Patents

Literature

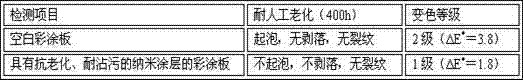

118results about How to "Lower wetting angle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

AlN ceramic bonded copper substrate and preparation method thereof

The invention provides an AlN ceramic bonded copper substrate which comprises an AlN ceramic substrate and copper foil bonded and connected onto the AlN ceramic substrate and is characterized in that a spinel structure compound modification layer is formed between the AlN ceramic substrate and the copper foil and comprises one or two of CuAlO2, CuAl2O4, Cu2O and CuO. The invention further provides a preparation method of the AlN ceramic bonded copper substrate. The method comprises the steps of spraying nano Cu2O on the surface of the AlN substrate, sintering in inert gas with a micro oxygen content and air sequentially, and then removing a surface oxide by a pickling manner. The prepared modification layer is tightly combined with matrix ceramic, and also has good affinity characteristic with the Cu foil. A uniform oxidation layer can be formed on the surface of the Cu foil by putting the Cu foil in a prepared solution at a certain temperature for specified time and more facilitates an AlN-DBC (direct bonded copper) technology.

Owner:NANJING ZHONGJIANG NEW MATERIAL TECH

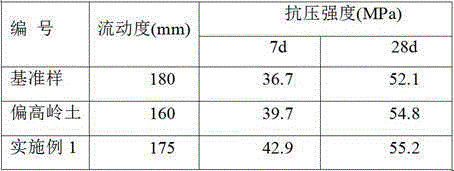

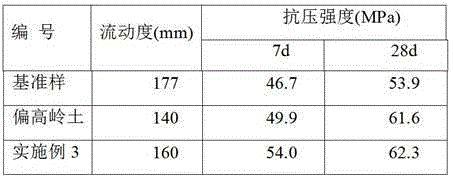

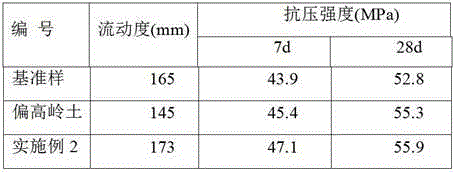

High-activity modified metakaolin-based mineral admixture for concrete and preparation method for mineral admixture

The invention relates to a high-activity modified metakaolin-based mineral admixture for concrete and a preparation method for the mineral admixture. The high-activity modified metakaolin-based mineral admixture for the concrete is prepared by mixing metakaolin and a composite modifying agent according to the mass ratio of 200:1 to 20:1, wherein the composite modifying agent is prepared by mixing 50 to 85 mass percent of stearic acid, 8 to 25 mass percent of calcium stearate and 7 to 25 mass percent of dimethyl silicone oil based on 100 mass percent. The high-activity modified metakaolin-based mineral admixture for the concrete and the preparation method for the mineral admixture have the advantages that 1) the early strength of the concrete can be remarkably strengthened; 2) the working performance of the concrete can be remarkably improved; 3) the osmosis resistance of the concrete can be improved; and 4) the mineral admixture is highly adapted to various kinds of cement and concrete additives.

Owner:WUHAN UNIV OF TECH +2

Low silver oxidation resistance active leadless solder

InactiveCN101214588AReduced activityImprove reliabilityWelding/cutting media/materialsSoldering mediaWettingWelding

A lower-Ag anti-oxidation lead-free solder relates to a lead-free solder. The invention solves the problems of high Ag content, high manufacture cost and poor wettability of the existing lead-free solder. The invention consists of the following components according to a weight percentage of 0.5 to 2.5 percent of Ag, 0.3 to 1.5 percent of Cu, 0.002 to 0.2 percent of P, 0.01 to 1.0 percent of Zn, 0.02 to 3.0 percent of Ti, 0.01 to 2.5 percent of Zr, 0.01 to 3.5 percent of Ni, 0.02 to 1.5 percent of mixed RE and the rest is Sn. Compared with the existing Sn-Ag-Cu solder under a same condition, the wetting angle of the lower-sliver anti-oxidation lead-free solder of the invention is reduced by 5 to 7 degrees, the anti-oxidation performance is improved by 14 to 20 percent and the creep strength is improved by 6 to 10 percent; thereby being able to acquire a joint with higher reliability from braze welding. The invention has the advantages of few Ag content and low manufacture cost.

Owner:HARBIN INST OF TECH

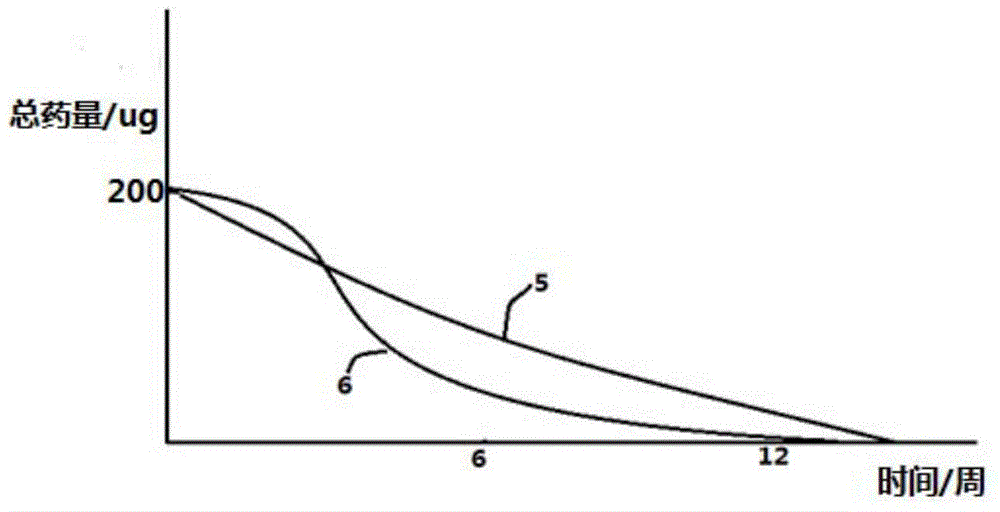

Developing degradable polymer stent and preparation method thereof

The invention provides a developing degradable polymer stent and a preparation method thereof. A plasma vapor deposition method is adopted to deposit a degradable developing material on the surface of a bracket; the prepared developing coating is not transmitted under X ray, so that the stent can be clearly seen under X ray, and therefore, some interferences of a metal developing material on MRI (magnetic resonance imaging) and CT (computed tomography) images are avoided, and problems that side effects are easily produced as biocompatibility of the metal developing material is poor, and the metal developing material cannot be degraded and left in a blood vessel cavity after the stent is degraded are solved; according to the method, activation hydrophilic treatment is carried out on the surface of the polymer bracket, so as to improve affinity between the polymer base body and the developing coating and effectively solve the coating dropping problem; besides, a protective coating which is slow in degradation rate is coated on the surface of the developing coating, so that too quick degradation of the developing coating is prevented, and therefore, follow-up can be still carried out in the later stage of implanting.

Owner:SHENZHEN SALUBRIS BIOMEDICAL ENG CO LTD

Porous carbon material and its preparation method

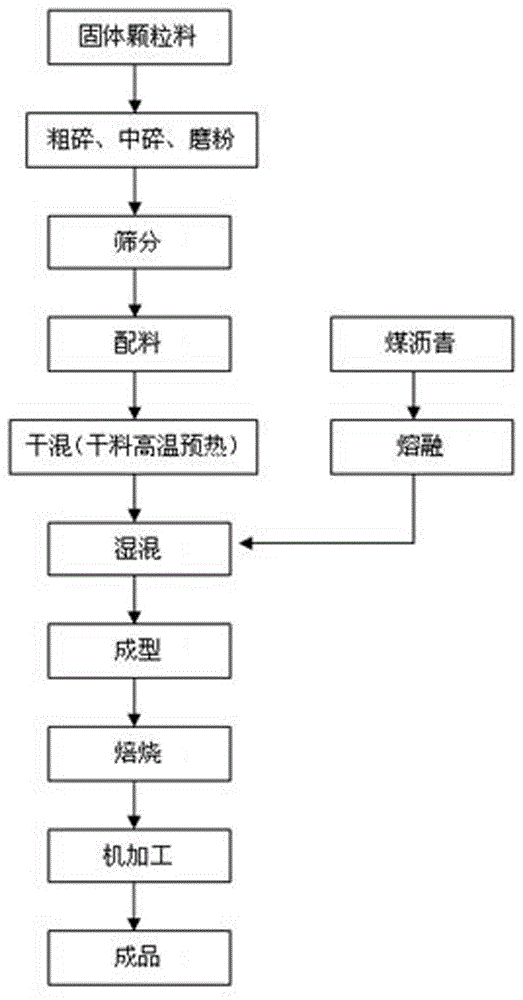

The invention discloses a porous carbon material and its preparation method. The preparation method provided by the invention successively comprises steps of: raw material and auxiliary material selection, pulverization, spheroidization, grading, burdening, mixing, molding, roasting and the like. Green petroleum coke and green pitch coke are creatively used as raw materials. A filtration materialprepared after spheroidization of a green coke powder has large contractility, high strength, uniform pore distribution, smooth pore path, high filtration precision and good transmissivity, is not easy to block during the purification process, is easy to regenerate, and has long service life. The porous carbon material prepared in the invention can be widely used as a filtration material, a thermal insulation material, a conductance electrode and the like.

Owner:ZIGONG YUXING CARBON PRODS

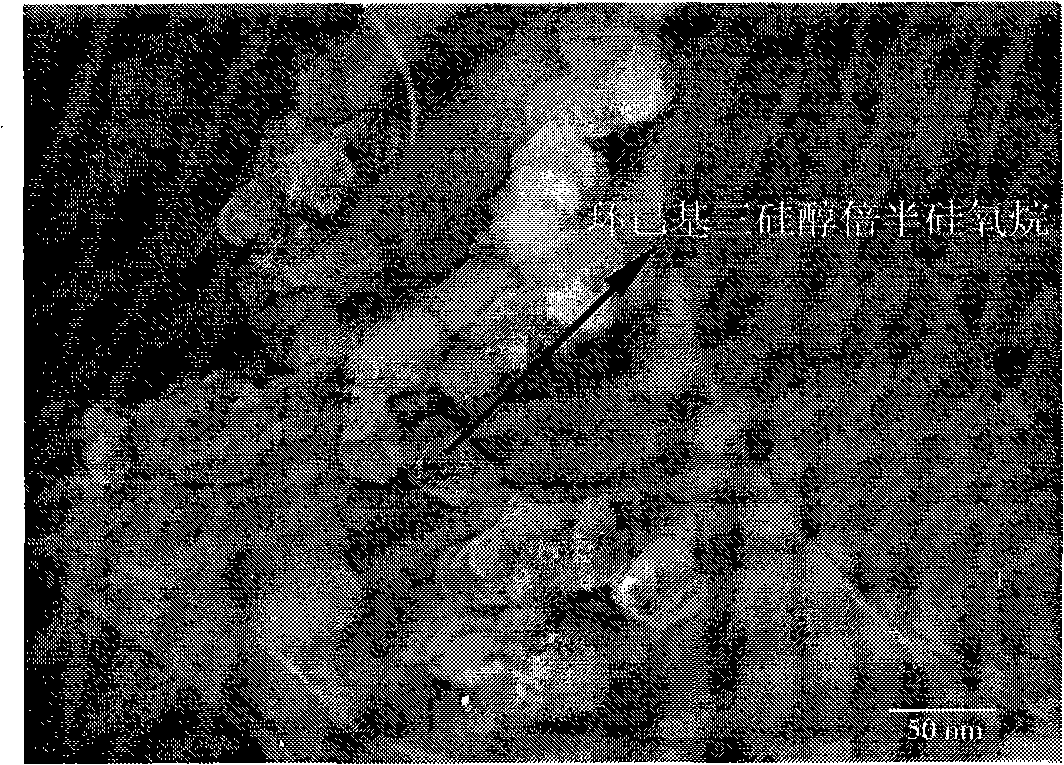

Nanostructure-enhanced tin-silver-copper-base leadless compound solder and preparation thereof

InactiveCN101279405AImprove mechanical propertiesImprove reliabilityWelding/cutting media/materialsSoldering mediaManufacturing technologyTin-silver-copper

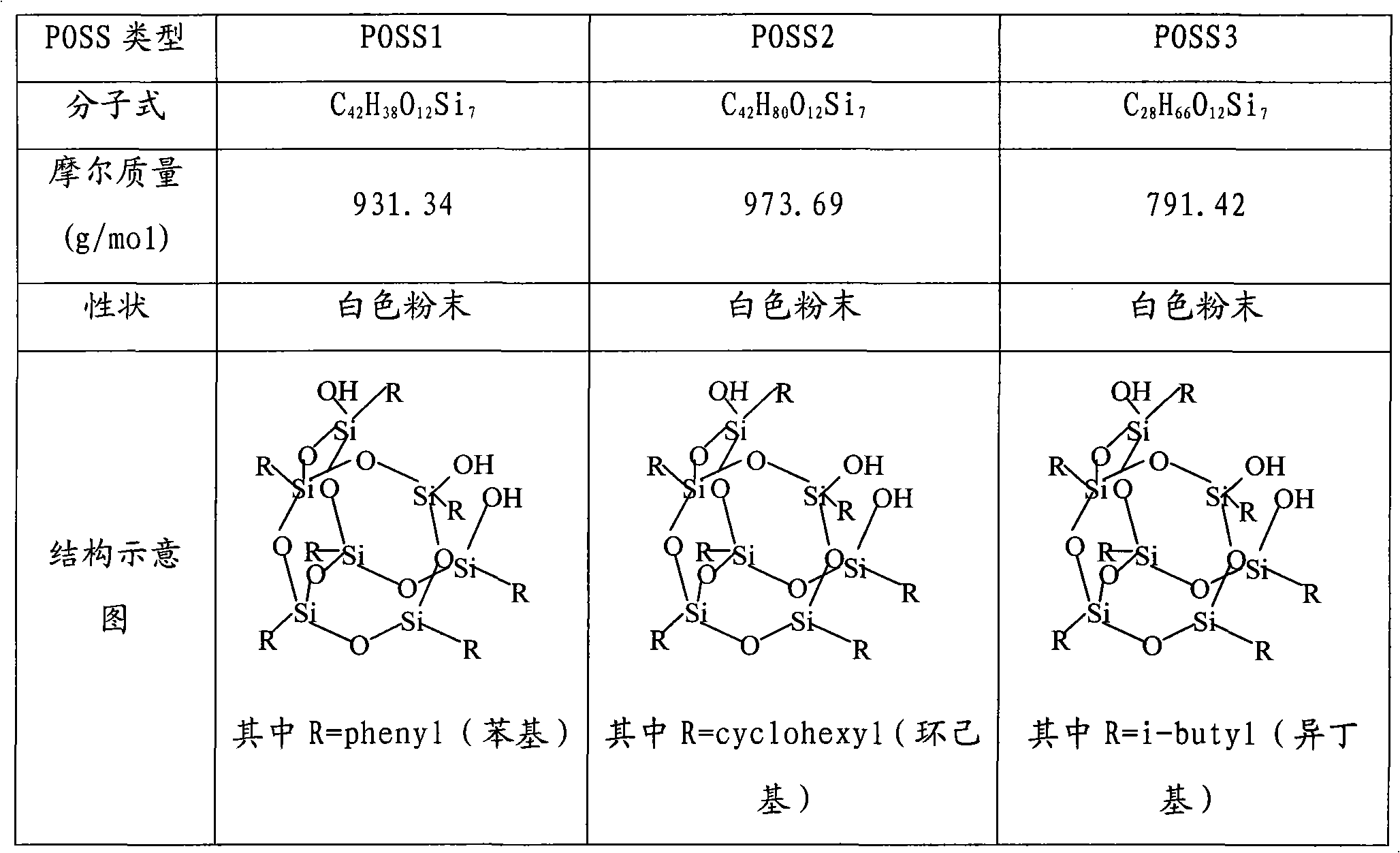

The invention relates to a tin, silver and copper based lead-free composite solder with enhanced nanometer-structure and a preparation method thereof, which belong to the technical field of the manufacturing of metal-based lead-free composite solders. The existing spreading process for SnSn-Ag-Cu series lead-free solder is characterized by poor processing performance, short creep rupture service life and high cost. The composite solder of the invention consists of 97 wt percent to 99 wt percent of commercial Sn-3.0Ag-0.5Cu solder paste and 1 wt % to 3 wt % of enhanced particles (POSS1, POSS2 or POSS3). The solder paste consists of 85 wt percent of Sn-3.0Ag-0.5Cu solder and 15 wt % of flux. The tin, silver and copper based lead-free composite solder with enhanced nanometer-structure is prepared by stirring and mixing the solder paste and enhanced particles according to the component concentration for 15 to 30 minutes. The composite solder of the invention has the advantages of good wettability and good creep rupture resistance, high shearing strength, excellent mechanical property, long creep rupture service life of the soldered joint and simple preparation process, etc.

Owner:BEIJING UNIV OF TECH

Aluminum-magnesium casting material for ladle liner and preparation method thereof

The invention relates to an aluminum-magnesium casting material for a ladle liner and a preparation method thereof. ACcording to the technical scheme, the method comprises the following steps: preparing 50-65wt% of microporous alumina particles serving as aggregate; preparing 10-15wt% of fine corundum particles, 15-30wt% of fine corundum powder, 2-8wt% of magnesium oxide powder, 2-8wt% of alpha-A12O3 powder and 2-8wt% of aluminum powder silica gel which are used as base materials; adding water which accounts for 3-10wt% of the sum of the aggregate and the base materials; evenly agitating, and molding in a vibrating manner; carrying out heat preservation at 100-150 DEG C for 12-36 hours, so as to prepare the aluminum-magnesium casting material for the ladle liner. The aluminum-magnesium casting material for the ladle liner prepared by the method has excellent slag resistance and thermal shock stability, and the service life of the aluminum-magnesium casting material for the ladle liner can be effectively prolonged.

Owner:WUHAN UNIV OF SCI & TECH

High-graphite carbon electrode and preparation method thereof

ActiveCN106376121ASmall coefficient of thermal expansionGood electrical and thermal conductivityElectric discharge heatingGraphite carbonGraphite electrode

The invention relates to a high-graphite carbon electrode. The high-graphite carbon electrode comprises the following constituents of a solid mixture and liquid coal pitch, wherein the liquid coal pitch accounts for 19-21% of the total mass of the solid mixture and the liquid coal pitch, and the solid mixture comprises the following constituents based on percent by mass: 30-50% of graphitized petroleum coke, 30-50% of graphitized anthracite and 20-40% of graphite scrap. The invention also relates to a method for preparing the abovementioned carbon electrode. By the carbon electrode, the usage amount of the graphite scrap in the high-graphite carbon electrode can be reduced, the production cost is reduced, moreover, the resistivity and the thermal expansion coefficient of the high-graphite electrode can also be reduced, and the integral strength of the electrode is improved without adding an impurity element.

Owner:河北顺天电极有限公司

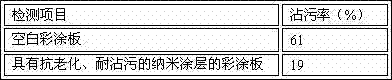

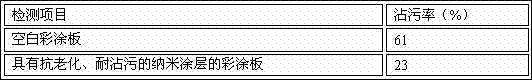

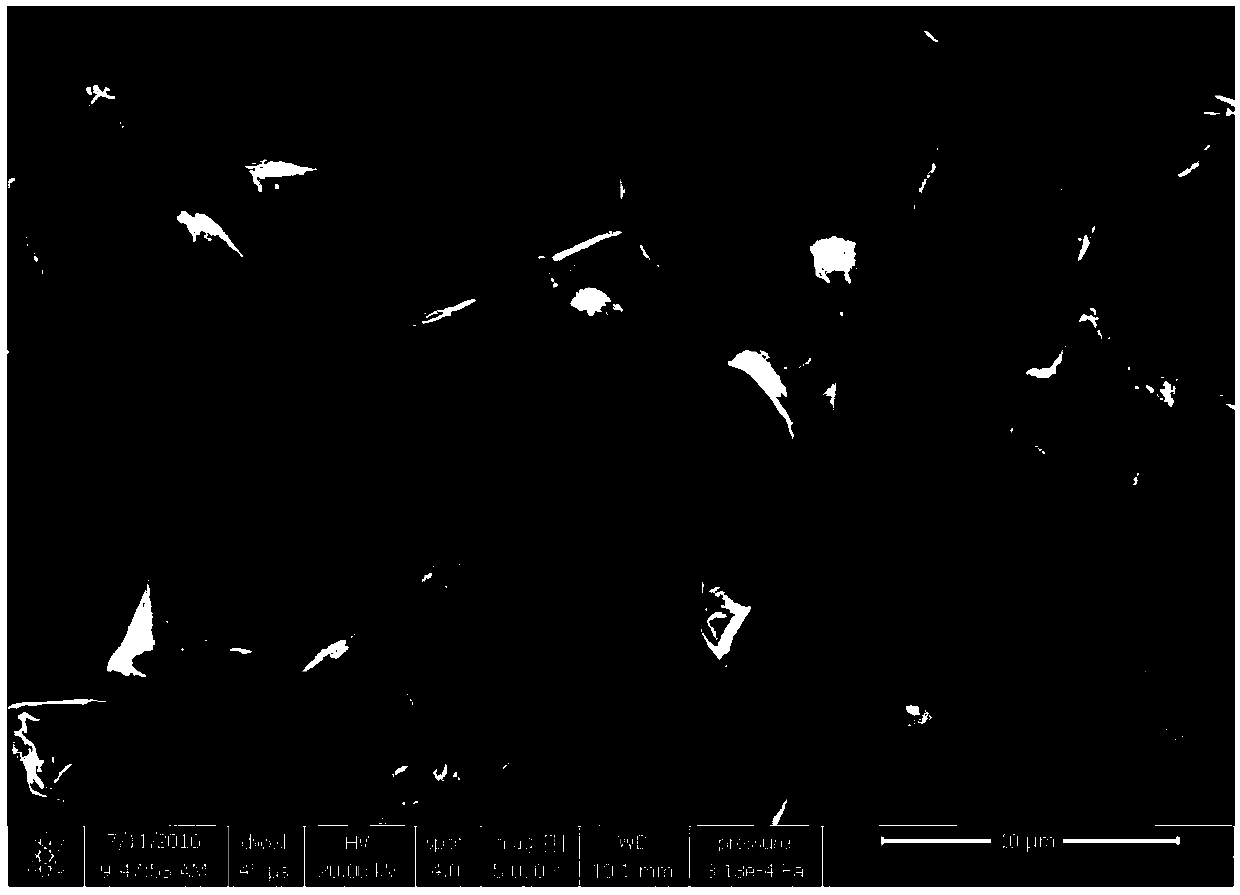

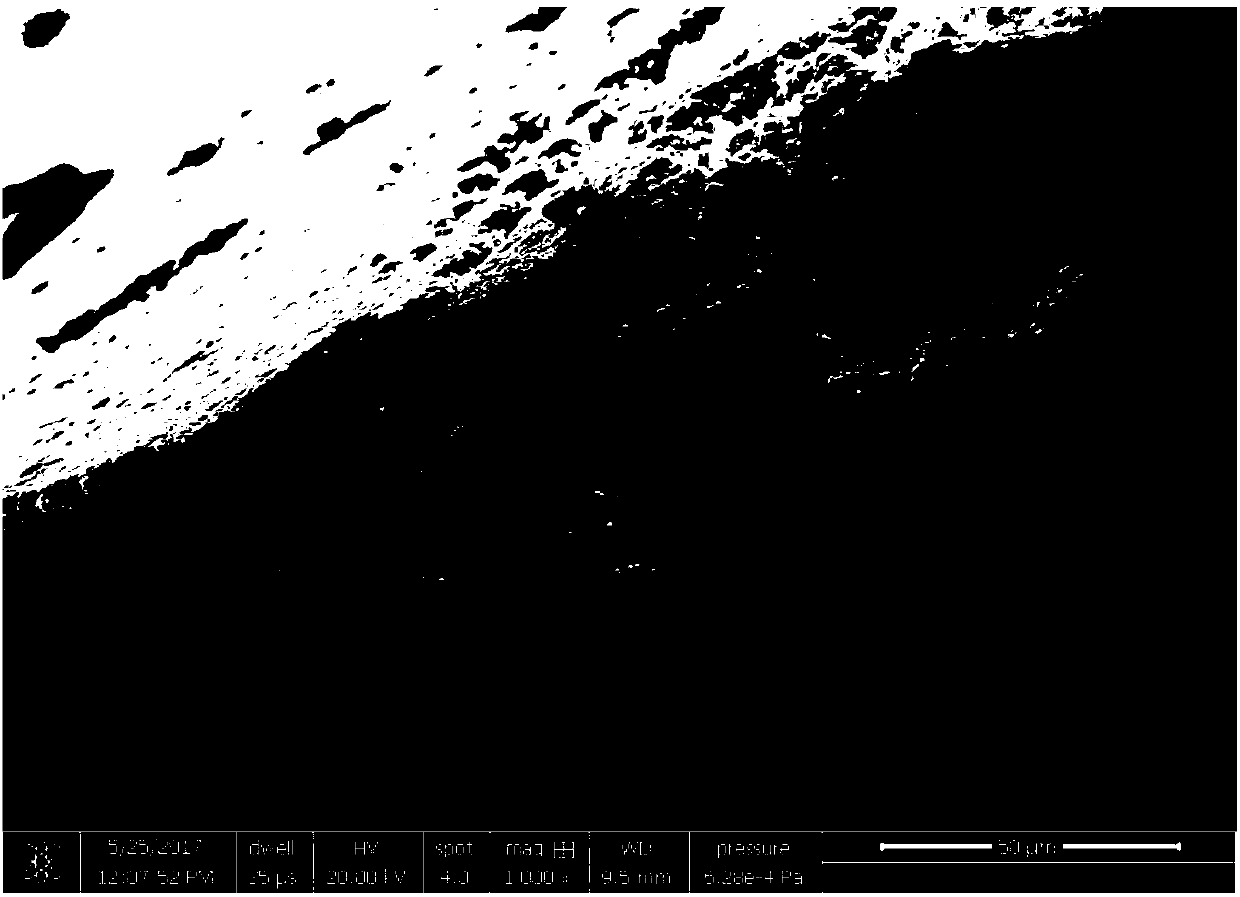

Nano-sol for forming anti-aging and stain-resistant nano-coating and preparation method and application thereof

The invention discloses nano-sol for forming an anti-aging and stain-resistant nano-coating and a preparation method thereof. The nano-sol for forming the anti-aging and stain-resistant nano-coating comprises the following components in percentage by weight: 0.1-10% of nano-TiO2 sol, 0.1-20% of sodium silicate, 0.1-5% of cerium oxide sol, 0-0.1% of colorant and the balance of water or mixed solution consisting of ethanol and water. The preparation method comprises the steps of firstly preparing the nano-TiO2 sol by adopting a sol-gel method, then preparing the Ce2O3 sol, then adding sodium silicate and the Ce2O3 sol into the nano-TiO2 sol, uniformly stirring, further adding the colorant, and finally adding the balance of water or the mixed solution consisting of ethanol and water to obtain the nano-sol for forming the anti-aging and stain-resistant nano-coating. The nano-coating which is used for a color-coated plate and obtained by coating has the properties of aging resistance, stain resistance, corrosion resistance and the like, and the service life of the color-coated plate can be prolonged.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

High performance leadless tin-copper solder for electronic elements

ActiveCN1583349AImproved physical properties and solderabilityLow resistivityPrinted circuit assemblingWelding/cutting media/materialsPrinted circuit boardCopper

A high-performance lead-less Sn-Cu solder for the welding on PCB contains Cu (0.66-0.82 wt.%), Ni (0.02-0.03), P (0.001-0.002), Ti (0.0005-0.0009), RE (0.001-0.01), Gu (0.0001-0.0002), Ag (0.01-0.5) and Sn (rest).

Owner:四川朗峰电子材料有限公司

Preparation method of disc type full silicon carbide filtering membrane

PendingCN107619296AStrong hydrophilic and oil repellentStrong chemical stabilityCeramicwareWork in processCross-flow filtration

The invention relates to a preparation method of a dynamic cross flow filtration disc type full silicon carbide filtering membrane, and belongs to the technical field of preparation of advanced ceramics. The preparation method comprises the following steps: weighing a coarse silicon carbide powder I, a fine silicon carbide powder II, a plasticizer and a pore forming material, stirring and dissolving the plasticizer into warm water, sequentially adding the coarse silicon carbide powder I, the fine silicon carbide powder II and the pore forming material, and mixing evenly; conducting compressionmoulding after drying and screening to obtain a biscuit; using the fine silicon carbide powder II and a binder to prepare a concentrated slurry, spraying the concentrated slurry on the outer edge ofthe biscuit, and adhering two biscuits together; sintering to obtain a support body for the disc type full silicon carbide filtering membrane; weighing a fine silicon carbide powder III, a dispersingagent and the binder, adding deionized water, and grinding to obtain a membrane coating solution; spraying the membrane coating solution on the outer surface of the support body, and drying to obtaina semi-finished product of the filtering membrane; and sintering the semi-finished product of the filtering membrane to obtain a finished product of the disc type full silicon carbide filtering membrane. The prepared silicon carbide ceramic membrane has the characteristics of high filtering precision and large separating flux.

Owner:SHANDONG UNIV OF TECH

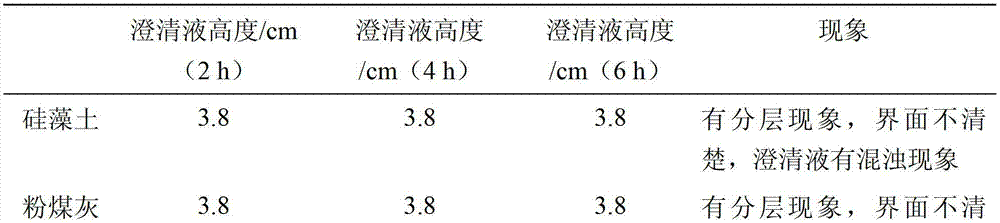

Extinguishing material for coal mine, and production method thereof

The invention relates to extinguishing material for coal mine and a production method thereof and belongs to the field of coal mine materials for fire preventing and extinguishing. The extinguishing material is made by mixing well 5-15wt% of attapulgite, 1-5wt% of salt-resistant super-absorbent polymer and water. Preparation of the salt-resistant super-absorbent polymer includes: adding 3 parts of acrylic acid into an ice bath, neutralizing with sodium hydroxide, adding 4 parts of acrylamide to from a monomer, and sequentially adding potassium peroxodisulfate accounting for 0.25% of the total weight of the monomer and N, N-methylene bisacrylamide accounting for 0.25% of the total weight of the monomer; heating a water bath to 70 DEG C, allowing for reaction for 7h, and filtering and drying the cooled reaction product. Aggregate using the attapulgite as colloid is fine in suspendability and large in specific area, the obtained colloid is remarkably uniform and long in shelf life.

Owner:BEIJING UNIV OF TECH

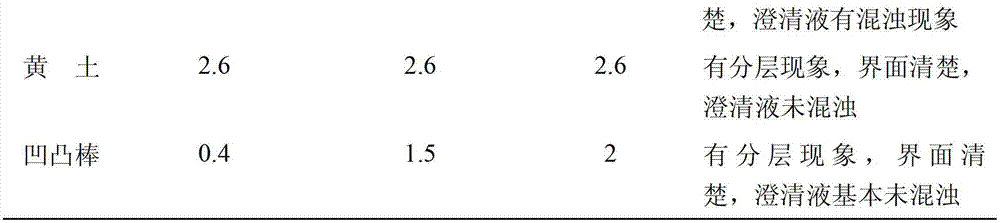

Energy filtrated magnetron sputtering plating method and apparatus for applying the method

InactiveCN101307430AAvoid damageImprove flatnessVacuum evaporation coatingSputtering coatingSputteringFiltration

The invention discloses an energy filtration magnetron sputtering coating method and a device for implementing the method. The method is as follows: a conductive filter screen which is connected with an anode is arranged between the surface of a substrate to be coated and sputtering target materials; ions generated by bombarded cathodic sputtering target materials during the sputtering coating process are filtered by the conductive filter screen and then sent to the coating growth surface of the substrate to be coated on the anode; when the ions generated by the sputtering target materials pass through the conductive filter screen, the conductive filter screen with high anode potential absorbs high-energy electrons in the ions and repels high-energy positive ions in the ions. The device can arrange the conductive filter screen with the high anode potential on an outer cover of the substrate on the basis of the prior device so as to inhibit the damage of high-energy particle bombardment on the substrate during the process of preparing a film by the magnetron sputtering technology, and surface grains of the prepared film are made to be more fine and more uniform and have higher flatness. Moreover, the device can be formed by modifying the prior device, is not large in modification and is easy to realize.

Owner:ZHENGZHOU UNIV

Easy-to-clean antiskid wear-resistant floor coating as well as preparation and use method thereof

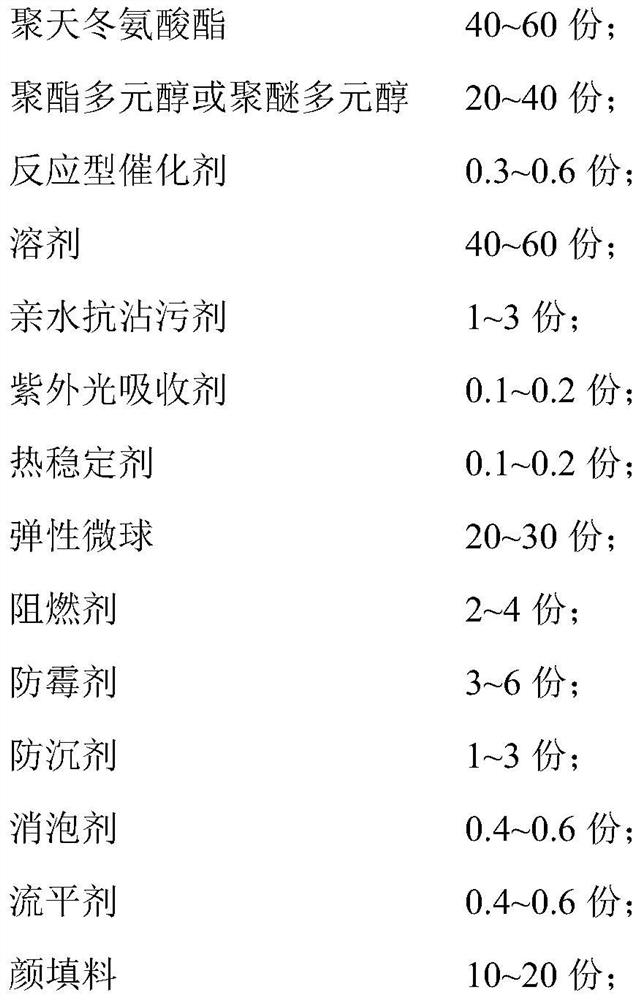

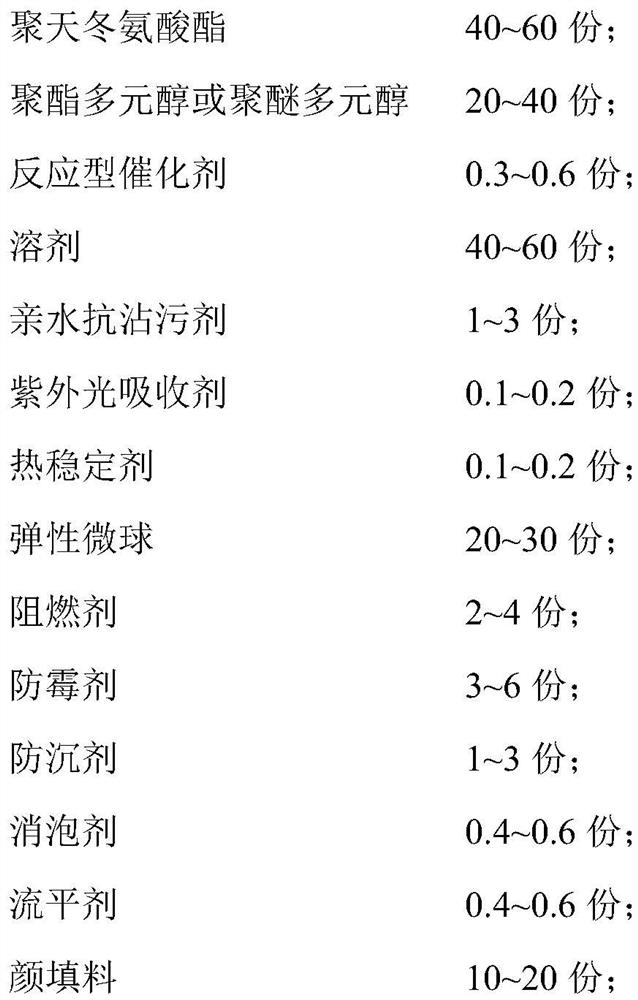

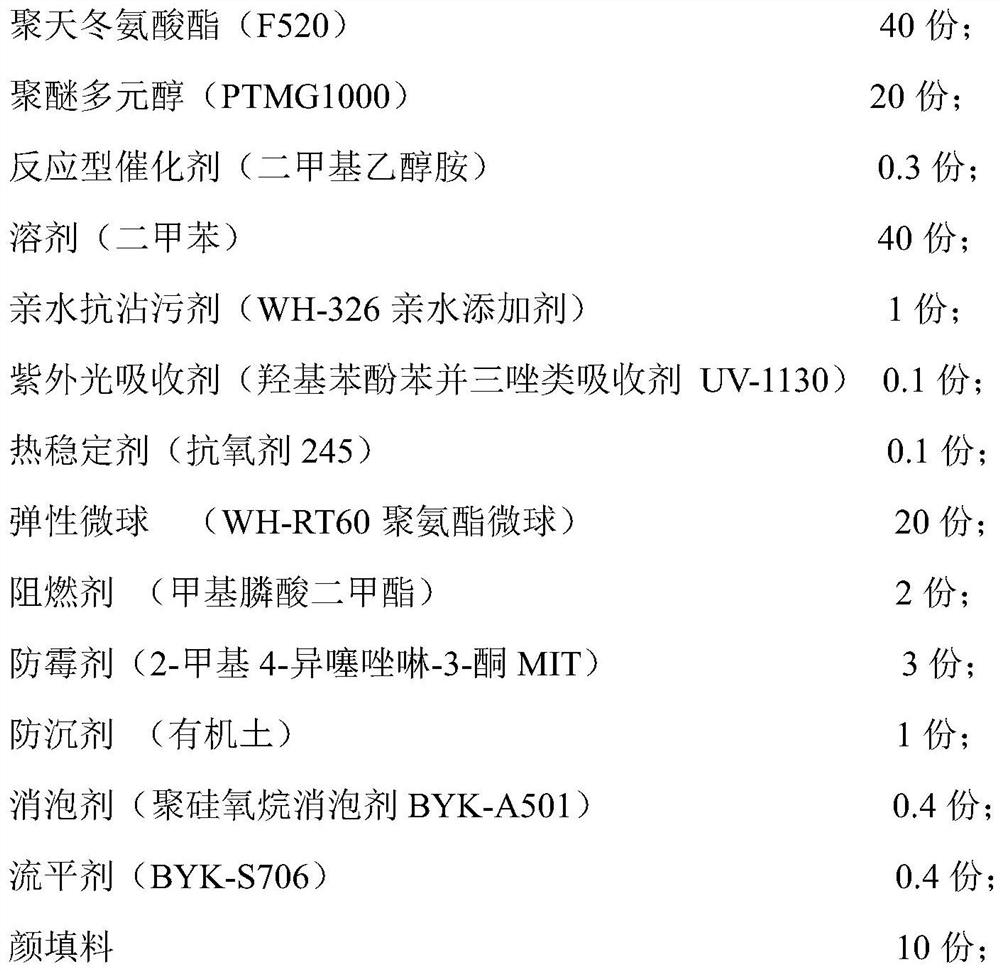

ActiveCN111995941AEasy to cleanImprove stain resistanceFireproof paintsAntifouling/underwater paintsPolyesterPolymer science

The invention relates to the technical field of industrial coatings, in particular to an easy-to-clean antiskid wear-resistant floor coating as well as a preparation method and a use method thereof. The coating comprises a coating component and a curing agent component, and the mass ratio of the coating component to the curing agent component is 100: (45-70). The coating component comprises polyaspartate, polyester polyol or polyether polyol, a reaction type catalyst, a solvent, a hydrophilic stain-resistant agent, an ultraviolet light absorber, a heat stabilizer, elastic microspheres, a flameretardant, a mildew preventive, an anti-settling agent, an antifoaming agent, a leveling agent and pigments and fillers. The curing agent component comprises an isocyanate prepolymer and polyisocyanate. The easy-to-clean antiskid wear-resistant floor coating has good antiskid, wear-resistant, easy-to-clean and stain-resistant properties, can meet the antiskid wear-resistant protection requirements of the floor surface with higher decorative requirements, and is simple in preparation method and process and beneficial to popularization.

Owner:WUHAN RES INST OF MATERIALS PROTECTION

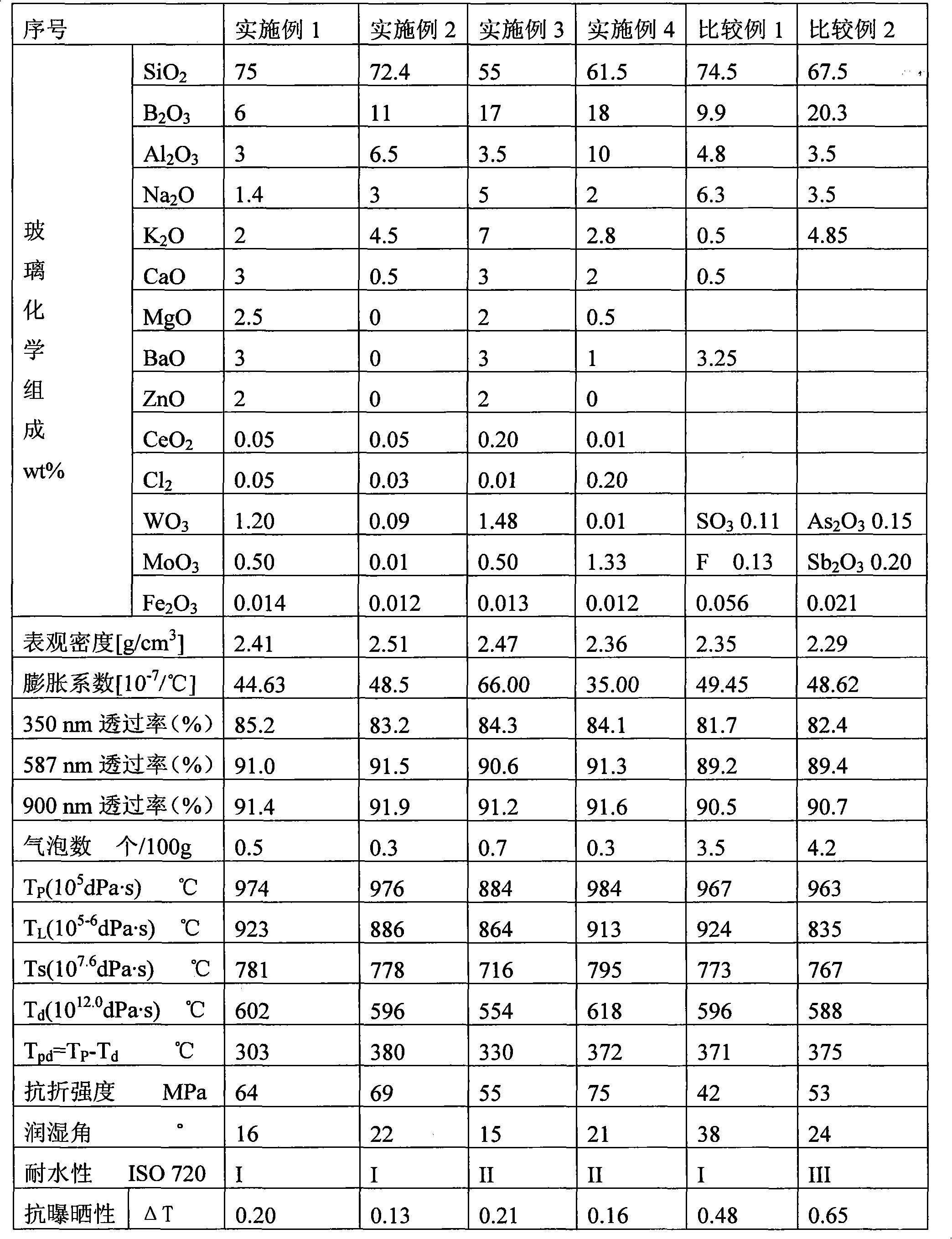

Glass for photo-thermal generation heat-collecting pipe

The invention relates to a glass for a photo-thermal generation heat-collecting pipe. A high precision glass pipe is prepared by a vertical, horizontal or viilo pull-pipe forming technology, thereby meeting the requirements of the glass pipe for a heat-collector which is required by a trench-type photo-thermal generation technique. The glass has high transmissivity of ultraviolet, visible light and near-infrared, high mechanical strength and chemical stability and anti-insolation; and the expansion coefficient of the glass is (36-68)*10-7 / DEG C, thereby meeting the requirements of matched seal and gas tightness of tungsten, molybdenum and kovar alloy. The glass comprises the following components by weight percent: 55-75% of SiO2, 6-18% of B2O3, 3-10% of Al2O3, 0.5-10.5% of MgO+CaO+BaO+ZnO, 3.4-12% of Na2O+K2O, 0.1-2.0% of WO3+MoO3, 0.01-0.20% of Cl2, 0.01-0.20% of CeO2 and no more than 0.015% of Fe2O3. The invention is characterized in that the glass belongs to a borosilicate glass system, satisfies the requirements of the high precise forming technology, does not contain harmful elements such as As2O3, Sb2O3, SO3 and the like, has good melt quality and environmental protection, and can prevent the surface from turning black and the bubble generation when seal processing.

Owner:BEIJING UNIV OF TECH

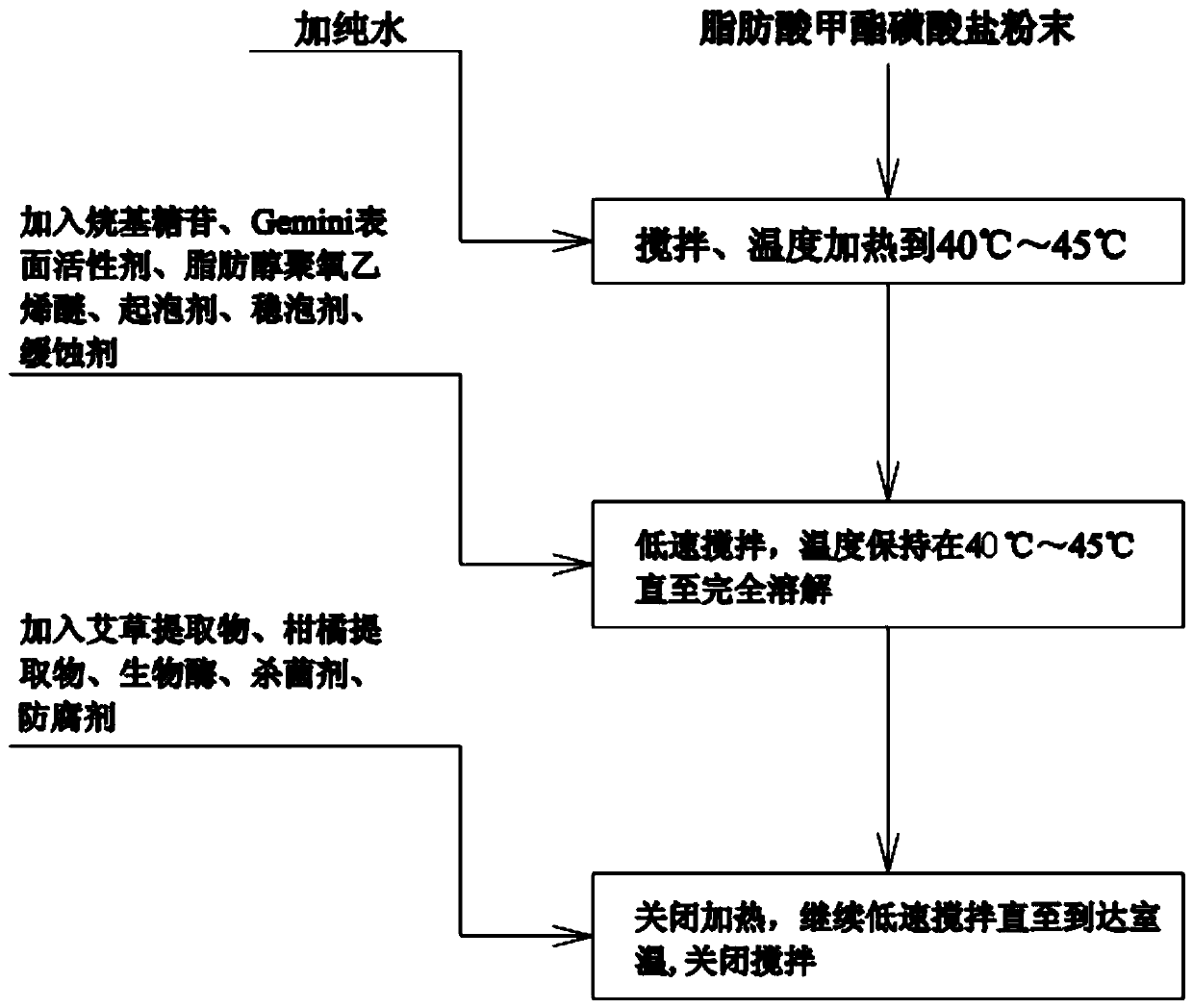

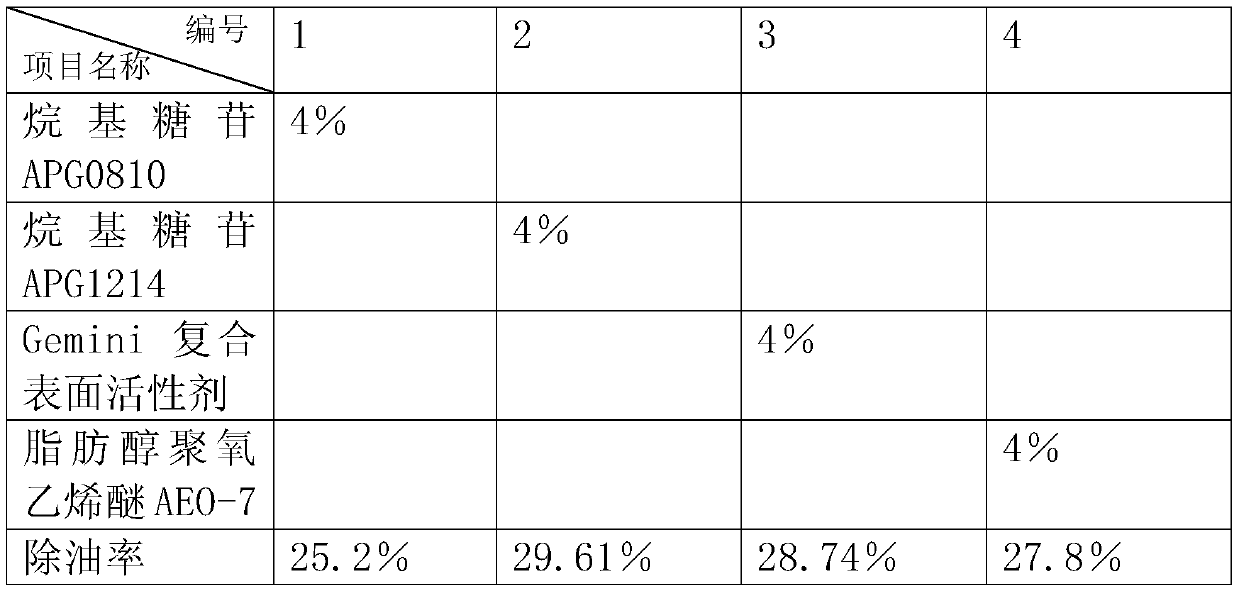

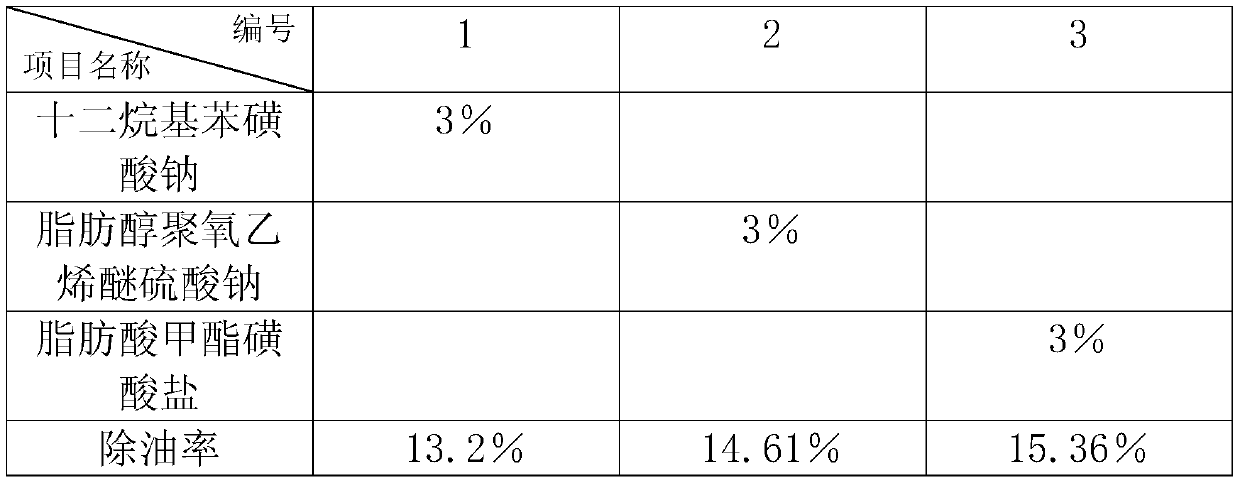

Kitchen anti-bacterial oil stain cleaning agent and preparation process thereof

InactiveCN110777007AGood for removing odorsMild effectInorganic/elemental detergent compounding agentsPolymeric surface-active compoundsBiotechnologyActive agent

The invention provides a kitchen anti-bacterial oil stain cleaning agent. The kitchen anti-bacterial oil stain cleaning agent is prepared from the following components in percentage by mass: 1%-4% ofalkyl glycoside, 1%-5% of a Gemini composite surfactant, 1%-4% of fatty alcohol-polyoxyethylene ether AEO-7, 1%-4% of fatty acid methyl ester sulfonate, 1%-4% of a wormwood extract, 0.5%-4% of a citrus extract, 1%-4% of a bio-enzyme, 1%-5% of a foaming agent, 1%-4% of a foam stabilizer, 0.5%-4% of a penetrating agent, 0.05%-1.5% of a preservative, 0.3%-3% of a corrosion inhibitor, 0.2%-3% of a PHregulator, and the balance of pure water. The novel surfactant with excellent traditional performance, the plant extracts and the bio-enzyme are adopted to be compounded, emulsification, wetting and permeation effects are good, the effects of cleaning agents in the market can be further achieved, meanwhile the PH value of the kitchen anti-bacterial oil removal cleaning agent is close to neutral, and thus the kitchen anti-bacterial oil removal cleaning agent is mild in action on human skin, remarkable in anti-bacterial effect and free of pungent smell and addition of solvents.

Owner:山立欣业新材料(广东)有限公司

Water spray-resistant UV gloss oil composition and preparation method thereof

ActiveCN106592327AImprove stabilityIncrease surface tensionSpecial visual effect coatingsCross-linkPhotosensitizer

The invention relates to a water spray-resistant UV gloss oil composition and a preparation method thereof. The composition comprises 30-60% of multifunctional acrylic resin, 30-60% of a monomer, 3-10% of a photoinitiator, 5-10% of a solvent, 0.1-1% of a photosensitizer, 0.1-3% of nanometer nonmetal oxide, 1-4% of a spray resistant assistant, and 1-3% of other assistants. The multifunctional acrylic resin is selected, and the proportion of the monomer is adjusted, so the solidification speed and the cross-linked stability of gloss oil are improved; and addition of nano-silica changes the surface morphology of the microstructure of a printed product, improves the surface tension, reduces the wetting angle and spreads water spray; and the extremely strong hydrophilicity of the composition makes the printed product and the film smooth, and reduces the water spray formation probability, so no droplets are formed on the surface of an elaborate box to keep the film transparent.

Owner:永发印务(东莞)有限公司

Method for manufacturing SnAgCu lead-free solder

InactiveCN102328157ASignificant refinement of tissueLow costWelding/cutting media/materialsSoldering mediaNitrogen gasCopper substrate

The invention discloses a method for manufacturing SnAgCu lead-free solder, which comprises the following steps of: mixing raw materials according to proportions, heating to 500 DEG C under the protection of a covering agent and nitrogen gas or under the vacuum condition, smelting for 0.5-1h to obtain alloy melt; heating the alloy melt to a temperature not lower than a temperature range that the alloy melt generates liquid-state structure transformation, and preserving heat for 15-30min; cooling to 500 DEG C, preserving heat for 0.5h, and then casting and solidifying to obtain a lead-free solder alloy ingot; and finally machining the alloy ingot into lead-free solder by adopting a transmission machining way. According to the lead-free solder prepared by adopting the method disclosed by the invention, solidification tissues are remarkably thinned and evenly distributed; in the welding process, a reaction layer at the joint part is remarkably thinned and the roughness is reduced; the solder is easy to melt, and the expandability of the solder and the wettability of the solder with a copper substrate are remarkably improved; besides, the thermal stability of welding joint tissues is remarkably improved, and therefore the operation reliability of related products in the service process is improved.

Owner:HEFEI UNIV OF TECH

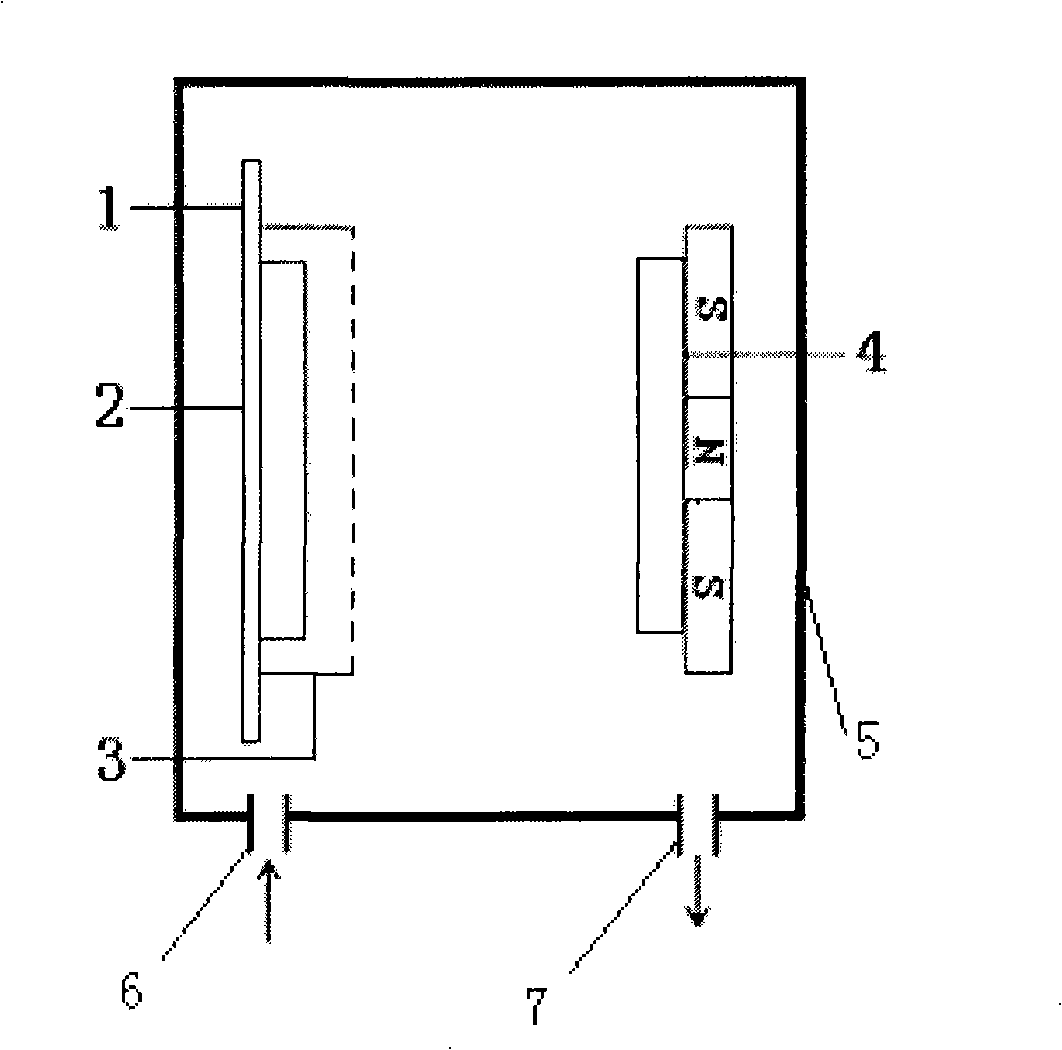

Heterogeneous nucleating agent toughening-modified phenolic resin foam and preparation method thereof

ActiveCN106009490ALower wetting angleImprove mechanical propertiesMechanical propertyOrganic chemistry

The invention discloses heterogeneous nucleating agent toughening-modified phenolic resin foam and a preparation method thereof. The preparation method of the foam comprises the following steps of preparing a heterogeneous nucleating agent and preparing the modified phenolic resin foam. According to the method, silane coupling agent modified graphene is added for regulating the foam pore structure; meanwhile, the synergistic effect of graphene nanoparticles is exerted, the defects that phenolic foam is poor in mechanical property, high in brittleness and prone to disengagement are effectively overcome, and wide application of the phenolic foam in the engineering field is promoted.

Owner:JIANGNAN UNIV

Silicon steel pickling promoter and preparation method thereof

The invention specifically relates to a silicon steel pickling promoter and a preparation method thereof. According to a technical scheme in the invention, the silicon steel pickling promoter is prepared from 0.1 to 5.0 wt% of a corrosion inhibitor, 10.0 to 50.0 wt% of an inorganic salt reducing agent, 0.1 to 5.0 wt% of an emulsifier, 5.0 to 20.0 wt% of an organic metal ion chelating agent, 0.1 to 5.0 wt% of a defoaming agent, 0.1 to 5.0 wt% of a synergist and 20.0 to 80.0 wt% of water through uniform mixing at normal temperature with stirring. The silicon steel pickling promoter provided by the invention has the characteristics of convenience in usage, high pickling efficiency, low cost, environment friendliness, a good corrosion inhibition effect, etc.

Owner:WUHAN UNIV OF SCI & TECH

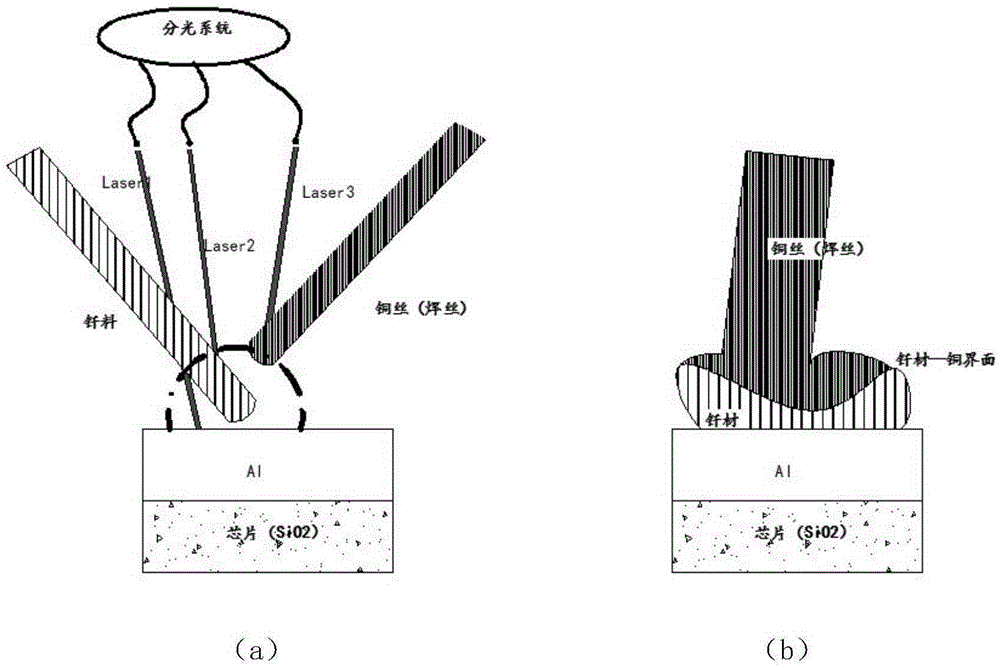

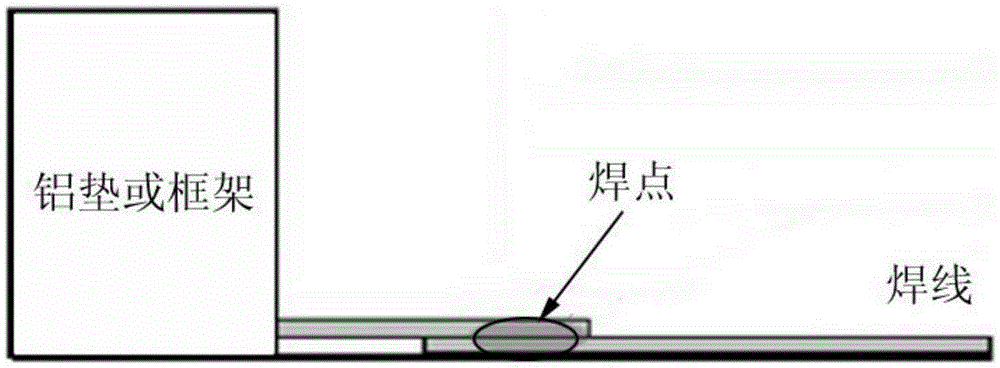

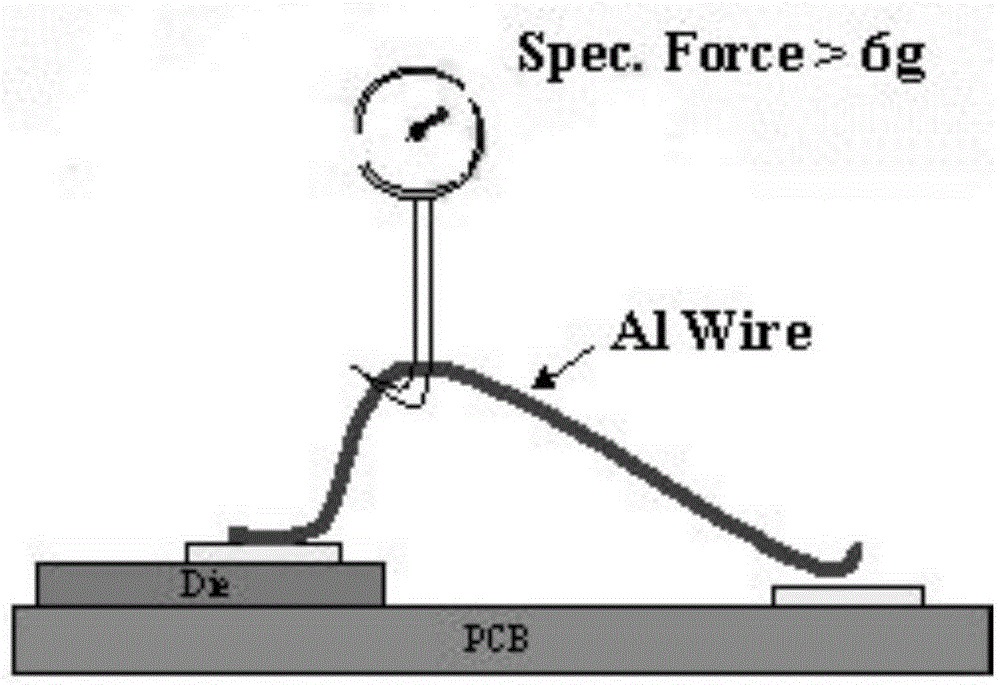

Lead welding technique for packaging semiconductor power device

ActiveCN105458434ANo stress damageIncrease flow resistanceWelding/cutting media/materialsMetal working apparatusManufacturing technologyStress Problem

The invention discloses a lead welding technique for packaging a semiconductor power device and belongs to the technical field of semiconductor power device packaging and manufacturing. According to the technique, lead connection is achieved through a brazing technique, and the brazing process is achieved through lasers, wherein lead connection refers to the completion of the welding process of a lead and a chip and the welding process of the lead and two welding points of a frame. In the welding process, the lead, the frame and a chip welding pad are preheated through direct laser spot radiation, the diameter of laser spots is 1 mm, and laser radiation time is 10 ms; and a brazing wire is heated through direct laser spot radiation, the diameter of the laser spots is 1 mm, and laser radiation time is 10 ms. By the adoption of the technique, the wet aluminum pad and the frame can be melted directly to achieve stable and reliable connection of the lead, the chip and the frame, the aluminum pad and the frame cannot be melted due to the fact that the temperature does not reach the melting point, and the aluminum pad and the frame are just preheated, so that the surfaces are stretched fully to assist in combination of the aluminum pad and liquid brazing filler metal and combination of the frame and the liquid brazing filler metal, and therefore mechanical damage, thermal damage and the stress problem existing in a traditional routing technique are avoided.

Owner:王伟

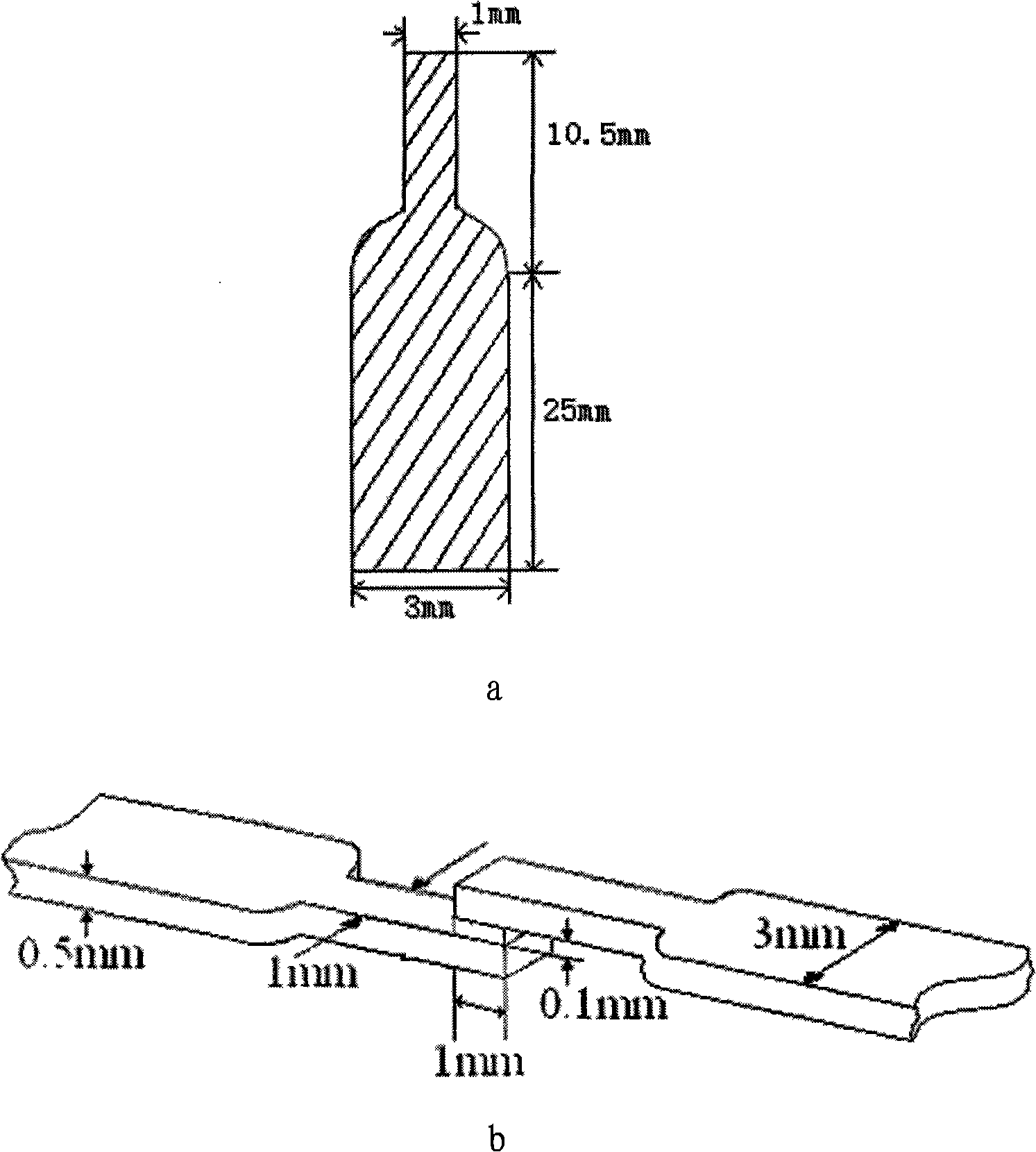

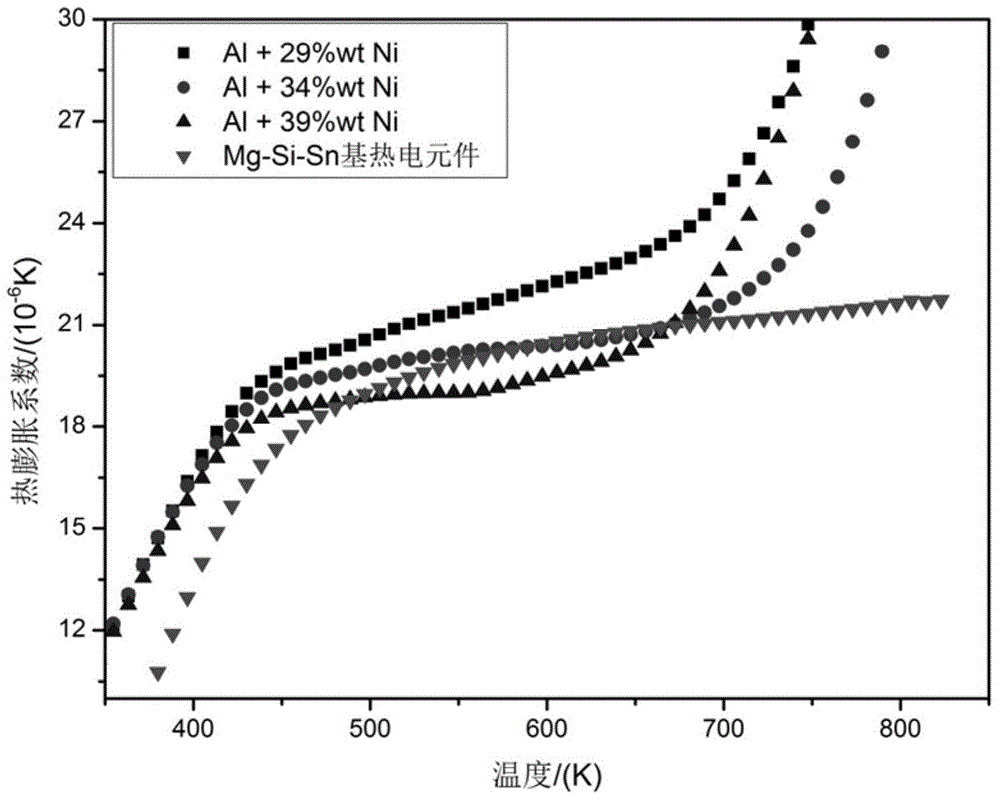

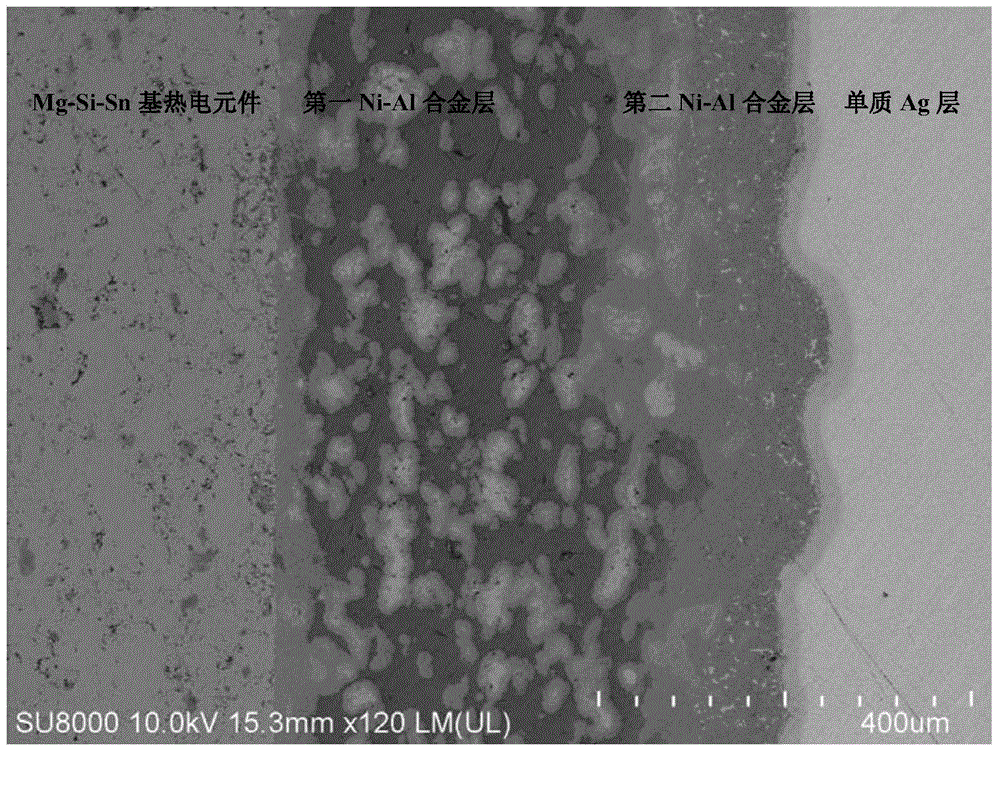

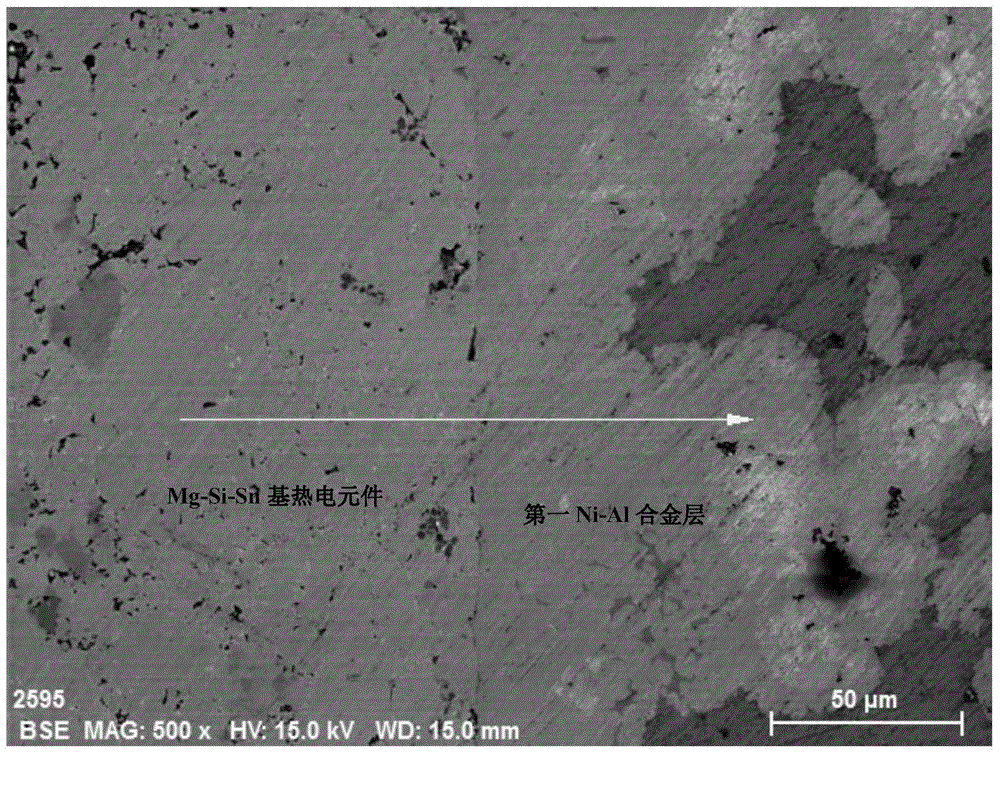

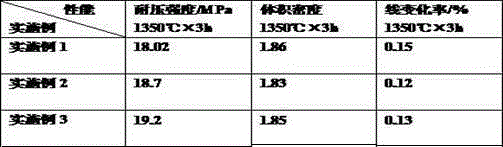

Layered electrode matched with Mg-Si-Sn-based thermoelectric element and connecting technology thereof

ActiveCN104362249AThermally matched wellAvoid it happening againThermoelectric device manufacture/treatmentThermoelectric device junction materialsElectrical resistance and conductanceInternal resistance

The invention relates to a layered electrode matched with a Mg-Si-Sn-based thermoelectric element and a connecting technology of the layered electrode. The electrode is of a three-layer structure, and sequentially comprises a first Ni-Al alloy layer, a second Ni-Al alloy layer and a simple substance Ag layer. Good heat matching between the multi-layer electrode and the Mg-Si-Sn-based thermoelectric element is achieved, interface heat stress can be reduced, and the service life can be prolonged. A small wetting angle is achieved, and the electrode can be directly welded to a current guide sheet. Good electrical property transition is achieved, contact resistance is smaller than five percent of internal resistance of the Mg-Si-Sn-based thermoelectric element, and the technology for connecting the Mg-Si-Sn-based thermoelectric element and the multi-layer electrode is simple and reliable.

Owner:WUHAN UNIV OF TECH

900 m<3> blast furnace taphole clay

InactiveCN104557087AImprove thermal conductivityImprove anti-scourabilityClaywaresTitanium nitrideSilicate Cement

The invention discloses 900 m<3> blast furnace taphole clay. The blast furnace taphole clay is characterized by comprising the following components in parts by weight: 6-10 parts of titanium nitride, 8-15 parts of aluminum nitride, 10-20 parts of pyrophyllite rawore, 1-3 parts of zirconium carbonate, 10-20 parts of ball clay, 2-4 parts of alumina powder, 12-20 parts of graphite powder, 0-1 part of silicate 425 cement, 3-8 parts of ferro-silicon nitride powder, 2-5 parts of anthracite culm, 3-8 parts of resin powder, 0.01-0.05 parts of polyether-modified polyorganosiloxane and 15-18 parts of an additional binder. With the use of the technical scheme, the taphole clay which is convenient to ram, resistant to molten iron erosion and stable in molten iron discharge is obtained, and the problems that a taphole becomes shallow and is free of washing resistance and molten iron erosion resistance, and the taphole clay is seriously polluted due to poor quality of the taphole clay used in a blast furnace at present can be solved.

Owner:甘肃俱进循环经济利用有限公司

Method for preparing active solder

InactiveCN1094810CLower wetting angleImprove welding qualityWelding/cutting media/materialsSoldering mediaMaterials scienceMetal

The Ag-Cu-Ti active solder is prepared with alloy powder containing Ag in 49-69 wt%, Cu in 30-50 wt% and Ti in 1-8 wt% and through a powder metallurgical process including mixing material, pressing, vacuum sintering, annealing, hot rolling and cold rolling. It has a melting point of 780-830 deg.c and purity over 99%. It has wide application range, can be used in braze welding between diamond and metal, ZrO2 ceramic and alloy steel, and results in high welding quality and simplified welding process.

Owner:SOUTH CHINA UNIV OF TECH

No-clean flux high in welding passing rate

InactiveCN106392380AExcellent soldering performanceNo residueWelding/cutting media/materialsSoldering mediaActive agentFilm-forming agent

The invention discloses no-clean flux high in welding passing rate, and belongs to the technical field of flux. The no-clean flux is specifically prepared from a solvent, an active agent, a film-forming agent, a surface active agent, a stabilizer and a corrosion inhibitor. The flux is high in welding aid capacity; the bad phenomena of hard skin films, caking, viscosity changing and the like are avoided; the viscosity is stable; corrosiveness is avoided; no residual solid exists on the surface of a welded object; cleaning is not needed; the phenomena of joint welding and short circuits are avoided after welding; the welding passing rate of a precision device can be guaranteed; and the no-clean flux is suitable for single-face circuit boards or copper plated and nickel plated circuit boards hard to weld.

Owner:ANHUI FEIDA ELECTRICAL TECH CO LTD

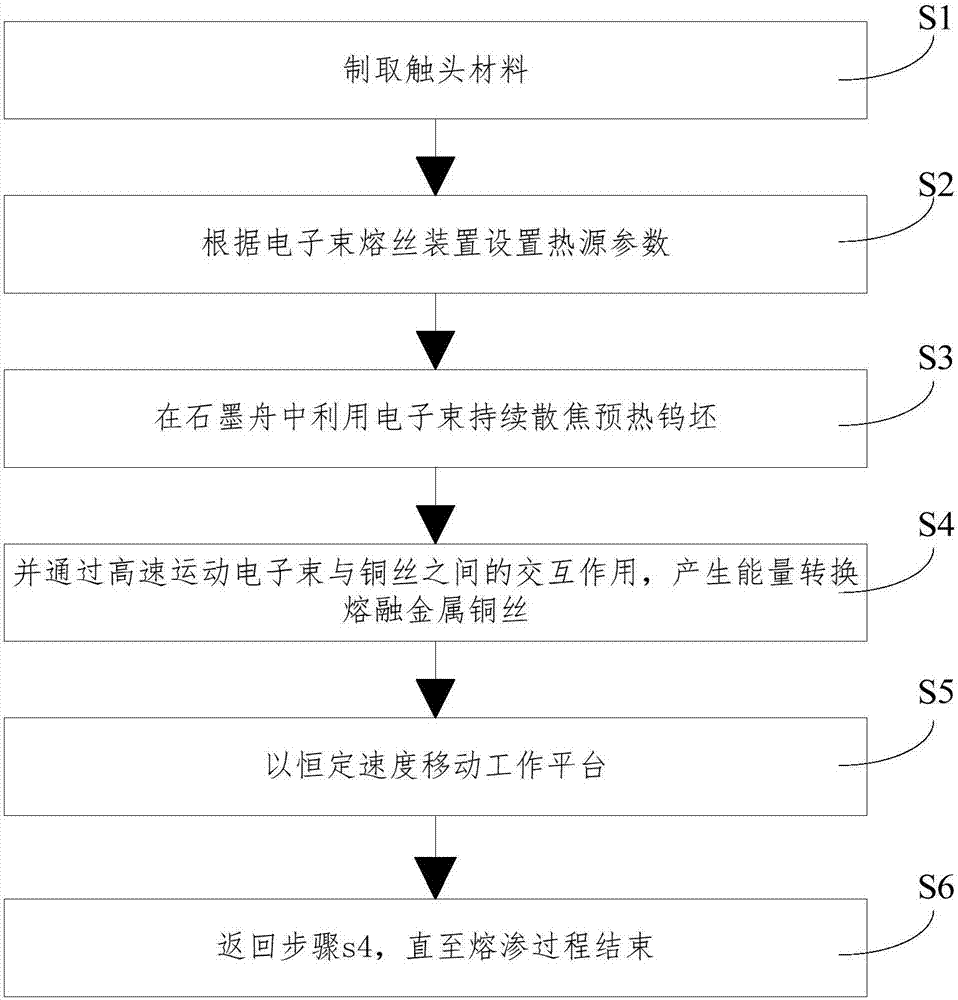

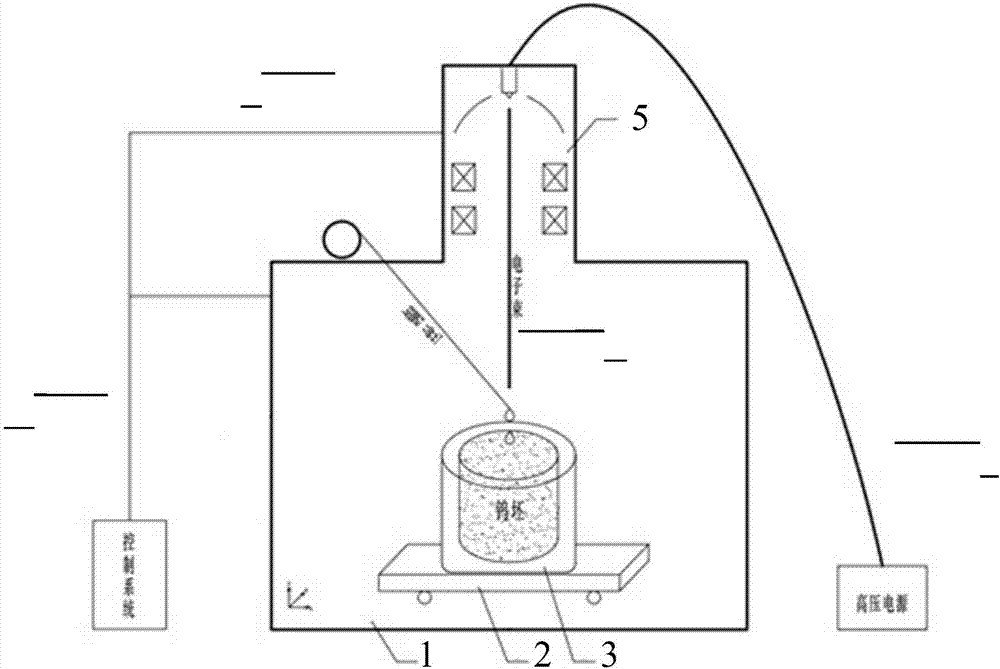

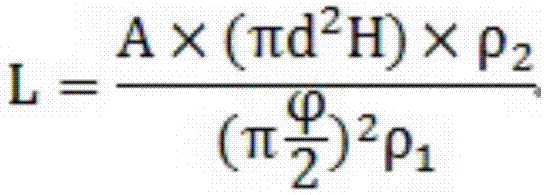

Method for preparing copper-tungsten contact through electron beam infiltration

ActiveCN106997811ALower wetting angleShorten the timeLine/current collector detailsContactsCopper wireGraphite

The invention discloses a method for preparing a copper-tungsten contact through electron beam infiltration. The method comprises the following steps in sequence: s1, preparing a contact material; s2, setting heat source parameters according to an electron beam fuse apparatus; s3, preheating a tungsten blank by continuous defocusing of an electron beam in a graphite boat; s4, adjusting an orientation relation between the electron beam and copper wires, and generating energy to convert molten metal copper wires by interaction between the high-speed-motion electron beam and copper wires; s5, moving a working platform at a constant speed; and s6, returning to the step s4 until the infiltration process is finished. The method has the advantages as follows: the electron beam infiltration method is particularly suitable for small-batch copper-tungsten alloy preparation of different mass fraction proportions, and only the copper wire lengths which can satisfy the mass fraction proportions need to be calculated in the manufacturing process; and meanwhile, the vacuum environment equipped in the electron beam apparatus is suitable for preparation of the copper alloy, so that oxidization can be avoided to the maximum degree and the infiltration effect can be improved.

Owner:XIAN ZHIRONG METAL PRINTING SYST CO LTD

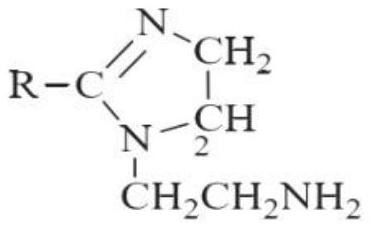

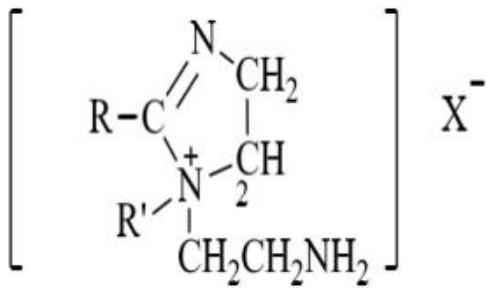

Metal corrosion inhibitor and preparation method thereof

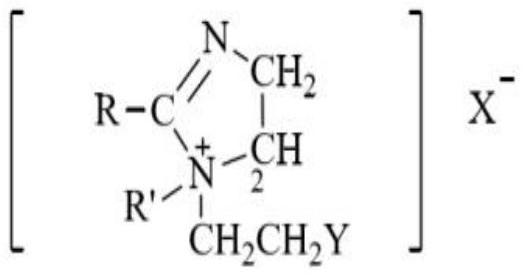

PendingCN112341393AIncrease profitLower wetting angleOrganic chemistryTriethylenetetramineBenzyl chloride

The invention discloses a metal corrosion inhibitor and a preparation method thereof. The preparation method comprises the process steps of a natural gas storage CO2 liquid-phase corrosion inhibitor and a natural gas storage CO2 gas-phase corrosion inhibitor. The preparation method of the CO2 liquid-phase corrosion inhibitor for the natural gas storage comprises the following steps: S1, carrying out amidation and cyclization reaction on cis-octadecenoic acid-9-enoic acid and triethylenetetramine serving as main components, and dehydrating twice to form a five-membered heterocyclic imidazolineintermediate; s2, the imidazoline intermediate and benzyl chloride are subjected to quaternization, and oil solubility is converted into water-soluble imidazoline quaternary ammonium salt; and S3, reacting the imidazoline quaternary ammonium salt with ethyl sulfur nitrogen, and introducing an ethyl sulfur nitrogen polar group, so that the imidazoline quaternary ammonium salt has more active adsorption sites to obtain the natural gas storage CO2 liquid-phase corrosion inhibitor 2-ethylthio-amino-ethyl-benzyl-1-heptadecenyl-imidazoline quaternary ammonium salt. The corrosion inhibitor has gas-phase corrosion inhibition and liquid-phase corrosion inhibition functions at the same time, and the use concentration of the corrosion inhibitor can be reduced to a low degree on the premise that the function of the corrosion inhibitor is not affected.

Owner:盘锦天诚源科技有限公司

Calcium carbonate surface-active agent

ActiveCN103432958AReduce surface tensionImprove workabilityTransportation and packagingMixingDiethylene glycol monobutyl etherActive agent

The invention provides a calcium carbonate surface-active agent and relates to a modifying agent used for calcium carbonate, and further provides a preparation method and using method thereof. The surface-active agent comprises the following components: stearic acid, isopropyl alcohol, ethylene-glycol, diethylene glycol monobutyl ether, isooctyl alcohol, aluminic acid ester, amino silicone oil, sorbitan monolaurate and polyoxyethylene sorbitan monolaurate. The activator modified calcium carbonate has an unprecedented effect; scagliola produced through filling of calcium carbonate is greatly improved in strength, rigidity, rigidity, especially shock resistance and scratch resistance, and is more compact and smoother. Meanwhile, the activator is low in cost; when the activator is added in a powder vertical mill for grinding the calcium carbonate to 600-mesh fine powder, 40 Yuan more is required for every ton of the calcium carbonate; and moreover, a DOP oil absorption value is smaller than 12, so that the economic benefit of the scagliola processing is greatly improved.

Owner:东莞市立信环保科技有限公司

Rare-earth multi-element alloy coating and hot-dip galvanizing method thereof

The invention discloses a rare-earth multi-element alloy coating and a hot-dip galvanizing method thereof. The rare-earth multi-element alloy coating comprises the following main components: rare earth, aluminum, nickel, magnesium and zinc. The hot-dip galvanizing method comprises the following steps: (1) mix-melting intermediate alloys, namely Al-RE-Mg and Zn-Ni; (2) mix-melting a multi-element rare-earth alloy; (3) dredging slag; (4) casting; and (5) applying. The rare-earth multi-element alloy coating and the hot-dip galvanizing method thereof have the advantages that: firstly, difficulty of directly adding multiple elements with different melting points into a zinc liquid to melt and the impossibility problem of adding high-melting-point elemental metal elements into the zinc liquid to melt are solved; secondly, the multiple elements can be completely and quickly molten and dispersed, so that the hot-dop galvanizing method is easy to operate and control in a practical production process; thirdly, the dilution capability, the dispersive capacity, the mobility and the uniformity of the zinc liquid are strengthened, so that the zinc consumption is reduced by 5%-15%, the cost is reduced and the benefits are increased; and fourthly, the corrosion resistance of the rare-earth multi-element alloy coating is doubled in comparison with that of a conventional hot dip galvanized coating.

Owner:江苏中远稀土新材料有限公司

Preparation method of diamond tool carcass powder FeCu30

The invention discloses a preparation method of diamond tool carcass powder FeCu30. The preparation method comprises the steps of: (1) preparation of a copper-chromium intermediate alloy; (2) preparation of a copper-chromium-zirconium alloy; and (3) preparation of FeCu30. The method enables the copper-chromium-zirconium alloy to have excellent stability and higher metal chromium yield, and can shorten the smelting time of the copper-chromium-zirconium alloy; and a diamond tool produced by powder containing two micro elements of chromium and zirconium is excellent in sharpness, life and self sharpness.

Owner:西峡县泰祥实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com