Modified acrylic resin varnish for anti-corrosion paint

An acrylic resin and modified technology, applied in the field of applied chemistry, can solve the problems of shortening the life of underwater structures, slowing down the speed of ships, fouling organisms, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

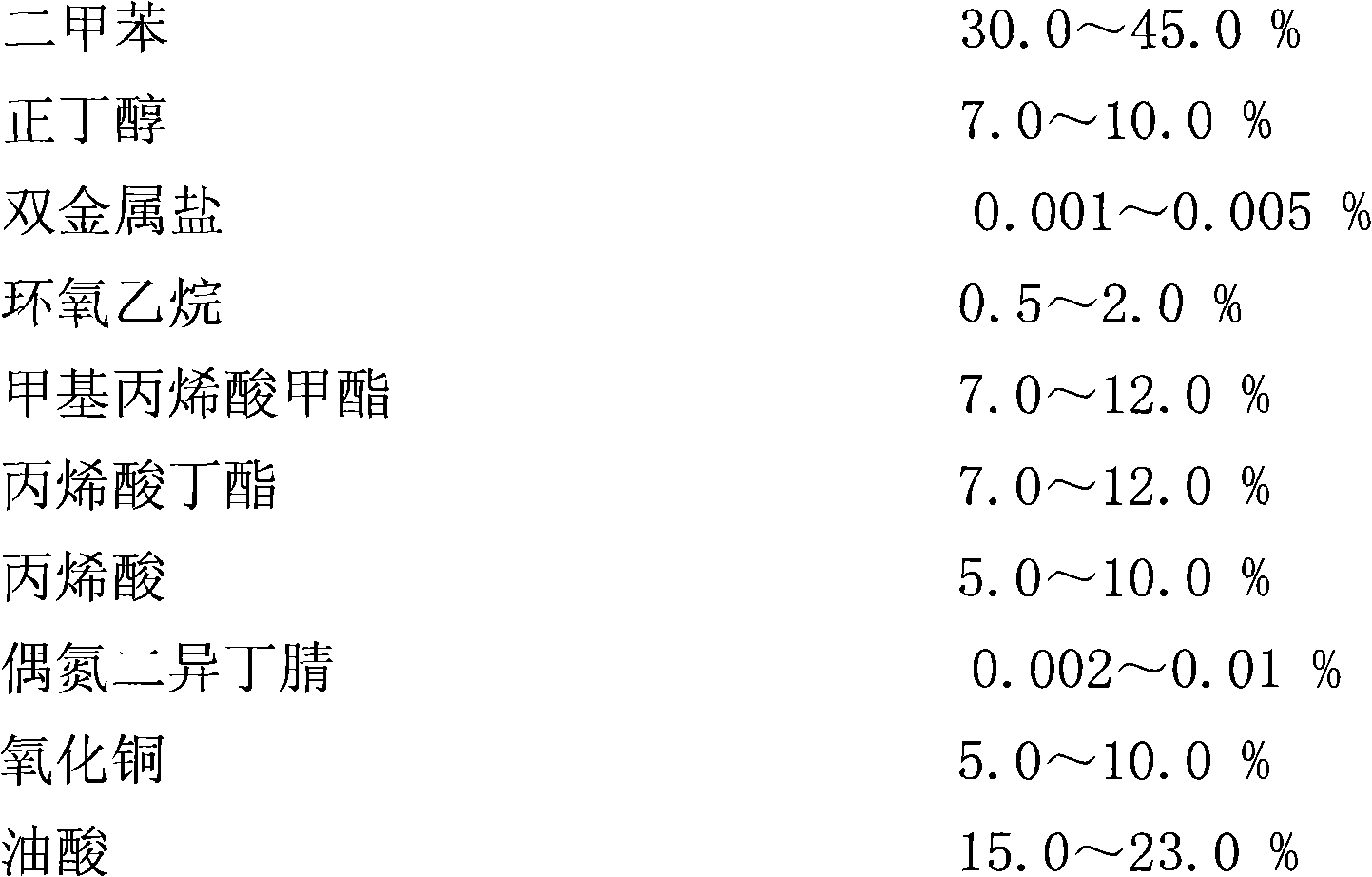

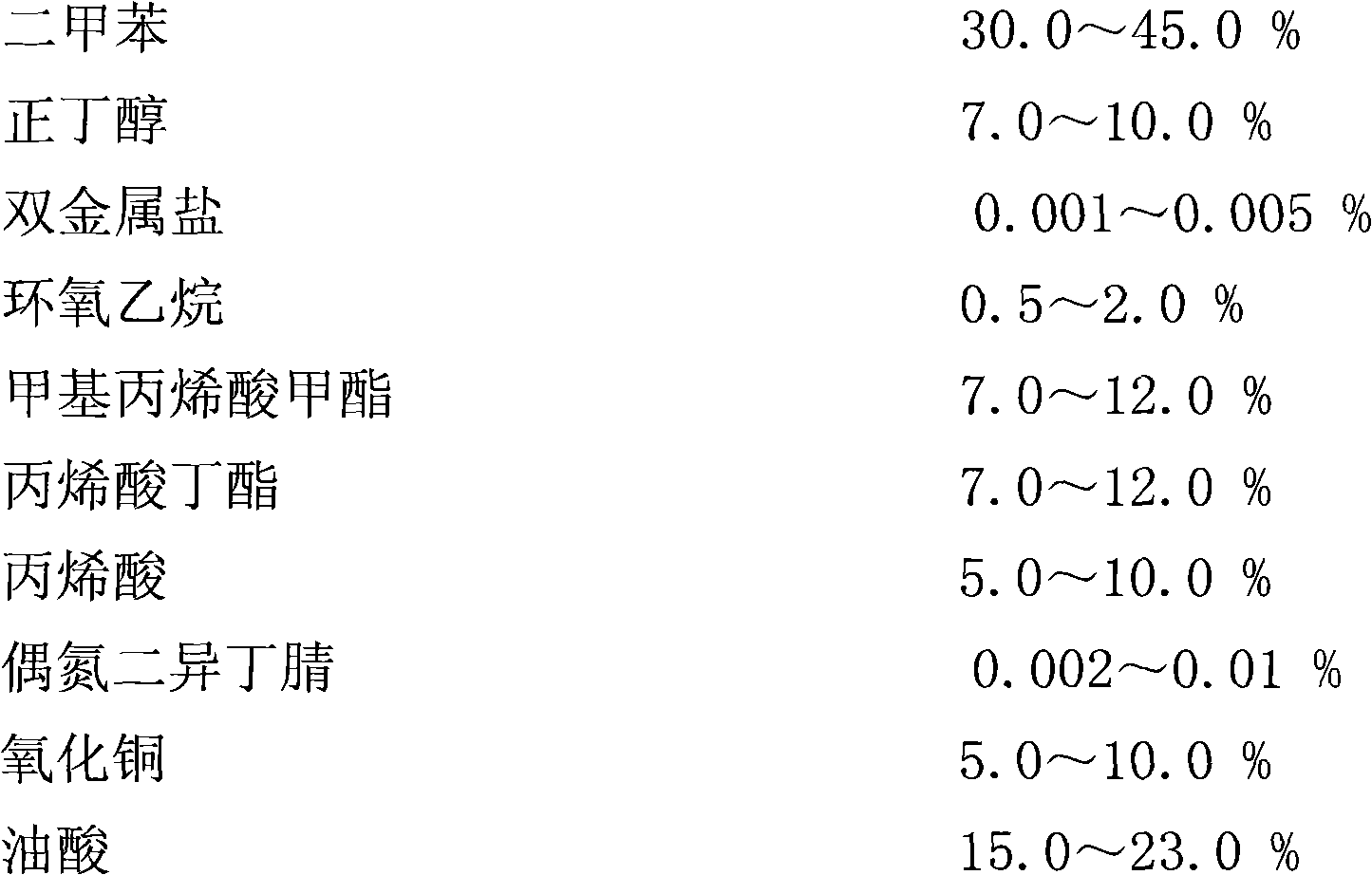

Method used

Image

Examples

Embodiment 1

[0013] Implementation example 1: the preparation technology of modified acrylic resin varnish is the following two steps:

[0014] In the first step, add 10g xylene, 1g n-butanol, 1.5g propylene oxide and 0.005g bimetallic salt to a 50mL three-necked flask equipped with a condenser tube, a thermometer and a stirrer, then stir and gradually heat to 100°C, keep warm for 60 minutes.

[0015] In the second step, the above reaction solution is transferred to a 250mL four-necked bottle equipped with a condenser, a thermometer, a stirrer and a dropping funnel, then stirred, and 32g of xylene and 8g of n-butanol are added while stirring, at 118 to 120 Under the temperature condition of ℃, add the mixed solution which has been mixed uniformly and contains 8.5g methyl methacrylate, 9.5g butyl acrylate, 5.5g acrylic acid and 0.2g initiator azobisisobutyronitrile dropwise at a uniform speed, and the dropping time is controlled at 60 minutes. After heat preservation for 120 minutes, cool...

Embodiment 2

[0016] Implementation example 2: the preparation technology of modified acrylic resin varnish is the following two steps:

[0017] In the first step, add 10 g of xylene, 1 g of n-butanol, 1 g of propylene oxide and 0.005 g of a double metal salt into a 50 mL three-necked flask equipped with a condenser, a thermometer and a stirrer. Then stir and gradually heat to 100°C and keep the temperature for 60 minutes.

[0018] In the second step, the above-mentioned reaction solution is transferred to a 250mL four-necked bottle equipped with a condenser, a thermometer, a stirrer and a dropping funnel, then stirred, and 30g of xylene and 8.5g of n-butanol are added while stirring. At a temperature of 120°C, add a mixed solution that has been mixed evenly and contains 9g methyl methacrylate, 9g butyl acrylate, 6g acrylic acid and 0.2g initiator azobisisobutyronitrile dropwise at a constant speed, and the dropping time is controlled for 60 minutes. Insulate for 120 minutes, cool to 35°C,...

Embodiment 3

[0019] Implementation example 3: the preparation technology of modified acrylic resin varnish is following two steps:

[0020] In the first step, add 12g xylene, 1g n-butanol, 1.5g propylene oxide and 0.004g bimetallic salt to a 50mL three-neck flask equipped with a condenser, a thermometer and a stirrer, then stir and gradually heat to 100°C, keep warm for 60 minutes.

[0021] In the second step, the above-mentioned reaction solution is transferred to a 250mL four-necked bottle equipped with a condenser, a thermometer, a stirrer and a dropping funnel, then stirred, and 31g of xylene and 7.5g of n-butanol are added while stirring. At a temperature of 120°C, add a uniformly mixed solution containing 8g of methyl methacrylate, 9g of butyl acrylate, 5g of acrylic acid and 0.2g of initiator azobisisobutyronitrile at a constant speed, and the dropping time is controlled at 60 minutes , keep warm for 120 minutes, cool to 35°C, then add 5.5g of copper oxide and 19.6g of oleic acid, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com