Filling apparatus and filling technique

A technology of equipment and filling slurry, which is applied in the direction of filling, mining equipment, safety devices, etc., can solve the problems of increasing equipment complexity and cost, complex equipment and process, and low capacity of tailing mortar, so as to simplify filling equipment and equipment Simple, concentrated and efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Embodiments of the present invention are described in detail below, examples of which are illustrated in the accompanying drawings, wherein like reference numerals refer to like elements throughout. The embodiments described below are used to explain the present invention by referring to the figures, and the embodiments are exemplary and should not be construed as limitations of the present invention.

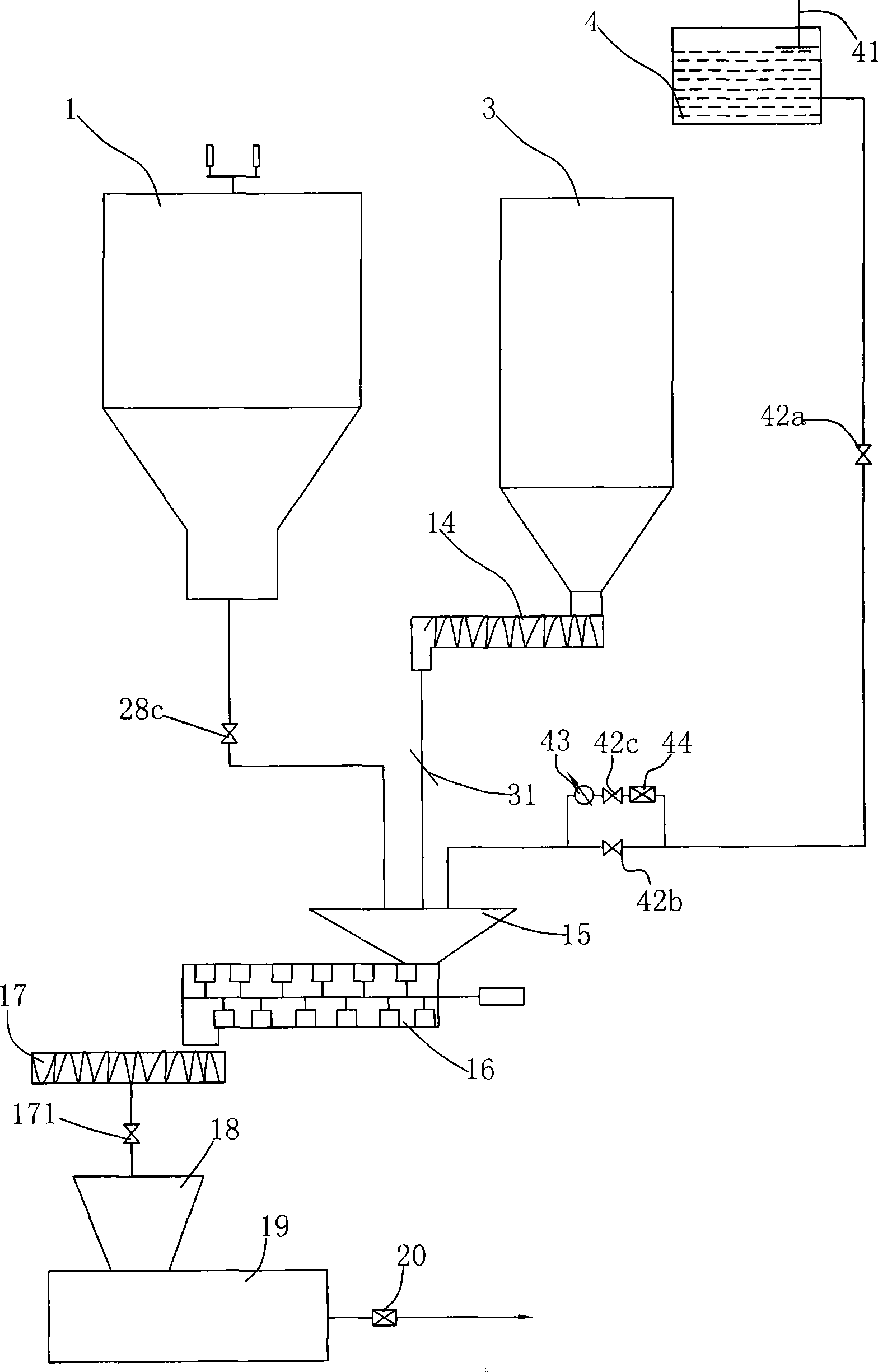

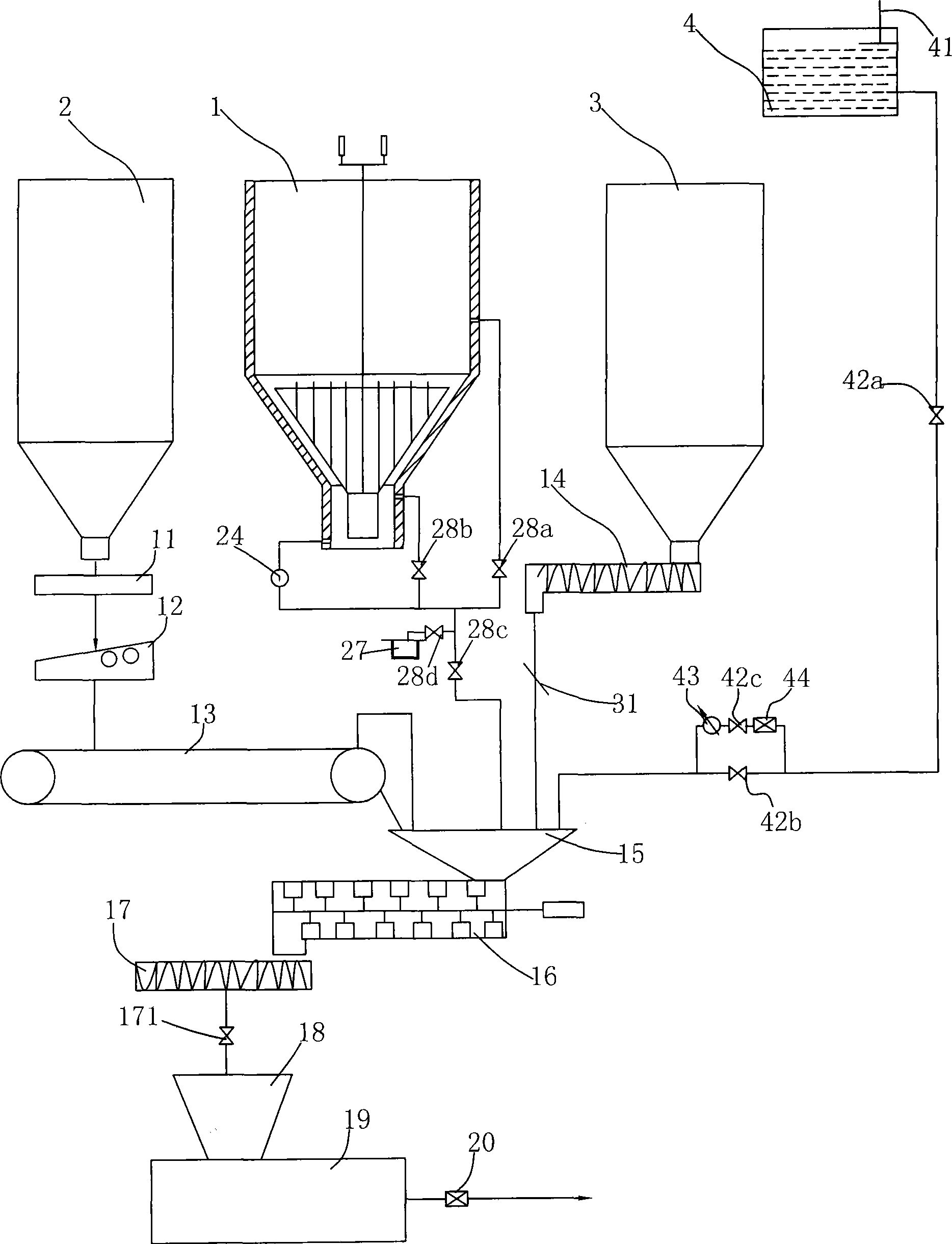

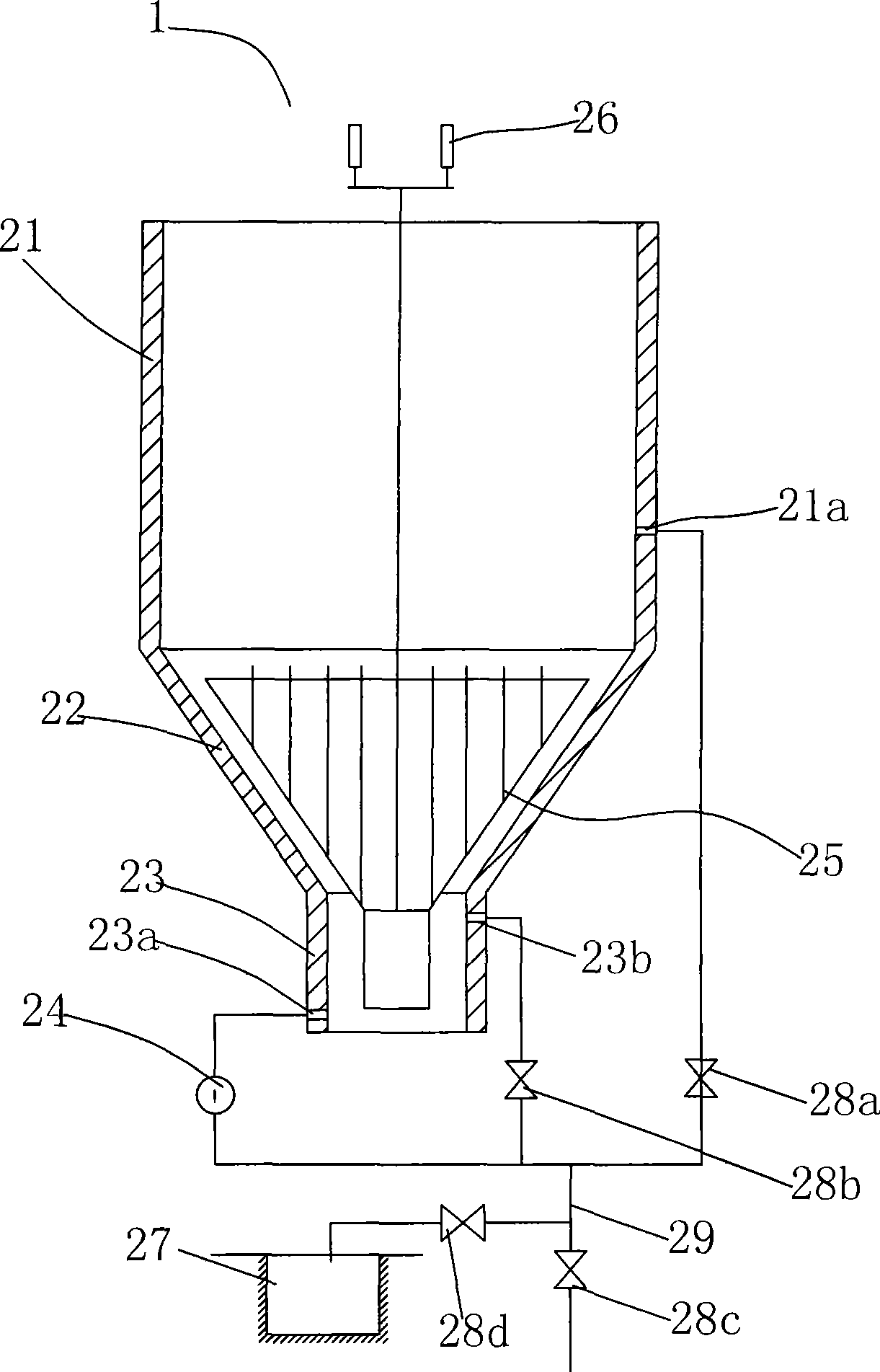

[0042] figure 1is a schematic diagram of a filling device with a deep cone thickener according to an embodiment of the present invention. As shown in 1, the filling equipment according to the embodiment of the present invention includes a deep cone thickener 1, a cement bin 3, a stirring device and a conveying device, and the deep cone thickener 1 is used to store and concentrate the tailing slurry from the ore dressing plant. The cement silo 3 is used for storing cement, such as cement, and the cement can be transported into the cement silo 3 by a cement tank truck. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com