Technique for continuous production of biological diesel oil with propagation waste oil

A technology of biodiesel and process method, which is applied in the field of continuous production of biodiesel by using animal and vegetable waste oil, which can solve the problems of high production cost, low yield and long reaction time of biodiesel, achieve fast reaction speed and increase productivity , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

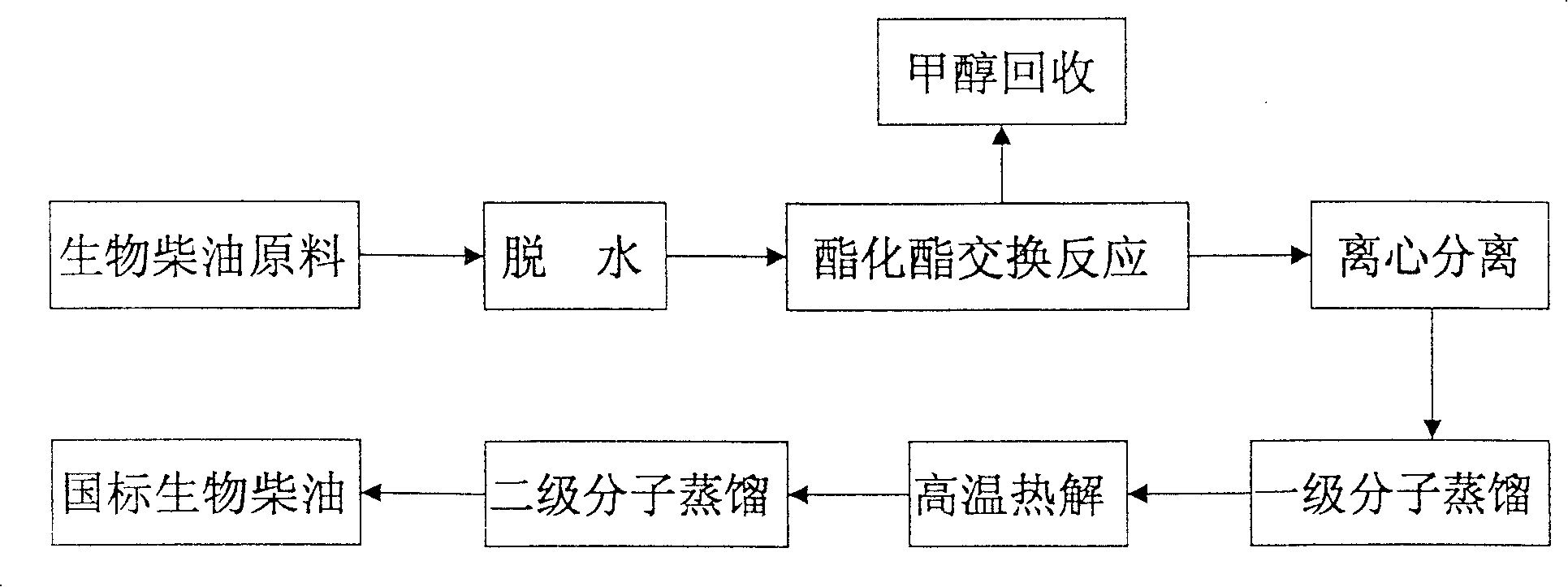

Image

Examples

Embodiment Construction

[0017] The biodiesel raw materials used in the present invention are waste cooking oil, high acid value oil, animal and vegetable oil, and oil bottoms.

[0018] 1) The biodiesel raw material is automatically sucked into the continuous vacuum esterification kettle under vacuum;

[0019] 2) The continuous vacuum esterification tank is heated by a heat-conducting oil boiler, and the biodiesel raw material is distilled, condensed and dehydrated at a vacuum temperature of 50-70°C and a vacuum degree of -0.075 to -0.095Mpa, and monitored by an online moisture meter , reduce the moisture content within 1%;

[0020] 3) Under vacuum conditions, the methanol and 1-1.2% acidic catalyst enters the continuous vacuum esterification tank equipped with dehydration-treated biodiesel raw material according to the raw material mass ratio of 20-30%, the concentration is 99%, and the acidic catalyst can be Choose more than 98% concentrated sulfuric acid, carry out esterification and transesterifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com