Phenol-ammonia-semi-coke wastewater treatment device and treatment method

A technology for wastewater treatment and charcoal wastewater, which is applied in multi-stage water treatment, water/sewage treatment, water treatment parameter control, etc. Operating costs, good water quality indicators, and the effect of reducing energy consumption per ton of water treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

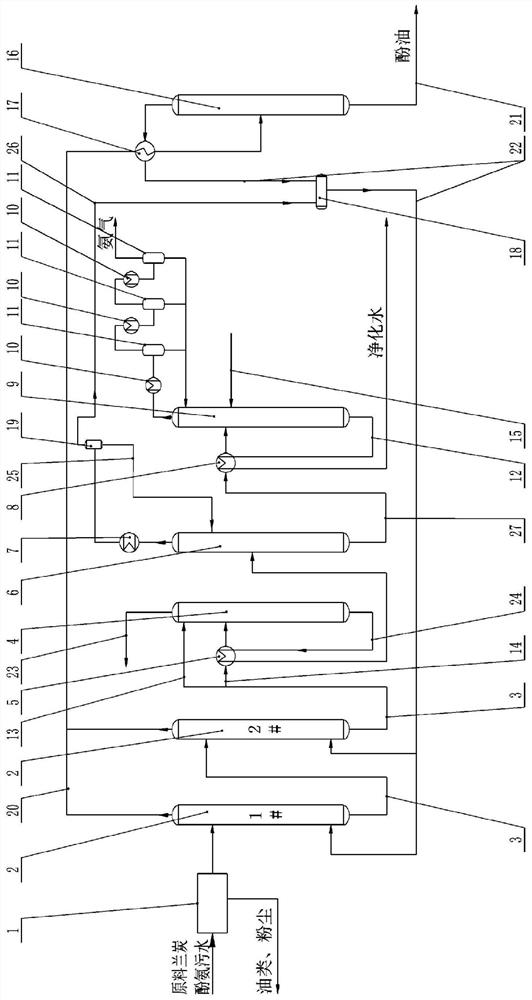

[0041] 100t / h phenol ammonium blue carbon wastewater raw material, COD content is 41500mg / L, oil content is 3800mg / L, total phenol content is 11800mg / L, ammonia nitrogen content is 8000mg / L, sulfide content is 2500mg / L, dust content It is 1500mg / L, the pH value is 9.5, and the temperature is 25°C. Attached figure 1 The intermediate treatment device is processed according to the treatment process steps, and the main process parameters are as follows:

[0042] (a) Oil separation and dust removal: use oil separator 1 to carry out preliminary purification of phenol ammonia blue carbon wastewater, and the raw material of phenol ammonia blue carbon wastewater directly enters oil separator 1, and light oil, heavy oil and impurities are extracted from the oil outlet. Oil-separating and dust-removing wastewater is produced at the water outlet, with an oil content of 2000mg / L and a solid dust content of 150mg / L.

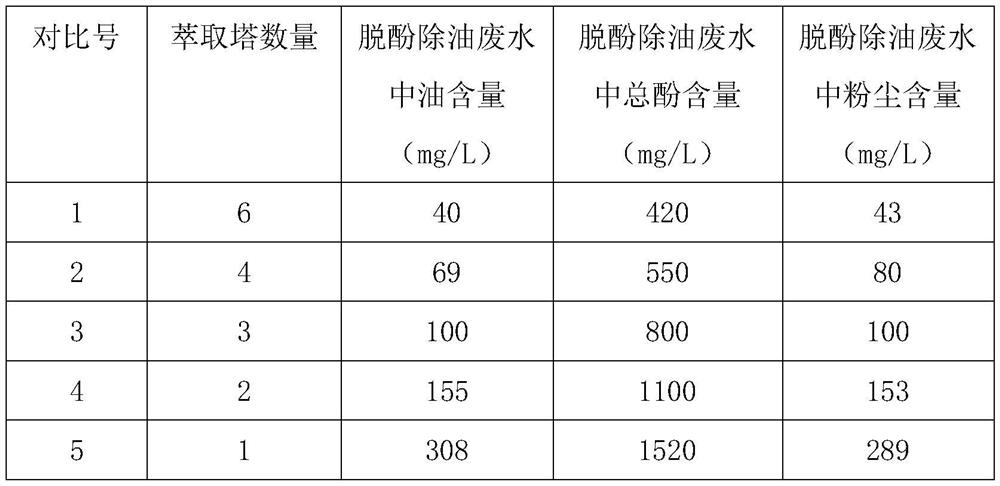

[0043] (b) Extraction dephenolization and oil removal: This example ado...

Embodiment 2

[0056] The treatment capacity is 50t / h phenol ammonium blue carbon wastewater raw material, the COD content is 39500mg / L, the oil content is 2700mg / L, the total phenol content is 8500mg / L, the ammonia nitrogen content is 5500mg / L, the sulfide content is 4000mg / L, the dust The content is 2300mg / L, the pH value is 5.6, and the temperature is 45°C. Attached figure 1 The process flow chart is processed, and the main process parameters are as follows:

[0057] (a) Oil separation and dust removal: use oil separator 1 to carry out preliminary purification of phenol ammonia blue carbon wastewater, and the raw material of phenol ammonia blue carbon wastewater directly enters oil separator 1, and light oil, heavy oil and impurities are extracted from the oil outlet. Oil-separating and dust-removing wastewater is produced at the water outlet, with an oil content of 1600mg / L and a solid dust content of 300mg / L.

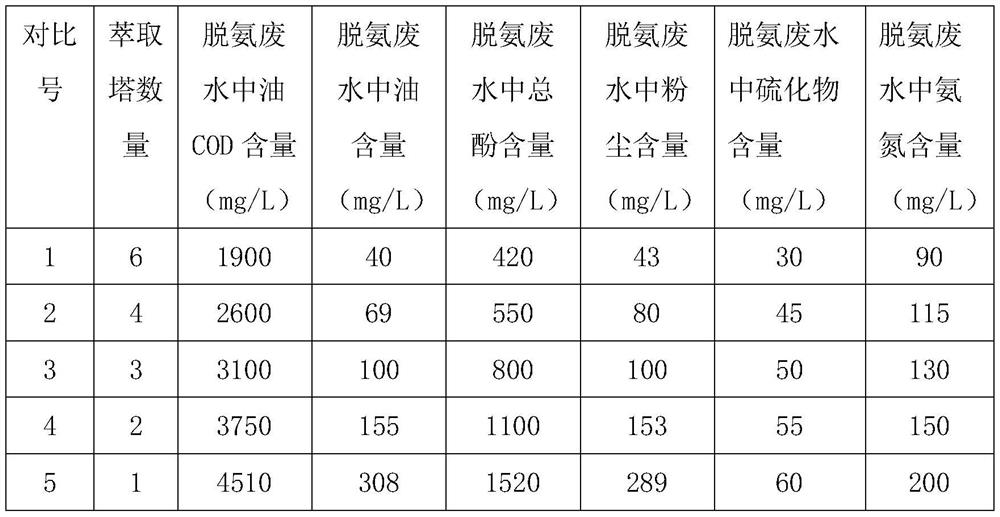

[0058] (b) Extraction dephenolization and oil removal: This example adopts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com