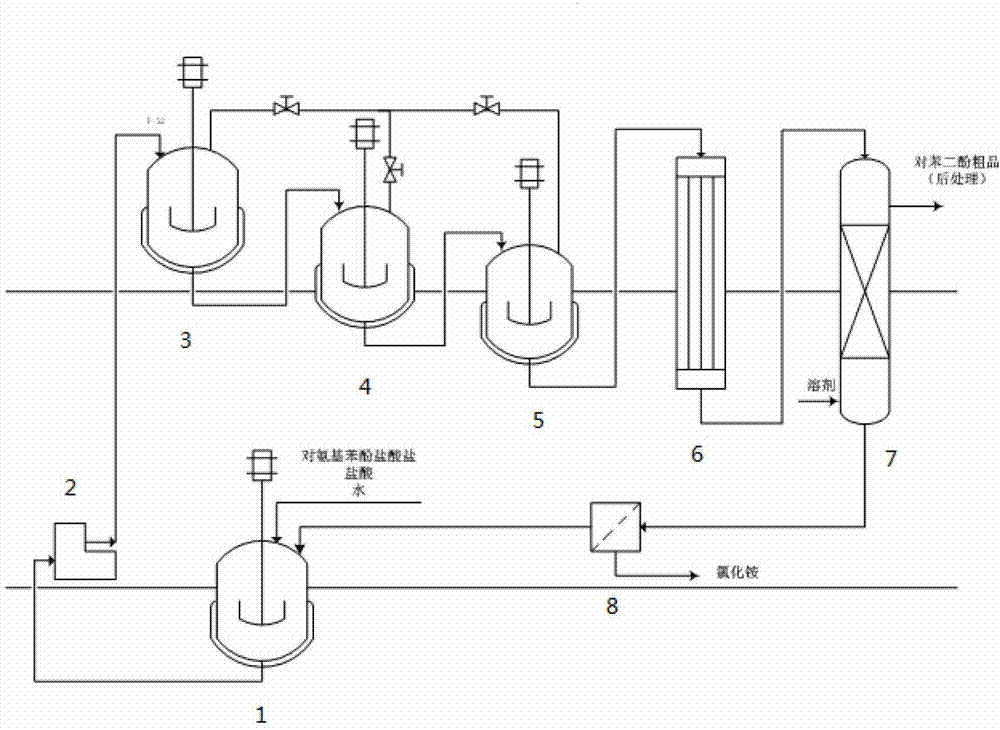

Production process for continuously hydrolyzing and producing hydroquinone through multi-kettles in series

A technology of hydroquinone and multiple kettles in series is applied in the field of continuous hydrolysis of multiple kettles in series to produce hydroquinone production technology, which can solve the problems of large amount of waste water, high energy consumption, low production capacity, etc., and achieves large material capacity and operation Safe, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

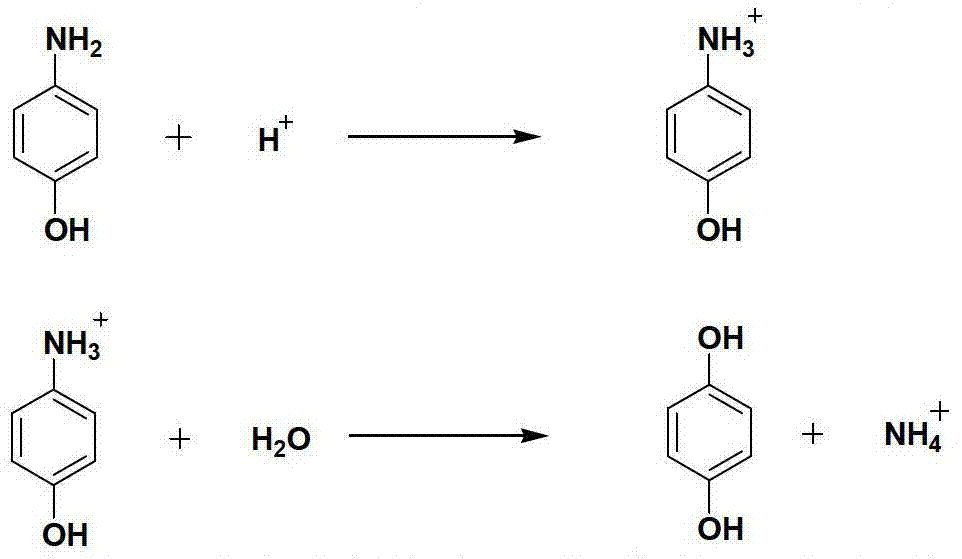

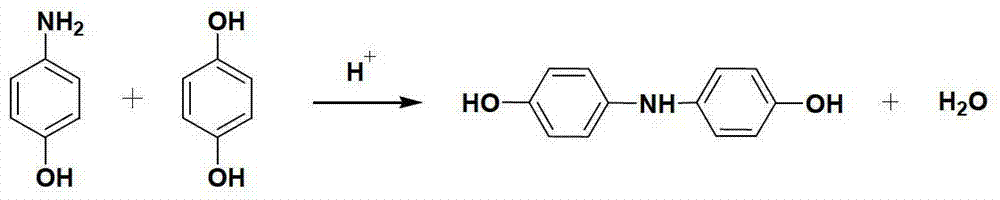

Method used

Image

Examples

Embodiment 1

[0038]Synthesize hydroquinone through three-stage serial tank reactors, each reactor has a volume of 100L, and maintain a certain position difference between the upper and lower reactors (the potential difference can be 0.1-1 meter), and each tank is connected in series through pipelines , The gas phase is connected in parallel to keep the pressure between the reactors in balance. Add water, 30% hydrochloric acid and p-aminophenol hydrochloride in the batching kettle of 3000L, determine p-aminophenol hydrochloride: hydrochloric acid: the mol ratio of water is 1:3:100, and material total amount is 2500L. The material is pumped from the batching tank into the reaction tank through the metering pump, and the flow rate is controlled at 0.8L / min. At the same time, under the condition that the pressure in each reactor is balanced, the reaction material flows from the upper level to the next level. The volume of the material in the reaction kettle is 80L, so that the reaction time of...

Embodiment 2

[0040] Hydroquinone is synthesized through three-stage series reactors, each reactor has a volume of 100L, and a certain positioning difference is maintained between the upper and lower reactors. Each reactor is connected in series through pipelines, and the gas phase is connected in parallel, so that the The pressure is balanced. Add water, 30% hydrochloric acid and p-aminophenol hydrochloride in the batching kettle of 3000L, determine p-aminophenol hydrochloride: hydrochloric acid: the mol ratio of water is 1:3:100, and material total amount is 2500L. The material is pumped into the reaction kettle from the batching tank through the metering pump, and the flow rate is controlled at 1.2L / min. At the same time, under the condition that the pressure in each reactor is kept balanced, the reaction material flows from the upper level to the next level by itself. The volume of the material in the reaction kettle is 80L, so that the reaction time of the reaction material in the kett...

Embodiment 3

[0042] Hydroquinone is synthesized through three-stage series reactors, each reactor has a volume of 100L, and a certain positioning difference is maintained between the upper and lower reactors. Each reactor is connected in series through pipelines, and the gas phase is connected in parallel, so that the The pressure is balanced. Add water, 30% hydrochloric acid and p-aminophenol hydrochloride in the batching kettle of 3000L, determine p-aminophenol hydrochloride: hydrochloric acid: the mol ratio of water is 1:4:50, and material total amount is 2500L. The material is pumped into the reaction kettle from the batching tank through the metering pump, and the flow rate is controlled at 1.2L / min. At the same time, under the condition that the pressure in each reactor is kept balanced, the reaction material flows from the upper level to the next level by itself. The volume of the material in the reaction kettle is 80L, so that the reaction time of the reaction material in the kettl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com