Impact wrench

一种冲击扳手、主轴的技术,应用在冲击扳手领域,能够解决减弱锤子旋转冲击力、阻碍主锤顺畅移动、未设置保持副锤旋转轴线等问题,达到增大惯性矩、强旋转冲击力的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

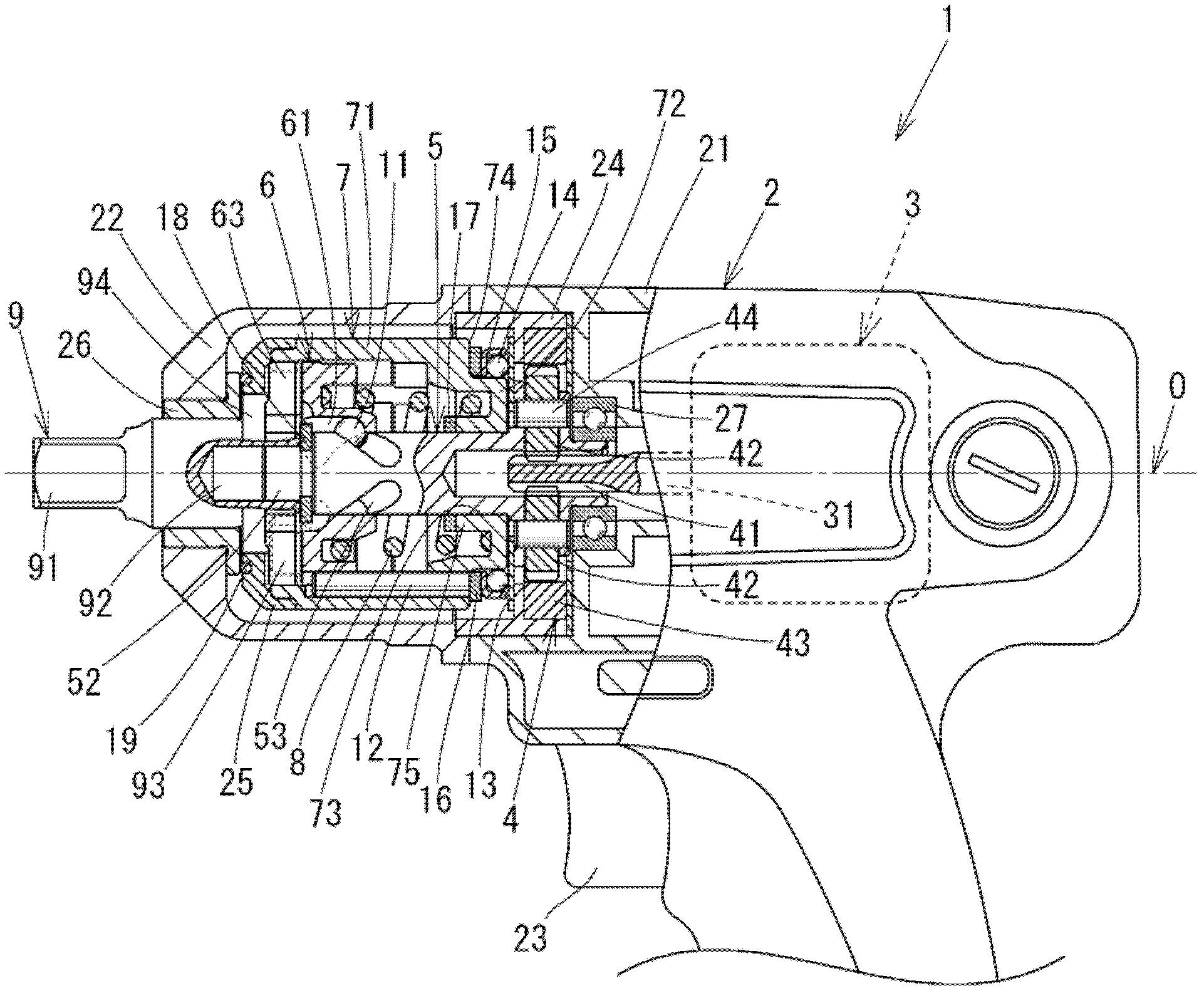

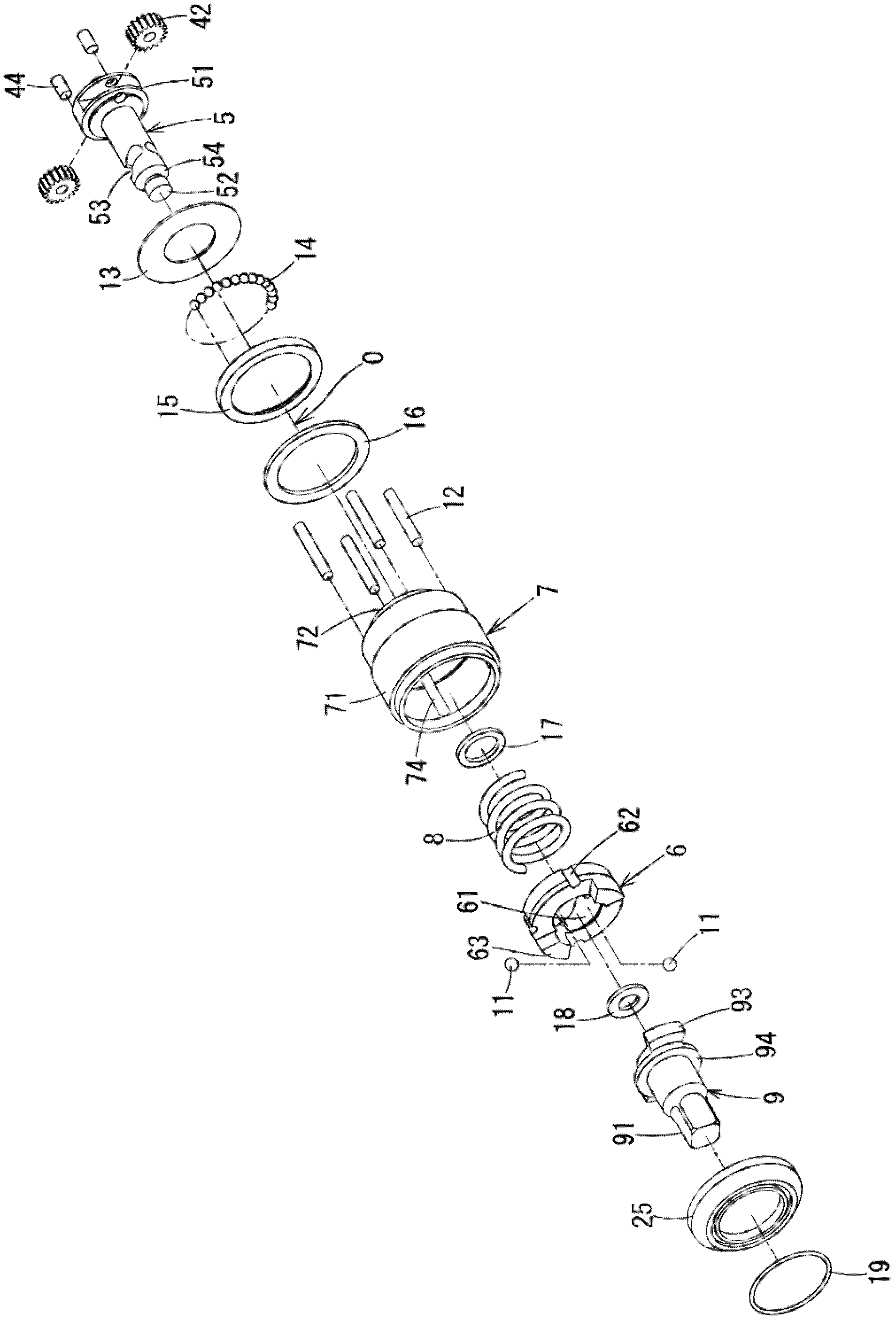

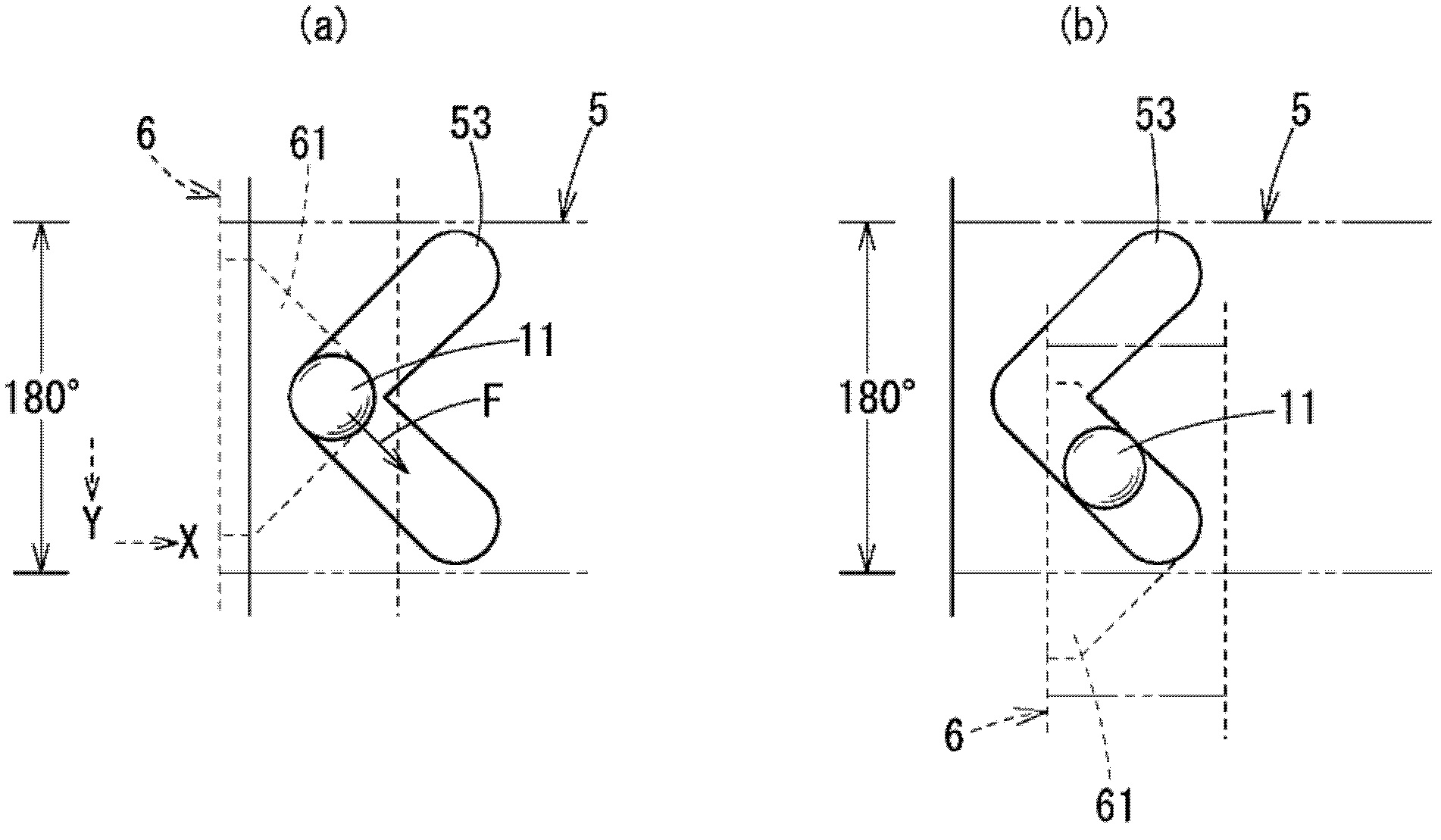

[0070] figure 1 It is a main part front view of the main part of the impact wrench according to the first embodiment of the present invention cut along the longitudinal plane including the axis of the main shaft. figure 2 is to express figure 1 Perspective view of the components of the impact wrench except the housing part.

[0071]

[0072] The impact wrench 1 includes: a housing 2 , an electric motor 3 , a rotation transmission mechanism 4 , a main shaft 5 , a main hammer 6 , an auxiliary hammer 7 , a spring 8 , and a mounting seat 9 . Hereinafter, the configuration and function of the above-mentioned components will be described respectively.

[0073] First, the casing 2 will be described. The housing 2 is composed of a resin housing 21 disposed at the rear of the impact wrench 1 and an aluminum clutch housing 22 disposed at the front, and the clutch housing 22 is fixed to the housing 21 with screws (not shown). Hereinafter, the side where the mounting base 9 is arra...

no. 2 approach

[0133] Figure 5 It is a main part front view of the main part of the impact wrench according to the second embodiment of the present invention cut along the longitudinal plane including the axis of the main shaft. The impact wrench 1a of the second embodiment is different from the impact wrench 1 of the first embodiment in that the structure of a core holding mechanism that holds the rotation axis of the sub hammer in a state aligned with the axis of the main shaft is different. Correspondingly, the main shaft 5, auxiliary hammer 7, and mounting seat 9 of the first embodiment are replaced with the main shaft 5a, auxiliary hammer 7a, and mounting seat 9a.

[0134] Hereinafter, the structure and operation of the impact wrench 1a will be described, focusing on the structure of the core holding mechanism. In addition, in Figure 5 in, with figure 1 Components having the same functions as the impact wrench 1 are denoted by the same reference numerals, and description thereof wi...

no. 3 approach

[0147] In the first and second embodiments, the impact wrench 1 using the mounts 9 and 9a for tightening bolts and nuts has been described, but by using the mount with a hole at the tip , It can also be used as an impact wrench for tightening small screws with notches or cross recesses, etc., and a hexagonal drill bit as a screwdriver bit (DRAIBA BITSTO) is inserted into the above-mentioned hole. Image 6 It shows the cross section of the front part of the impact wrench 1b according to the third embodiment of the present invention, and the impact wrench 1b is replaced by a mount 9b formed with a hole for inserting a hexagonal bit. figure 1 Mounting seat 9 for impact wrench 1 shown.

[0148] A drill insertion hole 95 for detachably attaching a hexagonal drill is formed along the axis O at the front portion of the mount 9b. In addition, a steel ball 97 engaged with a groove provided in the hexagonal bit is inserted into a hole 96 formed in the outer peripheral surface of the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com