Vertical superhigh-temperature continuous balling furnace

An ultra-high temperature, spheroidizing furnace technology, applied in the field of vertical ultra-high temperature continuous spheroidizing furnace, can solve the problems of short process chain, wide particle size range, not suitable for industrial scale production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

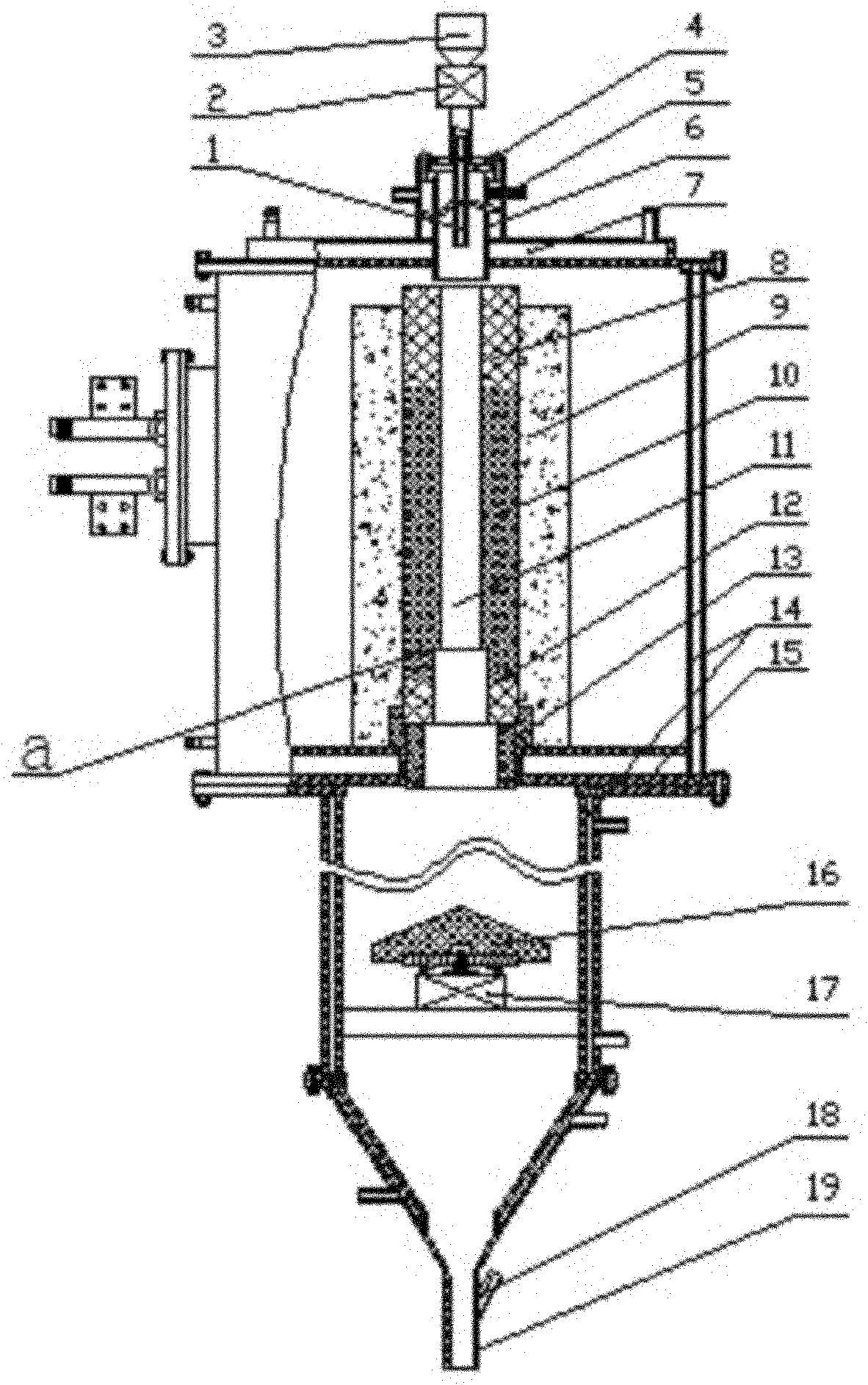

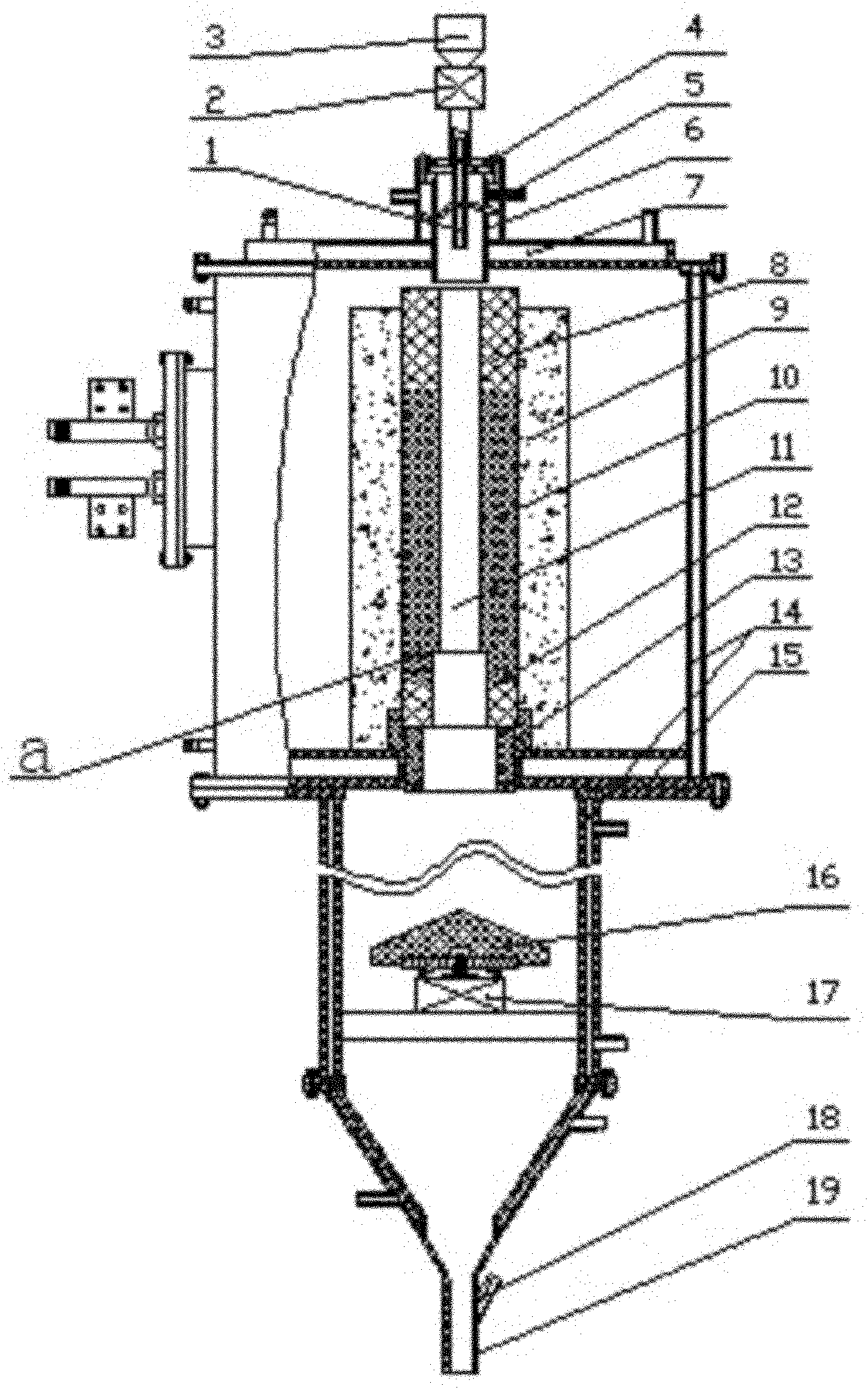

[0018] Referring to the above drawings, a vertical ultra-high temperature continuous spheroidizing furnace includes a feed pipe 1, a feed mechanism 2, a hopper 3, a furnace cover 7, a graphite tube 8, an insulation layer 9, a base 13, and a water-cooled furnace shell 14 , inner support seat 15, conical spinner 16, rotary drive mechanism 17, discharge pipe 19; it is characterized in that: the bottom of the coaxial through hole 11 that described graphite tube 8 center holes and base 13 center holes forms is from top As for the lower, from small to large coaxial step holes or coaxial horn-shaped holes, the number of steps in the coaxial through hole 11 has at least one step. In this embodiment, there are two steps. The horizontal plane a of the upper step is located in the tubular heating zone. 10 (the central cross-hatching area of the graphite tube 8 in the accompanying drawings), that is, the position of the horizontal plane a of the upper step is higher than the bottom plane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com