Control agent of dissolved and colloidal substances in paper machine circulating off-machine water and use method thereof

A technology of dissolving colloids and control agents, which is applied in the direction of inorganic compound addition, paper, papermaking, etc., can solve the problems of decreased efficiency of the retention system, a large amount of foam in the white water system, and broken holes in the paper web, so as to improve and reduce the closed circulation of white water. The effect of DCS content and water consumption reduction per ton of paper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

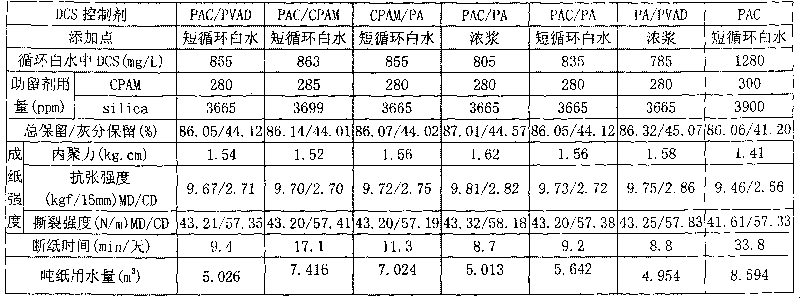

Embodiment 1

[0013] For the production of coated base paper, the white water of the paper machine is closed cycle, and the DCS control agent is a compound of PAC and PA, wherein the ratio of PAC to PA is 50:1. PA is medium to high molecular weight, high positive charge density, the addition point is short cycle white water, the addition amount of PAC is 250ppm (for tons of paper), and PA is 5ppm (for tons of paper). The white water of the paper machine was fully closed for one month, the DCS content in the white water was 835mg / L, the average daily paper breaking time of the paper machine was reduced from 33.8min to 9.2min, and the water consumption per ton of paper was reduced from 8.594m 3 Descend to 5.642m 3 . At the same time, the amount of auxiliary agent is reduced, and the strength of paper is improved.

Embodiment 2

[0015] The DCS control agent is a compound of PAC and PVAD, wherein the ratio of PAC to PVAD is 70:1. PVAD is characterized by high molecular weight and high positive charge density. The addition point is short-circulation white water, the addition amount of PAC is 200ppm (for tons of paper), and PVAD is 3ppm (for tons of paper). The white water of the paper machine was fully closed for one month, and the DCS content in the white water was 855mg / L. The average daily paper breaking time of the paper machine was reduced from 33.8 minutes to 9.4 minutes, and the water consumption per ton of paper dropped to 5.026m 3 . At the same time, the amount of retention additives is reduced, and the paper strength is also improved.

Embodiment 3

[0017] The DCS control agent is a compound of CPAM and PA, wherein the ratio of CPAM to PA is 15:10. CPAM is characterized by high molecular weight, medium and low positive charge density, and PA medium and high molecular weight, high positive charge density. The addition point is short-circulation white water, the addition amount of CPAM is 15ppm (for tons of paper), and PA is 10ppm (for tons of paper). The white water of the paper machine was fully closed for one month, the DCS content in the white water was 855mg / L, the average daily paper breaking time of the paper machine was reduced to 11.3min, and the water consumption per ton of paper was reduced to 7.024m 3 . At the same time, the amount of retention additives is reduced, and the paper strength is also improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com