Patents

Literature

48results about How to "Reduce effluent COD" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

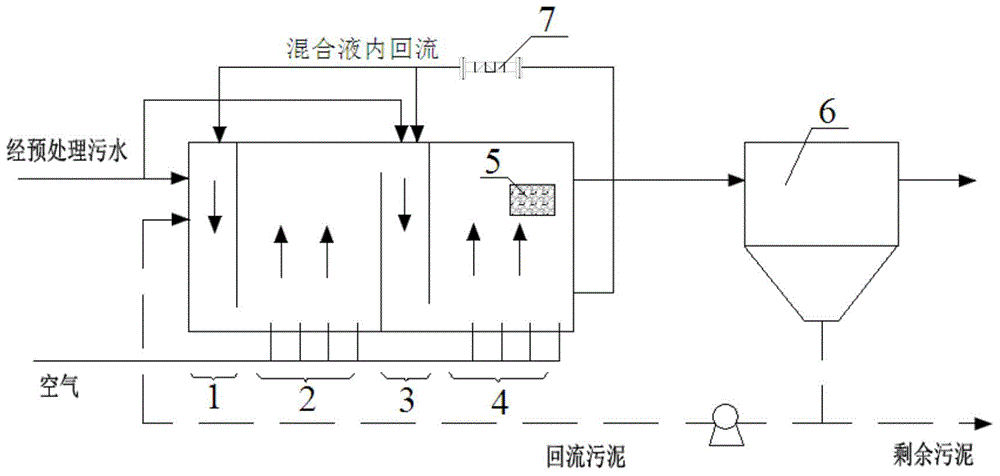

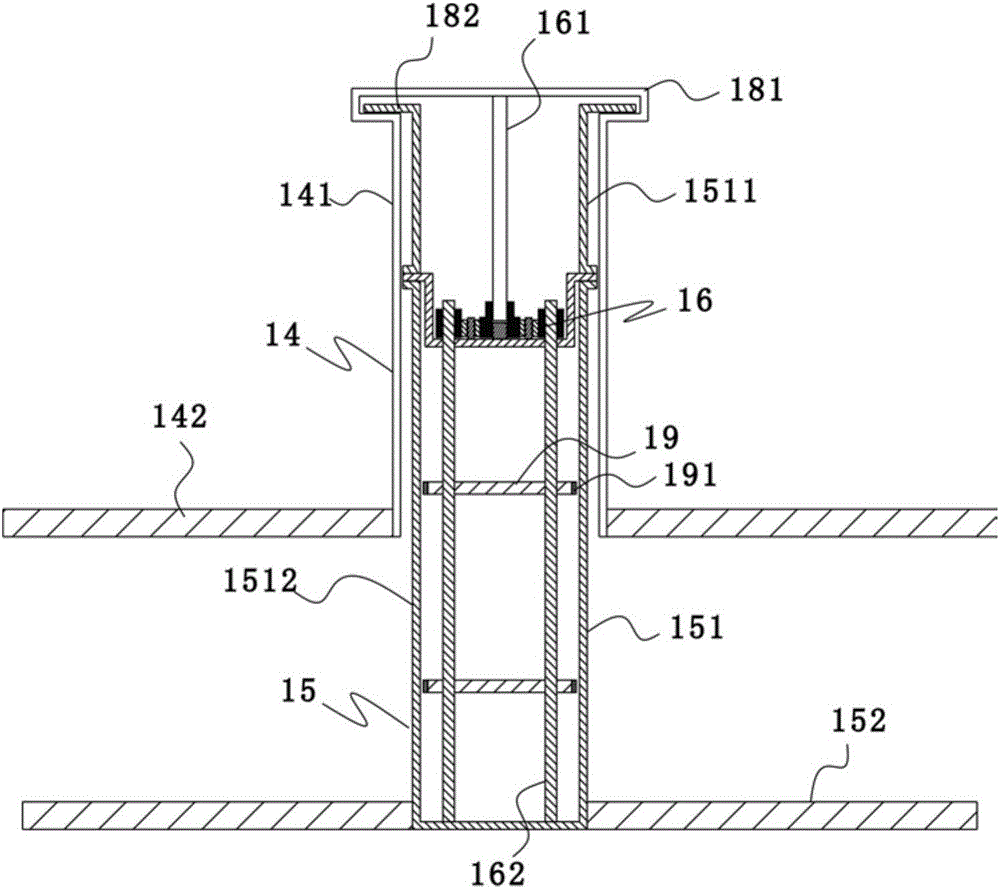

Wastewater treatment method using magnetism biological carrier and magnetic separation technique

InactiveCN101244884AEasy to handleSimple methodWater/sewage treatment by magnetic/electric fieldsMultistage water/sewage treatmentTherapeutic effectVolumetric Mass Density

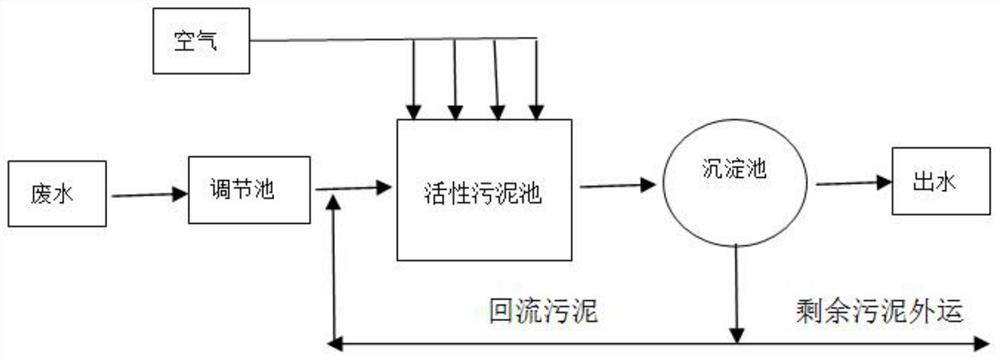

The invention relates to a sewage treatment method of adopting magnetic biological carrier and magnetic separation technique, belonging to the technical field of environmental protection, which comprises the following steps: magnetic biological carrier with density 1.0 to 1.4g / cm<3> and particle diameter 0.043 to 0.315mm is put into an aeration tank, the generated remained sewage can realize mud and water separation by magnetic separation technique, and then is put into a carrier de-molding separator, so as to realize the separation between mud and magnetic carrier, after magnetic separation, the magnetic carrier renews to be placed into the reactor, so as to realize recovery and reutilization of magnetic carrier. When the carrier additive is between 4 and 13g / L, the aeration amount is 50 to 100L / h, air apparent flow rate is 1.8 to 3.5m<3>(m<2> x h), waterpower retaining time is 1-5h, reflux ratio of the mixed liquid is 1-6, after checking, the removal ratio of effluent COD can reach 92.0 to 98.2%. When used for sewage treatment, the method in the invention has advantages of good treatment effect, simple method, strong controllability, and facility for industrial production; while obviously reducing effluent COD, the investment can be reduced and running cost can be lowered.

Owner:UNIV OF SCI & TECH BEIJING

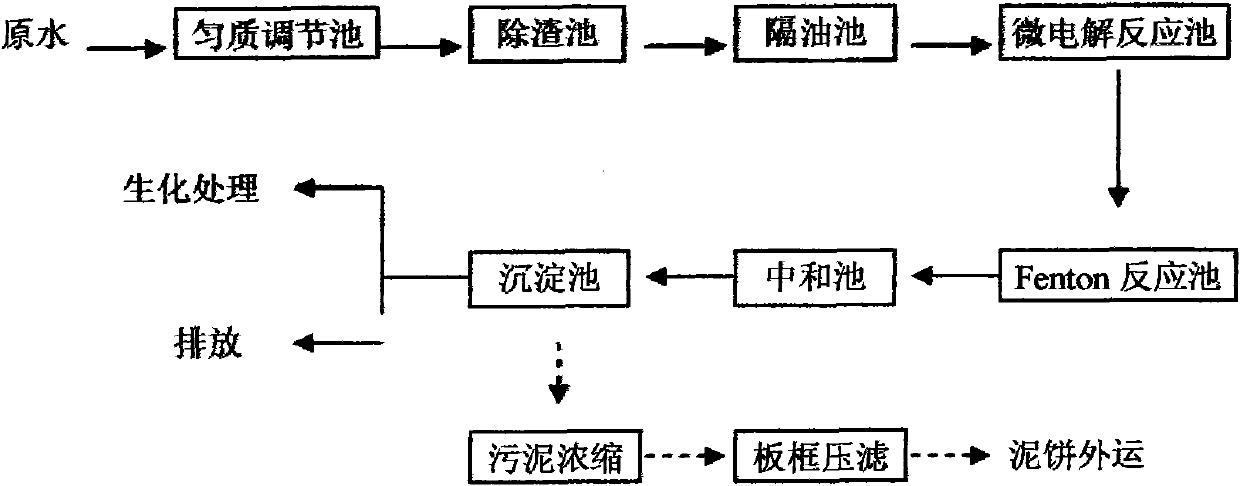

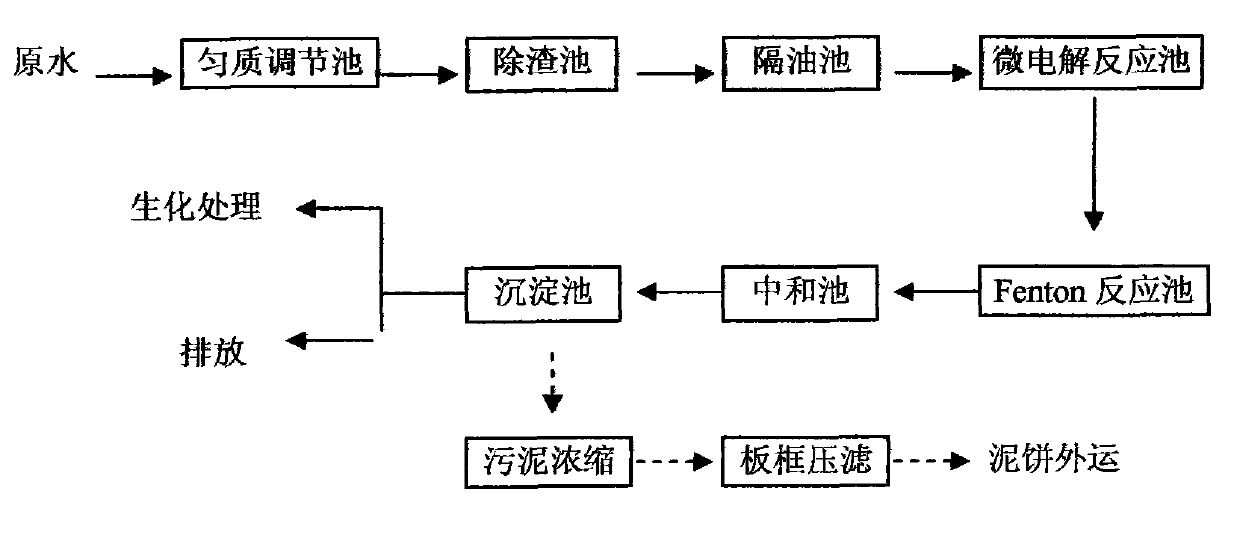

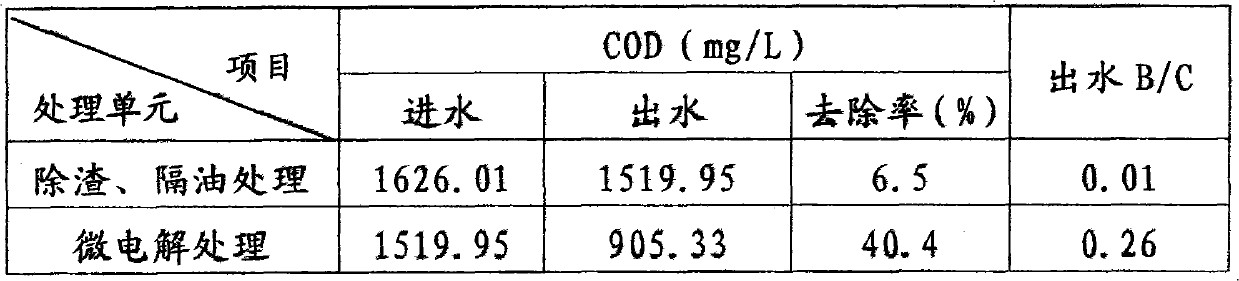

Pretreatment process of organic silicon wastewater

InactiveCN102001775AReduce loadReduce effluent CODMultistage water/sewage treatmentChemistryStrong acids

The invention discloses a pretreatment process of organic silicon wastewater, comprising the steps of homogeneous treatment, slag removal, oil removal, iron-carbon micro-electrolysis process, Fenton process, neutralization deposition and overflow and discharge of supernate. Aiming at the strong acid characteristic of the organic silicon wastewater, the iron-carbon micro-electrolysis can be directly carried out after the homogeneous impurity removal; partial COD (Chemical Oxygen Demand) can be degraded while the biochemical quality of the wastewater is improved and the pH value is improved; then hydrogen peroxide is directly added to form a Fenton system; a strong oxidant is formed to damage the structure of organic matters and chromophonic groups in the wastewater and effectively oxidize so as to remove the organic matters which are difficult to degrade and cannot be removed by the traditional wastewater treatment technology, and thereby the aims of further reducing the COD and improving the biodegradability of the wastewater can be improved. The organic silicon wastewater can reach the national third-grade discharge standard after being subjected to neutralization and the precipitation and reach the national first-grade discharge standard after being subjected to biochemical treatment. The pretreatment process has the advantages of low cost and stable treatment effect and is simple for operation.

Owner:蓝星环境工程有限公司

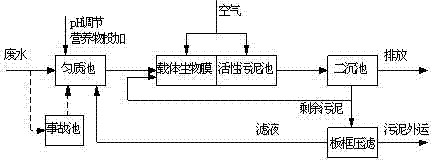

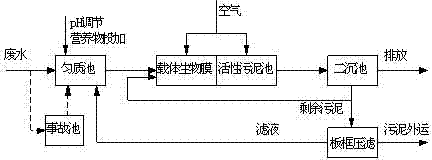

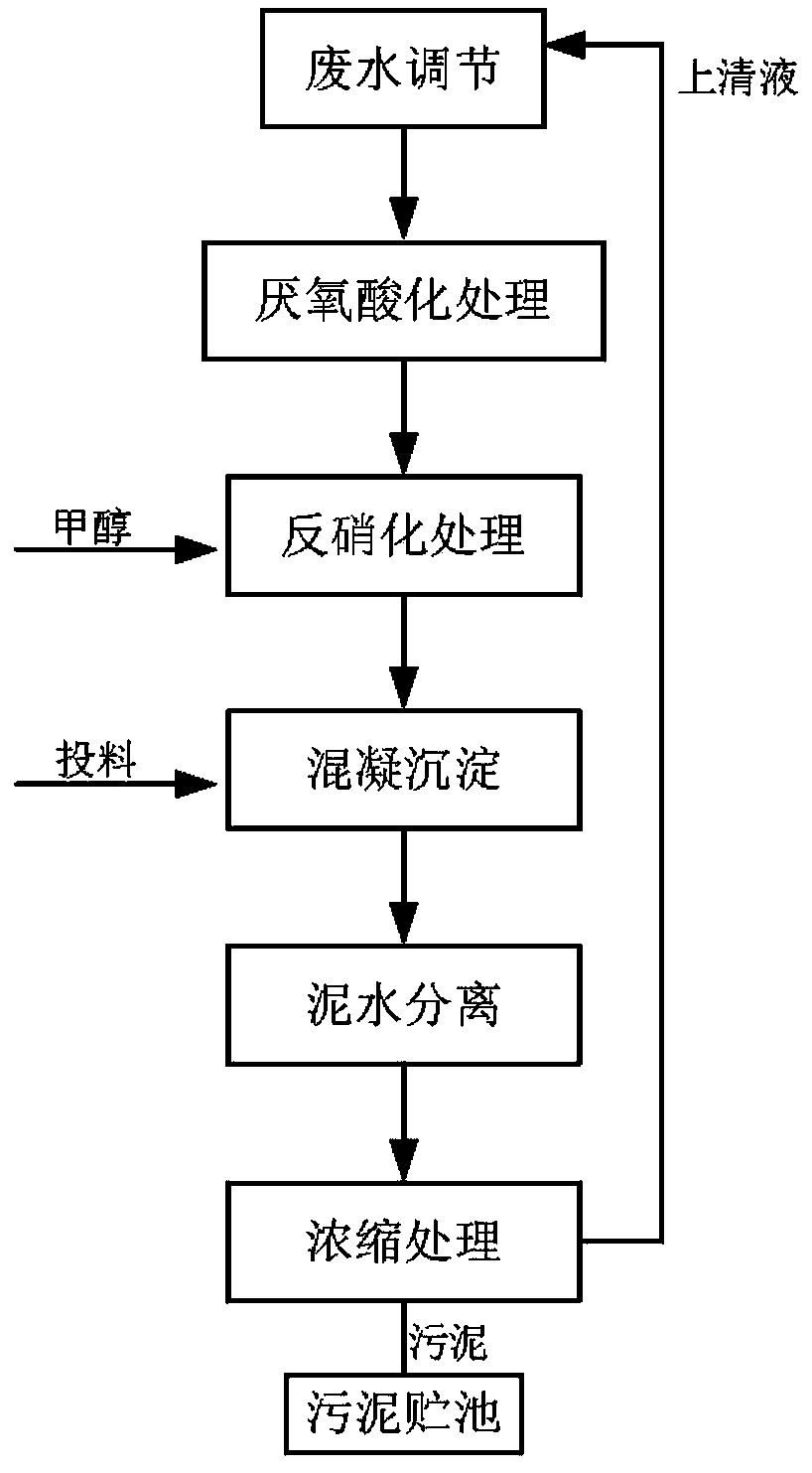

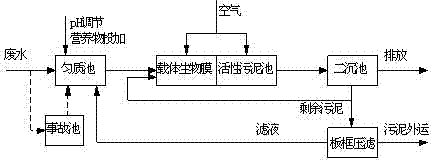

1,4-Butanediol Chemical Wastewater Treatment Process

ActiveCN102295384AImprove effective microbial sludge concentration and biological treatment performanceReduce effluent CODSludge treatment by de-watering/drying/thickeningMultistage water/sewage treatmentWater treatmentActivated sludge

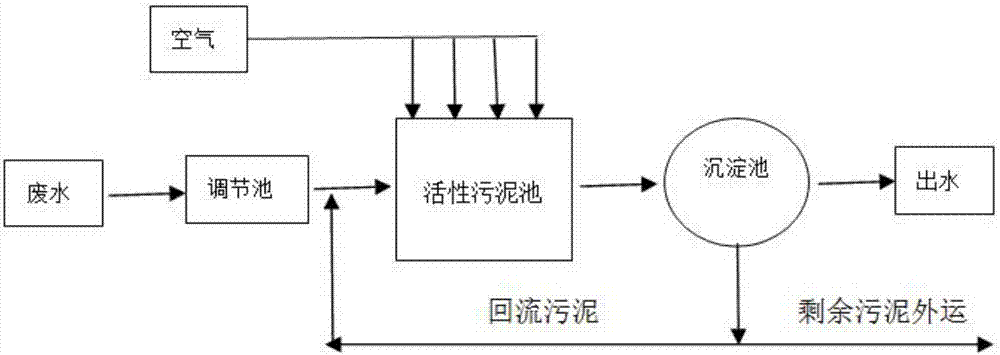

The invention relates to a 1,4-butanediol chemical waste water treatment technology, and belongs to the technical field of environment engineering. The 1,4-butanediol chemical waste water treatment technology comprises that high-density 1,4-butanediol production waste water is fed into a homogenization pond; the high-density 1,4-butanediol production waste water is fed into a two-stage aerobic reaction pond through an elevator pump; the high-density 1,4-butanediol production waste water treated by an aerobic reaction flows automatically into a settling pond; after muddy water is separated from the high-density 1,4-butanediol production waste water in the settling pond, the high-density 1,4-butanediol production waste water is discharged; and a part of the muddy water flows back to the two-stage aerobic reaction pond and the rest of the muddy water is dehydrated and then discharged, wherein a first section of the two-stage aerobic reaction pond is added with a biological carrier filling material and a second section of the two-stage aerobic reaction pond does not need a carrier filling material and is added only with sludge. The 1,4-butanediol chemical waste water treatment technology has the advantages of device work stabilization, high efficiency, stable quality of yielding water, convenience of automatic control, management and operation, and low operating cost.

Owner:博瑞德环境集团股份有限公司

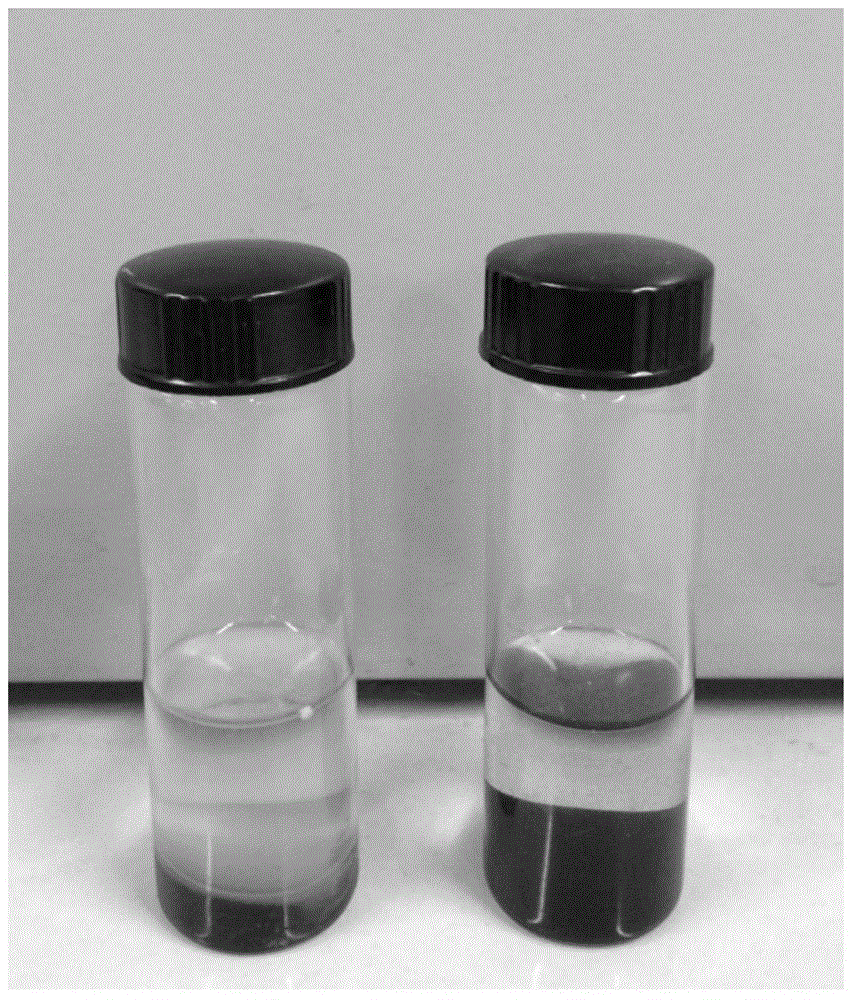

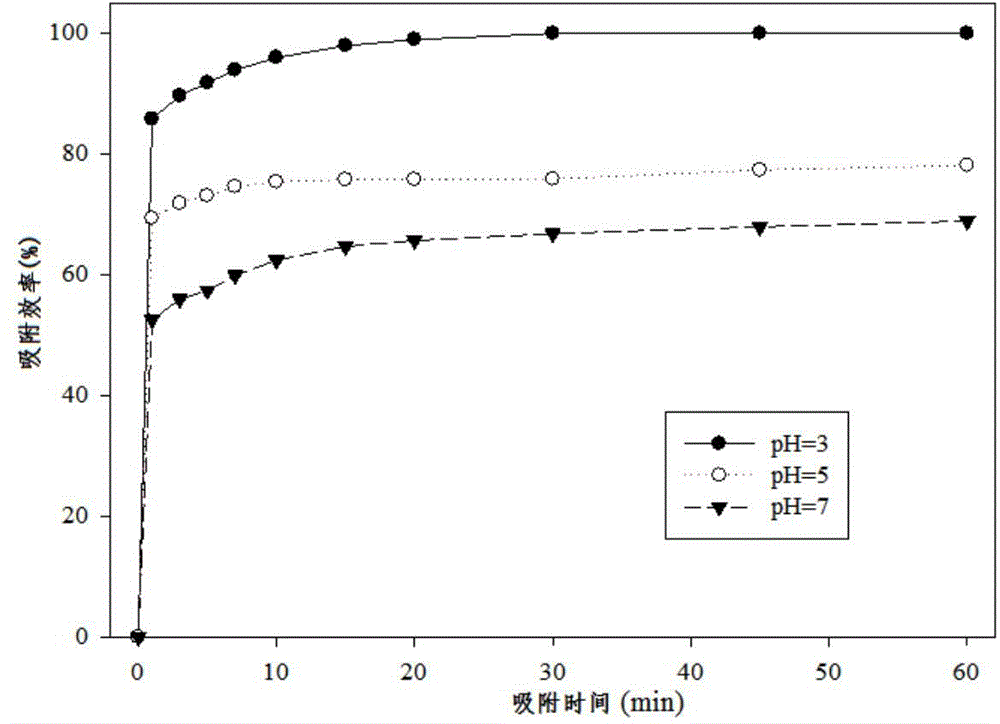

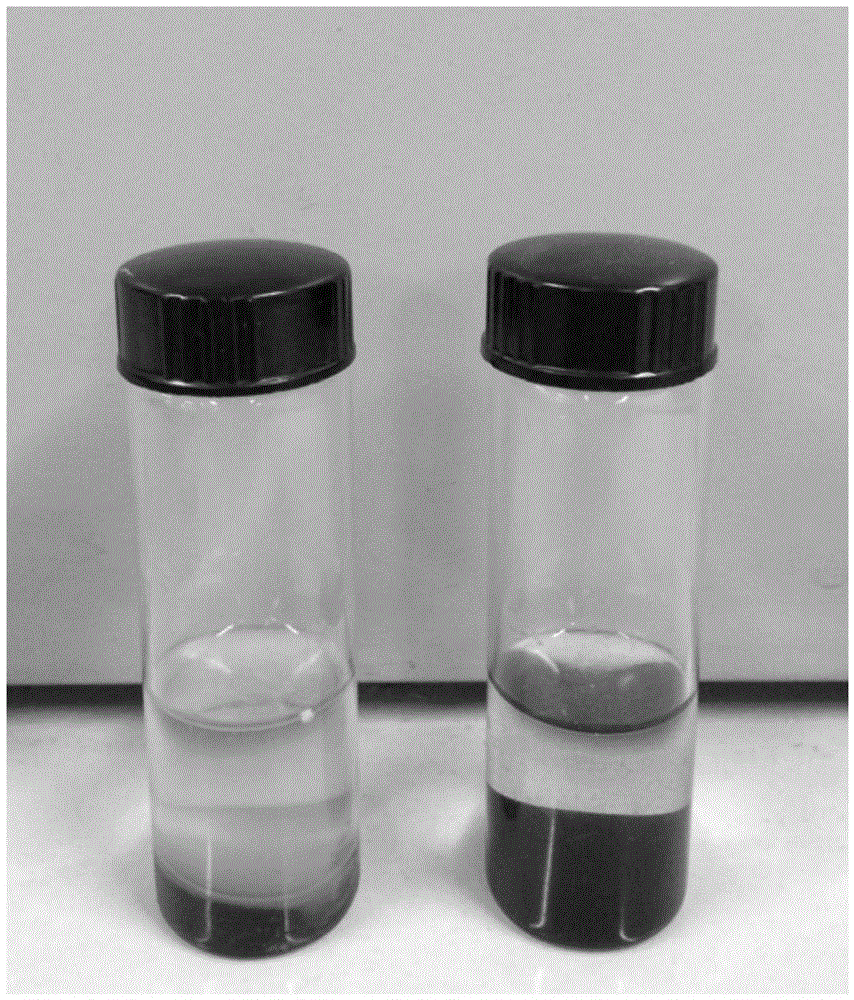

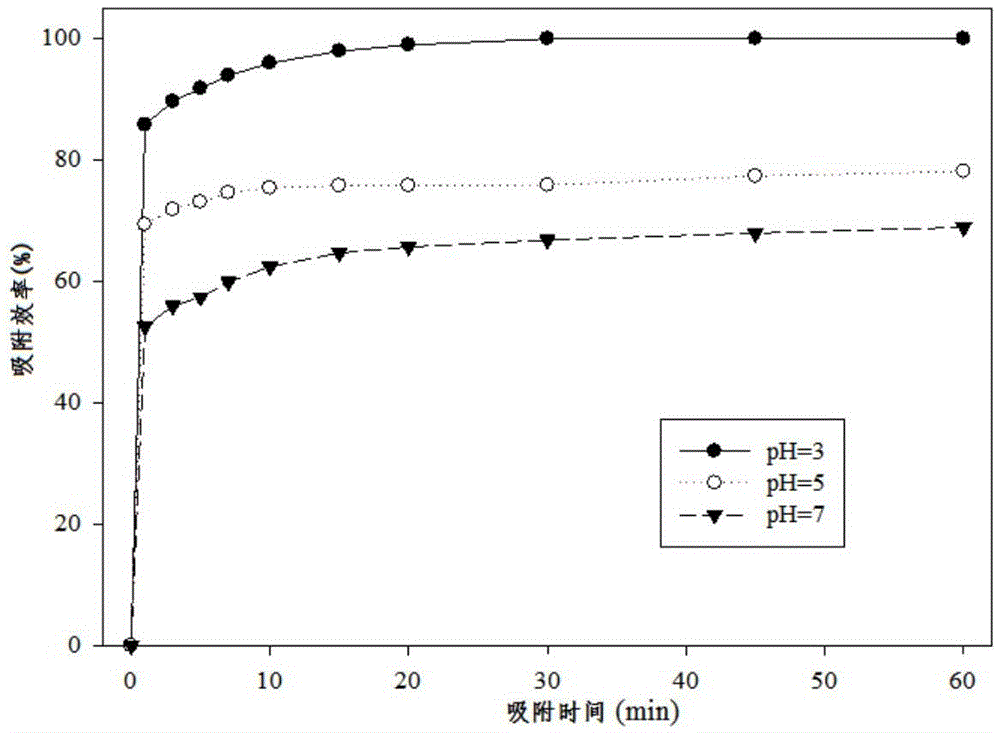

Modified FeS nano-particle as well as preparation method and application thereof

InactiveCN104478004AHigh reactivityLarge specific surface areaMaterial nanotechnologyIron sulfidesCross-linkWastewater

The invention provides a modified FeS nano-particle as well as preparation method and application thereof, wherein the modified FeS nano-particle comprises aFeS nano-particle and cross-linked polyvinylpyrrolidone; the cross-linked polyvinylpyrrolidone wraps on the surface of the FeS nano-particle to form a shell-core structure; the mass ratio of the cross-linked polyvinylpyrrolidone to the FeS nano-particle is (0.1-0.5):1.1. The preparation method of the modified FeS nano-particle c comprises the following step: importing N2 to stir and mix a cross-linked polyvinylpyrrolidone solution and a FeCl2.4H2O solution, dropwise adding an Na2F.9H2O solution under the condition of importing N2 and stirring to obtain the modified FeS nano-particle. The modified FeS nano-particle provided by the invention is high in reaction activity and large in specific surface area; both the Fe2+ and the S2- of the FeS nano-particle have reducing property and can be applied to the treatment of chromate wastewater, so that compared with the present widely applied zero-valent iron nano-particles, the modified FeS nano-particle is better in treatment effect.

Owner:HUNAN UNIV

Excess sludge treatment method

ActiveCN103771671AReduce the degree of flocculationGood dispersionSludge treatmentForest industryChemical oxygen demand

The invention discloses an excess sludge treatment method which comprises the following steps: adding excess sludge to a reaction tank, with high speed stirring at 15-50 DEG C, adding a surfactant and sodium percarbonate to the reaction tank, after 0.5-5h of reaction, adding nano zero-valent iron, at 15-50 DEG C reacting for 1-8h, sending the sludge into a magnetic separator to remove the nano zero-valent iron containing heavy metals in the sludge; performing mechanical dewatering of the treated sludge to respectively obtain purified sludge and water. The excess sludge treated by the method is low in water content and high in heavy metal removal rate, the treated water is low in (chemical oxygen demand) COD value, and the excess sludge treatment method is low in cost, green, and free of secondary pollution, and can lay a foundation for agricultural or forestry sludge or other resource method.

Owner:CHINA PETROLEUM & CHEM CORP +1

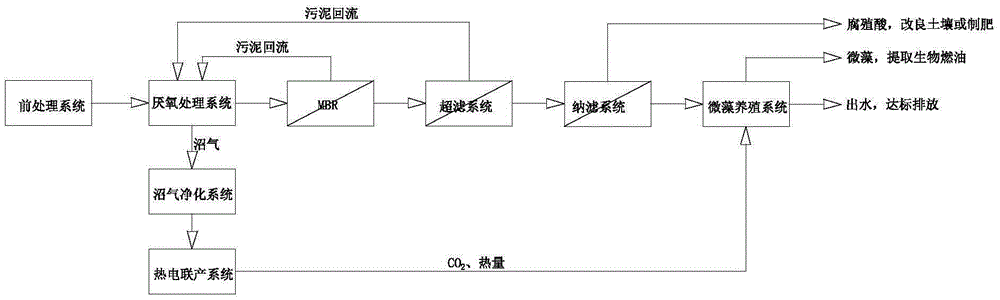

Novel livestock wastewater treatment process

ActiveCN105417877AReduce ammonia nitrogenLow in phosphorusWaste water treatment from animal husbandryWaste based fuelUltrafiltrationWater quality

The invention discloses a novel livestock wastewater treatment process. According to the novel process, after being subjected to solid-liquid separation through a pretreatment system, livestock wastewater sequentially enters an efficient anaerobic treatment system, an MBR, an ultrafiltration system and a nanofiltration system to be treated, then effluent flowing out of the nanofiltration system enters a microalgae cultivation system for microalgae cultivation, and effluent flowing out of the microalgae cultivation system can meet discharge standards and is discharged. Through the novel livestock wastewater treatment process, ammonia nitrogen, phosphorus and COD in wastewater can be effectively removed to improve the effluent quality, and meanwhile, by-products with economic values such as biogas, humic acid and microalgae are obtained.

Owner:SUZHOU CLEAR IND CO LTD

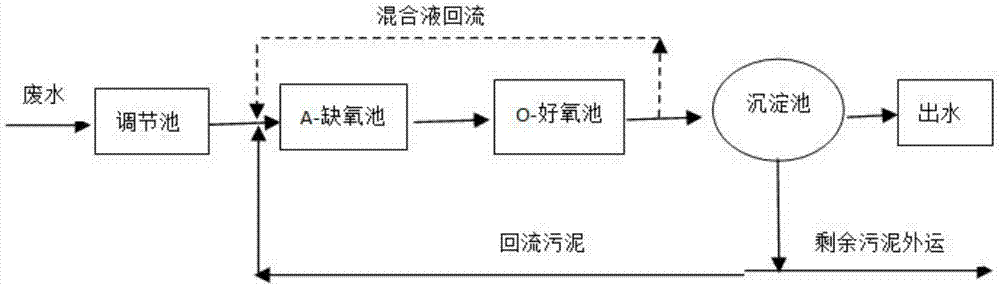

Method for treating waste water in aerobic and two-stage anoxic-aerobic ways

InactiveCN102795748AImprove removal efficiencyReduce back flowTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentAmmoniacal nitrogenChemical oxygen demand

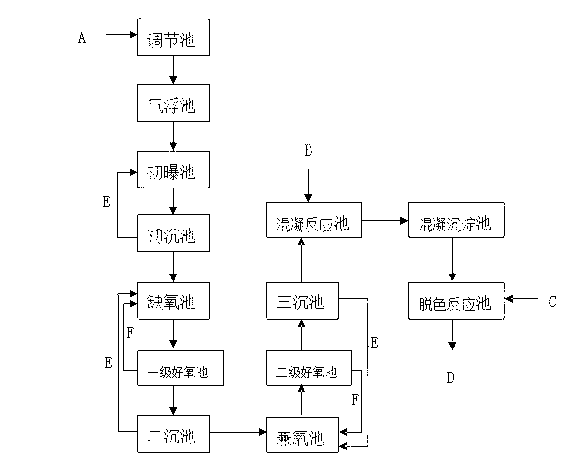

The invention discloses a method for treating waste water in aerobic and two-stage anoxic-aerobic ways. The waste water flows through a regulating tank, a primary aeration tank, a primary settling tank, an anoxic tank, a first-stage aerobic tank, a secondary settling tank, an aerobic tank, a second-stage aerobic tank, a triple settling tank, a coagulation reaction tank, a coagulation settling tank and a decolorizing tank in sequence, so that water is finally discharged within controlling indexes of the national standard. The anoxic tank, the first-stage aerobic tank and the secondary settling tank construct a first-stage anoxic-aerobic system; and the aerobic tank, the second-stage aerobic tank and the triple settling tank construct a second-stage anoxic-aerobic system. After treatment, the removing efficiencies of major organic pollutants, particularly ammonia nitrogen and total nitrogen in the coal chemical industry are increased greatly; due to the arrangement of a two-stage anoxic-aerobic system, the reflux amount of a nitration liquid is reduced, system energy consumption is lowered, and the removing efficiency of total nitrogen is increased greatly simultaneously; and due to the arrangement of a coagulation, decolorizing and reaction unit, the COD (Chemical Oxygen Demand) of discharged water is further lowered, and decolorizing, sterilizing and deodorizing functions are realized.

Owner:浙江汉蓝环境科技有限公司

Two-level copper removing technology for treating low-concentration comprehensive wastewater in PCB electroplating

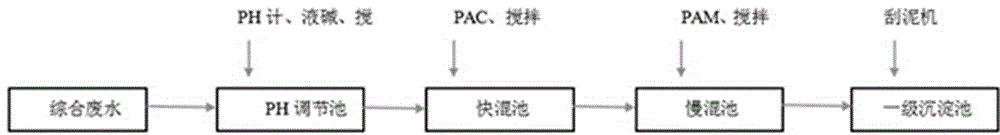

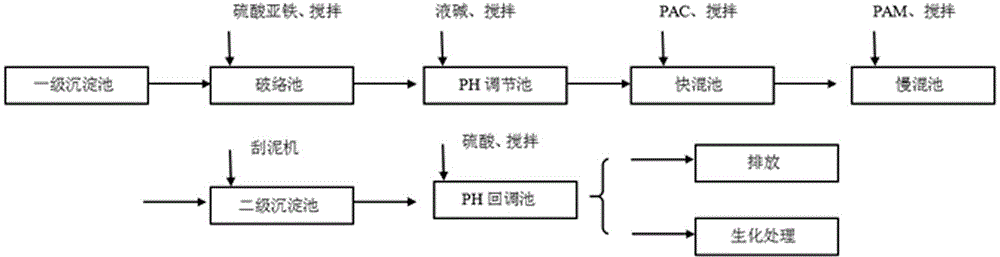

InactiveCN104944698AReduce dosageLow costWaste water treatment from metallurgical processMultistage water/sewage treatmentSludgeResource utilization

The invention discloses a two-level copper removing technology for treating low-concentration comprehensive wastewater in PCB electroplating. The two-level copper removing technology comprises a two-level copper removing process: hydrated copper ions in wastewater are removed in a primary cooper removing process; complex cooper irons are removed in a secondary cooper removing process. The two-level copper removing technology specifically comprises the following steps: after being lifted, the wastewater enters a pH adjustment tank; through pumping, an alkaline chemical agent is added to control the pH value of the wastewater to be 8.5-9; the adjusted wastewater I enters a quick mixing tank and a slow mixing tank in sequence; clear water obtained through primary precipitation is lifted through pumping and enters a complex breaking tank; a proper amount of ferrous sulfate is added for complex breaking; the pH value of the primarily treated wastewater is adjusted to be 8-9; the adjusted wastewater II enters the quick mixing tank and the slow mixing tank in sequence; the wastewater subjected to secondary precipitation enters a pH call-back tank for biochemical treatment; the standard wastewater is discharged. The two-level copper removing technology has the advantages that the chemical agent treatment cost is reduced, the discharged water quality is stabilized, the sludge minimization and the recovery value resource utilization are facilitated, and a high popularization value is achieved for wastewater treatment in the conventional PCB industry.

Owner:湖南景翌湘台环保高新技术开发有限公司

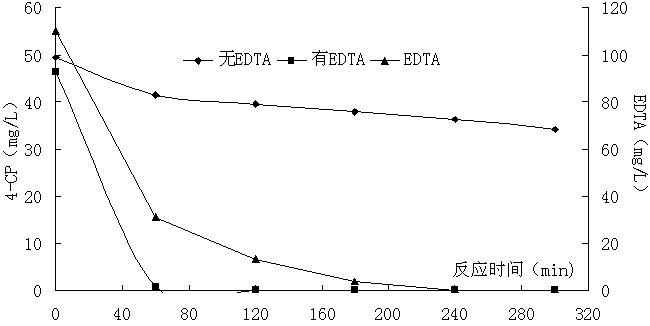

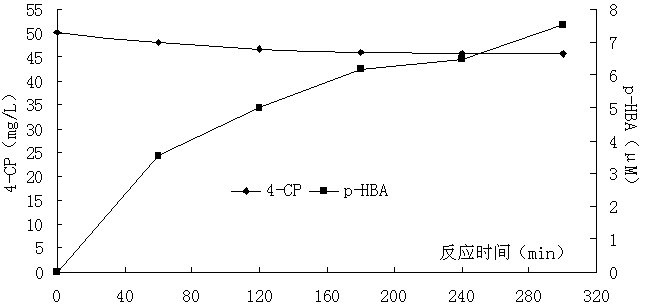

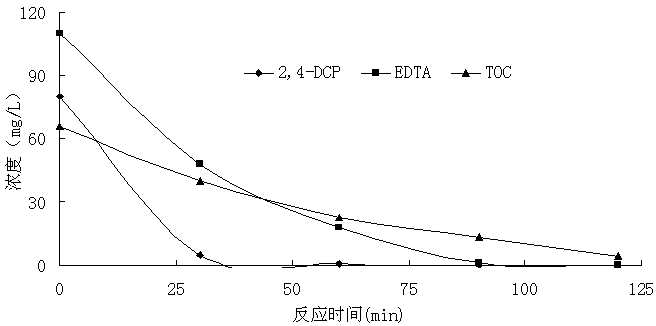

Method for oxidatively degrading chlorophenol substances by using EDTA (ethylene diamine tetraacetic acid)-reinforced bimetal aluminum-iron system

InactiveCN103011376AQuick breakdownPromote productionWater contaminantsWater/sewage treatment by flocculation/precipitationDecompositionWater quality

The invention relates to a method for oxidatively degrading chlorophenol substances by using an EDTA (ethylene diamine tetraacetic acid)-reinforced bimetal aluminum-iron system. Machined metal iron and metal aluminum used as raw materials are filled in a reactor. Before treatment, a certain amount of EDTA is previously added into the reactor, and aeration and stirring are simultaneously carried out after starting introducing water. In the water, the metal aluminum can easily generate hydrogen peroxide after aeration, the EDTA after aeration can promote the metal iron to activate molecular oxygen to generate oxydol and can eliminate the passivation layer on the iron surface to reinforce the leaching of ferrous ions, the ferrous ions immediately produce Fenton advanced oxidation reaction immediately after contacting the hydrogen peroxide, and the generated.OH is subjected to advanced oxidation reaction. Meanwhile, the generated iron and aluminum hydroxides have the capacity for adsorbing and removing pollutants, and thus, are beneficial to further enhancing the quality of effluent water. The invention has the advantages of low operating cost and simplified technical process, implements quick decomposition of the EDTA, and can not bring about combined pollution of the EDTA. The treatment cost is low. The FeO used by the technique is machining waste of metal workpieces, the AlO is the most abundant metal element on the earth crust, and both the FeO and AlO are cheap and accessible and can be used for a long time.

Owner:TONGJI UNIV

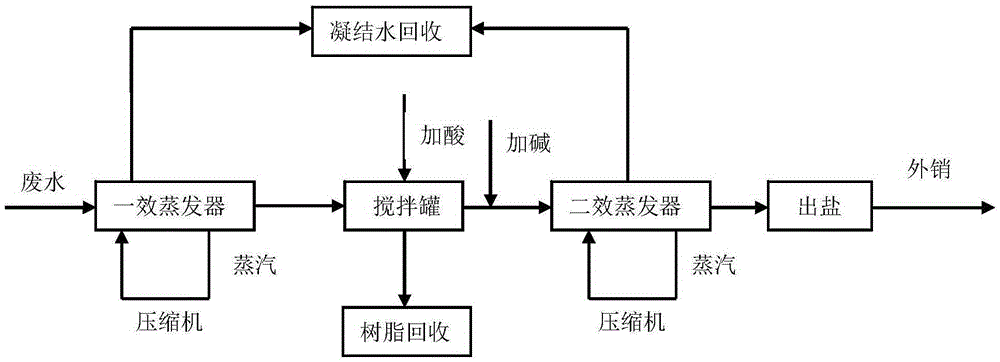

Method for treating rubber vulcanization accelerator wastewater by combination of MVR (mechanical vapor recompression) evaporation and chemical treatment

ActiveCN105417822AReduce sewage CODLow running costMultistage water/sewage treatmentNature of treatment waterChemistryVapor phase

The invention provides a method for treating rubber vulcanization accelerator wastewater by combination of MVR (mechanical vapor recompression) evaporation and chemical treatment. The method comprises the steps of putting wastewater into a first effect evaporator of the MVR, heating steam until the evaporating temperature of a vapor phase is 80 to 100 DEG C, evaporating supplied material wastewater and enabling the salt concentration of same to reach 15 percent to 25 percent; adding the wastewater with 15 percent to 25 percent of salt concentration by evaporating into a stirring tank with a stirring function for performing acid adjustment and adjusting the pH to 1 to 5, performing filter pressing and recycling resin after mixing and sedimenting for 30 to 60 min; adding alkali into the wastewater after filter pressing and adjusting the pH to 6 to 8, then entering into a second effect evaporator of the MVR for concentration, and separating salt by a centrifugal machine; the combination of the most energy-efficient MVR evaporation technology and chemical treatment is adopted, industrial salt which can be exported can be obtained, COD (Chemical Oxygen Demand) of the wastewater is greatly reduced, the effluent standard can be met after post processing; the COD of condensation water by MVR evaporation is very low and the condensation water can be reused for production, the water consumption of production is lowered, and the production cost is saved.

Owner:KEMAI CHEM

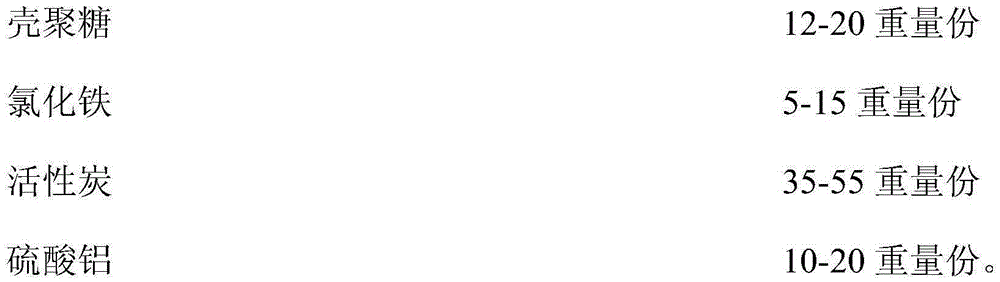

Wastewater treatment agent and application of wastewater treatment agent

InactiveCN105253972AImprove adsorption capacityEfficient functionWater/sewage treatment using germicide/oligodynamic-processWater/sewage treatment by flocculation/precipitationMedicineTurbidity

The invention provides a wastewater treatment agent and application of the wastewater treatment agent. The wastewater treatment agent mainly is prepared from the following ingredients in parts by weight: 12 to 20 parts by weight of chitosan, 5 to 15 parts by weight of ferric chloride, 35 to 55 parts by weight of active carbon and 10 to 20 parts by weight of aluminum sulfate. The wastewater treatment agent has the advantages that when the wastewater treatment agent is applied to wastewater treatment, and the adding quantity is 200mg / L, the wastewater turbidity removal rate can reach more than 95 percent; the total phosphorus removal rate can reach more than 90 percent; the COD removal rate can reach more than 33 percent; the BOD removal rate can reach more than 78 percent; in addition, the raw material resources of the wastewater treatment agent are rich; the cost is low; a better market application prospect is realized.

Owner:WUXI JIABANG ELECTRIC POWER PIPE FACTORY

Domestic sewage treatment agent and preparation method thereof

ActiveCN107758823AGood flocculation effectFast hydrolysisWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionPorous carbonTherapeutic effect

The invention discloses a domestic sewage treatment agent and a preparation method of the domestic sewage treatment agent. The domestic sewage treatment agent comprises the following raw materials inparts by weight: 12-15 parts of polyferric chloride, 20-30 parts of meerschaum, 5-10 parts of modified silkworm excrement based porous carbon material, 10-15 parts of sodium hydroxide, 12-15 parts ofpolyacrylamide, 10-15 parts of sodium carbonate and 1-5 parts of bio-based porous composite material. According to the treatment agent, two novel biological carbon materials are added, so that the adsorption purification capacity of the sewage treatment agent is improved; the treatment agent can effectively treat domestic sewage of residents under matching of the other raw materials, and is good in treatment effect, lower in cost and stable in performance; and treated pollution reaches a national sewage discharge standard.

Owner:SHANGHAI ZHONGHAILONG NEW ENERGY

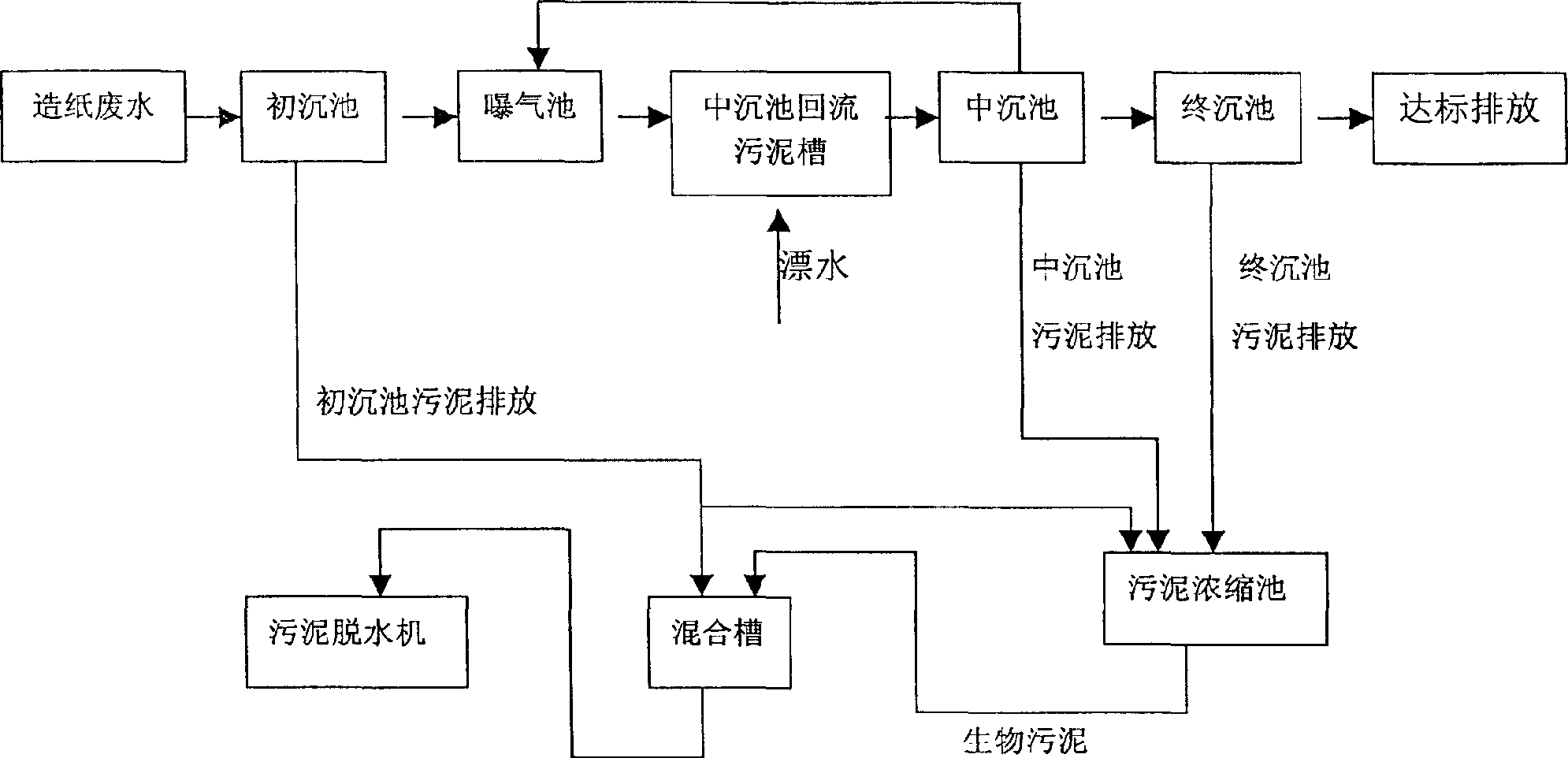

Method for handling waste water of paper making industry

InactiveCN1431158AAccelerated settlementControl swellingMultistage water/sewage treatmentSludgeWastewater

A process for treating paper-making sewage includes filtering primary deposition in initial deposition pool, discharging the sludge in mixing tank, flowing sewage in aerating pool, flowing in reflux sludge tank of middle deposition pool, adding bleaching water for killing bacteria, depositing in middle depositing pool and then in final depositing pool, pumping sludge back to sludge concentrating pool, and draining clean water. It has high effect on decreasing COD to 96 mg / L.

Owner:WUXI LONGCHEN GREENTECH CO LTD

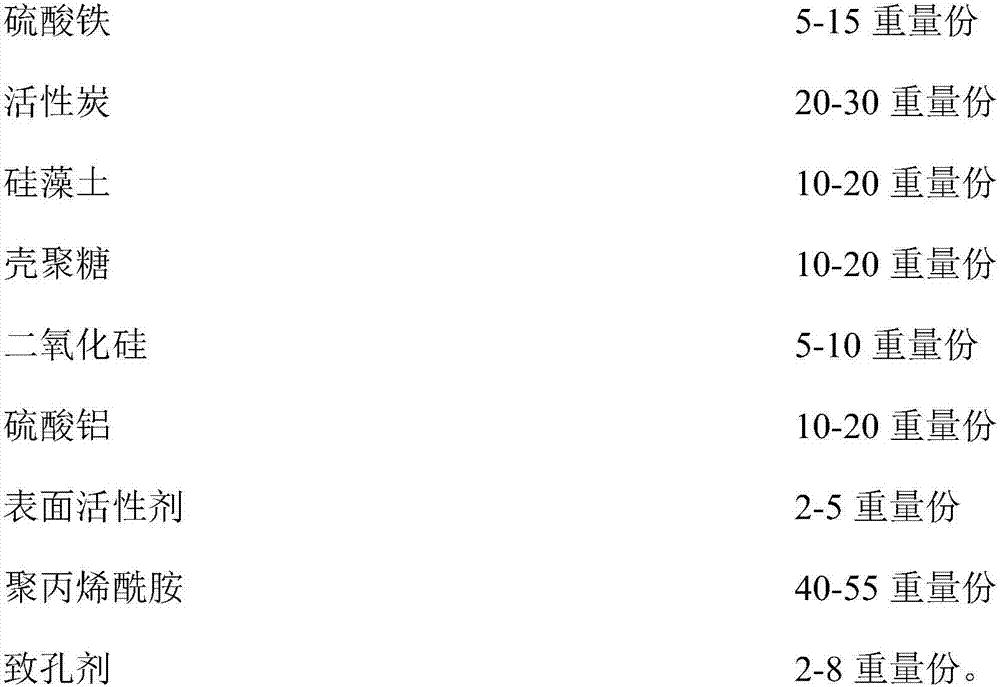

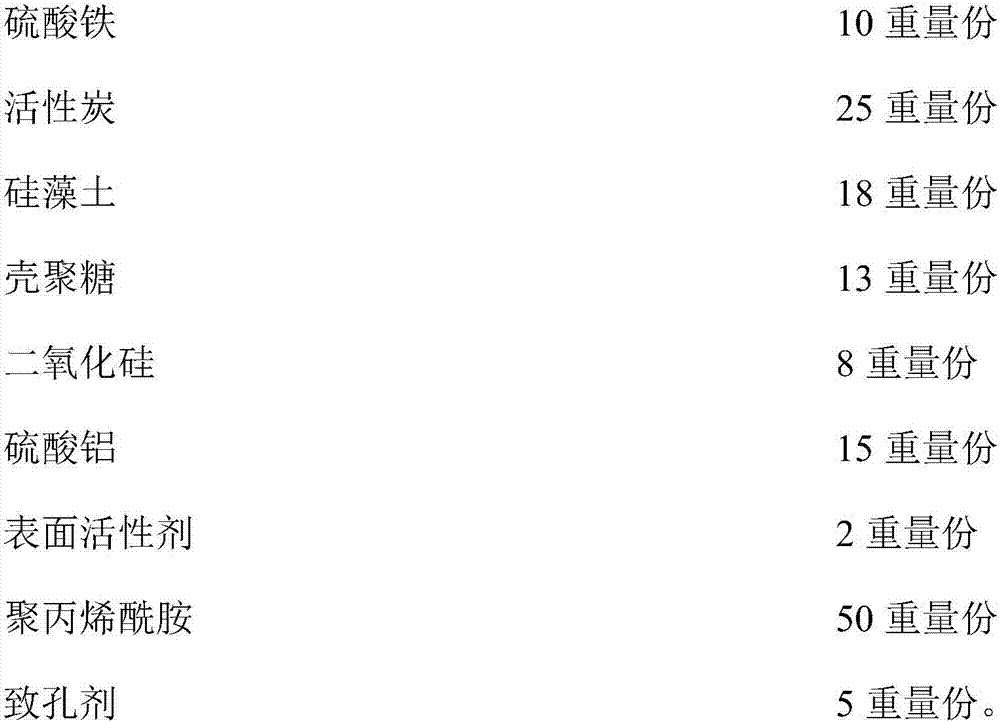

Water purifying composition, and preparation method and application thereof

InactiveCN107162142AAdsorptiveCoagulationSpecific water treatment objectivesWater contaminantsIron sulfateActivated carbon

The invention provides a water purifying composition and a preparation method and application thereof. The water purifying composition mainly comprises, by weight, 5 to 15 parts of iron sulfate, 20 to 30 parts of activated carbon, 10 to 20 parts of diatomite, 10 to 20 parts of chitosan, 5 to 10 parts of silicon dioxide, 10 to 20 parts of aluminum sulfate, 2 to 5 parts of a surfactant, 40 to 55 parts of polyacrylamide and 2 to 8 parts of a pore-forming agent. When 200 mg of the water purifying composition provided by the invention is applied to treatment of each L of wastewater, the removal rate of effluent turbidity can reach 95% or above; the removal rate of total phosphorus can reach 90% or above; the removal rate of COD can reach 34% or above; the removal rate of BOD is 78% or above; and antibacterial performance reaches 81% or above. The water purifying composition uses widely available raw materials, is low in cost and has good market prospects.

Owner:朱燕萍

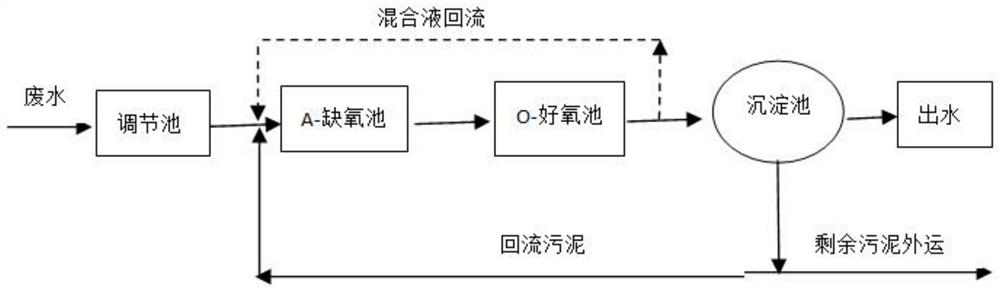

Biological enhanced nitrogen removal treatment method of degradation-resistant high-concentration organic industrial wastewater

ActiveCN104628136APromote nitrificationReduce COD valueWater treatment parameter controlWater contaminantsChemistryCarbon source

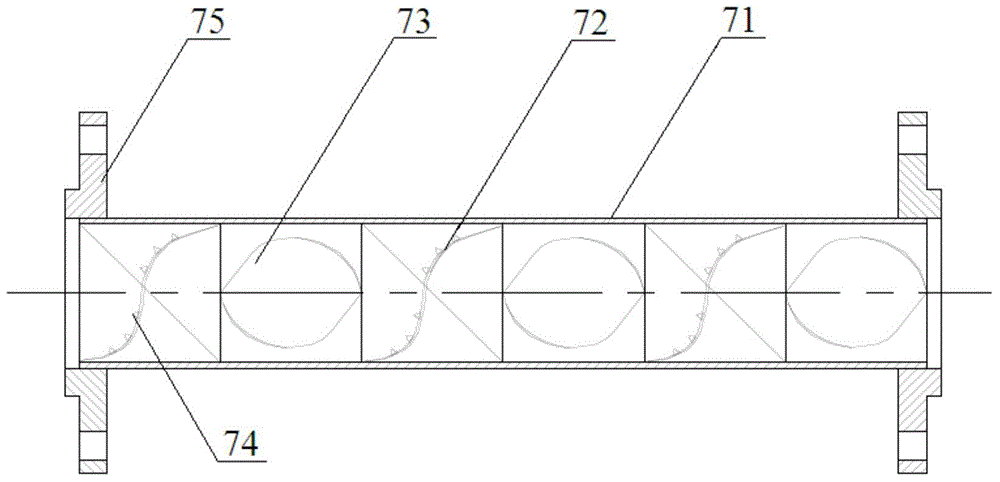

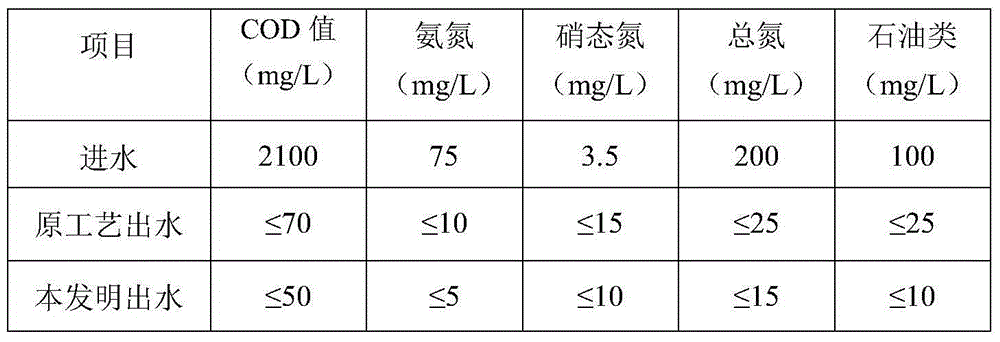

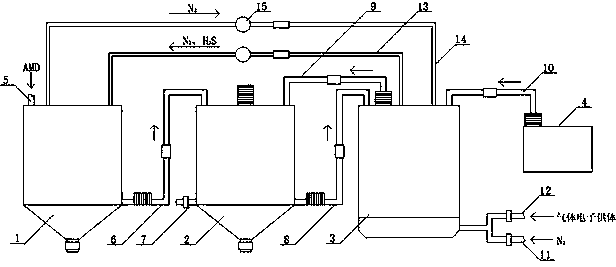

The invention relates to a biological enhanced nitrogen removal treatment method of degradation-resistant high-concentration organic industrial wastewater. The method comprises the following steps that biological enhanced nitrogen removal on sewage is carried out by using a device in which anoxic tanks and aerobiotic tanks are alternately distributed, continuously arrayed and are communicated with one another to ensure that raw water of the sewage separately flows into the anoxic tanks and effluent water from a tail-ended aerobiotic tank flows back to the anoxic tanks respectively through a backflow pipeline; a pipe type sludge crushing device is arranged on the backflow pipeline to ensure that organic matters contained in the sludge floc are exposed and released, and organic carbon sources of the anoxic tanks are supplemented along with backflow liquid, so that the denitrification efficiency is improved. Compared with the prior art, the biological enhanced nitrogen removal treatment method has the advantages that the pipe type sludge crushing device is additionally arranged, so that the decrement of the sludge sources is completed, the degradation capability of degradation-resistant organic matters by the sludge floc is also enhanced. By optimizing raw-water and water-inlet rate of a secondary anaerobic-aerobic technical process and equinoctial backflow rate, a biological membrane assembly is additionally arranged at the tail end of a secondary aerobiotic tank, so that the nitration efficiency of an aerobiotic work section is effectively improved, and the COD value, the ammonia nitrogen content and the total nitrogen level are relatively low.

Owner:EAST CHINA UNIV OF SCI & TECH

Method for treating weak acid blue AS dye production wastewater

ActiveCN104876397AMild reaction conditionsHigh degree of automationMultistage water/sewage treatmentSludgeCatalytic oxidation

The invention discloses a method for treating weak acid blue AS dye production wastewater. The method comprises the following steps: adjusting the pH value of the weak acid blue AS dye production wastewater to about 5; adding hydrogen peroxide into the wastewater according to a weight ratio of hydrogen peroxide to the wastewater being 1000:(5-10), uniformly mixing hydrogen peroxide and the wastewater, and then pumping the wastewater mixed with hydrogen peroxide into a cartridge filter for interception of suspended solids in the wastewater; triggering a 1.5-2.5 hours' catalytic oxidation reaction on organic substances in the wastewater under the catalytic action of a surface catalyst; pumping the wastewater subjected to the catalytic oxidation reaction into a biochemical water distribution reservoir, and adjusting the pH value of the wastewater to 7.5-8; pumping the wastewater with the adjusted pH value into a biochemical system for degradation of organic substances and total nitrogen in the wastewater, wherein the residence time is 18-30 hours; pumping a mixed solution comprising the wastewater subjected to degradation and sludge into a secondary sedimentation tank, wherein a standard supernatant is discharged and the sludge is treated later. Through the adoption of the method, the effluent chroma removing rate and the COD removing rate of the treated wastewater reach up to 94.0% and 96.0% respectively; the effluent can reach the discharge standards; the environmental and economic benefits are high.

Owner:JIANGSU ZHONGMEI HUACHAO SCI & TECH ENVIRONMENTAL PROTECTION CO LTD

Gas stripping internal circulation type treatment process and system for treating acid mine wastewater by utilizing SRB

InactiveCN110482795AAvoid reduction efficiency impactRapid alkali productionWaste water treatment from quariesWater contaminantsSulfate-reducing bacteriaNutrient solution

The invention discloses a gas stripping internal circulation type treatment process and a gas stripping internal circulation type treatment system for treating acid mine wastewater by utilizing SRB. The process comprises the steps of stripping a reaction zone to a reduction atmosphere, carrying out a biochemical reduction sulfur production reaction, carrying out a first precipitation reaction andcarrying out a second precipitation reaction; the system comprises a first precipitation reaction device, a second precipitation reaction device, a gas stripping reaction device and a nutrient solution storage device. According to the method, the influence of multiple (acid, heavy metal and sulfide) toxicity inhibition on the sulfate reduction efficiency can be avoided; in addition, sulfate reducing bacteria in the gas stripping reaction device are high in activity and quick in alkali production, the pH of the acid mine wastewater in the second precipitation reaction device can be directly neutralized to be neutral, pretreatment of the acid mine wastewater is not needed, and the cost is reduced; the sulfate reduction rate in the gas stripping reaction device is high, the sulfide yield is high, heavy metal ions in the acid mine wastewater in the precipitation reaction device can be rapidly removed, and meanwhile valuable metal is recycled.

Owner:KUNMING UNIV OF SCI & TECH

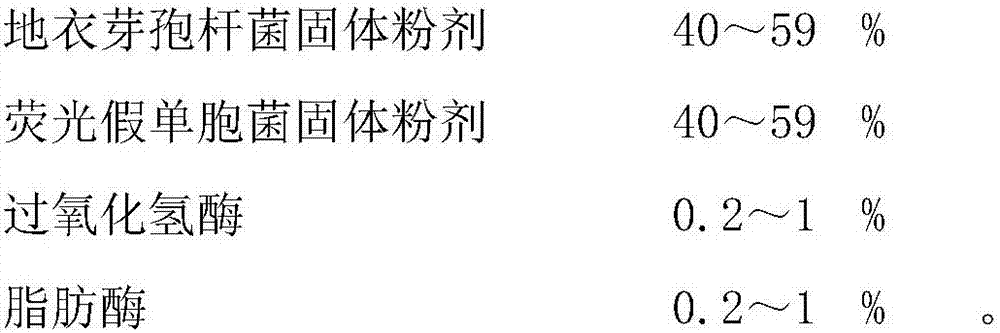

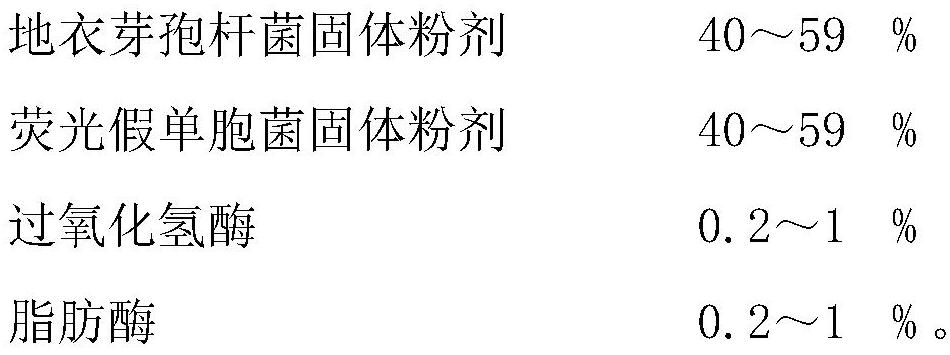

Composite microbial preparation for assisted treatment of waste cutting fluid, and use method thereof

ActiveCN107381828AToxic reductionReduce effluent CODWater contaminantsTreatment with aerobic and anaerobic processesBacillus licheniformisVegetable oil

The invention relates to a composite microbial preparation for assisted treatment of waste cutting fluid. The composite microbial preparation comprises Bacillus licheniformis solid powder, Pseudomonas fluorescens solid powder, catalase and lipase, wherein the four components are mixed, the obtained mixture is added to an active sludge pool, a contact oxidation pool or an aerobic tank, and sewage treatment is performed. According to the present invention, the Bacillus licheniformis and the Pseudomonas fluorescens rapidly grow and breed by using the easily-degraded organic matters in the sewage, and can rapidly degrade the macromolecular organic matters in the wastewater when the Bacillus licheniformis and the Pseudomonas fluorescens grow to achieve a certain concentration, the catalase can rapidly eliminate the OH. free radicals in the system so as to reduce the toxic effects on bacteria and improve the oxygen utilization rate, and the lipase is used for decomposing the organic matters such as animal and vegetable oils in the wastewater, such that various components work in the matched and synergetic manner, the COD in the effluent is significantly reduced, the components are simple and easy to obtained, the cost is low, the additional equipment is not required during the use, the operation is simple, the risk is low, the treatment efficiency of the system can be significantly improved, the stability of the system can be enhanced, the COD in the effluent can be reduced, and the final standard discharge can be achieved.

Owner:泰伦特生物工程股份有限公司

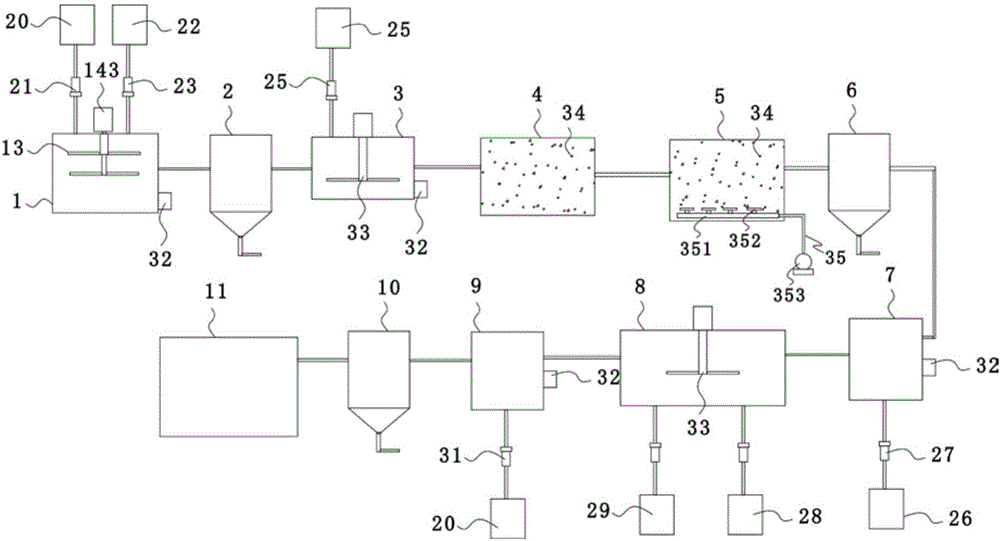

Treatment system and treatment method for antibiotic fermented wastewater

ActiveCN106830571AEfficient removalReduce COD contentTreatment using aerobic processesWater treatment compoundsFenton reactionWater quality

The invention discloses a treatment system and a treatment method for antibiotic fermented wastewater. The system comprises a coagulation reaction pond, a first settling pond, a first neutralization pond, an anaerobic pool, an aerobic pond, a second settling pond, an acid adjusting pond, a Fenton reaction pond, a second neutralization pond, a third settling pond and an oxidizing pond which are connected, wherein stirrers are arranged in the first neutralization pond, the second neutralization pond and the Fenton reaction pond; a first coagulation stirring device is arranged in the coagulation reaction pond; and suspended carriers are arranged in the anaerobic pool and the aerobic pond, and the aerobic pond is connected to an aerating device. The system and method disclosed by the invention can effectively reduce COD in pharmaceutical wastewater, improves the biodegradability of a wastewater effluent, and is good in wastewater treatment effect; and the equipment is good in impact resisting effect, can be suitable for relatively large water fluctuation generated by the pharmaceutical wastewater, and is long in service life.

Owner:SHAOXING HEQIAO JIANGBIN WATER TREATMENT

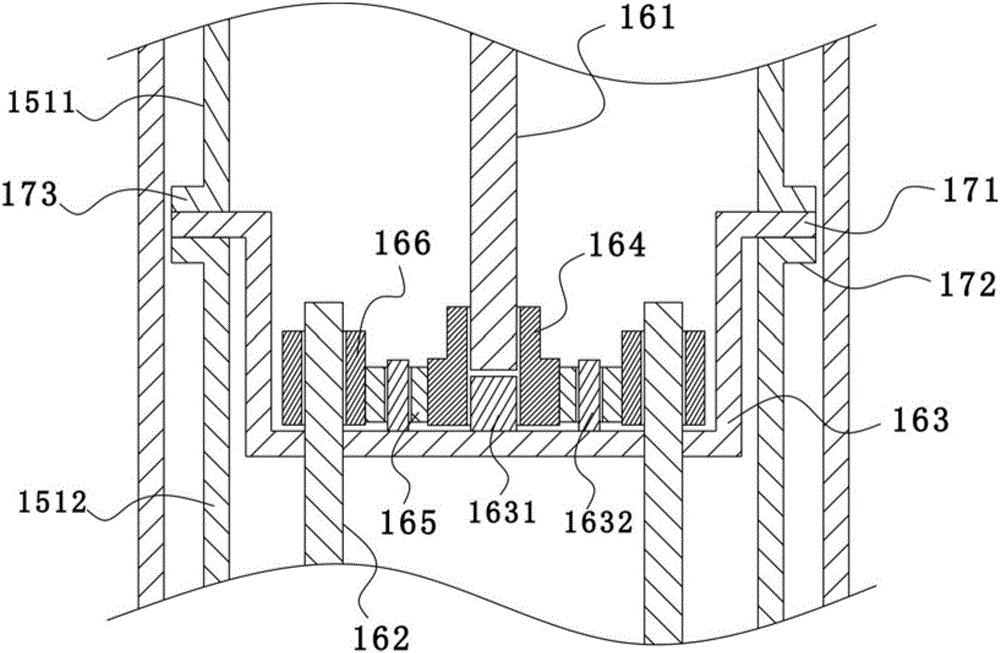

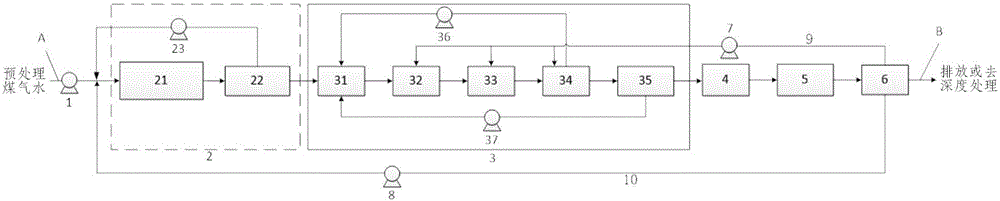

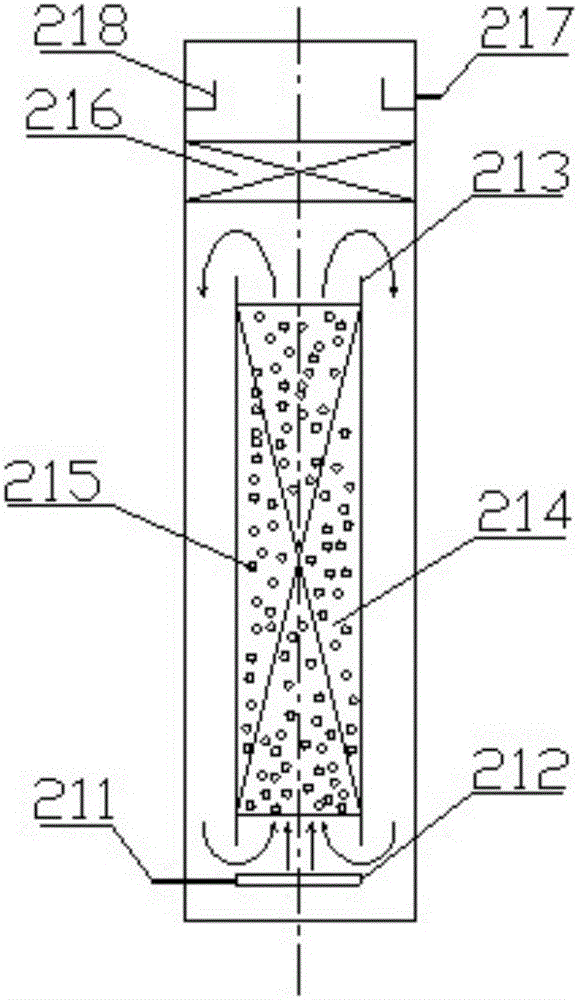

Biochemical treatment system and method of waste water through conny pressure gasification

InactiveCN105967445AReduce the concentration of pollutantsReduce adverse effectsWater contaminantsMultistage water/sewage treatmentWater pipePrecipitation

The invention discloses a biochemical treatment system and method for pressurized gasification waste water of crushed coal, which belongs to the field of waste water treatment. The coagulation reaction tank, the coagulation sedimentation tank and the clean water tank are connected in sequence; there is a defoaming water pipe between the clean water tank and the anoxic-multi-stage aerobic system; the lift pump is equipped with a device for introducing crushed coal pressurized gasification wastewater pretreatment effluent Water inlet pipe; the clean water pool is provided with an outlet pipe for discharging treated water. In this system, the dual-cycle anaerobic filler reaction system hydrolyzes large molecular organic matter into small molecular organic matter under anaerobic conditions, improving the biodegradability of wastewater; The effluent COD, ammonia nitrogen and total nitrogen are greatly reduced. The system has the advantages of good processing effect, low operation cost and simple operation.

Owner:BEIJING SOUND ENVIRONMENTAL ENG +1

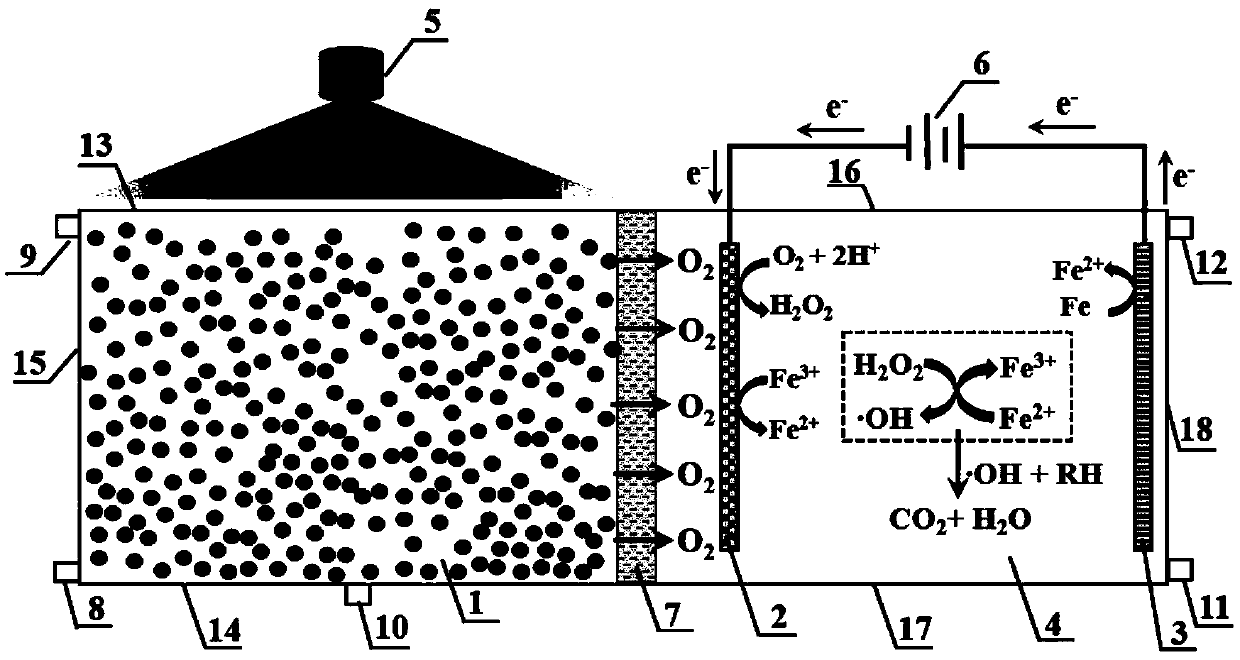

Water treatment device and application thereof

ActiveCN109516645ARealize online synthesisReduce energy consumptionBioreactor/fermenter combinationsBiological substance pretreatmentsEnergy expenditureChrominance

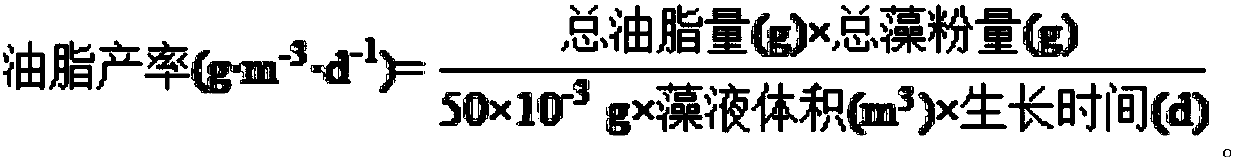

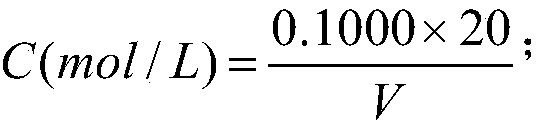

The invention discloses a water treatment device and application thereof, and belongs to the technical field of waste water treatment. The water treatment device can use microalgae photosynthesis forproviding O2 for the cathode reaction of electro-Fenton process; the H2O2 online synthesis is realized; the energy consumption of external aeration is greatly reduced; meanwhile, the water treatment device can realize microalgae grease production and contaminant efficient degradation; by using the device for sewage treatment for 13 d, the grease yield of microalgae in a microalgae growth chamber can be as high as 986 mg / L.d; by using the device for sewage treatment, the effluent COD, NH<4+>, N, TN and TP of the sewage in the microalgae growth chamber are respectively reduced by 57.8 percent, 74.4 percent, 64.9 percent and 84.4 percent in comparison with that of inflow; the effluent COD and the chrominance of the sewage in the electro-Fenton reaction chamber are respectively reduced by 92.6percent and 98.3 percent in comparison with that of inflow.

Owner:JIANGNAN UNIV

Water purifying agent composition and application thereof

InactiveCN107265547AAbundant resourcesBiologically activeWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionTurbidityWater treatment

The invention provides a water purifying agent composition and application thereof. The water purifying agent composition is mainly prepared from the following components by weight percent, which are 100 percent of the weight of the water purifying agent: 5 to 10 percent of chitosan, 20 to 30 percent of polymeric ferric sulfate, 10 to 20 percent of iron chloride, 40 to 50 percent of active carbon and 10 to 20 percent of aluminum sulfate. When the water purifying agent composition is applied to the waste water treatment, when the feeding amount is 200mg / L, the removal rate for the turbidity of waste water can reach up to 95 percent or more, the total phosphorus removal rate can reach up to 90 percent or more, the COD removal rate can reach up to 35 percent or more, and the BOD removal rate is 80 percent or more; and moreover, the water purifying agent composition is rich in source of raw materials, low in cost and good in market application prospect.

Owner:朱燕萍

Coking plant wastewater treatment process

PendingCN110776218AWater up to standardEffluent COD up to standardSludge treatmentWater contaminantsChemical oxygen demandSludge

The invention relates to the technical field of coking plant wastewater treatment, in particular to a coking plant wastewater treatment process. Specifically, a sodium carbonate solution is added in an aerobic section to provide alkalinity required by nitration reaction, ammonia nitrogen can basically be converted into nitrate nitrogen completely, at the same time, organic matters can be further degraded, so that the COD (Chemical Oxygen Demand) of final effluent water can reach the standard. According to the invention, after aerobic treatment, part of the wastewater flows back into an anoxictank to provide nitrate nitrogen for an anoxic section. According to the process provided by the invention, polyaluminum chloride or polyaluminum ferric chloride is added to the coagulation part, so that the precipitation performance of sludge at the precipitation part is improved, and the COD of effluent water is further reduced. According to the invention, cationic polyacrylamide is added into aconcentration tank to carry out flocculation reaction with sludge, so that the sludge dehydration efficiency is improved.

Owner:新晃县污水处理有限责任公司

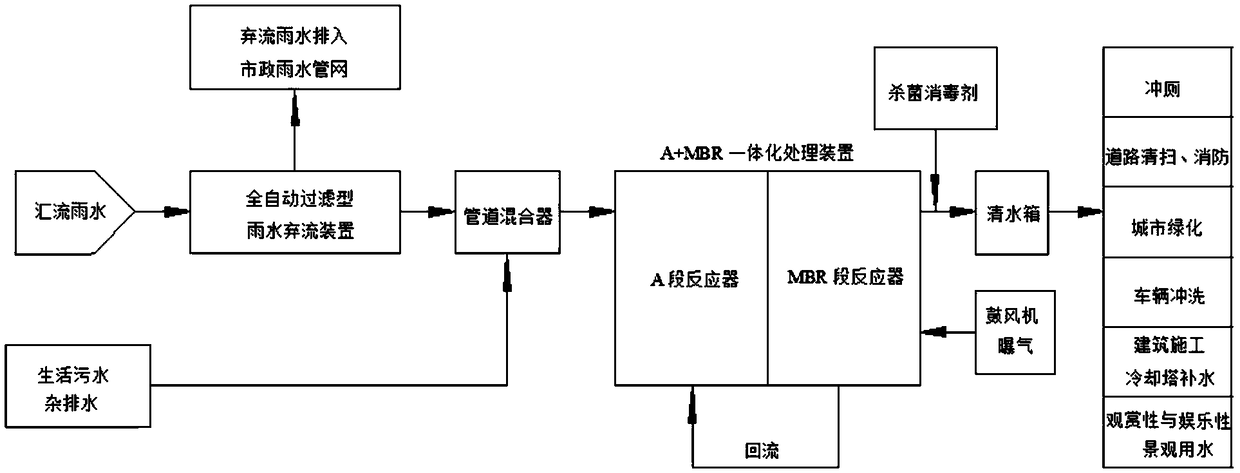

Rainwater and sewage integrated treatment process

InactiveCN109052803AStable water qualityStable waterSpecific water treatment objectivesTreatment involving filtrationAfter treatmentDisinfectant

The invention relates to a rainwater and sewage integrated treatment process. The process comprises the following steps: enabling rainwater conflux to be subjected to initial rainwater discarding, andthen mixing the obtained rainwater with domestic sewage and miscellaneous drainage by means of a pipeline mixer; then, enabling the obtained mixture to enter an A+MBR integrated treatment device, mixing effluent, obtained after treatment of the A+MBR integrated treatment device, with a disinfectant, and carrying out disinfection treatment. Compared with the prior art, the rainwater and sewage integrated treatment process provided by the invention has a high removal rate of chroma, biochemical oxygen demand (BOD), ammonia nitrogen and turbidity in the rainwater and the domestic sewage, is goodin effluent quality, simple in process flow and low in construction and operation costs, can realize full automation, is low in management and maintenance costs, and can bring considerable environmental benefits.

Owner:SHANGHAI EMPEROR OF CLEANING HI TECH

Excess sludge treatment method

ActiveCN103771671BReduce the degree of flocculationGood dispersionSludge treatmentForest industryChemical oxygen demand

The invention discloses an excess sludge treatment method which comprises the following steps: adding excess sludge to a reaction tank, with high speed stirring at 15-50 DEG C, adding a surfactant and sodium percarbonate to the reaction tank, after 0.5-5h of reaction, adding nano zero-valent iron, at 15-50 DEG C reacting for 1-8h, sending the sludge into a magnetic separator to remove the nano zero-valent iron containing heavy metals in the sludge; performing mechanical dewatering of the treated sludge to respectively obtain purified sludge and water. The excess sludge treated by the method is low in water content and high in heavy metal removal rate, the treated water is low in (chemical oxygen demand) COD value, and the excess sludge treatment method is low in cost, green, and free of secondary pollution, and can lay a foundation for agricultural or forestry sludge or other resource method.

Owner:CHINA PETROLEUM & CHEM CORP +1

1,4-butanediol chemical waste water treatment technology

ActiveCN102295384BIncrease concentrationEasy to handleSludge treatment by de-watering/drying/thickeningMultistage water/sewage treatmentActivated sludgeWater flow

Owner:博瑞德环境集团股份有限公司

Method for extracting high-concentration phenol-containing coal chemical industry wastewater at high temperature by using methyl isobuthyl ketone

ActiveCN103420442BImprove extraction efficiencyImprove efficiencyWater/sewage treatment by extractionHigh concentrationWastewater

The invention belongs to the field of extraction and phenol removal of high-concentration phenol-containing coal chemical industry wastewater and discloses a method for extracting a high-concentration phenol-containing coal chemical industry wastewater solvent at high temperature by using methyl isobuthyl ketone. The method comprises the following steps: mixing the methyl isobuthyl ketone and the high-concentration phenol-containing coal chemical industry wastewater by using a static mixer and clarifying by using an oil water separator to obtain an extraction phase and a raffinate phase; or directly extracting the methyl isobuthyl ketone and the high-concentration phenol-containing coal chemical industry wastewater in a mixing and clarifying device in advance to obtain an extraction phase and a raffinate phase; performing countercurrent extraction on the extraction phase and the raffinate phase in an extraction tower to obtain a secondary extraction phase and a secondary raffinate phase respectively; allowing the secondary extraction phase to enter a rectifying tower to separate to obtain the methyl isobuthyl ketone and crude phenol; allowing the secondary raffinate phase to enter another rectifying tower to separate to obtain the methyl isobuthyl ketone and extracted water; allowing the methyl isobuthyl ketone obtained through separation to enter a solvent storage tank in a concentrated mode and recycling; and allowing the extracted water to enter a subsequent biochemical treatment section to perform further treatment.

Owner:SOUTH CHINA UNIV OF TECH

Modified fes nanoparticle and its preparation method and application

InactiveCN104478004BHigh reactivityLarge specific surface areaMaterial nanotechnologyIron sulfidesCross-linkWastewater

The invention provides a modified FeS nano-particle as well as preparation method and application thereof, wherein the modified FeS nano-particle comprises aFeS nano-particle and cross-linked polyvinylpyrrolidone; the cross-linked polyvinylpyrrolidone wraps on the surface of the FeS nano-particle to form a shell-core structure; the mass ratio of the cross-linked polyvinylpyrrolidone to the FeS nano-particle is (0.1-0.5):1.1. The preparation method of the modified FeS nano-particle c comprises the following step: importing N2 to stir and mix a cross-linked polyvinylpyrrolidone solution and a FeCl2.4H2O solution, dropwise adding an Na2F.9H2O solution under the condition of importing N2 and stirring to obtain the modified FeS nano-particle. The modified FeS nano-particle provided by the invention is high in reaction activity and large in specific surface area; both the Fe2+ and the S2- of the FeS nano-particle have reducing property and can be applied to the treatment of chromate wastewater, so that compared with the present widely applied zero-valent iron nano-particles, the modified FeS nano-particle is better in treatment effect.

Owner:HUNAN UNIV

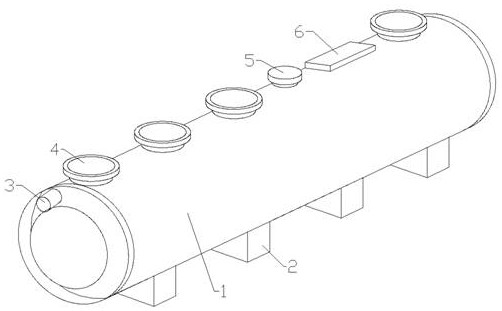

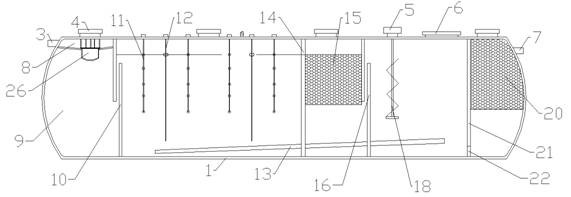

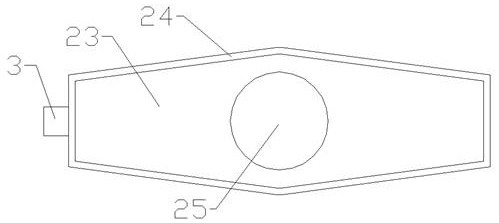

Rural domestic sewage purification tank

ActiveCN113402123AAvoid enteringHigh yieldTreatment involving filtrationTreatment with aerobic and anaerobic processesSewageEffluent

The invention relates to environmental protection equipment, in particular to a rural domestic sewage purification tank. The rural domestic sewage purification tank comprises a transversely arranged tank body, wherein a water inlet pipe is arranged at the first end of the tank body, a water outlet pipe is arranged at the second end of the tank body, a plurality of partition plates are arranged in the tank body and divide the tank body into a precipitation bin, an anaerobic bin, an aerobic bin and a filtering bin from the water inlet pipe to the water outlet pipe, a plurality of access holes are further formed in the tank body, an inflow water filtering device is arranged between the water inlet pipe and the precipitation bin, an isolation filtering device is arranged between the anaerobic bin and the aerobic bin, and an outflow water filtering device is arranged in the filtering bin. With the rural domestic sewage purification tank, the COD value of effluent is low, and the purpose of purifying sewage is achieved.

Owner:河南绿水青山环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com