Paperboard for anti-counterfeit cigarette

A technology for cardboard and cigarettes, which is applied in the field of papermaking, can solve problems such as increased production costs, low anti-counterfeiting function, and complicated equipment, and achieve the effects of improving the use effect, high anti-counterfeiting effect, and improving physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

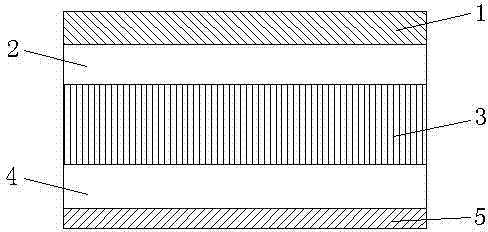

[0022] The anti-counterfeit cigarette cardboard of this embodiment includes a surface layer 2 , a core layer 3 , a bottom layer 4 , a coating layer 1 and a rubber layer 5 .

[0023] The surface layer is made of bleached chemical hardwood pulp and bleached chemical softwood pulp. The weight percentage of bleached chemical hardwood pulp is 50%, and the freeness is 390csf; the weight percentage of bleached chemical softwood pulp is 50%, and the freeness is 380csf.

[0024] The core layer is made of chemical mechanical wood pulp and bleached chemical hardwood pulp. The weight percentage of chemical mechanical wood pulp is 90%, and the freeness is 370csf; the weight percentage of bleached chemical hardwood pulp is 10%, and the freeness is 390csf.

[0025] The bottom layer is bleached chemical softwood pulp, bleached chemical hardwood pulp and natural color pulp. The weight percent of bleached chemical softwood pulp is 5%, and the freeness is 390csf; the weight percent of chemical...

Embodiment 2

[0035] The anti-counterfeiting cigarette cardboard in this embodiment includes a surface layer 2 , a core layer 3 , a bottom layer 4 , a coating layer 1 and a rubber layer 5 .

[0036] The surface layer is made of bleached chemical hardwood pulp and bleached chemical softwood pulp. The weight percentage of bleached chemical hardwood pulp is 60%, and the freeness is 380csf; the weight percentage of bleached chemical softwood pulp is 40%, and the freeness is 380csf.

[0037] The core layer is made of chemical mechanical wood pulp and bleached chemical hardwood pulp. The weight percentage of chemical mechanical wood pulp is 80%, and the freeness is 360csf; the weight percentage of bleached chemical hardwood pulp is 20%, and the freeness is 380csf.

[0038] The bottom layer is bleached chemical softwood pulp, bleached chemical hardwood pulp and natural color pulp. The weight percentage of bleached chemical softwood pulp is 5%, and the freeness is 380csf; the weight percentage of...

Embodiment 3

[0047] The anti-counterfeiting cigarette cardboard in this embodiment includes a surface layer 2 , a core layer 3 , a bottom layer 4 , a coating layer 1 and a rubber layer 5 .

[0048] The surface layer is made of bleached chemical hardwood pulp and bleached chemical softwood pulp. The weight percentage of bleached chemical hardwood pulp is 65%, and the freeness is 390csf; the weight percentage of bleached chemical softwood pulp is 35%, and the freeness is 380csf.

[0049] The core layer is made of chemical mechanical wood pulp and bleached chemical hardwood pulp. The weight percentage of chemical mechanical wood pulp is 70%, and the freeness is 370csf; the weight percentage of bleached chemical hardwood pulp is 30%, and the freeness is 380csf.

[0050] The bottom layer is bleached chemical softwood pulp, bleached chemical hardwood pulp and natural color pulp. The weight percentage of bleached chemical softwood pulp is 10%, and the freeness is 380csf; the weight percentage o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com