Packing material mixing device

A mixing device and packaging material technology, which is applied in the field of packaging material mixing devices, can solve problems such as uneven material distribution, motor damage, and high power, and achieve the effects of reducing starting power, increasing service life, and reducing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

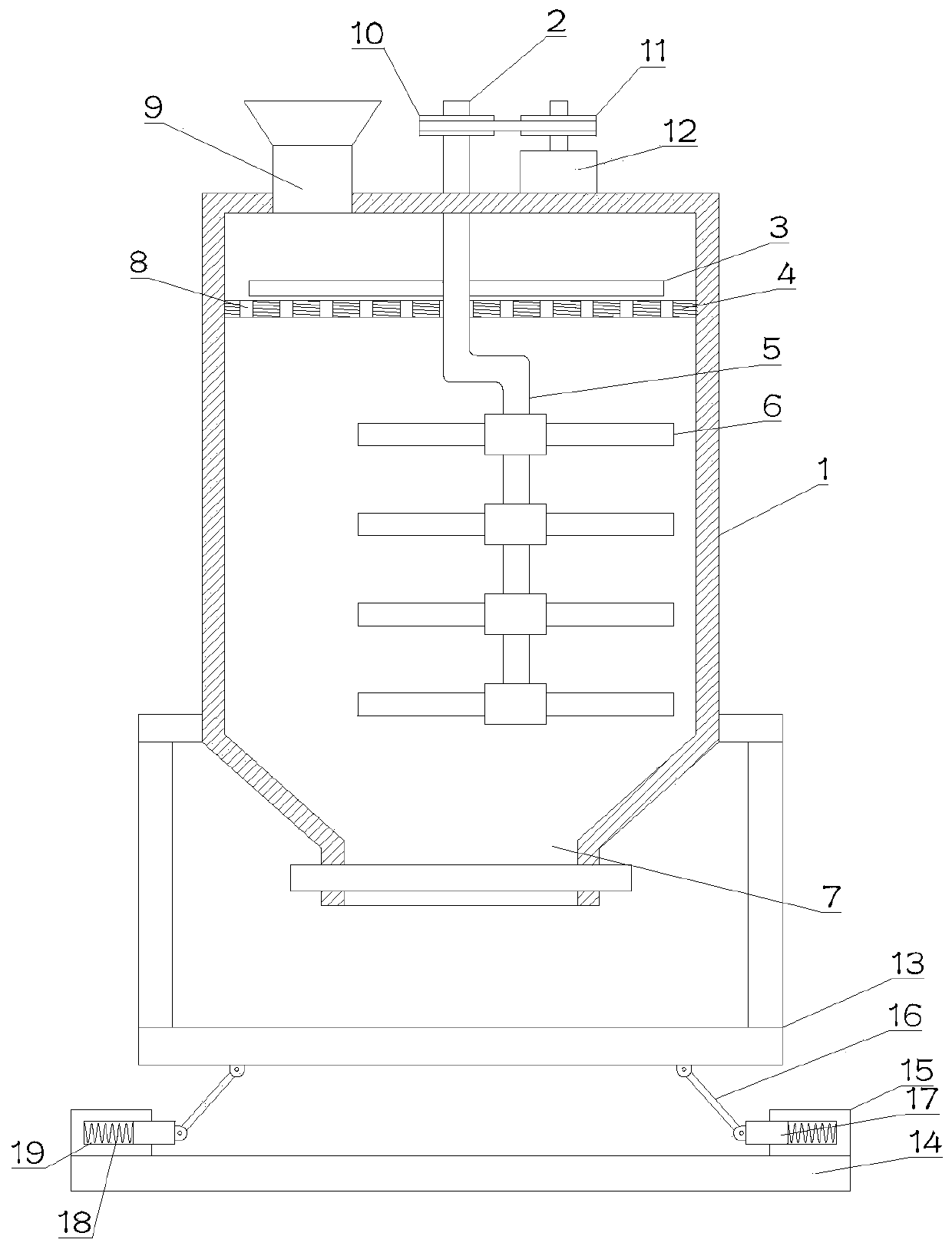

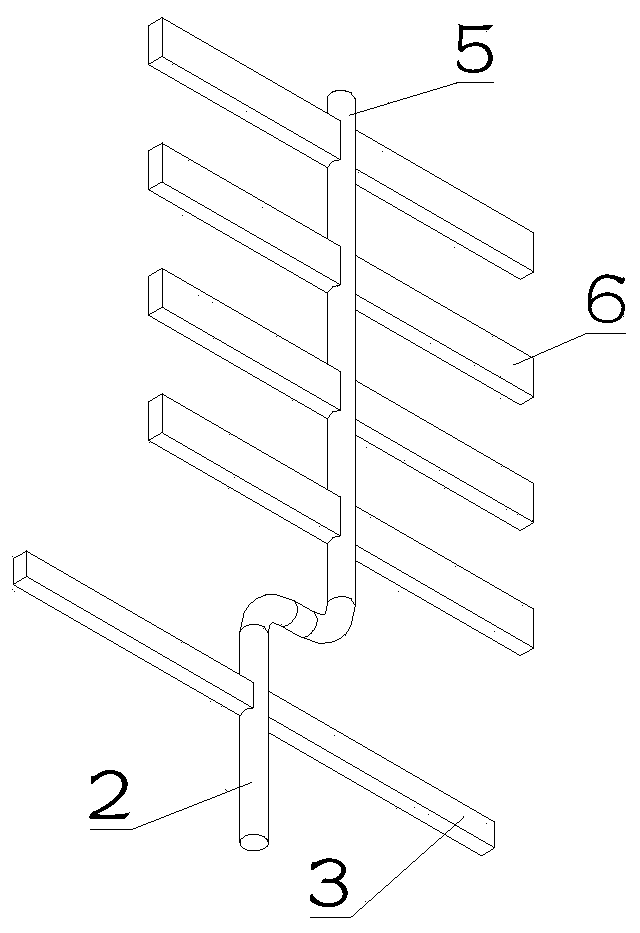

[0020] see Figure 1~3 , in Embodiment 1 of the present invention, a packaging material mixing device includes a mixing main body 1 with a cavity inside, and the cavity is set for mixing and stirring the materials; since the prior art usually mixes the materials directly All of them are added to the inside of the mixing body 1, resulting in uneven material distribution inside the mixing body 1, which requires a lot of power when starting up, which easily leads to damage to the motor on the equipment, so the inside of the mixing body 1 is fixedly installed with a distribution plate 4 , and a scraper 3 is pasted on the upper part of the material distribution plate 4, and the scraper 3 is fixedly installed on the outside of the stirring shaft 2, the upper part of the stirring shaft 2 is installed at the center of the mixing main body 1, and the bottom of the stirring shaft 2 A curved section 5 is provided, and a plurality of stirring rods 6 are arranged in an array on the curved ...

Embodiment 2

[0022] see Figure 1~3 The main difference between this embodiment 2 and embodiment 1 is that the bottom of the mixing body 1 is provided with a discharge port 7, and the discharge port 7 is provided for discharging the mixed material.

[0023] The mixing main body 1 is provided with a feeding hopper 9 , and the mixing main body 1 is provided for adding materials to be mixed into the mixing main body 1 .

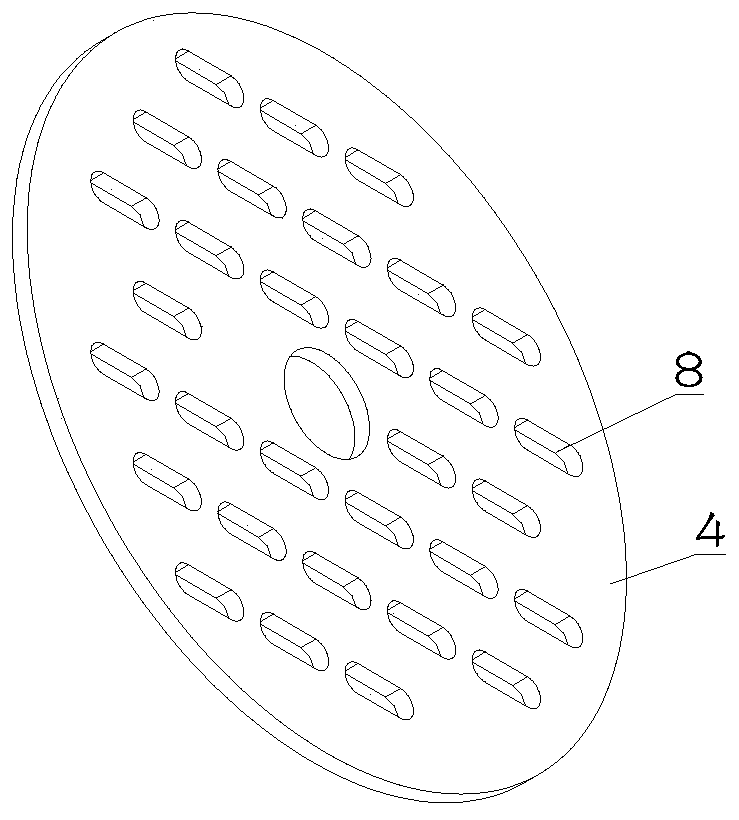

[0024] The material distribution plate 4 is provided with leakage holes 8 in an array, and the scraper 3 rotates to evenly drop the material to the bottom of the mixing body 1 through the leakage holes 8 .

[0025] The stirring rod 6 is welded and installed on the curved section 5 .

[0026] The shock-absorbing support includes a bracket 13, a base 14, a support base 15, connecting rods 16 and moving blocks 17 arranged on both sides of the bottom of the bracket 13, and the bracket 13 is fixedly installed on the bottom of the mixing body 1, and one end of the connecting rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com