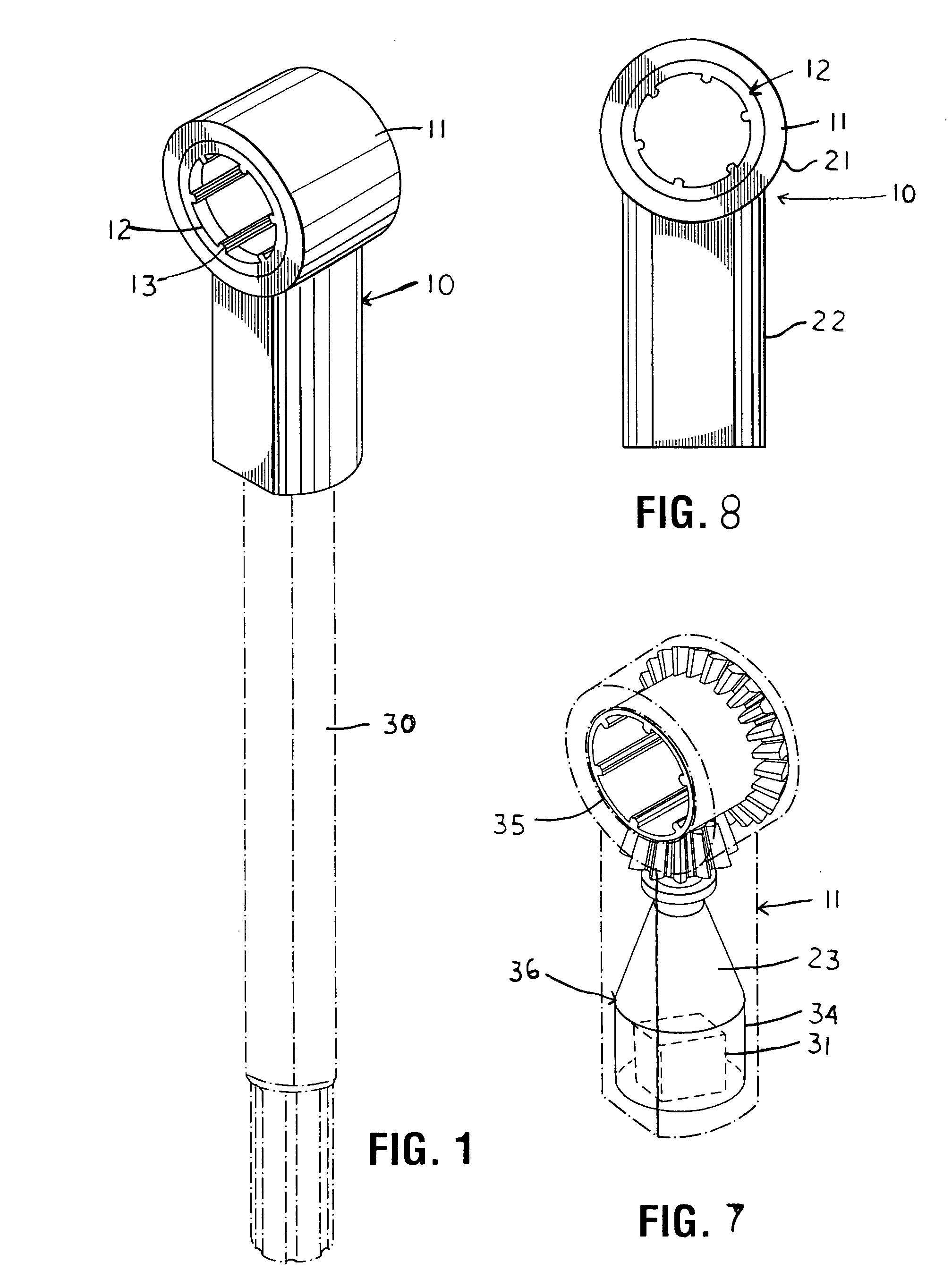

Gear head socket tool

A non-ratcheting socket tool for loosening or tightening nuts or bolts, especially when the nut or bolt head is located in a crowded area where there is inadequate space to pivot or rotate a handle of a wrench or ratchet. The gear head socket tool includes a slim streamlined housing including a straight beveled gear coaxially arranged around a sleeve or ring having a plurality of internal nut / bolt gripping wrench teeth, wherein the straight beveled gear teeth mate with beveled pinion gear teeth perpendicular thereto. An extension bar is inserted into the end of the gear head housing perpendicular to the gear head. Rotation of the extension bar with a ratchet, a breaker bar, strong arm or a power tool such as a pneumatic or electric impact wrench, or drill motor provides perpendicular torque to drive the gear head socket rotating the teeth turning the nut or bolt.

Owner:KISER CODY

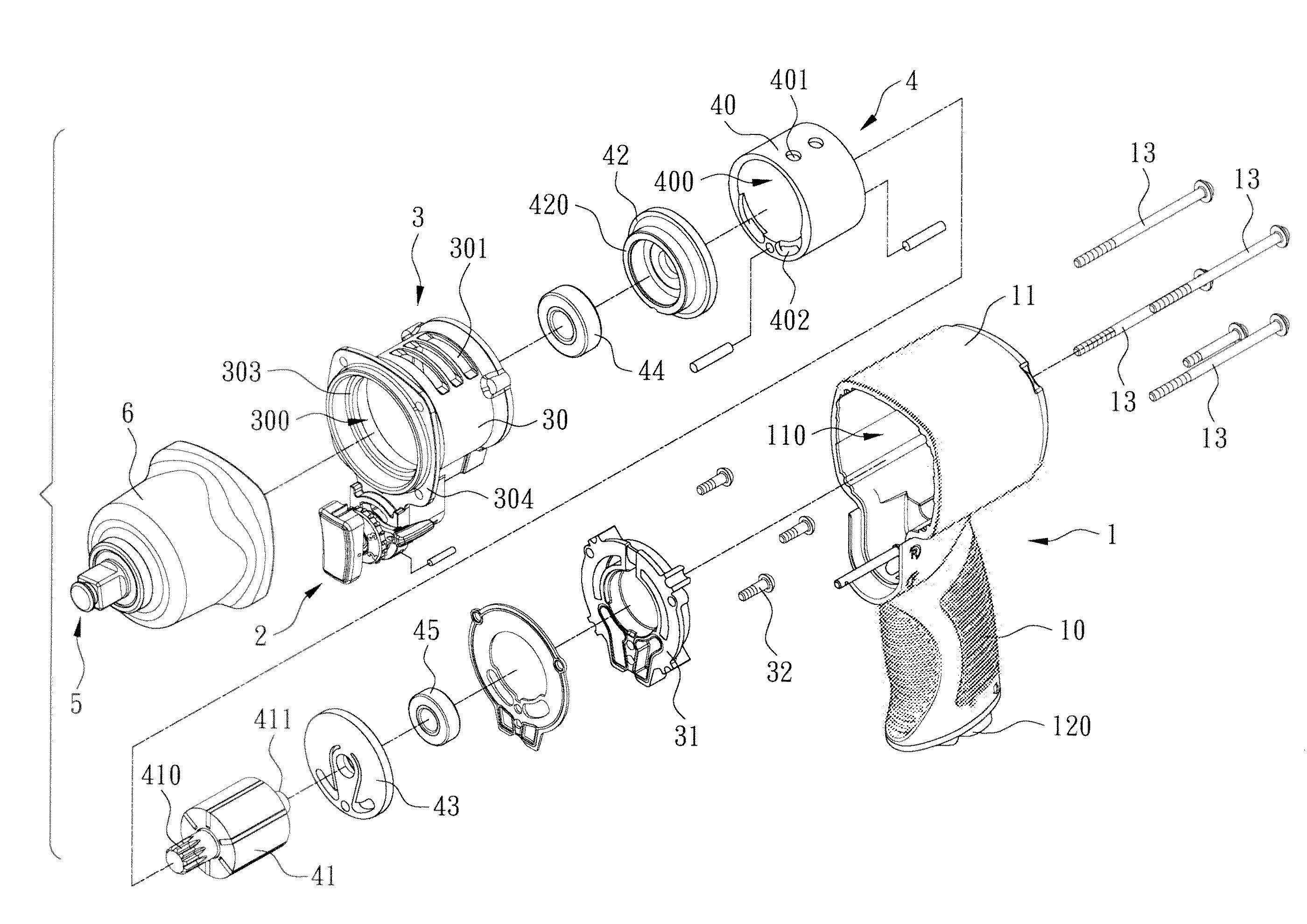

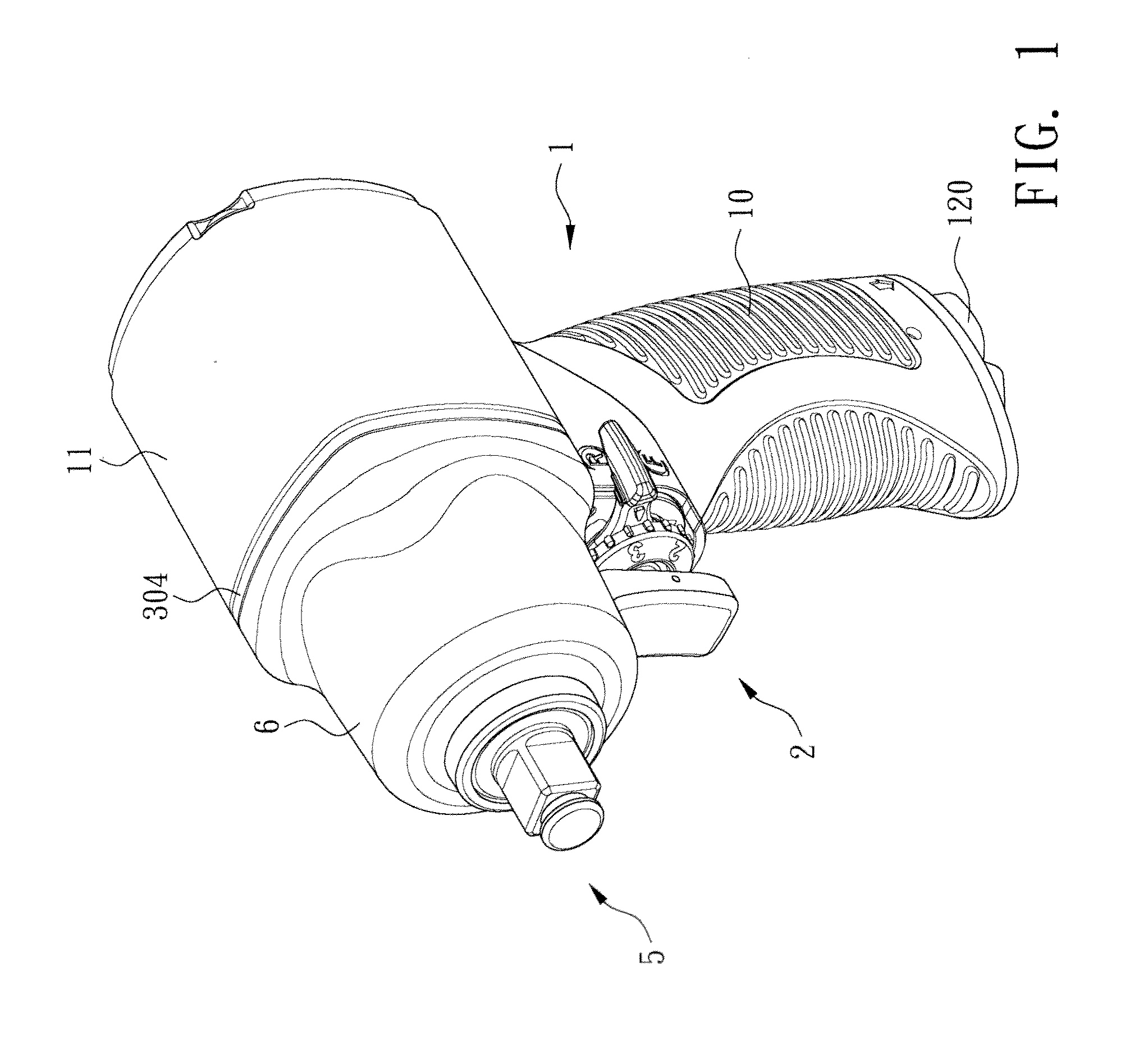

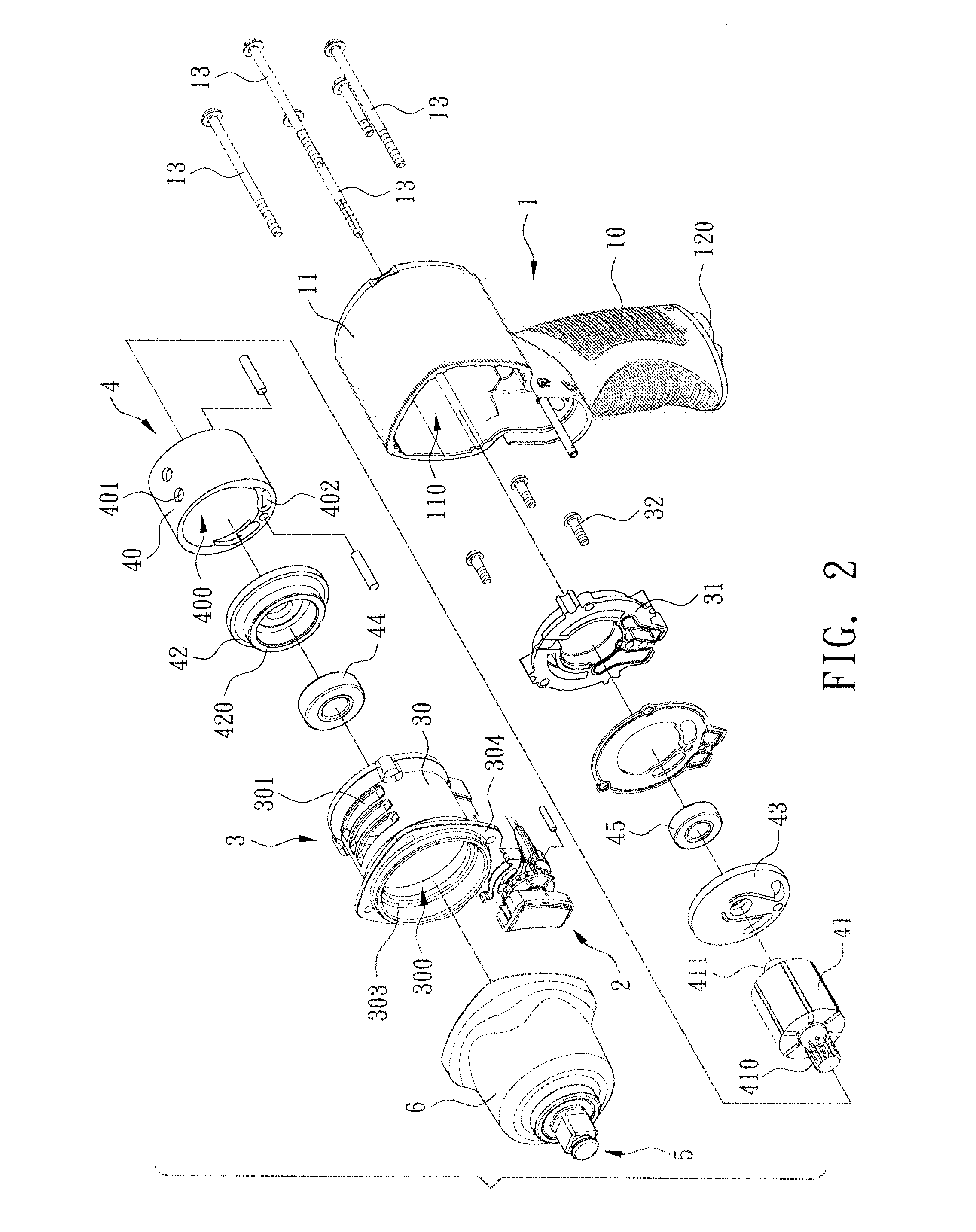

Structure of pneumatic impact wrench

InactiveUS20120138329A1Improve structural strengthLow costDrilling rodsConstructionsHardnessEngineering

An improved structure of a pneumatic impact wrench includes a main body, a plastic casing provided for fixing a motor casing and a motor module, the motor module having a cylinder for installing a rotor, the rotor being extended from an axle and supported by a bearing, the motor casing having an external case with a hardness greater than that of the plastic casing, and the external case being hollow and penetrating both ends to form a chamber for accommodating and installing a cylinder, and the external case having a stop ring protruded from an internal wall of the chamber and provided for blocking the cylinder, and an external case cover installed at a rear end of the external case for coupling and covering the external case cover.

Owner:STORM PNEUMATIC TOOL CO LTD

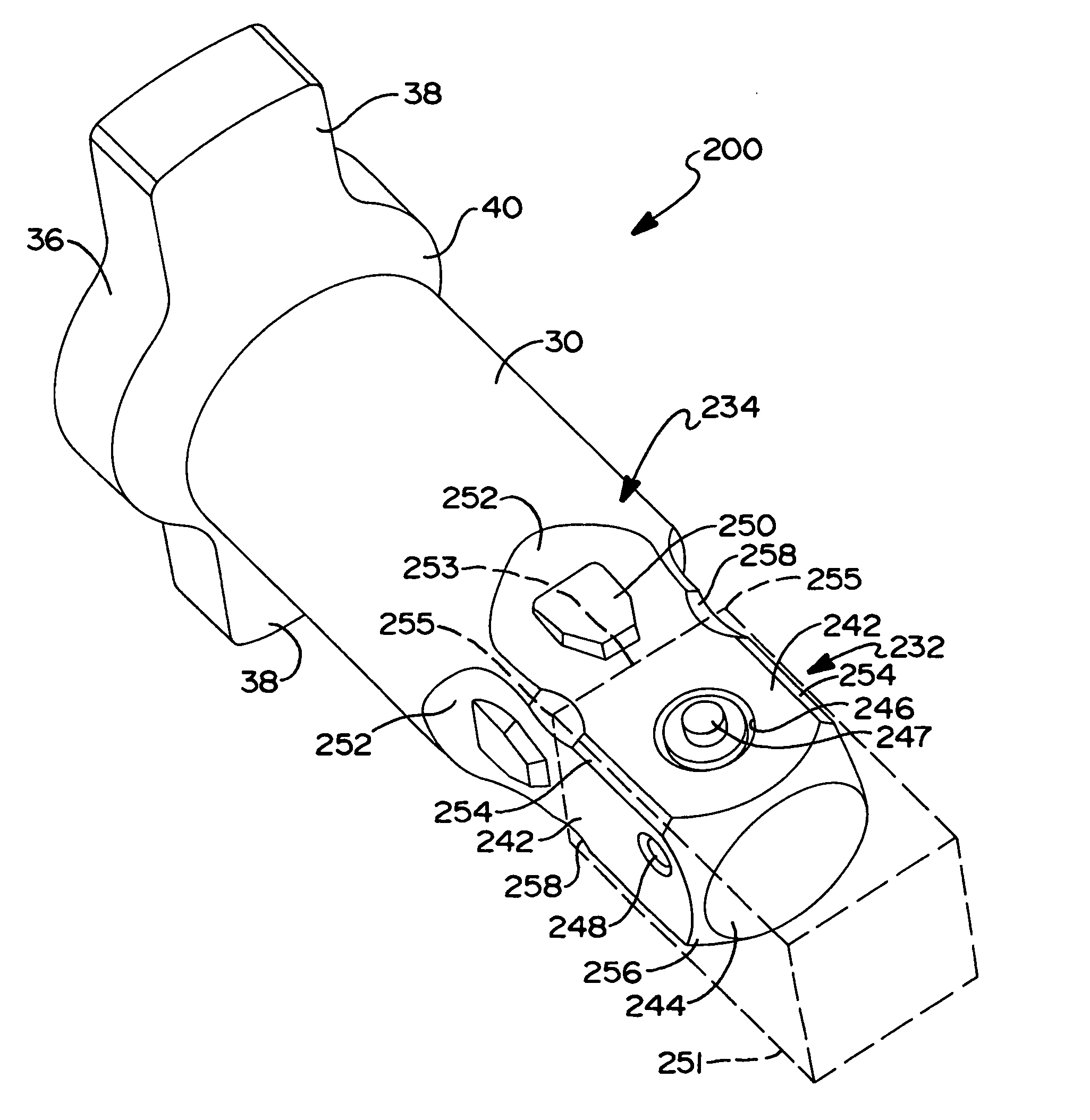

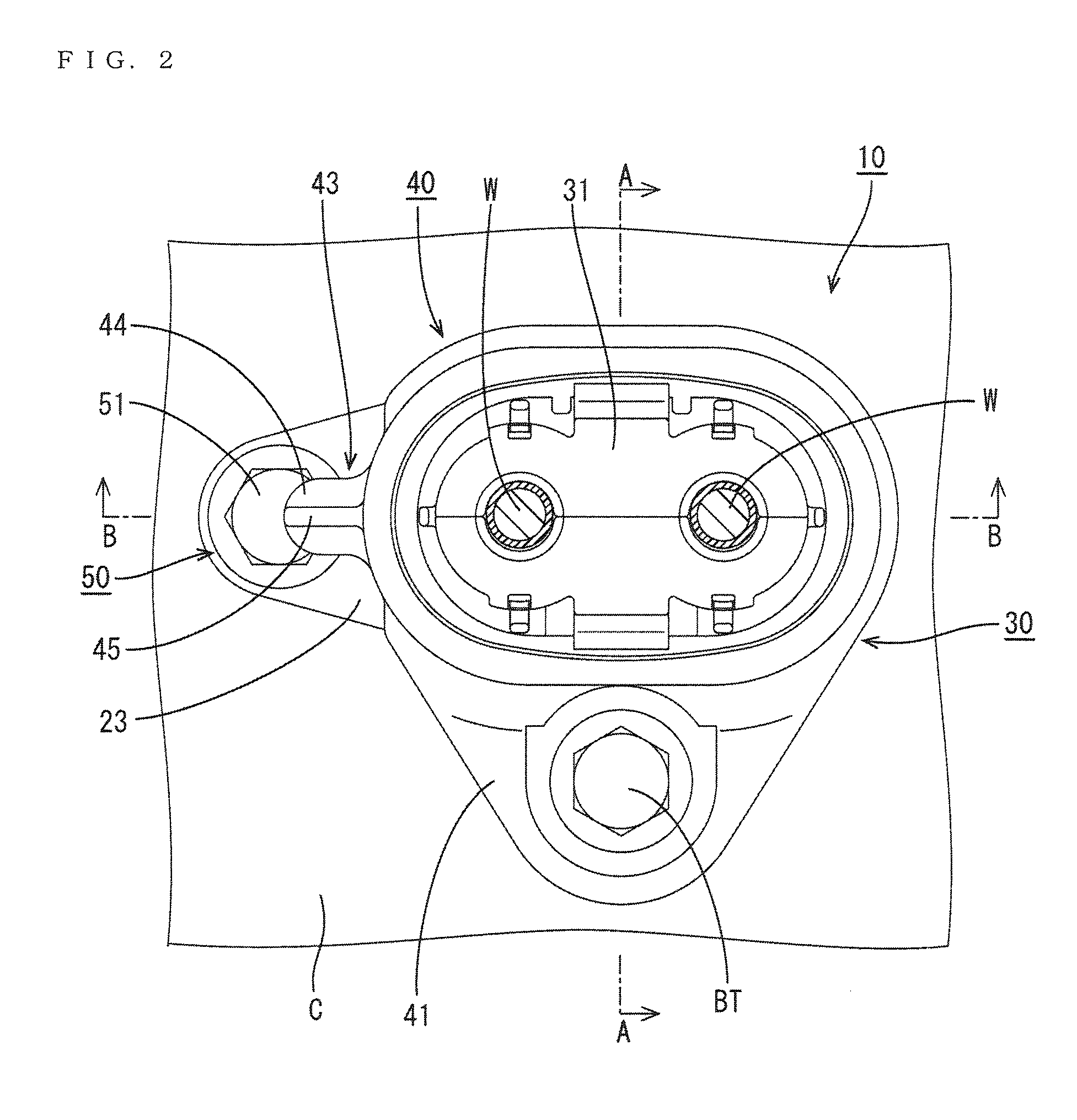

Double Hammer Clutch Impact Wrench

A power driven tool for rotating a mechanical fastener including a housing with a motor positioned in the housing. The motor includes a drive shaft that rotates relative to the housing. An impact mechanism in the housing is operatively connected to the motor drive shaft. The impact mechanism has a base, an output and a cam. The output and cam are rotatably mounted on the base. A pair of hammers are pivotally mounted on the base and selectively positioned by the cam. The cam biases the hammers to intermittently impact the output. A ratchet head assembly is operatively connected to the output of the impact mechanism. The ratchet head assembly includes an output member rotatably mounted on the housing to rotate the mechanical fastener. The assembly also includes a ratchet operable to limit rotation of the output member in a selected direction.

Owner:S P AIR

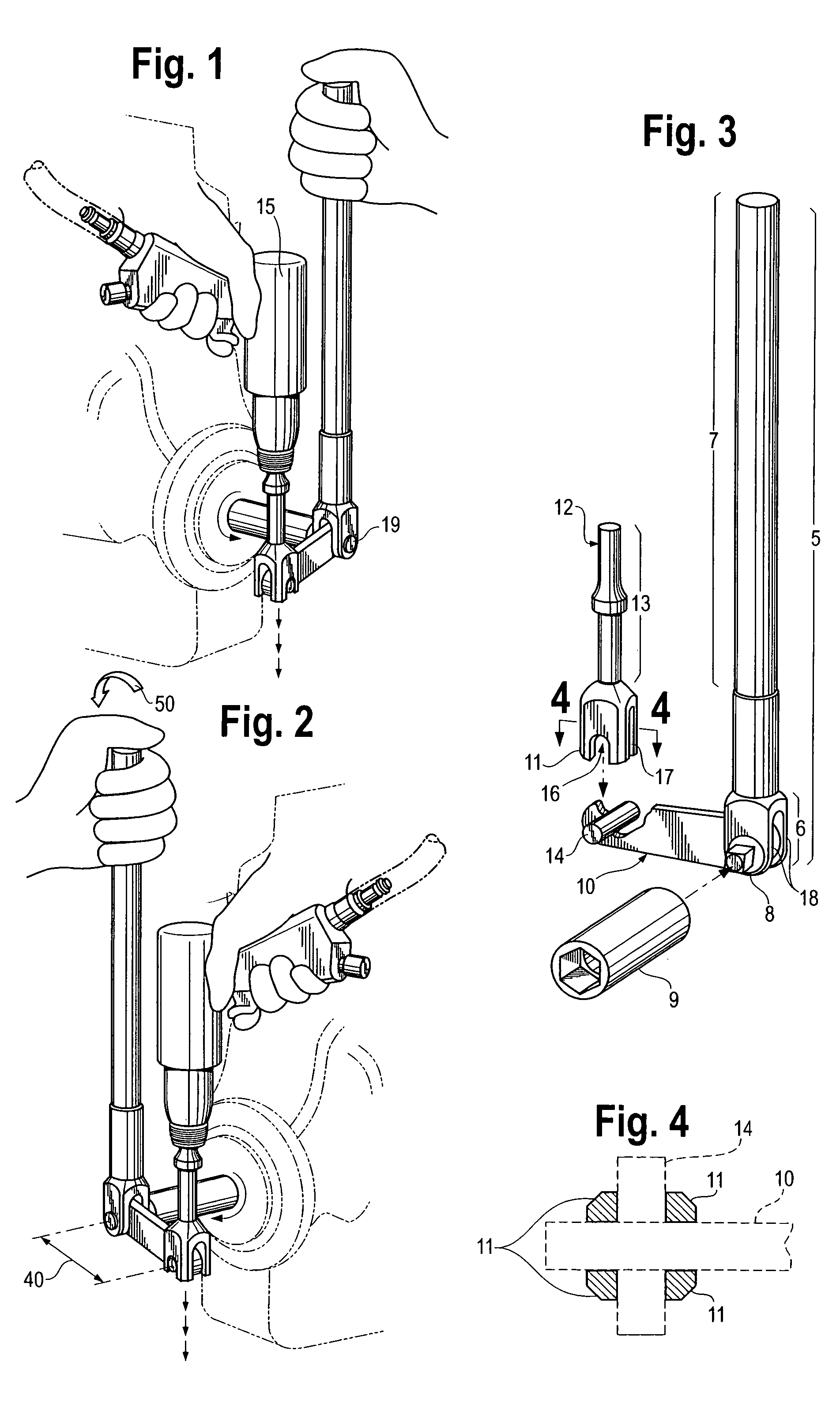

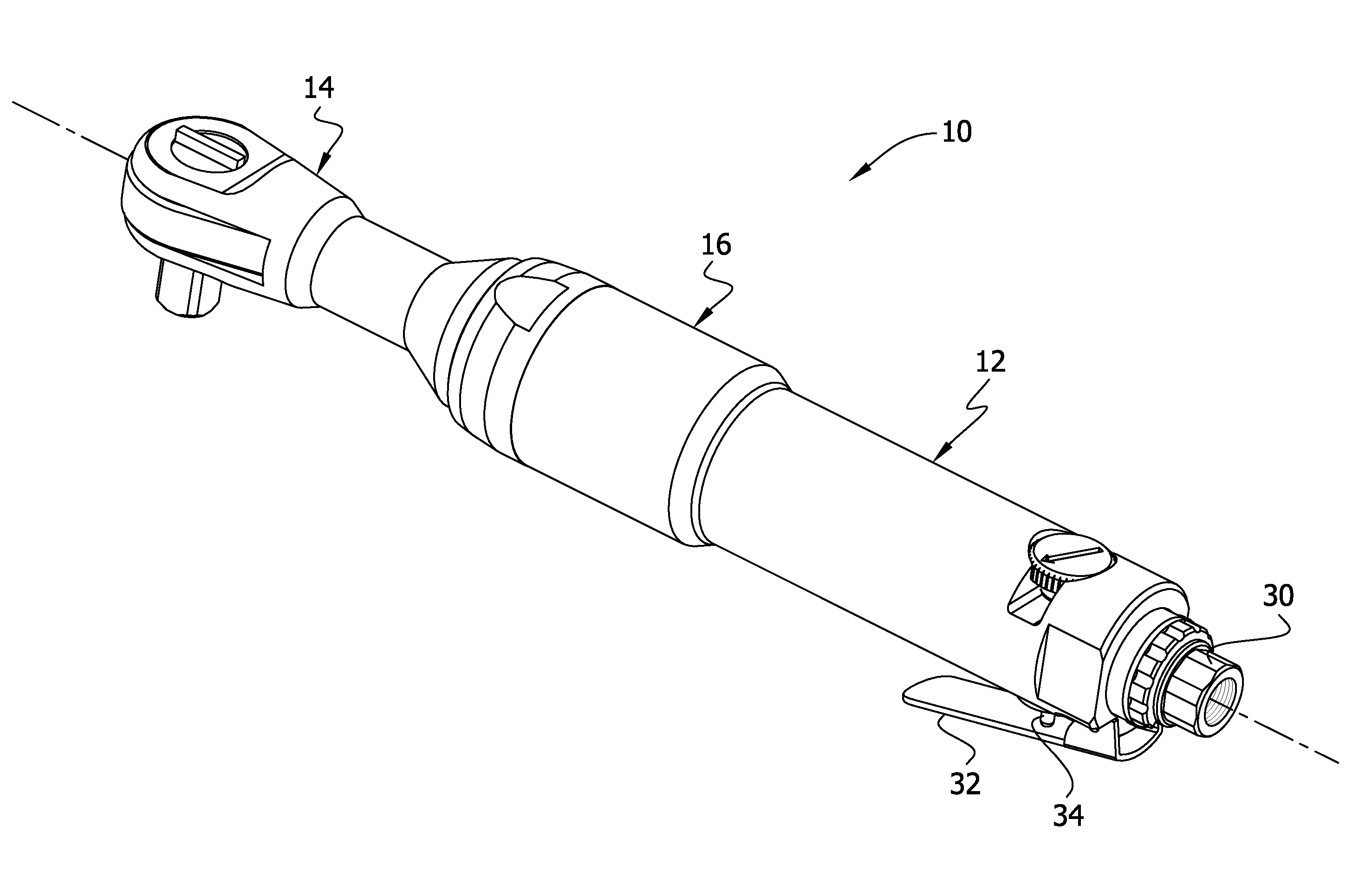

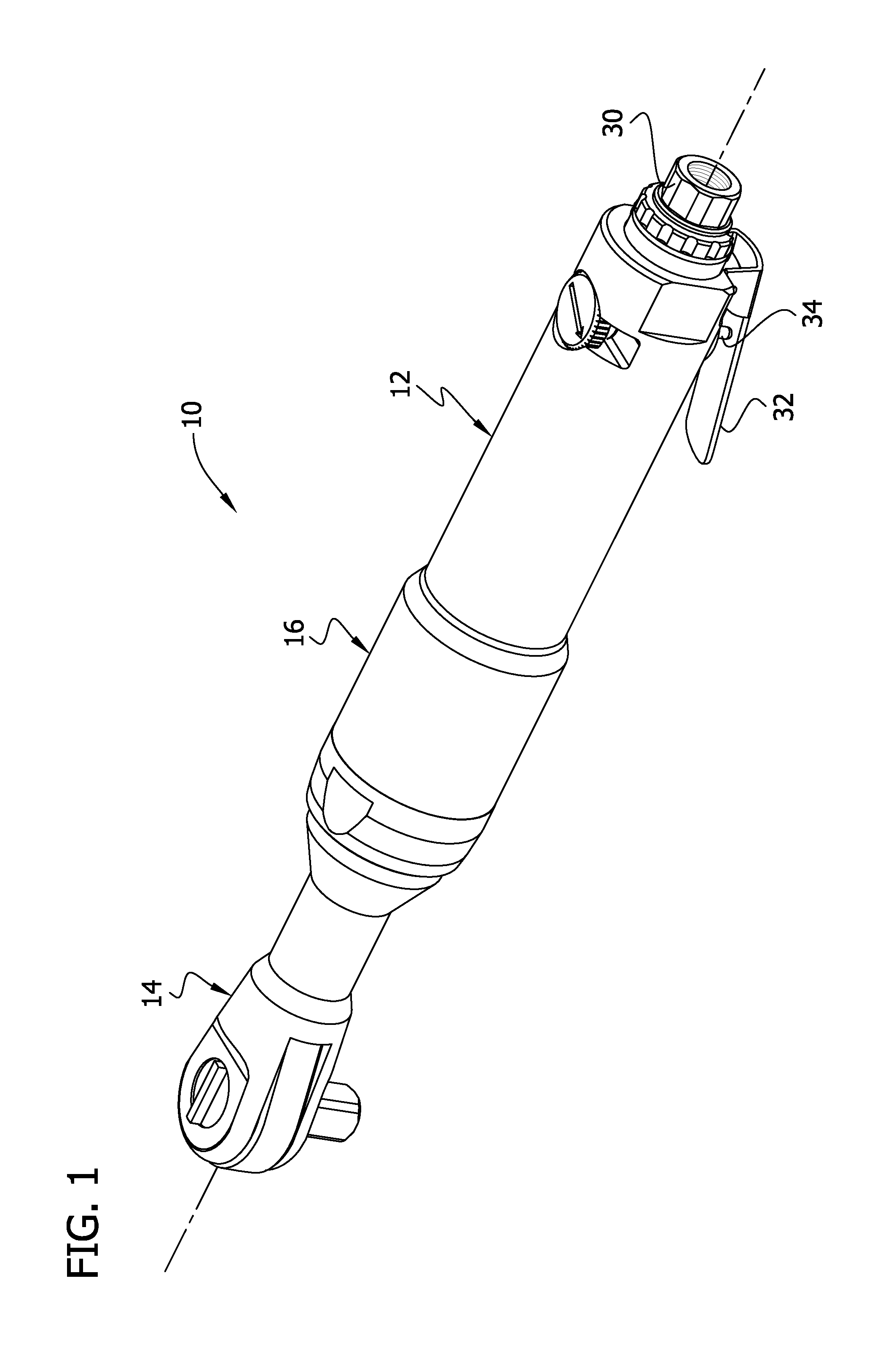

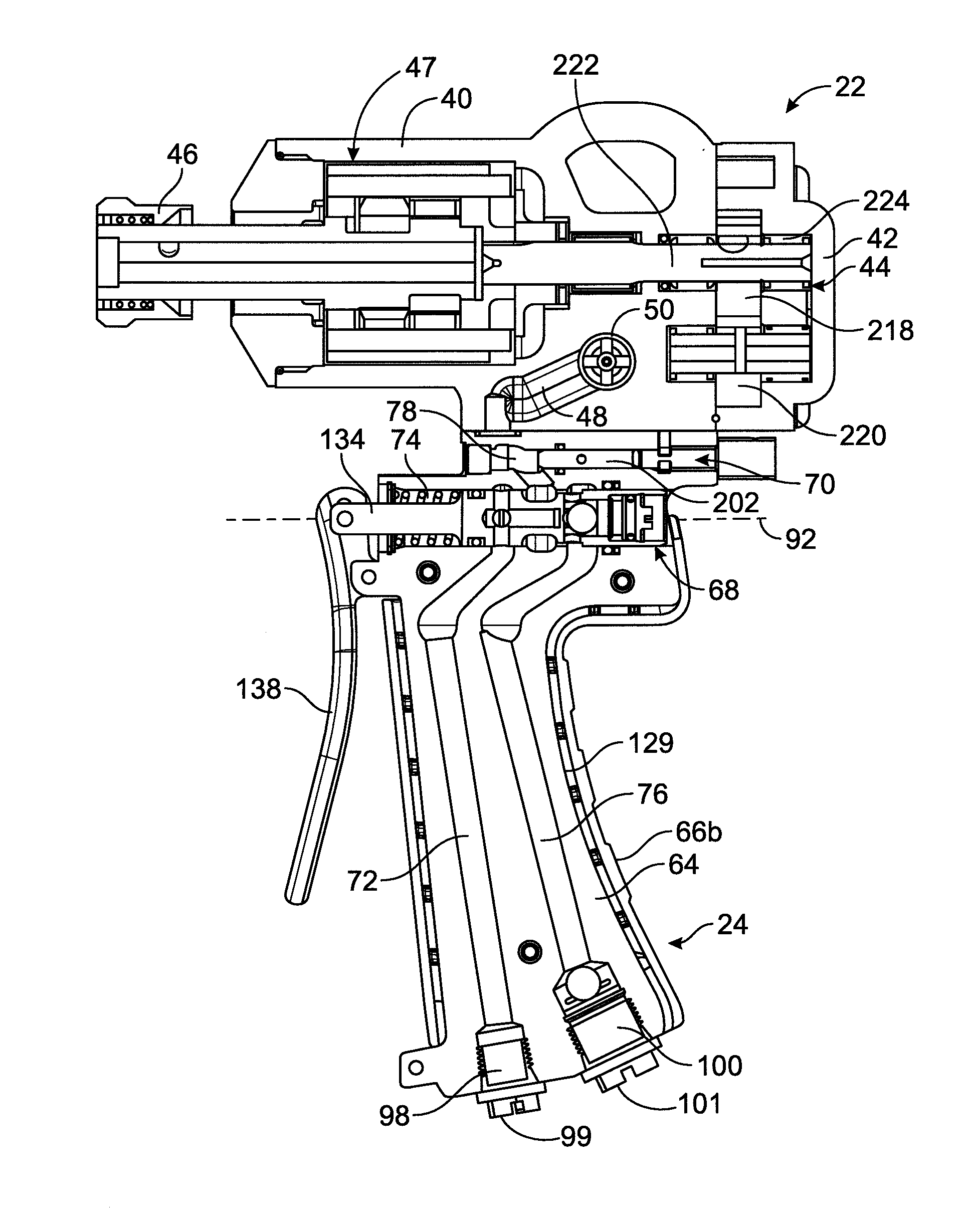

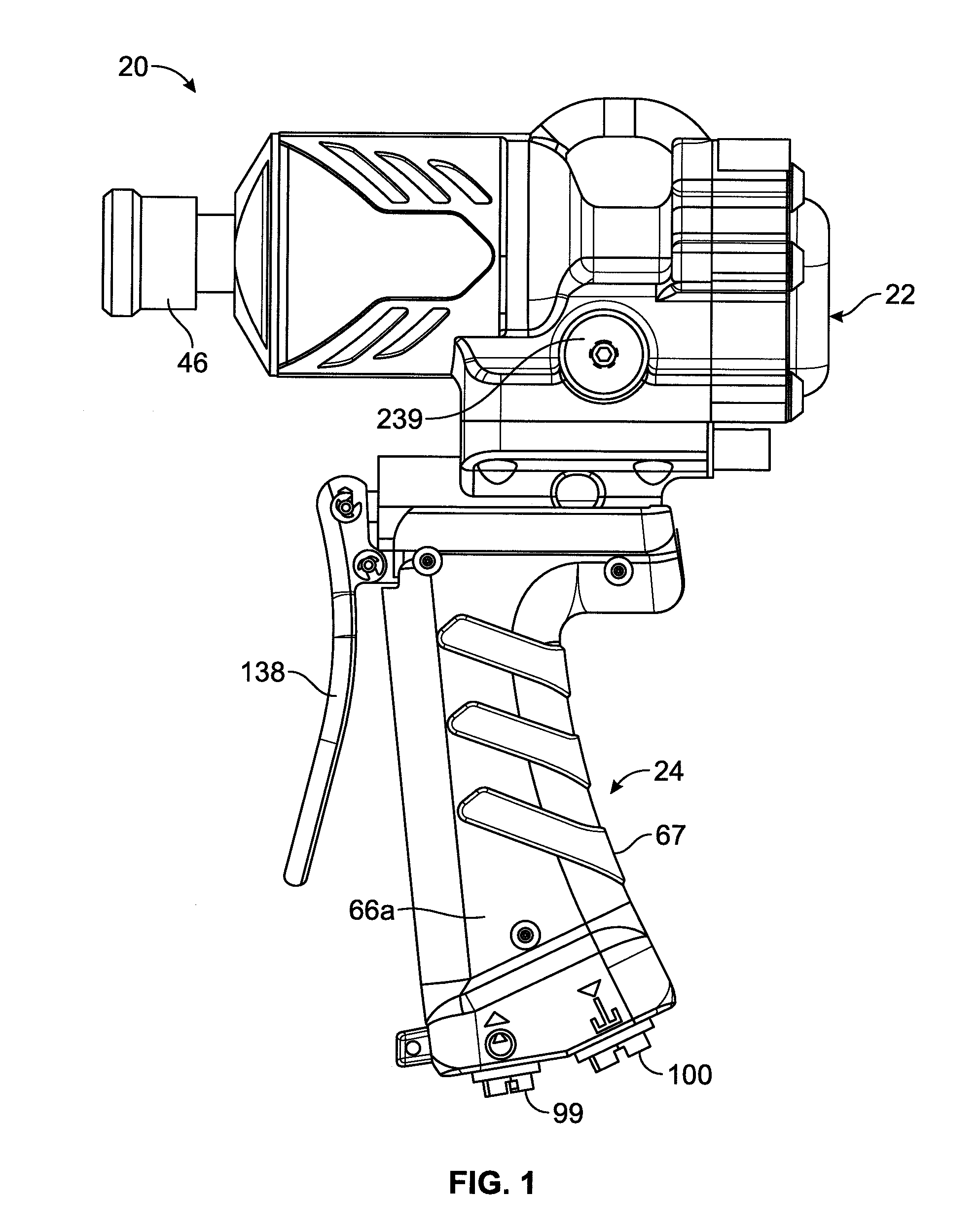

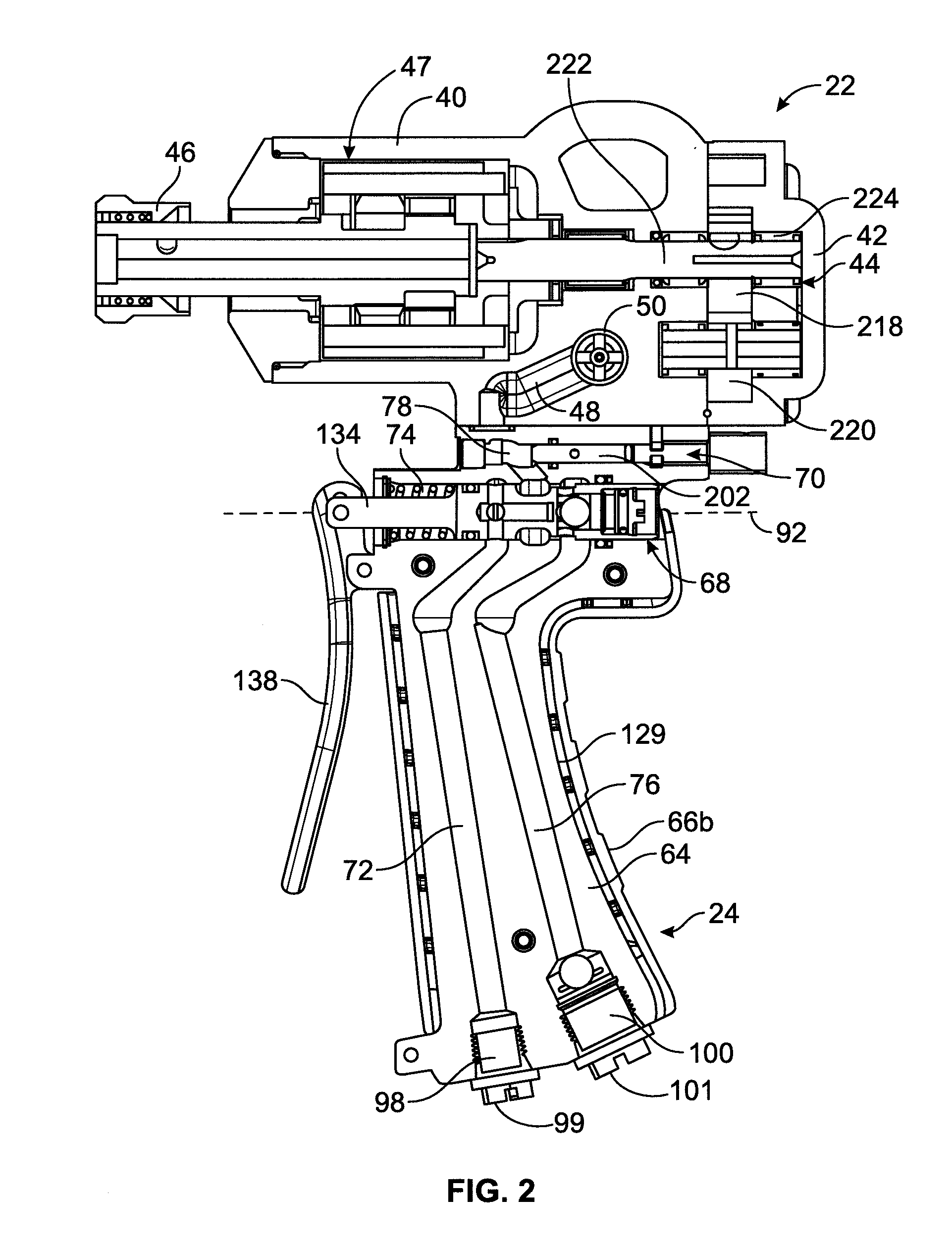

Air actuated pneumatic impact wrench lug bolt tool

The invention relates to a device utilizing compressed air for loosening and tightening fasteners that are located in hard to access areas. The device enables a single operator to stabilize the device while applying pressure via a pneumatic hammer to loosen or tighten fasteners. The device uses socket principles that enable the user to switch the sockets and provide a wide variety of options to accommodate the shapes and sizes of the fasteners.

Owner:H B PROD

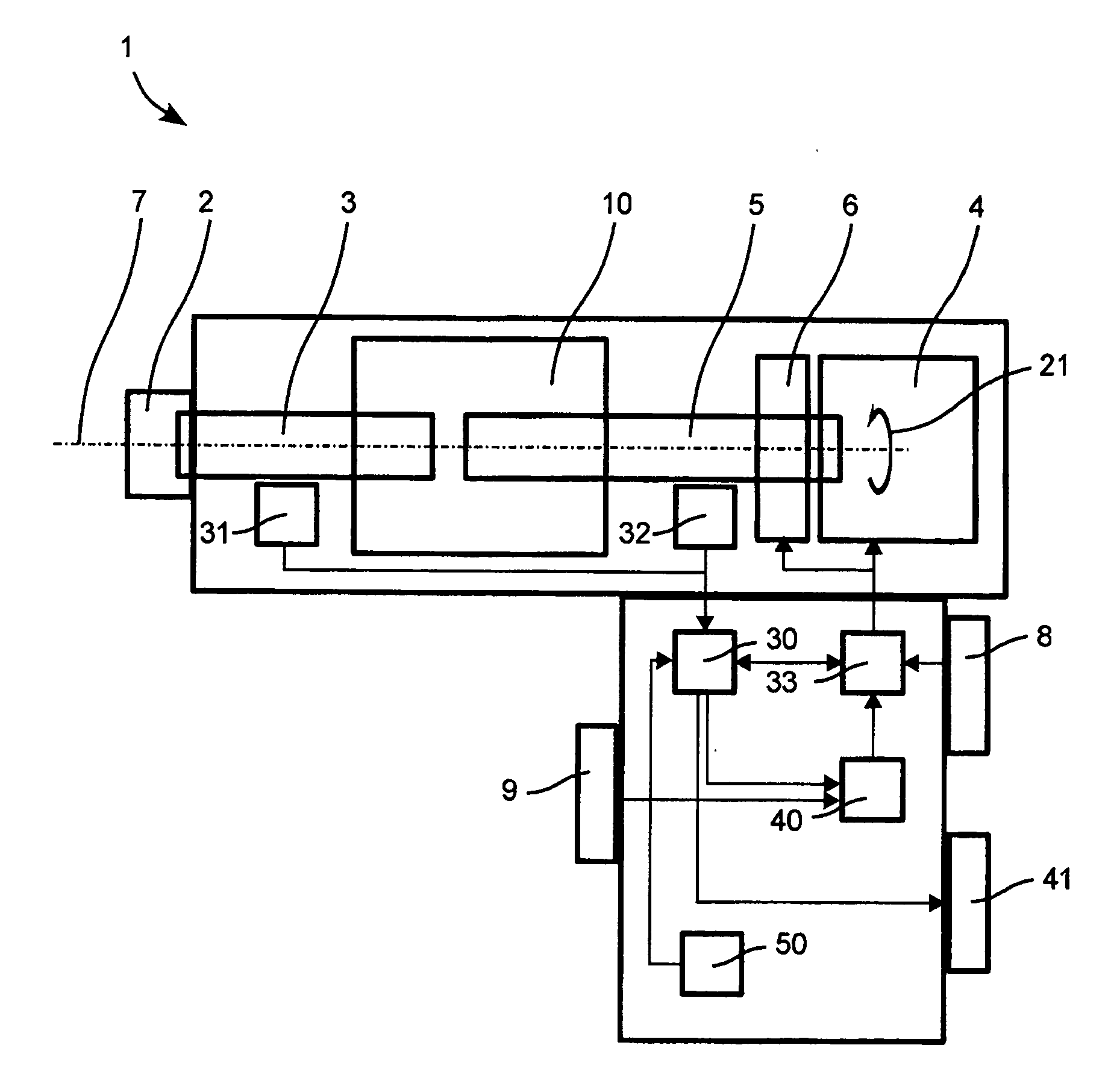

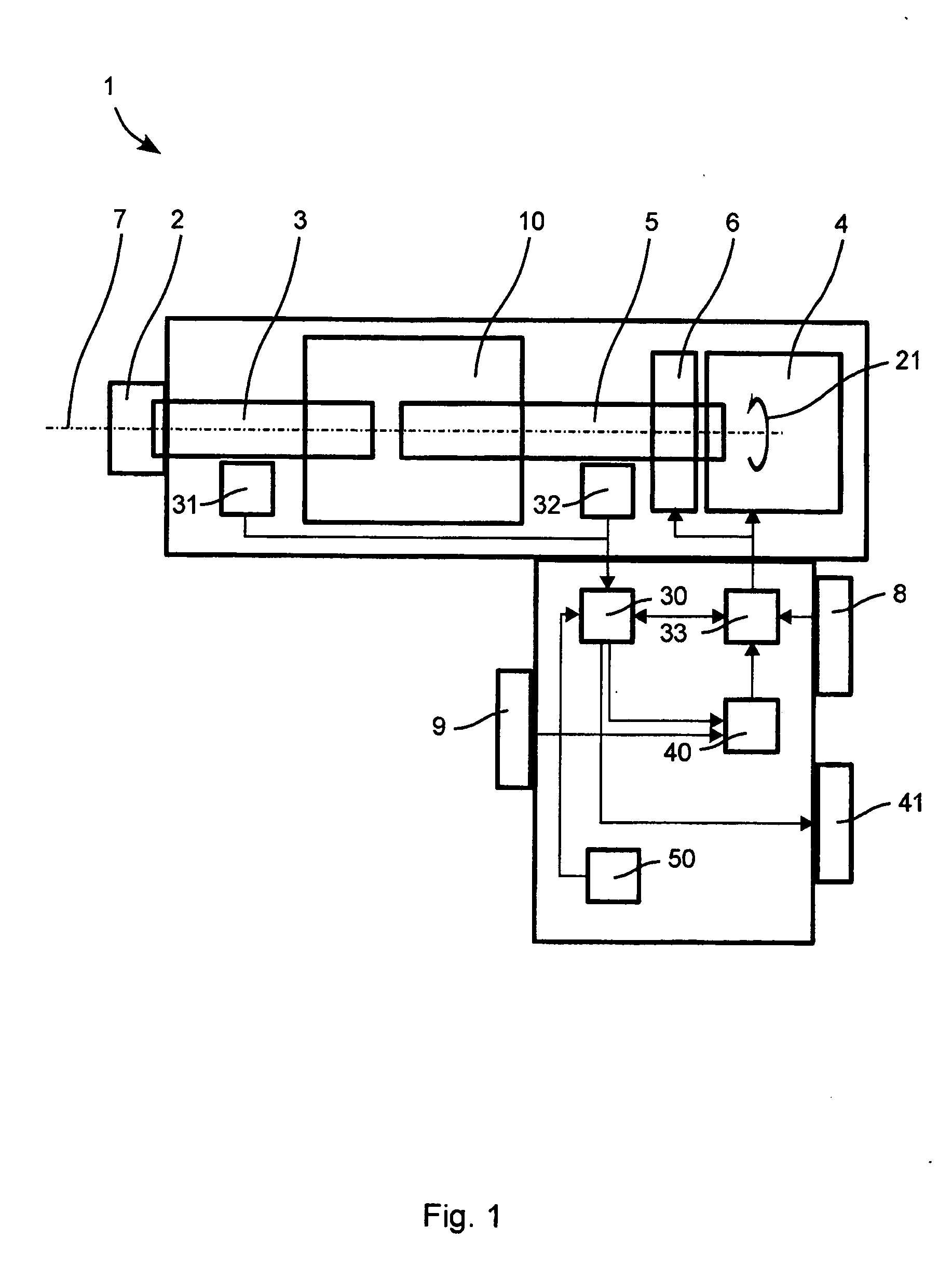

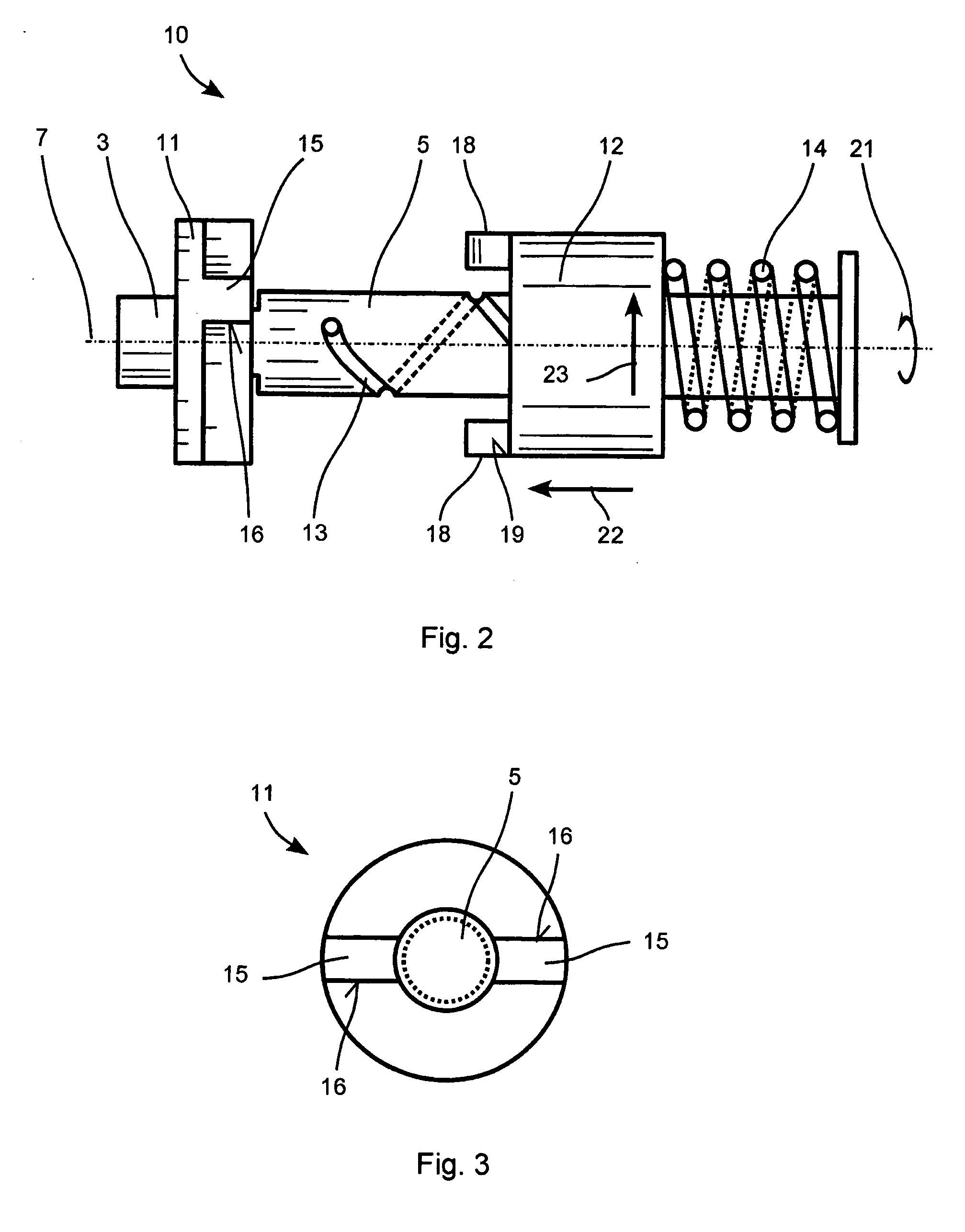

Impact wrench and control method for an impact wrench

A control method according for an impact wrench includes ascertaining whether the impact wrench applies an impact when the drive shaft rotates in a lower speed range. The speed of the drive shaft then is increased to a higher speed range as a function of an ascertained impact during the rotation in the lower speed range.

Owner:HILTI AG

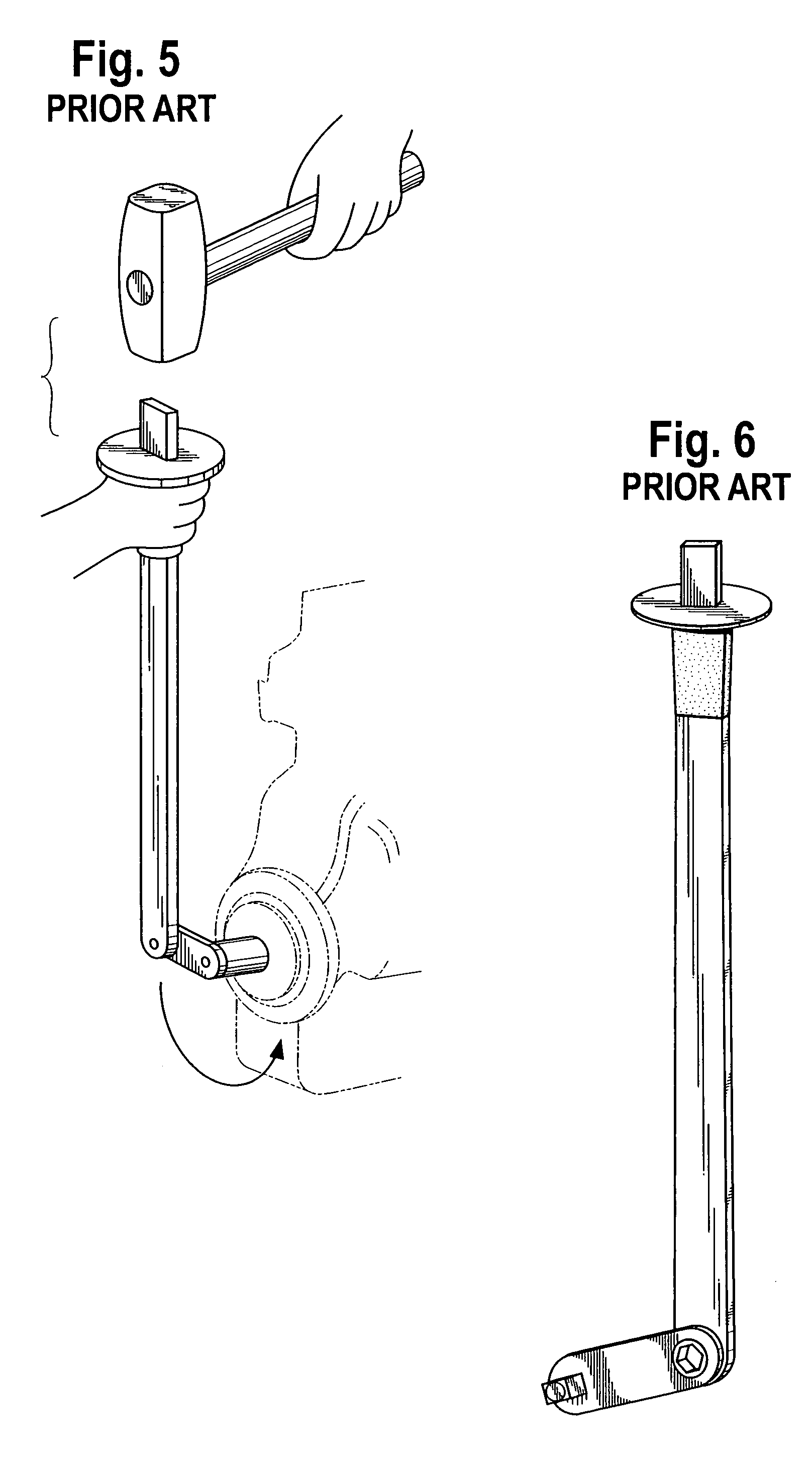

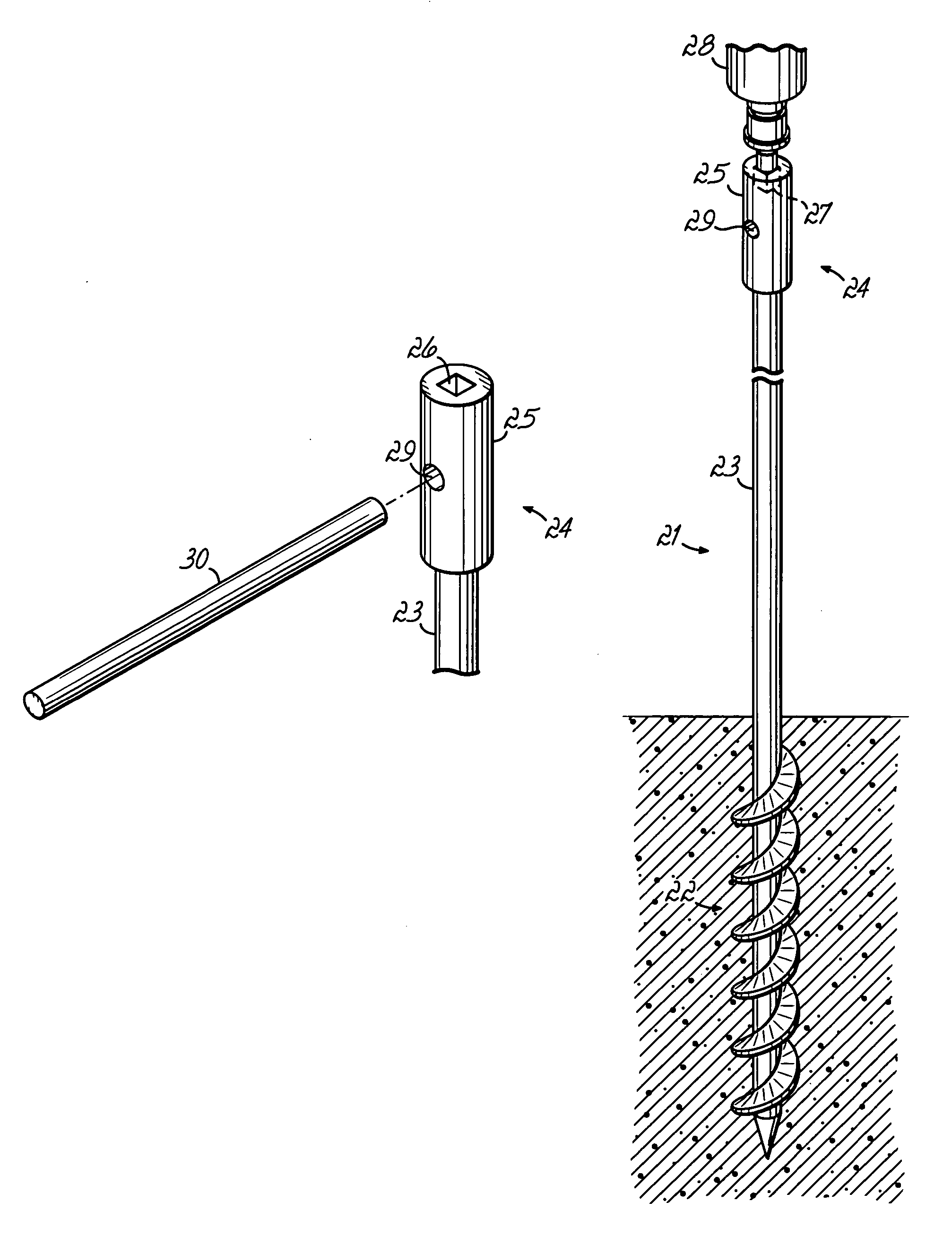

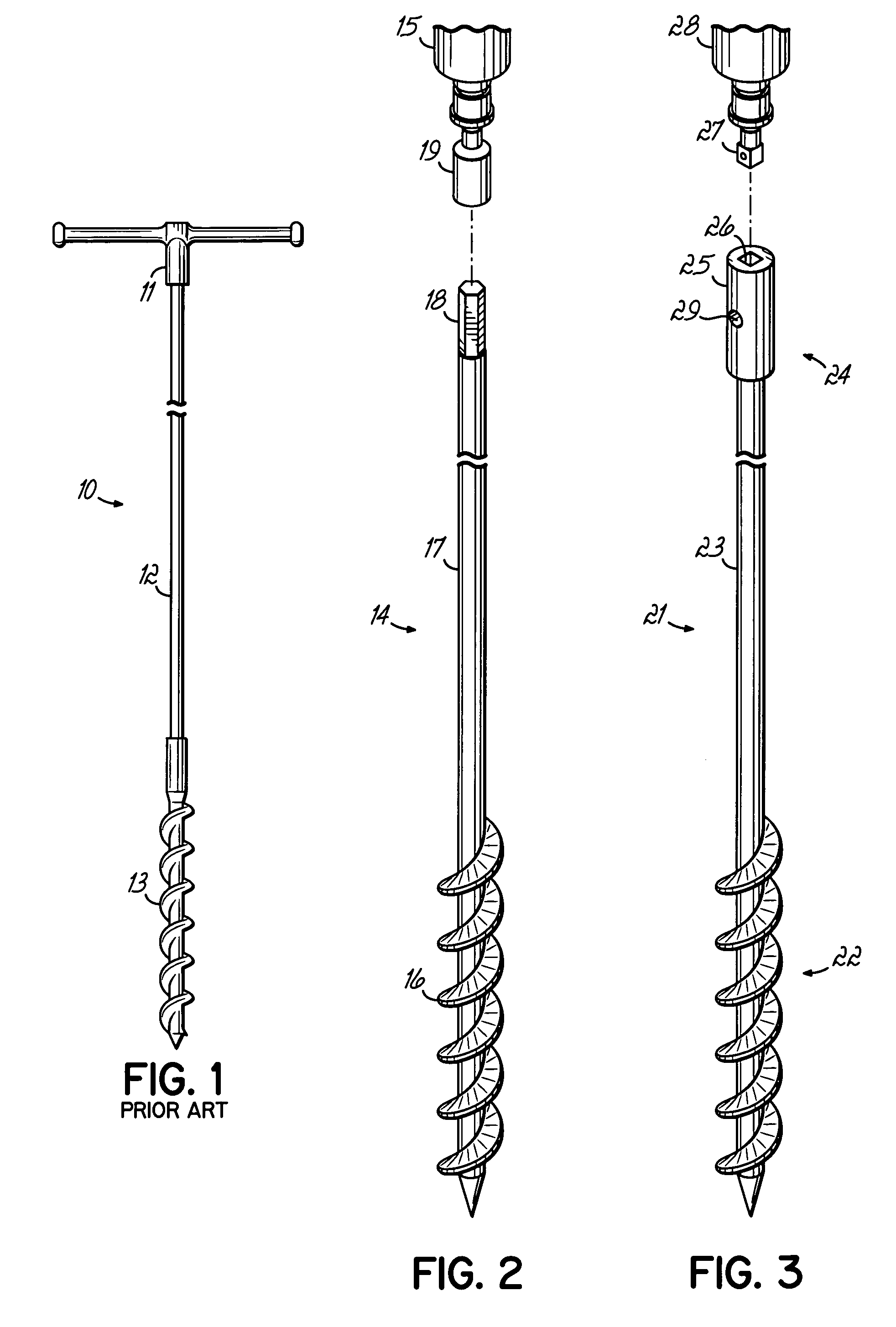

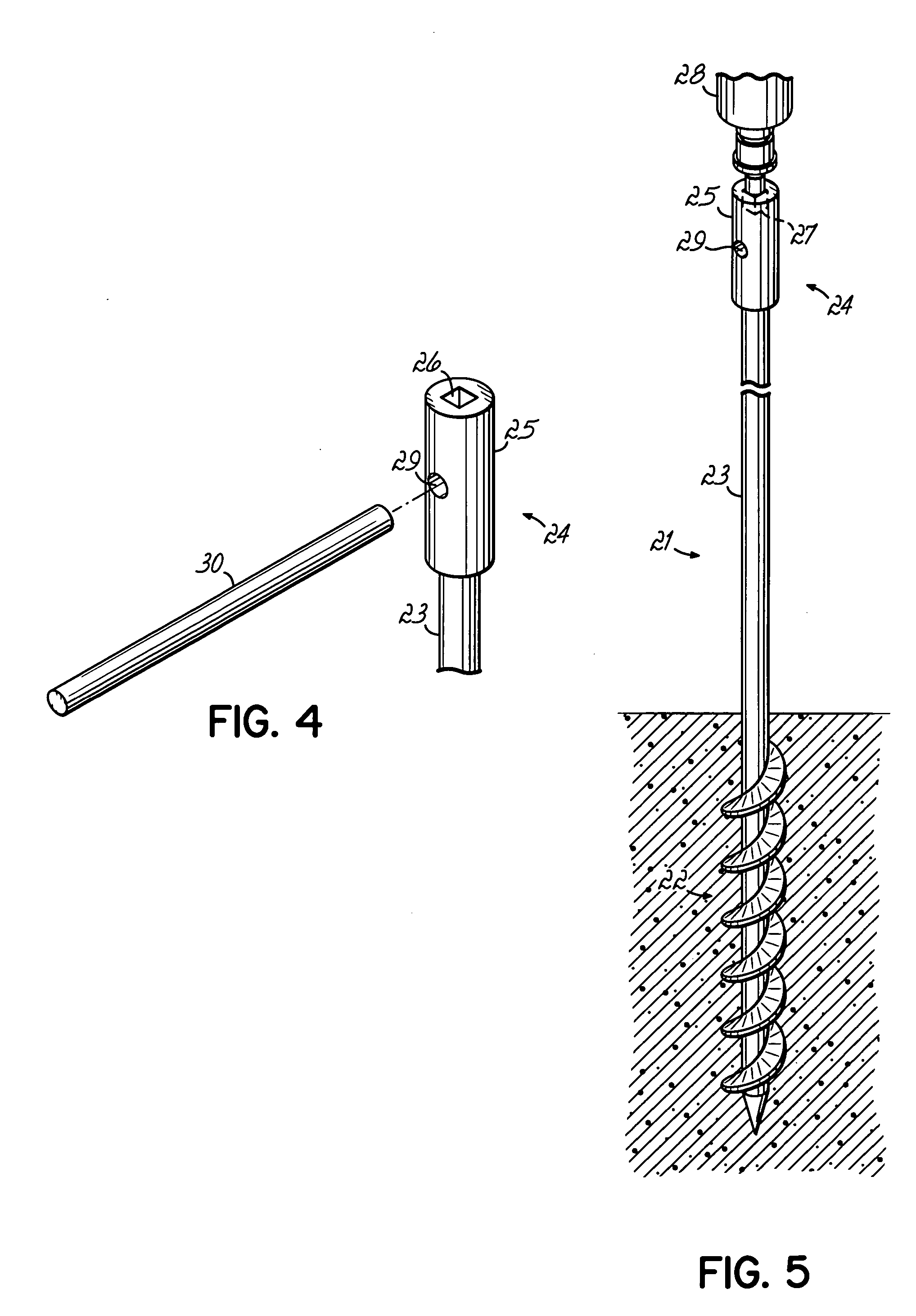

Ground rod

InactiveUS6963026B2Easy to installInstallation of lighting conductorsSpannersEngineeringImpact wrench

A ground rod includes first and second ends connected by a shaft portion. The first end has an auger configuration permitting it to be drilled into the ground. The opposite end is adapted to attached to either an electric drill or an impact wrench. This drastically reduces the time required to drive the ground rod into the ground. In an alternate embodiment, the ground rod also adapted to attach to a handle which allows it to be manually inserted or removed from the ground.

Owner:BRENNAN BOB

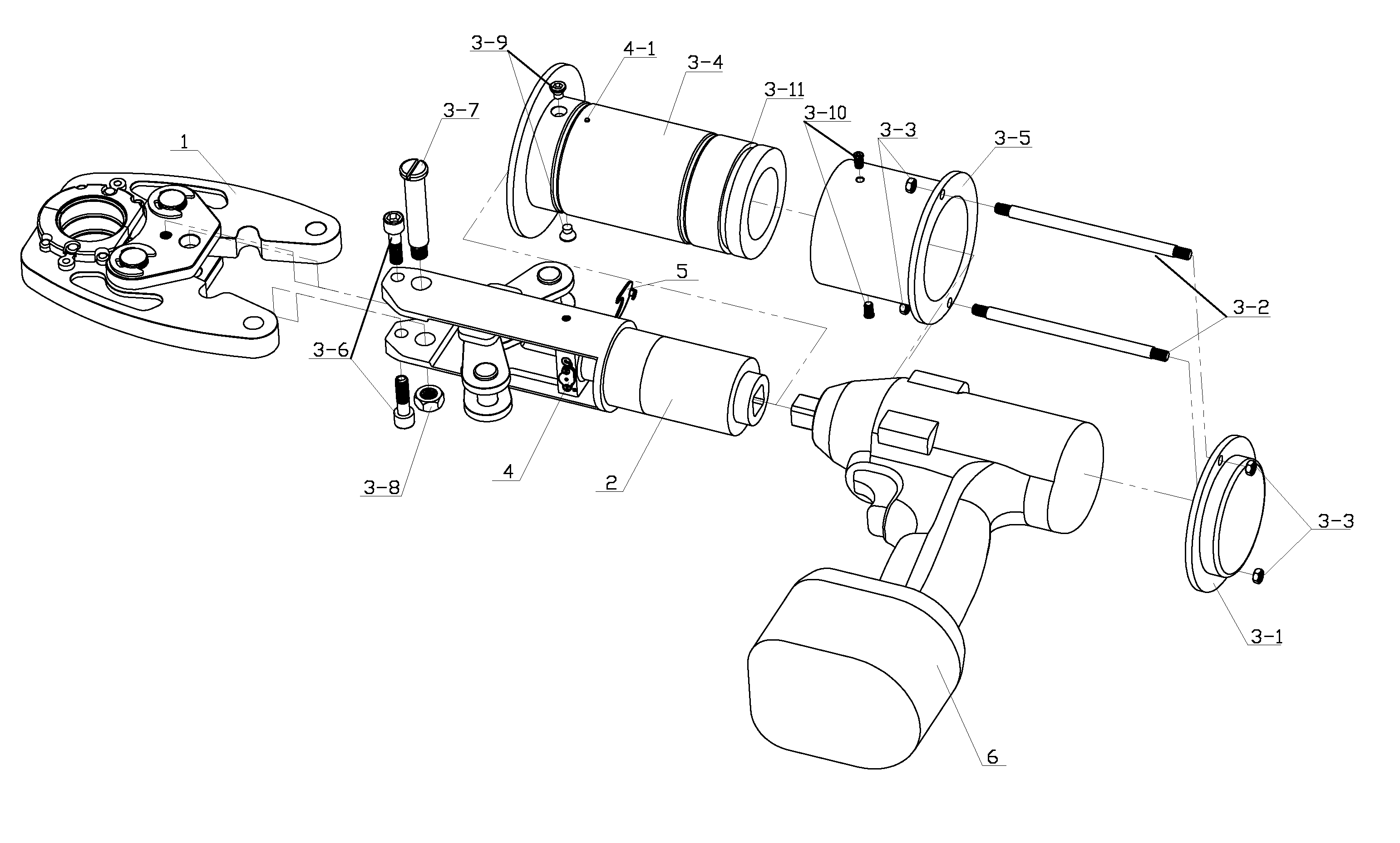

Crimping/cutting working head for impact wrench

InactiveUS8342001B2Quickly and conveniently replacedPracticalLine/current collector detailsDrawing diesImpact wrenchWrench

A power operated crimping / cutting tool driven by any type of impact wrench, with a crimping or cutting working head, includes a transmission unit, a connection unit, a process indication device and an adjustment device, wherein the transmission unit includes a jaw device and a transmission device, the jaw device is detachable, both the process indication device and the adjustment device are mounted on the transmission unit, the connection unit is sleevedly mounted at the impact wrench. The present invention can replace the jaw device according to different requirements.

Owner:LINK TECH TIANJIN METAL PROD

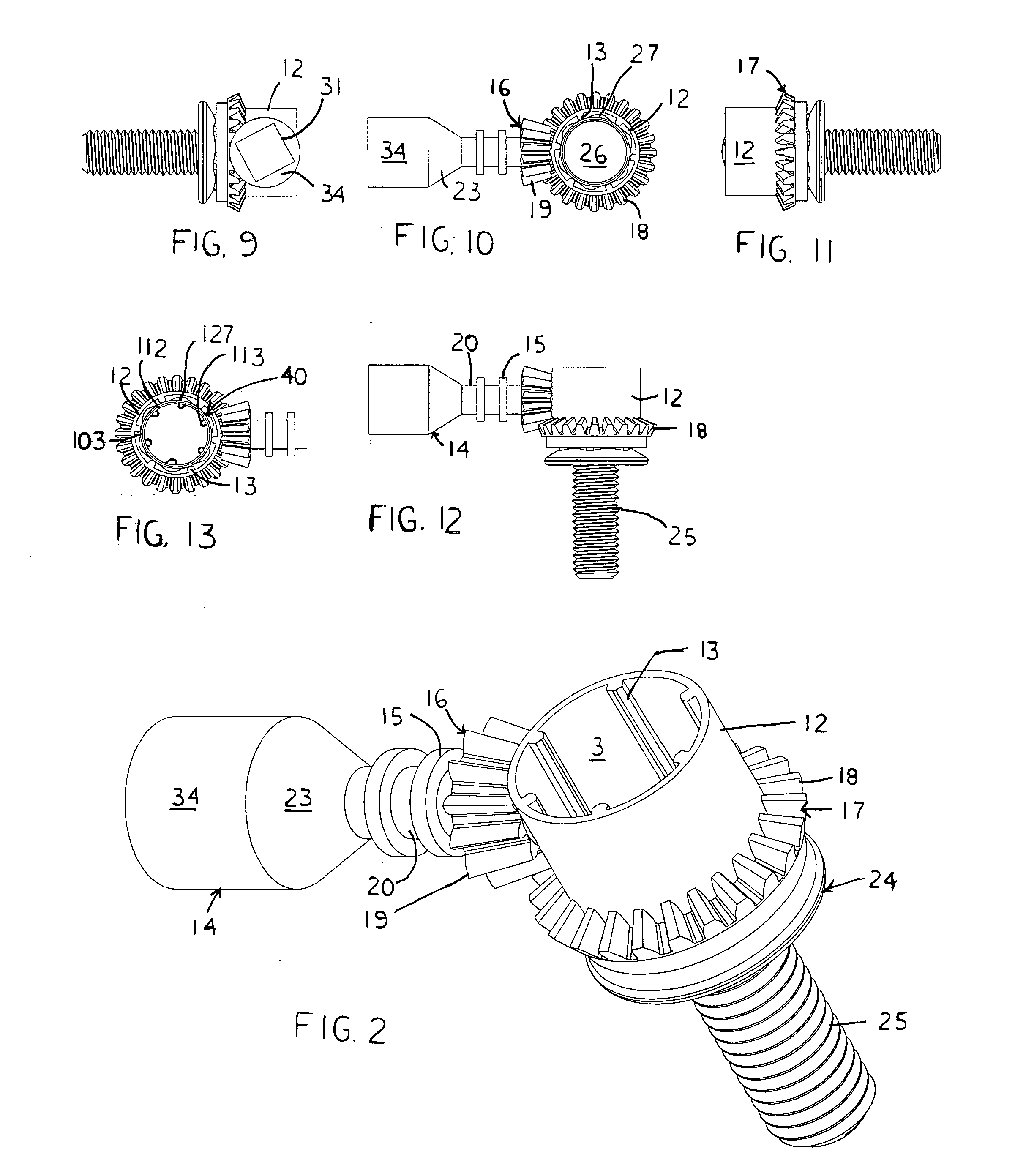

Jumbo hammer clutch impact wrench

A power driven tool for rotating a mechanical element. The tool includes a housing and motor. The motor has an output shaft. The shaft rotates relative to the housing. The tool also includes an impact drive axially fixed within the housing. The impact drive includes a base and an anvil shaft having an anvil. The impact drive includes an annular hammer having opposite impact lands pivotally mounted on the base for movement between three positions, including a forward position in which the hammer is positioned so one impact land engages the anvil, a reverse position in which the hammer is positioned so another of the impact lands engages the anvil, and a disengaged position in which neither of the impact lands engages the anvil. Further, the tool includes a ratchet mechanism. The ratchet mechanism includes an output drive mounted for rotation relative to the housing for rotating a mechanical element.

Owner:VESSEL FUKUCHIYAMA

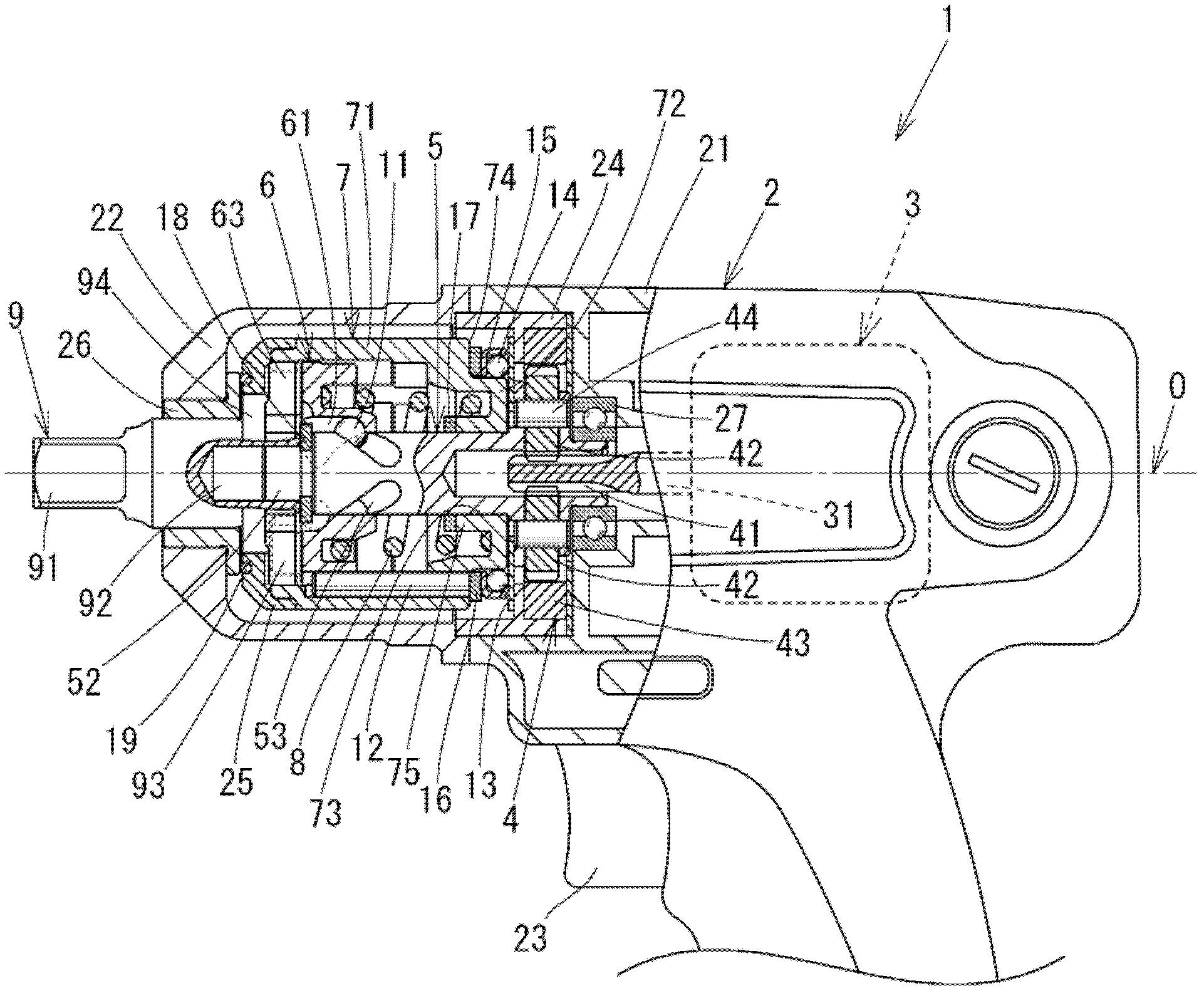

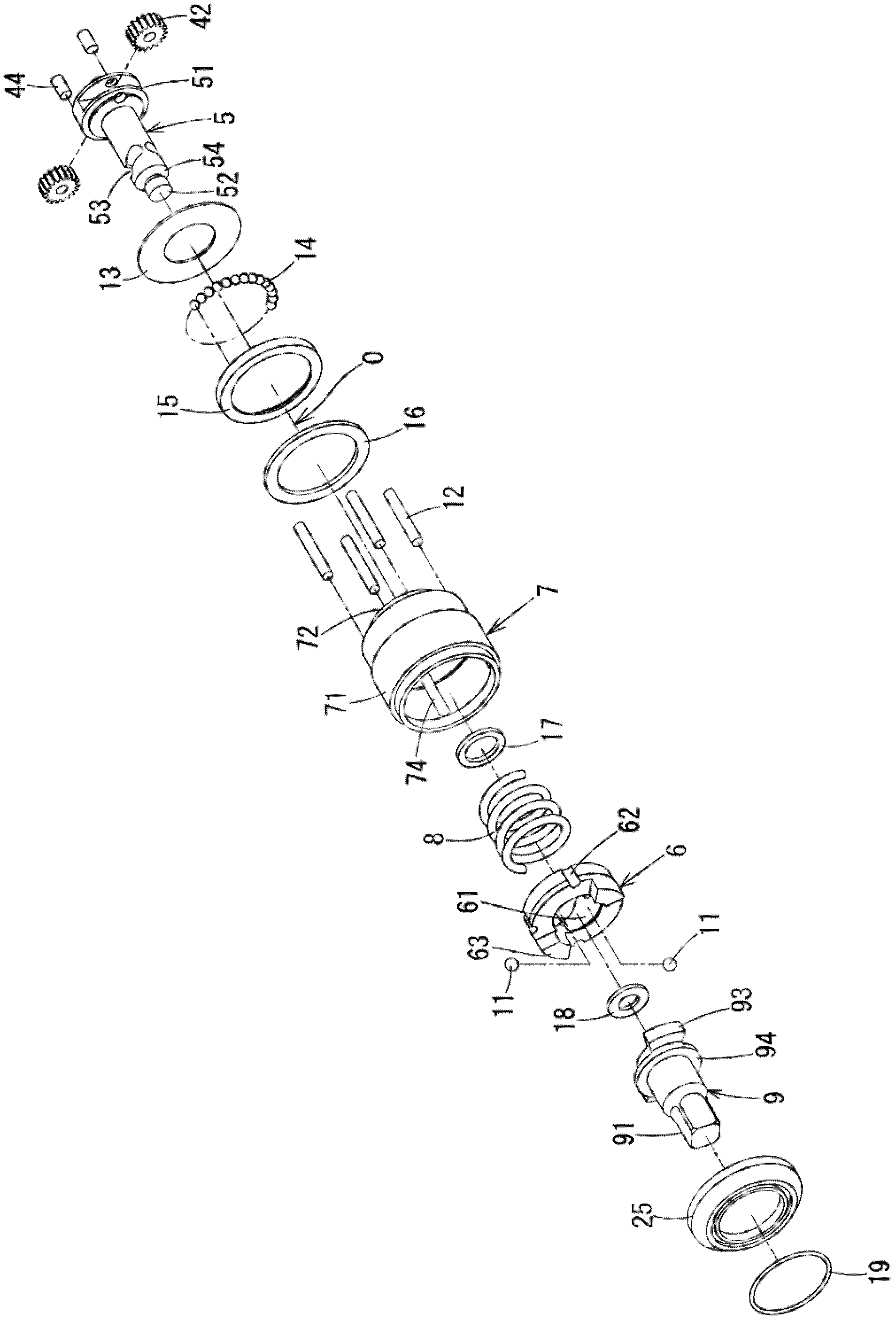

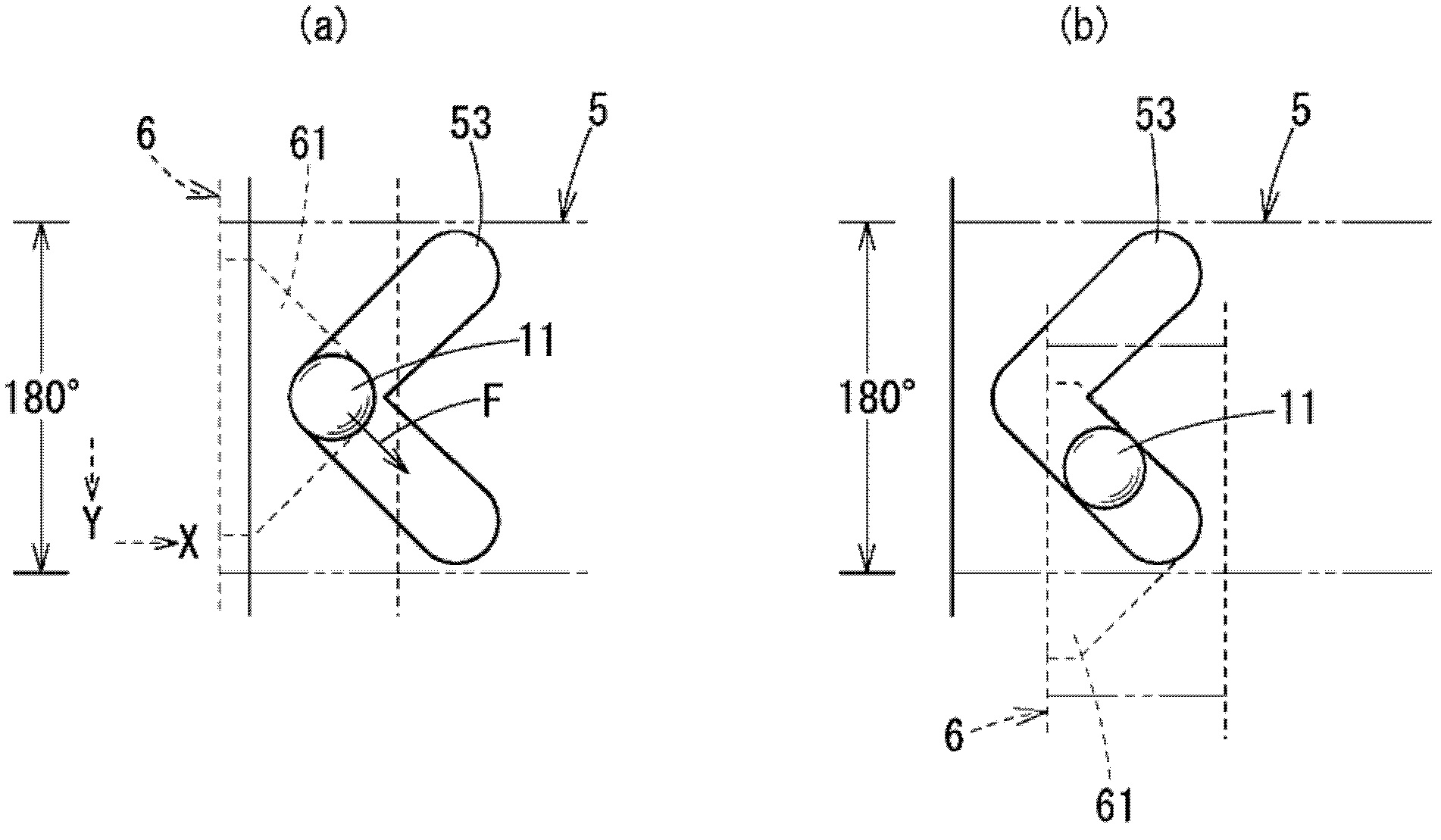

Impact wrench

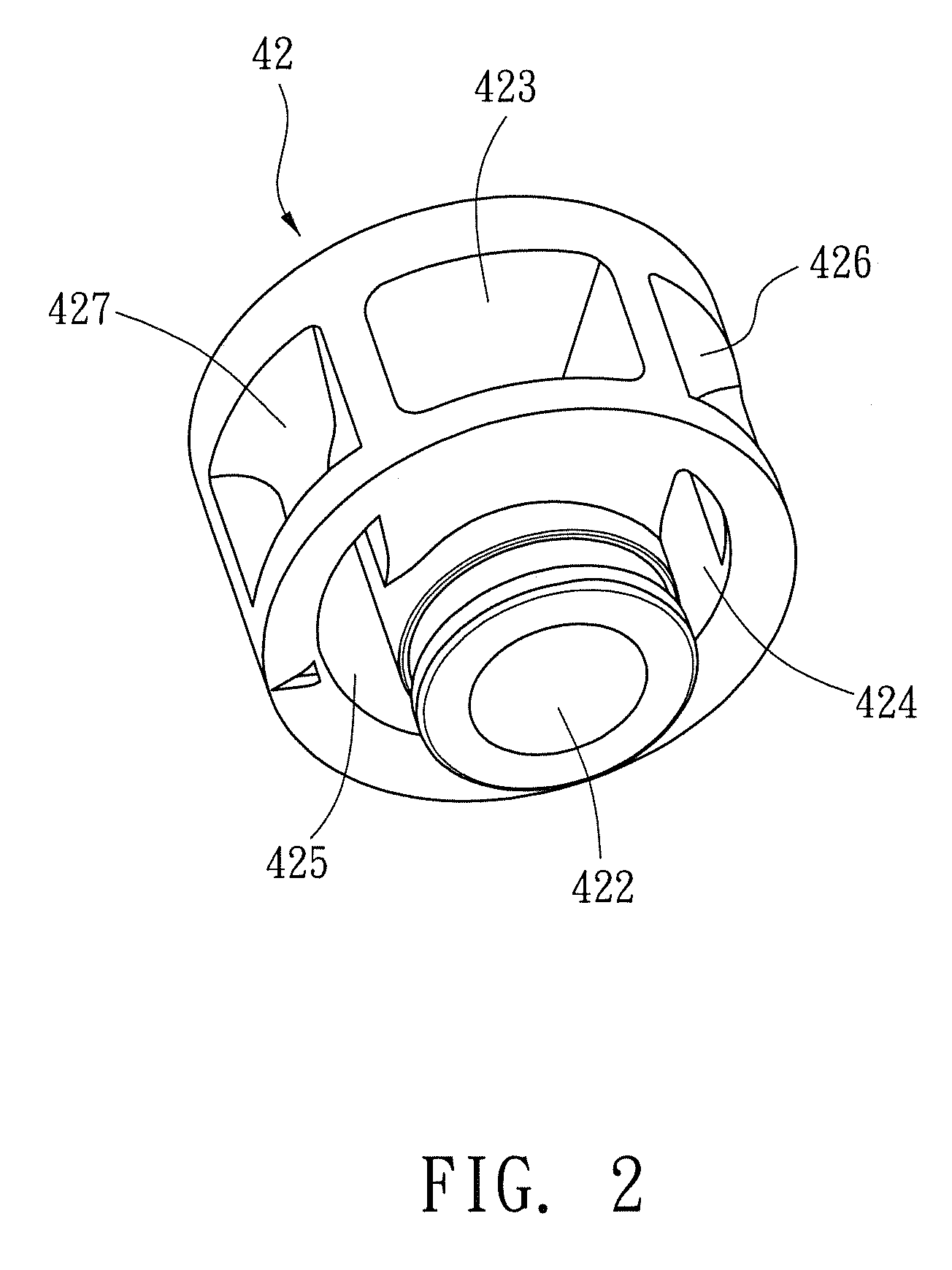

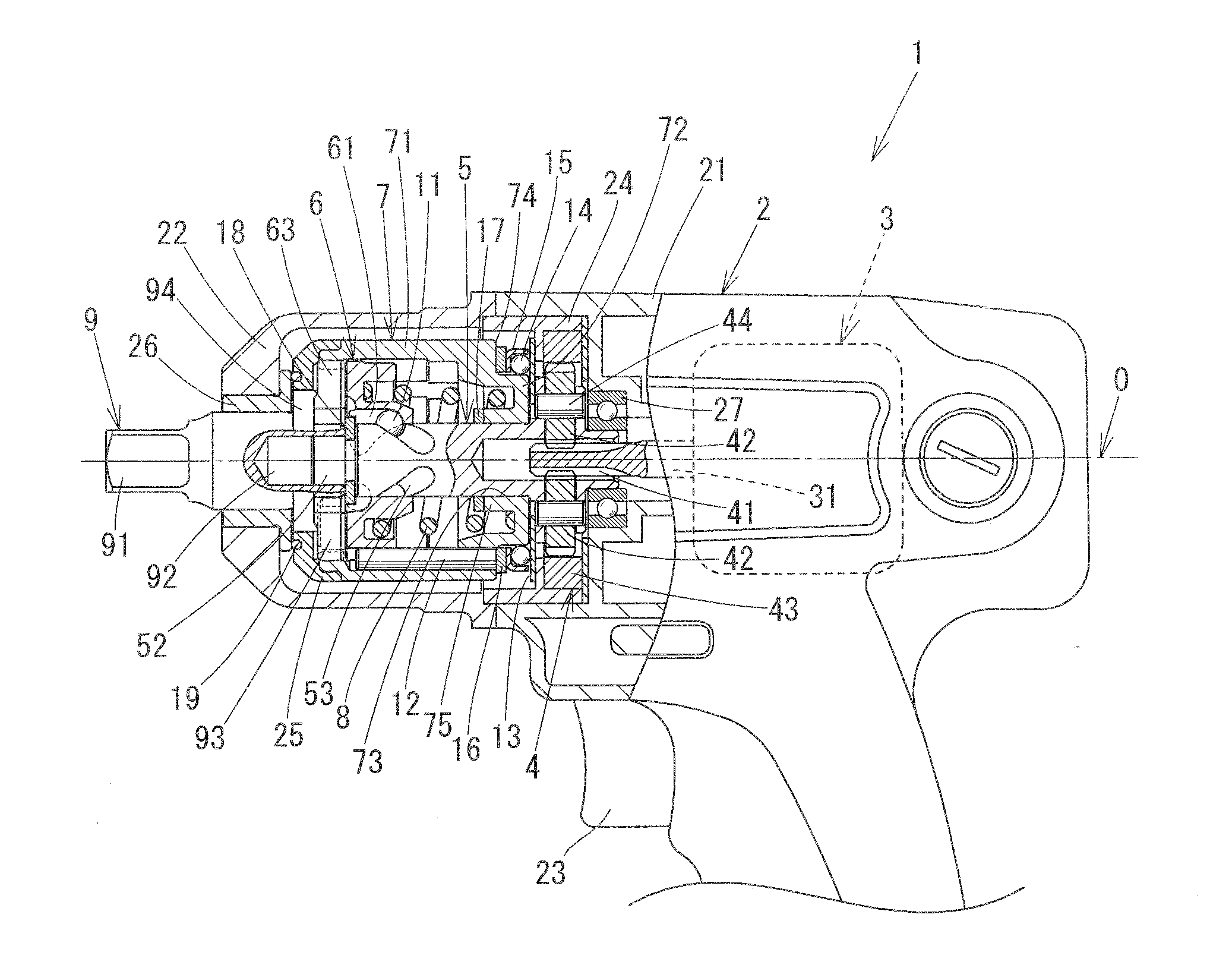

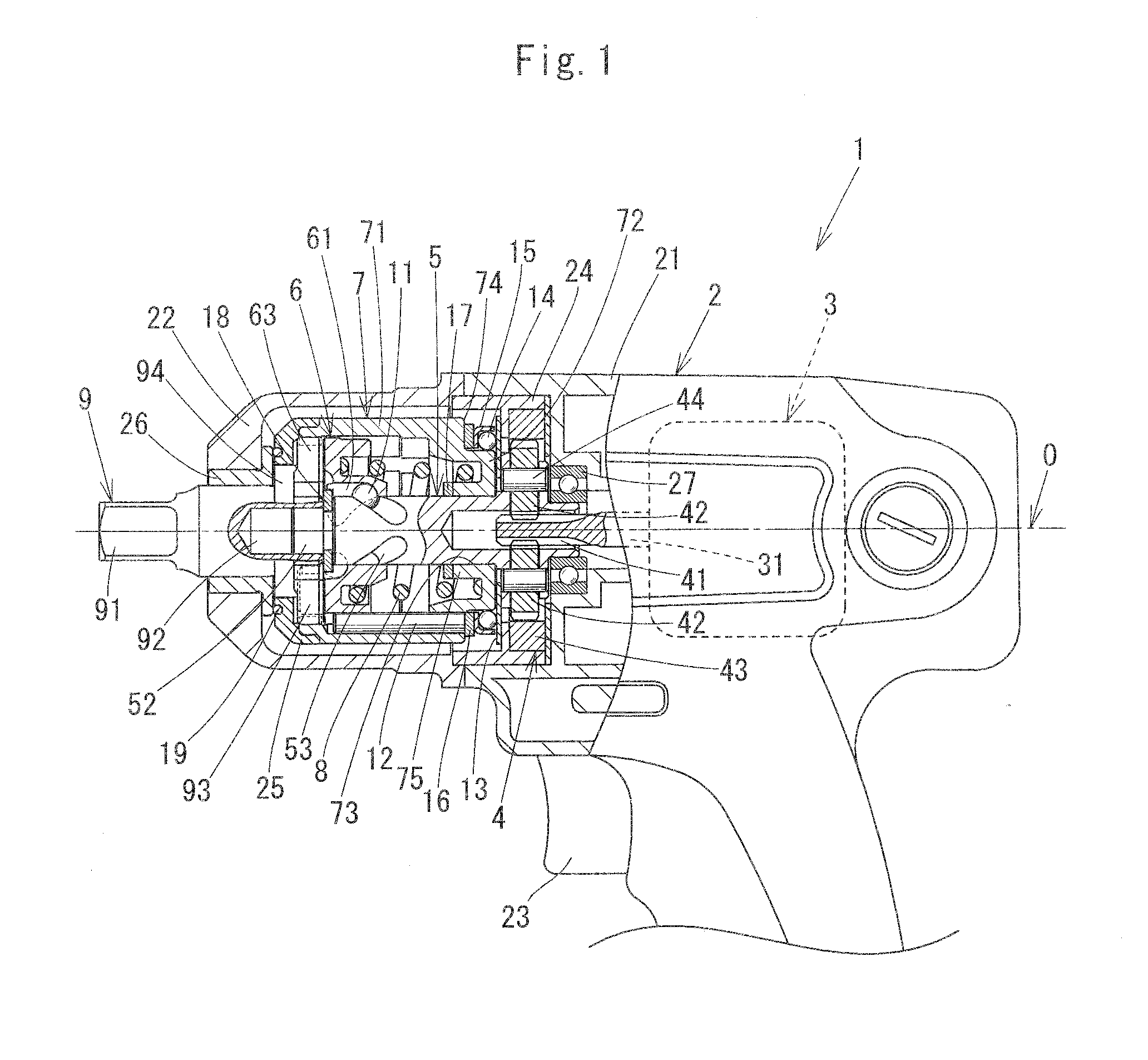

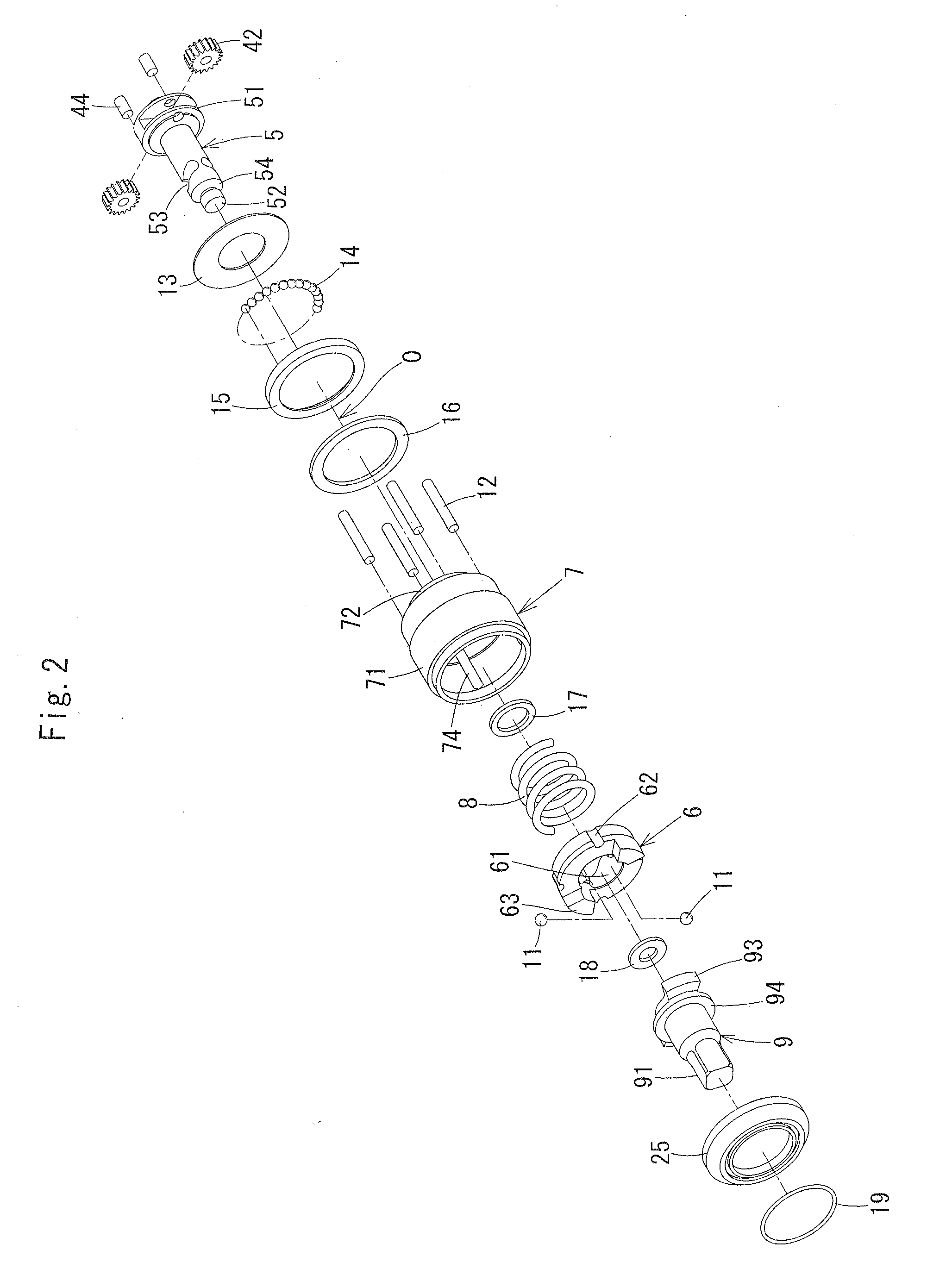

An impact wrench is provided that can mitigate vibrations in the axial direction without reducing the rotary impact force of hammers. The hammers are composed of a primary hammer (6) fitted to the outer circumference of a spindle (5) and a cylindrical secondary hammer (7) that is disposed so as to cover the primary hammer (6) and that rotates together with the primary hammer (6). Furthermore, the secondary hammer (7) is held by a axis holding means in a state in which the rotational axis of the secondary hammer (7) is coincident with the axis of the spindle (5) in order to prevent precession movement. With the use of the hammer configuration of the present invention, the mass of the primary hammer (6) can be decreased compared to that of the secondary hammer (7), and therefore it is possible to mitigate vibrations in the axial direction while maintaining the rotary impact force.

Owner:KUKEN CO LTD

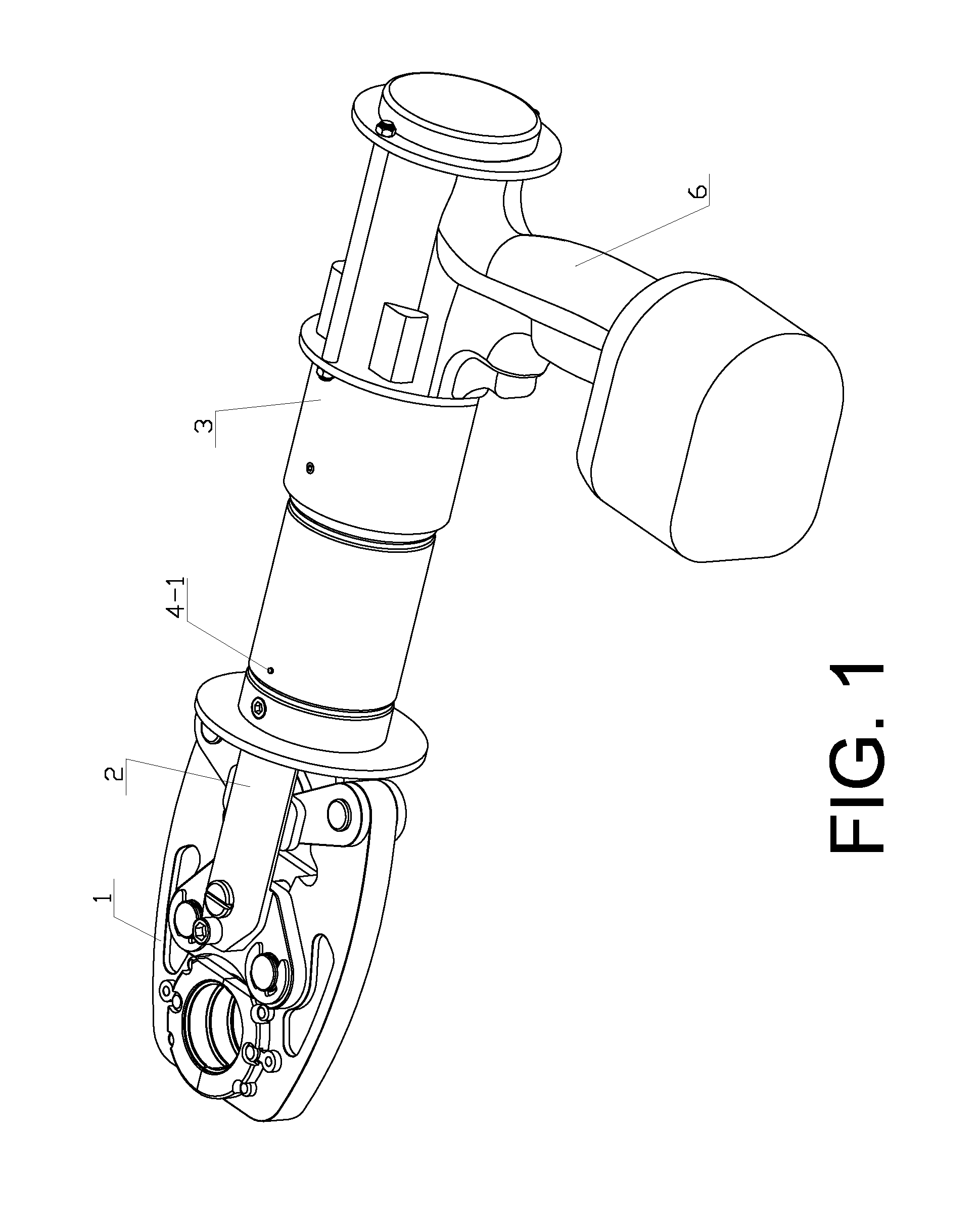

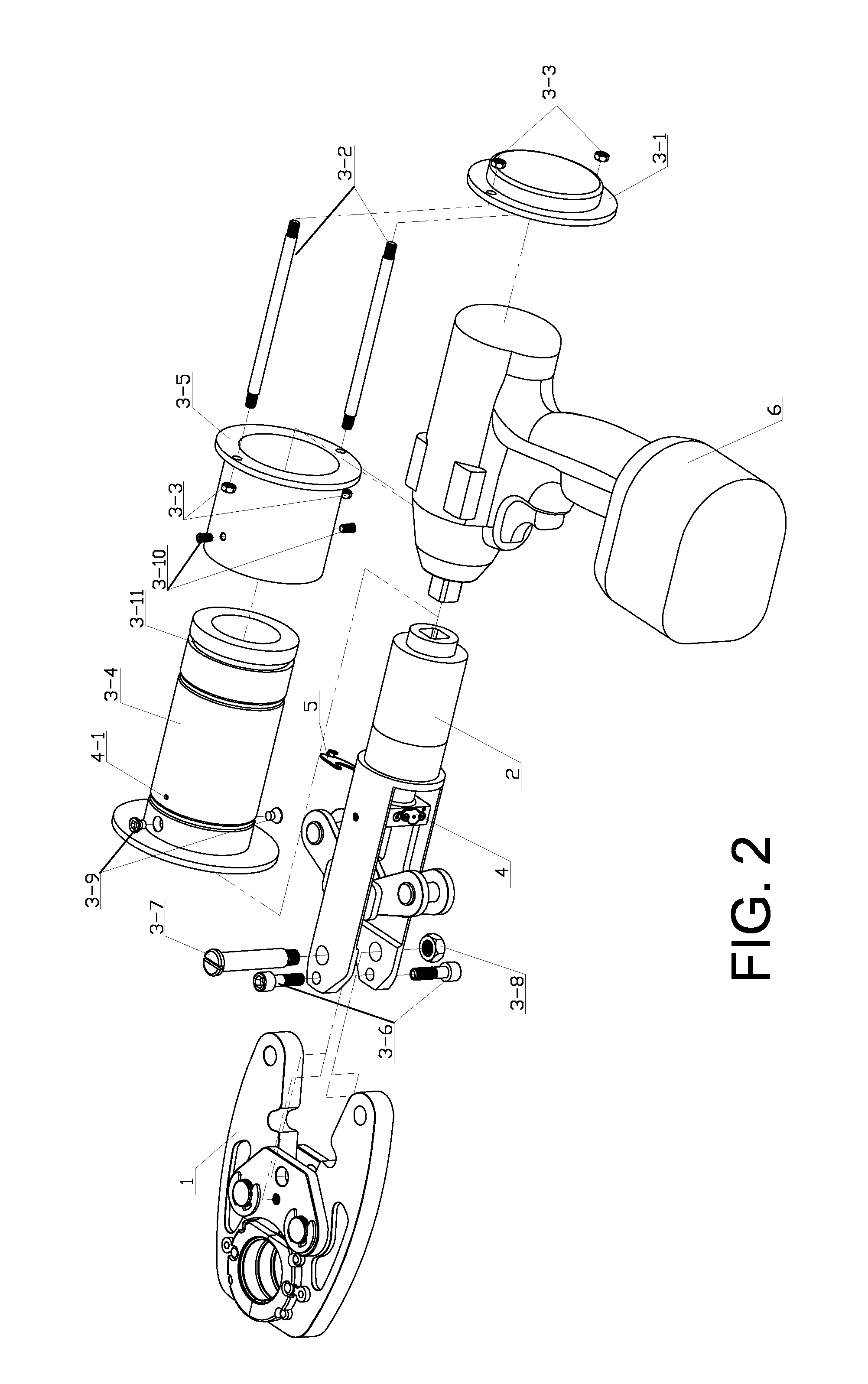

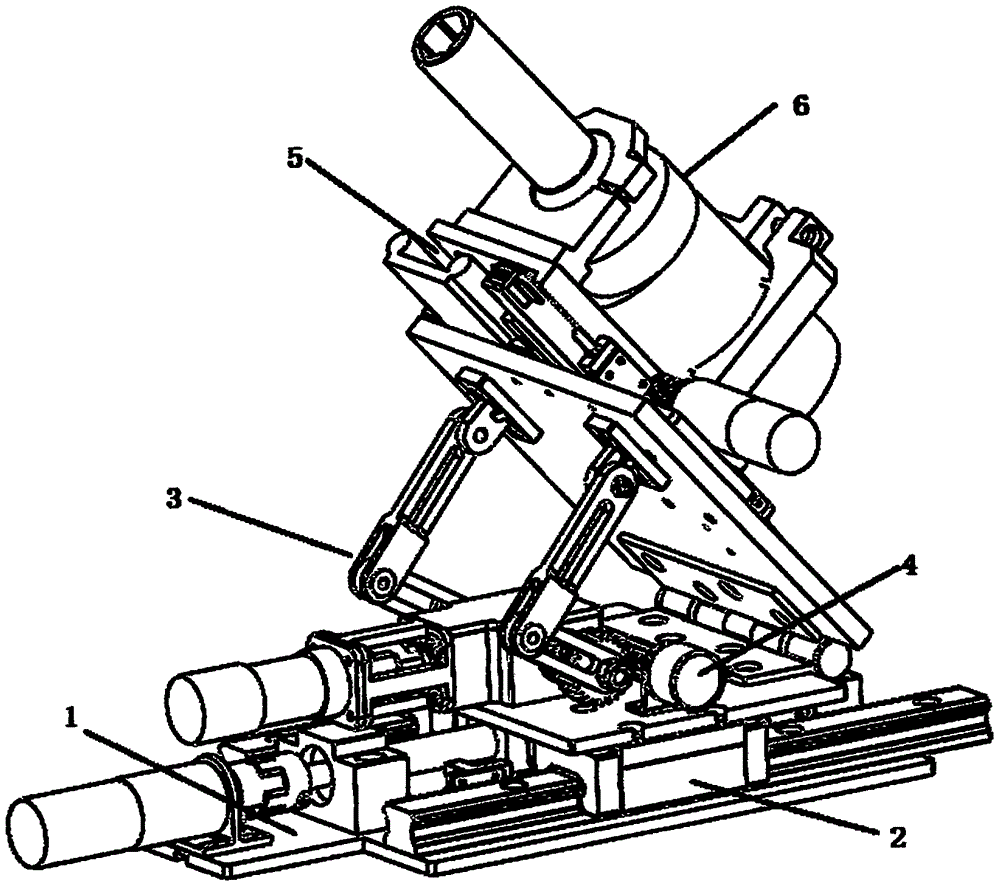

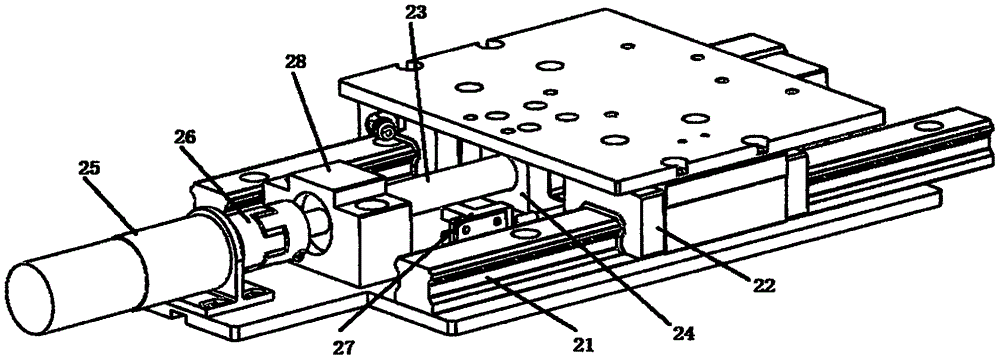

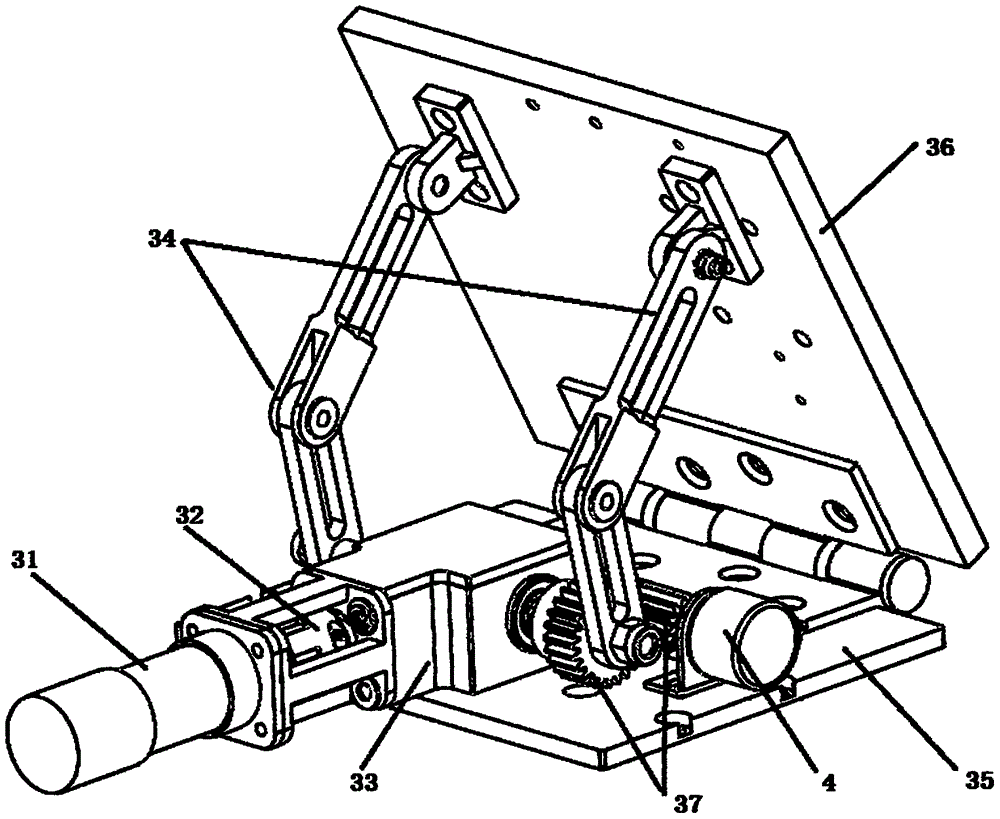

Execution mechanism of shakeproof hammer reset device for overhead lines

InactiveCN105896374AAdaptableReduce re-looseningPower driven toolsApparatus for overhead lines/cablesEngineeringDegrees of freedom

The invention provides an execution mechanism of a shakeproof hammer reset device for overhead lines. The execution mechanism comprises a mechanism bottom plate, a one-degree-of-freedom moving platform in a horizontal direction, a pitching adjustment mechanism, an impact wrench feeding mechanism, an impact wrench and a camera, wherein the mechanism bottom plate is taken as a support of the whole mechanism, the lower end of the mechanism bottom plate is connected with a shakeproof hammer reset device body, the moving platform comprises two parallel linear sliding rails and a sliding table, the types of the two parallel linear sliding rails are same, a lead screw driving part is arranged between the sliding rails and is used for achieving horizontal movement of the sliding table, the pitching adjustment mechanism comprises a 90-degree corner gear box and a pair of four-bar mechanisms, the pair of four-bar mechanisms are arranged at the two sides of the gear box, the gear box is used for transferring power from a motor in a vertical direction, the second degree of freedom is achieved through adjusting the angle of a workbench by the four-bar mechanisms, the impact wrench feeding mechanism comprises a one-degree-of-freedom sliding table, a gear rack transmission mechanism and a sensor, the third degree of freedom of the impact wrench is achieved through adjustment along a direction of a screwed bolt, the impact wrench and the camera are arranged at the tail end, and a shakeproof hammer bolt can be positioned and fastened through the reset device by the impact wrench. The execution mechanism is simple to abut and is high in reliability, manual operation can be substituted, and the execution mechanism is safe and reliable and is simple to operate.

Owner:BAICHENG POWER SUPPLY CO OF STATE GRID JILIN ELECTRIC POWER CO LTD +1

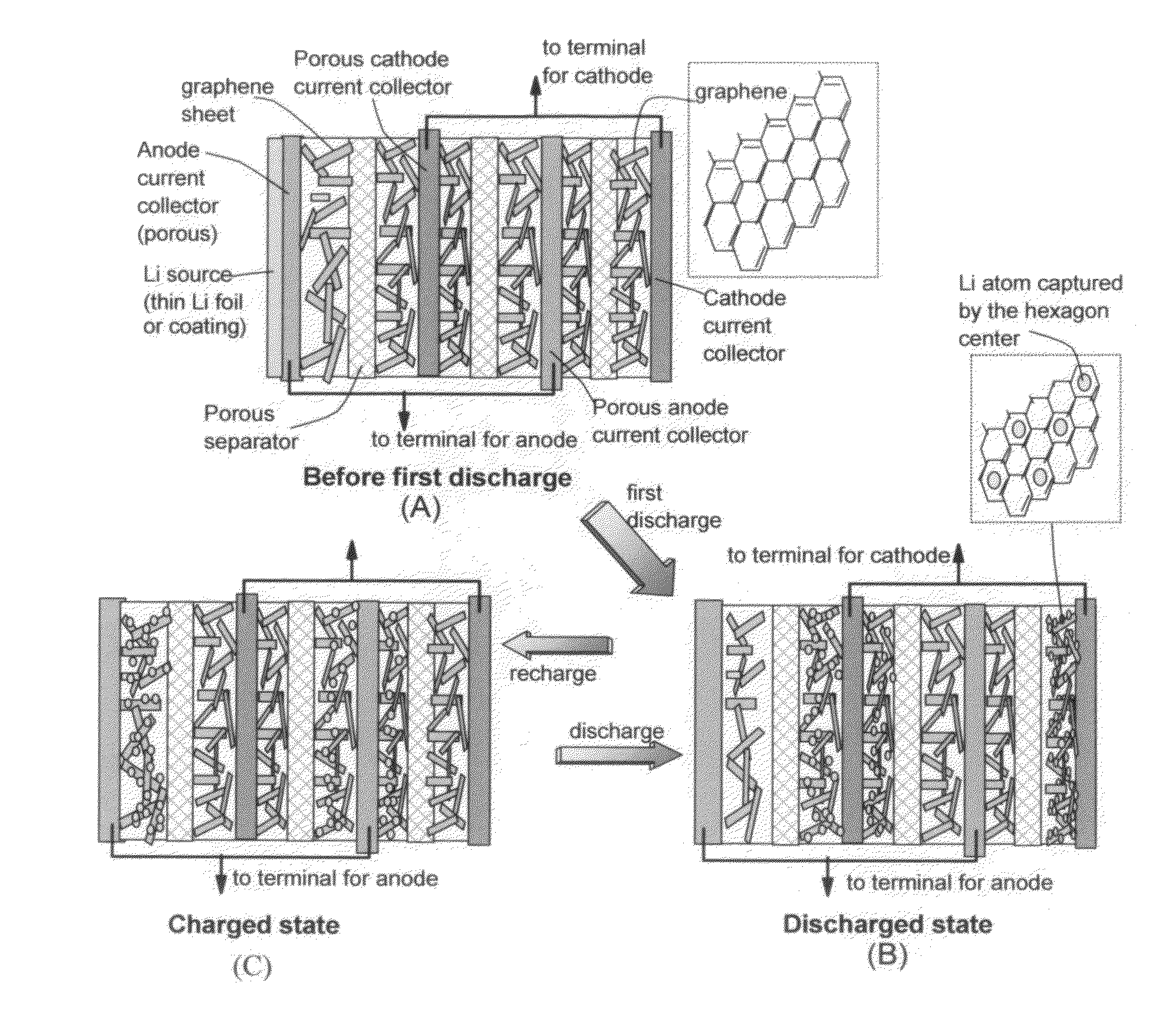

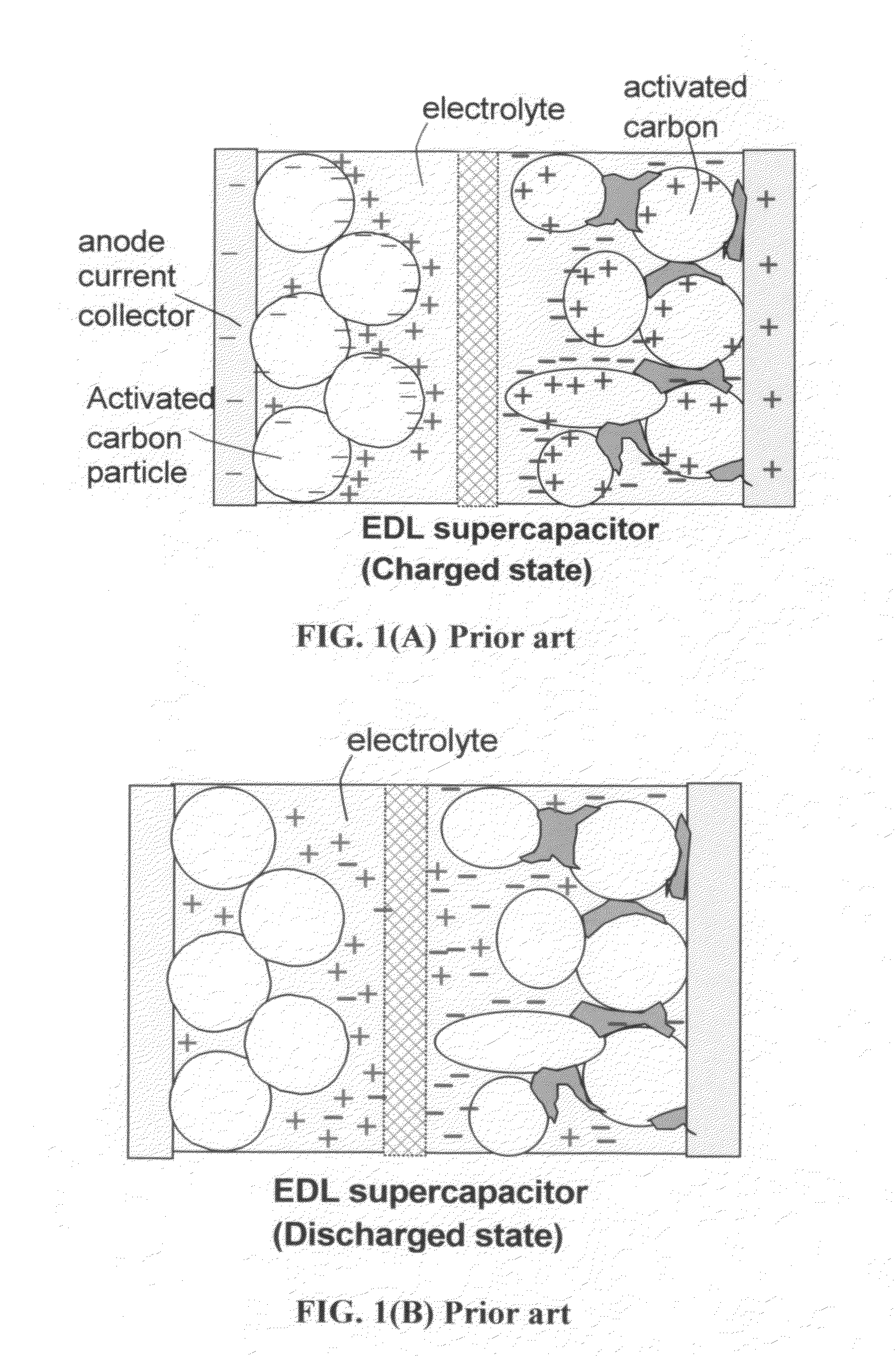

Surface-mediated cell-driven power tools and methods of operating same

ActiveUS20130213677A1Improve power densityEasy dischargeDrilling rodsCapacitor and primary/secondary cellsSanderAngle grinder

A portable power tool comprises an electric motor, actuator, or light-emitting hardware and a rechargeable power source connected to the electric motor, actuator, or light-emitting hardware, wherein the power source contains at least a surface-mediated cell (SMC). The power tools include, but are not limited to, impact driver, air compressor, alligator shear, angle grinder, band saw, belt sander, biscuit joiner, ceramic tile cutter tile saw, chainsaw, circular saw, concrete saw, cold saw, crusher, diamond blade, diamond tools, disc sander, drill, floor sander, grinding machine, heat gun, impact wrench, jackhammer, jointer, jigsaw, lathe, miter saw, nail gun, needle scaler, torque wrench, powder-actuated tools, power wrench, radial arm saw, random orbital sander, reciprocating saw, rotary reciprocating saw, rotary tool, sabre saw, sander, scroll saw, steel cut off saw, table saw, thickness planer, trimmer, wall chaser, wood router, or flashlight.

Owner:GLOBAL GRAPHENE GRP INC +1

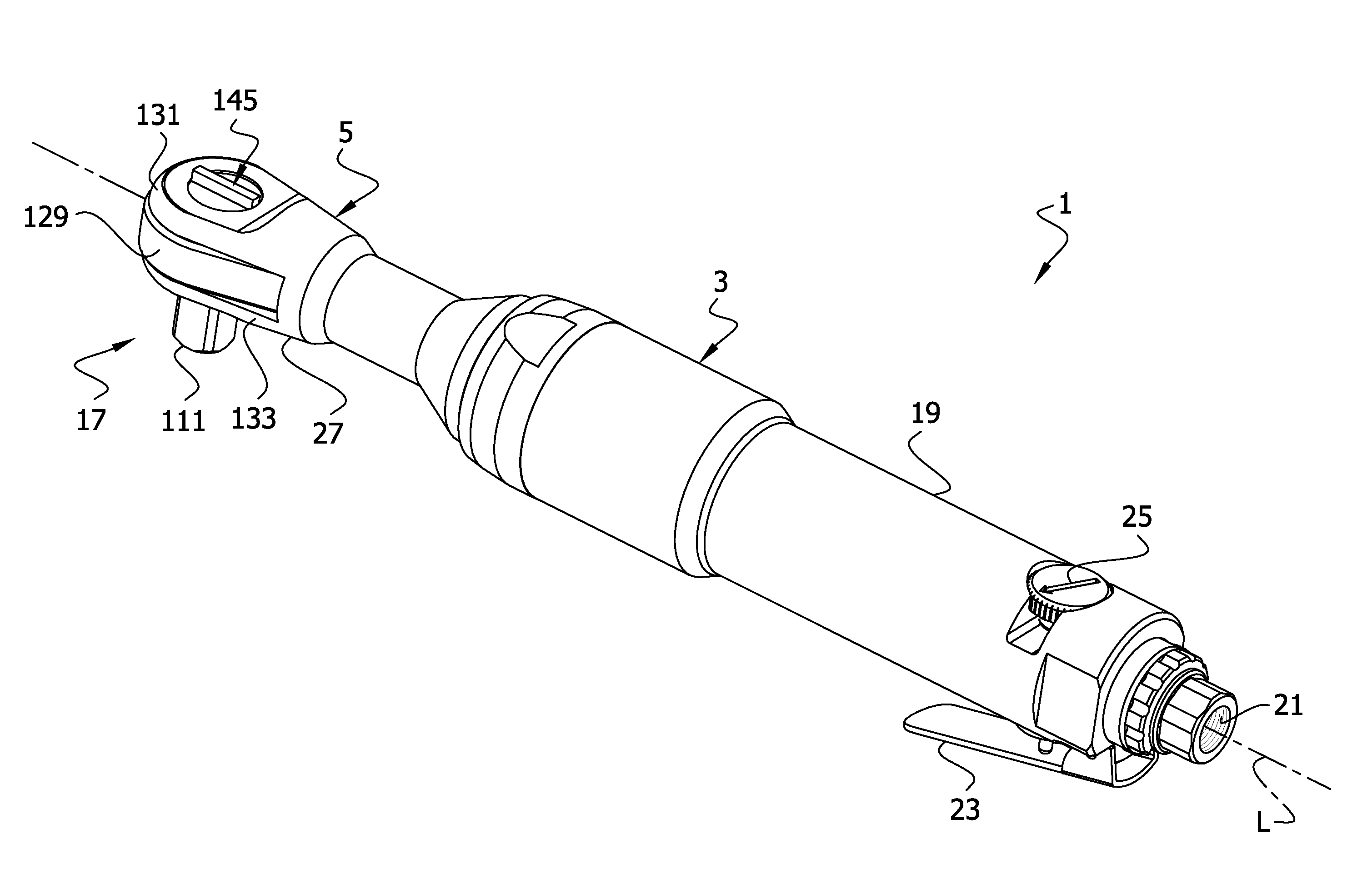

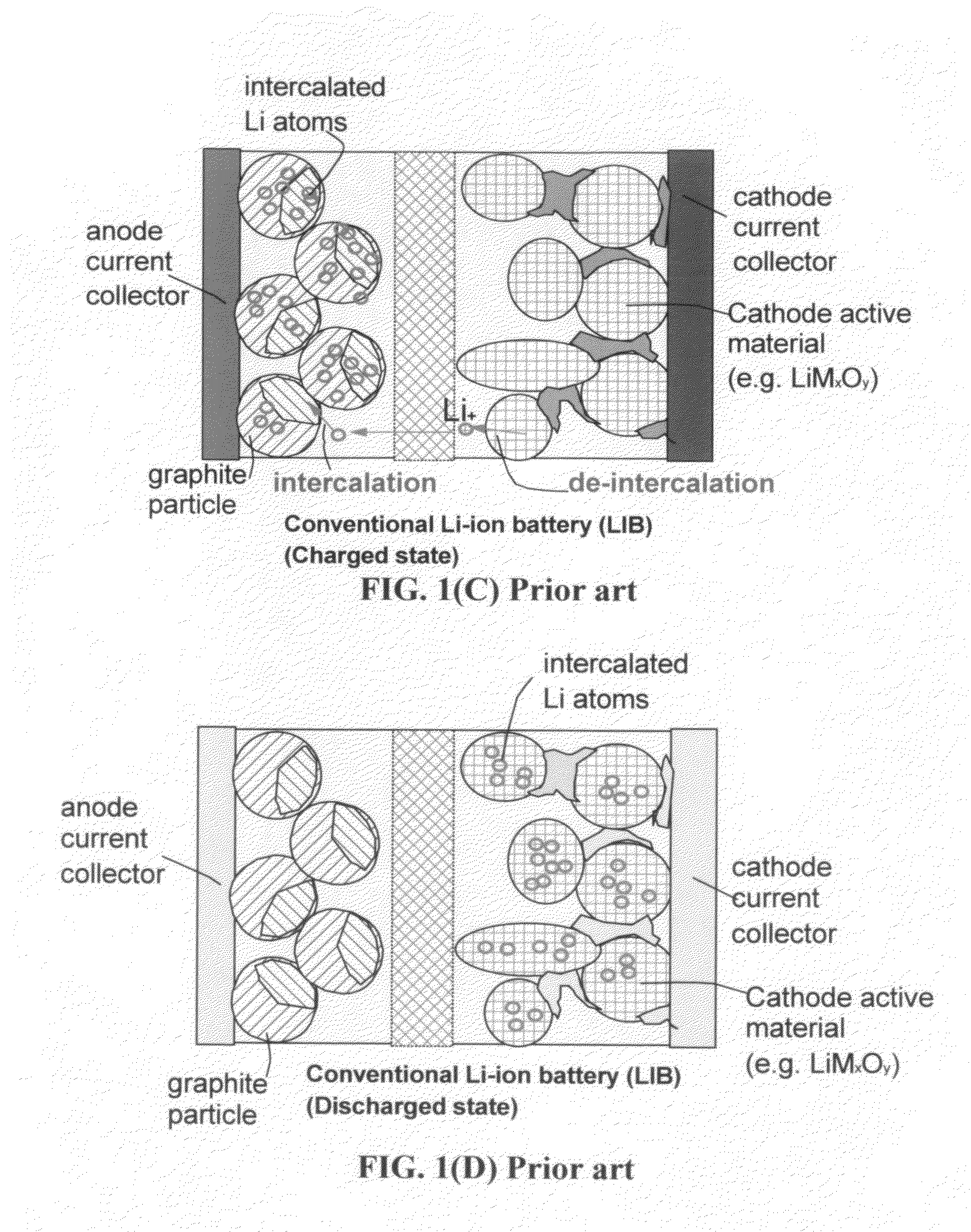

Impact wrench with improved redirection switch

InactiveUS20120325510A1Easy to operateSmooth functionConstructionsReciprocating drilling machinesRotational axisEngineering

An impact wrench with an improved redirection switch includes a housing, a motor shell, an on / off bar set, and a redirection switch. The pushing bar of the redirection switch and the redirection valve are connected in tandem along the same horizontal line. The rotational axis of the rotating redirection valve is perpendicular to the penetrating axis of the on / off bar set, instead of the same penetrating axis line. Therefore, the invention achieves the redirection effect without increasing the volume of its handle.

Owner:STORM PNEUMATIC TOOL CO LTD

Impact wrench

ActiveUS20120073845A1Increase the lengthQuality improvementPower driven toolsRotational axisImpact wrench

An impact wrench is provided that can mitigate vibrations in the axial direction without reducing the rotary impact force of hammers. The hammers are composed of a primary hammer fitted to the outer circumference of a spindle and a cylindrical secondary hammer that is disposed so as to cover the primary hammer and that rotates integrally with the primary hammer. Furthermore, the secondary hammer is held by a center holding means in a state in which the rotational axis of the secondary hammer is coincident with the axis of the spindle in order to prevent run-out movement. With the use of the hammer configuration of the present invention, the mass of the primary hammer can be decreased compared to that of the secondary hammer, and therefore it is possible to mitigate vibrations in the axial direction while maintaining the rotary impact force.

Owner:KUKEN

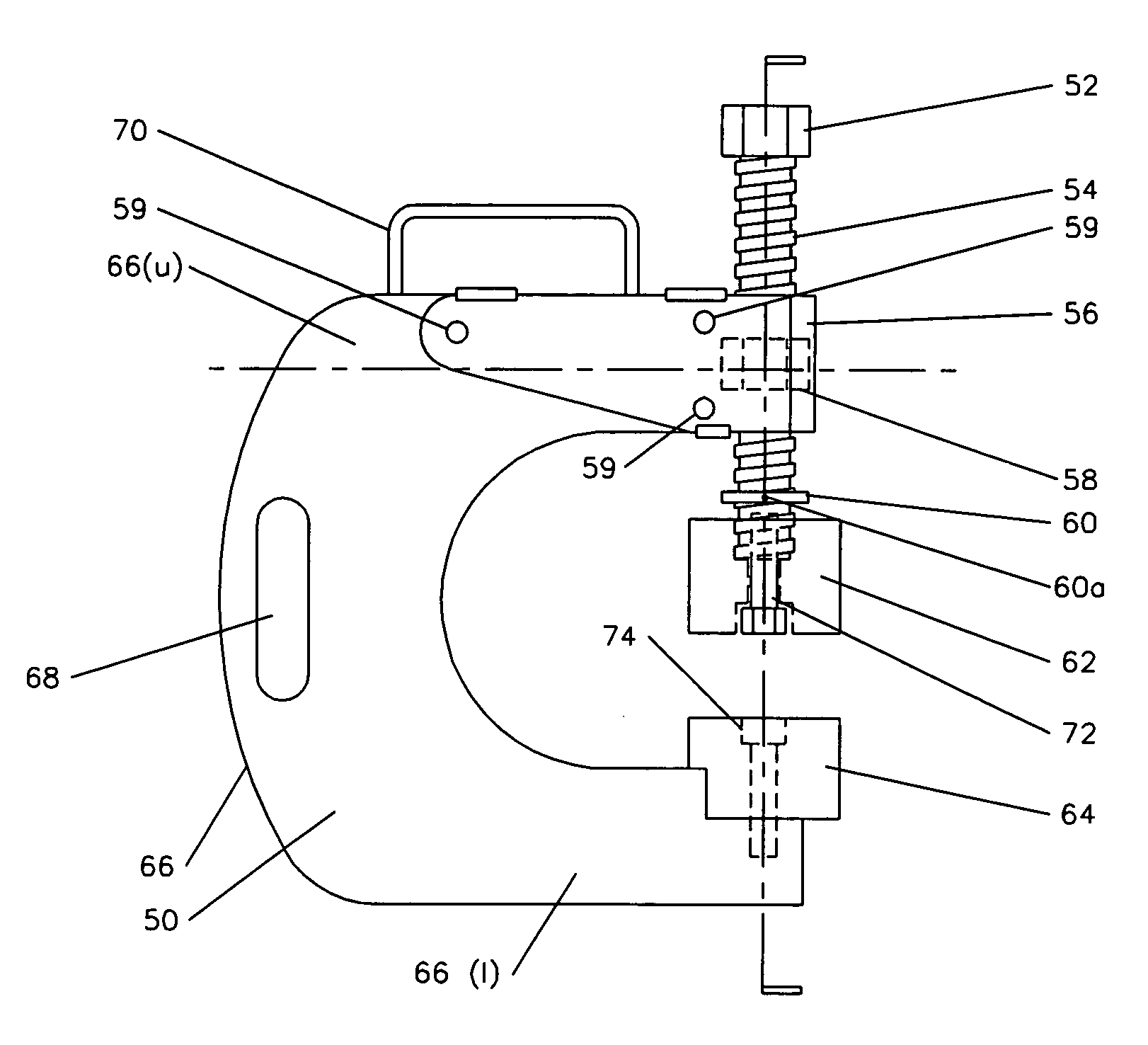

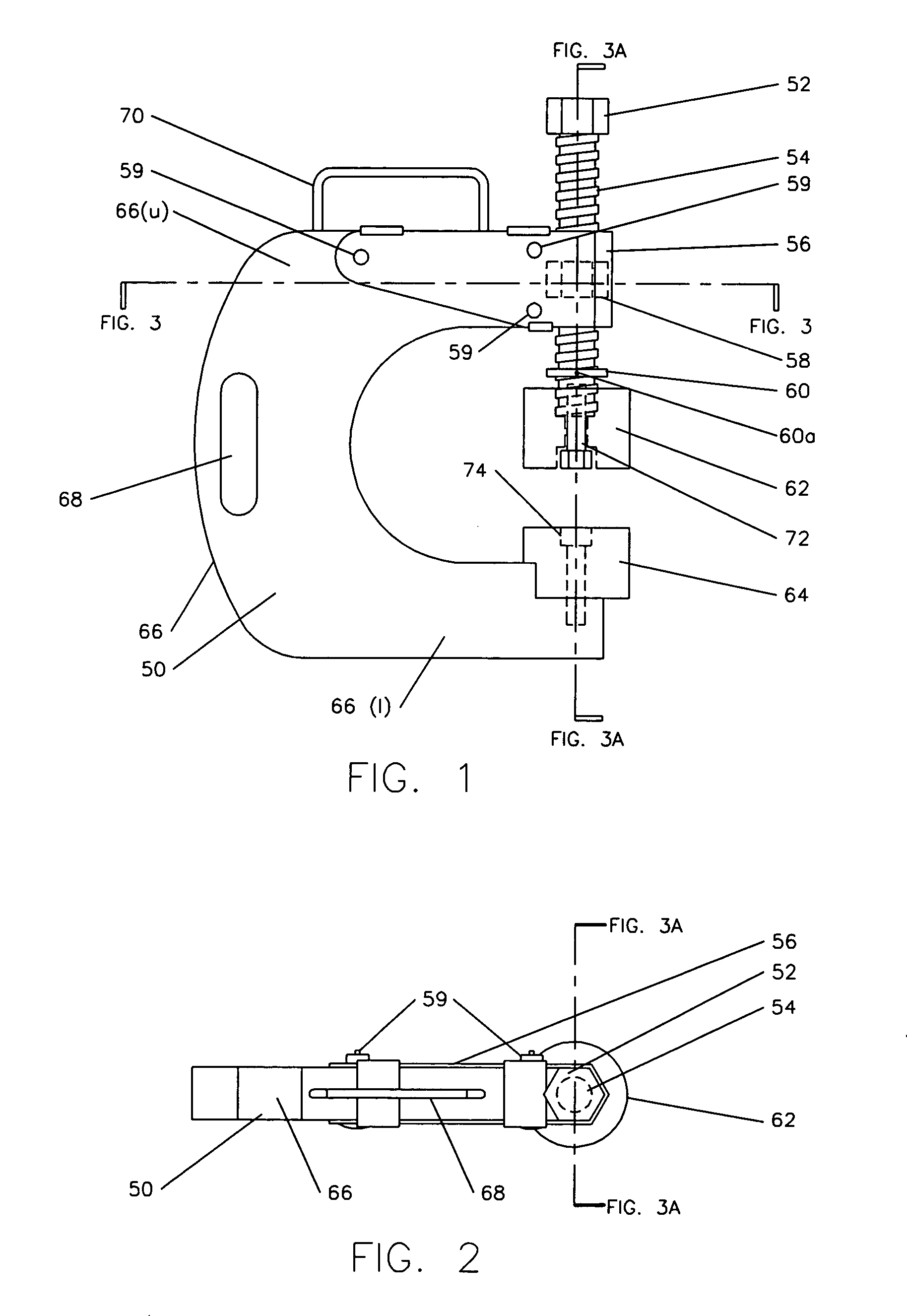

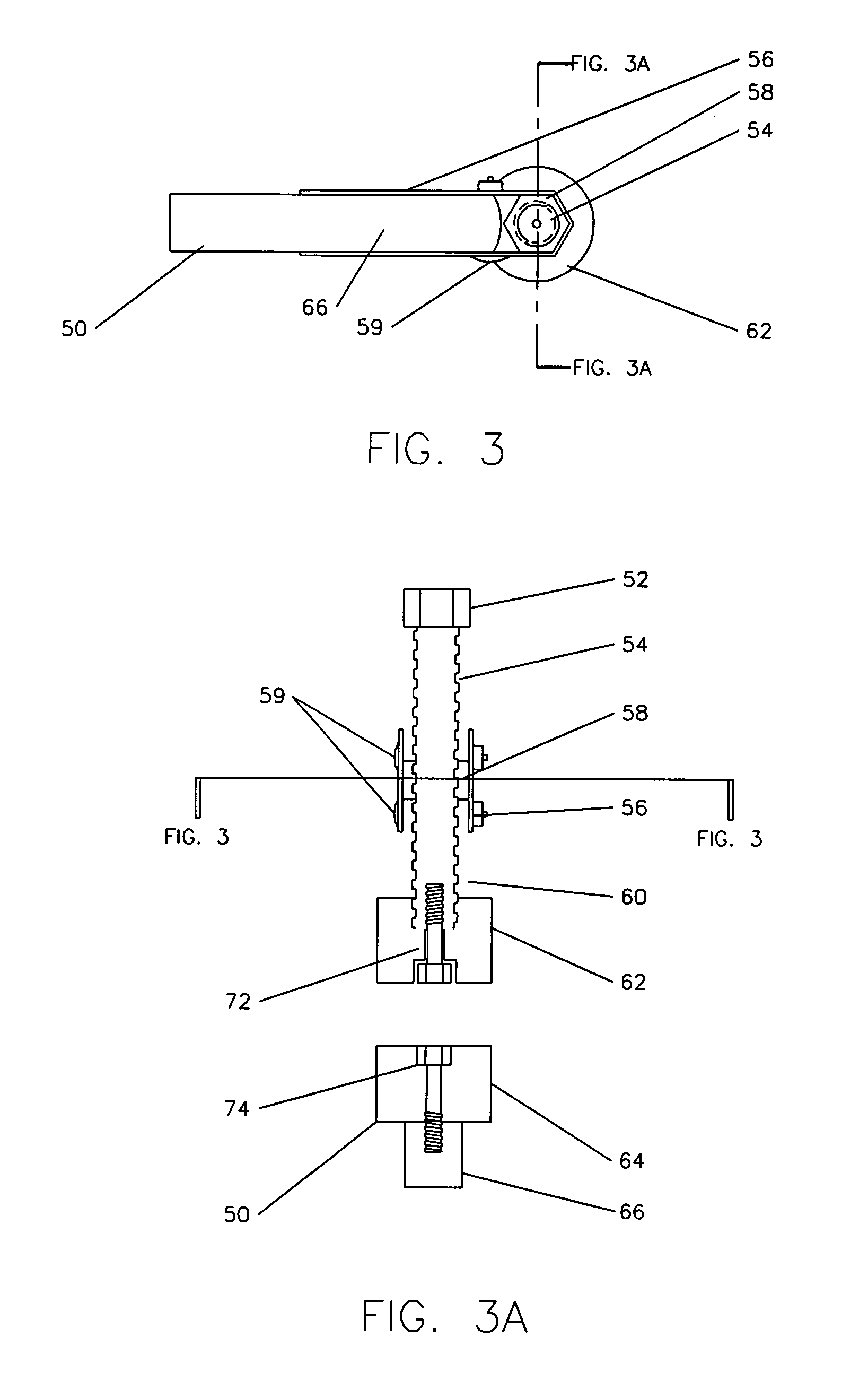

Threaded-rod-driven, mechanically-actuated, portable, truss press

A threaded-rod-driven, mechanically-actuated, portable truss press for repairing truss joints has a c-clamp body with a yoke, and upper and lower arms. A drive rod travel housing with an internally-threaded opening is attached to the upper arm of the c-clamp body. A threaded drive rod with a drive nut attached to the upper end transverses the travel housing. An upper platen is attached to the lower end of the drive rod. A lower platen is attached to the lower arm of the c-clamp body. The drive rod is mechanically actuated using either a pneumatic, electric, or battery-powered impact wrench with a properly-sized socket attached. When the drive rod is actuated in a clock-wise direction the upper platen moves towards the lower platen with sufficient force to compress the teeth of metal connector plates into the wooden members of a truss joint placed between the platens.

Owner:FORTUSS BUILDERS SUPPLY

Hydraulically Operated Tool Including A Bypass Assembly

Owner:GREENLEE TEXTRON

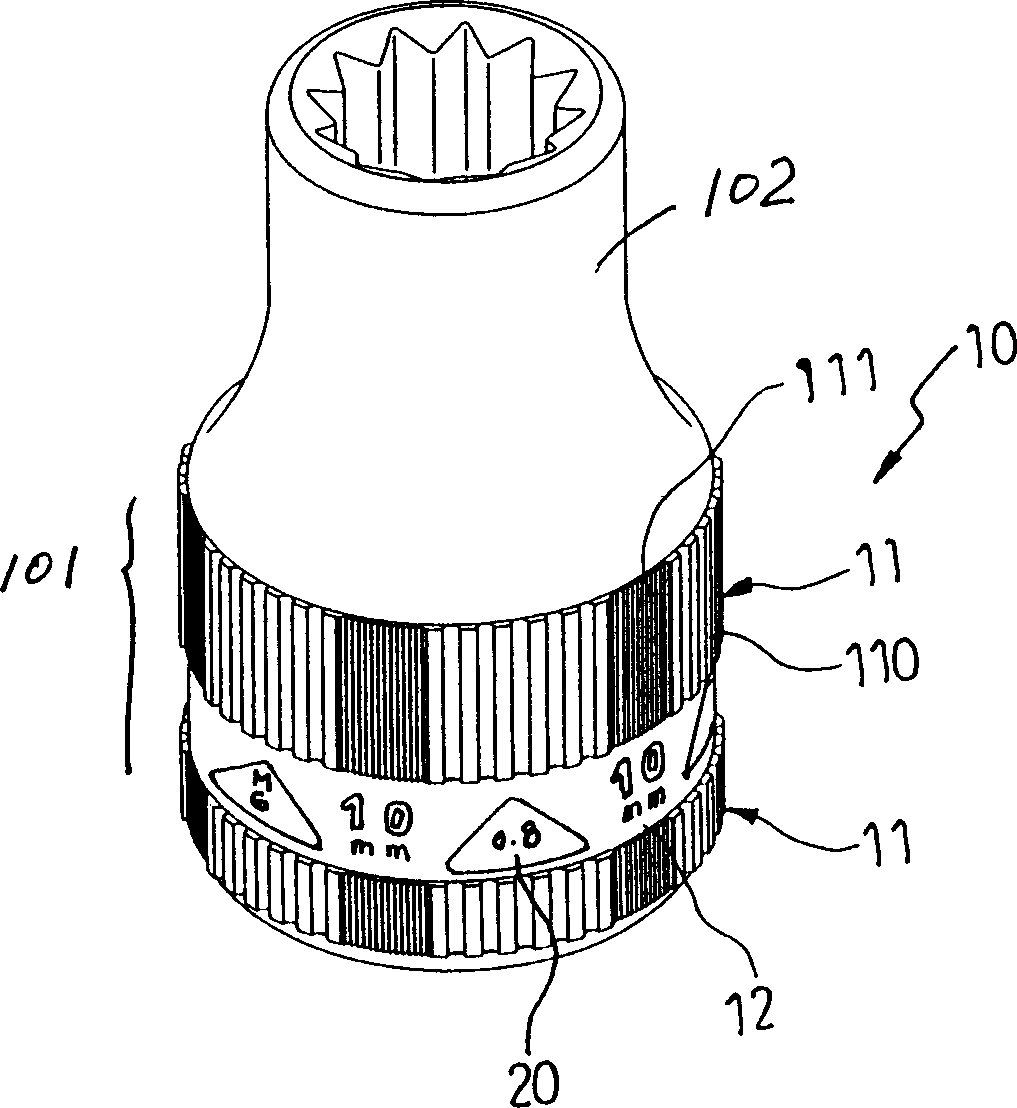

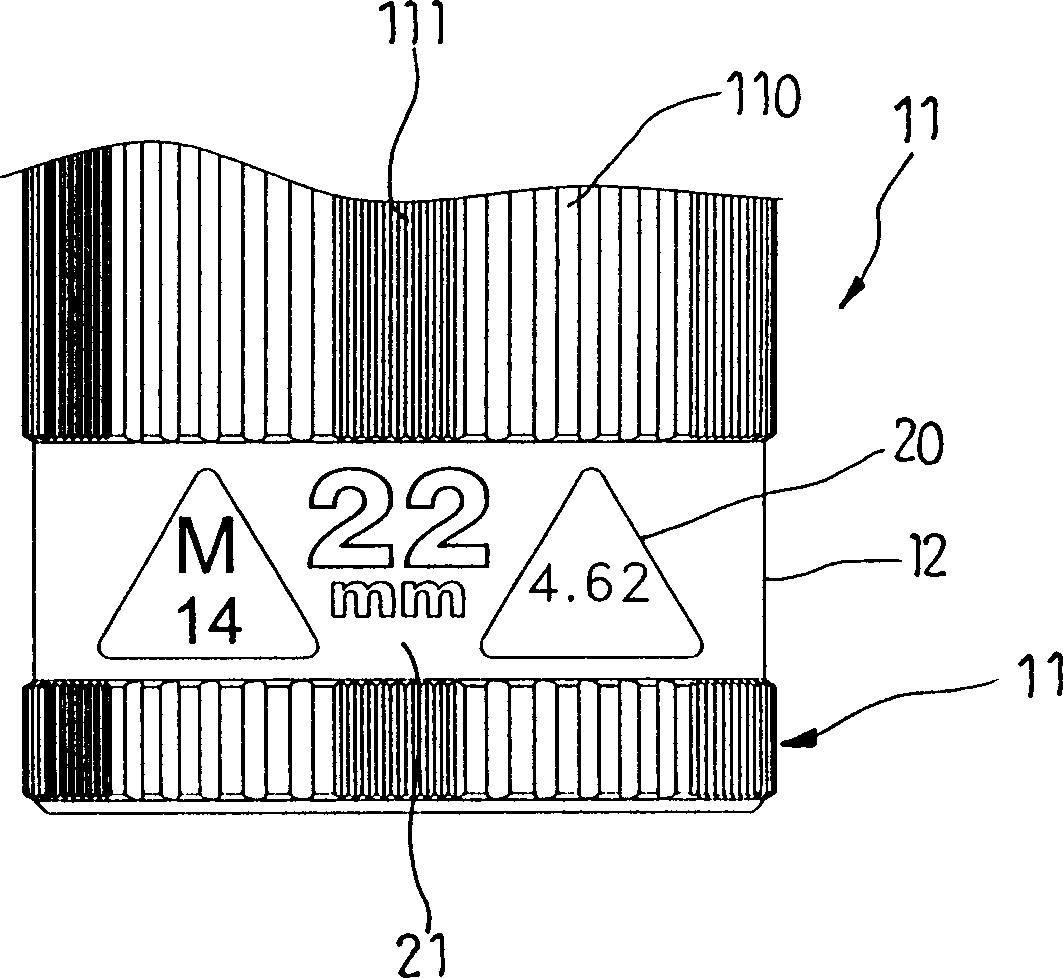

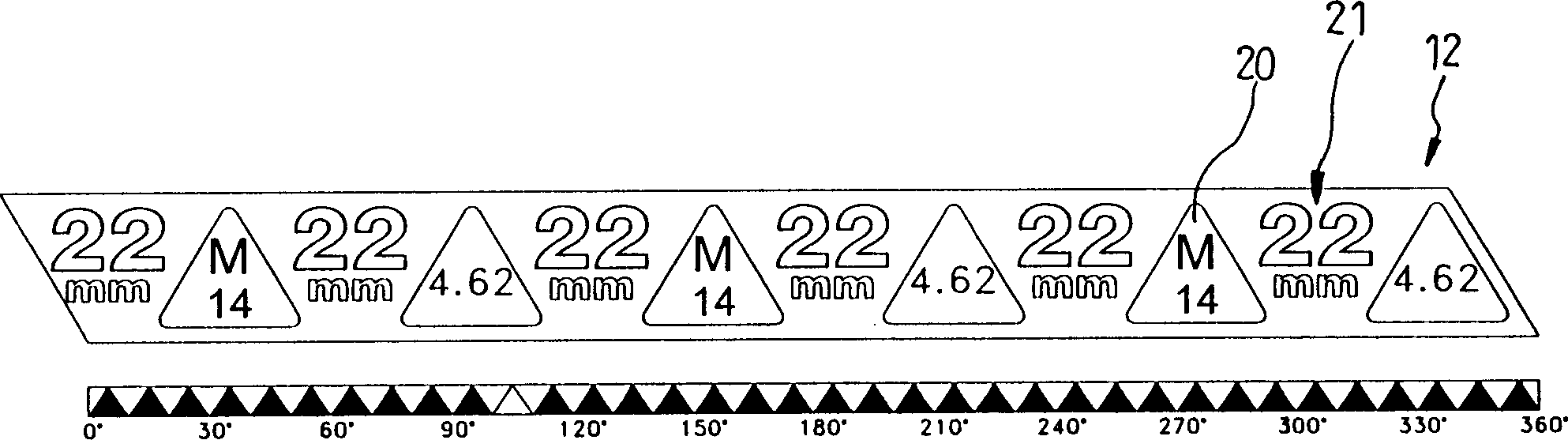

Impact wrench and method for making same

A socket wrench has an isometric body, whose cylindrical surface has a drive unit divided into two parts and a marker part between two parts of drive unit. In the drive unit the dense teeth and sparse teeth segments are alternative.

Owner:张 珍财

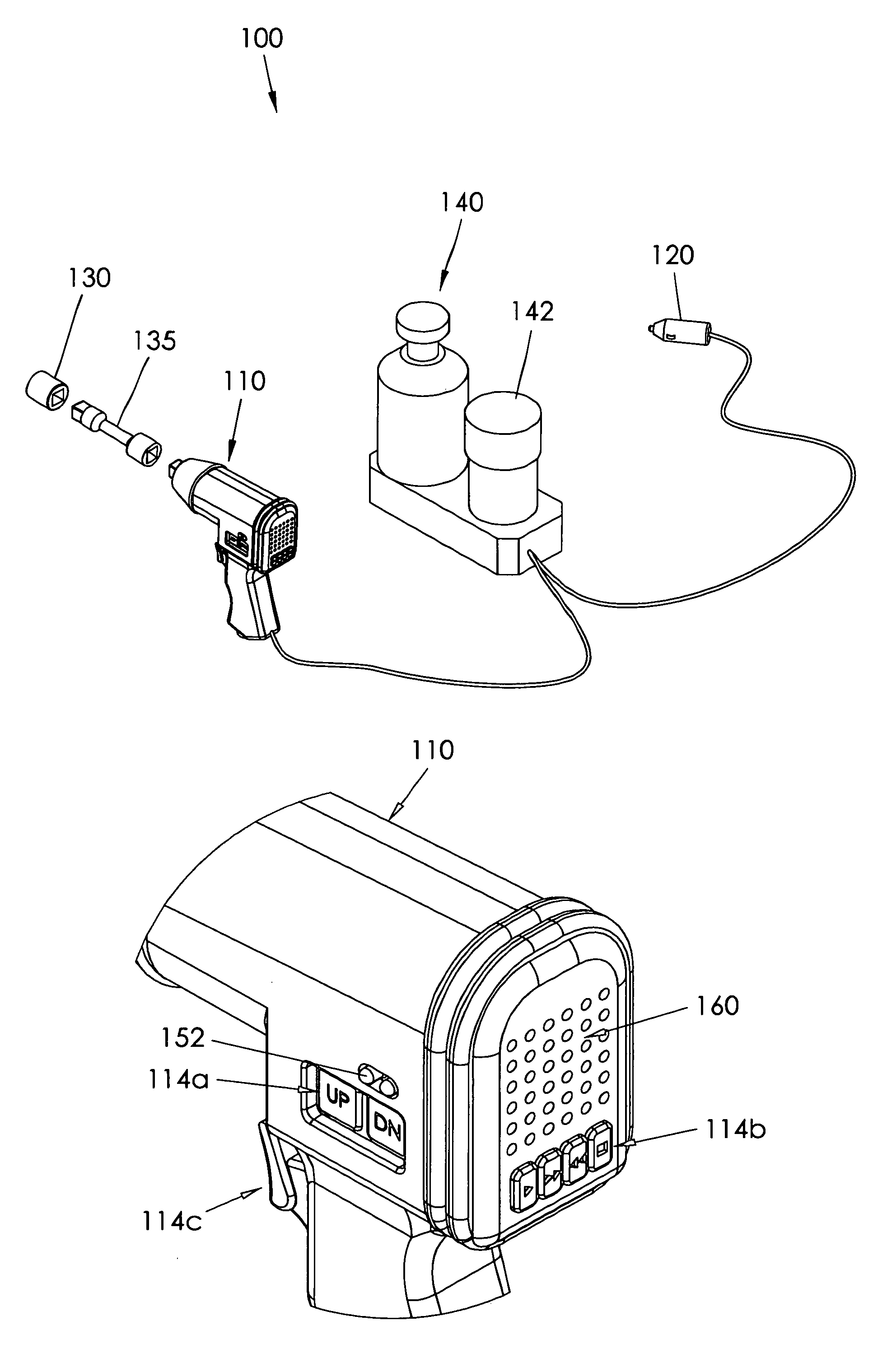

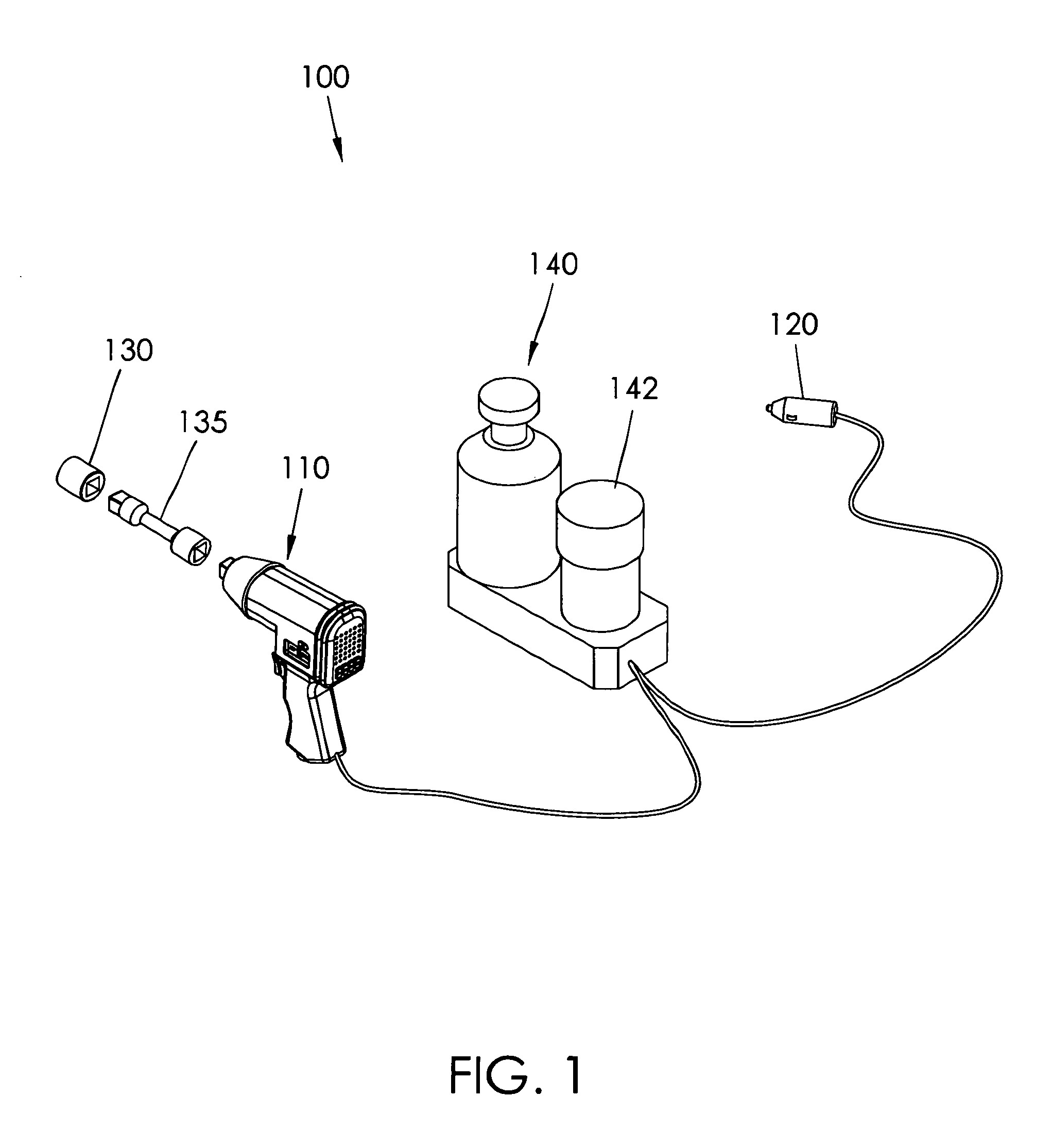

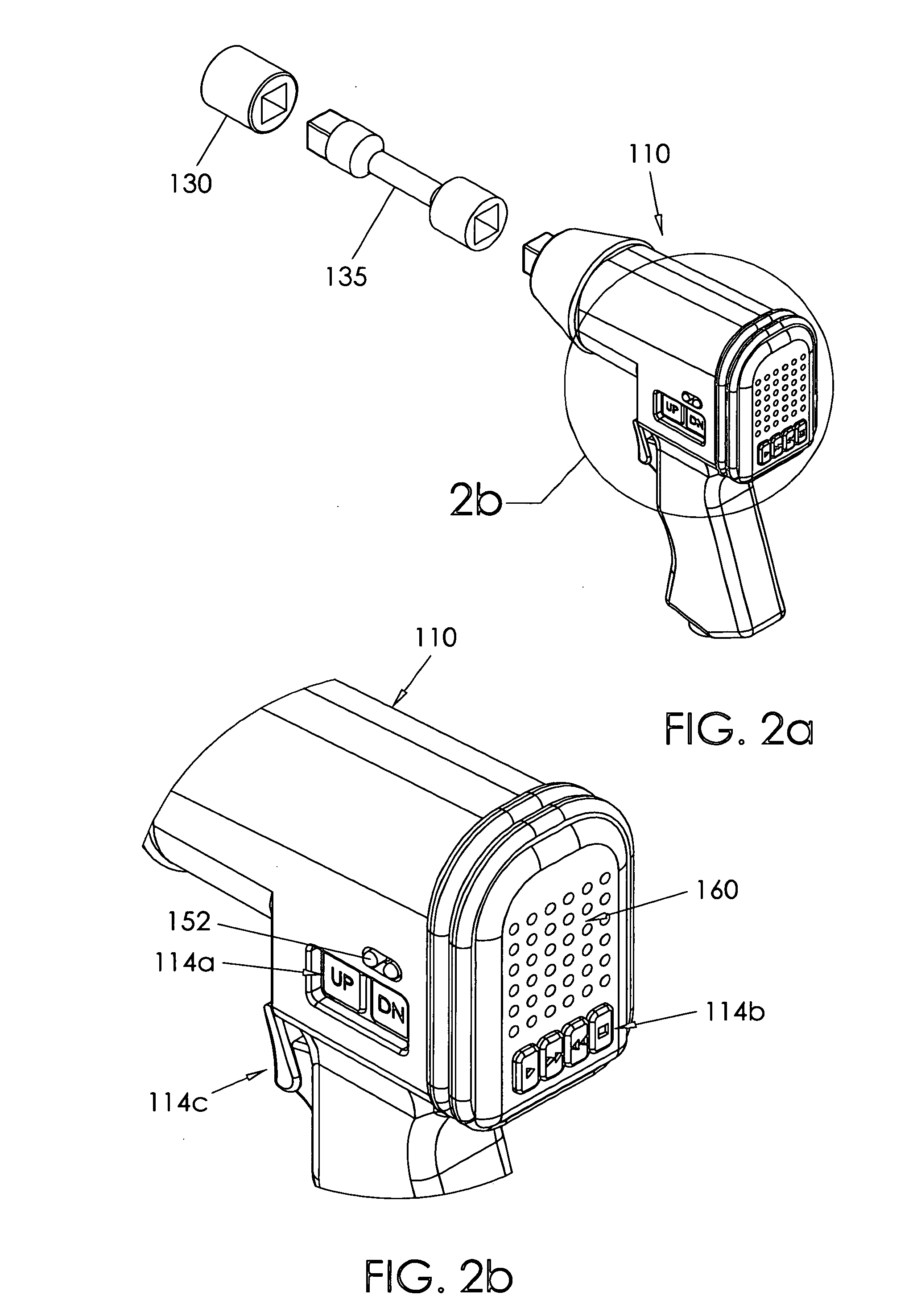

Tire changing kit

A tire changing kit includes a jack movable between lowered and raised configurations and an impact wrench. An electrical plug is configured for electrical communication with an automobile battery through an automobile outlet, the electrical plug being in electrical communication with the impact wrench for powering the impact wrench. The kit includes at least one socket configured to be rotated by the impact wrench for turning a lug nut. The impact wrench includes a processor, an electrical memory device in data communication with the processor, audio data relating to instructions for changing a tire, the audio data being stored in the memory device, a user input device in data communication with the processor, and programming in the processor actuate the jack and to cause the audio data to be provided to an audio speaker upon receiving certain audio instructions from the user input device.

Owner:MOORE DION D

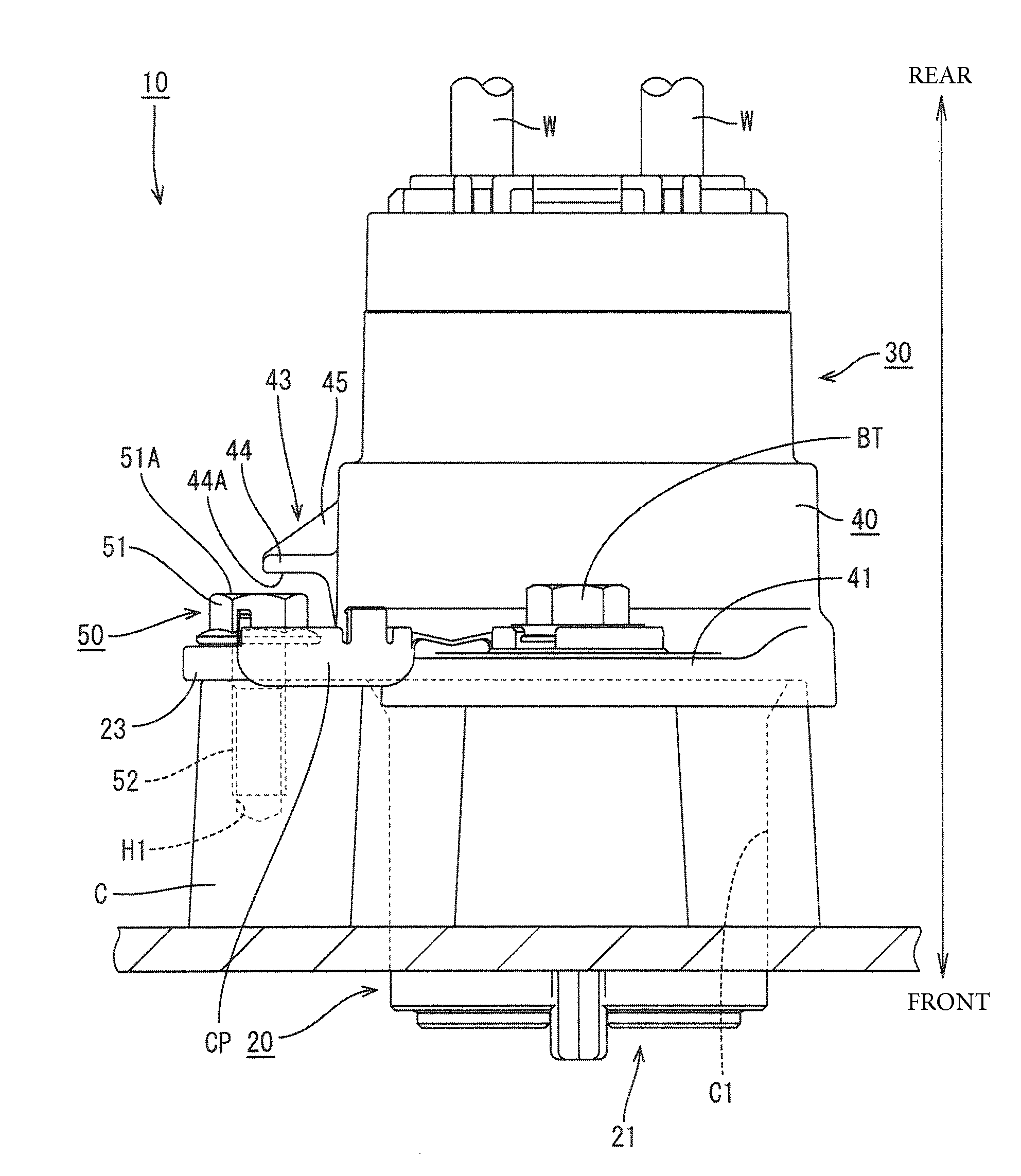

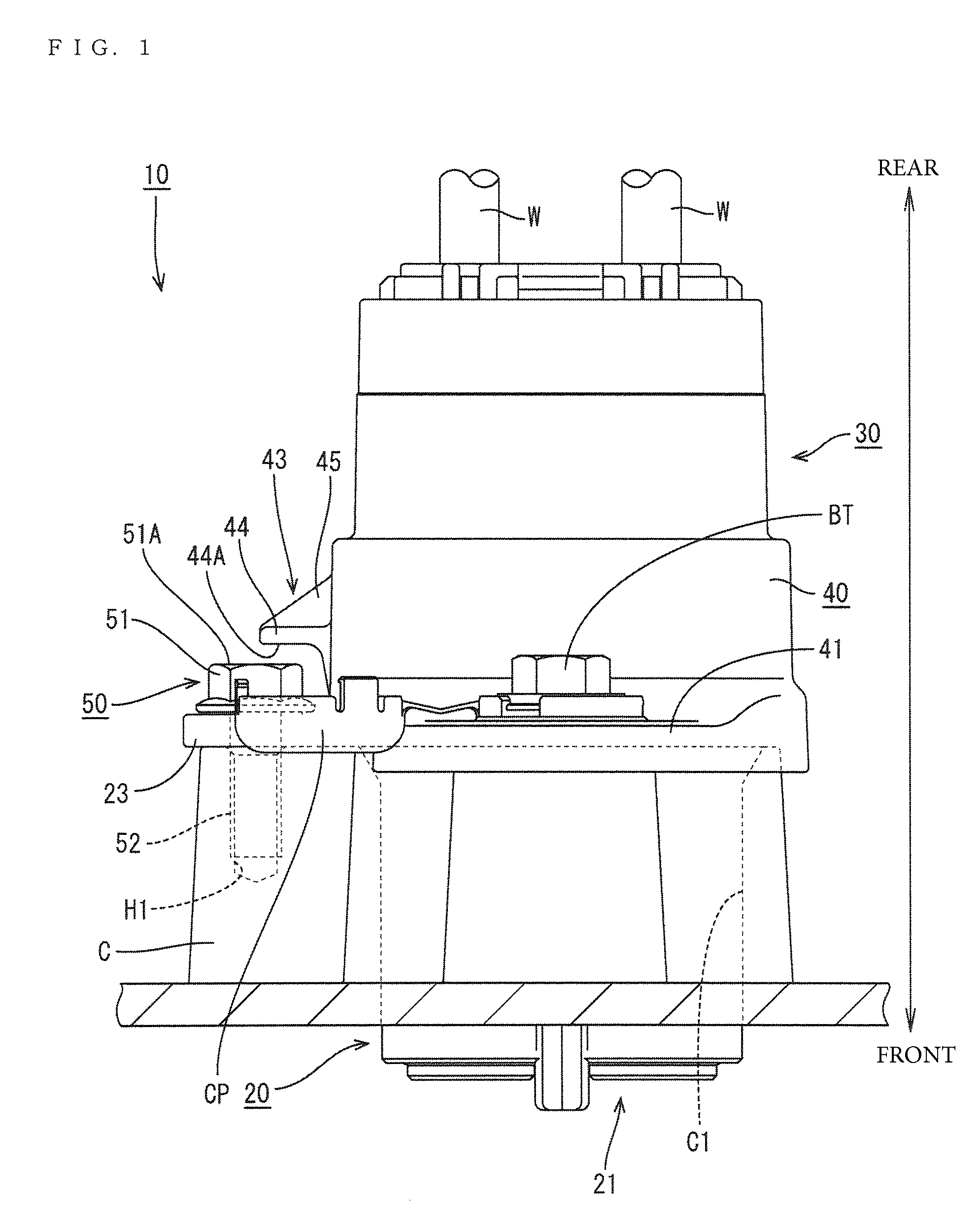

Device connector

ActiveUS20140127939A1High strengthSubstation/switching arrangement detailsCoupling parts mountingEngineeringImpact wrench

A device connector to be mounted and fixed to a case of a device includes a case-side connector to be fixed to the case by fitting a tool such as an impact wrench to a bolt head provided on a fixing bolt and tightening the fixing bolt into the case, a mating connector to be connected to the case-side connector and fixed to the case by tightening a connecting bolt into the case with the mating connector mounted on the case-side connector, and an access prohibiting portion provided on the mating connector and configured to prohibit the tool from being fitted to the bolt head by being arranged in proximity to the bolt head of the fixing bolt when the mating connector is mounted on the case-side connector.

Owner:SUMITOMO WIRING SYST LTD

Impact wrench having an improved anvil to square driver transition

An anvil adapted to be received within an impact wrench comprises a round body and a square head. The square head is formed at an end of the round body. A tapered ramp extends from the round body to the square head. A radius is formed in the tapered ramp. The radius is defined by a removal of material in the tapered ramp.

Owner:BLACK & DECKER INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com