High-salt-content dyeing wastewater treatment recovery zero discharge integration method

A printing and dyeing wastewater and integrated method technology, which is applied in textile industry wastewater treatment, multi-stage water treatment, water/sewage treatment, etc., can solve problems such as unified standards, prevent harmful gas emissions, overcome biochemical treatment difficulties, and improve overall sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

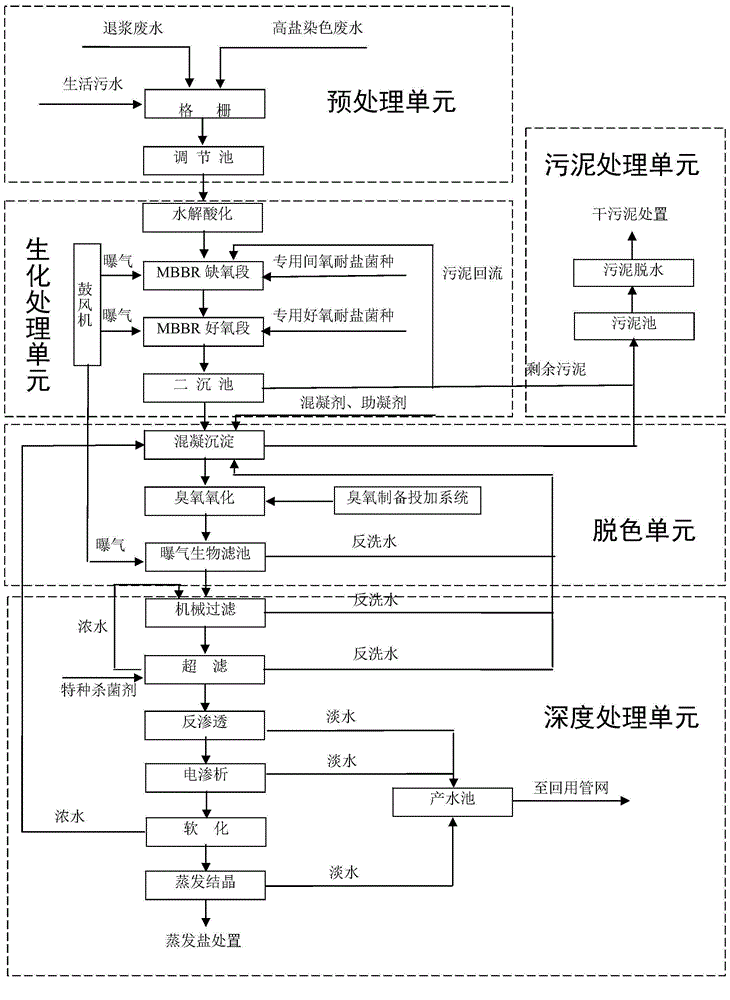

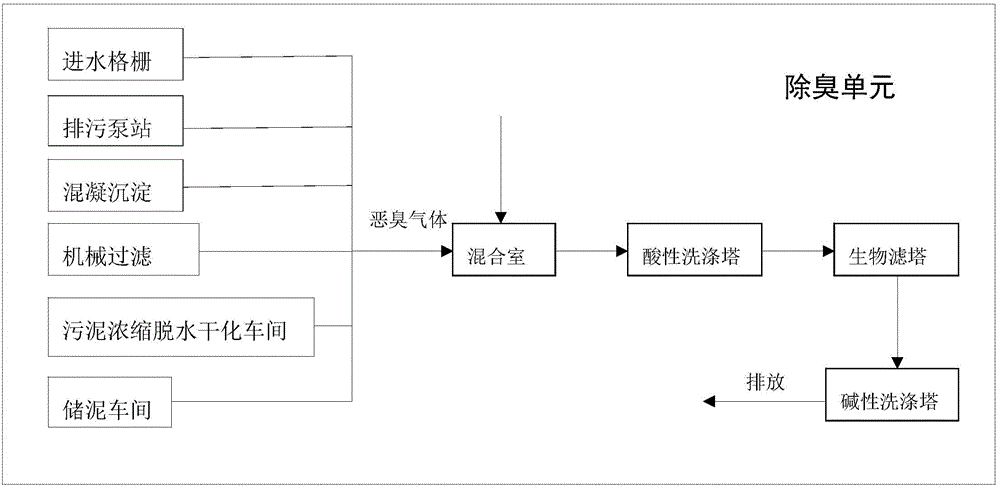

[0017] Example 1. High-salt printing and dyeing wastewater treatment reuse zero-discharge integrated method, such as figure 1 and figure 2 As shown, the integrated method is composed of six units: pretreatment unit, biochemical treatment unit, decolorization unit, advanced treatment unit, sludge treatment unit and deodorization unit:

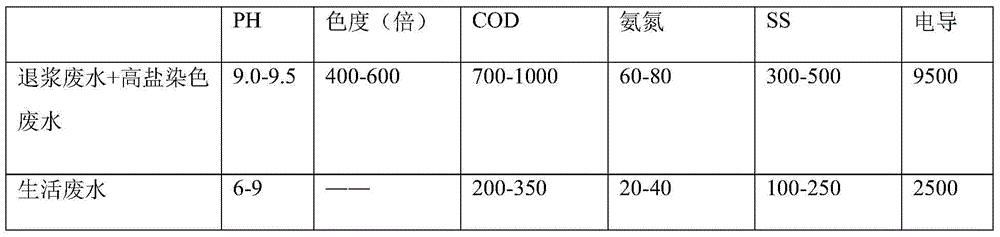

[0018] 1. Pretreatment unit: After the desizing wastewater from printing and dyeing enterprises is mixed with the dyeing wastewater with a salt content of more than 4000 mg / L, the solid particle impurities are removed through the grid, and then enters the regulating tank; the domestic sewage is also injected after the solid impurities are removed through the grid Adjusting tank: In the adjusting tank, domestic sewage, desizing wastewater and high-salt dyeing wastewater are mixed in equal proportions to form comprehensive wastewater;

[0019]2. Biochemical treatment unit: carry out hydrolysis and acidification to the comprehensive wastewater fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com