Patents

Literature

134results about How to "Quantitative low" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

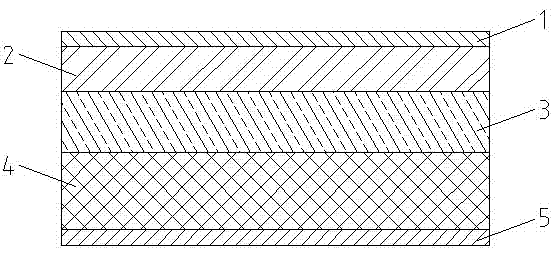

High-intensity environment-friendly craft paper and manufacturing method thereof

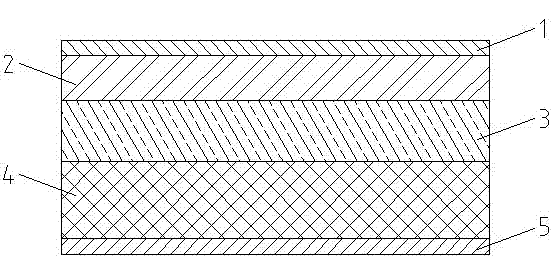

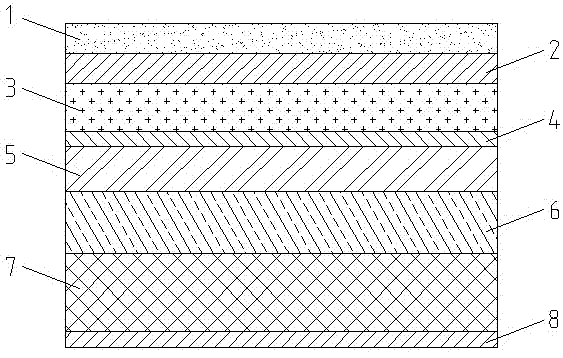

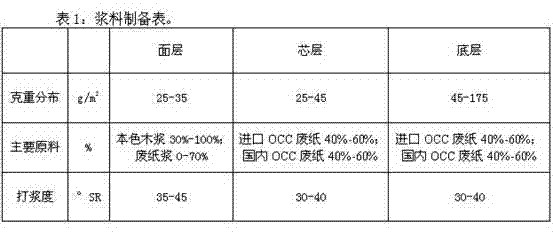

The invention relates to a high-intensity environment-friendly craft paper and a manufacturing method. Currently, the craft paper which is low in quantitation and low in wood pulp proportion, has high intensity, and is mainly made of secondary fiber is unavailable yet. The craft paper is characterized by consisting of a face layer, a core layer, a bottom layer, a front-side glue applying layer and a back-side glue applying layer; the sizing agent of the face layer is nature-color wood pulp; the sizing agent of the core layer is mid fiber and long fiber which are graded from the old corrugatedcontainer (OCC) secondary fiber; and the sizing agent of the bottom layer is short fiber which is graded from the OCC secondary fiber. The method for manufacturing the high-intensity environment-friendly craft paper comprises the steps of pulping, making glue and making paper, wherein the pulping comprises the steps of making the sizing agent of the face layer, making the sizing agent of the corelayer and making the sizing agent of the bottom layer. The craft paper is reasonable in structural design, low in quantitation, low in wood pulp proportion and high in intensity, and is mainly made of the secondary fiber. Moreover, the process is simple, the production cost is low, and the manufactured high-intensity environment-friendly craft paper has good quality.

Owner:JIAN GRP

Making method of ultrathin low-weight sound-absorbing decoration paper

ActiveCN103074807AQuantitative lowReduce consumptionSpecial paperPaper/cardboardSurface finishingFlame resistance

The invention discloses a making method of ultrathin low-weight sound-absorbing decoration paper. The existing sound-absorbing material is large in thickness and high in weight, and easily generates a fiber or dust and the like to damage a surrounding environment. The method comprises the steps that a plant fiber is beat till 15-30<0>SR is achieved, and mixed with a non-plant fiber; a chemical additive is added to a mixed fiber; the mixed fiber is subjected to paper making by a round wire or inclined wire paper machine to form raw paper; a fire retardant, an adhesive and the chemical additive are mixed to form a coating fluid; the raw paper is subjected to in-machine coating or out-machine coating to form semifinished sound-absorbing decoration paper; the semifinished sound-absorbing decoration paper is dried, subjected to surface finishing, and reeled into the sound-absorbing decoration paper; and a sound-absorbing paper decoration material which is good in strength, high in air permeability, small in thickness, light in weight, good in flame retardance, excellent in sound absorptivity, and good in decoration effect is obtained.

Owner:ZHEJIANG WINBON SPECIALTY PAPER +1

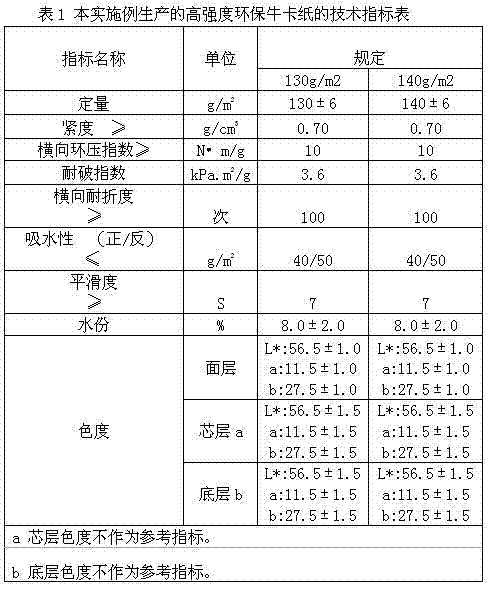

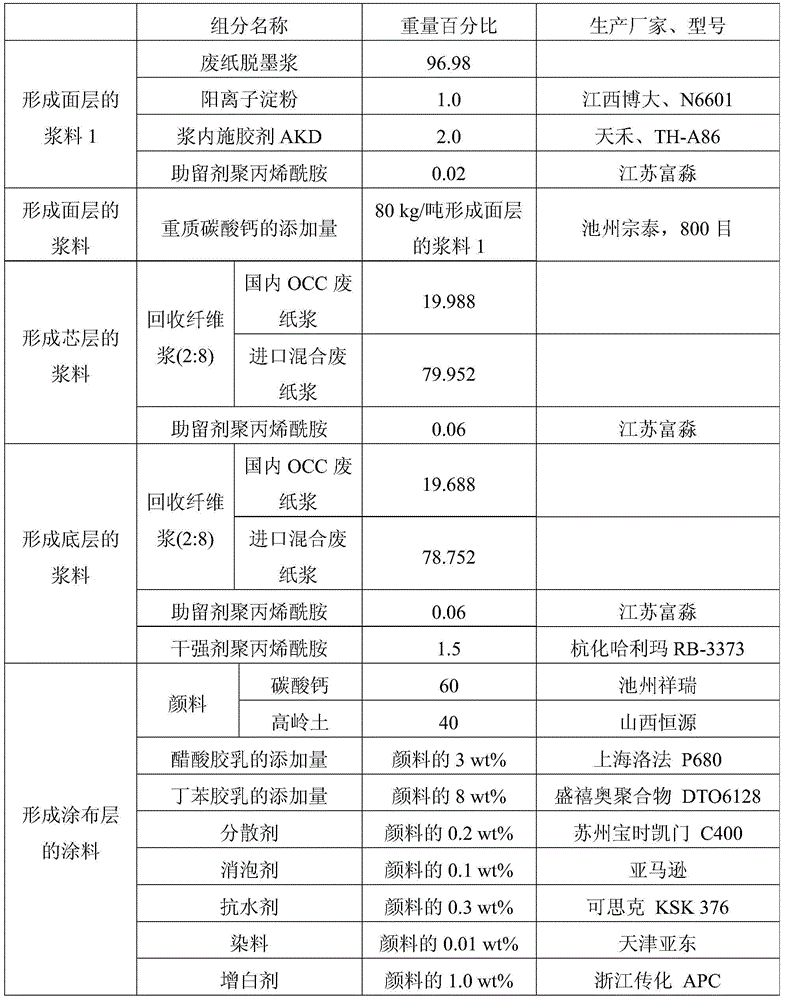

Coated natural kraft and manufacturing method thereof

ActiveCN102199898AHigh strengthIncreased ring compressive strengthDefoamers additionWater-repelling agents additionSurface layerPulp and paper industry

The invention relates to coated natural kraft and a manufacturing method thereof. The traditional coated kraft does not have the advantages of attractive appearance, environment friendliness, high strength and good printing performance. The coated natural kraft disclosed by the invention comprises natural kraft, a surface sizing layer and a surface coating layer and is characterized in that a bottom layer comprises OCC (Old Corrugated Case) waste paper pulp and a core layer comprises waste paper; a surface layer comprises natural wood pulp and waste paper pulp, wherein the weight percentage of the natural wood pulp is 30% to 90% and the balance is the waste paper pulp; the surface sizing layer comprises a front sizing layer and a back sizing layer; and the surface coating layer comprises a bottom coating layer, a middle coating layer and a surface coating layer. The manufacturing method for the coated natural kraft sequentially comprises a natural kraft preparing working procedure, a sizing working procedure, a coating working procedure and a molding working procedure. The coated natural kraft has the advantages of reasonable structure design, attractive appearance, environment friendliness, high strength, good printing performance, simple preparation technology, low production cost and good quality.

Owner:JIAN GRP

White manila board and preparation method thereof

ActiveCN104878659AQuantitative lowReduce manufacturing costSurface covering paperWater-repelling agents additionFiberPapermaking

The invention belongs to the technical field of papermaking, and particularly relates to a white manila board and a preparation method thereof. Three layers of forming nets and two passes of coating (curtain coating and knife coating) are adopted for the white manila board; moreover, a core layer and a bottom layer are manufactured by adopting recycled fiber pulp which is low-cost and is further more environment-friendly to replace wastepaper de-inked pulp; not only can a production process of the white manila board be greatly simplified and optimized, but also the consumption of chemicals and the power consumption can be greatly decreased, so that the qualified and low-basis-weight white manila board which more accords with market requirements can be produced with low cost.

Owner:JIAN GRP

High-permeability super black decorated base paper and preparation method thereof

ActiveCN103614949AImprove permeabilityImprove breathabilitySpecial paperPaper/cardboardTitaniumWet strength

The invention relates to high-permeability super black decorated base paper and a preparation method of the high-permeability super black decorated base paper, and belongs to the technical field of decoration base paper. The preparation method is characterized by comprising the following steps: taking pulp mixed from bleached softwood pulp and bleached hardwood pulp according to the mass ratio of 1:(3.6-4.4) as a main raw material; reducing the beating degree of bleached wood pulp to 32 SR, enabling the mass concentration to reach 4%, and then pumping into a repulping pond for later use; directly adding a black pigment to the repulping pond, wholly substituting kaoline for titanium dioxide to prepare the decorated base paper with a black and shiny color, the fluorescent whiteness of 6%-8%, the basis weight of 70-90g / m<2>, the ash content of 10%-15%, the wet strength of 6.5-9N, the dry strength of 35-50N, the water absorption of 20-35mm / 10 minutes and the air permeability of 15-20s / 100ml. The high-permeability super black decorated base paper disclosed by the invention has the advantages of uniformity in coloring, good covering power, high air permeability, low basis weight and high paper output ratio; a processed decorating plate is high in stereoscopic impression, pure and bright in color and luster, green and environmental-friendly without white patterns.

Owner:ZIBO OU MU SPECIAL PAPER

Production process of colored tissue paper

InactiveCN101748644AQuantitative lowGood strength requirementsCoatings with pigmentsPulp beating methodsFiber bundleColor tissue

The invention discloses a process for producing colored tissue paper by using 100 percent of wastepaper pulp. The process comprises the following steps of: pulp preparation: adding 100 percent of wastepaper pulp into a hydrapulper for breaking; removing impurities of thin films and the like by using a jig sieve; pulping through a high-frequency fluffer and a raffinator; and finally adding chemical raw materials and dye in a pulp blending tank, adjusting the density and feeding the mixture into a paper-making flow delivering system; paper making: diluting the pulp for making in a slushing tank by slushing, then removing sand by a deslagger and long fibers and fiber bundles by a selectifier screen, pumping into a head box and flowing into a net trough for filtering through a net; and finally squeezing, drying, reeling, splitting, packaging and warehousing. The quality of products reaches the national quality standard of 100 percent of wood pulp products and further reaches over B class according to the national standard.

Owner:福建省晋江优兰发纸业有限公司

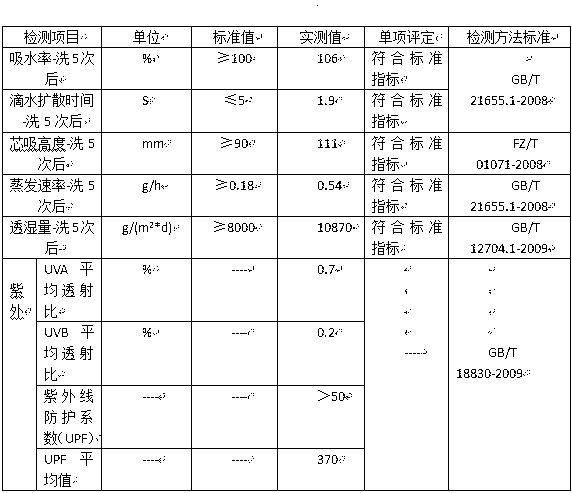

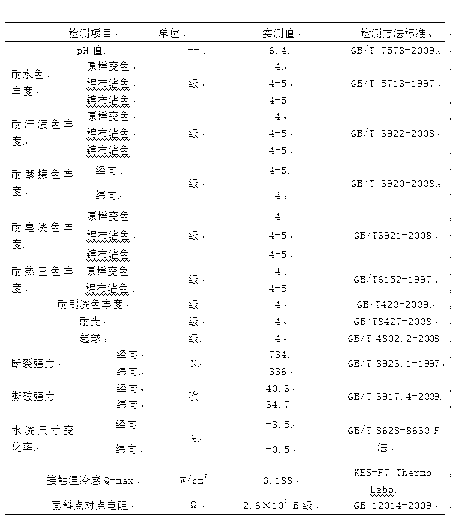

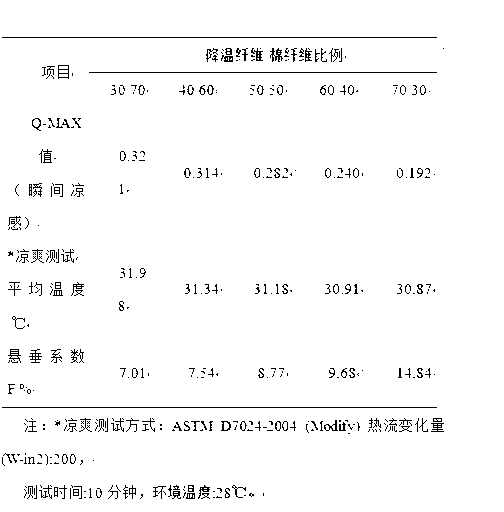

Tooling fabric with cooling function and uvio-resistant function

The invention relates to tooling fabric with a cooling function and an uvio-resistant function. A method for manufacturing the tooling fabric with the cooling function and the uvio-resistant function comprises a first step of using cooling master batch as raw materials and manufacturing the cooling master batch to slicing sheets, a second step of drying the slice sheets, a third step of carrying out spinning on the slicing sheets through a spinning box to manufacture nylon base cooling fibers, a fourth step of adopting a siro spinning technology to spin cotton fibers and the nylon base cooling fibers into blended yarn, and a fifth step of adopting technological measures of 'early opening, later weft insertion and on-machine tension slightly larger' to carry out weaving. A formula of the cooling master batch comprises PA6, bowlder powder, zirconium dioxide powder, silicon dioxide powder, stearic acid dispersants, polystyrene dispersants, low molecular wax dispersants and titanate coupling agents. The tooling fabric has functions of fast heat absorption and fast heat dissipation, and an everlasting cooling feature is guaranteed. Meanwhile, the tooling fabric further has a notable uvio-resistant feature.

Owner:ZHEJIANG LANTIANHAI FAB TECHNOLAGY CO LTD

M-aramid fiber mica paper and preparation method thereof

ActiveCN105544285AHigh mechanical strengthHigh dielectric strengthPaper/cardboardSynthetic cellulose/non-cellulose material pulp/paperSlurryUltimate tensile strength

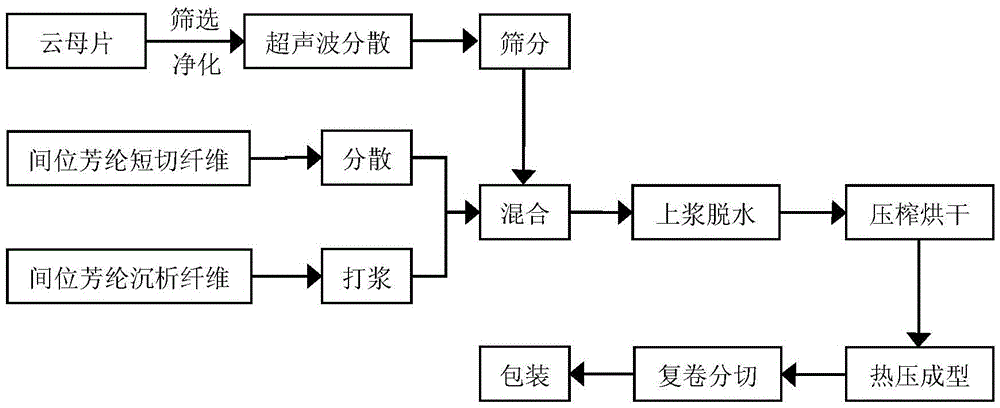

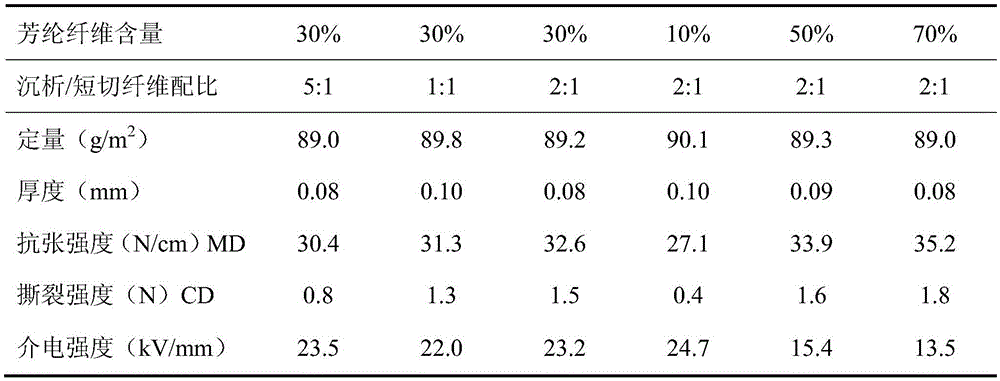

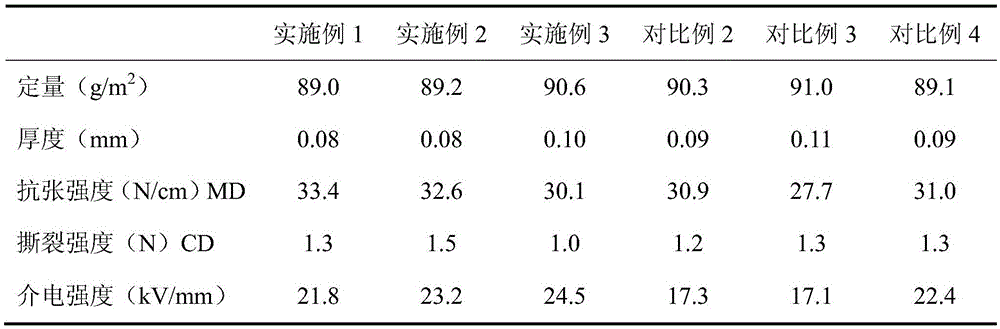

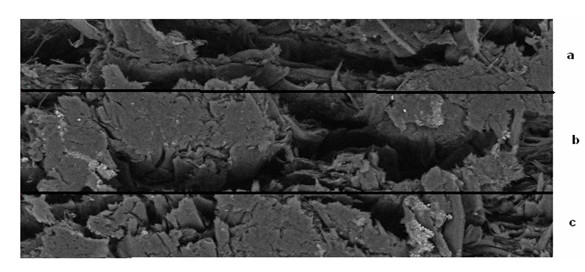

The invention relates to an m-aramid fiber mica paper and a preparation method thereof. The preparation method comprises preparing mica sheet slurry and m-aramid chopped fiber slurry, mixing and dispersing the mica sheet slurry, the m-aramid chopped fiber slurry and m-aramid fibrid slurry to obtain a uniform mixture, wherein the mixture comprises, by mass, 60-80% of the mica sheets and 20-40% of the m-aramid chopped fiber slurry and the m-aramid fibrid slurry and a mass ratio of the m-aramid fibrids to the m-aramid chopped fibers is (4-2): 1, based on the total mass of the oven dry raw materials, adding 0.01-0.1% by mass of a cationic polyacrylamide solution into the mixture, carrying out mixing to obtain uniform paper slurry, carrying out wet paper making on the paper slurry, carrying out drying and carrying out hot pressing to obtain the m-aramid fiber mica paper. The method utilizes the m-aramid chopped fibers as framework materials for reinforcement and utilizes the m-aramid fibrids as binder materials, and in hot pressing, a main body produces melting deformation and the mica sheets and the m-aramid chopped fibers are firmly inserted into the main body so that mica paper mechanical strength and dielectric strength are improved.

Owner:YANTAI METASTAR SPECIAL PAPER

Environment-friendly paper and preparation method thereof

InactiveCN101864691APromote absorptionGood printing adaptabilityInorganic fibres/flakesNon-fibrous pulp additionFiberPolyolefin

The invention provides environment-friendly paper and a preparation method thereof. The environment-friendly paper comprises the following components by weight percent: 65-85% of calcium carbonate fibers, 3-10% of thermoplastic starch, 10-20% of polyolefin resins and 2-5% of auxiliary components, wherein the calcium carbonate fibers are needle-like single-crystal fiber materials with average diameter of 0.5-1mu m and length diameter ratio being not less than 20 / 1; the thermoplastic starch is the micronized, plasticized and modified starch material; the polyolefin resins are polyethylene or polypropylene materials with melt index being 5-30; and the auxiliary components at least comprise surfactants with contents being not less than 1% and lubricants with contents being not less than 1%. The environment-friendly paper has the characteristics of low ration, little proportion and stable and uniform size, has good ink absorbency and printing adaptability, excellent performance indexes, such as whiteness, opacity, smoothness and tensile index and good texture and processability and can realize thermoplastic process. The environment-friendly paper accords with the present national development policy of the low carbon industry and has broad market prospect.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Manufacturing method of Pinfeng base paper

ActiveCN105586802AEasy to shapeImprove uniformityCoated paper substrateNon-macromolecular organic additionLogistics managementSlurry

The invention discloses a manufacturing method of Pinfeng base paper. The method comprises the following processing steps: pulping and preparing softwood pulp and hardwood pulp respectively; adding auxiliary materials; making wet paper sheets; carrying out pre-drying and surface sizing treatment; and carrying out post-drying, calendaring and finishing. Through research on slurry selection, slurry proportioning, a beating technology, a functional chemical additive added to the slurry and a digital printing assistant, measures of calendaring and the like are carried out by film-transfer surface sizing treatment by soft calendaring equipment; and the qualified Pinfeng base paper is manufactured by referring to related paper machine parameters. Compared with ordinary logistics label middle paper, the Pinfeng base paper has the advantages of low gram weight, high tensile strength, good internal bonding strength, high smoothness, low hygroscopic property, good surface strength, good digital printing effect, fine paper surface and good hand feeling, and is capable of completely replacing the ordinary logistics label middle paper and reducing the production cost for customers.

Owner:YUEYANG FOREST & PAPER CO LTD

Foaming thin sheet for cigarette and preparation method thereof

ActiveCN101433367AImprove the shortcomings of poor filling and burst resistanceLow densityTobacco preparationTobacco treatmentFoaming agentThin sheet

The invention provides a foaming flake added into cigarette. A foaming agent and foaming preparation technology are added into the prior technological process of flake, thereby effectively reducing the dosage of the flake, and reaching the aims of improving the filling value of the cigarette tobacco flake by 5 to 20 percent and improving the combustibility.

Owner:CHINA TOBACCO HUNAN INDAL CORP

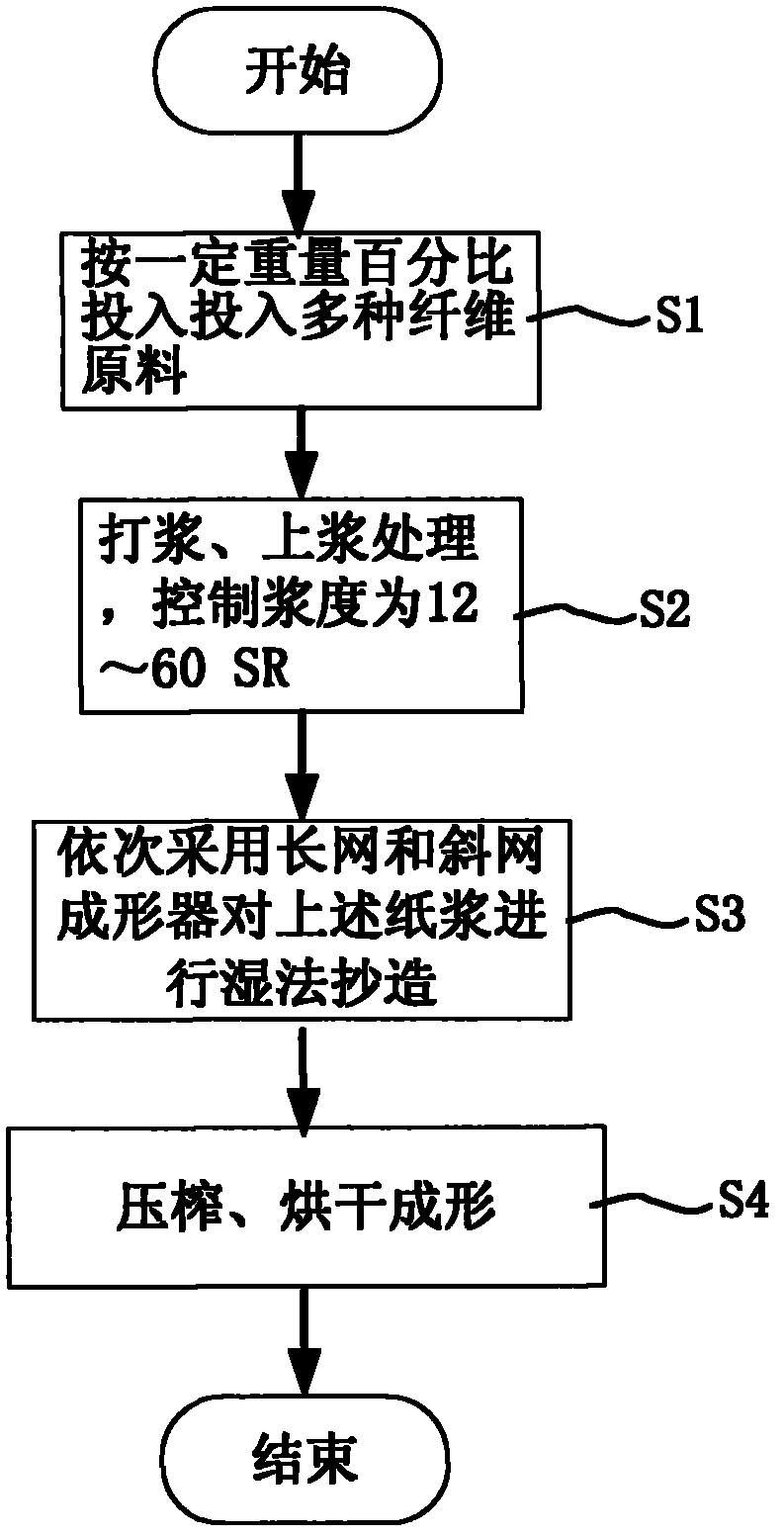

Process for making light-weight high-strength common gypsum board mask paper

The invention discloses a process for making light-weight high-strength common gypsum board mask paper, which comprises three procedures of material preparation, pulping and paper making. By adding various assistants to domestic waste newspaper and imported American waster paper based on a certain ratio and adjusting corresponding processes, the invention rationalizes the process route, realizes the reasonable matching of long and short fibers, improves the product quality, reduces the weight of the finished paper product, improves the physical strength, saves the resources, and greatly reduces the production cost of the gypsum board. The gypsum board mask paper produced by the process has the characteristics of light weight, high strength, attractive appearance and the like, and can completely substitute the imported product.

Owner:TAISHAN GYPSUM CO LTD

Bovine base solution packaging raw paper

The invention relates to a bovine base solution packaging raw paper used in production of liquid packaging boxes. The base solution packaging raw paper comprises a surface layer, a core layer, a base layer and a coating layer and is characterized in that the surface layer comprises chemical hardwood pulp and softwood pulp; the core layer comprises mechanical pulp, chemical hardwood pulp and unbleached pulp; the base layer comprises unbleached pulp; and the coating layer comprises calcium carbonate, porcelain clay, adhesive, a water-retaining agent and a water repellent agent. The base solution packaging raw paper disclosed by the invention has the advantages of environment protection, low cost, high physical strength as well as good decoration property and printing performance of products, accordance with the food requirement and no harm to human bodies, wherein the using amount of chemicals is reduced so that the environment pollution is reduced, and the using amount of chemicals is reduced so that the cost is reduced.

Owner:万国纸业太阳白卡纸有限公司

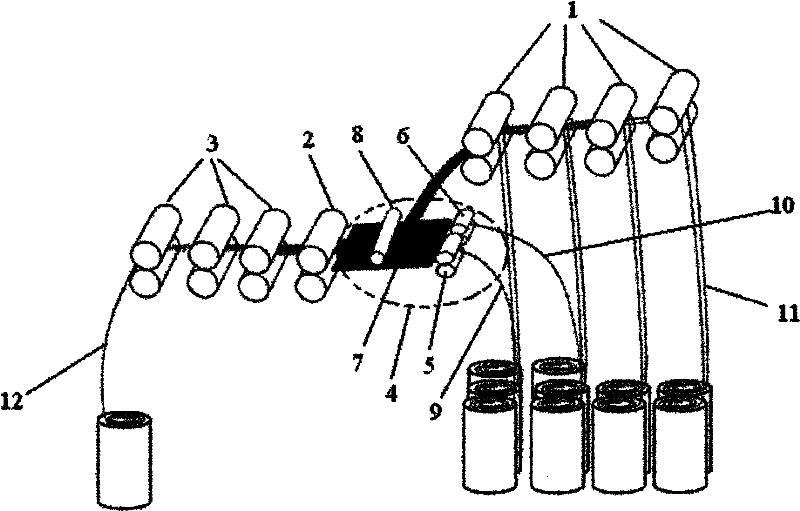

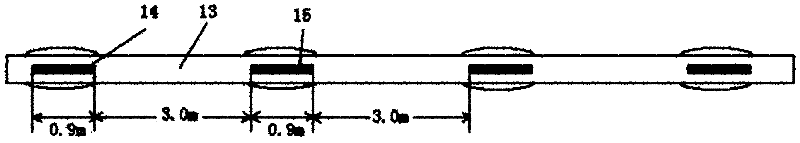

Overhead drawing device for segment colored cotton sliver production and method for segment colored cotton sliver production

ActiveCN102453985AGuaranteed smooth productionSimple structureDrafting machinesYarnYarnPulp and paper industry

The invention belongs to the field of cotton yarn spinning, and relates to an overhead drawing device for segment colored cotton sliver production and a method for segment colored cotton sliver production. The overhead drawing device comprises an overhead guide roller, a cotton feeding roller, a drafting roller and a drawing auxiliary feeder, wherein the overhead guide roller, the cotton feeding roller and the drafting roller are connected sequentially, and the drawing auxiliary feeder is connected with the cotton feeding roller, is positioned between the cotton feeding roller and the overhead guide roller, and is positioned below the overhead guide roller. The method for segment colored cotton sliver production is characterized in that the overhead drawing device is adopted for producing segment colored cotton slivers, and various colors of the produced segment colored cotton slivers change in segmented mode. The overhead drawing device is simple in structure, is easy to control in production and is capable of producing various styles of the segment colored cotton slivers.

Owner:HUAFU FASHION CO LTD

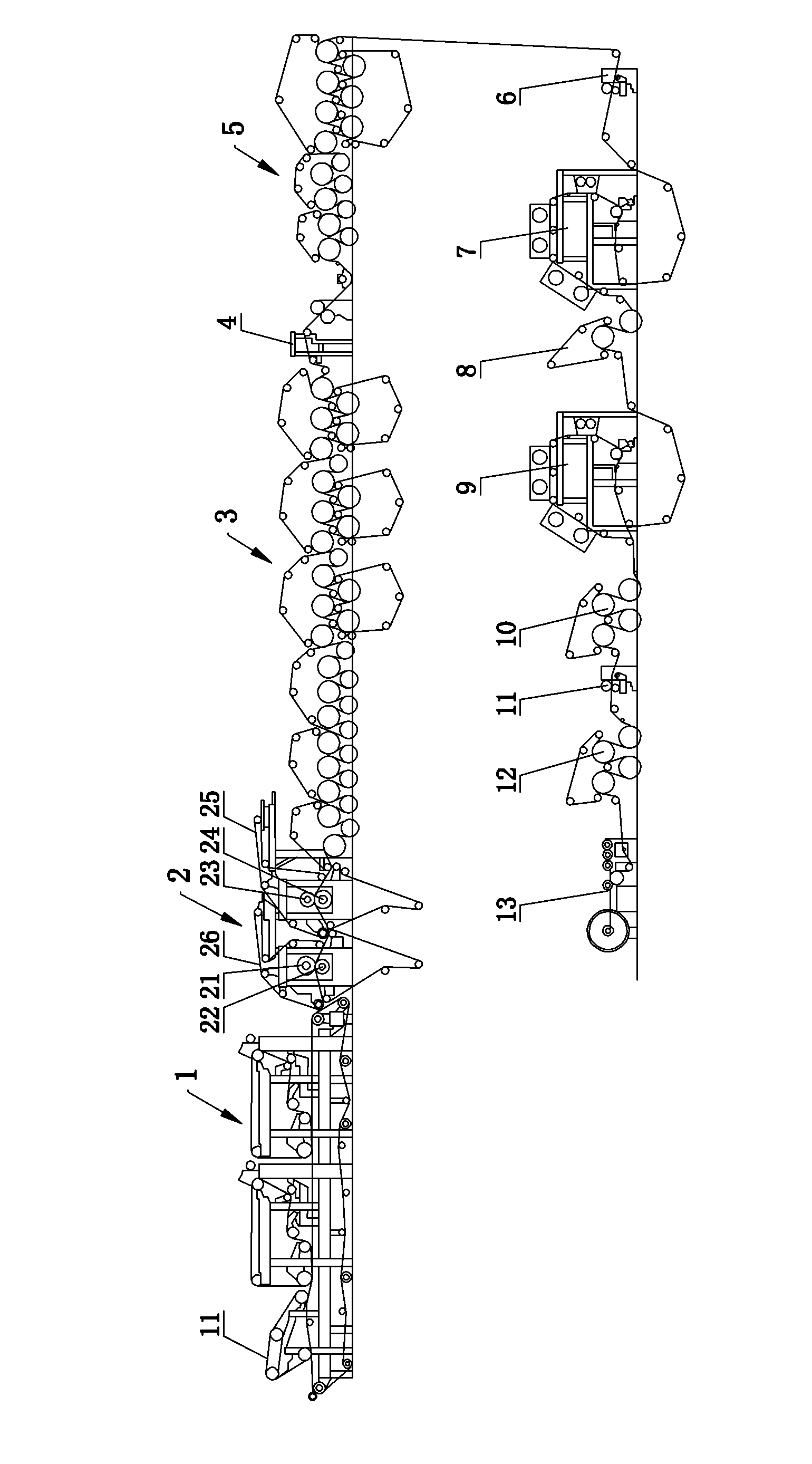

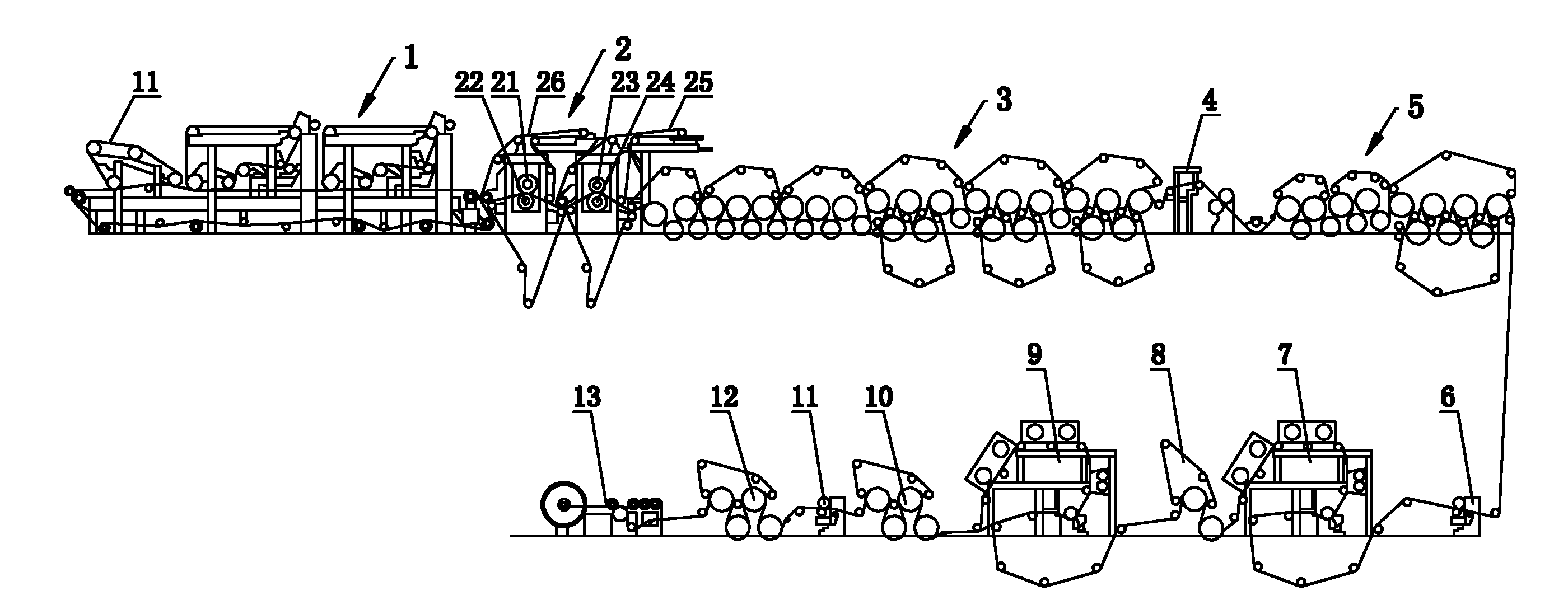

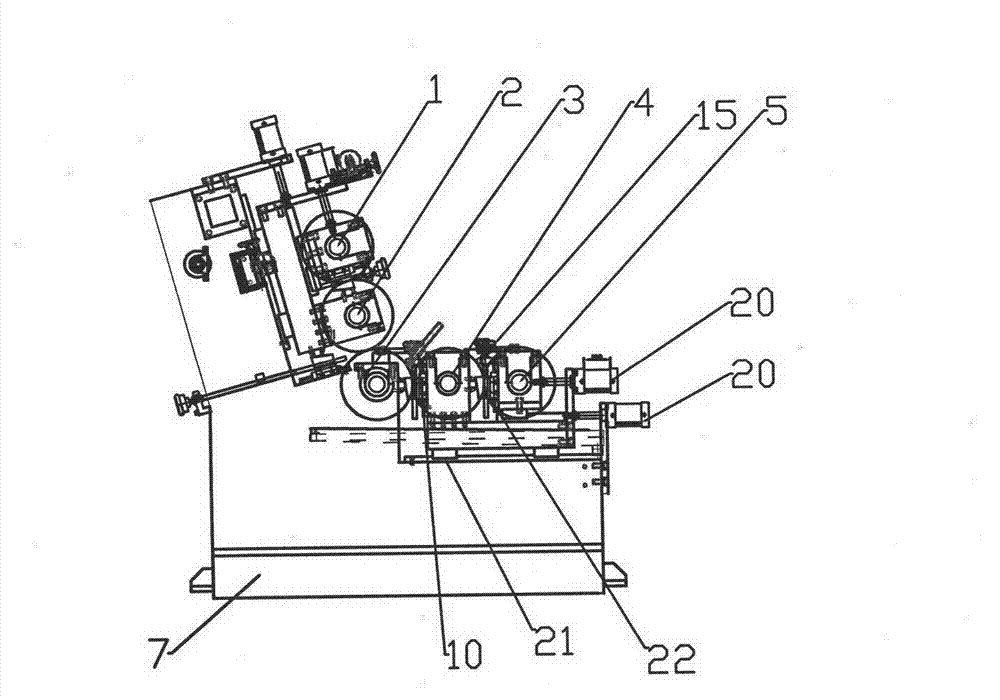

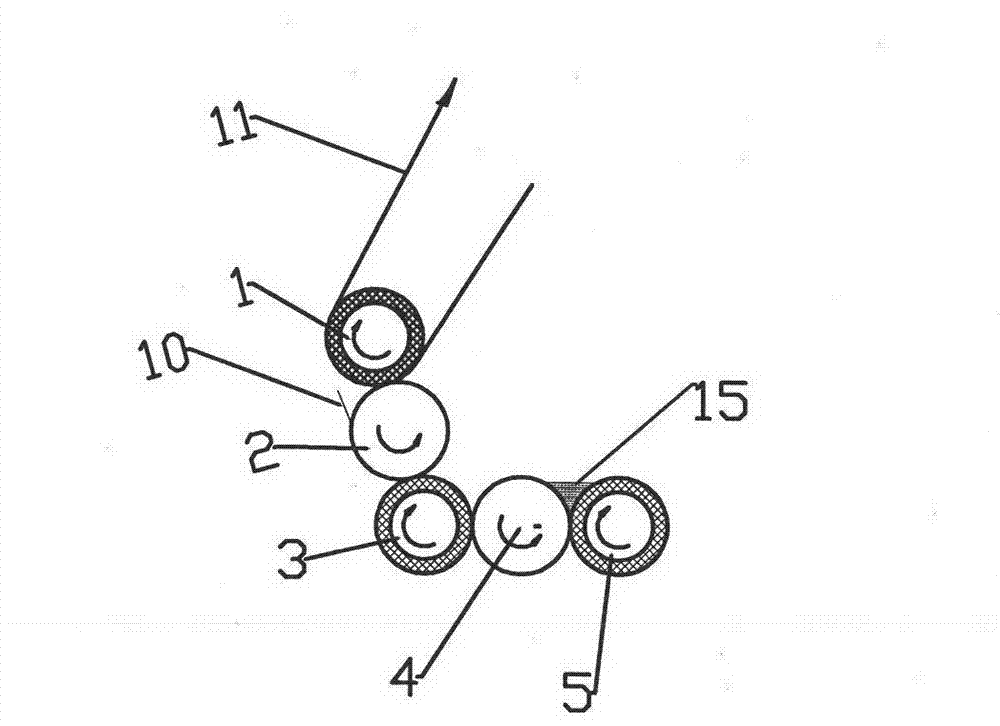

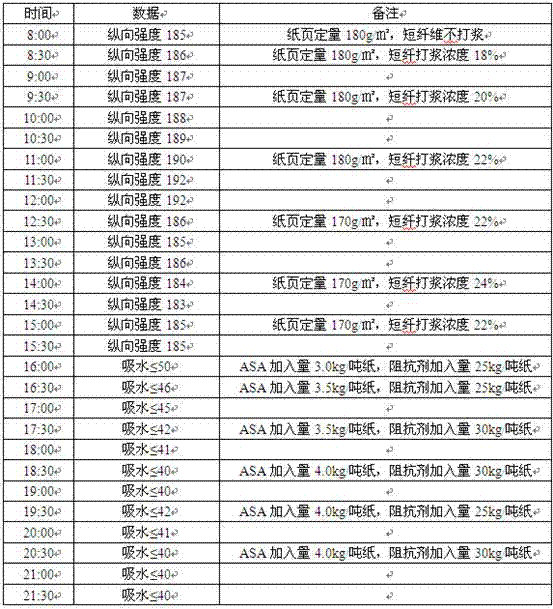

Light-coated kraft production equipment and method

ActiveCN102182098AMeeting the demands of high printing performanceImprove stiffnessSpecial paperPaper/cardboardCardboardSurface layer

The invention discloses light-coated kraft production equipment and a method. The production equipment comprises a triple net forming device, a squeezing device, a front drying device, a film transfer sizing machine, a rear drying device, a hard calendering device, a first scraper coating machine, a first scraper rear drying device, a second scraper coating machine, a second scraper rear drying device, a soft calendering device, a cooling device and a coiling forming device which are sequentially mounted on a rack. In the production of light-coated kraft by adopting the equipment, after the two sides of the original paperboard are sized by the film transfer sizing machine, the ink absorption uniformity of the kraft is improved; and through twice scraper coating, a good coating effect can be obtained at low coating quantity, and the requirement on high printing performance of the kraft can be met; and moreover, the bottom layer, lining layer and surface layer adopt different raw materials as well as proper proportions of raw materials respectively, and the produced light-coated kraft has low ration and high strength.

Owner:SHANDONG CENTURY SUNSHINE PAPER GROUP +1

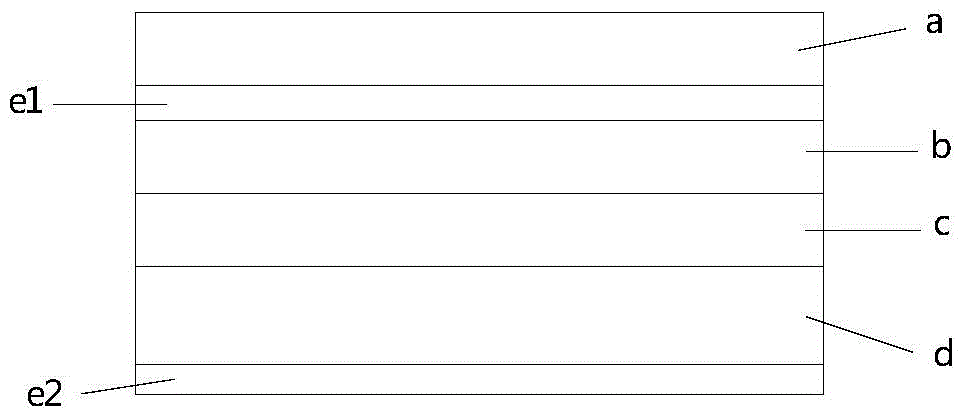

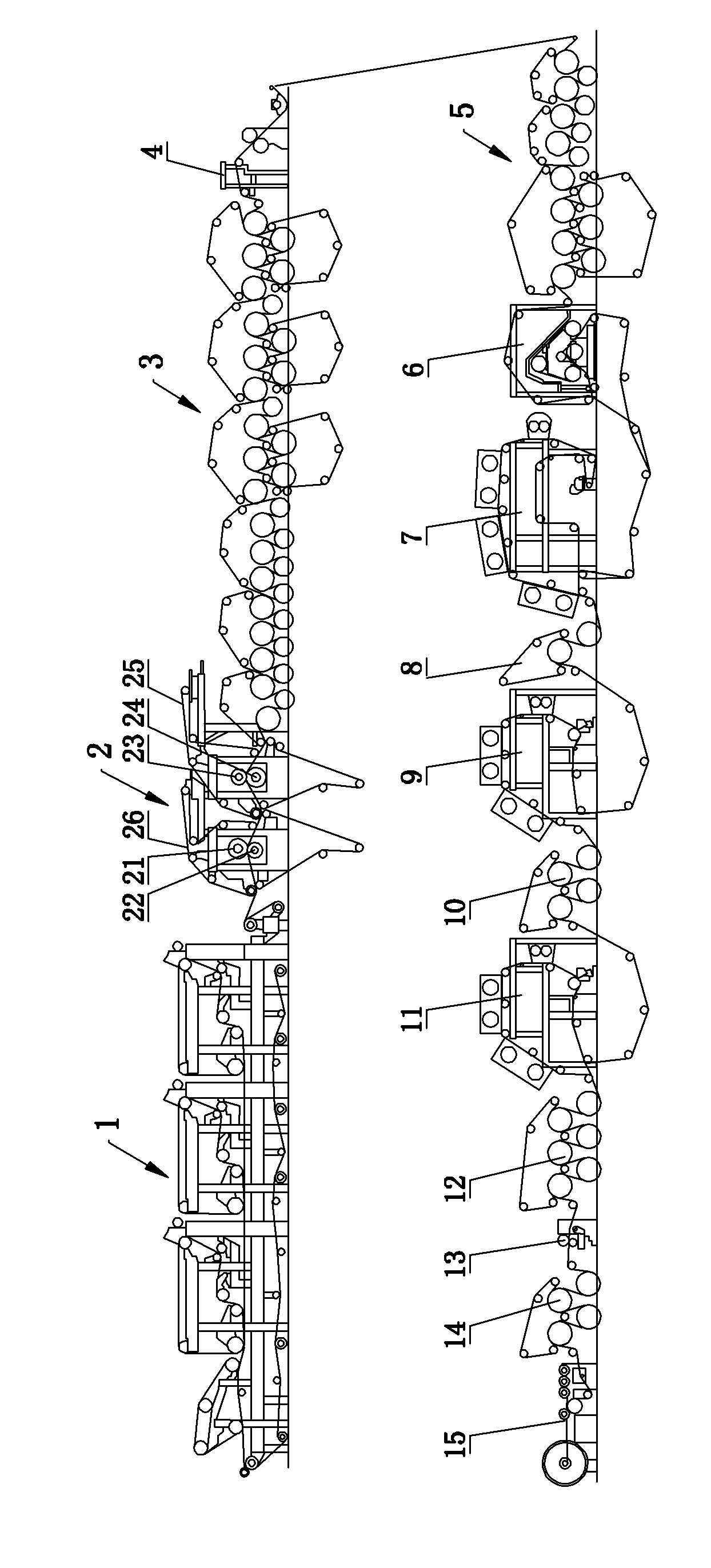

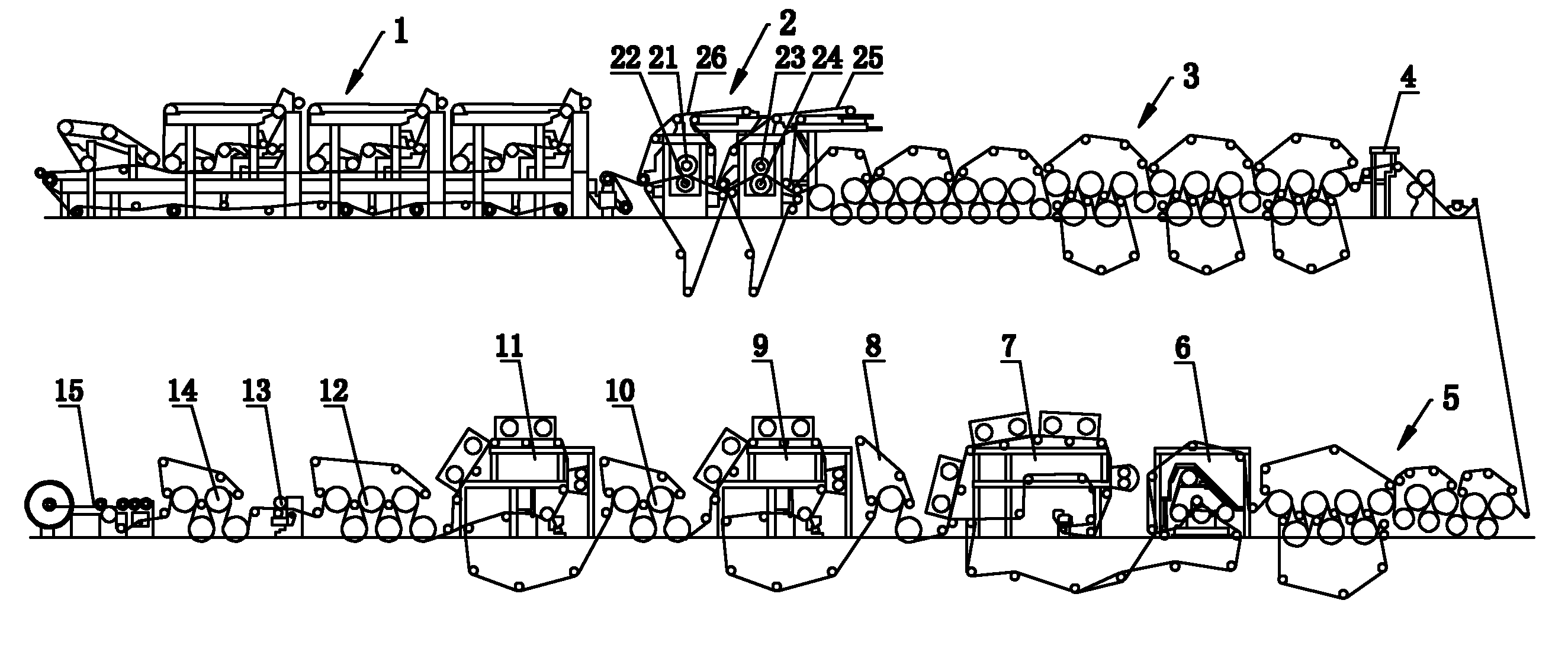

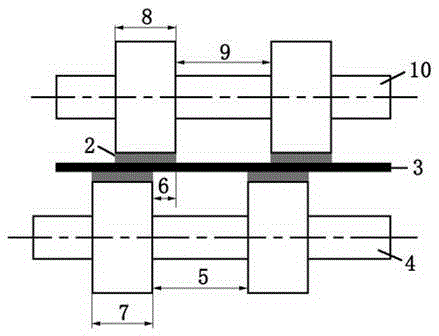

Four-stacked net forming equipment and method for producing coating kraft liner board

InactiveCN102182105AImprove uniformityIncrease coverageSpecial paperPaper coatingSurface layerEngineering

The invention discloses four-stacked net forming equipment and method for producing a coating kraft liner board. The equipment comprises a four-stacked net forming device, a pressing device, a pre-drying device, a surface sizing machine, a post-drying device, a belt calender, a curtain coater, a curtain coating post-drying device, a first blade coater, a first blade coating post-drying device, a second blade coater, a second blade coating post-drying device, a soft calendering device, a cooling device and a coiling forming device which are sequentially arranged on a machine frame. In the invention, When the coating kraft liner board is produced, the sizing is carried out on the surface layer to ensure that the uniformity of absorbing printing ink of the kraft liner board is improved; and during the coating, the respective superiorities of the curtain coating and the blade coating are combined and different raw materials with proper proportions are respectively adopted at the bottom layer, the core layer, the lining and the surface layer to ensure that the produced coating kraft liner board has the advantages of low basis weight, high strength, good bulk and high surface smoothness and can satisfy the requirements for the coating kraft liner board in different printing modes and different fields.

Owner:SHANDONG CENTURY SUNSHINE PAPER GROUP

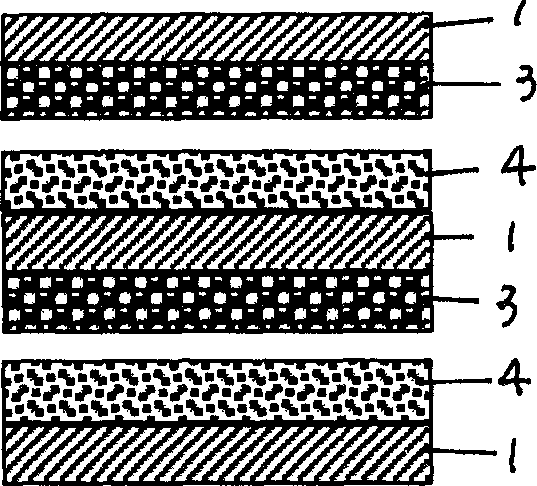

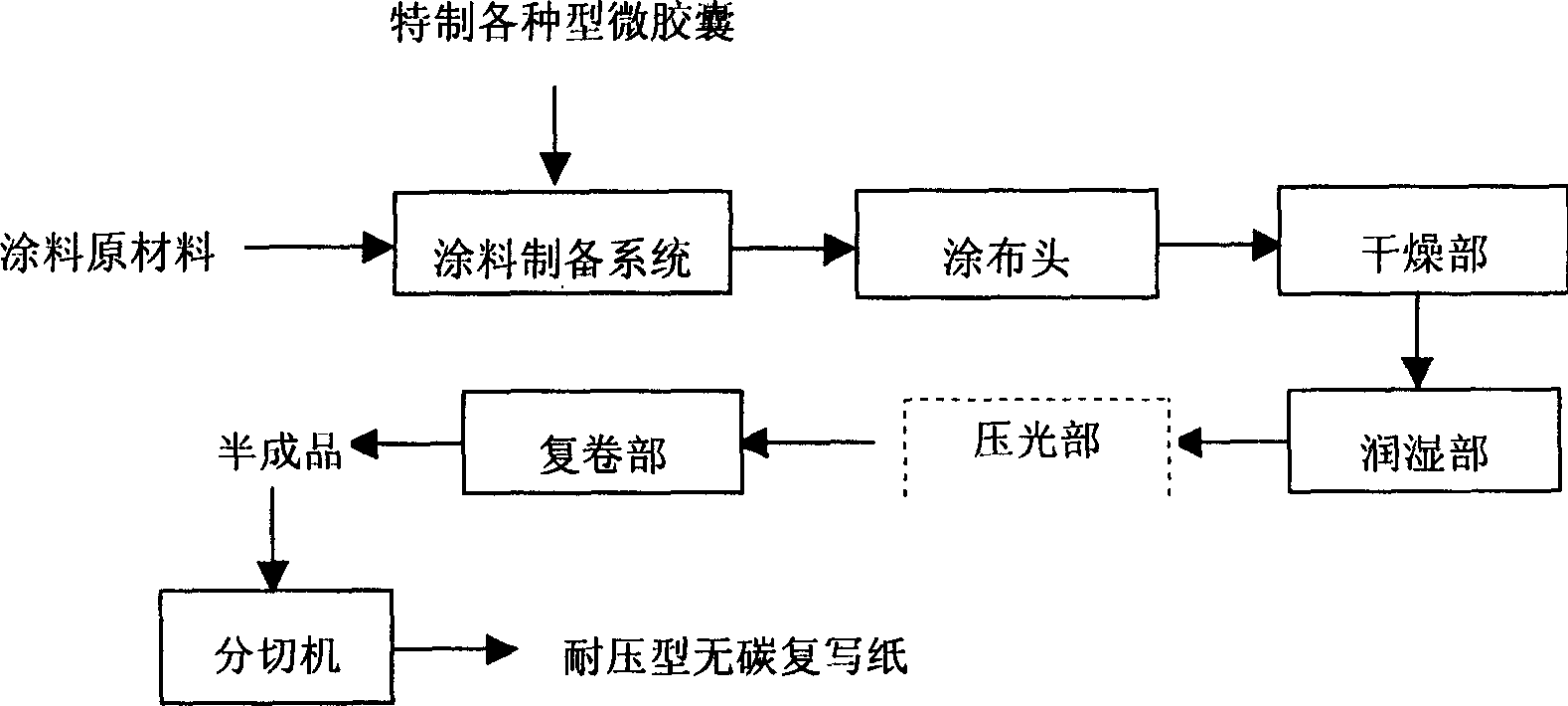

Pressure-resistant carbon-free duplicating paper and production thereof

InactiveCN1779071AImprove stress resistanceHigh opacityPaper/cardboardPaper/cardboard layered productsPulp and paper industryCarbonless copy paper

The invention is about a pressure carbon-free paper and its process. The aim of the invention is to solve the paper turning blue and skew ness in the roll-up printing process. The microcapsule is treated specially in the invention. The mean particle diameters about 3 microns and the opacity are about 75%. So it can be used for the double-sided printing and the word in the printing face is clear.

Owner:GUANGDONG GUANHAO HIGH TECH

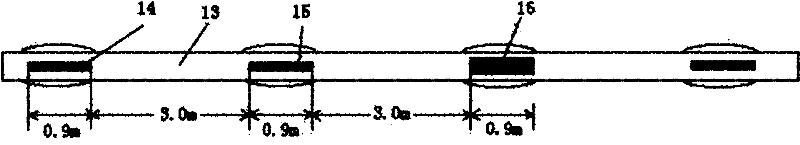

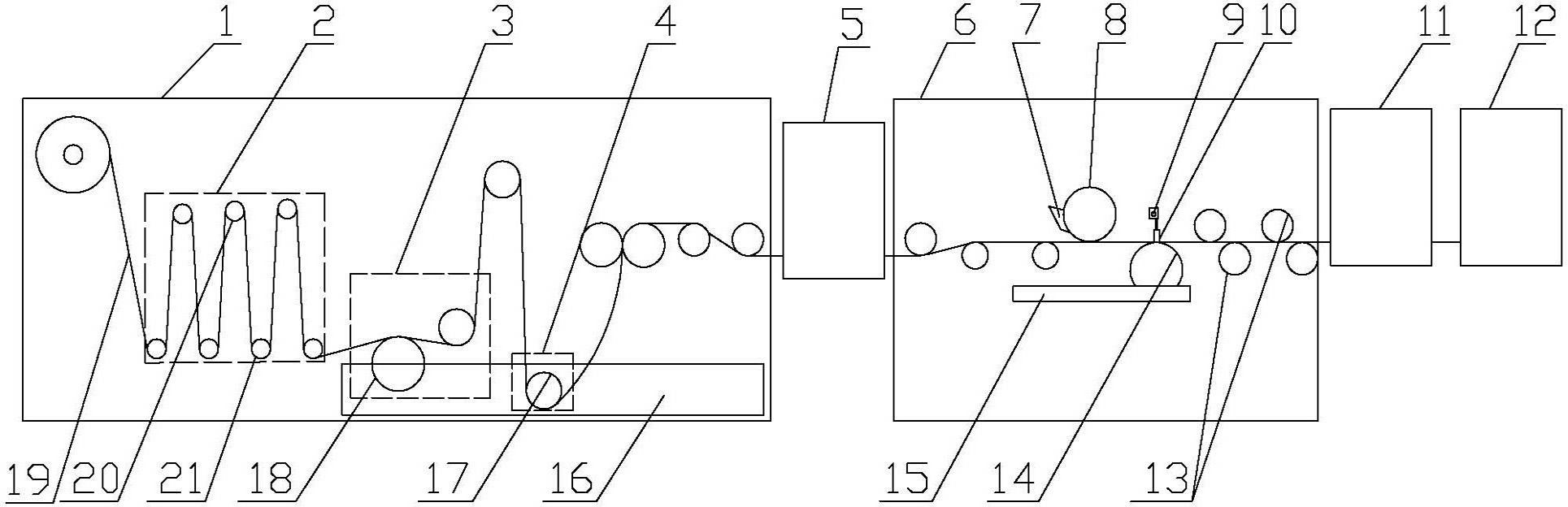

Decorative film coated paper for bamboo veneer and production method and device of decorative film coated paper

ActiveCN102251440AImprove wear resistanceImprove anti-agingNon-fibrous pulp additionSpecial paperAging resistanceRoom temperature

The invention discloses decorative film coated paper for a bamboo veneer, and a production method and a production device of the decorative film coated paper. The decorative film coated paper is prepared from low quantitative raw paper and has high sizing amount. The decorative film coated paper is characterized in that: the decorative film coated paper is prepared from raw paper (19) by primary sizing, primary drying, secondary sizing, secondary drying, shearing and packing through the production device of the decorative film coated paper; the surface sizing amount of the raw paper (19) is 140 to 180g / m<2>; and after the raw paper is stored at the room temperature of below 30 DEG C for 90 days and the abrasion resistance reaches 380 revolutions, the base of the raw paper is not exposed. The process is simple, the quantification of the raw paper is light, the produced product has good surface finishment and flatness, the board has good abrasion resistance, ageing resistance and corrosion resistance, and the storage time of the product is greatly prolonged.

Owner:益阳桃花江竹业发展有限公司

Production process of low-ration high-strength waterproof plaster board mask paper

ActiveCN101824765AGuaranteed lengthAvoid cutsCellulosic pulp after-treatmentSpecial paperFiberPulp and paper industry

The invention discloses a production process of low-ration high-strength waterproof plaster board mask paper, comprises the three steps of material preparation, pulp production and paper making. National waste newspaper, imported American wastepaper and various addictives are added according to a certain ratio and can be adjusted by corresponding processes, so that the invention has reasonable process path, realizes reasonable matching of long and short fibers, improves the quality of products, reduces the paper ratio of finished products, improves the physical strength, also saves resources, and greatly reduces the production cost of a plaster board. The plaster board mask paper produced by using the process has the characteristics of low ratio, high strength, favorable fireproof performance, attractiveness and the like and can completely replace imported products.

Owner:TAISHAN GYPSUM CO LTD

Acoustic insulation interlaced fabric

InactiveCN101187110ASimple processing technologyImprove weaving efficiencyNon-woven fabricsFiberFiberglass mesh

The invention provides a brand new weaving concept and method of sound insulation non-woven cloth, which adopts non-woven production technique and outputs fiber glass net after mechanic carding on the short fiber with length between 35mm and 68mm of the fiber glass. The invention has simple process and high weaving efficiency, improves the production value of the product, and uses the fiber glass, the hollow ceiba fiber and bamboo fiber as materials, and has light ration, excellent property and good economy and social benefit.

Owner:SHENGHONG GRP CO LTD

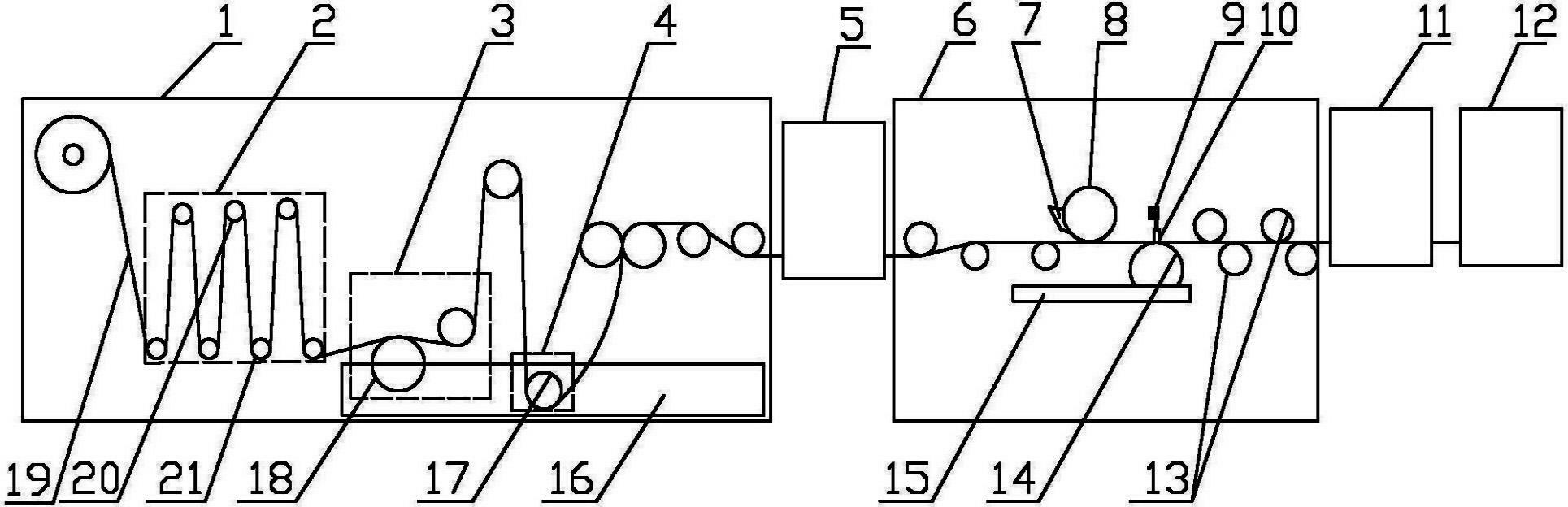

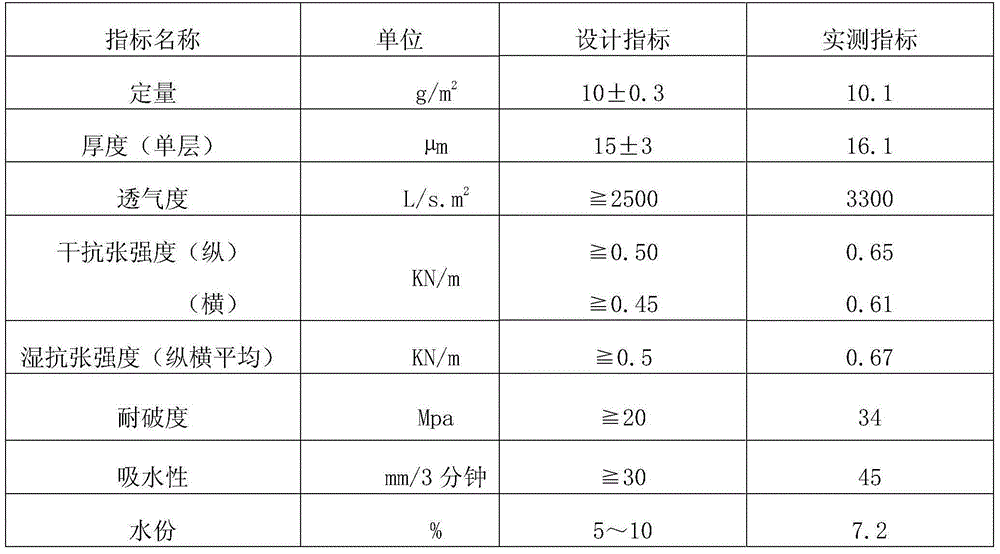

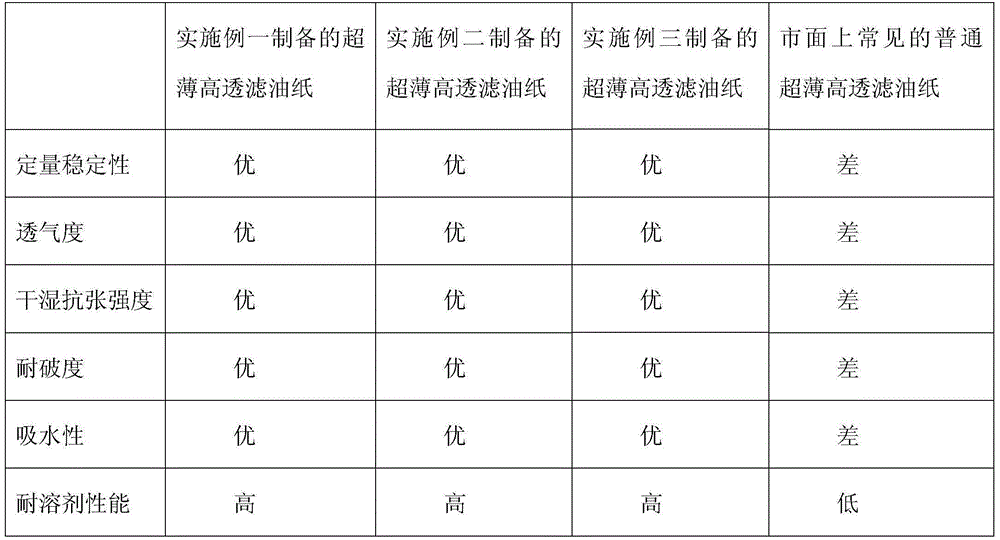

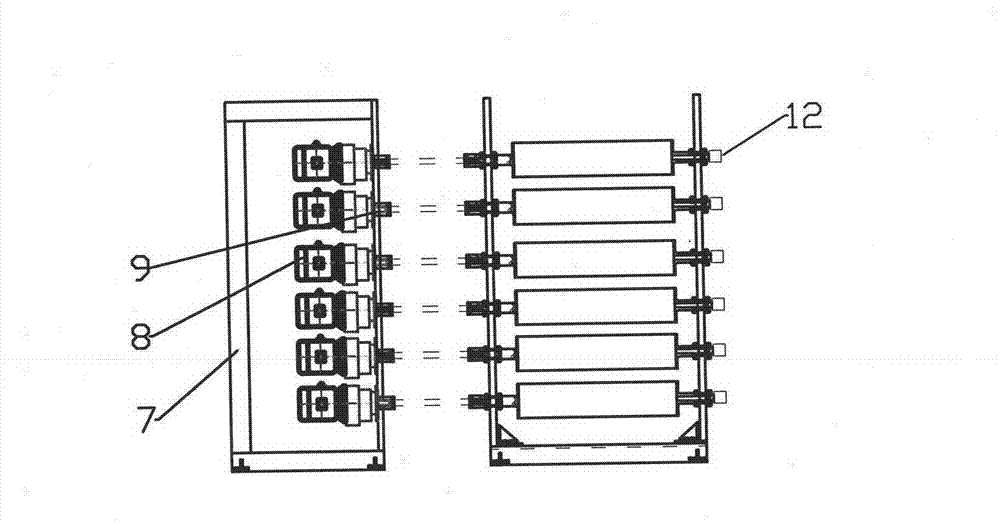

Ultrathin high-permeability oil filter paper and production method thereof

ActiveCN105220573AQuantitative lowQuantitatively stableReinforcing agents additionPaper/cardboardPapermakingFilter paper

The invention relates to an ultrathin high-permeability oil filter paper and a preparation method thereof. The filter paper is prepared with the raw materials of hemp pulp, chemical fiber, a wet strength agent and bamboo charcoal powder. Through the steps of pulp beating treatment, auxiliary agent addition, bamboo charcoal powder addition, papermaking and cutting, the ultrathin high-permeability oil filter paper is obtained. The filter paper and the production method have the following advantages: the produced ultrathin high-permeability oil filter paper is ultrathin and has low basis weight; the produced paper has stable basis weight, high air permeability, good filtering and absorption performance, good dry and wet strength, good bursting strength, good high-temperature resistance, good folding endurance, good acid and alkali resistances, good solvent resistance, and good application effect. The filter paper and the production method are suitable for popularization.

Owner:ZHEJIANG HUITONG ADVANCED MATERIALS CO LTD

Low basis weight damp-proof coated white board and preparation method thereof

InactiveCN106436477AHigh strengthSlightly highFlexible coversCoatings with pigmentsWhiteboardPolymer science

The invention discloses a low basis weight damp-proof coated white board which comprises a coated base paper board and a damp-proof coating layer. By adding of a moisture proof agent into surface pulp and prime pulp of the base paper board and coating of the surface with the damp-proof coating layer, the damp-proofing function can be cooperatively realized. The invention further discloses a preparation method of the damp-proof white board. The preparation method comprises the following steps: (1) slurry preparation, (2) dehydration and forming, (3) squeezing, (4) pre-drying, (5) coating, (6) after-drying, and (7) splitting. The white board prepared based on the preparation method is high in printing surface intensity and physical intensity and high in damp-proofing property; a user product is light in weight, and the packaging cost of a user is reduced; the production cost and the transportation cost of an enterprise are reduced; the market competitiveness is enhanced.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

Solvent-free silicon coating machine

InactiveCN102773195AQuantitative lowImprove the lubrication effectLiquid surface applicatorsCoatingsCouplingSolvent free

The invention discloses a solvent-free silicon coating machine, which is characterized by comprising a coating body and a transmission mechanism. The transmission mechanism comprises a rack, a gear speed-reducing variable frequency motor and a universal coupling section; the coating body comprises five or size roller wheels, a gap adjusting mechanism and a sliding mechanism; the coating body is connected with the transmission mechanism through the universal coupling section; and the gear speed-reducing variable frequency motor and the roller wheels are mounted on the rack. The solvent-free silicon coating machine provided by the invention has the advantage that the requirement on low-quantitative solvent-free silicon coating can be realized.

Owner:刘新会

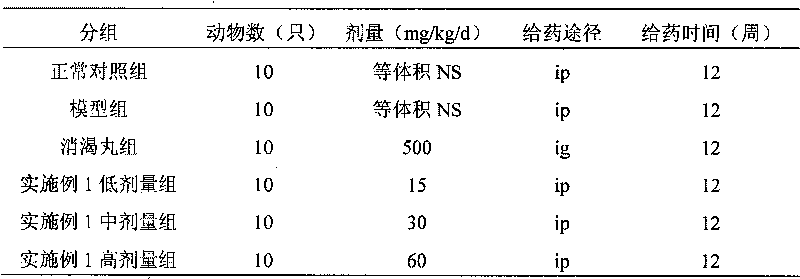

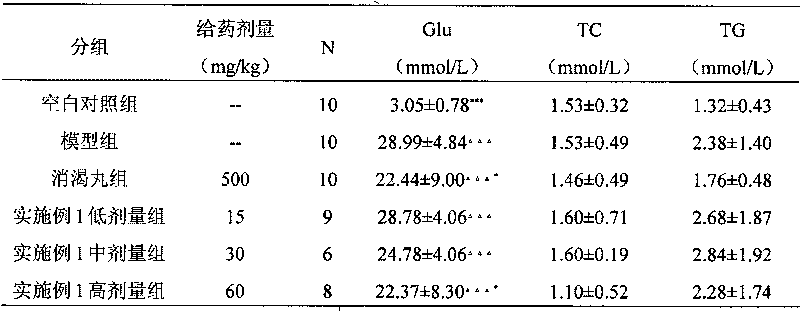

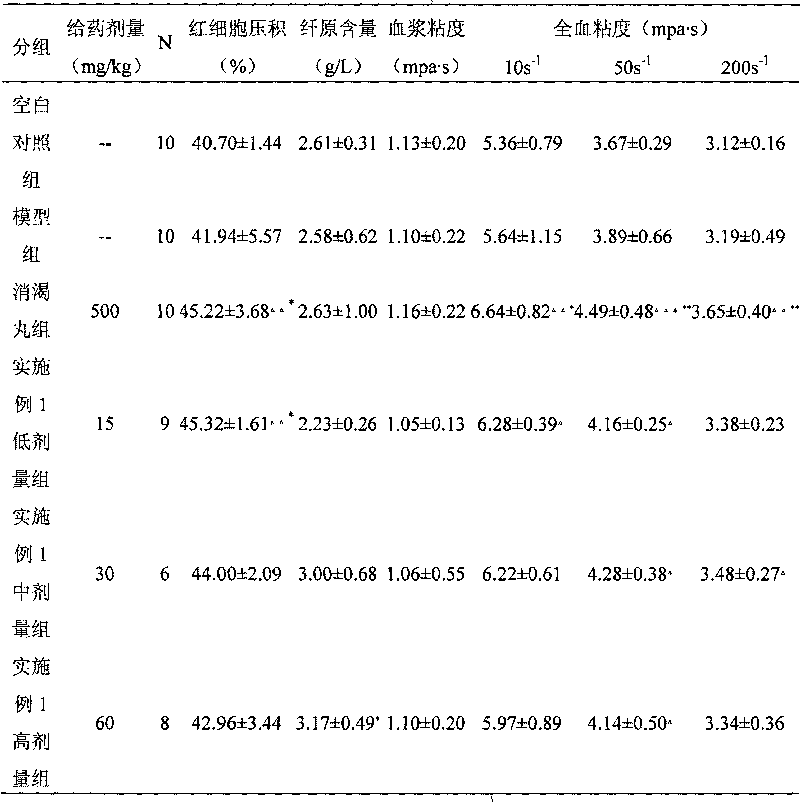

Application of pseudo-ginseng and extract thereof in preparing medicament for curing and/or preventing diabetic microangiopathies

ActiveCN101700265AImprove high viscosity stateImprove hypoxia toleranceMetabolism disorderUrinary disorderPANAX NOTOGINSENG ROOTPanax notoginseng extract

The invention relates to a new application of pseudo-ginseng, pseudo-ginseng extract, panax notoginseng saponins, and panax notoginseng saponins composite, namely, a new application in preparing medicament for curing and / or preventing diabetic microangiopathies.

Owner:许淑清

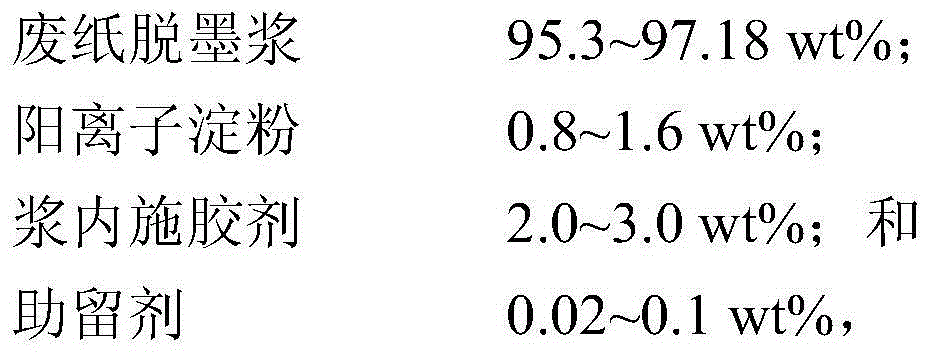

Production process of low-basis-weight damp-proof waterproof coveying paper

InactiveCN107313300ASave raw materialsReduce consumptionSurface covering paperWater-repelling agents additionHigh concentrationState of art

The invention relates to a production process of low-basis-weight damp-proof waterproof coveying paper, which belongs to the technical field of the preparation of gypsum board coveing paper, and can solve the problems in the prior art that the performance of the gypsum board coveing paper is influenced and the cost is high due to the addition of additives in the gypsum board coveing paper production process. The production process comprises two steps, i.e. pulping and papermaking, wherein in a papermaking OCC production line, a process for pulping short fibers at a high concentration is adopted, the papermaking adopts four-layer mesh composite molding, deinked pulp is smeared on a surface layer, four layers of pulp are injected onto a four-layer molding mesh by virtue of a pulp flowing box, then the pulp is subjected to one vacuum pressing, twice large-roller pressing, primary drying, surface gluing, later drying and winding, and finally the pulp is rewound into paper rolls with different specifications by virtue of a rewinding machine. The production process saves the energy, reduces the pollution, improves the paper strength, reduces the basis weight of the paper, and improves the damp-proof and waterproof characteristics of the paper.

Owner:山西强伟纸业有限公司

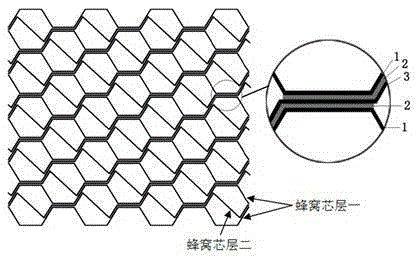

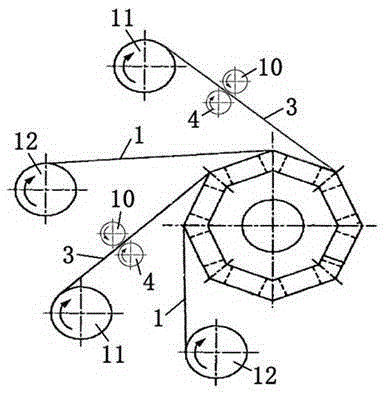

Honeycomb paper core innovation structure and core paper gluing technique

InactiveCN105415762AQuantitative lowHigh compressive strengthLaminationLamination apparatusHoneycombPulp and paper industry

The present invention relates to a honeycomb paper core innovation structure and a core paper gluing technique. The structure is characterized by consisting of honeycomb core layers I and honeycomb core layers II which are made of different materials; the honeycomb core layers II are staggered; and the shape of the honeycomb core layers II in honeycomb cells is determined by the adhesion size. The honeycomb core paper adhesion technique can be implemented in two ways. According to the adhesion technique in the first way, front and reverse surfaces of the two rolls of honeycomb core paper II are glued in a staggered manner, and the two rolls of honeycomb core paper I are respectively glued and compounded with the two rolls of honeycomb core paper II through an octagonal drum to obtain core paper. According to the adhesion technique in the second way, the first layer of the honeycomb core paper I is not glued, after being glued respectively in a staggered manner, the following three honeycomb core layers are respectively adhered to the previous honeycomb core layers, and then the last layer is glued in a staggered manner, and is glued to the previous cutting unit after being cut off by a cutter so as to form continuous core paper. Compared with the original process, the honeycomb paper core gluing technique provided by the present invention is seldom changed, and has the advantages of convenience in design, reasonable structure, high strength, easiness in material selection, simplicity, low cost and the like.

Owner:TIANJIN VOCATIONAL INST

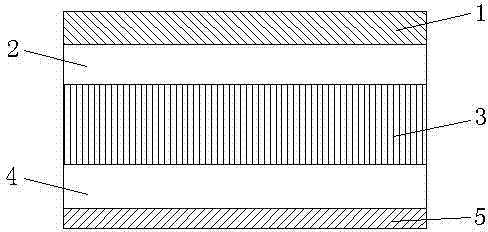

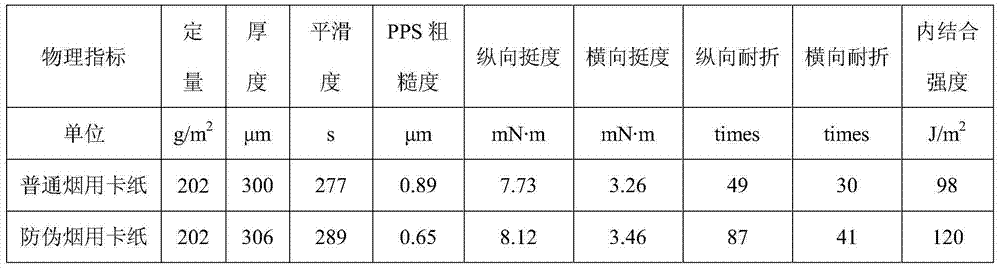

Paperboard for anti-counterfeit cigarette

InactiveCN103790069AIncrease bulkAchieve anti-counterfeiting effectCoatings with pigmentsSpecial paperSurface layerPaperboard

The invention discloses a paperboard for an anti-counterfeit cigarette. The paperboard comprises a surface layer, a core layer and a bottom layer, wherein the surface layer is bleached chemical wood pulp, the core layer is chemi-mechanical pulp and bleached chemical wood pulp, and the bottom layer is bleached chemical wood pulp and unbleached pulp. The bleached chemical wood pulp in the surface layer comprises 30-50% of bleached chemical softwood pulp and 50-70% of bleached chemical hardwood pulp in percentage by weight. The core layer comprises 60-90% of the chemi-mechanical pulp and 10-40% of the bleached chemical wood pulp in percentage by weight. The bottom layer comprises 60-95% of the bleached chemical wood pulp and 5-40% of the unbleached pulp in percentage by weight. According to the paperboard disclosed by the invention, as the bottom layer adopts the unbleached pulp and the bleached chemical pulp, paperboards in different colors can be obtained by adjusting the proportion of the unbleached pulp and the bleached chemical wood pulp so as to realize the anti-counterfeit effect. The paperboard is not easy to simulate. The paperboard disclosed by the invention is small in investment, and the production cost can be greatly lowered.

Owner:万国纸业太阳白卡纸有限公司

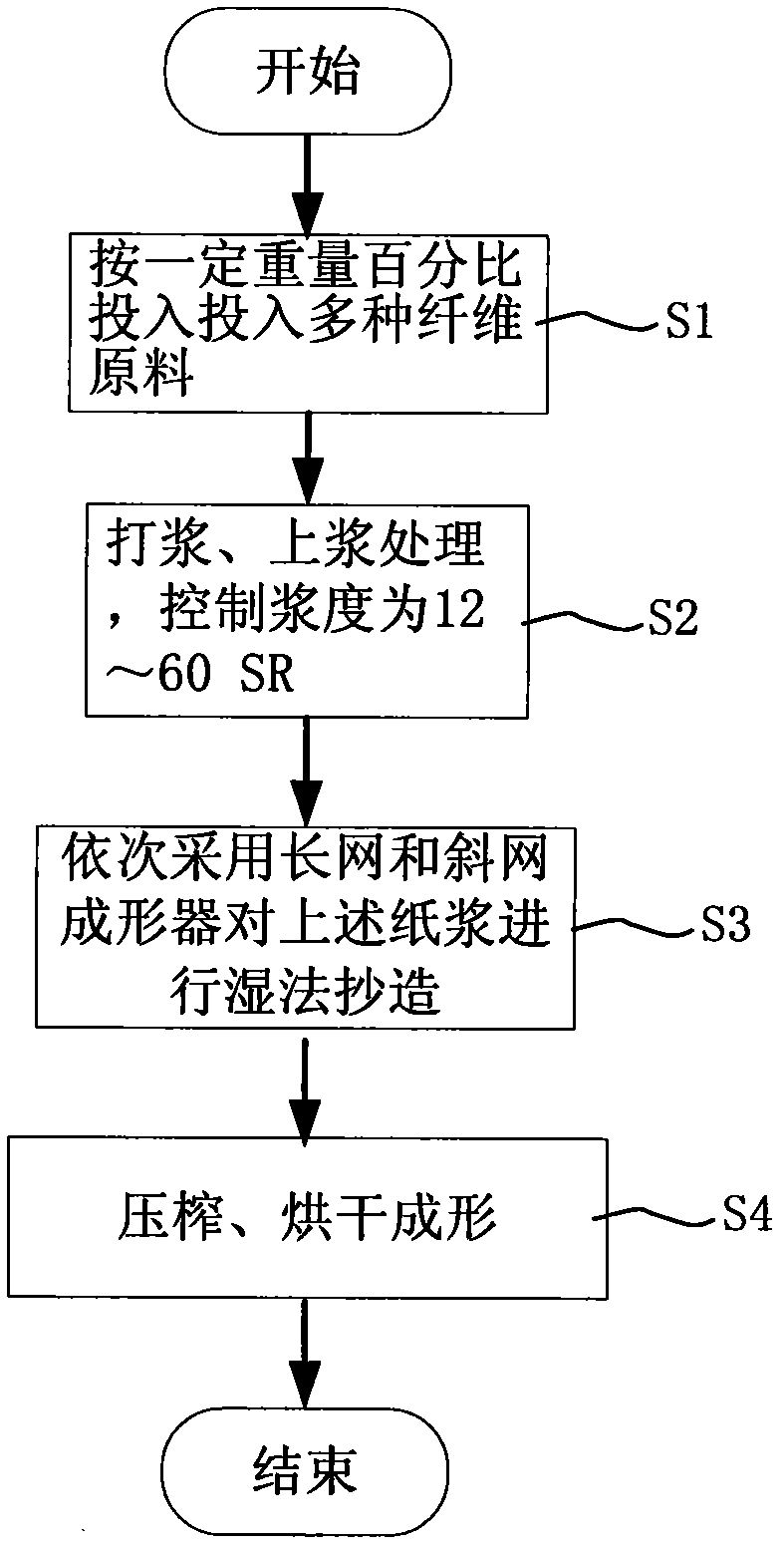

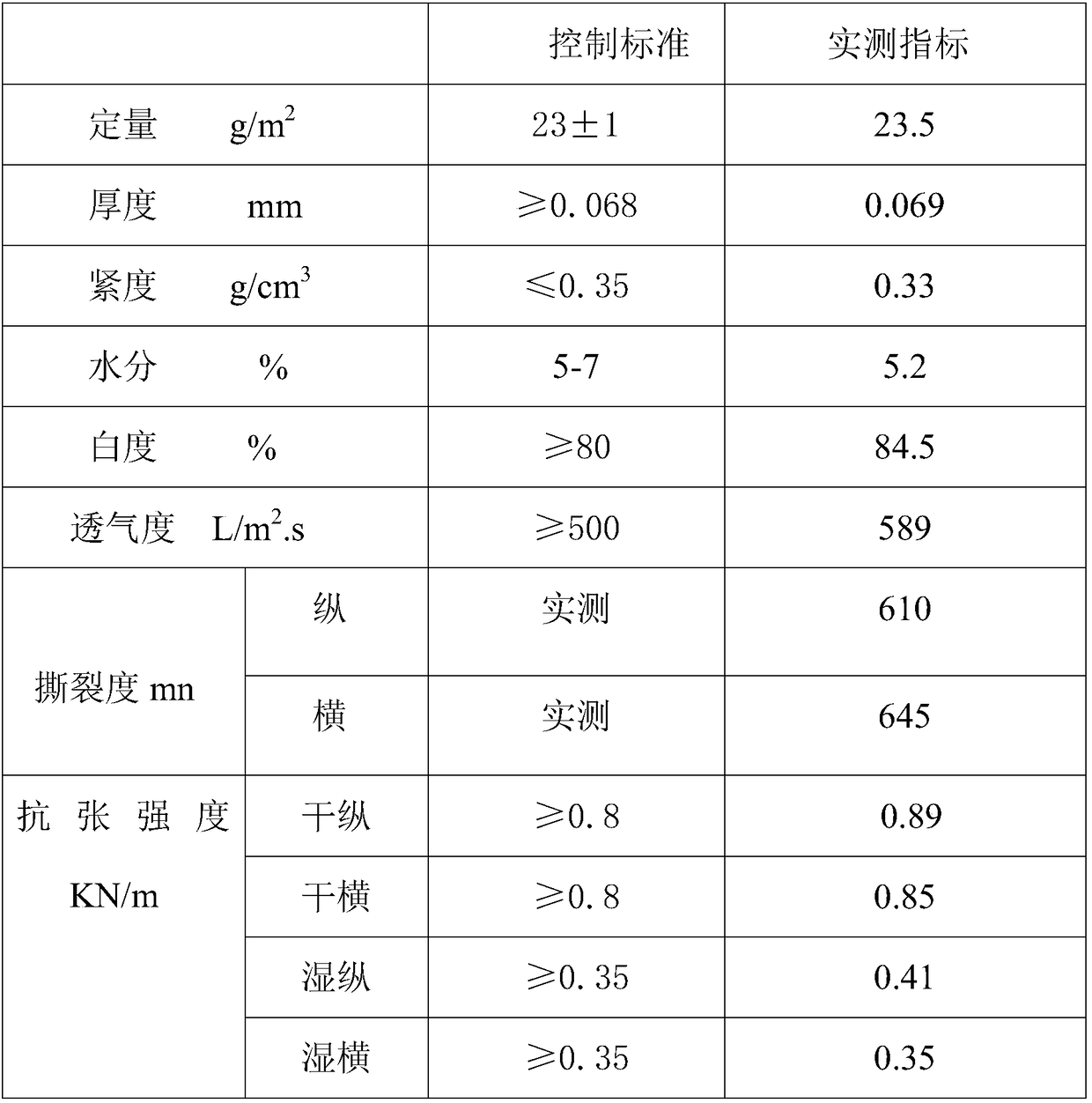

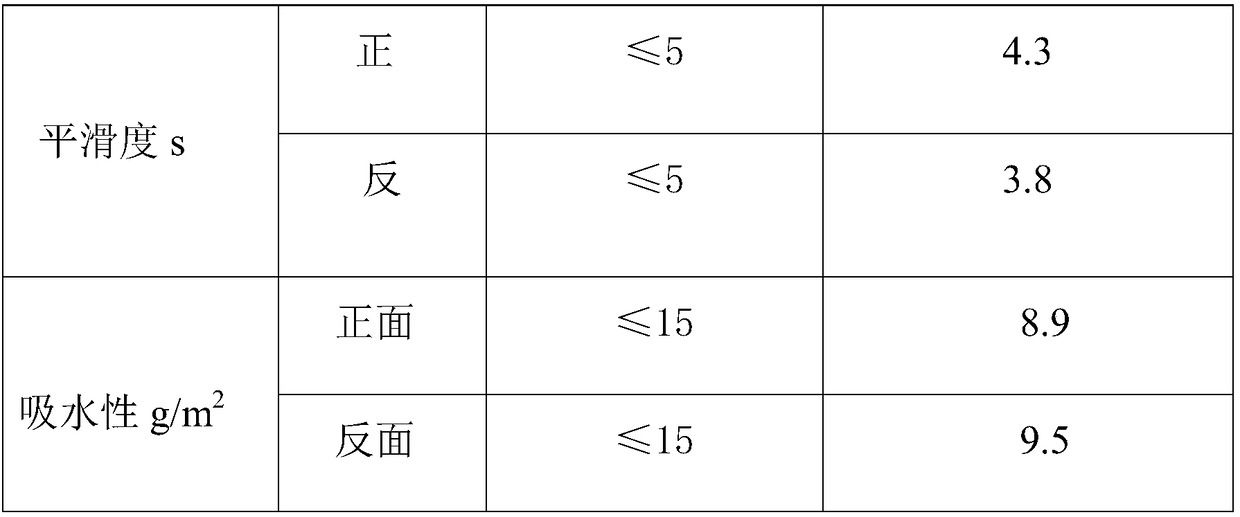

Colloidal gold immune matched water absorbent material and preparation method thereof

ActiveCN102619131AQuantitative lowImprove uniformityInorganic fibres/flakesPaper/cardboardPapermakingFiber

The invention discloses a colloidal gold immune matched water absorbent material and a preparation method thereof. The water absorbent material comprises the following compositions in percentage by weight: 20 to 80 percent of wood fiber, 10 to 40 percent of cotton fiber and 10 to 40 percent of special fiber. By the colloidal gold immune matched water absorbent material and the preparation method thereof, different pulps are blended and subjected to wet papermaking by combining a fourdrinier former and an inclined wire former, so that the colloidal gold immune matched water absorbent material with relative low weight and high uniformity is produced, and the cost is greatly reduced on the premise of meeting the requirement on accuracy of test paper for quick detection.

Owner:HANGZHOU XINHUA GROUP

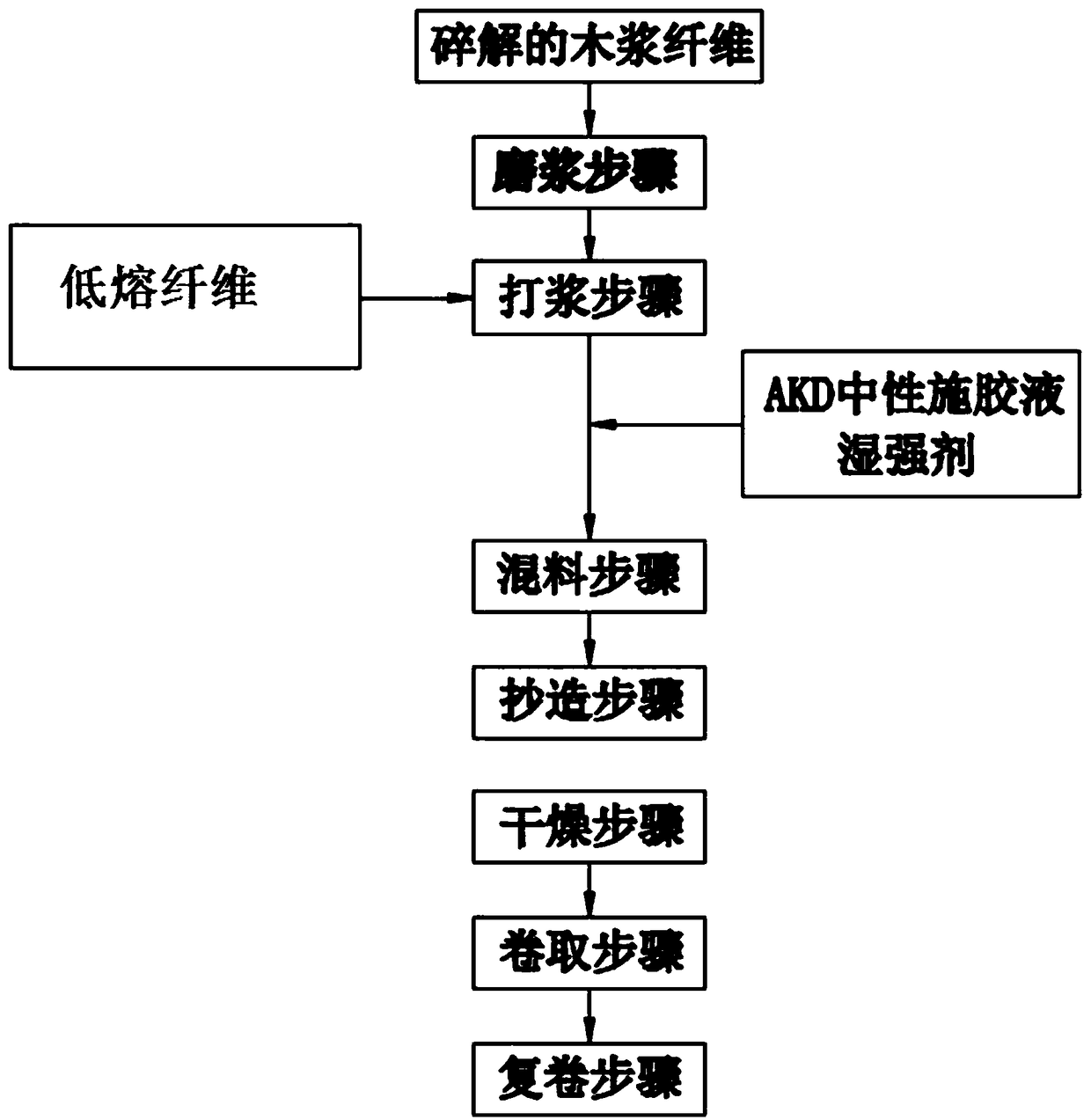

High-permeable medical adhesive tape base material and preparation method thereof

ActiveCN108914670AStrong air permeabilityStrong wrinkle resistanceWater-repelling agents additionPulp beating methodsPolyesterPunching

The invention discloses a high-permeable medical adhesive tape base material and a preparation method thereof. The adhesive tape base material comprises wood pulp fibers, polyester fibers, low meltingfibers, AKD neutral sizing liquid and wet strength agent liquid. The preparation method comprises a pulping step, a papermaking step, a drying step and a reeling step. In the pulping step, the AKD neutral sizing liquid and the wet strength agent liquid are added to a pulping pool and uniformly mixed. The high-permeable medical adhesive tape base material is prepared by mixing and pulping treatment of pure plant fibers and synthetic fibers through papermaking of a papermaking machine, and has the advantages of softness and loosening, homogeneous fibers, high air permeability, strong wrinkle resistance, easy-tearing while a product meets strength, uniform gluing and the like. The high-permeable medical adhesive tape base material is directly formed through adhesion between the fibers and melted adhesion without surface gluing reinforcement treatment, simple in processing technology, and low in manufacturing cost, and is a substitute good of a current medical cloth-based base material and a punching PE base material. Along with continuous improvement of human health requirements, a demand gap is large, and market prospect is extremely extensive.

Owner:山东杰高新材料科技(集团)有限公司

Preparation method of mixed material bleached chemimechanical pulp

InactiveCN108071041AIncrease resourcesIncrease bulkPretreatment with water/steamPretreatment with alkaline reacting compoundsWastewaterSlurry

The invention discloses a technique for preparing acacia and poplar mixed material bleached chemitmechanical pulp. The technique is mainly characterized in that a pulping mode in which magnesium basereplaces part of soda is that an additive bleaching accelerator is added into presoaking and bleaching liquid, and a disulfonic acid liquid brightening agent is added into a cooling helical inlet to improve the pulping and bleaching effect of an acacia and poplar mixed material, so that the slurry quality is improved. The high-yield pulp produced by the technique is higher in loose thickness, higher in light-scattering coefficient, higher in pulping yield, lower in pulping cost and lower in COD content in discharged wastewater. Adaptive materials produced from the high-yield pulp are wider inapplication range.

Owner:YUEYANG FOREST & PAPER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com