Kitchen anti-bacterial oil stain cleaning agent and preparation process thereof

An oil stain cleaning agent and kitchen technology, applied in the directions of detergent compounding agent, detergent composition, surface active detergent composition, etc., can solve the problems of high irritation, pungent smell, strong alkalinity, etc. , No irritating odor, excellent cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

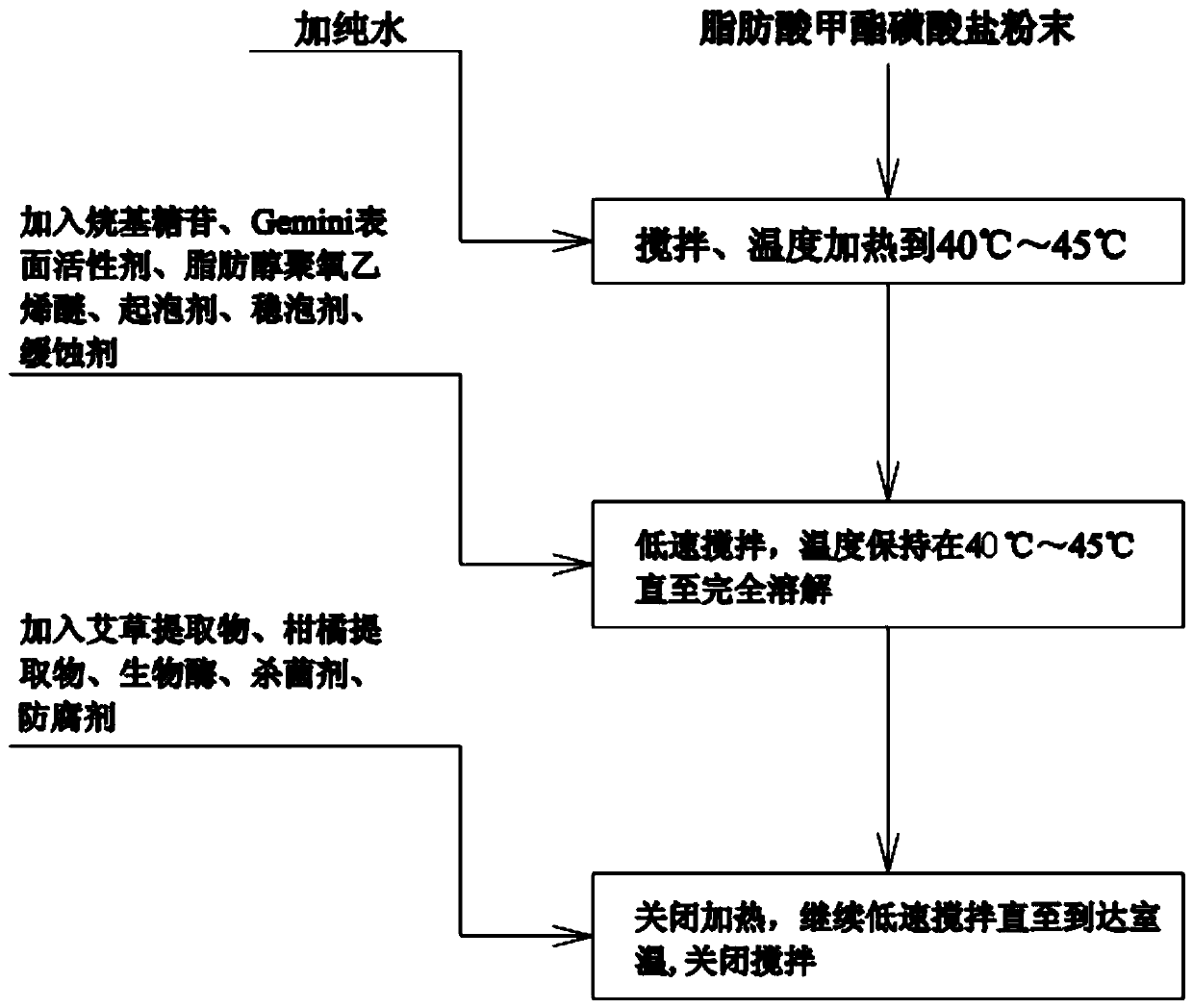

Method used

Image

Examples

Embodiment 1

[0039] The kitchen antibacterial oil stain cleaning agent comprises the following components by mass percentage: 4% of alkyl glucoside, 2% of Gemini composite surfactant, 1% of fatty alcohol polyoxyethylene ether AEO-7, 3% of fatty acid methyl ester sulfonate, Wormwood extract 1%, citrus extract 2%, biological enzyme 0.8%, foaming agent 1%, foam stabilizer 1.5%, penetrating agent 1.5%, preservative 0.08%, corrosion inhibitor 1.3%, PH regulator 1.2 %, the balance of pure water.

[0040] The alkyl glycoside is alkyl glycoside APG1214, the foaming agent is sodium lauryl sulfate, the foam stabilizer is lauryl dimethyl ammonium oxide, and the penetrating agent is fatty alcohol polyoxyethylene Ether JFC, the preservative is sodium benzoate, the corrosion inhibitor is sodium silicate and sodium carbonate complex, and the pH regulator is citric acid.

Embodiment 2

[0042] Kitchen antibacterial oil cleaning agent, including the following components by mass percentage: 2% of alkyl glycoside, 3% of Gemini composite surfactant, 3% of fatty alcohol polyoxyethylene ether AEO-7, 2% of fatty acid methyl ester sulfonate, Wormwood extract 2%, citrus extract 1%, biological enzyme 0.8%, foaming agent 2%, foam stabilizer 1.5%, penetrating agent 2%, preservative 0.08%, corrosion inhibitor 1.3%, PH regulator 1.2 %, the balance of pure water.

[0043] The alkyl glycoside is alkyl glycoside APG1214, the foaming agent is sodium lauryl sulfate, the foam stabilizer is lauryl dimethyl ammonium oxide, and the penetrating agent is fatty alcohol polyoxyethylene Ether JFC, the preservative is sodium benzoate, the corrosion inhibitor is sodium silicate and sodium carbonate complex, and the pH regulator is citric acid.

Embodiment 3

[0045]Kitchen antibacterial oil cleaning agent, including the following components by mass percentage: 3% of alkyl glucoside, 3% of Gemini composite surfactant, 2% of fatty alcohol polyoxyethylene ether AEO-7, 2% of fatty acid methyl ester sulfonate, Wormwood extract 1.5%, citrus extract 1.5%, biological enzyme 0.8%, foaming agent 2%, foam stabilizer 1.5%, penetrating agent 2%, preservative 0.08%, corrosion inhibitor 1.3%, PH regulator 1.2 %, the balance of pure water.

[0046] The alkyl glycoside is alkyl glycoside APG1214, the foaming agent is sodium lauryl sulfate, the foam stabilizer is lauryl dimethyl ammonium oxide, and the penetrating agent is fatty alcohol polyoxyethylene Ether JFC, the preservative is sodium benzoate, the corrosion inhibitor is sodium silicate and sodium carbonate complex, and the pH regulator is citric acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com