Patents

Literature

176results about How to "Reduce the reflux ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

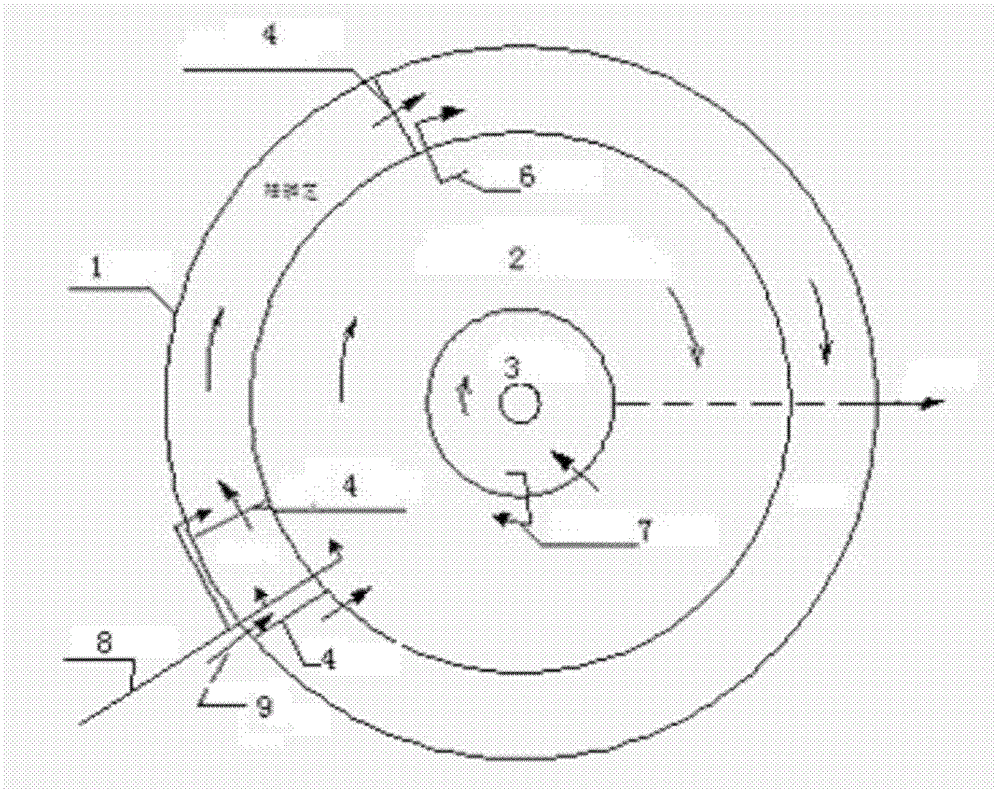

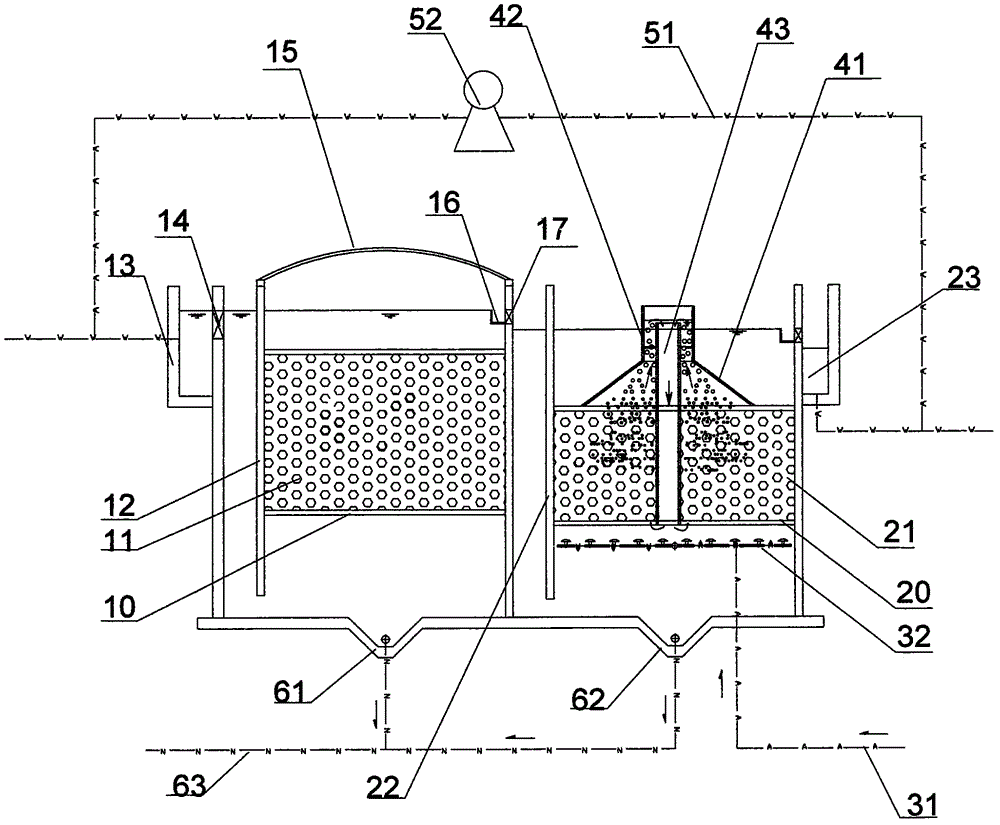

Integrated internal circulation type denitrification and decarburization bio-membrane reactor and operating method thereof

InactiveCN102659244AEfficient removalEfficient nitrogen and carbon removalTreatment with aerobic and anaerobic processesSludgeMembrane reactor

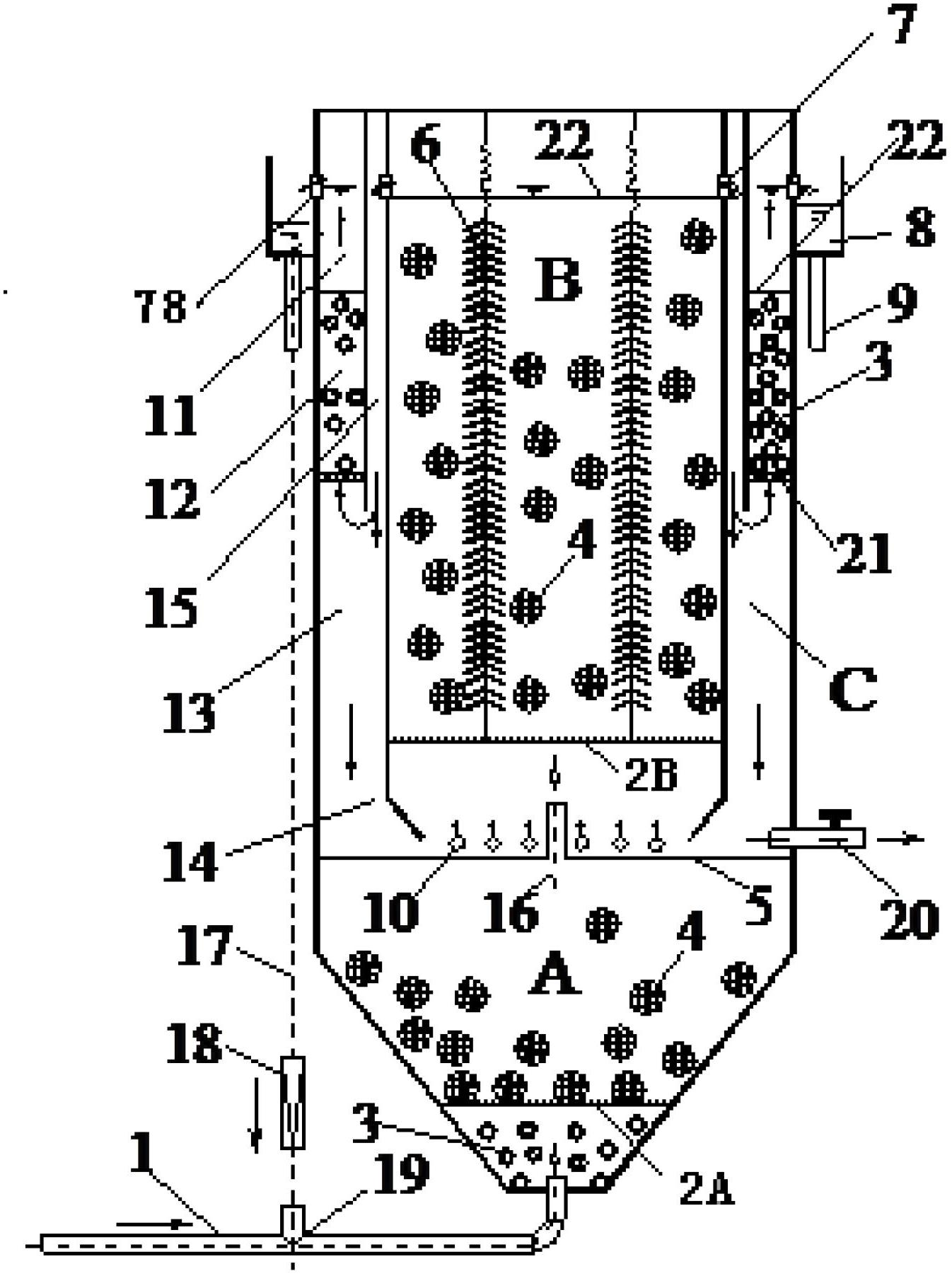

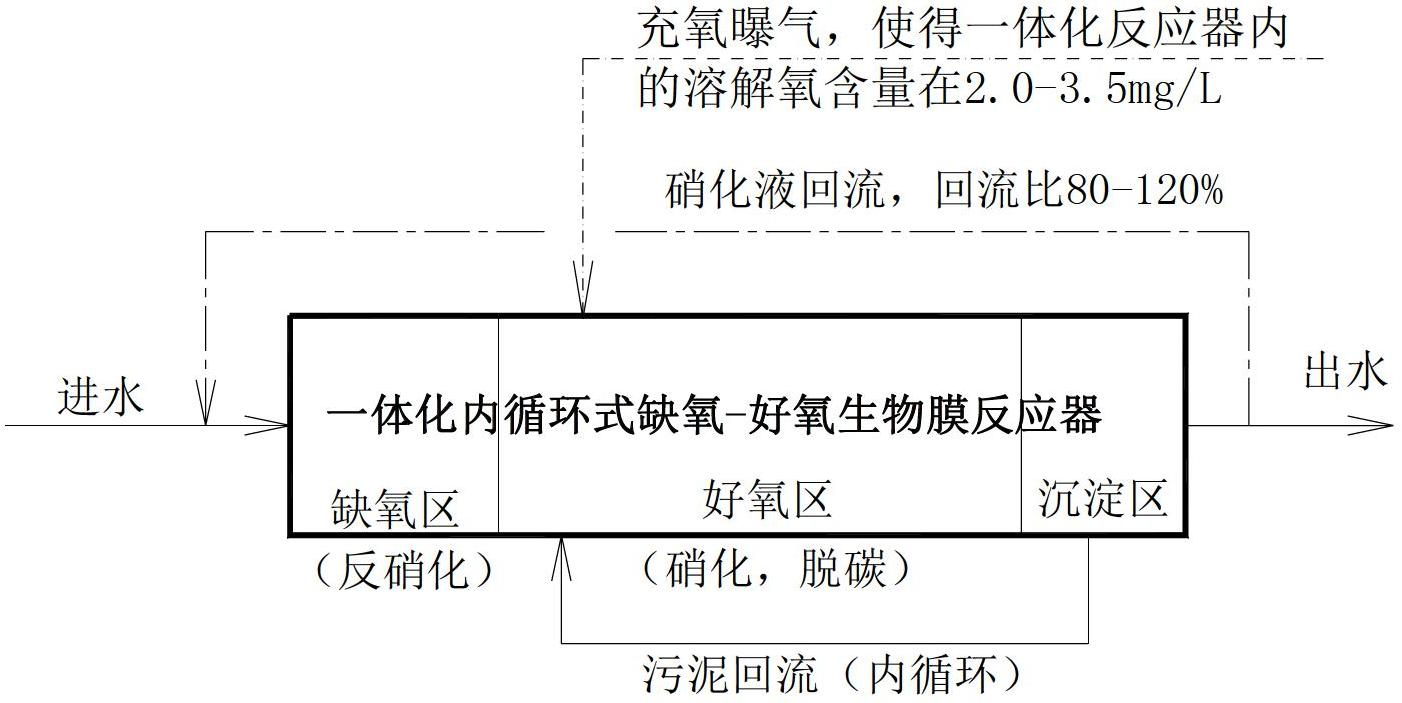

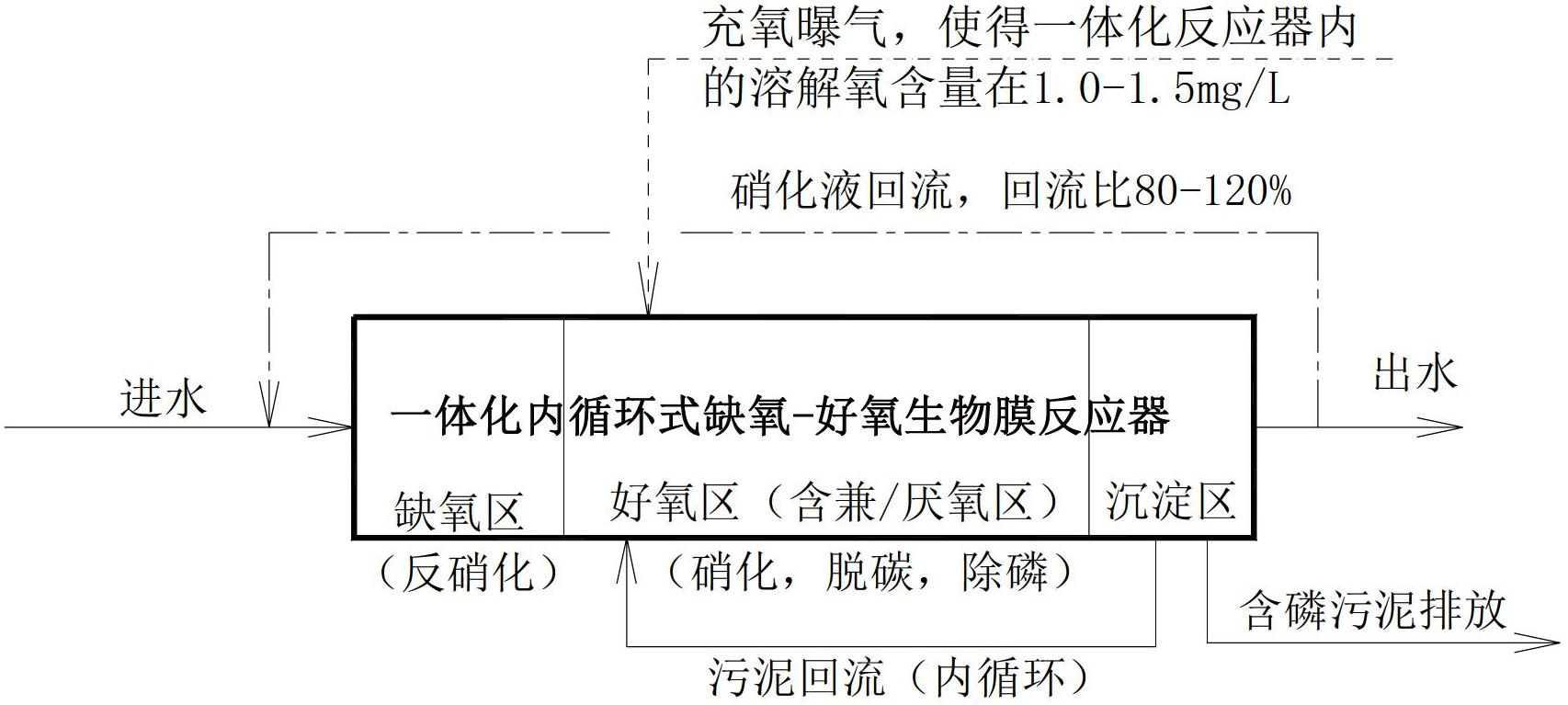

The invention provides an integrated internal circulation type denitrification and decarburization bio-membrane reactor and an operating method thereof. The main body of the reactor consists of an anoxic zone on the lower part, an aerobic zone on the upper part and a settling zone on the periphery of the aerobic zone; a composite filler is filled in the anoxic zone, and a water inlet pipe is communicated with the bottom of the anoxic zone; the aerobic zone is partitioned into a filler zone for adding a carrier on the upper part and a mud-water mixing zone on the lower part by adopting an orifice plate, the anoxic zone and the aerobic zone are partitioned through an impermeable partition plate, and a plurality of aeration pipes are arranged at the bottom of the aerobic zone and provided with air inlet pores; and the settling zone consists of three parts, namely a clean water zone, a contact settling zone and a sludge returning zone which are sequentially arranged from top to bottom, wherein the bottom of the sludge returning zone is provided with a sludge returning seam and communicated with the bottom of the aerobic zone. The reactor realizes zero power consumption in sludge returning, and is compact in structure; and a back flushing system is not required in the contact settling zone, and additional agents and carbon sources are not required, so that the reactor is low in running cost.

Owner:SUZHOU UNIV OF SCI & TECH

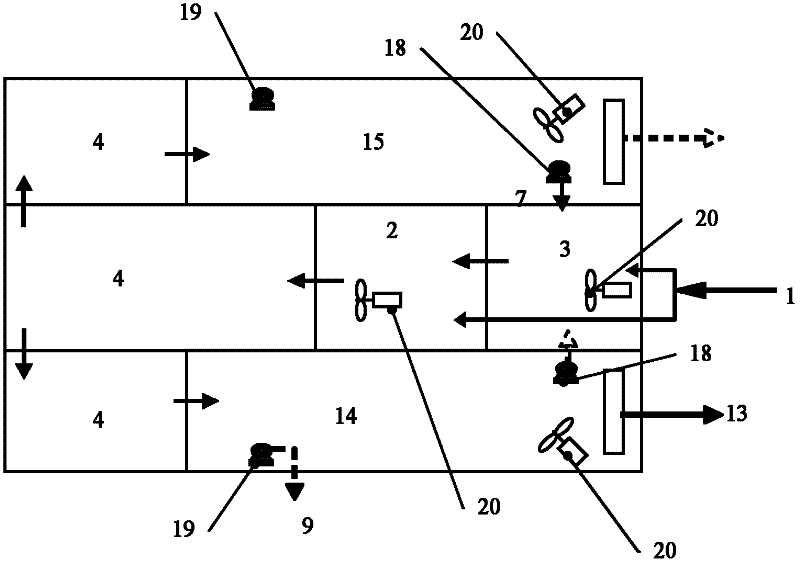

Multi-mode sequencing batch active sludge sewage treatment method and system

ActiveCN102502963AIncrease concentrationImprove phosphorus removal effectTreatment with aerobic and anaerobic processesAnaerobic aerobicNitrogen

The invention relates to a multi-mode constant-water-level sequencing batch active sludge sewage treatment method and system, belonging to the technical field of sewage treatment. The system comprises a sludge concentration pre-anoxic pond, an anaerobic pond, an anoxic pond, an aerobic pond, a facultative pond and a sequencing batch pond which are communicated, wherein the facultative pond runs in an aerobic or anoxic way. According to the system, multi-mode sewage treatment ways including an anaerobic-anoxic-aerobic mode, an anoxic-anaerobic-aerobic mode and an anaerobic-anoxic-aerobic-anoxic-aerobic mode can be performed. Due to the adoption of the sewage treatment method, the removing effects of nitrogen, phosphorus and organic matters can be enhanced, and equipment utilization ratio is increased.

Owner:THUNIP CORP LTD

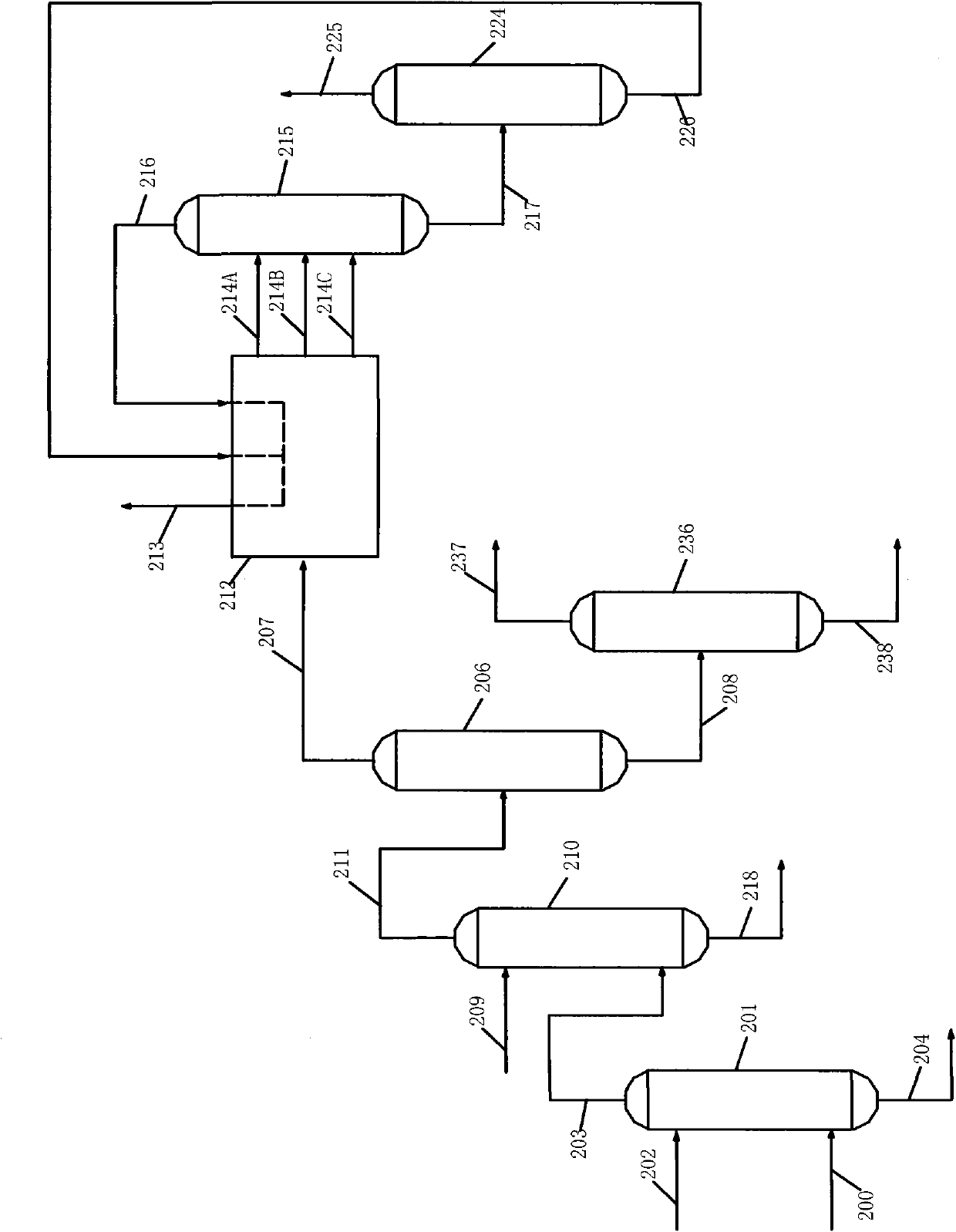

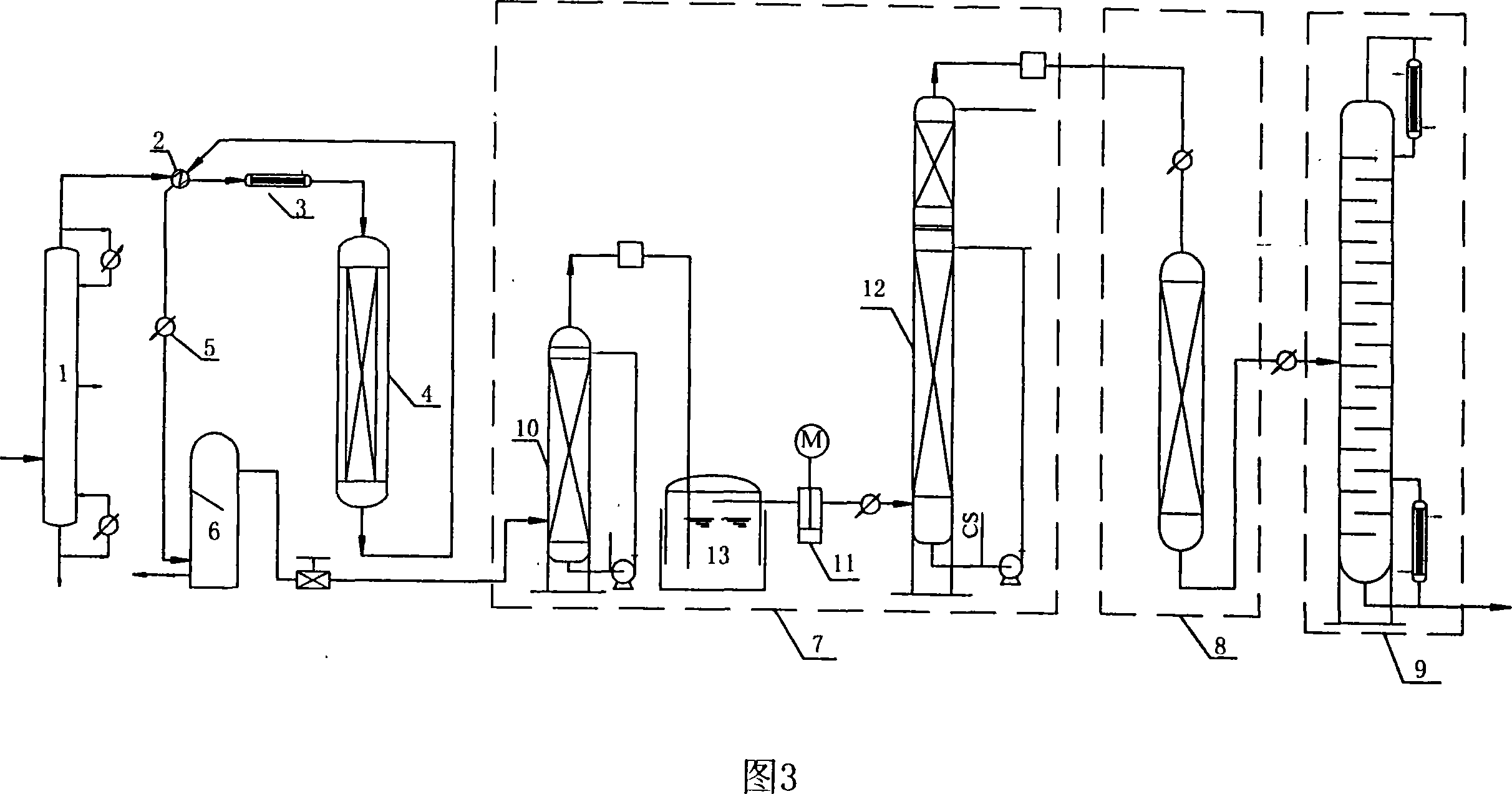

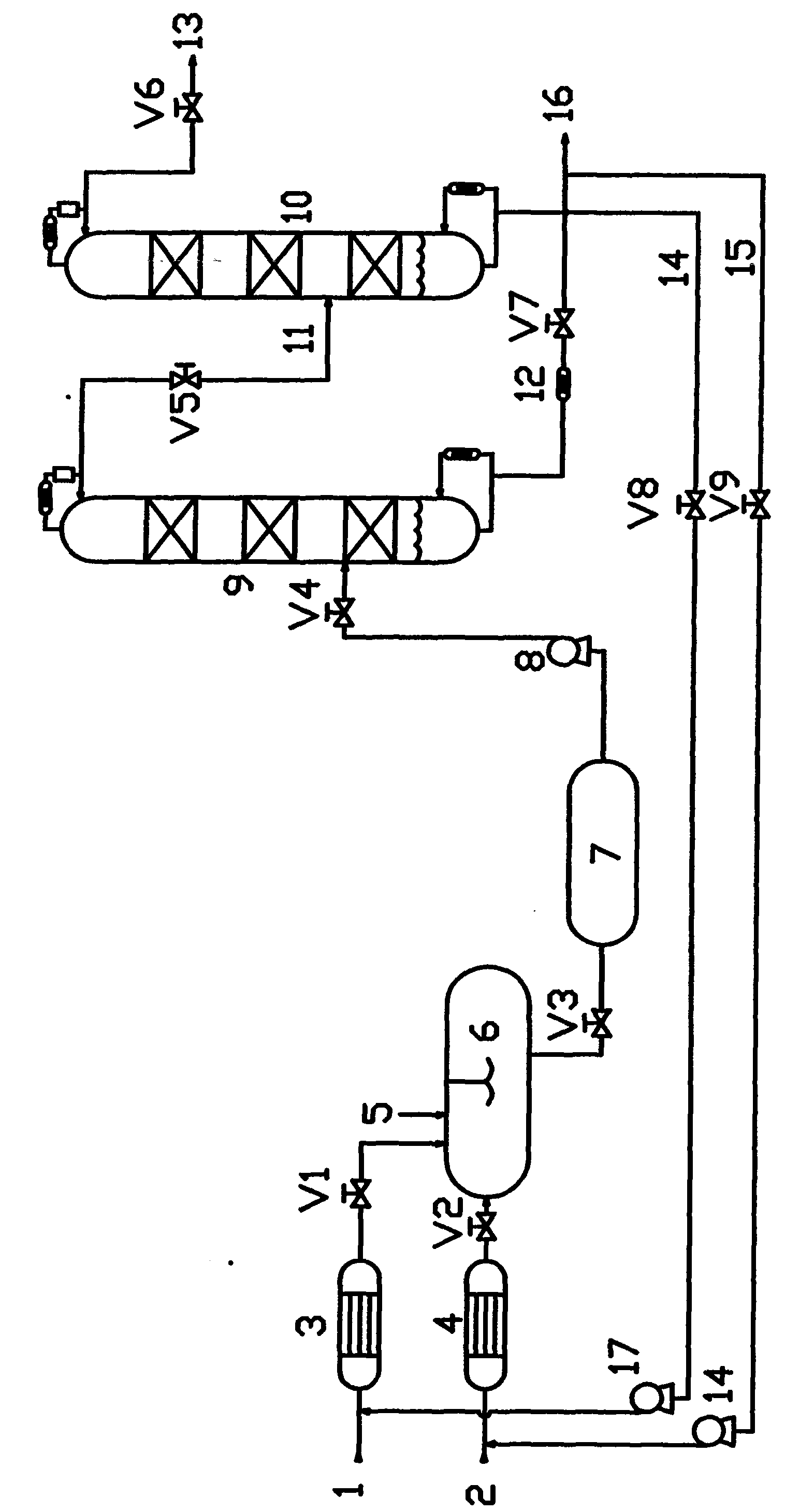

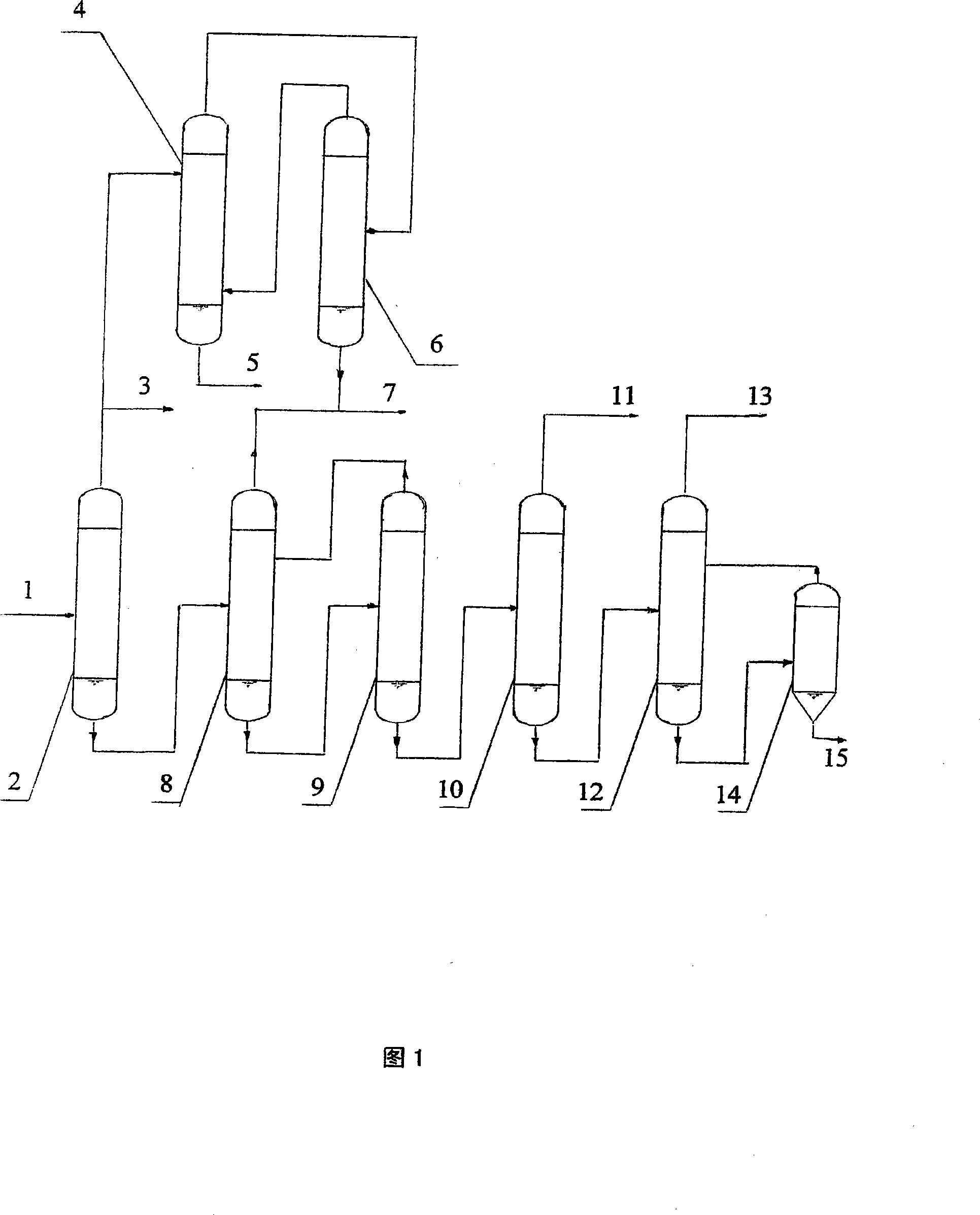

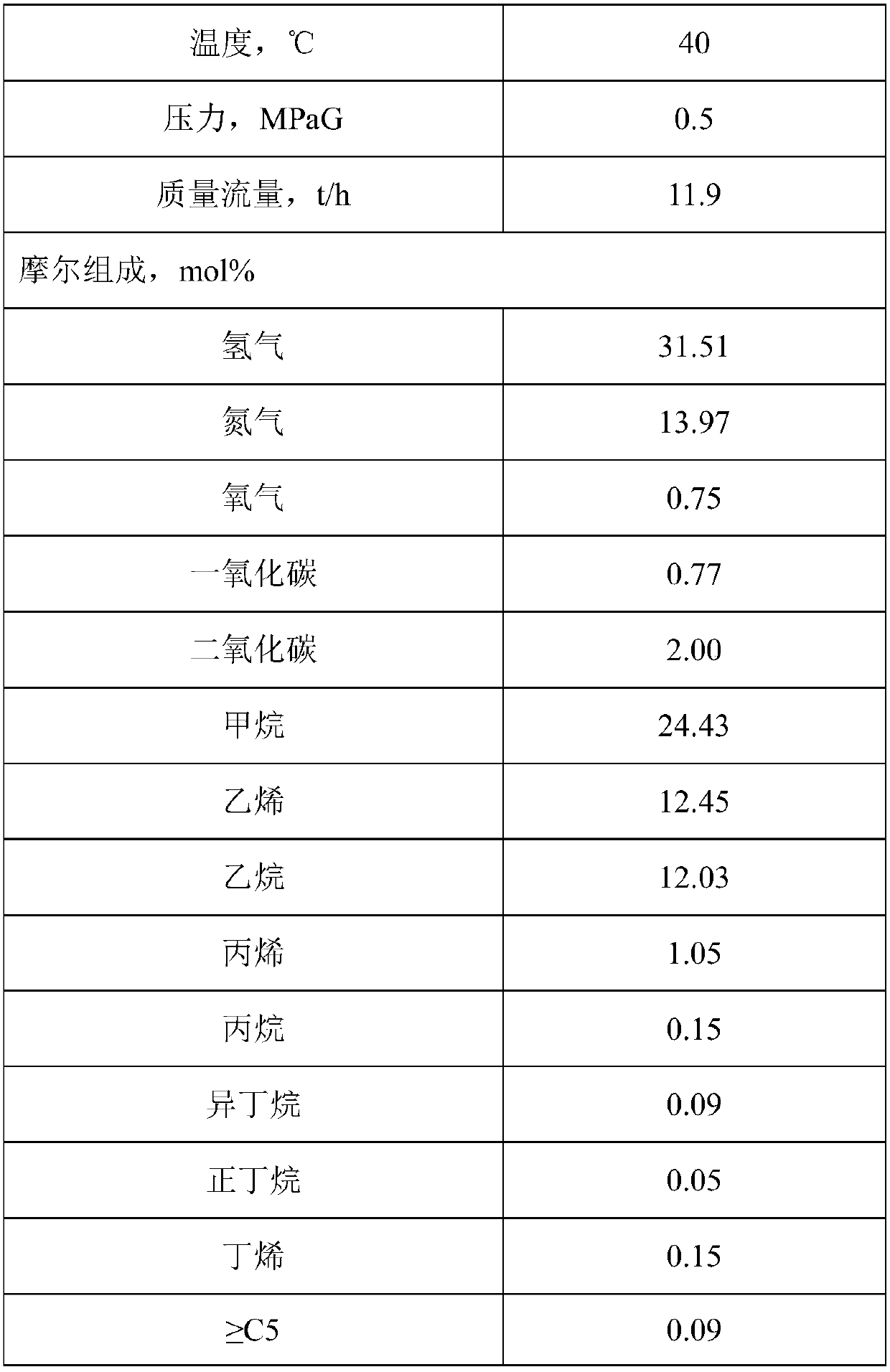

Technology for separating low carbon olefin gases

The invention discloses a technology for separating low carbon olefin gases, for solving the problems that hydrogen, methane, ethane and propane and other products with high purity can not be acquired and dimethyl ether and oxygen and carbon monoxide in impurities are not removed efficiently, etc. in the prior art. The technology is characterized in that a step of removing carbon monoxide and oxygen is added, methanol-to-olefin gas streams processed by removing carbon monoxide and oxygen enter into a deethanizing column, deethanizing column overhead streams successively pass through an ethene hydrogenation reactor, six separation pots, a low pressure demethanizing column and an ethene rectification column, etc. to separate to obtain ethene and ethane products, and deethanizing column bottom streams successively pass through a propyne hydrogenation reactor, a methane stripper and a propylene rectification column, etc. to separate to obtain propylene and propane products. According to the invention, polymer grade ethene and propylene products can be obtained, and hydrogen, methane, ethane and propane products, etc. with high purity can be obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

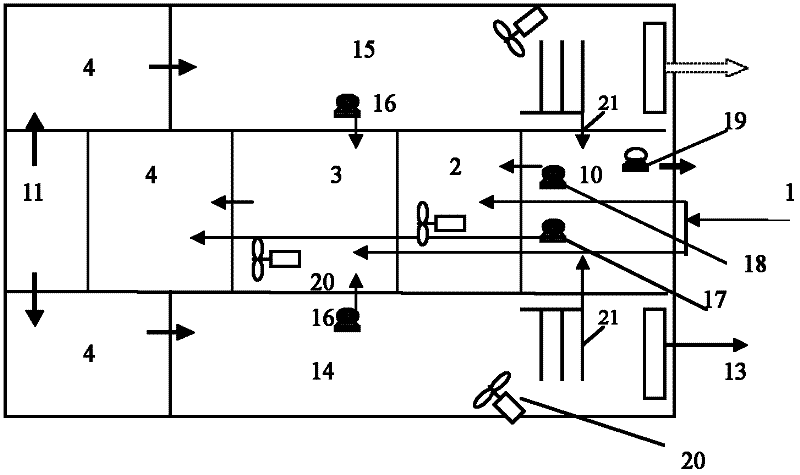

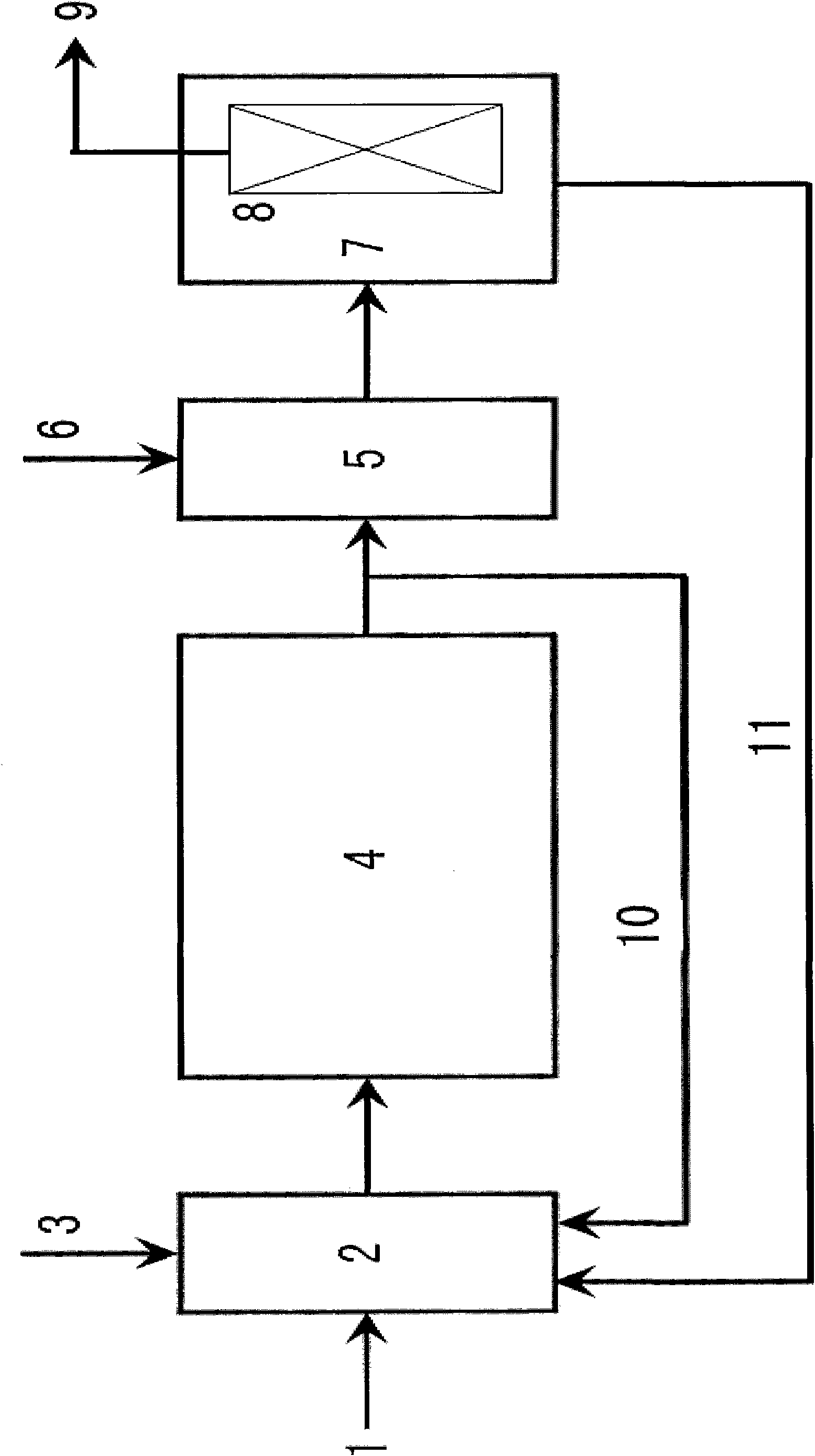

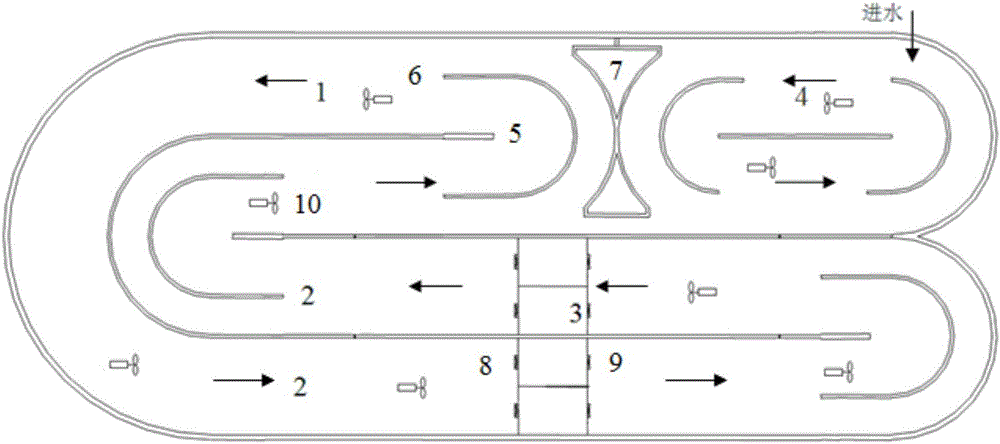

Double-reflux denitrification membrane-bioreactor (MBR) process for treating dry acrylic fiber waste water

InactiveCN102115297AGuaranteed removal effectImprove removal efficiencyMultistage water/sewage treatmentNitrogen removalReflux

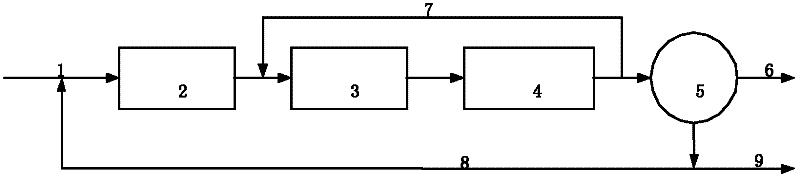

The invention belongs to a double-reflux denitrification membrane-bioreactor (MBR) process for treating dry acrylic fiber waste water, mainly aiming at treatment of high organic nitrogen with denitrification requirement and petrified dry acrylic fiber waste water which is difficult to degrade. The process comprises the following steps: feeding petrified dimethylformamide (DMF) dry acrylic fiber waste water into a front anoxic pool 2 from a water inlet 1, converting partial organic nitrogen into ammonia nitrogen under the anoxic condition, carrying out denitrification on a nitration liquid 10 refluxing to the front anoxic tank 2 by fully utilizing a waste water carbon source, and simultaneously compensating basicity 3 to the waste water; and then feeding entering the waste water into an aerobic pool 4, carrying out organism aerobic oxidation, organic nitrogen aerobic oxidation and ammonia nitrogen nitration under the abundant basicity, wherein the effluent contains a large amount of nitrates; refluxing the partial effluent to the front anoxic pool 2 for denitrification, and feeding the other effluent into a membrane separation pool 7; carrying out denitrification by utilizing an additionally arranged carbon source; and sucking with a micro-filter membrane assembly 8 so as to generate effluent 9, and refluxing a sludge concentrated liquid 11 to the front anoxic pool 2. The process is high in nitrogen removal efficiency.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

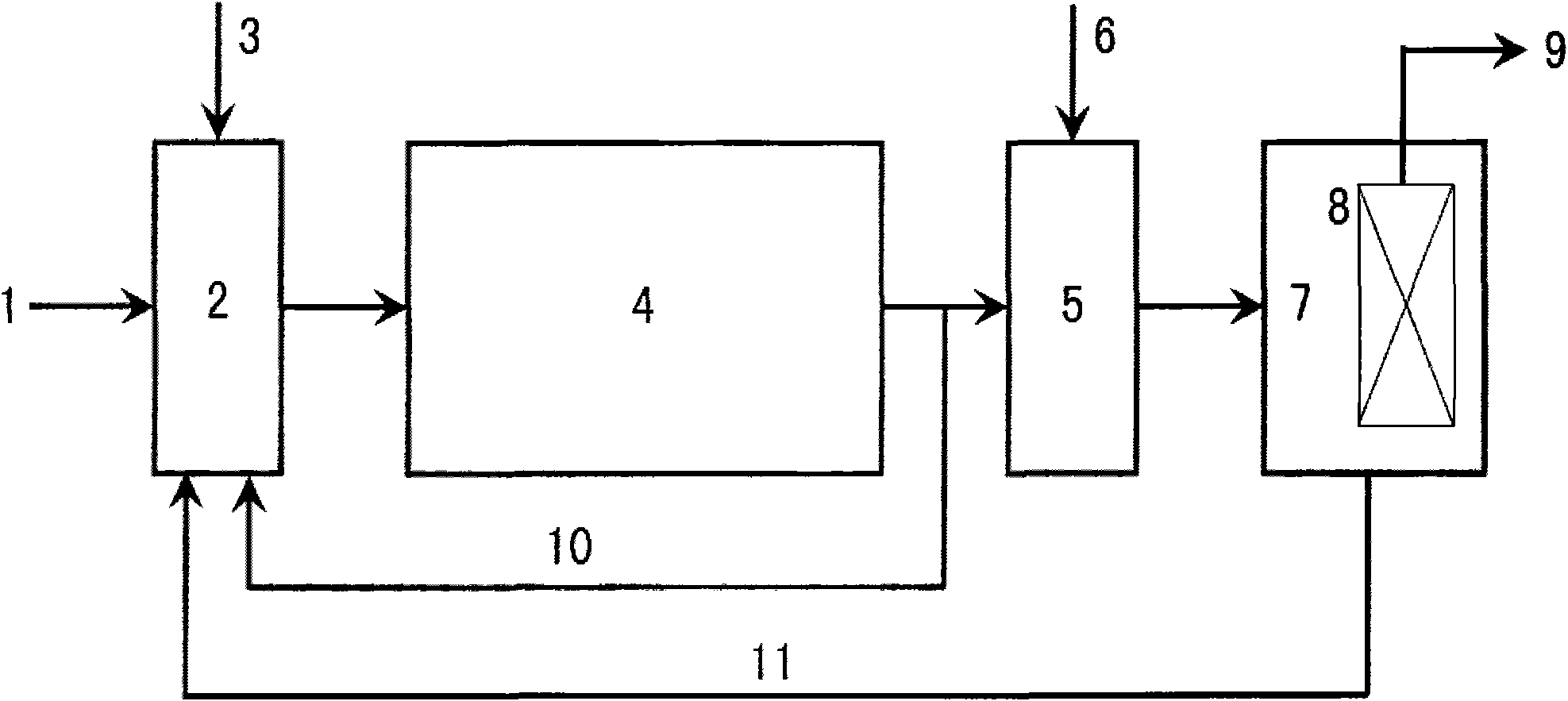

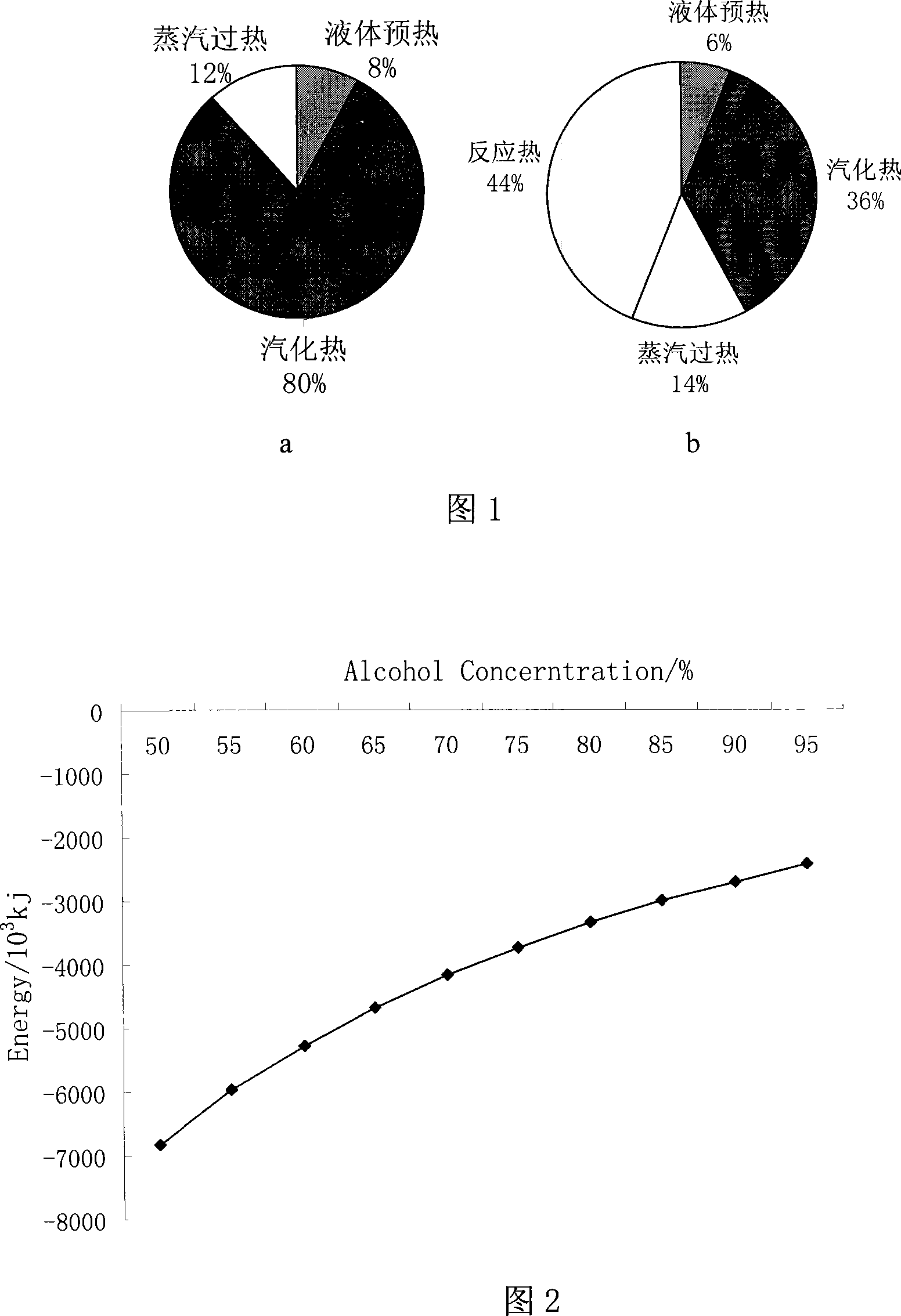

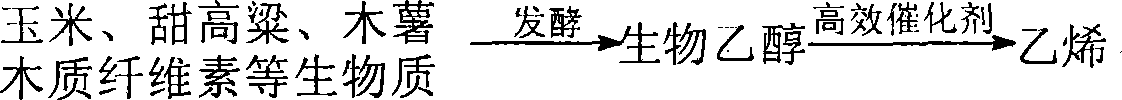

Process for producing ethylene by ethanol dehydration

InactiveCN101134704ANot affected by raw material concentrationImprove adaptabilityHydrocarbon from oxygen organic compoundsWater vaporBoiling point

The present invention is the process of producing ethylene with ethanol obtained through fermenting biomass as the material, and provides one biomass path of preparing ethylene. The present invention features the coupling of ethanol distilling process and chemically catalytic ethylene preparing process. The ethylene producing process includes: distilling 5-45 % concentration ethanol solution to obtain mixed ethanol-water vapor, heating the mixed ethanol-water vapor to 150-350 deg.c, catalytic reaction in a gas-solid reactor to obtain coarse ethanol product, cooling, gas-liquid separating to eliminate components with boiling point higher than 70 deg.c and obtain ethylene gas, and washing, drying and refining to obtain ethylene product. The ethylene producing process has low comprehensive power consumption, low cost and high marketability.

Owner:NANJING UNIV OF TECH

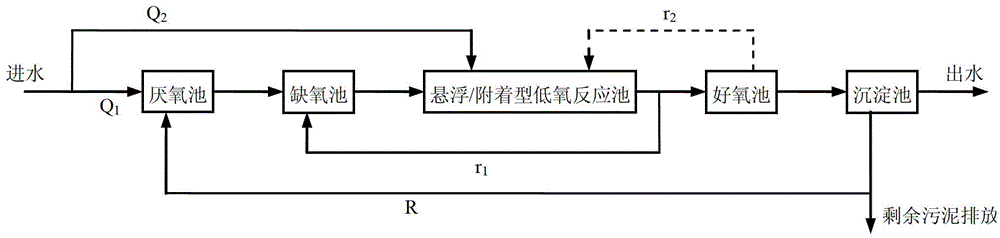

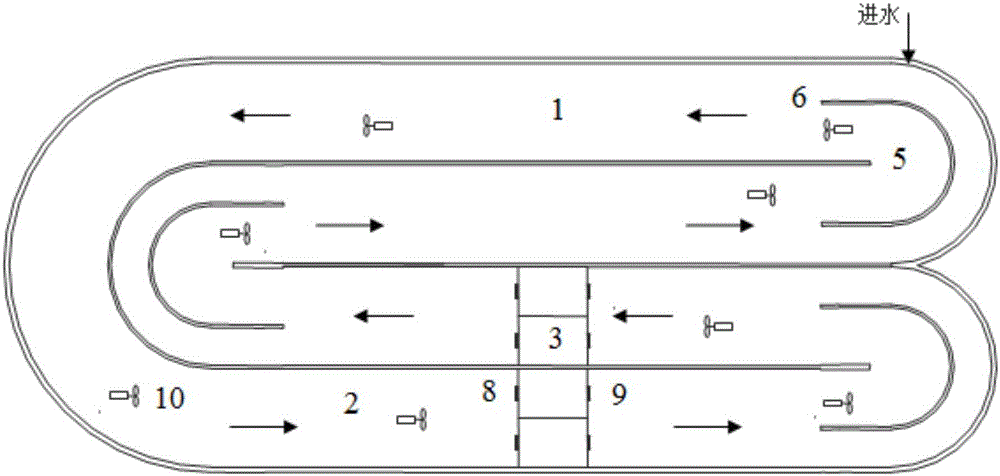

AALOO multipoint water feeding synchronization denitrification and dephosphorization process, operation method thereof, and used biological reaction tank

InactiveCN102718313ASimple processFlexible control and adjustmentTreatment with aerobic and anaerobic processesSludgeWater quality

The invention provides an AALOO multipoint water feeding synchronization denitrification and dephosphorization process. All pretreated wastewater Q1 enters an anaerobic tank, then flows through an anoxic tank, a low oxygen tank, a short-term aerobic tank and a precipitation tank sequentially, and then is discharged from the precipitation tank. Partial pretreated wastewater Q2 directly enters the low oxygen reaction tank, then flows through the short-term aerobic tank and the precipitation tank sequentially, and then is discharged from the precipitation tank. One part of precipitated sludge flows back to the anaerobic tank, and the other part of the precipitated sludge is discharged from the precipitation tank as excess sludge. Mixed liquid return channels are arranged between the low oxygen reaction tank and the anoxic tank, and the mixed liquid return channels are also arranged between the short-term aerobic tank and the low oxygen reaction tank. A returned sludge contact reaction region is arranged on the front end of the anaerobic tank, and water feeding points are arranged both on the front end region and the rear end region of the anaerobic tank. The method has a simple flow, and is adaptable to wastewater quality change, and is capable of removing nitrogen and phosphorus from wastewater with low carbon source and low oxygen consumption. The method is applicable to rebuilding or building of a municipal wastewater treatment plant which has nitrogen and phosphorus removing requirements.

Owner:国家城市给水排水工程技术研究中心 +1

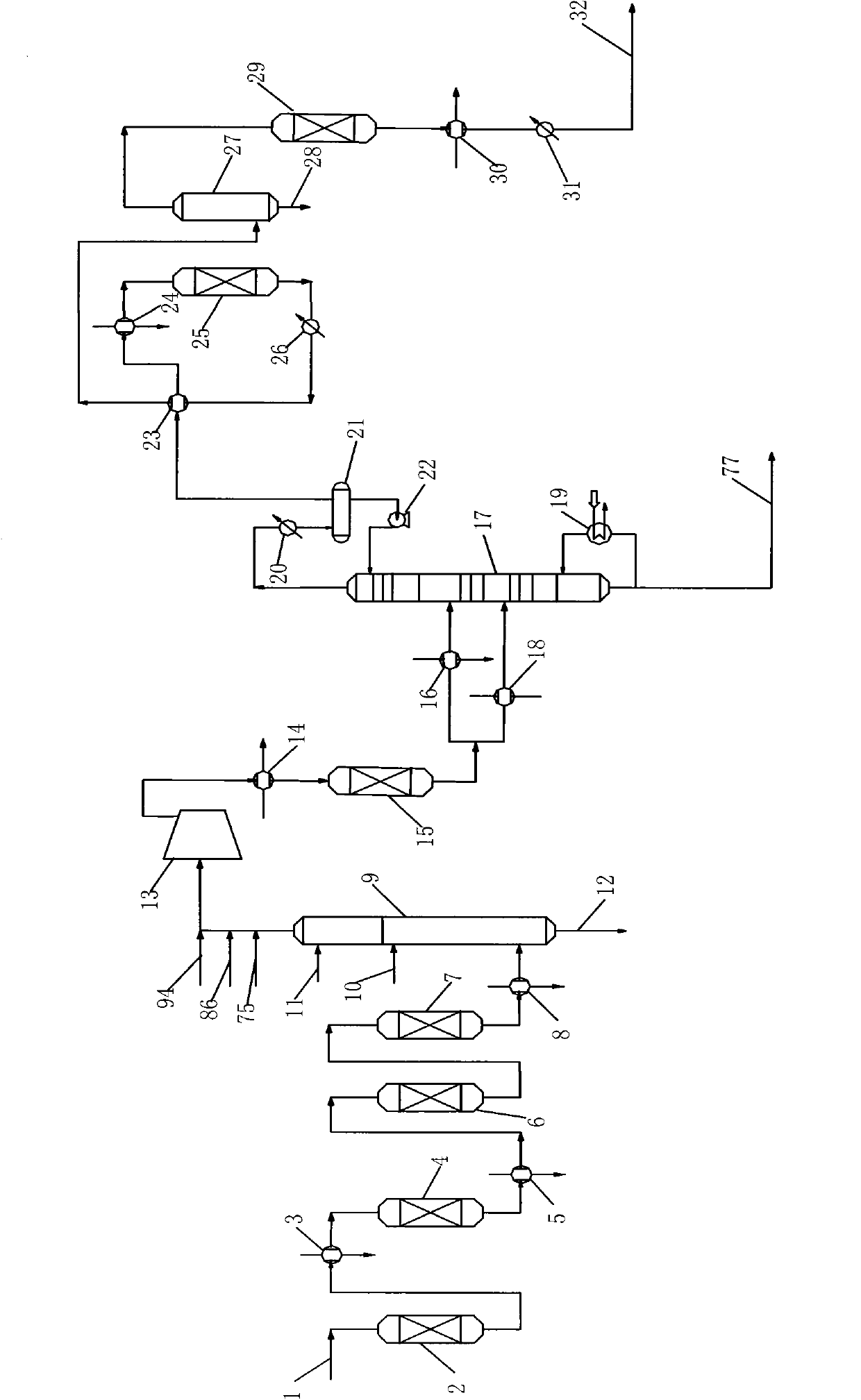

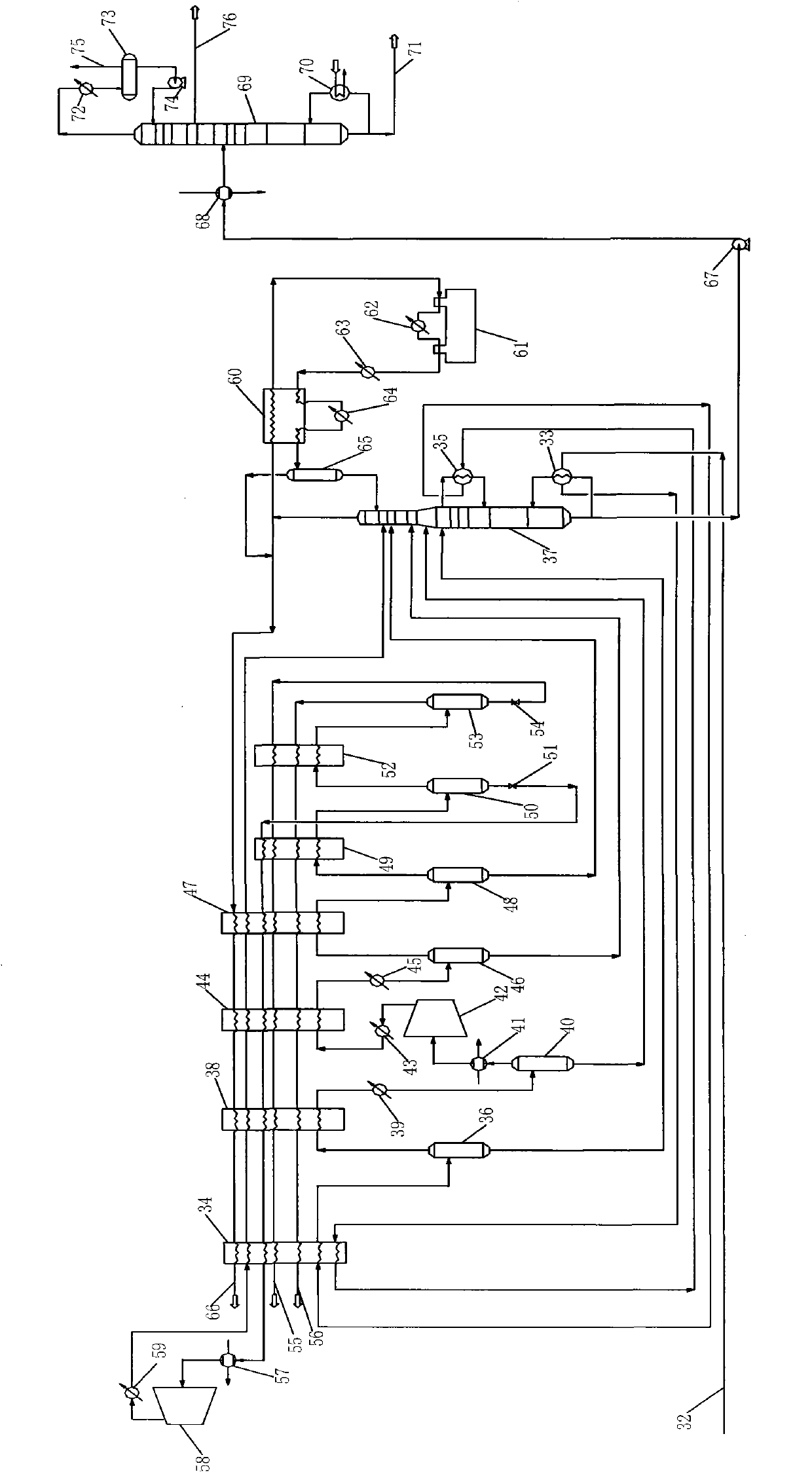

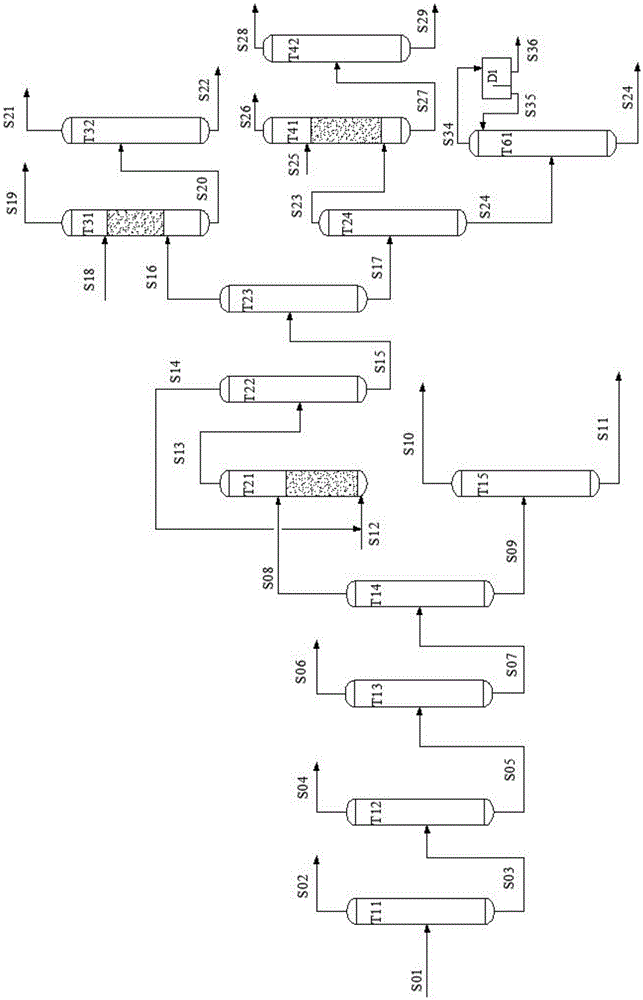

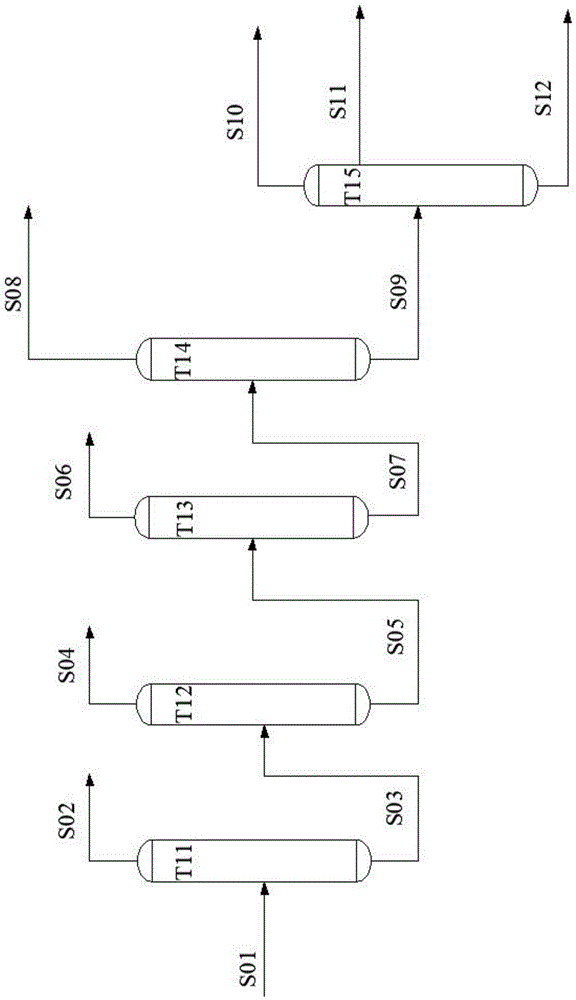

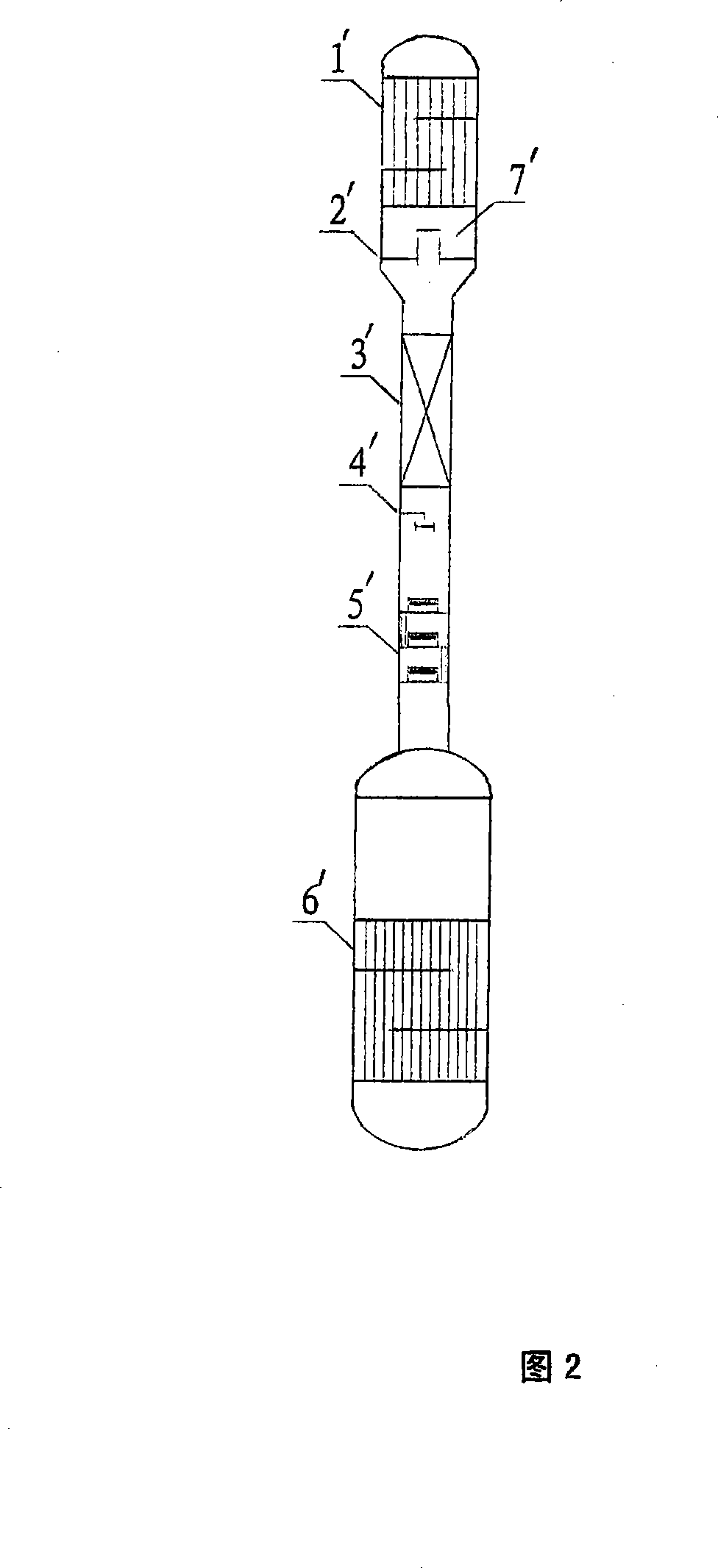

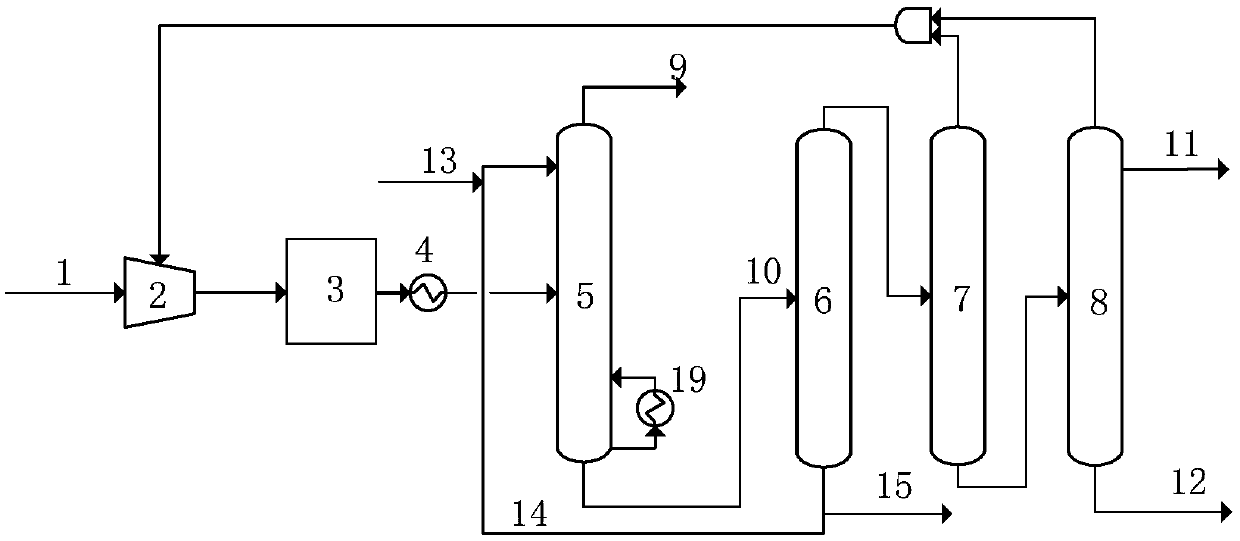

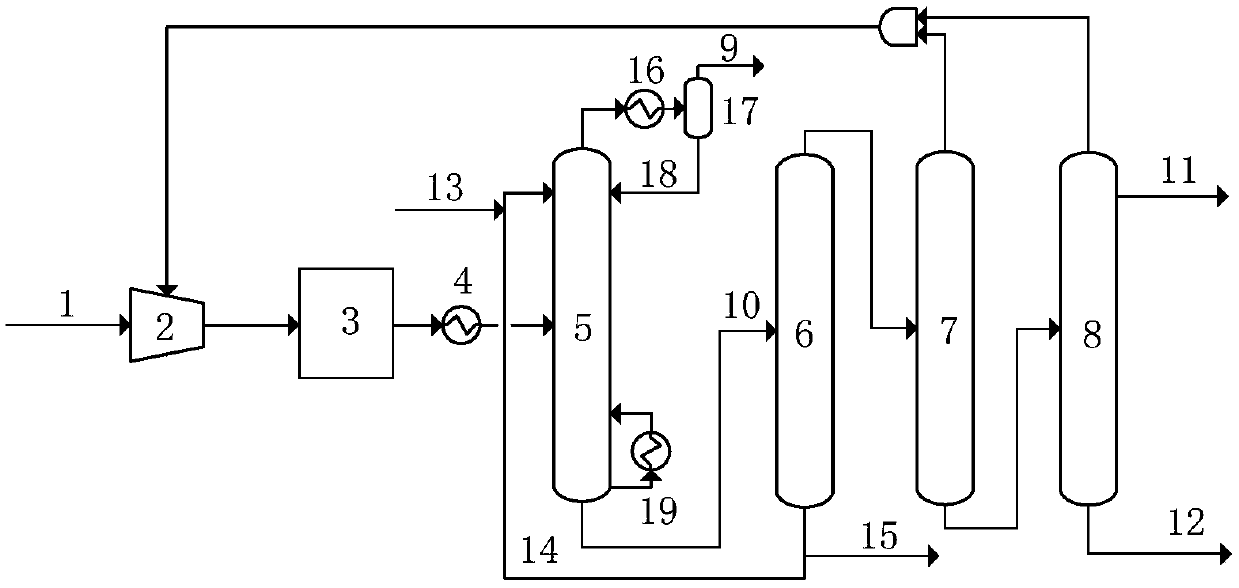

Cracking gas separation method and cracking gas separation apparatus

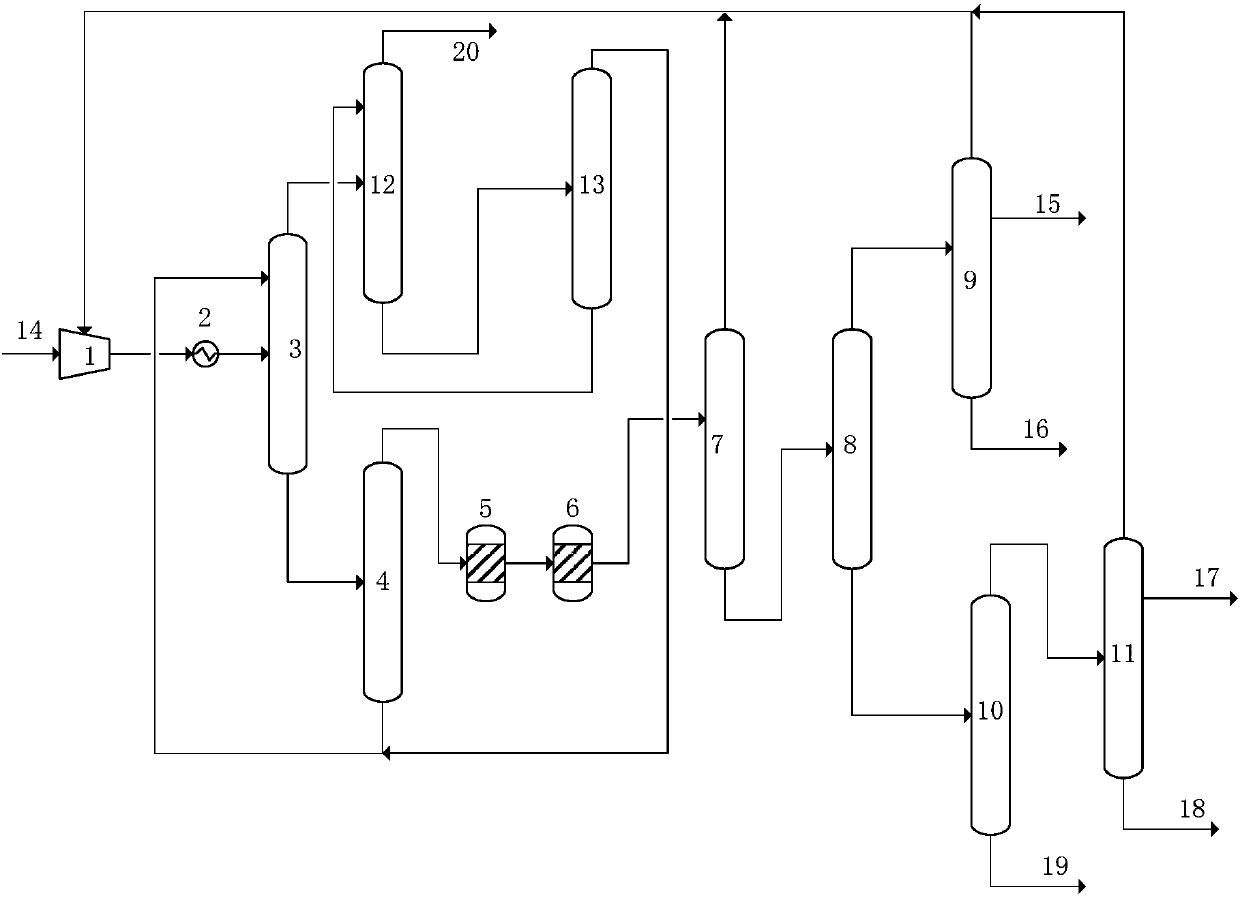

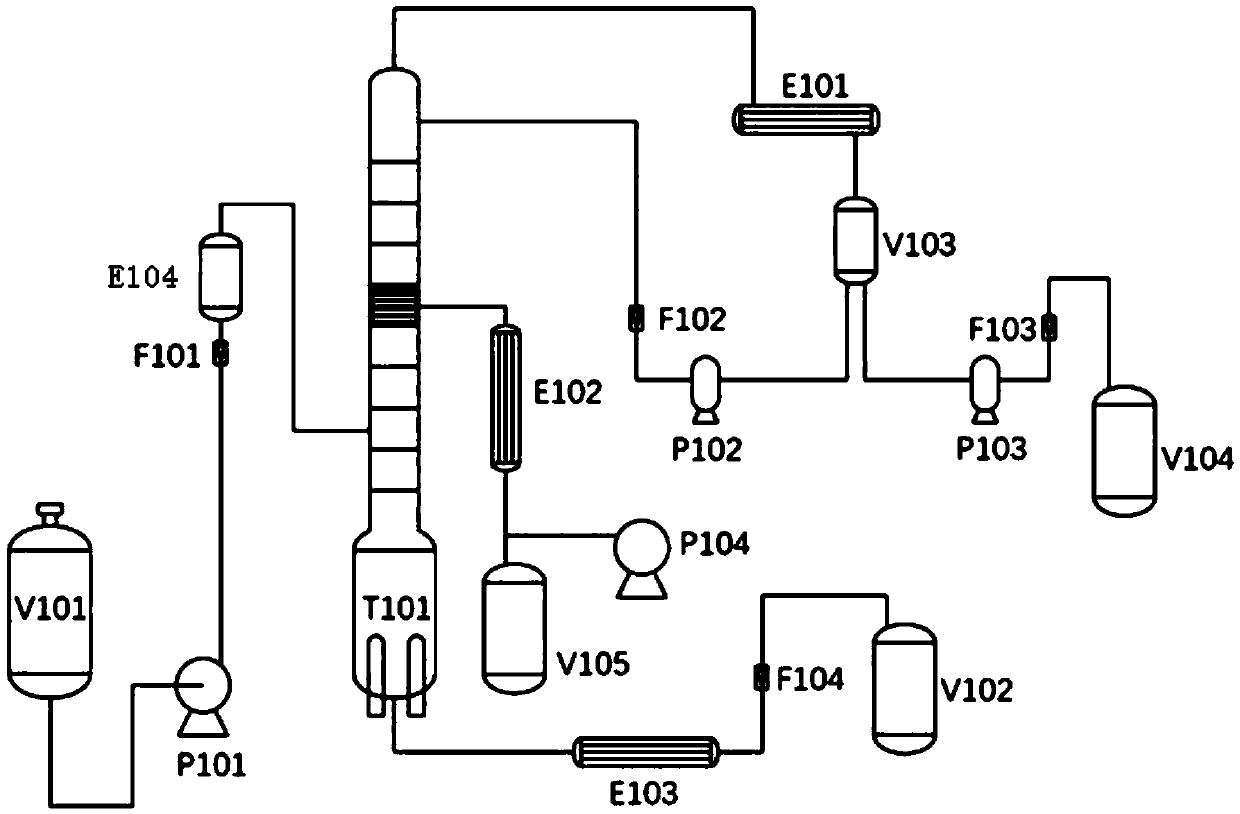

ActiveCN109912380AReduce the reflux ratioReduce loadGaseous fuelsDistillation purification/separationSolventChemical industry

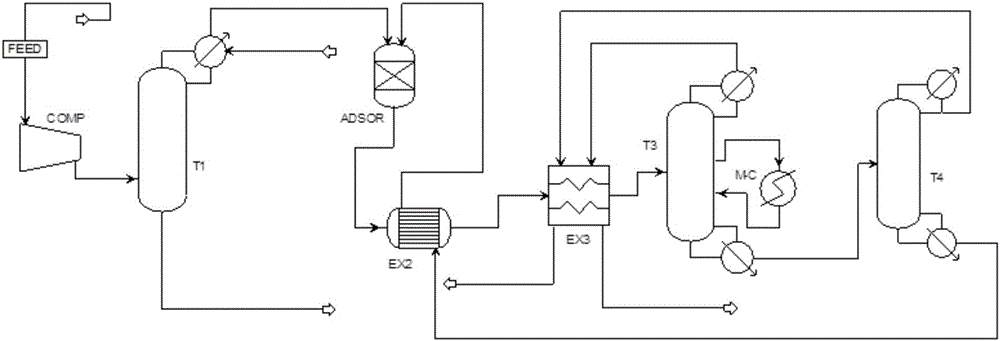

The invention belongs to the field of chemical industry gas separation, and relates to a cracking gas separation method and a cracking gas separation apparatus. The method comprises: (1) pressurizingcracking gas; (2) cooling the compressed gas, and conveying to an absorption tower; (3) making the stream on the top of the absorption tower enter a re-absorption unit or be cooled, and conveying thestream on the tower kettle to a desorption tower; (4) obtaining C2 concentrated gas from the top of the desorption tower, obtaining a lean solvent from the tower kettle, and returning the lean solventto the top portion of the absorption tower; (5) making the C2 concentrated gas enter a purification unit, and purifying; (6) making the purified C2 concentrated gas enter a methane removing tower, and conveying the material from the kettle of the methane removing tower to an ethane removing tower; (7) obtaining crude ethylene gas from the top of the ethane removing tower, conveying the crude ethylene gas to an ethylene rectification tower, and extracting the material from the kettle of the ethane removing tower as a liquefied gas product or conveying to a propane removing tower; and (8) extracting a polymerization-grade ethylene product from the top / side line of the ethylene rectification tower, wherein the material from the tower kettle is an ethane-rich product. According to the presentinvention, the method and the apparatus have advantages of simple process, high recovery rate, low energy consumption and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Industry formaldehyde waste water treatment and recycling recovery process thereof

InactiveCN101597117AEfficient recyclingRaise the gradeOrganic chemistryOrganic compound preparationDistillationHigh energy

The invention uses formaldehyde and excessive methanol to react and produce methylal under the effect of catalyst, then uses a rectification column to carry out separation twice to obtain the methylal with high purity reaction product and up-to-standard waste water in which the excessive methanol can be recycled. Compared with other conversion methods and high pressure distillation in literature documents, the industry formaldehyde waste water treatment and recycling recovery process thereof in the invention has the advantages that: (1) efficient recovery is realized, high grade methylal is obtained, and the aim of treating waste water is realized; (2) the process in the reaction stage is intermittent and is continuous in the separation stage, so that the process features large processing capability and high energy efficiency; (3) coupling usage, energy saving and consumption reducing of heat can be realized.

Owner:NANJING UNIV

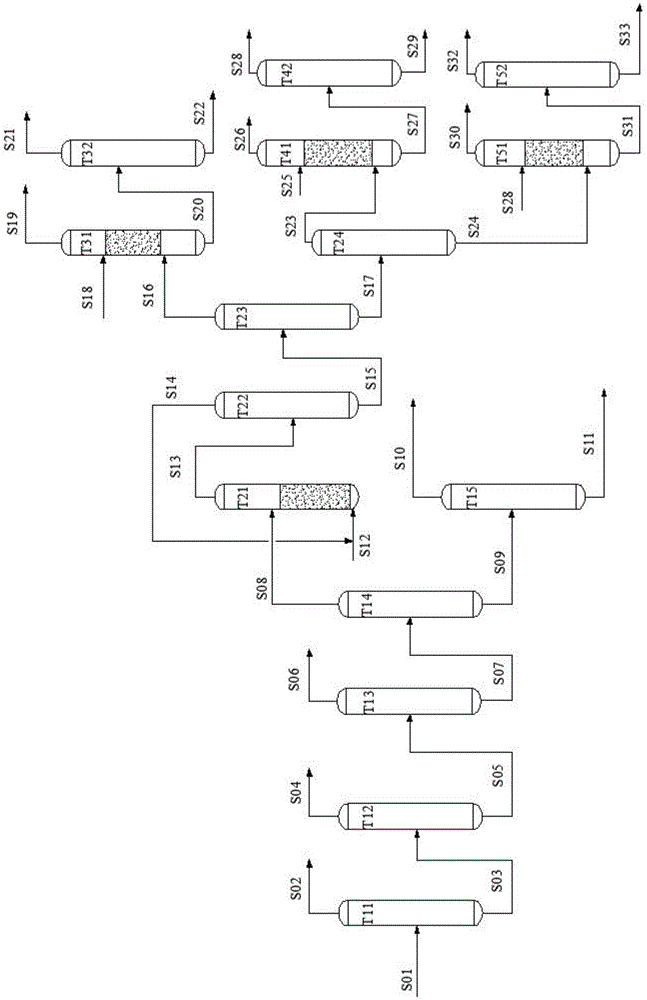

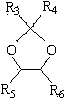

Reactive distillation coupled novel process and device for separating liquid-phase products of ethylene glycol from coal

ActiveCN105622337AReduce reflux ratio and theoretical numberReduce energy consumptionOrganic compound preparationChemical industryRefluxHeat sensitive

The invention relates to a process and a device for separating liquid-phase products of ethylene glycol from coal. The process includes respectively removing methanol and light components, then extracting ethylene glycol stream with heavy components by the aid of a reaction column of a propylene glycol and butylene glycol removal tower and acquiring ethylene glycol products by the aid of an ethylene glycol product tower; extracting ethylene glycol stream with propylene glycol and butylene glycol from a tower top of the propylene glycol and butylene glycol removal tower, carrying out acetal / ketal reactive distillation on the ethylene glycol stream with the propylene glycol and the butylene glycol, separating acetal / ketal products and then respectively carrying out hydrolysis and purification to obtain corresponding ethylene glycol, the corresponding propylene glycol and the corresponding butylene glycol. The process and the device have the advantages that the difficulty in removing propylene glycol and butylene glycol from ethylene glycol can be effectively lowered by means of applying acetal / ketal reaction, the reflux ratio and the total number of theoretical plates can be reduced, obvious energy conservation effects can be realized, and the quality of the thermal-sensitive ethylene glycol products can be guaranteed; the yield of the ethylene glycol products can be increased, and propylene glycol and butylene glycol products or butylene glycol acetal / ketal products further can be obtained by the aid of the method.

Owner:TIANJIN UNIV

Method for separating glycol and 1,2-butanediol

InactiveCN103772146AReduce solubilityImprove solubilityOrganic compound preparationHydroxy compound preparationTheoretical plateReflux

The invention relates to a method for separating glycol and 1,2-butanediol, which mainly solves the problems of high investment and energy consumption due to the fact that a very high reflux ratio and very high number of theoretical plates are required when a common rectification method is employed to separate and purify a material flow containing glycol and 1,2-butanediol, and severe separation conditions or a non-ideal separation effect when a common azeotropic rectification method is employed. The method better solves the problem by employing the technical scheme that the material flow containing glycol and 1,2-butanediol and a reactor enters from the upper part and the lower part of a reaction-azeotrope rectification tower respectively, a generated reaction product forms an azeotrope with glycol at the same time, a tower kettle obtains a material flow containing 1,2-butanediol, and after the azeotrope distilled from the tower top is subjected to condensation phase splitting, a glycol-rich phase at the lower layer is further refined to form a glycol product. The method can be used for industrial production of separating the material flow containing glycol and 1,2-butanediol.

Owner:CHINA PETROLEUM & CHEM CORP +1

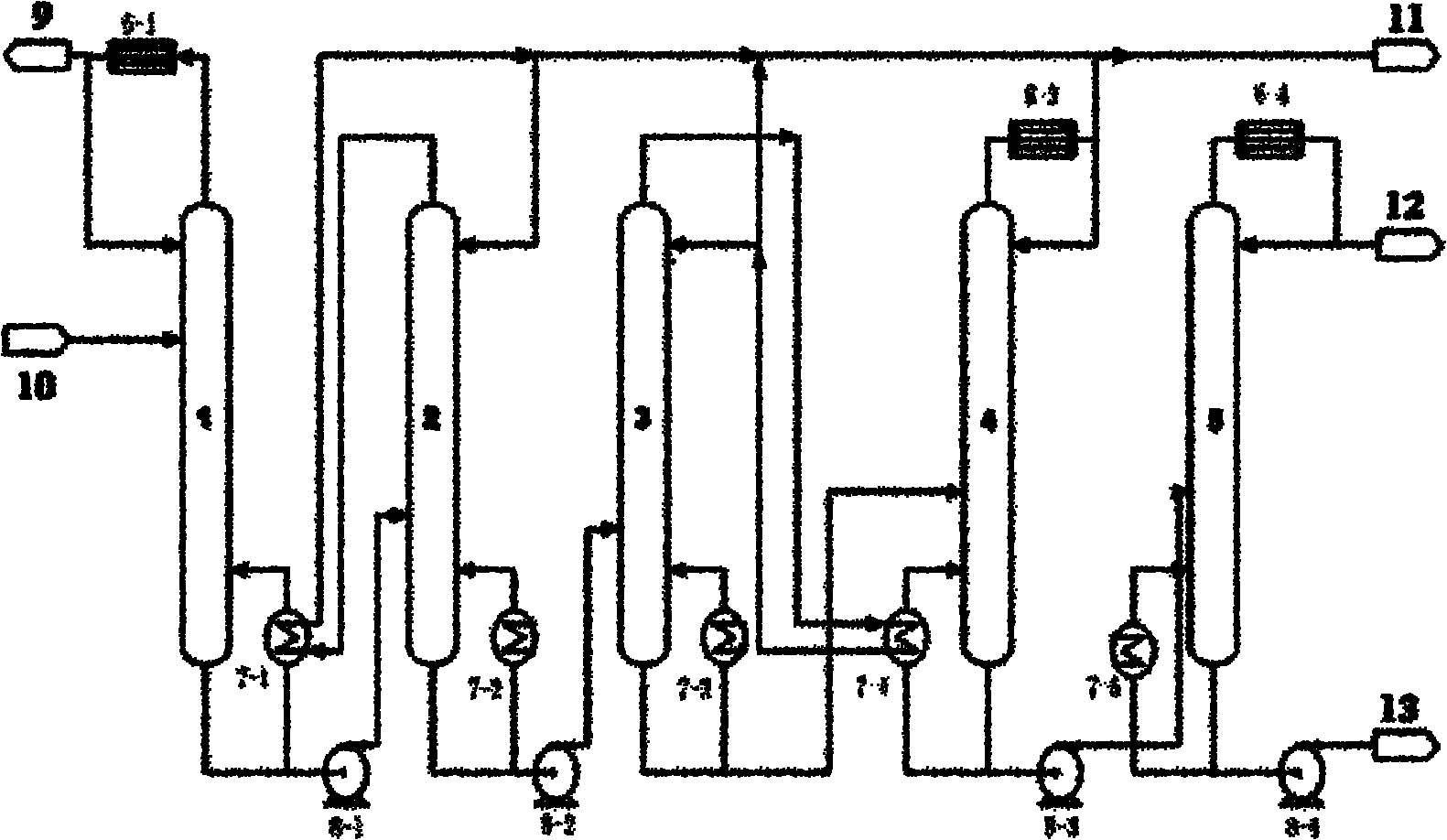

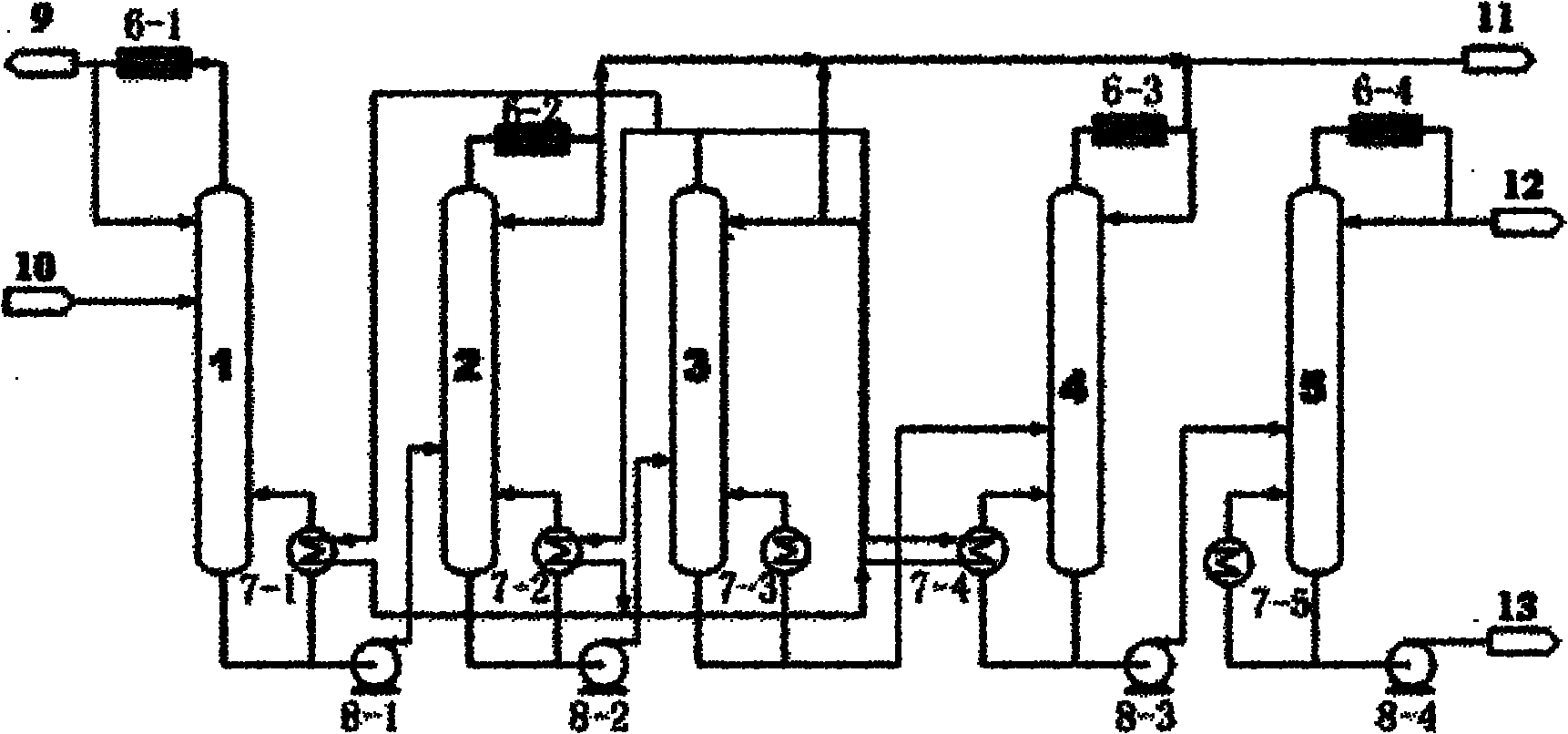

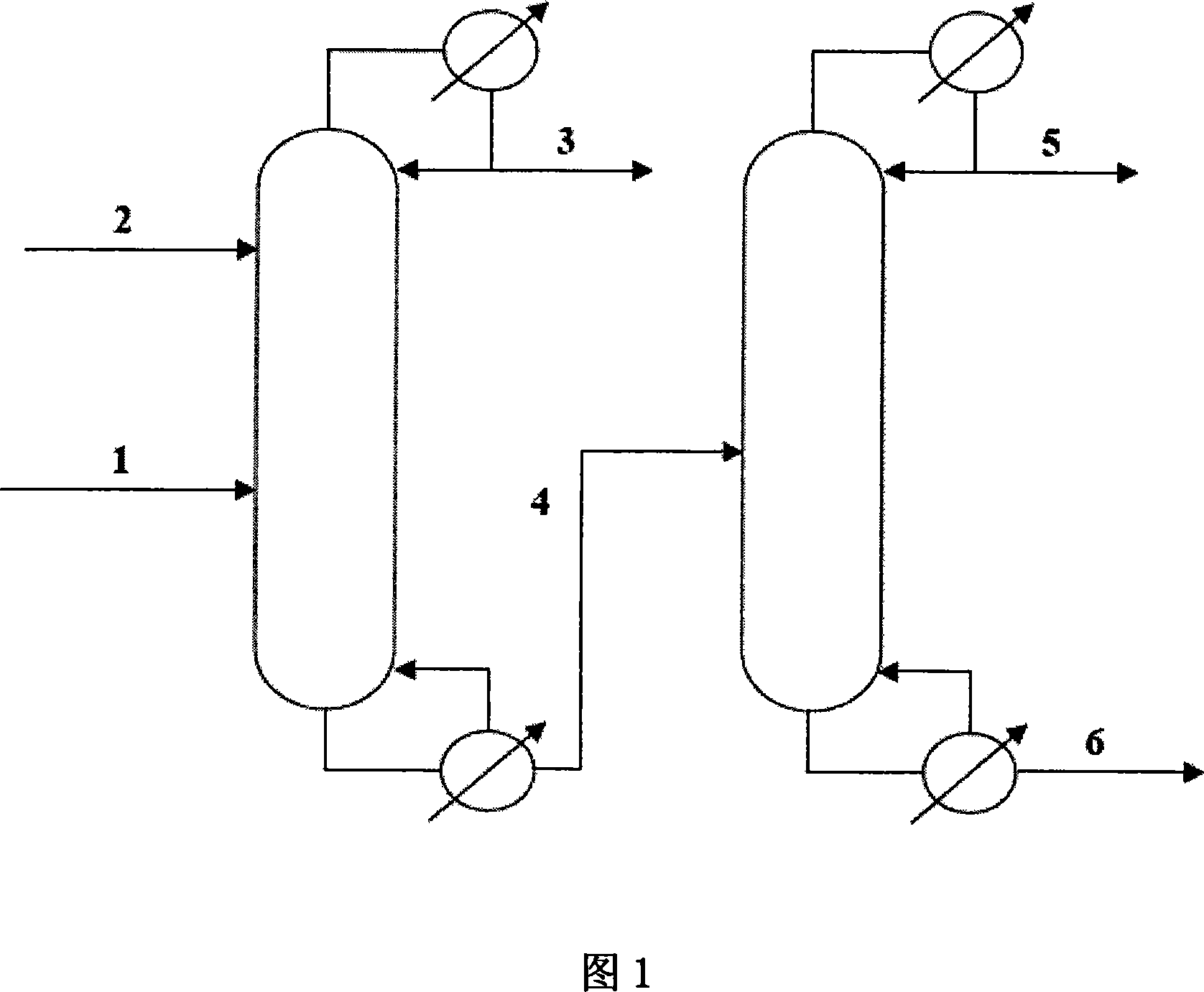

Large-scale methanol multi-effect energy-saving rectifying device and process

ActiveCN102039058AMake full use ofReduce exergy lossOrganic compound preparationChemical industryWastewaterProcess engineering

The invention relates to large-scale methanol multi-effect energy-saving rectifying device and process. Main equipment used in the process sequentially comprises a pre-rectifying tower, a second rectifying tower, a pressurizing tower, an atmospheric tower and a recovering tower, wherein the tops of the second rectifying tower, the pressurizing tower and the atmospheric tower are respectively usedfor discharging refined methanol, the top of the recovering tower is used for discharging fusel oil, and the bottom is used for discharging purified wastewater. Because one rectifying tower is additionally arranged, and the process parameter of each tower is adjusted, two methanol multi-effect energy-saving rectifying processes by five towers are obtained, the effective energy loss is reduced, thereby energy consumption is reduced. In addition, the diameter of each tower is reduced, the amplification effect of relevant equipment, caused by the oversize diameter of each tower, is greatly reduced. The process has the advantages of reasonable design, the energy is fully and reasonably utilized in the process, the energy consumption of the whole device used in the process is reduced by 20%-30% higher than that of the device used in the traditional double-effect process, and the purity of a product reaches the American AA-level standard.

Owner:TIANJIN UNIV

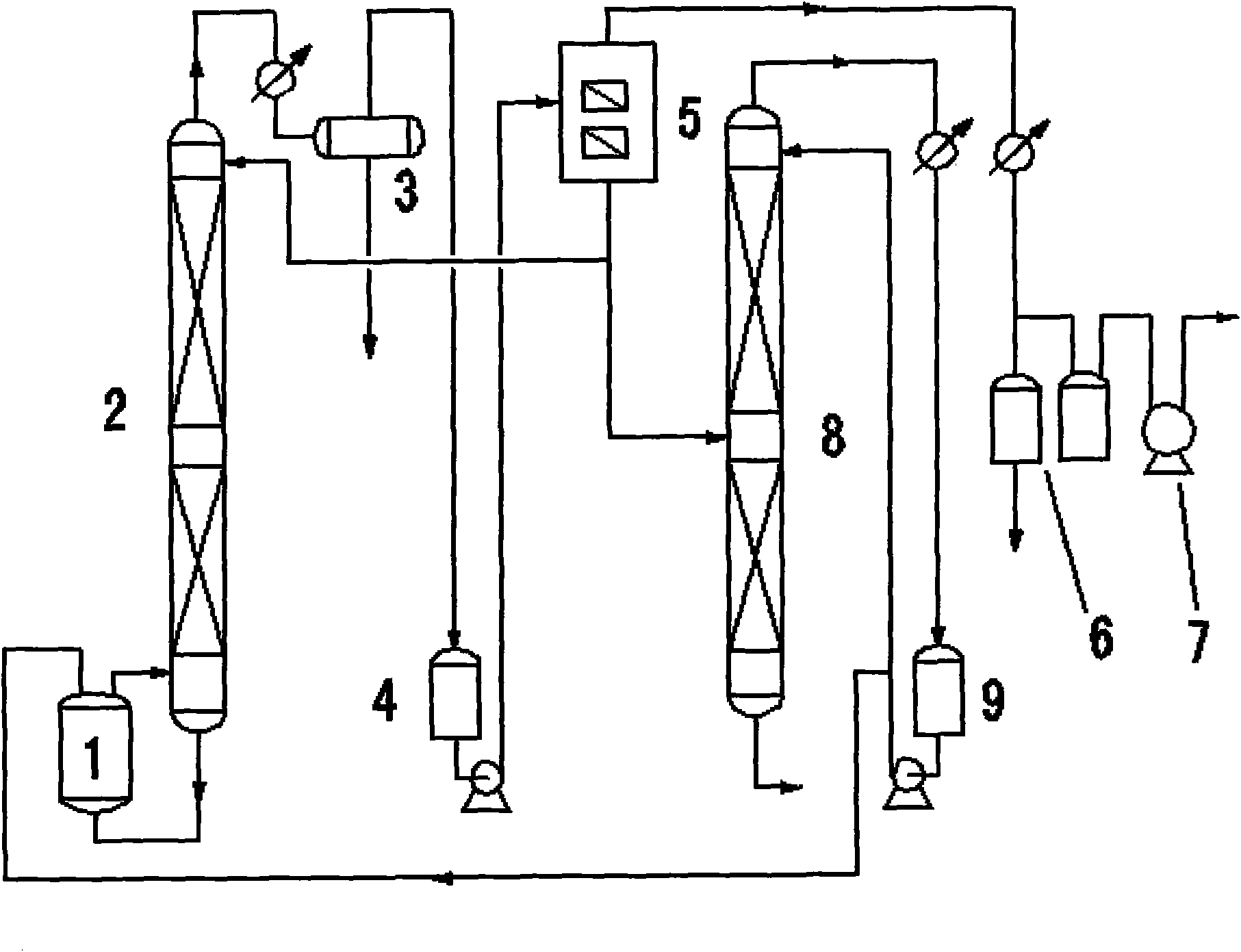

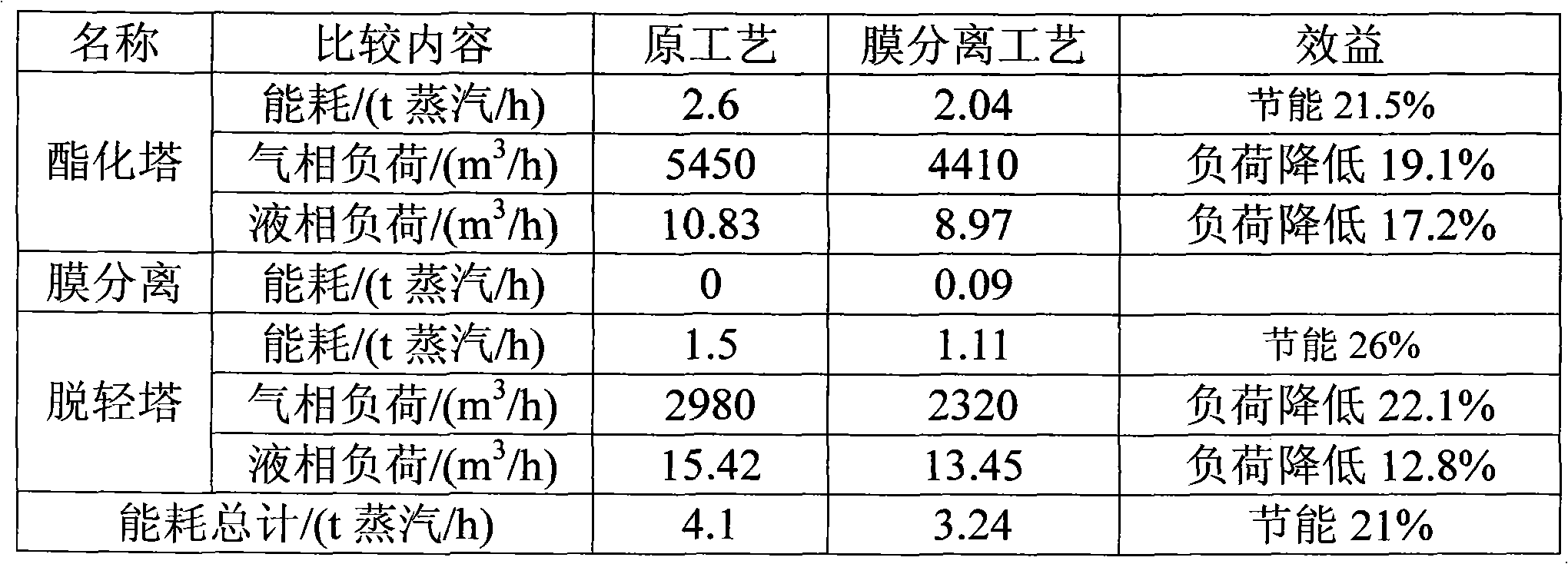

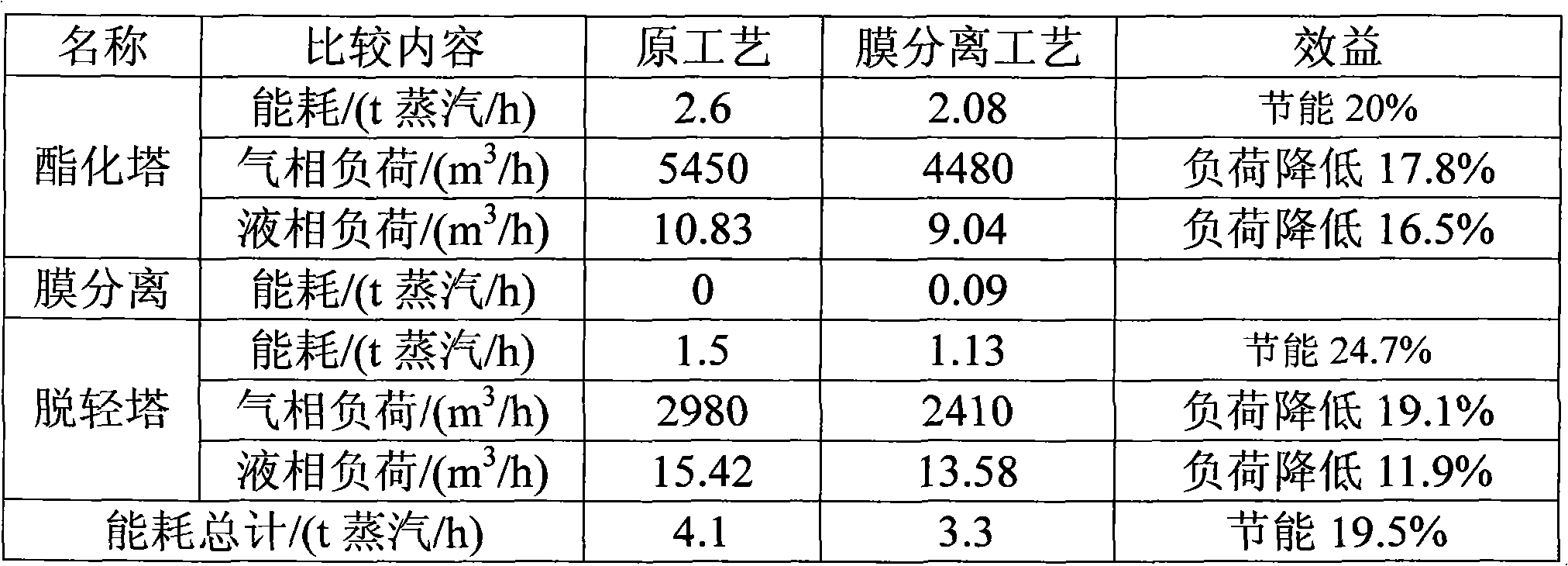

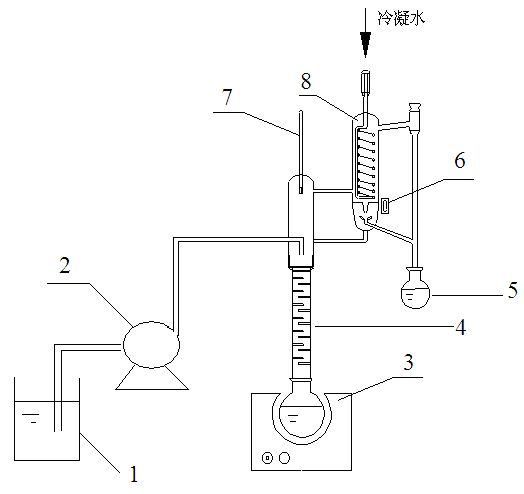

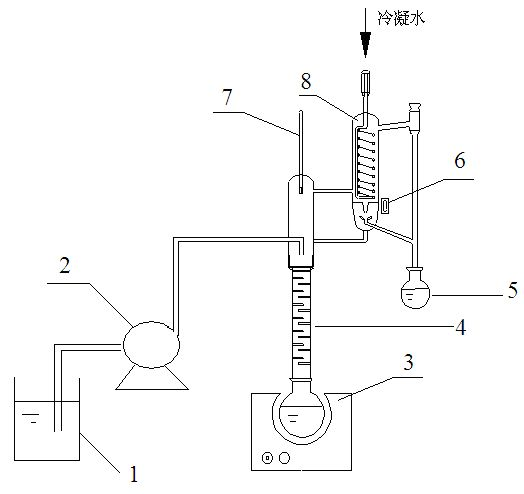

New energy-saving production process of ethyl acetate

InactiveCN102030639ARealize energy-saving productionReduce moisture contentOrganic compound preparationChemical industryAcetic acidNew energy

The invention relates to a new energy-saving production process of ethyl acetate. The process comprises the sections of esterification, light removal, refining and recovery, and the membrane separation section is added between the esterification section and the light removal section. The organic phase at the esterification tower top is subject to membrane separation to desorb most moisture, and one part of the treated organic phase returns to an esterification tower to reflow and the other part is sent to a light removal tower to be refined. The membrane separation section comprises a vacuum cover (with a membrane module inside), a condenser, a penetrating fluid tank, a buffer tank and a vacuum pump. The method provided by the invention can greatly reduce water circulating in the esterification and light removal sections, save the heating steam in the esterification tower and the light removal tower, reduce the loads of the esterification tower and the light removal tower and further improve the production capability of the esterification tower and the light removal tower.

Owner:江门天诚溶剂制品有限公司

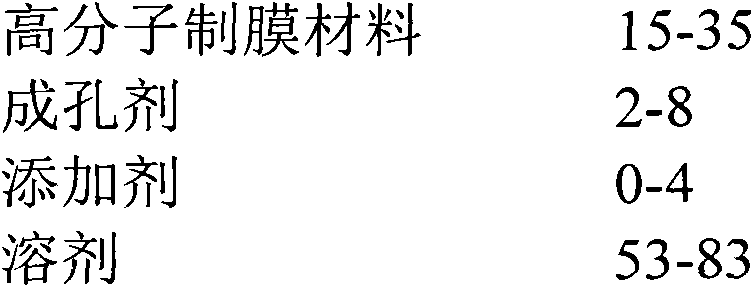

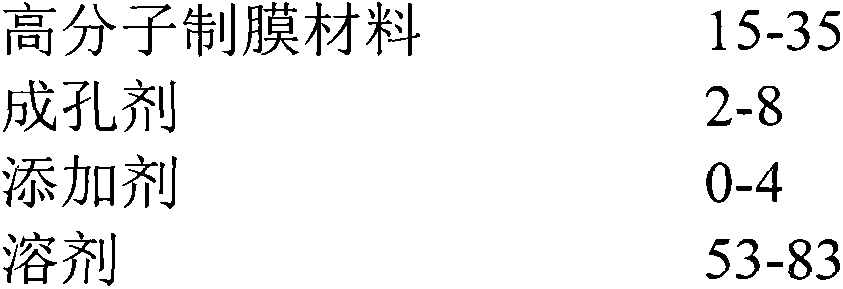

Internal pressure type fiber-reinforced filter membrane and preparation method thereof

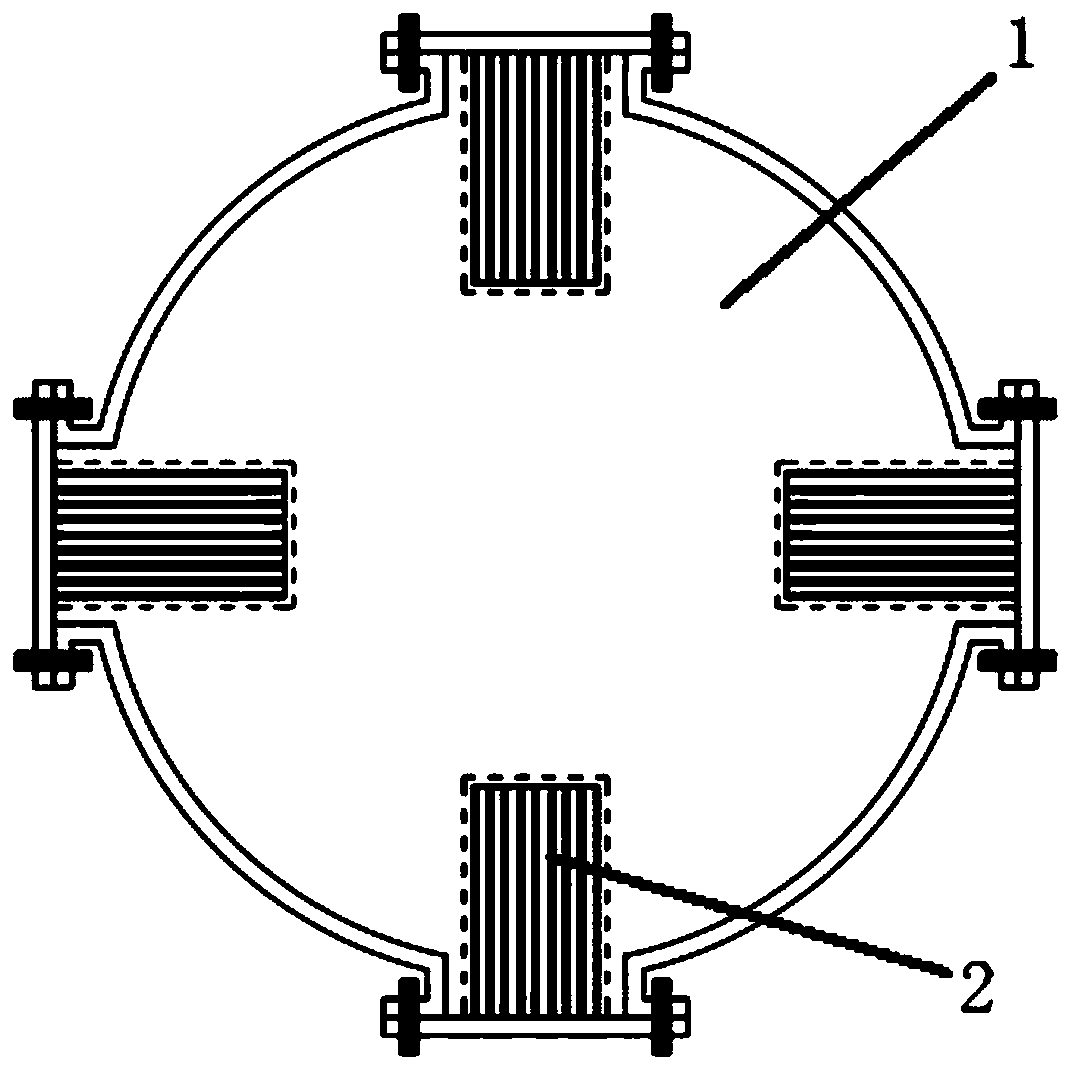

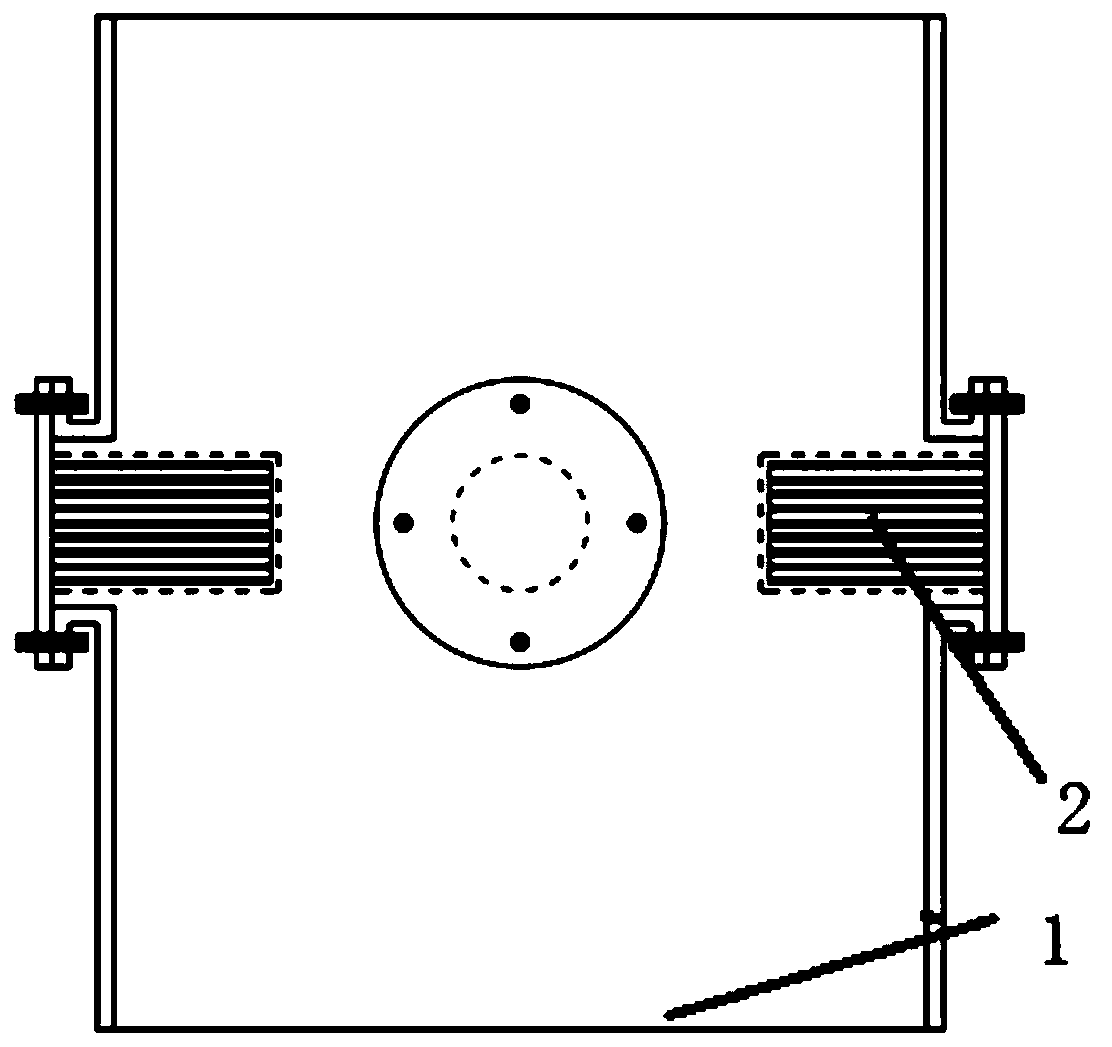

ActiveCN103949166ASimple designEasy to operateSemi-permeable membranesInternal pressureWater production

The invention relates to an internal pressure type fiber-reinforced filter membrane and a preparation method thereof. The internal pressure type fiber-reinforced filter membrane is formed by coating the inner surface of a hollow braided tube with a layer of high-polymer membrane casting liquid and carrying out solidification and water washing under the action of internal and external coagulating bath solutions. By preparing the membrane by virtue of the hollow braided tube, the membrane casting liquid and a spinneret plate coextruded by internal coagulating core liquid, a continuous membrane preparation process is realized; the high-polymer membrane casting liquid contains a hydrophilic agent, and thus the prepared fiber-reinforced filter membrane is high in flux and strong in anti-pollution capacity. The internal pressure type fiber-reinforced filter membrane has the beneficial effects that the filter precision is high, a pore structure of the membrane can be controlled by virtue of process parameters of a membrane casting liquid preparation process and a membrane preparation process, the cross flow of inlet water is realized, the reflux ratio is low, and the water production rate is high; compared with an internal pressure type filter membrane, the internal pressure type fiber-reinforced filter membrane has the advantages that a runner is wide and is unlikely to be blocked, feed liquid with high content of suspended solids can be directly processed, and the pretreatment cost is lowered.

Owner:盐城海普润科技股份有限公司

Separating method for ethylene-glycol and 1,2-butanediol

ActiveCN103772147AReduce solubilityReduce lossesOrganic compound preparationHydroxy compound preparationTheoretical platePhase splitting

The invention relates to a separating method for ethylene-glycol and 1,2-butanediol and mainly solves the problems that when the ethylene-glycol and the 1,2-butanediol are separated and purified in the prior art, a common precise distillation method requires very high reflux ratio and theoretical plate number, resulting in large investment and high energy consumption; an azeotropic distillation method is harsh in separation condition and undesirable in separating effect. According to the method adopting the technical scheme that material flow containing the ethylene-glycol and the 1,2-butanediol enters into an azeotropic rectification column from the lower part and an azeotropic agent enters the azeotropic rectification column from the top to obtain an azeotrope of the ethylene-glycol and the azeotropic agent at the top, the material flow containing the 1,2-butanediol is obtained in a tower kettle; after the azeotrope is subjected to condensation and phase-splitting, the azeotropic agent-rich phase at the upper layer returns to the azeotropic rectification column and continues performing azeotropic reaction while an ethylene-glycol-rich phase at the lower layer is subjected to refining to obtain the ethylene-glycol product, and the problems are well solved. Therefore, the method can be used for industrial production for separating the ethylene-glycol and the 1,2-butanediol.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for separating catechol/hydroquinone from phenol hydroxylation reaction solution

ActiveCN101225025AImprove liquidityAvoid carbonizationOrganic chemistryOrganic compound preparationReboilerHydroquinone products

The invention discloses a method of separating catechol / hydroquinone in phenol hydroxylation reaction solution, which is characterized in that: phenol and hydrogen peroxide are reacted under catalyst action to produce reaction solution comprising water, phenol, catechol, hydroquinone and tar; vacuum rectification dehydration, de-phenol, catechol separating, hydroquinone separating and tar removing are made upon the reaction solution to prepare the catechol and the hydroquinone product; thermal medium oil independent circulation stepwise condensation / heat mode is adopted for the distillation system separating the catechol and the hydroquinone; vertical sieve plate is adopted for stripping section of the distillation tower; high-efficiency structured packing is adopted for the distillation section; embedded type structure in the tower is adopted for the condenser and the reboiler of the distillation tower. The method of separating catechol / hydroquinone in phenol hydroxylation reaction solution has the advantages of solving the problems of difficultly liquefying the catechol and the hydroquinone for the condenser at the top part of the distillation tower and easily causing material condensing or gasifying due to small difference value between the boiling point and the freezing point during vacuum rectifying for the catechol and the hydroquinone, prolonging production period, lowering unit consumption of product and reaching more than 99% for product purity of the catechol and the hydroquinone.

Owner:SHANGHAI HUAYI NEW MATERIAL

Method for removing micro-benzene in solvent oil or hexane refining process

InactiveCN101234947ASimple processEasy to industrializeDistillation purification/separationBenzeneFurfural

A method for removing trace benzene in refinement of solvent oil or hexane principally comprises adding a composite extractant, which consists of furfurol and ethanediol, and raw material, i.e. solvent oil or industrial hexane, in a certain proportion, into an extraction and rectification tower by different positions. Then solvent oil distillate or industrial hexane product with lower than 50ppm benzene content is obtained at the tower top, while a mixture of heavy components in the raw material and the composite extractant is left in the tower kettle. The mixture returns into an extractant recovery tower for separation. Afterwards, heavy components in the raw material are distilled out from the tower top and the composite remains in the tower kettle for reuse. The method has the advantages of high benzene-removal efficiency, low cost, low energy consumption, strong application reliability, etc.

Owner:NANJING UNIV

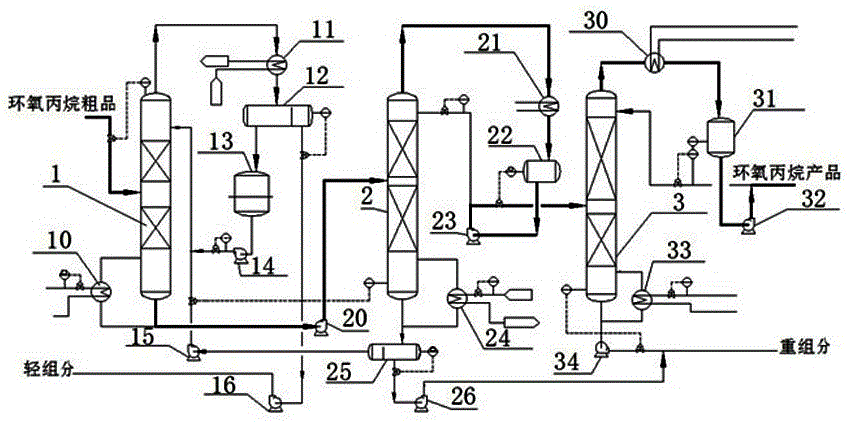

Epoxypropane refinement system and method

InactiveCN105669599ASolve the problem of pollution caused by recyclingSolve pollutionOrganic chemistryProcess engineeringTower

The invention discloses an epoxypropane refinement system which comprises an extraction tower, an extractant recovery tower and an epoxypropane rectification tower, wherein the middle part of the extraction tower is provided with an epoxypropane crude product inlet; the top of the extraction tower is provided with an extractant inlet; a tower bottom material outlet of the extraction tower communicates with a middle part material inlet of the extractant recovery tower; a tower top material outlet of the extractant recovery tower communicates with a middle part material inlet of the epoxypropane rectification tower; and the tower top of the epoxypropane rectification tower is provided with a high-purity epoxypropane material outlet. The system has the advantages of high product purity, low consumption, short process, less equipment and low investment.

Owner:江苏道尔顿石化科技有限公司

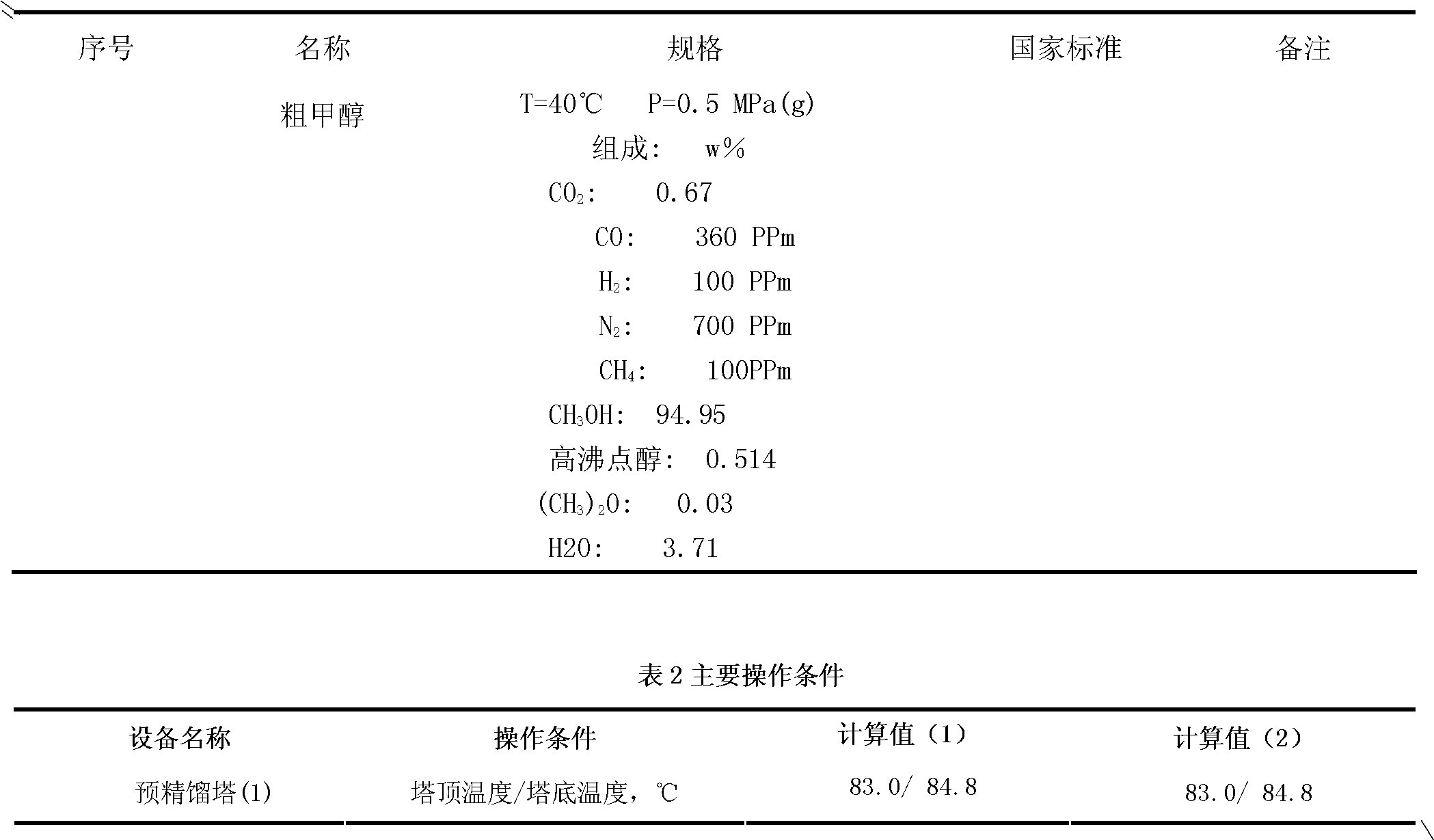

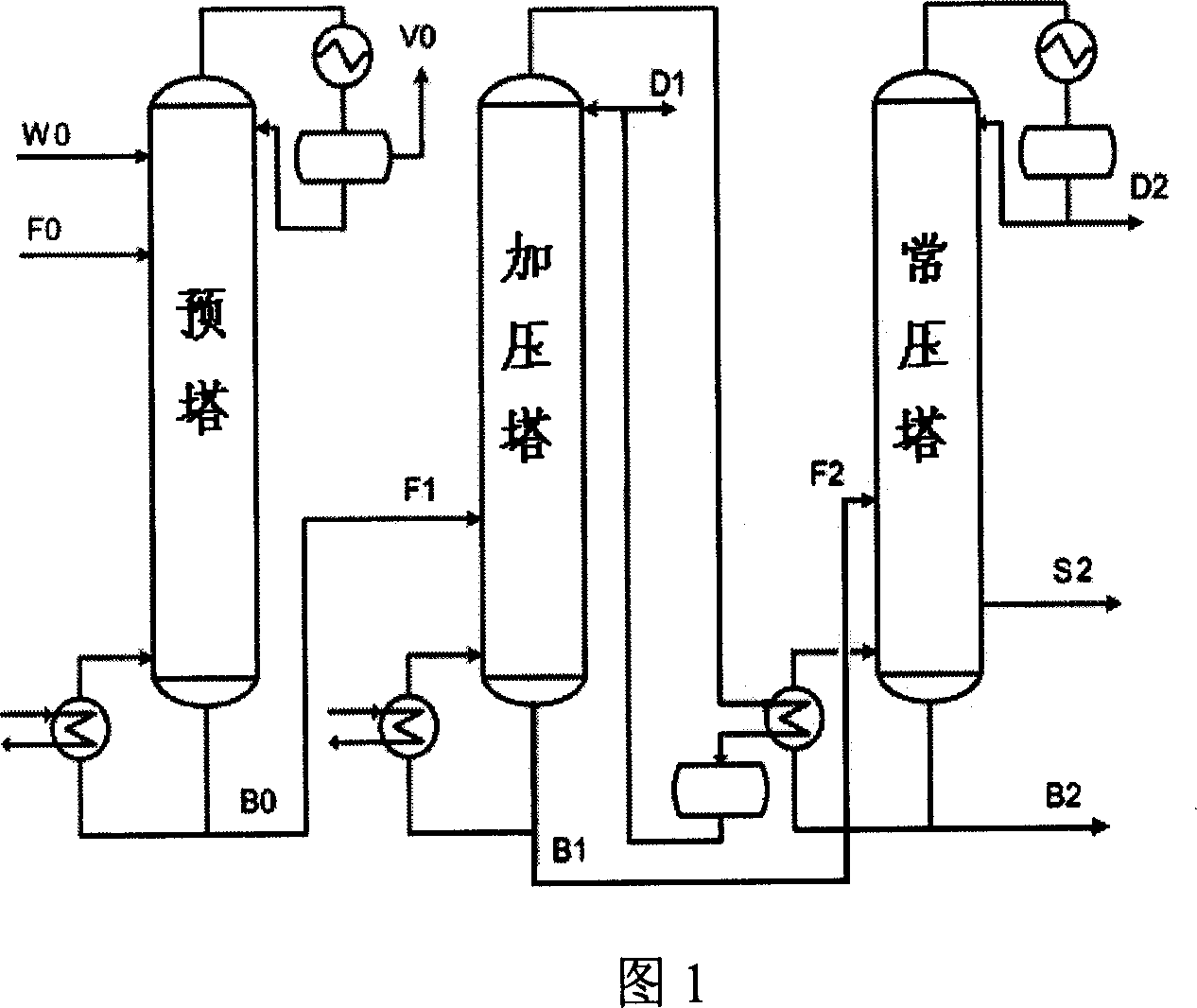

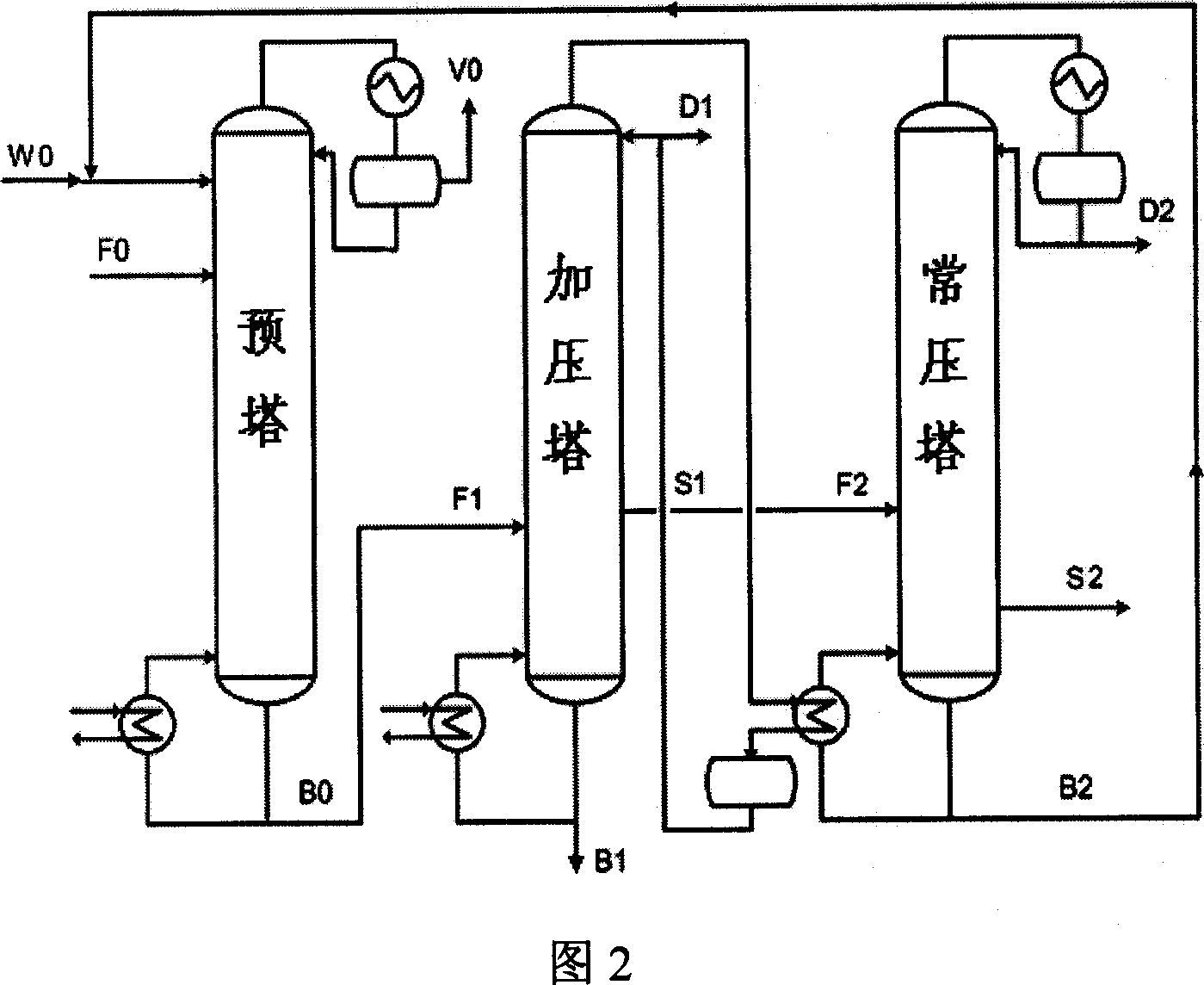

Rectifying and refining process of synthetic coarse methanol

InactiveCN1931807AIncrease feed concentrationReduce the amount of waterOrganic compound preparationHydroxy compound preparationAlcoholWastewater

The rectifying and refining process of synthetic coarse methanol includes the following steps: initial rectification of coarse methanol in a pre-rectifying tower with sodium hydroxide and extracting water fed from the tower top, and discharging the initially rectified methanol through the tower bottom while exhausting light impurity through the tower top; rectification in the pressurized tower and recovering rectified methanol from the tower top while exhausting waste water and discharging residual coarse methanol; rectification in the normal pressure tower and recovering rectified methanol while exhausting hetero alcohol oil from the side of the tower and returning industrial soft water from the tower bottom to the pre-rectifying tower. The present invention has low steam consumption and circular utilization of industrial soft water.

Owner:ZHEJIANG UNIV

Method for refining piperazine

The invention discloses a method for refining piperazine, which comprises the following steps of: adding piperazine reaction liquid in a tower of a rectifying column for heating separation; heating the reaction liquid in the tower to 130 DEG C-140 DEG C, controlling the reflux ratio to be 0.2-1:1, collecting 100 DEG C fractional water; continuing to heat to 140 DEG C -150 DEG C, controlling reflux ratio to be 2-5:1, collecting 119 DEG C fractional ethylene diamine; continuing to heat to 160 DEG C -170 DEG C, pumping an extraction agent into the rectifying column from an extraction agent inlet at the upper part of the rectifying column by using a microinfusion pump when the scale of a thermometer shows 140 DEG C, wherein the extraction agent is one of dihydric alcohol or triatomic alcohol of C2-C5; and controlling the reflux ratio to be 3-5:1, controlling the ratio of addition mass of the extraction agent per minute to extraction mass of piperazine per minute to be 0.05-0.2:1, and collecting 148 DEG C fractional piperazine which is pure piperazine. The method can improve the purity of the product and the separation efficiency and also can greatly reduce production cost since the extraction agent can be reused after being separated simply.

Owner:山西玉龙格兰特化工有限公司

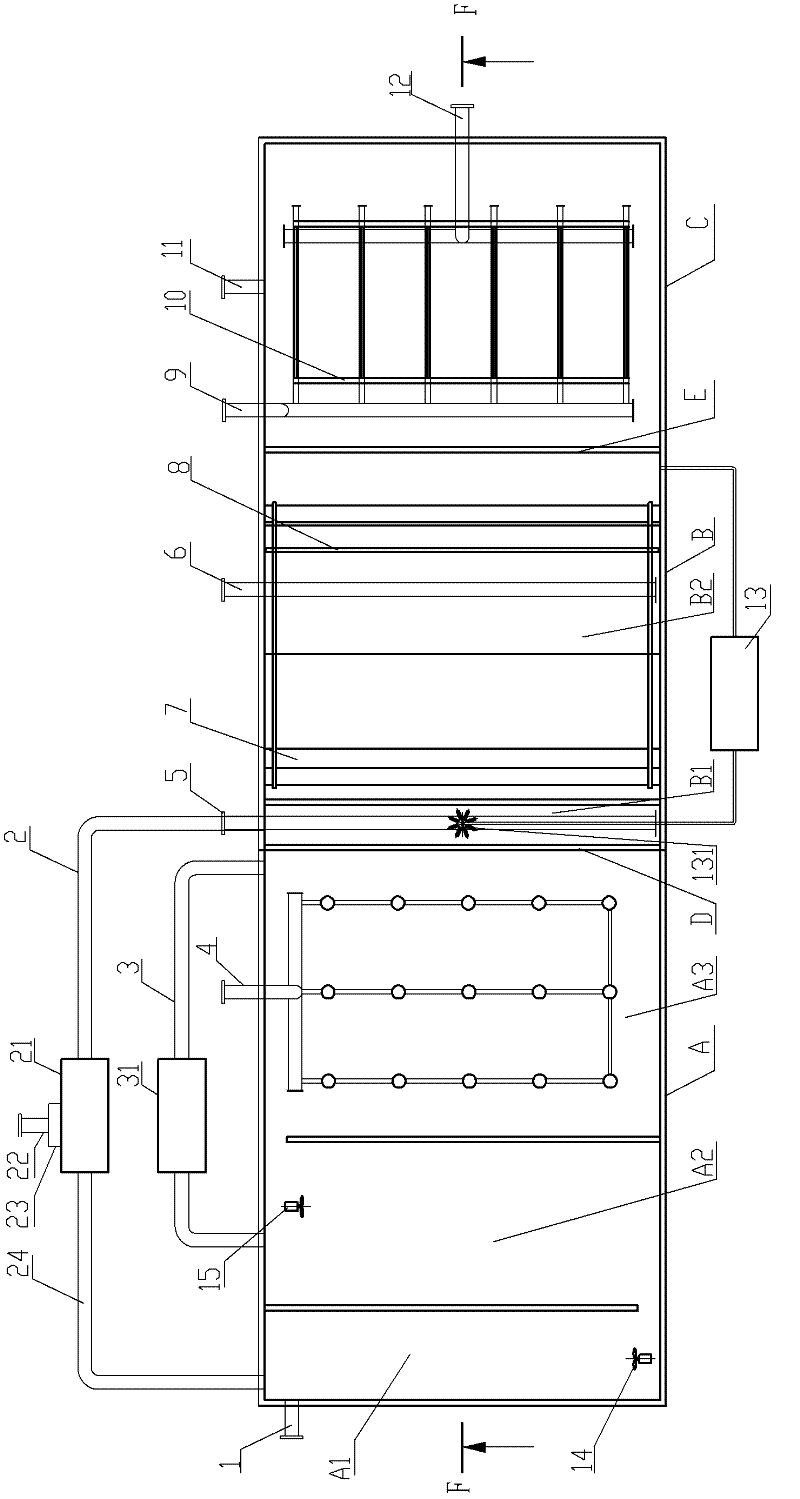

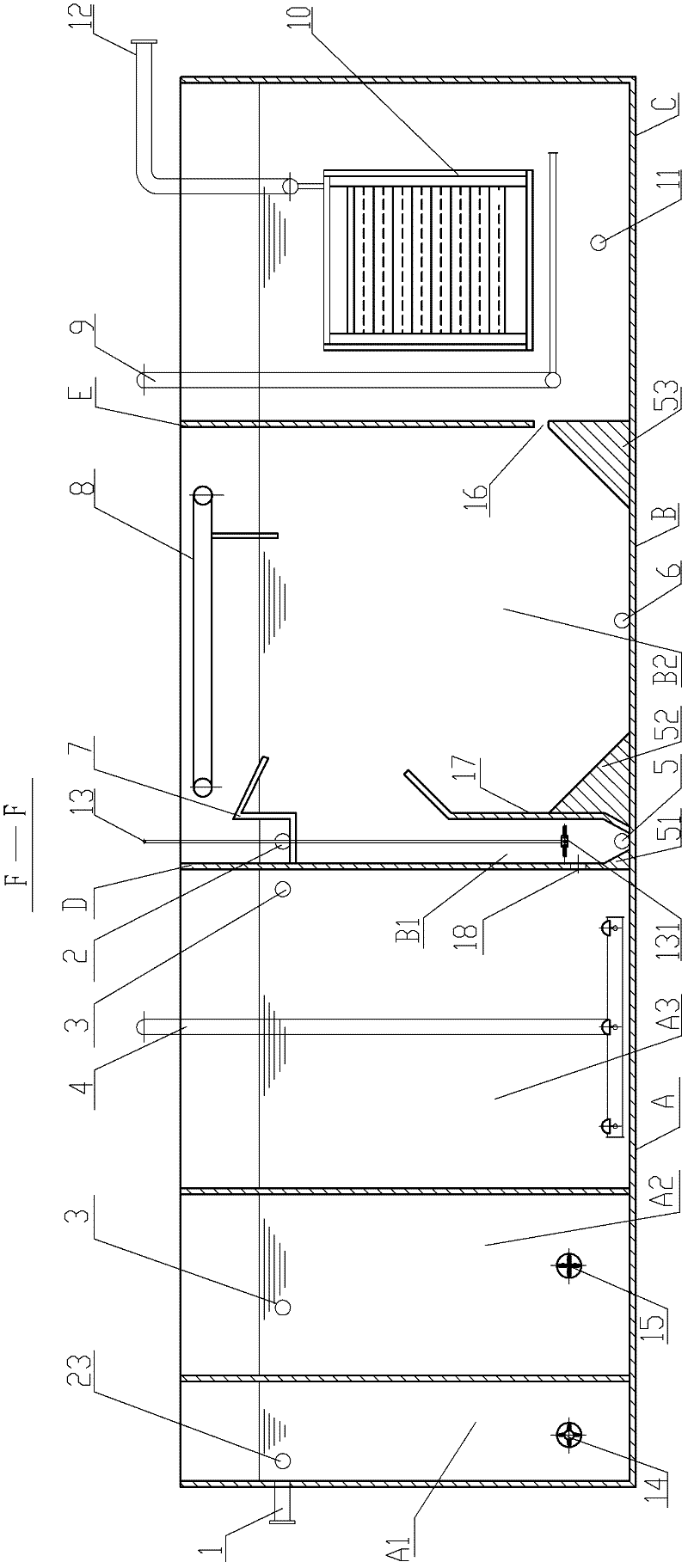

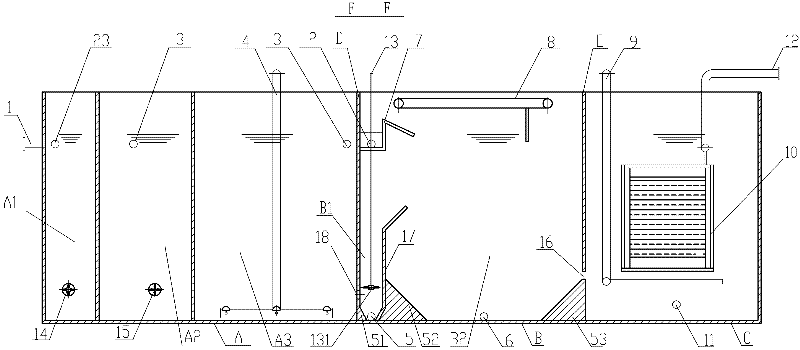

System integrating sewage treatment with sludge concentration

InactiveCN102642982AImprove throughputImprove reusabilityMultistage water/sewage treatmentTreatment pondSlag

The invention relates to a system integrating sewage treatment with sludge concentration. The system comprises a biological treatment tank and a membrane separation tank, wherein the biological treatment tank is connected with a water inlet pipe, a sludge backflow pipe and a mixed liquid backflow pipe; the membrane separation tank is connected with a water outlet pipe and a membrane separation sludge discharge pipe. The system is characterized in that an air flotation tank is additionally arranged between the biological treatment tank and the membrane separation tank to form an integrated tank sequentially partitioned by partition walls D and E; the air flotation tank is internally provided with an air flotation contact area close to the partition wall D; an air flotation separation area is arranged outside the air flotation area; the upper part of the air flotation tank is provided with a slag scraper and a slag discharging groove; a slag groove sludge pipe of the slag discharging groove is connected with a slag groove sludge discharging pipe and the biological treatment tank; the biological treatment tank is communicated with the air flotation tank through pore passages of the partition wall D; and the air flotation tank is communicated with the membrane separation tank through pore passages of the partition wall E; and the air flotation contact area and the air flotation separation area are respectively provided with an air flotation sludge pipe. The system integrating sewage treatment with sludge concentration has the advantages of concentrating and separating floating sludge in advance, lowering membrane pollution, improving membrane flux, reducing operation cost and protecting environment.

Owner:TIANJIN CARING TECH DEV

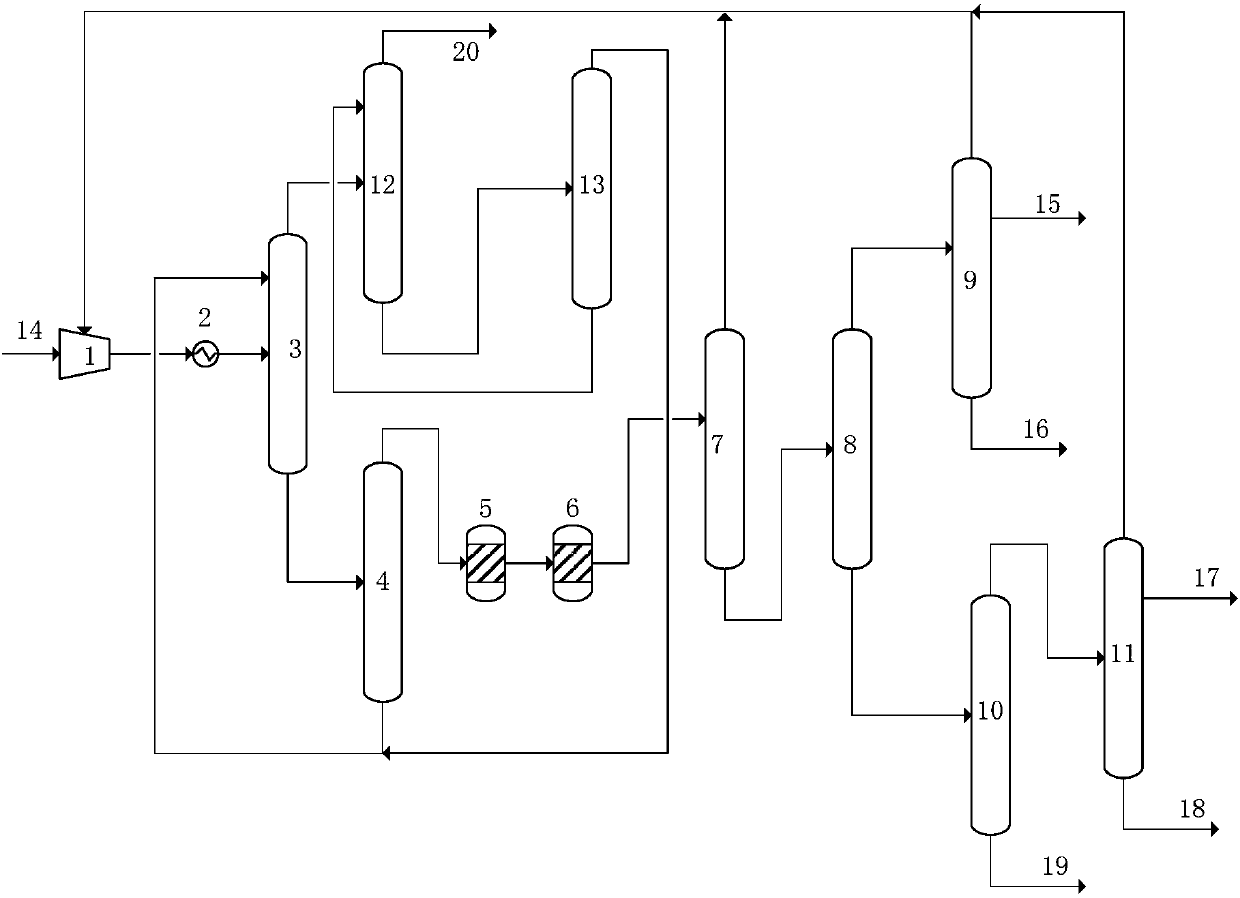

Method and device for separating ethylene from refinery plant dry gas

ActiveCN111320523AAvoid dependenceRaise the condensation temperatureDistillation purification/separationFractional condensation purification/separationProcess engineeringPropane

The invention belongs to the field of chemical engineering, and particularly discloses a method and a device for separating ethylene from refinery plant dry gas. The method comprises the steps of compression, purification, cooling, absorption, propane removal, methane removal, and ethylene refining. The method is based on a shallow cold oil absorption technology, directly produces a polymer-gradeethylene product from refinery plant dry gas on the premise that the refrigeration process is simplified, the cold consumption is reduced and the investment is saved, and has great industrial application prospects.

Owner:CHINA PETROLEUM & CHEM CORP +1

Anaerobic-aerobic bio-filter coupled sewage processing device and sewage processing method

InactiveCN104973688AImprove contact efficiencyImprove nitrogen removal efficiencyTreatment with aerobic and anaerobic processesAnaerobic aerobicWater treatment system

The invention provides an anaerobic-aerobic bio-filter coupled sewage processing device and a sewage processing method. The device comprises an anaerobic bio-filter, which is filled with an anaerobic filler layer that is covered by a bio-membrane containing anaerobic ammonia oxidation bacteria, anaerobic methanation bacteria, and denitrifying bacteria; an aerobic bio-filter, which is filled with an aerobic filler layer that is covered by a bio-membrane containing aerobic ammonia oxidation bacteria and nitrifying bacteria; an aeration device, which is arranged on the bottom of the aerobic bio-filter; a passive internal circulation device, which is arranged on the top of the aerobic bio-filter; and a backwater device, which comprises a backwater pipe and a backwater pump. The provided technical scheme couples the ammonia oxidization bacteria, methanation bacteria and denitrifying bacteria into a water treatment system, the methanation, ammonia oxidation, short-cut nitrification, and denitrification can be achieved synchronously, and thus the problems that in the biomembrane method, the contact efficiency between bacteria and sewage is low and the denitrification efficiency is low are solved effectively.

Owner:BEIJING NEWATT ENVIRONMENTAL ENG CO LTD

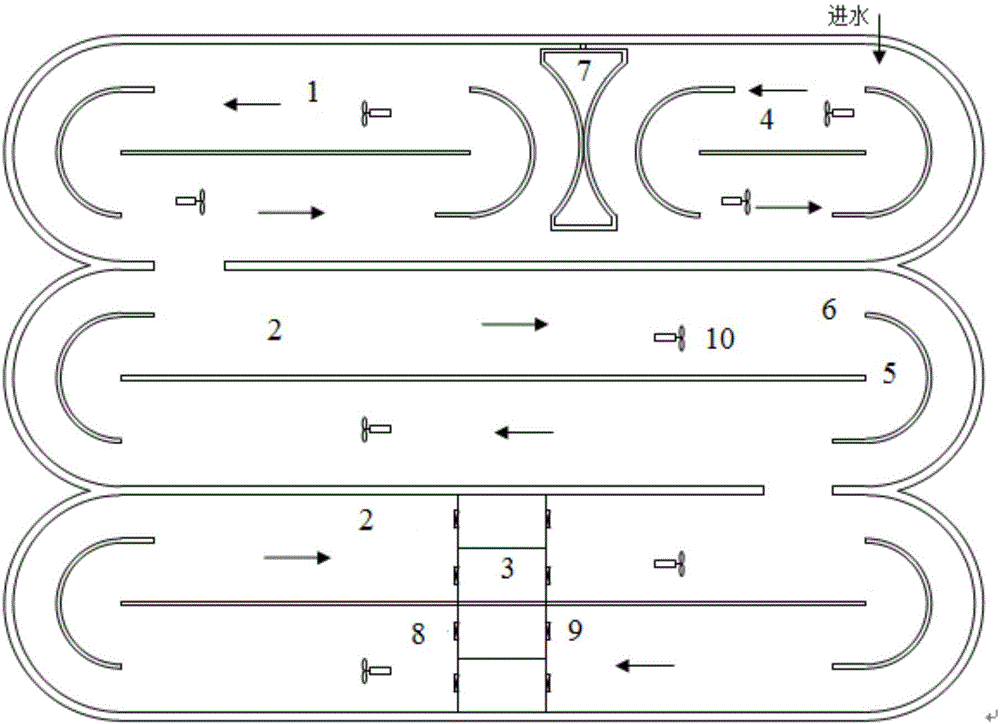

Oxidation ditch membrane bioreactor, wastewater treatment process and application thereof

PendingCN106315853AImprove the effectShort processBiological treatment apparatusTreatment with aerobic and anaerobic processesChemistryOptimal combination

The invention provides an oxidation ditch membrane bioreactor, a wastewater treatment process and an application thereof. An oxidation ditch is arranged in the oxidation ditch membrane bioreactor; the oxidation ditch membrane bioreactor comprises an anoxic zone and an aerobic zone which are continuously arranged or an anaerobic zone, the anoxic zone and the aerobic zone which are continuously arranged; one or more membrane bio-reaction zones are arranged in the aerobic zone; a sewage inlet is arranged in the anoxic zone or the anaerobic zone; the membrane bioreactor is organically combined with the oxidation ditch; the advantages of S-MBR and R-MBR are fully utilized; sludge backflow is reduced or cancelled; the technical process and the power equipment are simplified; as S-MBR running, the oxidation ditch membrane bioreactor can realize in-situ online cleaning and soaking cleaning; as R-MBR running, the oxidation ditch membrane bioreactor can increase the land use rate and simplify operation and maintenance; an aerating system is optimized; the pulse aeration is combined for guaranteeing the valid oxygen demand in each zone, so that energy consumption waste is avoided. According to the invention, through the optimal combination of the reactor, the processing effect of nitrogen and phosphorus removal can be enhanced, the energy consumption can be saved and the land occupation can be saved.

Owner:上海市净化技术装备成套有限公司

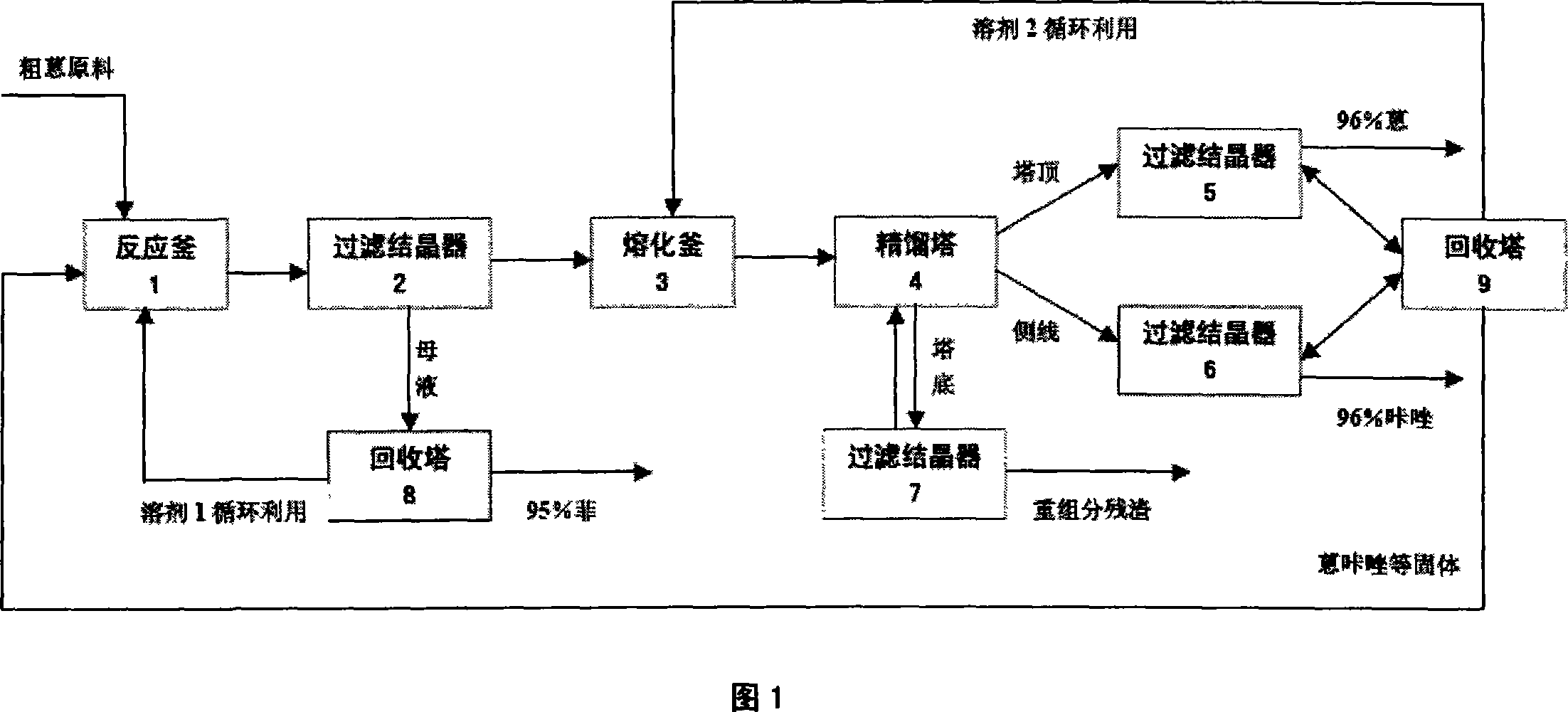

Method for refining high-purity anthracene and carbazole from crude anthracene

InactiveCN101229988AImprove product gradeImprove overall recoveryDistillation purification/separationCrystallisation purification/separationAnthraceneBenzene

The invention relates to a method for refining anthracene and carbazole with a high purity from the crude anthracene. The method mainly consists of four steps: crude benzene with a doffing phenanthrene, separation of the anthracene from the carbazole by a rectification, a crystal preparation of the anthracene and the carbazole as well as solvent recycle. Solvent 1 is firstly used for removing the phenanthrene from the crude anthracene. The obtained anthracene and carbazole solid is mixed with solvent 2 and is rectified. The obtained anthracene and carbazole is cooled, crystallized and washed, and the anthracene with the purity of more than 96 percent is obtained. The method completely solves the problem of easy blocking in the rectification system. The invention has a higher product grade and a high yield and continuous stable operation. The using solvent amount is low (only 1 / 2 to 2 / 3 of the original solvent amount is required); besides, the invention has the advantages of low energy consumption (saving 30 to 50 percent totally) and flexible operation. The invention is particularly applicable to the anthracene and carbazole production with a large production scale, high requirement for the quality and environment protection and energy saving.

Owner:NANJING UNIV

Device and method for preparing high-purity nitrogen monoxide from adipic acid production tail gases

ActiveCN105110304AReduce back flowReduce process energy consumptionChemical industryNitrous oxidesChemistryIntercooler

The invention relates to a device and method for preparing high-purity nitrogen monoxide from adipic acid production tail gases. The device comprises a compressor, an absorption tower, an adsorption device, a low-temperature rectifying tower and a low-temperature refining tower which are connected in sequence, wherein the low-temperature rectifying tower is provided with an intercondenser; airflow discharged from the adsorption device enters the low-temperature rectifying tower after being cooled through a heat exchanger; purge gases located at the top of the tower and treated by the intercondenser is delivered to a tail gas treatment system after the cold energy is recovered; a liquid flow at the bottom of the tower enters the low-temperature refining tower; high-purity N2O is obtained from the top of the low-temperature refining tower and is filled after cold energy is recovered; a pressurized absorption, pressurized adsorption and low-temperature rectification coupling method is adopted; and the low-temperature rectifying tower is internally provided with an intercooler, so that the process energy consumption is greatly reduced on the premise that the high purity of the product is ensured.

Owner:SHANGHAI JIAO TONG UNIV

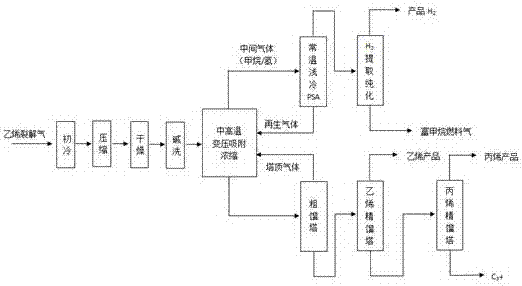

Separation method of ethylene cracking gas through full temperature range-pressure swing adsorption

ActiveCN107285986AConducive to cascading utilizationLittle change in temperatureDistillation purification/separationAdsorption purification/separationDistillationSelf-energy

The invention discloses a separation method of ethylene cracking gas through full temperature range-pressure swing adsorption and relates to the technical field of preparation of ethylene, propylene, hydrogen and the like and gas separation through pressure-swing adsorption. The separation method disclosed by the invention solves the problems existing in a sequential ethylene cracking gas separation (cryogenic distillation) method that the self energy of raw material gas cannot be fully utilized, the energy consumption in the separation process is higher, the product and recovery component purity or the yield are lower, and the like, and changes that a traditional pressure-swing adsorption method is only limited to the auxiliary effect of refined purification of ethylene tail gas and becomes basic separation unit operation as equally important as cryogenic distillation separation.

Owner:SICHUAN TECHAIRS

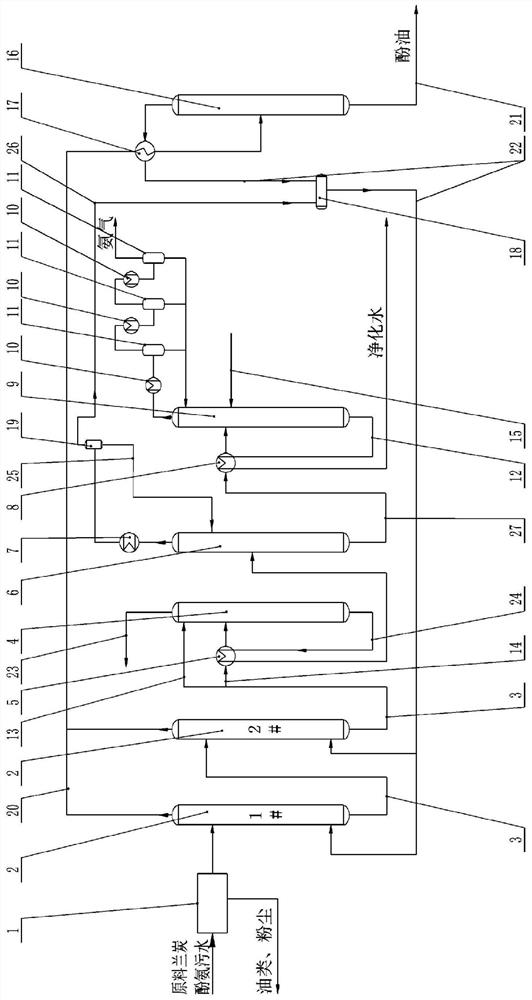

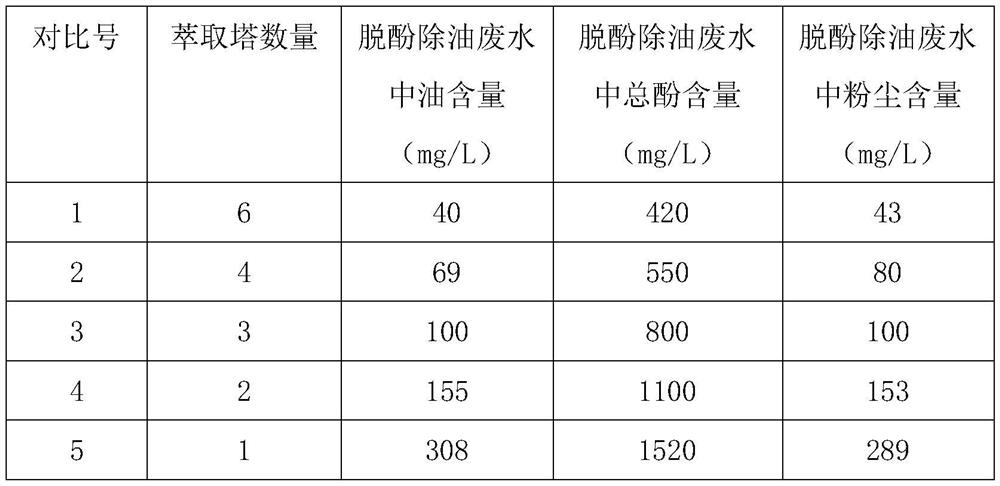

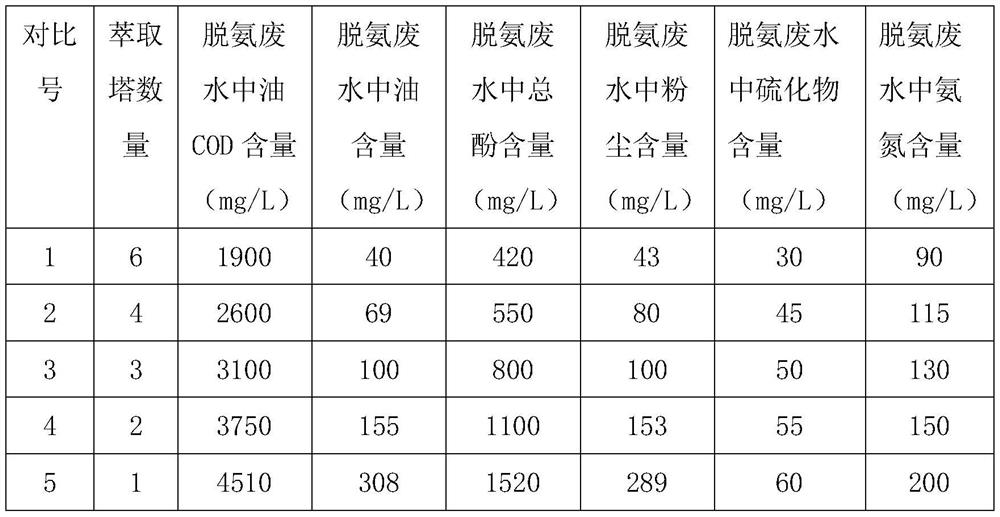

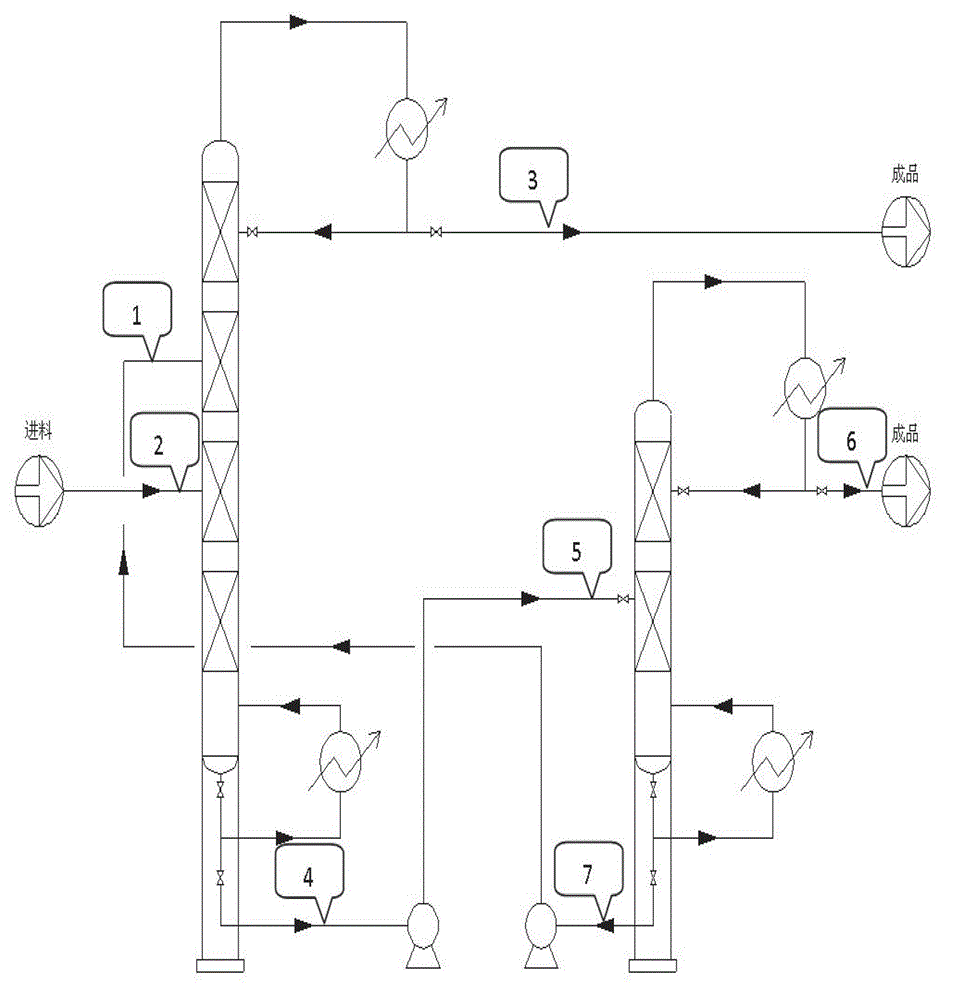

Phenol-ammonia-semi-coke wastewater treatment device and treatment method

PendingCN111732254AReduce CODImprove quality indicatorsWater treatment parameter controlFatty/oily/floating substances removal devicesProcess engineeringOrganic matter

The invention discloses a phenol-ammonia-semi-coke wastewater treatment device and a treatment method. The device comprises an oil separator, a plurality of extraction towers, a deacidification tower,a water tower, a deamination tower, an extraction agent circulating tank and a phenol tower. Organic matters and impurities such as oil, dust, phenol and the like in the phenol-ammonia raw material wastewater are removed by adopting an oil remover and an extraction oil removal method, so that the problems of device and equipment blockage, unqualified recovered product indexes, substandard effluent and the like in the traditional semi-coke phenol-ammonia wastewater treatment process are solved.

Owner:天津同创恒泰科技有限公司

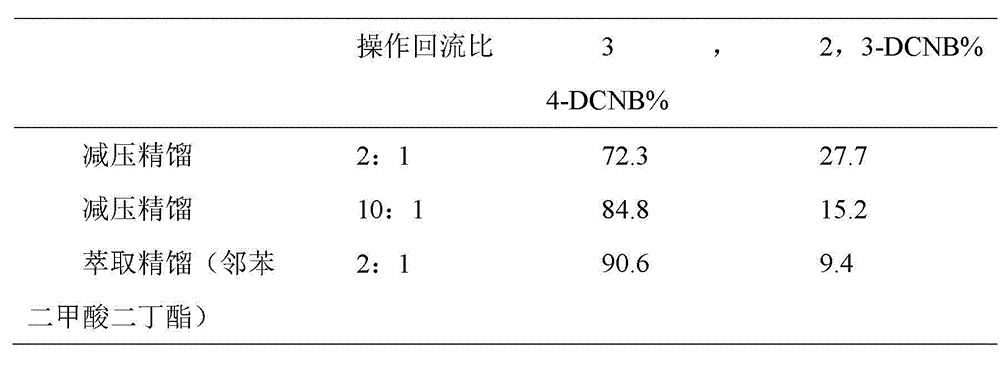

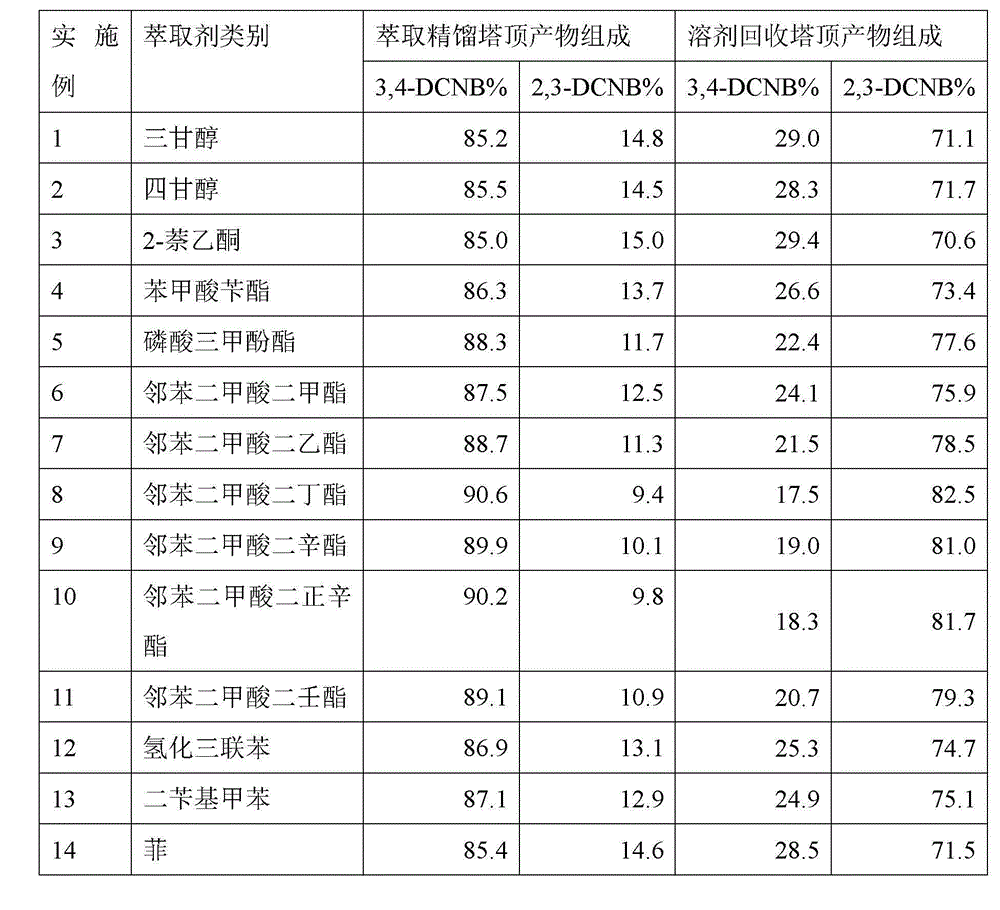

Method for separating 3, 4-dichloronitrobenzene crystallization mother liquor through extractive distillation

ActiveCN102875384ALess investment in equipmentReduce energy consumptionOrganic chemistryOrganic compound preparationKetoneChemistry

The invention relates to a method for separating 3, 4-dichloronitrobenzene from 2, 3-dichloronitrobenzene in 3, 4-dichloronitrobenzene crystallization mother liquor. Aiming at the characteristics of small isomer boiling point difference of the 3, 4-dichloronitrobenzene and the 2, 3-dichloronitrobenzene in low oil and difficulty in separation of the conventional method, alcohol, ketone, ester and aromatic hydrocarbon are used as an extraction agent to perform extractive distillation to obtain 3, 4-dichloronitrobenzene and 2, 3-dichloronitrobenzene distillates deviating from eutectic points, so that a foundation is laid for further purification.

Owner:JIANGSU YANGNONG CHEM GROUP +1

Urban sewage strengthening treatment method in cold area based on multi-point feed water adjustment

InactiveCN102001791AExtended staySmall volumeMultistage water/sewage treatmentNitrogenTherapeutic effect

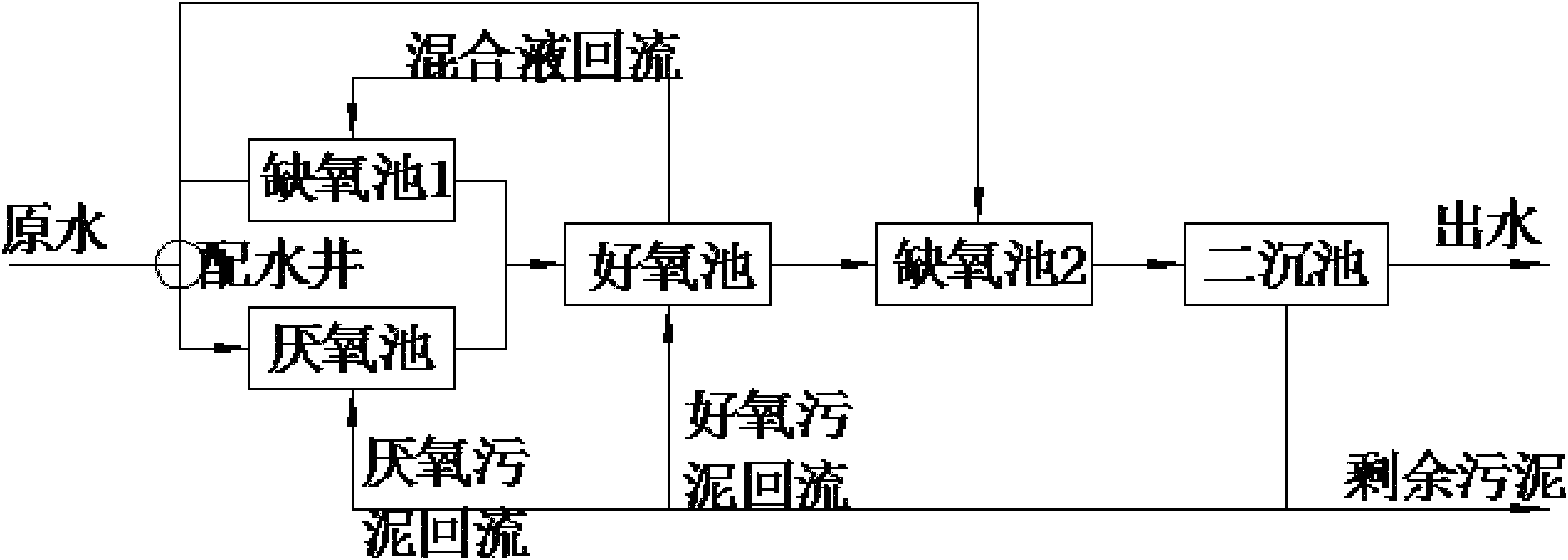

The invention discloses an urban sewage strengthening treatment method in a cold area based on multi-point feed water adjustment, which relates to an urban sewage strengthening treatment method and solves the problems of incapability of synchronous and efficient denitrogenation and dephosphorization, poor treatment effect, high running cost and unsuitability for treating urban sewage in the cold area in the traditional technology of treating the urban sewage. The method comprises the following steps of: firstly, primary precipitation of sewage: dividing effluent of a primary settling tank into two parts or three parts through a distribution well for distribution; and secondly, synchronously introducing the effluent mixing liquid of an anaerobic tank and an anoxic tank 1 and the reflowing sludge at the head end of an aerobic tank into the aerobic tank, introducing the effluent of the aerobic tank into an anoxic tank 2, introducing the effluent of the anoxic tank 2 into a secondary settling tank through water drop, discharging a supernatant as treated purified water, reflowing a part of sludge at the lower layer, and discharging the rest as the remaining sludge. The invention can synchronously carry out efficient denitrogenation and dephosphorization, has favorable treatment effect and low running cost and is suitable for treating the urban sewage in the cold area.

Owner:HARBIN INST OF TECH

Rectification-molecular sieve membrane coupling process and device for ternary water-containing eutectic system separation

ActiveCN111004090ASolve the problem of low separation production capacityReduce the reflux ratioSemi-permeable membranesEther separation/purificationMolecular sieveMembrane permeabilization

The invention relates to a rectification-molecular sieve membrane coupling process and a rectification-molecular sieve membrane coupling device for separation of a ternary water-containing eutectic system, and discloses a novel separation device for direct coupling of a rectifying tower and a membrane component. The novel separation device comprises a tower internal component and a membrane permeation unit internal component contained in a conventional rectifying tower. For ternary water-containing system separation, a molecular sieve membrane steam permeation device and a rectifying tower areingeniously combined into a whole, separation of a ternary azeotropic system through a single rectifying tower of a simple structure is achieved, and the separation efficiency is obviously improved.

Owner:NANJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com