Filling apparatus

A technology of equipment and filling slurry, which is applied to filling materials, mining equipment, safety devices, etc., to achieve the effects of cost reduction, large storage capacity, and high concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

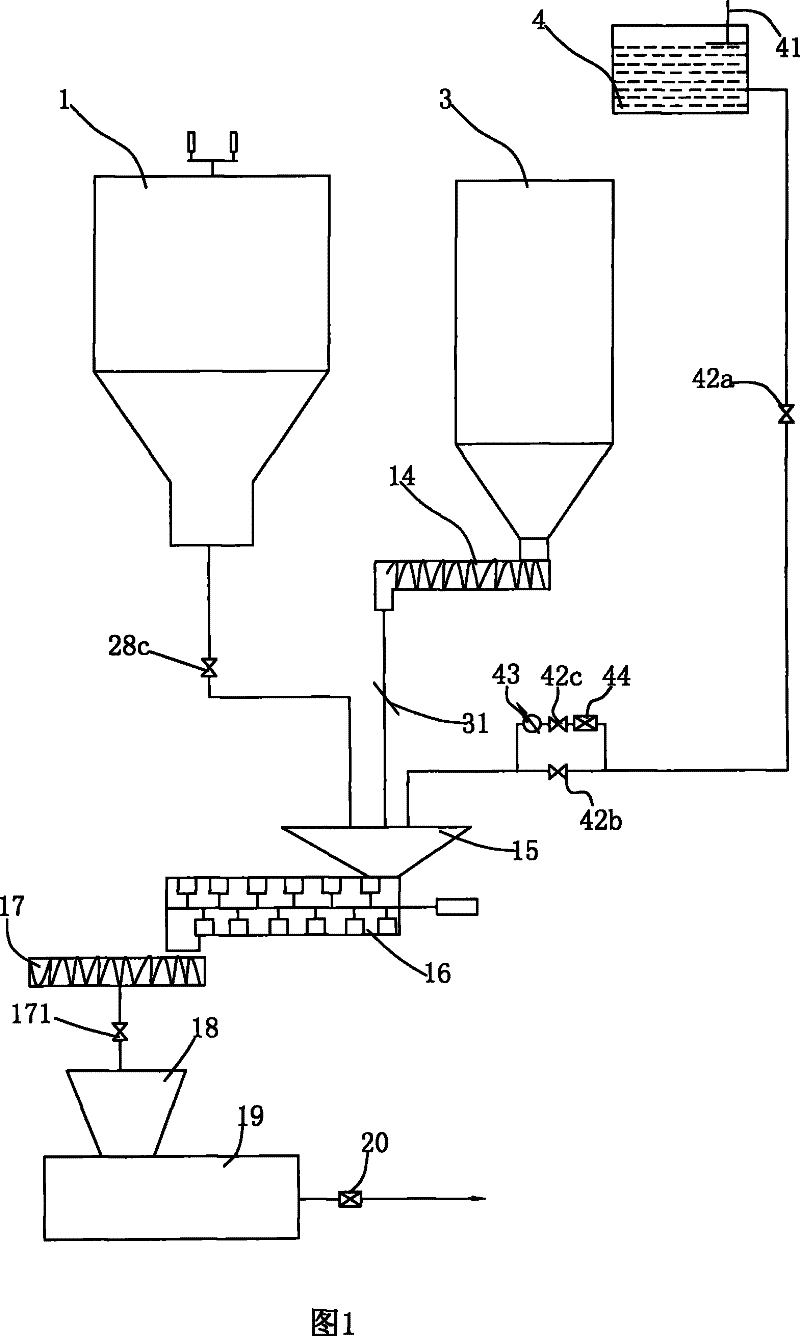

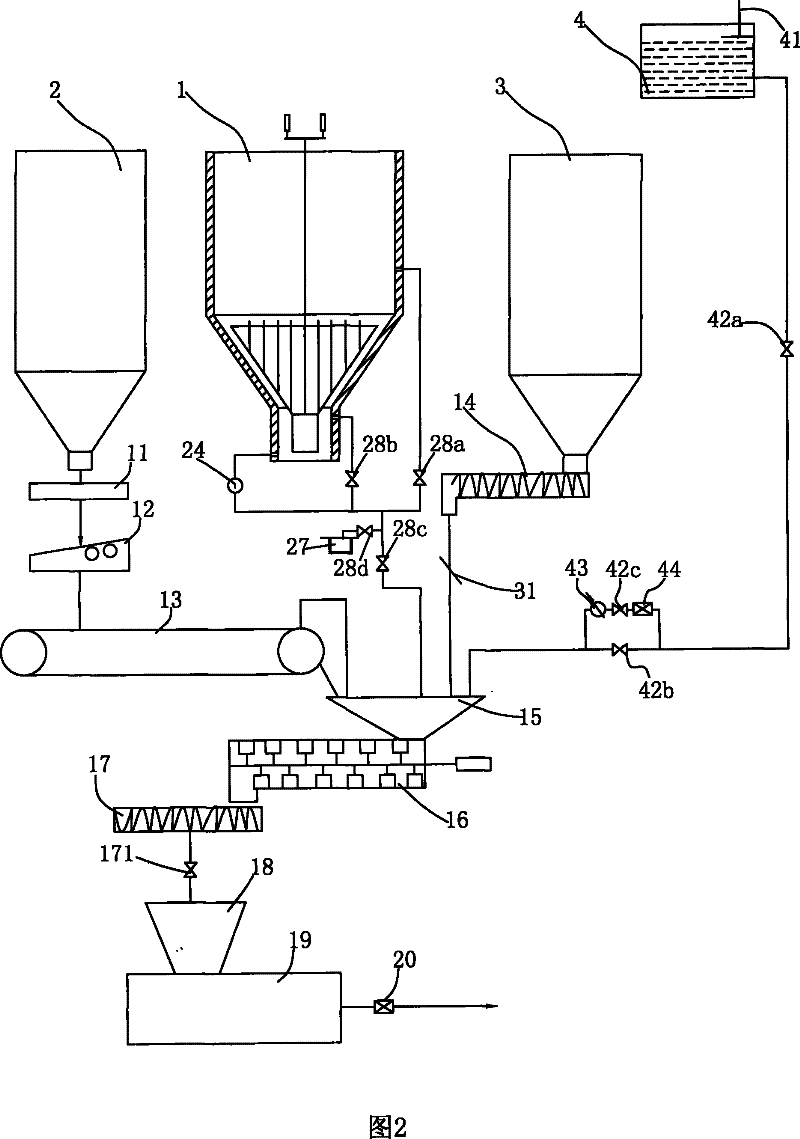

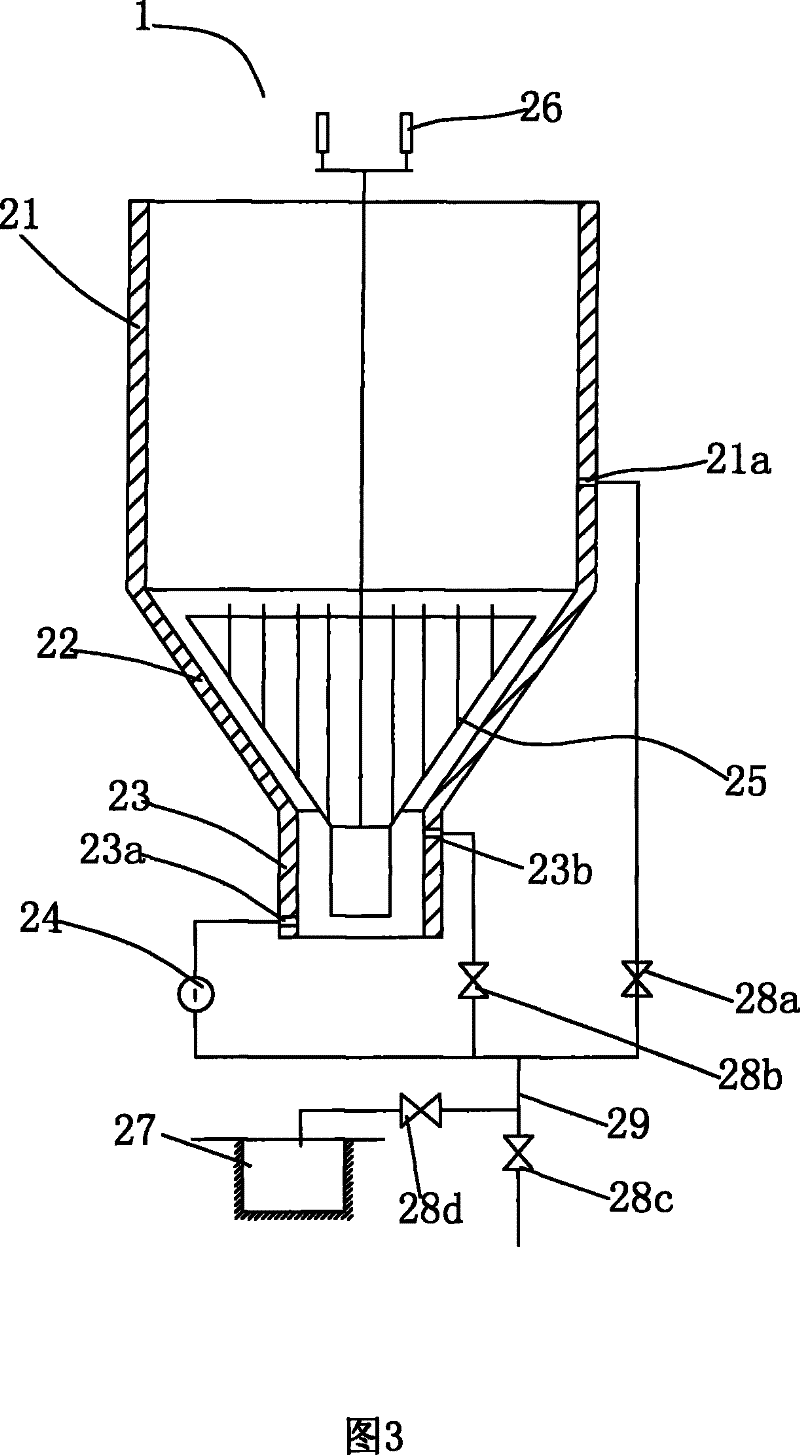

[0043] like figure 1 As shown, the filling equipment according to the embodiment of the present invention further includes a filling slurry concentration adjusting device which supplies water to the stirring device so as to adjust the filling slurry concentration.

[0044] More specifically, the device for adjusting the concentration of the filling slurry includes a pool 4 for storing water, and the pool 4 supplies water to the stirring device through a water supply pipeline; a liquid level gauge 41 arranged on the pool for indicating the water level in the pool 4; a flow meter 44, Flowmeter 44 is used for detecting the amount of the water that is supplied to stirring device from pond 4; With flow regulating valve 43, flow regulating valve 43 is used for regulating from pond to stirring device, for example the amount of the water that mixing hopper 15 (discussion below) supplies . In addition, a gate valve 42a may also be provided on the water supply pipeline for disconnecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com