Patents

Literature

108results about How to "Short reaction residence time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of preparing alpha-sulphonic acid fatty acid ester

InactiveCN101508660AImprove securityRelaxed reaction conditionsSulfonic acid preparationState of artReaction temperature

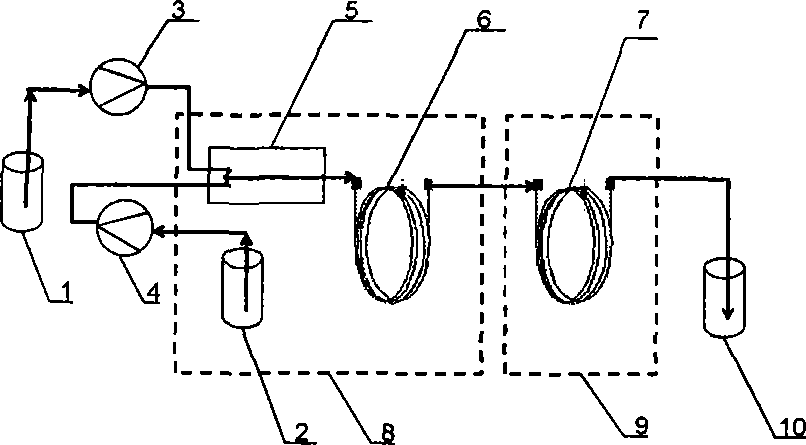

The invention relates to a method for preparing alpha-sulfonic fatty acid ester by sulfonating fatty acid ester, comprising the following steps: injecting the fatty acid ester and a sulfonating agent into a micro-structural reactor (5) and a reactor (6) inside diameter of which is a micro passage respectively, mixing and sulfonating the fatty acid ester and the sulfonating agent, controlling the reaction temperature between 50 and 100 DEG C, and controlling the reaction materials to stay for 1ms to 1s in the micro-structural reactor (5) and stay for 0.5 to 30 minutes in the micro-passage reactor (6); and then injecting the reaction materials into a micro-passage reactor (7), aging the reaction materials at a reaction temperature between 50 and 100 DEG C, and controlling the reaction materials to stay for 0.5 to 30 minutes in the micro-passage reactor to obtain the alpha-sulfonic fatty acid ester. In the method, the novel micro-structural reactor is adopted, the defect of difficult control due to strong reaction heat release in the prior art is overcome, the materials can be mixed evenly, the released reaction heat can be removed in time, the reaction time can be controlled accurately, and the method has the advantages of good sulfonating efficiency, simple and safe operation and good product quality.

Owner:NANJING UNIV OF TECH

Method of desulfurizing and denitrate simultaneously of exhaust gas by micro wave catalysis

The present invention discloses a flue gas purifying method capable of catalyzing flue gas by using microwave and simultaneously making desulfurization and denitration. Said method is characterized by that firstly, the catalyst is placed in a special-designed fixed bed reactor, then the normal-pressure simulated flue gas is introduced to make microwave catalytic desulfurization and denitration reaction. Its desulfurization and denitration efficiency is high, when the space velocity is 8000h-1 and the temperature is 150deg.C, its desulfurization rate can be up to 95% and its denitration rate can be up to 87%, and its catalyst can be regenerated and reused.

Owner:EAST CHINA UNIV OF SCI & TECH

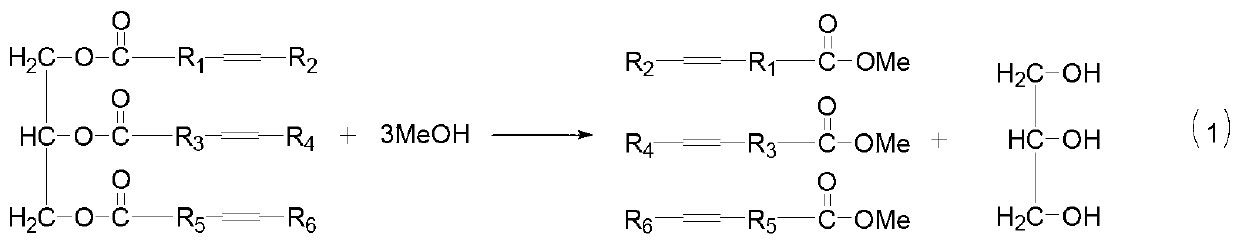

Method for preparing epoxidized fatty acid methyl ester with microreactor one-step method

ActiveCN102993133AImprove product qualityHigh epoxidation yieldOrganic chemistryDouble bondFatty acid methyl ester

The invention discloses a method for preparing epoxidized fatty acid methyl ester with microreactor one-step method, comprising the following steps: injecting oil and fat, low-carbon alcohol and basic catalyst in a first microstructure reactor of a microchannel modularized reaction device, wherein the mole ratio of oil and fat to low-carbon alcohol is 1:11-17, and remaining for 3-10 min at the temperature of 65-85 DEG C; mixing outlet material of the first microstructure reactor with hydrogen peroxide, organic acid, acidic catalyst and stabilizing agent in a second microstructure reactor of the microchannel modularized reaction device, wherein the mole ratio of number of double bonds in organic acid to number of double bonds in oil and fat is 11-17:1, and remaining 1-5 min at the temperature of 65-95 DEG C; guiding the outlet material of the first microstructure reactor in a separator, standing for demixing to remove aqueous solution at lower layer; washing an organic phase at the upper layer with water till the pH is 6.5-7.5; and drying to obtain epoxidized fatty acid methyl ester.

Owner:NANJING UNIV OF TECH

Method for preparing fatty acid ester by micro-channel reactor

InactiveCN101148409AHigh yieldWide adaptabilityOrganic compound preparationCarboxylic acid esters preparationAlcoholBiodiesel

The present invention relates to preparation of biodiesel oil, and is especially process of producing fatty ester as biodiesel oil with grease and alcohol as materials and through ester interchange reaction inside a micro channel reactor. The process has the following steps: injecting the mixture of grease, low carbon alcohol and acid catalyst into one micro channel reactor of 0.1-2.0 mm inner diameter; and reaction at normal pressure and 90-170 deg.c for 5-60 min to prepare fatty ester. The preparation process has the advantages of excellent material adaptability, continuous reaction, short reaction period, high fatty ester yield, etc.

Owner:NANJING UNIV OF TECH

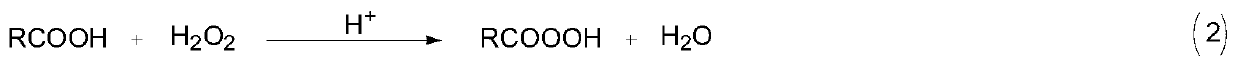

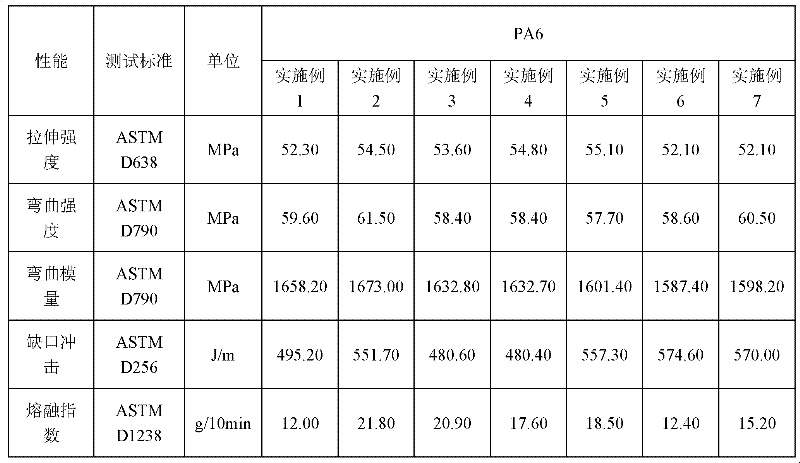

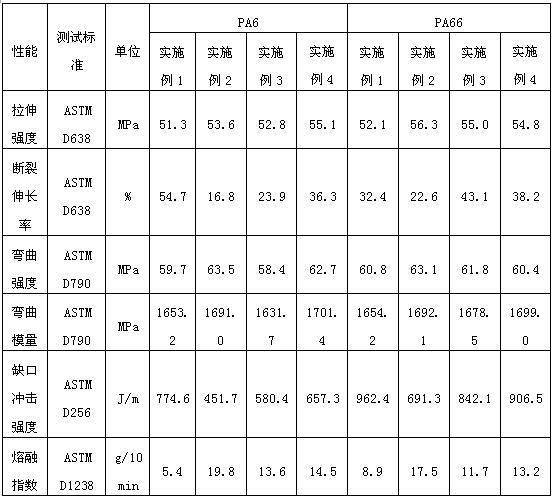

Ultrahigh-mobility propenyl elastomer grafting copolymer and preparation method thereof

The invention relates to an ultrahigh-mobility propenyl elastomer grafting copolymer and a preparation method thereof. The copolymer comprises the following components in percentage by weight (wt%): 50-100wt% of propenyl elastomer resin, 0-50wt% of polyolefin resin, 0.5-5wt% of grafted monomer, 0.01-2wt% of initiator, 0.1-1wt% of crosslinking inhibitor, 0.1-1wt% of antioxygen and 0.1-2wt% of liquid accessory ingredient, wherein other components except the initiator are mixed in a high-speed mixer at a certain ratio and are added into a double-screw extruder by main feeding; the initiator is added into the extruder by side feeding; and a product is obtained by fusing, plastifying, kneading, mixing, extruding from a handpiece, bracing, cooling, pelletizing and drying. Compared with the prior art, the ultrahigh-mobility propenyl elastomer grafting copolymer disclosed by the invention has the advantages of higher product grafting ratio, lower gel content, excellent comprehensive performance and excellent impact performance by the side feeding technology, and is especially suitable for thin-wall products and large producing pieces in the fields, such as interior / exterior trim parts ofautomobiles, bumpers, railway equipment and the like.

Owner:SHANGHAI SUNNY

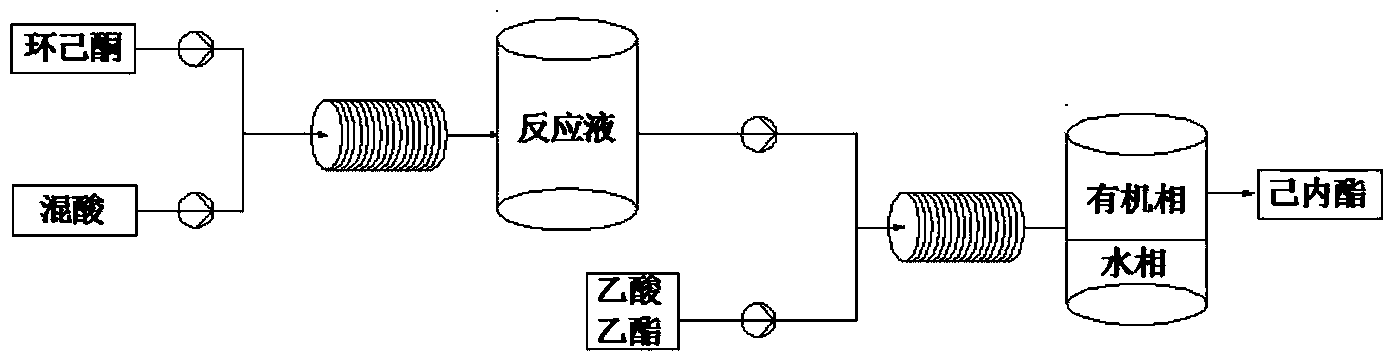

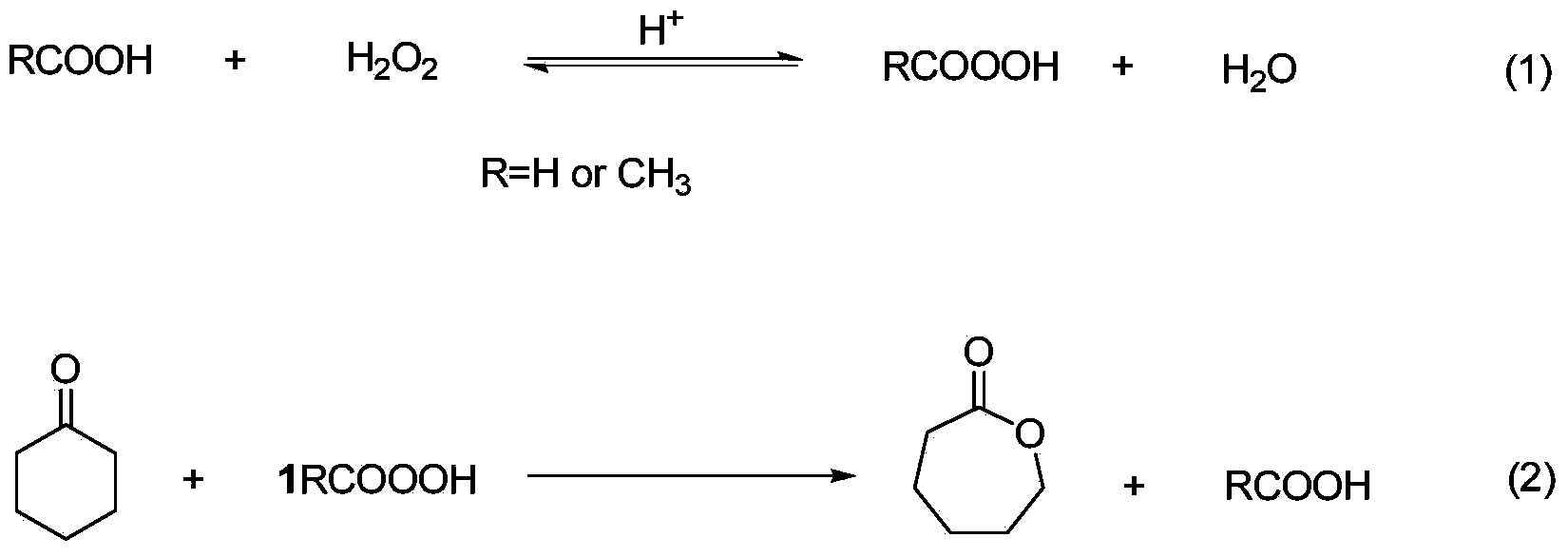

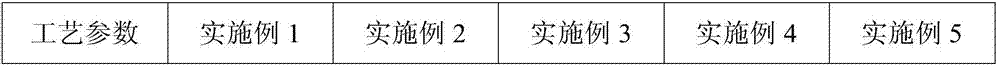

Method for preparing caprolactone through cyclohexanone catalyzed oxidation

InactiveCN104370873AHigh yieldEasy to operate and controlOrganic chemistryCyclohexanoneRetention time

The invention discloses a method for preparing caprolactone through cyclohexanone catalyzed oxidation. The method comprises the following steps: mixing aqueous solution of hydrogen peroxide and aqueous solution of formic acid, and adding a catalyst and a stabilizer, thereby preparing a mixed solution; respectively pumping cyclohexanone and the mixed solution into a micro-channel modular reaction device, reacting at the temperature of 45-100 DEG C, preserving the reaction retention time for 2-10 minutes, guiding the reaction products into a separation device, adding aqueous solution of Na2CO3 for washing and regulating the pH value to be neutral, extracting the aqueous solution by using ethyl acetate, merging obtained organic extracting solution, and performing spin evaporation to remove the solvent, thereby obtaining the target product caprolactone. The method disclosed by the invention refers to a continuous process, the preparation process is easy to operate and control, the safety is high, the reaction conditions are mild, the reaction time consumption is short, the product quality is stable, and after-treatment is simple. The method has the characteristics that the generation device is simple, easy in detachment and convenient to carry and move. Convenient adjustment can be performed by simply increasing or decreasing the number of the micro channels.

Owner:NANJING UNIV OF TECH

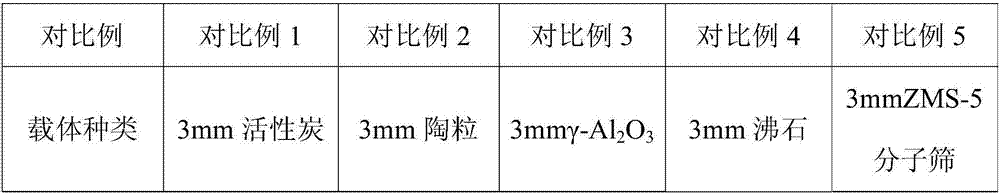

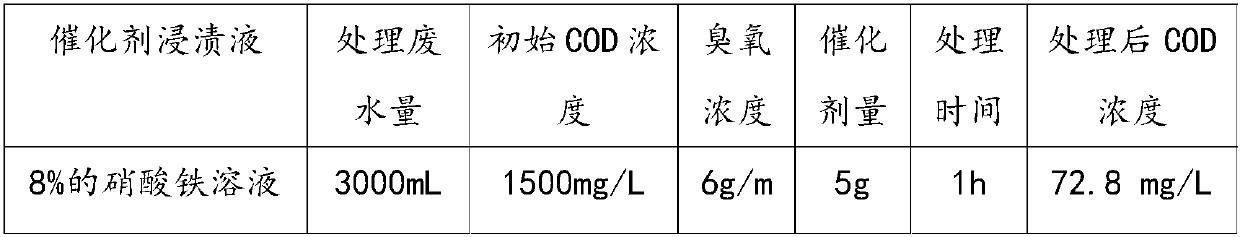

Preparation method of poly-metallic oxide-loaded catalytic ozonation catalyst and application

InactiveCN107051468AIncrease load capacityHeavy loadWater contaminantsNature of treatment waterMicrowaveNitrate

The invention discloses a preparation method of a poly-metallic oxide-loaded catalytic ozonation catalyst and an application. The preparation method of the catalyst comprises the following steps of: a, activating diatomite, the diameter of which is 1-3mm, in a microwave generator, then immersing the diatomite in a NaOH solution, and taking out the diatomite to dry to obtain pre-treated diatomite; b, immersing the pre-treated diatomite in a mixed solution of copper nitrate, nickel nitrate, manganese nitrate, cobalt nitrate and ferric nitrate to obtain a catalyst precursor; and c, drying the catalyst precursor, and roasting the catalyst precursor at a high temperature to obtain the poly-metallic oxide-loaded catalytic ozonation catalyst. By selecting diatomite as a carrier which is cheap and easily available, the preparation process is simple, and the catalyst is easy to recover and suitable for industrial production on a large scale. The poly-metallic oxide-loaded catalytic ozonation catalyst prepared by the preparation method is used for treating antibiotic industrial wastewater.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

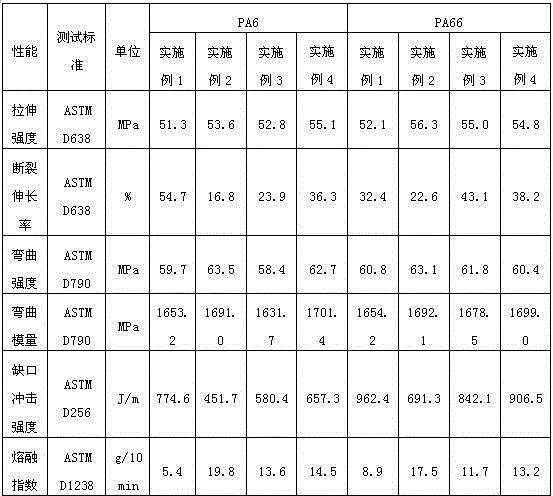

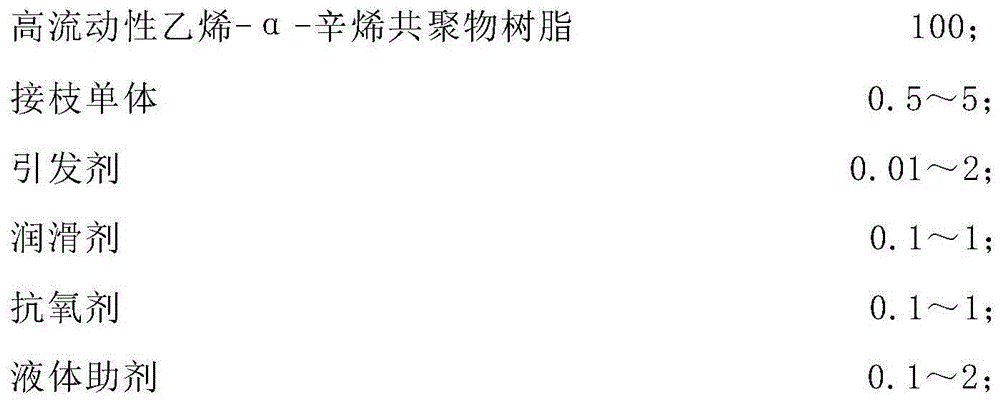

High-fluidity ethylene-alpha-octene graft copolymer and preparation method thereof

The invention relates to a high-fluidity ethylene-alpha-octene graft copolymer and a preparation method thereof. The copolymer is a graft copolymer, and comprises the following components by weight part: 100 parts of high-fluidity ethylene-alpha-octene copolymer (POE) resin, 0.5 to 5 parts of graft monomer, 0.01 to 2 parts of initiator, 0.1 to 1 part of lubricant, 0.1 to 1 part of antioxidant and 0.1 to 2 parts of liquid additive. Other components except the initiator are put in a high-speed mixer to be mixed in proportion and are added to a twin-screw extruder through a main feeder, and the initiator is added to the extruder through a side feeder to granulate to obtain a product. Compared with the prior art, through the side feeding technology, the high-fluidity POE graft copolymer has higher grafting yield and lower gel content; and in addition, because of the high fluidity of the graft copolymer, after being applied to nylon, the graft copolymer has better fluidity than that of the traditional toughener after the toughener is applied to the nylon, and has excellent comprehensive mechanical properties and impact properties.

Owner:SHANGHAI SUNNY

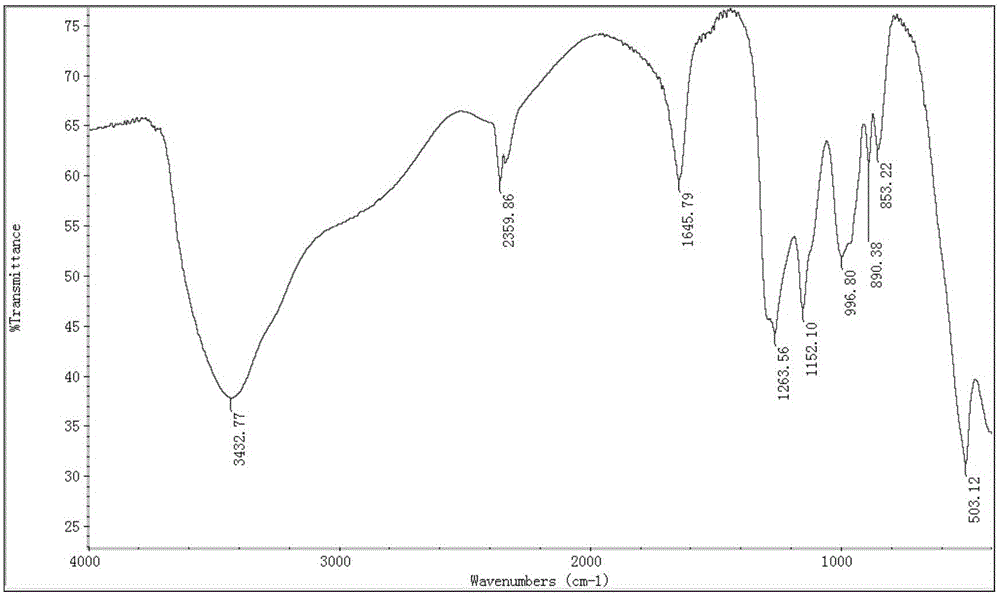

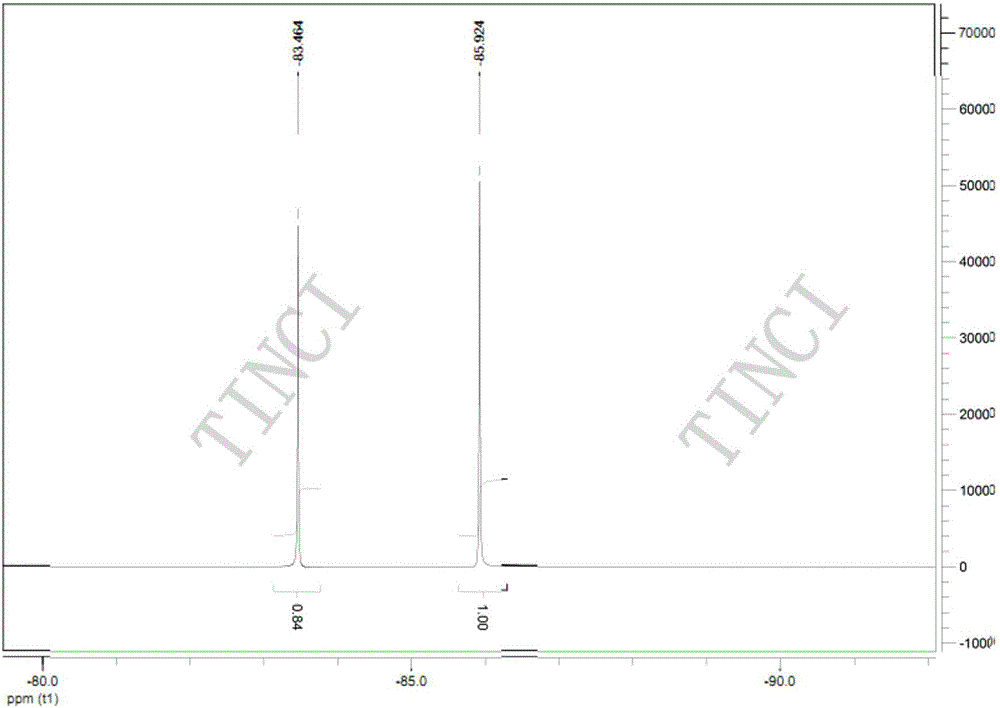

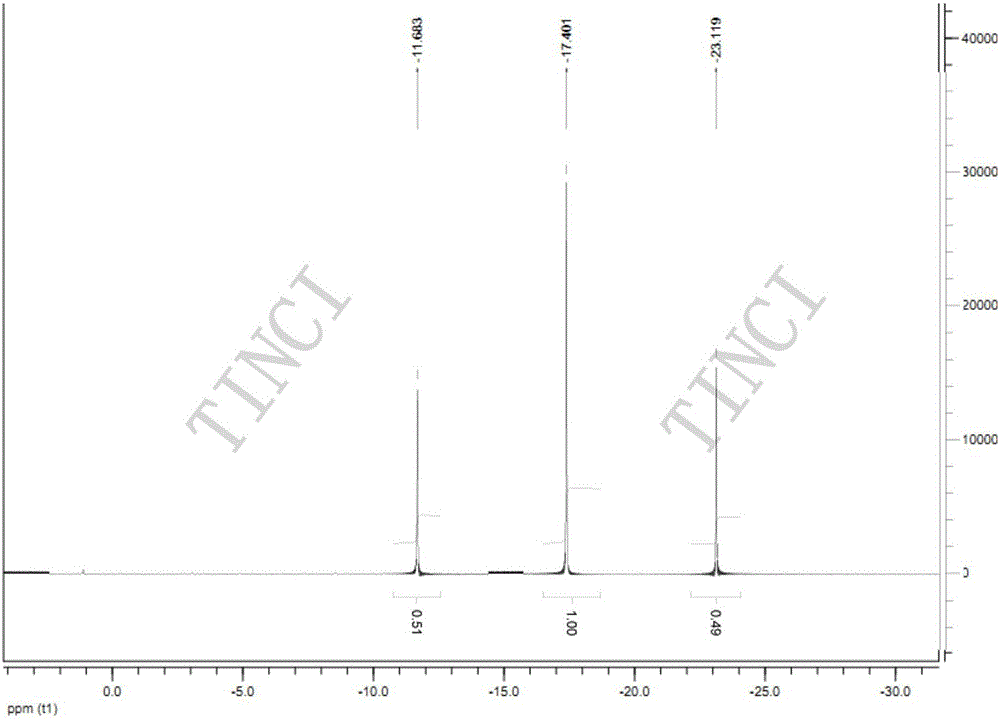

Method for preparing difluorophosphates

The invention belongs to the technical field of lithium-ion batteries and particularly relates to an efficient method for preparing difluorophosphates. The method comprises the following steps: metering a hexafluorophosphate solution with the concentration being 5wt% to 50wt% and a cyclosiloxane or an acetal, then, introducing the metered materials to a microchannel reactor, carrying out a reaction for 60 to 900 seconds at the temperature of 20 DEG C to 150 DEG C, carrying out membrane filtration on an obtained reaction solution, and then, carrying out concentrating and drying, thereby obtaining a corresponding difluorophosphate product. The method disclosed by the invention has the advantages that the process route is simple, the raw materials are readily available, the reaction efficiency is high, the energy consumption is low, the product purity is high, and the like.

Owner:JIUJIANG TINCI ADVANCED MATERIALS CO LTD

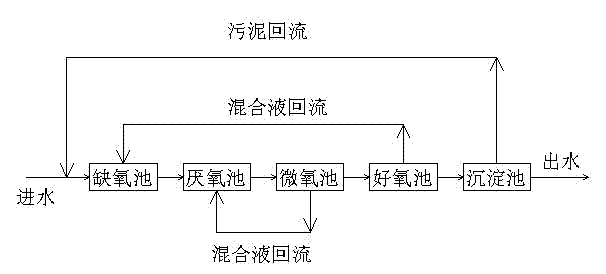

Method for removing ammonia nitrogen from industrial waste water produced in synthetic ammonia industry

InactiveCN102515352AReduce consumptionReduce removal rateTreatment with aerobic and anaerobic processesRetention timePollution

The invention discloses a method for removing ammonia nitrogen from industrial waste water produced in a synthetic ammonia industry. The method provided by the invention comprises the following steps that industrial waste water produced in a synthetic ammonia industry orderly enters into an anoxic pond, an anaerobic pond, a micro-oxygen pond, an aerobic pond and a sedimentation pond; a part of the industrial waste water in the micro-oxygen pond flows back to the anaerobic pond; a part of the industrial waste water in the aerobic pond flows back to the anoxic pond; and a part of the industrial waste water in the sedimentation pond flows back to a water inlet end of the anoxic pond. The method provided by the invention realizes anoxic denitrification, anaerobic ammoxidation and short-cut nitrification and denitrification in the same biological treatment system. The method provided by the invention realizes the short-cut nitrification and denitrification and thus saving an oxygen supply amount by 25% and an organic carbon source utilization amount by 40% and reducing reaction retention time and the capacity. The method provided by the invention realizes the anaerobic ammoxidation and thus reducing energy consumption and preventing secondary pollution. The method provided by the invention has a high ammonia nitrogen removal rate of above 99%. The method provided by the invention has a low alkali consumption amount in the whole flow and has a low operating cost.

Owner:ZHONGYUAN ENGINEERING COLLEGE

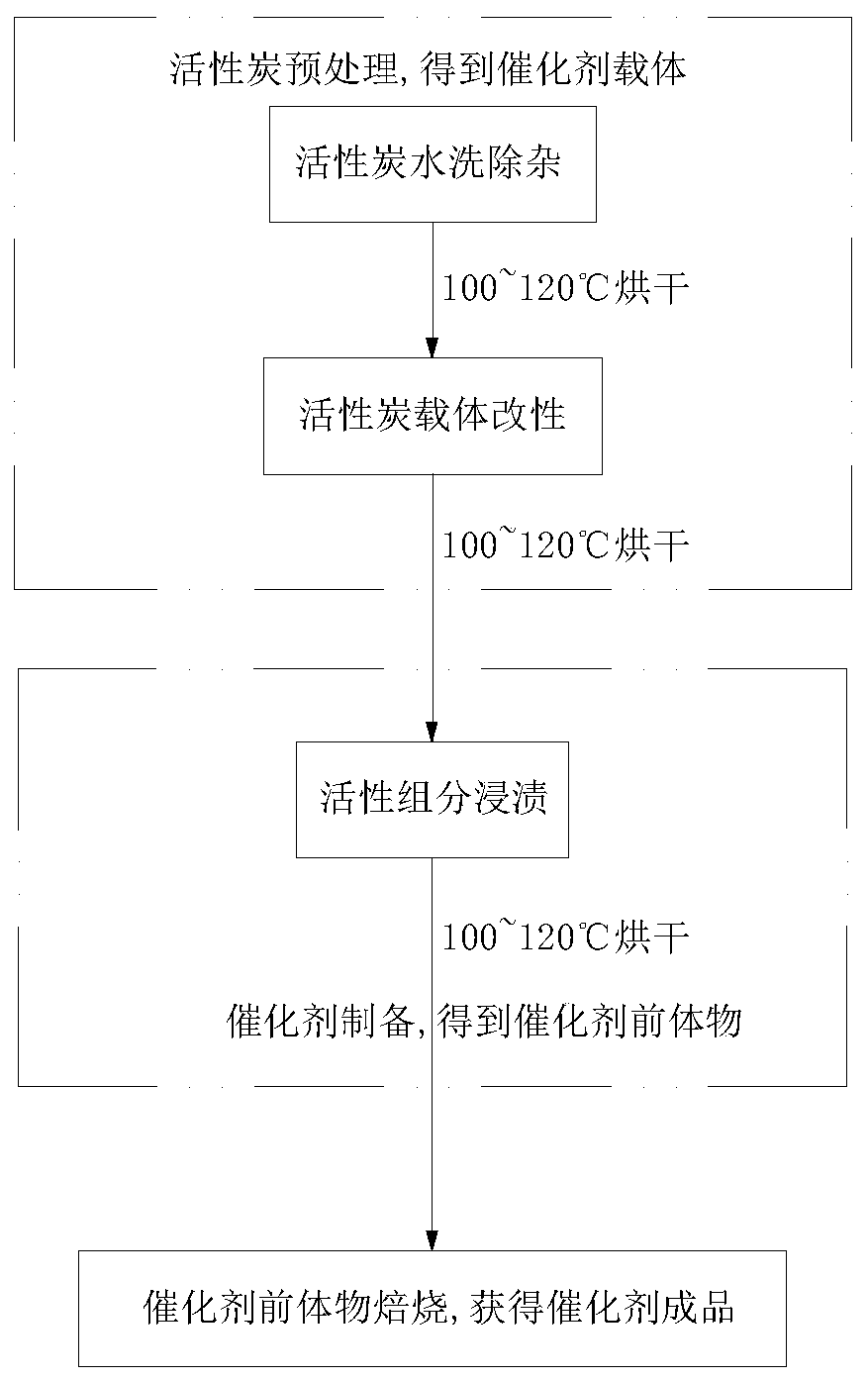

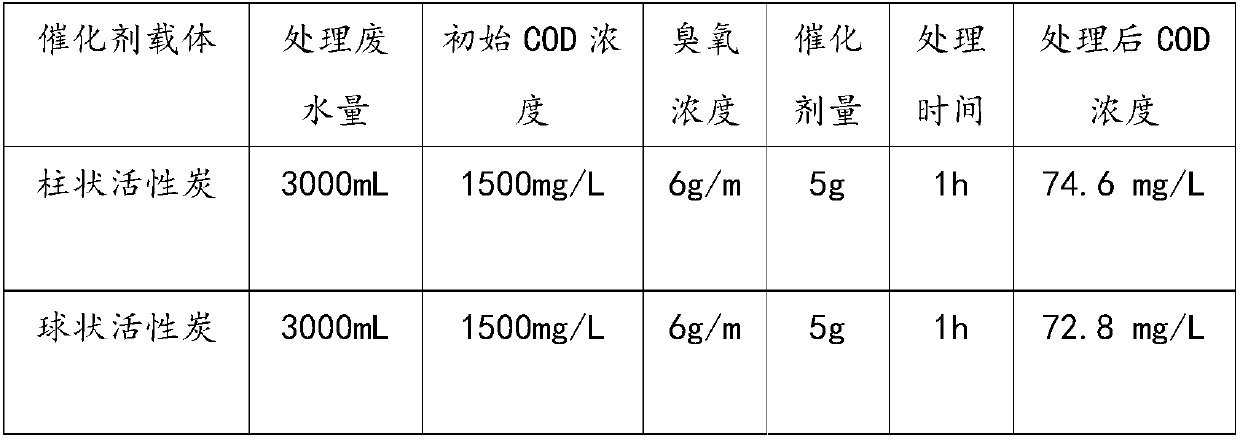

Catalytic ozonation catalyst and preparation method thereof

InactiveCN110052268AImprove catalytic oxidation performanceImprove processing efficiencyWater treatment compoundsWater contaminantsActivated carbonIndustrial effluent

The invention discloses a catalytic ozonation catalyst and a preparation method thereof. The preparation method includes following steps: (1), using activated carbon to wash for removing impurities; (2), modifying an activated carbon carrier; (3), soaking an active component to prepare a catalyst precursor; (4), calcining the catalyst precursor to obtain the catalytic ozonation catalyst. The catalytic ozonation catalyst prepared by the preparation method can be used for treating domestic sewage or industrial wastewater containing degradation-resistant organic matter, removal rate of high-degradation-difficulty organic matter in wastewater can reach higher than 95%, and the catalytic ozonation catalyst has the advantages of being efficient, environment-friendly, wide in application range and long in service life.

Owner:四川恒泰环境技术有限责任公司

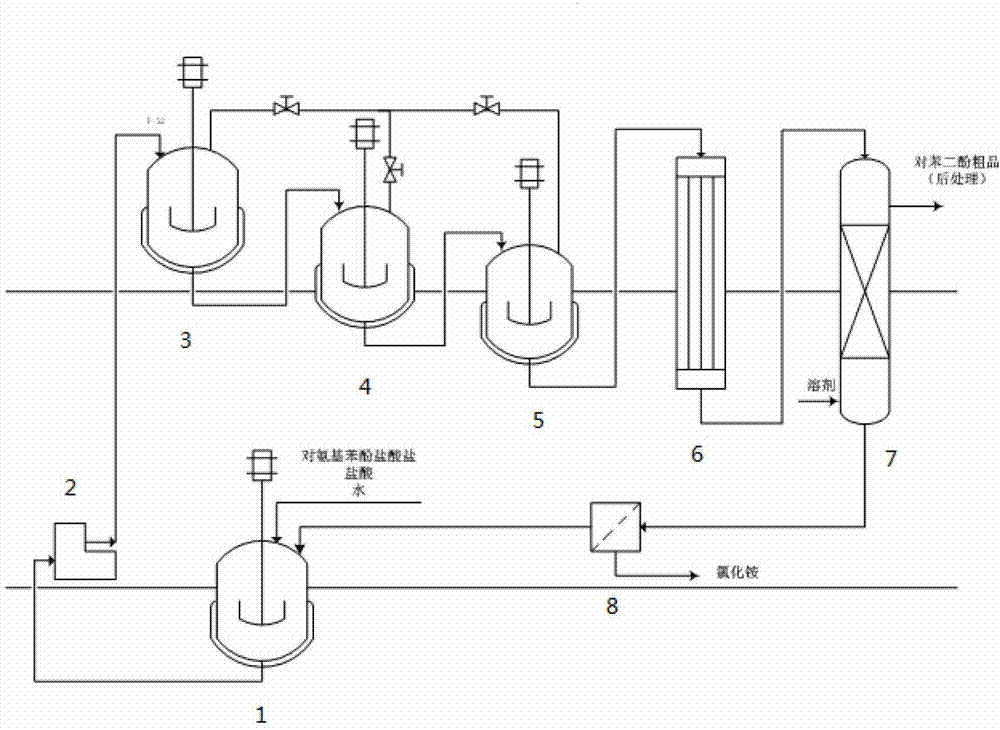

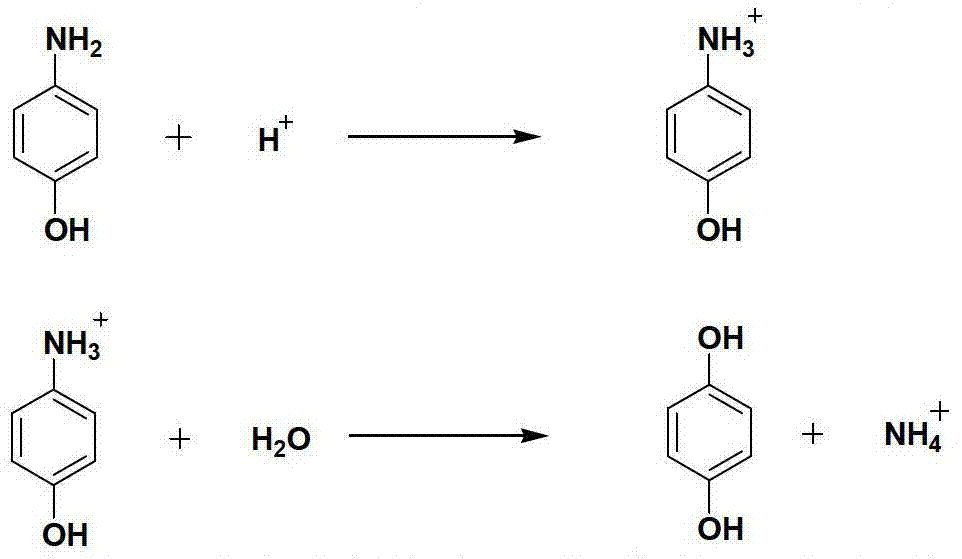

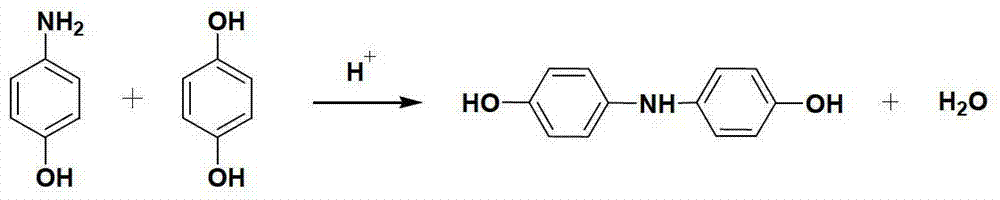

Production process for continuously hydrolyzing and producing hydroquinone through multi-kettles in series

ActiveCN103304380AContinuous production processEfficient production processOrganic chemistryOrganic compound preparationHydrolysatePotential difference

The invention belongs to the field of organic synthesis, and in particular relates to a production process for continuously hydrolyzing and producing hydroquinone through multi-kettles in series. The production process comprises the following steps of: adding materials including para aminophenol hydrochloride, hydrochloric acid and water into a dosing kettle and mixing the materials; after mixing the materials, adding the mixture into at least three serial reaction kettles, wherein the pressure in each reaction kettle is kept in balance, and a potential difference between the upper level and lower level of each reaction kettle is kept, so that reaction materials flow to the next stage of reaction kettle from the previous stage of reaction kettle for hydrolysis reaction; enabling a hydrolysate to flow out of the last stage of reaction kettle; enabling the hydrolysate to flow into a condenser; introducing the cooled hydrolysate into a continuous extraction tower; desolventizing an organic phase of the extraction tower to obtain a hydroquinone crude product. As water and acid are repeatedly used in a hydroquinone production process, waste water is remarkably reduced; as continuous production is adopted, the production efficiency is high; the production process has the advantages of high yield and simplicity in process control.

Owner:中国中化股份有限公司 +1

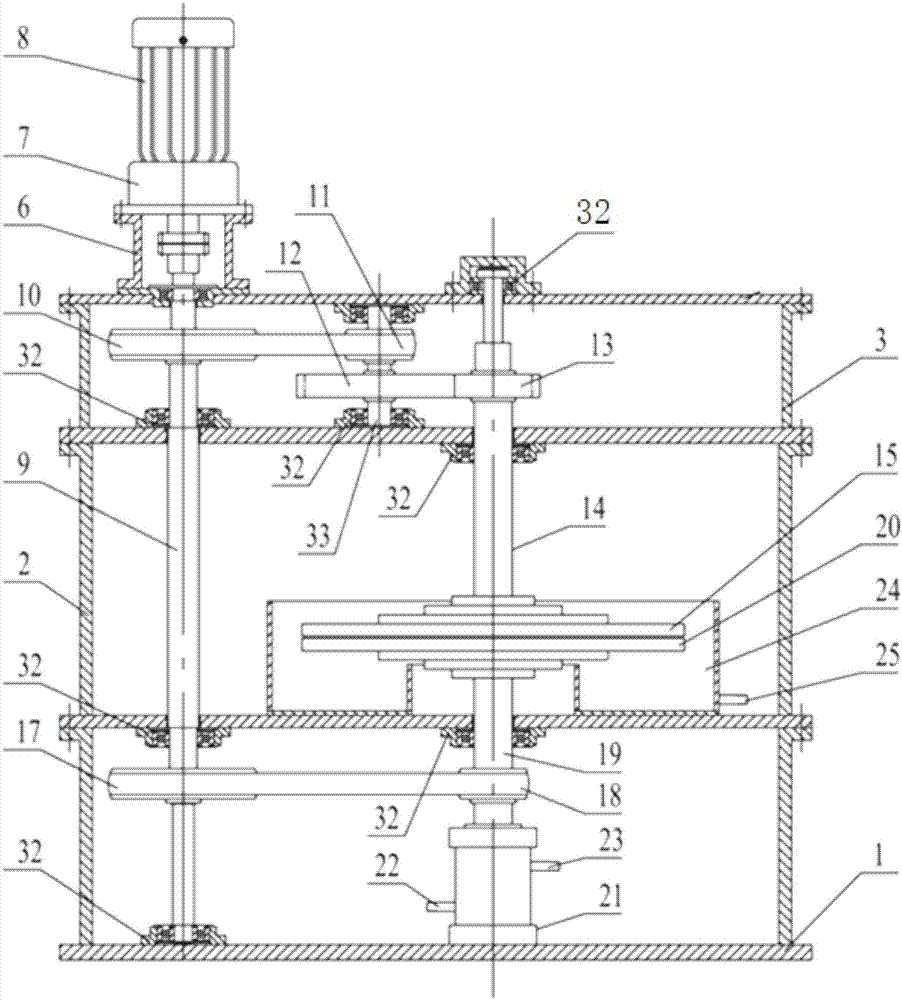

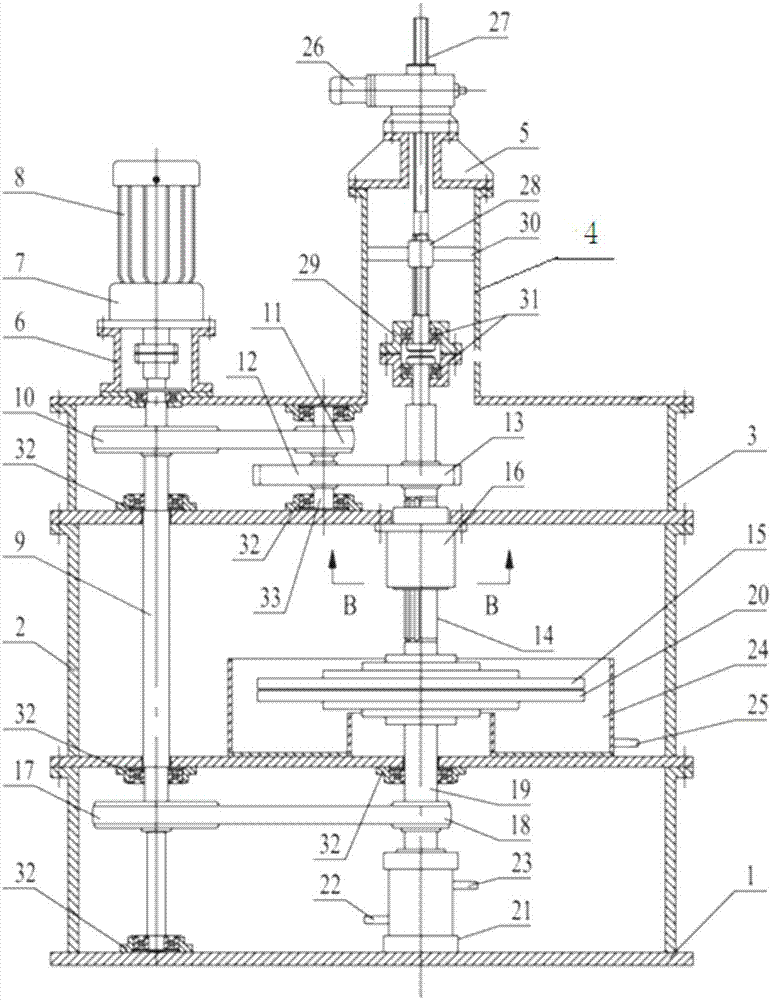

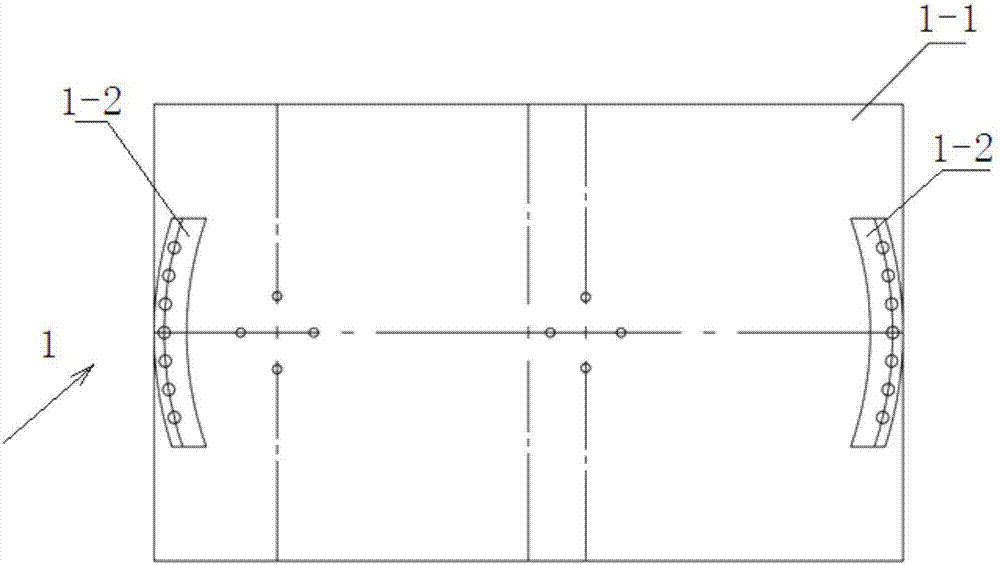

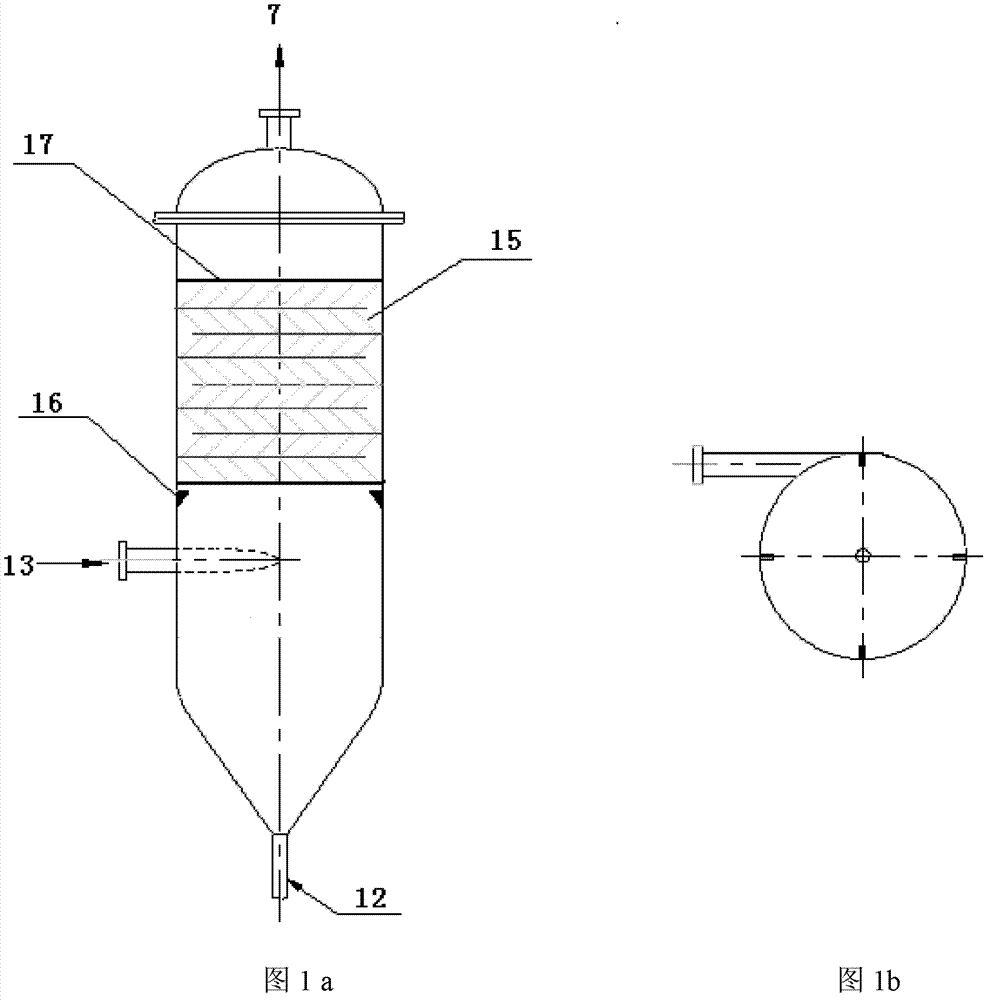

Supergravity field micro-reactor, and method for preparing nanometer material through liquid phase precipitation method

ActiveCN107224949AIncrease flow rateShort reaction residence timeMaterial nanotechnologyStrontium carbonatesMicroreactorSupporting system

The invention relates to a supergravity field micro-reactor for preparing a nanometer material. The supergravity field micro-reactor comprises a micro-reaction assembly, a material receiving groove provided with a material outlet, a first motor, a transmission system, a material inlet system and a support system, wherein the micro-reaction assembly comprises an upper disc and a lower disc, micro-grooves are respectively distributed on the bottom surface of the upper disc and the top surface of the lower disc, the center position of the lower disc is provided with a material inlet micro-pore channel, a 0.03-0.1 mm gap is arranged between the bottom surface of the upper disc and the top surface of the lower disc after the combination, the first motor drives the transmission system to operate so as to make the upper disc and the lower disc in the micro-reaction assembly rotate in opposite rotation directions, and an upper disc lifting system can be additionally arranged so as to conveniently adjust the gap between the bottom surface of the upper disc and the top surface of the lower disc in the micro-reaction assembly and wash the upper disc and the lower disc. With the supergravity field micro-reactor of the present invention, the nanometer material is prepared by using the liquid phase precipitation method, such that the high dispersion property and the uniform particle distribution of the nanometer material can be maintained while the treatment capacity can be increased and the clogging of the micro-reaction assembly can be avoided.

Owner:SICHUAN UNIV

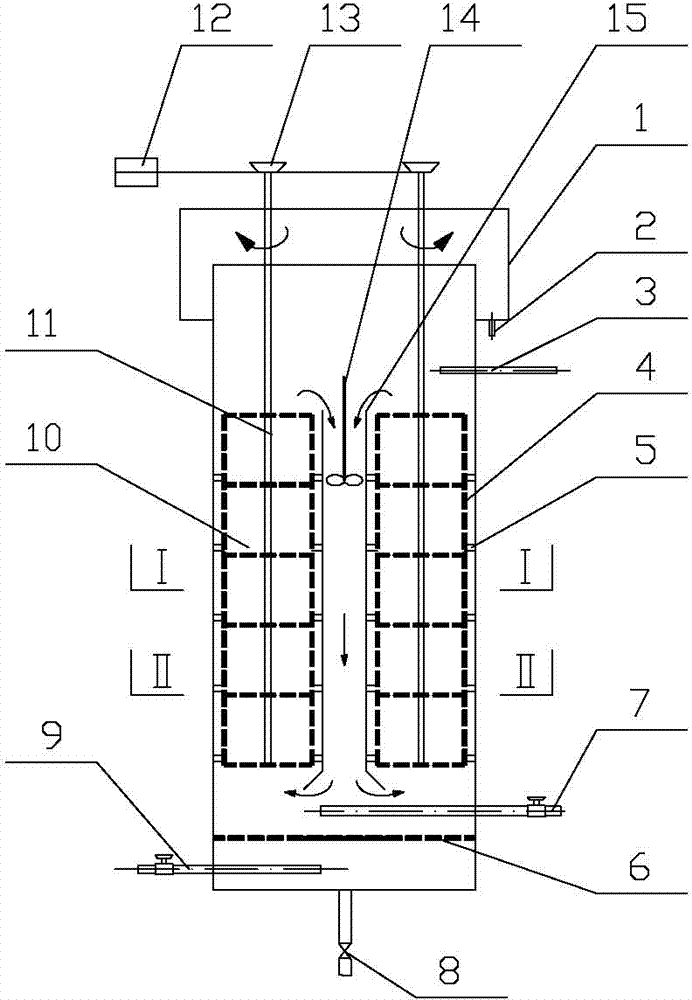

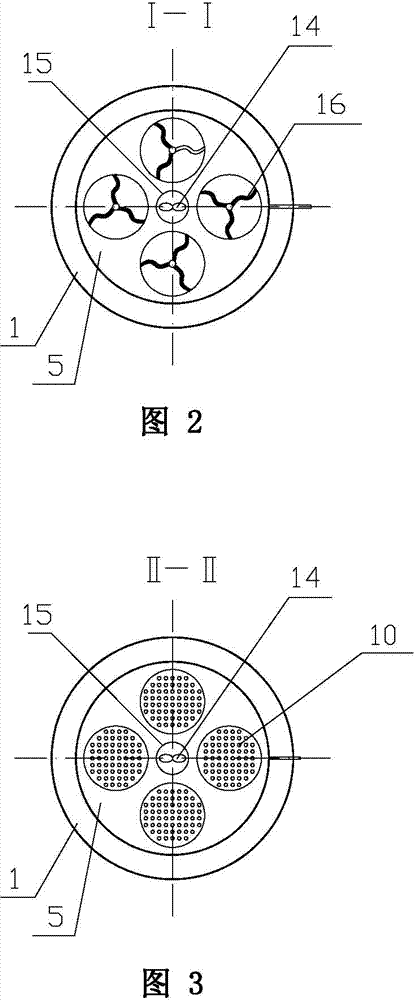

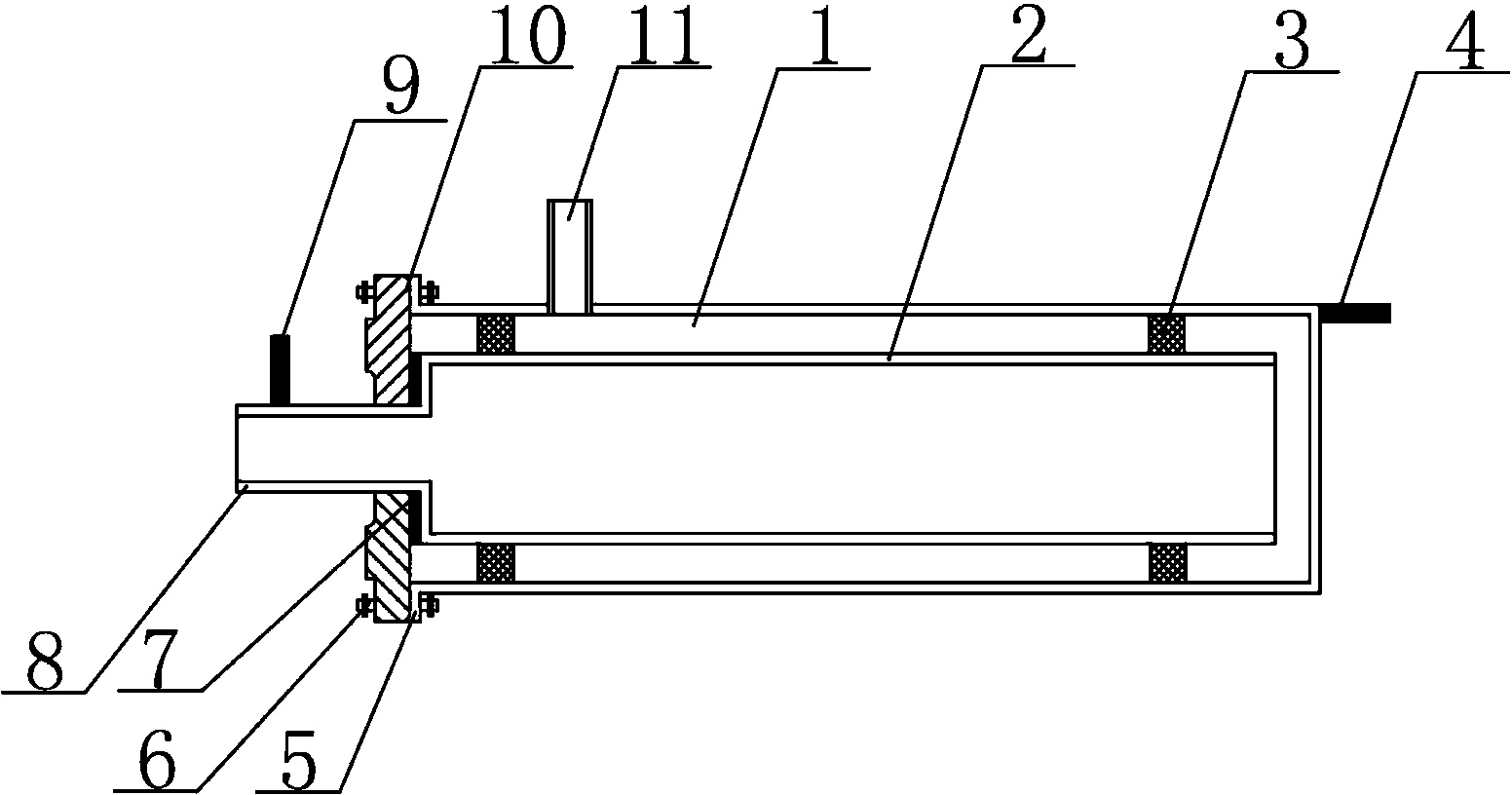

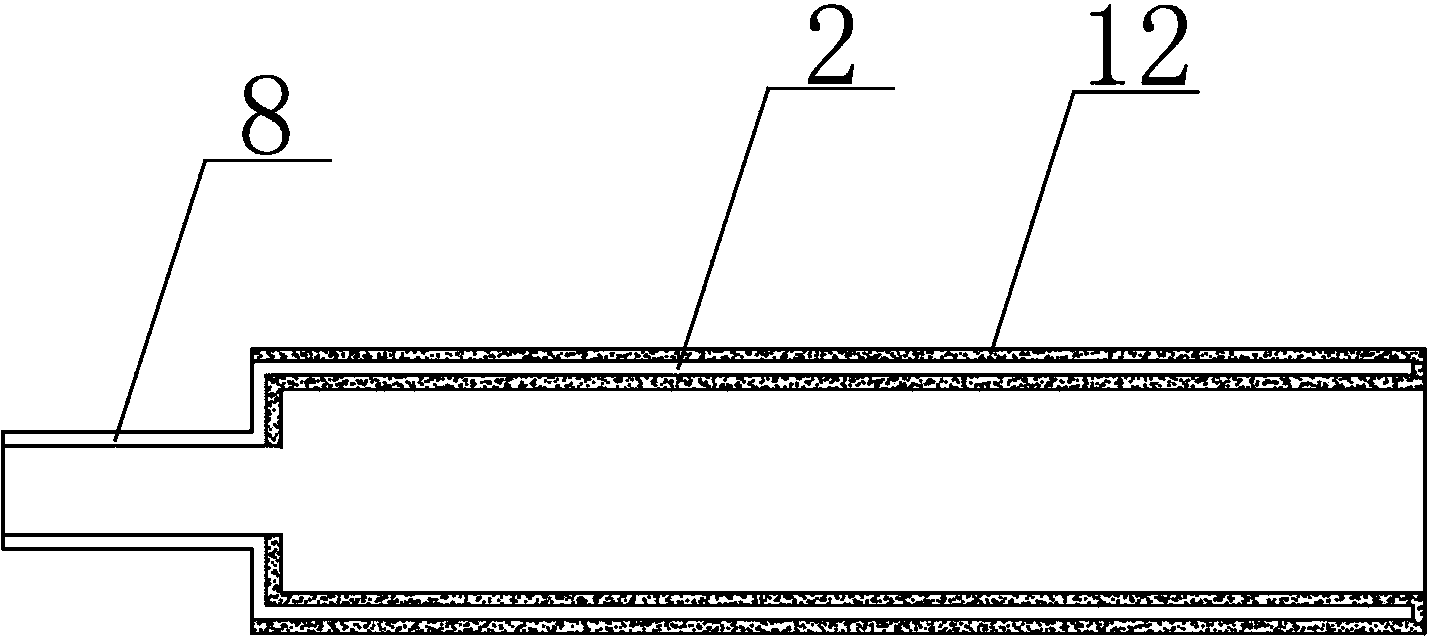

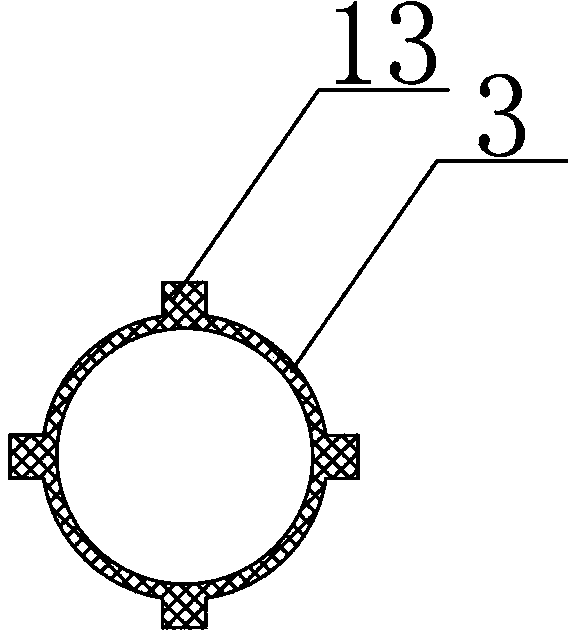

Immersed iron carbon micro electrolysis reactor

ActiveCN102276018BHardening will notCompact structureWater/sewage treatmentElectrolysisPhysical chemistry

The invention discloses an immersed iron carbon micro electrolysis reactor, which is characterized by comprising a reactor cylinder (1), wherein a plurality of porous cylinders (4) are arranged in the reactor cylinder (1); iron carbon filler is filled in the porous cylinders (4); central cylinders (15) are arranged in the middle of the porous cylinders (4) respectively; stirrers (14) are arrangedin the central cylinders (15) one by one; rotating shafts (11) are arranged in the porous cylinders (4) one by one and are provided with blades (16); and the lower part of the reactor cylinder (1) has a water inlet pipe (9) and the upper part of the reactor cylinder (1) has a water outlet pipe (2). The reactor solves the common problems of blockage of an iron carbon bed layer, hardening, passivating and the like of the conventional iron carbon micro electrolysis reactor, overcomes the drawback of overhigh energy consumption due to waste water treatment by co-rotation of waste water and iron carbon which are both placed in a rotating drum of the conventional iron carbon micro electrolysis reactor, and has the advantages of compact structure, small floor area, short retention time, low energy consumption and the like.

Owner:JIANGSU JINSHAN ENVIRONMENTAL PROTECTION TECH

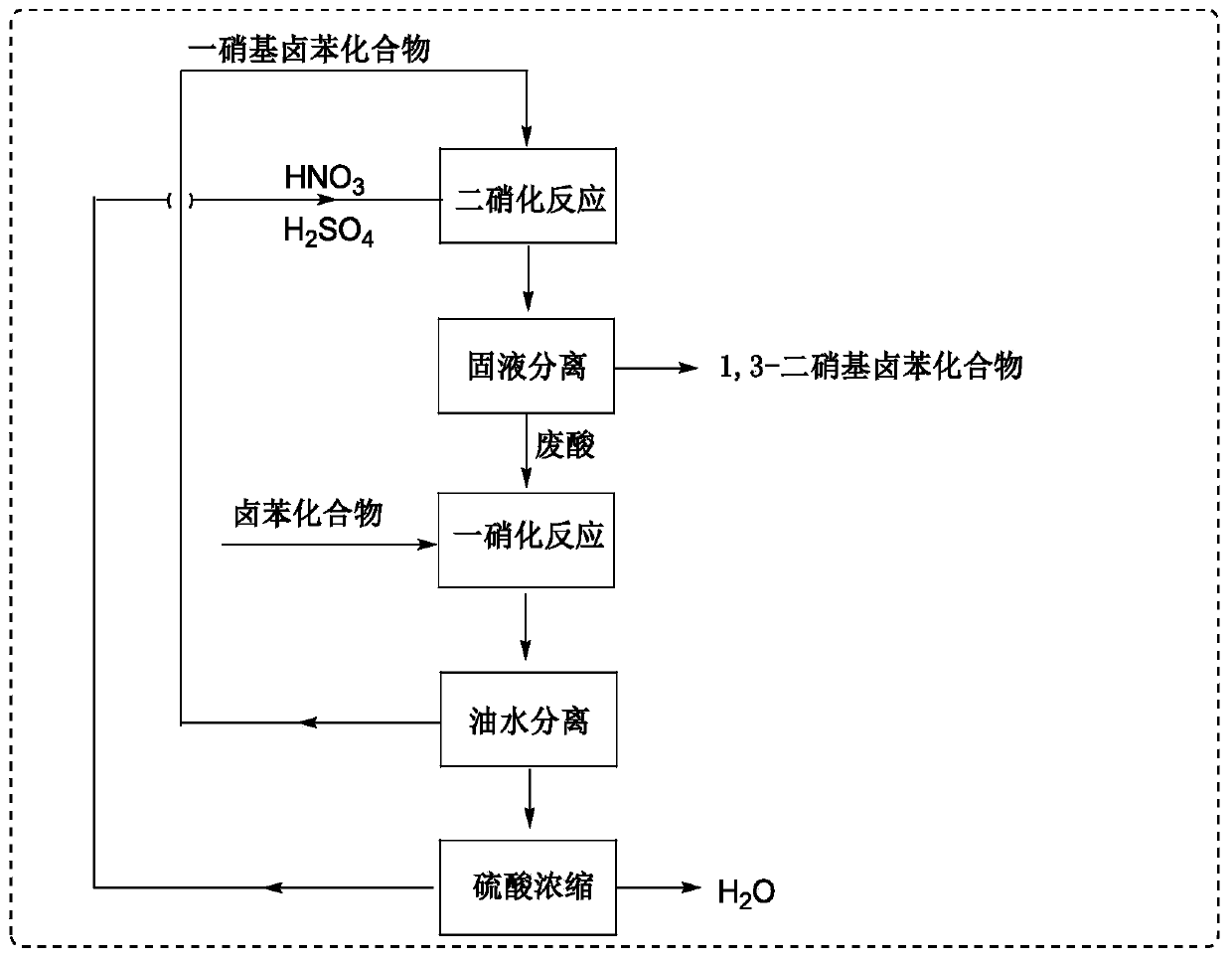

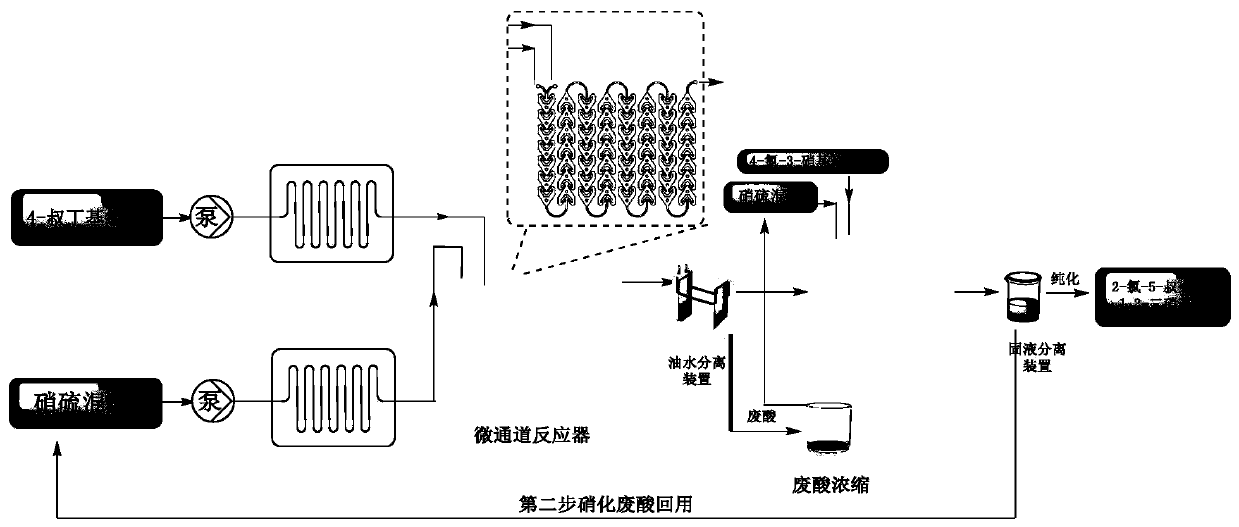

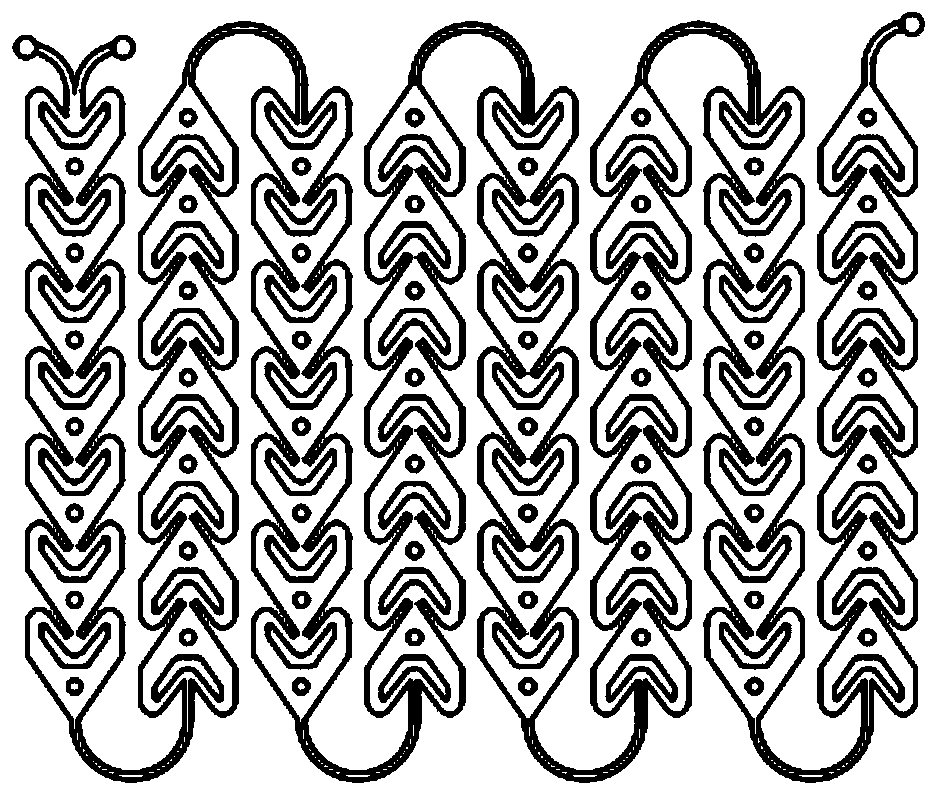

Method for synthesizing 1,3-dinitrohalobenzene compound

ActiveCN109970566ADropping time is longLong reaction heatSequential/parallel process reactionsChemical/physical/physico-chemical microreactorsMicroreactorNitration

The invention provides a method for synthesizing a 1,3-dinitrohalobenzene compound. The method comprises the following steps that A) a halogenated benzene compoundand mixed acid of nitric acid and sulfuric acid are subjected to a first nitrification reaction in a first-stage continuous flow microreactor, and oil-water separation is conducted to obtain a mononitrohalobenzene compound and first waste acid; B) the mononitrohalobenzene compound is drained into a second-stage continuous flow microreactor, a second nitrification reaction is conducted with the mixed acid of the nitric acid and the sulfuric acid, a generated nitration mixture is quenched at the outlet of the second-stage continuous flow microreactor, and filtering is conducted to obtain the 1,3-dinitrohalobenzene compound and second waste acid; C) the second waste acid is recycled to the first-stage continuous flow microreactor, a third nitration reaction with the halobenzene compound is carried out, the oil-water separation is conducted to obtain the mononitrohalobenzene compound and third waste acid, and steps B) and C) are repeated; the halobenzene compound has a structure shown in the formula I. The reaction time is short, the waste acid is less, and continuous production is achieved.

Owner:SHANDONG HIMILE CHEM TECH

Preparation method of C9 petroleum resin

The invention discloses a preparation method of C9 petroleum resin. The preparation method comprises the following steps of injecting any cracking C9 fraction or all fractions having a boiling range of 140-230 DEG C into a microchannel reactor having the inner diameter of 0.1-3.0mm, retaining the reaction materials in the microchannel reactor at a temperature of 170-280 DEG C for 1-30min, collecting reaction products and carrying out reduced-pressure distillation to obtain the C9 petroleum resin. The preparation method has the advantages that 1, the polymerization process is finished in the microchannel reactor without conventional stirring so that a reactor structure is simplified and power consumption is reduced, 2, the microchannel reactor has fast heat transfer and mass transfer capability so that isothermal polymerization in the reaction is realized easily and reaction retention time is very short, and 3, the polymerization process is operated continuously, reaction conditions can be freely changed, C9 petroleum resin chroma is shallow and a softening point can be adjusted.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing dimethyl diallyl ammonium chloride

ActiveCN104370754AEasy to operate and controlImprove securityOrganic compound preparationAmino compound preparationActivated carbonRetention time

The invention discloses a method for preparing dimethyl diallyl ammonium chloride, which comprises the following steps: mixing a 20-50 wt% dimethylamine aqueous solution and a 25-40 wt% sodium hydroxide water solution; respectively and simultaneously pumping chloropropene and the mixed solution into a microchannel modular reactor, and keeping at the temperature of 25-65 DEG C for 5-20 minutes; and introducing the discharged material of the microchannel modular reactor into a separator, standing to stratify, removing the supernatant turbid oil, taking the understratum water layer, regulating the pH value to 5-7, and carrying out vacuum distillation and activated carbon adsorption decolorization to obtain the high-grade dimethyl diallyl ammonium chloride water solution. The preparation method disclosed by the invention is a continuous process, and has the characteristics of controllable preparation technique, high safety, mild reaction conditions, short reaction retention time and stable product quality; and the production device is simple, and is easy for disassembly and assembly and convenient to carry and move. The device can be conveniently adjusted by simply increasing or decreasing the quantity of the microchannels.

Owner:NANJING UNIV OF TECH

Tubular electrolytic cell for domestic sewage treatment

InactiveCN103723797AExtended service lifeImprove protectionWater/sewage treatmentRetention timeBiochemical engineering

The invention discloses a tubular electrolytic cell for domestic sewage treatment. The tubular electrolytic cell is characterized in that the electrolytic cell is formed by sleeving a cathode external tube and an anode inner tube, wherein the cathode external tube is a titanium tube of which one end is sealed, a nozzle flange and a water inlet adapter tube are arranged at the other end of the titanium tube, and the water inlet adapter tube is perpendicular to the cathode external tube; the anode inner tube is a tube section of which one end is provided with a water outlet adapter tube; a ruthenium coating is arranged on an outer surface of the tube section; the water outlet adapter tube and the anode inner tube are in a manner of concentric circles; the anode inner tube is fixedly sleeved in the cathode external tube through a tetrafluoroethylene supporting piece; and the water outlet adapter tube is sleeved with a tetrafluoroethylene washer and is fixedly connected with a nozzle flange bolt through a flange cover. Compared with the prior art, the tubular electrolytic cell has the advantages that the operations of degradation of organic matters and sterilization and disinfection are performed in the same equipment, the reaction retention time is short, the tubular electrolytic cell is high in treatment efficiency, long in service life of electrodes, simple and convenient to operate, stable in operation and low in cost and is particularly suitable for narrow and small spaces of ship and marine structures.

Owner:ZHONGCHUAN NO 9 DESIGN & RES INST

Sulfonation reaction tail gas processing apparatus and application thereof

ActiveCN102949906ASolve the phenomenon of backmixingReduce entrainmentCombination devicesSulfur trioxideSolid particle

The invention relates to a sulfonation reaction tail gas processing apparatus and an application thereof. According to the invention, acidic sulfonation reaction tail gas enteres an alkaline wash tank; an alkali aqueous solution is delivered from the tank bottom to the alkali solution spray head on the upper part of the tank, and is jetted downwards; the alkali aqueous solution reversely contact the sulfonation reaction tail gas, such that sulfur trioxide is absorbed; solution obtained after alkaline wash is recycled; tail gas obtained after alkaline wash tangentially enters a cyclone separator with a flow rate of an empty-tower air flow speed of 3-4m / s; larger oil droplet particles accumulate at the bottom of the separator, and are discharged; tiny oil droplets rises; liquid foam and solid particles are separated from gas at a barb of an embedded baffle; gas containing tiny oil mist enters an electrostatic purifier, and rest oil mist is absorbed by high-voltage electrostatic field; and clean air is discharged. With the apparatus and the application provided by the invention, tail oil mist obtained after jet-type, continuous-tank and membrane-type sulfonation reactions can be effectively removed, wherein a removal rate is no lower than 99%. The apparatus and the application have the advantages of low energy consumption, no secondary pollution, convenient installation, low cost, and the like.

Owner:PETROCHINA CO LTD +1

High-fluidity ethylene-alpha-octene graft copolymer and preparation method thereof

The invention relates to a high-fluidity ethylene-alpha-octene graft copolymer and a preparation method thereof. The copolymer is a graft copolymer, and comprises the following components by weight part: 100 parts of high-fluidity ethylene-alpha-octene copolymer (POE) resin, 0.5 to 5 parts of graft monomer, 0.01 to 2 parts of initiator, 0.1 to 1 part of lubricant, 0.1 to 1 part of antioxidant and 0.1 to 2 parts of liquid additive. Other components except the initiator are put in a high-speed mixer to be mixed in proportion and are added to a twin-screw extruder through a main feeder, and the initiator is added to the extruder through a side feeder to granulate to obtain a product. Compared with the prior art, through the side feeding technology, the high-fluidity POE graft copolymer has higher grafting yield and lower gel content; and in addition, because of the high fluidity of the graft copolymer, after being applied to nylon, the graft copolymer has better fluidity than that of the traditional toughener after the toughener is applied to the nylon, and has excellent comprehensive mechanical properties and impact properties.

Owner:SHANGHAI SUNNY

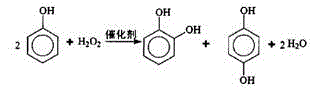

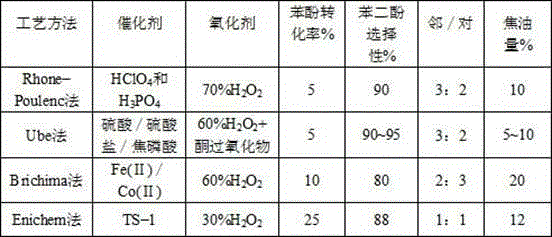

Phenol and hydrogen peroxide hydroxylation microchannel reaction method

InactiveCN105566072ADiffusion distance is shortLarge specific surface areaOrganic chemistryOrganic compound preparationPtru catalystOrganic synthesis

The invention belongs to the technical field of organic synthesis, and particularly relates to a phenol and hydrogen peroxide hydroxylation microchannel reaction method. The method comprises the steps of mixing the raw materials phenol, water, hydrogen peroxide and a water-soluble catalyst according to certain proportions to prepare a raw material solution, adding the raw material solution into a mixing tank, setting the reaction temperature of a microchannel reactor to be 30-150 DEG C, and inputting the raw material solution into the microchannel reactor at the flow rate of 5-150 mL / min through continuous charging and discharging for hydroxylation reaction, so that catechol and hydroquinone are obtained. The method is simple, operation is convenient, the conversion rate is high, selectivity is high, efficiency is high, and the content of tar in reaction liquid is low.

Owner:CHINA PETROLEUM & CHEM CORP +1

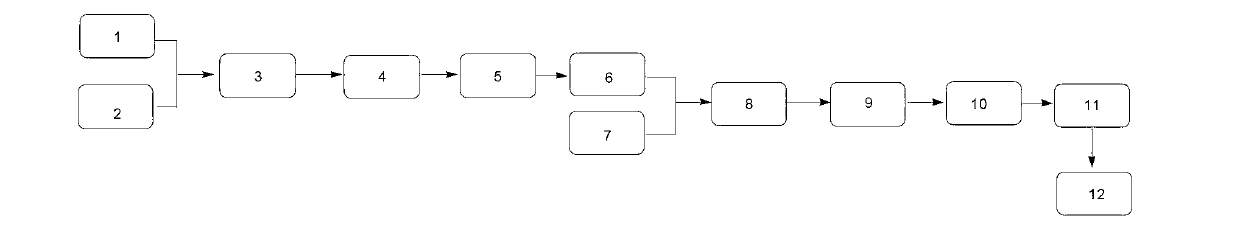

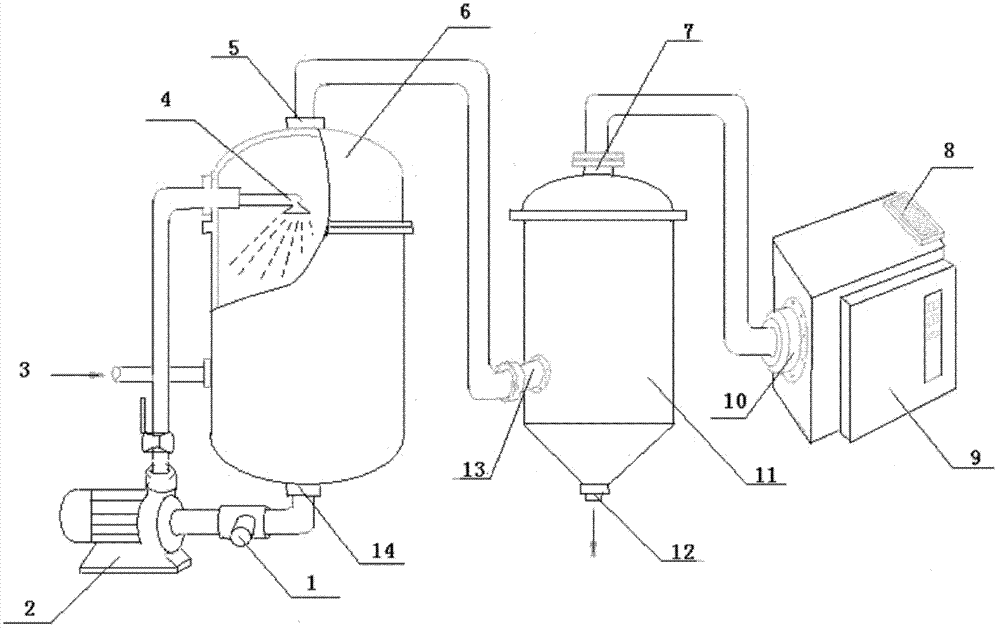

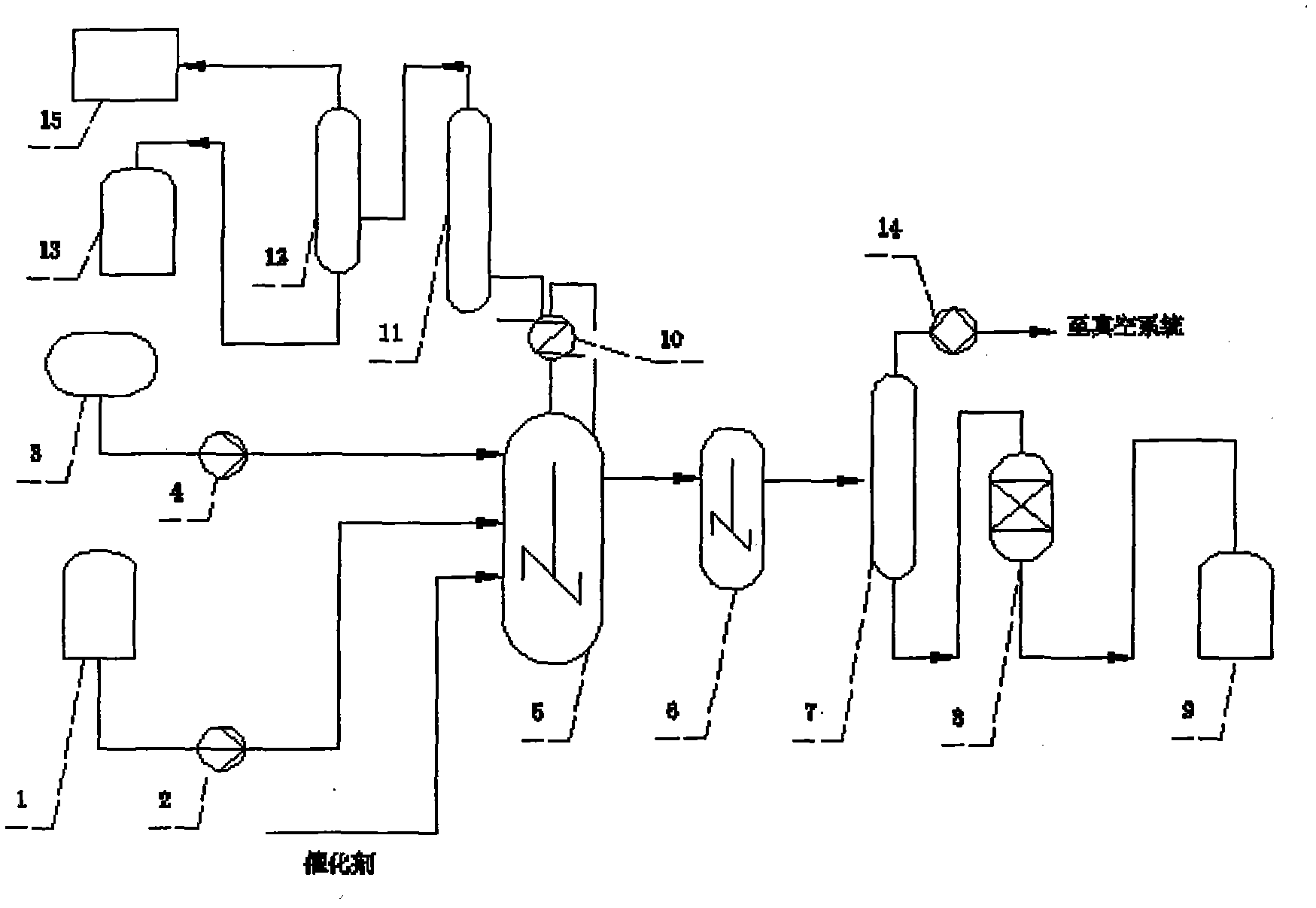

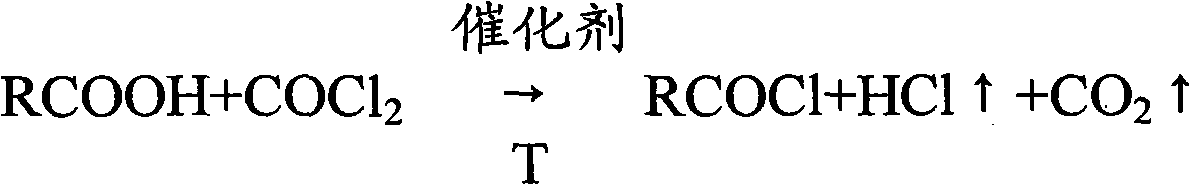

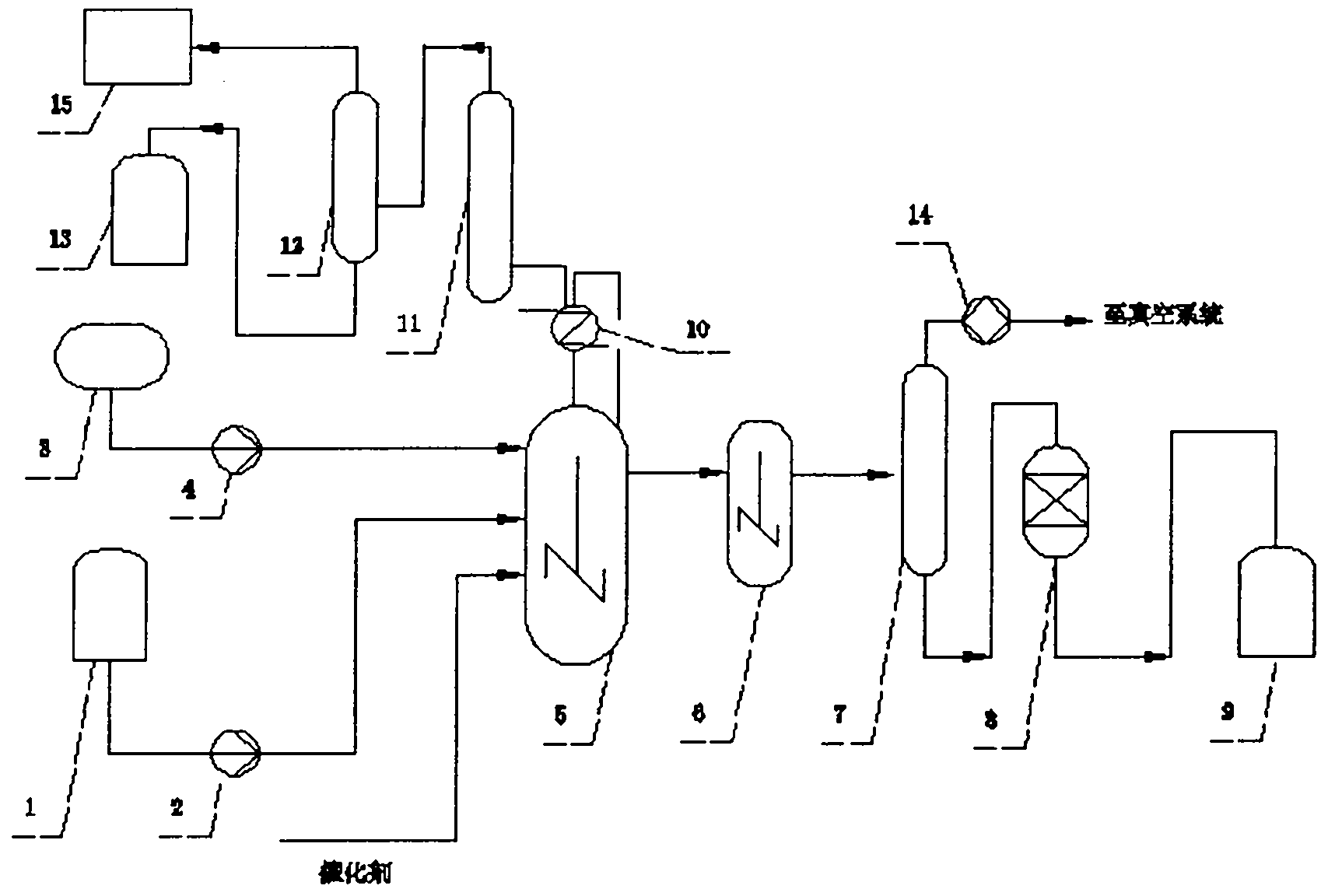

Method for producing stearoyl chloride and homologs thereof by liquid-phase phosgenation

InactiveCN102633620AIncrease the areaHigh speedOrganic compound preparationCarboxylic compound preparationGas phaseStearic acid

The invention relates to a method for producing stearoyl chloride and homologs thereof by liquid-phase phosgenation, which is characterized in continuous operation. The method comprises the following steps: simultaneously adding a raw material A, a catalyst and phosgene into a main photochemical reaction kettle (5), reacting in the main photochemical reaction kettle (5) and a photochemical reaction mature kettle (6), removing the phosgene by a negative pressure phosgene removal column (7), and decolorizing by a stearoyl chloride product decolorizing device (8) to continuously generate the stearoyl chloride product, wherein the raw material A is one of stearic acid and homologs thereof, or the mixture of two or three of the homologs. The invention solves the problems of long reaction time, low phosgene utilization ratio, multiple byproducts, low product purity, difficulty in absorbing and utilizing the generated HCl and CO2 gases, and the like in the existing technique for producing stearoyl chloride by gas-phase phosgenation, and provides a high-efficiency environment-friendly high-quality production technique of stearoyl chloride, homologs and homologic mixtures thereof.

Owner:甘肃银光聚银化工有限公司

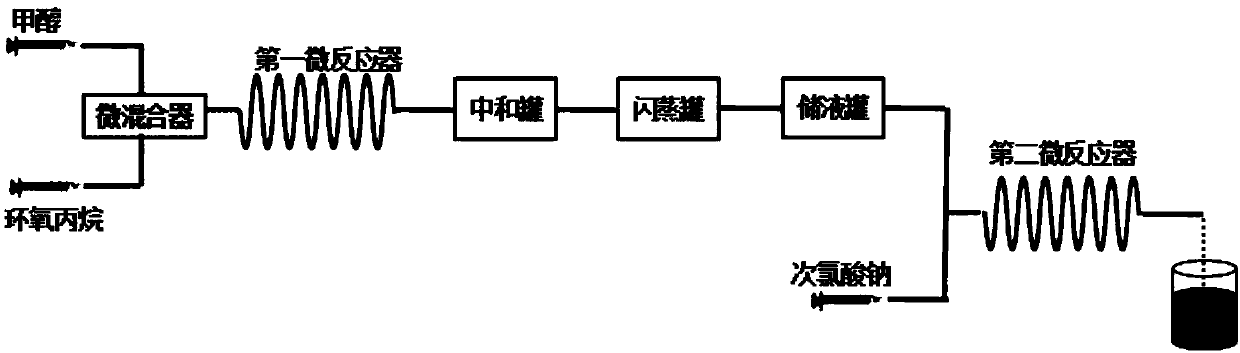

Method for preparing methoxyacetone by using microreaction device

ActiveCN107602358AEasy to operate and controlEasy to disassembleOrganic compound preparationEther preparation from oxiranesPropanolMicroreactor

The invention discloses a method for preparing methoxyacetone by using a microreaction device. The method comprises the following steps: mixing methanol with a basic catalyst to obtain a methanol solution; then pumping the methanol solution and epoxypropane into a micromixer in the microreaction device; sufficiently mixing and then introducing a mixed solution into a first microreactor in the microreaction device for reacting; after the reaction is ended, carrying out neutralizing and flash evaporation and concentration on a reaction solution to obtain 1-methoxy-2-propanol; pumping the 1-methoxy-2-propanol and an aqueous solution of sodium hypochlorite into a second microreactor in the microreaction device for reacting to obtain the methoxyacetone. According to the preparation method of the methoxyacetone, disclosed by the invention, the problems in the existing production can be overcome, the use of a complex catalyst is avoided, and the content of a byproduct is reduced; the production cost is low, the continuation degree of the process is high; the safety of the production process can be substantially improved; the quality of a product is improved.

Owner:NANJING UNIV OF TECH

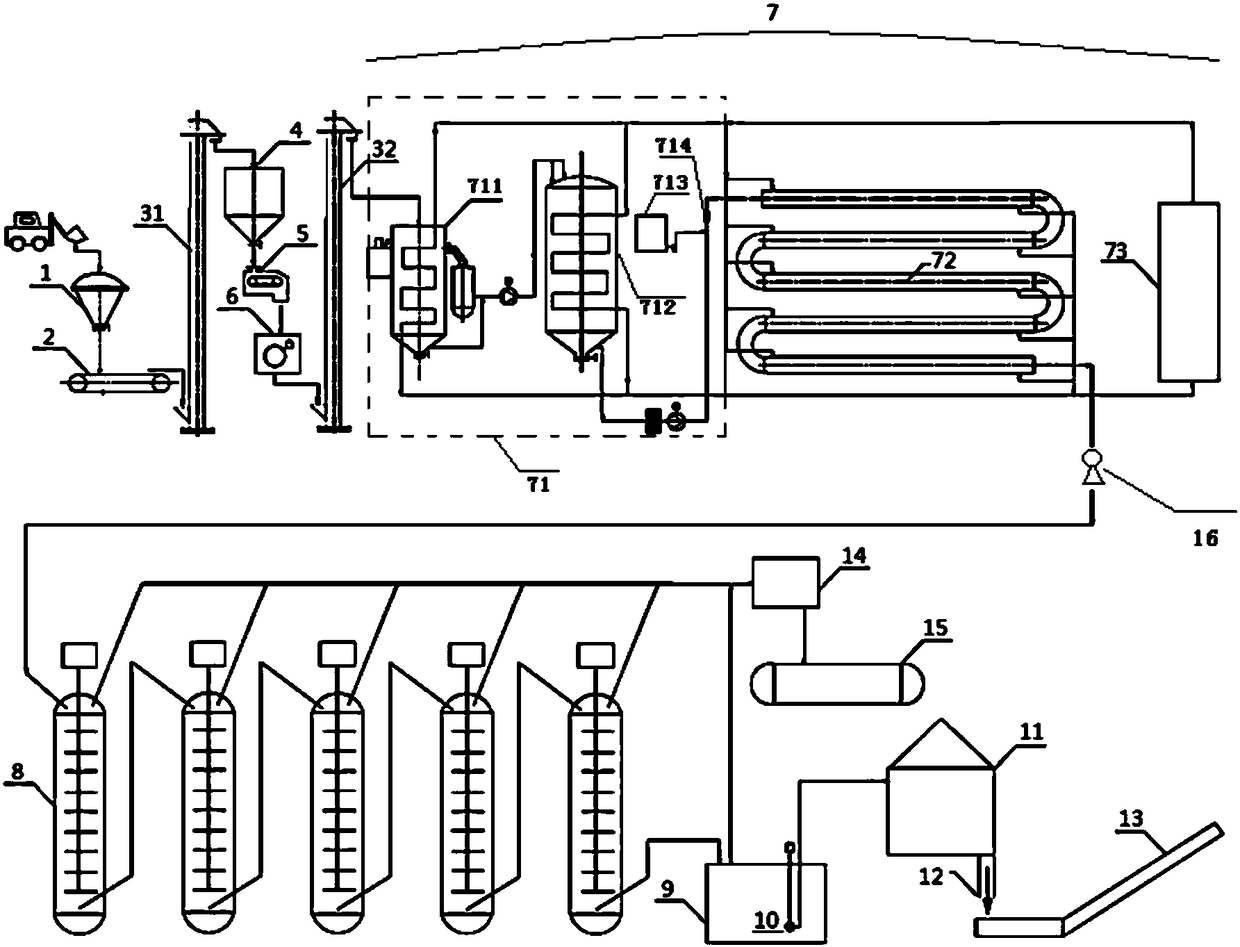

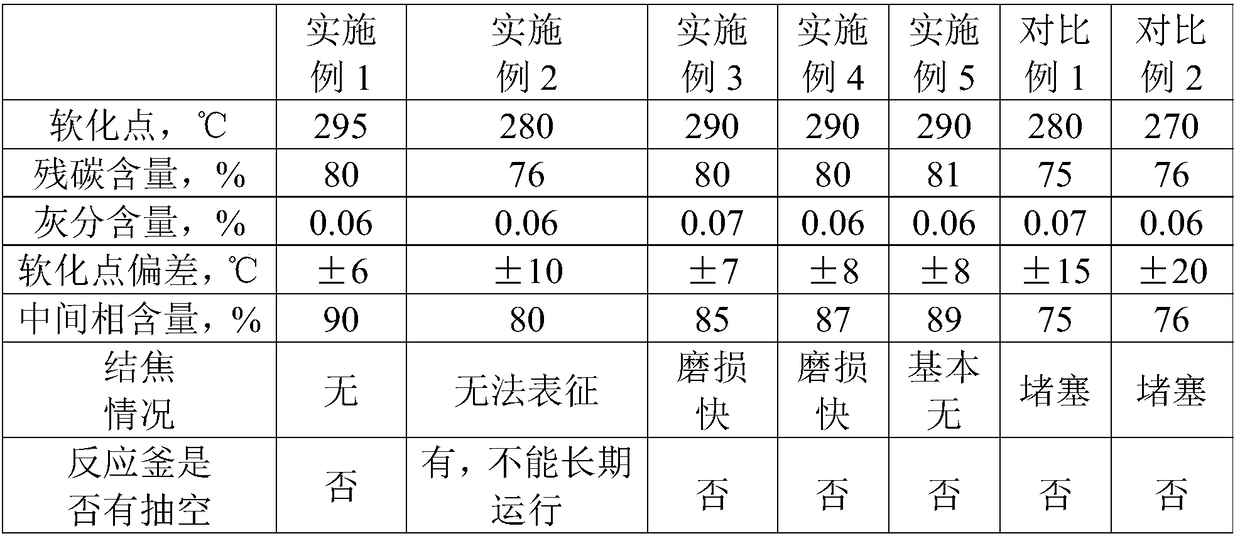

Mesophase pitch, and continuous production method and system thereof

ActiveCN108219813AShort reaction residence timeReduce in quantityWorking-up pitch/asphalt/bitumen by chemical meansWorking-up pitch/asphalt/bitumen by meltingProcess engineeringContinuous production

The invention relates to the field of mesophase pitch production, and discloses mesophase pitch, and a continuous production method and a continuous production system thereof. The system comprises a continuous heating feeding system (7) and a pitch polymerization reaction system (8) at downstream of the continuous heating feeding system (7); a discharging port of the continuous heating feeding system is connected with a feeding port of the pitch polymerization reaction system; the continuous heating feeding system comprises a pitch melting unit (71) and a pitch heating unit (72); the pitch polymerization reaction system comprises two to eight stages of reaction kettles which are connected in series and at least one stage of standby reaction kettle; the pitch heating unit comprises spaces for holding pitch and molten salt respectively. The method comprises the following steps: melting pitch; heating to a preset temperature to form pitch melt; adding the pitch melt into the pitch polymerization reaction system to perform contact reaction; heating the molten pitch through the molten salt, wherein the polymerization reaction system comprises two to eight stages of reaction kettles which are connected in series and at least one stage of standby reaction kettle. The produced mesophase pitch is high in quality controllability, uniform in softening point and high in stability; continuous production can be realized.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

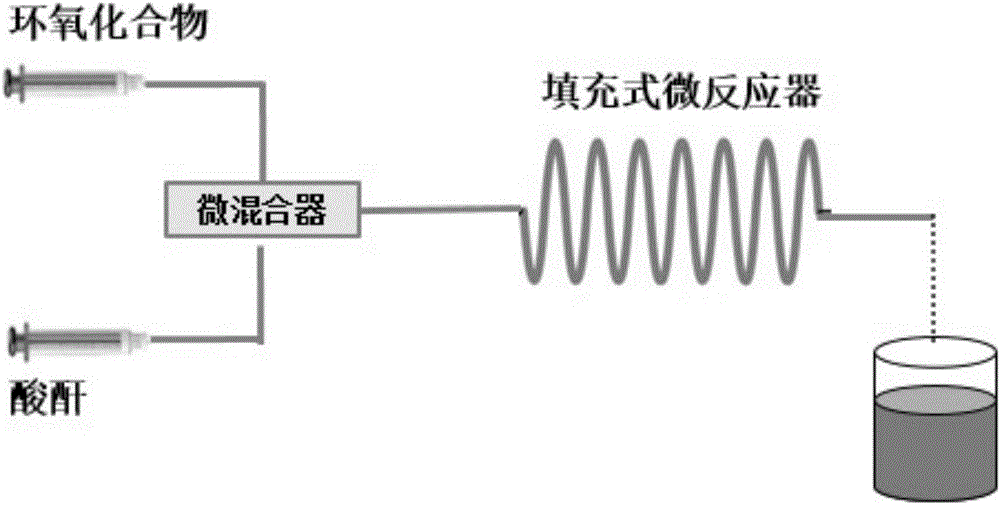

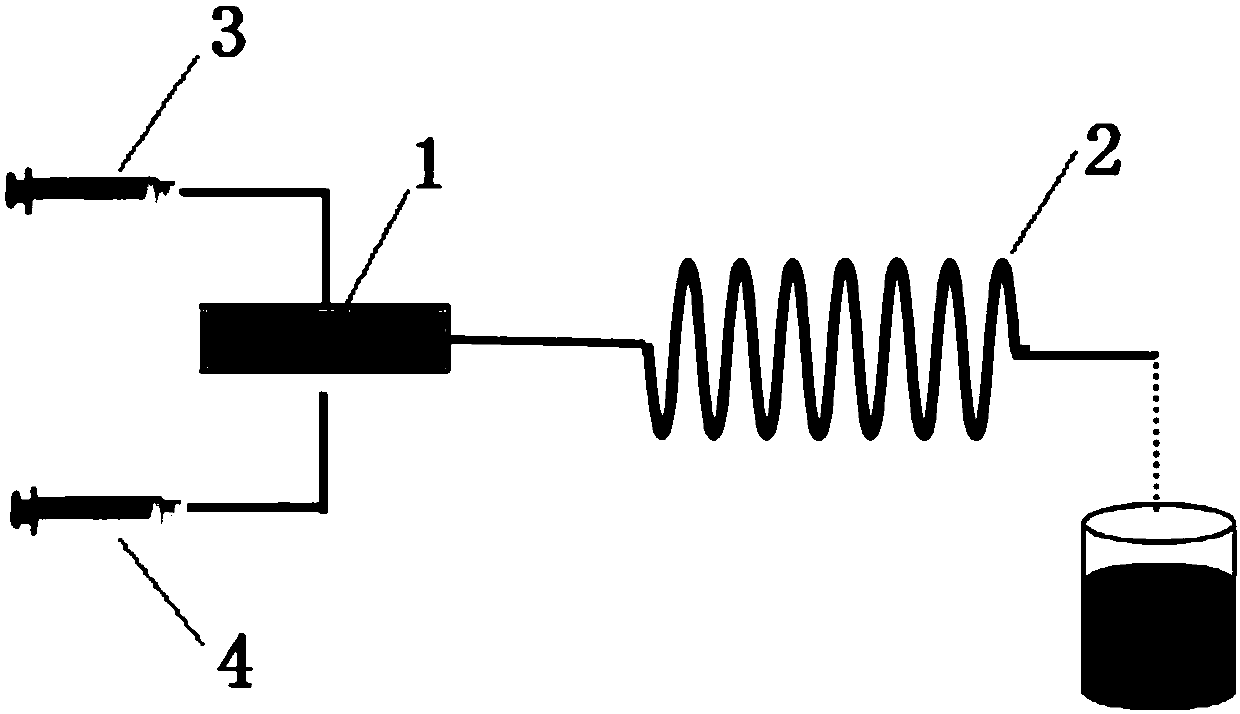

Method for preparing ring opening product of epoxide by adopting microreaction device

ActiveCN106431850AEasy to operate and controlEasy to disassembleMolecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsMicroreactorAcid anhydride

The invention discloses a method for preparing a ring opening product of an epoxide by adopting a microreaction device. The epoxide and acid anhydride are pumped into a micromixer of the microreaction device respectively at the same time and sufficiently mixed, a mixture is introduced into a microreactor of the microreaction device and subjected to sufficient reaction, a discharged product is washed and dried, and the ring opening product of the epoxide is obtained, wherein a catalyst is supported in the microreactor. Compared with the prior art, the catalyst which is low in cost, simple, available and easy to separate is used, the preparation process is simple and easy to control, and the product yield is high.

Owner:NANJING TECH UNIV

Method for preparing 1,4-dihydropyridine compounds by utilizing micro-reaction device

The invention discloses a method for preparing 1,4-dihydropyridine compounds by utilizing a micro-reaction device. The method comprises the following steps: mixing and dissolving aromatic aldehyde compounds, beta-dicarbonyl compounds and an ammonium salt so as to obtain a solution A; dispersing gamma-Fe2O3 nano-particles into absolute ethyl alcohol to obtain a solution B; respectively and simultaneously pumping the solution A and the solution B into a micro-mixer in the micro-reaction device, fully mixing, and introducing into the micro-reactor in the micro-reaction device to be reacted; centrifuging the discharged material in the micro-reactor to obtain an organic phase, washing the organic phase, performing vacuum concentration to obtain a coarse product, and separating and purifying thecoarse product, thereby obtaining the product. The highest yield of the 1,4-dihydropyridine compounds prepared by the invention can reach 99.9%, and the reason that the gamma-Fe2O3 nano-particles canbe repeatedly used by 30 times and the yield is invariable is because high catalytic activity can be always maintained when the product and toxins are continuously removed from the metal oxide surface. Moreover, any by-product is not produced in the method disclosed by the invention.

Owner:NANJING TECH UNIV

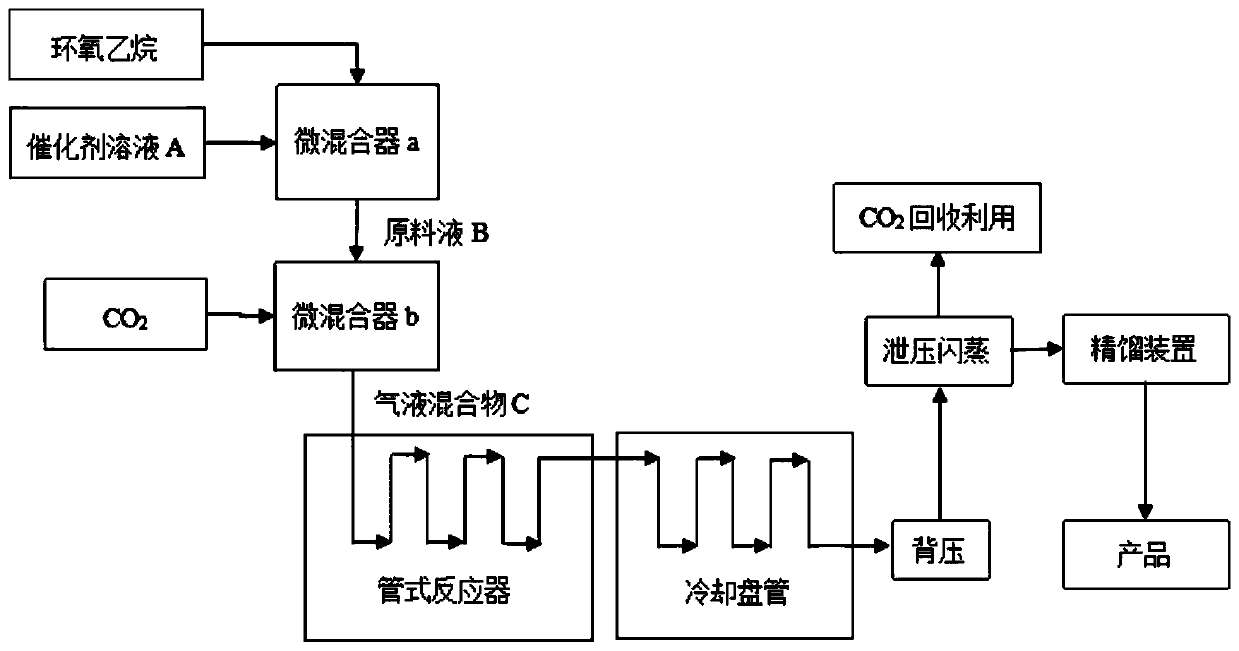

Method for continuously preparing ethylene carbonate

The invention relates to a method for continuously preparing ethylene carbonate. The method comprises the following steps: (1) mixing ethylene carbonate with a catalyst and water to obtain a catalystsolution A; (2) introducing CO2 into a reaction system, and performing back pressure regulation on the pressure of the reaction system to a required pressure by using a back pressure valve; (3) introducing the catalyst solution A and ethylene oxide into a micro-mixer, and quickly and uniformly mixing to obtain an ethylene oxide mixed solution B in which a catalyst is dissolved; (4) continuously introducing the mixed solution B and CO2 gas into a micro-mixer to obtain a gas-liquid mixture C, and enabling the gas-liquid mixture C to enter a tubular reactor for reaction; (5) introducing an obtained reaction liquid into a flash tank, and carrying out flash evaporation to separate out unreacted ethylene oxide, CO2 and water to obtain a primary product; and (6) rectifying the primary product obtained in the step (5) to obtain the product ethylene carbonate. The method is safe and efficient, and the reaction residence time is greatly shortened; the reaction efficiency is high, and the conversion rate of ethylene oxide is close to 100% in a short reaction residence time.

Owner:ZHEJIANG UNIV OF TECH

Continuous production method for vulcanization accelerator DPG

ActiveCN108586295ARealize continuous productionSmall liquid holding capacityOrganic chemistryOrganic compound preparationVulcanizationOrganic solvent

The invention provides a continuous production method for a vulcanization accelerator DPG. The method comprises the following steps that (1) diphenylthiourea, a catalyst, ammonium hydroxide and an organic solvent are mixed to obtain a reaction raw material mixture; (2) the reaction raw material mixture and an oxidizing agent are subjected to an oxidation reaction in a continuous flow reactor to obtain a reaction product; (3) the reaction product is post-treated to obtain the vulcanization accelerator DPG, wherein the organic solvent in step (1) can dissolve the diphenylthiourea and the vulcanization accelerator DPG. The method reduces the pressure in the reaction process, improves the utilization rate of the raw materials, stabilizes the product quality, greatly shortens the reaction timecompared with a conventional technology, improves the reaction yield, and effectively overcomes the disadvantage of traditional kettle type batch production.

Owner:KEMAI CHEM

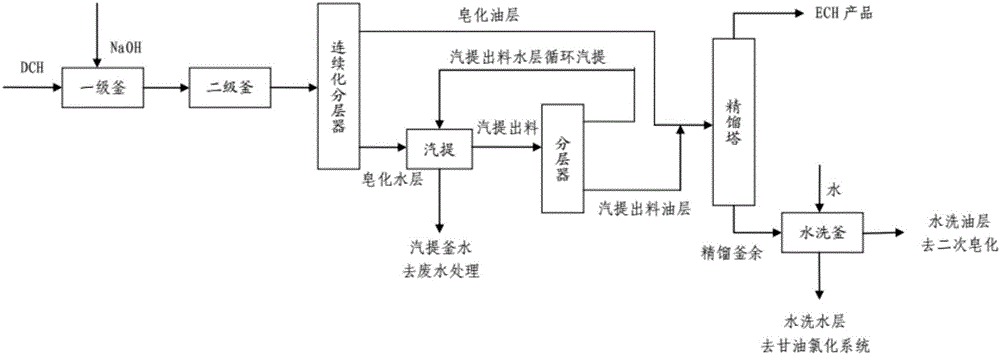

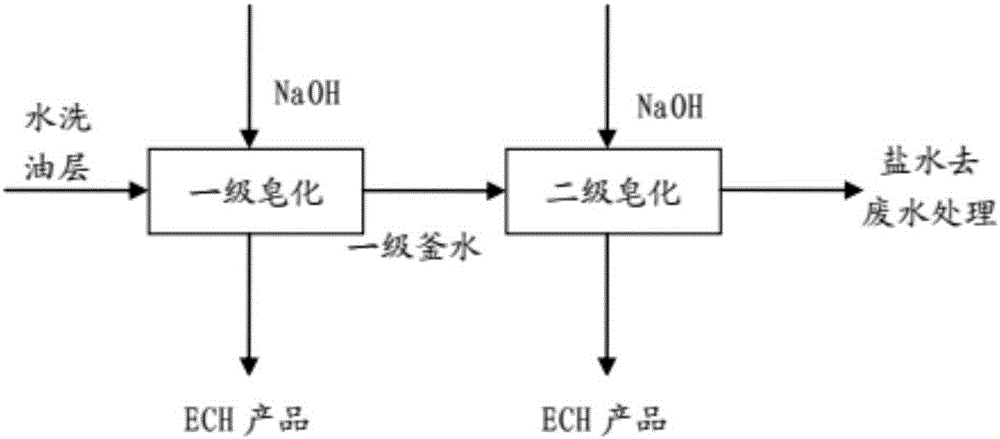

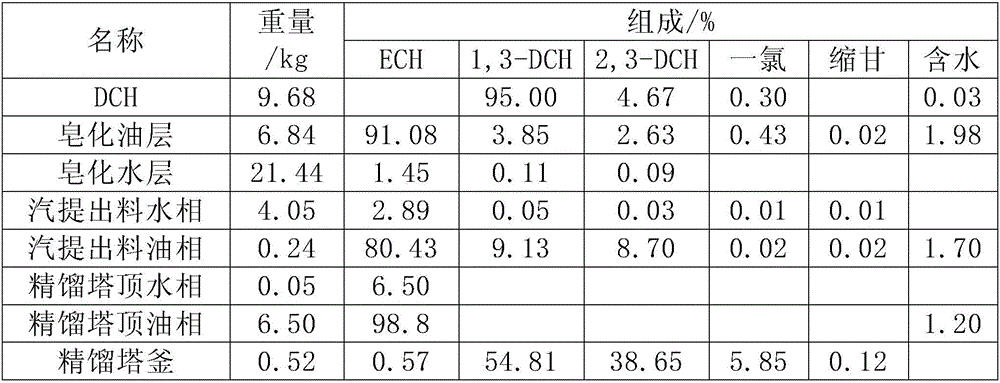

Process improvement for producing epichlorohydrin by using glycerin method dichloropropanol as raw material

ActiveCN106632149AAvoid hydrolysisShort reaction residence timeOrganic chemistryReaction speedEpichlorohydrin

The invention aim at providing a method for producing epichlorohydrin by using glycerin method dichloropropanol as a raw material with step-by-step saponification. Compared with the prior art, the process has the characteristics of mild reaction conditions, simple process, low alkali consumption, low brine TOC, high ECH yield, and the like. Different reaction speeds of each component in DCH are used, the step-by-step saponification method is used, firstly primary normal pressure intermittent or continuous saponification is used, oil and water are layered, an oil layer is rectified in order to obtain an ECH product, and negative pressure secondary saponification is carried out for unreacted DCH in a column reactor. A washing process is used, most monochloropropanediol in a primary saponification rectifying still residue is separated, monochloropropanedio and DCH in a washing water layer return to a glycerin chlorination system for reusage. After washing, negative pressure high alkali ratio is used for the primary saponification rectifying still residue in order to carry out secondary saponification, and continuous industrial production is realized.

Owner:JIANGSU YANGNONG CHEM GROUP +2

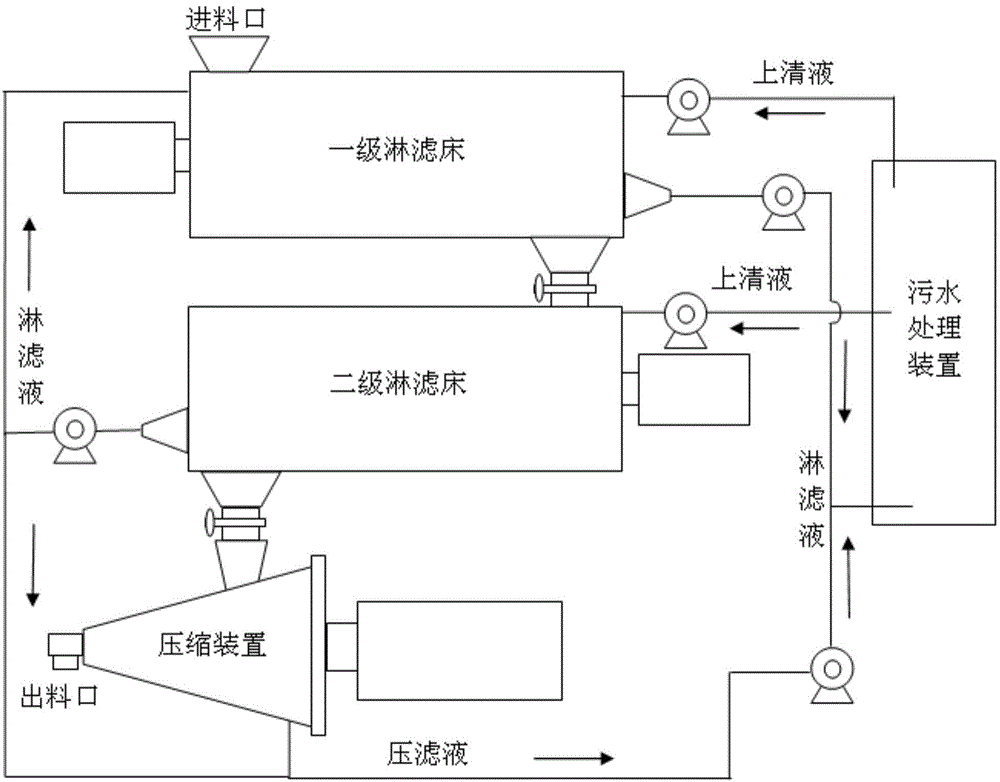

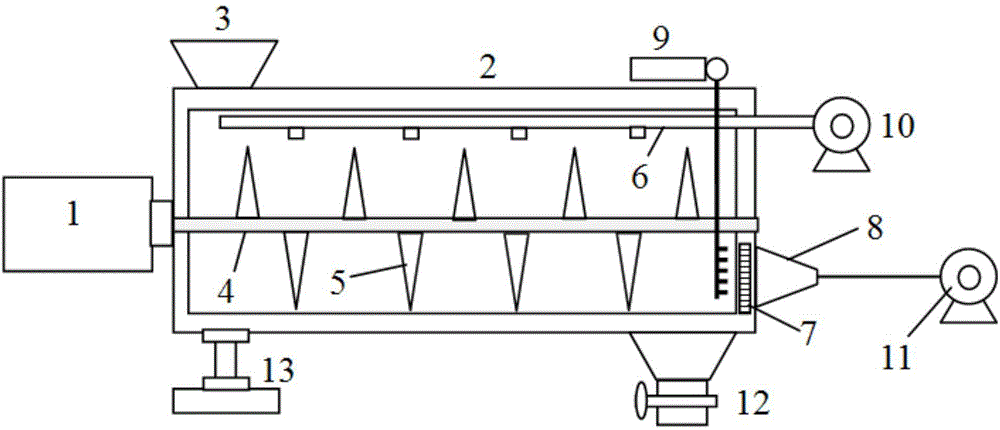

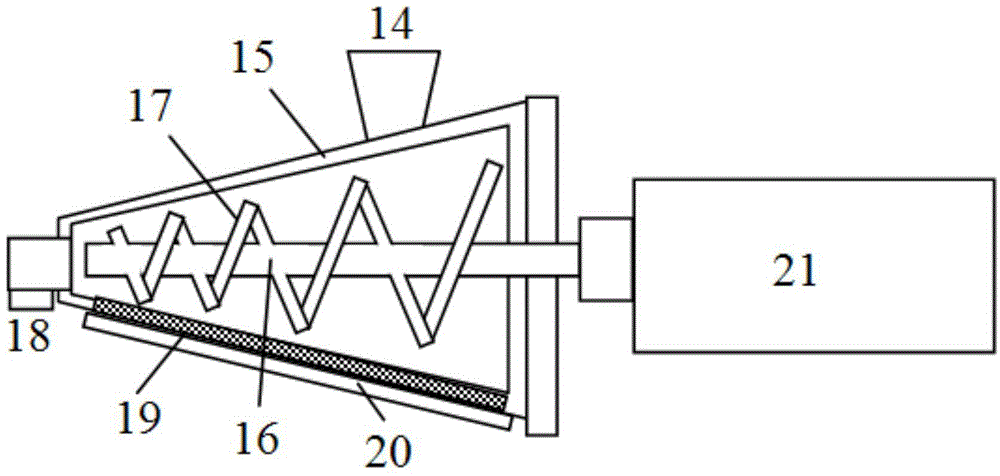

Novel multi-stage treatment process for leaching and compressing household garbage

InactiveCN104690017AReduce moisture contentReduce removalSolid waste disposalTransportation and packagingFiltrationWater circulation

The invention provides a novel multi-stage treatment process for leaching and compressing household garbage and belongs to the field of treatment of household garbage. The treatment process comprises a two-stage leaching bed reactor, a spiral compression device, a sewage treatment device and a water circulation system, wherein the treatment process comprises the following steps: introducing the garbage into a multi-stage leaching bed, leaching by using supernatant liquid of the sewage treatment device, fully leaching under the stirring action of blades to obtain sewage with high content of organic matters, collecting the sewage, continuing to leach by using a secondary leaching solution, pushing residual garbage into a press filtration part, extruding and dewatering until the water content in the garbage is smaller than 40%. By virtue of the novel multi-stage treatment process, the leaching components are removed in the municipal household garbage in the process; the residual garbage is dewatered and compacted; the organic wastewater generated in the process is aerobically or anaerobically treated; by virtue of combination of a plurality of processes, the purpose of quickly and efficiently reducing volume and quantity of the municipal household garbage is achieved.

Owner:DALIAN TEDA ENVIRONMENTAL PROTECTION +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com