Patents

Literature

88results about How to "Continuous production process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

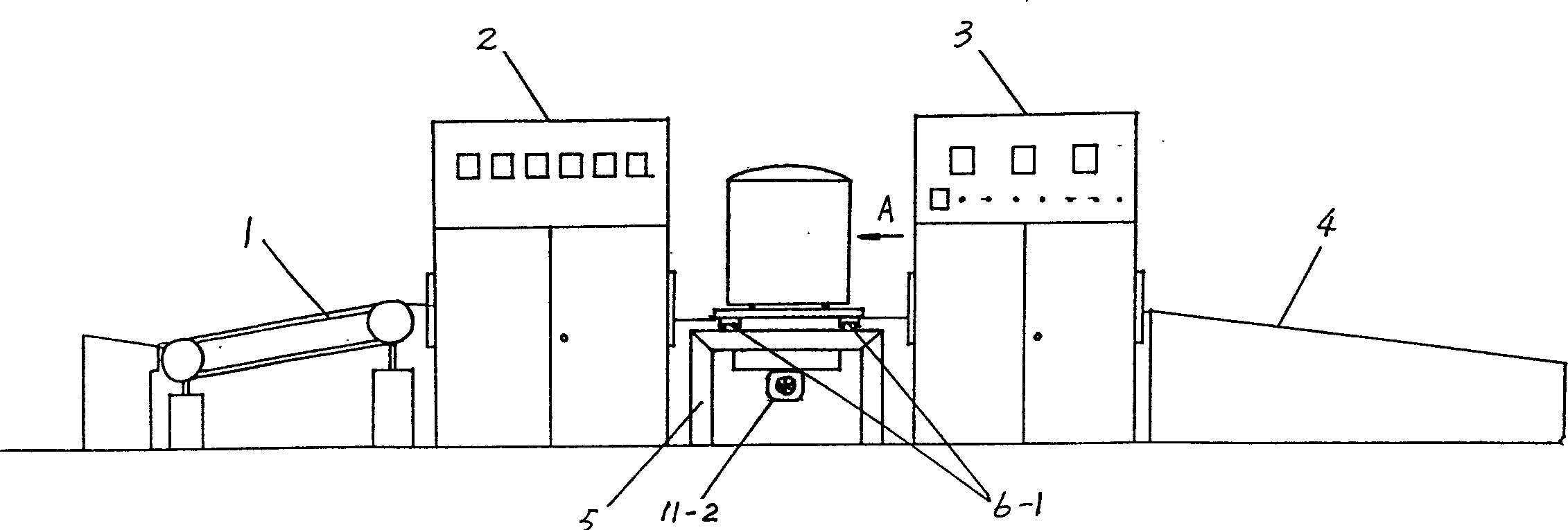

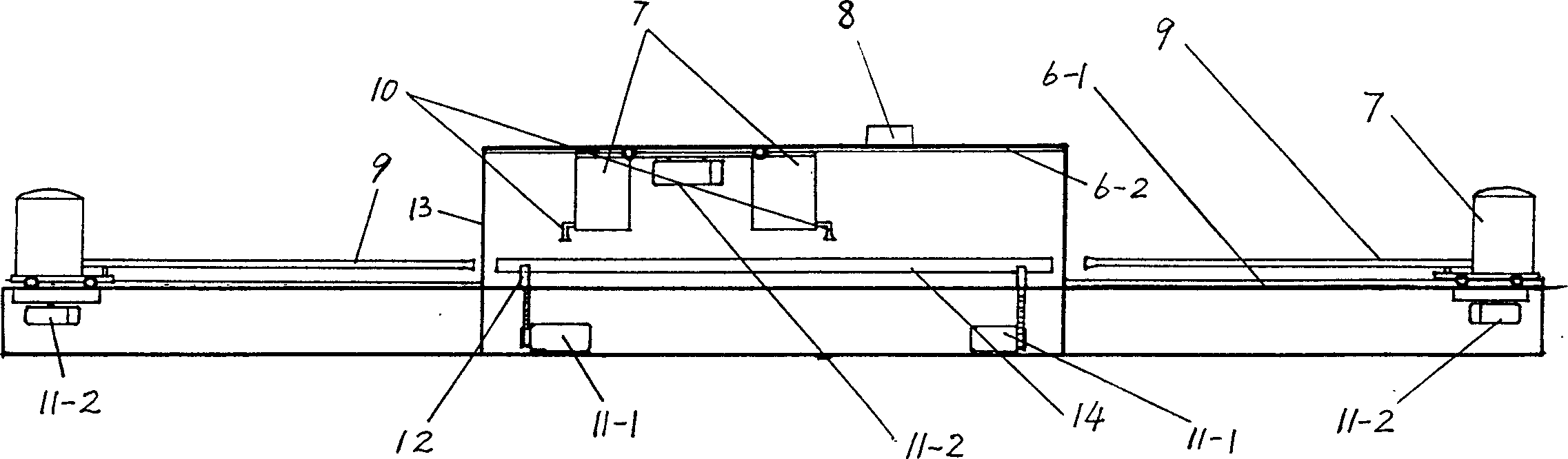

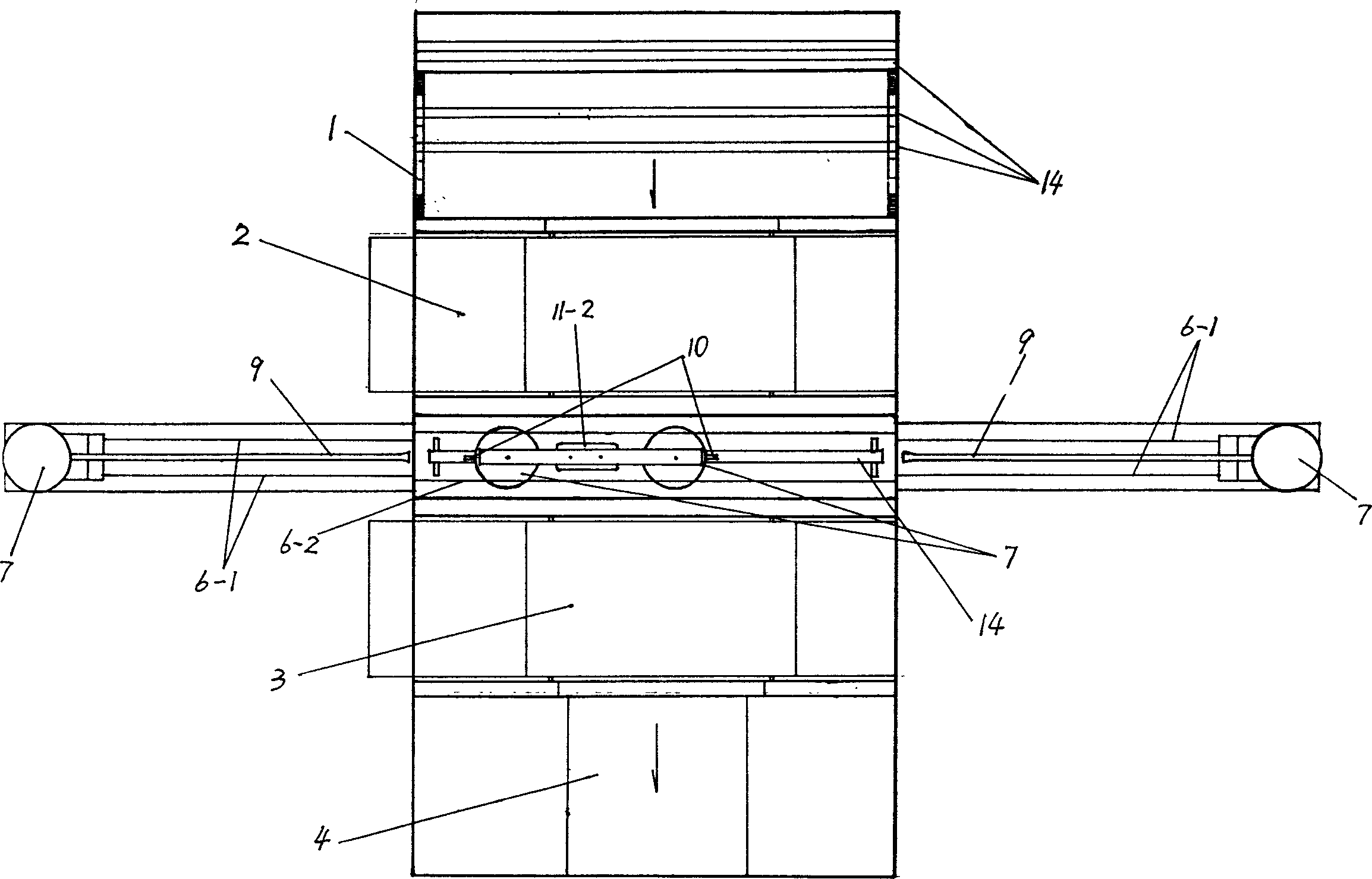

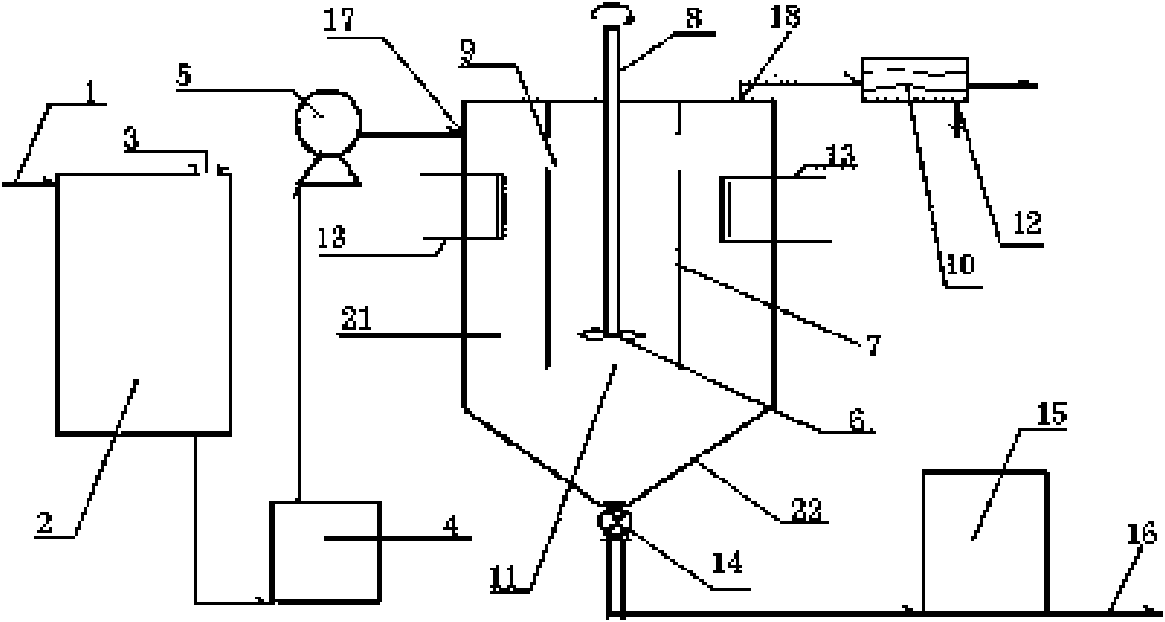

Electric heating type inside and outside spraying equipment and process for steel-plastic composite pipe

The present invention provides electrically heated composite steel-plastic pipe inside and outer spraying apparatus and technique to form homogeneous, smooth and clean plastic coating layer. The technological scheme is that the work bench is provided with two pairs of rotating wheels to support the steel pipe and with motor below them; two lower siding rails with siding fluidizing barrel, inner spraying nozzle and shifting motor; and upper sliding rail over the steel pipe and with two turned fluidizing barrels, outer spraying nozzle and shift motor. The technological process includes derusting, heating, spraying to the inner and outer walls, leveling and curing, cooling, inspection, and piling. The present invention may be used in water supplying pipe and water draining pipe production industry.

Owner:姜宜川

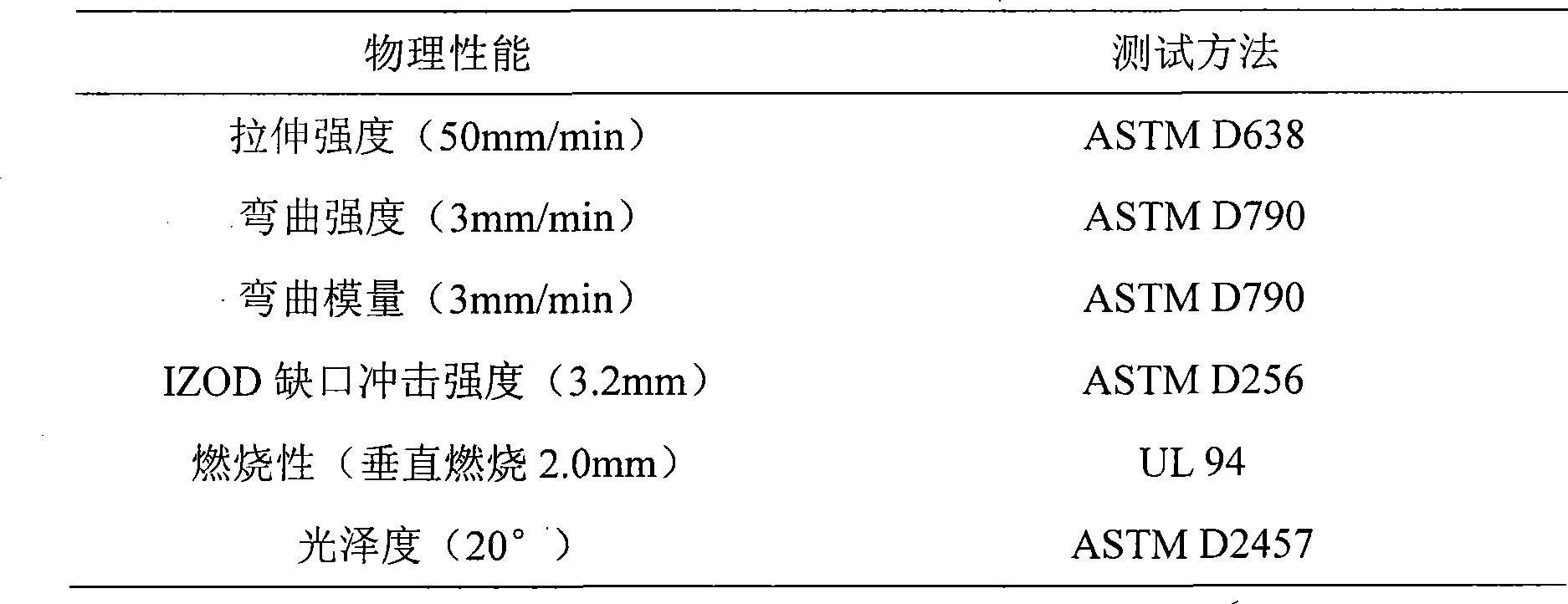

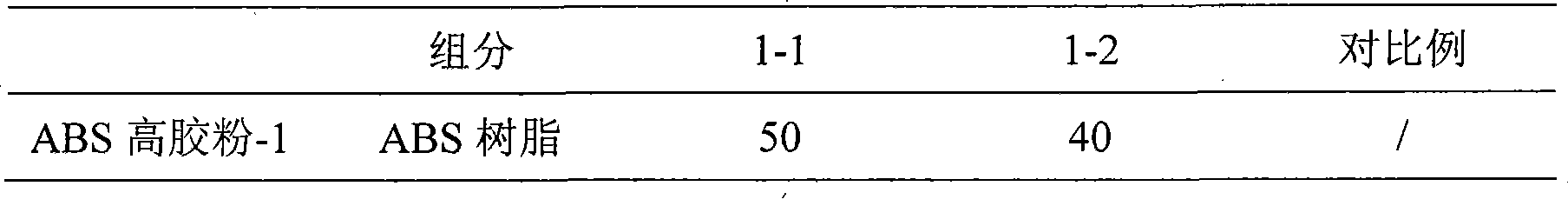

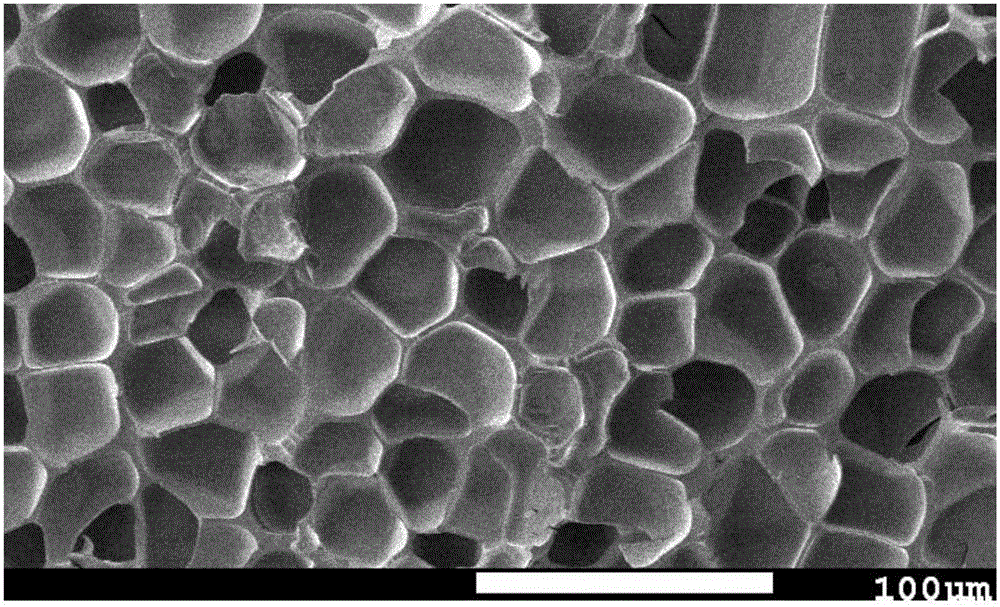

High gloss flame-retardant ABS modified resin and preparation thereof

The invention relates to the technical field of polymer material, in particular to a flame-retardant ABS modified resin having high glaze and a manufacturing method thereof. The invention provides the flame-retardant ABS modified resin having high glaze, which comprises ABS high glue powder, SAN resin, brominated flame retardant, antimonic flame retardant, antioxidizer, heat stabilizer and processing aid. The flame-retardant ABS modified resin is characterized in that the ABS has the rubber-particle size being less than 1mum. Based on maintaining excellent physical property of the original ABS resin, the flame-retardant ABS modified resin having high glaze has good flame retardant property and the high glaze of the surface. The flame-retardant ABS modified resin having high glaze can be prepared by traditional twin-screw extrusion process equipment, has the advantages of simple and continuous production flow, high production efficiency and stable product quality, and can be widely applied to the industries such as household electrical appliances having high glaze and flame-retardant requirements, automobile industry, etc.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

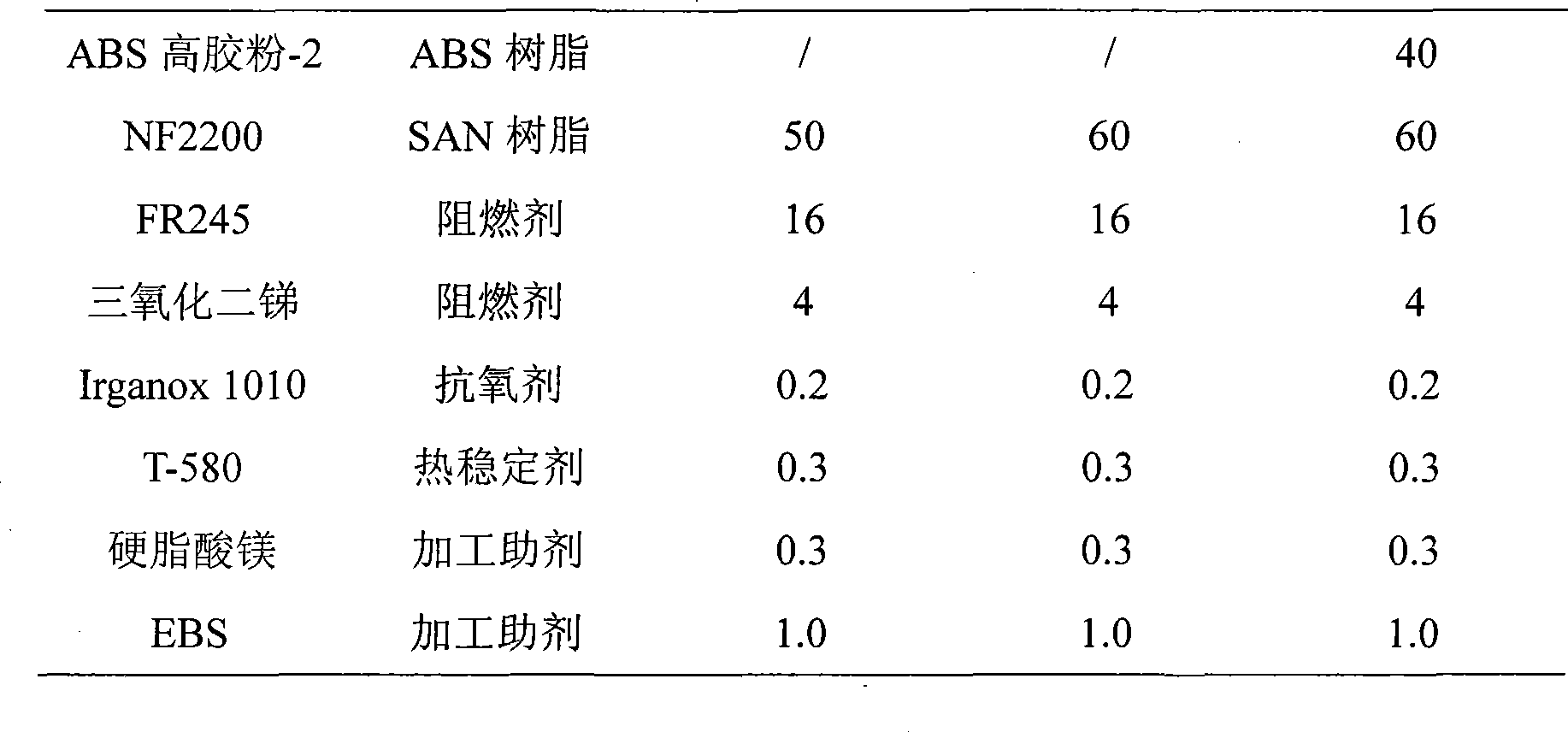

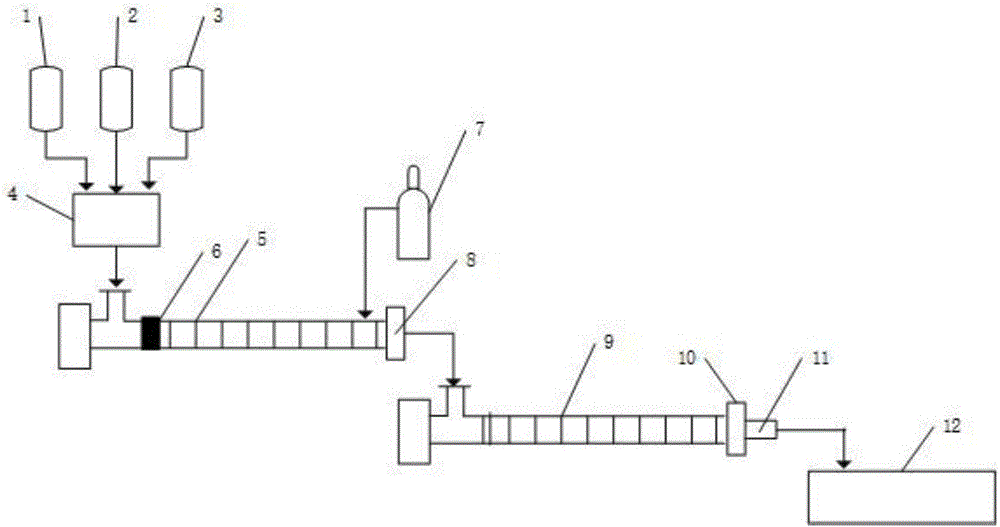

Foamed type TPU (thermoplastic polyurethane elastomer) material and preparation method thereof

The invention relates to a foamed type TPU (thermoplastic polyurethane elastomer) material and a preparation method thereof. The preparation method comprises the following steps: polymer polyol, diisocyanate and a chain extender are taken and poured into a casting machine to be mixed uniformly, then a mixture I is added to a first reactive extrusion machine for a polymerization reaction, and a TPU polymer melt is obtained; a physical foaming agent is injected into the tail end of a screw of the first reactive extrusion machine, the TPU polymer melt is mixed preliminarily with the physical foaming agent, and a mixture II is obtained; the mixture II is added to a second reactive extrusion machine, and the physical foaming agent and the TPU polymer melt are mixed uniformly to form a homogeneous system; the homogeneous system passes through a neck ring mold of the second reactive extrusion machine and then is subjected to underwater palletizing, and foamed thermoplastic polyurethane particles are obtained; the foamed thermoplastic polyurethane particles are dehydrated and dried, and the foamed type TPU material is obtained. The foamed type TPU material has stable foaming density, the batch-to-batch product quality is stable, central control monitoring is performed at any time, and the yield is increased.

Owner:MIRACLL CHEM

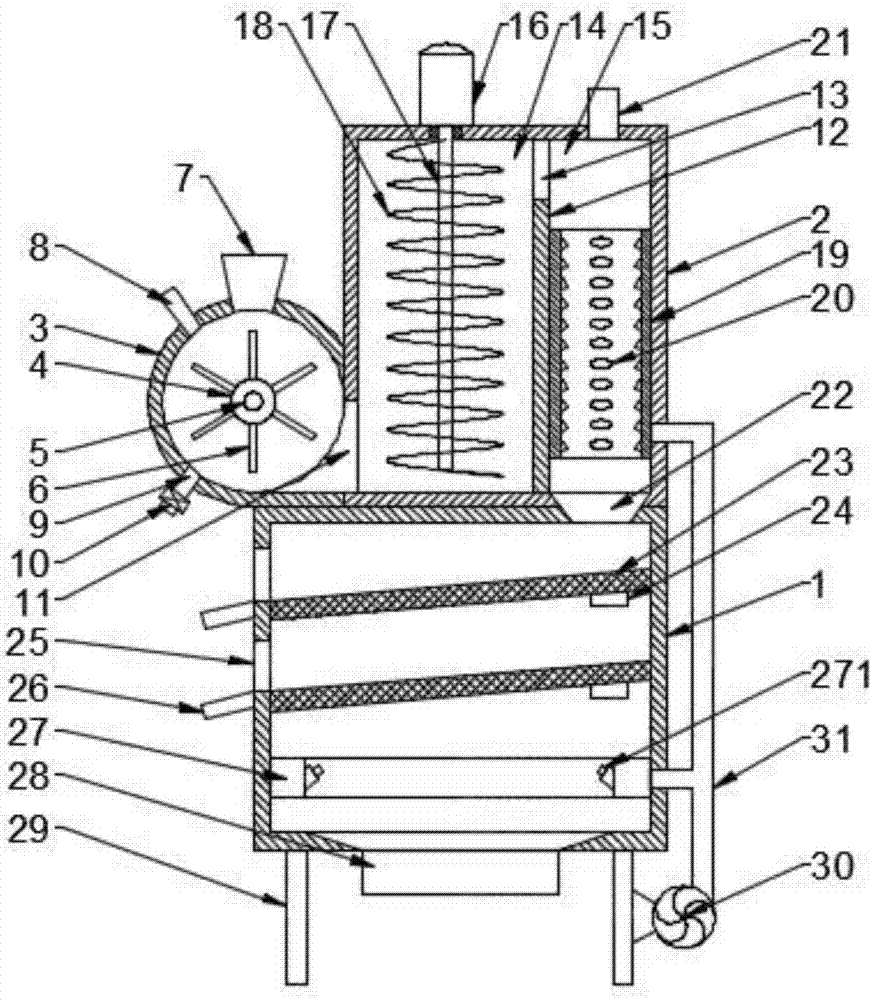

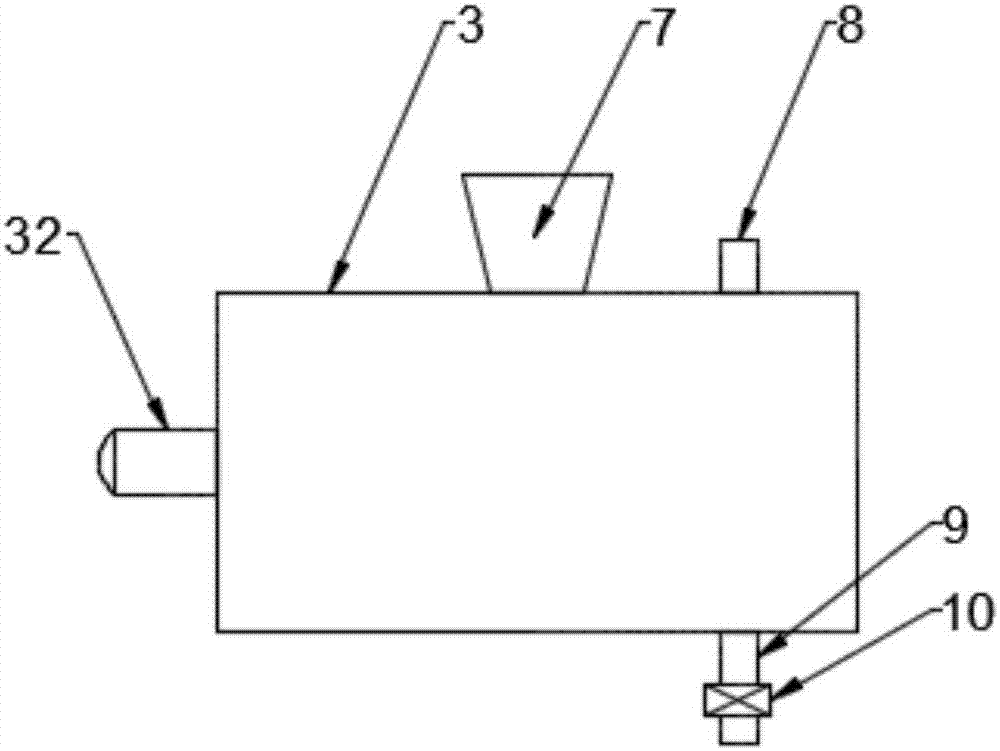

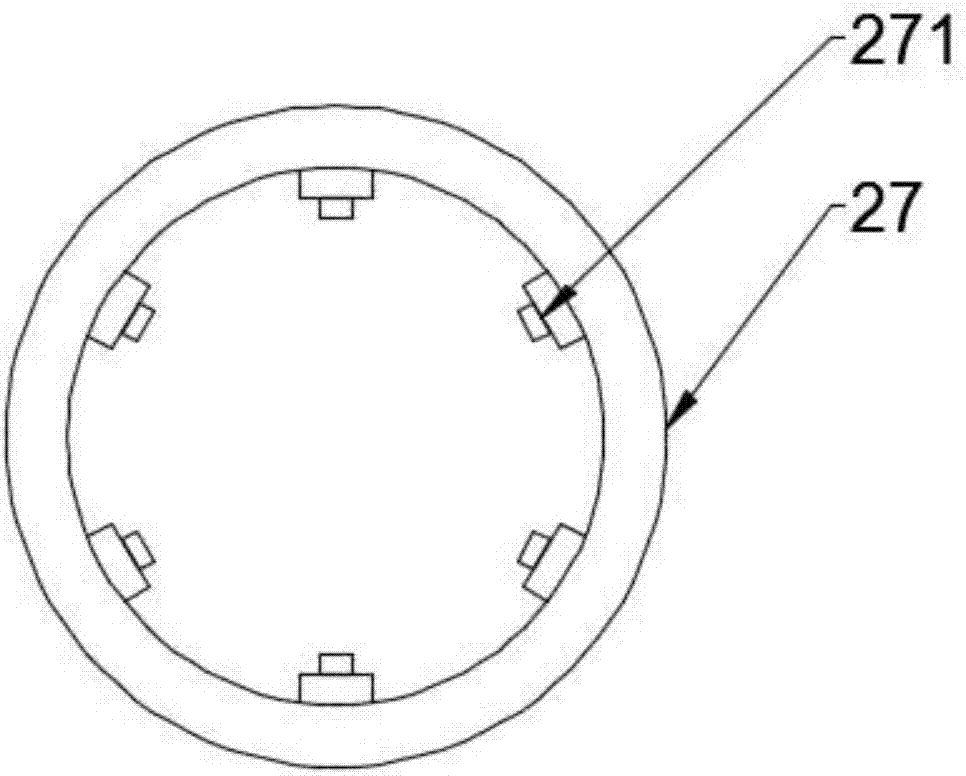

Crop seed cleaning, grading and drying all-in-one machine

InactiveCN107175234AReduce area requirementsSmall footprintSievingGas current separationAgricultural engineeringSmall footprint

The invention discloses a crop seed cleaning, grading and drying all-in-one machine. The crop seed cleaning, grading and drying all-in-one machine comprises a screening box, a transfer box and a cleaning box; the top end of the screening box is fixedly connected with the cleaning box and the transfer box, a rotating roller is arranged in the cleaning box, the rotating roller is rotatably connected to the cleaning box through a rotating shaft, multiple stirring blades are evenly arranged on the rotating roller, a partition board is arranged in an inner cavity of the transfer box, the inner cavity of the transfer box is partitioned by the partition board into a material extracting cavity and a drying cavity, a stirring rod is arranged in the material extracting cavity, and is sleeved with a packing auger, a first blowing device is sleeved with the drying cavity, multiple screening nets are evenly arranged in an inner cavity of the screening box from top to bottom, and a vibrator is arranged at the bottom end of each screening net. The cleaning box, the screening box and the drying mechanism are arranged at the same time, crop seeds can be subject to cleaning, cleaning, impurity removal and drying procedures on one device, the equipment occupied area is small, the requirement for the plant area is low, the production process is continuous, full-automation production is achieved, and work strength is low.

Owner:贵港市益福美农资有限公司

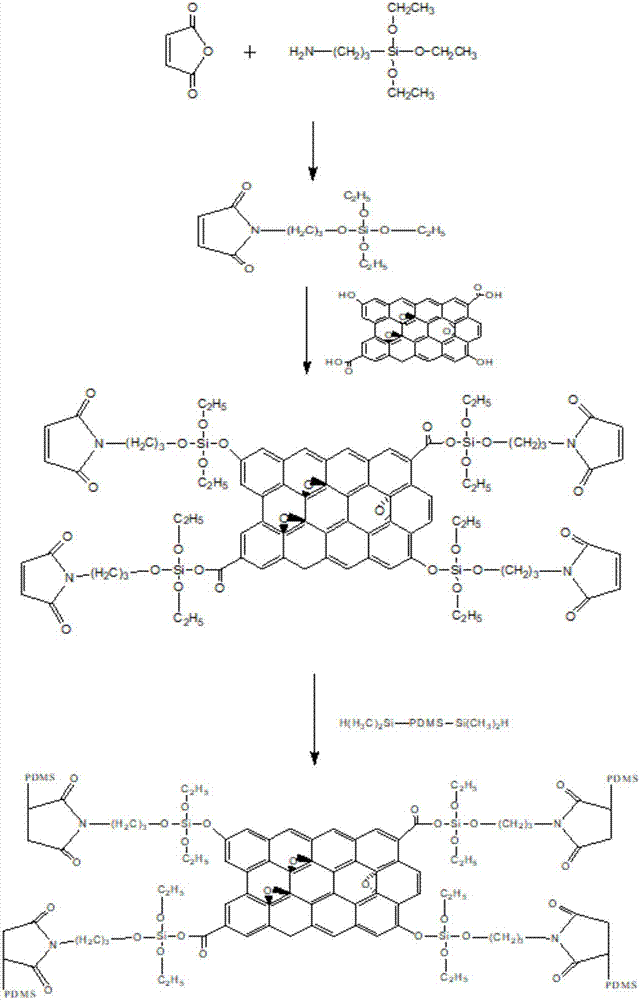

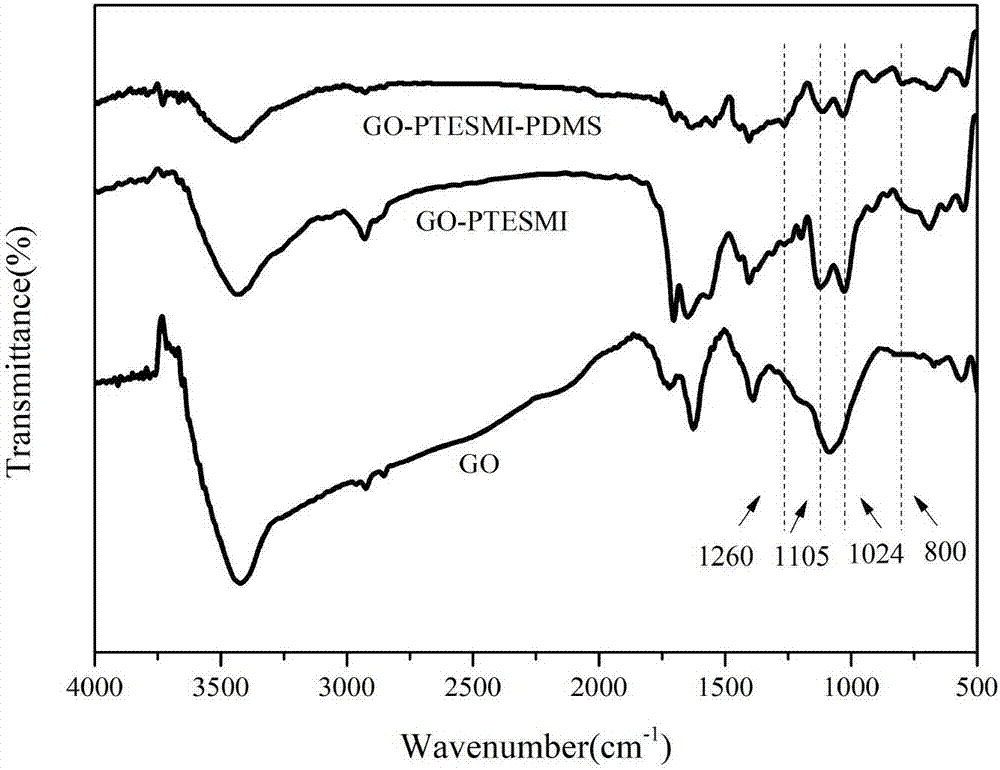

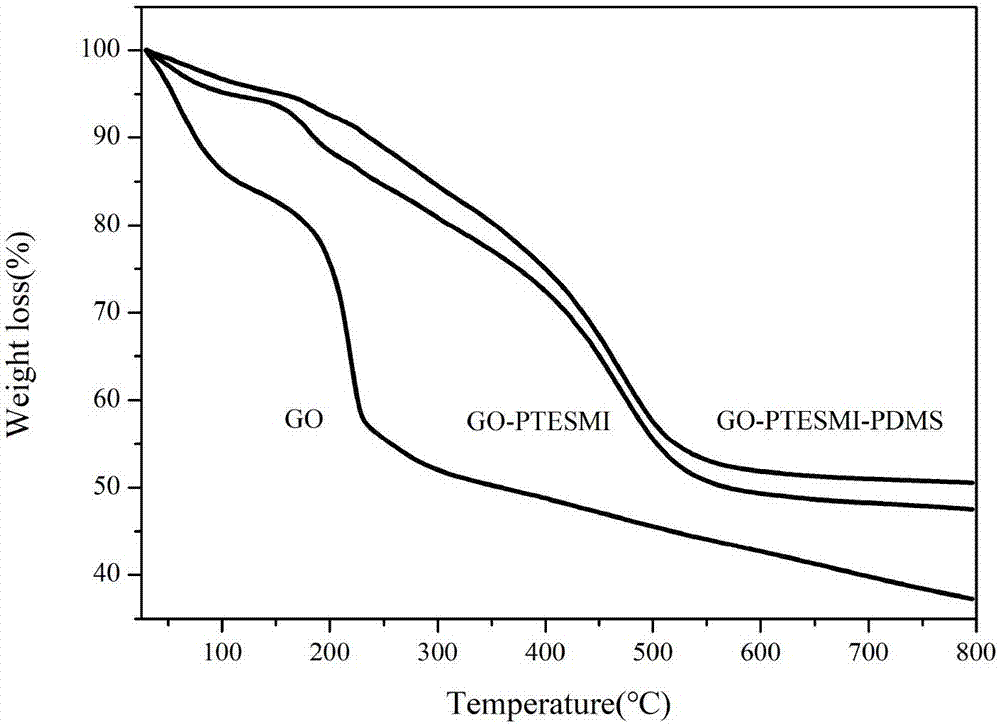

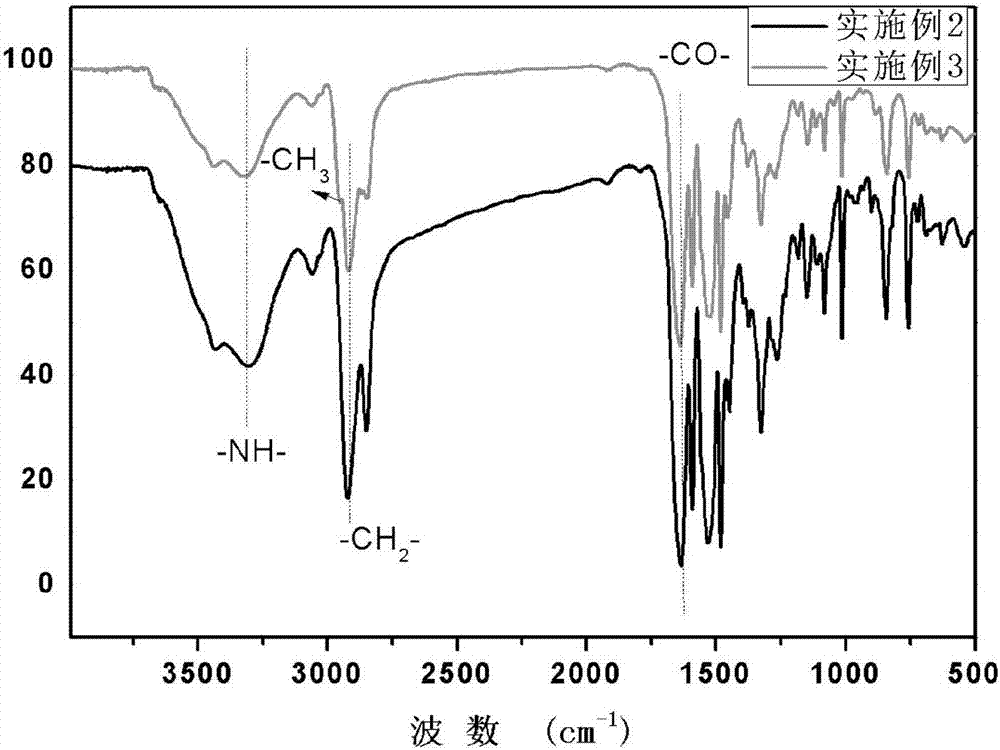

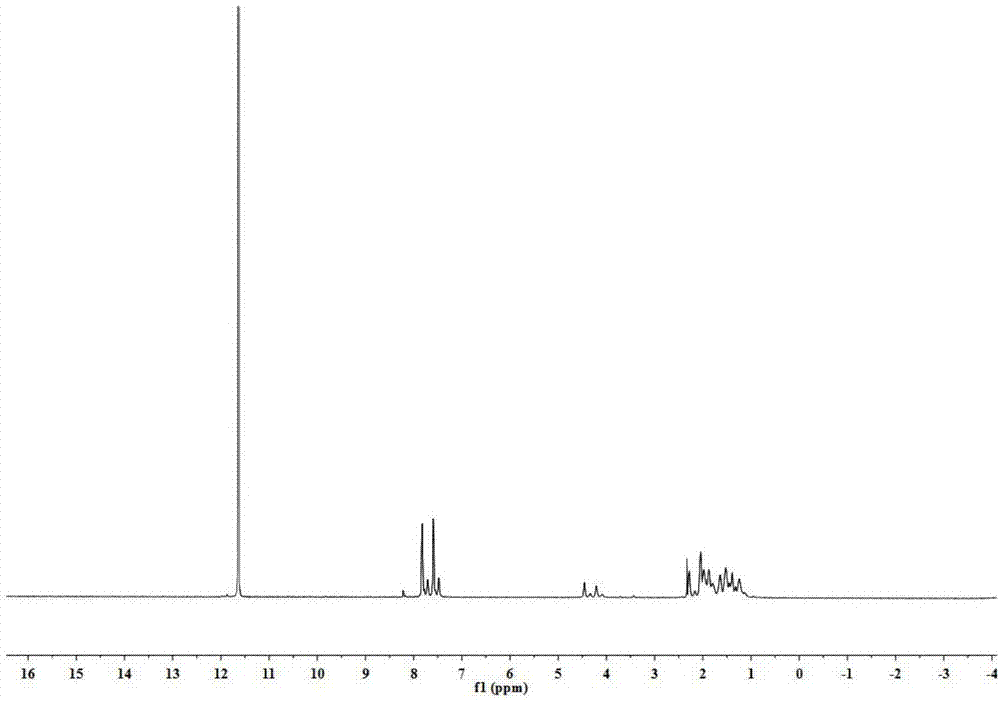

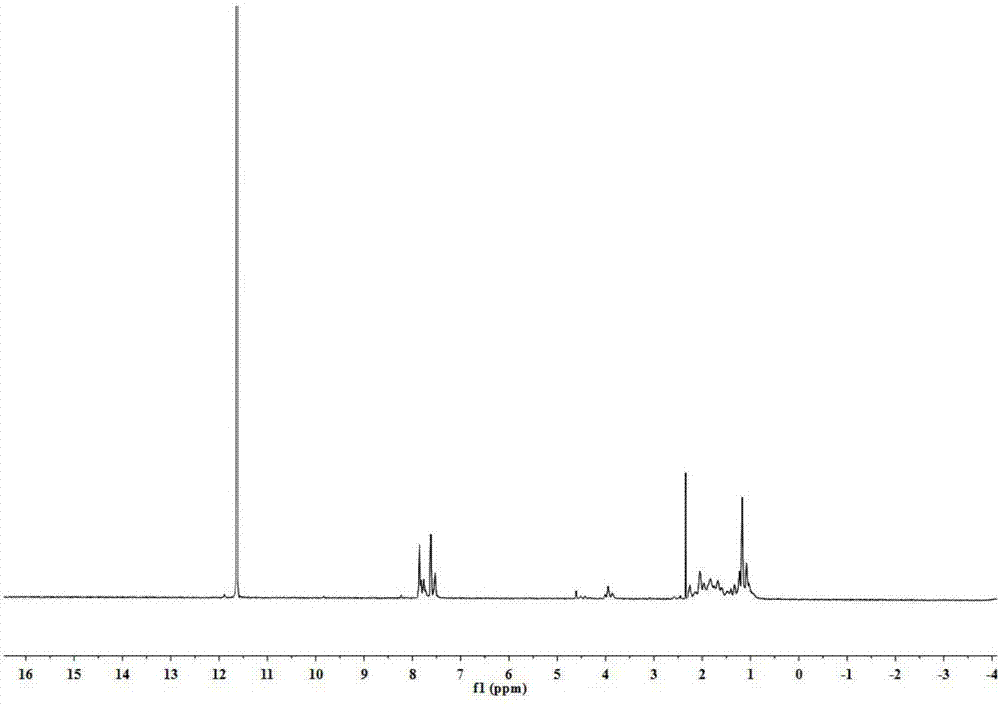

Functionalized GO (graphene oxide) and RTV (room temperature vulcanization) silicone rubber nanocomposite and preparation method thereof

The invention discloses a functionalized GO (graphene oxide) and RTV (room temperature vulcanization) silicone rubber nanocomposite and a preparation method thereof. The method comprises steps as follows: firstly, the surface of GO is grafted with maleimide siloxane, GO-PTESMI is obtained, then double bonds of maleimide on grafting chains in GO-PTESMI are subjected to a hydrosilation reaction with Si-H group terminated PDMS (polydimethylsiloxane) in a solution, and GO (functionalized GO) with surface linked with PDMS grafting chains containing imide groups is prepared; then the functionalized GO is dispersed in a dispersing agent uniformly, and the silicone rubber nanocomposite with different content of functionalized GO is prepared through solution blending. According to the invention, imide bonds and polysiloxane long chains are introduced to the surface of GO, so that interface interaction force and mechanical properties of the nanocompoiste can be improved simultaneously, and the RTV silicone rubber material with capacity of playing excellent performance of GO better is prepared.

Owner:FUJIAN NORMAL UNIV

Barium chloride production technology

InactiveCN101654274AReduce the number of devicesContinuous production processCalcium/strontium/barium chloridesChemistryBarium chloride

The invention discloses a technology for producing barium chloride by the witherite containing barium carbonate, which mainly comprises steps as follows: sulfur iron impurities are decomposed and oxidated to remove and the hydrated barium salt raw material liquid is prepared; the raw material liquid is electrically heated and concentrated in vacuum, which is driven by an axial flow pump, the solute is thermally crystallized to form the hydrated barium chloride dihydrate saturated crystalline; the crystallized hydrate is cooled to produce the serial barium salt products, wherein the vacuum heating condensation crystallization is a continuous production process; the whole technological process is implemented in the closed state; the by-products could be recycled; the crystallisation processis completed at one time and the production process is continuous. The products manufactured in the technological process has low impurity content, saves energy, is adaptive to the large-scale industrialization production and reduces the pollution and resource waste to a large extent.

Owner:重庆洋铭化工产品有限公司

Agricultural magnesium sulphate fertilizer and preparation thereof

The invention discloses an agricultural magnesium sulfate fertilizer and a preparation method thereof; wherein, the preparation method thereof comprises the following steps: (1) magnesia ore powder and water are fully stirred in a slurry mixer and prepared into magnesia slurry; (2) the mixed magnesia slurry is fed into a mixed reactor to be mixed and reacted with the vitriol continuously added into the mixed reactor; the adding amount of vitriol is adjusted to lead the reaction temperature of the mixed slurry at the outlet of the mixed reactor to be controlled between 121 DEG C and 155 DEG C; (3) the reacted mixed slurry is fed into a returning formation chamber for further reaction and curing, and the water in the materials is baked and vaporized by the self reaction heat of the mixed slurry to dry and solidify the materials; and (4) the cured mixed materials are shaped and packaged, thus becoming the finished product of the agricultural magnesium sulfate fertilizer. The preparation method of the agricultural magnesium sulfate fertilizer has the advantages of high production efficiency, high degree of mechanization, no waste water and solid waste discharge, and small pollution.

Owner:德钾盐亚太私人有限公司

Method for preparing polyethylene foam material by taking water as foaming agent

ActiveCN101519504APromote safe productionProduction environmental protectionFoaming agentPolymer science

The invention relates to a method for preparing a polyethylene foam material by taking water as a foaming agent. The method includes the steps that polyethylene is used as a raw material, water is used as the foaming agent, imvite, diatomite, fibrino, starch, polyacry lamide, and the like are used as water carriers, and a direct squeezing-out method is used for preparing polyethylene foam plastic. The invention does not use the organic foaming agent, thus, the production process of the technology has safety and environmental protection and can realize continuous production, and the foaming rate of the prepared polyethylene foam plastic is 3 to 20 times.

Owner:天津佰盛环保科技有限公司

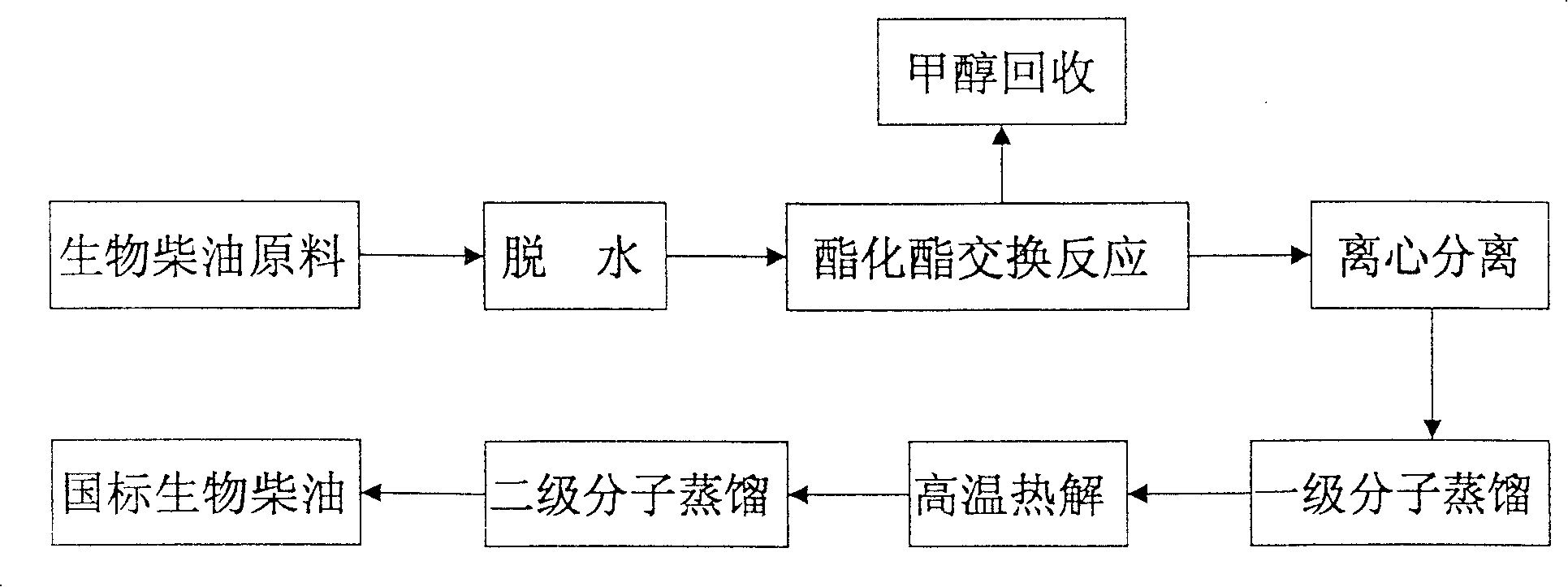

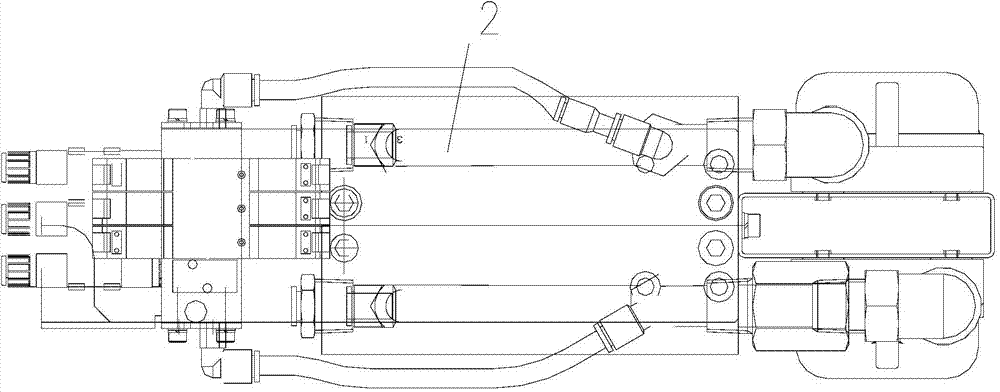

Technique for continuous production of biological diesel oil with propagation waste oil

InactiveCN101173176ALow production costSimple production processBiofuelsLiquid hydrocarbon mixture productionVegetable oilReaction rate

The invention provides a technological method that utilizes the waste oil of animals and plants to continuously produce biodiesel. The technical proposal of the invention is that, waste edible oil, high acid value oil, animal and vegetable oils, oil foot and other components are used as materials; dehydration treatment, esterification and transesterification, methanol recovery, separation of fatty acid methyl ester and glycerol according to densities by a centrifuge, molecule distillation deacidification, high temperature decomposition of ester soluble impurity, and molecule distillation deodorization are directly performed; the finished product, which is light yellow fatty acid methyl ester, namely 0<#> biodiesel, is acquired by continuous production. The method continuously and rapidly semi-automatically completes esterification and transesterification reaction to get fatty acid methyl ester under completely vacuum condition at a certain temperature, and the problems of high production cost, low yield and long reaction time of biodiesel production by common esterification method are effectively solved. The invention has the advantages of no three wastes produced during the whole production process, green environmental protection, obviously lowered labor intensity, easy operation, low energy consumption, effectively reduced production cost of the biodiesel, fast reaction rate, improved productivity, and fitness for large scale industrial production.

Owner:崔明林

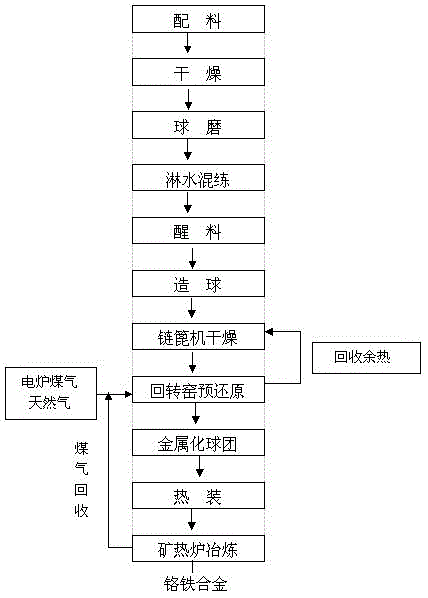

Method for producing ferrochrome

The invention discloses a method for producing ferrochrome and relates to chain grate-rotary kiln combined metalized pellet hot-filled methods for producing ferrochrome. The method is characterized in that a production process sequentially comprises the steps of proportioning materials, drying, carrying out ball milling, carrying out water-sprayed mulling, carrying out material waking, pelletizing, carrying out drying and preheating, carrying out rotary kiln pellet prereduction, carrying out hot filling and carrying out submerged-arc furnace smelting. According to the method disclosed by the invention, through material proportioning, ball milling and pelletizing, exhaust gas of a rotary kiln is used for drying and preheating in a chain grate, coal gas of a closed submerged-arc furnace and natural gas are used for heating, carbon in coke powder is used for reducing oxides of chromium and iron in chromite ore powder pellets, the comprehensive reduction rate of metal is controlled to reach 55-70%, the pellets are enabled to be metalized, and then, hot filling is used for carrying out transporting so as to supply high-carbon ferrochrome to submerged-arc furnace smelting. The method disclosed by the invention has the advantages that furnace conditions are effectively improved, the production process is stable in process, the reduction efficiency is high, the power consumption is low, the production cycle of the submerged-arc furnace is shortened, the consumption of the raw materials is low, the metal recovery rate is high, and the discharge of pollutants, such as dust and SO2, is low.

Owner:HEBEI TAIHANG FOUND MINERAL RESOURCES CO LTD

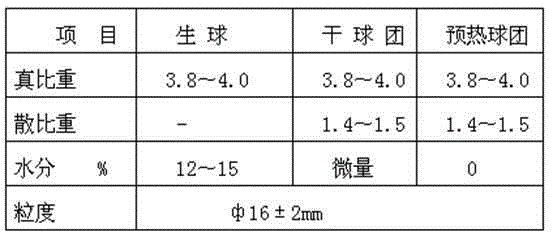

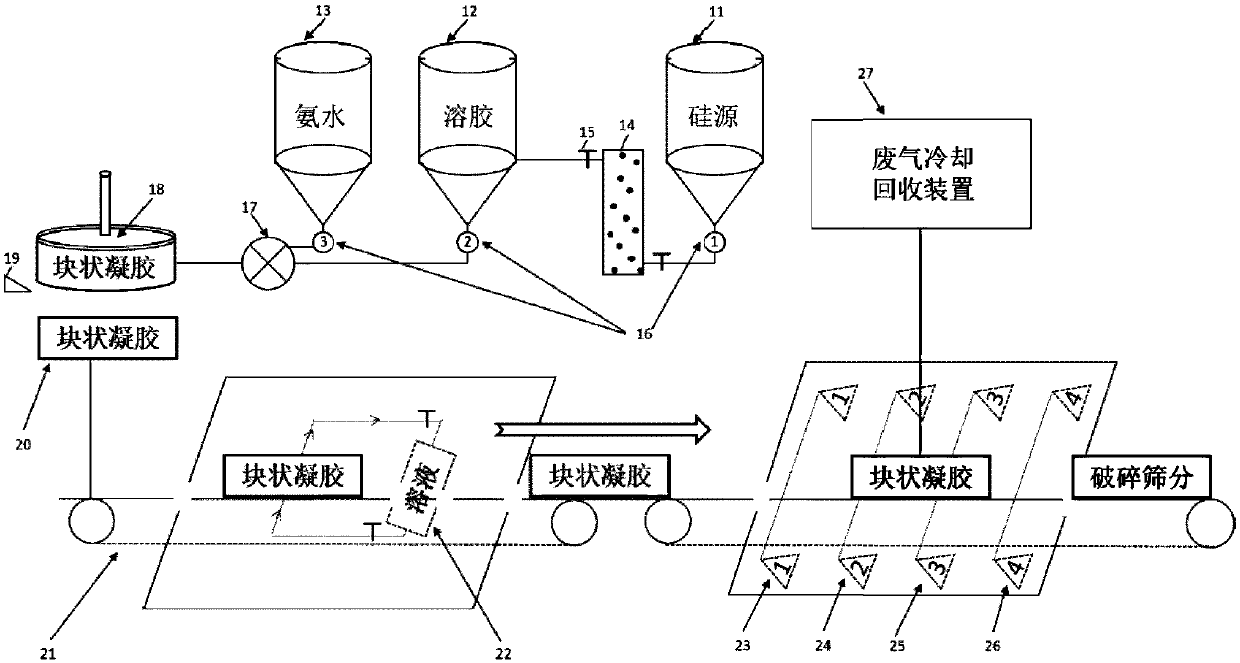

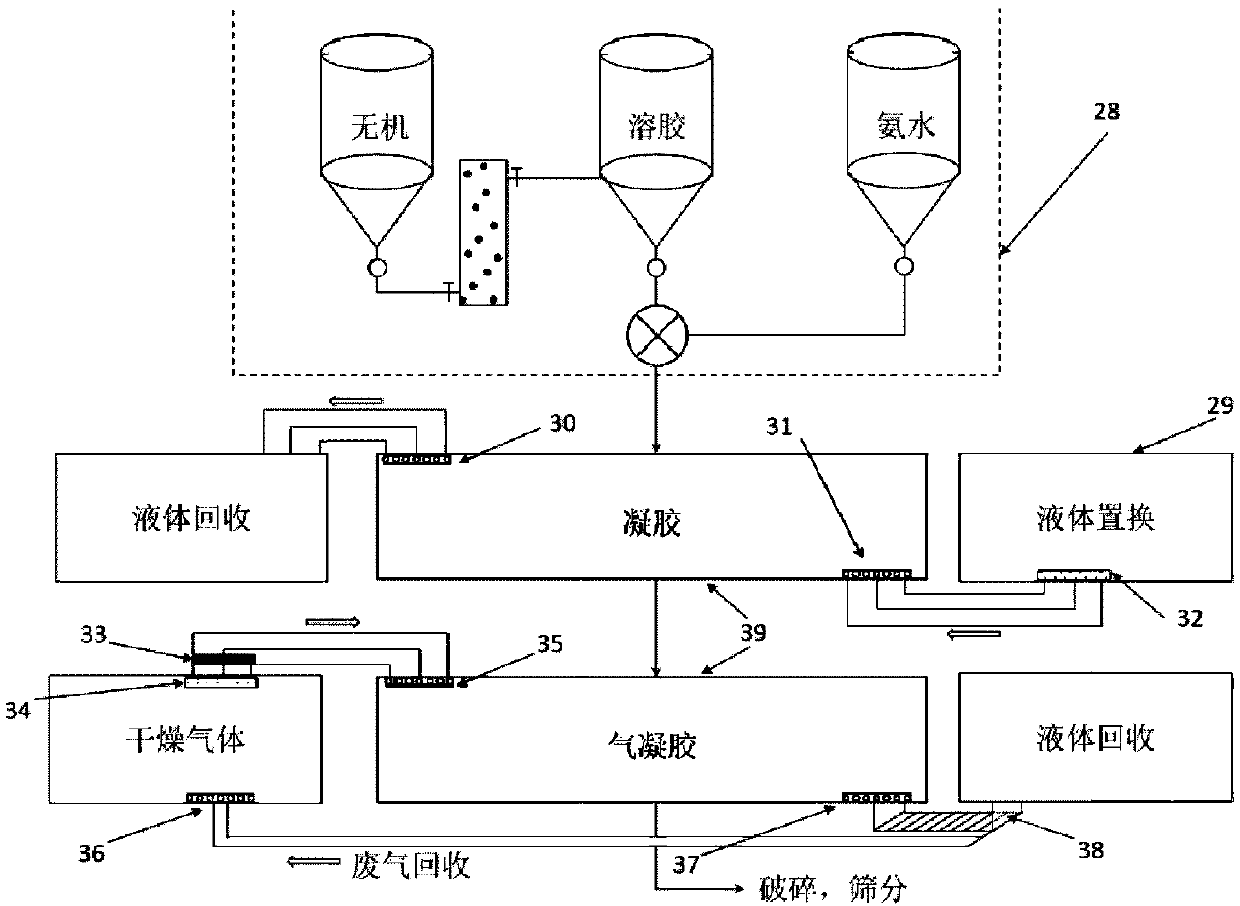

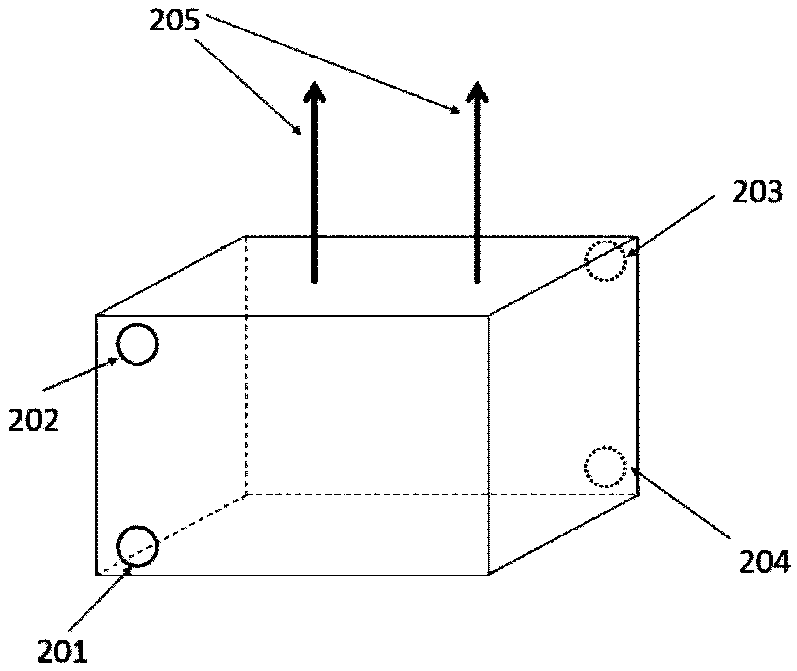

Method for continuously preparing boron-doped SiO2 aerogel

InactiveCN107662923APrecise thickness controlAccurate control of aging timeSilicon compoundsTransmittanceSmall footprint

The invention discloses a method for continuously preparing boron-doped SiO2 aerogel, belonging to the preparation field of novel porous materials. According to the method, by setting a preparation system with the functions of raw material feeding, sol preparation, gel preparation, solvent replacement, gel drying and waste material recycling, a large number of boron-doped SiO2 aerogel can be continuously produced. The method has the advantages that the occupied area of equipment is small, the preparation process is continuous and controllable, the production energy consumption is reduced, theequipment cost is lowered, and the labor cost is lowered. The prepared boron-doped SiO2 aerogel has good mechanical property, light transmittance performance and high-temperature stability.

Owner:CANEW TECH SHENZHEN CO LTD

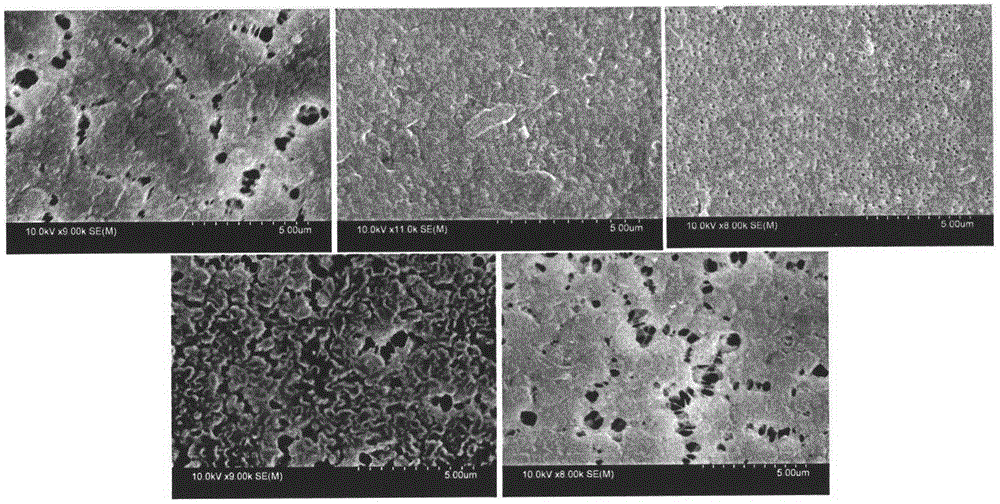

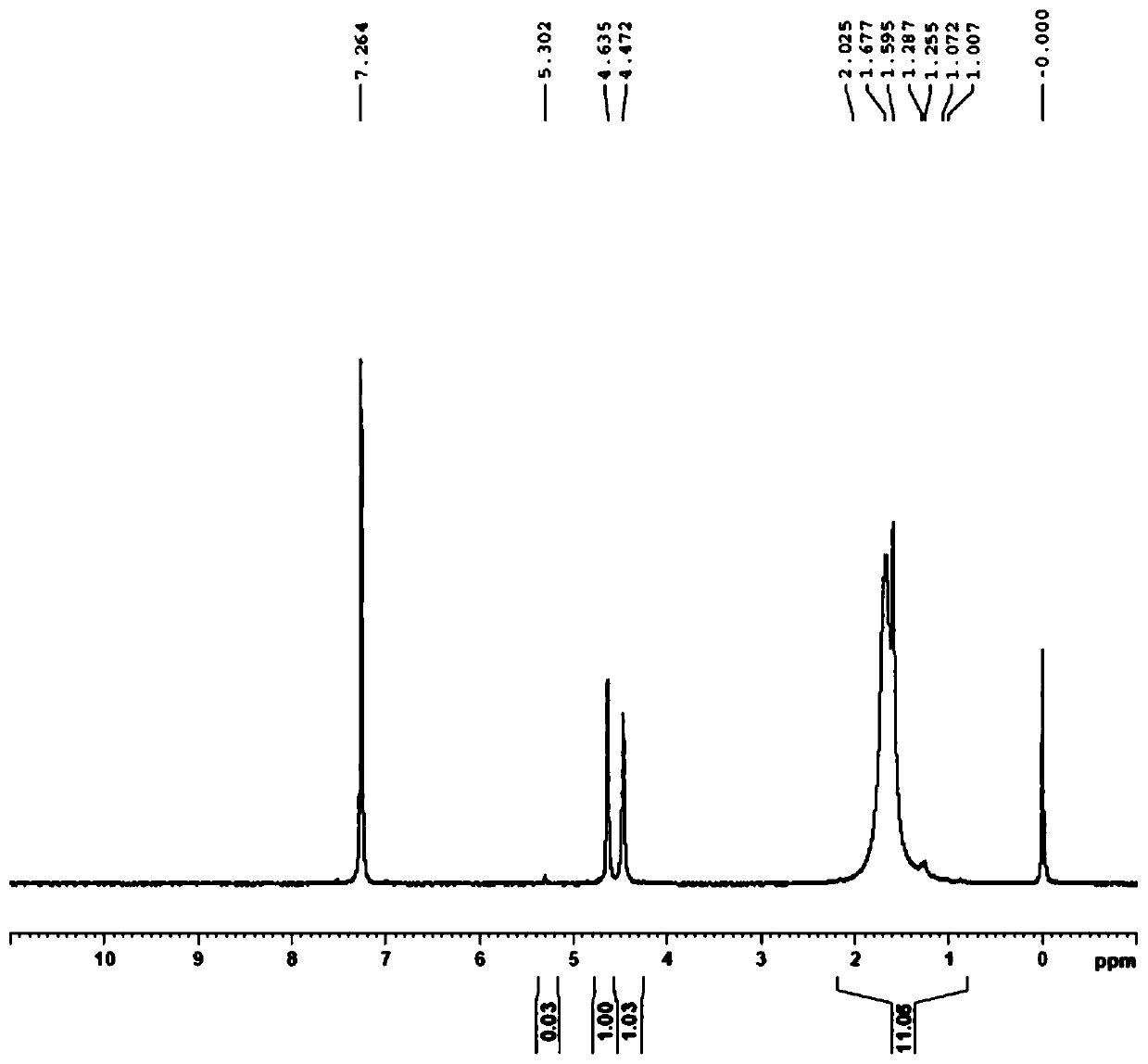

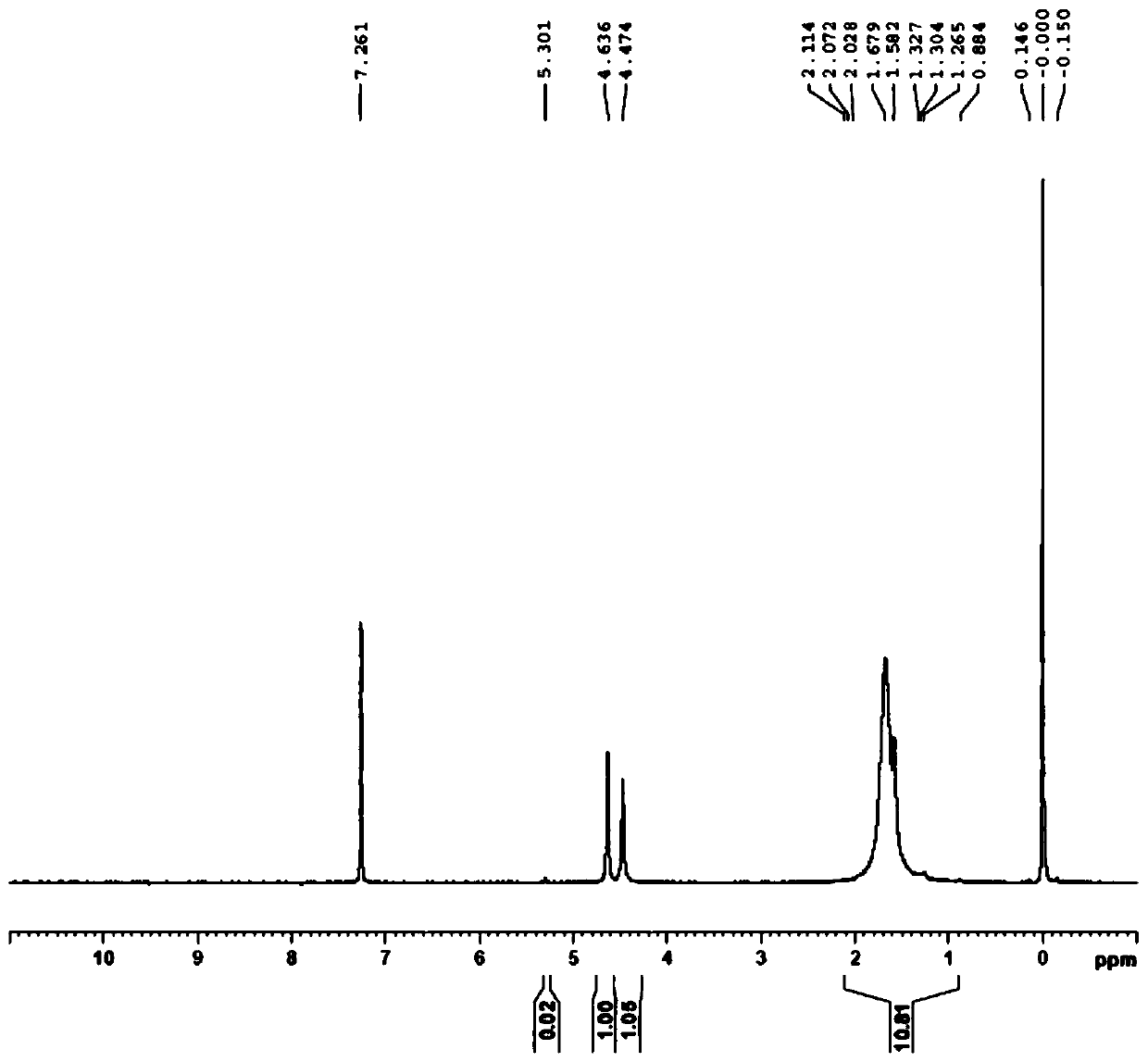

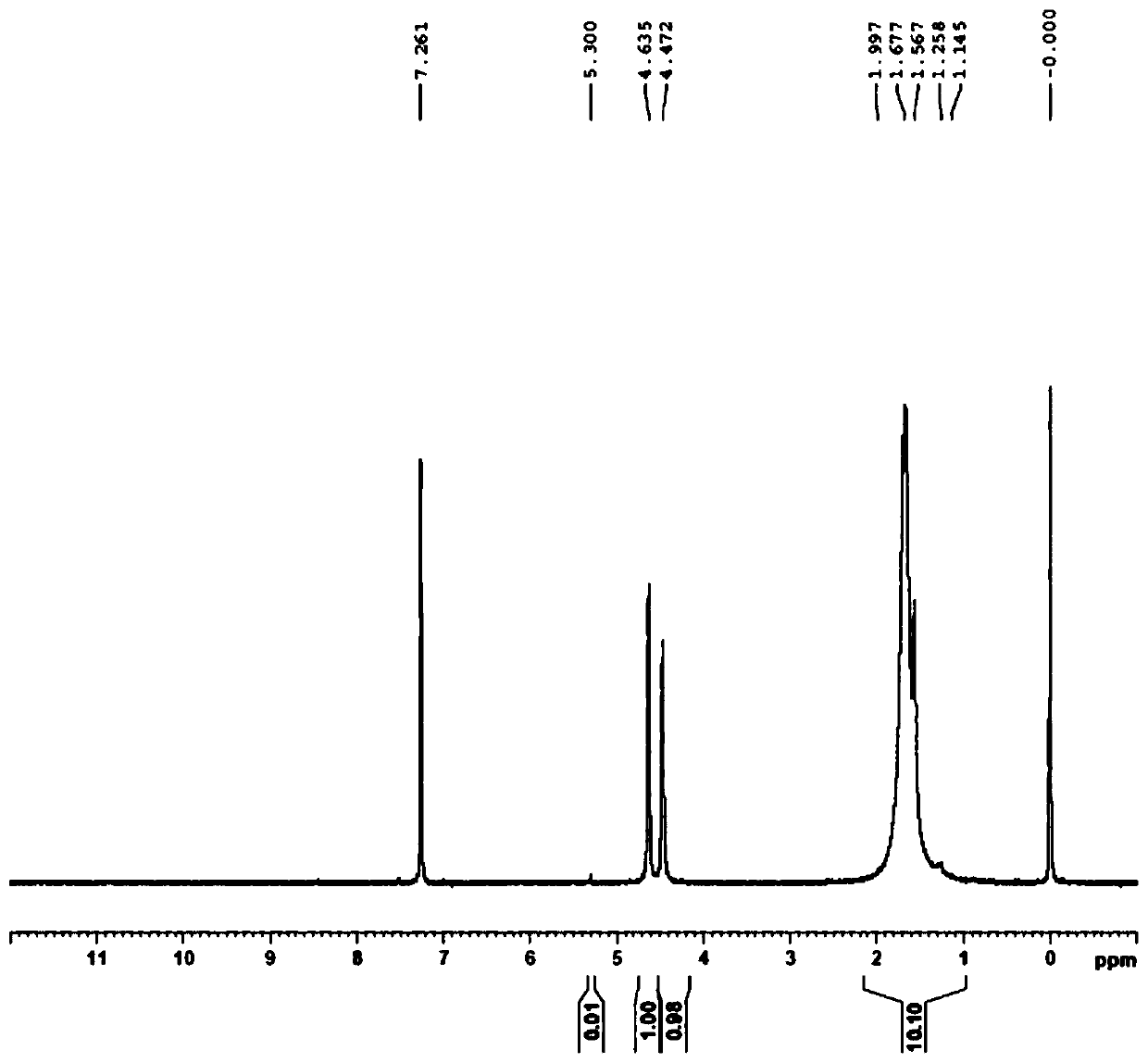

Formula for preparing polyvinylidene fluoride and carbon nanotube composite film and preparation method of formula

InactiveCN106693726ASimple preparation processContinuous production processSemi-permeable membranesWater bathsComposite film

The invention relates to a formula for preparing a polyvinylidene fluoride and carbon nanotube composite film and a preparation method of the formula. The method comprises the following steps: 1, weighing a certain amount of MWCNTs, taking dimethylformamide (DMF) as a solvent, and carrying out ultrasound treatment on MWCNTs in DMF for 40 minutes to enable MWCNTs to be dispersed fully; 2, drying polyvinylidene fluoride (PVDF) powder in an oven for a period of time before use to remove water; 3, adding the PVDF powder in a MWCNTs / DMF system to prepare a casting solution, violently stirring in constant-temperature water bath at the temperature of 70 DEG C for 4 hours, and enabling the PVDF powder to be dissolved fully to obtain a uniform solution; 4, sealing the obtained casting solution, and leaving the casting solution standstill during the whole night at room temperature to remove foam; 5, scraping the film on a clean glass plate with a 300 mu m film scraping bar, soaking a liquid film, together with the glass plate, in distilled water bath after 1 minute, and washing the film with deionized water to remove a residual solvent after the film is cured and is stripped from the glass plate automatically; and 6, finally, soaking the film in the deionized water for 48 hours, then taking part of the film and naturally air-drying the film at room temperature to obtain the PVDF / MWCNTs composite film. The preparation method is simple, high in operability, low in energy consumption and low in pollution.

Owner:TIANJIN POLYTECHNIC UNIV

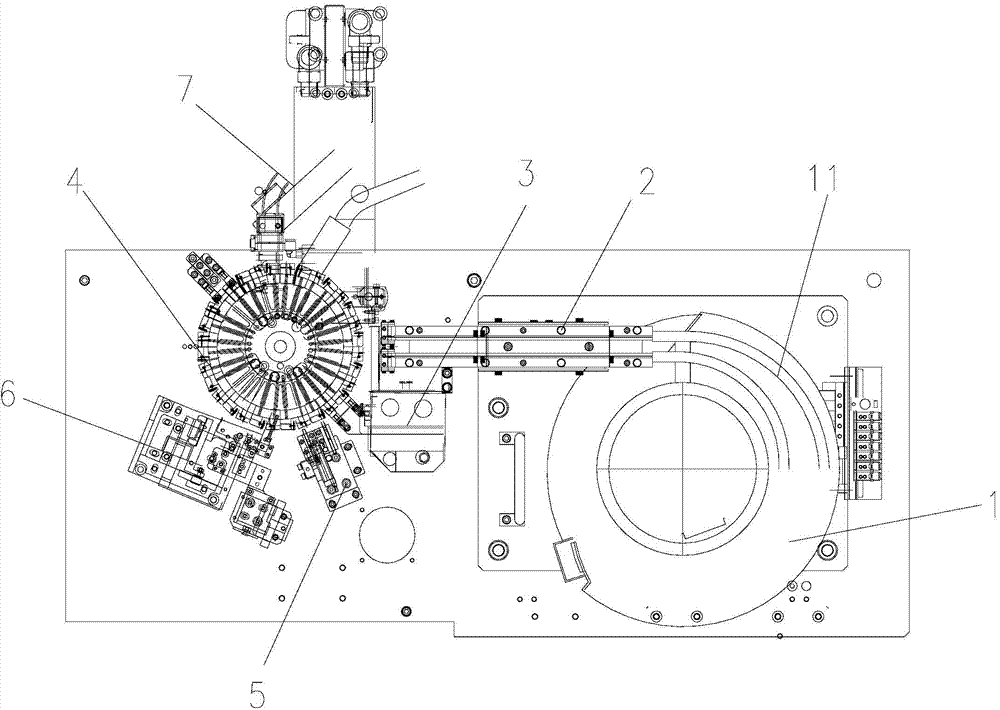

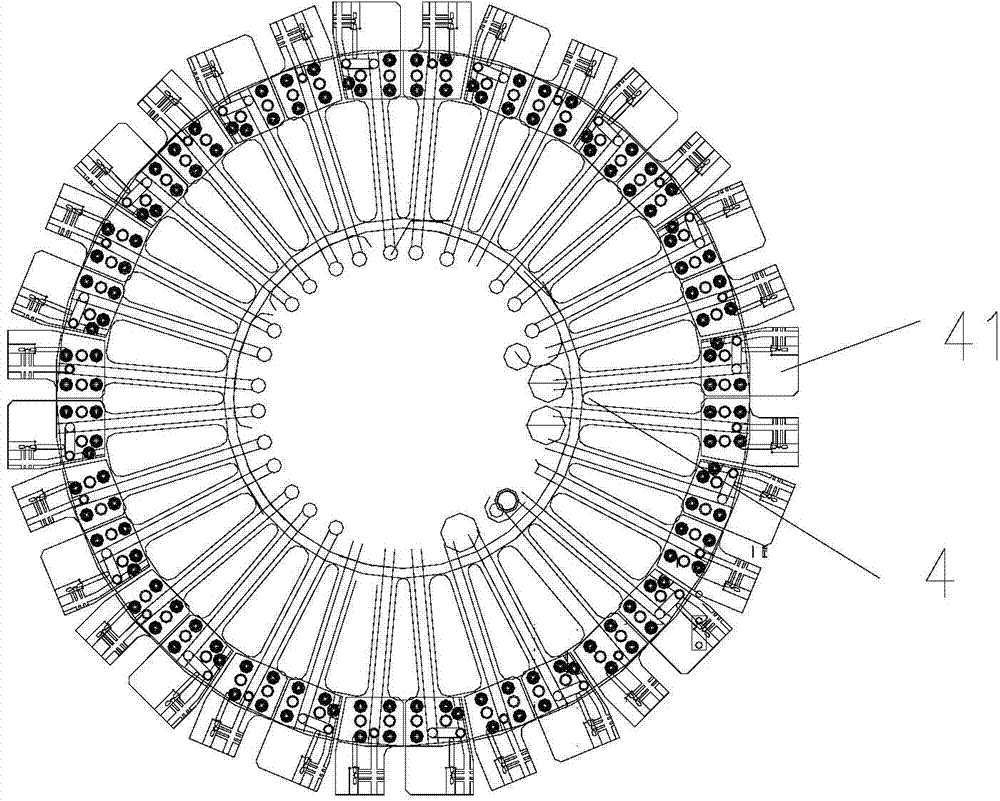

LED (Light Emitting Diode) device sorting machine

The invention provides an LED (Light Emitting Diode) device sorting machine which comprises a feeding mechanism, a lifting device, a rotating disc, a testing mechanism and a sorting device, wherein the rotating disc is connected with a step motor; the feeding mechanism comprises a vibrating feeding disc and two rows of straight vibrating tracks; two feeding channels are arranged on the vibrating feeding disc; one ends of the two straight vibrating tracks are respectively connected with outlets of the feeding channels of the vibrating feeding disc. According to the LED device sorting machine, measurement of brightness, hue and electric parameter characteristics can be alternately carried out on two LED devices at the same time; feeding is carried out through the two feeding channels of the vibrating feeding disc and the two rows of tracks, so that the feeding efficiency can be enhanced. The lifting device is provided with a double-head lifting mouth, so that the two LED devices can be lifted at the same time; the sorting device is provided with two rows of suction devices, so that the damage to the LED devices caused by single-channel suction negative pressure in the prior art can be decreased, the sorting correctness is high, the sorting speed is high, the manual interference is less, the production process is continuous, the automation degrees is high and the production cost is reduced.

Owner:苏州嘉大电子有限公司

Polyolefin substrate adhesion promoter and preparation method thereof

Owner:XI AN JIAOTONG UNIV +1

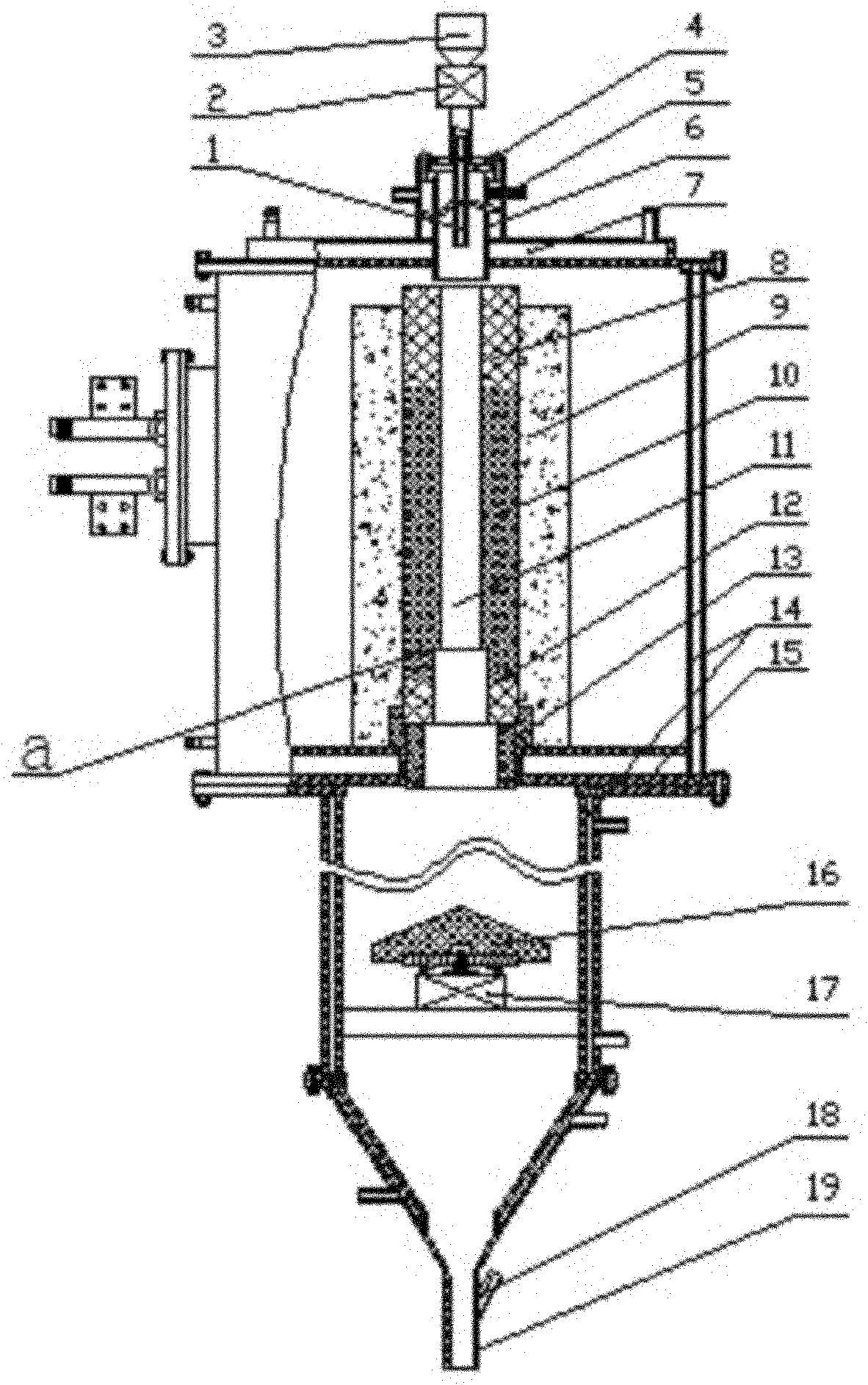

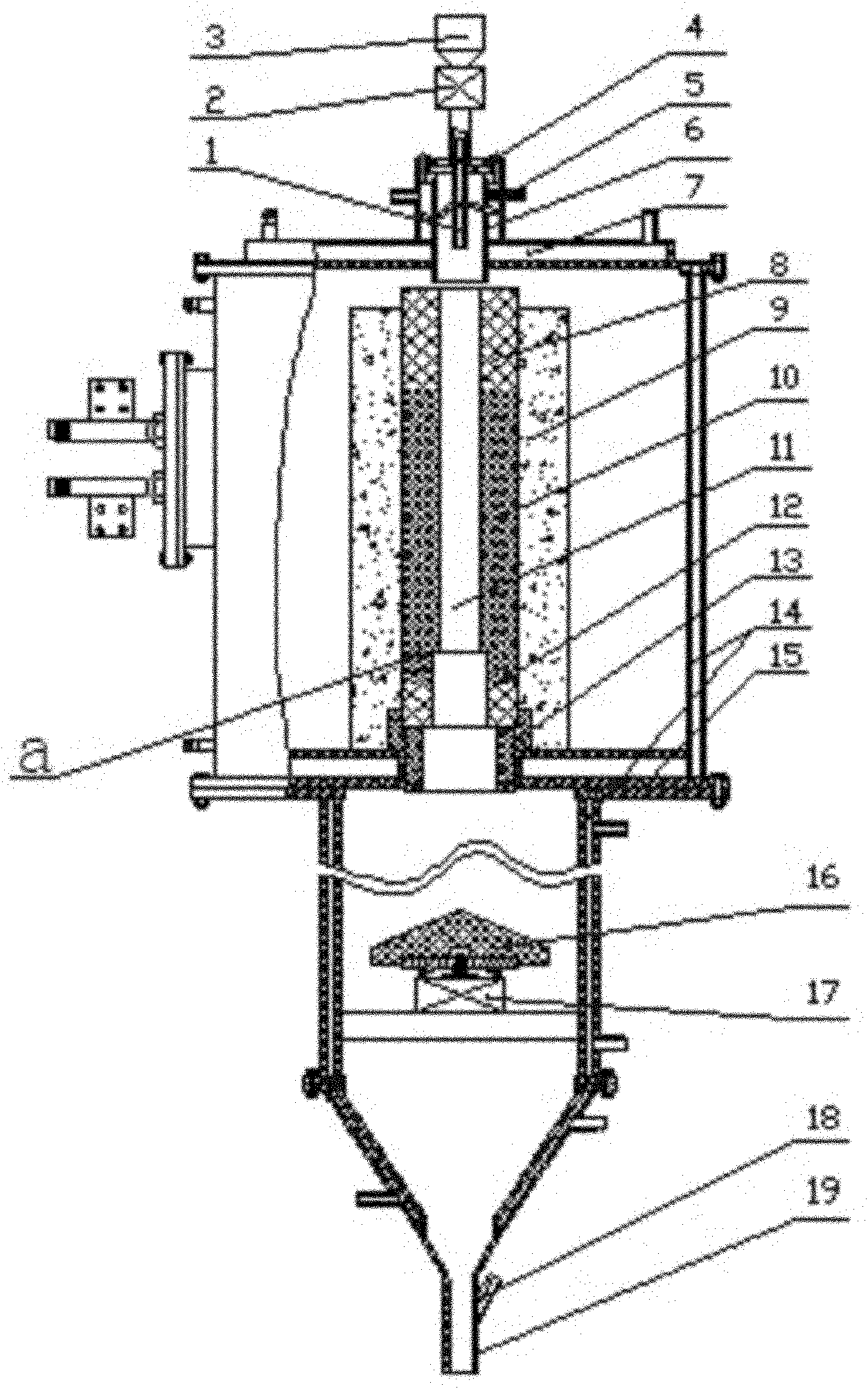

Vertical superhigh-temperature continuous balling furnace

ActiveCN101912974AAvoid enteringThe production process is simple and easy to controlGraphiteMaterials science

The invention relates to a vertical superhigh-temperature continuous balling furnace which comprises an upper part, a middle part and a lower part of a furnace body; the furnace is internally overlapped with bases, and a blanking channel is formed by the bases, a through hole in a graphite pipe and a feeding pipe which is arranged above the graphite pipe and corresponds to the graphite pipe; the graphite pipe is internally provided with a tubular heating area; the bottom of the through hole is provided with step holes with the same axle center from top to bottom and small to big; and the horizontal plane of an upper step is arranged in the tubular heating area, so that the outlet temperature of a blanking through hole in the heating area can be increased, the material is prevented from solidifying near an outlet and blocking the blanking channel due to the low temperature, the material is ensured to smoothly flow, and high-efficiency and low-consumption production can be realized.

Owner:株洲弗拉德科技有限公司

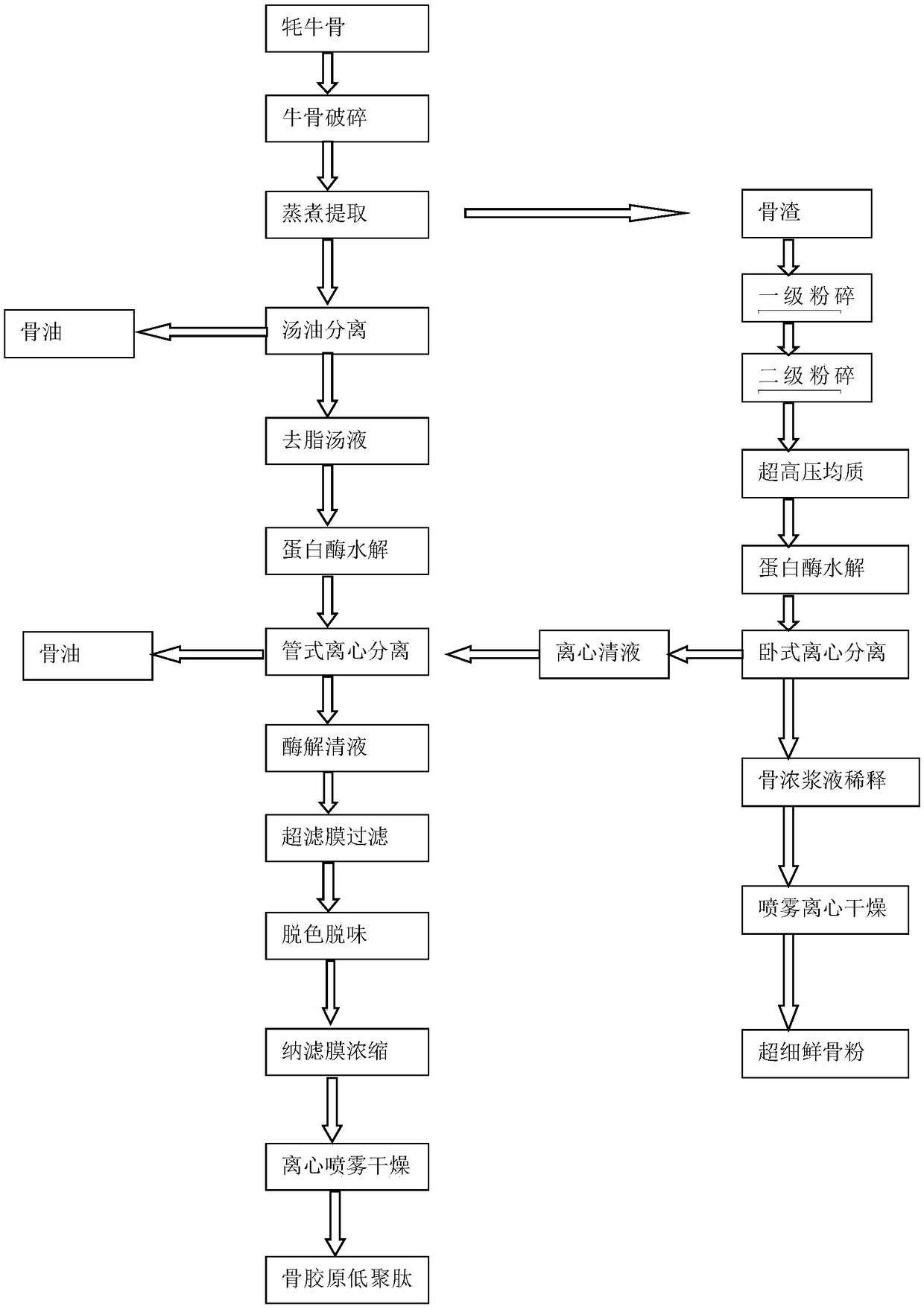

Method for processing yak bones by biotechnology

InactiveCN109287841AIncrease contactIncrease surface areaUltrafiltrationMulti-step food processesUltra high pressureFiltration

The invention relates to a method for processing yak bones by biotechnology. The method comprises the following steps: step 1, crushing yak bones to 3cm-6cm, putting the crushed yak bones into a cooking pot and performing high temperature and high pressure extraction to obtain oil-containing bone soup and oil-containing bone dregs; step 2, preparing the oil-containing bone soup obtained in the step 1 into ossein oligopeptide, and specifically, sequentially performing the following steps: soup-oil separation, protease hydrolysis, tubular centrifugal separation, filtration by an ultrafiltrationmembrane, discoloration and deodorization, concentration by a nanofiltration membrane and centrifugal spray drying; and step 3, preparing the oil-containing bone dregs obtained in the step 1 into superfine fresh bone meal, and specifically, sequentially performing the following steps: primary crushing, secondary crushing, ultra-high-pressure homogenization, protease hydrolysis, horizontal centrifugal separation, thick pulp dilution and centrifugal spray drying.

Owner:王书敏

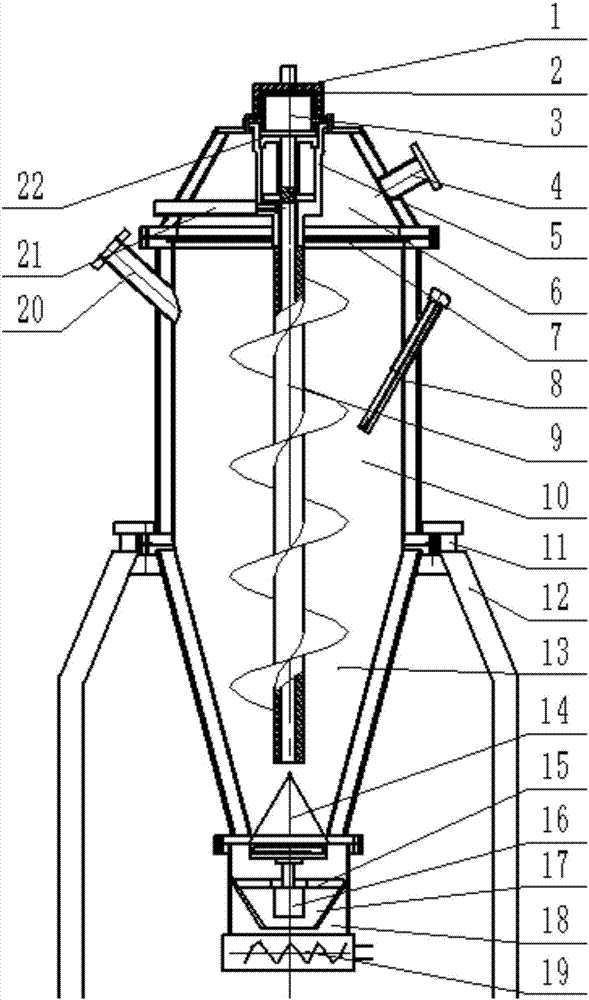

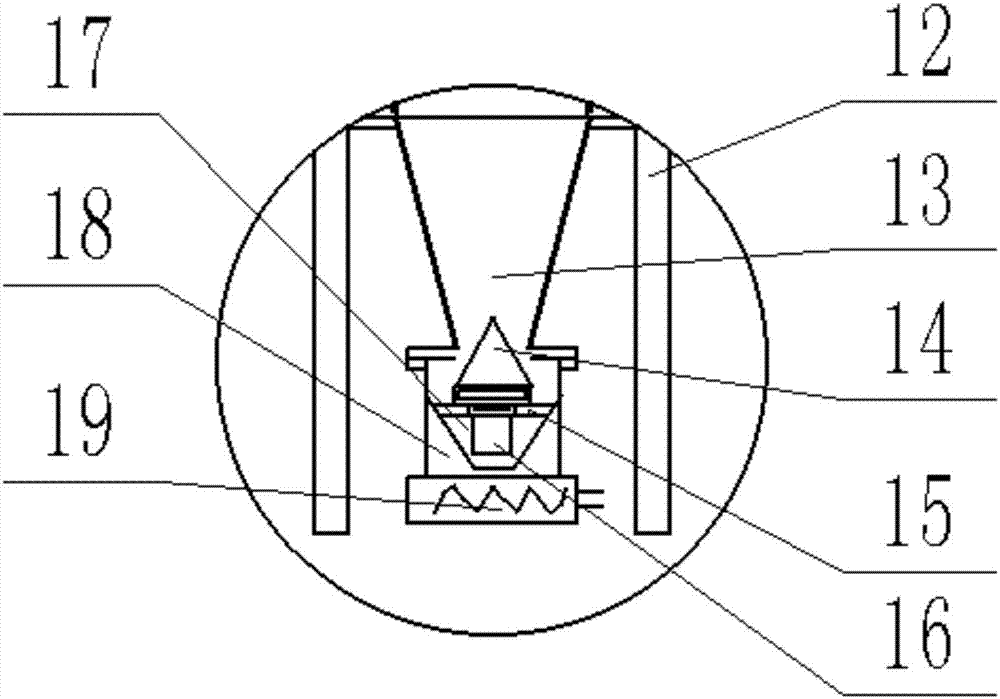

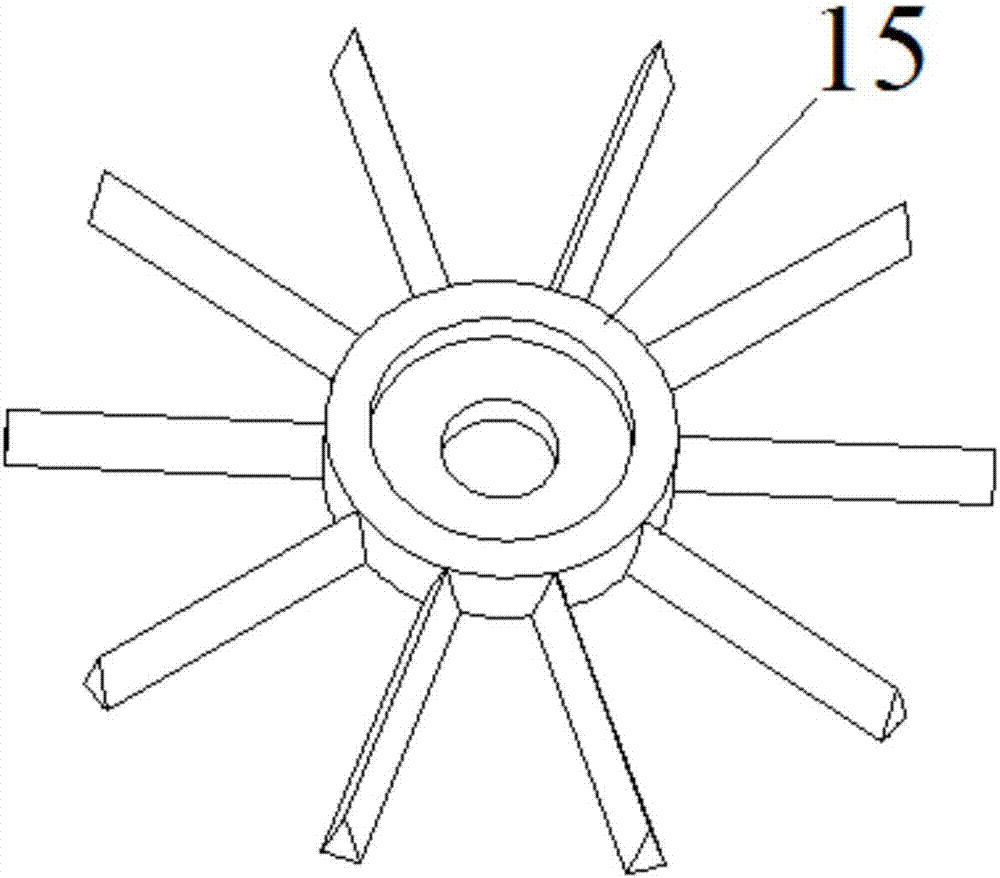

Spiral material mixing pneumatic dryer

ActiveCN107084611ALow boiling pointLow drying temperatureGranular material dryingFinal product manufactureAir bearingEngineering

The invention discloses a spiral material mixing pneumatic dryer. The spiral material mixing pneumatic dryer is characterized by comprising a magnetic coupler, a vacuumizing and nitrogen air outlet, a seal device, an upper cylinder, a screen net, a sampling device, a spiral hollow shaft, a middle cylinder, a pressure sensor, a bottom frame, a lower cylinder, a conical discharging plate, a flower-shaped supporting plate, an air cylinder, a discharging conical cylinder, a discharging cylinder, a spiral conveyor, a feeding opening, a hot nitrogen inlet and an air bearing; the magnetic coupler comprises a first magnet, a partition plate and a second magnet; according to the dryer, the manner that three methods of vacuum drying, hot air convection drying and thermal radiation conduction drying are combined is adopted to dry powder; under the stirring effect of the spiral hollow shaft, hot air makes contact with the powder, and the drying efficiency is high; hot nitrogen flowing through the interior of the spiral hollow shaft enables the temperature of the spiral hollow shaft to rise, the high-temperature spiral hollow shaft carries out radiation heat transfer on the powder, and the powder is uniformly dried.

Owner:HEBEI UNIV OF TECH +1

Yellowing-resistant antioxidation flame-retardant semi-aromatic polyamide and preparation method thereof

The invention discloses yellowing-resistant antioxidation flame-retardant semi-aromatic polyamide and a preparation method thereof. Semiaromatic nylon salt, nylon salt, caprolactam, catalysts and deionized water are added into a reaction kettle; nitrogen is introduced for air replacement; heating reaction is performed; the temperature is lowered; soft water is sprayed into the kettle through a spraying opening of the reaction kettle; dilution pulping and filtering are performed on the materials in the reaction kettle; then, solid oligomers are dried, and then the yellowing-resistant antioxidation flame-retardant semi-aromatic polyamide oligomer particle dry bases are obtained; the oligomer particle dry bases are added into a reaction extrusion machine; the screw rod rotating speed, the feeding speed and the temperature of each section of an extruding machine are controlled; exhaust, extrusion, particle cutting and drying are performed; the yellowing-resistant antioxidation flame-retardant semi-aromatic polyamide resin with high molecular weight is obtained. The yellowing-resistant antioxidation flame-retardant semi-aromatic polyamide has the characteristics of high temperature resistance, flame-retardant performance, antioxidation and yellowing resistance. The preparation method also has the advantages of high yield and green and environment-friendly effects.

Owner:SICHUAN UNIV

Preparation method for preparing sulfitation fatliquor by use of waste oil

ActiveCN103540695AWide variety of sourcesLow quality and good priceLeather impregnationLeather industryOil and grease

The invention belongs to the technical field of leather chemicals, and discloses a leather fatliquor containing sulfitation waste oil and a preparation method of the fatliquor. The method comprises the following steps: enabling the refined waste oil to react with monoethanolamine to obtain amidated waste oil; enabling the amidated waste oil to react with maleic anhydride to obtain succinate; and enabling the succinate to react with sodium hydrogen sulfite to obtain the sulfitation fatliquor. The method disclosed by the invention not only can meet the environmental need for treating gutter oil to increase the added value of the gutter oil, but also can provide the much-needed oil raw material for the leather industry; the raw materials are easily available, the cost is low, and the method is simple and convenient; moreover, the conditions in the preparation process are mild, the discharge of three wastes is avoided, and industrial production is easy to realize.

Owner:ZHEJIANG SHENGHUI CHEM

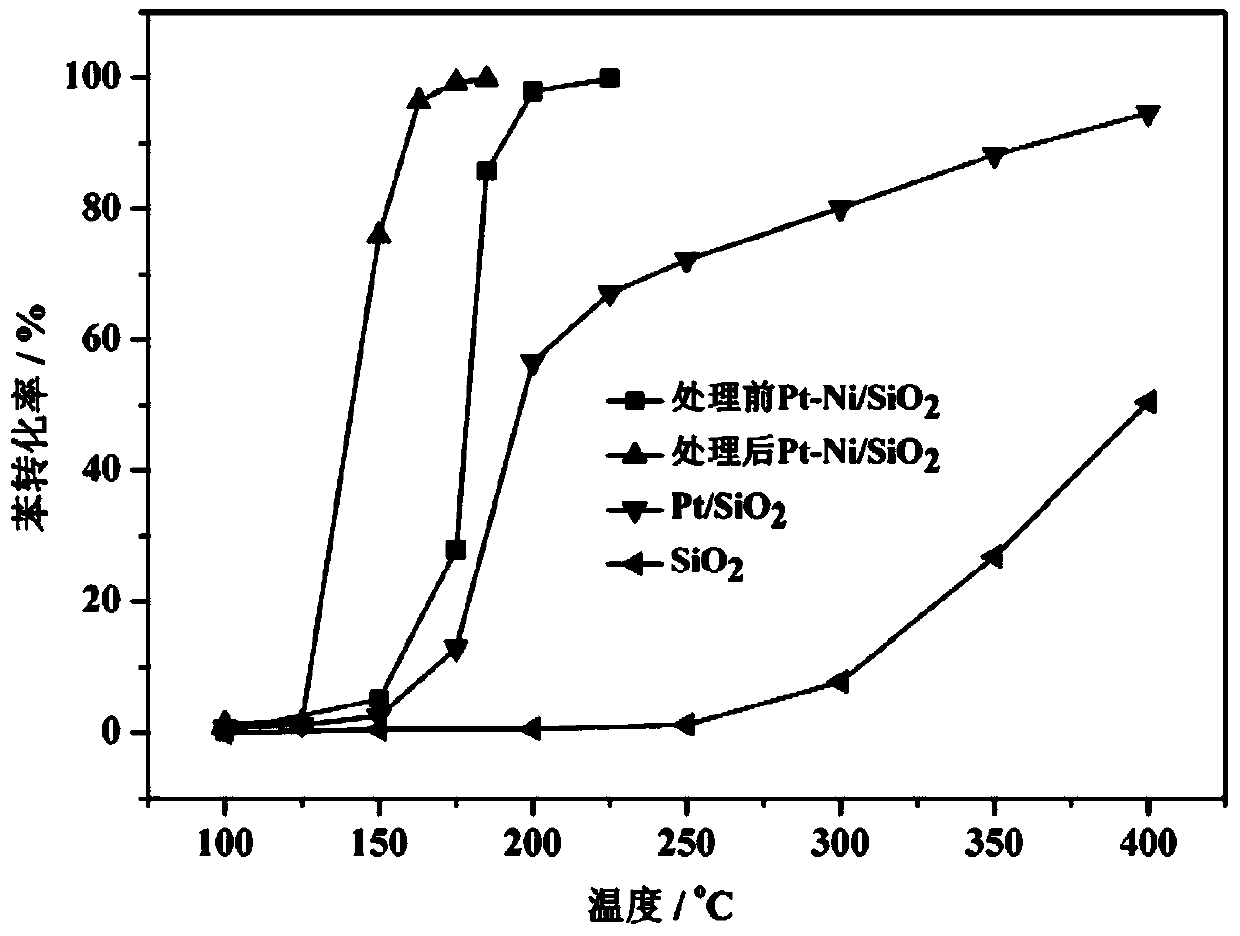

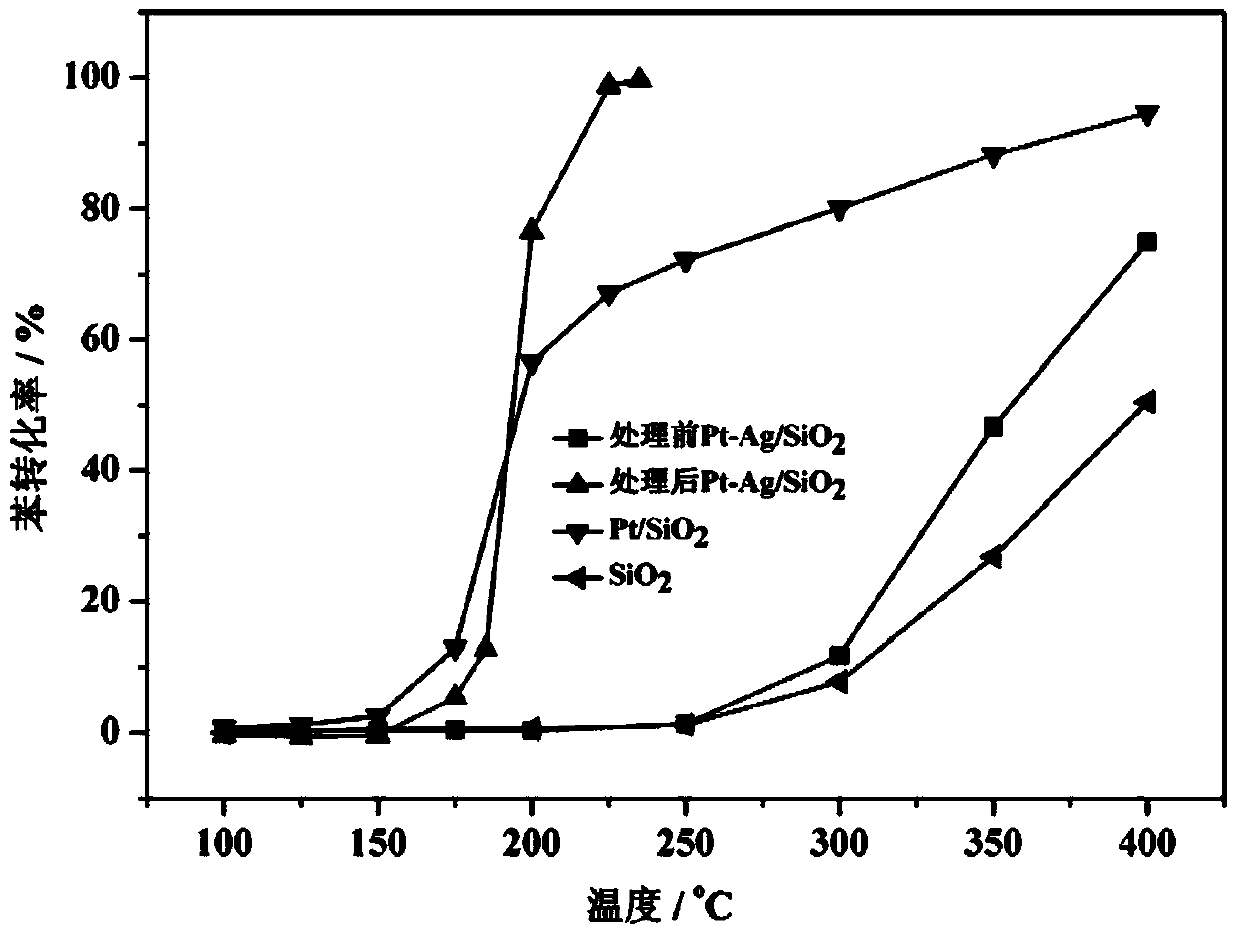

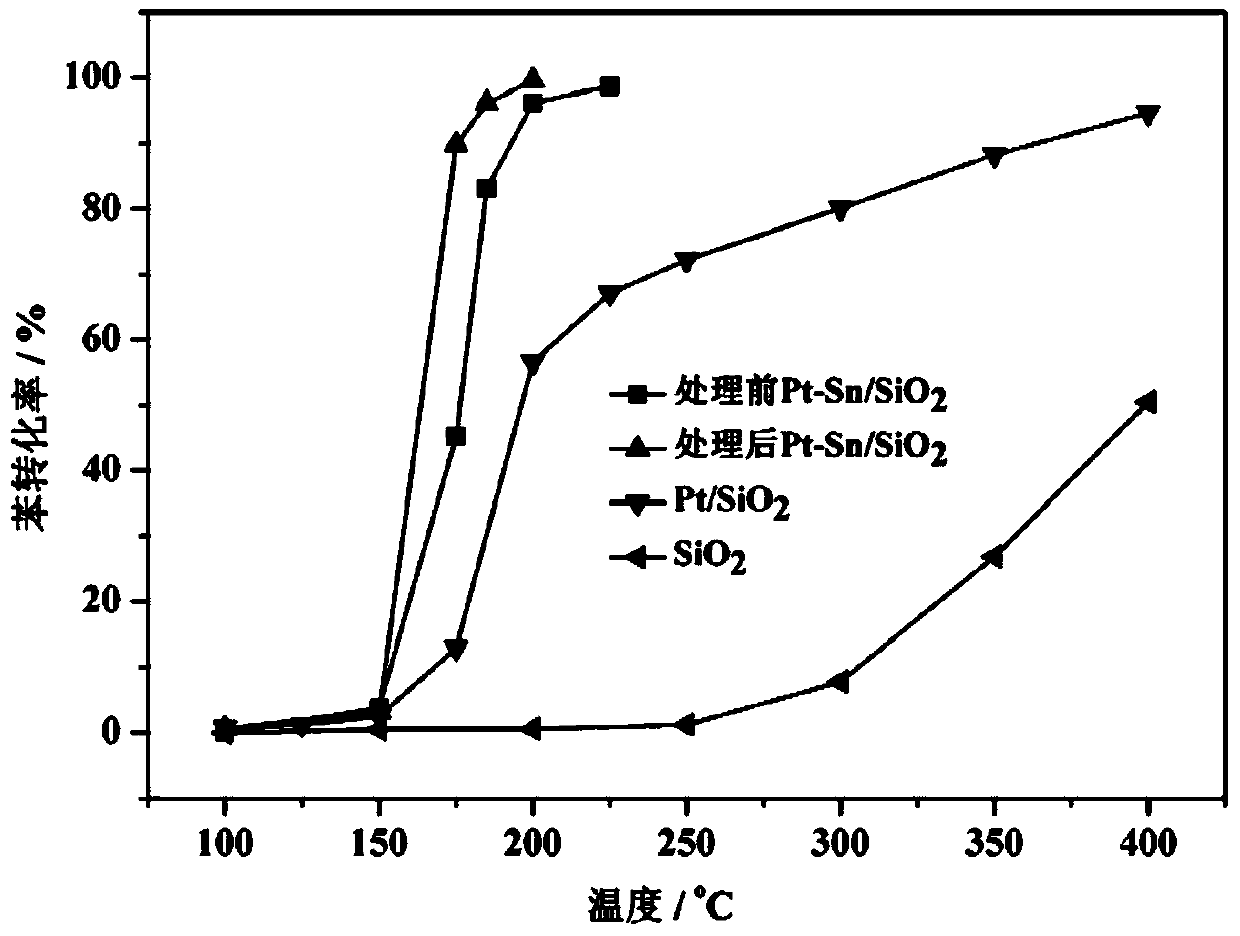

Method for improving catalytic oxidization activity of VOCs catalyst

ActiveCN104174411AHigh catalytic oxidation activityReduce manufacturing costDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsAcid etchingCatalytic oxidation

The invention relates to a method for improving the catalytic oxidization activity of a VOCs catalyst. The alloy catalyst prepared by adopting a flame spray pyrolysis method is subjected to high-temperature reduction, acid etching and the like, so that the catalytic oxidization activity of the catalyst can be remarkably improved. The catalyst carrier is an oxide or simple substance which cannot be dissolved by acid, the active component is Pt or / and Au and at least one alloy that is formed by metal dissolvable by acid. The metal dissolvable by acid can be partially or entirely etched during etching. Due to the porous structure of the etched alloy, the contact area between the active component and a reactant can be increased, and the mass transfer process can be enhanced, so that the catalytic oxidization activity of the catalyst can be improved. The method for improving the load type catalyst is simple in technology, and continuous and controllable in process, and large-scale production is easily realized.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for preparing Kaoline colloid

InactiveCN1579725AReduce consumption costReduce labor costsCatalyst carriersClay processing apparatusKaolin clayColloid

The invention discloses a kaolin colloid preparation method which including following steps: (1)Kaolin is transferred to preparation locale by container, than is inputted into the kaolin store jar; (2)Machine crash the kaolin in the store jar until the average diameter less than 150mum; (3) The kaolin powder after crashing is transferred to the next step by screw transport; (4) Blend the necessary liquid material for kaolin colloid and the kaolin powder, and prepare the kaolin colloid. This method can reach the continuum and automation of the preparation procession, and decrease the material consume and labor cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

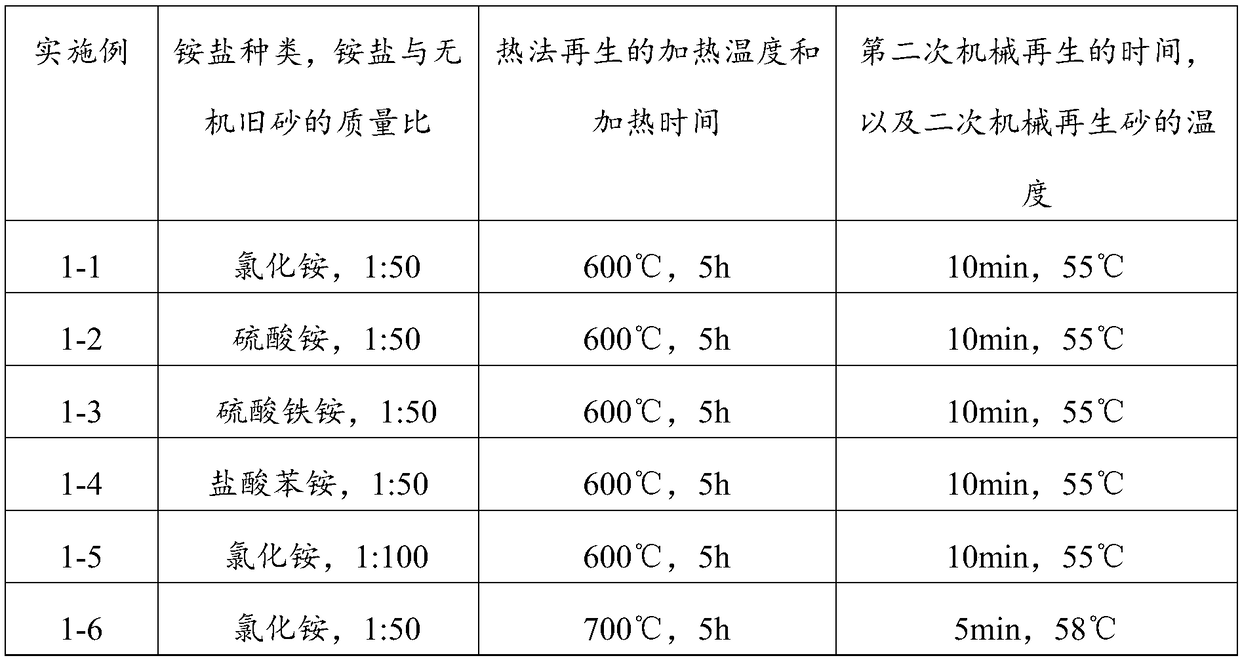

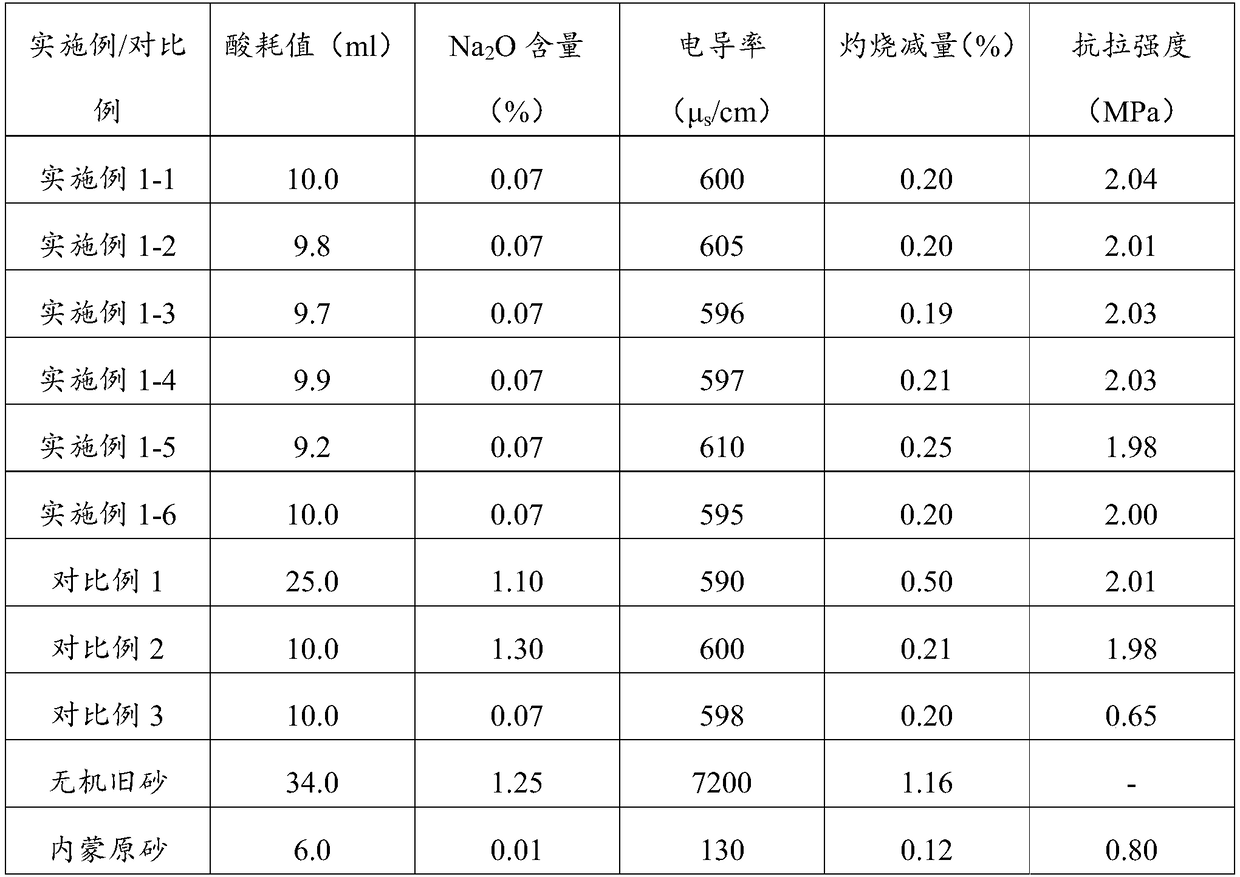

Reclaiming method for inorganic old sand

InactiveCN109158528ALong roasting timeContinuous production processMould handling/dressing devicesLoss on ignitionSodium oxide

The invention relates to a reclaiming method for inorganic old sand. The reclaiming method for the inorganic old sand comprises the following steps: (1) first-time mechanical reclaiming: crushing theinorganic old sand to obtain primary mechanical reclaimed sand; (2) hot-method reclaiming: heating the primary mechanical reclaimed sand to obtain hot-method reclaimed sand; (3) second-time mechanicalreclaiming: mechanically grinding the hot-method reclaimed sand, and meanwhile cooling to obtain secondary mechanical reclaimed sand; and (4) removing broken impurities in the secondary mechanical reclaimed sand to obtain inorganic reclaimed sand. The content of sodium oxide in the inorganic reclaimed sand obtained by the method is lower than 0.1%, the inorganic reclaimed sand can be directly used as facing sand, the strength of the inorganic reclaimed sand is not lower than crude sand, the loss on ignition and the acid demand value of the inorganic reclaimed sand are close to the loss on ignition and the acid demand value of the crude sand, and the performance of the product is excellent.

Owner:HEFEI RENCHUANG CASTING MATERIAL CO LTD

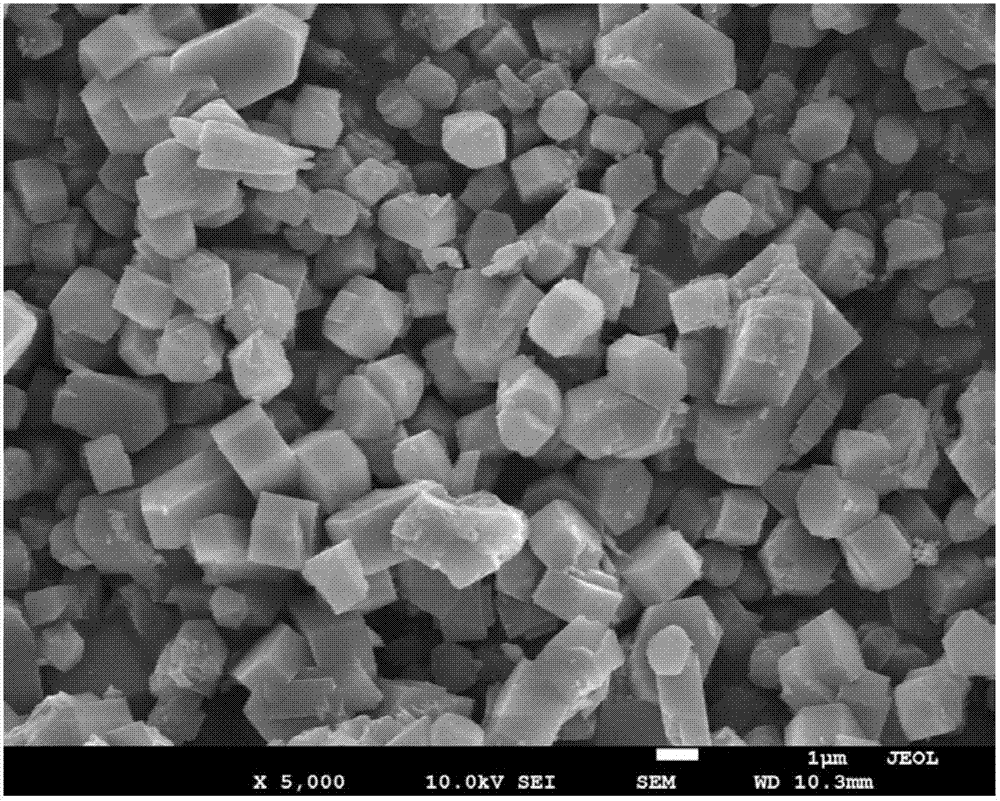

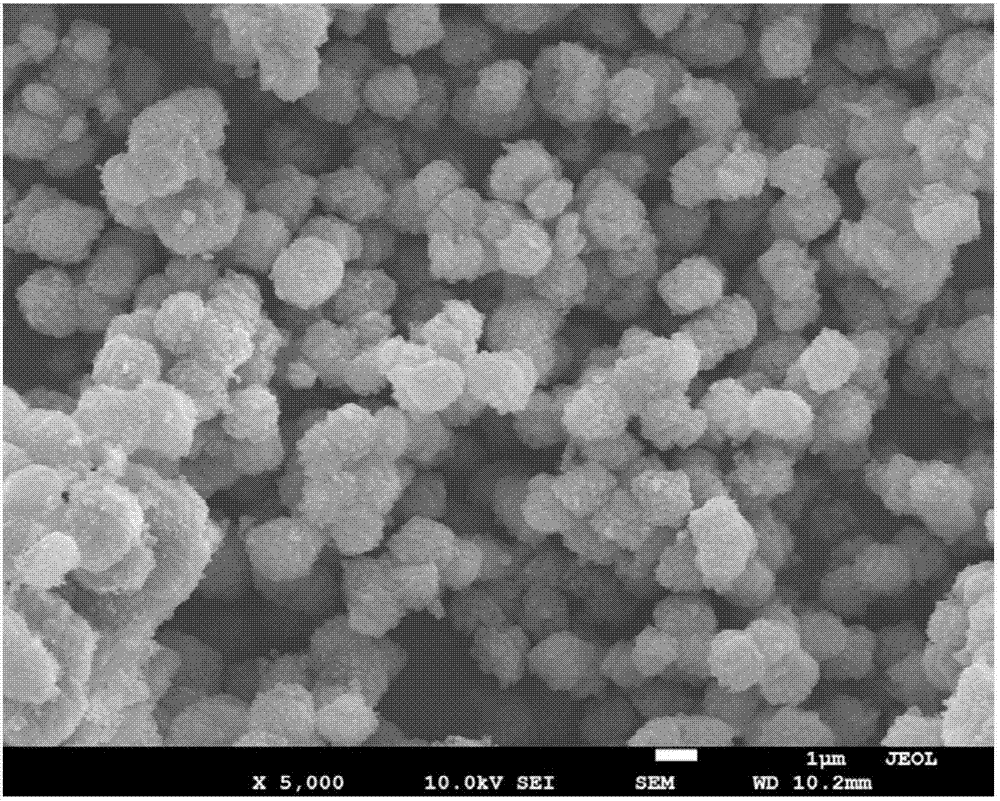

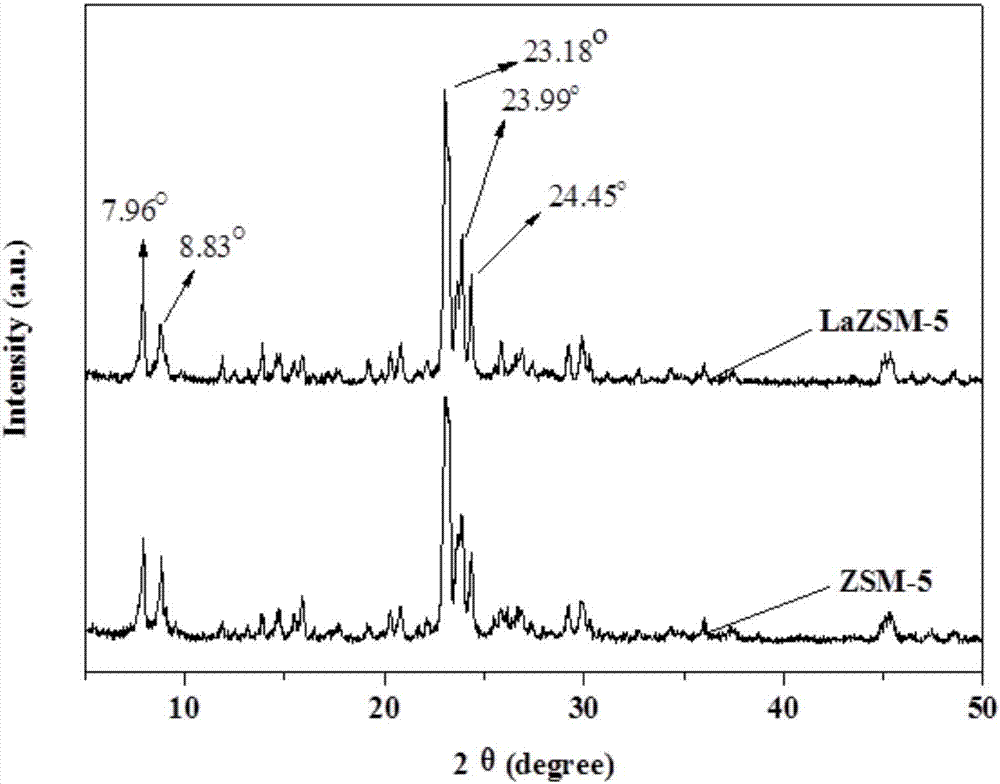

Preparation method of LaZSM-5 molecular sieve, its application and using method

InactiveCN107162015AHigh catalytic activityHigh esterification rateMolecular sieve catalystsOrganic compound preparationMolecular sievePtru catalyst

The invention discloses a preparation method of a LaZSM-5 molecular sieve, its application and a using method. The LaZSM-5 molecular sieve compounded by an in-situ synthesis method is used as a catalyst for compounding glycerol ester of rosin; catalytic activity of LaZSM-5 molecular sieve in the esterification reaction is enhanced by increasing L acid center amount on the LaZSM-5 molecular sieve. Besides, the production technique of compounding glycerol ester of rosin by the catalyst of the LaZSM-5 molecular sieve is continuous; the preparation method is gentle in reaction condition, convenient to operate, clean and environment-friendly, low in cost, high in efficiency, strong in practicability, and easy to carry out the industrial production and application.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

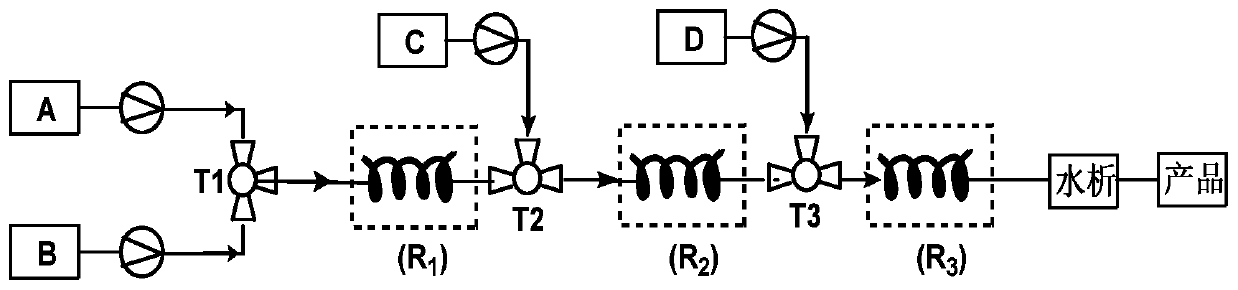

17 alpha-acetoxy-6-methylenepregn-4-ene-3,20-dione preparation method

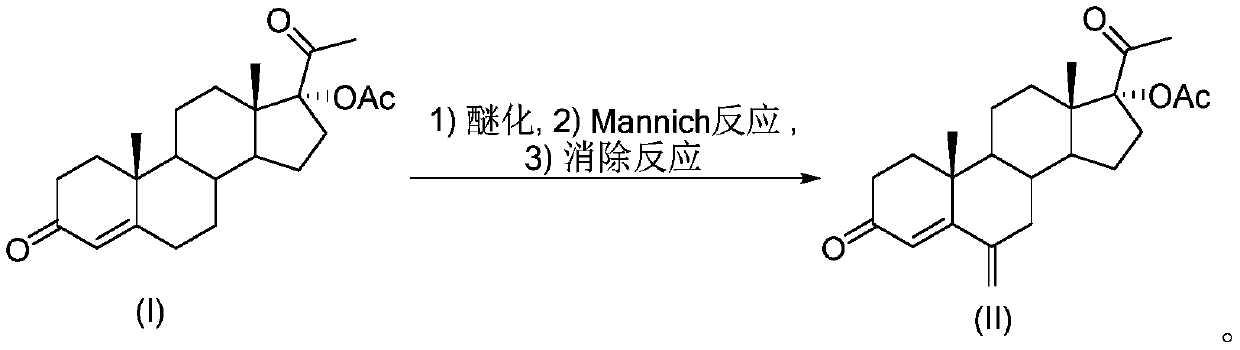

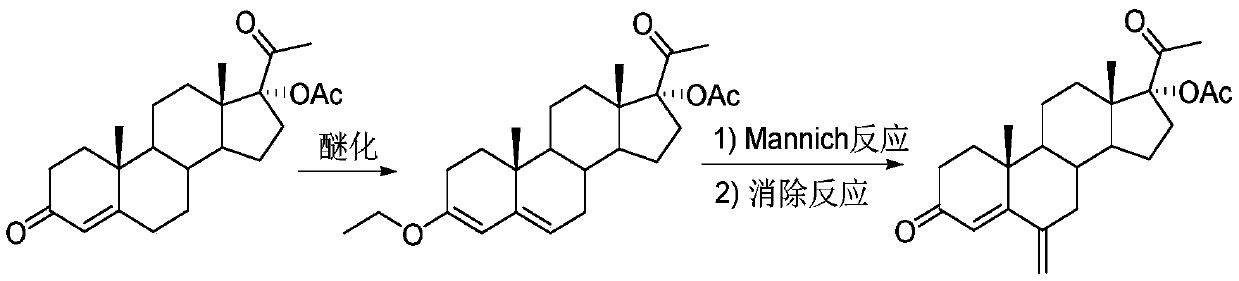

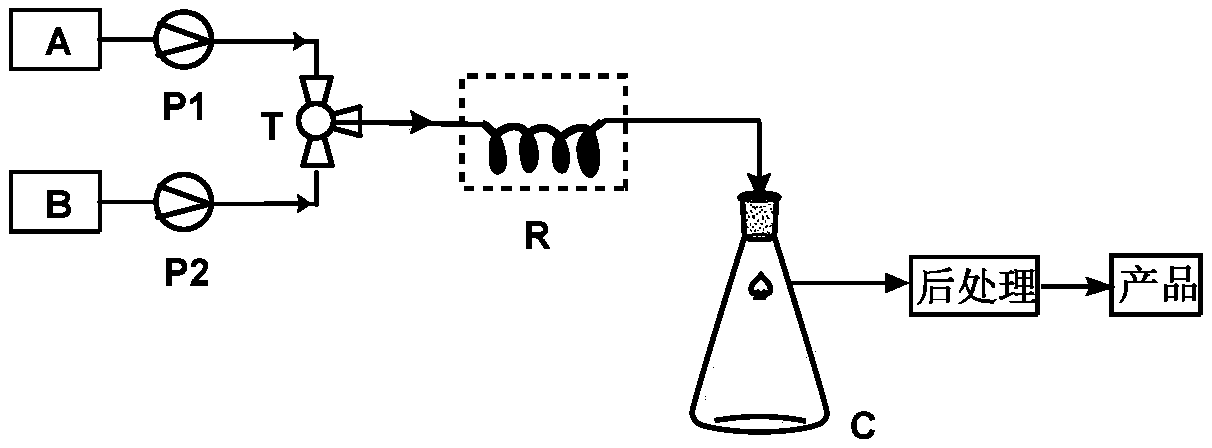

InactiveCN110590890ASmall amount of online responseEasy temperature controlSteroidsChemical/physical/physico-chemical stationary reactorsMannich reactionHeat transfer efficiency

The invention discloses a 17 alpha-acetoxy-6-methylenepregn-4-ene-3,20-dione preparation method, which comprises: carrying out an etherification reaction, a Mannich reaction and an elimination reaction on 17 alpha-hydroxyprogesterone acetate represented by a formula (I) and used as an initial raw material in a tubular reactor to obtain a product 17 alpha-acetoxy-6-methylenepregn-4-ene-3,20-dione represented by a formula (II), wherein the reaction formula is defined in the specification. According to the present invention, by using the tubular reaction mode approximate to plug flow, the materials are hardly backmixed during the reaction, the mass transfer and heat transfer efficiency is good, the generation of side reactions is remarkably reduced, and the method has advantages of high product yield, high product purity, easy operation, few three-waste and the like, and is suitable for industrial production.

Owner:台州仙琚药业有限公司

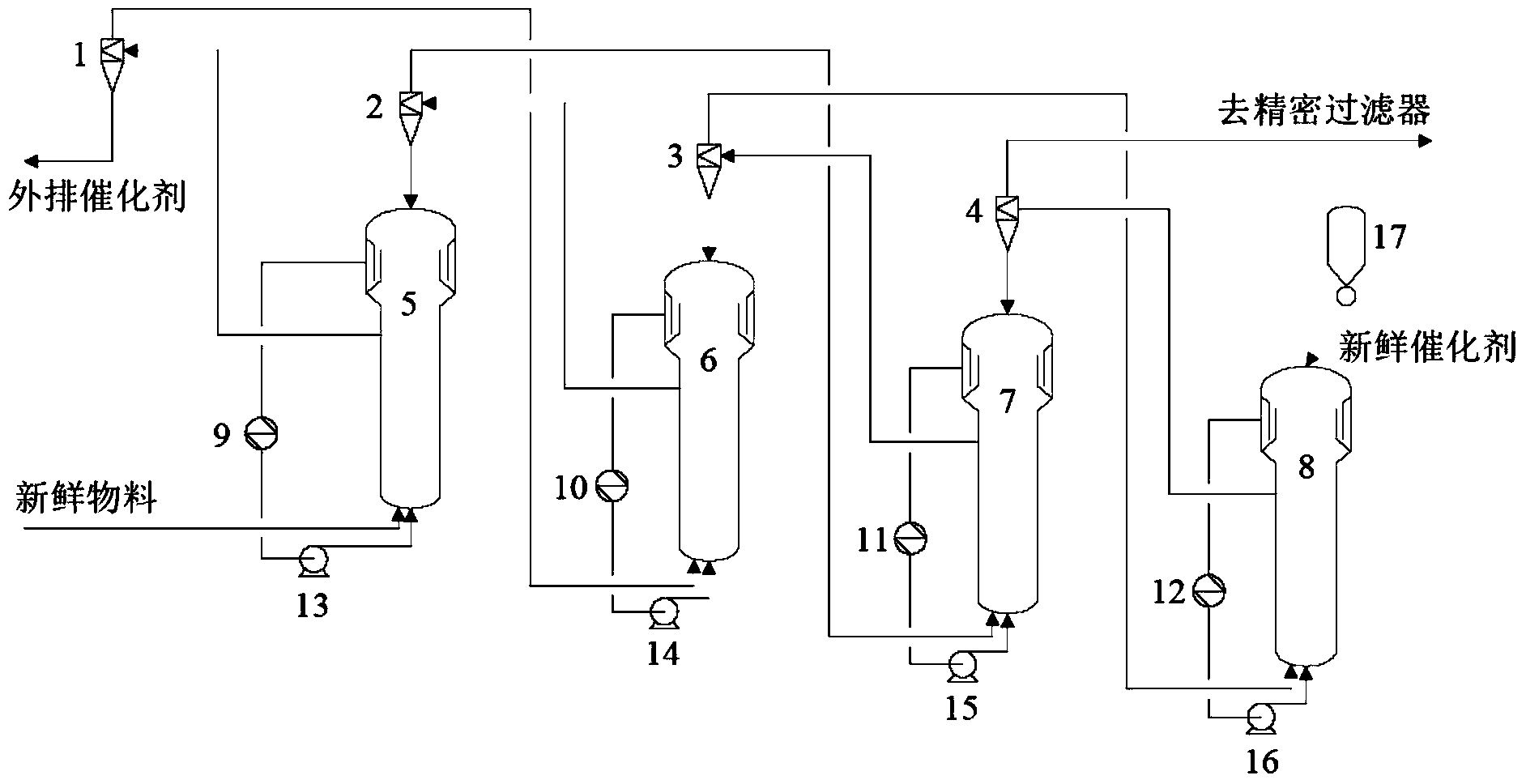

Continuous isosynthesis method and continuous isosynthesis device of ethylidene norbornene

ActiveCN103980084AAvoid switchingSolving Intermittent Operation ProblemsHydrocarbon by isomerisationCycloneNorbornene

The invention relates to a continuous isosynthesis method and a continuous isosynthesis device of ethylidene norbornene. The continuous isosynthesis method of the ethylidene norbornene comprises the following steps: forming a multi-stage reactor group by adopting two or more isomeric fluidized bed reactors; continuously introducing a fresh vinyl norbornene raw material into a reaction system through the first-stage reactor of the multi-stage reactor group for fluidized reaction to obtain ethylidene norbornene products, and continuously discharging through the last-stage reactor of the multi-stage reactor group; and continuously introducing a fresh catalyst into the reaction system through the last-stage reactor for participating in the fluidized reaction, sequentially carrying out liquid-solid separation through interstage cyclone separators arranged between all-stage reactors of the multi-stage reactor group, and then discharging out of the first-stage reactor.

Owner:SHANGHAI HUACHANG ENVIRONMENT PROTECTION

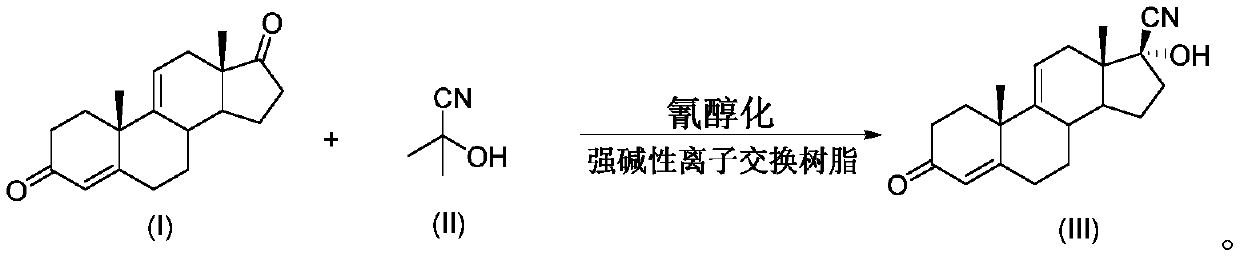

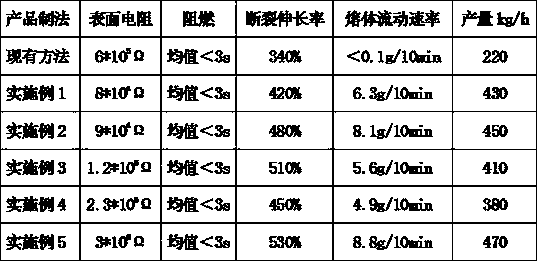

Method for preparing 17beta-cyano-17alpha-hydroxy-9-dehydroandrostenedione

InactiveCN111320665ASmall amount of online responseReduce backmixingSteroidsChemical/physical processesOrganic solventIon exchange

The invention discloses a method for preparing 17 beta-cyano-17 alpha-hydroxy-9-dehydroandrostenedione. The method comprises the following steps: (1) dispersing 9-dehydroandrostenedione (I) and acetone cyanohydrin (II) into an organic solvent; (2) carrying out a cyanohydrination reaction on the obtained mixed raw material liquid in a tubular reactor filled with strongly basic ion exchange resin, and (3) carrying out post-treatment on the material liquid after the cyanohydrination reaction to obtain 17beta-cyano-17alpha-hydroxy-9-dehydroandrostenedione (III), the reaction formula of which is shown in the specification.

Owner:台州仙琚药业有限公司

Physical cross-bonding high molecular water resin Cataplasma substrate and preparing method thereof

InactiveCN101199496AIncrease productivityLow costPharmaceutical non-active ingredientsSheet deliveryEthylenediaminePotassium persulfate

The invention provides a preparation method for a substrate of physical crosslinking polymer hydrogel cataplasm. The preparation process includes the following steps: add sodium hydroxide solution in acrylic acid for reaction, then add tetramethyl ethylenediamine and potassium persulfate and stir the mixture to be even to get A solution; heat the A solution for reaction to get B solution; add glycerol and tartaric acid into the B solution and stir the mixture thoroughly to get C solution; add aluminum salt into the C solution and stir thoroughly to get condensed D solution, and finally smear the condensed D solution on a non-woven fabric and cover the non-woven fabric with an antisticking membrane. In this way the substrate of physical crosslinking polymer hydrogel cataplasm can be prepared. The invention does not affect or change the chemical properties of the added medicine, can be formed by coating and pressing and has the advantages of high moisture content rate, no stimulation to skin, good permeability and no pollution to clothes and is convenient to carry and use and can be used to prepare polymer hydrogel cataplasm-a novel formulation of plaster for external use.

Owner:SOUTH CHINA UNIV OF TECH

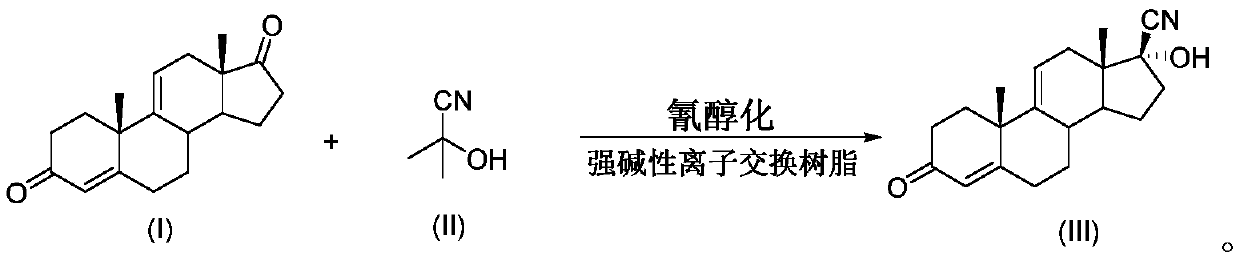

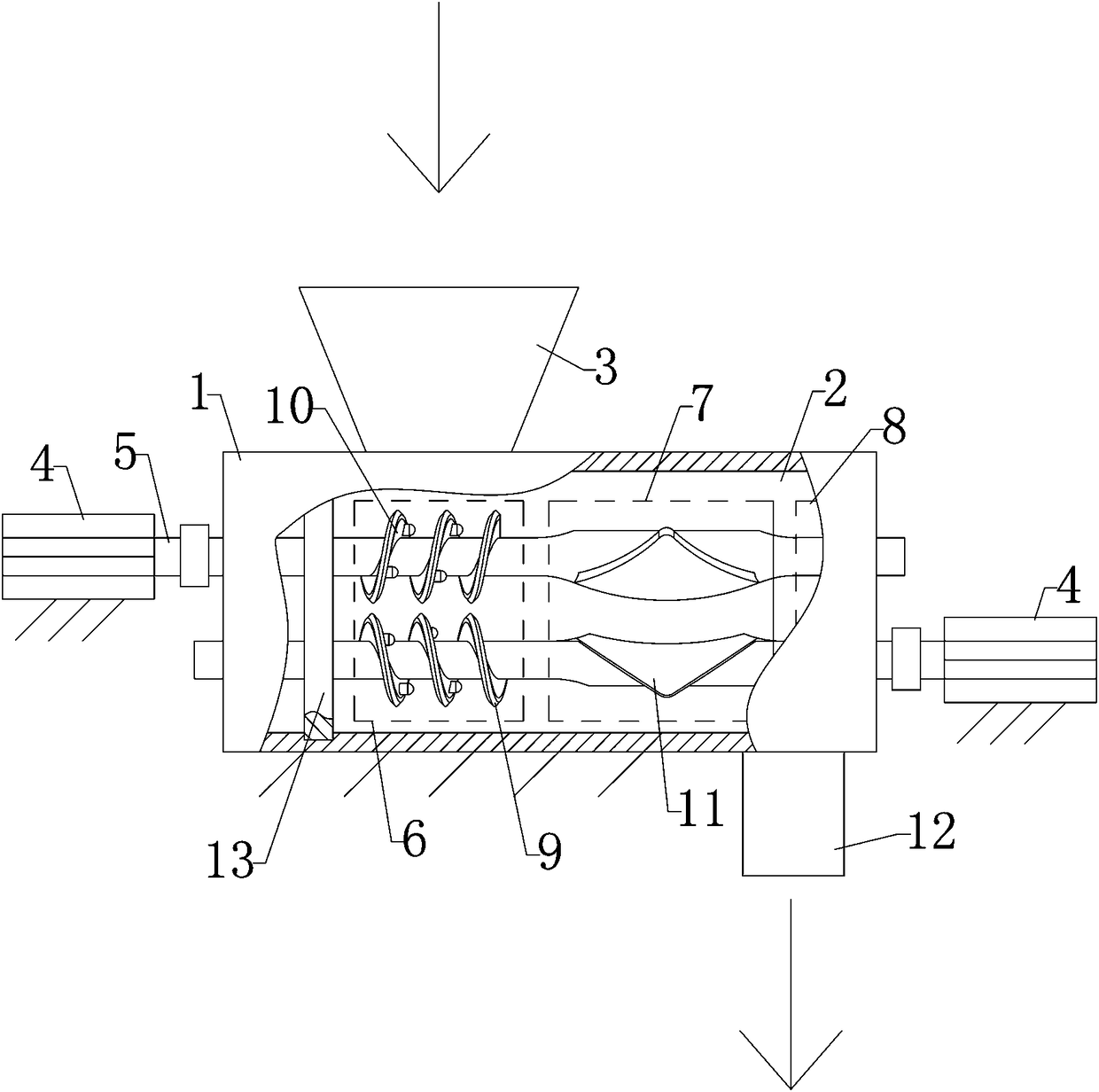

Antistatic flame-retardant master batch and preparation method thereof

The invention relates to the field of antistatic flame-retardant master batch processing, in particular to an antistatic flame-retardant master batch and a preparation method thereof. The antistatic flame-retardant master batch mainly comprises the following components in parts by mass: 20-50 parts of linear low density polyethylene (LLDPE), 2-10 parts of ethylene vinyl acetate (EVA), 1-8 parts ofpolyolefin elastomer (POE), 5-12 parts of conductive carbon black, 1-6 parts of coated red phosphorus, 0.1-4 parts of a processing aid and 2-10 parts of a compatilizer. The formula does not contain polyethylene wax or low-molecular dispersants, a conventional repeated batch-type internal mixing feeding mode is changed, and feeding frequency is reduced, so that the problem of bearing performance defects of the downstream products caused by too much additives is solved, stability of product quality is improved, and comprehensive cost is reduced. Through the arrangement of double-shaft mixing rotary shafts and through a multi-section sectional design, the edges of the mixing stirring paddles on a mixing section are of a two-edge structure, materials are uniformly mixed through the mixing section in a movement process, is subjected to exhausting, and then are sent into the extrusion granulating machine for molding, and the materials do not need to be pressed after mixing in the mixing section, so that the shear damage force to a carbon black structure in the mixing process is reduced.

Owner:SHANDONG DONGHONG PIPE IND

Preparation method of 1,1'-bis (tert-butylphosphine) ferrocene palladium chloride

The invention discloses a preparation method of a palladium complex, namely a preparation method of 1,1'-bis(tert-butylphosphine)ferrocene palladium chloride, which comprises the following steps: 1. dissolving palladium metal salt in diluted hydrochloric acid; 2, enabling the metal solution to pass through an anion exchange resin column to enable chloropalladate radicals to be exchanged on resin;3, enabling the 1,1'-bis(di-tert-butylphosphine)ferrocene (DtBPF) solution to flow through the resin to obtain red turbid liquid; and 4, filtering, and washing the precipitate with ethanol to separatethe resin and the precipitate. The preparation method disclosed by the invention is simple to operate, capable of realizing continuous production, high in product purity, recyclable in reaction liquid and high in metal utilization rate.

Owner:JIANGSU SINOCOMPOUND CATALYST

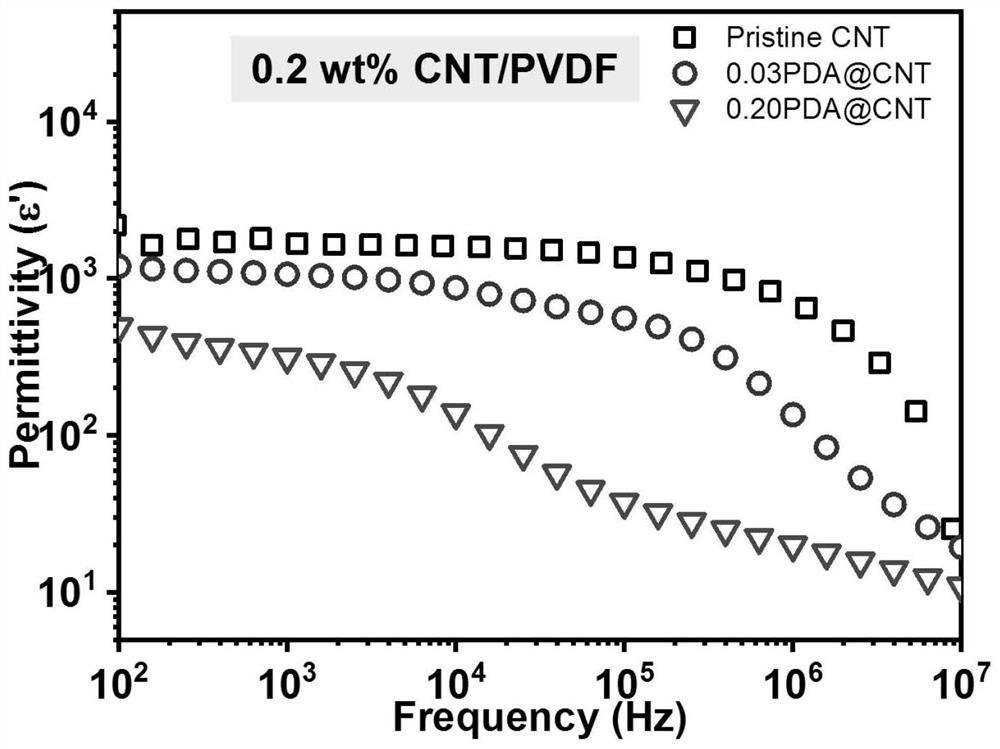

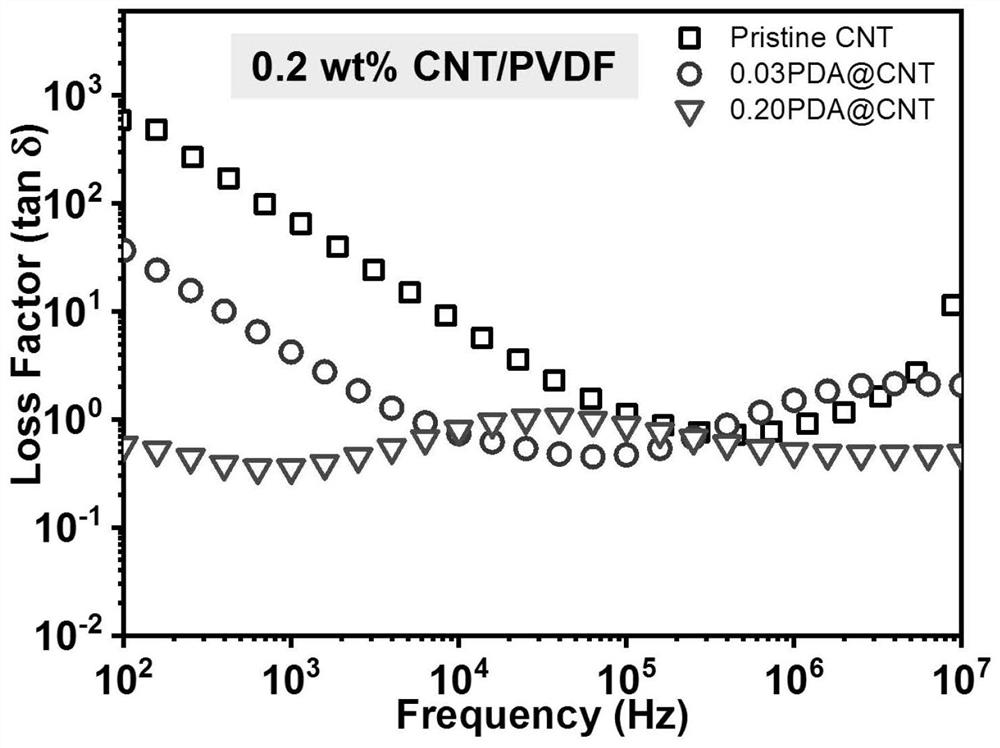

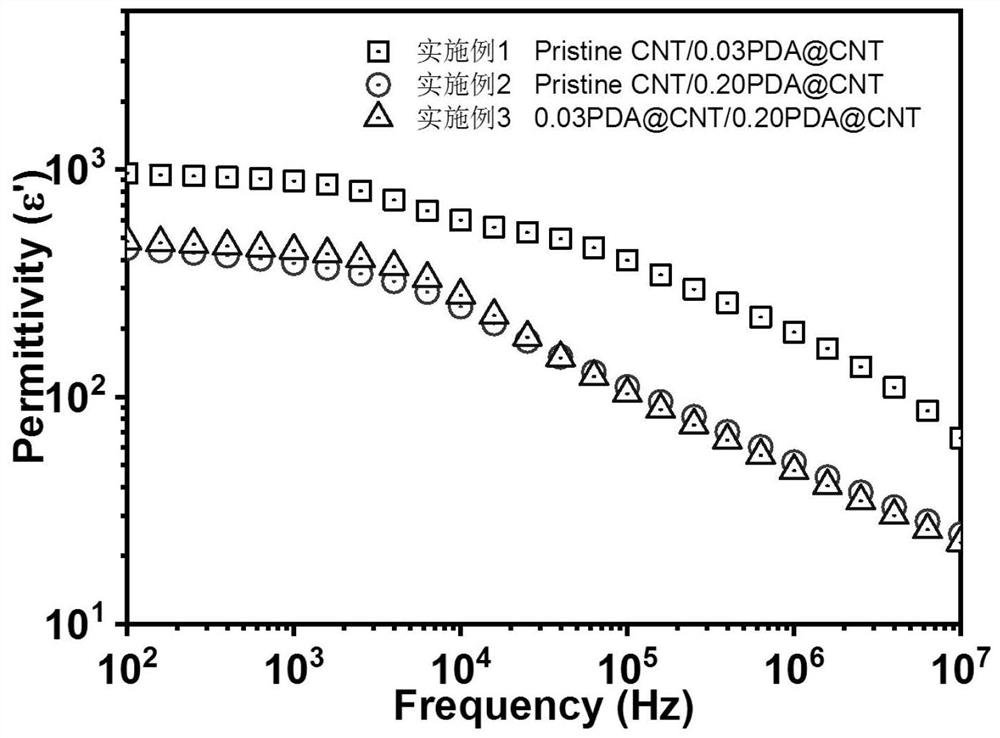

Conductive particle filled polymer layered composite dielectric material and preparation method thereof

The invention discloses a conductive particle filled polymer layered composite dielectric material which comprises the following components in percentage by mass: 99.8% of polyvinylidene fluoride resin, 0-0.1% of multi-walled carbon nanotubes and 0.1-0.2% of polydopamine surface modified coated carbon nanotubes. The invention also provides a preparation method of the polydopamine surface modified coated carbon nanotubes and a preparation method of the conductive particle filled polymer layered composite dielectric material. According to the conductive particle filled polymer layered composite dielectric material, surface small organic molecule coating modification and layered physical distribution control in the prior art are combined, the interface polarization effect is promoted, meanwhile, formation of a conductive path in the vertical direction can be remarkably inhibited, and the conductivity loss is reduced.

Owner:JIANGSU JICUI ADVANCED POLYMER MATERIAL RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com