Heat dissipation device and manufacturing method thereof

a technology manufacturing method, which is applied in the direction of solid-state devices, metal-working devices, semiconductor devices, etc., can solve the problems of affecting the smooth flow of working fluid, and the inability of heat dissipation device to tightly attach to the heat generation component. , to achieve the effect of avoiding thermal resistance and increasing assembly tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

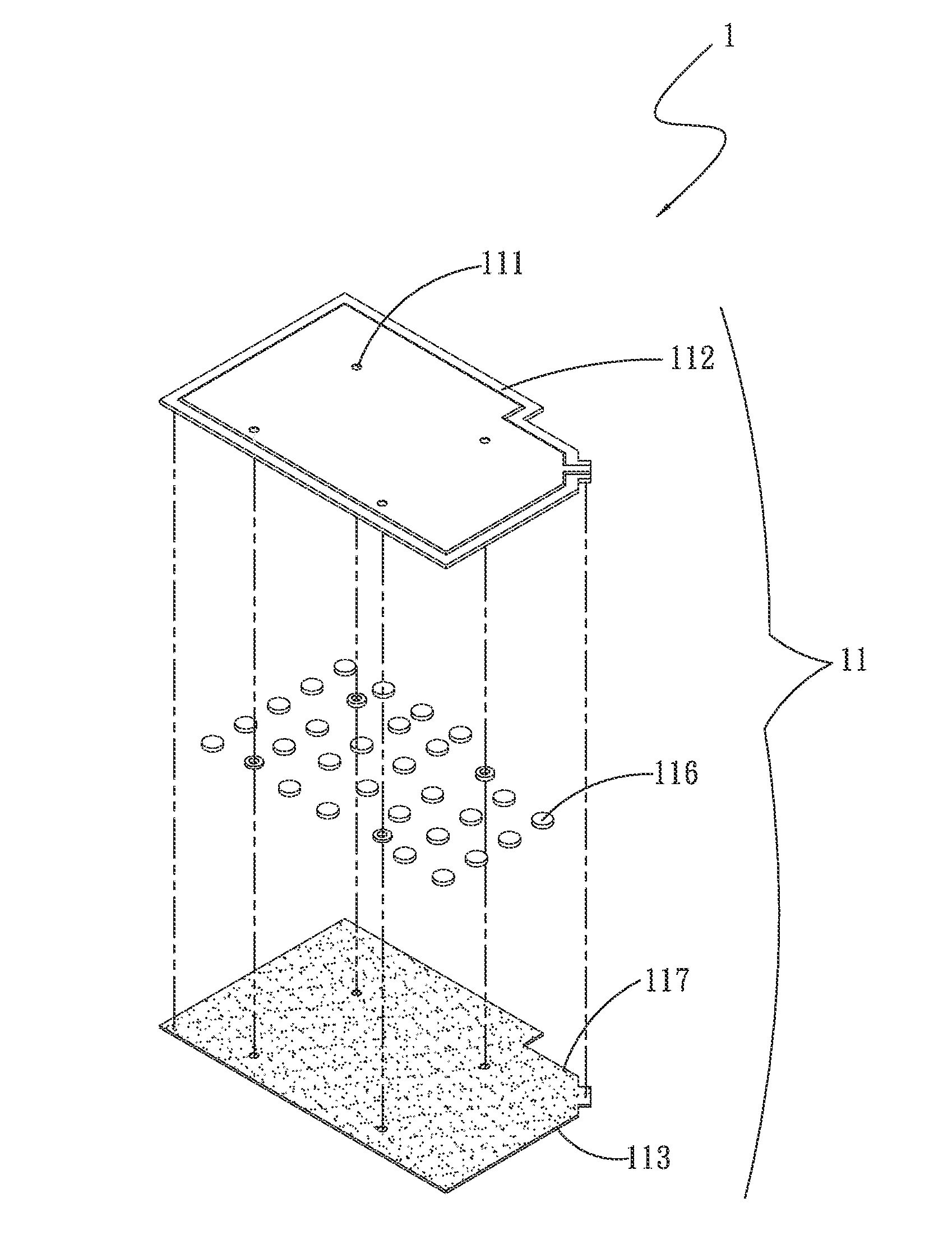

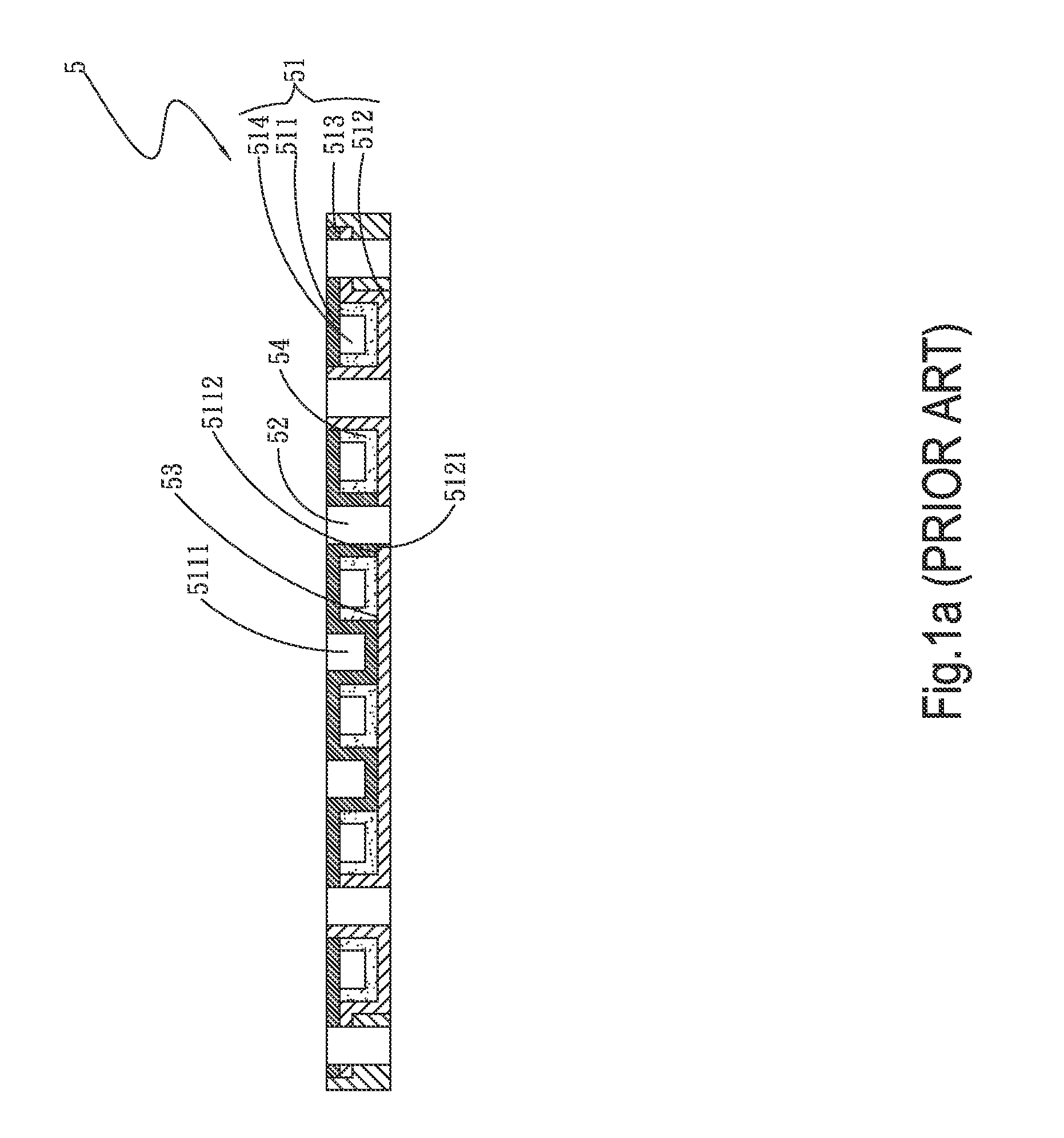

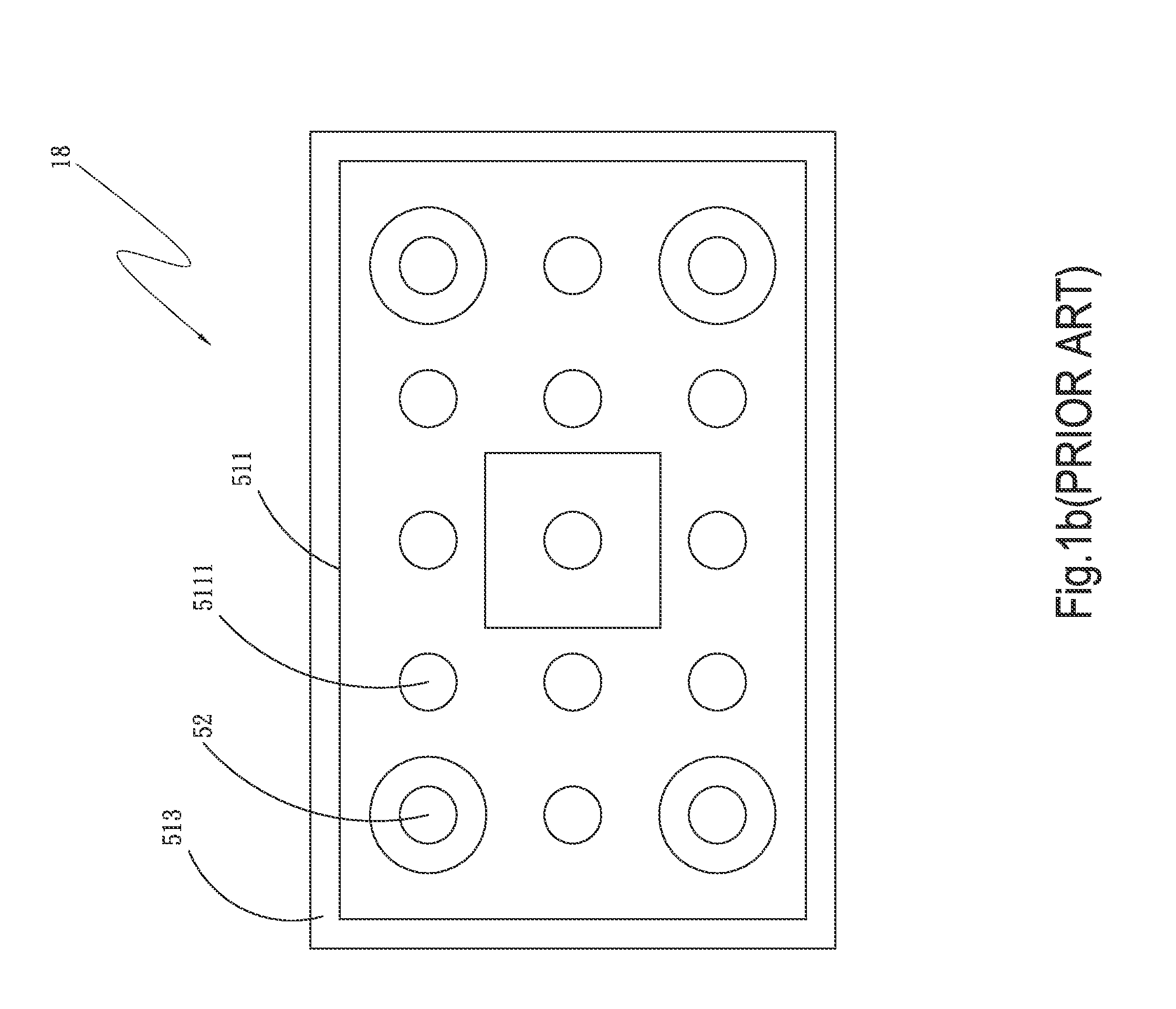

[0038]Please refer to FIGS. 2, 3 and 4. FIG. 2 is a perspective exploded view of a first embodiment of the heat dissipation device of the present invention. FIG. 3 is a perspective assembled view of the first embodiment of the heat dissipation device of the present invention. FIG. 4 is a sectional view taken along line A-A of FIG. 3. According to the first embodiment, the heat dissipation device 1 of the present invention includes a main body 11 and at least one fixing hole 111.

[0039]The main body 11 has a first board body 112 and a second board body 113 corresponding to the first board body 112. The first and second board bodies 112, 113 are mated with each other to define a chamber 114. The chamber 114 has a first inner side 1141 and a second inner side 1142. A working fluid 115 and multiple support pillars 116 are disposed in the chamber 114. At least one capillary structure 117 is disposed on a surface of the chamber 114. Two ends of the support pillar 116 are connected to the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| capillary structure | aaaaa | aaaaa |

| heat transfer efficiency | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com