Patents

Literature

87results about How to "Reduce starting power" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

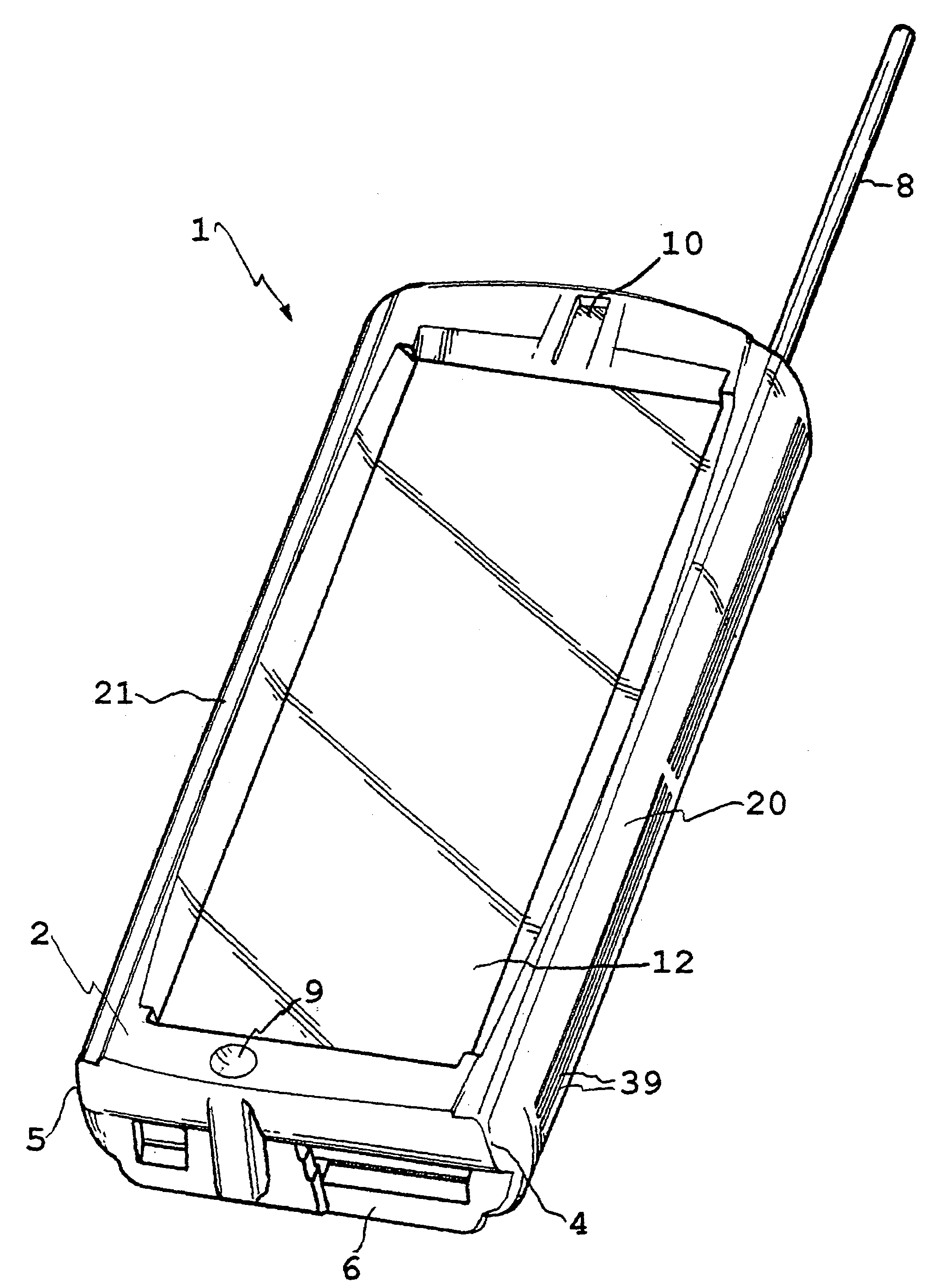

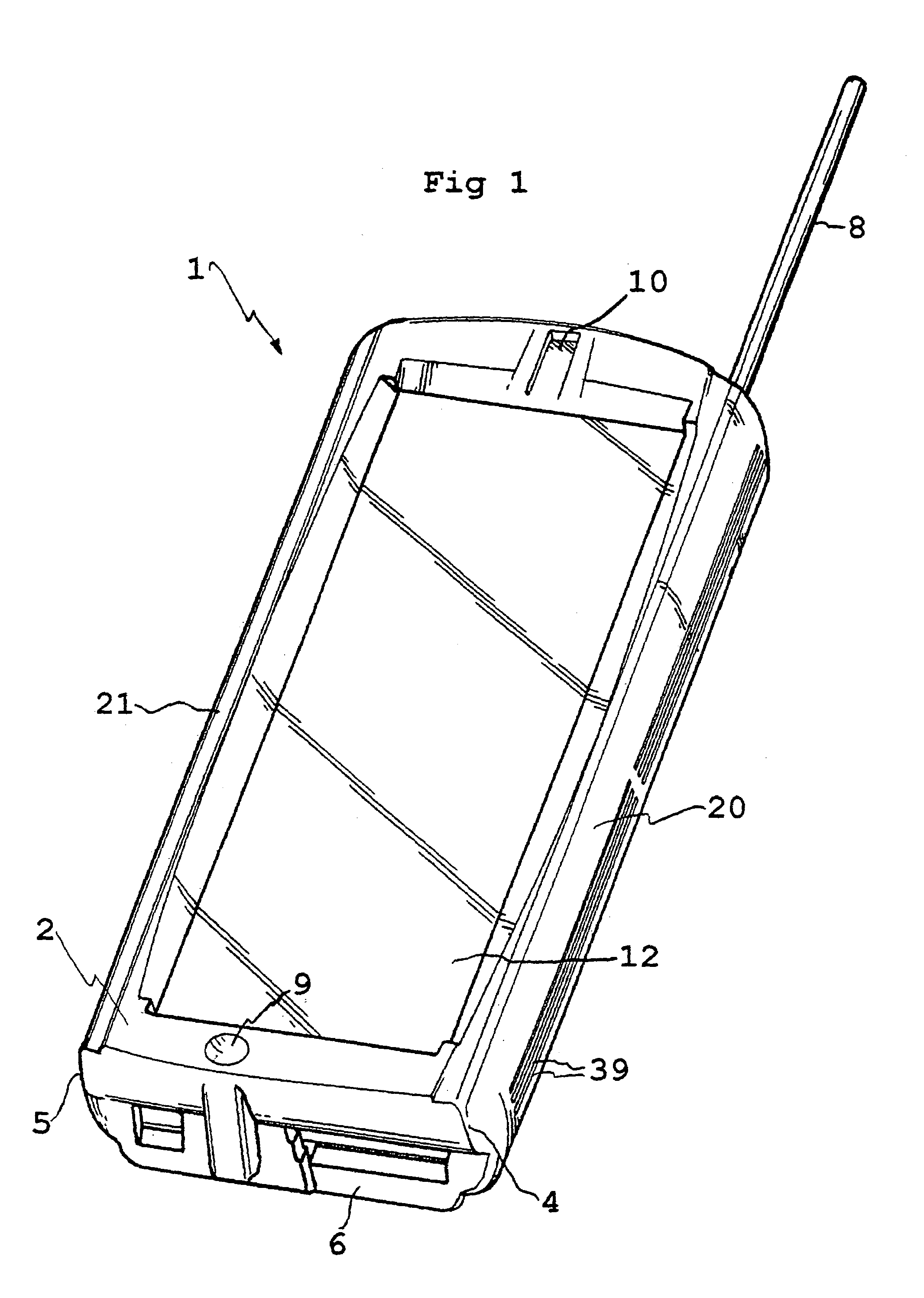

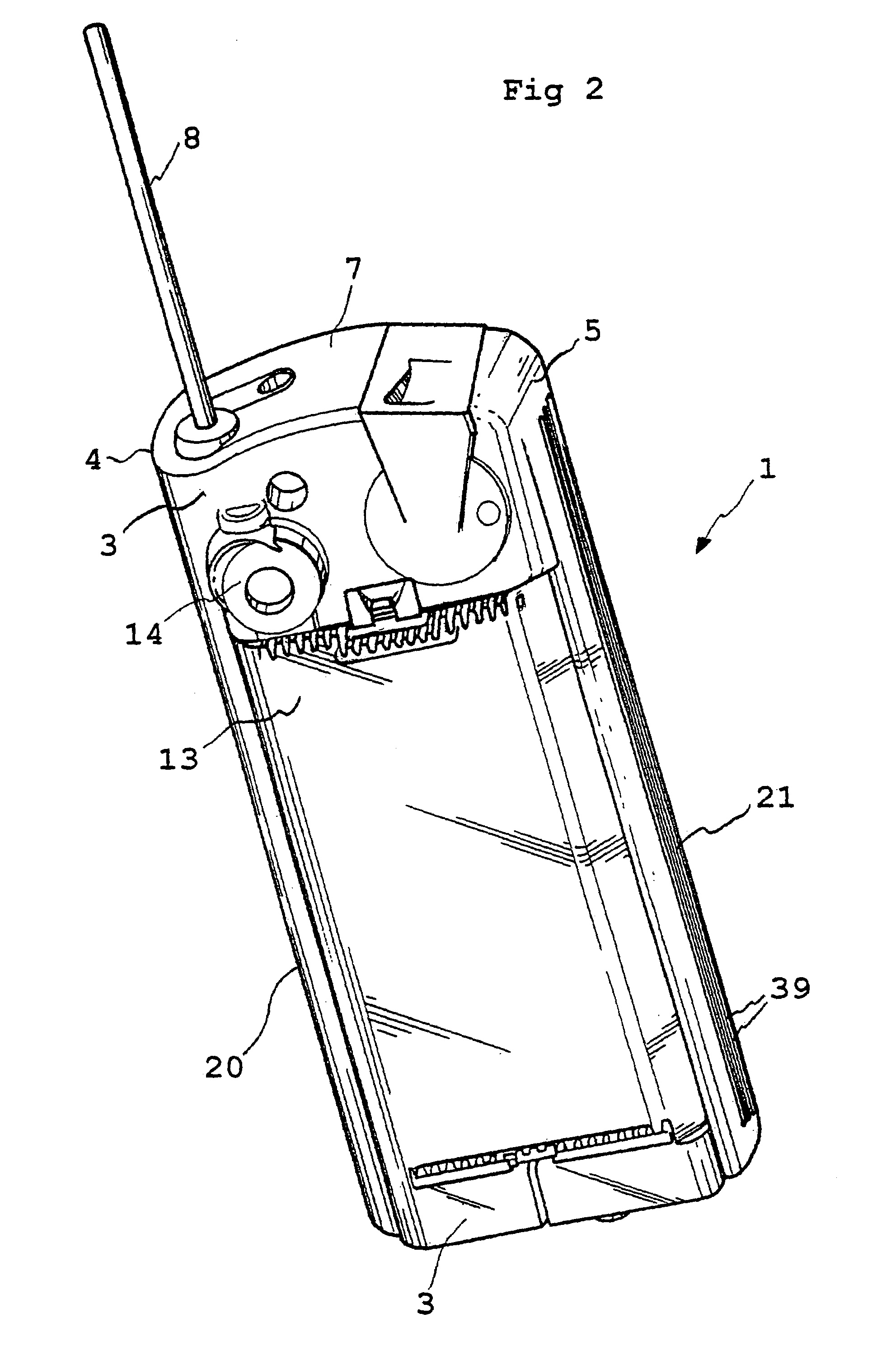

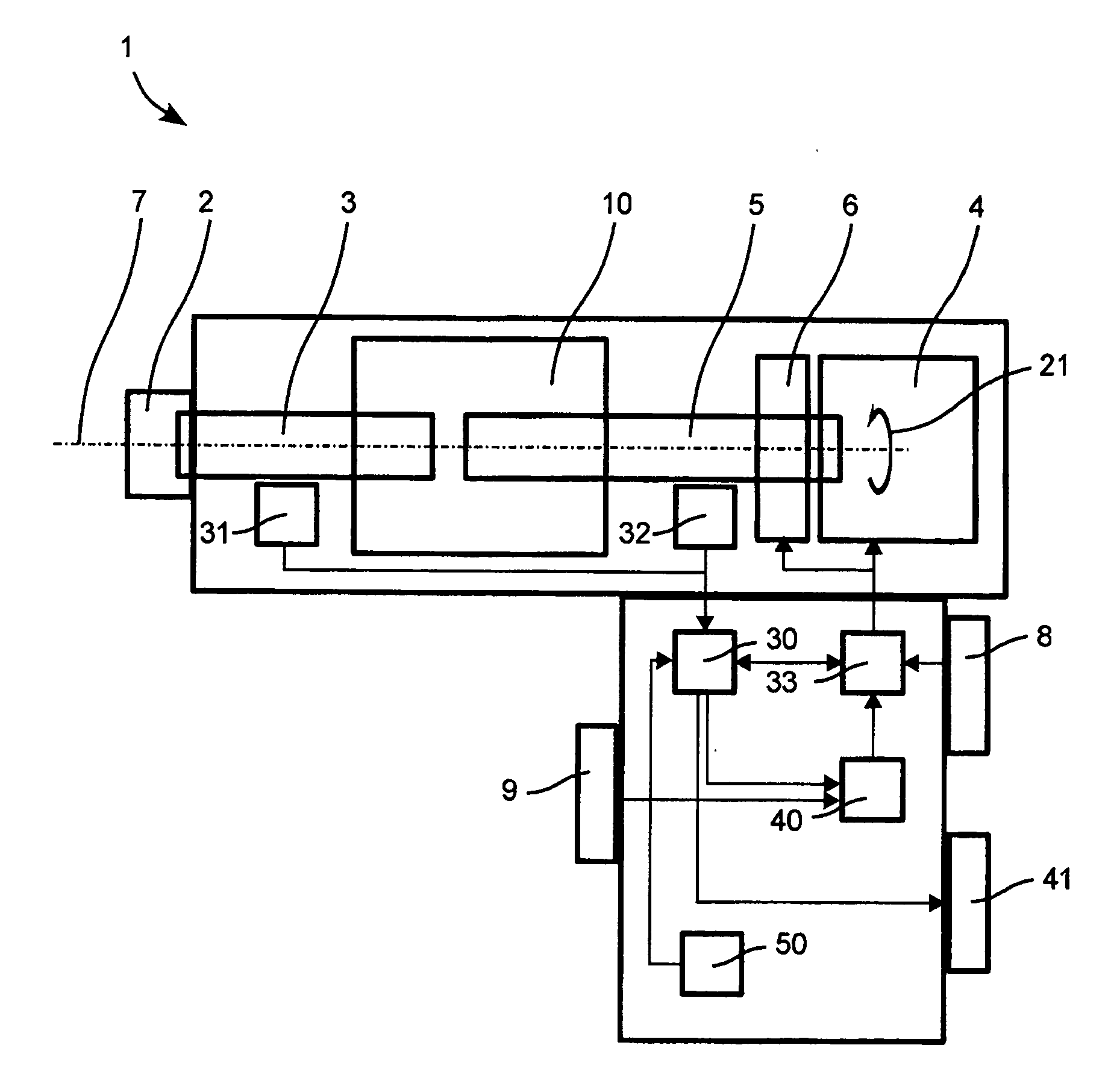

Handheld or pocketsized electronic apparatus and hand-controlled input device

InactiveUS7236159B1Small sizeReduce contact areaInput/output for user-computer interactionTransmission systemsDisplay deviceEngineering

A handheld or pocketsized electronic apparatus, such as a mobile telephone, having a display unit and a touch surface that is position-sensitive in a first and second direction for control of the electronic apparatus; the display unit having a display area taking up most of the front side of the apparatus and the touch surface being sufficiently narrow to fit on the side edge of the apparatus and curved in the first direction to convex shape, thus making it simple for a user to control the apparatus with one hand, without the display being hidden, and in an ergonomically correct manner, whereby control of the apparatus is attained without the use of a keyboard or similar input device.

Owner:SPECTRONIC

Impact wrench and control method for an impact wrench

A control method according for an impact wrench includes ascertaining whether the impact wrench applies an impact when the drive shaft rotates in a lower speed range. The speed of the drive shaft then is increased to a higher speed range as a function of an ascertained impact during the rotation in the lower speed range.

Owner:HILTI AG

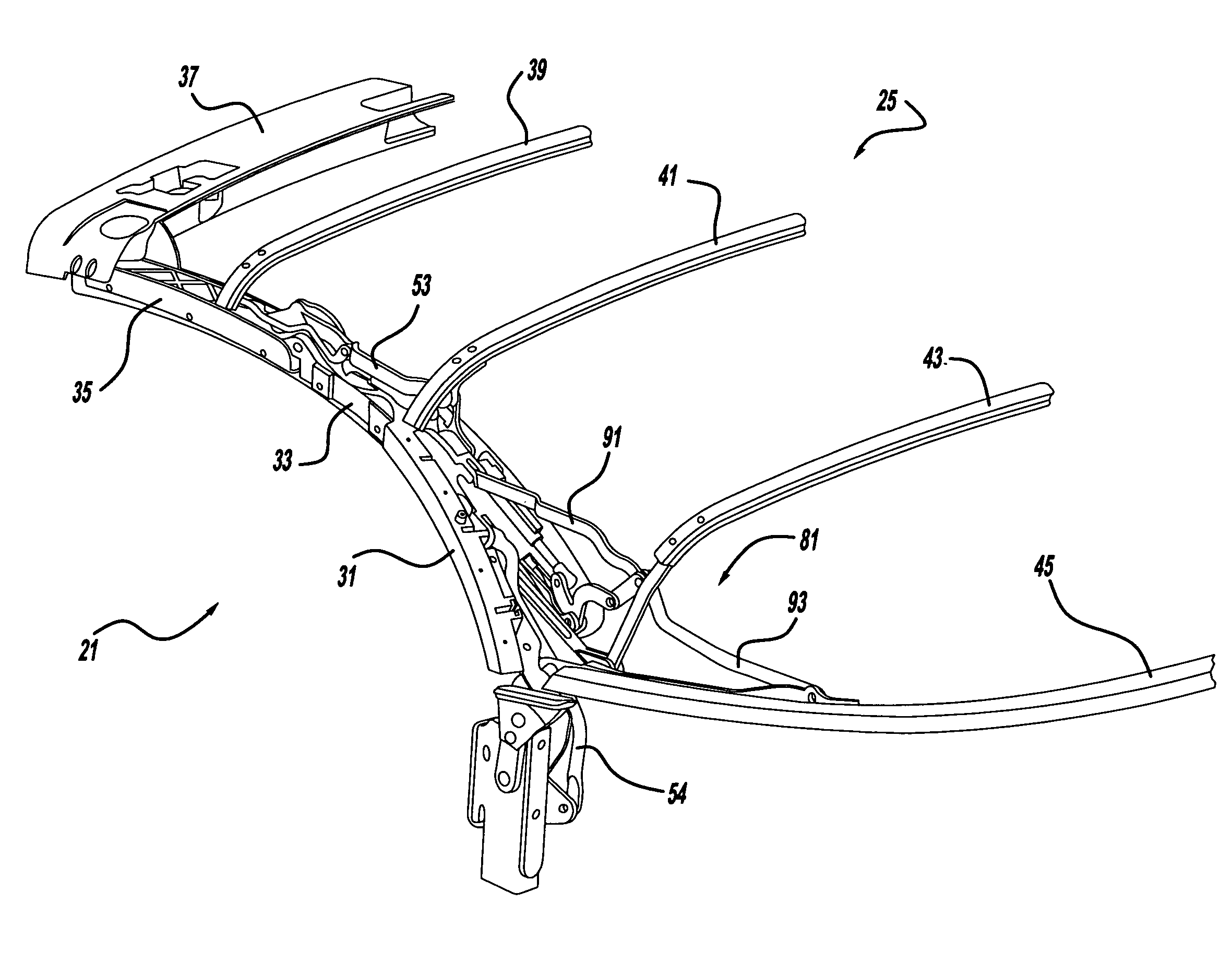

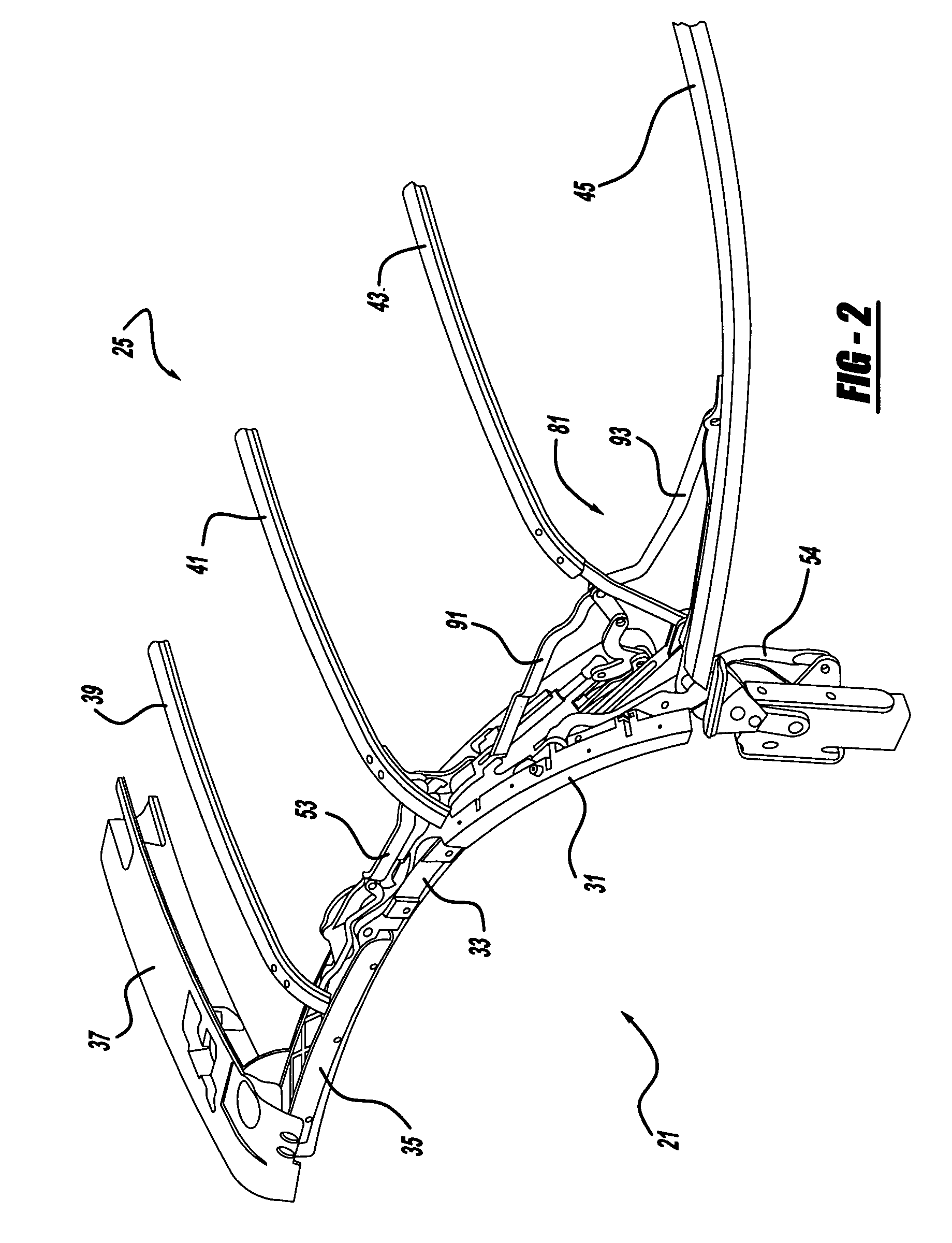

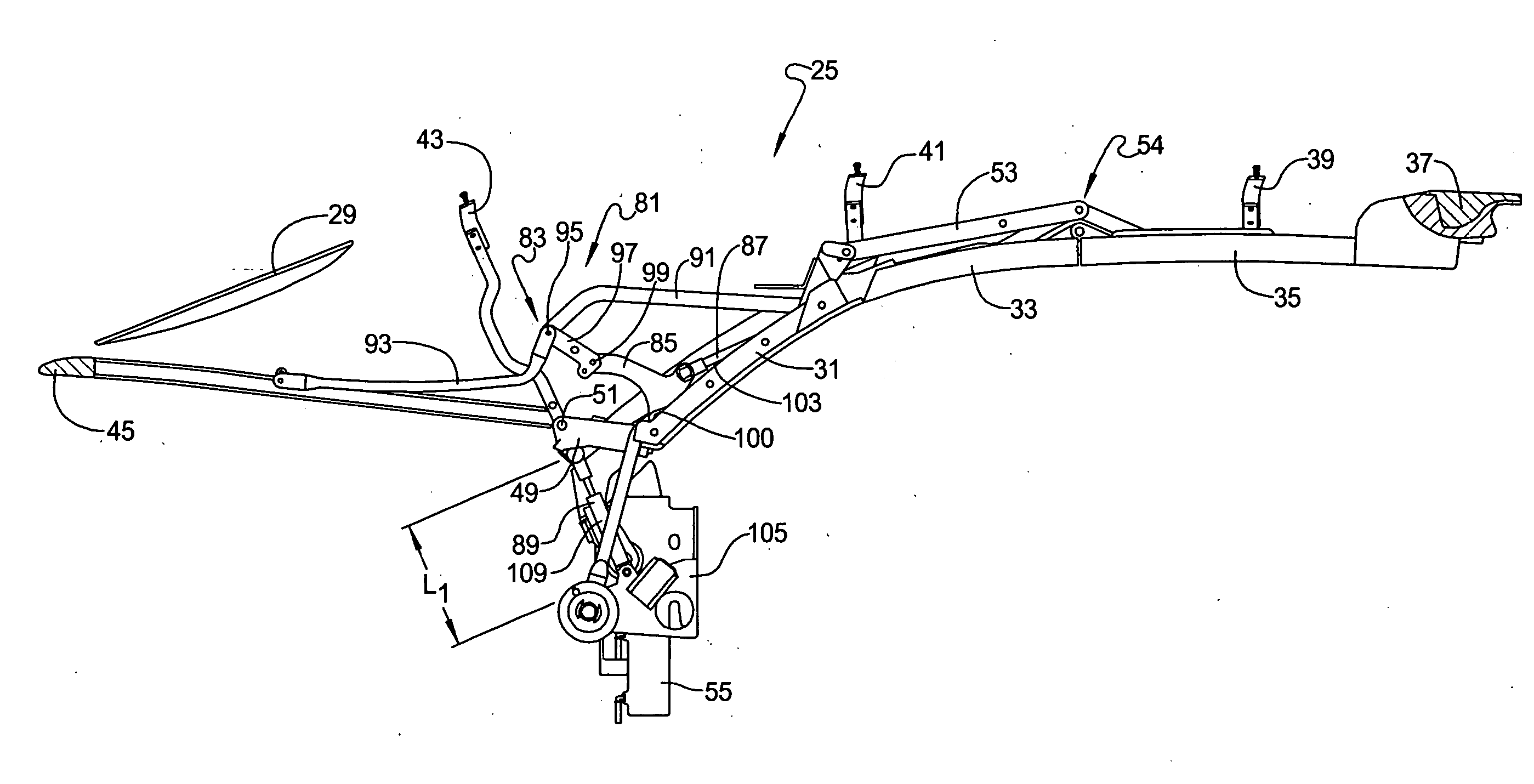

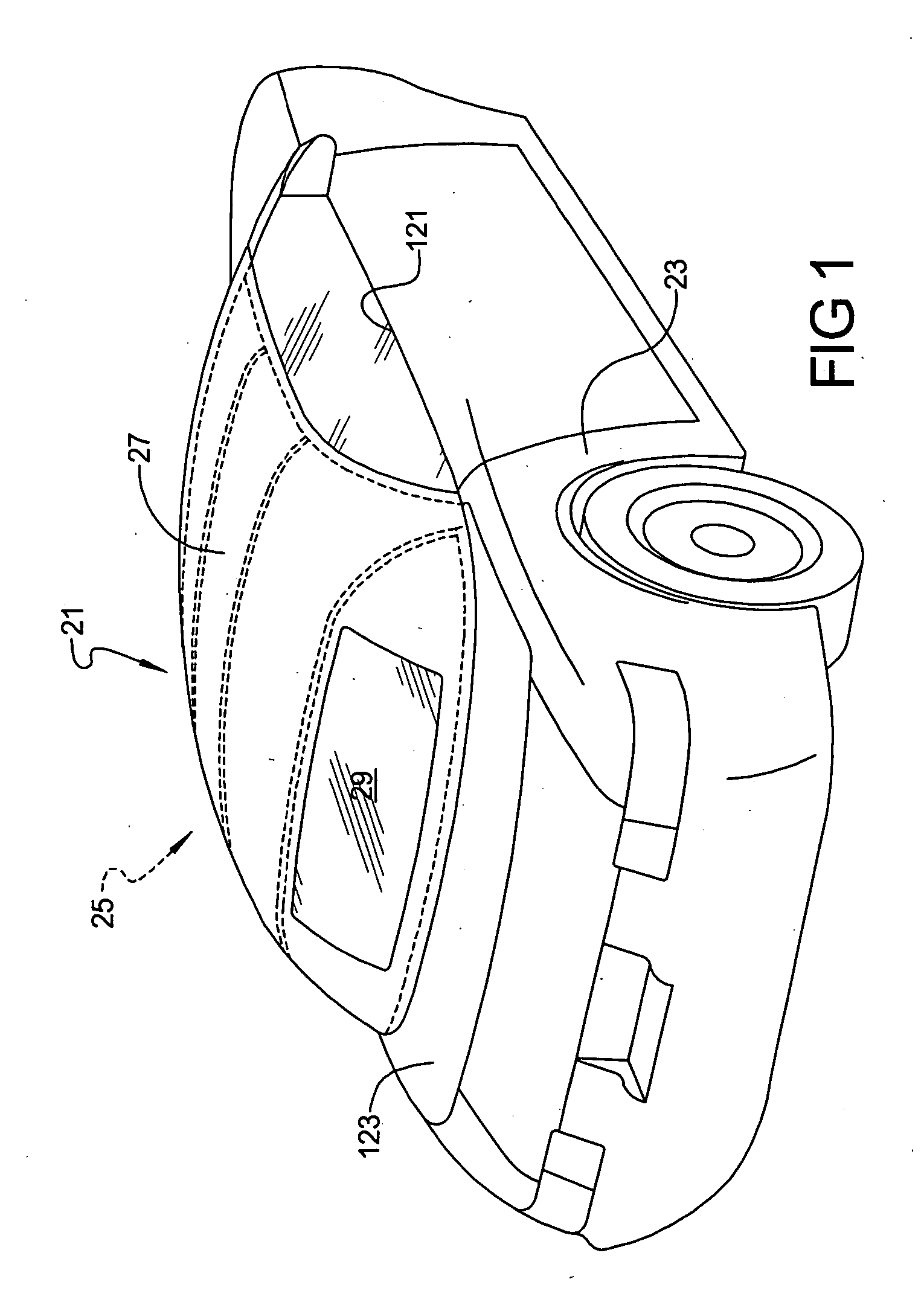

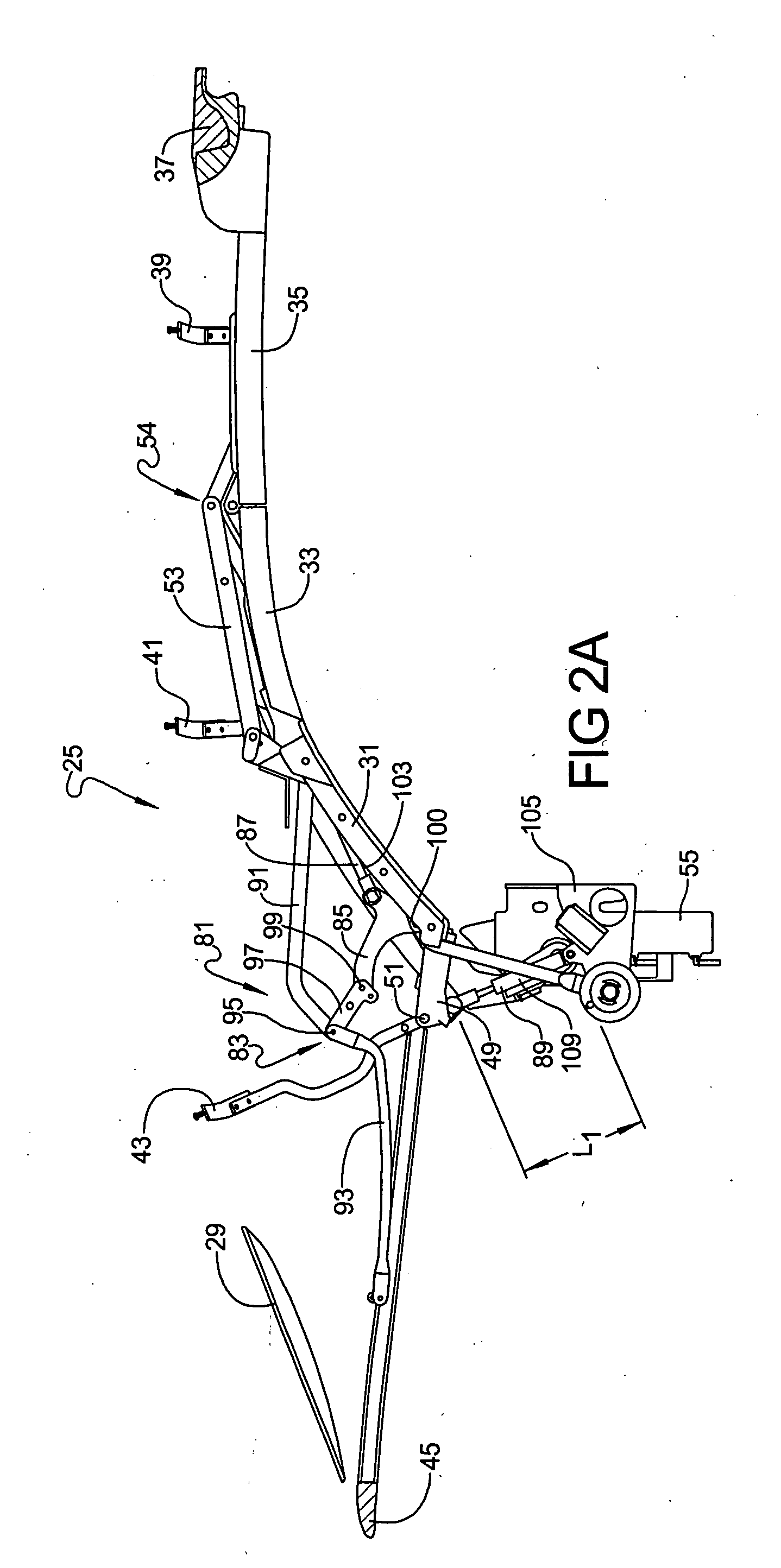

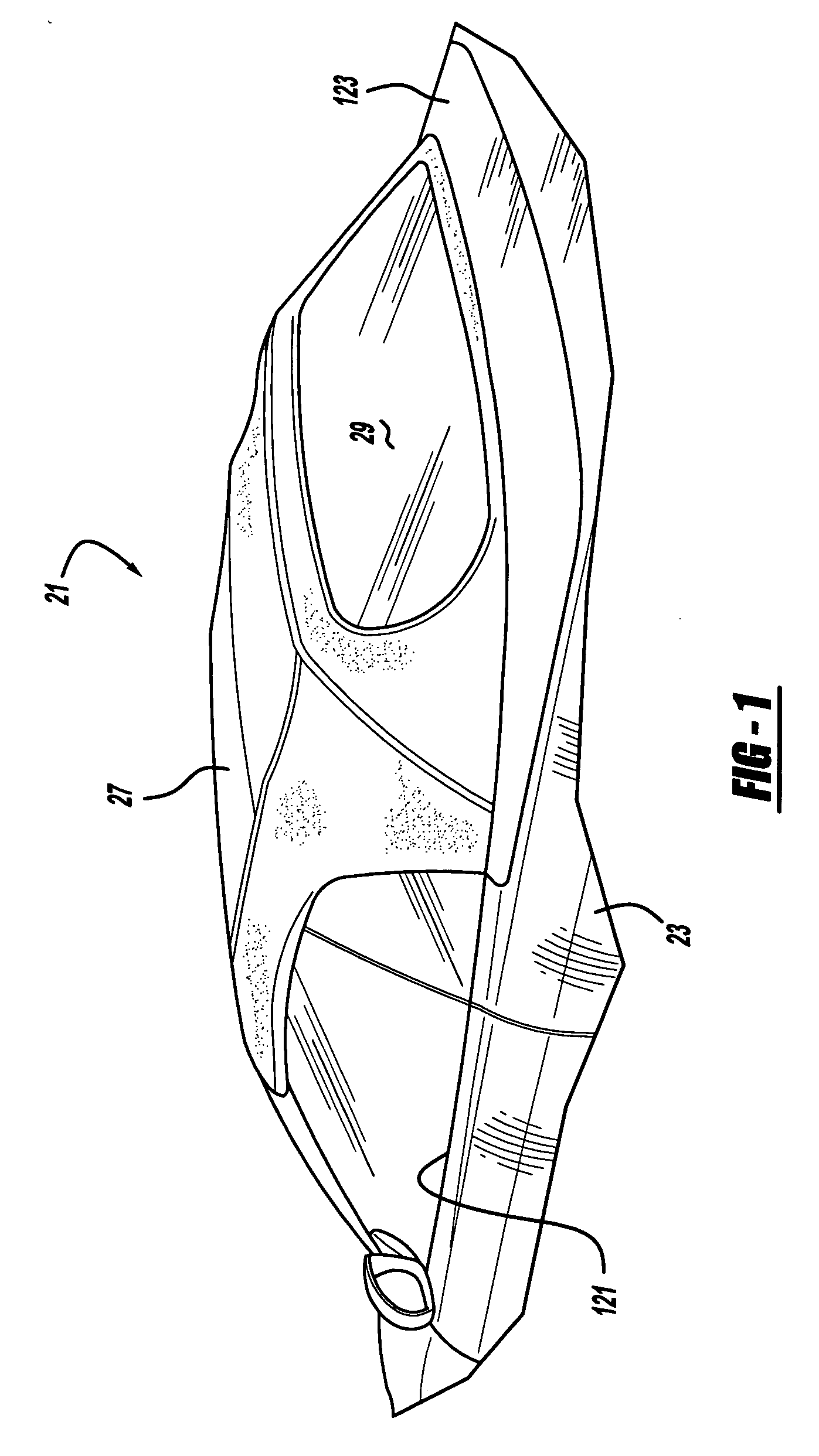

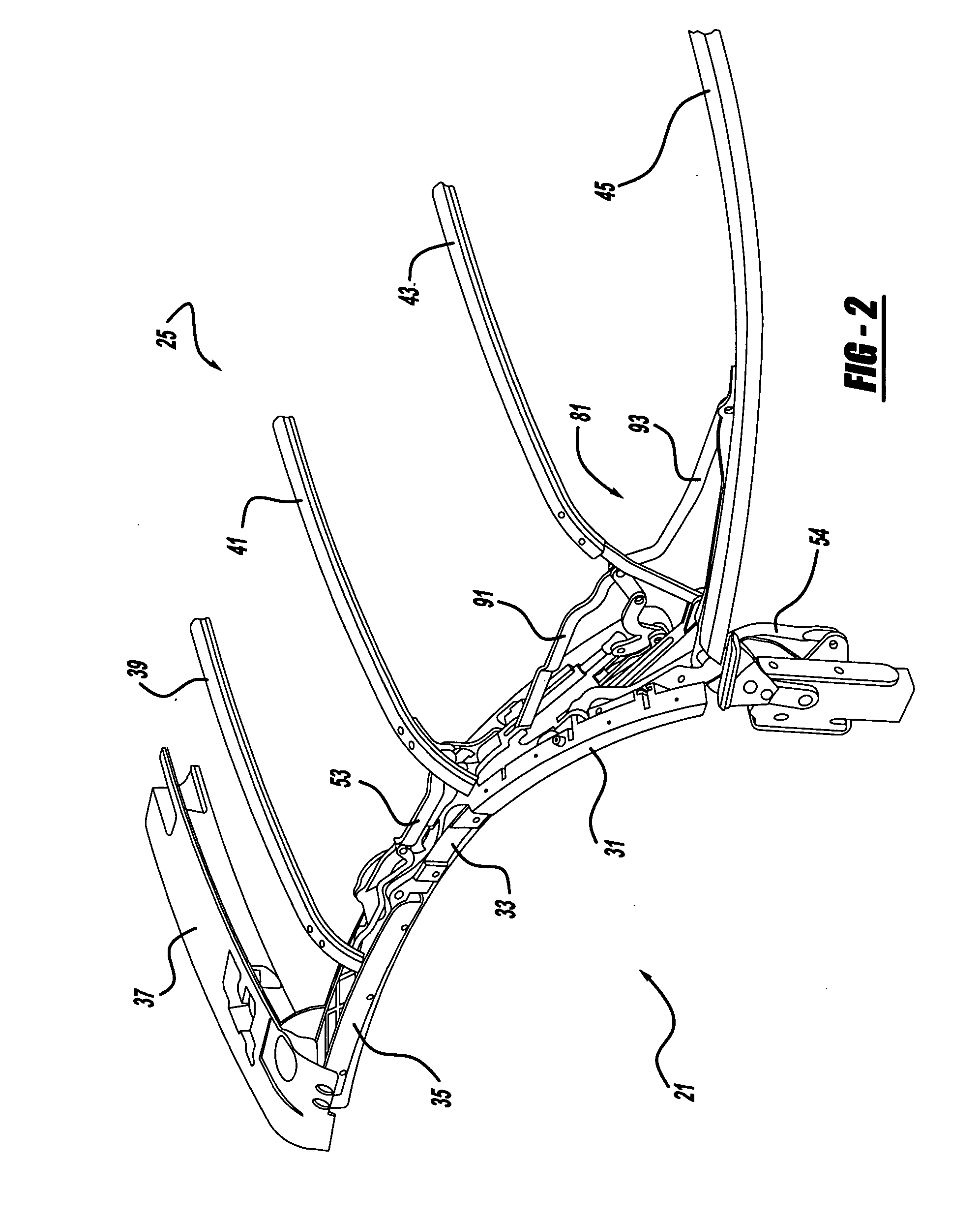

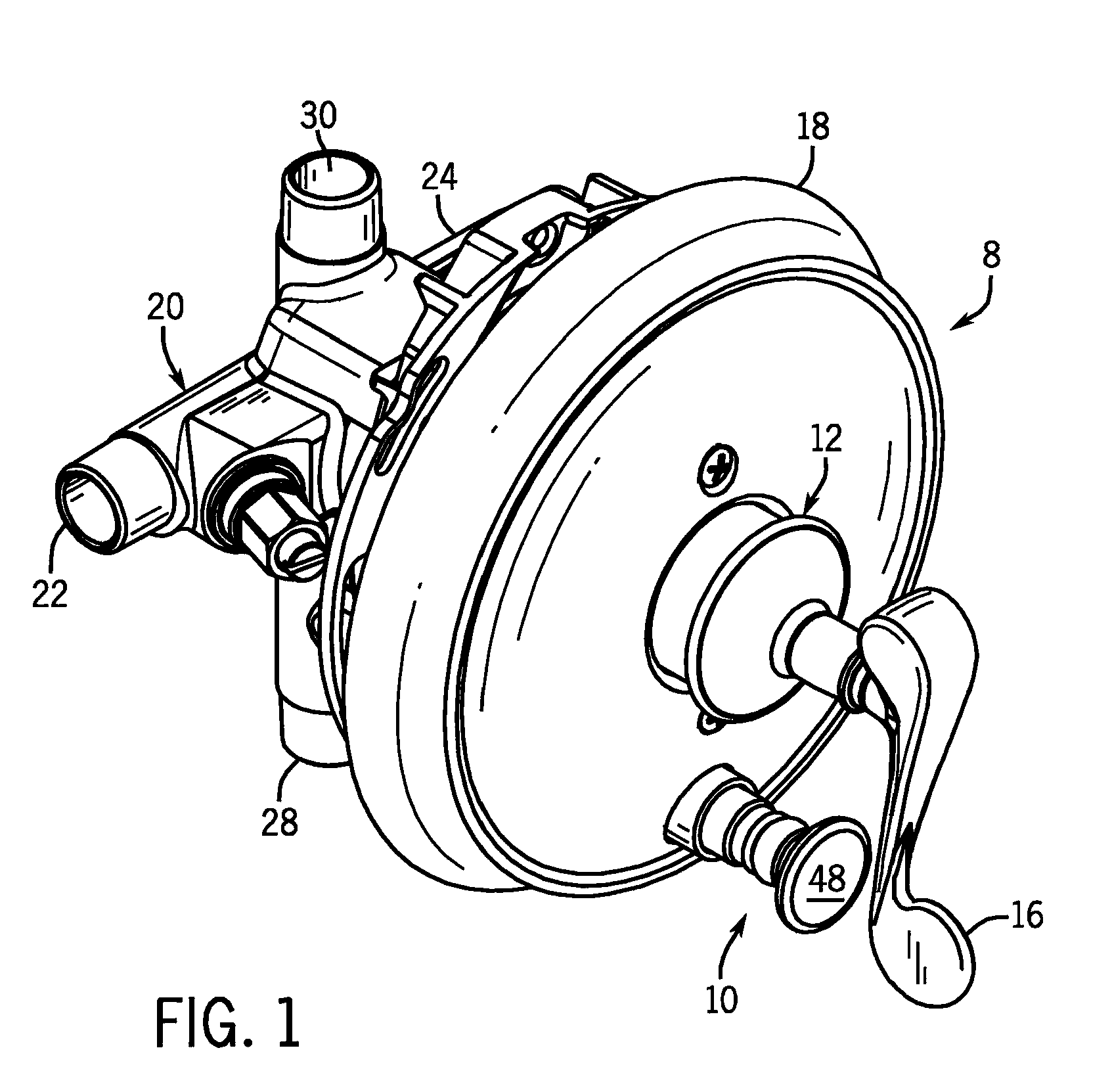

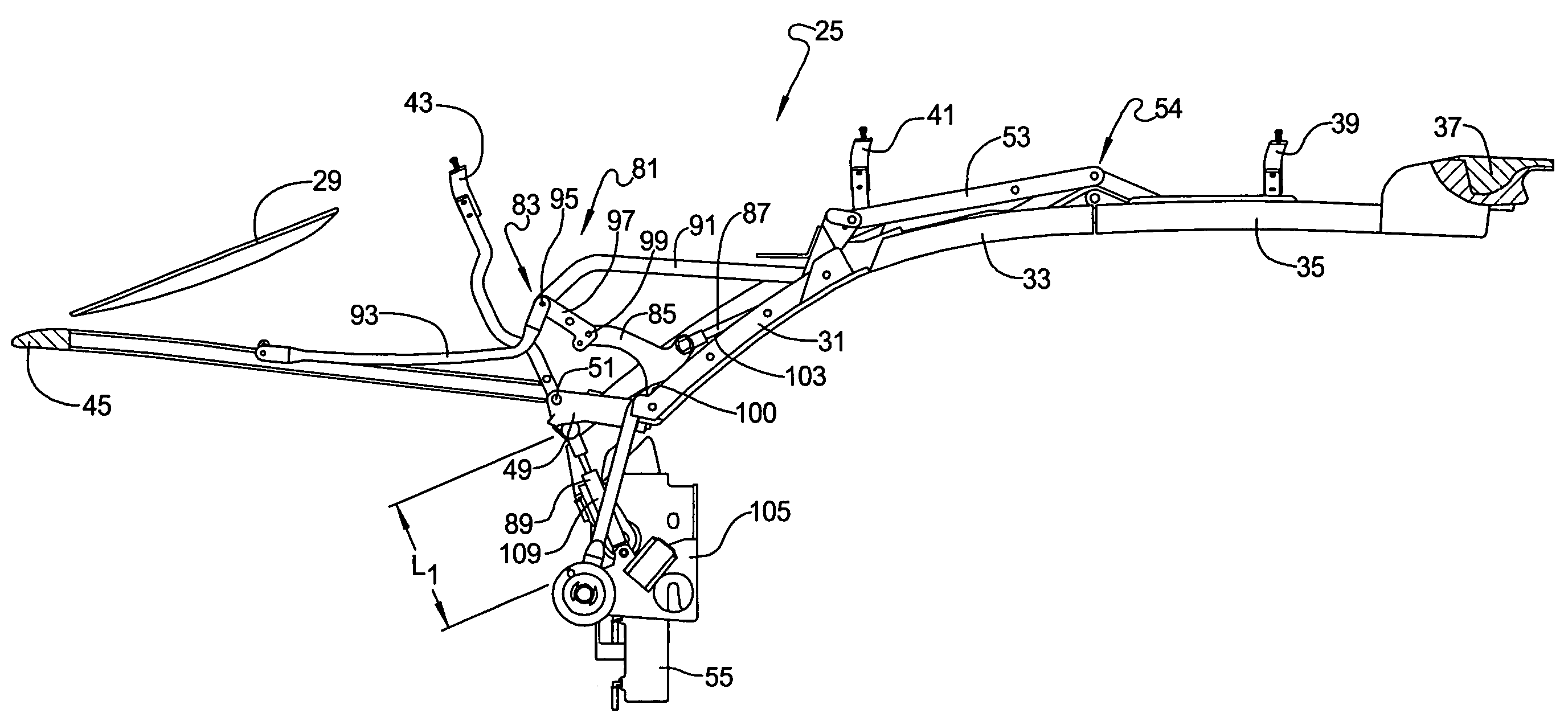

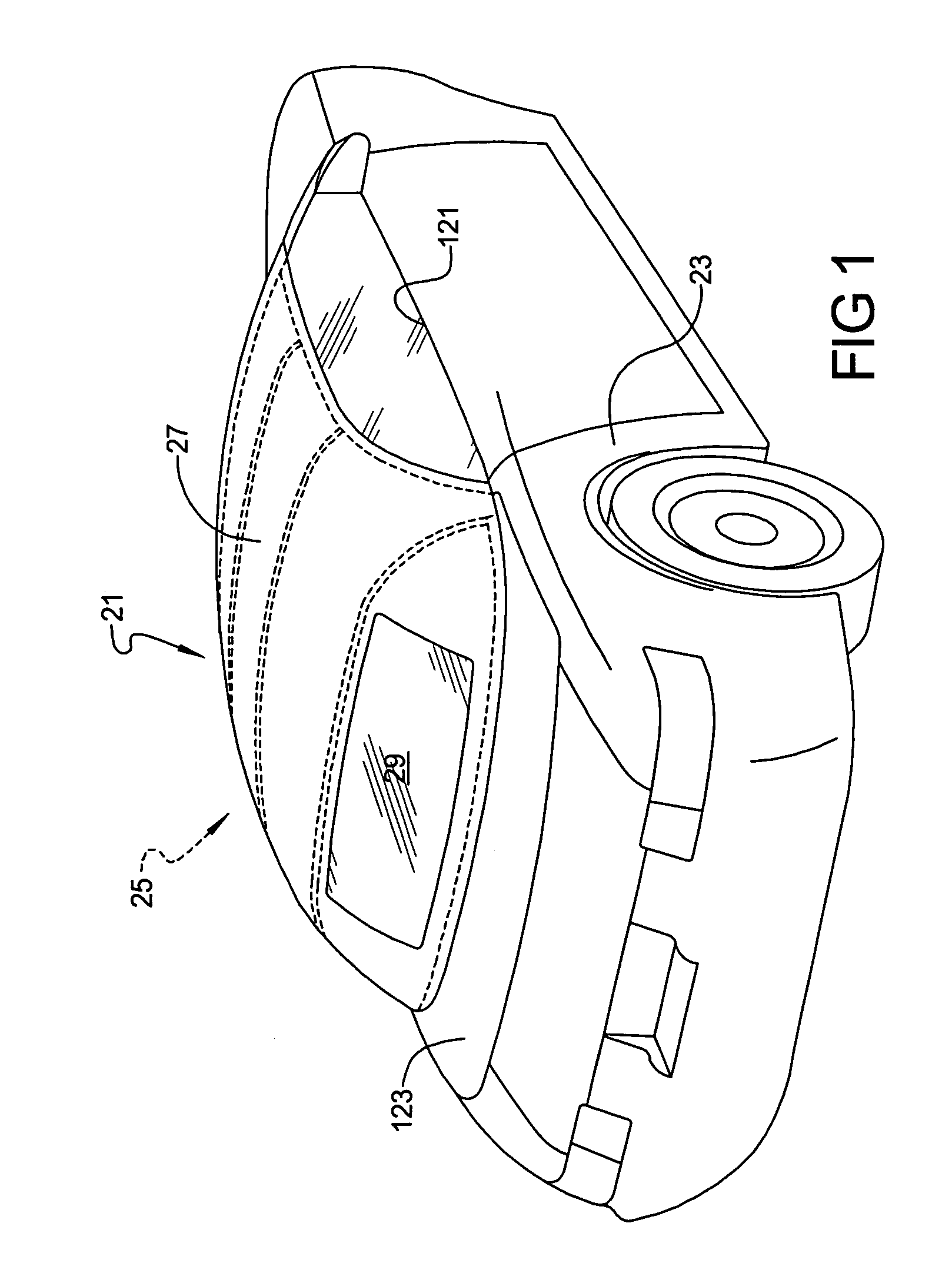

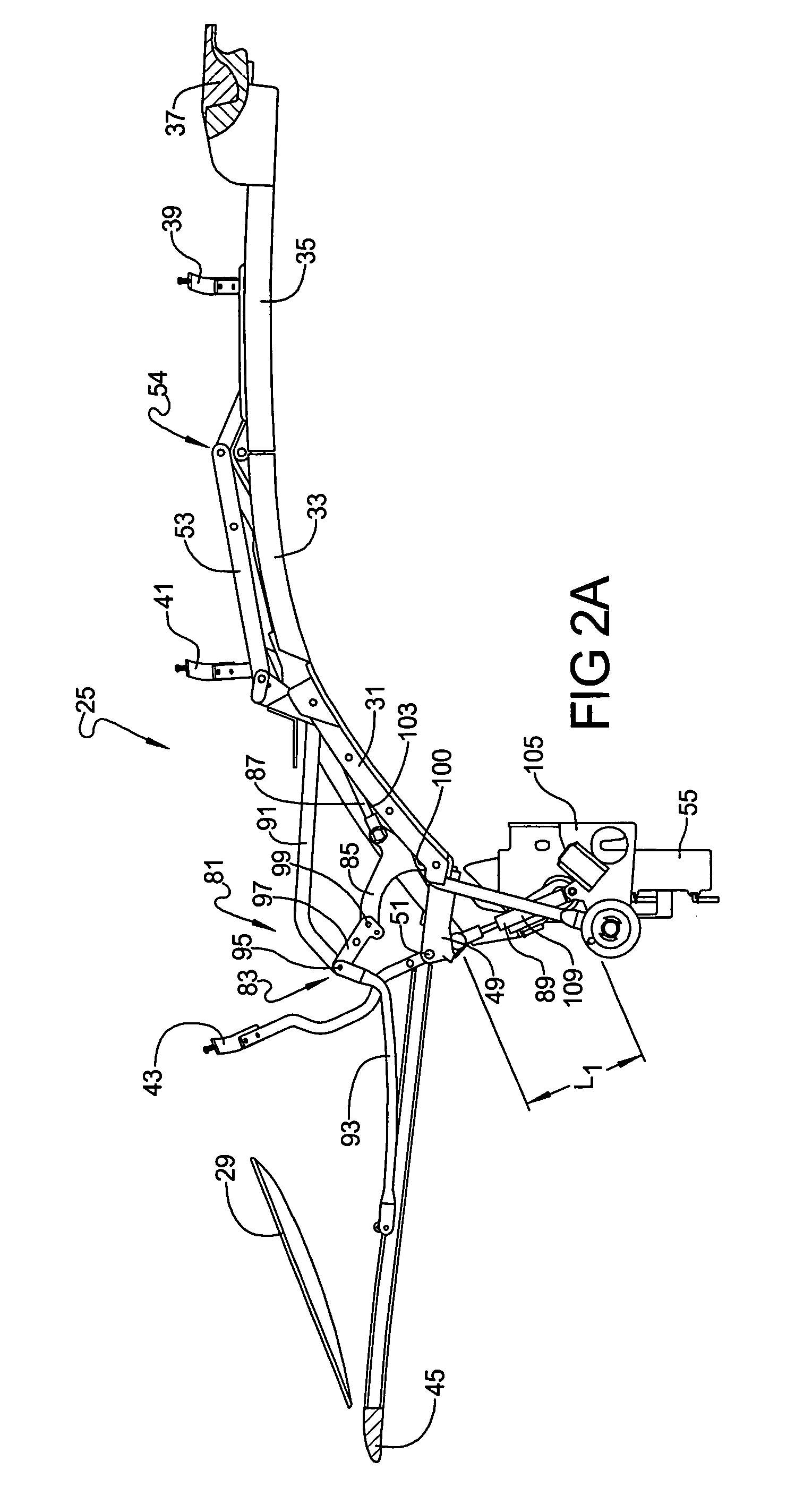

Convertible vehicle top stack mechanism

InactiveUS7032951B2Reduce starting powerEasy to assembleEngine sealsVehicle sealing arrangementsEngineeringActuator

A convertible vehicle top stack mechanism includes a moveable rearmost roof bow and an actuator. In an other aspect of the present invention, a linkage assembly couples a rearmost roof bow to a side rail. A further aspect of the present invention employs a rotatable member or crank to drive a set of buggy links in order to raise and lower an active number five roof bow.

Owner:SPECIALTY VEHICLE ACQUISITION

Blast mitigation system

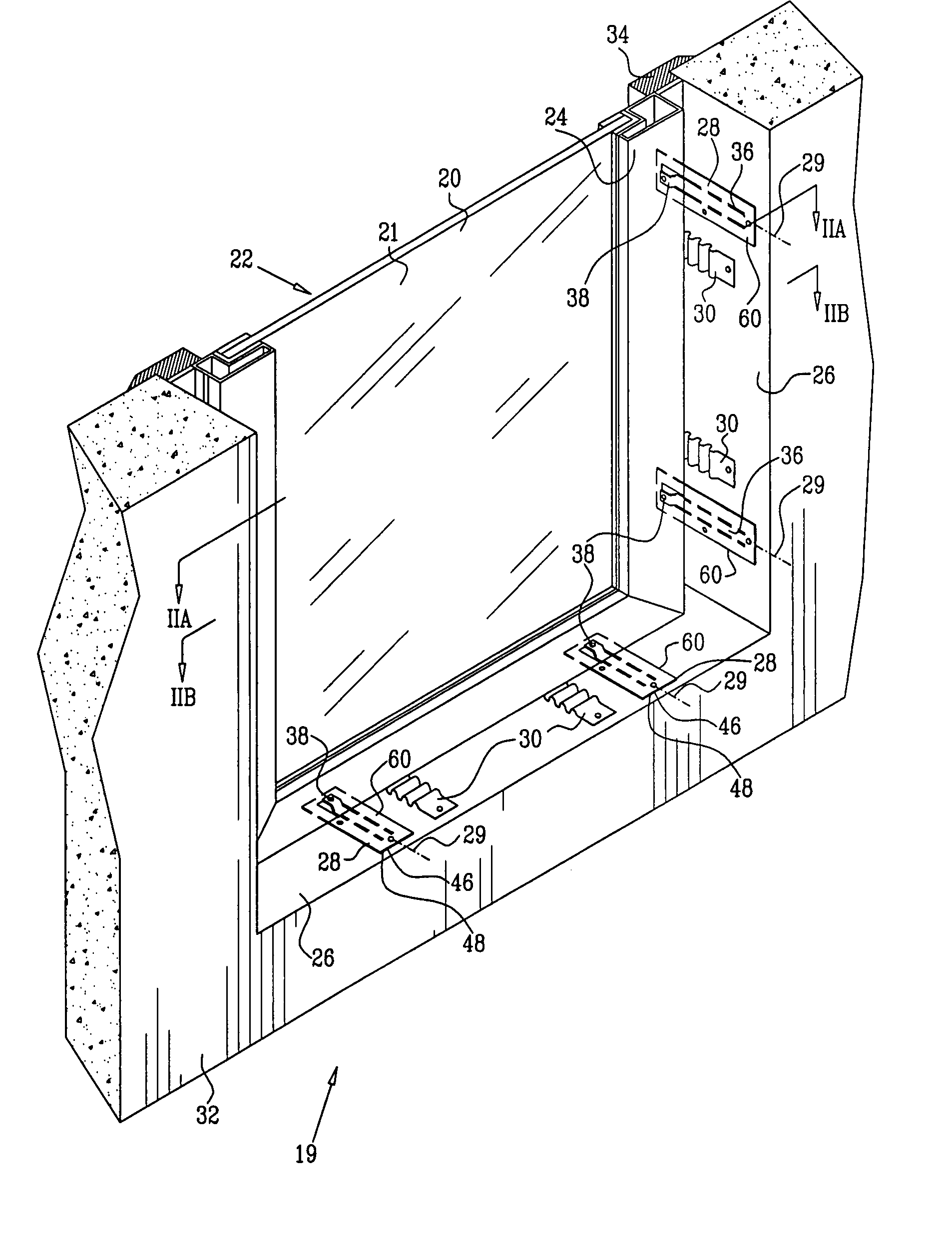

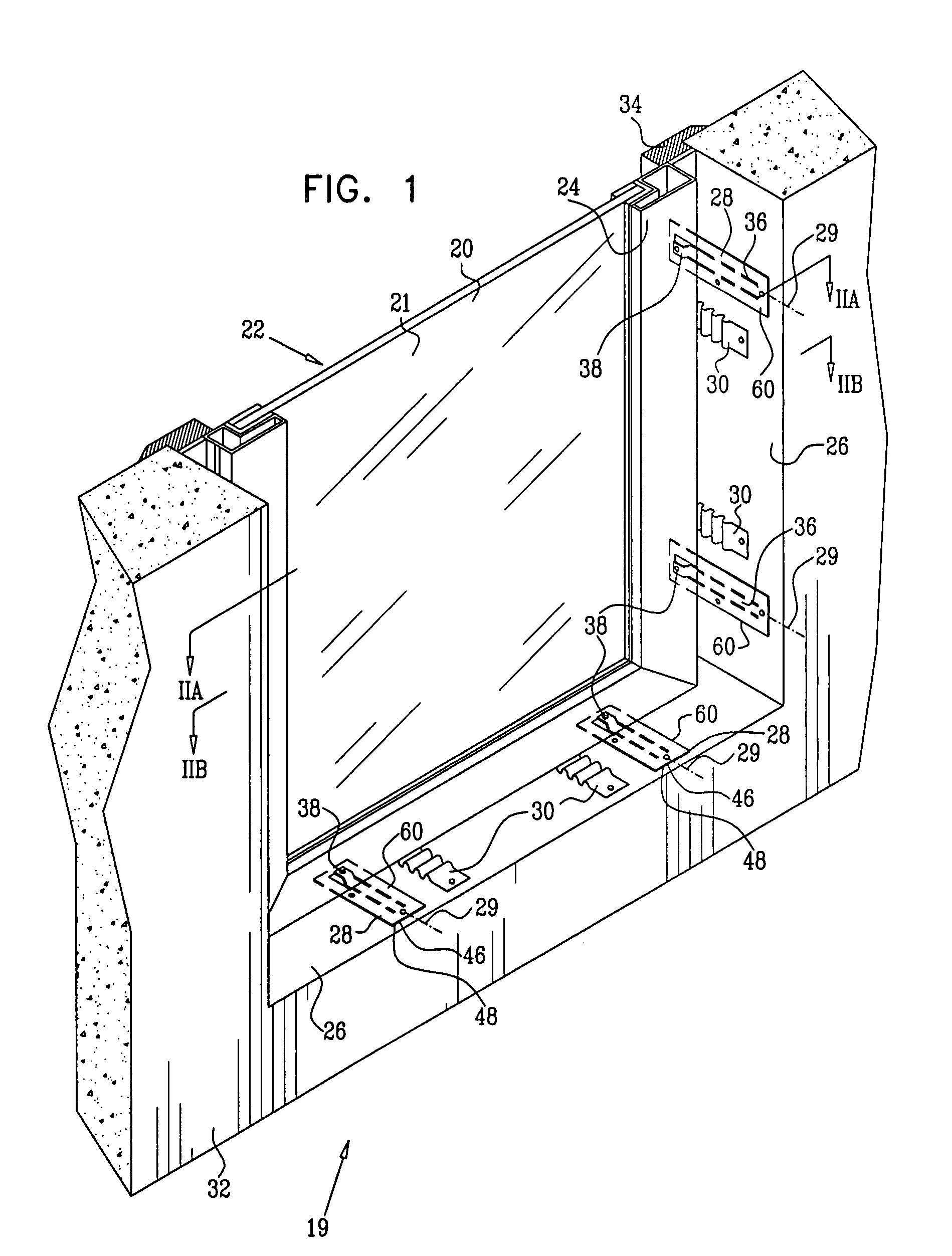

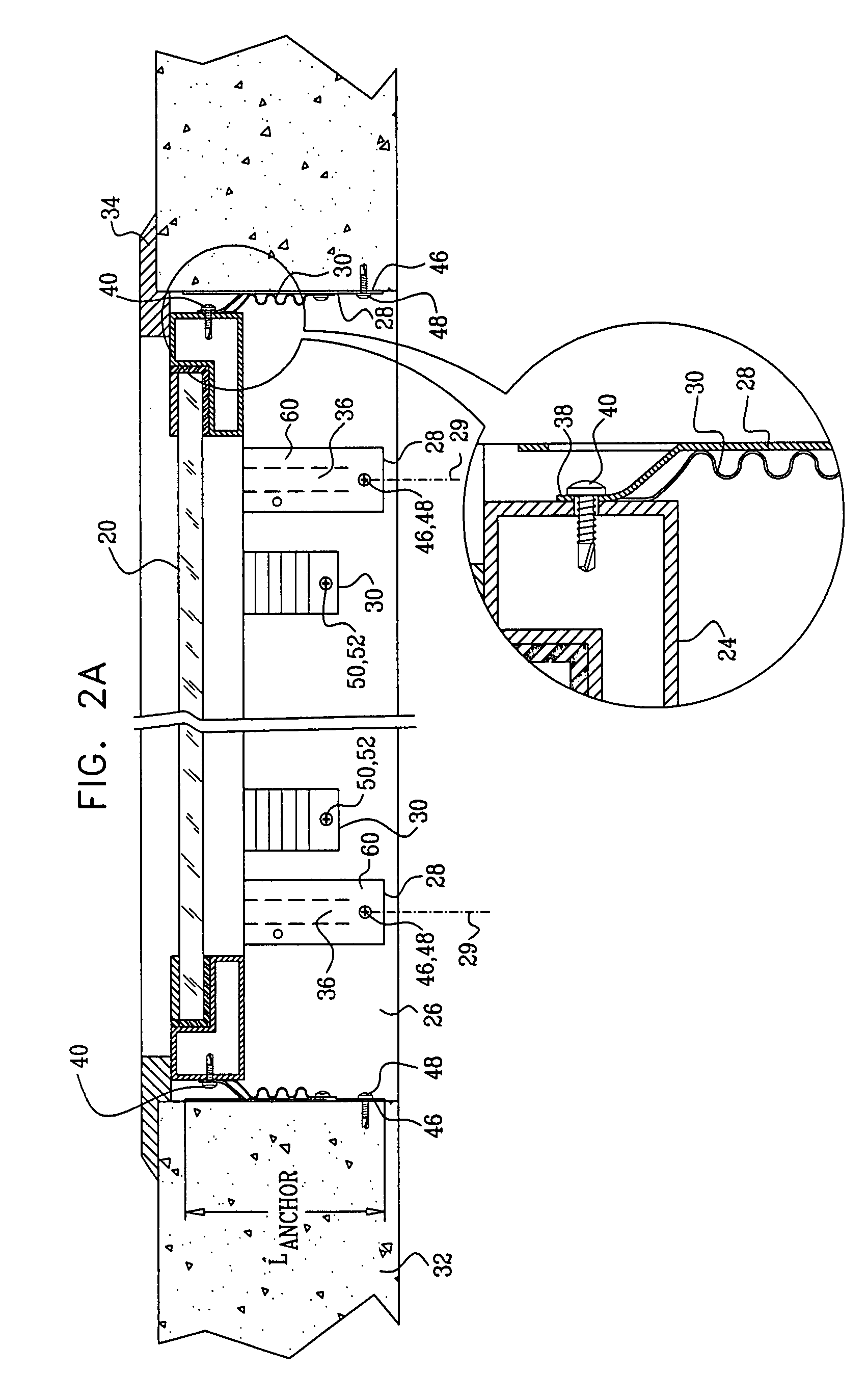

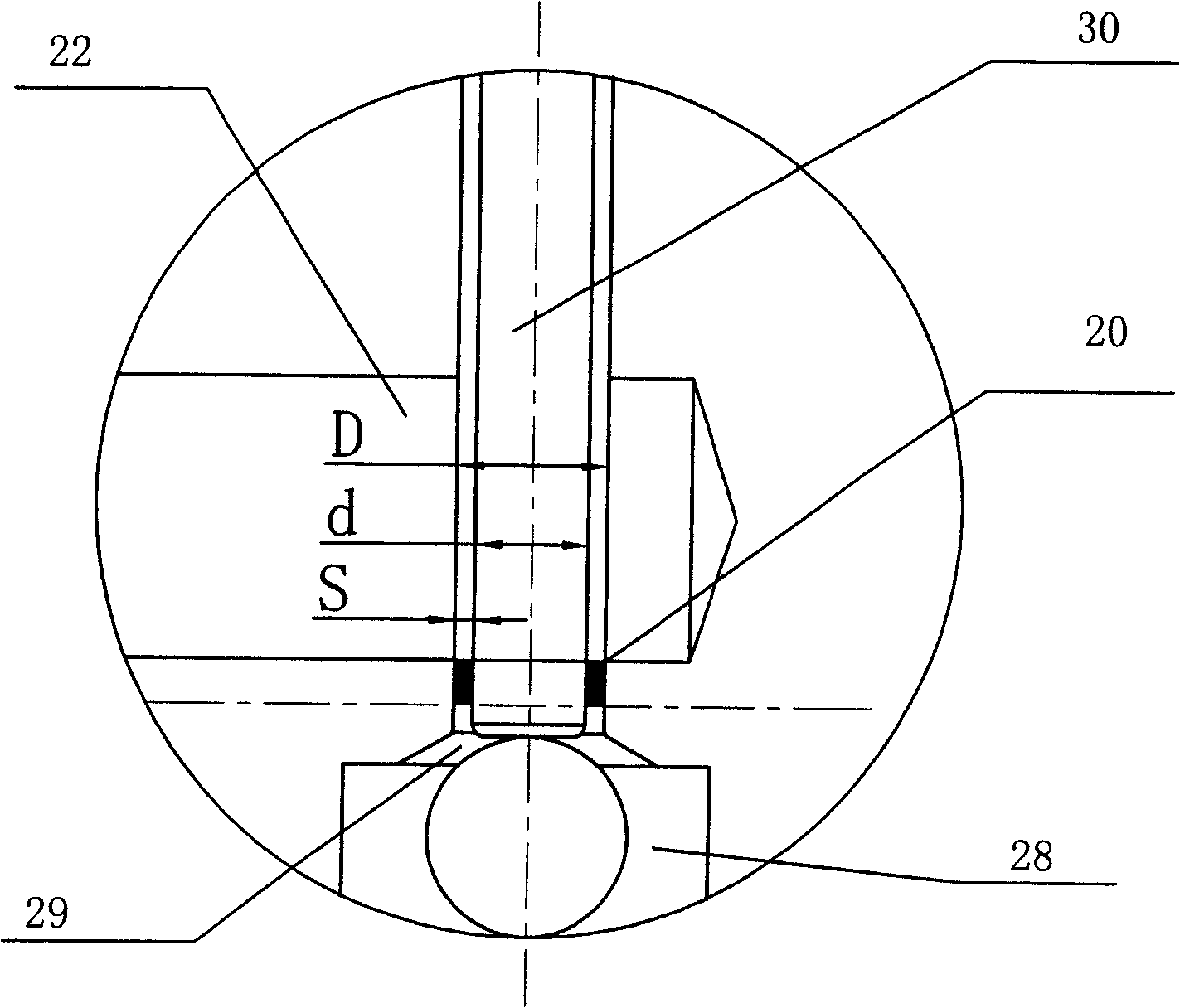

InactiveUS20080086960A1Reduce effectReduce impactShutters/ movable grillesBuilding repairsAbsorbed energyEngineering

A blast-resistant window assembly (19), including a window opening (22), and a window (20) sized to fit within the window opening. The assembly further includes at least one anchor (28), which consists of a base plate (60) connected to the window opening. The anchors have a tongue (36), which is connected to the window and is fixed to the base plate at a shear region (61) that is configured so that under force of a blast against the window, the tongue shears away from the base plate, thereby absorbing energy of the blast.

Owner:EMEK MORDECHAY

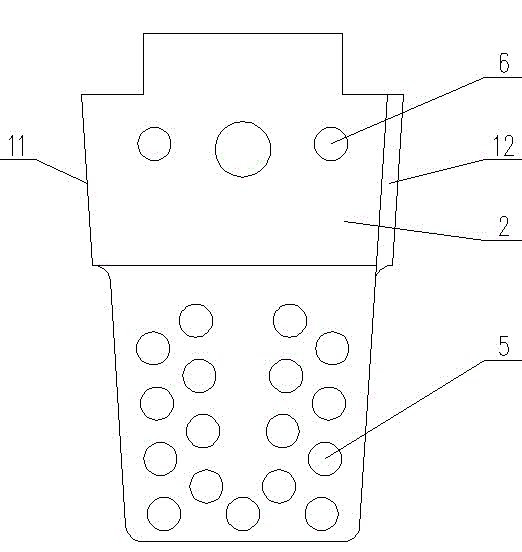

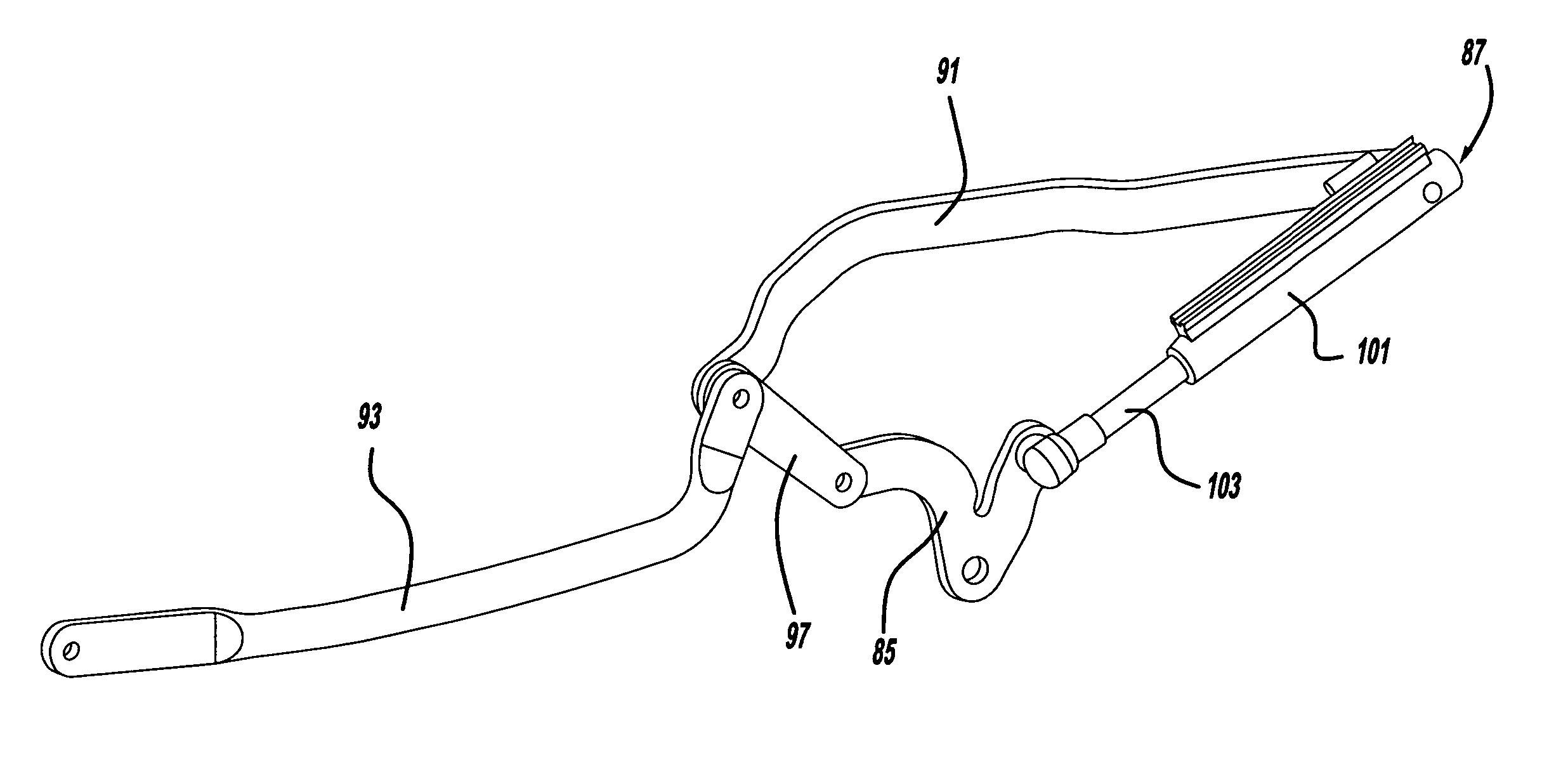

Convertible roof bow control mechanism

InactiveUS20060152033A1Reduces activation forceReduce operationEngine sealsVehicle sealing arrangementsActuatorControl theory

A vehicle convertible roof including a rearmost roof member, a side roof rail, an actuator and a link having a length that varies between a first length and a second as the rearmost roof member moves between a nominal and raised position. The adjustable length link is fixed at the second length during retraction and extension of the side roof rail of the vehicle convertible roof.

Owner:SPECIALTY VEHICLE ACQUISITION

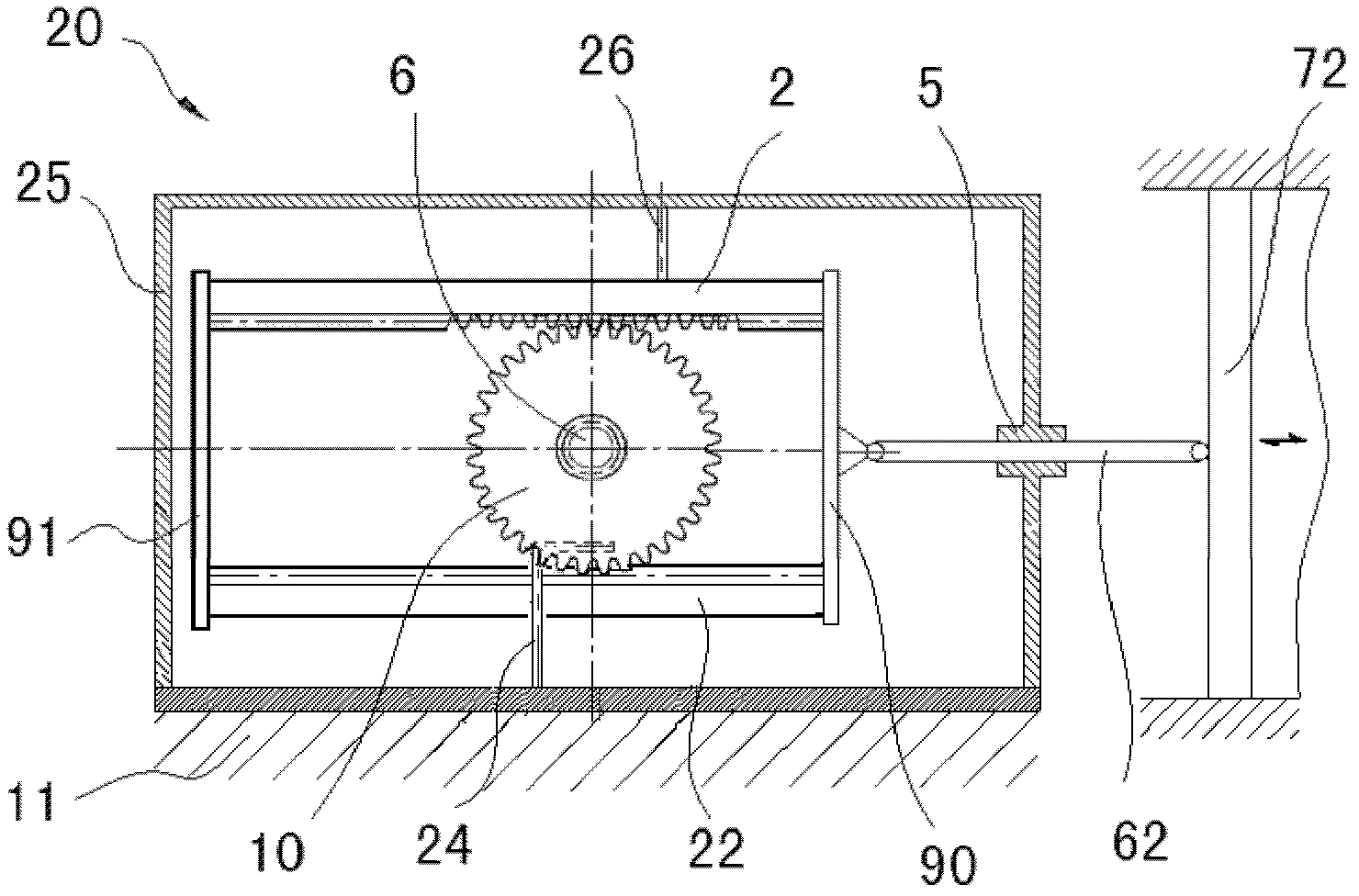

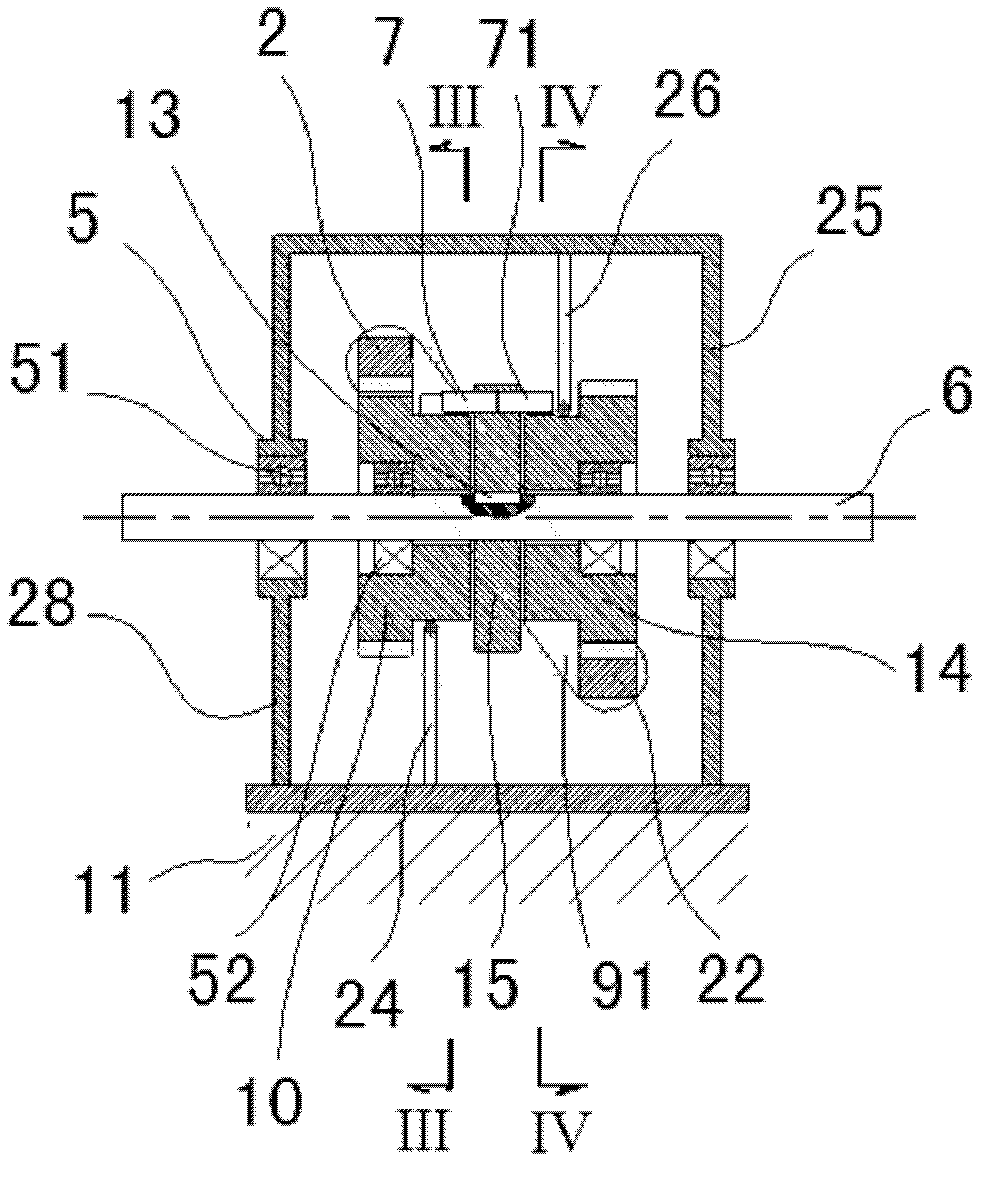

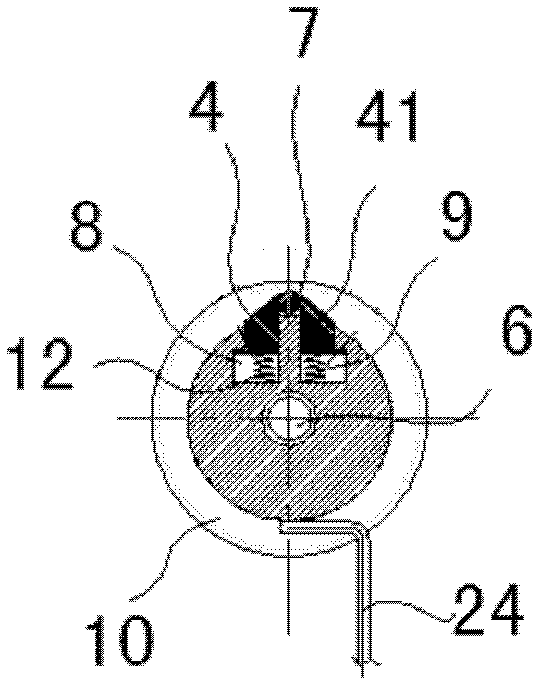

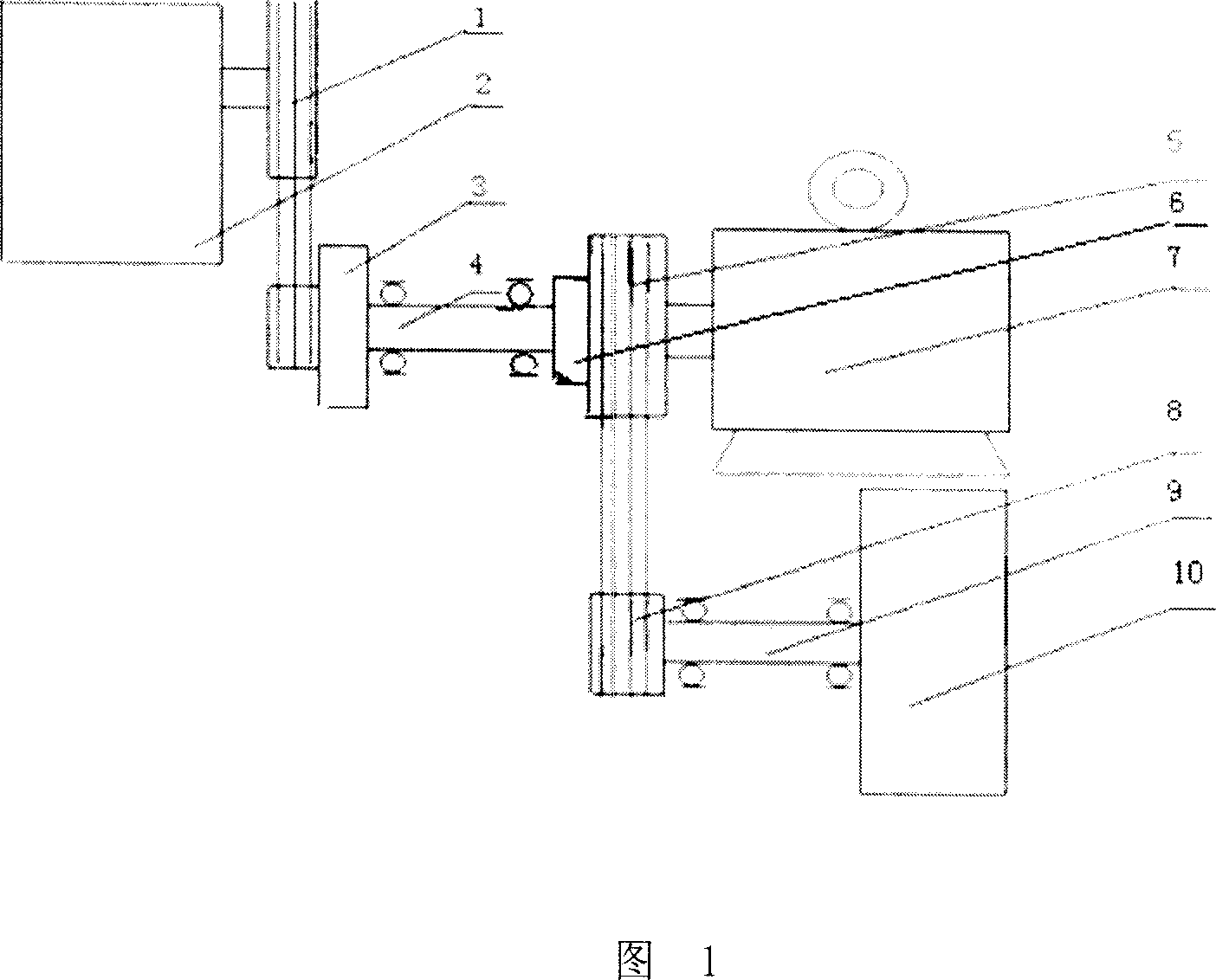

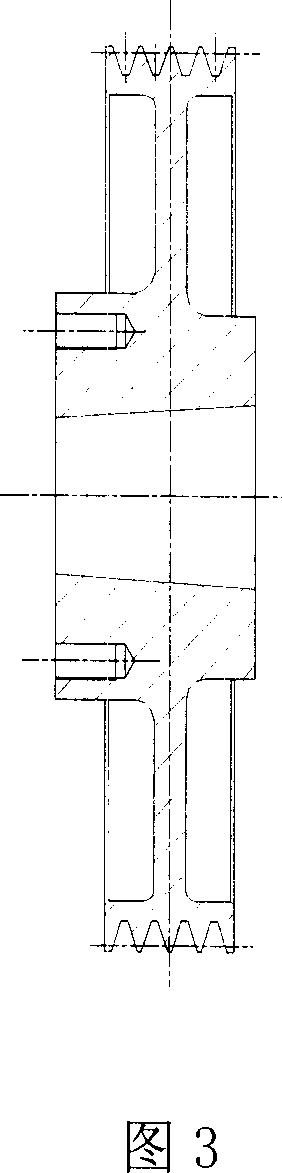

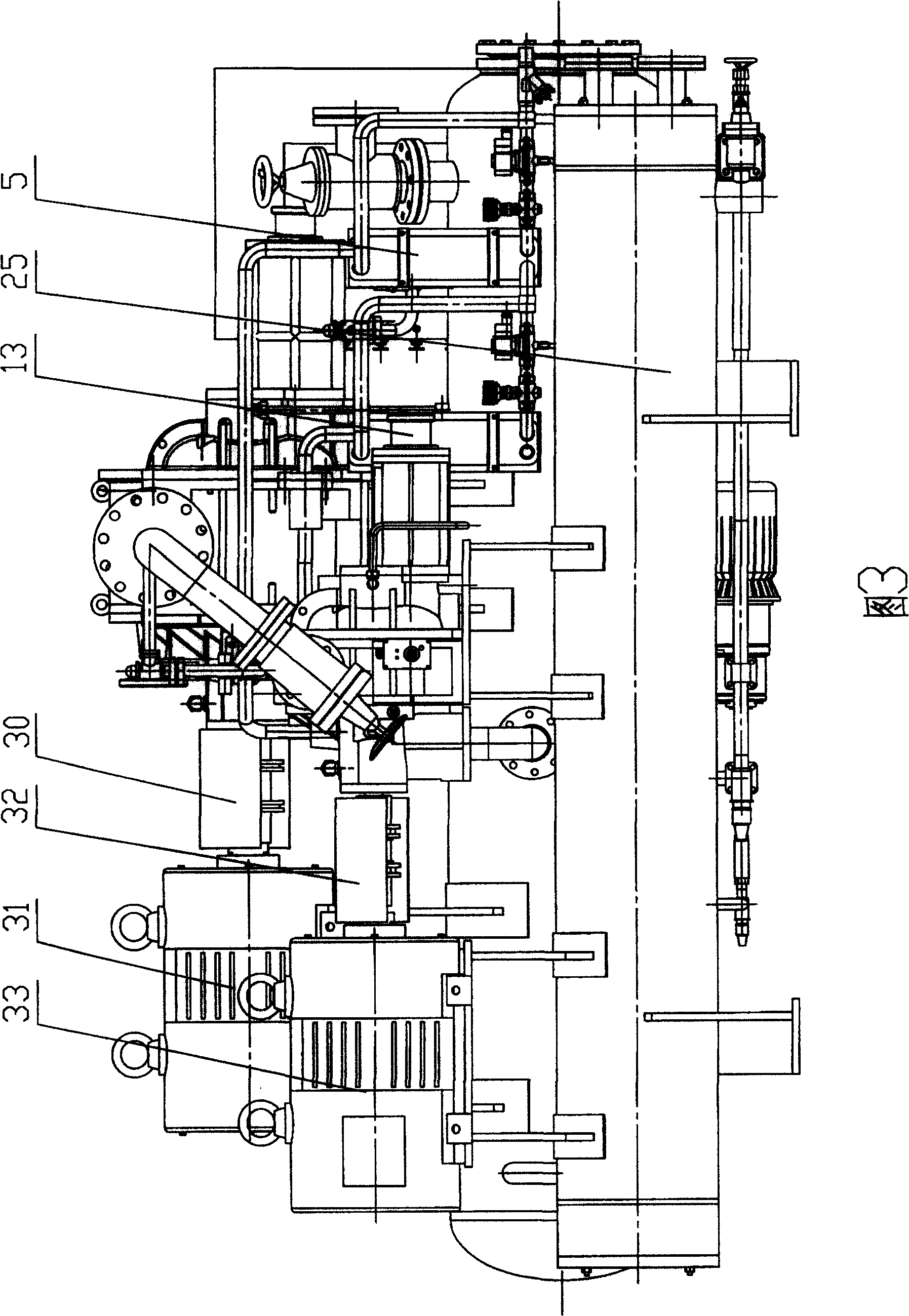

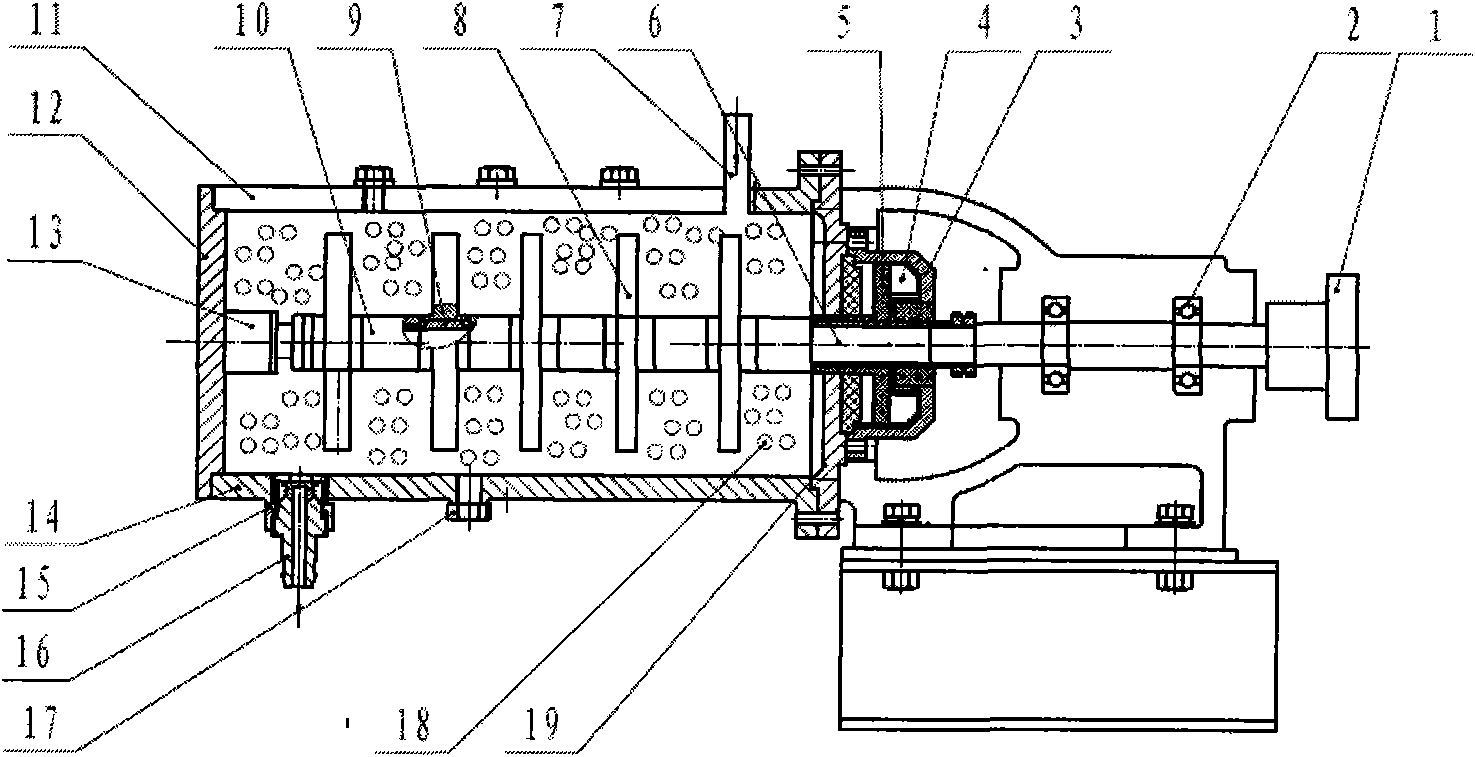

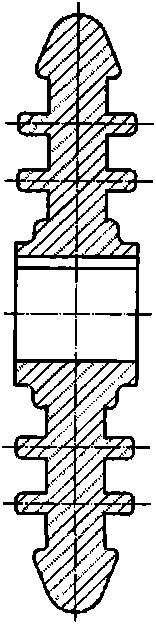

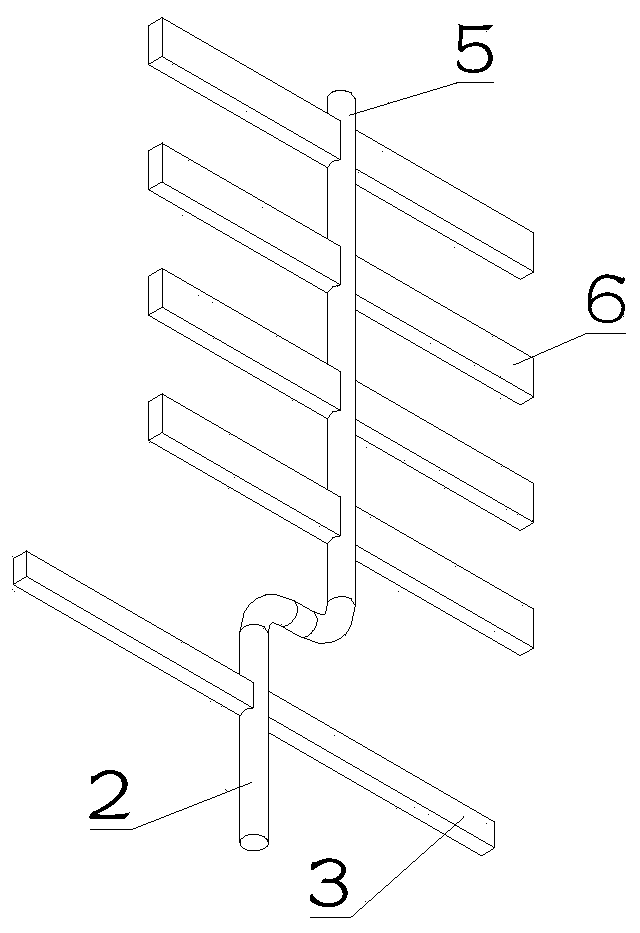

Rotary motion and reciprocating motion converting device

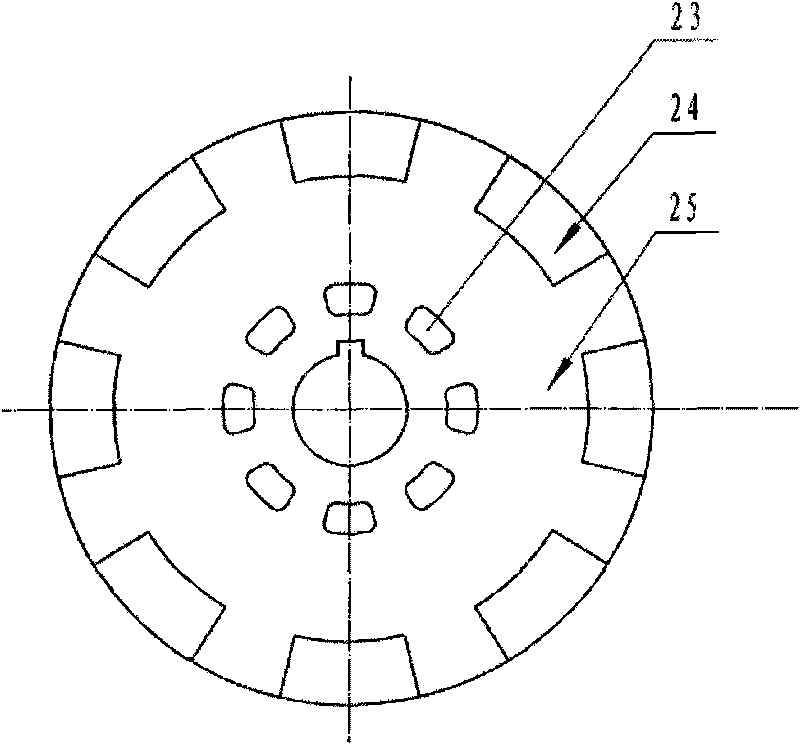

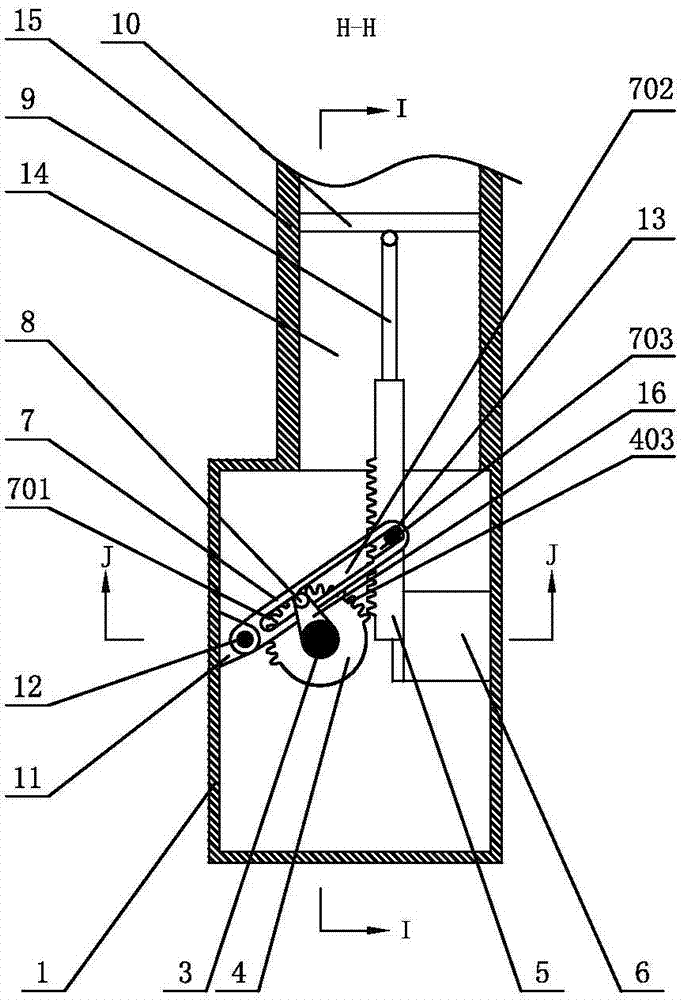

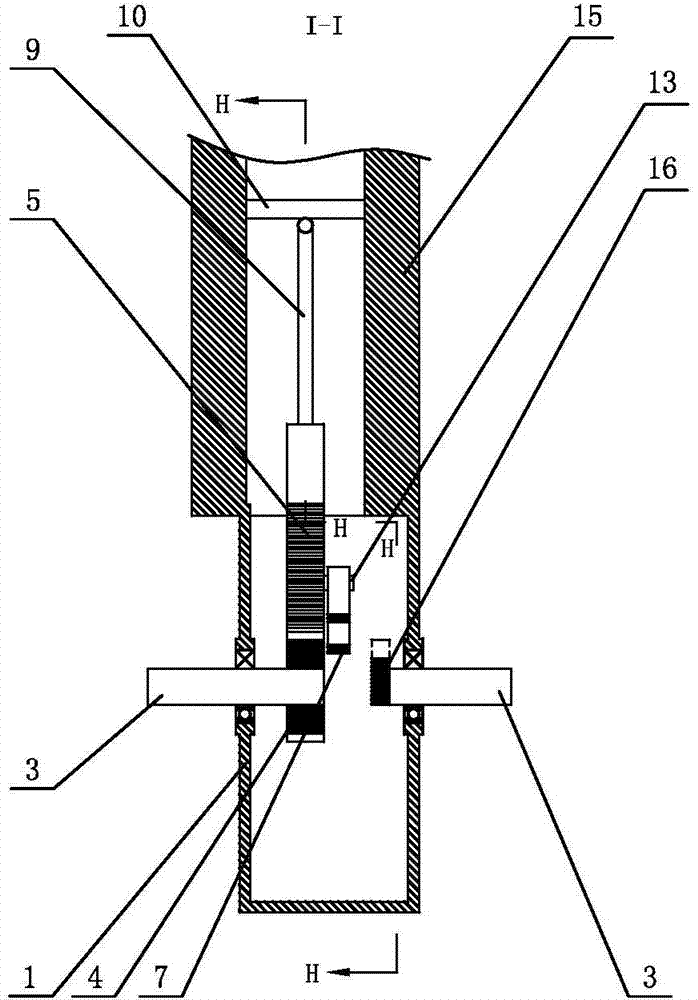

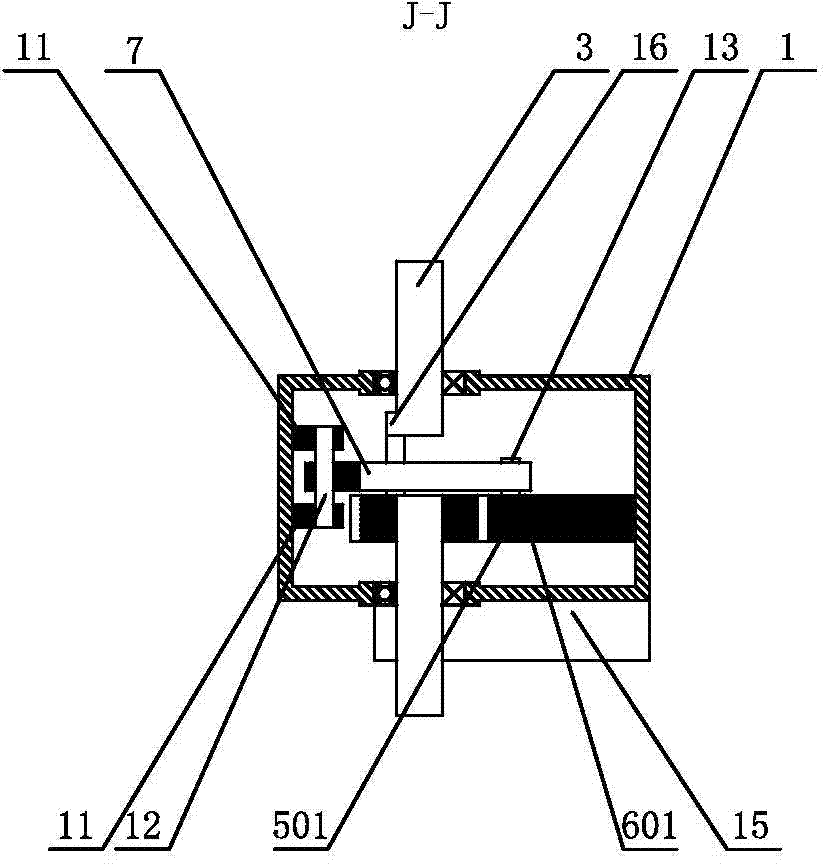

InactiveCN102207179AReasonable power transmission and movement mode conversionIncrease tangential forceFriction gearingsPistonReciprocating motion

The invention relates to a rotary motion and reciprocating motion converting device (20) which comprises pistons (72, 74, 76, 78), wherein one end of each piston rods (62, 64) is connected with the pistons (72, 74, 76, 78); a shell (25) is installed on a base seat (11); a side wall (28) of the shell (25) is provided with a bearing seat (5); a transmission shaft (6) is installed in the bearing seat (5); the transmission shaft (6) is provided with transmission wheels (15, 17); the edge parts of the transmission wheels (15, 17) are provided with column pins (7, 71) extending out axially; a first gear (10) and a second gear (14) which can rotate relative to the transmission shaft (6) are installed close to the transmission wheels (15, 17); the first gear (10) and a first rack (2) are meshed mutually; the second gear (14) and a second rack (22) are meshed mutually; the first rack (2) and the second rack (22) are respectively positioned at two sides of the transmission shaft (6); connecting plates (90, 91) are connected with the end parts of the first rack (2) and the second rack (22); the connecting plates (90,91) are connected with other ends of the piston rods (62, 64); tooth-free parts of the first gear (10) and the second gear (14) are respectively provided with pin grooves (9, 21); the pin grooves (9, 21) are internally provided with sliding blocks (32, 42) which are matched with the column pins (7, 71); and the restoration springs (12, 121) are arranged below the sliding blocks (32, 42). Thus the conversion between the rotary motion and the reciprocating motion is realized.

Owner:安里千

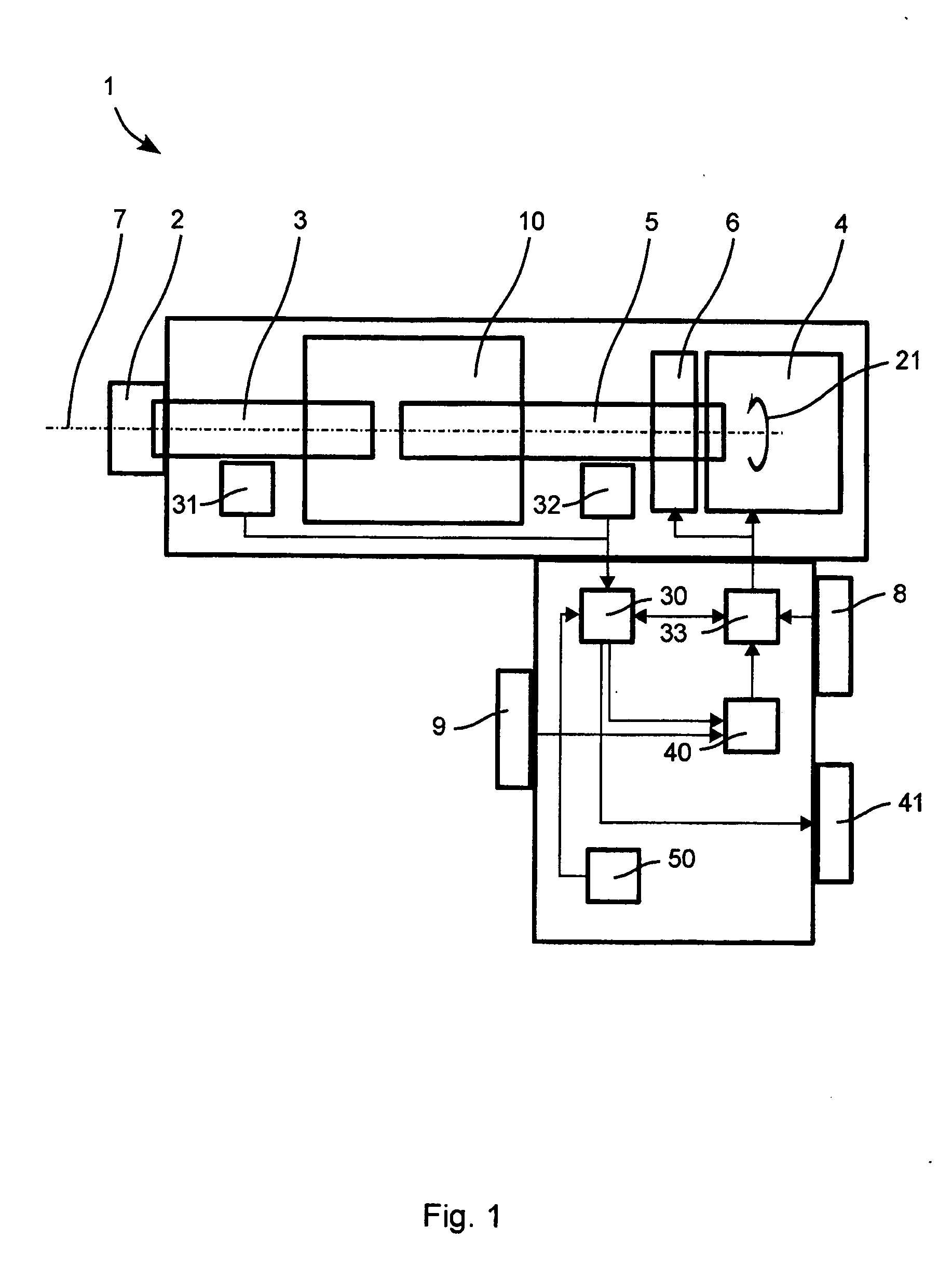

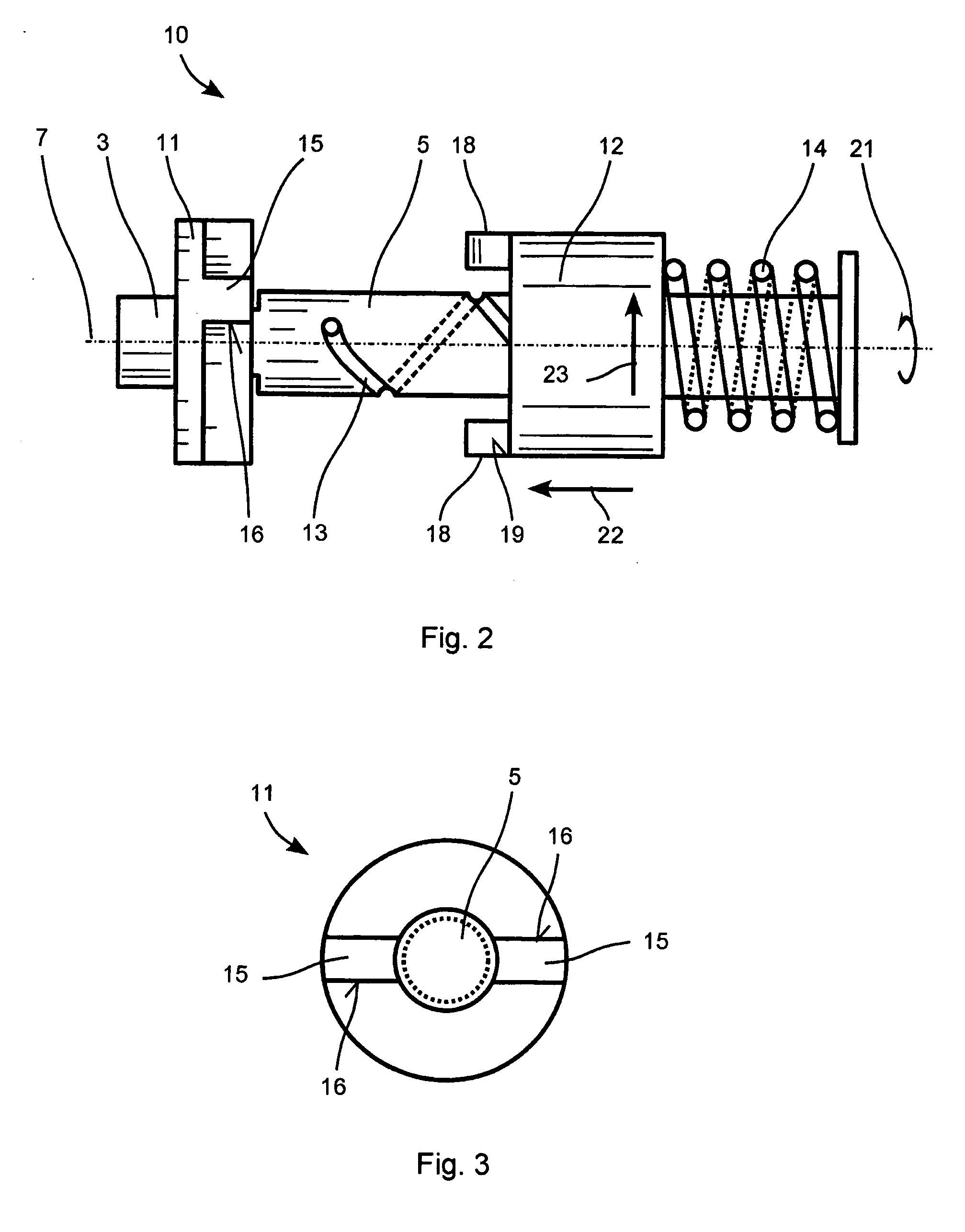

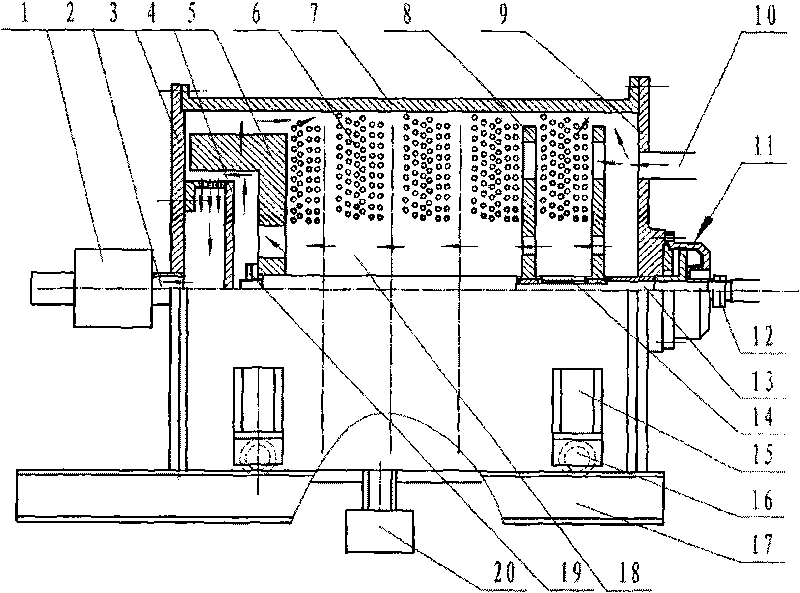

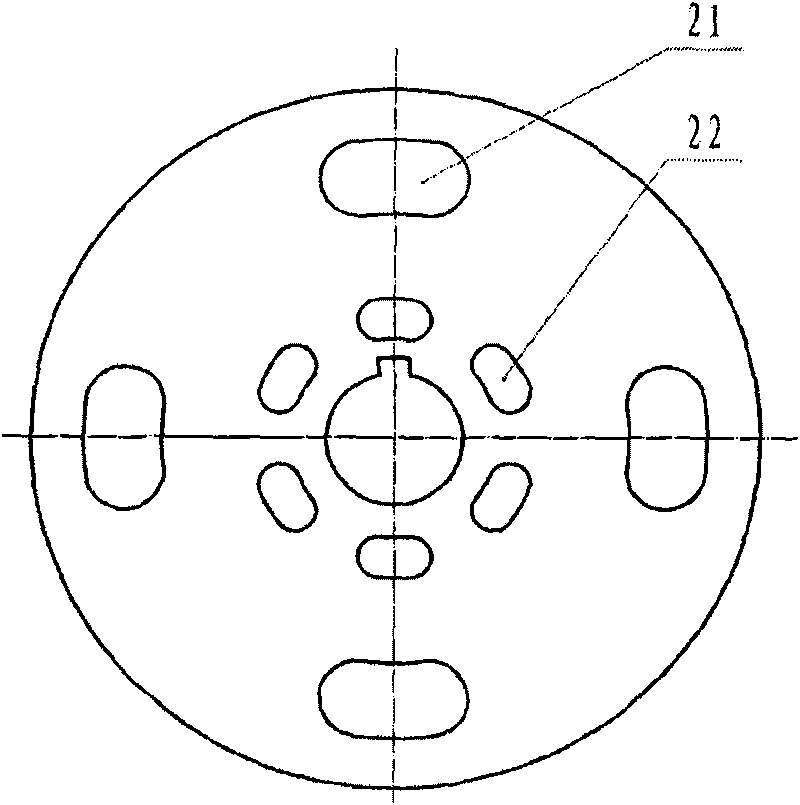

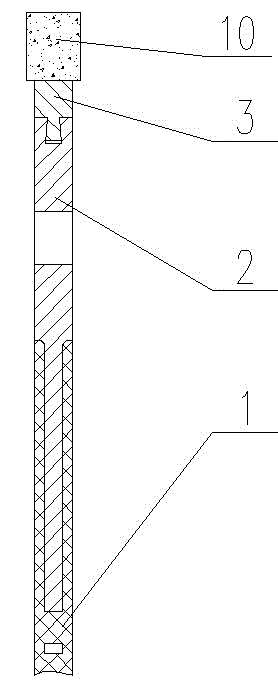

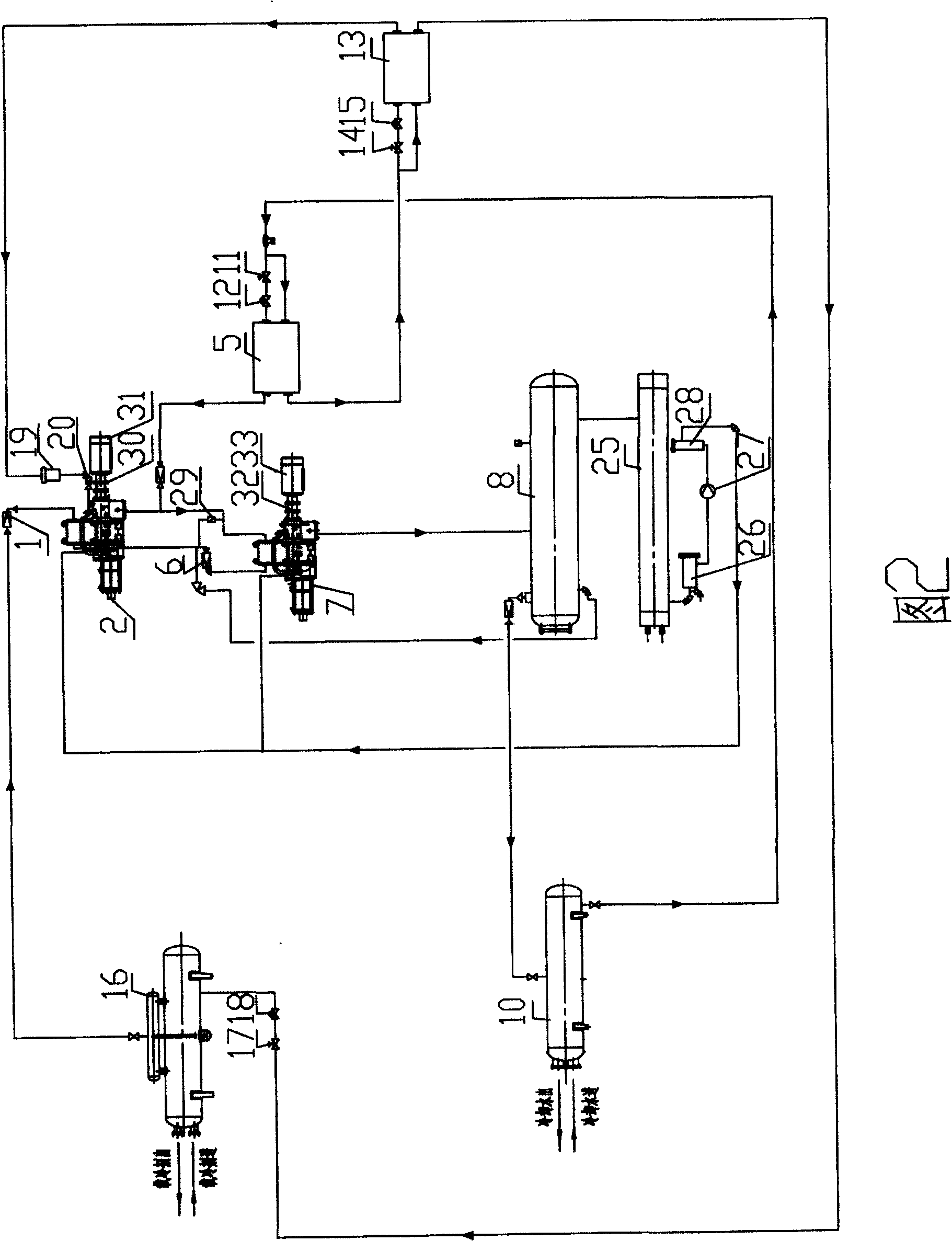

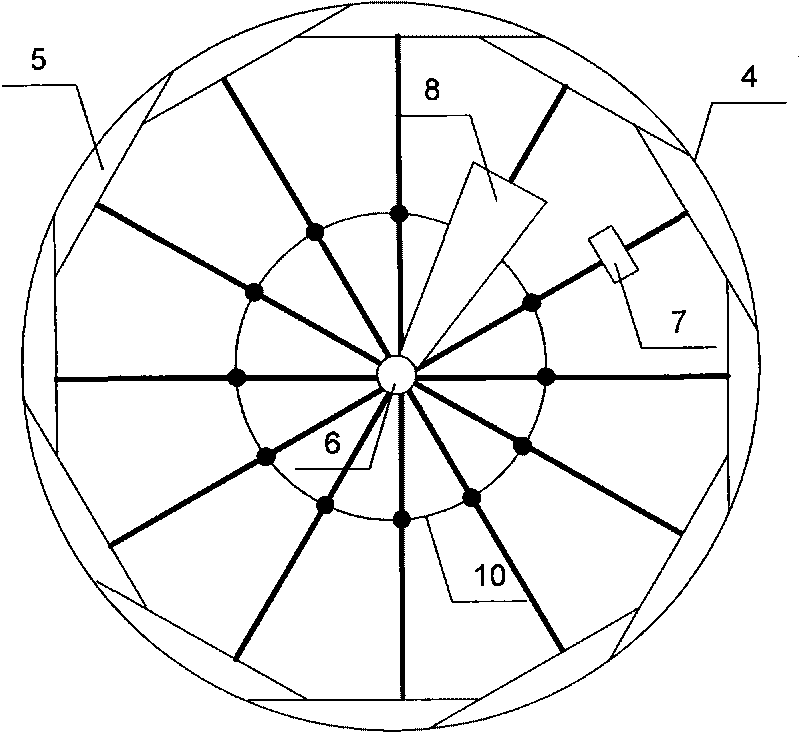

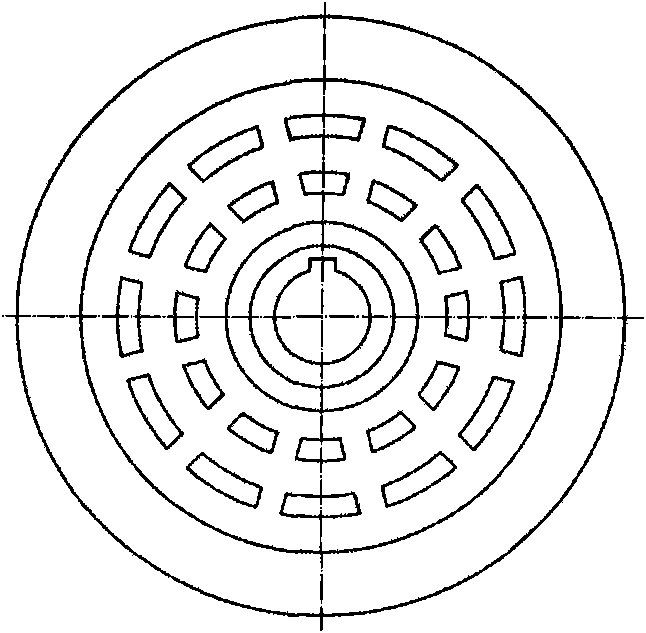

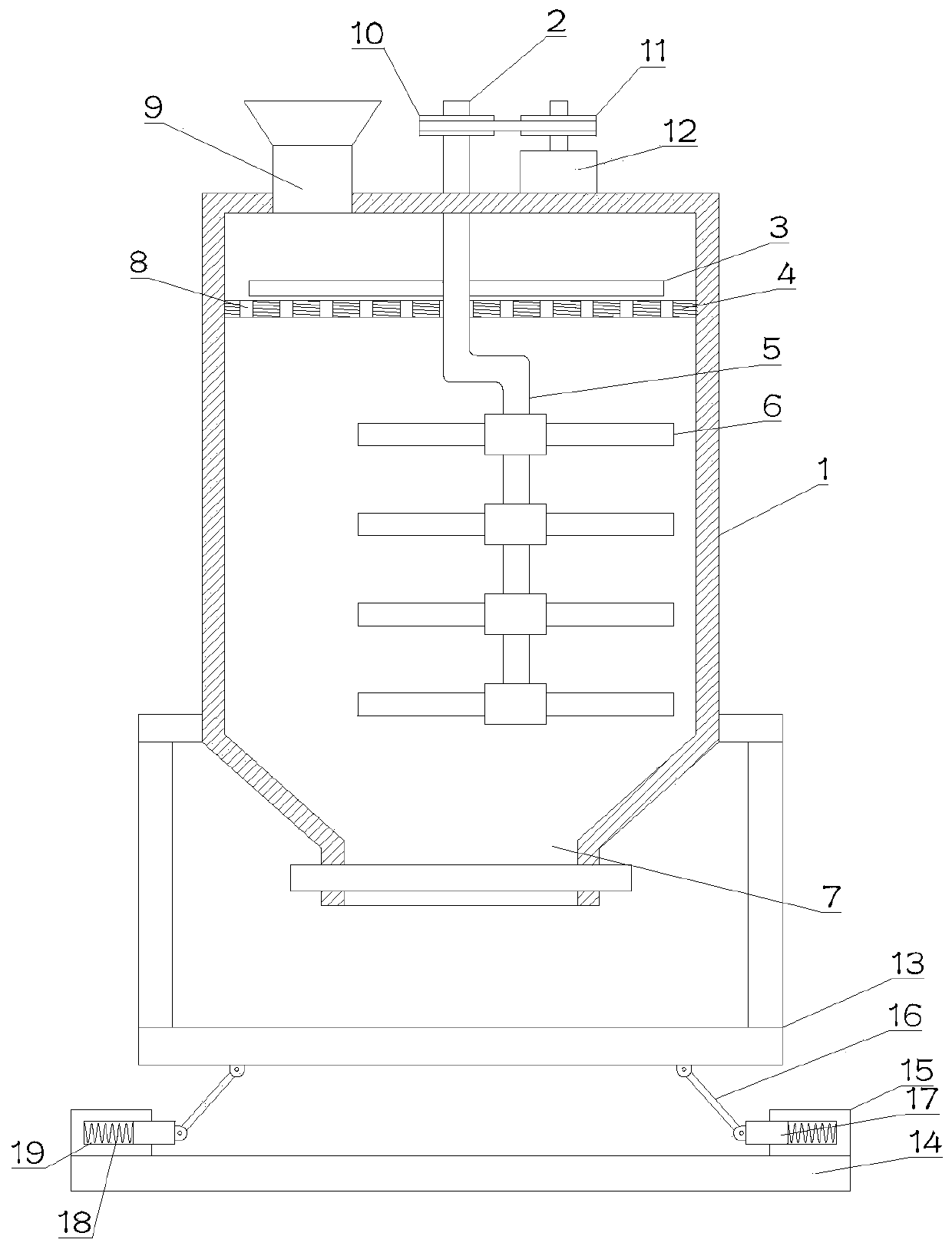

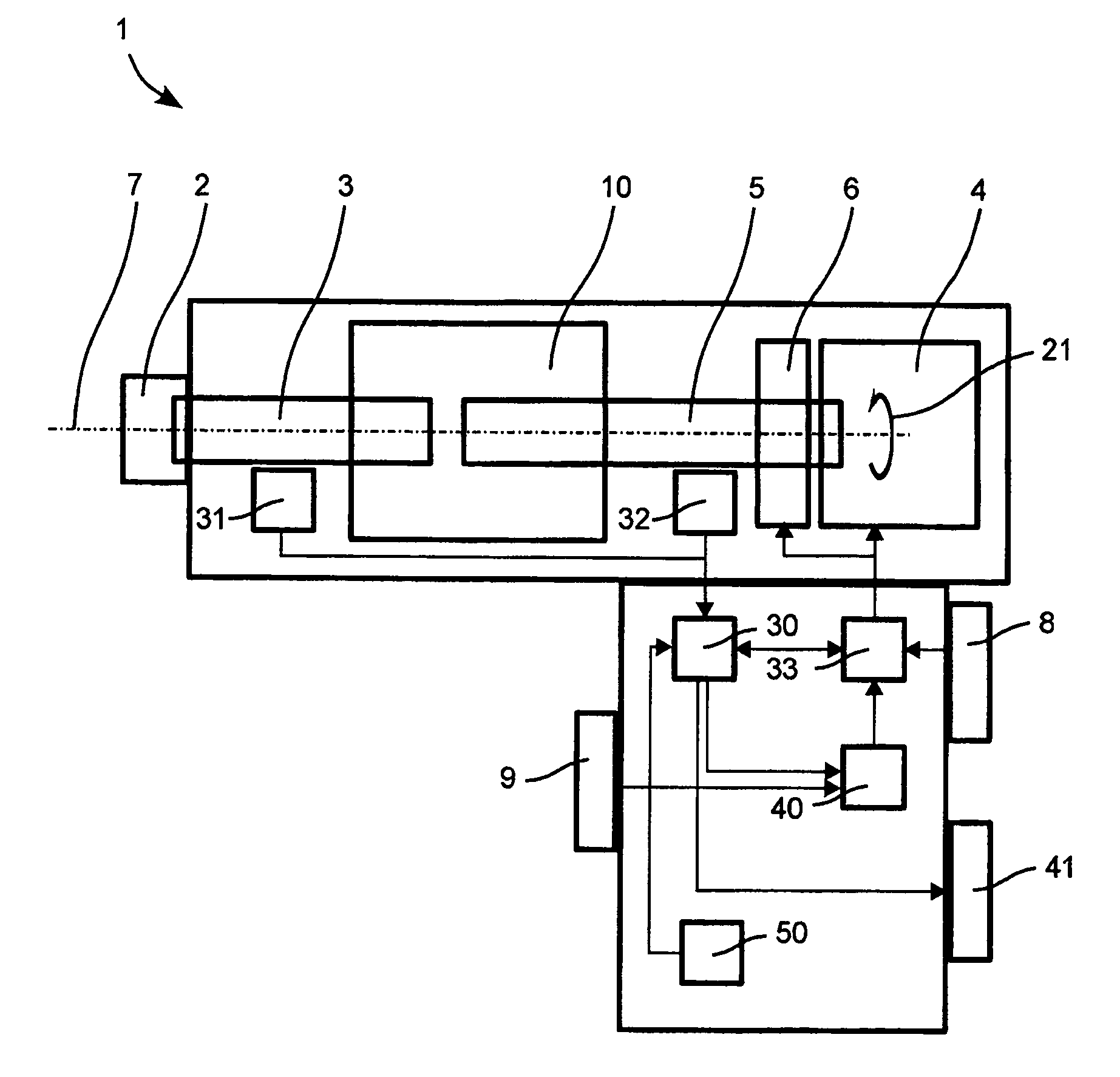

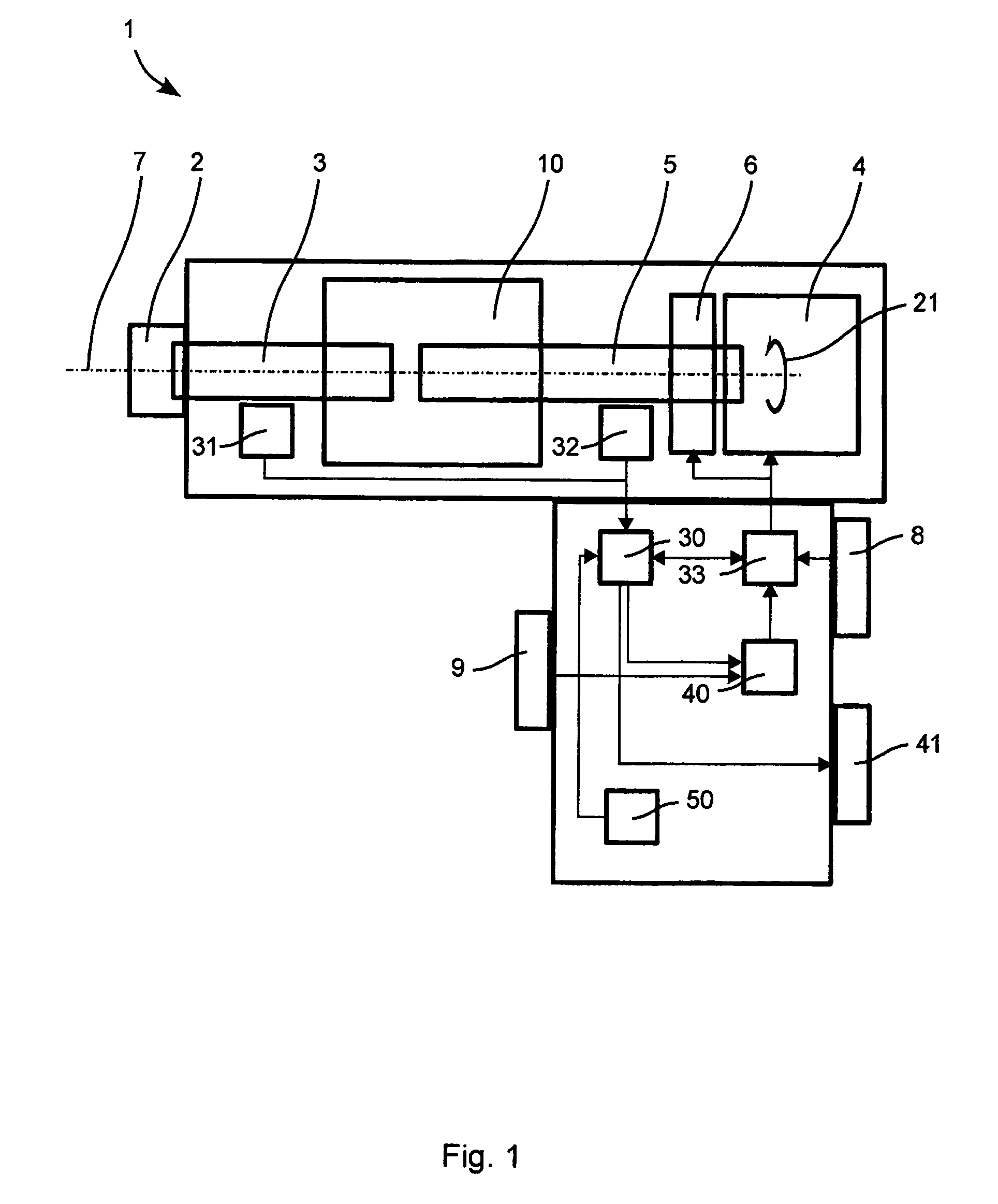

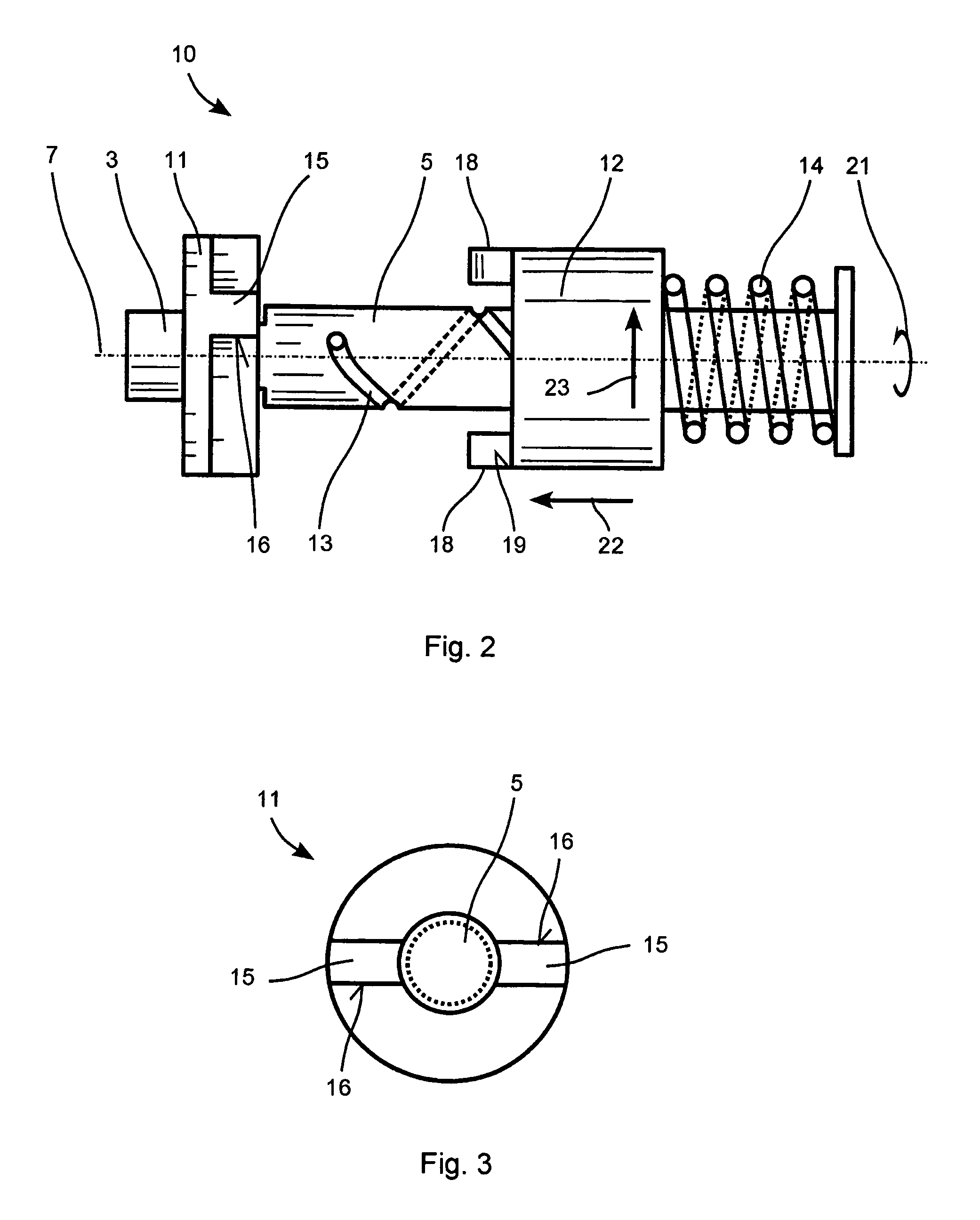

Horizontal grinding mill with built-in classifying turbine

InactiveCN101700504AOvercoming frictional resistanceReduce starting powerEngine sealsGrain treatmentsImpellerTurbine

The invention relates to a horizontal grinding mill with built-in classifying turbine, the technical solution of which is that a grinding chamber [18] is filled with grinding medium [6], a medium discharging valve [20] is installed on the middle of the bottom of a cylinder [7], a feeding pipe [10] is above a right end cover [9] of the grinding chamber [18] and a medium discharging pipe [2] is concentrically communicated with the grinding chamber [18] by a left end cover [3]. The length of the cylinder [7] is 1.5 to 2.5 times of the diameter thereof. A fairing [4] is fixedly installed on the left end cover [3] of the grinding chamber [18]. A classifying turbine [5] is vertically installed on the left end of a spindle [13]. A clearance between the classifying turbine [5] and the left end cover [3] is 5mm to 10mm. Five to eight mixing turbines [8] are vertically installed on the spindle [13]. The distance between the mixing turbines [8] decreases gradually from left to right and the right distance is 0.9 to 0.95 times of the left distance. The right end of the spindle [13] is connected with a driving mechanism by the right end cover [9] and a sealing device [11]. The invention has low starting power and can grind and classify with a function of selectively grinding.

Owner:WUHAN UNIV OF SCI & TECH +1

Engine transmission mechanism capable of replacing crankshafts and connecting rods and linkage power transmission mechanism

InactiveCN104500667AImprove conversion efficiencySave energyTransmission elementsFluid gearingsActuatorRound bar

The invention discloses an engine transmission mechanism capable of replacing crankshafts and connecting rods. The engine transmission mechanism comprises sector gears, racks and rotary arms. Each sector gear is mounted at an end of a spindle, the racks can slide on guide plates and can be reset by the aid of the rotary arms, the racks and the gear sectors are alternately meshed with one another, the spindles can rotate along with the driving sector gears and output power, journals on the side surfaces of the sector gears and resetting round bars on the side surfaces of the racks alternately drive the rotary arms by the aid of journal slide grooves and reset slide grooves to swing in a reciprocating manner, the journal slide grooves and the reset slide grooves are formed in the rotary arms, end teeth at one end of each sector gear are separated from end teeth at one end of the corresponding rack when pistons are positioned at lower dead centers, collision of the journals and ports of the journal slide grooves can be prevented by the journals by the aid of guide grooves of the rotary arms, collision of end teeth at the other end of each sector gear and end teeth at the other end of the corresponding rack can be prevented by the journals by the aid of the guide grooves when the pistons cross upper dead centers, and accordingly reciprocating linear movement of the pistons and rotation movement of the sector gears can be stably switched over. The engine transmission mechanism has the advantages that the engine transmission mechanism can replace crankshaft and connecting rod transmission actuators, accordingly, inherent shortcomings of crankshaft and connecting rod mechanisms can be overcome, and the conversion efficiency of engines can be greatly improved.

Owner:安里千

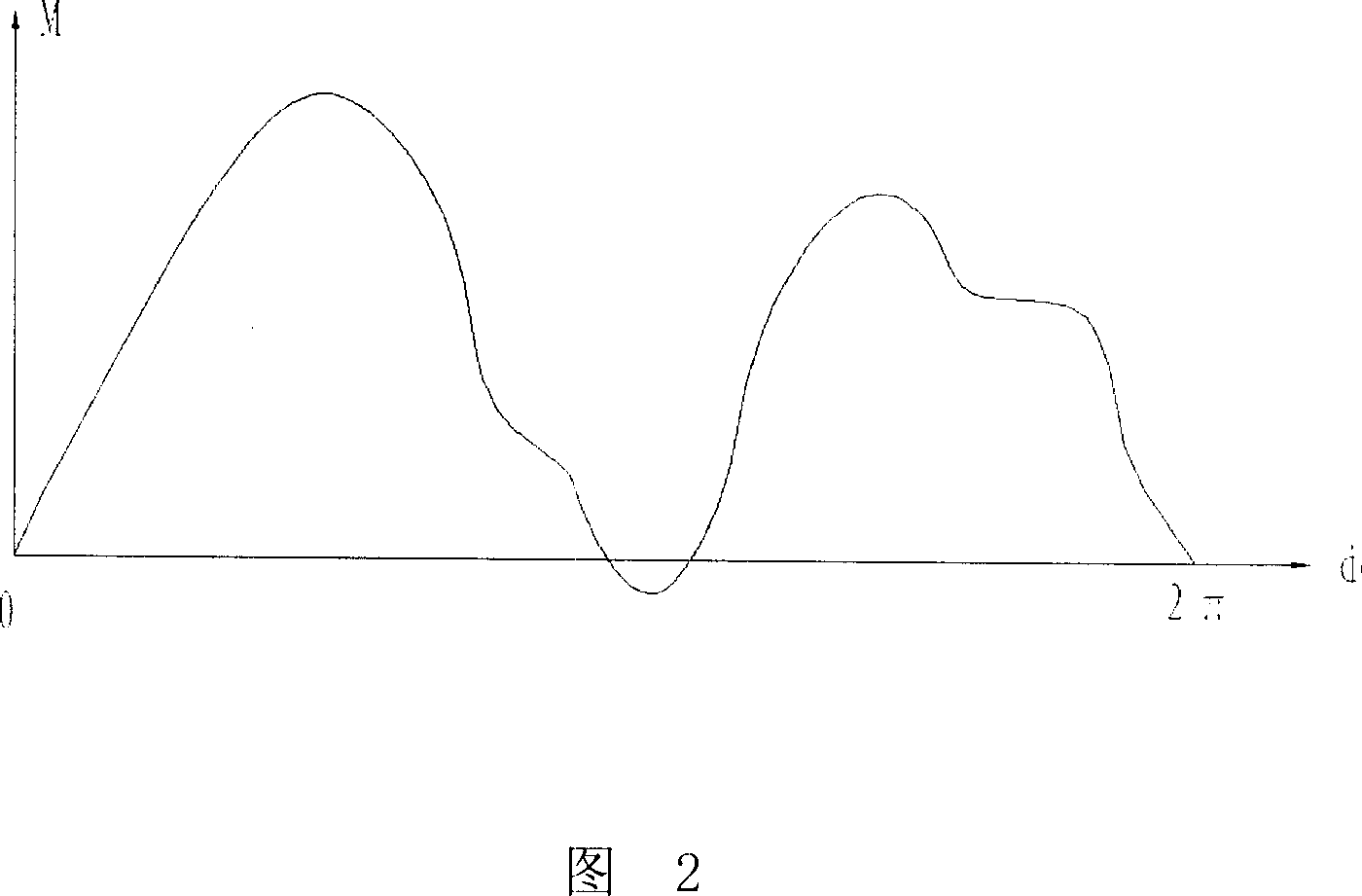

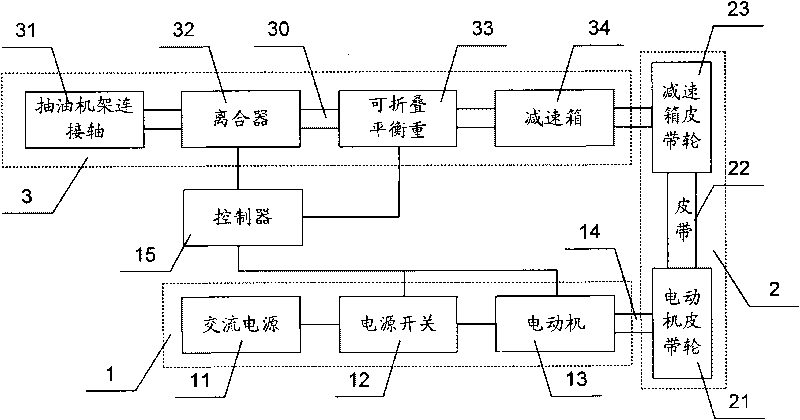

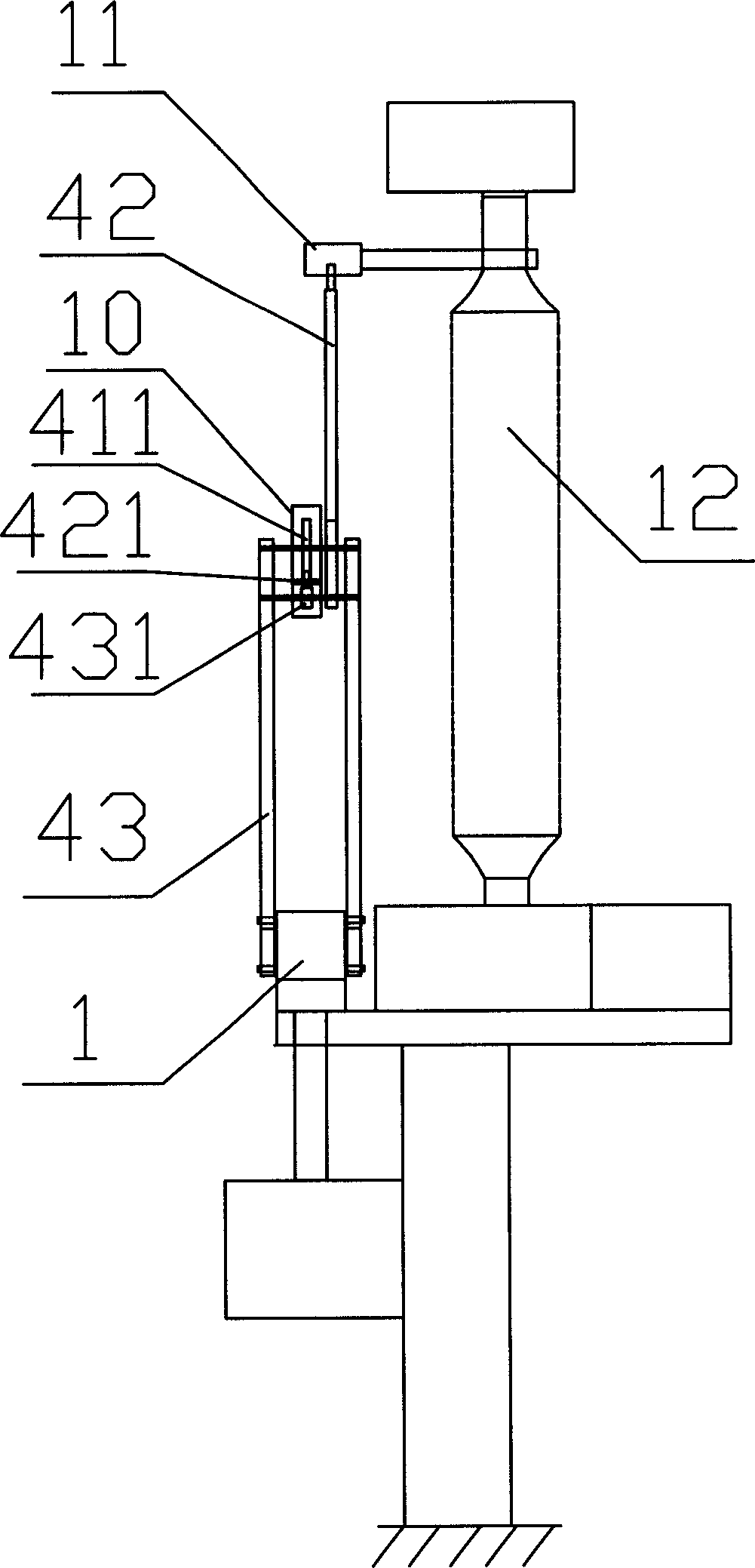

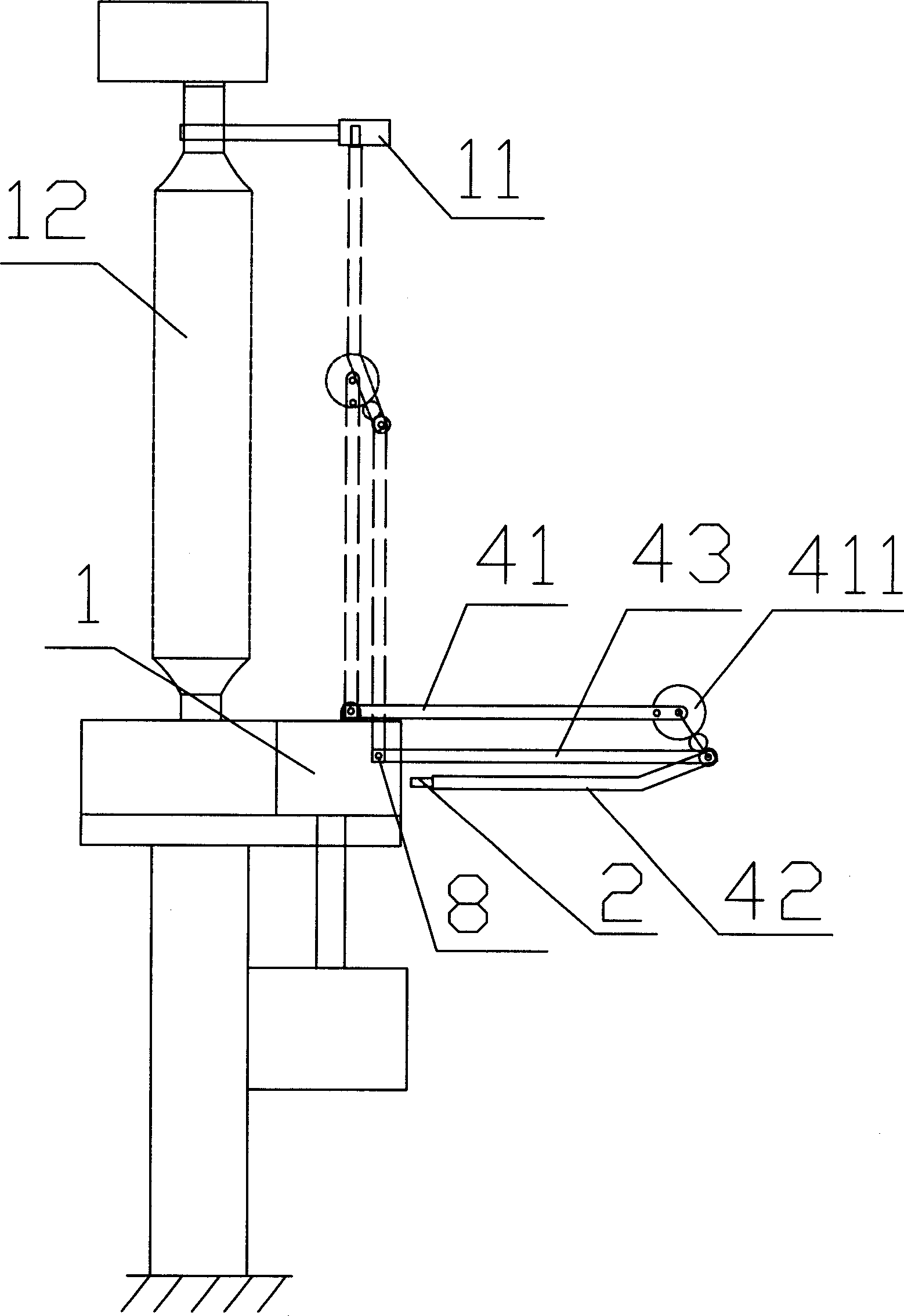

Method of raising motor efficiency in pumping unit and energy balance device therefor

InactiveCN101046144AReduce starting powerReduce the range of slip variationGearingFluid removalMotor driveElectric machine

The present invention is method of raising motor efficiency of pumping unit and energy balance device therefor. The present invention features that one energy balance device is mounted between the gear box and the motor of the pumping unit. Before starting the pumping unit, the motor drives the flywheel in the energy balance device to rotate for storing energy; after the flywheel reaches certain rotation speed, the energy balance device is combined to the gear box to start the pumping unit; and after the pumping unit is started, the motor and the energy balance device drive the pumping unit together. The present invention has the features of reduced motor power, raised motor efficiency and saving in power.

Owner:DAQING OILFIELD CO LTD

Energy-saving environment-friendly polymer-based composite material matrix of diamond circular saw blade

InactiveCN102744789AReduce startup power and self-consumptionFeatures of simple production processStone-like material working toolsFiberWorking environment

The invention discloses an energy-saving environment-friendly polymer-based composite material matrix of a diamond circular saw blade. The energy-saving environment-friendly polymer-based composite material matrix comprises a matrix and an embedded part, wherein the embedded part is embedded on the outer circumference of the matrix; the matrix is made from a polymer-based composite material; and an exposed part external end face of the embedded part is welded with at least one diamond saw tooth. With adoption of the polymer-based composite material, about 2 / 3 weight is reduced compared with the traditional steel-based body, so that the starting power and self consumption of the motor are greatly reduced, and the manufacturing process is very simple and convenient, thereby the energy-saving and low-carbon effect stands out. In addition, an interface between a large number of resins and reinforced fiber exists in the base body, so that the noise when the stone is sawn is reduced obviously, and the working environment is improved.

Owner:NANPI FEILONG HARDWARE PROD CO LTD

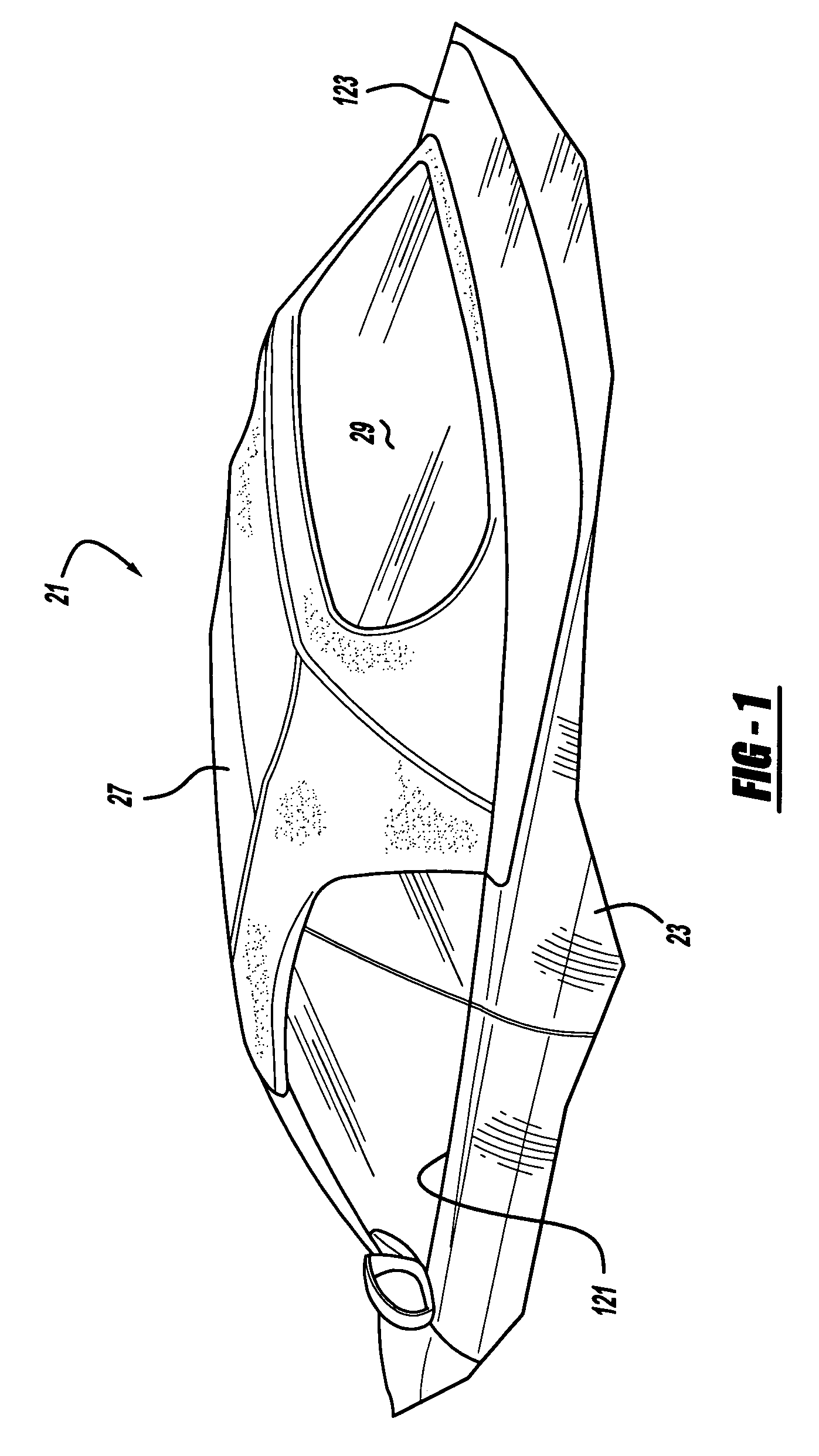

Convertible vehicle top stack mechanism

InactiveUS20050189781A1Reduce starting powerReducing acceleration spikeEngine sealsVehicle sealing arrangementsBuggy vehicleEngineering

A convertible vehicle top stack mechanism includes a moveable rearmost roof bow and an actuator. In an other aspect of the present invention, a linkage assembly couples a rearmost roof bow to a side rail. A further aspect of the present invention employs a rotatable member or crank to drive a set of buggy links in order to raise and lower an active number five roof bow.

Owner:SPECIALTY VEHICLE ACQUISITION

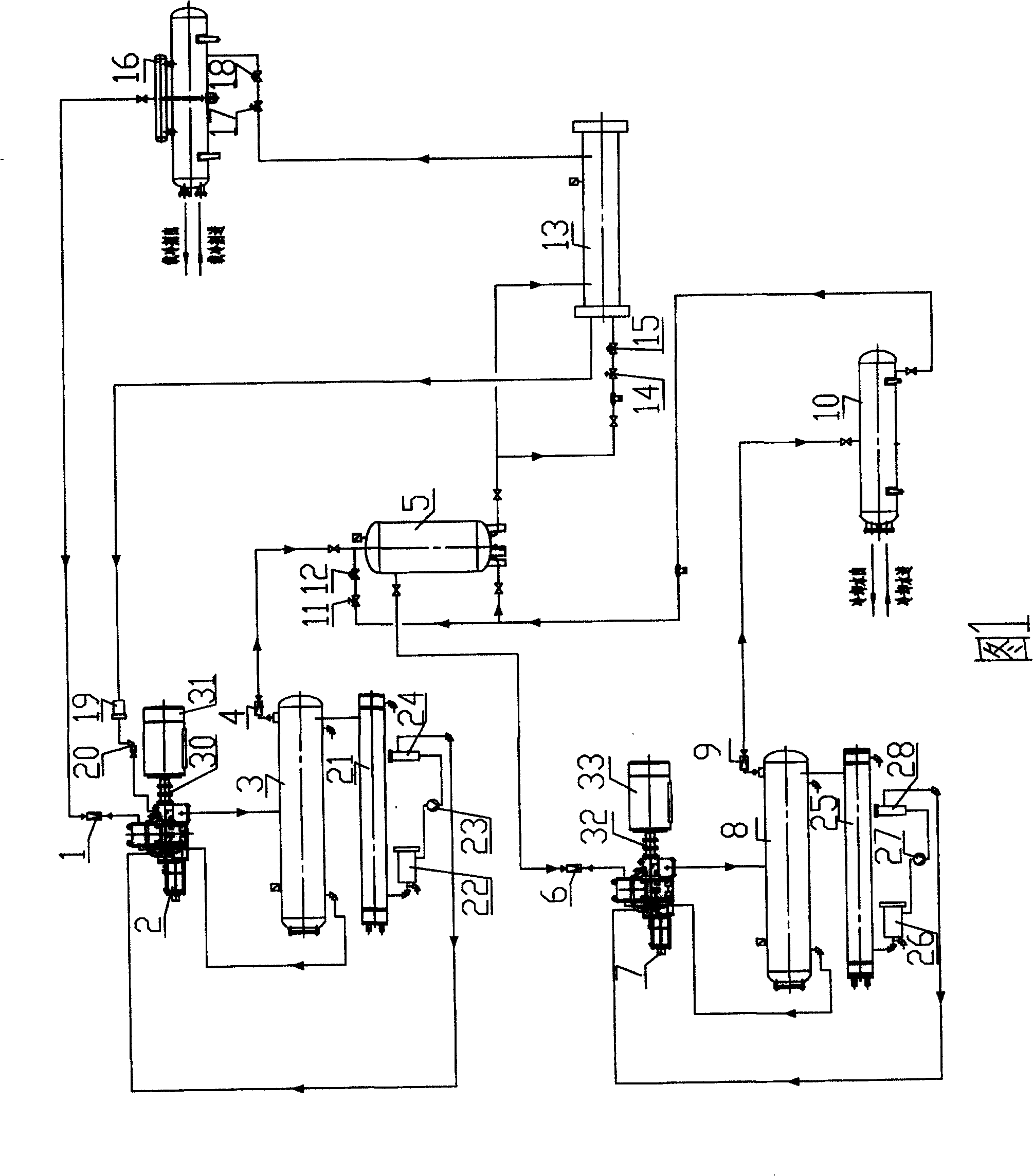

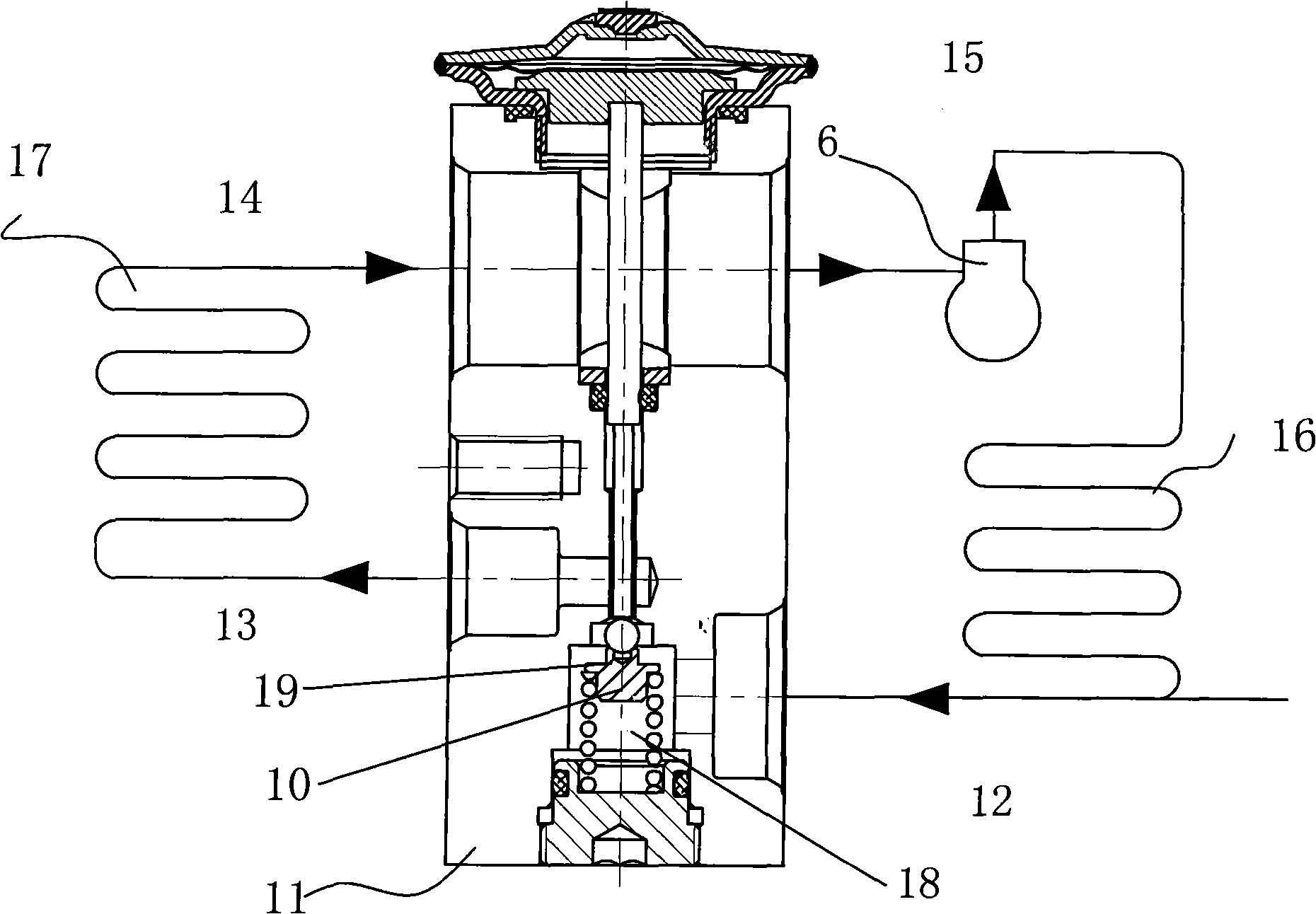

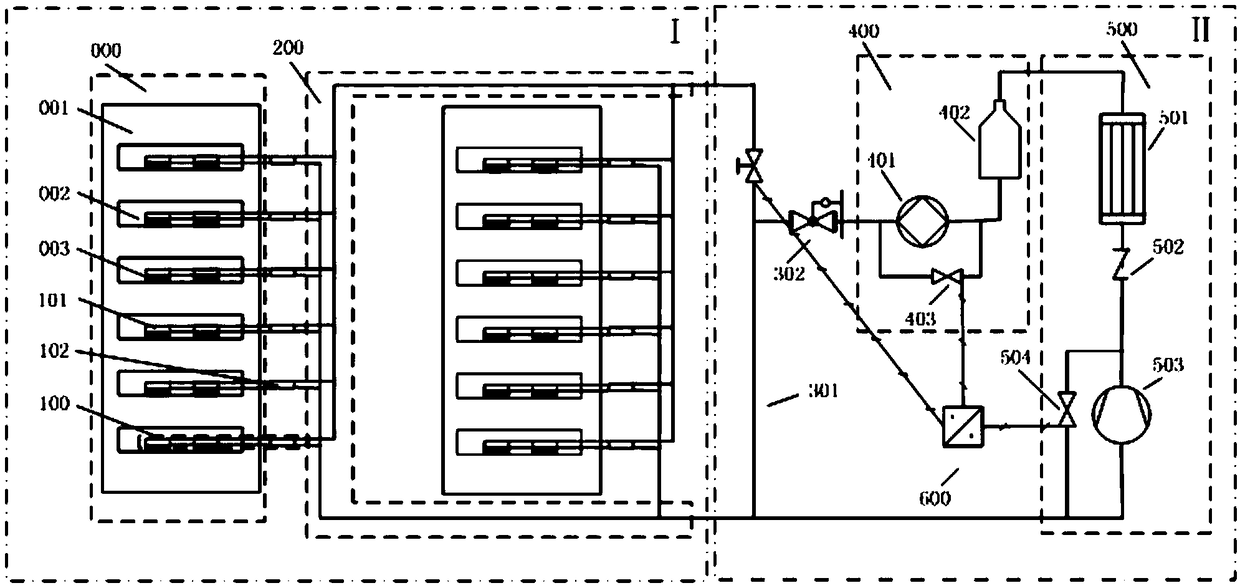

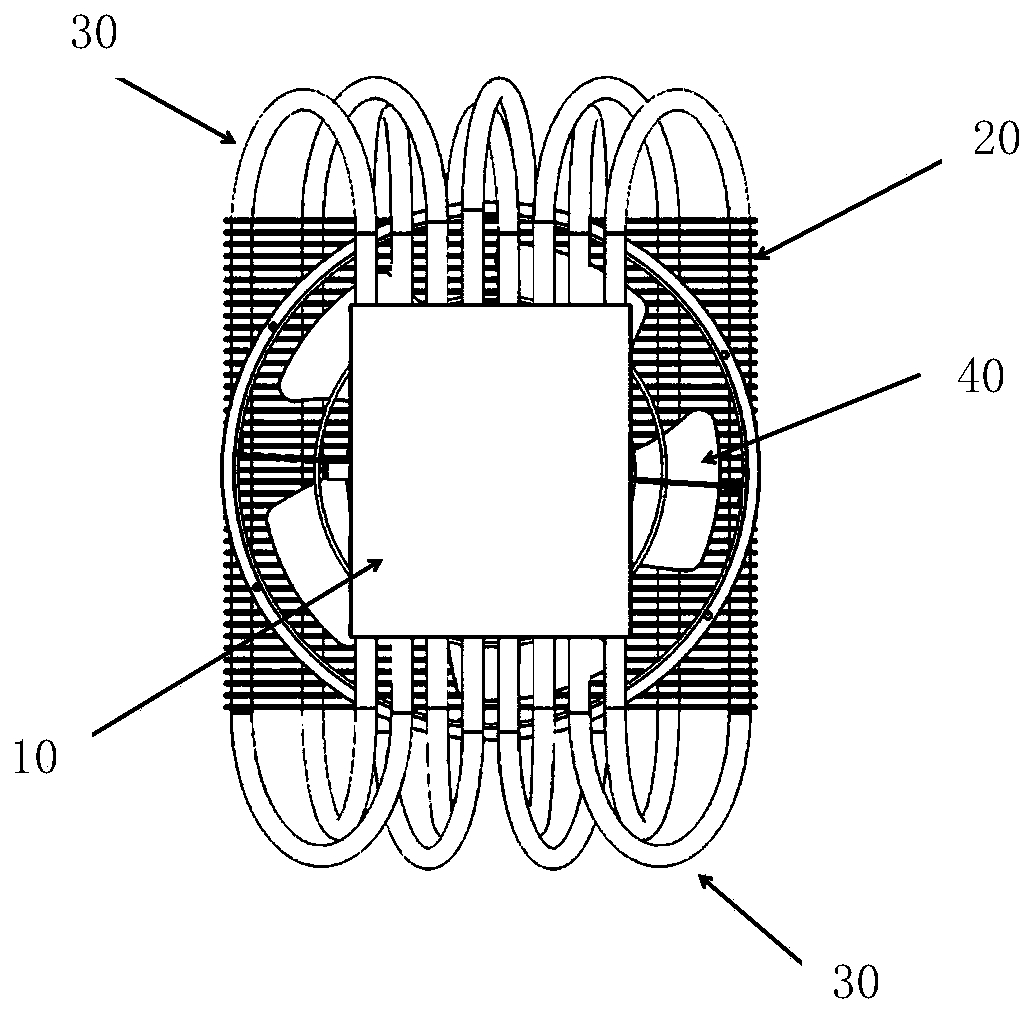

Dual-locomotive and dual-stage screw refrigerating compressor set

ActiveCN100447501CLow powerRun energy savingCompression machines with non-reversible cycleCompression machines with cascade operationRefrigeration compressorDual stage

This kind of double-machine, double-screw cold compressor system mainly consists of evaporator, compressor in low-pressure zone, compressor in high-pressure zone, recycle unit to separate oil, condenser, condenser in the middle part, low-pressure economizer system. There is no inspiration passage between evaporator and compressor in high-pressure zone. The vent on compressor in low-pressure zone connects directly with the air entry on compressor in high-pressure. Compressors low-pressure zone and high-pressure zone share one recycle unit of oil separation. Condenser, condenser in the high-pressure zone, economizer system in low-pressure zone and evaporator are linked up in that order so that part of the refrigerating medium can absorb enough heat to boil and evaporate, provide vapor at a temperature near saturation to the compressor in the high-pressure zone and supply vapor to the compressor in the low-pressure zone. Meanwhile, the other part of refrigerating medium will be passed to the evaporator after being cooled twice for recycle. It is the best choice among the products of refrigeration and deepfreeze in low temperature because of its tidy and compact structure, reasonable layout, small size, stable and credible operation, low cost and high cooling performance.

Owner:武汉新世界制冷工业有限公司

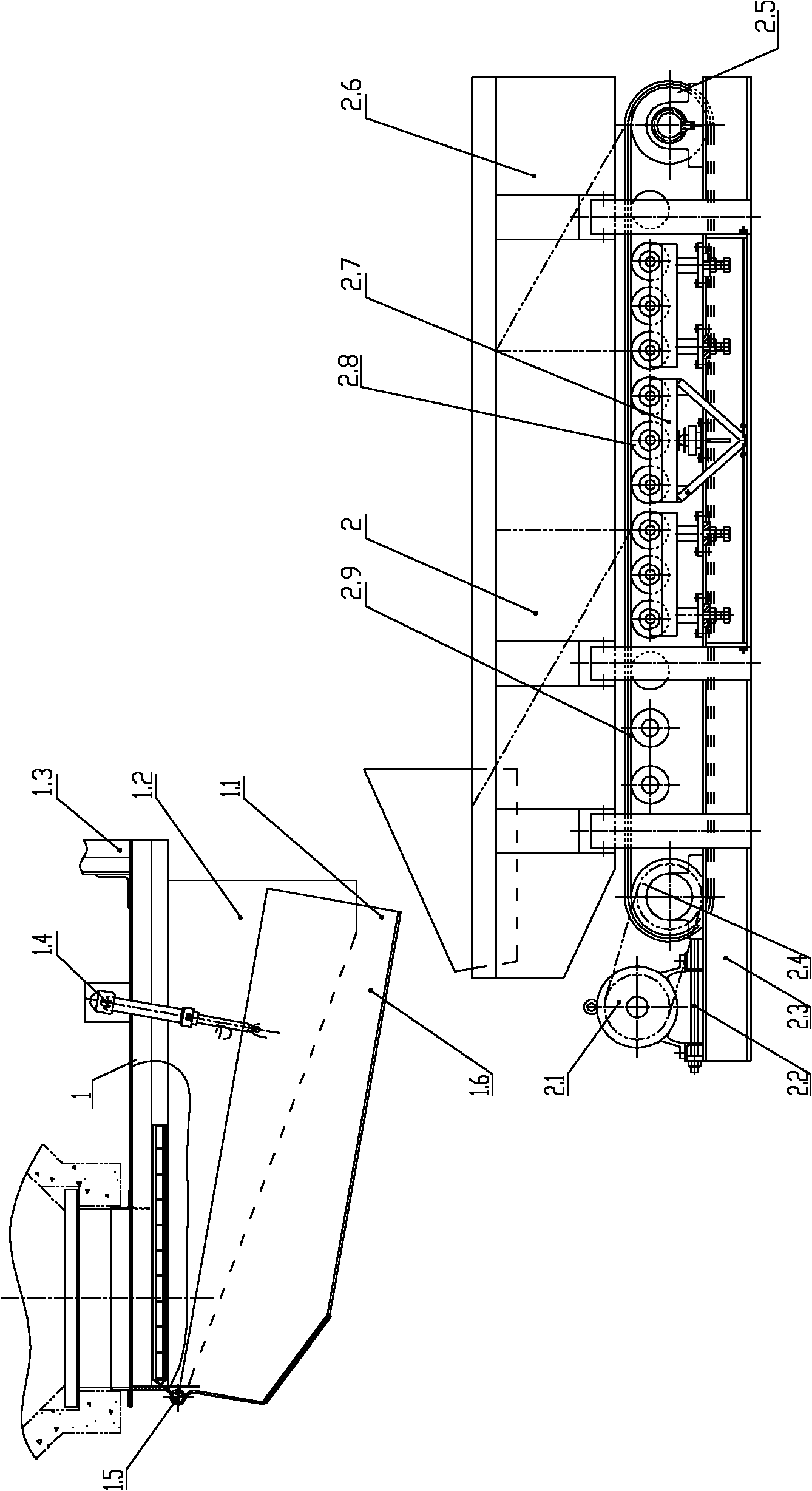

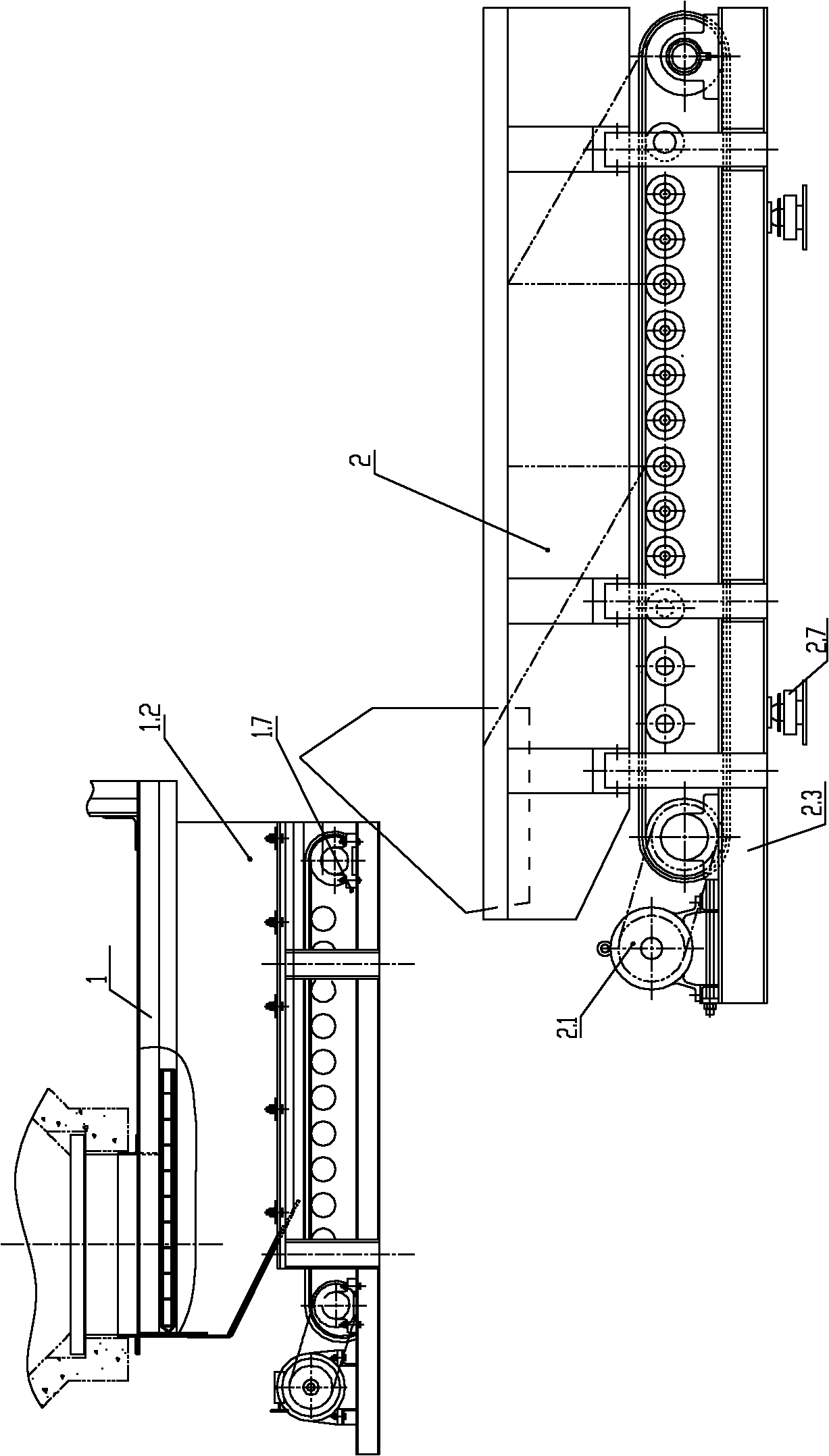

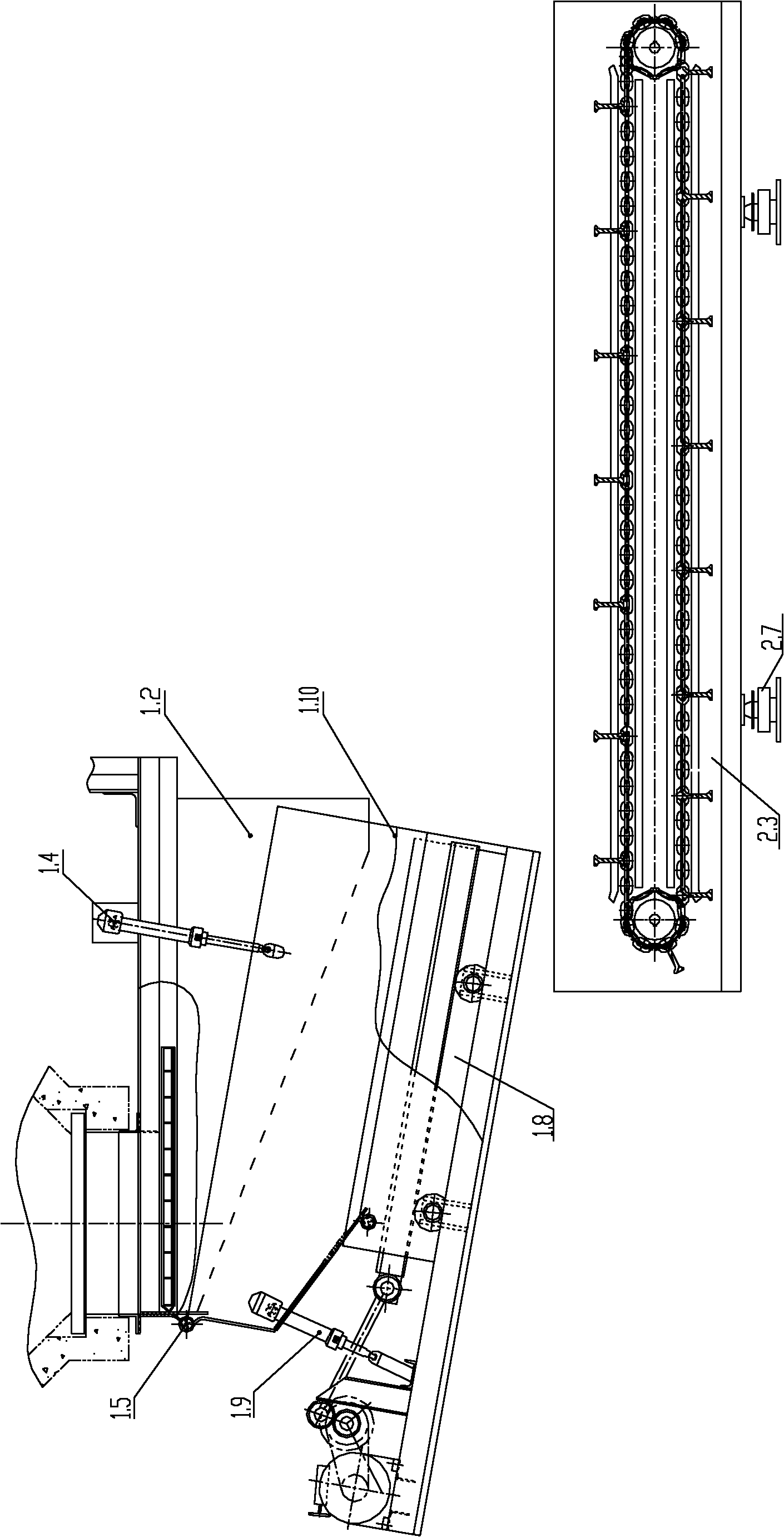

Impact-free interference removal high-precision gravimetric feeder

InactiveCN102009827AReduce starting powerReduce operating powerCleaningWeighing apparatus with automatic feed/dischargeEngineering

The invention belongs to mine, metallurgy and port equipment, and particularly relates to an impact-free interference removal high-precision gravimetric feeder. The feeder consists of a receiving part and a weighing transfer part, wherein the receiving end of the weighing transfer part is positioned at the discharge hole of the receiving part. The gravimetric feeder has reasonable and compact structure, optimized weighing mode, no interference, low fault and high precision.

Owner:刘素华

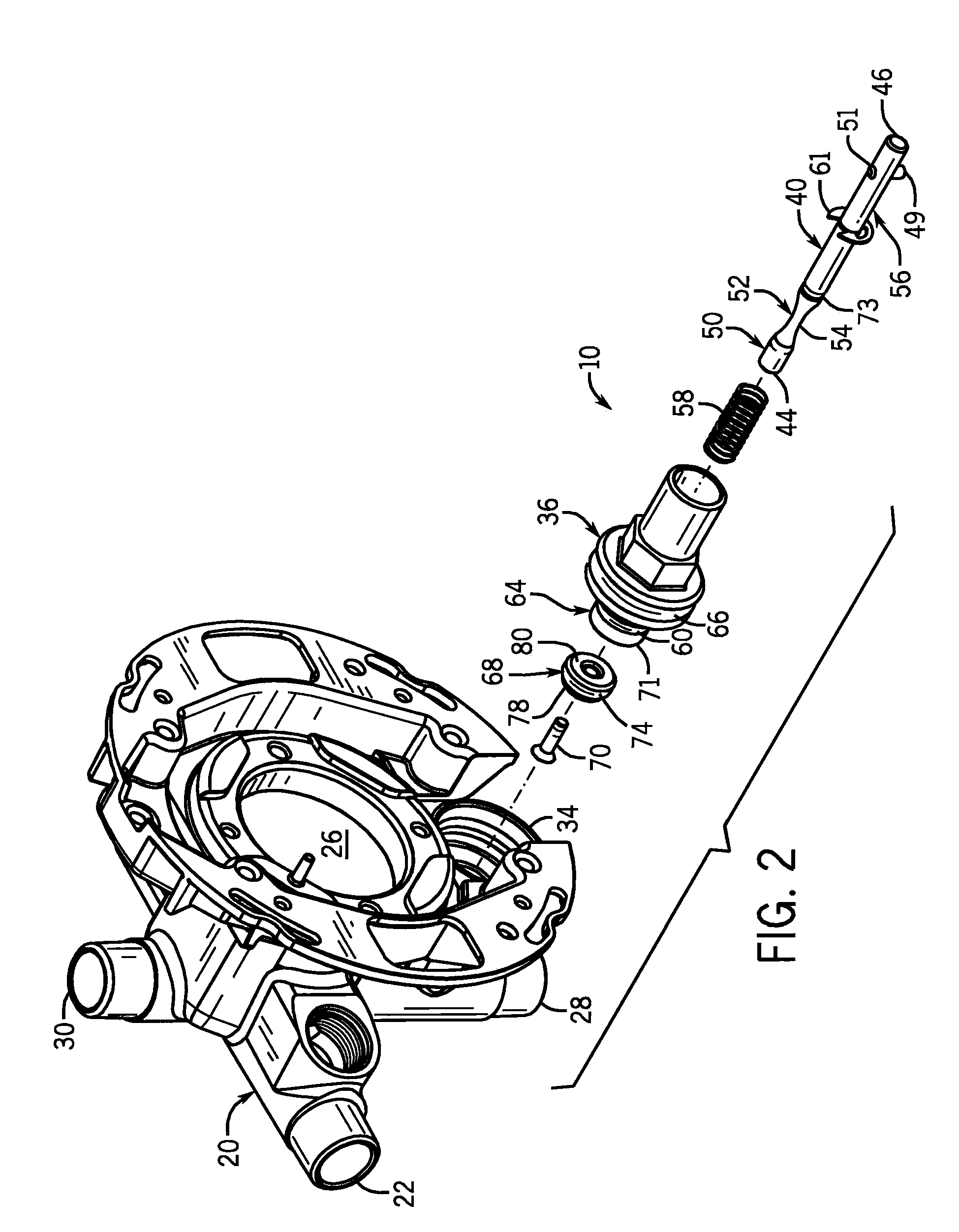

Diverter valve

ActiveUS8312897B2Reduce the cross-sectional areaReduce needDomestic plumbingMultiple way valvesEngineeringVALVE PORT

A diverter valve is disclosed for use in a shower mixer valve or the like. It is constructed to reduce the force needed to be applied by the bather to actuate the diversion. There is a diverter stem that is moveable between a non-diverted and diverted position. The diverter stem includes an upstream portion and a reduced cross sectional waist portion downstream of the upstream portion. The reduced portion interacts with the diverted fluid to reduce the force required to move the diverter stem from the non-diverted to the diverted position.

Owner:KOHLER CO

Vibration grinding method with active impact and rotational grinding of grinding medium

InactiveCN106345570AParticipating mass is smallReduce starting powerPreparing sample for investigationGrain treatmentsEngineeringSpring force

The invention relates to a vibration grinding method with active impact and rotational grinding of a grinding medium. A stepless speed regulation motor is used to drive an oscillating shaft, a grinding medium is arranged at the lower end of the oscillating shaft which is provided with an eccentric block, and the grinding medium and the eccentric block are fixed in a proper position of the oscillating shaft at a certain included angle, so that the excitation force mainly acts on the horizontal surface; and the grinding medium and the eccentric block rotate with the stepless speed regulation motor through a transmission device, and actively impact on a material under the action of the excitation force in a grinding chamber and generate rotational grinding with the rotation of the motor. The vibration grinding method provided by the invention has the advantages of high grinding efficiency, low energy consumption, fine grinding size, good spring force condition, and the like.

Owner:SHAANXI UNIV OF SCI & TECH

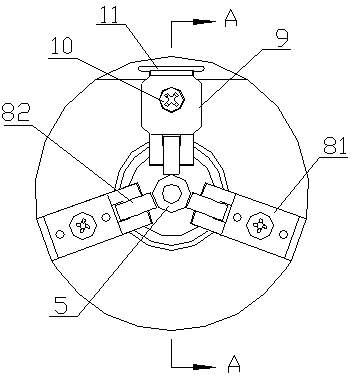

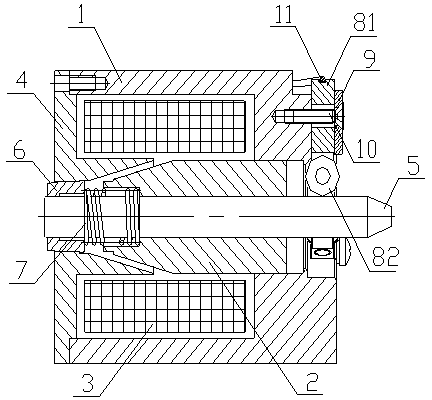

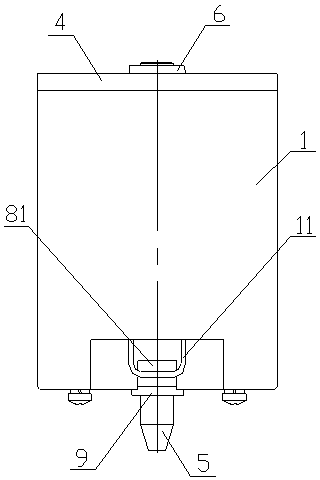

Inner armature type high precision positioning electromagnet

ActiveCN103996486AElimination of positioning errors and deformation stressHigh positioning accuracyElectromagnets with armaturesEngineeringElectromagnet

The invention discloses an inner armature type high precision positioning electromagnet which comprises a shell, an armature, a coil, an end cover and a positioning shaft. One end of the shell is sealed through the end cover, three supporting assemblies are arranged at the end, far away from the end cover, of the shell, bearings of the three supporting assemblies are all tightly attached to the positioning shaft, and the positioning shaft can move freely in the axial direction of the positioning shaft. Two supporting assemblies are fixed supporting assemblies, another supporting assembly is a movable supporting assembly, and a kidney-shaped hole is formed in a supporting block of the movable supporting assembly in the length direction of the supporting block. A screw sequentially penetrates through a pressing plate and the kidney-shaped hole and then is connected with the shell. A compressed spring is arranged at the end, far away from the positioning shaft, of the movable supporting assembly, one end of the compressed spring is fixedly connected with the shell, and the other end of the compressed spring is tightly pressed on the supporting block of the movable supporting assembly. By means of the inner armature type high precision positioning electromagnet, gap variation caused by temperature variation can be compensated automatically, and high positional accuracy and low temperature drift are achieved.

Owner:CHONGQING HUAYU ELECTRIC GRP

Convertible roof bow control mechanism

InactiveUS7100962B2Reduce starting powerReducing operating envelopeEngine sealsVehicle sealing arrangementsActuatorControl theory

A vehicle convertible roof including a rearmost roof member, a side roof rail, an actuator and a link having a length that varies between a first length and a second as the rearmost roof member moves between a nominal and raised position. The adjustable length link is fixed at the second length during retraction and extension of the side roof rail of the vehicle convertible roof.

Owner:SPECIALTY VEHICLE ACQUISITION

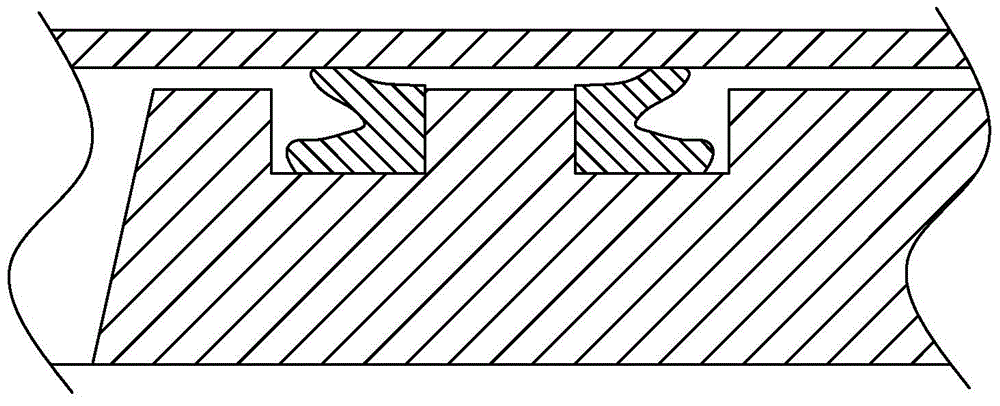

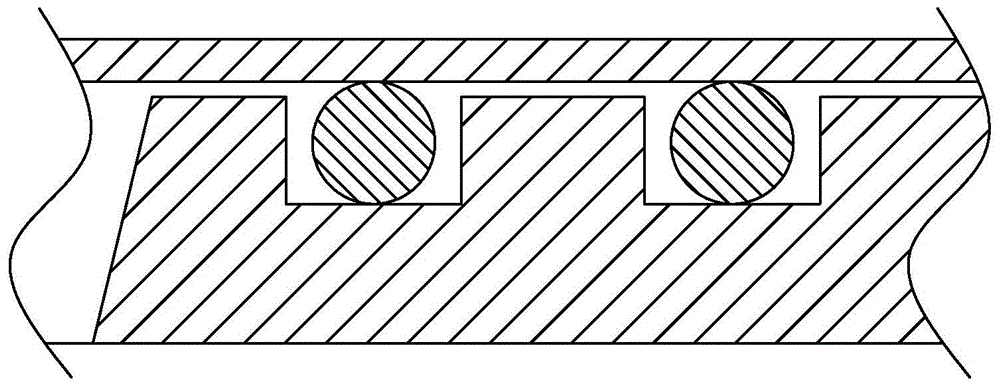

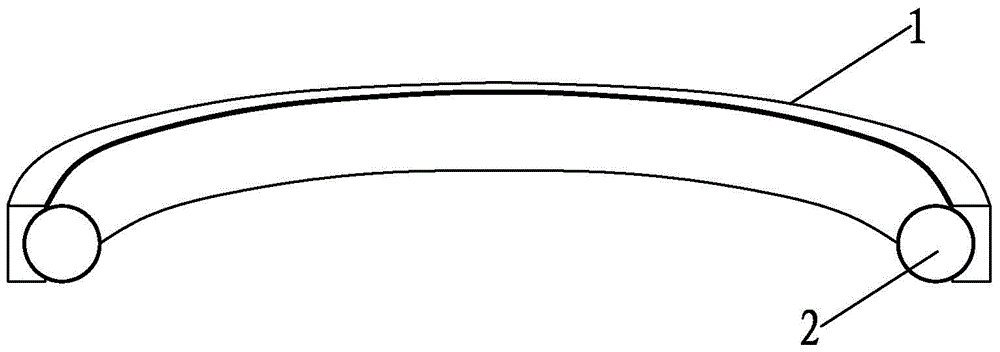

Sealing ring special for piston of injector of pipe-free liquid dropping machine

The invention discloses a sealing ring special for a piston of an injector of a pipe-free liquid dropping machine. The sealing ring comprises an outer sealing ring body in interference sealing contact with the inner wall of a cylinder of the injector and an inner sealing ring body in interference sealing contact with an installation groove of the piston of the injector. The inner sealing ring body is in an O shape. An arc-shaped groove is formed in one side face, back to the inner wall of the cylinder of the injector, of the outer sealing ring body. The part of the inner sealing ring body is embedded in the arc-shaped groove and is interference sealing contact with the arc-shaped groove. By the adoption of the sealing ring special for the piston of the injector of the pipe-free liquid dropping machine, friction force and start force in the moving process of the piston of the injector are reduced, the crawling phenomenon is eliminated, and the sealing ring is resistant to a medium and small in deformation in the moving process.

Owner:HUAQIAO UNIVERSITY +1

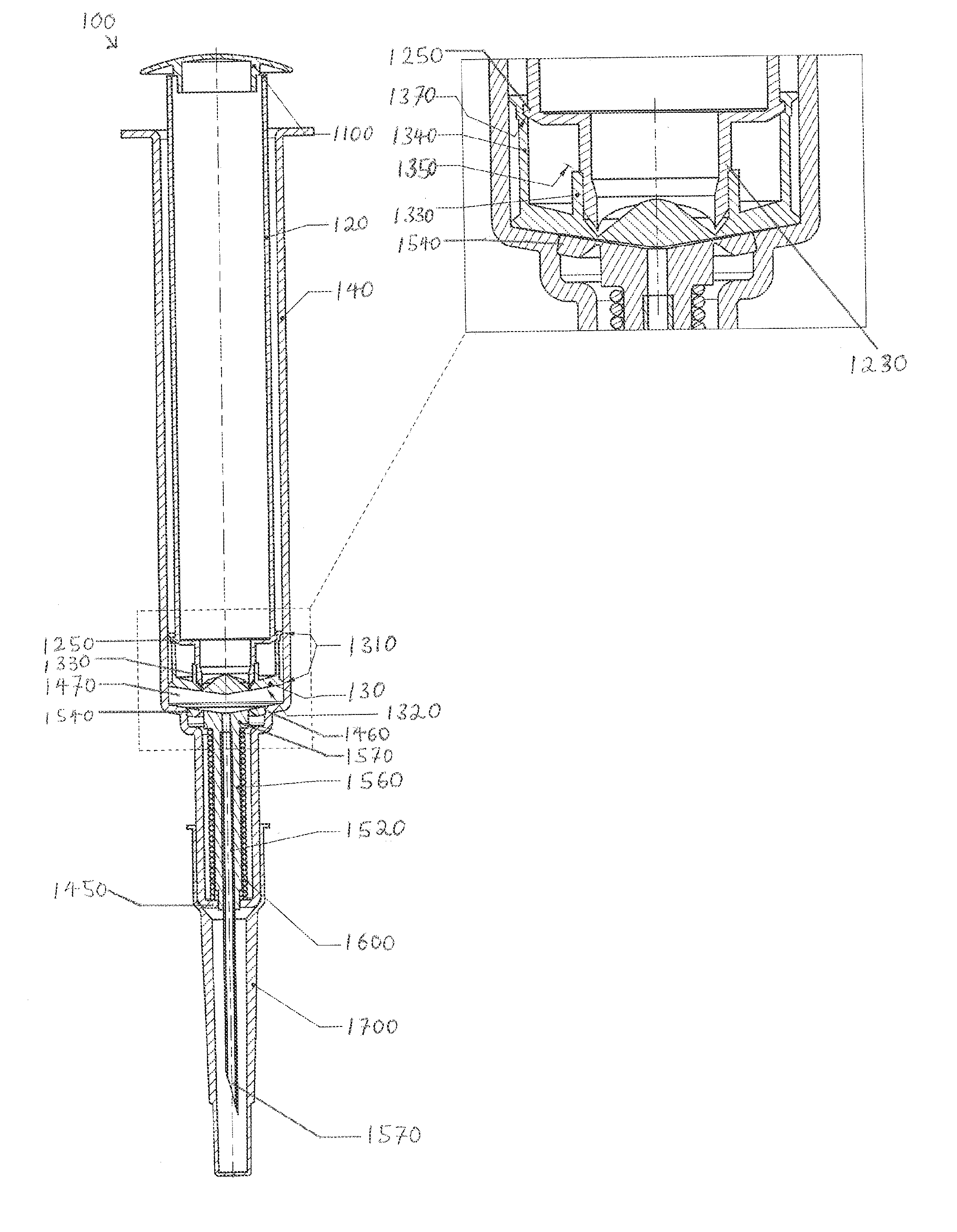

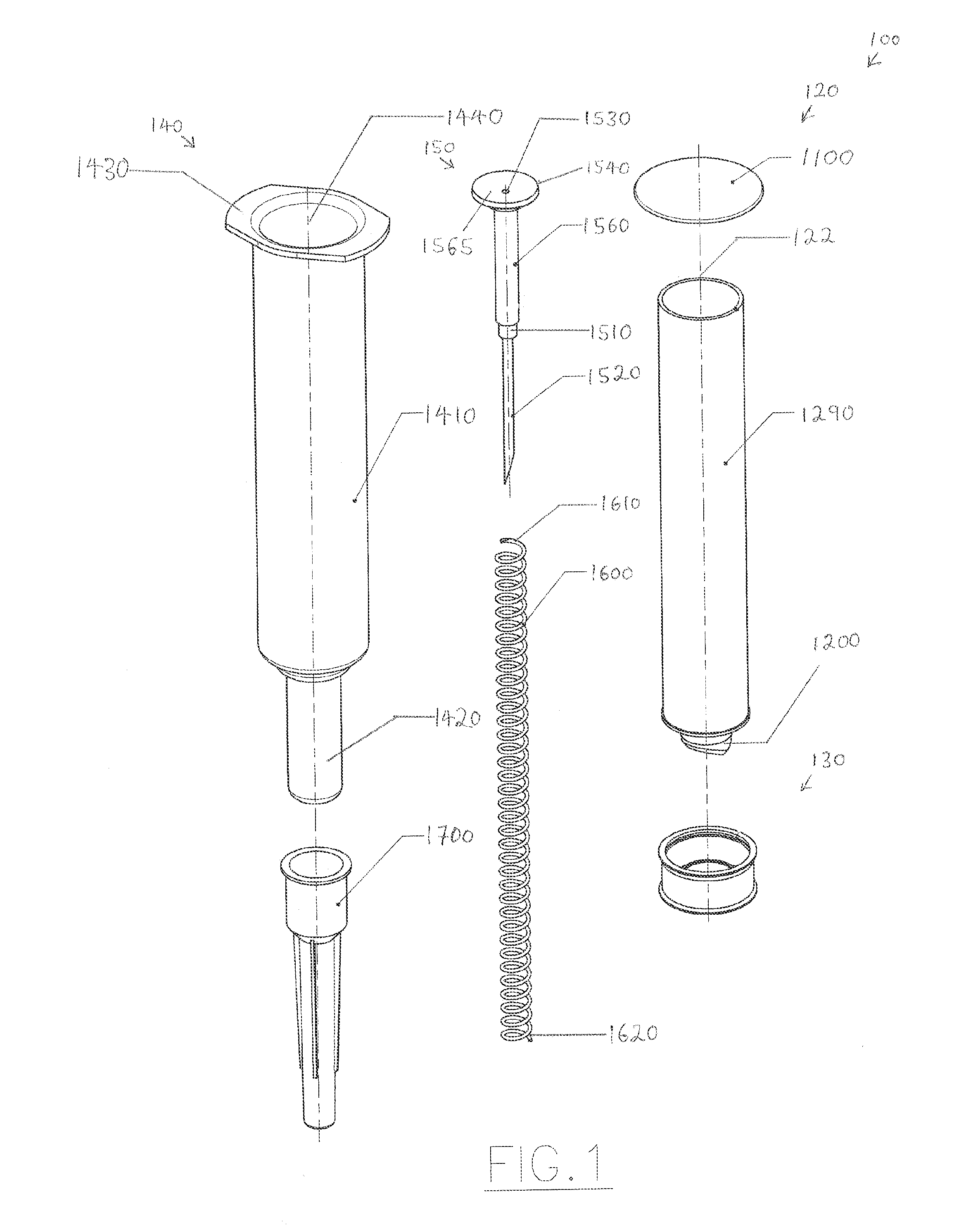

Retractable syringe with a cutting crown

InactiveUS8864706B2Reduce starting powerPrevent reuseInfusion syringesMedical devicesSyringe needleScrew thread

Owner:INTUITIVE CREATIONS PTE

Beam-pumping unit

InactiveCN101748994AImprove efficiencyEvenly distributed inertiaFlexible member pumpsFluid removalClutchPower grid

The invention relates to a beam-pumping unit, which includes a motor, an actuating device and a pumping unit device connected in sequence; the pumping unit device comprises the connection shaft of the frame of the pumping unit, a foldable balancing weight, and a clutch which disconnects the connection shaft of the frame of the pumping unit and the foldable balancing weight when starting the motoras well as reconnects the connection shaft of the frame of the pumping unit and the foldable balancing weight when starting the pumping unit. The foldable balancing weight is set to be under an unfolded state when starting the motor, and under the folded state when starting the pump unit. The beam-pumping unit breaks through the design concept of the current pumping unit, sets the balancing weight of a 'monolithic block' pumping unit into the foldable balancing weight, and uses a mechanical energy storing principle to improve the efficiency of the motor of the pumping unit. The beam-pumping unit not only can reduce the installed power of the motor of the pumping unit to radically solve the technical defect of 'big Marathi car' of the motor of the pumping oil in the oil field, and also canimprove the efficiency of the motor during the running process of the pumping unit, and reduce the impact on power systems.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

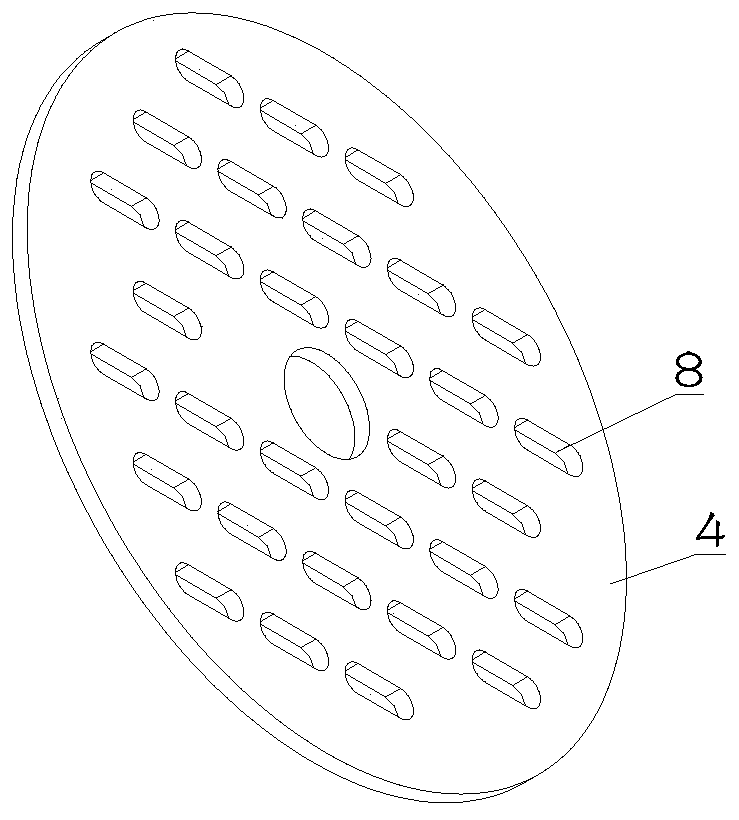

Micro-fine particle grade horizontal grinding device

InactiveCN101549312AIncreased useful power coefficientReduce over-crushingGrain treatmentsImpellerEnergy density

The invention concretely relates to a micro-fine particle grade horizontal grinding device. The grinding device is composed of a grinding chamber and a drive mechanism; the barrel installation center line of the grinding chamber is horizontal and the horizontal length in the barrel is 1.5-2.5 times of the inner circle diameter of the barrel and the inner surface of the barrel is abrasion resistance material and the grinding medium (18) is filled into the barrel; the 5-8 agitating vanes (8) are vertically mounted on the main axle (6) coincident with the barrel center line and a material discharging device is set at the right downside of the left end of the barrel and a material feeding port (7) is set on the right upside of the right end of the barrel; the left end of the main axle (6) is mounted in a bearing liner (13) and the bearing linear (13) is fixed on the center of the left end cover (12) of the barrel and the right end of the main axle (6) passes through a bearing (2) and is connected with the motor by a shaft coupling (1); an accessory impeller (5) is mounted on the main axle (6) of the right side of the barrel. The material pulp of the device is brushed under the high-speed mobile grinding medium colliding, grinding action with features of simple start, large medium energy density and high grinding efficiency.

Owner:WUHAN UNIV OF SCI & TECH +1

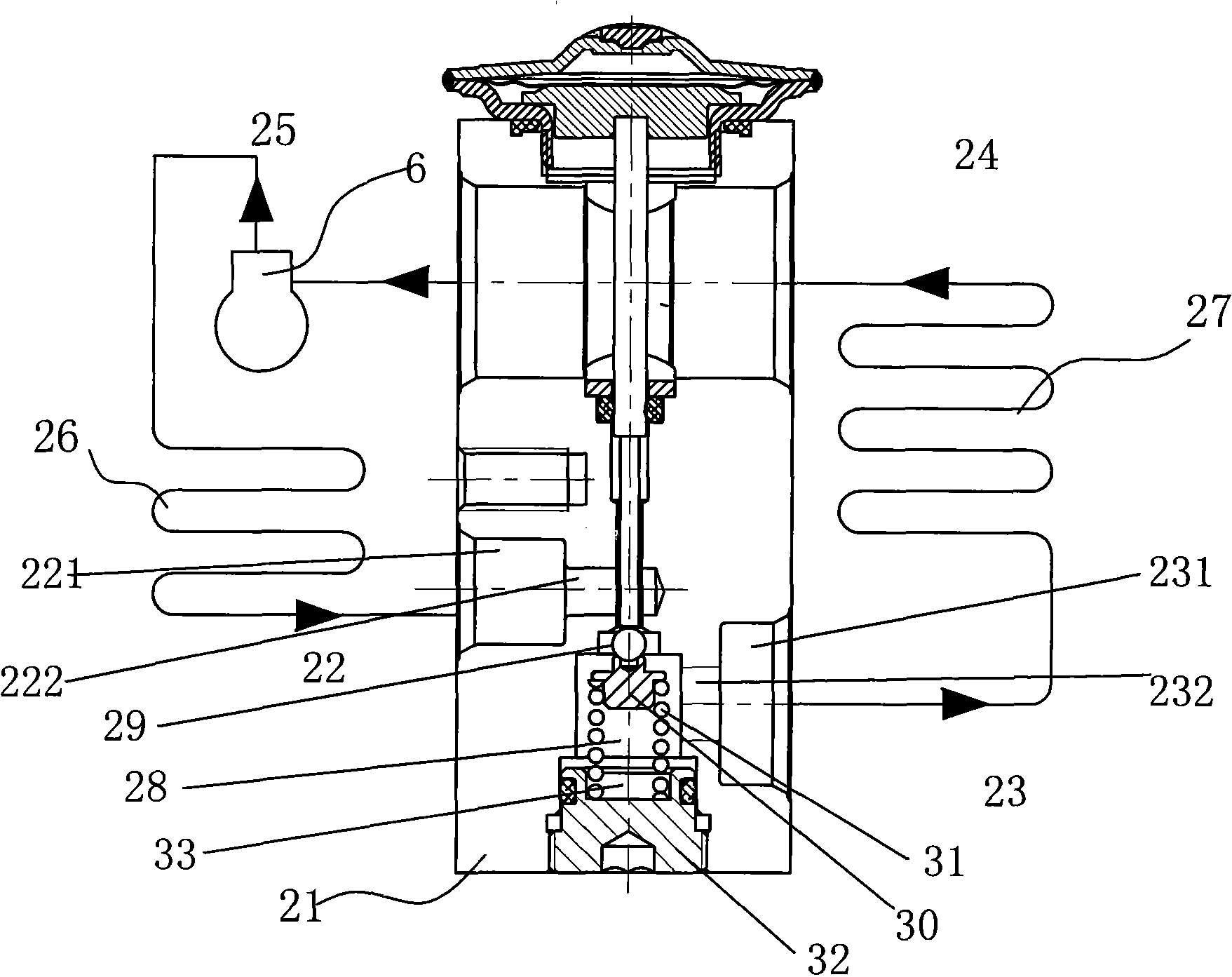

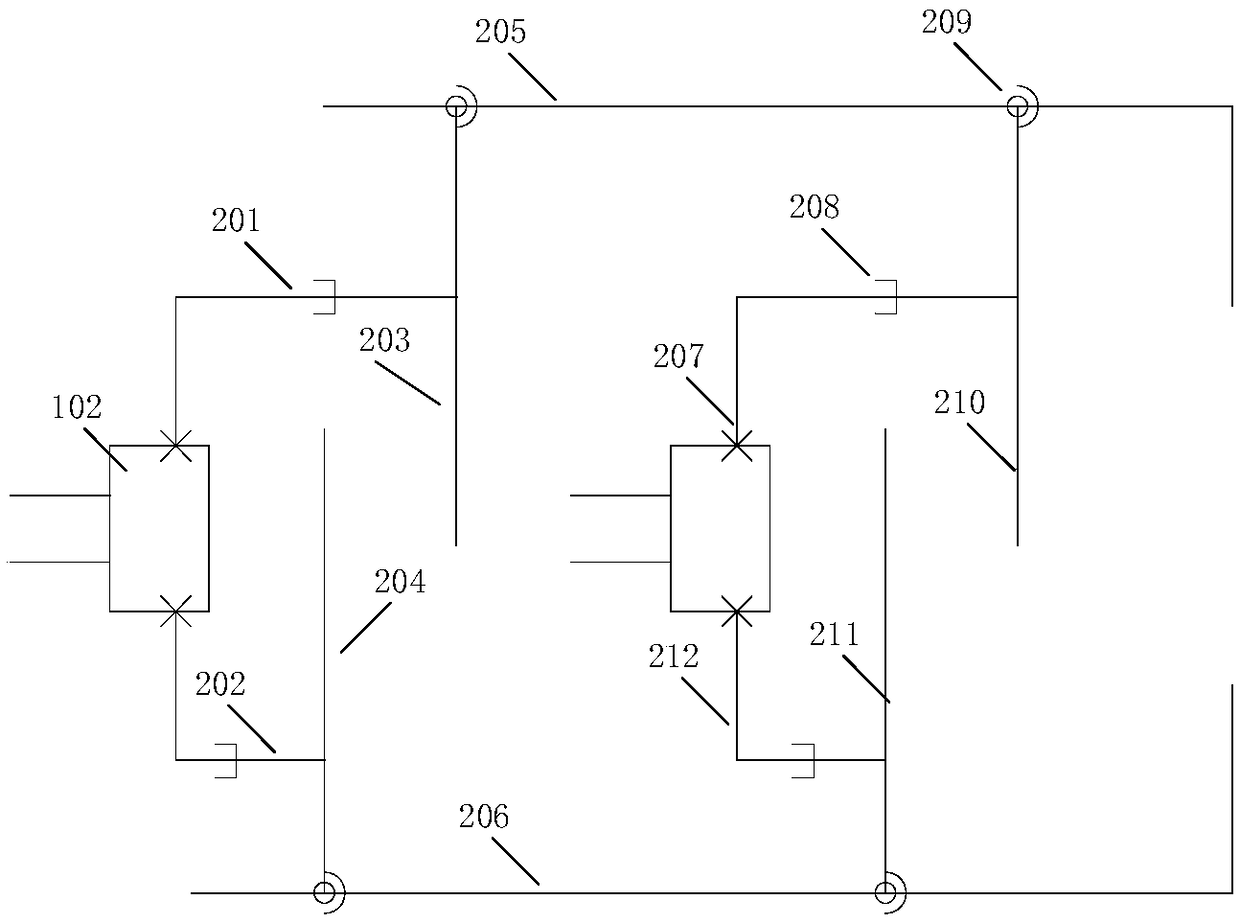

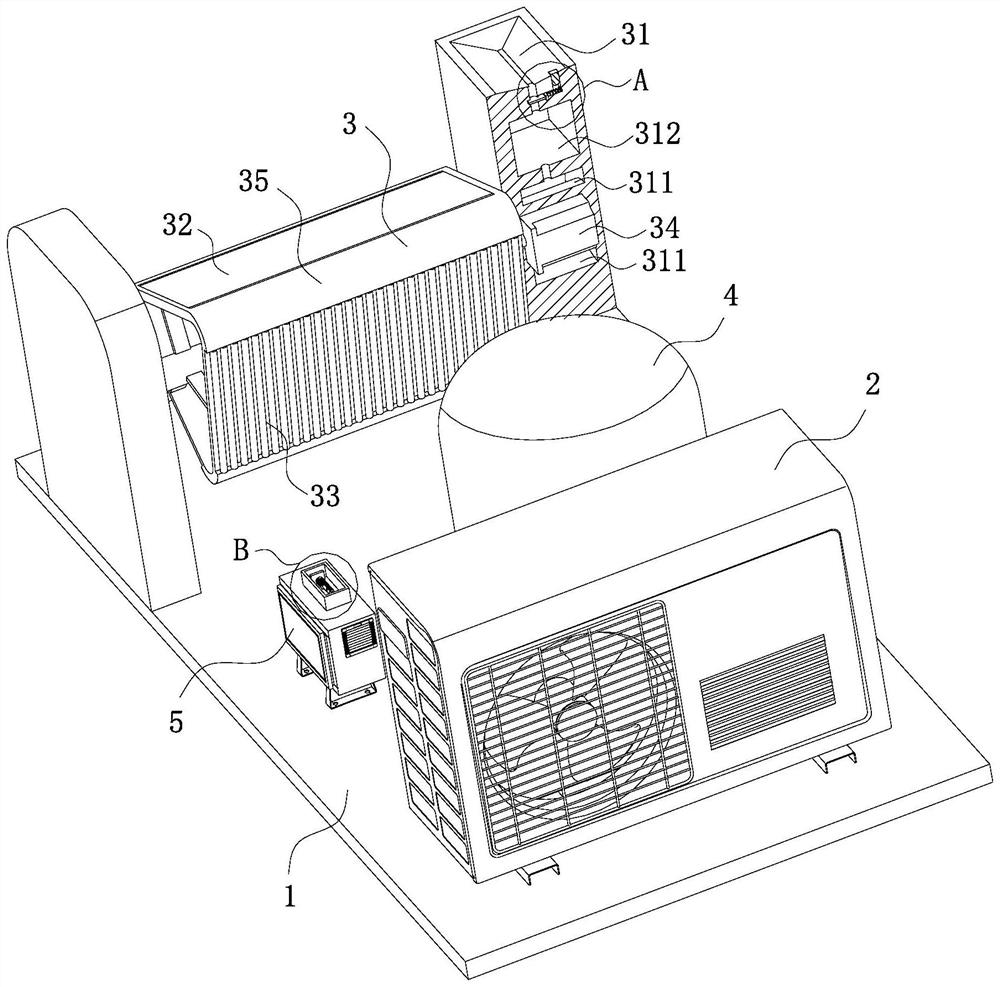

Thermal expansion valve

InactiveCN101493159AReduce vibrationReduce noiseOperating means/releasing devices for valvesValve members for absorbing fluid energyInlet channelSteel ball

The invention discloses an energy-saving heating power expansion valve having low vibration and little noise, comprising a valve body, a first inlet channel and a first outlet channel; wherein, the first inlet channel is communicated with a condenser outlet of an air conditioning refrigeration system, and the first outlet channel is communicated with an evaporator inlet of the air conditioning refrigeration system. A second inlet channel of refrigeration agent is communicated with an evaporator outlet of the refrigeration system, and a second outlet channel of the refrigeration agent is communicated with a compressor inlet of the refrigeration system. As the first inlet channel is positioned above the first outlet channel, the refrigeration agent is led in from the middle part of a transmission rod comprising a steel ball, and the transmission rod is prevented from vibrating; when an air conditioner stops running, the first inlet channel is communicated with the first outlet channel, so that the energy consumption needed for starting the air conditioner is reduced; a gap between the transmission rod and the valve body is controlled to lead the bubble contained in the refrigeration agent to be miniaturized, thus reducing the flow noise of the refrigeration agent.

Owner:杭州通产机械有限公司

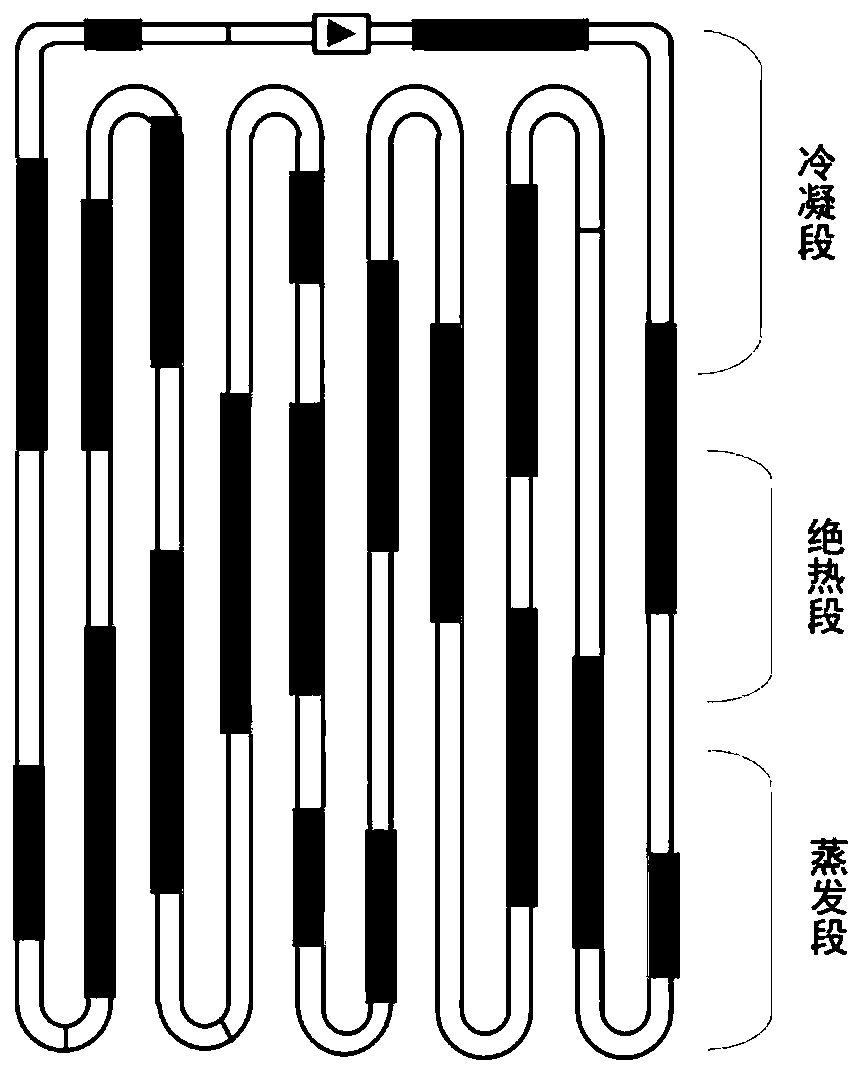

Data center heat dissipation system with direct connection between loop heat pipe and refrigeration cycle pipe

ActiveCN109496110AReduce energy consumptionReduce noiseCooling/ventilation/heating modificationsMicro-loop heat pipeData center

The invention relates to a data center heat dissipation system with direct connection between a loop heat pipe and a refrigeration cycle pipe. The system comprises a loop heat pipe unit, a circulatingworking-medium fast joint unit, and a refrigerant circulation unit. The loop heat pipe unit includes a gas pipe, a liquid pipe, an evaporation end and a condensation end; liquid generated by condensation in the condensation end flows through the liquid pipe to the evaporation end; the evaporation end is adhered to a chip in a server; and heat generated by the chip in the server heats the liquid to generate gas by evaporation and the gas returns to the condensation end along the gas pipe. The condensation end is connected to a refrigeration cycle pipe of the refrigerant circulation unit through the circulating working-medium fast joint unit; the circulating working medium transmits the heat generated by the condensation end of the loop heat pipe unit to a condenser of the refrigerant circulation unit; and the heat is exchanged to the outdoor space by the condenser. Because of direct connection between the heat pipe and the refrigeration cycle pipe, the heat exchange link and the temperature difference loss from the chip to the refrigeration circulation are reduced; and the energy consumption and noises caused by the traditional machine room heat dissipation technology are reduced.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

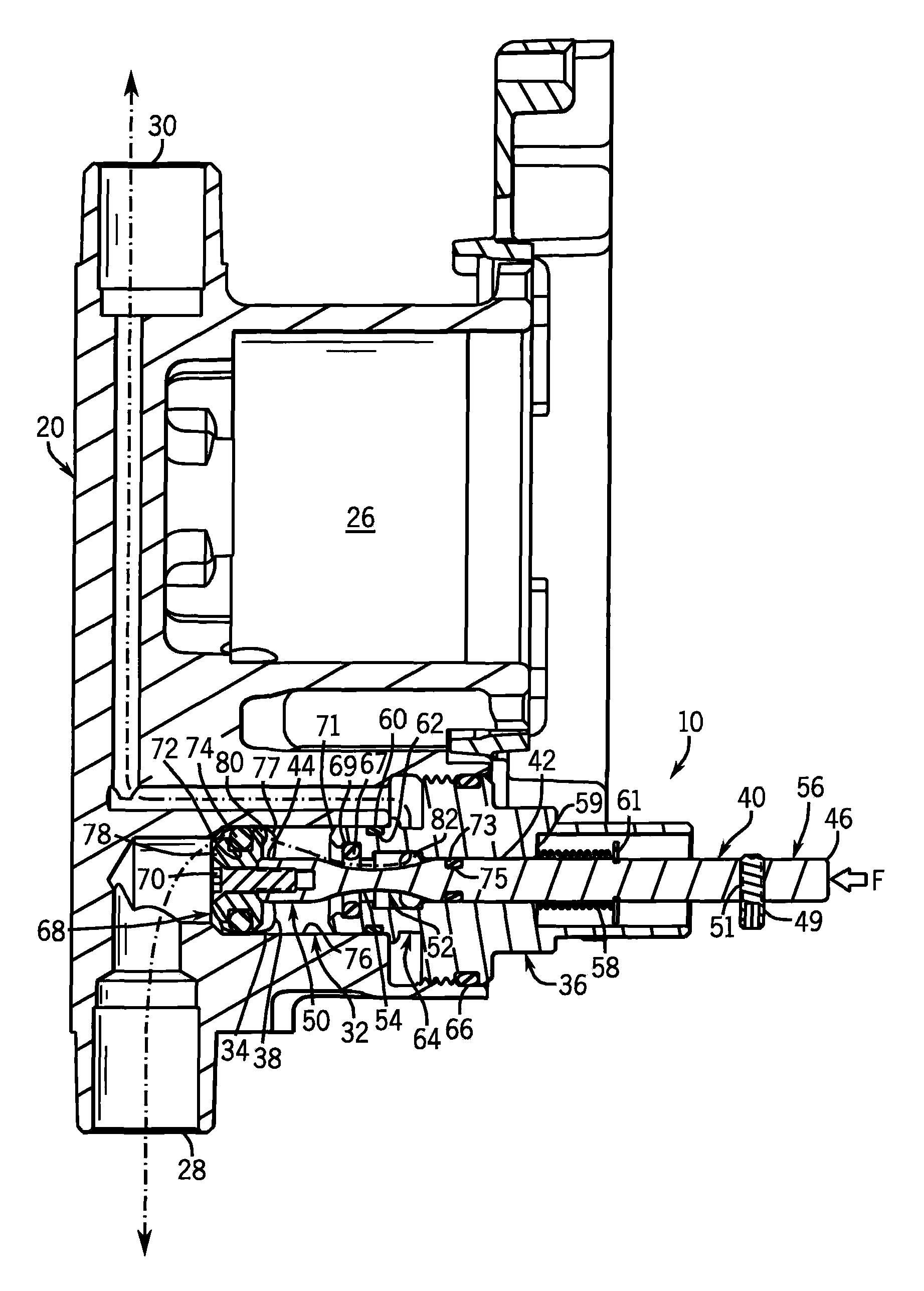

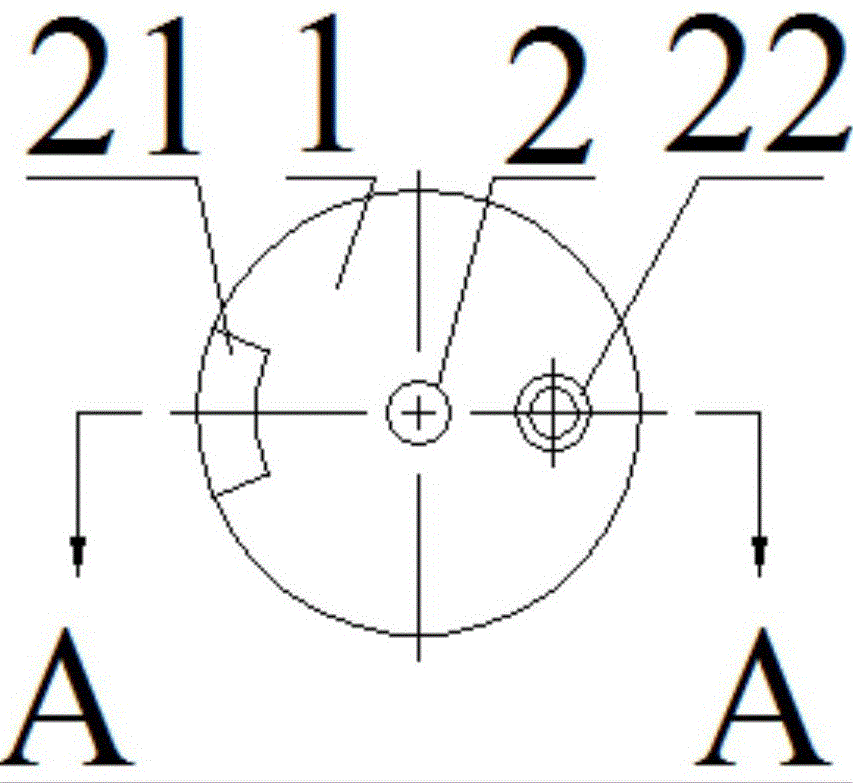

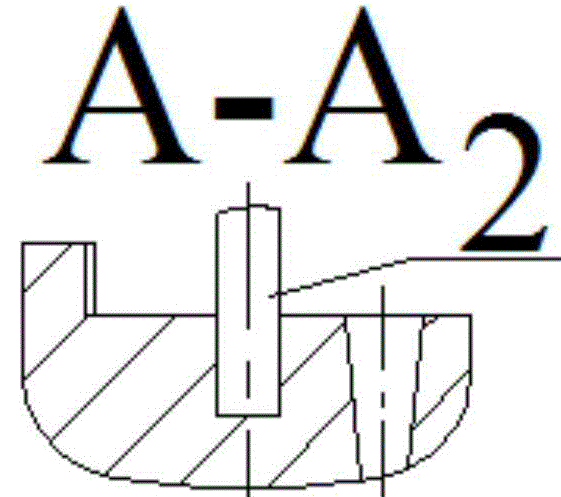

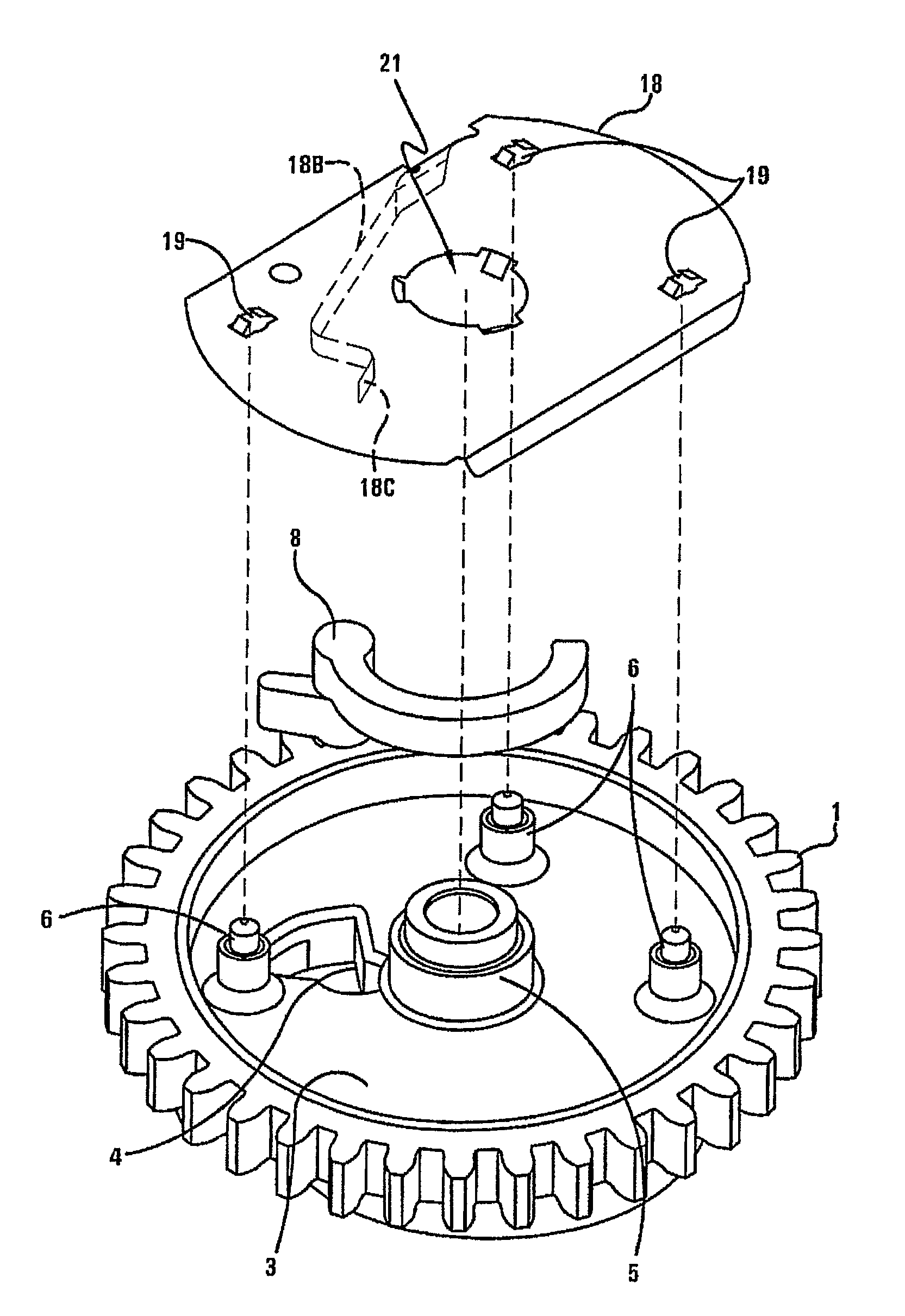

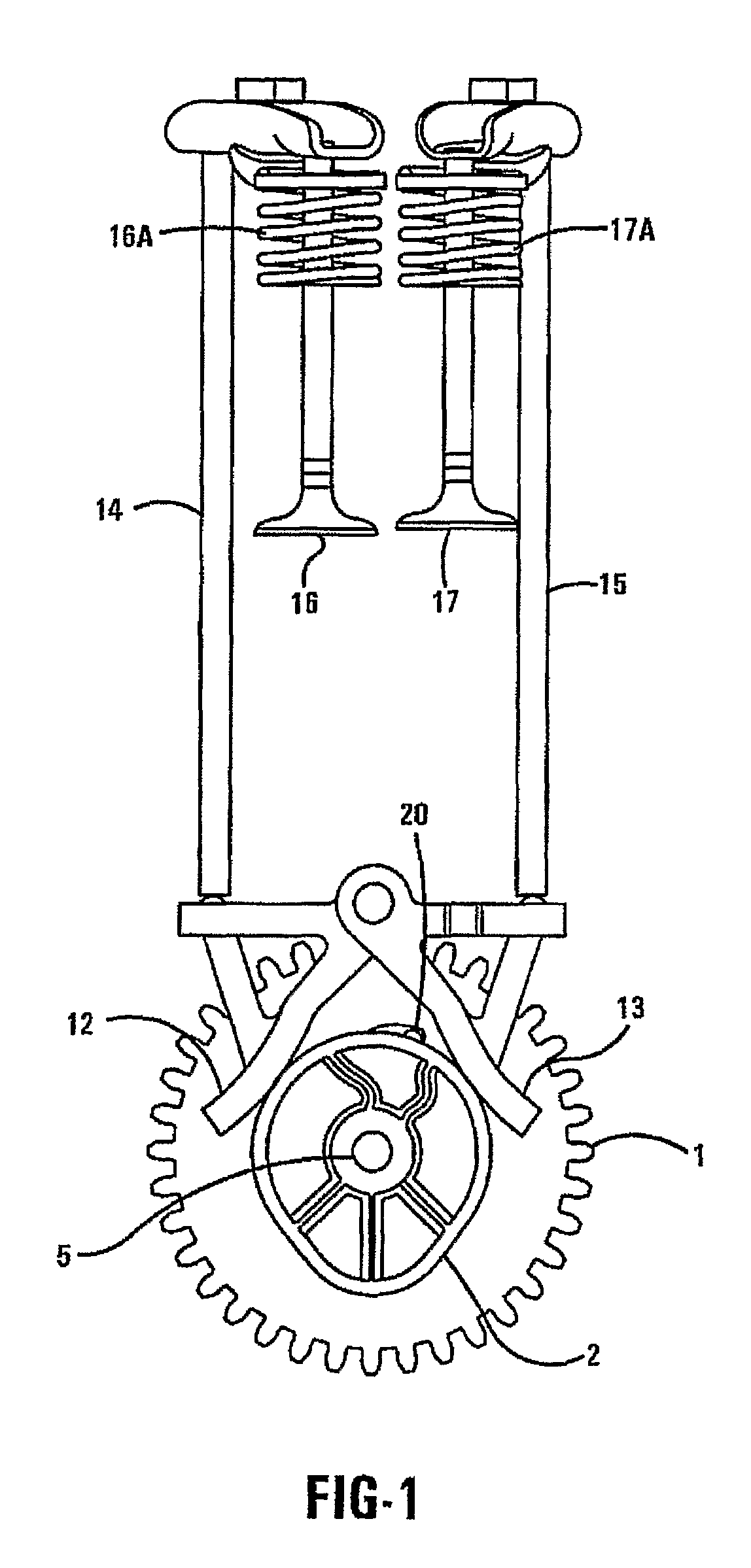

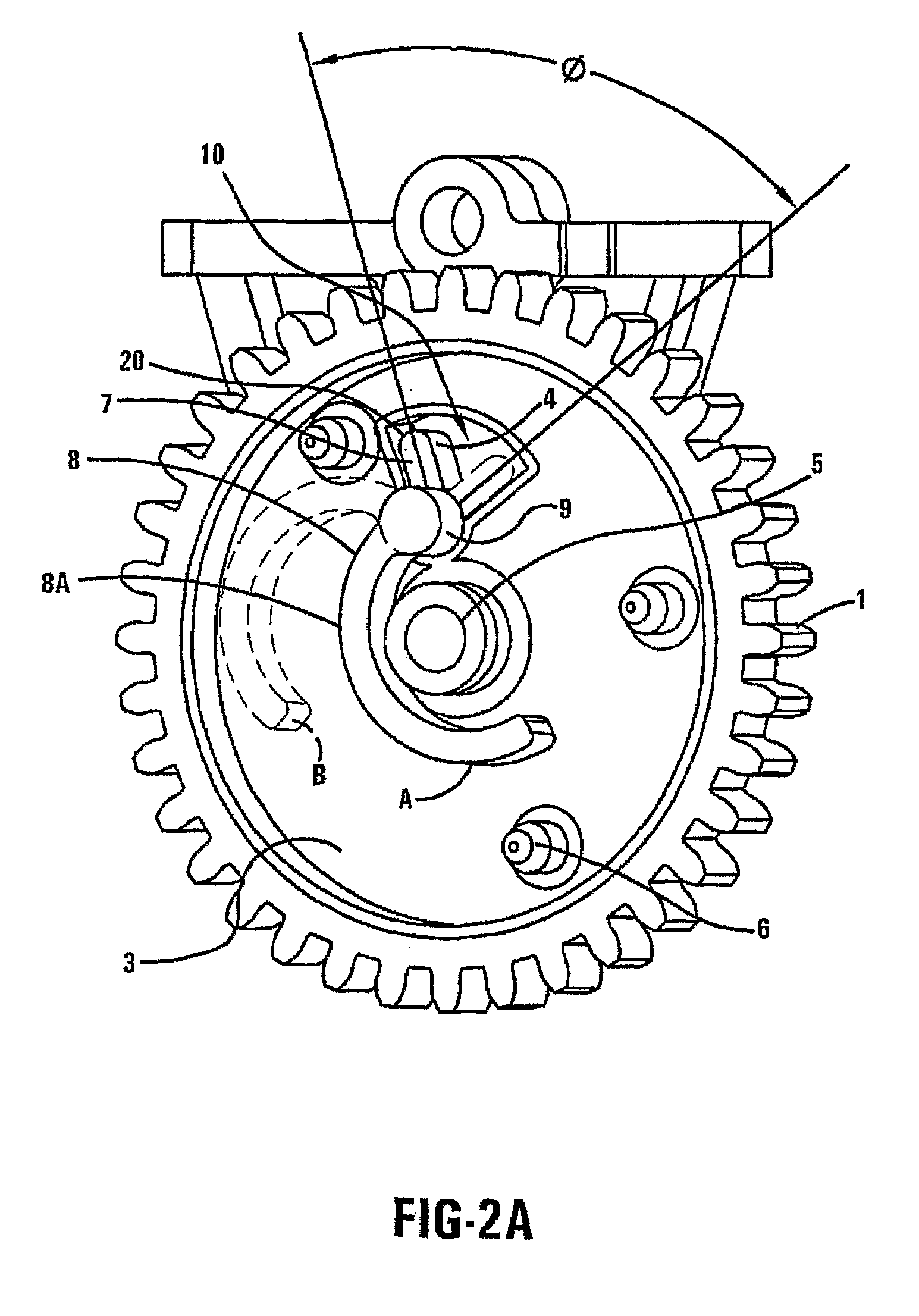

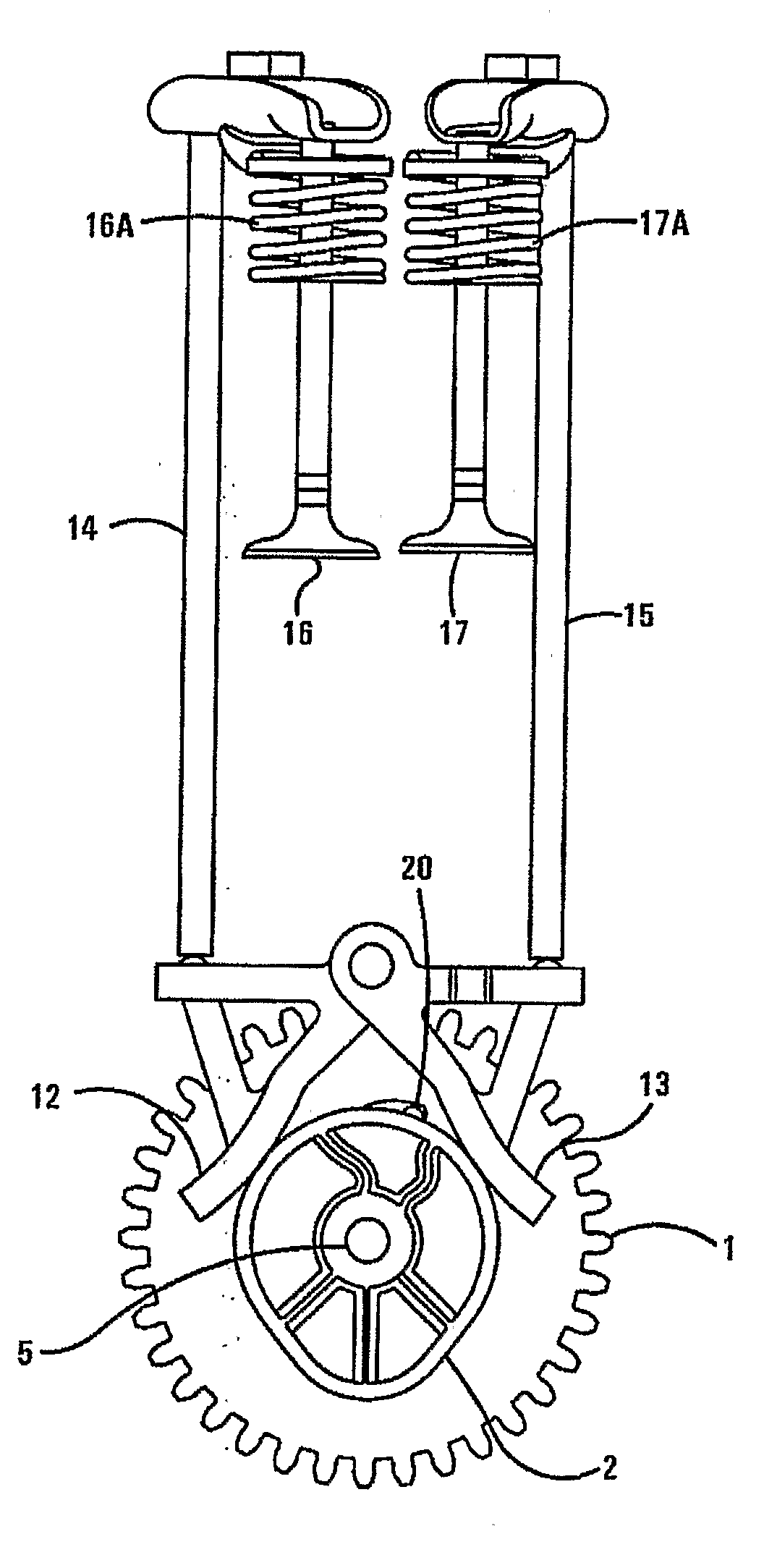

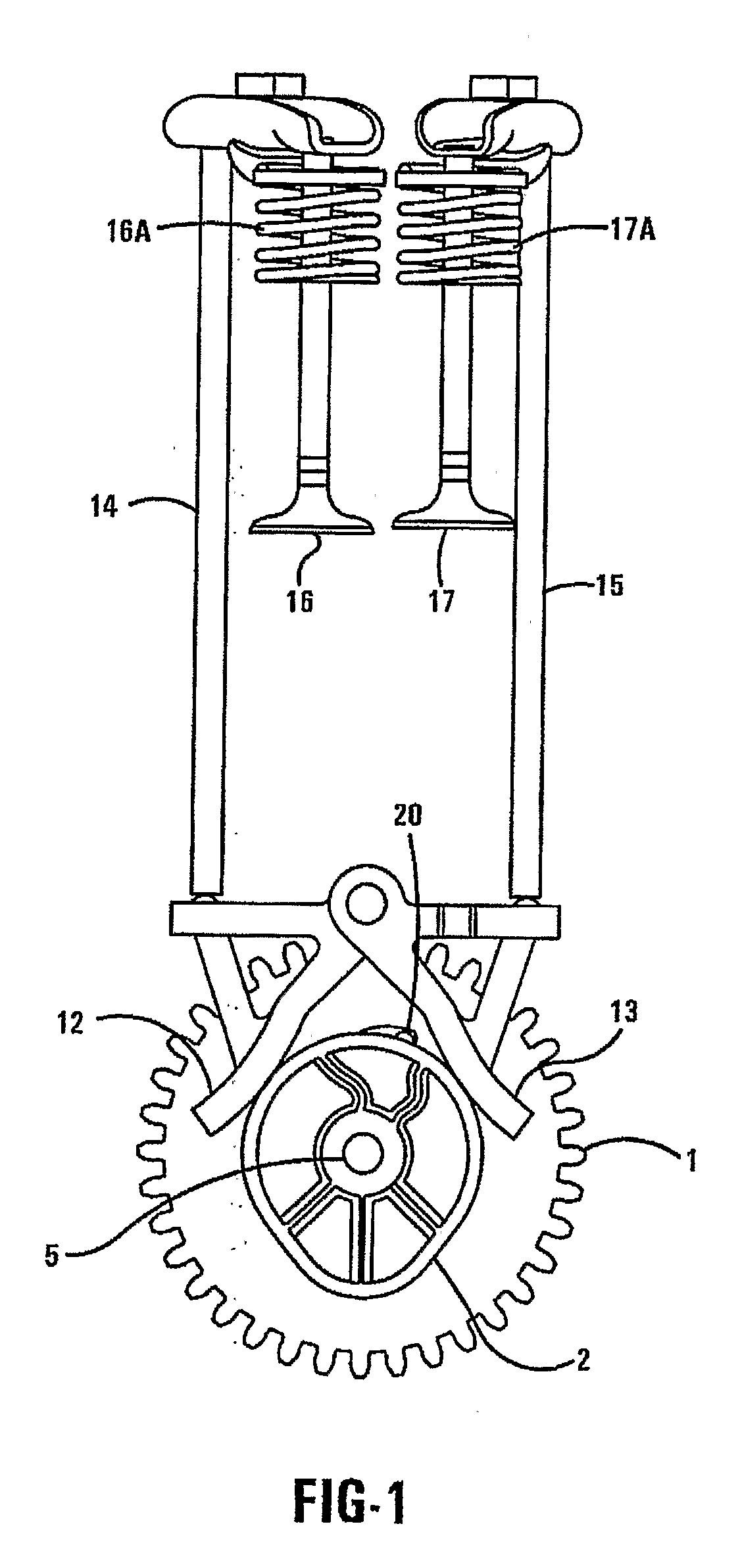

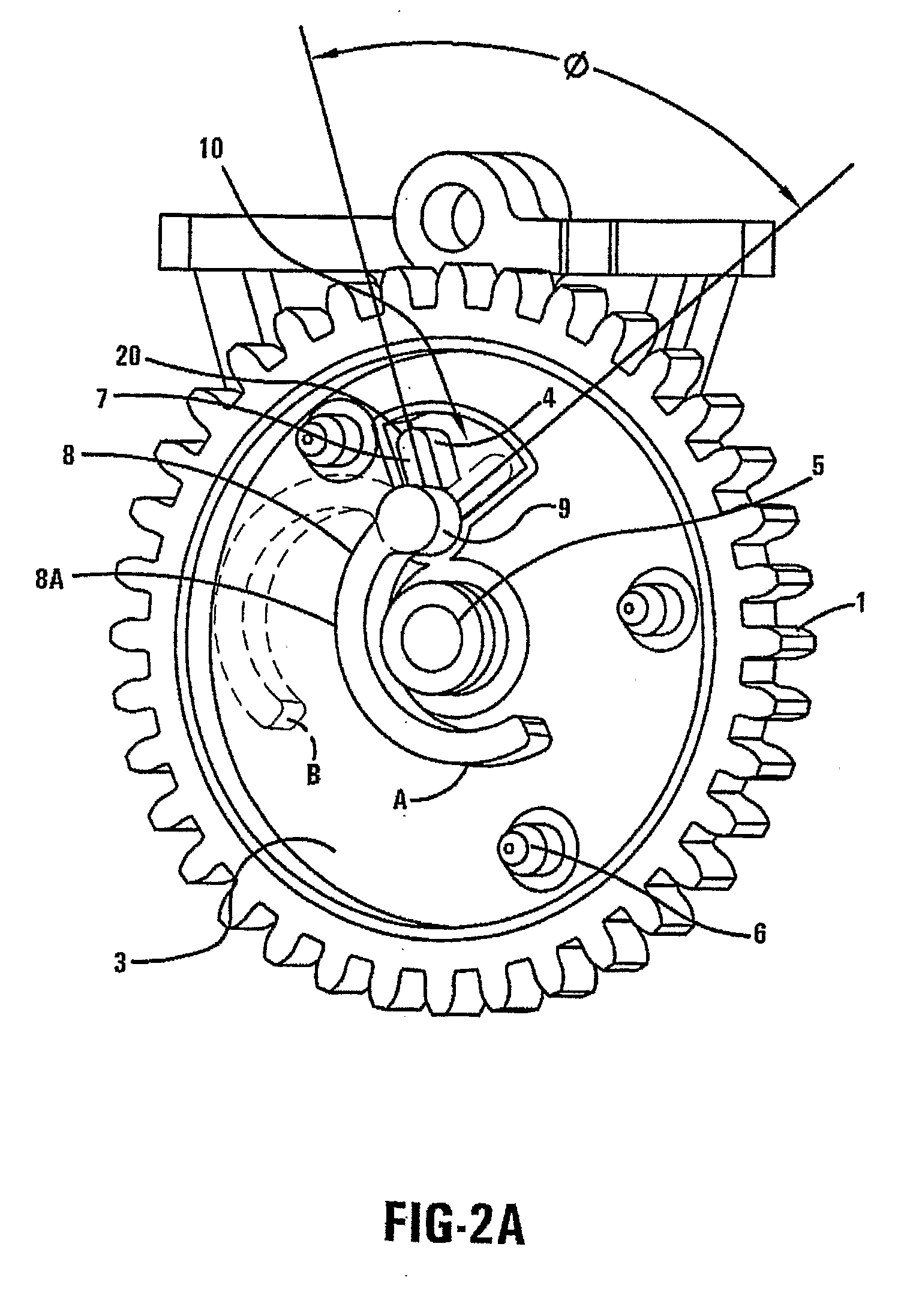

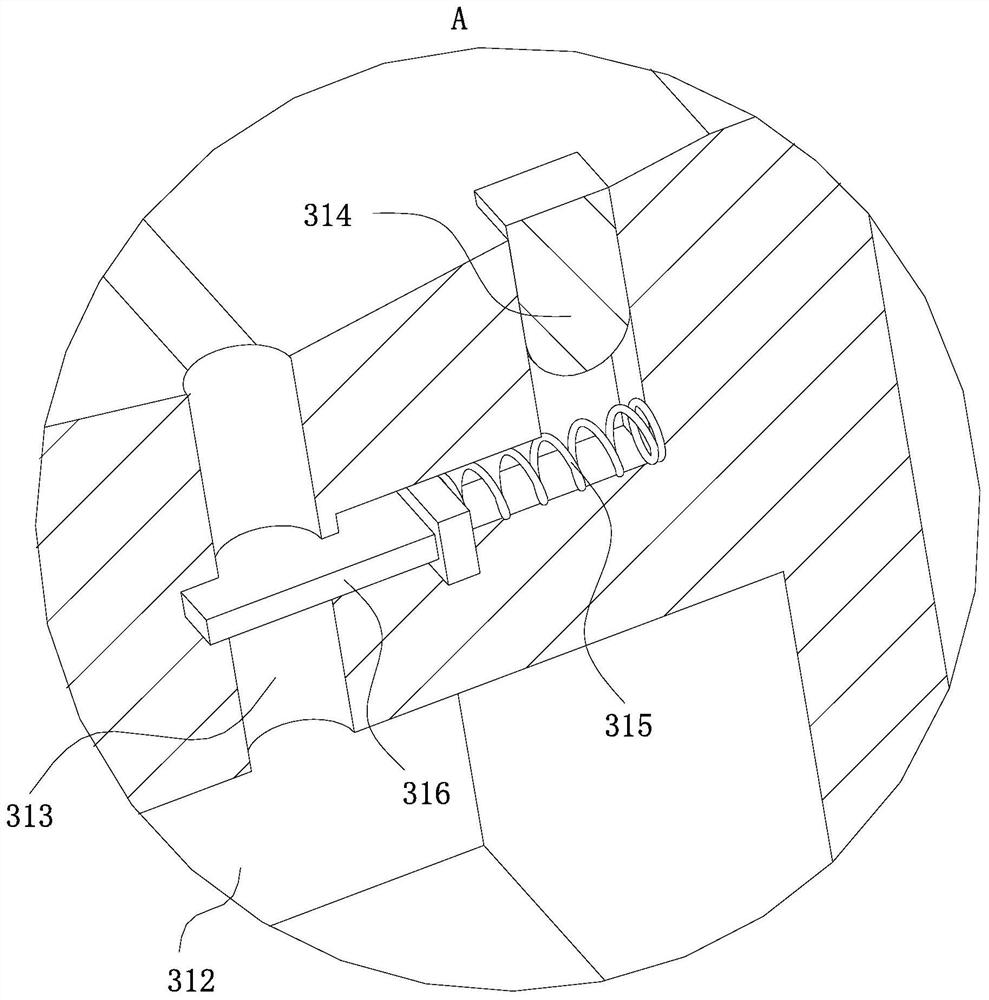

Automatic decompression mechanism for an engine

InactiveUS7552706B2Reduce starting powerActuation can be preventedValve arrangementsMachines/enginesLow speedGear wheel

An automatic decompression mechanism for selectively actuating a cylinder valve of an engine so as to reduce the starting force required to start the engine. The mechanism includes a cam gear, a centrifugal member, and a cover member comprising an integrally formed biasing means for biasing and retaining the centrifugal member in the cam gear. The biasing means urges the centrifugal member into a decompression position when the cam gear is rotating at a lower speed, wherein a projecting portion of the centrifugal member actuates the valve mechanism to reduce the starting force required to start the engine. During normal engine operation, the centrifugal member pivots into a non-decompression position wherein the projecting portion of the centrifugal member recedes below the cam profile surface so as to prevent the projecting portion from actuating the valve mechanism.

Owner:MTD PRODUCTS

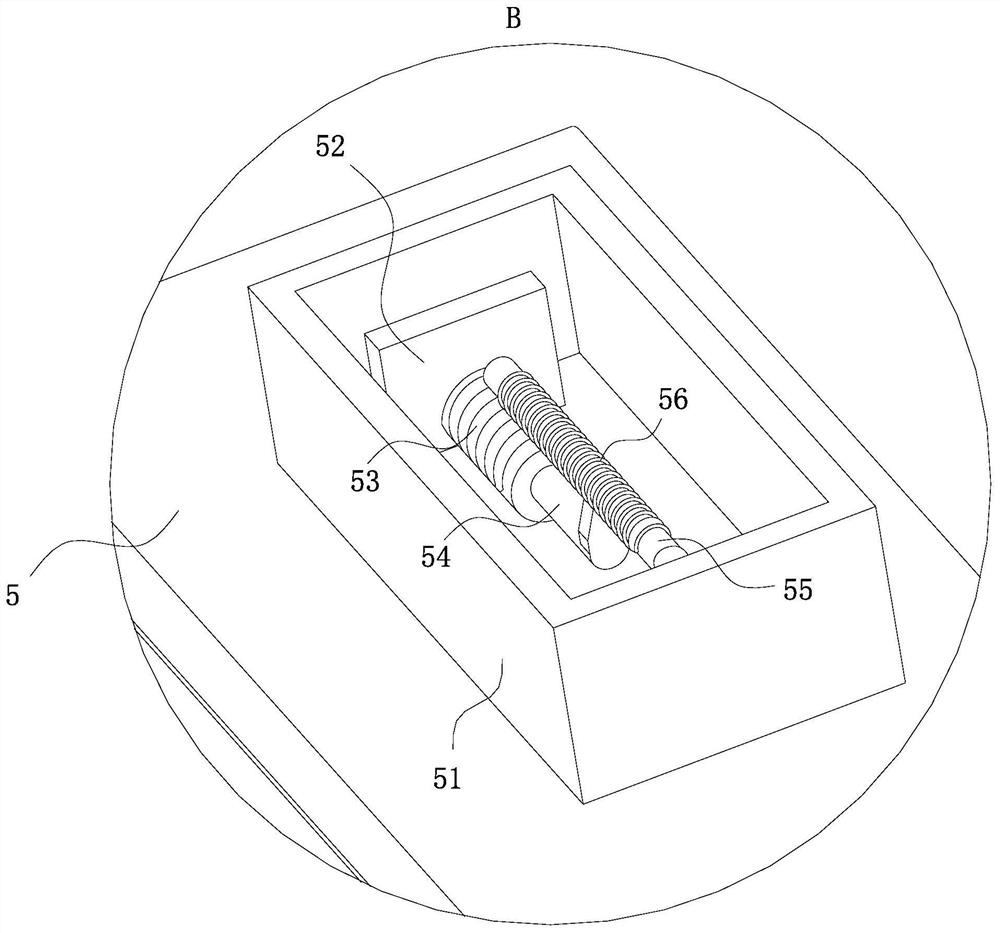

Packing material mixing device

InactiveCN110883968AReduce starting powerSpread evenlyNon-rotating vibration suppressionPack materialMechanical engineering

The invention discloses a packing material mixing device, and relates to the technical field of packing material production equipment. The packing material mixing device comprises a mixing main body which is internally provided with a cavity. The cavity is formed to mix and stir materials. A dividing plate is fixedly installed inside the mixing main body. A scraping plate is arranged on the dividing plate in an attached mode. The scraping plate is fixedly installed on the outer side of a stirring shaft. The upper portion of the stirring shaft is installed in the center of the mixing main body.A bent section is arranged at the bottom of the stirring shaft, and a plurality of stirring rods are arranged on the bent section in an array. The bottom of the mixing main body is provided with a shock absorption support. The mixing main body is further provided with a driving assembly used for driving the stirring shaft to rotate. The packing material mixing device is low in starting power andeven in material mixing.

Owner:ANHUI THE PARKSON SOURCE PACKAGING MATERIALS

Impact wrench and control method for an impact wrench

A control method according for an impact wrench includes ascertaining whether the impact wrench applies an impact when the drive shaft rotates in a lower speed range. The speed of the drive shaft then is increased to a higher speed range as a function of an ascertained impact during the rotation in the lower speed range.

Owner:HILTI AG

Automatic Decompression Mechanism for an Engine

InactiveUS20090064958A1Reduce starting powerActuation can be preventedValve arrangementsMachines/enginesCylinder ValveCam

An automatic decompression mechanism for selectively actuating a cylinder valve of an engine so as to reduce the starting force required to start the engine. The mechanism includes a cam gear, a centrifugal member, and a cover member comprising an integrally formed biasing means for biasing and retaining the centrifugal member in the cam gear. The biasing means urges the centrifugal member into a decompression position when the cam gear is rotating at a lower speed, wherein a projecting portion of the centrifugal member actuates the valve mechanism to reduce the starting force required to start the engine. During normal engine operation, the centrifugal member pivots into a non-decompression position wherein the projecting portion of the centrifugal member recedes below the cam profile surface so as to prevent the projecting portion from actuating the valve mechanism.

Owner:MTD PRODUCTS

Illuminance control solar energy and air energy coupling system

ActiveCN111678263AIncrease profitImprove efficiencyPhotovoltaic supportsSolar heating energyWater storage tankEngineering

The invention belongs to the technical field of water heating systems and specifically relates to an illuminance control solar energy and air energy coupling system. The system comprises air energy heat pumps, solar energy ends, water storage tanks and control cabinets, wherein one air energy heat pump, one solar energy end, one water storage tank and one control cabinet are mutually connected into an integral whole. Each solar energy end comprises a mounting base, a mounting support, a solar power generation panels and solar water heating pipes, wherein a photoresistor I is mounted on the mounting support; the solar water heating pipes are mounted on the mounting support; the mounting base is fixedly connected to the ground; the mounting support is mounted on the mounting base; a motor ismounted in the mounting base; and the mounting support is connected with an output shaft of the motor. An illuminance controller is mounted on the upper portion of the corresponding control cabinet.A transparent panel is mounted above the corresponding illuminance controller. Sunlight can go into the illuminance controllers. The resistance value of the illuminance controllers is in direct proportion to the illuminance intensity. The illuminance control solar energy and air energy coupling system improves the solar energy and air energy coupling effect and increases the utilization rate of solar energy.

Owner:NANJING QIJING ENVIRONMENTAL TECH CO LTD

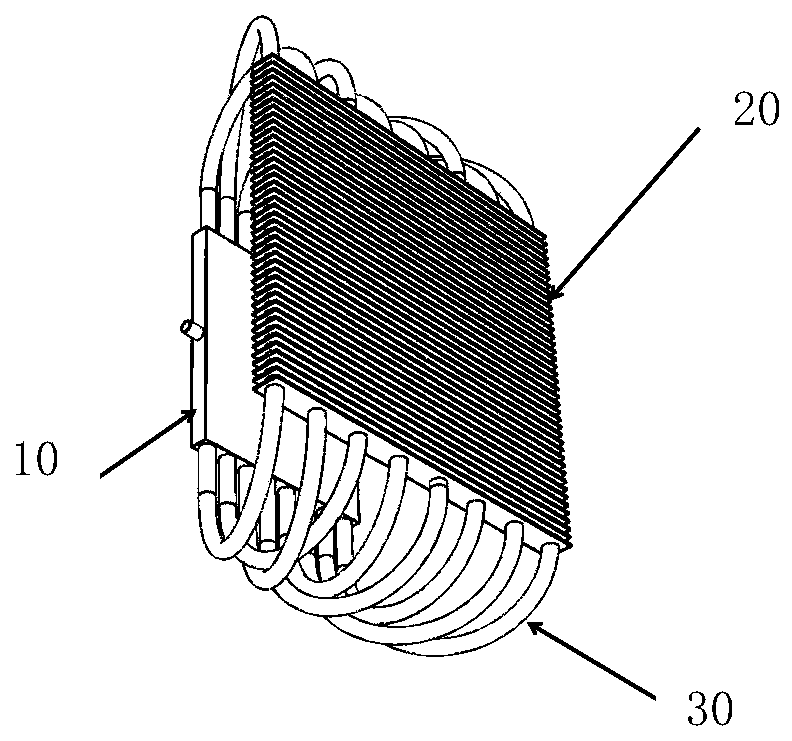

Heat dissipation device with three-dimensional pulsation heat pipes

InactiveCN110455106AAvoid dry outAvoid thermal resistanceIndirect heat exchangersHeat resistanceClosed loop

The invention discloses a heat dissipation device with three-dimensional pulsation heat pipes. The heat dissipation device comprises an evaporation unit, a condensation unit, and a heat insulation unit, wherein a plurality of evaporation pulsation heat pipes and a plurality of condensation pulsation heat pipes are arranged in a plane; one end of each evaporation pulsation heat pipe communicates with one end of the corresponding condensation pulsation heat pipe through a first elbow, and the other end of each evaporation pulsation heat pipe communicates with the other end of the corresponding condensation pulsation heat pipe through a second elbow; and the plurality of evaporation pulsation heat pipes communicate with the plurality of condensation pulsation heat pipes through the pluralityof first elbows and the plurality of second elbows to form a closed-loop passage. According to the heat dissipation device with the three-dimensional pulsation heat pipes, on the basis of existing two-dimensional heat pipes, an evaporation section and a condensation section are arranged on two parallel planes which are parallel to each other, the evaporation section and the condensation section are connected through the elbows to form the closed loop, and the burning-dry phenomenon caused by excessive quantity of the elbows of a traditional heat pipe evaporation section is avoided; and a flat-plate structure can be well connected with a heat source, unnecessary heat resistance is avoided, and heat exchange performance is improved.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

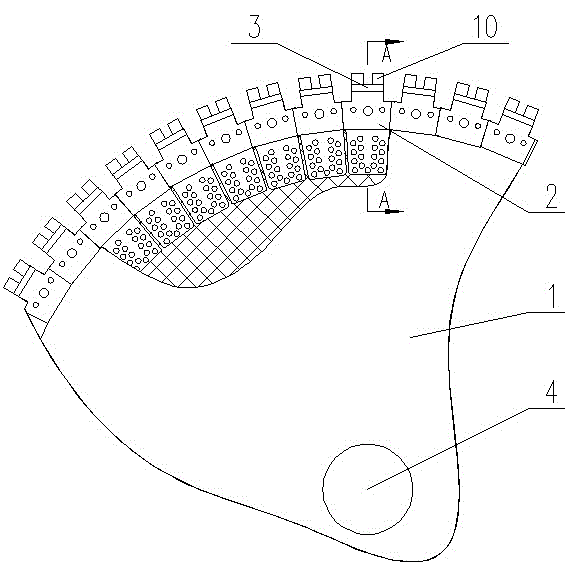

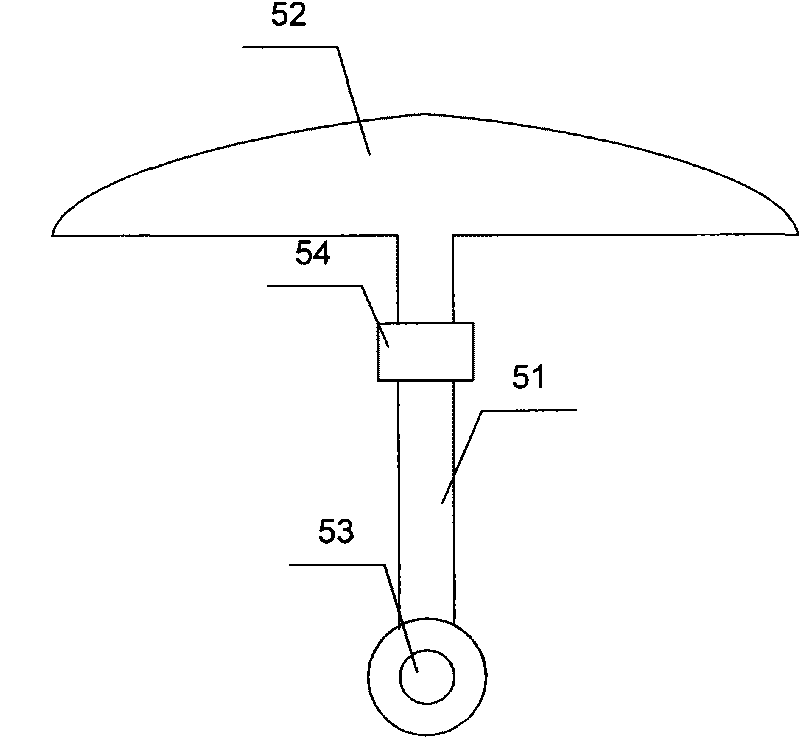

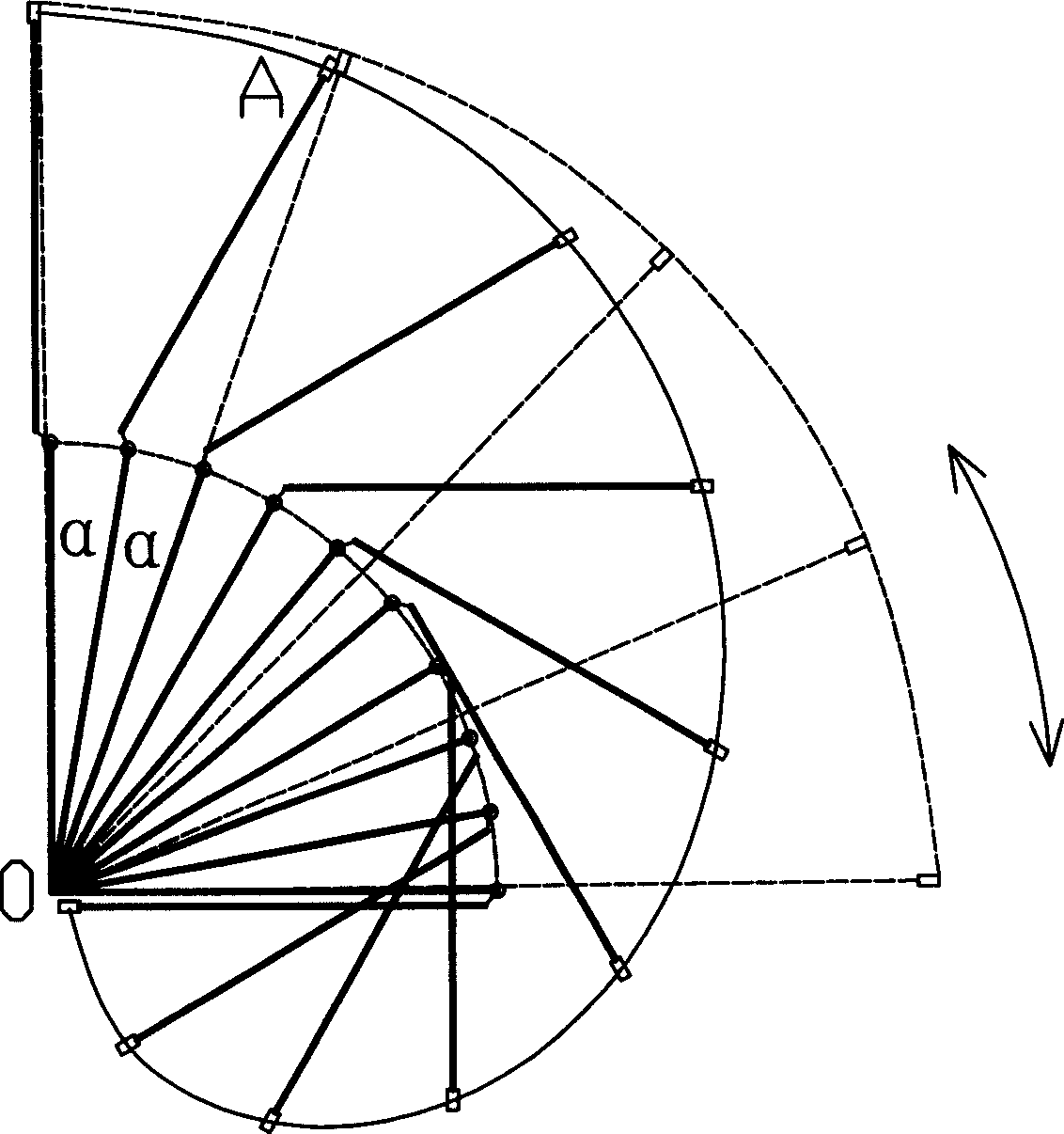

Fast involute grounding switch with ultrahigh-voltage

InactiveCN1747088AReduce inertial impact forceExtended service lifeContact driving mechanismsSwitches with movable electrical contactsPower line networkUltra high voltage

The invention is used in ultra high- voltage or extreme high -voltage power line network. A folded connecting lever is mounted on the power output shaft of gearbox. There is a moving contact on the top of the folded connecting lever.

Owner:王光顺

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com