Patents

Literature

502results about How to "The production process is simple and easy to control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing porcelain granules by using fly ash

InactiveCN101585698AImprove protectionSave natural resourcesFluid removalCeramic materials productionExpanded clay aggregateSlurry

The invention discloses a method for preparing porcelain granules by using fly ash, which comprises the following steps: putting fly ash, potassium feldspar and quartz as raw materials into a ball mill respectively, dry-milling the raw materials, sieving the milled raw materials respectively, removing iron from the sieved fly ash, putting the fly ash after iron removal, the sieved potassium feldspar and quartz and kaolin into the ball mill, and wet-milling and evenly mixing the materials to form mixed slurry; and granulating the mixed slurry by adopting a pressure type spray granulator, putting the granules into an alumina crucible, placing the alumina crucible into a silicon-carbon rod resistance furnace, sintering and naturally cooling the granules, and taking out the granules to obtain the high-strength porcelain granules. The method for preparing the porcelain granules by using the fly ash is not only favorable for saving natural resources and reducing the production cost, but also favorable for environmental protection. The fly ash does not need to be crushed by a high-power crusher, and the fly ash is mixed evenly. The production process is easy to control, and has little energy consumption; the strength of the prepared fly ash porcelain granules can reach 60 to 120MPa; and the porcelain granules have good properties of light weight, high temperature resistance, corrosion resistance and the like, and can be used as a fracturing propping agent for middle and deep layer oil-gas fields.

Owner:SHAANXI UNIV OF SCI & TECH

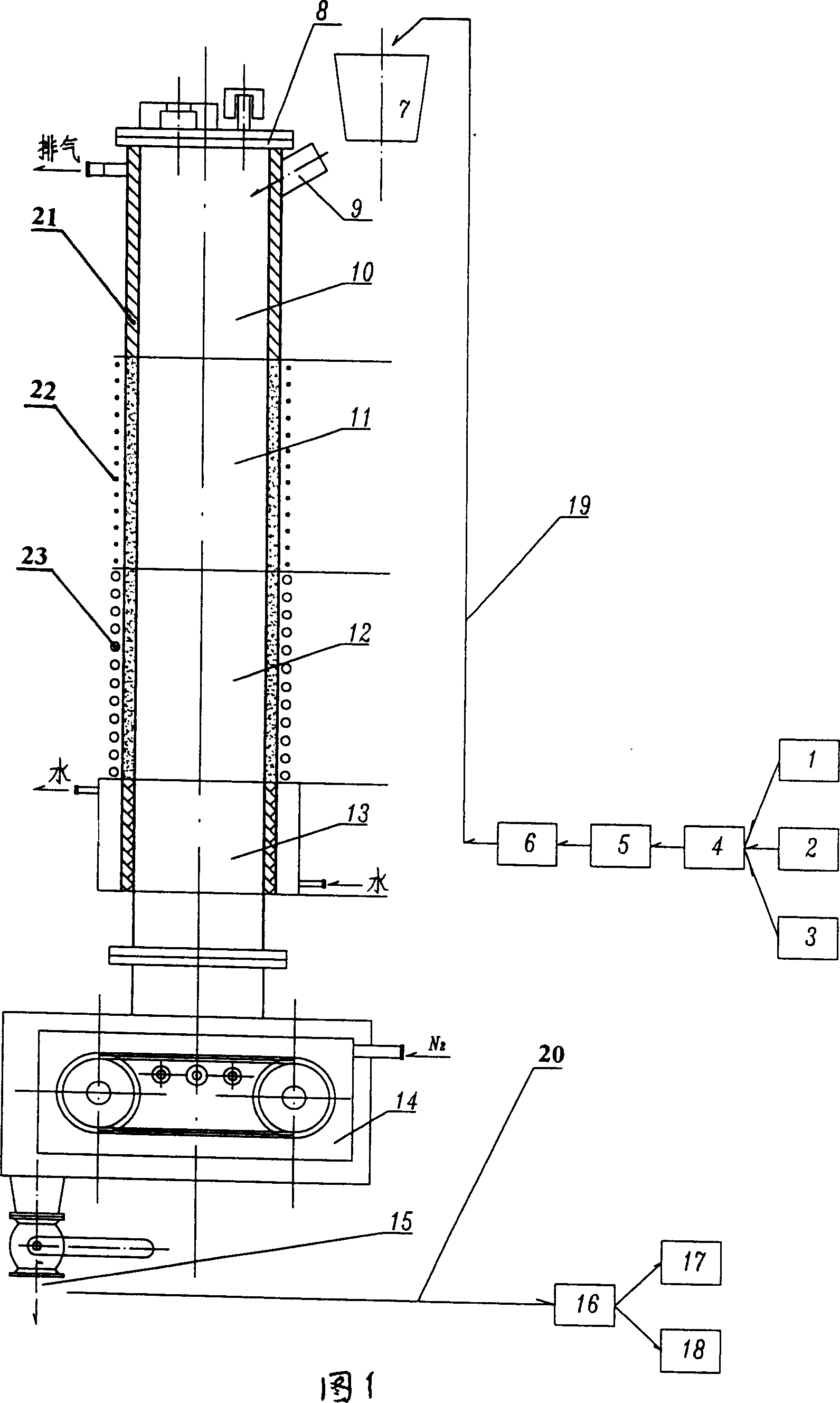

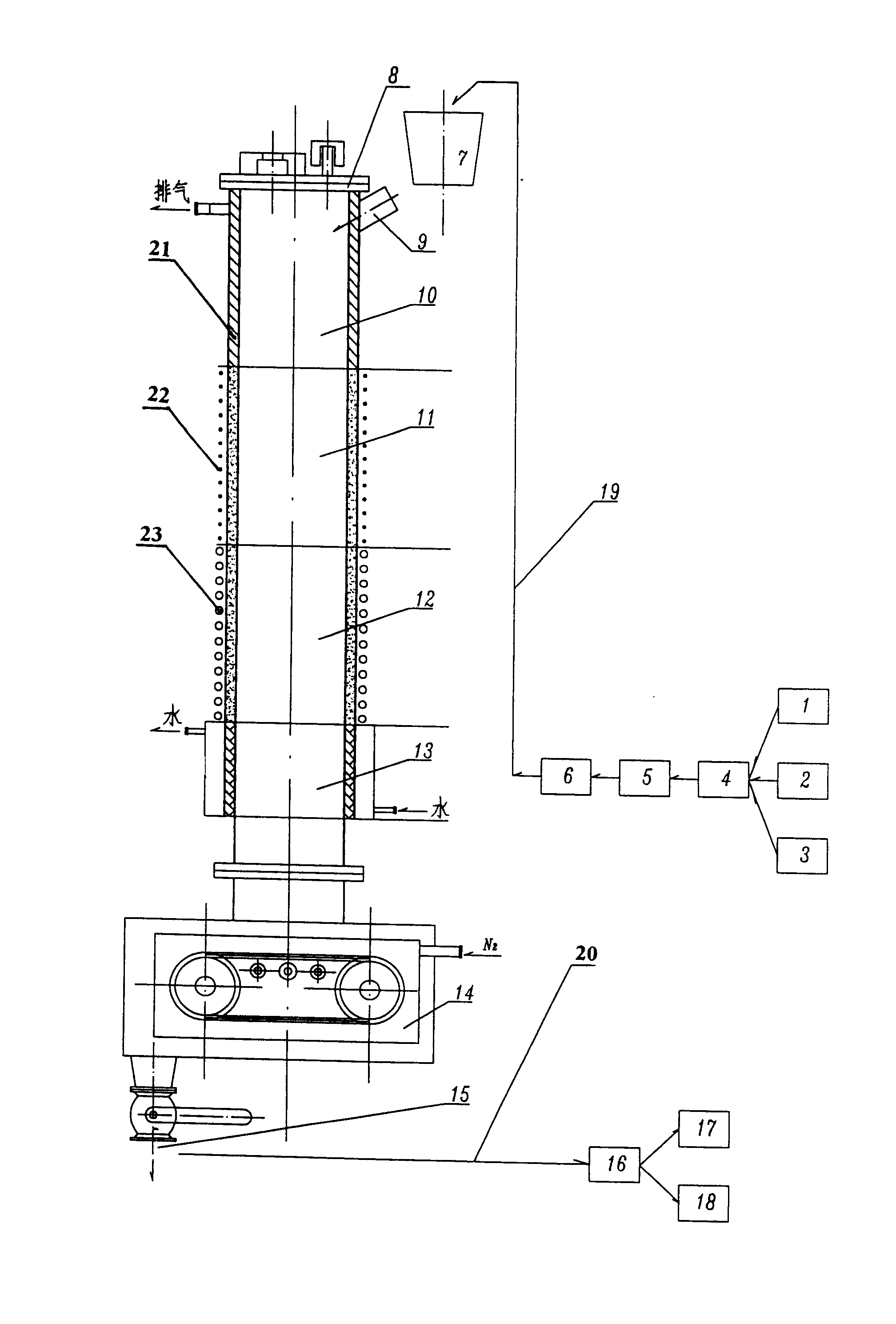

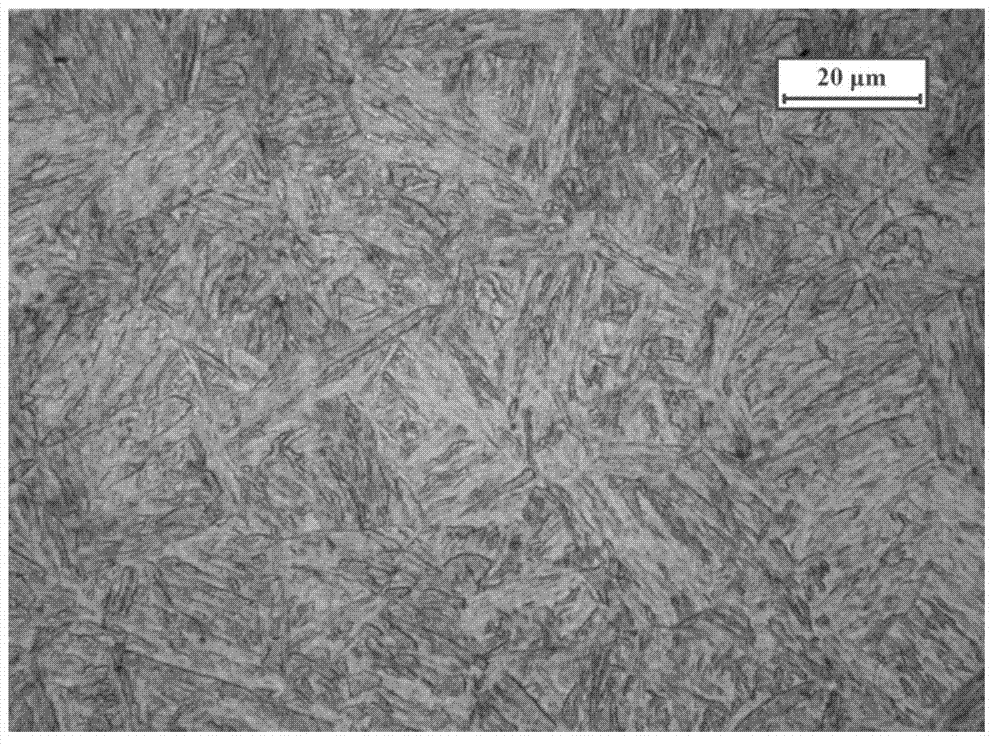

Mn-containing creep-resisting rolled zinc alloy belt material and preparation method thereof

InactiveCN101906555AOutstanding advantagesHighlight positive effectsRoll mill control devicesMetal rolling arrangementsRare-earth elementManganese

The invention relates to a Mn-containing creep-resisting rolled zinc alloy belt material. The material comprises the following components in percentage by weight: 0.5 to 3.0 percent of copper, 0.01 to 2.0 percent of manganese, 0.05 to 0.3 percent of titanium and the balance of zinc and less than 0.05 percent of impurities. An alloy component can also contain the following component in percentage by mass: 0.01 to 0.5 percent of X, wherein the X is at least one of aluminum and rare earth elements (Ce+La). A method for preparing the material comprises the following steps of: smelting by a protective covering method and adding alloy elements in the forms of pure zinc, Zn-Cu, Zn-Ti, Cu-Mn, pure aluminum and Ce+La composite rare earth, wherein a smelting temperature is between 650 and 740 DEG C; pouring at the temperature of between 420 and 480 DEG C; uniformly annealing cast ingots at the temperature of between 350 and 380 DEG C for 6 to 10 hours; performing hot rolling for multiple times at the temperature of between 220 and 280 DEG C, wherein total deformation is between 60 and 95 percent; performing cold rolling, wherein the total deformation is between 50 and 80 percent; and after rolling, annealing at the temperature of between 180 and 200 DEG C for 2 to 3 hours. The alloy of the invention has high creep resistance, hot processing performance and mechanical property and is suitable for the fields of building decoration, transportation, instruments, meters and the like.

Owner:CENT SOUTH UNIV

Sea water corrosion resistant steel for ocean drilling/production platform and preparation method thereof

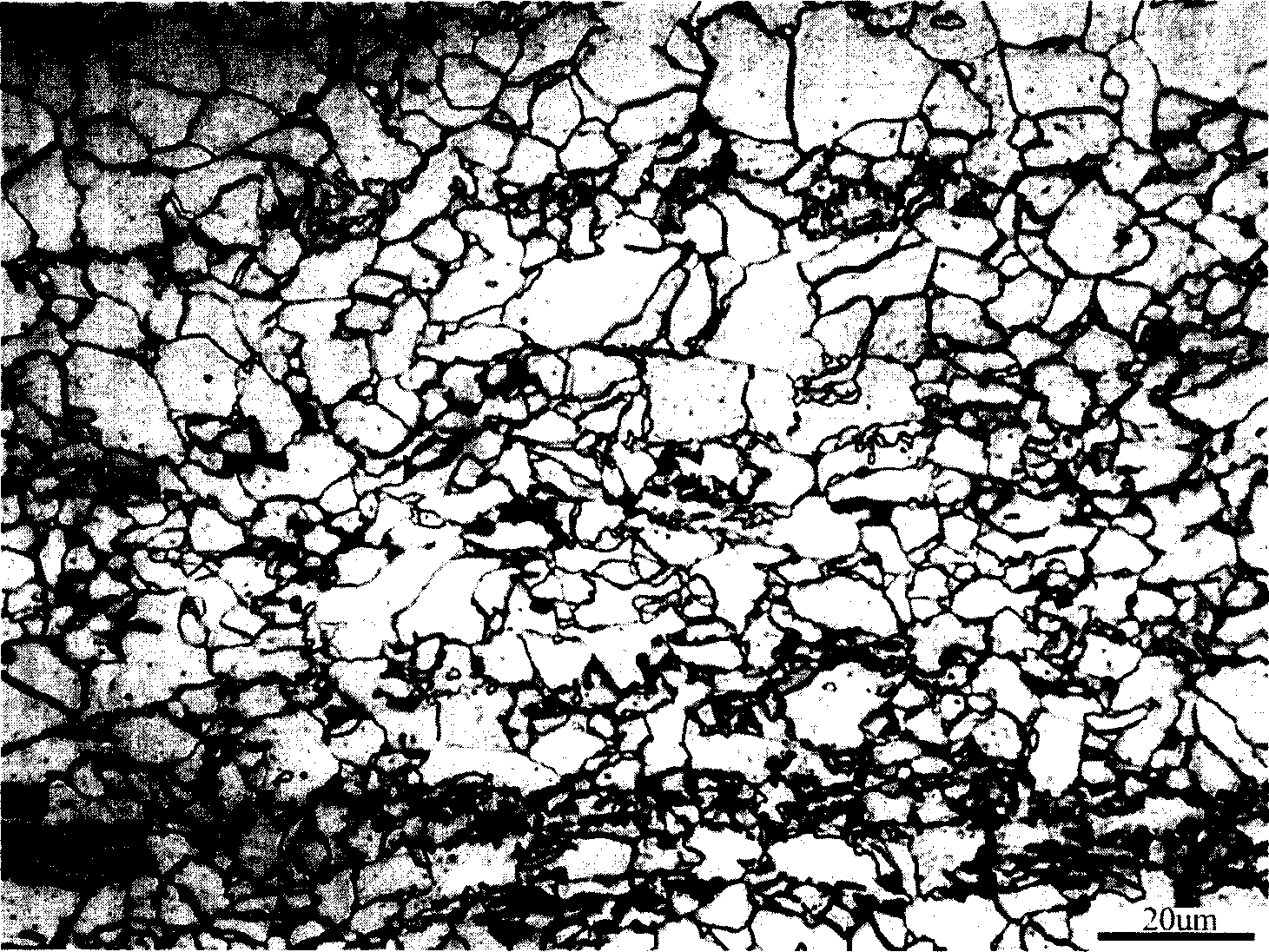

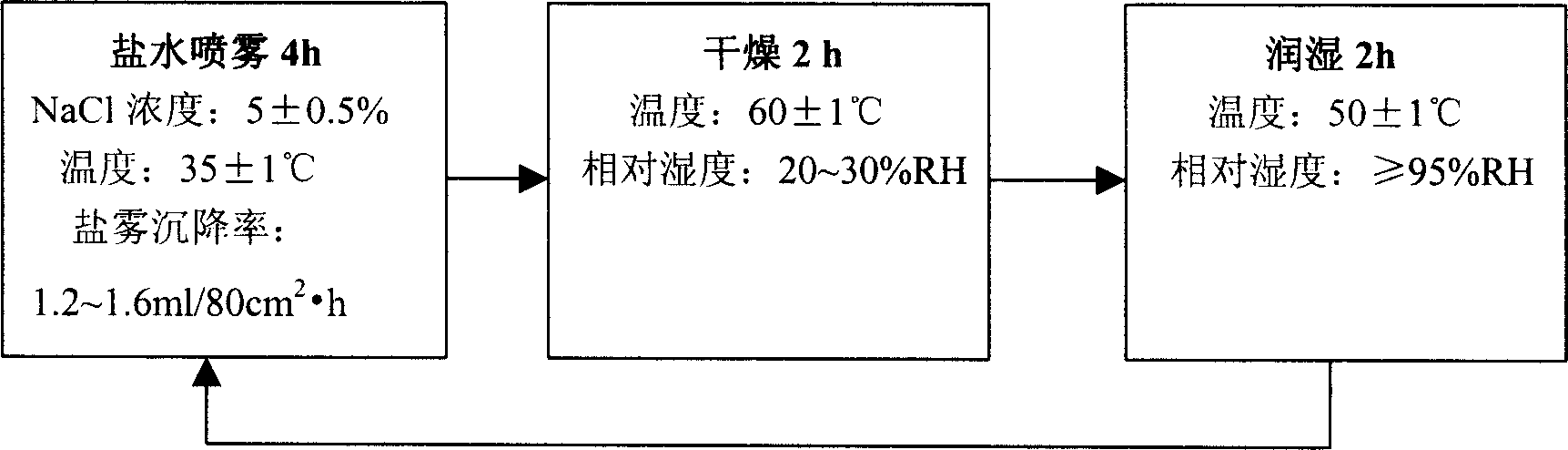

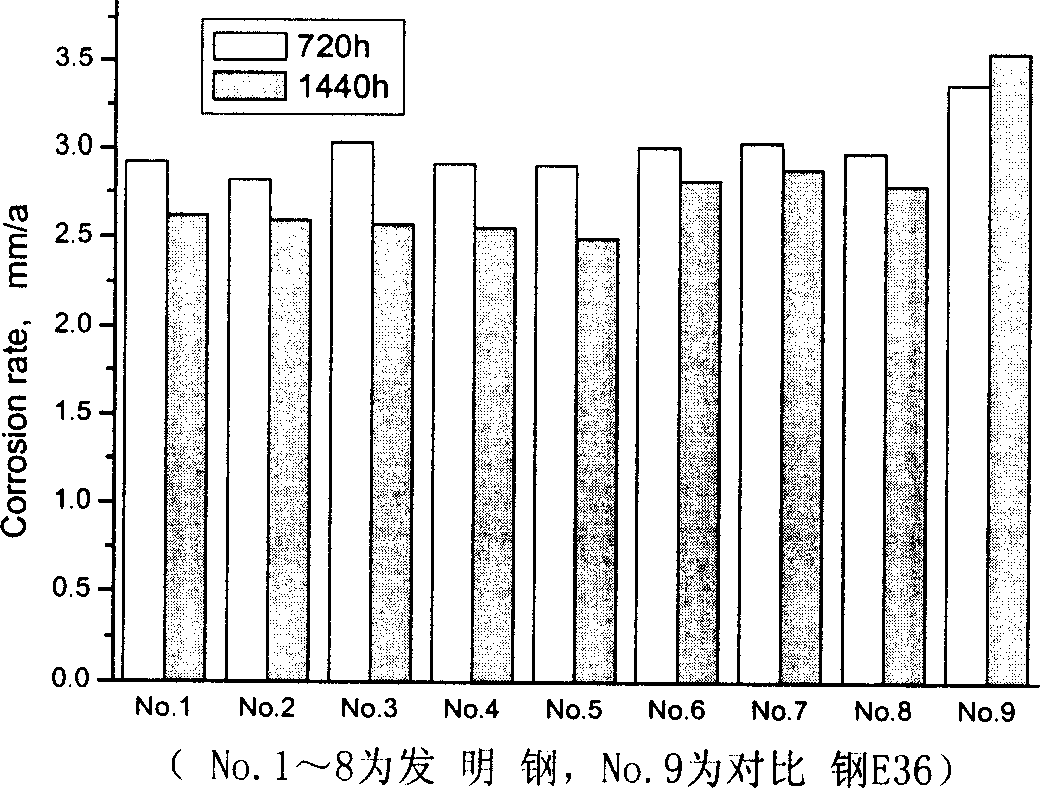

InactiveCN1908217AReduce unevennessAvoid corrosionRoll mill control devicesWelding/cutting media/materialsChemical compositionImpurity

the invention discloses a marine exploiting platform steel of erosion property of sea water resistance, which comprises the following parts: 0.03-0.09% C, 0.90-1.60% Mn, 0.10-0.50% Si, 0.006-0.020% P, 0.004-0.100% Cr, 0.02-0.40% Cu, 0.010-0.060% Als, 0.005-0.060% Nb, 0.005-0.030% Ti, Fe and impurity. the manufacturing method comprises the following steps: desulfurizing; blowing; disposing through vacuum; casting continually; rolling.

Owner:武钢集团有限公司

Composite microbial feed additive for beasts and birds and production method

ActiveCN101461453AGuaranteed shelf lifeLow costAnimal feeding stuffPediococcus acidilacticiLivestock

The invention relates to a composite microorganism livestock and poultry feed additive and manufacturing method thereof, belonging to the feed technology field. The invention discloses a composite microorganism livestock and poultry feed additive, which is characterized in comprising composite bacterium powder in 1.0-15% of total mass protion; wherein, the composite bacterium powder is compatible of any two or more of the lactobacillus, yeast, pediococcus acidilactici and fecal streptococcus. the strains in the microorganism feed additive of the invention can symbiose to each other, which is favorable to performance their biological activities, and can keep enough shelf life and live bacteria quantity. The invention also achieves the advantages of controlled production process, lower cost and stable product quality.

Owner:BIOGROWING CO LTD

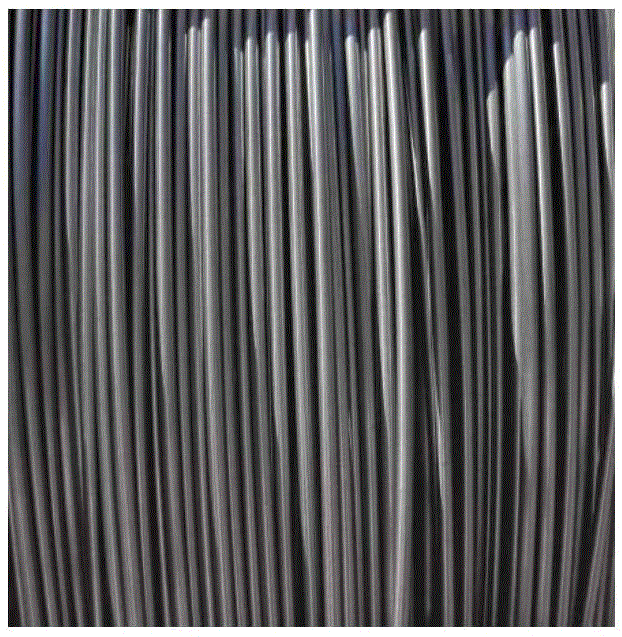

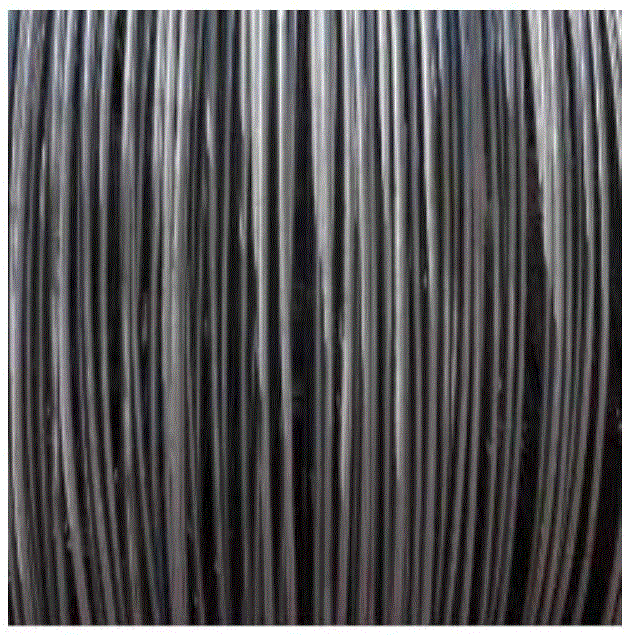

Manufacturing method of nuclear nickel-base high-temperature alloy GH 4145 wire

The invention provides a manufacturing method of a nuclear nickel-base high-temperature alloy GH 4145 wire and belongs to the technical field of high-temperature alloy wire machining. The method includes the steps that after being blended according to the mass percent, raw materials are subjected to vacuum induction and vacuum consumption duplex smelting and cast into an alloy ingot; the alloy ingot is homogenized so as to be forged into an alloy ingot blank, and the alloy ingot blank is then subjected to flaw detection and finishing and hot-rolled into a wire rod with the diameter phi ranging from 8 mm to 12 mm; the wire rod is subjected to solution treatment and is rounded, peeled and coated with a film; drawing and annealing are performed sequentially, the wire rod is pulled into the alloy wire with the required diameter, and the GH 4145 alloy wire is obtained. By the adoption of the nuclear nickel-base high-temperature alloy wire, the whole process is free of acid pickling, the special nuclear requirement is met, and meanwhile the finished wire is high in size accuracy, good in surface quality, even in component and structure and excellent in mechanical performance and processing performance. The method can be widely applied to the machining field of the nuclear nickel-base high-temperature alloy wire.

Owner:CENT IRON & STEEL RES INST

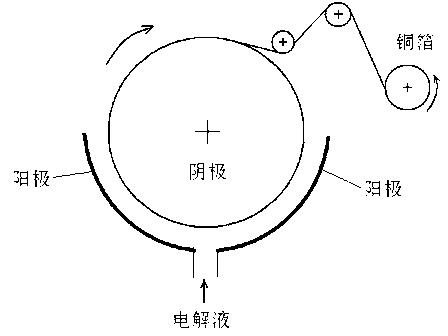

Mixed additive for removing internal stress of electrolytic copper foil and method for producing low-stress copper foil

ActiveCN103173812AThe production process is easy to controlProduct quality is stableCopper foilHydroxyethyl cellulose

The invention relates to a mixed additive for removing internal stress of an electrolytic copper foil and a method for producing a low-stress copper foil and belongs to the technical field of production of a high-precision electrolytic copper foil. The mixed additive for removing internal stress of the electrolytic copper foil comprises gelatin, hydroxyethyl cellulose and liquid additive. The method for producing the low-stress copper foil by using the mixed additive comprises the steps of preparing high-purity cathode copper and sulfuric acid into mixed solution of sulfuric acid and copper sulfate at 60-95 DEG C under the condition of stirring in the presence of air, wherein Cu<2+> is 85-100g / L and H2SO4 is 100-120g / L; adjusting the temperature of electrolyte to 45-60 DEG C and the flow to 50-70m<3> / h; adding 20-50mg / L of Cl<->, adding the mixed additive, with a drum titanium tube which continuously rotates as a cathode and arc titanium as an anode, carrying out copper electrolytic deposition and lastingly stripping to obtain 12-70 microns copper foil under the condition of the direct current of which the current density is 55-70A / dm<2>. The thickness of the copper foil is controlled by adjusting the rotation speed of the cathode; and the obtained copper foil has excellent performances.

Owner:SHANDONG JINBAO ELECTRONICS

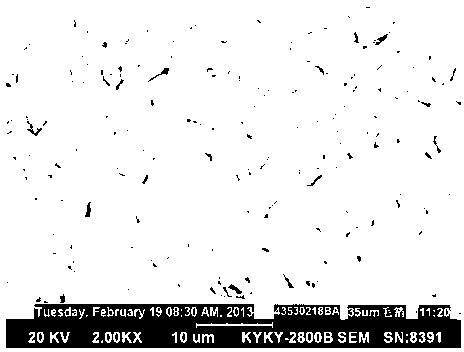

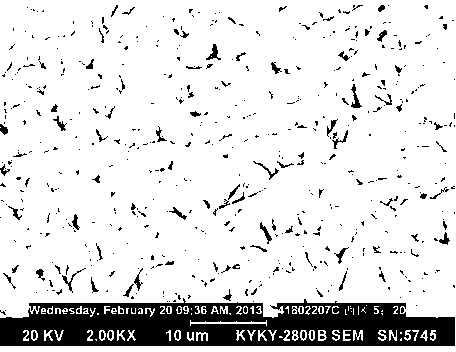

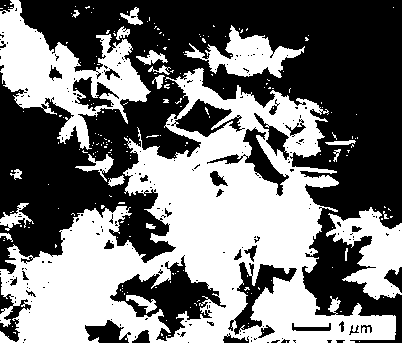

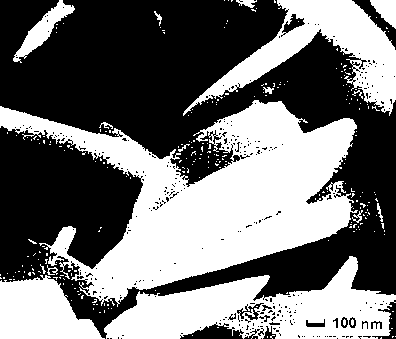

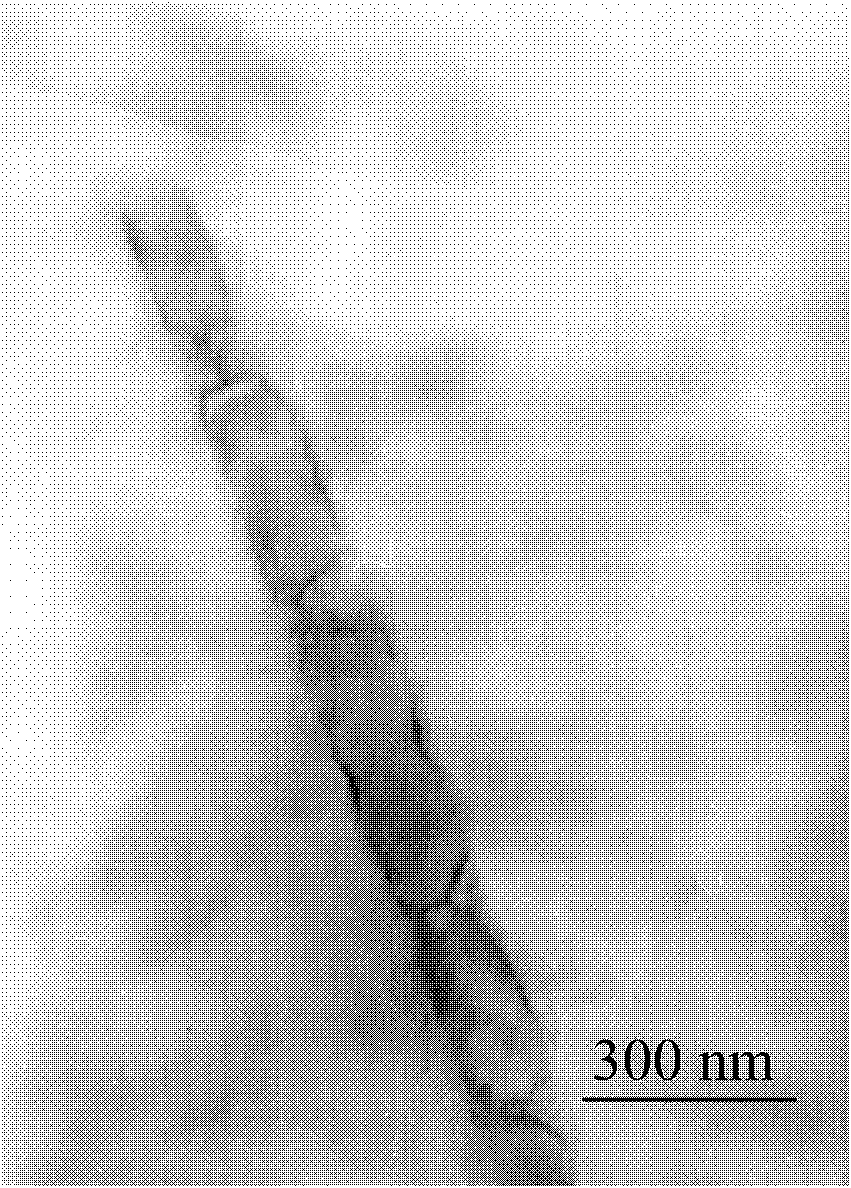

Method for preparing hexagonal molybdenum disulfide nanosheet as anti-friction additive

ActiveCN103073060AReduce manufacturing costThe production process is simple and easy to controlMaterial nanotechnologyMolybdenum sulfidesTube furnaceHydrothermal synthesis

The invention discloses a method for preparing a hexagonal molybdenum disulfide nanosheet as an anti-friction additive. An additive-assistant hydrothermal synthesis method is adopted. The preparation method comprises the following steps: synthesizing a carbon ball from a high molecular compound as a carbon source by a Stober method; dissolving Na2MO4, Na2S and NH2OH.HCl in water to obtain a solution; adding the prepared nano carbon ball and uniformly dispersing the nano carbon ball in the solution by centrifugal stirring; adjusting the pH value of the solution to 6 to 8 with acid, and stirring the obtained solution and then moving the solution to a stainless steel reaction kettle for thermostatic reaction to obtain a reaction product; and separating the reaction product and annealing the product in a tube furnace of 400 to 600 DEG C to obtain the hexagonal molybdenum disulfide nanosheet. The preparation method is simple in process, and the prepared product is high in purity and yield, and excellent in antifriction and anti-wearing and lubricating property, and can serve as the anti-friction additive of lubricating oil and fat.

Owner:苏州惠丰润滑材料有限公司

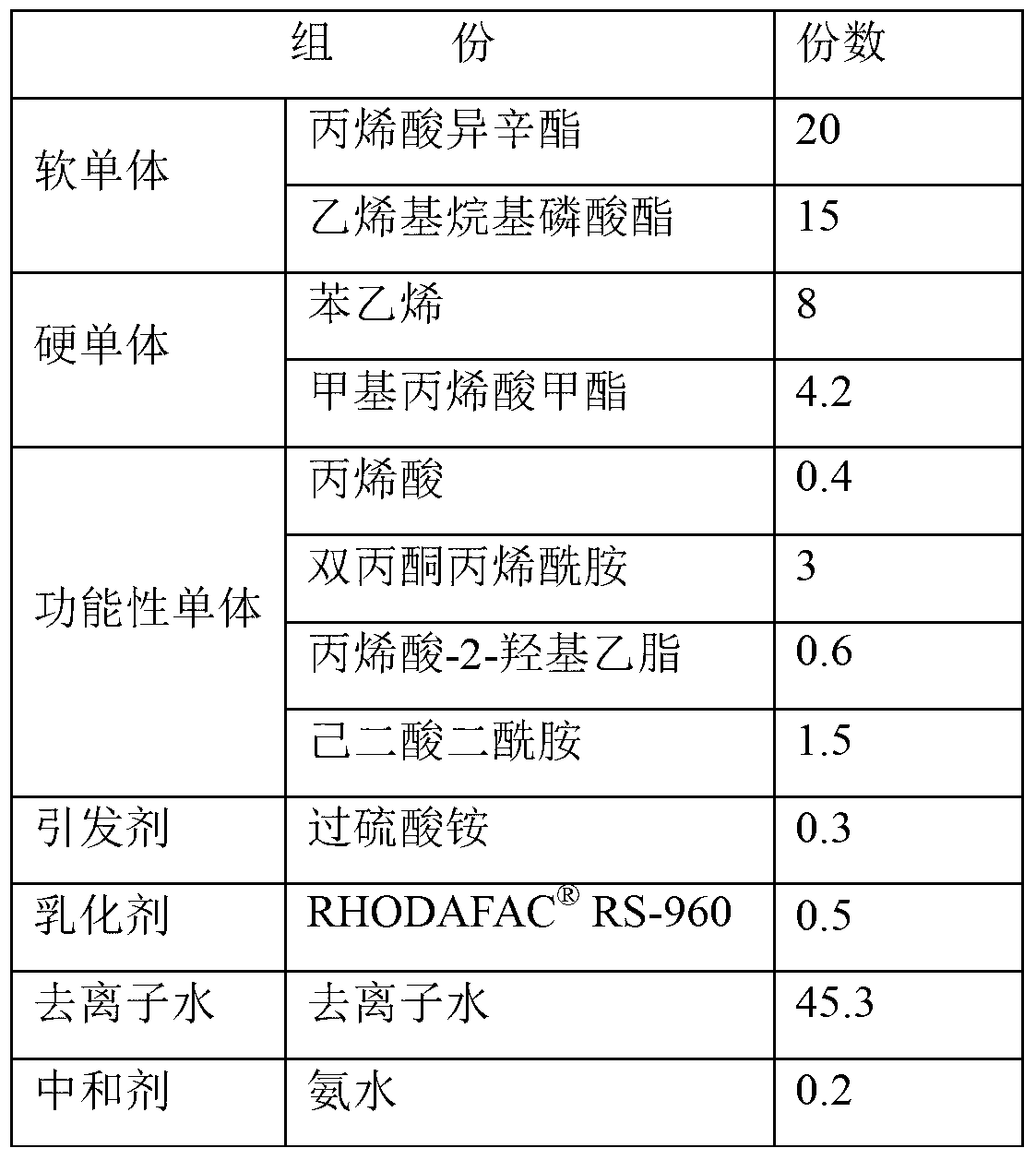

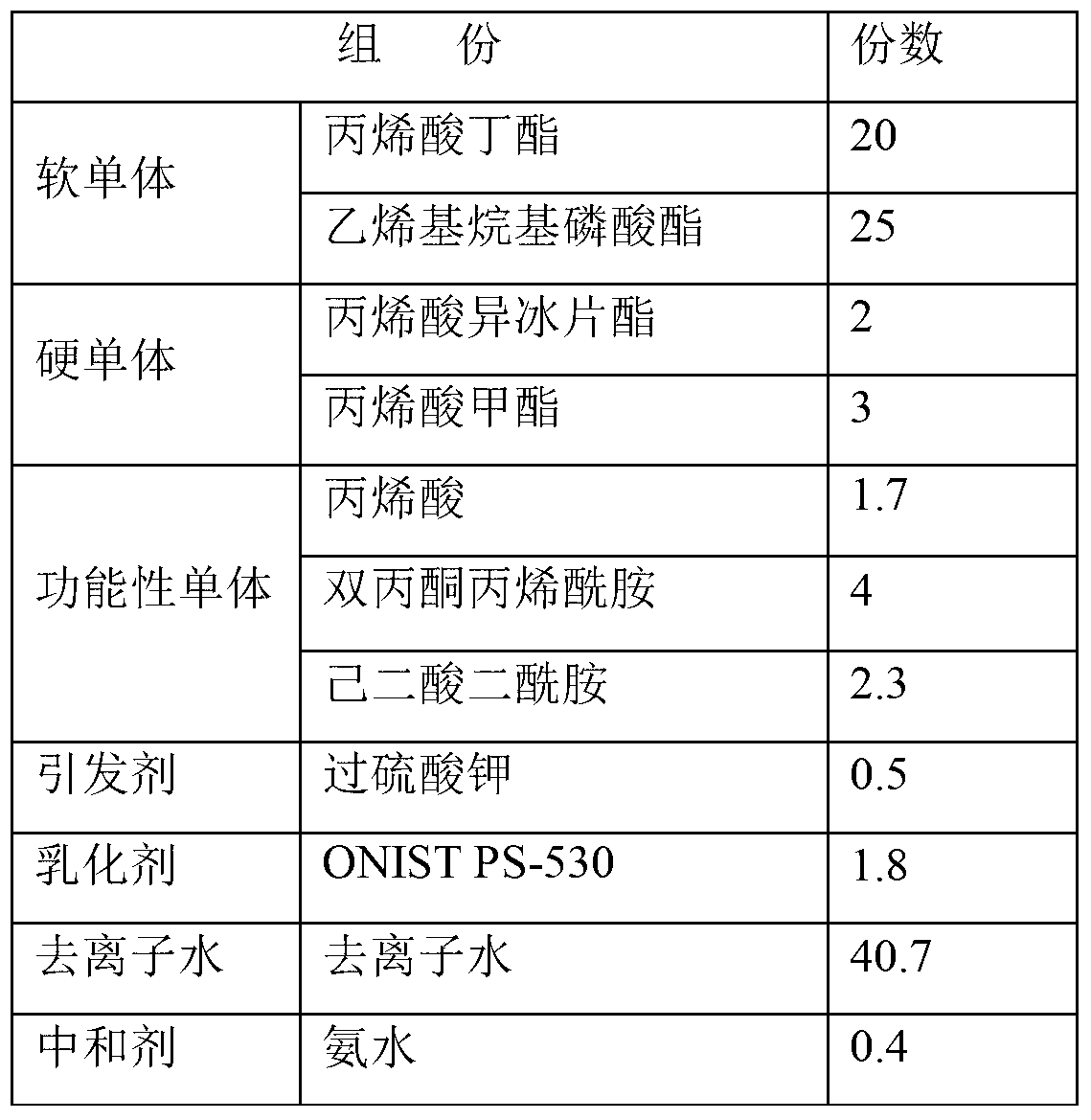

Environmental protection fire retardation type textile printing coating material and preparation method thereof

ActiveCN103225215AImprove flame retardant performanceFeel goodDyeing processTextile printerEngineering

The present invention discloses an environmental protection fire retardation type textile printing coating material and a preparation method thereof. According to the present invention, a fire retardation type acrylate is adopted as a main base material to prepare a fire retardation type coating material for textile printing, wherein the prepared fire retardation type coating material self-extinguishes within 5 seconds after leaving fire, and has characteristics of good fire retardation effect, good elasticity, low cost, excellent washing fastness resistance, and excellent color fastness; during a production process and a use process of the product, no formaldehyde is released, an environmental protection characteristic is provided, and the product does not contain heavy metals and alkyl phenol substances, and is an environmentally friendly and green product; and the preparation method has characteristics of easy production process control, high production efficiency and stable system, and is suitable for industrial scale production.

Owner:连云港百利合新材料发展有限公司

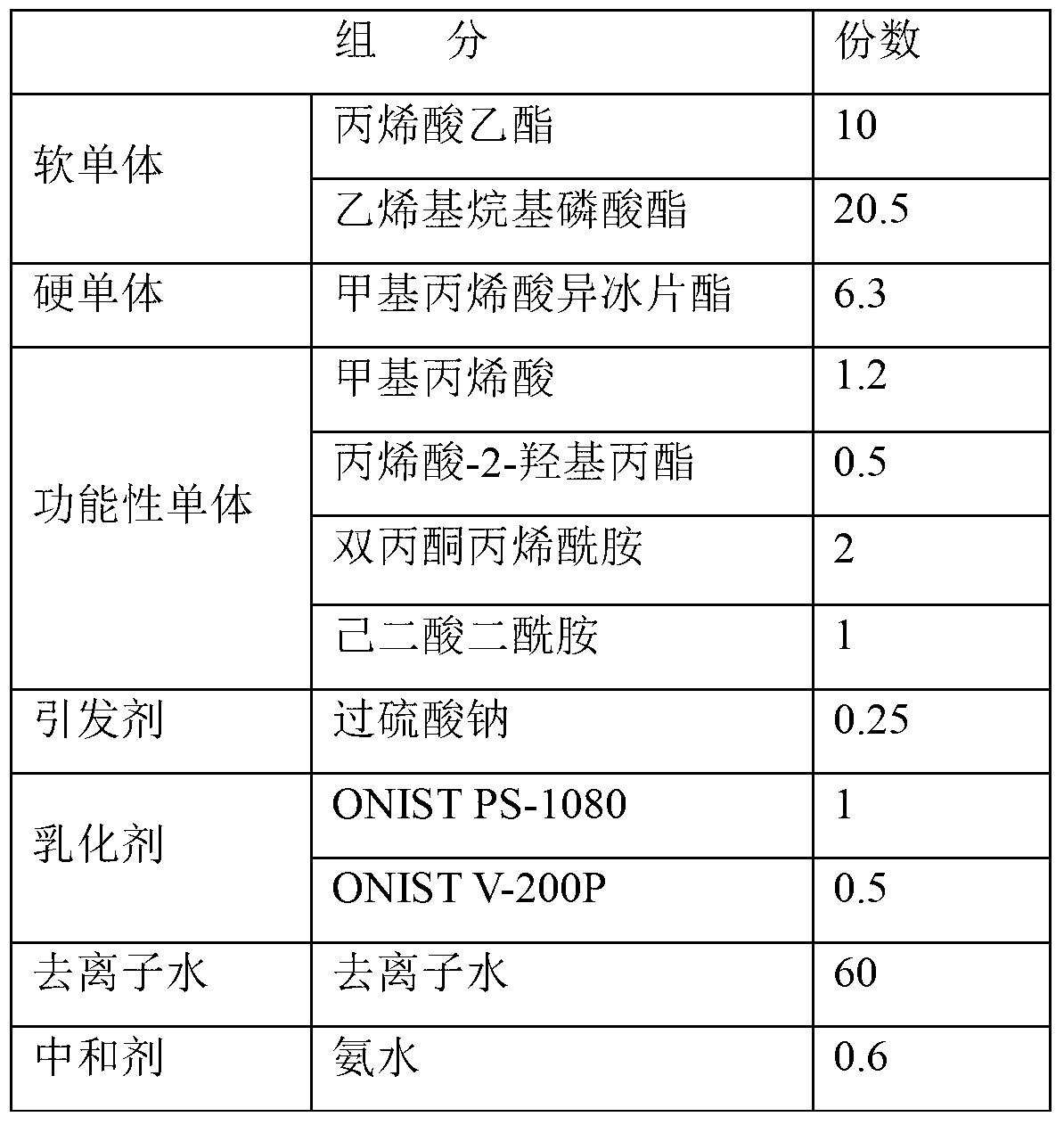

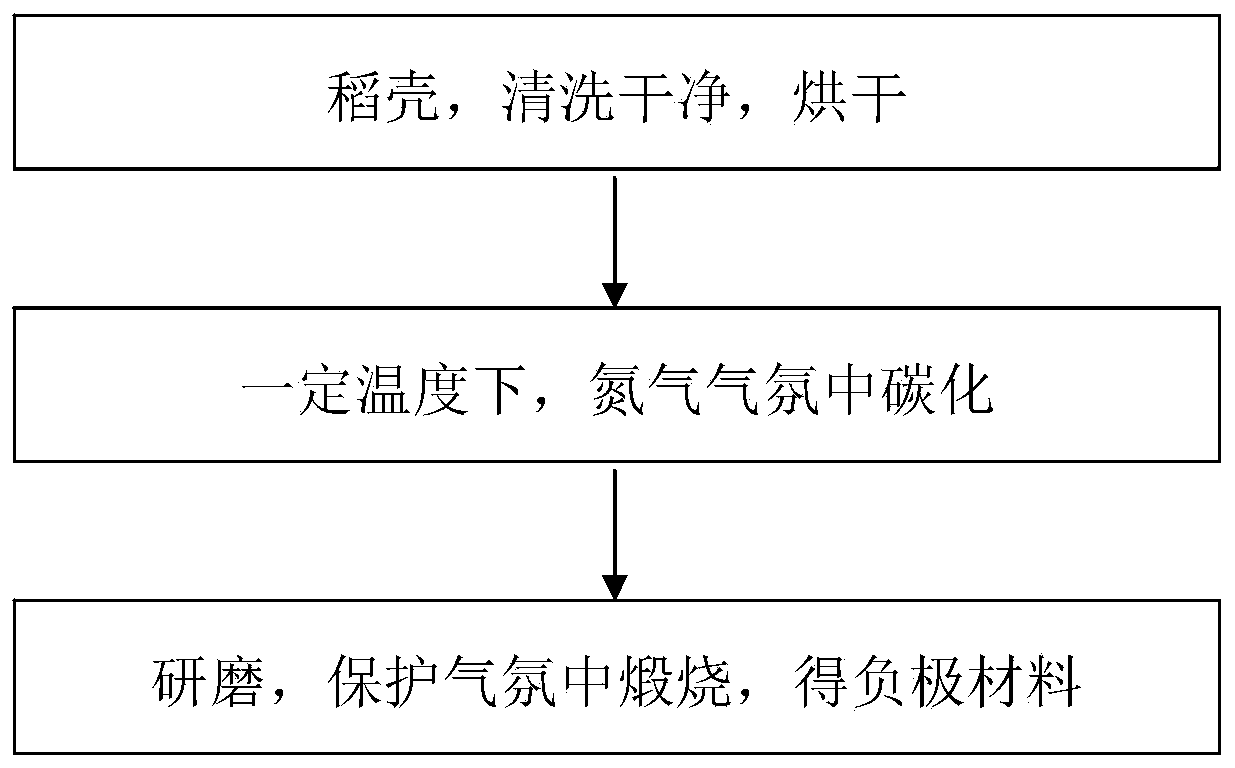

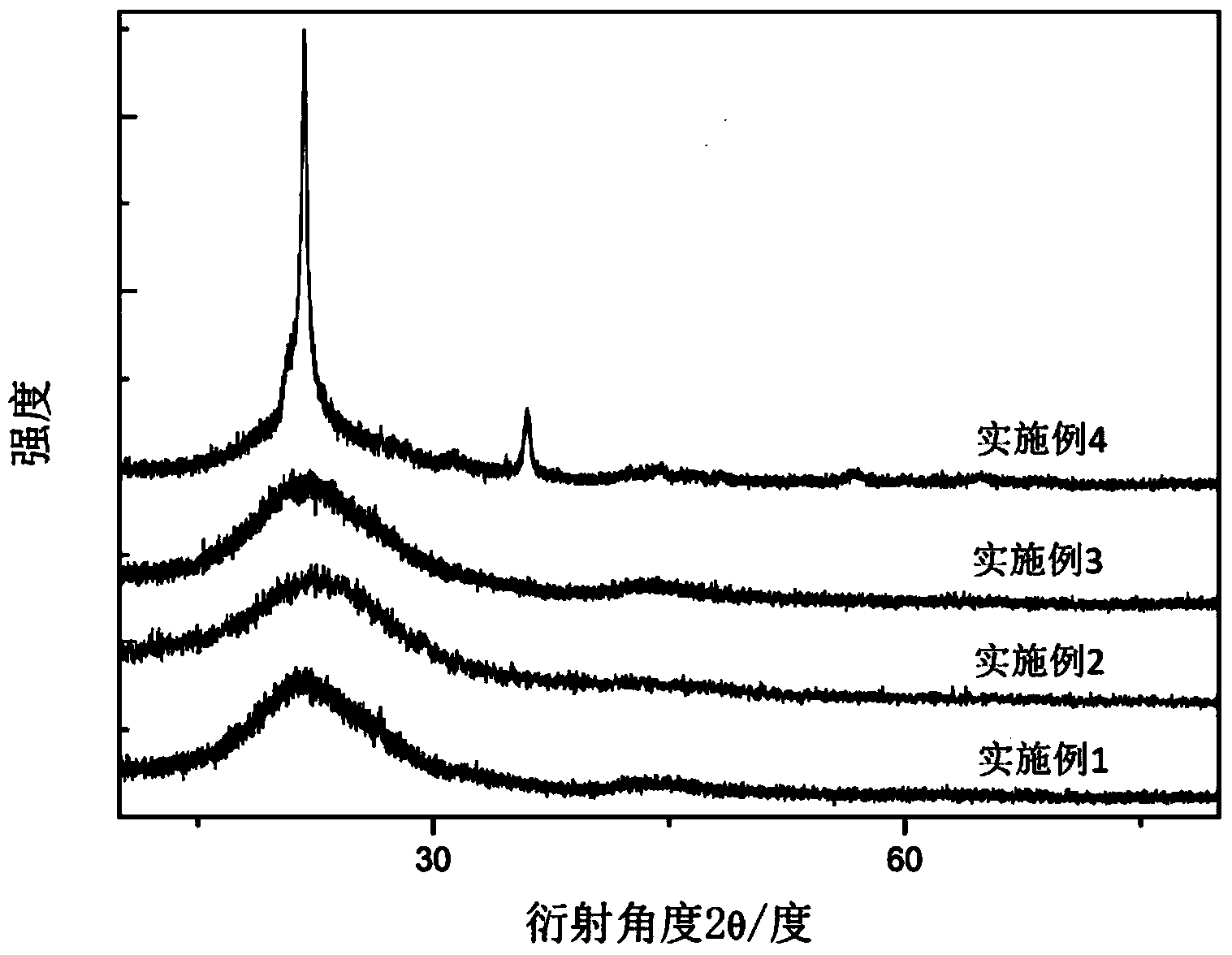

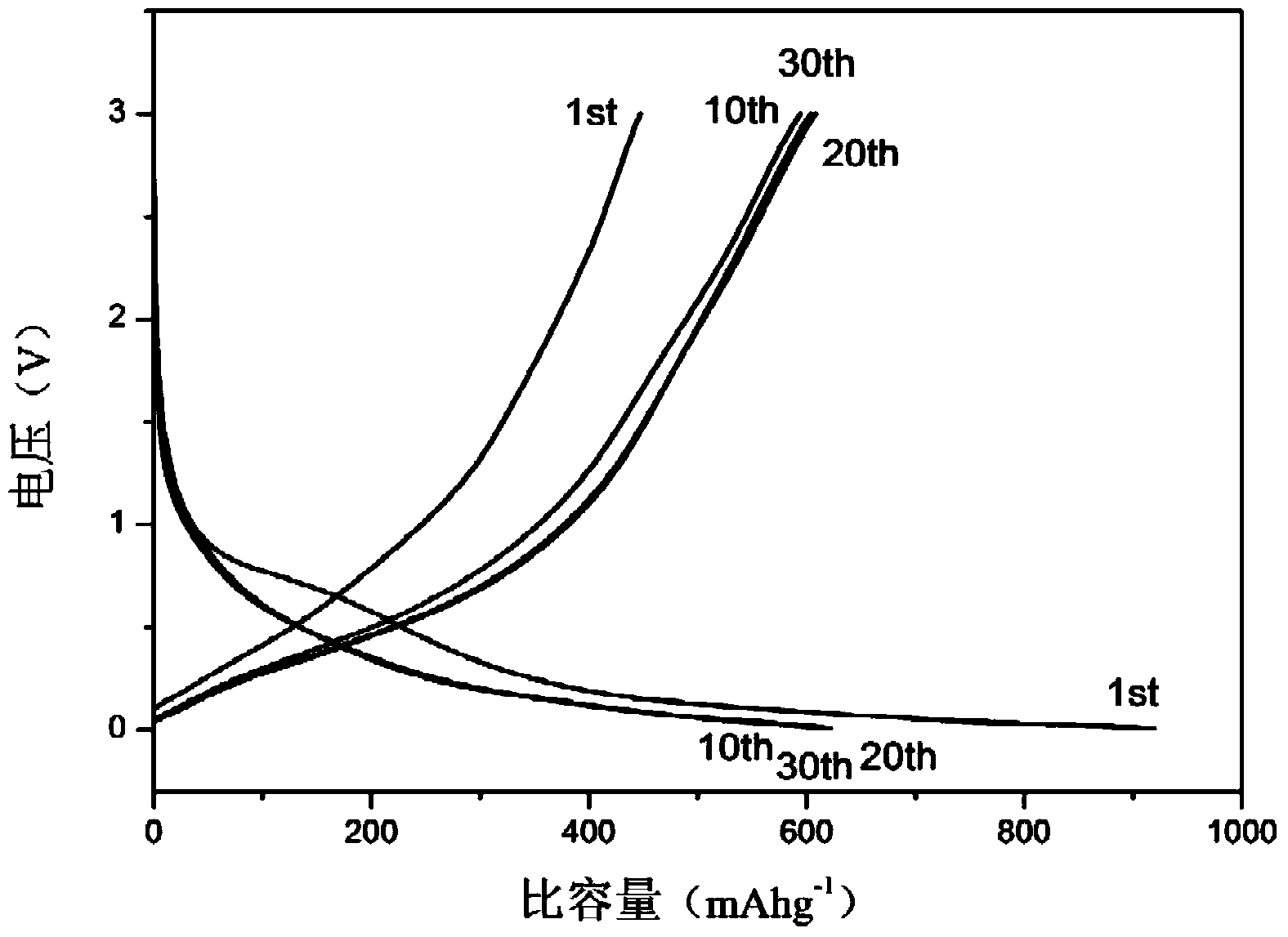

Method for preparing negative electrode material of lithium ion secondary battery

InactiveCN103647043ALow voltage platformEasy to storeCell electrodesSecondary cellsArgon atmosphereLow voltage

The invention discloses a method for preparing a negative electrode material of a lithium ion secondary battery, which belongs to the technical field of lithium ion batteries. With rice hulls as raw materials, a negative electrode material of an SiO2 / C lithium ion secondary battery is prepared by two steps of carbonization and high temperature treatment, wherein the carbonization step is carried out as follows: carbonizing in a nitrogen atmosphere at a temperature of 200-700 DEG C for 0.5-2 hours, and naturally cooling to obtain carbonized rice hulls; the high temperature treatment step is carried out as follows: grinding the carbonized rice hulls into powder, maintaining the temperature in a hydrogen or / and argon atmosphere at 700-1000 DEG C for 3-5 hours to obtain an electrode material; or only the carbonization step is carried out to prepare the electrode material. According to the method disclosed by the invention, raw material sources are wide, waste utilization cost is low, the preparation process is simple and easy, the energy consumption is low, and the environmental-friendly effect is achieved; the prepared negative electrode material has the characteristics of low voltage platform, high capacity, stable circulation performance and long service life.

Owner:JILIN UNIV

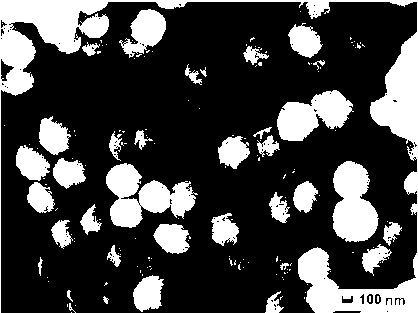

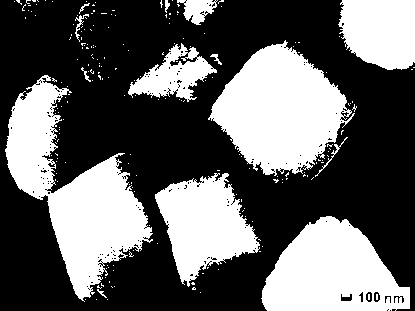

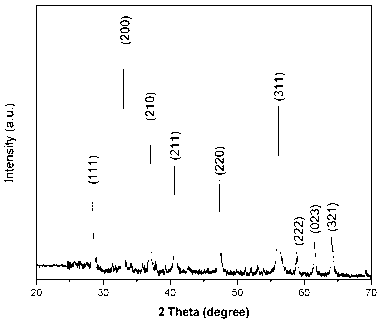

Mesoporous perovskite photovoltaic material and preparation method thereof

ActiveCN105514276APrecise control of pore sizeHigh puritySolid-state devicesSemiconductor/solid-state device manufacturingElectron holePerovskite solar cell

The invention discloses a mesoporous perovskite photovoltaic material and a preparation method thereof. The preparation method of the mesoporous perovskite photovoltaic material specifically comprises the following steps: (1) preparing metal halide nanometer microspheres; and (2) preparing a mesoporous perovskite photovoltaic material. The particle size of the metal halide nanometer microspheres can be adjusted through parameters such as reaction temperature. Therefore, by implementing the technical scheme in the embodiment of the invention, the aperture of the mesoporous perovskite material can be adjusted accurately. For a solar cell prepared by using the mesoporous perovskite material as the absorption layer of the perovskite solar cell, mesopores increase the contact area between the absorption layer and the hole transport layer of the solar cell, and therefore, the number of holes transported by the hole transport layer is increased when the solar cell is working, the electron-hole separation rate is increased, the electron-hole recombination rate is effectively reduced, and the photoelectric conversion efficiency is increased.

Owner:SUZHOU FULANG OPTICAL MATERIALS CO LTD

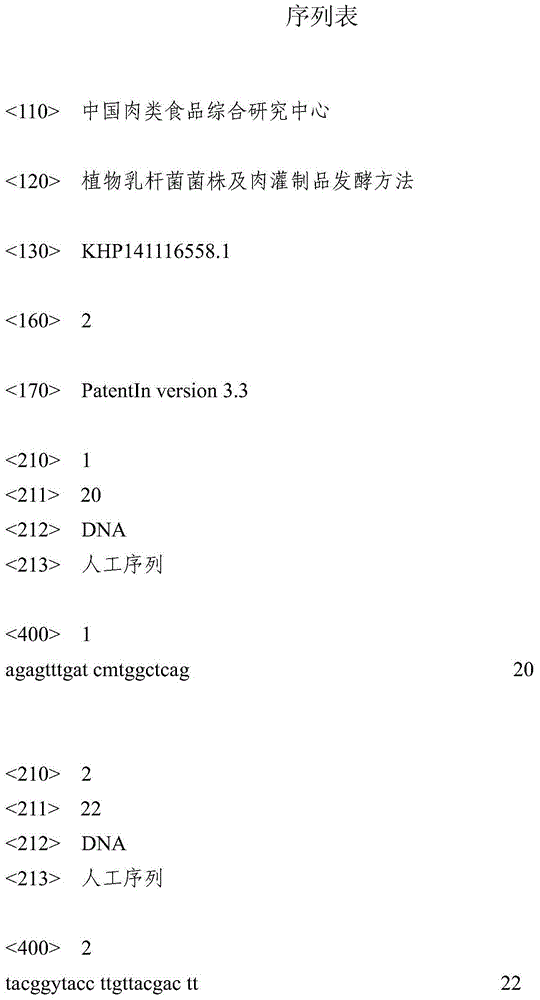

Lactobacillus plantarum strain and fermentation method of canned meat products

InactiveCN104560808AResidue reductionGrowth inhibitionBacteriaLactobacillusLactobacillus plantarumFlavor

The invention relates to a lactobacillus plantarum strain (lactobacillus plantarum) which is preserved in the general microorganism center of China Committee for Culture Collection of Microorganisms on September 28th, 2014, and the preservation number is CGMCC No.9741. The invention further provides a fermentation agent for canned meat products containing the lactobacillus plantarum strain, and a fermentation method of the canned meat products. When air-dried sausages produced by the method provided by the invention are compared with air-dried sausages through natural fermentation, the fermentation period of the air-dried sausages is shortened, the production technology is easy to control, the product quality is steady, the flavor and the mouth feel are better, the residual quantity of nitrite of products is low, the air-dried sausages produced by the method provided by the invention can be directly eaten without hot processing, and the nutrient components and the flavor are better protected.

Owner:CHINA MEAT RES CENT

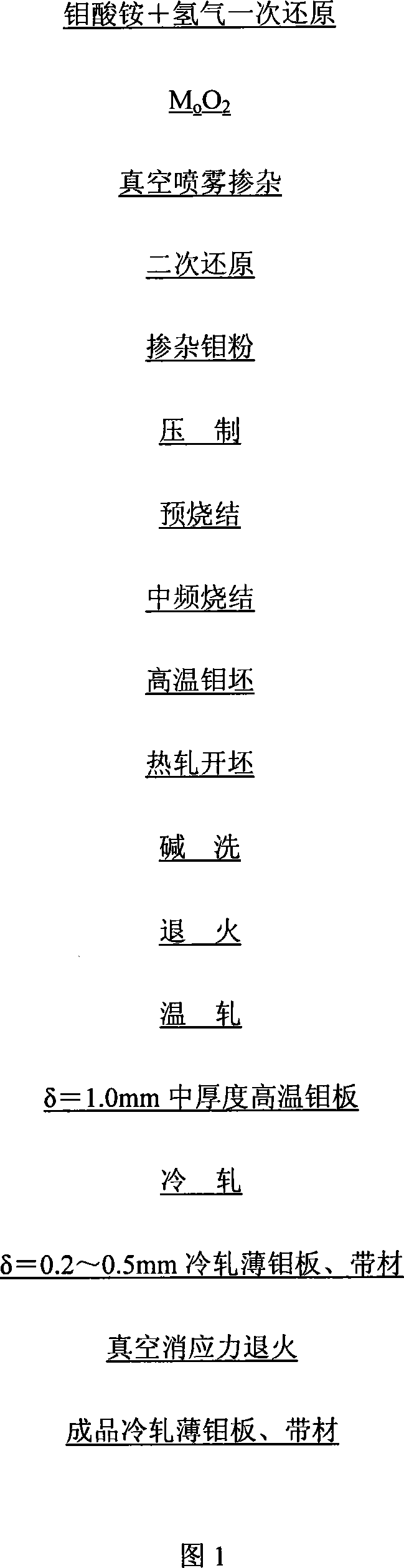

Method for preparing Mo-Si-Al-K cold-rolling thin molybdenum plate band

The invention relates to a Mo-Si-Al-K cold rolling thin molybdenum strip and a preparation method thereof. The invention is characterized in that the preparation process is: sintering the Mo-Si-Al-K into high temperature molybdenum billet; pre-annealing before the rolling at the temperature of 1300-1400 DEG C; implementing the hot rolling cogging processing on the high temperature molybdenum billet with the first pass deformation of 20 to 30 percent; implementing the intermediate annealing, the alkali washing and the warm rolling at the temperature of 900-1100 DEG C when the rolling deformation reaches to 70 to 75 percent to obtain a middle thick molybdenum strip; cold cooling the middle thick molybdenum strip into the specification of a finally finished product; implementing the vacuum stress relief annealing on the finished product at the temperature of 800-850 DEG C. And then the high temperature cold rolling thin molybdenum strip required by the invention is obtained. The product obtained through the invention is provided with strong high temperature strength and high recrystallization temperature. The cold rolling thin molybdenum strip product has the good properties of surface quality, high size precision, strong high temperature strength, good plasticity, long service life, etc. and can be widely used to produce molybdenum crucibles, boats, anodes of transmitting tubes with large power (U type), gate molybdenum tubes, heating unit, heat shields and other structural parts.

Owner:JINDUICHENG MOLYBDENUM CO LTD

Enhanced highlight ABS (Acrylonitrile-Butadiene-Styrene) composite material and preparation method thereof

The invention discloses an enhanced highlight ABS (Acrylonitrile-Butadiene-Styrene) composite material and a preparation method thereof. The enhanced highlight ABS composite material comprises the following raw materials in percentage by weight: 50%-75% of ABS resin, 10%-25% of AS (acrylonitrile) resin, 10%-25% of nanoscale glass beads, 1%-3% of a coupling agent, 1%-3% of a compatibilizer, 0.5%-2% of a lubricating agent, 0.5%-3% of a stabilizer and 0.5%-2% of an antioxidant. The preparation method comprises the following steps of: soaking and activating sub-nanoscale glass beads by using a coupling agent, uniformly mixing the sub-nanoscale glass beads with the ABS resin, the compatibilizer, the lubricating agent, the stabilizer, the antioxidant and the like in a high-speed mixer, and finally carrying out melt blending and extrusion on a twin-screw extrusion machine. The prepared ABS composite material has the characteristics of good high-low temperature resistance, ageing resistance and chemical corrosion resistance, excellent glossiness, high strength, impact resistance and the like, and is easy to process. The production processes of the ABS composite material are simple and easy to control and low in cost; and the preparation method is suitable for industrial production.

Owner:合肥科拜尔新材料股份有限公司

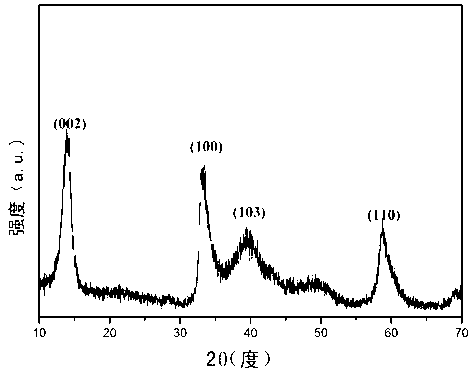

Preparation method of graphene oxide/iron disulfide composite nano particles

InactiveCN102910615AUniform particle sizeGood dispersionMaterial nanotechnologyCarbon compoundsHydration reactionPolyvinyl alcohol

The invention relates to nano FeS2 materials, and particularly relates to a preparation method of graphene oxide / iron disulfide composite nano particles. According to the preparation method of the graphene oxide / iron disulfide composite nano particles, ferrous chloride tetrahydrate (FeCl2.4H2O) and sulfur powder are used as raw materials, are dissolved in water together with surfactant polyvinyl alcohol (PVA) and polyvinylpyrrolidone (PVP), and then mixed with graphene oxide under a certain pH (potential of hydrogen) condition; the obtained mixed solution is arranged in a reaction kettle and sealed, is held for 12 hours to 24 hours in a constant-temperature box at 180 DEG C to 200 DEG C by using a hydrothermal method, is cooled to normal temperature, stood and separated, centrifugally washed and dried, finally the graphene oxide / iron disulfide composite nano particles can be obtained.

Owner:JIANGSU UNIV

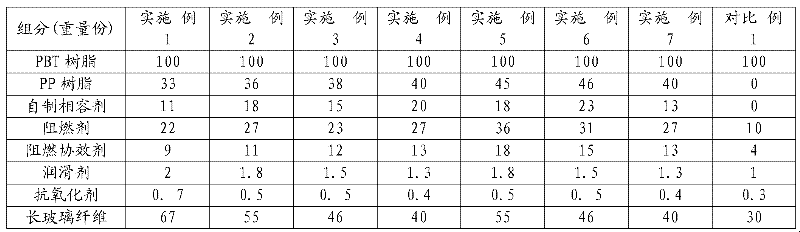

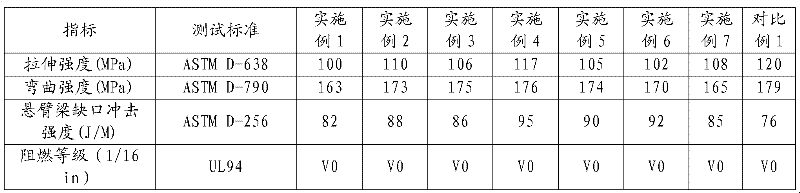

Glass fiber reinforced PBT (Poly Butylenes Terephthalate)/PP (Polypropylene) alloy material and preparation method thereof

The invention discloses a glass fiber reinforced PBT (Poly Butylenes Terephthalate) / PP (Polypropylene) alloy material and a preparation method thereof. The glass fiber reinforced PBT / PP alloy material consists of the following components in parts by weight: 100 parts of PBT resin, 30-50 parts of PP resin, 10-25 parts of home-made compatilizer, 20-40 parts of flame retardant, 8-20 parts of flame retardant synergist, 1-3 parts of lubricant, 0.2-1.5 parts of antioxidant and 35-70 parts of glass fiber, wherein the home-made compatilizer is one or more of PP-grafted maleic anhydride, POE (Polyolefin Elastomer)-grafted polyglycidyl acrylate or acrylic ester-grafted ternary ethylenepropylene elastomer. In the PBT / PP alloy material, the home-made PBT / PP alloy compatilizer is selected, so that the compatibility of a PBT / PP alloy is improved, the comprehensive mechanical performance is enhanced, and the technical problems of low gap impact performance, high production cost and poor PP size stability of the PBT in the prior art are solved greatly.

Owner:SHENZHEN KEJU NEW MATERIAL

Method for manufacturing composite straightening roll by overlaying

ActiveCN102430839ASurfacing less smoke and dustEasy to remove slagArc welding apparatusWelding/cutting media/materialsMetal workingMaterials science

The invention discloses a method for manufacturing a composite straightening roll by overlaying, comprising the steps of: at first, manufacturing a straightening roller body tempered by 42 CrMo; then overlaying a transitional layer which is 2-4mm thick on the straightening roller body; and then manufacturing a deposited metal working layer on the transitional layer through submerged arc overlaying. The roll surface of the straightening roll manufactured by the method for manufacturing the composite straightening roll by overlaying has the advantages of corrosion resistance, high temperature resistance, abrasion resistance and steel adhering resistance.

Owner:CHANGZHOU BAOLING HEAVY IND MACHINERY

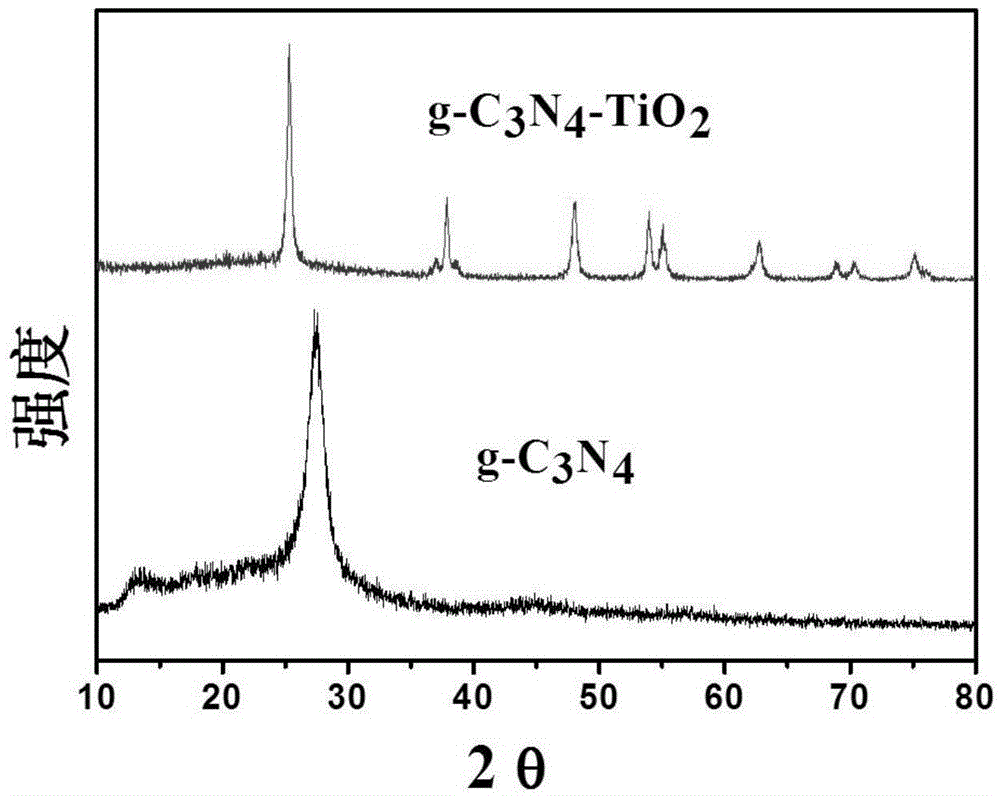

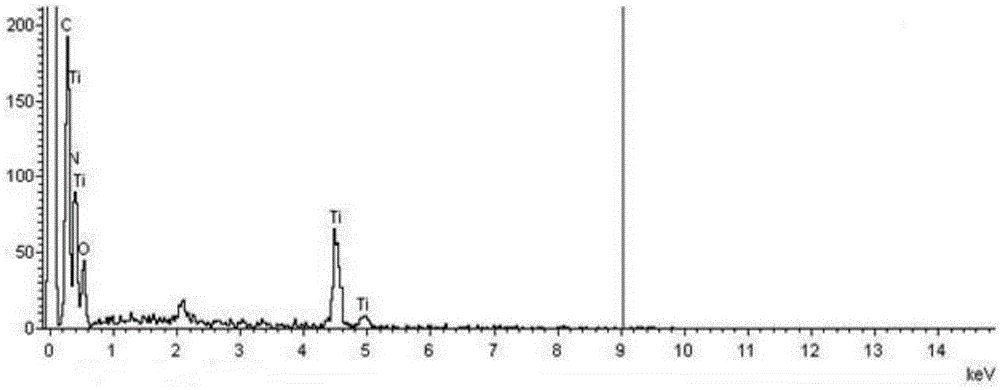

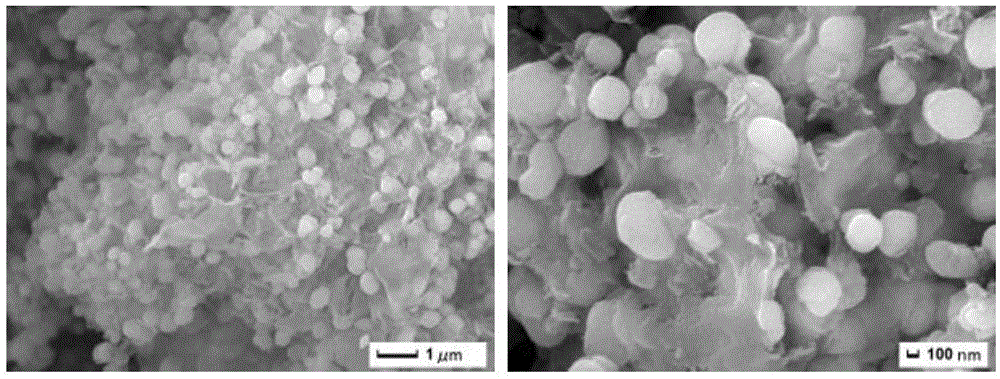

Preparation method of g-C3N4-TiO2 mesoporous composite visible light catalyst

InactiveCN105618097AIncrease marginImprove photocatalytic efficiencyPhysical/chemical process catalystsOrganic acidVisible light photocatalytic

The invention provides a preparation method of a g-C3N4-TiO2 mesoporous composite visible light catalyst. The preparation method comprises the following steps: firstly performing high-temperature annealing on urea in a quartz crucible; dispersing g-C3N4 nano sheets obtained into organic acid, adding tetrabutyl titanate, agitating, moving a solution into a reaction kettle and sealing; after thermostatic reaction, finally separating an obtained reaction product, washing, and drying, so as to obtain the g-C3N4-TiO2 mesoporous composite visible light catalyst through high-temperature annealing. The preparation method provided by the invention is low in cost, simple and easy to control in production process, high in product yield and suitable for large-scale industrial production.

Owner:ZHENJIANG COLLEGE

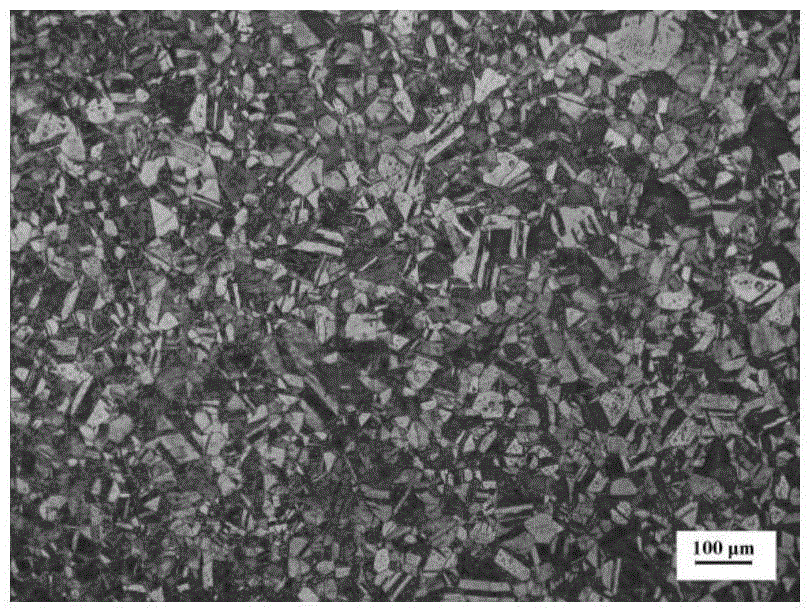

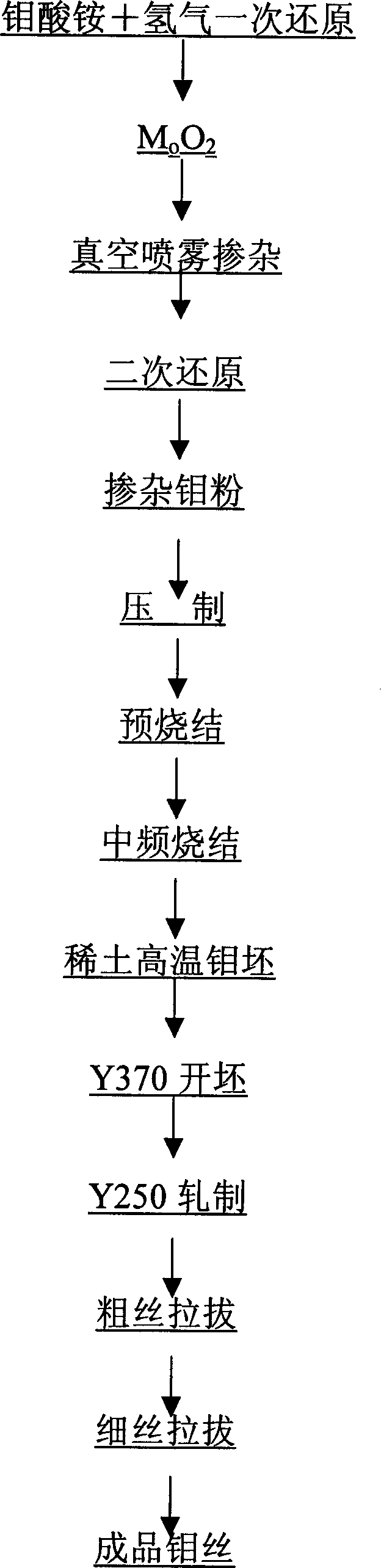

Rare earth molybdenum alloy wire and preparation method thereof

InactiveCN1876875ARaise the recrystallization temperatureHigh strengthTemperature control deviceHeat treatment process controlRare earthAlloy

The invention relates to a rare-earth molybdenum alloy wire and its process for preparing. The invention is characterized in that the said alloy wire contains two rare-earth oxides including lanthanum oxide and Y oxide(mass %) which is 0.4 %-1.0% of the alloy amount and the proportion by weight of lanthanum oxide and Y oxide is 4:1. The process for preparing is different from the traditional powder metallurgy productive technology, which includes performing double-cone vacuum drying and liquid-solid doping at molybdenum dioxide stage, then performing secondary reduction to prepare binary rare-earth doping molybdenum powder, finally preparing rare-earth doping molybdenum wire with Mo-La-Y of 0.5-0.8mm diameter by impression, agglomeration and pressure processing procedure. Compared with the pure molybdenum, the product is of good high-temperature behavior and high recrystallization temperature which increases by 300-500 DEG C than the pure molybdenum, and is of high intensity and abrasive resistance, low ductility and long durability, which has wide application in the mechanical process industry.

Owner:JINDUICHENG MOLYBDENUM CO LTD

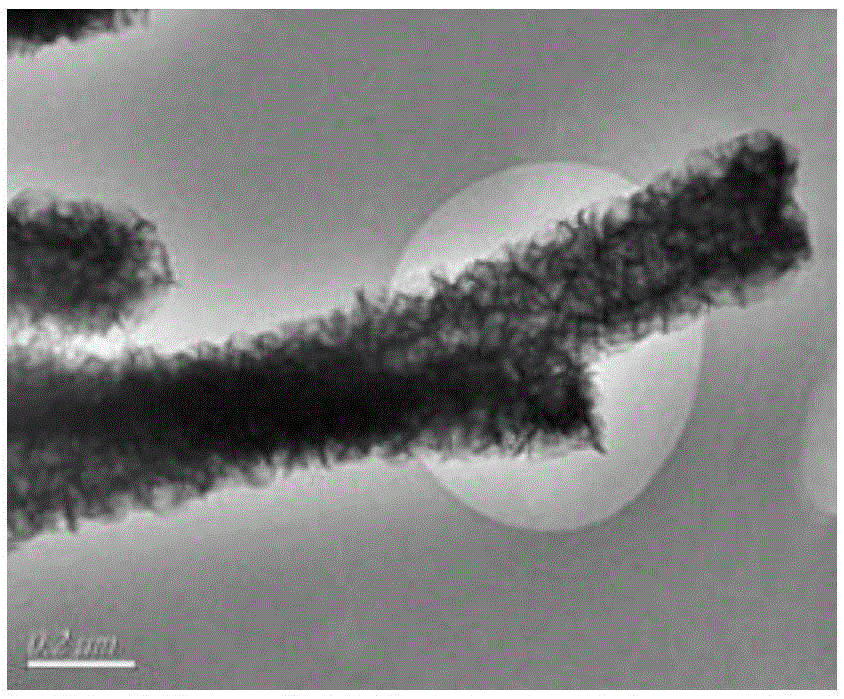

Preparation method of tungsten disulfide nanotube

InactiveCN102134100AReduce the temperatureLow costNanotechnologyTungsten compoundsReducing atmosphereSolvent

The invention relates to a preparation method of a tungsten disulfide nanotube, comprising the following steps of: with (NH4)2WS4 as a raw material, preparing, soaking, pyrolyzing and separating a template. The preparation method of the tungsten disulfide nanotube is characterized by comprising the following steps of: soaking the AAO (Anodic Aluminum Oxide) template into a DMSO (Dimethylsulfoxide) solution of the (NH4)2WS4 with the concentration of 0.2-0.4 mol / L for at least half hour; taking out the AAO template, volatilizing solvent DMSO, then placing in a reducing atmosphere and calcining at 500-600 DEG C for 1-2 hours; and cooling, and then separating to obtain the WS2 nanotube from the AAO template. The preparation method has a simple process; and in addition, the prepared WS2 nanotube has uniform, consistent and controllable diameter.

Owner:HEFEI UNIV OF TECH

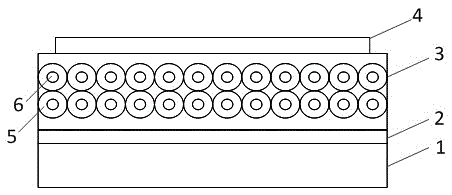

Perovskite-type solar cell and preparation method

ActiveCN105609643AImprove photoelectric conversion efficiencyIncrease contact areaSolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellMetal electrodes

The invention discloses a perovskite-type solar cell and a preparation method. The perovskite-type solar cell sequentially consists of a transparent conductive substrate, a dense electron transmission layer, a composite light absorption layer and a metal electrode layer, wherein the composite light absorption layer is formed by a core shell structure where perovskite wraps P-type semiconductor quantum dots. Because the composite light absorption layer of the solar cell employs the core shell structure where perovskite wraps P-type semiconductor quantum dots and the perovskite fully contacts with the quantum dots, the contact area of the quantum dots with a perovskite structural layer is increased. Moreover, the advantage that the perovskite can be used as a hole transmission layer is employed, thereby improving the efficiency of light hole separation, and improving the photoelectric conversion efficiency of the cell.

Owner:HAIMEN THE YELLOW SEA ENTREPRENEURSHIP PARK SERVICE CO LTD

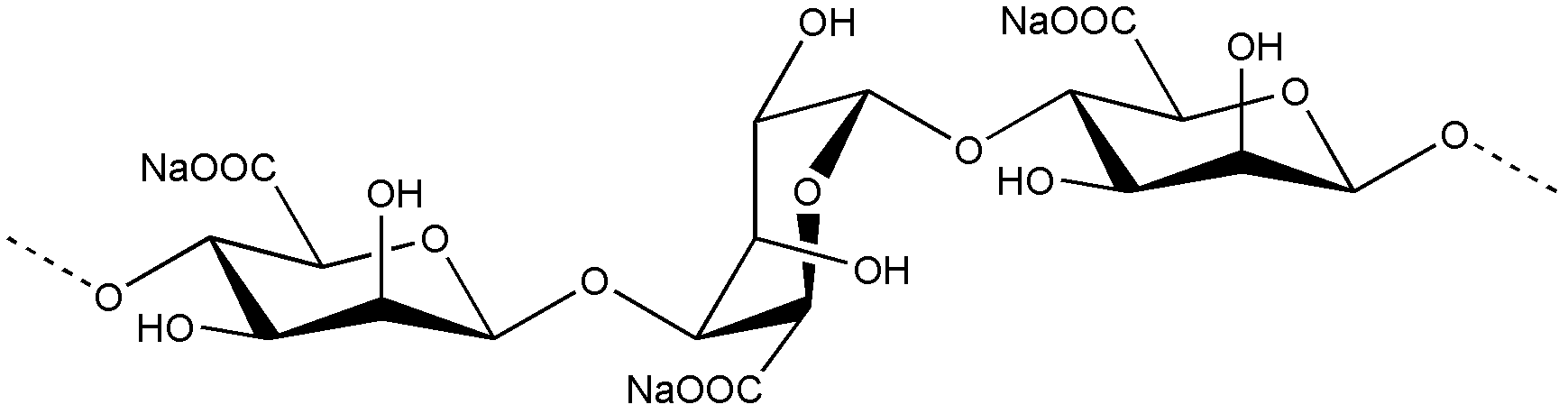

Enzymolysis-chemistry combined method for producing sodium alginate

ActiveCN102321191AThe production process is easy to controlChange the high energy consumption and high pollutionChemical industryCombined method

The invention relates to the field of seaweed chemical industry, and specifically provides an enzymolysis-chemistry combined method for producing sodium alginate. The method comprises steps of: mixing pretreated alga and compound enzyme at 45-60 DEG C and a pH of 4.5-6.5, reacting for 13-26 h, carrying out an enzymolysis, filtering and converting the filtrate to obtain sodium alginate; and addingalkali liquor in the precipitate after the enzymolysis, reacting for 2-4 h at 50-80 DEG C, calcifying a filtrate after filtering, and adding sodium carbonate into calcified precipitate to convert into sodium alginate. The method of the invention can fundamentally solve drawbacks of high energy consumption and high pollution of a traditional production technology. According to one ton of sodium alginate and iodine coproduct produced by the enzymolysis-chemistry combined method of the invention, fresh water for production is reduced by 38%, and coal is reduced by 23%, and soda acid waste water generated is reduced by 52% less; and the method can increase yield by 9-11% compared with a conventional chemical production technology.

Owner:SHANDONG JIEJING GROUP CORP

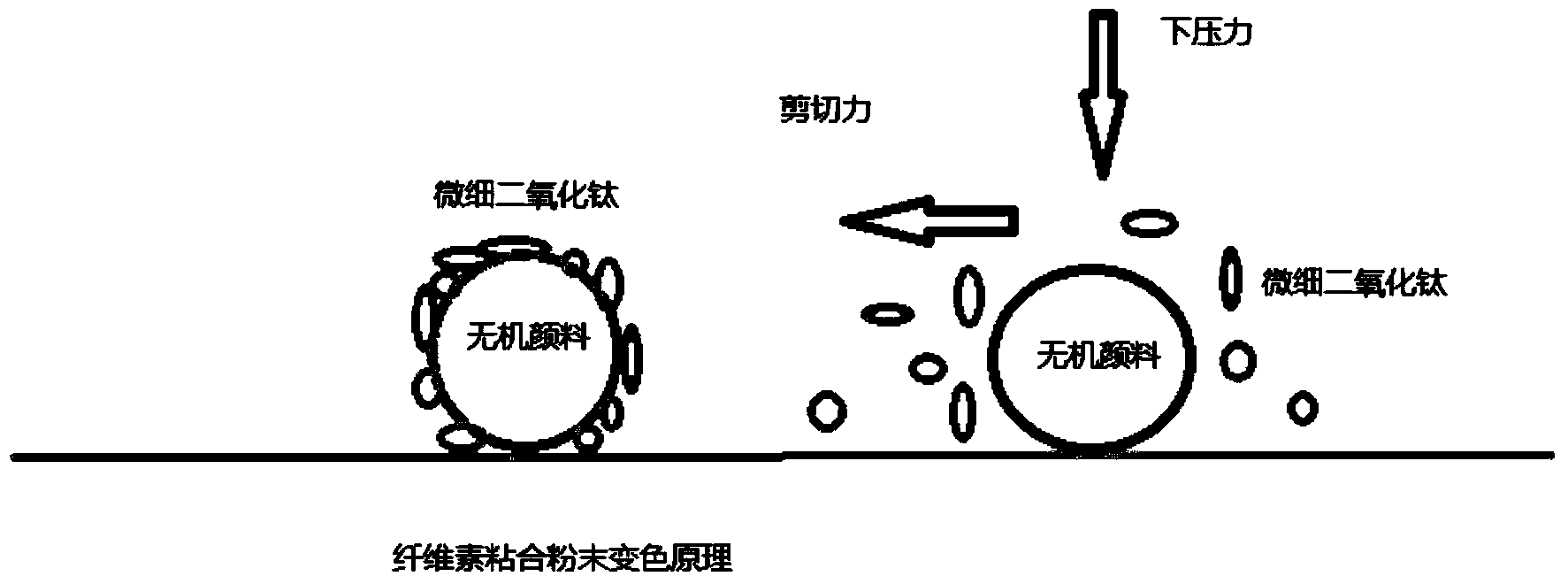

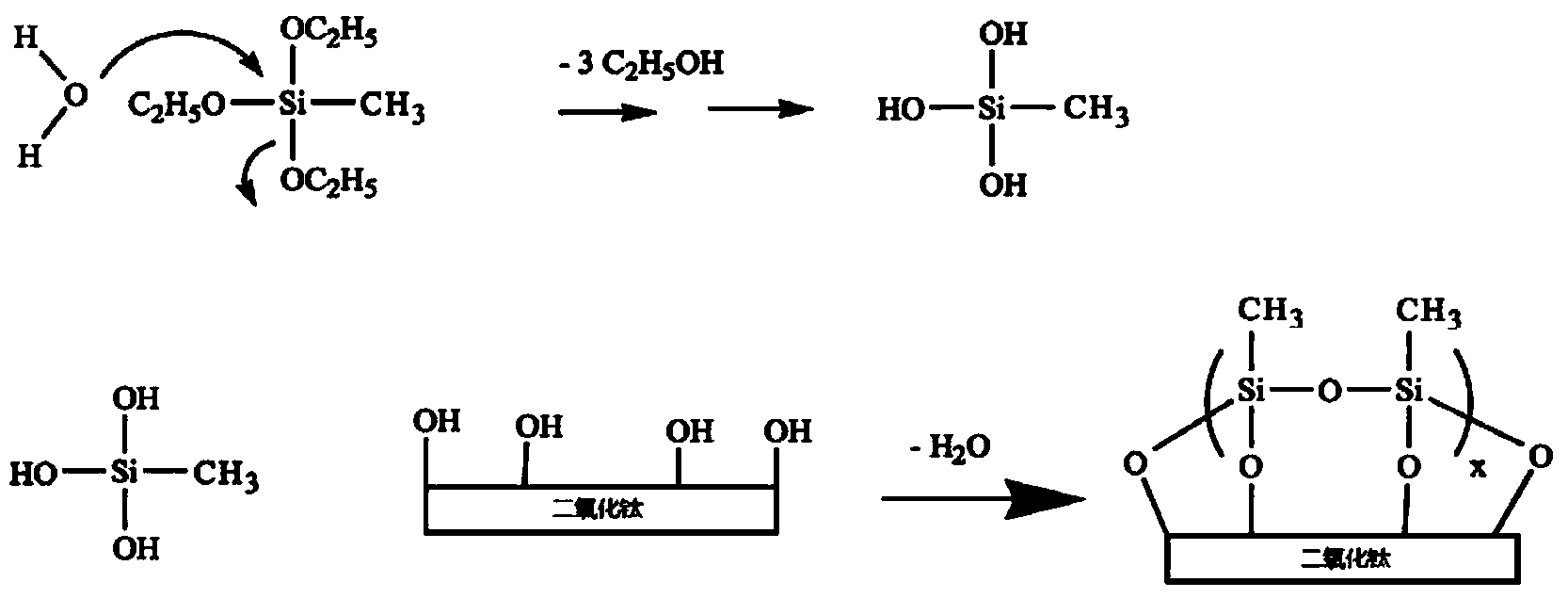

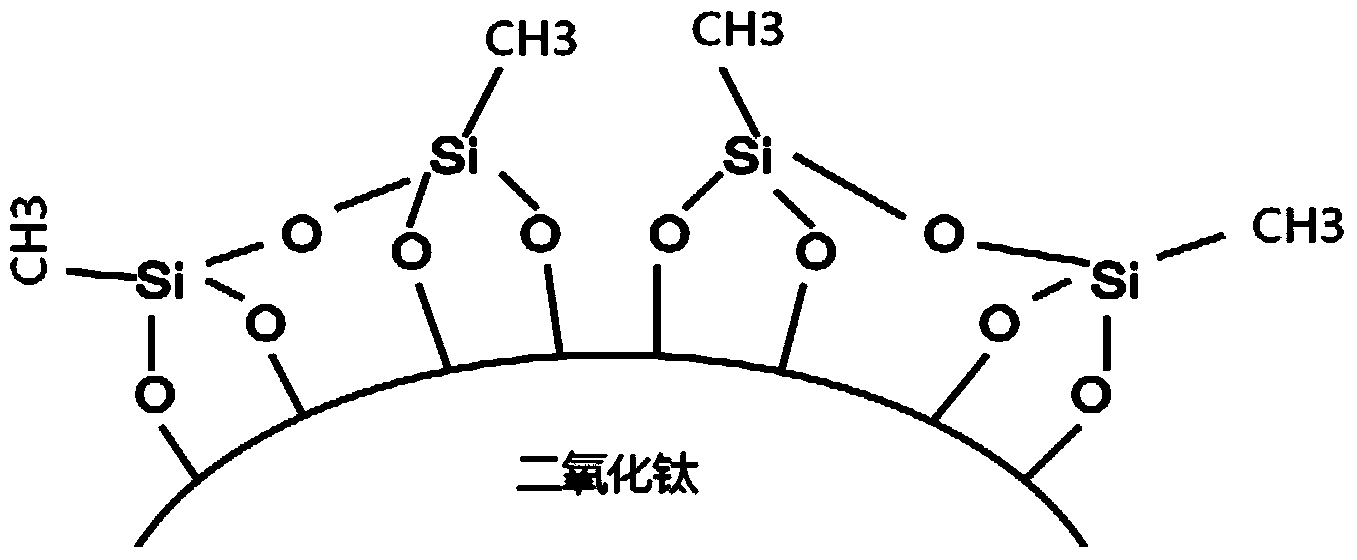

Controllable discolouring foundation cream/liquid foundation

ActiveCN104069014AFast discolorationWith discoloration effectCosmetic preparationsBody powdersSilylationIron oxide

The invention relates to controllable discolouring foundation cream / liquid foundation and a preparation method thereof. The preparation method of the controllable discolouring foundation cream / liquid foundation comprises the following steps: providing a powder premix compound containing titanium dioxide and inorganic pigment, for the coloured foundation cream / liquid foundation, wherein the titanium dioxide is subjected to triethoxy methyl silylation surface treatment, and the inorganic pigment is subjected to triethoxy octyl silylation surface treatment. The controllable discolouring foundation cream / liquid foundation has the advantages that completely different surface treatment methods are adopted for the titanium dioxide and inorganic pigment (ferric oxide) in the foundation cream / liquid foundation, so that surface properties of the two powders are obviously different;the discolouring foundation cream / liquid foundation prepared by utilizing the titanium dioxide and inorganic pigment is controllable and quick in discolouring effect; covering power is high; colours are diverse; the discolouring foundation cream / liquid foundation is safe and harmless; a production process is simple.

Owner:SHANGHAI CO FUN BIOTECH

High temperature molybdenum alloy wire and its preparing method

InactiveCN1900338ASimple processHigh tensile strengthTemperature control deviceHeat treatment process controlAlloyHigh wear resistance

The present invention is high temperature molybdenum alloy wire and its alloy consists of K 0.05- 1.0 wt%, Si 0.1-0.5 wt% and Al 0-0.05 weight %, except Mo, O and inevitable impurities. The alloy is prepared through double cone vacuum dry liquid-solid doping in the MoO2 stage, secondary reduction to preparing K, Si and Al doped Mo powder, pressing, sintering and other steps, and is further produced into molybdenum alloy wire of 0.5-0.8 mm diameter through press work and other steps. The molybdenum alloy wire has high tensile strength, high wear resistance, simple production process and other advantages.

Owner:JINDUICHENG MOLYBDENUM CO LTD

High-heat-resisting glass-fiber reinforced polyester composite material and preparing method

The present invention discloses a kind of high-heat-resistant, glass-fiber-enhanced, polyester composite and its preparation method. The components (weight percentage) are: polyester 45-95%; nucleating agent-sodium stearic acid 0.3-5%; brominated flame retardant 5-30%; flame retardant synergist 4-10%; toughening agent 1-6%; antioxidant 0.1-1%; lubricant 0.1-5%; glass fiber 5-50%. The present invention uses organic-nucleating-agent sodium stearic acid, acrylic core-shell copolymer toughening agent and epoxy-group-containing material as chain extender, thus, increases the crystallization rate of PET, makes the prepared composite forming at a lower temperature, that is 70-100 degree C. Therefore, no oil heating machine needs to be added, which reduces the energy consumption, and meanwhile ensures the material's high heat resistance, high strength and high impact resistance; the material is low in cost, simple in preparation process, and easy to control its production process.

Owner:SHENZHEN KEJU NEW MATERIAL

HB360-level wear-resistant steel plate and preparation method thereof

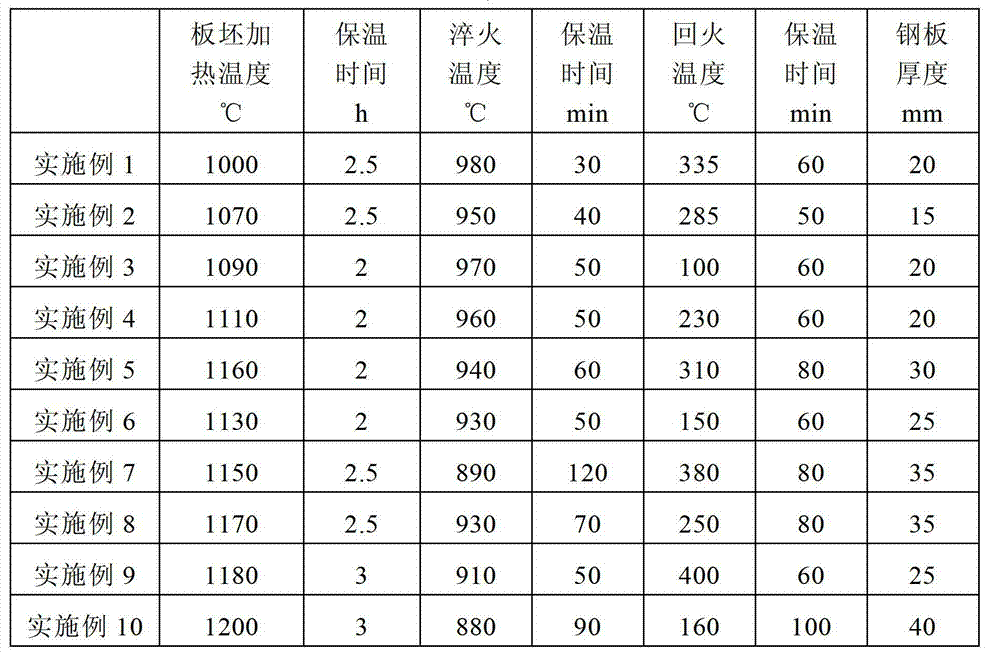

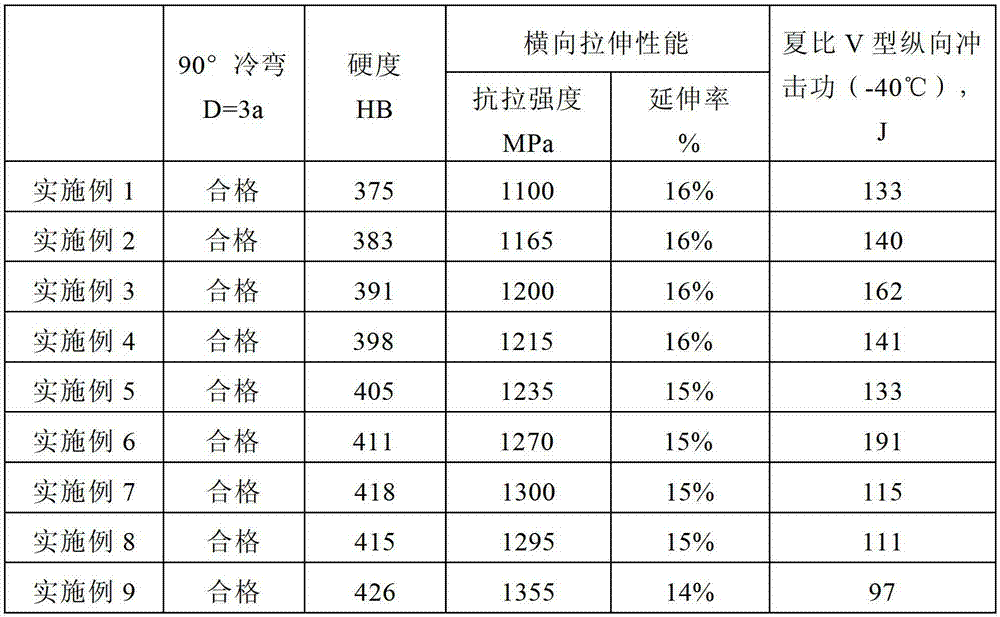

The invention discloses an HB360-level wear-resistant steel plate and a preparation method thereof. The HB360-level wear-resistant steel plate comprises the following components in percentage by weight: 0.08%-0.20% of C, 0.10%-1.00% of Si, 1.00%-2.00% of Mn, not more than 0.015% of P, not more than 0.010% of S, not more than 1.20% of Cr, not more than 0.80% of Mo, not more than 1.00% of Ni, not more than 0.080% of Nb, 0.010%-0.100% of Al, 0.0005%-0.0040% of B, 0.005%-0.050% of Ti, 0.0010%-0.0080% of Ca, not more than 0.080% of N, not more than 0.0080% of O, not more than 0.0004% of H and the balance of Fe and inevitable impurities, wherein (Cr / 5+Mn / 6+50B) is not less than 0.20% and not more than 0.55%, (Mo / 3+Ni / 5+2Nb) is not less than 0.02% and not more than 0.45%, (Al+Ti) is not less than 0.01% and not more than 0.13%. The tensile strength of the steel plate is 1100MPa-1400MPa, the elongation of the steel plate is 14%-16%, the Brinell hardness of the steel plate is 360HB-440HB, the Charpy longitudinalV-shaped longidutional impact power at -40 DEG C is 80J-120J. The steel plate obtained by the components through each thermal treatment process is high in strength hardness, good in flexibility, easy to weld, excellent in mechanical machining performances and suitable for easy-wearing components in various mechanical devices.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for preparing inert porcelain ball by using aluminum oxide dust-recovery powder

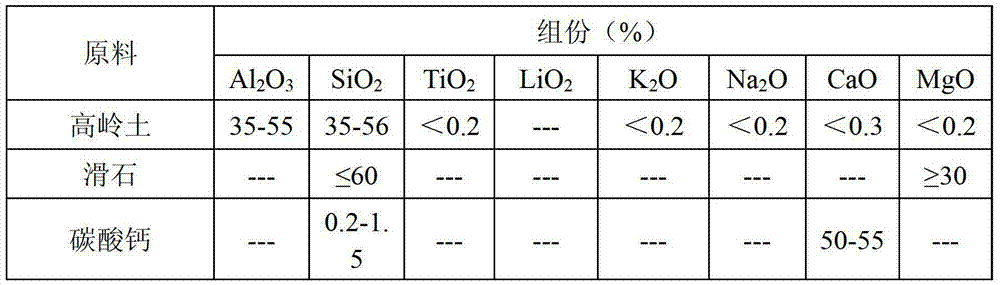

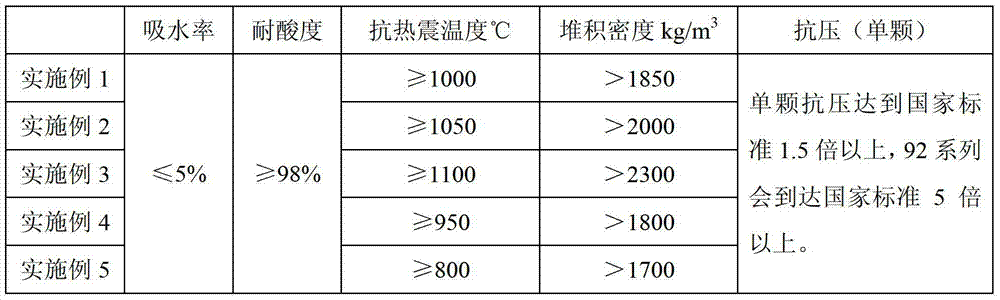

The invention discloses a method for preparing an inert porcelain ball by using an aluminum oxide dust-recovery powder and belongs to the technical field of new materials. A lot of aluminum oxide dust-recovery powder is used in the formulation of the method disclosed by the invention, the cost is obviously reduced, meanwhile a waste material is used and the environment is protected. According to the method disclosed by the invention, a composite sintering aid comprising calcium carbonate, talcum, and spodumene mineral powder is added into the formulation to facilitate the formation of magnesia-alumina spinel and mullite for enhancing in the product so as to improve the thermal shock resistance and strength of a product; a little kaolin is added into the formulation for improving the plasticity of a perform body, promoting molding conveniently and improving the strength of a green body; meanwhile in order to reduce the high energy consumption caused by wet ball milling, the powder for preparing the inert porcelain ball disclosed by the invention is subjected to continuous dry wet milling; the inert porcelain ball prepared by the method disclosed by the invention has the characteristics of high temperature resistance, high strength, good thermal shock resistance and the like, is excellent in comprehensive performance, and is completely suitable for requirements for a catalyst carrier and supporting performance in various industries.

Owner:JINGANG NEW MATERIALS

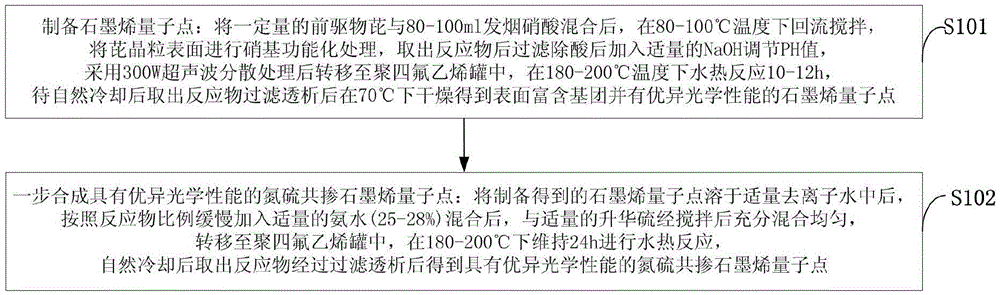

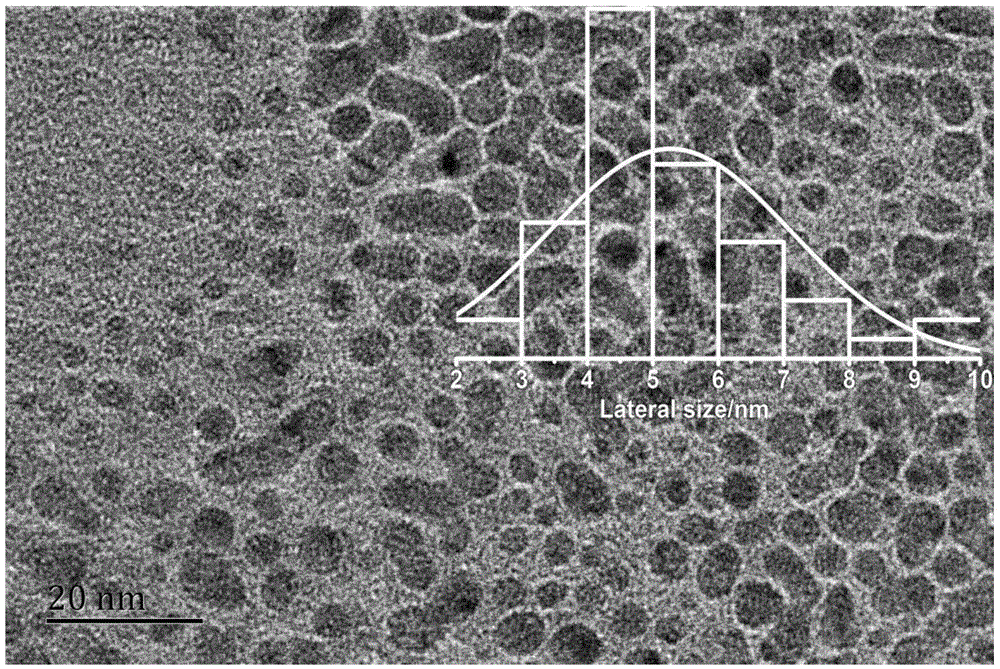

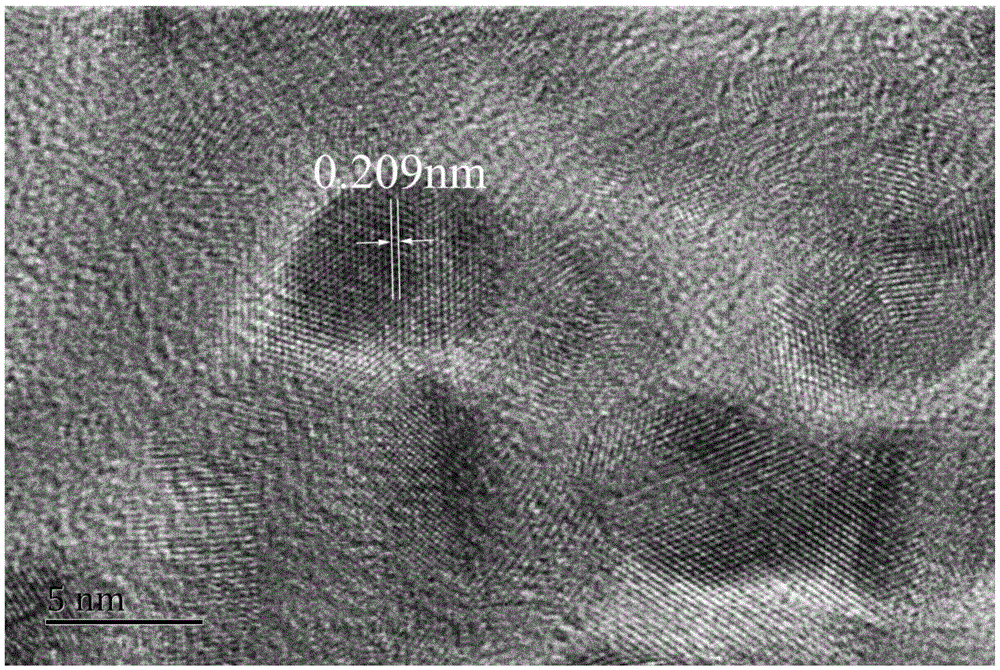

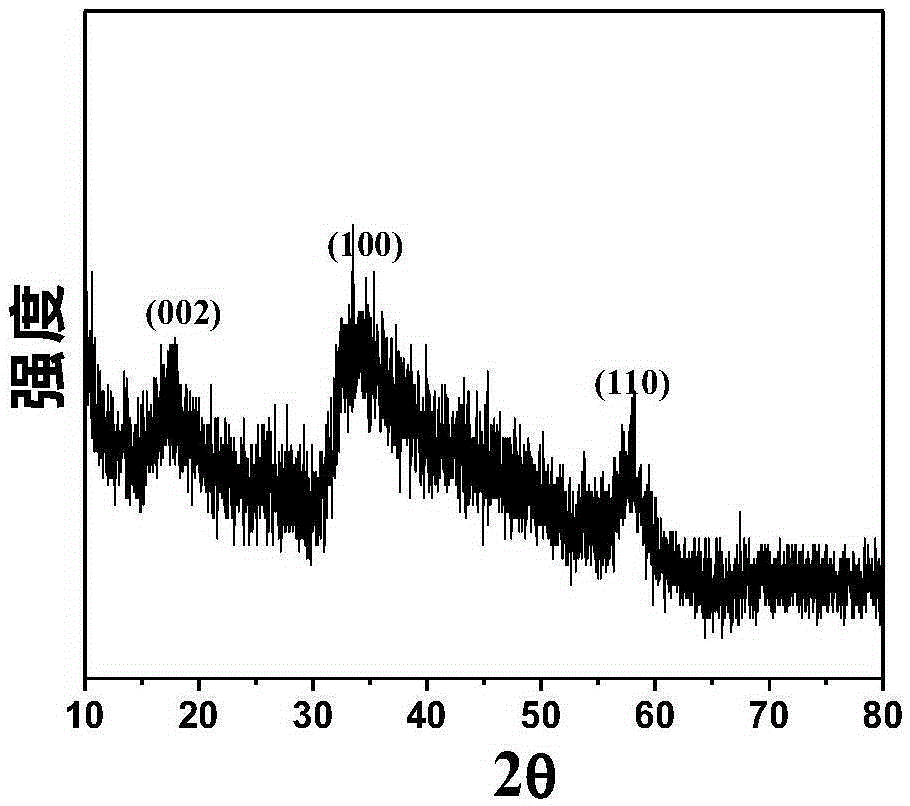

Nitrogen and sulfur-codoped graphene quantum dot and preparation method thereof

InactiveCN105567230AThe production process is simple and controllableLow equipment requirementsPhysical/chemical process catalystsWater/sewage treatment by irradiationCvd grapheneIon

The invention discloses a nitrogen and sulfur-codoped graphene quantum dot and a preparation method thereof. The preparation method comprises the steps that after a precursor pyrene is mixed with 80-100 ml of fuming nitric acid, refluxing and stirring are performed, nitro functionalizing treatment is performed on the surfaces of pyrene grains, a reactant is taken out, filtered and deacidified, an appropriate amount of NaOH is added to regulate the PH value, dispersion treatment is performed by adopting 300-W ultrasonic waves, the reactant is transferred into a polytetrafluoroethylene tank for a hydrothermal reaction, and after natural cooling is performed, a reactant is taken out, filtered, dialyzed and then dried; after a graphene quantum dot is dissolved into an appropriate amount of deionized water, an appropriate amount of ammonia water is added according to the proportion of the reactant, uniform mixing is performed, the mixture and an appropriate amount of sublimed sulfur are fully mixed to be uniform through stirring, the mixture is transferred into a polytetrafluoroethylene tank, a hydrothermal reaction is performed for 24 h by keeping the temperature of 180 DEG C-200 DEG C, and after cooling is performed, a reactant is taken out, filtered and dialysed to obtain the nitrogen and sulfur-codoped graphene quantum dot. The preparation method is simple in synthesis process, high in yield and finished product rate, environmentally friendly, poisonless, few in impurity and capable of easily obtaining the raw materials.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

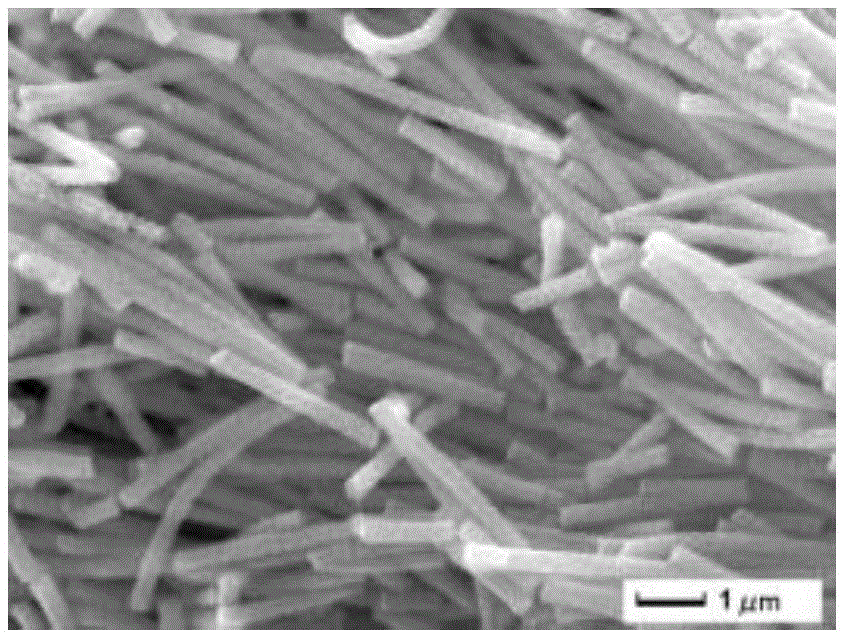

Preparation method of flower-shaped molybdenum disulfide nano-rods

ActiveCN105366727AHigh yieldLow costNanotechnologyMolybdenum sulfidesSodium molybdateRoom temperature

The invention provides a preparation method of flower-shaped molybdenum disulfide nano-rods. The preparation method comprises steps as follows: a surfactant is dissolved in water firstly, sodium molybdate, sodium sulfide and glucose are added and stirred, and the pH value of a solution is regulated to 6-8; the solution is transferred to a reaction kettle for sealing and is cooled to the room temperature after a thermostatic reaction, and a reaction product is obtained; finally, the reaction product is separated, washed and dried, and the flower-shaped molybdenum disulfide nano-rods are obtained. The preparation method is low in cost, the production technology is simple and easy to control, the product yield is high, and the preparation method is suitable for large-scale industrial production.

Owner:ZHENJIANG COLLEGE

Oil-resistant HIPS (high impact polystyrene) refrigerator inner container material and preparation method thereof

ActiveCN103265784AHigh strengthGood oil resistanceDomestic cooling apparatusLighting and heating apparatusElastomerIcebox

The invention discloses an oil-resistant HIPS (high impact polystyrene) refrigerator inner container material and a preparation method thereof. The oil-resistant HIPS refrigerator inner container material is prepared from the following raw materials in percentage by weight: 80-95% of HIPS, 2-5% of compatibilizer, 1-5% of oil-resistant elastomer, 0.5-2% of lubricant, 0.5-3% of stabilizer and 0.5-2% of antioxidant. The preparation method comprises the following steps: mixing the HIPS and stabilizer, adding the compatibilizer, oil-resistant elastomer, lubricant and antioxidant, evenly mixing, sending into a double screw extruder together, carrying out melt blending extrusion, cooling and granulating. The HIPS refrigerator inner container material disclosed by the invention has the characteristics of favorable low temperature resistance, favorable aging resistance, favorable edible oil corrosion resistance, high toughness, high strength and the like, and is easy to process; and the preparation method has the characteristics of simple and controllable production procedure and low cost, and is suitable for industrial production.

Owner:合肥科拜尔新材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com