Epoxypropane refinement system and method

A technology of propylene oxide and refining system, applied in the direction of organic chemistry, etc., can solve the problem of not being able to obtain high-purity propylene oxide, and achieve the effects of high purity of propylene oxide product, improving separation efficiency, and reducing reflux ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

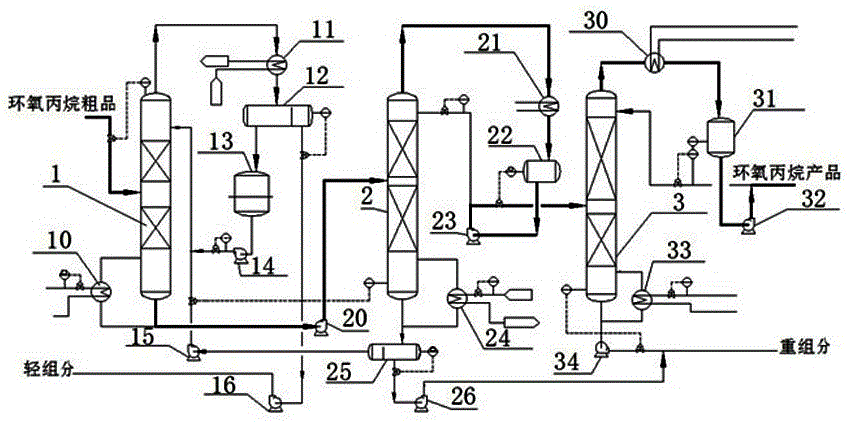

[0039] A propylene oxide refining system, such as figure 1 Shown, comprise extraction tower 1, extraction agent recovery tower 2 and propylene oxide rectification tower 3, the middle part of extraction tower 1 is provided with propylene oxide crude product raw material import, the top of extraction tower 1 is provided with extraction agent inlet, extraction tower 1 The bottom material outlet of the tower is connected to the middle material inlet of the extraction agent recovery tower 2 through the recovery tower feed pump 20, and the tower top material outlet of the extraction agent recovery tower 2 is connected to the middle material inlet of the propylene oxide rectification tower 3 through a pipeline Generally, the top of the propylene oxide rectifying tower 3 is provided with a high-purity propylene oxide material outlet.

[0040] In this particular embodiment, the extraction tower is also equipped with an extraction tower condenser 11 and a first stratifier 12, and the to...

Embodiment 2

[0047] A method for refining propylene oxide, using C6 n-hexane as an extraction agent to determine the required process parameters for the rectification system of the present invention, specifically comprises the following steps:

[0048] (1) Extraction and separation in the extraction tower

[0049] The crude propylene oxide from the propylene oxide cyclization unit at 96°C is sent to the middle of the extraction tower, and the extractant at 54°C is sent to the top of the extraction tower in a liquid phase state, and the mass ratio of crude propylene oxide to the extractant is controlled as 1:2.7, the top operating temperature of the extraction tower is controlled at 98°C, the operating temperature at the bottom of the tower is controlled at 120°C, the reflux ratio in the tower is controlled at 1:1.3, and the crude propylene oxide and the extractant are directly exchanged in the tower. The content of propylene oxide in the light components at the top of the tower is less tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com