Patents

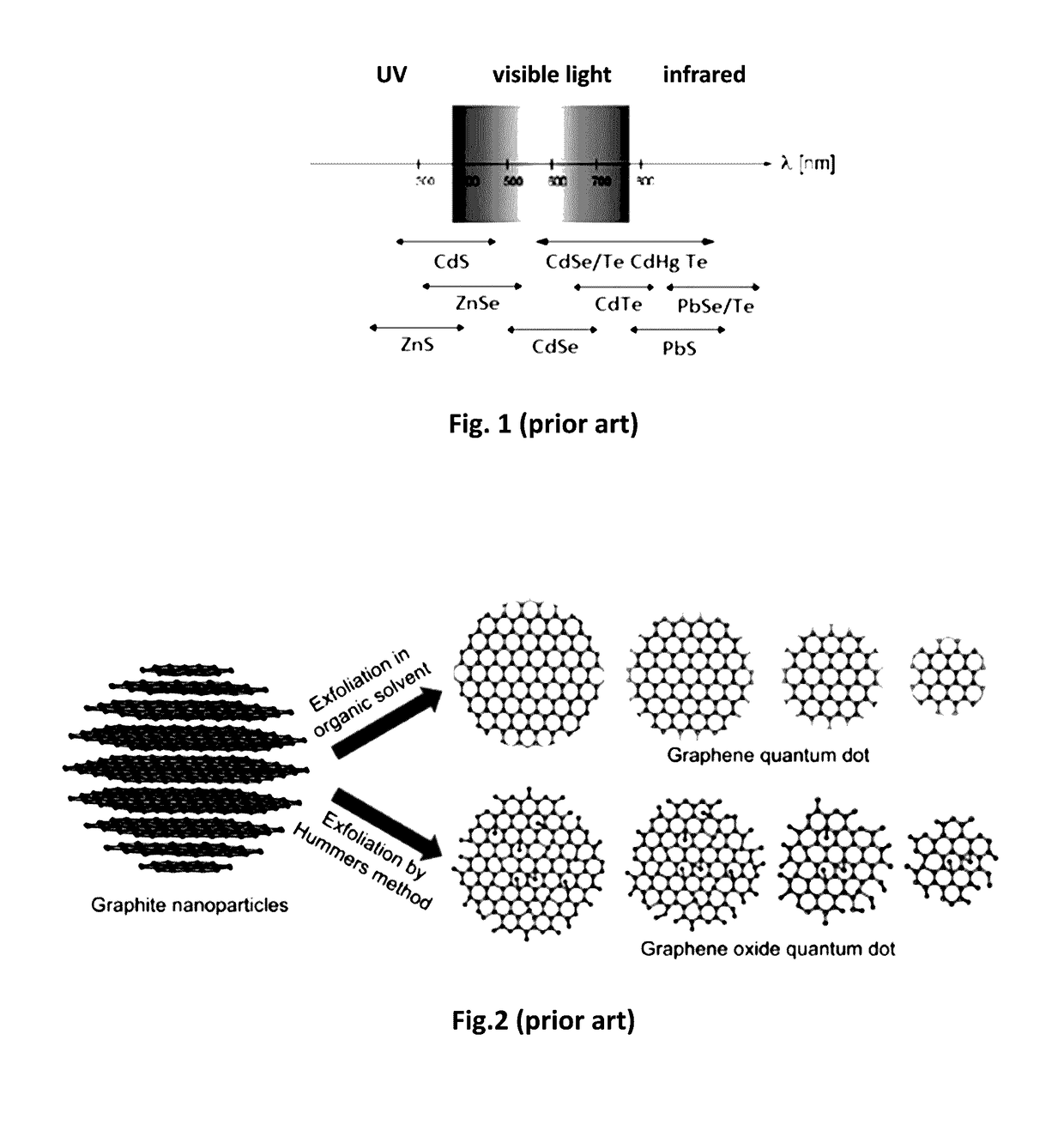

Literature

107 results about "Graphene nanoparticles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

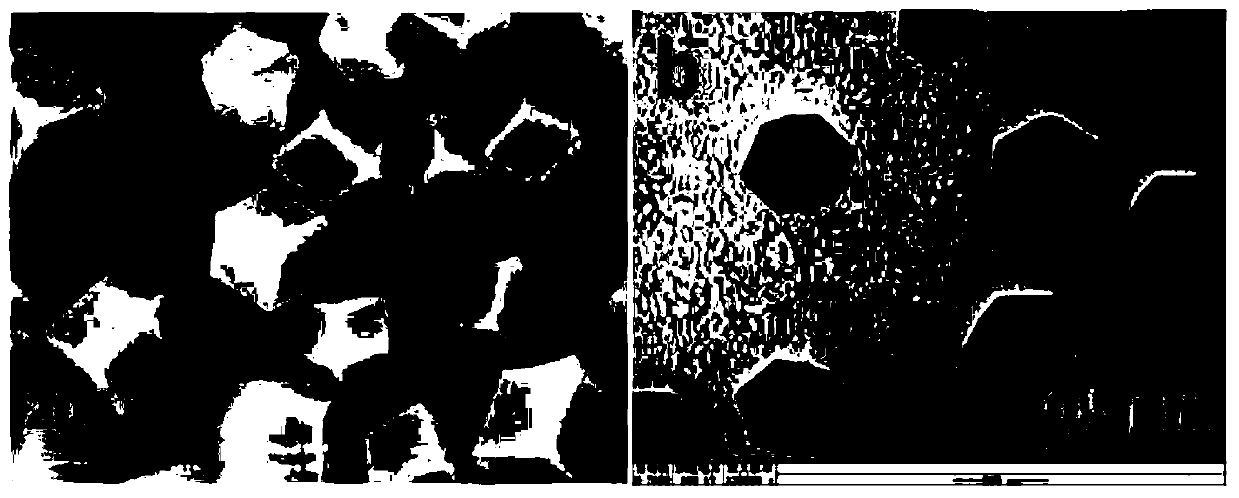

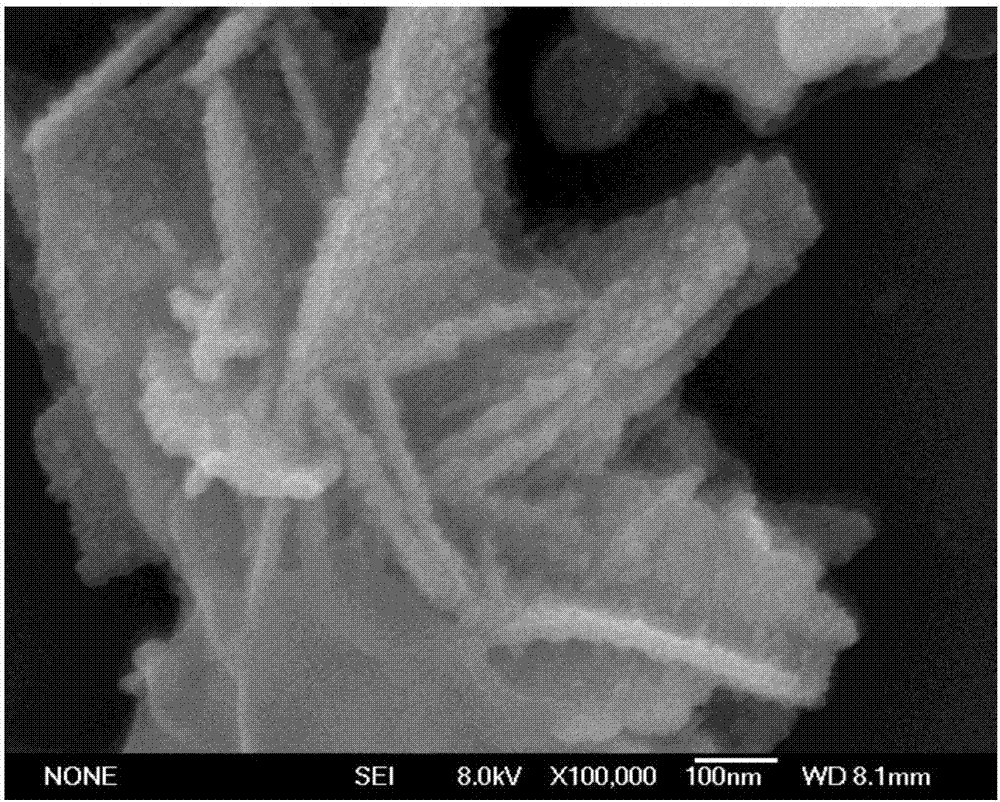

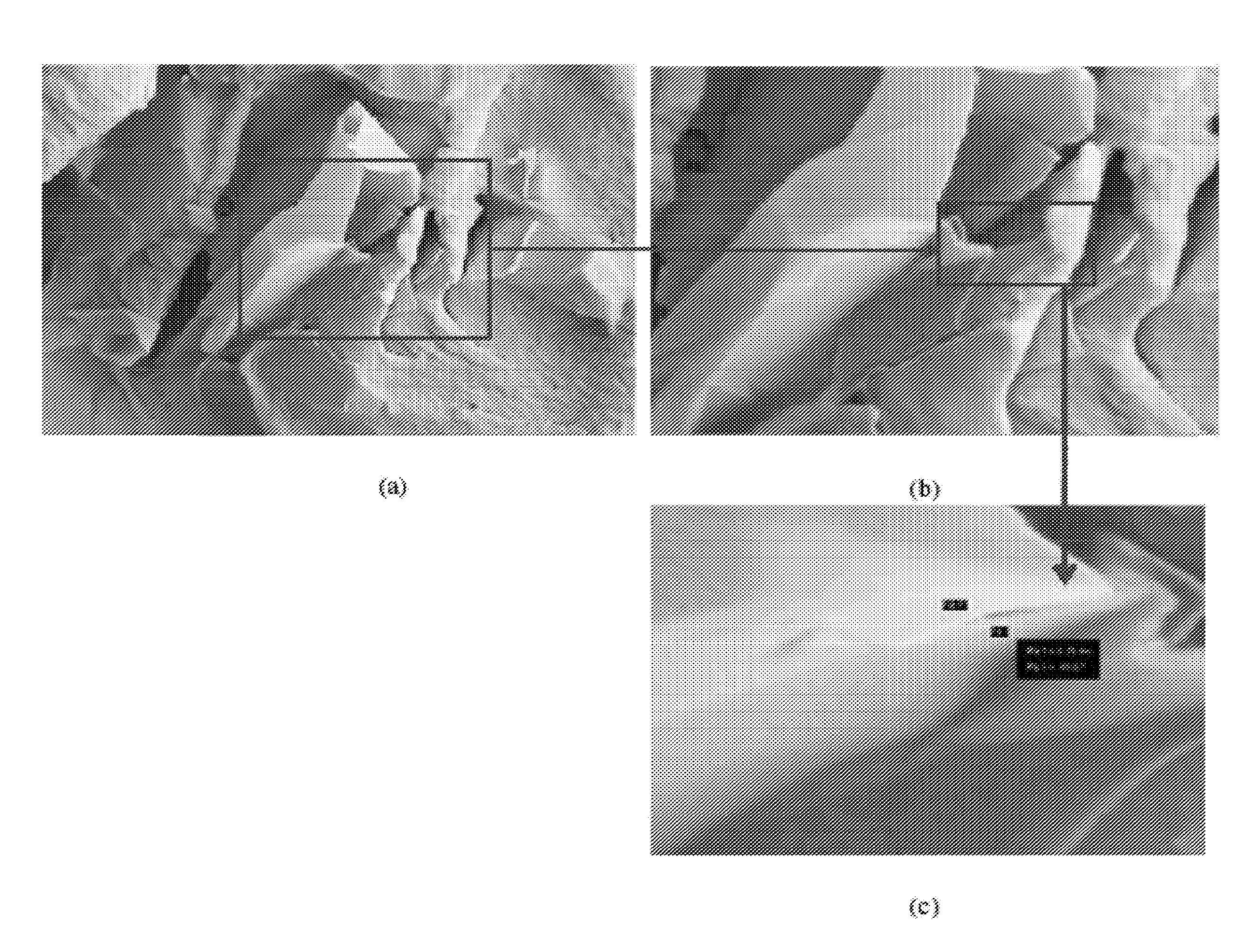

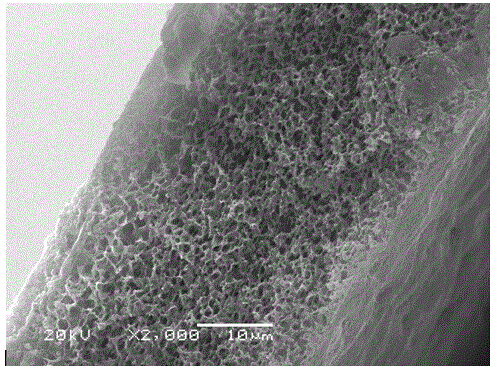

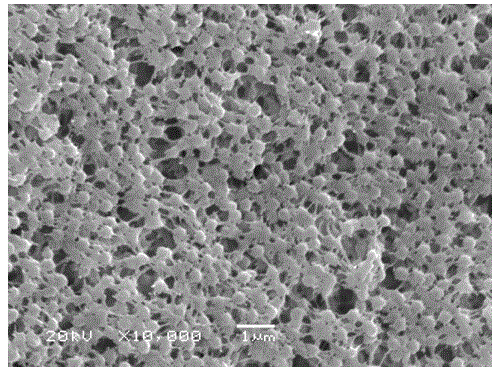

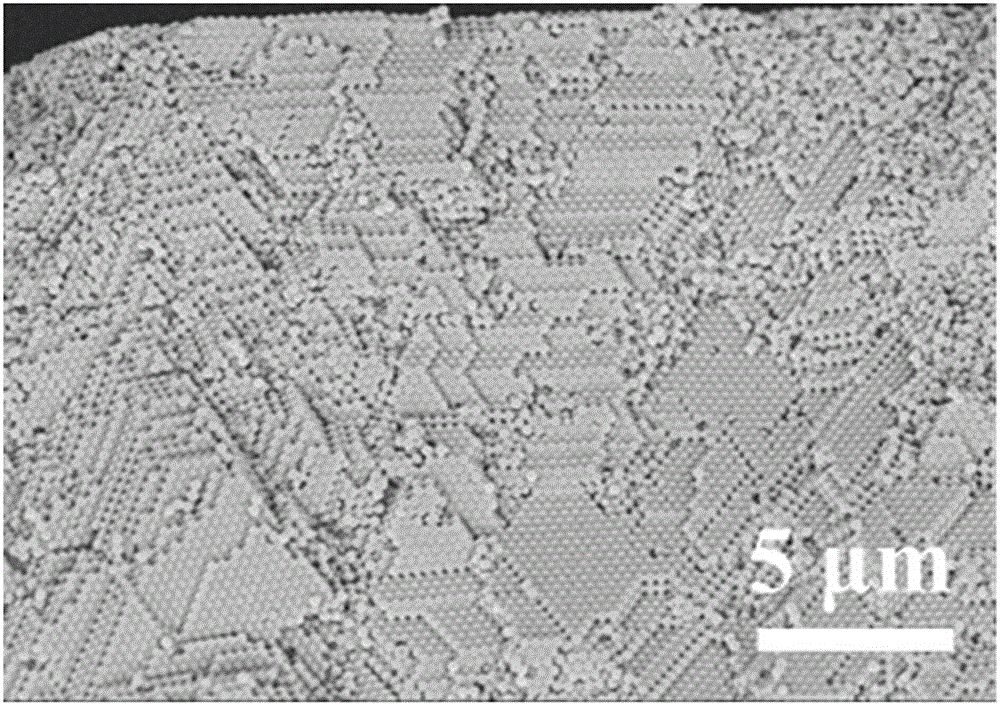

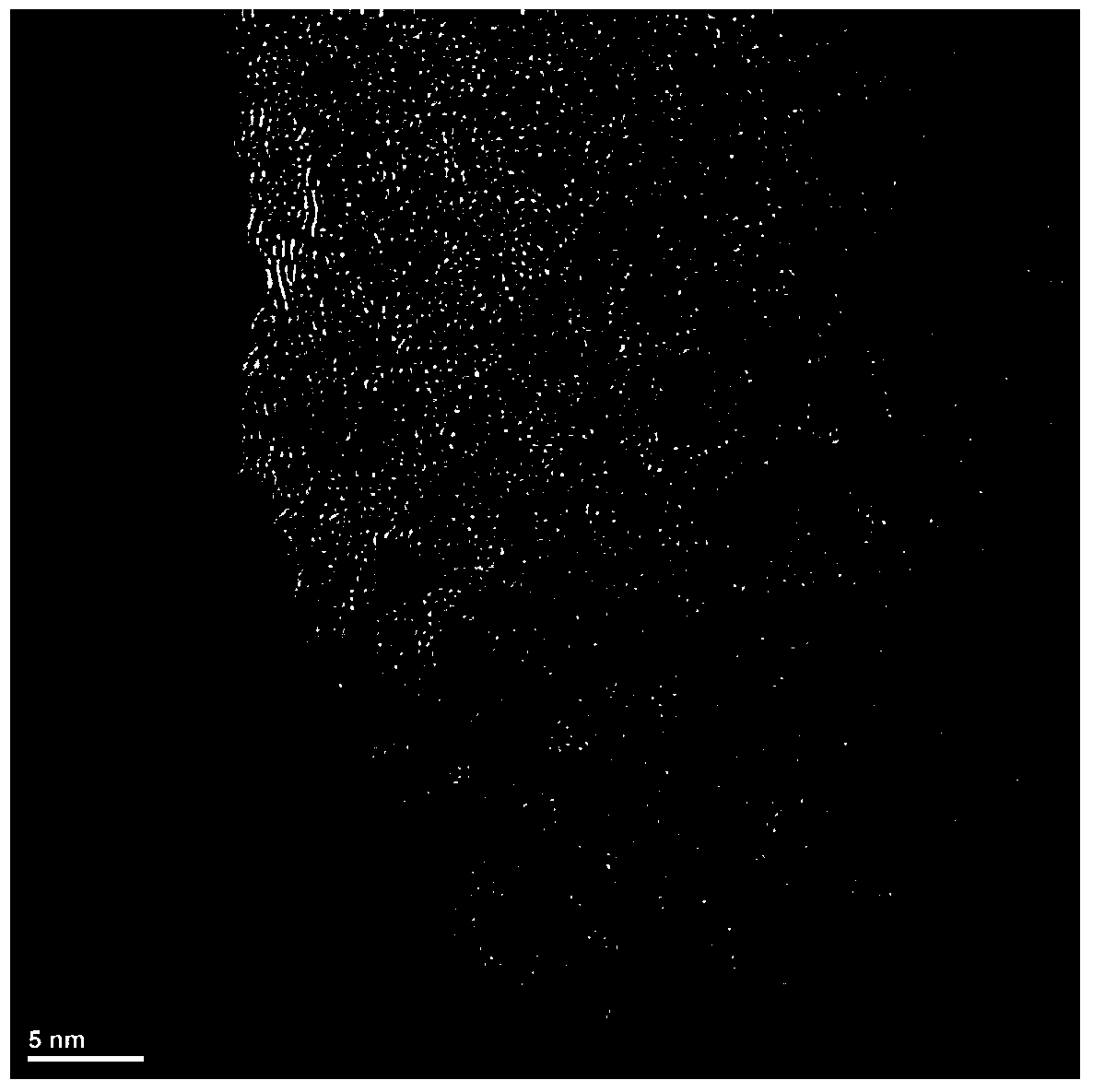

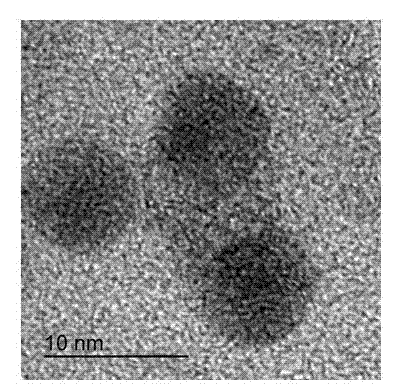

Graphene nanoscrolls are formed by decoration of magnetic nanoparticles. After decoration with maghemite nanoparticles the graphene spontaneously form nanoscrolls. The dark cylinders in the upper part of the image shows graphene nanoscrolls that are covered with a smooth layer of small particles.

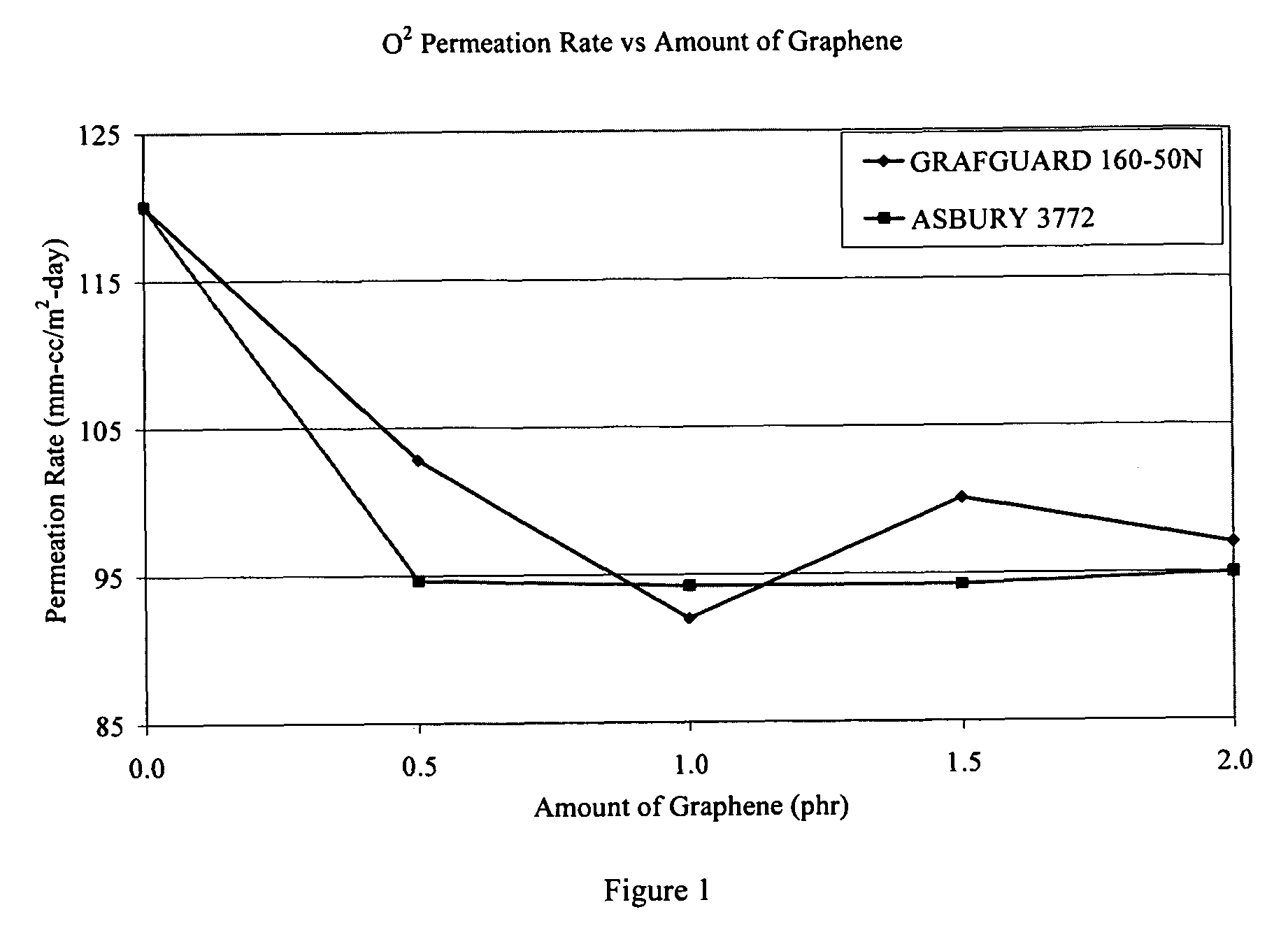

Graphite Nanocomposites

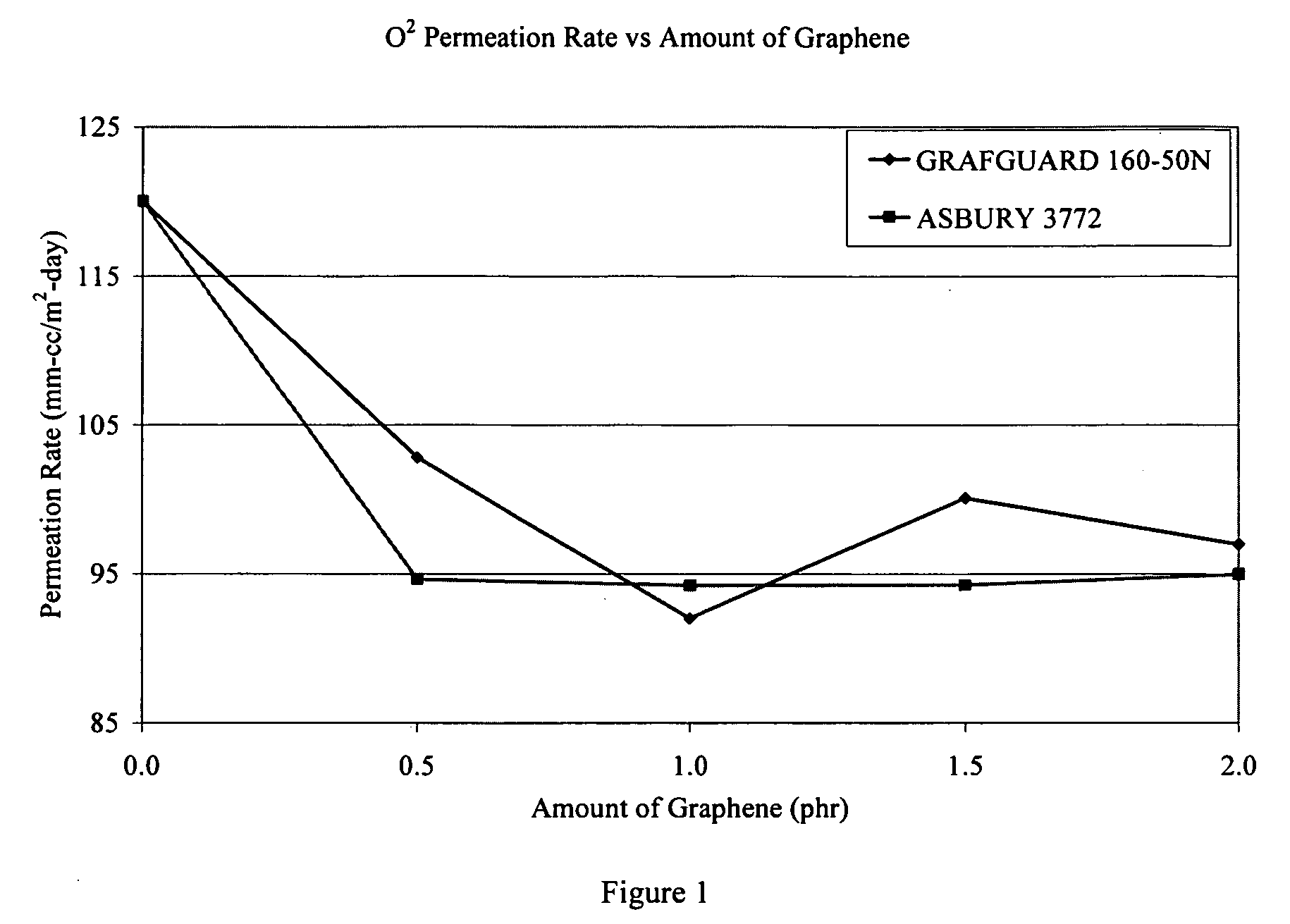

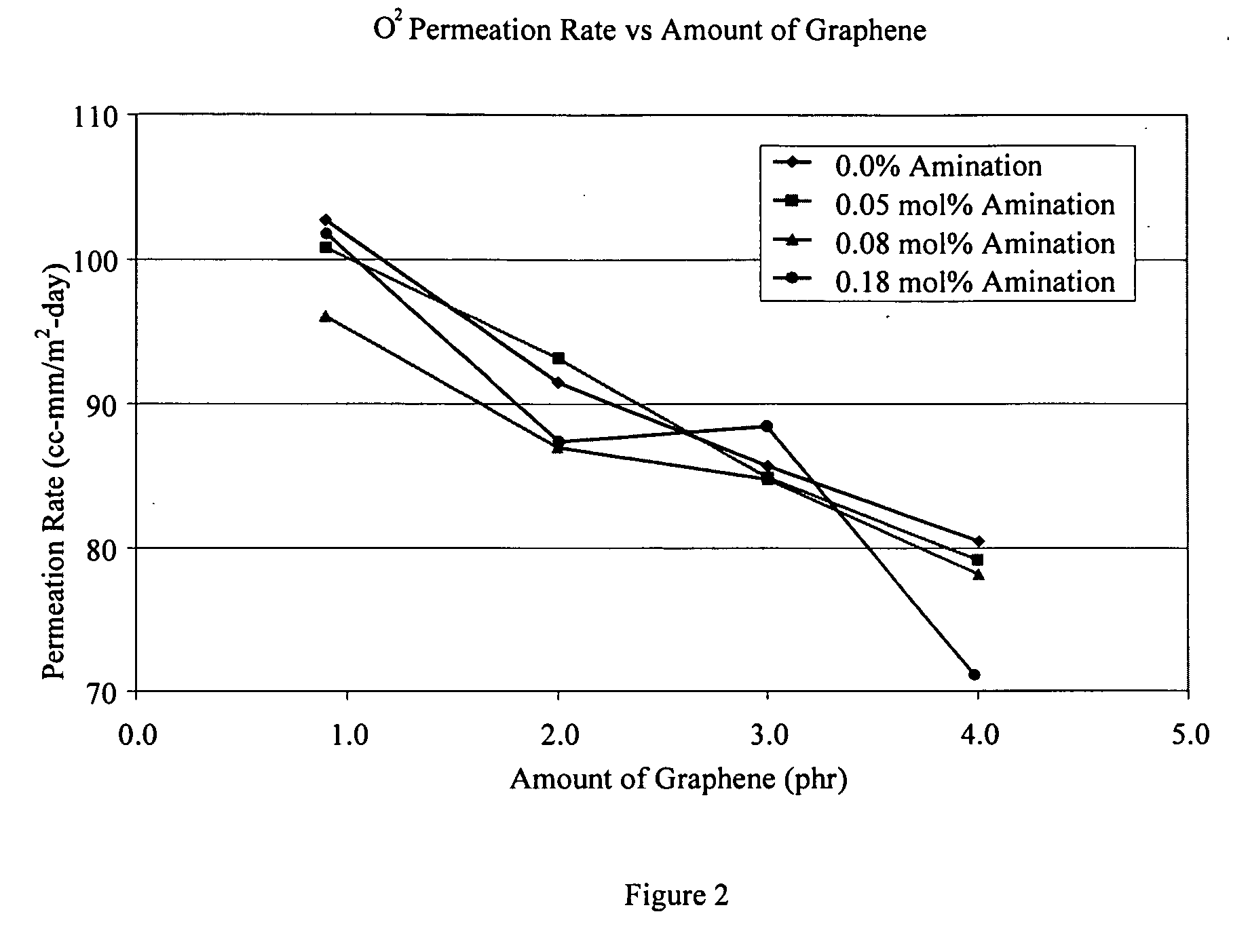

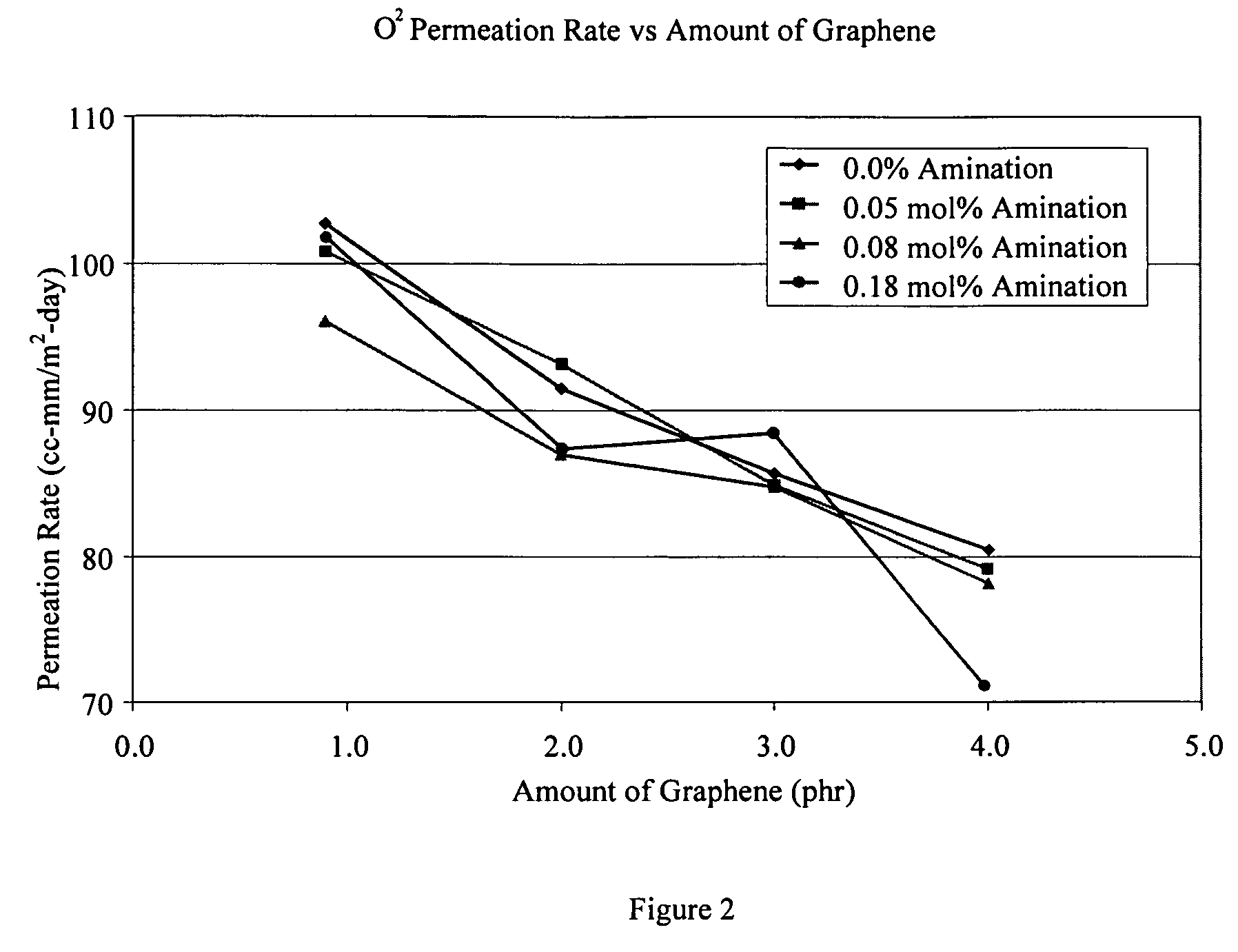

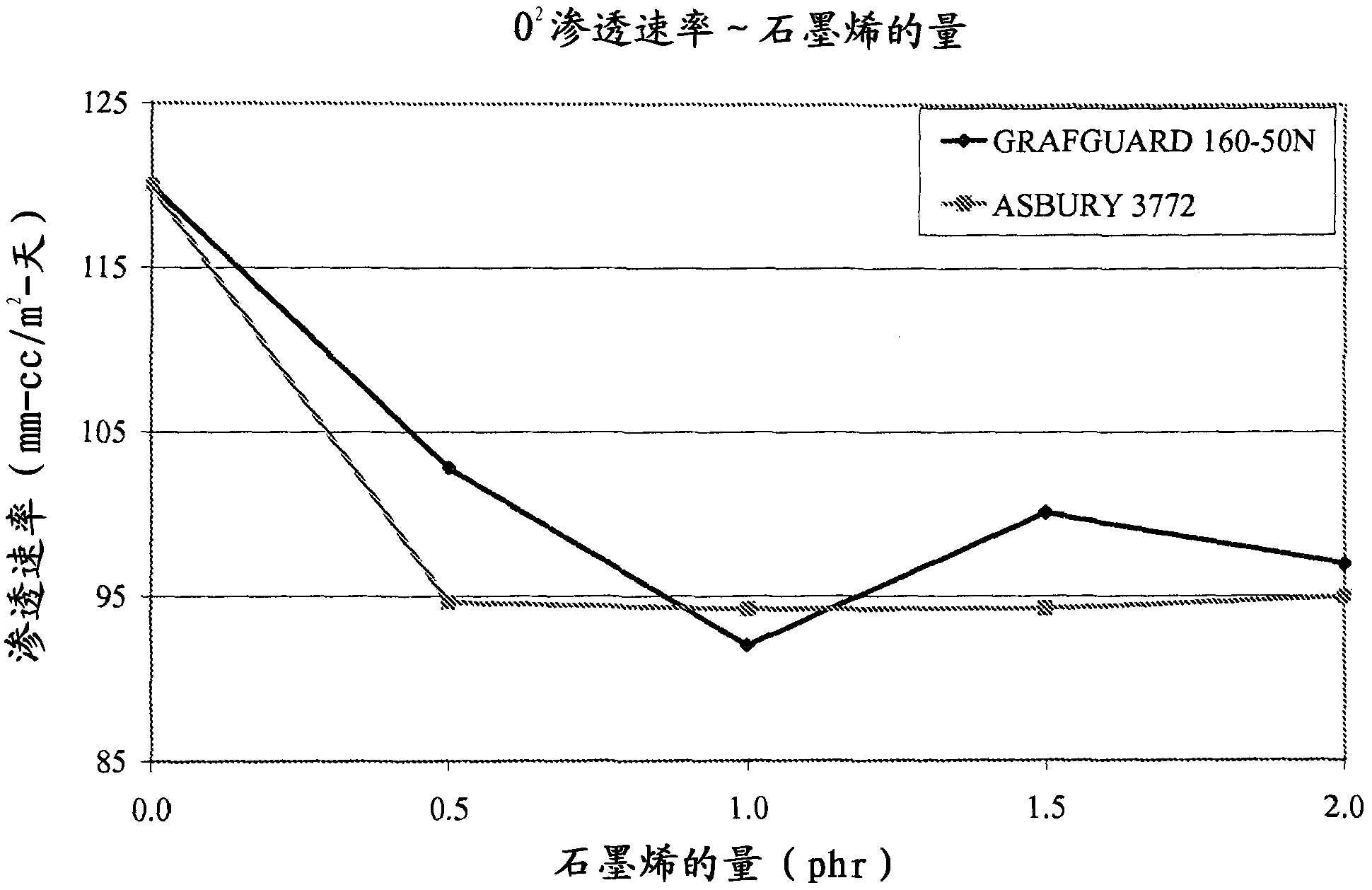

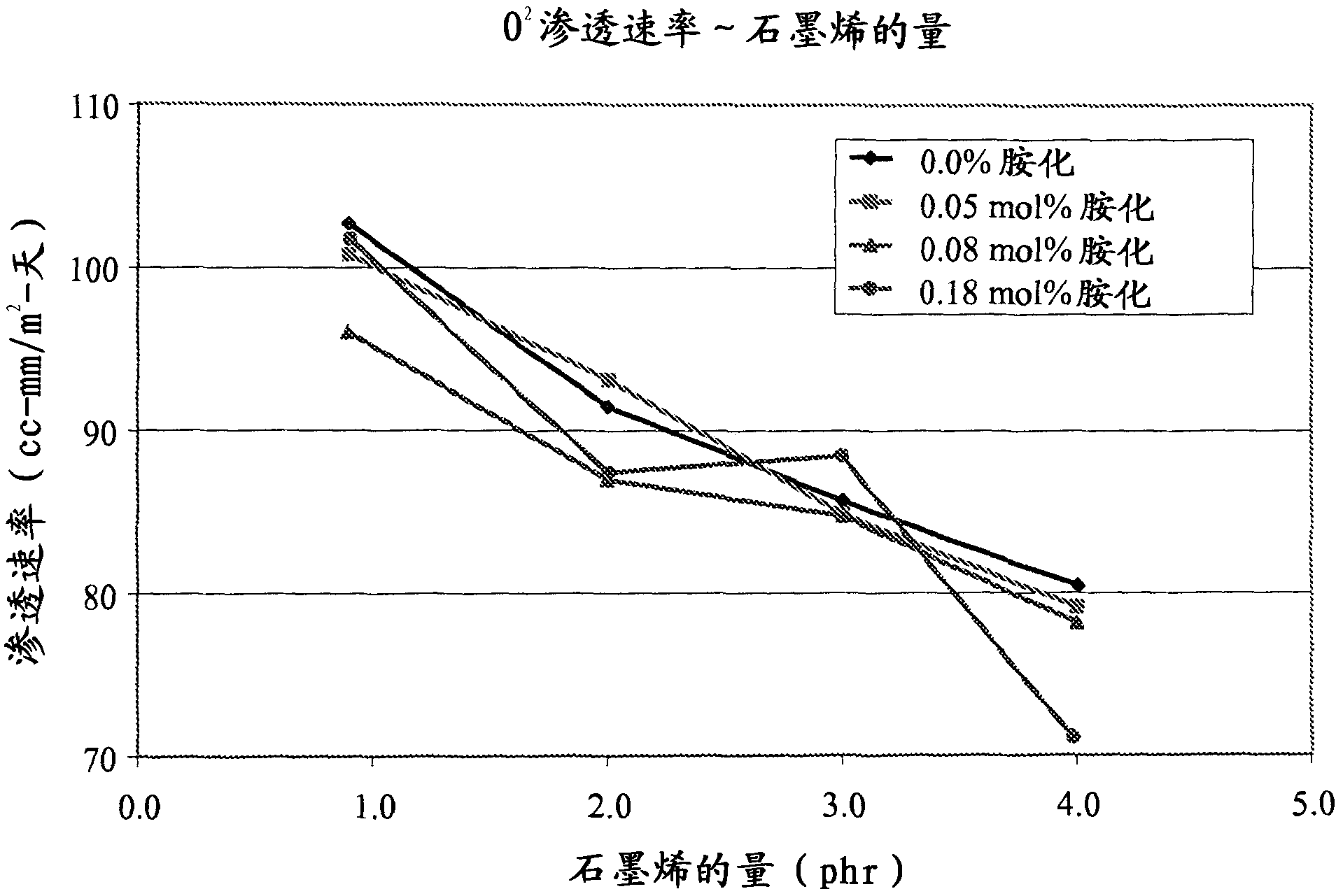

ActiveUS20100036023A1Improve retentionEasy to processMaterial nanotechnologySpecial tyresNanometreGraphene nanoparticles

Owner:EXXONMOBIL CHEM PAT INC

Graphene-fullerene-like molybdenum disulfide compounded lubricating oil additive and preparation method thereof

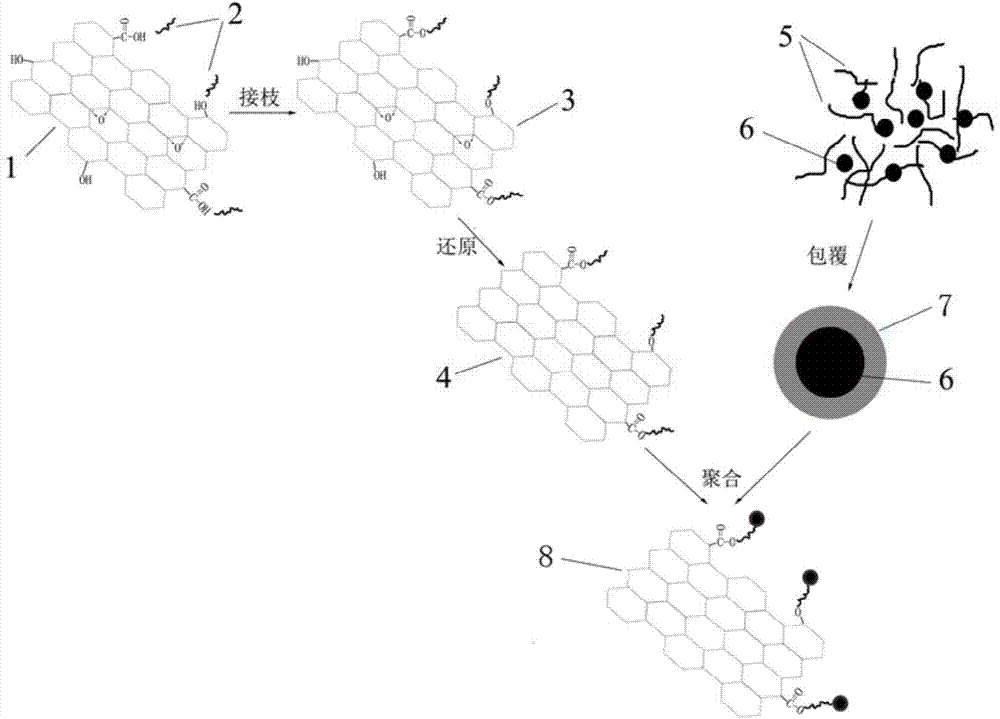

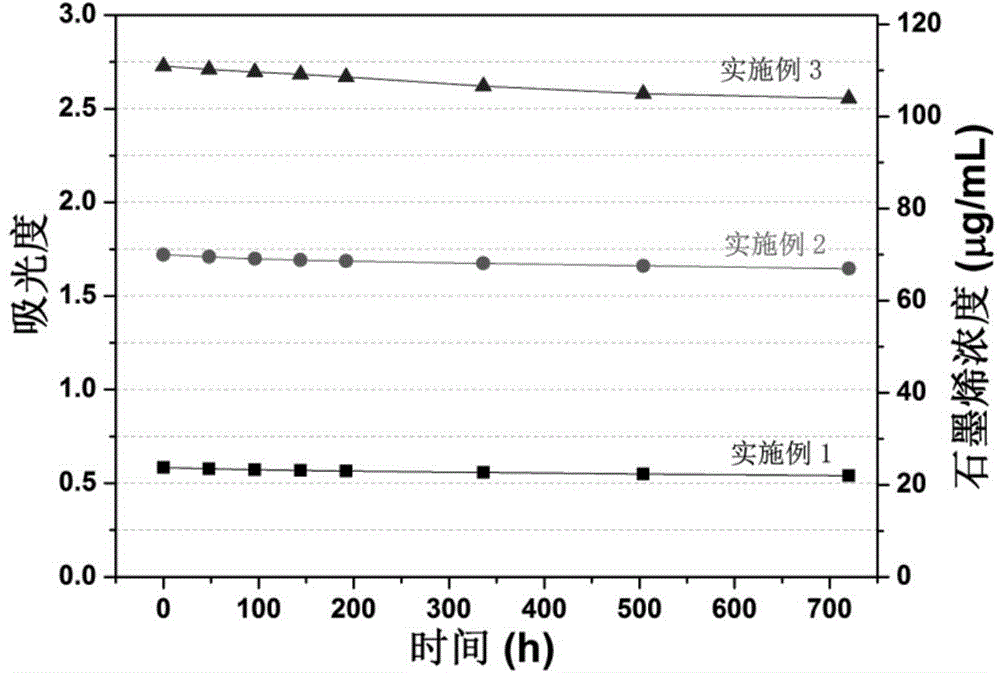

The invention discloses a graphene-fullerene-like molybdenum disulfide compounded lubricating oil additive and a preparation method thereof. The method is implemented by taking oxidized graphene and fullerene-like molybdenum disulfide nanoparticles as raw materials through carrying out surface grafting on oxidized graphene nanoparticles by using lipophilic 3-(methyl acryloyl oxy) propyl-trimethoxysilane (KH-570), and carrying out reduction by using hydrazine hydrate, so that grafted graphene nanoparticles are formed; wrapping the fullerene-like molybdenum disulfide nanoparticles with polystyrene (PS), so that PS / IF-MoS2 nano composite microspheres are formed; and finally, inducing KH-570 and PS to have a polymerization reaction, so that graphene-fullerene-like molybdenum disulfide compounded nanoparticles are formed. The compounded nanoparticles prepared according to the invention are used as a lubricating oil additive, and can be steadily dispersed in lubricating oil for a long time, and various organic dispersants are not required to be added.

Owner:NANJING UNIV OF SCI & TECH

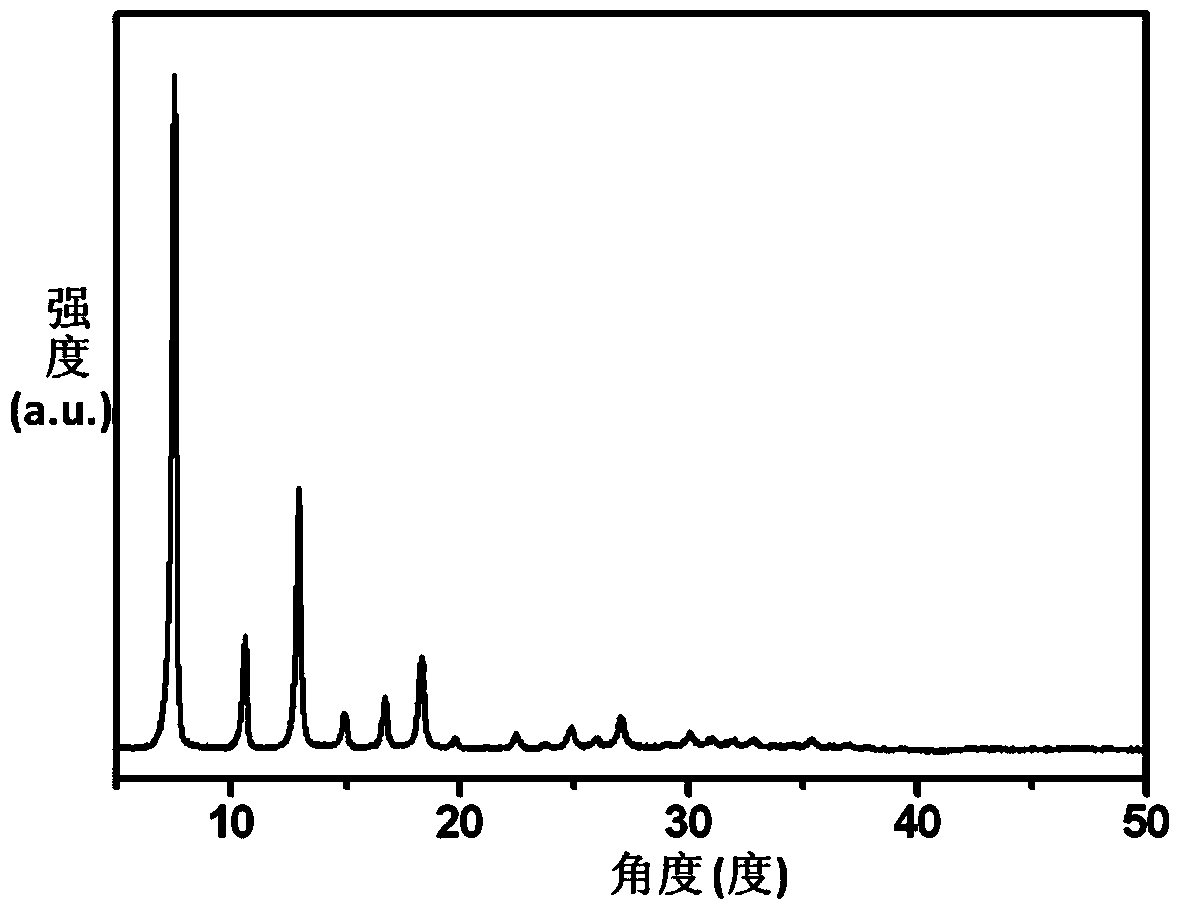

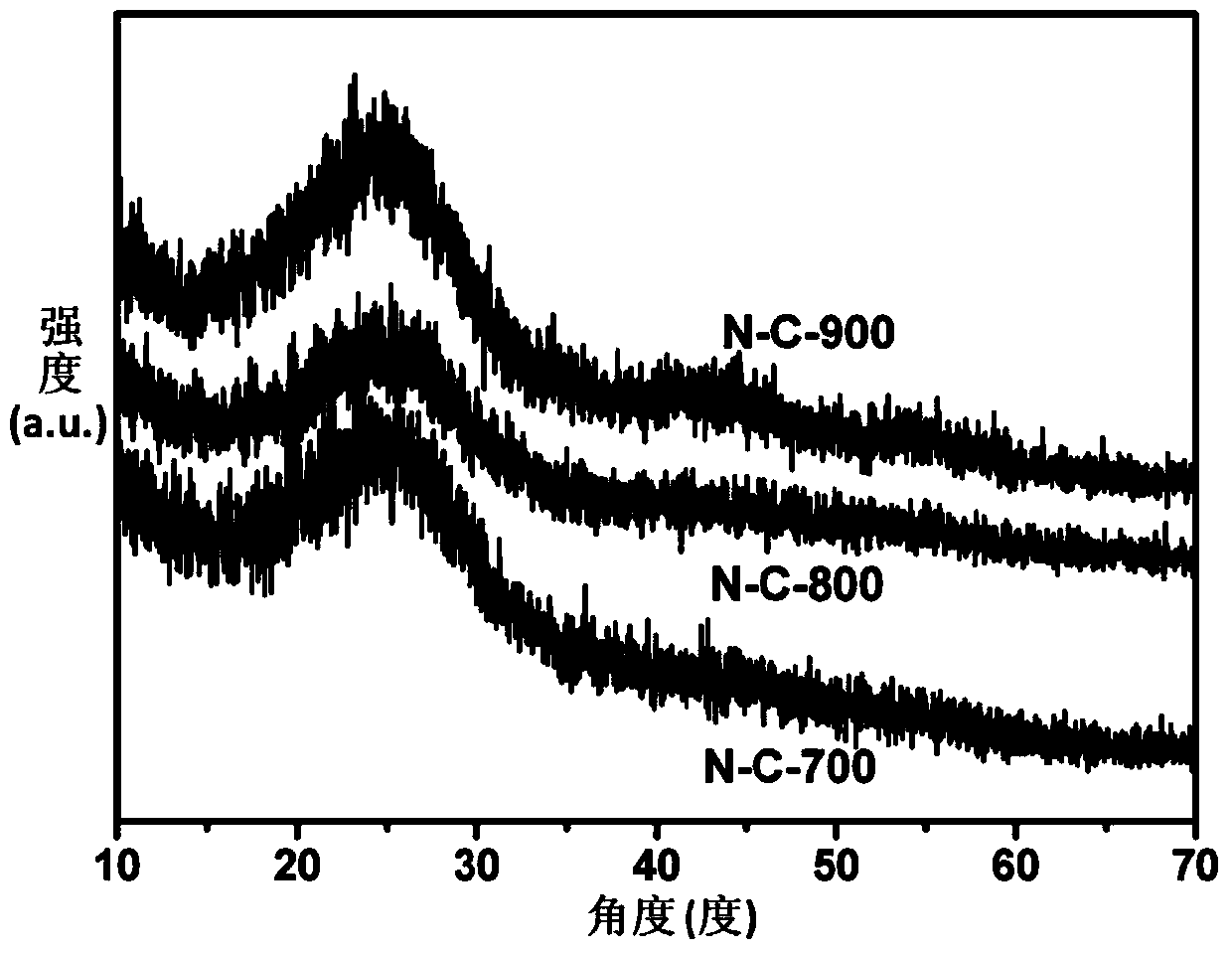

Preparation method of high-nitrogen-doped graphene nanoparticles and application of high-nitrogen-doped graphene nanoparticles as negative material of lithium ion battery

ActiveCN104201385AEasy to dopeHigh nitrogen contentMaterial nanotechnologyCell electrodesDoped grapheneZinc nitrate

The invention provides a preparation method of high-nitrogen-doped graphene nanoparticles and application of the high-nitrogen-doped graphene nanoparticles as a negative material of a lithium ion battery. The corresponding method comprises the following steps: slowly dropwise adding a preset quantity of zinc nitrate (Zn(NO3)) methanol solution into a methanol mixed solution which is prepared from a preset amount of 2-methylimidazole (C4H6N2) and a preset amount of polyvinylpyrrolidone (PVP), magnetically stirring and standing for preset time, carrying out centrifugal separation to obtain ZIF-8(a complex formed by zinc and 2-methylimidazole) nanoparticles; and putting the obtained ZIF-8 nanoparticles in a high-temperature furnace and calcining at 600-1,000 DEG C for preset time in the nitrogen atmosphere to obtain the high-nitrogen-doped graphene nanoparticles. The preparation process of the high-nitrogen-doped graphene nanoparticles is simple, and the high-nitrogen-doped graphene nanoparticles are uniform in shape, relatively large in specific surface and high in content of nitrogen, and have great application potentials in aspects of lithium ion batteries, electrochemical energy storage, catalysis and the like. The preparation method of the high-nitrogen-doped graphene nanoparticles is simple and efficient, safe and liable to implement, short in synthesis cycle, is capable of preparing a large quantity of high-nitrogen-doped graphene nanoparticles and is expected to be popularized and industrially applied.

Owner:UNIV OF SCI & TECH OF CHINA

Graphite nanocomposites

ActiveUS7923491B2Improve retentionEasy to processMaterial nanotechnologyPaper coatingElastomerGraphite

Owner:EXXONMOBIL CHEM PAT INC

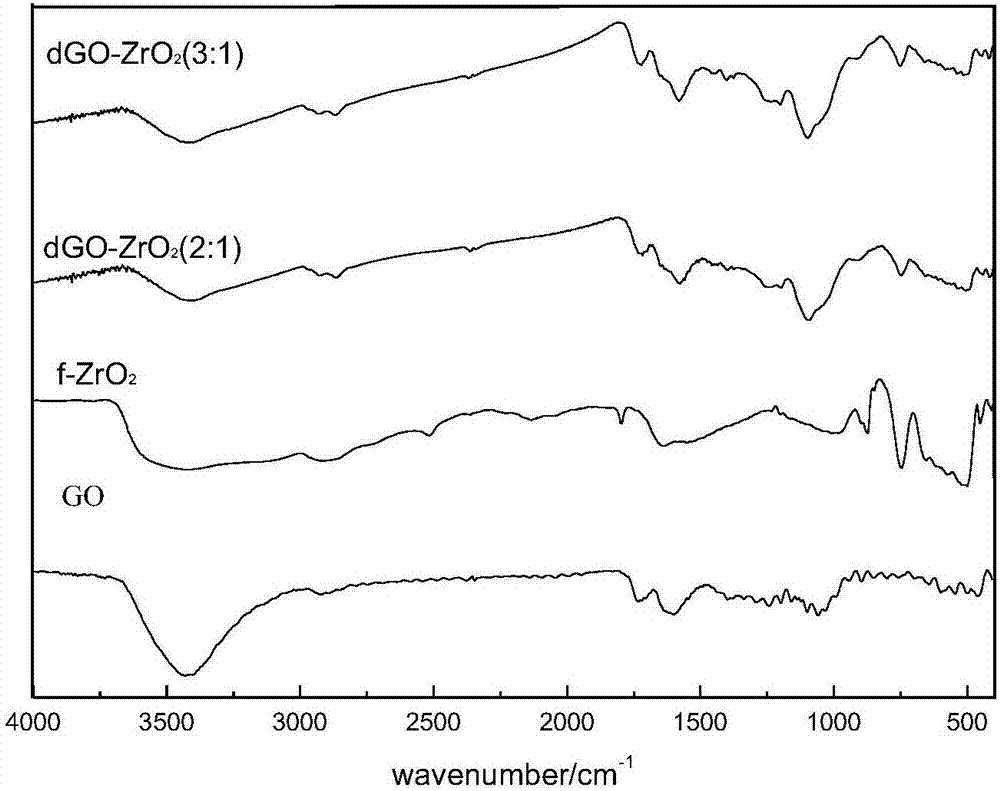

Graphene nanoparticle composite material and preparation method thereof

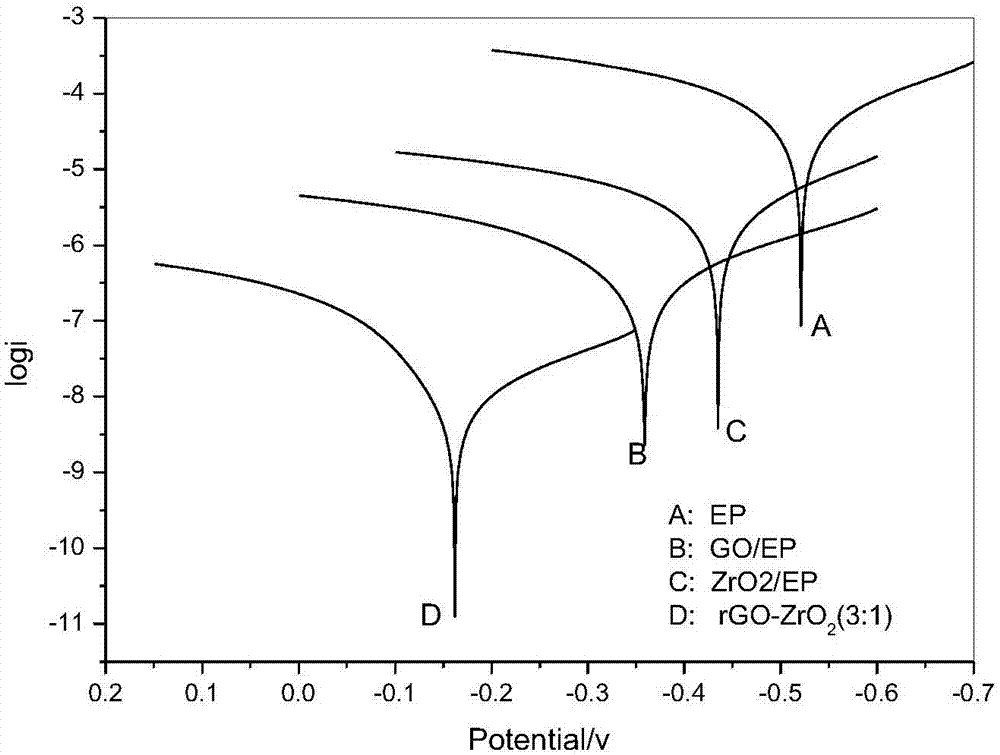

ActiveCN107400396AEasy to operateMild reaction conditionsGrapheneAnti-corrosive paintsEpoxyCvd graphene

The invention relates to the field of composite materials and in particular to a nanoparticle / graphene composite material and a preparation method thereof. In order to utilize the oxygen-containing functional groups on the surface of graphene oxide, the invention aims at providing the nanoparticle / graphene composite material and the preparation method thereof. According to the preparation method, hydroxyl and epoxy group on the surface of the graphene oxide are simultaneously modified by fully utilizing the oxygen-containing functional groups on the surface of the graphene oxide; the prepared nanoparticle / graphene composite material can be widely applied to the fields of composite materials, anticorrosive coating materials and the like.

Owner:QINGDAO UNIV OF SCI & TECH +1

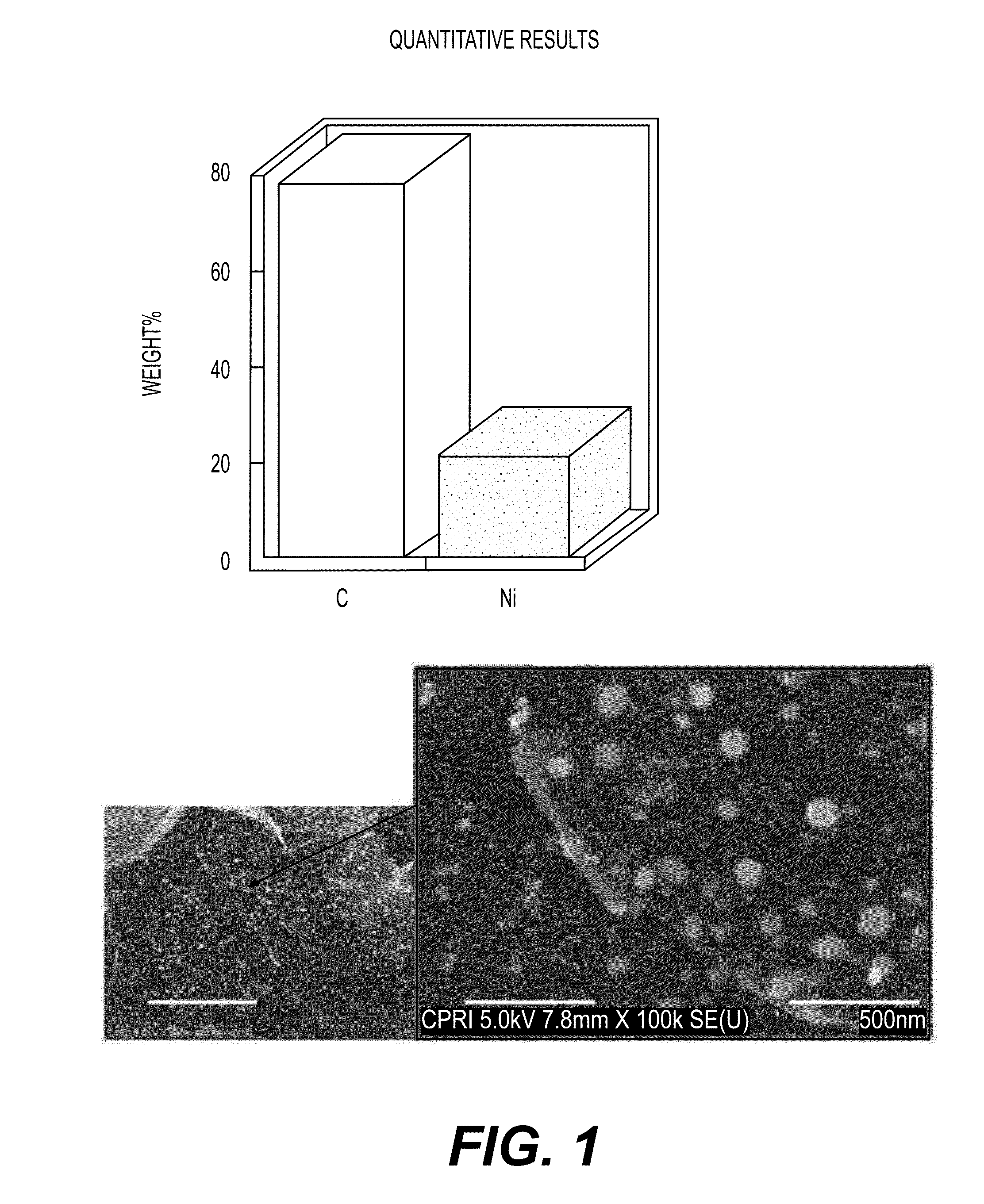

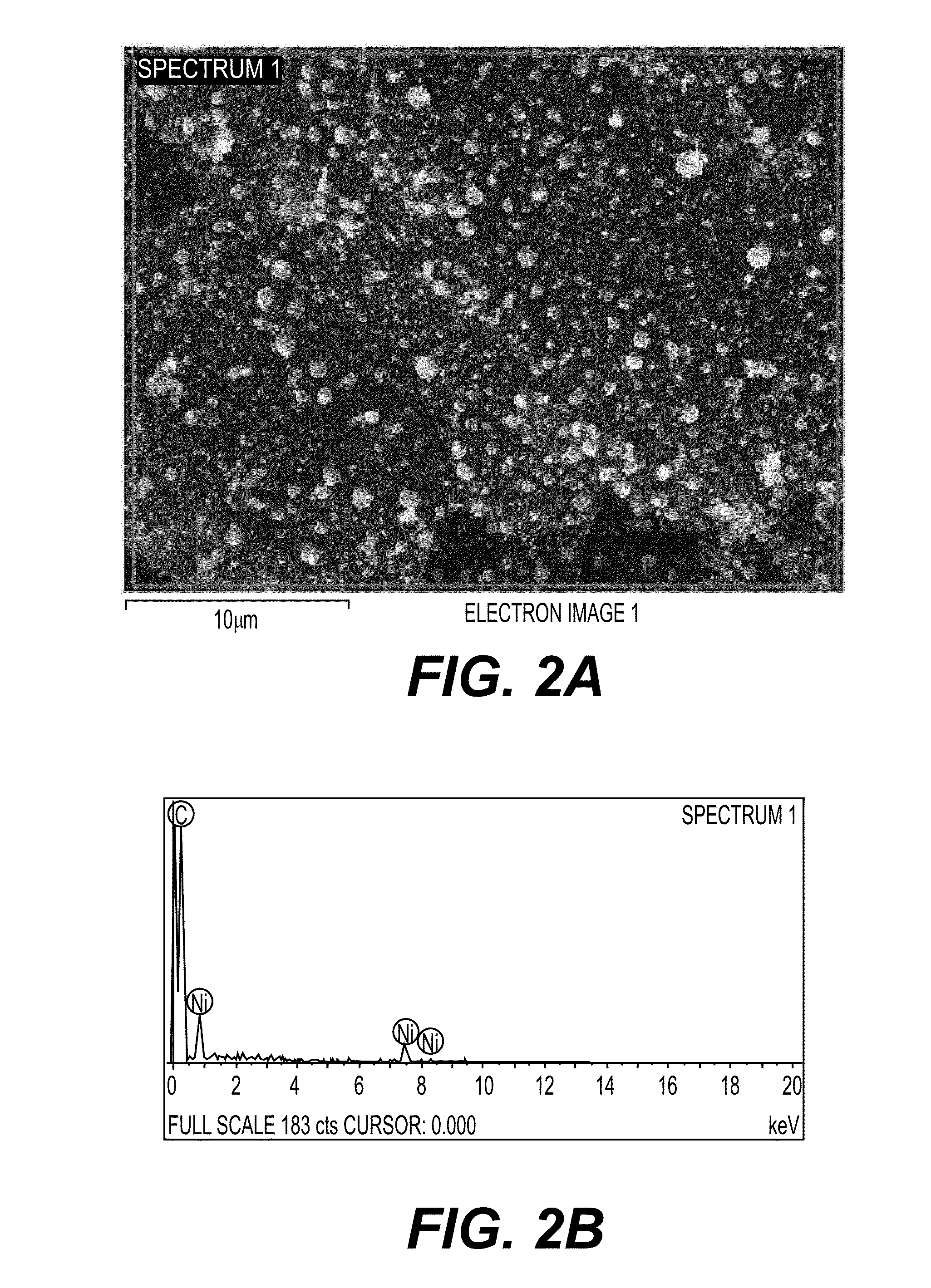

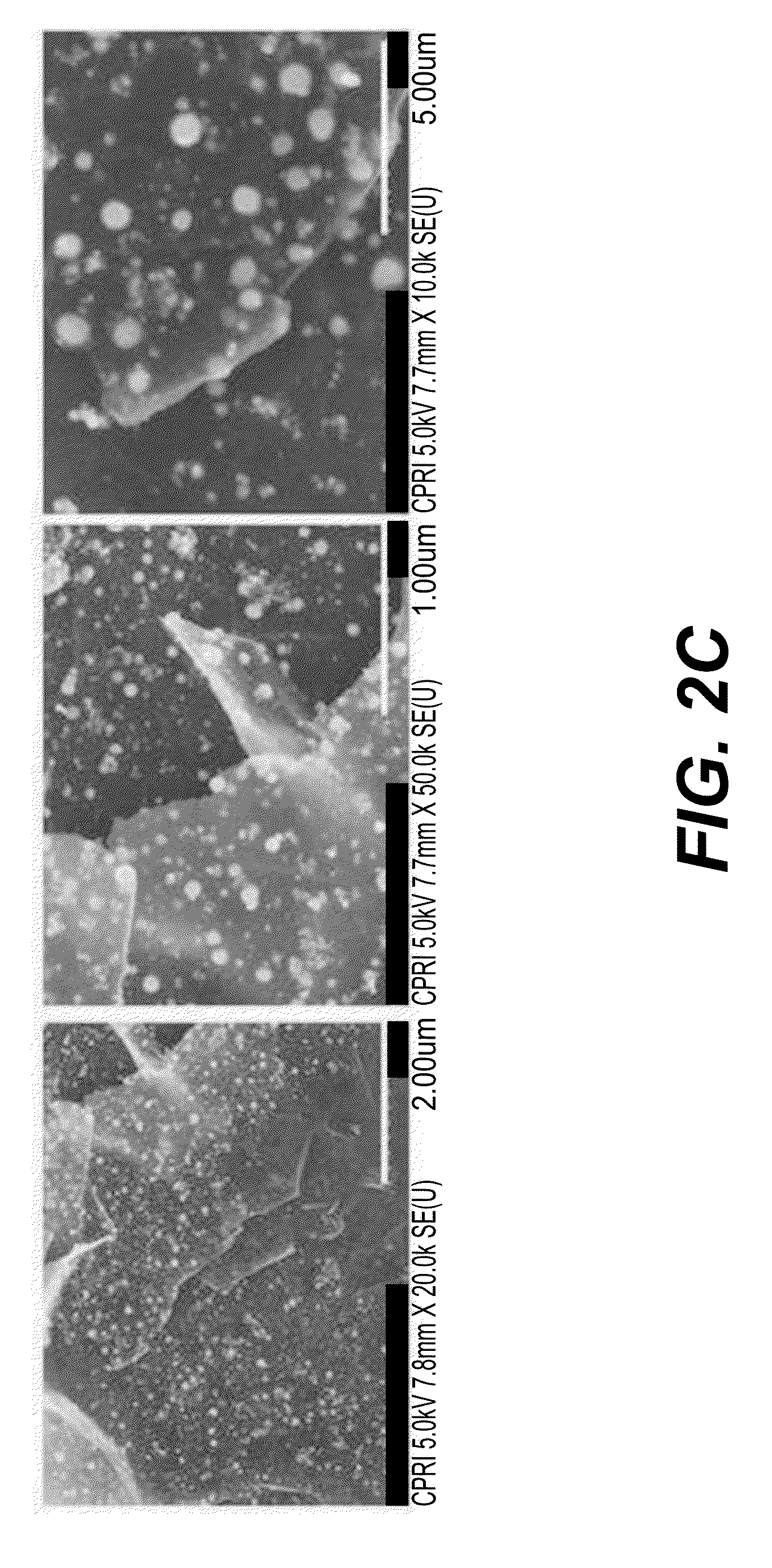

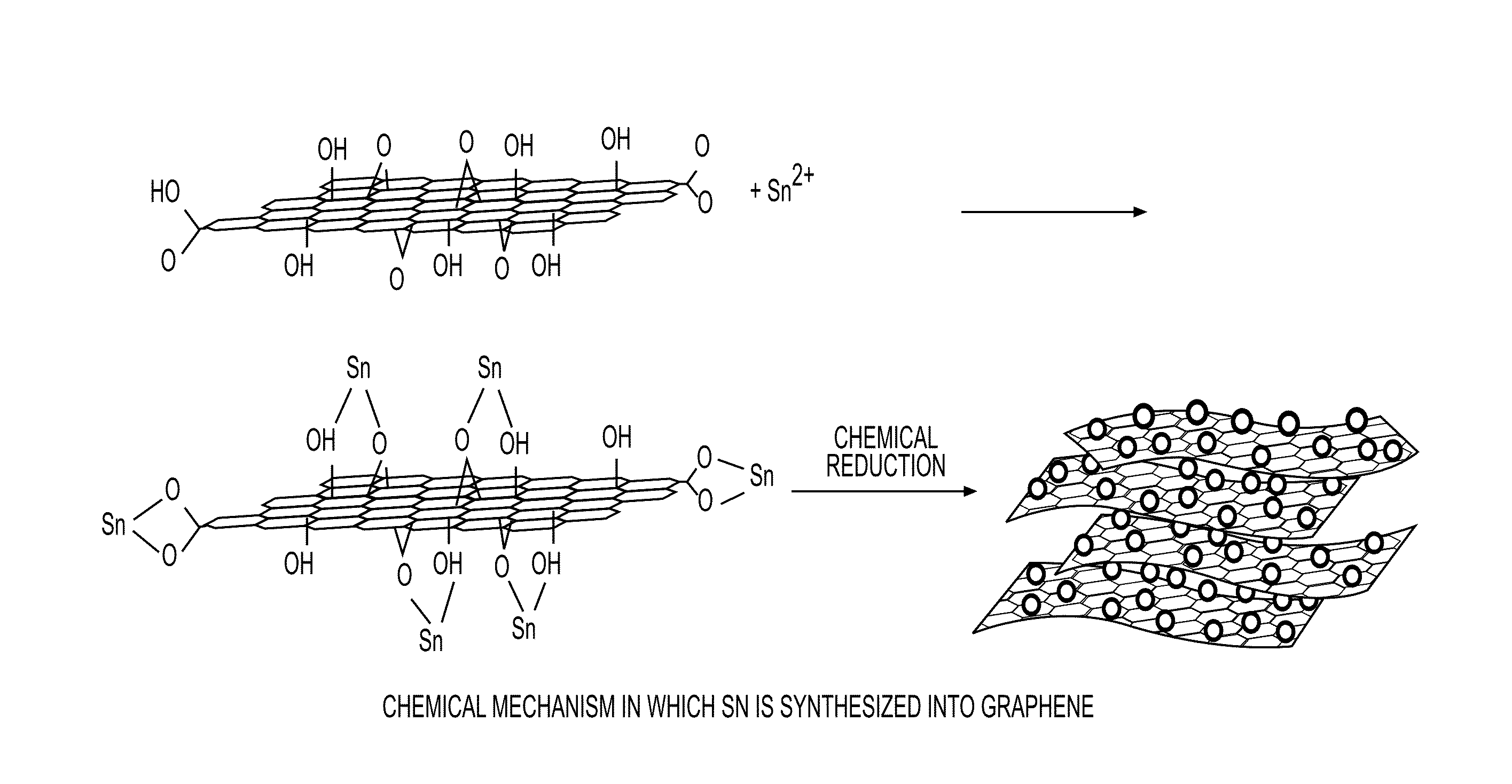

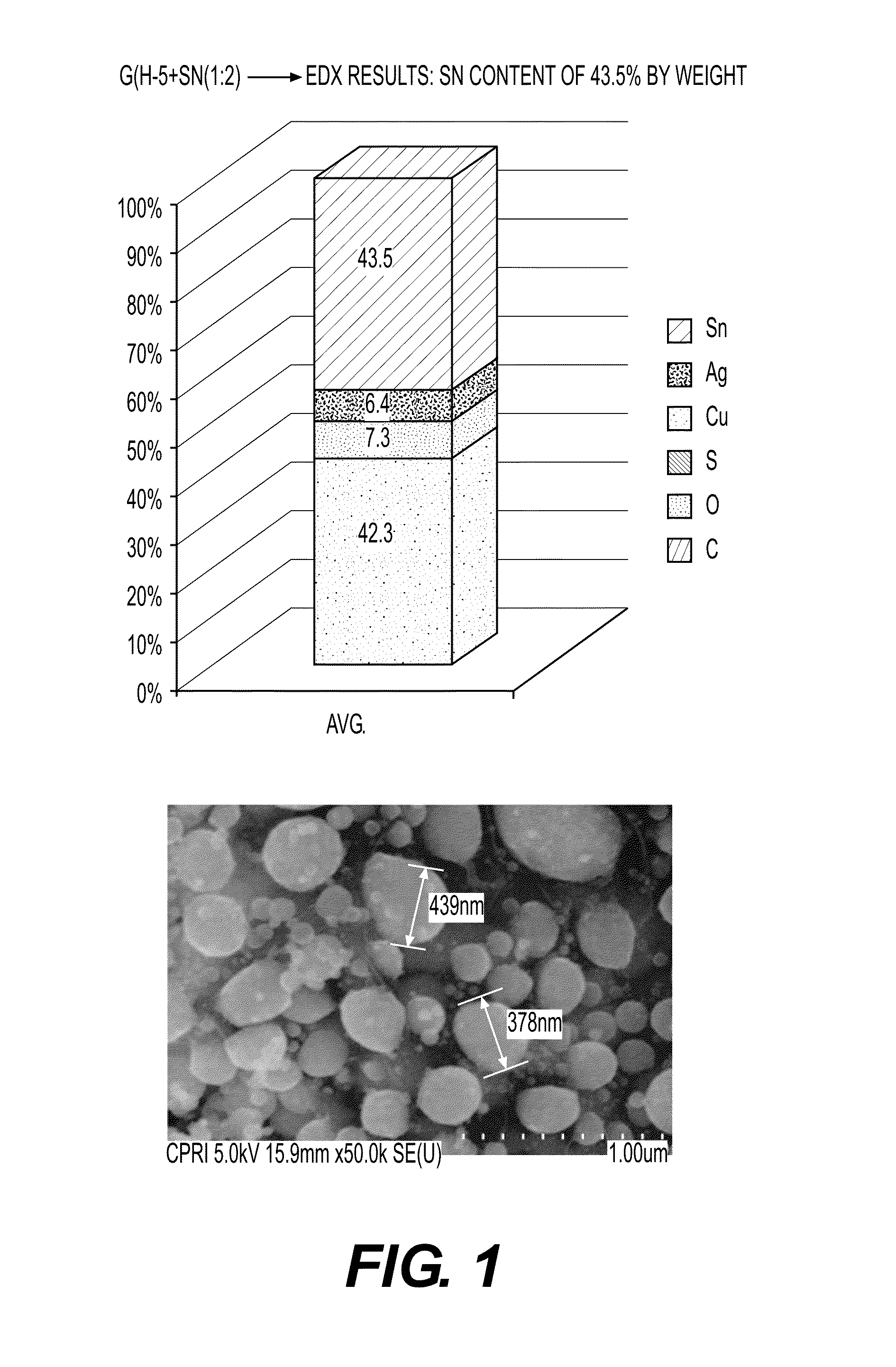

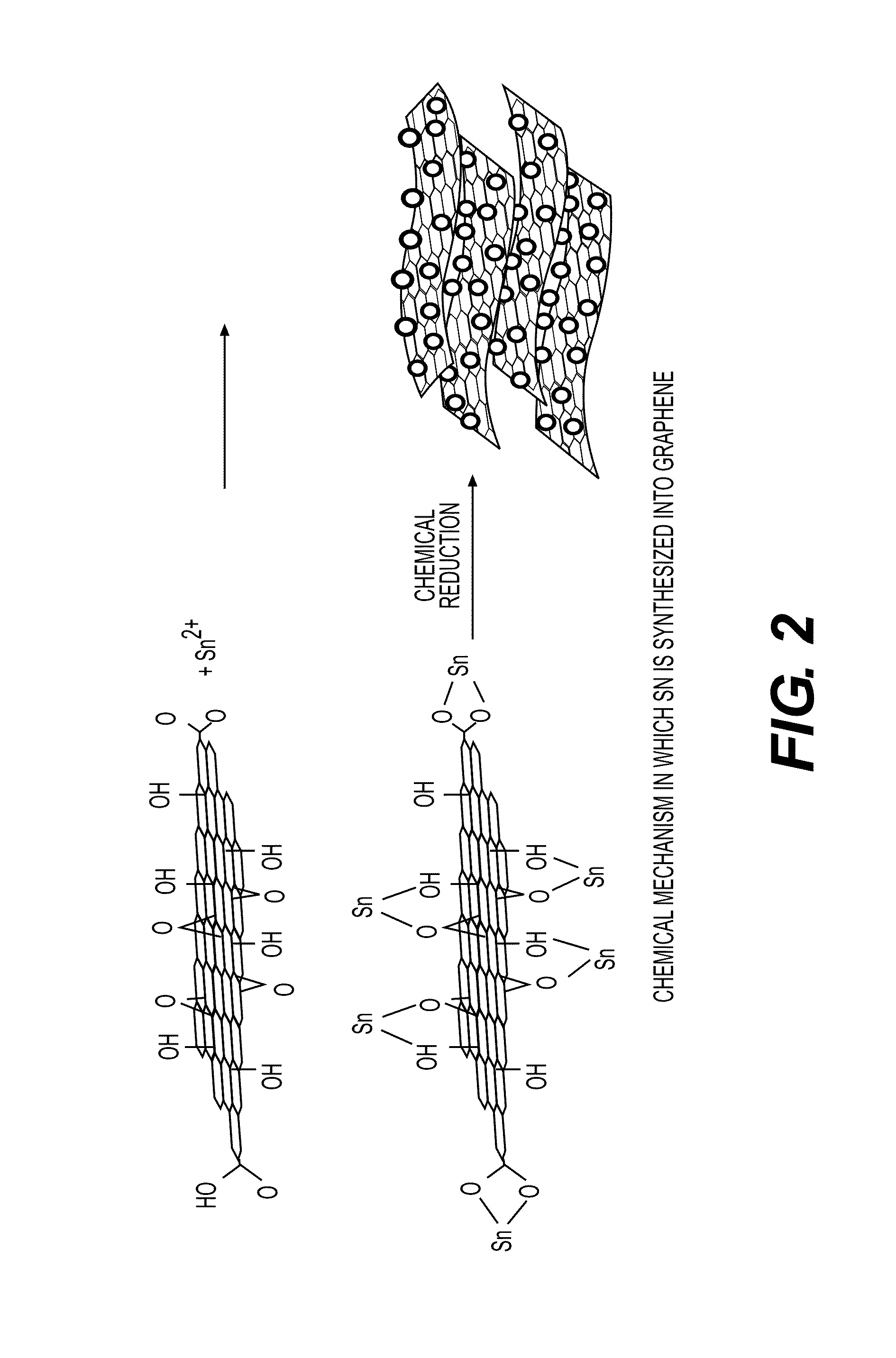

Graphene-nano particle composite having nanoparticles crystallized therein at a high density

InactiveUS20150179294A1Improve mechanical propertiesImprove electrical characteristicsSynthetic resin layered productsConductive materialNanoparticle ComplexHigh density

The present invention relates to a graphene-nanoparticle composite having a structure in which nanoparticles are crystallized at a high density in a carbon-based material, for example, graphene, and, more particularly, to a graphene-nanoparticle composite capable of remarkably improving physical properties such as contact characteristics between basal planes of graphene and conductivity since nanoparticles are included as a large amount of 20 to 50% by weight, based on 100% by weight of graphene, and a method of preparing the same.

Owner:CHEORWON PLASMA RES INST

Graphene-NANO particle composite having NANO particles crystallized therein at a high density

InactiveUS20140219906A1Excellent mechanical and electric characteristicImprove conductivityCell electrodesIndividual molecule manipulationHigh densityNanoparticle Complex

The present invention relates to a graphene-nanoparticle composite having a structure in which nanoparticles are crystallized in a carbon-based material, for example, graphene, at a high density, and, more particularly, to a graphene-nanoparticle composite capable of remarkably improving physical properties such as contact characteristics between basal planes of graphene and conductivity, wherein nanoparticles are included as a large amount of 30% by weight or more, based on 100% by weight of graphene, and crystallized nanoparticles have an average particle diameter of 200 nm or more, and a method of preparing the same.

Owner:CHEORWON PLASMA RES INST

Graphene nano particle compound aerogel microspheres and preparation method thereof

InactiveCN105498649AUniform sizeAvoid uneven loadAerogel preparationMicroballoon preparationFreeze-dryingMicrosphere

The invention relates to graphene nano particle compound aerogel microspheres and a preparation method thereof, and belongs to the field of functional materials. The graphene nano particle compound aerogel microspheres are prepared from, by weight, 100 parts of deionized water, 0.05-1.5 parts of graphite oxide and 0.1-5 parts of nano particles. The raw materials are subjected to 1,600W ultrasound wave irradiation for 60 min to 180 min after being mixed to be prepared into a graphene oxide nano particle dispersion solution, the graphene oxide nano particle dispersion solution is atomized into graphene oxide nano particle drop microspheres through a spraying method, the graphene oxide nano particle drop microspheres are put in a cooling bath for receiving liquid collection, graphene oxide nano particle cold microspheres are obtained through filtering, and graphene oxide nano particle compound aerogel microspheres are obtained after freeze drying; the graphene nano particle compound aerogel microspheres are obtained through a thermal reduction method or chemical reduction method. The products are uniform in size, are provided with a porous net structure, are evenly loaded with metal / inorganic nano particles, and are low in mass and small in density. Meanwhile, the preparation method is easy to operate, simple and efficient.

Owner:SICHUAN UNIV

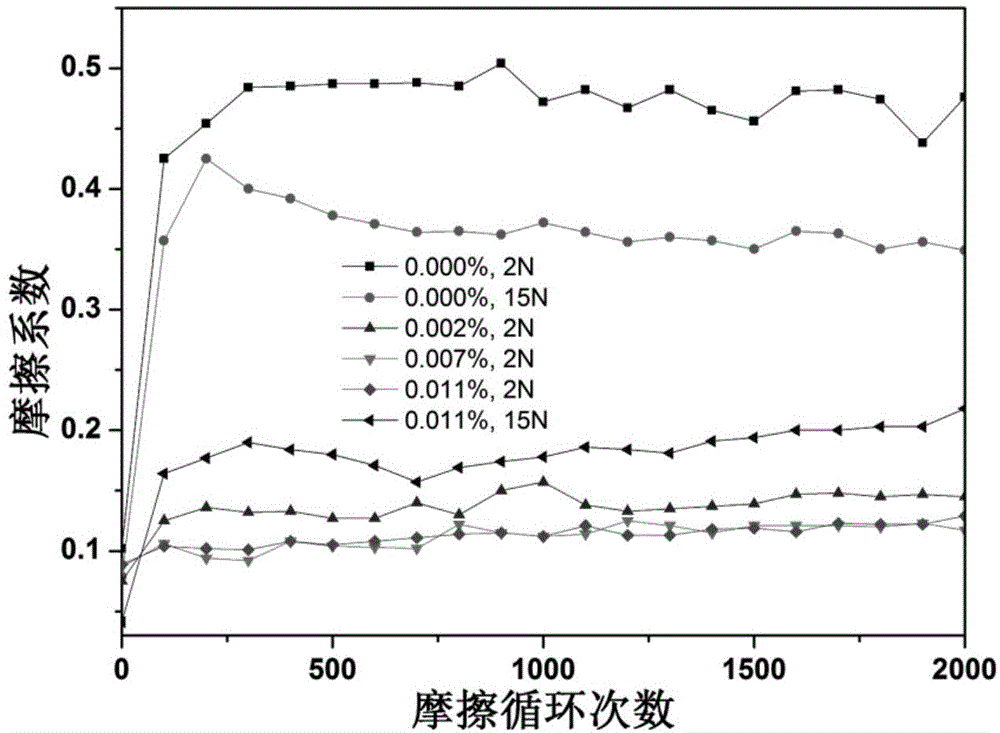

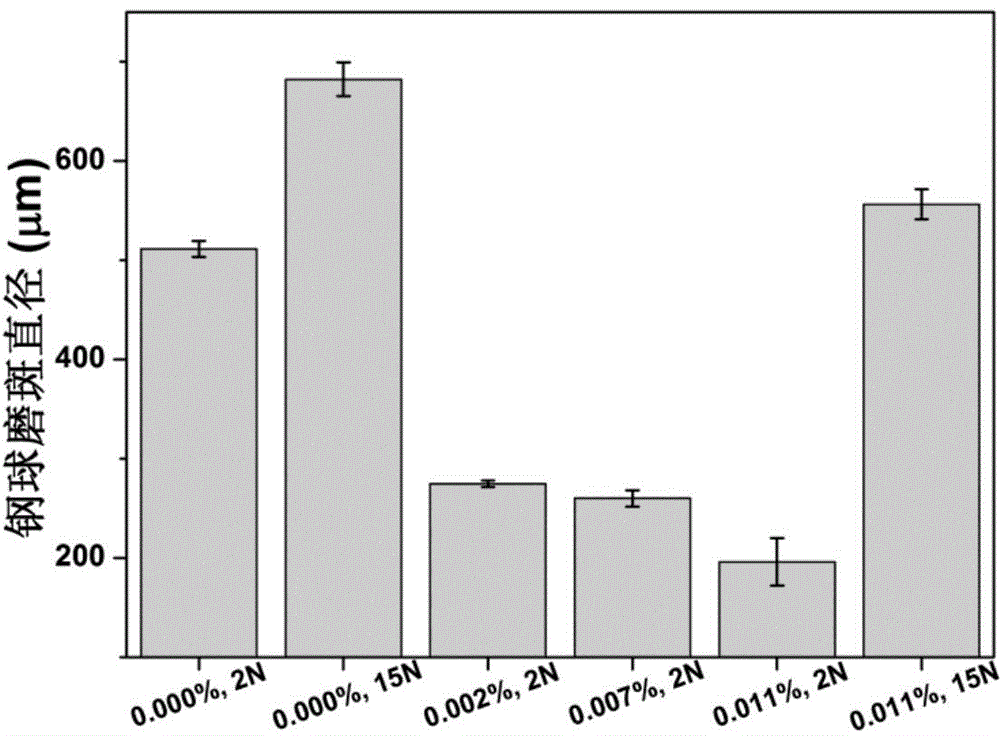

Method for preparing graphene water-based lubricating agent in situ

InactiveCN104593130ASimple preparation processEasy to prepareLubricant compositionWater basedFriction reduction

The invention discloses a method for preparing a graphene water-based lubricating agent in situ, belonging to the field of application of graphene serving as a nanometer lubricating additive. The lubricating agent consists of graphene nanoparticles, a surface modifier and purified water. The method comprises the following preparation steps: 1, dissolving a surfactant in deionized water according to a ratio, thereby obtaining a liquid; 2, uniformly dispersing graphene powder in the liquid; 3, performing ultrasonic cavitation treatment on the graphene dispersion liquid; 4, standing the liquid for a certain time, and taking the upper liquid; 5, performing centrifugal separation treatment on the obtained liquid; and 6, collecting the supernatant of the centrifuged liquid, thereby obtaining the water-based lubricating agent containing graphene prepared in situ. The method disclosed by the invention is simple in feasible, and the dispersion stability of the graphene is high. The friction test result proves that according to the extremely small addition amount (0.001-1 percent) of the graphene, the anti-wear and friction reduction properties of the lubricating agent can be greatly improved, and excellent characteristics such as good inherent cooling property, high machinability and environment friendliness of the water-based lubricating agent are not influenced.

Owner:BEIHANG UNIV

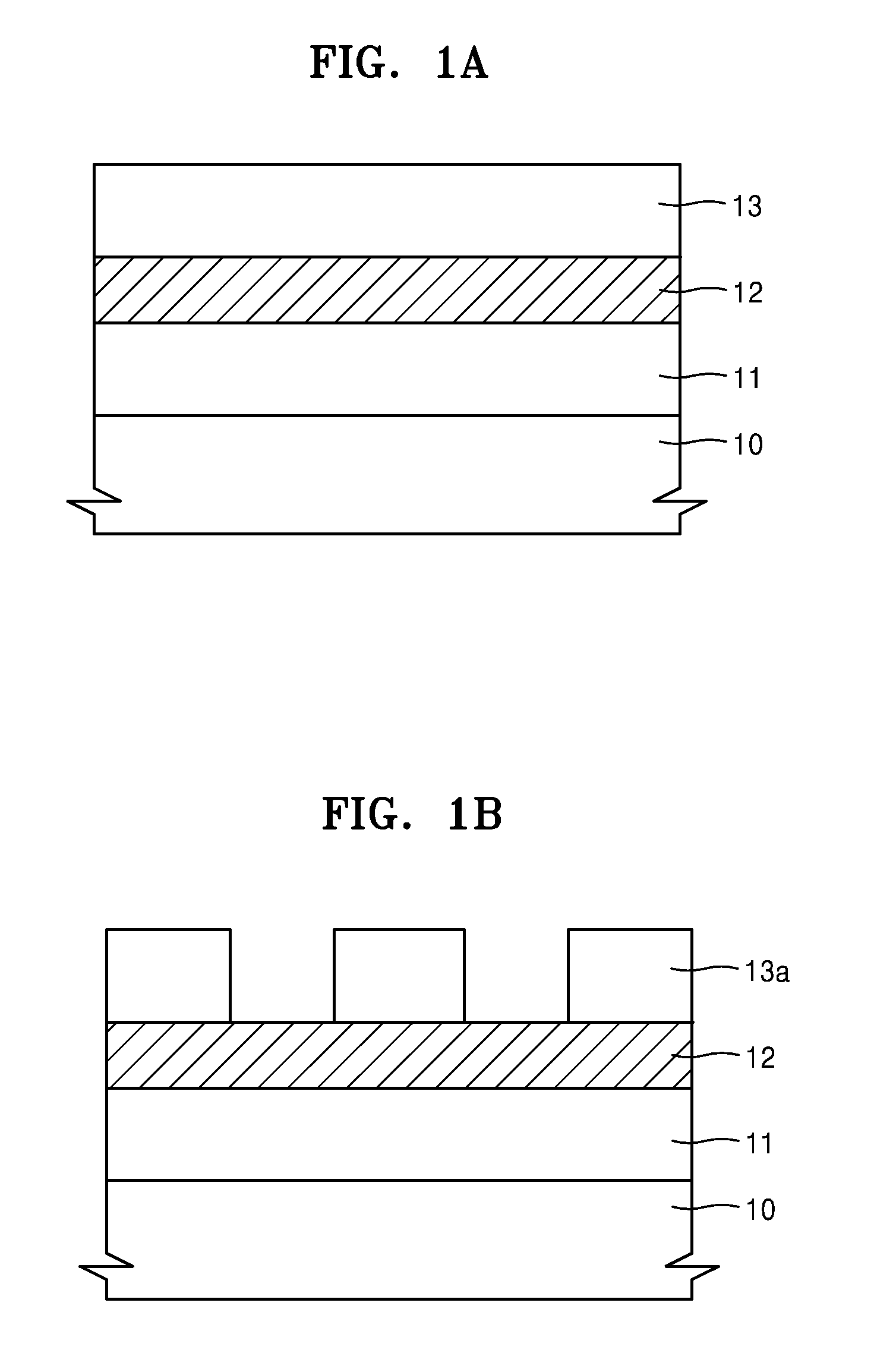

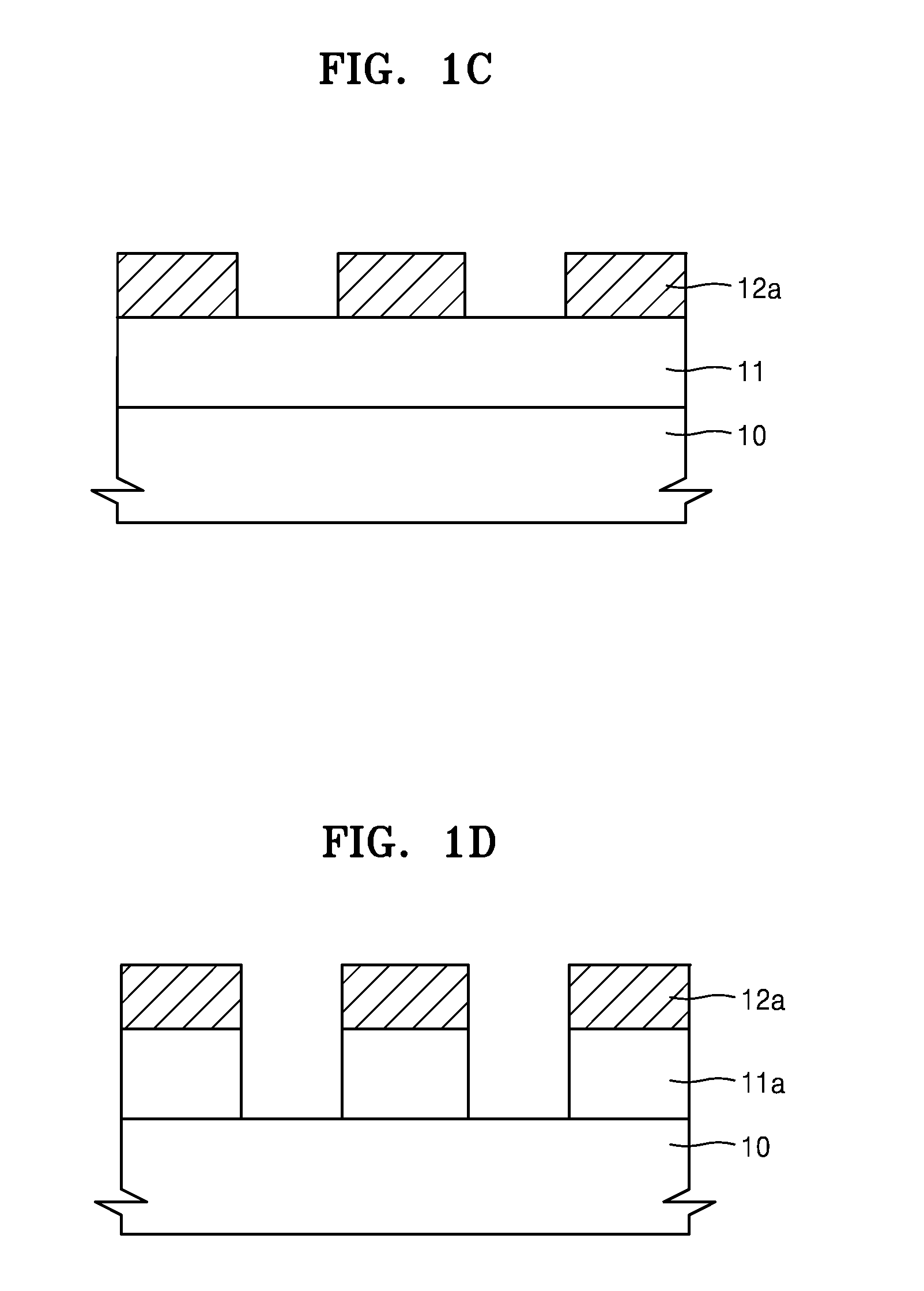

Hardmask composition and method of forming pattern using the hardmask composition

ActiveUS20160291472A1Excellent etch resistanceGrapheneSemiconductor/solid-state device manufacturingGraphitePolymer chemistry

Owner:SAMSUNG ELECTRONICS CO LTD

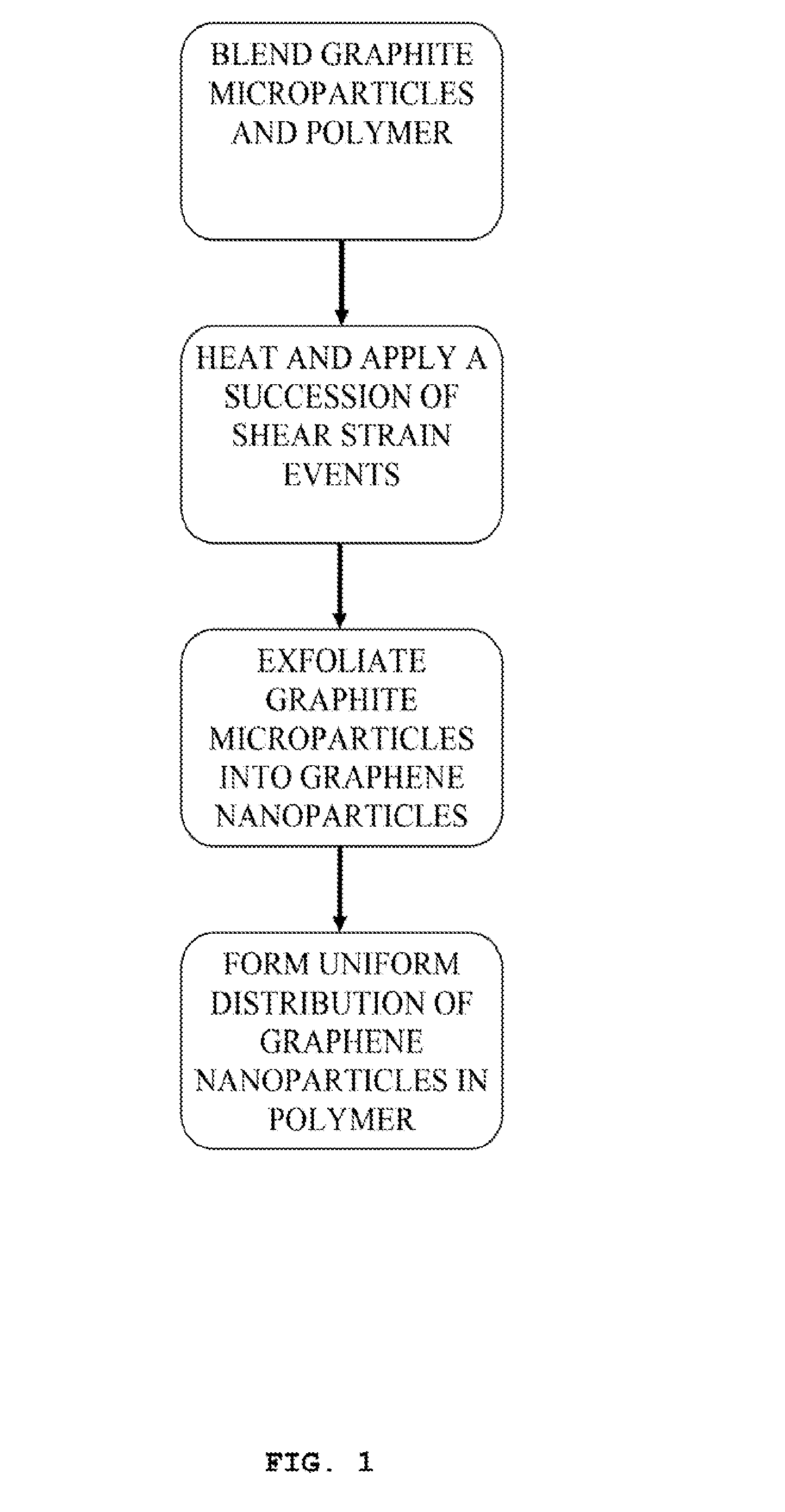

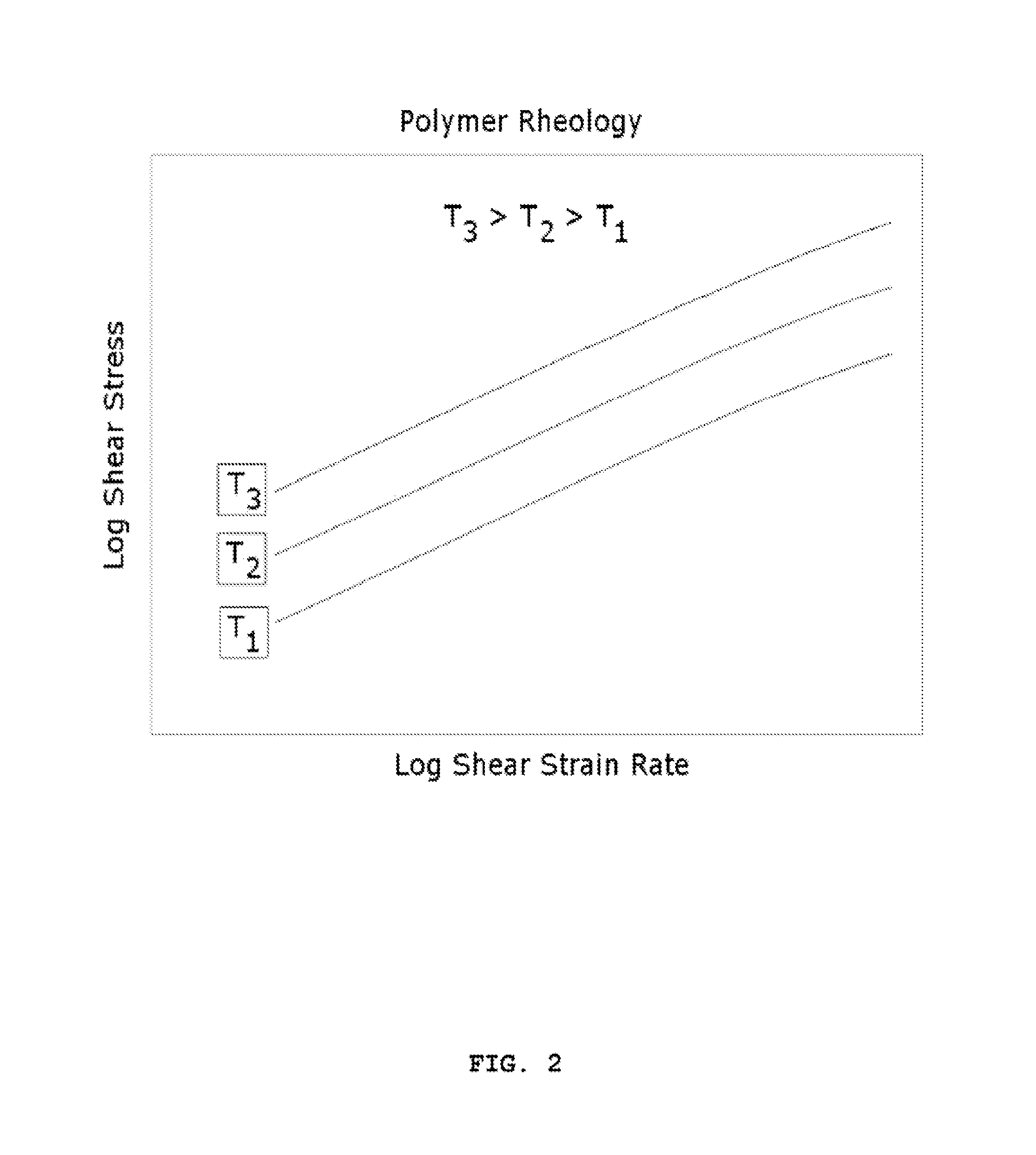

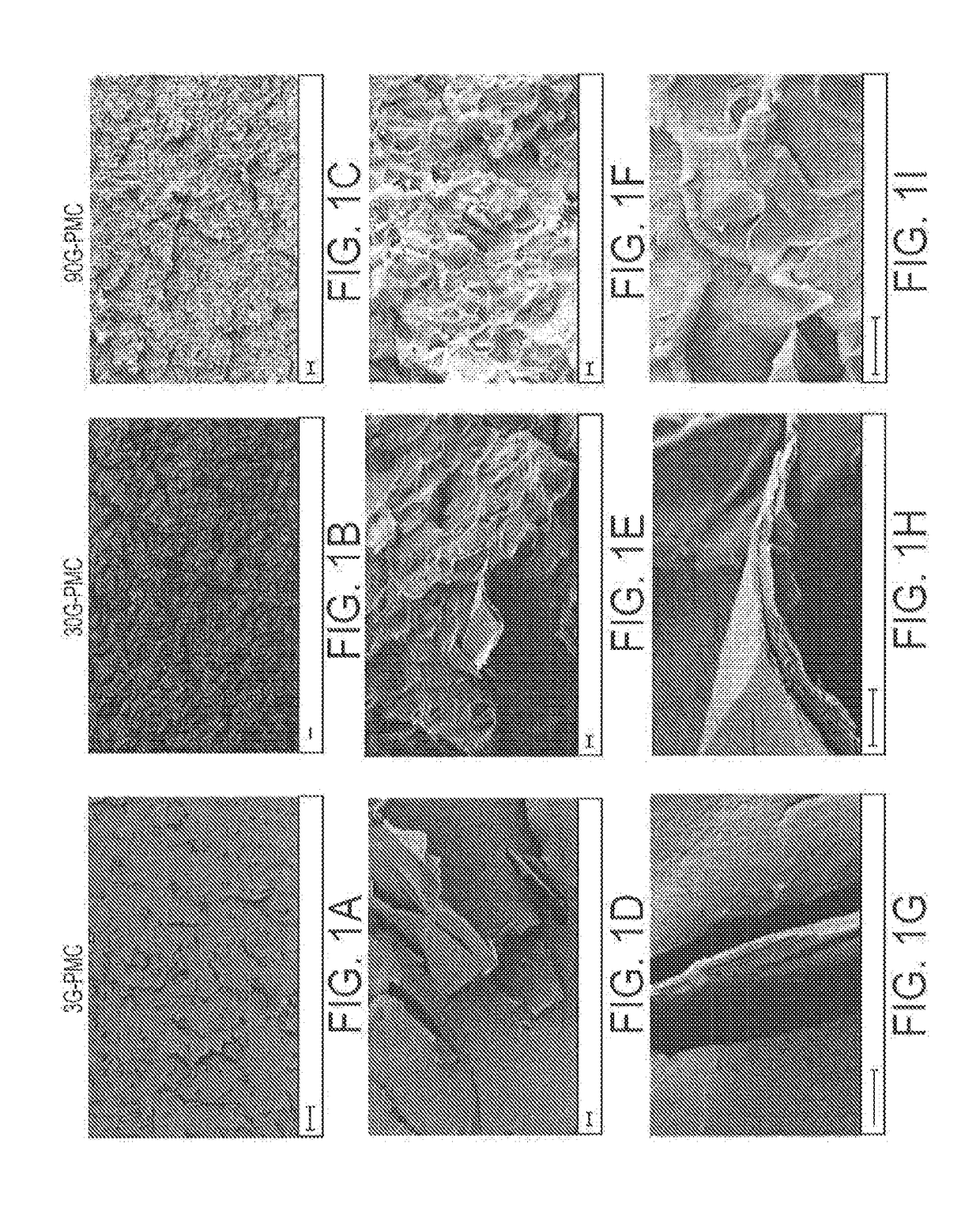

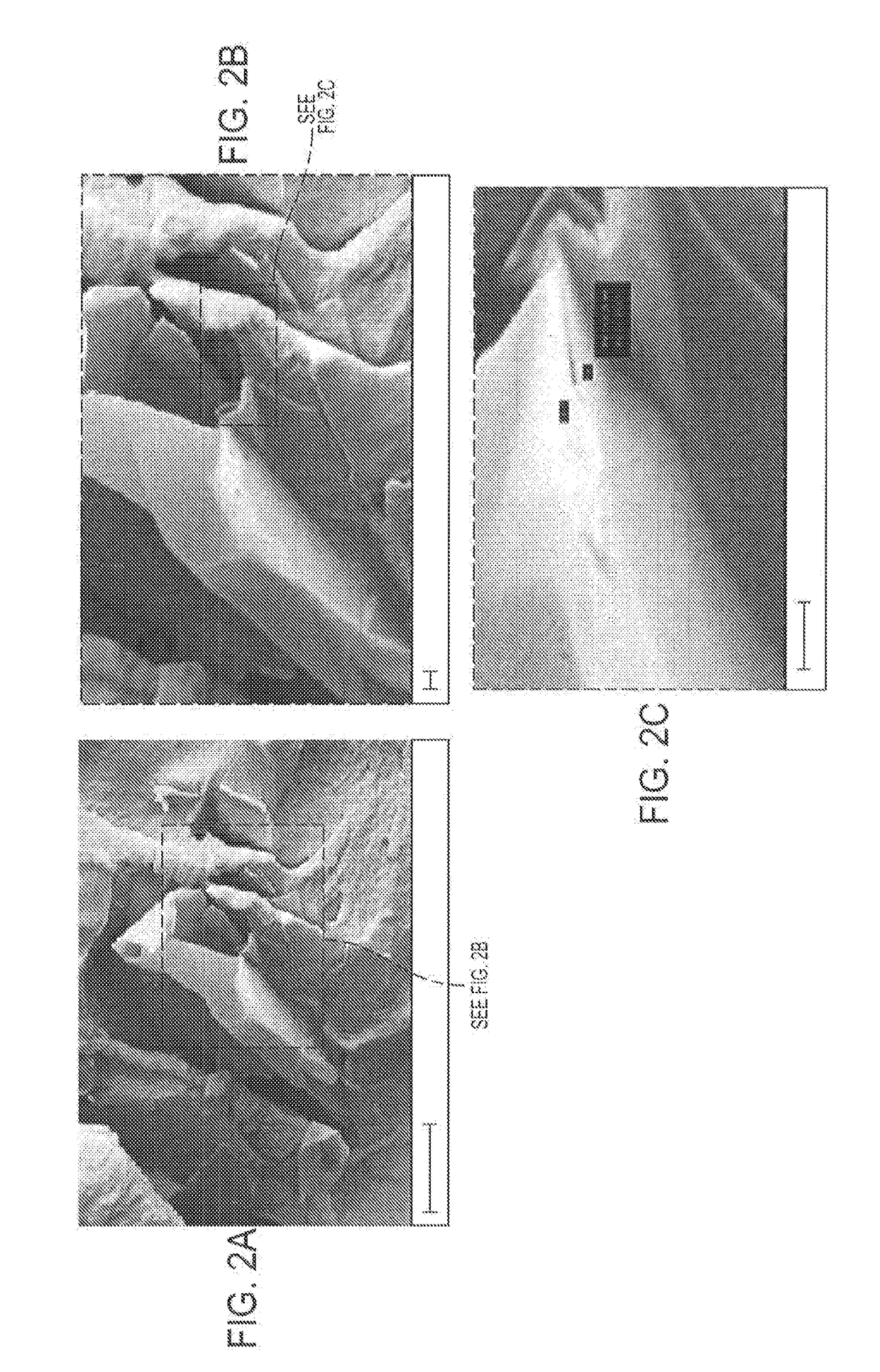

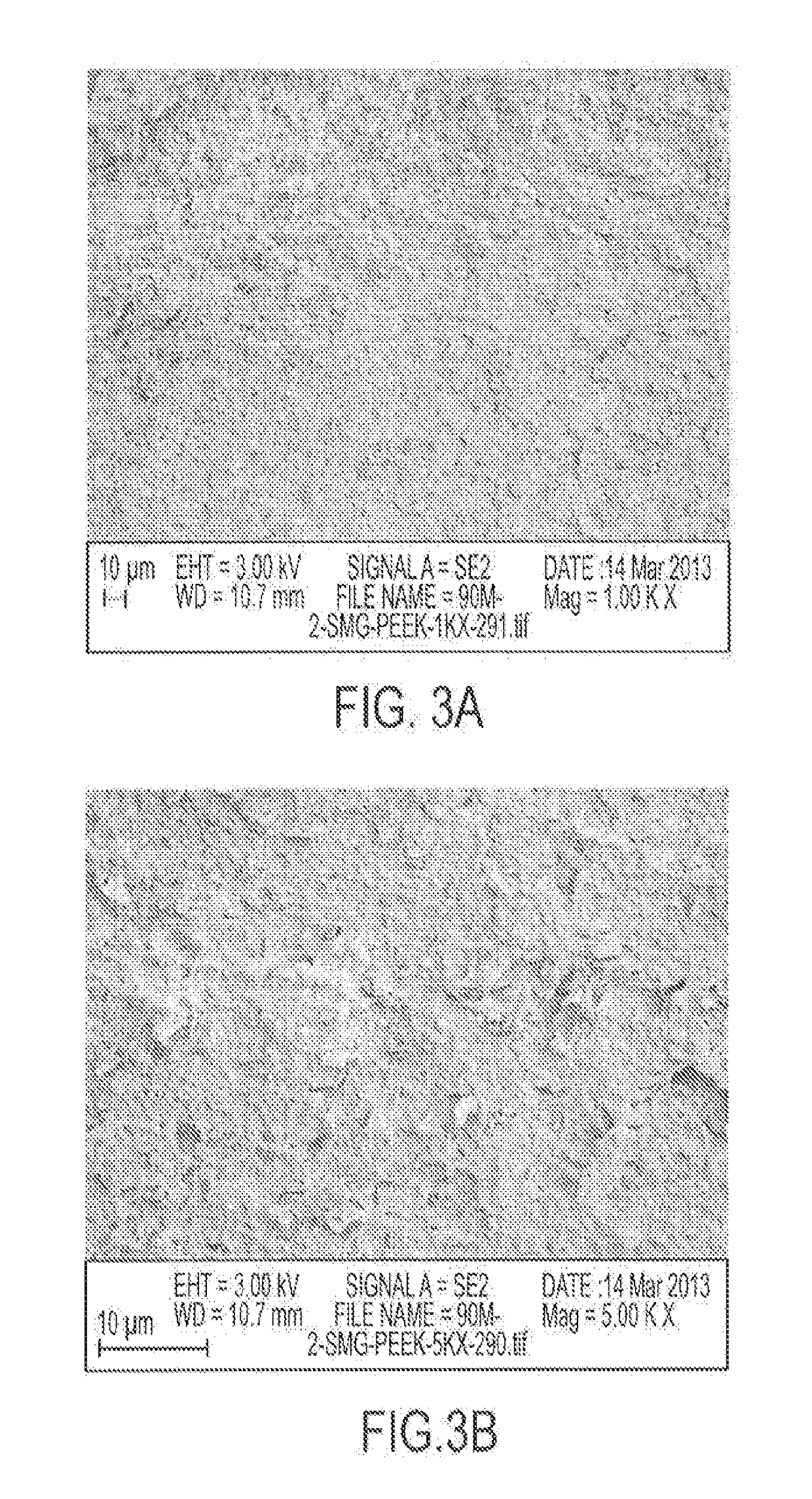

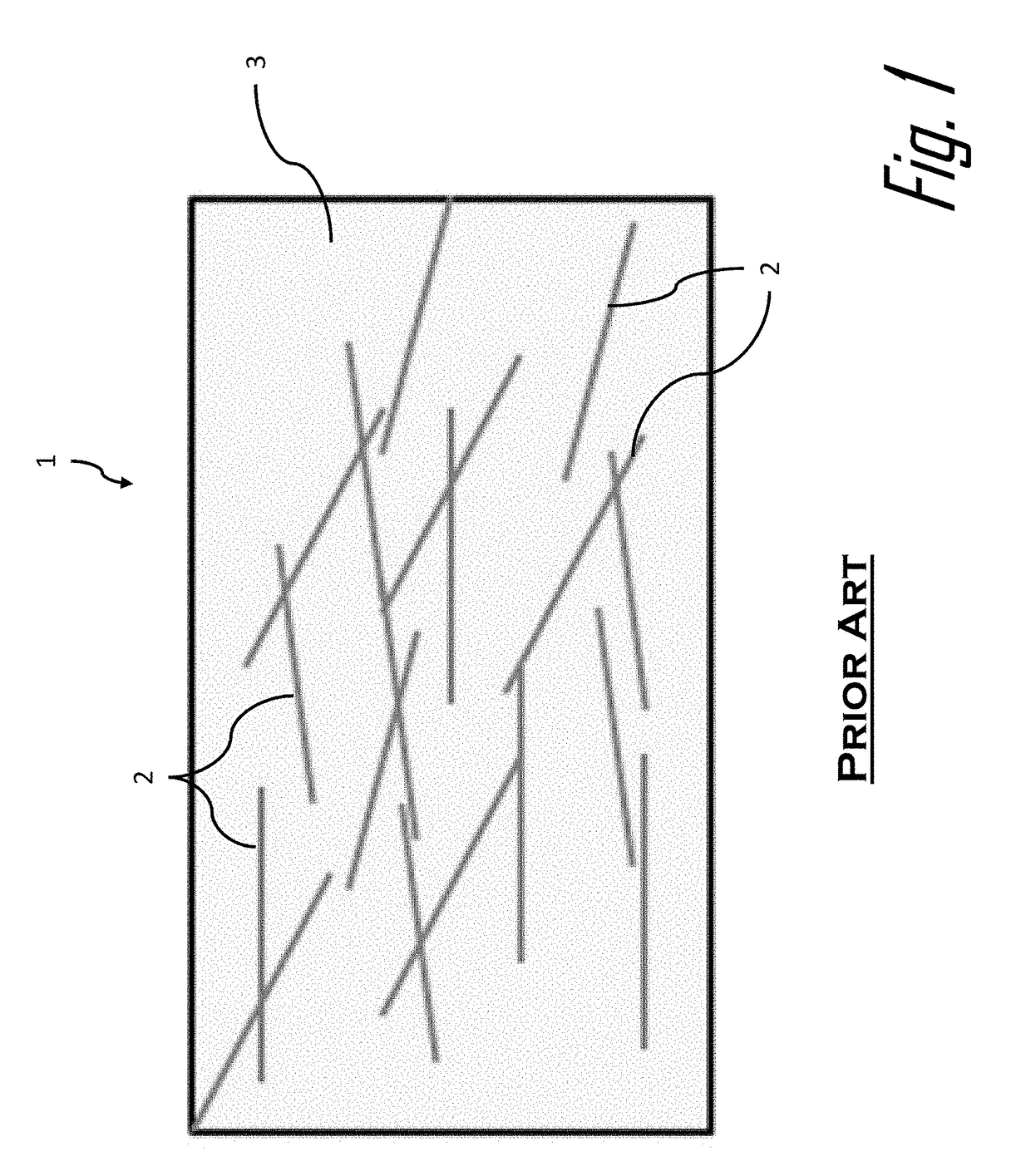

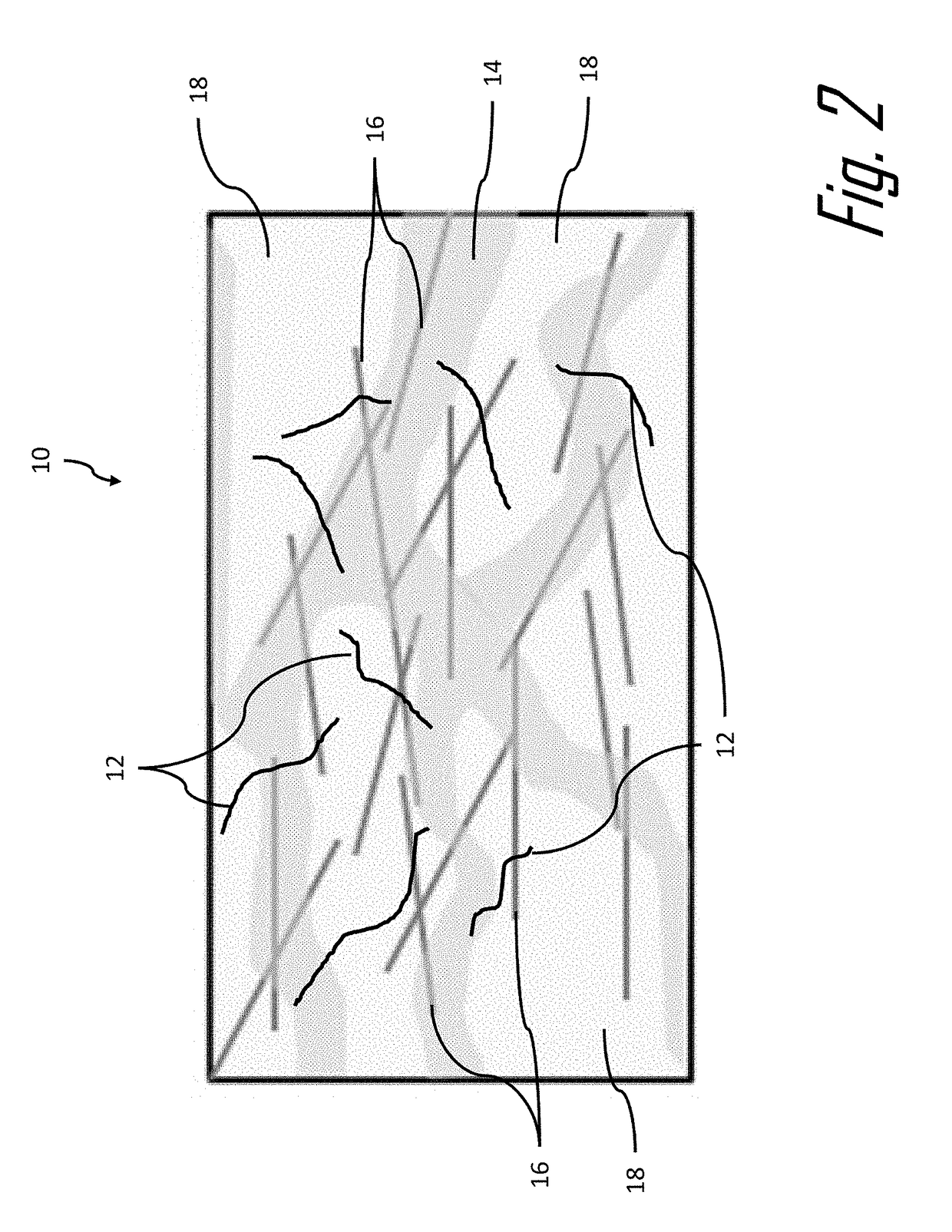

In Situ Exfoliation Method to Fabricate a Graphene-Reinforced Polymer Matrix Composite (G-PMC)

ActiveUS20150267030A1High bonding strengthHigh strengthLayered productsGraphenePolymer scienceMicroparticle

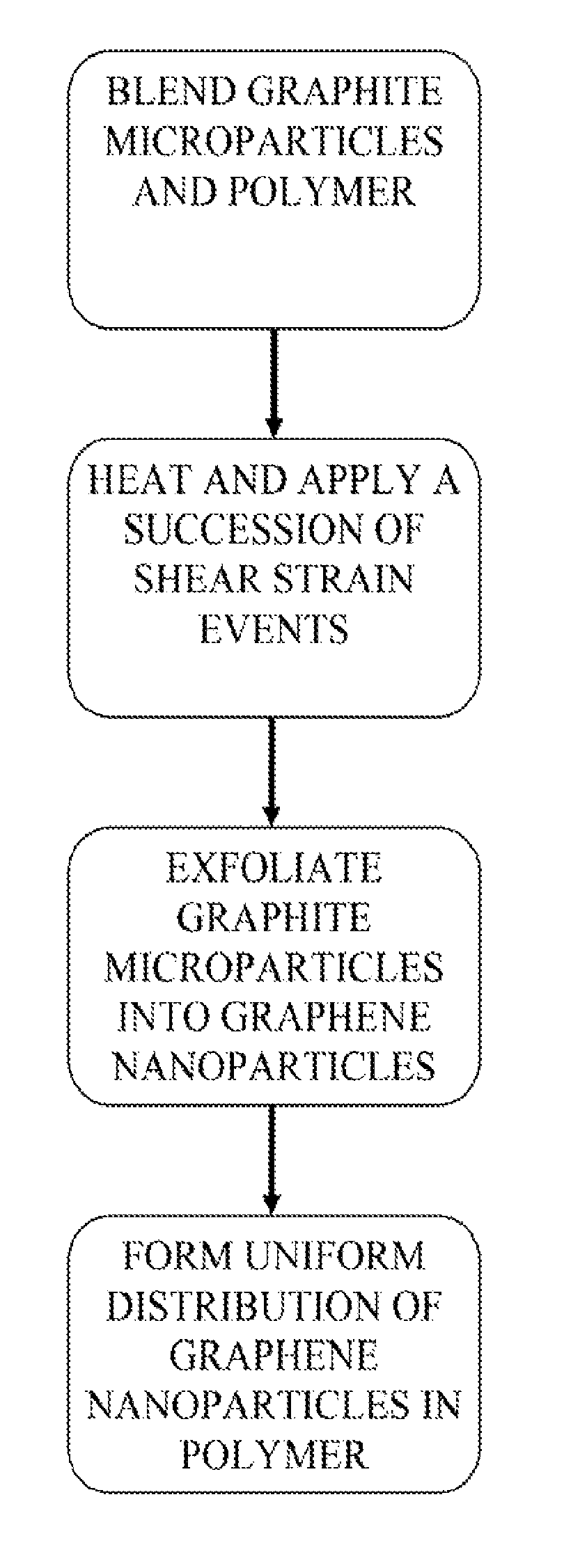

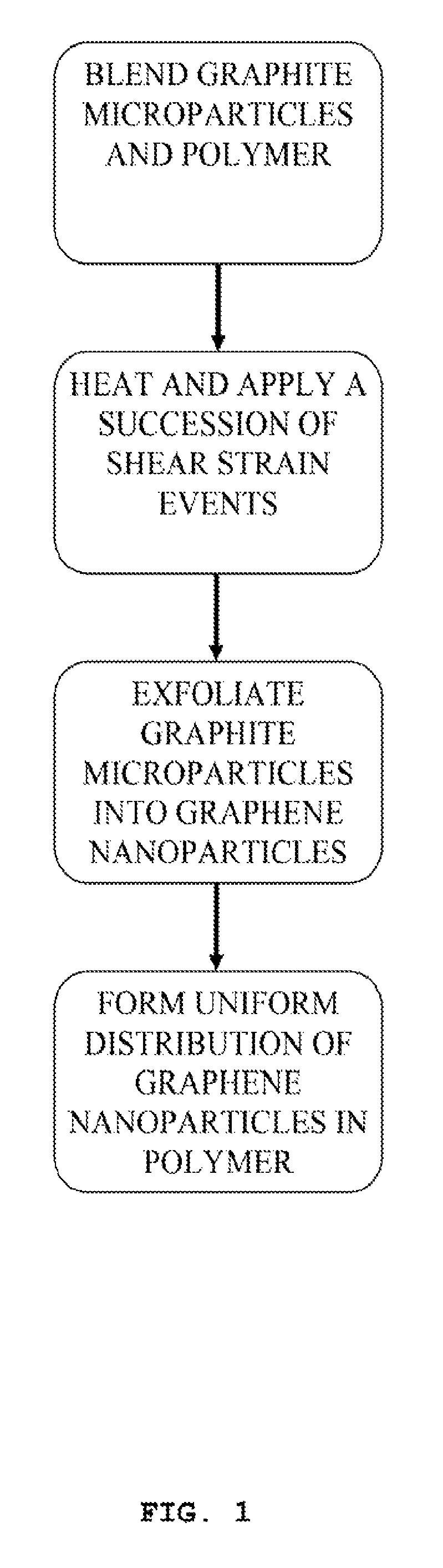

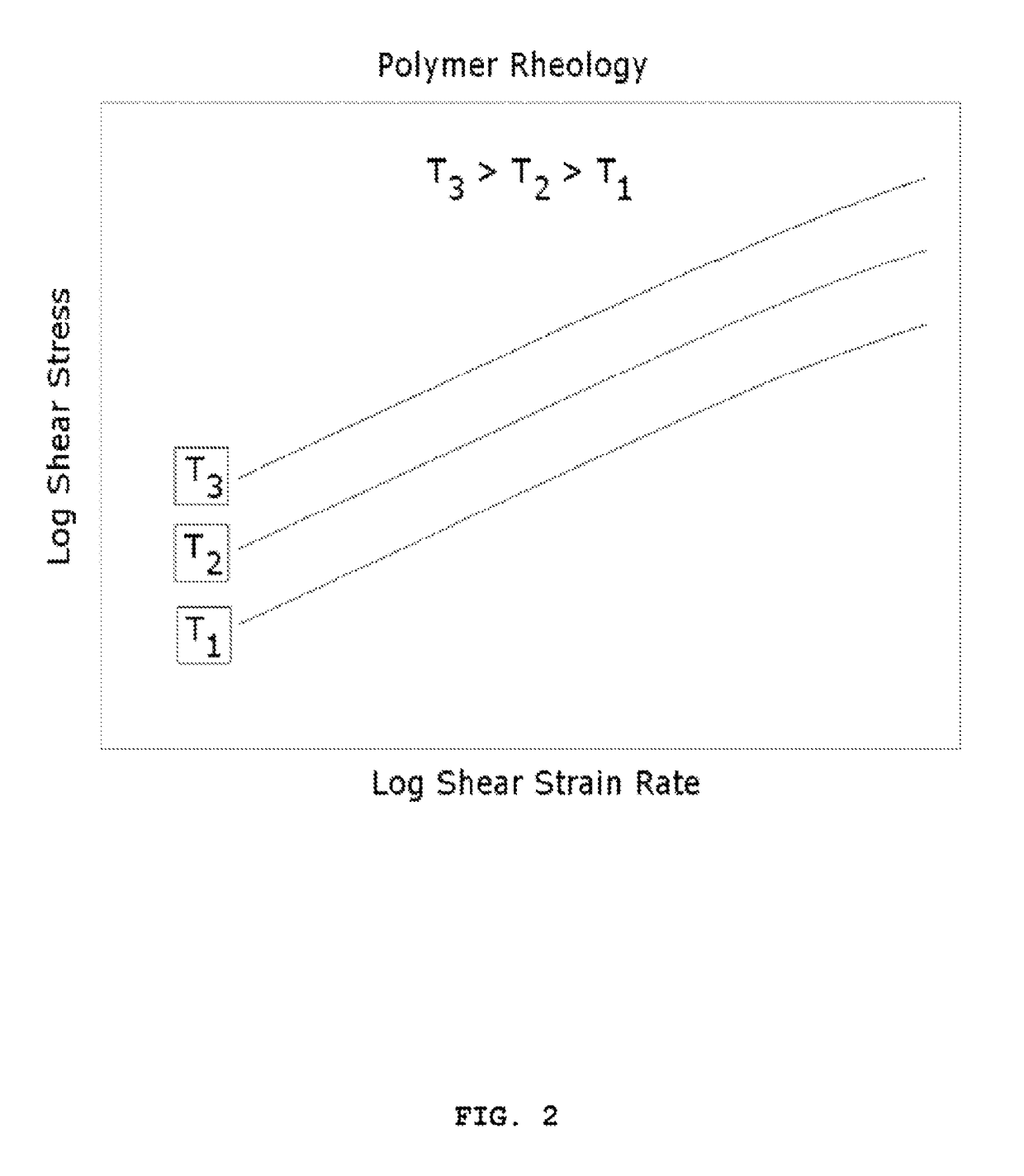

A method for forming a graphene -reinforced polymer matrix composite is disclosed. The method includes distributing graphite microparticles into a molten thermoplastic polymer phase; and applying a succession of shear strain events to the molten polymer phase so that the molten polymer phase exfoliates the graphite successively with each event until at least 50% of the graphite is exfoliated to form a distribution in the molten polymer phase of single- and multi-layer graphene nanoparticles less than 50 nanometers thick along the c-axis direction.

Owner:RUTGERS THE STATE UNIV

Graphene-Reinforced Polymer Matrix Composites

ActiveUS20170218141A1Improve mechanical propertiesHigh strengthGraphiteSingle layer graphenePolymer scienceSingle layer graphene

A graphene-reinforced polymer matrix composite comprising an essentially uniform distribution in a thermoplastic polymer of about 10% to about 50% of total composite weight of particles selected from graphite microp articles, single-layer graphene nanoparticles, multilayer graphene nanoparticles, and combinations thereof, where at least 50 wt % of the particles consist of single- and / or multi-layer graphene nanoparticles less than 50 nanometers thick along a c-axis direction. The graphene-reinforced polymer matrix is prepared by a method comprising (a) distributing graphite microparticles into a molten thermoplastic polymer phase comprising one or more matrix polymers; and (b) applying a succession of shear strain events to the molten polymer phase so that the matrix polymers exfoliate the graphite successively with each event until at least 50% of the graphite is exfoliated to form a distribution in the molten polymer phase of single- and multi-layer graphene nanoparticles less than 50 nanometers thick along a c-axis direction.

Owner:RUTGERS THE STATE UNIV

Graphite nanocomposites

ActiveCN102112299AExcellent air retentionImprove machinabilityMaterial nanotechnologyTyresElastomerGraphite

Owner:EXXONMOBIL CHEM PAT INC

Preparation method of high-flux PVDF (polyvinylidene fluoride) porous membrane

ActiveCN104971631AIncrease water fluxImprove hydrophilicitySemi-permeable membranesEngineeringBovine serum albumin

The invention discloses a preparation method of a high-flux PVDF porous membrane. The method comprises the following steps: mixing PVDF, a highly hydrophilic polymer, a pore-forming additive, deionized water, a solvent and graphene powder, curing, stirring, standing, defoaming so as to obtain membrane casting liquid, and forming a wet membrane from the membrane casting liquid in a scraping manner; pre-evaporating the wet membrane in air, putting the pre-evaporated membrane in a solidification bath, and soaking to obtain a primary membrane in the deionized water; putting the primary membrane in the deionized water, performing heating activation, soaking in absolute ethyl alcohol and n-butyl alcohol, and airing in the air. According to the method, graphene nano-particles with two-dimensional structures are used as additives, the pure water flux can be up to 800L*m<-2>*h<-1> or more, and the rejection rate on bovine serum albumin is 98% or more; the hydrophilic polymer is added for performing the activation on the primary membrane, so that the hydrophilia of the PVDF membrane is greatly improved, and the membrane surface contact angle is up to 59.8 degrees; a porous membrane material is adopted, so that the structure is controllable, and the pore diameter range is controlled to be within 0.1-5 microns.

Owner:CENT SOUTH UNIV

In situ exfoliation method to fabricate a graphene-reinforced polymer matrix composite (G-PMC)

Owner:RUTGERS THE STATE UNIV

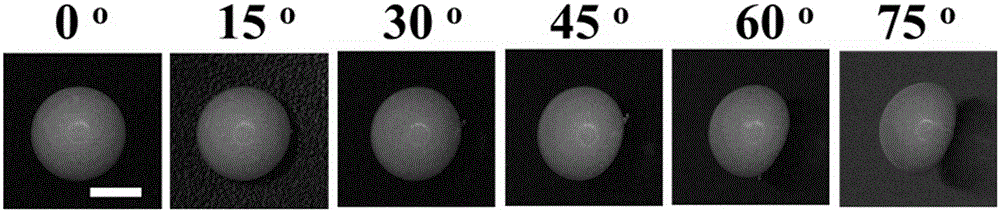

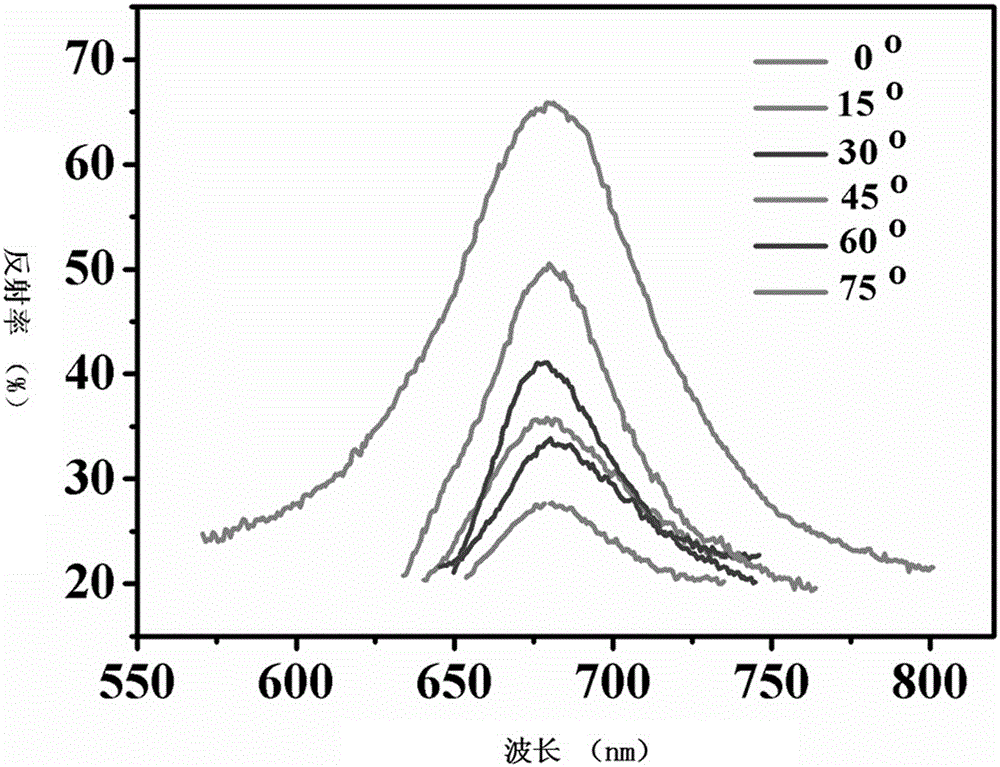

Morphology-controllable and color angle-independent photonic crystal particle and preparation method thereof

InactiveCN105177714ASimple control of shapeEliminate color angle dependenceFrom gel statePolycrystalline material growthMicrosphereSpherical shaped

The invention discloses a morphology-controllable and color angle-independent photonic crystal particle and its preparation method. The preparation method comprises the following steps: mixing Fe3O4 nanoparticles, carbon black nanoparticles, graphene nanoparticles or a mixture of the Fe3O4 nanoparticles, carbon black nanoparticles and graphene nanoparticles with an emulsion containing monodisperse colloidal microspheres; printing a mixture obtained onto a superhydrophobic substrate by a spraying, dispensing or inkjet mode so as to form emulsion droplets with diameter being 11microns -1.6 mm; and drying to obtain the ellipsoidal color angle-independent colored photonic crystal particle with its length-diameter ratio being controllable. The photonic crystal particle is colourfast and environmentally friendly and has a wide application prospect in fields of pigment, display, sensing and the like.

Owner:HEBEI NORMAL UNIV

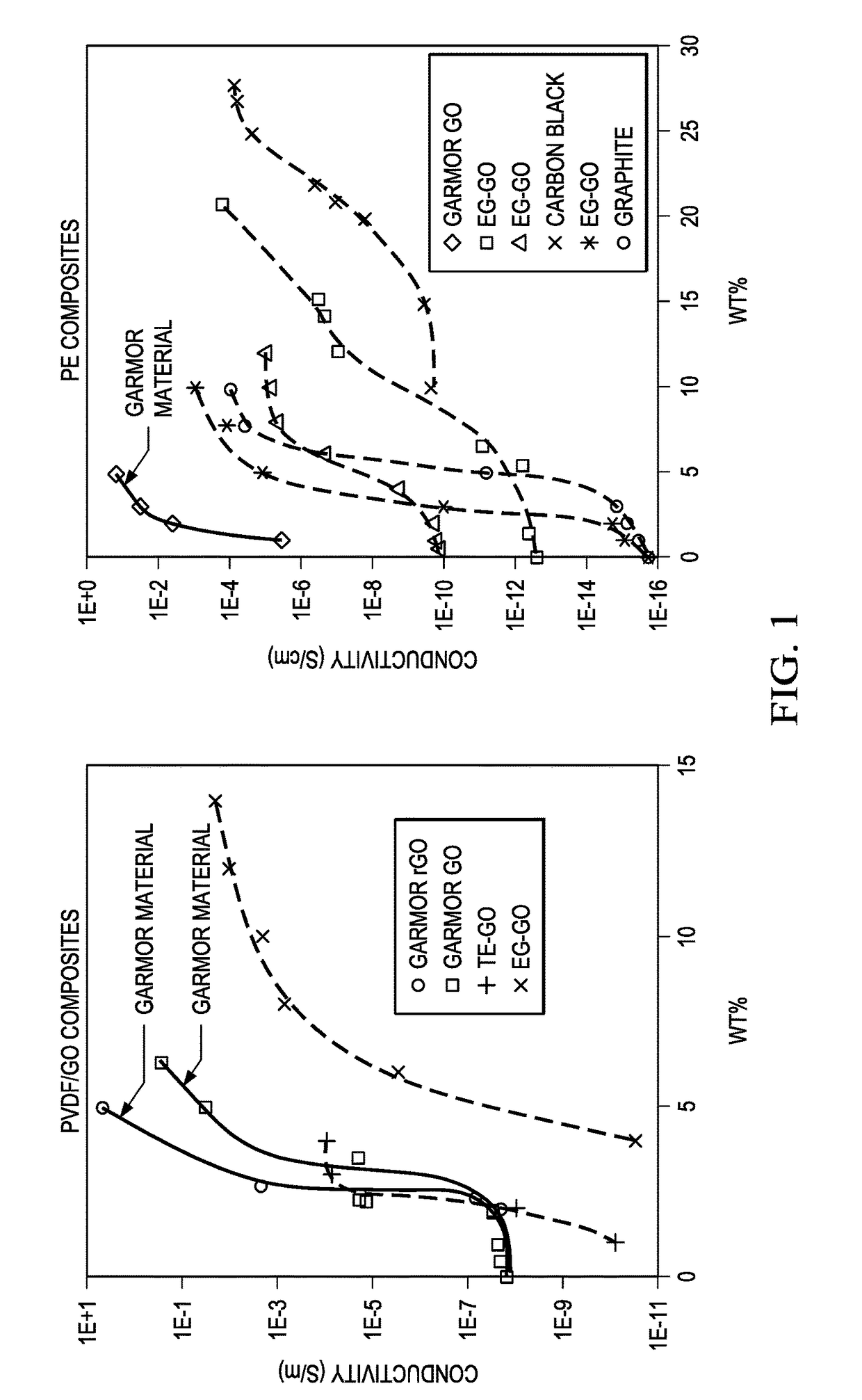

Electrically conductive hybrid polymer material

ActiveUS9901018B1Magnetic/electric field screeningCoupling device detailsCarbon fibersConductive polymer

An electrically conductive hybrid polymer material is described herein. The hybrid polymer material includes 0.01% to 1% by weight of carbon nanoparticles, 1% to 10% by weight of a conductive polymeric material, 1% to 20% of electrically conductive fibers having a metallic surface and 69% or more by weight of a nonconductive polymeric base material. The carbon nanoparticles may be carbon nanotubes, graphite nanoparticles, graphene nanoparticles, and / or fullerene nanoparticles. The conductive polymeric material may be an inherently conductive polymer, a radical polymers, or an electroactive polymer. The electrically conductive fibers may be stainless steel fibers, metal plated carbon fibers, or metal nanowires. The nonconductive polymeric base material may be selected from materials that are pliable at temperatures between −40° C. and 125° C. or materials that are rigid in this temperature range. The hybrid polymer material may be used to provide EMI shielding for wire cables of housings of electrical assemblies.

Owner:APTIV TECH LTD

Preparation method of graphene-ZnO nanoparticle composite material

ActiveCN103482614ASmall grain sizeSimple methodMaterial nanotechnologyZinc oxides/hydroxidesZinc bromideFiltration

The invention discloses a preparation method of a graphene-ZnO nanoparticle composite material. The preparation method comprises the following steps: step 1): dissolving raw materials, namely graphene oxide and zinc salt, in water according to a certain mass ratio and uniformly mixing; step 2): separating the graphene oxide from the well mixed liquid, obtained in the step 1, by centrifugation or suction filtration and washing with water or alcohol; and step 3) performing heat treatment on the product, obtained in the step 2, in air or oxygen to get the graphene-ZnO nanoparticle composite material, wherein the zinc salt is one of zinc fluoride, zinc chloride, zinc bromide, zinc sulfate, zinc nitrate, zinc acetate and zinc phosphate, the heat treatment temperature is 150-1000 DEG C, and the heat treatment time is 5s-10h. The preparation method disclosed by the invention is simple, green and environment-friendly, and can effectively reduce the use of chemical reagents.

Owner:SOUTHEAST UNIV

Method for preparing grapheme-Ag nano-particle composite material

The invention discloses a method for preparing a grapheme-Ag nano-particle composite material. The method includes the steps: firstly, dissolving raw oxidized grapheme and Ag salt into solvents according to mass ratio and uniformly mixing the solvents; secondly, separating out the oxidized grapheme, and cleaning and drying the oxidized grapheme by the solvents in the first step; and thirdly, performing heat treatment for the oxidized grapheme obtained in the second step in vacuum or specific atmosphere at the temperature of 30-800 degrees Celsius for 5 seconds to 5 hours to obtain the grapheme-Ag nano-particle composite material, wherein the specific atmosphere includes one of nitrogen, argon or hydrogen. The grapheme-Ag nano-particle composite material can be obtained by heat treatment without adding reducing agents. The method is simple, usage of chemical reagents is effectively decreased, cost is reduced, environmental damage is decreased, and the method is green and environment-friendly.

Owner:SOUTHEAST UNIV

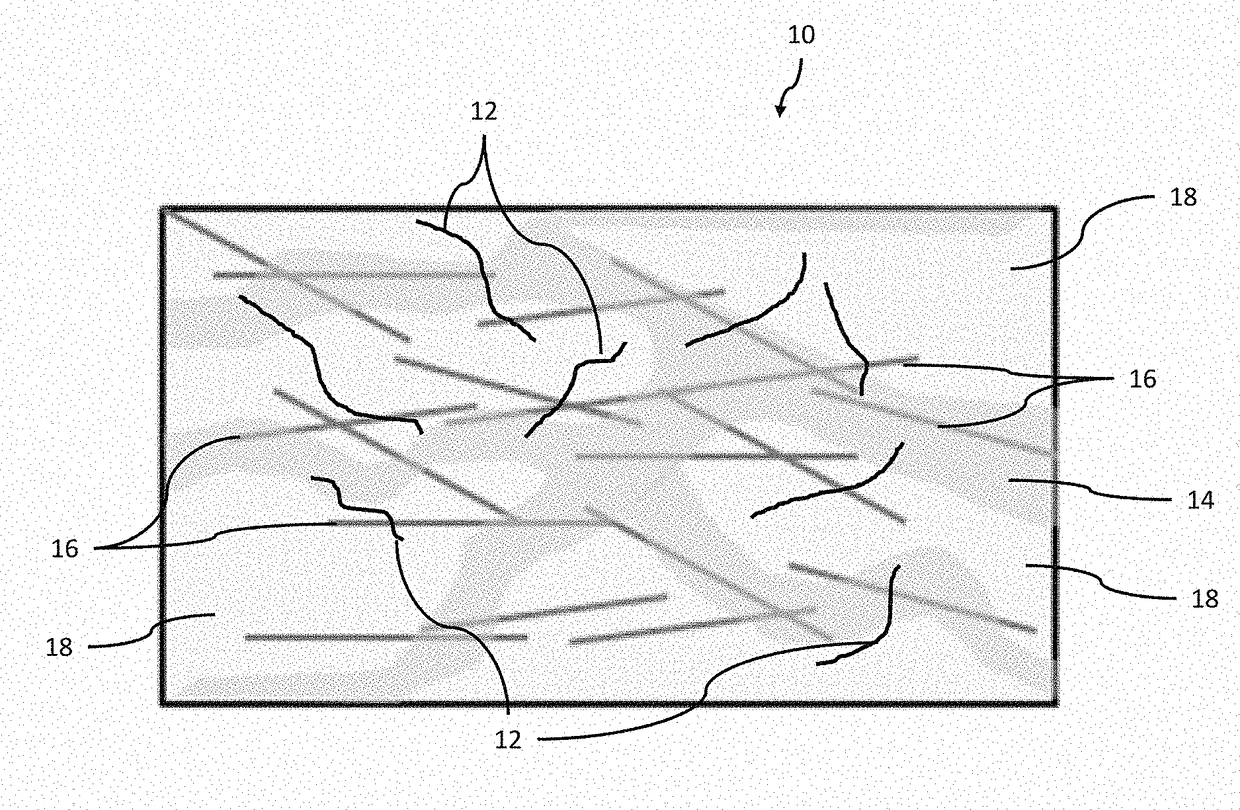

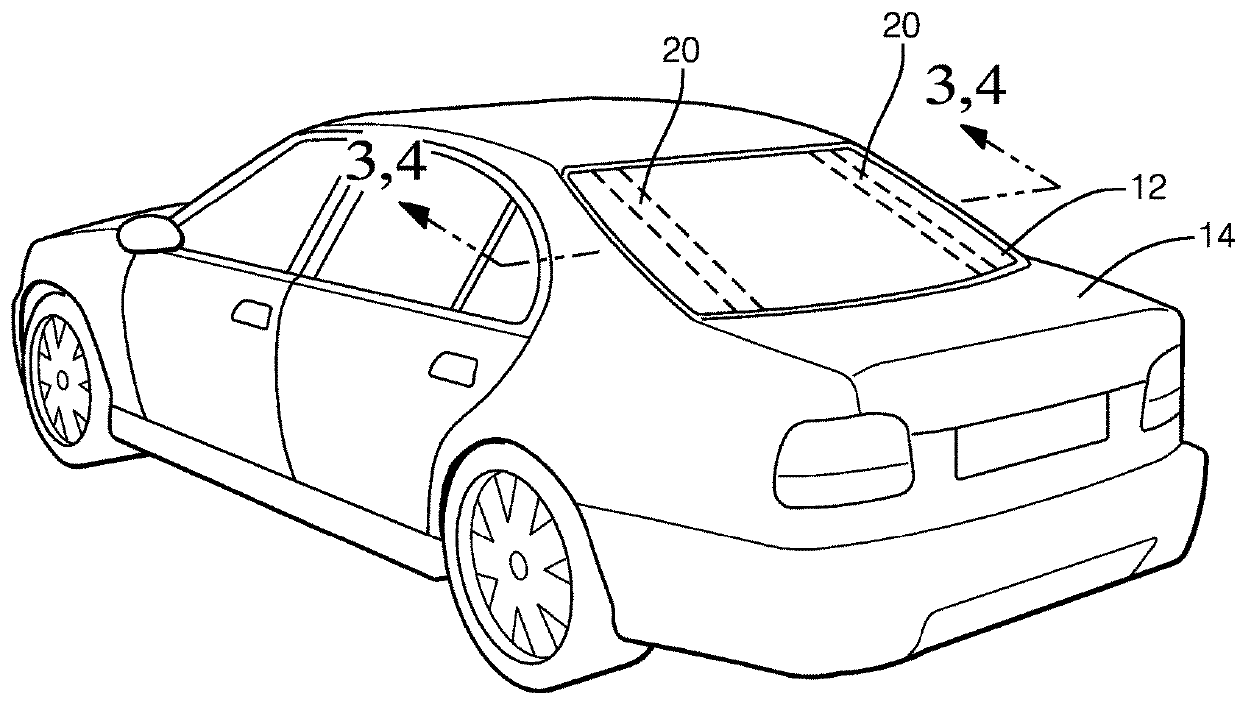

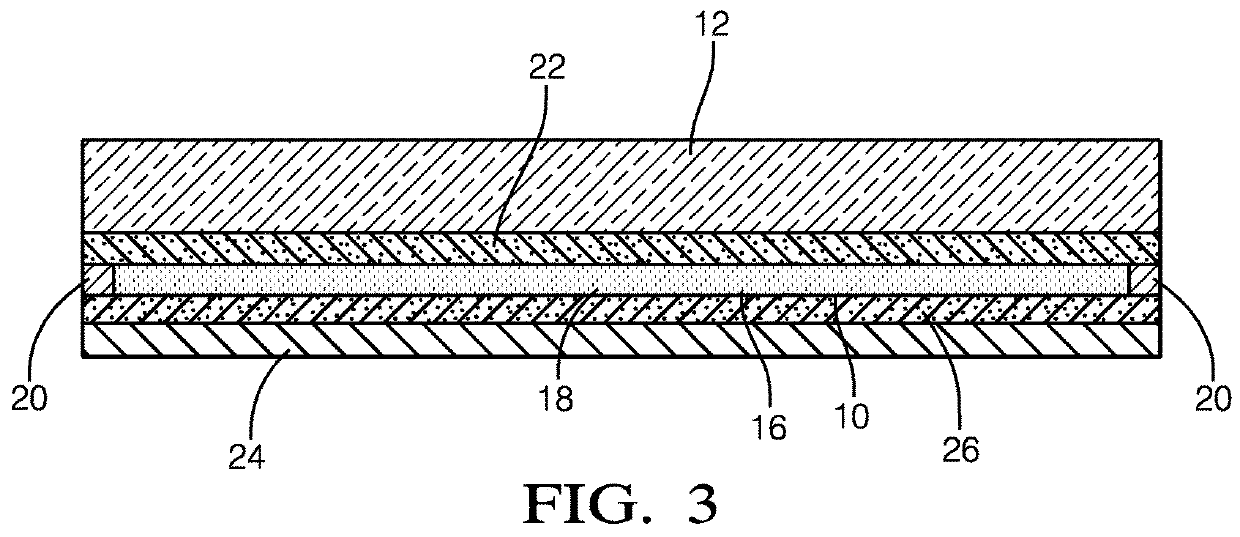

Electrically conductive polymer film

An electrically conductive polymer film is presented. The electrically conductive polymer film includes a polymeric base material, a plurality of electrically conductive nanoparticles randomly oriented within the polymeric base material, and a pair of electrodes electrically interconnected with the plurality of electrically conductive nanoparticles. The electrodes are configured to be connected to an electrical power source. The polymeric base material may e.g. be polyethylene, polypropylene, polyvinyl chloride, polycarbonate, acrylic, polyester, and / or polyamide. The plurality of electrically conductive nanoparticles may be metallic nanowires, metal-plated nanofibers, carbon nanotubes, graphene nanoparticles, and / or graphene oxide nanoparticles. The plurality of electrically conductive nanoparticles may also or alternatively include an inherently conductive polymer such as polylanine, 3,4-ethylenedioxythiophene, 3,4-ethylenedioxythiophene polystyrene sulfonate, and / or 4,4-cyclopentadithiophene. The plurality of electrically conductive nanoparticles may be substantially uniformly distributed throughout the polymeric base material.

Owner:APTIV TECH LTD

Method for preparing PVDF-TrFE/graphene high performance composite material

InactiveCN108264710AExcellent preparation performanceIncrease power generation capacityFlat articlesElectricityPvdf trfe

The invention discloses a method for preparing PVDF-TrFE high performance piezoelectric film. The method is divided into the following steps of 1, evenly stirring PVDF-TrFE powder and graphene nanoparticles in a DMF solution by using an ultrasonic stirrer and a mechanical stirrer; 2, initially crystallizing an obtained mixed solution in a drying oven; 3, axially stretching film after initial crystallization on a stretching machine; 4, conducting heat treatment on the film after stretching; 5, performing polarization on the film after the heat treatment. The method has advantages of low cost, high piezoelectric performance, simple operation and low process requirements.

Owner:海宁盛台材料科技有限公司

Graphene-reinforced polymer matrix composites

ActiveUS10329391B2Improve mechanical propertiesHigh strengthGraphiteSingle layer grapheneMicroparticleGraphite

Owner:RUTGERS THE STATE UNIV

Uniform Dispersing of Graphene Nanoparticles in a Host

PendingUS20180030277A1Good dispersionImproved exfoliationPigmenting treatmentMaterial nanotechnologyPolymer compositesCvd graphene

The present invention includes a simple, scalable and solventless method of dispersing graphene into polymers, thereby providing a method of large-scale production of graphene-polymer composites. The composite powder can then be processed using the existing techniques such as extrusion, injection molding, and hot-pressing to produce a composites of useful shapes and sizes while keeping the advantages imparted by graphene. Composites produced require less graphene filler and are more efficient than currently used methods and is not sensitive to the host used, such composites can have broad applications depending on the host's properties.

Owner:UNIV OF CENT FLORIDA RES FOUND INC +1

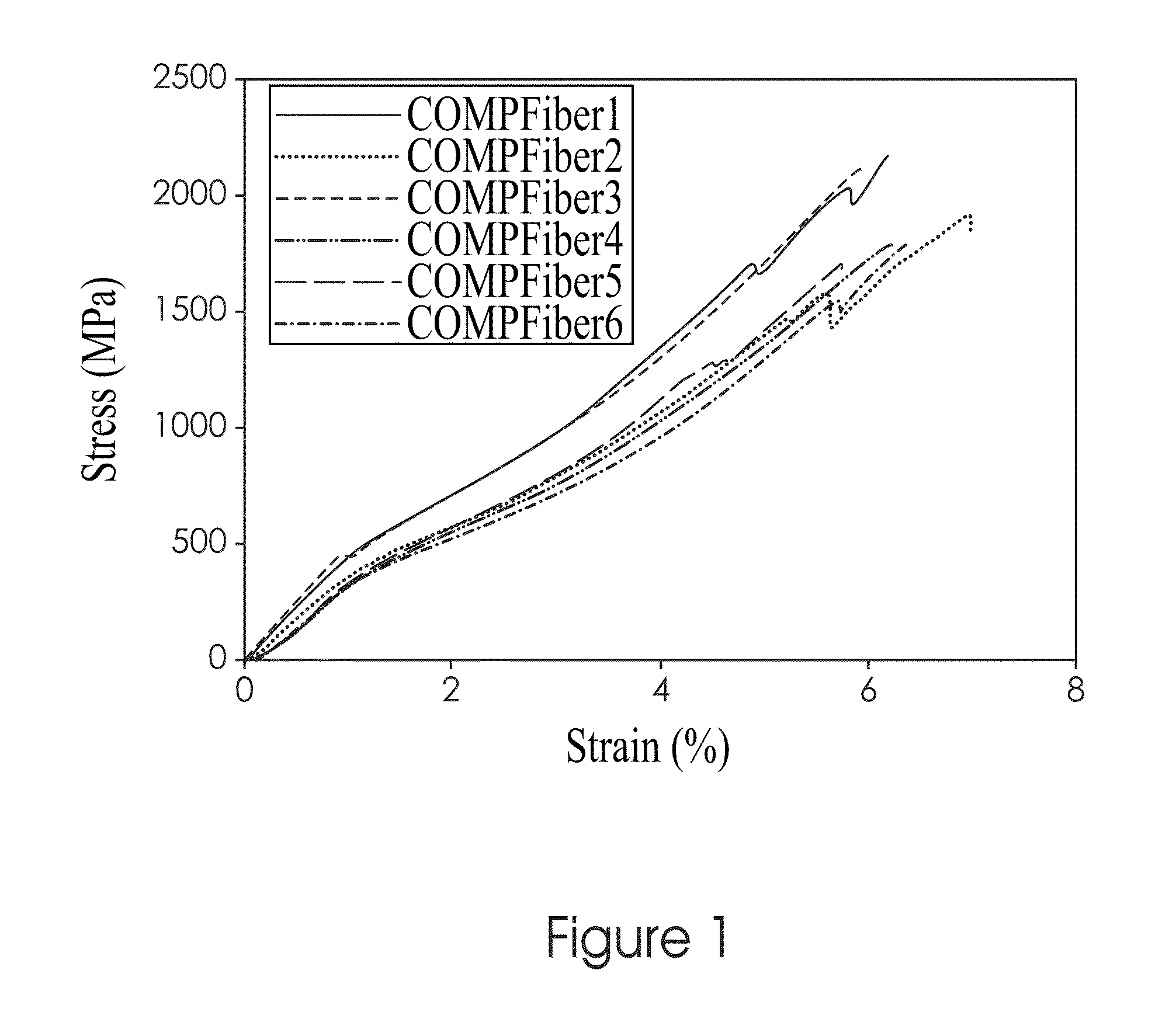

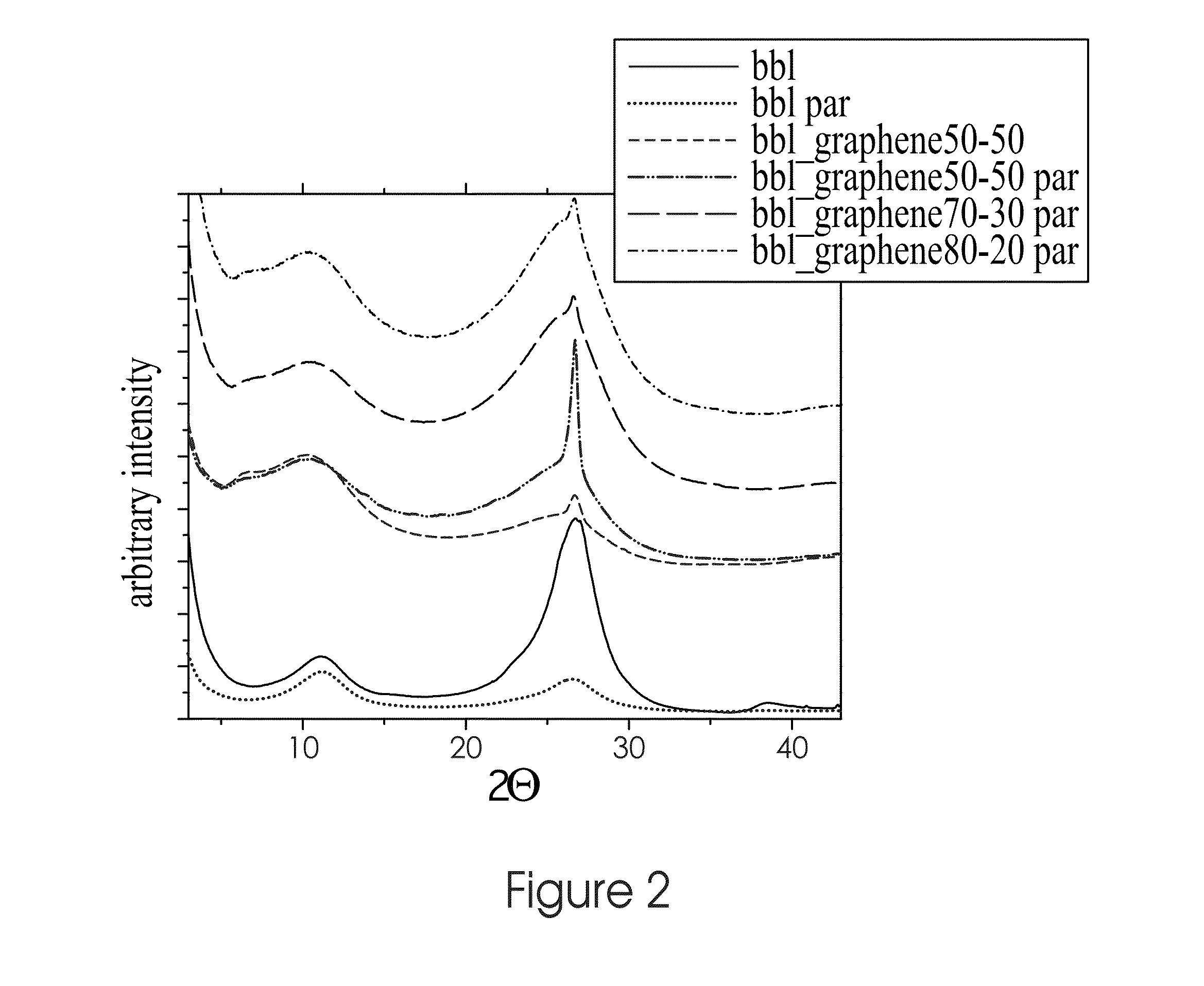

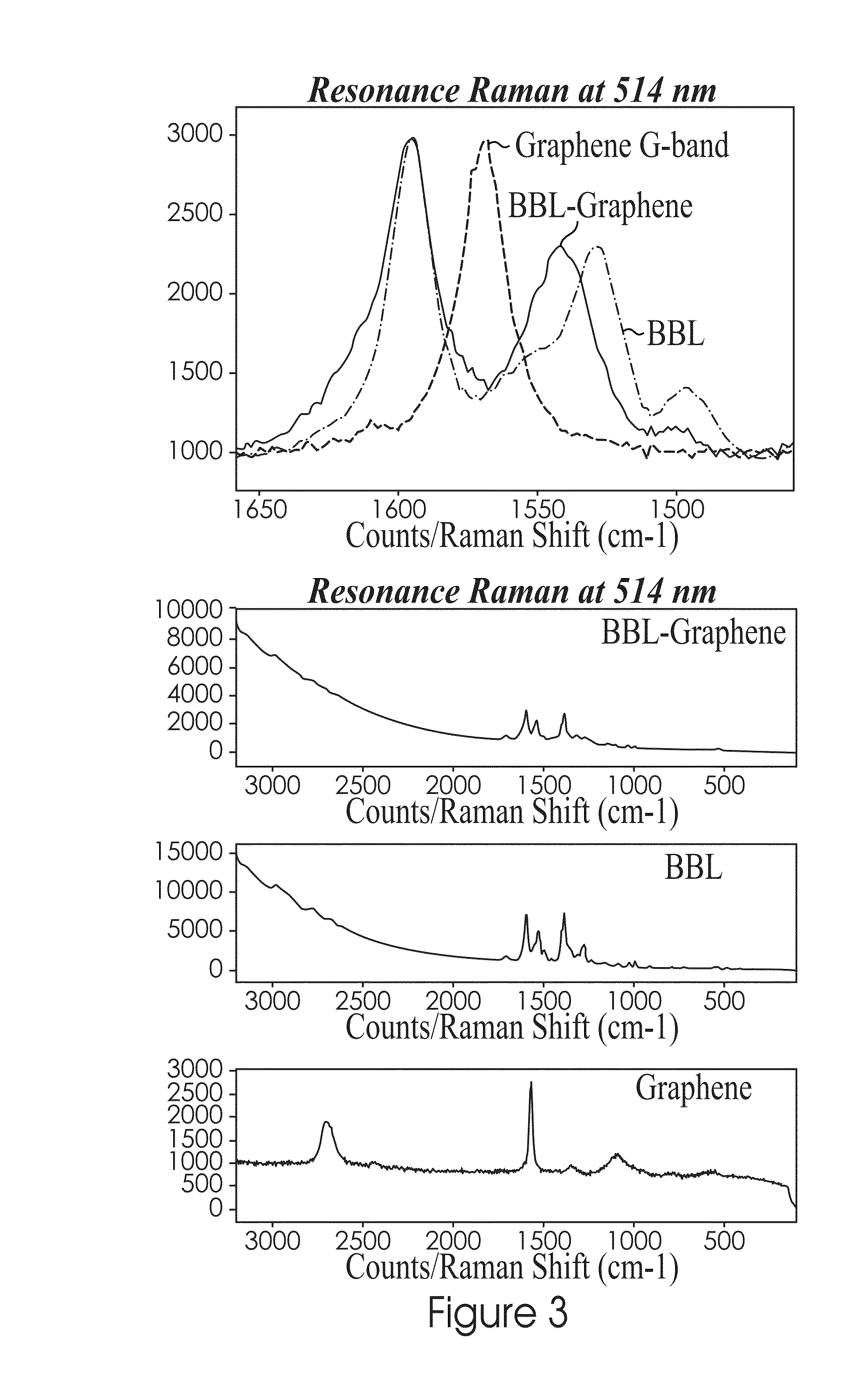

Composites comprising rigid-rod polymers and graphene nanoparticles and process for making the same

InactiveUS20150218730A1High strengthMaterial nanotechnologyArtificial filament washing/dryingFiberPolymer science

The present invention relates to composites comprising rigid-rod polymers and graphene nanoparticles, processes for the preparation thereof, nanocomposite films and fibers comprising such composites and articles containing such nanocomposite films and fibers.

Owner:TJC POLYMER INC

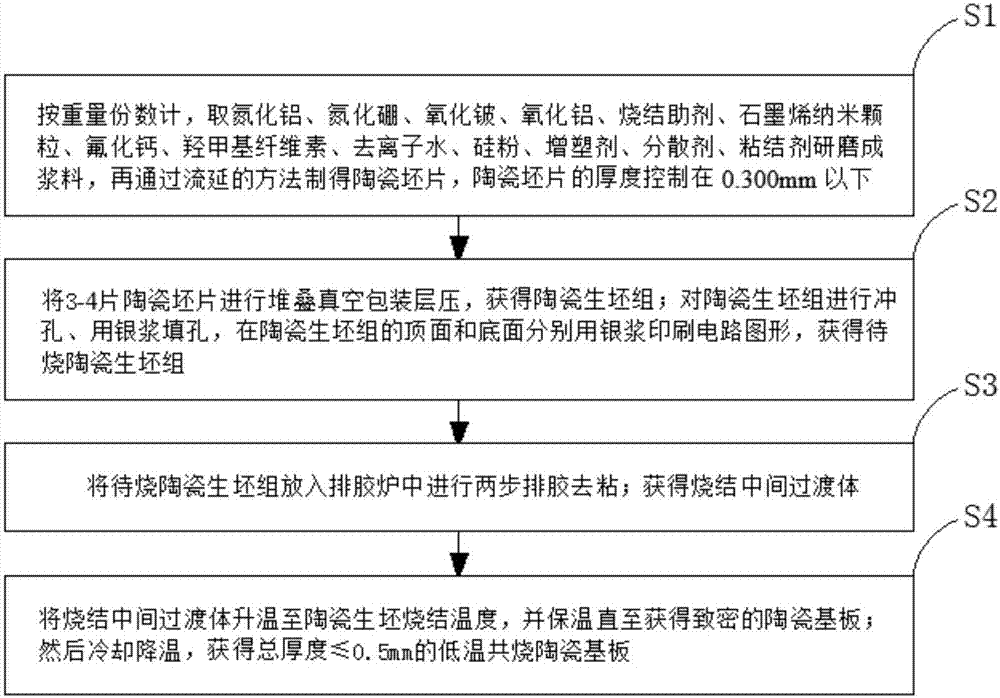

Forming and sintering method of low temperature co-fired ceramic substrate

The invention relates to a forming and sintering method of a low temperature co-fired ceramic substrate; the method comprises the steps of preparing ceramic body sheets; stacking the ceramic block sheets, packaging in vacuum, and laminating to obtain a ceramic green body set; punching the ceramic green body set, filling holes with silver paste and, printing circuit patterns on top and bottom surfaces of the ceramic green body set via silver paste to obtain a ceramic green body set to be fired; placing the ceramic green body set to be fired into a rubber removal furnace and performing two-step rubber removal and gluing to obtain a sintered intermediate transition part; heating the sintered intermediate transition part to ceramic green body sintering temperature, and holding the temperature until a compact ceramic substrate is obtained; cooling to obtain the low temperature co-fired ceramic substrate. Compared with the prior art, the method of the invention has the advantages that the combination of aluminum nitride, boron nitride and beryllium oxide decreases cost and maintains heat-dissipating performance; by adding graphene nanoparticles, heat can be transferred, and compactness of the ceramic substrate is also improved; the physiochemical prosperities of the ceramic substrate are optimized via hydroxymethyl cellulose.

Owner:FUJIAN HUAQING ELECTRONICS MATERIAL TECH

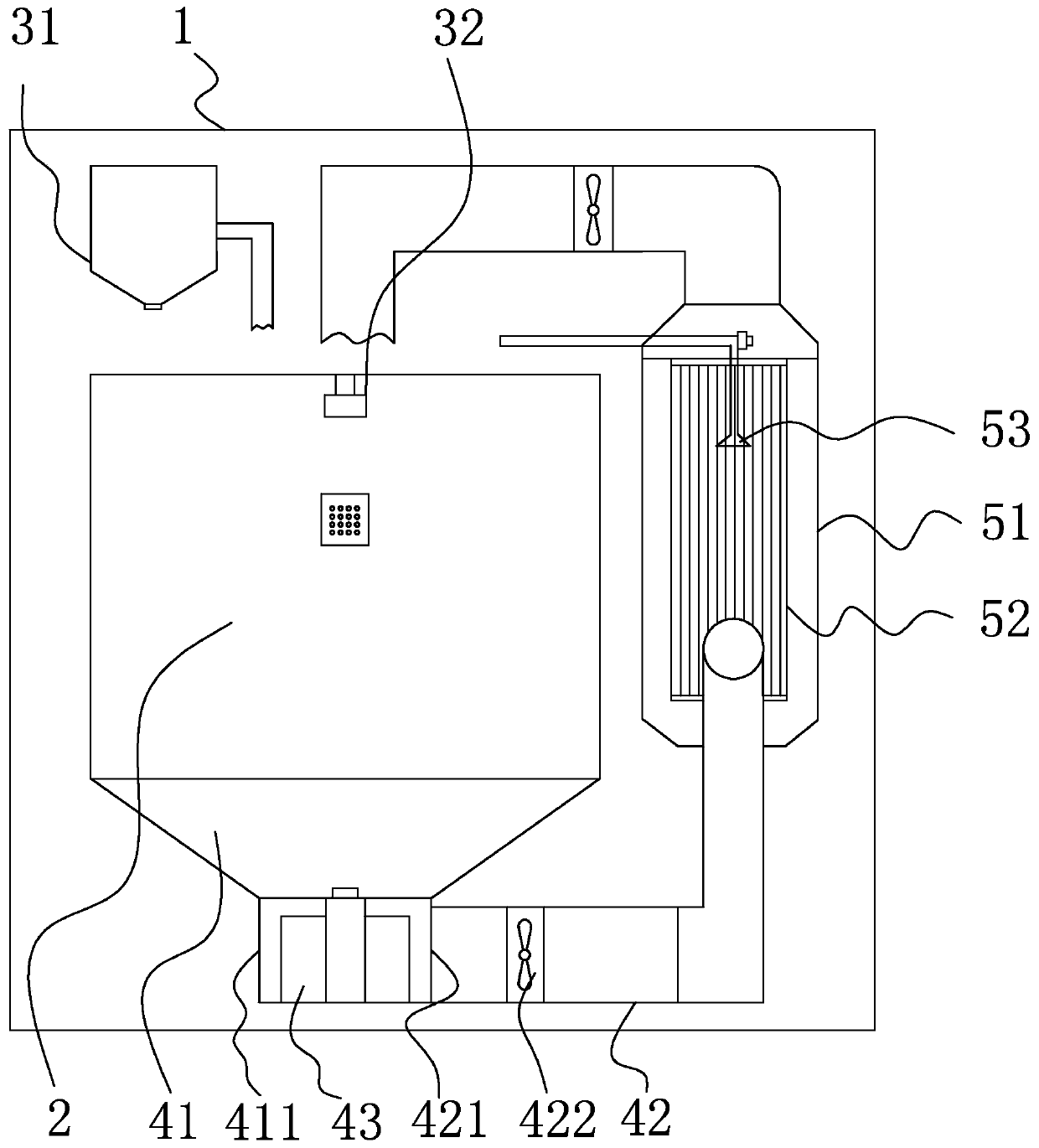

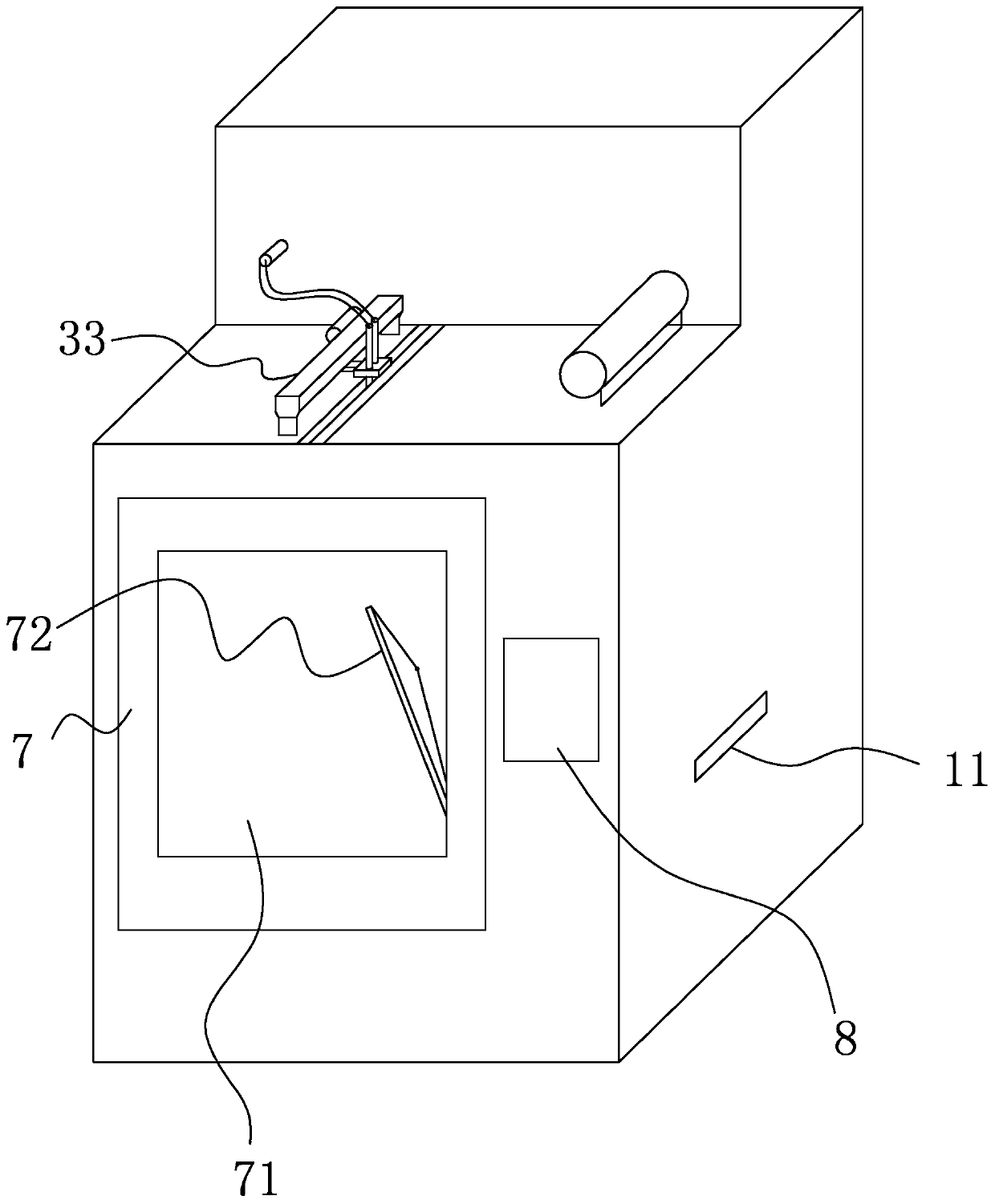

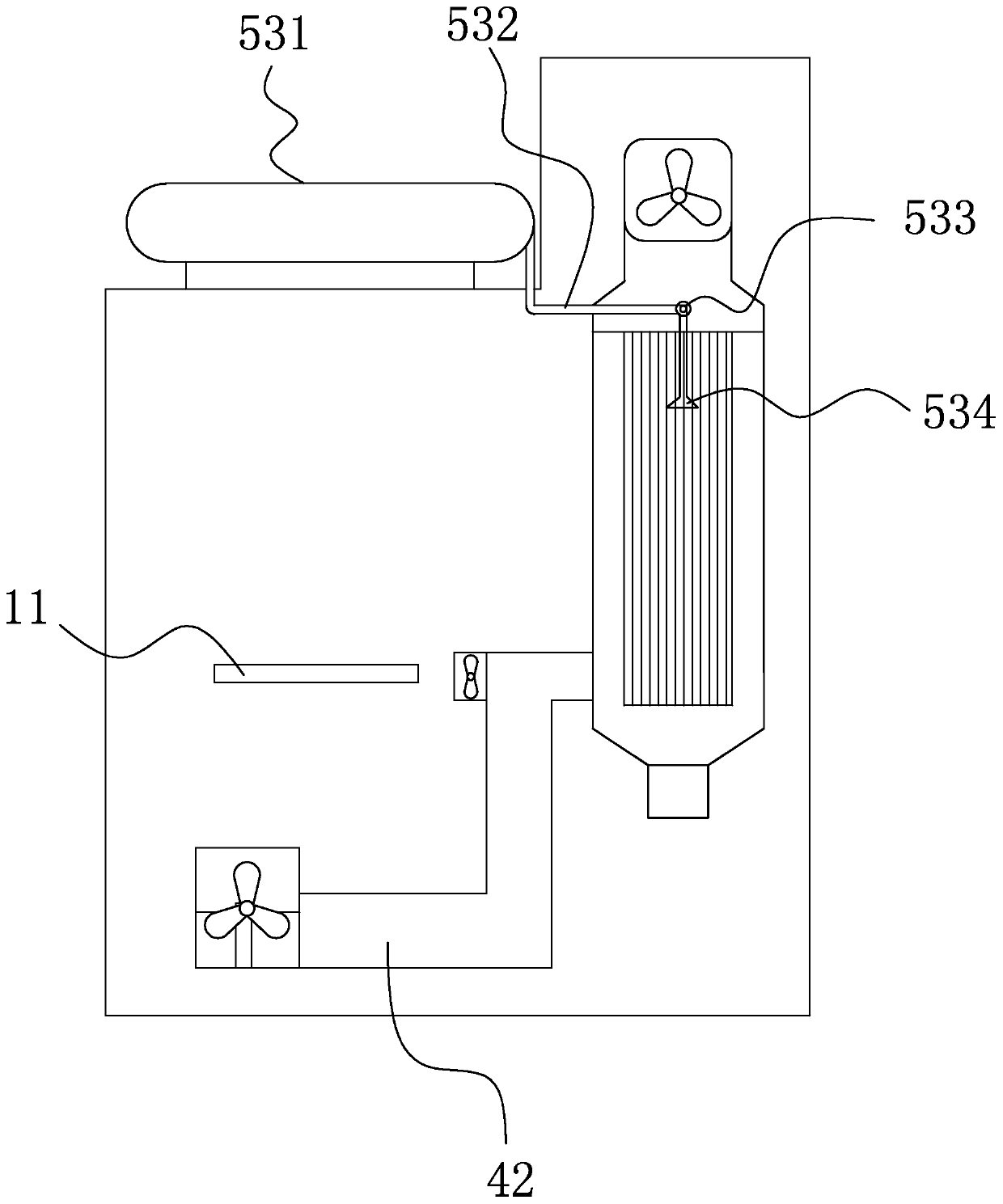

Graphene spraying device and spraying process thereof

PendingCN109794389AReduce manufacturing costEasy to operateLiquid spraying apparatusSpray boothsMetallurgyCopper foil

The invention discloses a graphene spraying device and a spraying process thereof. The graphene spraying device comprises a box body, wherein a spraying chamber, a feeding device, a recycling device,a powder filtering device and a hot air drying device are arranged in the box body; and graphene powder is sprayed on a PET film or a copper foil in the spraying chamber; and excess graphene powder isrecycled through the recycling device. According to the graphene spraying device and the spraying process thereof, graphene nanoparticles which are lightest, smallest and can float in the air are used as coating materials, a material film is coated with graphene in a spraying mode, so that the production cost is greatly reduced, and the operation is convenient.

Owner:珠海市光环自动化科技有限公司

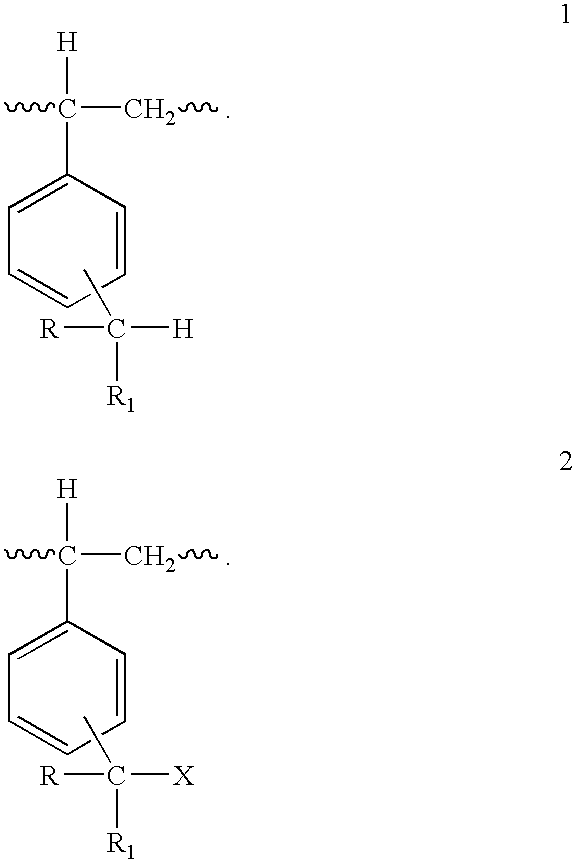

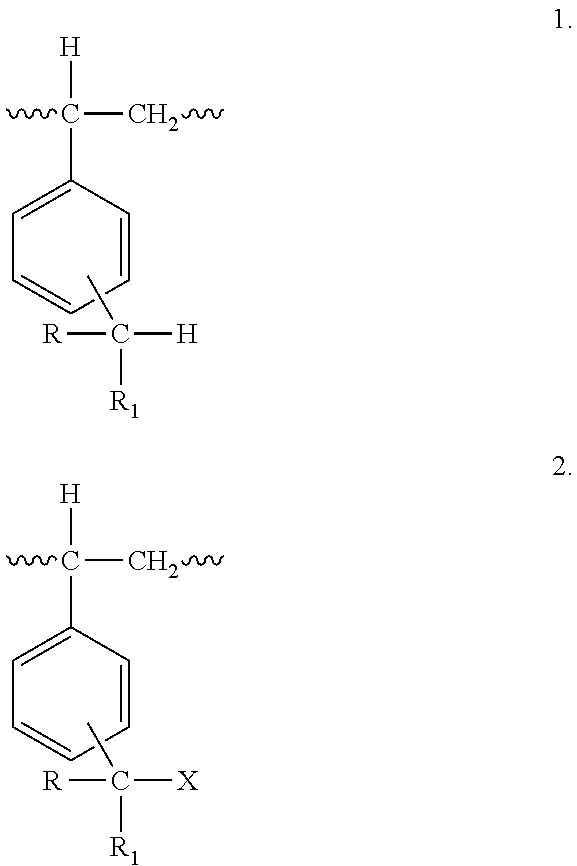

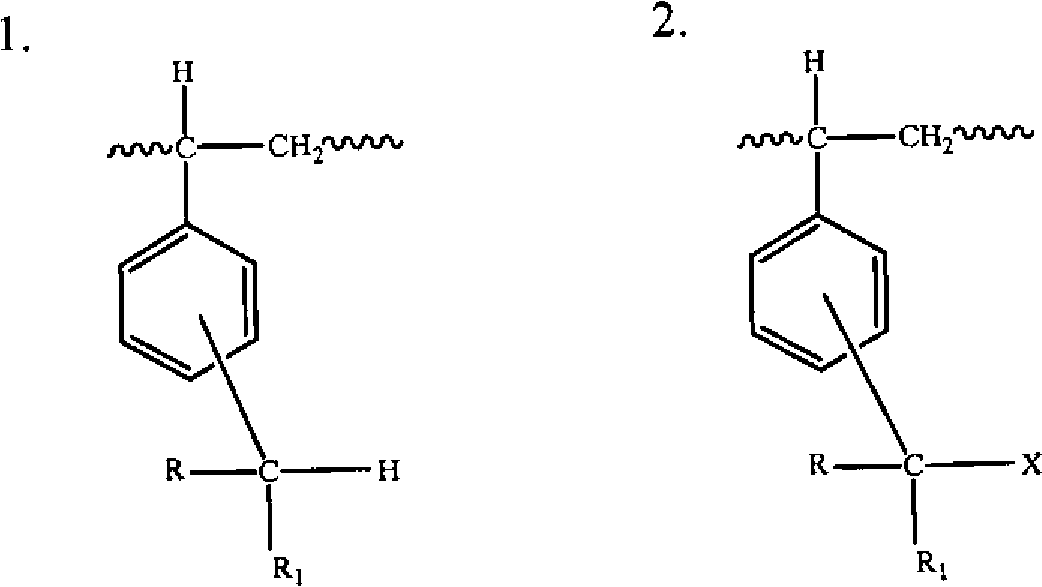

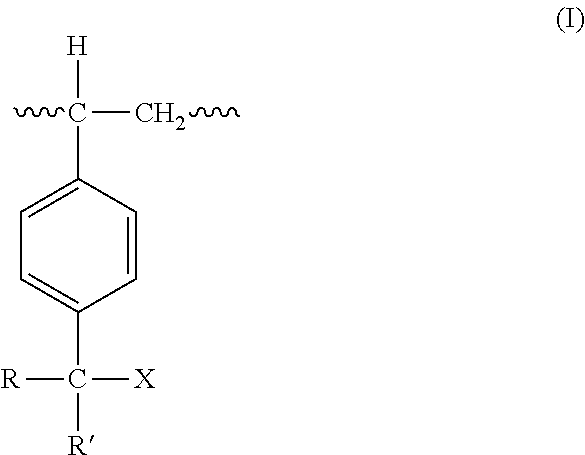

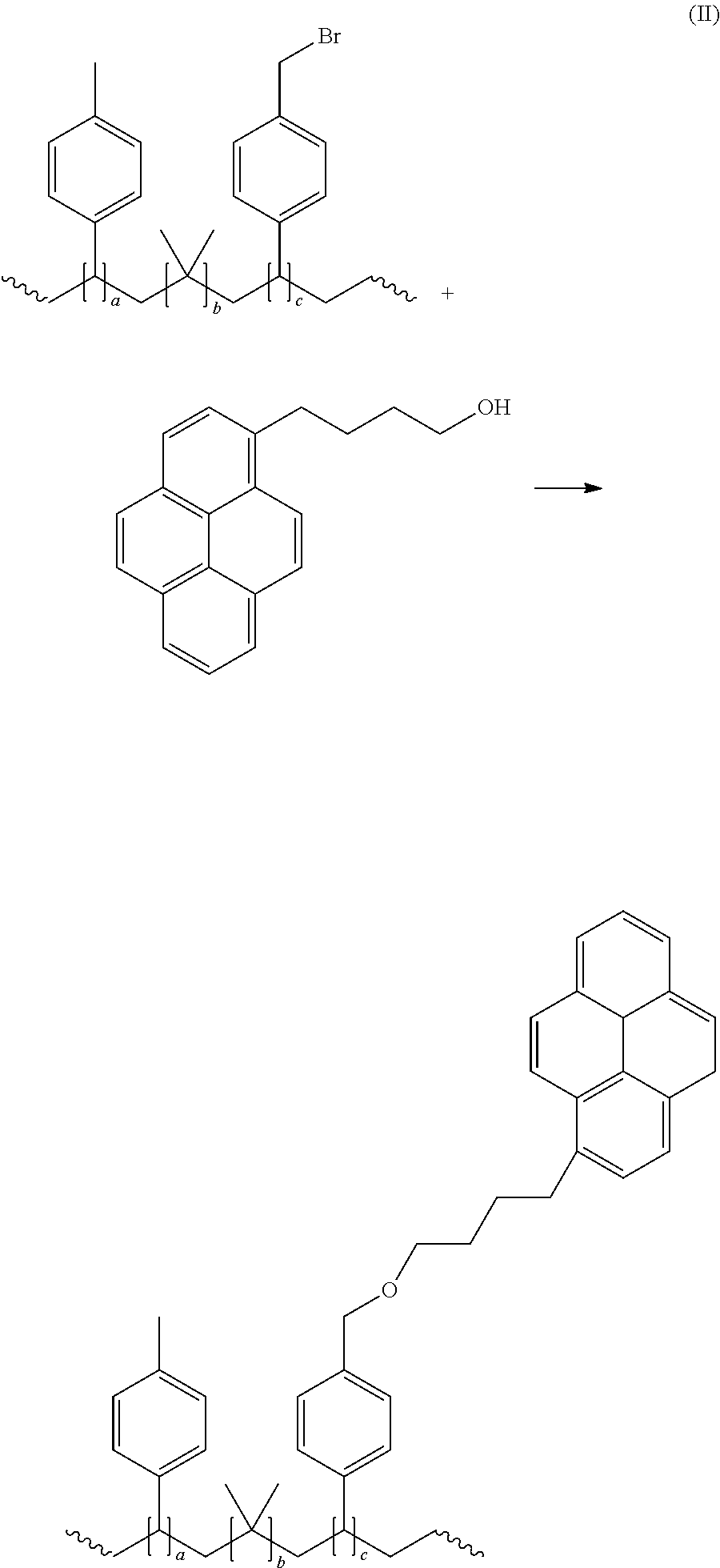

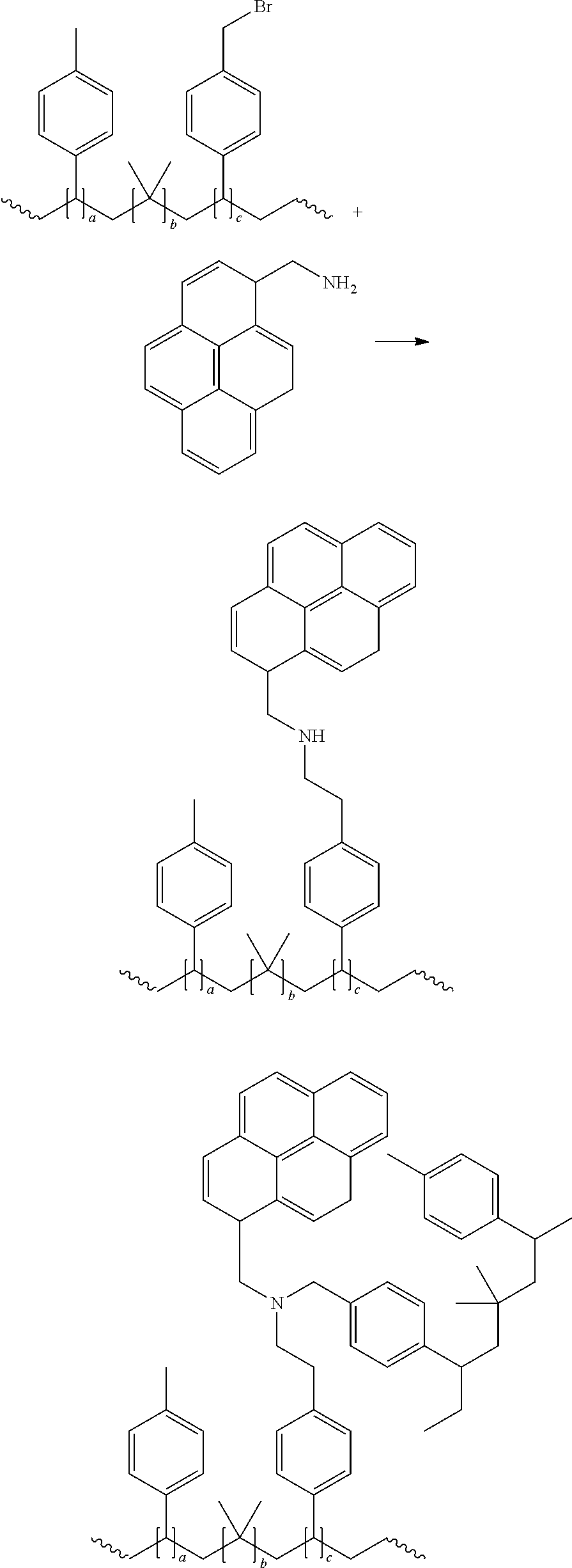

Polycyclic Aromatic Hydrocarbon Functionalized Isobutylene Copolymers for Dispersing Graphene and Graphite

ActiveUS20170088688A1Inorganic pigment treatmentSpecial tyresPolycyclic aromatic hydrocarbonElastomer

Polycyclic aromatic hydrocarbon (PAH) functionalized isobutylene copolymers, methods for making a PAH functionalized isobutylene copolymer comprising combining a halogenated copolymer with a PAH in a solvent under basic conditions at a temperature ranging from 30° C. to 150° C., the use of these PAH functionalized copolymers as a dispersant in elastomeric nanocomposite compositions comprising a halobutyl rubber matrix and nanoparticles of graphite or graphene, and a tire innerliner or innertube produced from these elastomeric nanocomposite compositions is disclosed.

Owner:EXXONMOBIL CHEM PAT INC

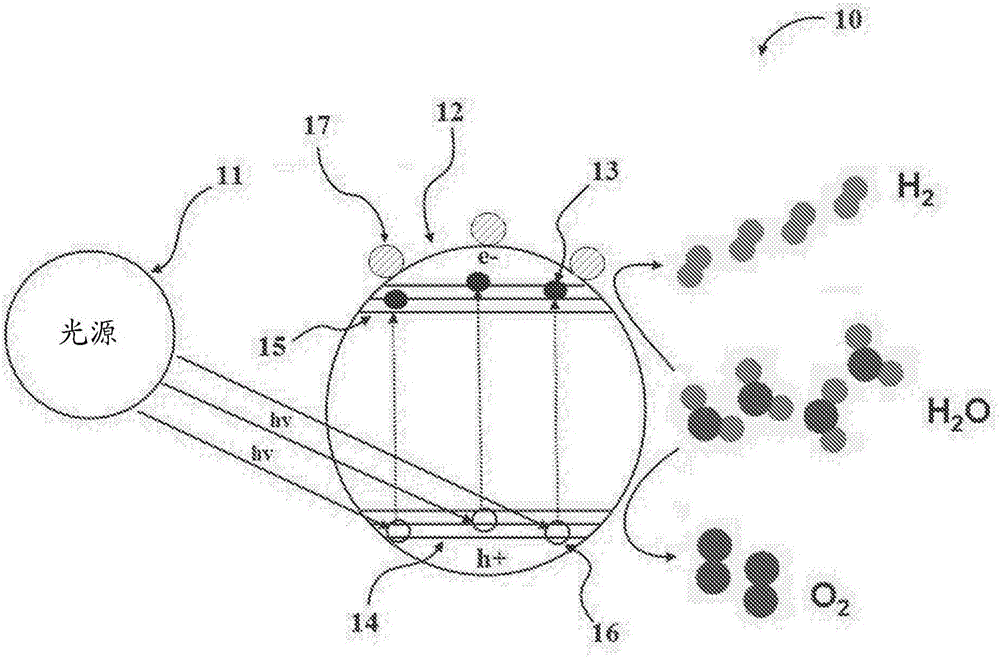

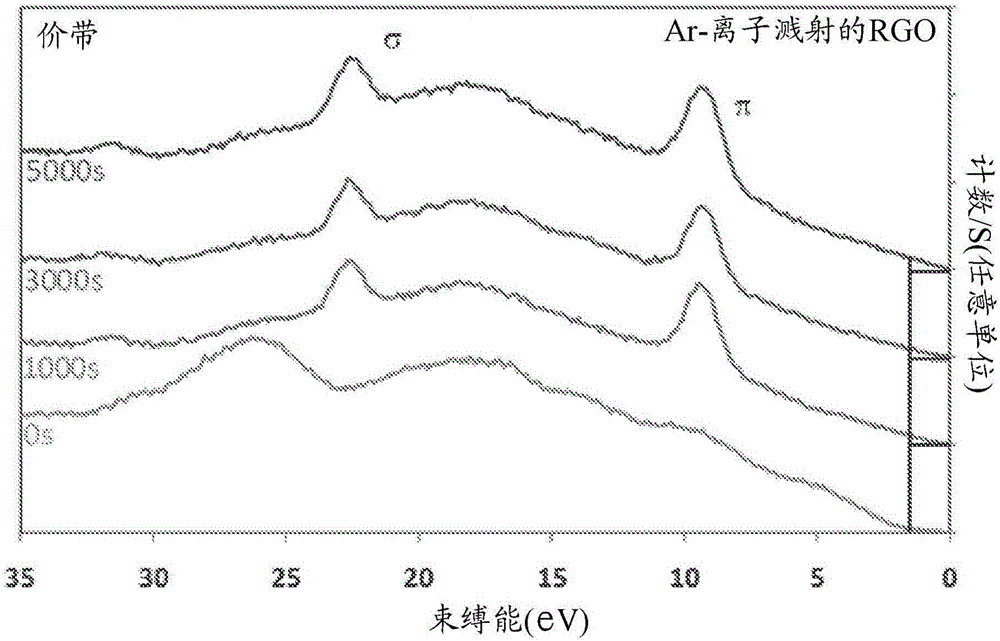

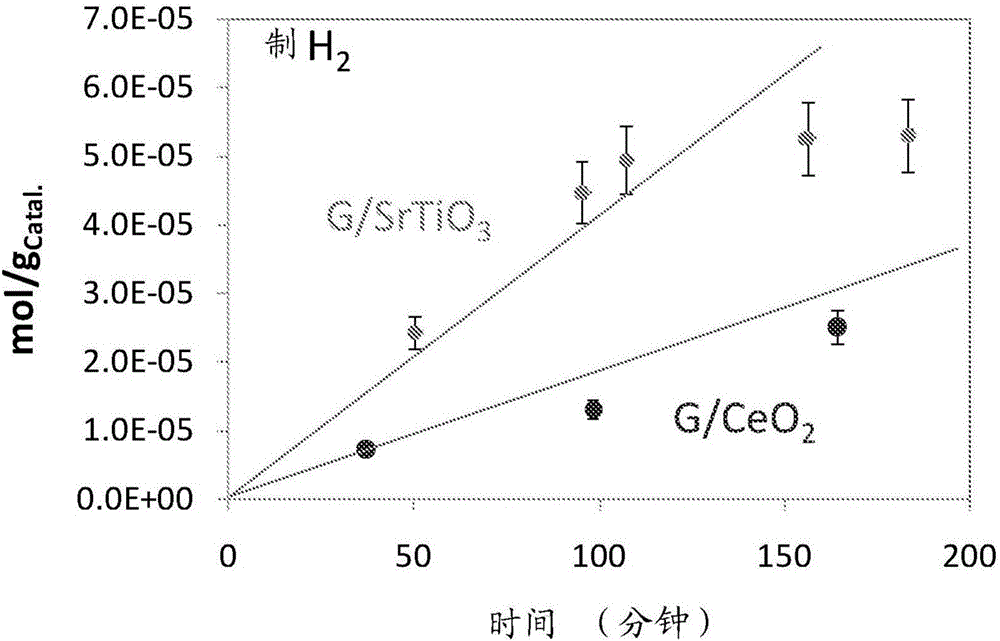

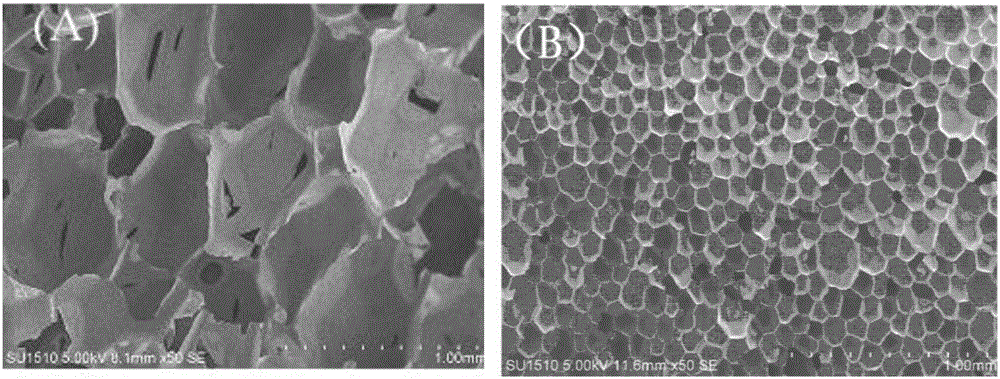

Hydrogen production from water using photocatalysts comprising metal oxides and graphene nanoparticles

InactiveCN105813730AOxygen/ozone/oxide/hydroxideWater/sewage treatment by irradiationPhysical chemistryGraphite

Disclosed is a photocatalyst, and methods for its use, that includes graphene nanostructures attached to the surface of a photoactive metal oxide semiconductor selected from SrTiO3 or CeO2, wherein the photoactive metal oxide semiconductor is a microstructure or larger.

Owner:SABIC GLOBAL TECH BV

Heterogeneous nucleating agent toughening-modified phenolic resin foam and preparation method thereof

ActiveCN106009490ALower wetting angleImprove mechanical propertiesMechanical propertyOrganic chemistry

The invention discloses heterogeneous nucleating agent toughening-modified phenolic resin foam and a preparation method thereof. The preparation method of the foam comprises the following steps of preparing a heterogeneous nucleating agent and preparing the modified phenolic resin foam. According to the method, silane coupling agent modified graphene is added for regulating the foam pore structure; meanwhile, the synergistic effect of graphene nanoparticles is exerted, the defects that phenolic foam is poor in mechanical property, high in brittleness and prone to disengagement are effectively overcome, and wide application of the phenolic foam in the engineering field is promoted.

Owner:JIANGNAN UNIV

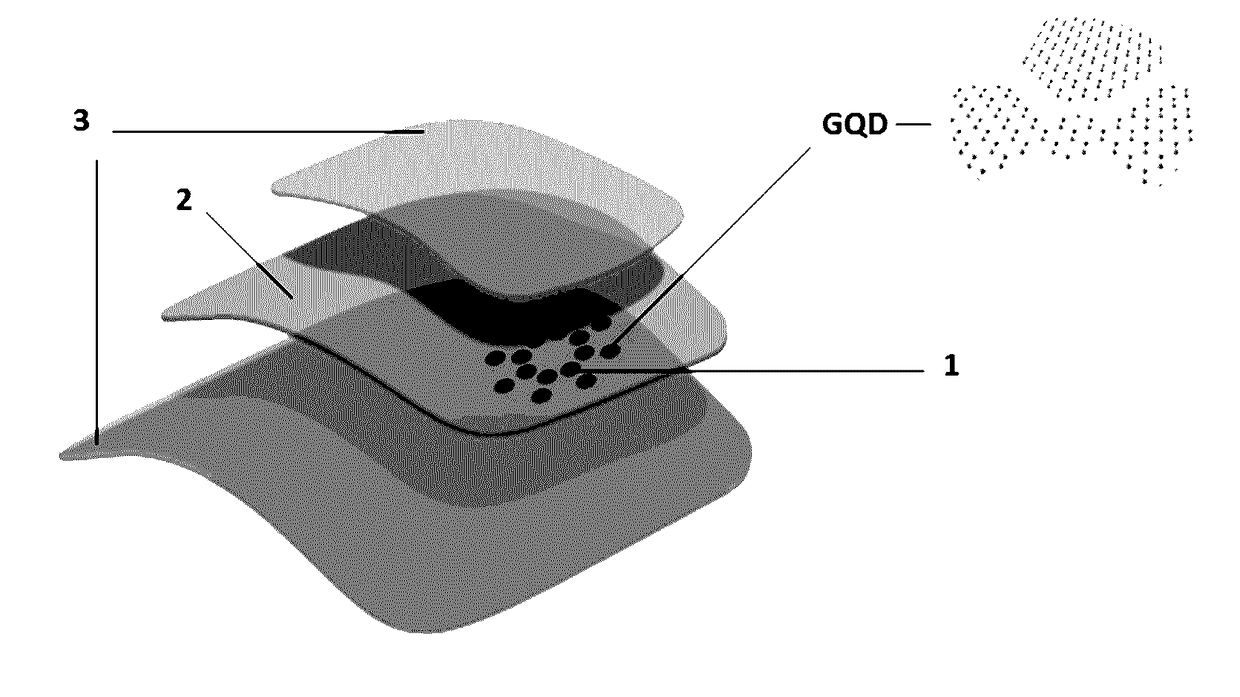

Security element against counterfeiting security printing, especially banknotes

InactiveUS20170089012A1Non-fibrous pulp additionPaper-money testing devicesGraphene nanocompositesOptoelectronics

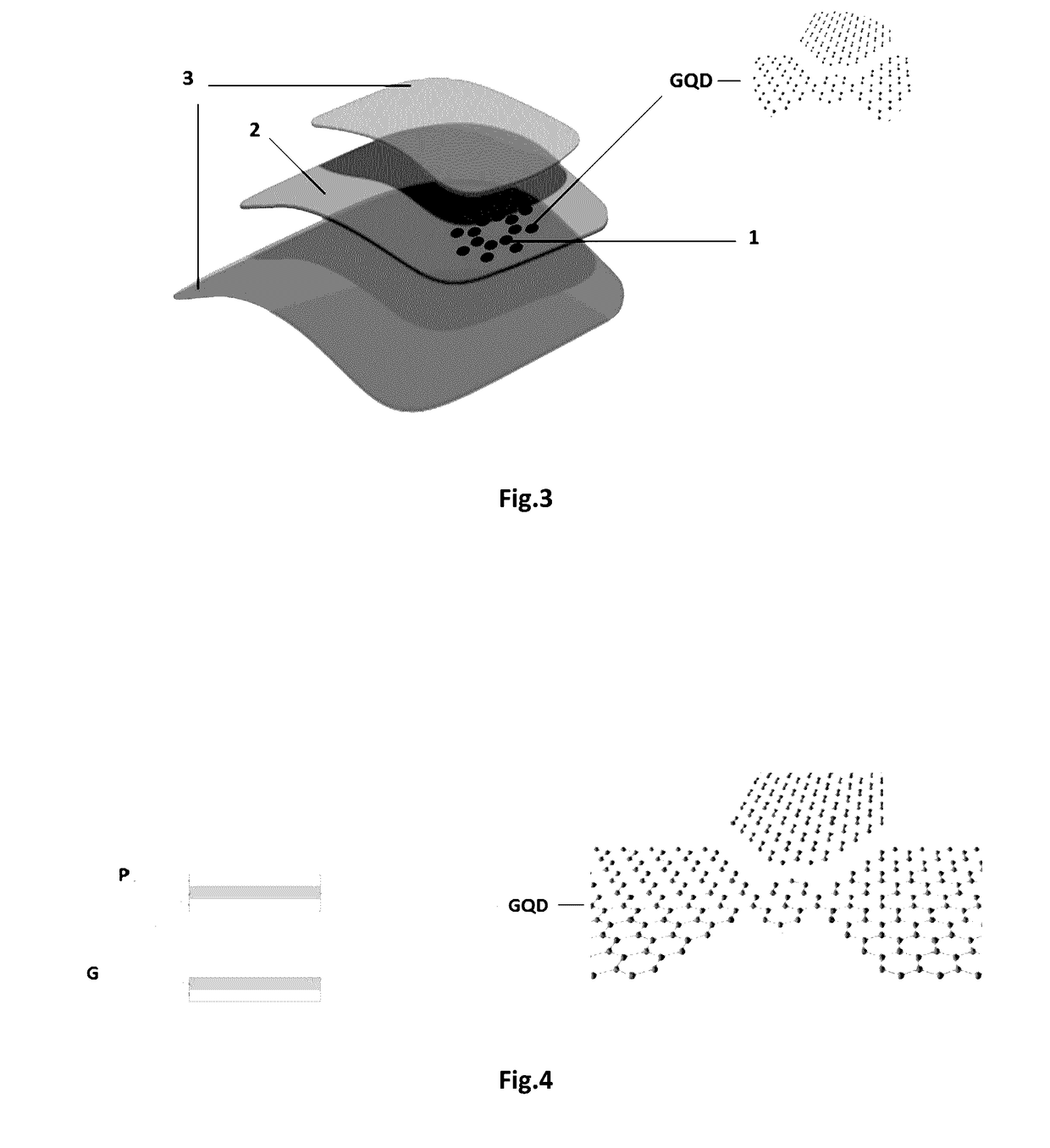

The present invention is a security feature against counterfeiting security printing, in particular banknotes, having at least one graphene quantum dot (GQD) that has a graphene nanoparticle diameter ranging from 0.5 nm to 60 nm, and containing from 1 to 90 layers of graphene disposed in the flexible layer of graphene nanocomposite material, where the elastic layer of graphene nanocomposite material comprises at least one layer of graphene arranged on the adhesive layer. The invention also includes the use of the security feature according to the invention, and a method and system for verifying the authenticity of security printing.

Owner:RYBKA WOJCIECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com