Polymetallic-ore-dressing wastewater coagulating sedimentation device and method

A technology of mineral processing wastewater and coagulation and sedimentation, which is applied in the fields of mining wastewater treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve the large difference in mineral processing wastewater treatment, the effluent cannot meet the reuse requirements, and the mineral processing wastewater is difficult to be efficient Problems such as flocculation and clarification, to achieve the effect of reducing equipment footprint, increasing contact time, and efficient separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1: A unit treatment test of 30L of raw wastewater was carried out in a coagulation reaction tank. The pH value of the tested polymetallic ore dressing wastewater is 7.6, SS117g / L, COD280mg / L, heavy metals As1.05mg / L, Pb25.1mg / L, Be8.2mg / L in the wastewater. Add 30L of raw wastewater into the coagulation reaction tank, and pump in the liquid coagulant polysilicate aluminum ferric sulfate, and the pumped amount of the coagulant solution with a mass concentration of 8.4g / L (calculated as aluminum) accounts for the total volume of the wastewater The percentage example is 1%, the stirring speed is controlled at 200rpm, and the reaction is 2min; then pump the coagulant aid mainly based on methyl cellulose, and the pumping amount of the coagulant aid with a mass concentration of 1g / L accounts for the percentage of the total volume of the wastewater For example, 0.5%, then react for 2 minutes, after standing for 1 minute, take the supernatant water for testing, the pH v...

Embodiment 2

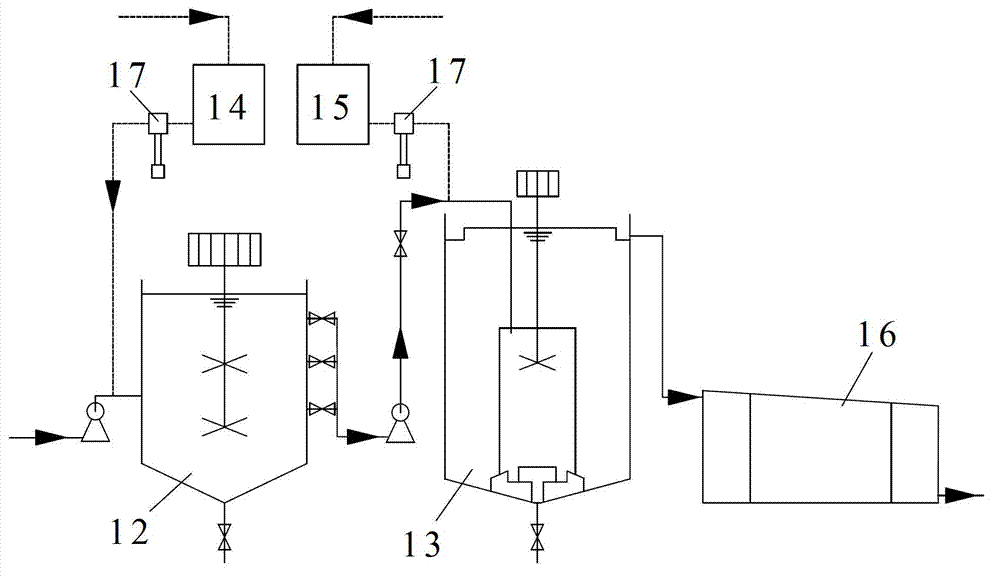

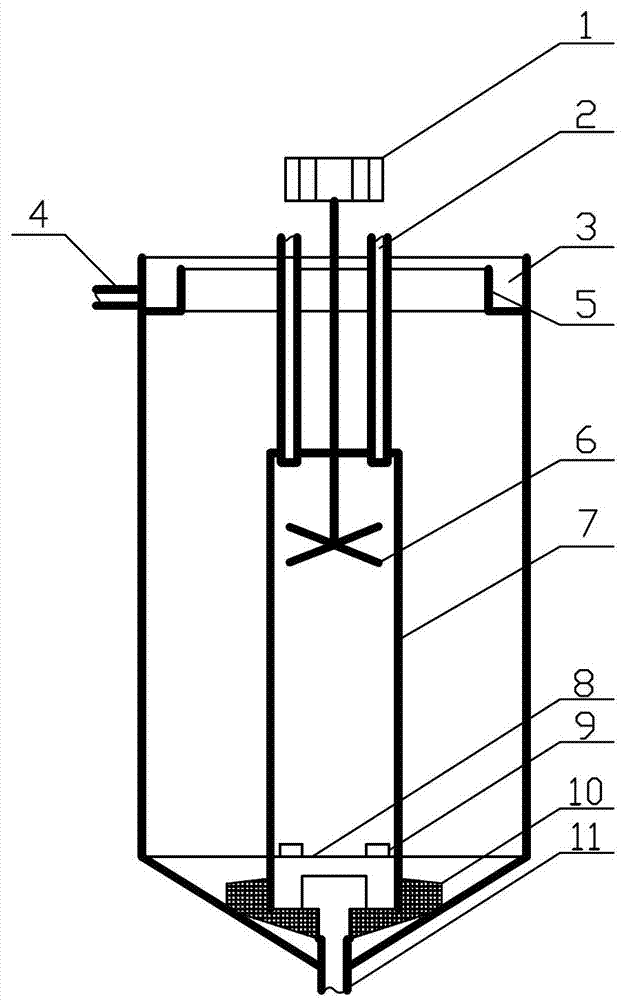

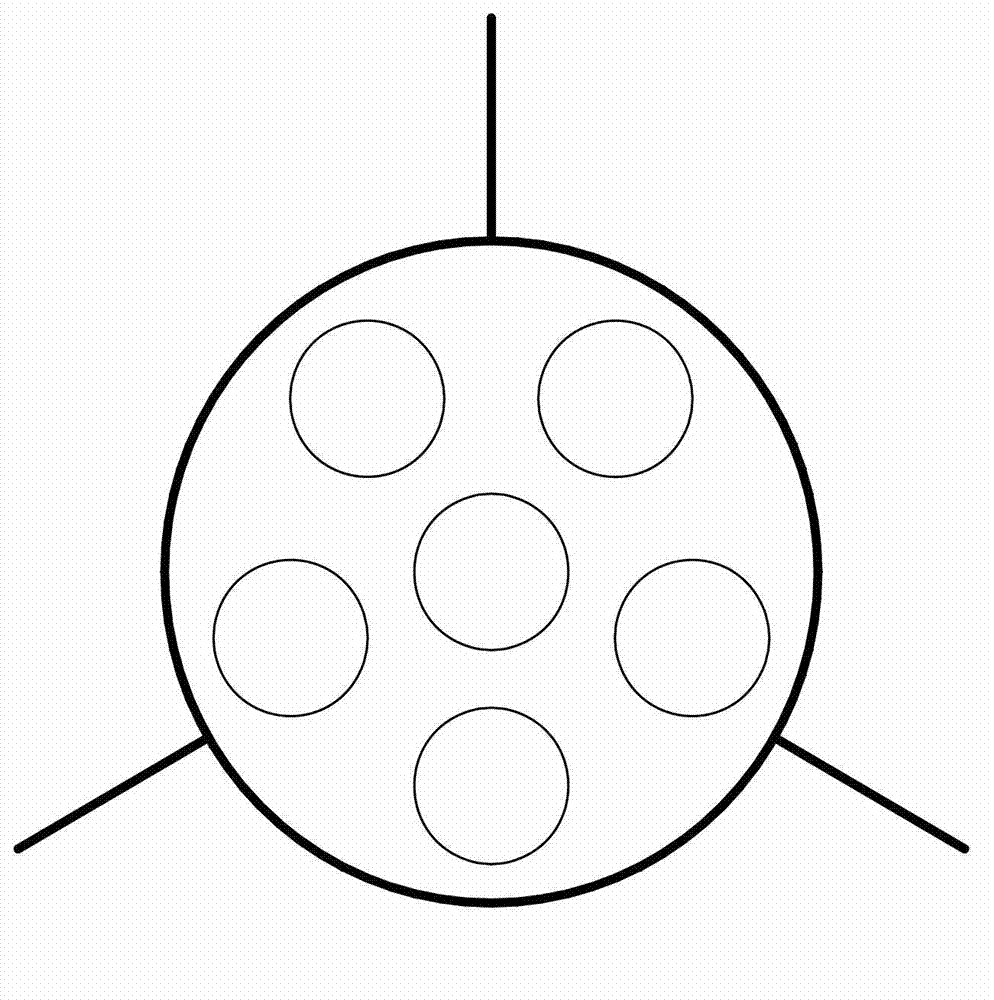

[0039] Embodiment 2: Utilize the pilot test system designed according to the present invention, carry out flow and be 100m 3 / h, continuous 2h pilot test. Adopt the waste water water quality with embodiment 1. The beneficiation wastewater and the polyaluminum chloride-based coagulant are simultaneously pumped into the coagulation reaction tank through the sewage pump, and the pumped volume of the coagulant solution with a mass concentration of 27g / L accounts for 1.5% of the total volume of the wastewater. , the stirring speed was controlled at 300rpm, and the reaction time was 2min. The waste water after the coagulation reaction is pumped into the coagulation aid mainly composed of polyacrylamide into the flocculation-sedimentation-separation integrated device in the delivery pipeline. The percentage of the total volume of wastewater is 0.5%, the stirring speed is controlled at 200rpm, and the reaction is 2min; the suspended solids in the wastewater are coarsened by floccula...

Embodiment 3

[0040] Embodiment 3: Utilize the pilot test system designed according to the present invention, carry out flow and be 100m 3 / h, continuous 3h pilot test. Adopt the waste water water quality with embodiment 1. The beneficiation wastewater and the polyaluminum chloride-based coagulant are simultaneously pumped into the coagulation reaction tank through the sewage pump, and the pumped volume of the coagulant solution with a mass concentration of 27g / L accounts for 1.5% of the total volume of the wastewater. , the stirring speed was controlled at 300rpm, and the reaction time was 2min. The waste water after the coagulation reaction is pumped into the coagulation aid mainly composed of polyacrylamide into the flocculation-sedimentation-separation integrated device in the delivery pipeline. The percentage of the total volume of wastewater is 0.5%, the stirring speed is controlled at 200rpm, and the reaction time is 2min; the suspended solids in the wastewater are coarsened by flo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com