Patents

Literature

37results about How to "Improve paper performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

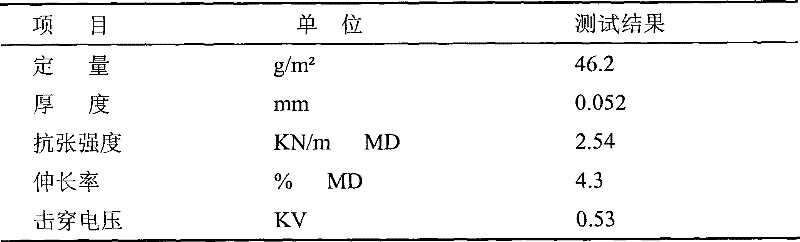

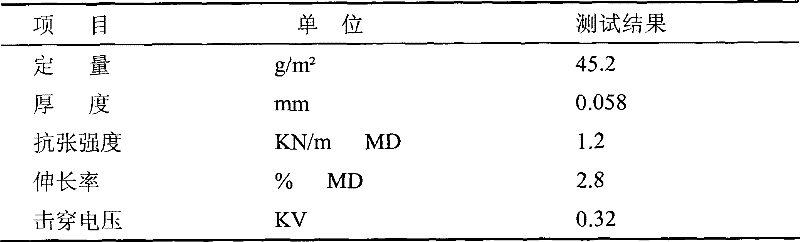

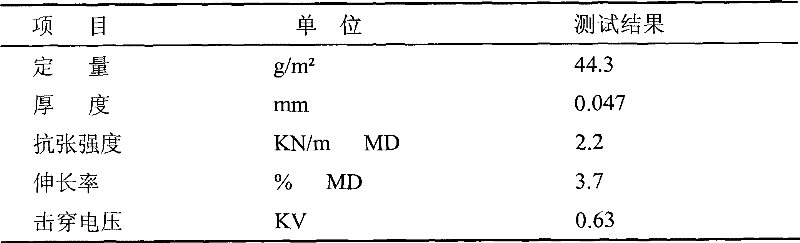

Preparation method of regenerated aramid composite paper

ActiveCN109457533AImprove hydrophilicityFacilitate the grafting reactionPaper/cardboardSynthetic cellulose/non-cellulose material pulp/paperHigh pressureAramid

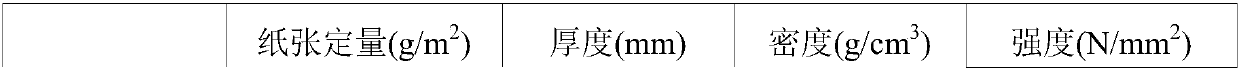

The invention discloses a preparation method of regenerated aramid composite paper. The preparation method includes: pretreating para-aramid chopped fiber, para-aramid pulp fiber and meta-aramid pulpfiber, mixing, loosening to form a uniform fiber / aqueous suspension, adding a papermaking aid into the suspension, dewatering, and molding to obtain composite aramid raw paper; dissolving the meta-aramid fiber by using organic solvent / inorganic salt solution to obtain an aramid solution, dropwise adding the prepared aramid solution into the structure of the aramid composite raw paper, putting thearamid composite raw paper into the air for regeneration, after the regeneration is completed, hot pressing the paper a high temperature and high pressure, and cleaning residual organic solvent and inorganic salt by using water to obtain high-strength aramid composite paper. The quantity of the high-strength aramid composite paper is 20 to 200 g / m2, the thickness is 10 to 300 micrometers, the mechanical strength is greatly improved, and the tensile strength is improved by 20 times.

Owner:SOUTH CHINA UNIV OF TECH +1

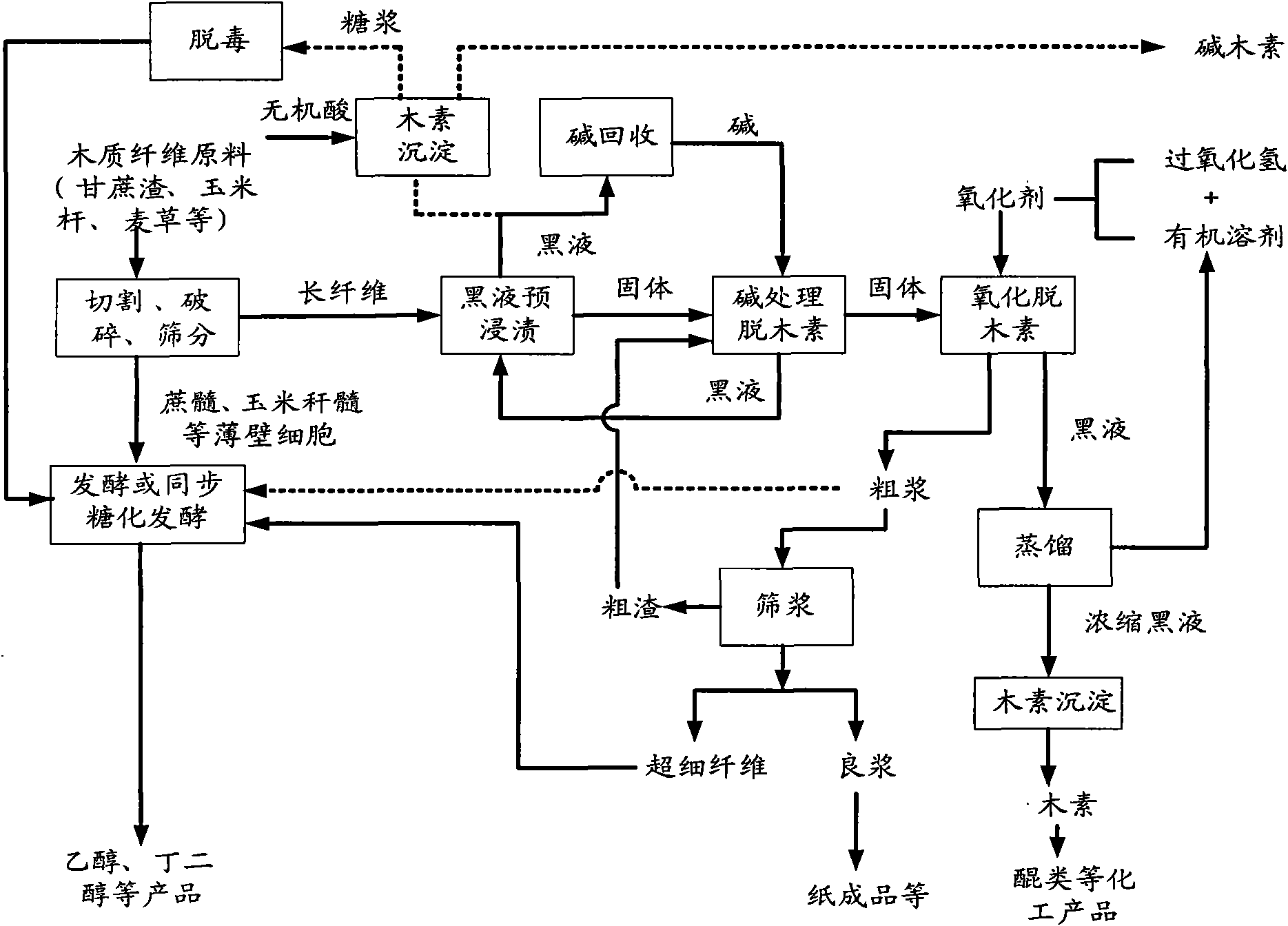

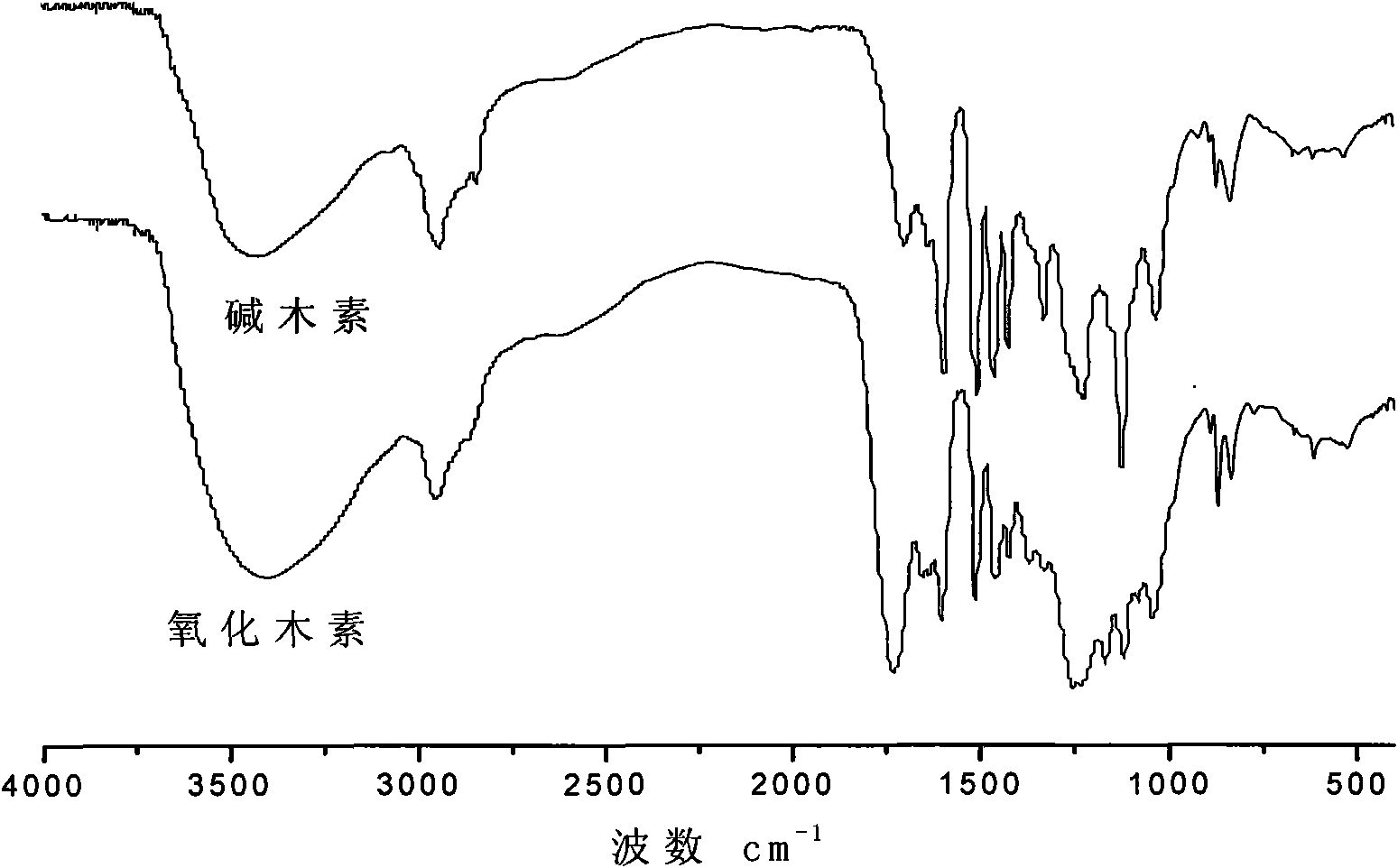

Biorefinery method of wood fiber material

InactiveCN101555667AEfficient removalHigh hydroxyl contentPretreatment with alkaline reacting compoundsBiofuelsFiberCellulose

The invention relates to a biorefinery method of wood fiber material, comprising the following steps of: (1) crushing and screening material so as to obtain long fiber, short fiber and powder; (2) adopting the two-step method of alkaline treatment and oxidation treatment to treat the long fiber obtained by the step (1) and preparing into pulp; and / or implementing synchronous diastatic fermentation on the short fiber and powder obtained by the step (1) and ultra-fine fiber and part of accepts obtained by the step (2) and preparing into alcohol. In the method, black liquid after alkaline treatment is prepared into alkali lignin; and the black liquid after oxidation treatment recovers the solvent and the oxidized lignin is prepared. The method can comprehensively utilize the wood fiber material to produce pulp, alcohol and lignin products. The obtained pulp has higher yield and better pulp performance compared with the sulfate pulp with the same material. The pulp can obtain higher enzymolysis rate with less usage of cellulose. The method has no sulfur and chloride elements, simultaneously reduces discharge of wastewater and has good environment friendliness.

Owner:TSINGHUA UNIV

Method for making paperboards by using paper mill sludge

The invention provides a method for making paperboards by using paper mill sludge. The method comprises the following steps: by using paper mill sludge as auxiliary materials for making the paperboards by adopting an interlayer filling technology, fully mixing the paper mill sludge subjected to impurity removal pretreatment with a reinforcing agent, uniformly applying a mixture between two wet paper sheets, pressing, drying and finishing, thus forming the paperboards similar to sandwich structures. Compared with a conventional technology for making the paperboards through wet-end paper mill sludge addition, the method provided by the invention has the advantages that the added paper mill sludge can be mostly remained in the paperboards so as to form packing layers, thus the retention of the paper mill sludge in the paper boards is increased, and the method is simple in process, strong in operability and convenient to implement through an interlayer spraying method in a conventional papermaking process. The paper mill sludge is added to the paperboard making process so as to make the paperboard products meeting the quality requirements, so that the cost of fiber raw materials is saved for papermaking enterprises, and the purpose of digesting paper mill sludge solid waste in the enterprises is also achieved; the method is an effective approach for the resource utilization of the paper mill sludge.

Owner:SHAANXI UNIV OF SCI & TECH

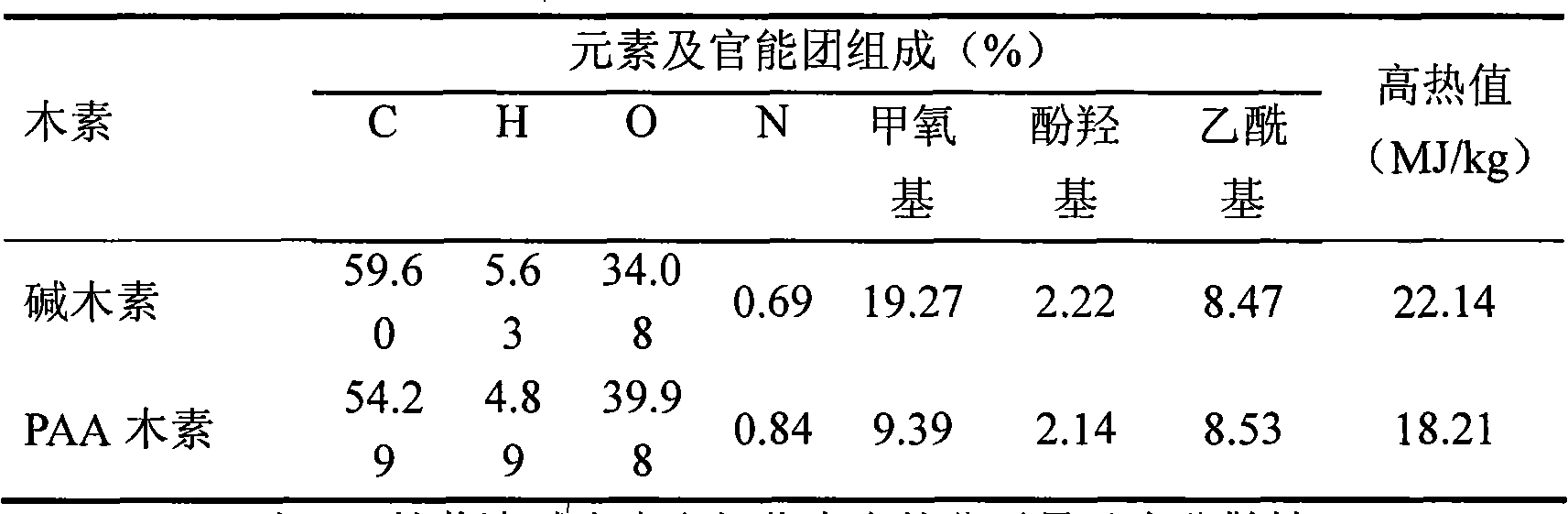

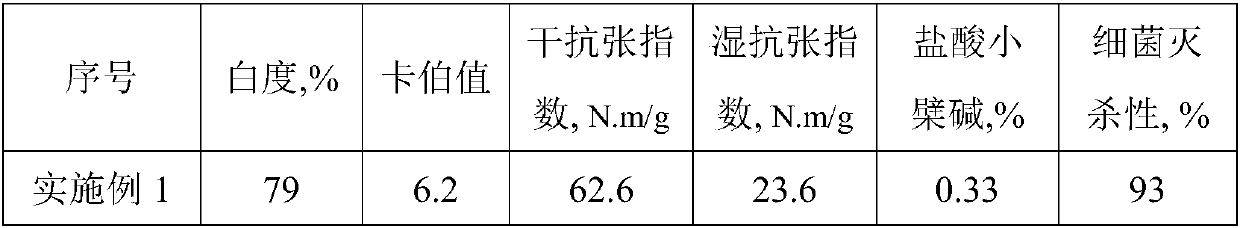

Control agent of dissolved and colloidal substances in paper machine circulating off-machine water and use method thereof

InactiveCN101691719AImprove retentionGuaranteed uptimeDefoamers additionPaper/cardboardAluminium chlorohydratePolyacrylamide

The invention discloses control agent of dissolved and colloidal substances (DCS) in paper machine circulating off-machine water and a use method thereof. The control agent is prepared by mixing the polymeric aluminium and cationic polymer, wherein the mass ratio of the polymeric aluminium to the cationic polymer is 87-99%:1-13%; the cationic polymer is one or the mixture of some types of polyamine, cationic polyacrylamide and polyvinyl amidine; and control agent is added into the paper machine short circulation off-machine water or paper stock under flow, the use level of polymeric aluminium is 100ppm-300ppm and the use level of cationic polymer is 3ppm-15ppm. The invention greatly reduces the DCS content in the paper machine circulating off-machine water, ensures that the DCS content in the circulating off-machine water is controlled below 900mg / L, improves the sealing and circulating degree of the off-machine water, reduces water consumption of paper, and simultaneously improves the performances of paper stock reservation and paper machine operation and the performance of paper.

Owner:GOLD EAST PAPER JIANGSU

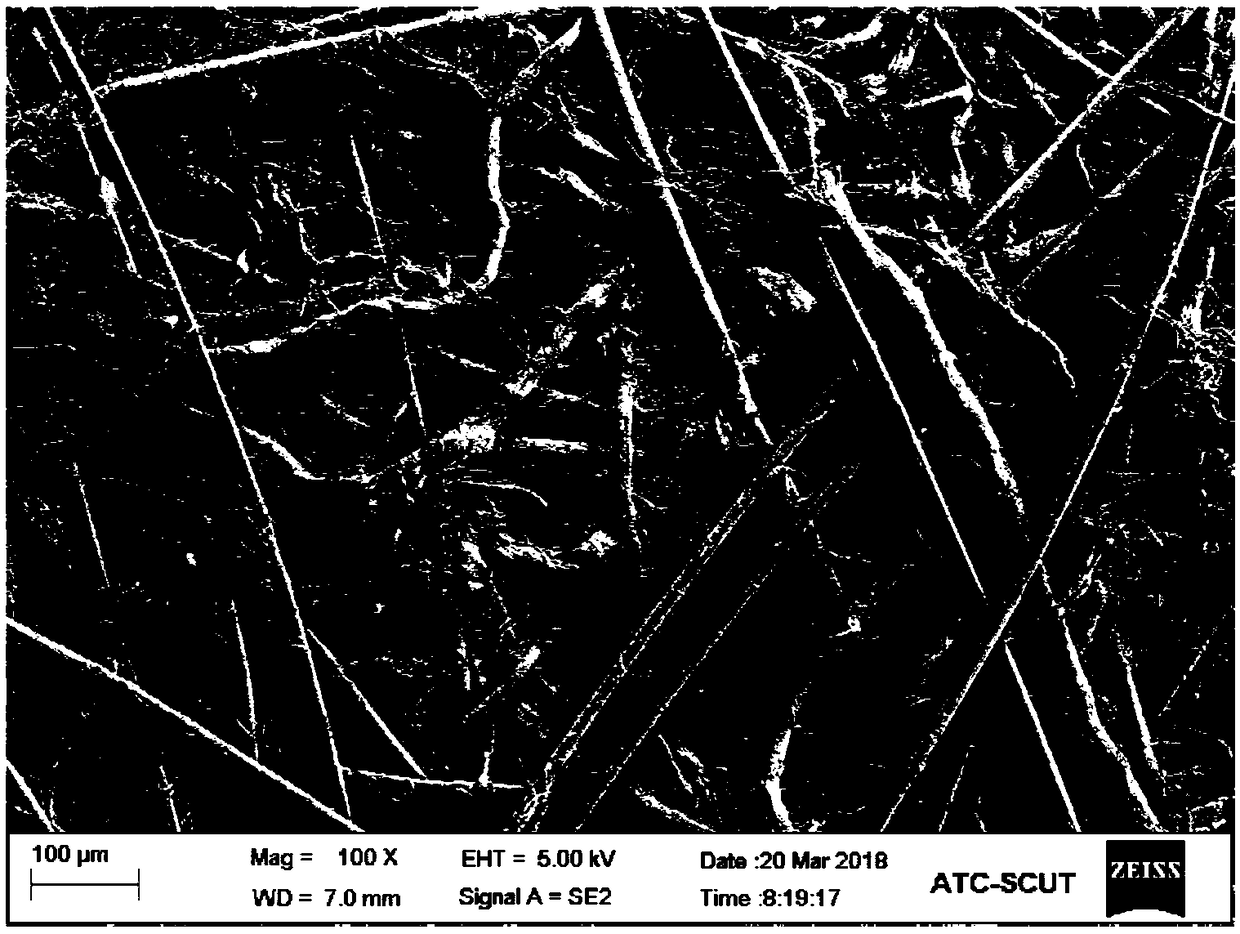

Para-aramid nanofiber/high-performance carbon fiber composite paper and preparation method thereof

ActiveCN113293640AIncrease surface areaDeep scarPaper/cardboardSynthetic cellulose/non-cellulose material pulp/paperPolymer scienceAdhesive

The invention belongs to the field of papermaking technologies and materials, and particularly relates to para-aramid nanofiber / high-performance carbon fiber composite paper and a preparation method thereof. By utilizing the characteristics of a large specific surface area, easy dispersion in an aqueous solution and the like of para-aramid nanofibers, the para-aramid nanofibers can replace a traditional wet strength agent and an adhesive for pulp; the para-aramid nanofibers can be fully and uniformly mixed with a high-performance carbon fiber solution, and a wet paper sheet of para-aramid and carbon fibers is prepared through wet papermaking; then a para-aramid nanofiber dispersion liquid is subjected to spraying and sizing on the surface of the aramid wet paper sheet; then compounding, drying and forming are conducted; and thus, the sprayed and compounded paper sheet can remarkably improve the uniformity and mechanical strength of the composite paper, improve the production efficiency of a composite paper-based material and the like, and can fully realize the compounding of the carbon fibers and the aramid fibers. A composite material prepared by using the method has good heat resistance and chemical stability and excellent heat conduction and electric conduction performance.

Owner:山东聚芳新材料股份有限公司

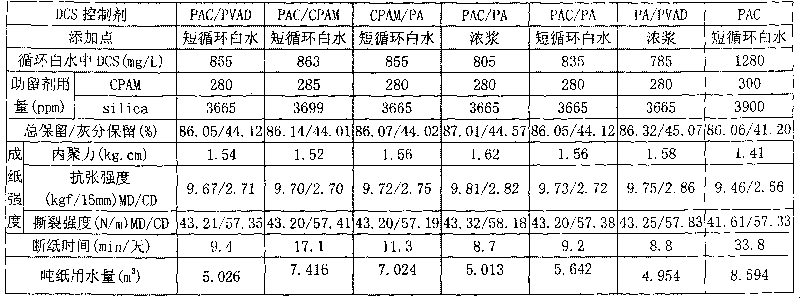

Antibacterial paper towel and preparation method thereof

InactiveCN109914138AHigh whitenessEfficient degradationAntibacterial agentsCosmetic preparationsFiberMicrowave radiometry

The invention relates to an antibacterial paper towel and a preparation method thereof, and discloses a process for papermaking by using Qianjinfang medicine residue, wherein the process comprises: microwave pretreatment, fermentation, washing, paper making, extracting of medicinal ingredients from waste liquid, paper modification and the like. According to the present invention, the short fiber is prepared by using the Qianjinfang medicine residue, and the long fiber property of the cotton fiber is combined, such that the prepared antibacterial paper towel has good tensile property; the prepared antibacterial paper towel has remarkable wet strength through internal sizing and surface application; by using the microwave radiation method and the biological method, harmful chemicals are notintroduced during the whole process, such that the hygienic characteristics of the paper are ensured; and the medicinal ingredients are extracted from the pulping waste liquid, and are mixed with thebase medicine liquid component comprising Cortex Ailanthi, Sophora flavescens Ait, Cortex Moutan, frankincense and borneol, and the obtained mixture is applied on the paper, such that the obtained antibacterial paper towel has good anti-inflammatory and antibacterial effects, can prevent microbial infection, does not have irritation and side effects on the skin and vaginal mucosa, and is suitablefor women.

Owner:ZHUZHOU QIANJIN PHARMA

Synthetic fiber paper for highly heat-resistant circuit board with negative thermal expansion coefficient and preparation method and application

InactiveCN104674594AExpansion coefficient can be controlledGuaranteed uniformityNon-fibrous pulp additionPaper/cardboardPapermakingPrinted circuit board

The invention relates to synthetic fiber paper for a highly heat-resistant circuit board with negative thermal expansion coefficient and a preparation method and application. The synthetic fiber paper is prepared from the following components in percentage by weight: 10-90% of structural fiber and the balance of viscose fibers, wherein the viscose fibers are fibers with negative thermal expansion coefficient and are selected from poly-p-phenylene terephthamide precipitation fibers and / or poly (p-phenylene terephthalamide) pulp. The preparation method comprises the following steps: preparing the structural fibers and viscose fibers into papermaking pulp; papermaking and moulding by a wet process; and hot-rolling and calendering to prepare the synthetic fiber paper. X-Y axis thermal expansion coefficient (CTE) in a plane of the synthetic fiber paper is negative and can offset CTE of thermosetting resin in a substrate of a printed circuit board, so that the printed circuit board is relatively stable and reliable, and the synthetic fiber paper can be applied to preparing a reinforcing material of the substrate of the printed circuit board.

Owner:深圳昊天龙邦复合材料有限公司

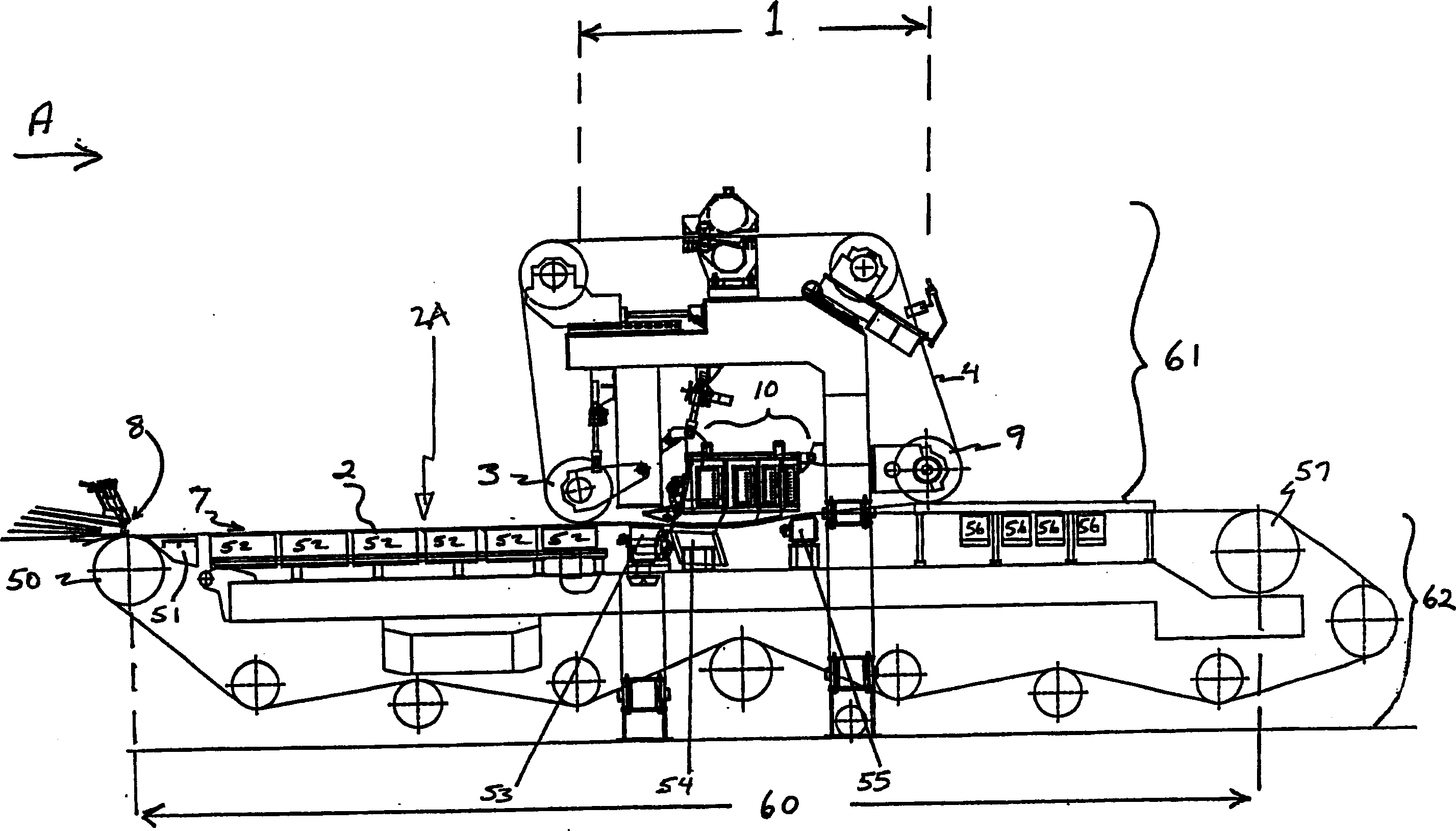

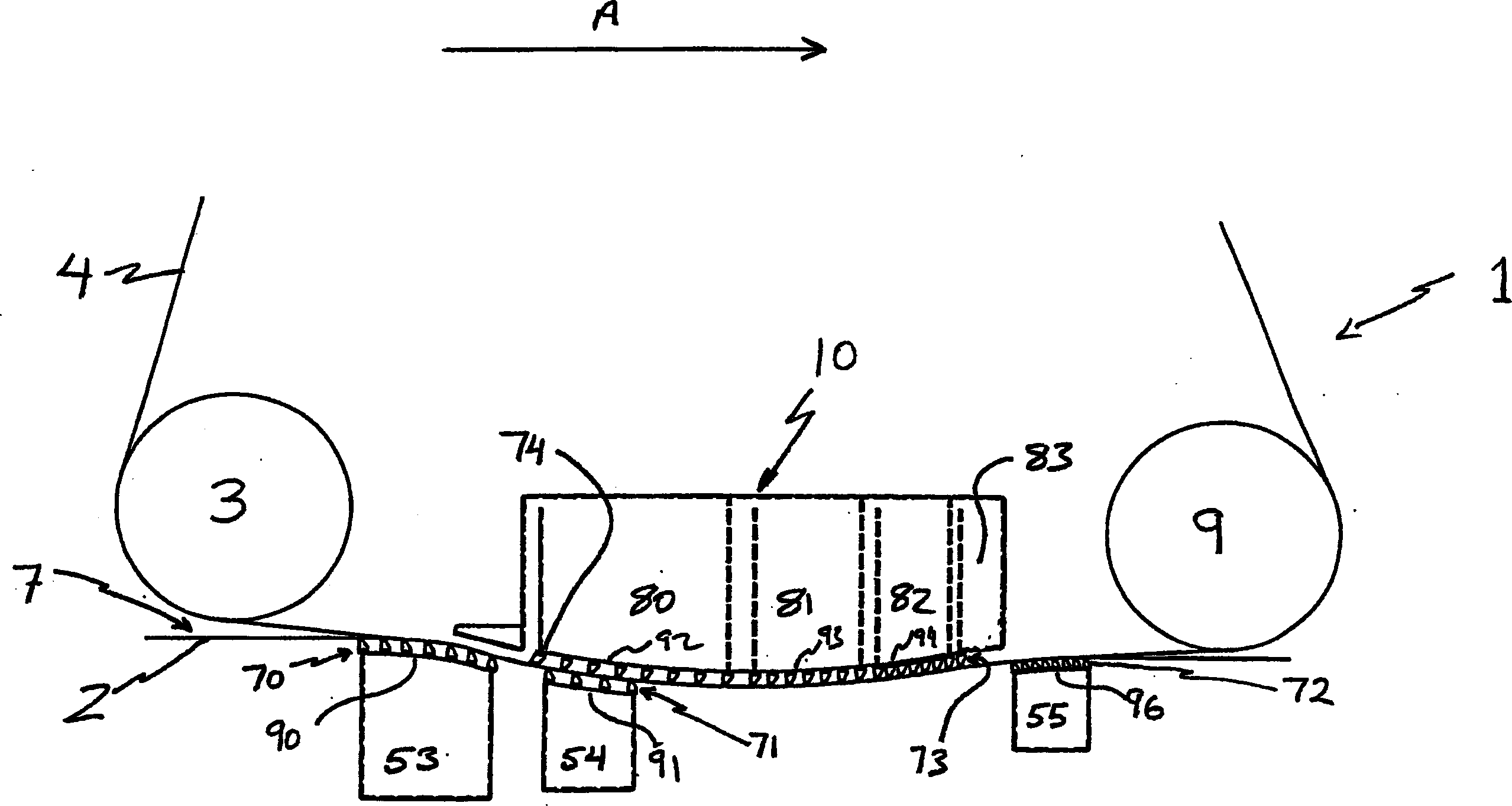

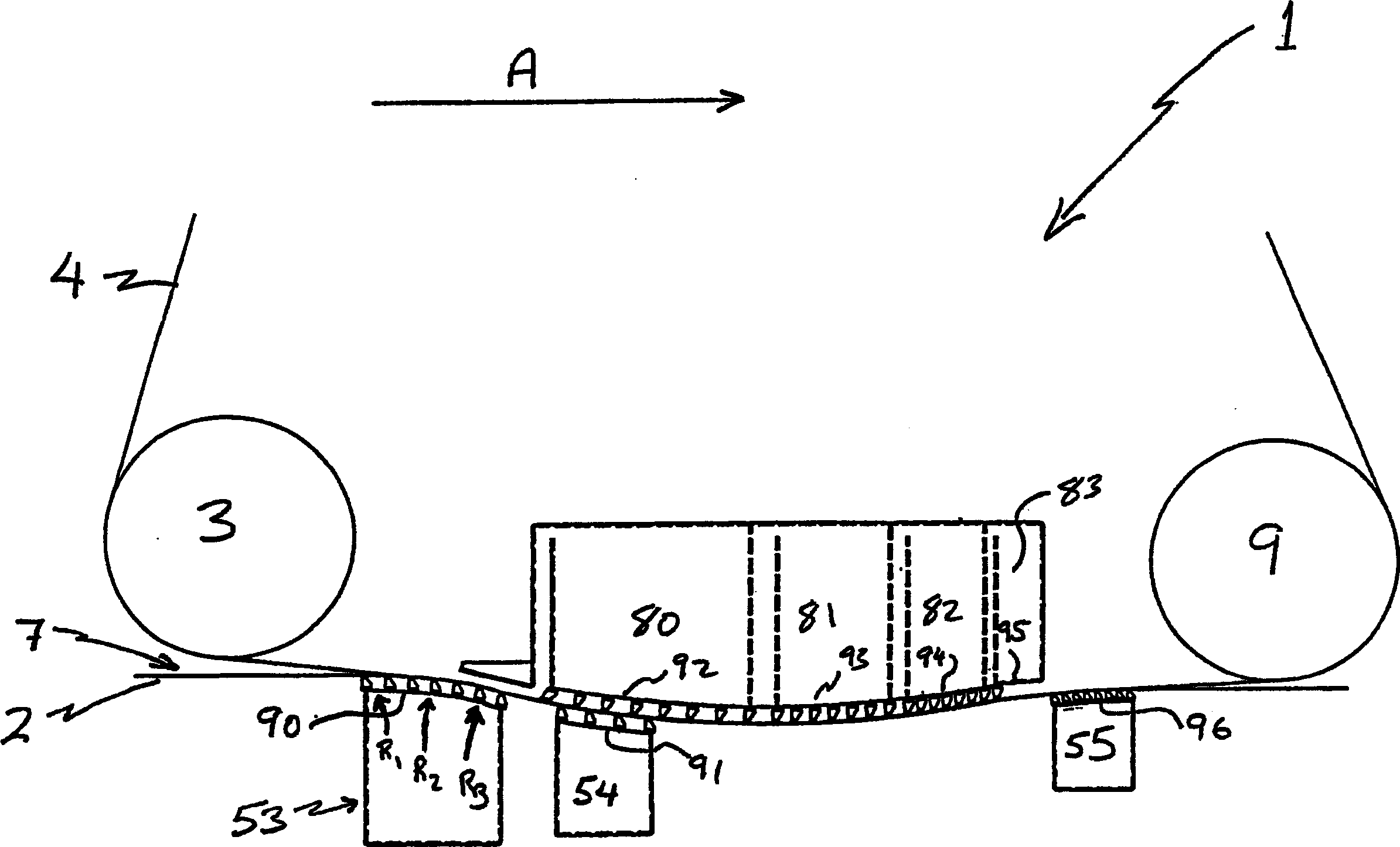

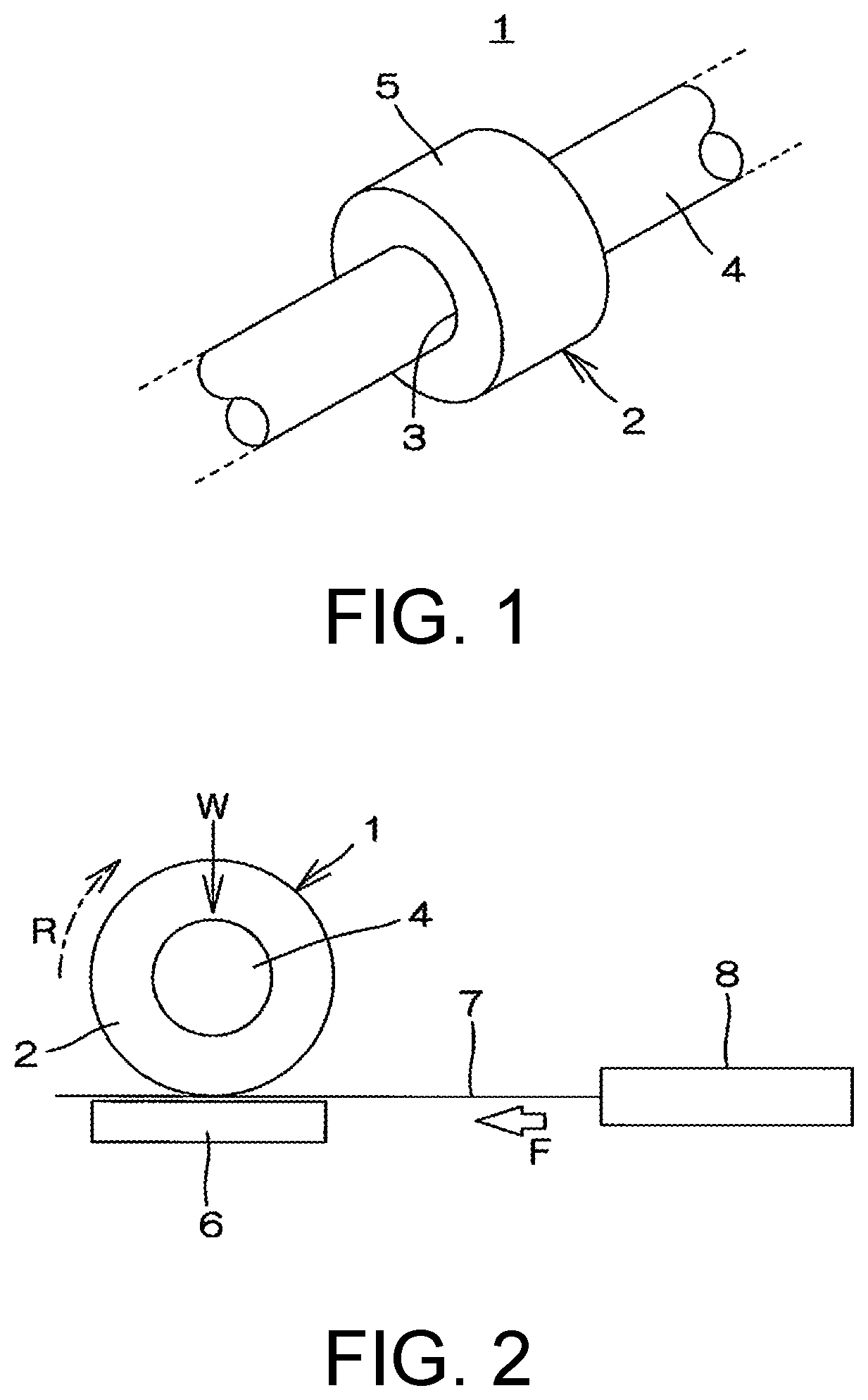

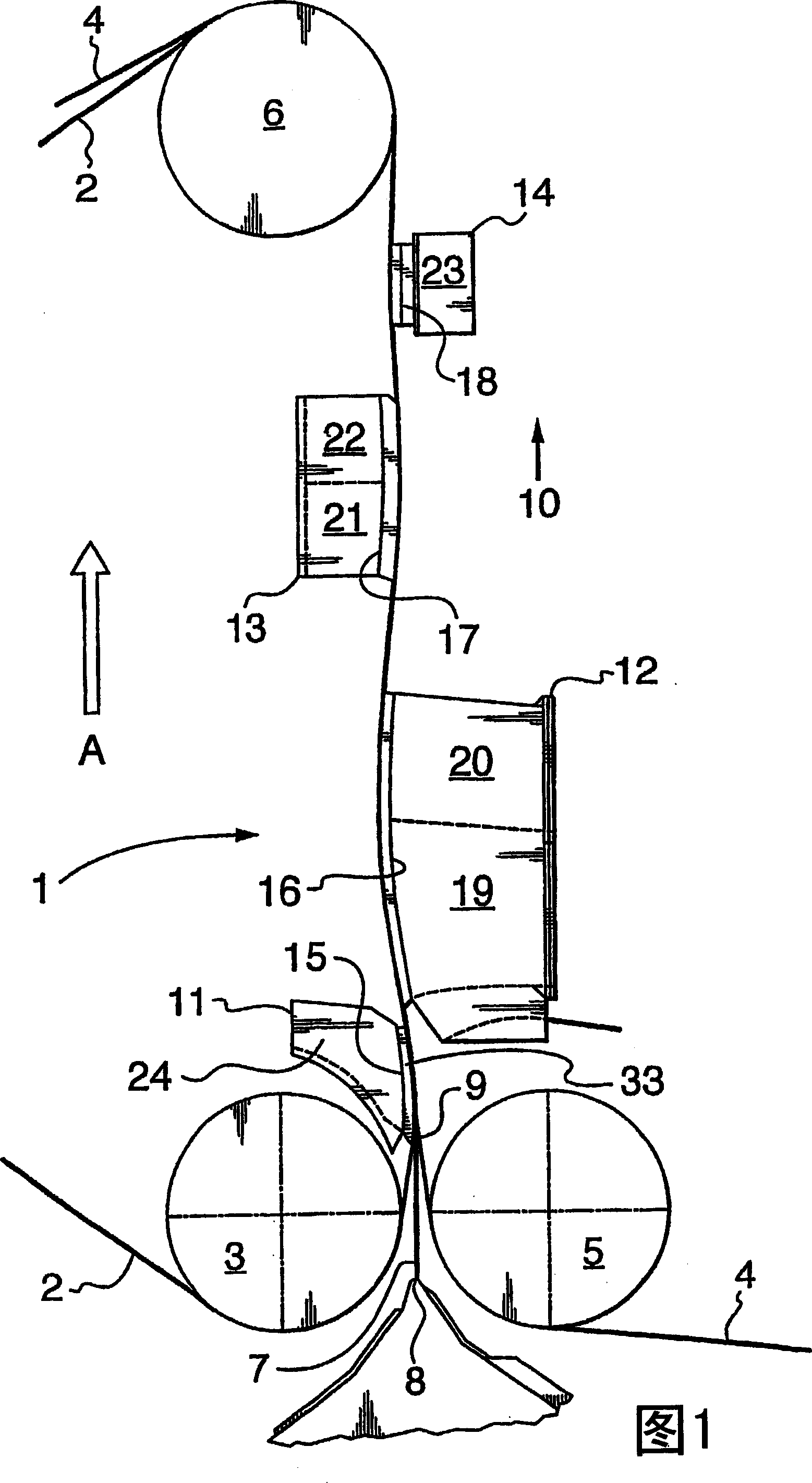

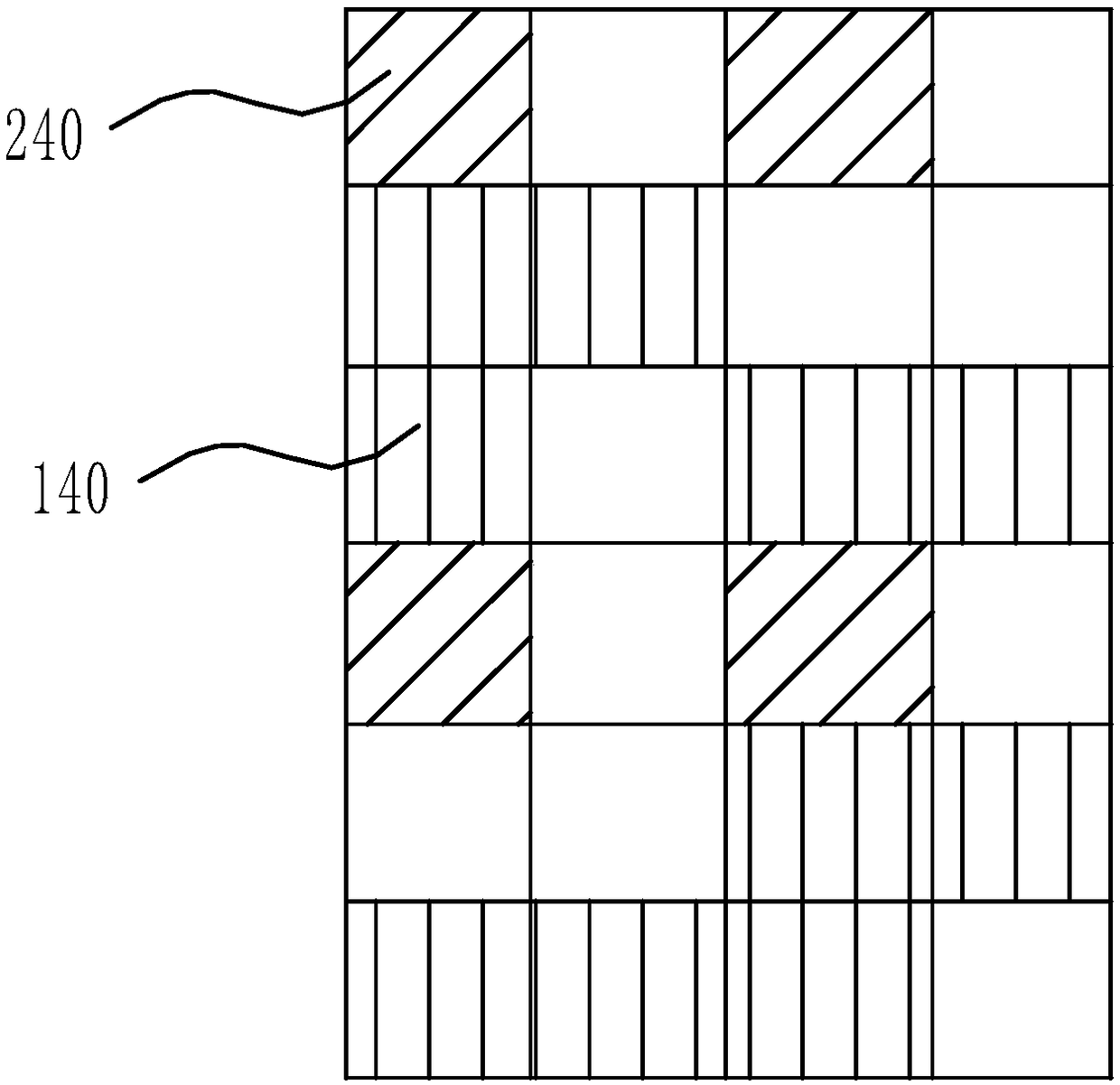

Hybrid type forming section for a paper making machine

A twin fabric hybrid forming section for paper making machine is described in which: the pitch of the fabric support elements decreases progressively in the machine direction; the level of vacuum applied to the forming fabrics through the dewatering boxes increases in the machine direction; the two forming fabrics together with the stock sandwiched between them traverse at least four separate and distinct vacuum zones within the forming section as they proceed in the machine direction; the level of vacuum applied to the last of the at least four separate and distinct vacuum zones is higher than the level of vacuum applied to the first of the separate and distinct vacuum zones; the level of vacuum applied to the at least four separate and distinct vacuum zones follows a preselected profile; and the dewatering boxes carrying the fabric support elements are arranged so that the fabric support elements are located in an alternating sequence on the machine sides of both of the forming fabrics.

Owner:ASTENJOHNSON

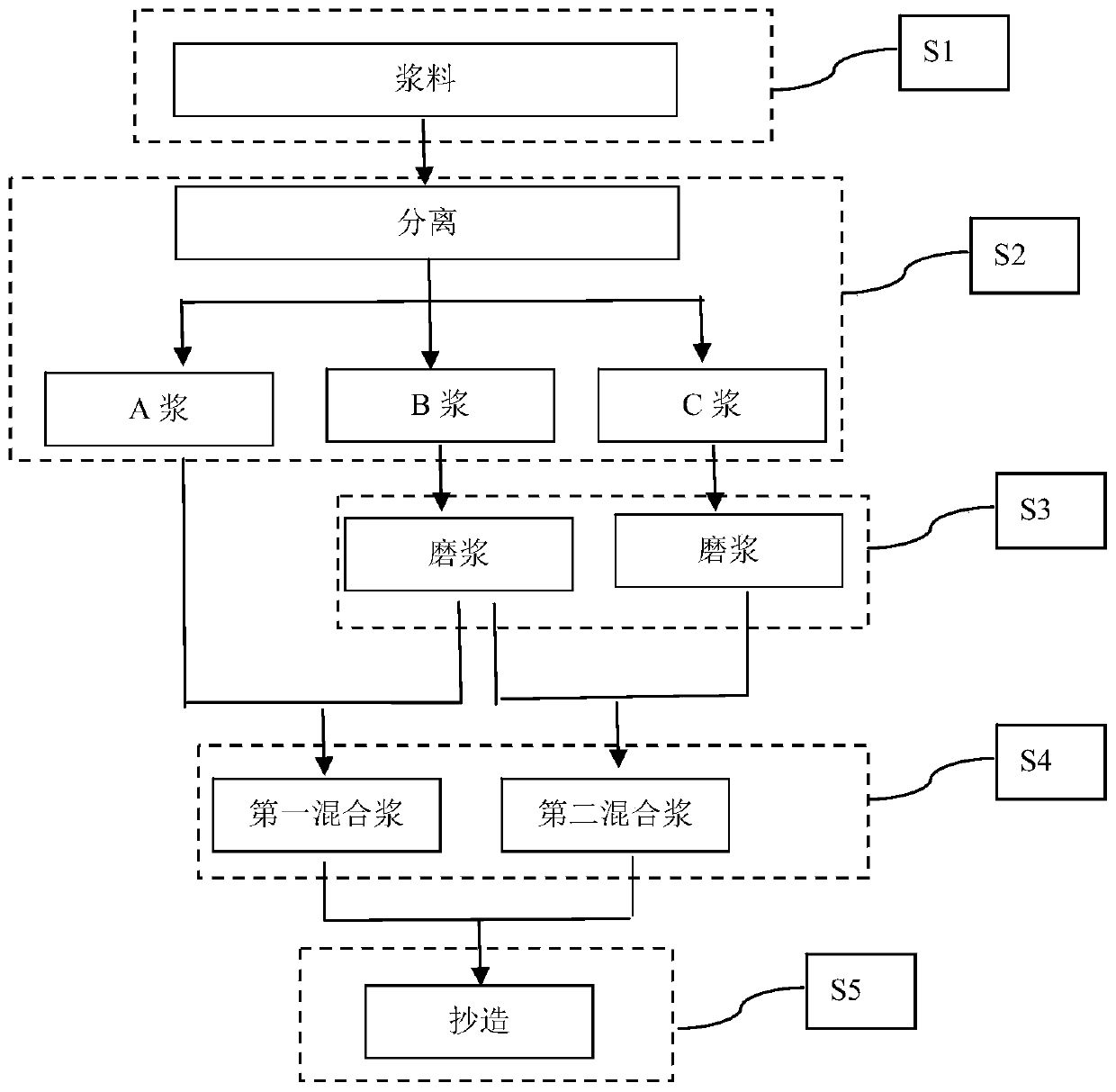

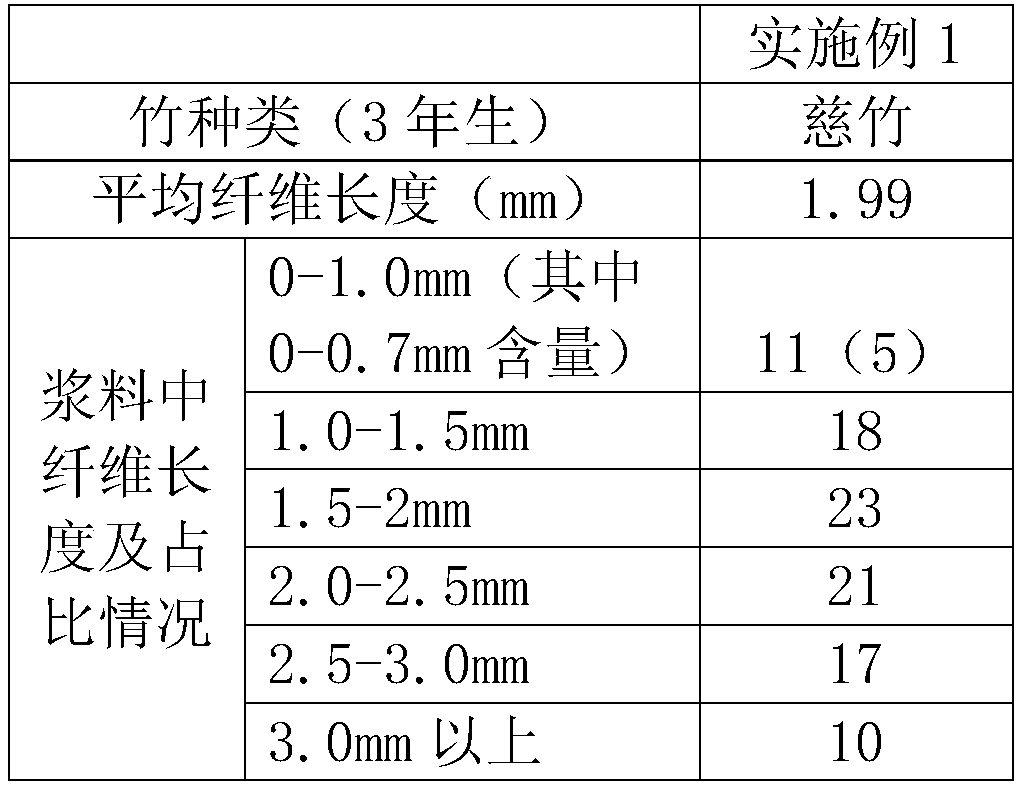

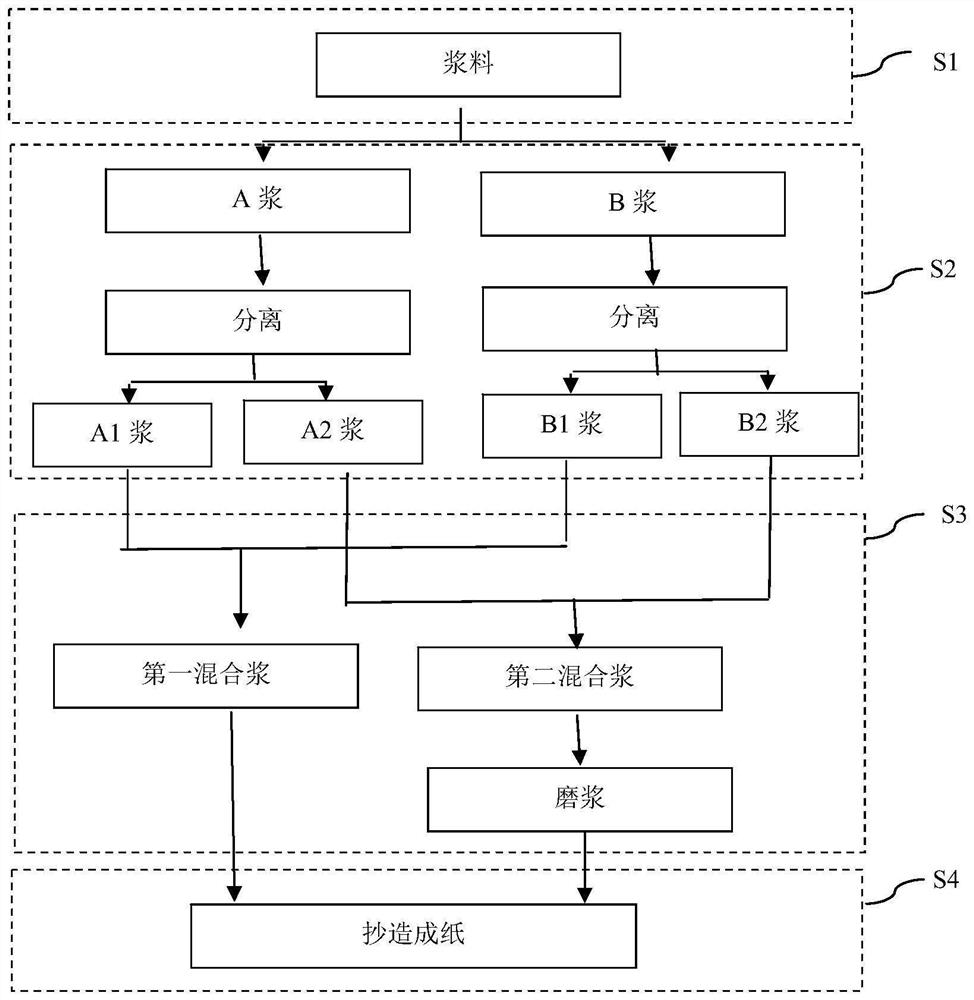

Manufacturing method of bamboo pulp household paper and household paper

ActiveCN110904735AGood molding effectImprove efficiencyReinforcing agents additionPaper/cardboardFiberWet strength

Embodiments of the invention provides a manufacturing method of bamboo pulp household paper. The method comprises the following steps: providing pulp with bamboo pulp as a main material, separating and grading the pulp; grinding pulp with long fibers as a main material; mixing pulp mainly comprising fibers having lengths smaller than the lengths of the long fibers and larger than the lengths of short fibers with short fiber pulp and the long fiber pulp respectively so as to form first mixed pulp and second mixed pulp respectively; and manufacturing paper from the first mixed pulp and the second mixed pulp. With the above steps, energy consumption is reduced, and the efficiency of a softening agent and a wet strength agent is improved; and the proportion and distribution of bamboo pulp fibers with different lengths in the first mixed pulp and the second mixed pulp are adjusted, so the bamboo pulp fibers can be mixed more uniformly, and thus, the forming performance of the pulp is improved, the requirement of a crescent-shaped paper machine is met, and paper forming performance is further improved. The invention further provides the household paper manufactured by using the manufacturing method of the bamboo pulp household paper.

Owner:TAI SEN ENERGY CO LTD

Aramid paper, manufacturing method therefor, and use thereof

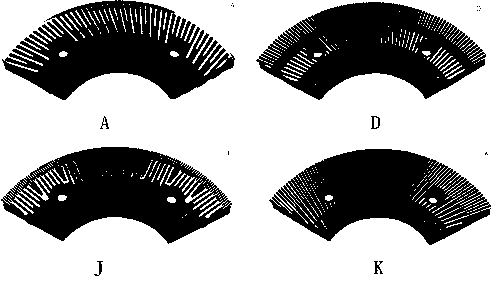

ActiveCN107849813AImprove mechanical propertiesReduce weightPlastic/resin/waxes insulatorsSpecial paperFibrilAramides

The present invention relates to an aramid paper for a honeycomb, which is manufactured by mixing, with aramid flock, aramid pulp having a fiber length equal to or longer than a predetermined length and a fibril developed at a level equal to or higher than a predetermined level, at a predetermined rate; wholly aromatic aramid paper for an electrical insulating sheet, the paper having excellent paper formation and thus having a uniform electrical insulation property, and being manufactured by mixing aramid pulp having fines, the content of which is equal to or more than a predetermined rate, ata predetermined rate; laminated aramid paper which has a uniform thermal expansion coefficient, uniform electrical conductivity, and uniform thermal conductivity, and is formed by laminating, throughcalendaring, aramid paper having excellent paper formation on aramid paper having excellent paper strength; and a method for manufacturing the same. The aramid paper according of the present invention can be applied to a material or a component, which requires precision and should have a little difference in a physical property, such as a thermal expansion coefficient, electrical conductivity, orthermal conductivity. More particularly, the aramid paper has excellent paper strength and excellent paper formation and thus can be applied to a honeycomb, an electrical insulating sheet, a PCB substrate, etc. Moreover, the method can remove poor transfer of base paper, non-uniformity of strength, and cohesion between flocks in manufacturing aramid paper.

Owner:KOLON IND INC

Manufacturing method of bamboo pulp household paper and household paper

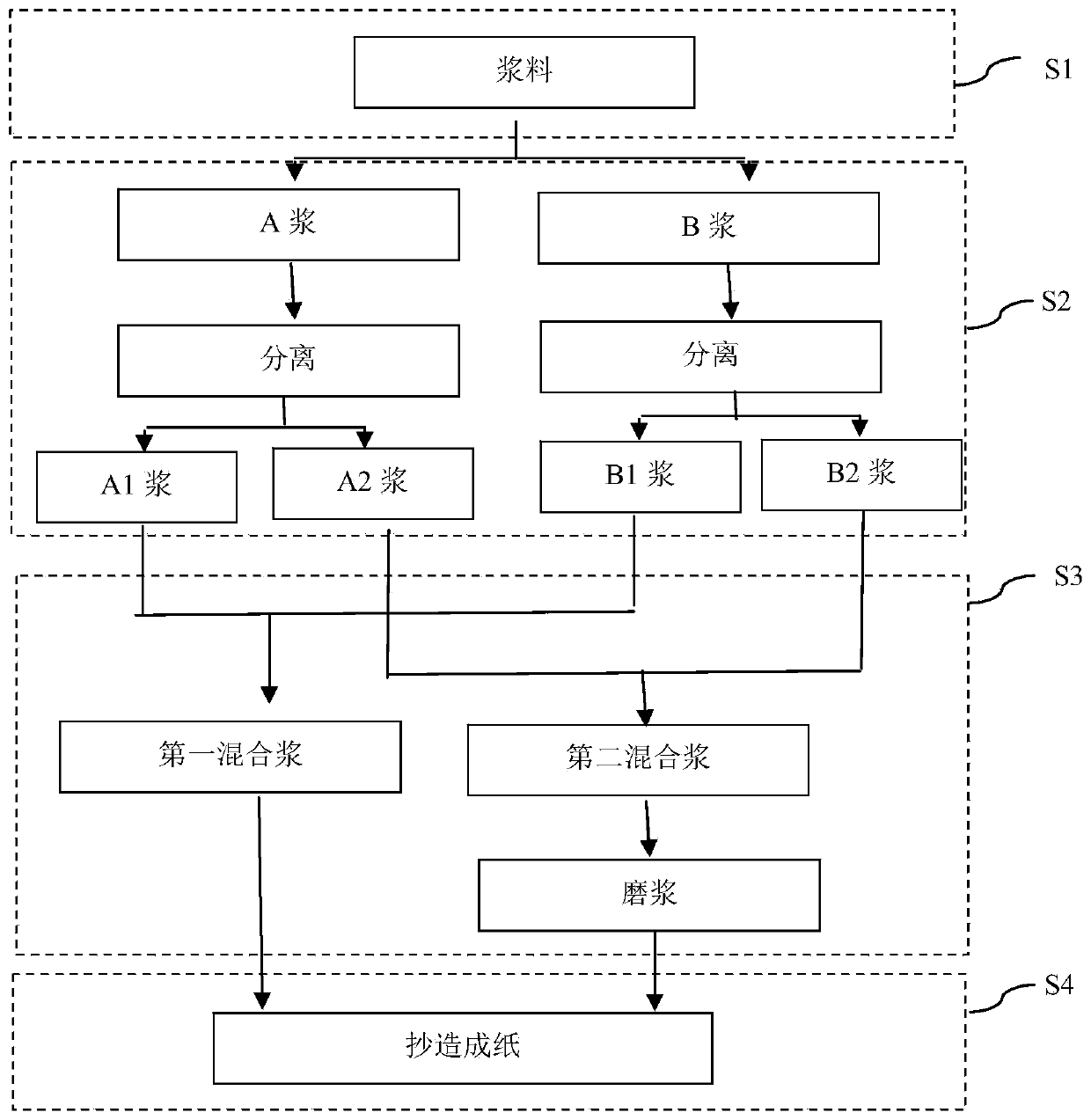

ActiveCN110924227AGood formabilityImprove efficiencyReinforcing agents additionPaper/cardboardFiberPapermaking

The embodiment of the invention provides a papermaking method of bamboo pulp household paper. The papermaking method comprises the following steps: taking bamboo pulp as main pulp, dividing a slurry into a slurry A and a slurry B; separating the slurry A and the slurry B; mixing the separated slurries to form a first mixed slurry and a second mixed slurry; grinding the second mixed pulp; adoptingthe first mixed pulp and the ground second mixed pulp for papermaking in a papermaking machine; wherein the papermaking machine is a crescent-shaped papermaking machine; slurry distribution and grading treatment are adopted, so that the distribution and proportion of fibers with different lengths in the bamboo pulp can be adjusted; on one hand, energy consumption can be reduced, and the efficiencyof softeners and wet strength agents is improved; on the other hand, after distribution and proportion of fibers with different lengths in the bamboo pulp are adjusted, the pulp has better forming performance, the papermaking requirement of a crescent-shaped papermaking machine is met, meanwhile, the paper forming performance of paper is improved, and the invention further provides the householdpaper manufactured through the bamboo pulp household paper papermaking method.

Owner:四川永丰浆纸股份有限公司

Aramid paper, manufacturing method therefor, and use thereof

ActiveUS10407829B2Improve mechanical propertiesReduce weightPlastic/resin/waxes insulatorsSpecial paperElectrical insulation paperAramides

Owner:KOLON IND INC

Starch adhesive

InactiveCN106753034ASimple recipeEasy to prepareNon-macromolecular adhesive additivesStarch adhesivesPolyolPolypropylene glycol

The invention discloses a starch adhesive. The starch adhesive is prepared from raw materials in parts by weight as follows: 40-50 parts of corn starch, 8-10 parts of borax, 10-12 parts of water, 6-8 parts of solid sodium hydroxide, 5-7 parts of pressure-sensitive adhesive composition, 6-10 parts of polypropylene glycol, 6-8 parts of polyol, 5-7 parts of potassium pyroantimonate and 1-2 parts of a synergist. The starch adhesive has the characteristics that surface strength of finished paper is excellent, linting and dusting trend is reduced obviously and the usage amount of latex is reduced.

Owner:QINGDAO JUNENG PIPELINE EQUIP CO LTD

Method for synergistic treatment to improve effect of oxygen-alkali pulping

The invention discloses a method for synergistic treatment to improve the effect of oxygen-alkali pulping and belongs to the technical field of pulping and papermaking. The method comprises: pretreating raw materials through hot water at 30-60 DEG C, carrying out screw extrusion according to a compression ratio of 1: 1.5 to 1: 4, feeding the extruded materials into a digester, and adding a free radical controlling agent into the digester in digestion so that the oxygen-alkali pulping effect is improved. Compared with the conventional oxygen-alkali pulping method, the method utilizes combination of hot water pretreatment, spiral extrusion conveying and a free radical control agent to improve a fine pulp yield of oxygen-alkali pulping by 4-7%, reduce a Kappa number by 2.1 to 3.4 and improvewhiteness by 4% ISO to 6% ISO.

Owner:KUNMING UNIV OF SCI & TECH

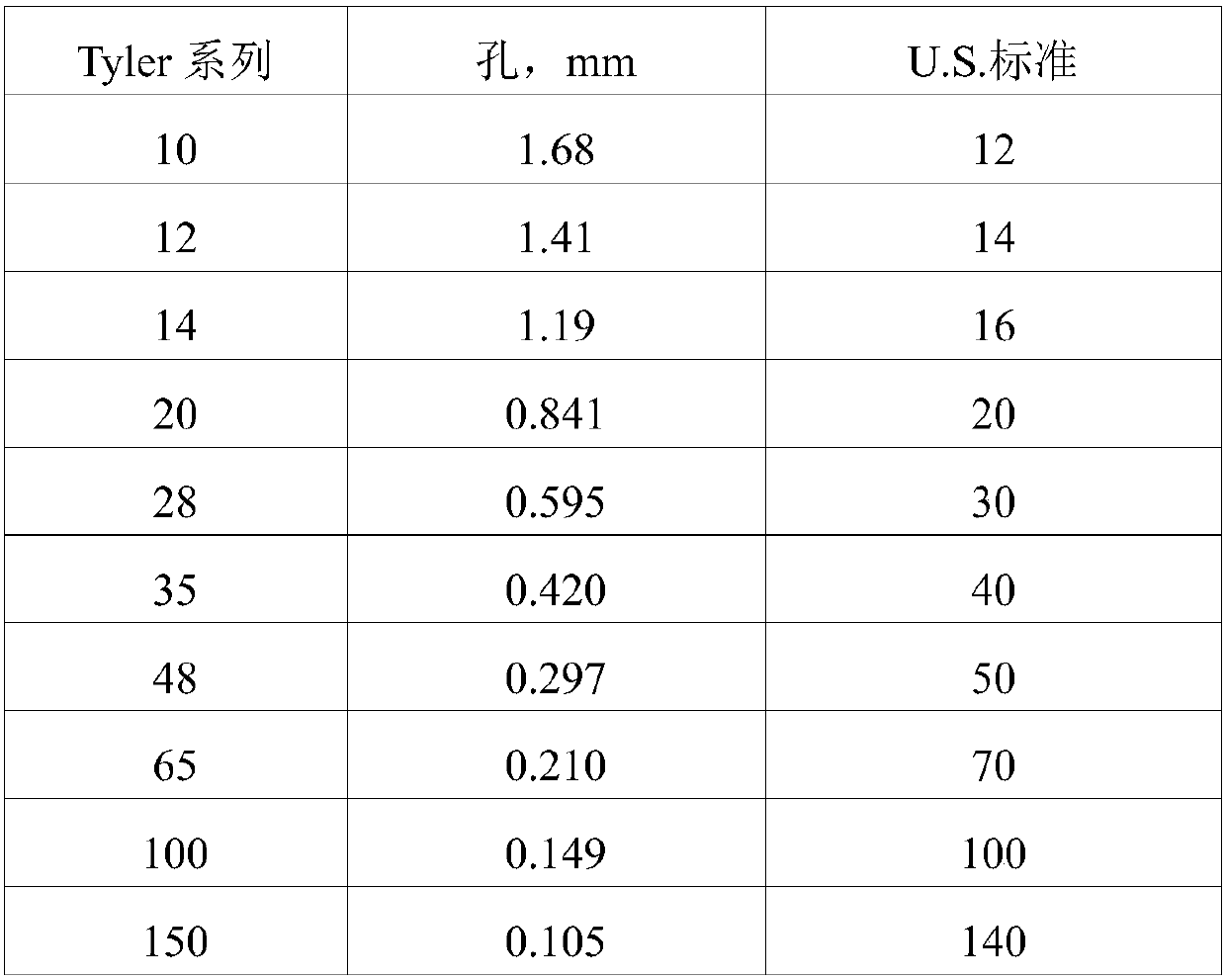

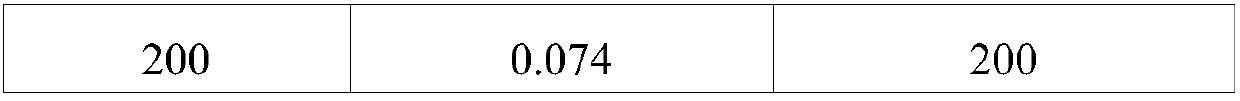

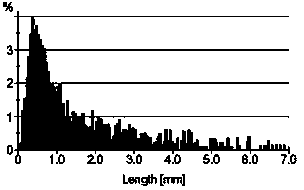

Method for preparing tobacco sheet paper base from tobacco stems

The invention discloses a preparation method of tobacco sheet paper base made from tobacco stems. Tobacco stems are used as raw materials to prepare paper, including the steps of dipping, refining, beating, and sheeting; the invention changes the traditional technical prejudice and habit of controlling the refining by controlling the current of the refiner, and creatively adopts the control of grinding The pulp grinding disc, the refining gap, the number of refining stages and the refining concentration are realized. The invention systematically optimizes the refining process conditions, adopts two-stage or three-stage refining, the refining concentration is 20%, and the refining gaps of the first stage and the second stage are respectively 0.4mm and 0.20mm. The present invention analyzes the relationship between the refining process and the performance of tobacco stem fibers through overall research, and summarizes the optimal controllable refining conditions, which ensures that the prepared tobacco stem pulp has the longest fiber length and the highest bulk thickness of the paper. The good quality of the reconstituted tobacco leaves is guaranteed, the performance of the paper base of the tobacco sheet is comprehensively improved, and finally a technical basis is provided for improving the quality of the tobacco sheet and the quality of the cigarette.

Owner:CHINA TOBACCO GUANGDONG IND +1

Rubber composition and paper feeding roller formed of the same

InactiveUS20200002109A1High tensile strengthImprove paper performanceElectrographic process apparatusArticle feedersAmorphous silicon dioxideCross linker

Provided are a rubber composition capable of imparting a high tensile strength to a roller main body so as to be able to be used for equipment that allows paper to pass through at high speed, while maintaining high abrasion resistance of the roller main body and a favorable paper feeding performance of the paper feeding roller; and a paper feeding roller. There is provided a rubber composition contains: a rubber that includes a non-oil extended EPDM having an ethylene content of 55 to 72%; and more than 20 parts by mass and 30 parts by mass or less of a filler, and 2.5 parts by mass or more of a peroxide crosslinking agent per 100 parts by mass of the rubber, in which the filler contains 15 to 30 parts by mass of an amorphous silica per 100 parts by mass of the rubber.

Owner:SUMITOMO RUBBER IND LTD

Aramid paper, manufacturing method therefor, and use thereof

ActiveUS20180142415A1Improve mechanical propertiesReduce weightPlastic/resin/waxes insulatorsSpecial paperElectrical insulation paperAramides

The present disclosure relates to an aramid paper for a honeycomb, which is prepared by mixing, with an aramid floc, an aramid pulp having a fiber length equal to or longer than a predetermined length and a fibril development equal to or higher than a predetermined level, at a predetermined ratio, a wholly aromatic aramid paper for an electrical insulation paper having superior paper formation property and thus having uniform electrical insulation property, which is prepared by mixing an aramid pulp having a fines content equal to or higher than a predetermined ratio at a predetermined ratio, a laminated aramid paper having a uniform thermal expansion coefficient, uniform electrical conductivity and uniform thermal conductivity, which is prepared by laminating an aramid paper with superior paper formation property on an aramid paper with superior paper strength by calendering, and a method for preparing the same. The aramid paper according to the present disclosure is applicable to a material or a component which requires precision with little difference in physical properties such as a thermal expansion coefficient, electrical conductivity and thermal conductivity. Specifically, it is applicable to a honeycomb, an electrical insulation paper, a PCB substrate, etc. because it has superior paper strength and paper formation property. Moreover, the method for preparing an aramid paper can solve the problems of poor transfer of a base paper, nonuniformity of strength and aggregation between flocs.

Owner:KOLON IND INC

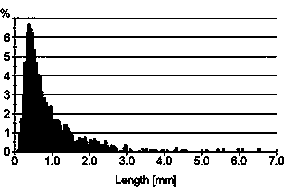

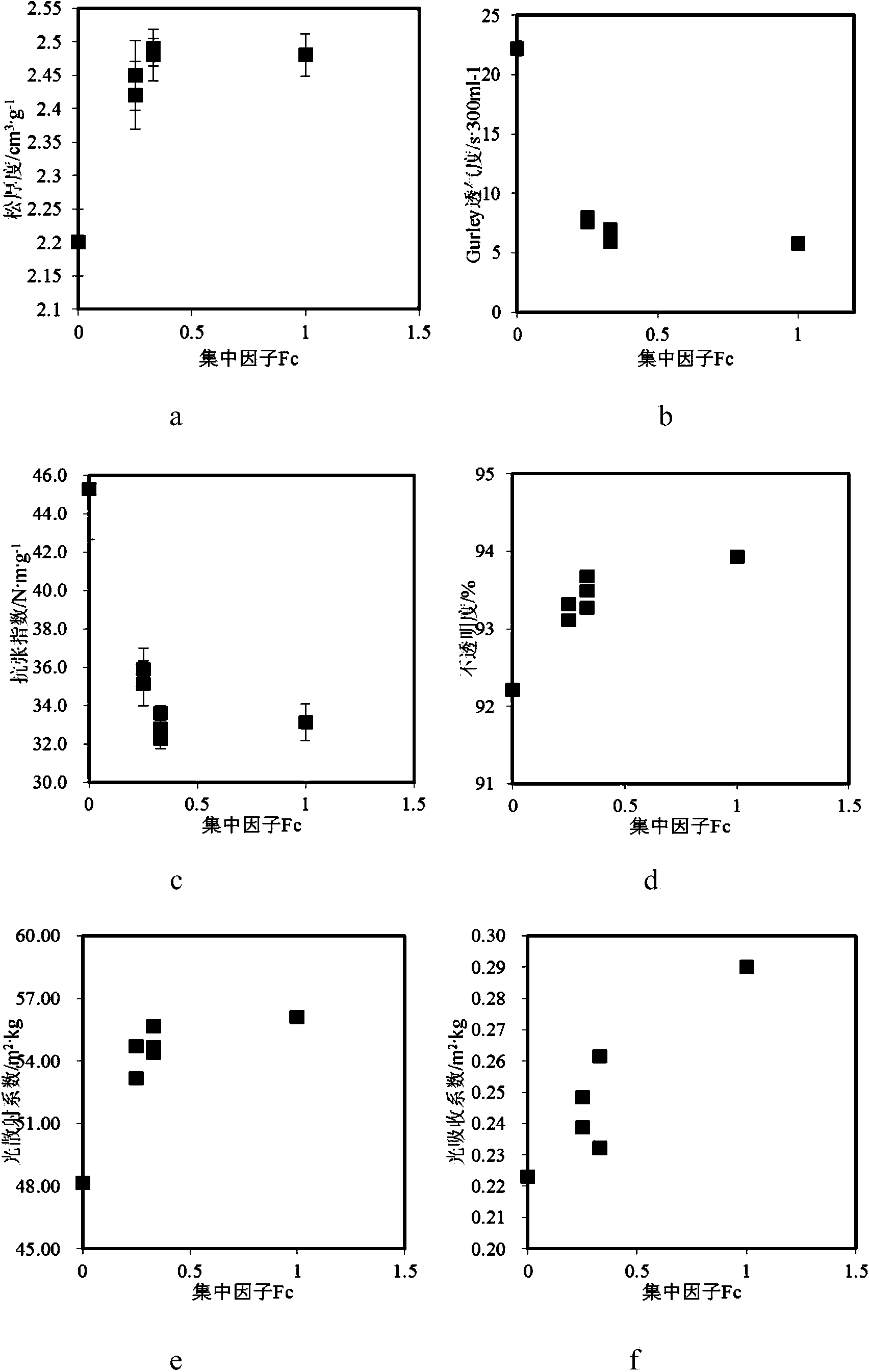

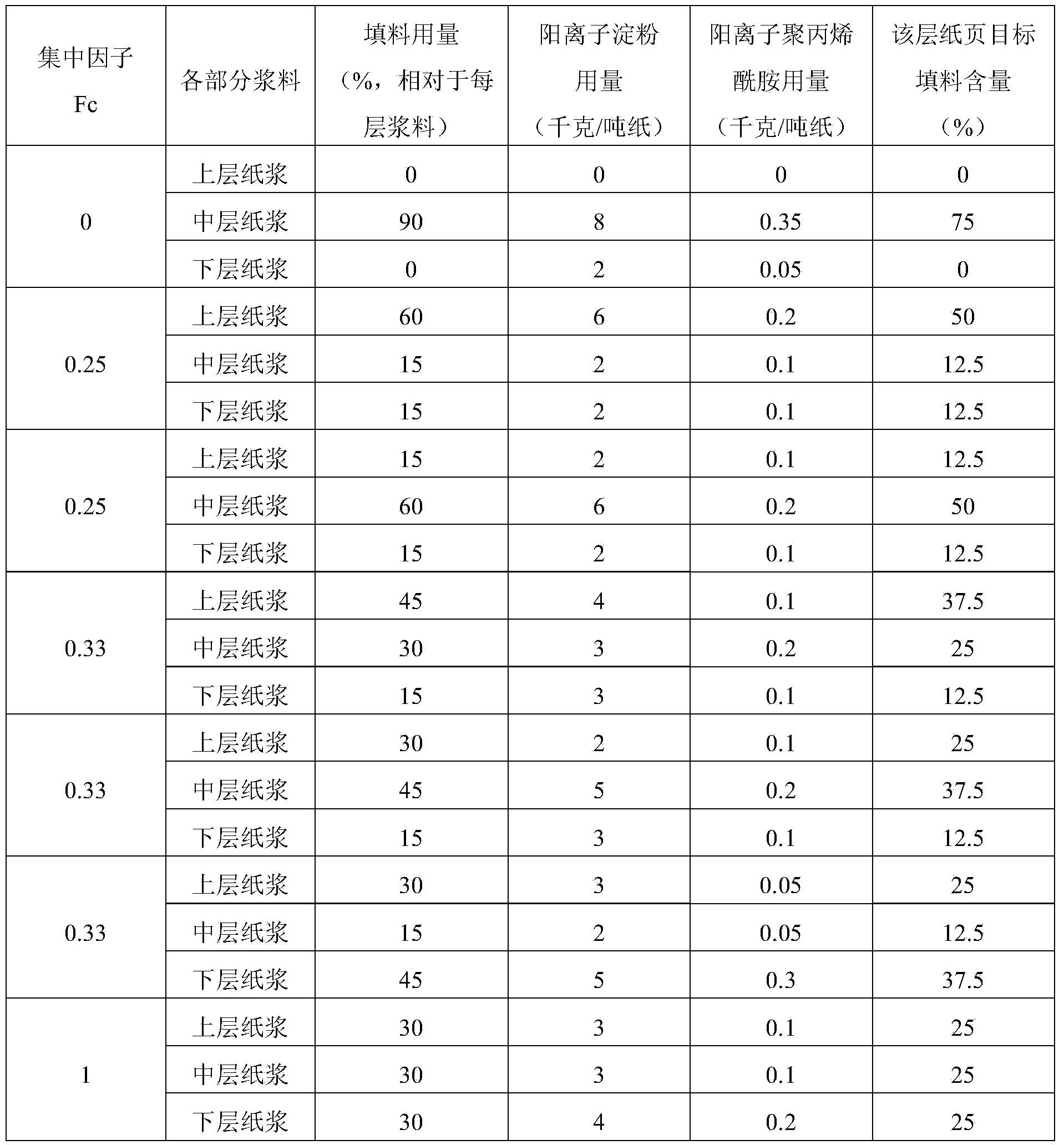

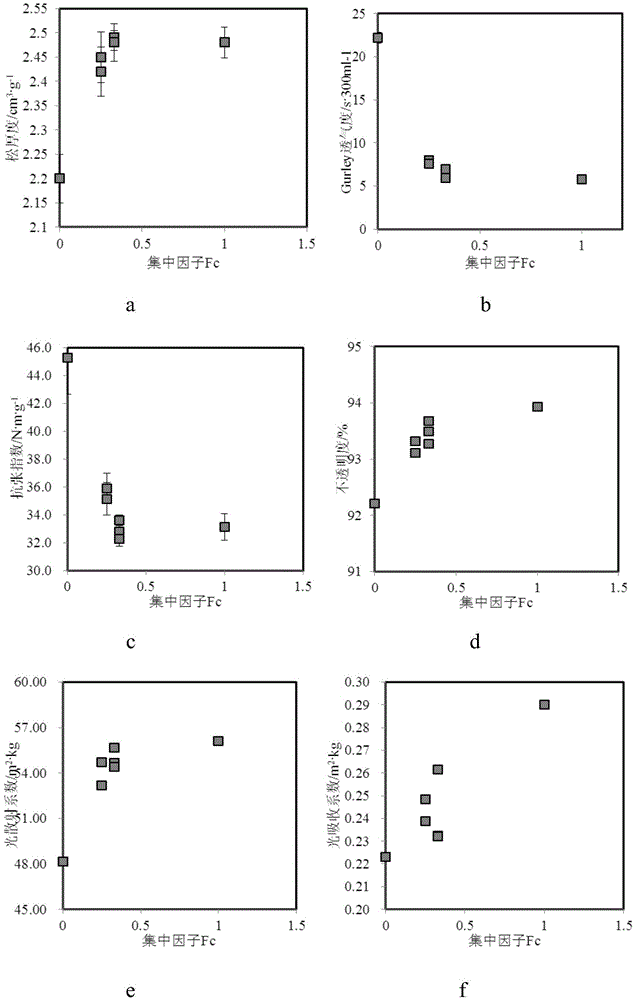

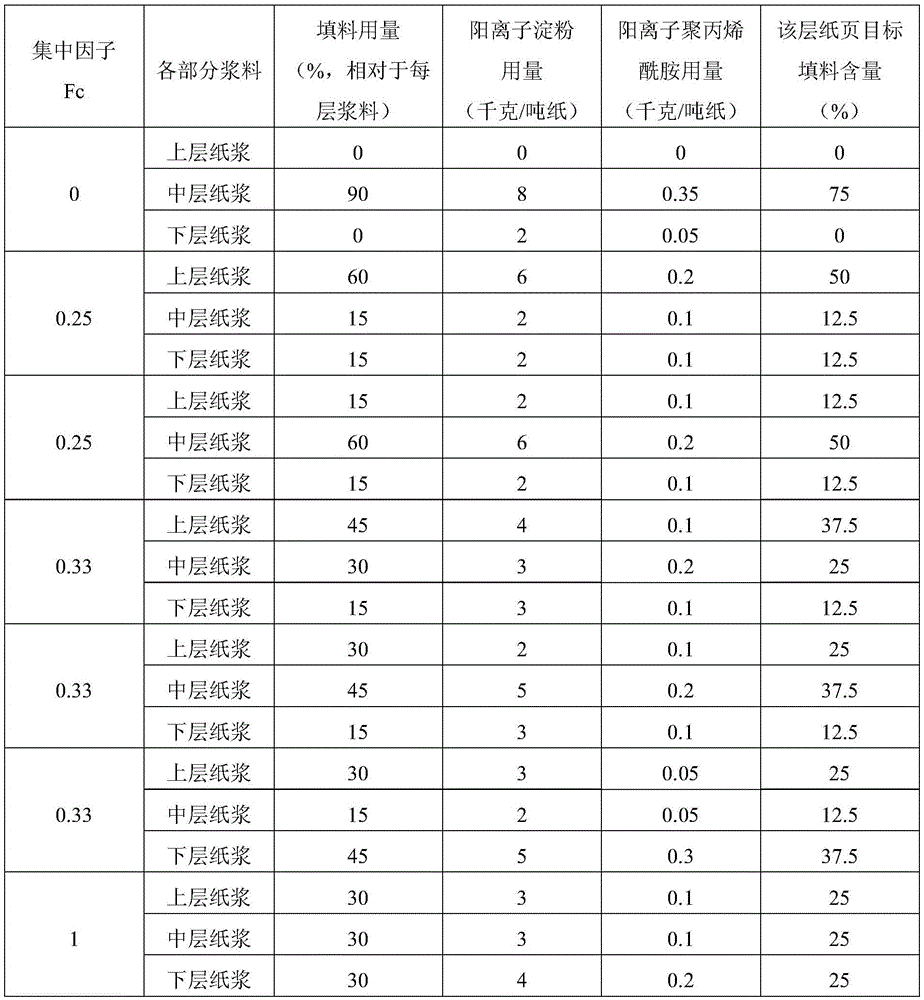

Method for optimizing paper structure to improve performance of finished paper

ActiveCN104109980AImprove paper performanceImprove product qualityPulp beating methodsInorganic compound additionPaper sheetPhysical strength

The invention discloses a method for optimizing a paper structure to improve the performance of finished paper. The method comprises the steps of size degradation of paper pulp, defibrination, preparation of filler suspension liquid and manufacturing of paper with the pulp, wherein when the paper is manufactured with the pulp, three paper layers are combined for manufacturing, and the concentration factor Fc of filler in the paper is regulated to achieve improvement on bulk, air permeability, physical strength and optical performance of the filled paper when the content of the filler is fixed. The distribution factor of the filler is optimized to improve the performance of the finished paper, distribution of the filler in the paper structure is adjusted to play the advantages of the filler to the maximum extent, and the purpose of improving the performance of the finished paper is achieved. The method is simple and easy to operate, the performance of the target finished paper is adjusted according to needs, the performance of the finished paper is improved in a modern paper making machine by optimizing the concentration factor and adjusting the distribution of the filler, and therefore the quality of the finished paper is improved.

Owner:SHAANXI UNIV OF SCI & TECH

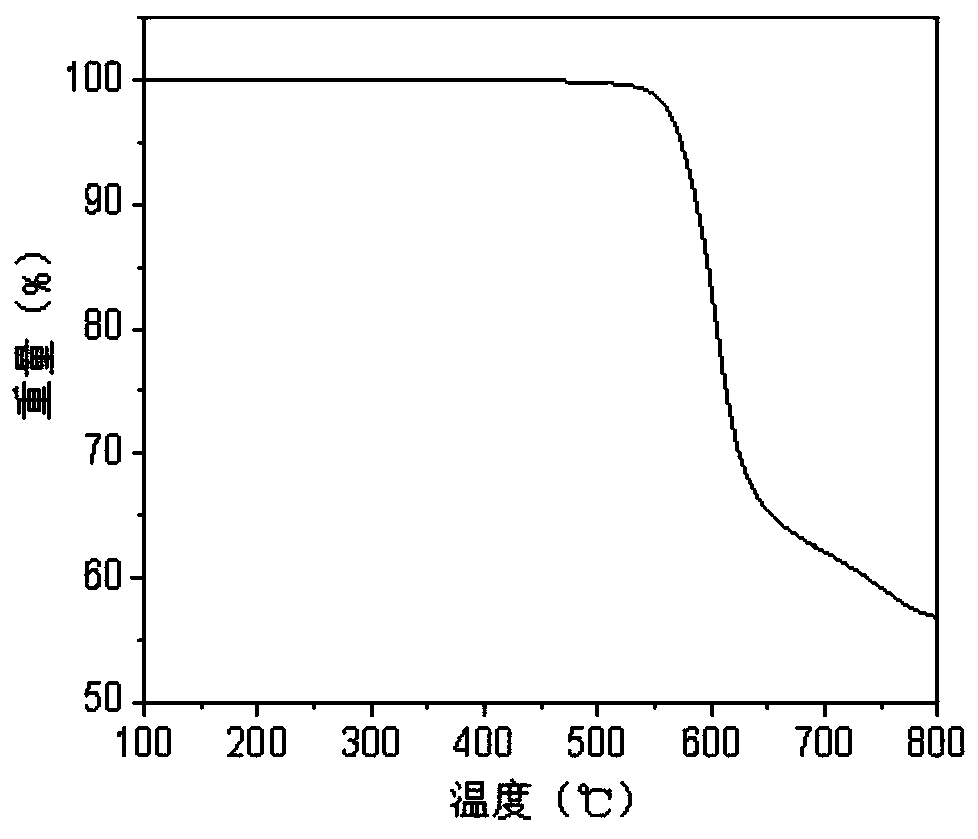

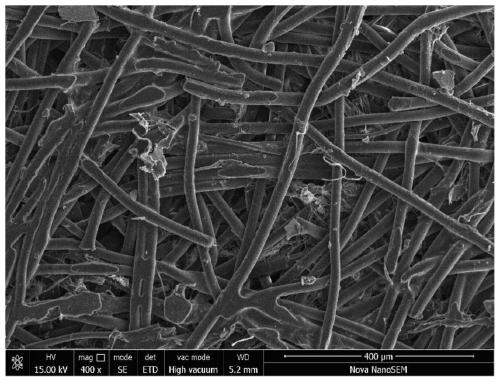

Polyether ether ketone fiber composite paper and preparation method thereof

ActiveCN110373955BImprove paper performanceImprove performanceSpecial paperPaper/cardboardPolymer sciencePoly ether ether ketone

Owner:JILIN UNIV

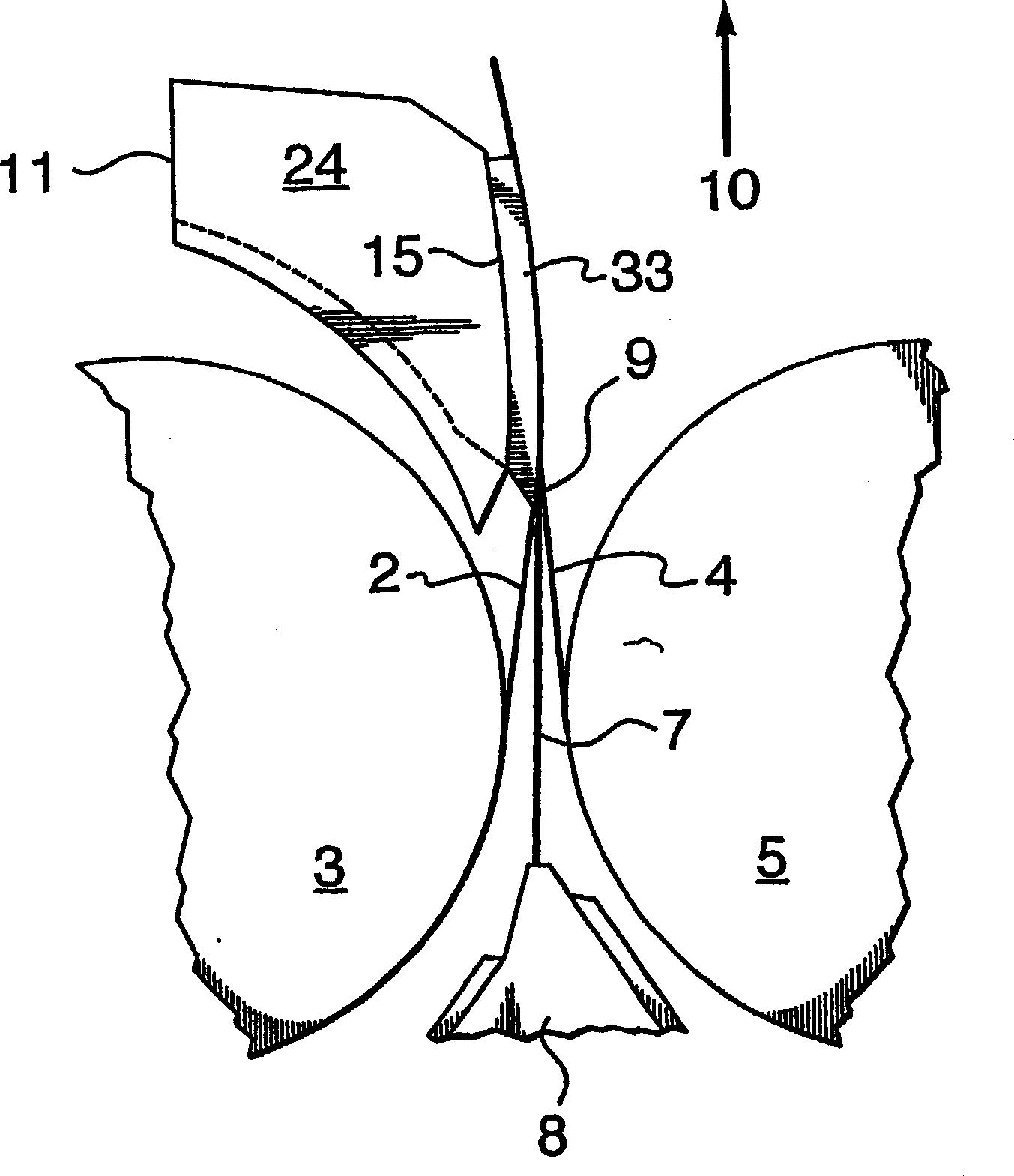

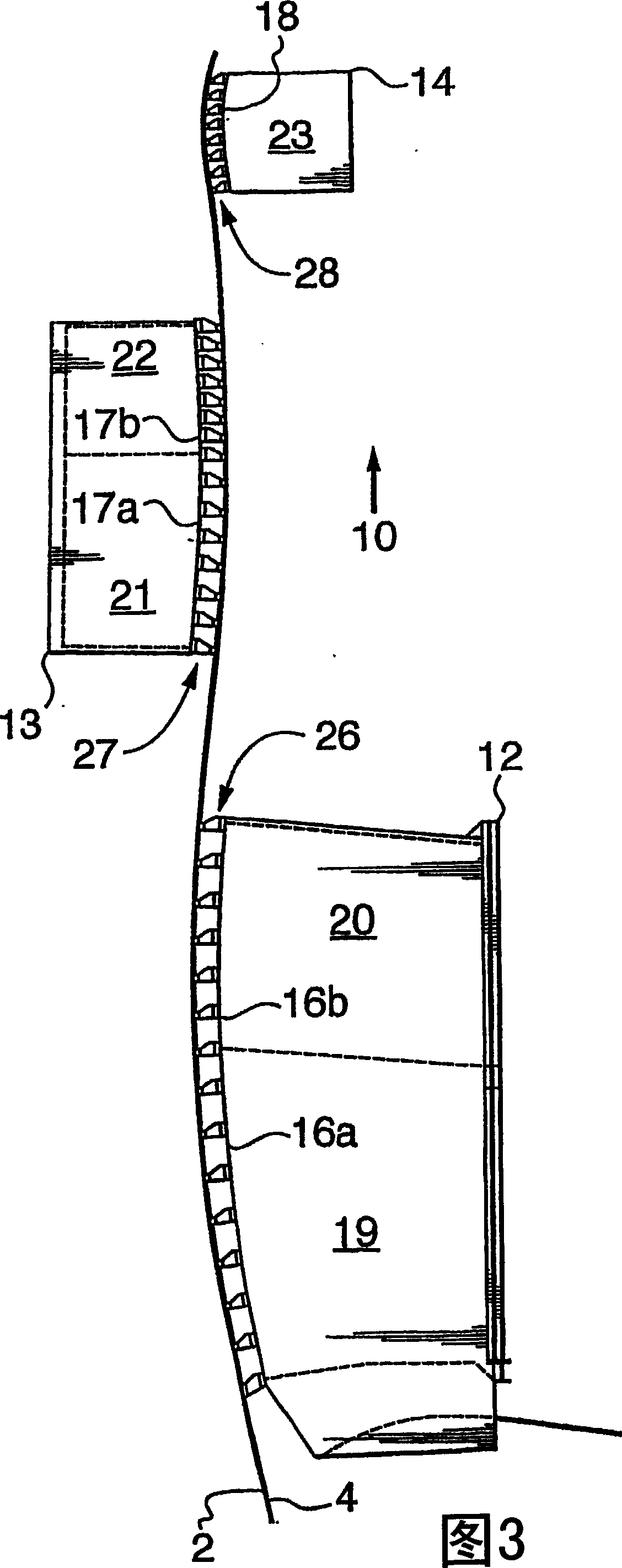

Gap type forming section for a two fabric paper making machine

A twin fabric gap former forming section (1) for paper making machine is described in which: the pitch of the fabric support elements (26, 27, 28) decreases progressively in the machine direction; the level of vacuum applied to the forming fabrics (2, 4) through the dewatering boxes (11, 12, 13, 14), increases in the machine direction; the two forming fabrics (2, 4) together with the stock (7) sandwiched between them traverse at least four separate and distinct vacuum zones (24, 19, 20, 21, 22, 23) within the forming section as they proceed in the machine direction; the level of vacuum applied to the last of the at least four separate and distinct vacuum zones is higher than the level of vacuum applied to the first of the separate and distinct vacuum zones; the level of vacuum applied to the at least four separate and distinct vacuum zones follows a pre-selected profile; and the dewatering boxes (11, 12, 13) and (14) carrying the fabric support elements (26, 27, 28) are arranged so that the fabric support elements (26, 27, 28) are located in an alternating sequence on the machine sides of both of the forming fabrics (2, 4).

Owner:ASTENJOHNSON

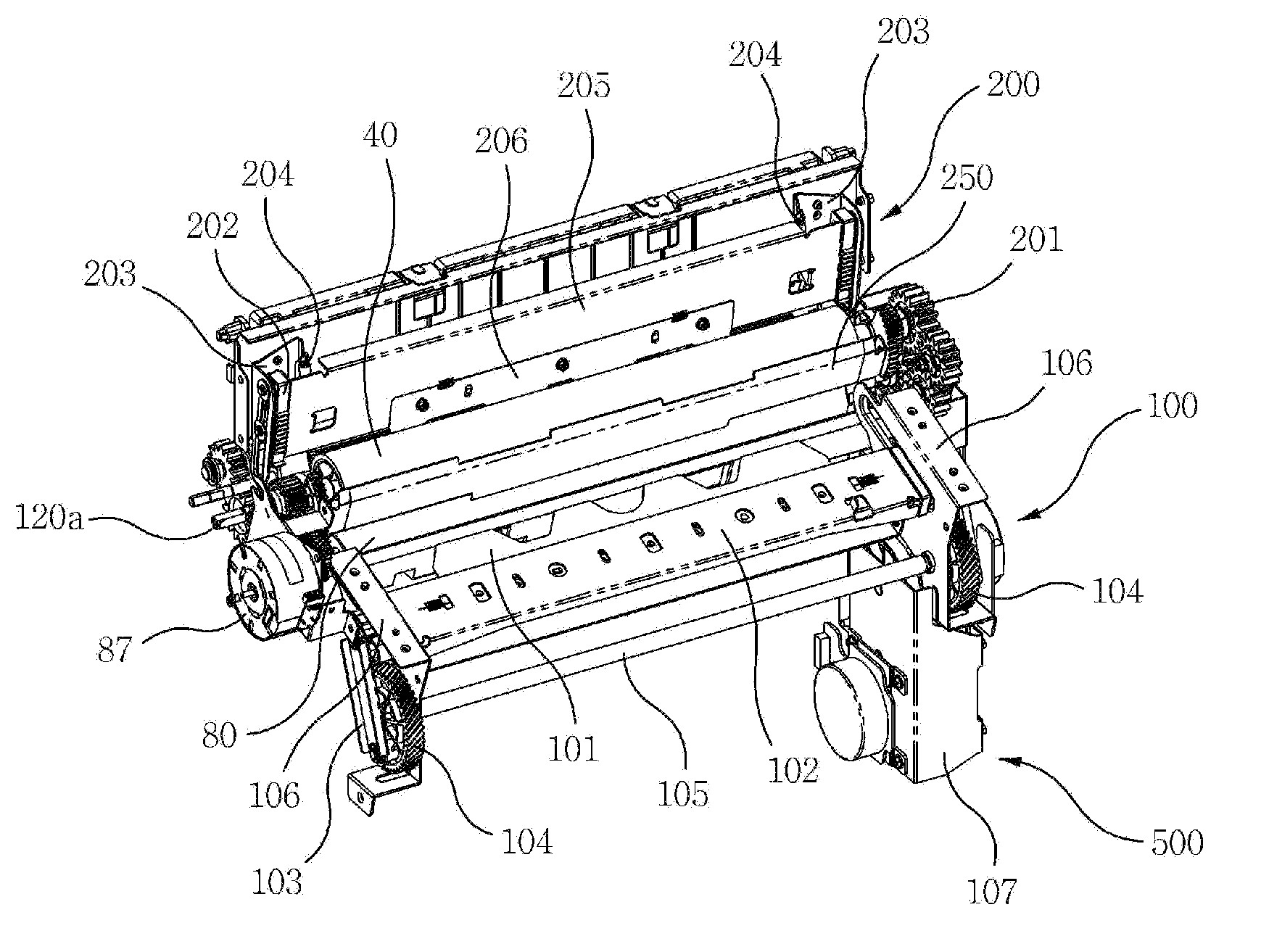

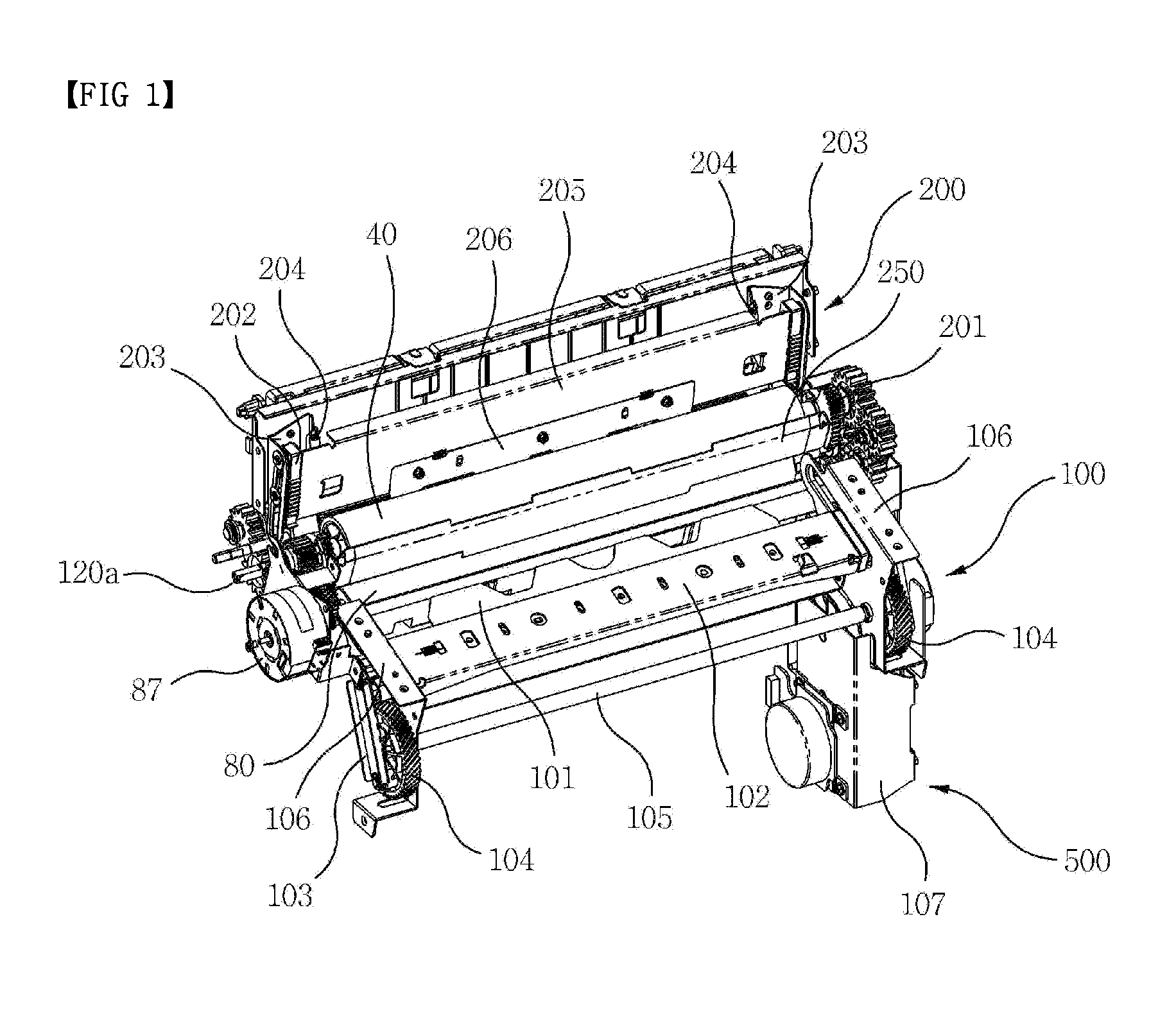

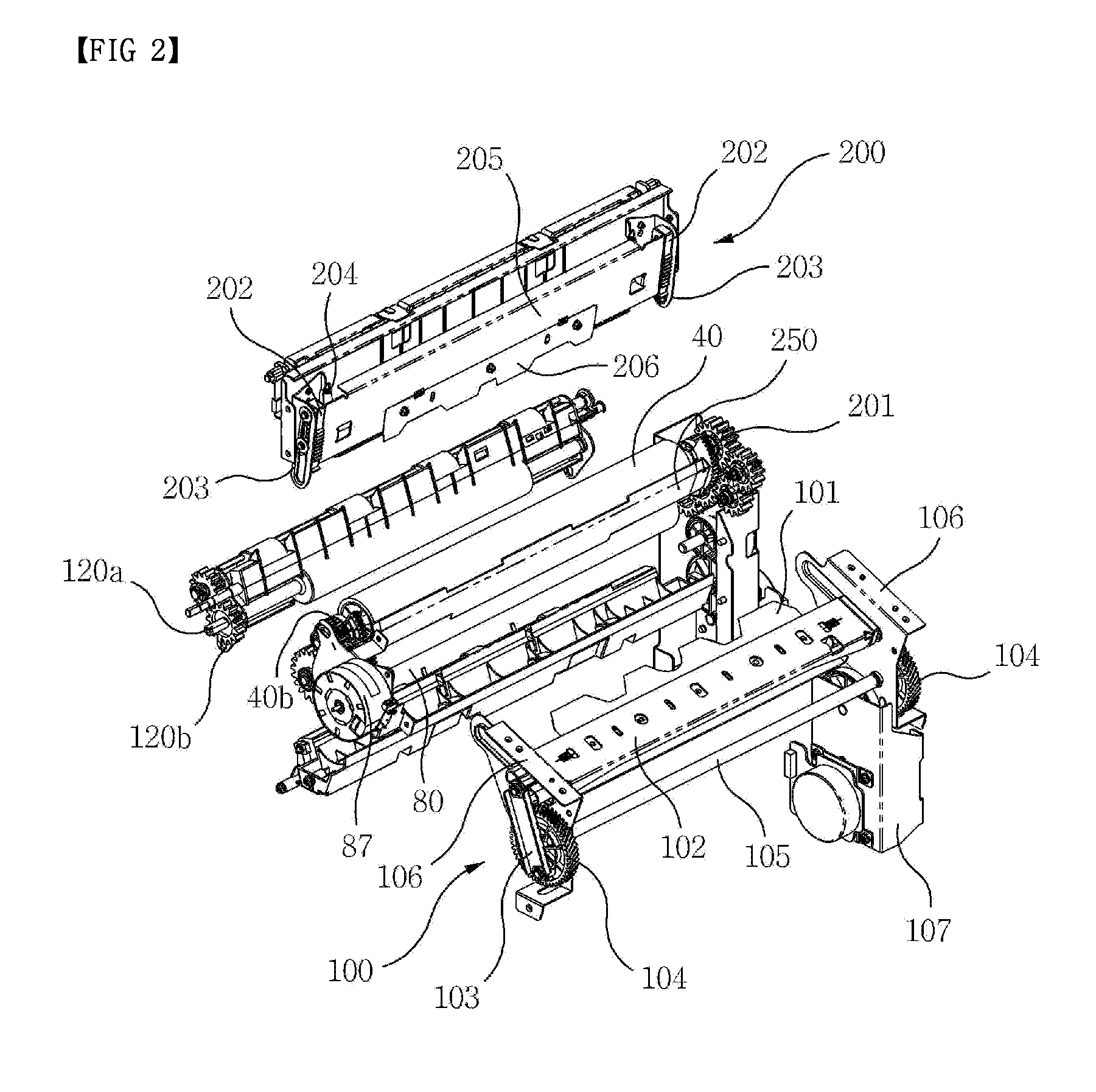

Paper folding apparatus for binding machine

ActiveUS20120046153A1Simple and inexpensive structureImprove paper performanceMechanical working/deformationFunction indicatorsGear wheelPulp and paper industry

Disclosed is a paper folding apparatus for a binding machine, capable of discharging paper sheets by folding the paper sheets twice. The paper folding apparatus includes a first knife unit and a second knife unit. The first knife unit has a first feeding path and a pair of first paper folding rollers. The second knife unit has a second feeding path and a pair of second paper folding rollers. A paper arranging guide is installed in front of the pair of first paper folding rollers, and the second knife unit includes a pinion, a rack selectively engaged with the pinion, a rack guide configured to provide a path on which the rack is moved, a resilient member resiliently supporting the rack, and a second paper folding knife configured to move back and forth between the second paper folding rollers in association with a moving direction of the rack.

Owner:BIZTECHONE

Method for preparing synthetic paper containing polysulfone amide precipitation fibers

ActiveCN101392475BHigh modulusHigh strengthSynthetic cellulose/non-cellulose material pulp/paperPhysical paper treatmentPolymer scienceAdditive ingredient

The invention provides a synthetic fiber paper, which contains the following ingredients in parts of weight: 5-95 parts of structural fiber and 5-95 parts of splicing fibers, wherein, the structural fiber is polyisophthaloyl metaphenylene diamide fiber and the splicing fiber is polysulfonamide precipitated fiber. The synthetic fiber paper is produced by the following steps: the structural fiber and the splicing fiber are made into be formed by a wet method and hot-rolled to obtain the paper. The synthetic fiber paper provided by the invention has high intensity conservation rate under the high temperature, excellent paper-making overall properties compared with the insulation paper made of full para-fiber, meta-fiber and full polysulfonamide material, and is more suitable for the insulation requirement under high-temperature environment.

Owner:LONGPONT

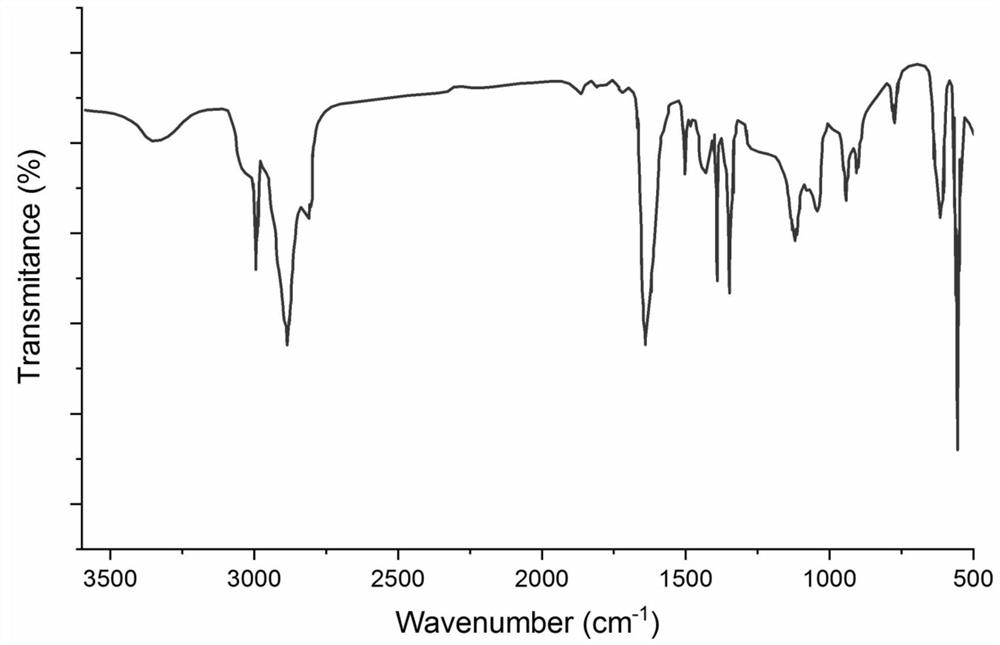

Cationic waterborne polyurethane emulsion as well as preparation method and application thereof

ActiveCN113024767AImprove retentionGood effectNon-fibrous pulp additionPaper/cardboardFiberPolymer science

The invention discloses a cationic waterborne polyurethane emulsion as well as a preparation method and application thereof, and belongs to the technical field of papermaking. According to the invention, toluene-2, 4-diisocyanate (TDI) is used as a main reaction raw material, polyethylene glycol (PEG-200, 400, 600 or 800) is used as a soft segment, tetrahydrofuran (THF) is used as a solvent, and 2, 4, 6-tri (dimethylaminomethyl) phenol is used as an end-capping reagent, and because the 2, 4, 6-tri (dimethylaminomethyl) phenol carries positive charges in an aqueous solution, the prepared waterborne polyurethane emulsion also carries positive charges, and under the action of charge attraction, the waterborne polyurethane emulsion can be well retained on negatively charged paper fibers. Besides, the cationic waterborne polyurethane emulsion prepared by the invention can be used as a papermaking wet end additive, obviously enhances the paper effect (the dry and wet strength, the tearability and the folding strength, especially the wet strength are obviously improved), and has a certain sizing effect. Moreover, the auxiliary agent can also be used for coating the surface of paper, so that the surface strength of the paper is improved, and even the surface porosity is adjusted.

Owner:ZHEJIANG HENGDA NEW MATERIAL CO LTD

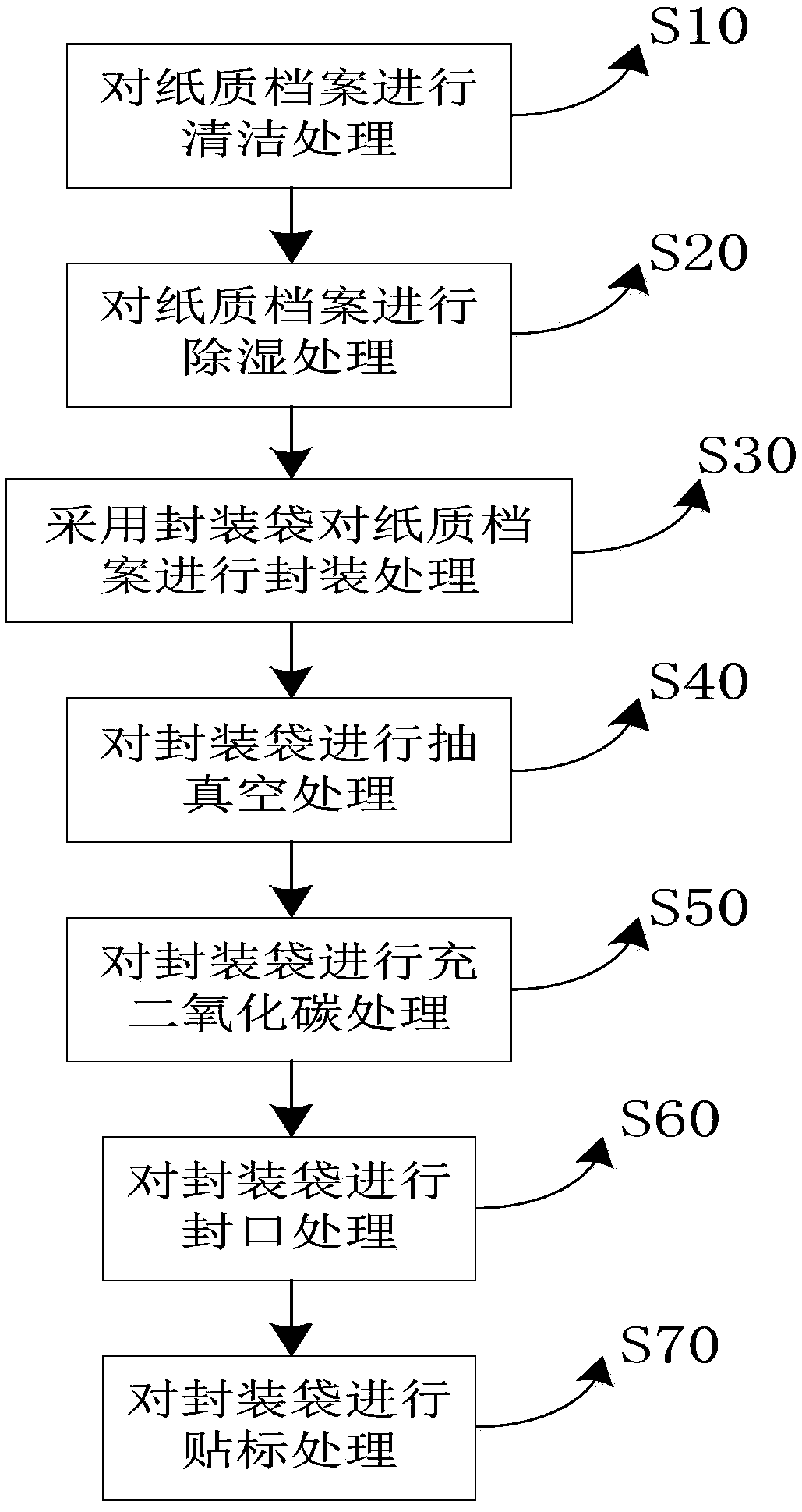

Paper file storing method and sealing file bag thereof

InactiveCN109664635AGood insecticidal effectImprove paper performanceFiling appliancesCarbon dioxideVacuum pumping

The invention relates to the field of article storing, in particular to a paper file storing method and a sealing file bag thereof. The storing method comprises the following steps that S30, packagingbags with different materials are selected according to different sealing grades, a paper file is arranged in a file box, and the file box is arranged in one packaging bag; S40, vacuum pumping treatment is carried out on the packaging bag; S50, carbon dioxide filling treatment is carried out on the packaging bag; and S60, sealing treatment is carried out the packaging bag. The invention further relates to the sealing file bag for the paper file storing method. According to the paper file storing method, the paper files can be stored for a long time, and the method enables the paper file to maintain good paper performance for a long time.

Owner:JIANGXI ACAD OF AGRI SCI

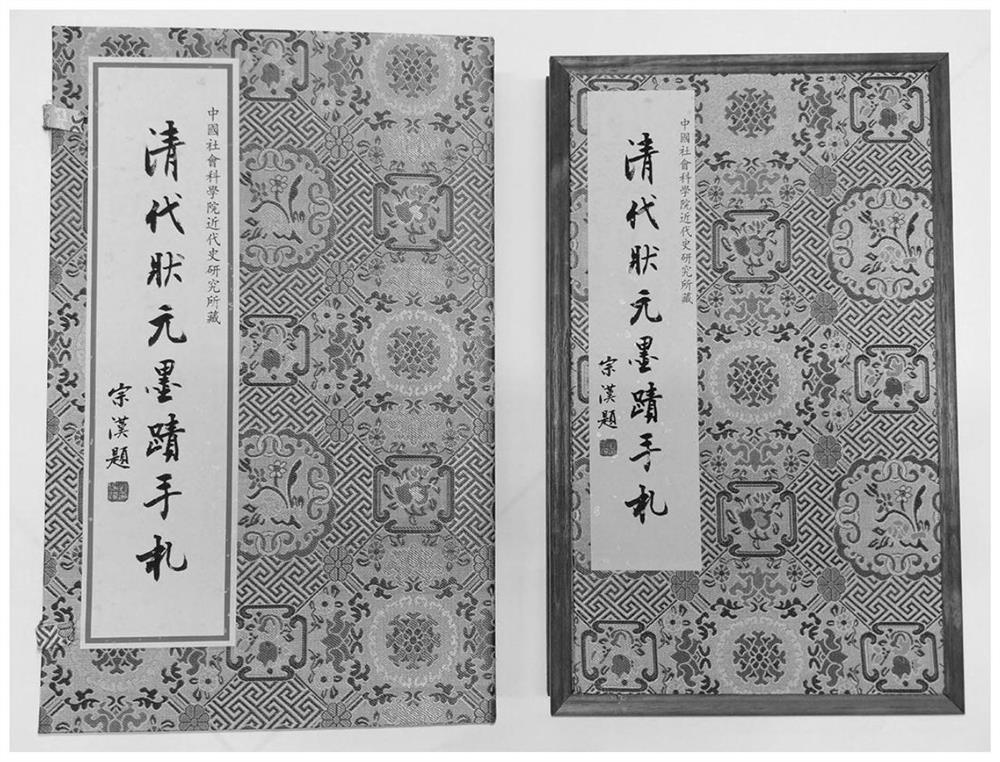

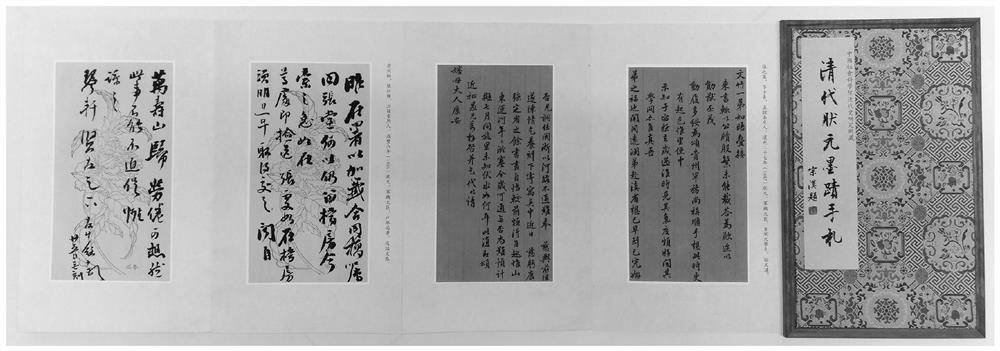

A picture book mounting process

ActiveCN114030316BHigh damage strengthAvoid scatterMechanical working/deformationBio-packagingEngineeringComputer science

The invention relates to an atlas mounting process. The process of the invention can continuously present single-page handwritten notes, letters, rubbings or documents to prevent scattering and loss, and at the same time has the functions of protection and visual beautification. firm. The invention adopts the double-layer continuous design of the carrying backing paper, has high strength and high paper performance, and the document is adhered to the art paper, which is suitable for long-term use and preservation. In addition, the length of the carrying backing paper is continuous to the entire album, the damage resistance of the inner core of the entire album is improved, and the durability of stretching and folding is several times higher than that of conventional albums.

Owner:久明国际文化(北京)有限公司

A method for optimizing paper structure and improving paper performance

ActiveCN104109980BIncrease bulkImprove breathabilityPulp beating methodsInorganic compound additionPapermakingTarget concentration

The invention discloses a method for optimizing paper structure and improving paper-making performance, comprising: pulp disintegration, pulp refining, preparation of filler suspension and paper sheet making: during paper sheet making, three-layer paper sheets are laminated In the papermaking method, by adjusting the concentration factor Fc of the filler distribution in the paper, the purpose of improving the bulk, air permeability, physical strength and optical properties of the filled paper can be achieved when the filler content is fixed. By optimizing the filler distribution factor to improve paper performance, by adjusting the distribution of fillers in the paper structure, to maximize the advantages of fillers, so as to achieve the purpose of improving paper performance. The method of the invention is simple and easy to operate, and can regulate the performance of the target paper according to the needs. In a modern paper machine, by optimizing the concentration factor and adjusting the distribution of fillers, the purpose of improving paper performance can be achieved, thereby improving product quality.

Owner:SHAANXI UNIV OF SCI & TECH

A production method of corrugated medium paper with improved deinking efficiency

ActiveCN109629297BImprove deinking efficiencyHigh Ink Removal RatePulp liquor regenerationWashing/displacing pulp-treating liquorsDeinkingFiber

The invention discloses a production method of corrugated medium paper with improved deinking efficiency, which comprises a soaking activation step, a hydraulic pulping step, a screening and slag removal step, a rubbing centrifugal deinking step, a bleaching step, a washing and concentrating step and a pulp storage step. Use a neutral deinking agent to directly rub the waste paper fibers for centrifugal deinking, and separate the ink through the process cooperation between activated ink and centrifugal deinking, which reduces the amount of alkaline deinking agent used and further reduces waste paper making The production cost is reduced, the deinking efficiency and ink removal rate are improved, the whiteness is improved, and the pollution to the environment is reduced.

Owner:东莞顺裕纸业有限公司

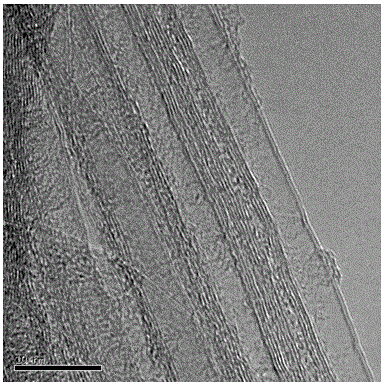

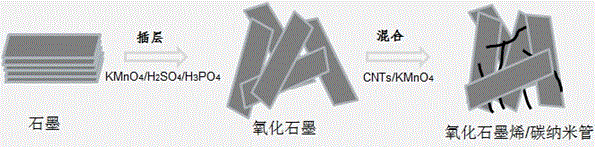

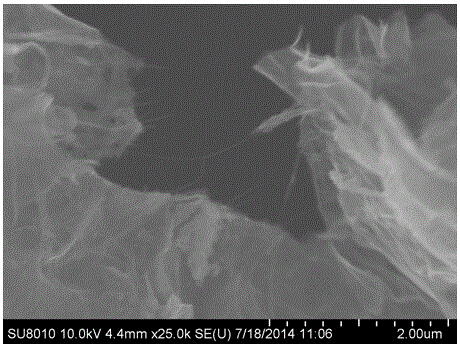

A kind of preparation method of graphene/carbon nanotube composite material

InactiveCN104852021BImprove paper performanceHas a nanoporous structureMaterial nanotechnologyGraphiteNanotubeDouble walled

The invention discloses a method of a graphene / carbon nanotube composite material. The method comprises the following steps: treating graphite serving as a raw material with a strong oxidant expansion separation method to obtain graphene oxide; adding carbon nanotubes; dispersing the carbon tubes in an oxidizing way; and performing the treatment of separation, washing, reduction and the like to obtain the graphene / carbon nanotube composite material, wherein the carbon nanotubes are single-wall carbon nanotubes, double-wall carbon nanotubes and multi-wall carbon nanotubes. The method has the advantages that graphene preparation is combined with a carbon tube compounding process, and a strong oxidant left in the preparation of graphene is used for dispersing the carbon nanotubes in an oxidizing way, so that the compounding cost can be reduced, and the efficiency is increased. In particular for carbon nanotubes gathered into bundles, the strong oxidant left in the preparation of graphene can be used for performing oxidation intercalation among the tube walls of carbon tube bundles to disperse the carbon tubes, so that uniform compounding of the carbon tubes with graphene is realized.

Owner:TIANJIN NORMAL UNIVERSITY

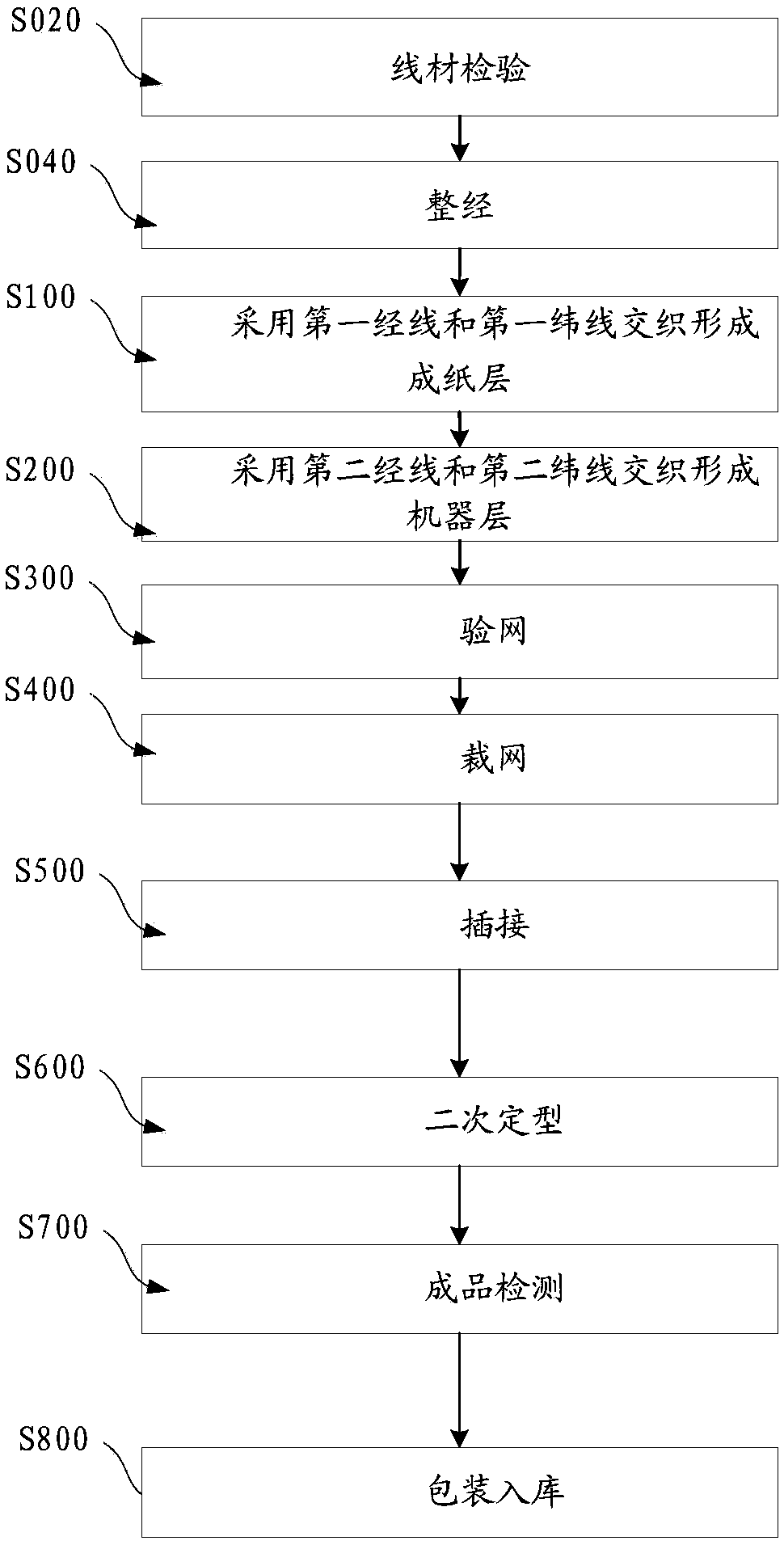

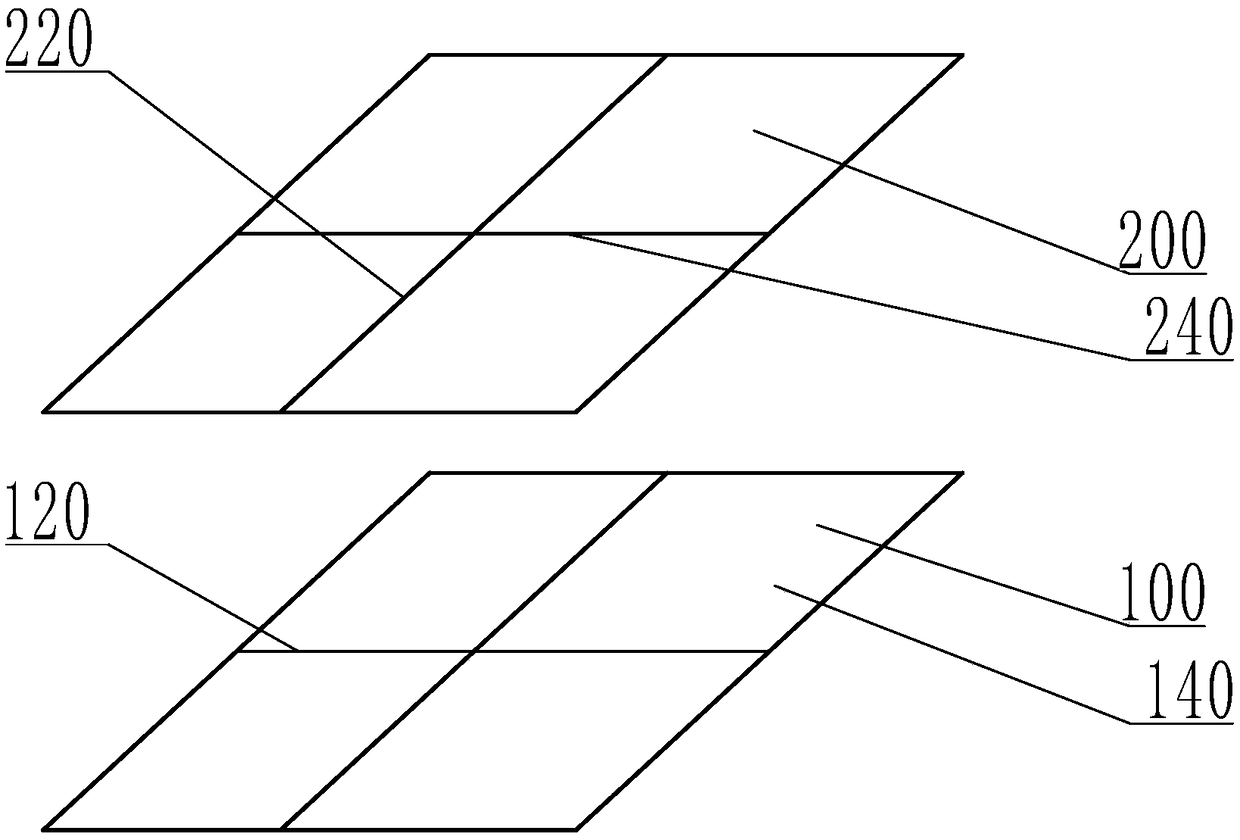

A manufacturing method of a double-warp flat wire drying net and a double-warp flat wire drying net

ActiveCN106087181BImprove paper performanceIncrease contact areaFilament/thread formingWoven fabricsScreen printingPolyester

The invention discloses a double-warp flat wire drying net and a method for manufacturing the double-warp flat wire drying net. The double-warp flat wire drying net includes a machine layer and a paper-forming layer arranged on the machine layer; the paper-forming layer consists of The first warp thread and the first weft thread are interwoven; the machine layer is formed by the second warp thread and the second weft thread interweaving, and the minimum organizational unit is composed of 4 polyester monofilaments as warp threads and 6 polyester monofilaments as weft threads. The present invention increases the contact area with the paper by using the first warp and the second warp, so that the paper has a good paper-making effect, no screen printing, minimal longitudinal extension, and long service life; the first weft and the second weft are used , one of which has a rectangular cross-section, which reduces the stagger between the upper and lower layers of the drying wire, has no internal wear, and improves wear resistance. At the same time, it runs under the maximum tension of the paper machine without stretching and retracting, and the stability is improved. Reinforced for longer service life.

Owner:JIANGSU JINNI ENGINEERED FABRIC CO LTD

A kind of bamboo pulp household paper making method and household paper

ActiveCN110924227BGood formabilityImprove efficiencyReinforcing agents additionPaper/cardboardFiberPaper production

An embodiment of the present invention provides a bamboo pulp household papermaking method, comprising: making bamboo pulp as the main pulp, and distributing the pulp into A pulp and B pulp, and separately separating A pulp and B pulp, and mixing The separated pulp forms the first mixed pulp and the second mixed pulp, and after the second mixed pulp is refined, the first mixed pulp and the refined second mixed pulp are used to make paper in the paper machine, The paper machine described is a crescent-shaped paper machine. By distributing the slurry and then classifying, the distribution and proportion of fibers of different lengths in the bamboo pulp can be adjusted. On the one hand, it can save energy and improve the softener and wet strength. On the other hand, after adjusting the distribution and proportion of fibers of different lengths in the bamboo pulp, the pulp has better forming performance, which meets the needs of the crescent-shaped paper machine and improves the paper-forming performance of the paper. Provided is a household paper produced by using the above bamboo pulp household paper production method.

Owner:四川永丰浆纸股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com