Method for handling waste water of paper making industry

A treatment method and technology for papermaking wastewater, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. Water quality exceeds the standard and other problems, to achieve good sedimentation, water quality stability, control the effect of sludge bulking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

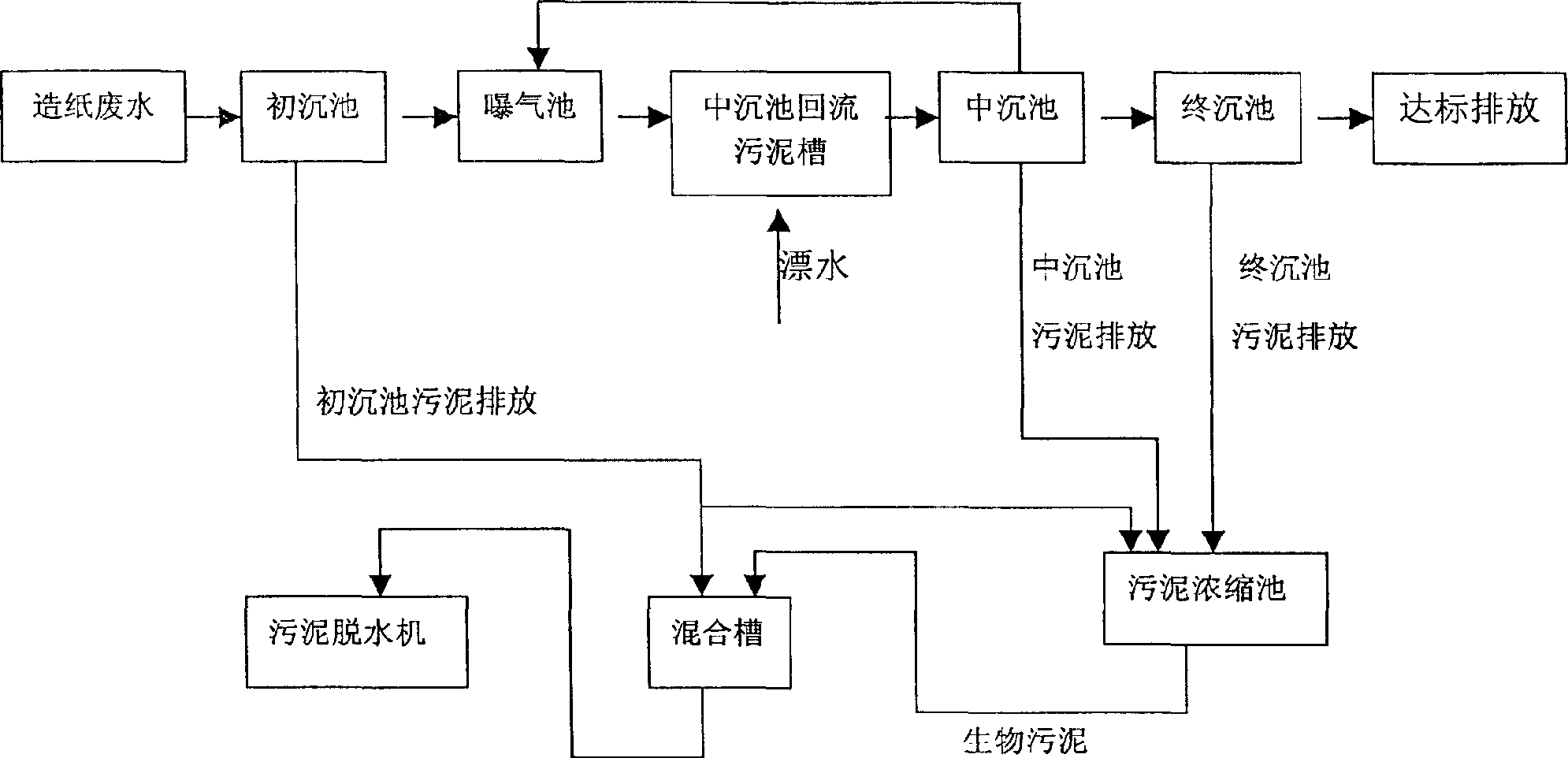

[0013] Process flow of the present invention is as follows:

[0014] In the invention, the waste water from pulping and paper making is transported to the waste water treatment plant through pipelines, and firstly passes through a sewage blocker, and then filters and removes some large sundries with a filter screen. The filtered wastewater enters the primary sedimentation tank, and a flocculation cabin is placed in the center of the primary sedimentation tank. There are two agitators in the cabin for continuous stirring to produce mechanical flocculation. After the wastewater enters the flocculation cabin and is stirred, it is flocculated by gravity. The tank flows into the sedimentation body of the primary sedimentation tank for settlement. The temperature of the outlet water in the primary sedimentation tank must be controlled at 15-35°C. If the water temperature exceeds 35°C, in order to avoid the death of bacteria in the aeration tank, the cooling tower must be turned on to...

Embodiment 2

[0016] Adopt the technical process in the embodiment 1 of the present invention to treat wastewater, when the concentration of floating water is 10%, the amount of floating water added is: 0.0012% (percentage by weight), and the metering pump is used to continuously add it to the return sludge tank of the middle sedimentation tank . The sludge settlement ratio SV can be controlled below 75% (the original process treats wastewater, SV reaches 98%), the COD of the effluent drops to 96mg / l (the original process treats the wastewater, and its effluent COD is 128mg / 1), and the sludge settles The performance is good, and no sludge bulking phenomenon occurs.

Embodiment 3

[0018] The present invention adopts the technological process in embodiment 1, 2 to process waste water, and the concentration of bleaching water is: 12%, and its adding amount of bleaching water is: 0.0015% (percentage by weight). The wastewater treated by the aeration tank is continuously added to the return sludge tank of the intermediate sedimentation tank by a metering pump. The sludge sedimentation ratio SV can also be controlled at 75%, and the effluent COD can be controlled at 96mg / 1. The sludge sedimentation performance is good, and the same Sludge bulking did not occur.

[0019] The bleaching water (chemical name: sodium hypochlorite) that adopts among the present invention is purchased in the market.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com