Patents

Literature

151results about How to "Guaranteed removal rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multi-mode sequencing batch active sludge sewage treatment method and system

ActiveCN102502963AIncrease concentrationImprove phosphorus removal effectTreatment with aerobic and anaerobic processesAnaerobic aerobicNitrogen

The invention relates to a multi-mode constant-water-level sequencing batch active sludge sewage treatment method and system, belonging to the technical field of sewage treatment. The system comprises a sludge concentration pre-anoxic pond, an anaerobic pond, an anoxic pond, an aerobic pond, a facultative pond and a sequencing batch pond which are communicated, wherein the facultative pond runs in an aerobic or anoxic way. According to the system, multi-mode sewage treatment ways including an anaerobic-anoxic-aerobic mode, an anoxic-anaerobic-aerobic mode and an anaerobic-anoxic-aerobic-anoxic-aerobic mode can be performed. Due to the adoption of the sewage treatment method, the removing effects of nitrogen, phosphorus and organic matters can be enhanced, and equipment utilization ratio is increased.

Owner:THUNIP CORP LTD

Struvite circulating crystallization method for treating synthetic ammonia wastewater

InactiveCN102336504AReduce processing costsGuaranteed removal rateBio-organic fraction processingMultistage water/sewage treatmentMagnesium saltRaw material

The invention relates to a struvite circulating crystallization method for treating synthetic ammonia wastewater. The method comprises the following steps of: A, adding soluble phosphate and magnesium salt into the synthetic ammonia wastewater at the ammonium nitrogen concentration of 1,000-2,065mg / L; B, adding alkali into the acquired struvite solid, and performing pyrolysis at the temperature of between 80 and 100DEG C for 1 to 3 hours; C, treating the synthetic ammonia wastewater by using a pyrolysis solid product, and adding a small amount of magnesium salt, wherein ammonia generated in the pyrolysis process is absorbed by a dilute acid solution, and the obtained ammonium salt is used as a raw material for producing a fertilizer; and D, using struvite which cannot be recycled as a sustained-release fertilizer. For the synthetic ammonia wastewater at the ammonium nitrogen concentration of 1,000-2,065mg / L, the struvite can be recycled for 3 to 6 times, the ammonia nitrogen removal rate is higher than 87 percent, the ammonium nitrogen concentration of effluent is lower than 200mg / L, agents are saved through recycle, and nitrogen resources are recycled. The pretreated wastewater meets the requirement of an A / O biochemical treatment process on nitrogen and phosphorus, and can be subjected to biochemical treatment further.

Owner:TONGJI UNIV

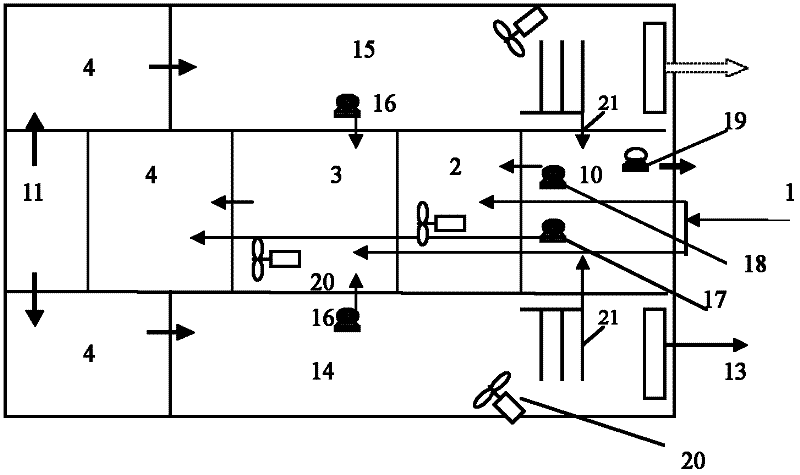

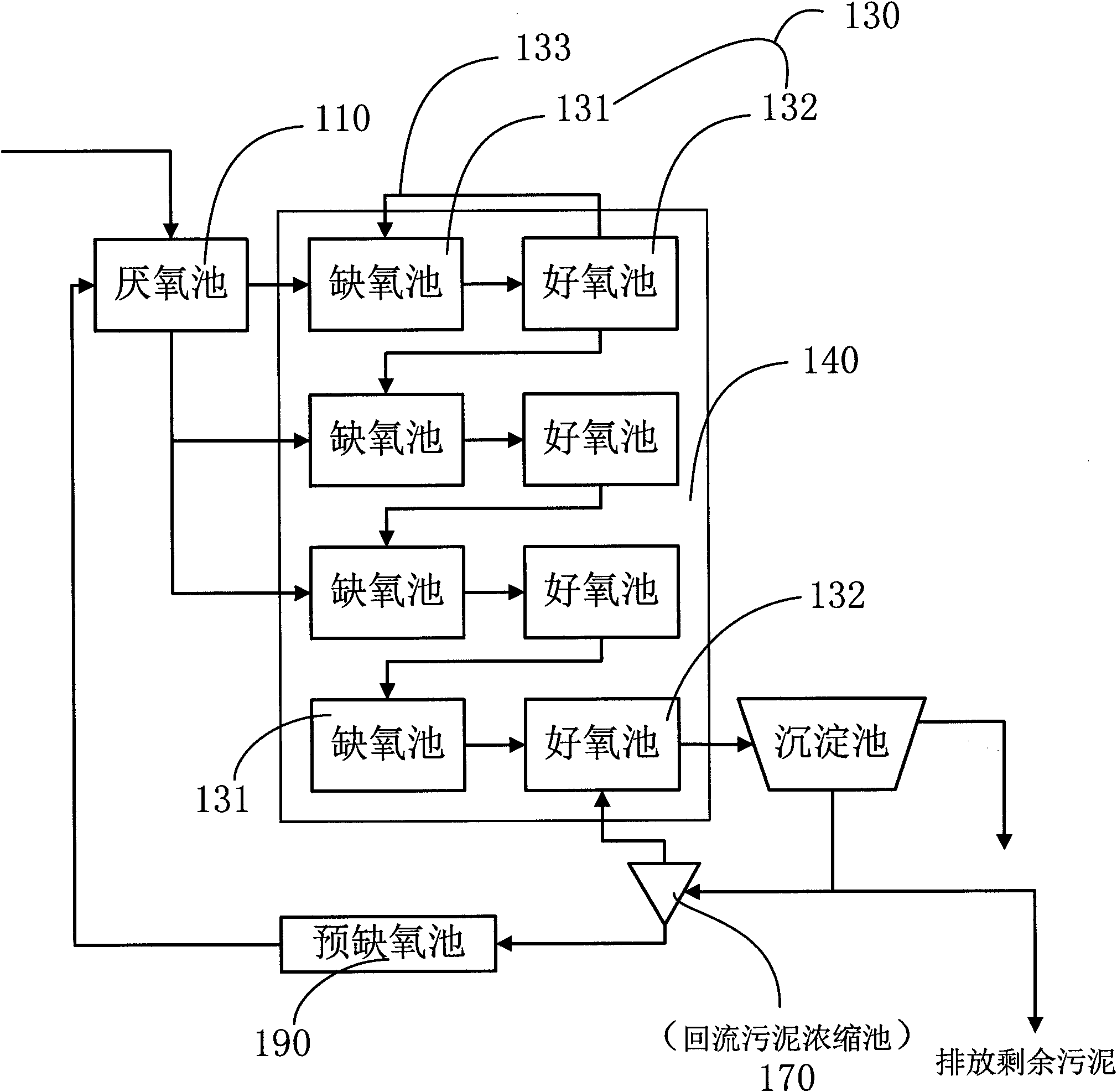

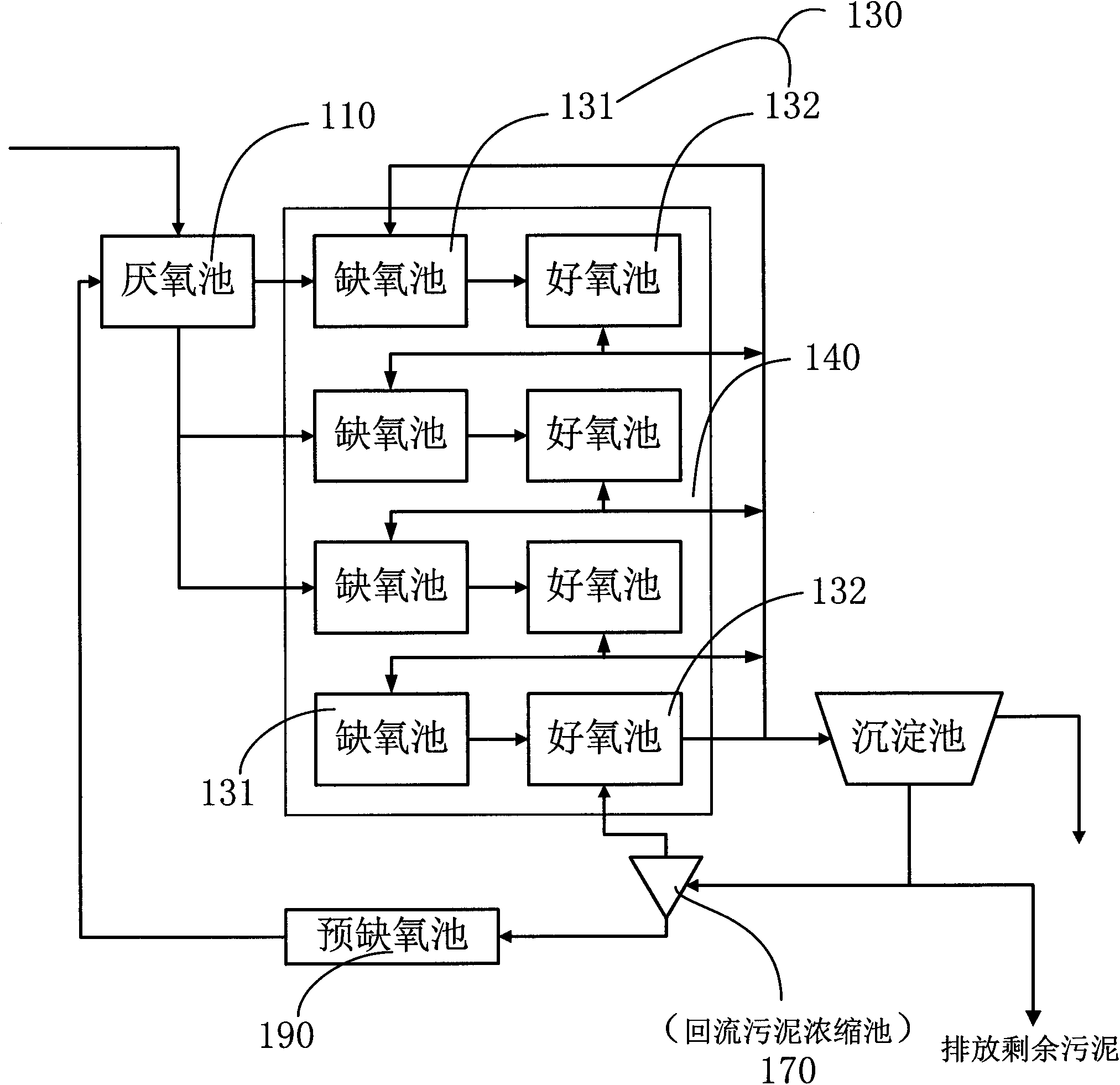

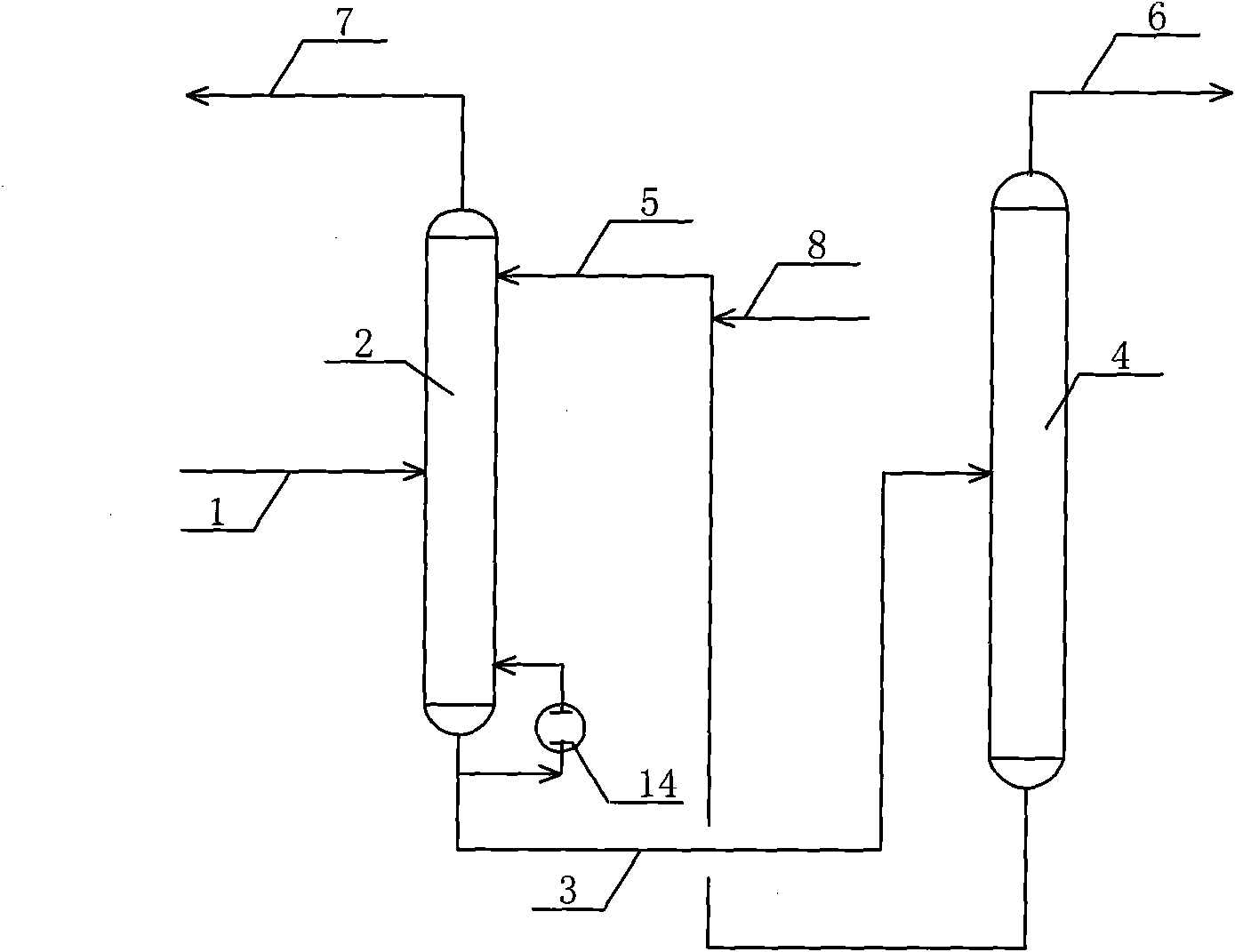

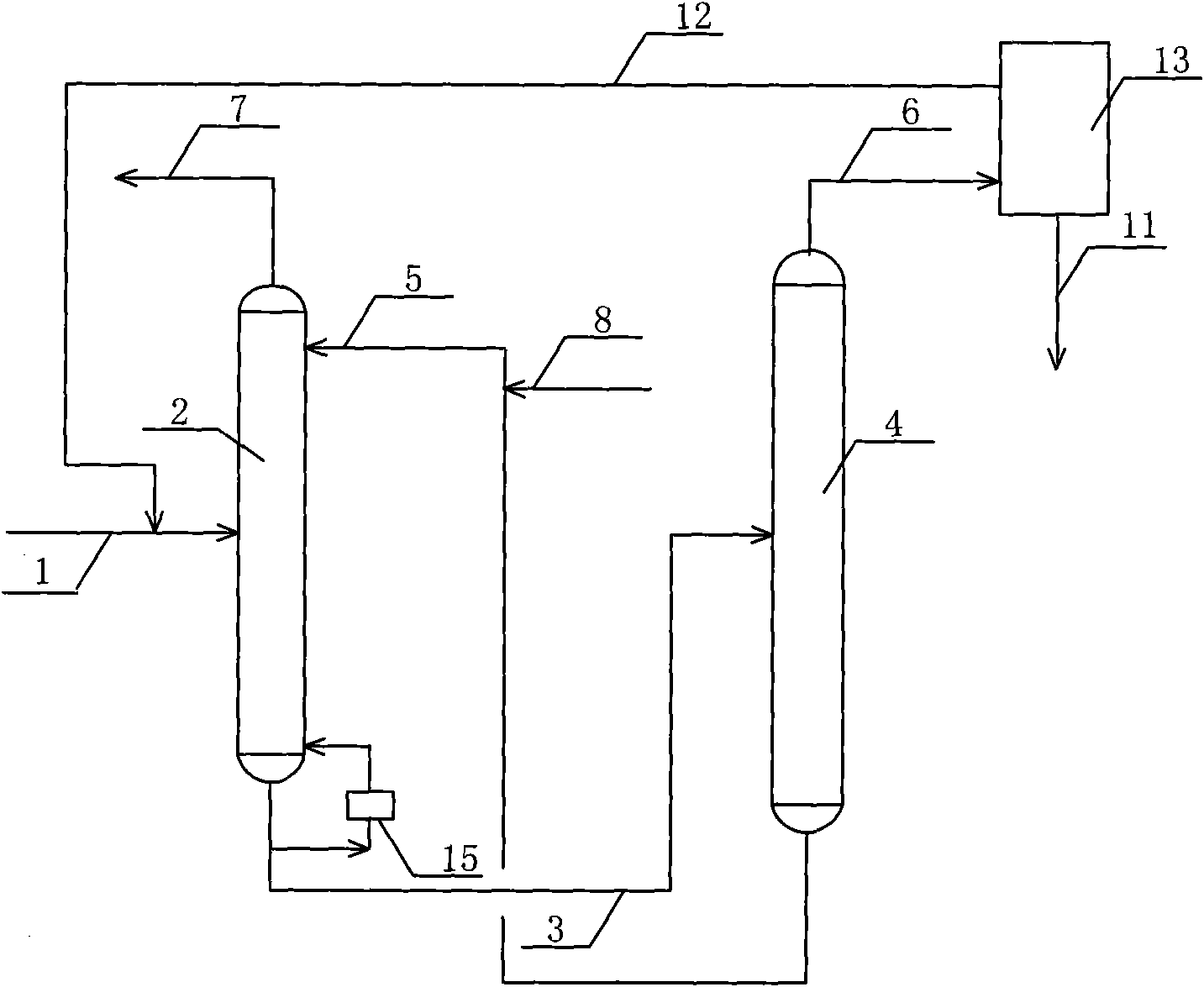

Multi-level biological nitrogen and phosphorus removal sewage treatment method and device

InactiveCN101885559AImprove filtration efficiencyReduce dilutionMultistage water/sewage treatmentBiological water/sewage treatmentSludgeNitrogen

The invention discloses a multi-level biological nitrogen and phosphorus removal sewage treatment method. The method comprises the following steps of: introducing sewage into an anaerobic pond; introducing the sewage treated in the anaerobic pond into an anoxic pond at the front section of an anoxic-aerobic treatment unit; draining all sewage into a settling pond through an aerobic pond of the last level; draining the settled sludge into a returned sludge concentration pond; draining supernatant in the returned sludge concentration pond into the aerobic pond of the last level; and draining the sludge in the returned sludge concentration pond into the initial anaerobic pond through a pre-anoxic pond for circular treatment. The invention also provides a corresponding treatment device. The method and the device have the advantages of only adding the returned sludge concentration pond and the pre-anoxic pond compared with the A2O process in the prior art and improving the reaction efficiency by adjusting the connection relationship among the reaction ponds.

Owner:CORSTAR ENVIRONMENTAL EQUIP SHANGHAI

Method for complex-precipitation aluminum removal in rare earth solution

ActiveCN105624440AReduce concentrationLow equipment requirementsProcess efficiency improvementChemistryHydroxyquinolines

The invention relates to a production method for removing aluminum (Al<3+>) and purifying rare earth from a rare earth solution and belongs to the field of rare earth hydrometallurgy and chemistry. The method comprises the following steps that (1) raw materials are prepared, the pH value of the rare earth solution is smaller than or equal to 3, the concentration of REO is 20 g / L-300 g / L, and the concentration of Al2O3 is 0.8 g / L-3 g / L; a complex precipitant is one of hydroxyquinoline or ramifications of the hydroxyquinoline; and (2) precipitation aluminum removal is conducted, the complex precipitant is added into the rare earth solution prepared in the step (1), stirring is conducted at the constant temperature, a reaction is conducted, the pH value of the solution is adjusted, precipitation is conducted, and aluminum-removed rare earth liquid is obtained through vacuum filtration and separation. According to the production method, the rare earth solution containing a large quantity of aluminum ions is treated through the hydroxyquinoline or the ramifications of the hydroxyquinoline, the aluminum ions can be removed from the rare earth solution, the effect that the aluminum ion removal rate reaches 90% or above is guaranteed, the rare earth loss ratio is not larger than 5%, and the aluminum ion concentration in the rare earth solution is greatly decreased.

Owner:JIANGXI UNIV OF SCI & TECH

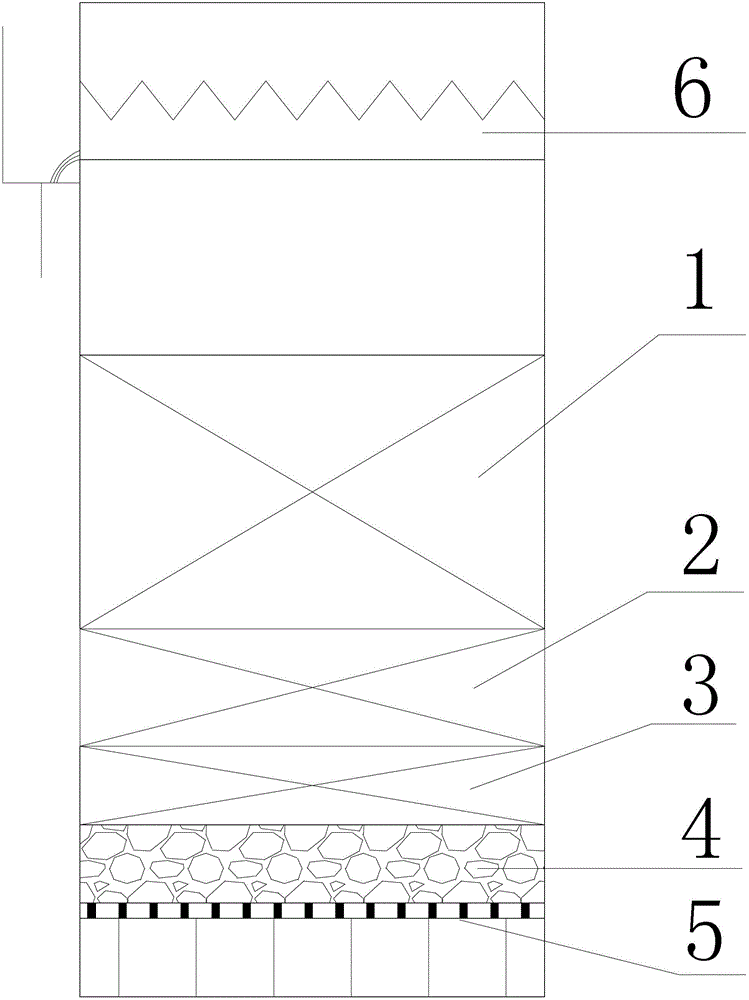

High efficiency fluidization upward flow multilayer composite filter material biological filter tank coupled with ozonation and water treatment method thereof

InactiveCN102745863AGuaranteed removal rateGuarantee the water qualityMultistage water/sewage treatmentBiomassFilter material

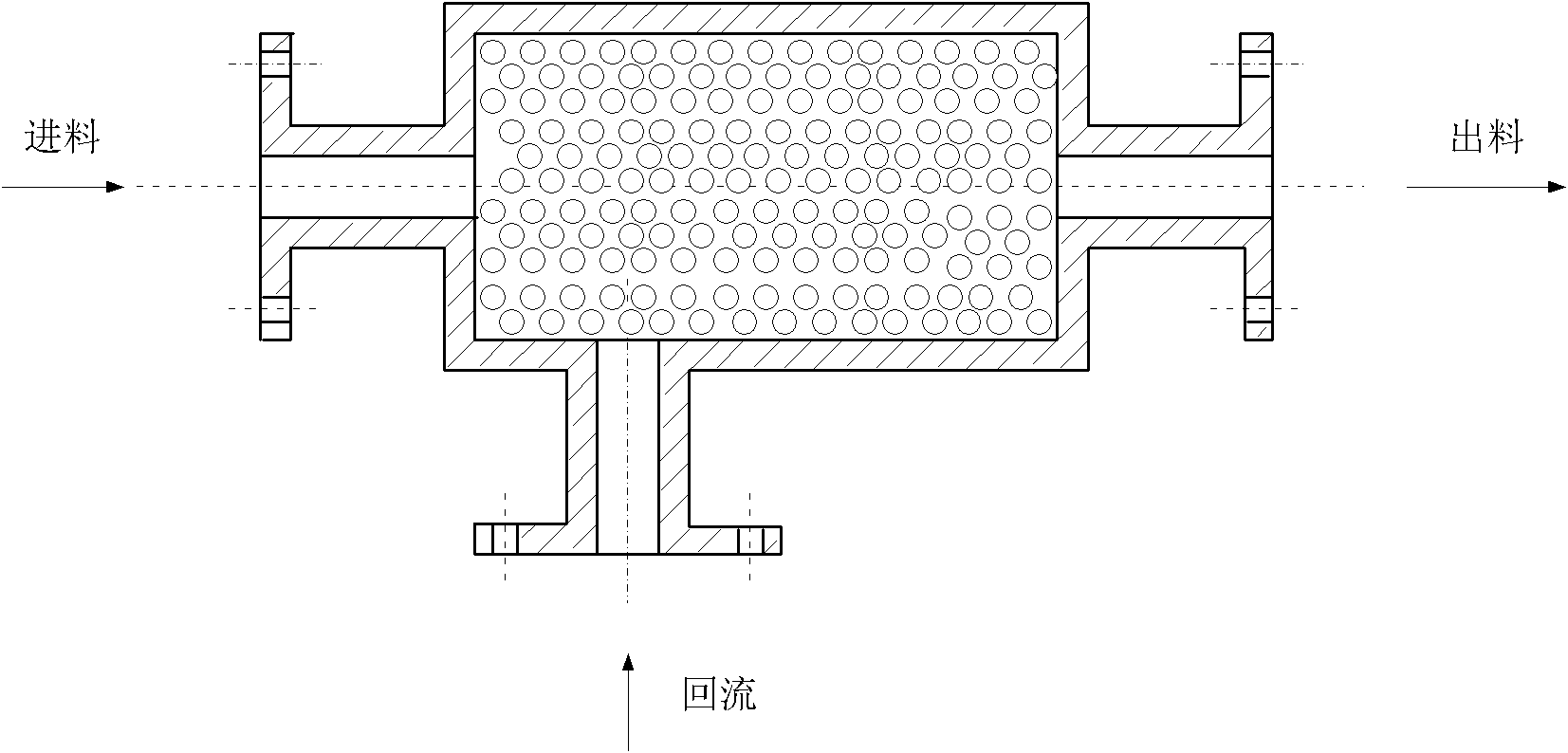

The invention provides a high efficiency fluidization upward flow multilayer composite filter material biological filter tank coupled with ozonation and a water treatment method thereof, relating to a biological filter tank and a water treatment method using the biological filter tank. The biological filter tank is composed of an upper filter material, a medium filter material, a lower filter material and a supporting layer, wherein the upper filter material is active carbon, anthracite or biological ceramsite, the medium filter material is modified zeolite, natural zeolite or synthetic zeolite and the lower filter material is a phosphorus functional material. The filter tank is characterized by fast start, a complex and stable biological phase, great biomass, high activity, strong impact resistance, a filter material expansion rate of 0% to 50%, small resistance at the head of the filter tank, high mass transfer efficiency of materials, oxygen and pollutants, a high utilization rate of filter layers and filter materials and small possibility of occurrence of hardening of the filtering materials. The filter tank is applicable to treatment of raw water in which the concentration of water source phosphorus, ammonia nitrogen and organic pollutants fluctuates and can stably operate at a low temperature.

Owner:HARBIN INST OF TECH

Preparation method of high-flux composite polyamide reverse osmosis membrane

ActiveCN109173741AGood water permeabilityGuaranteed removal rateMembranesReverse osmosisReverse osmosisPolyethylene glycol

The invention relates to a preparation method of a high-flux composite polyamide reverse osmosis membrane. The preparation method comprises the following steps: (1) preparing a polysulfone support base membrane: dissolving polysulfone and a hydrophilic substance in a polar solvent according to a certain ratio in order to obtain a mixed solution, filtering the obtained solution after the polysulfone is completely dissolved, defoaming the obtained filtrate at a predetermined temperature for a predetermined time, uniformly coating a nonwoven fabric, used as a support base material, with the obtained defoamed polysulfone solution, performing solidifying treatment, and repeatedly rinsing the solidified polysulfone support base membrane with deionized water, wherein the mass concentration of polysulfone in the mixed solution is 14-17%, the hydrophilic substance is polyethylene glycol or polyvinylpyrrolidone, and the mass concentration of the hydrophilic substance is 0.1-1%; and (2) coating with an aqueous phase solution; and (3) coating with an oil phase solution. The flux of the reverse osmosis membrane prepared by the method is increased, so the working efficiency and the working ability are improved, and the removal rate of sodium chloride is ensured; and the preparation method has the advantages of simplicity in operation, cost saving, and easiness in application to commercial large-scale production.

Owner:HUNAN KEENSEN TECH CO LTD

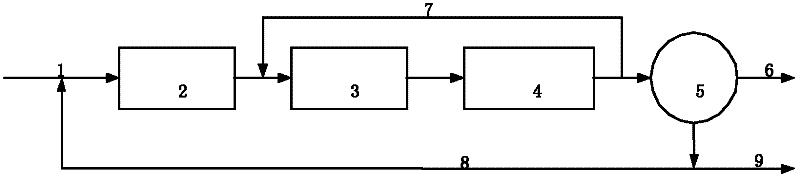

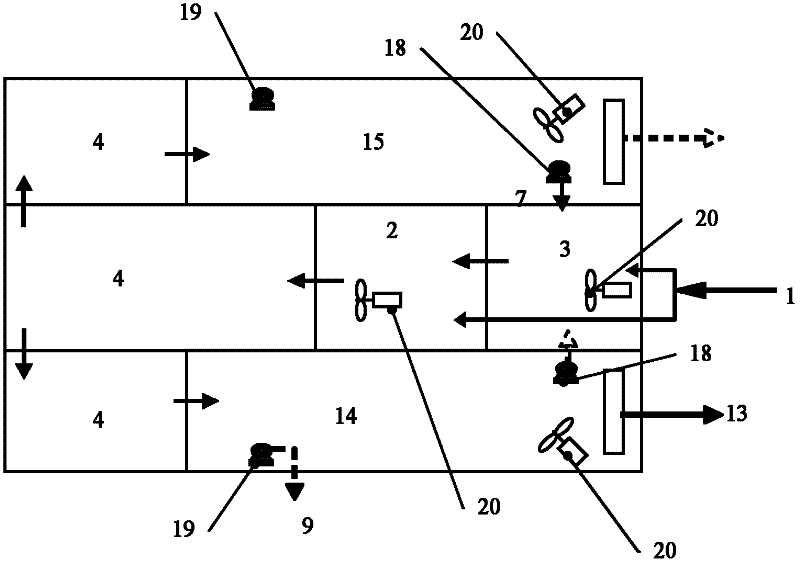

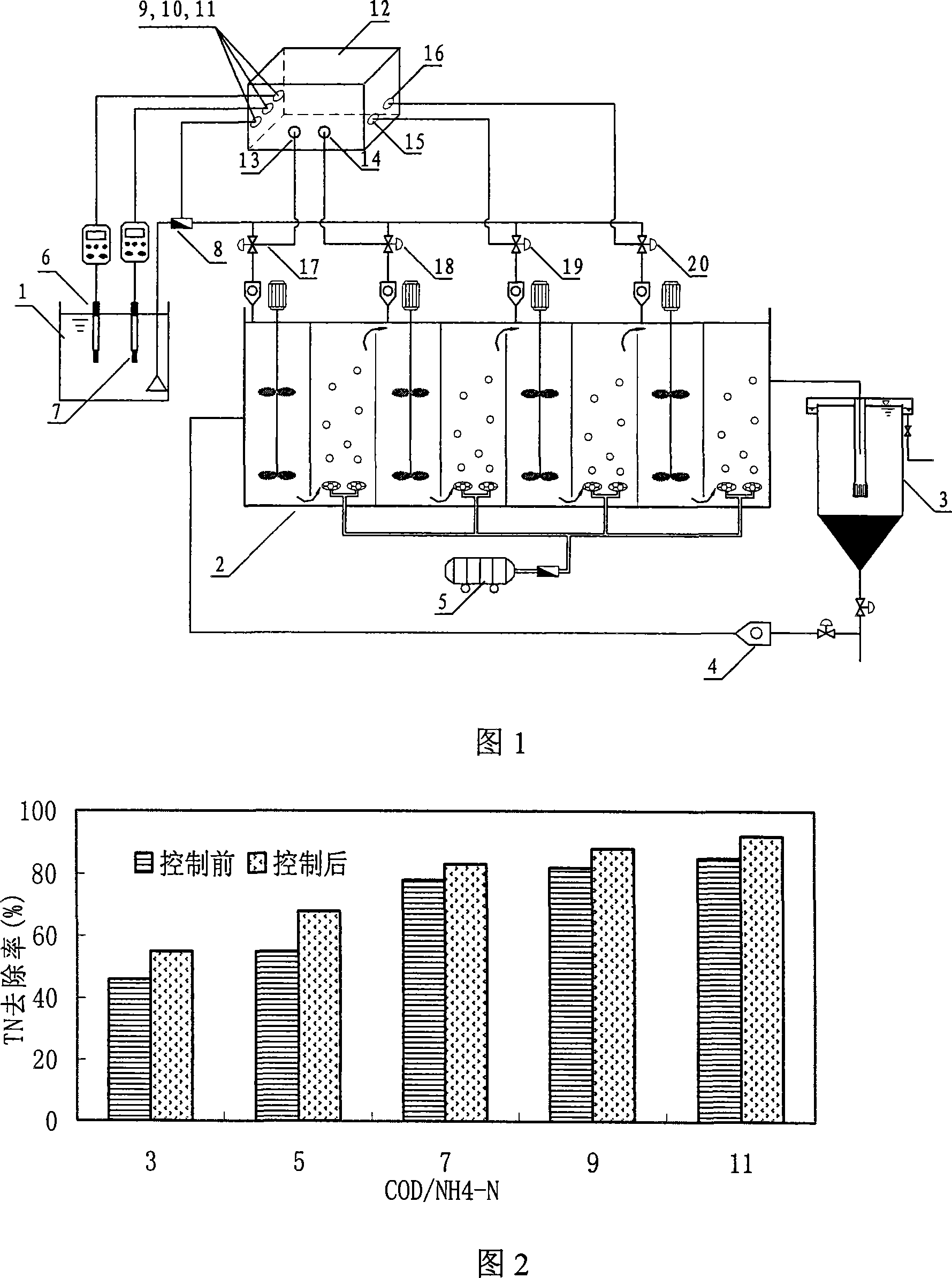

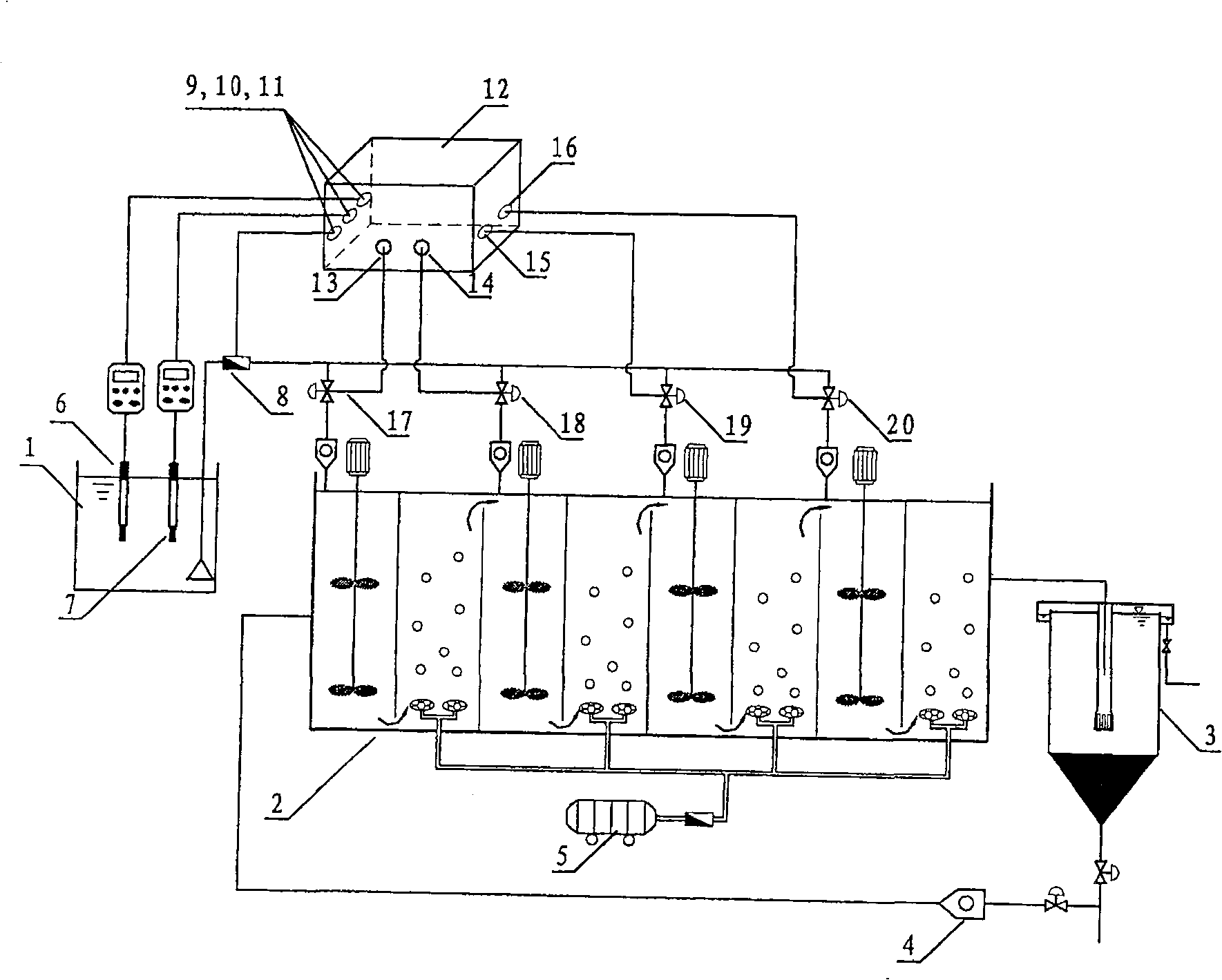

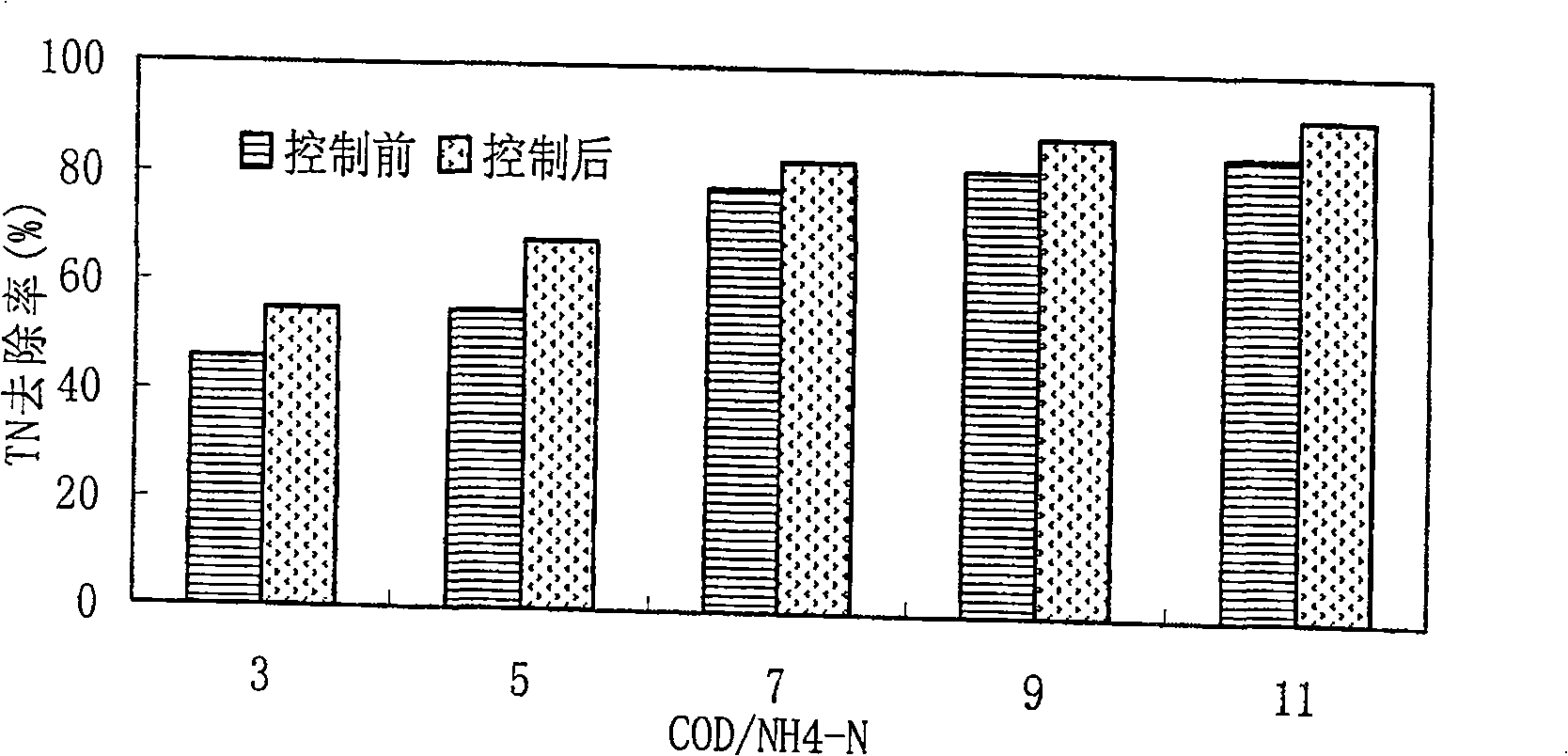

Control device and method for four-section water-feeding A/O technique water-feeding flow rate distribution process

ActiveCN101143750AGuaranteed removal rateAdjust the distribution ratio in real timeSustainable biological treatmentBiological water/sewage treatmentActivated sludgeDistribution control

A control device and method for the influent flow distribution of the four-step water intake A / O process belongs to a sewage treatment system area by using an activated sludge method. The operation of a prior step feed process can not optimize the flow distribution according to the influent quality; the system can not fully utilize the nitrification and denitrification capacity of each step, and the carbon source in the influent can not be fully utilized during the denitrification process; the operation cost of the prior step feed process is high with a poor processing effect. The control device and method for the influent flow distribution of the four-step water intake A / O process of the invention inputs the on line collected ammonia nitrogen and COD signals into an influent flow distribution controller; the output of the flow regulation signal acts on a frequency conversion speed governor of a water intake pump of each step after the rule and algorithm, and regulates the influent flow distribution of the system of each step. The invention can improve the nitrification and denitrification effect of the step feed process and fully utilizes the carbon source in the influent during the denitrification process. The operation cost of the invention is low with good effluent effects and a simple control structure. The invention is easy to be realized.

Owner:BEIJING UNIV OF TECH

Maize straw charcoal, method for utilizing maize straw charcoal to remove triclosan from water and application

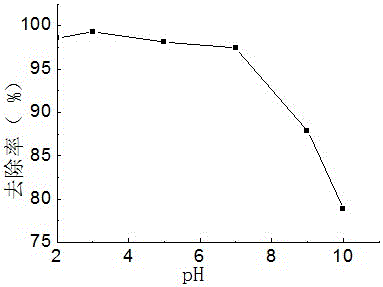

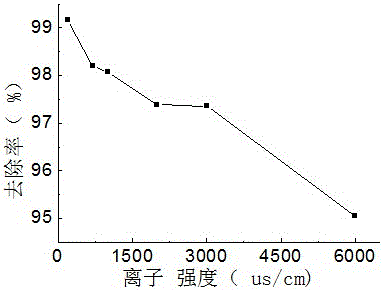

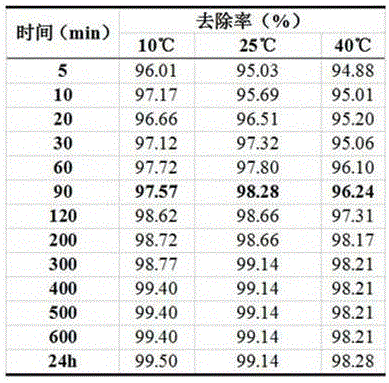

InactiveCN105854810AGuaranteed removal rateEmbody economyOther chemical processesWater contaminantsTriclosanResource utilization

The invention relates to a maize straw charcoal, a method for utilizing the maize straw charcoal to remove triclosan from water and application. The maize straw charcoal is prepared according to the following steps: (1) drying and smashing; (2) anaerobically carbonizing for 120-180min by adopting temperature programming under the condition of 500-700 DEG C; (3) cooling in a furnace to room temperature; and (4) soaking in hydrochloric acid, washing with deionized water till the eluate is neutral, drying till constant weight is achieved, grinding and filtering through a 60-mesh sieve. The maize straw charcoal is taken as an absorbent and is put into the triclosan-containing water for absorbing and removing triclosan, so that the problem of difficulty of treating the antibiotics in water is solved. The environment problem caused by the burning of straws is also solved, the wastes are turned into wealth, the resource utilization of maize straw is realized and the maize straw charcoal has high economic benefit and social benefit.

Owner:SOUTH CHINA INST OF ENVIRONMENTAL SCI MEP

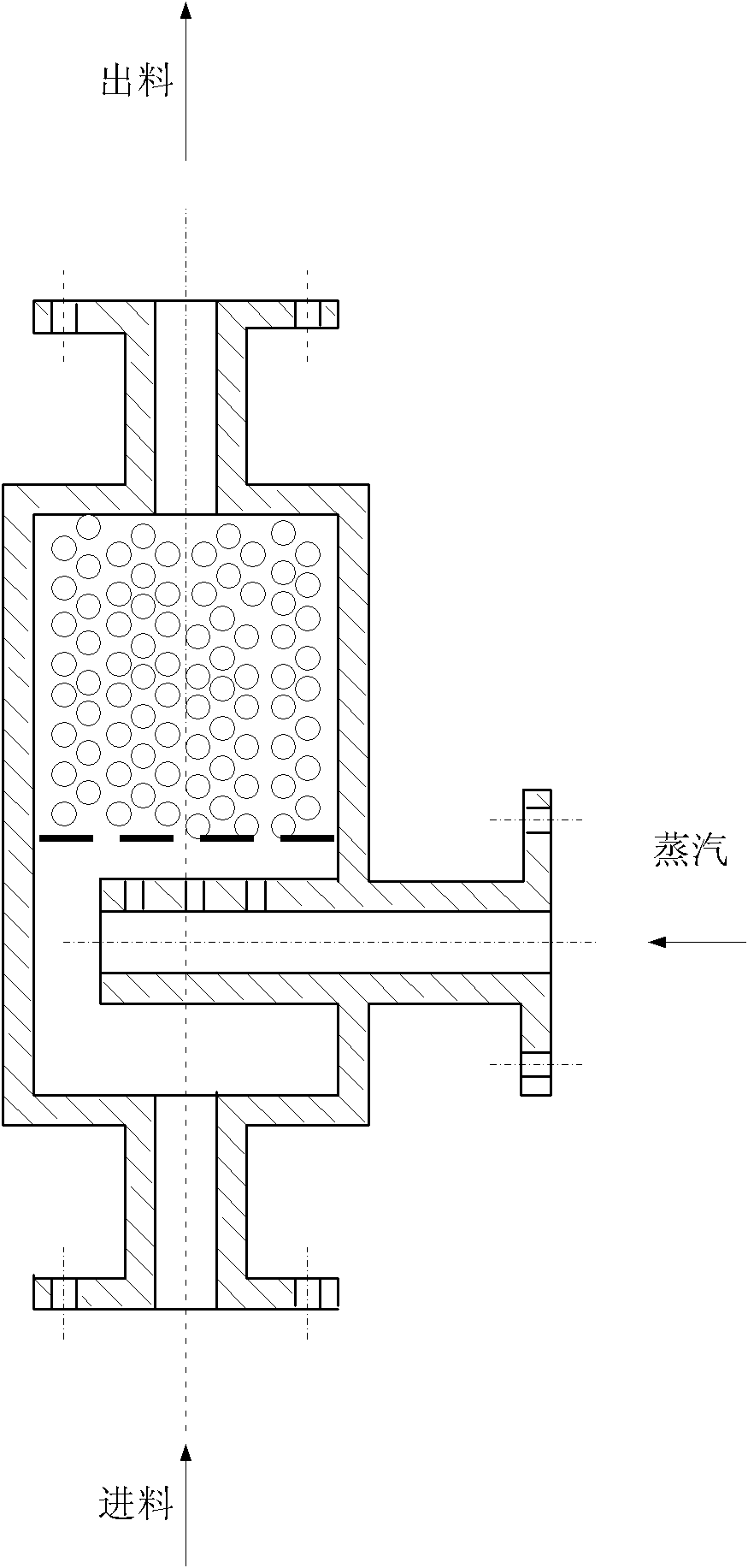

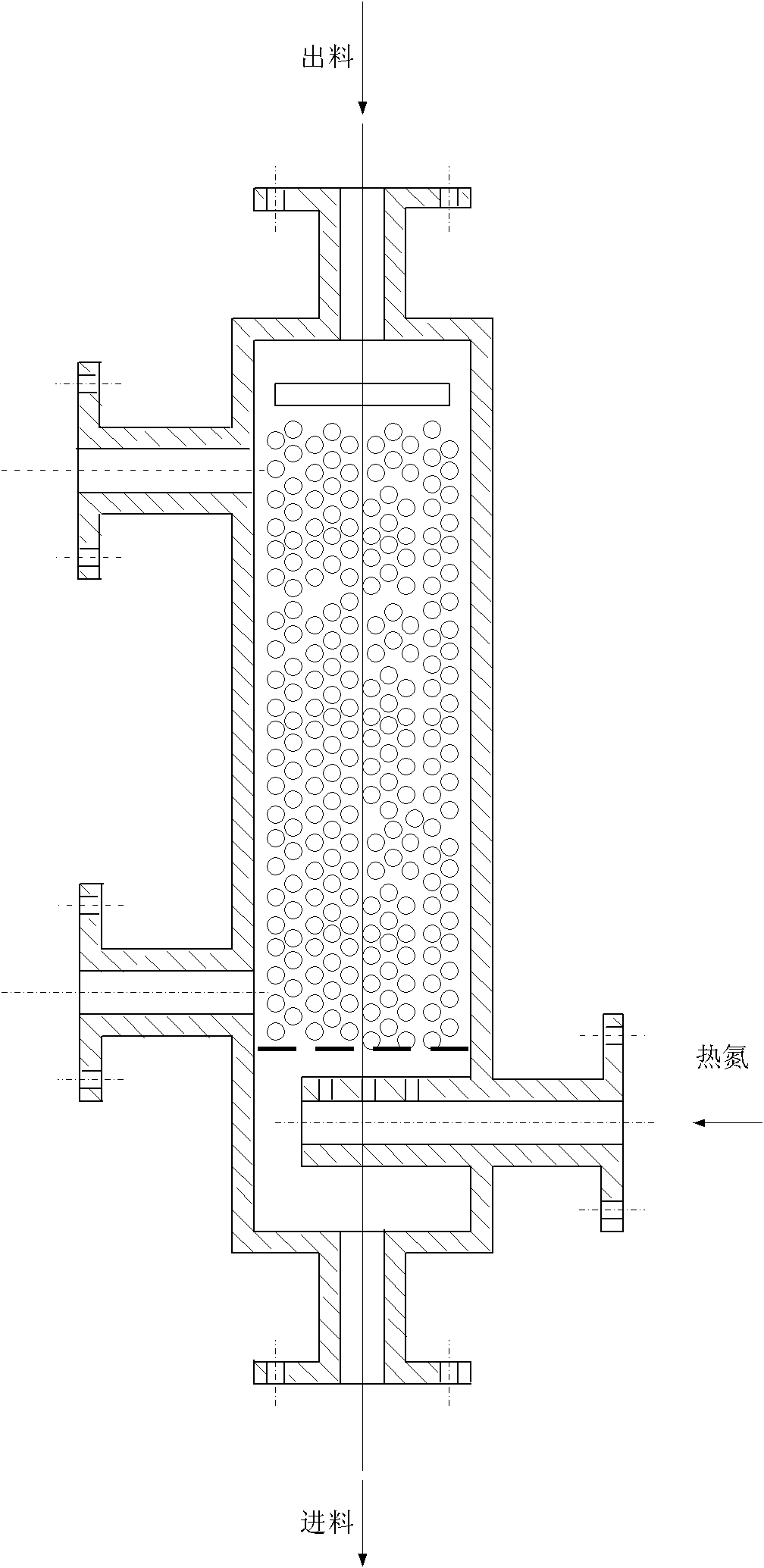

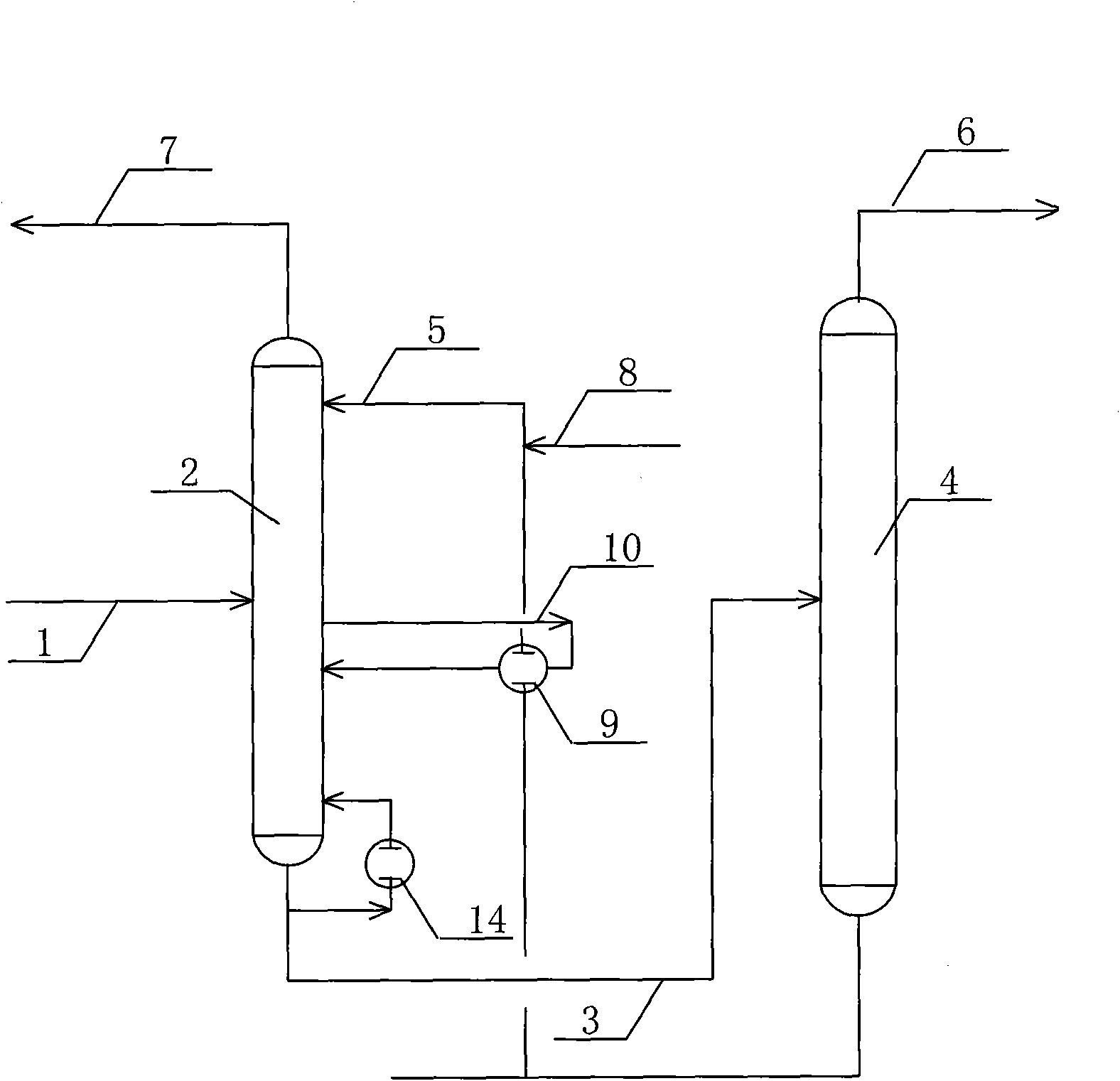

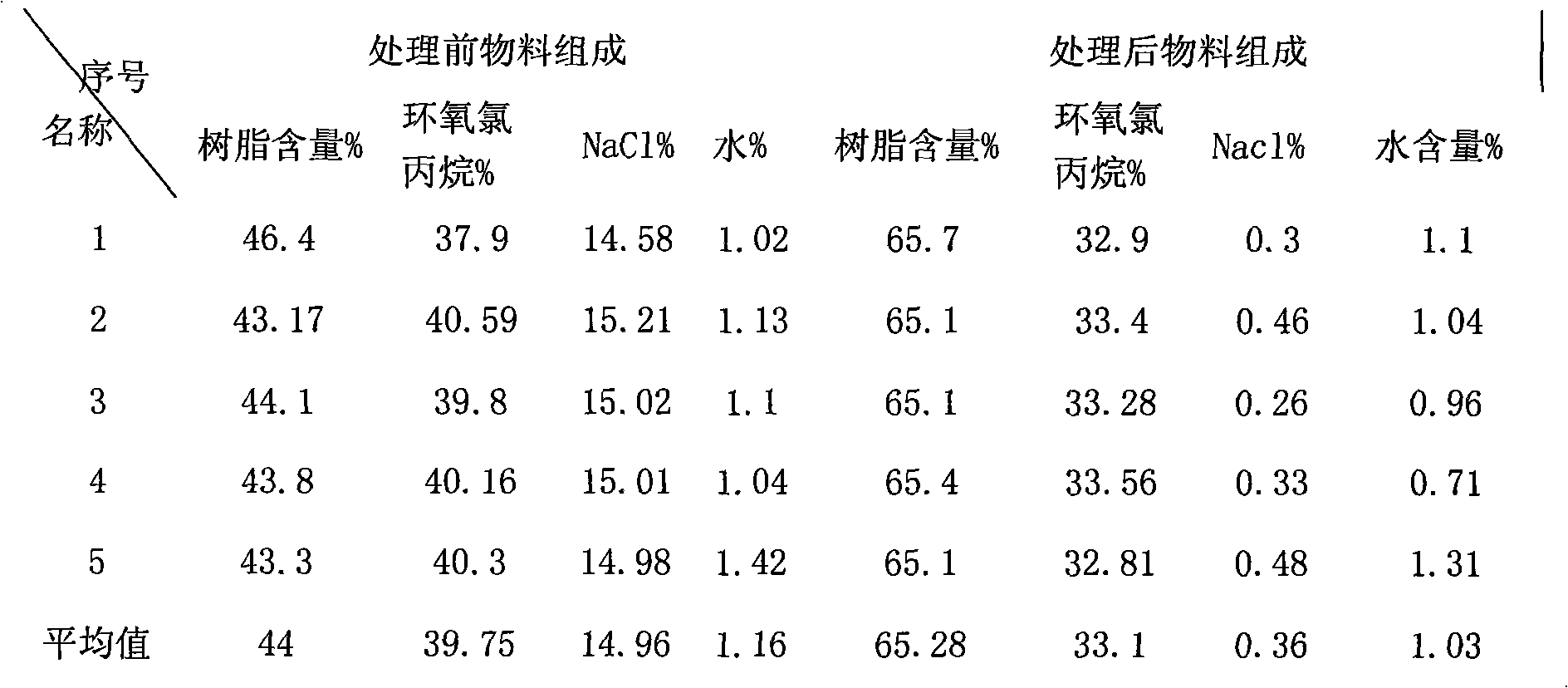

Method and device for reducing volatile matters of o-cresol-formaldehyde epoxy resin

ActiveCN102464792AUniform film formationGuaranteed removal rateMultiple-effect evaporationEpoxyVapor–liquid separator

The invention discloses a method and device for reducing volatile matters of an o-cresol-formaldehyde epoxy resin. The method comprises the following step of: performing a two-stage desolventizing step, including a coarse desolventizing step and a fine desolventizing step to remove a solvent and a high-boiling residue component from an o-cresol-formaldehyde epoxy resin. The device comprises a feed pump, a first pipeline mixer, a falling film evaporator, a gas-liquid separator, a primary removal extraction pump, a second pipeline mixer, a thin-film evaporator, a packing tower and a secondary removal extraction pump which are connected in sequence, wherein a part of an o-cresol-formaldehyde epoxy resin solution output by the gas-liquid separator returns to the first pipeline mixer through areflux pump; a steam inlet / outlet is formed in the second pipeline mixer; and both the gas-liquid separator and a film evaporator are provided with a volatile matter gas-phase outlet. According to the method and the device for reducing the volatile matters of the o-cresol-formaldehyde epoxy resin, volatile matters of a product can be reduced to be below 0.05 percent, and the performance of the product applied to an electronic molding compound can be improved remarkably.

Owner:CHINA PETROCHEMICAL CORP

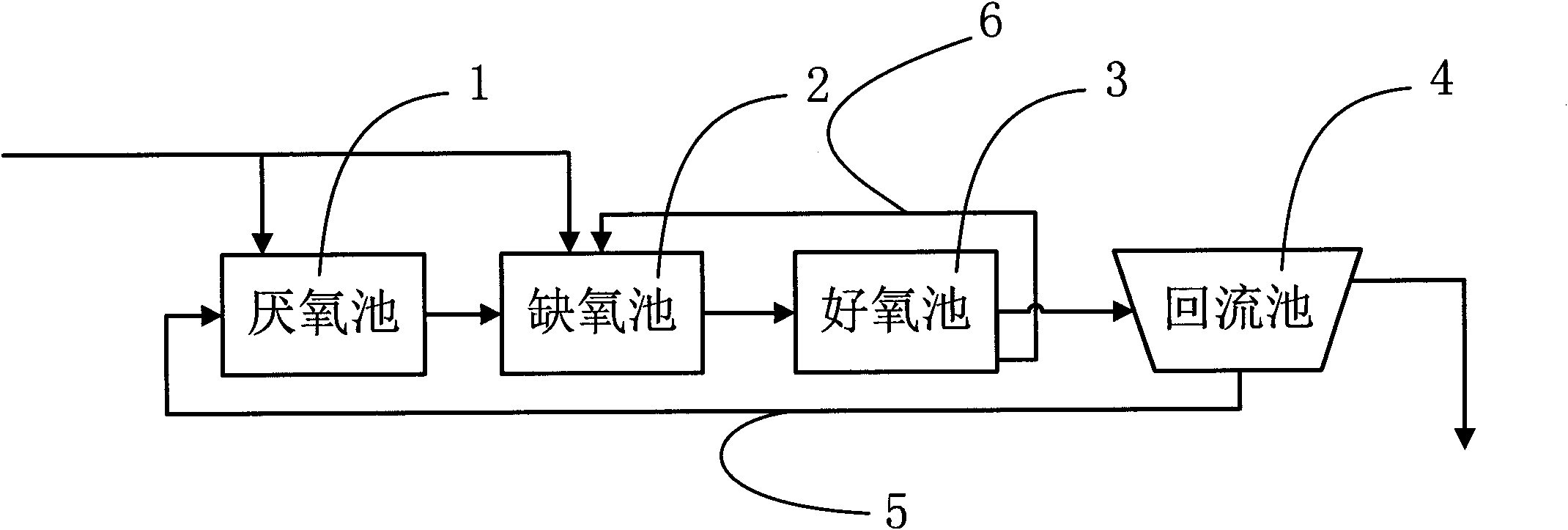

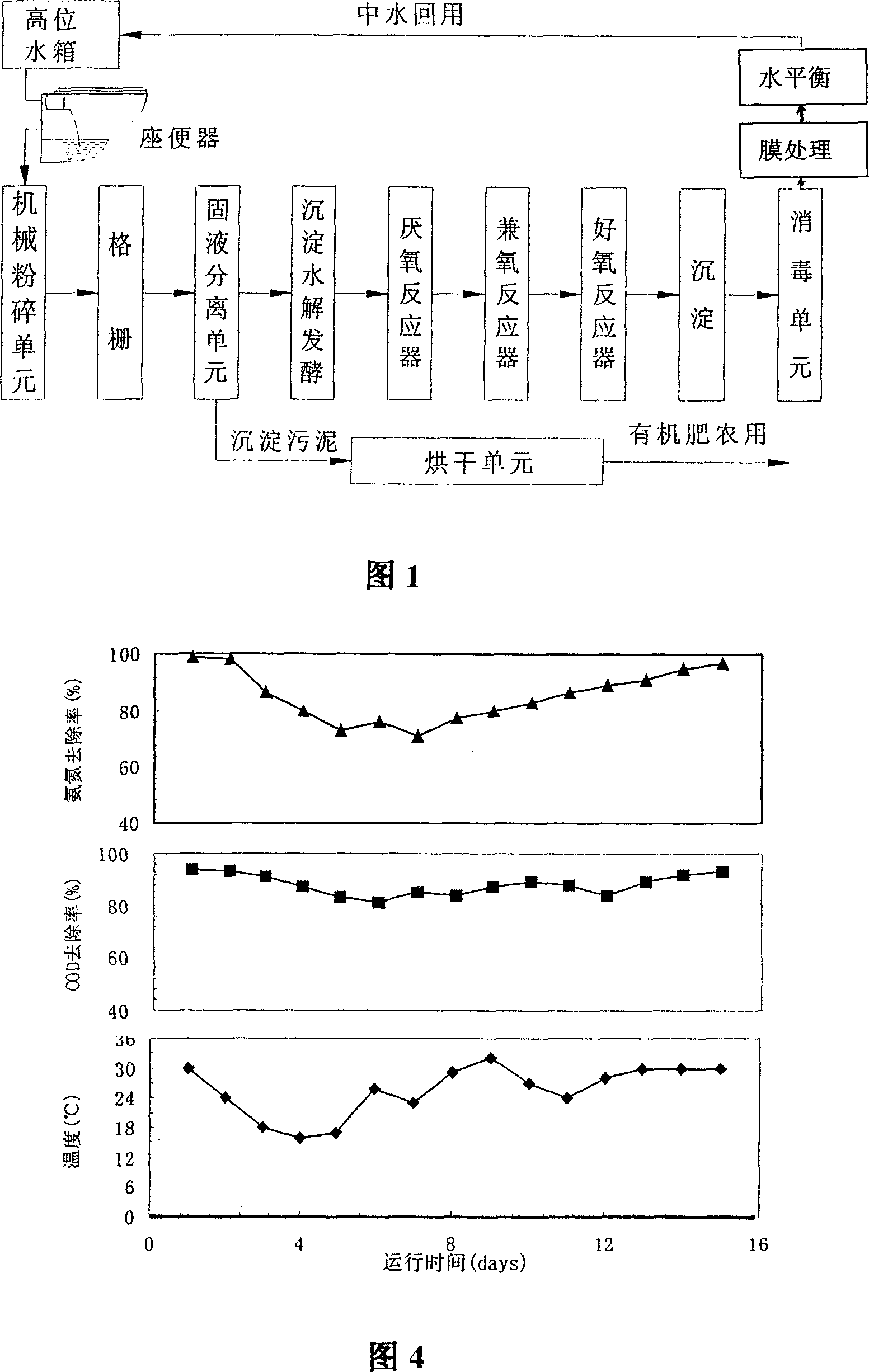

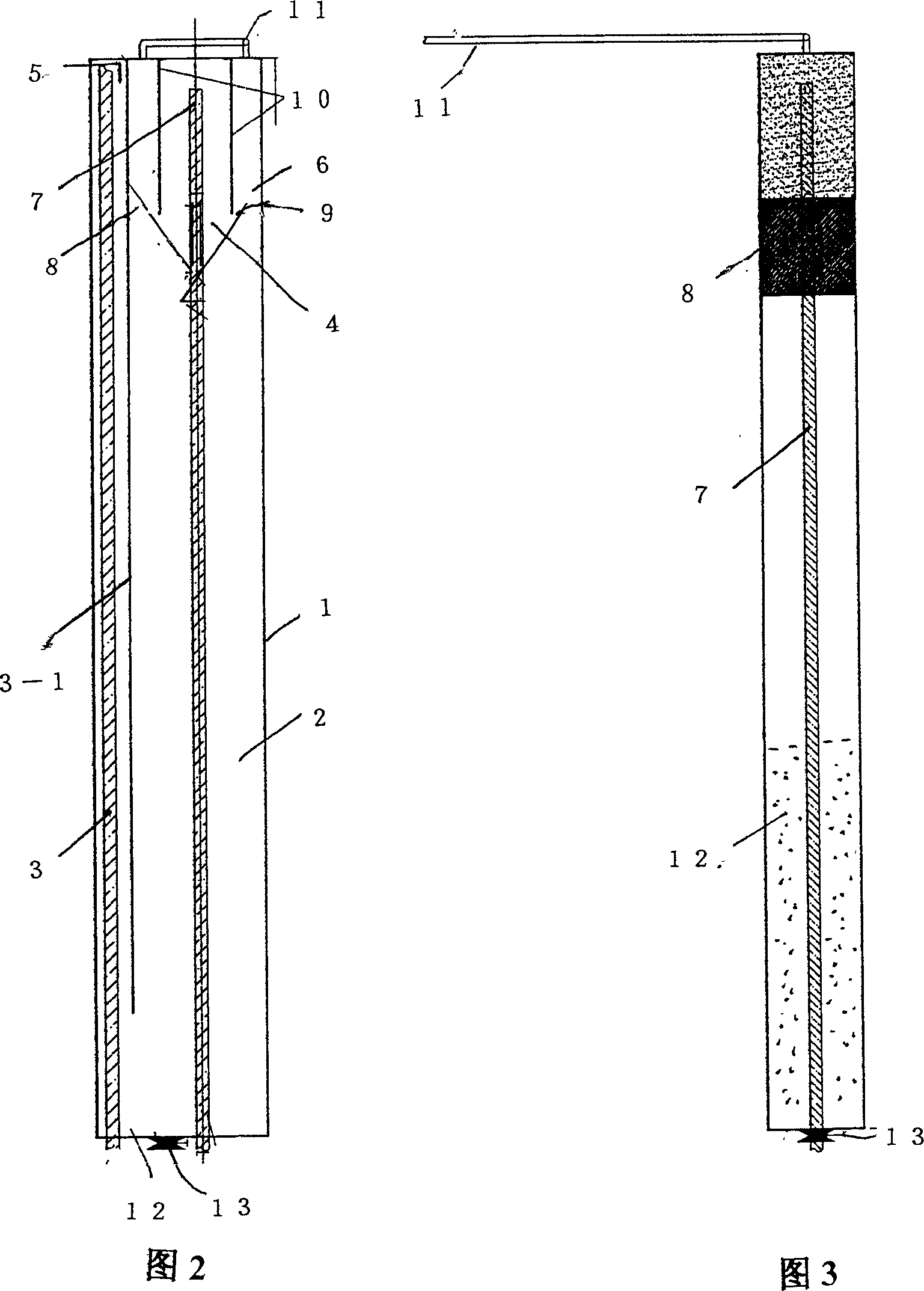

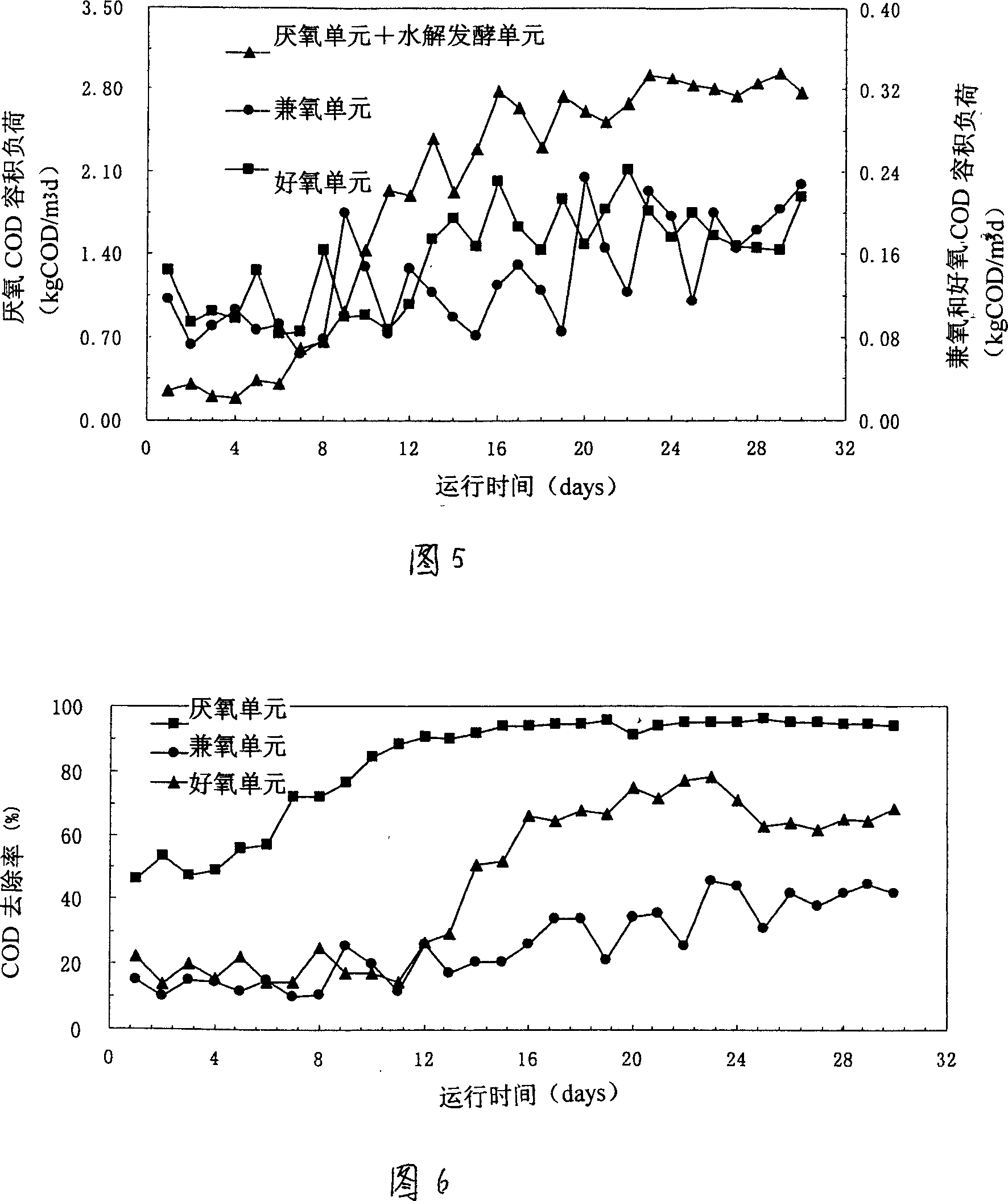

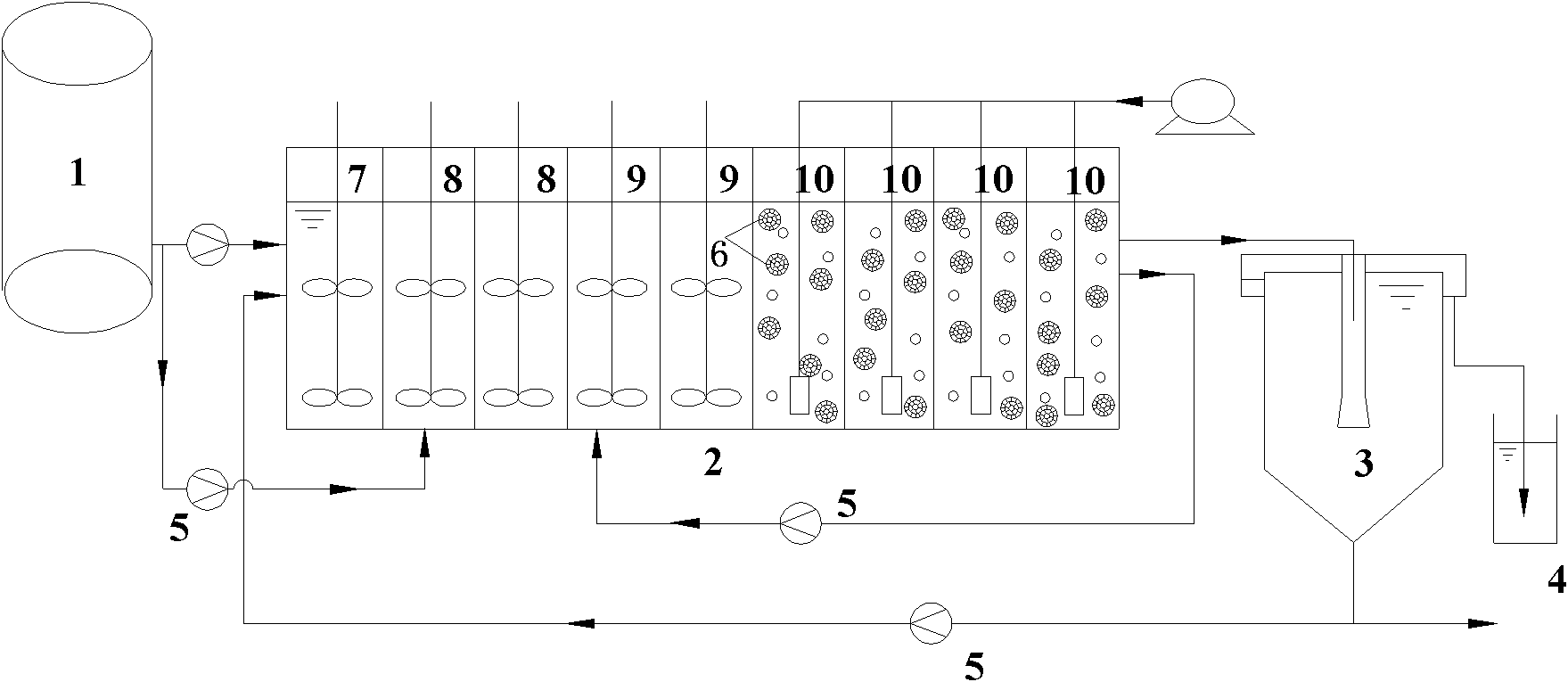

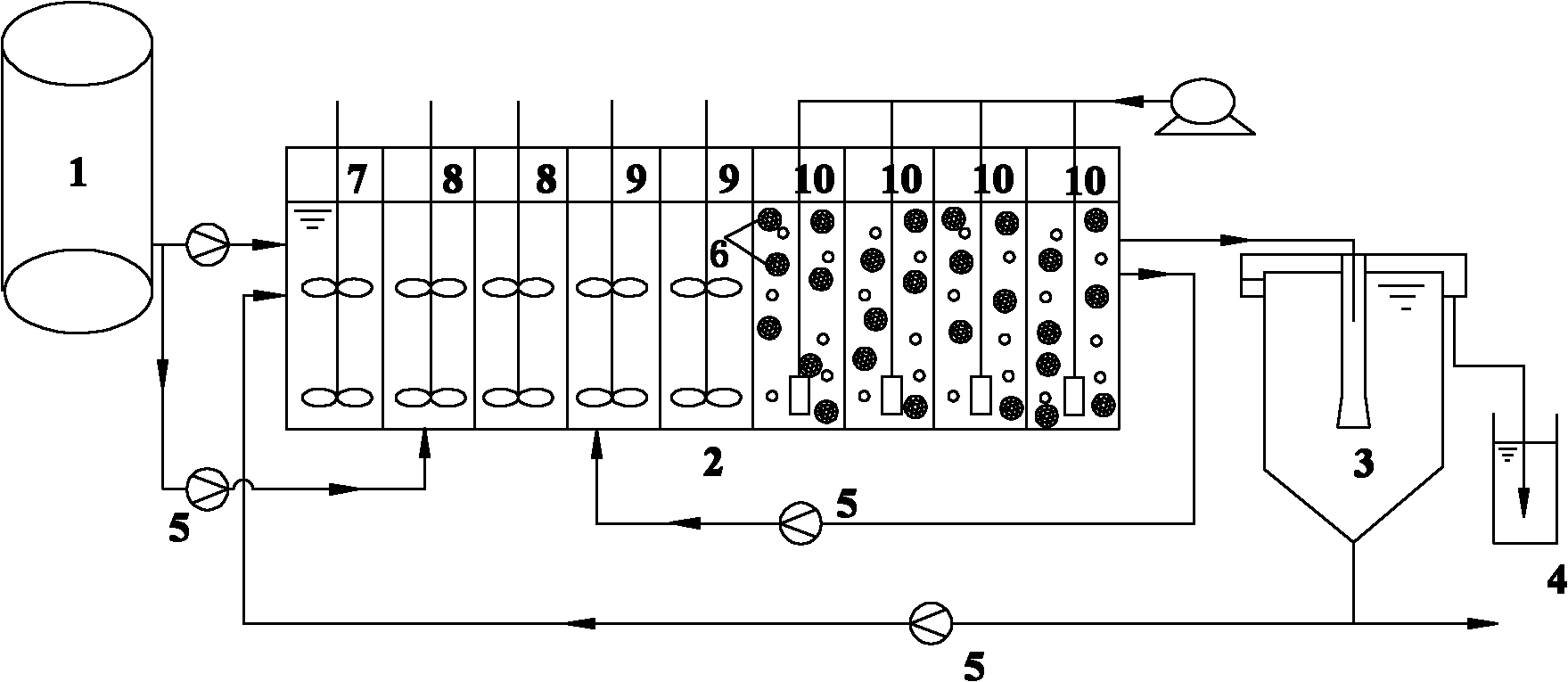

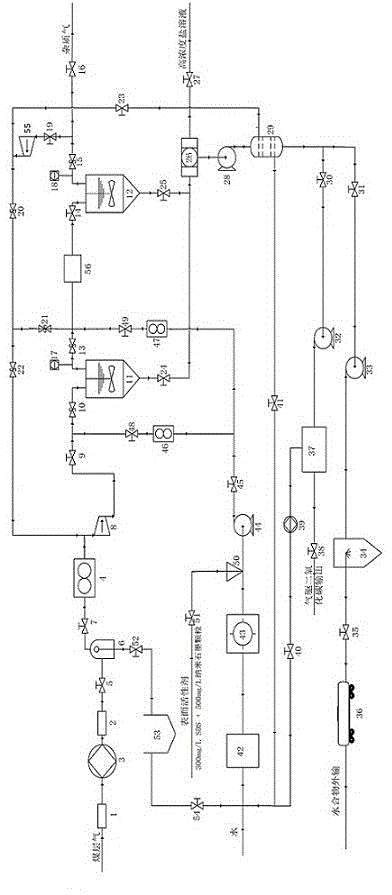

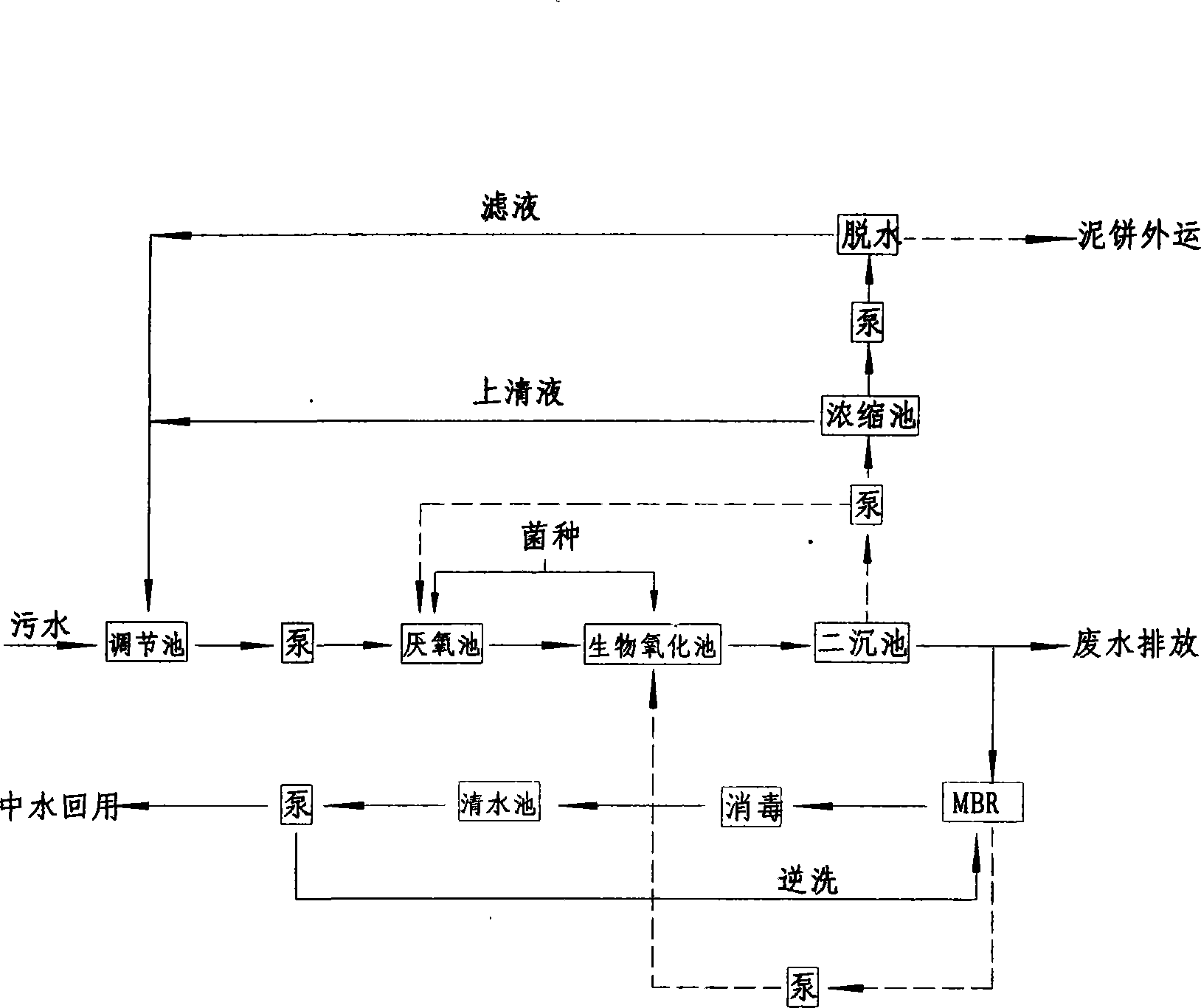

Biological treatment method and device for ecological system of sewage circulation utilization

InactiveCN101016186AImprove processing efficiencyGuaranteed removal rateWater/sewage treatment by irradiationTreatment with aerobic and anaerobic processesControl systemWater flow

The invention discloses a biological disposing method of effluent through circulating ecological system, which comprises the following steps: 1) predisposing waste water; separating solid from liquid or liquid from liquid; obtaining supernatant; 2) entering the supernatant into serial anaerobic and aerobic disposing disposal; cutting and guiding disposed flow through guide flow or conductive pipe; setting three-phased separating device to reinforce anaerobic disposal; 3) sterilizing the water; 4) pumping or reflowing water from sterilizing device to container; controlling dissolved oxygen density or air aerating time; setting the air cutting and aerating time at 1:0.4-5.

Owner:戴立明

Device and method for processing aerobic biofilm bypass flow A2O (Anaeroxic-Anoxic-Oxic) process of low C/N (Carbon-Nitrogen) urban sewage

InactiveCN102086062ASolve the problem of sludge age contradictionExtended sludge ageTreatment with aerobic and anaerobic processesSludgeOxygen

The invention discloses a device and method for processing the aerobic biofilm bypass flow A2O (Anaeroxic-Anoxic-Oxic) process of low C / N (Carbon-Nitrogen) urban sewage, belonging to the field of sewage treatment. The method comprises the following steps of: enabling partial raw water and the returned sludge of a secondary sedimentation tank to together enter a pre-anoxic zone of an A2O reactor; removing nitric nitrogen in the refluxed sludge by denitrifying bacteria through denitrification; enabling the raw water to simultaneously enter an anaerobic zone of the A2O reactor, absorbing a great amount of biodegradable organic matter by poly-p bacteria in the anaerobic zone, storing in vivo in a PHAs mode and releasing a great amount of phosphor; and enabling mixed liquid and nitrified liquid from the aerobic terminal to together enter the anoxic zone of the A2O reactor, carrying out denitrification by using the denitrifying bacteria with the nitric nitrogen as an electronic receptor and organic matter as an electronic donator, and carrying out denitrification dephosphorization by using denitrification dephosphorization bacteria with the nitric nitrogen as the electronic receptor and the in-vivo PHAs as the electronic donator. The aerobic zone of the A2O reactor is mainly used for nitrification.

Owner:BEIJING UNIV OF TECH

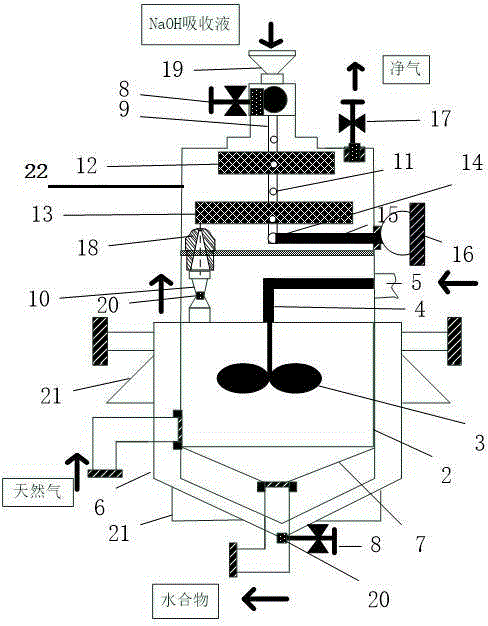

Super-gravity type desulfurization and decarburization device integrating hydrate method and membrane method

ActiveCN105385479AIncrease profitGuaranteed removal rateGaseous fuelsDispersed particle separationFlueChemistry

The invention belongs to the field of natural gas curing separation, and in particular relates to a device for desulfurizing and decarburizing industrial flue gases, oilfield exploitation gases and gases generated in other processes by combining a hydrate method with a membrane method and introducing a super-gravity technology. By combining the hydrate method with the membrane method and introducing the super-gravity technology based thereon to perform deep desulfurization and deacidification on natural gas, the removal rates of acid gases including H2S and CO2 in the natural gas are greatly improved, so that the device can be applied to purification and separation of onshore and marine oilfield natural gases, particularly the treatment of natural gases in remote districts and certain small gas fields; and the device can be used for removing the acid gases including H2S and CO2 in the natural gases effectively to ensure that the natural gases reach a pipeline transportation standard.

Owner:CHANGZHOU UNIV

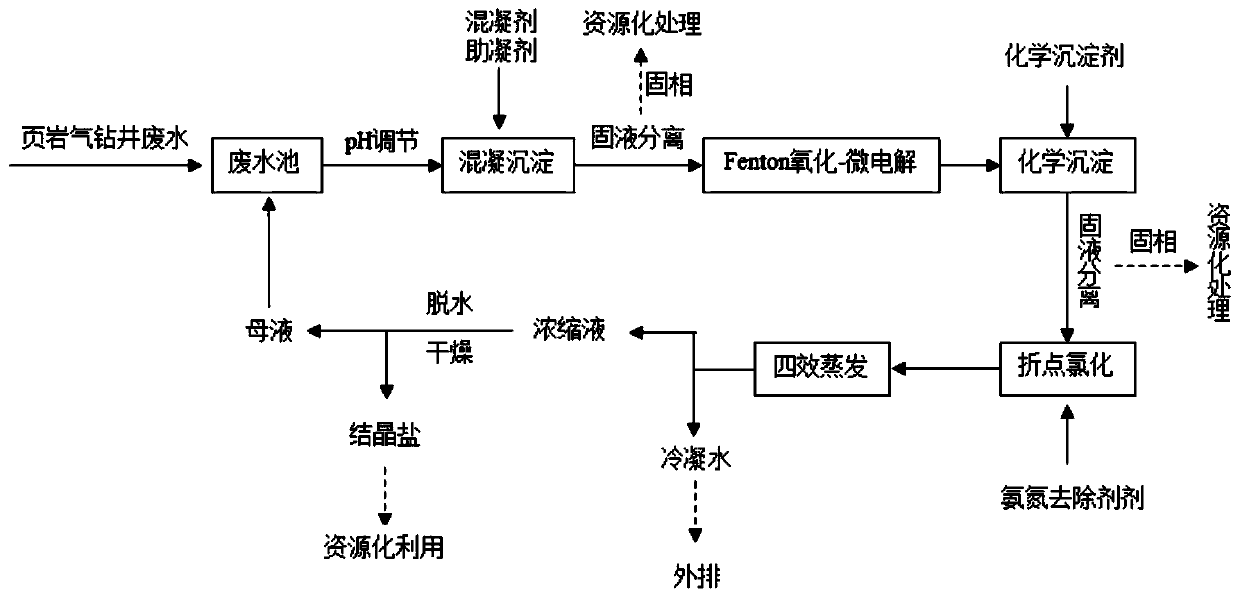

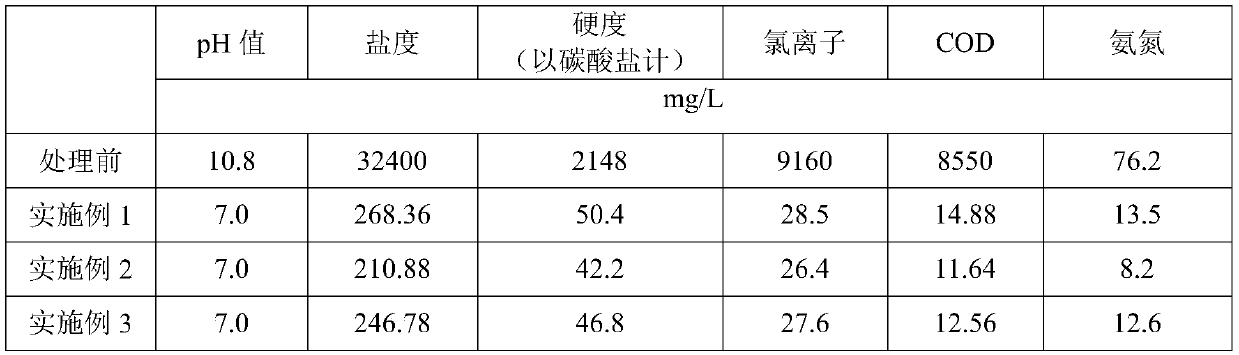

Shale gas drilling wastewater treatment method

InactiveCN109928563ASimple processReduce CODWaste water treatment from quariesMultistage water/sewage treatmentVacuum evaporationPrecipitation

The invention provides a shale gas drilling wastewater treatment method. The Shale gas drilling wastewater treatment method comprises the following steps that S1, the pH of drilling wastewater is adjusted to be 8-11, a coagulant and a coagulant aid are added, after uniform stirring, static settlement is conducted, and then solid-liquid separation is conducted; S2, the pH of clear liquid obtained through solid-liquid separation in the step S1 is adjusted to be 2-5, hydrogen peroxide and a Fe / C filler are added, and air is pumped in for reaction for 1.5-2 h; S3, the pH of the wastewater treatedin the step S2 is adjusted to be 9-11, a chemical precipitation agent is added, the temperature is controlled to be 80 DEG C, uniform stirring is conducted, reaction is conducted for 20-40 min, and then solid-liquid separation is conducted; S4, the pH of clear liquid obtained through solid-liquid separation in the step S3 is adjusted to be 7-9, an ammonia-nitrogen removing agent is added, and reaction is conducted for 20-30 min; and S5, the wastewater treated in the step S4 is treated through a low-temperature vacuum evaporation method, and thus condensed water and concentrated liquor are obtained. According to the shale gas drilling wastewater treatment method, the shale gas drilling wastewater is sequentially subjected to coagulating sedimentation, Fenton oxidation-microelectrolysis, chemical precipitation, ammonia-nitrogen removing and four-effect evaporation treatment, the conventional indexes in the treated drilling wastewater can reach the primary standard of the wastewater comprehensive discharging standard.

Owner:重庆市涪陵页岩气环保研发与技术服务中心

Device and method for purifying and concentrating coal bed gas and treating produced water

ActiveCN104479780AIncrease concentrationEasy to transportGaseous fuelsMultistage water/sewage treatmentHigh concentrationFlame arrester

The invention relates to the technical field of exploitation and utilization of coal bed gases, and in particular relates to a device and a method for purifying and concentrating a coal bed gas and treating produced water. The device comprises a wet flame arrester, a water ring vacuum pump, a gas flow meter, a one-way gas valve, a separator, a fireproof and explosion-proof compressor, a safety valve, a hydrate generating unit, a gas-liquid two-phase valve, a gas concentration monitor, a stop valve, a filter, a one-way liquid valve, a slurry pump, a three-phase separator, a granulating machine, a stop valve, an outer transportation vehicle, a hydrate decomposing unit, a water pump, an ice making device, a grinding device, a liquid flow meter, a Laval spray valve and a clarifier. Two hydrate reactors are adopted to fix CO2 and methane in the coal bed gas respectively, and the CO2 released after regeneration is used as a gas-driving raw gas for improving the recovery ratio of the coal bed gas, so that the release of CO2 of a gas field is reduced, and high-concentration methane hydrate is granulated and transported outwards for application; and a salt draining effect during formation of the hydrate is used to ensure that a lot of salt-containing produced water during exploitation of the coal bed gas can be treated to meet requirements for reinjection to a stratum layer, so that resources are saved, and the environment is protected.

Owner:江苏智芯今创科技有限公司

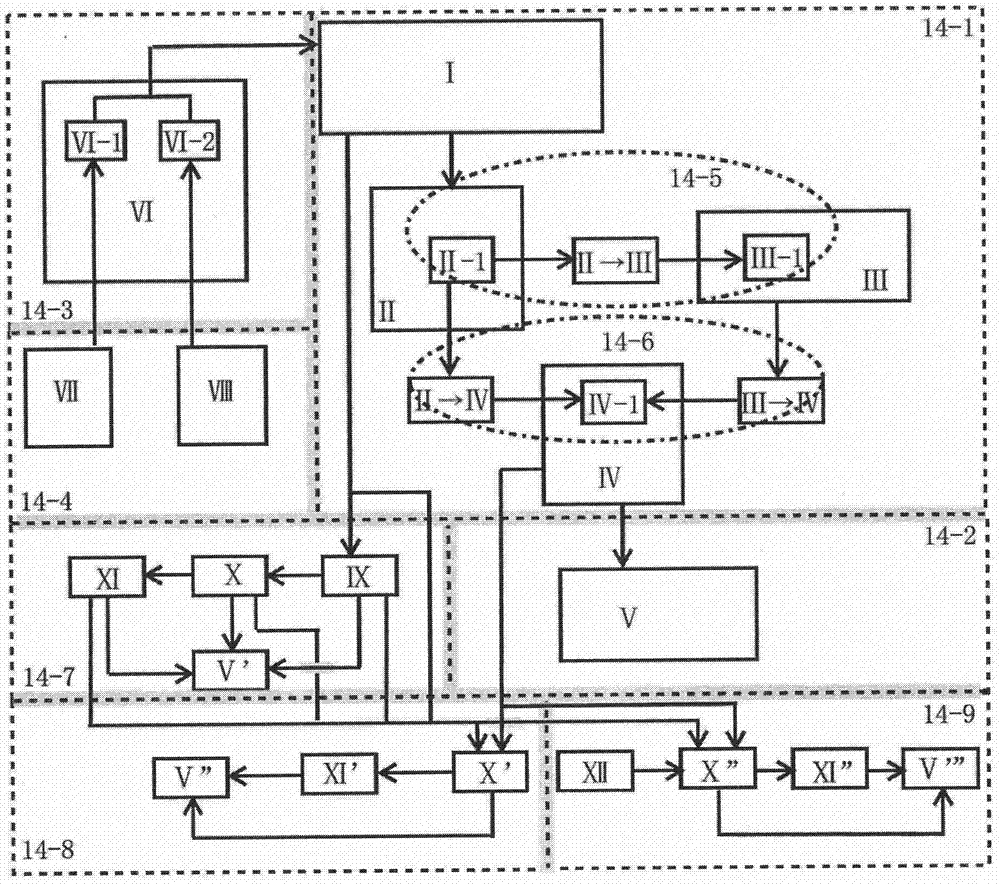

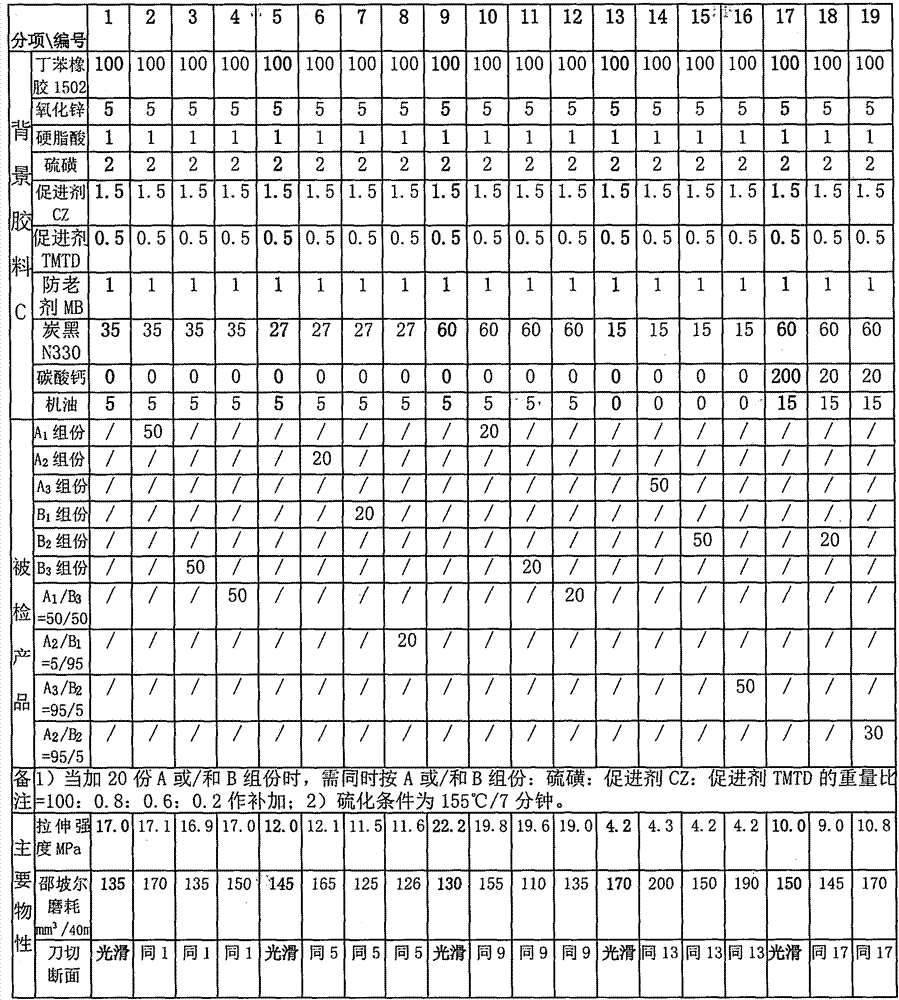

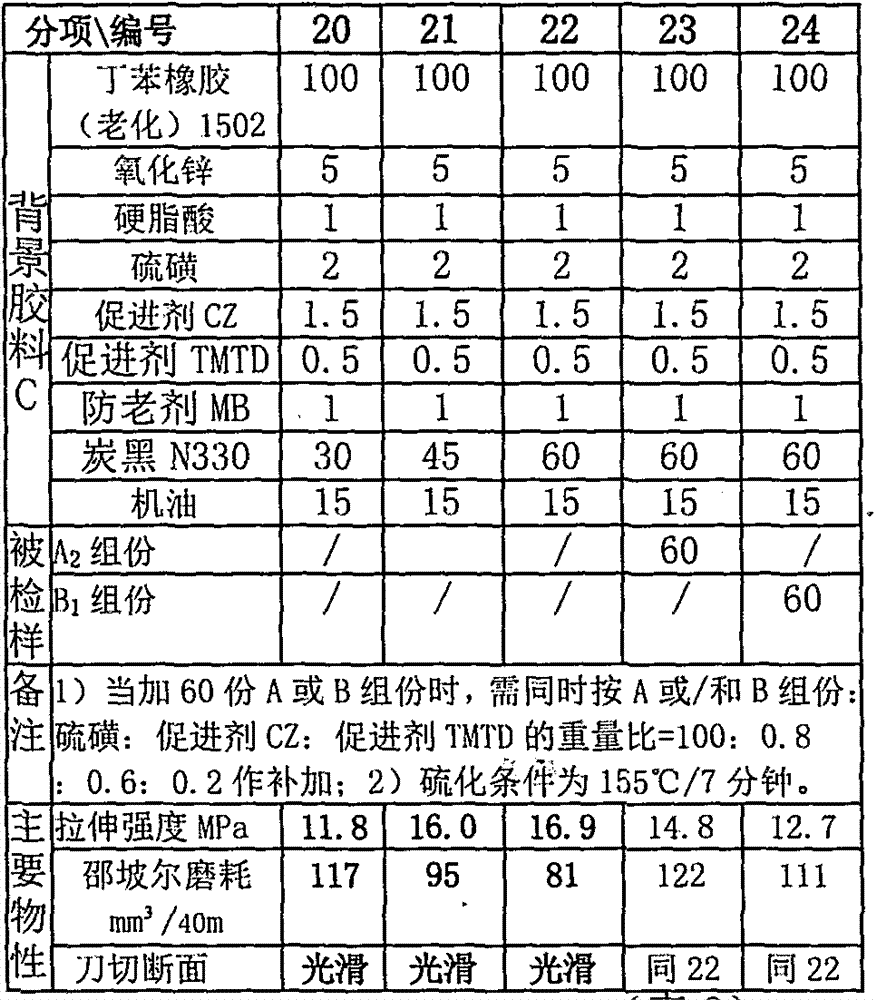

Reclaimed rubber or reclaimed-rubber-doped rubber or rubber-plastic composition product and production method thereof

The invention provides reclaimed rubber or reclaimed-rubber-doped rubber or rubber-plastic composition product and a production method thereof, and relates to component A thermo-plastically produced, or / and component B ground at normal temperature, or A / B composition, or A- or / and B-doped rubber or rubber-plastic composition; the product is characterized in that, in terms of environmental protection, 3-5 g of A or / and B sample is taken, a polyester film is placed on at each of the top and boom of the sample, the sample is then placed on a vulcameter or a Mooney viscosity meter and is heated at 180 DEG C for 10 min, the sample is taken out and placed still at room temperature for not shorter than 5 min, the top and bottom polyester films on the sample are removed and stacked, the films are observed under a fluorescent lamp, yellow staining the polyester films is never darker than 101C or 601C on the national standard color (PANTONE) card, or / and the films never produce a characteristic offensive odor that is any one of or a combination of any of coal tar odor, pine tar odor, aromatic hydrocarbon oil odor and asphalt odor, or / and choking odor; the A / B composition is characterized in that the components A and B are premixed in any ratio in the weight ratio range of 95 / 5 to 5 / 95.

Owner:鱼伟令 +4

Method for advanced treatment of ammonia nitrogen sewage

ActiveCN101172735AGuaranteed reuseFast reproductive metabolismWater/sewage treatment bu osmosis/dialysisTreatment with aerobic and anaerobic processesWater qualityEmission standard

The invention relates to a method for deep treatment of ammonian sewage, and the method belongs to the technical field of the environment protection. The invention conducts integration and innovation based on the traditional ammonian sewage treatment method and combines the physical, chemical and biological treatments, namely, an improved oxygen-poor and aerobic technique, film separation and biological treatment are adopted in the treatment of the eutrophic water which is low in BOD5, and then the eutrophic water is discharged or reused after the treatment under the standard. The invention has the advantages of low capital construction and work, good water treatment, no secondary pollution and state discharge standard conformity of the discharged water, etc., thereby being widely used in the treatment of the eutrophic water with the density of the BOD5 being 48.5mg / L.

Owner:ASIA PACIFIC ENVIRONMENTAL CORP

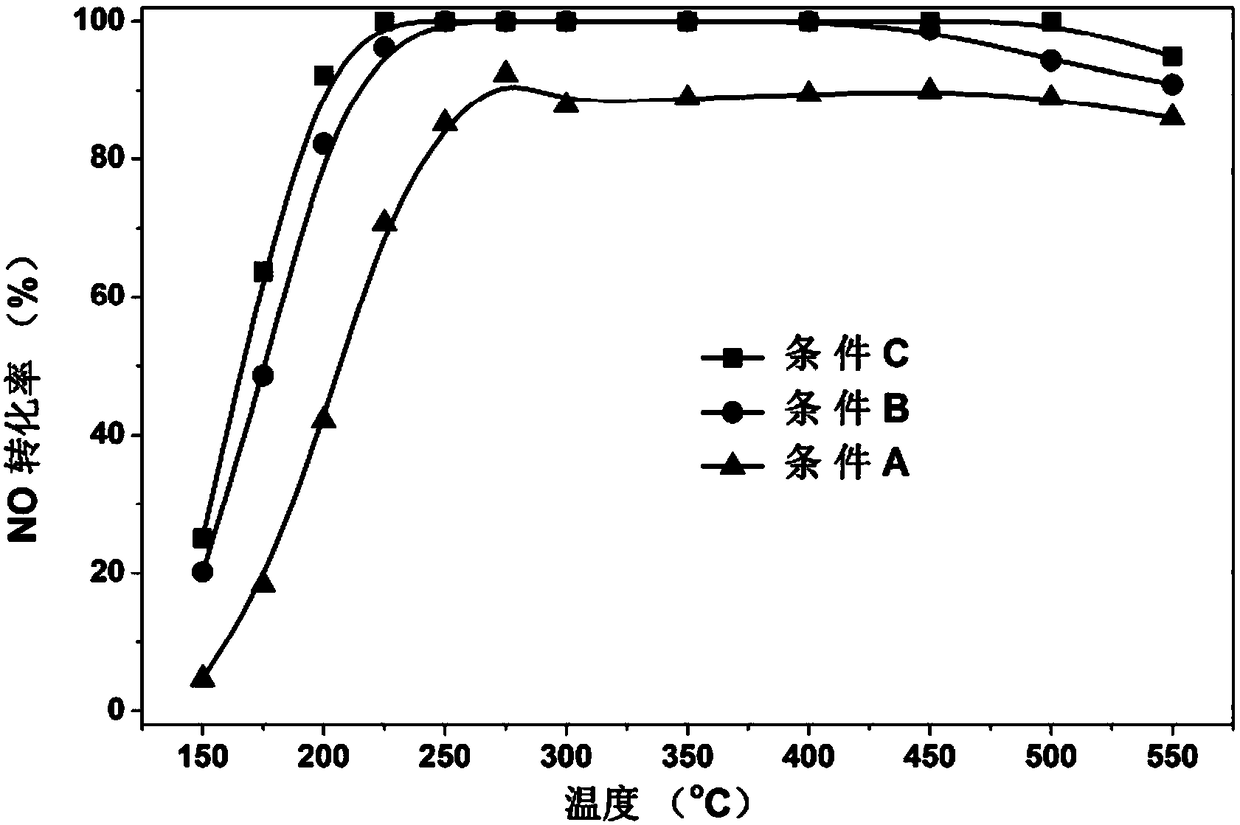

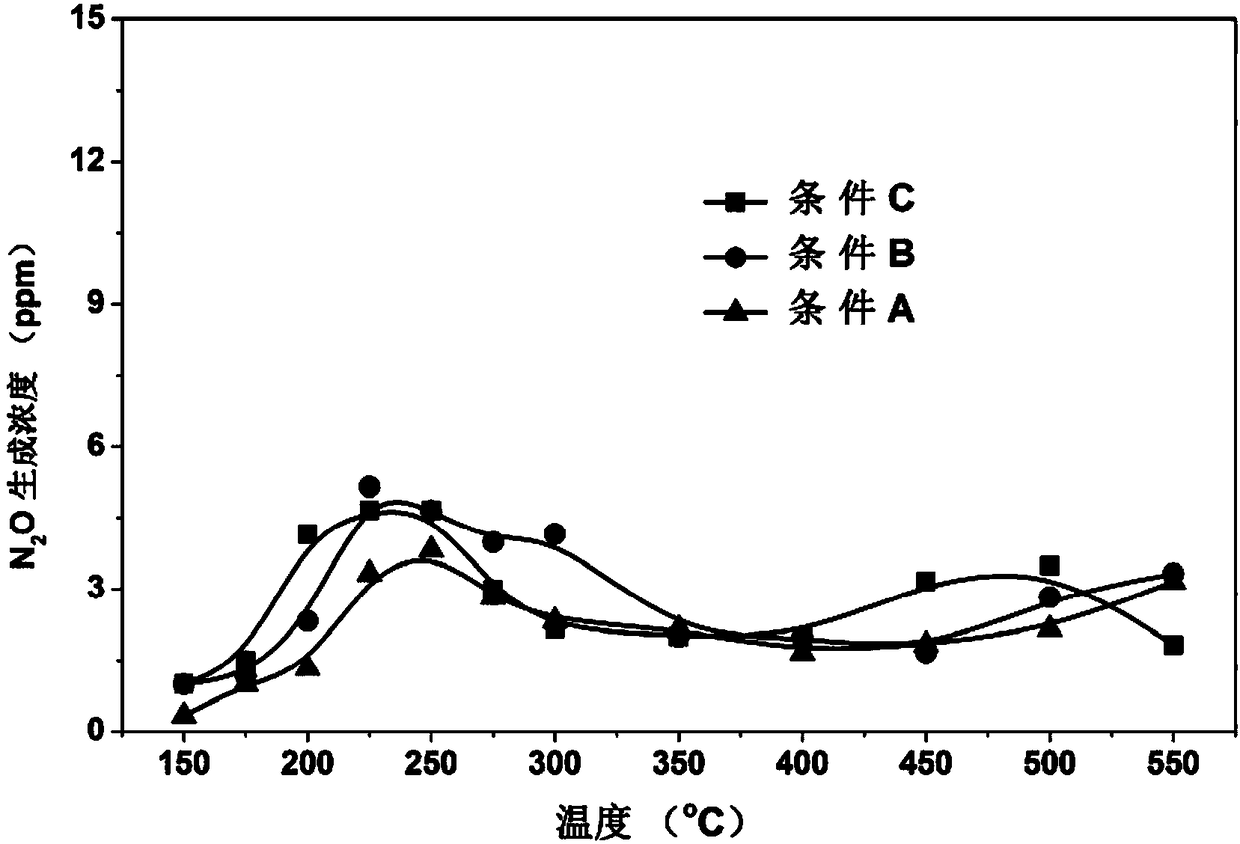

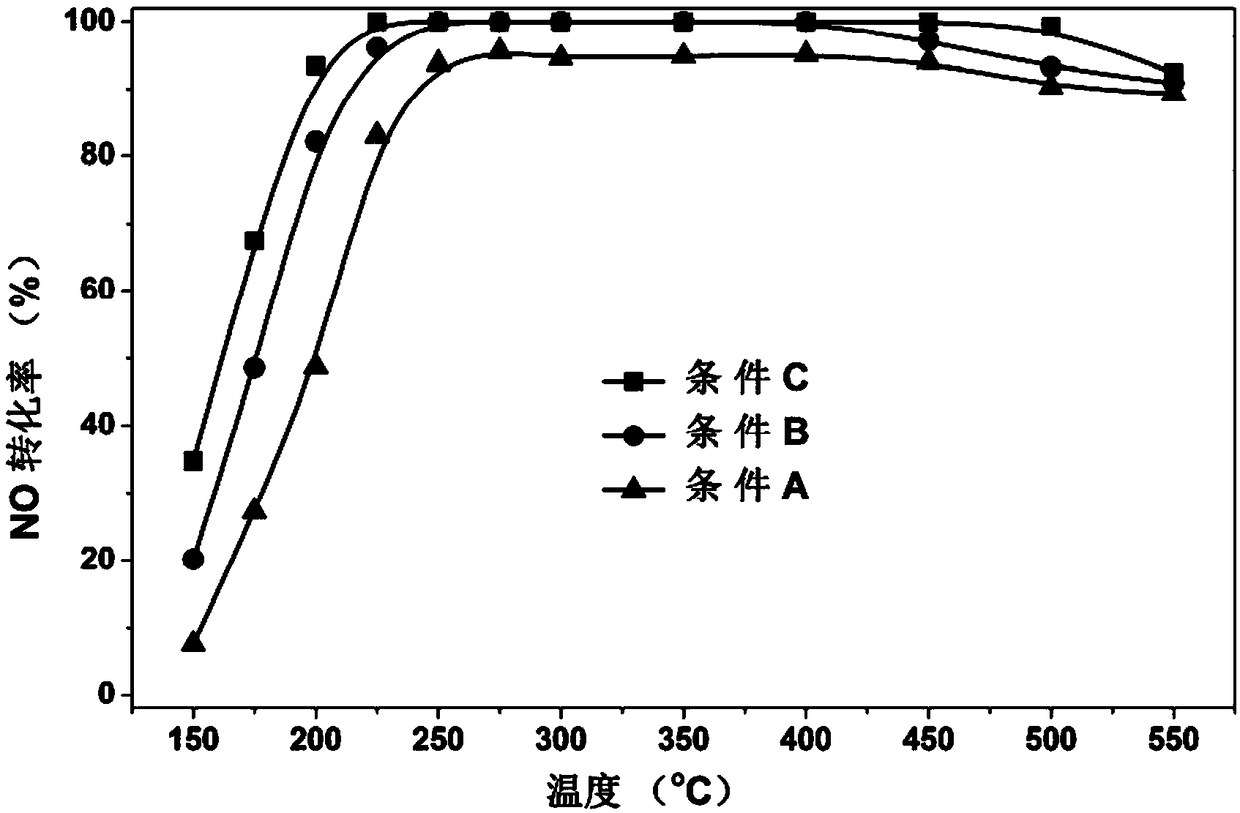

Composite catalyst for NH3-SCR reaction and preparation method and application thereof

InactiveCN108097301AGuaranteed removal rateWide temperature operating windowNitrous oxide captureMolecular sieve catalystsIon exchangeCalcination

The invention provides a composite catalyst for an NH3-SCR reaction and a preparation method and the application of the composite catalyst for the NH3-SCR reaction. The composite catalyst takes a molecular sieve as a carrier, and is loaded on transition metal on the molecular sieve to be taken as an active component through ion exchange. The method disclosed by the invention comprises the following steps: firstly, mixing the molecular sieve with a salt solution of the transition metal to perform an ion exchange reaction, and then carrying out solid-liquid separation and calcination to obtain an AEI molecular sieve catalyst. The composite catalyst prepared by the invention is non-toxic and harmless on used raw materials and simple and easy in preparation method and has the characteristics of high catalytic activity, low N2O formation amount, wide operating temperature window, capability of adapting to high-altitude velocity reaction conditions and the like, and suitability for carryingout catalytic purification of moving-source exhaust gases and stationary source flue gas nitrogen oxides as represented by diesel vehicle exhaust gases.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

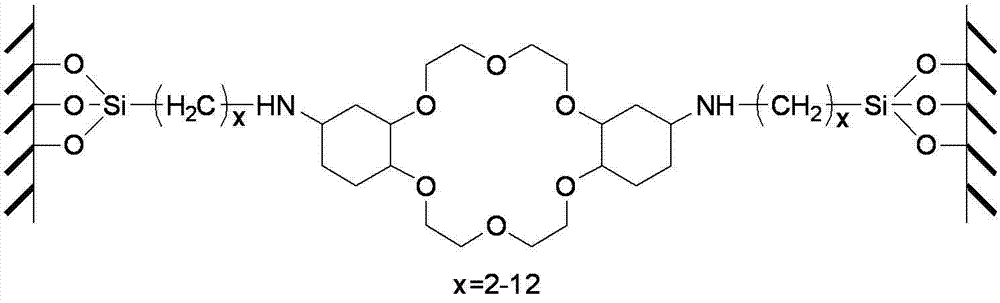

Method for separating palladium from waste water by double-arm bonding-type alicyclic crownether silicon resin

ActiveCN102849823AImprove separation efficiencyGuaranteed removal rateWater contaminantsWater/sewage treatment by ion-exchangeFluid phaseOrganic chemistry

The invention discloses a method for separating precious metal palladium through selective adsorption from palladium-containing waste liquid by using double-arm bonding-type alicyclic crownether silicon resin, and belongs to the technical field of heavy metal ion separation. The method comprises the following steps: firstly adding double-arm bonding-type alicyclic crownether silicon resin into palladium-containing waste liquid according to a ratio of 0.01-1.0 of the weight of the double-arm bonding-type alicyclic crownether silicon resin to the volume of the palladium-containing waste liquid, then stirring or oscillating at a temperature of 5-50 DEG C for 20-300 min; filtering and separating the solid phase from the liquid phase, determining the residual concentration of palladium ions in the liquid phase, comparing with an initial concentration to calculate the separation recovery rate; eluting the double-arm bonding-type alicyclic crownether silicon resin with a nitric acid solution of 0.01-3 mol / L, repeatedly washing with deionized water, drying to obtain regenerated resin. The method provided by the invention is high in separation speed for palladium ions in the palladium-containing waste liquid, high in separation efficiency, strong in adaptability, recyclable in materials, and low in cost.

Owner:TSINGHUA UNIV

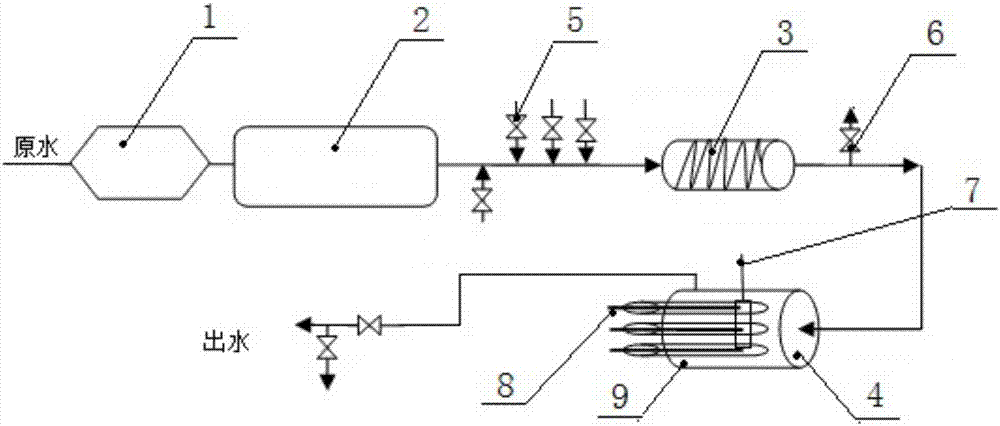

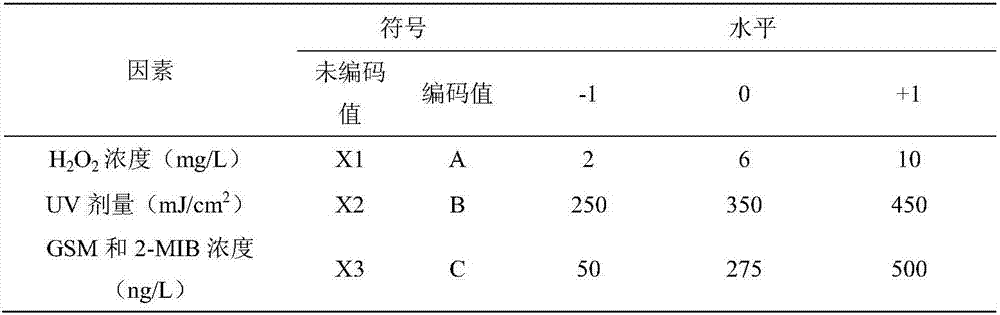

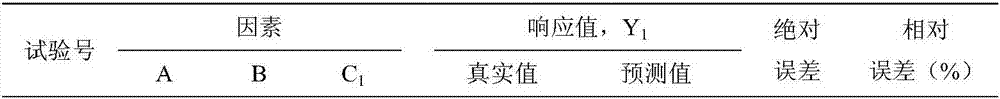

Response surface method-based UV/H2O2 process parameter optimization method

ActiveCN106986413ARealize automatic adjustmentGuaranteed removal rateWater/sewage treatment by irradiationSpecial data processing applicationsAutomatic controlProcess engineering

The invention discloses a response surface method-based UV / H2O2 process parameter optimization method which comprises the following steps: (1) designing an RSM (Response Surface Method) mixing experiment for removing a target organic matter; (2) performing the RSM mixing experiment for removing the target organic matter; (3) arranging multiple drug feeding points in a UV / H2O2 advanced oxidation pilot test device, wherein the multiple drug feeding points are respectively used for feeding H2O2 and labeling the target organic matter in a water distribution test; (4) building a target organic matter removal model, performing multi-regression fitting on experimental data by applying Design-Expert software, and building a regression equation; (5) performing variance and relevance analysis through the regression equation by adopting ANOVA (Analysis of Variance) of a response surface secondary model; and (6) determining process parameters. According to the response surface method-based UV / H2O2 process parameter optimization method, frequent adjustment of the process parameters in an actual engineering application process is simplified; and after being built, the model can be linked with an automatic control system of a UV / H2O2 advanced oxidation reactor, so as to realize automatic adjustment of the process parameters, and the cost is effectively reduced.

Owner:SHANDONG WATER & WASTEWATER MONITORING CENT

Refining method of virgin gas containing ethane used in process for preparing ethylbenzene by ethane

ActiveCN101665397AReduce loss rateHigh yieldEthylene productionHydrocarbonsThermal desorptionEthylene

The invention discloses a desorption method of propylene in virgin gas containing ethylene used in a process for preparing ethylbenzene by dilute ethylene, comprising the following steps: virgin gas containing ethylene enters an absorption tower from the middle and is in countercurrent contact absorbent entering the absorption tower from the upper part; the refined virgin gas absorbed by the absorbent enters in a reaction part of an ethylbenzene unit to react with benzene to obtain ethylbenzene; saturable absorbent is used for desorption by adopting a low-pressure thermal desorption; and the desorbed absorbent is circularly used. By the process, after the virgin gas containing ethylene is refined, the loss ratio of the refined ethylene gas is smaller than 2 percent, and the removal percent of propylene is 95-99.9 percent.

Owner:CHINA PETROCHEMICAL CORP +1

Control device and method for four-section water-feeding A/O technique water-feeding flow rate distribution process

ActiveCN100535803CGuaranteed removal rateAdjust the distribution ratio in real timeSustainable biological treatmentAdaptive controlActivated sludgeDistribution control

A control device and method for the influent flow distribution of the four-step water intake A / O process belongs to a sewage treatment system area by using an activated sludge method. The operation of a prior step feed process can not optimize the flow distribution according to the influent quality; the system can not fully utilize the nitrification and denitrification capacity of each step, and the carbon source in the influent can not be fully utilized during the denitrification process; the operation cost of the prior step feed process is high with a poor processing effect. The control device and method for the influent flow distribution of the four-step water intake A / O process of the invention inputs the on line collected ammonia nitrogen and COD signals into an influent flow distribution controller; the output of the flow regulation signal acts on a frequency conversion speed governor of a water intake pump of each step after the rule and algorithm, and regulates the influent flow distribution of the system of each step. The invention can improve the nitrification and denitrification effect of the step feed process and fully utilizes the carbon source in the influent during the denitrification process. The operation cost of the invention is low with good effluent effects and a simple control structure. The invention is easy to be realized.

Owner:BEIJING UNIV OF TECH

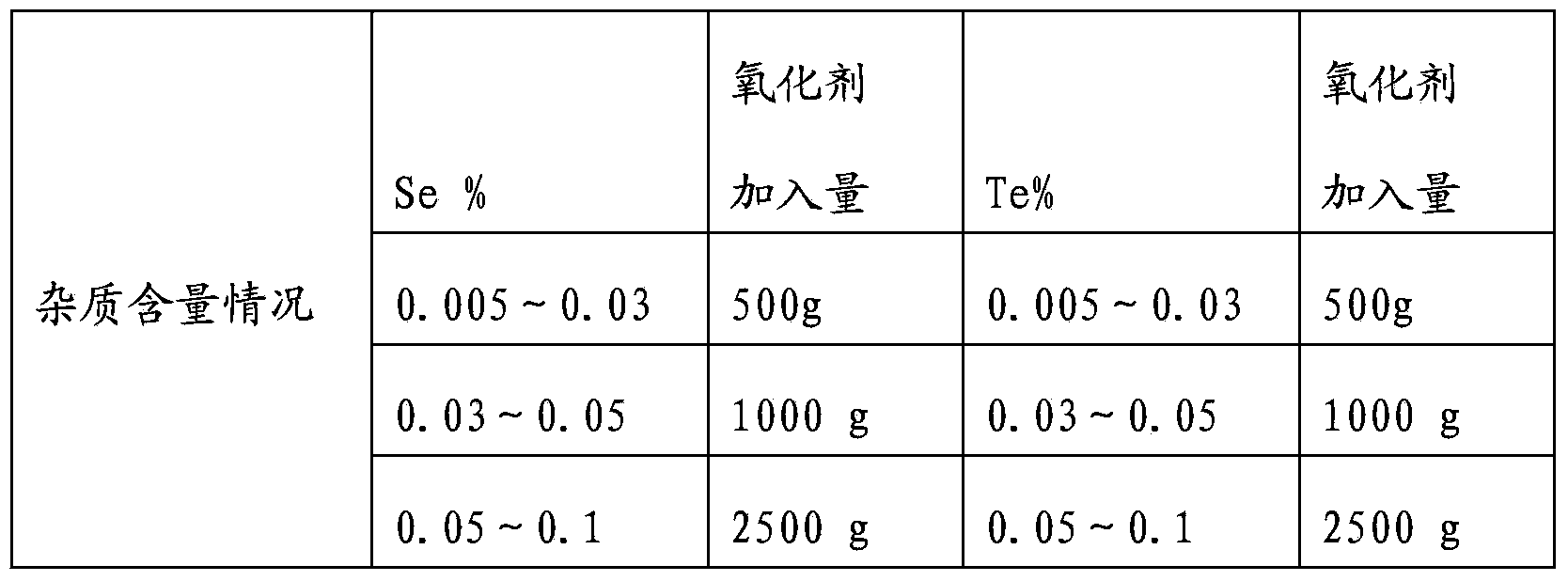

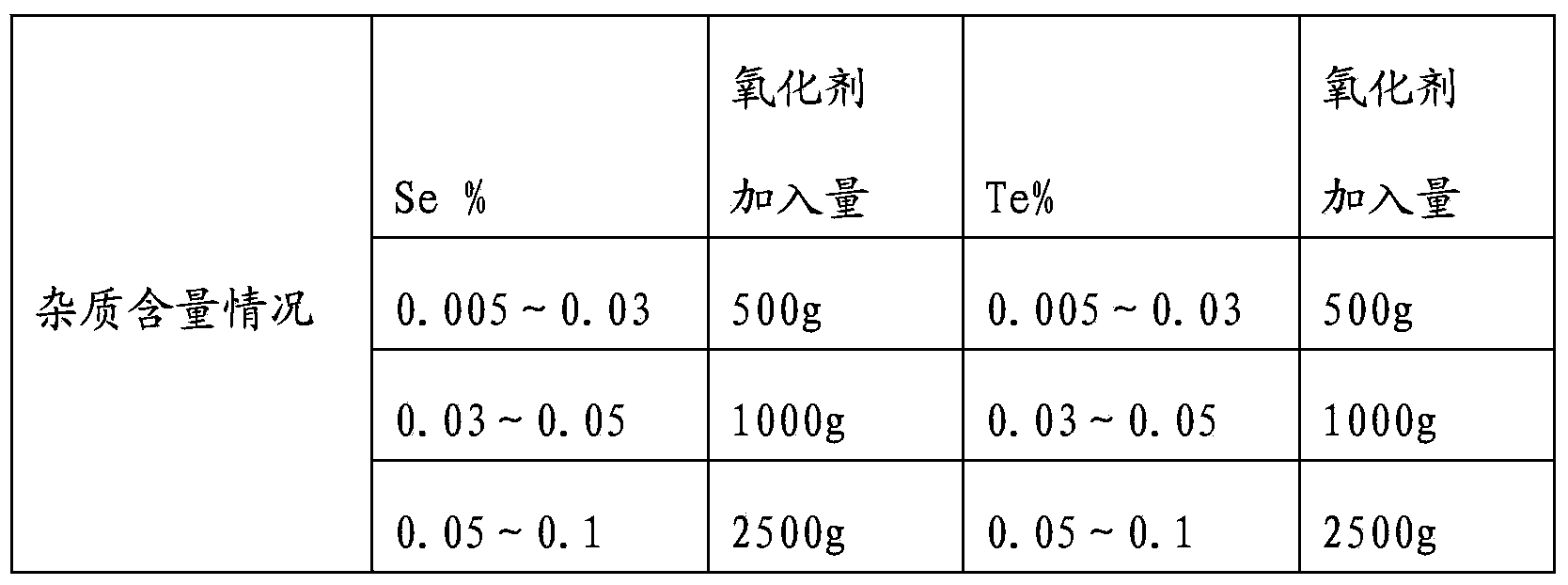

Method for removing impurities contained in high-impurity crude silver

ActiveCN103526232AEfficient removalGuaranteed removal ratePhotography auxillary processesElectrolysisCrucible

The invention relates to a method for removing impurities contained in high-impurity crude silver. The method comprises the following several steps of: melting crude silver; adding an oxidizing agent; dredging slag; pouring a pole plate; carrying out electrolytic refining; washing silver sand; drying; carrying out fusion casting forming. The method disclosed by the invention can be used for effectively removing the principal impurities contained in high-impurity crude silver and separating and enriching the impurities by grasping the addition time and addition amount of the oxidizing agent when a crude silver raw material is melted, ensures the removal rate of the impurities, reduces the corrosion degree of a fusing agent on a crucible, ensures the quality and grade of an electrolytic product, reduces the unit power consumption cost of an electrolytic refining process, ensures the purity and color of the product and enhances the economic benefit.

Owner:SHANDONG GUODA GOLD

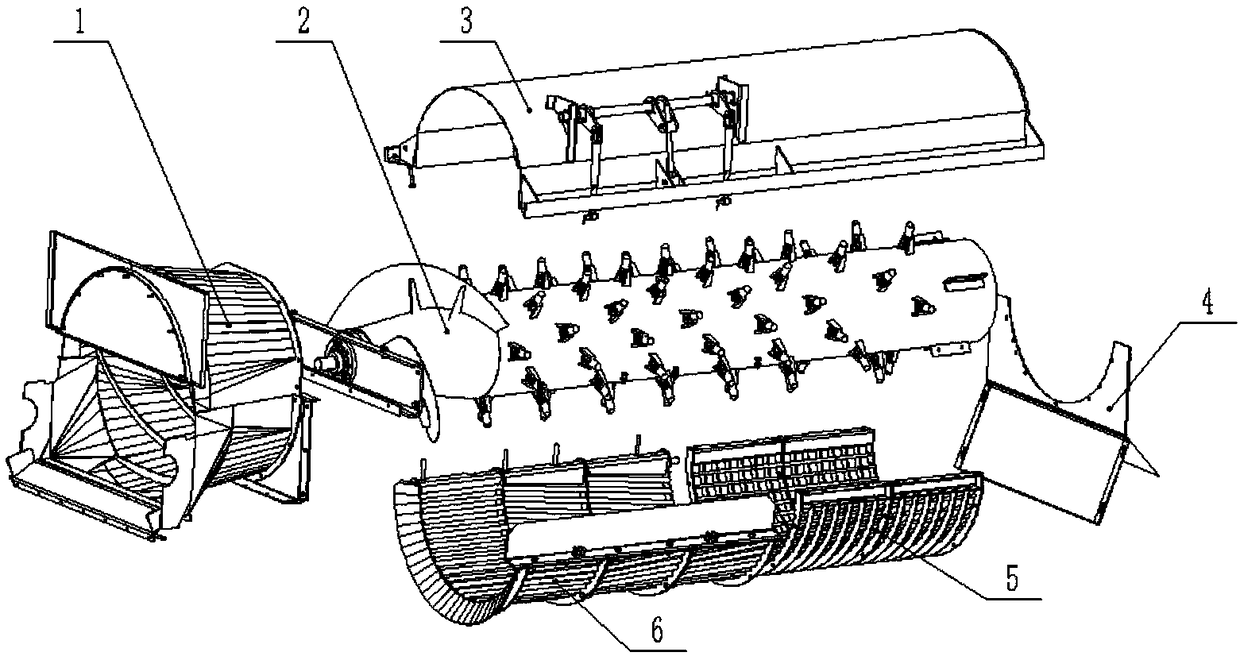

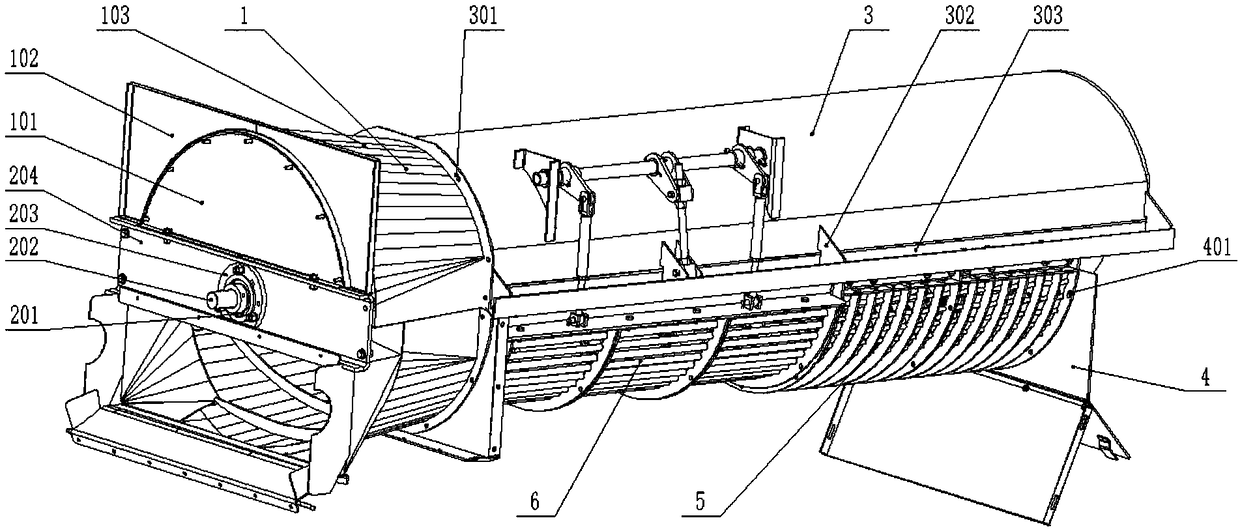

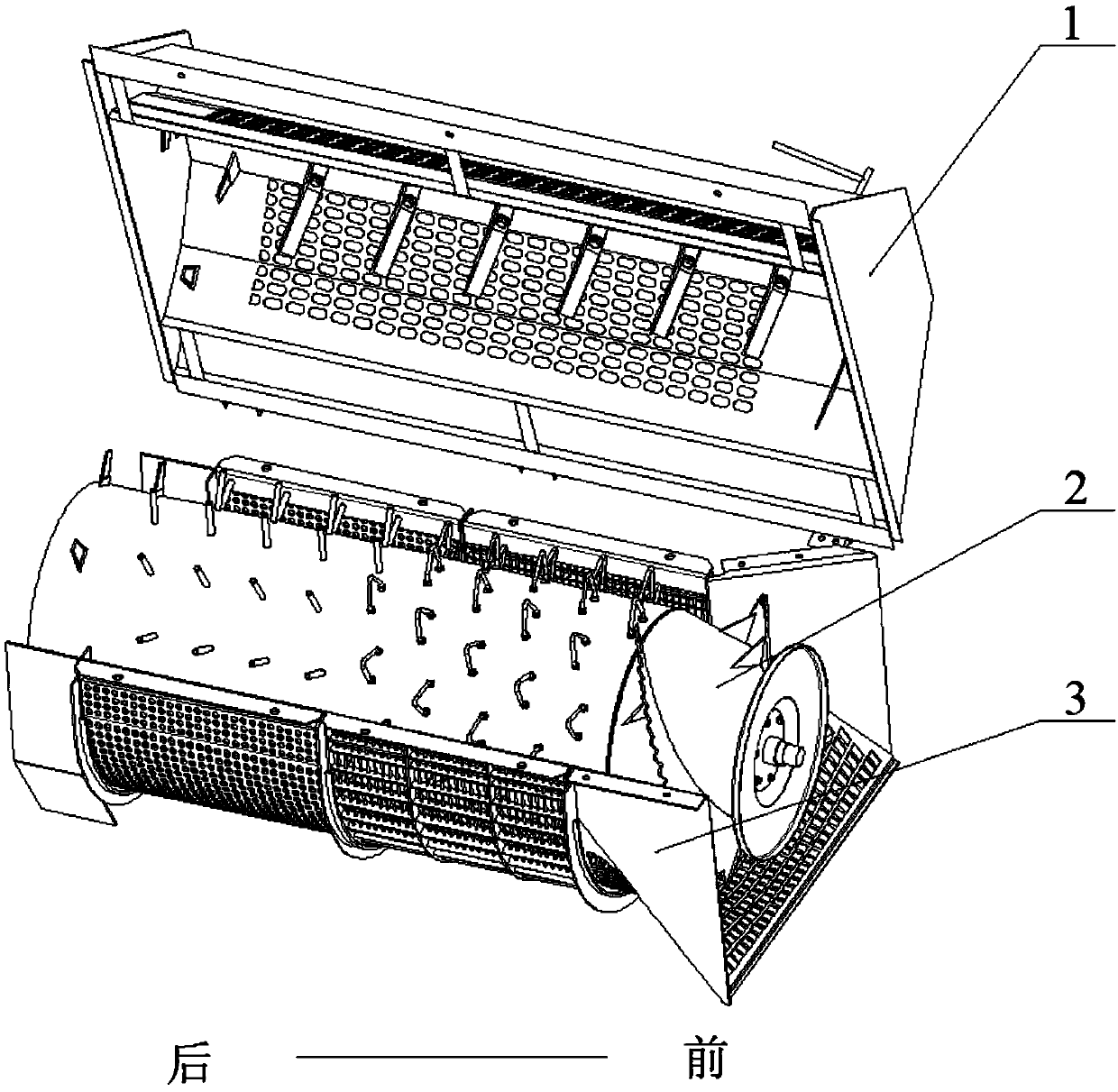

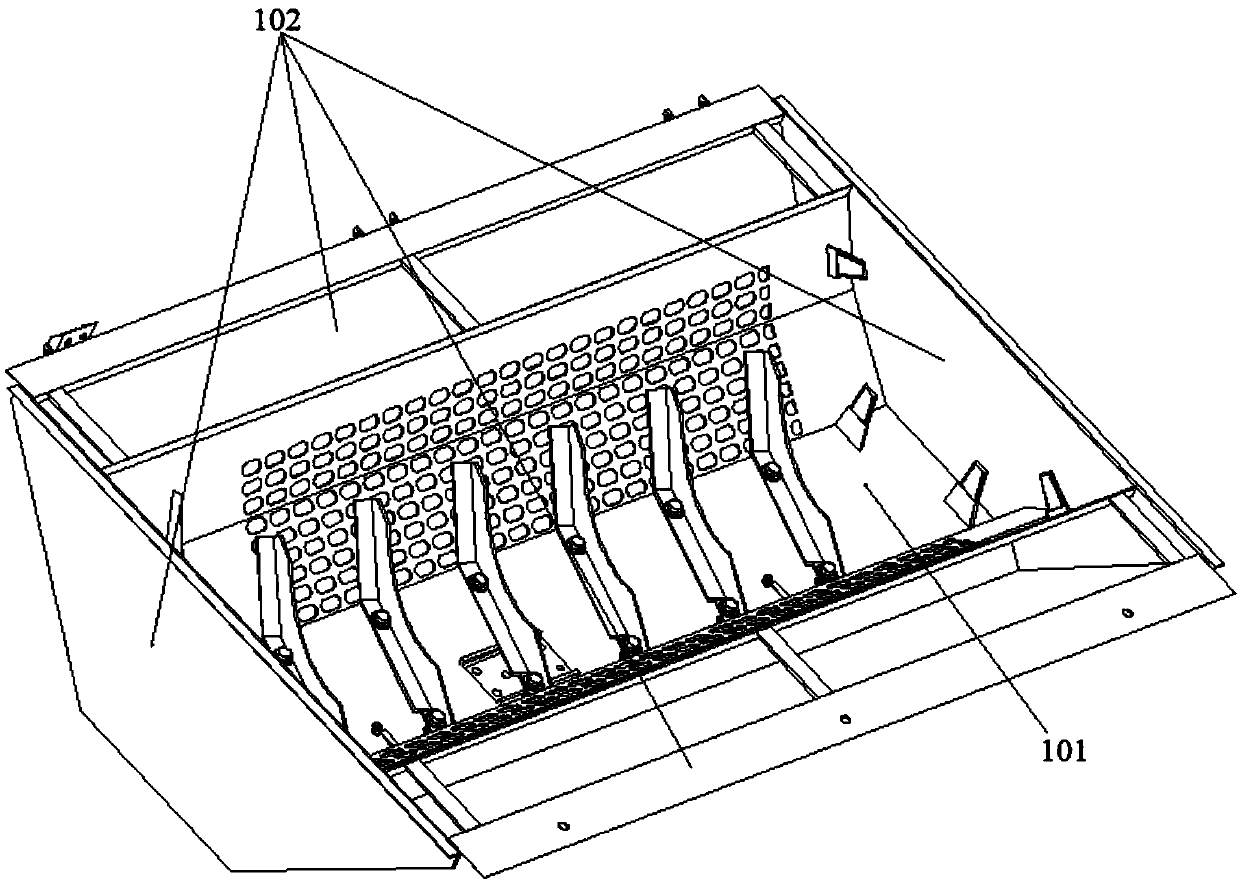

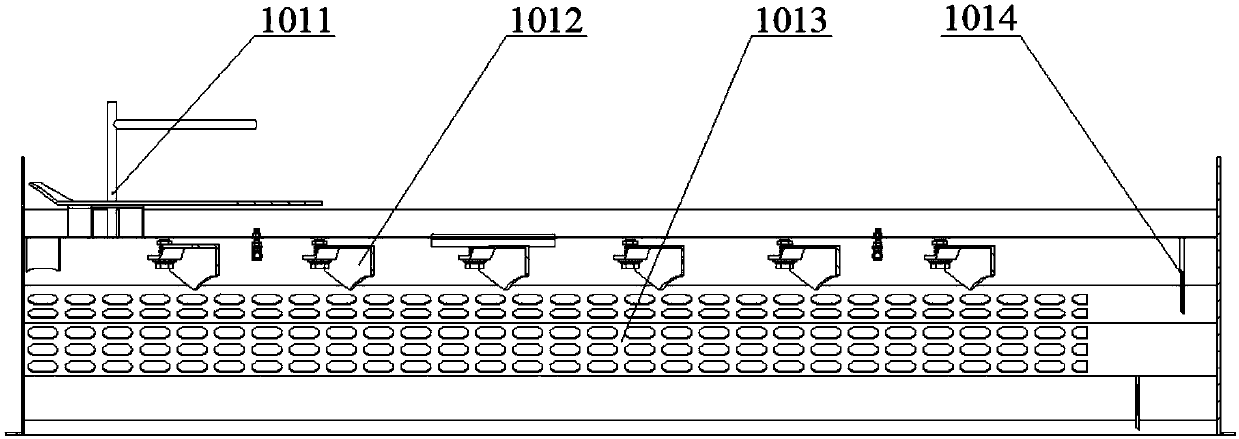

Low-damage anti-clogging gap-adjustable longitudinal-axial-flow high-water-content corn threshing and separation device

The invention discloses a threshing and separation device. The device comprises a feeding protection cover, a threshing roller, a top cover, a separation concave plate, a threshing concave plate and racks; the threshing roller is rotatably mounted on the rear rack, the feeding protection cover is mounted on the front rack and located in front of the threshing roller, the top cover is mounted abovethe threshing roller, the threshing concave plate and the separation concave plate are mounted below the threshing roller separately, and the distance between the threshing concave plate and the feeding protection cover is smaller than that between the separation concave plate and the feeding protection cover. The threshing and separation device can ensure that the corn threshing process under high water content is completed, and reduce the grain breakage rate or even ensure that no grains are broken.

Owner:CHINA AGRI UNIV

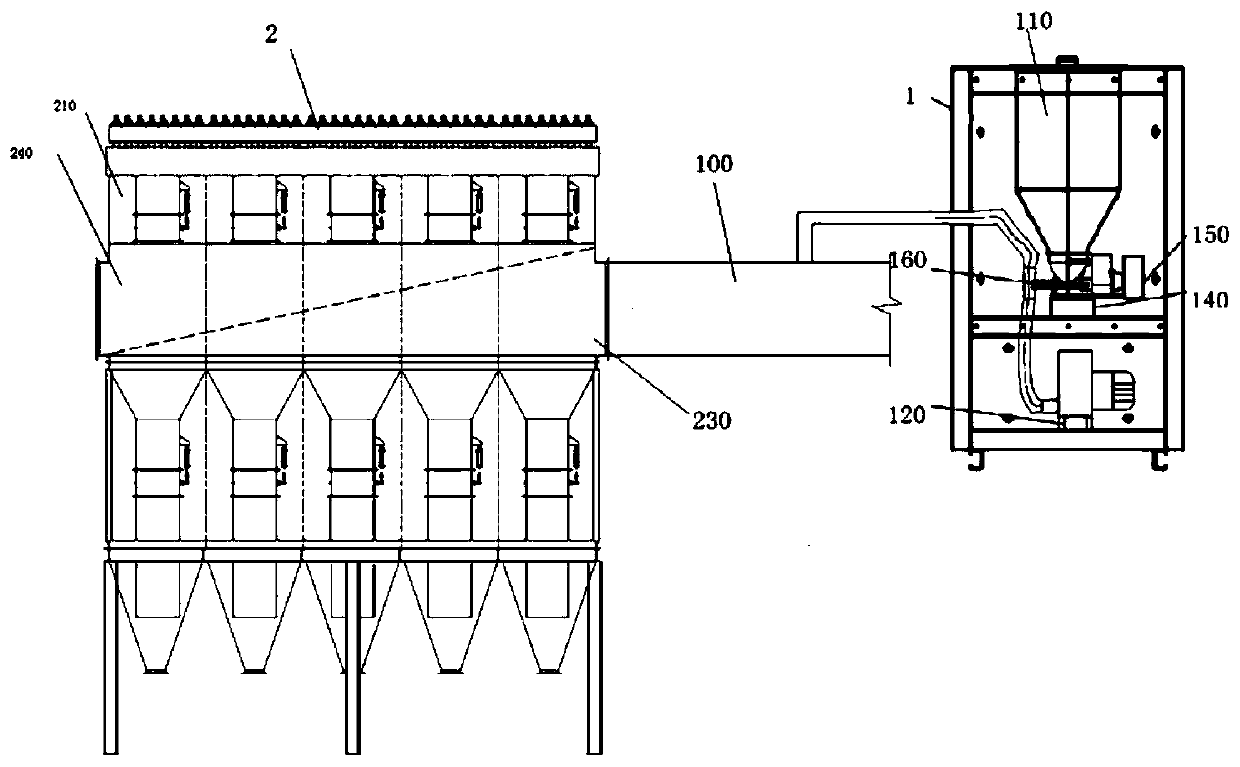

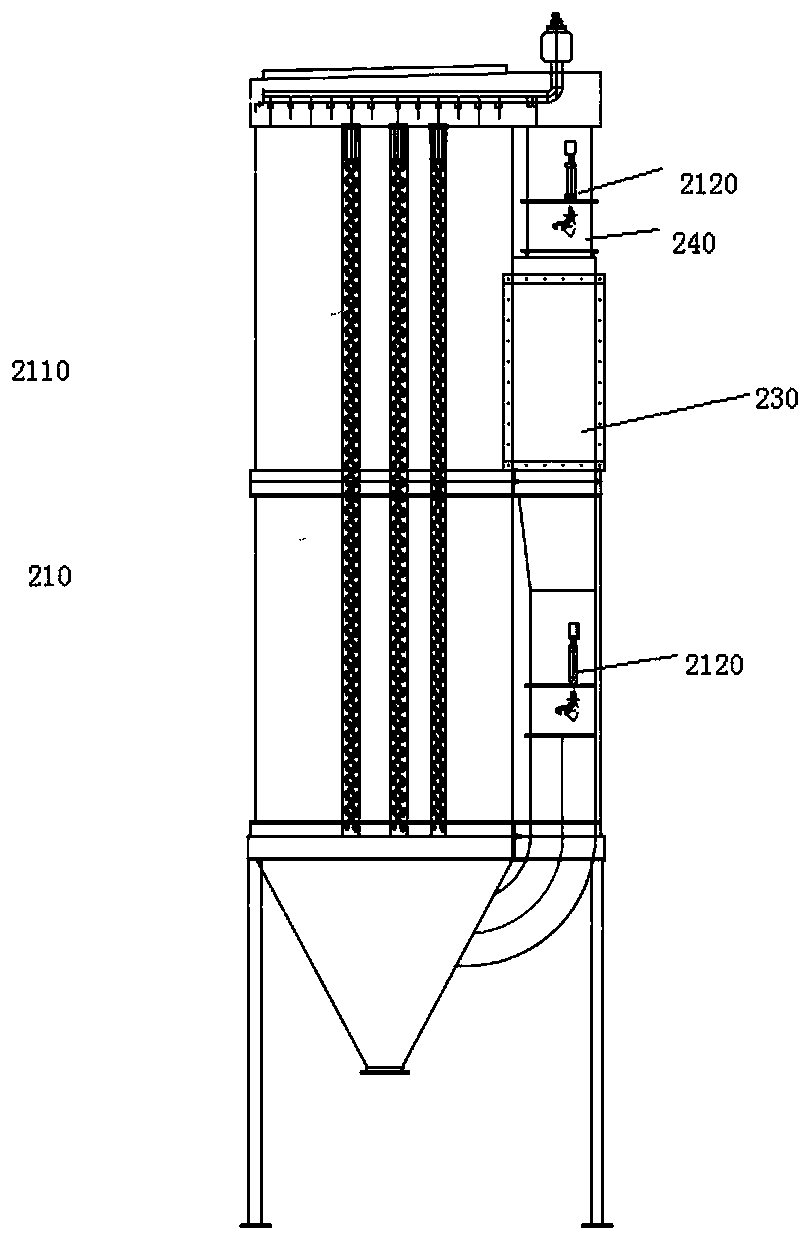

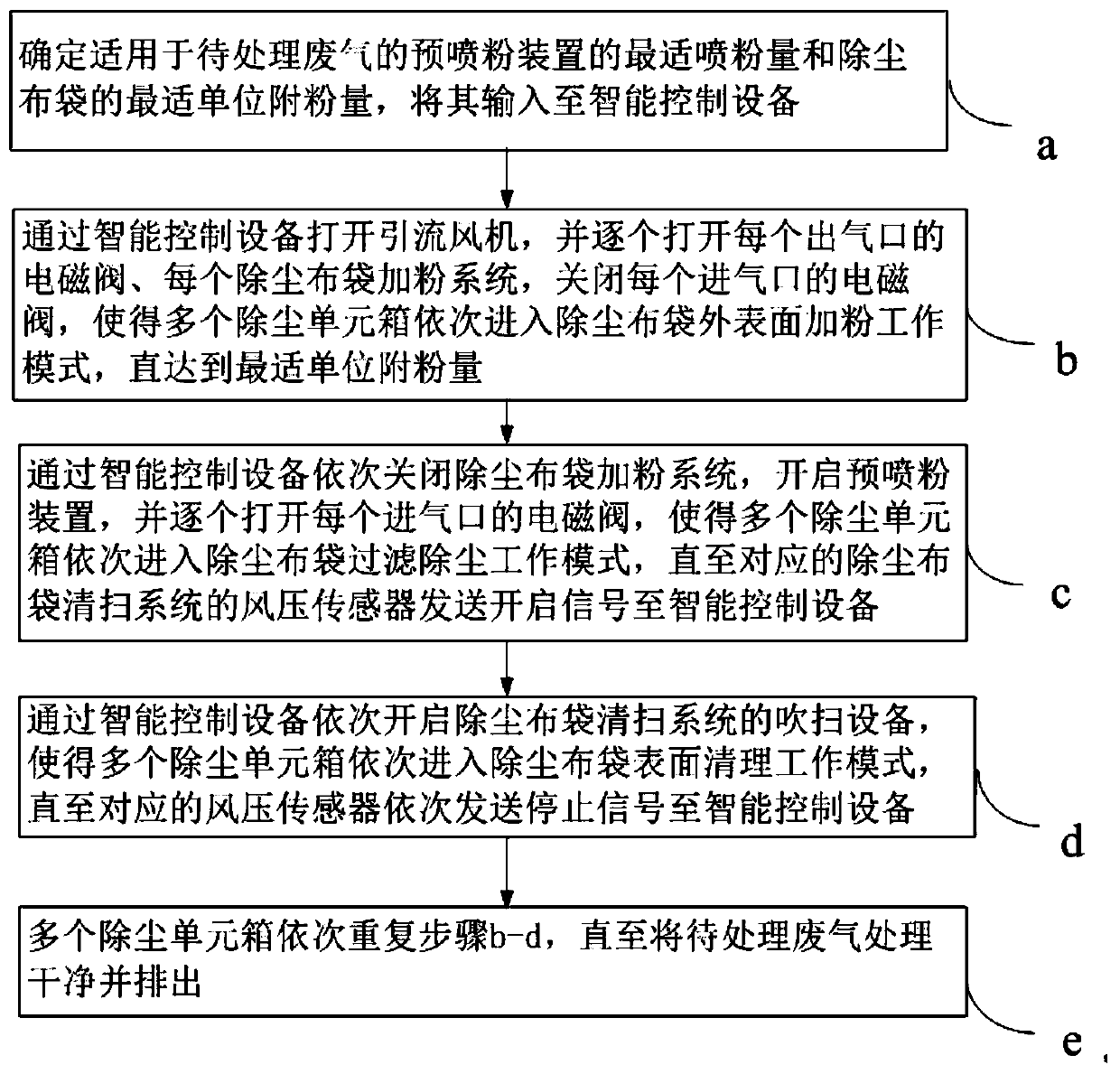

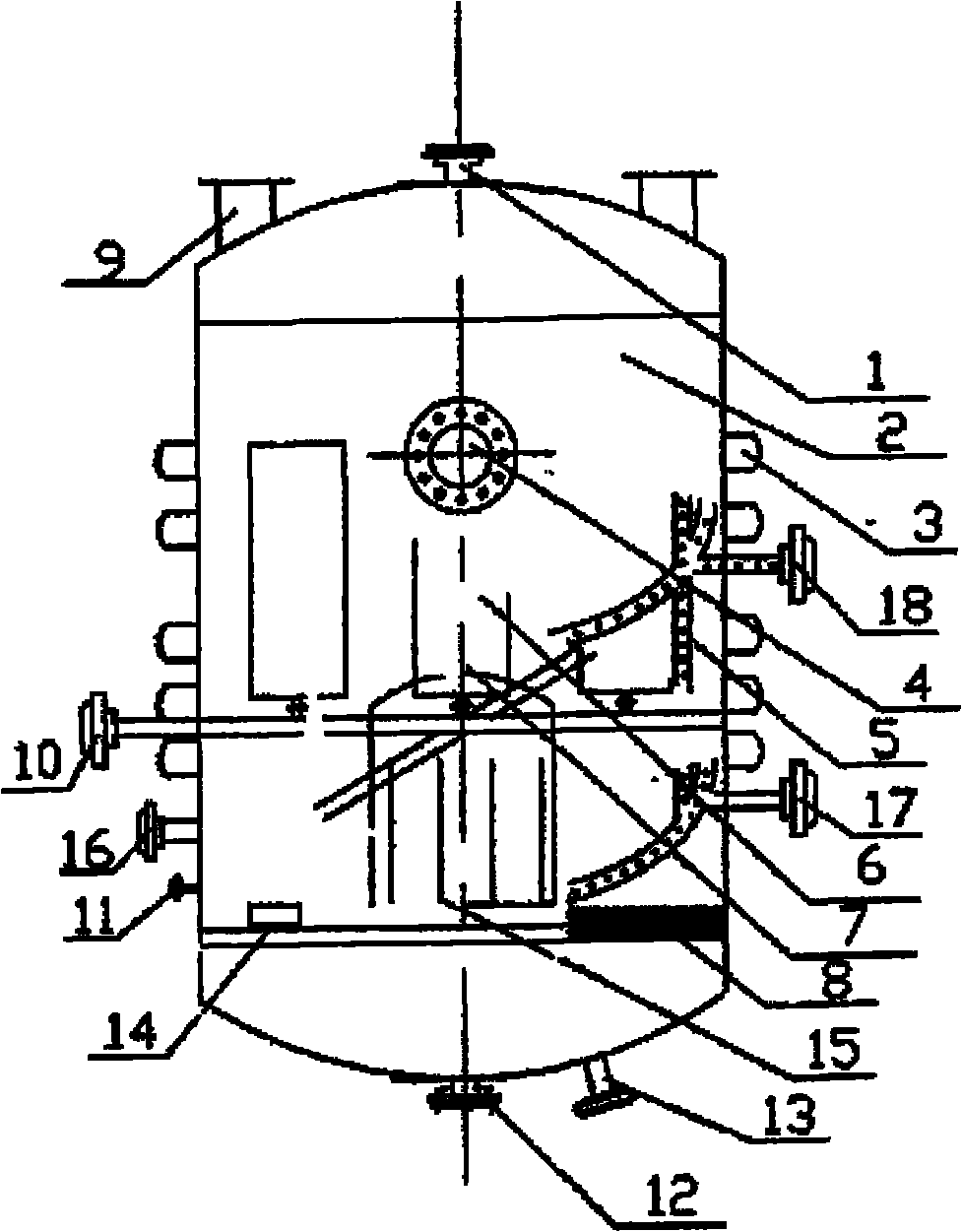

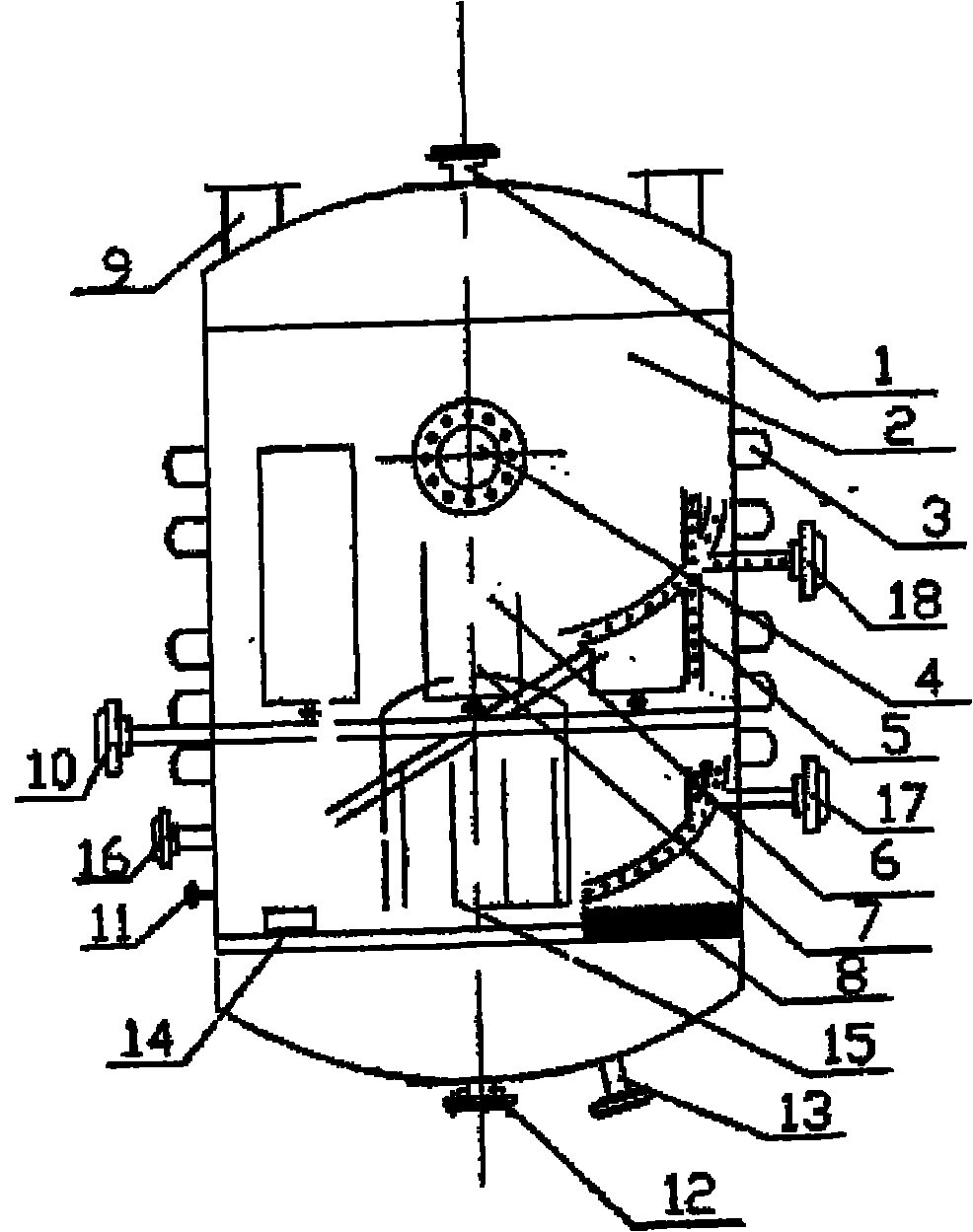

Processing system and method for waste gas containing sticky dust

PendingCN109758841AGuaranteed removal rateEnsure the removal rate of viscous dust in the exhaust gas and the removal rateDispersed particle filtrationHuman health protectionFiltrationFilter material

The invention relates to a processing system and method for waste gas containing sticky dust. The processing system for the waste gas comprises a pre-powder-injection device, bag-type dust removal equipment and intelligent control equipment, wherein a material outlet of the pre-powder-injection device and an inlet of the bag-type dust removal equipment are arranged on a waste gas pipeline in sequence along an airflow direction of the waste gas; the bag-type dust removal equipment is provided with a plurality of dust removal unit boxes working independently, wherein each dust removal unit box has three working modes: adding powder to an outer surface of the dust removal bag, removing dust through filtration by the dust removal bag and cleaning a surface by the dust removal bag; the intelligent control equipment is used for controlling the plurality of dust removal unit boxes to work in sequence; and each dust removal unit box is circularly switched to work under the three working modes,and when at least one dust removal unit box is under the working mode of removing dust through filtration by the dust removal bag, the pre-powder-injection device is opened. According to a technologycombining pre-powder-injection with bag-type powder coating, the technical problems in the prior art that the sticky dust of the waste gas is adhered to the surface of a filtering material to block the filtering material and cannot be cleaned are solved; meanwhile, a sticky dust removal rate in the waste gas is guaranteed to be greater than or equal to 90%; the technology is intensified; and operation cost is low.

Owner:JINHUA ANKE ENVIRONMENTAL PROTECTION TECHNOLOGY CO LTD

Demineralizing, purifying and filtering device in epoxy resin production

ActiveCN101805441AFast filteringUnique sealing structureStationary filtering element filtersEpoxyWax

The invention discloses a demineralizing, purifying and filtering device in epoxy resin production. A material inlet is arranged on the upper part of a filter. A material outlet pipe / vacuum joint is arranged on the lower part of the filter. An upper set, a middle set and a lower set of filter cores are arranged in the filter. The first set of filter core is arranged on the lower part in a horizontal paving form. The second set of filter core is arranged on the first set of filter core and the third set of filter core, a filtering medium adopts a wax filter core, and the wax filter core is connected with a first filter liquor collecting pipe. The third set of filter core adopts a leaf filtering plate as the filtering medium, and the leaf filtering plate is vertically arranged between the first set of filter core and the third set of filter core and connected with a second filter liquor collecting pipe. An upper and a lower nitrogen / dry steam inlets are arranged on the filter and connected with a nitrogen boiling bed. The invention has reasonable structure, can ensure the separation of salt, aged resin and epoxy resin, and has no influence on the production process and the product quality of the epoxy resin.

Owner:NANTONG XINGCHEN SYNTHETIC MATERIAL

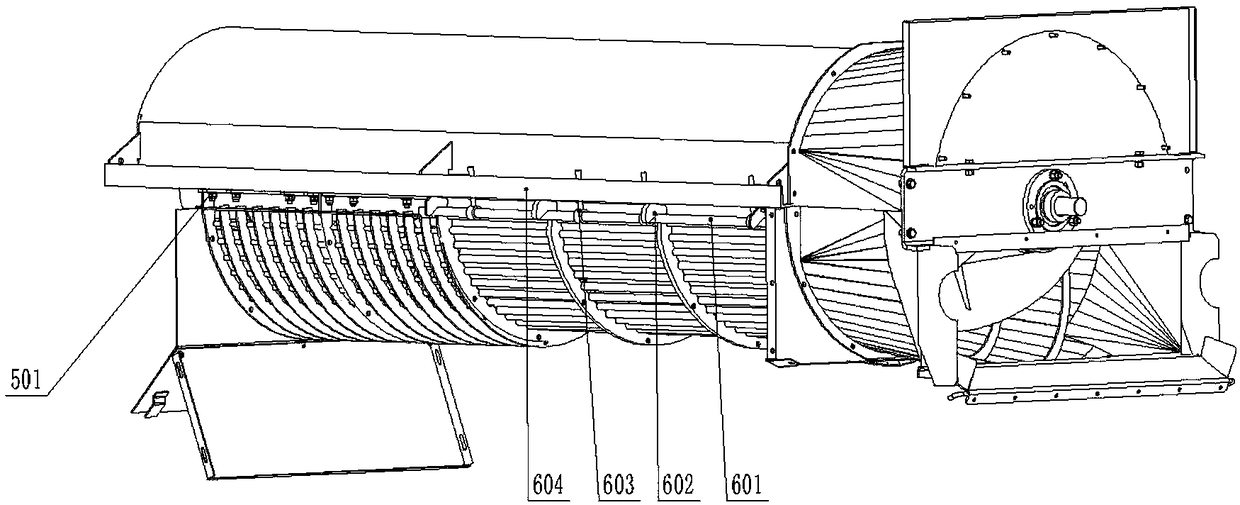

Forced feeding, threshing, separating and smashing integrated device for first-harvest rice

PendingCN109588120AClear division of laborReduce breakage rateMowersThreshersSpiral bladeEngineering

The invention provides a forced feeding, threshing, separating and smashing integrated device for first-harvest rice. The forced feeding, threshing, separating and smashing integrated device for first-harvest rice comprises a closed multifunctional threshing cylinder, a flow guide separable grass breaking top cover and a combined concave plate, wherein the threshing cylinder comprises a cylinder shaft feeding head and a cylinder body, a spiral blade is mounted on the feeding head, and an arc tooth group, a spike tooth group and a roller rotating blade group are distributed on the circumferenceof the cylinder body sequentially; the combined concave plate is located below the closed multifunctional threshing cylinder and comprises a transition concave plate, a threshing concave plate, a separating concave plate and a grass guiding concave plate sequentially; the flow guide separable grass breaking top cover is mounted above the closed multifunctional threshing cylinder and comprises a top cover inner shell and reinforcing plates, and the top cover inner shell comprises an adjusting mechanism, flow guide bars, punching plates and top cover fixed blades. The forced feeding, threshing,separating and smashing integrated device is applicable to feeding, threshing, separating and smashing of the first-harvest rice with different characteristics, has the advantages of compact structure, large separation area, light weight and the like, can effectively improve threshing performance and efficiency of the first-harvest rice and has lower power consumption.

Owner:JIANGSU UNIV

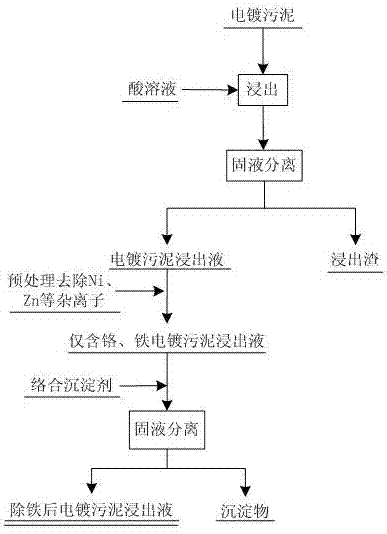

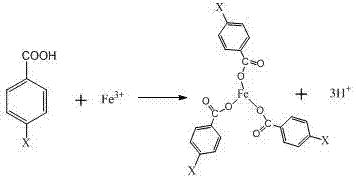

Method for separating chromium from iron in electroplating sludge leaching liquid through complexing precipitation

ActiveCN107201447AAchieve removalGuaranteed removal rateProcess efficiency improvementBenzoic acidPregnant leach solution

The invention discloses a method for separating chromium from iron in electroplating sludge leaching liquid through complexing precipitation. Benzoic acid or derivatives of the benzoic acid are used as complexing precipitants to separate chromium ions from iron ions in the electroplating sludge leaching liquid where only Fe3+ and Cr3+ are left after Ni, Zn, Cu and other hetero-ions are removed through pretreatment, and the iron ions contained in the leaching liquid are removed in a precipitation mode. By controlling the using amount of the complexing precipitants, the reaction temperature, the solution pH value and the reaction time, the removing rate of the iron ions in the electroplating sludge leaching liquid can reach 95% or above, and the loss of the chromium does not exceed 5%. Compared with the prior art, the method for separating the chromium from the iron through complexing precipitation has the low requirements for equipment and is easy to operate, and an obtained precipitate is easy to filter and has no pollution to the environment.

Owner:JIANGXI UNIV OF SCI & TECH +1

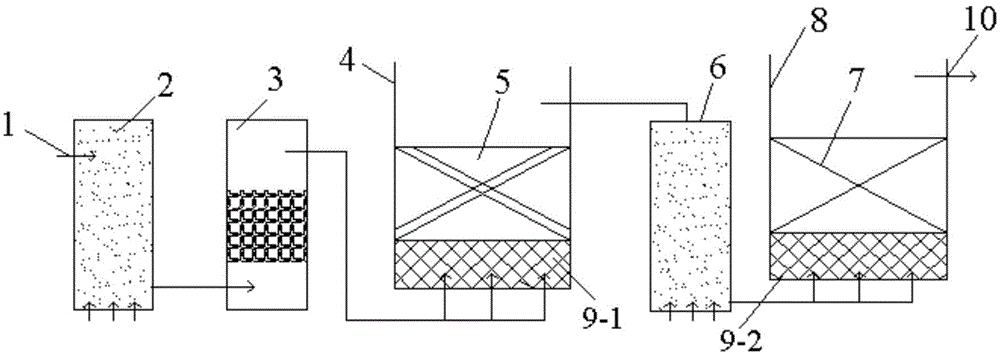

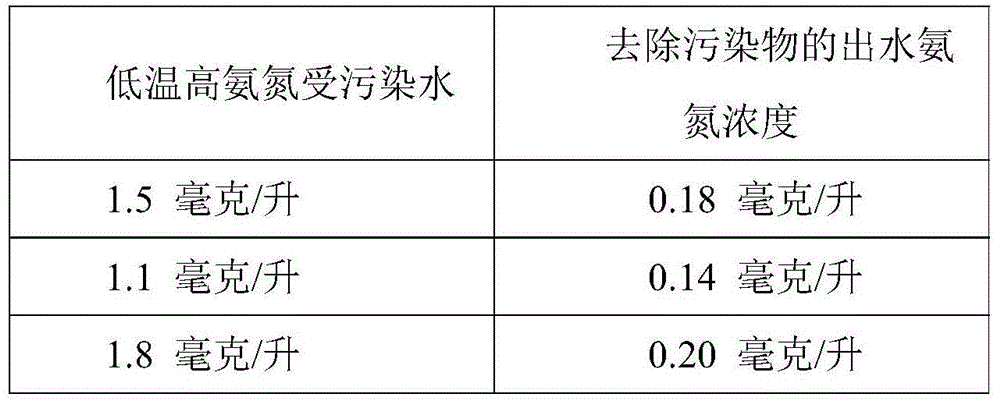

Two-stage deep-bed upward flow composite filter material biological filter and method for treating low-temperature high-ammonium-nitrogen polluted water by utilizing same

ActiveCN104876395AEfficient removalImproved shock load capabilityWater contaminantsMultistage water/sewage treatmentBiological filterCatalytic oxidation

The invention relates to a two-stage deep-bed upward flow composite filter material biological filter and a method for treating low-temperature high-ammonium-nitrogen polluted water by utilizing the same, and relates to a water treatment device and a water treatment method. The method can be used for solving the problems of the traditional method for treating low-temperature heavily-polluted water that the capability for degrading ammonium-nitrogen and organic matters in the water is remarkably lowered, the organic matters and ammonium-nitrogen pollutants in the water cannot be degraded, and the sudden increment of the pollutant concentration cannot be handled. An apparatus comprises a first-stage upward-flow biological filter, a second-stage upward-flow biological filter, a nitrogen charging unit, a composite filter material layer, a main body filter material layer, a first carrying layer and a second carrying layer. The method comprises the following steps: carrying out the treatment on the low-temperature high-ammonium-nitrogen polluted water passing by a water inlet end, an ozone contact oxidation unit, an ozone catalytic oxidation unit, the first-stage upward-flow biological filter, the nitrogen charging unit and the secondary upward-flow biological filter, obtaining the water with pollutants removed, and discharging the purified water by virtue of a water outlet end for external supply. The method for treating the low-temperature high-ammonium-nitrogen polluted water by utilizing the two-stage deep-bed upward flow composite filter material biological filter is applicable to treating the low-temperature high-ammonium-nitrogen polluted water.

Owner:HARBIN INST OF TECH

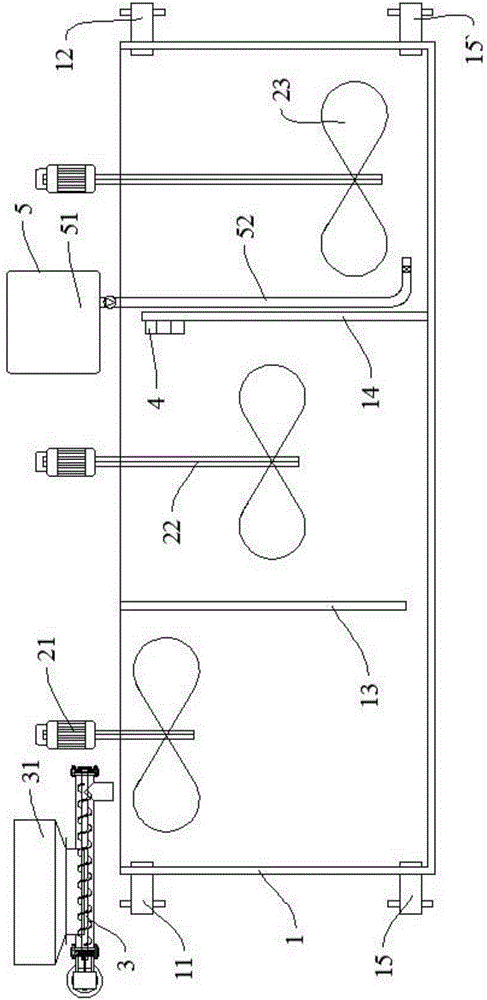

Accurate feeding method and device in sewage treatment processes

InactiveCN104944553AGuaranteed removal rateSaving castEnergy based wastewater treatmentWater/sewage treatment by flocculation/precipitationPropellerPollutant

An accurate feeding device in sewage treatment processes comprises a reaction tank, propellers, a medicine feeding machine, a liquid level meter, a medicine supplementing machine, a flow valve, a flow meter, a temperature sensor, a PH value sensor, a DO sensor, a suspended solid sensor, a conductivity sensor and a computer control system. Blades of the propeller of a front section tank body are located on the upper portion of a tank body, blades of the propeller of a back section tank body are located at the bottom of the tank body, the medicine supplementing machine is erected above the liquid level of the back section tank body, medicine liquid is contained in a storage box of the medicine supplementing machine, a liquid outlet of the storage box is connected with a medicine applying pipe through a pump, a pipe opening of the medicine applying pipe stretches into the position under the propeller of the back section tank body, and the pipe opening of the medicine applying pipe is provided with a one-way valve to prevent sewage in the tank body from flowing backwards. The invention further provides an accurate feeding method in the sewage treatment processes. By utilizing the method that medicine feeding is firstly performed and medicine supplementing is secondly performed and synthesizing water temperature and environment factors, accurate medicine feeding is achieved, the removal rate of pollutants is guaranteed, the medicine applying amount is saved, and the cost is saved.

Owner:JIANGSU LV CHUAN ENVIRONMENTAL PROTECTION TECH

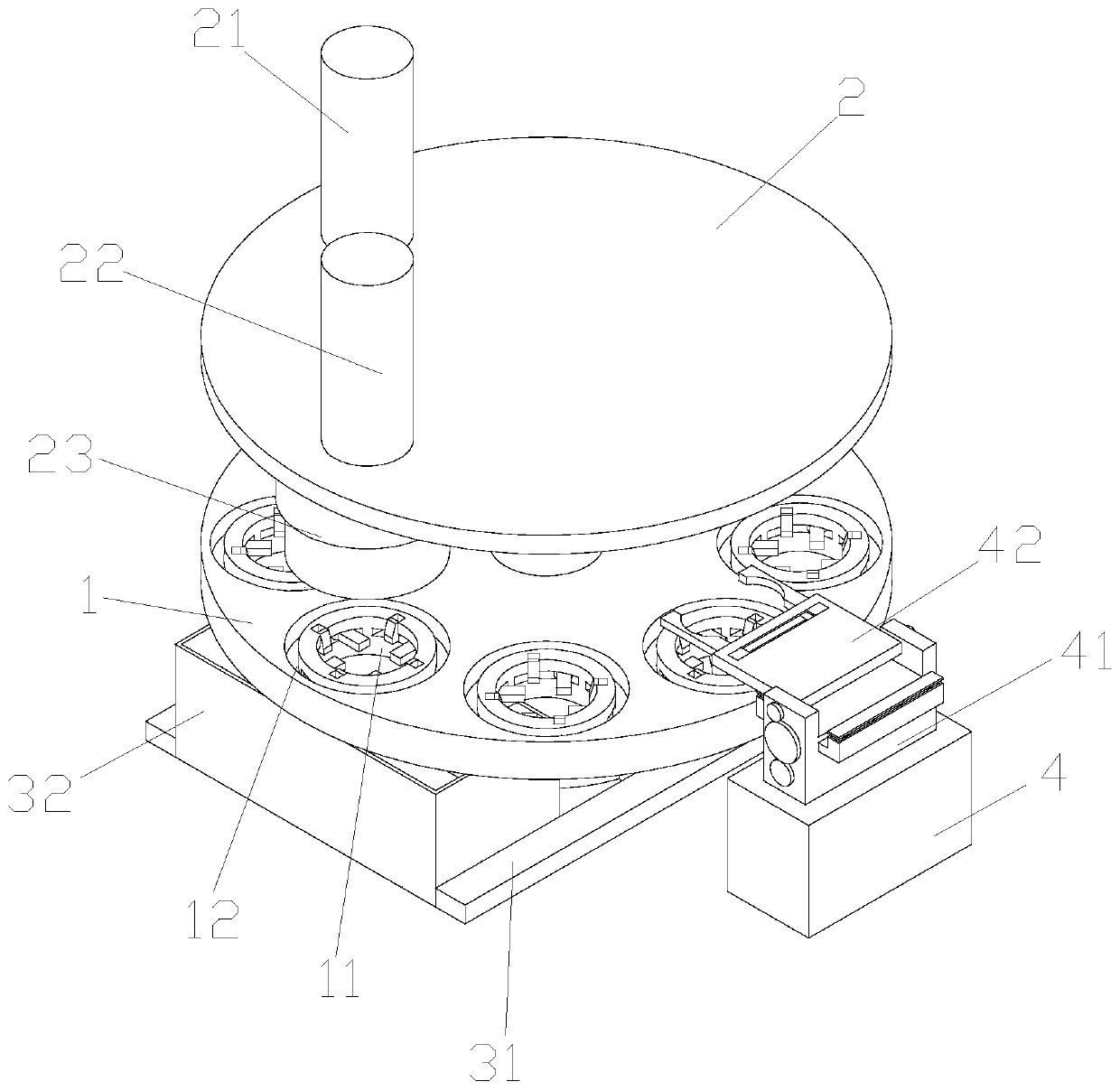

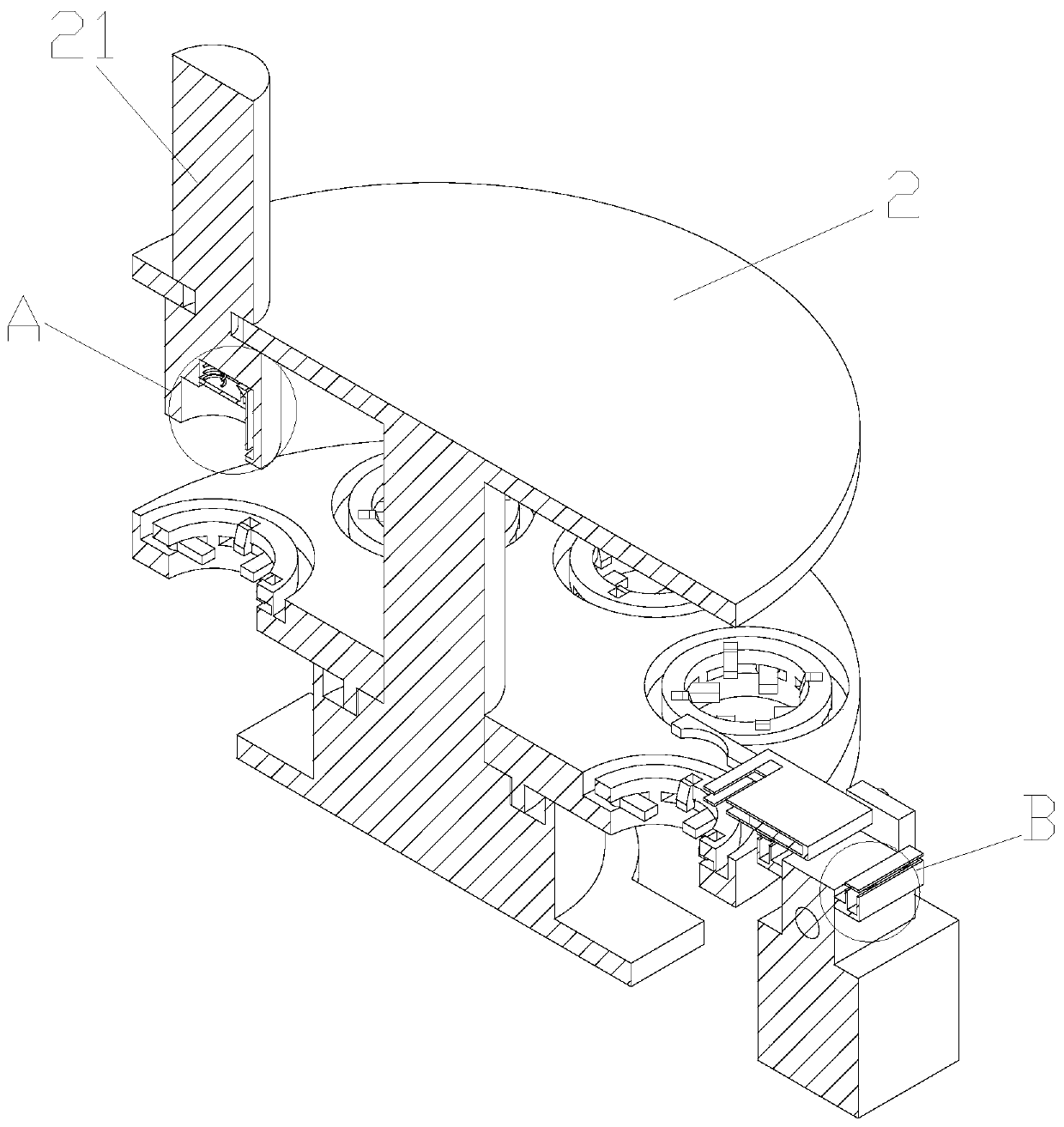

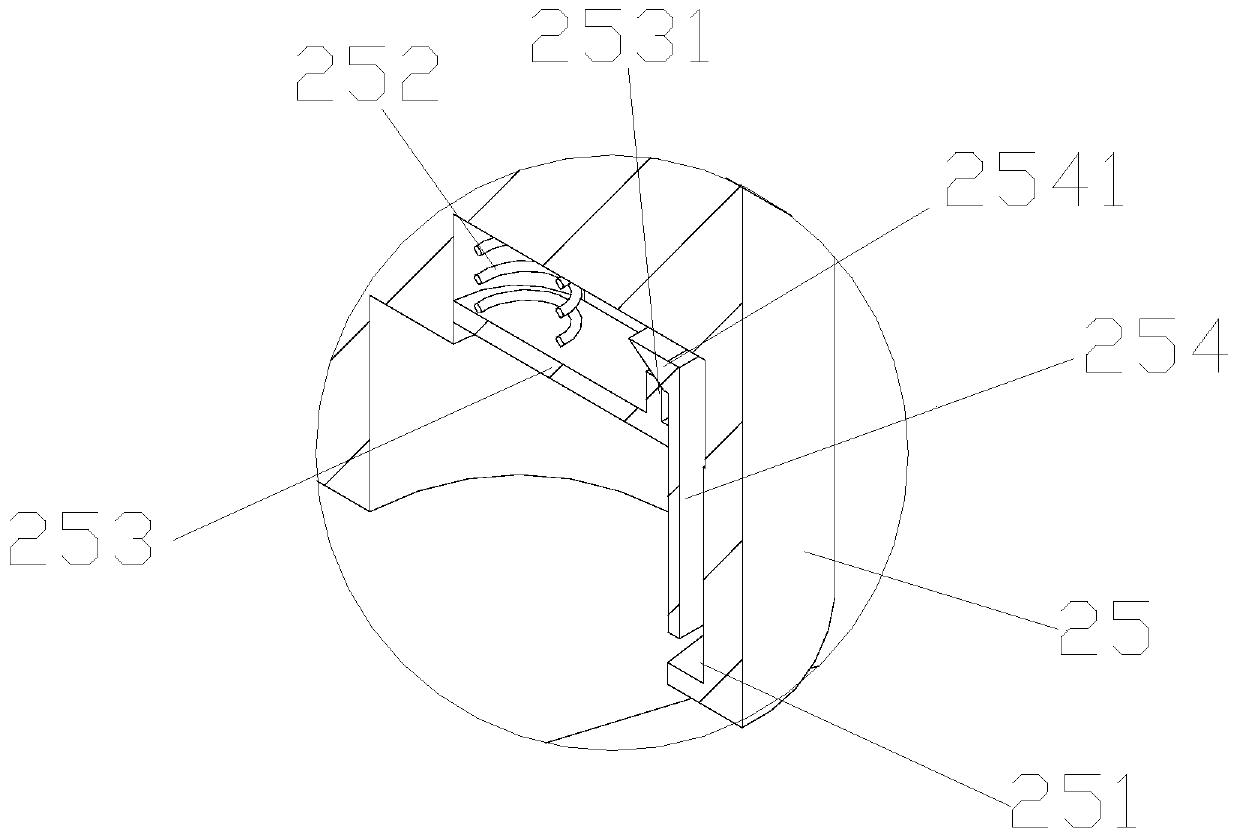

Production line for production of LED lamps

The invention discloses a production line for production of LED lamps. The production line involves a rotating table, a base and a mounting plate, wherein the base is arranged at the bottom of the rotating table, and the mounting plate is arranged above the rotating table; a centre shaft is arranged on the base, the centre shaft is arranged on the rotating table in a penetrating mode, a first driving motor used for driving the rotating table to rotate is arranged on the base, and a plurality of fixing grooves are formed in the rotating table; a detection assembly and a driving assembly are arranged on the mounting plate, transmission grooves matched with the driving assembly are formed in the rotating table, and the transmission grooves are arranged on the outer sides of the fixing grooves; and after the driving assembly is embedded into the transmission grooves, the fixing grooves are in a through state. The driving assembly is matched with the transmission grooves, so that defectiveproducts are directly removed when the detection assembly detects the defective products, manual screening is not needed in the later stage, the defective product removal rate is guaranteed, the defective products are prevented from being mixed with finished products, and the quality of lamp bulb final products is guaranteed.

Owner:ZHEJIANG MEIKE ELECTRICAL APPLIANCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com