Method for preparing epoxy fatty acid methyl ester

A technology of epoxy fatty acid methyl ester and fatty acid methyl ester, which is applied in the field of preparation of plasticizer epoxy fatty acid methyl ester, can solve problems such as low level of equipment and self-control, inability to realize continuous production, backward synthesis process, etc., to avoid Effects of by-product generation, good operability, and easy preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

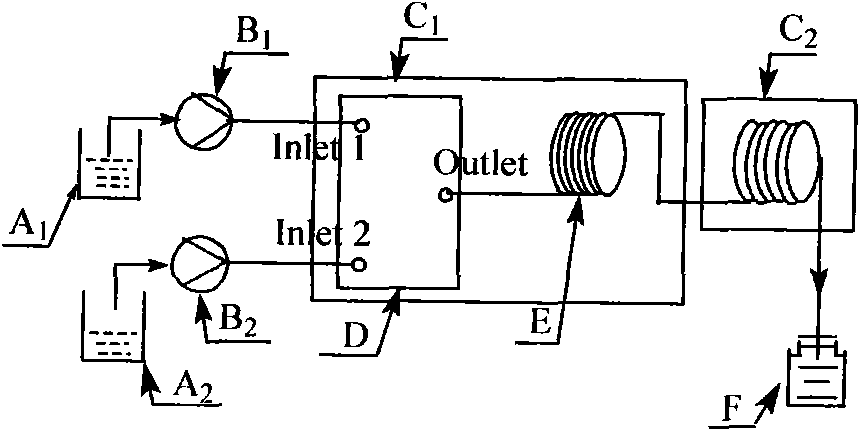

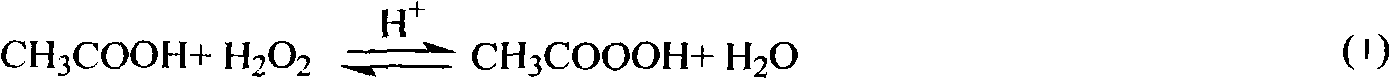

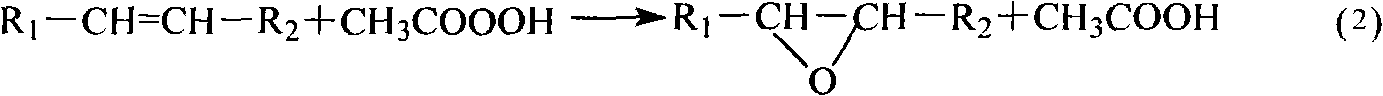

Method used

Image

Examples

Embodiment 1

[0027] 30% hydrogen peroxide and formic acid are mixed according to the molar ratio of hydrogen peroxide and formic acid as 1.2:1, 5% sulfuric acid catalyst is added in the mixed solution, the stabilizer is 1% urea, and the dihydrogen peroxide in formic acid and fatty acid methyl ester is respectively mixed. The molar ratio of the number of bonds is 1.0:1 and injected into a micro-mixing reactor with temperature control at 50° C. through a high-pressure pump. The micro-mixer is a T-shaped curved channel glass micro-mixer (T-mixer, Mixcrogalss, Germany), the channel size (μm) is 50×210000 (diameter×length), and the residence time is 4.94ms; the inner diameter is 1mm, the length is 3.2m polytetrafluorocapillary, and the residence time is 0.5min. Submerge in an ice-water bath to terminate the reaction. Collect reaction product, product solution has obtained the product containing epoxidized fatty acid methyl ester through liquid separation, washing, drying, and its titration obta...

Embodiment 2

[0029] Mix 45% hydrogen peroxide and formic acid according to the molar ratio of hydrogen peroxide and formic acid at 1.0:1, add 1.0% sulfuric acid catalyst in the mixed solution, stabilizer is 1.5% EDTA, respectively press the double bond in formic acid and fatty acid methyl ester The molar ratio of the number is 1.2:1 and injected into the micro-mixing reactor with temperature control at 75 °C through a high-pressure pump. The micro-mixer is a T-shaped curved channel glass micro-mixer (T-mixer, Mixcrogalss, Germany ), the channel size (μm) is 50×210000 (diameter×length), and the residence time is 4.10ms; followed by a PTFE capillary with an inner diameter of 1mm and a length of 8m, and the PTFE tube is immersed in an ice-water bath to terminate reaction with a residence time of 1 min. Collect reaction product, product solution has obtained the product containing epoxidized fatty acid methyl ester through liquid separation, washing, drying, and iodine value is 9.3g I 2 / 100g...

Embodiment 3-8

[0031] Using the same reaction conditions as in Example 1 and Example 2, the micro-mixer is changed into a small size stainless steel tee (inner diameter is 1.0mm) or a cross-toed micro-mixer (HPIMM, IMM, Germany), and its channel size (μm) It is 25×21×37, or V2 (IMM, Germany), and the residence time in the micro-mixer and the microchannel reactor are 2.1 ms and 10 min, respectively. The iodine value and epoxy value of the obtained epoxidized fatty acid methyl ester product are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Iodine value | aaaaa | aaaaa |

| Iodine value | aaaaa | aaaaa |

| Iodine value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com