Environmental protection fire retardation type textile printing coating material and preparation method thereof

A printing paint and flame-retardant technology, which is applied in the field of environmentally friendly flame-retardant textile printing paint and its preparation, can solve the problems of difficult self-extinguishing when away from fire, unsatisfactory flame-retardant effect, and higher requirements for flame-retardant performance. Smoke effect, good gloss and color retention, obvious flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The preparation method of environment-friendly flame-retardant textile printing paint comprises the following steps:

[0040] 1) Preparation of flame-retardant acrylic emulsion: a. Dissolve the phosphate emulsifier in an appropriate amount of deionized water according to the formula, add soft monomer, hard monomer and functional monomer while stirring, and continue to stir and mix. and make it into a pre-emulsion for use; b. Dissolve the initiator with an appropriate amount of deionized water and make it into an initiator solution for use; c. Take 2-15% of the pre-emulsion and 40-60% of the initiator solution , mixed evenly with the remaining deionized water in the formula quantity, raised the temperature to 80-85°C, and reacted for 10-30 minutes; added the remaining pre-emulsion and initiator solution dropwise, and raised the temperature to 85-90°C after 2-4 hours of dropping ℃ heat preservation and aging for 1-2 hours, lower the temperature to below 40 ℃, add ammonia ...

Embodiment 1

[0046] 1) Preparation of environmentally friendly flame-retardant acrylic emulsion:

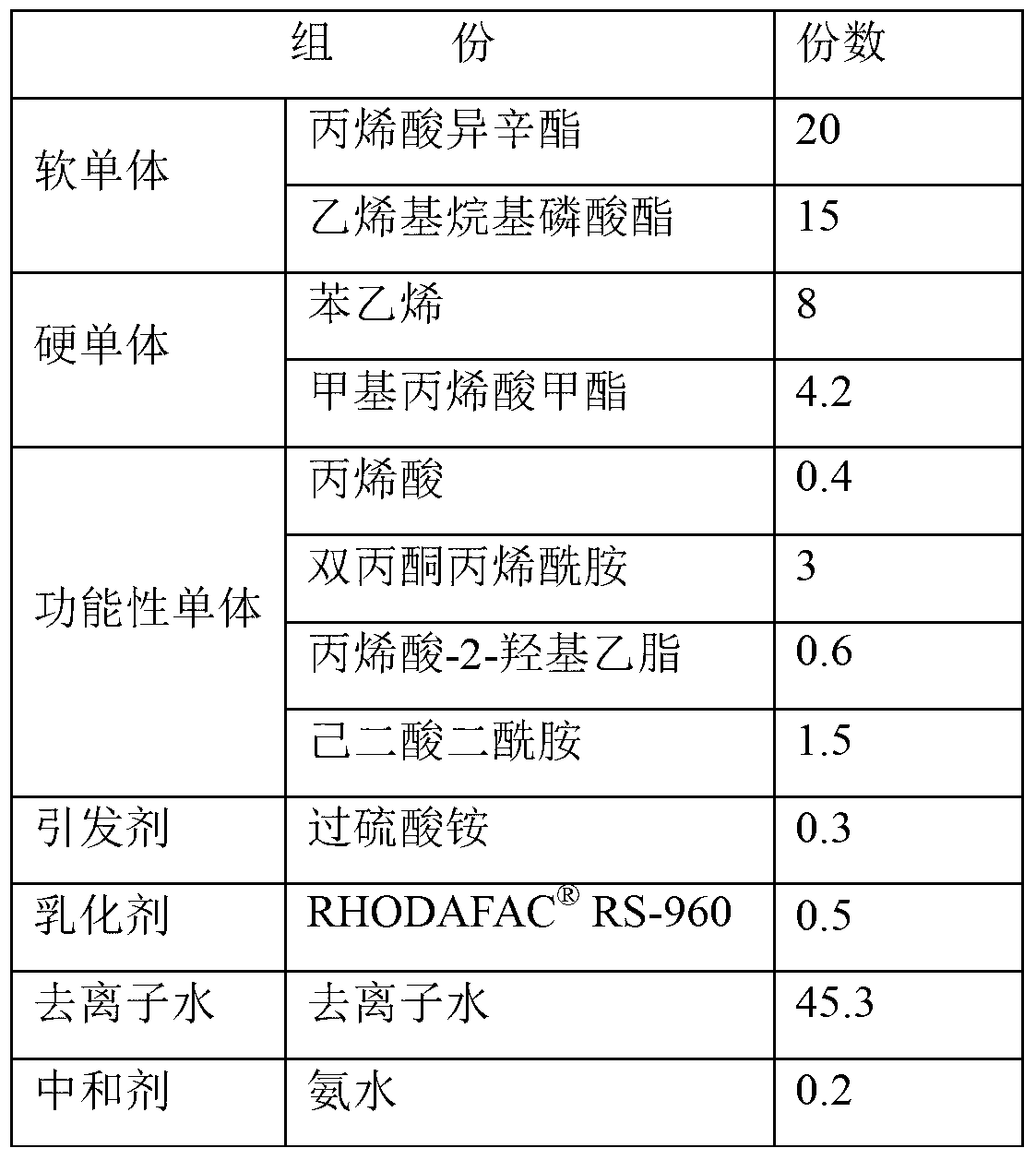

[0047] The composition of the environmentally friendly flame retardant acrylic emulsion is as follows:

[0048]

[0049] a. Add the emulsifier according to the formula Dissolve RS-960 in 1 / 4 of the deionized water in the formula, add soft monomers, hard monomers, and functional monomers while stirring, continue to stir and mix well, and prepare a pre-emulsion for use;

[0050] b. Dissolve ammonium persulfate with 1 / 3 of the deionized water in the formula quantity, and prepare an initiator solution for use;

[0051] c. In a four-necked flask with a stirrer, a thermometer, a condensing reflux device and a dropping device, add the remaining deionized water, the above 8% pre-emulsion, and 40% initiator solution, mix well, and heat up to 85°C, react for 10 minutes; add the remaining pre-emulsion and initiator solution dropwise, after 3 hours of dropwise addition, raise the temperature to 90°...

Embodiment 2

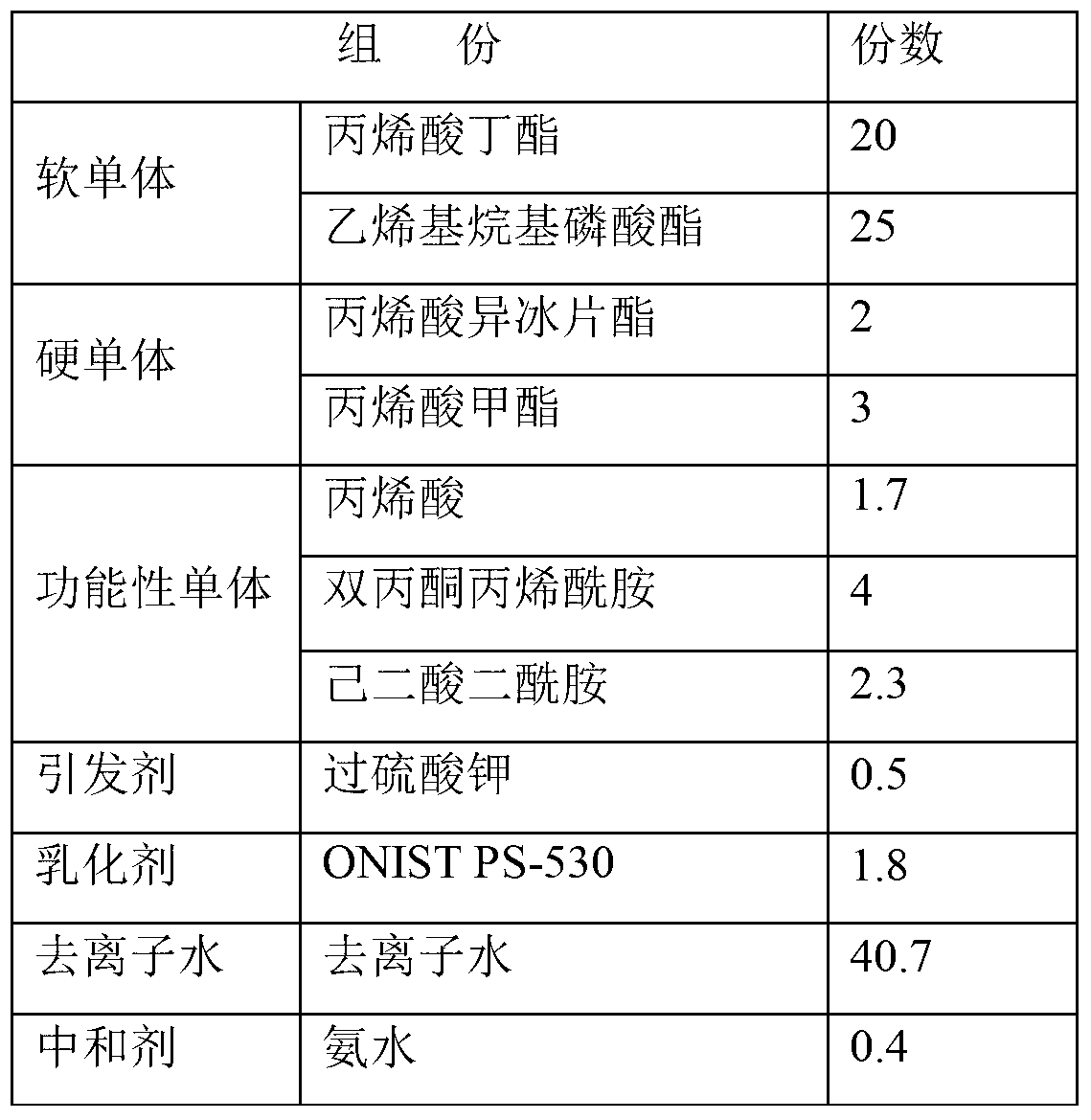

[0057] 1) The preparation of environmentally friendly flame-retardant acrylic emulsion is as follows:

[0058] Composition of environmentally friendly flame retardant acrylic emulsion:

[0059]

[0060] a. Dissolve emulsifier in 1 / 3 deionized water, stir, add soft monomer, hard monomer, functional monomer, stir to obtain pre-emulsion;

[0061] b. Dissolve potassium persulfate with 1 / 2 deionized water to prepare initiator solution for use;

[0062] c. In a four-necked flask with a stirrer, a thermometer, a condensing reflux device and a dropping device, add the remaining deionized water, 2% of the above-mentioned pre-emulsion, add 50% of the total amount of the initiator, and continue to heat up to 82°C, react for 15 minutes; start to add the remaining monomer mixture and initiator aqueous solution dropwise, and the dropwise addition is completed in 4 hours. After all the dropwise addition is completed, the temperature is raised to 85°C and incubated for 1.5 hours, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com