Patents

Literature

2020 results about "Textile printing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Textile printing is the process of applying colour to fabric in definite patterns or designs. In properly printed fabrics the colour is bonded with the fibre, so as to resist washing and friction.Textile printing is related to dyeing but in dyeing properly the whole fabric is uniformly covered with one colour, whereas in printing one or more colours are applied to it in certain parts only, and ...

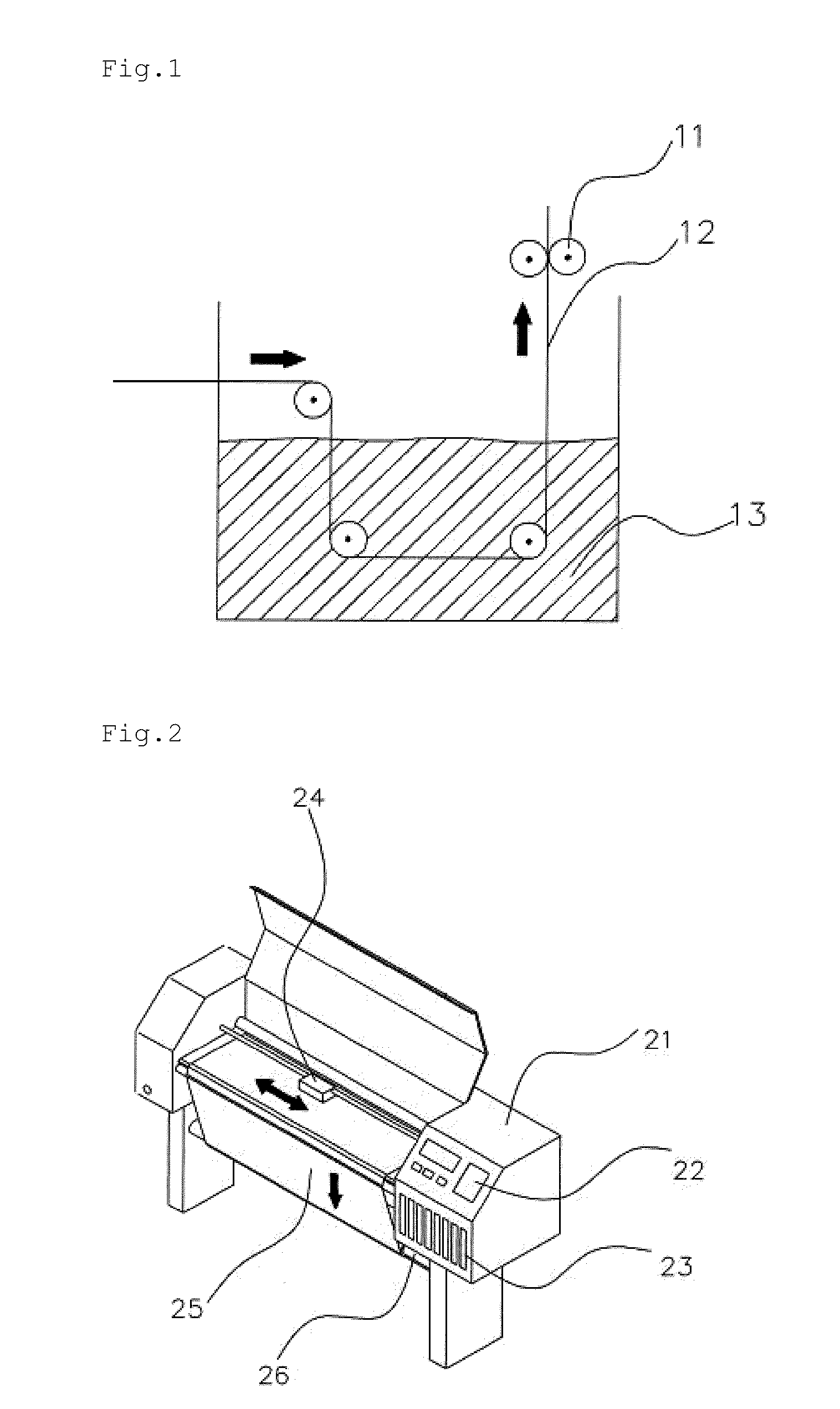

Method of dyeing fabric by using dye

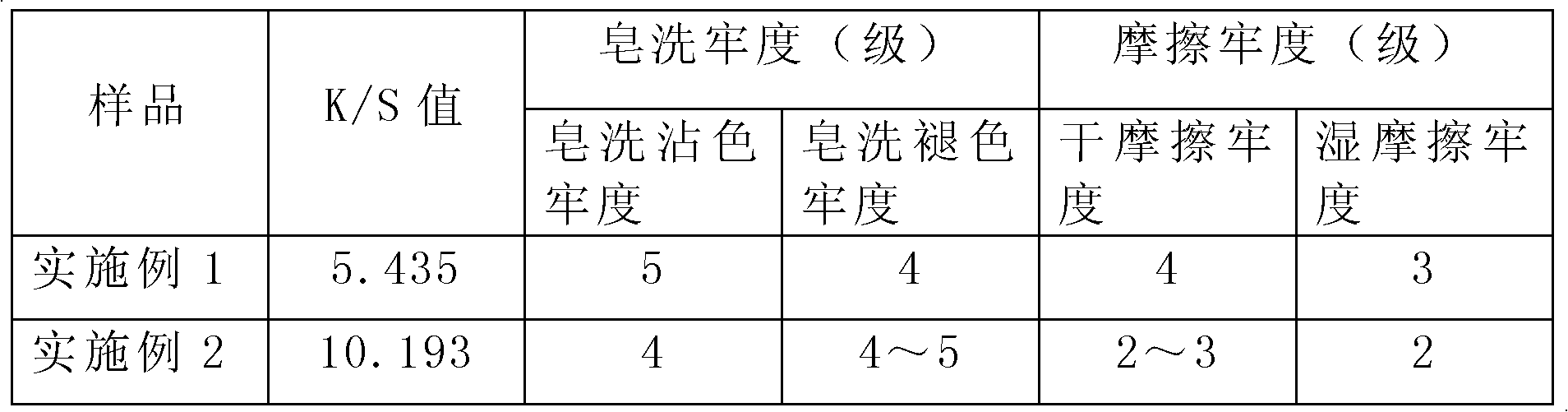

ActiveCN102535194ASoft touchImprove washing fastnessBiochemical fibre treatmentDry-cleaning apparatus for textilesTextile printerEngineering

The invention provides a method for dyeing fabric by using a dye, belonging to the technical field of textile printing and dyeing and aiming to the solve the problems of complex process, low dyeing rate, poor dyeing uniformity and poor color fastness and hand feel of dyed fabric of the existing method for dyeing the fabric by using the dye. The method comprises the following steps of: desizing the fabric, scouring, bleaching and mercerizing; adding the dye, a cationic modifier, a leveling agent, a dispersant, an alkaline reagent and a wet rubbing fastness enhancer to water, and mixing uniformly to prepare a dyeing solution; soaking the fabric into the dyeing solution, and controlling temperature and liquor ratio to dye; steaming the dyed fabric for colour fixation, washing by water and drying to finish dyeing the fabric by using the dye. The method for dyeing the fabric by using the dye is simple, ensures the high dyeing rate and the uniform dyeing, and ensures that the dyed fabric has good washing fastness and rubbing fastness and a soft feel.

Owner:台州东海翔染整有限公司

Treatment solution for inkjet textile printing, method for inkjet textile printing, and inkjet textile printed product

ActiveUS20110102497A1High image densityExcellent in coating film durabilityOther chemical processesDuplicating/marking methodsTextile printerCarboxymethyl cellulose

The present invention has its object to provide a treatment solution for inkjet textile printing that causes few remaining marks even when applied to a fabric. The present invention relates to a treatment solution for inkjet textile printing, the treatment solution comprising at least: 1) a water-soluble polyvalent metal salt; 2) at least one resin component selected from the group consisting of a nonionic resin emulsion, an anionic resin emulsion, and a carboxymethyl cellulose; 3) at least one surfactant component selected from the group consisting of a nonionic surfactant, an anionic surfactant, and an amphoteric surfactant; and 4) an aqueous medium, the treatment solution being applied to a fabric before printing of an ink composition for inkjet textile printing.

Owner:SAKATA INX

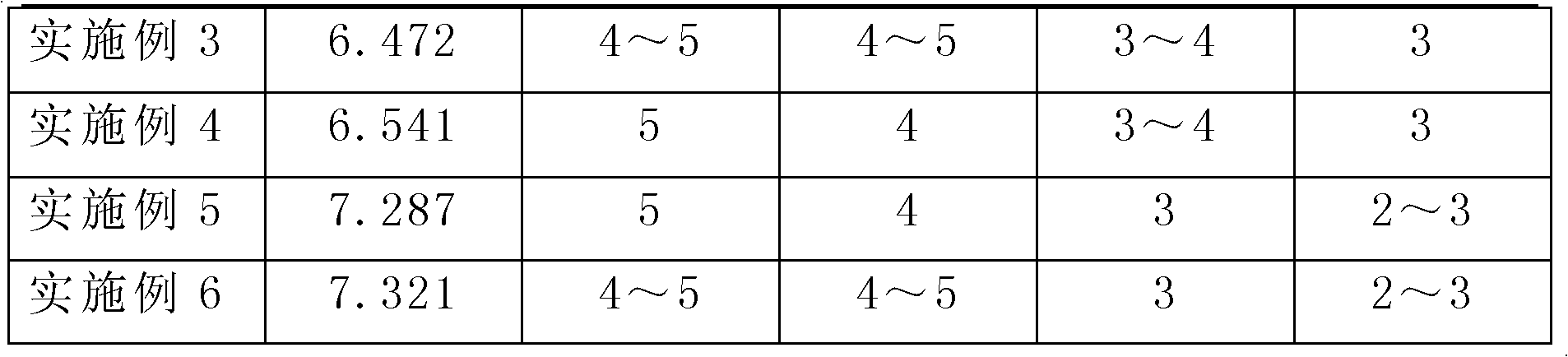

Printing and dyeing waste water treatment method based on film technology

ActiveCN101041532AOvercome costsUnsatisfactory processing effectWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentTextile printerWater based

The invention discloses a disposing method of textile printing waste water based on film technology involving a waste water disposing method, which comprises the following steps: adjusting pH and COD value of integrated waste water; pumping into flocculate tank; adding into flocculant; pumping into flocculating setting vessel; getting clarified solution; pumping into membrane biological reactor; proceeding biological treatment; getting dialysate; pumping into counter osmotic separating system; proceeding counter osmotic separation; getting reverse osmosis dialysate; recycling; making concentrated liquid flow into oxide adsorbing tank; refluxing into flocculating setting disposal process; proceeding twice flocculating setting dispose; reaching to two grade emission standard; discharging the eligible reverse osmosis dialysate; adding ClO2 to oxide ineligible reverse osmosis dialysate; adsorbing with activated char; adjusting pH value with alkali liquor; depositing in storing tank.

Owner:SUNTAR MEMBRANE ENVIRONMENT TECH

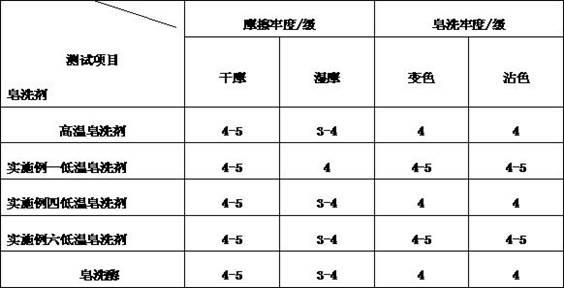

Low-temperature scouring and bleaching agent and preparation method thereof and preprocessing technique

InactiveCN101037842AReduce the bleaching temperatureThe effect of the pretreatment process is obviousBleaching apparatusTextile treatment by spraying/projectingTextile printerBenzene

The present invention realtes to a low temperature scouring and bleaching agent belonging to the pretreatment process technology field of the textile printing and dyeing industry, a manufacturing method thereof and a pretreatment process. Said low temperature scouring and bleaching agent consists of promoter QR2010 consisting of carbon tetrachloride, acetic acid esters, alkyl benzenes, emulsifying agents and scouring agents; promoter QR2011 consisting of potassium hydroxide, carbonates and penetrating agents; and promoter QR2020 consisting of acyls and nitriles activating agents and builders. Said three promoters are prepared using routine methods and are deposited solely. When used, the three promoters, together with hydrogen peroxide, are mixed according to different proportions to prepare solutions. Said low temperature scouring and bleaching agent is capable of annealing, boiling and bleaching a variety of cotton as well as cotton blending textiles at any temperature ranging from 40 DEG C to 80 DEG C, and being processed at different scouring and bleaching equipments, with a whiteness of higher than 80% and a capillary effect of 10-20 cm. Compared with the process in existing, the amount used of hydrogen peroxide activating agent is 1 / 7 to 1 / 5 of that originally used, the total energy consumption is reduced, the tonnage of used water is decreased, and billet flaws such as holes bleached by oxygen and lycra folded crepes sourced and bleached are avoided.

Owner:SHANGHAI QIRUI TEXTILE CHEM

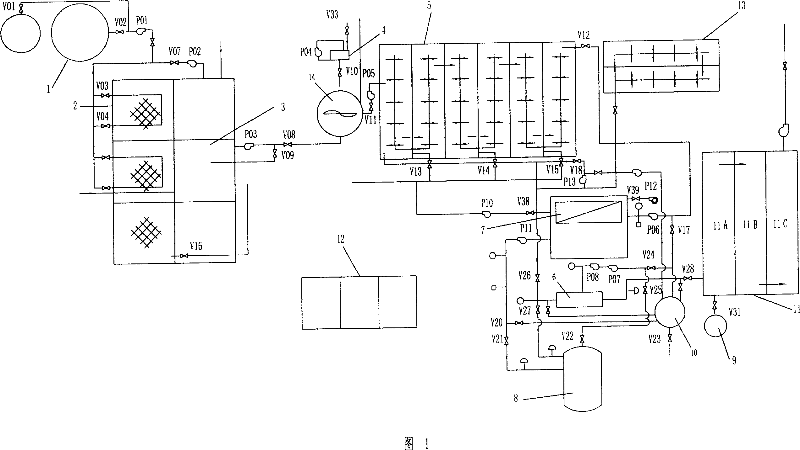

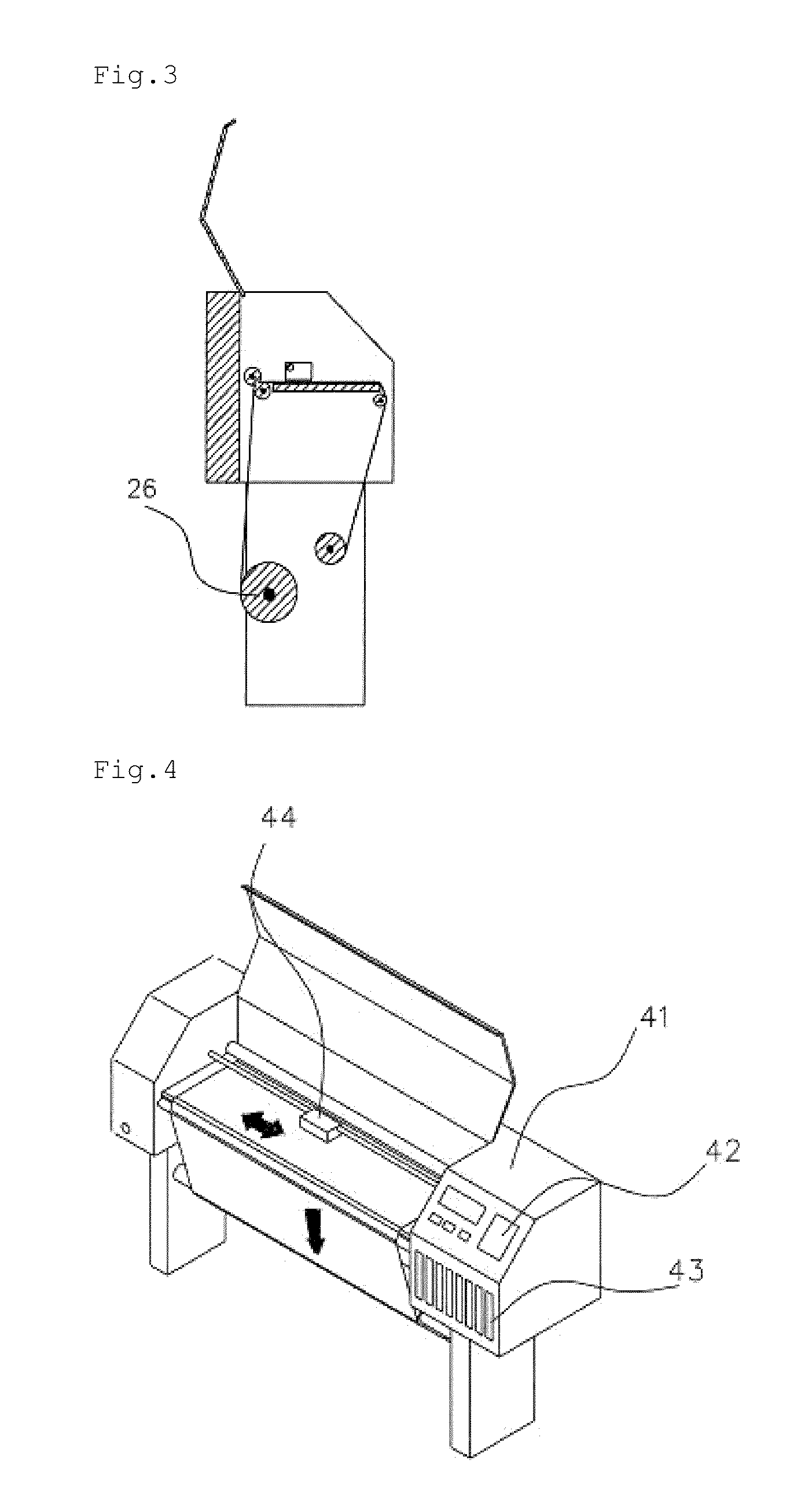

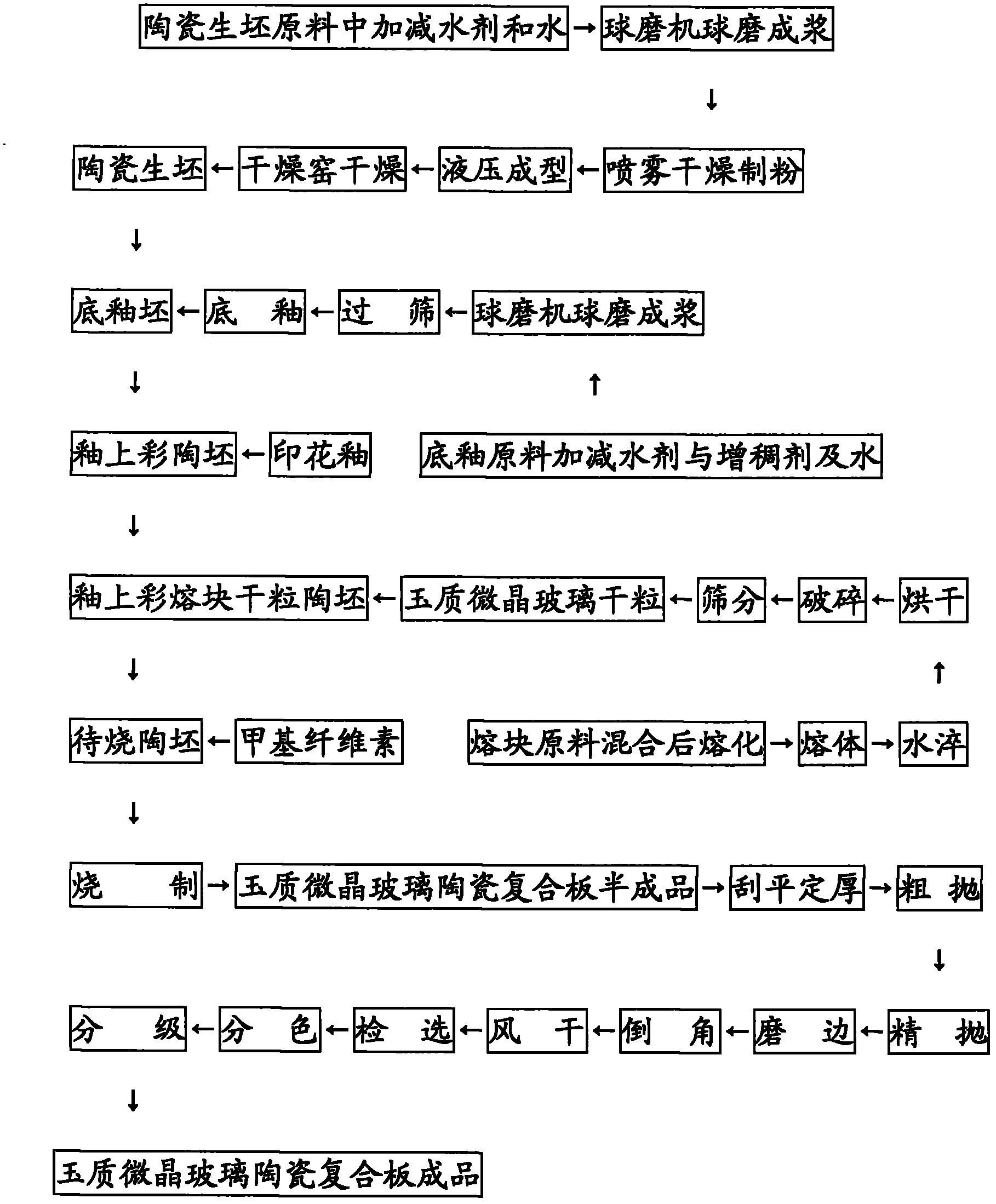

Textile printing method and apparatus applying inkjet printer

InactiveUS20090293209A1Good colorDeterioration in feelingTypewritersDyeing processTextile printerPre treatment

A textile printing method applying inkjet printer comprises the steps for feeding a fabric by a fabric feed roller, applying a pretreatment liquid to the fabric by jetting the pretreatment liquid installed in a pretreatment liquid reservoir installed respective containers filled with individual compositions of a pretreatment liquid, so that such individual compositions are concurrently mixed and applied on the fabric surface to pretreat the fabric by operation of a control unit depending upon the fabric material through a pretreatment head, drying the pretreatment liquid applied to the fabric through a drier, and printing on the dried fabric by jetting the ink installed in a ink reservoir through the printing head. The pretreatment head, the drier and the printing head are serially arranged so that the steps for applying a pretreatment liquid, drying the pretreatment liquid and printing on the dried fabric are concurrently performed.

Owner:INTEC CO LTD

Production technology of flexible silk azelon laschel blanket

ActiveCN102912552ABright colorSoft and delicateWarp knittingHeating/cooling textile fabricsTextile printerEngineering

The invention relates to a production technology of a flexible silk azelon laschel blanket. The production technology comprises the following steps of: chaining, beaming, knitting, bleaching, sizing, dyeing, soaping, mellowing, drying and postprocessing and the like. The production technology of the flexible silk azelon laschel blanket provided by the invention optimizes a spinning technology, and techniques of weaving, front finishing, textile printing (dyeing) and after finishing according to characteristics of flexible silk azelon and acrylic fibers, so that a functional blanket meeting new requirements that consumers pursue comfort and heath and the like is produced. The flexible silk azelon laschel blanket provided by the invention is bright in color, soft, fine and smooth in hand feeling, and mothproof and mildewproof, and simultaneously has health-care functions of far infrared emission and anions and the like.

Owner:ZHEJIANG TRUELOVE CARPET IND SCI & TECH

Environment protection type pigment resin printing adhesive agent capable of self crosslinking at low-temperature, and preparation thereof

InactiveCN101220563ASimple processLow costEster polymer adhesivesDyeing processPolyesterSodium bicarbonate

The invention belongs to the water-base adhesive technical field, in particular to an environment-protecting pigment printing binder which auto-crosslinks in the low temperature and a preparation method thereof which includes a polymeric monomer is added into the water solution of the composite emulsifier and the sodium bicarbonate, and the mixture is stirred so as to obtain the pre-emulsion; the pre-emulsion is added into a reaction vessel in lots, a polymerization is initiated, and a styrene-acrylic emulsion base which crosslinks in the low temperature is obtained; the pH value is adjusted, a crosslinking agent is added and the needed binder is obtained. The pigment printing binder obtained by the preparation of the method does not comprise formalin, alkyl phenol polyoxyethylene ether and other harmful substances. The finished textile printing obtained by using the binder has the advantages of soft hand feeling, brilliant color, wear resistant, and high soaping fastness, etc.; the textile printing used for the cotton cloth, polyester-cotton can get better effect. The mixture of the binder and the synthetic thickener can modulate the proper textile printing pulp, and is applicable to plate printing and net-tube printing.

Owner:FUDAN UNIV

Salt-free pad steam continuous dyeing method for active dye

InactiveCN101200859AFor quick replacementGood reproducibilityDyeing processLiquid/gas/vapor textile treatmentTextile printerSalt free

The present invention relates to a continuous saltless pad-steam dyeing method with reactive dyes, which belongs to the novel technical field of textile printing and dyeing. After being singed, desized, boiled, bleached and mercerized, the half-finished product of cellulosic fibre woven fabric is dyed in the process of the continuous dyeing technique of padding, steam fixation, water washing, soaping, water washing and drying by the reactive dyes. The half-finished product of the preprocessed cellulosic fibre woven fabric is produced by pad dyeing, steaming and water washing, wherein, dyeing solution is composed of M reactive dyes, leveling agent, fixation alkali agent and water, and the mixture ratio is as follows: M reactive dyes: 0.01 percent to 10 percent, leveling agent: 0.1 percent to 0.2 percent, fixation alkali agent: 1.5 percent to 4 percent, and water: balance. The method is different from the conventional continuous dyeing technique of padding, drying, padding and steaming, which uses reactive dyes, and also different from the shortened wet-steaming technique with reactive dyes. On the conventional continuous padding machine, the novel method can fulfill the whole process of reactive dyeing without a hot-air padding machine and only with a developing and soaping range, thus greatly saving energy and reducing cost.

Owner:SHANXI CAIJIA PRINTING & DYEING

Ink for inkjet textile printing

InactiveUS20100214352A1Improve concentrationViscosity of ink increaseDuplicating/marking methodsInksVitrificationTextile printer

An ink for inkjet textile printing comprising a pigment, a water-dispersible resin, water, and a water-soluble organic solvent, wherein the water-soluble organic solvent comprises a polyol having an SP value within a range from 10 to 15.5 (cal / cm3)1 / 2, and the water-dispersible resin comprises a urethane resin having a glass transition point within a range from −35 to 10° C.

Owner:RISO KAGAKU CORP

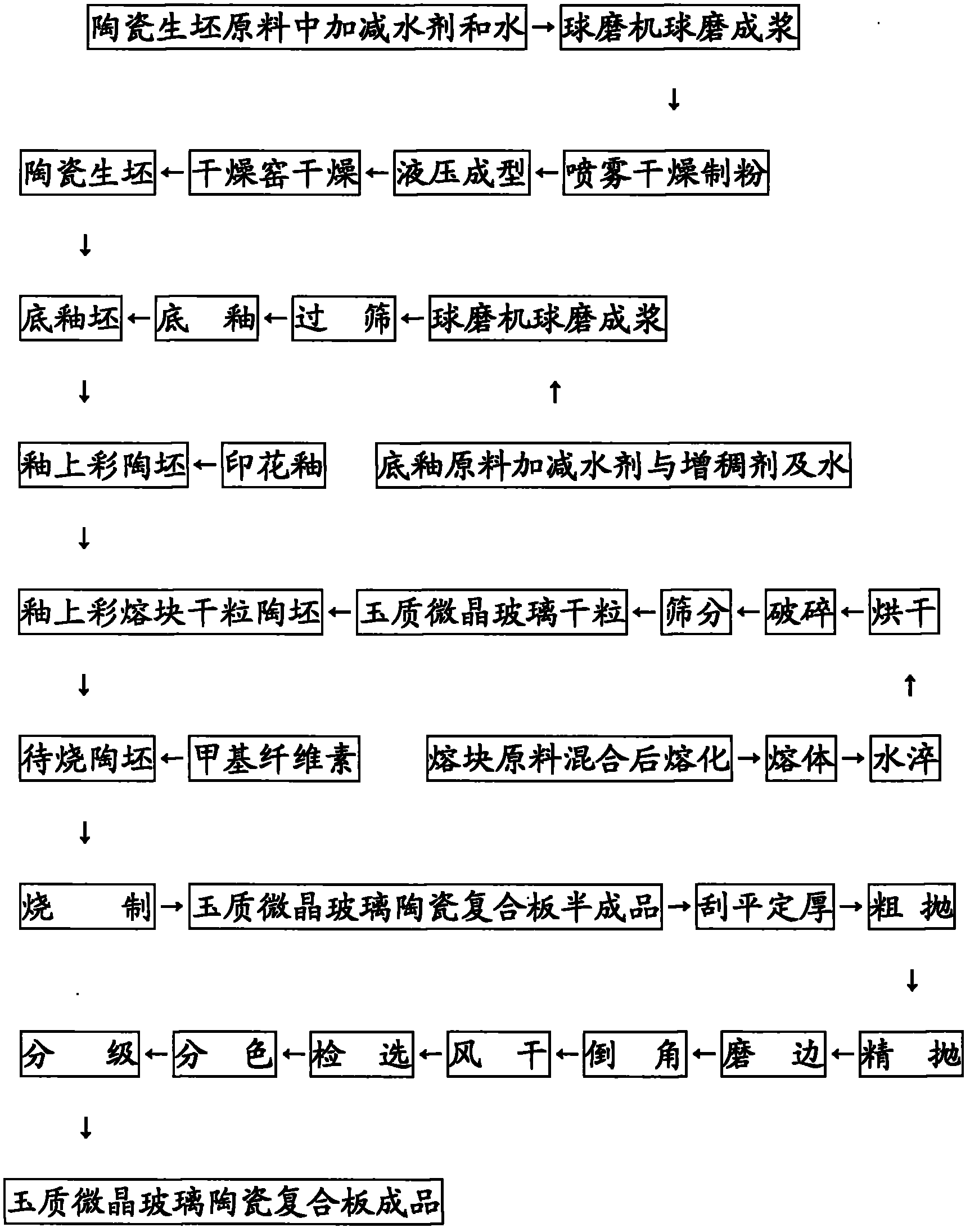

Method for preparing jadeite microcrystal glass ceramic composite board

The invention relates to a method for preparing a jadeite microcrystal glass ceramic composite board, and relates to the technical field of building materials. The method comprises the following steps of: on the basis of a key technology of 'jadeite microcrystal glass clinker dry granules obtained by selecting materials within a preset range of product ingredients', applying a ground coat on a ceramic blank to obtain a ground coat blank, and printing textile printing glaze on the ground coat blank to obtain an over-glaze colored ceramic blank; applying the jadeite microcrystal glass clinker dry granules on the over-glaze colored ceramic blank to obtain over-glaze colored clinker dry granular greenware, spraying methylcellulose for fixing to obtain greenware to be fired; and firing the greenware to be fired to obtain a semi-finished product, strickling, calibrating thickness, polishing coarsely, polishing finely, edging, chamfering, airing, sorting, performing color separation, and grading to prepare a finished product of the jadeite microcrystal glass ceramic composite board. The method is used for producing jadeite microcrystal glass ceramic composite boards, and adapts to a primary or secondary sintering process; and the product is high in quality, high in surface strength and wear resistance and wide in application range, and has a unique jadeite texture and a high comprehensive benefit.

Owner:GUANGDONG BODE FINE IND CONSTR MATERIAL

White ink composition for ink jet textile printing and ink jet textile printing process

ActiveUS20080268156A1Superior in coating film durability and laundering fastnessHigh whitenessInorganic pigment treatmentDuplicating/marking methodsTextile printerVitrification

The object of the invention is to provide a white ink composition for ink jet textile printing by which even if printing is carried out without discoloring the dye of textile piece, the whiteness degree of a dyed article obtained is high and the dyed article superior in coating film durability and laundering fastness is further obtained without losing the drape of the textile piece. The invention is directed to a white ink composition for ink jet textile printing including a white pigment, a polymer dispersant, an anionic resin emulsion and an aqueous medium, wherein the polymer dispersant is a polymer dispersant (A) obtained by neutralizing a anionic water-soluble resin having a glass transition temperature of 0 to 80° C., an acid value of 100 to 300 mgKOH / g and a mass average molecular weight of 5000 to 30000 with a basic compound, and the anionic resin emulsion is an anionic resin emulsion (B) with a glass transition temperature of at most 0° C., and the mass ratio of the content of the polymer dispersant (A) and that of the anionic resin emulsion (B) is (A) (B)=1 / 5 to 1 / 10 converted to each solid content.

Owner:SAKATA INX

Process for making anti-infrared multifunctional camouflaged color cloth

InactiveCN101397708AShort production processHue once goodFibre treatmentSingeingFiberTextile printer

The invention relates to a textile printing and dyeing technique, in particular to a manufacturing technique of an infrared ray resistant multi-functional camouflage fabric. The technique flow is as follows: original cloth seaming, singeing, old rolling, 180 pre-treatment, shaping, mercerizing, ground dyeing, pattern printing, baking, aging, stentering of post treatment, examination and acceptance; wherein, the ground dyeing flow is as follows: padding liquor, two groups of infrared rays and drying; a formula adopted in the ground dyeing flow comprises 2g / l to 10g / l of dispersion dyes, 5g / l to 15g / l of vat dyes and 0.01g / l to 1.0g / l of infrared ray resistant regulators; the formula of pattern printing is as follows: 2kg to 15.7kg of dispersion material, 2. kg / l to 10.5kg / l of vat material and 0.01kg to 2.5kg of infrared ray resistant regulators; post treatment has the function compatibility of multiple functions which are water proofing, oil repellence, ventilation, crease resistance and static resistance. The technique has the advantages of having short production procedure, color phase with good uniformity, stable infrared reflectivity, low cost, multiple functions, mainly using environment friendly dyes and being suitable for infrared ray resistant camouflage fabric products with different fibers and different specifications.

Owner:XIANYANG JIHUA NEW 30 DYEING & PRINTING

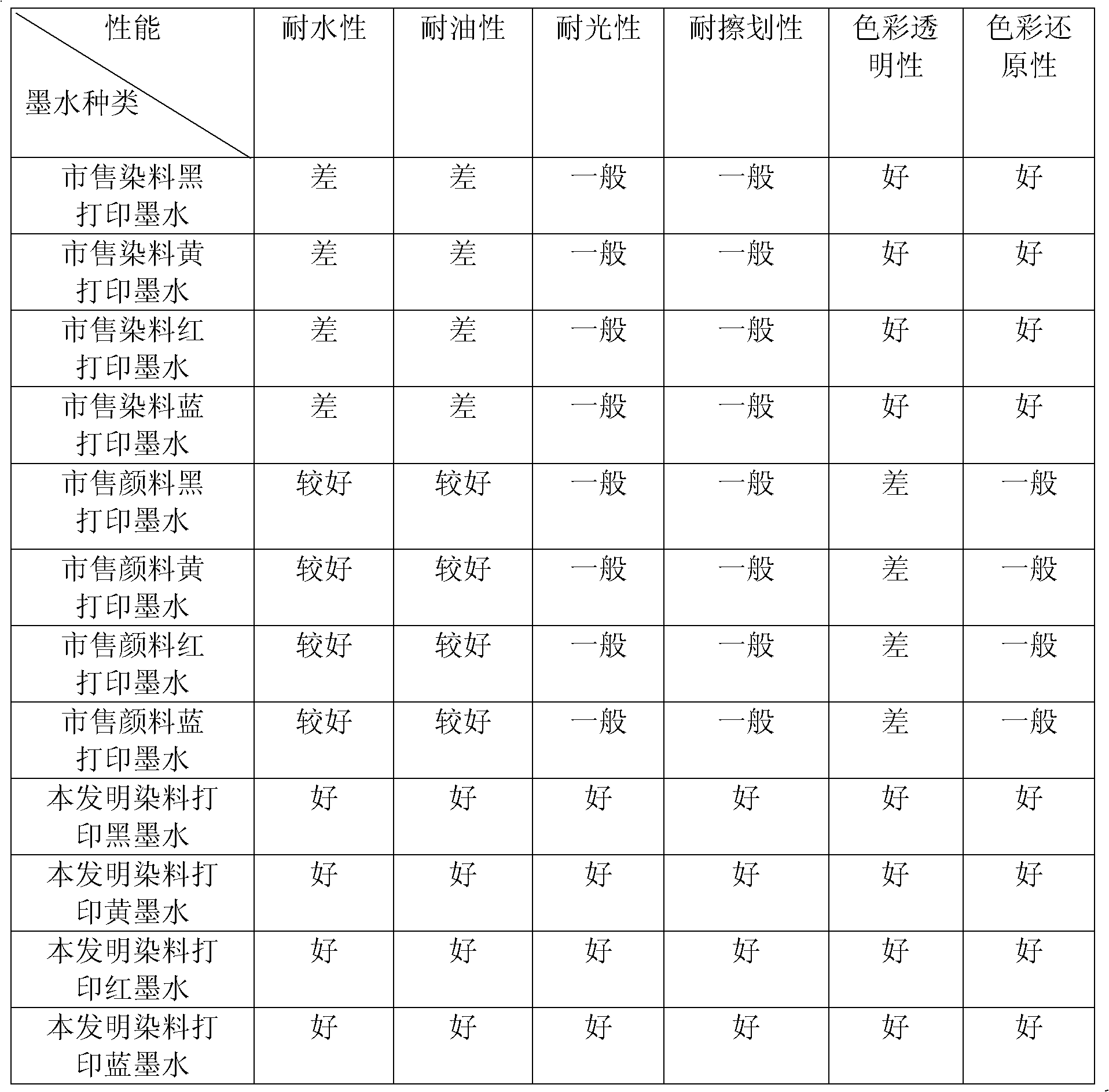

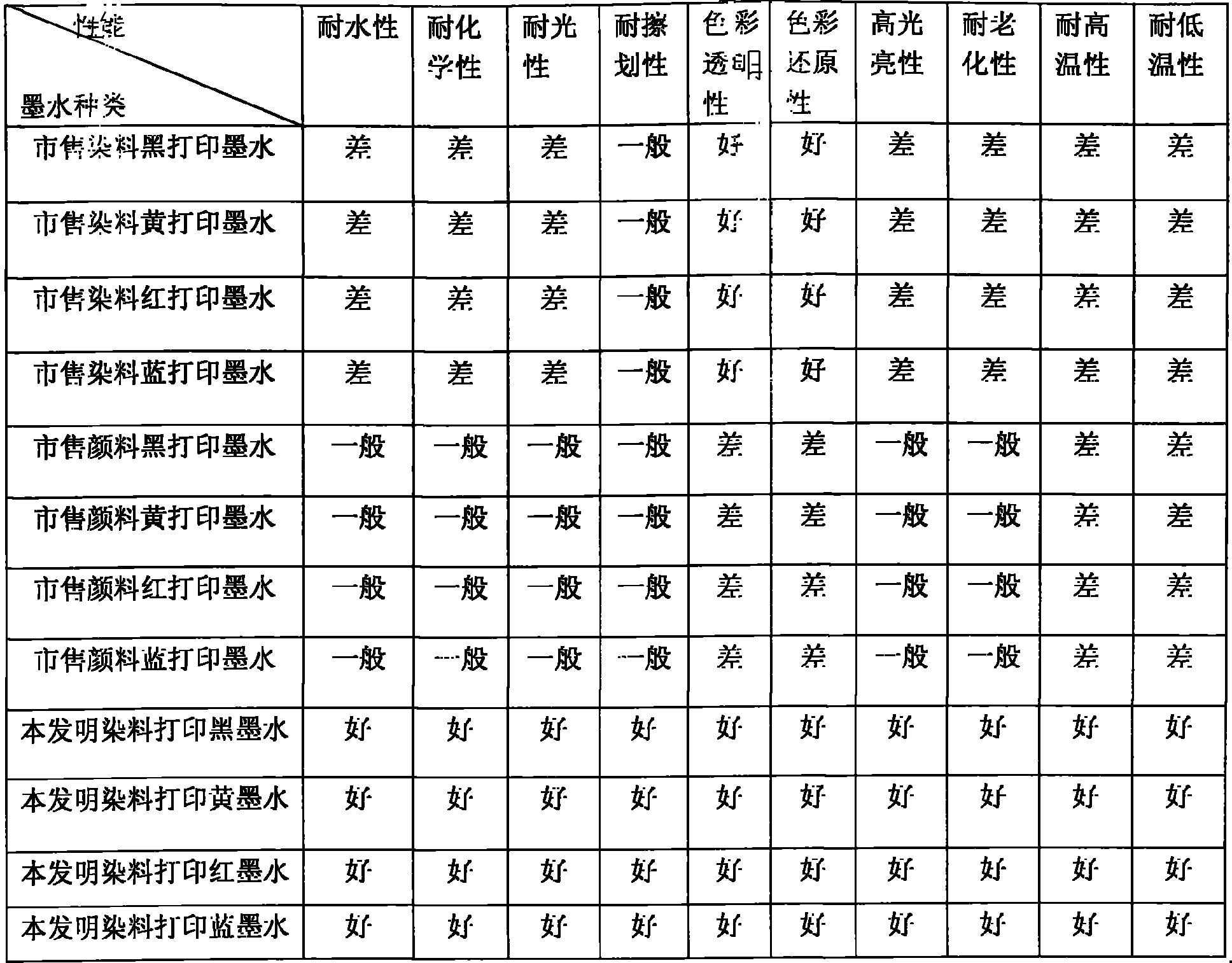

Water-based dye ink and application thereof

InactiveCN101805542AOvercome LightfastnessOvercome fading under lightInksDyeing processTextile printerWater based

The invention discloses a water-based dye ink and an application thereof. The water-based dye ink comprises the following components in percent by weight: 0.2 to 12 percent of water-soluble dye, 55 to 80 percent of modified acrylic resin emulsion, 0.01 to 1 percent of ultraviolet absorbent and balance of water, and different additives can be added. The dye ink can be applicable to the fields such as jet ink, cipher paint ink, textile printing ink, water-type printing ink, fountain pen ink and water ball pen ink, and has the advantages of water resistance, oil resistance, scratch resistance, illumination resistance, high temperature resistance, low temperature resistance, good color reducibility, duration and the like.

Owner:鲁继烈

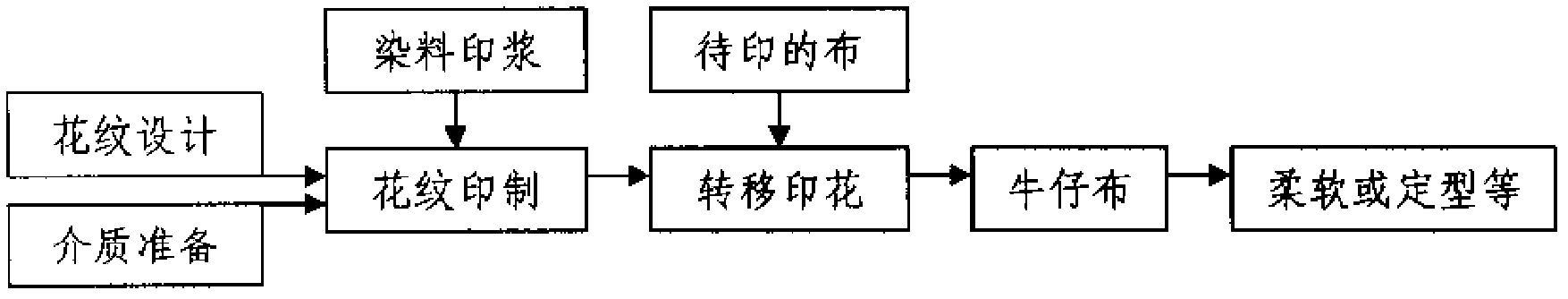

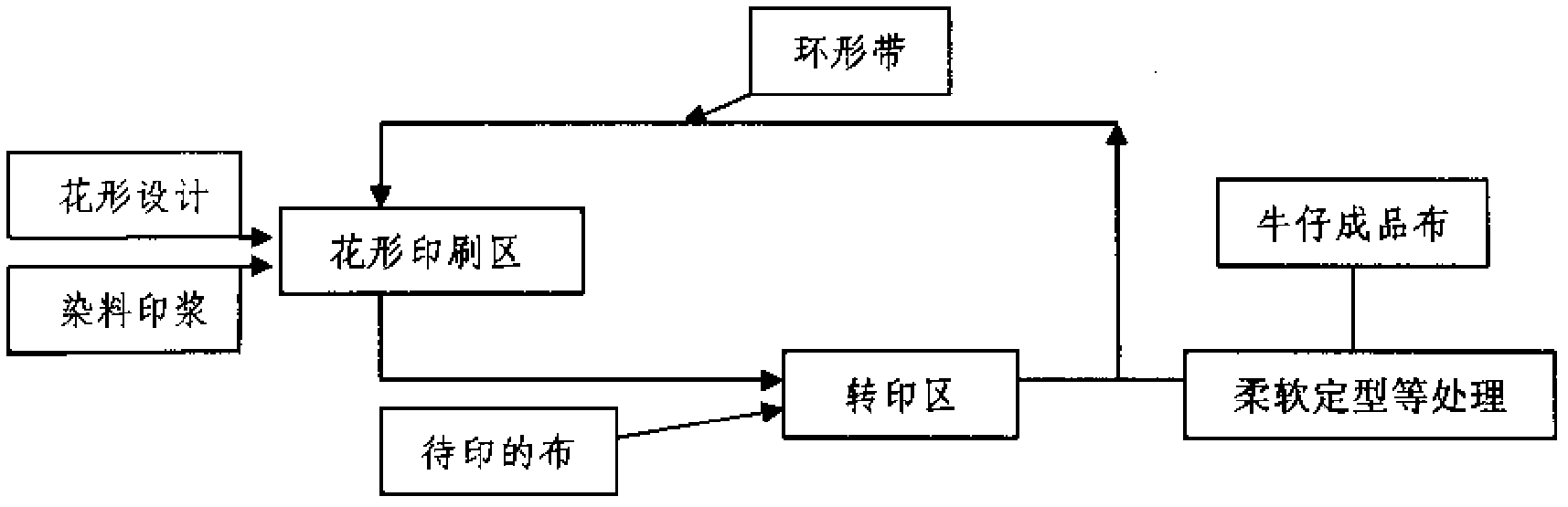

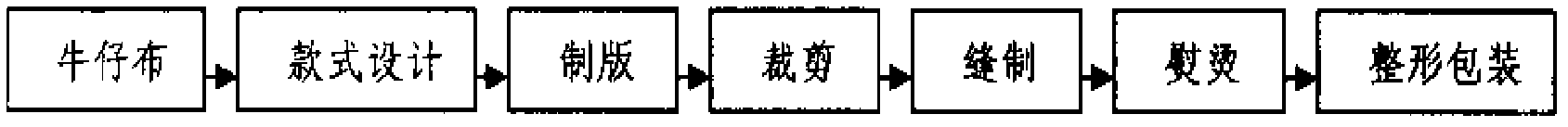

Printing technology for pure cotton or polyester-cotton jean

InactiveCN102304862APrinting process does not consume waterNo sewageTransfer printing processDyeing processWater basedFiber

The invention discloses a printing technology for pure cotton or polyester-cotton jean, belonging to the technical field of textile printing and dyeing. The printing technology comprises the following steps: firstly, preparing a dye into water-based ink suitable for intaglio printing; pretreating fiber fabrics to be served as cloth to be printed; preparing a medium capable of undertaking the printing of figures; designing figure patterns; printing the designed figure patterns on the medium in a common printing mode to obtain a transfer printing medium; carrying out transfer printing of the figures on the transfer printing medium to the cloth by a transfer machine to finish the printing of the jean; and carrying out the processes of softening, shaping and the like with the traditional padding-shaping machine as required. The printing technology has the beneficial effects that the jean with the traditional jean style can be printed, no water is consumed for printing, no sewage is generated, and the printing technology belongs to the clean production technology.

Owner:北京三丽科技有限公司

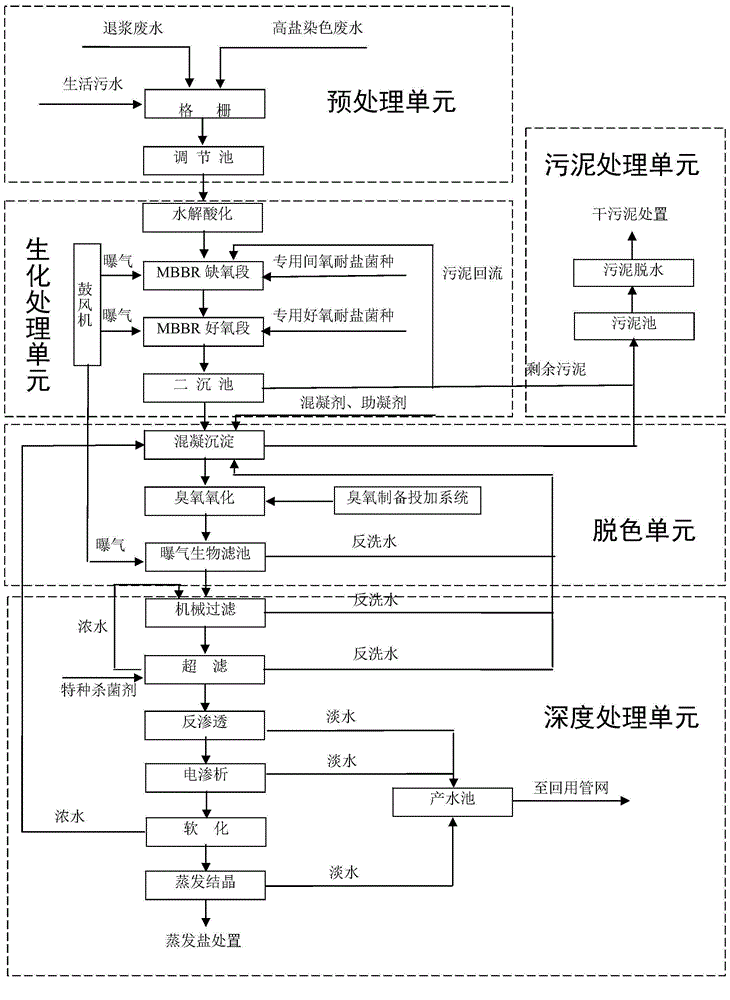

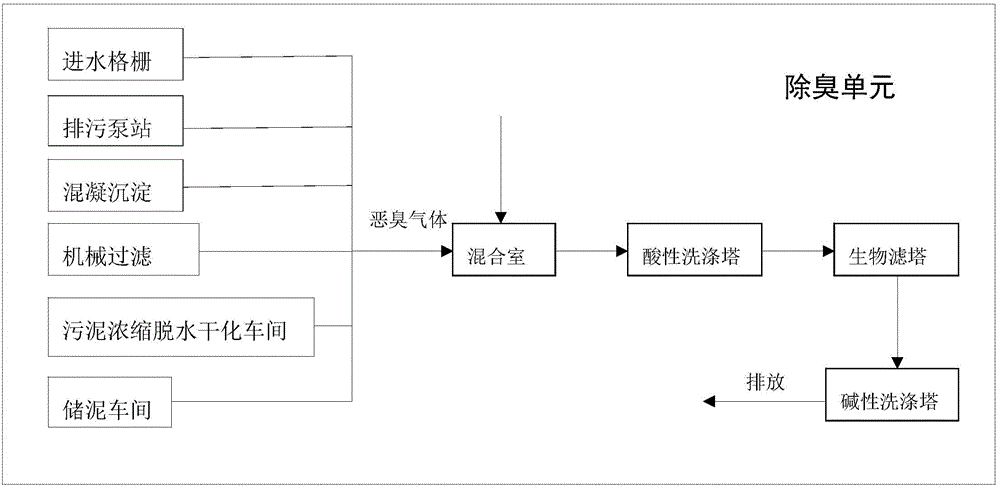

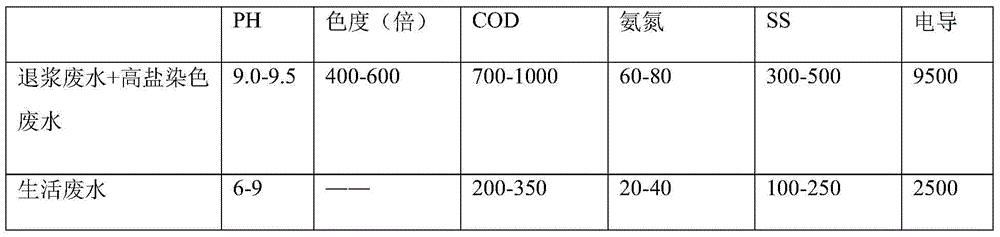

High-salt-content dyeing wastewater treatment recovery zero discharge integration method

ActiveCN104478174APromote growthAvoid emissionsSludge treatment by de-watering/drying/thickeningTreatment using aerobic processesTextile printerSalt content

The invention belongs to the technical field of sewage treatment, and particularly discloses a high-salt-content dyeing wastewater treatment recovery zero discharge integration method. The method can perform deep treatment recovery on the high-salt-content dyeing wastewater to obtain production water for textile printing industry, thereby achieving the goal of zero discharge. The integration method is composed of a pretreatment unit, a biochemical treatment unit, a decolorization unit, an advanced treatment unit, a sludge treatment unit and a deodorizing deodorization unit. The integration method is mainly used for treating high-salt-content dyeing wastewater.

Owner:XINJIANG ENVIRONMENTAL ENG TECH

Modified polyurethane resin emulsion dye ink and application thereof

ActiveCN101914324AHigh color reproductionRaw materials are abundant and completeFibre treatmentInksTextile printerUltraviolet

The invention discloses a modified polyurethane resin emulsion dye ink and an application thereof. The modified polyurethane resin emulsion dye ink comprises the following components based on weight ratio: 0.1-12% of solvent dye and / or water-soluble dye, 13.5-49.8% of polyurethane resin solid content, 0.01-1% of ultraviolet absorber and the balance of solvent, wherein various additives can be added in the dye ink. The dye ink disclosed in the invention can be used in the fields such as jet ink, cipher paint ink, textile printing ink, aqueous printing ink, fountain pen word ink, rolling maker ink, coating, leather finishing agent, surface finishing and the like, and has the advantages of good storage stability, excellent water resistance, chemical resistance and light resistance, favorable mechanical performance, high brightness, high and low temperature resistance, ageing resistance, good color reproducivity and transparency, easily-obtained raw materials, simple manufacture, easy detection, low cost and wide market application prospect.

Owner:GUANGDONG BANGGU CHEM TECH

Dyeing and finishing process for sea silk fabric

InactiveCN101413207AStrong damageSoft touchDry-cleaning apparatus for textilesBleaching apparatusFiberTextile printer

The invention discloses a dyeing and finishing technology for seaweed fiber fabrics, which belongs to the technical field of textile printing and dyeing. The dyeing and finishing technology comprises the following steps of pre-treatment, dyeing and after-treatment, wherein pre-treatment adopts the treatment technology of enzyme-deoxidized annealing and bleaching-bath method; and the fabrics are placed into a dye jar with a bath ratio between 1 to 5 and 1 to 30 at a normal temperature, added with an immersing working fluid, heated to a temperature of between 70 and 100 DEG C, bleached, subjected to heat insulation for 30 to 60 minutes, subjected to water scrubbing and standby for dyeing. The dyeing and finishing technology adopts the treatment technology of enzyme-deoxidized annealing and bleaching-bath method; the capillary effect of the fabrics is more than 10.5 centimeters; the brightness reaches more than 82; and the strength loss is less than 10 percent. The dyeing technology of one bath two stage process shortens the processing time for 50 percent, is energy-saving and reduces consumption.

Owner:ZHEJIANG GANGLONG WEAVING TECH

Water soluble pigment ink-jetting printing ink

This invention has disclosed a kind of water soluble pigment type to gush out and print blackly Colored ink, it is by the pigment, water soluble organic solvent, deionized water, Antiseptic, hand in and unite the acrylic acid resin, the surface-active agent by oneself, moist Wet pharmaceutical, dispersant, it is worth 10 that pH regulates the pharmaceutical. Group's cost inventing The water soluble pigment type textile printing ink shows the following characteristics 1) 25deg.C viscidity of hour is 6Mpa.S, 2) PH is worth 10.0, Between dyne 45 of surface tension / centimeter. Have bright in luster, And the fabric is dealt with before not needing going on, the aftertreatment is very simple Wait for the advantage, namely only need to bake proper hot 190deg.C to the fabric 5 minutes of 210deg.C cylinder press for one minute, but does not need the uapour to steam, Water-washing can get print stamp the finished product.

Owner:游在荣 +1

Textile printing and dyeing pretreating agent and application thereof

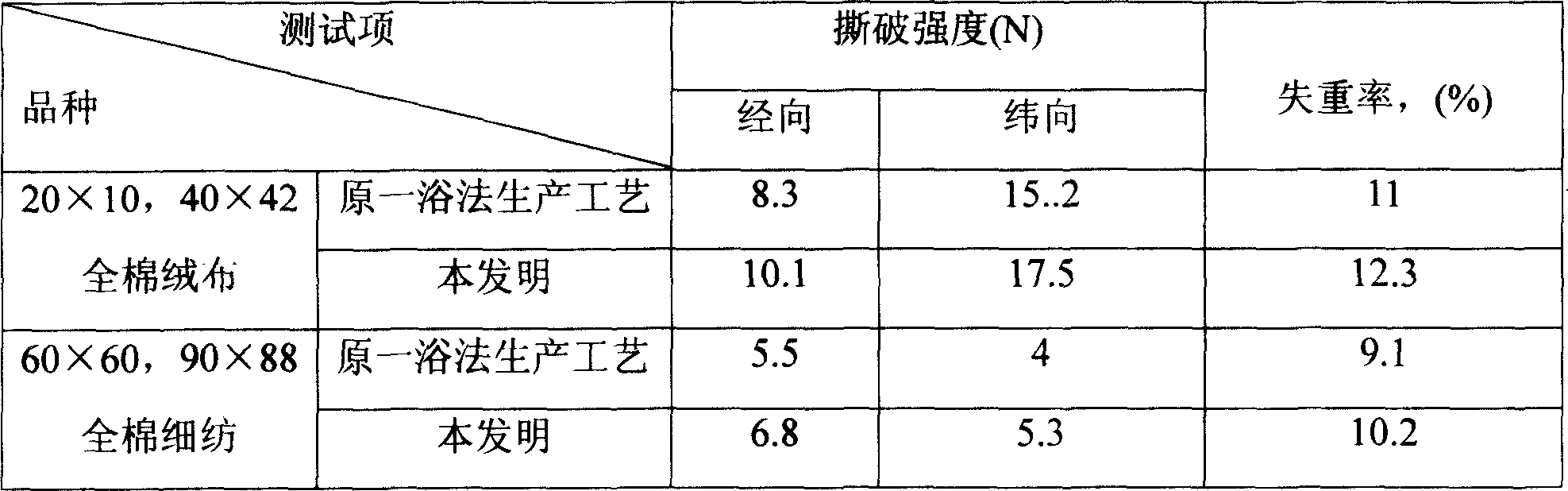

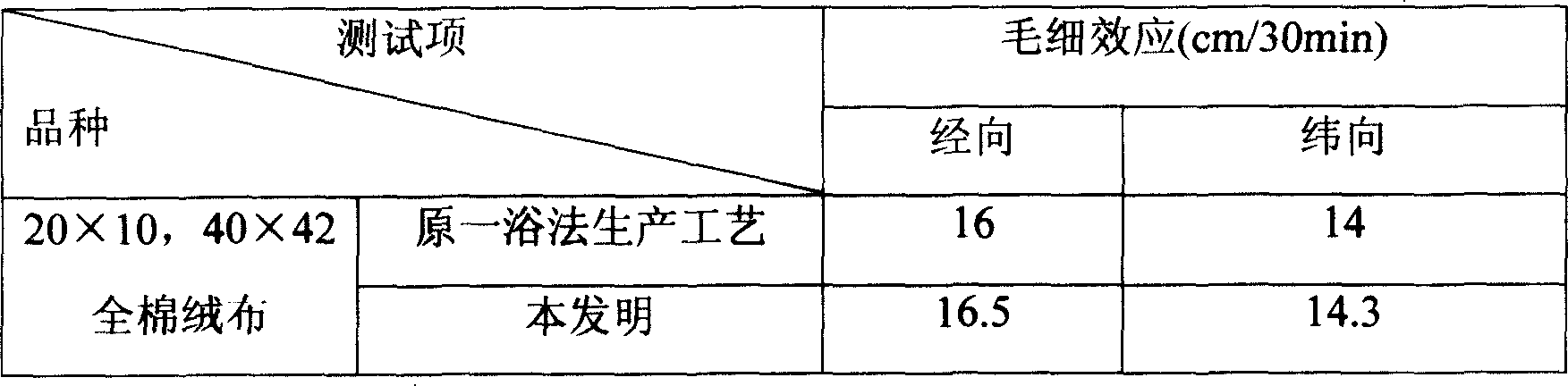

InactiveCN100999869ANo reduction in tear strengthFully desizingBiochemical fibre treatmentTextile printerEngineering

The present invention discloses one kind of pre-treating agent for fabric printing and dyeing and its application. The pre-treating agent includes pre-treating water solution in 40-60 wt% and promoter in 40-60 wt%. The pre-treating agent may be used in the pre-treatment of cotton fabric and blended fabric before printing and dyeing. The cotton fabric and blended fabric treated with the pre-treating agent has full desizing, no degradation in strength and easy printing and dyeing.

Owner:SHENDA NO 2 PRINTING DYEING FINISHING CO LTD SHANGHAI

Textile dyeing method

InactiveCN102002834AIncrease profitSmall particle sizeTextile treatment containersTextile treatment with treating outlet contectFiberTextile printer

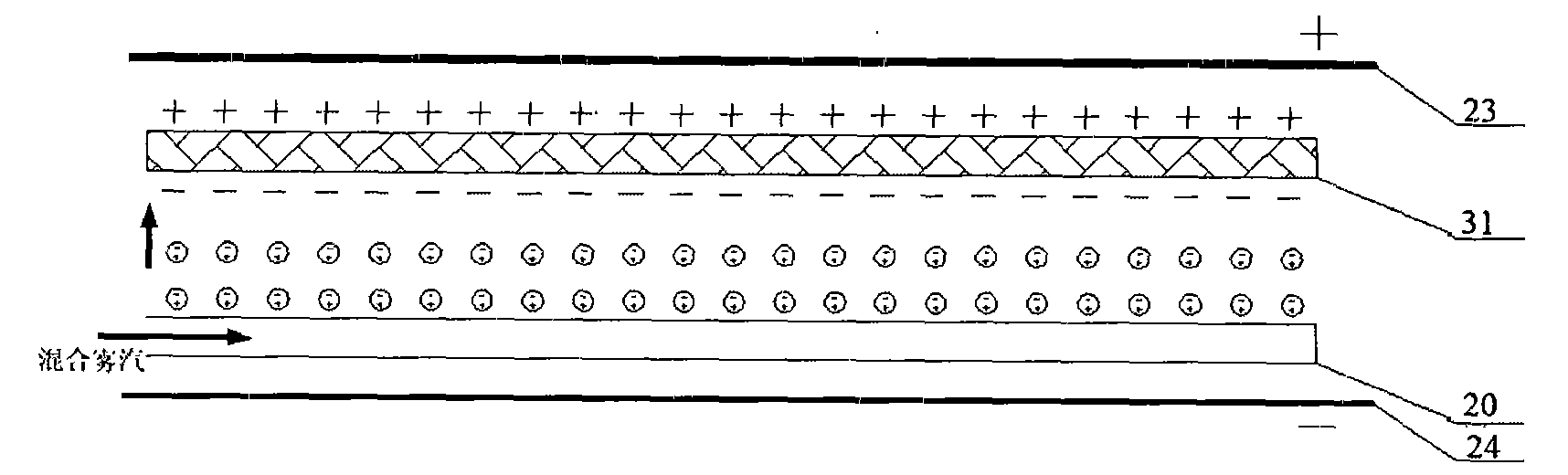

The invention relates to a method for dyeing textile materials and products thereof, and belongs to the field of textile printing and dyeing processing. In the method, prepared dye solution is subjected to ultrasonic atomization to form dye solution microbeads, and the dye solution microbeads directionally infiltrate the textile under the action of certain pressure and an electric field so as to complete the dyeing process. Due to the adoption of the technical scheme, dye solution atomized microbeads prepared from the dye solution through a high-frequency ultrasonic atomizer have smaller grain size, a small dispersion range on the textile and more fine and smooth dyeing effect; the dye solution atomized microbeads enter fibers more easily under the action of the air pressure and the electric field, and have better dyeing effect; and the atomized microbeads carry less solution, the utilization rate of the dye is high, water can be saved and the environmental pollution is lightened. The dyeing method has a wide application range, low energy consumption and light pollution, and is suitable for small-batch and multi-variety printing technology development direction.

Owner:WUHAN TEXTILE UNIV

Method for dyeing textile by dye liquor prepared by mutually dissolving organic solvent and water

The invention relates to a method for dyeing textile by dye liquor prepared by mutually dissolving organic solvent and water and belongs to the technical field of textile printing and dyeing processing. The dye liquor applies organic solvent soluble in water and lower than water in boiling point, and dye is soluble in water and insoluble in organic solvent, so that effective liquor ratio is lowered, distribution coefficient of dye on fiber is changed, and dye uptake is of dye is increased. Adding the organic solvent allows boiling point of the dye liquor to reduce, energy is saved, water consumption in dyeing process is greatly reduced, the organic solvent can be recycled and reused, and discharge of waste liquor is reduced. The dyeing process includes performing twice-soaking and twice-rolling accelerant solution to textile, and solid accelerant is prevented from being precipitated out at a great amount by being added in dyeing process. The method is low in water consumption, utilization rate of dye is increased, energy consumption is low, the organic solvent can be recycled and reused, and cleaning and dyeing are achieved simultaneously.

Owner:WUHAN TEXTILE UNIV

Cation hybrid collosol and method for improving clearness and fastness of decoration printing

InactiveCN101117769AFeel goodImprove anti-seepage performanceFibre treatmentDyeing processTextile printerColour fastness

The present invention relates to a cation hybrid sol and a firm for increasing clarity and firmness of textile printing, which belongs to the textile chemical industry field. The present invention is characterized in that solvent, cation compound, precursors and deionized water are added into a reaction vessel in turn, after being agitated and evenly mixed, catalyst is added into the mixture, and agitated under room temperature and cation hybrid sol is obtained. After diluting the cation hybrid sol and deionized water as per specified ratio, a textile is padded and finished in the sol, and the finished textile is dried. The present invention can improve the anti-bleeding performance of the ink color printing of the textile; and clarity, depth and vividness of color of the ink color printing products are increased; paint / pigment on the textile can be fixed, meanwhile, the combined effect of the cation hybrid sol and paint / pigment make aggregation for fixation of the paint / pigment, and color firmness of the textile color printing is increased.

Owner:JIANGNAN UNIV

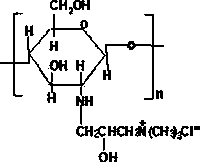

Preparation method of quaternary ammonium salt chitosan and organic silicon composite modified cationic water-based polyurethane fixing agent

ActiveCN103709364AMeet living requirementsWith antibacterial health functionDyeing processWater basedTextile printer

The invention relates to the technical field of fixing agent, and provides a preparation method of quaternary ammonium salt chitosan and organic silicon composite modified cationic water-based polyurethane fixing agent. When being used for a fixing aftertreatment process of textile printing and dyeing, the fixing agent prepared through the method can effectively enhance dry / wet rubbing color fastness of textile. The preparation method mainly comprises the following steps: (1) performing quaternary ammonium salt chitosan modified polyurethane prepolymer reaction; (2) performing organic silicon terminating reaction; and (3) neutralizing, and performing ionizing reaction.

Owner:FUJIAN QINGYUAN TECH

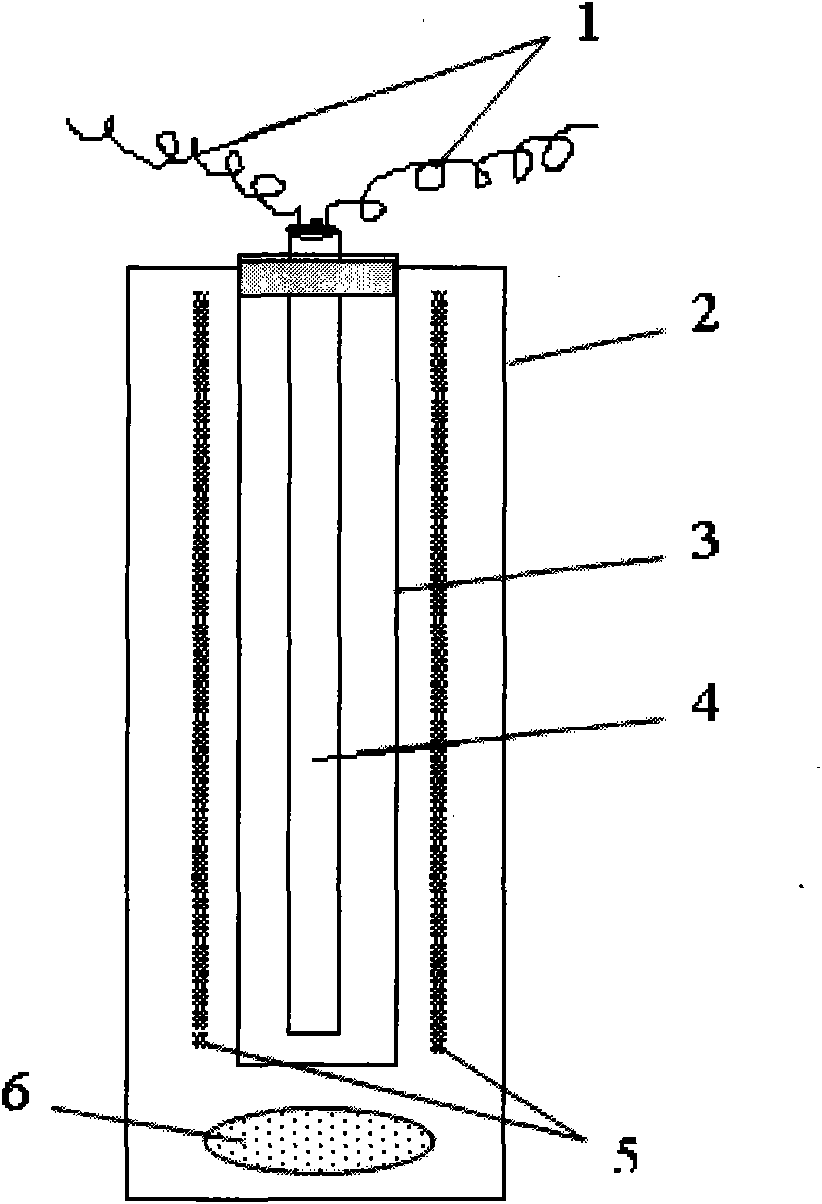

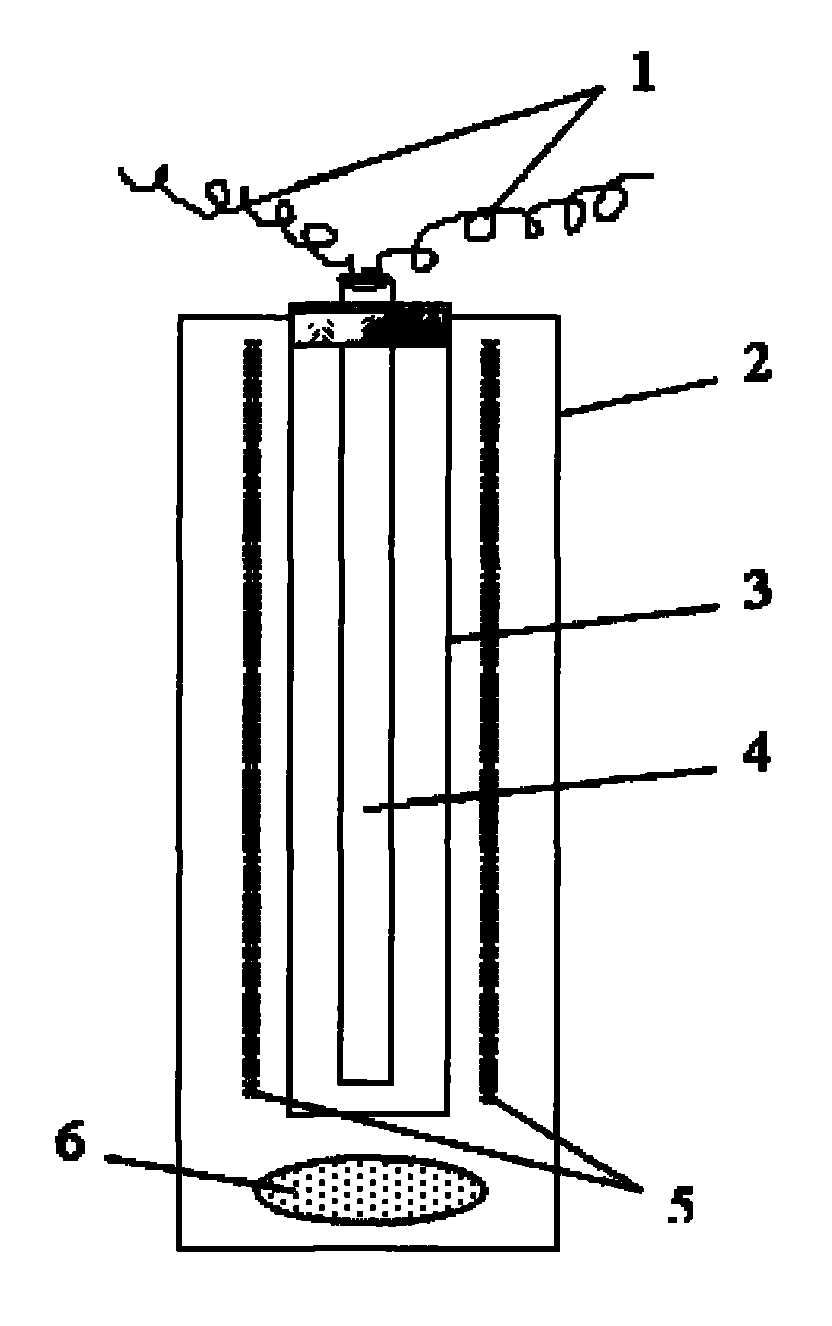

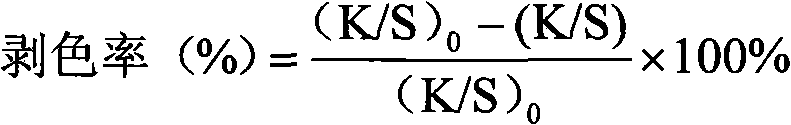

Stripping processing method of textile printing defective items

InactiveCN101787644AHas strong oxidizing propertiesReductiveBleaching apparatusDyeing processTextile printerUltraviolet lights

The invention discloses a stripping processing method of textile printing defective items, which implements stripping processing on printing defective items and particularly on dyeing defective items by using an active material which is generated by initiating and catalyzing an oxidant or a reducing agent under ultraviolet light and low temperature and has strong oxidability or reducibility as a stripping agent so as to be convenient for the rehandling or redyeing of textiles. Because of the adoption of various active materials which are generated by ultraviolet light initiation and optical catalysis as the stripping agent, the method can obtain an approving stripping effect under normal pressure and temperature, thereby avoiding the consumption of a large amount of energy sources in a traditional high-temperature stripping method and the use of a large amount of reducing agent, oxidant and the like. The stripping technology of the invention has the advantages of high efficiency, energy saving, emission reduction, simple equipment and process and short procedures.

Owner:SUZHOU UNIV

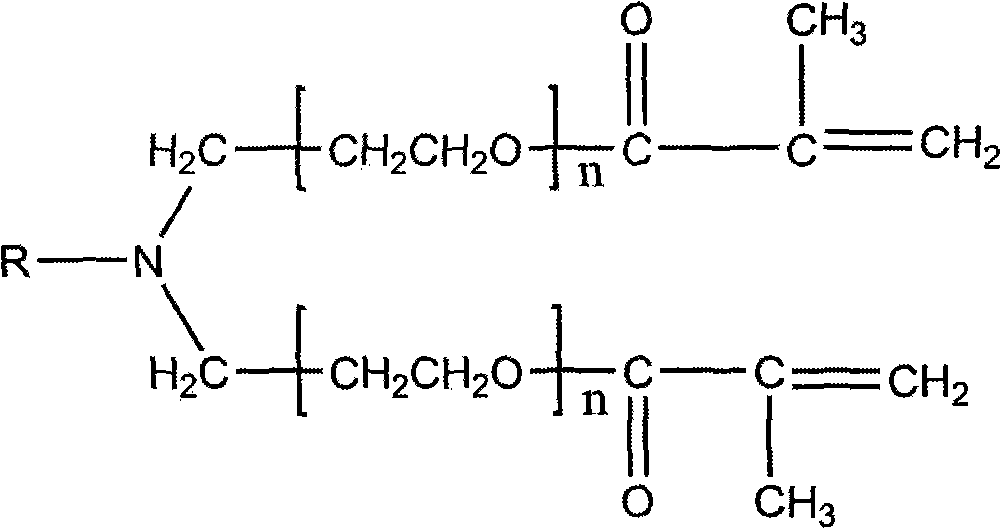

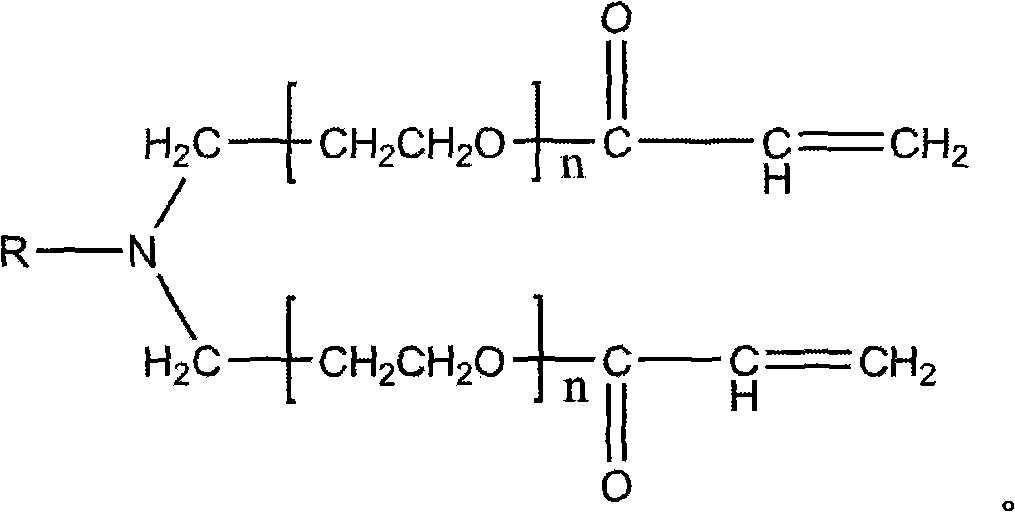

Thickening agent synthesized by acrylic ester and preparation method thereof

InactiveCN101619543AGood thickening effectStrong electrolyte resistanceOrganic compound preparationDyeing processTextile printerSodium methoxide

The invention discloses a preparation method for synthesizing a thickening agent by acrylic ester. The thickening agent synthesized by acrylic ester comprises crylic acid, acrylamide, 25 percent of ammonia water, a functional monomer, EDTA, deionized water, tasteless kerosene, 3<#> white oil, diallyl phthalate, ammonium persulphate, Span 80 and isomeric hexadecanol polyethenoxy ether, wherein the functional monomer is prepared from alicyclic amine polyethenoxy ether, methyl methacrylate, nitroxide free radical pipradrol and sodium methoxide. The preparation method synthesizes a special weak cation type (methyl) acrylic ester functional monomer by adopting an ester exchange method, and the functional monomer and vinyl monomers of the acrylic acid, the acrylamide, and the like are adopted to synthesize a textile printing thickening agent by adopting inverse emulsion polymerization. The thickening agent has the characteristics of high thickening capacity, strong electrolyte resistant capacity and good water-retaining property.

Owner:成都德美精英化工有限公司

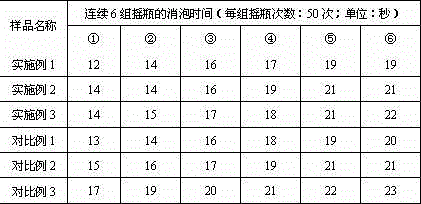

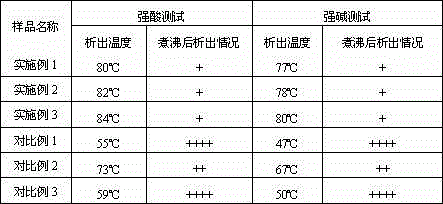

Preparation method of organic silicon defoaming agent used for textile printing and dyeing

ActiveCN103603215AImprove stabilityGood defoaming performanceDyeing processTextile printerPolymer science

The invention relates to a preparation method of an organic silicon defoaming agent used for textile printing and dyeing. By adding a catalyst, an organic silicon composition and polyether modified polysiloxane react under high temperature and strong shearing conditions, and the obtained organic silicon defoaming agent has excellent stability in strong acid-base systems, and also maintains excellent antifoaming and foam-suppresssing performance at the same time.

Owner:JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

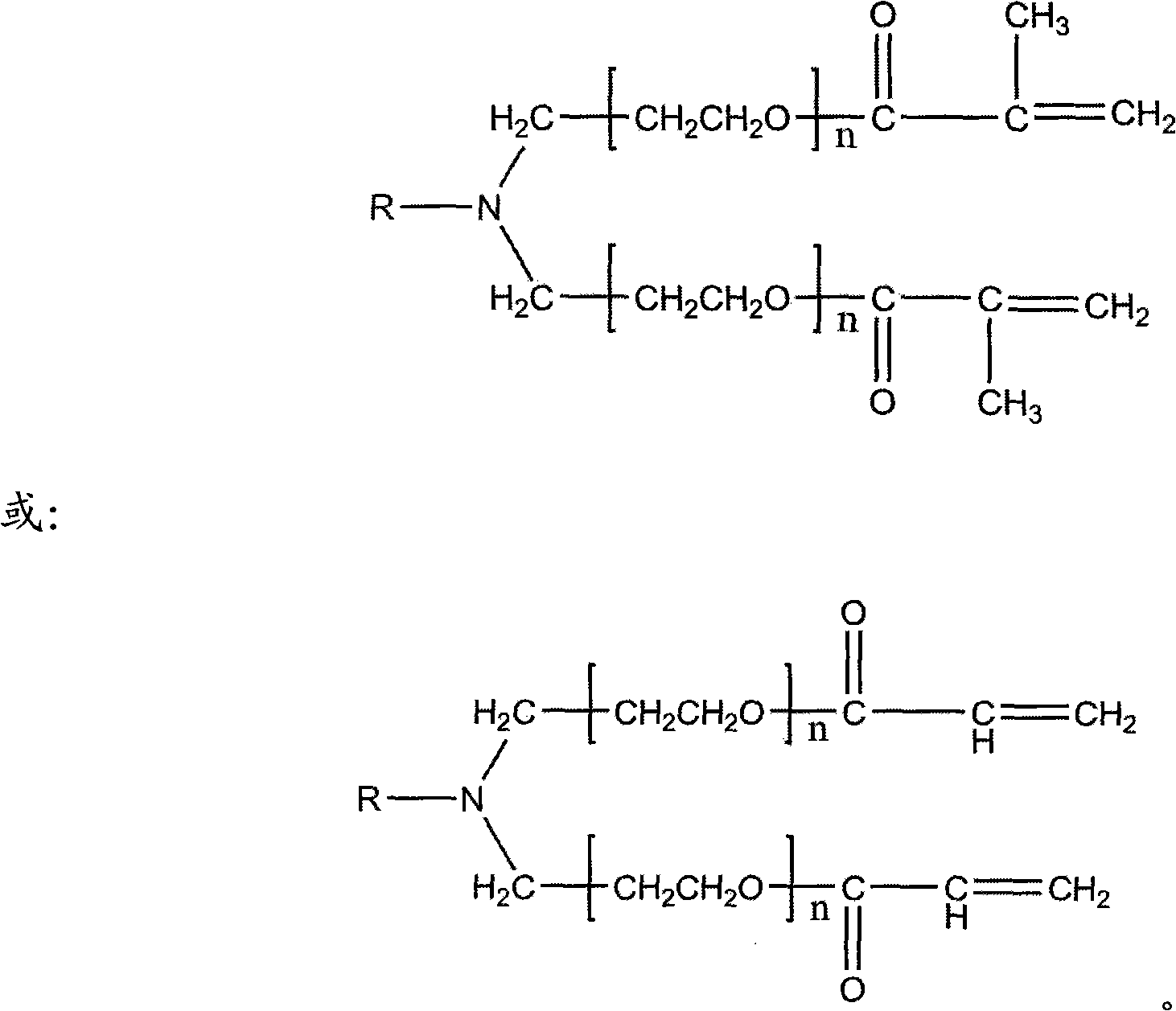

Method for inkjet textile printing

ActiveUS20140186533A1Avoid bleedingHigh densityDyeing processSpecial surfacesTextile fiberTextile printer

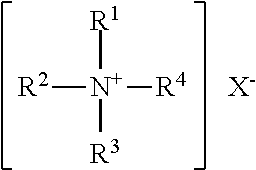

Method for inkjet textile printing comprising a printing step for printing an aqueous pigment ink on a specifically pretreated portion of a textile fiber product by an inkjet process,wherein said specific pretreatment is performed by applying at least:(A) a quaternary ammonium salt type cationic surfactant represented by the formula (1) below, and(B) a block isocyanate compoundto the entire textile fiber product or a required portion thereof,and said aqueous pigment ink comprises at least a pigment, an aqueous liquid as a solvent or dispersion medium, and:(C) a water-soluble dispersing agent having a crosslinking property,(D) a self-emulsifying type urethane resin, and(E) a block isocyanate compound.[Two of R1 to R4: alkyl having 8 to 18 carbon atoms; the remaining two: methyl or ethyl; X−: anion.]

Owner:MATSUI SHIKISO KAGAKU INDSHO

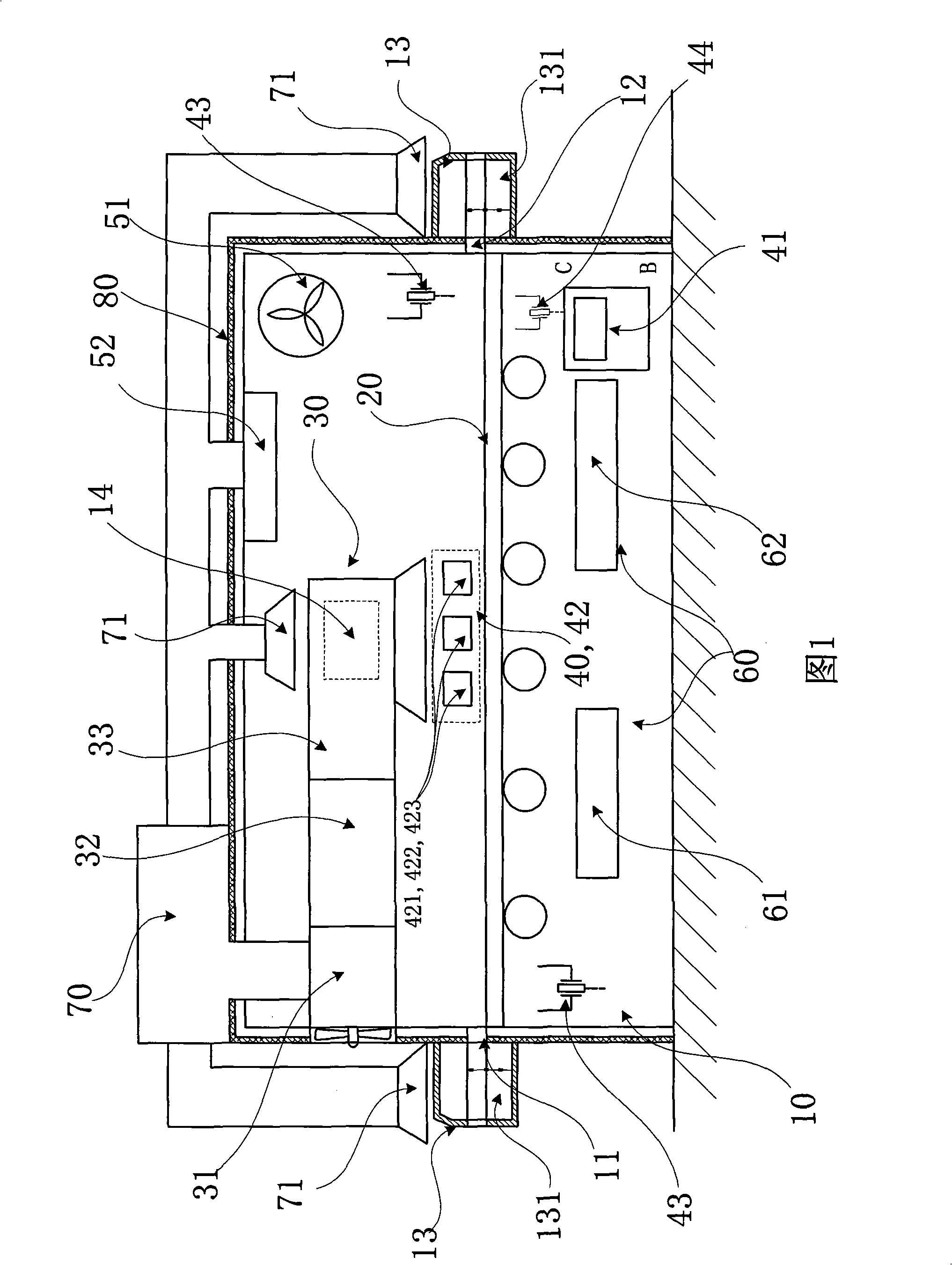

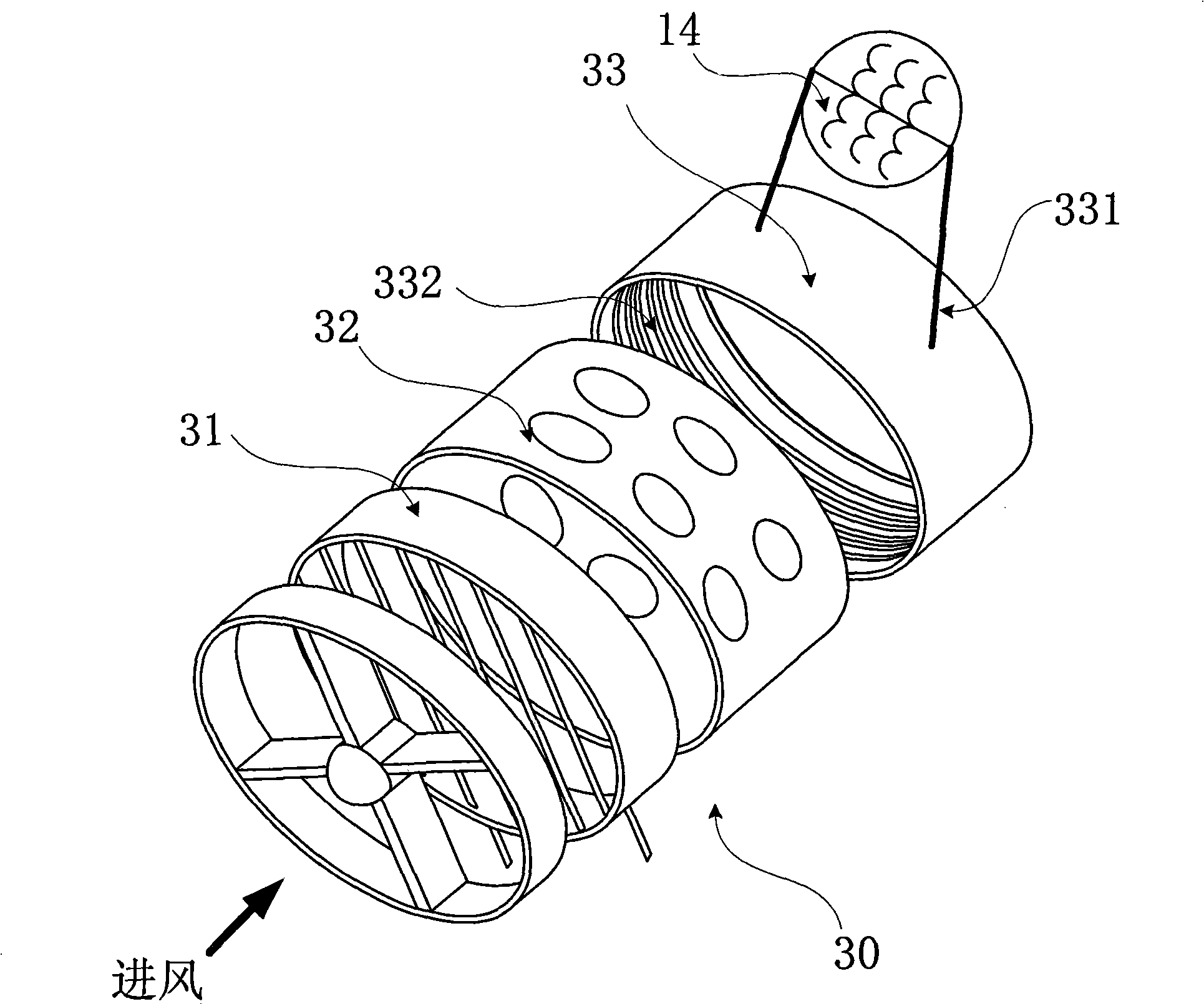

Drying apparatus of textile printing machine

InactiveCN101348032AImprove thermal efficiencySave electricityPrinting press partsTextile printerLow voltage

A drying device for a textile printing machine comprises a drying box body (10), a material transmission device (20), a main heating device (30), a control system (40) and an air supply system (50); wherein, the main heating device (30) comprises a heat pump heating unit (31), an electromagnetic wave heating unit (32) and a low-voltage heating unit (33), which are respectively responsible for the heat supply of the areas of 0-80 DEG C, 80-120 DEG C and above 120 DEG C; the voltage of low-voltage heating is not larger than 80V. Furthermore, the drying device further comprises a waste heat recovery device (70) and an insulating layer (80). After adopting the technical proposal, the novel drying device is characterized by high heat efficiency, electric energy saving and small heat loss and has the advantages of reducing production cost and protecting the environment.

Owner:杨栋 +1

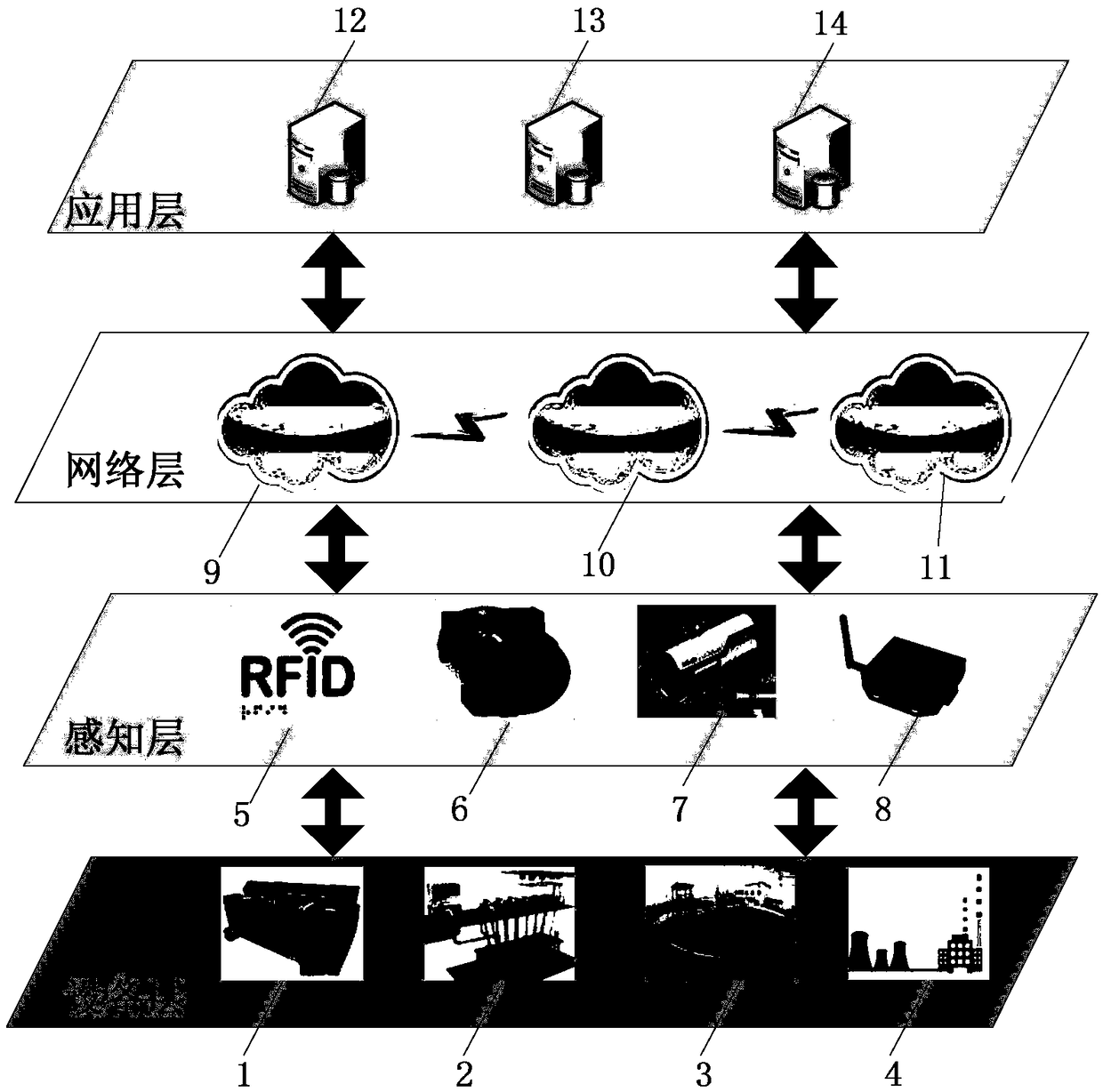

A system architecture of a digital factory in the textile printing and dyeing industry

InactiveCN109003038AImprove practicalityRealize vertical interconnectionParticular environment based servicesCo-operative working arrangementsTextile printerData information

The invention discloses an overall structure of a digital factory in the textile printing and dyeing industry, comprising a device layer, a sensing layer, a network layer and an application layer, wherein the device layer is in signal connection with the sensing layer, the sensing layer is in signal connecrtion with the network layer, and the network layer is in signal connection with the application layer. The device layer is used for carrying out concrete actual production and production-related processes of a textile printing and dyeing factory; the sensing layer is used for realizing the acquisition of the production and production-related data information of the textile printing and dyeing equipment corresponding to the device layer. The network layer is used for realizing the transmission of the information obtained by the sensing layer. The application layer establishes a corresponding database according to the collected information, and is used for realizing the functions of supply chain analysis and optimization, equipment and system fault diagnosis and prediction, quality management and analysis, production planning and scheduling, etc. Through the implementation of the industrial internet of things, the invention realizes the overall interconnected wireless coverage of the production equipment, realizes the mobility and paperlessness, and creates the intelligent manufacturing basic environment of Anytime, Anywhere and Anydivision.

Owner:SHENYANG INST OF AUTOMATION GUANGZHOU CHINESE ACAD OF SCI +1

Low-temperature soaping agent as well as preparation method and application thereof

ActiveCN102660404AAvoid stainsHas anti-scaling effectOrganic non-surface-active detergent compositionsDyeing processTextile printerSodium acetate

The invention relates to the technical field of textile printing and dyeing and provides a low-temperature soaping agent. The low-temperature soaping agent can soap surface dyeing of a dyed object at a lower temperature (60 DEG C), is not easy to foam, can chelate metal ions, has stronger combined dyeing capability and effectively prevents from staining. Meanwhile, the invention further provides a method for preparing the low-temperature soaping agent and an application of the low-temperature soaping agent. The low-temperature soaping agent is prepared from the following components in percentage by weight: 50-75% of maleic-acrylic copolymer, 5-15% of a surfactant, 0.1-0.5% of a de-foaming agent, 1-5% of ethanediamine di-o-hydroxyphenyl sodium acetate and the balance of de-ionized water.

Owner:冠宏股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com