Patents

Literature

2251 results about "Fatty acid methyl ester" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

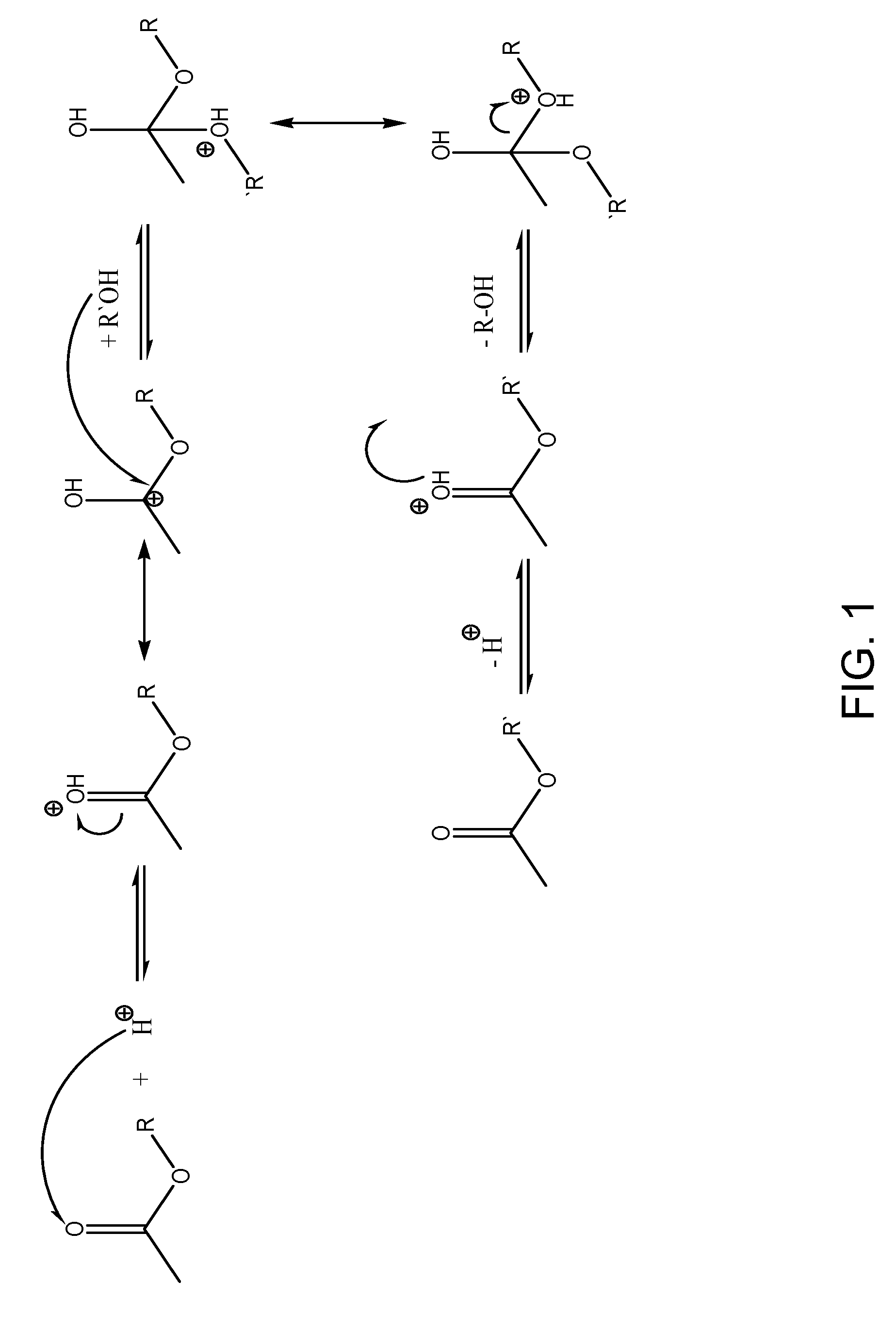

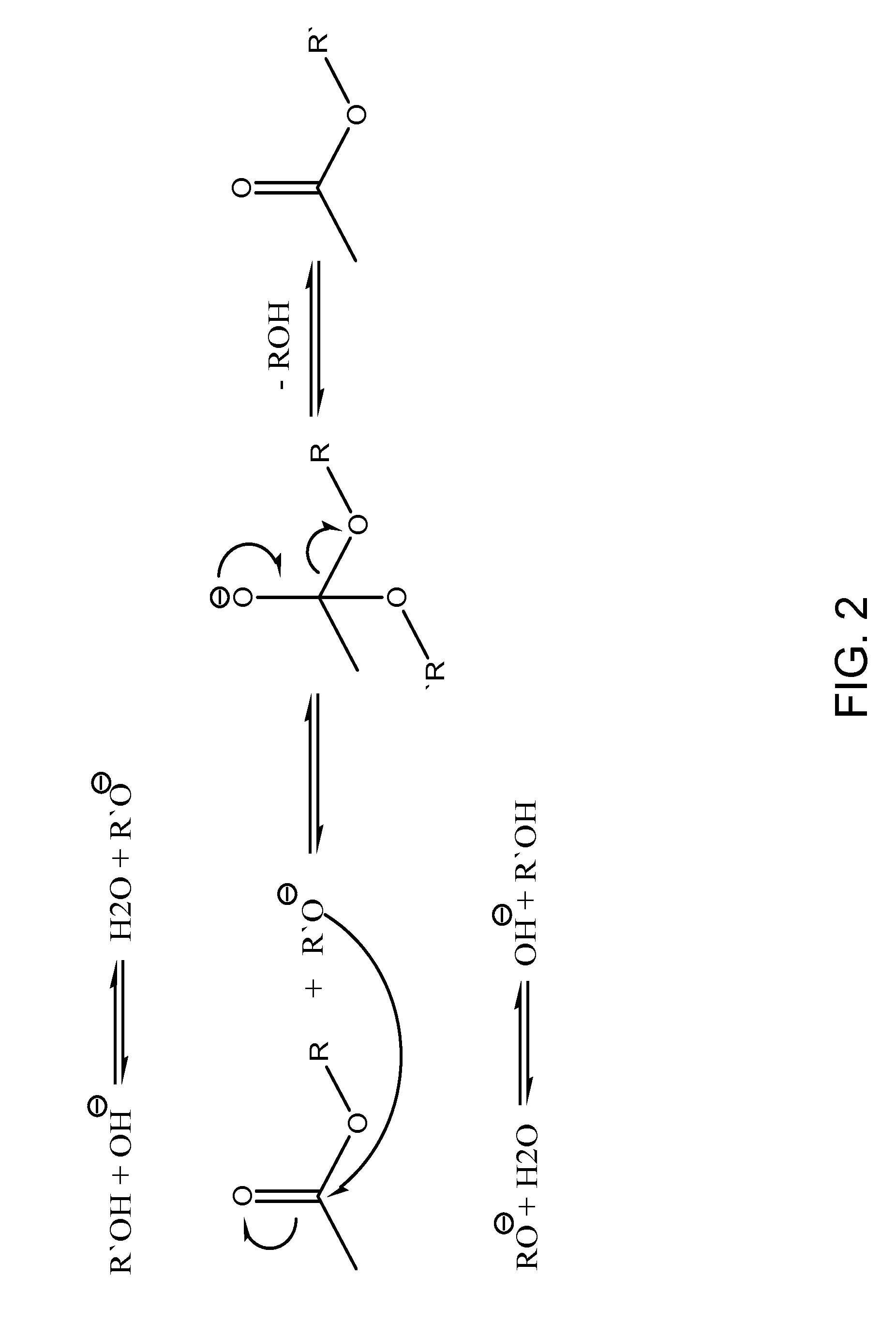

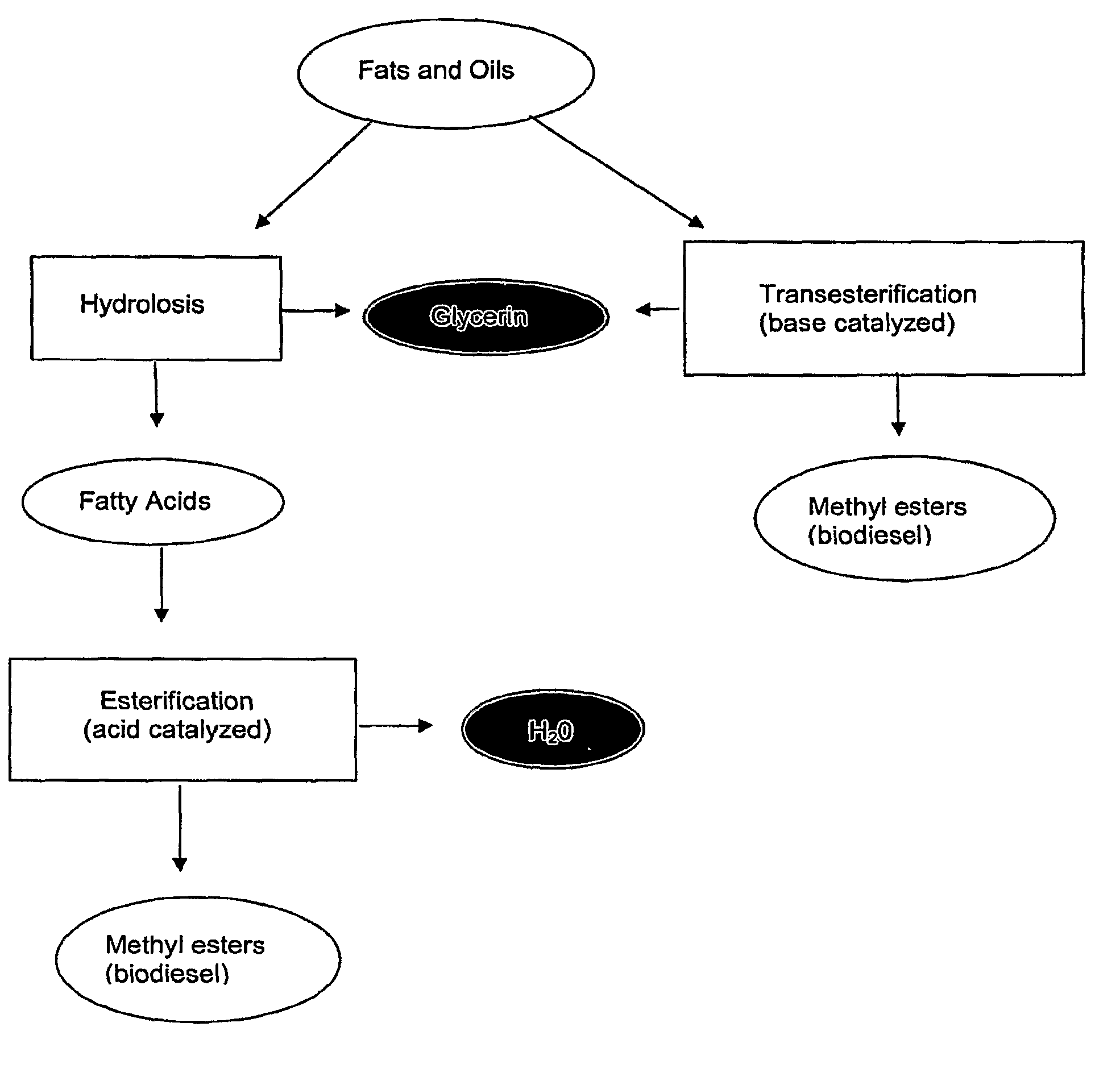

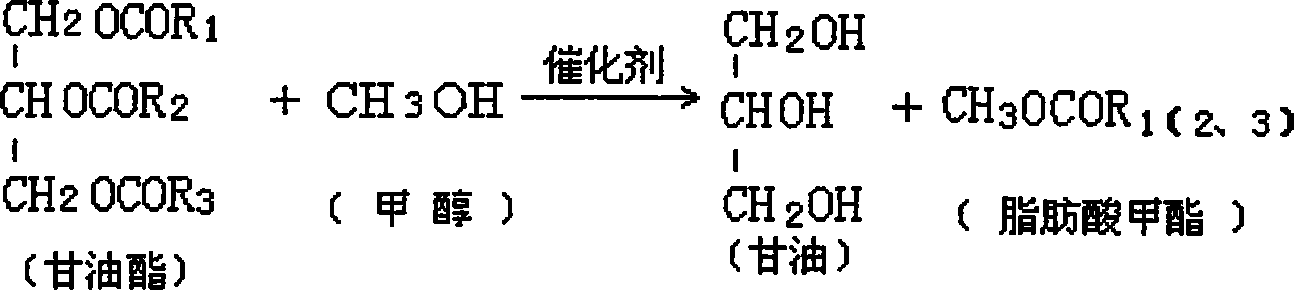

Fatty acid methyl esters (FAME) are a type of fatty acid ester that are derived by transesterification of fats with methanol. The molecules in biodiesel are primarily FAMEs, usually obtained from vegetable oils by transesterification. They are used to produce detergents and biodiesel. FAMES are typically produced by an alkali-catalyzed reaction between fats and methanol in the presence of base such as sodium hydroxide, sodium methoxide or potassium hydroxide. One of the reasons for FAME use in biodiesel instead of free fatty acids is to nullify any corrosion that free fatty acids would cause to the metals of engines, production facilities and so forth. Free fatty acids are only mildly acidic, but in time can cause cumulative corrosion unlike their esters. As an improved quality, FAMEs also usually have about 12-15 units higher cetane number than their unesterified counterparts.

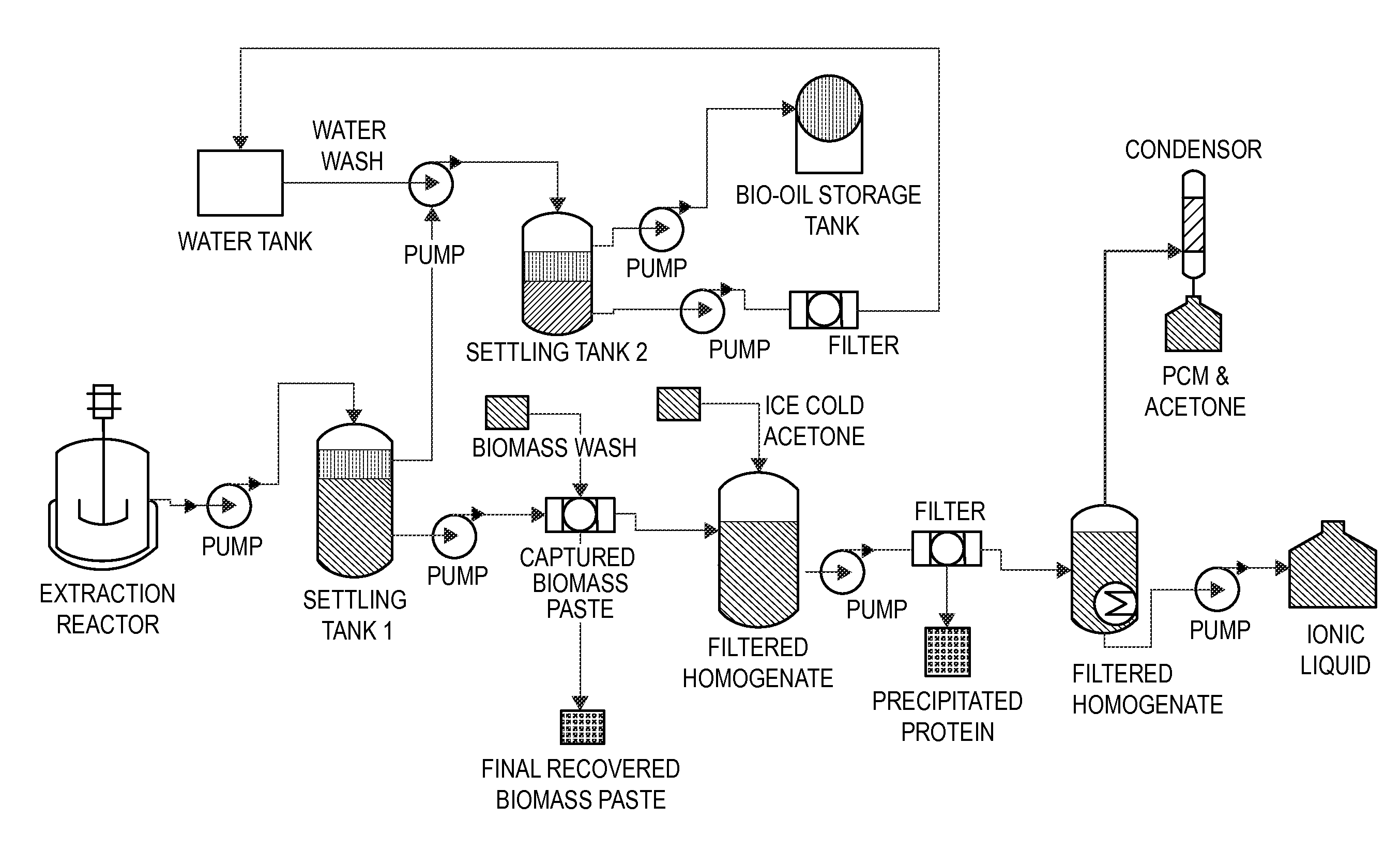

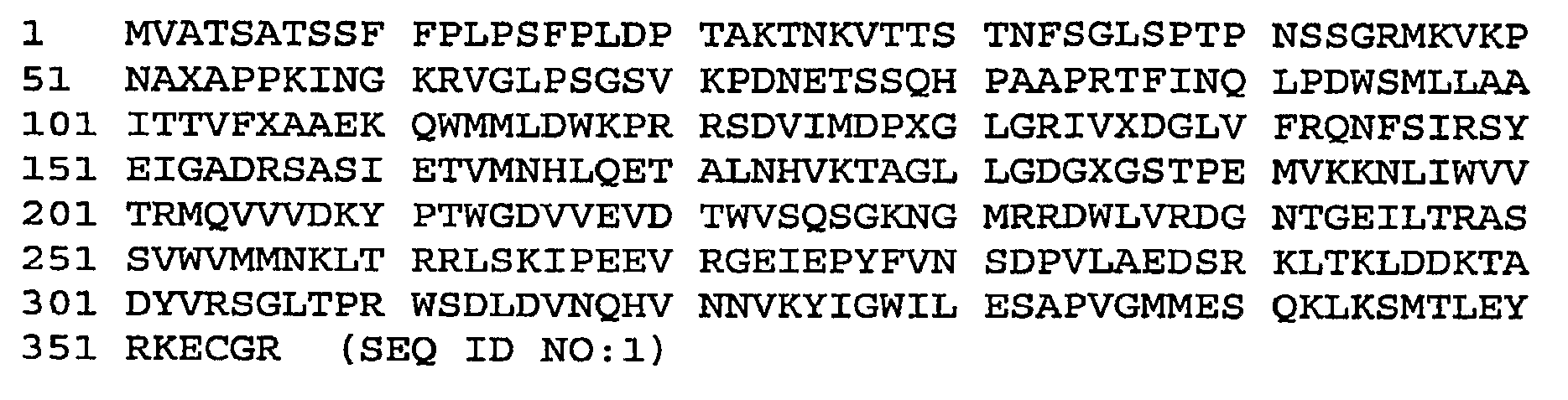

Methods and compositions for extraction and transesterification of biomass components

InactiveUS20090234146A1Fatty oils/acids recovery from wasteFatty acid esterificationTransesterificationBiofuel

Methods and compositions are disclosed for the direct transesterification and extraction of bio-lipids and bio-oils in the production of biofuel, particularly fatty acid methyl ester products.

Owner:UNIV OF HAWAII

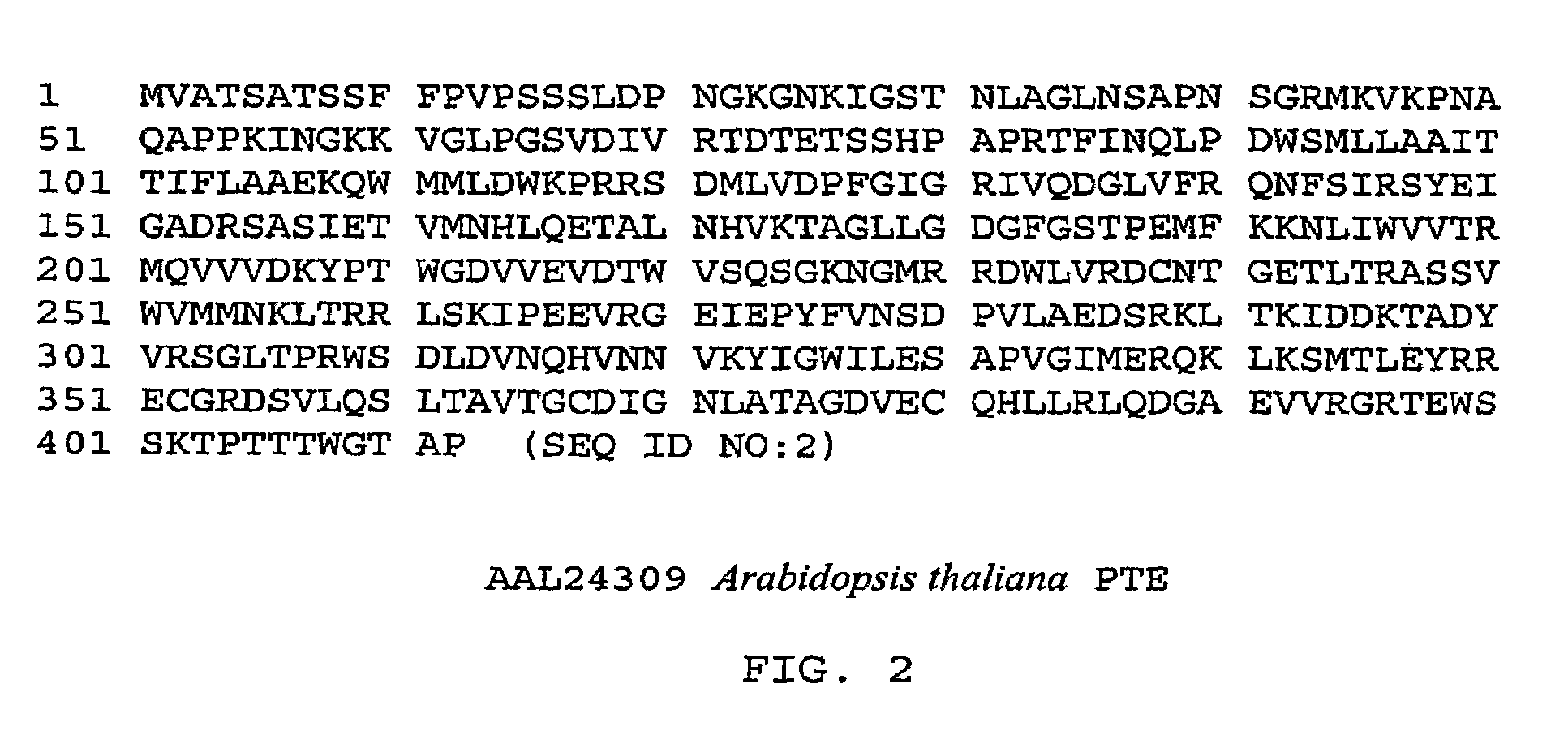

Fatty acid blends and uses therefor

ActiveUS20100058651A1Maintain good propertiesEffect cold flow propertyFatty acid esterificationFatty acids production/refiningFatty acid methyl esterMedium chain fatty acid

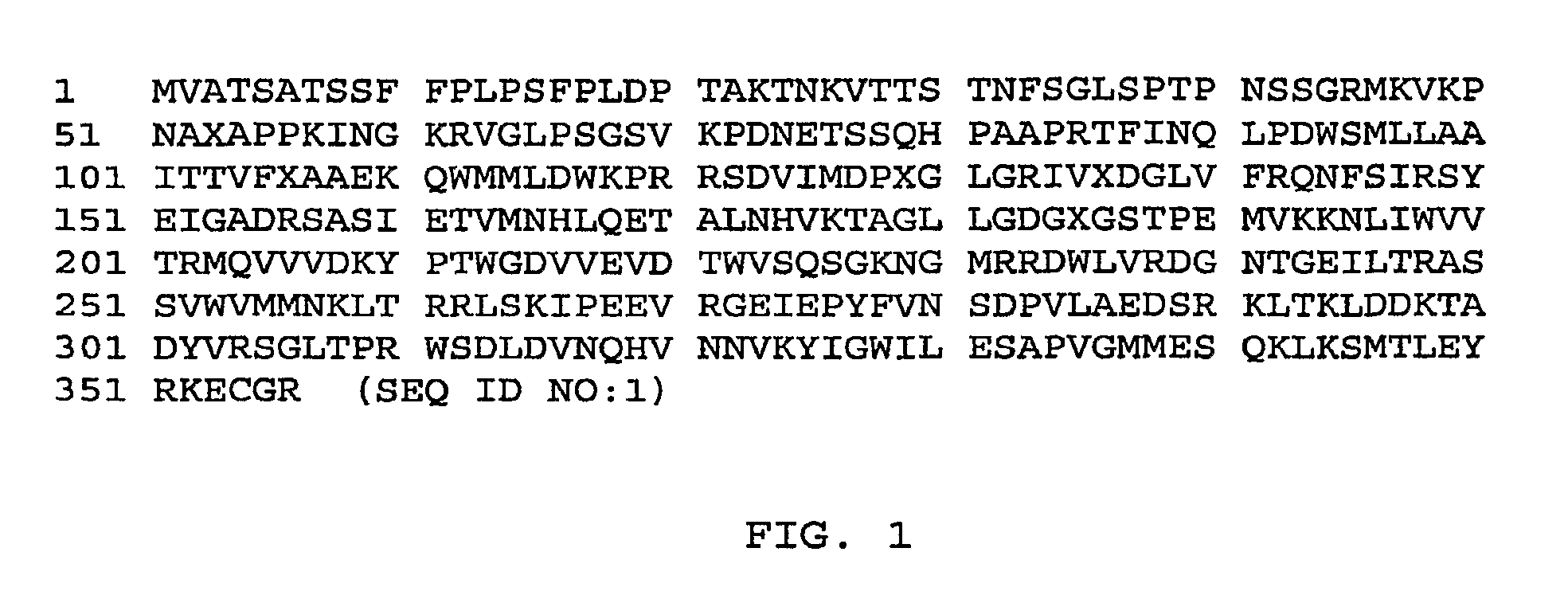

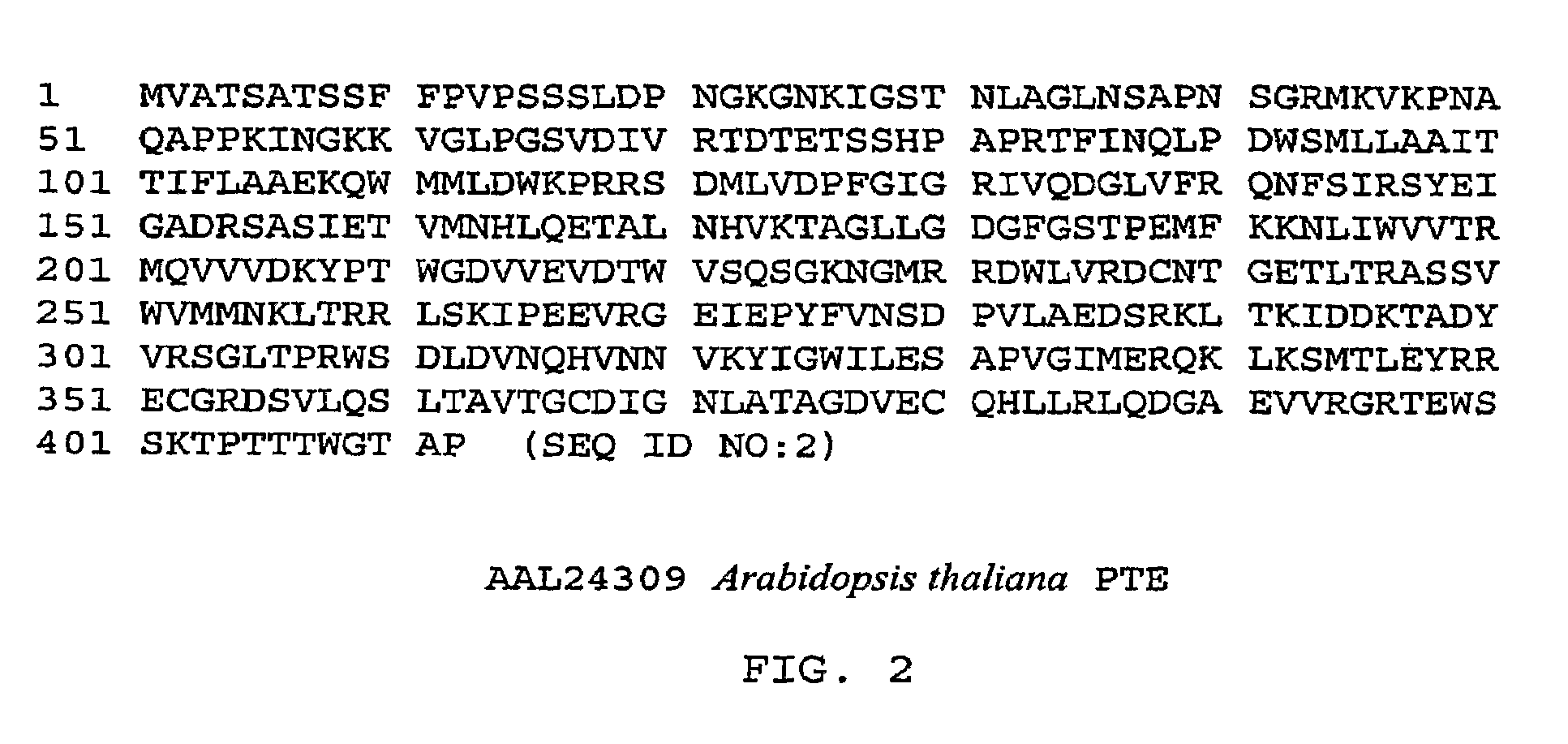

Provided herein are blends oils or fatty acids comprising more than 50% medium chain fatty acids, or the fatty acid alkyl esters thereof, and having low melting points. Such blends are useful as a fuel or as a starting material for the production of, for example, a biodiesel. Also provided genetically altered or modified plants, modified such that the amount of medium chain fatty acids generated by the plant are increased. Further provided is a method of predicting the melting point of a blend of fatty acid methyl esters and the use of such a method for identifying blends suitable for use as, for example, a biodiesel.

Owner:CIBUS

Method for producing biological diesel oil by using high-acidity waste animal and vegetable oil

InactiveCN1412278ASolve pollutionReduce pollutionLiquid hydrocarbon mixture productionBio-feedstockVegetable oilPtru catalyst

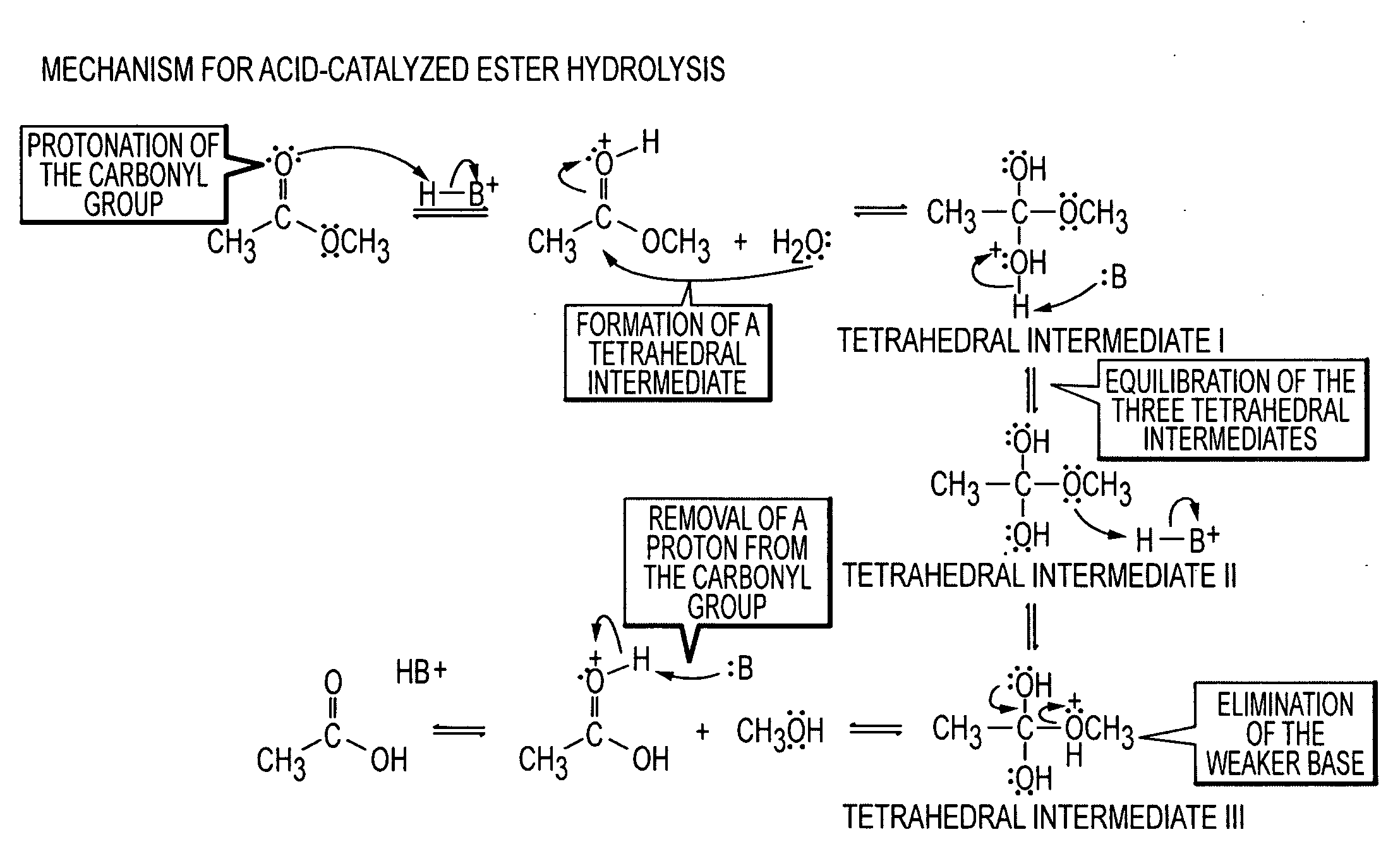

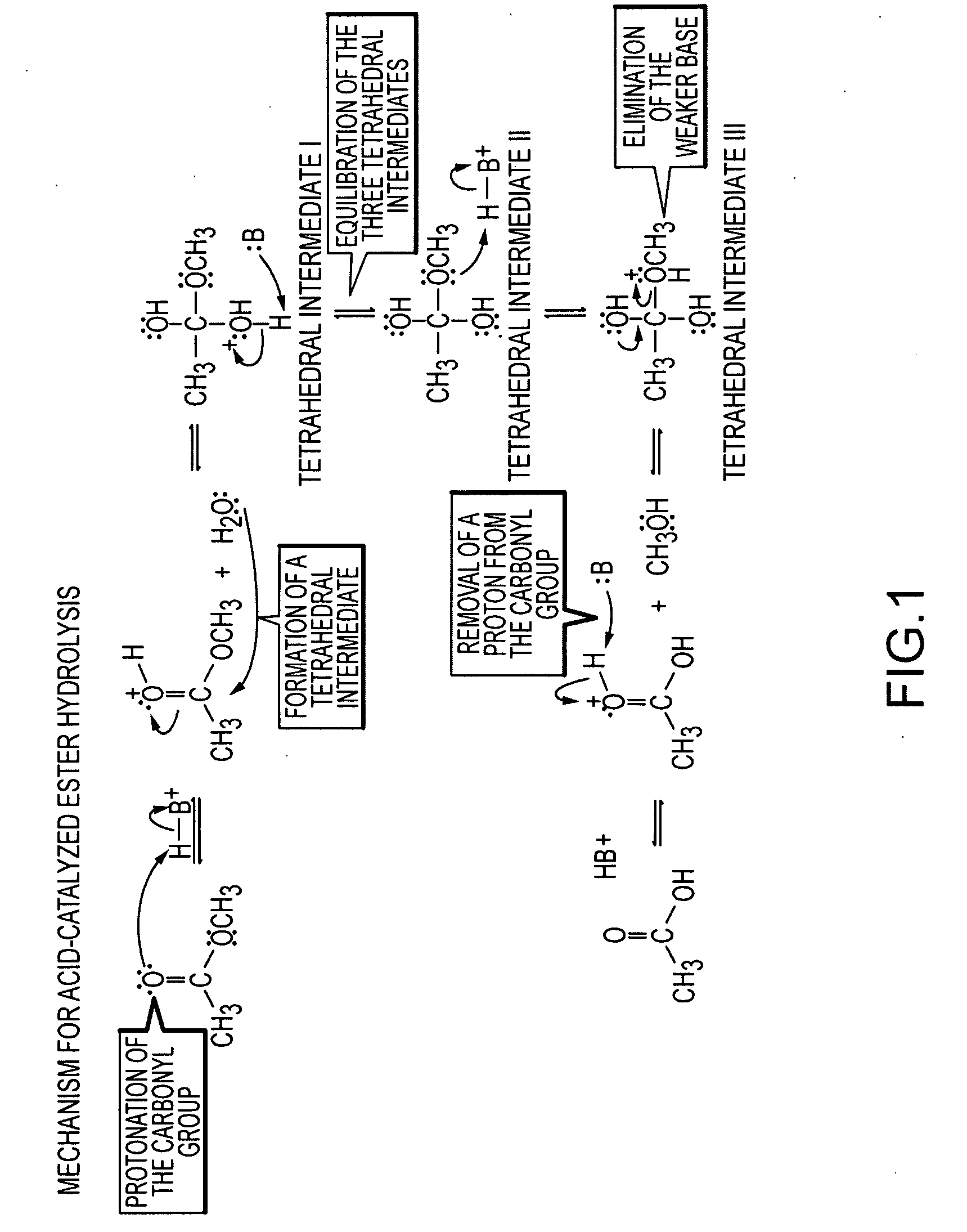

The present invention relates to a method for producing biological diesel oil-fatty acid methyl ester by using waste animal and vegetable oil with high acid value. It is characterized by that it adopts acidic catalysis method, under the action of acidic catalyst is makes the waste animal and vegetable oil react with low carbon alcohol, and adopts the following four steps: (1) dewatering; (2) esterification and ester exchange; (3) phase separation; and (4) decolouring so as to produce the invented biological diesel fatty acid methyl ester.

Owner:宋庭礼 +1

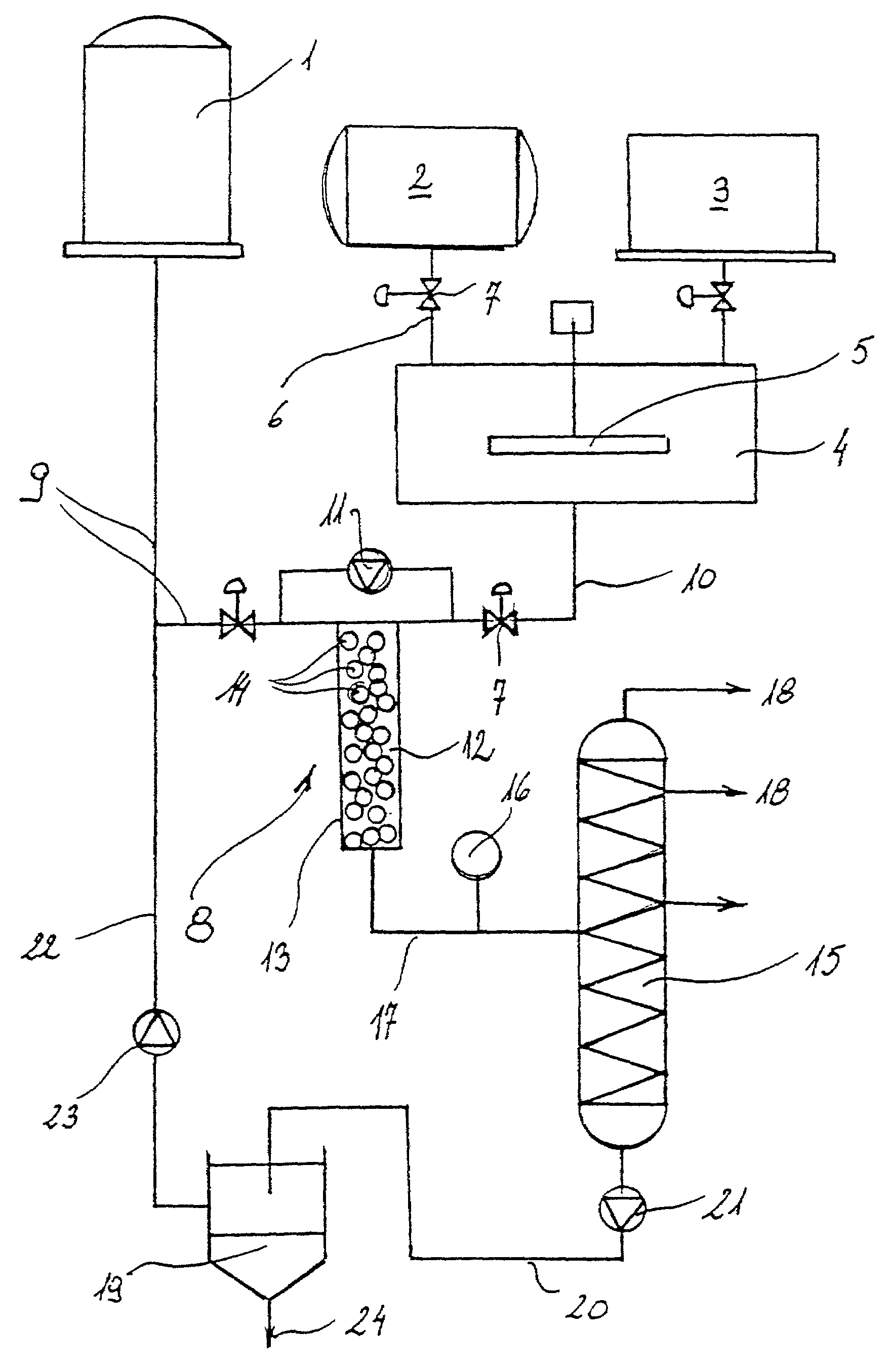

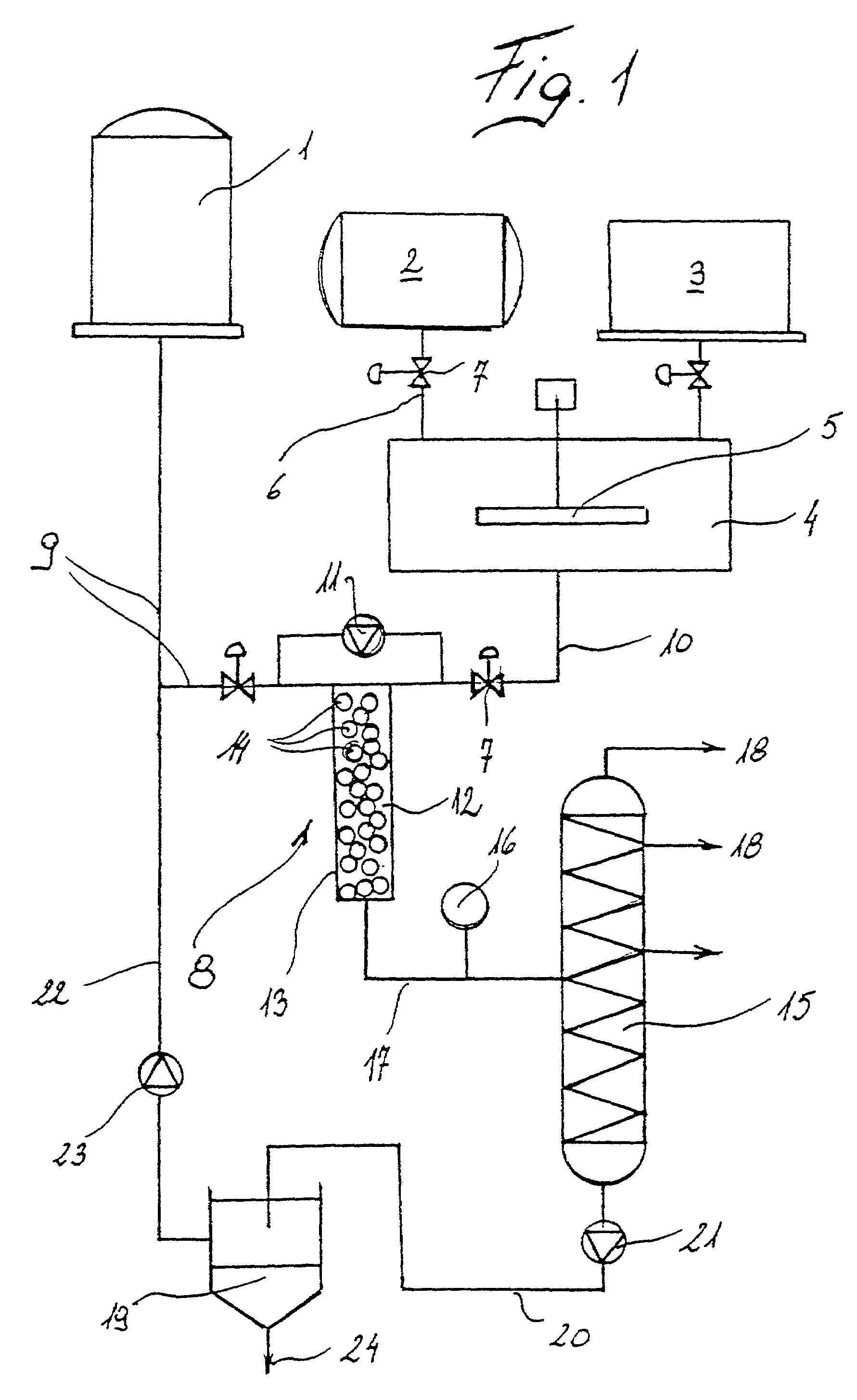

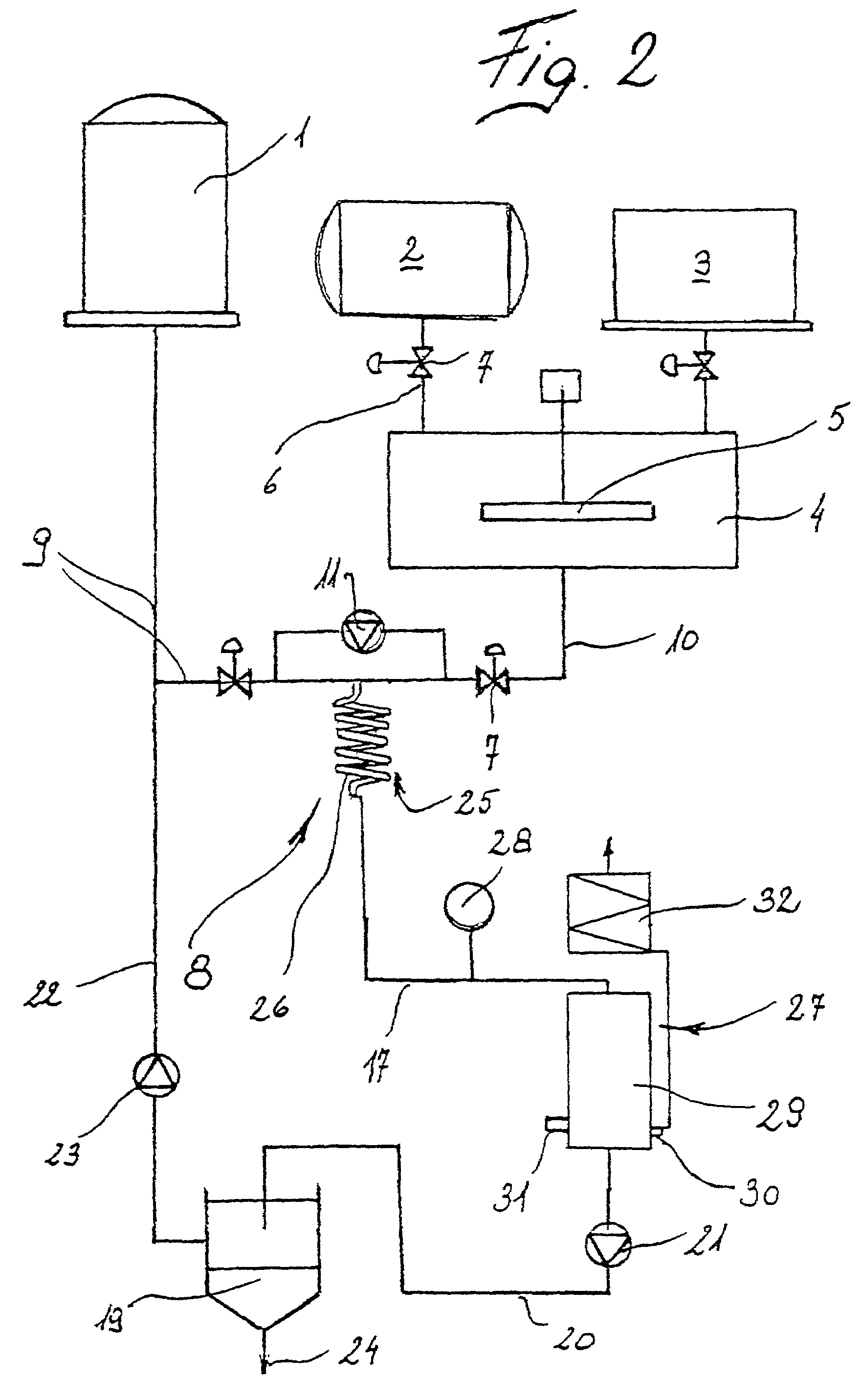

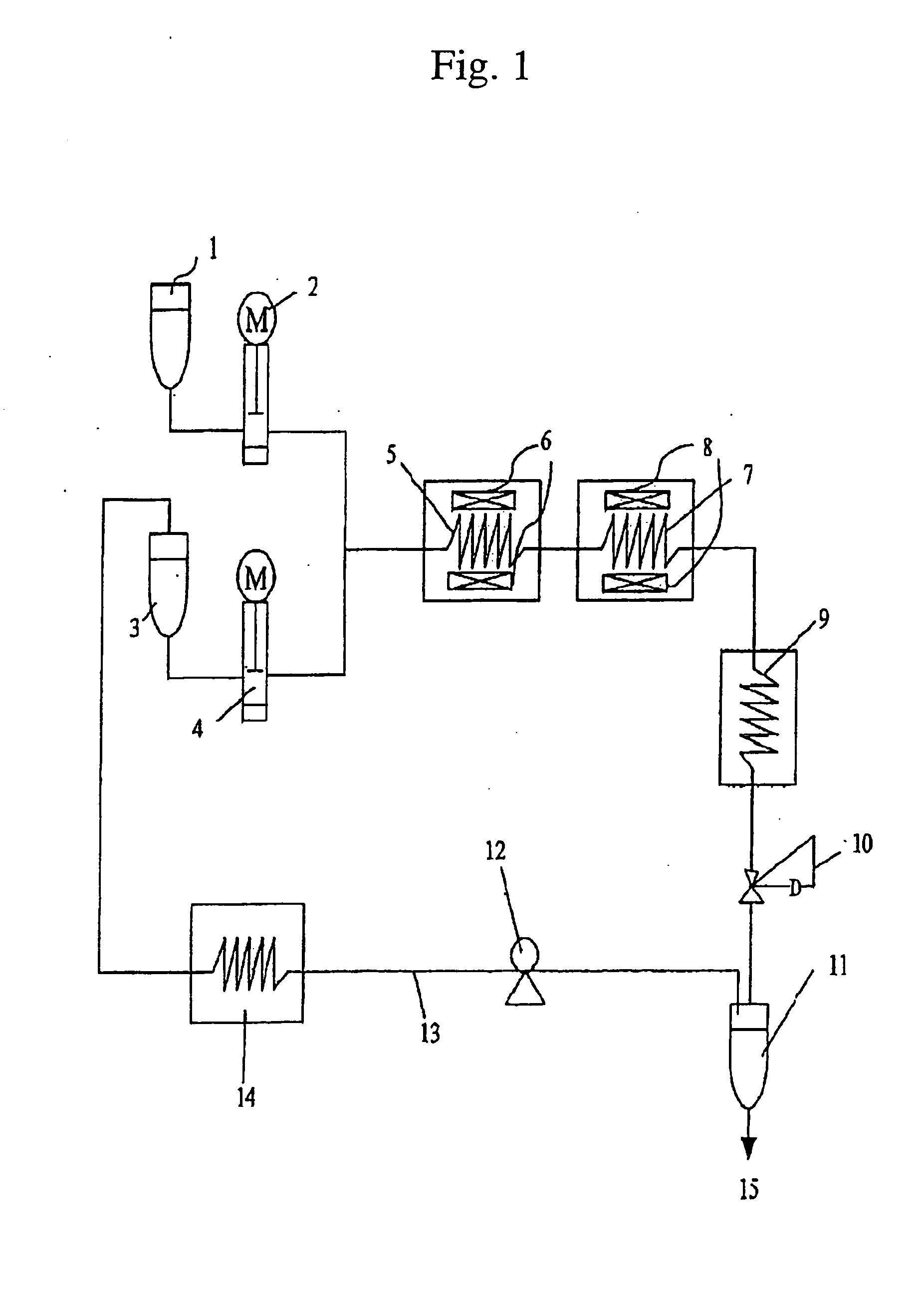

Method for producing fatty acid methyl ester and equipment for realizing the same

InactiveUS7045100B2Avoid disadvantagesRational productionPressurized chemical processFatty acid esterificationAlcoholTransesterification

Method for producing fatty acid methyl ester, including compounding saturated and unsaturated higher fatty substances from at least one of vegetable and animal with an alkaline solution dissolved in alcohol to form a mixture. The method also includes emulsifying the mixture to reach a chemical balance state in a reaction section, wherein fats are transesterified into fatty acid methyl ester, wherein border surfaces of the mixture are enlarged by dynamic turbulence in the reaction section and the transesterification is performed under pressure, and wherein the pressure is reduced during transesterification. The method further includes after reaching a chemical balance state, separating residues from the fatty acid methyl ester in a phase separation section. Apparatus for producing fatty acid methyl ester.

Owner:AMERICAN RENEWABLE FUELS

Fatty acid blends and uses therefor

ActiveUS8029579B2Maintain good propertiesEffect cold flow propertyFatty oils/acids recovery from wasteFatty acid esterificationPolymer scienceFatty acid methyl ester

Owner:CIBUS

Continuous algal biodiesel production facility

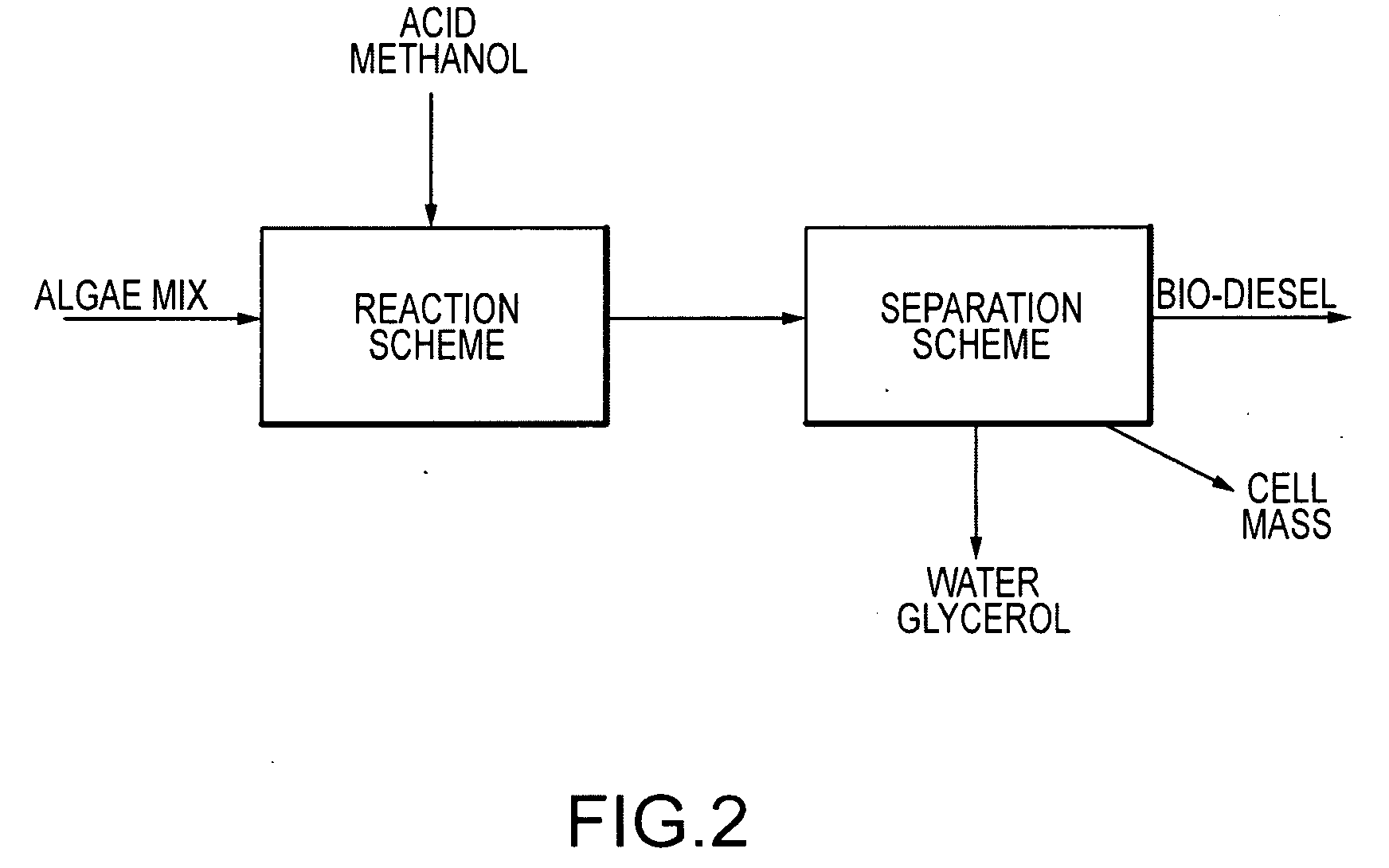

Embodiments of the present invention concern methods, compositions, and apparatus for the continuous conversion of algal lipids into biodiesel. In some embodiments, the biodiesel is formed in a multi-step sequence, the first steps occurring in the presence of water and a strong acid wherein the lipids are released from the algae by means of mechanical and chemical action and are then hydrolyzed to free fatty acids. In a subsequent step, this free fatty acid mixture is reacted with methanol to generate fatty acid methyl esters (also known as biodiesel). Such methods produce biodiesel from algal lipids without the requirement for separate algal cell lysis or lipid extraction or purification prior to the acid catalysis sequence. In other embodiments, the multi-step acid catalysis sequence occurs at 100° C. at two atmospheres of pressure.

Owner:COLORADO STATE UNIVERSITY +1

Process for the preparation of fatty acid methyl ester from triglyceride oil by transesterification

InactiveUS20060080891A1Produced cost-effectivelyReduce water contentFatty oils/acids recovery from wasteFatty acid esterificationTransesterificationUnit operation

The present invention relates to an improved process for the preparation of biodiesel from triglyceride oils through transesterification, particularly the fatty acid methyl ester of oil mechanically expelled from whole seeds of Jatropha curcas, a plant with potential for cultivation on wastelands in India and other countries, all unit operations being carried out at ambient temperature.

Owner:COUNCIL OF SCI & IND RES

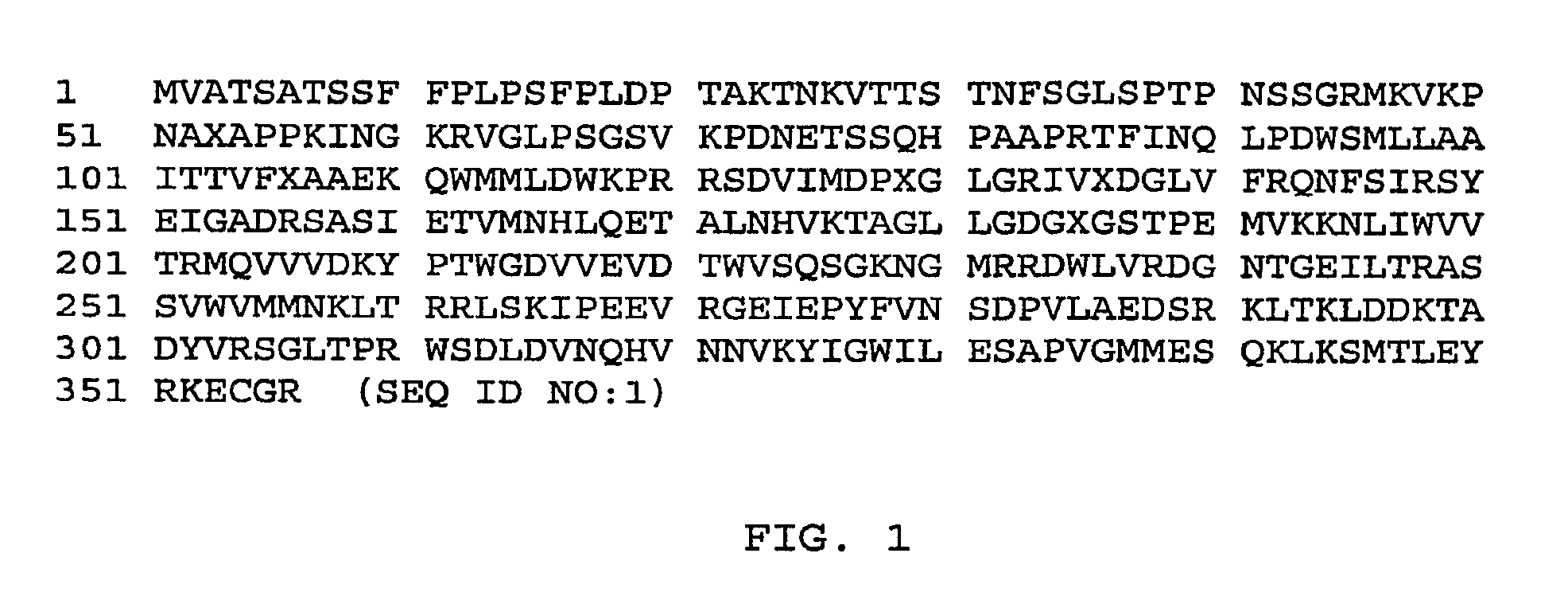

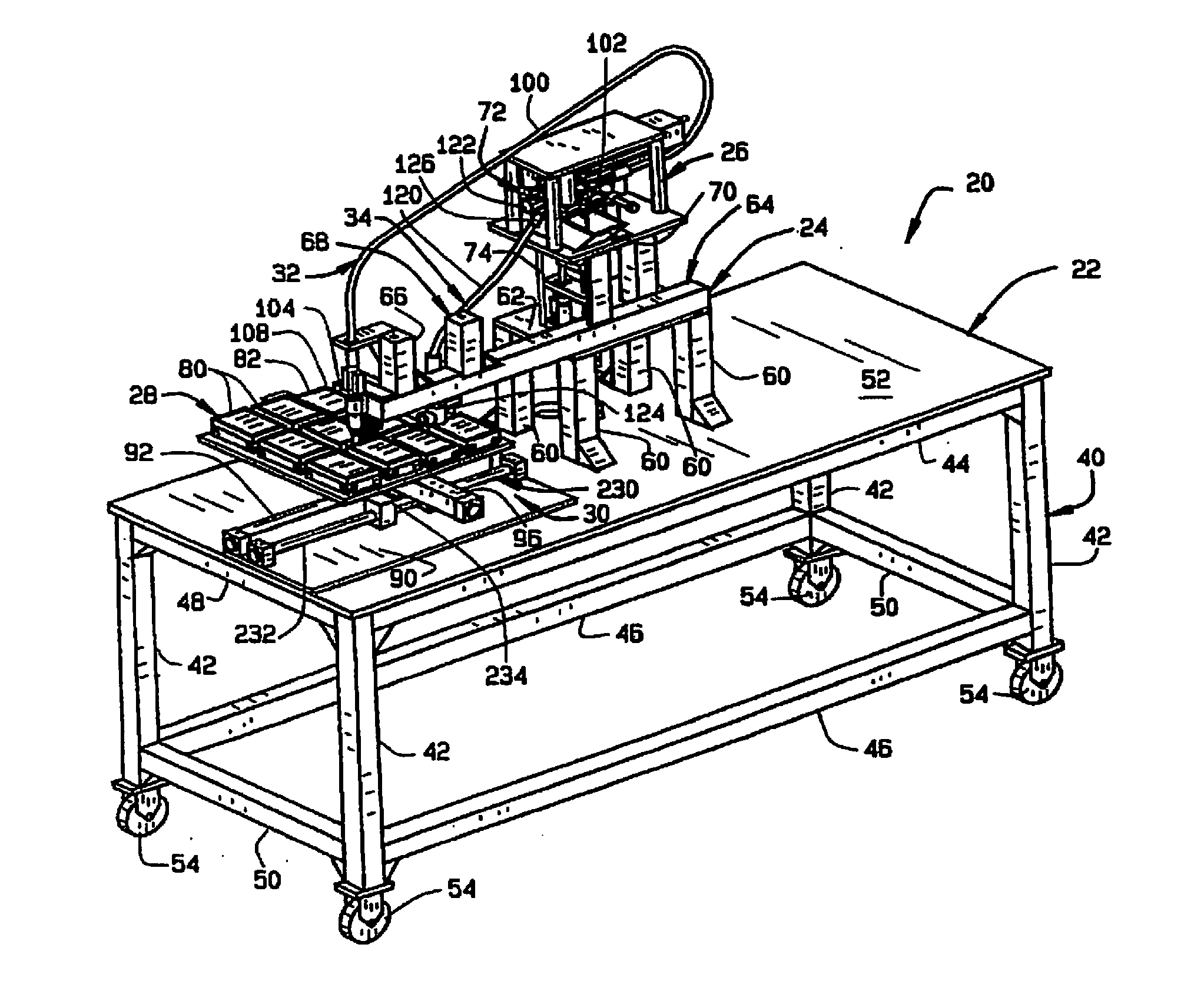

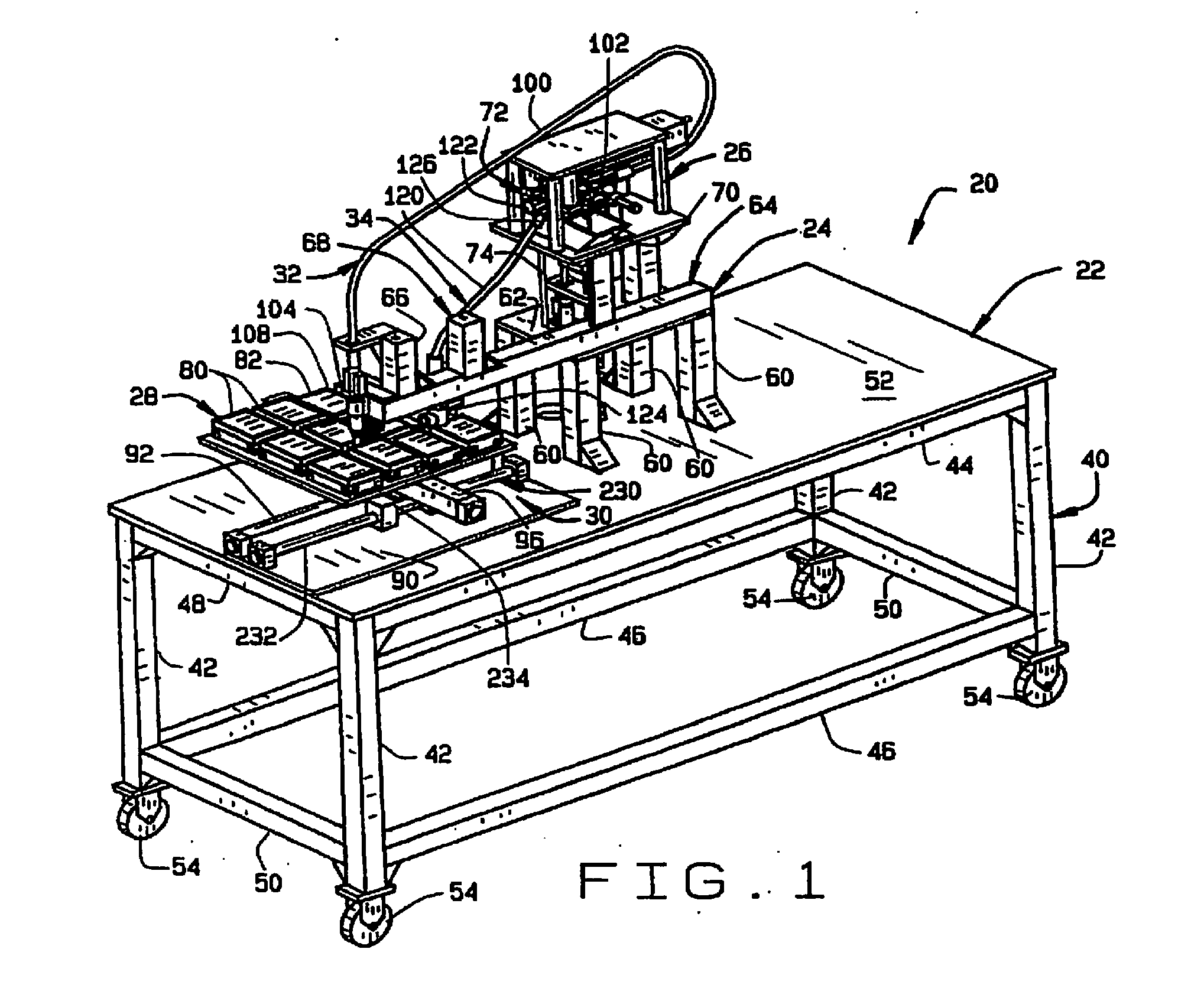

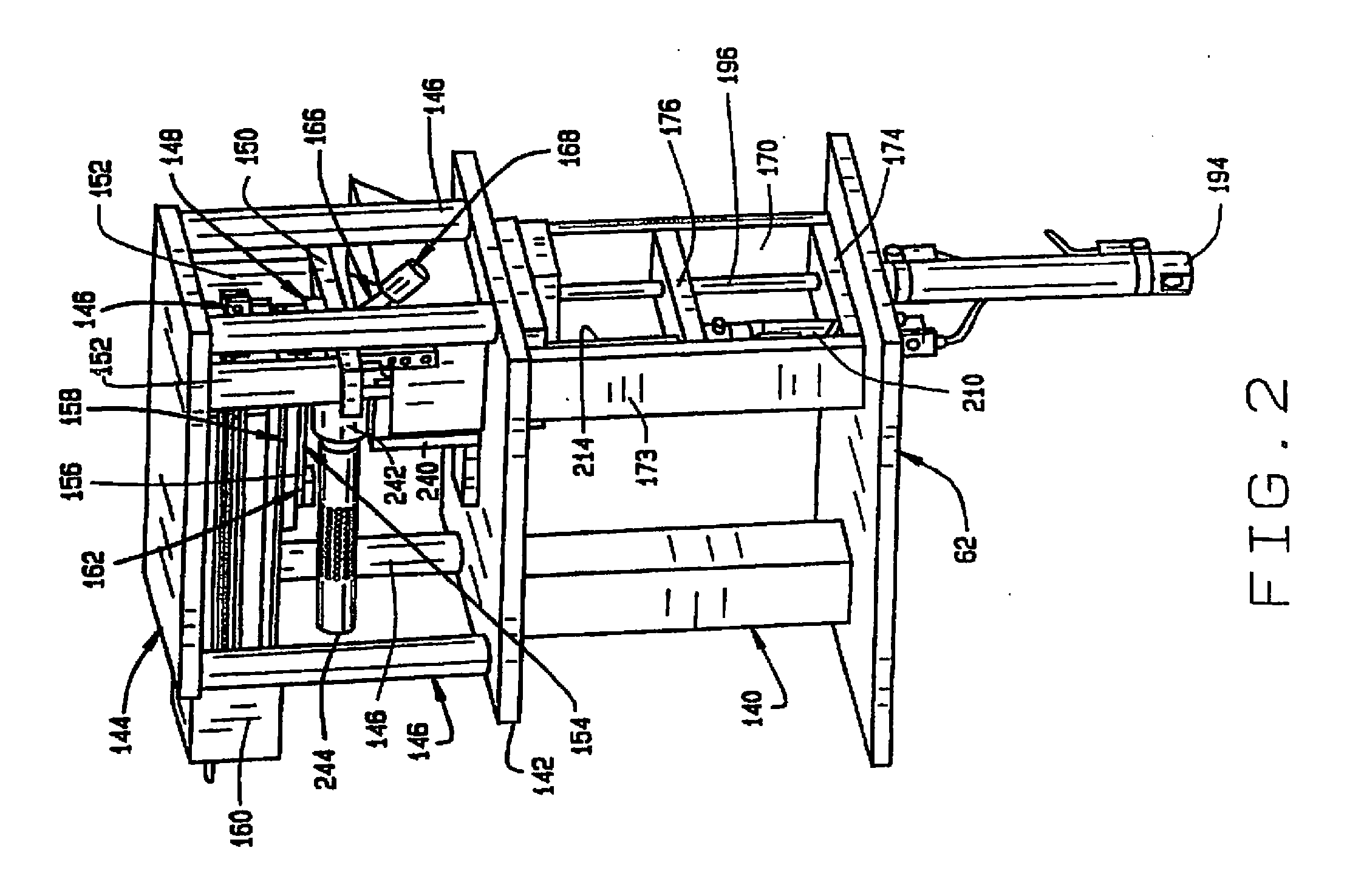

High throughput screening of fatty acid composition

InactiveUS20070048872A1Process can be speededEasy to sampleBiological testingFatty-oils/fats productionHigh-Throughput Screening MethodsAdemetionine

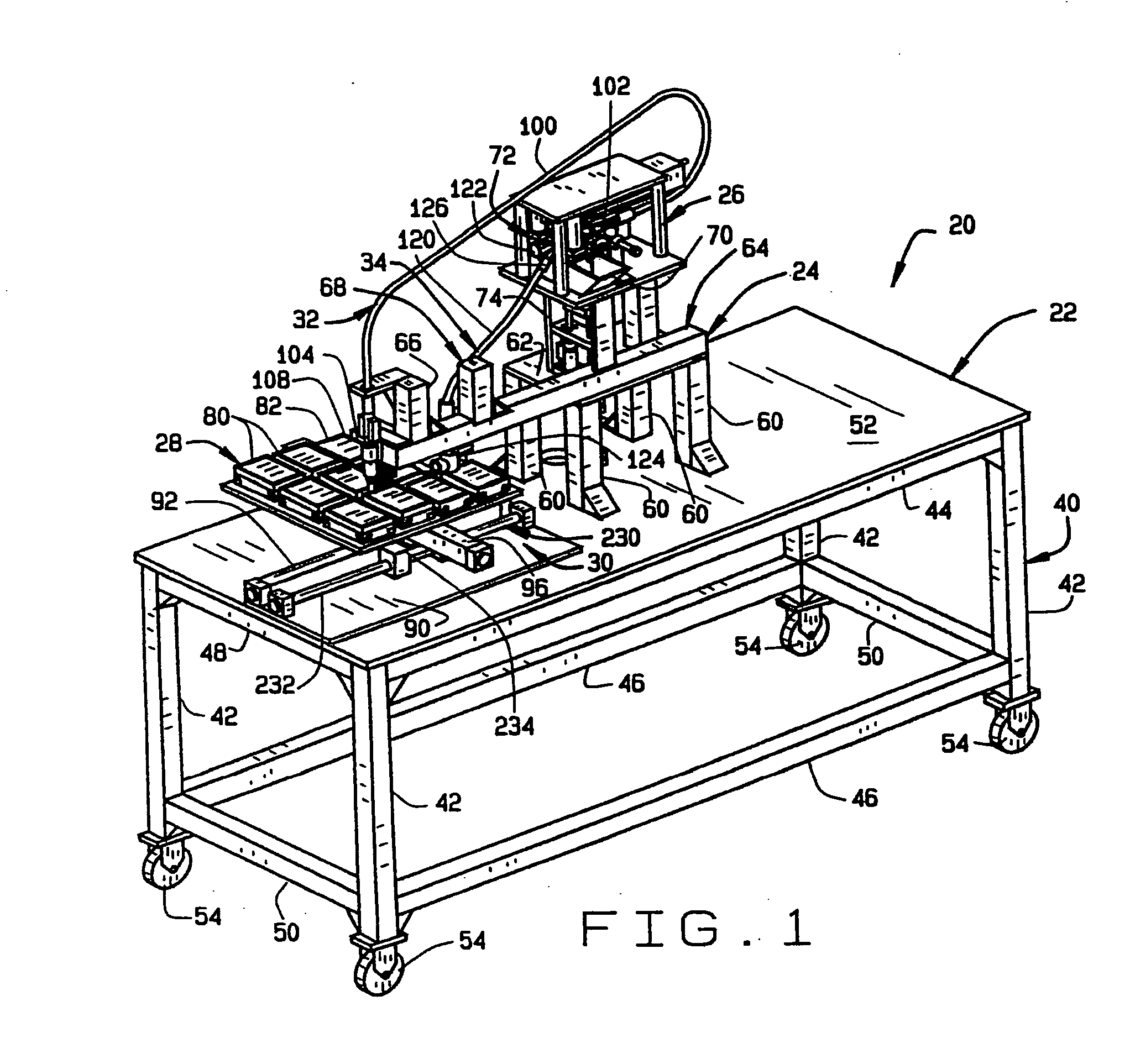

A method for the high throughput screening of fatty acid characteristics in seeds is provided. The method comprises feeding seeds individually to a sampling station; removing a sample from the seed in the sampling station; conveying the sample to a compartment in a sample tray; converting extracted oil from the sample in the sample tray to form a mixture of fatty acid methyl esters; and analyzing the mixture of fatty acid methyl esters from the sample to determine the fatty acid profile of the corresponding seed.

Owner:MONSANTO TECH LLC

Elimination of trans-unsaturated fatty acid compounds by selective adsorption with zeolites

InactiveUS6229032B1Low yieldLow costFatty oils/acids recovery from wasteFatty acid hydrogenationPartial hydrogenationDouble bond

A novel process for the selective elimination of fatty acid compounds containing carbon-carbon double bonds in trans configuration from a substrate containing cis- and trans-isomers of said fatty acid compounds, by selective adsorption by a microporous zeolite material is disclosed. The pore size and shape of usable zeolite materials enable differentiation between cis- and trans-isomers of unsaturated fatty acid chains. The zeolite materials used have a selectivity ratio alphatrans / cis higher than 1.00; this ratio is defined based on the elution properties of cis and trans double bond containing fatty acid methylesters dissolved in n-hexane during a column chromatography experiment with the zeolite material as the stationary phase and n-hexane as the mobile phase. Besides selective adsorption of trans-unsaturated fatty acid compounds, simultaneous or subsequent total or partial hydrogenation of the double bonds in said compounds can be carried out while using the same or similar zeolite material, containing finely dispersed catalytic active metals. The majority of these catalytic active sites must be inside the pores.

Owner:K U LEUVEN RES & DEV

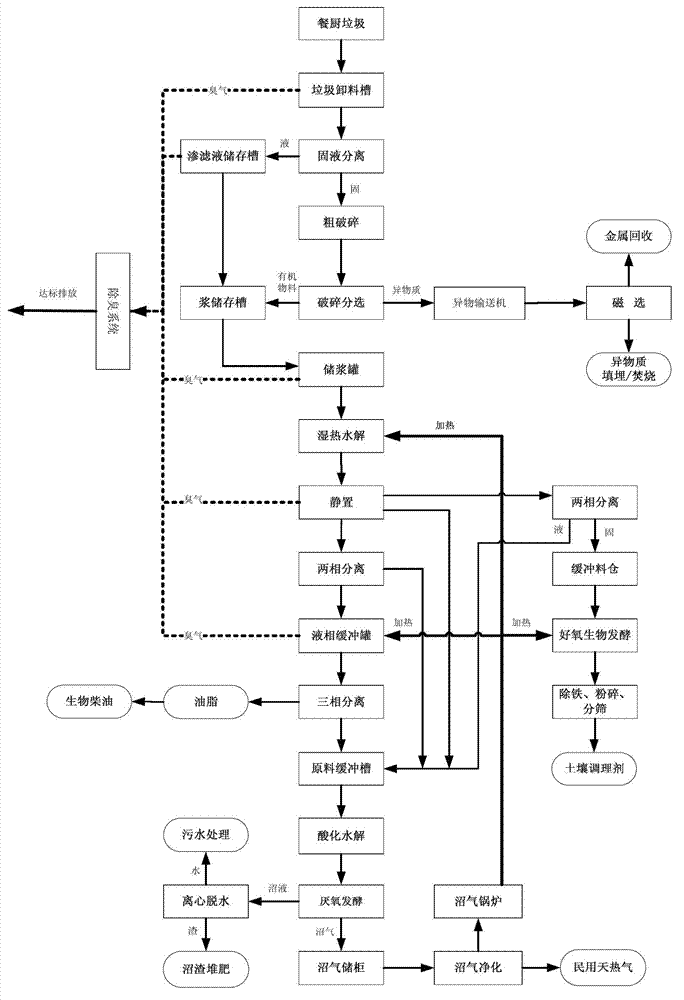

Harmless disposal method of kitchen garbage

InactiveCN102921704AShorten the processing chainPromote engineering applicationSolid waste disposalFurniture waste recoveryOil and greaseEconomic benefits

The invention relates to a harmless disposal method of kitchen garbage, which comprises the following steps of: (1) pretreatment: after unloading the kitchen garbage, performing solid-liquid separation, rough crushing, crushing and sorting and performing magnetic separation, and recycling metal substances mixed in the kitchen garbage; (2) hydrothermal hydrolysis: after the pretreatment, adopting the hydrothermal hydrolysis to fully inactivate viruses and bacteria in the kitchen garbage, separating out animal and vegetable fatty oil from the kitchen garbage, and hydrolyzing organic materials at the same time; (3) using the fatty oil obtained in the step (2) as an industrial fatty oil material or further performing deep processing to obtain fatty acid methyl ester or biodiesel; mixing and proportioning the pasty organic materials and then conveying into an anaerobic fermentation system; and conveying large granular organic materials into an aerobic biological fermentation device. The method provided by the invention realizes harmless disposal of the kitchen garbage mainly by the pretreatment and the hydrothermal hydrolysis process, increases the conversion rate of biological energy of the kitchen garbage and increases the economic benefit of kitchen garbage recycling products.

Owner:CHINA URBAN CONSTR DESIGN & RES INST CO LTD +2

Production method of biodiesel oil using high acid ralue animal and vegetable grease

InactiveCN1556174AAchieve cycleAchieve recyclingBiofuelsLiquid hydrocarbon mixture productionOil and greaseAlcohol

A process for preparing the biological diesel oil from the animal fat or vegetative oil with high acid number includes esterifying by glycerine under existance of strong acid catalyst, distilling in azeotropic solvent for removing water, mixing with methanol, transesterifying reacting to remove glycerine, water washing, and low-temp treating for removing high-smelting-point substances to obtain methyl ester of fatty acid, which is just the biological diesel oil.

Owner:INST OF OIL CROPS RES CHINESE ACAD OF AGRI SCI

Branched, substantially unsaturated fatty alcohol sulfates

Branched, substantially unsaturated fatty alcohol sulfates are produced by a process which comprises the steps of: (a) dimerizing unsaturated C16-22 fatty acid to form a dimer fraction and a monomer fraction comprised of branched, substantially unsaturated fatty acids and straight chain saturated fatty acids, (b) removing the monomer fraction from the dimerization step, (c) converting the branched, substantially unsaturated fatty acids from step (b) into the corresponding fatty acid methyl esters, (d) hydrogenating the branched, substantially unsaturated fatty acid methyl esters with the double bonds intact to form the corresponding branched, substantially unsaturated fatty alcohols and (e) sulfating and neutralizing the branched, substantially unsaturated fatty alcohols. The fatty alcohol sulfates thus produced exhibit improved performance properties and greater oxidative stability than standard unsaturated fatty alcohol sulfates.

Owner:COGNIS DEUT GMBH & CO KG

Method for producing epoxy plasticizer using waste grease

InactiveCN101070510AHarm reductionReduce dosageFatty oils/acids recovery from wasteFatty acid esterificationEpoxyDistillation

Owner:江苏向阳科技有限公司

Process for the preparation of fatty acid methyl ester from triglyceride oil by transesterification

InactiveUS7666234B2Speed up the processFatty oils/acids recovery from wasteFatty acid esterificationTransesterificationTriglyceride

The present invention relates to an improved process for the preparation of biodiesel from triglyceride oils through transesterification, particularly the fatty acid methyl ester of oil mechanically expelled from whole seeds of Jatropha curcas, a plant with potential for cultivation on wastelands in India and other countries, all unit operations being carried out at ambient temperature.

Owner:COUNCIL OF SCI & IND RES

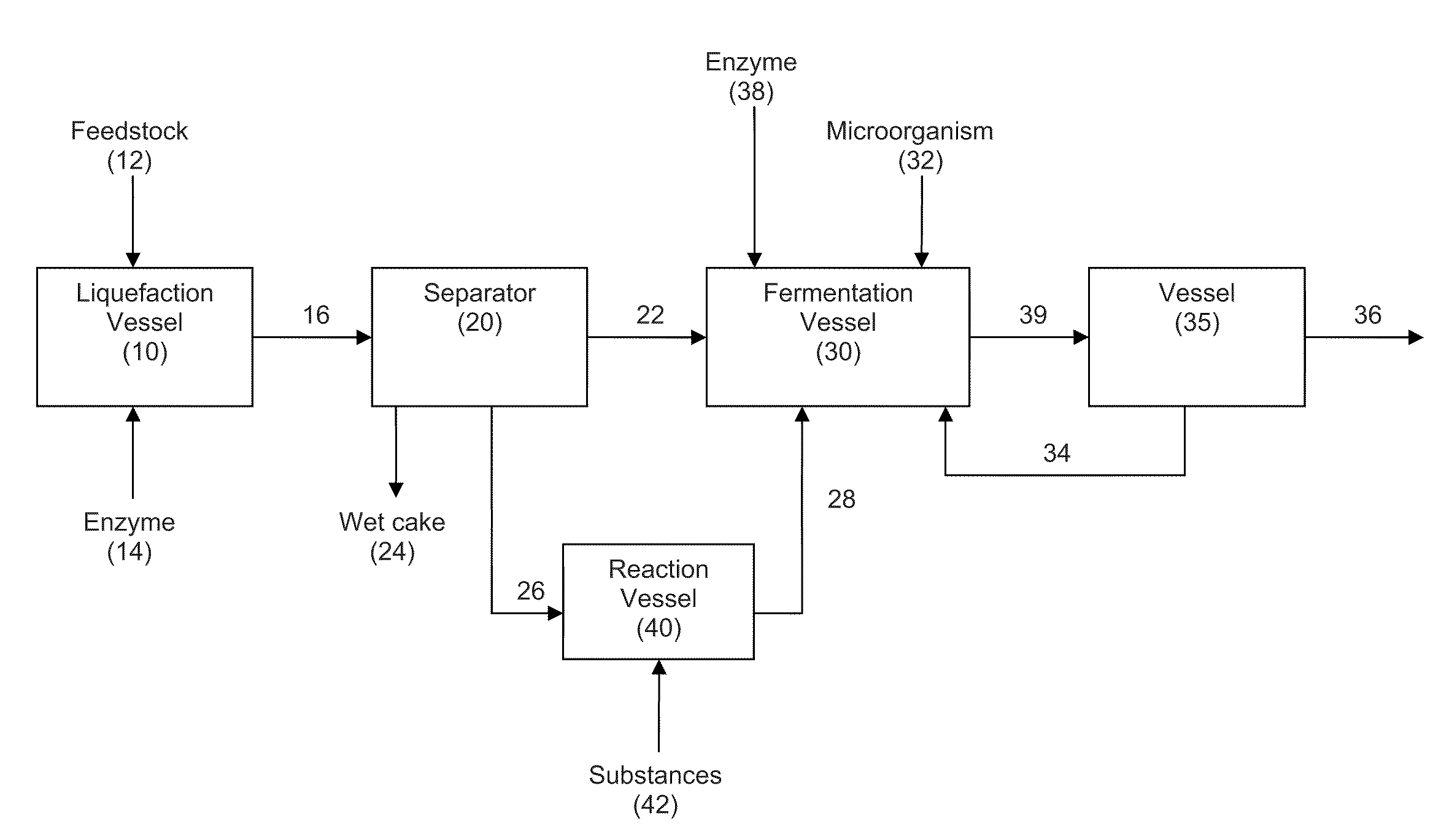

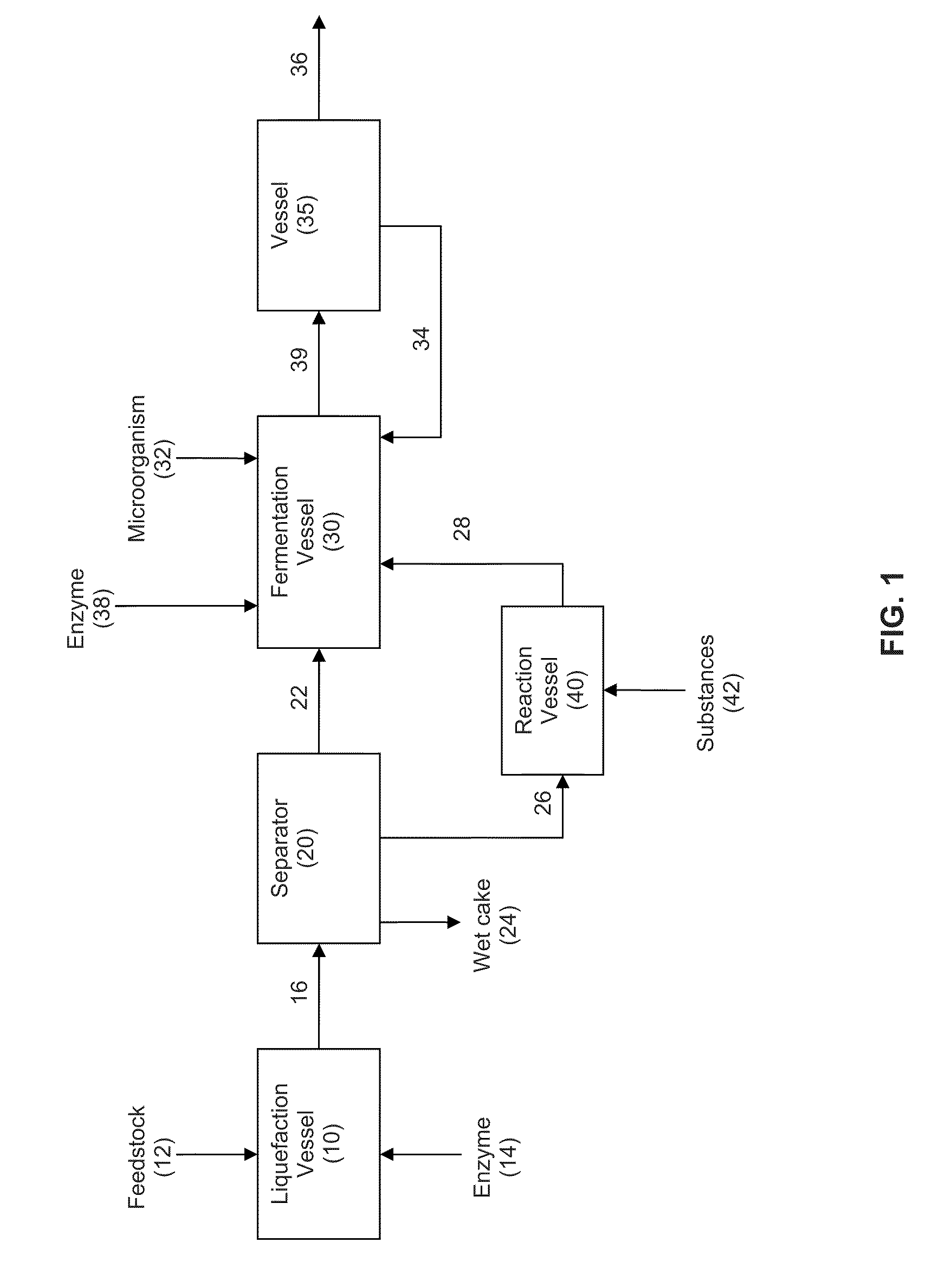

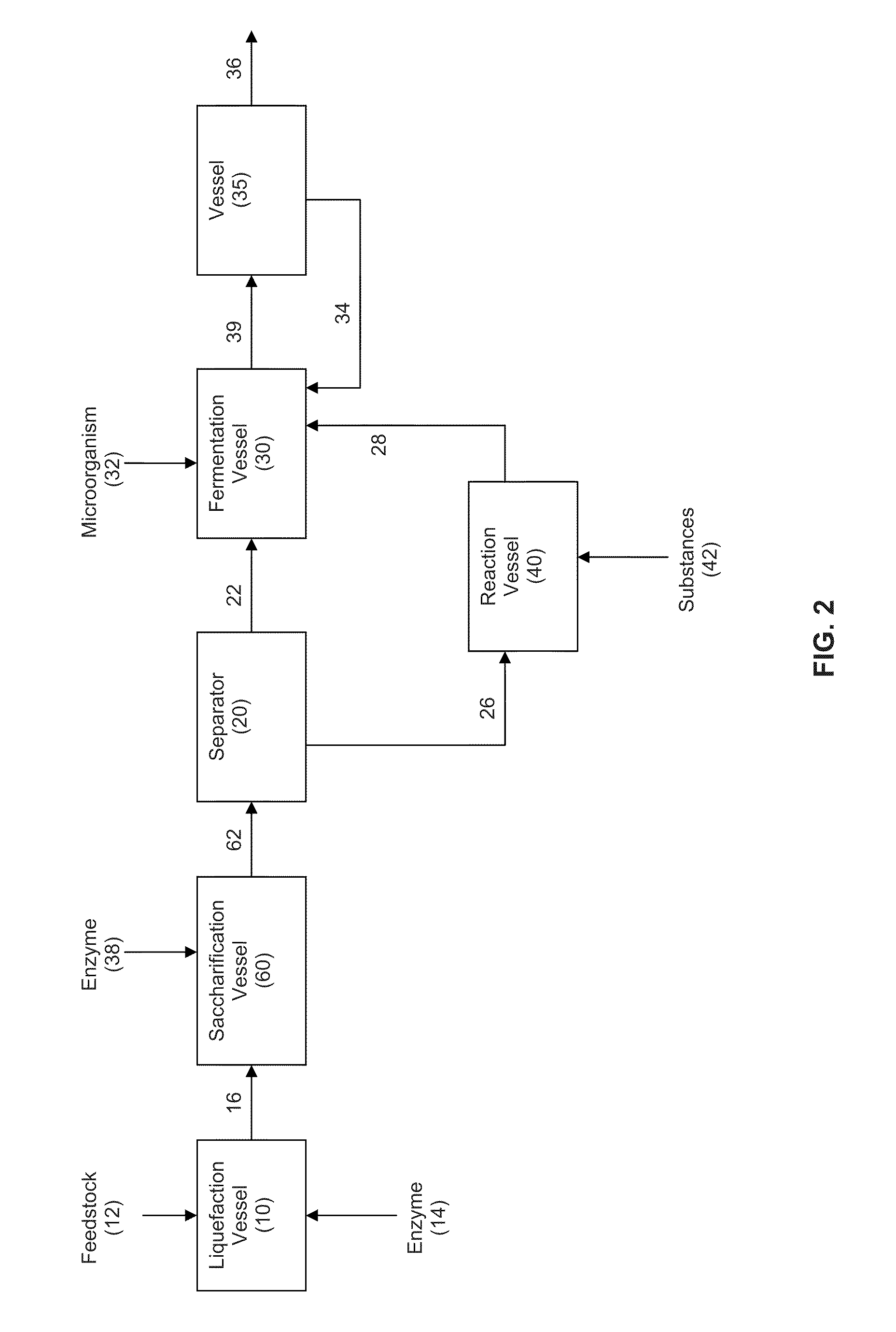

Extraction solvents derived from oil for alcohol removal in extractive fermentation

ActiveUS20110312044A1Reduce the amount requiredReduce decreaseFatty oils/acids recovery from wasteOxygen-containing compound preparationSolventFatty alcohol

In an alcohol fermentation process, oil derived from biomass is chemically converted into an extractant available for in situ removal of a product alcohol such as butanol from a fermentation broth. The glycerides in the oil can be chemically converted into a reaction product, such as fatty acids, fatty alcohols, fatty amides, fatty acid methyl esters, fatty acid glycol esters, and hydroxylated triglycerides, and mixtures thereof, which forms a fermentation product extractant having a partition coefficient for a product alcohol greater than a partition coefficient of the oil of the biomass for the product alcohol. Oil derived from a feedstock of an alcohol fermentation process can be chemically converting into the fermentation product extractant. The oil can be separated from the feedstock prior to the feedstock being fed to a fermentation vessel, and the separated oil can be chemically converted to a fermentation product extractant, which can then contacted with a fermentation product comprising a product alcohol, whereby the product alcohol is separated from the fermentation product.

Owner:GEVO INC

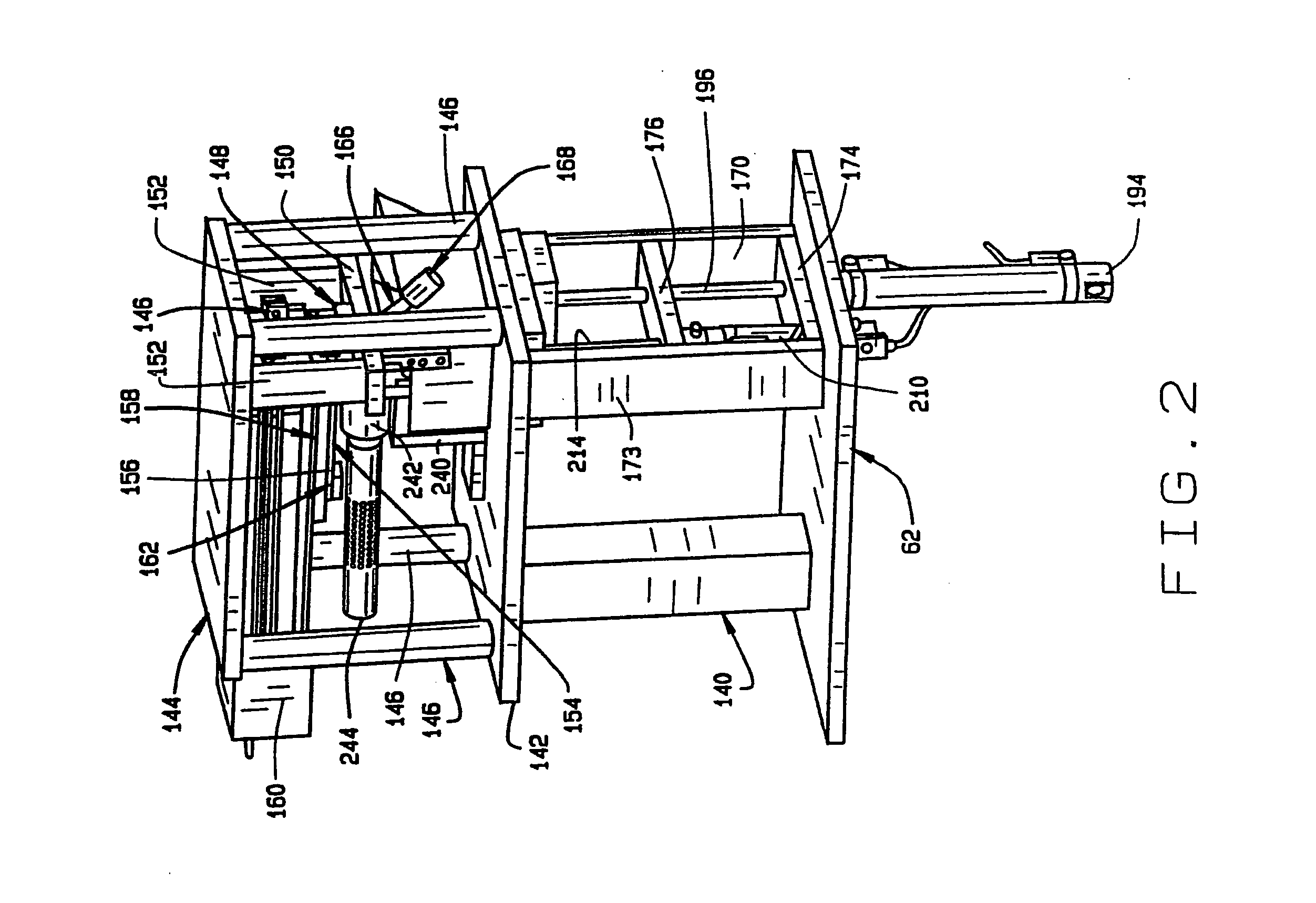

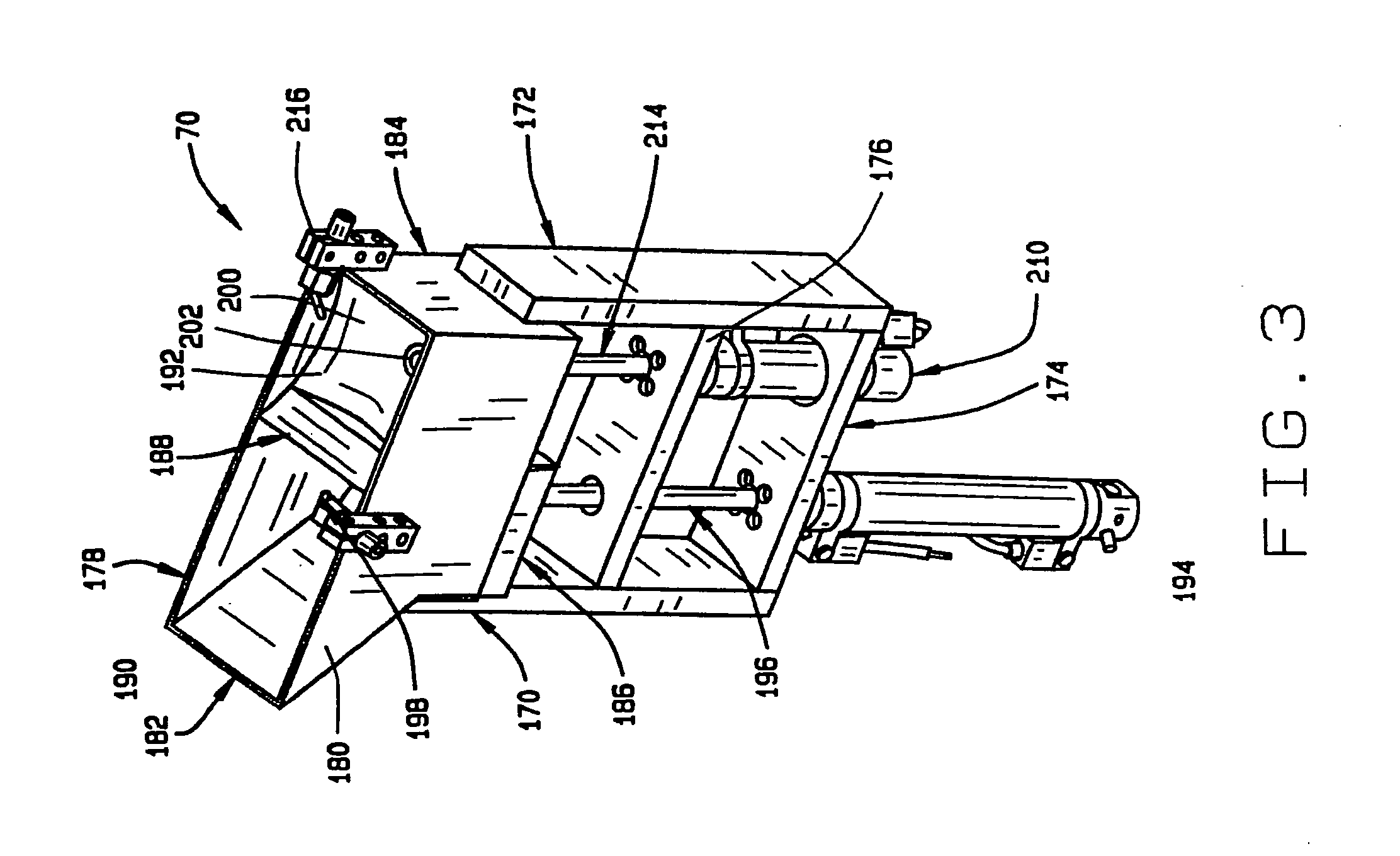

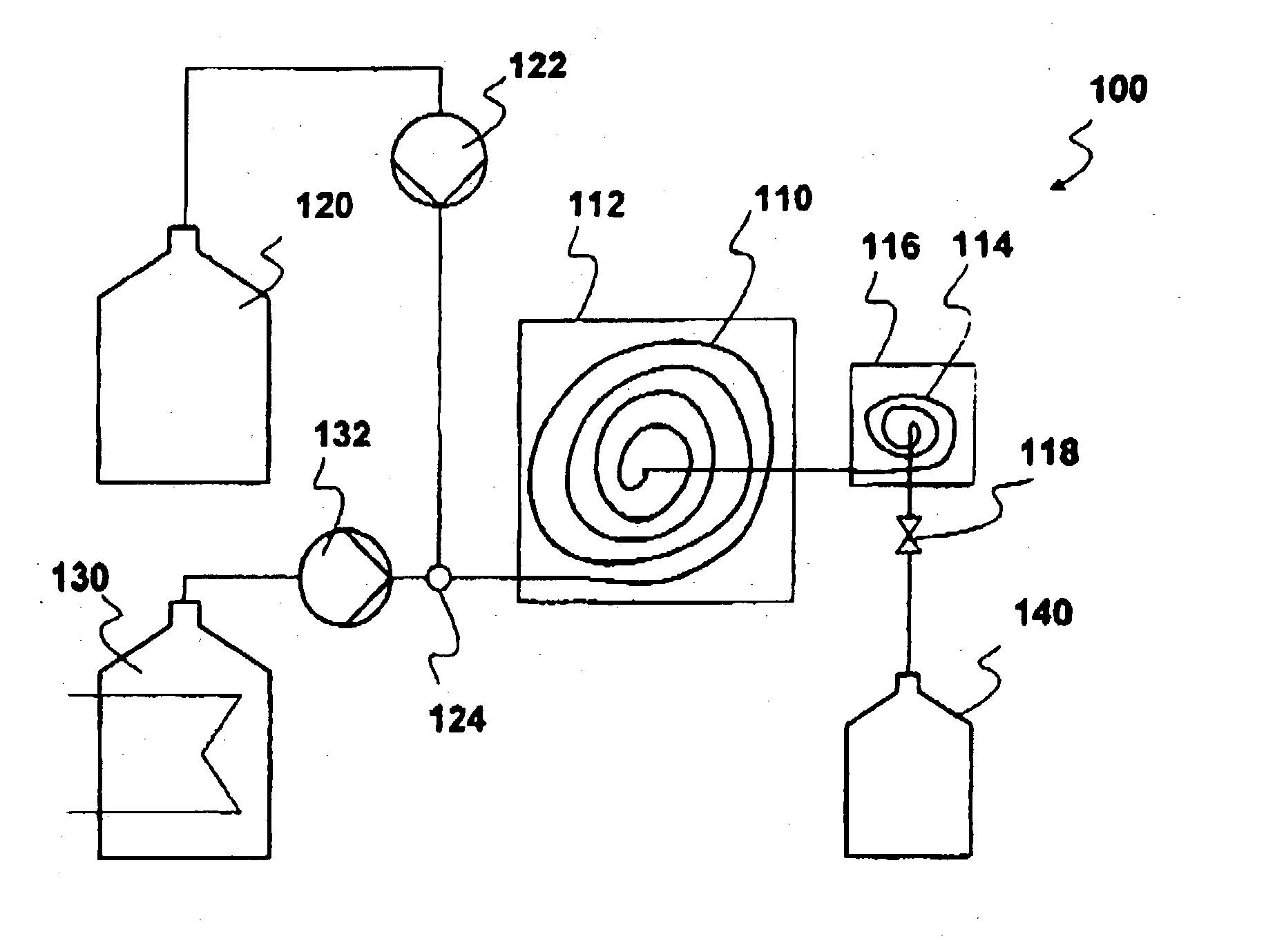

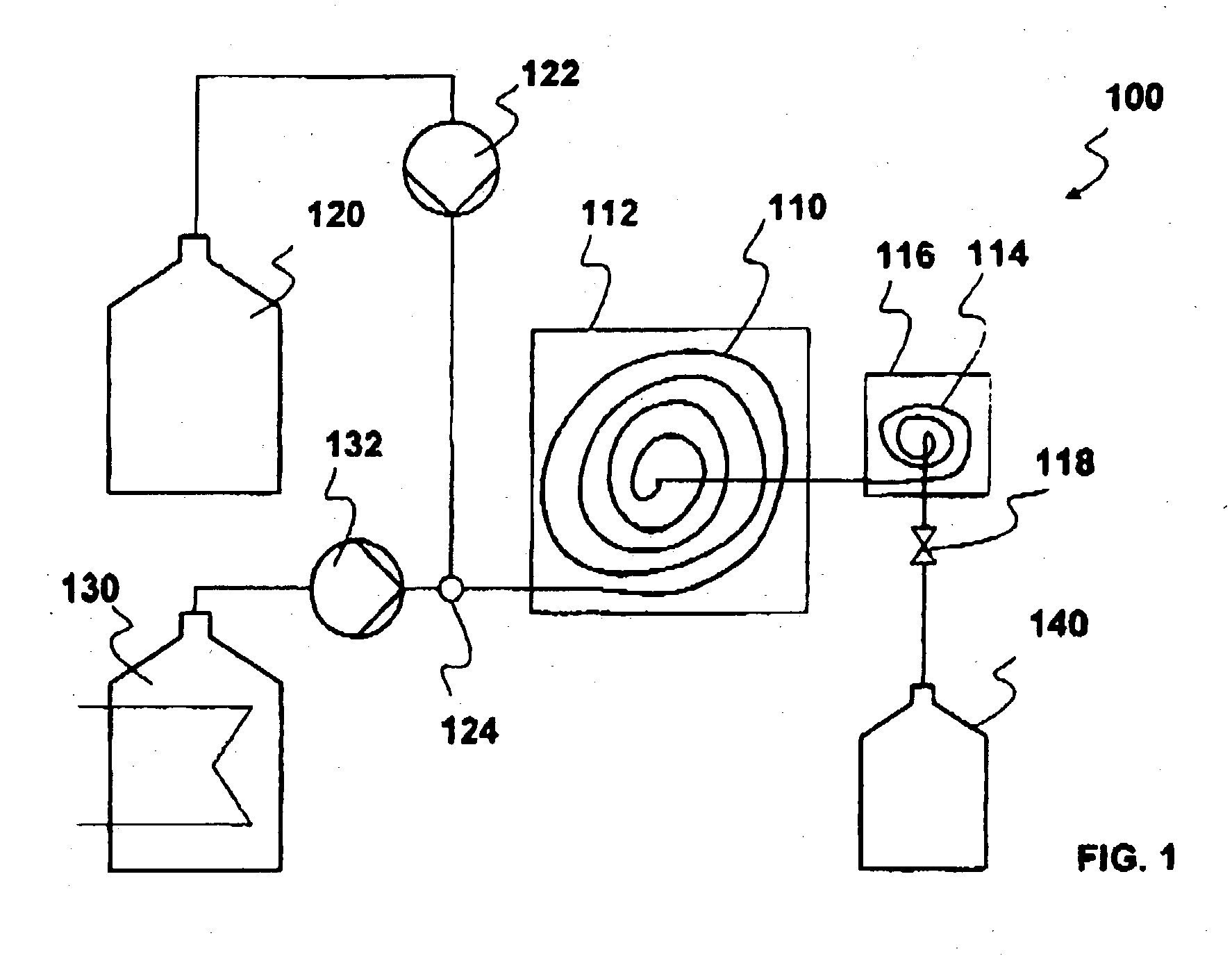

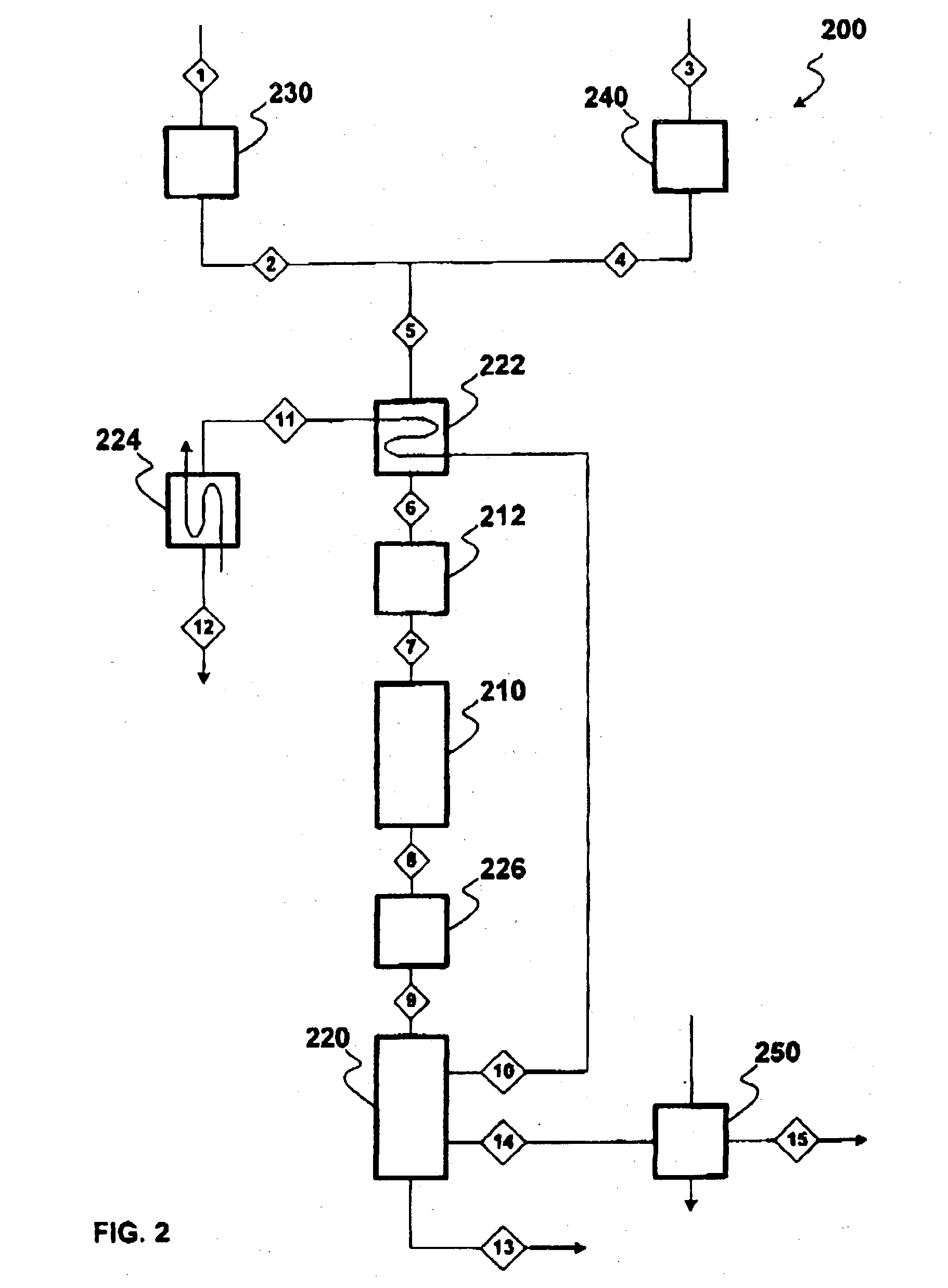

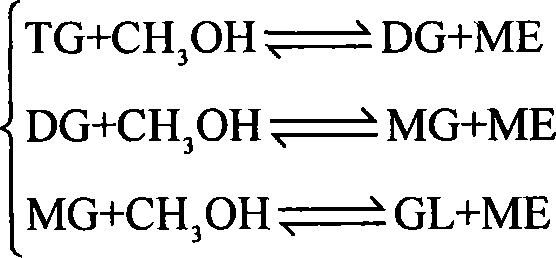

Continuous transesterification process

InactiveUS20030229238A1Increase shearFacilitate transesterification reactionFatty oils/acids recovery from wasteFatty acid esterificationTransesterificationTG - Triglyceride

A process for converting at least one triglyceride feedstock to at least one fatty-acid methyl ester product is disclosed. The process includes a continuous, plug-flow environment with a single-pass residence time as low as about 10 seconds, and a conversion of at least 70 percent.

Owner:ORBITEK +1

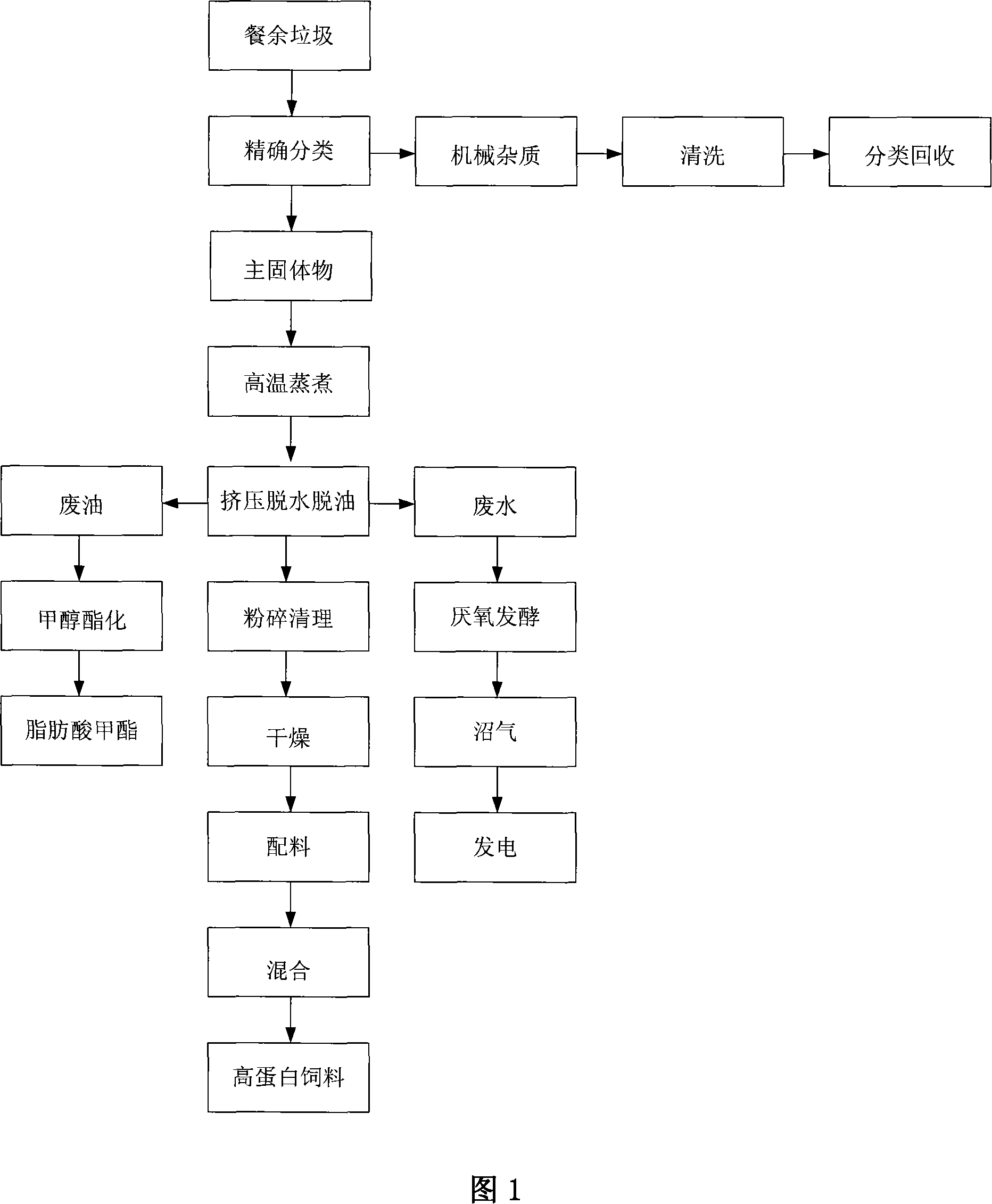

Method for comprehensive processing garbage of food and recycling to use

ActiveCN101130194AAccurate classificationRealize resource processingFood processingSolid waste disposalWaste oilFatty acid methyl ester

The invention discloses a synthetic processing recycling reusing method of residual dining rubbish, which comprises the following steps: cutting to remove package bag, waste table cloth and plastic bag; vibrating and sieving to pick chopstick; using magnet to attract bottle cap; washing the separated materials mechanically; collecting splitly; boiling main solid material under 130-150 deg. c for 30-60 min; squeezing the boiled material to separate solid from liquid; proceeding oil-water separation for the squeezed water and oil through centrifuging; doing anaerobic ferment for the waste water to produce methane; esterifying waste oil and carbinol to prepare fatty acid methyl ester. The invention eliminates secondary pollution during environmental protection and disposal, which is a reasonable, industrial, scaling, non-harmful, resourcing disposing pattern for the dining rubbish with good applying prospect.

Owner:鲁控环保(苏州)有限公司

High throughput screening of fatty acid composition

ActiveUS20120180386A1Process can be speededEasy to sampleSpectrum investigationSeed and root treatmentHigh-Throughput Screening MethodsSolvent

A method of accumulating a quantity of seeds having a desired fatty acid characteristic is provided. The method includes removing a sample from each seed in a population of seeds while maintaining the germination viability of the seeds; contacting each sample with a solvent to form a mixture comprising fatty acid methyl esters; analyzing the mixture of fatty acid methyl esters from each sample to determine the fatty acid profile of the corresponding seed; selecting seeds having at least one desired fatty acid characteristic based on the analysis of the samples removed from the seeds; cultivating plants from the selected seeds; recovering seeds from the cultivated plants, wherein the recovered seeds are a subsequent generation of the selected seeds; and repeating the operations for one or more generations of the recovered seeds to thereby accumulate the quantity of seeds having the desired fatty acid characteristic.

Owner:MONSANTO TECH LLC

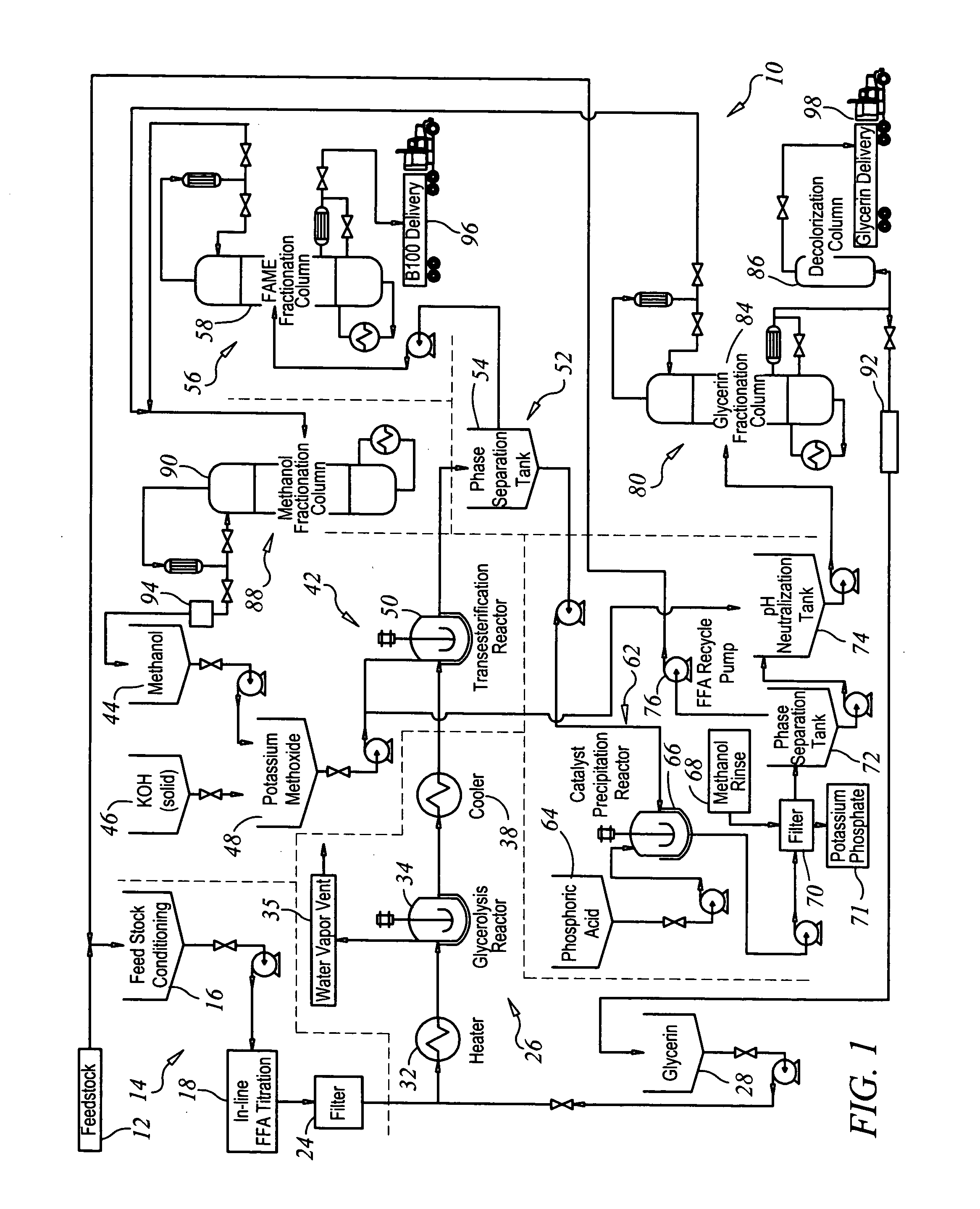

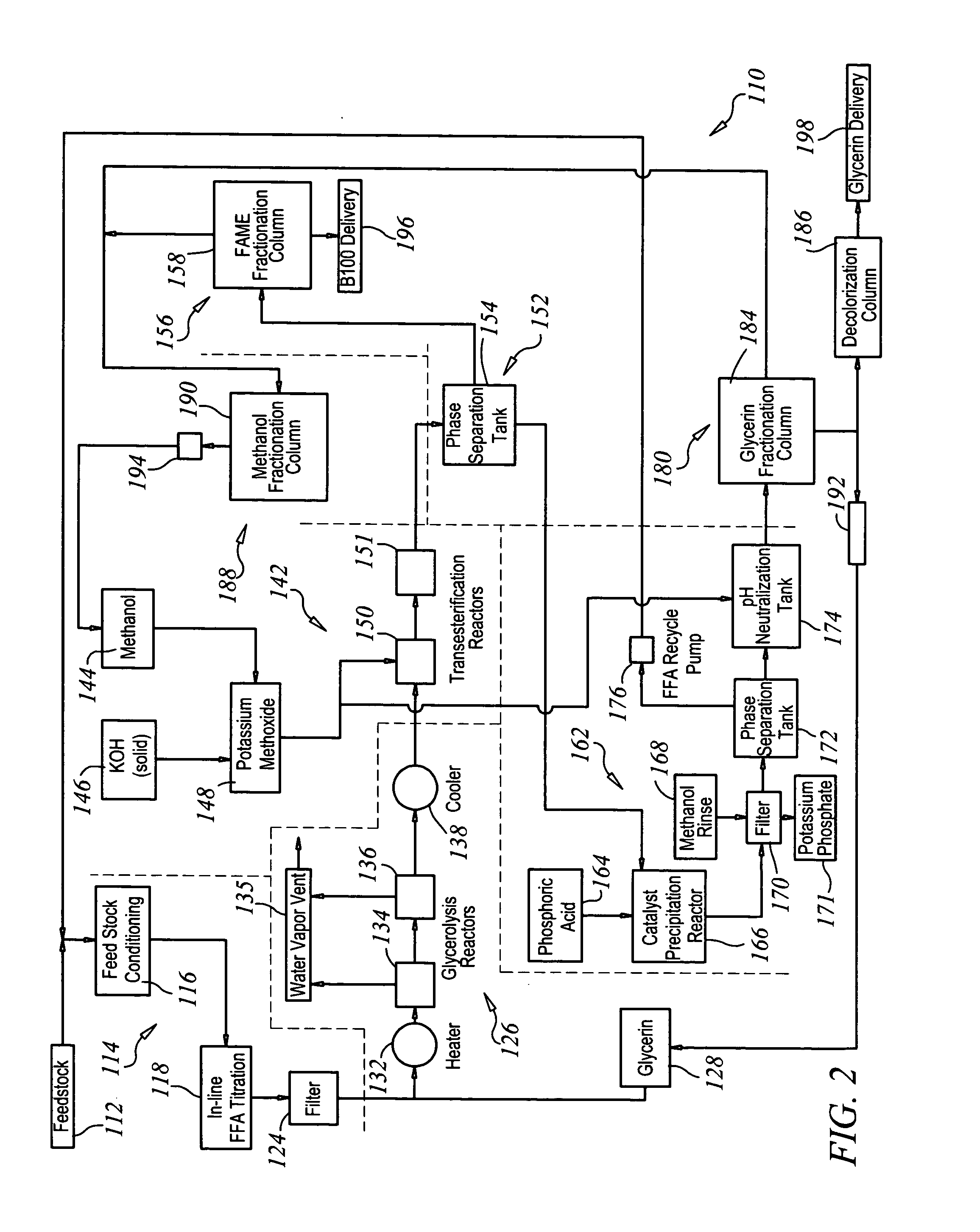

Production of biodiesel and glycerin from high free fatty acid feedstocks

ActiveUS20070277429A1Increase wasteLow costFatty oils/acids recovery from wasteFatty acid esterificationGlycerolGlycerolysis

A system and method for converting a high free fatty acid grease feedstock to biodiesel. The process comprises a glycerolysis reaction to convert free fatty acids to glycerides and a base catalyzed transesterification reaction to produce fatty acid methyl esters and glycerin in the absence of solvents. In preferred embodiments, both glycerin and methanol are recycled. The process can process a feedstock containing up to 100 percent free fatty acid content to produce biodiesel and glycerin with minimal waste generation.

Owner:REG SENECA LLC +1

Method for preparing biodiesel under catalysis of ionic liquid

InactiveCN102031202ALow costHigh activityFatty acid esterificationBiofuelsAlcoholReaction temperature

The invention discloses a method for preparing biodiesel under catalysis of ionic liquid. The method comprises the following steps of: mixing the ionic liquid, short-chain alcohol and free fatty acid or high-acid-value oil and fat to perform a reaction at a certain temperature; and synthesizing fatty acid methyl ester, namely the biodiesel or synthesizing the biodiesel by a two-step method. The conventional ionic liquid is low in cost and the activity of the ionic liquid is obviously improved within the limited reaction temperature range, so the ionic liquid can be separated, recovered and reused easily after the reaction is finished. The method has the characteristics of simple catalytic system, reusability and simple process.

Owner:XISHUANGBANNA TROPICAL BOTANICAL GARDEN CHINESE ACAD OF SCI

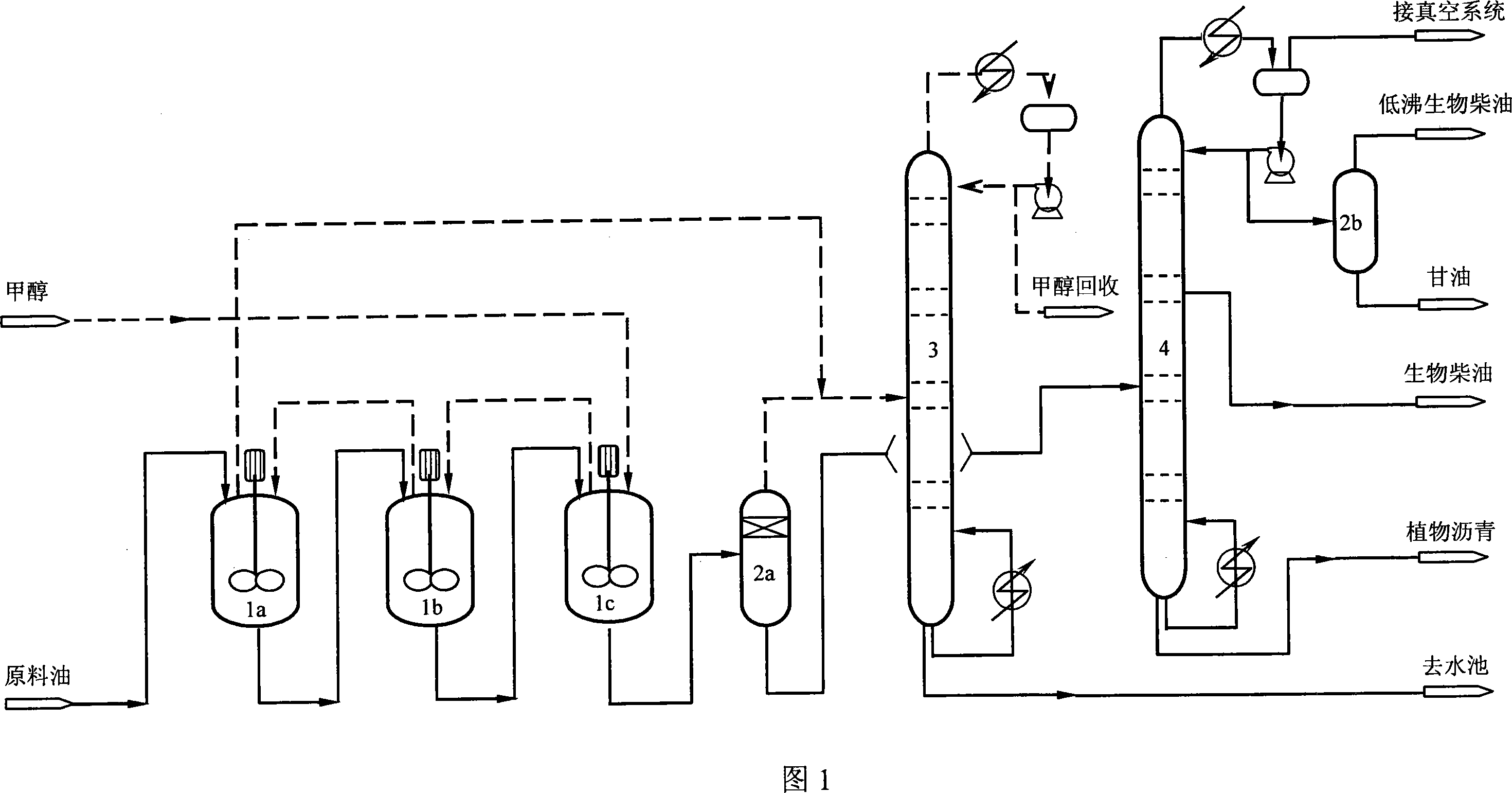

Solid catalysis process of preparing biodiesel oil continuously with high acid value material

InactiveCN101067091AHigh activityLow costPhysical/chemical process catalystsFatty acid esterificationOil and greaseRenewable energy technology

The present invention is solid catalysis process of preparing biodiesel oil continuously with high acid value material, and belongs to the field of grease chemistry and regenerable energy source technology. The process includes following four steps: material pre-treating, reaction, methanol rectifying recovery and vacuum rectification of fatty acid methyl ester; and features the high acid value material, such as acidified oil, waste edible oil, etc. The present invention has the advantages of low material cost, high activity and easy separation of the solid catalyst, high esterification efficiency, high product purity, high yield, less waste, no pollution, etc.

Owner:TSINGHUA UNIV +1

Method for preparing alkane by high fatty acid ester

InactiveCN101597508ASimple preparation processLow reaction temperatureLiquid hydrocarbon mixture productionHydrocarbonsAlkaneReaction temperature

The invention discloses a method for preparing alkane by high fatty acid ester, which is characterized in that liquid-phase catalytic hydrogenation deoxidation is carried out on the high fatty acid ester to obtain the alkane. The high fatty acid ester, catalyst and solvent are added into a reactor, then hydrogen is charged into the reactor with reaction pressure at 1-10MPa and temperature at 210-320 DEG C, and the reaction time is 4-7h; the high fatty acid ester is fatty acid methyl ester containing 8-22 carbon atoms or fatty acid ethyl ester containing 8-22 carbon atoms; catalyst uses a multi-wall carbon nanotube as carrier and 2-10% of palladium in percentage by weight as active component ; the solvent is one of n-hexane, n-heptane, n-octane, dodecane, or hexadecane. In the invention, the preparation process is simple, the reaction temperature is low, the usage of solvent is less, the combustion high value of the target product is high, and the catalyst can be recycled.

Owner:ZHEJIANG UNIV

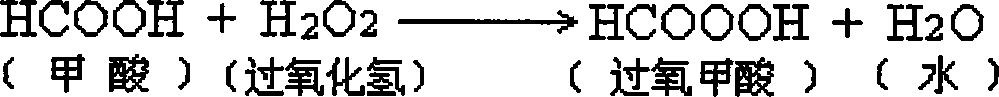

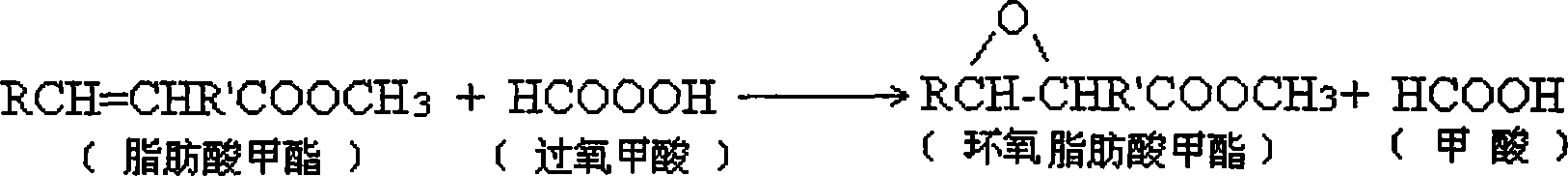

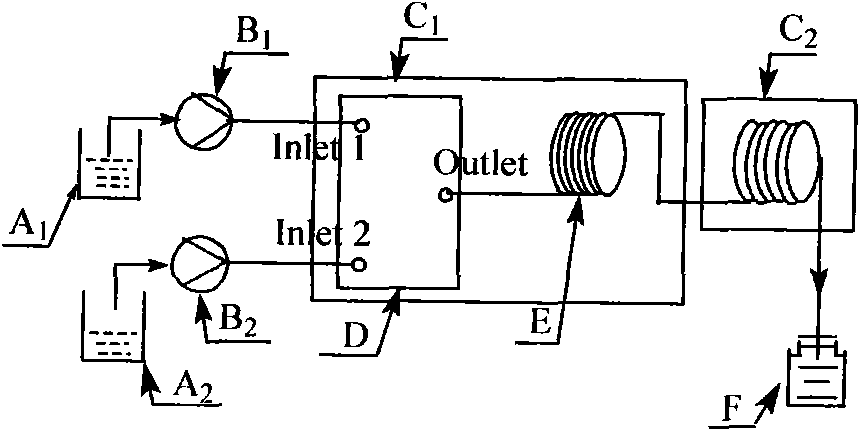

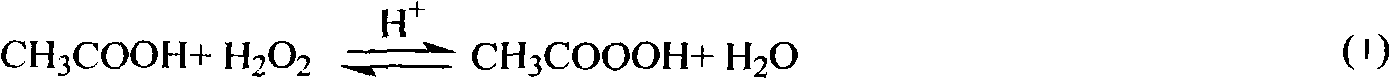

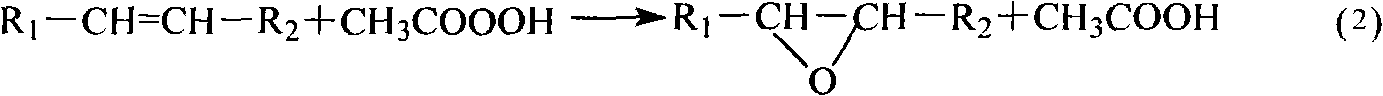

Method for preparing epoxy fatty acid methyl ester

The invention relates to a method for preparing epoxy fatty acid methyl ester. The method comprises the following specific steps of: mixing hydrogen peroxide and formic acid or acetic acid; adding a catalyst and a stabilizer into mixed liquor; pumping fatty acid methyl ester into a microstructure reactor; separating the epoxy fatty acid methyl ester from a reacted material; introducing a reaction product into a separator; standing to delaminate lower layer water solution; washing an upper layer organic phase with water; and drying the washed upper layer organic phase to obtain the epoxy fatty acid methyl ester. In the entire process of the method, a strong exothermic reaction is performed, and a peroxy acid synthesis reaction is performed together with an epoxidation reaction, so that the epoxy fatty acid methyl ester is synthesized in situ at one time. The production process has the advantages of high safety, low energy consumption, continuity and high product quality by adopting micro-reaction production technology of the invention.

Owner:NANJING UNIV OF TECH

Method for separating saturated and unsaturated fatty acid esters and use of separated fatty acid esters

InactiveUS20050232956A1Easily robust processEasily scalable processFatty oils/acids recovery from wasteCosmetic preparationsAlcoholUnsaturated fatty acid ester

A method for treating a fatty acid methyl ester. The method can include mixing the fatty acid methyl ester with an amount of urea and an amount of alcohol to make (i) a urea / fatty acid methyl ester ratio of from about 0 wt / wt to about 1 wt / wt and (ii) an alcohol / fatty acid methyl ester ratio of from about 4 vol / wt to about 8 vol / wt, heating the fatty acid methyl ester / urea / alcohol mixture to a temperature at which a homogenous mixture is obtained, cooling the fatty acid methyl ester / urea / alcohol mixture to a temperature where a solid phase and a liquid phase are formed, and separating the solid phase from the liquid phase.

Owner:PURDUE RES FOUND INC

Method of making biodiesel oil by subcritical methanol phase solid acid alkali catalytic oil fat ester exchange

InactiveCN1718679ASolve interphase mass transfer problemsShort reaction timeBiofuelsLiquid hydrocarbon mixture productionOil and greaseGlycerol

A process for preparing biologic diesel oil from plant oil and methanol includes such steps as proportionally adding plant oil and methanol into high-pressure reactor, adding solid catalyst, reaction, separating out catalyst, laying aside for layering, distilling the mixture of methanol and methyl ester of fatty acid on upper layer to obtain methyl ester of fatty acid (biologic diesel oil ) and distilling the mixture of methanol and glycerine on lower layer to obtain glycerine.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Highly-efficient lubricant for drilling fluid

InactiveCN101735778AImprove the lubrication effectIncrease the extreme pressure valueDrilling compositionPolyesterPhosphate

The invention discloses a highly-efficient lubricant for a drilling fluid. The highly-efficient lubricant comprises the following components in percentage by weight: 10 to 40 percent of white oil, 30 to 70 percent of fatty acid methyl ester or methyl oleate, 5 to 20 percent of polyester, 2 to 8 percent of organic phosphate, 1 to 6 percent of oilness extreme-pressure additive, 0.5 to 2 percent of emulsifier OP-10 and 0.5 to 2 percent of span-80. The invention also discloses a method and steps for preparing the highly-efficient lubricant for the drilling fluid. The highly-efficient lubricant can enhance the lubricating property of the drilling fluid and increase an extreme pressure value of the drilling fluid, and is suitable for the demand of ordinary drilling and use in a high-difficulty highly deviated directional well and a horizontal well.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Method for producing epoxy plasticizer dirty oil and vegetable and animal waste oil

A method for producing epoxy plasticizer from refused animal and vegetable oil is carried out by adding refused oil 97-99.8wt% and porous carrier solid acid 0.2-3wt% into reactor, inducing into gas-phase methanol at 95-130degree, agitating for 1-4hrs, esterification reacting, separating out solid acid, adding liquid 70-80wt%, methanol 15-25wt% and solid alkali catalyst 1-5wt% into reactor, agitating at 50-65degree and normal pressure for 0.5-2hrs, separating out to obtain aliphatic acid methoxy-carbonyl, adding hydrogen peroxide 25-5wt%, methane acid 2.5-10wt% and sodium tripolyphosphate 0-1wt% into aliphatic acid methoxy-carbonyl 55-70wt%, agitating for 8-10hrs at 60+-5degree, reacting, separating out acid water, neutralizing, washing and dewatering to obtain the final product. It's simple, cheap and has less consumption.

Owner:江苏悦达卡特新能源有限公司

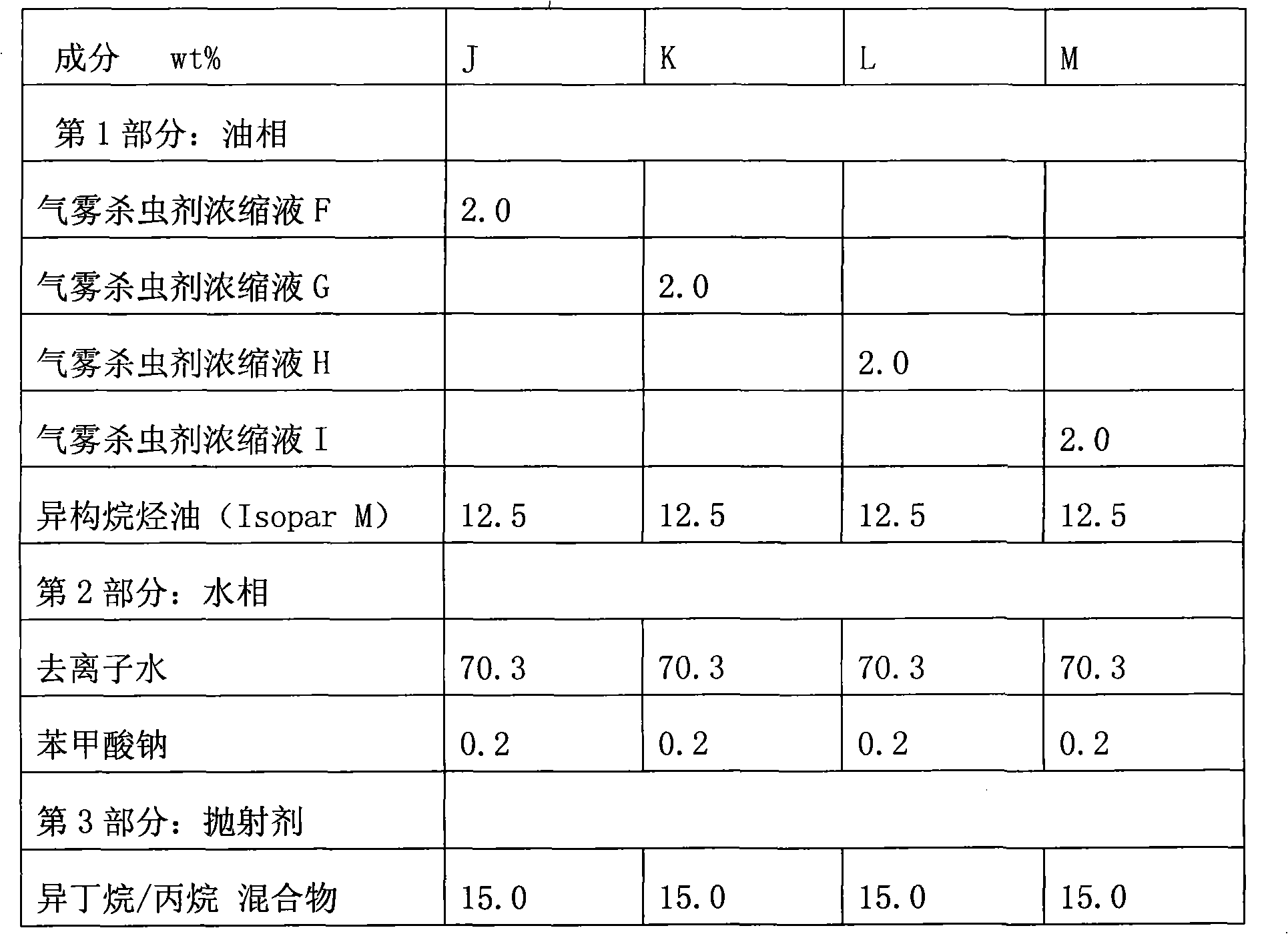

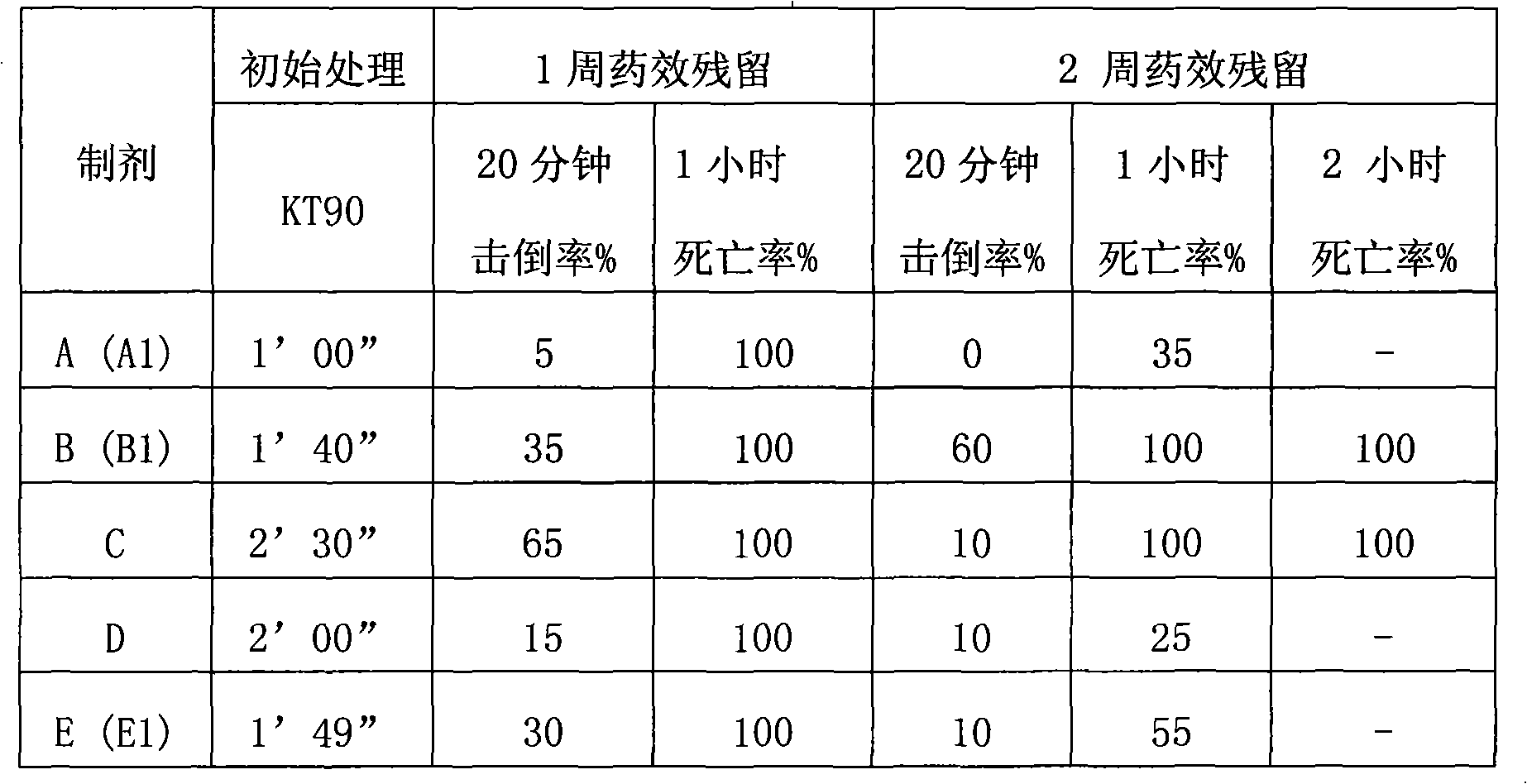

Insecticidal composition concentrated solution and method of use thereof

ActiveCN101406177ADelay drug resistanceLong-term control and prevention effectBiocideArthropodicidesAntioxidantSolvent

The invention discloses a concentrated solution for a pesticide composition and an application method thereof. An active ingredient of the concentrated solution for the pesticide composition is pyrethrins or pyrethroid, a solvent is fatty acid methyl ester or fatty acid ethyl ester, and an additive comprises a food-grade or natural antioxidant and an emulsifying agent. The concentrated solution for the pesticide composition can also comprise plant essential oil which is taken as a synergistic agent. The concentrated solution for the pesticide composition has the advantages that the concentrated solution for the pesticide composition is a pesticide composition with quick knockdown and long-acting effect; and the fatty acid methyl ester as the solvent is a low-volatility organic compound and a material with low maximum ozone generation activity, which reduces the harm of a pesticide to human beings and the environment. The concentrated solution for the pesticide composition forms an oil-in-water emulsifying preparation after the dilution to directly serve as a spraying agent for disinsectization application, or forms a water-in-oil demulsifying agent after being mixed with water and odorless gas to serve as an aerosol for disinsectization application. The concentrated solution for the pesticide composition can be used for the control of insect damage of winged insects and reptiles, indoor dust mites, head louses or body louses of human beings and so on, and the anthelminthic treatment of clothes, and can also be used as a sterilizing agent and a fungicide on a target object.

Owner:SICHUAN LOMON BIO TECH CO LTD +1

Process for non-catalytically producing biodiesel fuel without yielding by-product

InactiveUS20060288636A1Fatty oils/acids recovery from wasteFatty acid esterificationReaction temperatureFatty acid methyl ester

This invention provides a process for producing biodiesel fuel from vegetable or animal oils and fats or wastes thereof and methanol that does not use a catalyst and does not generate glycerin as a by-product. In this process, vegetable or animal oils and fats or wastes thereof are mixed with methanol, and a methanolysis reaction is carried out at a reaction temperature of between 370° C. and 500° C., a reaction pressure of between 20 MPa and 60 MPa, and a reaction period of between 4 minutes and 12 minutes without the use of a catalyst. This invention also provides biodiesel fuel that is mainly composed of fatty acid methyl esters, monoacylglycerol, and diacylglycerol.

Owner:INC ADMINISTRATIVE AGENCY NAT AGRI & BIO ORIENTED RES ORG

Resaturation of asphalt shingles

InactiveUS6495074B1Efficient use ofExtended service lifeRoof covering using tiles/slatesOther chemical processesAsphalt shingleEmulsion

A method of maintaining as well as restoring the condition of weathered asphalt shingles and strips which are applied to flat roofs, pitched roofs, or vertical walls. The process involves applying resaturant neat or as a water emulsion. Suitable resaturants include fatty acid methyl esters, petroleum distillates, and water emulsions thereof. The process restores the suppleness and softness of the weathered shingles or strip and adds about three years to the lifetime of the roof. The process may be repeated for additional lifetime extension.

Owner:SHINGLE LIFE INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com