Patents

Literature

67results about How to "Avoid thermal resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

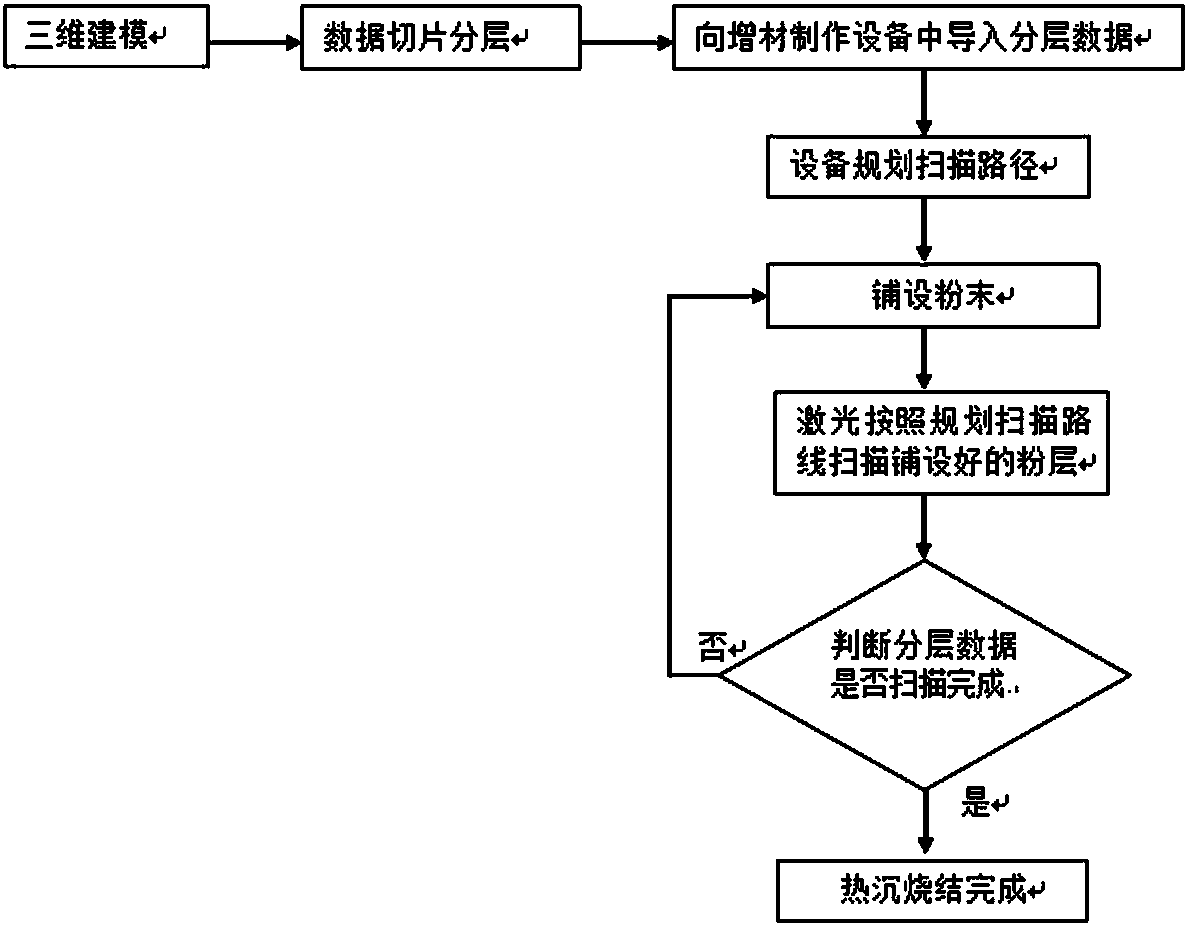

Method for manufacturing heat sink body

ActiveCN104028758AReduced time for structural optimization and product manufacturingImprove thermal performanceIncreasing energy efficiencyThree dimensional modelHeat sink

The invention discloses a method for manufacturing a heat sink body. The method aims at solving the problems that in the traditional heat sink manufacturing process, heat resistance is increased due to multilayer welding, and a heat sink body needs to be manufactured through multiple processes and is short in service life. The method includes the steps that three-dimensional modeling is conducted on the whole structure of the heat sink body; a three-dimensional model is guided to a workbench computer, and the printing angle and positions are set according to the structure of a three-dimensional pattern; a powder layer laid on a base plate of a workbench in advance is sintered into two-dimensional shapes corresponding to the powder layer through high-energy laser beams according to the scanning path; powder as thick as the powder layer is laid on the workbench on which one layer of pattern is sintered, and lasers scan the powder according to the scanning path of the layer until the whole three-dimensional pattern is finished. Through the structure, the heat sink body has the advantages that pressure distribution is uniform and the service life of the heat sink body is prolonged.

Owner:CHENGDU 3D CHANGE TECH

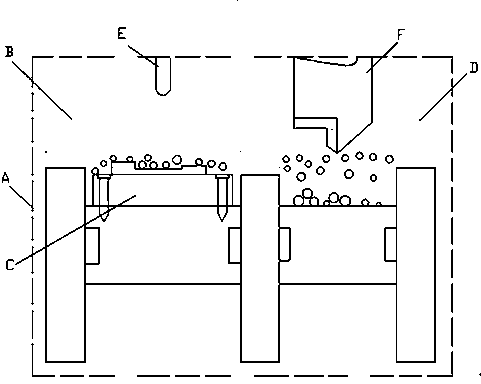

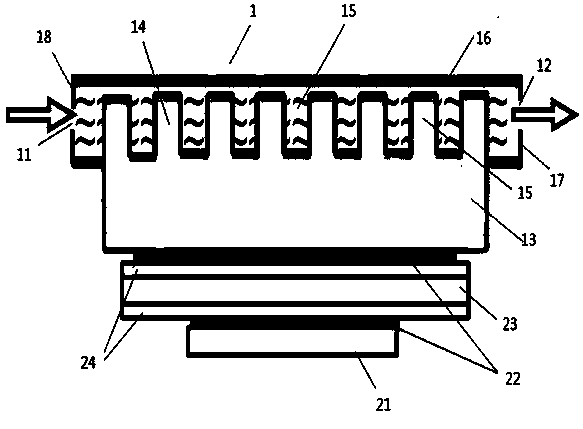

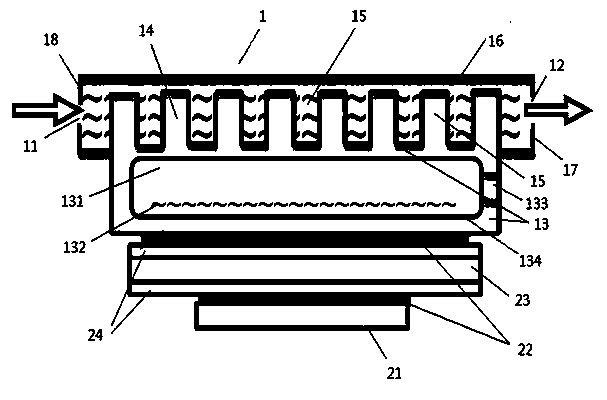

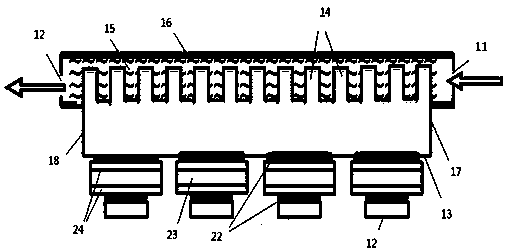

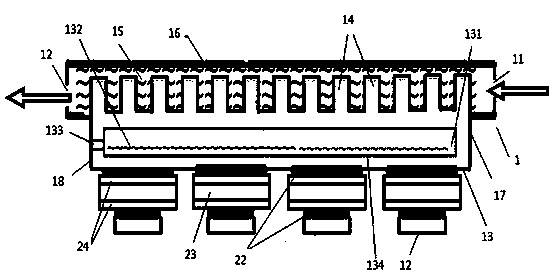

Radiating packaging structure of semiconductor power device

InactiveCN103413794AImprove cooling effectCompact structureSemiconductor/solid-state device detailsSolid-state devicesHeat resistanceSilica gel

The invention provides a radiating packaging structure of a semiconductor power device. The radiating packaging structure of the semiconductor power device is provided with a radiating shell body containing cooling liquid, wherein the inner side of a cover plate of the radiating shell body is provided with radiating assemblies and further forms a fluid flow passage, and meanwhile the other side of the cover plate serves as a substrate of the semiconductor power device, namely, the radiating packaging structure and the semiconductor power devices are integrally formed, so the structure is very compact. The radiating packaging structure is characterized in that due to the integrated packaging structure, heat resistance produced by silica gel with a low heat conductivity coefficient is avoided, the radiating assemblies are located on the other side (namely the substrate) of the cover plate, heat from the power device can be directly dissipated, and meanwhile, the radiating effect of the semiconductor power device is greatly improved under the action of turbulent flow of the radiating assemblies.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Heat dissipation device based on carbon nanotube arrays and low temperature co-fired ceramics and preparation method

InactiveCN101826494ASimple process conditionsLow costSemiconductor/solid-state device detailsSolid-state devicesHeat resistanceCarbon nanotube

The invention provides a heat dissipation device based on carbon nanotube arrays and low temperature co-fired ceramics and a preparation method, belonging to the heat dissipation technology of microelectronic devices. The heat dissipation device comprises a low temperature co-fired ceramic substrate with a micro channel embedded inside. Carbon nanotube arrays are prepared on the surface of the low temperature co-fired ceramic substrate and a heating device connected with a circuit of the low temperature co-fired ceramic substrate is fixed on the carbon nanotube arrays. The device makes the most of the advantage that the low temperature co-fired ceramic substrate is easy to be machined into three-dimensional structure, the micro channel is manufactured in the substrate and most heat generated by the heating device is led away through convective heat exchange of the micro channel; and meanwhile, the carbon nanotube arrays and the low temperature co-fired ceramics are closely jointed with the heating device, thus reducing the microvoids generated on the joint interface by the traditional methods such as welding, avoiding heat resistance caused by the microvoids, weakening the heat resistance between the heating device and the low temperature co-fired ceramic substrate and improving the heat dissipation capability of the heat dissipation device.

Owner:PEKING UNIV

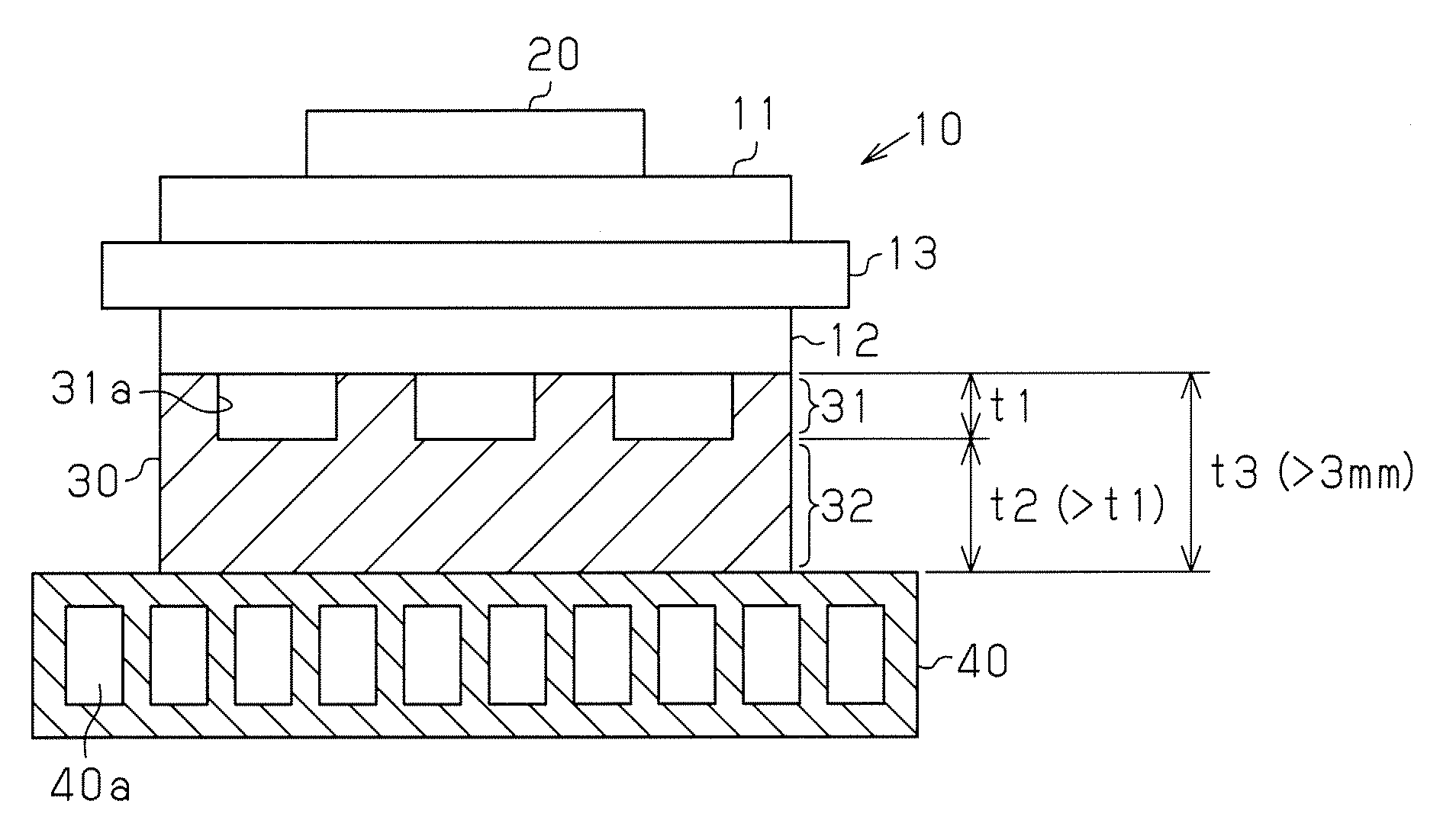

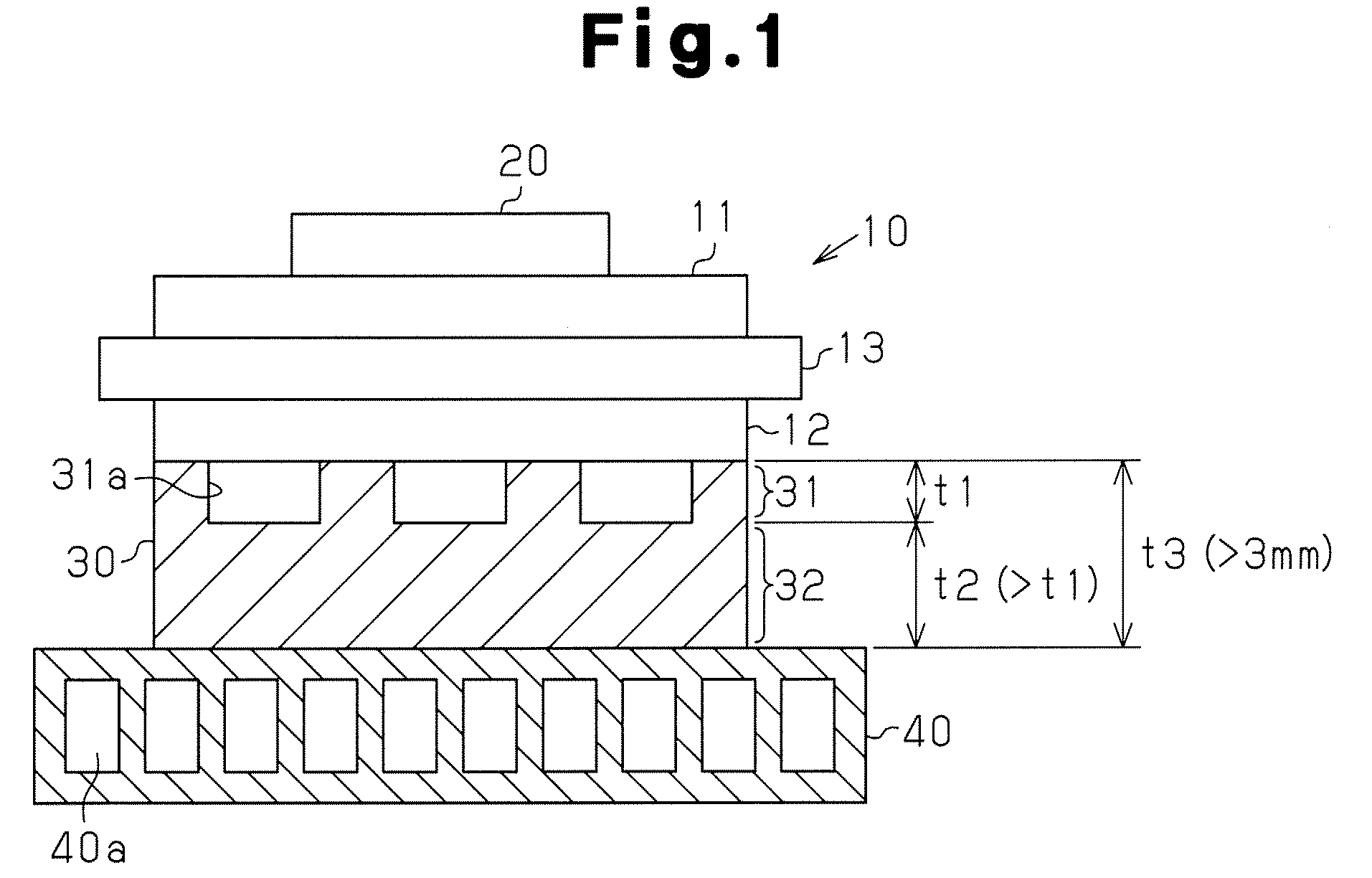

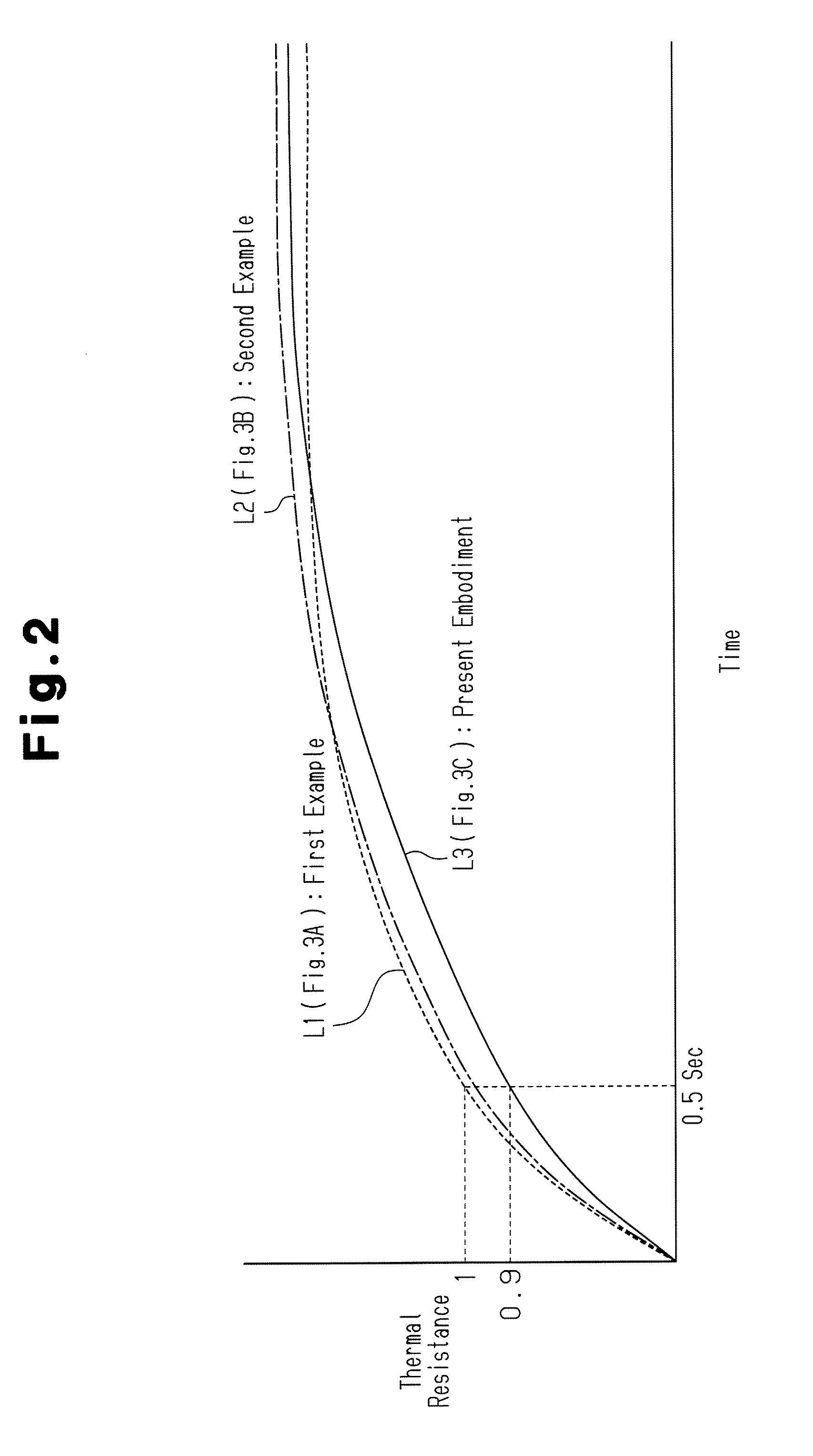

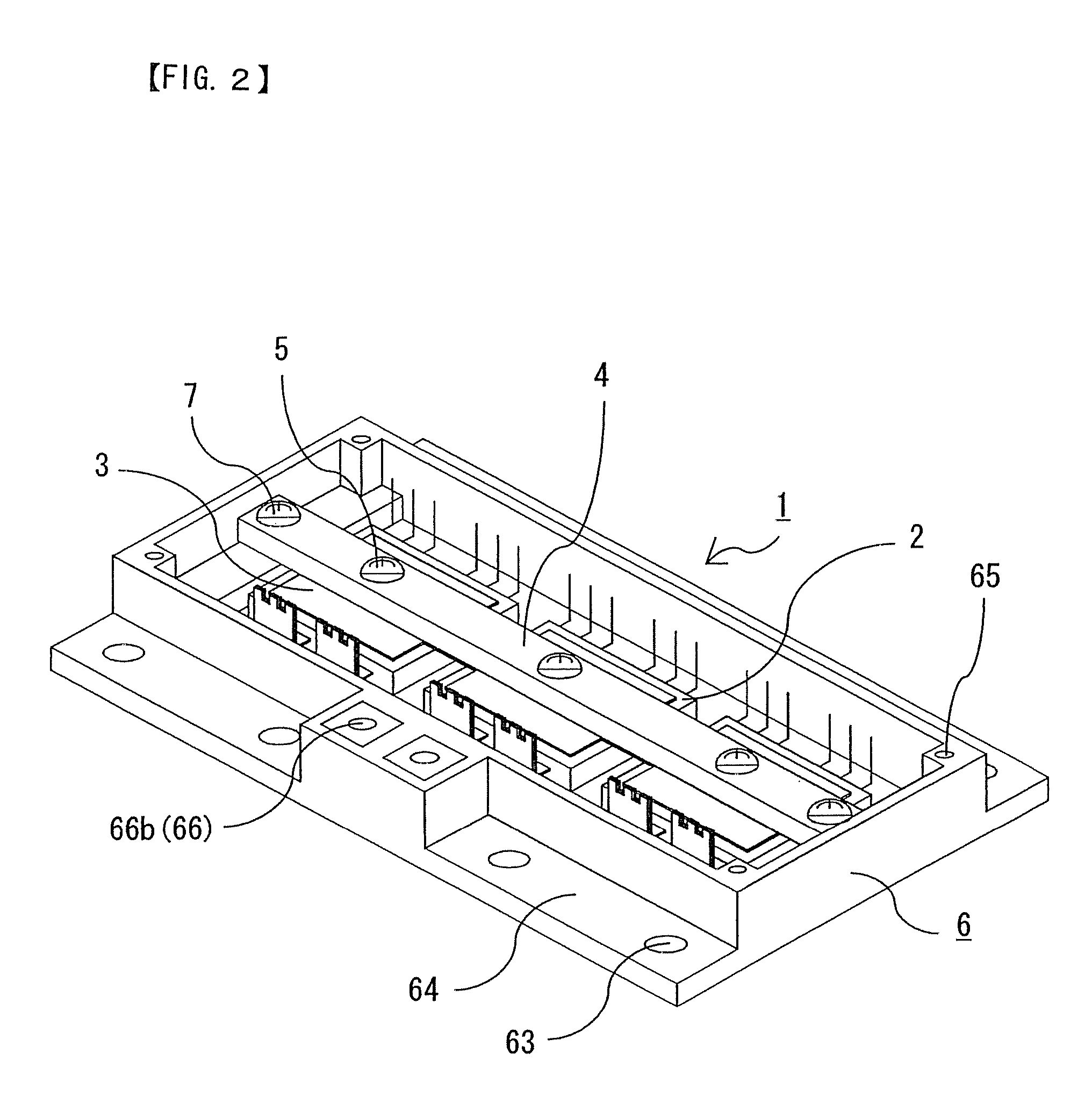

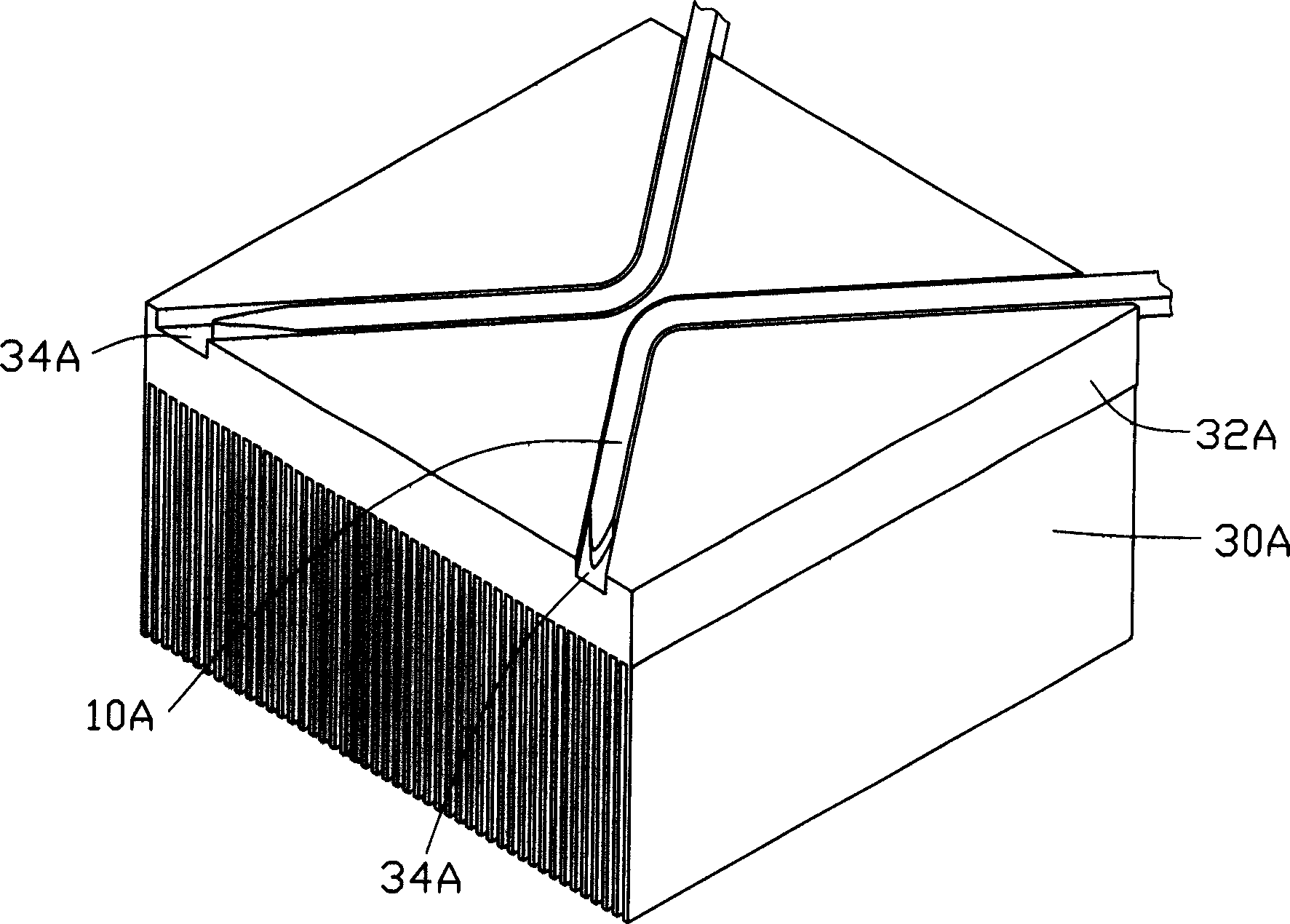

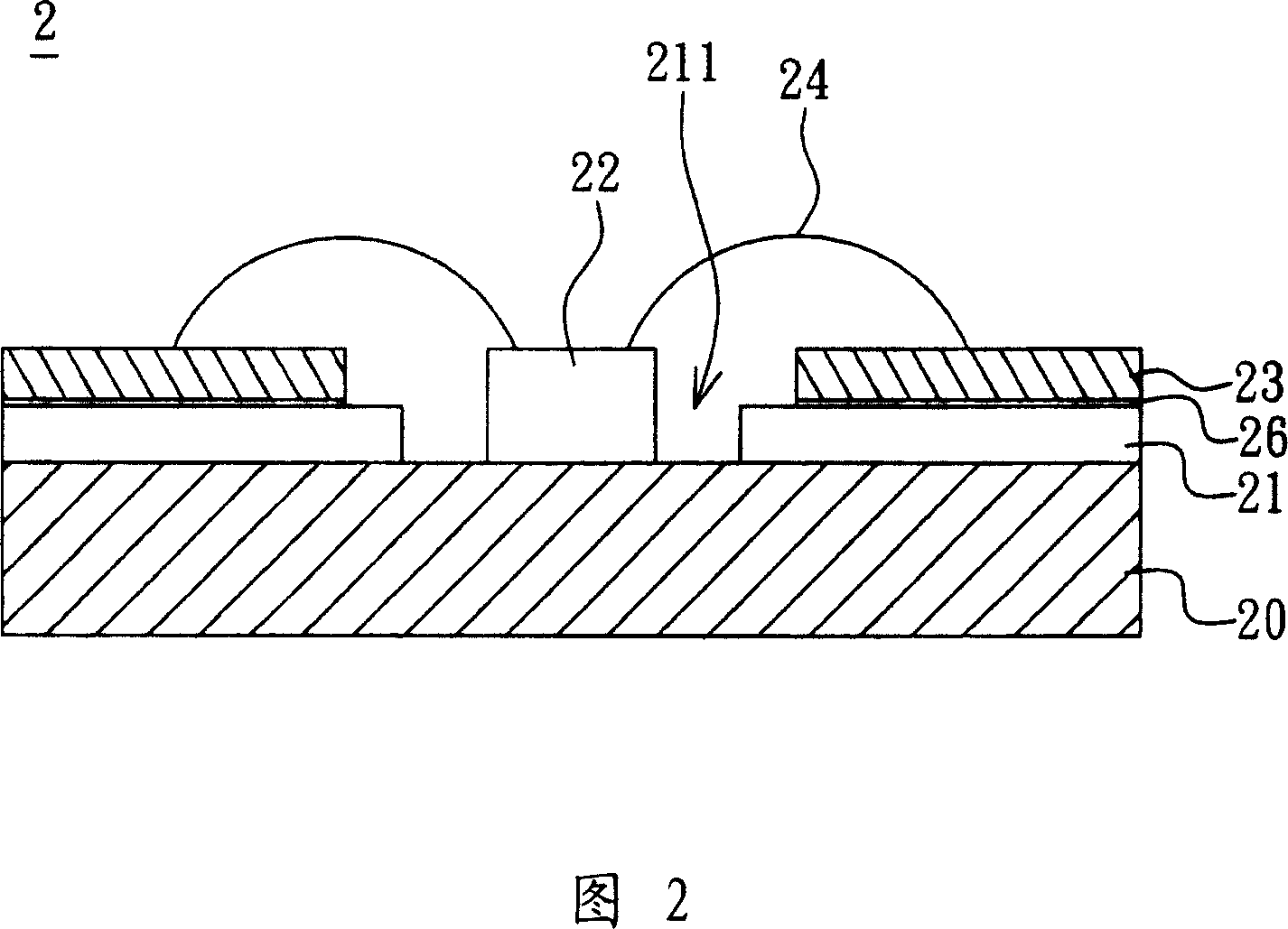

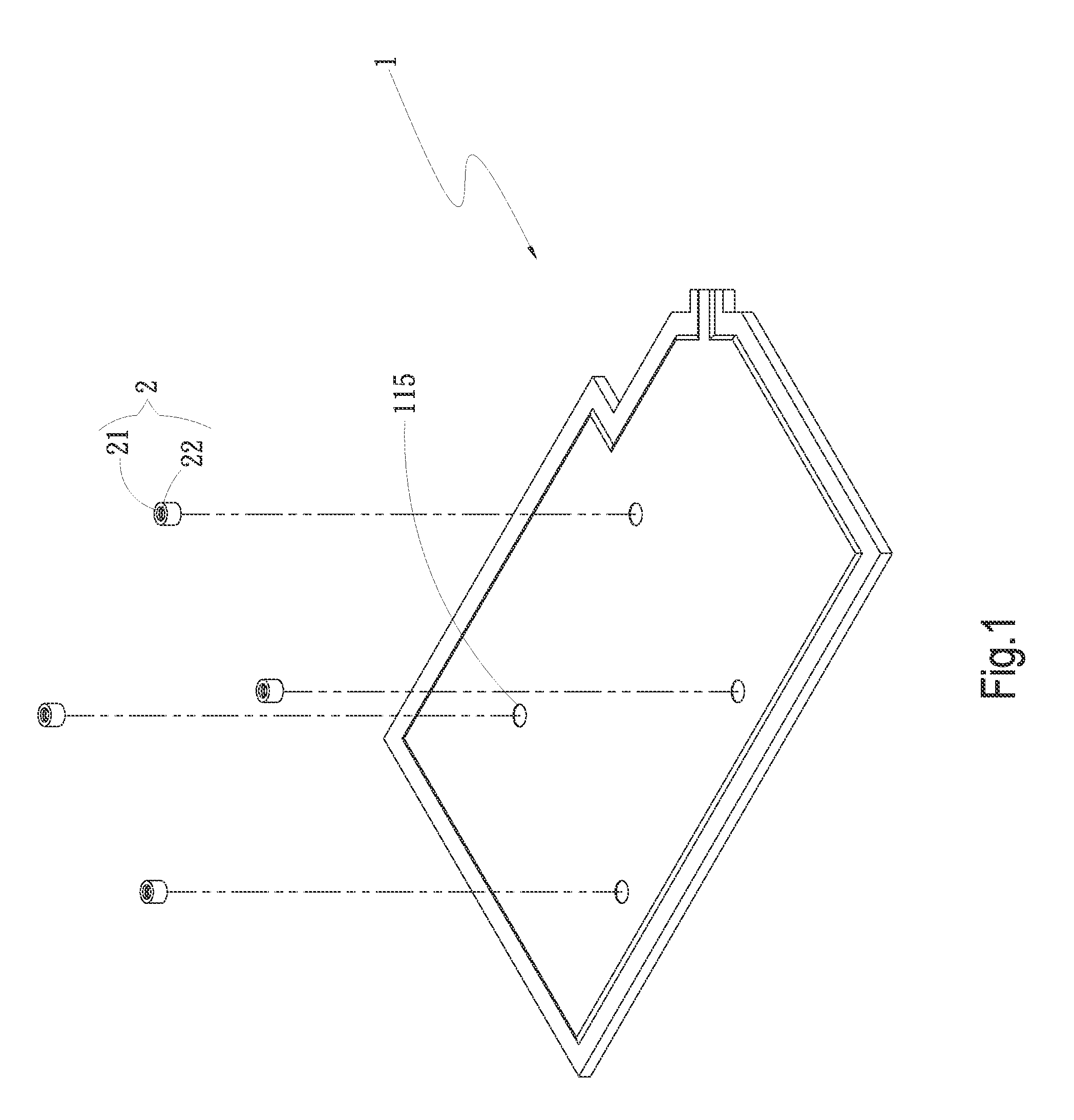

Heat dissipation apparatus

InactiveUS20090147479A1Low costRelieve pressureSemiconductor/solid-state device detailsSolid-state devicesStress reductionMaterials science

A heat dissipation apparatus including an insulation substrate, a heat sink, and a heat mass member. The insulation substrate includes a first surface serving as a heated body receiving surface and a second surface opposite to the first surface. A heat sink is thermally coupled to the second surface of the insulation substrate. A heat mass member includes a stress reduction portion and a heat mass portion arranged so that one is above the other. The stress reduction portion includes a plurality of recesses in at least either one of a surface facing toward the insulation substrate and a surface facing toward the heat sink of the heat mass member. The heat mass portion has a thickness that is greater than that of the stress reduction portion, and the heat mass member has a thickness that is greater than three millimeters.

Owner:TOYOTA IND CORP +1

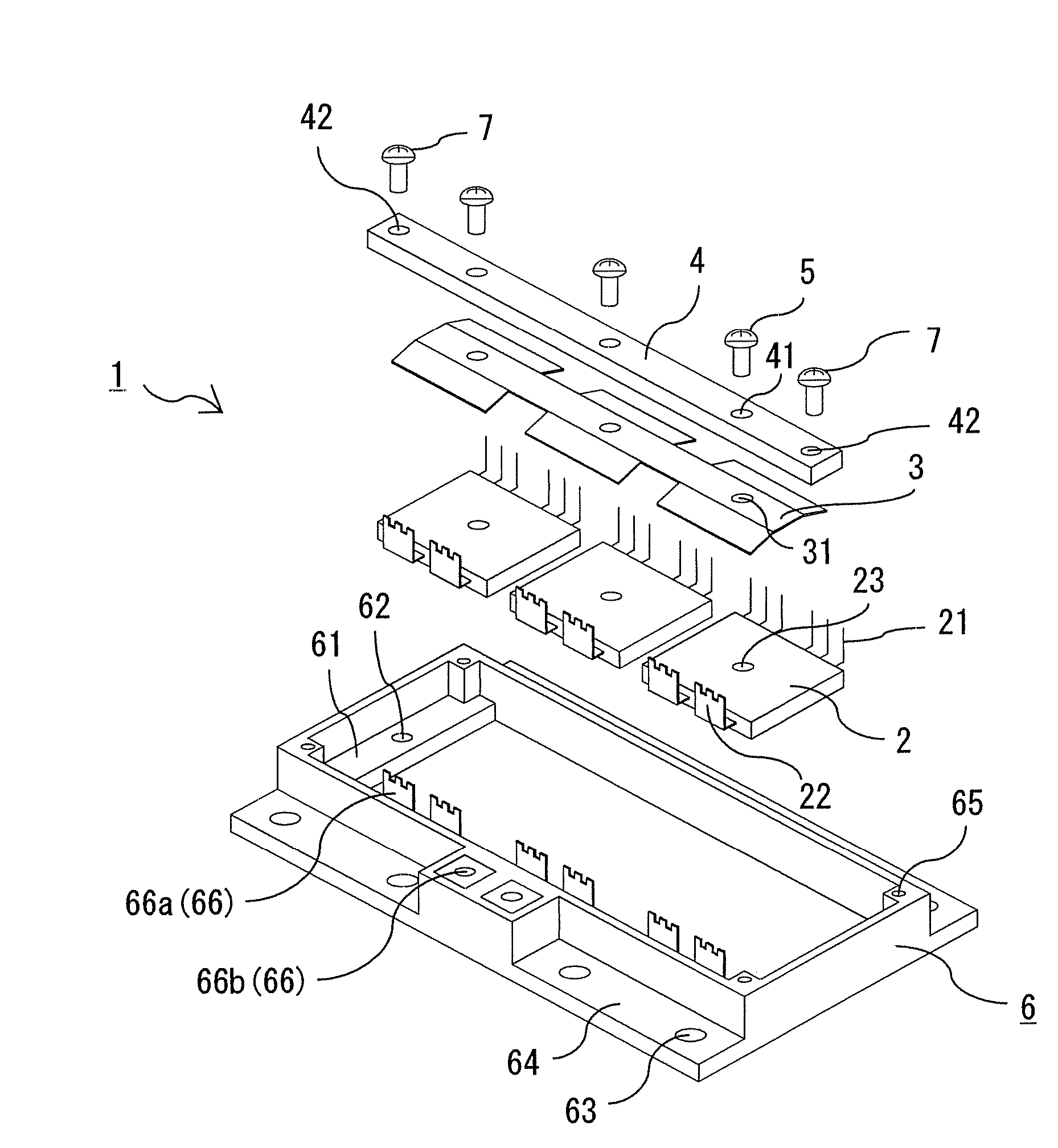

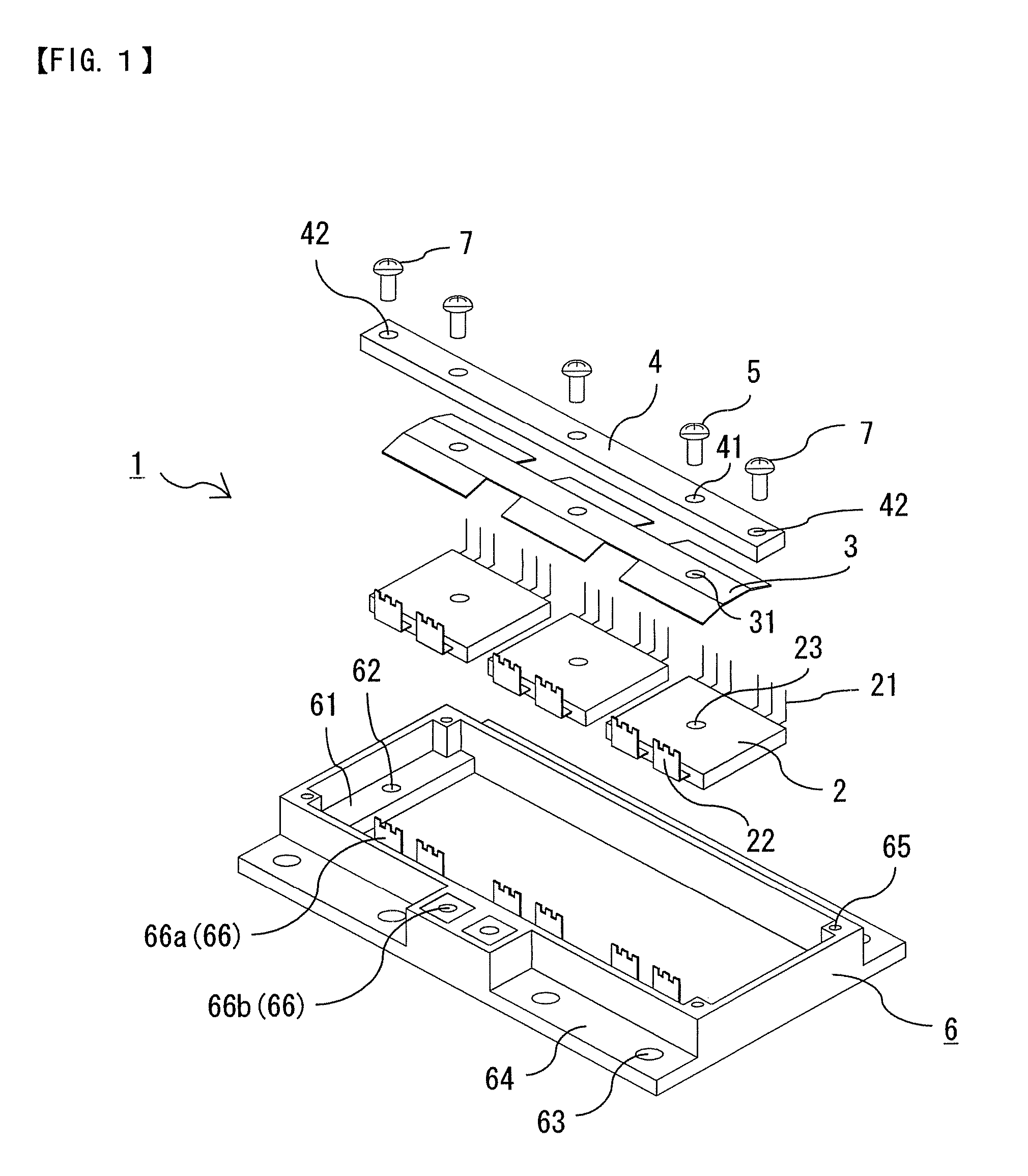

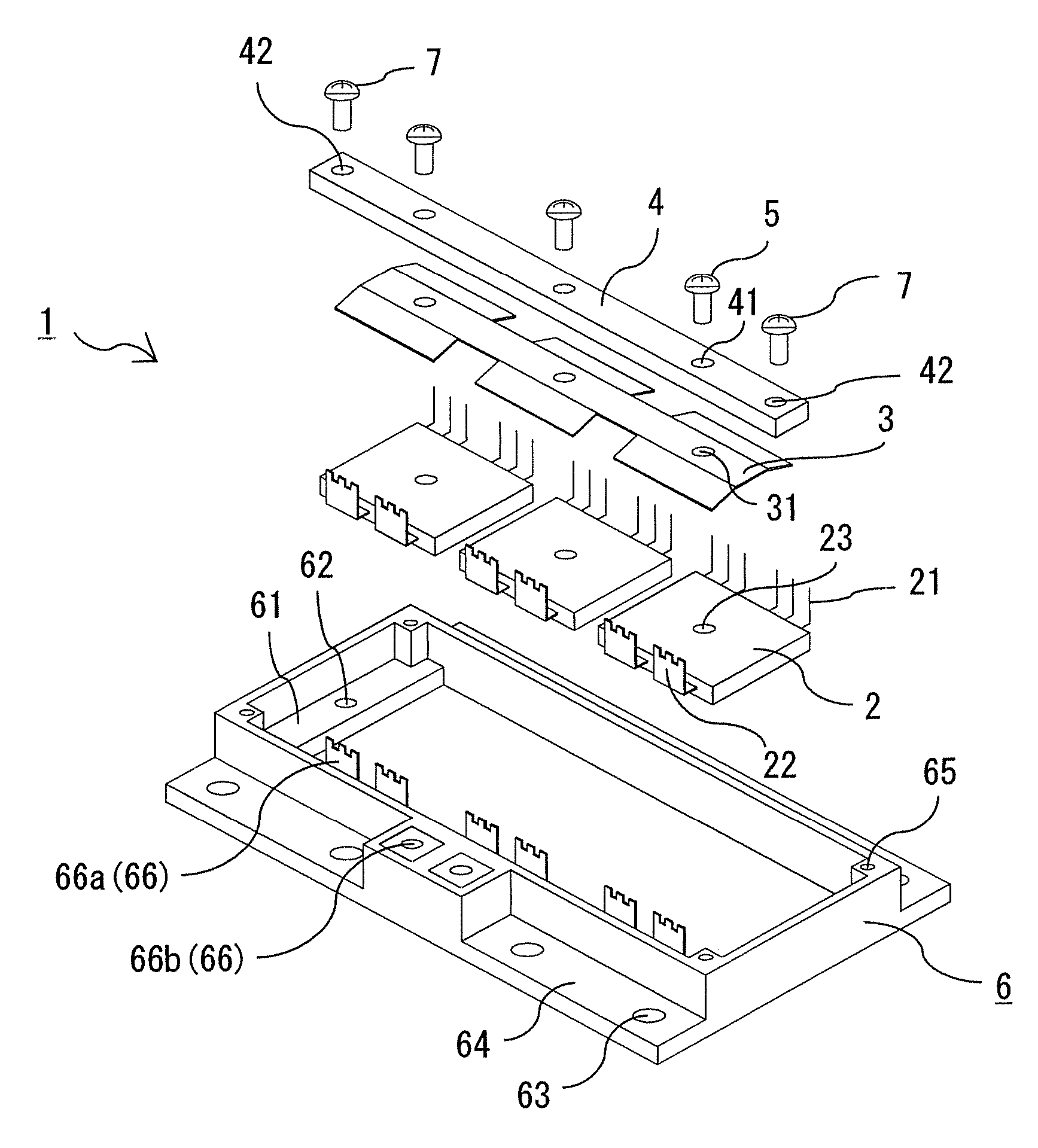

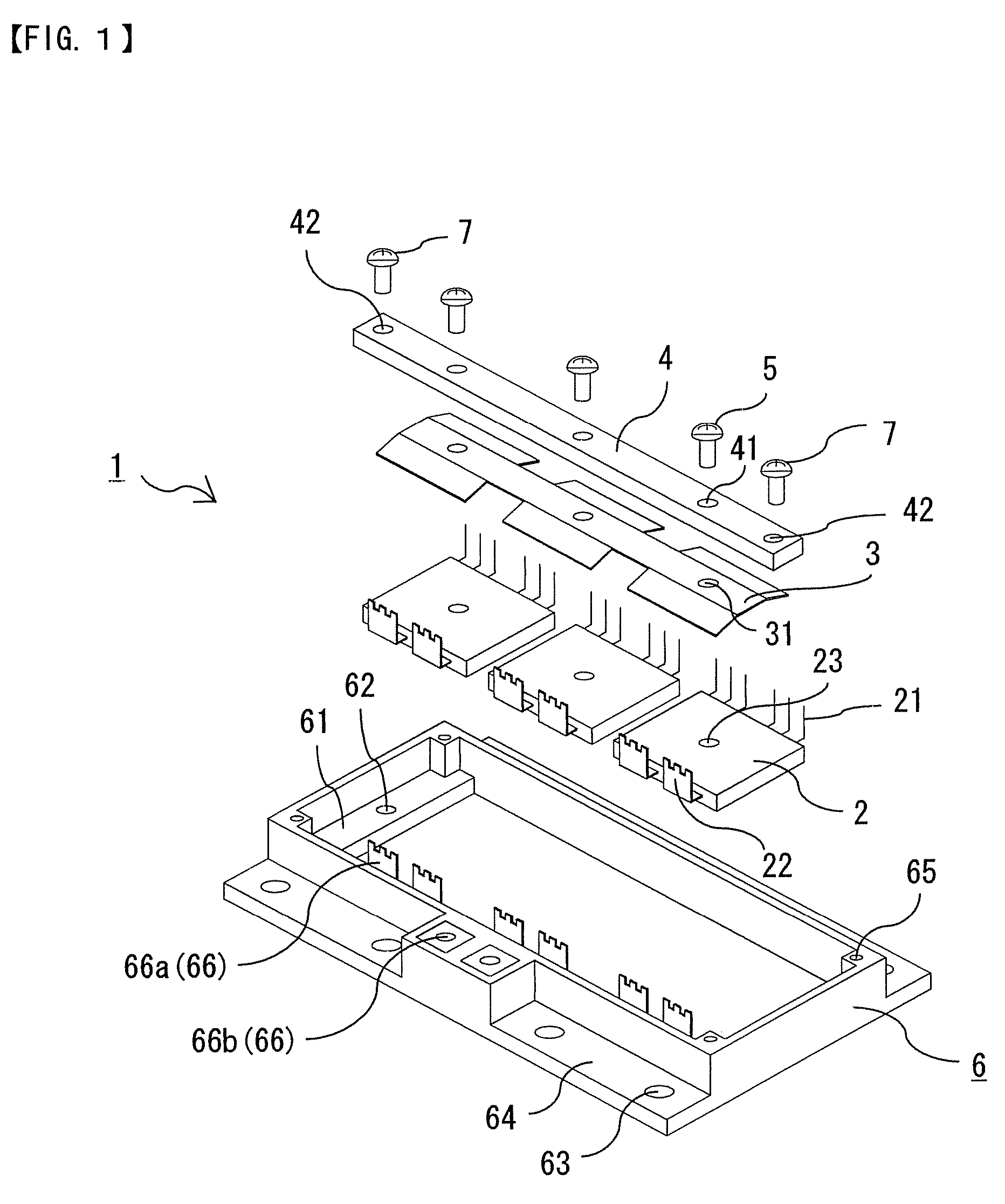

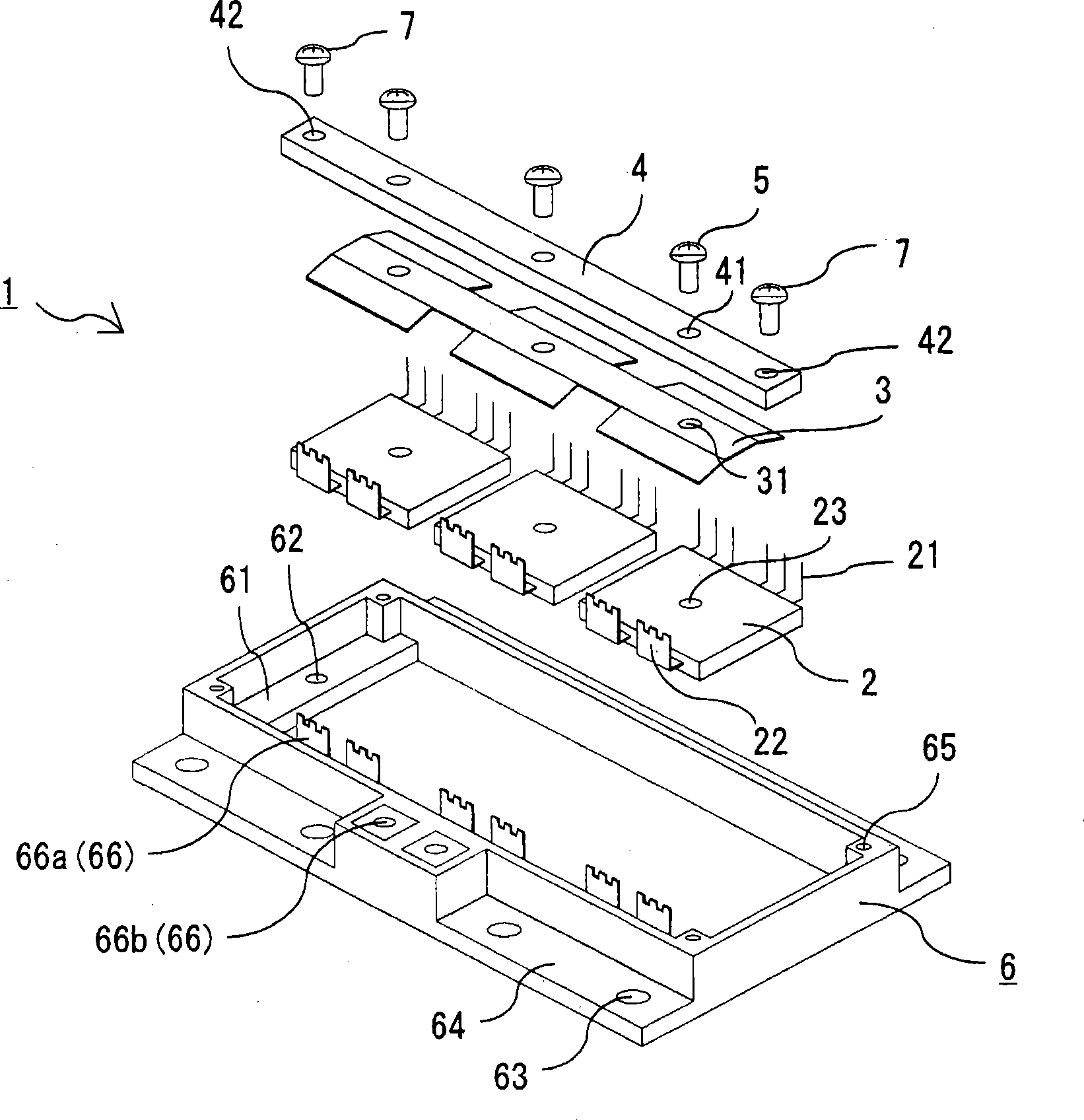

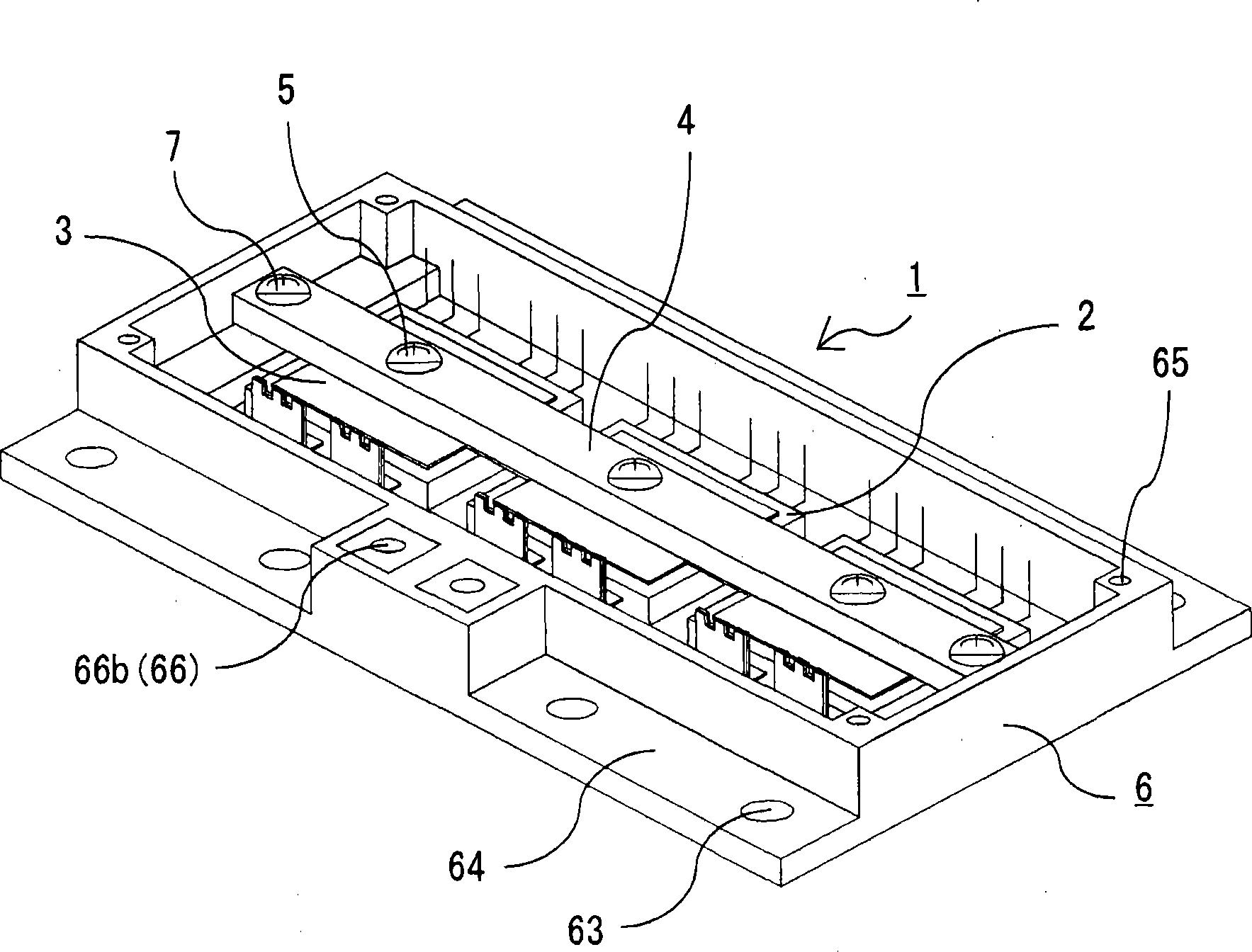

Semiconductor device

ActiveUS20090039504A1Small sizeReduce weightSemiconductor/solid-state device detailsSolid-state devicesProduction rateEngineering

The present invention is intended to obtain a semiconductor device that is reduced in size, weight, and cost and improved in performance stability and productivity.The semiconductor device includes a semiconductor module in which a semiconductor element is sealed with a resin, a reinforcing beam fixed to an upper surface of the semiconductor module via a plate-like spring, and a frame part to which both ends of the reinforcing beam are fixed, the frame part being disposed in such a fashion as to enclose from four directions an outer periphery of the semiconductor module, plate-like spring, and the reinforcing beam.

Owner:MITSUBISHI ELECTRIC CORP

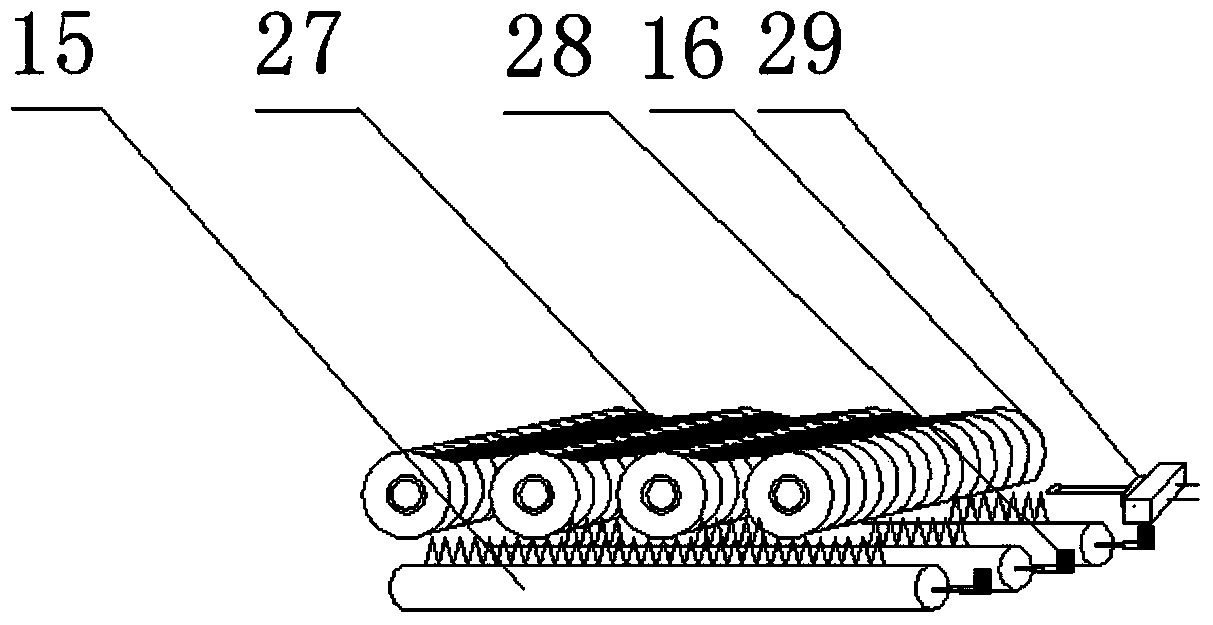

Manufacturing method of heat radiation device

InactiveCN1753172AAvoid thermal resistanceReduce thermal resistanceSemiconductor/solid-state device detailsSolid-state devicesHeat spreaderRadiation

The invention is a method for manufacturing radiating device, including the following steps of: 1) providing at least a hot tube; 2) providing a radiator, comprising a base, where there is a channel arranged on one side of the base to hold at least a part of the hot tube; 3) providing a welding rod, and in order placing the welding rod, and hot tube in the channel and putting the welding rod in between the hot tube and radiator; 4) heating to melt the welding rod and using a plane to press the channeled side of the base. Because the fluidity of the welding rod is worse, after melted, the welding rod can fill up the gap between the hot tube and radiator, able to avoid the thermal resistance generated because of the air.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

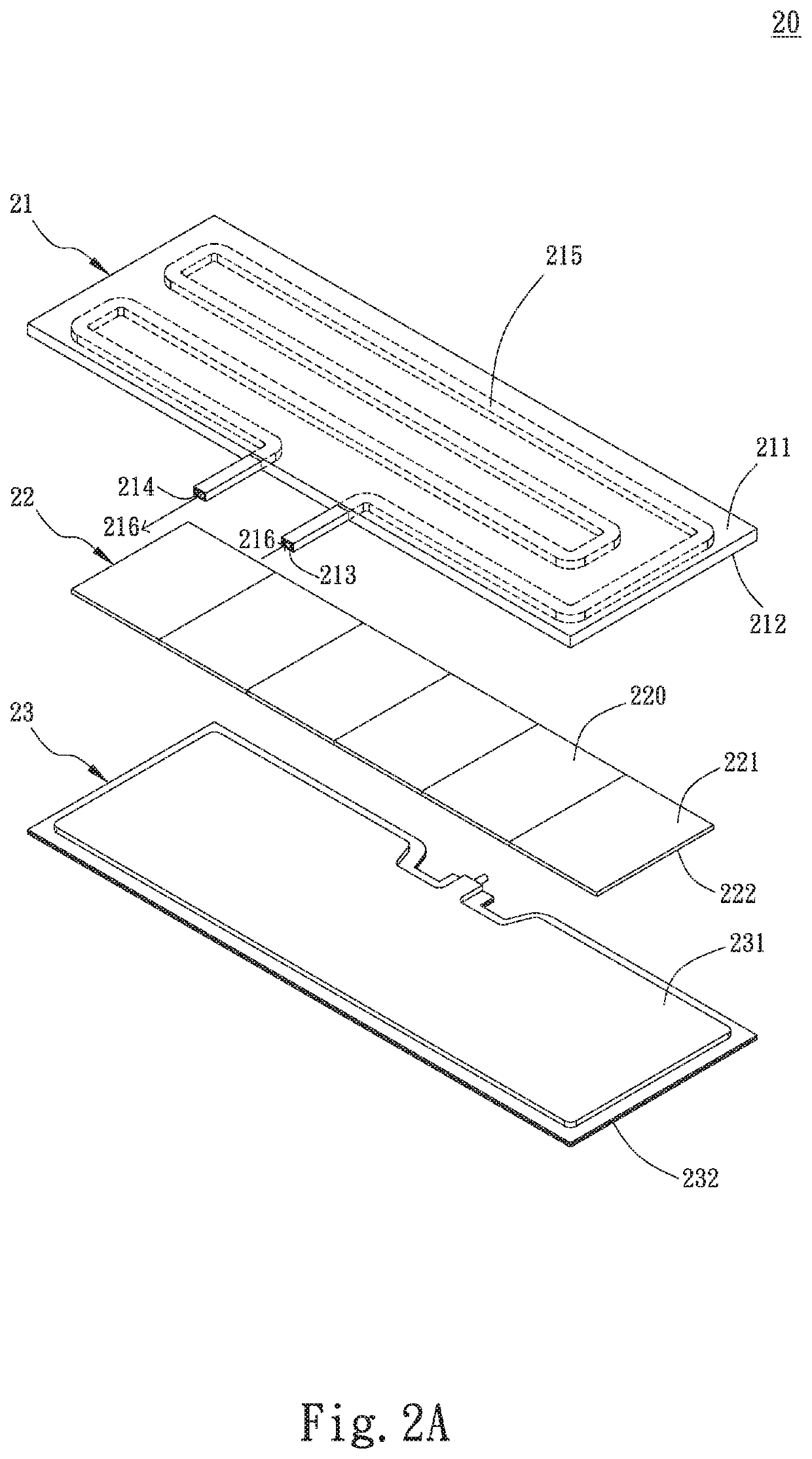

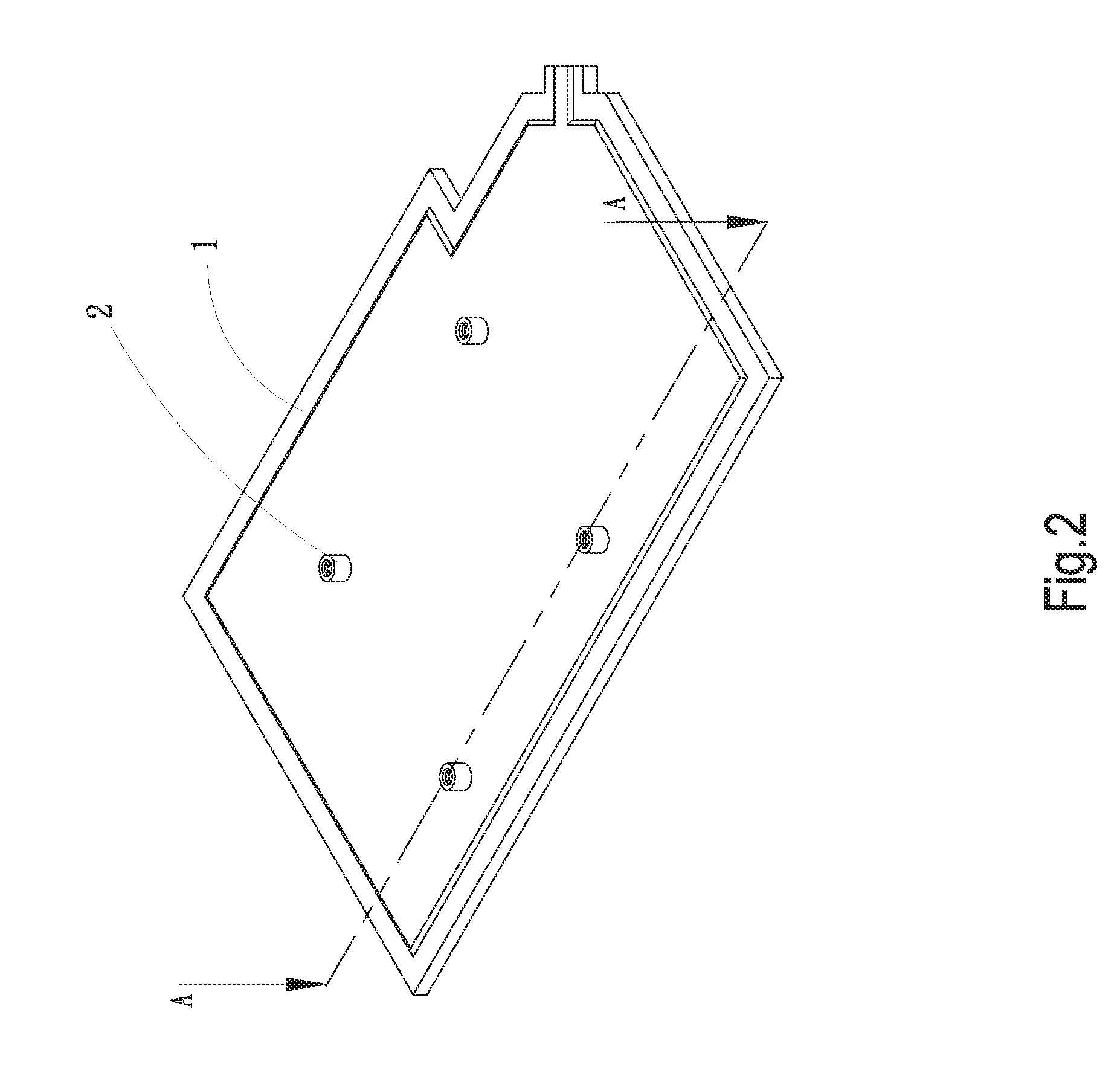

Heat dissipation device and manufacturing method thereof

InactiveUS20130098592A1Improve tightnessAvoid thermal resistanceSemiconductor/solid-state device detailsSolid-state devicesWorking fluidEngineering

A heat dissipation device and a manufacturing method thereof. The heat dissipation device includes a main body and at least one fixing hole. The main body has a first board body and a second board body corresponding to the first board body. The first and second board bodies are mated with each other to define a chamber. A working fluid and multiple support pillars are disposed in the chamber. At least one capillary structure is disposed on a surface of the chamber. The fixing hole is formed on the main body in a position where any support pillar is positioned. The fixing hole passes through the first and second board bodies and the support pillar. According to the above arrangement, the airtightness of the chamber of the main body can be ensured. Also, the heat spreader can be tightly connected with other components.

Owner:ASIA VITAL COMPONENTS SHENZHEN CO LTD

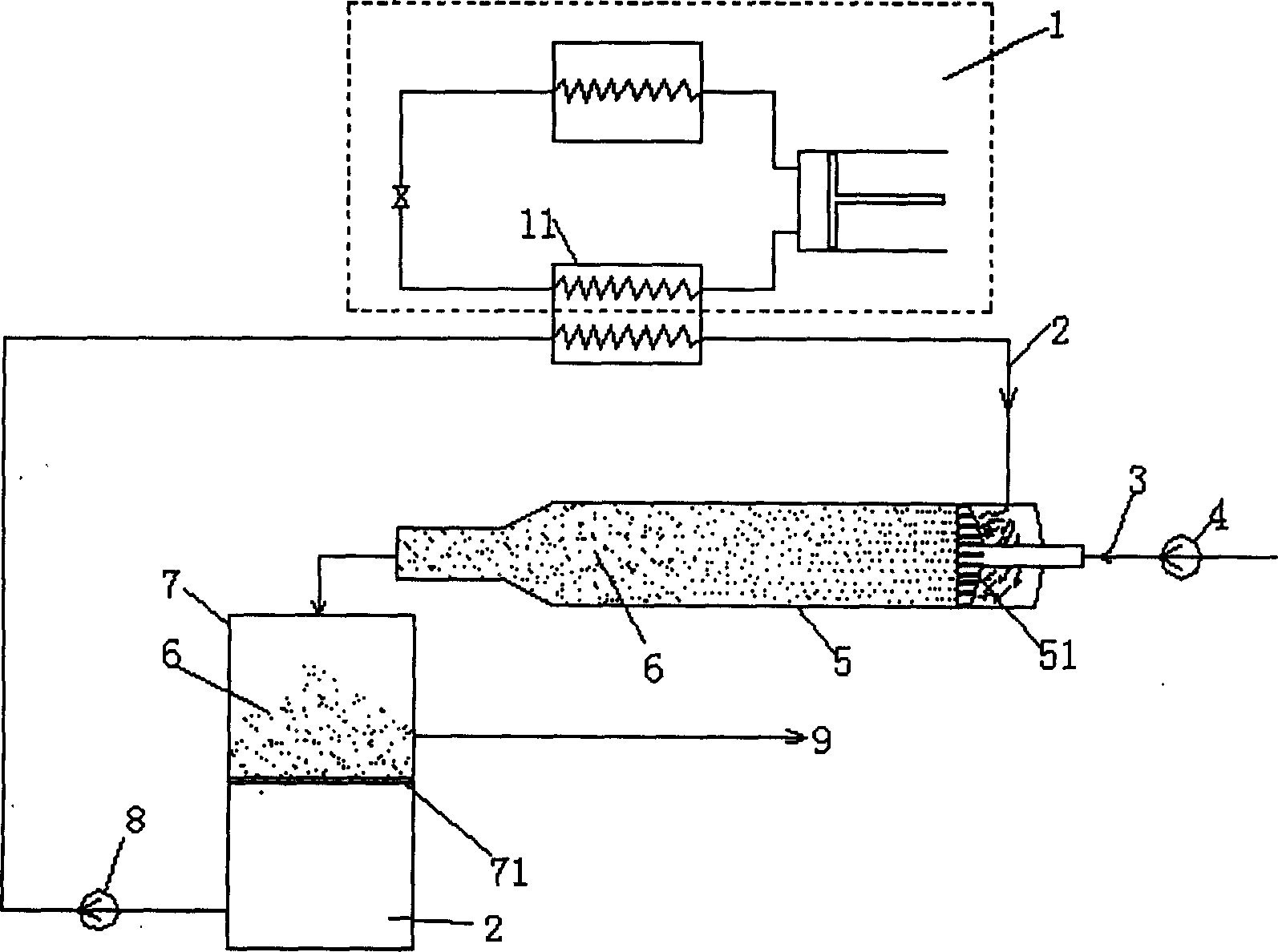

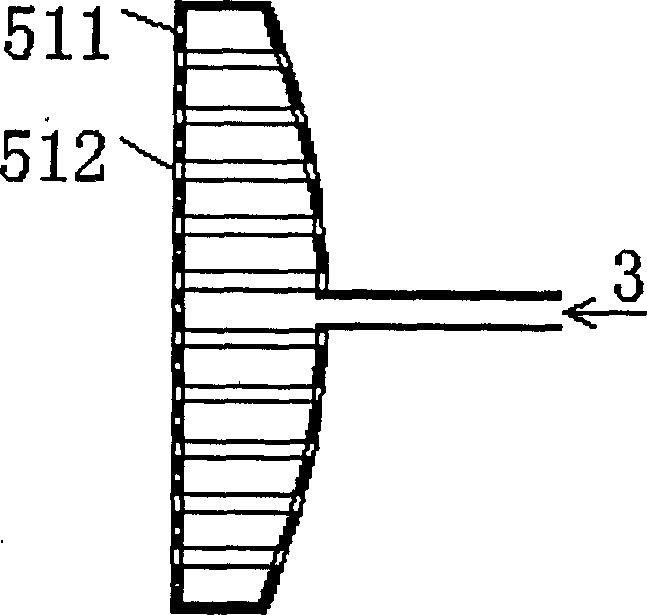

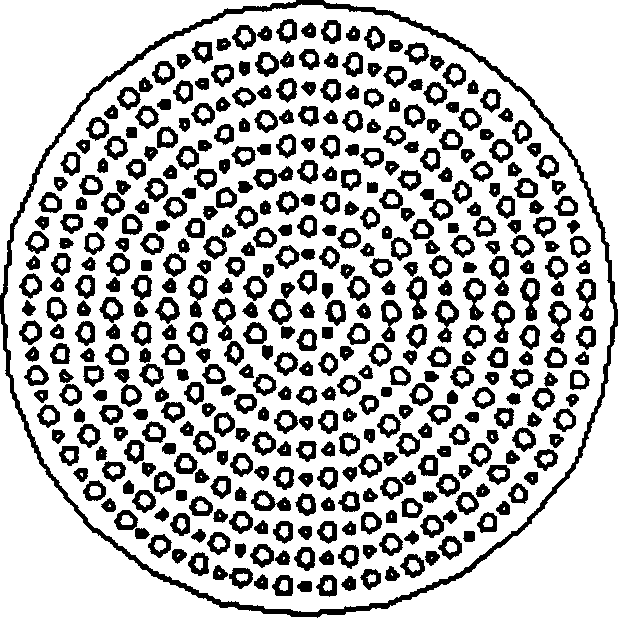

Method and apparatus for making fluidic ice

The present invention is fluid ice making method and apparatus. The method includes cooling the cool carrying medium in fluid to below 0 deg.c with evaporator, spraying ice making water to the cooled cool carrying medium in fluid to form mixed fluid of ice grain and cool carrying medium and separating ice from the cool carrying medium in fluid to obtain fluid ice. The apparatus for making fluid ice includes evaporator, ice making unit, water sprayer, filter with filtering net and circulating pump connected via pipeline. The present invention has high heat efficiency, high practicality, simple structure and low running cost.

Owner:SOUTHEAST UNIV

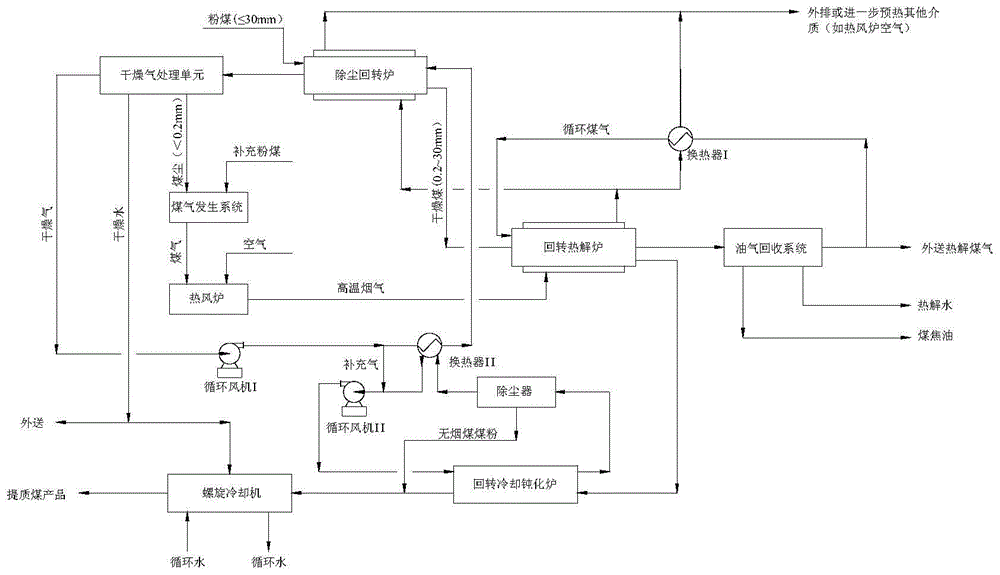

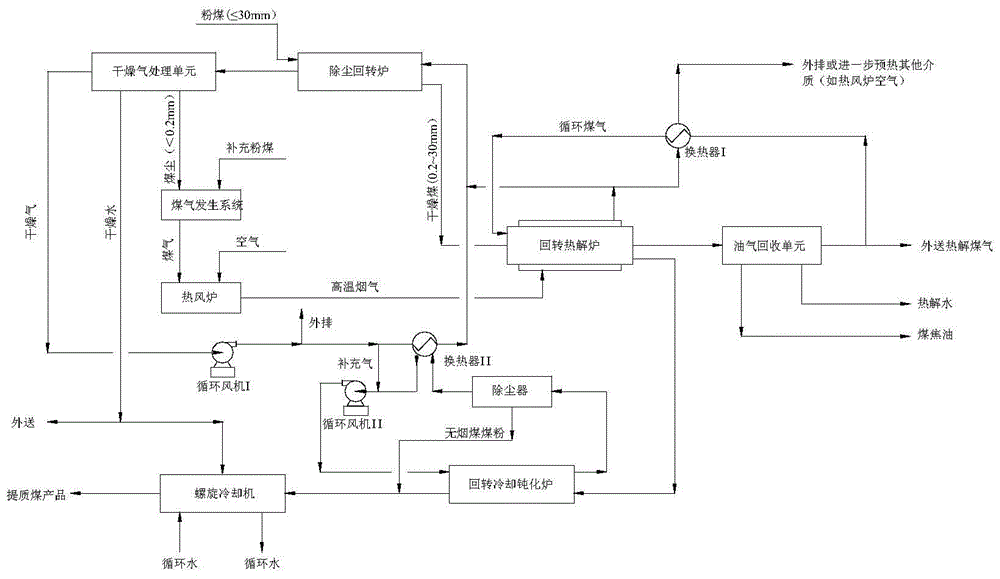

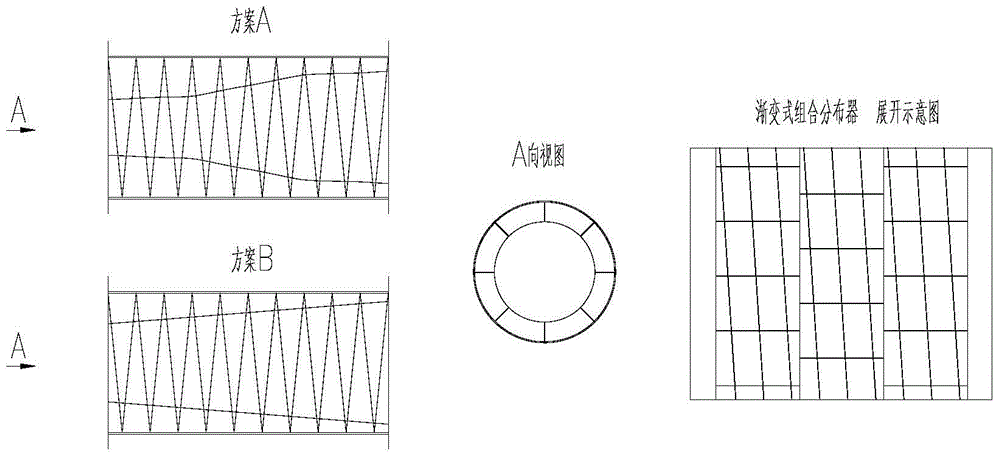

Gas-circulating method for pyrolysis production of anthracite in coal powder rotary furnace

ActiveCN104789244AHigh yieldReduce consumptionIndirect heating destructive distillationSpecial form destructive distillationCoal dustAnthracite

The invention provides a method for pyrolysis production of anthracite in a coal powder rotary furnace. The method relates to a coal powder dust removing rotary drying furnace system, an external-heating rotary furnace pyrolysis system with a coal gas circulation function, a rotary cooling passivation system with a heat recovery function, and an oil gas recovering system, wherein the coal powder dust removing rotary drying furnace system is used for heating coal powder to 110 to 280 DEG C and removing coal dust of which the particle size is smaller than 0.2 mm; drying water is recovered and fed to a downstream spiral cooling machine to be used for anthracite cooling and humidification; the coal dust obtained after separation is fed to a coal gas generating system to generate fuel, namely coal gas; after dust removing, coal is sent to a downstream rotary pyrolysis system for pyrolysis; high-temperature anthracite is generated, and cooled; the cooled anthracite is passivated at a middle-low temperature; the passivated anthracite is cooled in the spiral cooling machine; water is sprayed on the cooled passivated anthracite for humidification; the humidified anthracite is sent out; high-temperature oil gas produced in the process enters the oil gas recovering system to obtain coal tar, pyrolyzed water and coal gas. Part of the produced pyrolyzed coal gas returns to the pyrolysis furnace after preheating in a circulating manner, while the other part of the produced pyrolyzed coal gas is sent out.

Owner:SHAANXI COAL & CHEM IND GRP SHENMU TIANYUAN CHEM IND +1

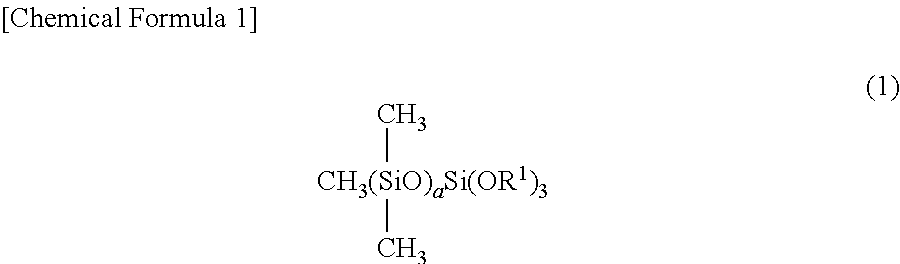

Heat conductive silicone composition, heat conductive layer, and semiconductor device

ActiveUS20150357261A1Avoid thermal resistanceSuppression resistanceSemiconductor/solid-state device detailsSolid-state devicesPtru catalystDevice material

Provided is a heat conductive silicone composition disposed between a heat generating electronic component and a member for dispersing heat, wherein the heat conductive silicone composition contains (A) an organopolysiloxane having at least two alkenyl groups in one molecule and having a dynamic viscosity at 25° C. of 10 to 100,000 mm2 / s, (B) a hydrolyzable dimethylpolysiloxane having three functional groups at one end expressed by formula (1), (C) a heat conductive filler having a heat conductivity of 10 W / m° C. or higher, (D) an organohydrogenpolysiloxane expressed by formula (2), (E) an organohydrogenpolysiloxane containing a hydrogen directly bonded to at least two silicon atoms in one molecule other than component (D), and (F) a catalyst selected from the group consisting of platinum and platinum compounds. The heat conductive silicone composition provides a cured object having a storage modulus, loss modulus, and coefficient of loss within appropriate ranges; peeling and pump out during heating / cooling cycle tending not to occur, and increases in thermal resistance being suppressed.

Owner:SHIN ETSU CHEM IND CO LTD

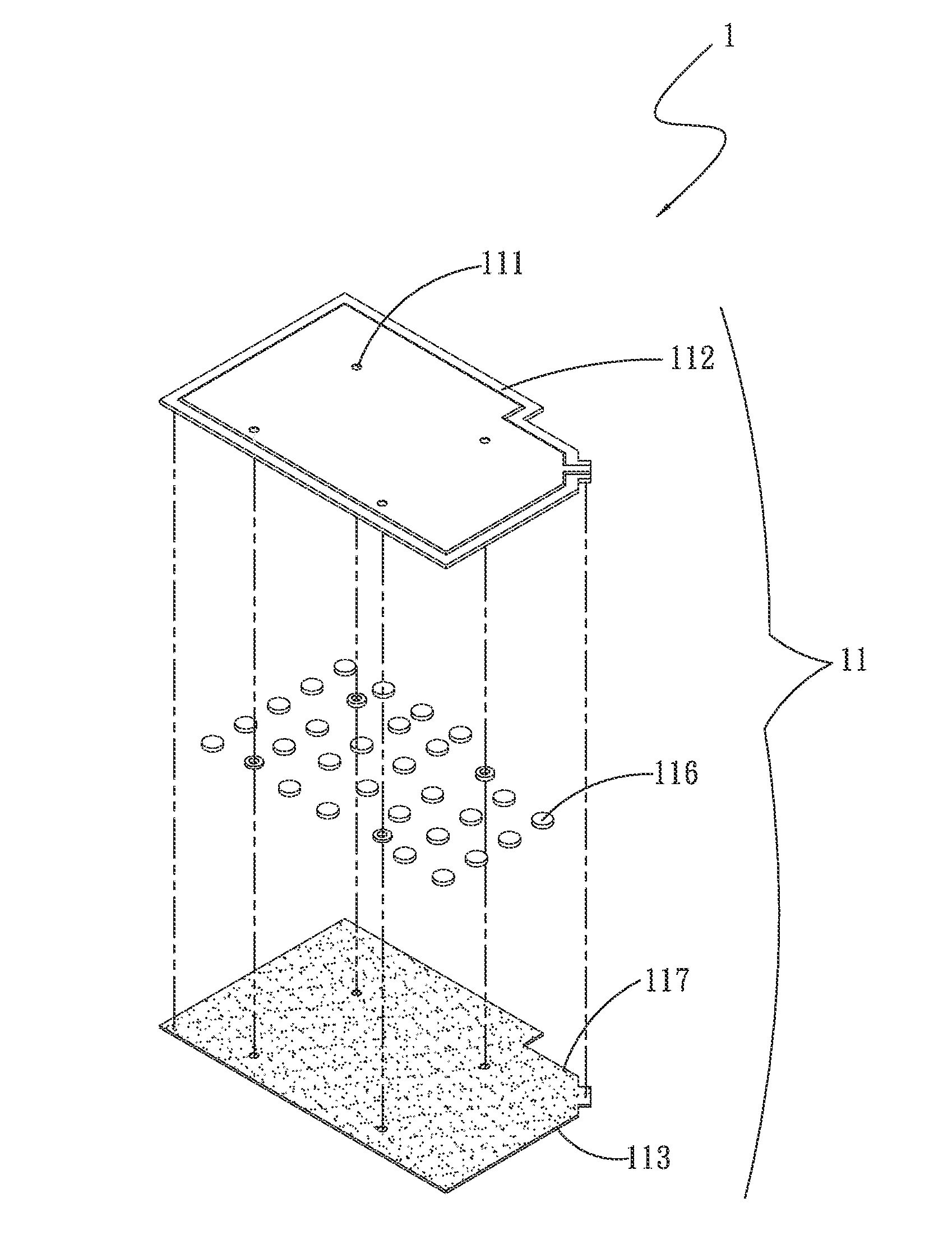

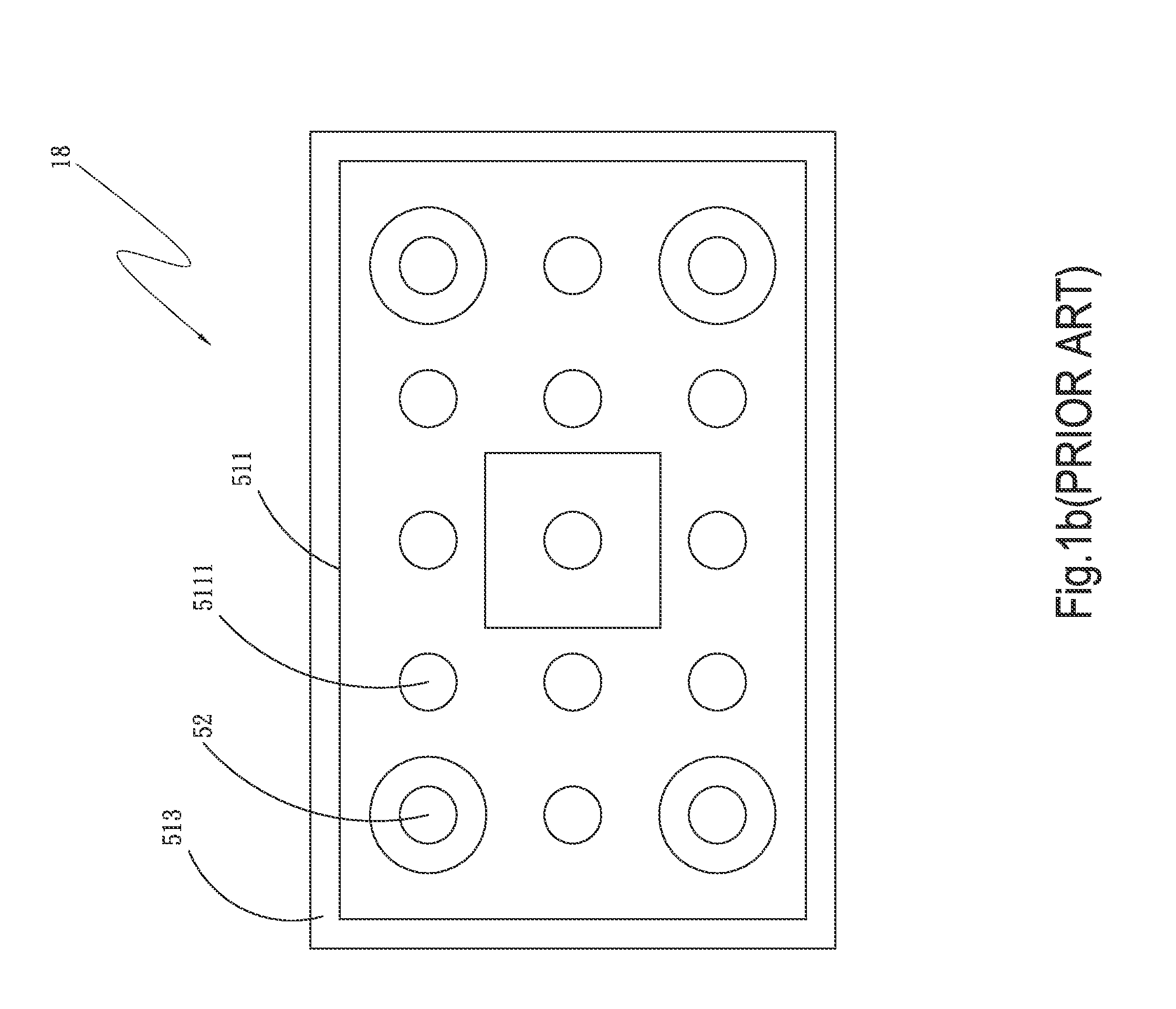

Packaging structure of integrated power control unit

ActiveCN103413790AImprove the stability of useExtended service lifeSemiconductor/solid-state device detailsSolid-state devicesProcess engineeringPower control

The invention provides a packaging structure of an integrated power control unit. Heating elements are not distributed according to a traditional functional module. All the heating elements are distributed in a scattered mode. The problems of the use conditions, power and the like of the heating elements achieving the same function and different functions are comprehensively considered, the heating elements achieving the same function are distributed on a main substrate at intervals, the heating elements achieving the different functions are also distributed on the main substrate at the same time, and therefore under the different use conditions, the heating quantities of different areas on the whole main substrate are even to the great extent. On the one hand, even heating provides the powerful guarantee for even heat dissipation, on the other hand, the simplification of the integrated heat dissipation structure is facilitated, and then the packaging structure is beneficial to meeting the small-size requirement of the control unit. Meanwhile, the even heating is also beneficial to improving the use stability of the main substrate and prolonging the service life of the main substrate.

Owner:SHANDONG INST OF ADVANCED TECH CHINESE ACAD OF SCI CO LTD

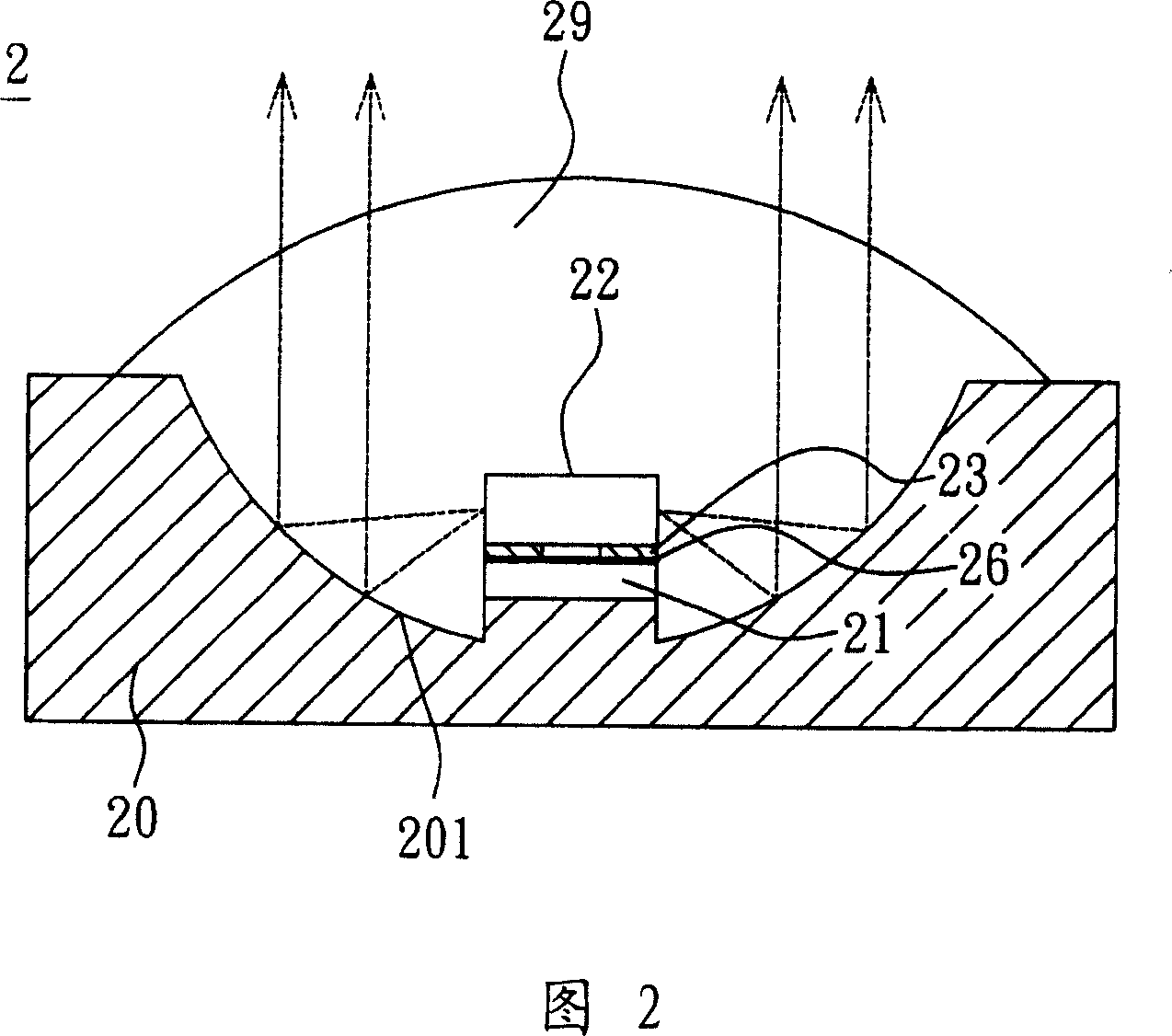

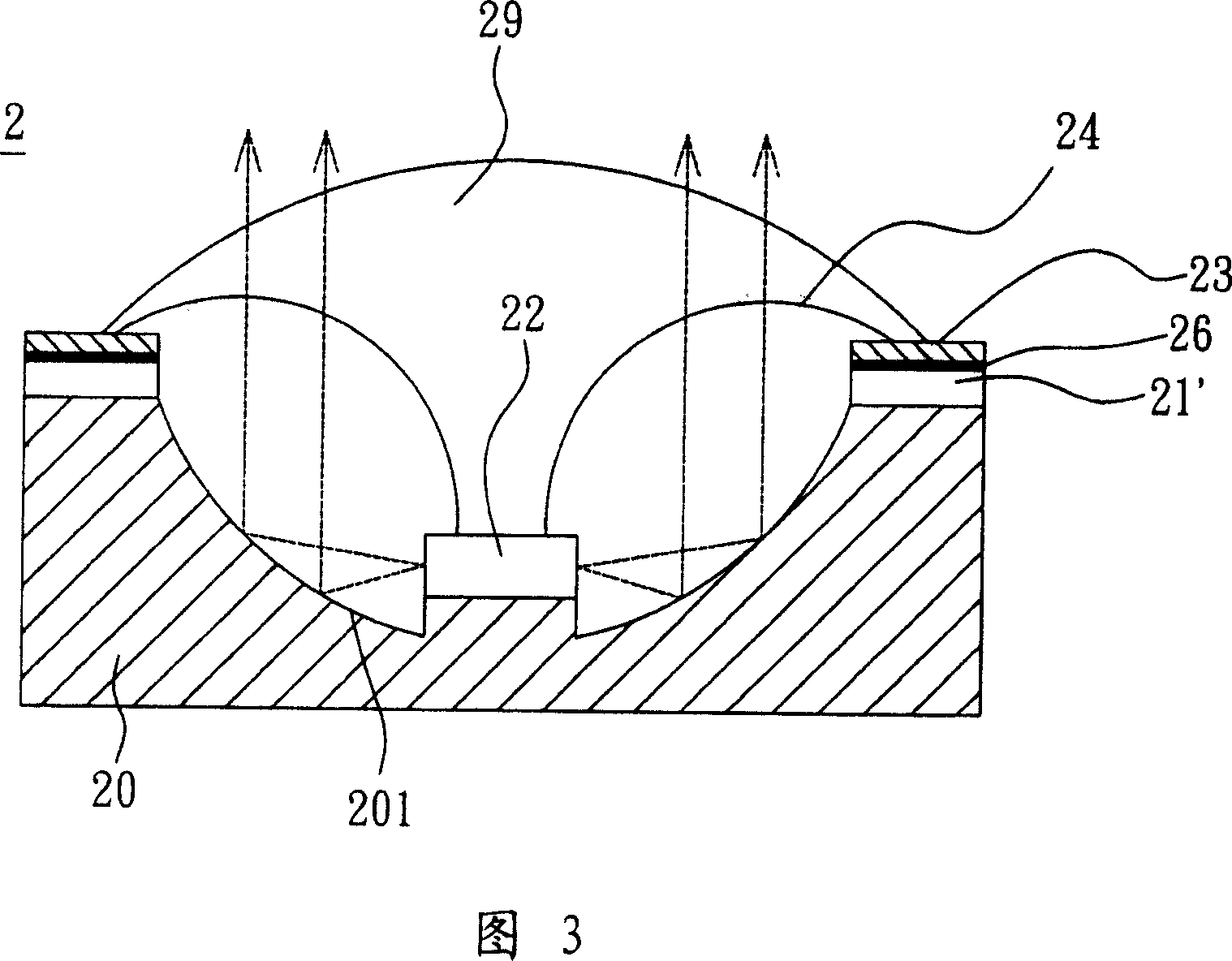

Lighting device

InactiveCN101079461AGood cooling effectExtended service lifeSemiconductor/solid-state device detailsSolid-state devicesLighter deviceLight emitting device

Owner:DELTA ELECTRONICS INC

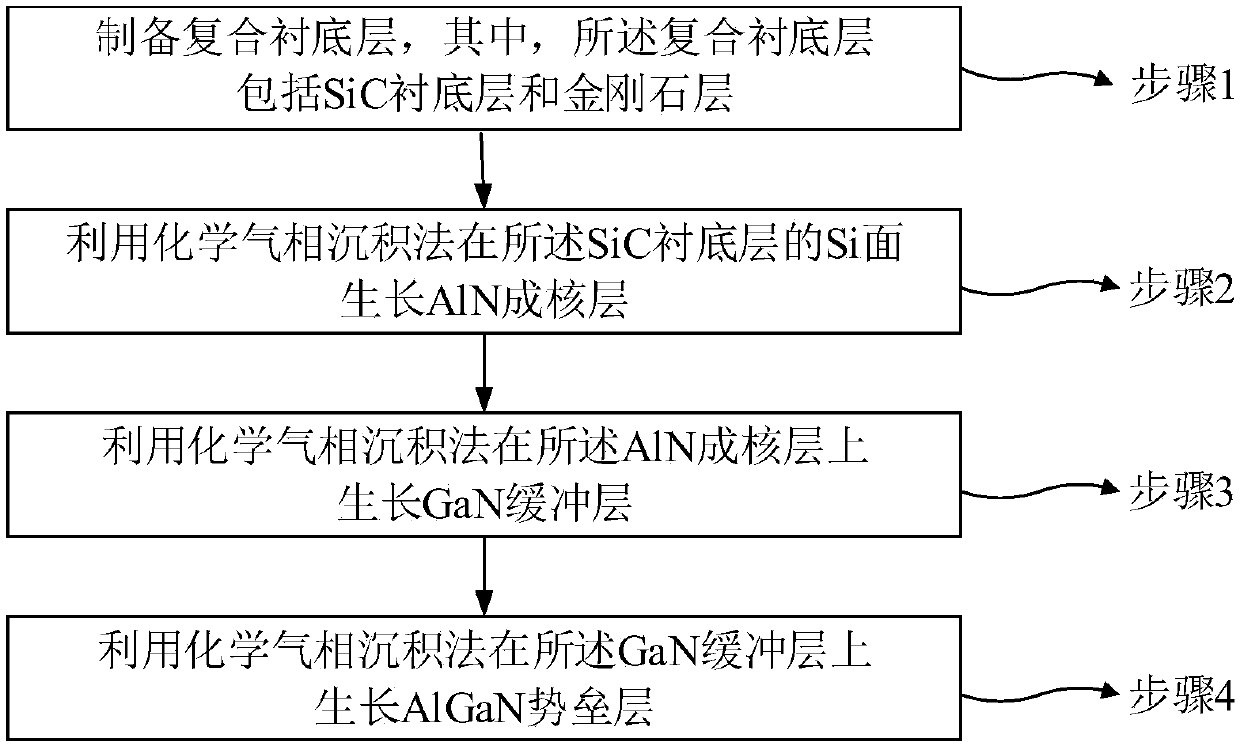

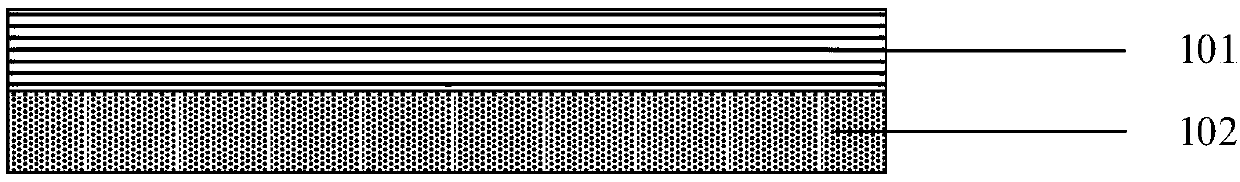

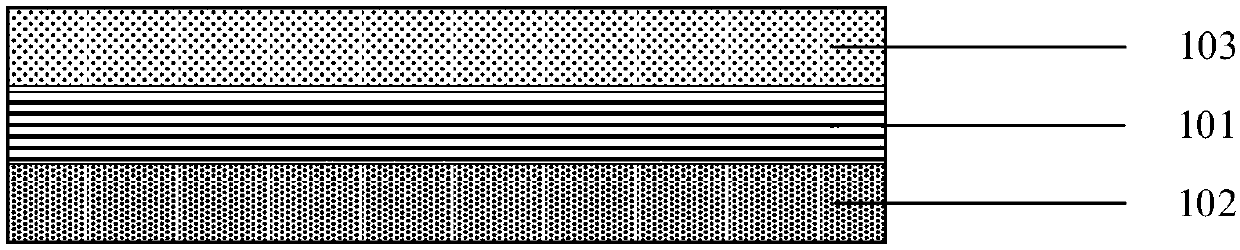

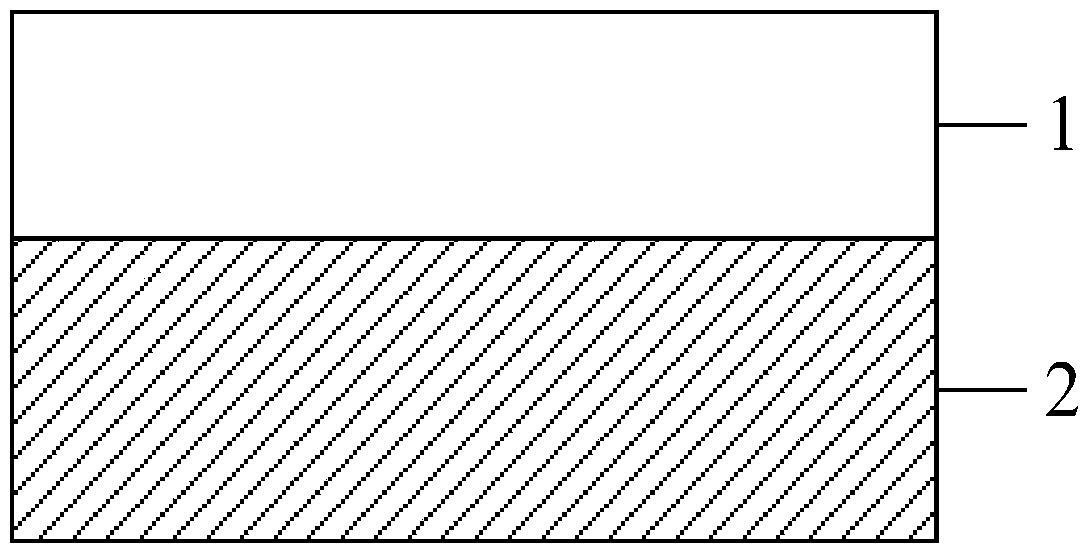

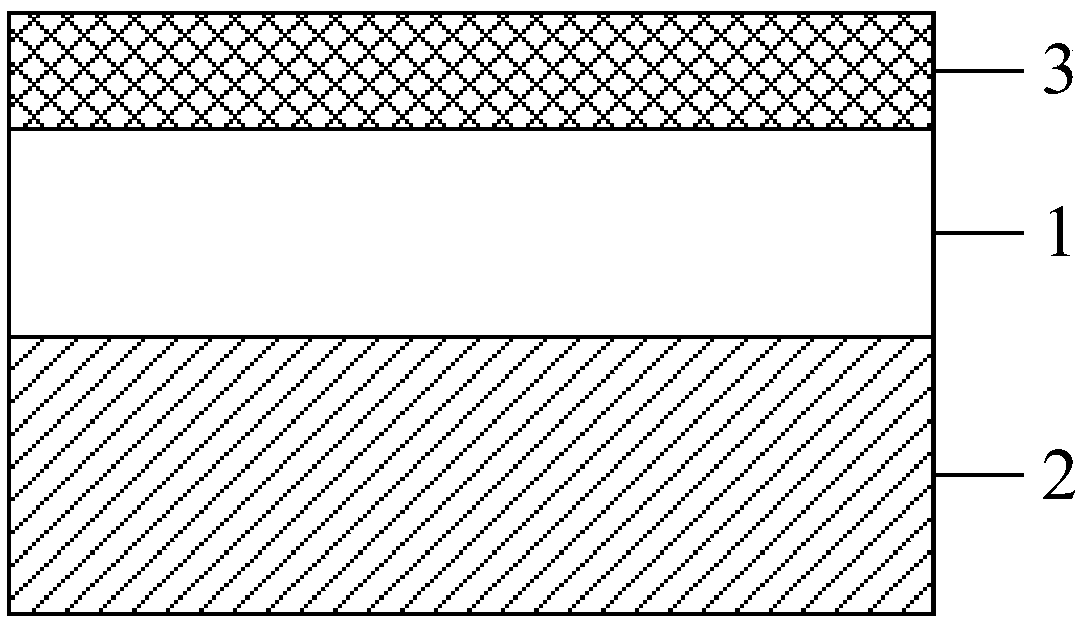

Semiconductor device based on SiC/diamond composite substrate layer and preparation method thereof

InactiveCN110828293AImprove cooling effectAvoid thermal resistanceSemiconductor/solid-state device detailsSolid-state devicesPhysicsSic substrate

The invention relates to a semiconductor device based on a SiC / diamond composite substrate layer and a preparation method thereof. The preparation method of the semiconductor device comprises steps that a composite substrate layer is prepared, and the composite substrate layer comprises a SiC substrate layer and a diamond layer; an AlN nucleating layer is grown on the Si surface of the SiC substrate layer by using a chemical vapor deposition method; a GaN buffer layer is grown on the AlN nucleating layer by using a chemical vapor deposition method; an AlGaN barrier layer is grown on the GaN buffer layer by using a chemical vapor deposition method. The preparation method is advantaged in that the SiC substrate layer with high quality and the diamond layer with high thermal conductivity arecombined to form the SiC / diamond composite substrate layer structure, and high thermal conductivity of the diamond layer is utilized to improve heat dissipation capability of growing a high-power nitride semiconductor material purely on the SiC substrate layer.

Owner:XIDIAN UNIV

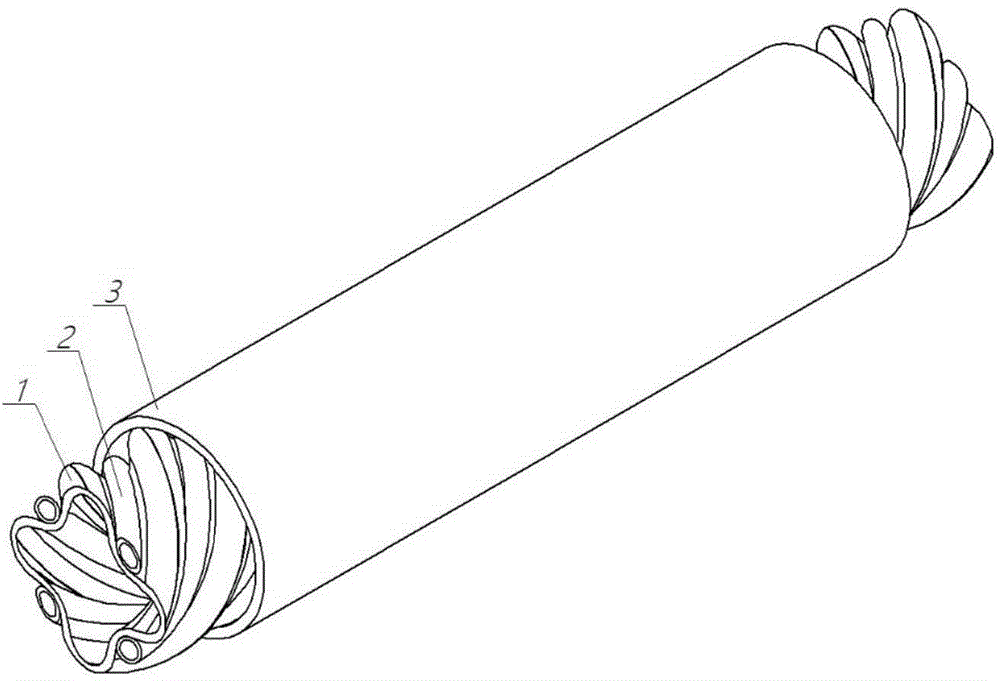

Coaxial wound heat exchanger

InactiveCN105277021AEasy to wrapCompact structureStationary tubular conduit assembliesThermal insulationEngineering

Disclosed is a coaxial wound heat exchanger in the field of heat exchange devices. The coaxial wound heat exchanger comprises a spiral fluted tube, a plurality of capillary tubes and a thermal insulation layer, wherein each capillary tube is wound in a corresponding groove between outer screw threads of the spiral fluted tube; the thermal insulation layer covers the spiral fluted tube and the capillary tubes; the flowing medium in the spiral fluted tube is a refrigerating medium, the flowing media in the capillary tubes are freezing media, and the refrigerating medium and the freezing media flow in a reverse-flow mode. According to the coaxial wound heat exchanger, the size of the heat exchanger can be reduced, and the heat exchange efficiency of the heater exchanger can be improved.

Owner:SHANGHAI JIAO TONG UNIV

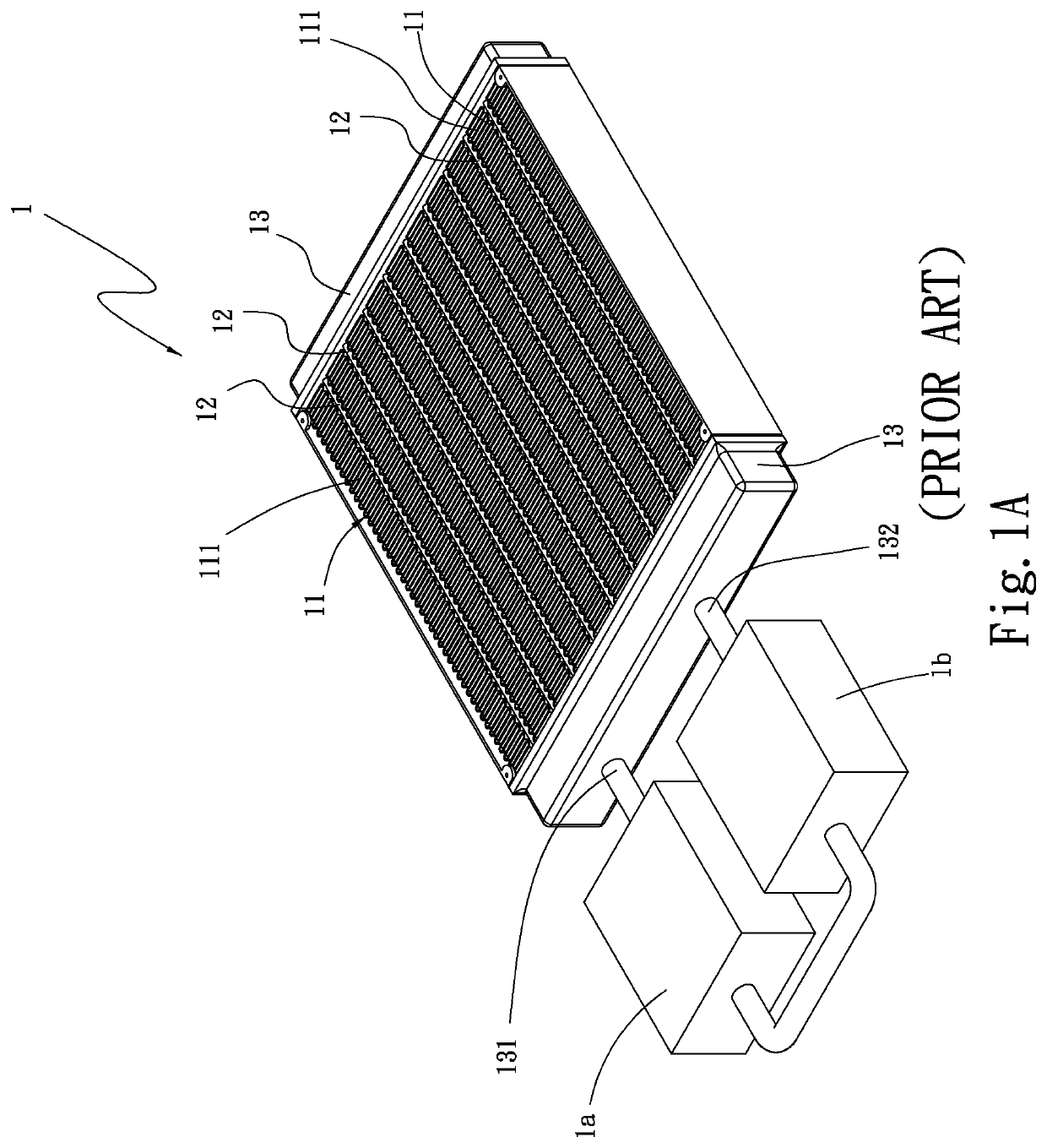

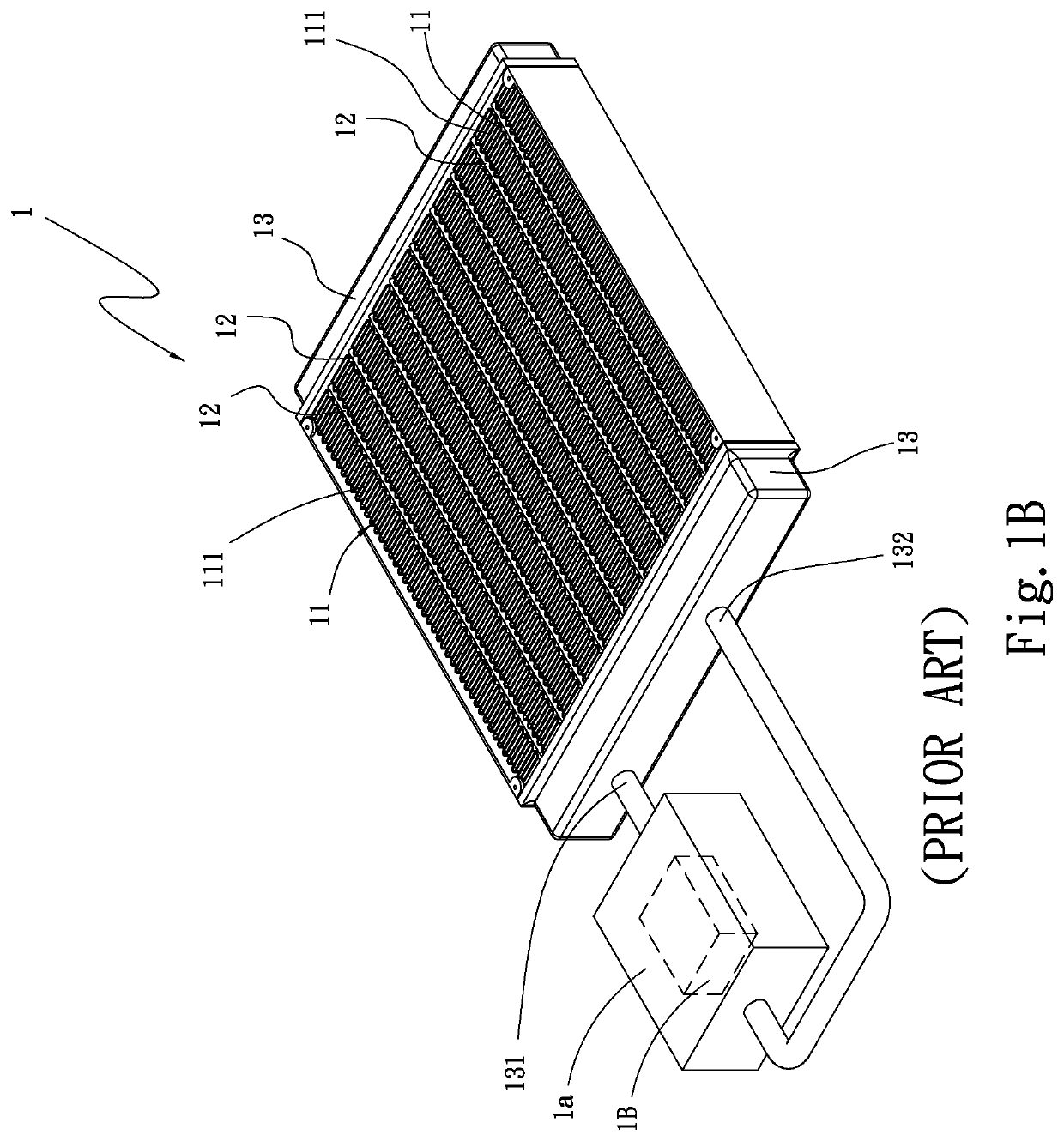

Composite water-cooling radiator structure

ActiveUS20210018229A1Increase air contact areaUpgraded heat dissipation efficiencyDigital data processing detailsSemiconductor/solid-state device detailsEngineeringHeat spreader

A composite water-cooling radiator structure includes at least a cooling plate, a cooling chip unit and a vapor chamber. The cooling plate has a first upper surface and a first lower surface; a liquid flowing section, through which a first working liquid flows; and an inlet and an outlet communicating with the liquid flowing section. The cooling chip unit is located beneath the cooling plate and has a cold end and a hot end; and the cold end is in contact with the first lower surface of the cooling plate. The vapor chamber is located beneath the cooling chip unit and has a second upper surface and a second lower surface; and the second upper surface is in contact with the hot end of the cooling chip unit. With the superposed cooling plate, cooling chip unit and vapor chamber, the composite water-cooling radiator structure provides good heat dissipation effect.

Owner:ASIA VITAL COMPONENTS SHENZHEN CO LTD

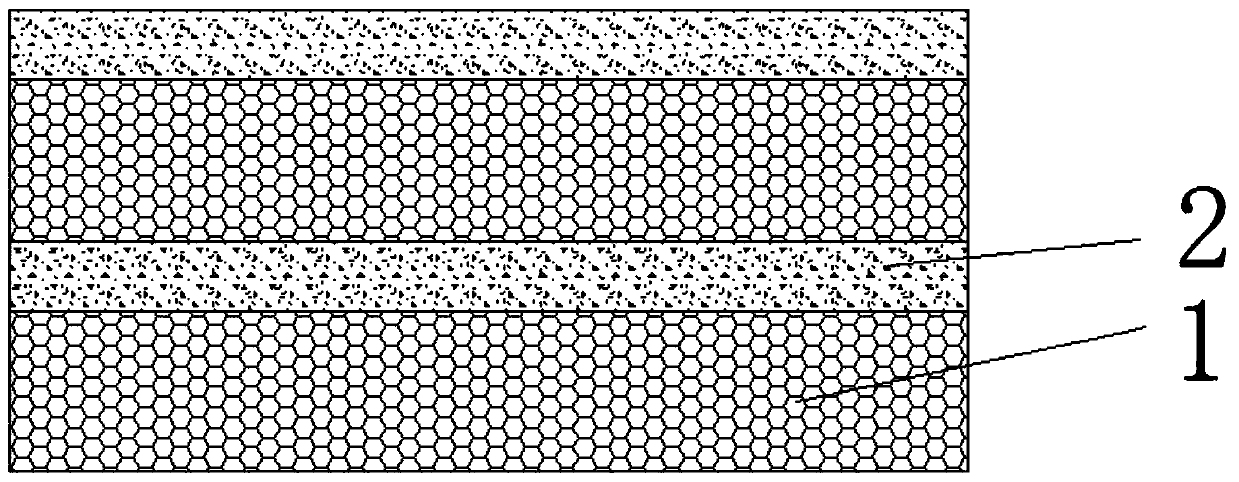

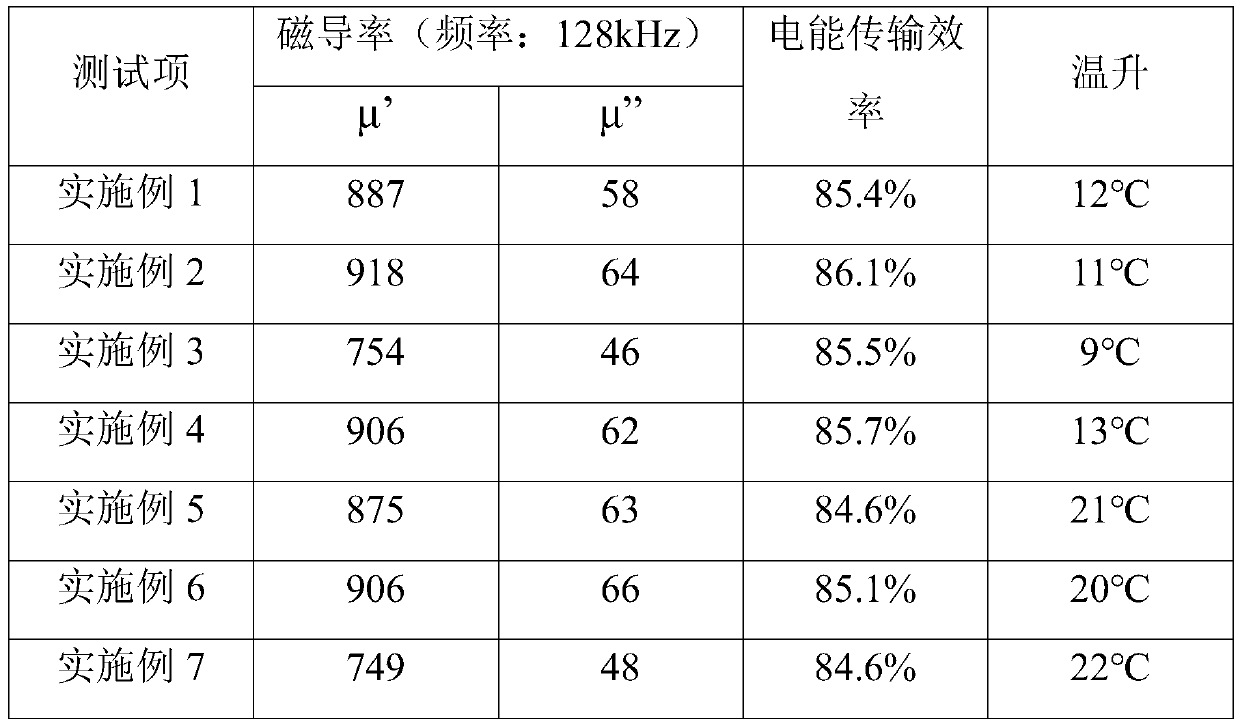

High-thermal-conductivity composite magnetism isolating sheet for wireless charging receiving end and preparation method thereof

ActiveCN110911114AReduce thermal resistanceImprove cooling effectTransformers/inductances coolingTransformersElectric resistivityThin sheet

The invention belongs to the technical field of wireless charging, and discloses a high-thermal-conductivity composite magnetism isolating sheet for a wireless charging receiving end and a preparationmethod of the high-thermal-conductivity composite magnetism isolating sheet. The composite magnetism isolating sheet for the high-thermal-conductivity wireless charging receiving end is a composite material formed by alternately compounding nanocrystalline sheets and a composite material layer, and the composite material layer comprises a thermal conductive filler, a magnetic conductive filler and a binder. According to the preparation method, the surface of the magnetic conductive powder is uniformly coated with the heat conductive powder, so that the electrical conductivity of the magneticpowder can be effectively reduced. And meanwhile, even if the composite magnetic powder has a bridging phenomenon in the composite material layer, the heat conductive powder with excellent insulativity on the surface of the magnetic powder can play a certain role in isolation, so that the resistivity of the composite layer is greatly improved, and the improvement of the charging efficiency of thesystem is facilitated.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

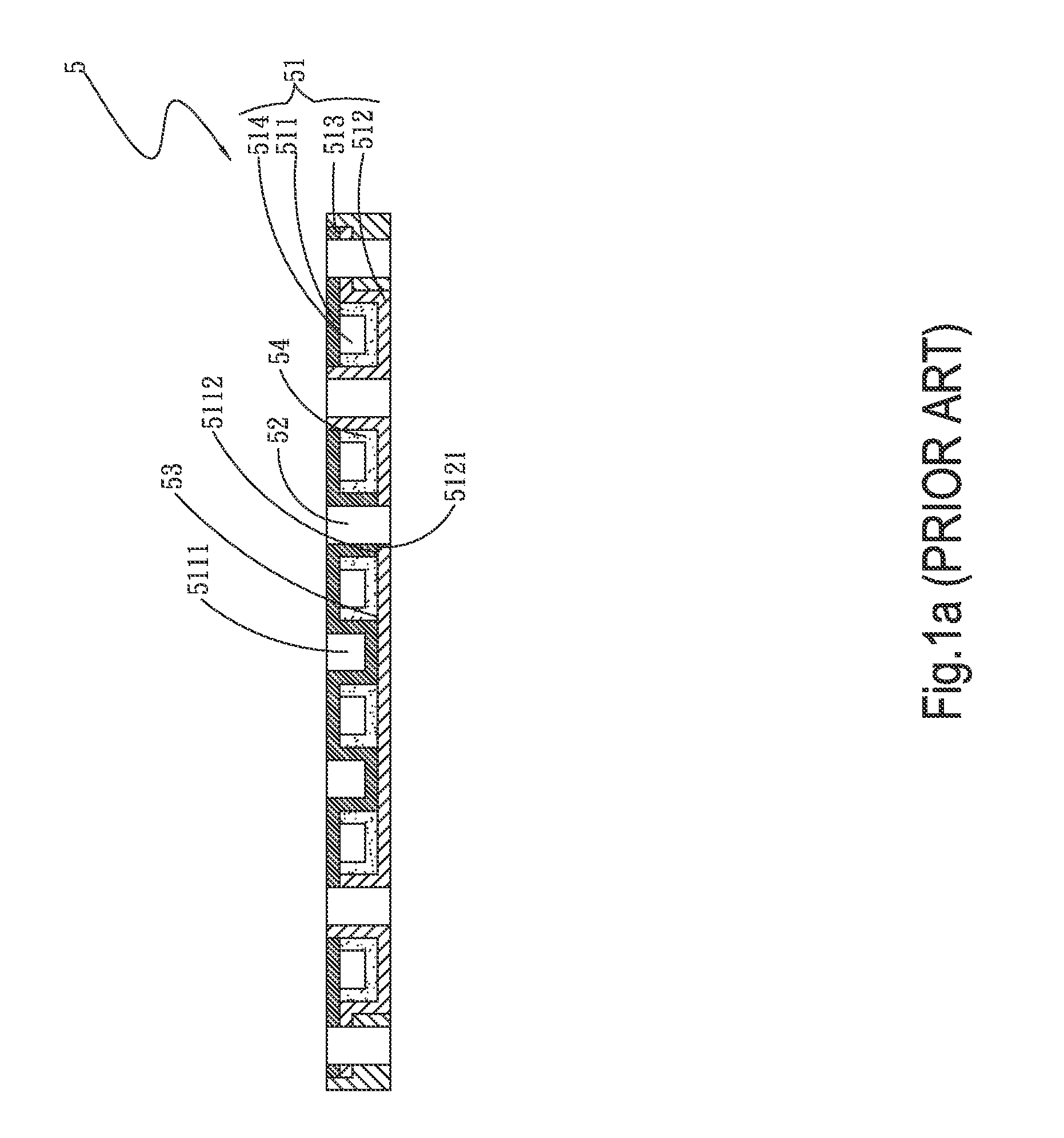

Semiconductor device

ActiveUS7880299B2Reduced in size and weight and costIncrease productivitySemiconductor/solid-state device detailsSolid-state devicesProduction ratePower semiconductor device

The present invention is intended to obtain a semiconductor device that is reduced in size, weight, and cost and improved in performance stability and productivity.The semiconductor device includes a semiconductor module in which a semiconductor element is sealed with a resin, a reinforcing beam fixed to an upper surface of the semiconductor module via a plate-like spring, and a frame part to which both ends of the reinforcing beam are fixed, the frame part being disposed in such a fashion as to enclose from four directions an outer periphery of the semiconductor module, plate-like spring, and the reinforcing beam.

Owner:MITSUBISHI ELECTRIC CORP

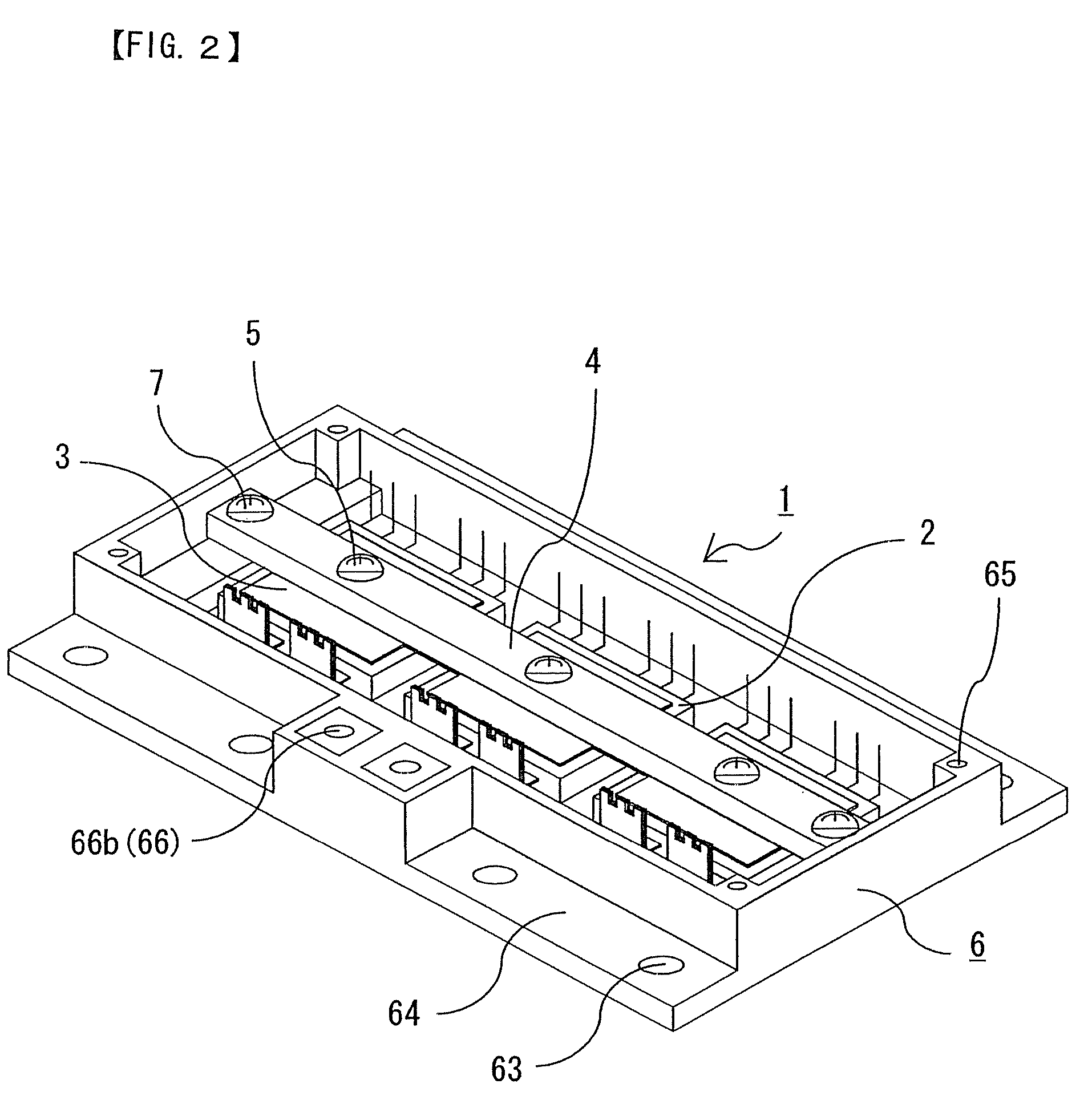

Semiconductor device based on composite substrate and preparation method thereof

InactiveCN110828292ASolve the difference in heat dissipationQuality improvementSemiconductor/solid-state device detailsSolid-state devicesDevice materialComposite substrate

The invention relates to a semiconductor device based on a composite substrate and a preparation method thereof. The preparation method comprises steps of selecting a Si substrate layer; growing a diamond layer on a lower surface of the Si substrate layer; growing an AlN nucleating layer on an upper surface of the Si substrate layer; growing a GaN buffer layer on an upper surface of the AlN nucleating layer; and growing an AlGaN barrier layer on an upper surface of the GaN buffer layer. The preparation method is advantaged in that the Si substrate layer with high quality and the diamond layerwith high thermal conductivity are combined to form the Si / diamond composite substrate structure, and high thermal conductivity of the diamond layer is utilized to solve a problem of poor heat dissipation caused by growing a high-power nitride semiconductor material purely on the Si substrate layer.

Owner:XIDIAN UNIV

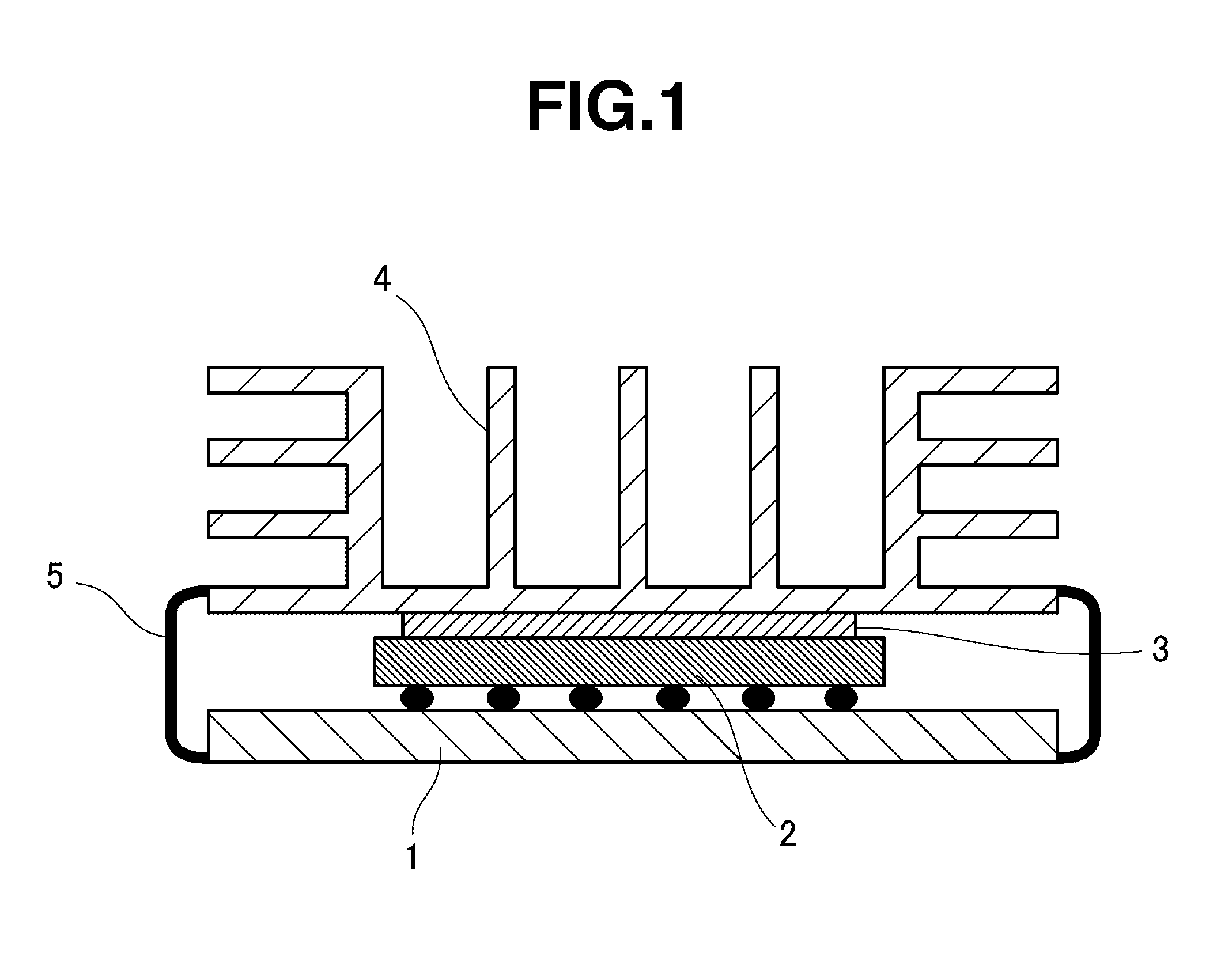

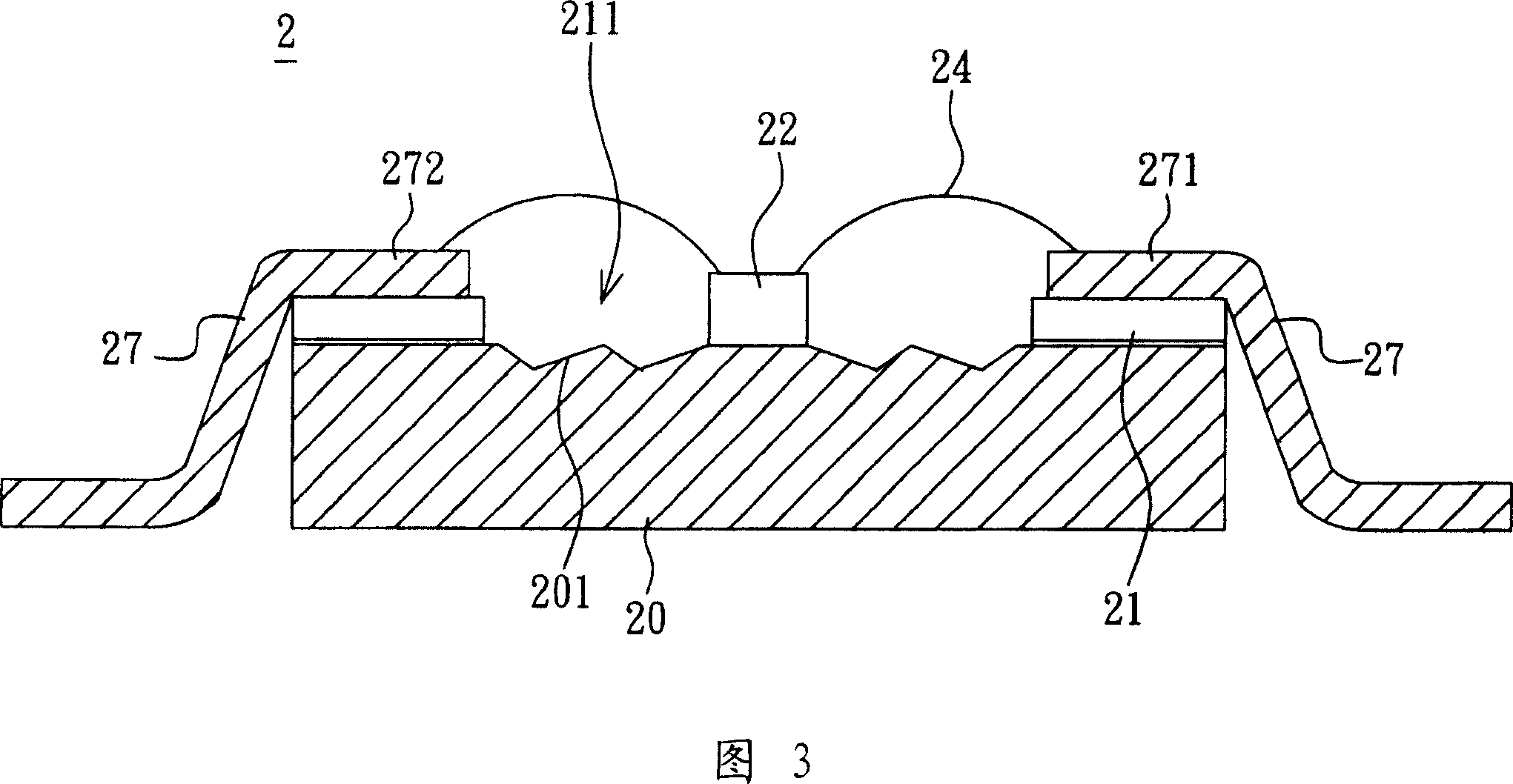

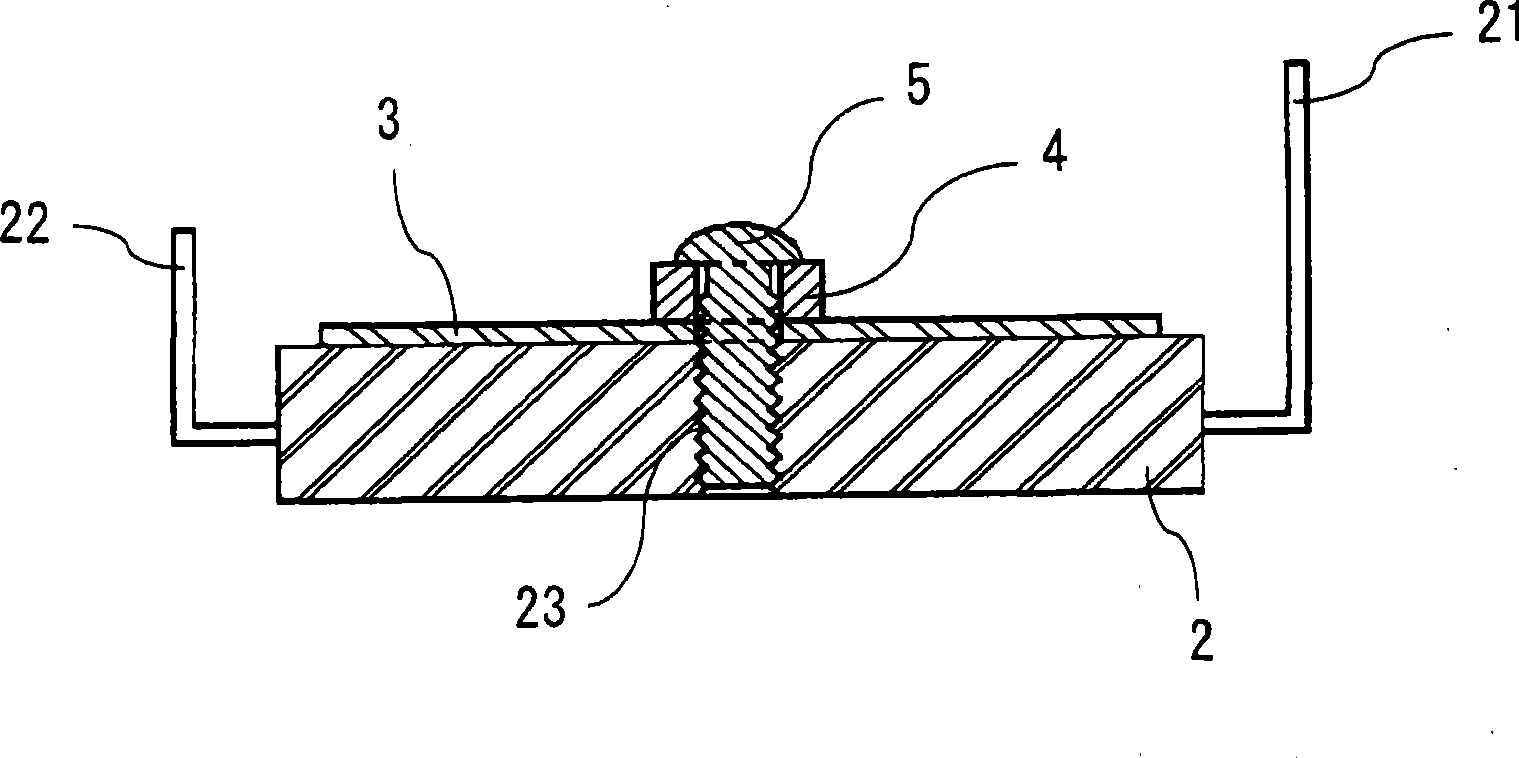

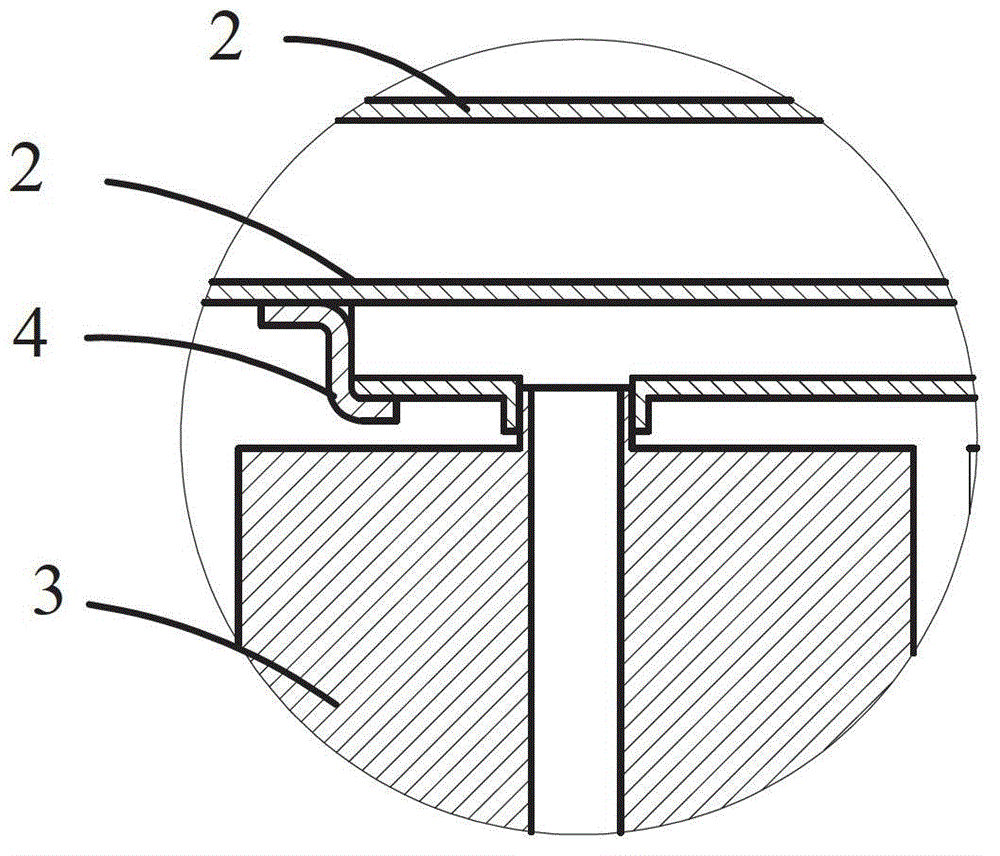

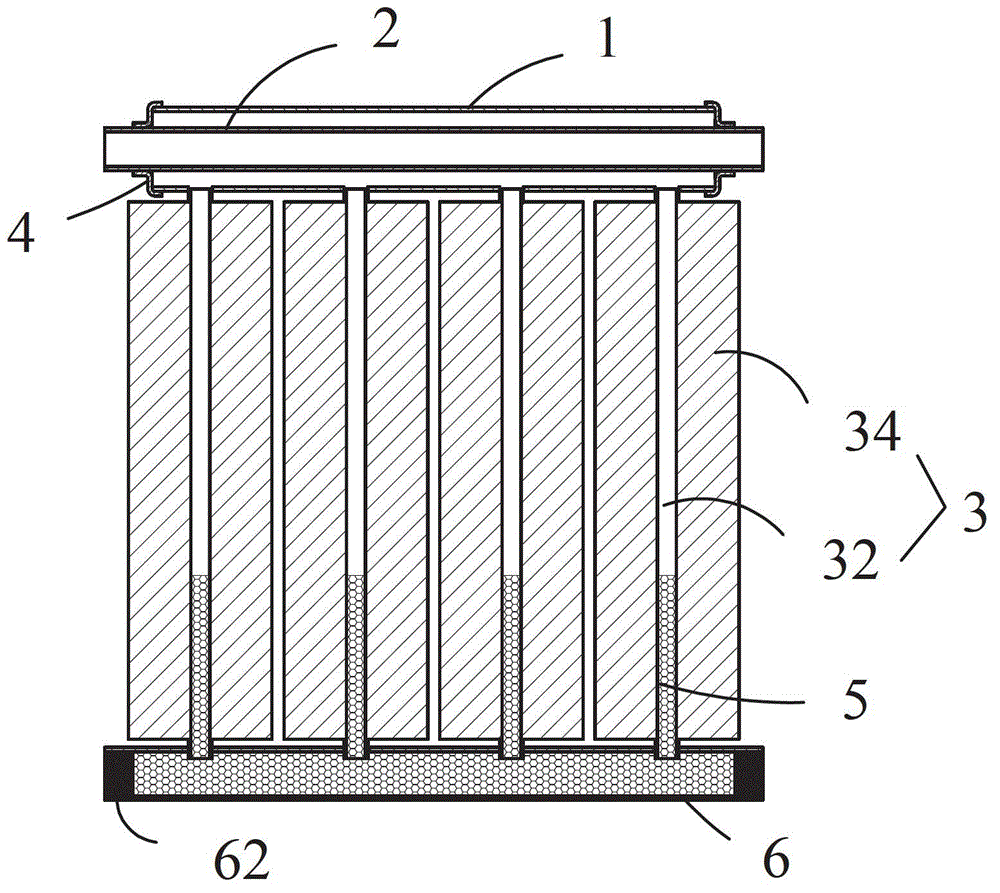

Semiconductor device

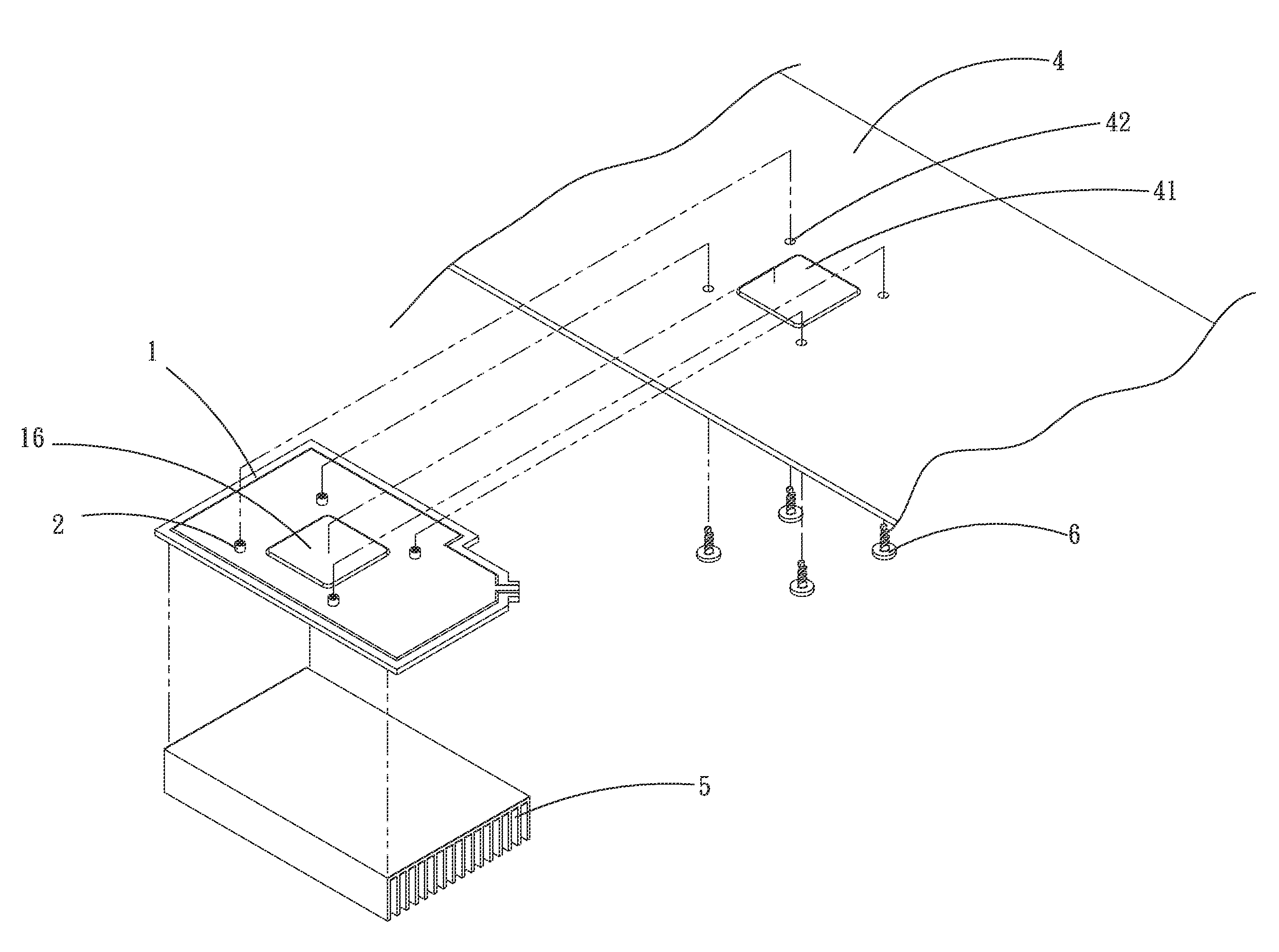

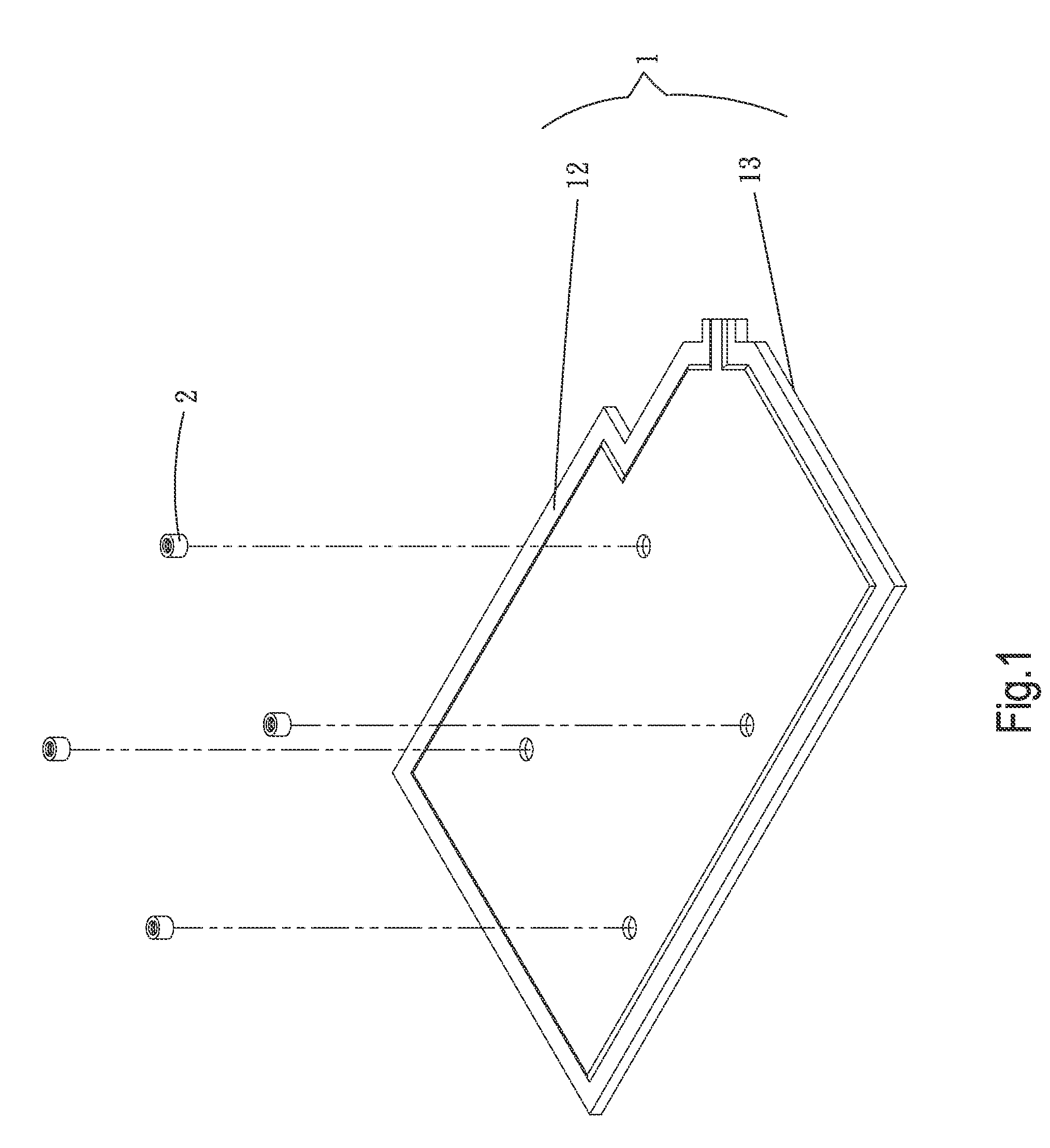

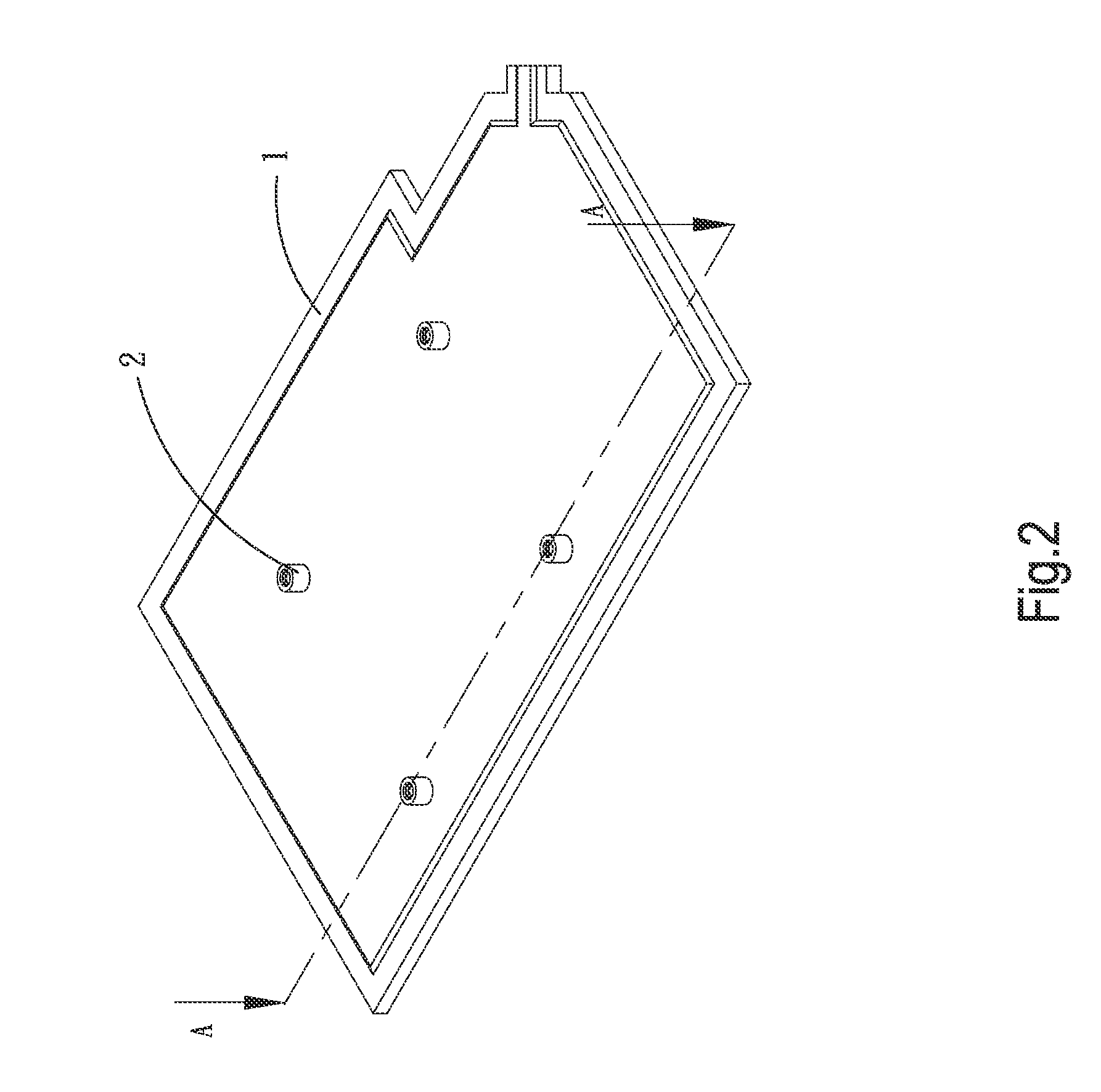

ActiveCN101364575ALow costImprove performanceSemiconductor/solid-state device detailsSolid-state devicesMiniaturizationSemiconductor device

The present invention is intended to obtain a semiconductor device that is reduced in size, weight, and cost and improved in performance stability and productivity. The semiconductor device (1) includes a semiconductor module (2) in which a semiconductor element is sealed with a resin, a reinforcing beam (4) fixed to an upper surface of the semiconductor module (2) via a plate-like spring (3), and a frame part (6) to which both ends of the reinforcing beam (4) are fixed, the frame part (6) being disposed in such a fashion as to enclose from four directions an outer periphery of the semiconductor module (2), plate-like spring (3), and the reinforcing beam (4).

Owner:MITSUBISHI ELECTRIC CORP

Lighting device

InactiveCN101079460AExtended service lifeImprove light extraction efficiencyLaser detailsSemiconductor/solid-state device detailsLight emitting deviceLighter device

The invention discloses a luminous device, which comprises the following parts: base, at least one luminous element and protective layer, wherein the base has a structure to elevate the luminous efficiency on the surface; the luminous element lies on the preset position of base with ray reflected, gathered and emitted to improve the emitting efficiency, which improves the luminous efficiency of luminous device.

Owner:DELTA ELECTRONICS INC

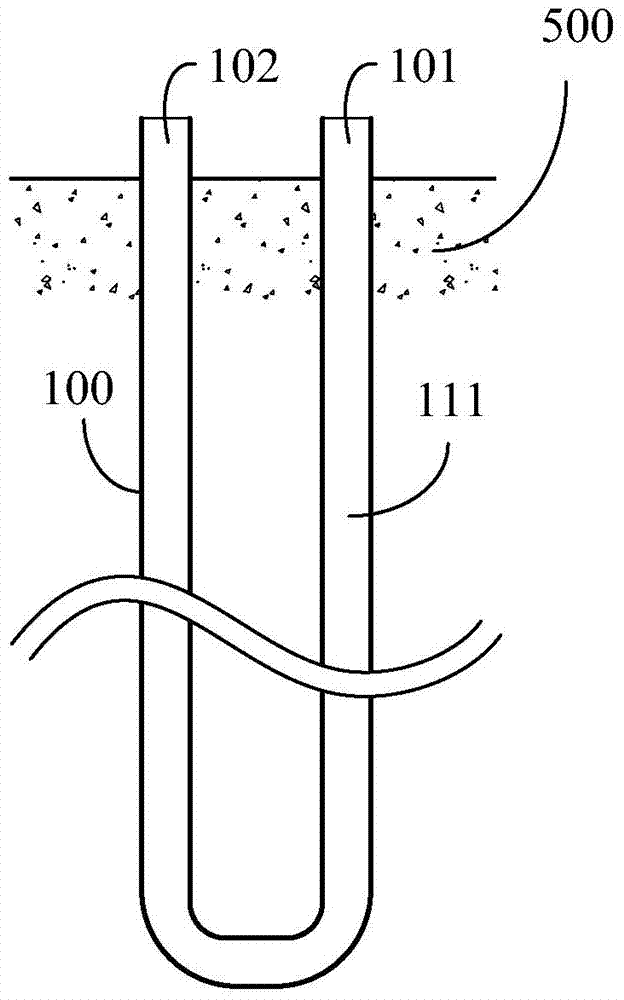

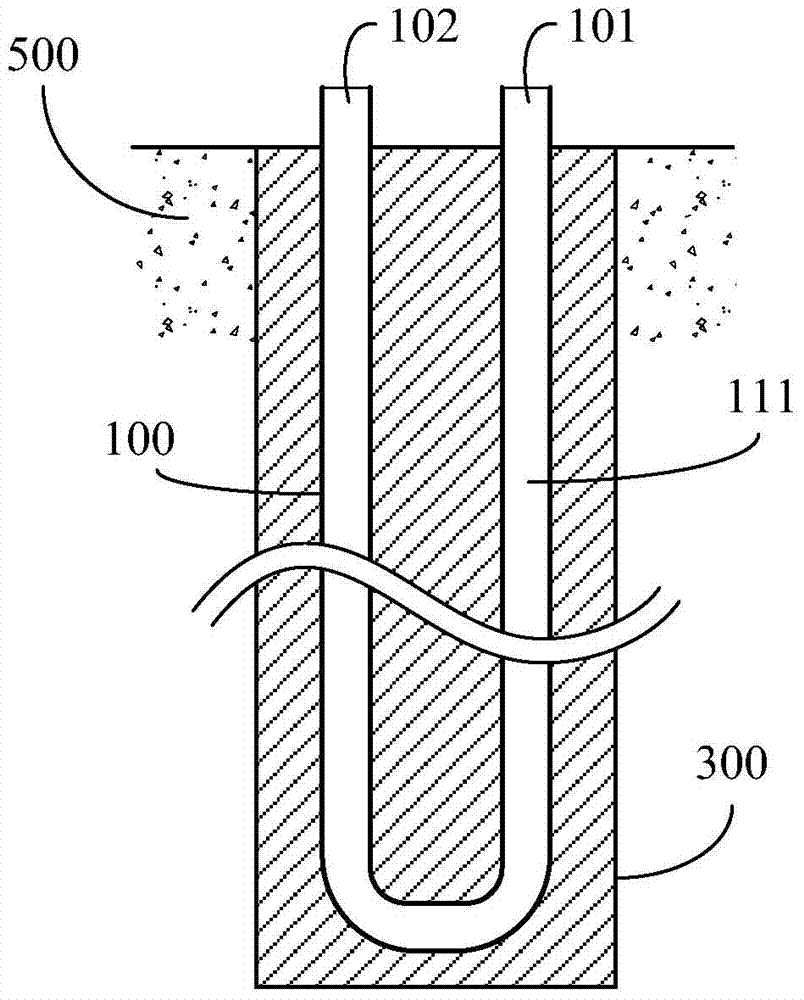

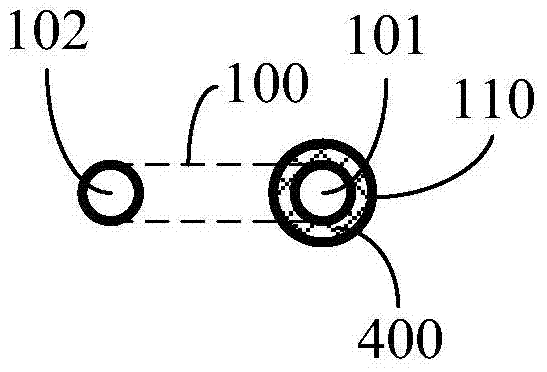

Pipe member equipped with heat insulation core pipeline, auxiliary heat conduction structure and U-shaped annularly-distributed pipeline

InactiveCN103712502AAvoid thermal resistanceAvoid loss of thermal energyThermal insulationOther heat production devicesEngineeringConductive materials

The present invention relates to a pipe member equipped with heat insulation core pipeline, auxiliary heat conduction structure and U-shaped annularly-distributed pipeline. The U-type pipeline is capable of transferring thermal energy with each other in a radiate arrangement, wherein the piping segments of the U-type fluid piping inlet end and / or outlet end of the U-type piping capable of thermal energy transmission with each other in the radiate arrangement are directly made of thermal insulating materials, or a thermal insulating structure is installed between the inlet end and the outlet end; and the exterior of the thermal insulating device (400) is further installed with an auxiliary thermal conductive structure (110) made of thermal conductive material, thereby preventing the thermal insulating device (400) from generating thermal resistance in the columnar thermal conductive body (300) in order to reslove a problem that temperature difference energy loss caused by heat conduction arising from the temperature difference resulting from adjacency when thermal conductive fluid with temperature difference passing through.

Owner:杨泰和

Triple-oxygenation gasification combustion method for coal-fired furnace

InactiveCN1400425AHigh thermal efficiencyReduce contentNon-combustible gases/liquids supplyCombustorProcess engineering

The triple oxygenizing gasification combustion method for coal-fired furnace adopts mechanical coal-feeding equipment to continuously feed the coal according to the combustion requirements for furnace combustion. The high temp. produced in the furnace by primary air combustion can make coal implement natural gasification, coking and combustion, and the carbon oxide and sulfur dioxide inflammable matters are passed through secondary pultipoint different angles in the furnace cavity and mixed with air, and passed through third air porous plate tube combustor, and can be fully combusted, so thatit can make coal obtain full combustion to raise thermal efficiency, but also can protect environment. Said invention is applicable to various boilers, furnaces and kilns.

Owner:韩永勤

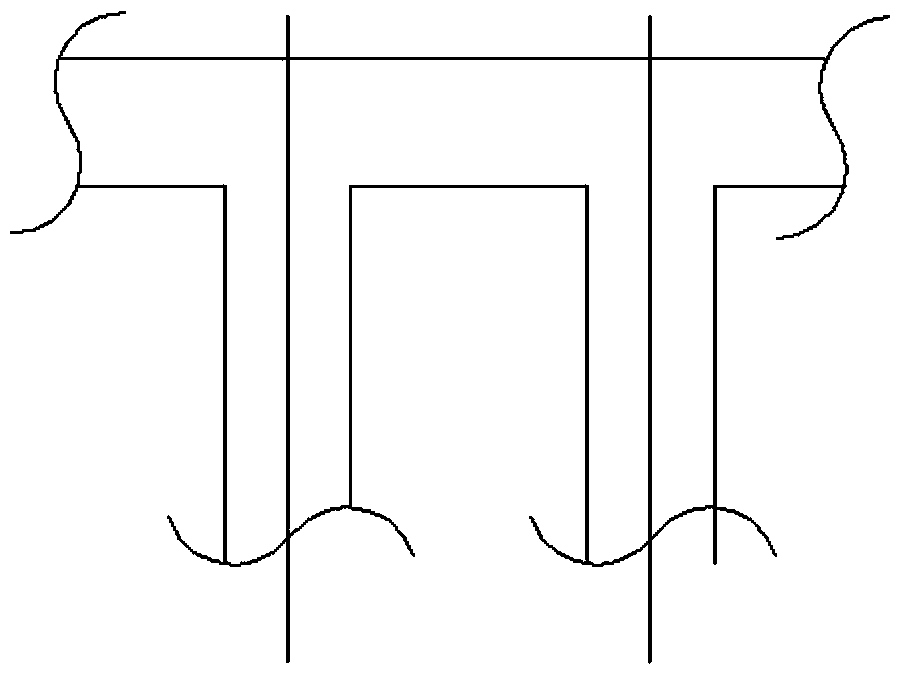

Flat plate collector with heat pipes

InactiveCN102878697AEasy to useSolve the ills of foulingSolar heating energySolar heat devicesFrost crackFrost

The invention discloses a flat plate collector with heat pipes. An absorber plate core of the flat plate collector comprises an upper communicated header, a heat exchange pipe and heat collecting pipes; each heat collecting pipe comprises a heat collecting runner and heat collecting fins arranged on the two sides of the heat collecting runner; the heat exchange pipe is arranged in the upper communicated header, and the tail end and the head end of the heat exchange pipe extend out of the upper communicated header; the two ends of the upper communicated header are sealed with the heat exchange pipes; the upper communicated header is arranged above the heat collecting runners and communicated with a plurality of heat collecting runners; the upper openings of the heat collecting runners are lower than the bottom of the upper communicated header, and the bottom ends of the heat collecting runners are sealed; the heat collecting runners are filled with heat pipe media; and the heat collecting runners and the heat collecting fins are of an integral structure. The flat plate collector has the advantages that as the heat collecting pieces are formed through one-time extrusion, the problems on firmness and heat resistance caused by laser welding or ultrasonic welding are avoided; the defects of frost cracking of a common heat collector in winter and scaling of a pipeline of a common flat plate collector are overcome; and a channel can be formed in each heat collecting runner, and thus the heat transfer effect of the flat plate collector can be improved effectively.

Owner:王超生 +1

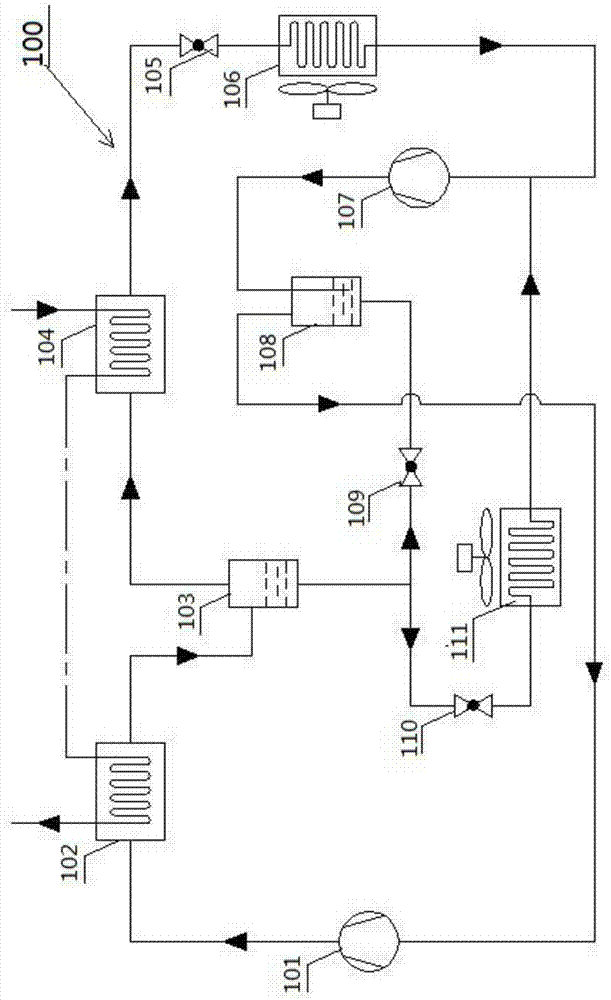

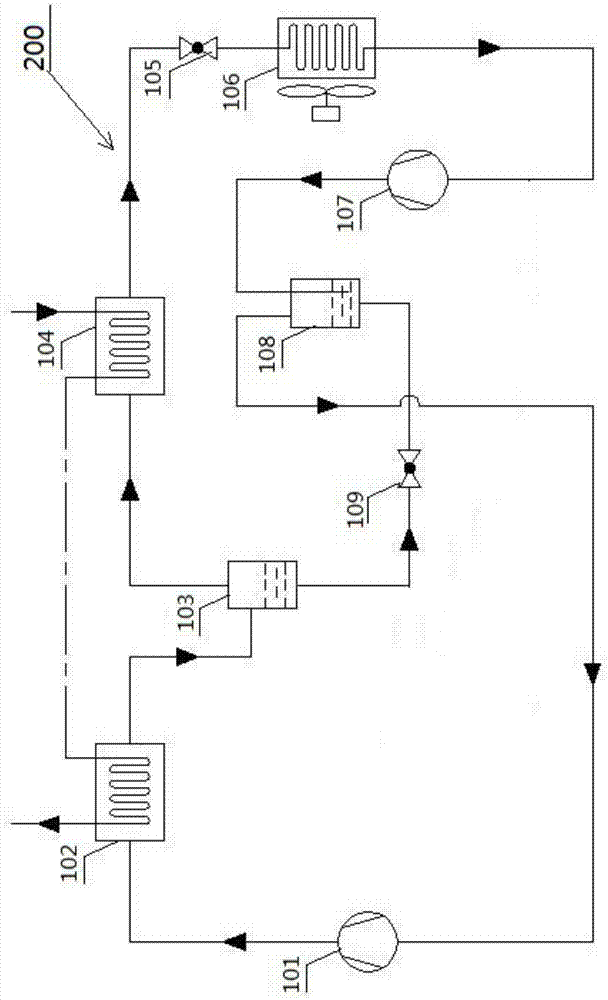

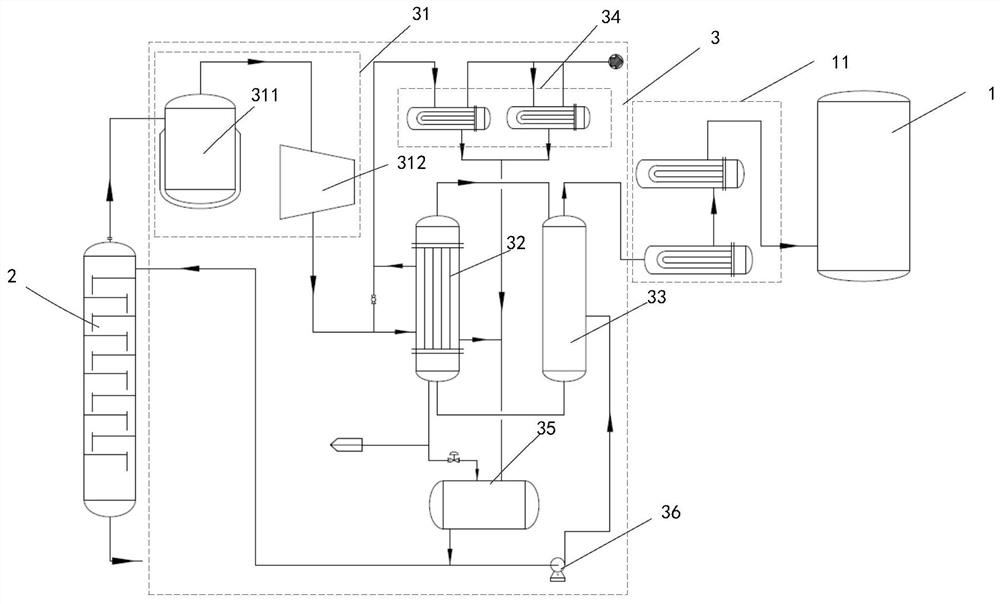

Double-temperature condensing two-stage compressing heat pump system

InactiveCN103697627AReduce lossesSmall heat transfer temperature differenceHeat pumpsEvaporationEngineering

The invention provides a double-temperature condensing two-stage compressing heat pump system. The double-temperature condensing two-stage compressing heat pump system is characterized by comprising a high pressure stage compressing mechanism, a low pressure stage compressing mechanism, a high temperature stage condensing mechanism, a low-temperature stage condensing mechanism, a high temperature stage evaporation mechanism, a low temperature stage evaporation mechanism, a frictional condensing mechanism, a heat exchanging mechanism, a first throttle mechanism, a second throttle mechanism and a third throttle mechanism; the high pressure stage compressing mechanism, the high temperature stage condensing mechanism, the frictional condensing mechanism, the low temperature stage condensing mechanism, the first throttle mechanism, the low temperature stage evaporation mechanism, the low pressure stage compressing mechanism and the heat exchanging mechanism are sequentially connected to form into a loop; the frictional condensing mechanism is connected with the second throttle mechanism and the third throttle mechanism; the third throttle mechanism is connected with the high pressure stage evaporation mechanism; the high pressure stage evaporation mechanism is connected with the low pressure stage compressing mechanism; the second throttle mechanism is connected with the heat exchanging mechanism. The double-temperature condensing two-stage compressing heat pump system has the advantages of reducing energy loss, improving stability of system operation, meanwhile enabling low temperature heat source in different stages to be used and enabling heat of a low temperature condensing mechanism to be fully used.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

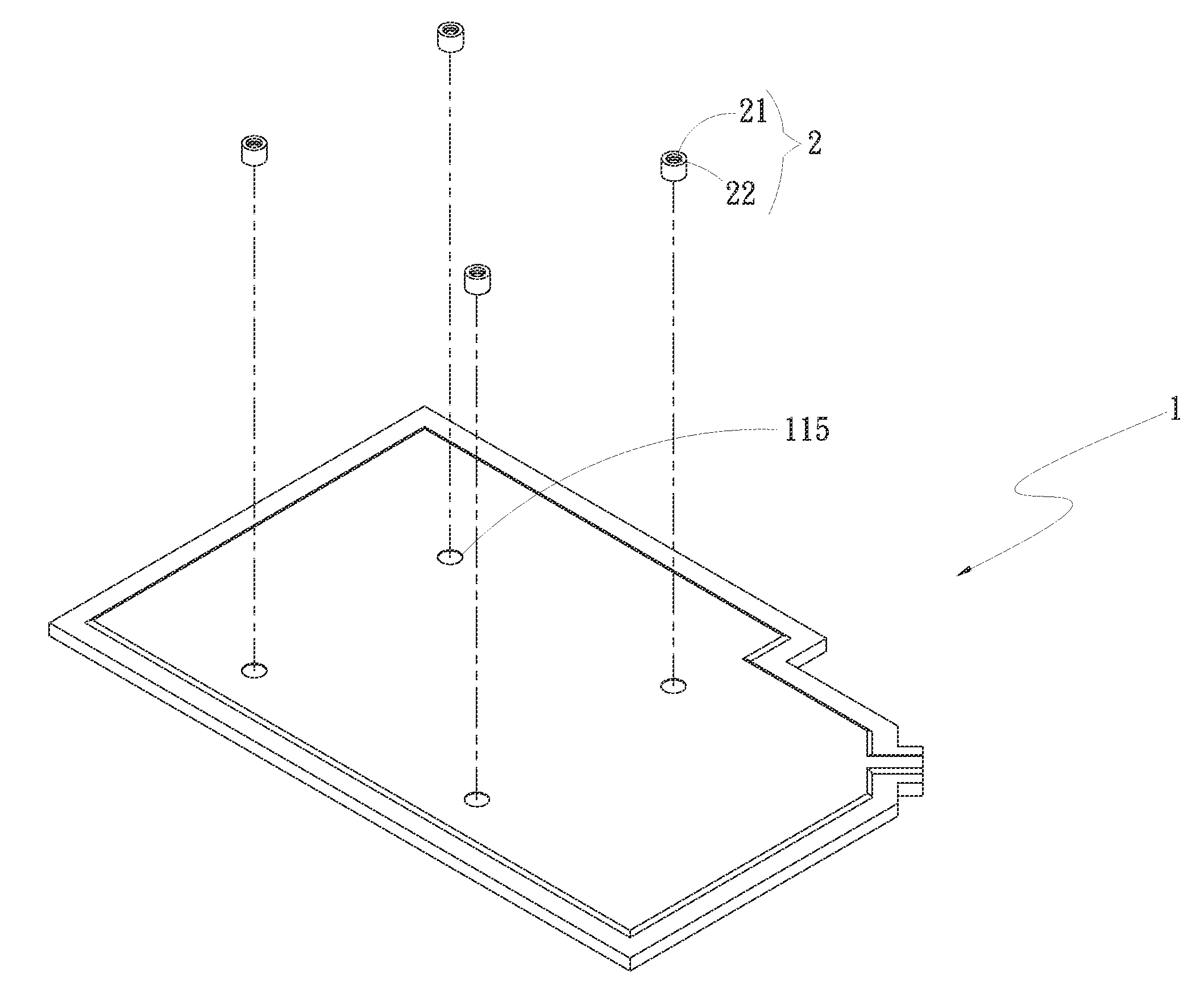

Heat dissipation element with mounting structure

InactiveUS20130043005A1Avoid undesirable thermal resistanceBlocking can be undesirableReinforcing meansSemiconductor/solid-state device detailsWorking fluidEngineering

A heat dissipation element with mounting structure includes a main body and a plurality of mounting elements. The main body includes a first side and a second side, between which a chamber is defined; a plurality of supports located in the chamber and respectively connected at two opposite ends to the first side and the second side of the main body; a working fluid filled in the chamber; and at least one wick structure layer internally attached to the chamber. The mounting elements respectively define an axial bore and have an end extended through the first side of the main body into the supports to thereby connect to the main body. With these arrangements, the heat dissipation element with the mounting elements connected thereto can tightly contact with a heat-generating element and maintain the chamber in the main body in an airtight state without leakage.

Owner:ASIA VITAL COMPONENTS SHENZHEN CO LTD

Heat dissipation device with mounting structure

InactiveUS20130042999A1Avoid undesirable thermal resistanceBlocking can be undesirableSemiconductor/solid-state device detailsSolid-state devicesWorking fluidElectrical and Electronics engineering

A heat dissipation device with mounting structure includes a main body and a plurality of mounting elements. The main body includes an internally defined chamber having a first side and an opposite second side; a plurality of supports located in the chamber and respectively having two ends connected to the first side and the second side of the chamber; a working fluid filled in the chamber; and a plurality of connection sections in the form of recesses formed on an outer surface of the main body at positions corresponding to the supports in the chamber. The mounting elements are connected to the connection sections. With these arrangements, the heat dissipation device with the mounting elements connected to one outer surface thereof can maintain the chamber in the main body in an airtight state and ensure tight contact of it with a heat-generating element.

Owner:ASIA VITAL COMPONENTS SHENZHEN CO LTD

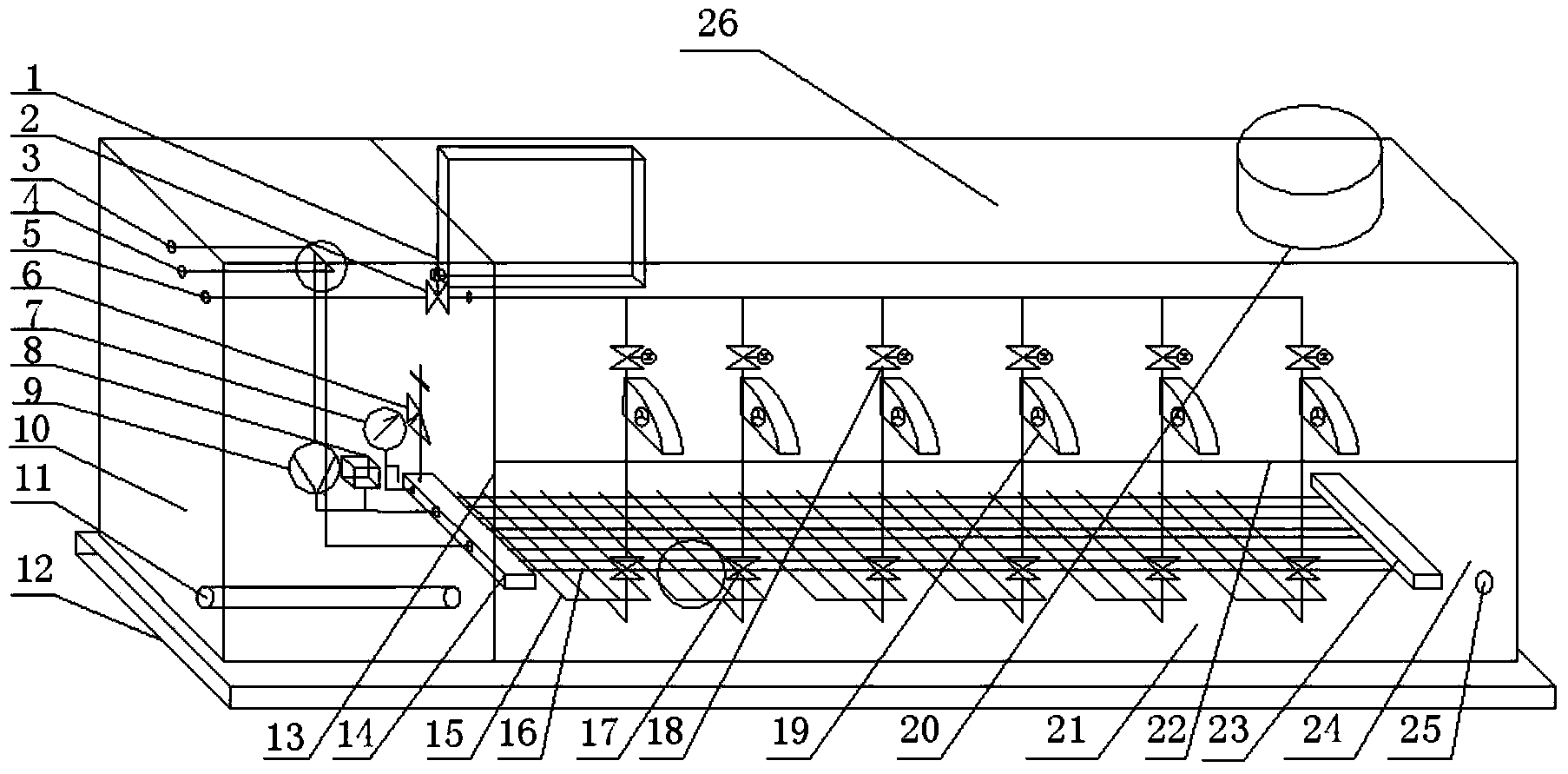

Premixed closed module gas-fired boiler

ActiveCN103591681AHigh thermal efficiencyIncrease profitWater heatersGaseous fuel burnerCombustion chamberCombustor

The invention discloses a premixed closed module gas-fired boiler. The premixed closed module gas-fired boiler comprises an airtight combustion chamber composed of an upper plate, a face plate, a rear plate and a side plate, and a unit base used for fixing the airtight combustion chamber; a water inlet and a water outlet arranged on the face plate are connected into a water inlet and a water outlet of a front divergence water tank through a water inlet pipeline and a water outlet pipeline respectively, wherein the water inlet of the face plate is also connected with a built-in circulating pump through the water inlet pipeline; a rear divergence water tank is installed on the surface opposite to the front divergence water tank, and the front divergence water tank is communicated with the rear divergence water tank through a metal fin tube heat exchanger; a fuel gas connector on the face plate is communicated with a fuel gas header pipe; a fuel gas main valve is installed on the fuel gas header pipe; a plurality of branch pipes are connected into the part, behind the valve, of the fuel gas header pipe in parallel; the tail ends of the branch pipes are connected with a group of calandria combustors which are connected in parallel. According to the premixed closed module gas-fired boiler, an ignition system of the boiler is improved, so that a combustor, a heat exchange system and other internal devices of an existing gas-fired boiler are integrated and optimized; an intelligent control system is matched with the boiler for use, so that internal friction of the boiler is reduced, the automation degree of the boiler is increased, and thermal efficiency of the boiler is improved.

Owner:DALIAN SHENGDING IND EQUIP

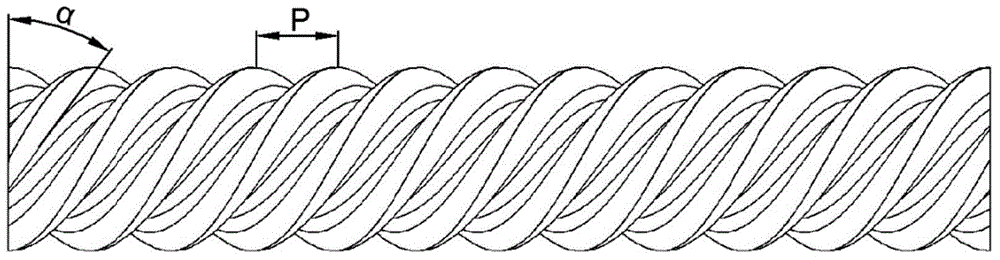

Flat plate collector with worm pipes

InactiveCN102878701AEasy to useSolve the ills of foulingSolar heating energySolar heat devicesFrost crackHot runner

The invention discloses a flat plate collector with worm pipes. The flat plate collector comprises a frame; high-light-transmission tempered glass is embedded on the frame; an absorber plate core is arranged below the tempered glass and comprises a heat exchange pipe, heat exchange volutes and heat collecting pipes as many as the heat exchange volutes; each heat collecting pipe comprises a heat collecting runner and heat collecting fins which are integrally formed on the two sides of the heat collecting runner; the heat exchange pipes pass through a plurality of heat exchange volutes; the upper part of each heat collecting runner is communicated with one corresponding heat exchange volute, and the lower part of each heat collecting runner is sealed independently; and the heat exchange pipe, the heat exchange volutes and the heat collecting runners form a closed space which is filled with a heat pipe medium. The flat plate collector has the advantages that as the heat collecting pieces are formed through one-time extrusion, the problems on firmness and heat resistance caused by laser welding or ultrasonic welding are avoided; the defects of frost cracking of a common heat collector in winter and scaling of a pipeline of a common flat plate collector are overcome; and a channel can be formed in each heat collecting runner, and thus the heat transfer effect of the flat plate collector can be improved effectively.

Owner:王超生 +1

Chloromethane recovery system and method

ActiveCN113828121AImprove heat transfer efficiencyHigh pressure and high heat exchange efficiencyChemical industryDispersed particle separationProcess engineeringChlorosilane

The invention provides a chloromethane recovery system and a chloromethane recovery method. The chloromethane recovery system comprises a chlorosilane mixed monomer synthesis tower, a chlorosilane mixed monomer separation tower and a chloromethane recovery device, wherein the chlorosilane mixed monomer synthesis tower is connected with the chlorosilane mixed monomer separation tower; the chlorosilane mixed monomer separation tower is connected with a chloromethane recovery device; the chloromethane recovery device comprises a chloromethane compression device, a chloromethane heat exchanger, a chloromethane buffer tank, a condensing device, a chloromethane return tank and a chloromethane feeding pump; the chloromethane compression device is connected with the chlorosilane mixed monomer synthesis tower; the chloromethane heat exchanger and the chloromethane buffer tank form a communicating vessel structure, and the chloromethane heat exchanger is connected with the condensing device; and the chloromethane buffer tank is connected with the chlorosilane mixed monomer synthesis tower. According to the invention, through mutual conversion of gas and liquid two-phase circulation, heavy components in the chloromethane are finally removed, the purity of the recovered chloromethane is improved, thermal resistance is effectively prevented from being formed, and the driving period of the system is prolonged.

Owner:XINJIANG JINGSHUO NEW MATERIALS CO LTD +1

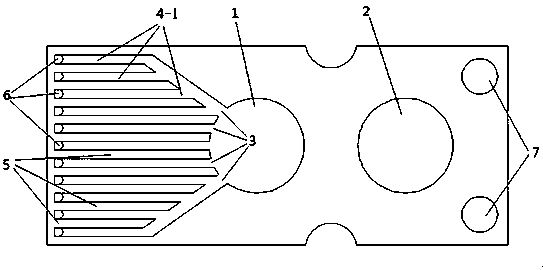

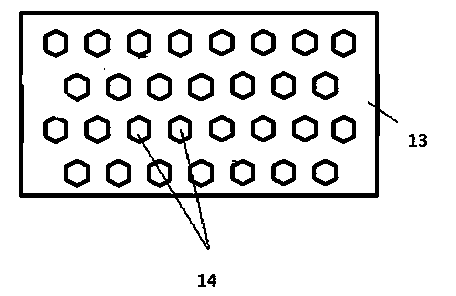

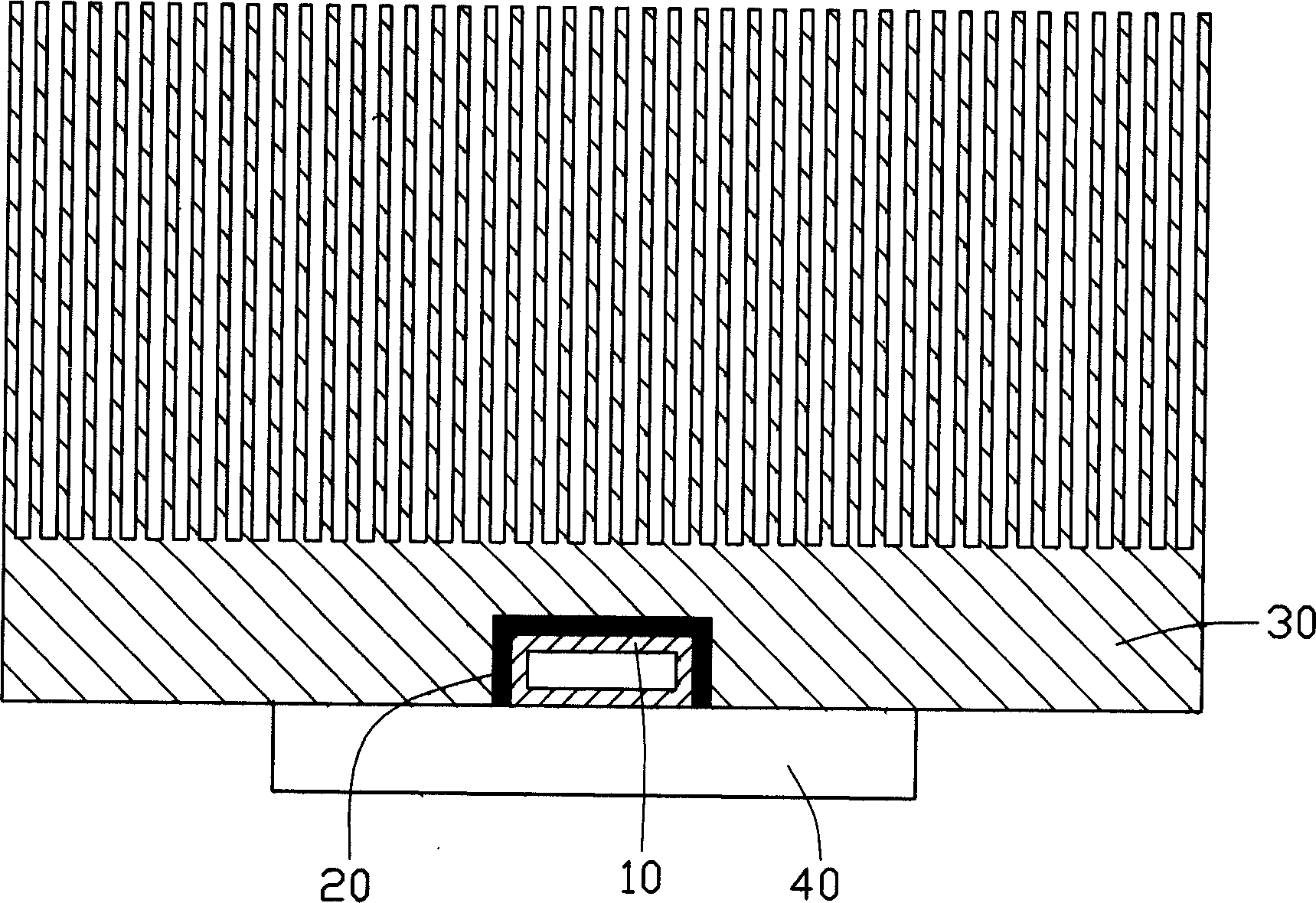

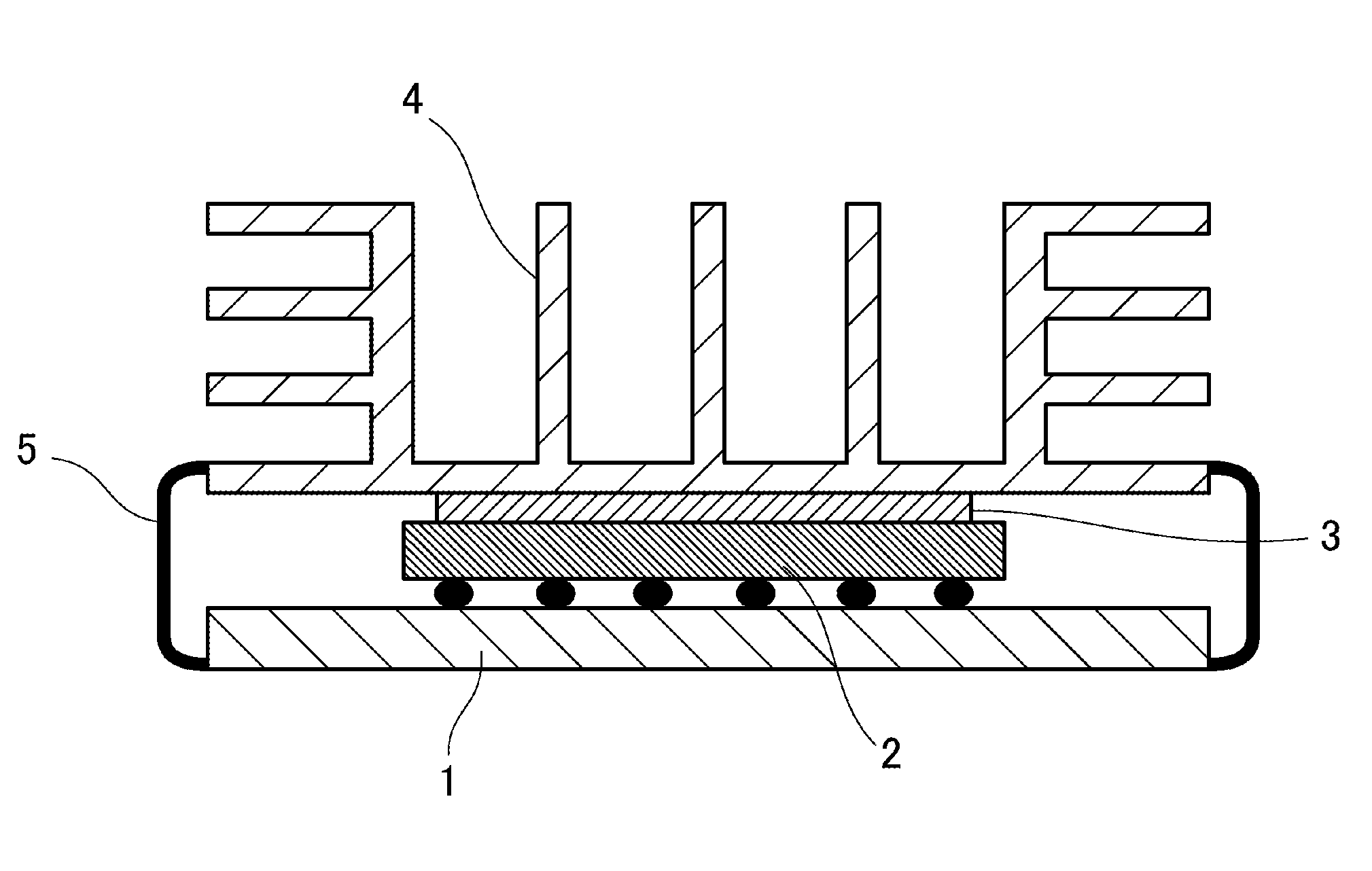

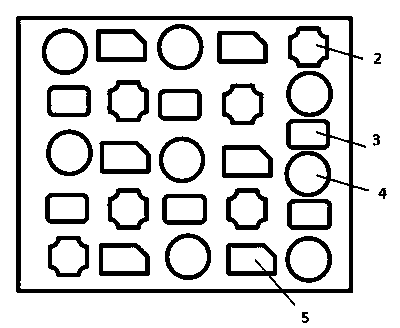

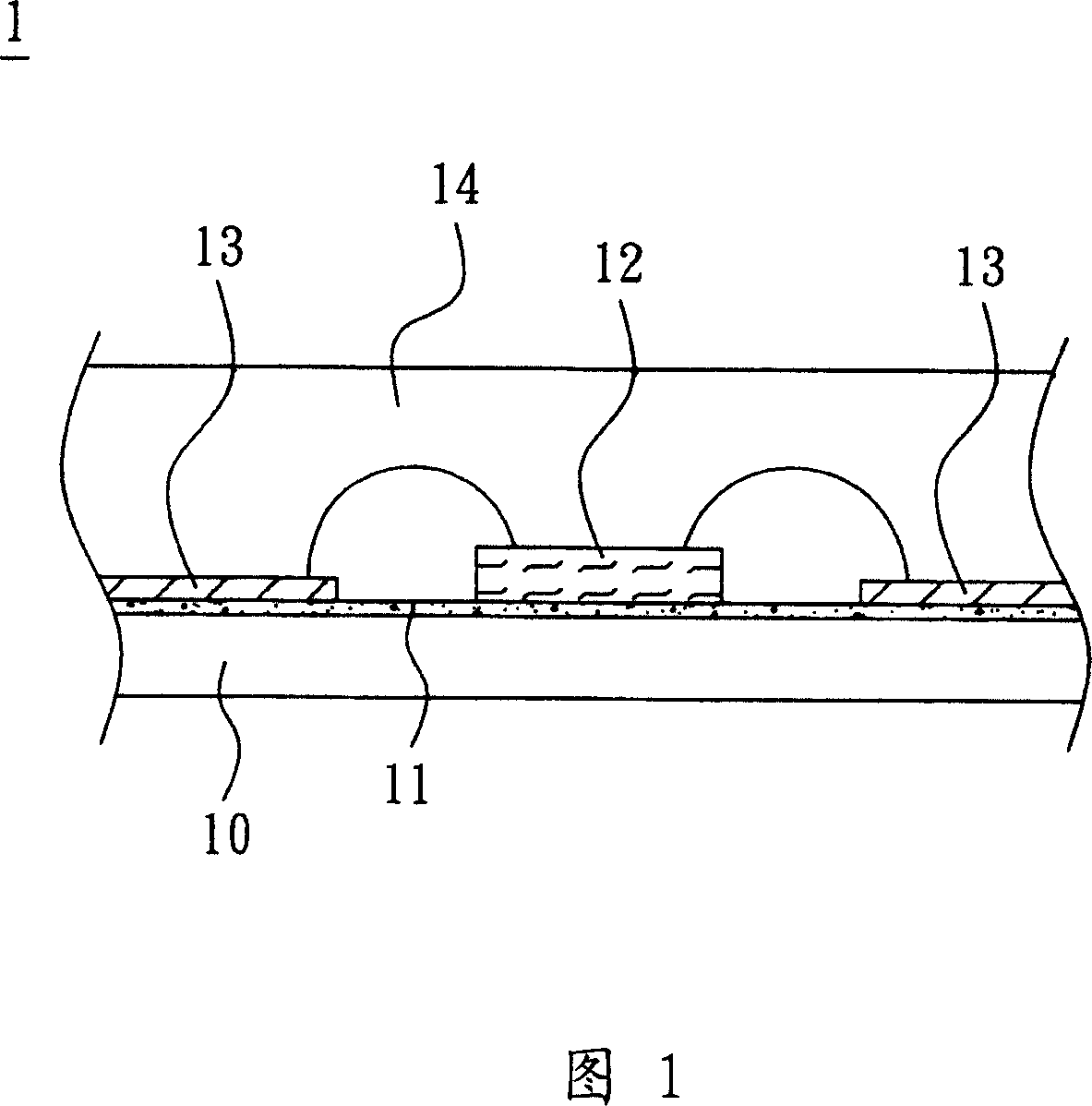

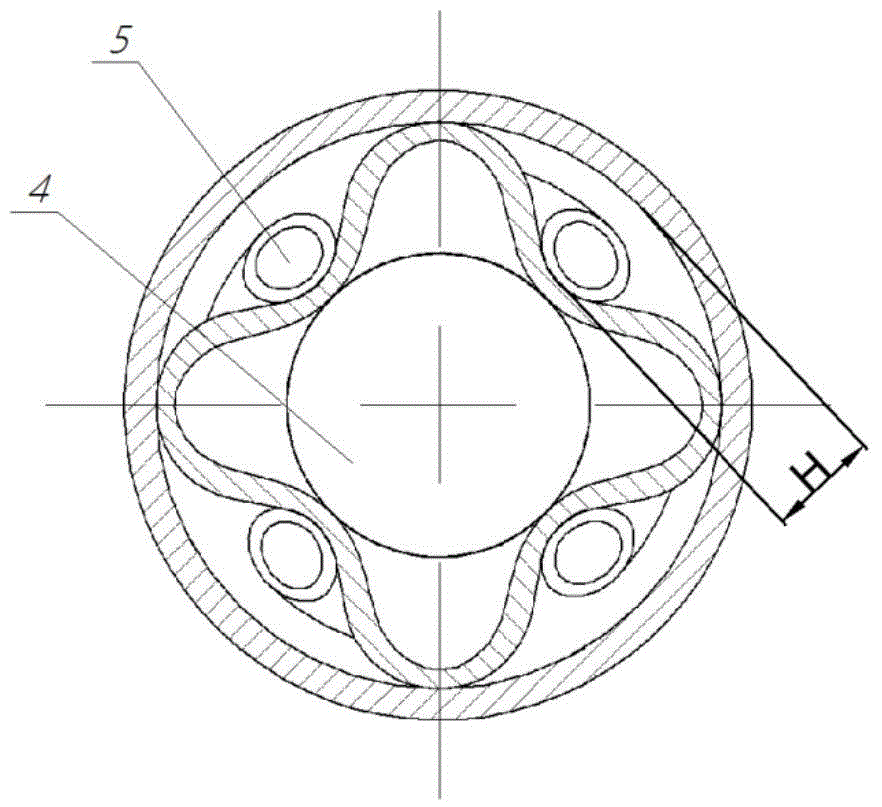

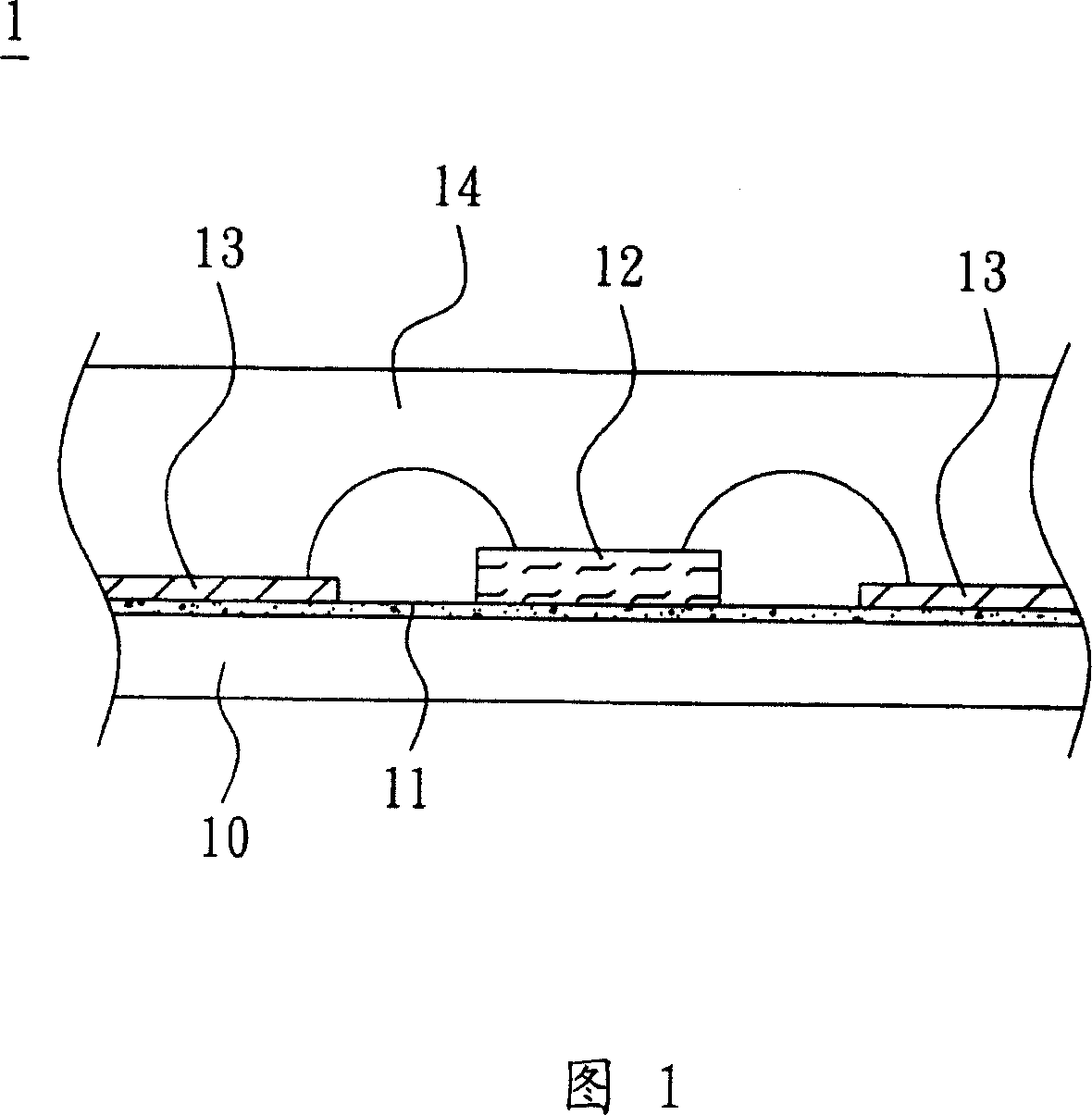

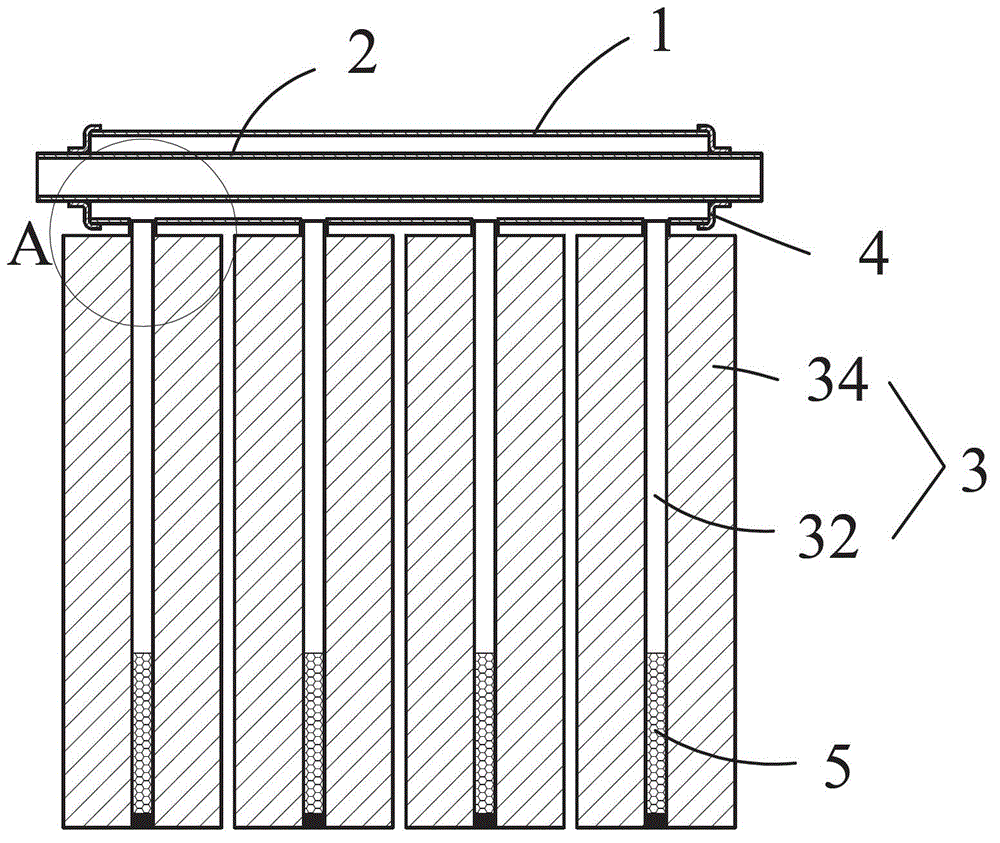

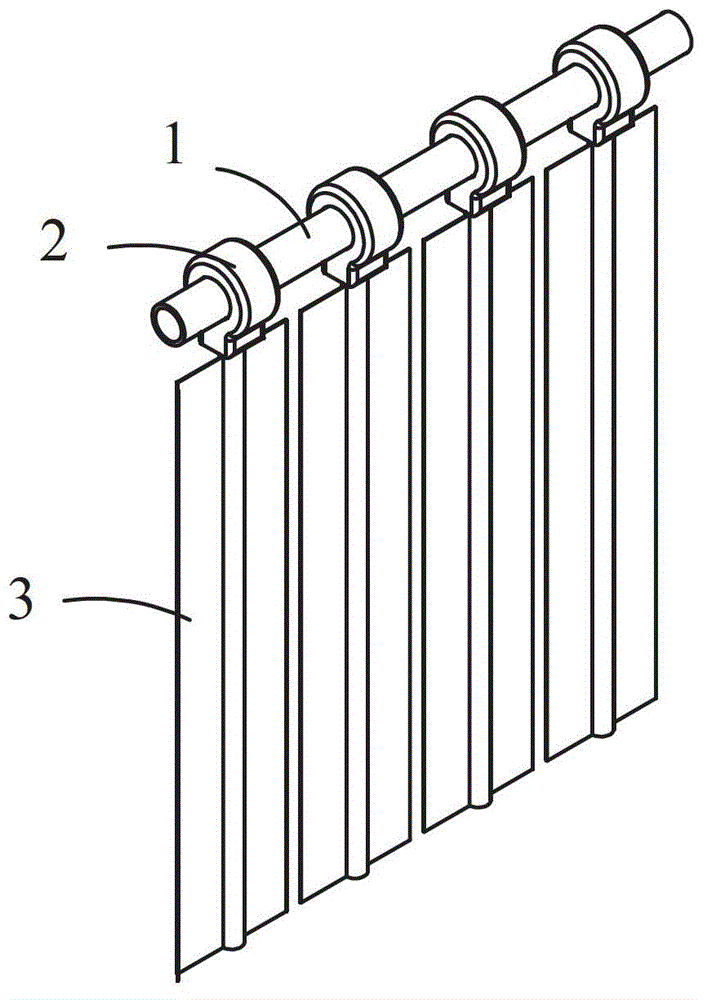

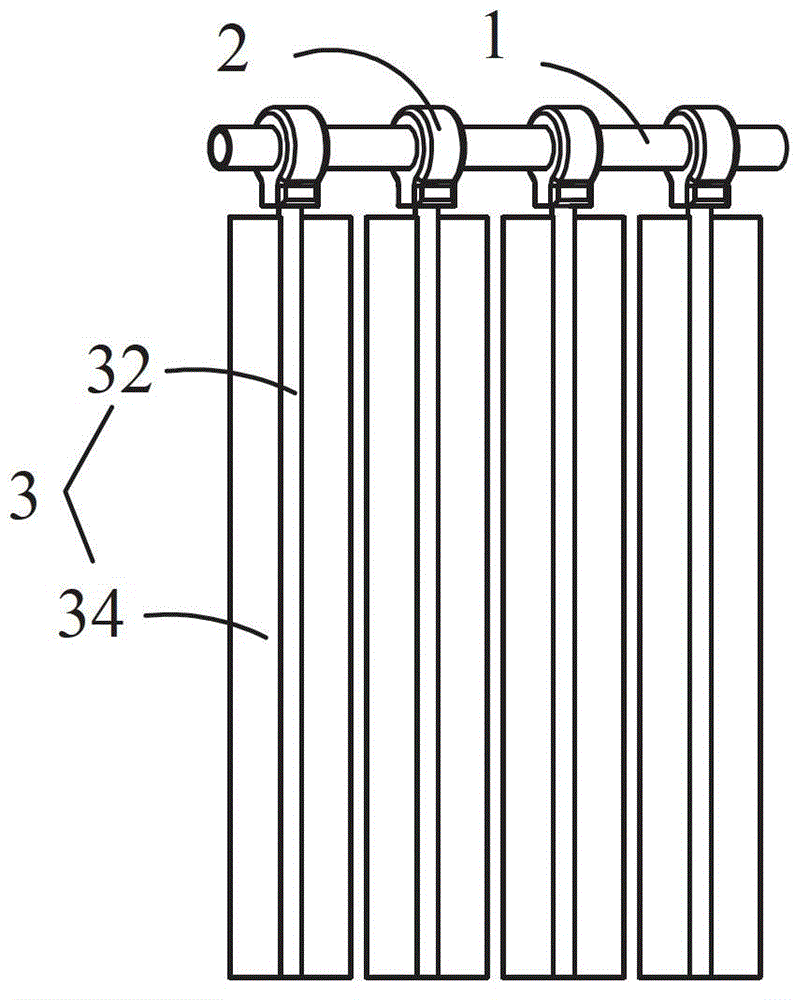

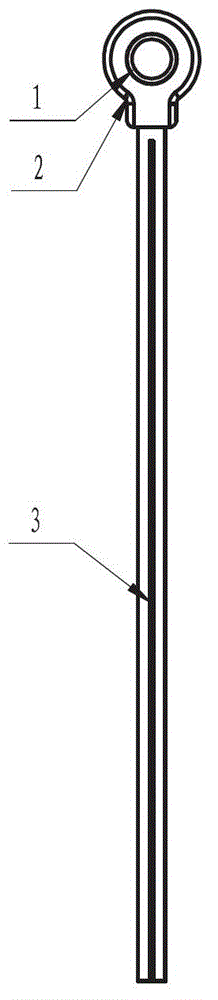

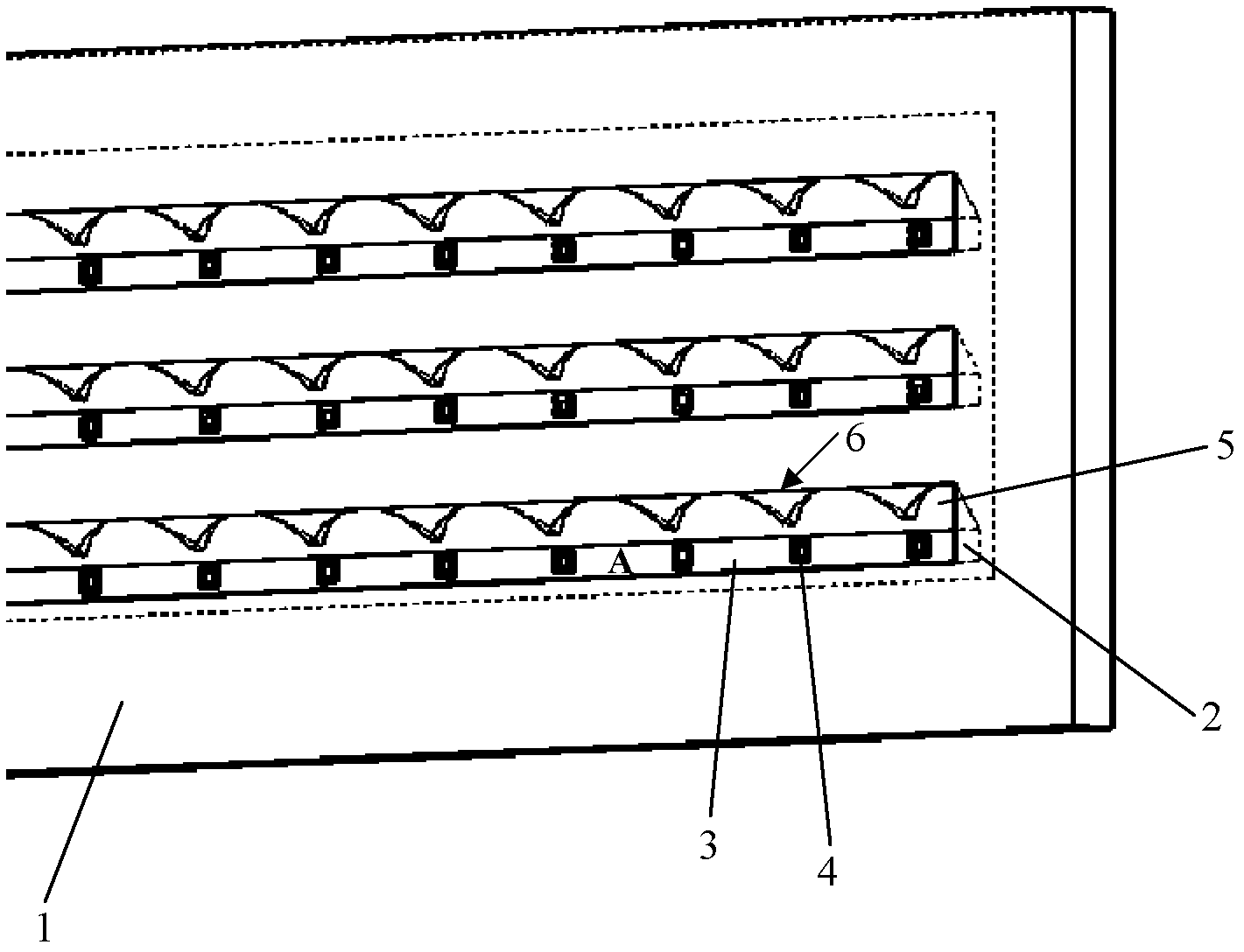

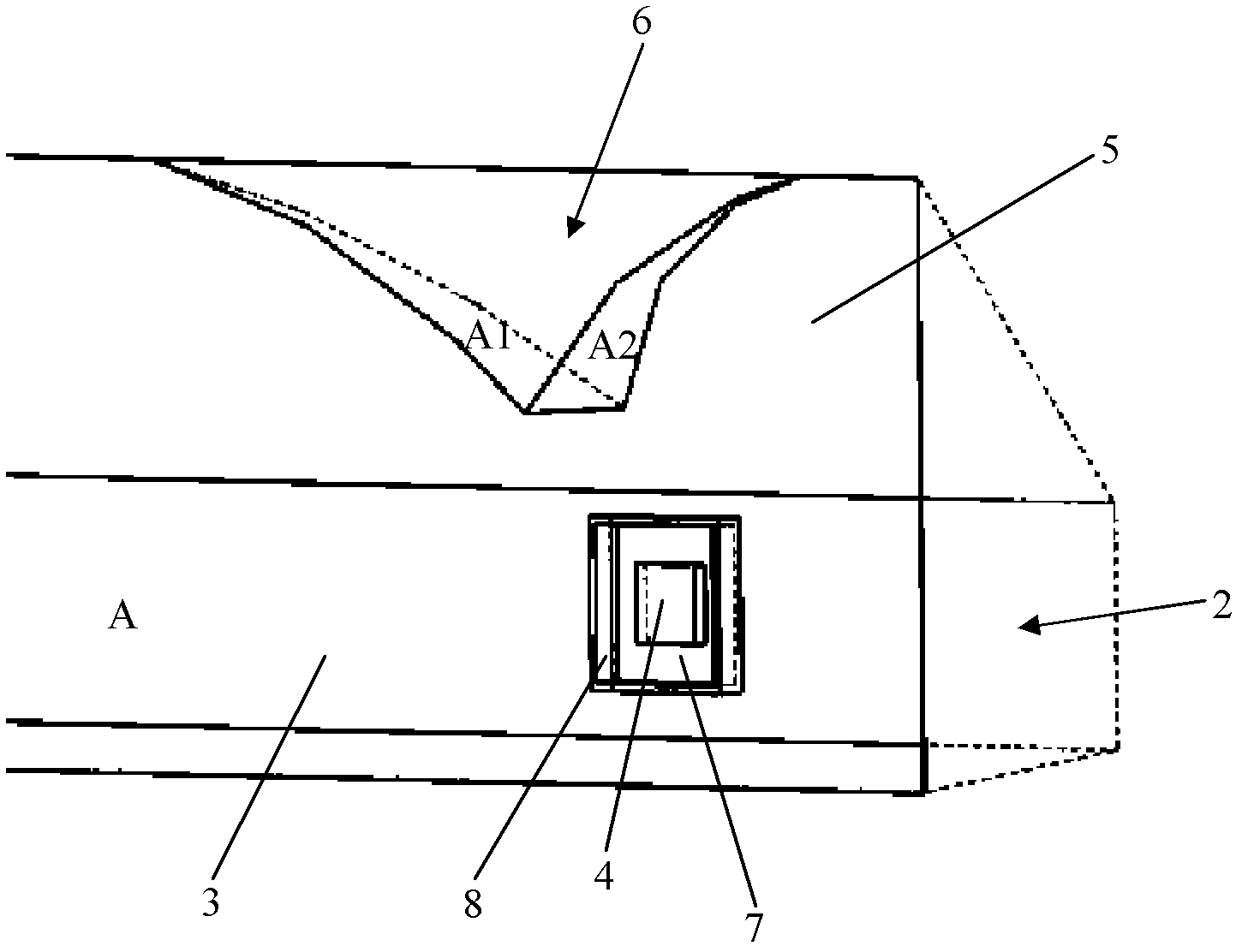

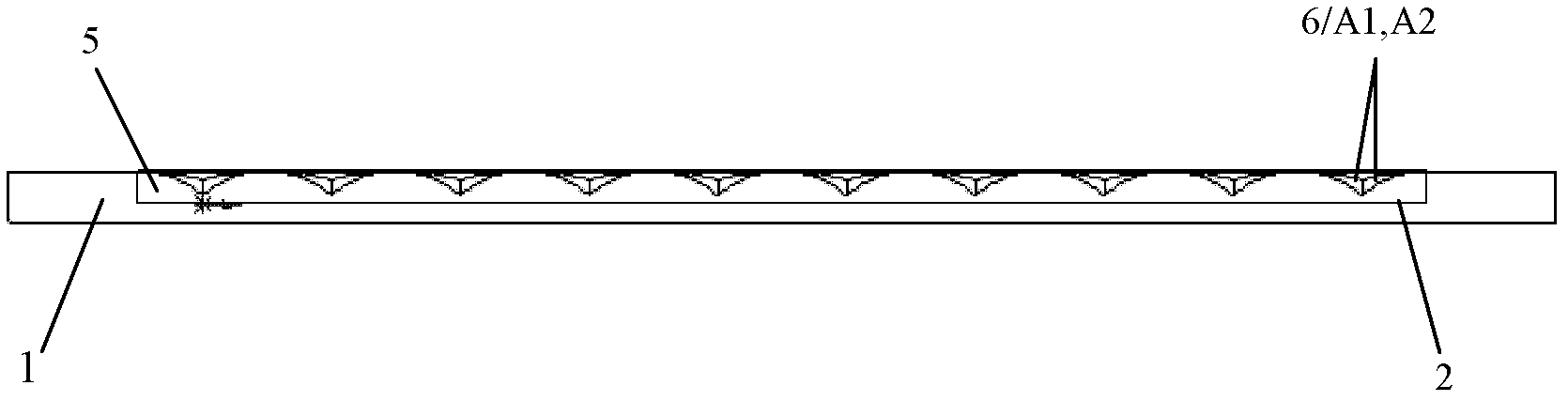

LED (Light Emitting Diode) light emitting module and manufacturing method thereof

InactiveCN103016965AAvoid thermal resistanceAchieving Polarized ReflectionMechanical apparatusPoint-like light sourceHeat resistanceOn board

The invention relates to an LED (Light Emitting Diode) light emitting module, which is provided with a bottom plate (1) with at least one groove (2) and at least one printed circuit board (3) with an LED chip (4) array, wherein the at least one printed circuit board (3) is arranged in the groove (2) respectively; the LED light emitting module is characterized in that each LED chip (4) is directly arranged on the printed circuit board (3) by using a COB (Chip On Board) process; and a reflector (5) which is positioned on a side wall of the groove (2) is also arranged to reflect light from the LED chip (4). In addition, the invention also relates to a manufacturing method of the LED light emitting module. According to the LED light emitting module, a polarization effect can be produced, so that the LED light emitting module is particularly suitable for roadway lighting; and the LED light emitting module also has the advantages of simple structure, low cost and small heat resistance.

Owner:OSRAM GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com