High-intensity environment-friendly craft paper and manufacturing method thereof

A kraft paper, high-strength technology, applied in the field of papermaking, can solve the problems of inability to effectively improve the quality of coated white-faced kraft paper, difficult to produce kraft paper, low proportion of wood pulp, etc. The effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

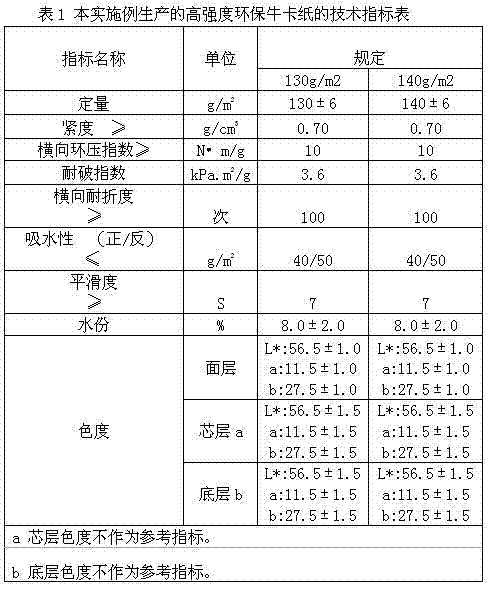

Examples

Embodiment

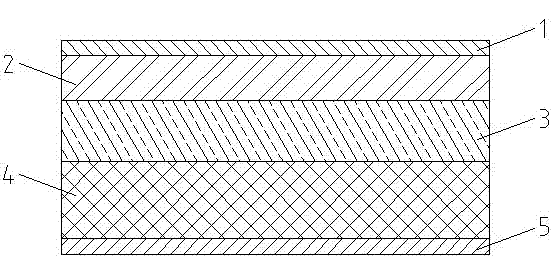

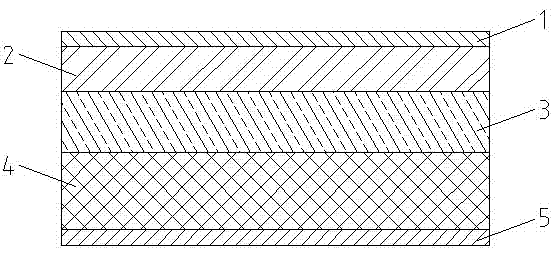

[0023] see figure 1 , the high-strength environmentally friendly kraft cardboard in this embodiment is composed of a surface layer 2, a core layer 3, a bottom layer 4, a front sizing layer 1 and a back sizing layer 5, wherein the lower surface of the core layer 3 is fixed on the bottom surface of the bottom layer 4 On the upper surface, the lower surface of the surface layer 2 is fixed on the upper surface of the core layer 3, the lower surface of the front sizing layer 1 is fixed on the upper surface of the surface layer 2, and the upper surface of the back sizing layer 5 is fixed on the bottom layer 4 on the lower surface of the . In this embodiment, the surface layer 2, the core layer 3 and the bottom layer 4 can be dyed with dye, so that the colors of the surface layer 2, the core layer 3 and the bottom layer 4 in the finished paper are consistent.

[0024] The slurry of surface layer 2 in this embodiment is uncolored wood pulp, and this uncolored wood pulp is made up of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com