Multi-mode sequencing batch active sludge sewage treatment method and system

An activated sludge and sequencing batch technology, which is applied in the field of multi-mode constant water level sequencing batch activated sludge improved sewage treatment, can solve the problems such as the need to improve the phosphorus removal effect, and achieve enhanced denitrification and NO3-N concentration Reduced, good effect, good effect of mud discharge method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

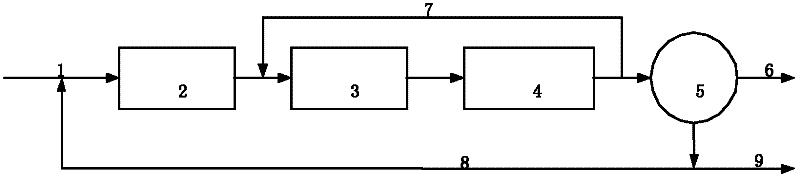

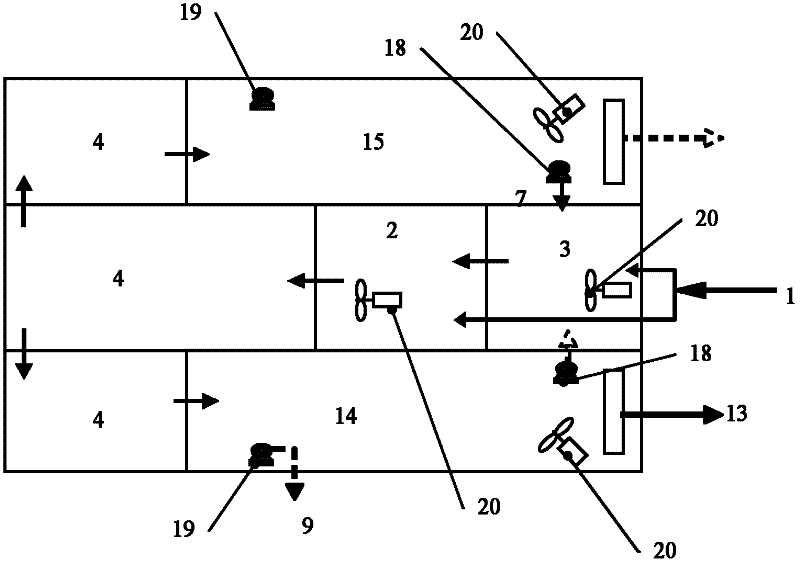

[0058] The present invention proposes a multi-mode constant water level sequence batch type activated sludge improved sewage treatment system, which includes a continuous tank grid in the middle and two symmetrically arranged constant water level first and second sequence batch tanks. The continuous tank grid in the middle includes: sludge thickening pre-anoxic tank, anoxic tank, anaerobic tank and the first aerobic tank. The facultative tank is set in the rear of the first aerobic tank, and the aerobic tank is equipped with aeration Head Valve and Agitator. The aerobic pool also includes a second and a third aerobic pool, which are respectively connected to the first and second sequence batch pools, and the second and third aerobic pools are arranged symmetrically with the first and second sequence batch pools on both sides of the continuous pool grid. On the side, there is a porous mud suction pipe in the batch batch tank; the anoxic tank is connected with the anaerobic tank...

Embodiment 2

[0059] Example 2: Treatment of sewage in anaerobic-anoxic-aerobic mode

[0060] The process of sewage is as follows: first, some or all of the sewage pretreated by the grille and the grit chamber enters the anaerobic tank, and is mixed with the return sludge from the sludge thickening pre-anoxic tank, so that the phosphorus accumulating bacteria in it can absorb Phosphorus is released by the volatile acid produced by the hydrolysis and acidification of sewage, and the residence time is 1 hour. The sewage in the pool is mixed with part of the sewage pretreated by the grid and the grit chamber, and at the same time, the mixed liquid in the aerobic pool flows into the anoxic pool through the pump to remove the nitrate brought by the return liquid, and the residence time is 1.0 hours; The sewage continues to flow into the aerobic tank and the first batch tank (at this time, the first batch tank is in the first half cycle of mixed liquid reflux, reaction, and static sedimentation),...

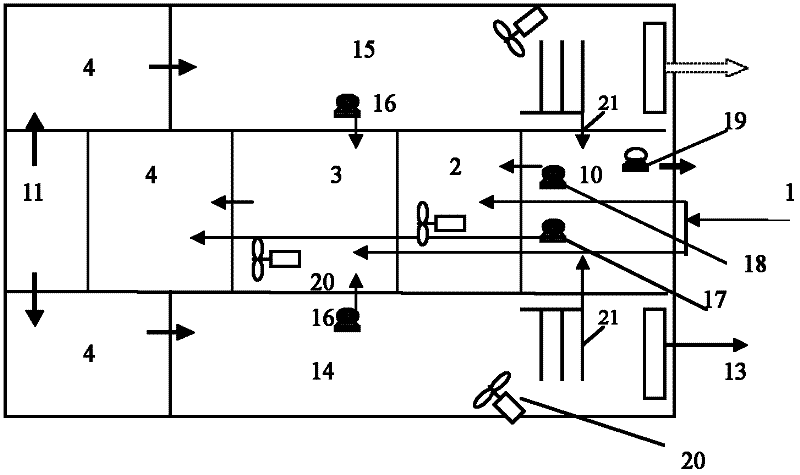

Embodiment 3

[0078] Example 3: Treatment of sewage in anoxic-anaerobic-aerobic mode

[0079]The process of sewage is as follows: part of the sewage pretreated by the grid and the grit chamber enters the anoxic tank, mixes with the concentrated sludge in the sludge concentration pre-anoxic tank, and at the same time refluxes with the mixed solution returned in the aerobic tank, The nitrate brought in the reflux liquid is removed, the volume ratio of the reflux sludge to the total system influent, that is, the reflux ratio, is 0.6:1, and the volume ratio of the reflux mixed liquid to the total system influent, that is, the reflux ratio is 1:1, and the retention The time is 2.0 hours; the sewage in the anoxic tank enters the anaerobic tank together with part of the sewage that has been pretreated by the grid and the grit chamber, and the two are mixed to make the phosphorus accumulating bacteria in it absorb the volatile acid produced by the hydrolysis and acidification of the sewage To relea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen consumption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com