Patents

Literature

133results about How to "Fast hydrolysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Intensive processing method for stalk articles or agricultural castoff

InactiveCN101492700AEasily hydrolyzedCompletely hydrolyzedBiofuelsMicroorganism based processesFiltrationMonopotassium phosphate

The invention provides a method for intensive processing of straw-type materials or wastes of agriculture and forestry. The method has the following steps: the straw-type materials or the wastes of agriculture and forestry are first ground and then soaked in hot water; hydrolyzation is carried out by diluted acid or monopotassium phosphate solution, the hydrolyzate is used for producing furfural or xylose, solid content after the hydrolyzation is washed and added with alkali substances for neutralization, then cellulase and feruloyl esterase are added to synergetically hydrolyze cellulose in solid content, the cellulose is broken down into 6-carbon monosaccharide and exists in sugar liquor; adsorption filtration is carried out on the sugar liquor by activated carbon, then high-temperature sterilization and cooling are carried out on the sugar liquor before inoculation of fermentation strain to produce acetone, butanol and ethanol by fermentation; the method of the invention maximizes the application of the straw-type materials or the wastes of agriculture and forestry, thus turning existing wastes into the valuables while finding new raw material sources and a new method for producing acetone, butanol and ethanol and bringing more economic and social benefits to the enterprises and the society.

Owner:ZHENGZHOU DAYANG GREASE CHEM EQUIP

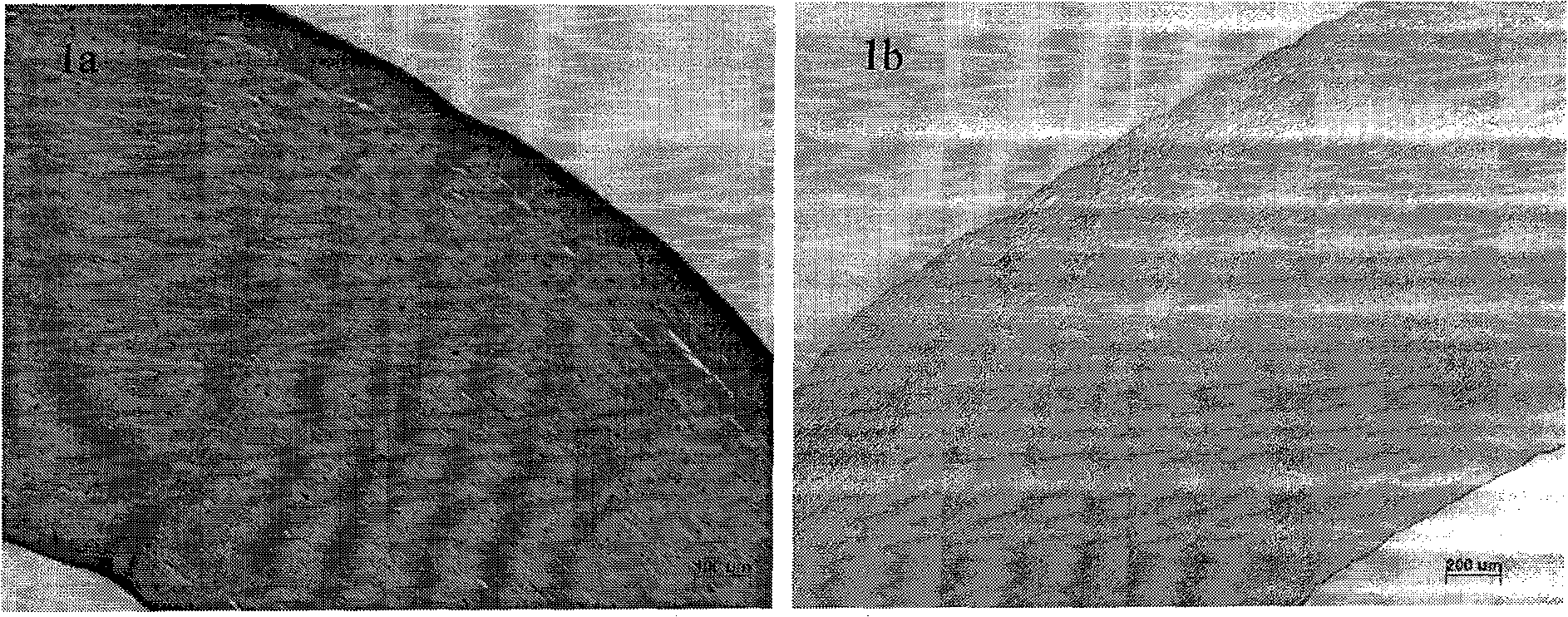

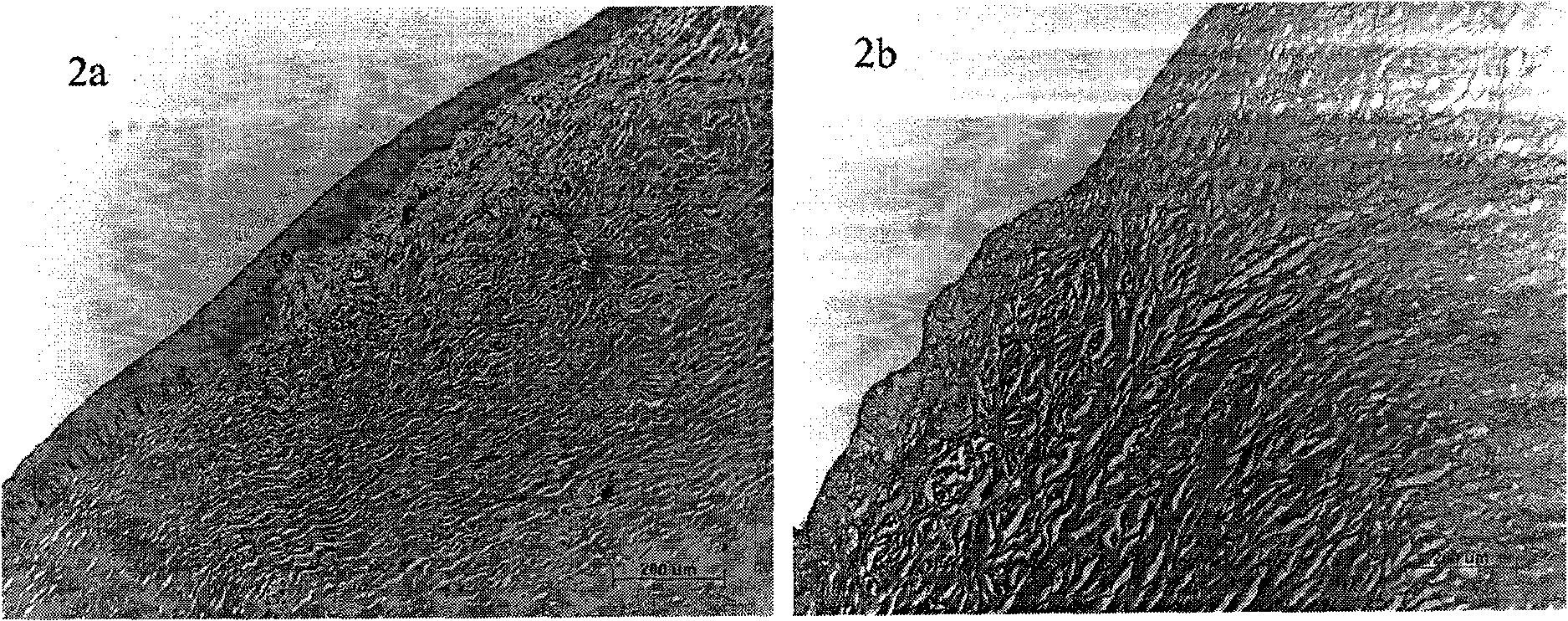

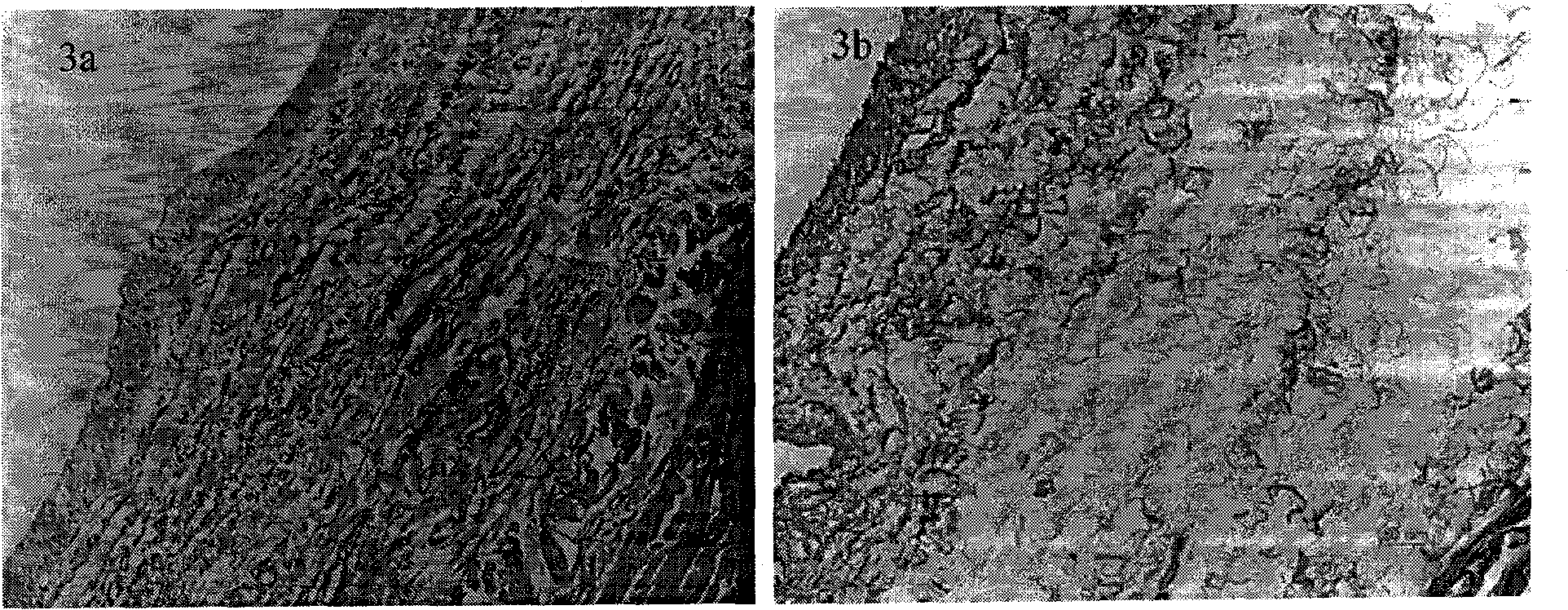

Method for preparing acellular matrix

InactiveCN101274106AStrong decellularization specificityStrong specificityTissue regenerationProsthesisDiseasePhospholipase

The invention discloses a method of preparing acellular matrixes by using phospholipase. The method of the invention is characterized in that stand-by organ tissue is first pre-treated and then added into solution containing the phospholipase to prepare the acellular matrixes under a controlled condition; the prepared acellular matrixes are then washed. By adopting the preparation method of the invention, the obtained acellular matrix can have good physical property and biological function. Therefore, the preparation method in the invention is not only a great breakthrough in the tissue engineering, but also opens a new way for clinical treatment of diseases. The preparation method of the invention has the advantages of reliable theory, simple and flexible process technique, good product reproducibility and is very easy to be industrialized.

Owner:ZHONGSHAN OPHTHALMIC CENT SUN YAT SEN UNIV

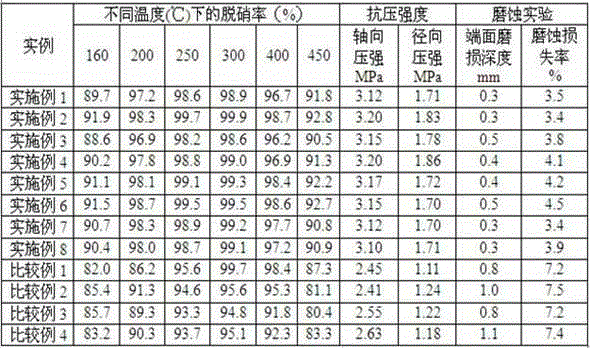

SCR (Selective Catalytic Reduction) flue gas denitrification catalyst and preparation method thereof

InactiveCN106732759AFast hydrolysisTightly boundMolecular sieve catalystsDispersed particle separationCarboxylic saltPolyacrylamide

The invention discloses a preparation method of an SCR (Selective Catalytic Reduction) flue gas denitrification catalyst. The preparation method comprises the following steps: (1) firstly preparing a mixed solution of titanium sulfate and amino carboxylate, adding powdered molecular sieve into the mixed solution for dipping, and carrying out drying and roasting to prepare a TiO2-molecular sieve composite carrier; (2) dipping the TiO2-molecular sieve composite carrier prepared in the step (1) into dipping liquid containing an active component and an adjuvant precursor, and carrying out drying and roasting to obtain denitrification catalyst powder; (3) mixing the denitrification catalyst powder obtained in the step (2) with glass fiber, wood pulp, polyacrylamide, carboxymethyl cellulose, ammonia water and deionized water, and carrying out kneading, aging, extrusion, drying and roasting to obtain a cellular denitrification catalyst. The preparation method is simple in preparation process and low in cost; the obtained denitrification catalyst is wide in active temperature range, high in denitrification activity and high in SO2 and H2O poisoning resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Absorbable copolyesters of poly(ethoxyethylene diglycolate) and glycolide

InactiveUS20080103284A1Fast absorptionFast hydrolysisSuture equipmentsProsthesisDiethylene glycolCopolyester

A semi-crystalline, absorbable copolyester composition comprising the reaction product of a polycondensation polyester and at least one lactone, wherein the polycondensation polyester comprises the reaction product of diglycolic acid and / or a derivative thereof and diethylene glycol; and the copolyester comprises about 30 to 50% by weight of the polycondensation polyester based on the total weight of the copolyester.

Owner:ETHICON INC

Novel process for producing calcium enriched animal hydrolyzed protein using complex enzyme hydrolyzing chicken bone mud

The invention relates to a new process for preparing animal protolysate containing high calcium with complex enzyme hydrolysized chicken bone mud, which is characterized in that it comprises the following steps: disintegrating chicken bone ultramicroly to make bone mud, formulating bone mud suspending solution, heating under 80-100 Deg .C for 20-30 minutes, cooling to temperature proper for enzyme reaction, regulating pH value, adding complex enzyme for reacting for a certain time, then heating to 85-90 Deg. C and keeping for 10-20 minutes for sterilization, and getting product which is concentration of sepia, semitransparent or stramineous powder. The invention resolves problems of odour of raw material and bitter caused by enzymolysis, the product most of which is short peptide and free amino acid can be adsorbed easily by human body which increase comprehensive utilization ratio of product, and the product possess certain action for inhibiting angiotonin zymose.

Owner:FUZHOU UNIV

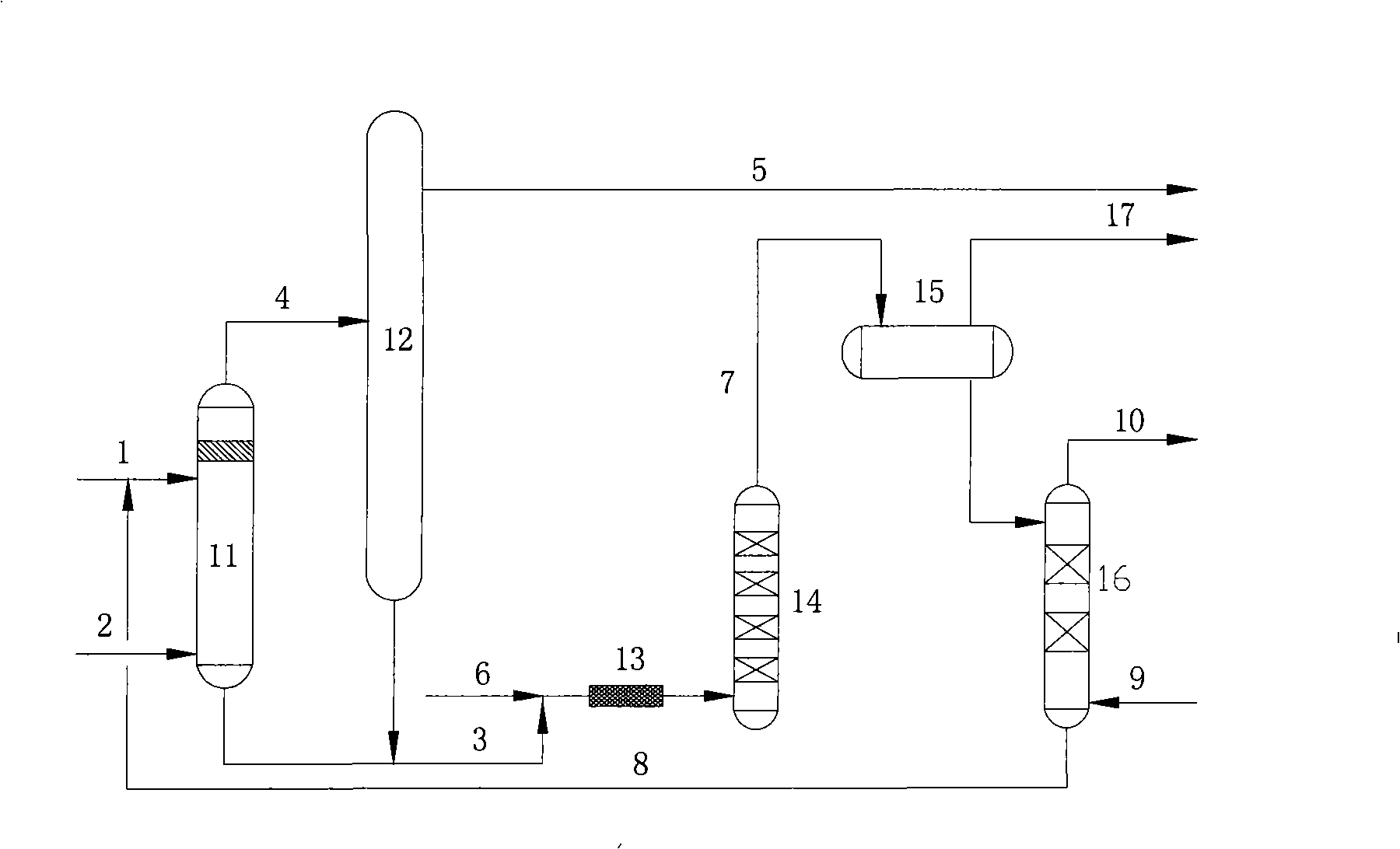

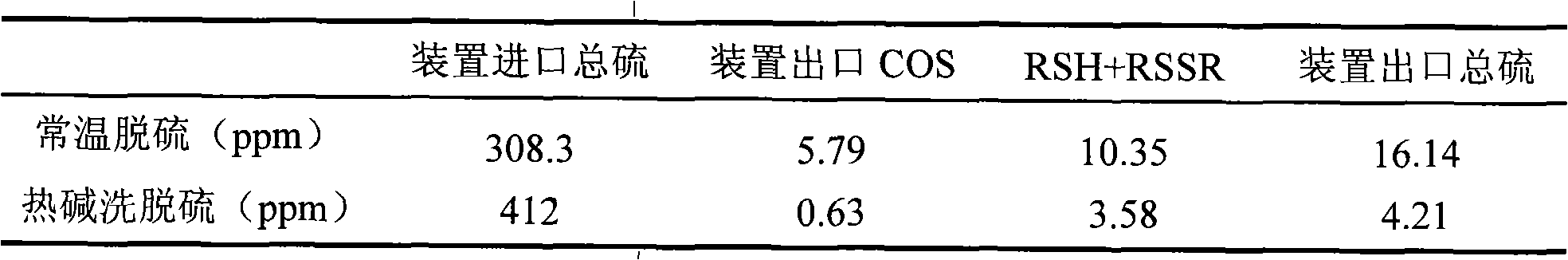

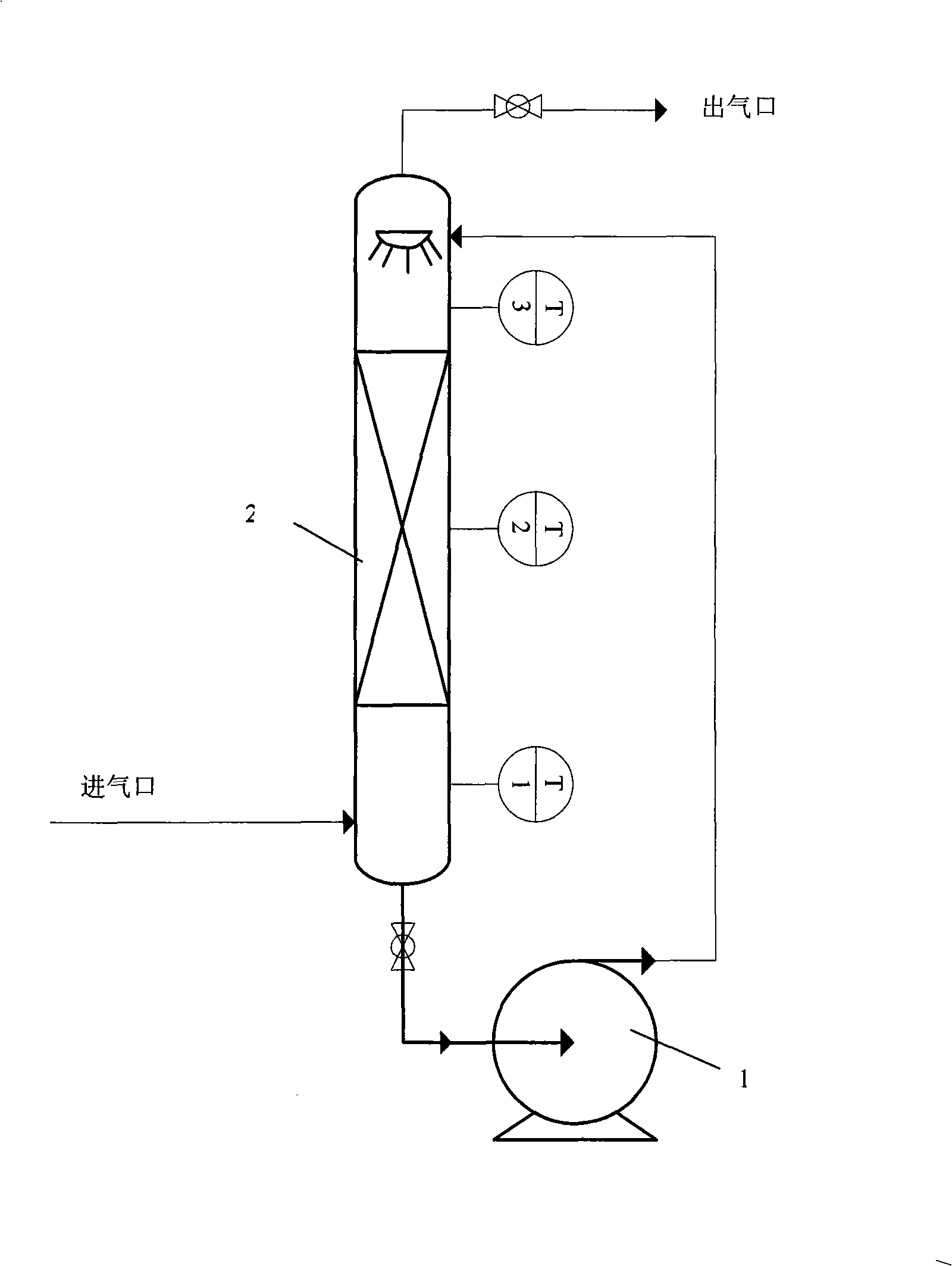

Hot-soda washing desulfurization method

ActiveCN101319150AHigh operating temperatureEasy to operateGaseous mixture working upComing outSulfur

The present invention discloses a method for desulfurating by thermokalite washing, belonging to the desulfuration technical field. In order to solve the problems that the prior art is inconspicuous in desulfuration effect, not good in separation effect of liquid hydrocarbon and alkali liquor, low regeneration efficiency of alkali liquor, large in environment protection pressure, etc., a liquid-liquid converse thermokalite washing tower is adopted for removing the sulfur in liquefied gas by thermokalite at a higher temperature, an alkali liquor sedimentation tower is adopted for separating the alkali liquor and the liquefied gas, and then related equipment such as an alkali liquor regeneration tower, etc. is adopted for removing sulfide from a system. The method improves the operating temperature of the alkaline tower, quickens the conversion rate of sulfur in various forms, and can convert the sulfur in various forms in the liquid hydrocarbon into sulfide or disulphide, etc.; The titanium, cyanine and cobalt catalysts are omitted, and thus the cost of the catalyst is economized; the liquid hydrocarbon come out from the alkaline tower enters an alkali liquor knockout tower, the staying time is increased, and thus the effect of separation of the liquefied gas from the alkali liquor is better.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for comprehensively extracting oat polypeptide and oat glucan

The invention relates to a method for comprehensively extracting oat polypeptide and oat glucan, which comprises the following steps: dissolving oat flour into deionixed water with certain temperature, centrifugally filtering and filtering by a diatomite plate frame for multiple times and separating the mixed solution to obtain an oat protein solid and filtrate; treating the filtrate obtained by separating with low-temperature alpha-amylase under a certain condition and filtering the mixed solution by the diatomite plate frame to obtain supernatant liquid; filtering the supernatant liquid by using an ultrafiltration membrane the cut-off molecular weight of which is 50,000Da-100,000Da and obtaining cut-off solution which is oat glucan solution; and repeatedly dissolving the separated oat protein solid with deionized water the pH value of which is 9-11, adding alkali protease for hydrolyzing, adjusting the pH value, standing and settling and filtering by using the diatomite plate frame to obtain oat polypeptide solution. By using the invention, raw materials are fed for one step, oat polypeptide and oat glucan can be simultaneously obtained and organic solvent is not used. In addition, the invention has the advantages of low operation temperature, energy saving, environmental protection and high safety.

Owner:广州贝塔健康生物科技有限公司

Process for preparing high-purity trifluoromethyl sulphonic acid

ActiveCN101402591AFast hydrolysisAdequate responseElectrolysis componentsOrganic compound preparationAlkaline earth metalDistillation

The invention relates to a process method for preparing high-purity trifluoromethane sulfonic acid. The process method comprises the following steps: firstly, hydrolyzing trifluoromethane sulfuryl fluoride gas prepared by an electrochemical fluorination method in alkaline metal or alkaline-earth metal hydroxide solution, recrystallizing the generated trifluoromethane sulphonate in a solvent to purify, and then reacting the trifluoromethane sulphonate with 100 percent of sulfuric acid in the presence of silicon dioxide to obtain an initial product of the trifluoromethane sulfonic acid, and finally purifying the trifluoromethane sulfonic acid through reduced pressure distillation. The process method not only effectively improves the hydrolysis speed of the trifluoromethane sulfuryl fluoride gas, leads the trifluoromethane sulfuryl fluoride gas to react more completely, and improves the yield, but also effectively reduces the content of F<-> in the trifluoromethane sulfonic acid product, and improves the purity of the product.

Owner:PERIC SPECIAL GASES CO LTD

Method for hydrolyzing chitosan and chitin

InactiveCN101723989ALow costFast hydrolysisSugar derivativesOligosaccharidesChitin formationReaction speed

The invention relates to a method for hydrolyzing chitosan and chitin to prepare monosaccharide and oligosaccharide by using ionic liquid as a reaction medium and using protonic acid as a catalyst under the condition of heating. Particularly, the method comprises the following steps: dissolving the chitosan or the chitin into the ionic liquid, adding acid and water into the solution, and heating the solution to perform reaction so as to obtain a hydrolysis product of which the yield reaches up to 70 percent based on total reducing sugar. The method has the advantages of mild operation condition, high reaction speed, reusability of the ionic liquid, low cost, simple process, environmental friendliness and the like, provides a new method for efficiently degrading the chitosan and the chitin, and develops a new path for preparing general oceanic chemicals and medicinal health-care products in large scale.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

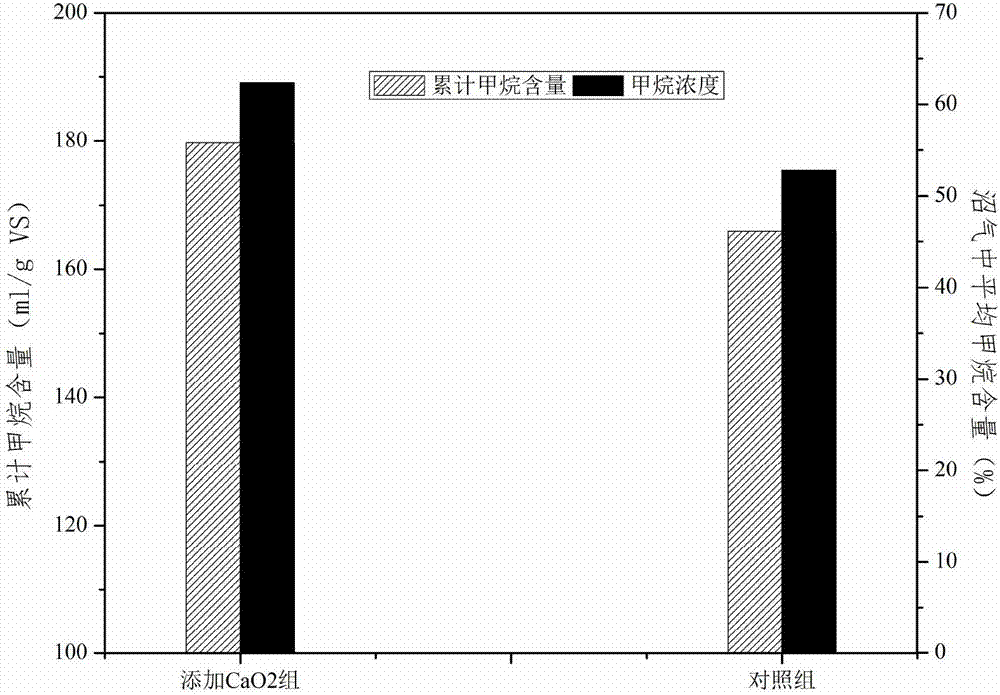

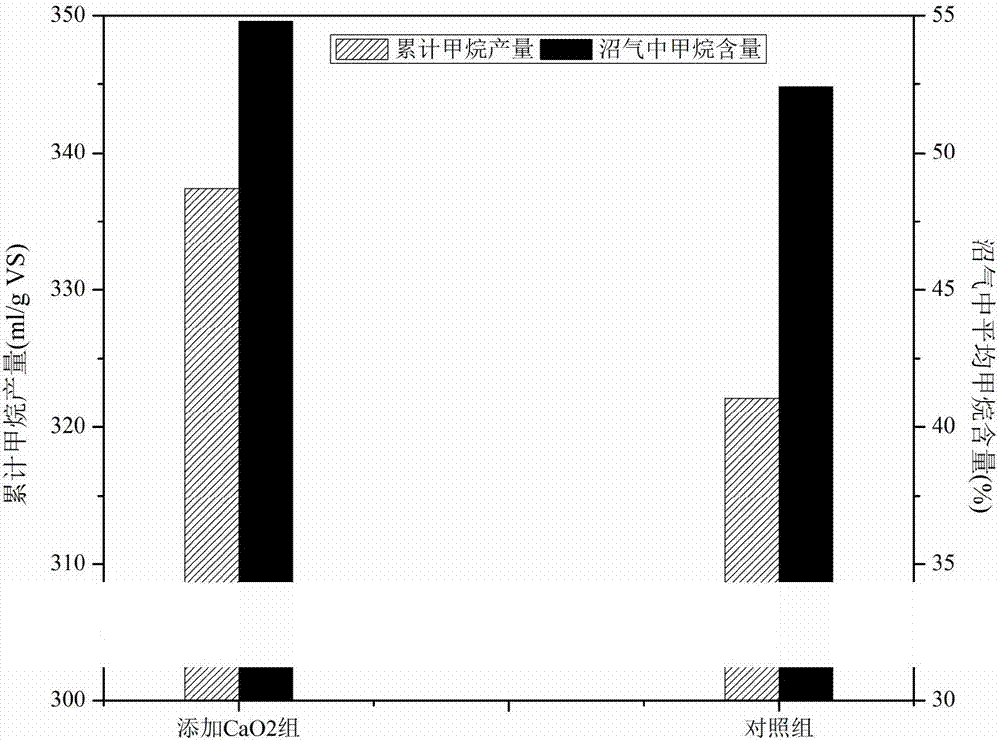

Method for improving efficiency of methane production through anaerobic fermentation and methane content in biogas

InactiveCN106929540AIncrease contentFast hydrolysisWaste based fuelFermentationMethane productionBiogas production

The invention belongs to the field of biogas production through anaerobic fermentation of organic solid wastes and particularly discloses a method for improving the efficiency of methane production through anaerobic fermentation and the methane content in a biogas. CaO2 is added to organic solid waste fermentation raw materials to form a microaerobic environment, thereby improving the efficiency of methane production through anaerobic fermentation and the methane content in the biogas. The method is mainly applied to the field of biogas production through anaerobic fermentation of the organic solid wastes such as straws and manure; the hydrolysis rate of anaerobic fermentation can be improved through adding a little of CaO2 to a reaction system, the methane content in the biogas is increased and the stability of a fermentation system is improved.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

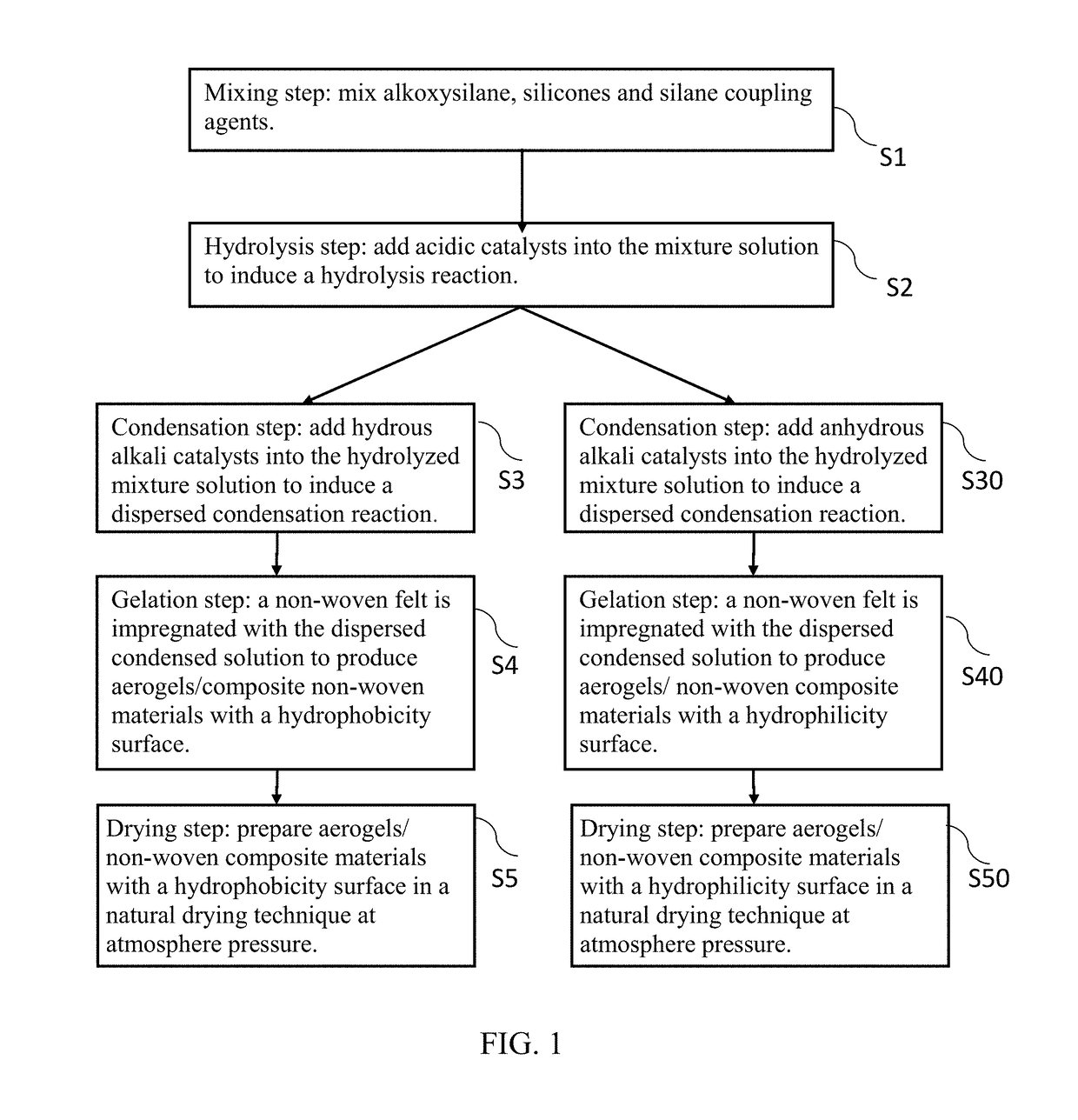

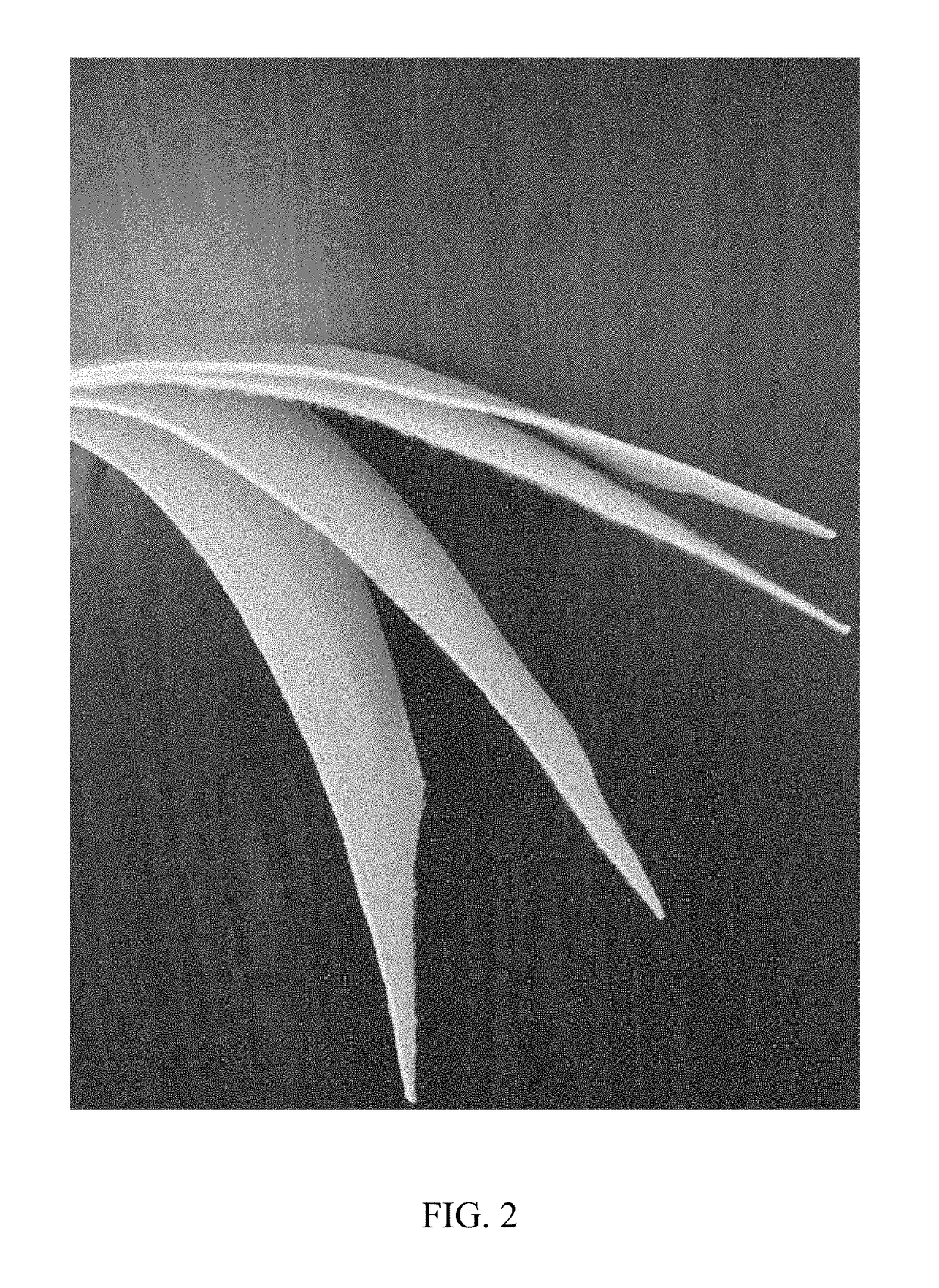

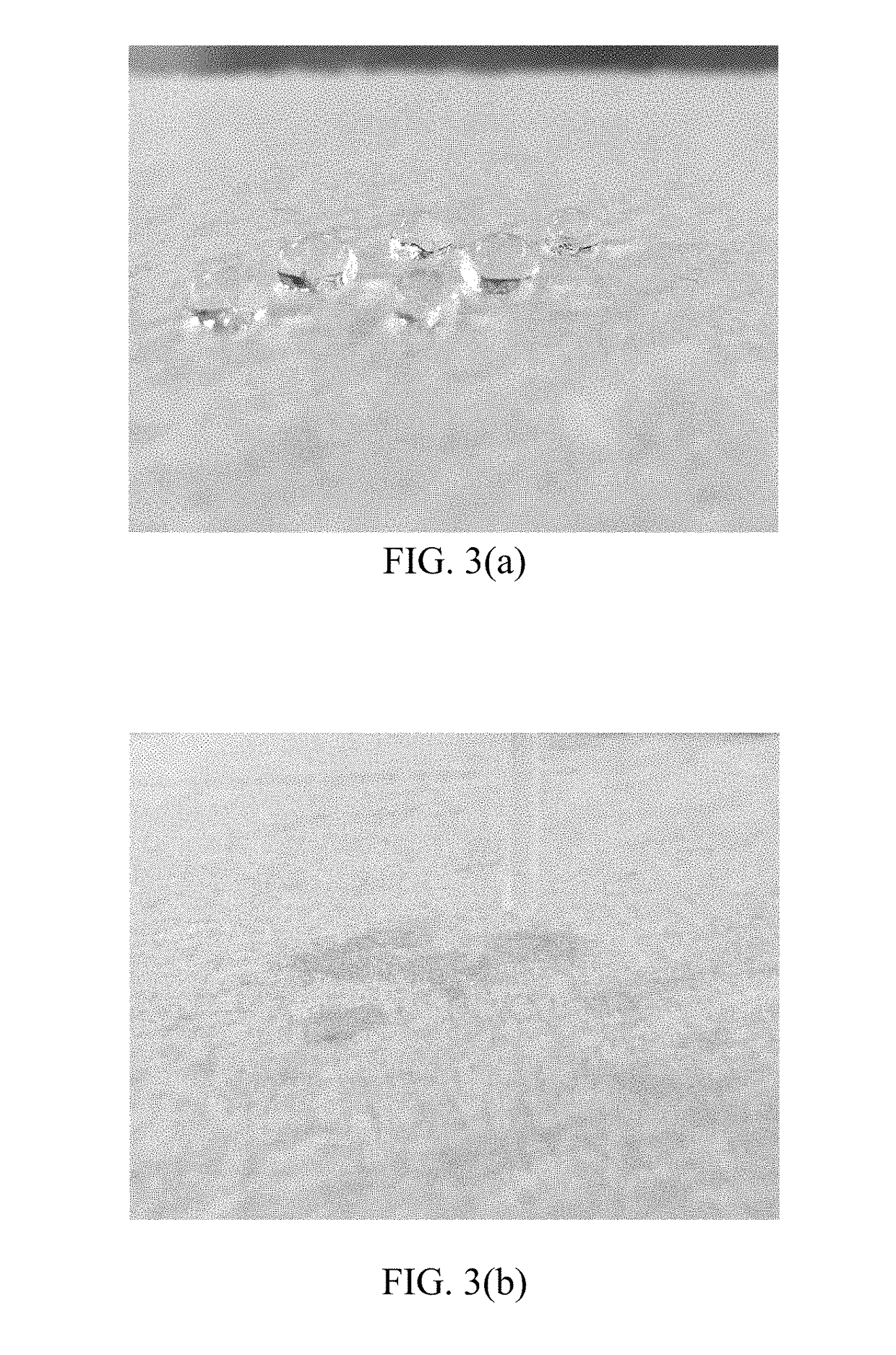

Method of preparing aerogels/nonwoven composites fireproof and heat-insulating materials

ActiveUS20190055374A1Soft materialModerate hydrophilicityLiquid surface applicatorsOrnamental textile articlesSilanesSilicon dioxide

Owner:KUN SHAN UNIVERSITY

Ceramic fire-resistant functional filling material as well as preparation method and purpose thereof

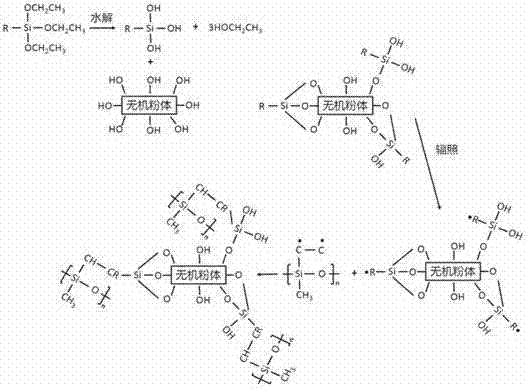

InactiveCN107501946AIncrease filling volumeEvenly dispersedNon-macromolecular adhesive additivesOther chemical processesGraft reactionHigh energy

The invention belongs to the technical field of a ceramic organic silicon fire-resistant material, and concretely discloses a ceramic fire-resistant functional filling material as well as a preparation method and a purpose thereof. The filling material is prepared from 80 to 120 parts of ceramic forming powder, 1 to 5 parts of silane coupling agents, 10 to 20 parts of diluting agents, 0.01 to 0.03 part of pH regulators, 2 to 6 parts of ethenyl polysiloxane and 2 to 10 parts of ceramic auxiliary agents. The ceramic forming powder is subjected to surface treatment through the silane coupling agents; grafting reaction is performed with polysiloxane in high-energy rays, so that good compatibility is achieved with organic silicon materials, so that the ceramic conversion rate can be improved. The method is applicable to the preparation of the ceramic fire-resistant material using the organic silicon materials as substrates. The filling material has excellent fire-resistant performance, good processing performance, low cost and convenient and fast production; meanwhile, the dispersion performance of the powder body is excellent; the ceramic forming effects of the prepared material in the flame combustion process is greatly promoted; the formed ceramic body is hard; good fire-resistant and heat-insulation functions are realized.

Owner:成都众一高材科技有限公司

Choline chloride eutectic solvent as well as preparation method and application thereof

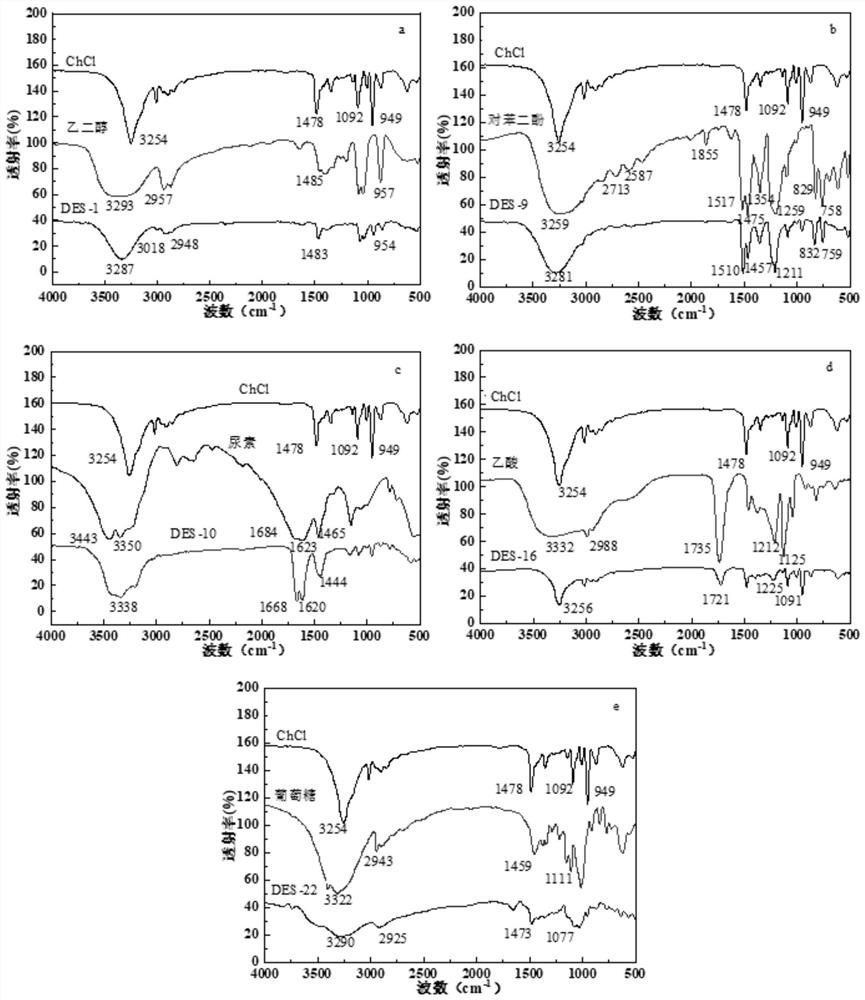

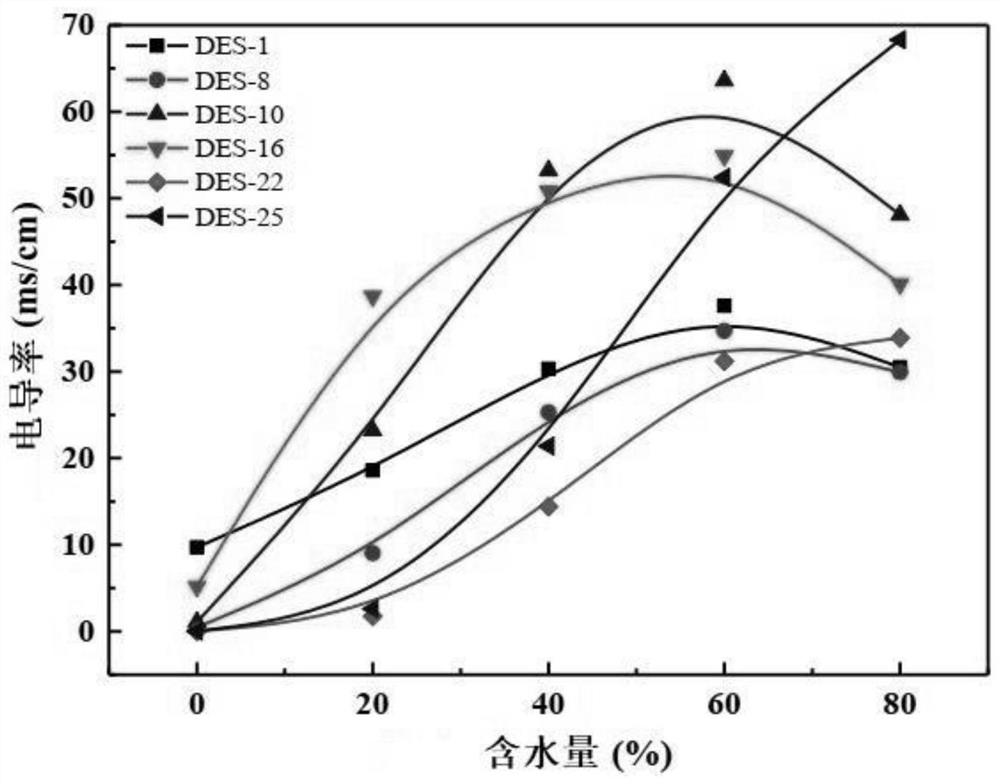

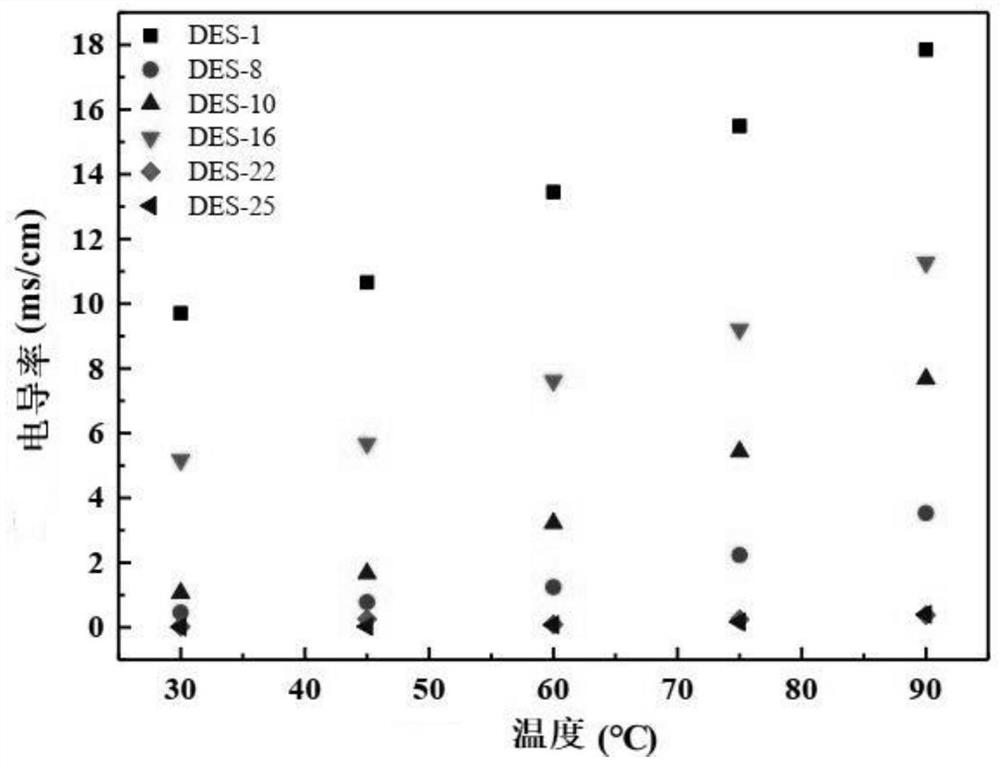

PendingCN113461975ARich varietyEasy to synthesizeBulk chemical productionPhysical chemistryIonic liquid

The invention provides a choline chloride eutectic solvent and a preparation method and application thereof, and belongs to the technical field of ionic liquid application. In the invention, choline chloride (ChCl) and a hydrogen bond donor are polymerized by adopting a direct heating method to obtain the choline chloride eutectic solvent; the choline chloride deep eutectic solvent has little influence on the environment, is easy to synthesize, has little influence on the crystal structure, polymerization degree and thermal stability of microcrystalline cellulose, and can be well applied to the field of non-dissolving pretreatment microcrystalline cellulose.

Owner:JIANGSU UNIV

Method for manufacturing high-refractive index TiO2/organic silicon hybrid coating

InactiveCN101935457AHigh molecular weightHigh refractive indexRefractive indexTemperature resistance

The invention provides a method for manufacturing a high-refractive index TiO2 / organic silicon hybrid coating, which is mainly characterized by comprising the following steps: dripping a phenyl-containing organic silicon monomer into mixed solution of absolute ethanol, deionized water and an inorganic acid; heating and stirring for a certain time period; adding gamma-glycidyloxypropyltrimethoxysilane to perform a cross-linking reaction to obtain high-refractive index organic silicon sol; stopping heating, dripping mixed solution of absolute ethanol and deionized water by using afterheat; adding a titanium alkoxide to obtain netty nano composite organic silicon hybrid sol; and preparing the hybrid coating by a spinning process. The coating, after being solidified with heat, has the characteristics of high refractive index, high light transmittance, high-temperature resistance and high bonding strength. The refractive index of the coating increases with the increase of TiO2 content; in addition, the introduction of the phenyl improves the refractive index of the organic silicon sol and reduces the scattering of the coating. The method has the characteristics of simple and feasible preparation process and large scale production.

Owner:SHENZHEN UNIV

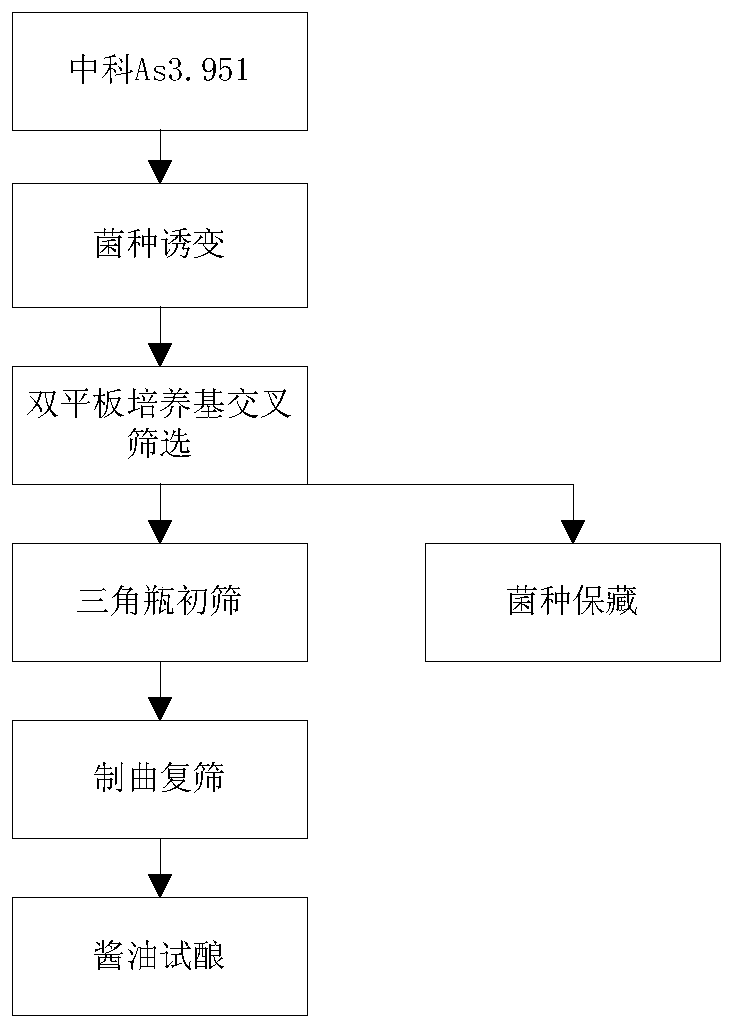

Aspergillus oryzae ZA184 and use thereof

The invention relates to the technical field of food processing and microbial fermentation, in particular to aspergillus oryzae ZA184 and use thereof in soy sauce brewing. The aspergillus oryzae ZA184can increase the pH of koji, enhance the activity of the koji enzymes (such as neutral protease, alkaline protease, leucine aminopeptidase and glutaminase), and improve the contents of amino nitrogen, total nitrogen and glutamic acid in soy sauce, so that the flavor and quality of the soy sauce is improved, the fermentation cycle can be significantly shortened, and the production efficiency is improved.

Owner:GUANGDONG HAITIAN INNOVATION TECH CO LTD +2

Production method of silicon dioxide aerogel functional material

InactiveCN109851380AHigh compressive strengthImprove physical crosslink strengthCeramicwareLayered structureIon

The invention relates to a production method of a silicon dioxide aerogel functional material, and belongs to the technical field of aerogel. According to the production method of the silicon dioxideaerogel functional material, through carbonization treatment, the silicon dioxide aerogel functional material is produced, not only can an original nano-porous network structure be maintained, but also the silicon dioxide aerogel functional material has a plurality of excellent property such as a high specific surface area, low mass density and nanoscale continuous pores, and the mechanical performance is good; and montmorillonoid is a two-dimensional molecular-sieve-like porous substance, due to the fact that the montmorillonoid has performance of a large specific surface area, large adsorption capability and the like, the montmorillonoid is applied to a wide variety of aspects of adsorption, hydrogen storage, catalysis, bioseparation, electron devices, chromosorb supports and the like, through carbonization treatment, the swelling capability of a layered structure and exchangeable performance of positive ions of the montmorillonoid are used for inserting the inorganic positive ions into layers of the montmorillonoid, and the layers of the montmorillonoid are distracted to form two-dimensional pore channels with openings, so that the adsorption capability and the mechanical performance of the silicon dioxide aerogel functional material are improved.

Owner:谢吉萍

Preparation method of konjak gum serial products

The invention provides a preparation method of konjak gum serial products, belonging to the konjak gum modification technique. The characteristics of high viscosity and low solubility of the konjak gum limits the application range of the konjak gum. The method of the invention comprises the following steps: compositing beta-glucanase and beta-mannanase, controlling the enzyme proportion, enzyme addition amount and enzymolysis time to enzymatically degrade the high concentration konjak powder so as to reduce the viscosity of the konjak powder; and processing by drying and the like to obtain white, standardized serial products with an adjustable viscosity of 500-5,000mpa.s. Due to the different functions and application characteristics of degradation products with different viscosities, a product with a certain viscosity can be added into jelly, soft sweets and drinks as a food additive to play a role of retaining water, gelatinizing and thickening. The complex enzyme technique of the invention can shorten the enzymolysis time, and the controllable degradation technique expands the use range of konjak gum and has high application value.

Owner:JIANGNAN UNIV

Prepn process of high concentration polymerized aluminium sulfate flocculant

InactiveCN1974426AHigh degree of polymerizationIncrease concentrationAluminium compoundsWater/sewage treatment by flocculation/precipitationWater bathsHigh concentration

The present invention discloses preparation process of high concentration polymerized aluminum sulfate flocculant. The preparation process includes two steps of preparing high concentration stable sodium metaaluminate solution and polymerization reaction. During the preparation of high concentration stable sodium metaaluminate solution, sodium gluconate is added into sodium hydroxide solution at 100-120 deg.c, aluminum hydroxide, stabilizer and initiator ammonium persulfate are also added. The polymerization reaction includes dissolving sodium carbonate in small amount of water, adding sodium silicate solution and sodium metaaluminate solution to obtain alkali intermediate product, high speed dispersing aluminum sulfate solution in a water bath and adding the alkali intermediate product slowly, mixing, stirring at 55-60 deg.c to mature and obtain high concentration polymerized aluminum sulfate flocculant. The flocculant has high stability, alumina content of 8.21-10.84 % and basicity of 65.90-72.93 %.

Owner:SOUTH CHINA UNIV OF TECH

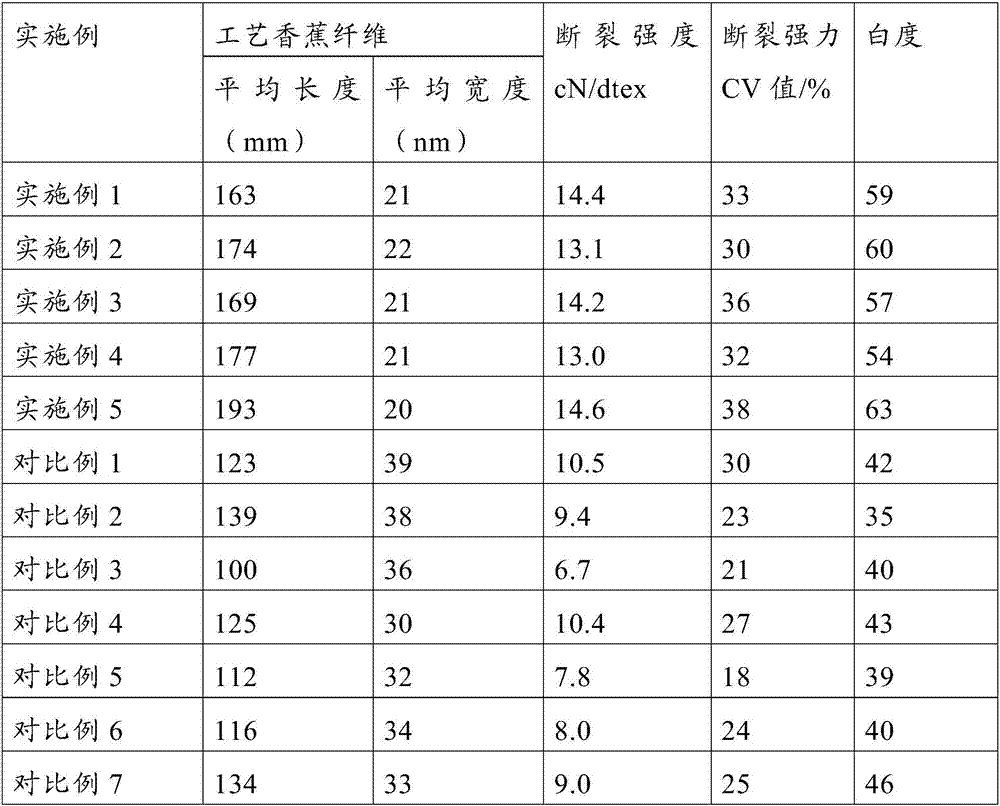

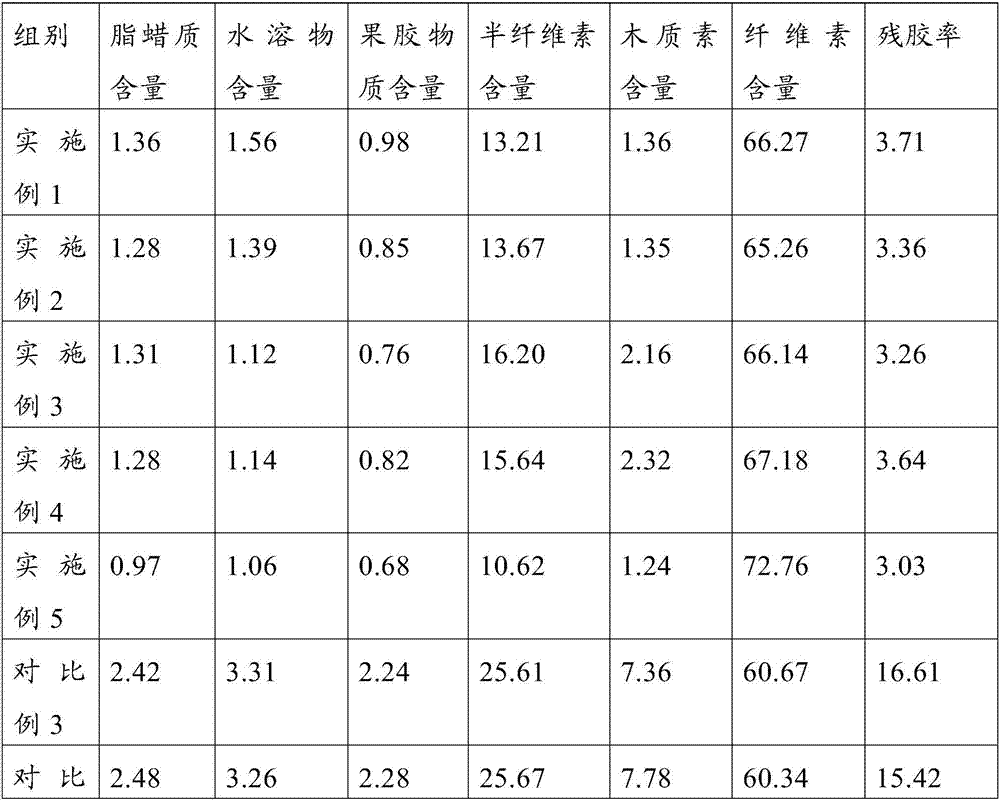

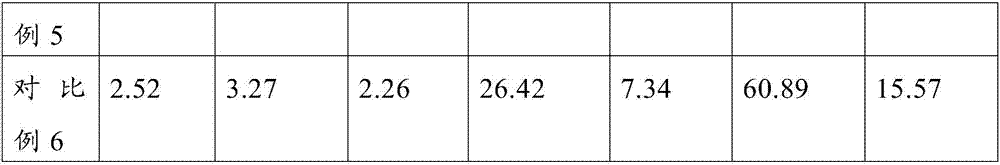

Method of using steam explosion technology to extract and degum banana fibers

The invention discloses a method of using a steam explosion technology to extract and degum banana fibers. The method comprises the following steps: (1) carrying out steam explosion extraction; (2) performing a pre-acid treatment; (3) cleaning; (4) carrying out enzymatic degumming; (5) carrying out steam explosion degumming; (6) performing primary bleaching; (7) performing secondary bleaching; and (8) carrying out a post treatment. At first a pre-acid treatment is carried out, and then biological enzymes and steam explosion are combined to effectively increase the yield of banana fiber. At the same time, the residual gum content of banana fibers is reduced, and thus the environment pollution is avoided.

Owner:HAIKOU EXPERIMENTAL STATION CHINESE ACAD OF TROPICAL AGRI SCI

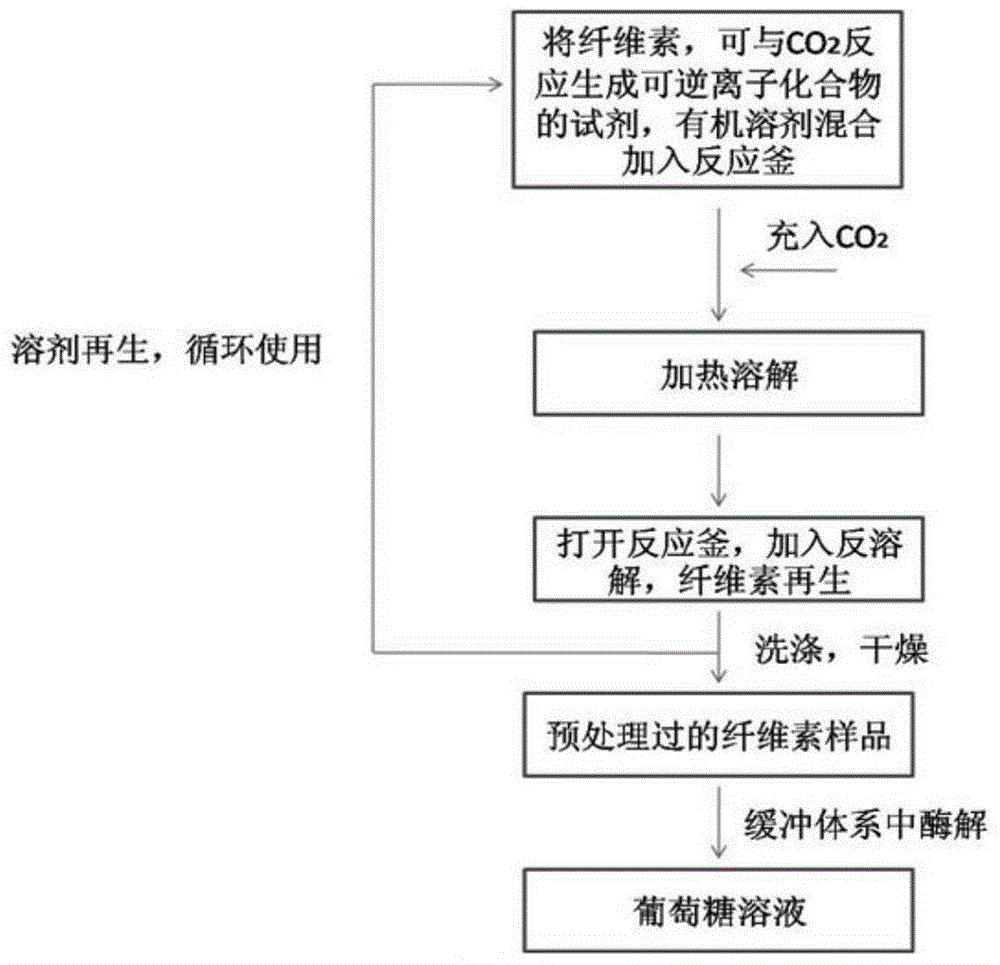

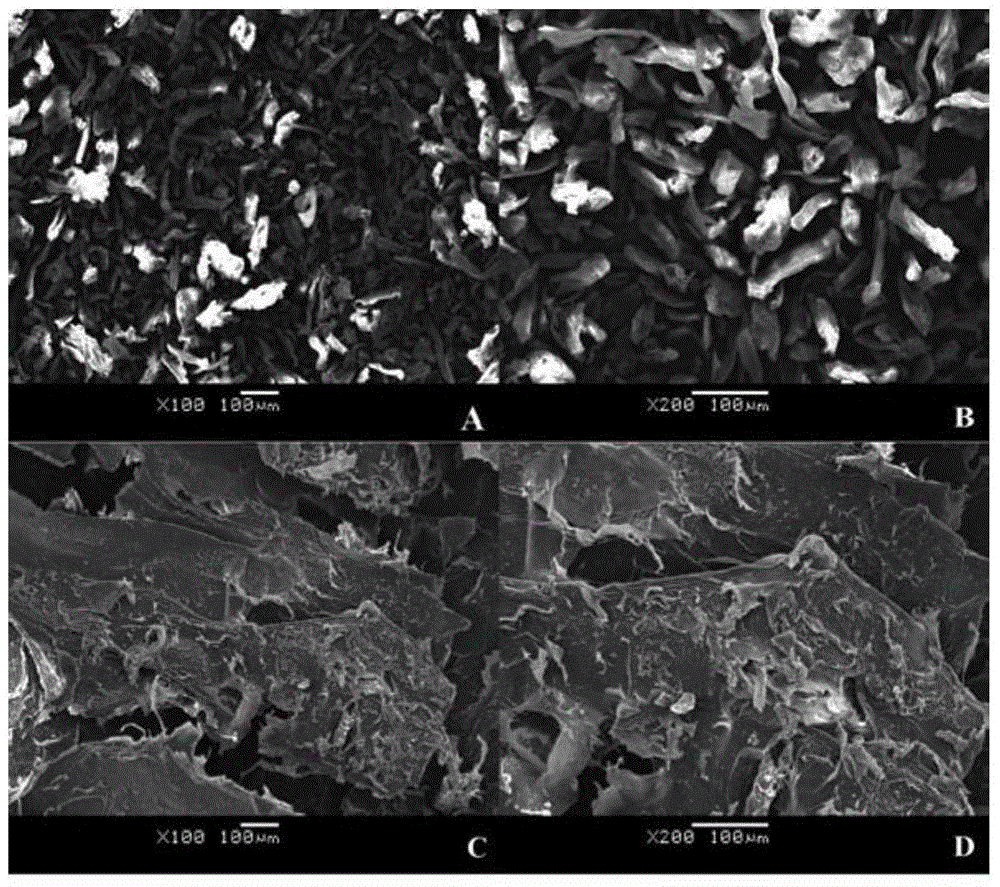

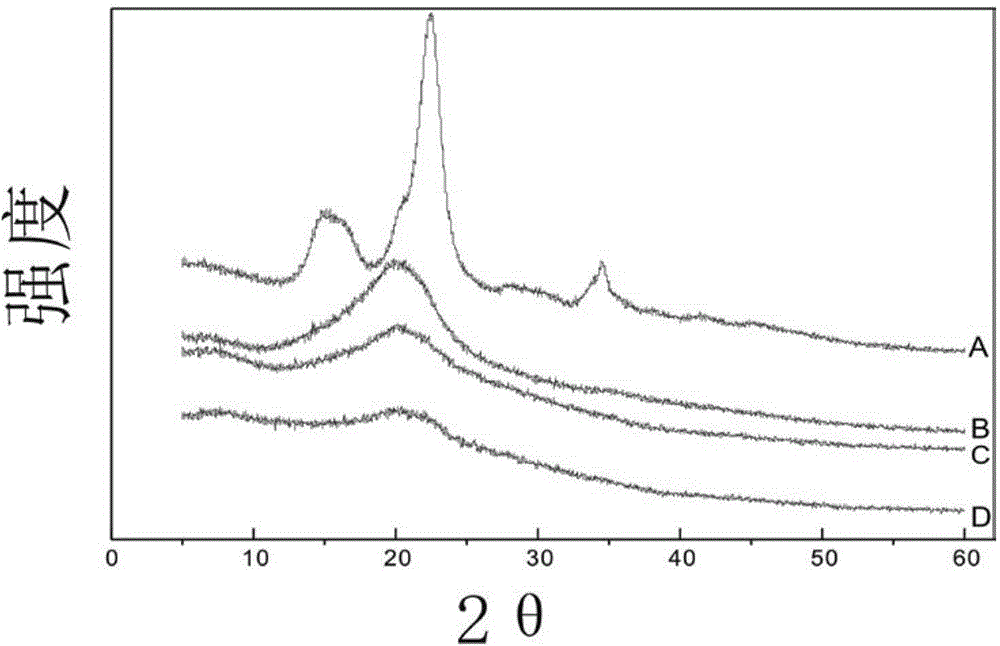

Method for improving cellulase hydrolysis sugar field

The invention provides a method for improving cellulase hydrolysis sugar field. The method comprises the following steps: (1) taking cellulose as a raw material; (2) dissolving the cellulose in a CO2 switch-type ionic compound or a mixed solvent consisting of the CO2 switch-type ionic compound and an organic solvent, thereby obtaining a cellulose-containing solution; (3) adding an anti-solvent into the cellulose solution, regenerating, filtering and separating the dissolved cellulose, thereby obtaining the pretreated cellulose material; and (4) taking a certain amount of regenerated cellulose, adding a buffer solution and cellulase for performing enzymolysis, thereby obtaining the glucose solution. The CO2 switch-type ionic compound or the mixed solvent consisting of the CO2 switch-type ionic compound and the organic solvent serves as a solvent, the cellulose is subjected to dissolving pretreatment, and the method has the advantages that the process is simple, the solvent cost is low, the operation is convenient, the solvent can be recycled, the cellulase hydrolysis speed is high, the sugar yield is high and the like.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

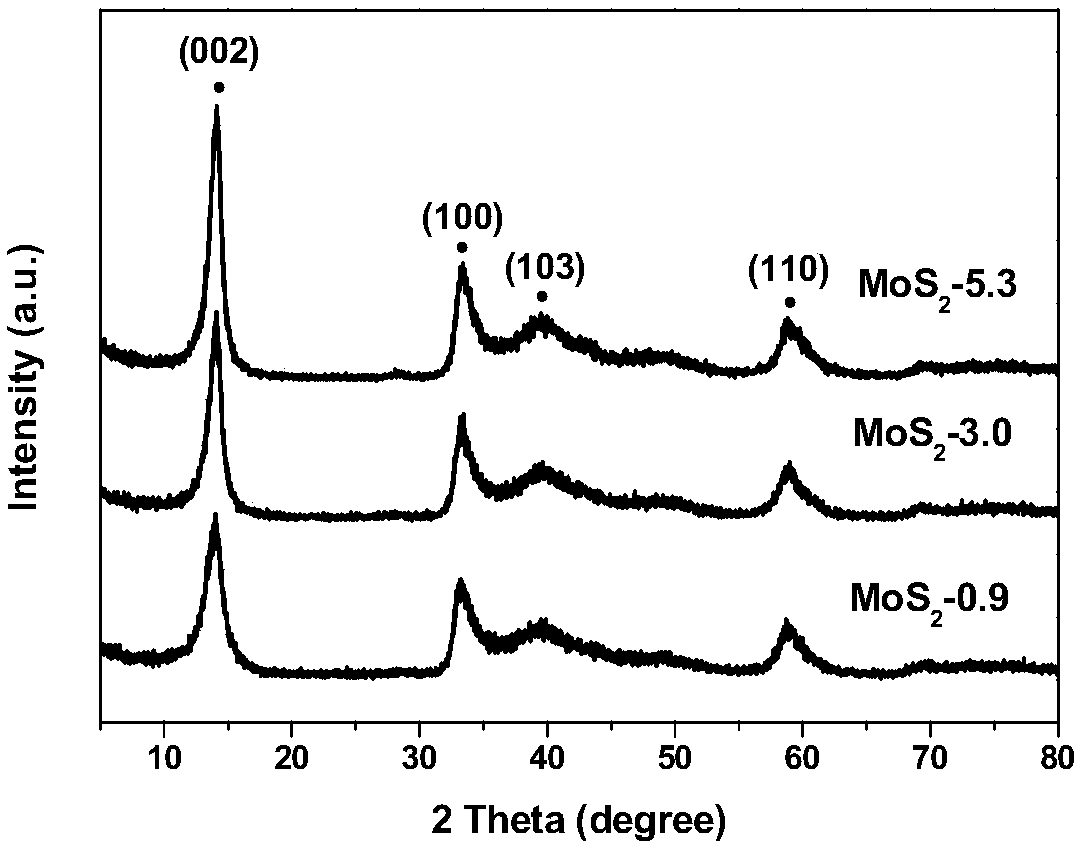

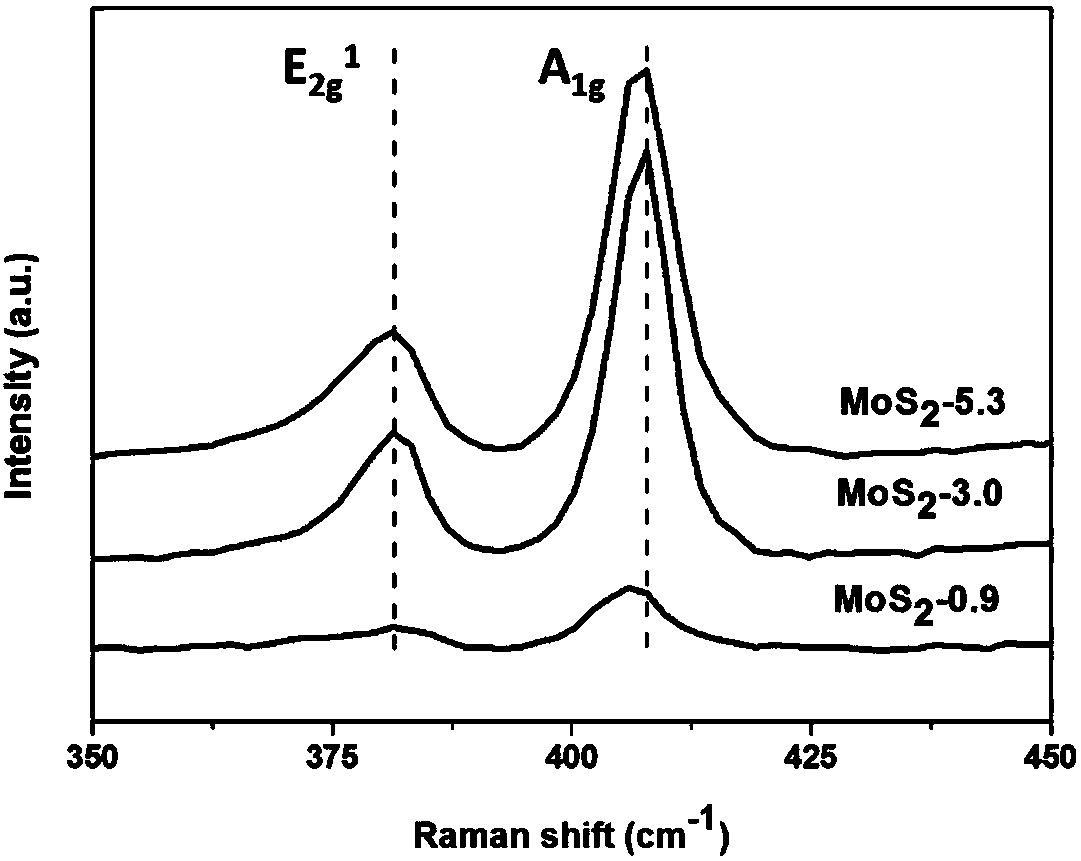

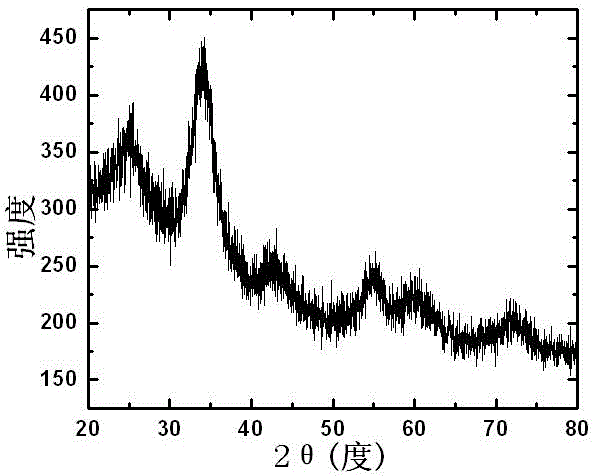

Shape-controlled preparation method of MoS2 nano particles

InactiveCN108217728AFast grain sizeRefine the grain sizeMaterial nanotechnologyMolybdenum sulfidesHydrodesulfurizationSulfur

The invention discloses a shape-controlled preparation method of MoS2 nano particles. The shape-controlled preparation method disclosed by the invention mainly comprises the following steps: sequentially adding a molybdenum source and a sulfur source into deionized water for stirring until the substances are completely dissolved, adding acid or alkali and adjusting the pH value of a solution to acertain value, wherein the ratio of the molybdenum source to the sulfur source is (1 to 2) to (1 to 6) and the pH value is 0.1 to 14; putting the obtained solution into a hydrothermal reactor, carrying out static reaction at the reaction temperature of 160 to 350 DEG C for 2 to 72 hours; after the reaction is ended, cooling, washing and carrying out vacuum drying to obtain shape-controlled MoS2 nano particles. The synthetic method disclosed by the invention has the advantages of mild conditions, simple operation, controllable particle shape, homogeneous products, high yield and the like. The MoS2 synthesized by the preparation method disclosed by the invention has a good application prospect in the fields of gasoline and diesel hydrodesulfurization, photoelectric catalysis, lithium ion batteries, super capacitors, lubrication and the like.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

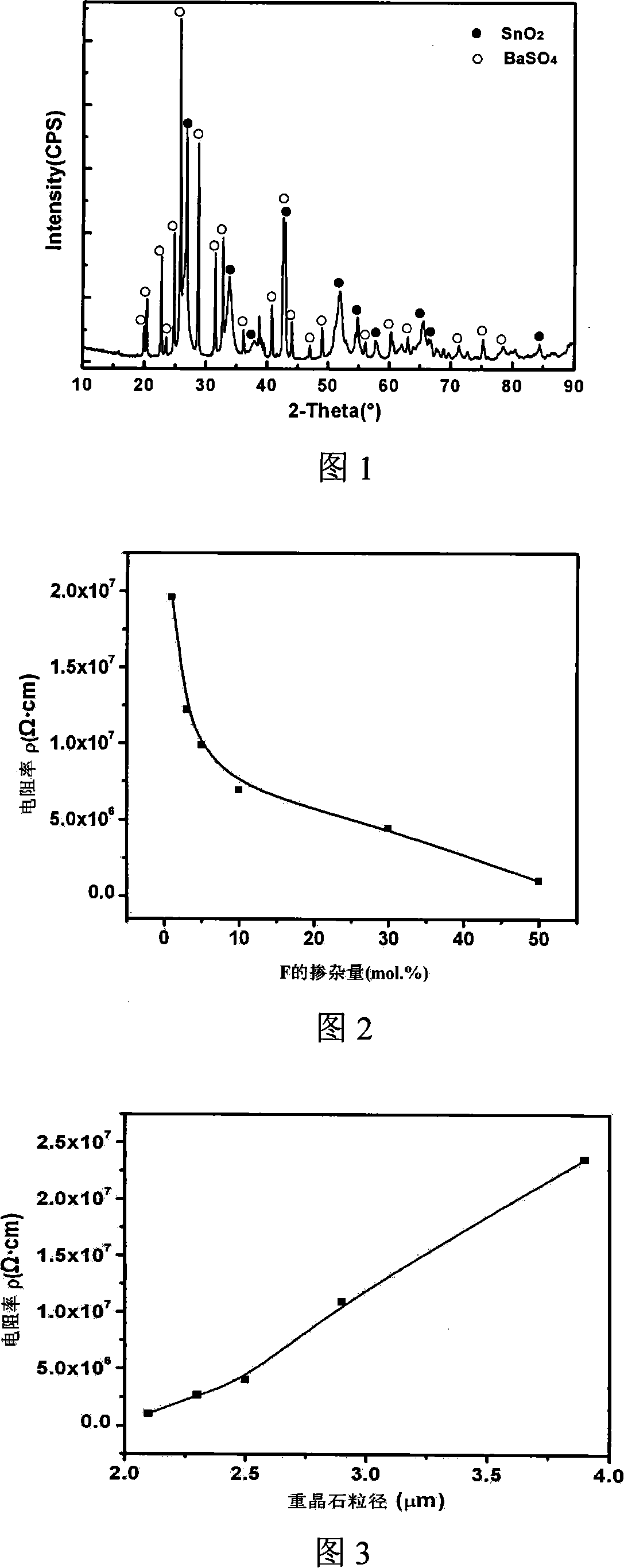

Production method for barite composite conducting material

InactiveCN101174496AContribute to dispersionSmall particle sizeConductive materialCable/conductor manufactureDispersityReaction temperature

The invention discloses a method for preparing barite compound conductive material, which is characterized in that: high-purity barites are ball milled to 0.5 to 5.0 Mum of the particle size through method of powders prepared by wet chemical, the barite powders are put in distilled water after being filtered, dried and grinded, simultaneously, polyethylene glycol is added as dispersing agent; the NH4F solution and the SnCl4 4H2O ethanol solution are mutually dissolved with each other, then, the solution is dropped in the distilled water of the barite powders, the quantity of materials is controlled as F: Sn 1:99 to 50:50, simultaneously, the pH value is controlled as 3 to 5, the reaction temperature is 20 to 60 DEG C, then be roasted after being stirred, air pump filtrated and dried. The invention has the advantages that the metal oxide coats on the barite surface more uniformly, the obtained compound conductive material is low colored, the conductibility is more stable, the dispersity is strong and the application performance is greater.

Owner:CENT SOUTH UNIV

Method for recovering TDA (Toluene Diamine) from residues and wastes formed in preparation process of TDI (Toluene Diisocyanate)

InactiveCN103787894ALow costFast hydrolysisAmino compound purification/separationOrganic compound preparationChemical treatmentToluene diisocyanate

The invention relates to a method for preparing an important chemical raw material TDA (Toluene Diamine) by carrying out chemical treatment at ordinary pressure on residues and wastes formed in the preparation process of TDI (Toluene Diisocyanate). The method comprises the steps of heating a mixture of crushed TDI residues and ethylene glycol at ordinary pressure till boiling reflux; then adding triethylenetetramine and a NaOH water solution, continuously reacting at 100 DEG C, and finally adding water to a system for cooling to obtain a primary hydrolysis product; carrying out salting-out on the hydrolysis product through a saturated sodium chloride solution, carrying out fractional extraction on the hydrolysis product through dichloromethane, and then carrying out reduced pressure distillation on an extract to prepare the TDA. According to the invention, the yield of the TDA accounts for 60% of the weight of added TDI solid residues, and the purity of the TDA is 95%. The method disclosed by the invention carries out hydrolysis on the TDI residues at ordinary pressure without needing a high-pressure reaction kettle, thereby greatly reducing the cost of production equipment; the method disclosed by the invention is outstanding in economic benefit.

Owner:UNIV OF JINAN

Method for high-temperature and high-pressure acid degumming of tussah silk

The invention discloses a method for high-temperature and high-pressure acid degumming of tussah silk. Firstly, acid, a penetrant and water are mixed, degumming liquid is obtained, silk is soaked with the degumming liquid, and degumming is carried out under the conditions that the pressure is 1.0-3.0 MPa and the temperature is 100-140 DEG C. The tussah silk is treated through the high-temperature and high-pressure acid degumming method, the hydrolysis speed of sericin and the breaking speed of protein peptide bonds are increased, degumming time is short, the degumming rate can reach 13%, the breaking strength of the silk obtained after degumming can be kept at about 620 N, the strength losses of the silk are small, and rapid degumming of the tussah silk is achieved.

Owner:EASTERN LIAONING UNIV

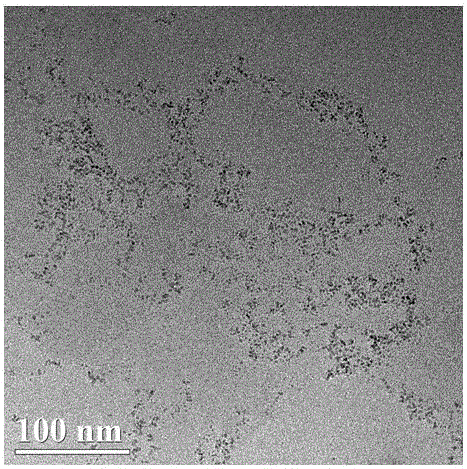

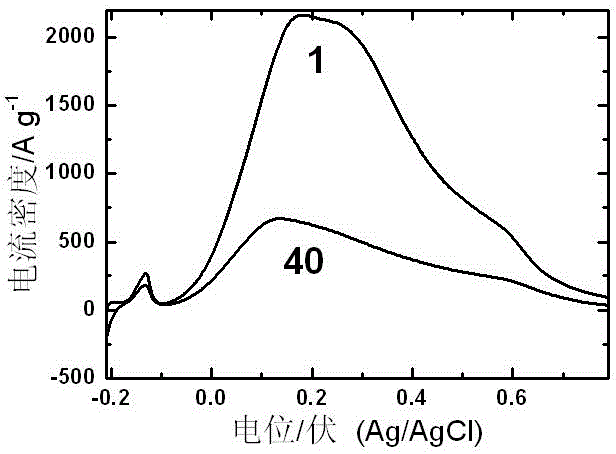

Palladium oxide catalyst used for direct formic acid fuel cell and preparation method thereof

ActiveCN106602081AAvoid autocatalytic effectsSmall particle sizeCell electrodesFinal product manufactureCarbon nanotubeSolvent

The invention discloses a palladium oxide catalyst used for direct formic acid fuel cells and a preparation method of the palladium oxide catalyst. The preparation method comprises the following steps: dissolving palladium chloride to be prepared into a water solution, adding sodium citrate or potassium citrate, and adjusting the pH value of the solution to be 9 to 13; then putting the solution into a microwave reactor to carry out a microwave reaction for 3 to 30 minutes, and carrying out backflow and magnetic stirring while reacting so as to obtain a palladium oxide colloid solution; after the palladium oxide colloid is cooled, adding commercial carbon powder or carbon nano tubes to collect palladium oxide; and finally carrying out suction filtration, washing a filter cake cleanly, carrying out vacuum drying, and grinding to obtain the carbon-loaded palladium oxide catalyst. The palladium oxide catalyst uses water as a solvent, is green and environmentally-friendly, and is free of any organic matter to be involved into the reaction in the whole process; the catalyst is free of the addition of any protective agent with high molecular weight, and post-processing is not needed after catalyst preparation; the reaction time is short, and the energy consumption is saved; the process for preparing the palladium oxide catalyst in the invention is simple, and batch industrial production is easy to realize.

Owner:SOUTH CHINA UNIV OF TECH

Full-polyester fabric printing and dyeing process and method

InactiveCN108978266AIncrease concentrationFast hydrolysisDyeing processLiquid/gas/vapor textile treatmentHigh concentrationYarn

The invention discloses a full-polyester fabric printing and dyeing process and a method. The method comprises the following steps of preparation before printing and dyeing of full-polyester fabric, and preparation of clean water in the whole printing and dyeing process; putting the full-polyester fabric onto a goods checking station, and mainly checking the abnormalities of yarn drawing-out, pirnbarre, yellow spot, mildew spot and the like in a fabric blank; checking whether the fabric variety is matched with the required fabric variety or not; under the normal condition, checking each batch. The method has the advantages that by feeding potassium hydroxide into the softened clean water, the alkaline reduction treatment is performed on the full-polyester fabric; the concentration of thepotassium hydroxide in the clean water is effectively increased via the clean water with the temperature of 90 to 100 DEG C; by adding the full-polyester fabric, the alkaline reduction treatment can be effectively performed, so as to solve the problem of influence to the dyeing treatment of the full-polyester fabric due to higher concentration of alkaline in the existing full-polyester fabric; byusing the clean water to flush, the alkaline dirt at the outer surface of the fully-polyester fabric is cleared, thereby avoiding the influence to the treatment of bleaching due to bringing of the alkaline dirt into a reaction kettle.

Owner:SHAOXING XINGMING DYEING & FINISHING CO LTD

Ultra-thin alumina ceramic substrate preparation method

The invention relates to the technical field of alumina ceramics, particularly to an ultra-thin alumina ceramic substrate preparation method. A purpose of the present invention is to solve the problemof too high sintering temperature of the alumina ceramic substrate in the prior art. The method comprises: (1) carrying out surface modification on aluminum oxide powder; (2) preparing a slurry; (3)carrying out casting molding; (4) stamping, wherein the billet tape obtained in the step (3) is stamped to obtain a billet sheet; (5) discharging glue, wherein the billet sheet is placed into a glue discharge furnace, and is subjected to first glue discharge under a nitrogen atmosphere, heating is performed to a temperature of 450-550 DEG C at a heating rate of 0.8-2 DEG C / min, thermal insulationis performed for 35-60 min, second glue discharge is performed in an air atmosphere, heating is performed to a temperature of 180-250 DEG C at a heating rate of 2-5 DEG C / min, and thermal insulation is performed for 80-120 min; and (5) sintering, wherein the billet sheet after the glue discharge in the step (5) is placed into a sintering furnace, and is sintered for 12-20 h at a sintering temperature of 1550-1600 DEG C.

Owner:FUJIAN HUAQING ELECTRONICS MATERIAL TECH

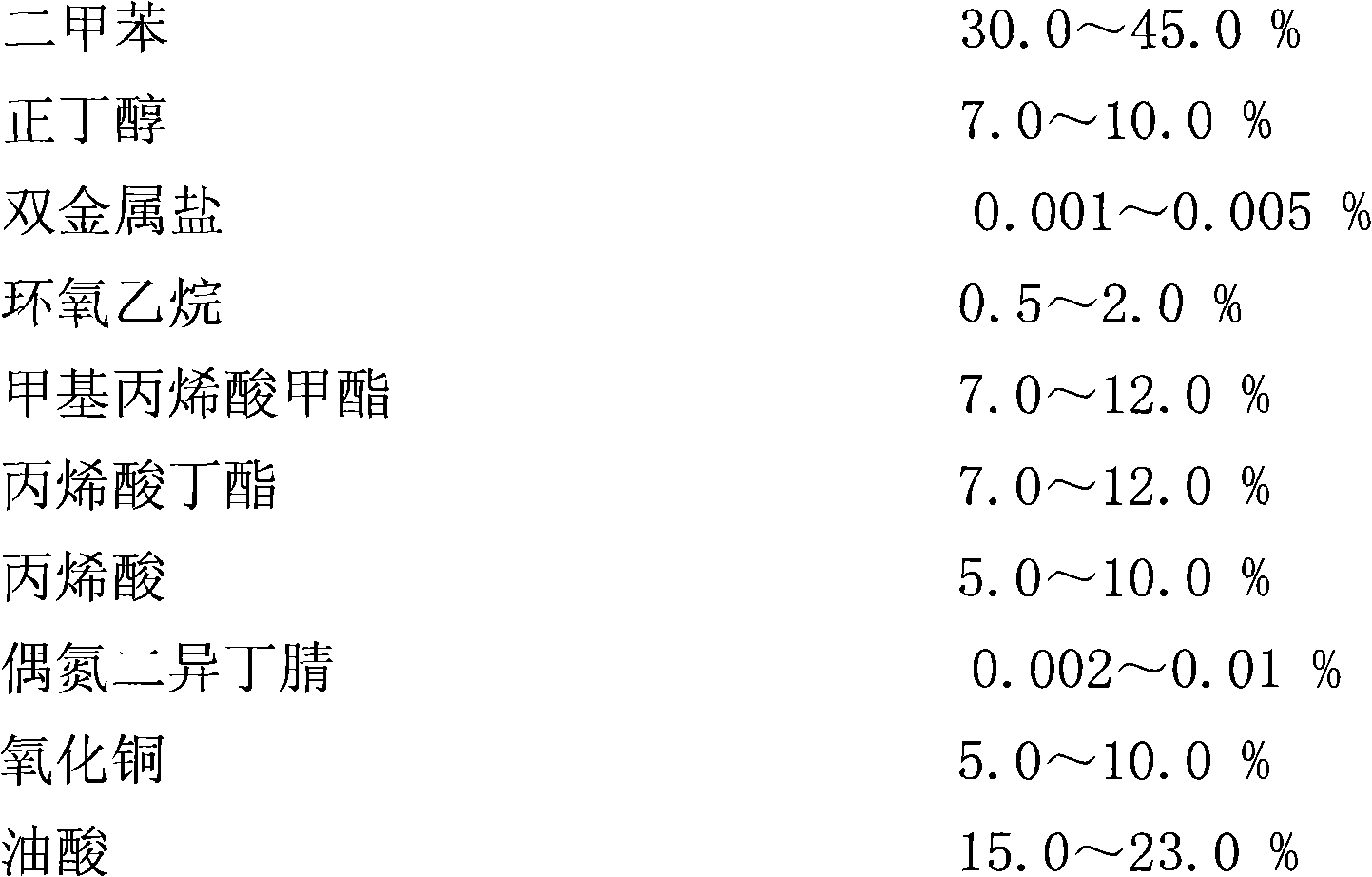

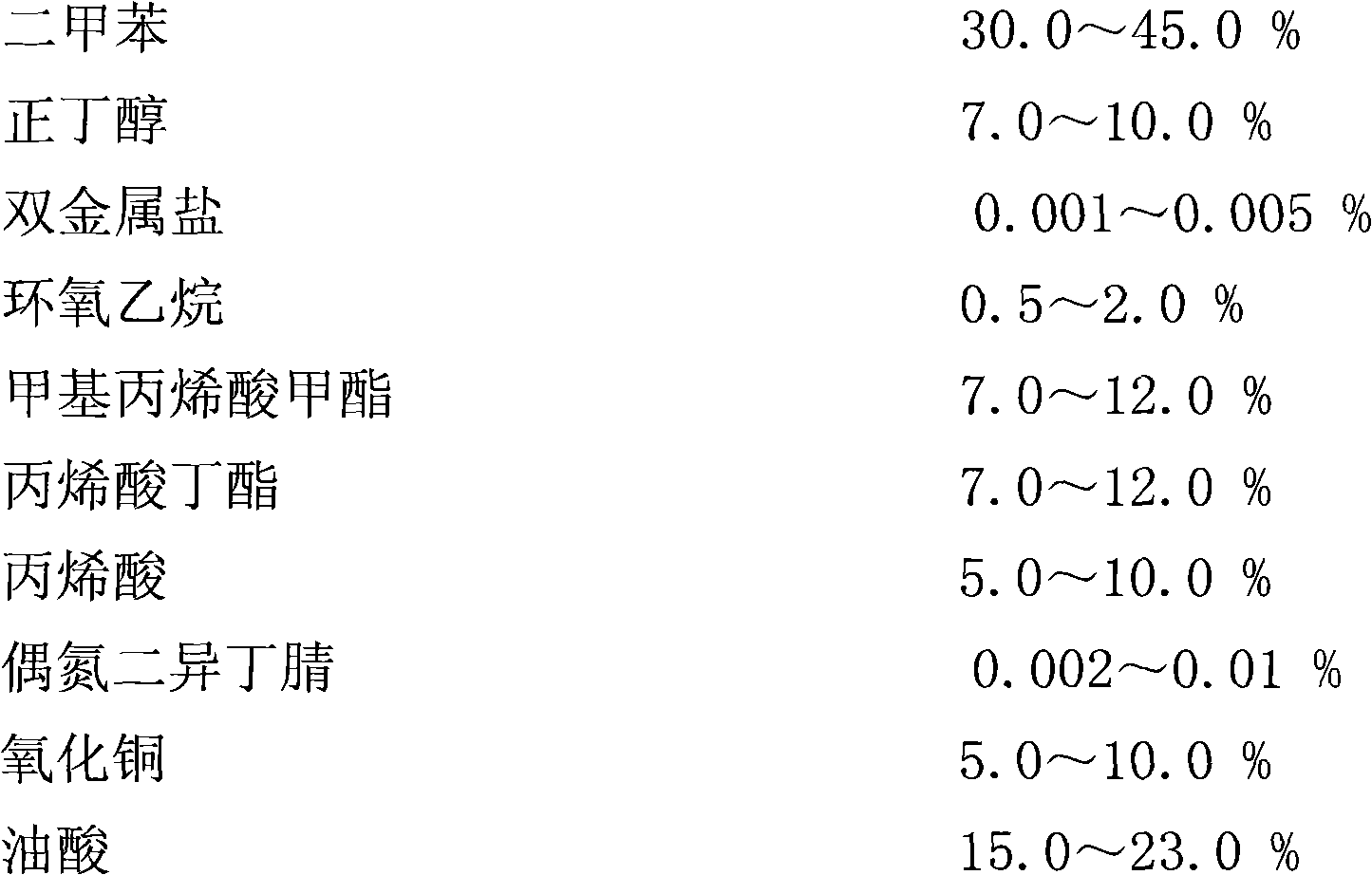

Modified acrylic resin varnish for anti-corrosion paint

InactiveCN102040897AExtended storage timeImprove surface activityAntifouling/underwater paintsPaints with biocidesAcrylic resinCopper oxide

The invention relates to a modified acrylic resin varnish for anti-corrosion paint, belonging to the field of applied chemistry. The invention overcomes the shortages that the traditional varnish commonly has short preserving time, cannot effectively control the seepage speed of copper ions, cannot control the self-polishing speed and cannot prevent pollution for a long time. In the invention, the preparation process of the modified acrylic resin varnish is divided into two steps of: firstly, adding bimetal salt used as a catalyst to a certain amount of xylene and n-butyl alcohol solvent, and then adding ethylene oxide at certain temperature to finish polymerization reaction; secondly, adding a certain amount of xylene and n-butyl alcohol solvent to the reaction liquid again, and then dropwise adding methyl methacrylate, butyl acrylate, acrylic acid and initiator azodiisobutyronitrile at certain temperature, adding cupric oxide and oleic acid after finishing the polymerization reaction, and then refluxing and shunting so as to obtain the modified acrylic resin varnish. The invention is applied to pollution prevention of an underwater structure and has the characteristics of long varnish endurance, no cracks and self-polishing performance.

Owner:NORTHEAST NORMAL UNIVERSITY

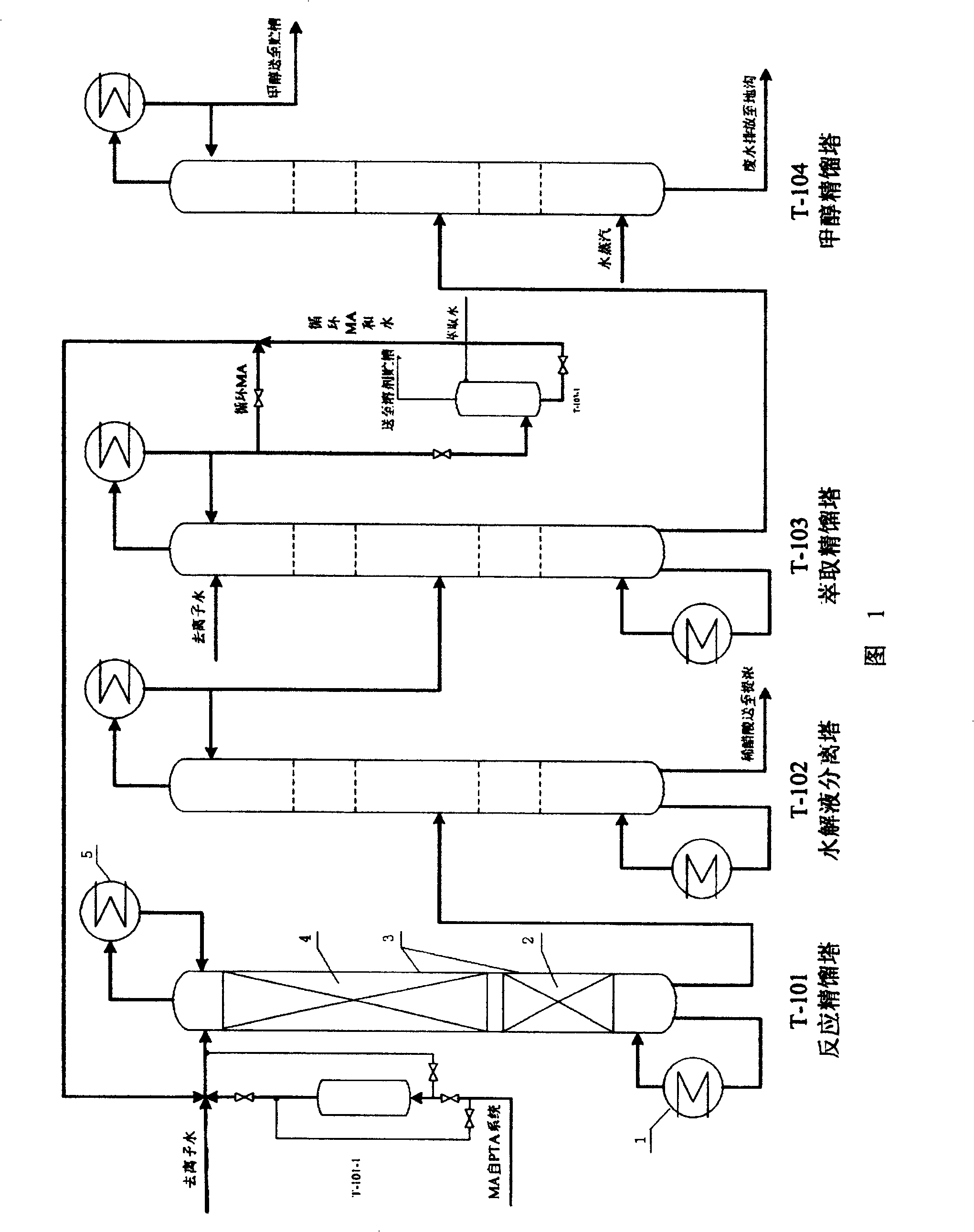

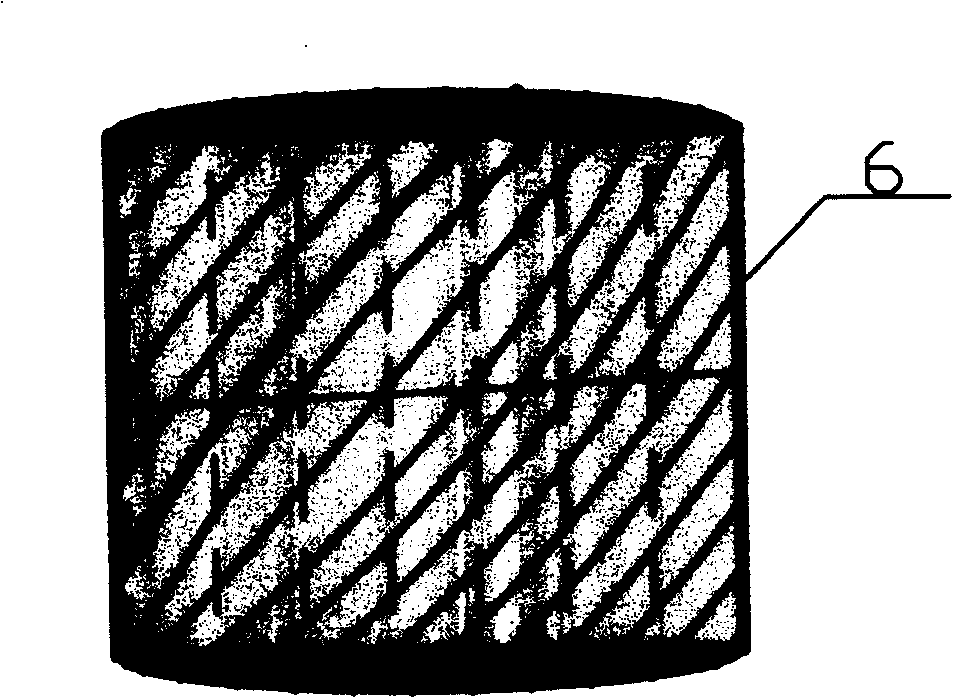

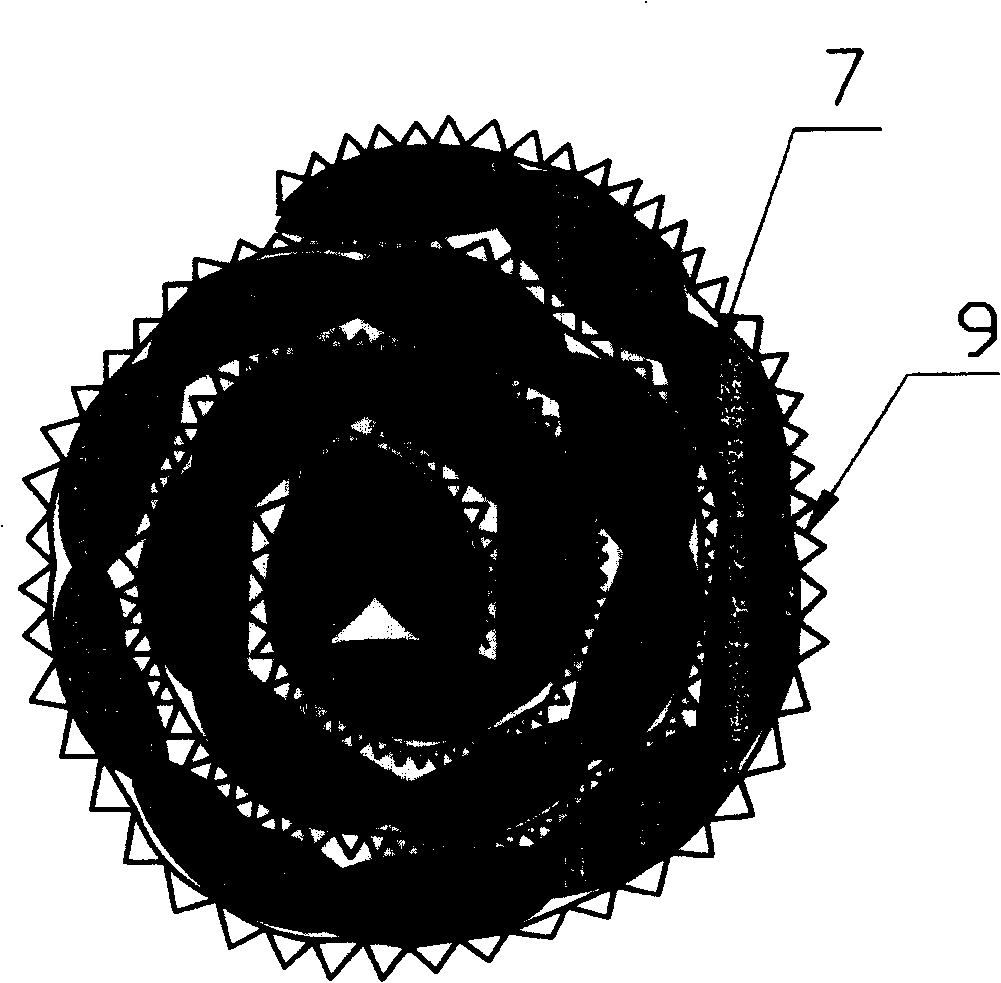

Hydrolysis process of methyl acetate as by-product of producing refined terephthalic acid and apparatus thereof

InactiveCN100418939CIncrease hydrolysis rateHas industrial application valueOxygen-containing compound preparationOrganic compound preparationHydrolysateIon-exchange resin

The present invention discloses technological process and apparatus for hydrolyzing methyl acetate as the side product of refined terephthalic acid production. The technological process includes the following steps: the mixing between methyl acetate through active catalyst protecting column and methyl acetate through eliminating organic impurity and the catalytic hydrolysis reaction in the reaction area filled into cationic exchange resin inside the catalytic rectification tower; refluxing the un-hydrolyzed reactant in controlled ratio to the reaction area; and pumping out the liquid hydrolysate. The corresponding hydrolysis apparatus is one cylindrical tower in the diameter greater than 0.5 m and height greater than 20-24 m, and its catalytic rectification section has one catalyst bed layer in 6 m over thickness and comprising intersected catalyst structure units. The present invention can realize industrial scale hydrolysis of methyl acetate in required hydrolysis rate within 50-80 wt%.

Owner:FUZHOU UNIV

Domestic sewage treatment agent and preparation method thereof

ActiveCN107758823AGood flocculation effectFast hydrolysisWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionPorous carbonTherapeutic effect

The invention discloses a domestic sewage treatment agent and a preparation method of the domestic sewage treatment agent. The domestic sewage treatment agent comprises the following raw materials inparts by weight: 12-15 parts of polyferric chloride, 20-30 parts of meerschaum, 5-10 parts of modified silkworm excrement based porous carbon material, 10-15 parts of sodium hydroxide, 12-15 parts ofpolyacrylamide, 10-15 parts of sodium carbonate and 1-5 parts of bio-based porous composite material. According to the treatment agent, two novel biological carbon materials are added, so that the adsorption purification capacity of the sewage treatment agent is improved; the treatment agent can effectively treat domestic sewage of residents under matching of the other raw materials, and is good in treatment effect, lower in cost and stable in performance; and treated pollution reaches a national sewage discharge standard.

Owner:SHANGHAI ZHONGHAILONG NEW ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com