Fibrous web of paper or board and method of making the same

A technology of fiber webs and webs, applied in the field of multi-layer cardboard, known to prepare fiber webs, can solve the problems of densification, high drying shrinkage, reduction of paper machine speed and productivity, and increase of energy required for drying. Achieve the effect of less quality change, improved uniformity, and good weight structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

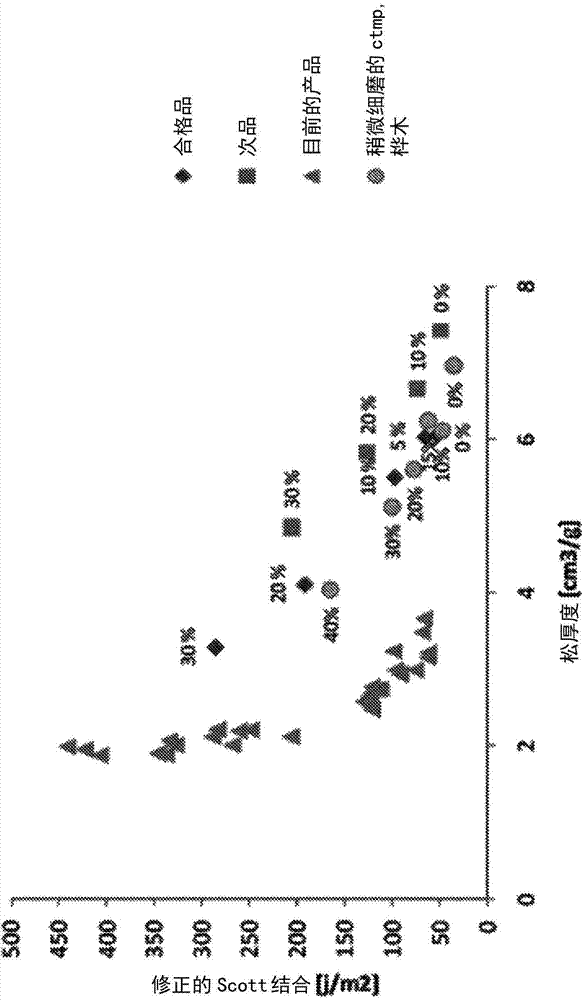

[0048] Foam-forming handsheets of size 38.5 cm x 26.5 cm were prepared by the following procedure: by using a drill (3500 rpm), water was mixed with sodium dodecyl sulfate (SDS) as a surfactant at a ratio of 0.15-0.2 g / l Prepare foam by mixing until the air content in the foam is 60-70%. The target air content of the foam is determined by the foaming device; when the foam reaches the target air content, the level of the foam surface no longer rises, and the mixing begins to reduce the bubble size of the foam. When the foam was ready, a fiber suspension containing CTMP and NFC (Daicel KY-100G, 10.7%) was mixed with the prefabricated foam. Continue mixing until the target air content is reached again. Under steady conditions, the distance between fiber particles in the foam remains constant and no flocculation occurs. Thereafter, the foam was decanted into handsheet molds and filtered through a Fourdrinier screen using an exhauster and vacuum chamber. Fourdrinier wires are of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com